Patents

Literature

2172 results about "Thermal transmittance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal transmittance is the rate of transfer of heat through matter. The thermal transmittance of a material (such as insulation or concrete) or an assembly (such as a wall or window) is expressed as a U-value.

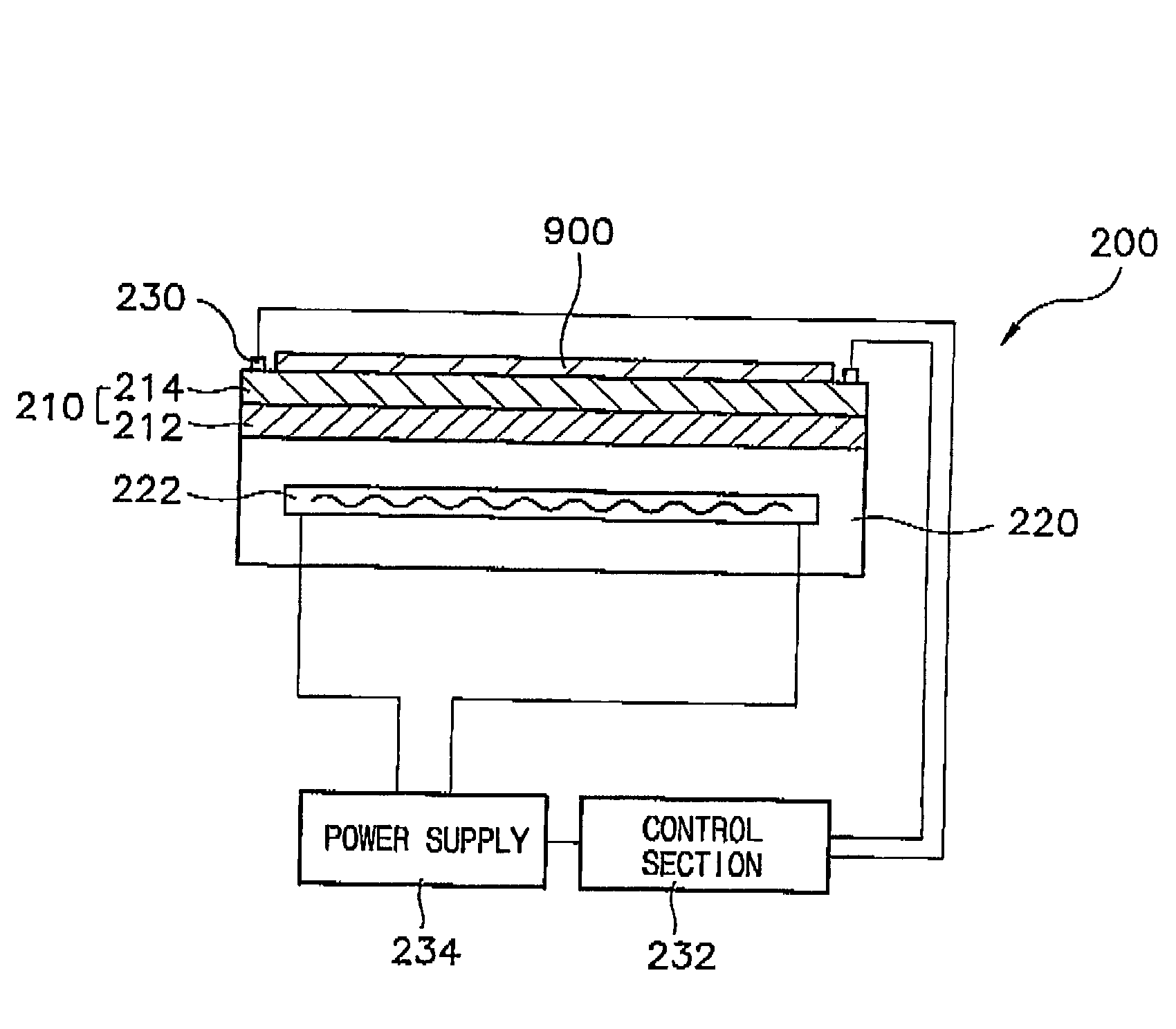

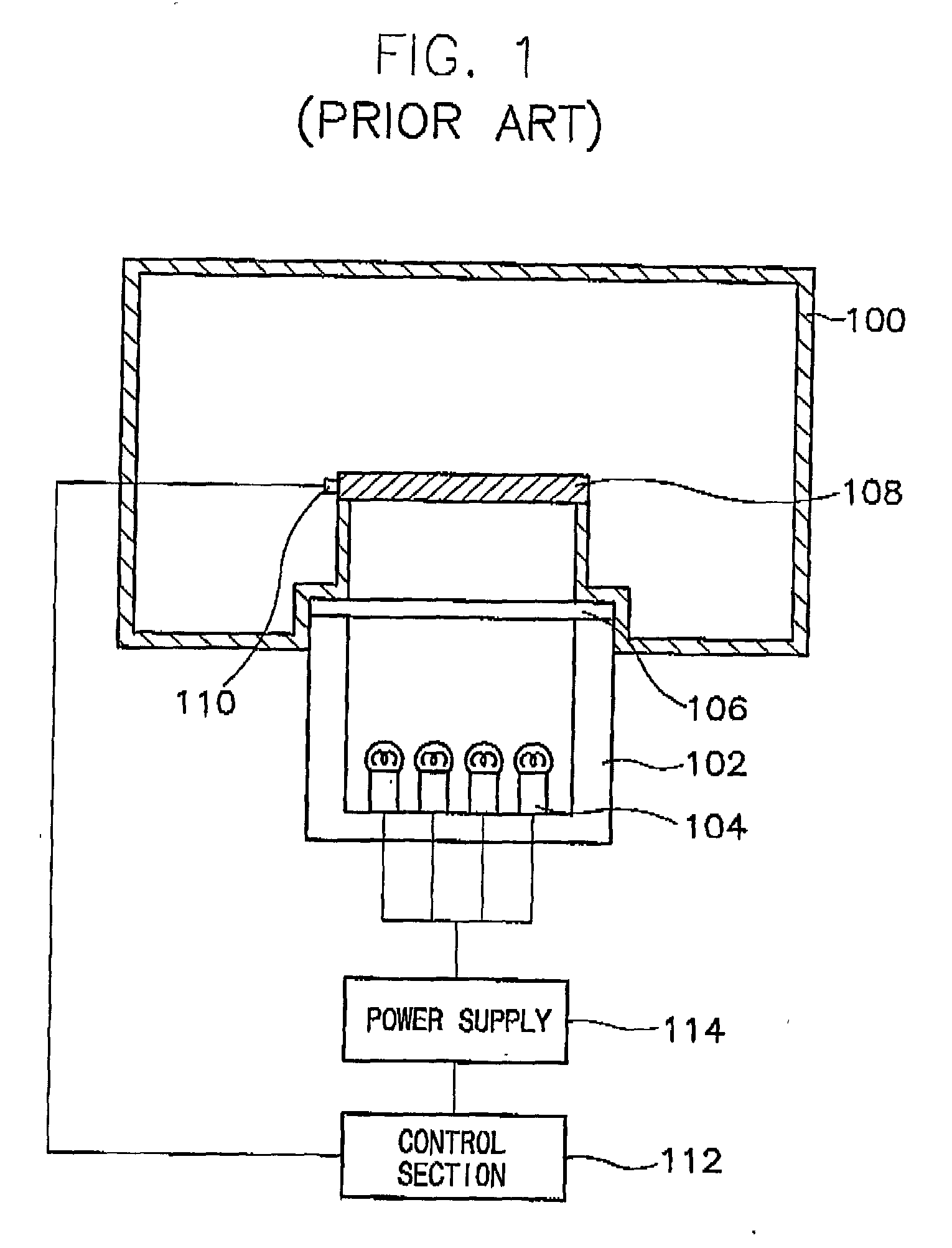

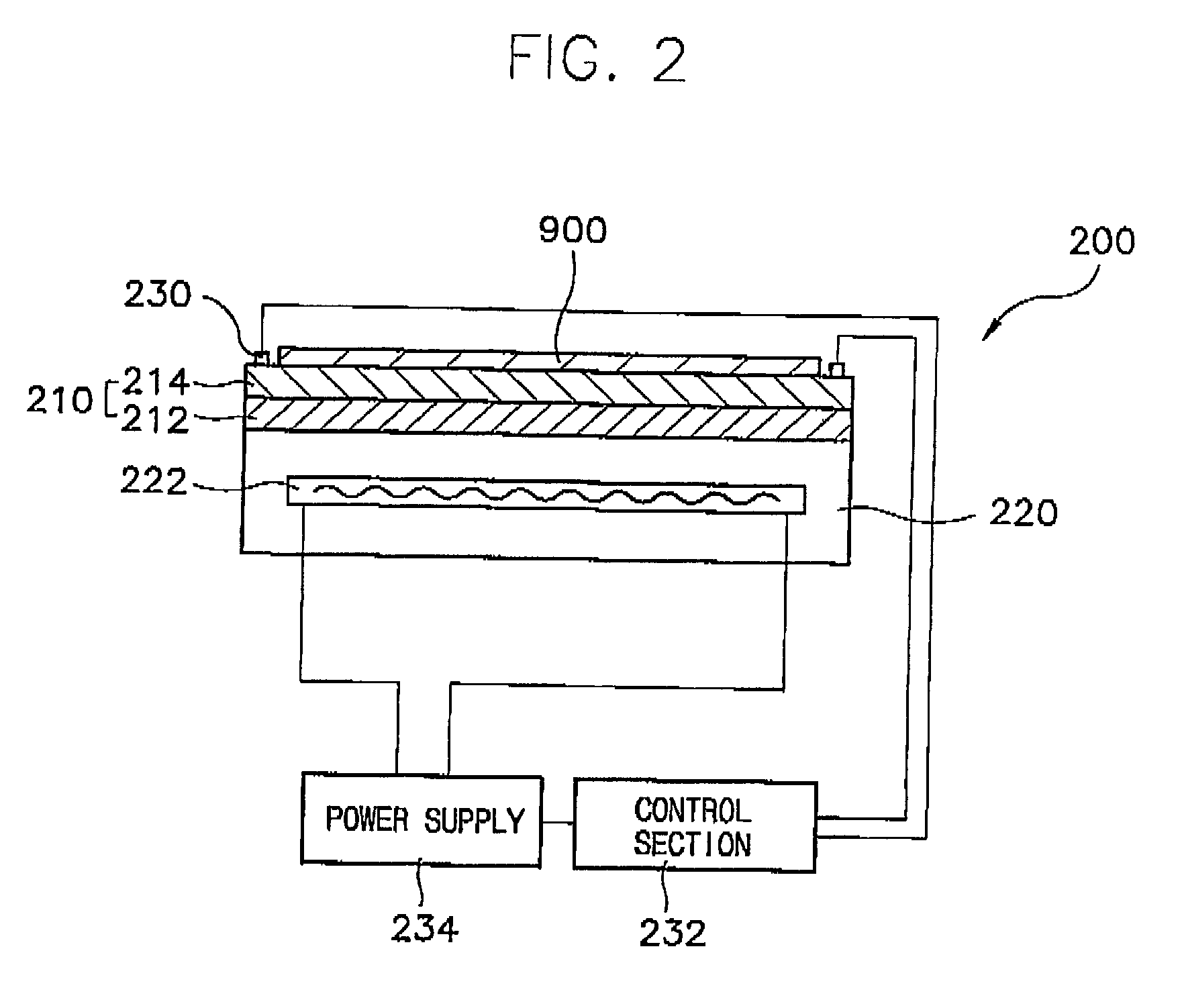

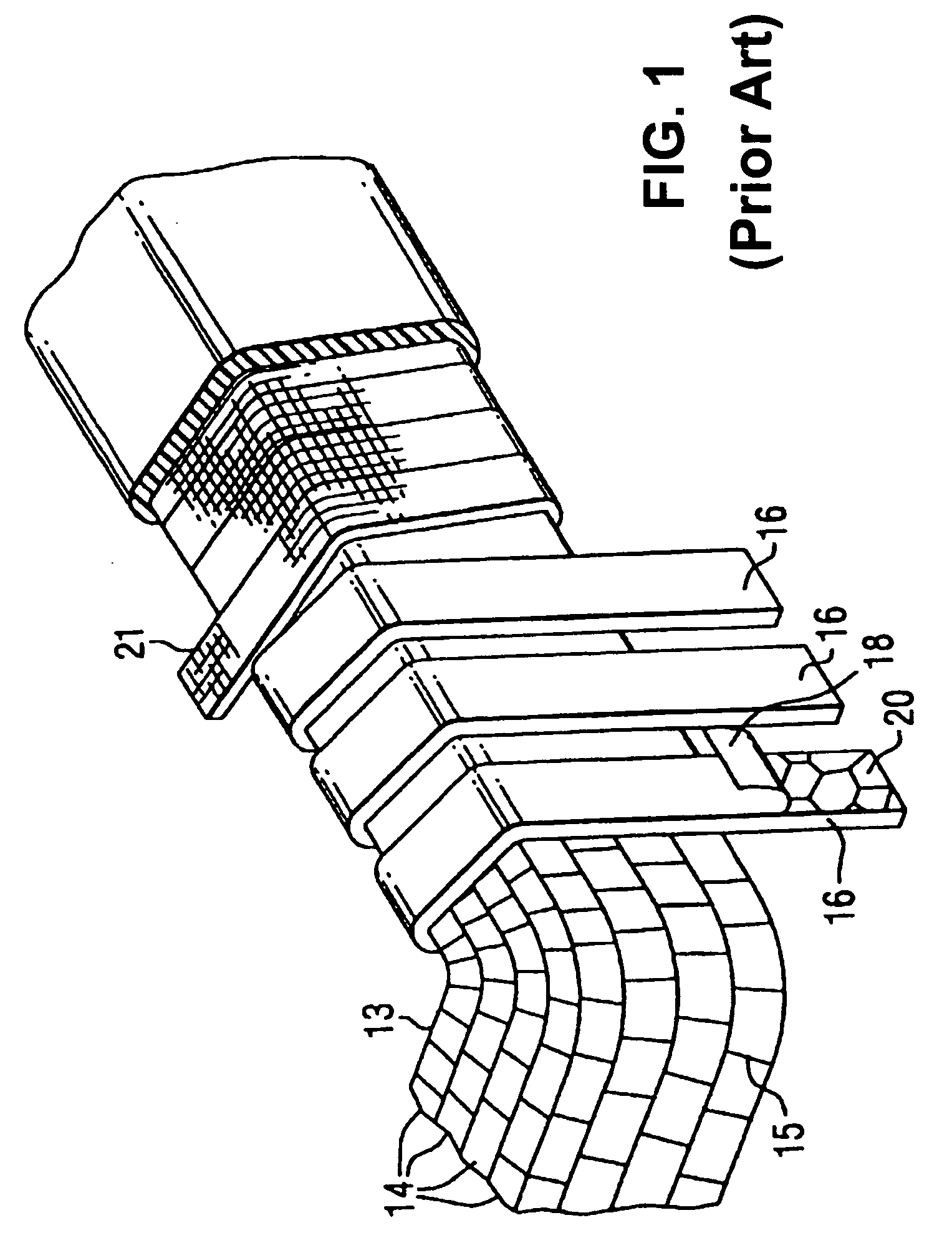

Apparatus for processing a substrate including a heating apparatus

InactiveUS20030066826A1Drying solid materials with heatMuffle furnacesProduction rateDevice material

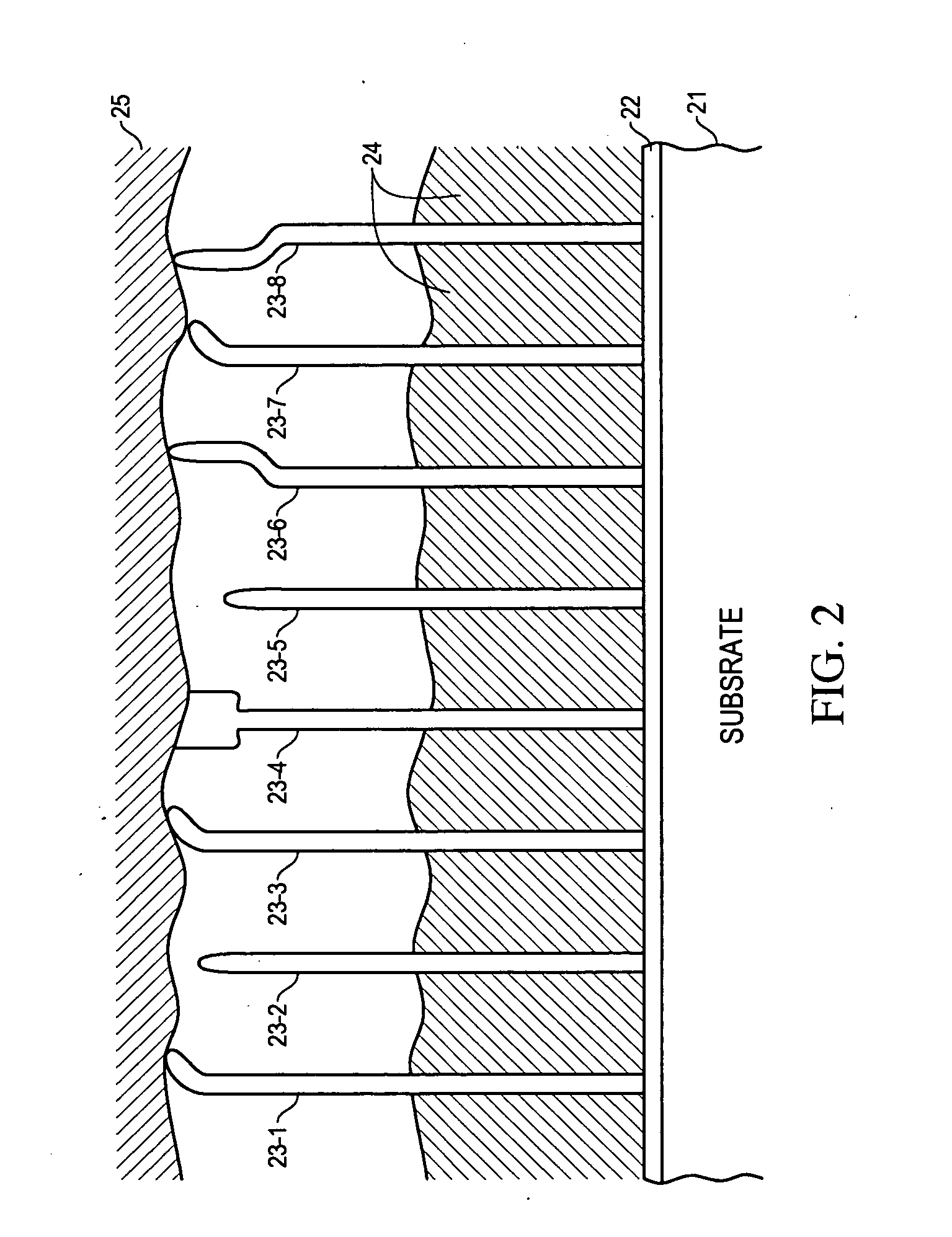

An apparatus for heating a substrate of a semiconductor device includes a hot plate, on which a semiconductor substrate is placed, and a heater for heating the hot plate. The hot plate is preferably a composite plate including a plurality of plates having different thermal conductivities from each other. For example, a first plate adjacent to the heater can be made of aluminum, which has a relatively high thermal conductivity. A second plate, laminated on top of the first plate, can be made of titanium or stainless steel, which both have a thermal conductivity lower than aluminum. A composite hot plate as disclosed herein is better able to maintain a constant temperature and a uniform temperature distribution in order to more uniformly heat a substrate and to reduce an amount of energy required for the heating process. In addition, the reliability and productivity of the semiconductor device manufactured by the apparatus can be improved.

Owner:SAMSUNG ELECTRONICS CO LTD

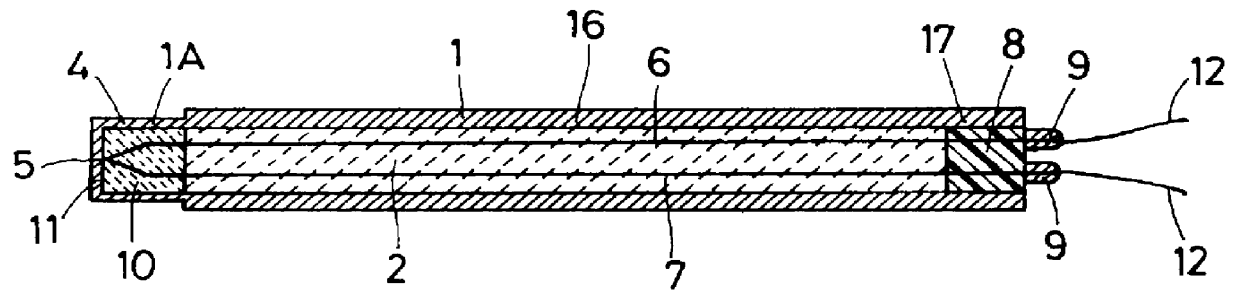

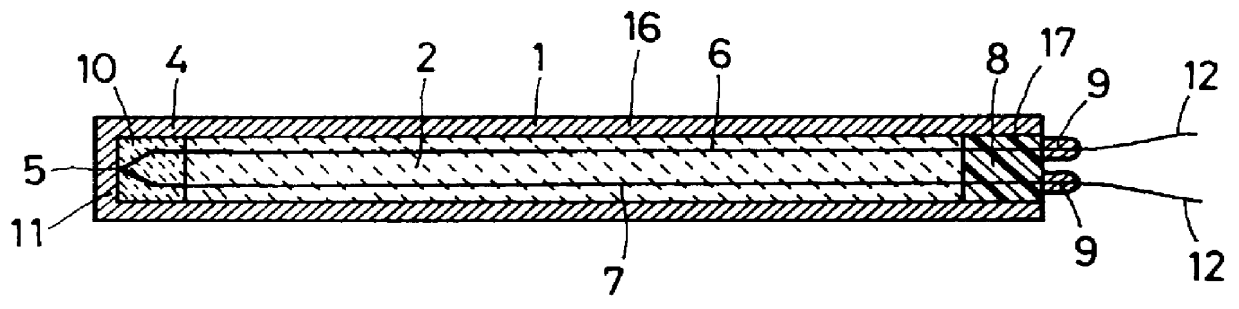

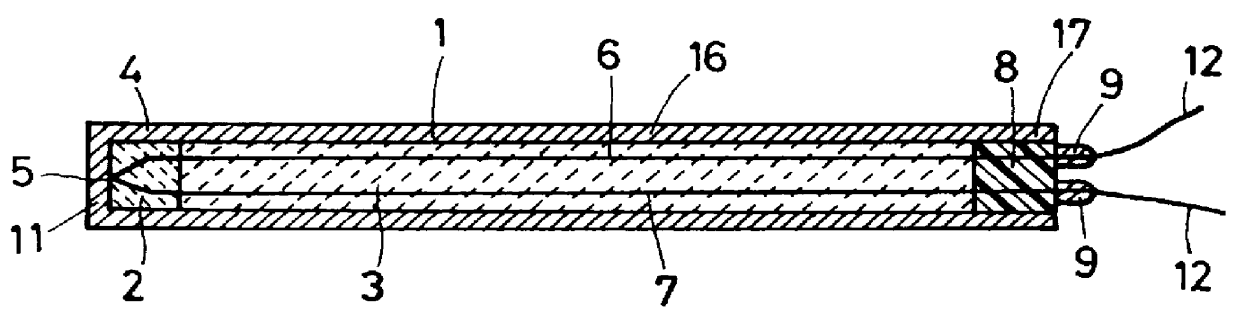

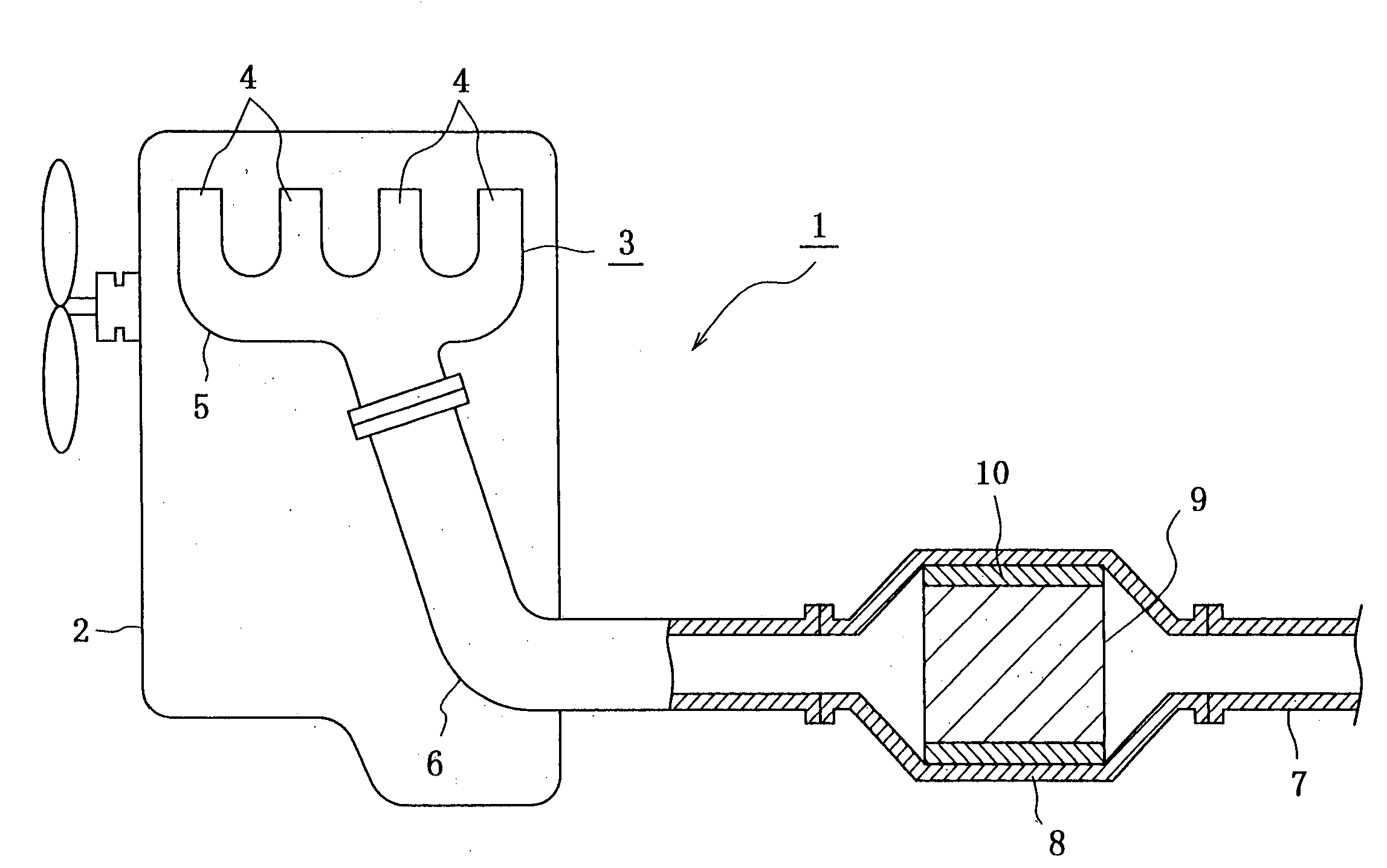

Ceramic sheath type thermocouple

InactiveUS6102565AThermometer detailsThermometers using electric/magnetic elementsHeat resistanceWhiskers

This ceramic sheath type thermocouple has a long service life, an improved temperature measuring responsibility and an improved temperature measuring precision, and enables repetitive use. The ceramic sheath type thermocouple has its protective tube 1 formed of a heat resisting ceramics selected from silicon nitride, sialon and silicon carbide. In the protective tube 1 are installed a pair of W-Re wires that are connected to form a joint portion constituting a temperature measuring point 5. A filler made of Si3N4 reaction-sintered ceramics is loaded into the front end portion of the protective tube to enclose the W-Re wires. Another filler made of SiC whisker with a heat conductivity smaller than that of the filler of the front end portion is loaded into the rear portion of the protective tube. An inert gas is sealed in the protective tube. Alternatively, the temperature measuring portion may be formed by exposing from the front end portion of the protective tube the joint portion where the ends of the W-Re wires are connected. The temperature measuring portion is coated with a cover film that is made of silicon carbide, silicon nitride or a composite of these, all having excellent heat resisting and corrosion resisting properties.

