Patents

Literature

161 results about "Polymer dielectrics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

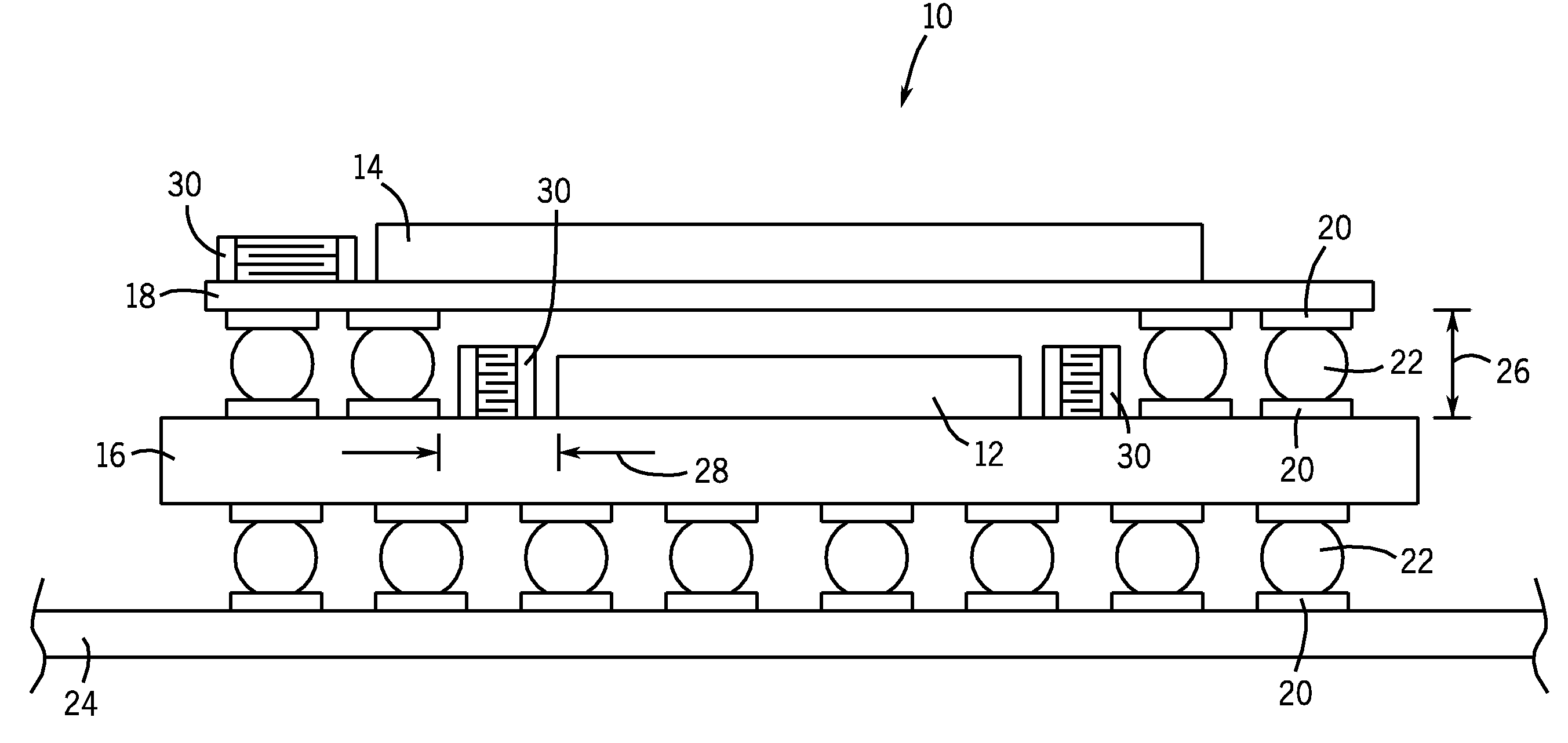

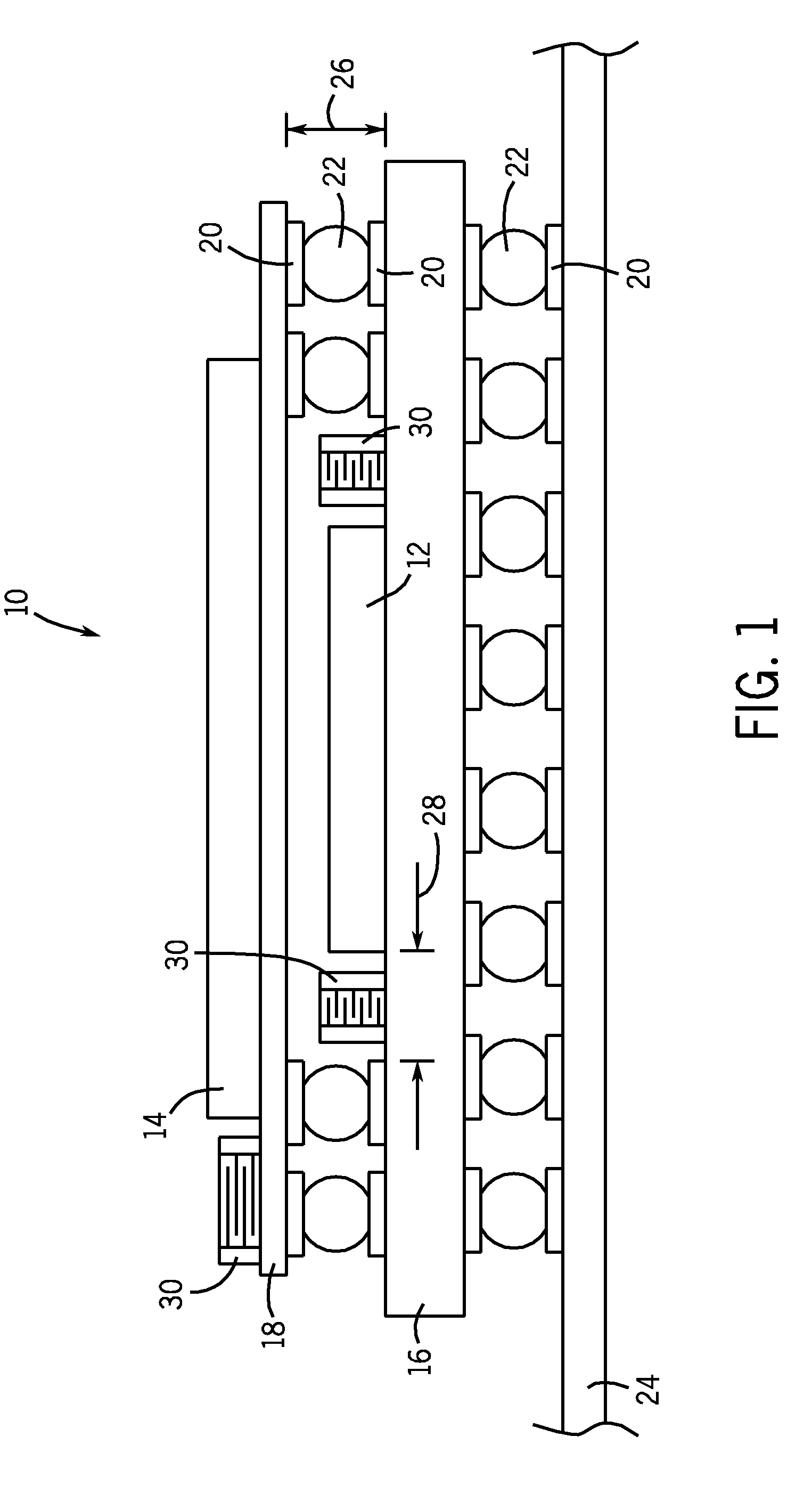

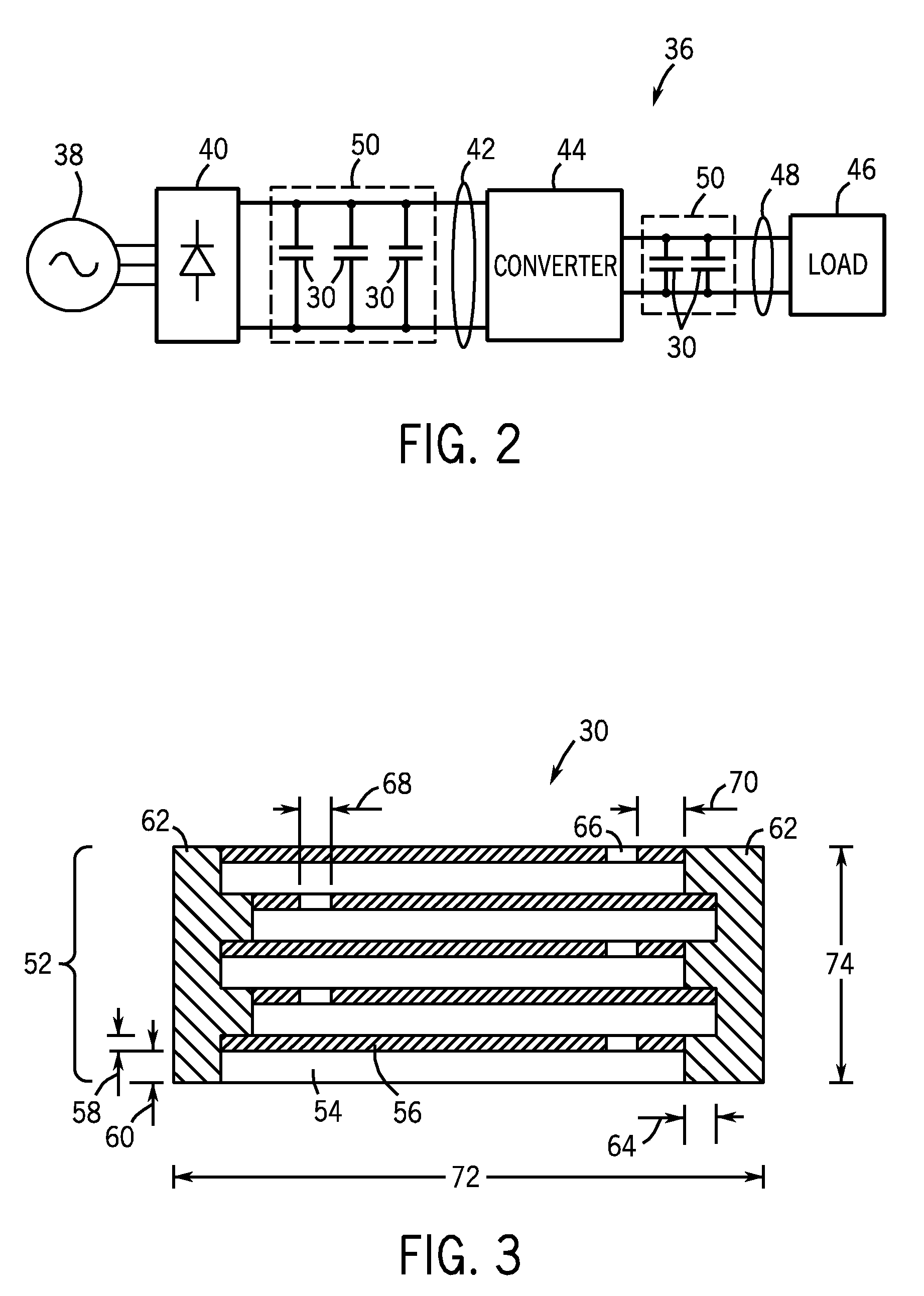

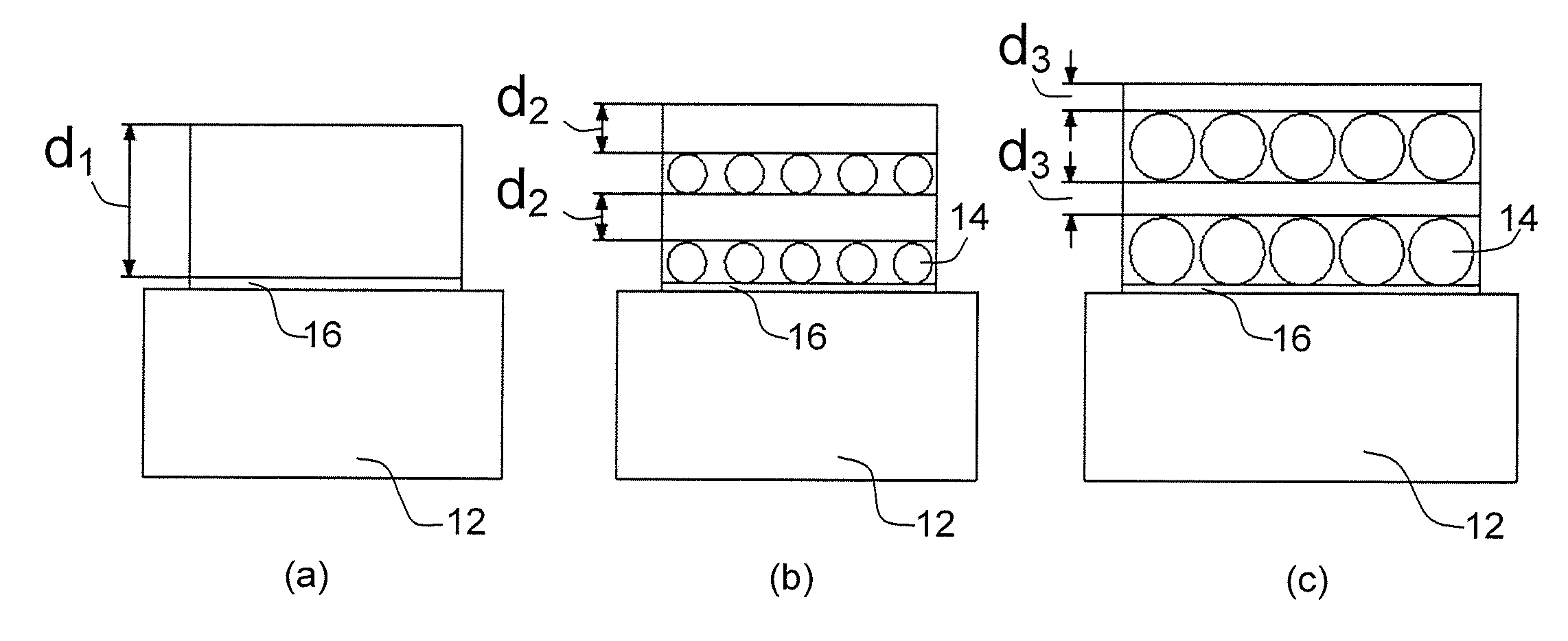

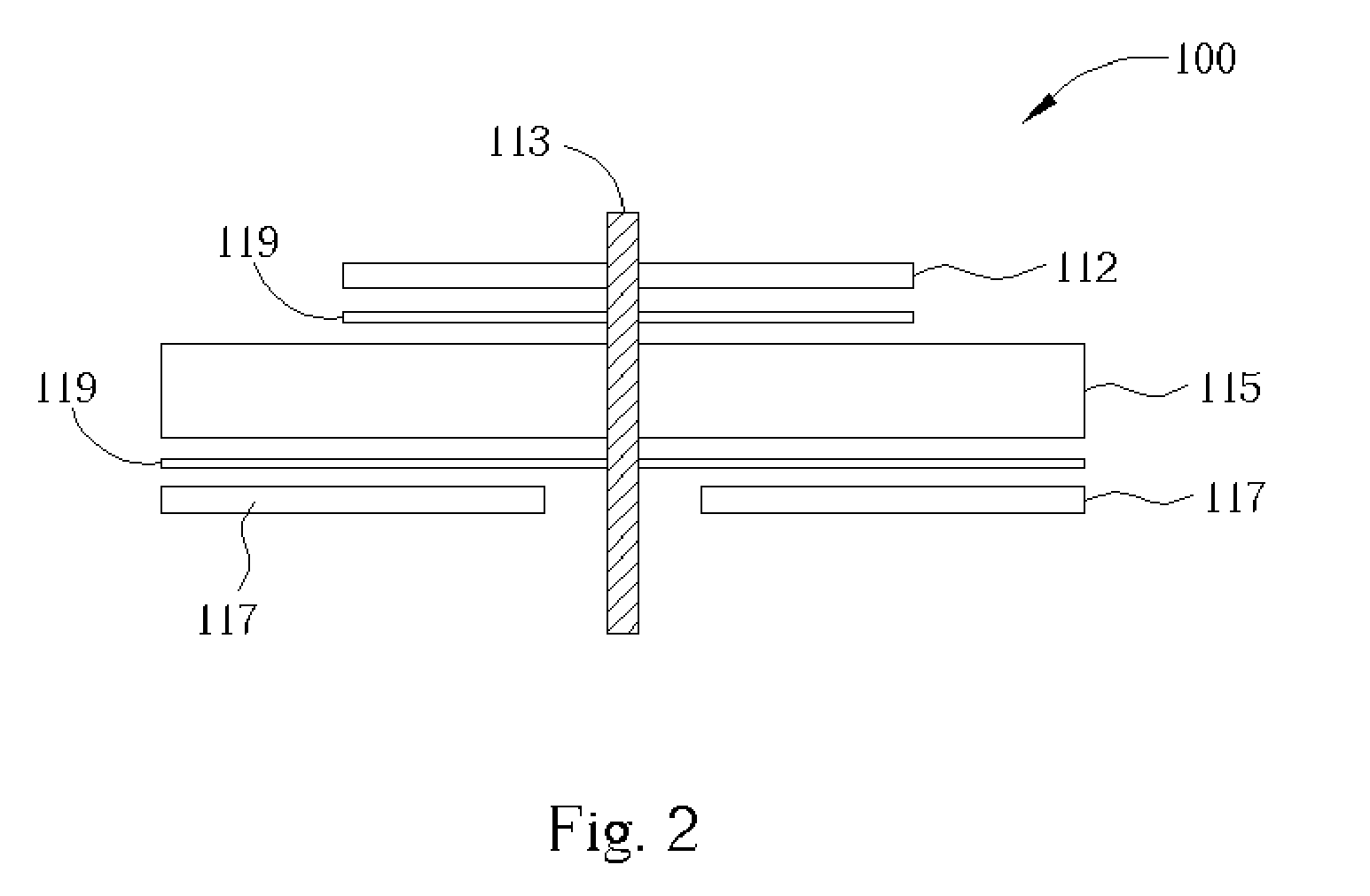

High-temperature capacitors and methods of making the same

High-temperature, multiple-layer polymer (MLP) capacitors with a stacked electrode arrangement are disclosed. The capacitor electrodes are separated by a polymer dielectric that is stable at high temperatures. In some embodiments, the polymer dielectric also has a high permittivity and is filled with high-permittivity nanoparticles, which enables the capacitor to achieve a very high capacitance density.

Owner:GENERAL ELECTRIC CO

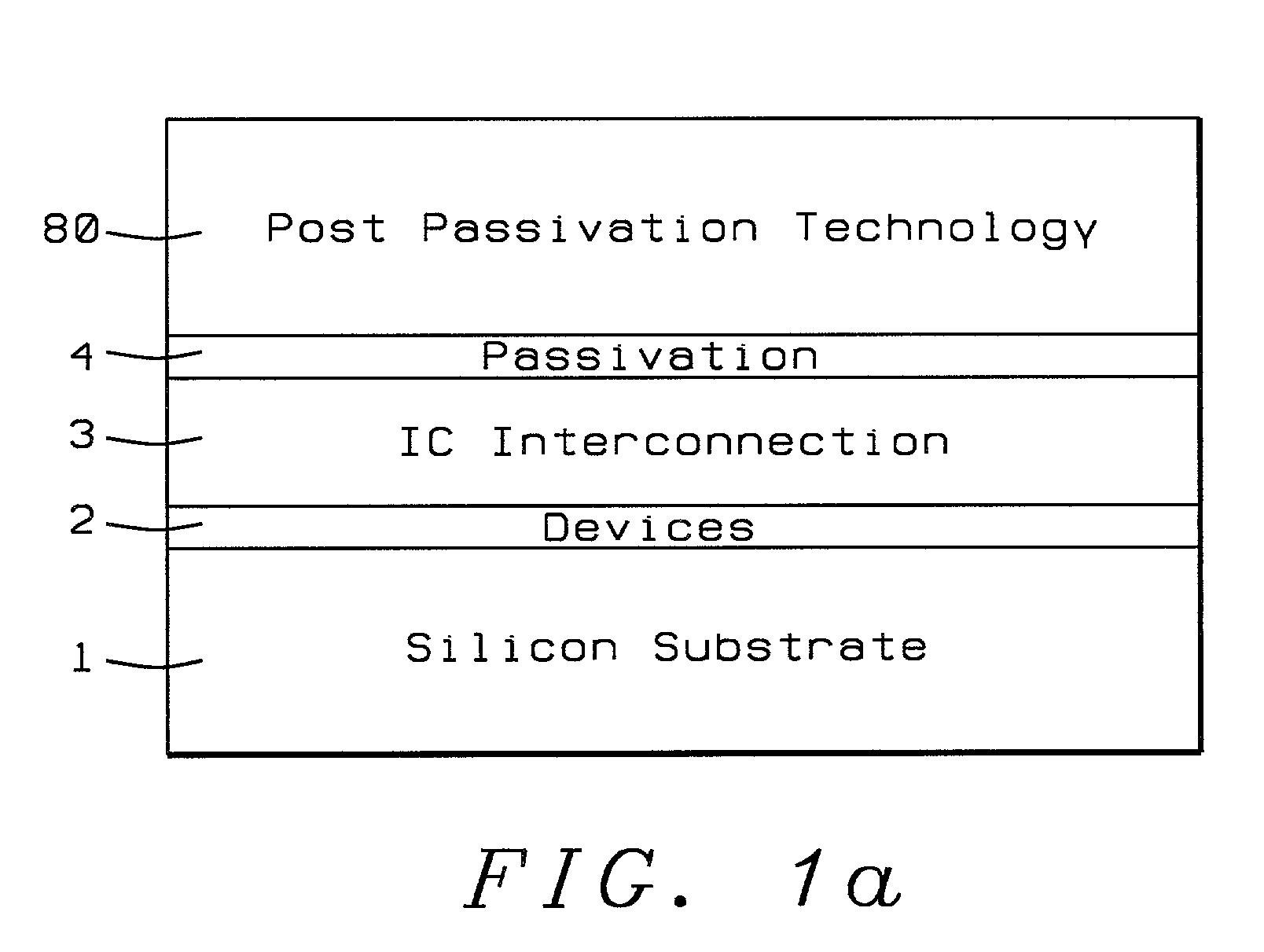

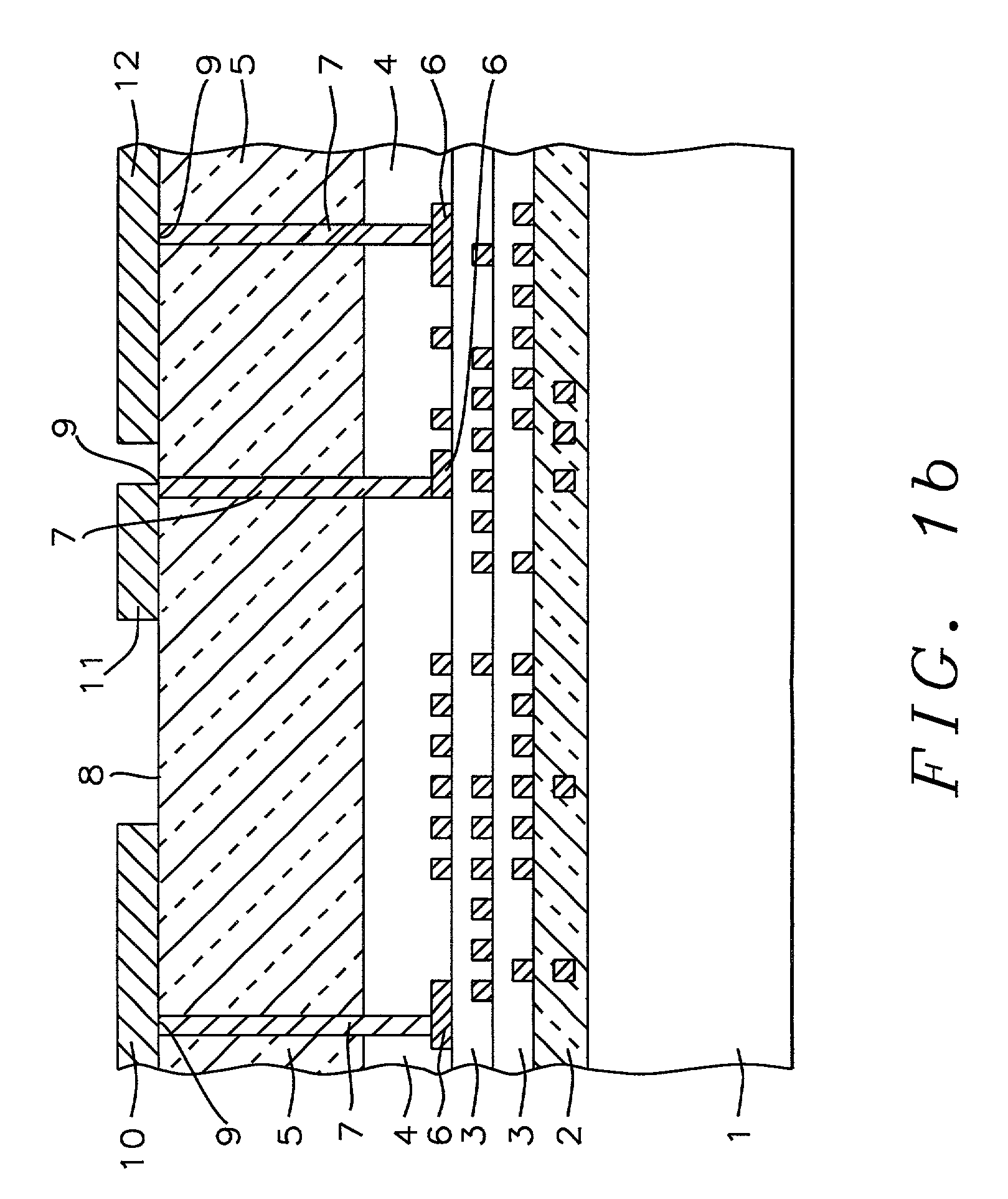

Post passivation method for semiconductor chip or wafer

InactiveUS7405149B1Improve performanceReduce resistive voltage dropSemiconductor/solid-state device detailsSolid-state devicesPolymer dielectricsSemiconductor chip

The present invention adds one or more thick layers of polymer dielectric and one or more layers of thick, wide metal lines on top of a finished semiconductor wafer, post-passivation. The thick, wide metal lines may be used for long signal paths and can also be used for power buses or power planes, clock distribution networks, critical signal, and re-distribution of I / O pads for flip chip applications. Photoresist defined electroplating, sputter / etch, or dual and triple damascene techniques are used for forming the metal lines and via fill.

Owner:QUALCOMM INC

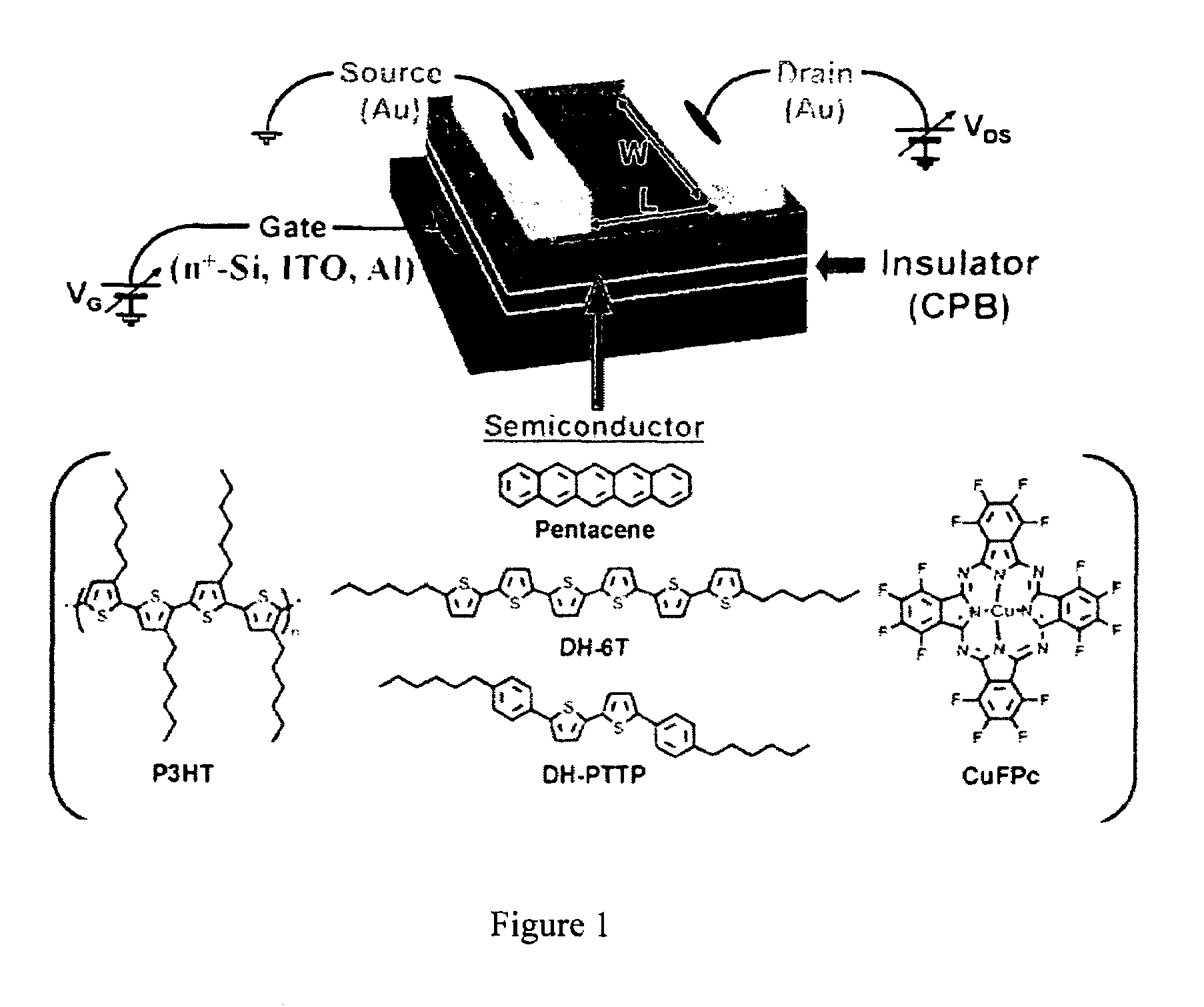

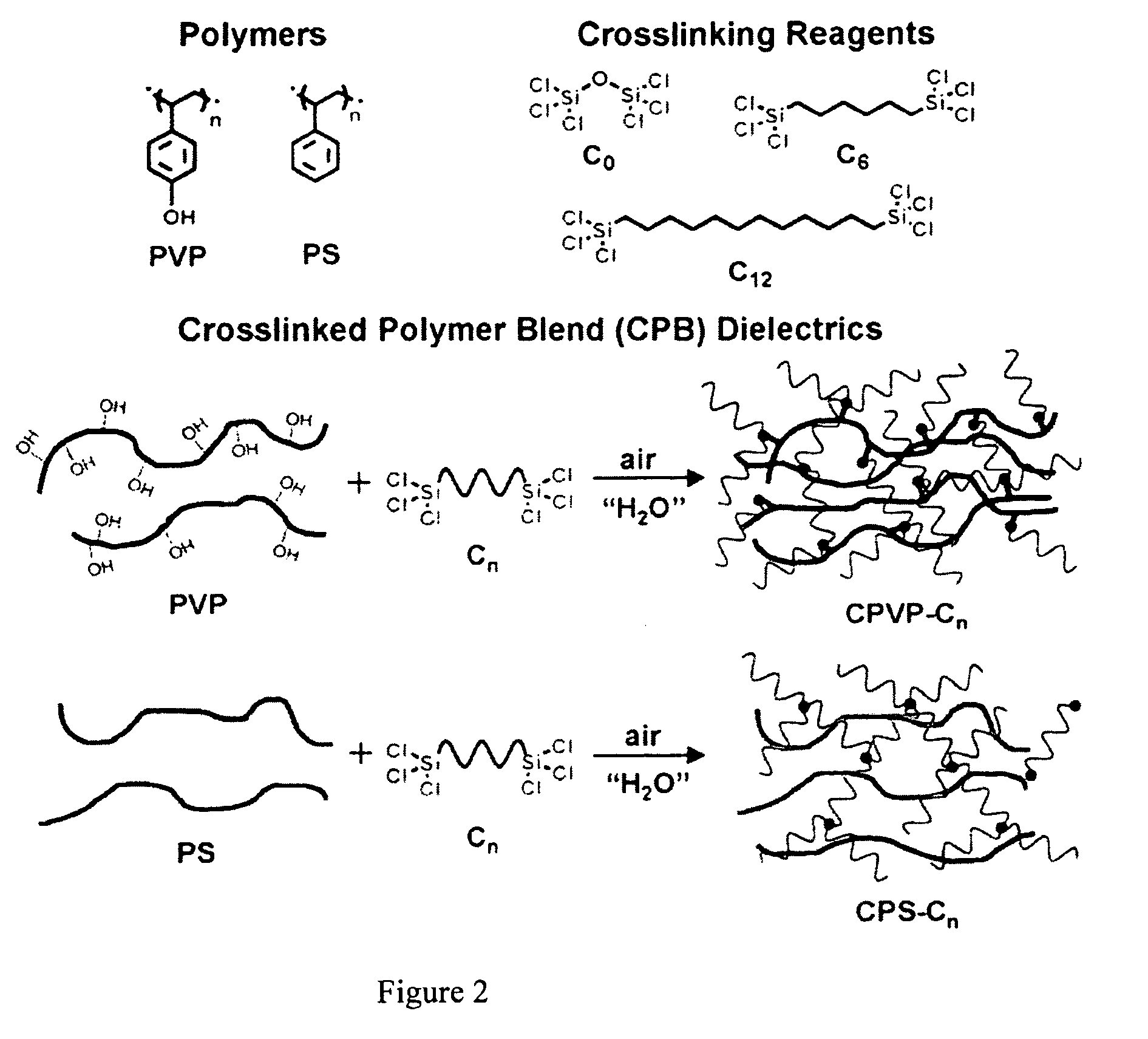

Siloxane-polymer dielectric compositions and related organic field-effect transistors

InactiveUS7605394B2Group 4/14 element organic compoundsFibre treatmentPolymer dielectricsOrganic field-effect transistor

Dielectric compositions comprising siloxane and polymeric components, as can be used in a range of transistor and related device configurations.

