Patents

Literature

82 results about "Screening techniques" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The tumbler screening technique is a separation method that applies an elliptical movement in three dimensions, which helps to efficiently produce very fine materials.

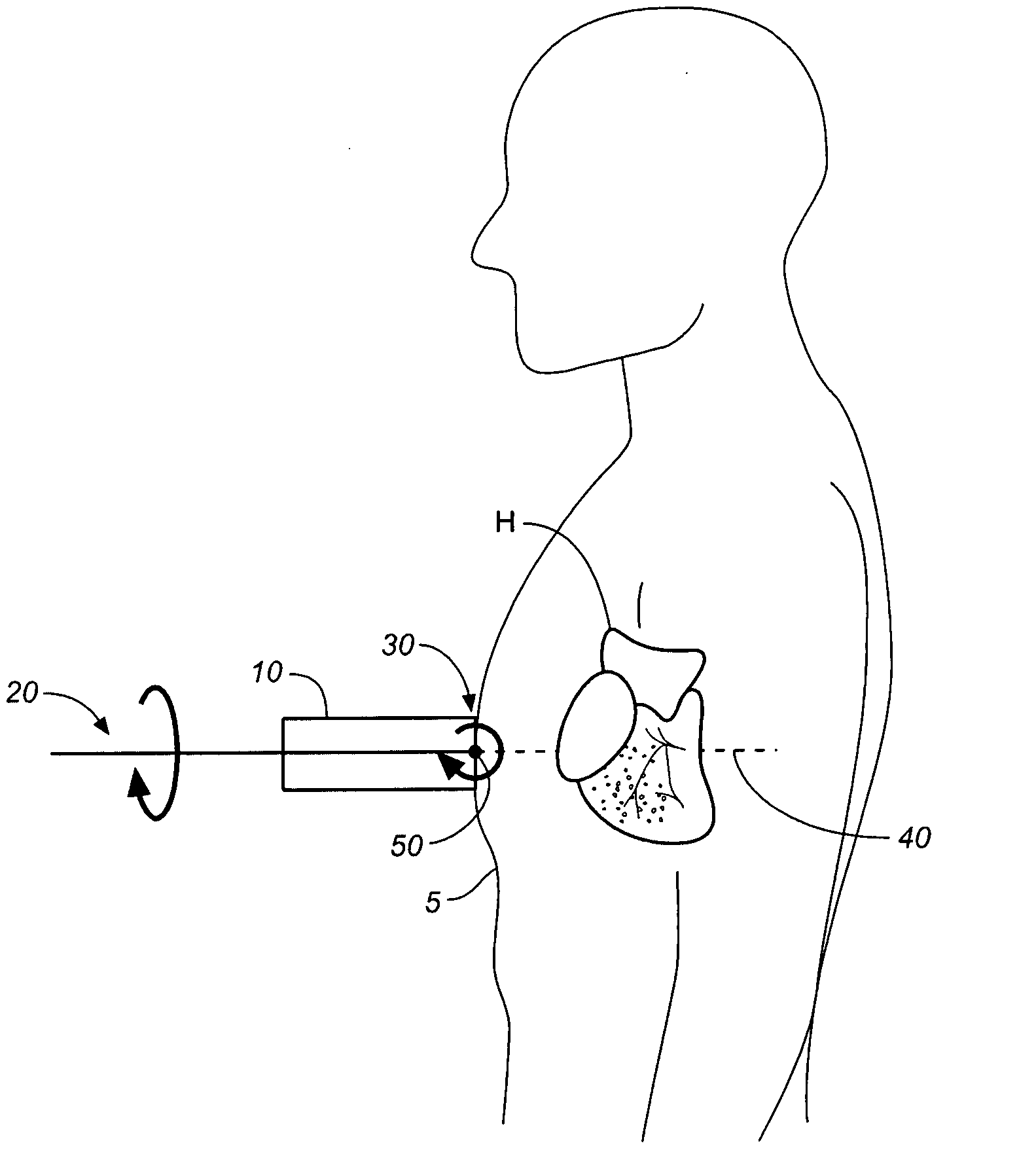

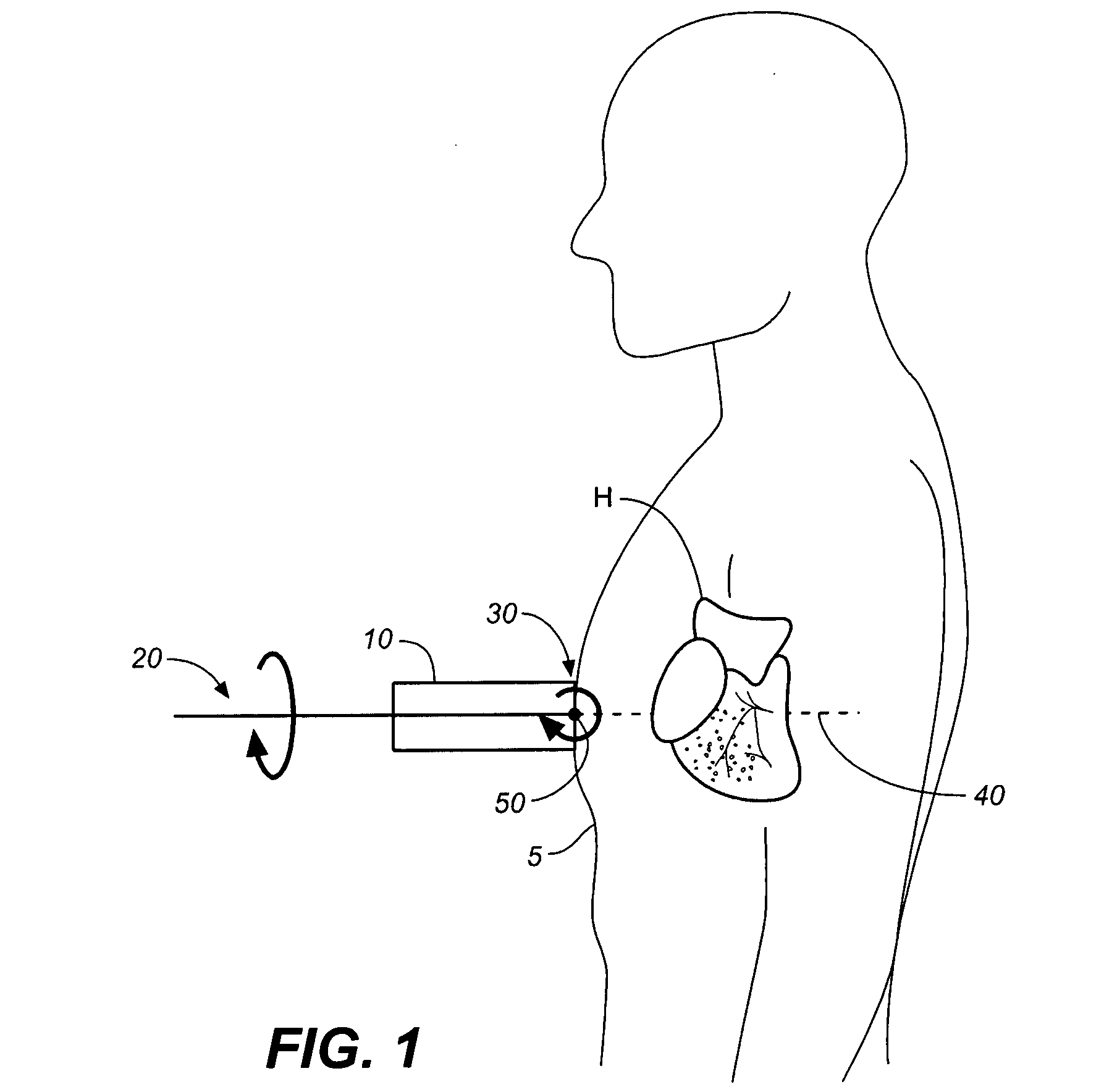

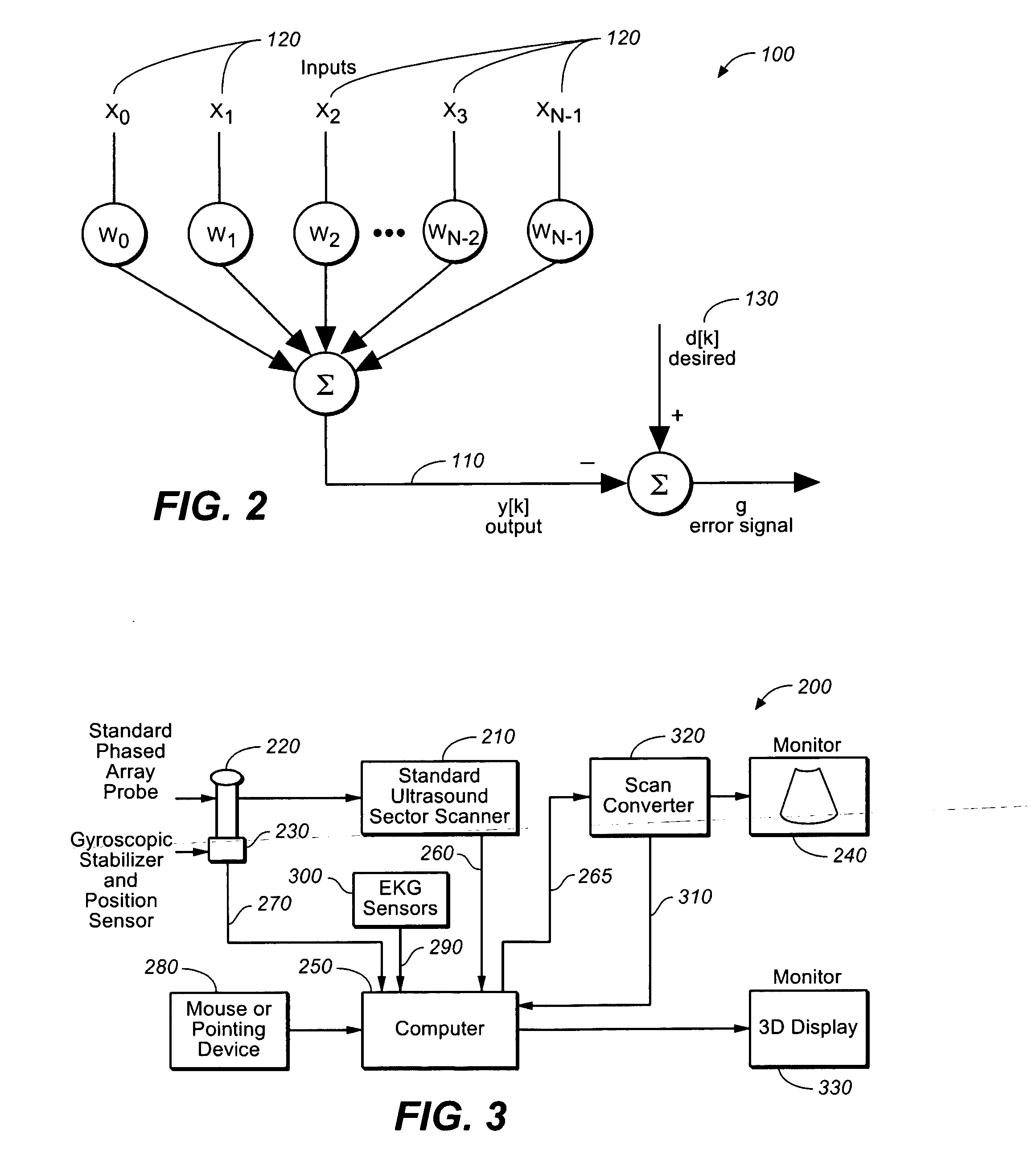

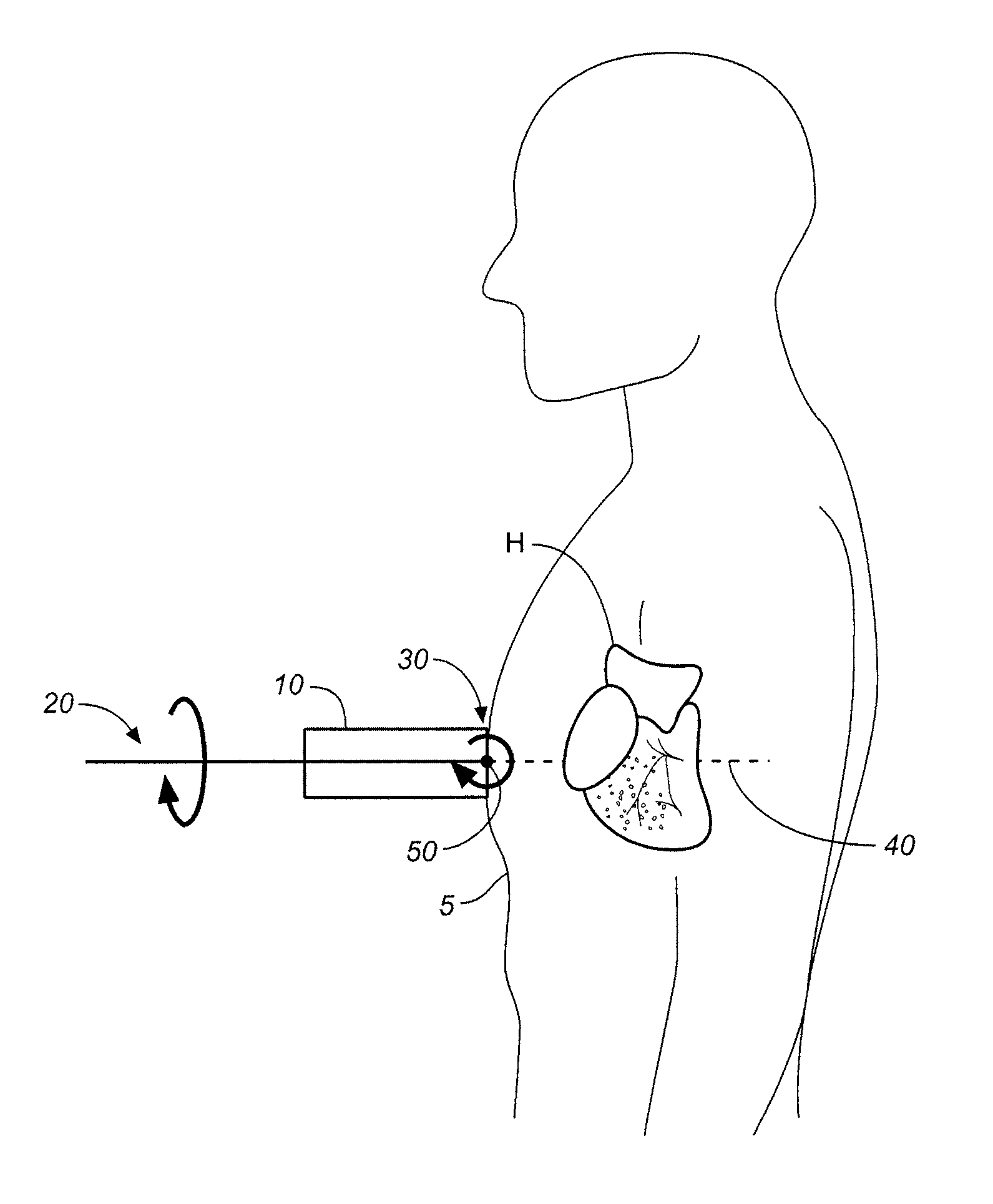

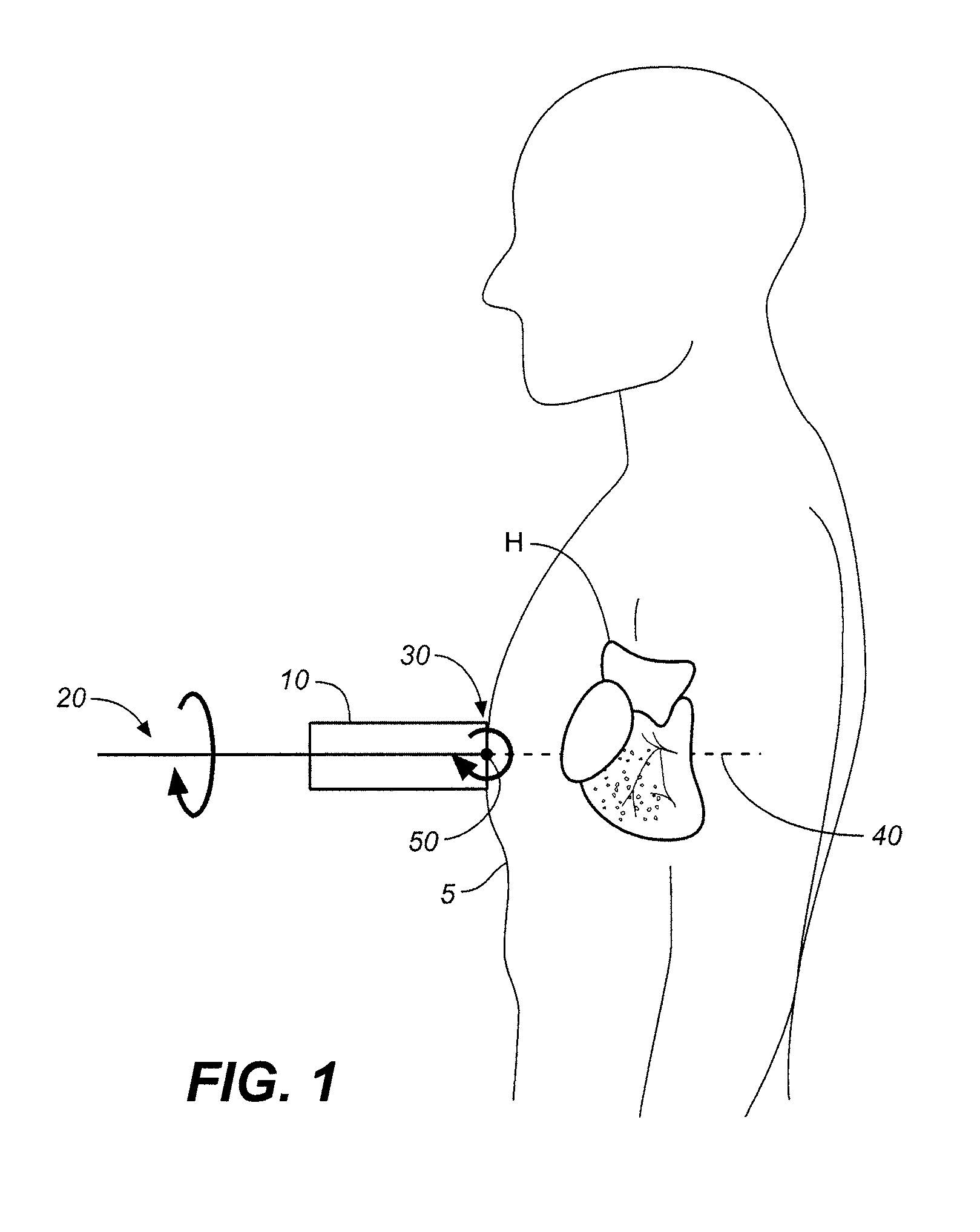

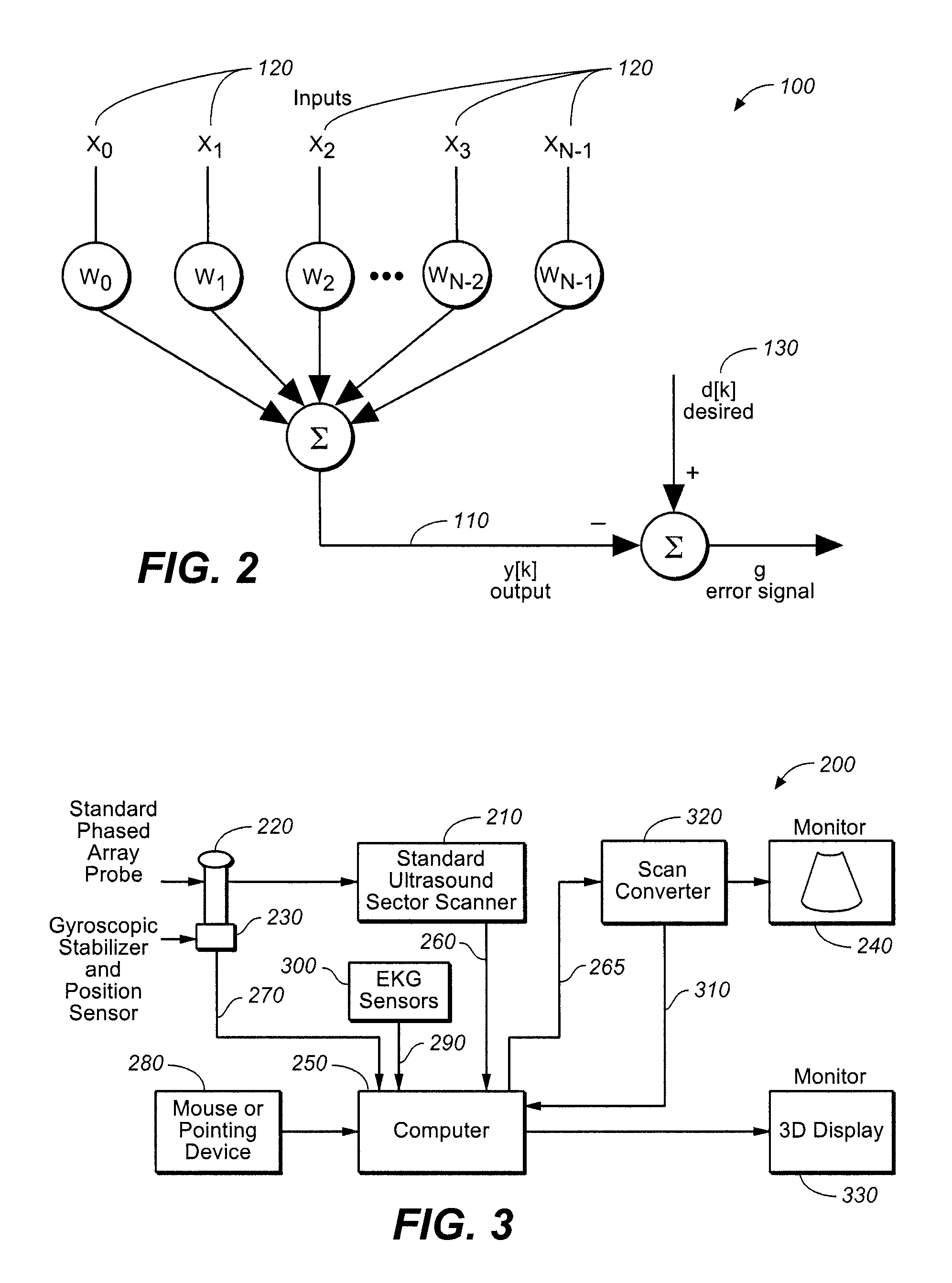

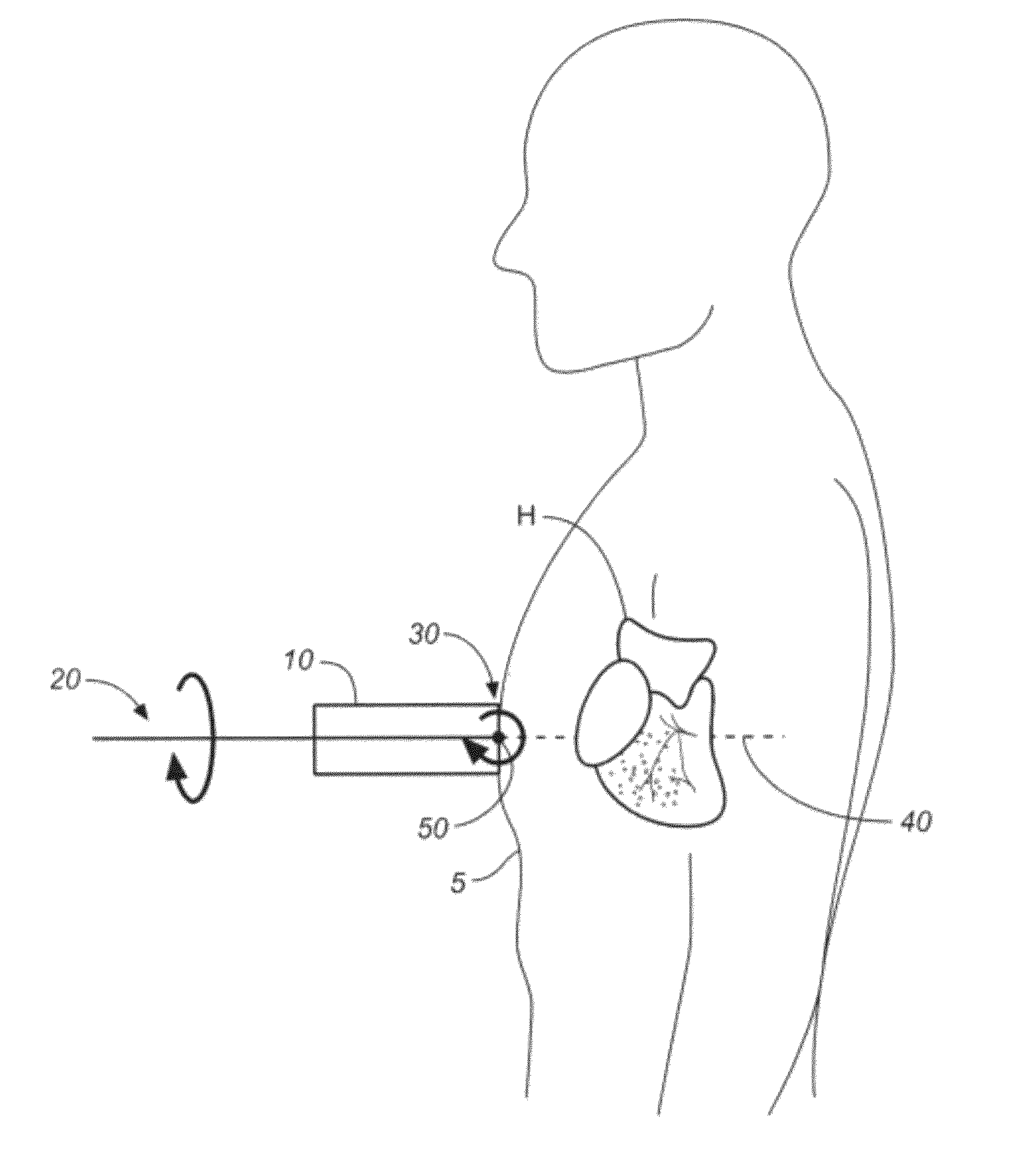

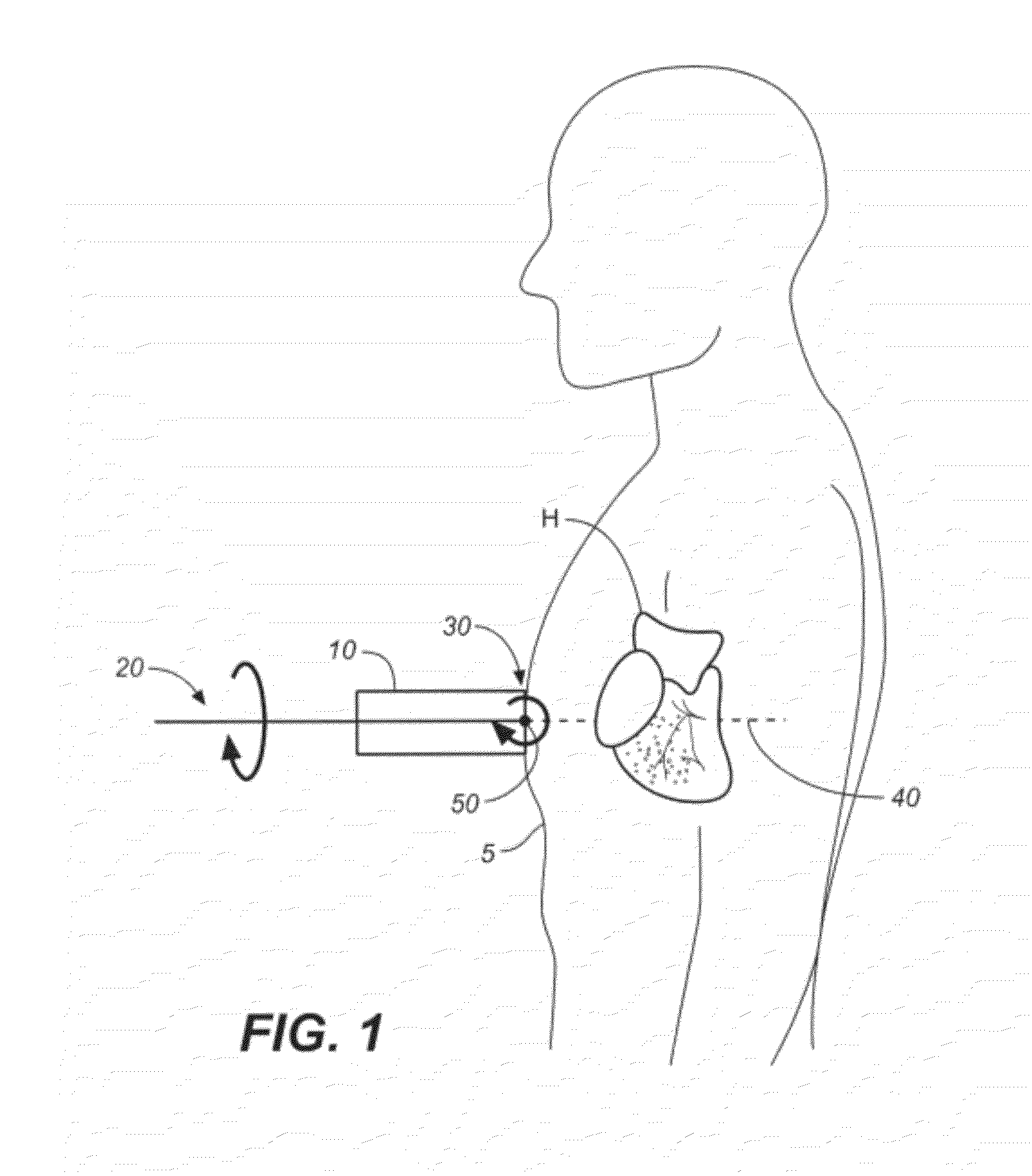

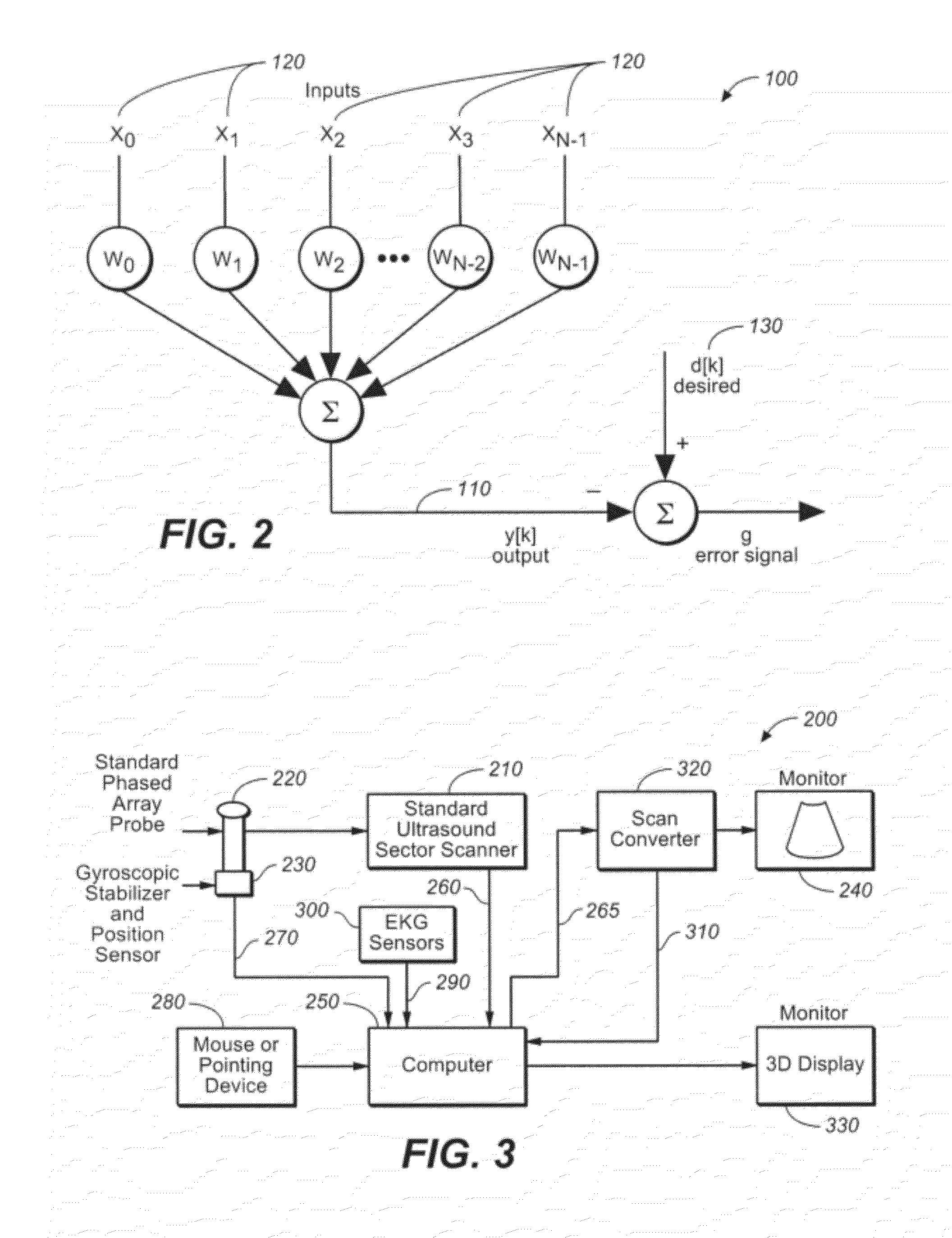

