Micro-nano multi-layer composite dielectric materials and preparation method and device thereof

A dielectric material, micro-nano multi-layer technology, applied in the field of material science, can solve the problems of polymer performance degradation, etc., to achieve the effect of improving dispersion, product dielectric constant and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

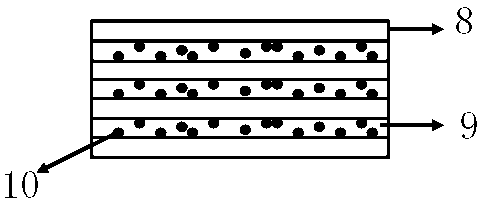

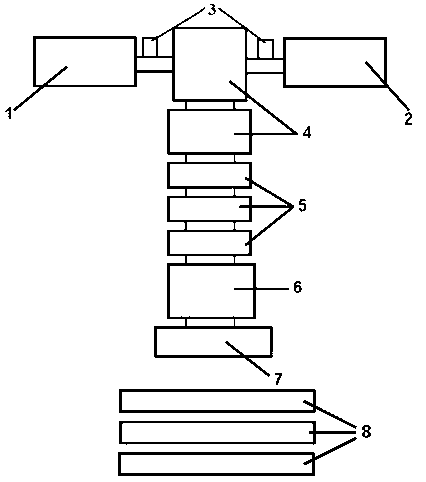

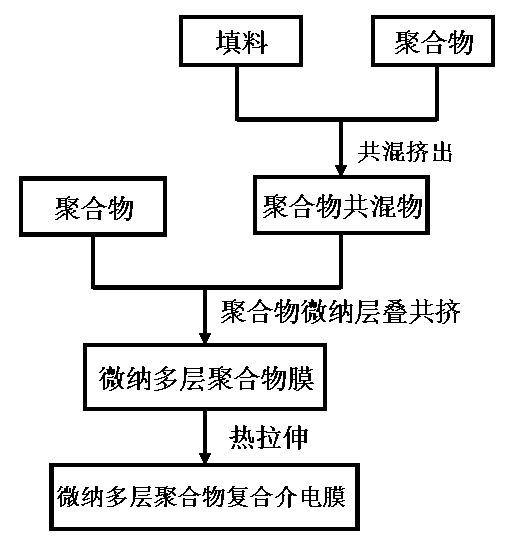

[0016] The preparation method of the micro-nano multi-layer composite dielectric material is to mix 50 parts of PVDF and MWNT first, and then add them to a twin-screw extruder for blending and extrusion to obtain a PVDF / MWNT blend; the remaining PVDF and PVDF / MWNT blends are respectively added to different extruders of the special polymer micro-nano lamination co-extrusion device for multi-layer co-extrusion, and the extruded film material is thermally stretched to obtain alternating PVDF layers 8 and PVDF / MWNT layers 9 The finished product, PVDF / MWNT layer 9 is distributed with disentangled multi-walled carbon nanotubes 10, and the multi-walled carbon nanotubes 10 are dispersed in a line shape; the single-layer thickness of the prepared PVDF layer 8 or PVDF / MWNT layer 9 is 50nm; The hot stretching specifically means that after the film material is extruded from the extruder, the temperature of the extruded film material has not been significantly lowered, and it is pulled b...

Embodiment 2

[0018] Embodiment 2 of the present invention: micro-nano multi-layer composite dielectric material, it comprises polymer layer and polymer blend layer, is alternate structure between polymer layer and polymer blend layer; In the material layer, the filler is evenly distributed in the polymer matrix in one or more forms of spherical, flake, linear or rod; calculated in parts by weight, the polymerization in the polymer layer and the polymer blend layer The total amount of the material matrix is 88 parts, and the filler of the polymer blend layer is 12 parts; the polymer matrix is polyvinylidene fluoride (PVDF), and the filler is modified polyaniline (PANI).

[0019] The preparation method and the device used are the same as in Example 1.

Embodiment 3

[0020] Embodiment 3 of the present invention: micro-nano multi-layer composite dielectric material, it comprises polymer layer and polymer blend layer, is alternate structure between polymer layer and polymer blend layer; In the material layer, the filler is evenly distributed in the polymer matrix in one or more forms of spherical, flake, linear or rod; calculated in parts by weight, the polymerization in the polymer layer and the polymer blend layer The total amount of the material matrix is 80 parts, and the filler of the polymer blend layer is 20 parts; the polymer matrix is polyvinylidene fluoride (PVDF), and the filler is nano barium titanate (nBaTO 3 ).

[0021] The preparation method and the device used are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Single layer thickness | aaaaa | aaaaa |

| Single layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com