Owner:NORTHWESTERN UNIV

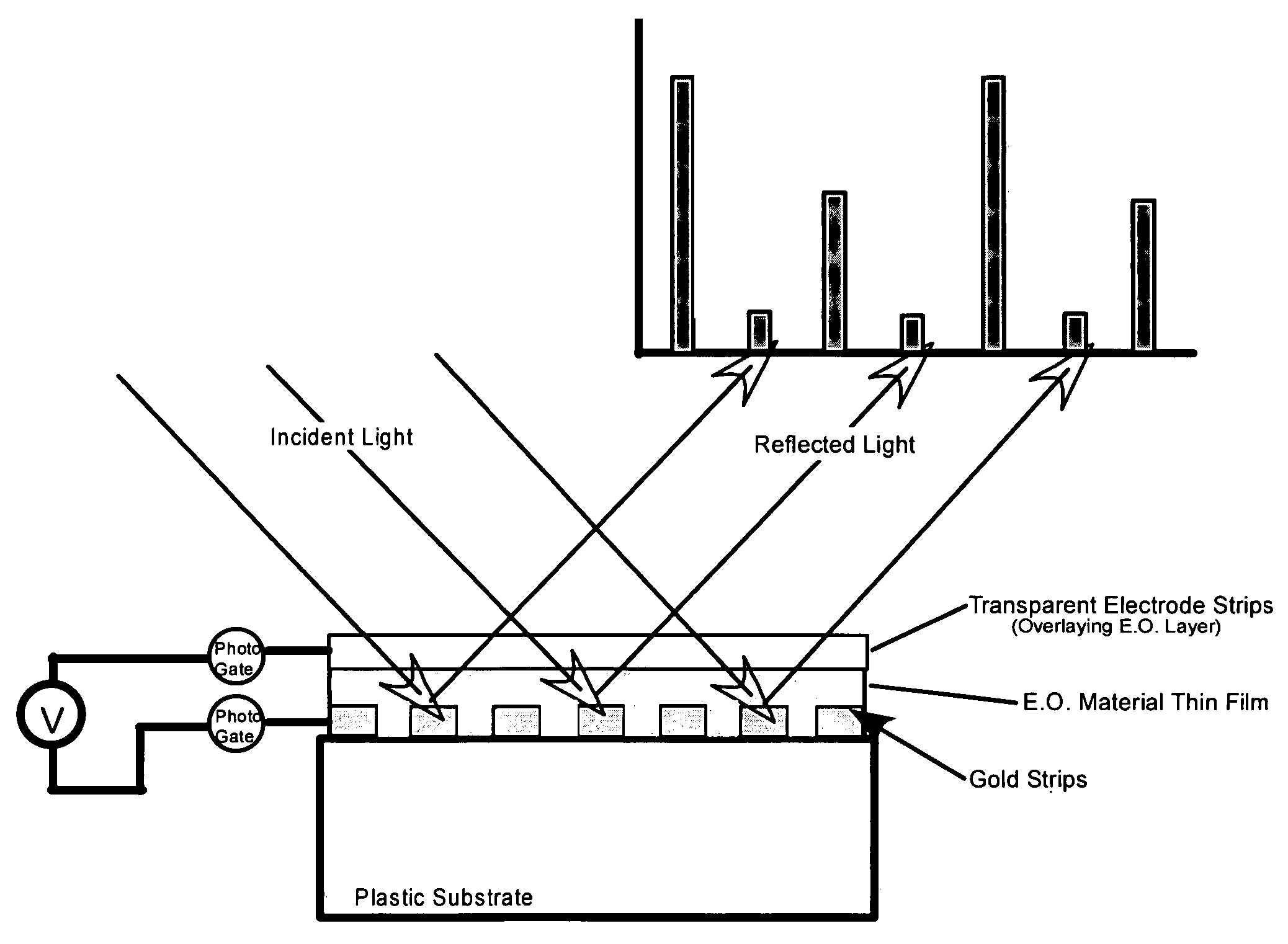

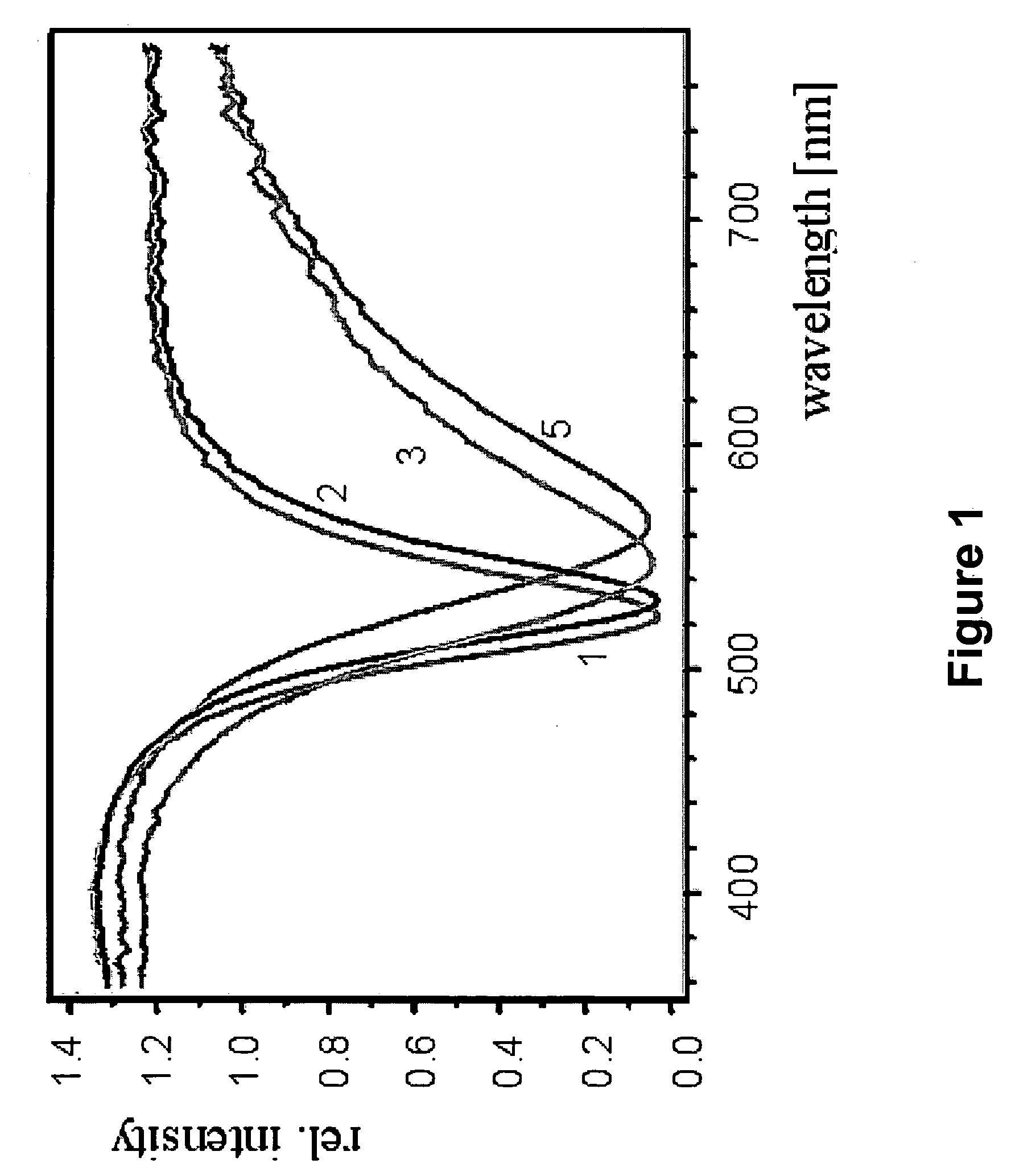

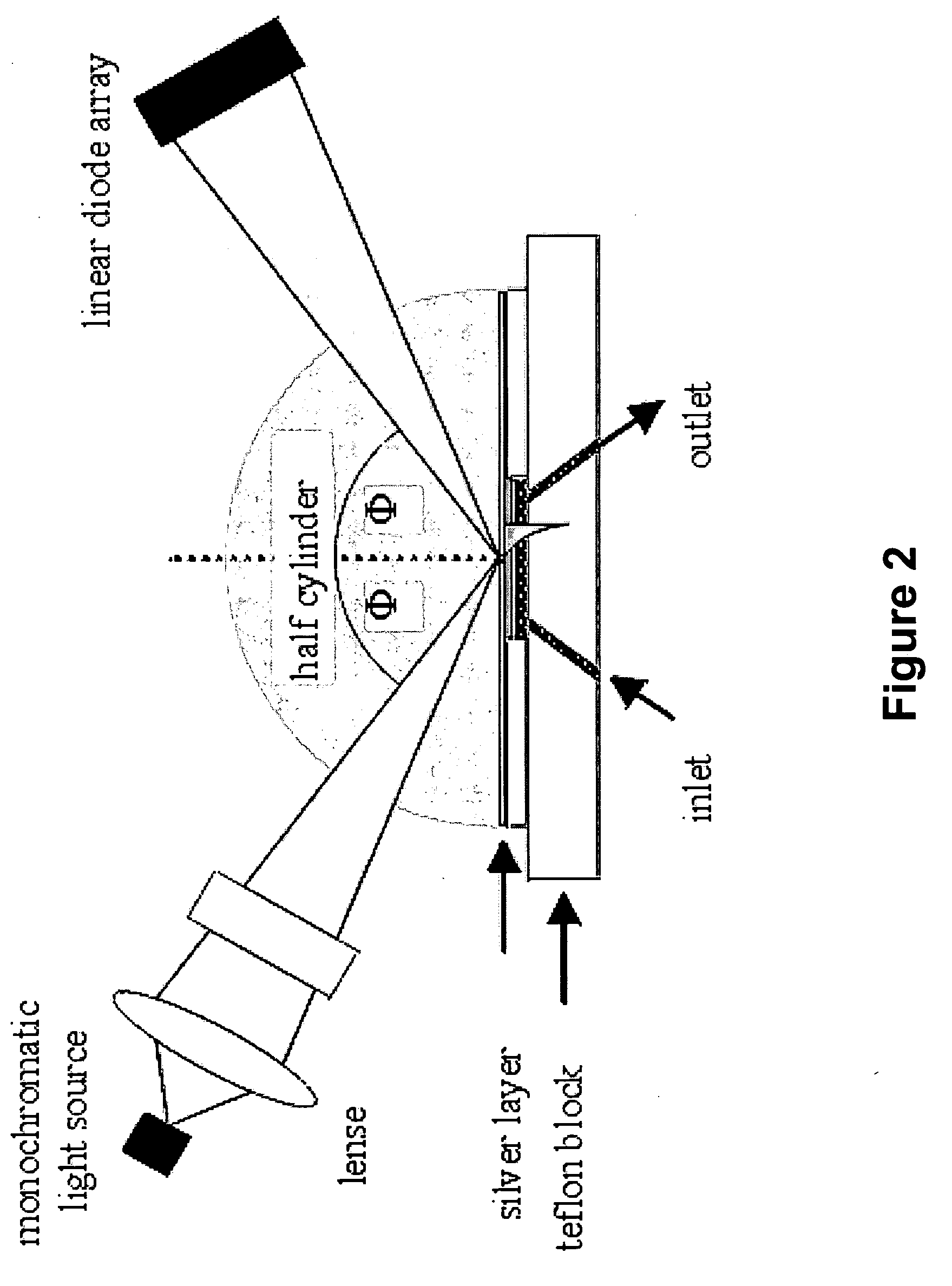

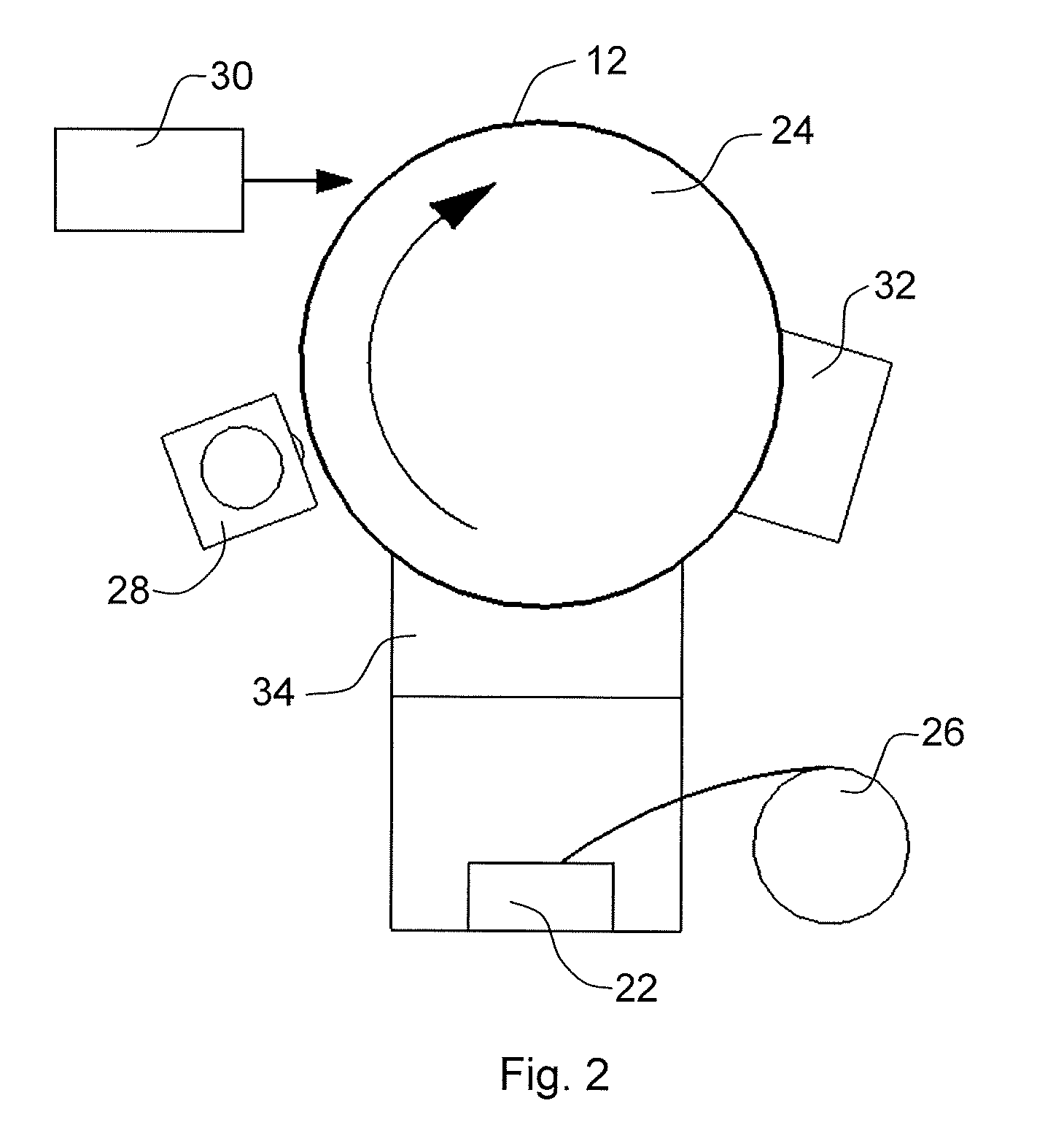

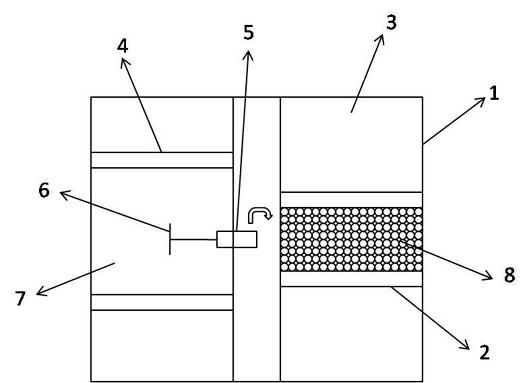

Electro-optic array interface

InactiveUS20050248829A1Improve interconnect densityStatic indicating devicesScattering properties measurementsAngle of incidencePolymer dielectrics

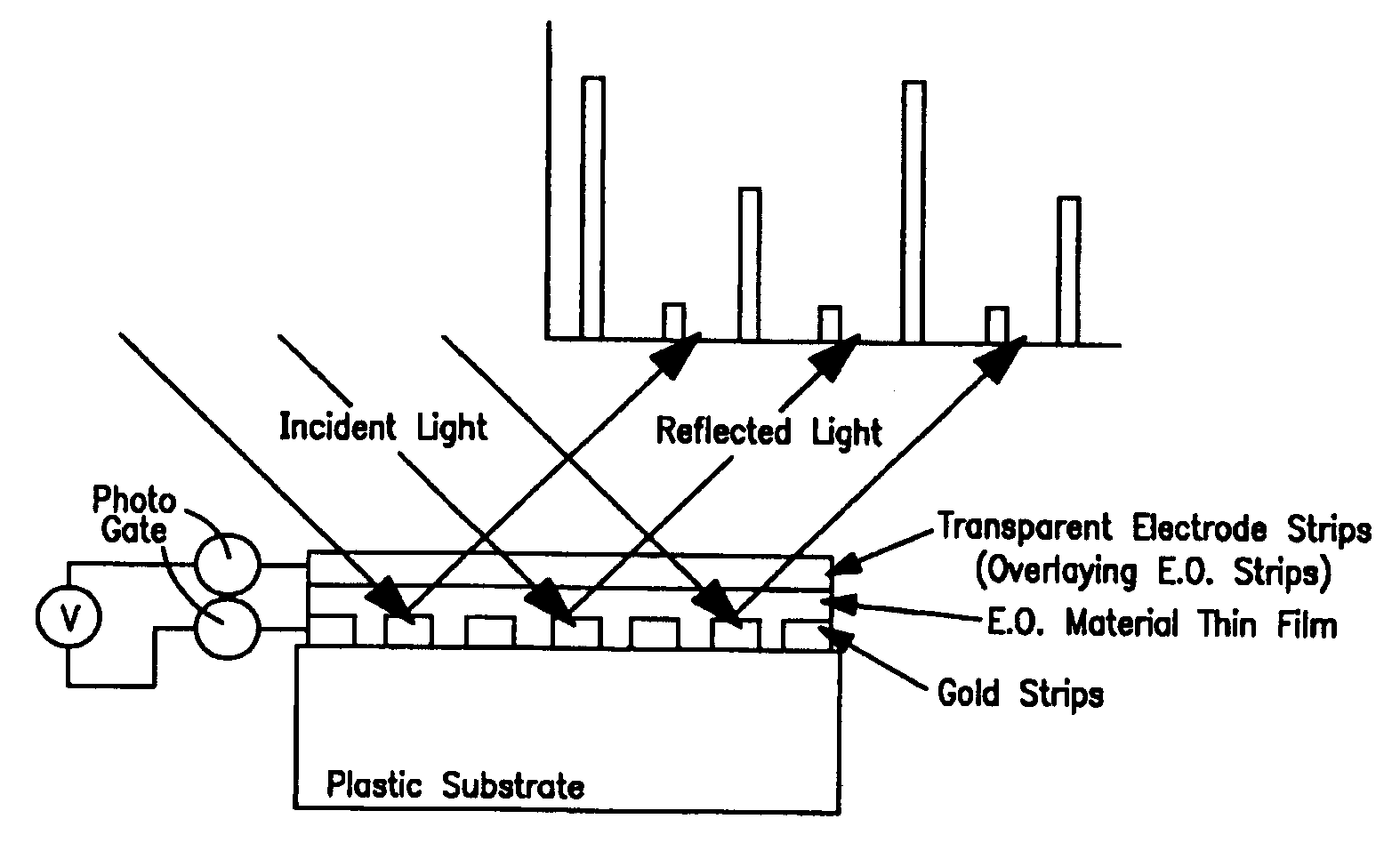

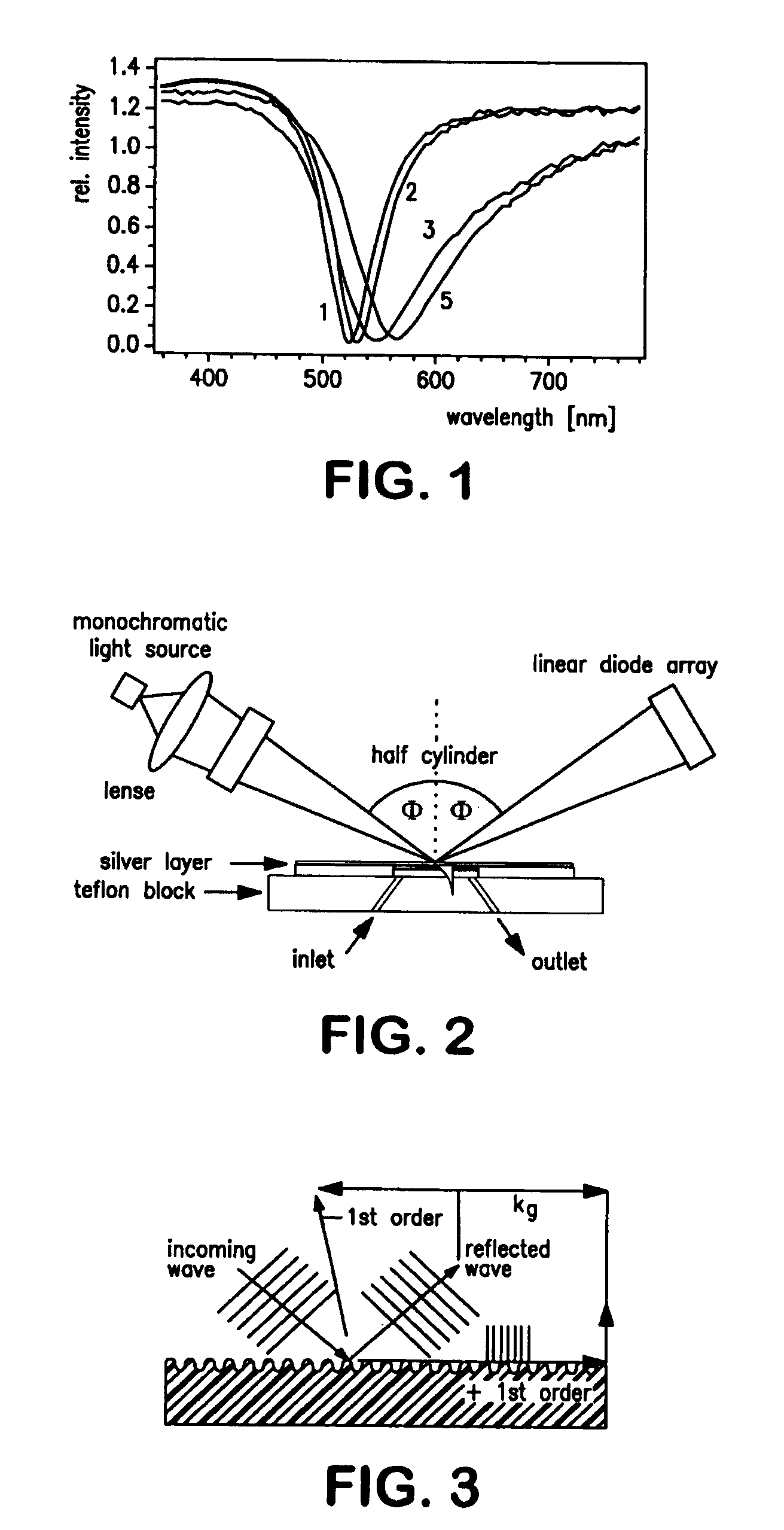

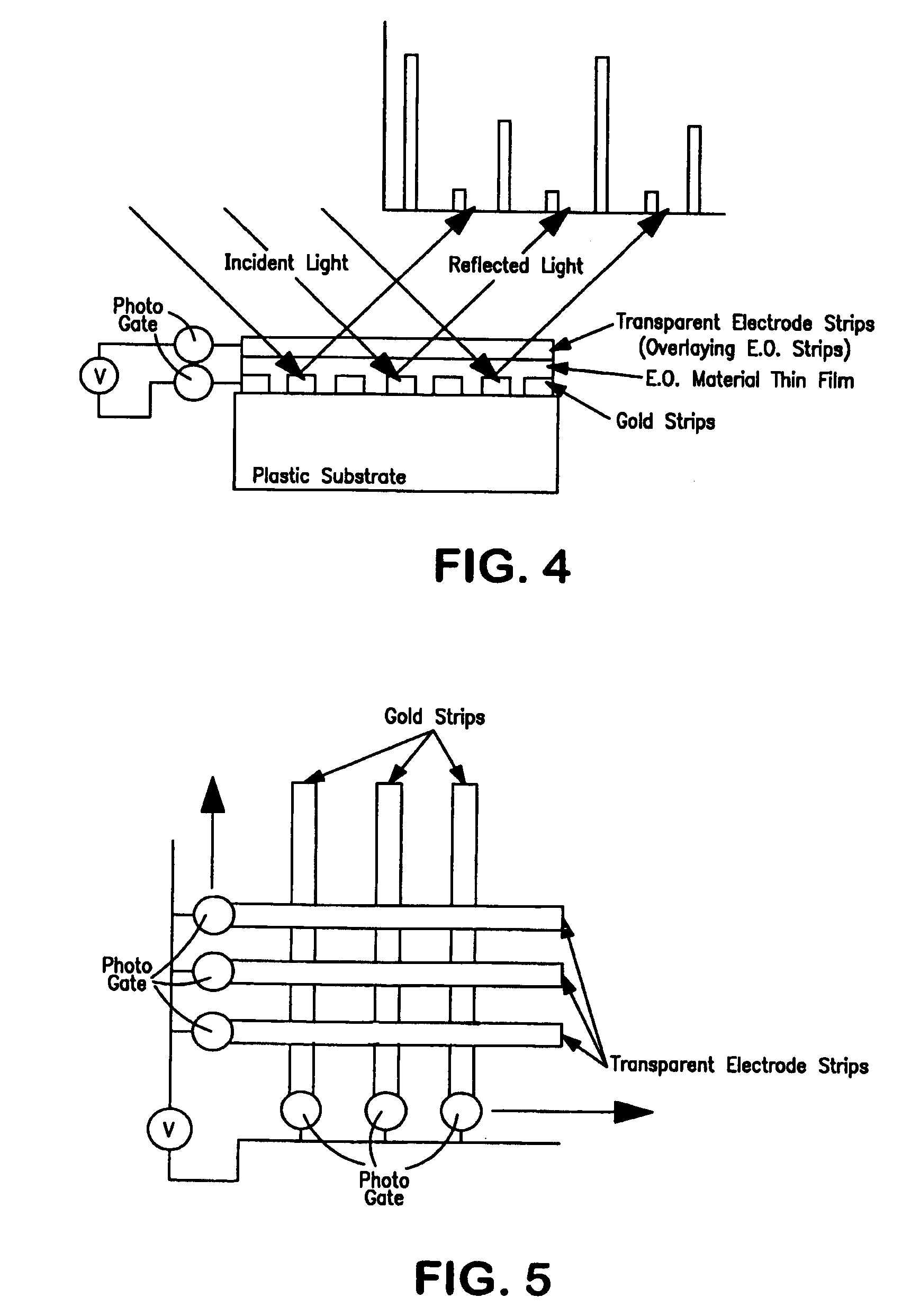

A grating coupled surface plasmon resonance optical modulator is disclose. A electro-optic polymer dielectric is deposited on the metallic surface of a diffraction grating to provide a metal / dielectric interface. A surface plasmon will propagate at the metal / dielectric interface in a resonant condition, e.g., when the metal surface is illuminated by transverse magnetic (TM) polarized light of the appropriate wavelength, angle of incidence and phase velocity. In the present invention, phase velocity is controlled by the diffraction grating. A transparent electrode deposited on the electro-optic layer allows an electrical potential to be applied across the electro-optic polymer. The applied electrical potential (voltage) changes the index of refraction of the electro-optic polymer, thereby disrupting the resonant condition to produce an optically detectable change in reflectance of incident light from the metal layer. The disclosed grating coupled surface plasmon resonance optical modulator may be configured as an electronically or optically addressable array.

Owner:CIENCIA

Polymer dielectric medium with low dielectric constant and low loss and preparation method of polymer dielectric medium

InactiveCN103980664AGood dispersionImprove thermal conductivitySynthetic resin layered productsEpoxyHeat conducting

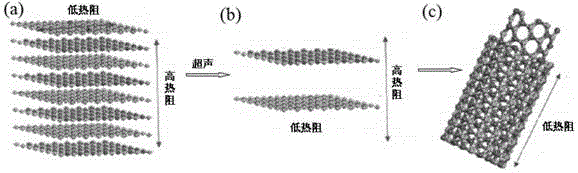

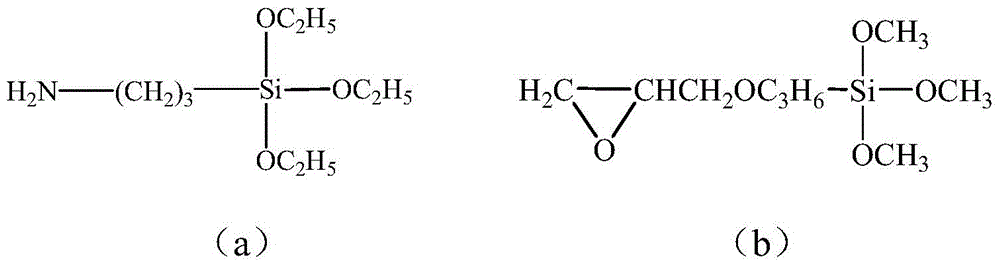

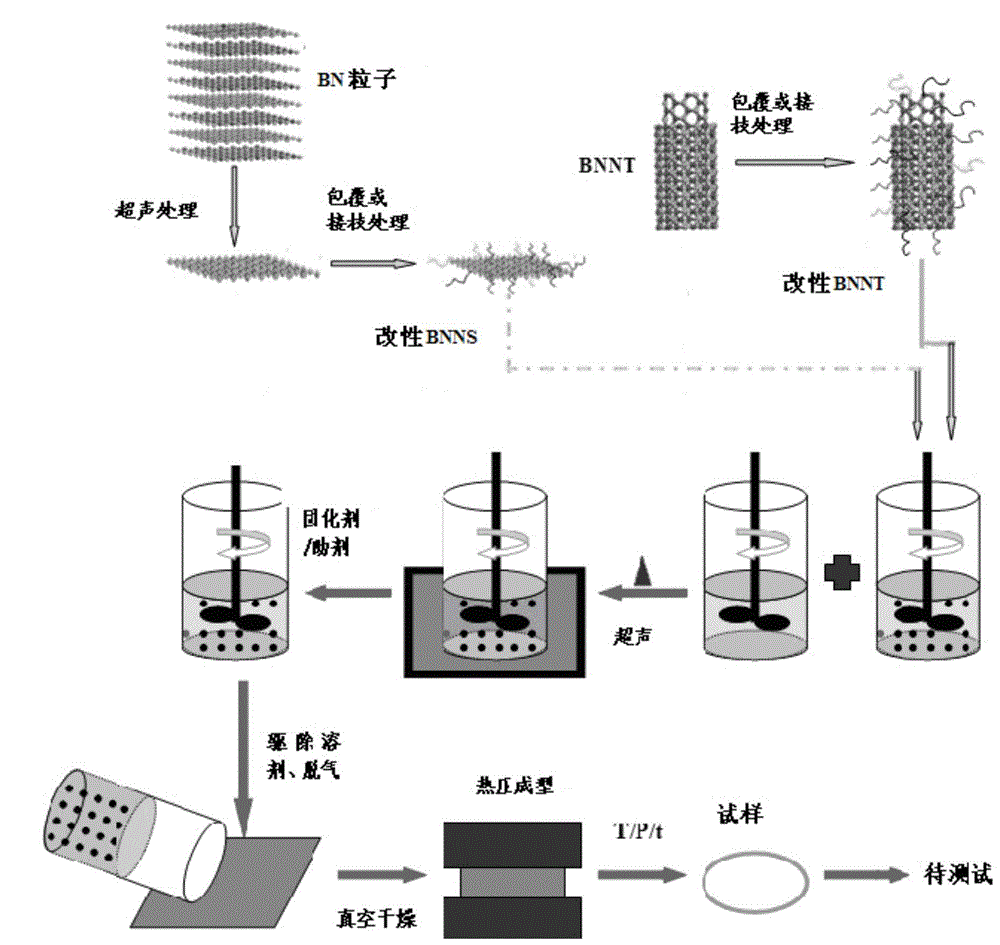

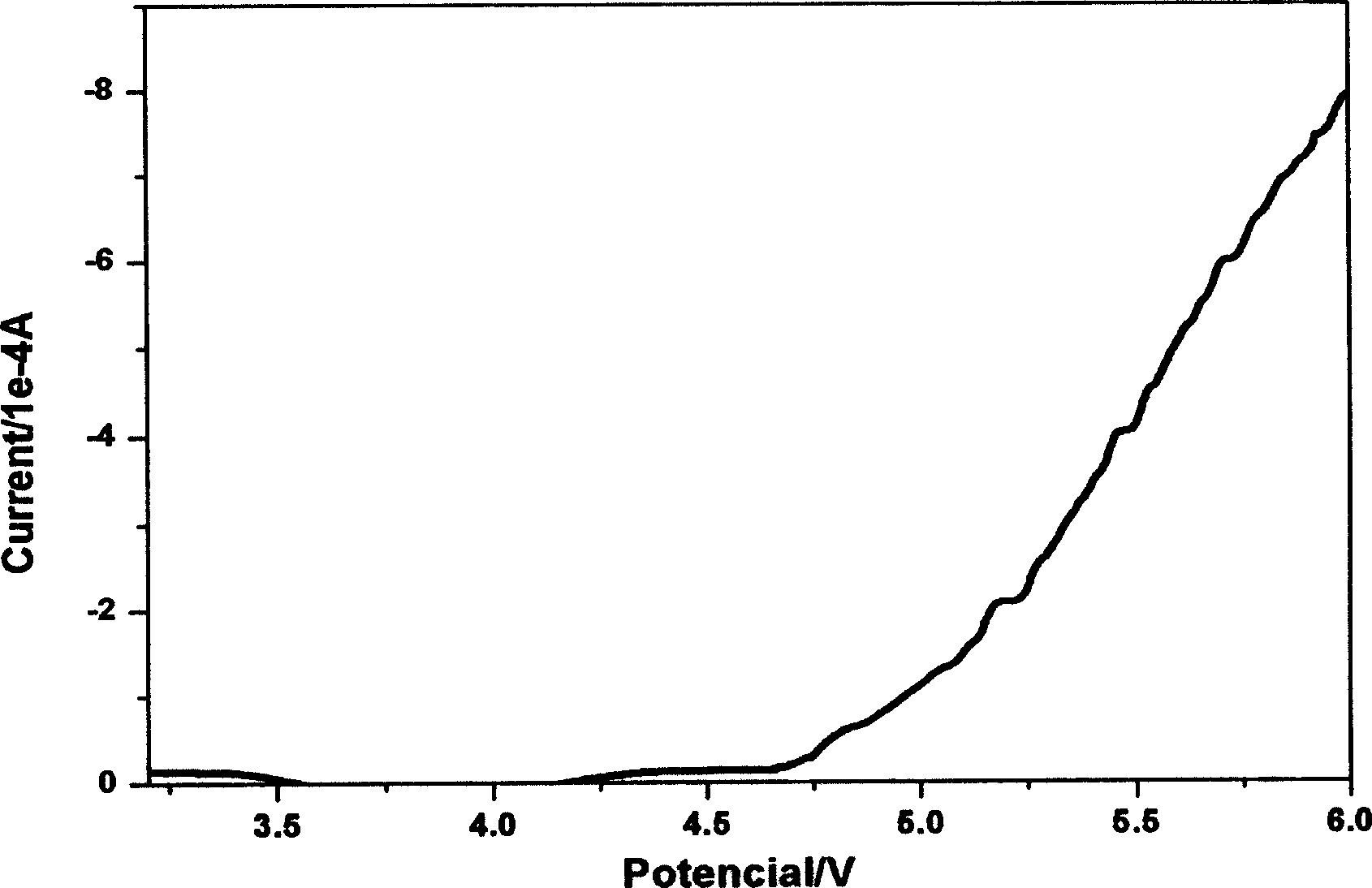

The invention discloses a polymer dielectric medium with low dielectric constant and low loss and a preparation method of the polymer dielectric medium. The polymer dielectric medium comprises the following raw materials: 50-60% of epoxy resin system, and 40-50% of mixed boron nitride nanoparticles, wherein the mixed boron nitride nanoparticle is a mixture of a boron nitride nanotube and a boron nitride nanotube; the epoxy resin system is formed by 100phr of epoxy resin E-51, 85phr of methyl hexahydrophthalic anhydride and 1phr of benzyl dimethylamine in a mixing manner. The thermal breakdown voltage of the polymer dielectric medium is significantly improved by the polymer dielectric material with high heat conductivity and high electric breakdown, the service life is prolonged, the dielectric constant and loss and the heat expansion coefficient are reduced, the mechanical strength and the tenacity are improved, the highest heat conductivity can be up to 5.26W / mK, the volume resistivity is about 1014ohm.cm, the thermal breakdown voltage is about 2-3kV / mm higher than that of the similar heat-conducting polymer dielectric medium, and the dielectric constant and the loss are a little lower than those of pure resin.