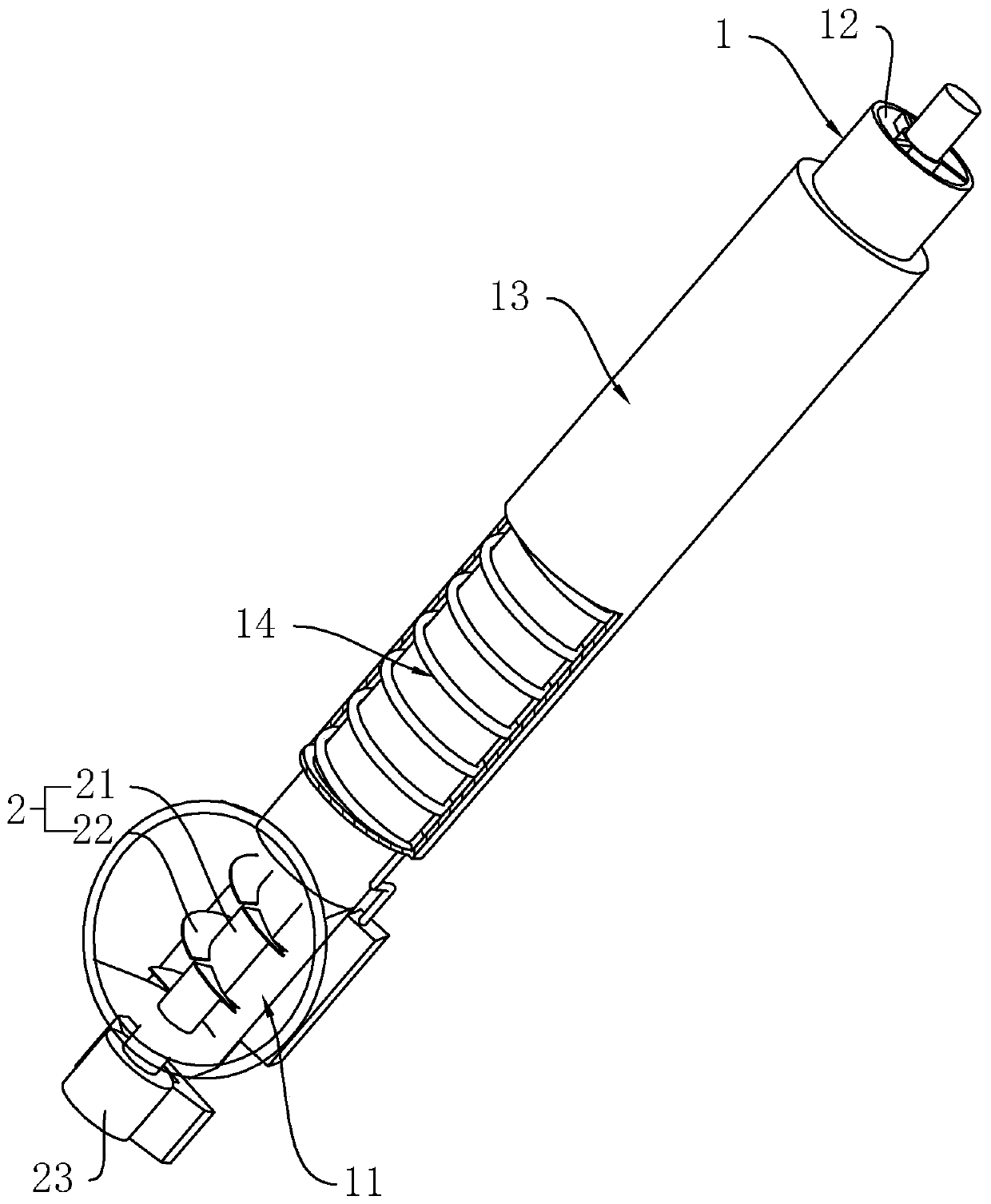

Method and apparatus to visualize the coronary arteries using ultrasound

ActiveUS20070238999A1Improved three dimensional imageReduce noiseImage enhancementImage analysisBLOOD FILLEDScreening techniques

A non-invasive screening technique for visualizing coronary arteries which overcomes the problems of visualizing the curved arteries by projecting the three dimensional volume of the arteries onto a two dimensional screen. Blood filled areas, and in particular, the coronary arteries and veins, are highlighted to contrast them with other nearby tissues using non-linear classification and segmentation techniques. Data is gathered as a sequence of 2D slices stored as a 3D volume. Software is employed to interpolate voxels intermediate to the slices. Wiener filtering or LMS spatial filtering can be implemented on each 2D scan to improve lateral resolution and reduce noise prior to the use of the scan data with the classification and segmentation algorithms. A traditional handheld ultrasound probe is employed to enable the technician to locate the area of interest, but a gyroscopic stabilizer is added to minimize unwanted variation on two axes of rotation while scanning through angles on the third axis of rotation.

