Nano carbon doped electrocatalyst for fuel cell, and application of nano carbon doped electrocatalyst

An electrocatalyst and fuel cell technology, applied in battery electrodes, physical/chemical process catalysts, circuits, etc., to achieve the effects of fast speed, easy operation, and high anti-poisoning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

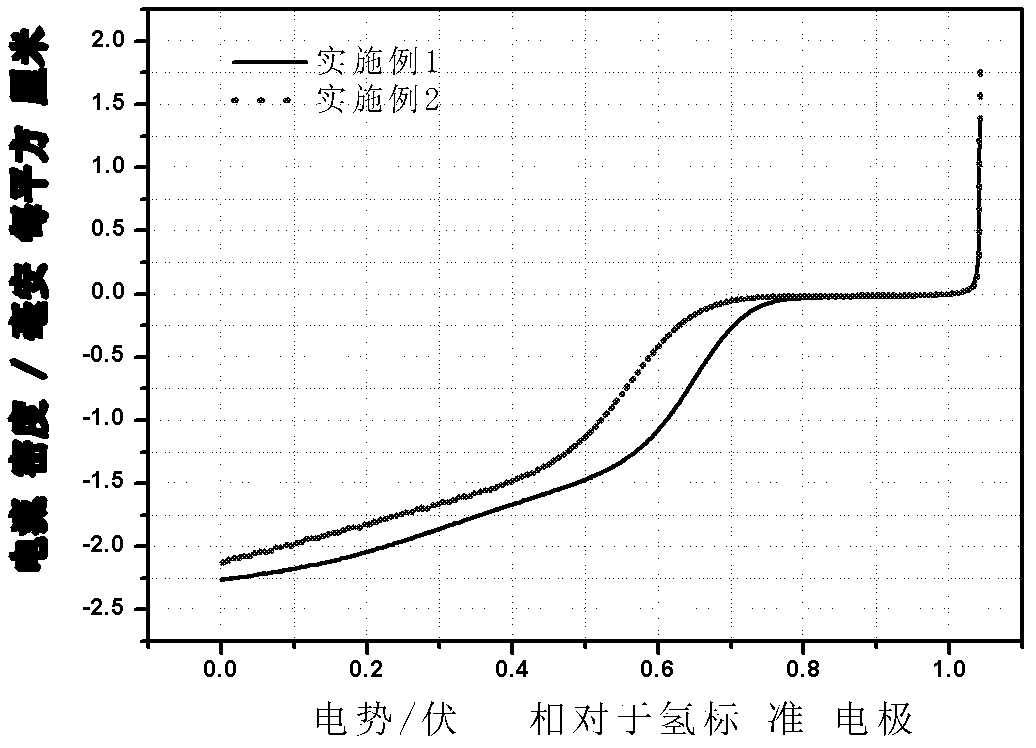

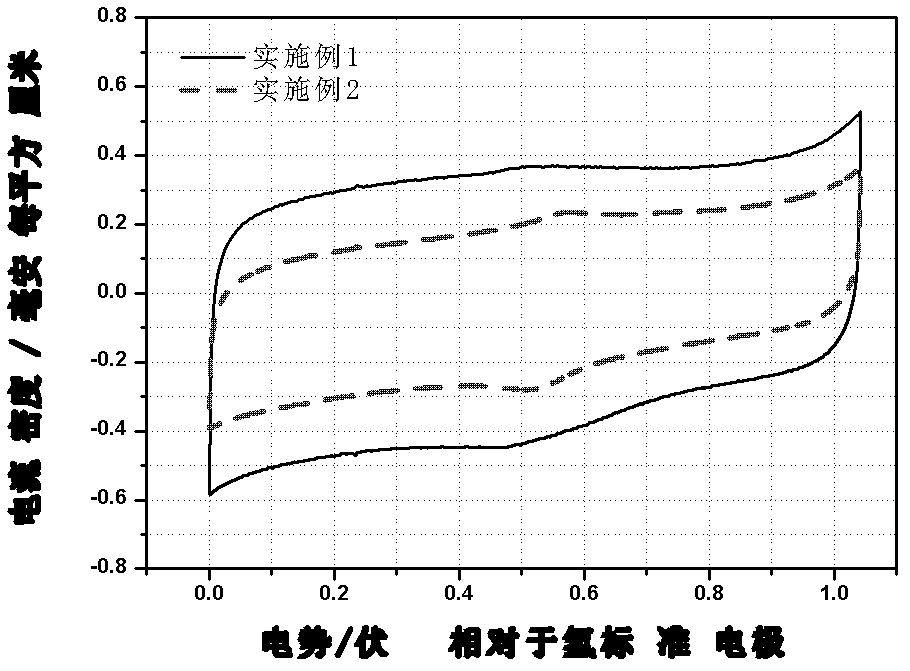

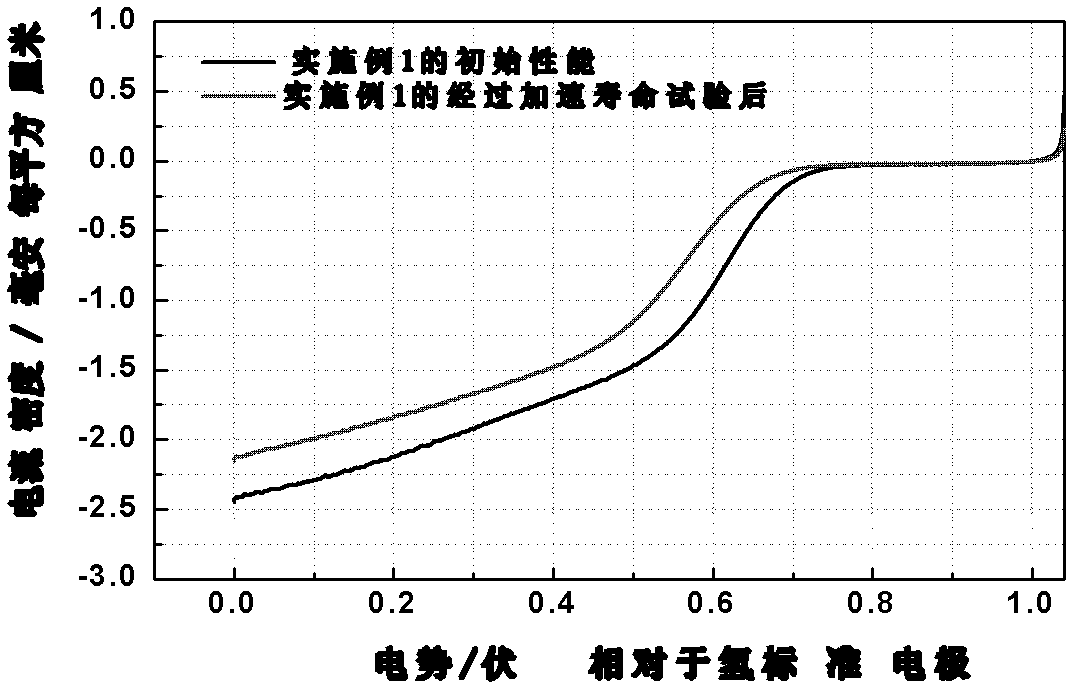

Embodiment 1

[0047] Non-noble metal catalysts doped with Co metal and nitrogen. Take 0.13g Co(NO 3 ) 2 .6H 2 Dissolve O in 10 ml of ethanol, and ultrasonically mix to obtain solution A; dissolve 2.66 ml of N-containing organic precursor hexanediamine in 20 ml of ethanol, and ultrasonically mix to obtain solution B; Dropwise into A, the color of solution A changed from purple to light purple, and gradually changed to blue, and finally turned to khaki to obtain C; then it was sealed, and after stirring for 2 hours, the XC-72 carbon The powder was added to the above mixture C, and after ultrasonically mixed uniformly, continued stirring for 1 h, and then the microwave in the microwave reactor with the output power of 700W was stopped for 10 seconds for 10 seconds, and the microwave and the residence process were repeated three times to obtain the mixture D; the slurry D was placed in a water bath. Evaporate to dryness at 60°C; vacuum dry at 85°C to obtain solid powder E; treat solid powder...

Embodiment 2