Owner:XIAN UNIV OF SCI & TECH

Production for gel polymer electrolyte

ActiveCN1645662AHigh mechanical strengthImprove electrochemical stabilityOrganic electrolyte cellsSecondary cellsPolymer electrolytesPolymer science

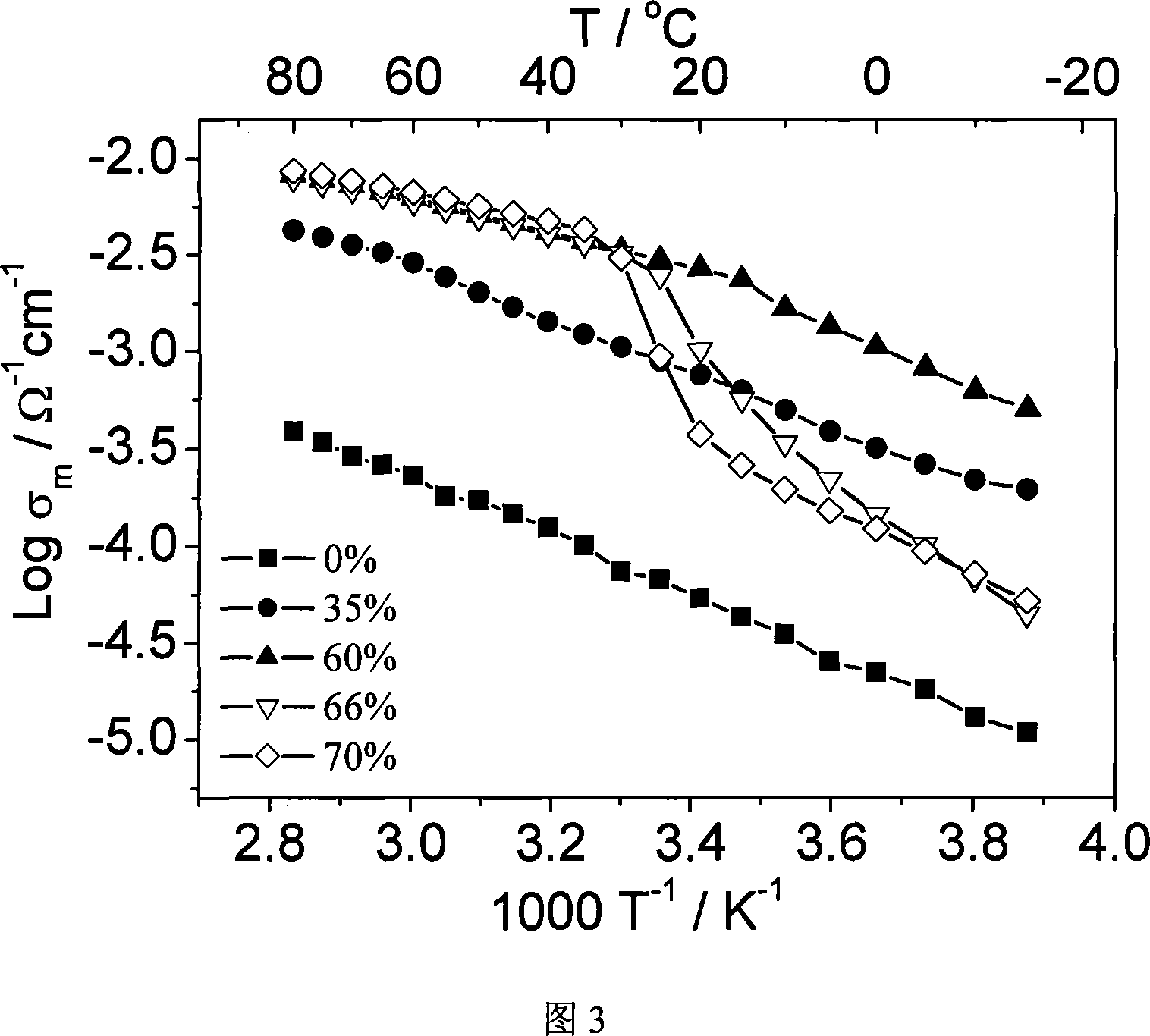

The method includes following step: two monomers are mixed according to the ratio of 1.0 to 1.0-9.0; then it mixes with thermal booster and liquid lithium ion battery solution to form the fore body of gel polymer dielectric; the fore body is injected into half finished battery. the half finished battery is vacuumized and sealed; the half finished battery is made thermal polymerization reaction, and the gel polymer dielectric is obtained.

Owner:SHENZHEN CAPCHEM TECH

Compound polymer electrolytic material and preparation method thereof

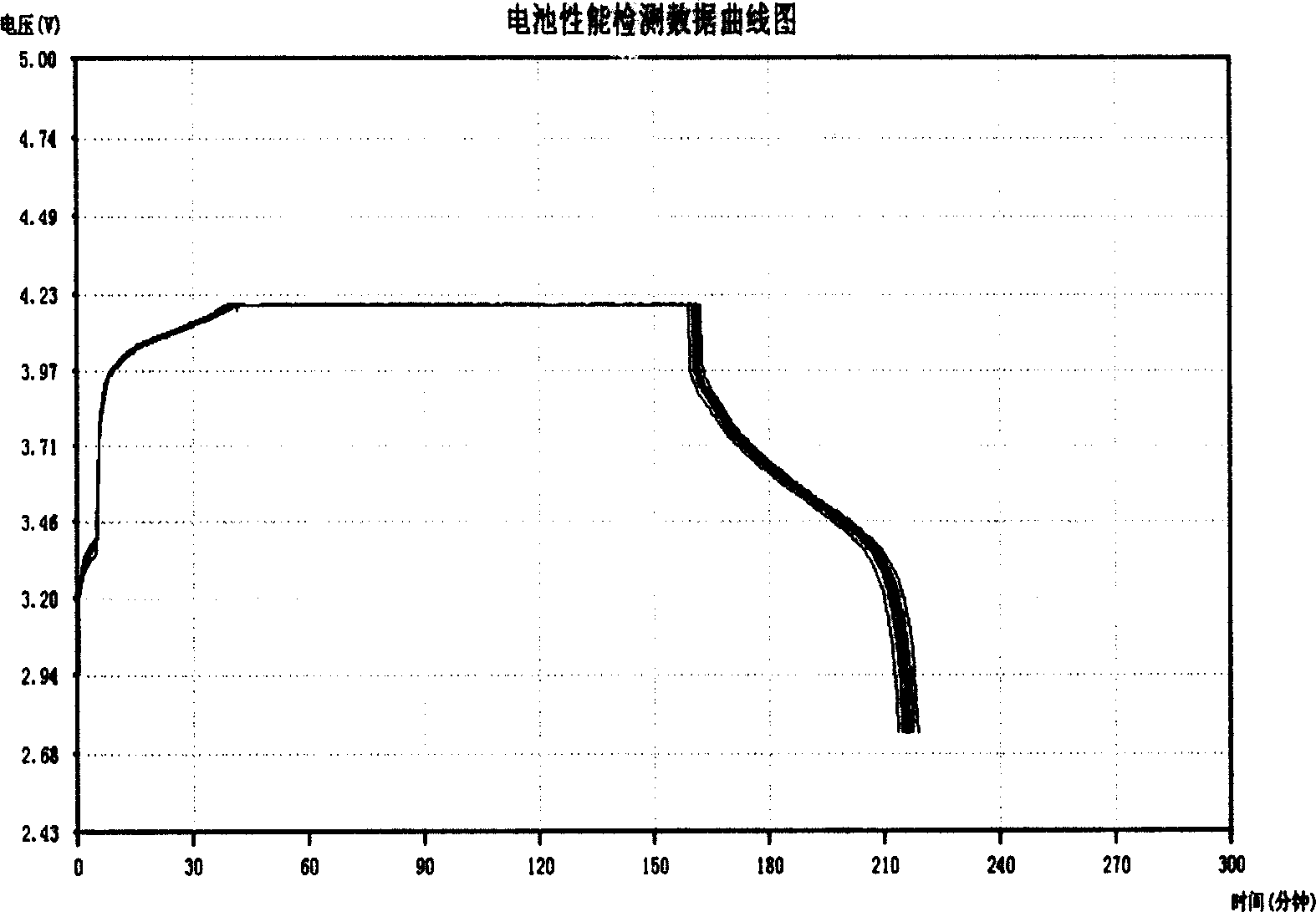

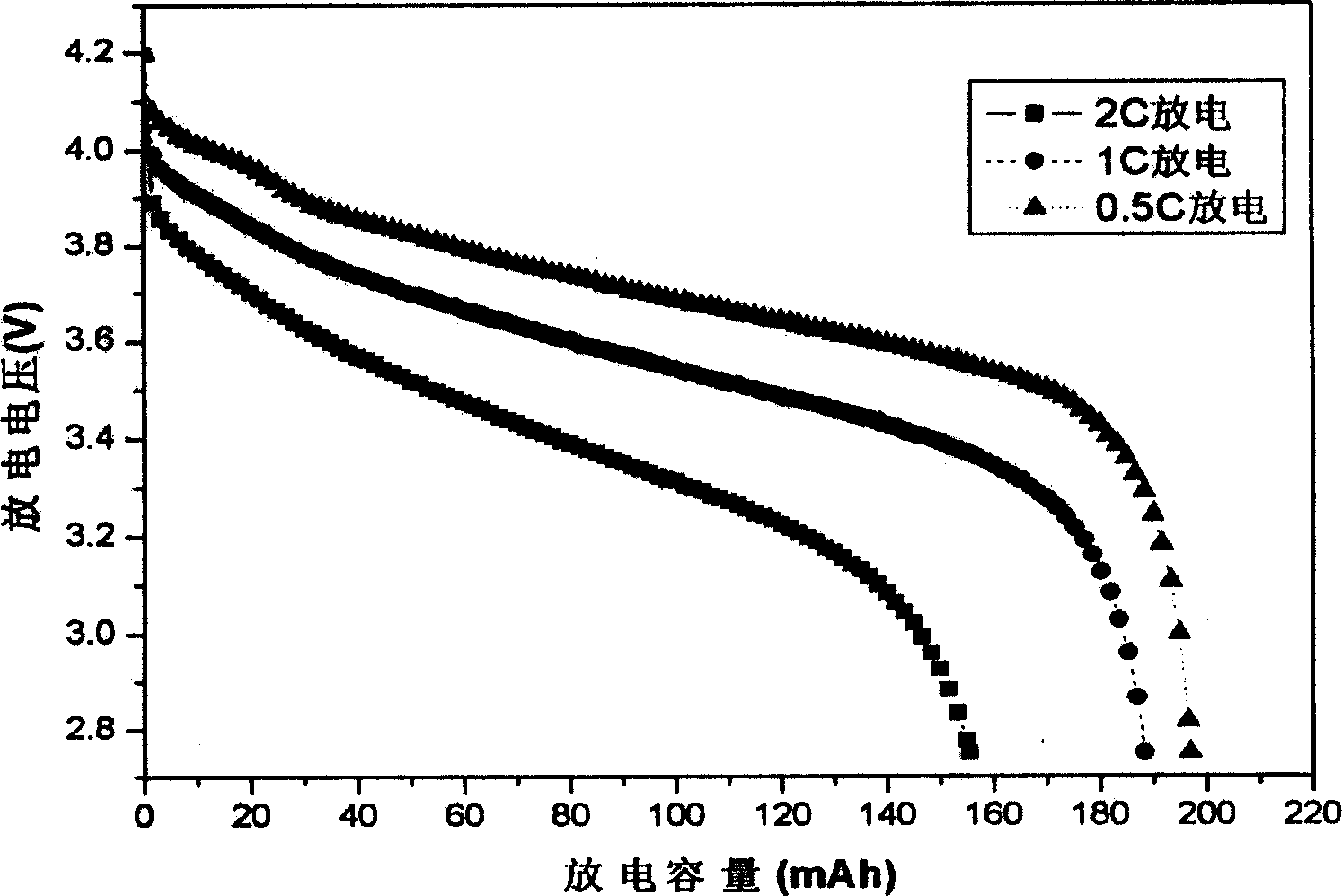

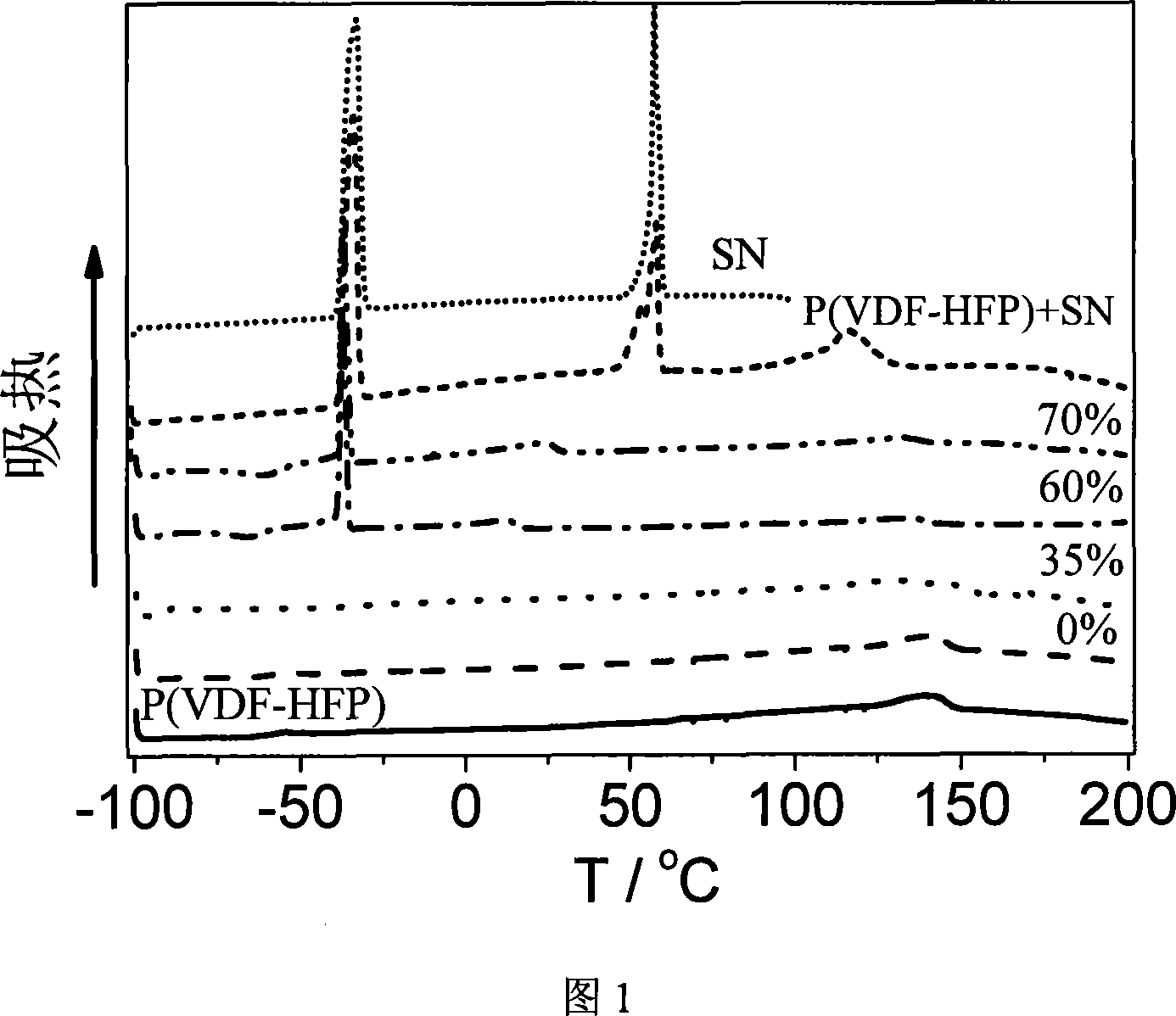

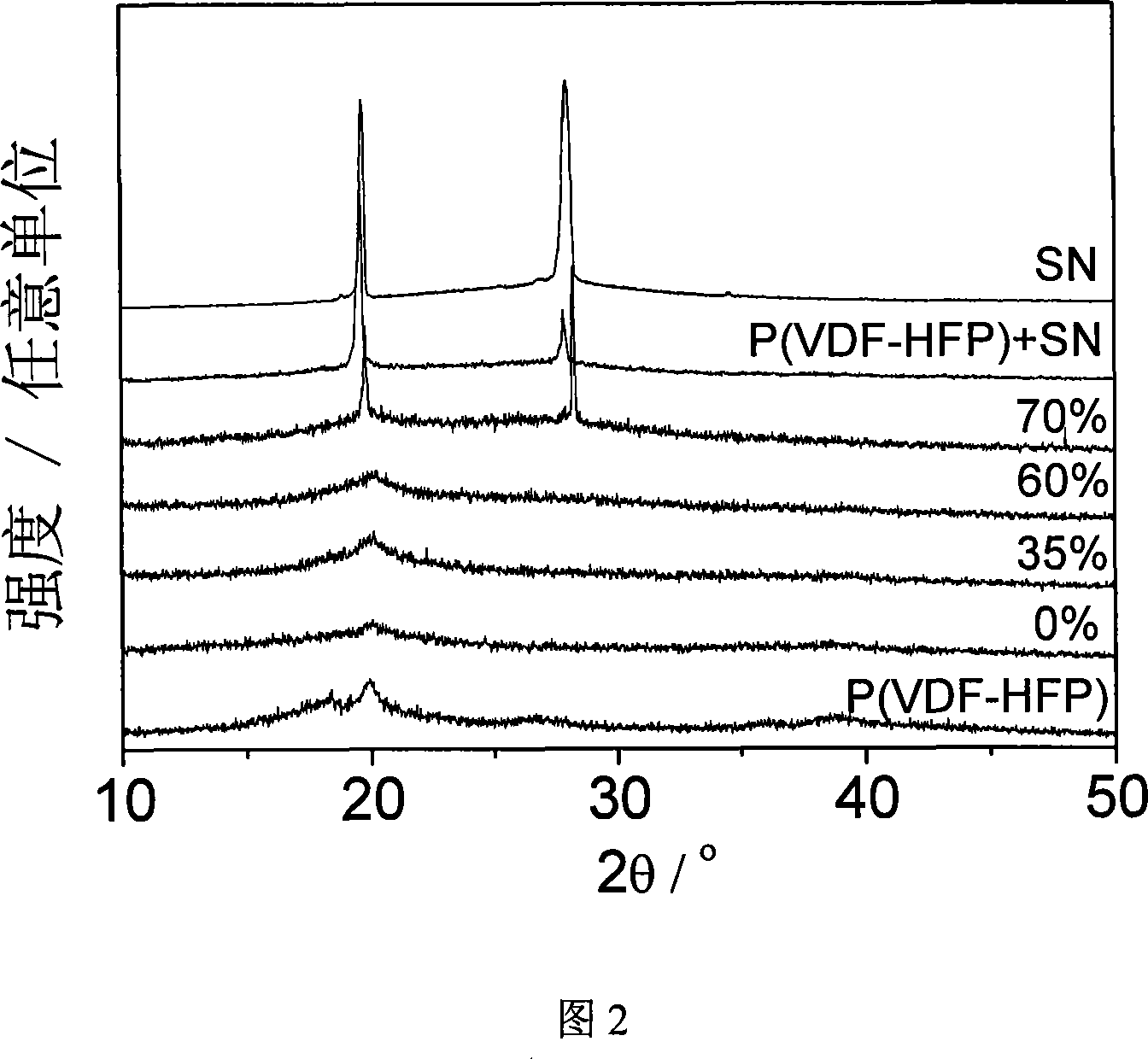

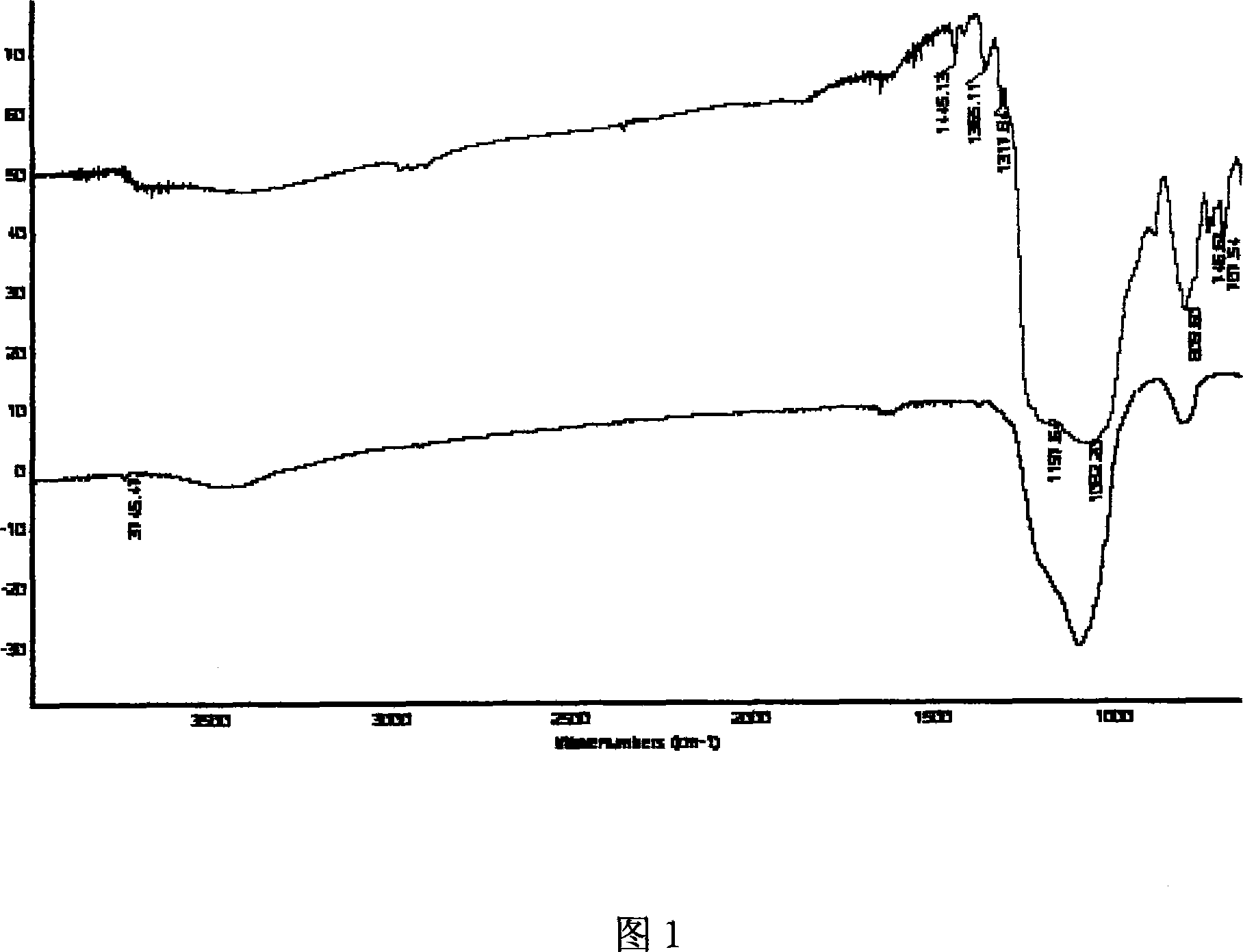

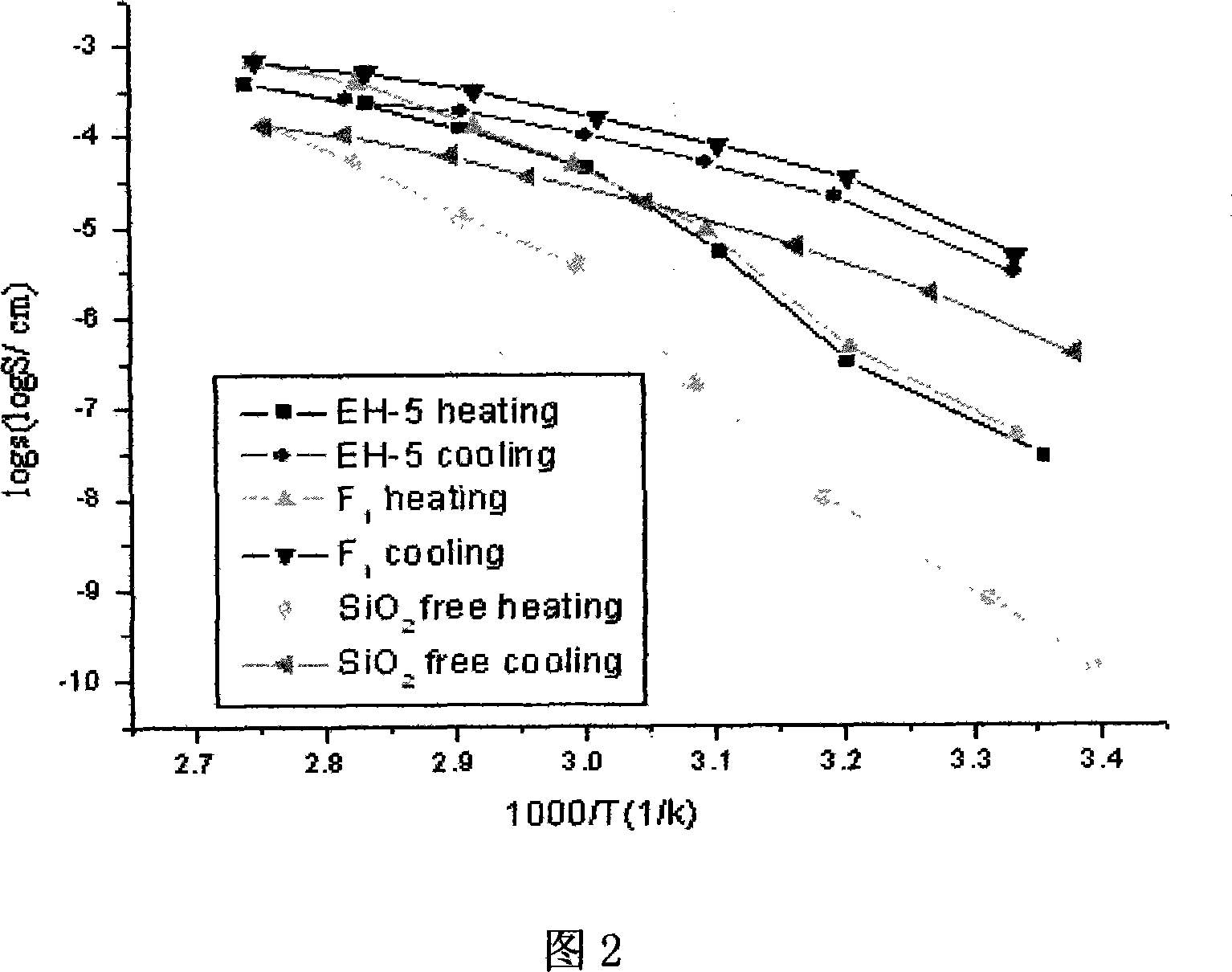

This invention relates to a compound type polymer dielectric stuff and its preparation method, belong to electrochemistry and new energy stuff region. It composed by copolymer of fluoro ethylene and hexafluoro-propylene, lithium salts and plastic crystal stuff. Processing steps: take copolymer, lithium salts and plastic crystal stuff, use solvent to dissolve, whip go as far as uniformity, then pour above solution to teflon tooting, evaporate solvent, finally vacuum drying. While this compound type electrolyte stuff in rather wide temperature range and all components are solid-state, the ionic conductivity can reach using standard of lithium Secondary Battery. It overcomes shortcoming of traditional gel-type polymer dielectric that liquid electrolyte easily leak as well as plastic crystal electrolyte unease form film, and also combine the merit that polymer dielectric easily form film as well as plastic crystal electrolyte has high room temperature ionic conductivity.

Owner:UNIV OF SCI & TECH BEIJING

Electro-optic array interface

InactiveUS7057786B2Static indicating devicesScattering properties measurementsAngle of incidencePolymer dielectrics

A grating coupled surface plasmon resonance optical modulator is disclosed. A electro-optic polymer dielectric is deposited on the metallic surface of a diffraction grating to provide a metal / dielectric interface. A surface plasmon will propagate at the metal / dielectric interface in a resonant condition, e.g., when the metal surface is illuminated by transverse magnetic (TM) polarized light of the appropriate wavelength, angle of incidence and phase velocity. In the present invention, phase velocity is controlled by the diffraction grating. A transparent electrode deposited on the electro-optic layer allows an electrical potential to be applied across the electro-optic polymer. The applied electrical potential (voltage) changes the index of refraction of the electro-optic polymer, thereby disrupting the resonant condition to produce an optically detectable change in reflectance of incident light from the metal layer. The disclosed grating coupled surface plasmon resonance optical modulator may be configured as an electronically or optically addressable array.