Owner:ISUZU MOTORS LTD

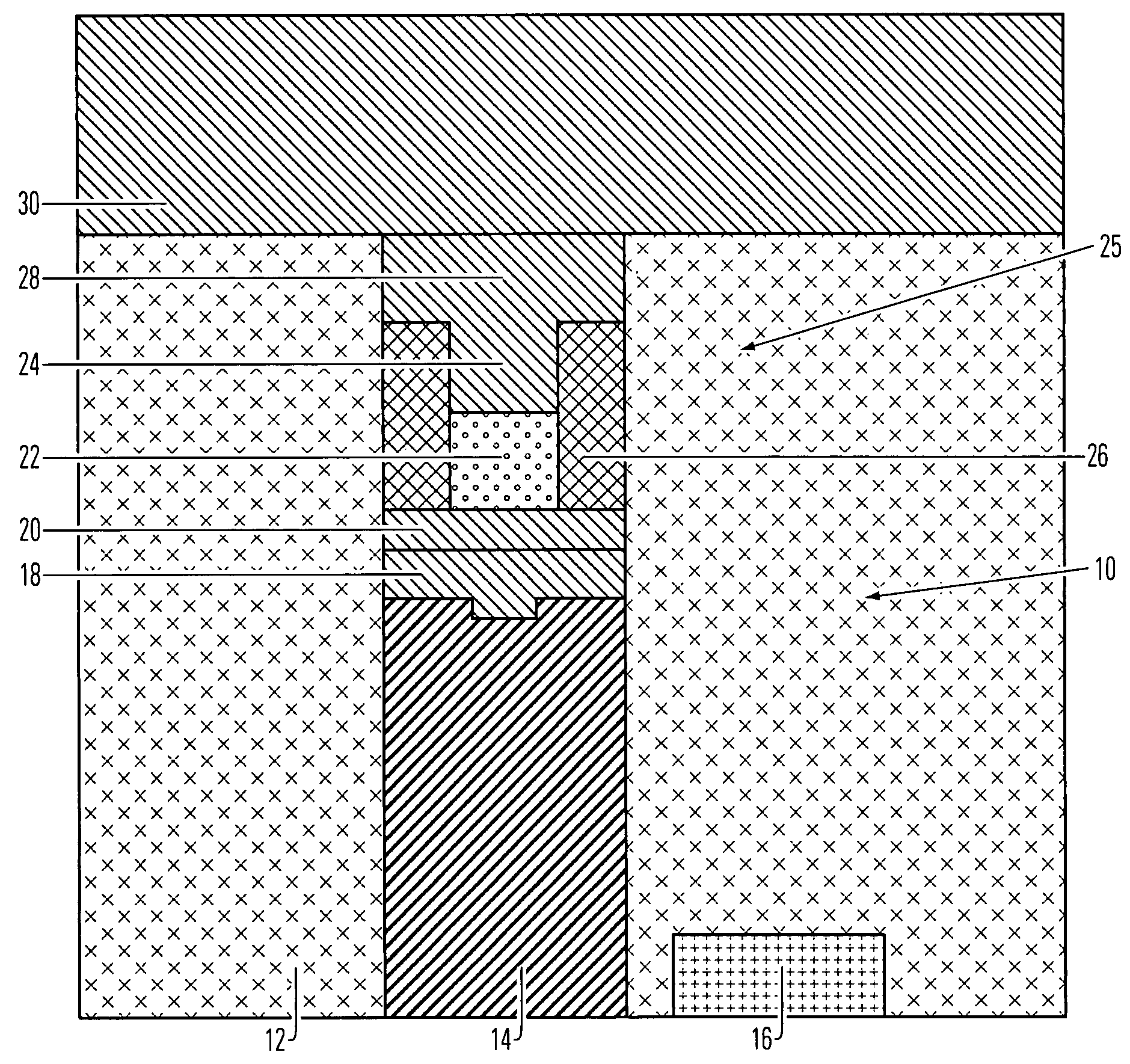

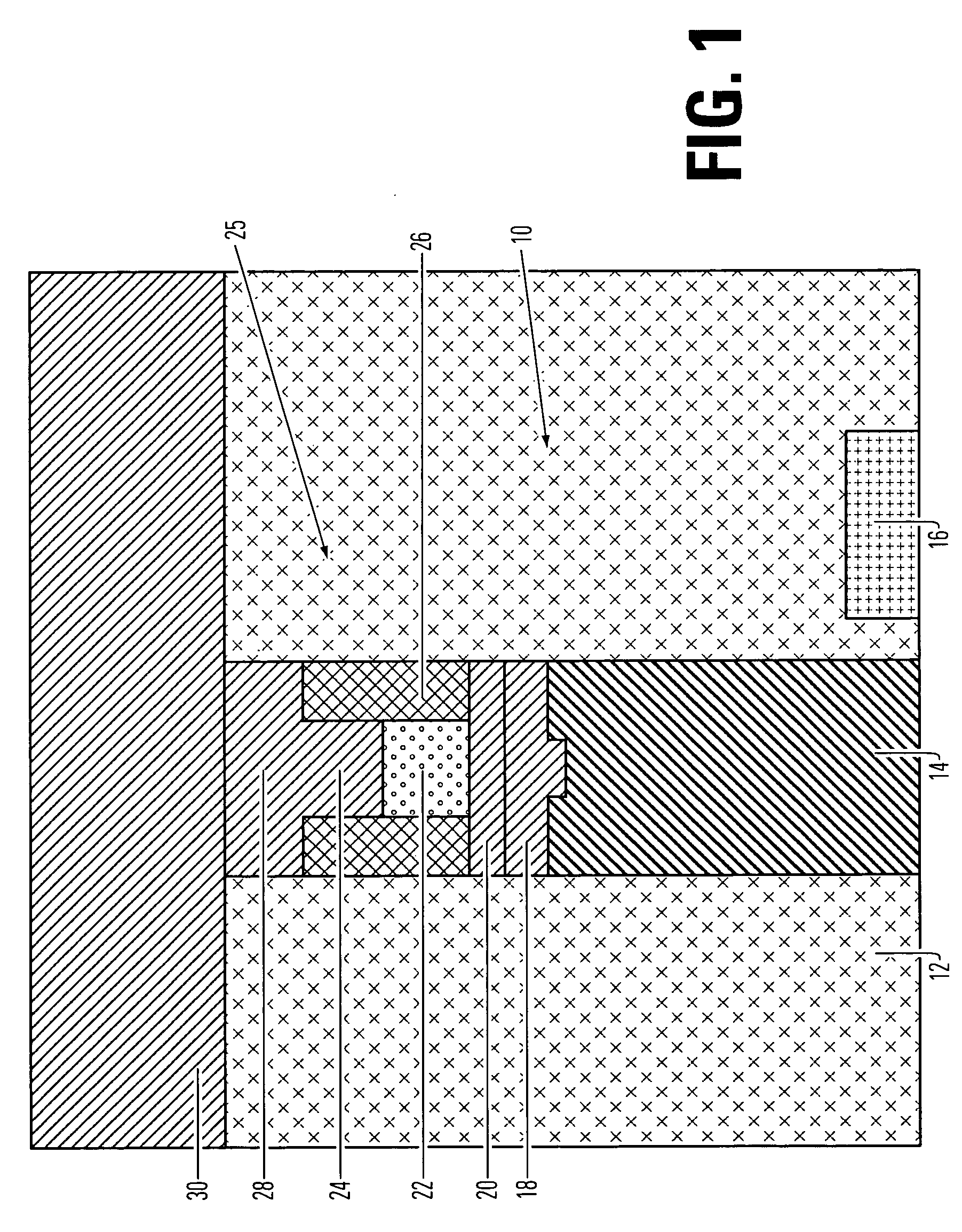

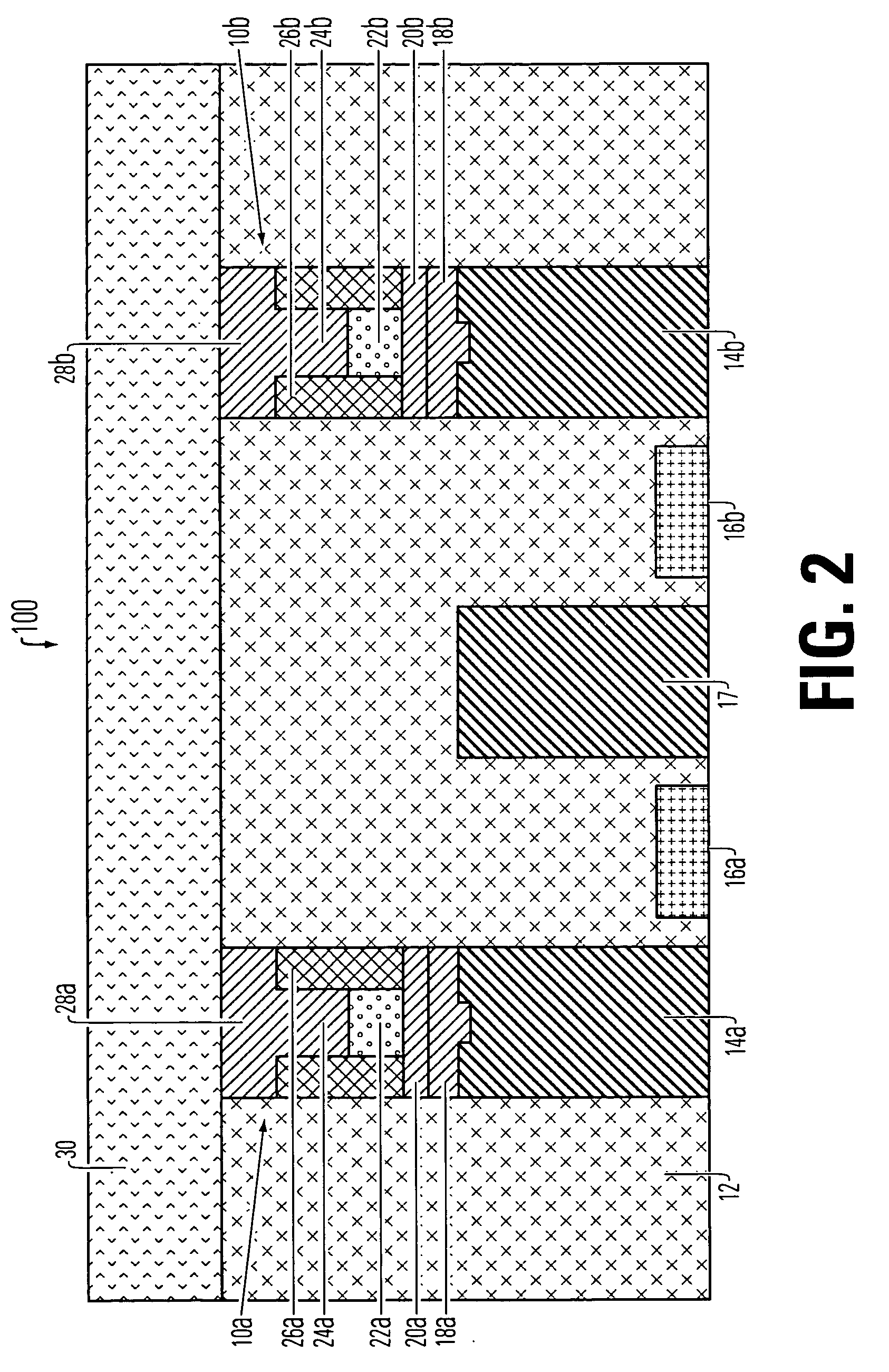

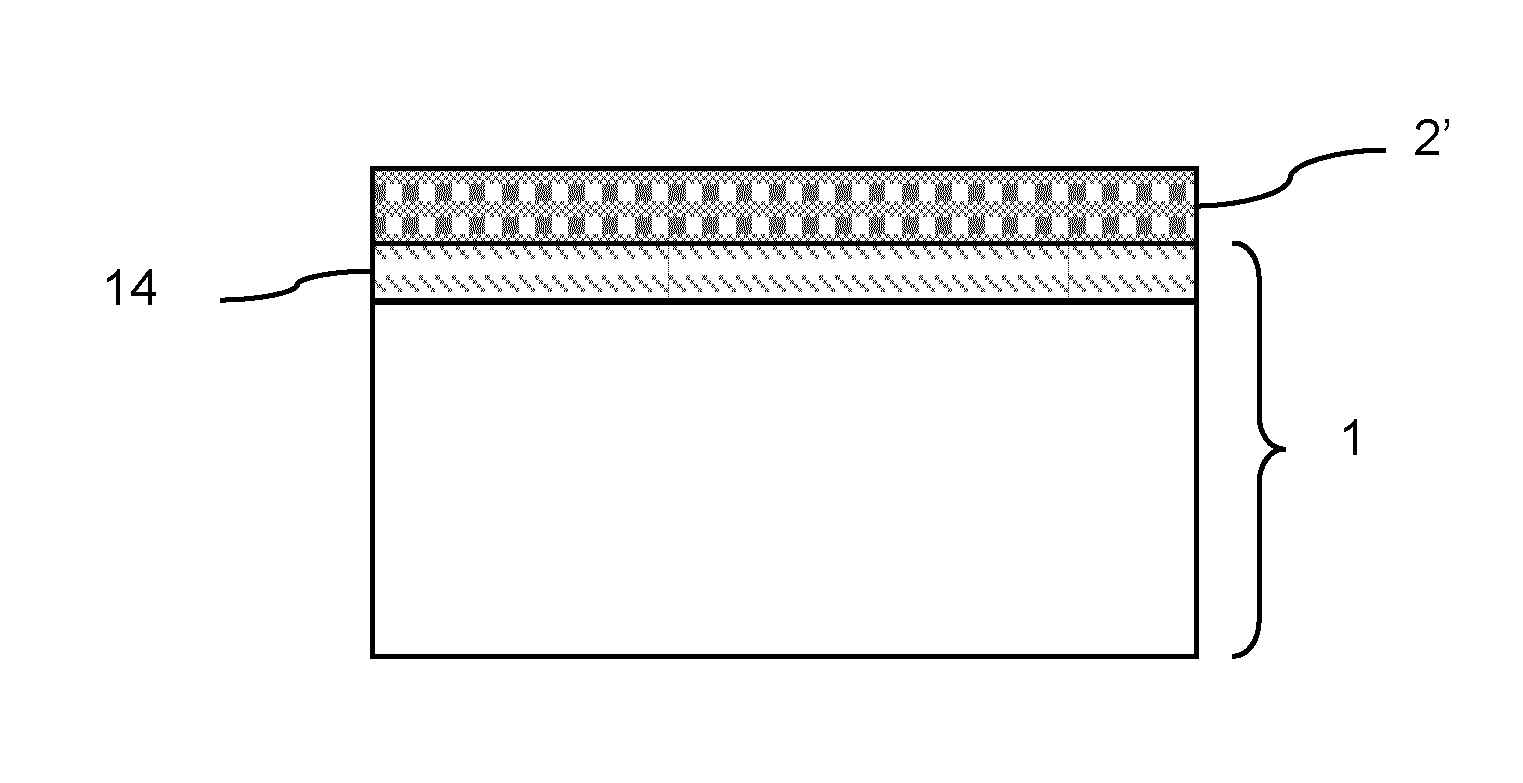

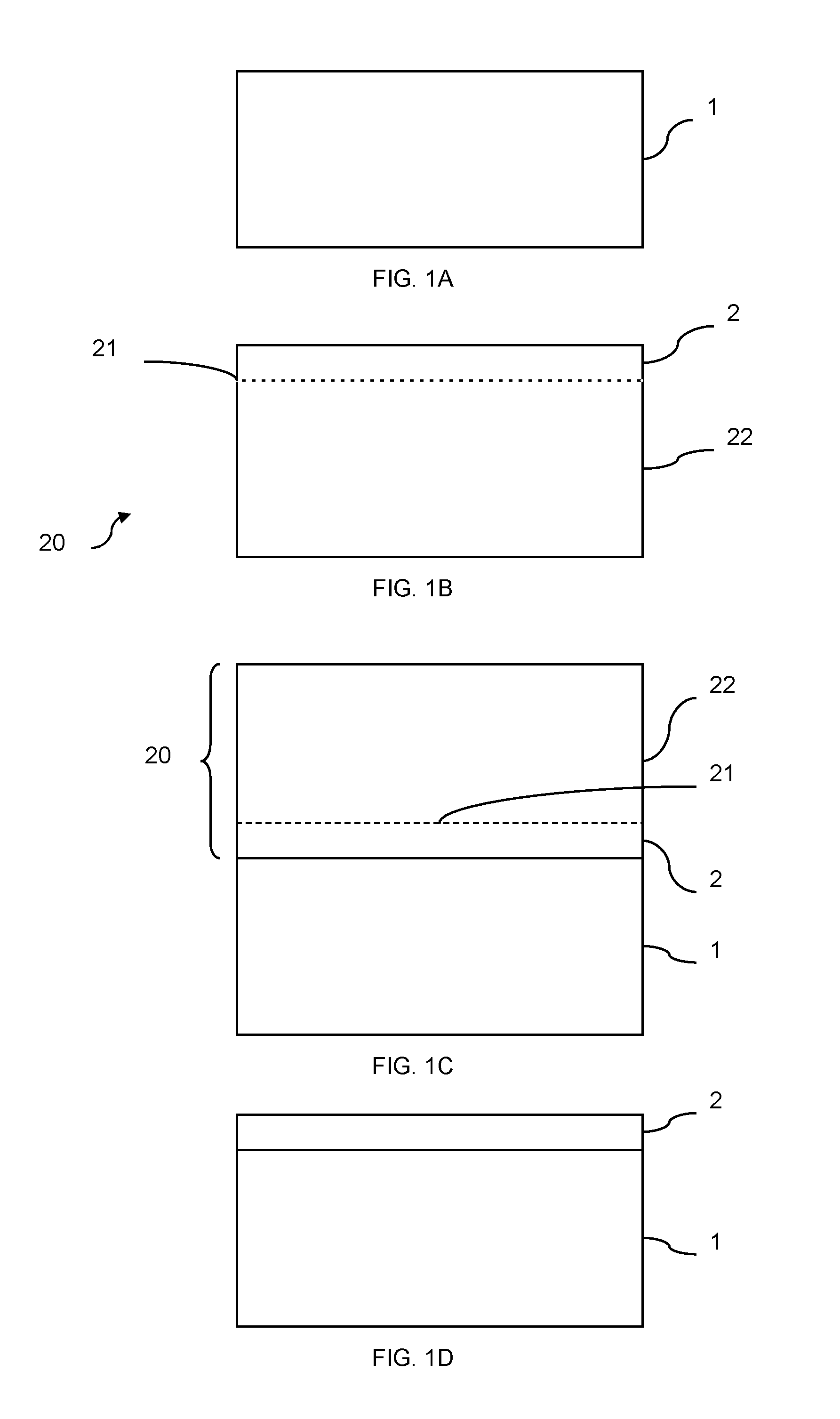

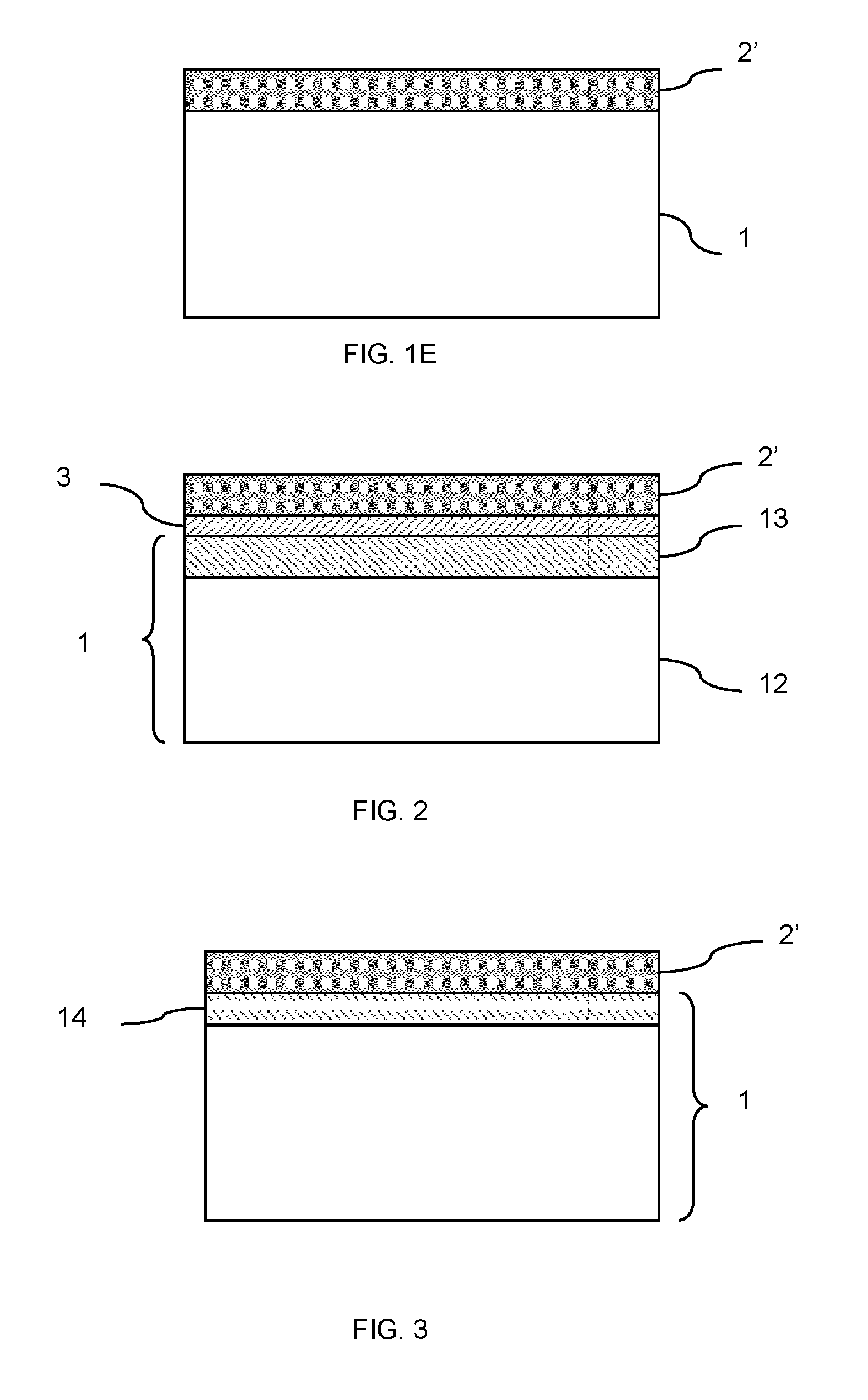

Thermally contained/insulated phase change memory device and method (combined)

ActiveUS20070108430A1Improve heat transfer characteristicsImprove insulation performanceSolid-state devicesBulk negative resistance effect devicesPhase-change memoryDielectric layer

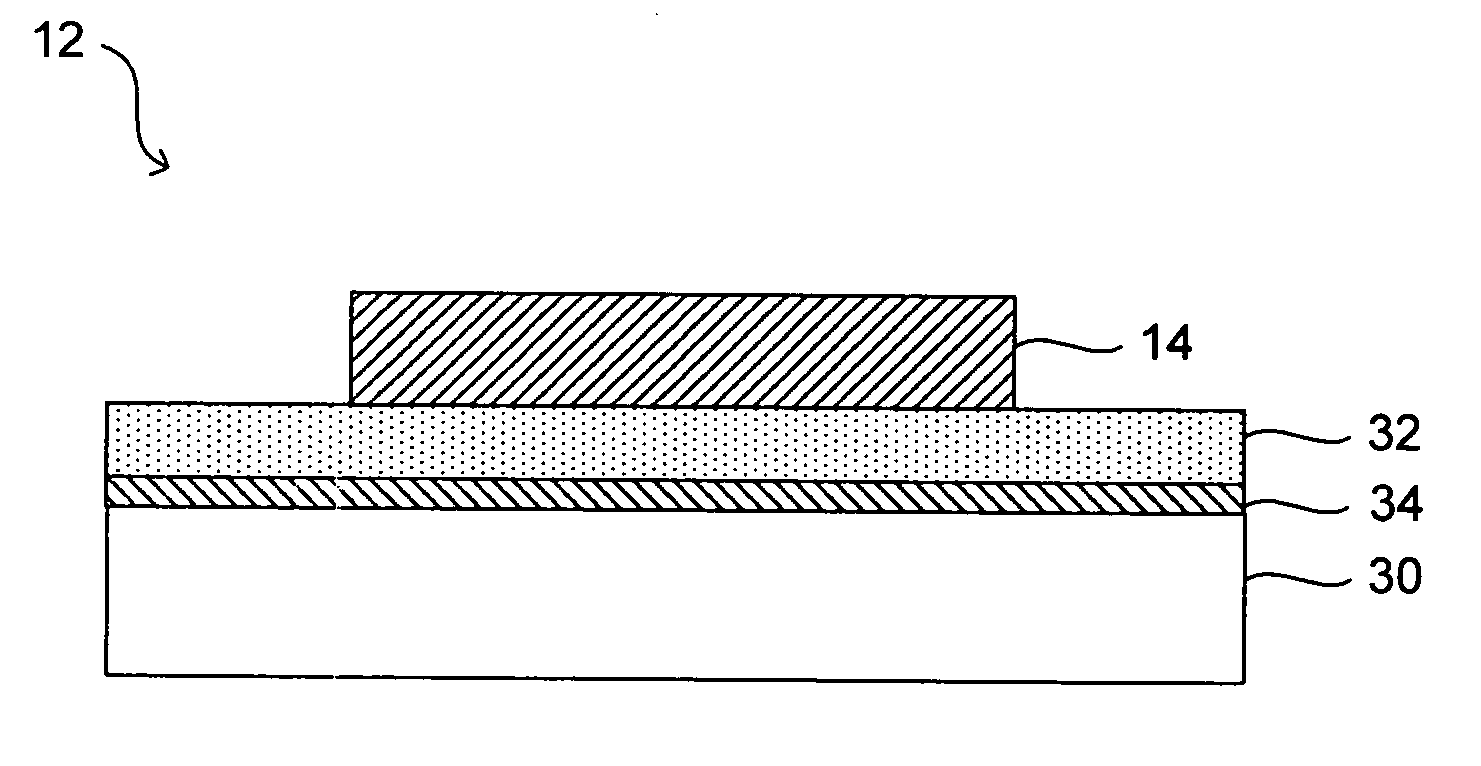

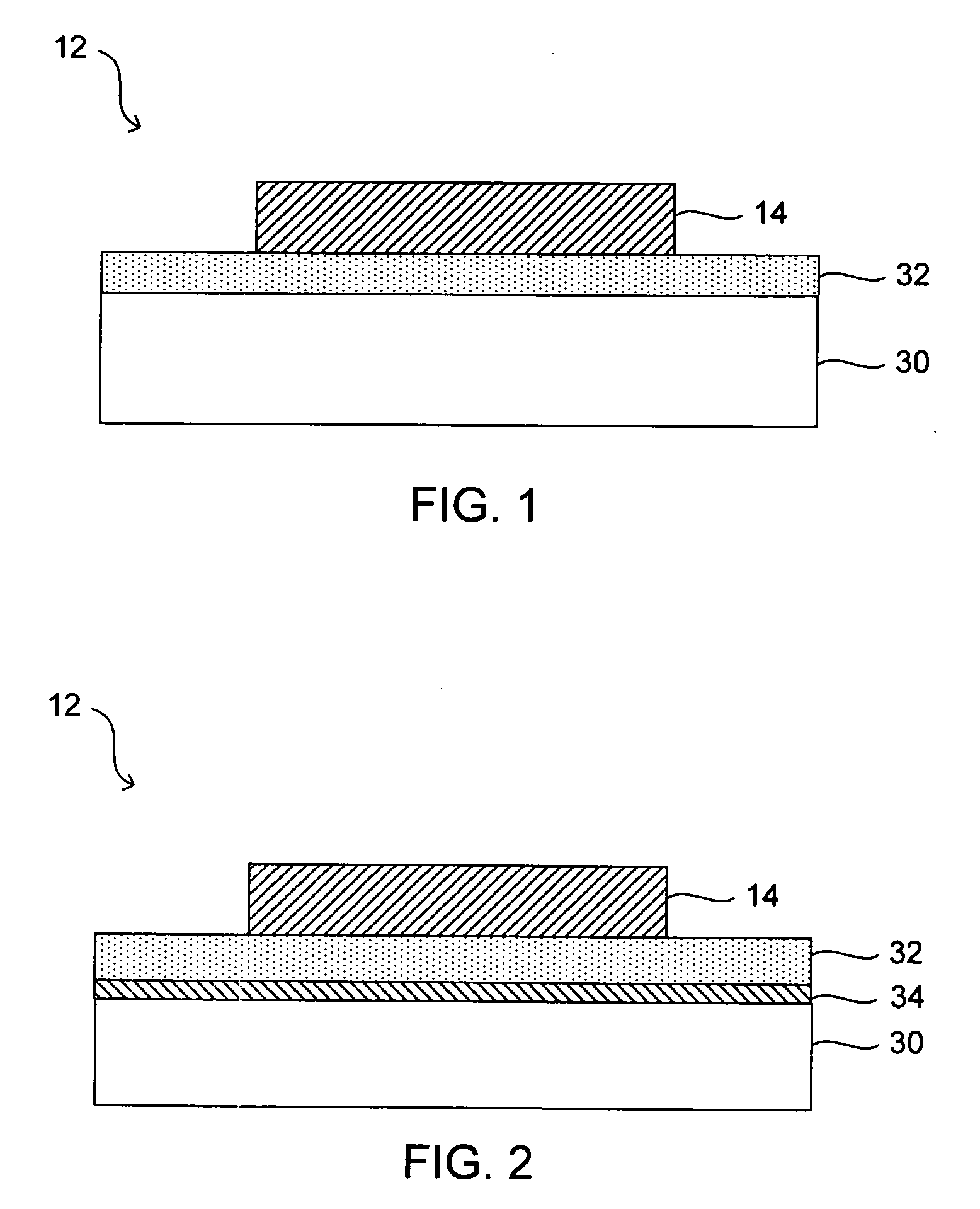

A memory device with improved heat transfer characteristics. The device first includes a dielectric material layer; first and second electrodes, vertically separated and having mutually opposed contact surfaces. A phase change memory element is encased within the dielectric material layer, including a phase-change layer positioned between and in electrical contact with the electrodes, wherein the lateral extent of the phase change layer is less than the lateral extent of the electrodes. An isolation material is positioned between the phase change layer and the dielectric layer, wherein the thermal conductivity of the isolation material is lower than the thermal conductivity of the dielectric material.

Owner:MACRONIX INT CO LTD

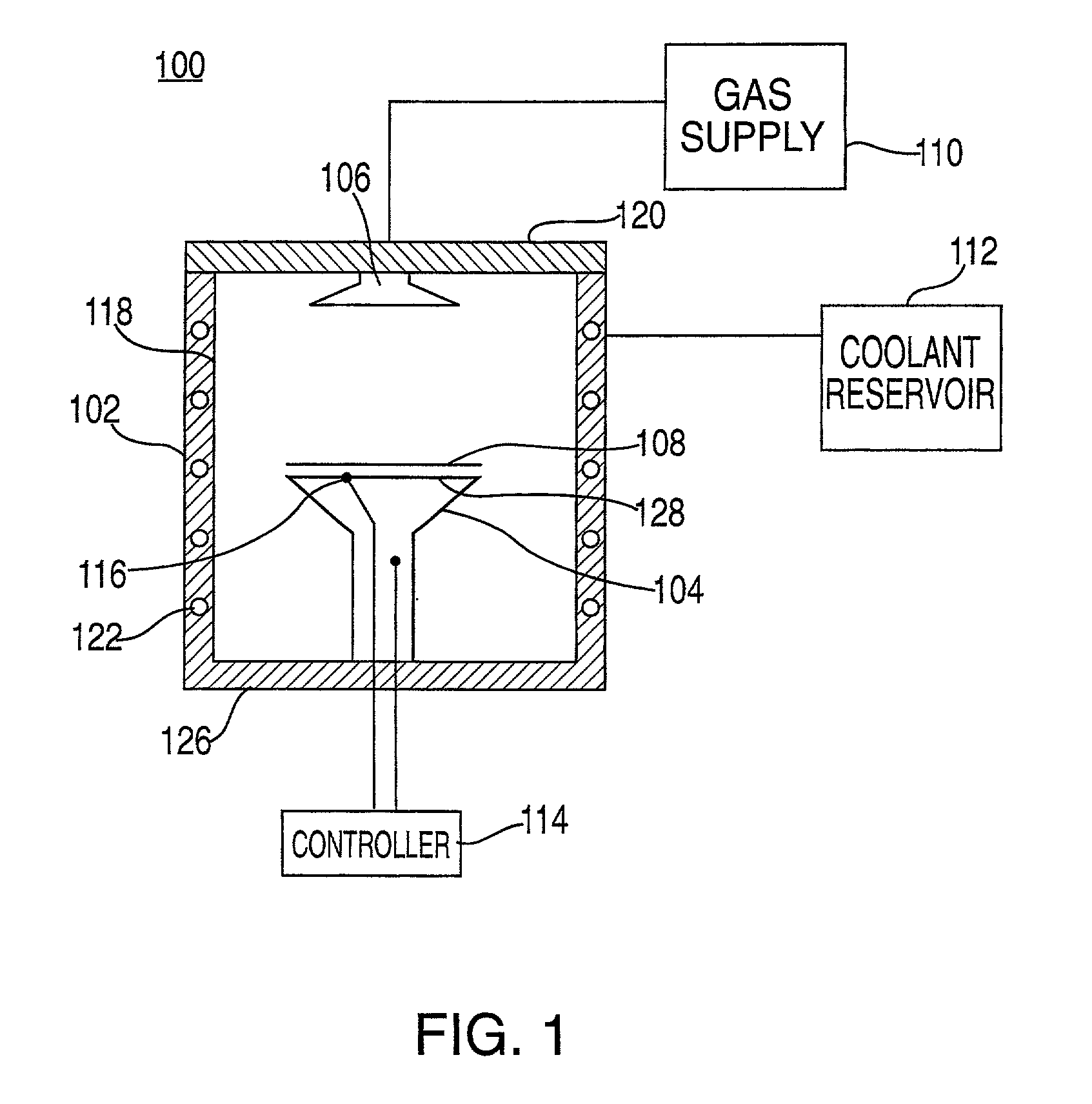

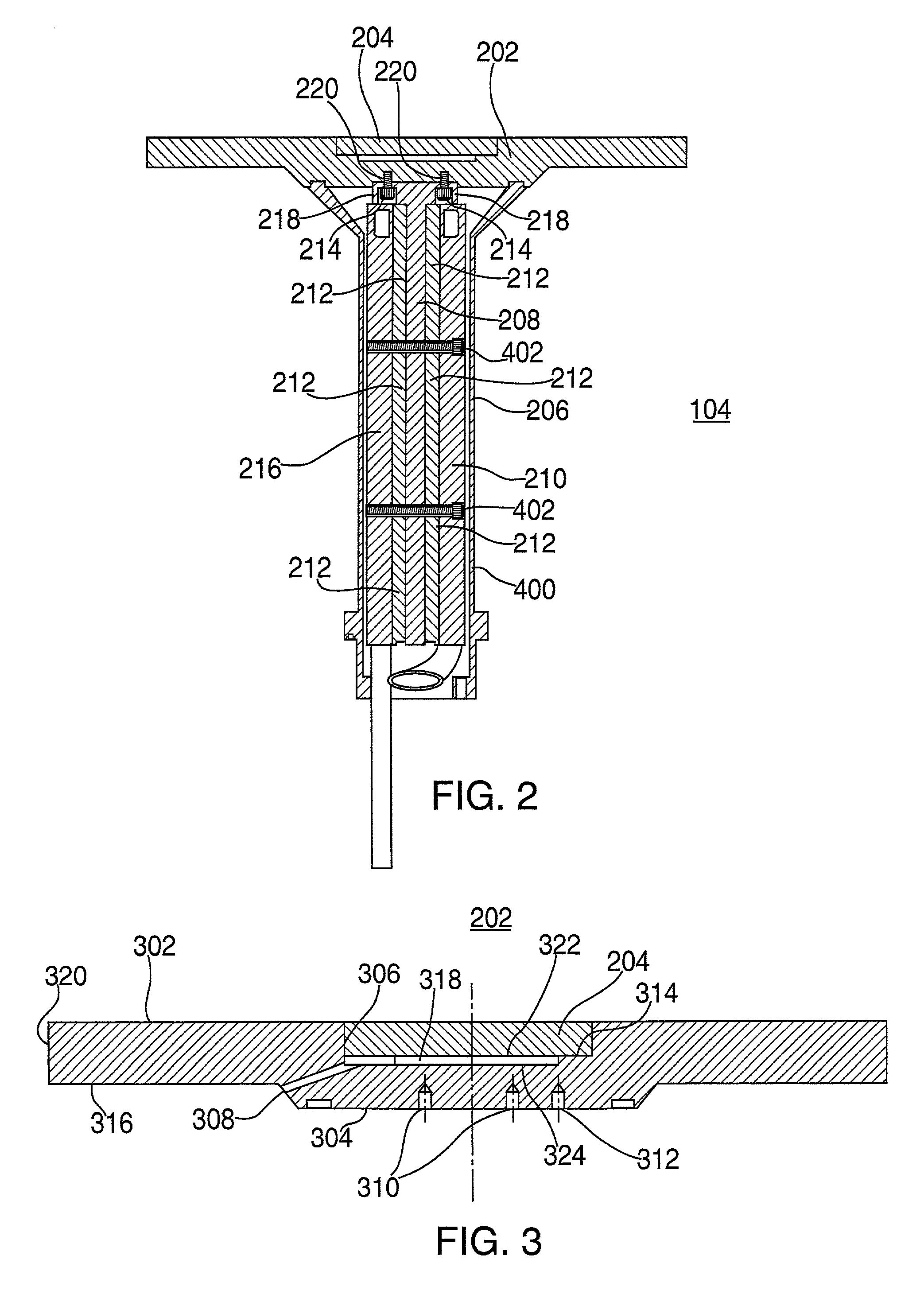

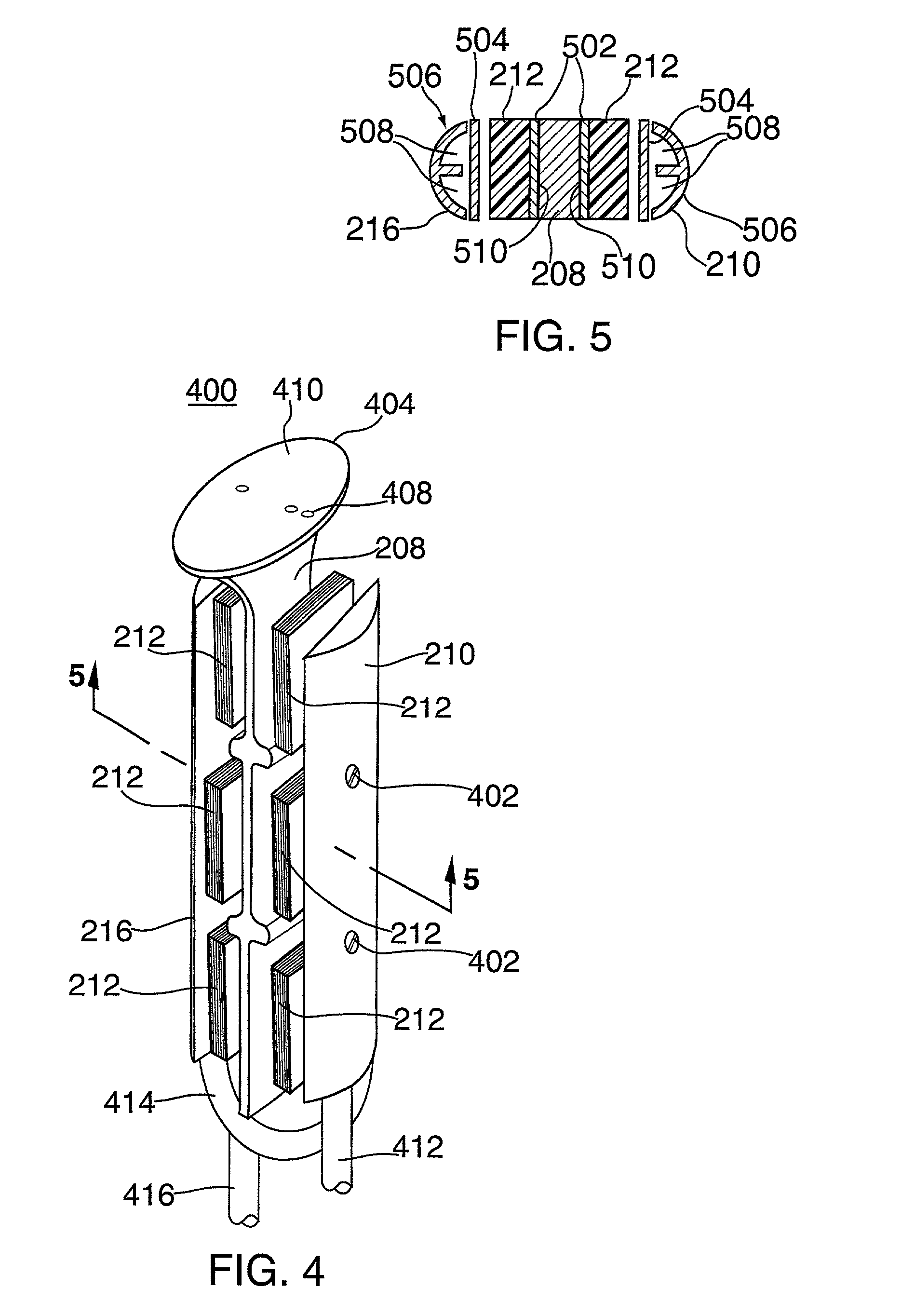

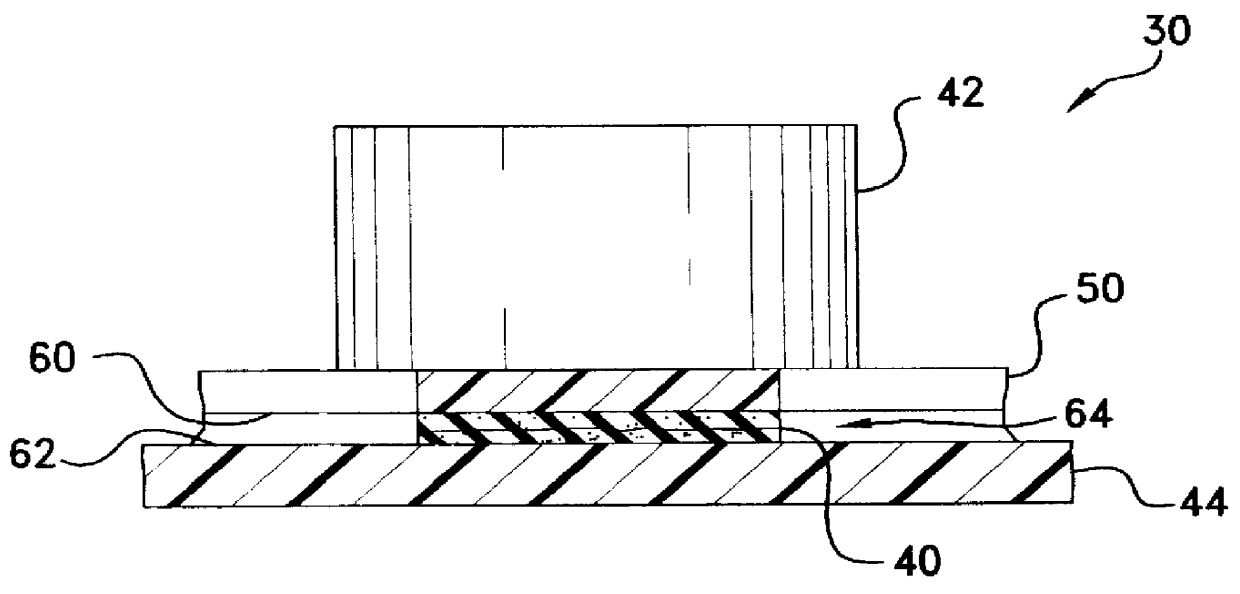

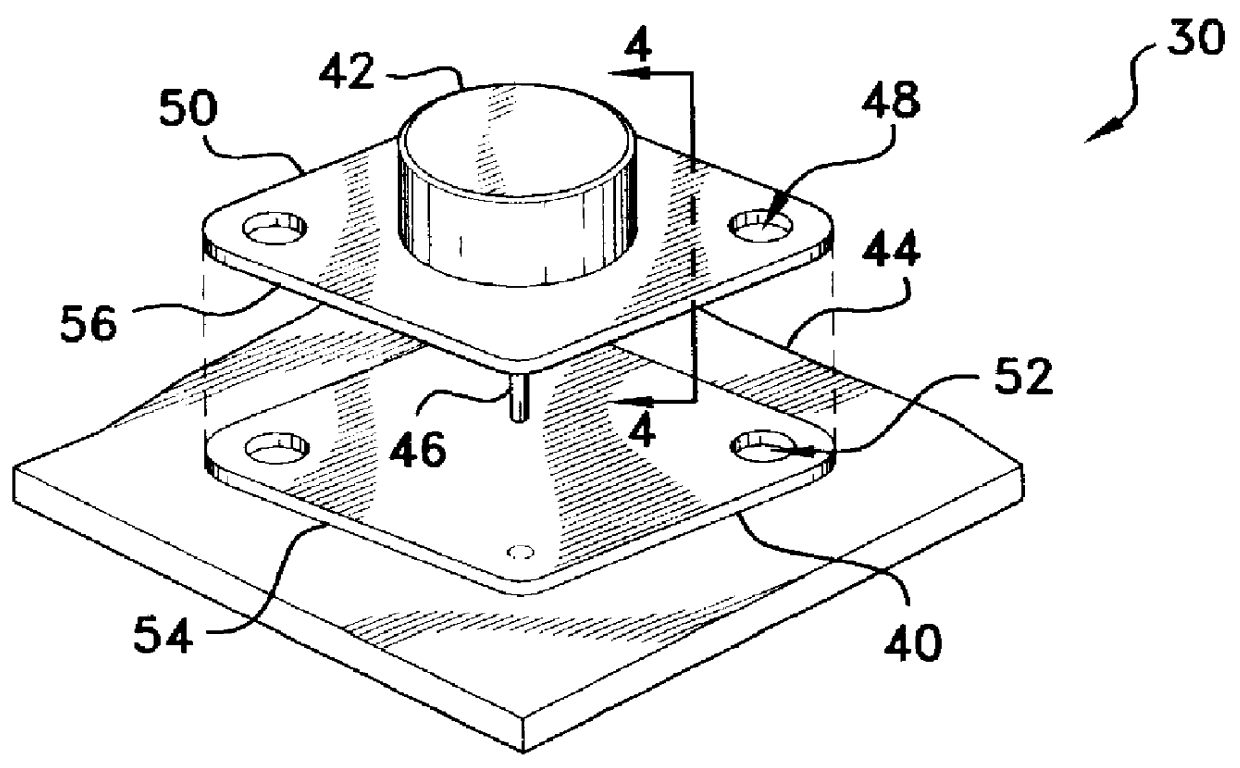

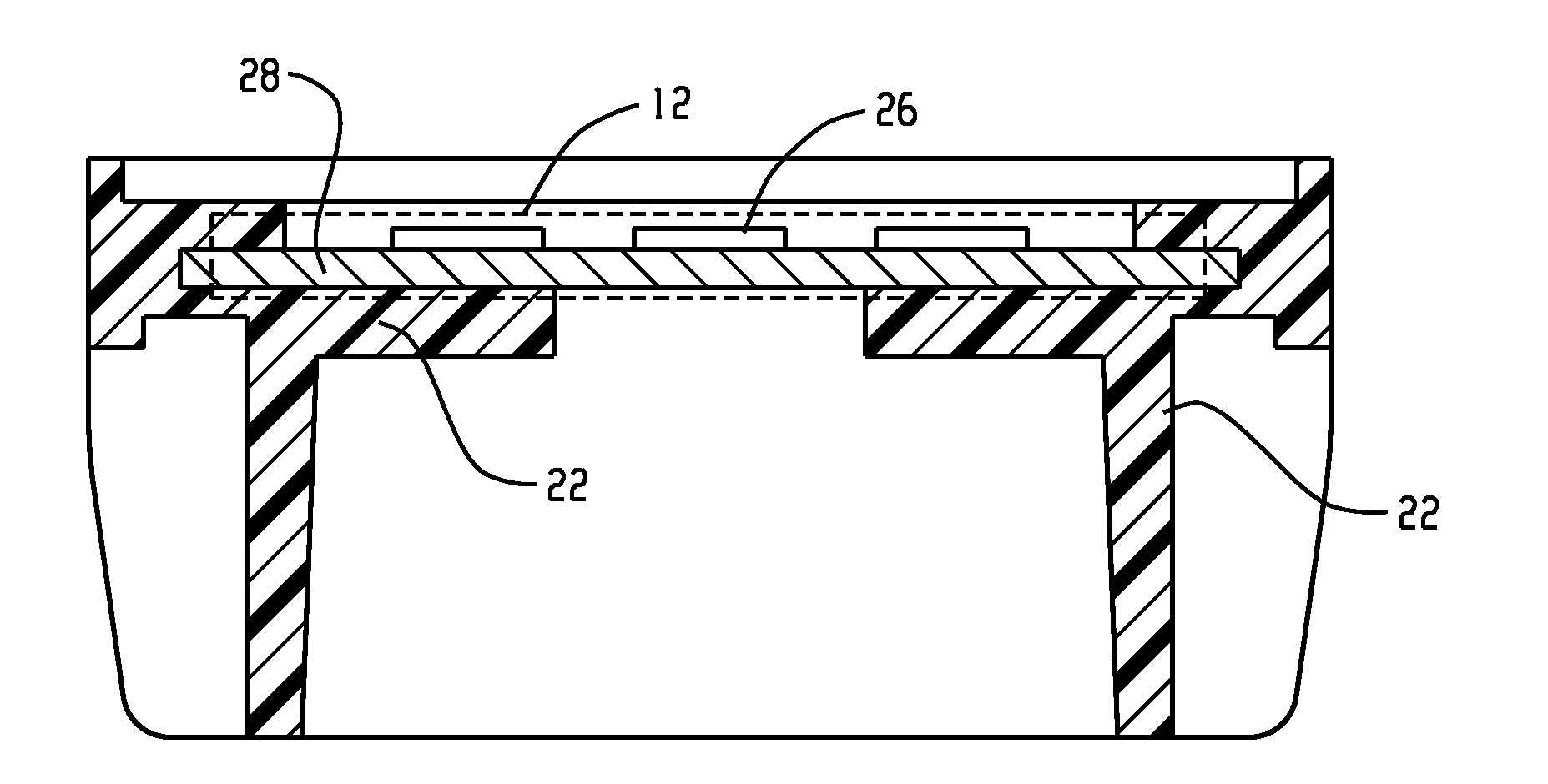

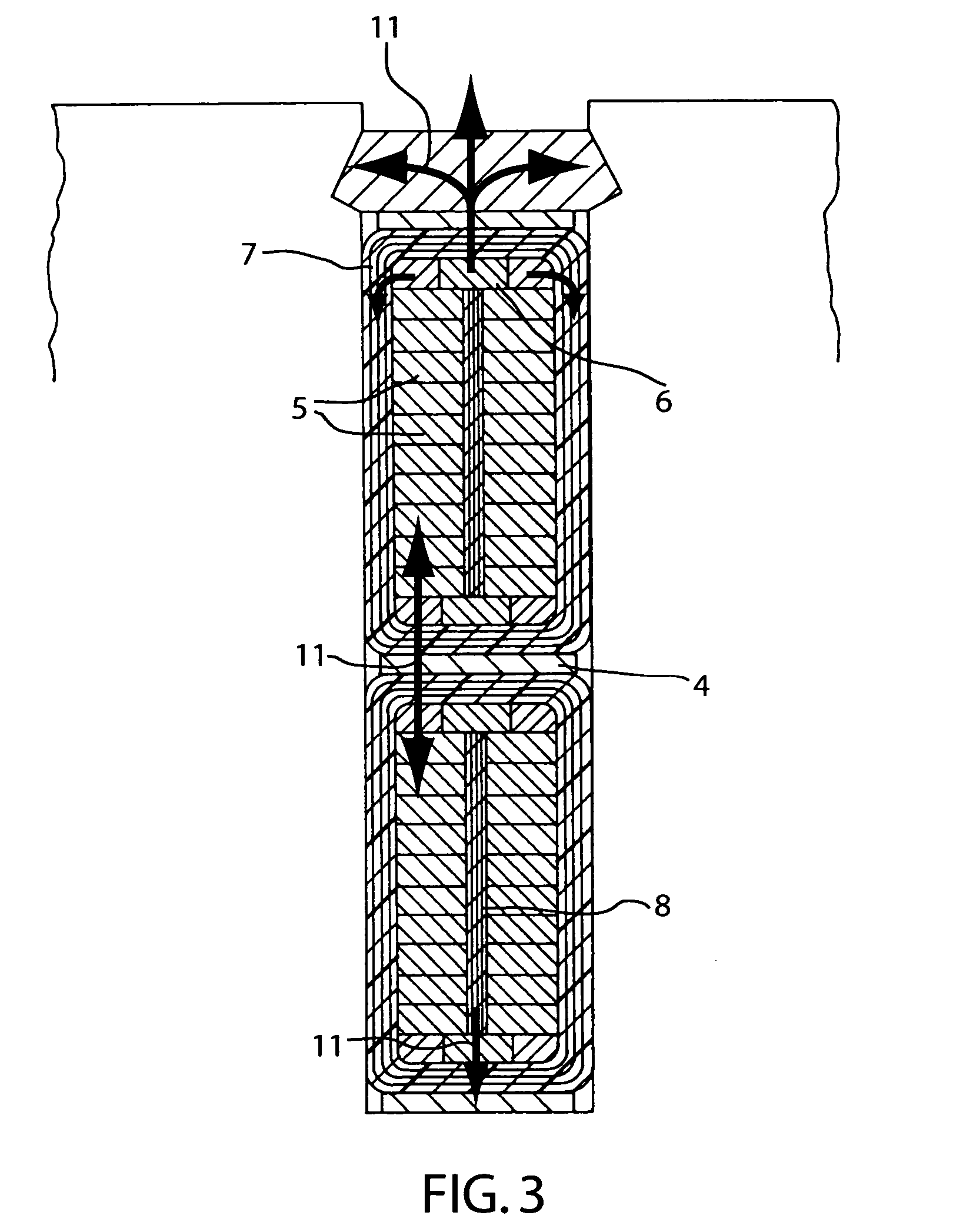

Pedestal with a thermally controlled platen

InactiveUS20010004880A1Liquid surface applicatorsSemiconductor/solid-state device manufacturingEngineeringThermal transmittance

A workpiece support having dichotomy of thermal paths therethrough is provided for controlling the temperature of a workpiece support thereon. In one embodiment, a workpiece support includes a platen body having a plug centrally disposed in a workpiece support surface of the platen body. A lower surface of the plug defines a void between the plug and a bottom of the bore. The void creates a dichotomy of thermal paths through the platen body thus controlling the temperature of a wafer support surface. Alternatively, the plug and platen body may be fabricated from materials having different rates of thermal conductivity to created the dichotomy of thermal paths in addition to or in absence of the void.

