Proton exchange membrane fuel cell multi-layer membrane electrode structure and its preparing method

A proton exchange membrane, electrode structure technology, applied in battery electrodes, structural parts, circuits, etc., can solve the problems of high contact resistance, unfavorable proton conduction, etc., to improve battery performance, improve catalyst utilization, and improve utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

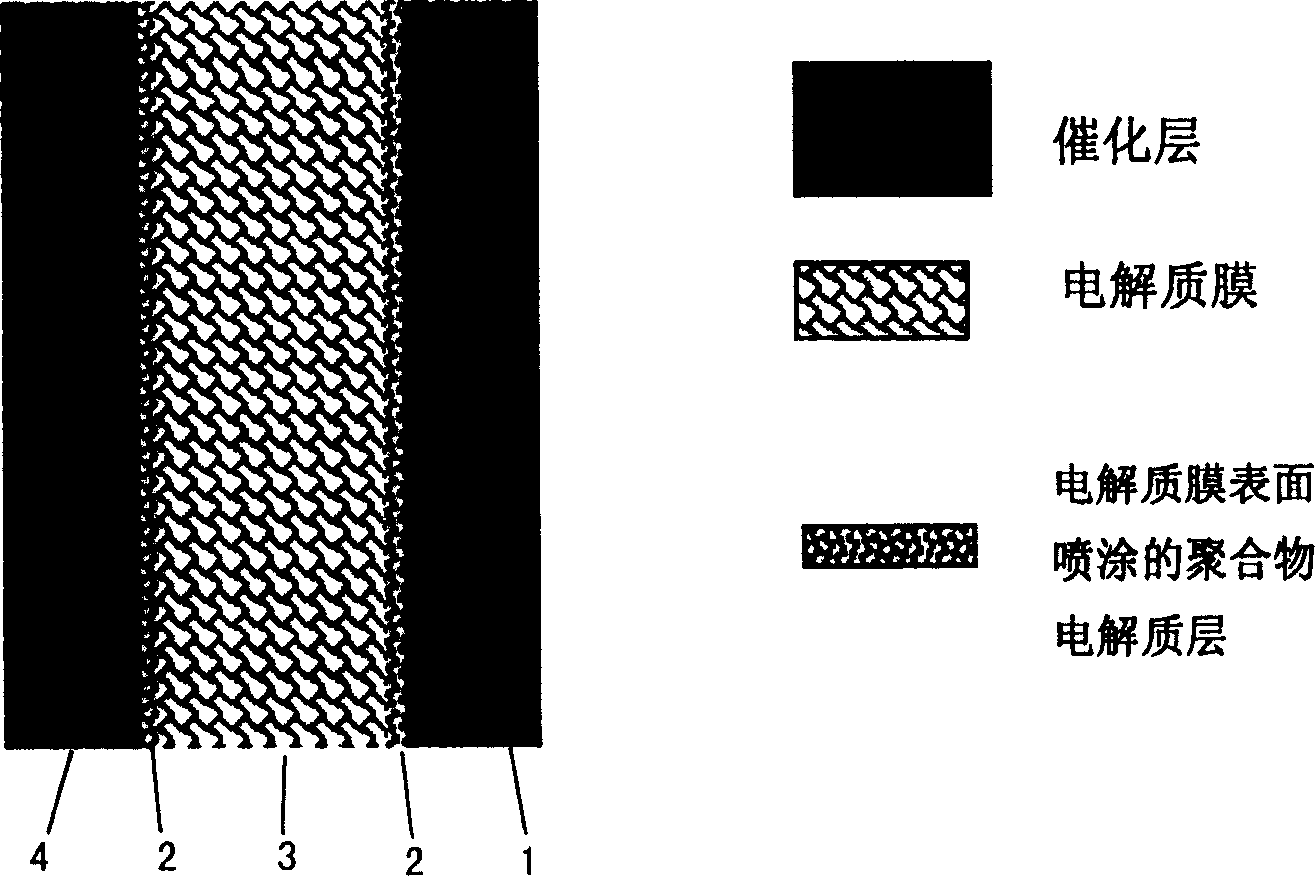

preparation example Construction

[0045] 1. Preparation of proton exchange membrane multilayer structure: under 0.02-0.10MPa negative pressure, press 0.1-5.0mg / cm on the surface of H-type or Na-type Nafion membrane 2 The amount of spray polymer electrolyte 2, such as Nafion (5%) solution or Na-type Nafion solution.

[0046] 2. Preparation of catalyst slurry: use a primary balance to weigh a certain amount of Nafion solution, then add a certain amount of mixed solvent of alcohols and water, the mass ratio of alcohols to water is 100:1-1:100. Then add an appropriate amount of catalyst, the content of Nafion is: 5-50%. The ratio of solvent to catalyst is 50:1-5:1. Mix and sonicate evenly.