Owner:CIENCIA

Ionic polymer devices and methods of fabricating the same

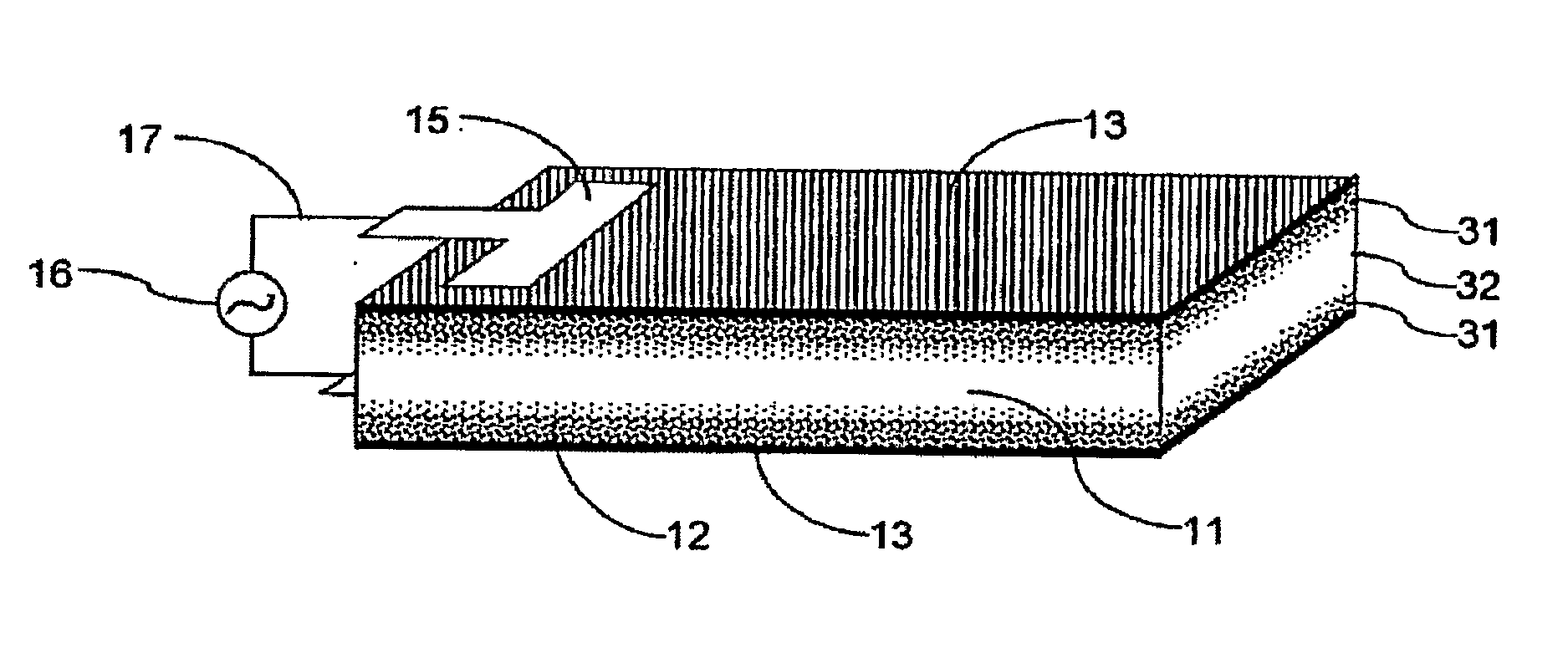

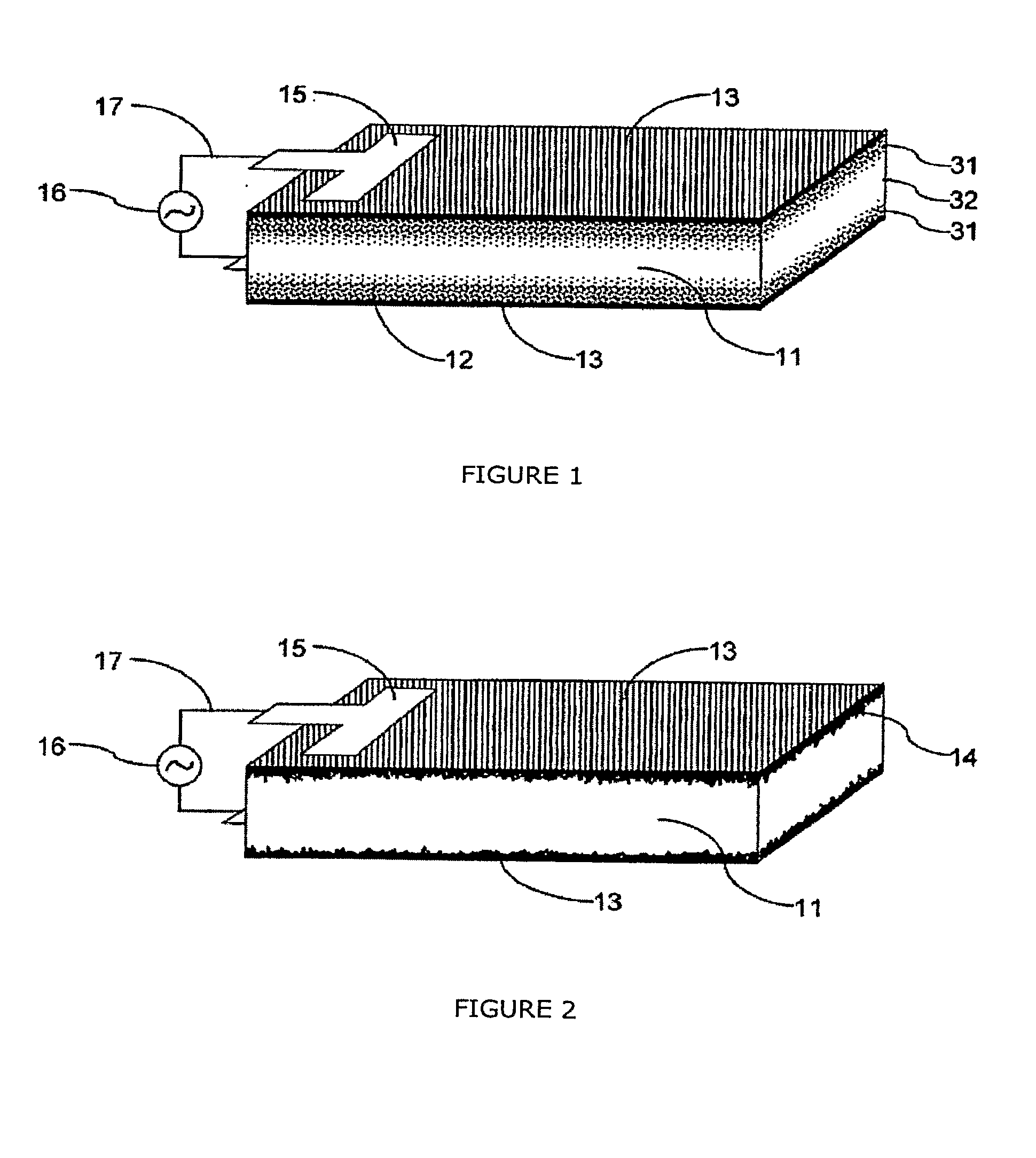

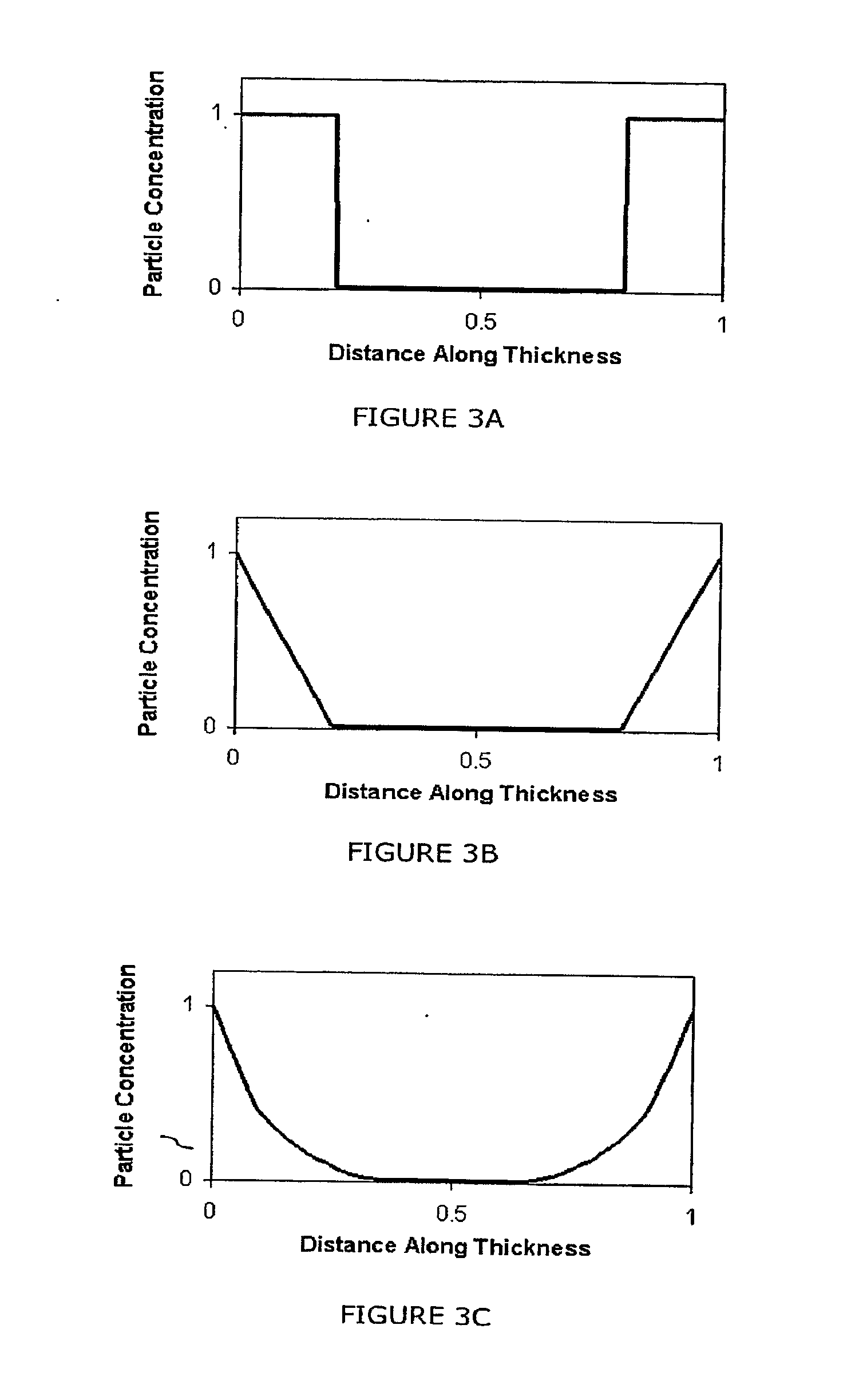

InactiveUS20090032394A1Simpler and cheap and faster manufacturing processIncrease capacitanceCellsCell electrodesPolymer dielectricsConcentration gradient

An embodiment provides an ionic polymer device comprising two extended electrode layers comprising a plurality of conductive particles, wherein the plurality of conductive particles form a concentration gradient in each of the two extended electrode layers, an ionic polymer dielectric layer between two extended electrode layers, and at least one conductive layer on outer surfaces of two extended electrode layers. Another embodiment provides an ionic polymer device comprising a polymer composite with a plurality of surface features on two opposite surfaces, and at least one conductive layer on each of said two opposite surfaces. One embodiment provides a method of making an ionic polymer device, comprising forming a partially cured polymer-metallic salt layer, reducing the metallic salt to form a plurality of metal particles, thereby forming a first extended electrode layer and a second extended electrode layer at and near opposite surfaces of the ionic polymer device.

Owner:HITACHI CHEM CO LTD +1

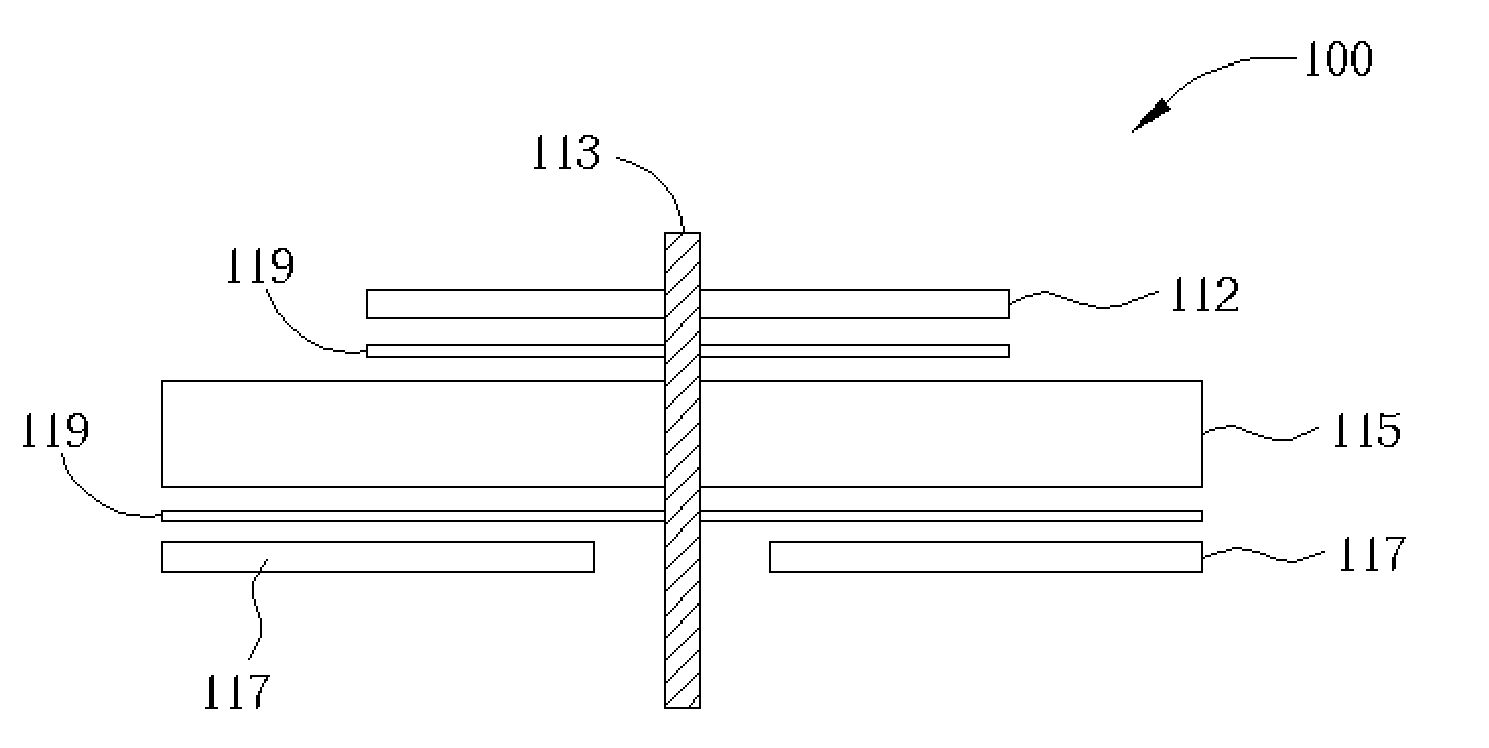

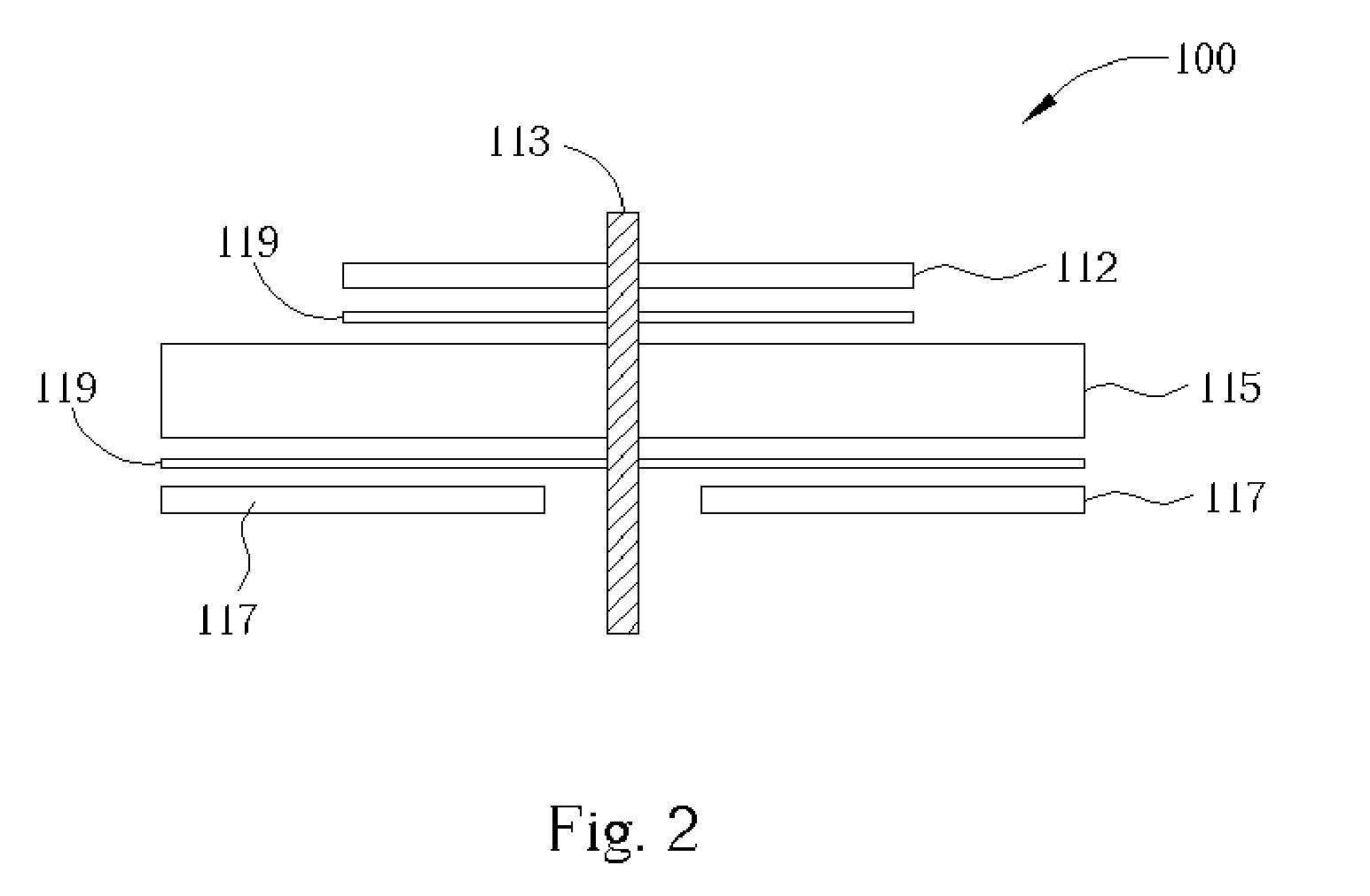

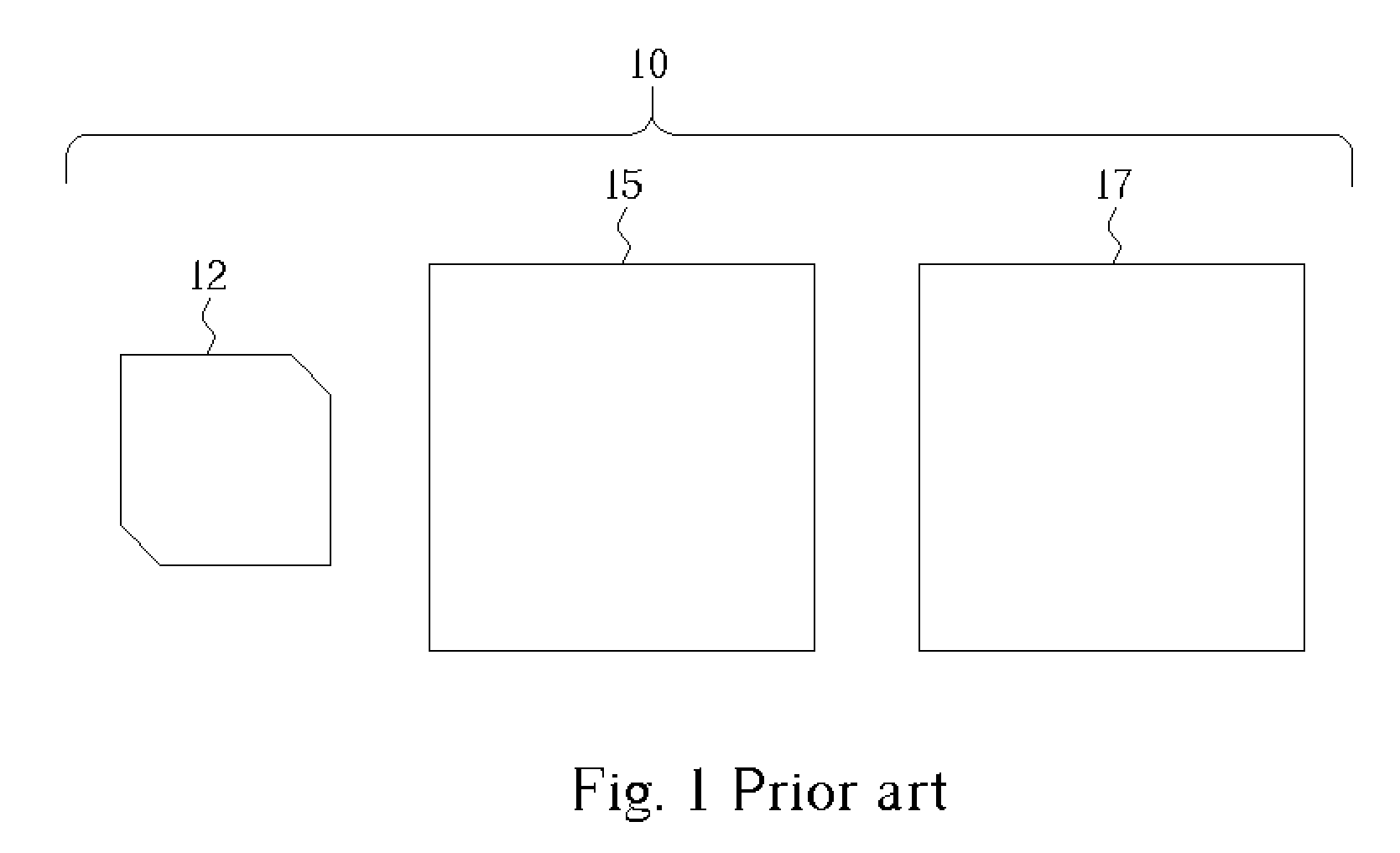

Patch Antenna Utilizing a Polymer Dielectric Layer

ActiveUS20060017616A1Improve adhesionSmall sizeSimultaneous aerial operationsRadiating elements structural formsPolymeric surfaceElectrical conductor

A patch antenna includes a metallic ground plate, a metallic radiating element, and a polymer plastic dielectric layer sandwiched between the radiating element and the ground plate. Top and bottom surfaces of the dielectric layer are primed with polymeric surfactants to provide better adhesive characteristics at low temperatures. The radiating element is fixed to the dielectric layer by compressing an adhesive layer applied to the radiating element between the radiating element and the priming layer applied to the top surface of the dielectric layer. The ground plate is fixed to the dielectric layer by compressing another adhesive layer applied to the ground plate between the ground plate and the priming layer applied to the bottom surface of the dielectric layer. A low noise amplifier may be integrated with the antenna by sharing the common ground plate and connecting the amplifier's signal trace to the radiating element via a conductor pin.

Owner:WISTRON NEWEB

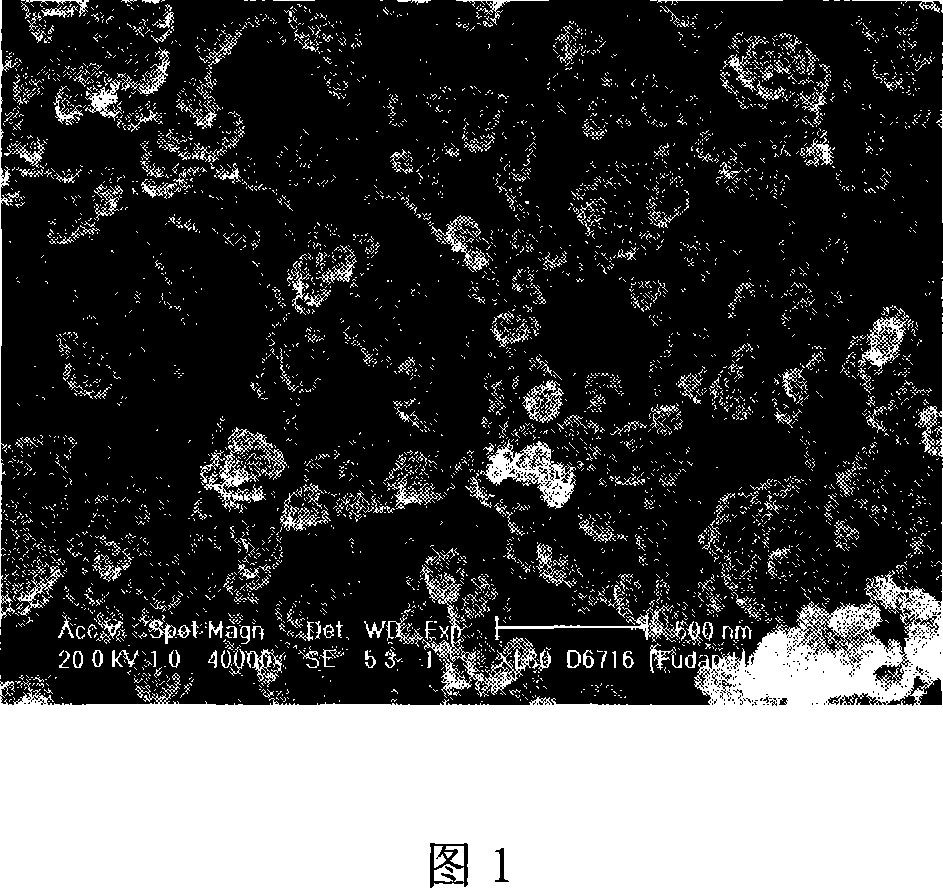

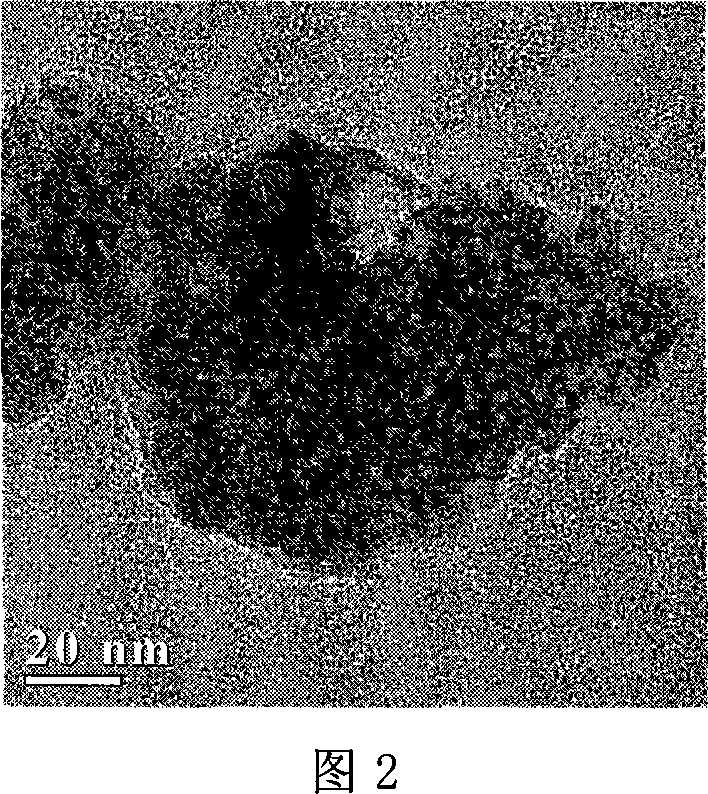

Organic inorganic composite polymer electrolyte and preparation method and application thereof

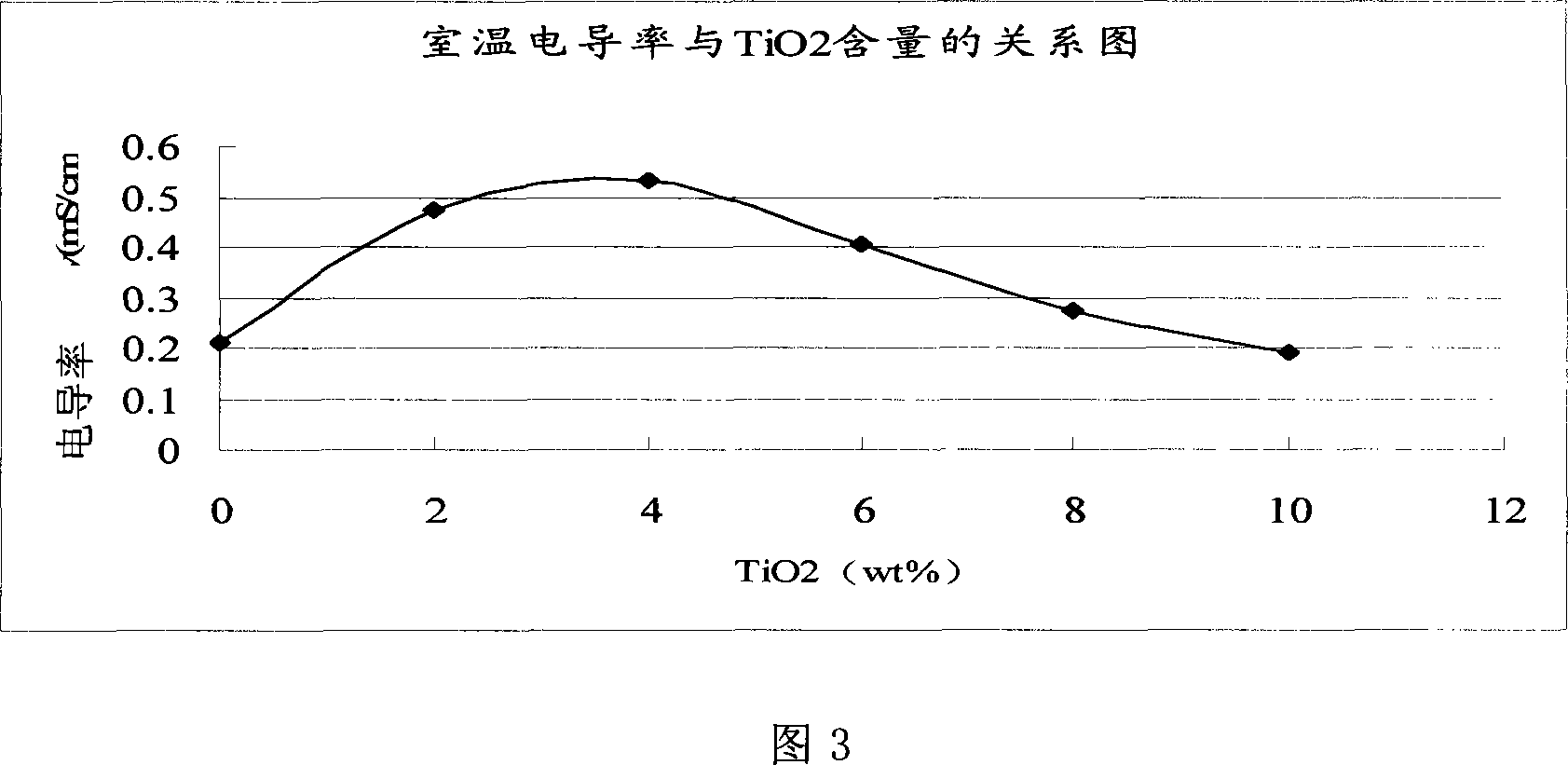

InactiveCN101045762AInhibition of agglomerationImprove ionic conductivitySecondary cellsPigment treatment with non-polymer organic compoundsPolymer dielectricsAcrylonitrile

This invention belongs to electrochemical techniques region, relates to the preparation method and application of a sort of organic inorganic compound polymer dielectric. The process includes: by emulsion polymerization, use polyacrylic acid methyl ester to carry out coverture modification hand ling to nanometer titanium dioxide particle; by solution polymerization method, carry out copolymerization of acrylonitrile and acrylonitrile methyl ester to modified nanometer titanium dioxide particle, obtain organic inorganic compound polymer. This compound polymer could as polymer dielectric stuff of lithium ion Secondary Battery, possess good ionic conductivity and mechanical property.