Owner:MAUI IMAGING

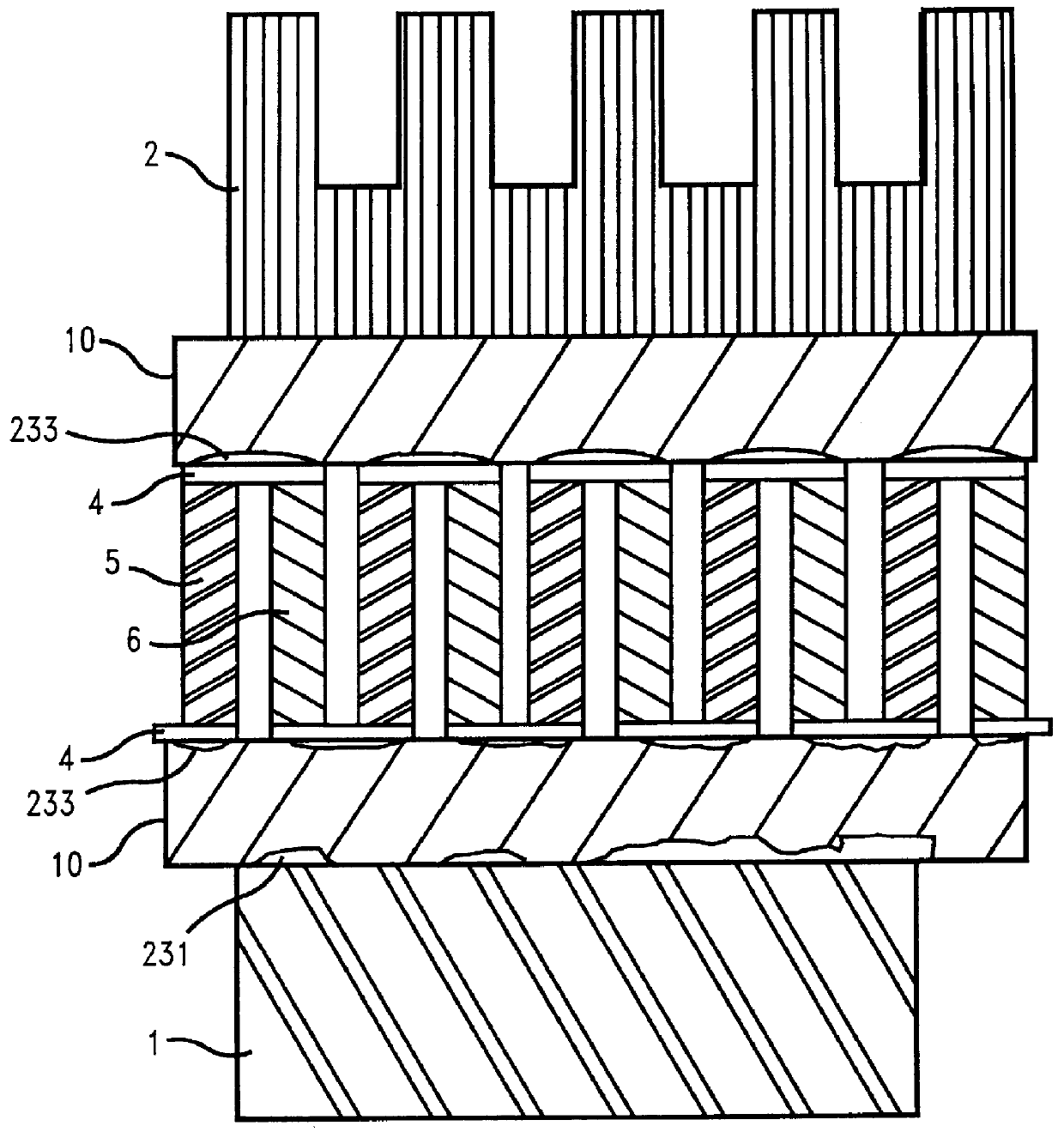

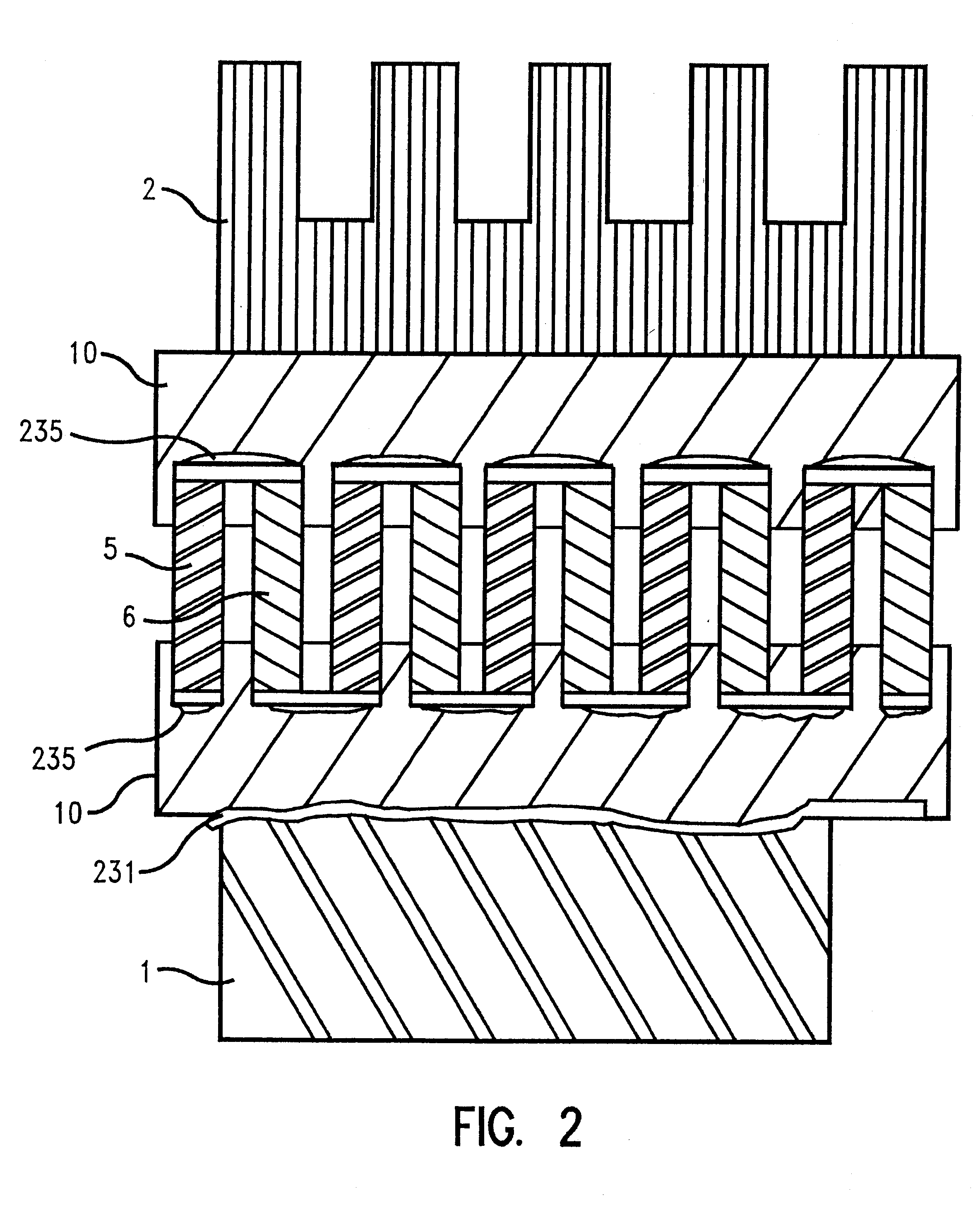

Thermoelectric devices and methods for making the same

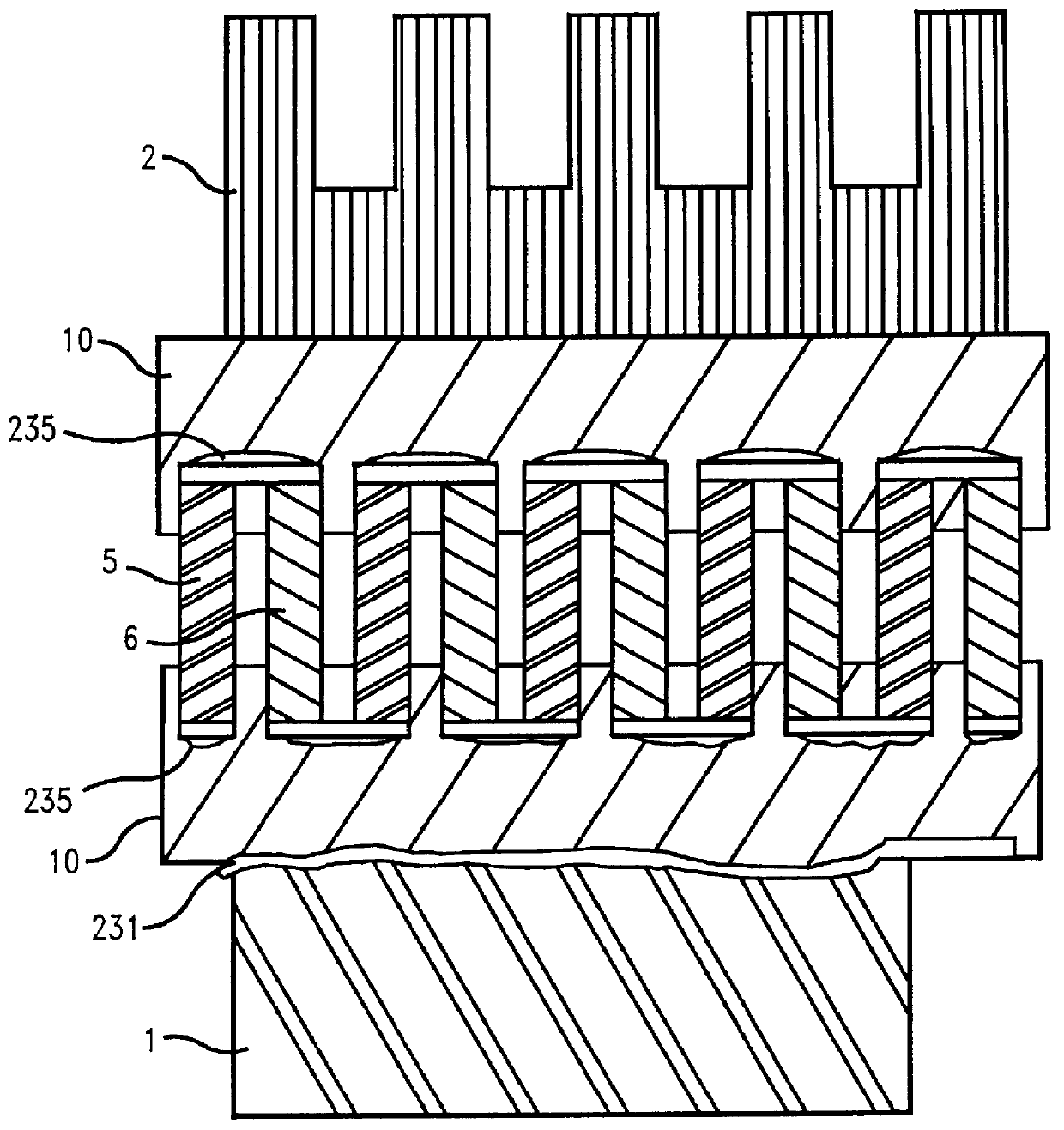

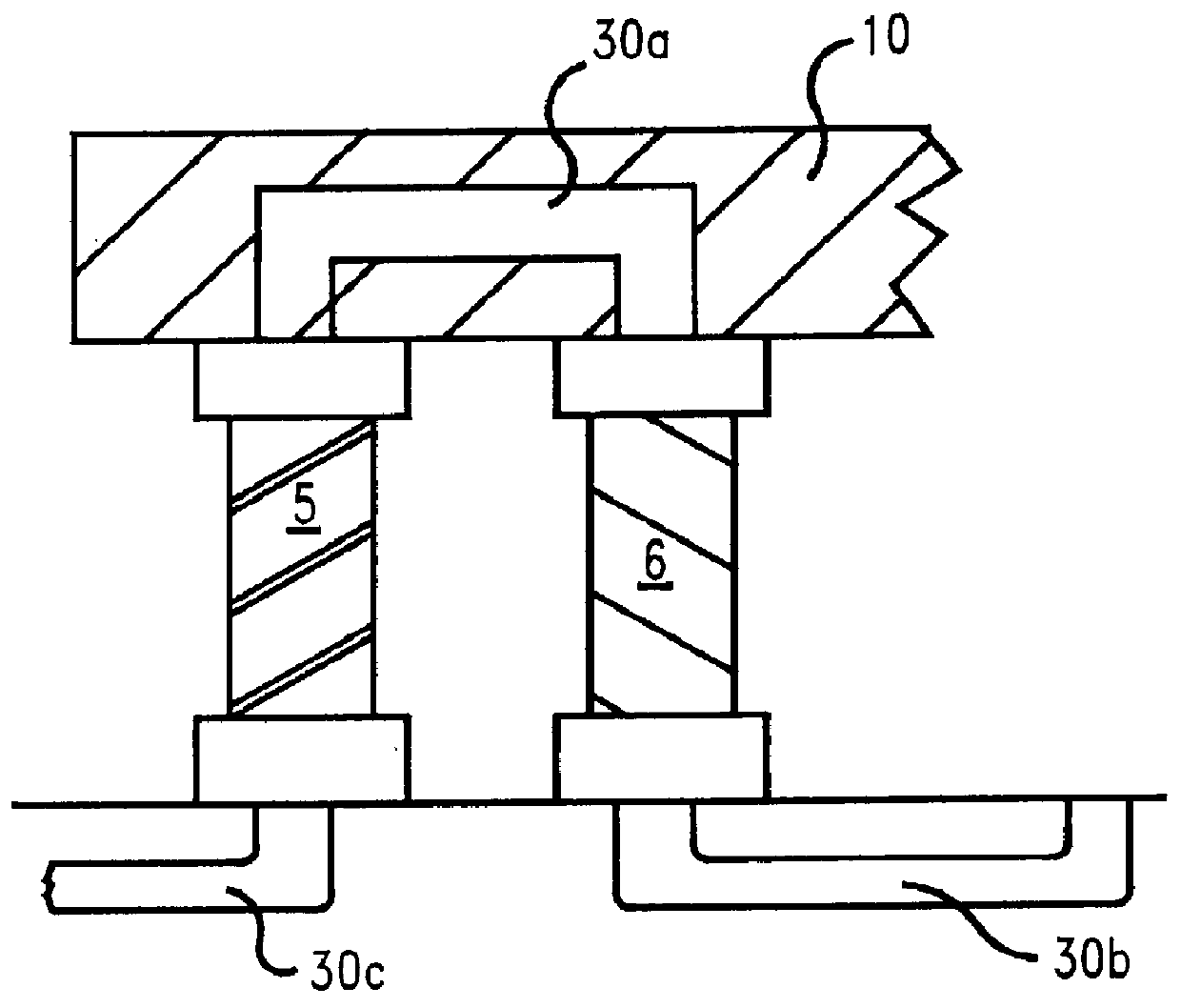

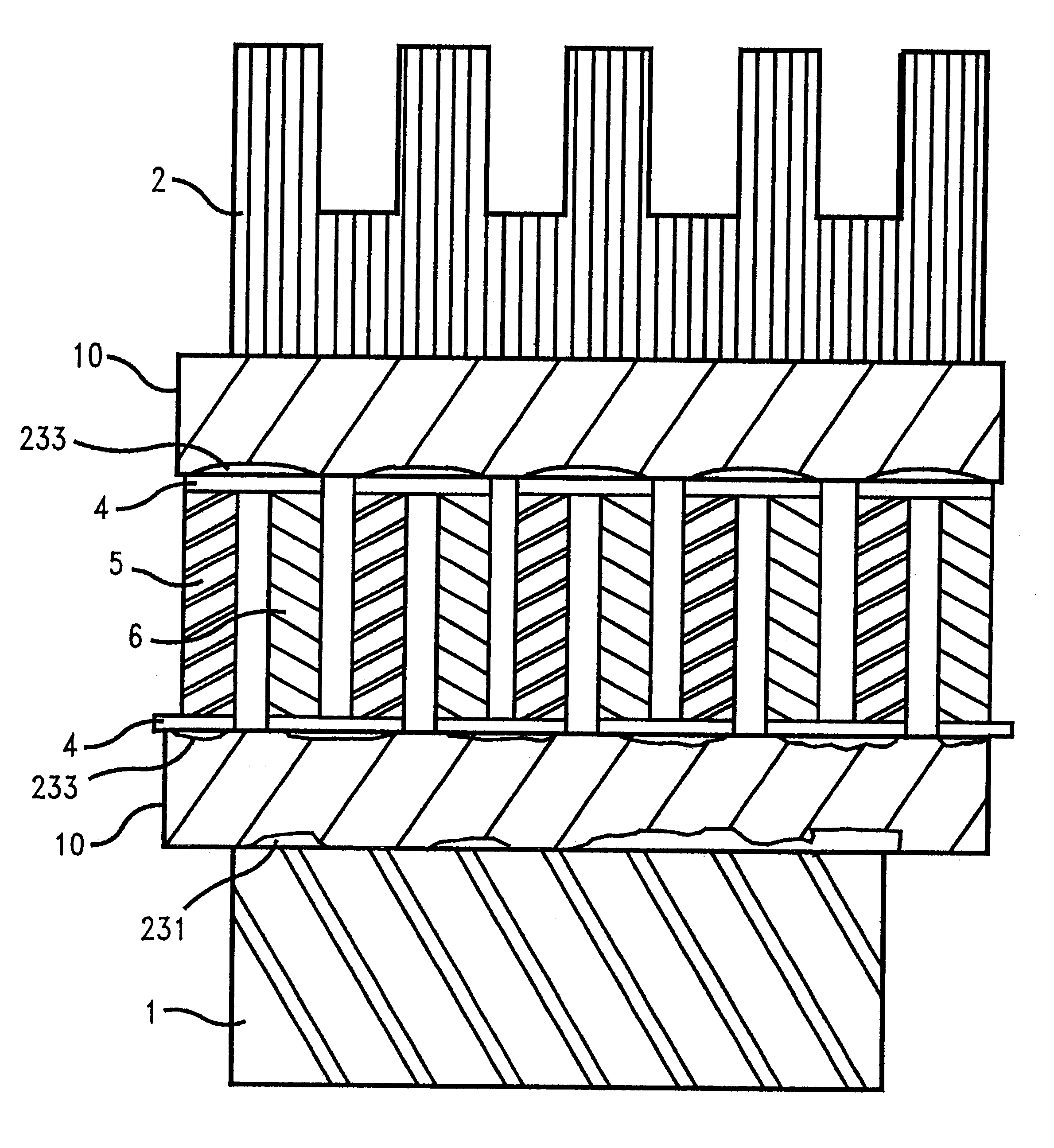

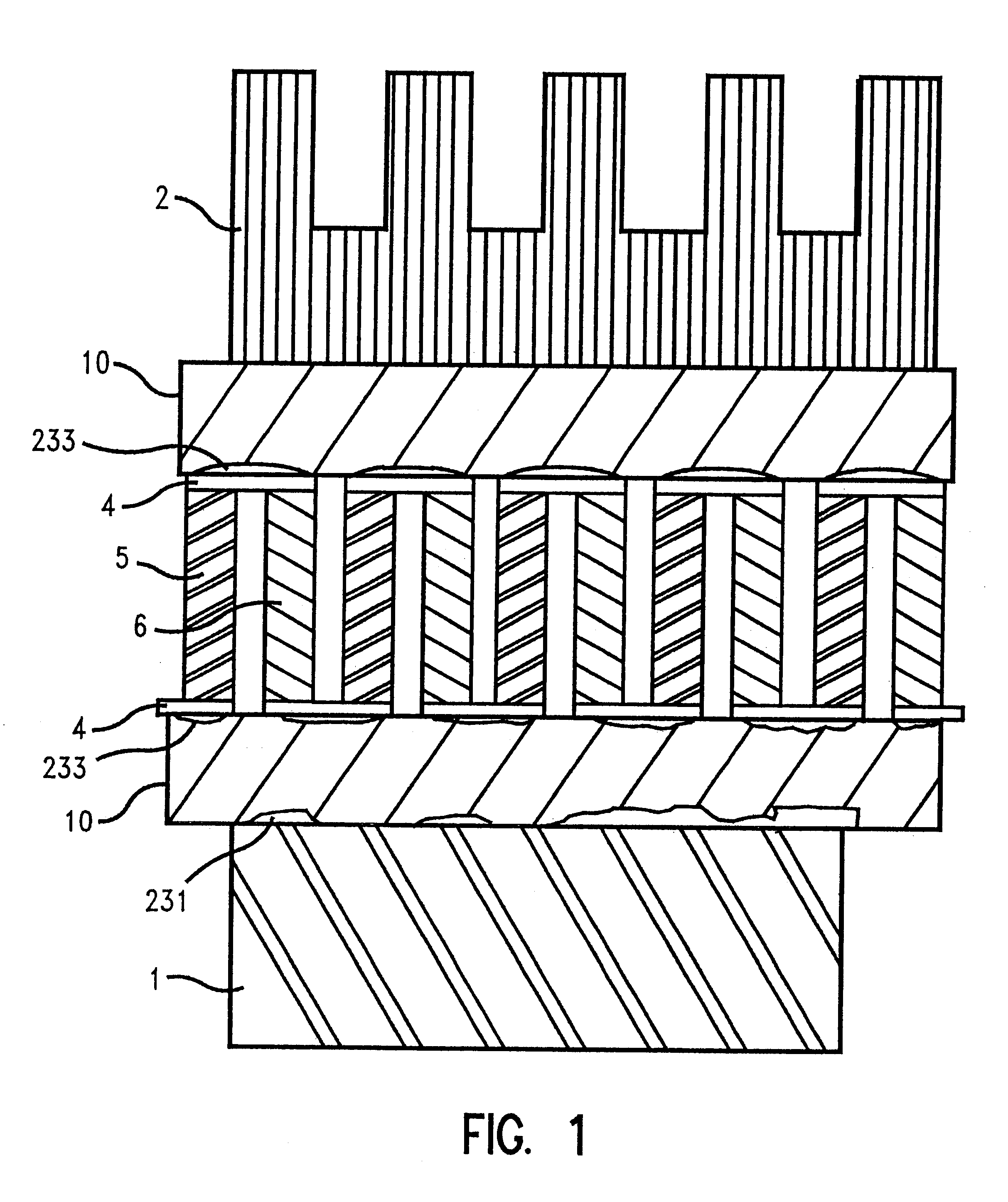

InactiveUS6121539AMaximize heat flowMaximize flowThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsScreening techniquesThermal energy

Thermoelectric devices having enhanced thermal characteristics are fabricated using multilayer ceramic (MLC) technology methods. Aluminum nitride faceplates with embedded electrical connections provide the electrical series configuration for alternating dissimilar semiconducting materials. Embedded electrical connections are formed by vias and lines in the faceplate. Methods are employed for forming tunnels through lamination and etching. A portion of the dissimilar materials are then melted within the tunnels to form a bond. Thermal conductivity of the faceplate is enhanced by adding electrically isolated vias to one surface, filled with high thermal conductivity metal paste. A low thermal conductivity material is also introduced between the two high thermal conductivity material faceplates. Alternating semiconducting materials are introduced within the varying thermal conductivity layers by punching vias within greensheets of predetermined thermal conductivity and filling with n-type and p-type paste. Alternating semiconducting materials may also be patterned in linear or radial fanout patterns through screening techniques and lamination of wire structures. A liquid channel within the faceplate is used to enhance thermal energy transfer. Thermoelectric devices are physically incorporated within the IC package using MLC technology.

