Heat conductive silicone grease composition

A heat-conducting silicone grease and composition technology, applied in the direction of heat exchange materials, chemical instruments and methods, can solve the problems of low initial temperature absorption rate at the hot end and limited space for improving thermal conductivity, so as to improve heat dissipation efficiency and use The effect of life, strong practical value, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

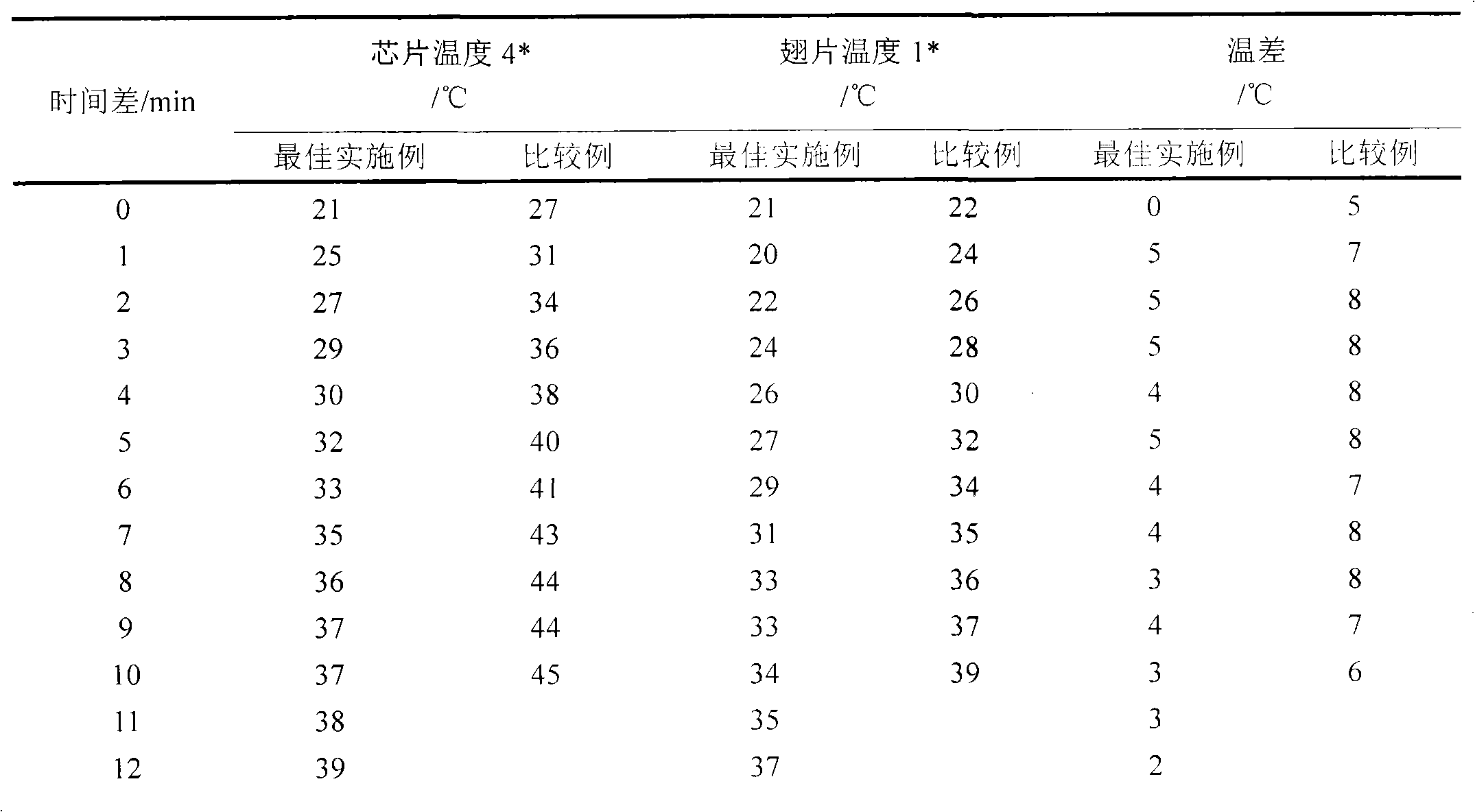

Examples

Embodiment 1

[0064] The additive components and their mass ratios used are as follows: the mass ratio of carbon nanotubes, graphene, and particles is 1:6:3, and the volume ratio of the additives as a whole to silicone oil is 6:4.

[0065] The purity of the carbon nanotubes in the above preferred embodiments is ≥95wt%, and the ash content is ≤0.2wt%.

[0066] The particles in the above preferred embodiment are phase-change capsules wrapped in paraffin wax, the material including paraffin wax is aluminum oxide, the phase-transition temperature is 29°C, and the average particle size is 60um.

[0067] The silicone oil described in the above preferred embodiments is a mixture of simethicone and hydrogen-containing silicone oil with a viscosity of 500,000 cSt at 25°C.

[0068] Preparation

[0069] Pour graphene and particles with a mass ratio of 6:3 into a small amount of silicone oil for pre-mixing, and slowly add carbon nanotubes of the required quality under the condition of mechanical stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com