Owner:FUDAN UNIV

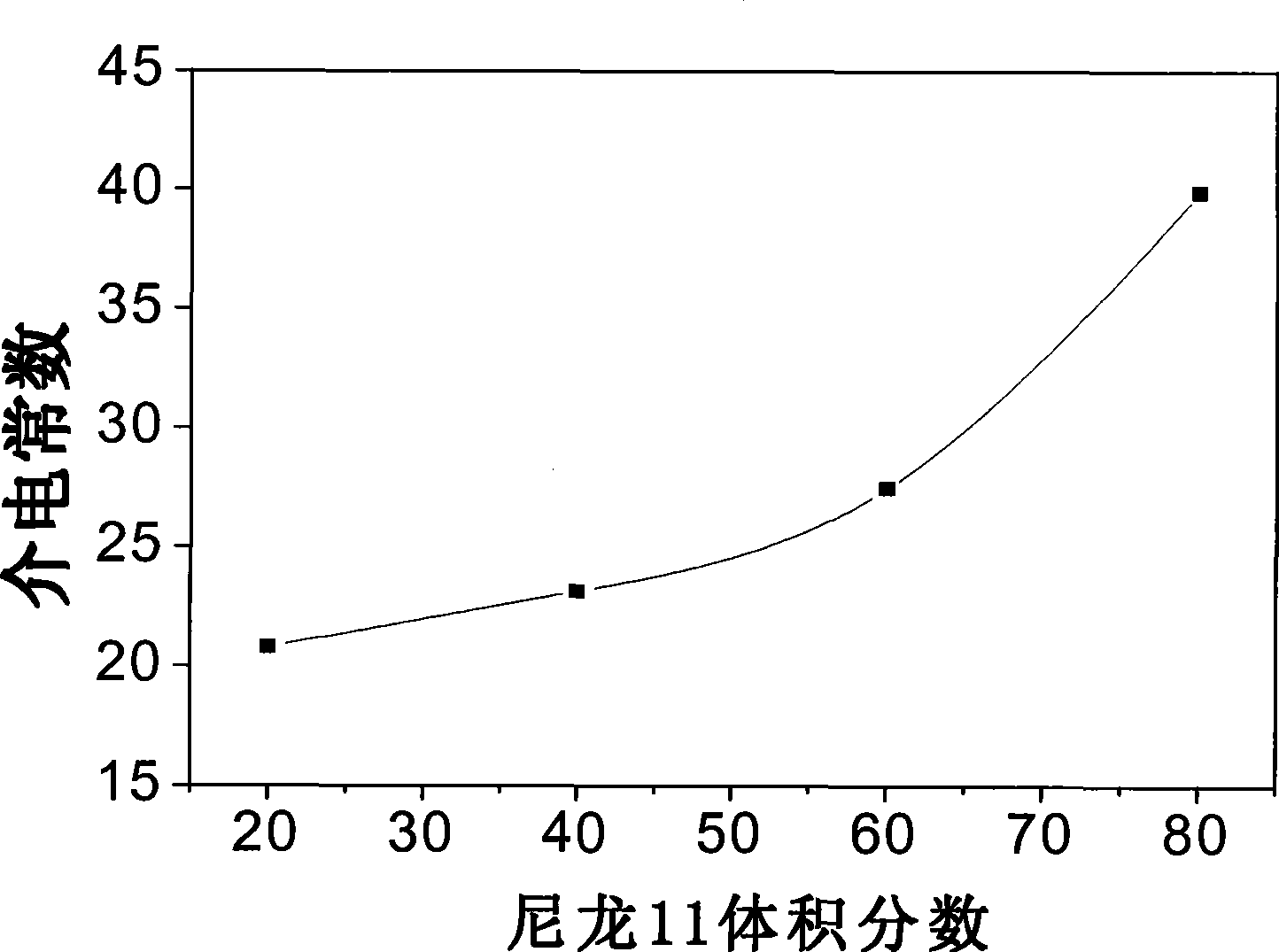

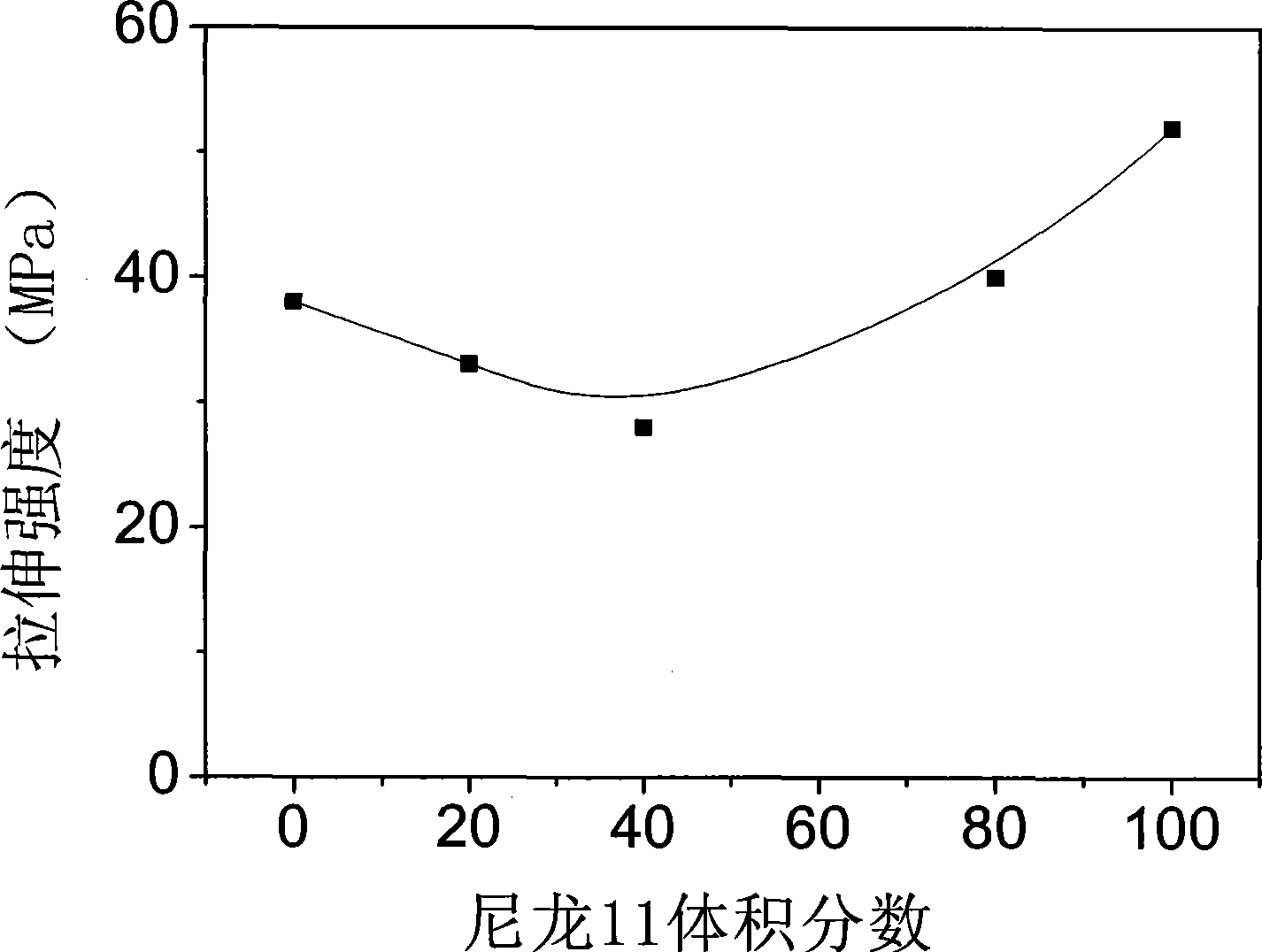

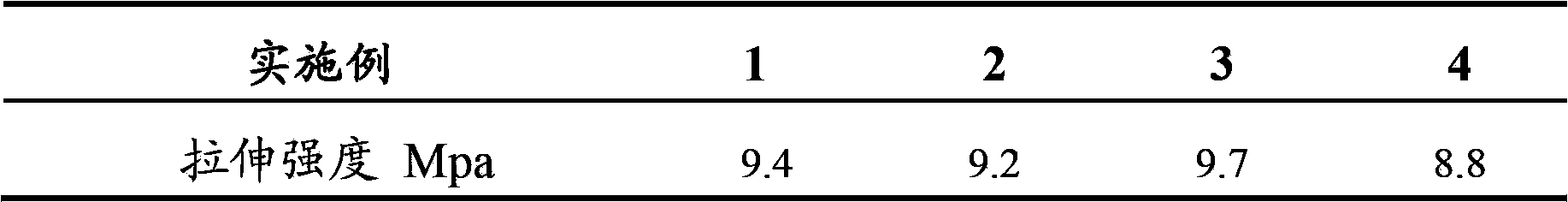

Flexible polymer dielectric material for electrical condenser and preparation thereof

The invention relates to a flexible polymer dielectric material used for a capacitor and the preparation thereof. The material is the blending material of fluorine-containing polymer and nylon, wherein, the fluorine-containing polymer is any one of polyvinylidene fluoride, vinylidene fluoride- trifluoroethylene copolymer and vinylidene fluoride-tetrafluoroethylene copolymer; the nylon is any one of PA7, PA9, PA11, PA7 / PA9, PA7 / PA11, PA9 / PA11 and PA7 / PA9 / PA11. The volume ratio between the nylon and the fluorine-containing polymer is 10%-90%: 90%-10%. The preparation steps comprises: 1) under the condition that the temperature is 150-230 DEG C and the rotating speed is 15-50r / min, the nylon and the fluorine-containing polymer are mixed in mixing equipment according to the volume ratio of 10%-90%: 90%-10%, and then the mixture is cooled naturally; 2) the mixture obtained in the step 1) is pressed for shaping in a mould, the mould pressing temperature is 150-230 DEG C, the mould pressing pressure is 10-25MPa, and the pressing time is 15-30min; the pressed mixture is cooled when in pressure maintaining, so that the flexible polymer dielectric material is obtained. The flexible polymer dielectric material has good mechanical property and higher dielectric constant; the property needed by the material can be adjusted by regulating the mixture ratio between the nylon and the fluorine-containing polymer, so that the invention is especially suitable for preparing film dielectric material.

Owner:WUHAN UNIV OF TECH

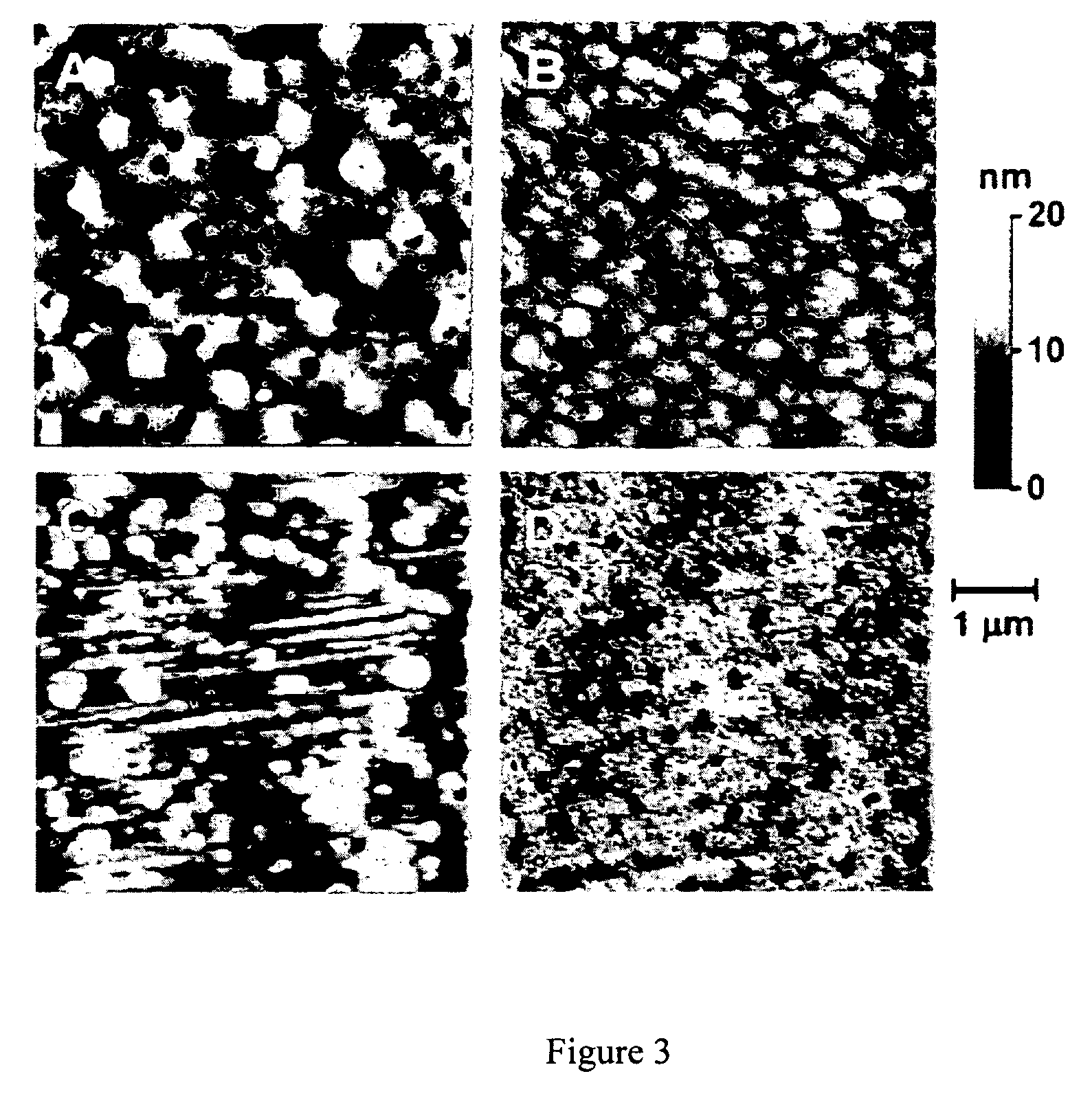

Nano-structured dielectric composite

ActiveUS20120003449A1Increase plasmon resonance effectHigh strengthSynthetic resin layered productsOptical articlesPolymer dielectricsNanoparticle

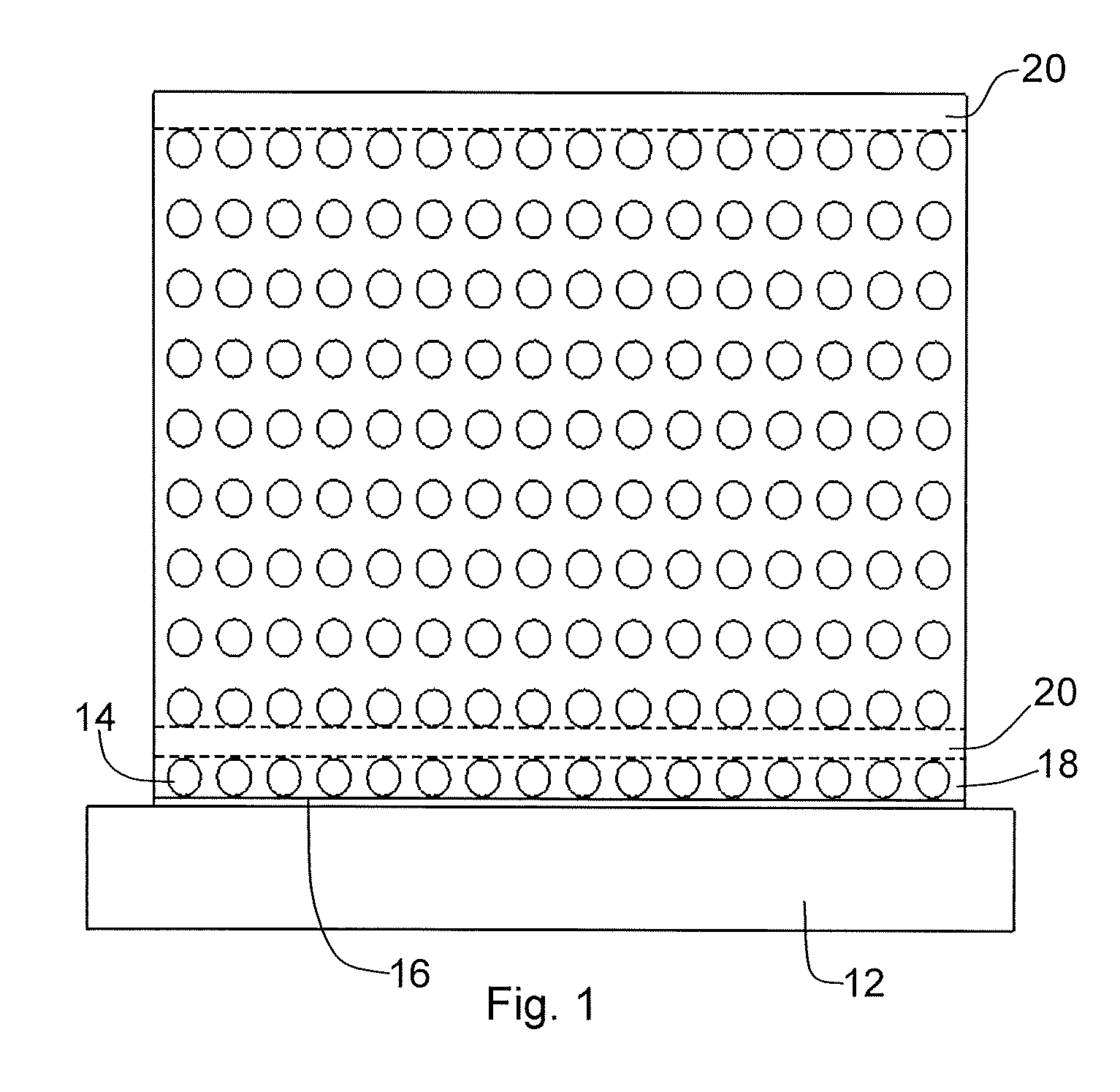

A multilayer dielectric structure is formed by vacuum depositing two-dimensional matrices of nanoparticles embedded in polymer dielectric layers that are thicker than the effective diameter of the nanoparticles, so as to produce a void-free, structured, three-dimensional lattice of nanoparticles in a polymeric dielectric material. As a result of the continuous, repeated, and controlled deposition process, each two-dimensional matrix of nanoparticles consists of a layer of uniformly distributed particles embedded in polymer and separated from adjacent matrix layers by continuous polymer dielectric layers, thus forming a precise three-dimensional nanoparticle matrix defined by the size and density of the nanoparticles in each matrix layer and by the thickness of the polymer layers between them. The resulting structured nanodielectric exhibits very high values of dielectric constant as well as high dielectric strength.

Owner:SIGMA LAB OF ARIZONA

Patch antenna utilizing a polymer dielectric layer

ActiveUS7053833B2Low costIncreased durabilitySimultaneous aerial operationsRadiating elements structural formsPolymeric surfaceElectrical conductor

A patch antenna includes a metallic ground plate, a metallic radiating element, and a polymer plastic dielectric layer sandwiched between the radiating element and the ground plate. Top and bottom surfaces of the dielectric layer are primed with polymeric surfactants to provide better adhesive characteristics at low temperatures. The radiating element is fixed to the dielectric layer by compressing an adhesive layer applied to the radiating element between the radiating element and the priming layer applied to the top surface of the dielectric layer. The ground plate is fixed to the dielectric layer by compressing another adhesive layer applied to the ground plate between the ground plate and the priming layer applied to the bottom surface of the dielectric layer. A low noise amplifier may be integrated with the antenna by sharing the common ground plate and connecting the amplifier's signal trace to the radiating element via a conductor pin.

Owner:WISTRON NEWEB

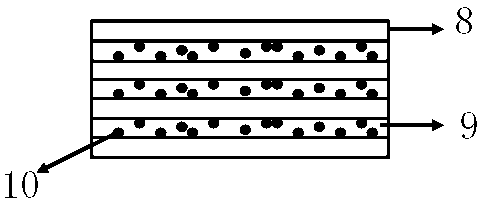

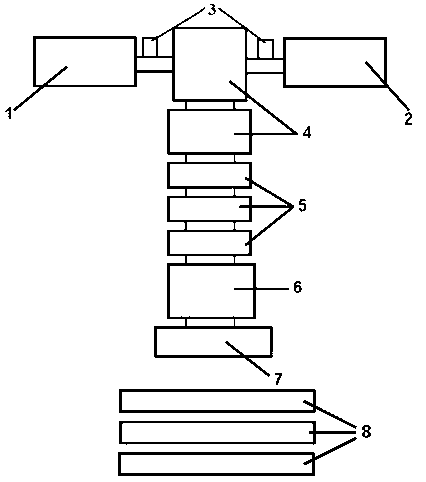

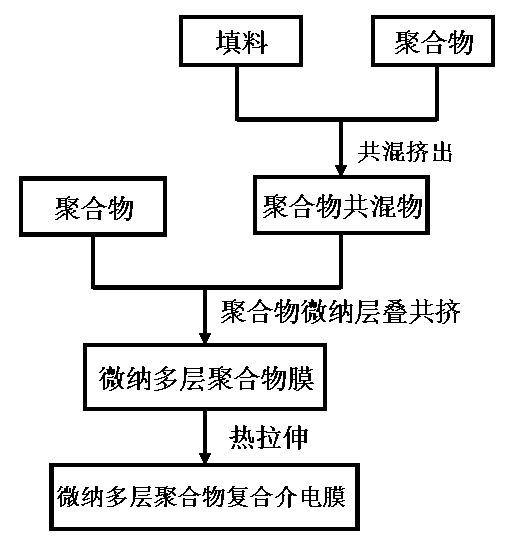

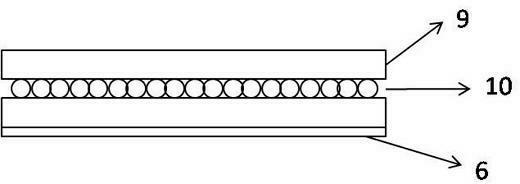

Micro-nano multi-layer composite dielectric materials and preparation method and device thereof

InactiveCN103129070AGood dispersionEasy to operateSynthetic resin layered productsPolymer sciencePolymer dielectrics

The invention discloses micro-nano multi-layer composite dielectric materials and a preparation method and a device thereof. The micro-nano multi-layer composite dielectric materials comprise a polymer layer and a polymer blend layer, and the polymer layer and the polymer blend layer interlace with each other. In the polymer blend layer, one kind or more kinds of padding among globular padding, flakiness padding, threadiness padding and rodlike padding are evenly distributed in a polymer matrix. According to the micro-nano multi-layer composite dielectric materials and the preparation method and the device thereof, the padding is added into the polymer matrix, a specialty polymer micro-nano stacking and co-extruding device is used, a polymer dielectric membrane with a micro-nano multi-layer structure is prepared, thus dispersibility of the padding is improved effectively and modified padding is evenly distributed in the polymer matrix in a product, and therefore the purpose of controlling the dielectric property of a polymer is realized. In the preparation process of the micro-nano multi-layer composite dielectric materials, no solvent or binder exists, production cost is low, the micro-nano multi-layer composite dielectric materials are environment friendly, continuous production can be achieved, and the dielectric constant of the obtained product is improved notably.