Owner:IBM CORP

Thermoelectric devices and methods for making the same

InactiveUS6262357B1Maximize heat flowMaximize flowThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsThermal energyScreening techniques

Thermoelectric devices having enhanced thermal characteristics are fabricated using multilayer ceramic (MLC) technology methods. Aluminum nitride faceplates with embedded electrical connections provide the electrical series configuration for alternating dissimilar semiconducting materials. Embedded electrical connections are formed by vias and lines in the faceplate. Methods for forming tunnels through lamination and etching are employed. A portion of the dissimilar materials are then melted within the tunnels to form a bond. Thermal conductivity of the faceplate is enhanced by adding electrically isolated vias to one surface, filled with high thermal conductivity metal paste. A low thermal conductivity material is also introduced between the two high thermal conductivity material faceplates.Alternating semiconducting materials are introduced within the varying thermal conductivity layers by punching vias within greensheets of predetermined thermal conductivity and filling with n-type and p-type paste. Alternating semiconducting materials may also be patterned in linear or radial fanout patterns through screening techniques and lamination of wire structures. A liquid channel within the faceplate is used to enhance thermal energy transfer.Thermoelectric devices are physically incorporated within the IC package using MLC technology.

Owner:INT BUSINESS MASCH CORP

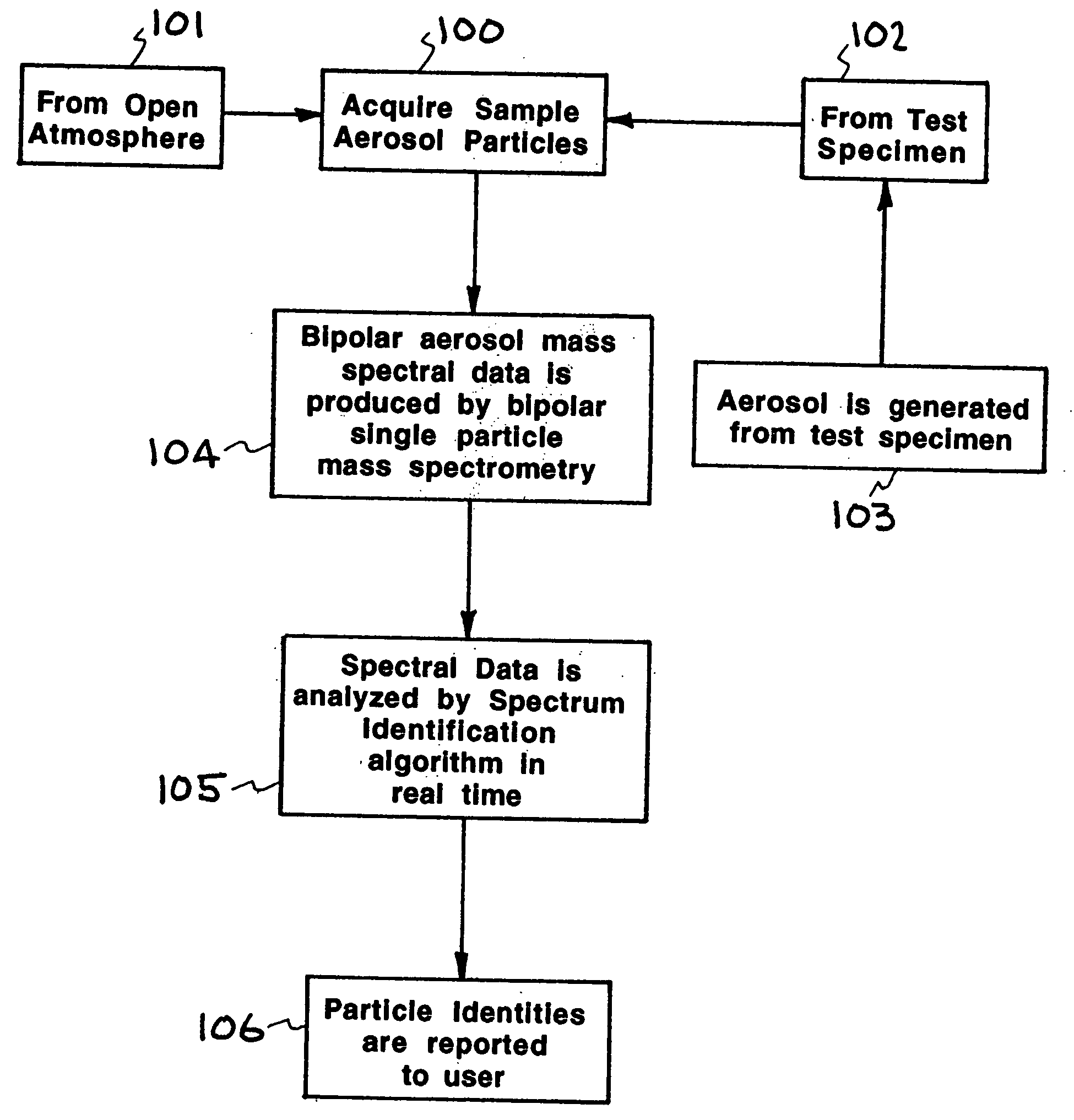

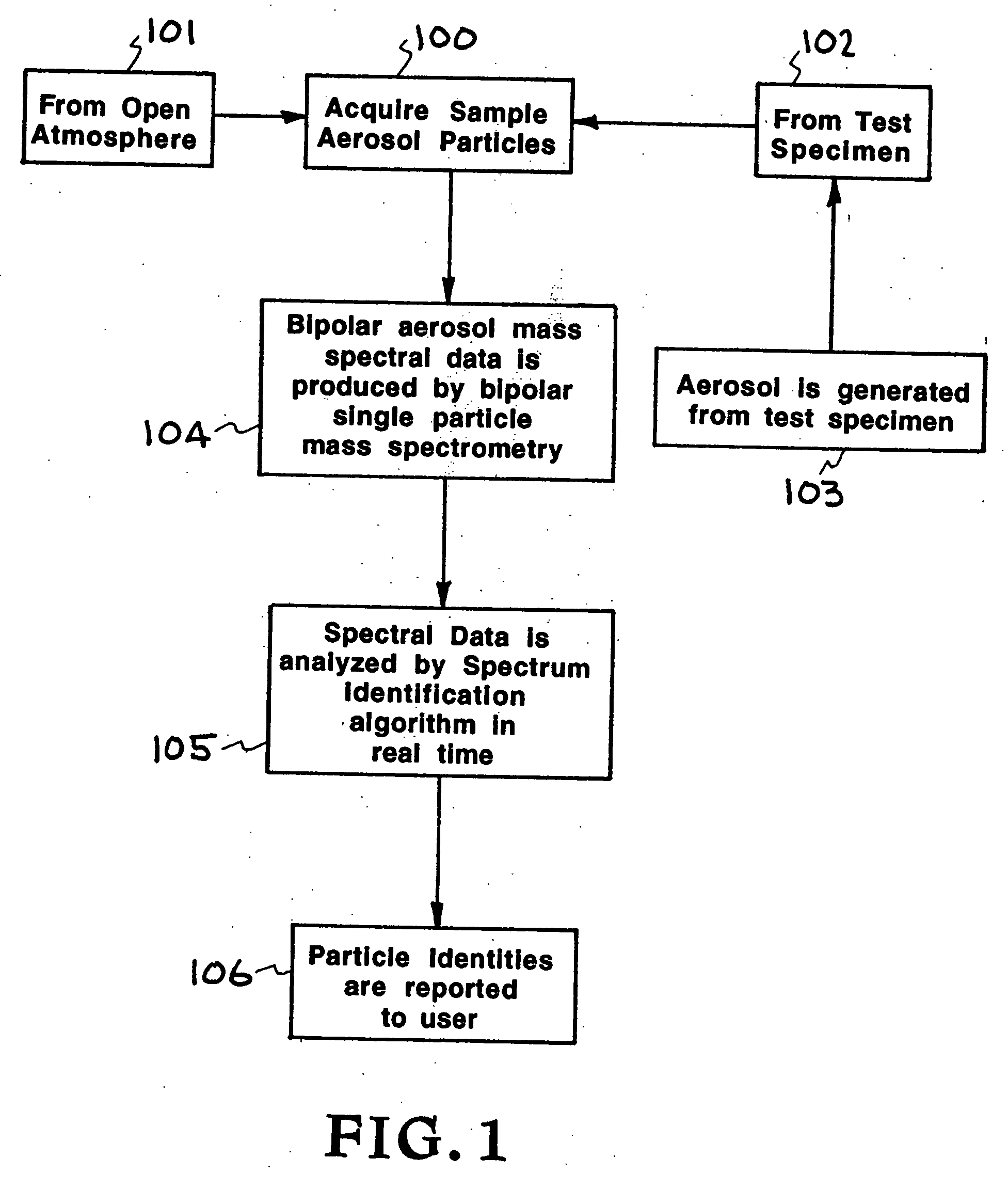

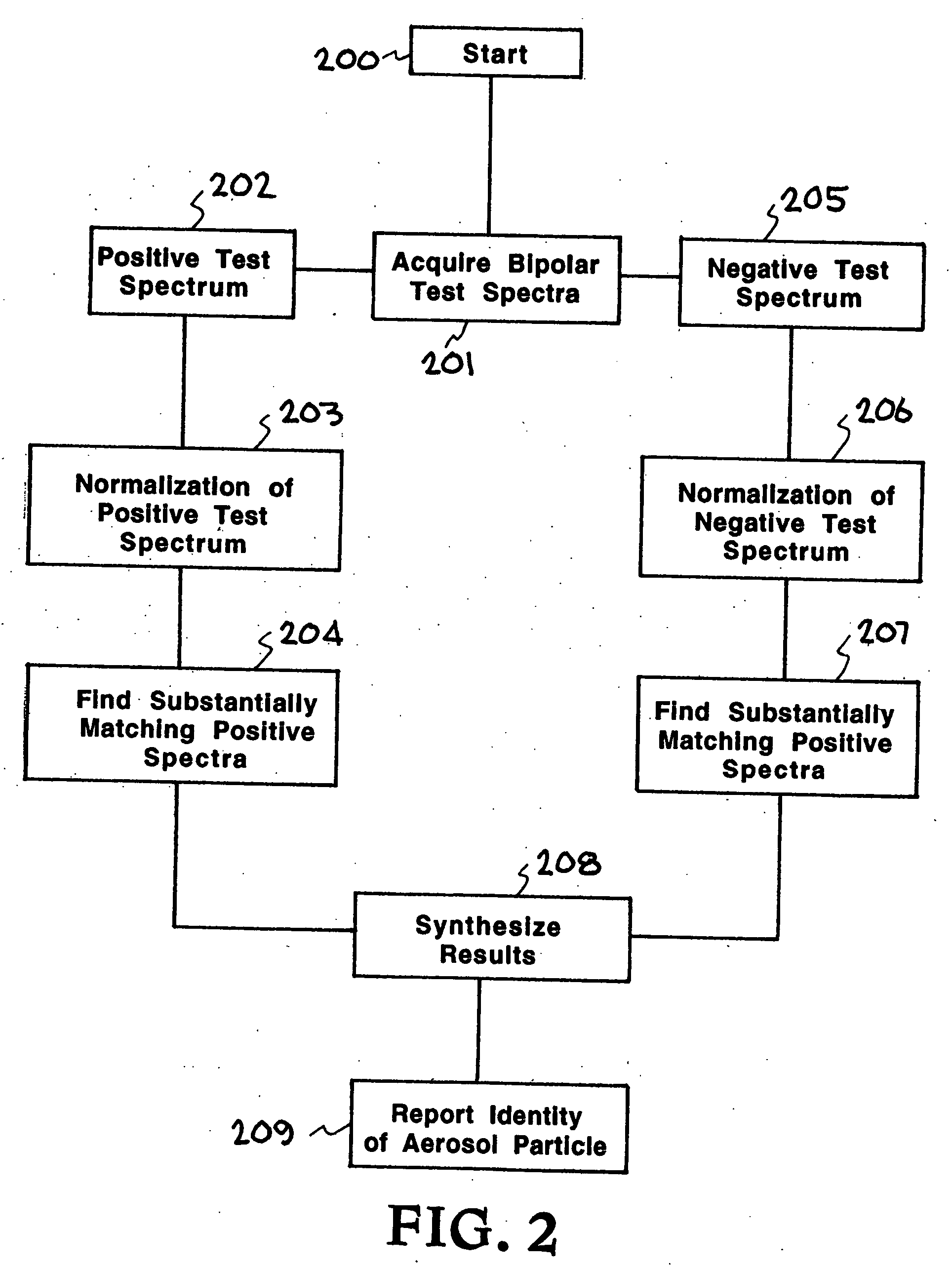

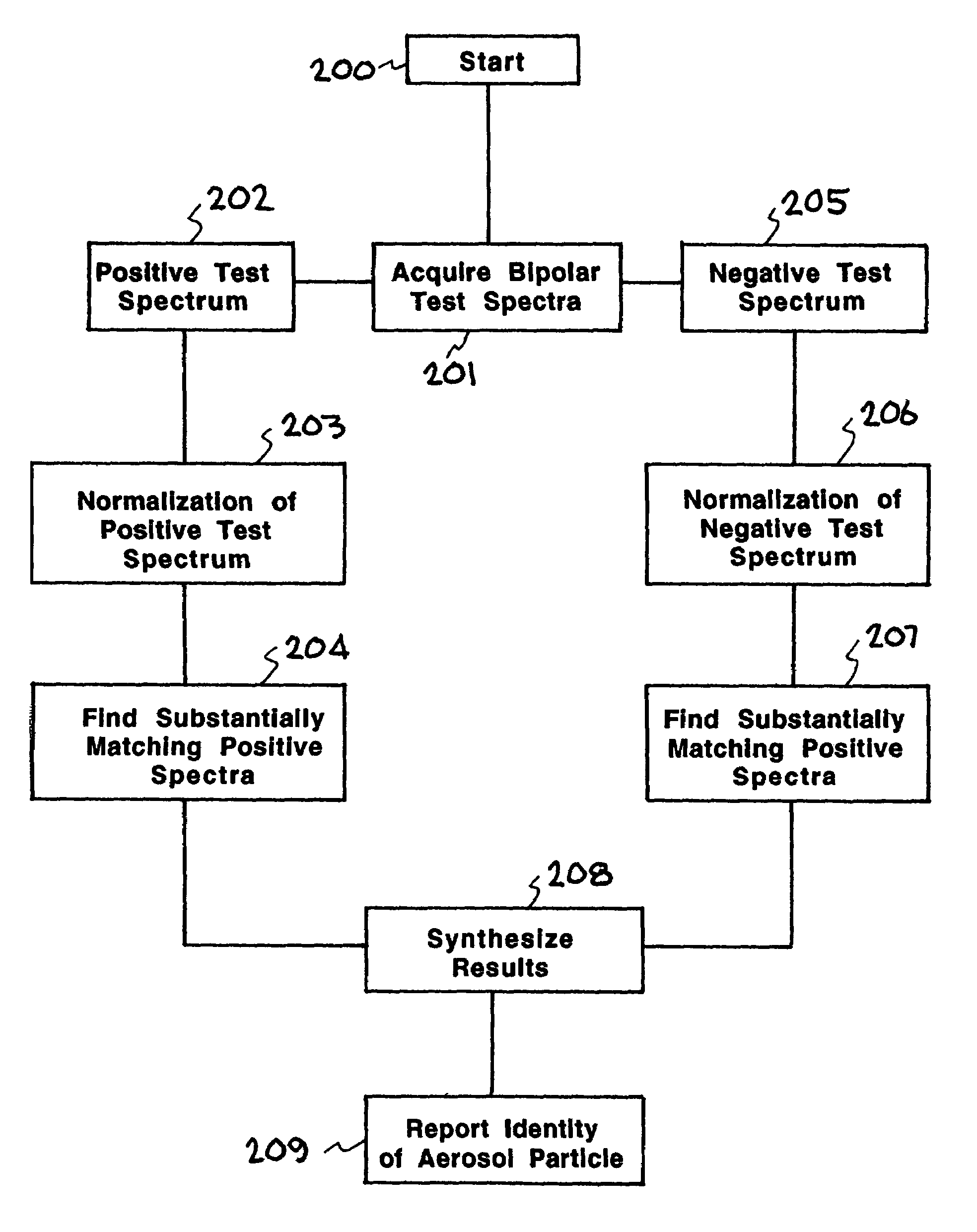

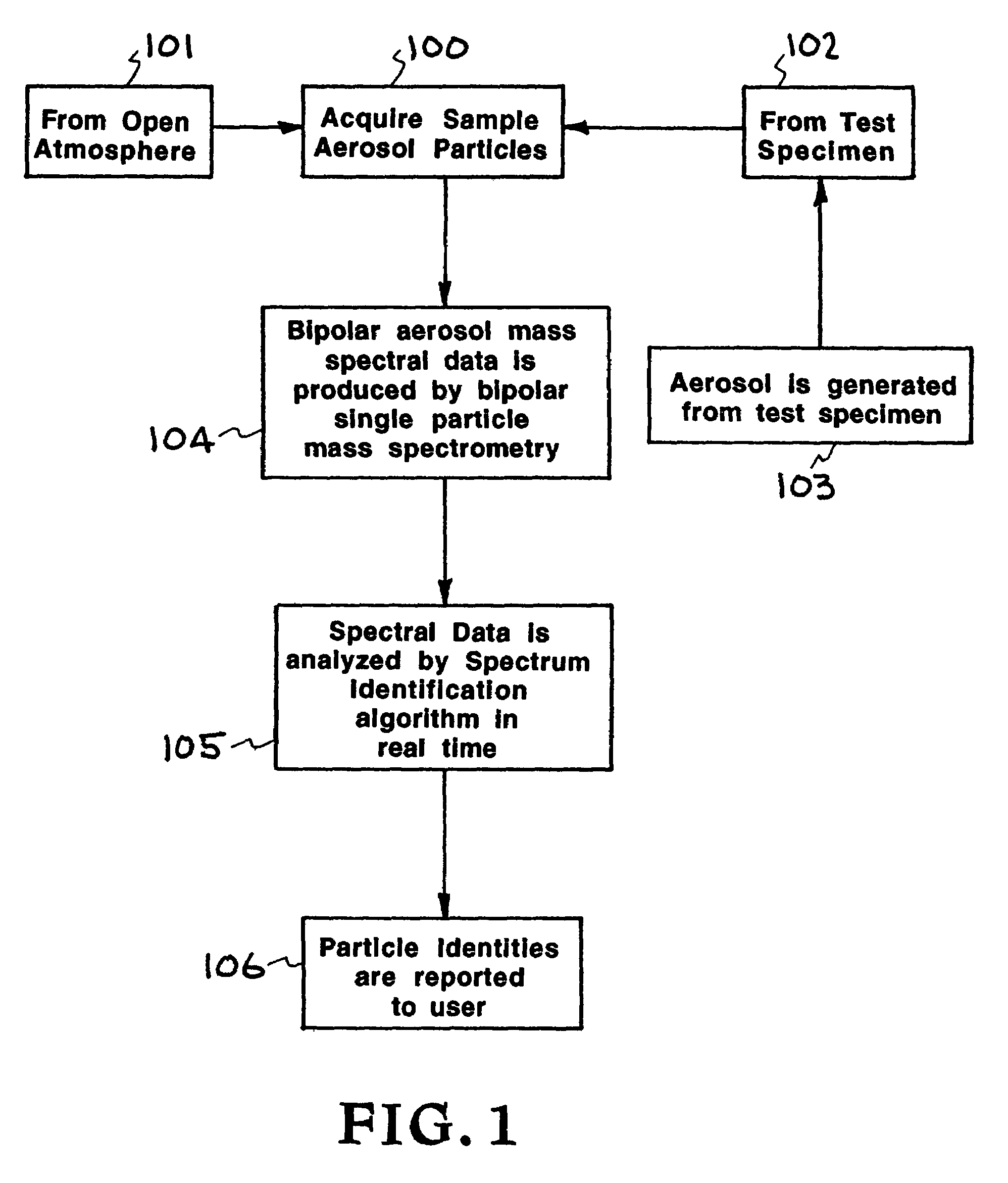

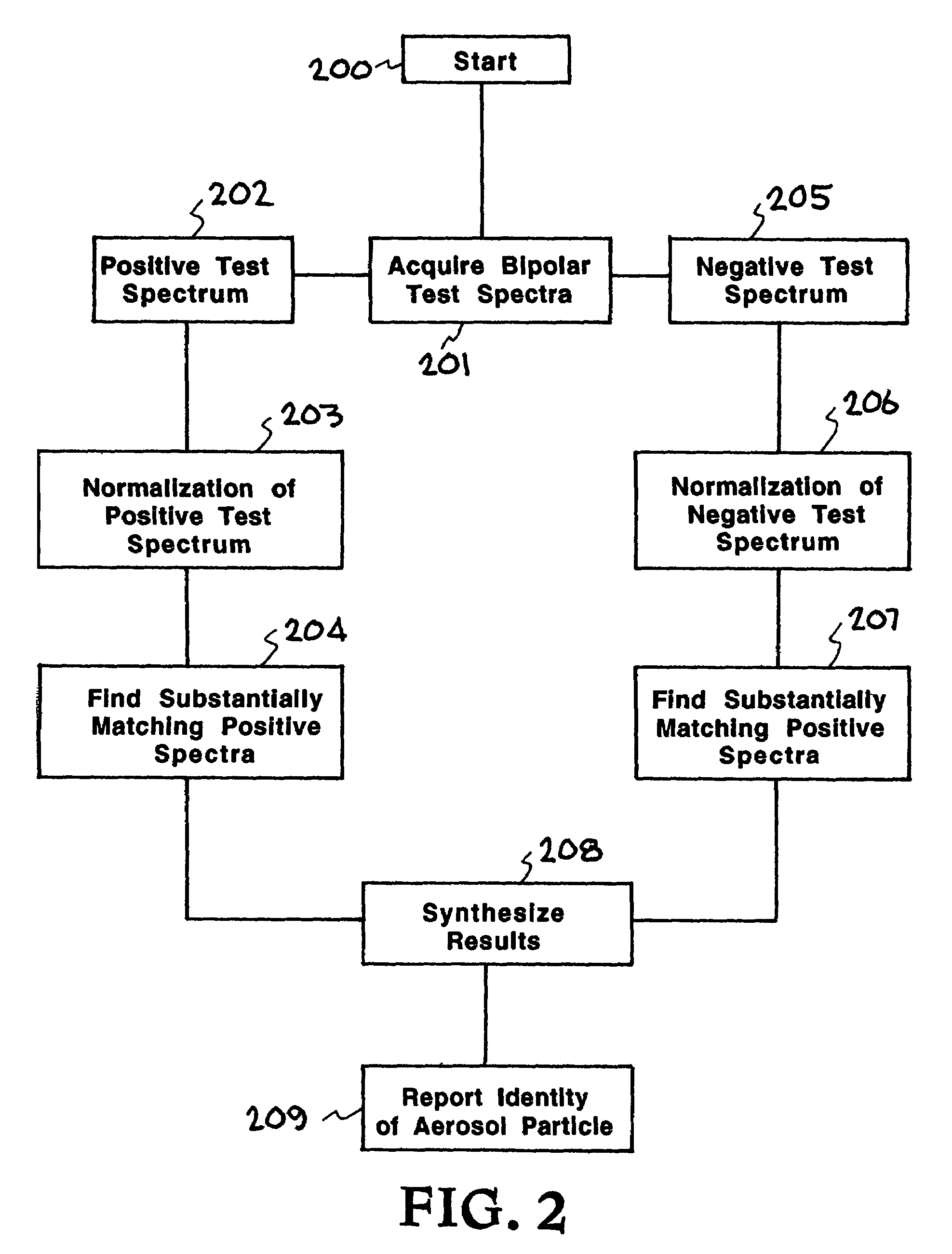

Real-time detection method and system for identifying individual aerosol particles

InactiveUS20050073683A1Reduce activationTime-of-flight spectrometersMaterial analysis by optical meansScreening techniquesFluorescence