[0049] Take 0.0694g Co(NO 3 ) 2 Dissolved in 10ml of ethanol solvent, ultrasonically mixed uniformly to obtain solution A; dissolved N organic precursor hexamethylenediamine containing 0.00143mol in 20ml of ethanol, and ultrasonically mixed uniformly to obtain solution B; Add dropwise to A to obtain C; then seal it, continue stirring for 2h, add XC-72 carbon powder to the above mixture C, after ultrasonically mixing evenly, continue stirring for 1h, and then in a microwave reactor with an output power of 700W The microwave was stopped for 10 seconds for 10 seconds and repeated three times to obtain mixture D; the slurry D was evaporated to dryness at 60°C on a water bath; vacuum dried at 85°C to obtain solid powder E; the solid powder E was treated at 700°C in a nitrogen atmosphere 2 hours.

Embodiment 3

[0051] Take 0.402g Fe(NO 3 ) 3 .6H 2 Dissolve O in ethanol solvent, and ultrasonically mix evenly to obtain solution A; dissolve N organic precursor hexamethylenediamine containing 0.00357 mol in 30 ml of isopropanol, and ultrasonically mix to obtain solution B; B was dropped into A dropwise to obtain C; then it was sealed, and after continuing to stir for 2 hours, 0.39 g of XC-72 carbon powder was added to the above mixture C, and after ultrasonically mixed uniformly, the stirring was continued for 1 hour, and then the output power was The microwave in the 700W microwave reactor was stopped for 10 seconds for 10 seconds, and repeated three times to obtain mixture D; the slurry D was evaporated to dryness on a water bath at 60°C; vacuum-dried at 85°C to obtain solid powder E; the solid powder E was placed in a nitrogen atmosphere Treated at 900°C for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com