[0047] 3. Catalyst layer preparation: spray the catalyst slurry on both sides of the proton exchange membrane with a multilayer structure under a negative pressure of 0.02-0.10 MPa to obtain a membrane electrode (MEA). Alternatively, the catalyst slurry is sprayed or brushed onto the PTFE membrane, and then pressed onto the...

Embodiment 1

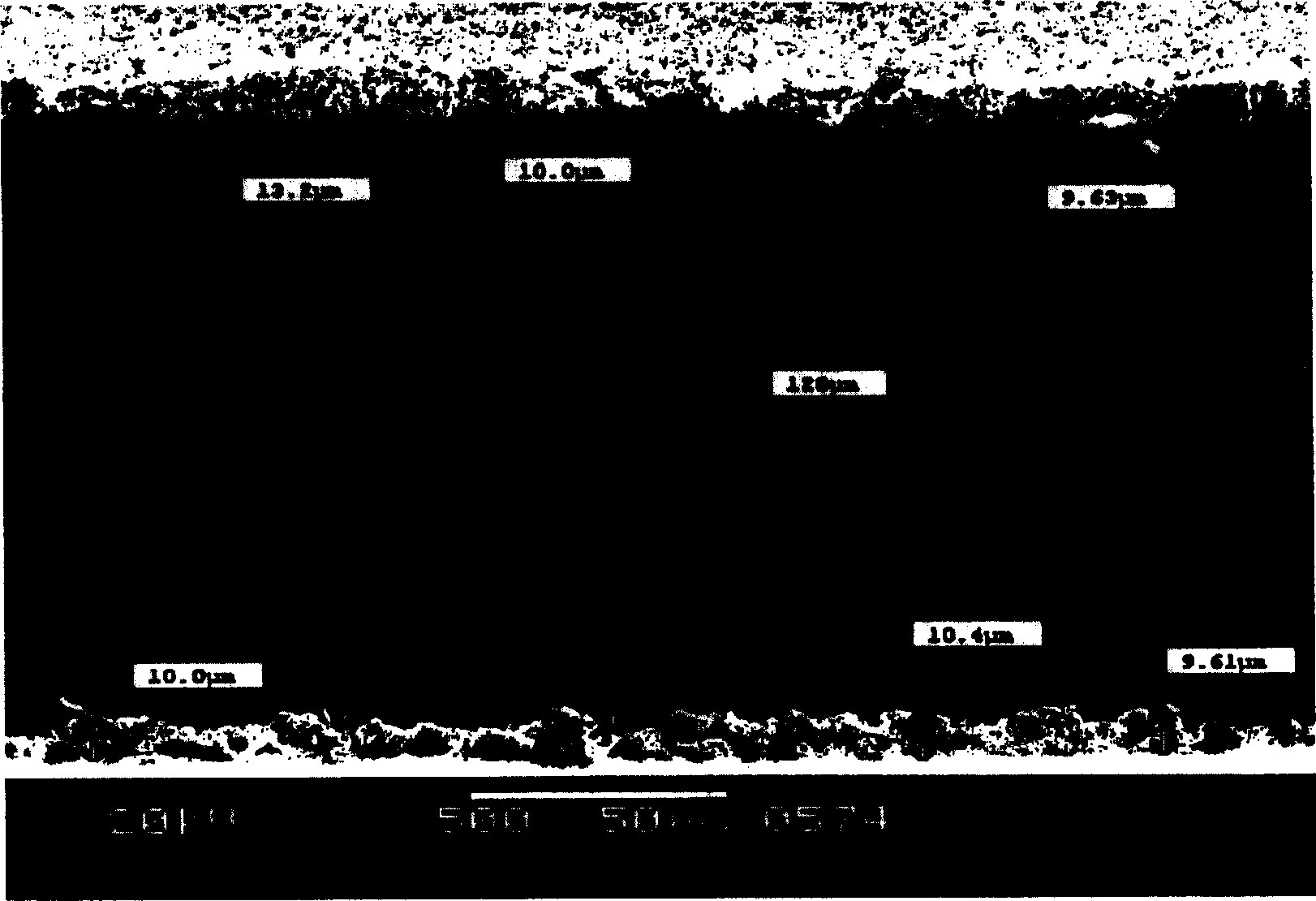

[0052] a. Take a piece of Nafion 115 film (Dupont) was treated at a certain temperature (60°C) and negative pressure (0.06MPa) for 30 minutes. Take by weighing 320mg Nafion (5% aqueous solution, EW value is 1100), dilute with 1600mg isopropanol (chemically pure, Shenyang Reagent No. cm 2 . Accurately weigh 96mg of PtRu black (Johnson Matthey), add a mixed solution of absolute ethanol and water (water: absolute ethanol=1:20, mass ratio) and mix evenly, then add 400mg 5% Nafion, continue to stir and mix evenly to obtain a catalyst Slurry, sprayed on the membrane, the final catalyst loading is 3.2mg / cm 2 .