An improved method and system of identifying individual aerosol particles in real time. Sample aerosol particles are collimated, tracked, and screened to determine which ones qualify for mass spectrometric analysis based on predetermined qualification or selection criteria. Screening techniques include one or more of determining particle size, shape, symmetry, and fluorescence. Only qualifying particles passing all screening criteria are subject to desorption / ionization and single particle mass spectrometry to produce corresponding test spectra, which is used to determine the identities of each of the qualifying aerosol particles by comparing the test spectra against predetermined spectra for known particle types. In this manner, activation cycling of a particle ablation laser of a single particle mass spectrometer is reduced.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Method and apparatus to visualize the coronary arteries using ultrasound

ActiveUS8105239B2Improved three dimensional imageReduce noiseImage enhancementImage analysisBLOOD FILLEDScreening techniques

A non-invasive screening technique for visualizing coronary arteries which overcomes the problems of visualizing the curved arteries by projecting the three dimensional volume of the arteries onto a two dimensional screen. Blood filled areas such as the coronary arteries and veins, are highlighted to contrast with other nearby tissues using non-linear classification and segmentation techniques. Data is gathered as a sequence of 2D slices stored as a 3D volume. Software interpolates voxels intermediate to the slices. Wiener filtering or LMS spatial filtering can be implemented on each 2D scan to improve lateral resolution and reduce noise prior to the use of the scan data with the classification and segmentation algorithms. A traditional handheld ultrasound probe is employed to enable the technician to locate the area of interest, but a gyroscopic stabilizer is added to minimize unwanted variation on two axes of rotation.