Owner:贵州省复合改性聚合物材料工程技术研究中心

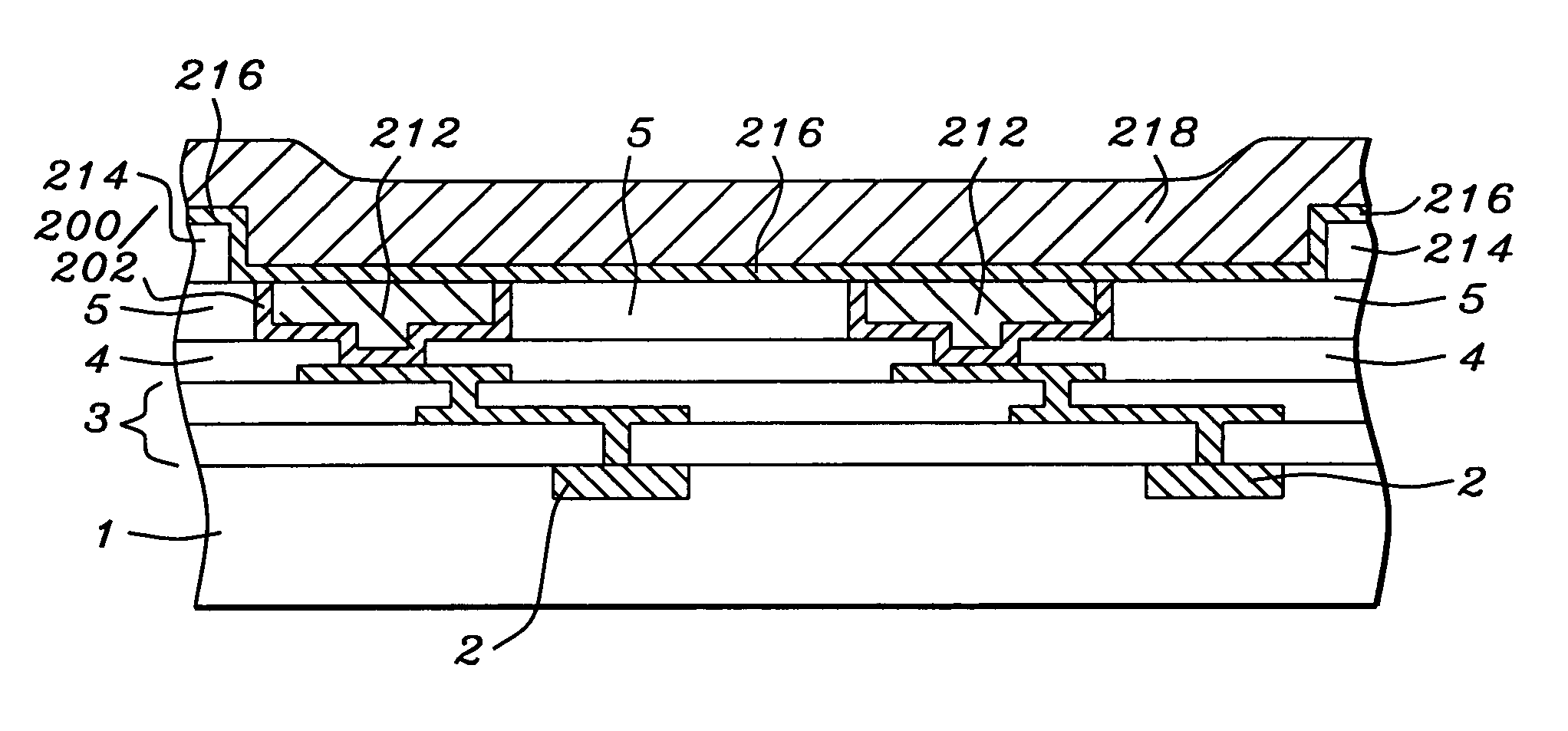

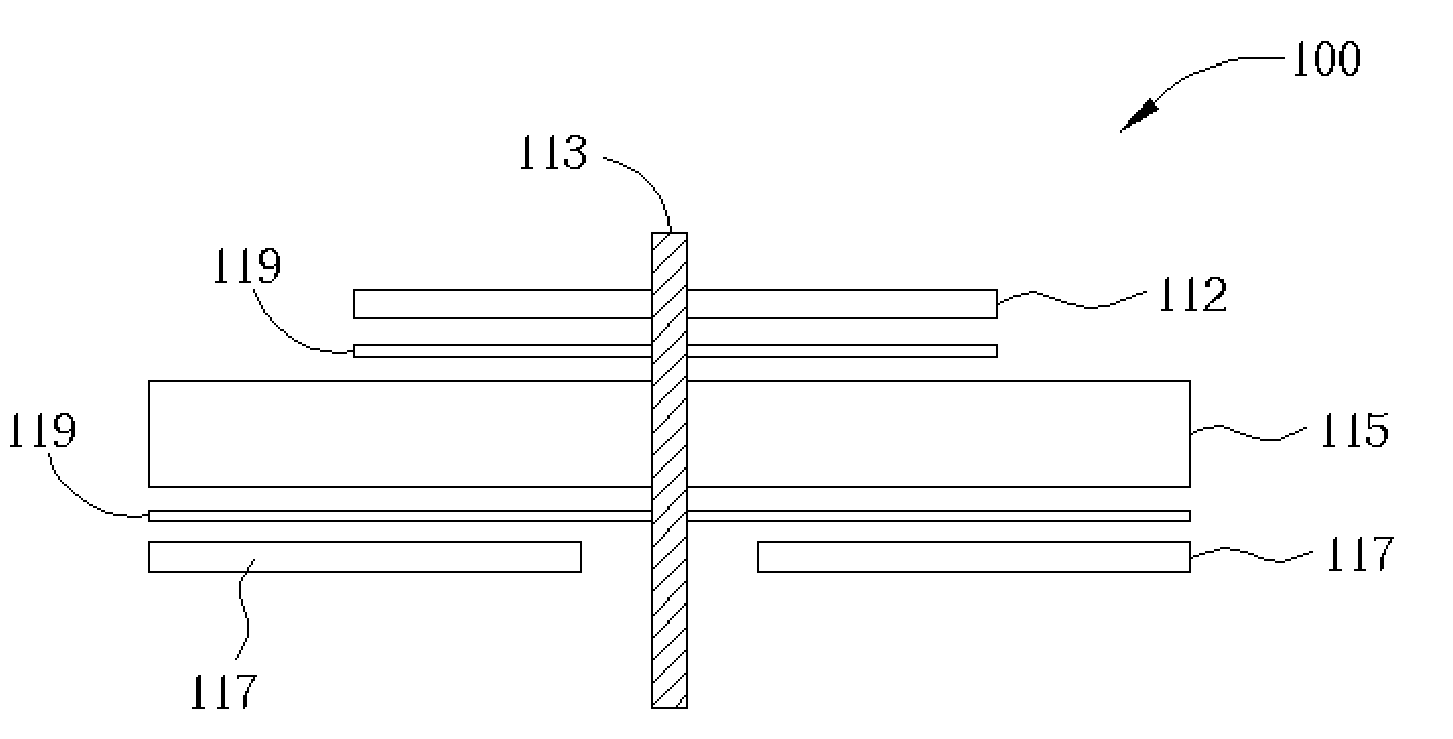

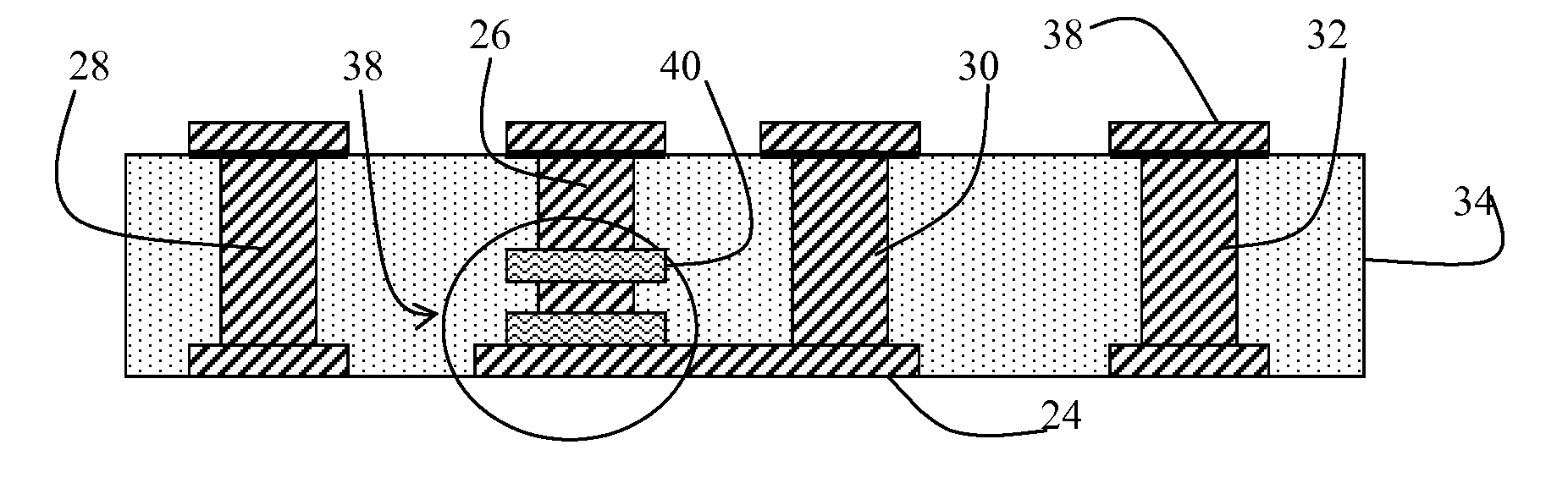

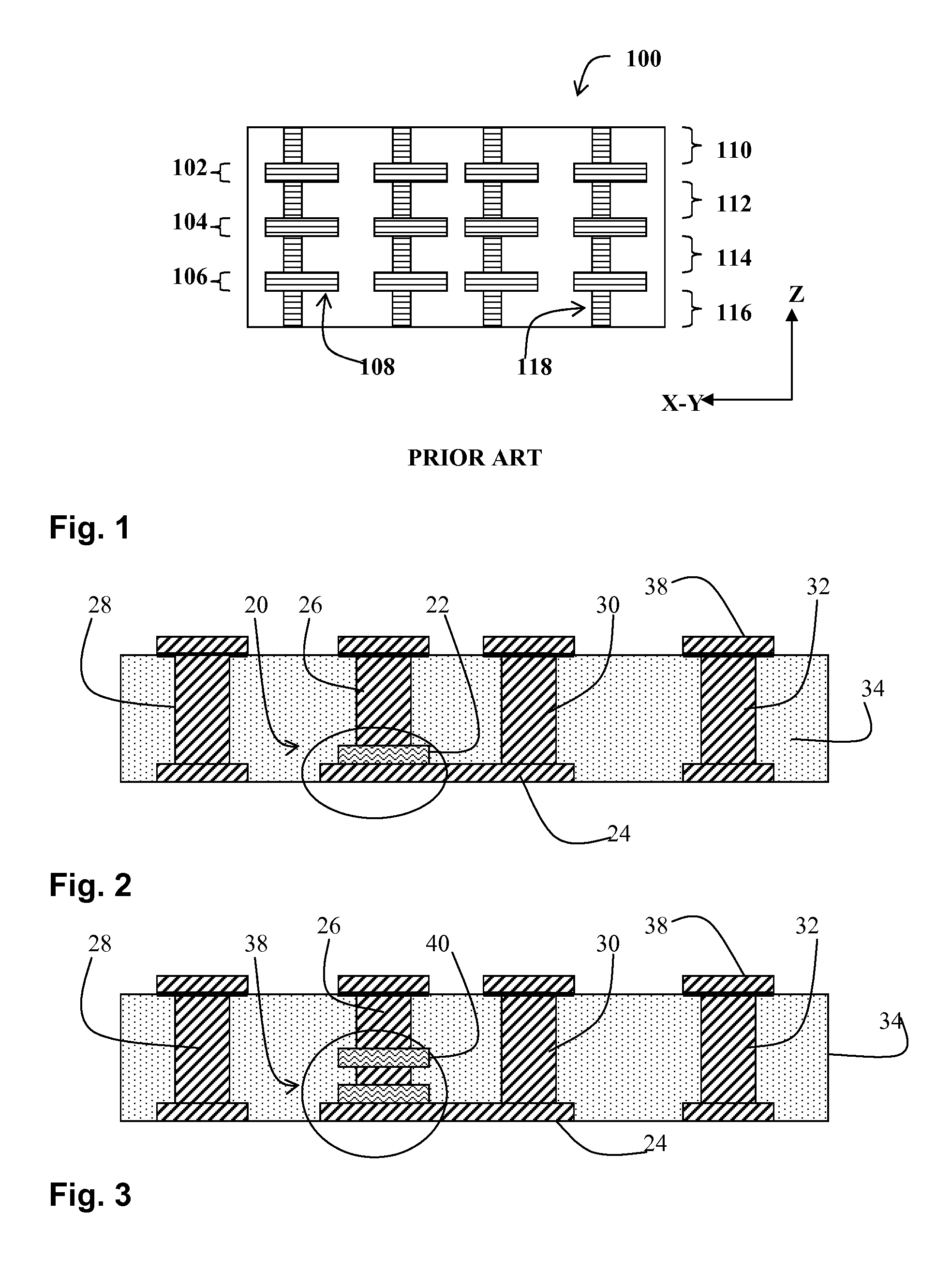

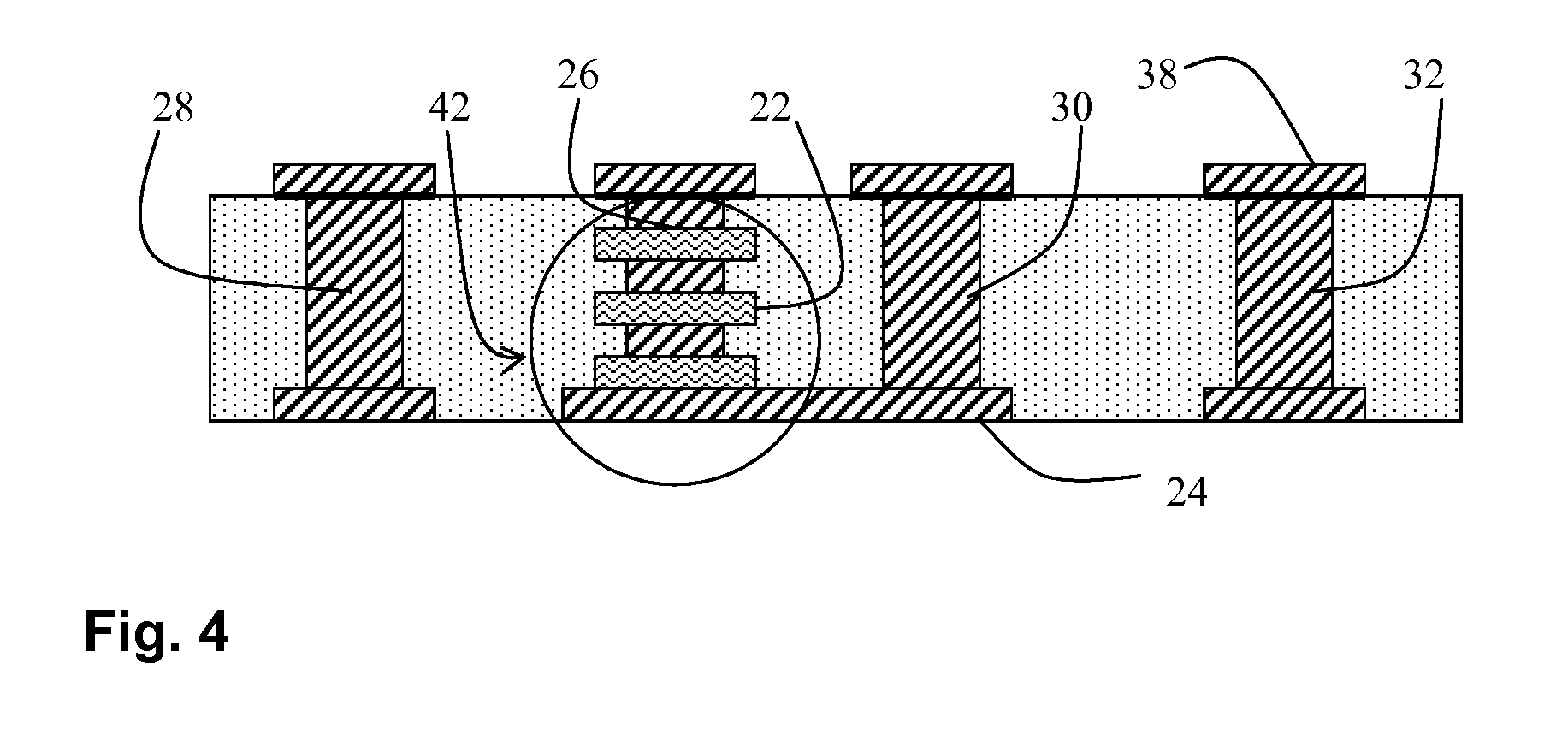

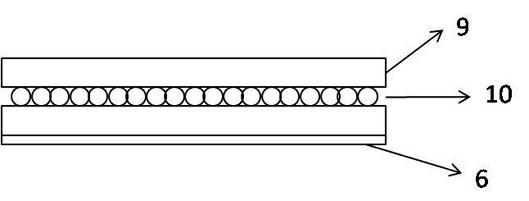

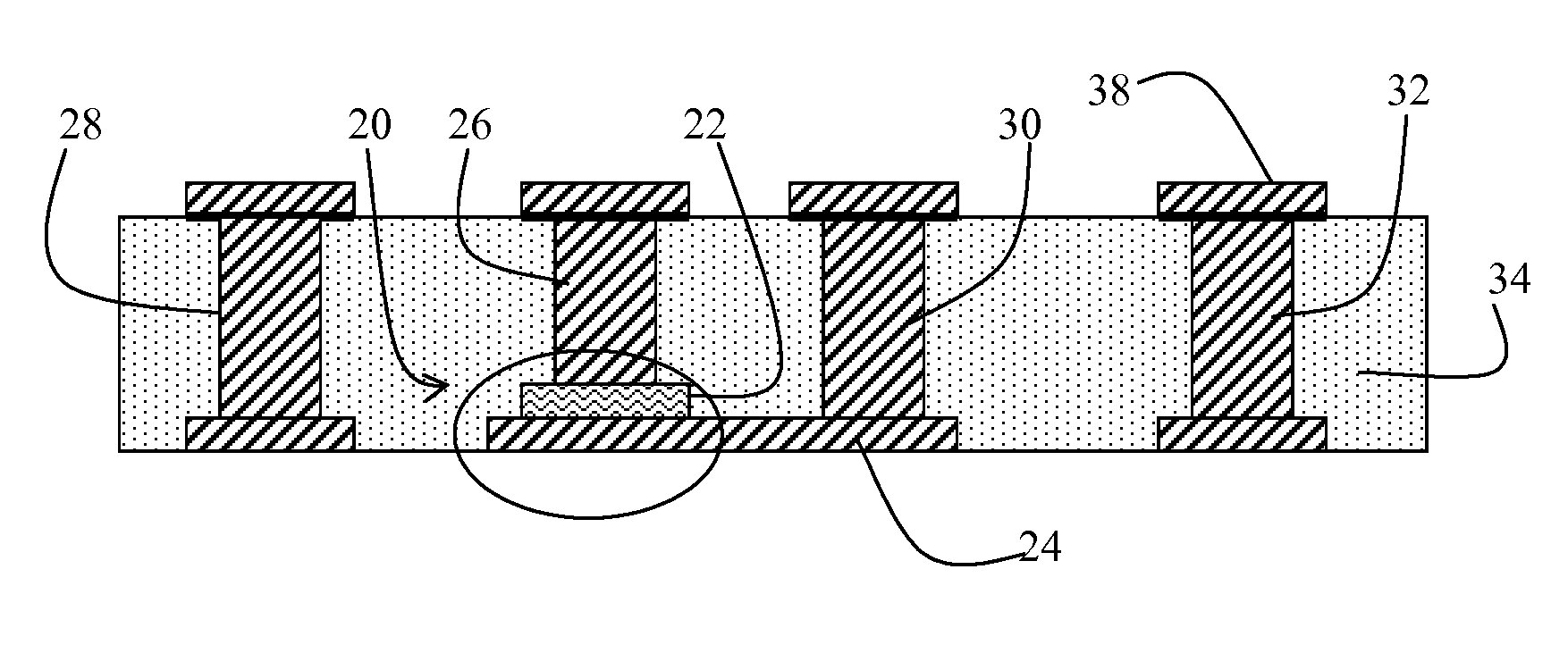

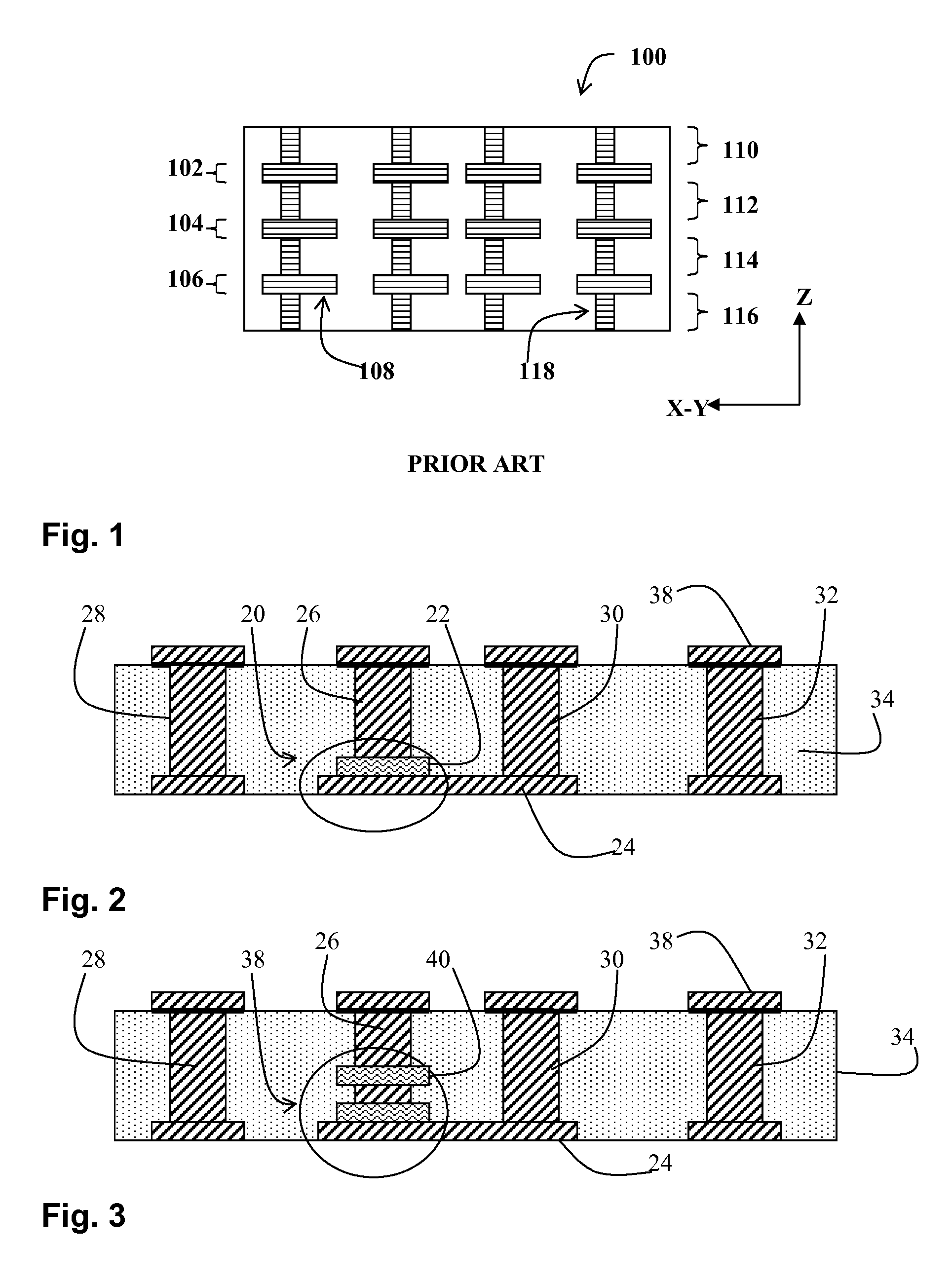

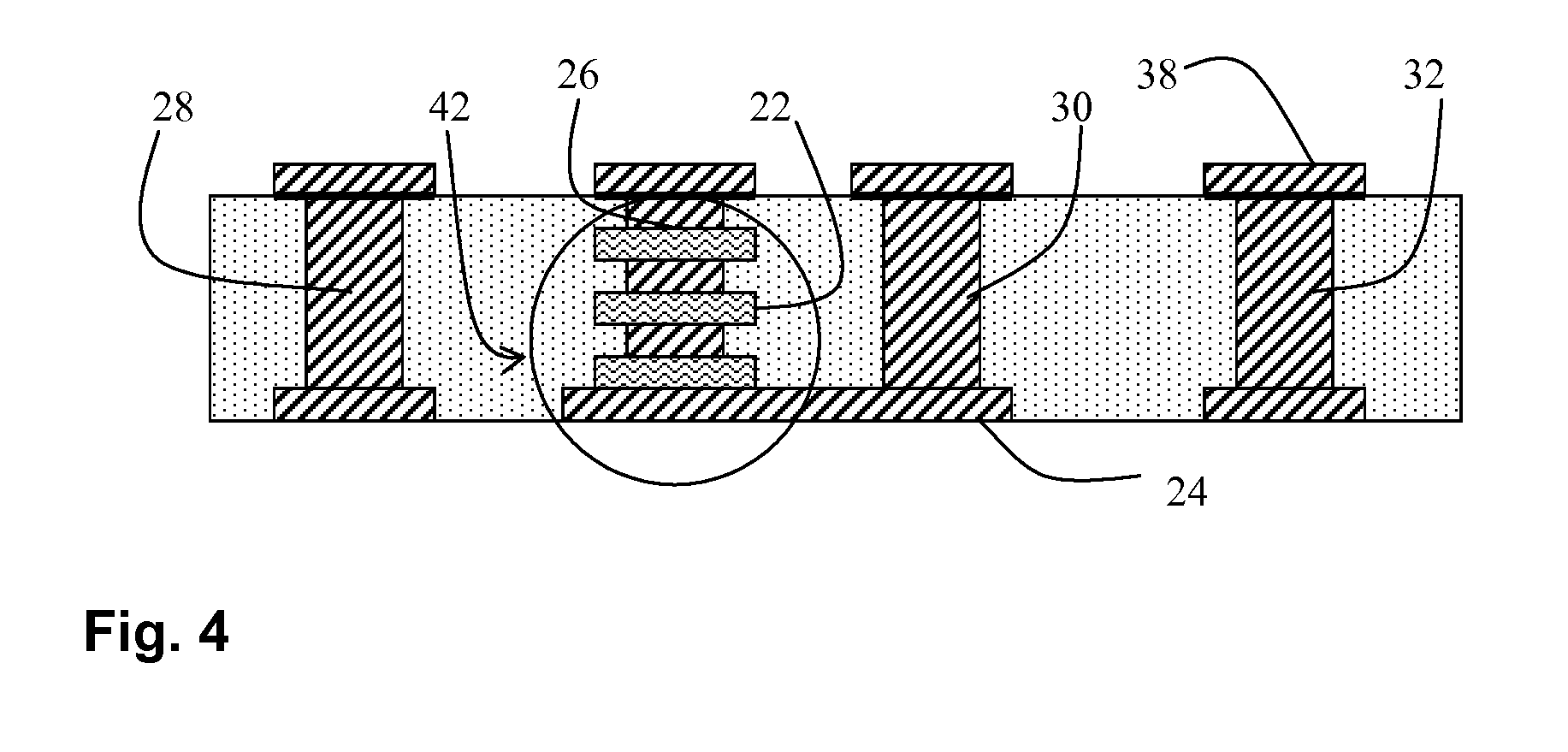

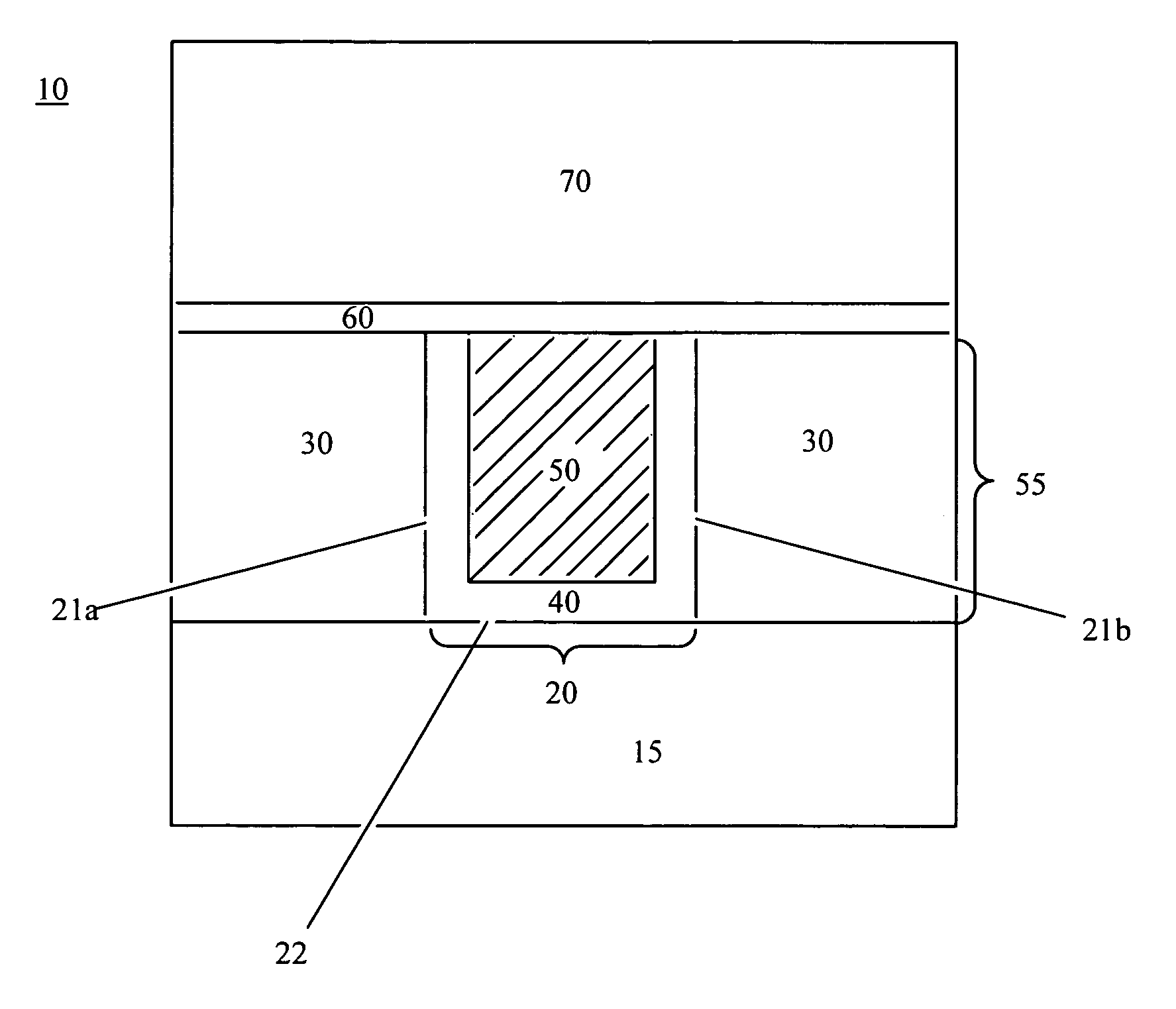

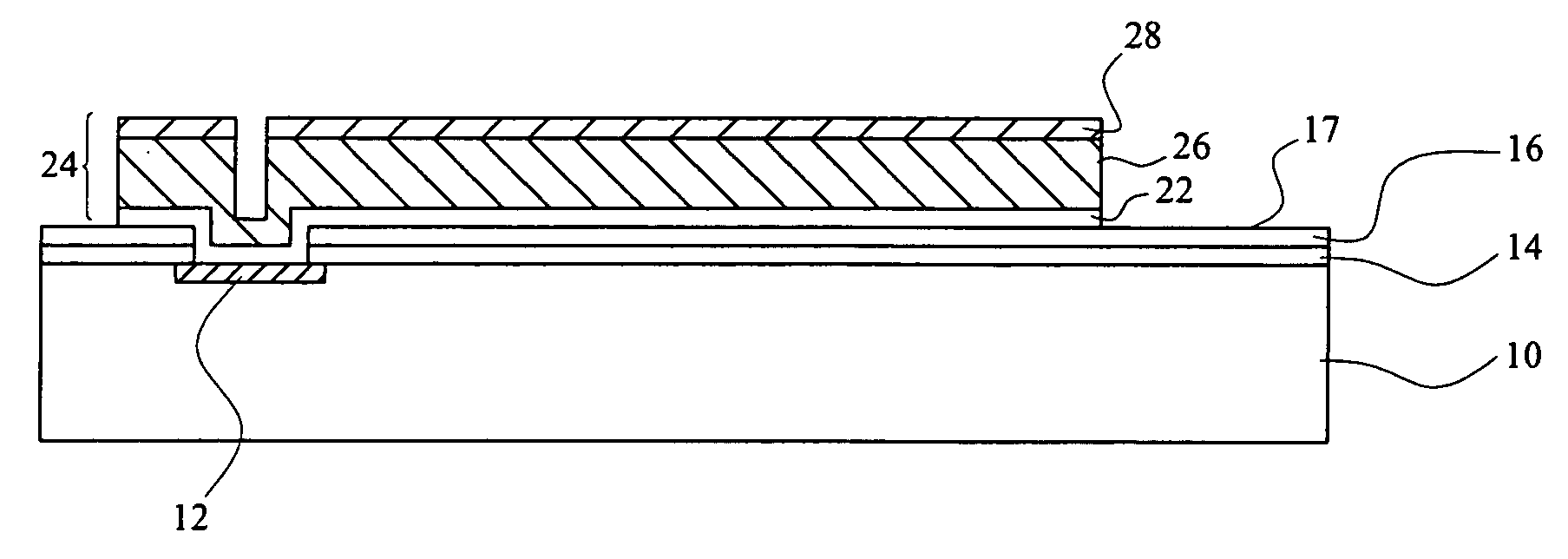

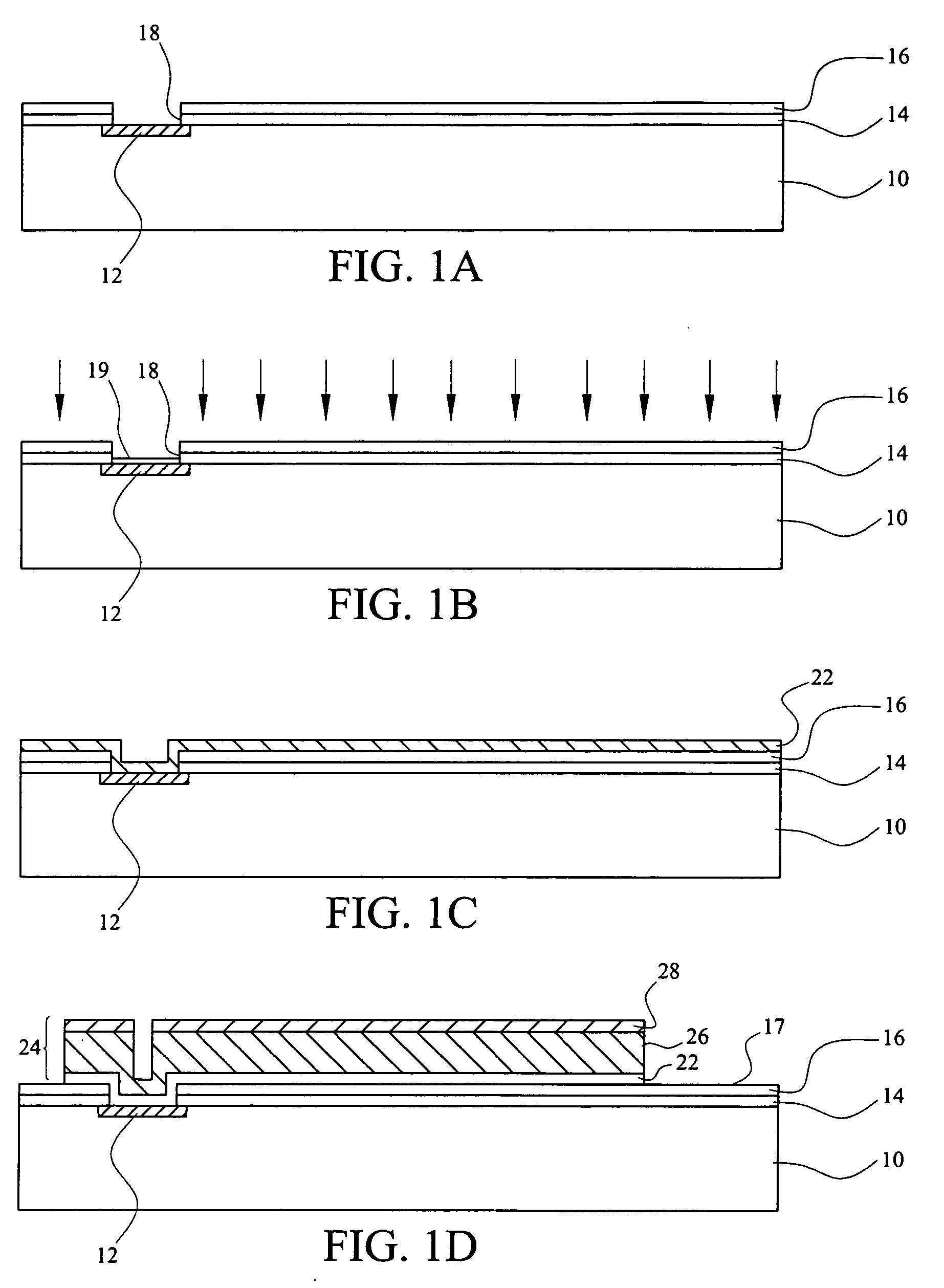

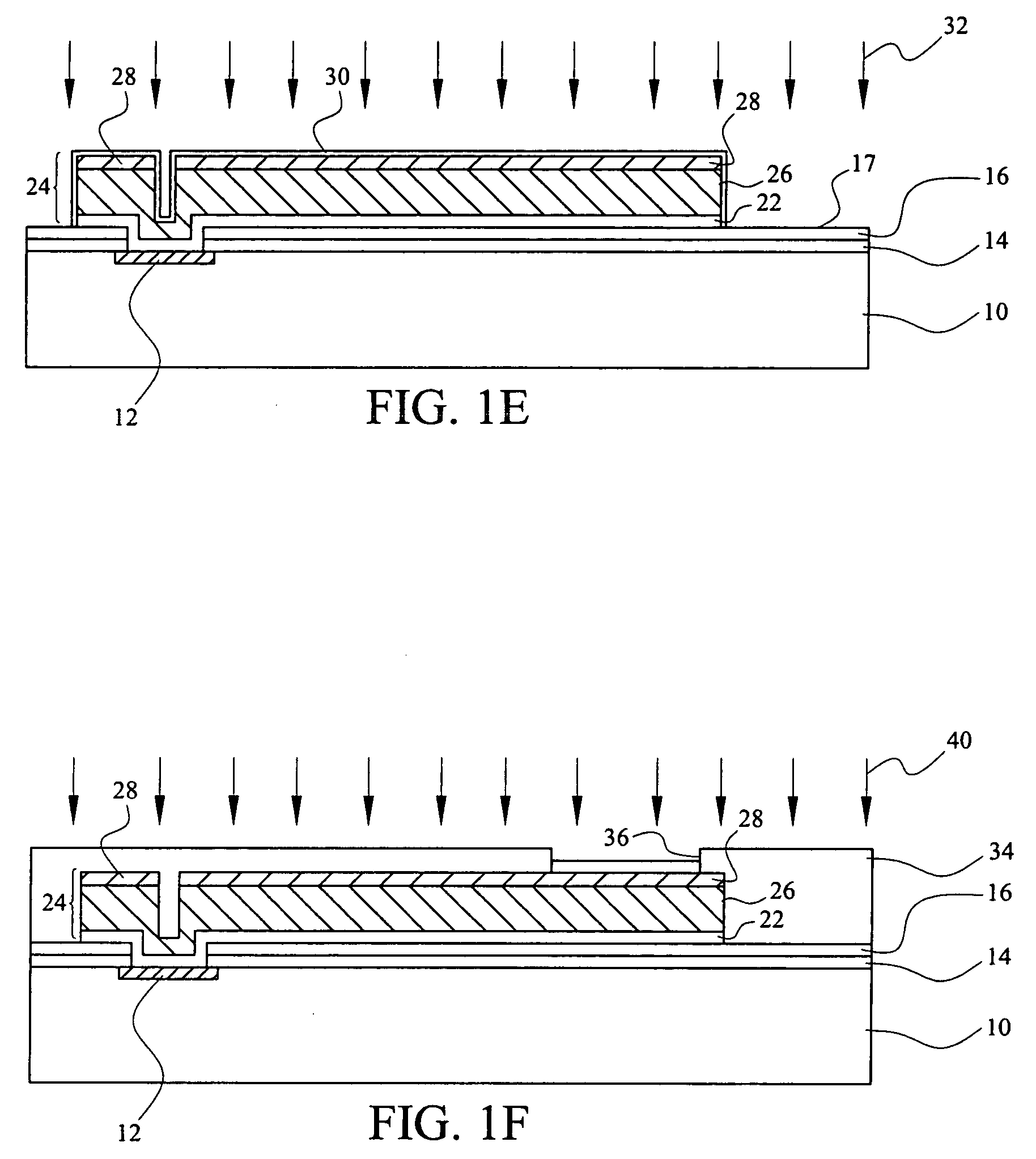

Thin Film Capacitors Embedded in Polymer Dielectric

ActiveUS20150043126A1Small sizeAvoid tarnishingFixed capacitor electrodesThin/thick film capacitorPolymer dielectricsMetal electrodes

Owner:ZHUHAI ADVANCED CHIP CARRIERS & ELECTRONICS SUBSTRATE SOLUTIONS TECH

Method for preparing nanocomposite dielectric film

InactiveCN102632675AImprove conductivityExcellent dielectric propertiesFixed capacitor dielectricSynthetic resin layered productsPolymer scienceComposite film

The invention discloses a method for preparing a nanocomposite dielectric film. The method comprises the following steps of: firstly obtaining a polymer dielectric film by a Langmuir-Blodgett (LB) film method; secondly preparing a high-dielectric inorganic / organic composite nanoparticle film on the polymer dielectric film by the LB film method; and finally preparing a polymer dielectric film on the composite nanoparticle film by the LB film method, thereby forming a high-dielectric composite film material with nanoparticles dispersed in a polymer. The polymer-nanoparticle composite dielectric film material prepared by the method overcomes the shortcomings of the prior art, and the preparation method is reasonable and simple, and easy to operate.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

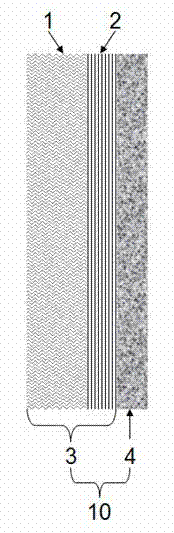

Soft type polymeric compound lithium battery and preparation method thereof

InactiveCN102738469ALight in massStrong impact resistanceFinal product manufactureElectrode carriers/collectorsCarbon fibersPolymer dielectrics

The invention relates to a soft type polymeric compound lithium battery and a preparation method thereof. The soft type polymeric compound lithium battery is characterized by comprising a positive electrode piece which takes aluminize carbon cloth as a current collector, a negative electrode piece which takes coppered carbon fibre cloth as a current collector, and a partition plate which is a compound polymer dielectric film and arranged between the positive electrode piece and the negative electrode piece, wherein an aluminium model film is used for external packing. The soft type polymeric compound lithium battery provided by the invention has the advantages of strong shock resistance property, high safety feature, high mechanical property and good flexility.

Owner:CHINA FIRST AUTOMOBILE

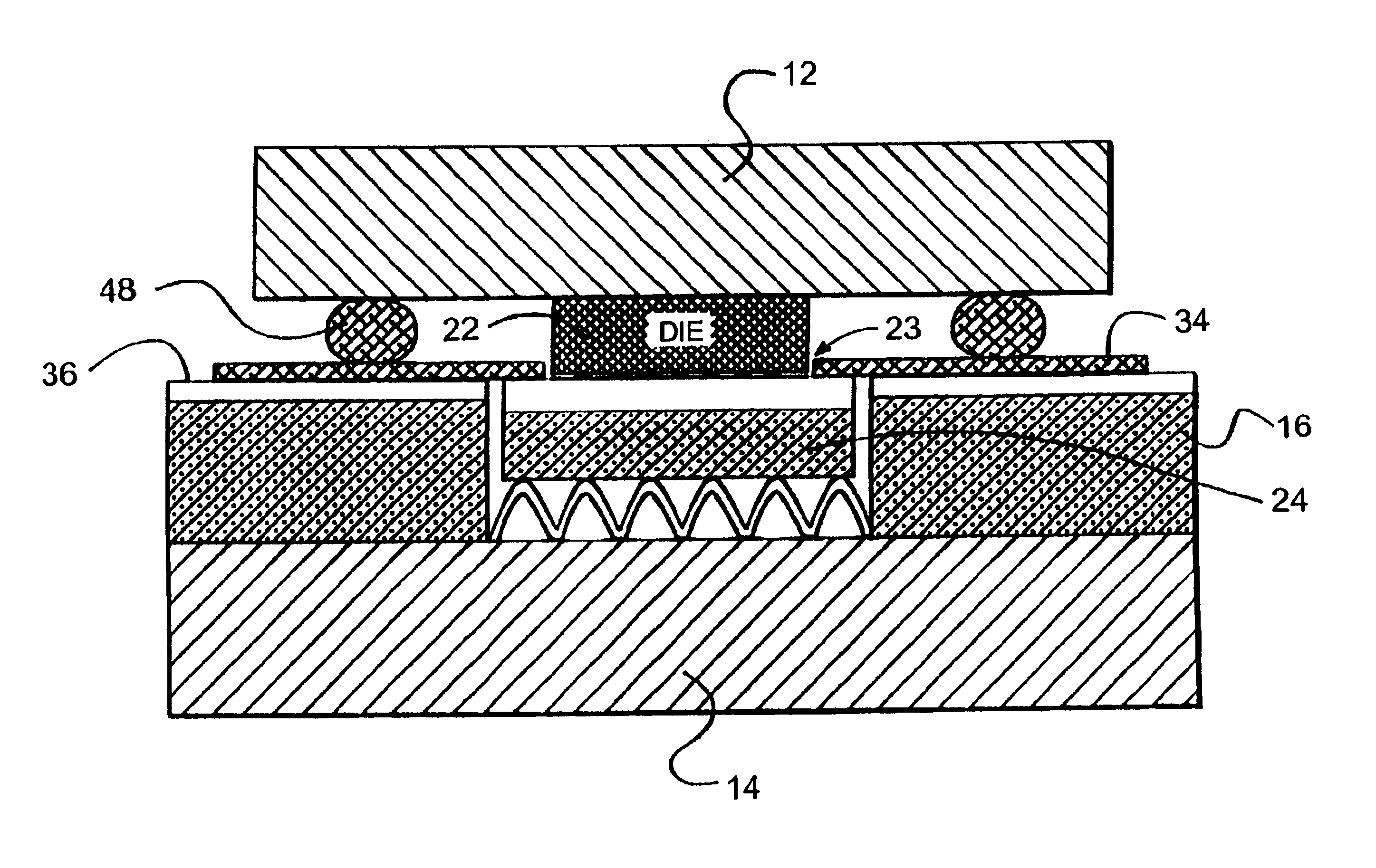

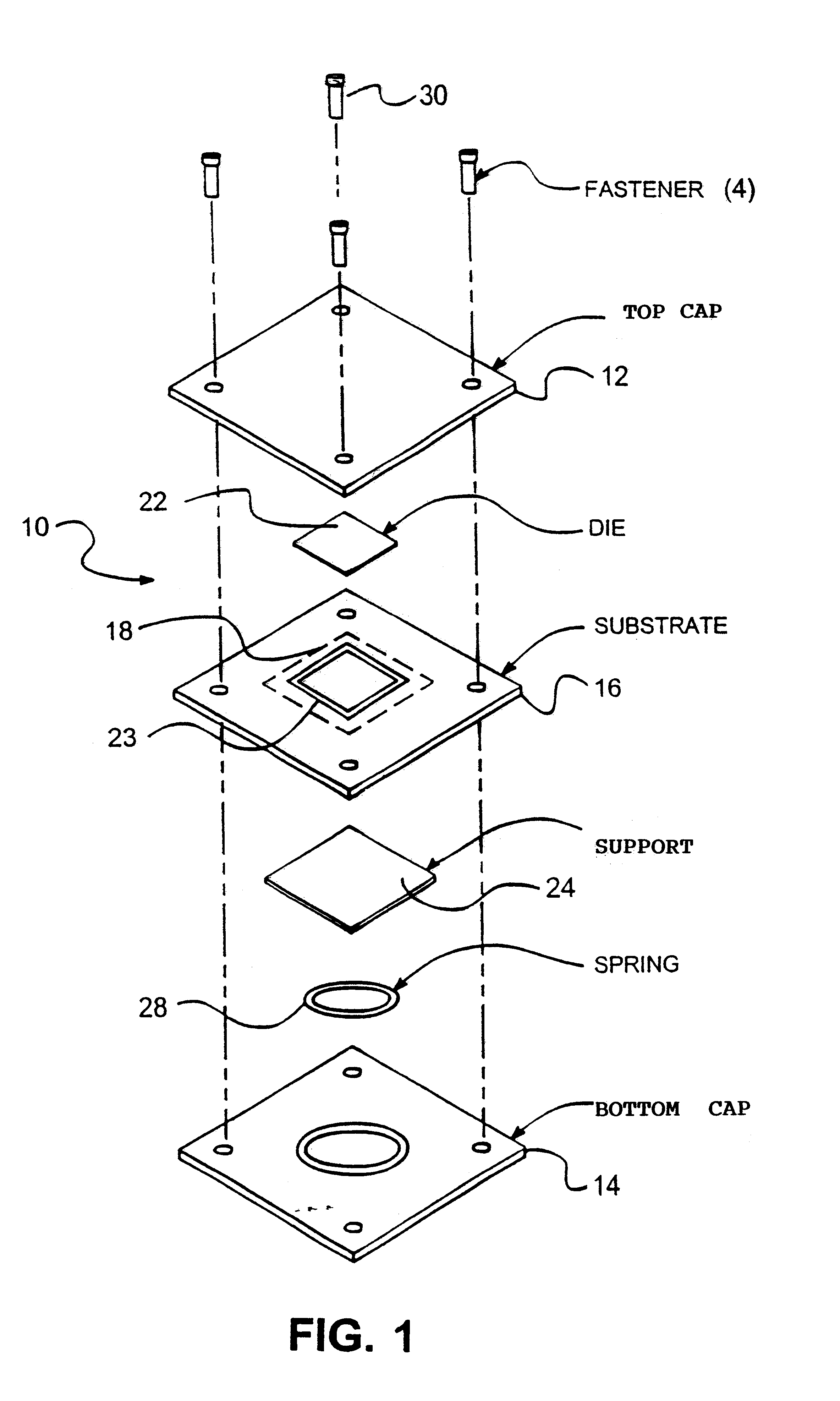

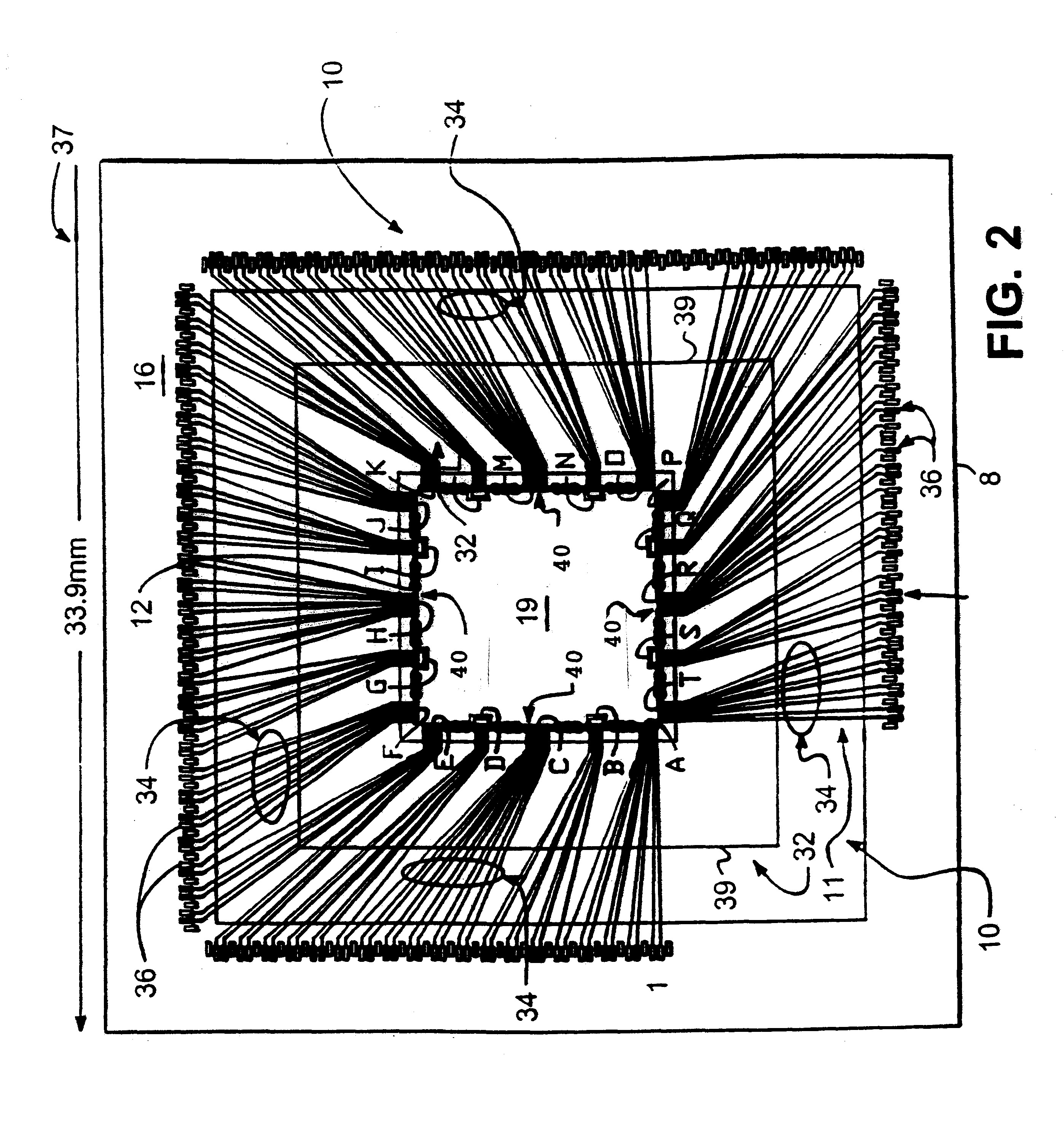

Bare die carrier

InactiveUS6937044B1Easy to reachEasy to dropElectronic circuit testingMeasurement instrument housingContact padPolymer dielectrics