Owner:APPLIED MATERIALS INC

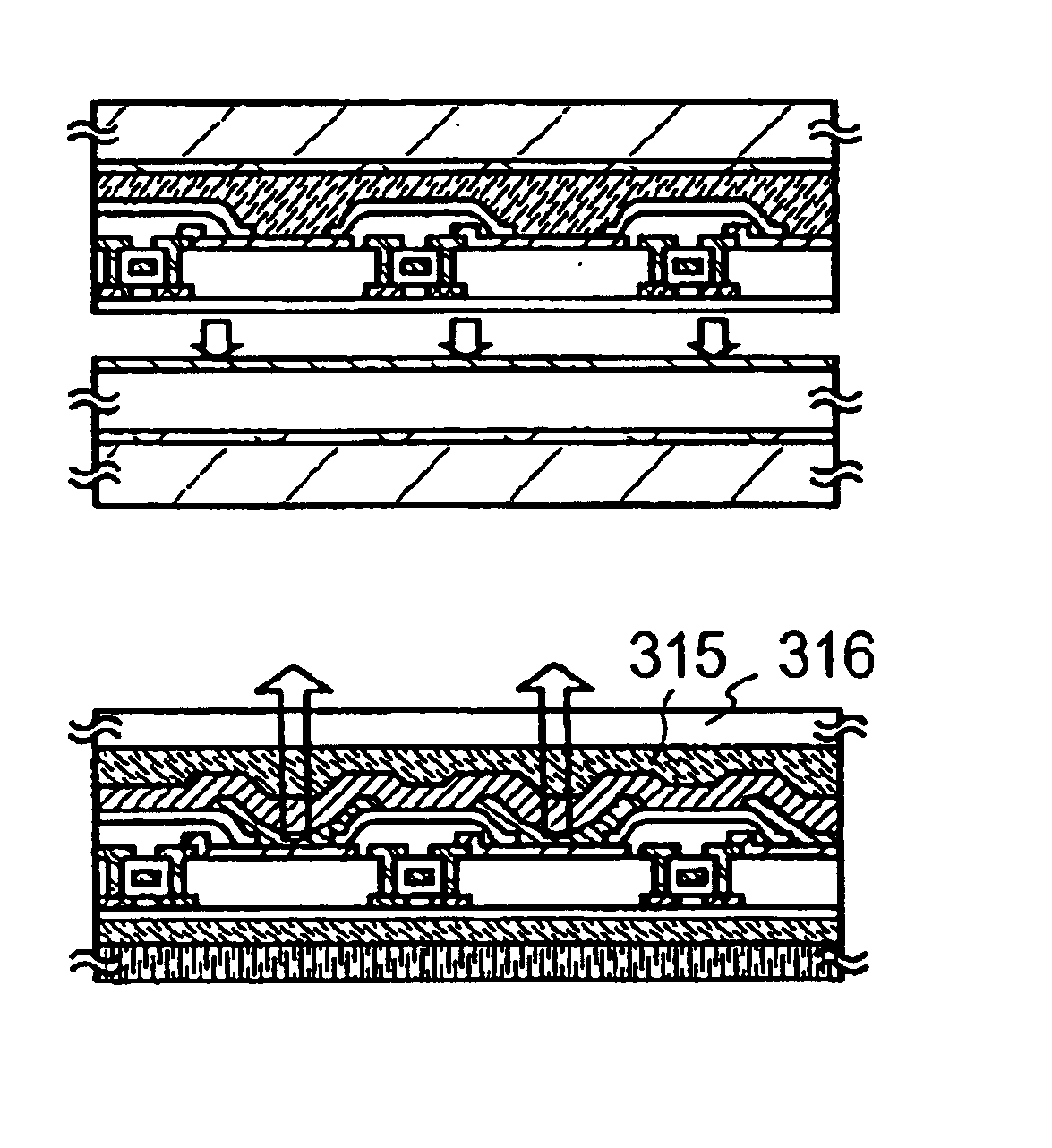

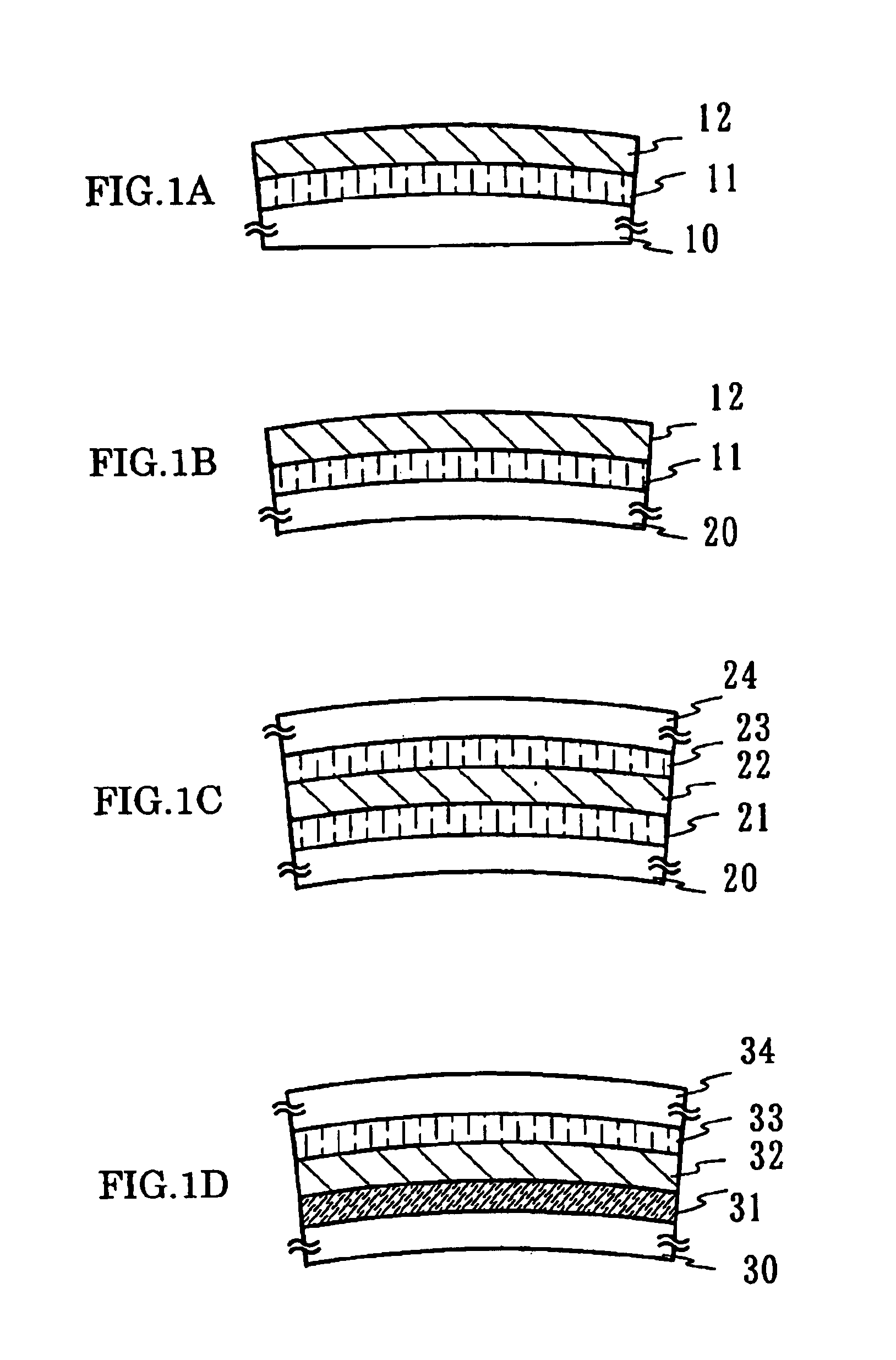

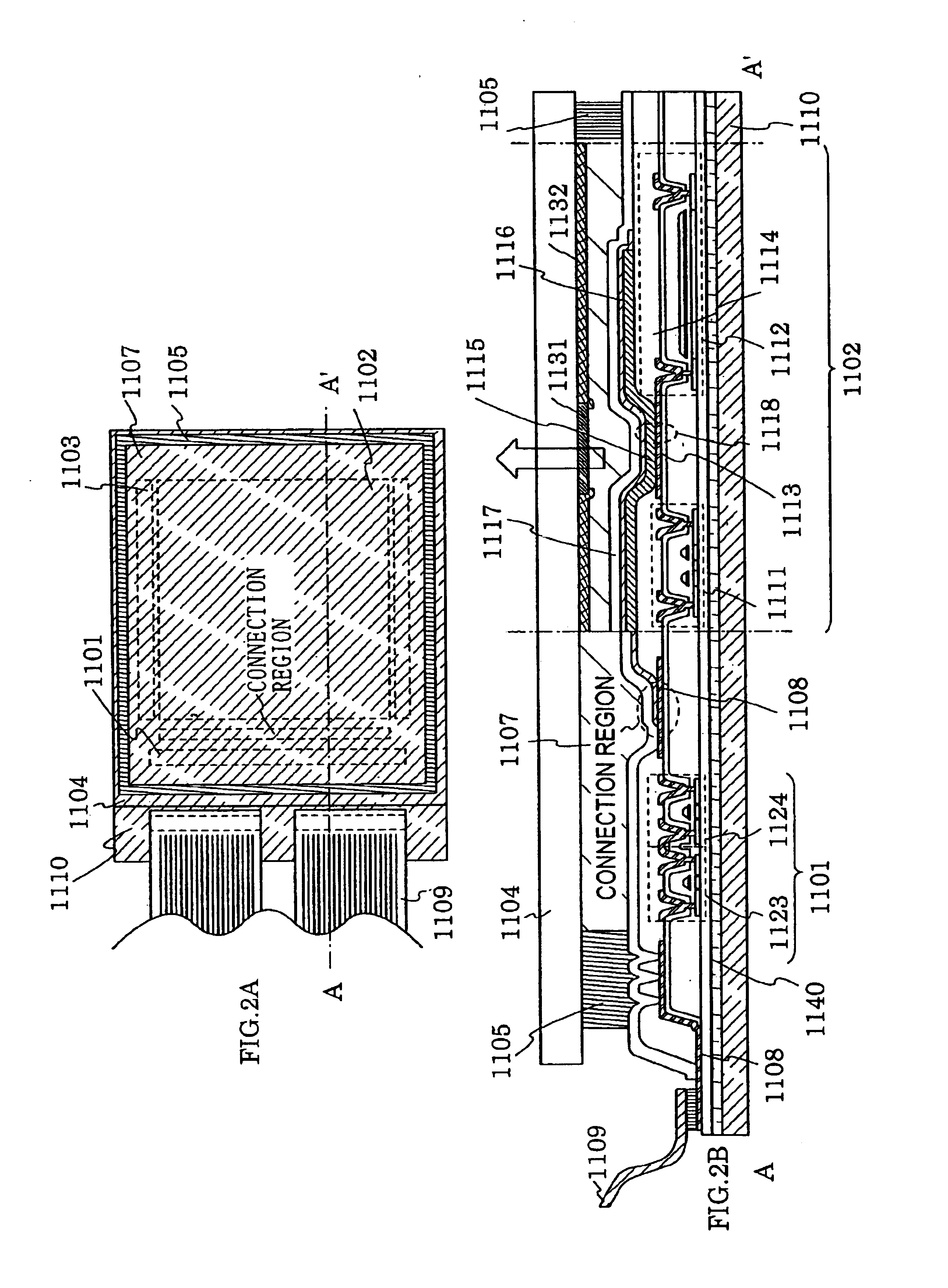

Semiconductor apparatus and fabrication method of the same

InactiveUS7067392B2Inhibit deteriorationImprove thermal conductivityTransistorFinal product manufactureDevice formThin-film diode

It is an object of the present invention to provide a semiconductor device capable of preventing deterioration due to penetration of moisture or oxygen, for example, a light-emitting apparatus having an organic light-emitting device that is formed over a plastic substrate, and a liquid crystal display apparatus using a plastic substrate. According to the present invention, devices formed on a glass substrate or a quartz substrate (a TFT, a light-emitting device having an organic compound, a liquid crystal device, a memory device, a thin-film diode, a pin-junction silicon photoelectric converter, a silicon resistance element, or the like) are separated from the substrate, and transferred to a plastic substrate having high thermal conductivity.

Owner:SEMICON ENERGY LAB CO LTD

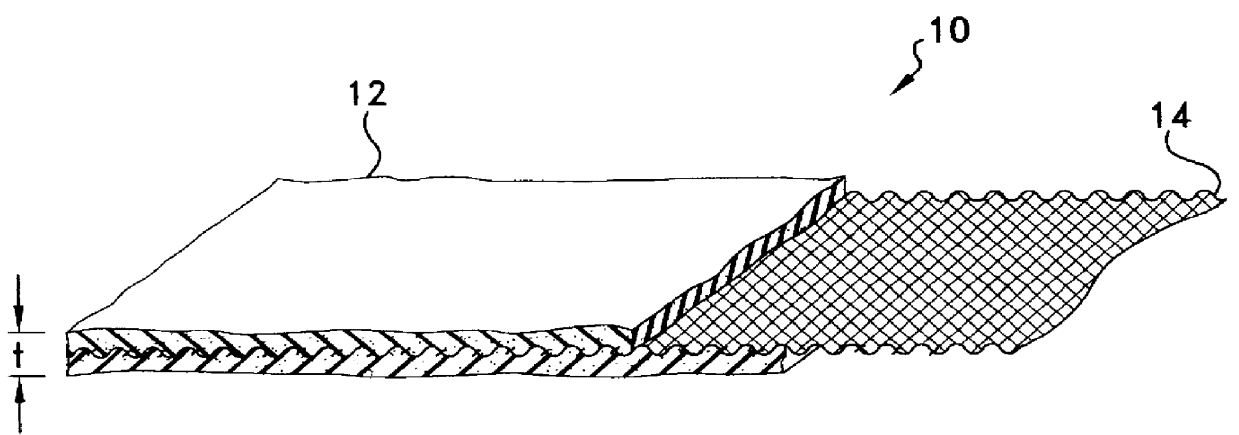

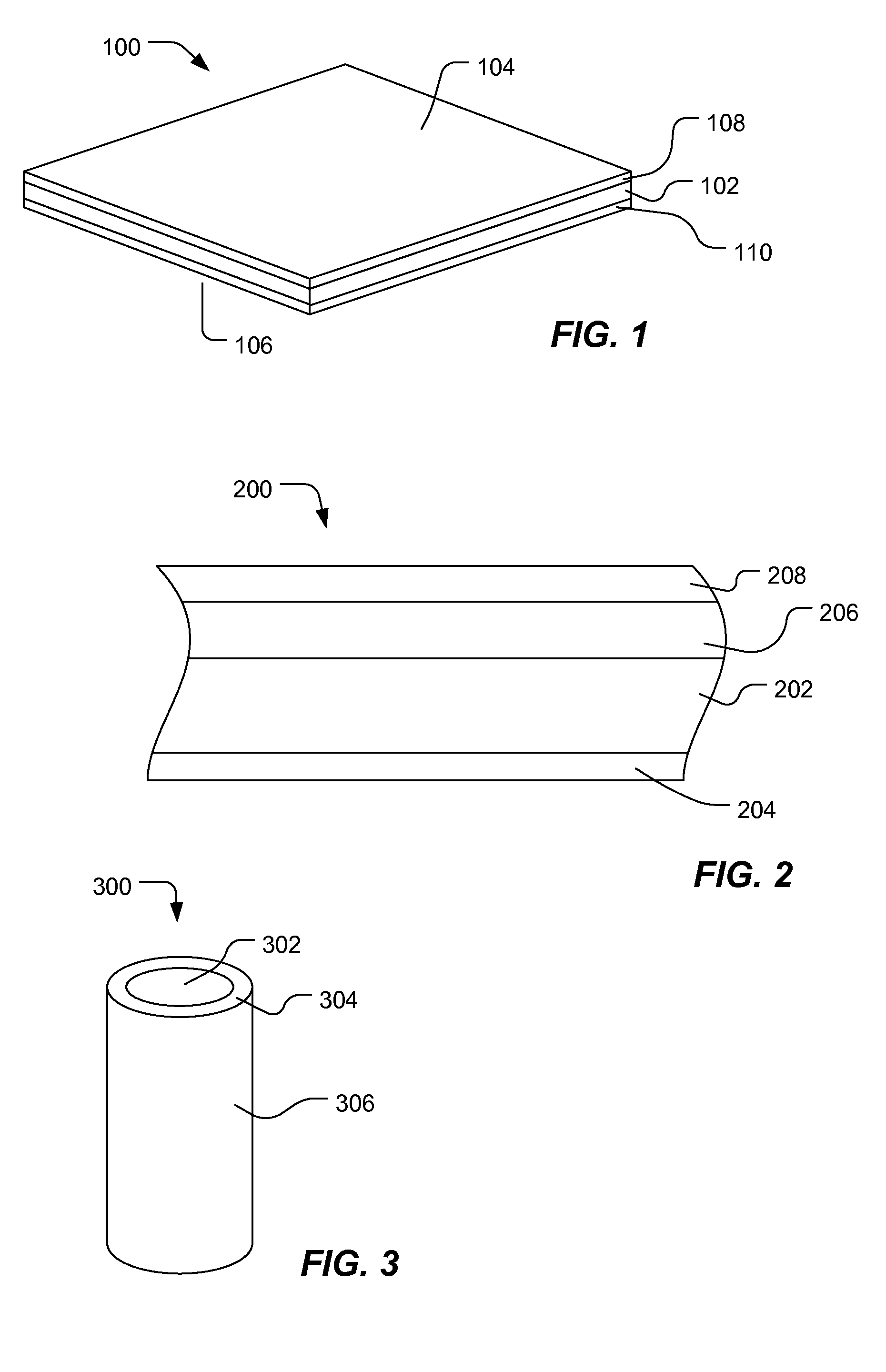

High dielectric strength thermal interface material

InactiveUS6096414AImprove performanceMaintain good propertiesOther chemical processesSynthetic resin layered productsThermal conductivityThermal transmittance

A thermally-conductive, electrically insulative interface for conductively cooling a heat-generating source, such as an electronic component, having an associated thermal dissipation member such as a heat sink. The interface is provided as a cured sheet of a curable material formulated as a blend of a curable silicone binder, and a particulate alumina, i.e., aluminum oxide (Al2O3), filler. The interface is observed to exhibit a thermal conductivity of at least about 0.8 W / m-K and a wet dielectric breakdown strength of at least about 475 Vac / mil.

Owner:PARKER INTANGIBLES LLC

Heat conductive silicone grease composition

ActiveCN102634212AImprove thermal conductivityExtended service lifeHeat-exchange elementsCarbon nanotubeGraphite

The invention discloses a heat conductive silicone grease composition which mainly contains a carbon nano tube, graphite, phase-change capsule particles and silicone oil, wherein the carbon nano tube can speed up the conduction of heat further; the phase-change capsule particles are used for improving the initial temperature absorption velocity of a heat end; the phase-change capsule particles, the carbon nano tube and graphite in a fluid form full-three-dimensional network distribution of particles (phase-change capsule), a line ( the carbon nano tube) and a plane (graphite) in the fluid finally. The heat conductive silicone grease composition provided by the invention has high heat conduction rate and low heat resistivity, the heat radiation efficiency of the heat conductive silicone grease is improved greatly, the service life of the heat conductive silicone grease is prolonged greatly, and the heat conductive silicone grease composition has high practical value.

Owner:HUZHOU MINGSHUO OPTOELECTRONICS TECH CO LTD

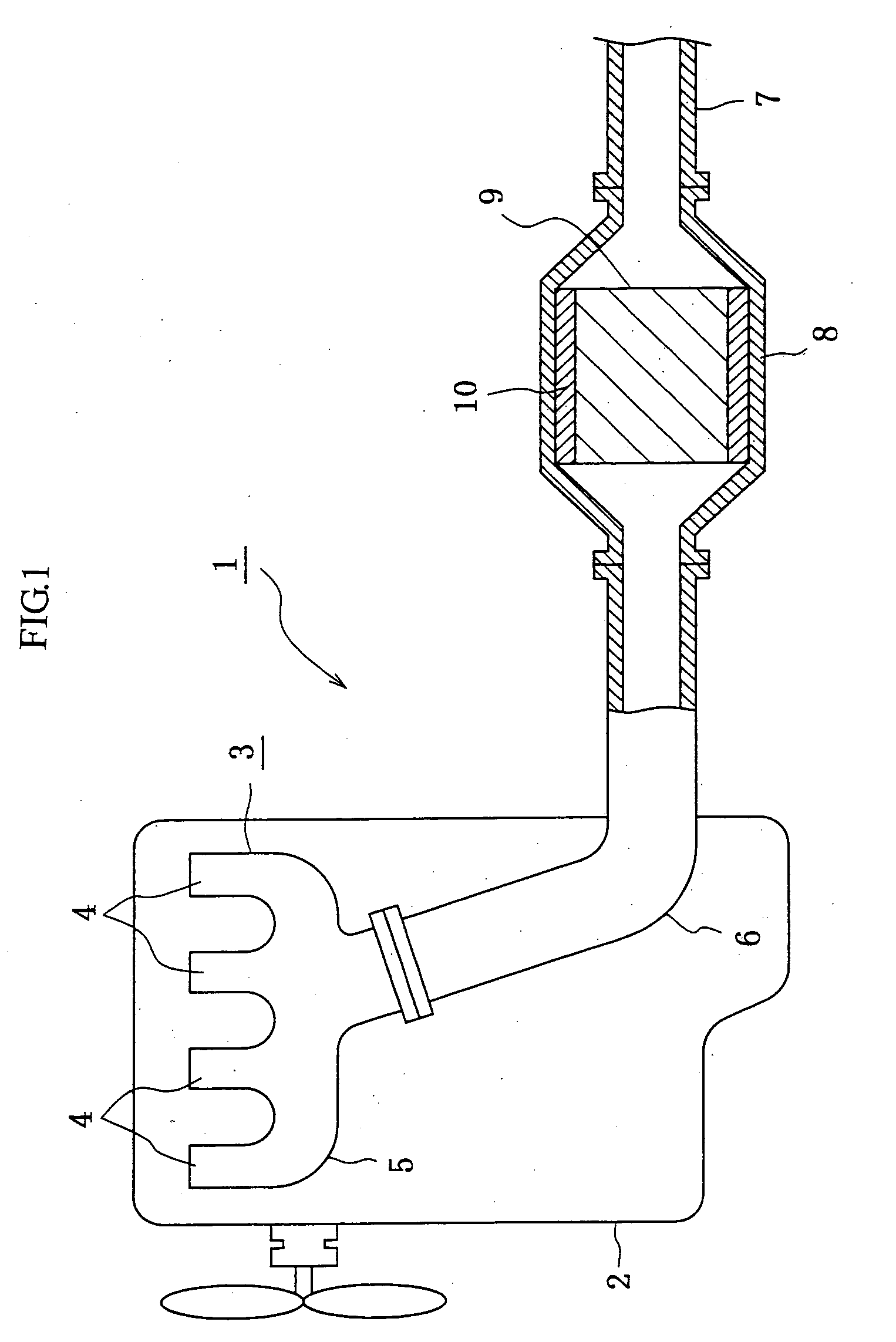

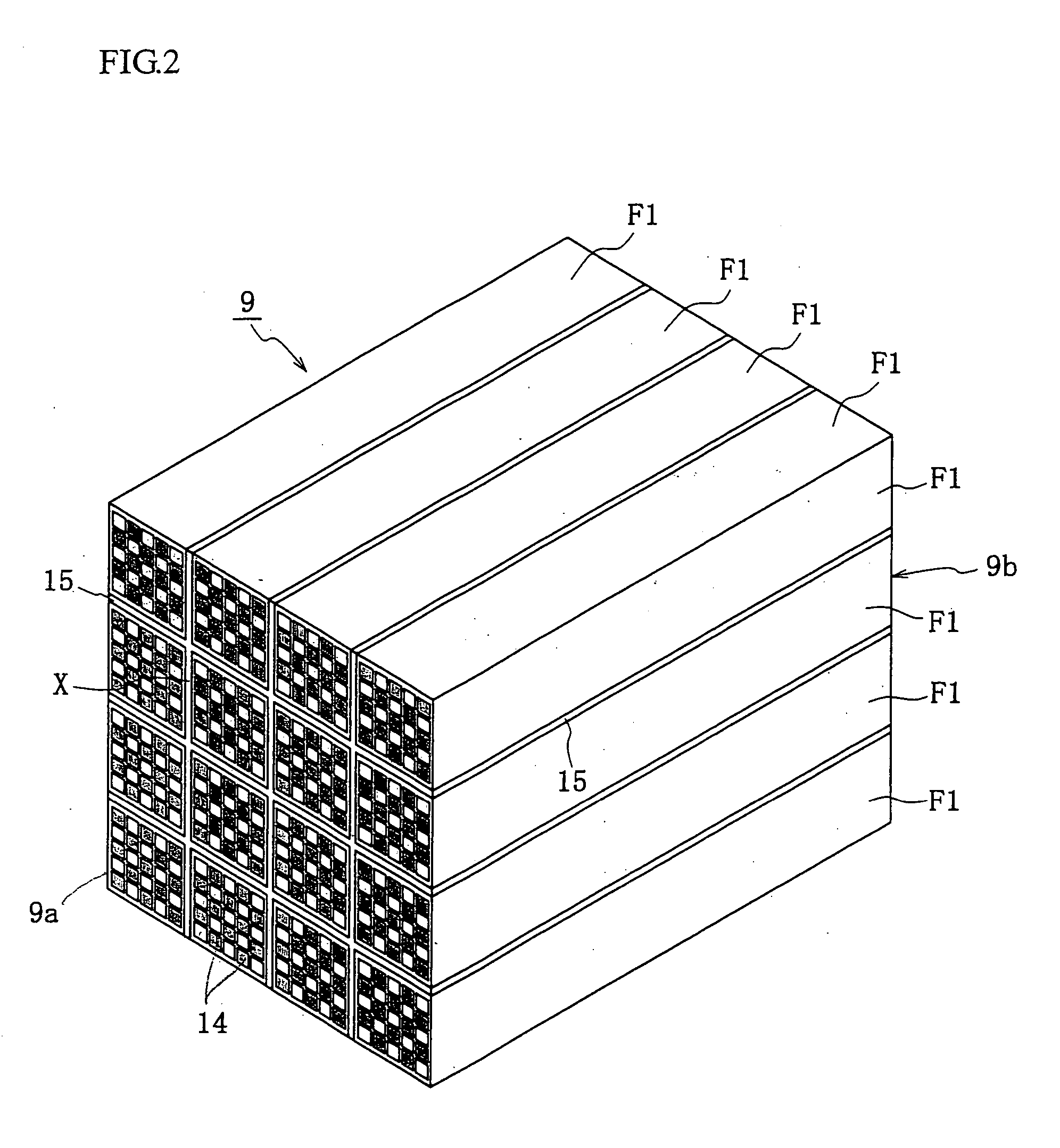

Ceramic filter and exhaust gas decontamination unit

ActiveUS20050102987A1Improve filtering efficiencyExtended service lifeCombination devicesInternal combustion piston enginesMetallurgyActive component

It is to provide a filter for an exhaust gas having a high thermal conductivity irrespective of a relatively high porosity or showing characteristics that the whole of the filter containing a high refractive index substance or pigment is easily warmed but hardly cooled while making low the thermal conductivity of the filter as a whole. This filter is provided with a catalyst coat layer formed by carrying a catalyst active component on a surface of a porous ceramic carrier, in which a porosity of the porous ceramic carrier is 40-80% and a substance or a pigment indicating a thermal conductivity as the filter of 3-60 W / mk or having a large refractive index at a thermal conductivity of 0.3-3 W / mk.

Owner:IBIDEN CO LTD

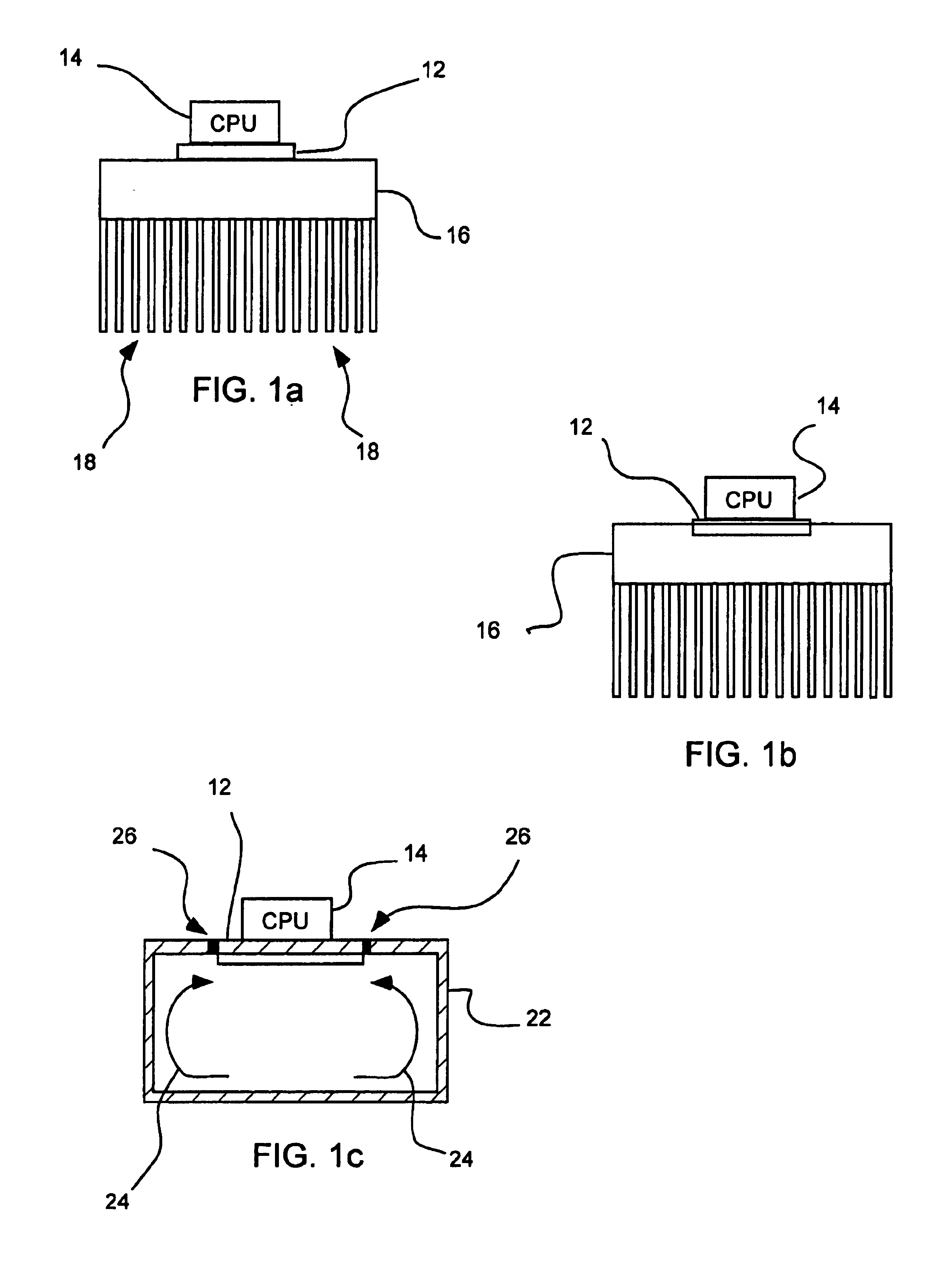

Heat spreader with high heat flux and high thermal conductivity

InactiveUS20080225489A1Maintain a constant temperatureSemiconductor/solid-state device detailsSolid-state devicesGas phaseEngineering

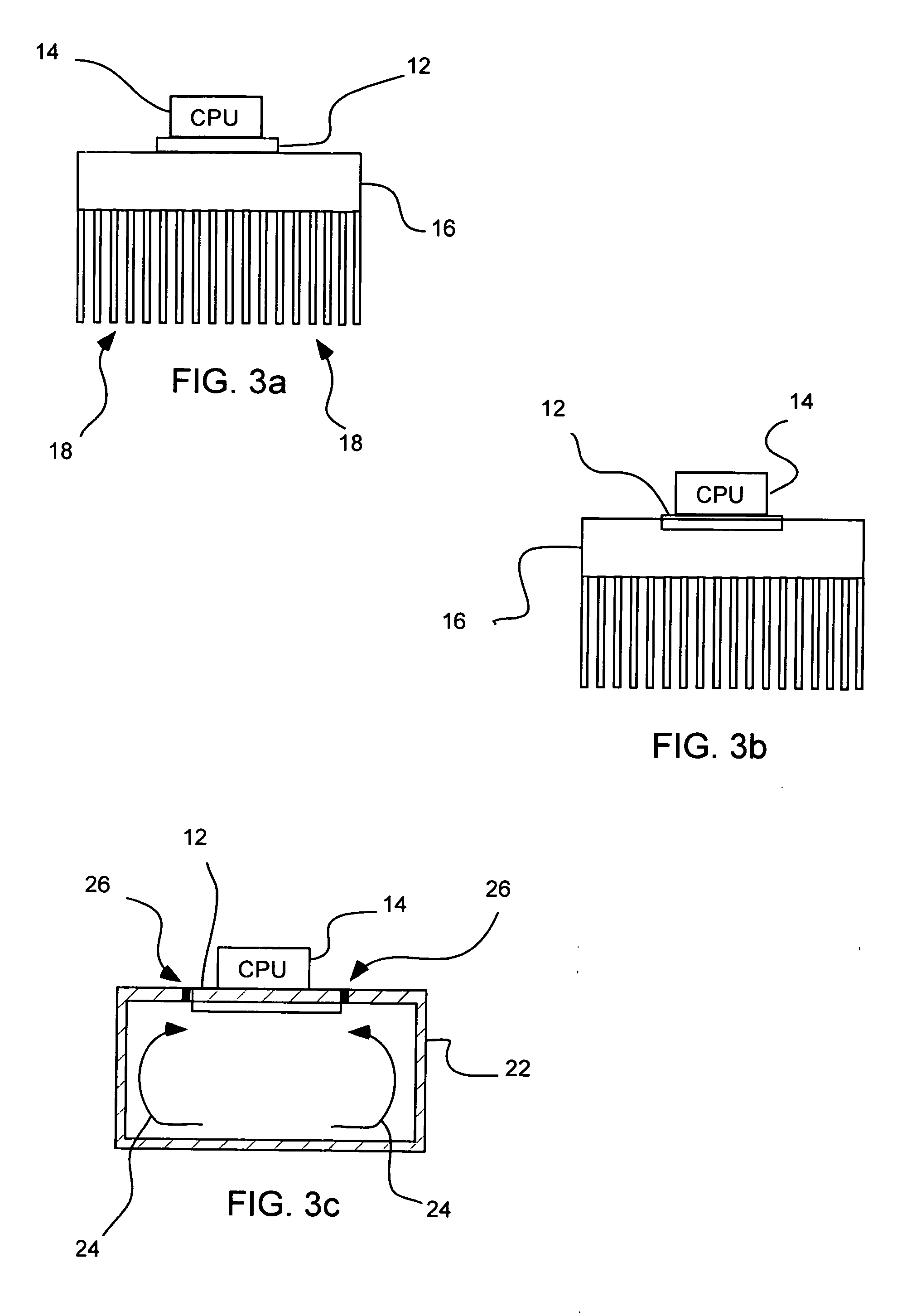

A heat spreader for transferring heat from a heat source to a heat sink using a phase change coolant, includes an array of cells, each cell having at least one microporous wick for supporting flows of the coolant in the liquid phase, via capillary action, within the spreader from proximate the heat sink to proximate the source and at least one macroporous wick for supporting flows of the coolant, in the liquid and vapor phase, within the spreader from proximate the source to proximate the heat sink.