[0053] Spray 1mg / cm on the other side of Nafion 115 2 Nafion solution (Nafion dry weight). Accurately weigh 50mg of Pt black (Johnson Matthey), add a mixed solvent of absolute ethanol and water (water: absolute ethanol = 1: 20 mass ratio) and mix uniformly, then add 160mg 5% Nafion, mix uniformly to obtain catalyst slurry, spray on film. The loading amount of the ca...

Embodiment 2

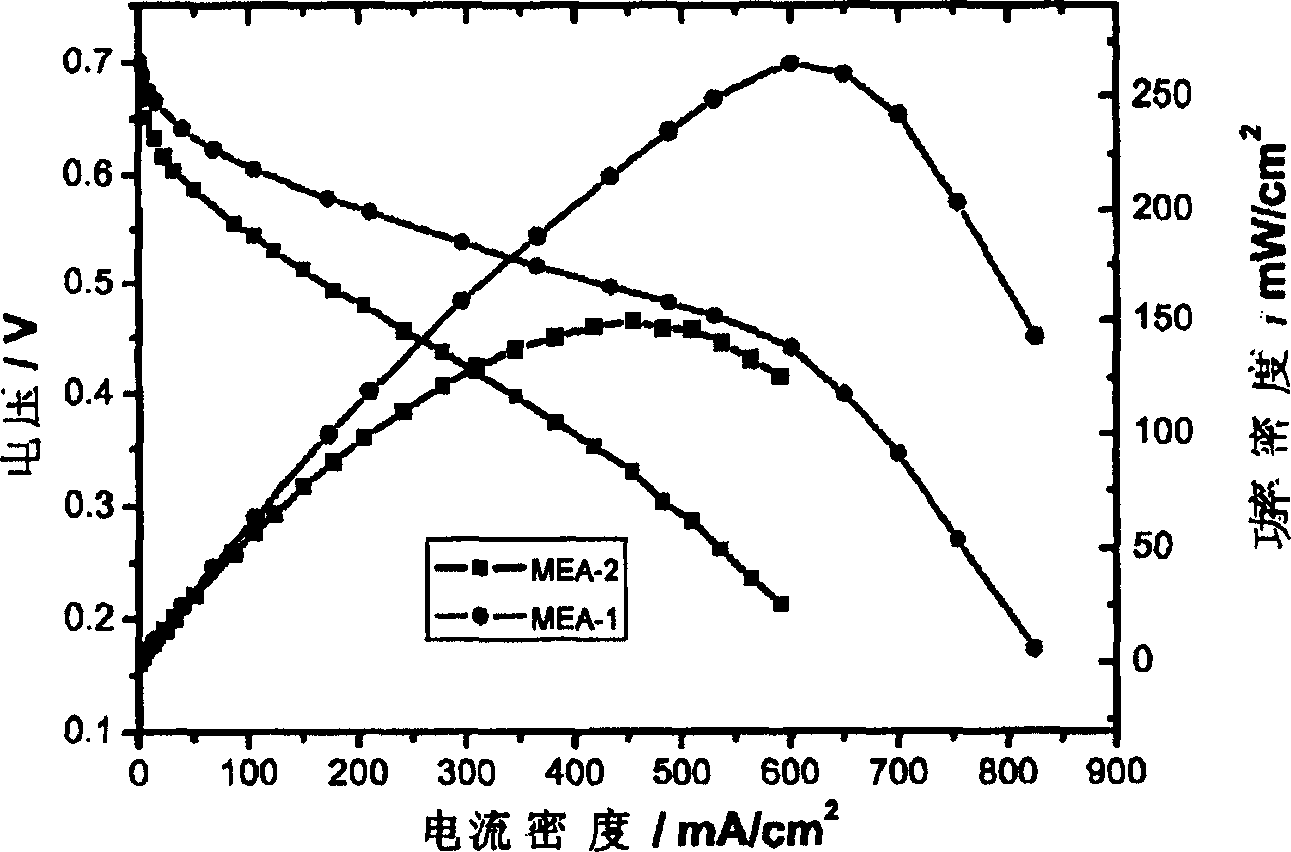

[0066] Prepare the slurry according to the steps in Example 1, then spray the catalyst slurry on the PTFE membrane, and the electrode loadings are respectively: anode: PtRu black (Johnson Matthey), 3.0 mg / cm 2 , Nafion content 20wt.%. Cathode: Pt / C (60wt%) (Johnson Matthey) 2.1mg / cm 2 , Nafion content is 15wt.%. Spray 0.5mg / cm on both sides of the Na-type Flemion membrane according to the steps of Example 1 2 Nafion (Na form, dry weight) solution. Then at 230°C, nitrogen N 2 Treated under protected conditions for 2 hours. Cut out the PTFE membrane prepared above, the size is 2×2cm 2 , placed on both sides of the sodium Nafion 115 membrane treated as above, preheated at 170°C for 1 minute, kept at 43MPa for 1.5 minutes, took it out to cool, removed the PTFE membrane, and then hydrogenated the Flemion membrane with the catalytic layer After that, the cathode and anode diffusion layers are placed on both sides to assemble the battery.

[0067] The performance of the membra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com