A bare semiconductor circuit die carrier is provided for use in the test of semiconductor circuits, the carrier, comprising: a substrate defining an opening and an outer perimeter; a multiplicity of I / O pads disposed about the perimeter; an interconnect circuit which includes a composite of a multiplicity of individual electrical conductors which are formed in a polymer dielectric; wherein the interconnect circuit overlays a top surface of the substrate and extends across the opening so as to form a flexible membrane that spans the opening; a multiplicity of die contact pads connected to the conductors are disposed about the flexible membrane with particles deposited on the die contact pads; a fence upstanding from the membrane and sized to receive a test die; a top cap that rests upon the die when the die is received within the fence; a bottom cap that rests against a bottom surface of the substrate; and a fastener for securing the top cap to the bottom cap with the die disposed therebetween.

Owner:SV PROBE PTE LTD

Water repelling soliquoid of nano TiO2 and its prepn.

InactiveCN1834166AOvercoming van der Waals gravityImprove stabilityInorganic pigment treatmentSulfonatePolymer dielectrics

This invention discloses a method for preparing a hydrophobic suspension of titanium dioxide nanoparticles. In the method sodium methylene dinaphthalene sulfonate is used as a high-efficiency wetting agent to adsorb on the surface of titanium dioxide nanoparticles, and acts as a polymer dielectric medium in water to facilitate the infiltration and diffusion of water molecules into the nanoparticles until complete wetting. Moreover, a high-shear dispersing mulser is used, and a composite dispersing system composed of polyacrylate, sodium methylene dinaphthalene sulfonate and lignosulfonate is added. During the dispersing process, new surface formed by nanoparticle separation can be covered by the dispersant in time to form double electric layer and obtain a stable hydrophobic suspension of titanium dioxide nanoparticles. The method can solve the problem of poor stability faced by conventional nanoscale dispersing systems, and facilitate wide applications of nanotechnology in such fields as textile, coating, ceramics and environmental protection.

Owner:HUANGHAI HI TECH MATERIALS JILIN PROV

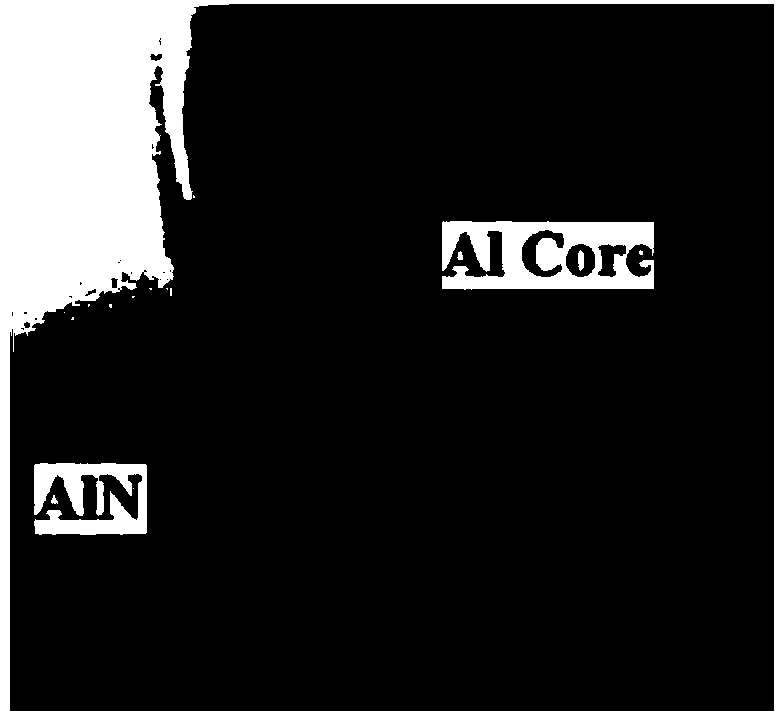

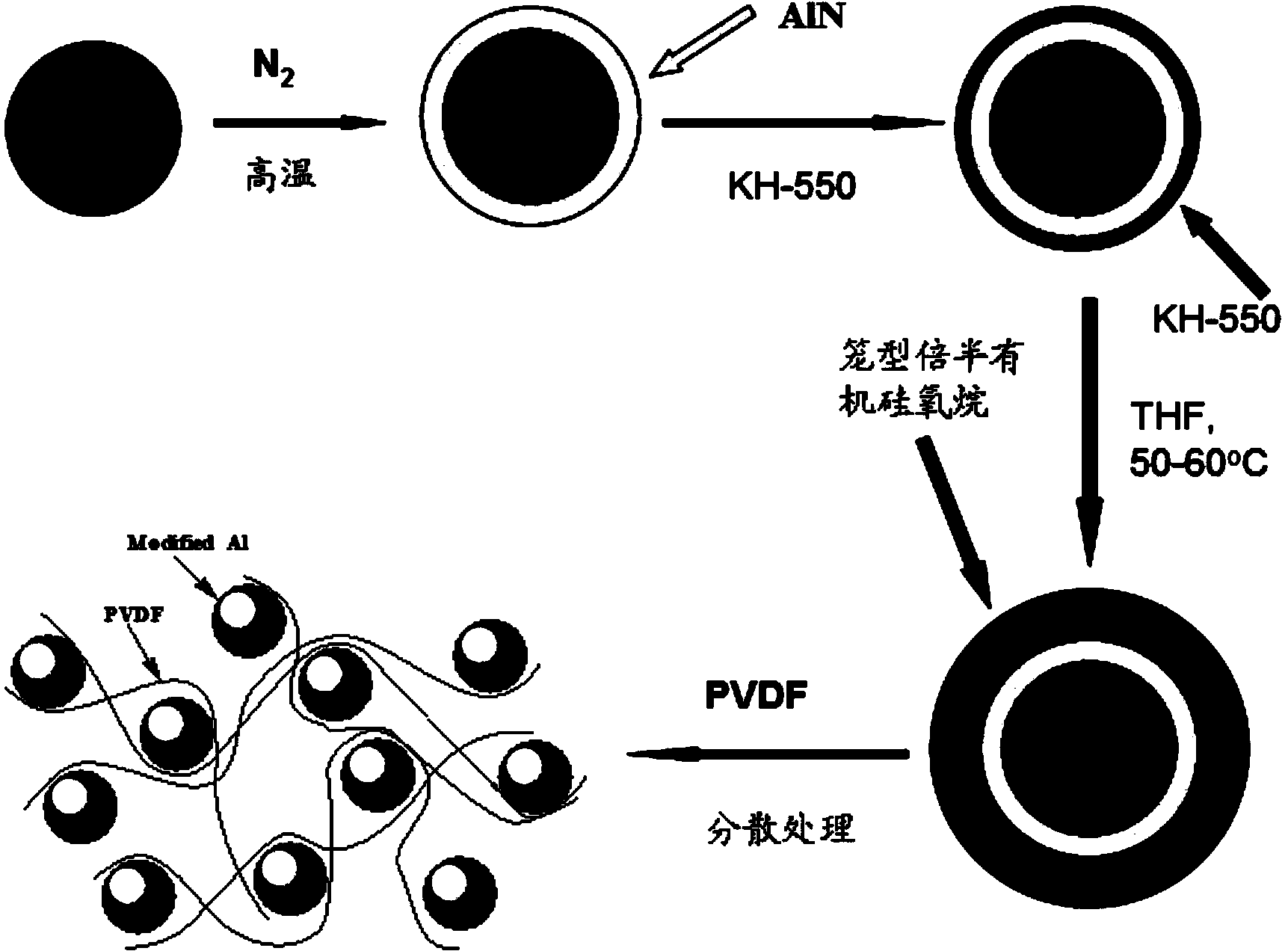

Aluminum particle/PVDF polymer dielectric medium and preparation method thereof

ActiveCN104231498AImprove thermal conductivityHigh dielectric constantSynthetic resin layered productsPolymer scienceMetallic aluminum

The invention relates to an aluminum particle / PVDF polymer dielectric medium and a preparation method thereof. The method comprises the following steps: carrying out surface modification treatment for composite-structure aluminum nanoparticles (that is, aluminum nitride is used as a shell, and metallic aluminum is used as a core) of which the surfaces are subjected to direct nitriding treatment, mixing with PVDF, and then carrying out ultrasonic treatment, dispersion, drying and hot-pressing to prepare the aluminum particle / PVDF polymer dielectric medium. The prepared polymer dielectric medium material has high heat conductivity, high dielectric constant and low loss. When the prepared polymer dielectric medium material is used as a thin film capacitor, the thermal breakdown voltage is improved, and the service life is prolonged. The preparation process is relatively simple, and the processing performance is good. The highest heat conductivity of the polymer dielectric medium is 1.92W / mK, the dielectric constant is about 60 under low frequency of 50Hz, and the loss is lower than 0.25. Compared with the same kind of aluminum particle / polymer system without nitriding treatment for the surface and surface modification treatment, the thermal breakdown voltage of the polymer dielectric medium is higher than about 1.5-2.0kV / mm, and the polymer dielectric medium is suitable for being used on occasions with higher voltage.

Owner:XIANYANG TIANHUA ELECTRONICS SCI & TECH

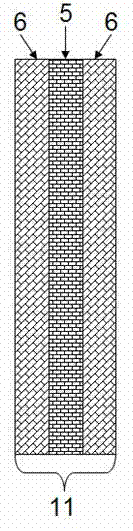

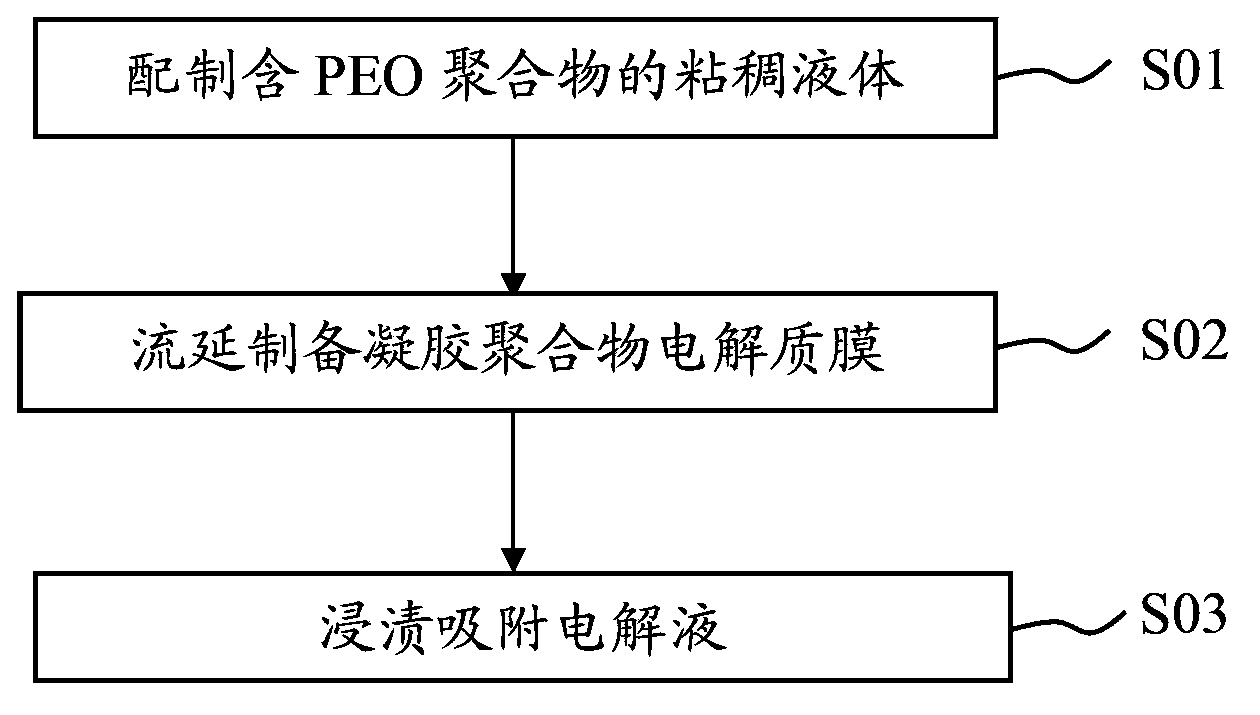

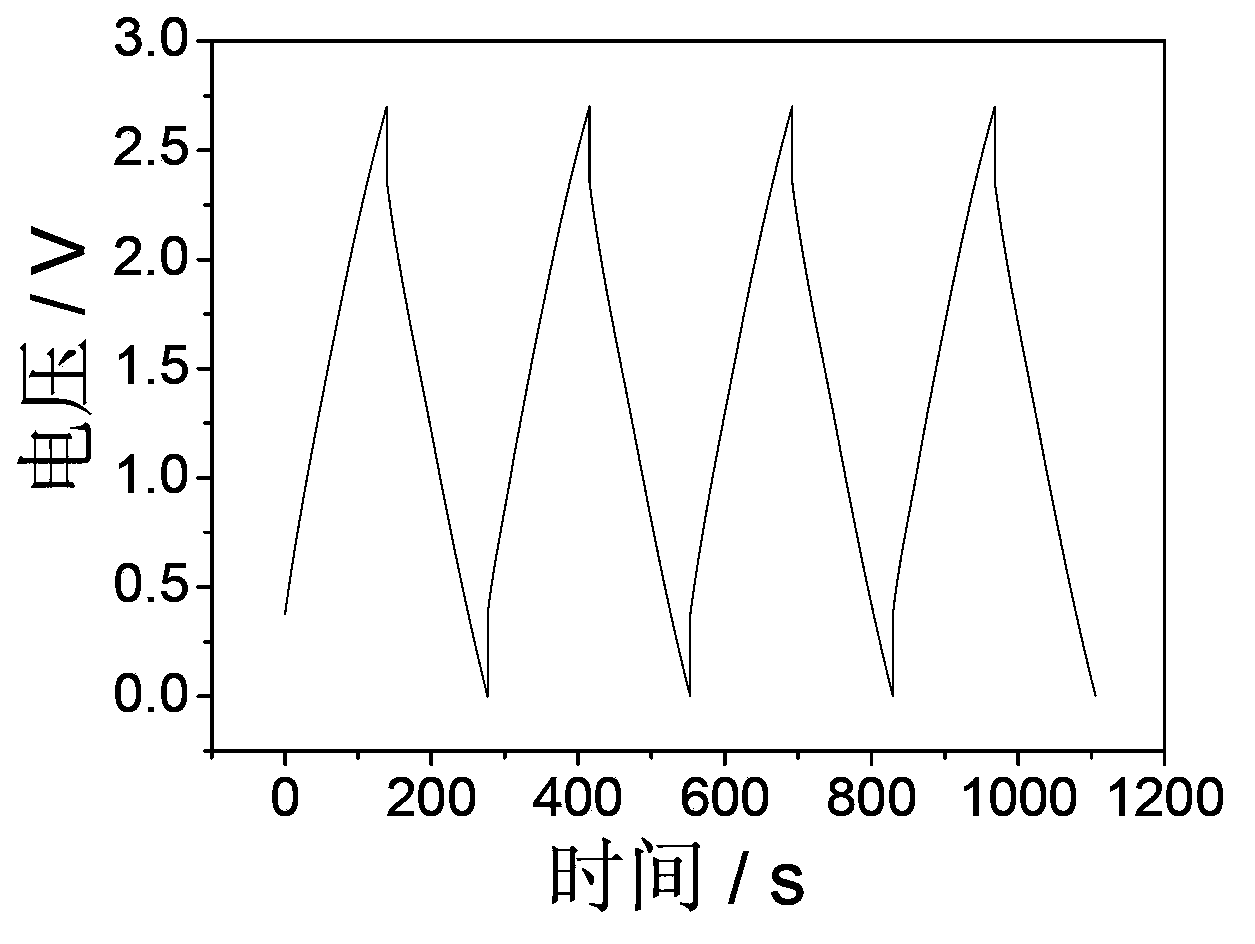

Gel polymer electrolyte, preparation method for the same, super capacitor and application thereof

InactiveCN103680968AImproves ability to absorb electrolytesImprove conductivityCapacitor electrolytes/absorbentsViscous liquidPolymer electrolytes

This invention discloses a gel polymer electrolyte, a preparation method for the same, a super capacitor and an application thereof. The gel polymer electrolyte preparation method includes steps of preparing viscous liquid containing PEO polymer, preparing gel polymer dielectric films through curtain coating and dipping and absorbing the electrolyte. The super capacitor contains the gel polymer electrolyte. The preparation method for the gel polymer electrolyte is simple in preparation, mature in technology and high in rate of finish products and efficiency, and effectively reduces the production cost. The gel polymer electrolyte prepared by the method has strong mechanical strength and high conductivity. The super capacitor containing the gel polymer electrolyte is high in the rate of finished products and low in production cost, and has excellent chemical properties and expands the application range of the super capacitor.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

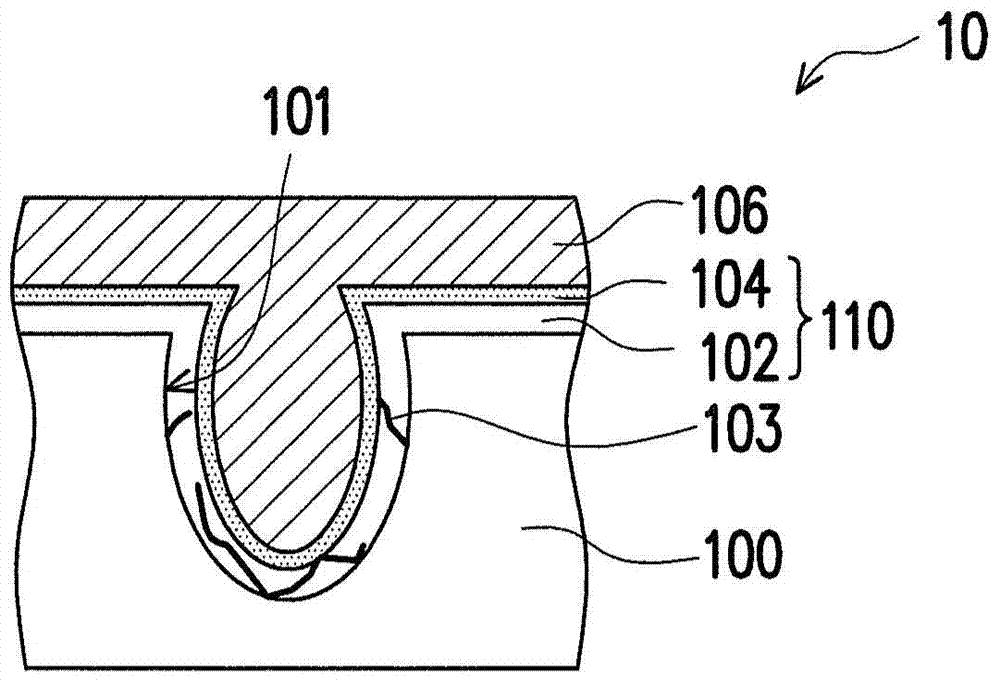

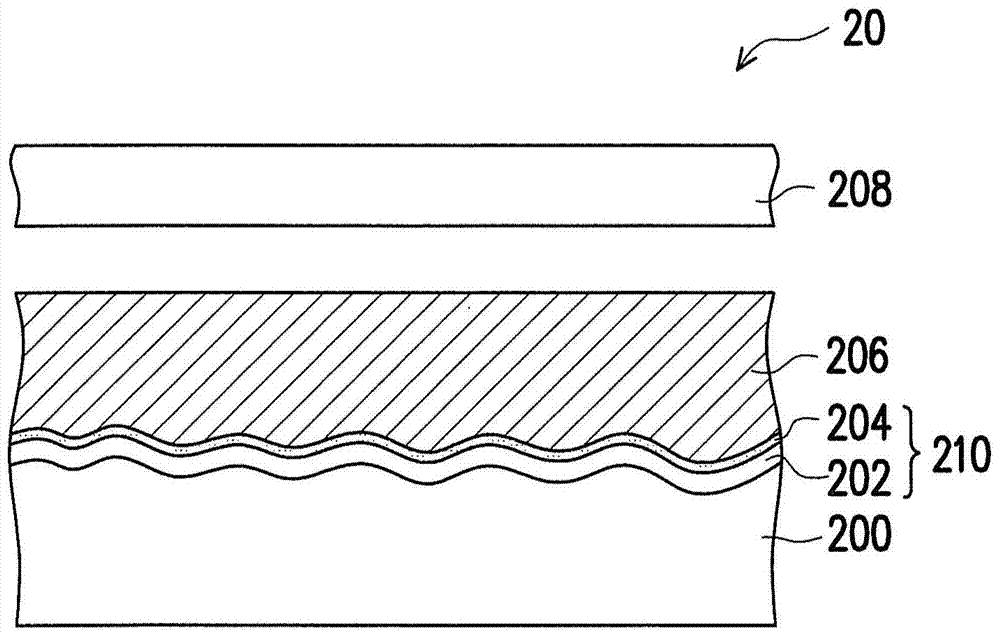

Thin film capacitors embedded in polymer dielectric

ActiveUS9349788B2Avoid tarnishingSmall sizeThin/thick film capacitorFixed capacitor electrodesMetal electrodesDielectric layer

Owner:ZHUHAI ADVANCED CHIP CARRIERS & ELECTRONICS SUBSTRATE SOLUTIONS TECH

Composite mesoporous silica (IL/SiO2) for encapsulating ionic liquid and preparation and application thereof

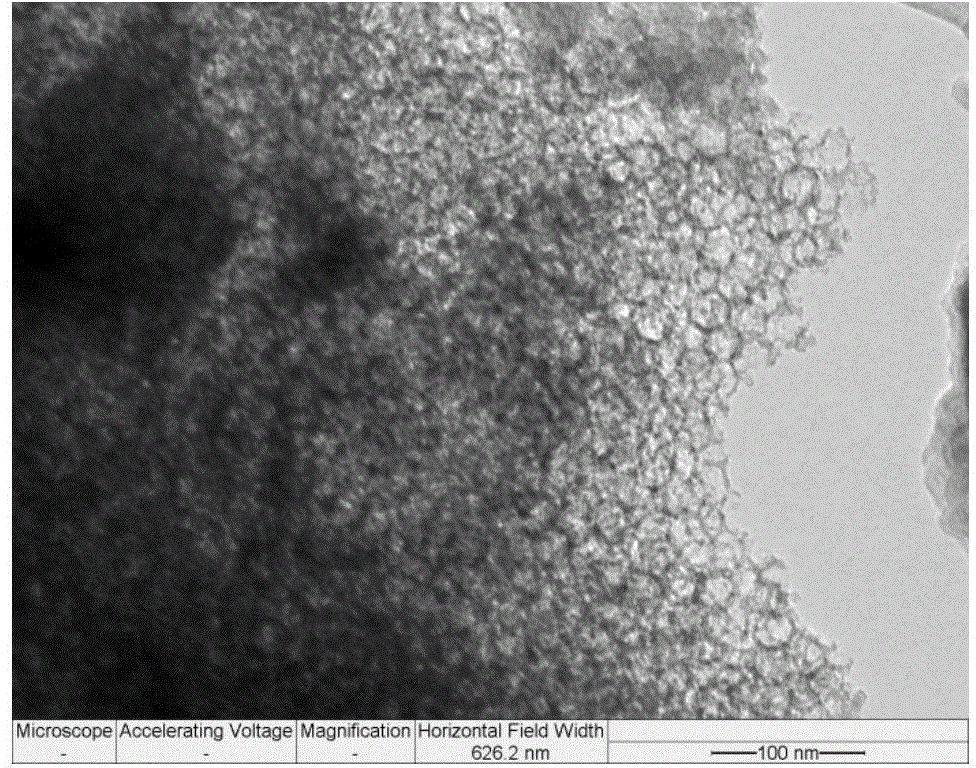

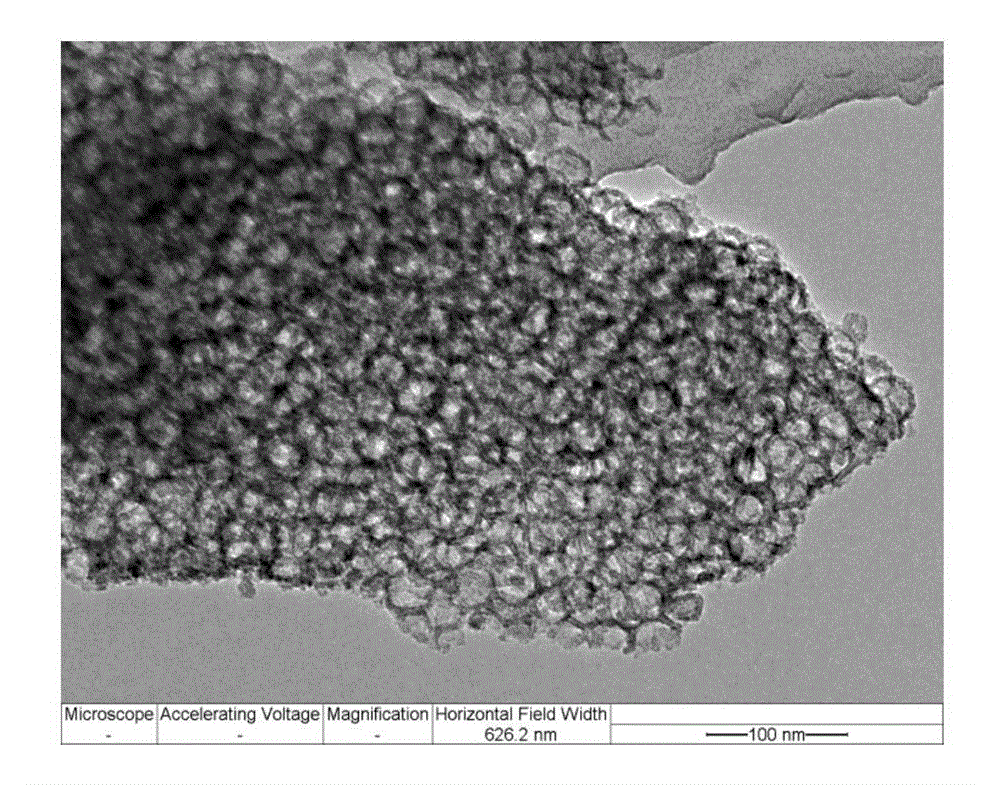

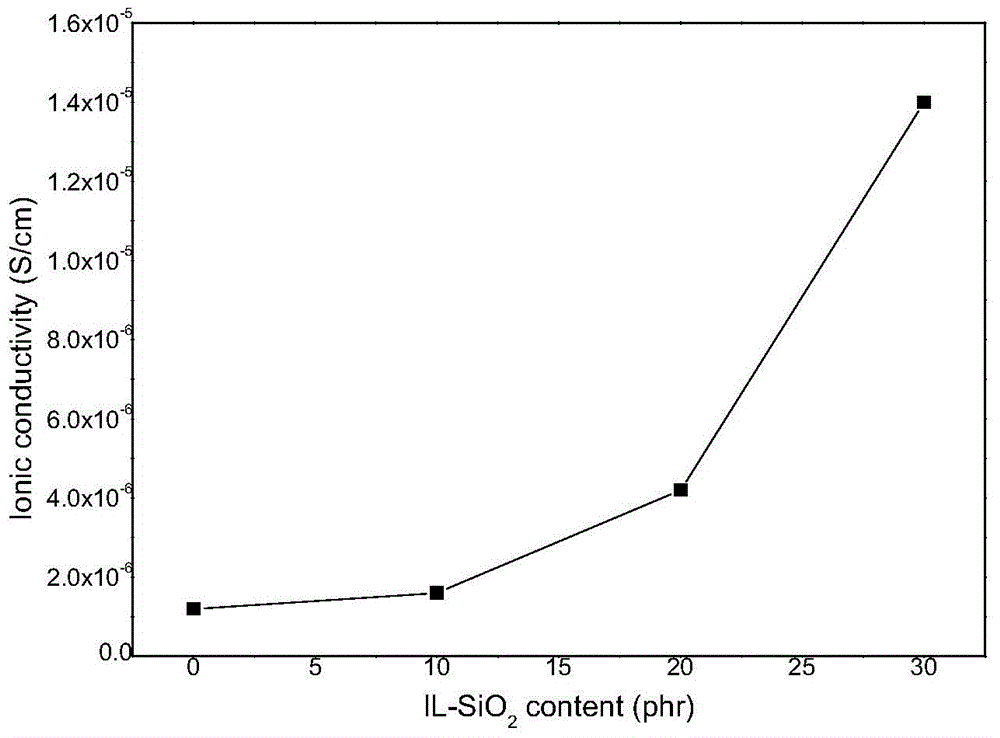

InactiveCN104466237AImprove conductivityImprove mechanical propertiesFinal product manufactureElectrolyte accumulators manufacturePolymer dielectricsAcrylonitrile

The invention relates to composite mesoporous silica (IL / SiO2) for encapsulating ionic liquid and preparation and application thereof. The IL / SiO2 is a composition formed from 1-carboxymethyl-3-methylimidazole bis(trifluoromethane)sulfonimide salt (ionic liquid, IL for short) and mesoporous silica, the mesoporous silica is expanded through a pore-expanding agent, and the aperture range is 10-15 nanometers; the IL / SiO2 is applied to all-solid-state polymer electrolyte of a lithium ion battery, and a raw material comprises the following components in parts by weight: 100 parts of carboxylic acrylonitrile butadiene rubber, 2.0-3.0 parts of vulcanizing agents, 20-60 parts of lithium salt and 0.1-30 parts of IL / SiO2. Compared with the prior art, the composite mesoporous silica (IL / SiO2) disclosed by the invention can be used for effectively solubilizing the lithium salt by being applied to a polymer dielectric, thereby providing a lithium ion migration channel. The polymer electrolyte prepared by applying the composite mesoporous silica (IL / SiO2) has the advantages of higher room-temperature conductivity and excellent mechanical properties.