Owner:TELEDYNE LICENSING

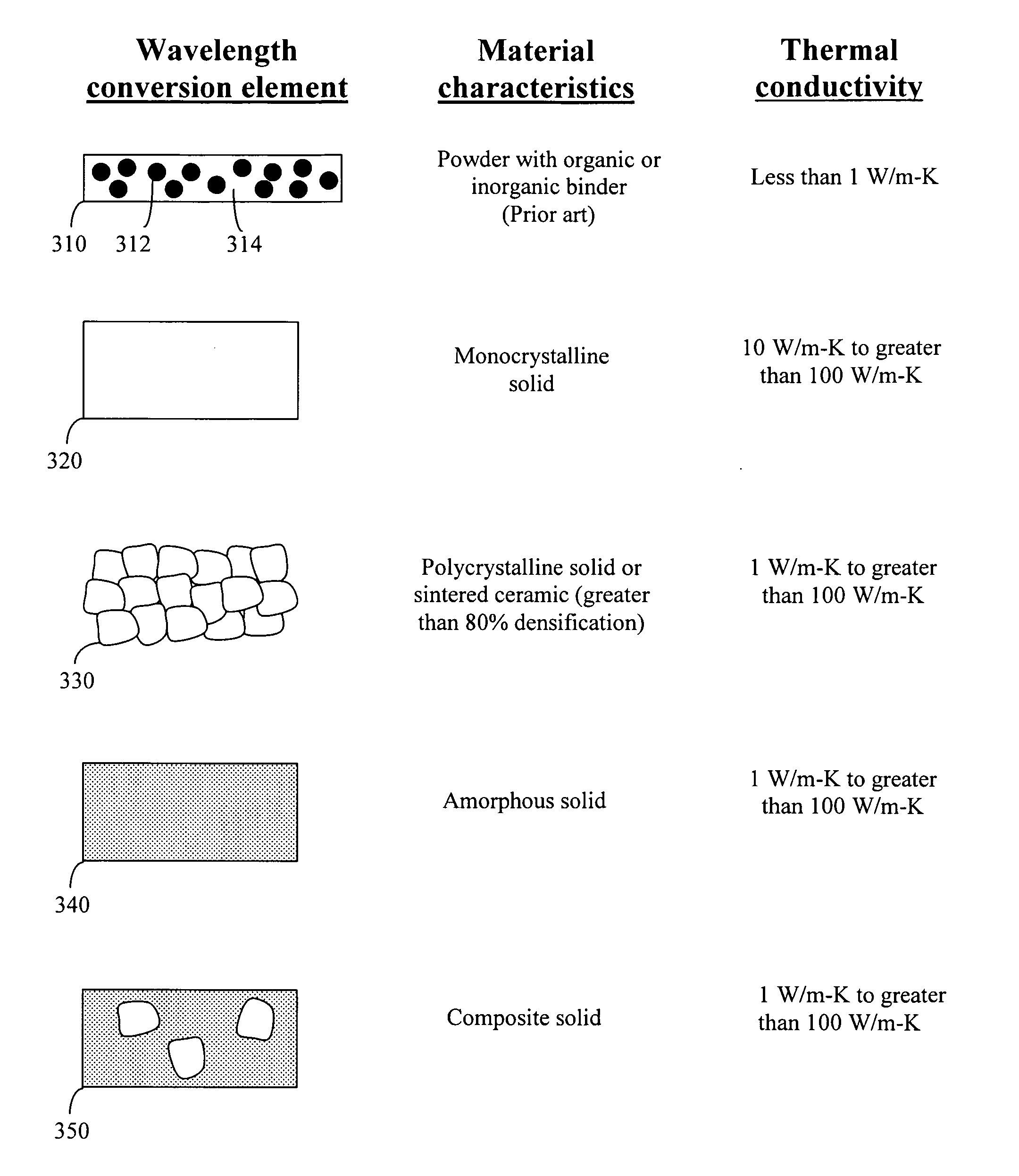

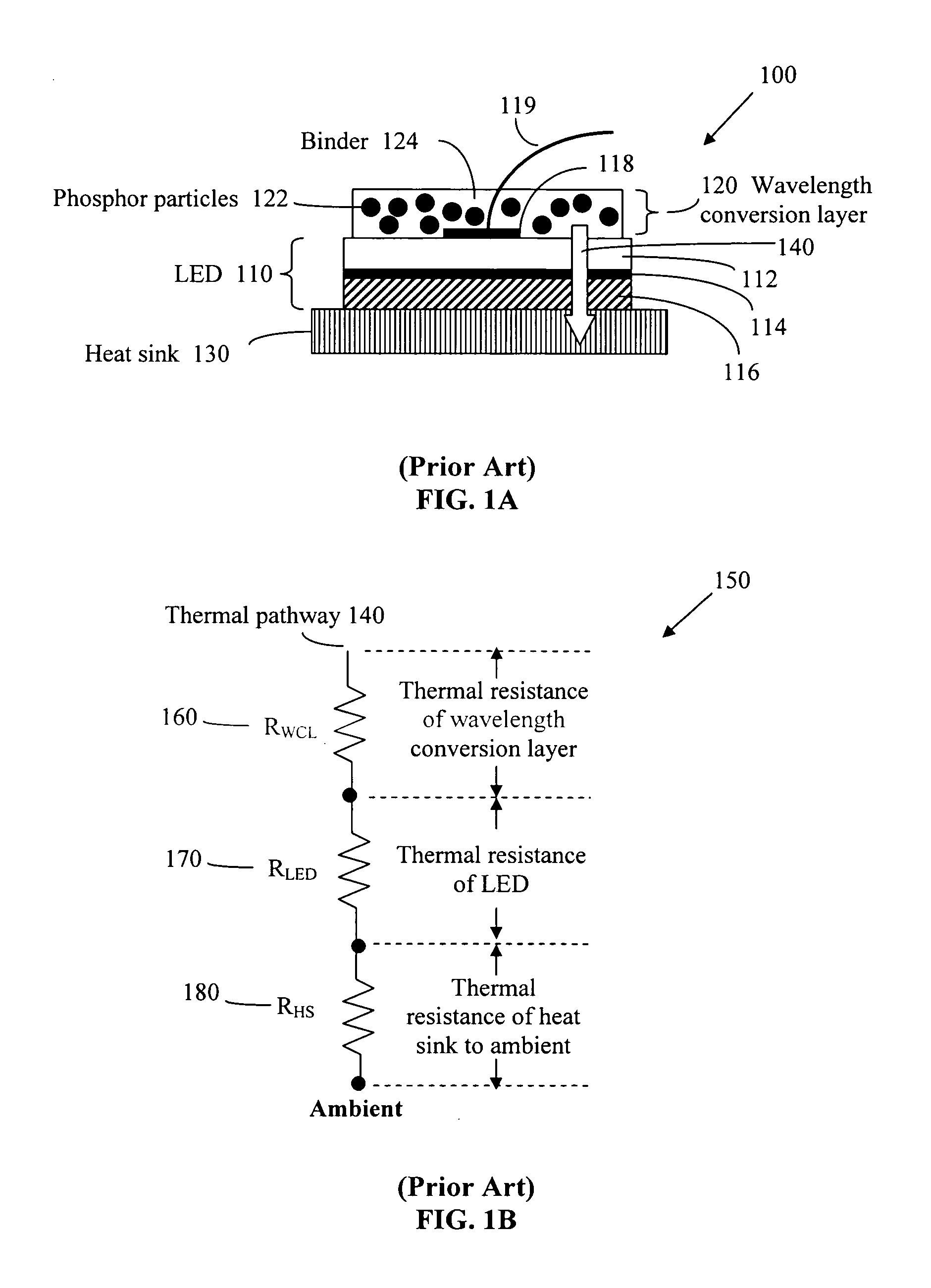

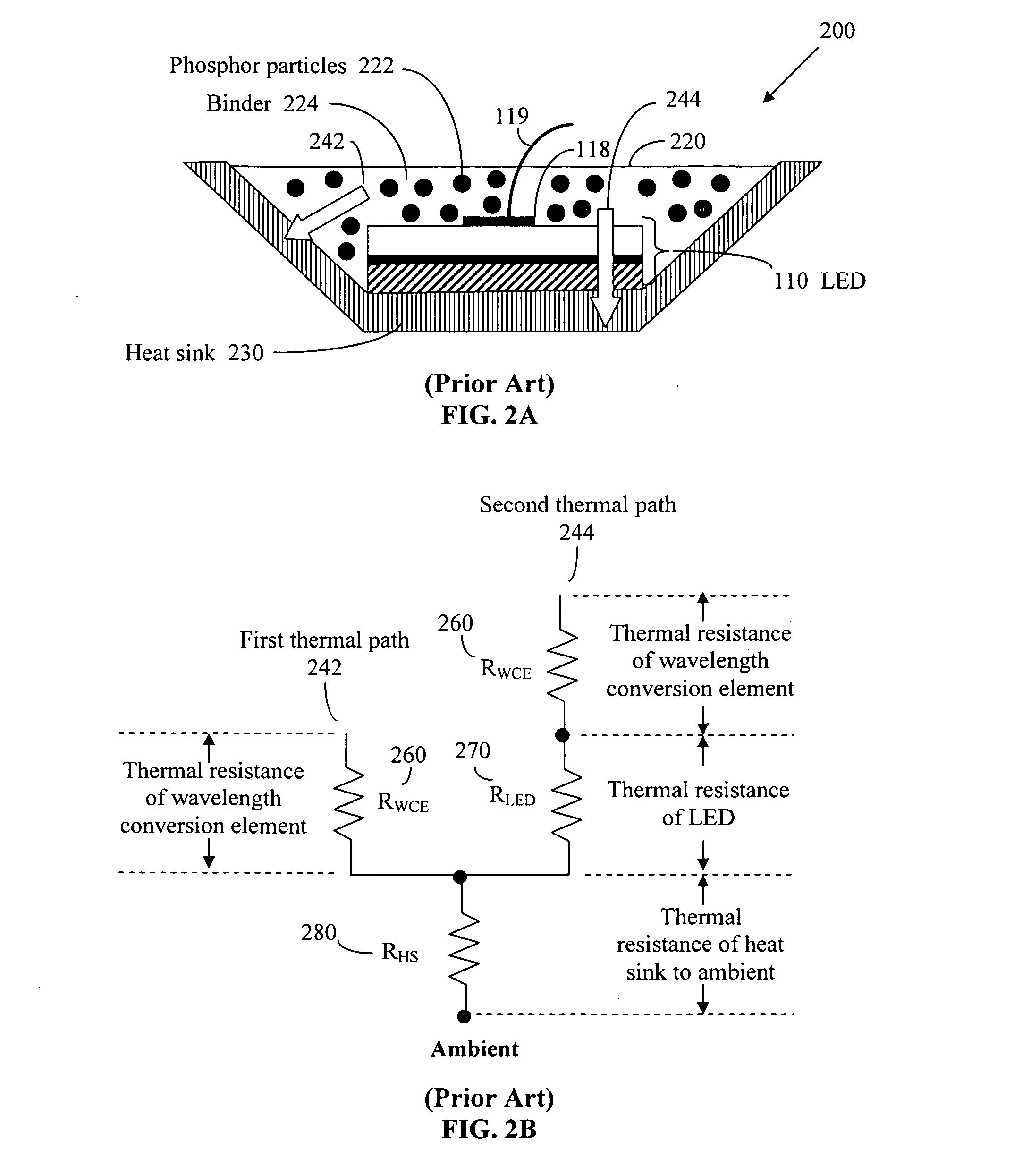

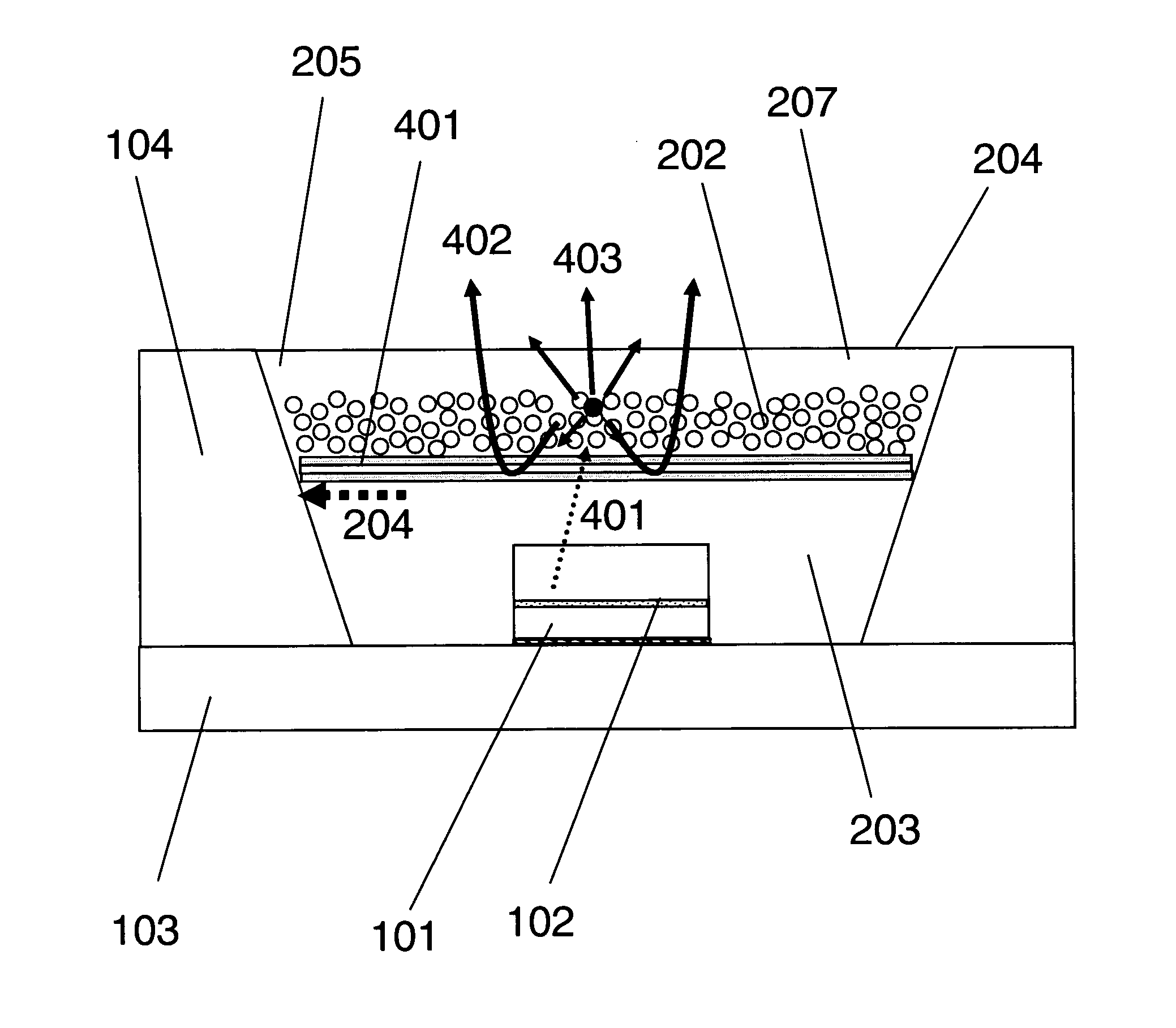

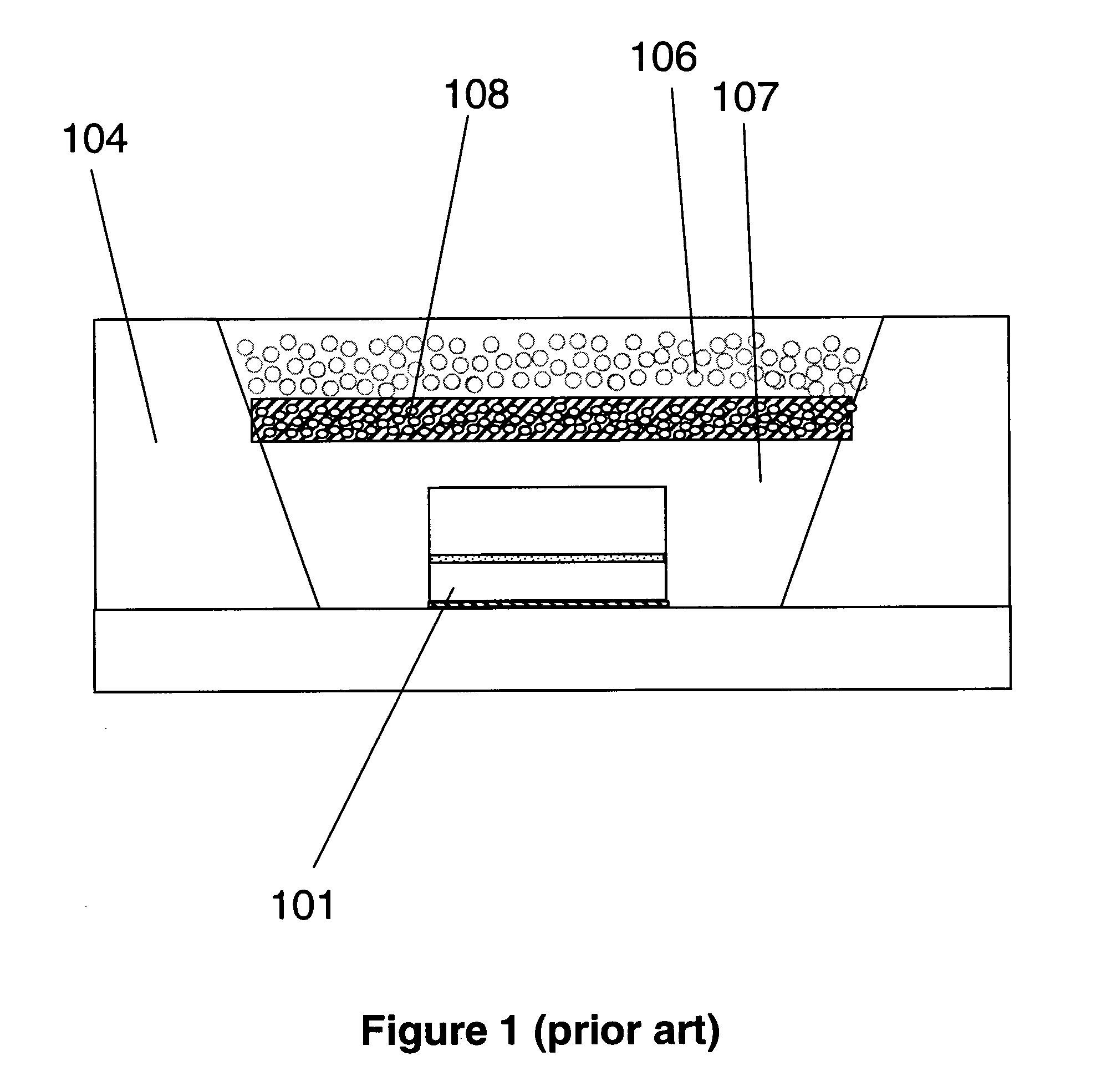

Compact light conversion device and light source with high thermal conductivity wavelength conversion material

InactiveUS20080149166A1Dissipate quicklyAvoid overall overheatingPV power plantsSolid-state devicesSingle crystalThermal contact

A light conversion device and high-intensity, solid-state light source utilize wavelength conversion elements with a thermal conductivity greater than 1 watt per meter per degree Kelvin (W / m-K). Exemplary materials that have high thermal conductivity include monocrystalline solids, polycrystalline solids, substantially densified ceramic solids, amorphous solids or composite solids. The light conversion device and high-intensity, solid-state light source have at least one heat sink that is in direct thermal contact with the wavelength conversion element. The heat sink quickly dissipates heat generated within the wavelength conversion element in order to prevent the wavelength conversion element from overheating and undergoing thermal quenching of the wavelength conversion and light emission.

Owner:GOLDENEYE

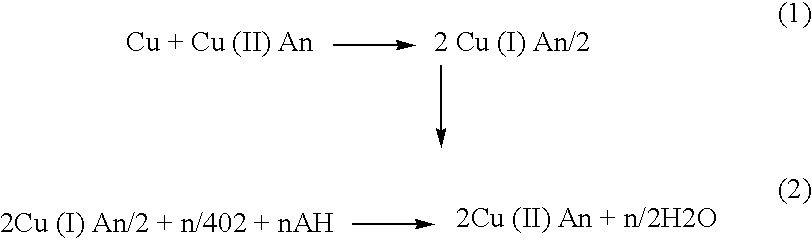

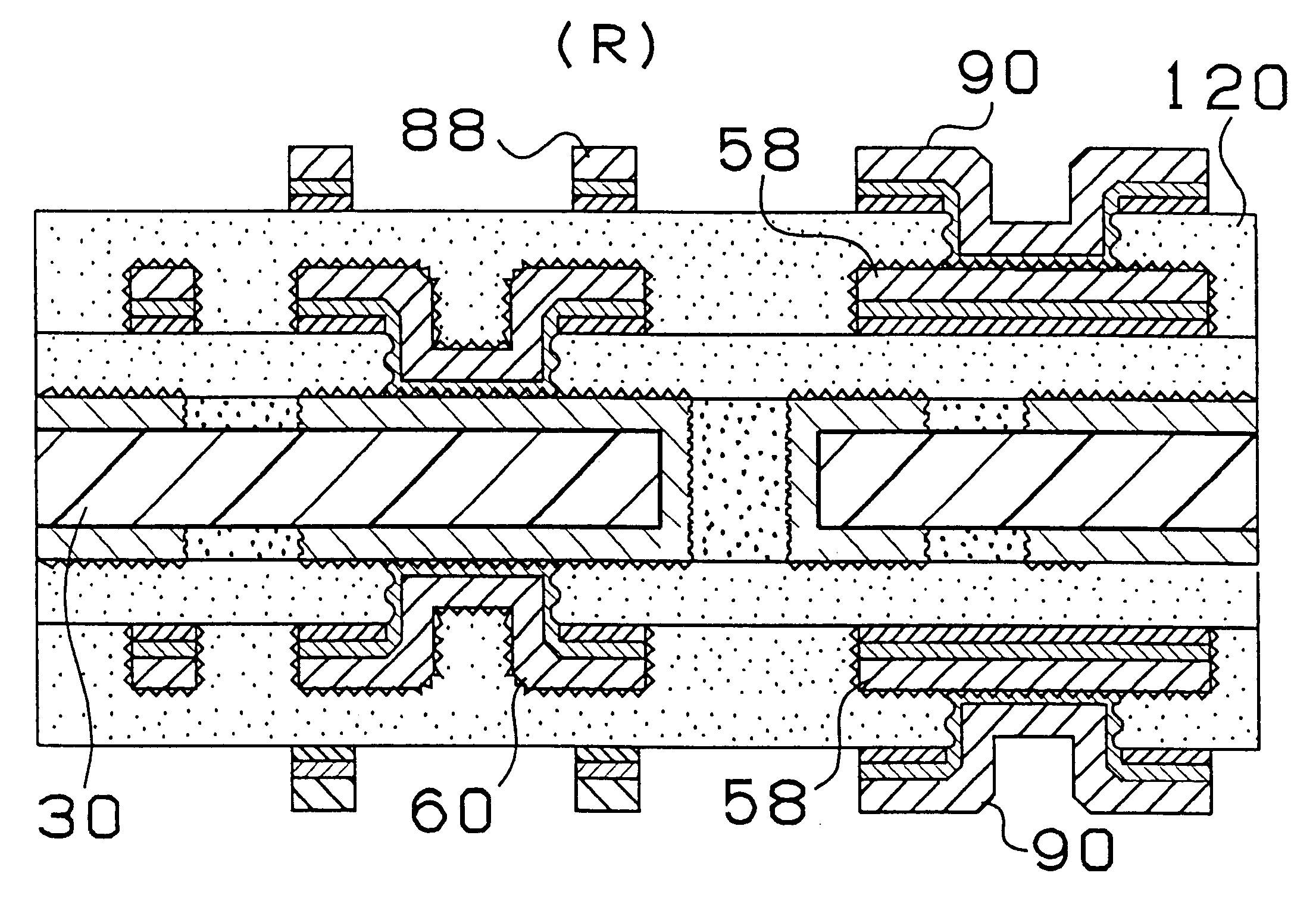

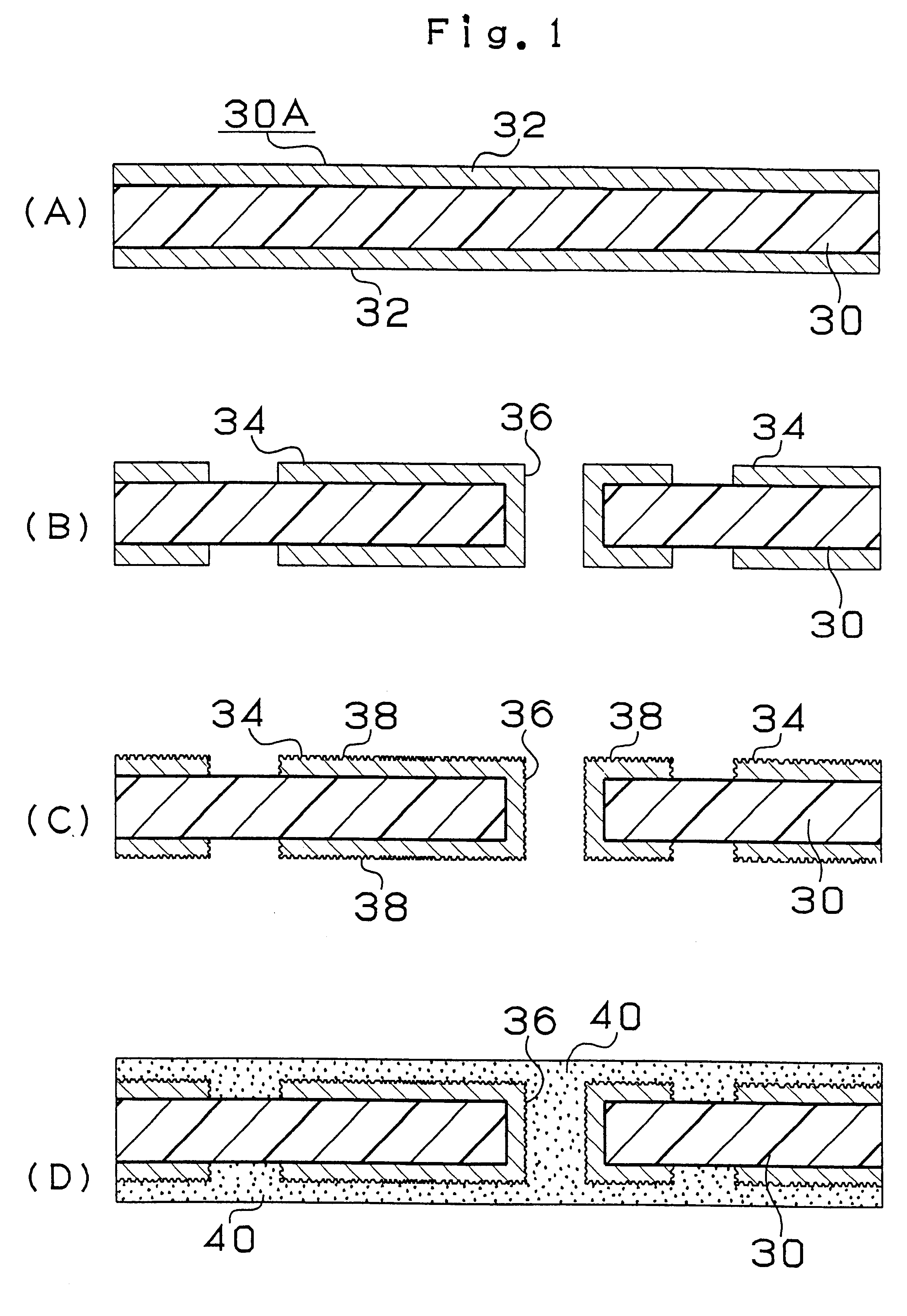

Manufacturing method of a multilayered printed circuit board having an opening made by a laser, and using electroless and electrolytic plating

InactiveUS6591495B2Satisfactory productivityAvoid separationSolid-state devicesInsulating layers/substrates workingCopper foilPulse shaping

An opening is formed in resin by a laser beam so that a via hole is formed. Copper foil, the thickness of which is reduced to 3 mum by etching to lower the thermal conductivity, is used as a conformal mask. Therefore, an opening is formed in the resin and the number of irradiation of pulse-shape laser beam is reduced. Thus, occurence of undercut of the resin, which forms an interlayer insulating resin layer, can be prevented and the reliability of the connection of the via holes can be improved.

Owner:IBIDEN CO LTD

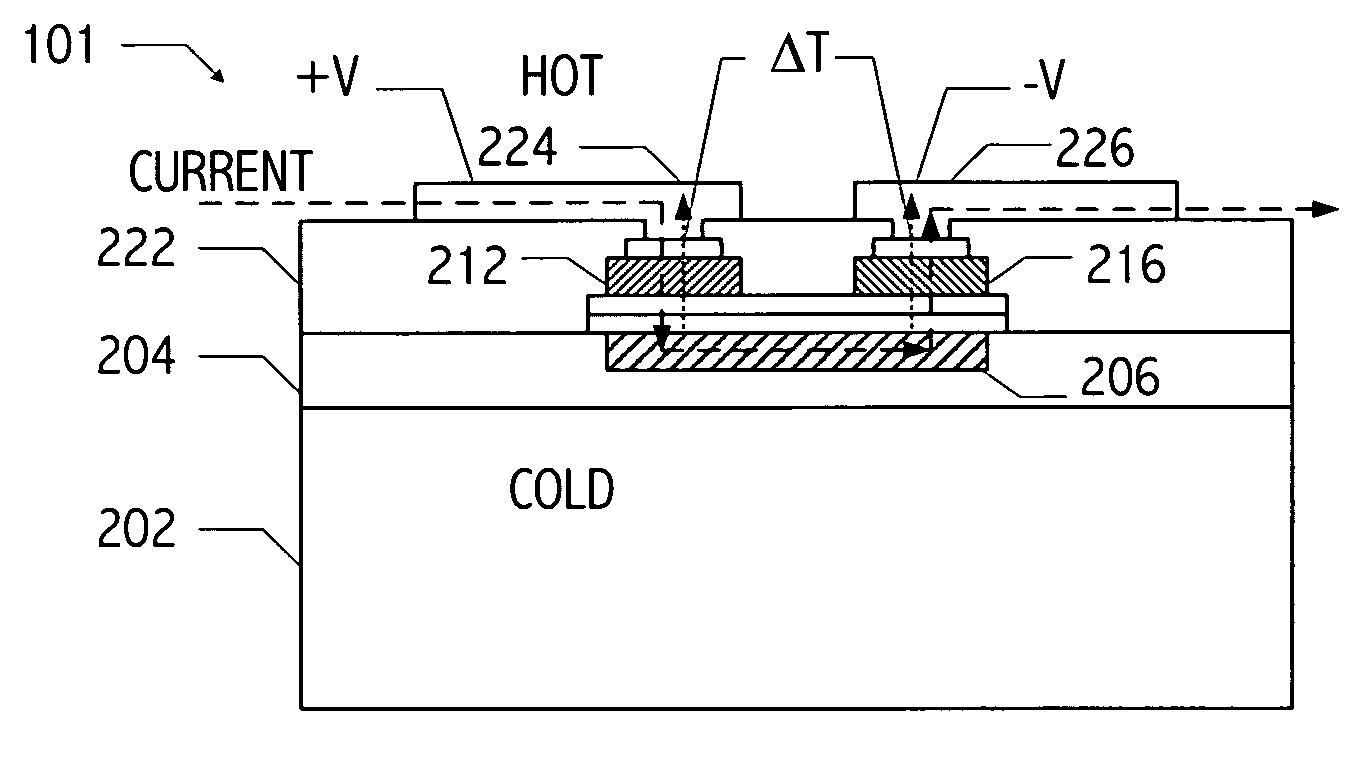

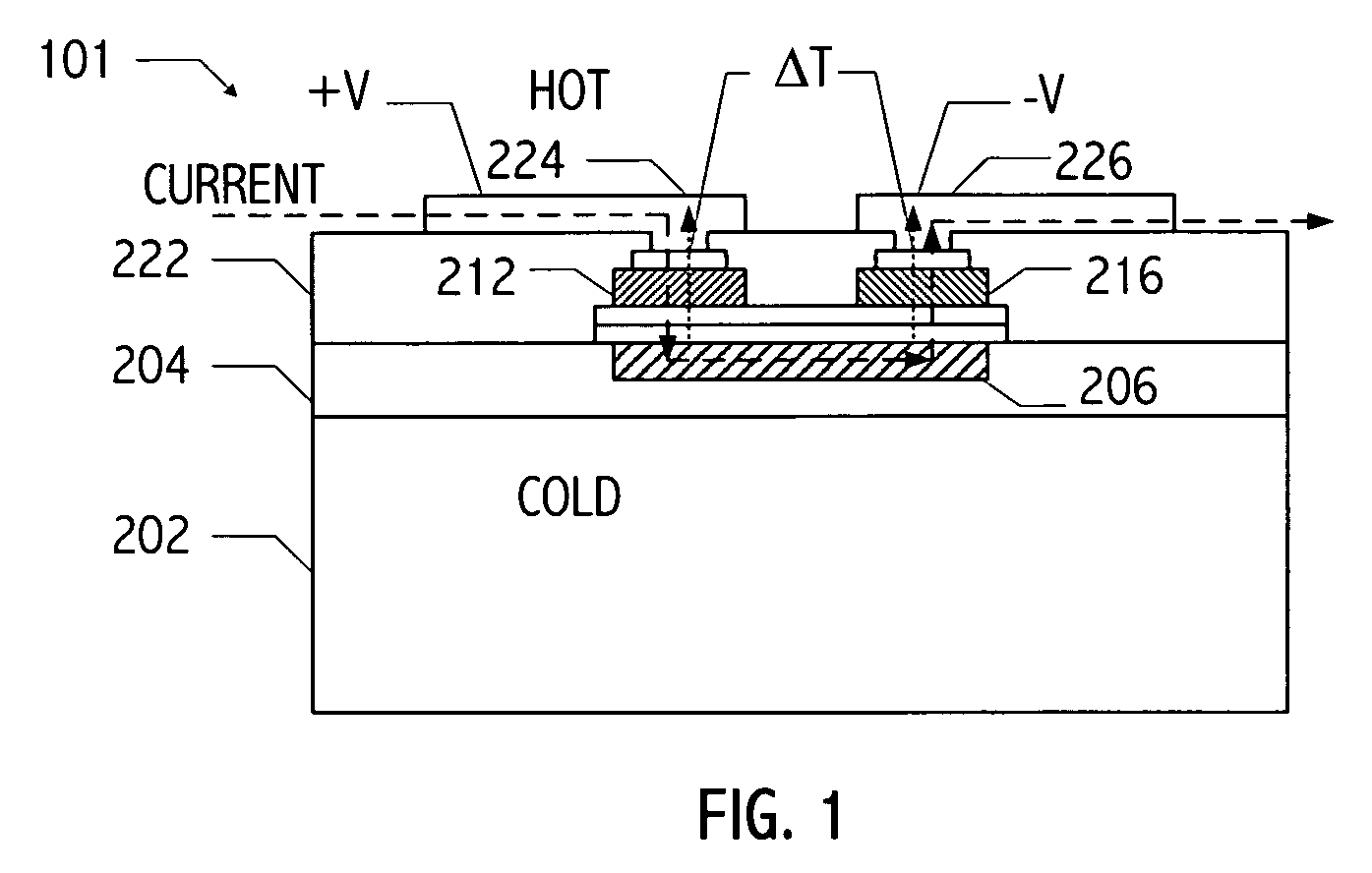

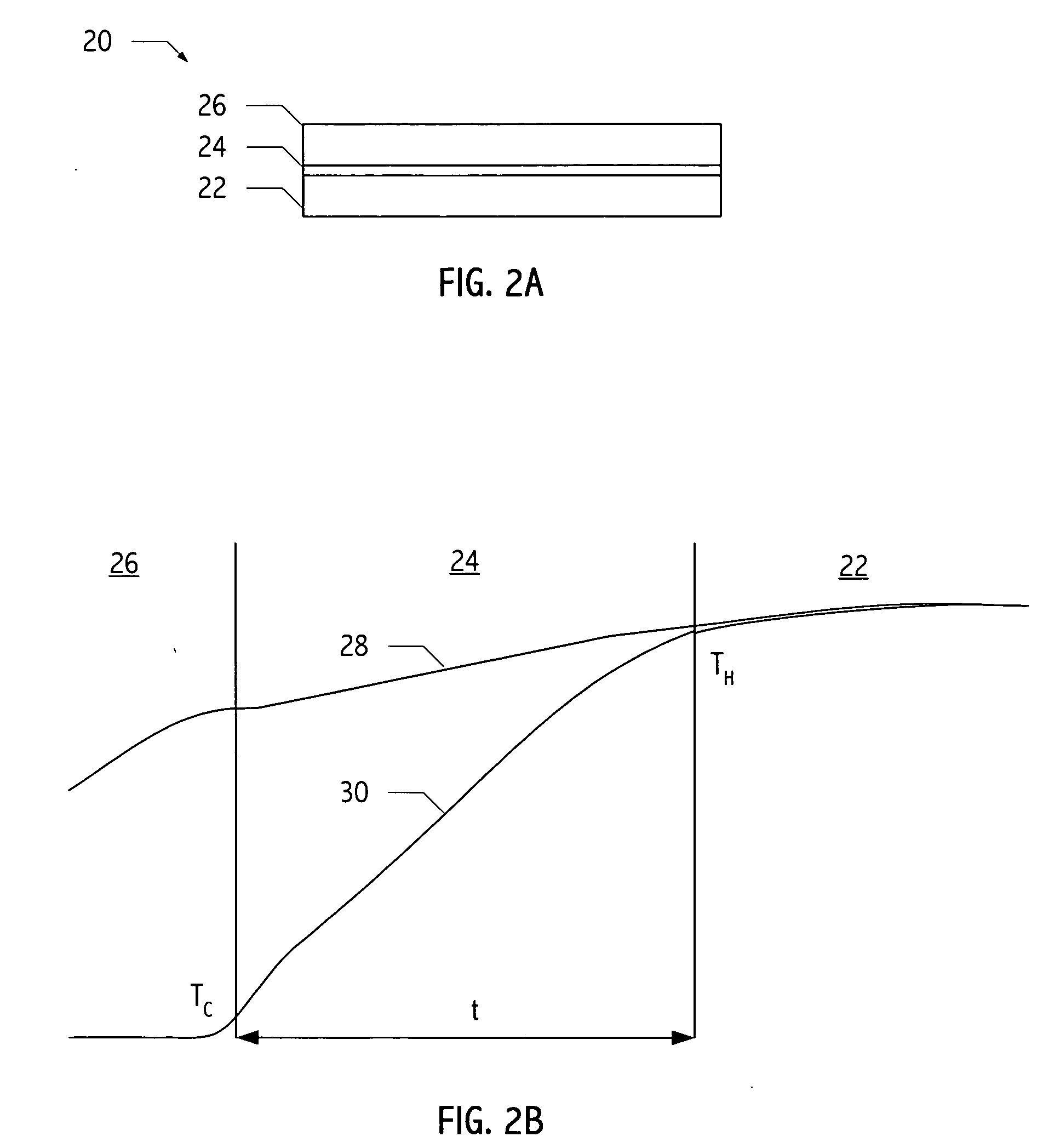

Method for forming a thin-film thermoelectric device including a phonon-blocking thermal conductor

InactiveUS20050150535A1Reduce needReduction in electron thermal conductivityThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentElectrical conductorLiquid metal

A vertical, monolithic, thin-film thermoelectric device is described. Thermoelectric elements of opposing conductivity types may be coupled electrically in series and thermally in parallel by associated electrodes on a single substrate, reducing the need for mechanisms to attach multiple substrates or components. Phonon transport may be separated from electron transport in a thermoelectric element. A thermoelectric element may have a thickness less than an associated thermalization length. An insulating film between an electrode having a first temperature and an electrode having a second temperature may be a low-thermal conductivity material, a low-k, or ultra-low-k dielectric. Phonon thermal conductivity between a thermoelectric element and an electrode may be reduced without a significant reduction in electron thermal conductivity, as compared to other thermoelectric devices. A phonon conduction impeding material may be included in regions coupling an electrode to an associated thermoelectric element (e.g., a liquid metal).

