Micro-nano fiber blending material as well as preparation method and application thereof

A micro-nano fiber and nano-fiber technology, applied in the field of textiles, can solve the problems of micro-nano fiber thickness limitation, low production efficiency, loose structure, etc., and achieve the effect of excellent performance, high strength and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

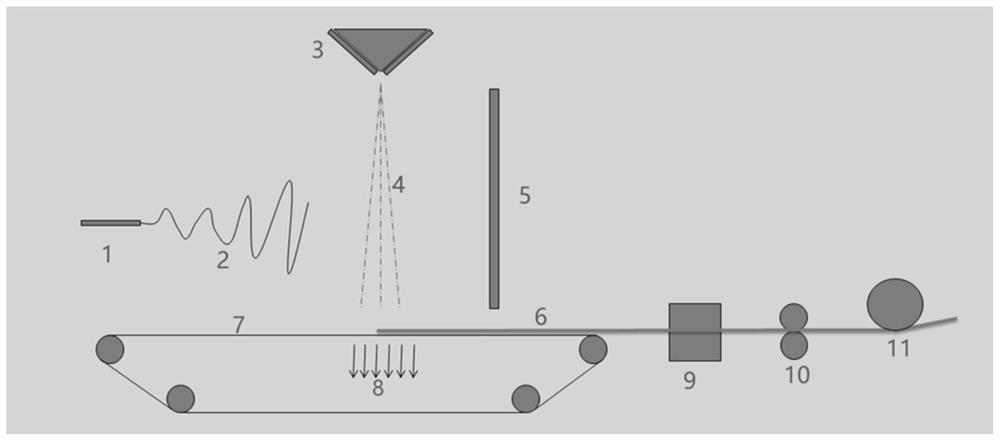

Method used

Image

Examples

Embodiment 1

[0029] Preparation of a micro-nano fiber blend material

[0030] Step 1: Dissolve PAN electrospinning powder in DMF solvent and stir it magnetically for 4 hours to obtain an electrospinning solution with a mass fraction of 15%. Take PP slices for melt blowing and set aside;

[0031] Step 2: Set the receiving distance of electrospinning to 15cm, and the spinning voltage to 29KV. Set the melt blown receiving distance to 24cm, the extrusion temperature to 260°C, the wind pressure to 120Kpa, the under-net suction to 4000r / min, and the drying temperature to 150°C;

[0032] Step 3: Turn on the electrospinning device and the meltblown device, and prepare the micro-nano fiber blended filter material online.

[0033] The micro-nano fiber blend material prepared in this example can be used as an air filter material.

Embodiment 2

[0035] Preparation of a micro-nano fiber blend material

[0036] Step 1: Dissolve PAN electrospinning powder in DMF solvent and stir it magnetically for 4 hours to obtain an electrospinning solution with a mass fraction of 12%. Take PP slices for melt blowing and set aside;

[0037] Step 2: Set the electrospinning receiving distance to 15cm, and the spinning voltage to 25KV. Set the receiving distance of melt blown to 33cm, the extrusion temperature to 260°C, the wind pressure to 130Kpa, the under-net suction to 5000r / min, and the drying temperature to 150°C;

[0038] Step 3: Turn on the electrospinning device and the meltblown device, and prepare the micro-nano fiber blended filter material online.

[0039] The micro-nano fiber blend material prepared in this example can be used as a sound-absorbing material.

Embodiment 3

[0041] Preparation of a micro-nano fiber blend material

[0042] Step 1: Dissolve PAN electrospinning powder in DMF solvent and stir it magnetically for 4 hours to obtain an electrospinning solution with a mass fraction of 14%. Take PP slices for melt blowing and set aside;

[0043] Step 2: Set the electrospinning receiving distance to 14cm, and the spinning voltage to 30KV. Set the receiving distance of melt blown to 33cm, the extrusion temperature to 260°C, the wind pressure to 130Kpa, the under-net suction to 5000r / min, and the drying temperature to 150°C;

[0044] Step 3: Turn on the electrospinning device and the meltblown device, and prepare the micro-nano fiber blended filter material online.

[0045] The micro-nanofiber blend material prepared in this example can be used as an oil-absorbing material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com