Owner:SHANGHAI JIAO TONG UNIV

Siloxane epoxy polymers for low-k dielectric applications

ActiveUS7019386B2Improve performanceSemiconductor/solid-state device detailsSolid-state devicesEpoxyPolymer dielectrics

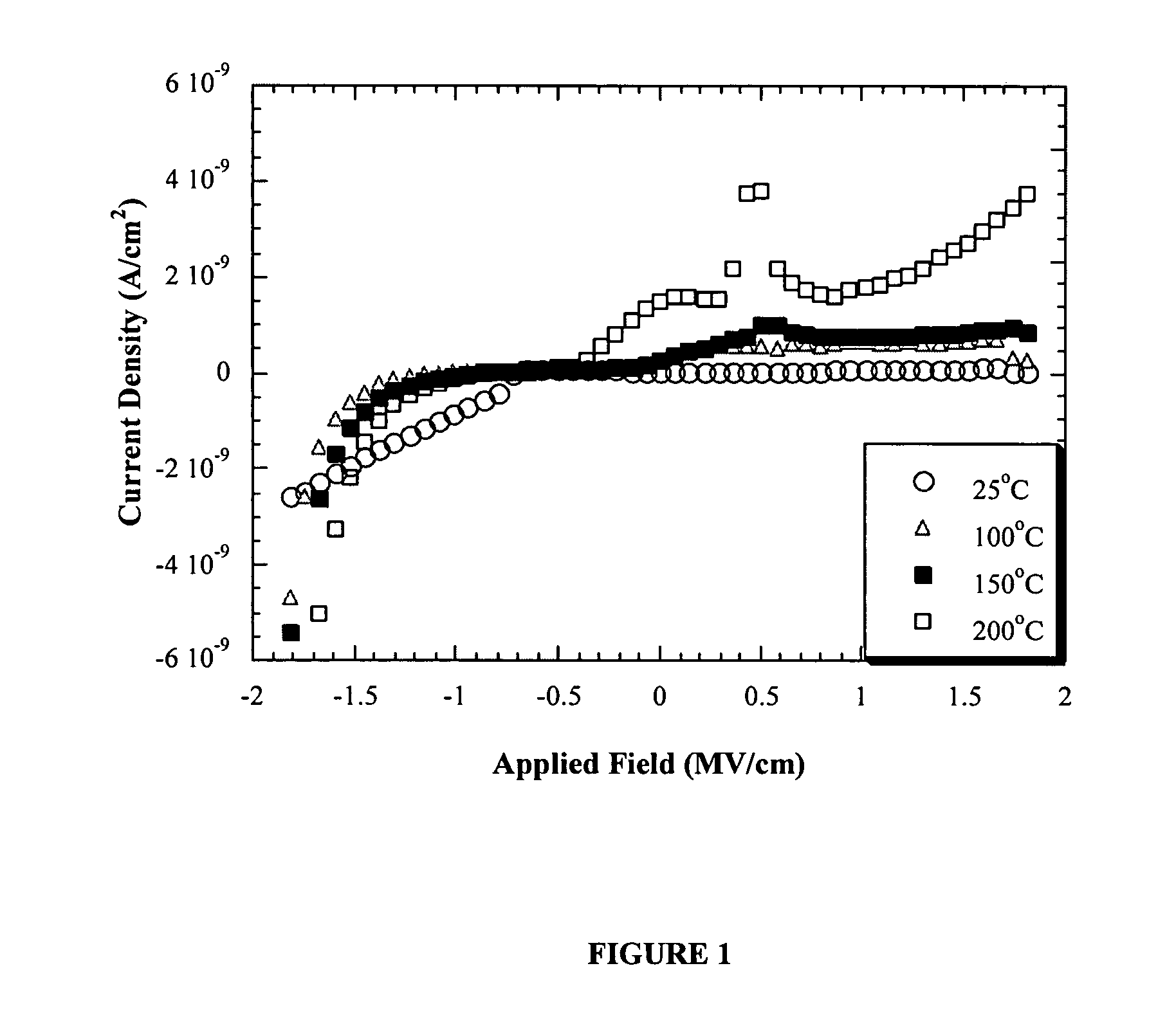

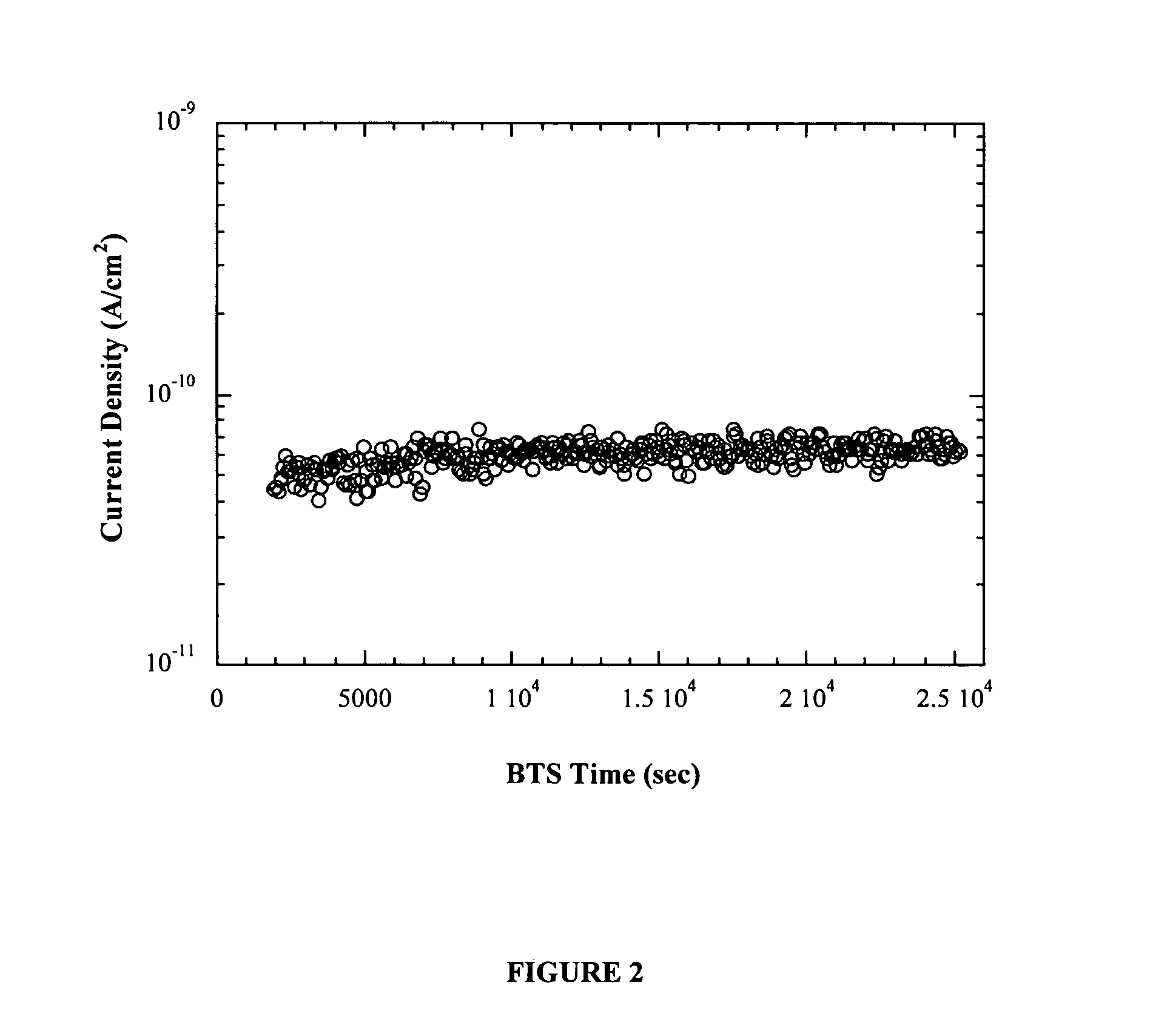

Semiconductor devices employing siloxane epoxy polymers as low-κ dielectric films are disclosed. The devices include a semiconductor substrate, one or more metal layers or structures and one or more dielectric films, wherein at least one dielectric film in the devices is a siloxane epoxy polymer. Use of siloxane epoxy polymers is advantageous, in part, because the polymers adhere well to metals and have dielectric constants as low as 1.8. Thus, the disclosed semiconductor devices offer much better performance than devices fabricated using conventional dielectric materials. Furthermore, the siloxane epoxy polymer dielectrics are fully curable at low temperatures, exhibit low leakage currents, and remain stable at temperatures greater than 400° C. making them particularly attractive for use in the semiconductor industry

Owner:POLYSET +1

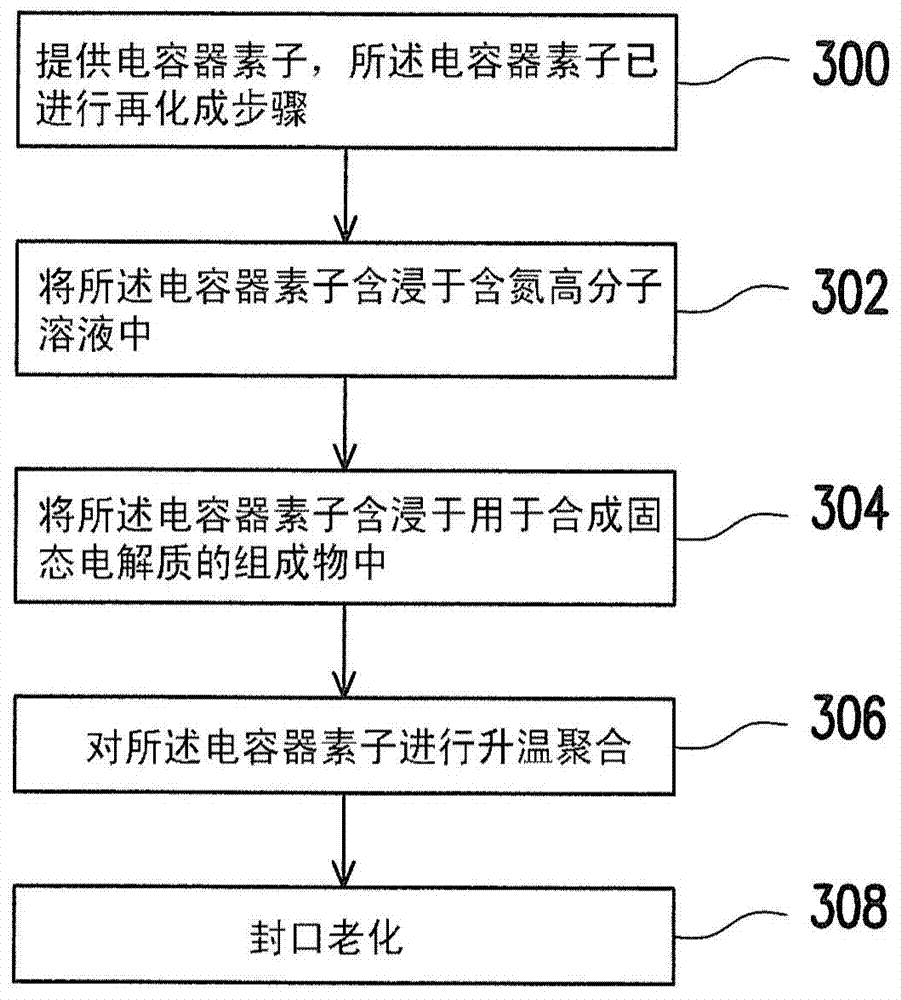

Composite electrode and electrolytic capacitor

ActiveCN104752061AImprove insulation performanceIncrease drapeFixed capacitor electrodesSolid electrolytic capacitorsElectrolysisComposite electrode

Provided is a composite electrode including a metal layer and a composite dielectric layer. The composite dielectric layer includes a metal oxide dielectric layer and a polymer dielectric layer. The composite dielectric layer overlays the metal layer. The polymer dielectric layer includes a nitrogen-containing polymer and overlays the metal oxide dielectric layer. An electrolytic capacitor is also provided. The electrolytic capacitor has a polymer dielectric layer made of a nitrogen-containing polymer, and such polymer dielectric layer is beneficial to increase the insulating property of the metal oxide dielectric layer and the coverage property of the conductive polymer. Thereby, the conventional leakage current can be significantly reduced and the yield can be improved.

Owner:IND TECH RES INST

Method and apparatus for polymer dielectric surface recovery by ion implantation

InactiveUS20060113640A1Semiconductor/solid-state device detailsSolid-state devicesInsulation layerPolymer dielectrics

In one embodiment, the disclosure relates to a method and apparatus for surface recovery of a polymer insulation layer through implantation. The method includes providing a substrate having thereon a conductive pad and an insulation layer, optionally processing the conductive pad to remove oxide layer formed on the conductive pad and conducting ion implantation to recover dielectric properties of the insulation layer.

Owner:TAIWAN SEMICON MFG CO LTD

Functional group linken on surface of polymer electrolyte nano SiO2 and preparation method thereof

InactiveCN101045830AGood dispersionReduce the crystalline phase contentPigment treatment with non-polymer organic compoundsSecondary cell detailsPolymer electrolytesNano sio2

This invention relates to a kind of polymer dielectric nanometer SiO2 linkage upper surface functional group. It is hydrophobicity functional group with Si - CH2CH2( CF2) 5CF3 topcoated; the particle size of nanometer SiO2 is 7 to 20 nm, specific surface area is 150 to 300 sq m / g. Hydrophobicity quality of this invention is good for dispersing at PEO group polymer dielectric system, thereby could reduce crystalline phase content og this system, advance conductivity.

Owner:杜洪彦 +1

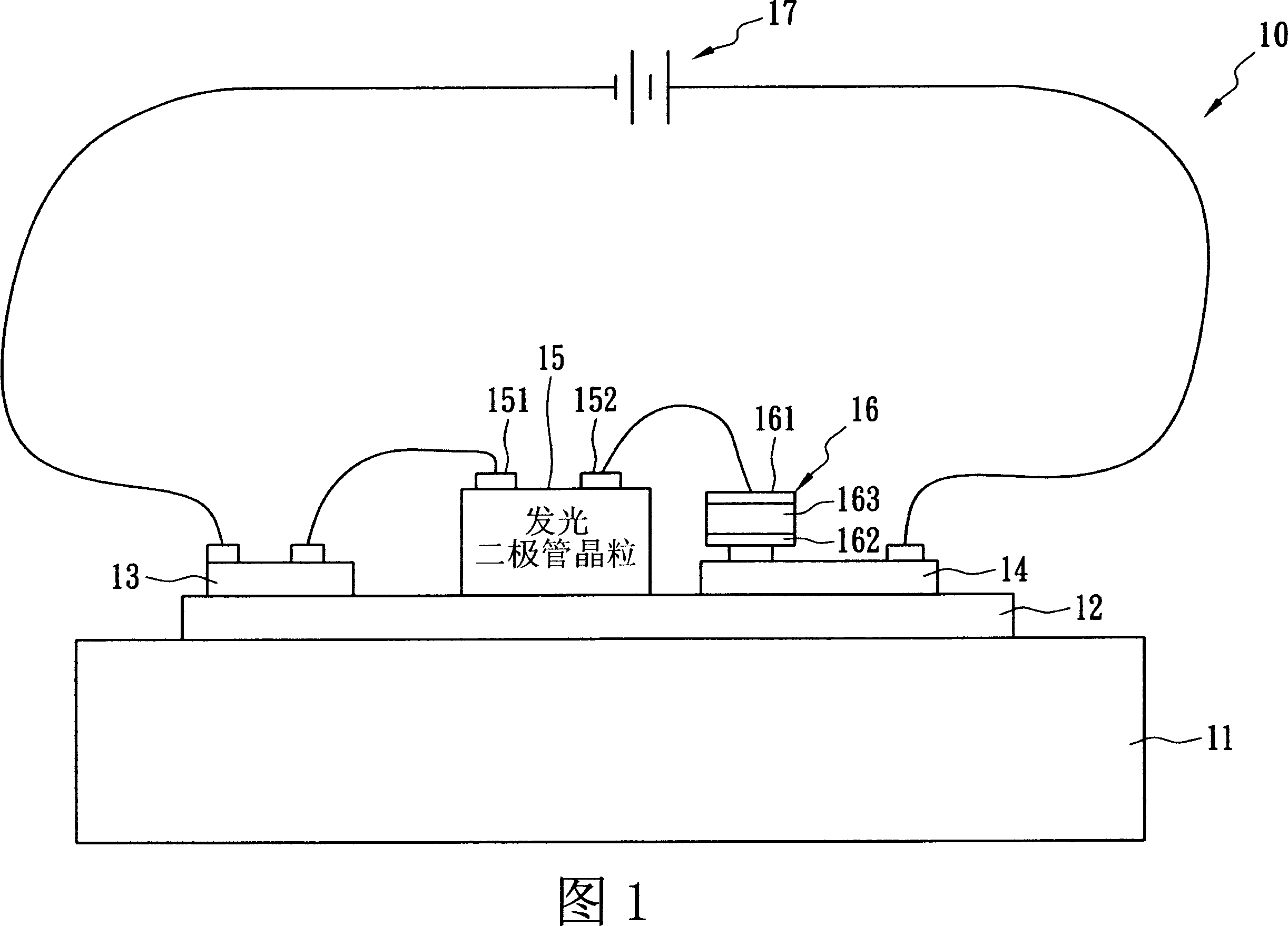

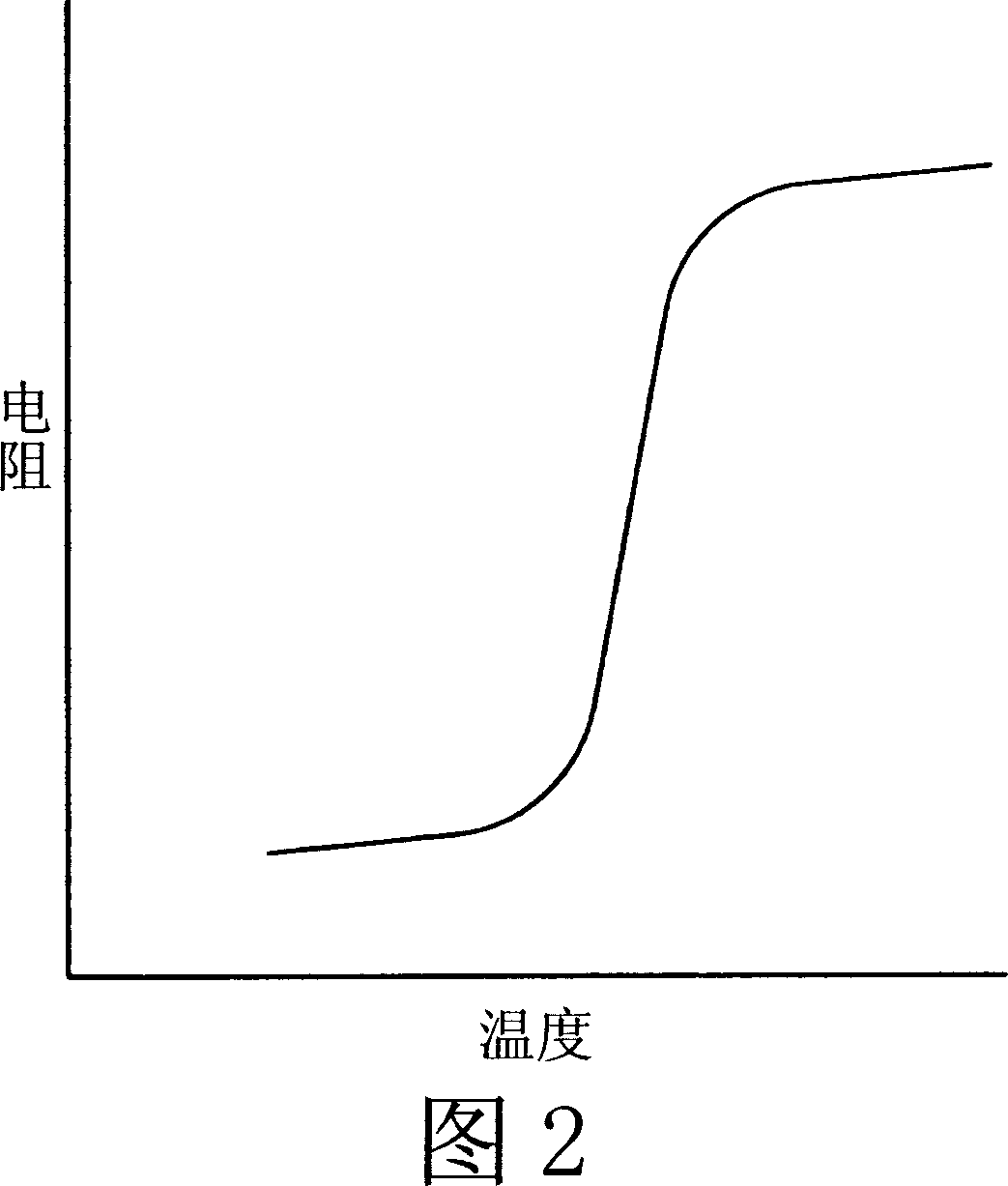

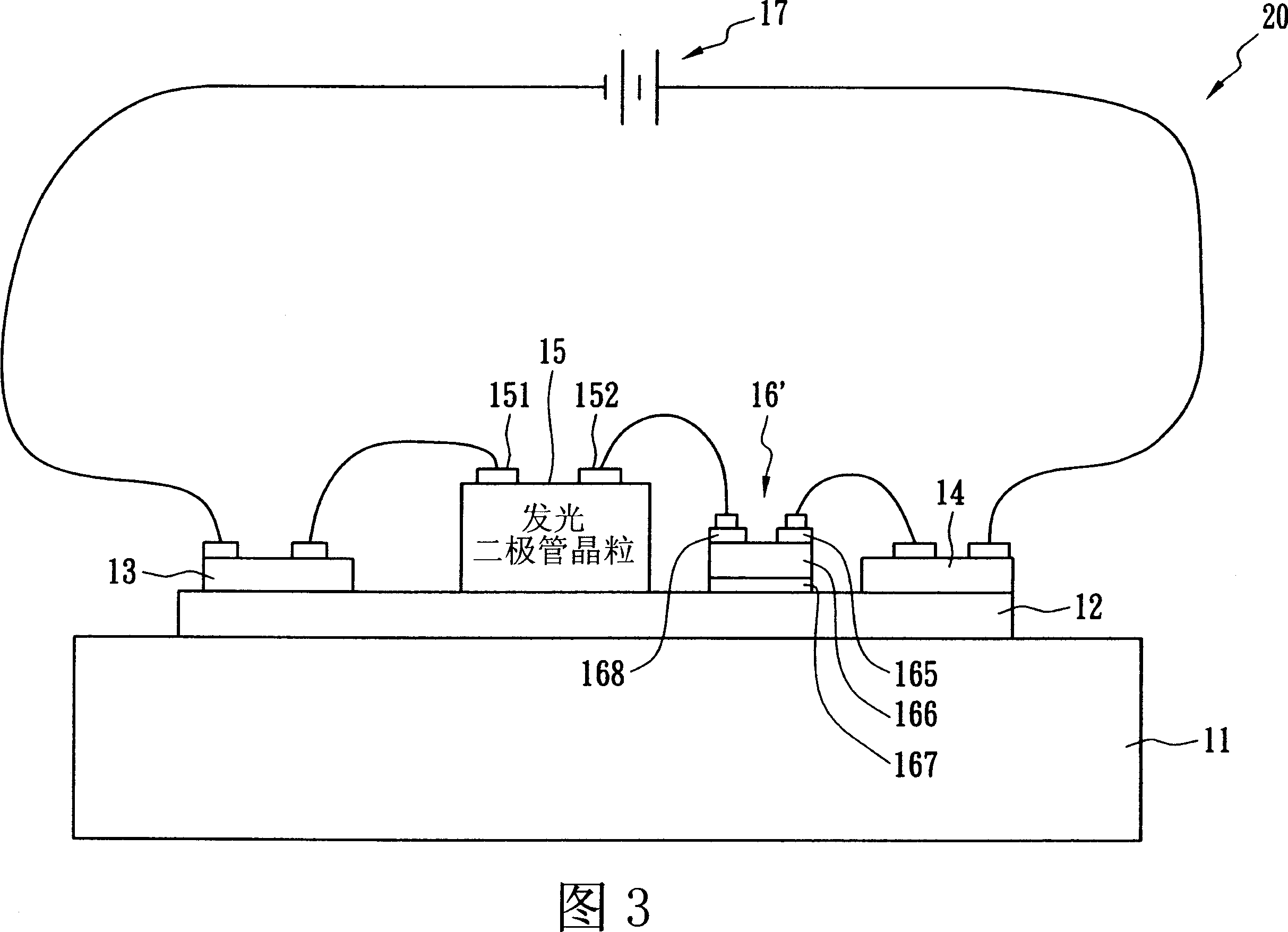

LED device with temp. control function

InactiveCN101000938AHas a positive temperature coefficient characteristicIncrease elasticitySemiconductor/solid-state device detailsLighting heating/cooling arrangementsElectricityTemperature control

The invention discloses a LED device with a temperature controlling function, which includes: a LED grain, a cooling unit, a thermal conductivity layer and a temperature controlling component. The described cooling unit and the thermal conductivity layer on the surface of the cooling unit carriers the LED grain, which cools for the LED grain when the LED grain connects the power (i.e. light). The described temperature controlling component series between the LED grain and the power, which has a character of positive temperature coefficient, and the distance between the LED grain and the component, is less than 3 cm. The described thermal conductivity layer can be composed of polymer dielectric materials and thermal conductivity is larger than 1.0W / mK (room temperature 25deg.C).

Owner:POLYTRONICS TECH

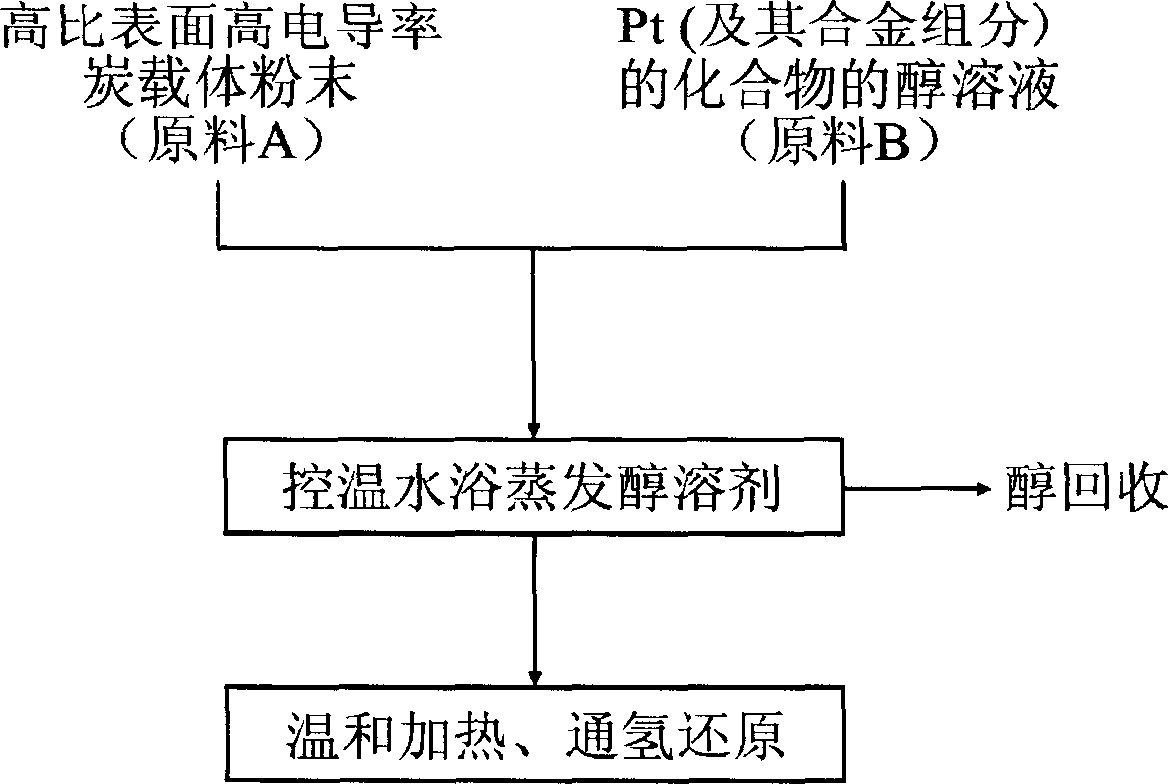

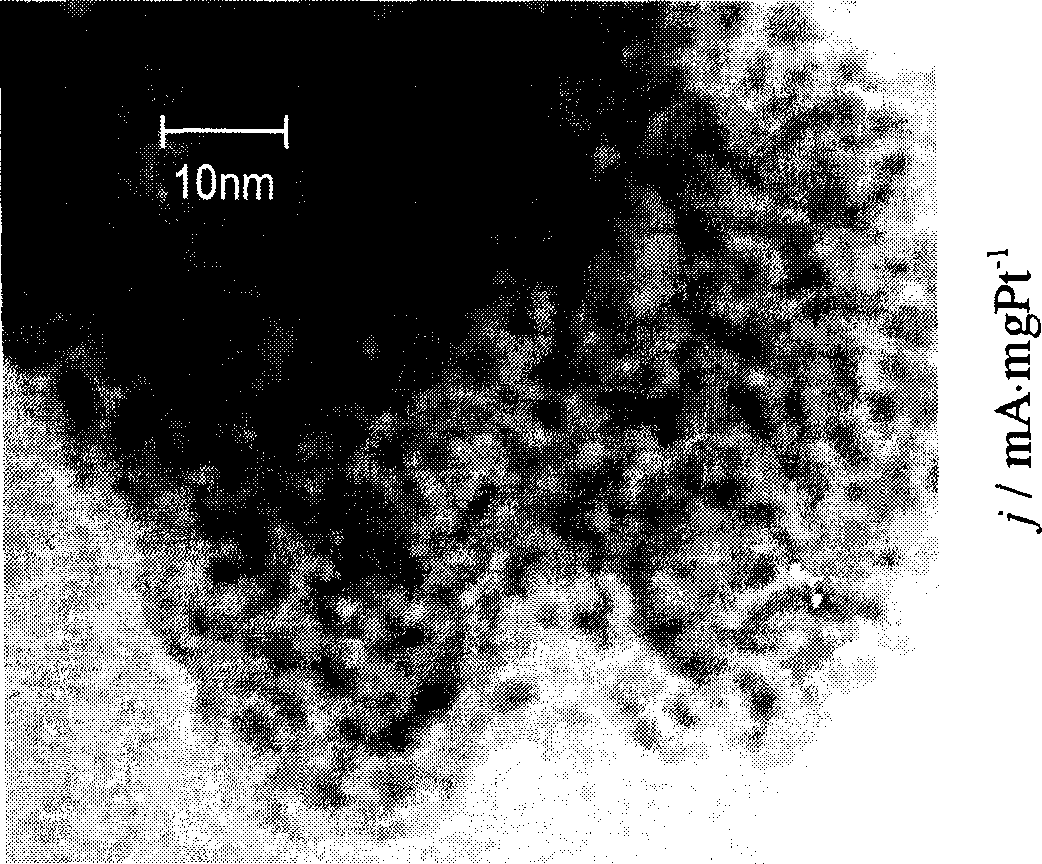

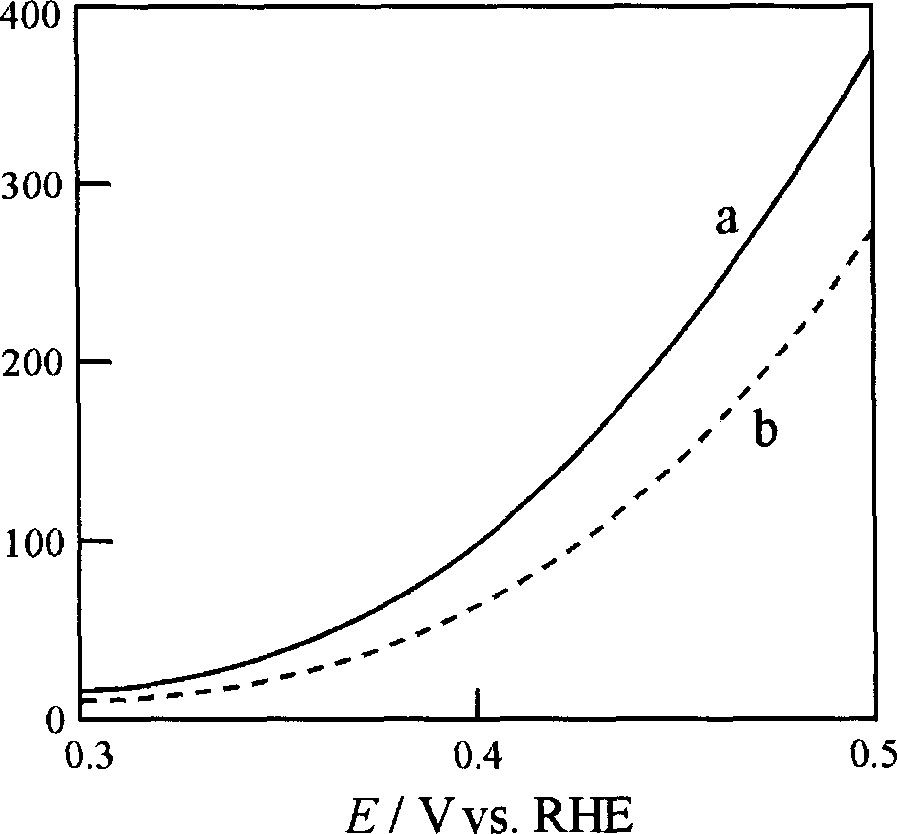

Process for preparing fuel cell carbon-carried Pt-based catalyst

InactiveCN1402367AEvenly distributedEasy to operateCell electrodesMetal/metal-oxides/metal-hydroxide catalystsWater bathsPolymer dielectrics

The invented preparing method includes only two steps. First, mixing the alcoholic solution of the compound of platinum (and alloy constituent) with the carbon carrier fully, making the admixture evenly. The alcohol solvent is vaporized by use of the water bath at the controlled temperature. Then, the dry powder obtained is deoxidized in hydrogen at the condition of mild heating. The granularity of the platinum (alloy) obtained by the method is 1-2 nm with evenly distributed on the carbon carrier. The catalyst possesses the better performances of the electrocatalysis reaction relevant to the polymer dielectric film fuel cell such as oxidation of hydrogen and deoxidization of oxygen, oxidation of carbon monoxide, oxidation of methanol. The invention provides the features of easy of operation, without need of filtering and washing only need of a little cheap chemicals.

Owner:WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com