Owner:NANOCOOLERS

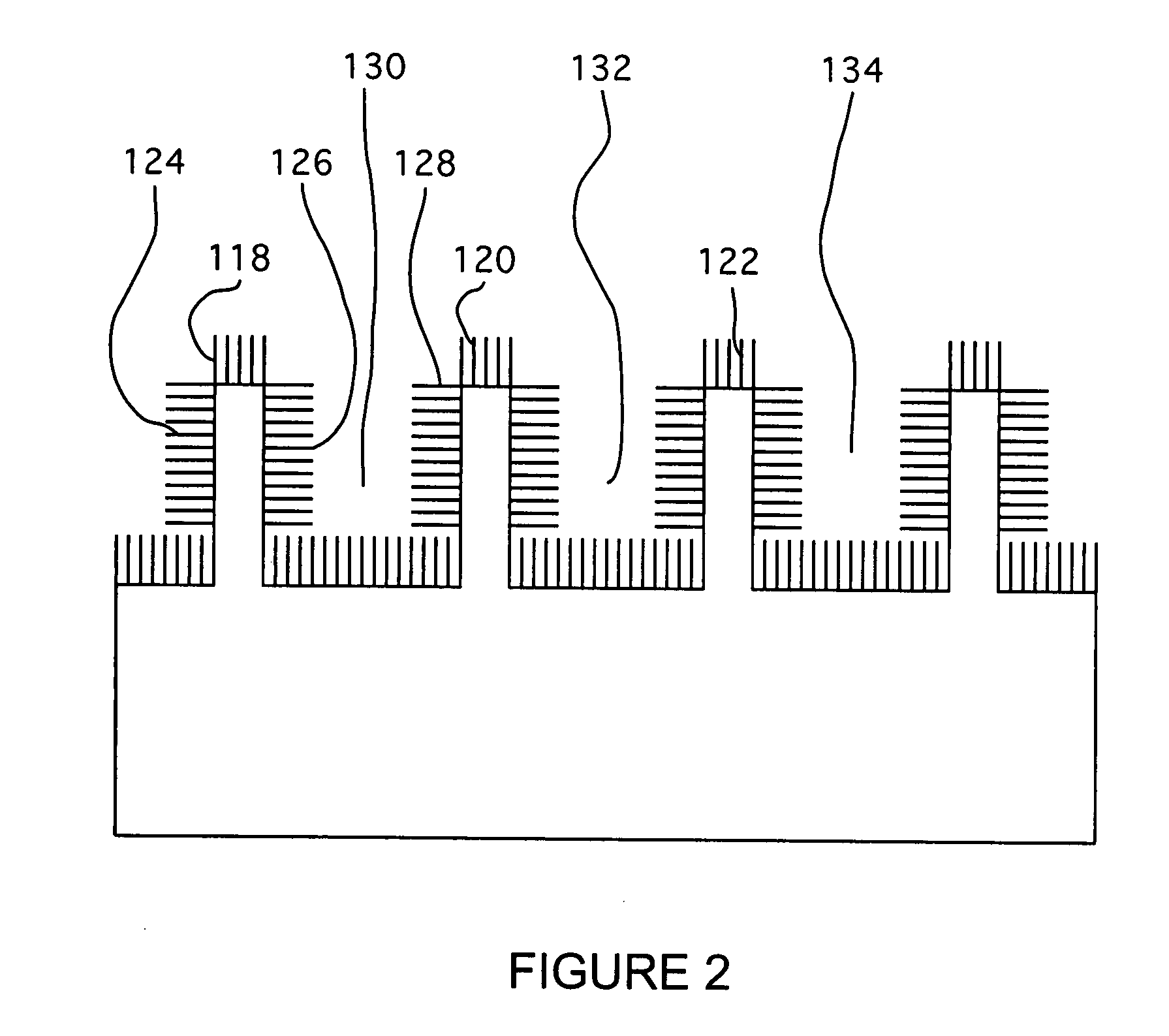

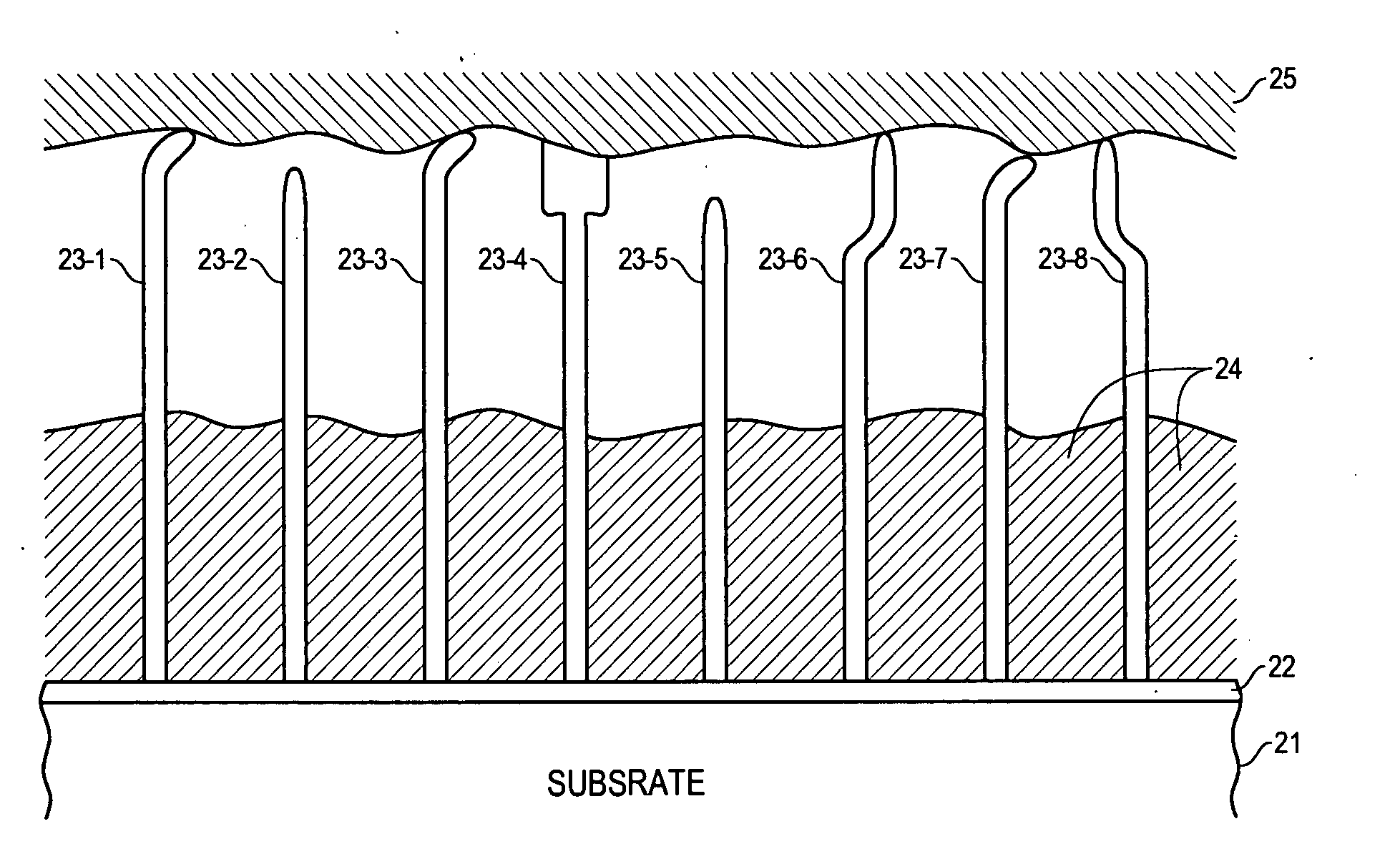

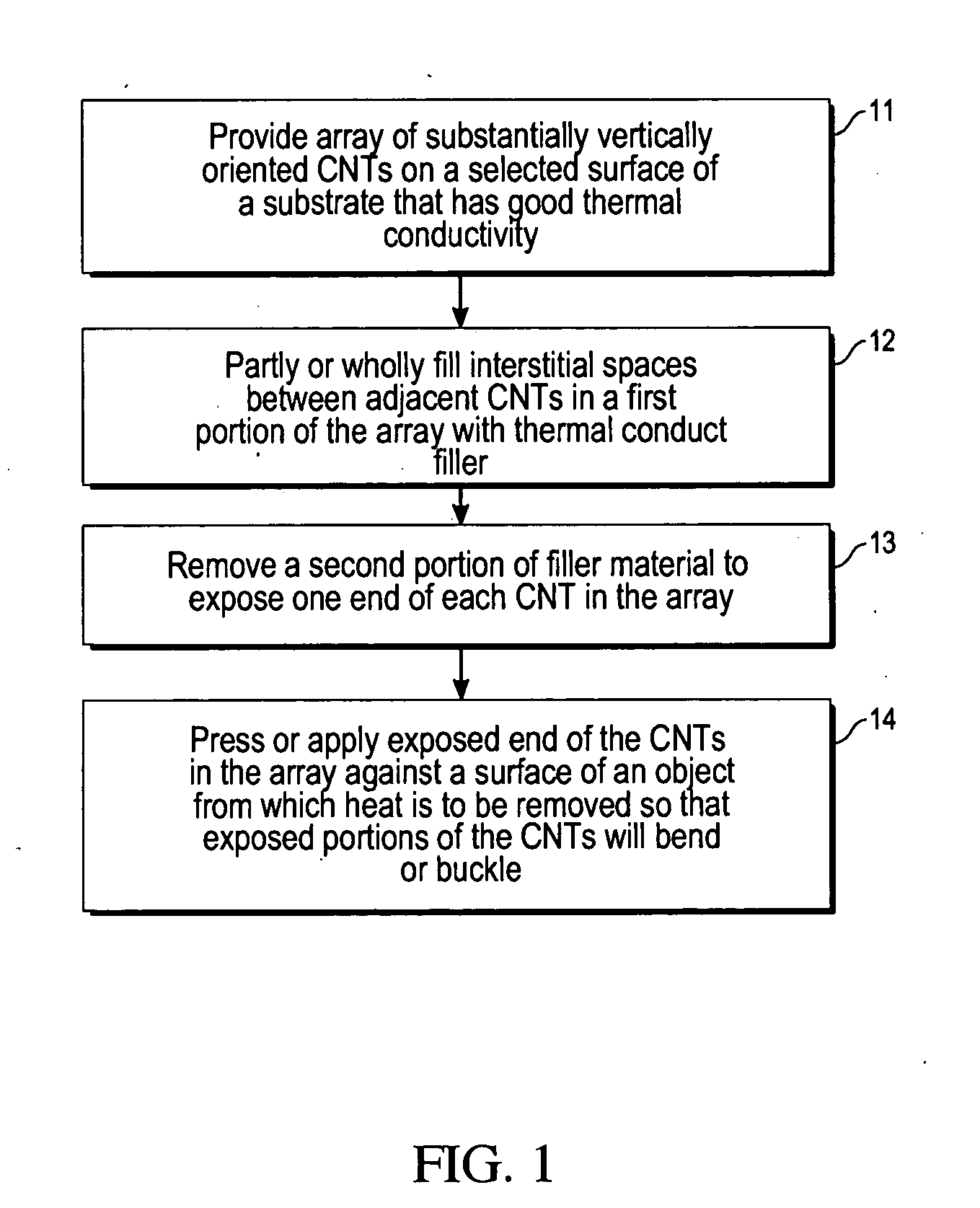

Nanoengineered thermal materials based on carbon nanotube array composites

InactiveUS20050224220A1High mechanical strengthImprove cooling effectMaterial nanotechnologySemiconductor/solid-state device detailsHeat fluxFilling materials

A method for providing for thermal conduction using an array of carbon nanotubes (CNTs). An array of vertically oriented CNTs is grown on a substrate having high thermal conductivity, and interstitial regions between adjacent CNTs in the array are partly or wholly filled with a filler material having a high thermal conductivity so that at least one end of each CNT is exposed. The exposed end of each CNT is pressed against a surface of an object from which heat is to be removed. The CNT-filler composite adjacent to the substrate provides improved mechanical strength to anchor CNTs in place and also serves as a heat spreader to improve diffusion of heat flux from the smaller volume (CNTs) to a larger heat sink.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Diamond composite heat spreaders having low thermal mismatch stress and associated methods

InactiveUS20060113546A1Present inventionImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesThermal conductivityThermal transmittance

A diamond composite heat spreader having a low thermal mismatch stress can improve reliability and cost of diamond-based heat spreaders. A diamond composite heat spreader can have a thermally conductive base and a diamond film in thermal contact with the thermally conductive base. The diamond film and the thermally conductive base can have a residual thermal mismatch stress which is less than about 75% of a residual thermal mismatch stress which would result from forming the diamond film on the thermally conductive base using a high temperature deposition process at 700° C. The diamond film can be formed on the thermally conductive base using a low temperature vapor deposition process performed at a temperature from about 10° C to less than 700° C, and typically lower than about 450° C. The diamond films further have high thermal diffusivity and thermal conductivity which allow for dramatic improvements in heat transfer away from a heat source without the need for growing a thick diamond film. By providing a low temperature deposition of the diamond film, residual thermal mismatch stress can be significantly reduced, while allowing for use of well known heat spreaders such as standard copper heat spreaders and associated technologies.

Owner:SUNG CHIEN MIN

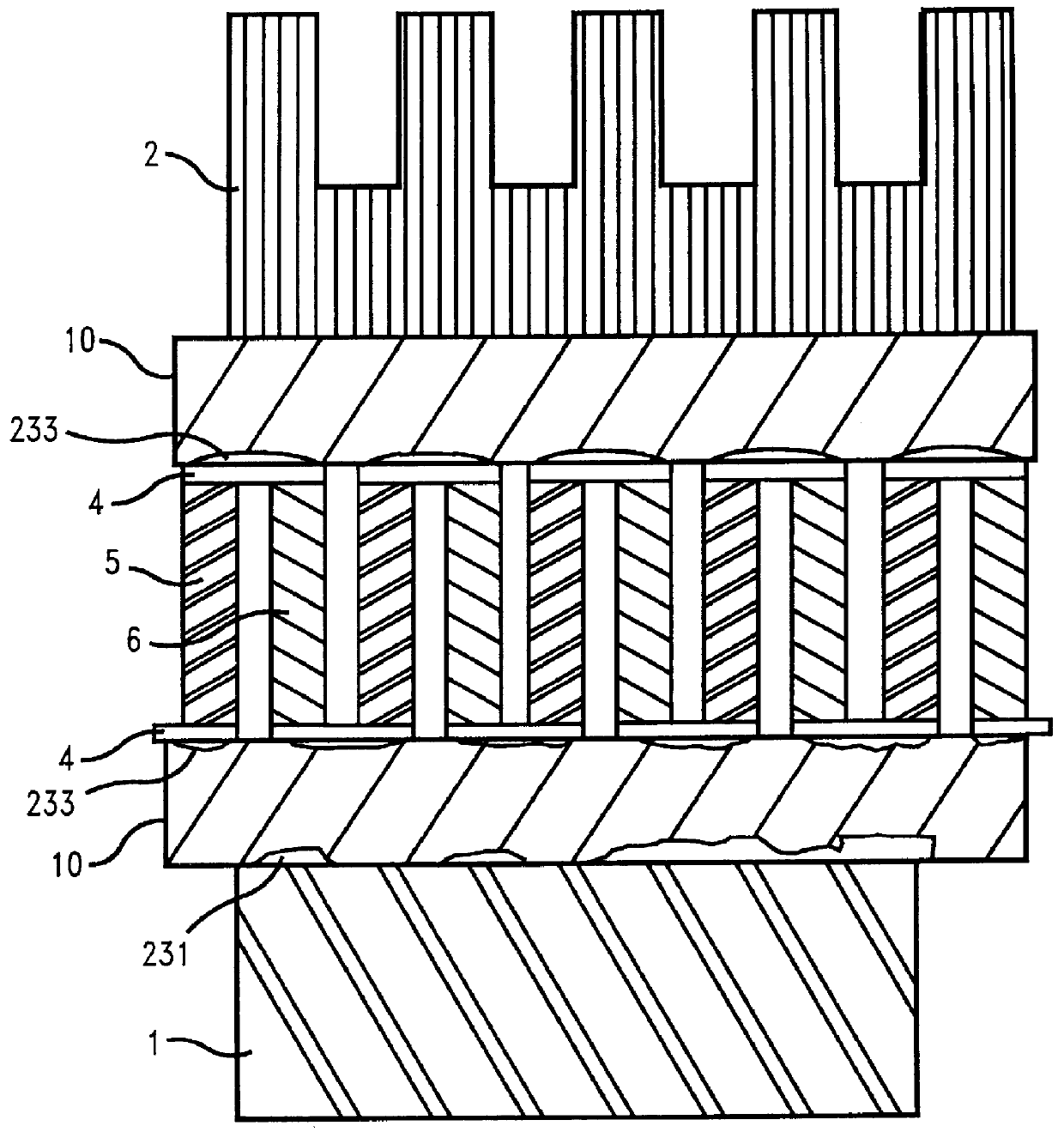

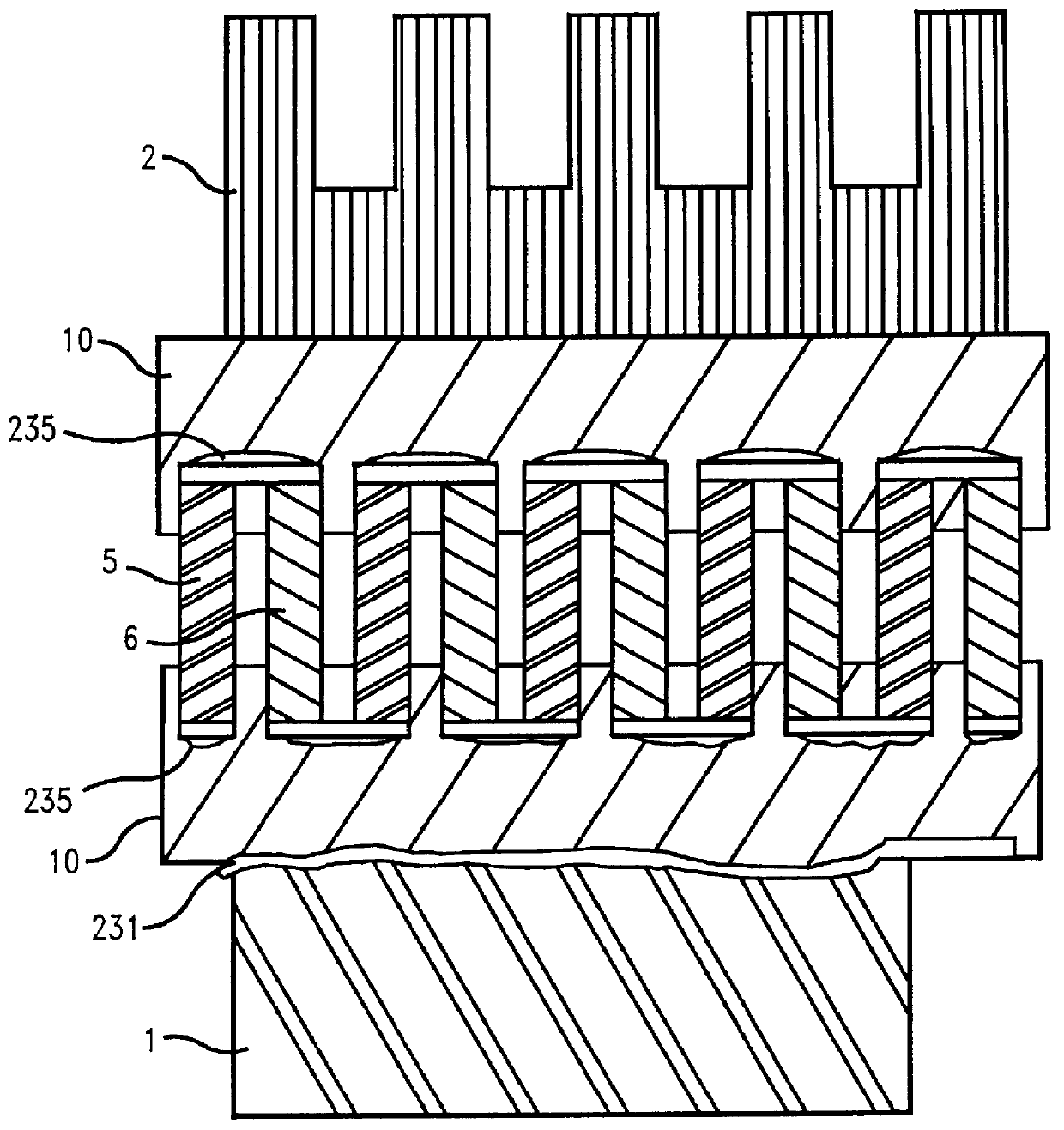

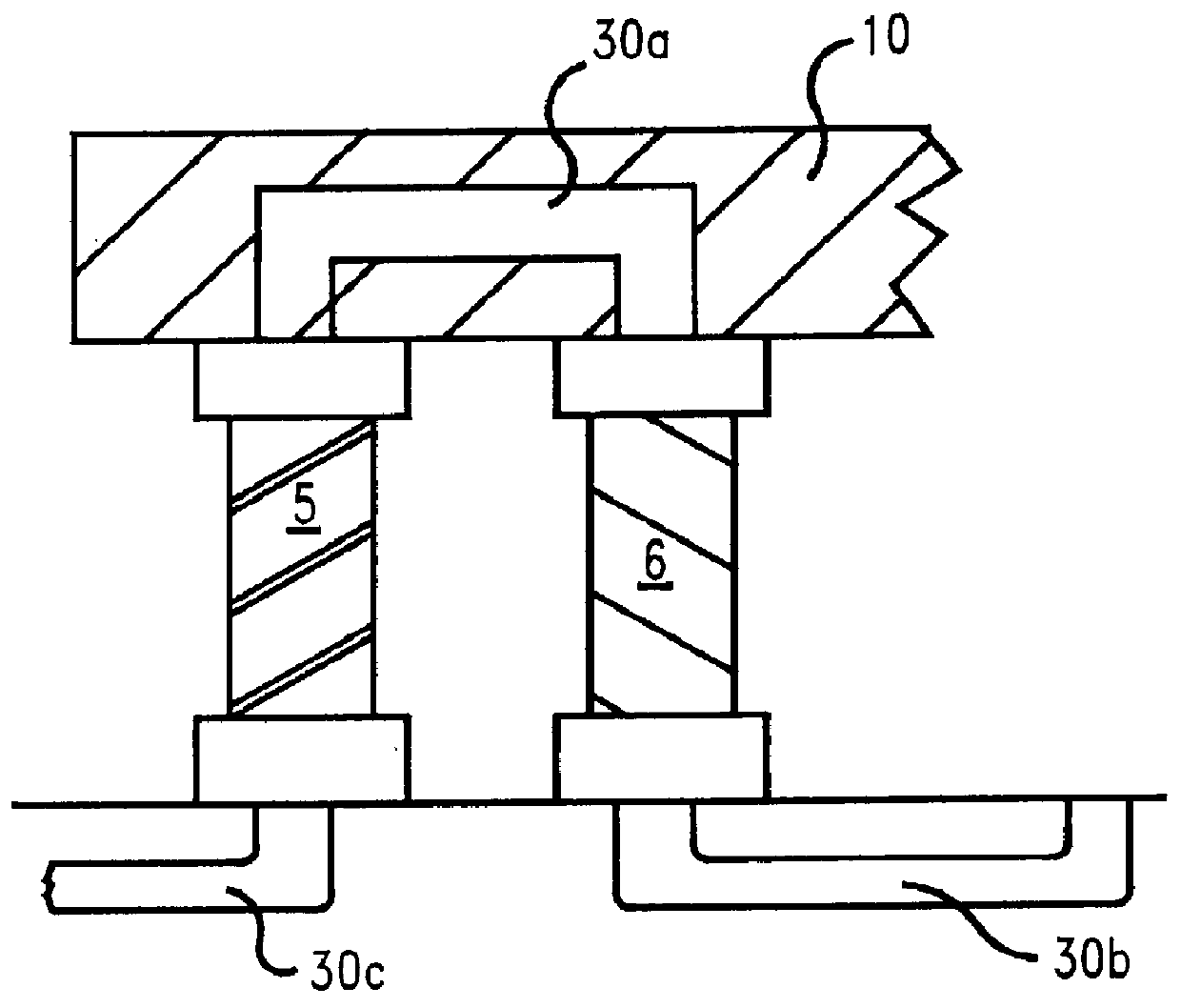

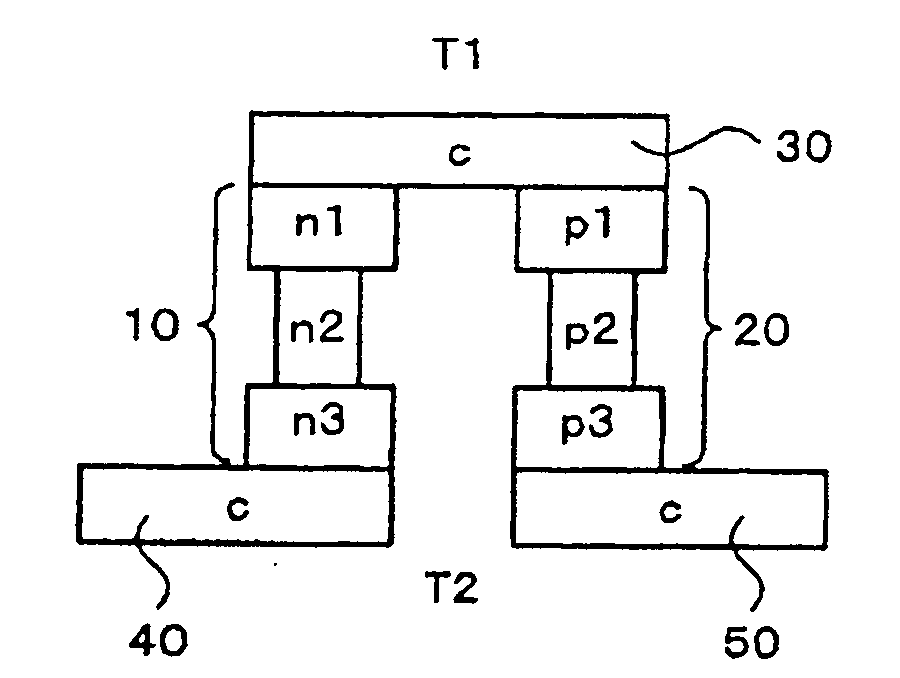

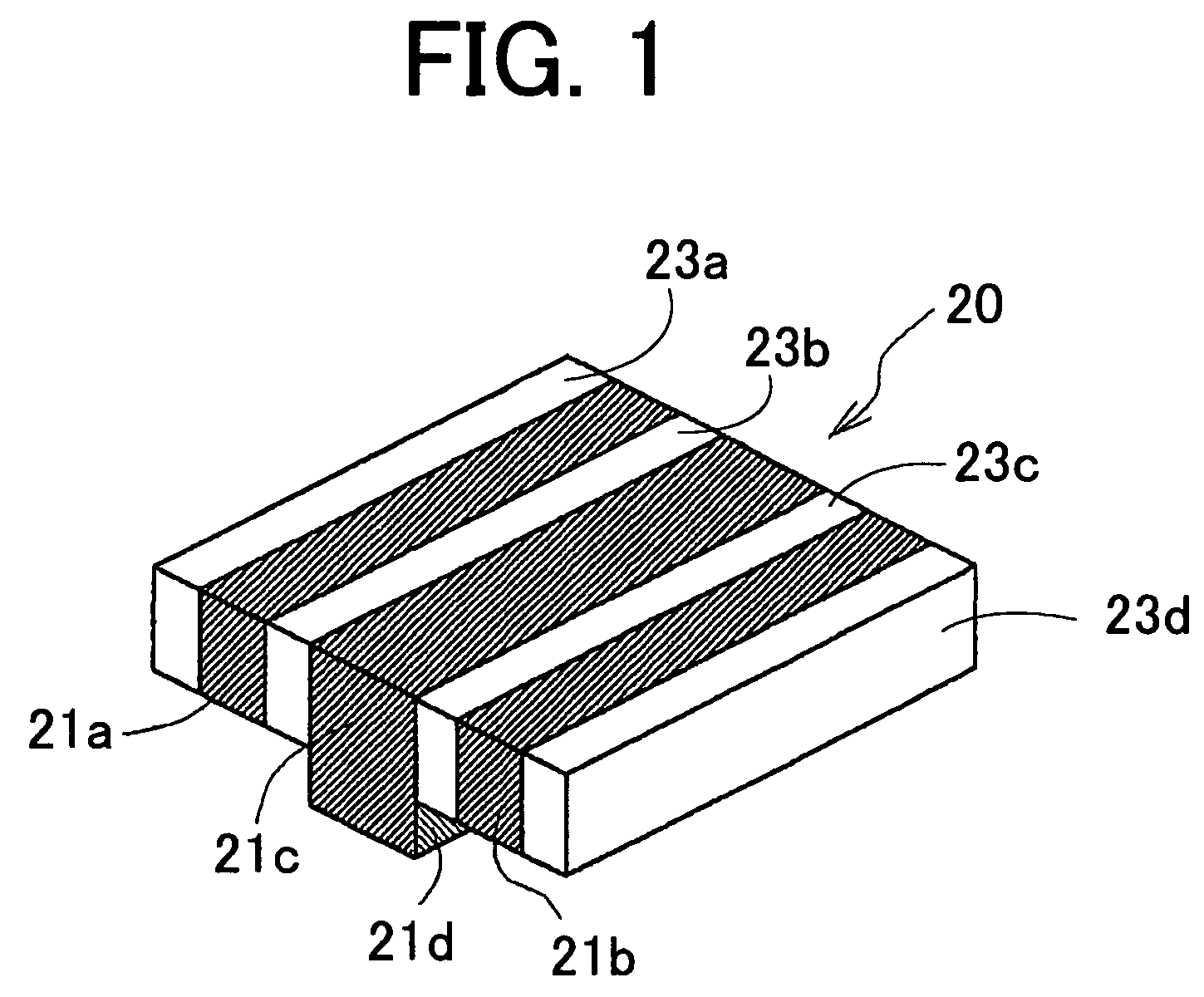

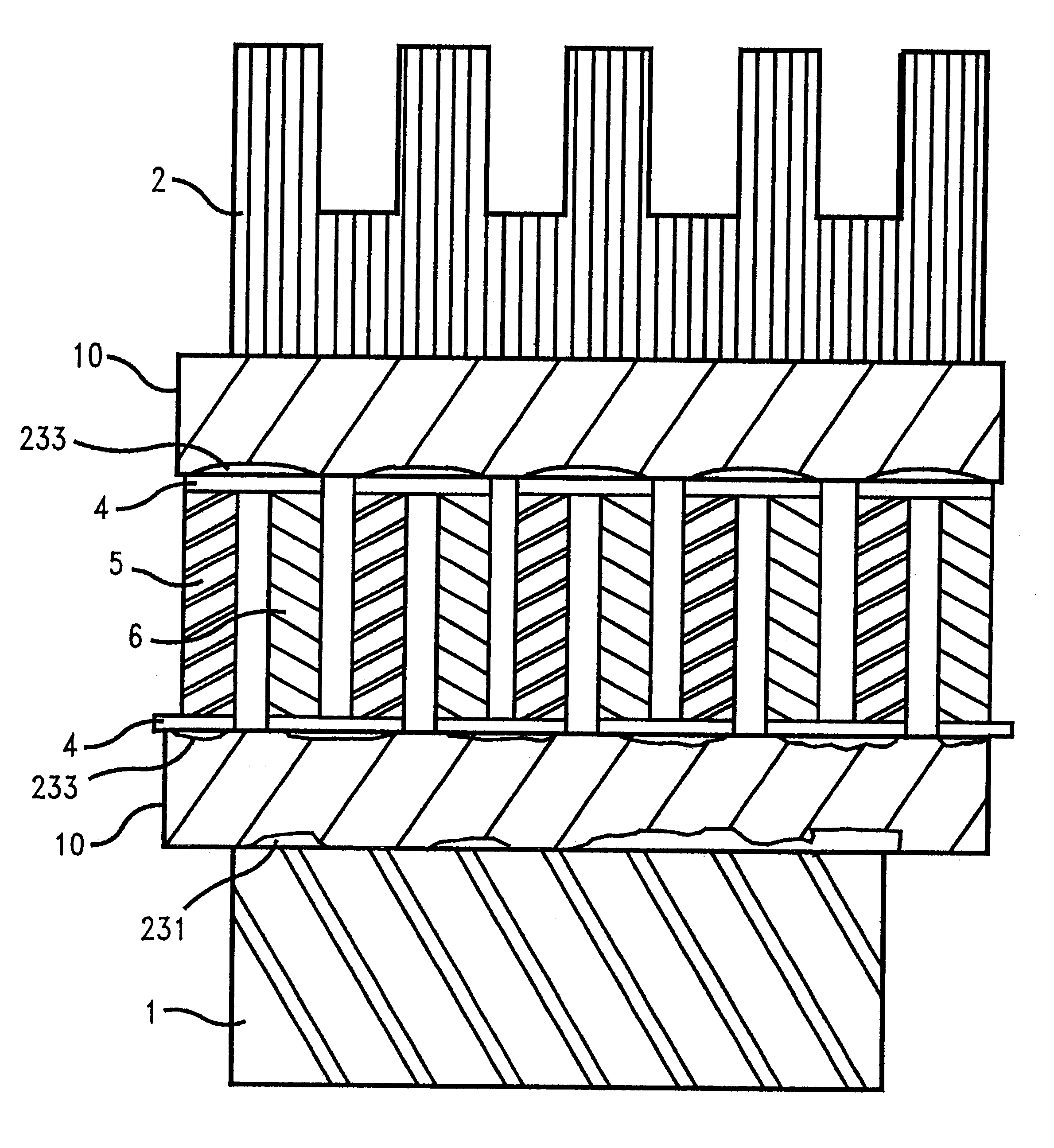

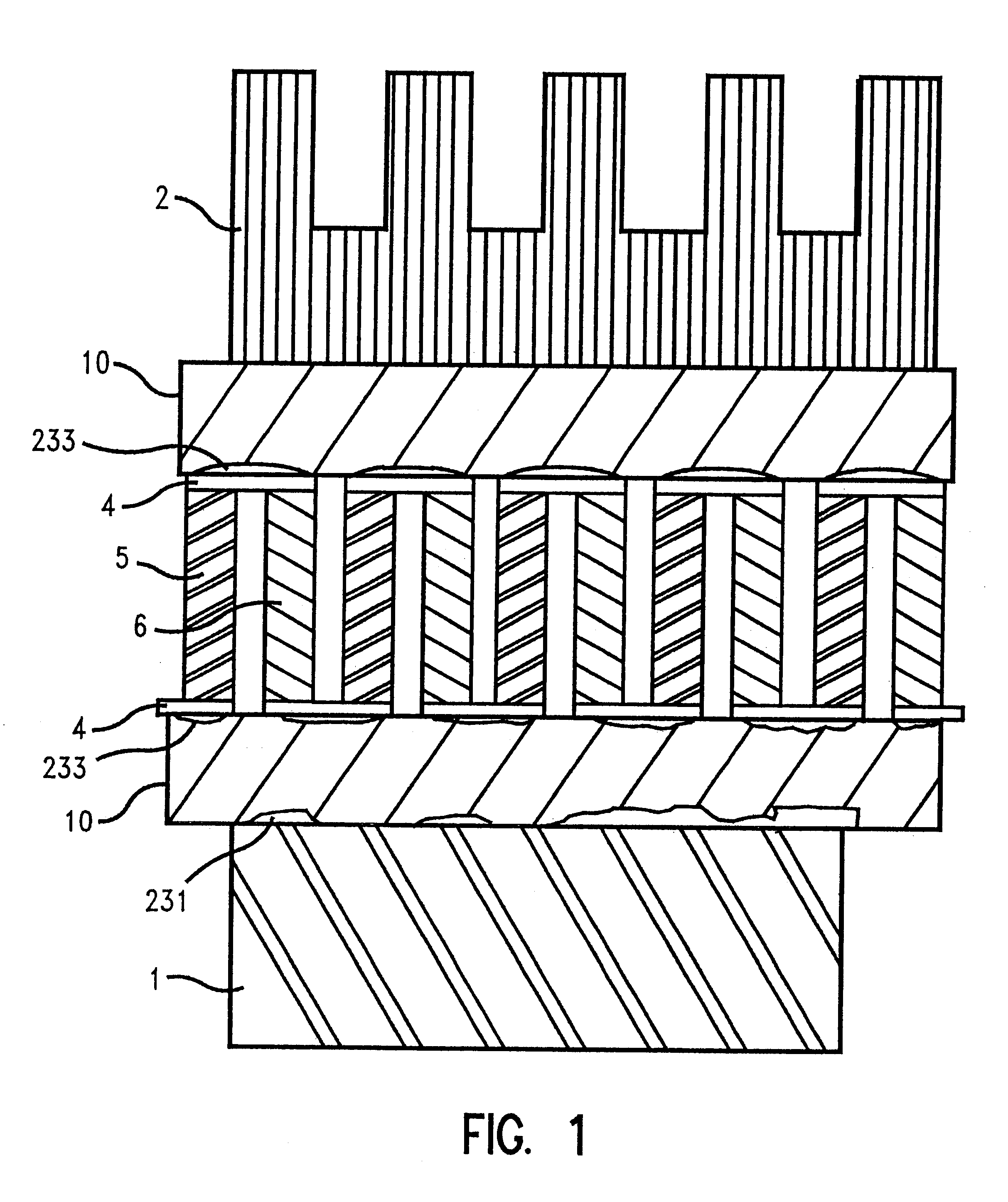

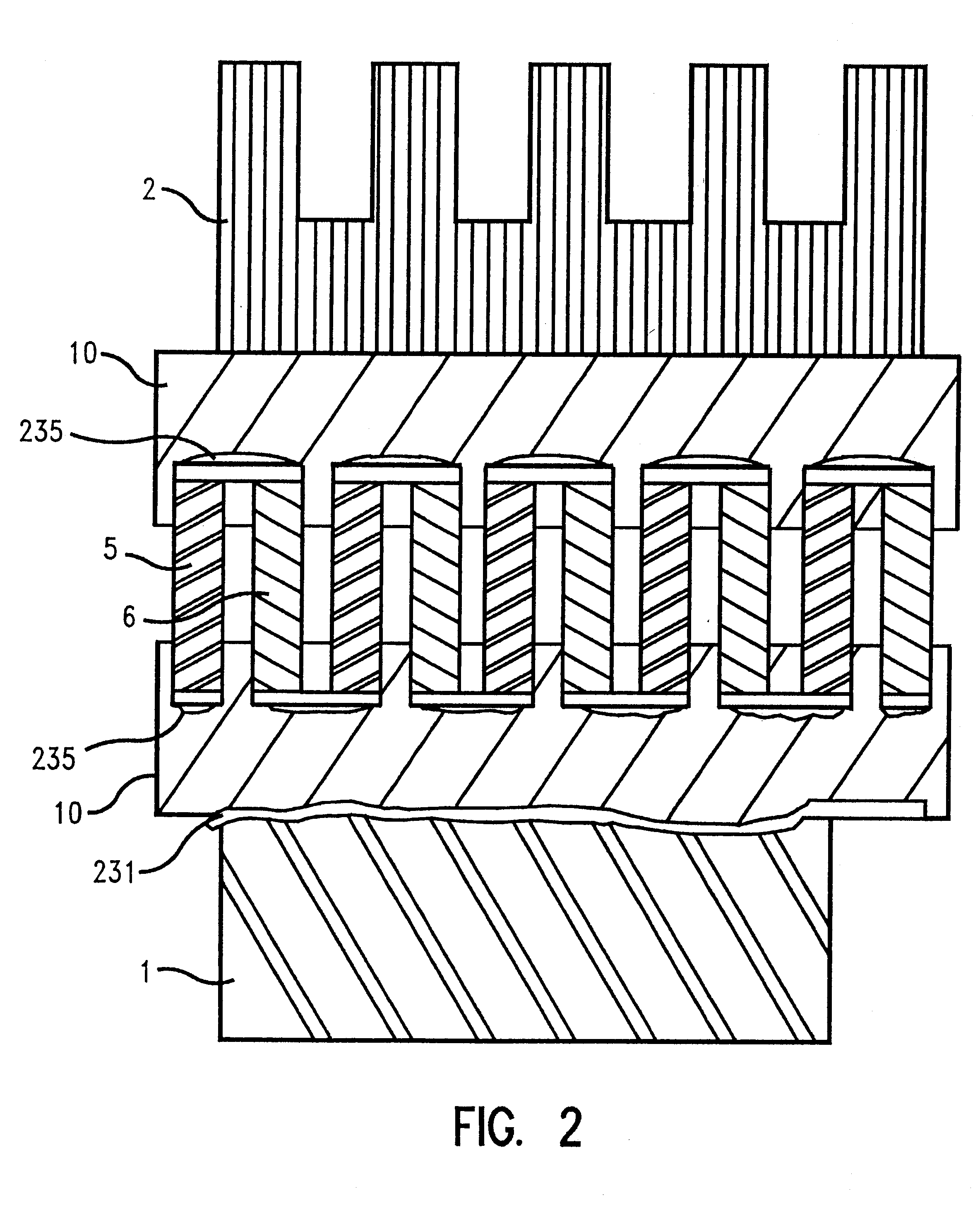

Thermoelectric devices and methods for making the same

InactiveUS6121539AMaximize heat flowMaximize flowThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsScreening techniquesThermal energy

Thermoelectric devices having enhanced thermal characteristics are fabricated using multilayer ceramic (MLC) technology methods. Aluminum nitride faceplates with embedded electrical connections provide the electrical series configuration for alternating dissimilar semiconducting materials. Embedded electrical connections are formed by vias and lines in the faceplate. Methods are employed for forming tunnels through lamination and etching. A portion of the dissimilar materials are then melted within the tunnels to form a bond. Thermal conductivity of the faceplate is enhanced by adding electrically isolated vias to one surface, filled with high thermal conductivity metal paste. A low thermal conductivity material is also introduced between the two high thermal conductivity material faceplates. Alternating semiconducting materials are introduced within the varying thermal conductivity layers by punching vias within greensheets of predetermined thermal conductivity and filling with n-type and p-type paste. Alternating semiconducting materials may also be patterned in linear or radial fanout patterns through screening techniques and lamination of wire structures. A liquid channel within the faceplate is used to enhance thermal energy transfer. Thermoelectric devices are physically incorporated within the IC package using MLC technology.

Owner:IBM CORP

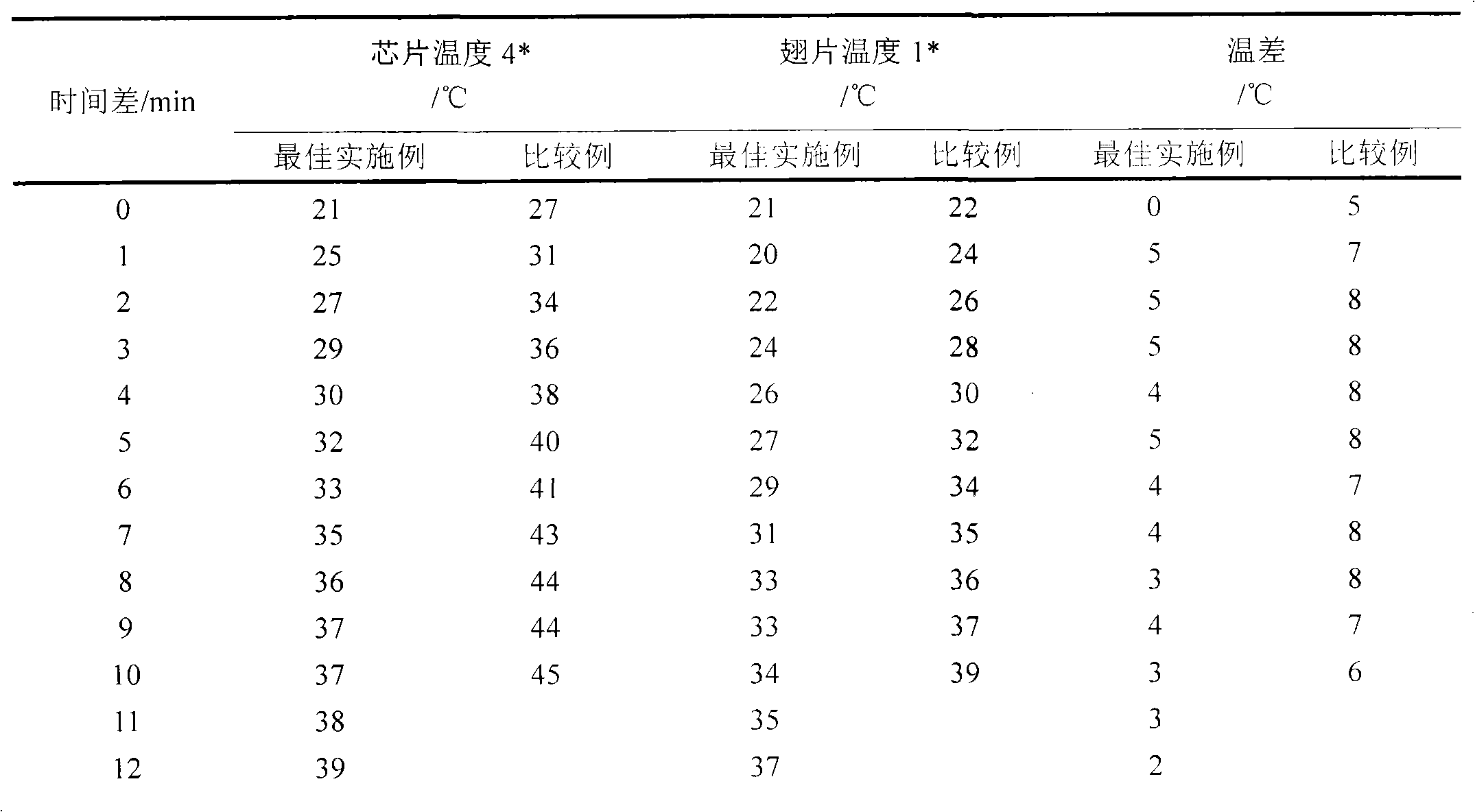

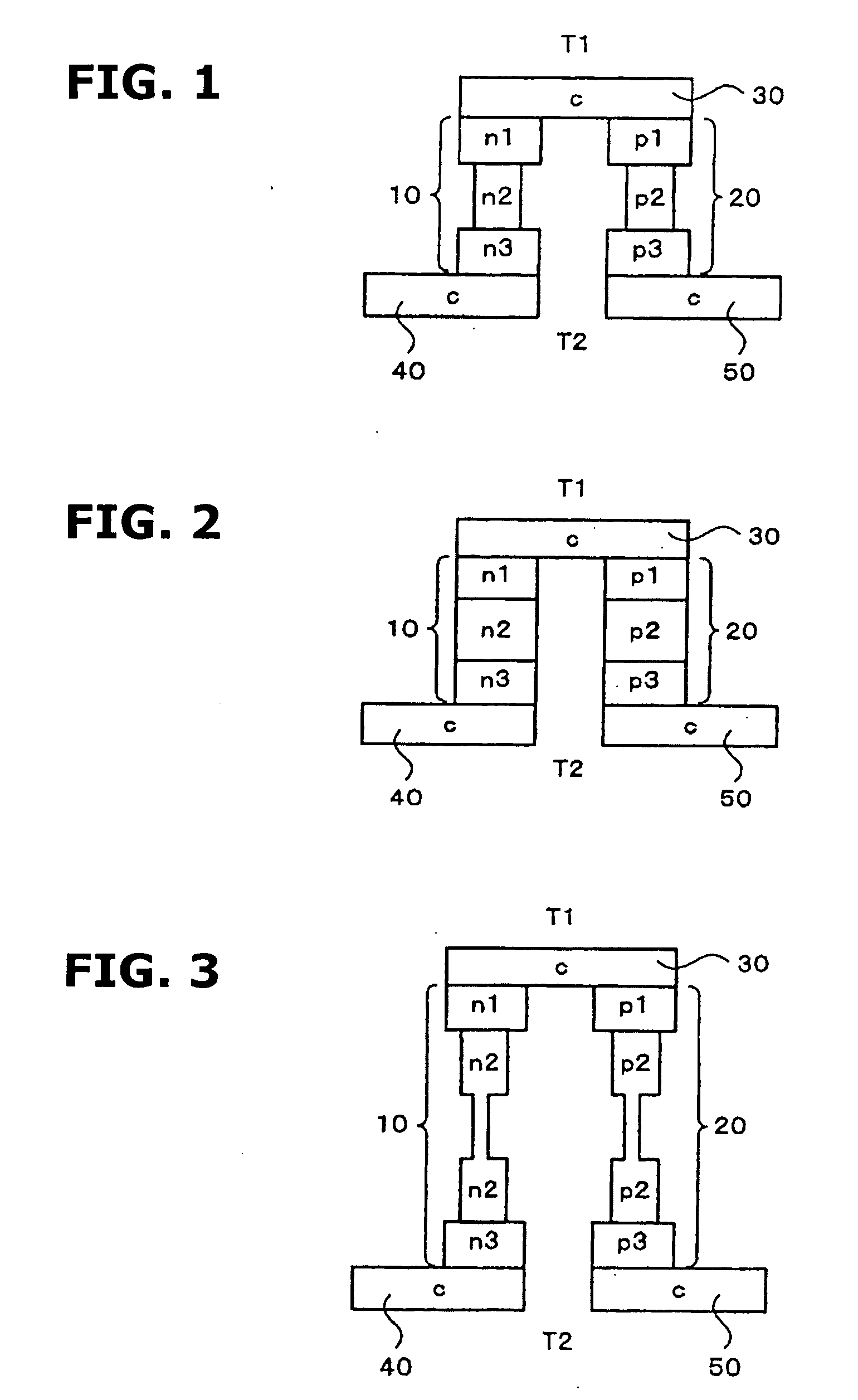

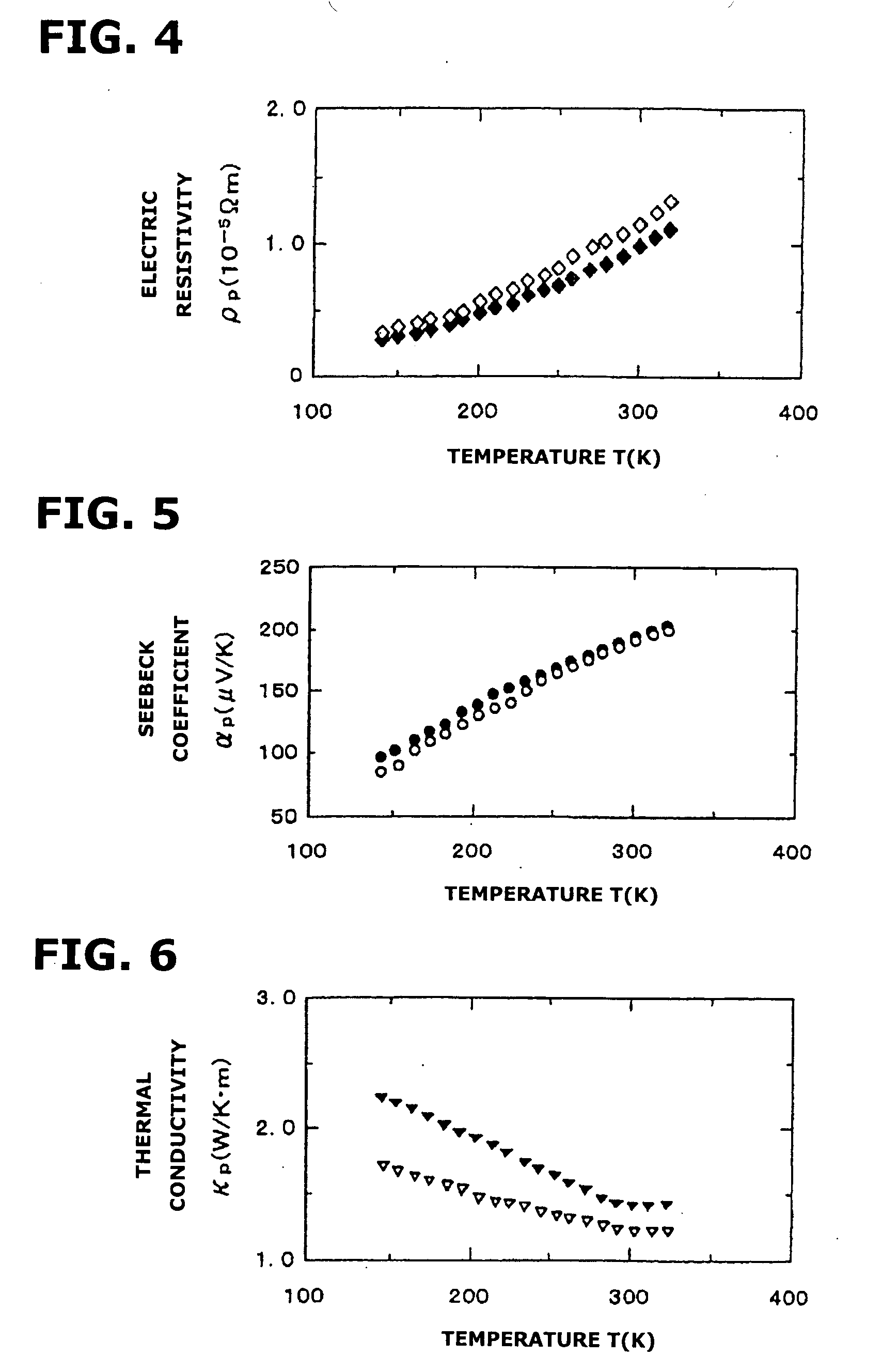

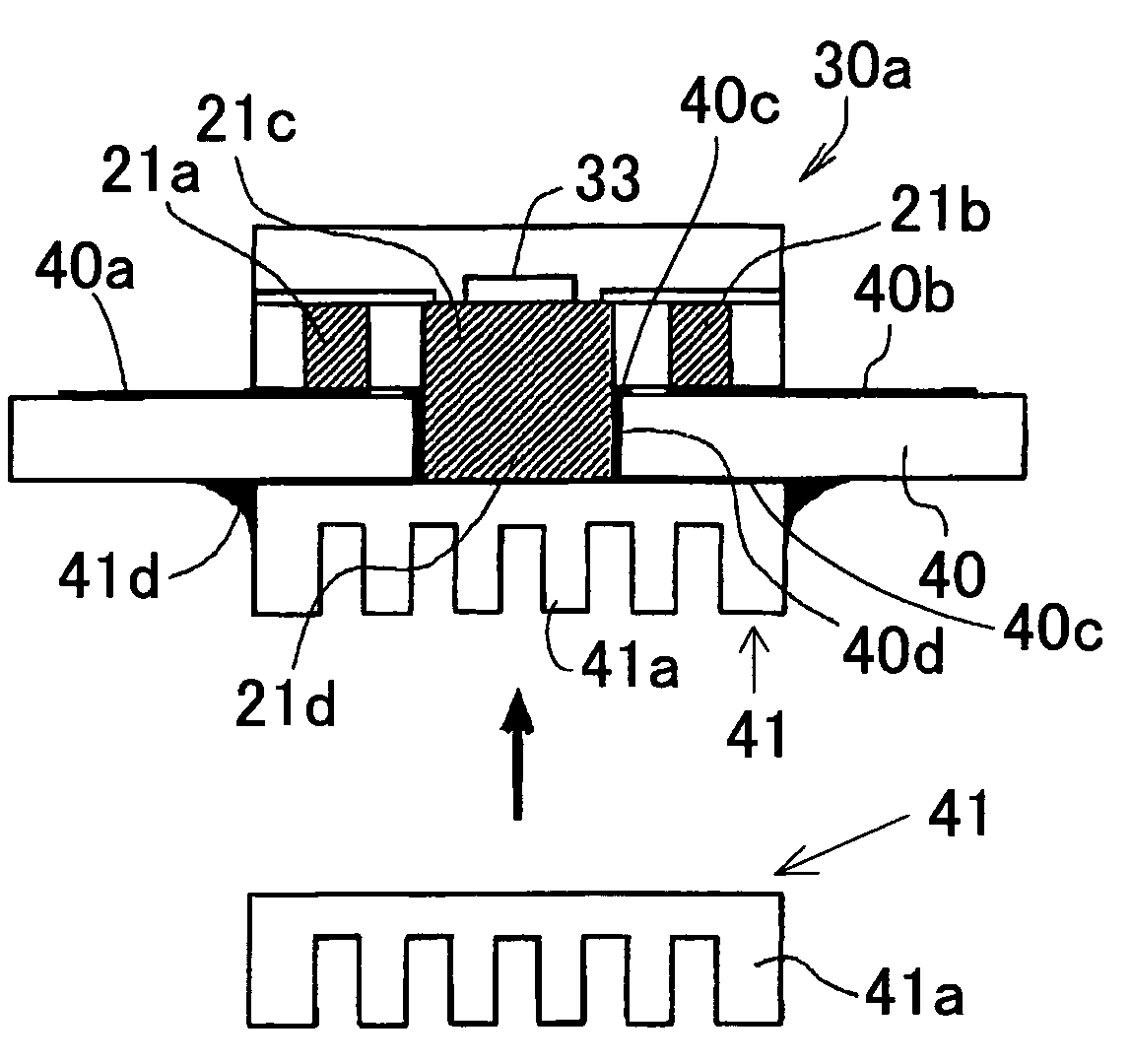

Structure of Peltier Element or Seebeck Element and Its Manufacturing Method

InactiveUS20090007952A1Heat movement weakenedImprove efficiencyThermoelectric device with peltier/seeback effectSemiconductor/solid-state device manufacturingAmorphous siliconTemperature difference

A Peltier or Seebeck element has first and second conductive members having different Seebeck coefficients. To decrease the heat conduction from one to the other end of each of the conductive members, the cross-section area at the intermediate part in the length direction is smaller than those at both ends parts. In place of the decrease of the cross-section, the shape of the cross-section of the intermediate part of each of the conductive members may be changed by dividing the intermediate part into pieces, or amorphous silicon or the like having a heat conductivity lower than those of the materials of both end parts may be used for the material of the intermediate part. In such a way, a high-performance Peltier / Seebeck element such that the difference between the temperature of the heated portion of the Peltier / Seebeck element and the opposite portion can be kept to a predetermined temperature difference for a long time and its manufacturing method are provided.

Owner:MEIDENSHA ELECTRIC MFG CO LTD +2

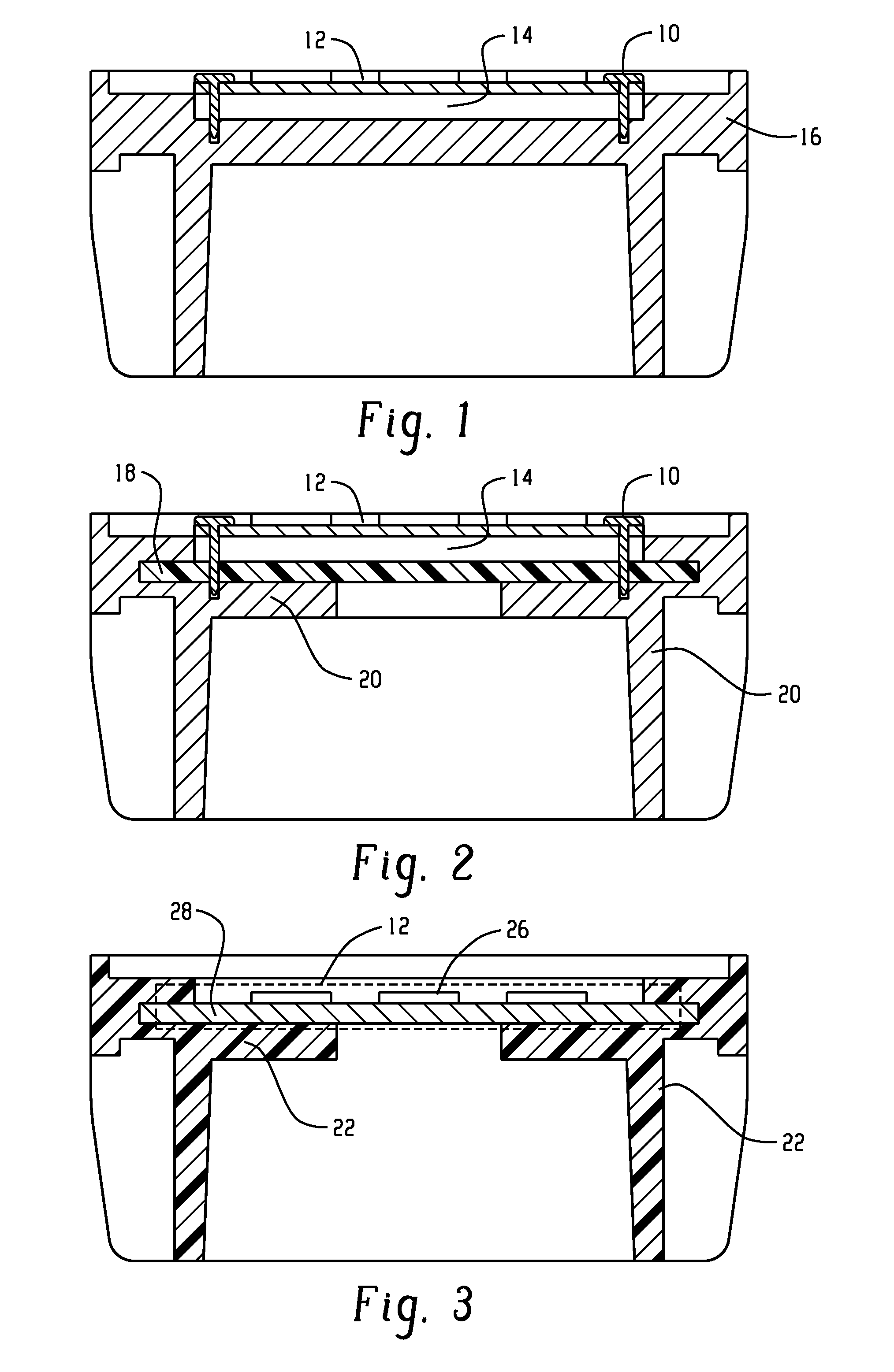

Light emitting device provided with electrically conductive members having high thermal conductivity for thermal radiation

InactiveUS7218041B2Improve cooling effectImprove conductivityPoint-like light sourceSolid-state devicesThermal radiationLight emitting device

A light emitting device has a plurality of conductive members with good heat conductivity provided in a base member, the conductive members are isolated by insulating members provided between the conductive members. A light emitting element device is mounted on the base member. An light emitting diode is provided in the light emitting device and mounted on conductive member. A projection is outwardly projected from the heat conductive member for cooling the LED.

Owner:CITIZEN ELECTRONICS CO LTD

Fluororesin radiating paint and preparation method thereof

ActiveCN103131274AReduce thermal contact resistanceHigh thermal conductivityCoatingsCarbon nanotubeElectron transfer

The invention discloses fluororesin radiating paint and a preparation method thereof. The paint mainly comprises an electron transfer type organic compound, graphene, a carbon nanotube, titanium white, other additives and fluororesin, wherein the fluororesin is a paint brand having the highest comprehensive property at present; the electron transfer type organic compound can greatly enhance the thermal radiation rate of the paint; the graphene and the carbon nanotube can further accelerate thermal conduction; and the electron transfer type organic compound, the carbon nanotube and the graphene finally form a full three-dimensional network distribution of granules (electron transfer type organic compound), wires (carbon nanotube) and planes (graphene) in a fluid. The fluororesin radiating paint disclosed by the invention has high thermal radiation rate, high thermal conductivity and low thermal resistance, can realize radiation cooling, and simultaneously has the effects of self cleaning, acid / alkali resistance and super high insulativity, thereby having high practical value.

Owner:明朔(北京)电子科技有限公司

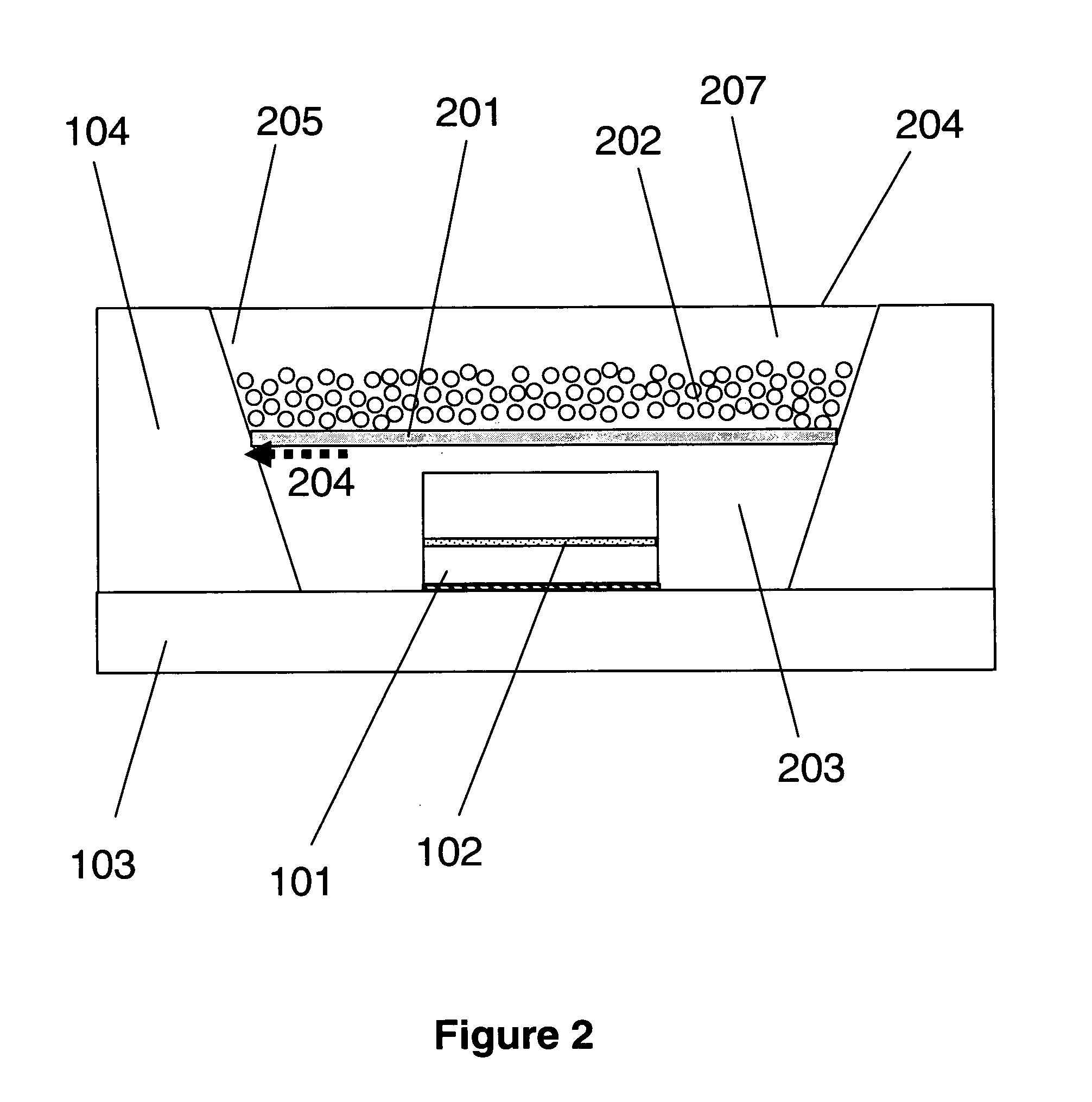

Light emitting module with optically-transparent thermally-conductive element

ActiveUS20110001157A1Extended service lifeThe process is compact and efficientSolid-state devicesSemiconductor/solid-state device manufacturingLength waveInorganic materials

A light emitting module with improved optical functionality and reduced thermal resistance is described, which comprises a light emitting device (LED), a wavelength converting (WC) element and an inorganic optically-transmissive thermally-conductive (OTTC) element. The WC element is capable of absorbing light generated from the LED at a specific wavelength and re-emitting light having a different wavelength. The re-emitted light and any unabsorbed light exits through at least one surface of the module. The OTTC is in physical contact with the WC element and at least partially located in the optical path of the light. The OTTC comprises one or more layers of inorganic material having a thermal conductivity greater than that of the WC element. As such, a compact unitary integrated module is provided with excellent thermal characteristics, which may be further enhanced when the OTTC provides a thermal barrier for vertical heat propagation through the module but not lateral propagation.

Owner:LUMILEDS HLDG BV

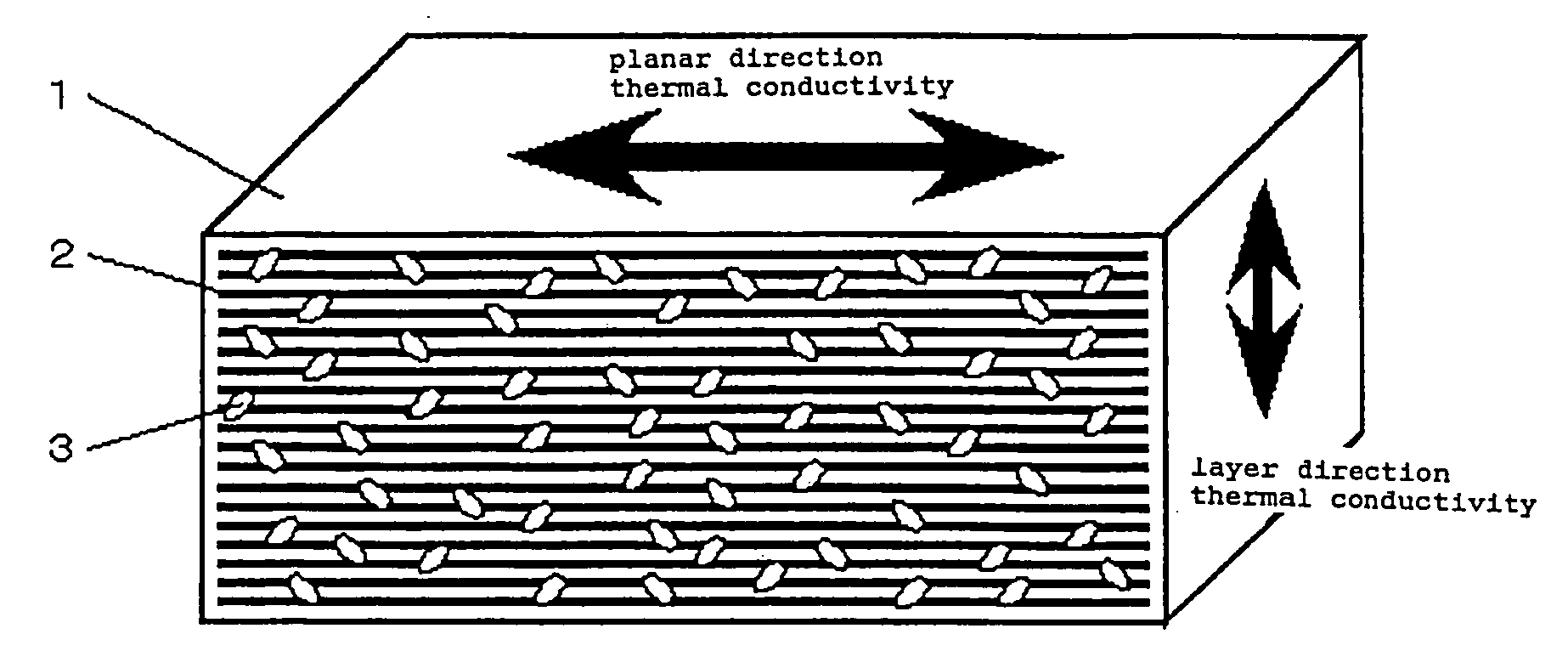

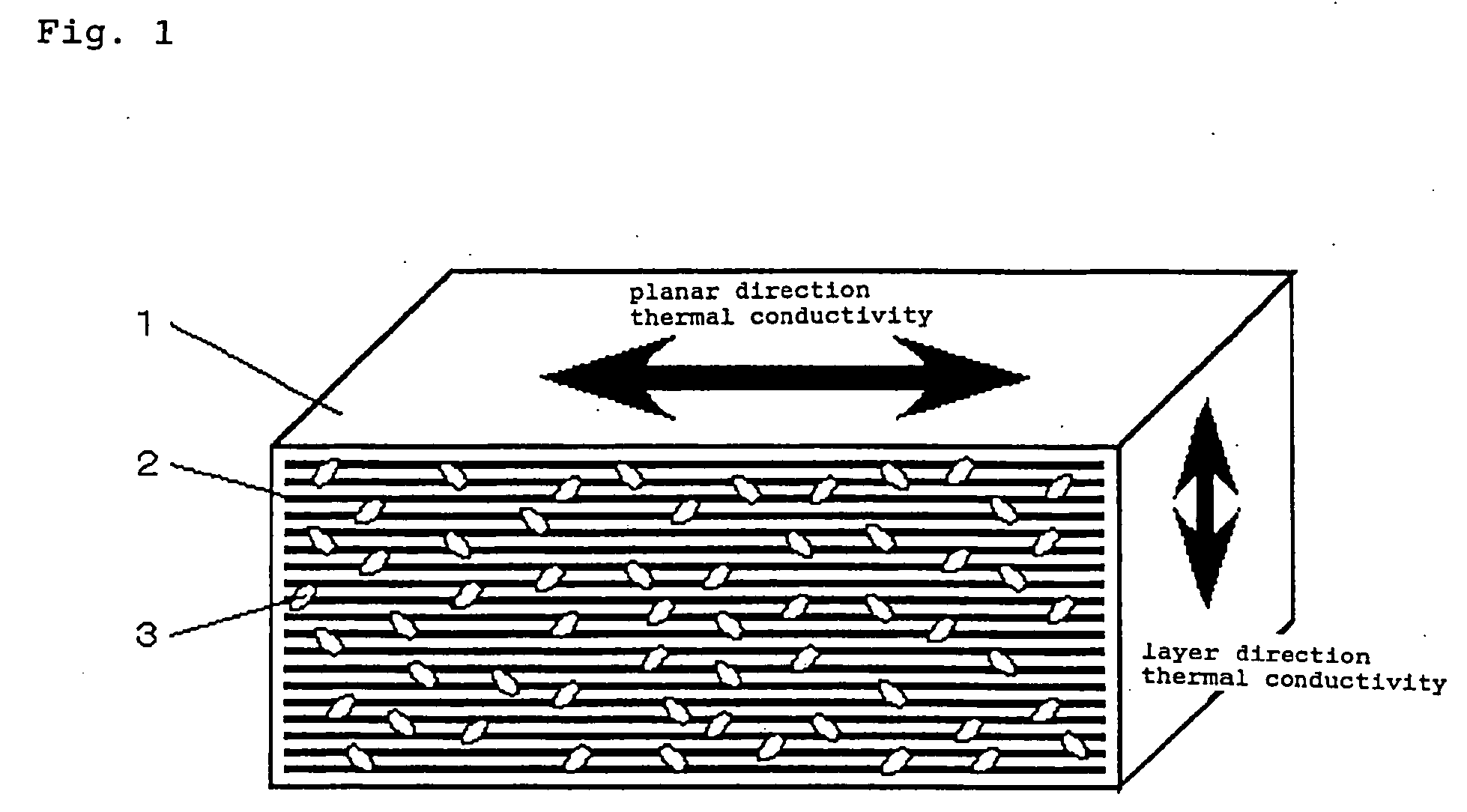

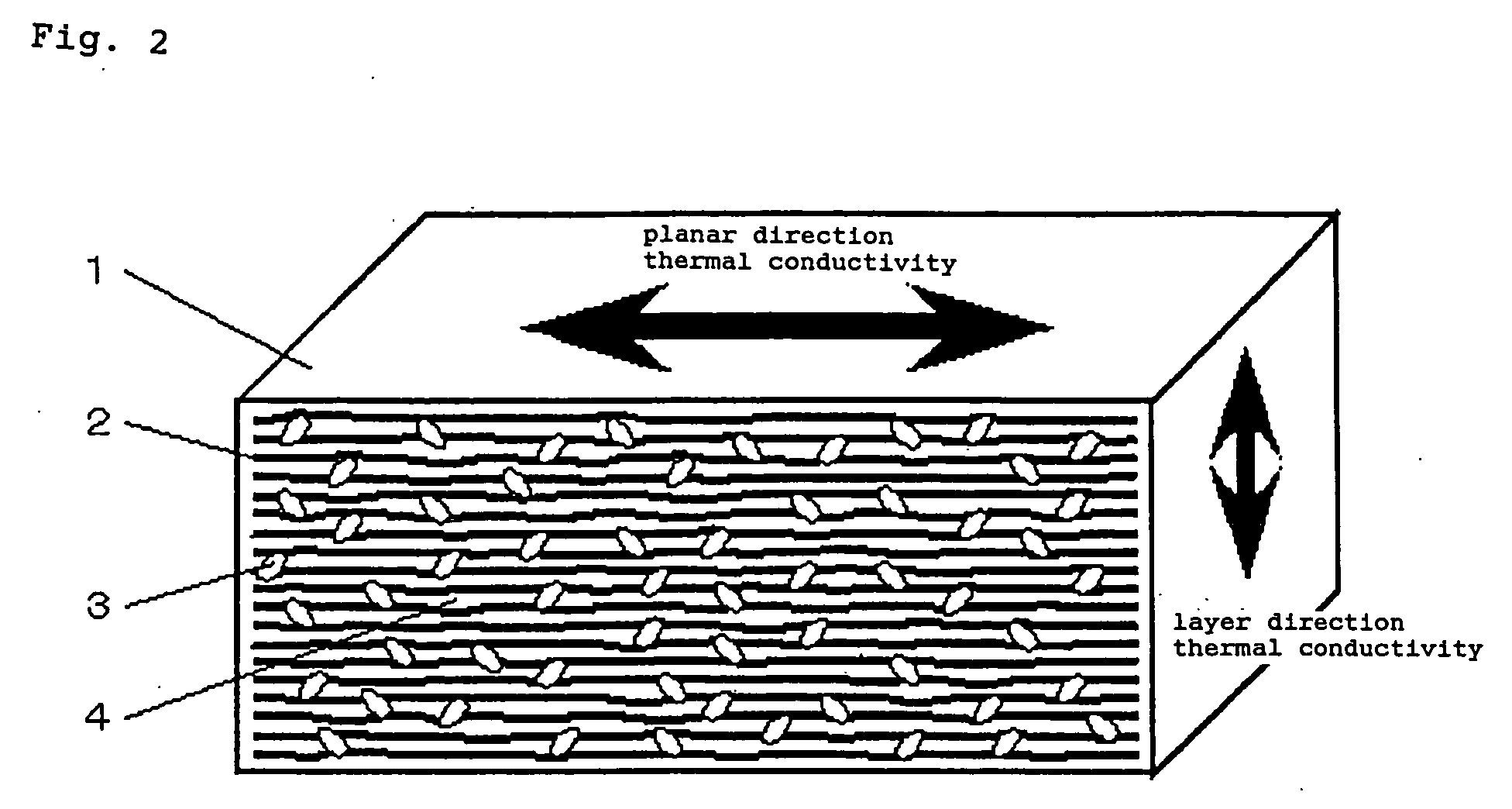

High thermal conductivite element, method for manufacturing same, and heat radiating system

ActiveUS20060035085A1Improve thermal conductivityLess spaceMaterial nanotechnologyLayered productsOptoelectronicsGraphite

It is an object of the present invention to provide a high thermal conductive element that has improved thermal conductivity in the layer direction while retaining the high thermal conductivity characteristics in the planar direction possessed by graphite. The present invention is a high thermal conductive element in which carbon particles are dispersed in a graphite-based matrix, wherein (1) the c axis of the graphene layers constituting the graphite are substantially parallel, (2) the thermal conductivity κ∥ in a direction perpendicular to the c axis is at least 400 W / m·k and no more than 1000 W / m·k, and (3) the thermal conductivity κ⊥ in a direction parallel to the c axis is at least 10 W / m·k and no more than 100 W / m·k.

Owner:PANASONIC CORP

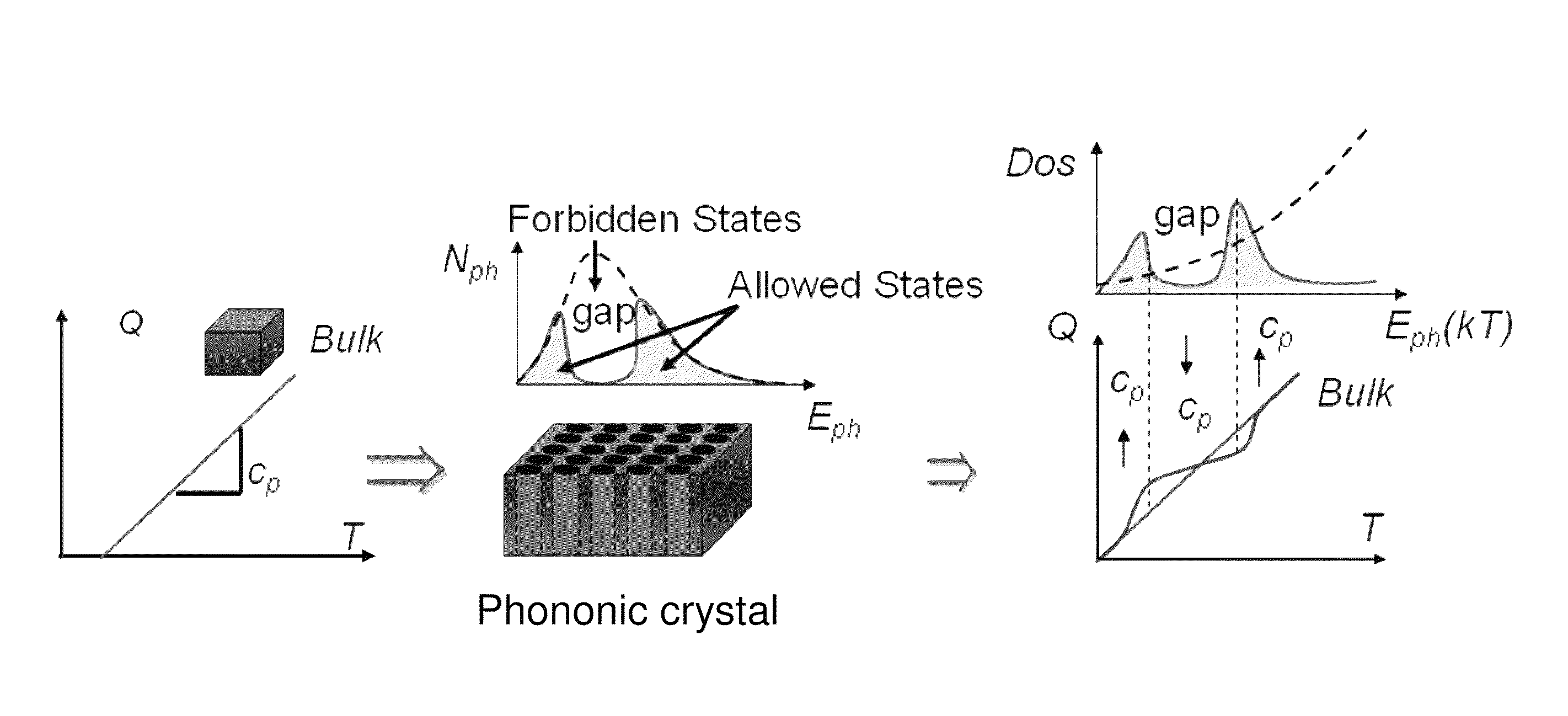

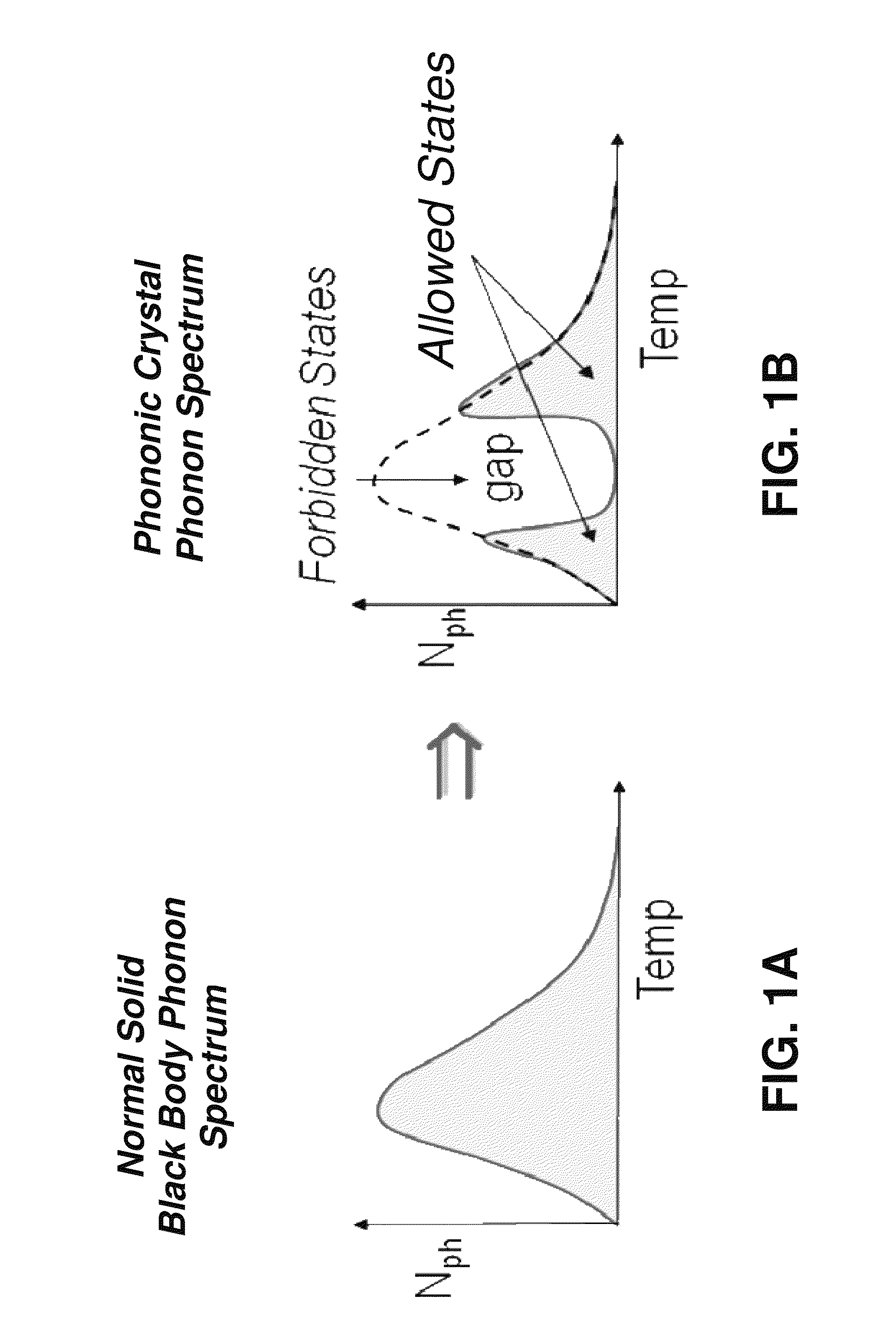

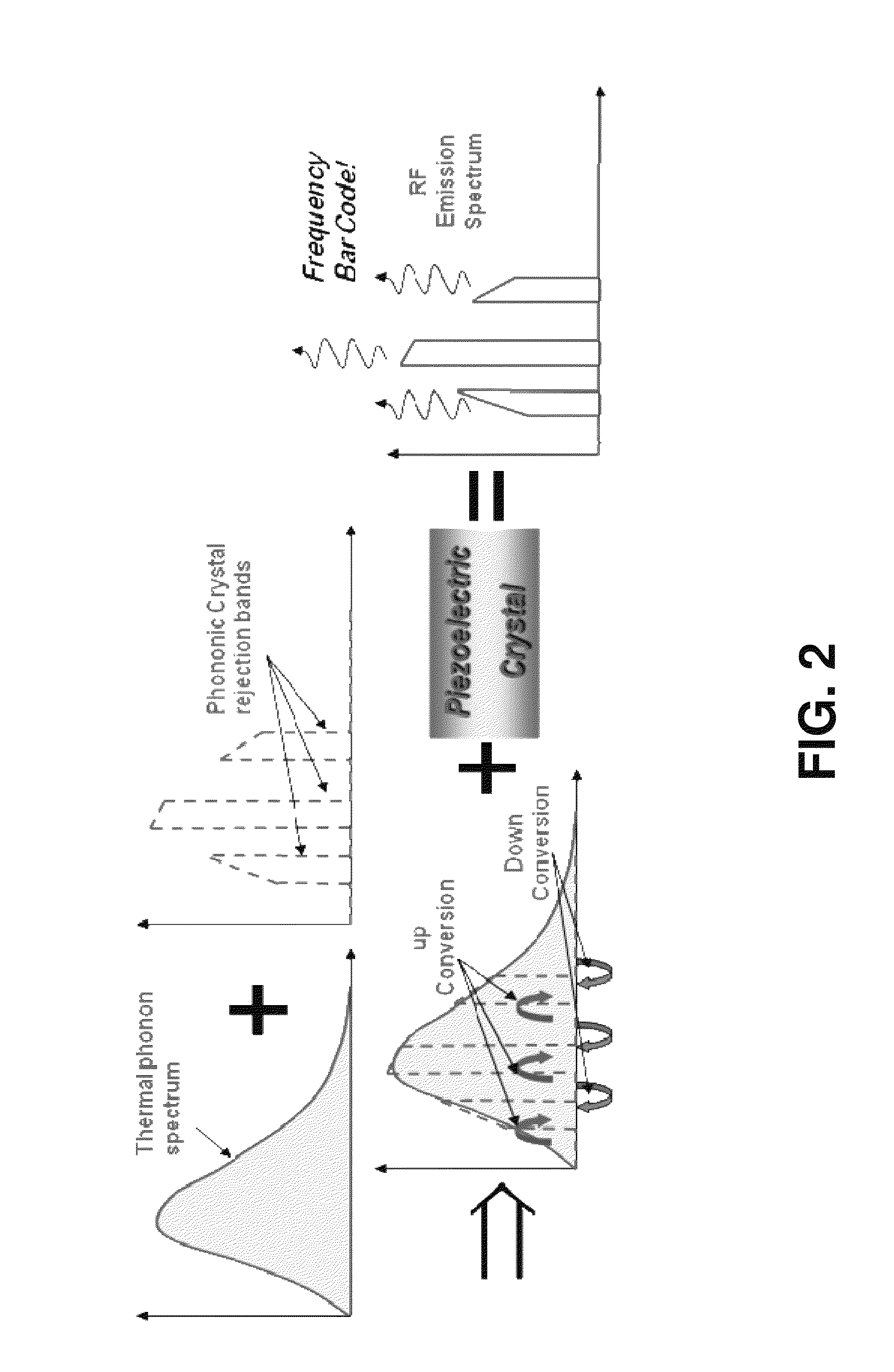

Phononic crystal devices

ActiveUS8094023B1Low thermal conductivityRaise the ratioFire alarmsElectric signalling detailsThermoelectric materialsDielectric

Phononic crystals that have the ability to modify and control the thermal black body phonon distribution and the phonon component of heat transport in a solid. In particular, the thermal conductivity and heat capacity can be modified by altering the phonon density of states in a phononic crystal. The present invention is directed to phononic crystal devices and materials such as radio frequency (RF) tags powered from ambient heat, dielectrics with extremely low thermal conductivity, thermoelectric materials with a higher ratio of electrical-to-thermal conductivity, materials with phononically engineered heat capacity, phononic crystal waveguides that enable accelerated cooling, and a variety of low temperature application devices.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Diamond composite heat spreader having thermal conductivity gradients and associated methods

InactiveUS6987318B2Easy to controlVariable thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesParticulatesThermal transmittance

A diamond composite heat spreader having a variable thermal conductivity gradient can improve control of heat transfer based on a specific application. A diamond-containing region of the heat spreader can contain diamond particles such that the diamond concentration and / or the diamond particle size a varied to produce a desired thermal conductivity gradient. Regions proximate to a heat source can have a higher thermal conductivity than regions further away from the heat source. Thin diamond films can also be used in conjunction with the particulate diamond in order to provide a region of maximum thermal conductivity adjacent a heat source. By providing a variable thermal conductivity gradient, more expensive materials such as diamond film and larger diamond particles can be selectively used in regions closer to a heat source, while allowing for cheaper smaller diamond particles and materials to be used farther away from the heat source where thermal conductivity can be lower without sacrificing overall performance.

Owner:RITEDIA CORPORATION

Thermoelectric devices and methods for making the same

InactiveUS6262357B1Maximize heat flowMaximize flowThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsThermal energyScreening techniques

Thermoelectric devices having enhanced thermal characteristics are fabricated using multilayer ceramic (MLC) technology methods. Aluminum nitride faceplates with embedded electrical connections provide the electrical series configuration for alternating dissimilar semiconducting materials. Embedded electrical connections are formed by vias and lines in the faceplate. Methods for forming tunnels through lamination and etching are employed. A portion of the dissimilar materials are then melted within the tunnels to form a bond. Thermal conductivity of the faceplate is enhanced by adding electrically isolated vias to one surface, filled with high thermal conductivity metal paste. A low thermal conductivity material is also introduced between the two high thermal conductivity material faceplates.Alternating semiconducting materials are introduced within the varying thermal conductivity layers by punching vias within greensheets of predetermined thermal conductivity and filling with n-type and p-type paste. Alternating semiconducting materials may also be patterned in linear or radial fanout patterns through screening techniques and lamination of wire structures. A liquid channel within the faceplate is used to enhance thermal energy transfer.Thermoelectric devices are physically incorporated within the IC package using MLC technology.

Owner:INT BUSINESS MASCH CORP

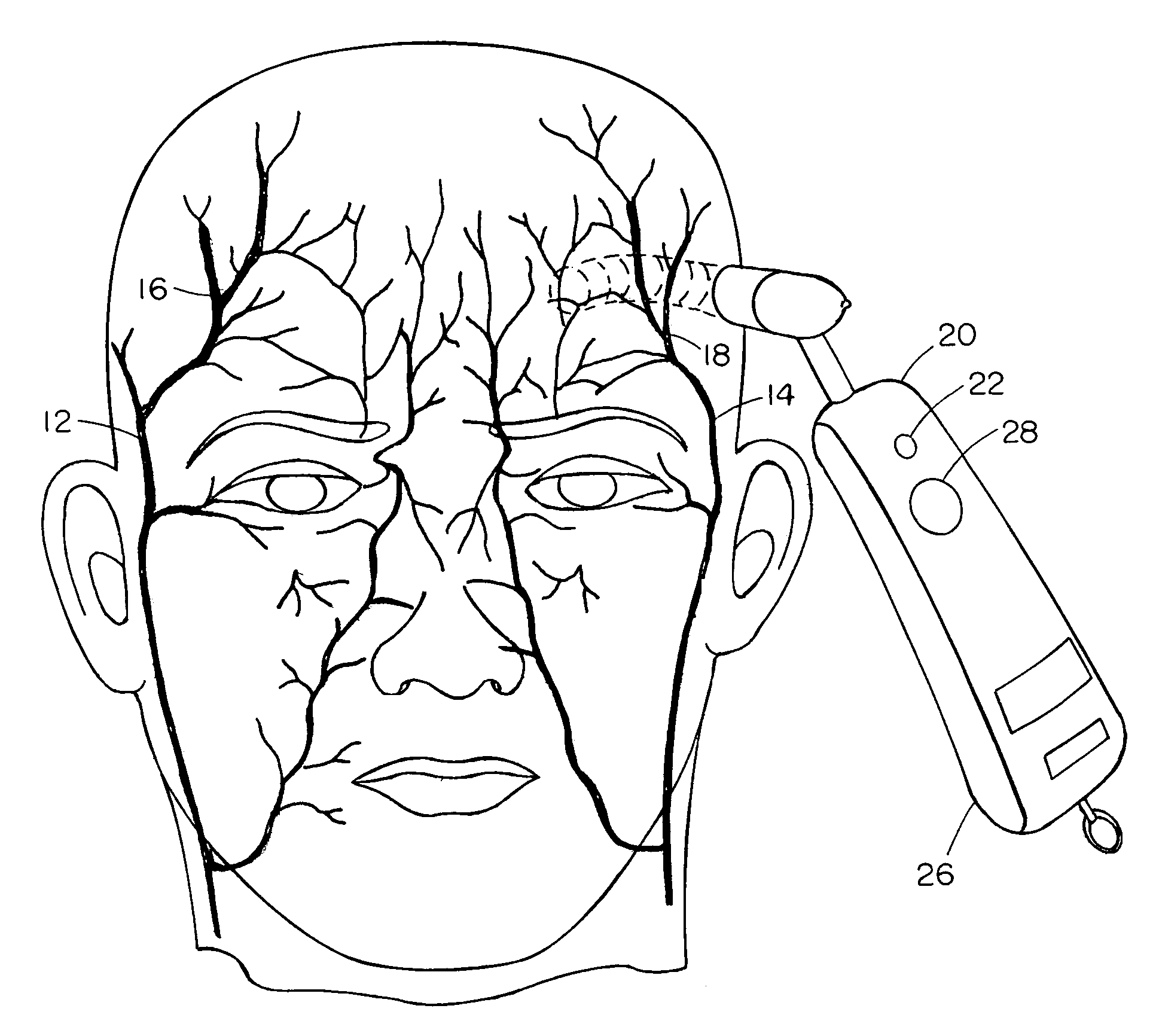

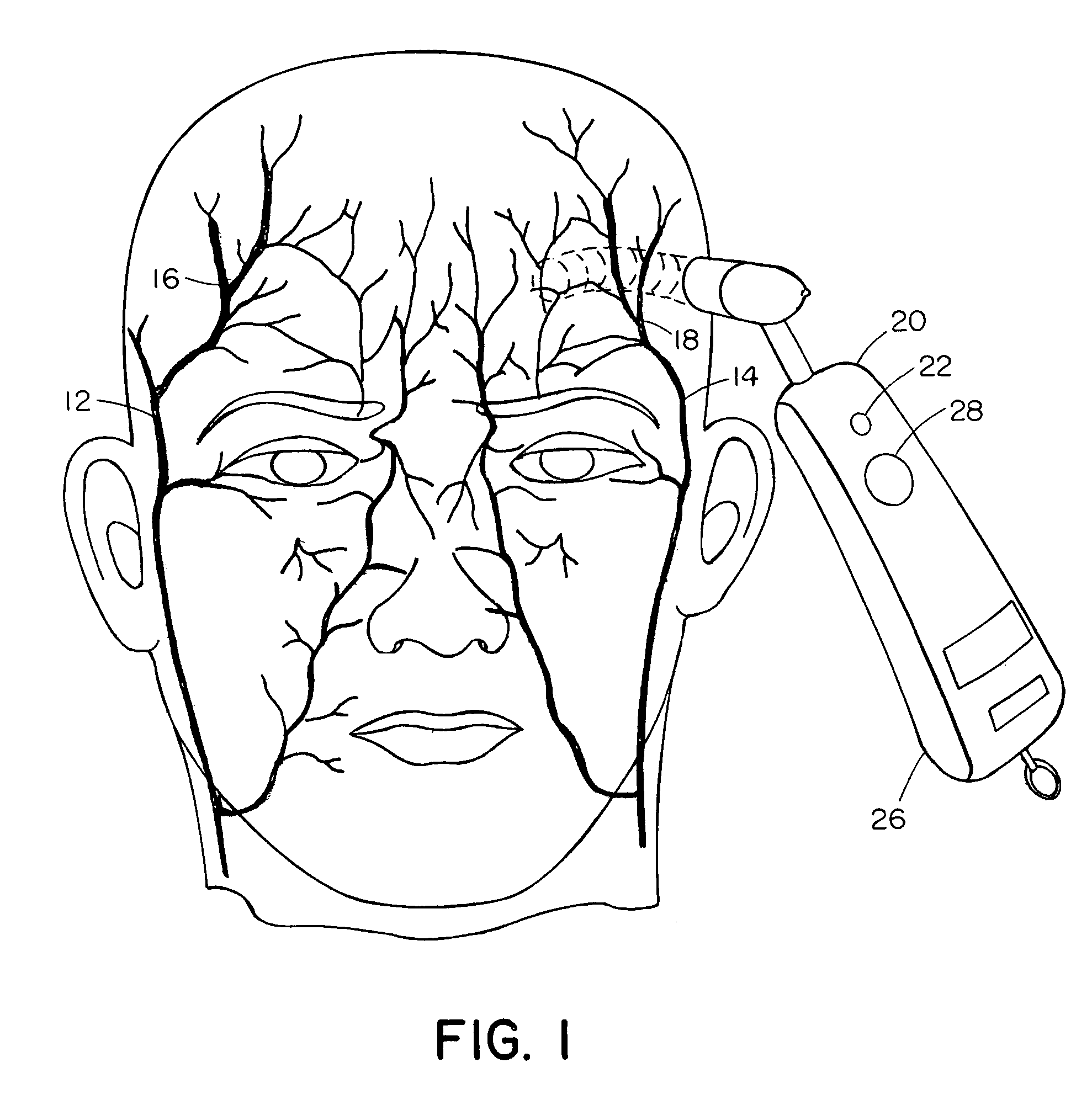

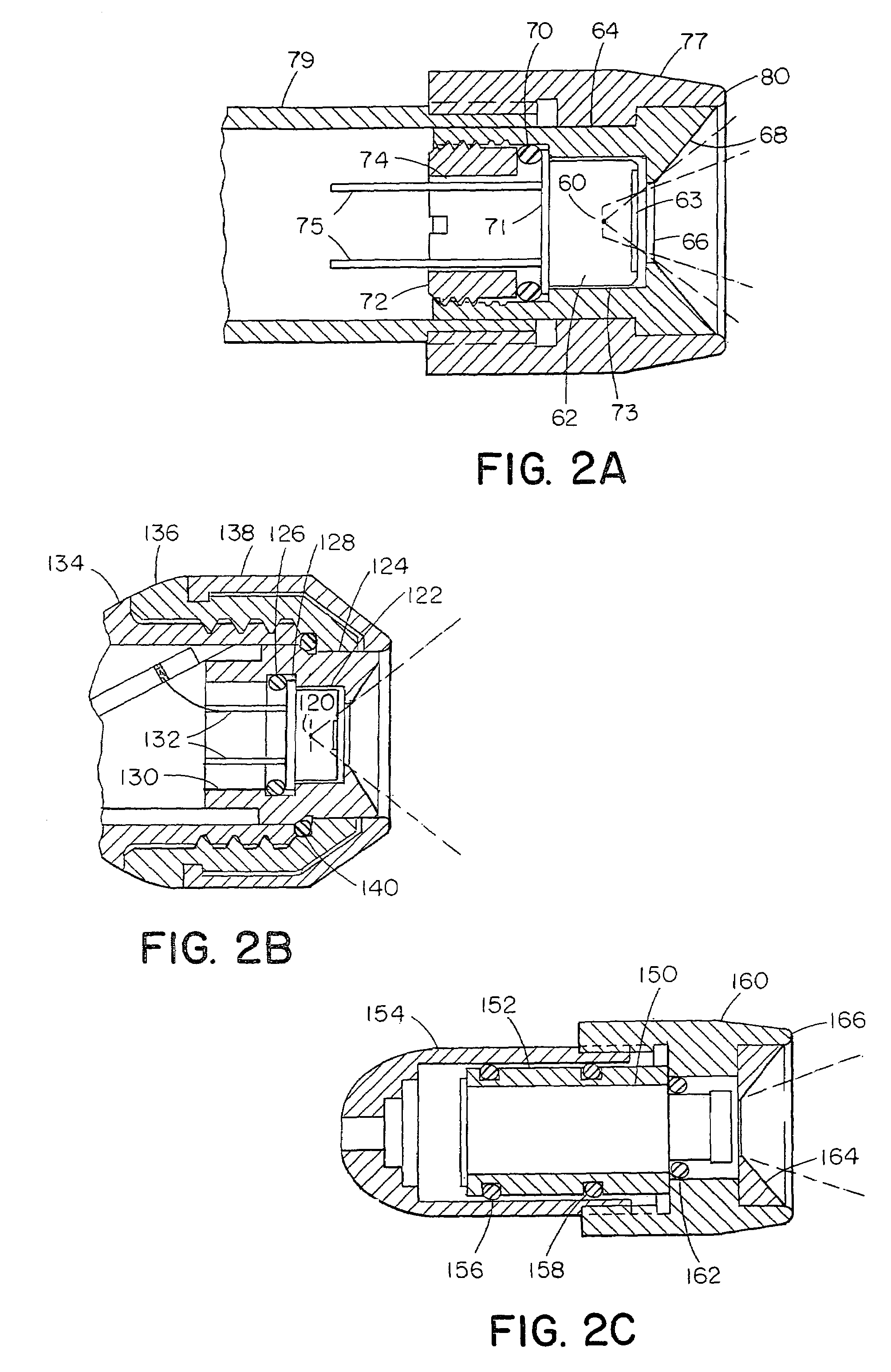

Temporal artery temperature detector

InactiveUS7346386B2Convenient temperature readingDoubles assuranceThermometer detailsSensing radiation from moving bodiesBody temperature measurementRadiation sensor

Body temperature measurements are obtained by scanning a thermal radiation sensor across the side of the forehead over the temporal artery. A peak temperature measurement is processed to compute an internal temperature of the body as a function of ambient temperature and the sensed surface temperature. The function includes a weighted difference of surface temperature and ambient temperature, the weighting being varied with target temperature through a minimum in the range of 96° F. and 100° F. The radiation sensor views the target surface through an emissivity compensating cup which is spaced from the skin by a circular lip of low thermal conductivity.

Owner:EXERGEN CORPORATION

Electronic device for radiofrequency or power applications and process for manufacturing such a device

ActiveUS20130294038A1Semiconductor/solid-state device manufacturingElectrical apparatus contructional detailsPower applicationElectronic component

The invention relates to an electronic device for radio frequency or power applications, comprising a semiconductor layer supporting electronic components on a support substrate, wherein the support substrate comprises a base layer having a thermal conductivity of at least 30 W / m K and a superficial layer having a thickness of at least 5 μm, the superficial layer having an electrical resistivity of at least 3000 Ohm·cm and a thermal conductivity of at least 30 W / m K. The invention also relates to two processes for manufacturing such a device.

Owner:SOITEC SA

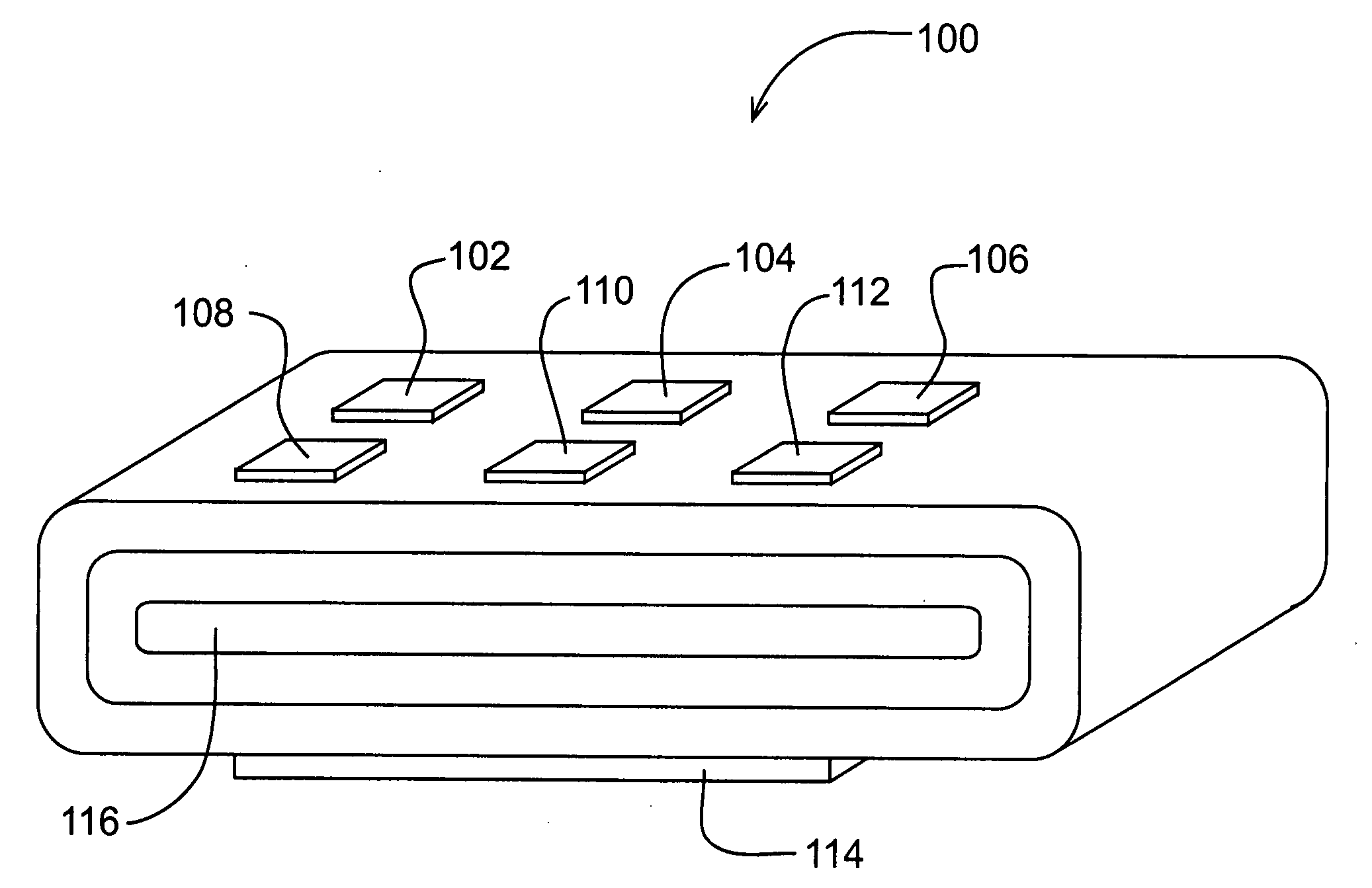

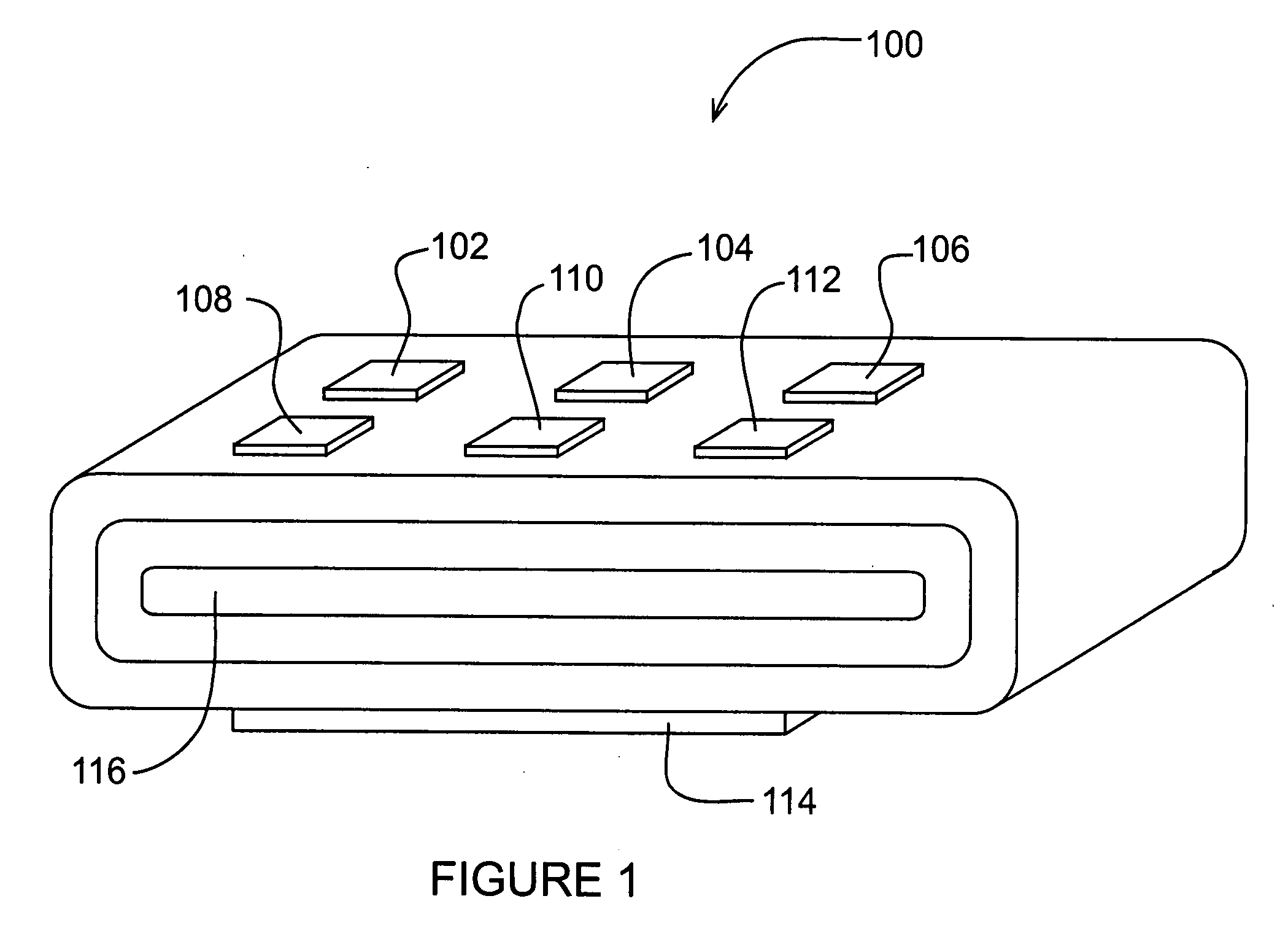

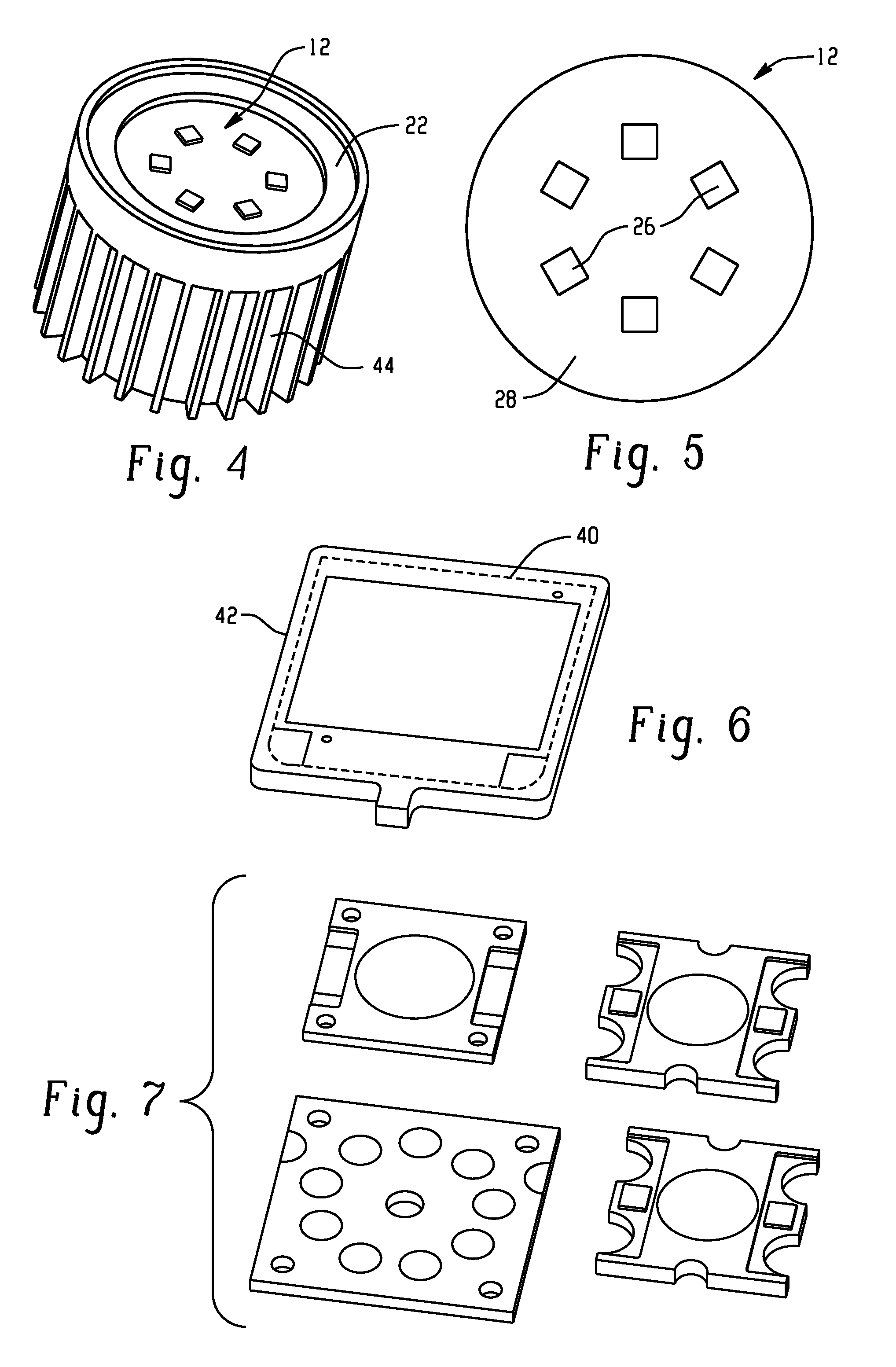

LED plastic heat sink and method for making and using the same

In an embodiment, heat sink system can comprise: an integrally formed plastic heat sink and a printed circuit board package, wherein the plastic heat sink comprises a thermally conductive plastic having a thermal conductivity of at least 1.0 W / mK. In another embodiment, hybrid heat sink system, comprising: an integrally formed plastic heat sink and an insert, wherein the plastic heat sink comprises a thermally conductive plastic, the plastic heat sink and the insert each having a cylindrical shape, and wherein the insert comprises a feature of lancing provisions, corrugations, embossing, holes, or a combination comprising at least one of the foregoing features.

Owner:SHPP GLOBAL TECH BV

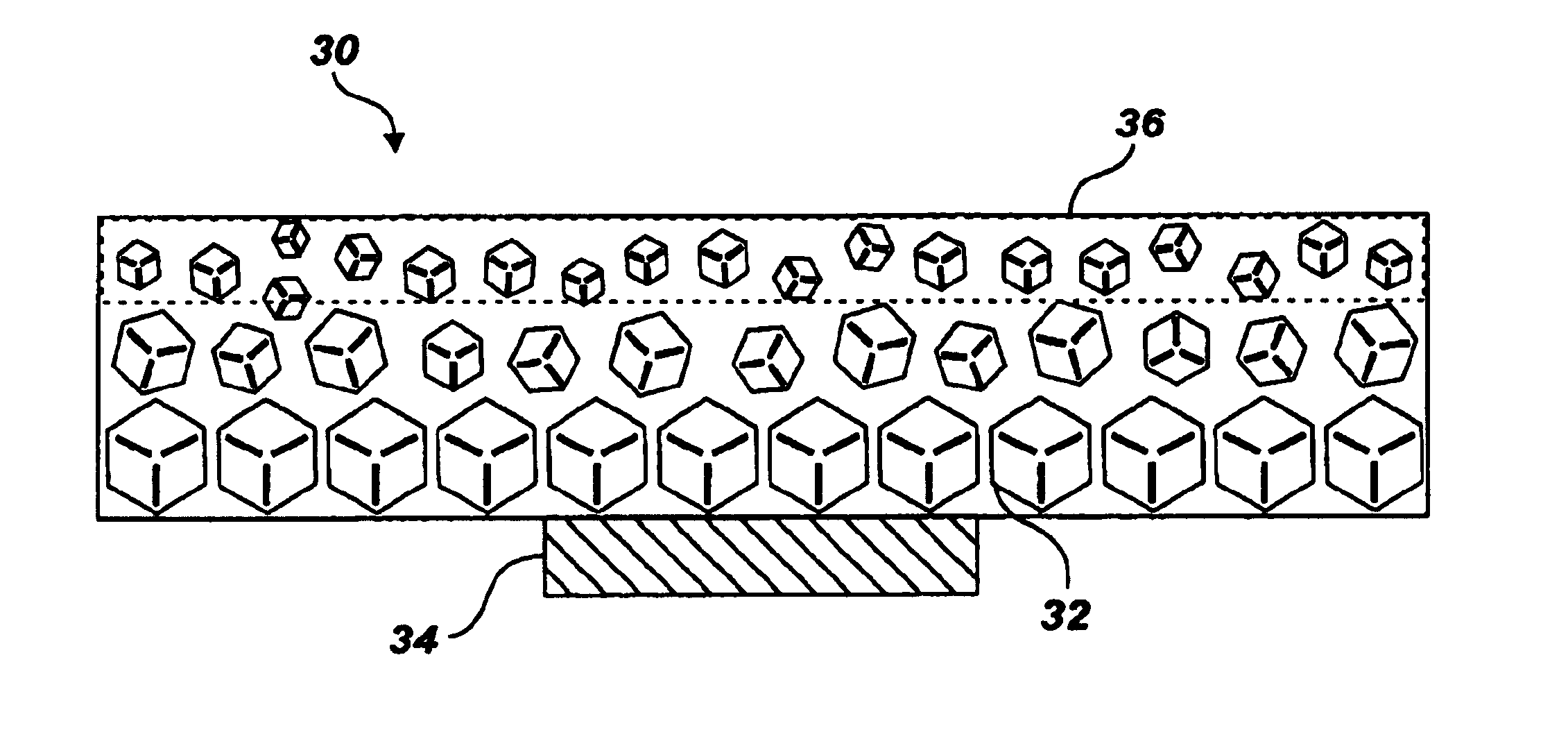

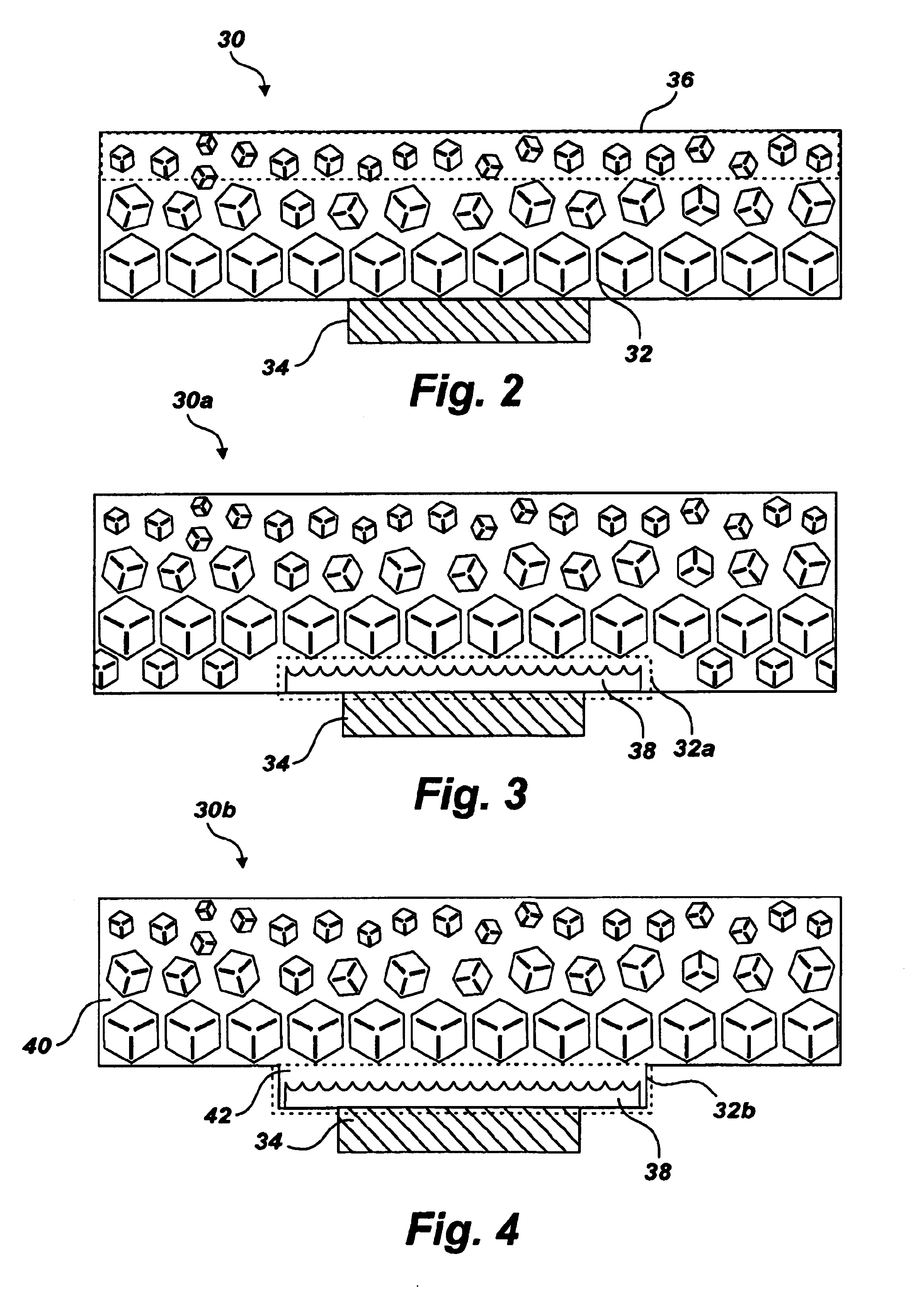

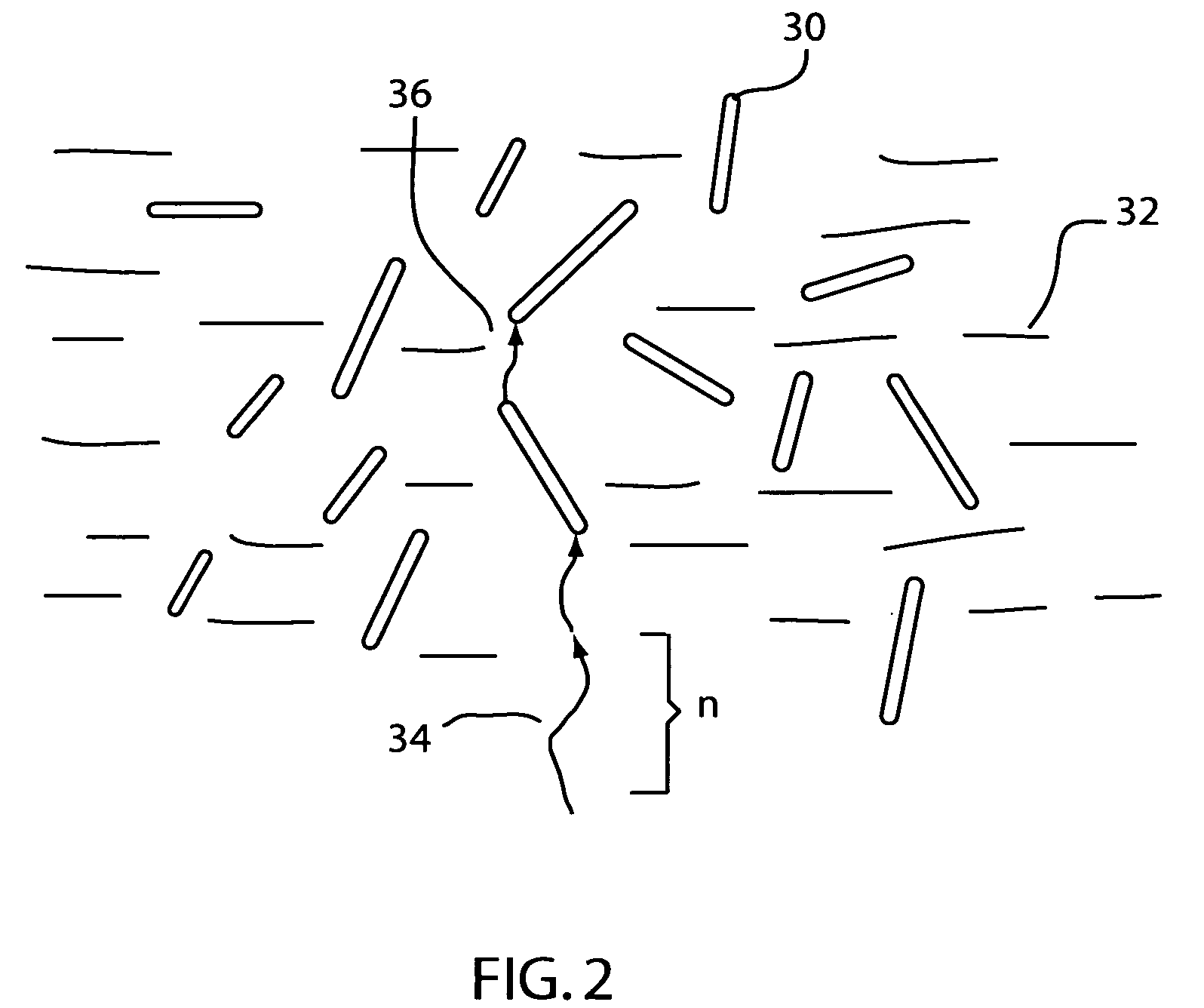

High thermal conductivity materials incorporated into resins

InactiveUS20050277349A1Easy to transportReduce distanceSpecial paperSynthetic resin layered productsResin matrixElectrical resistivity and conductivity

In one embodiment the present invention provides for a high thermal conductivity resin that comprises a host resin matrix 32 and a high thermal conductivity filler 30. The high thermal conductivity filler forms a continuous organic-inorganic composite with the host resin matrix, and the high thermal conductivity fillers are from 1-1000 nm in length and have an aspect ratio of between 3-100.

Owner:SIEMENS ENERGY INC

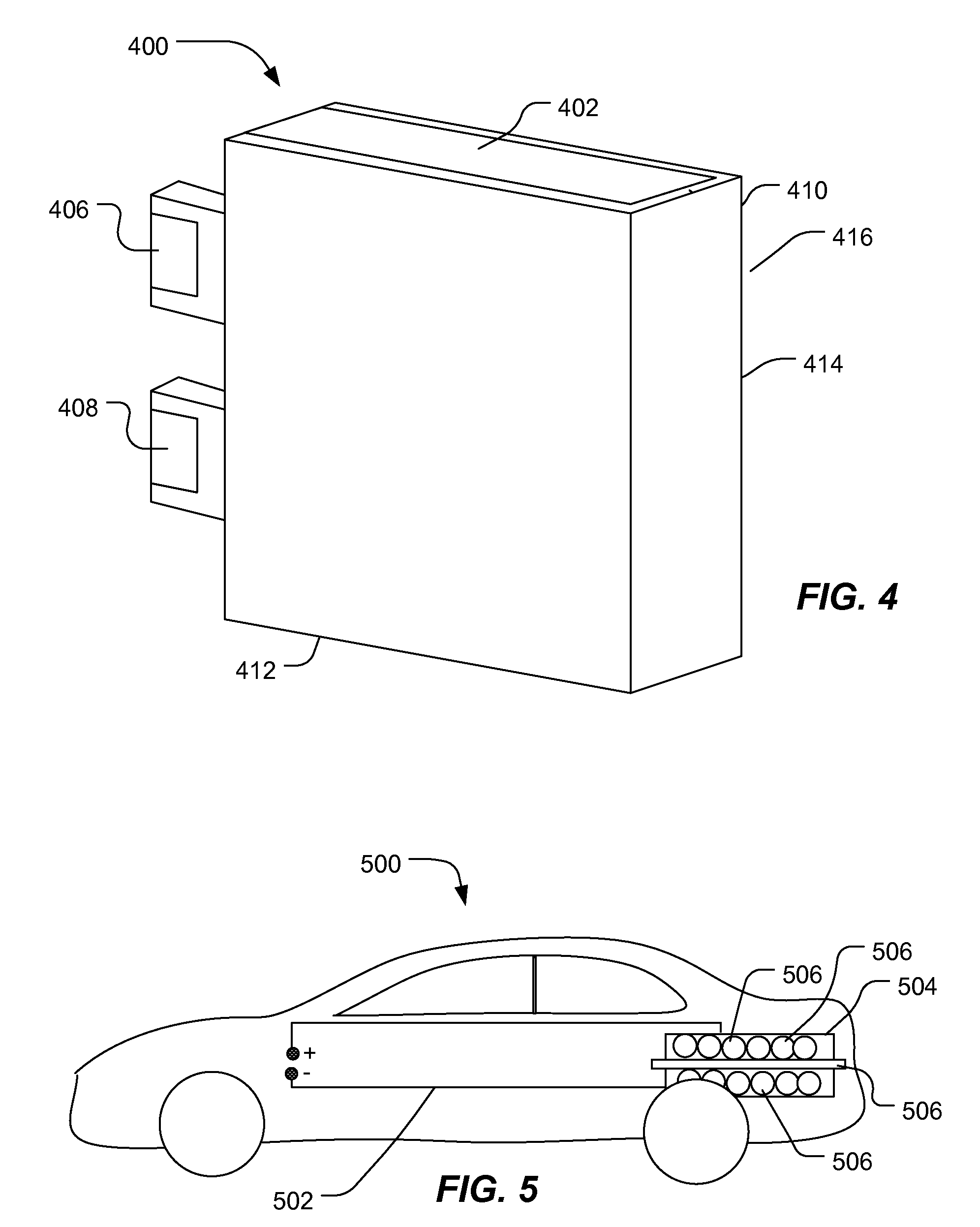

Thermally conductive foam material

An energy supply system includes an energy storage device including a housing. The energy supply system also includes a sheet material in contact with the housing. The sheet material includes a foam layer. The sheet material has a thermal conductivity of at least 0.1 W / mK and a thickness of at least 0.3 mm.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS CORP

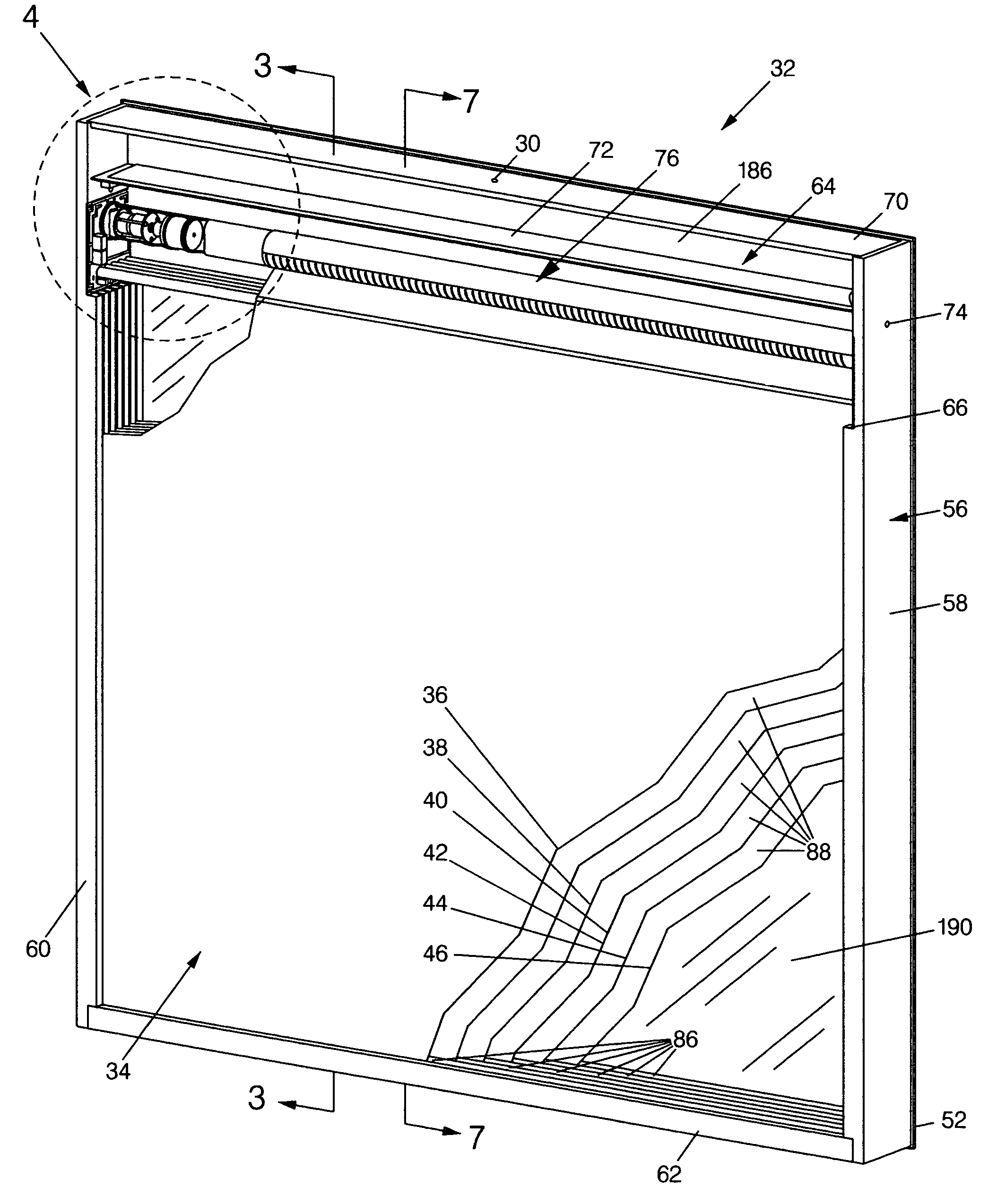

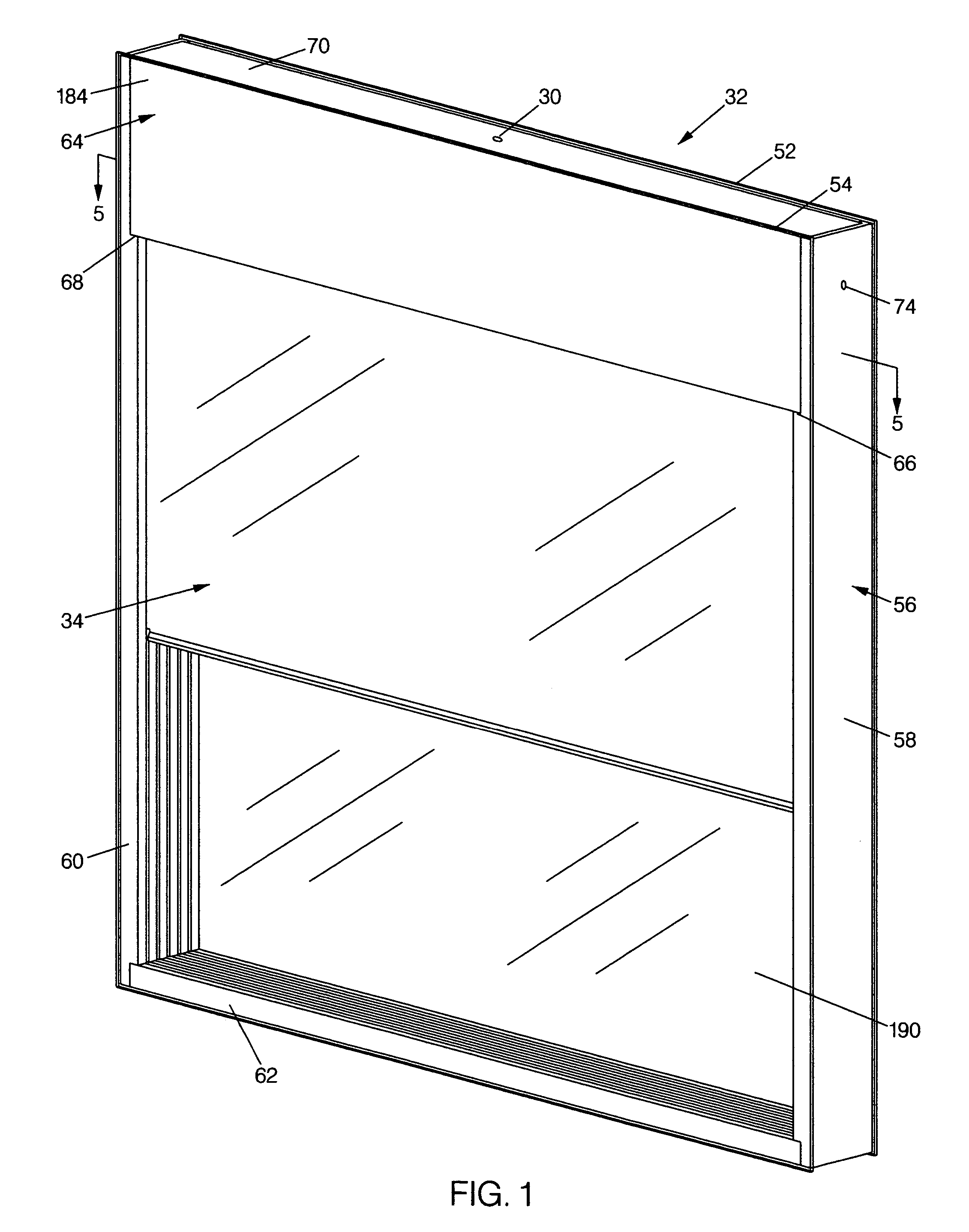

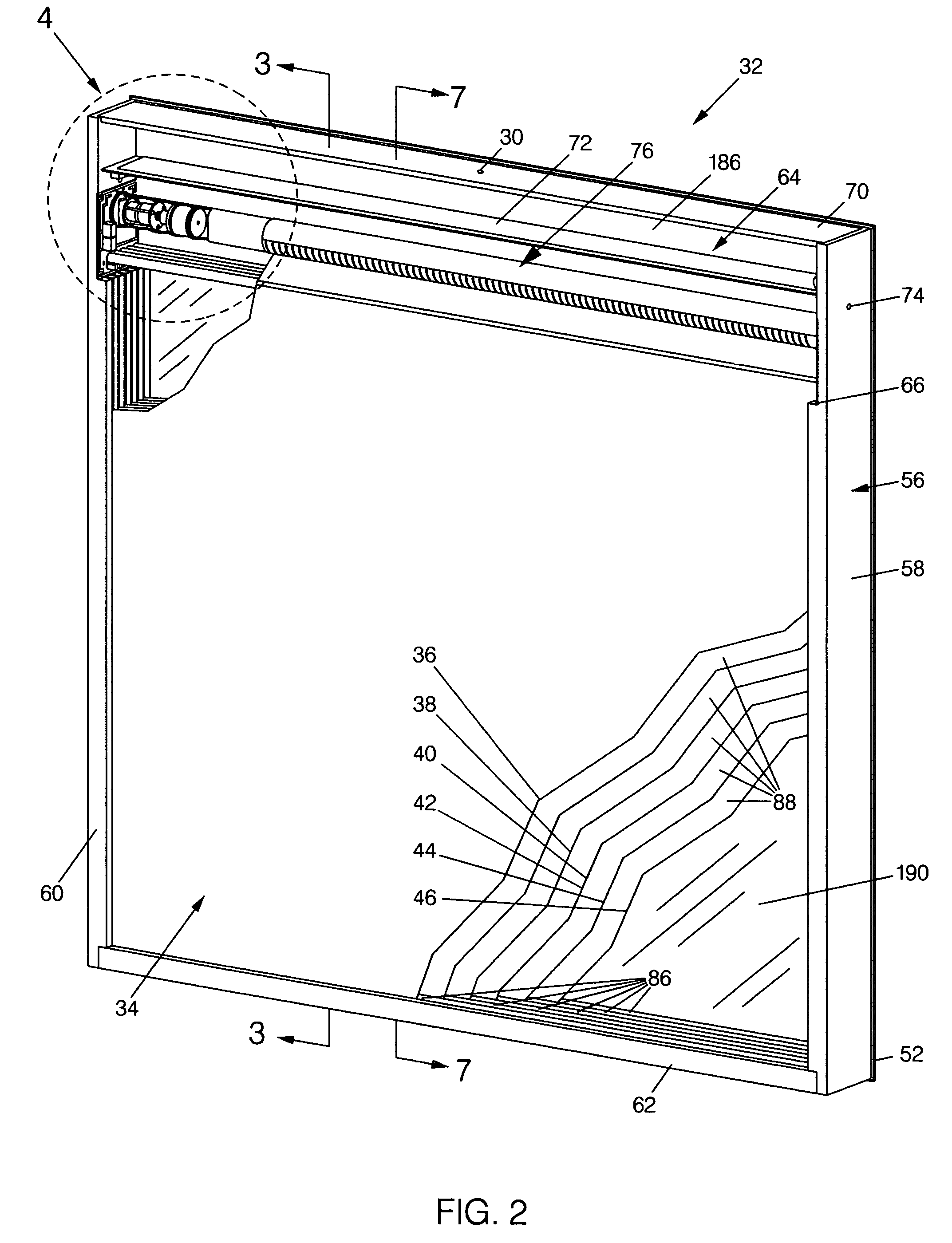

Multi-layered film window system

InactiveUS7281561B2Improve reflectivityReduce transmissionShutters/ movable grillesLight protection screensControl systemSheet film

A high R-rating window assembly storing multiple, reciprocating reflective flexible film layers in a sealed housing between rigid (e.g. glazed) layers. The glazed layers are separated on the order of 3 to 5-inches and are secured to low thermal conductivity framework pieces. The framework is capped with a motorized roller and film housing and the assembly is evacuated and filled with a desiccated, inert dry gas. Several plastic, reflective coated films are supported under tension in planar parallel relation between the glazing layers from the motorized roller and several guide rollers and guide tracks. Location sensors responsive to indicia on the films identify film position. Temperature sensors monitor ambient, internal and user set thermal conditions to control film exposure. The films are operable via a room control system and window controllers to define open, closed and partial exposure conditions. Alternative control functions may control film exposure in relation to room occupancy.

Owner:ANDERSON DONALD +1

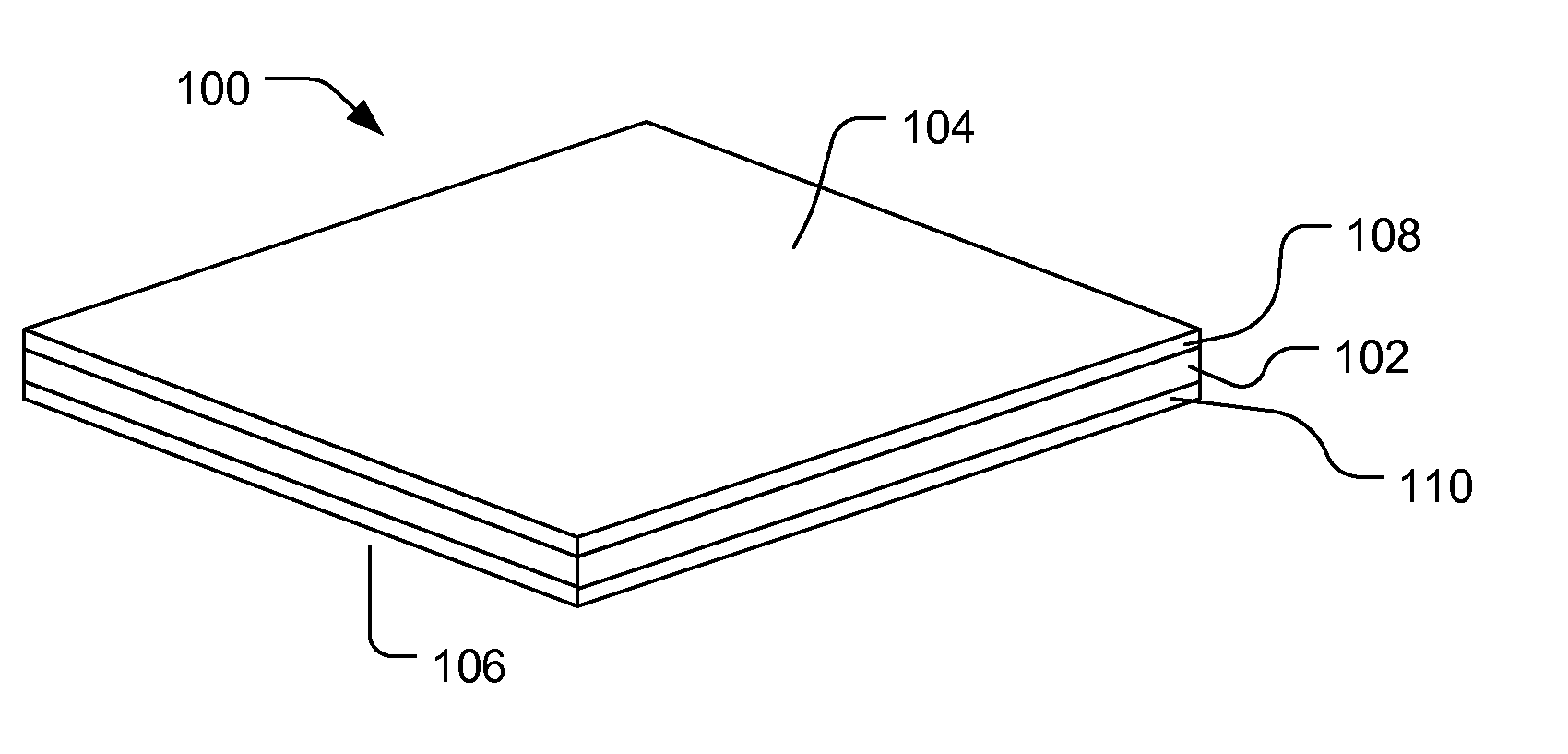

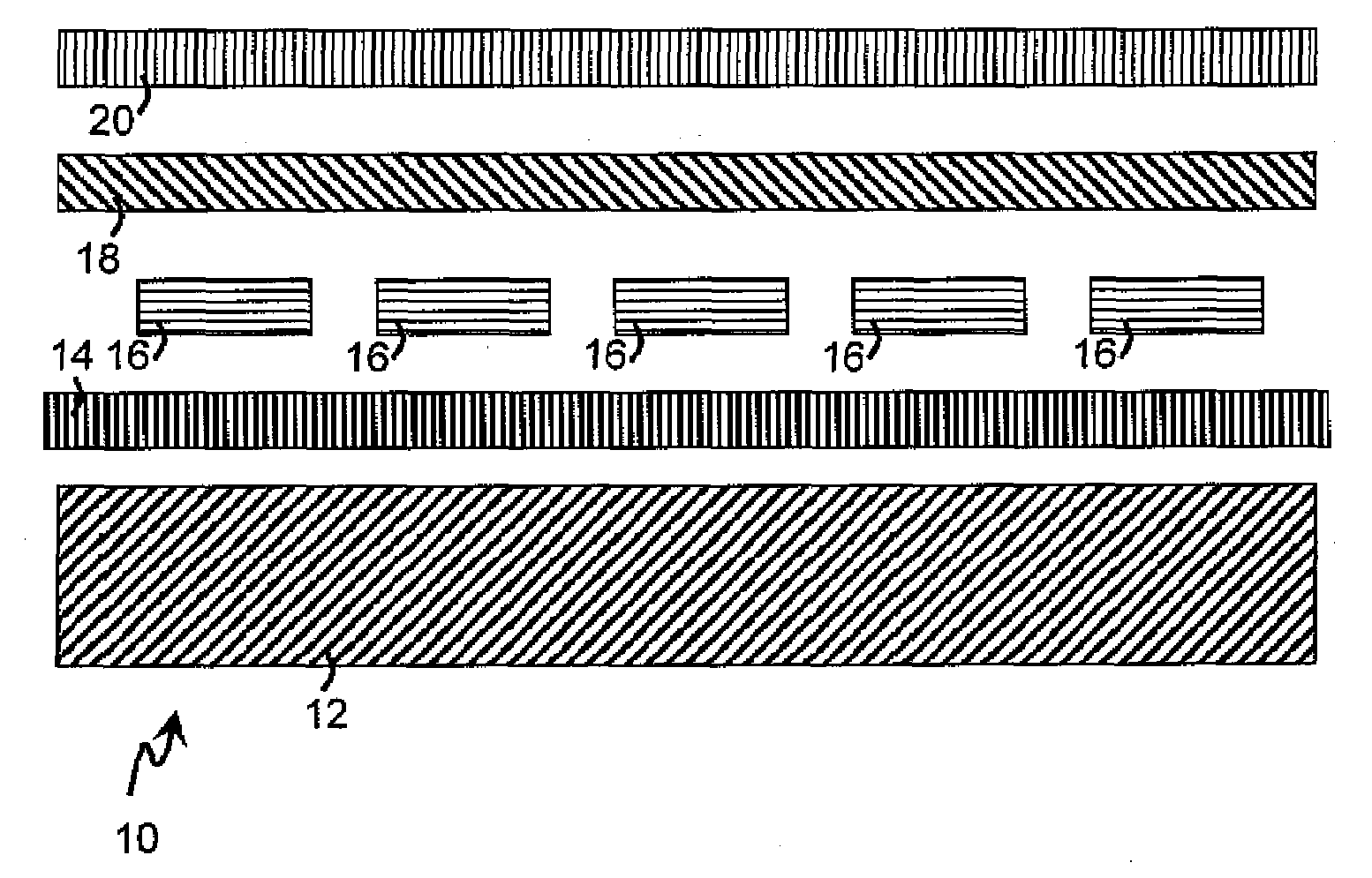

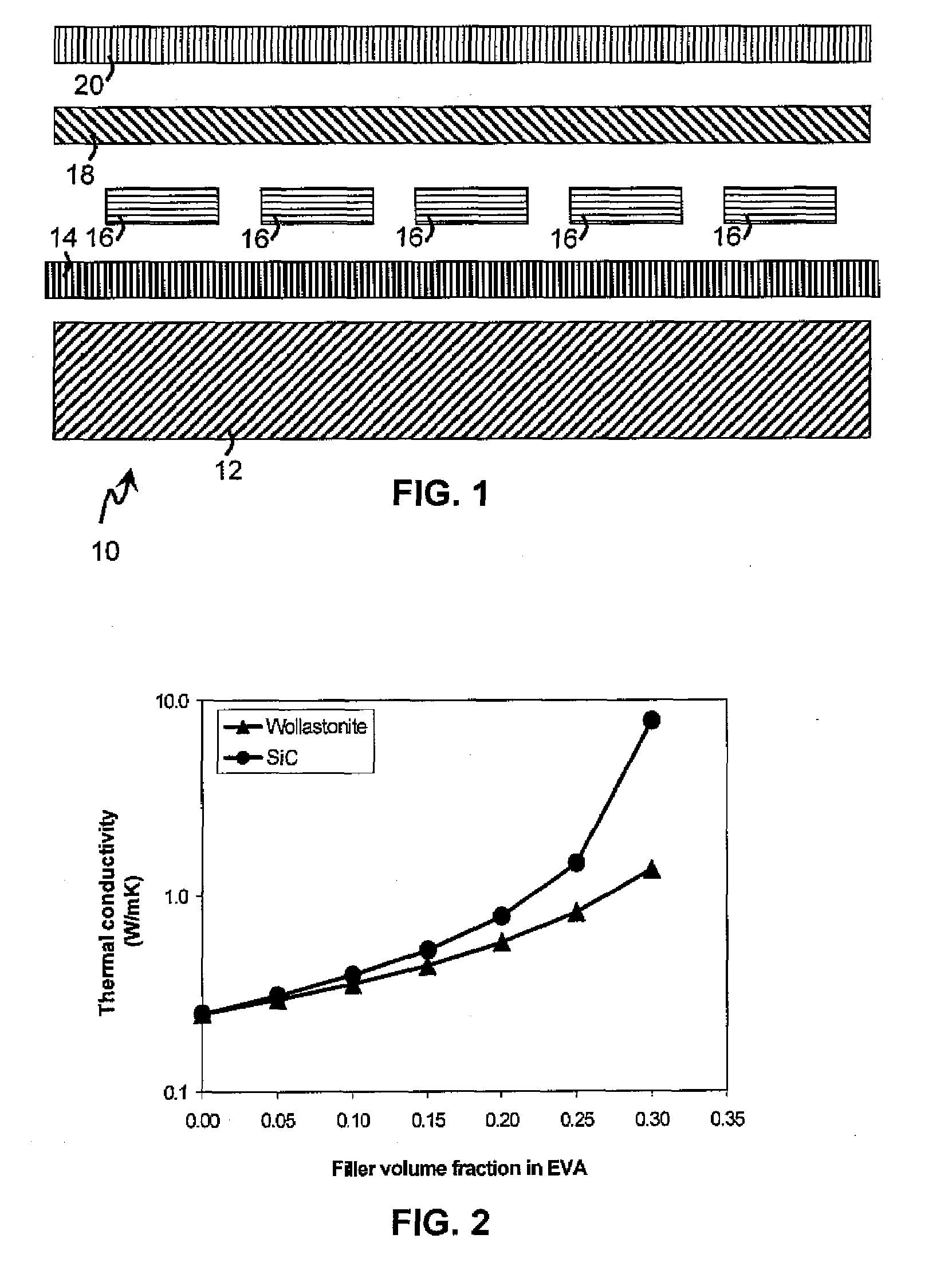

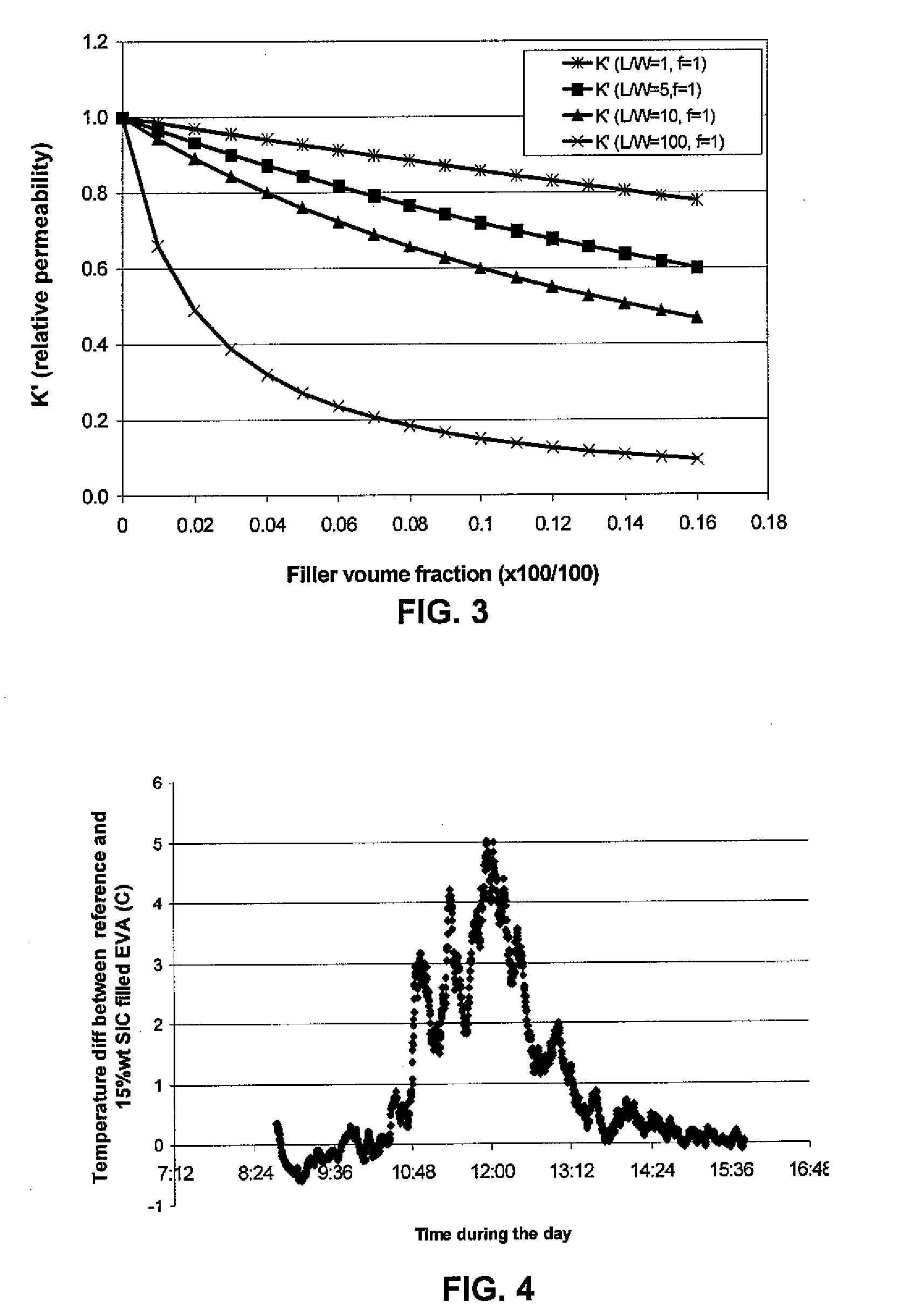

Thermal Conducting Materials for Solar Panel Components

InactiveUS20090255571A1Optimize power outputImprove efficiencyPV power plantsElectrical equipmentEngineeringSolar cell

This invention relates to solar panels with improved encapsulants and backsheets for greater power output and / or increased efficiency by using materials with higher thermal conductivity than conventional solar panels. According to certain embodiments the improved materials include fillers while maintaining sufficient dielectric properties. According to certain other embodiments, the invention includes a solar panel with the improved encapsulant between solar cells and the improved backsheet. The invention also includes a method of making a solar panel including the improved materials.

Owner:BP CORP NORTH AMERICA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com