Owner:MAUI IMAGING

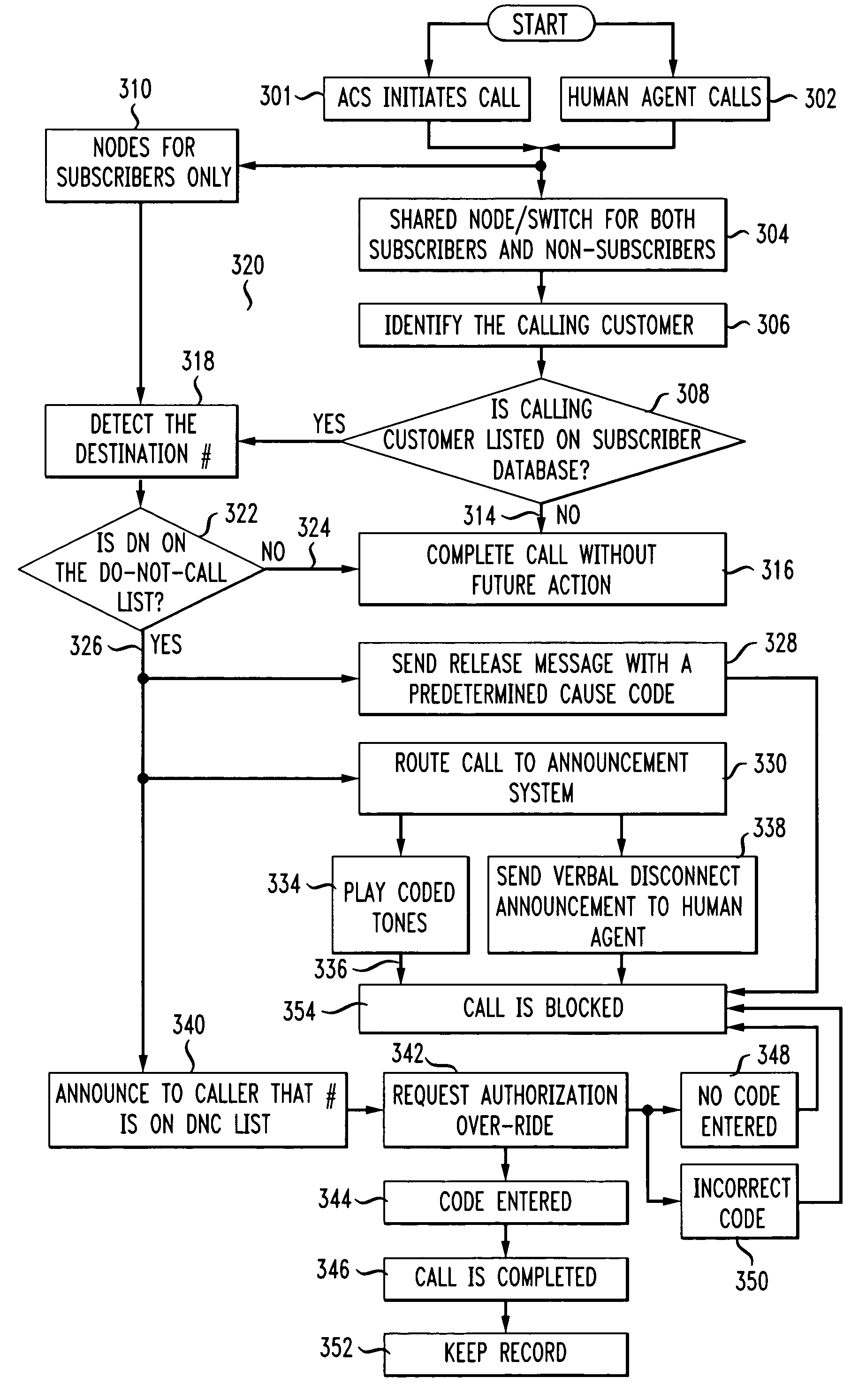

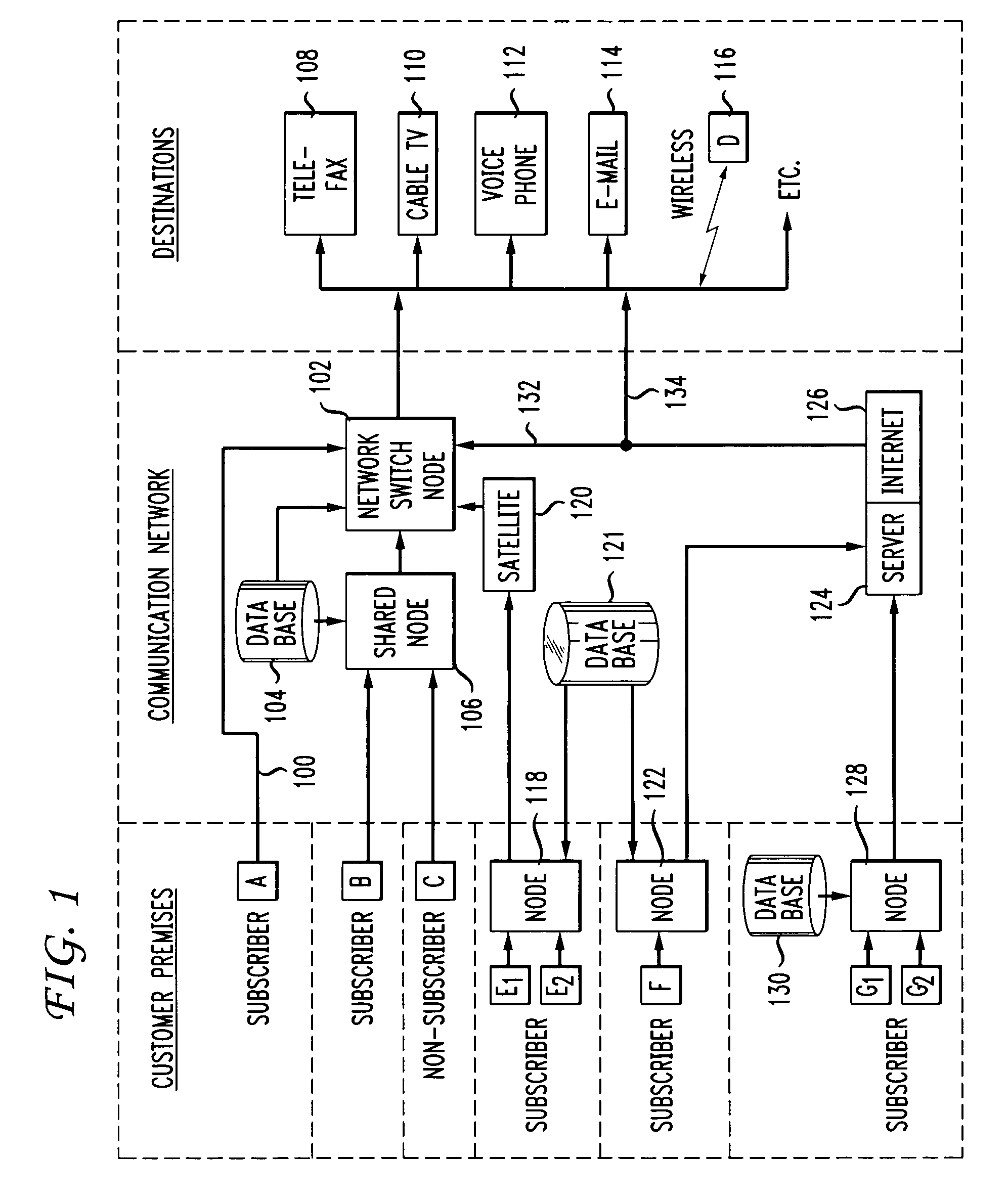

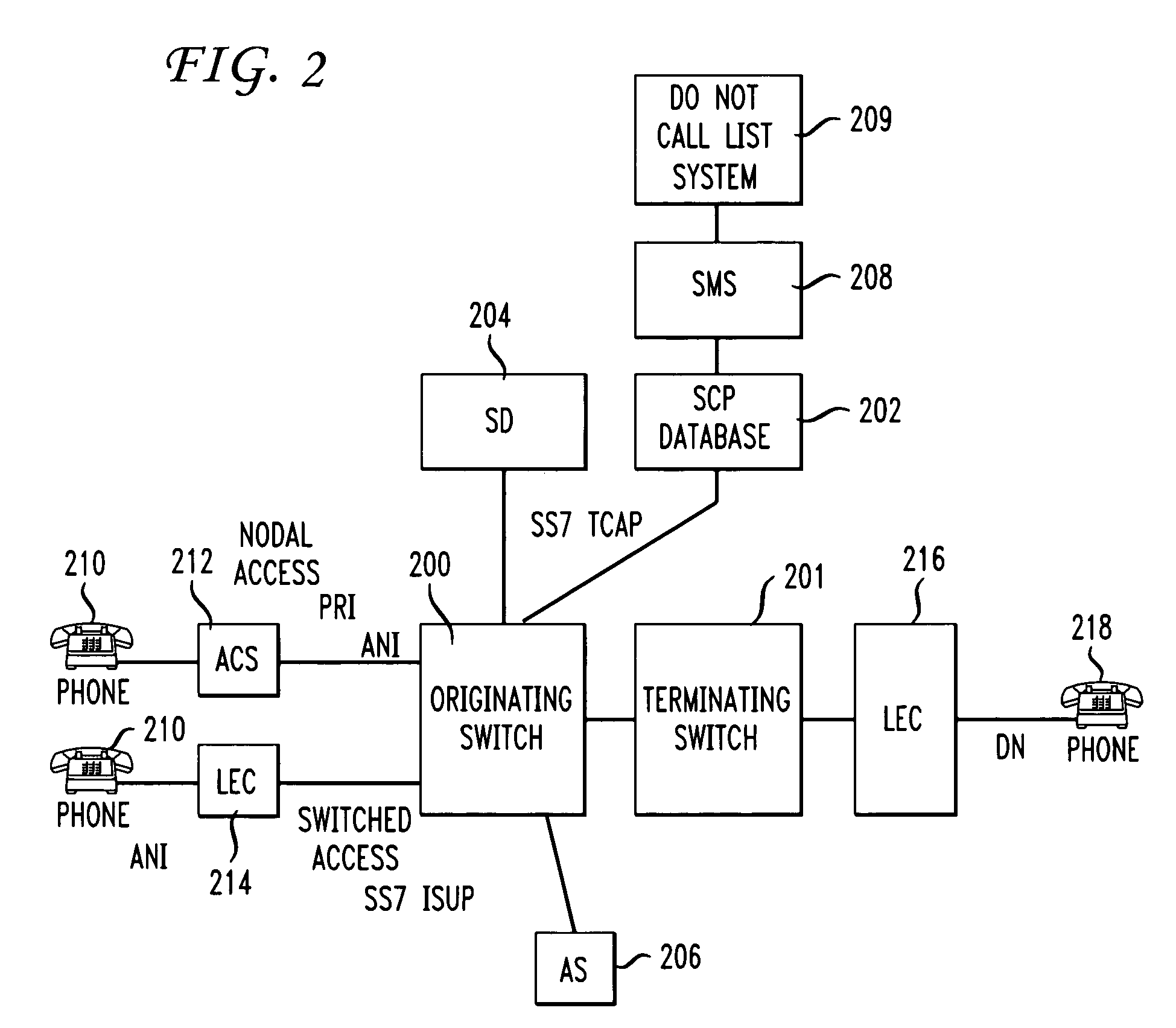

Database service for telemarketers to screen and block selected telecommunication messages

ActiveUS7099444B1Block deliverySpecial service for subscribersGraded-service arrangementsScreening techniquesDatabase services

A method and apparatus for screening and blocking certain telecommunications sent via a communication network by telemarketers or other message senders is disclosed. This service is provided to subscribing parties that initiate the telecommunications. A periodically updated “do-not-contact” database is incorporated in cooperation with network nodes to block screened messages from being delivered to an intended destination that is listed in the database. Screening and blocking can be accomplished on the customer premises or at a network node shared with non-subscribing parties. The network node ignores messages sent from non-subscribing parties. Various marking or screening techniques can be used to identify those telecommunication messages sent from or on behalf of subscribing message senders. Blocking is accomplished by various techniques including audio disconnect instructions routed back to a human agent, or actuating coded signals to automatically cancel delivery in accordance with the updated database.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO

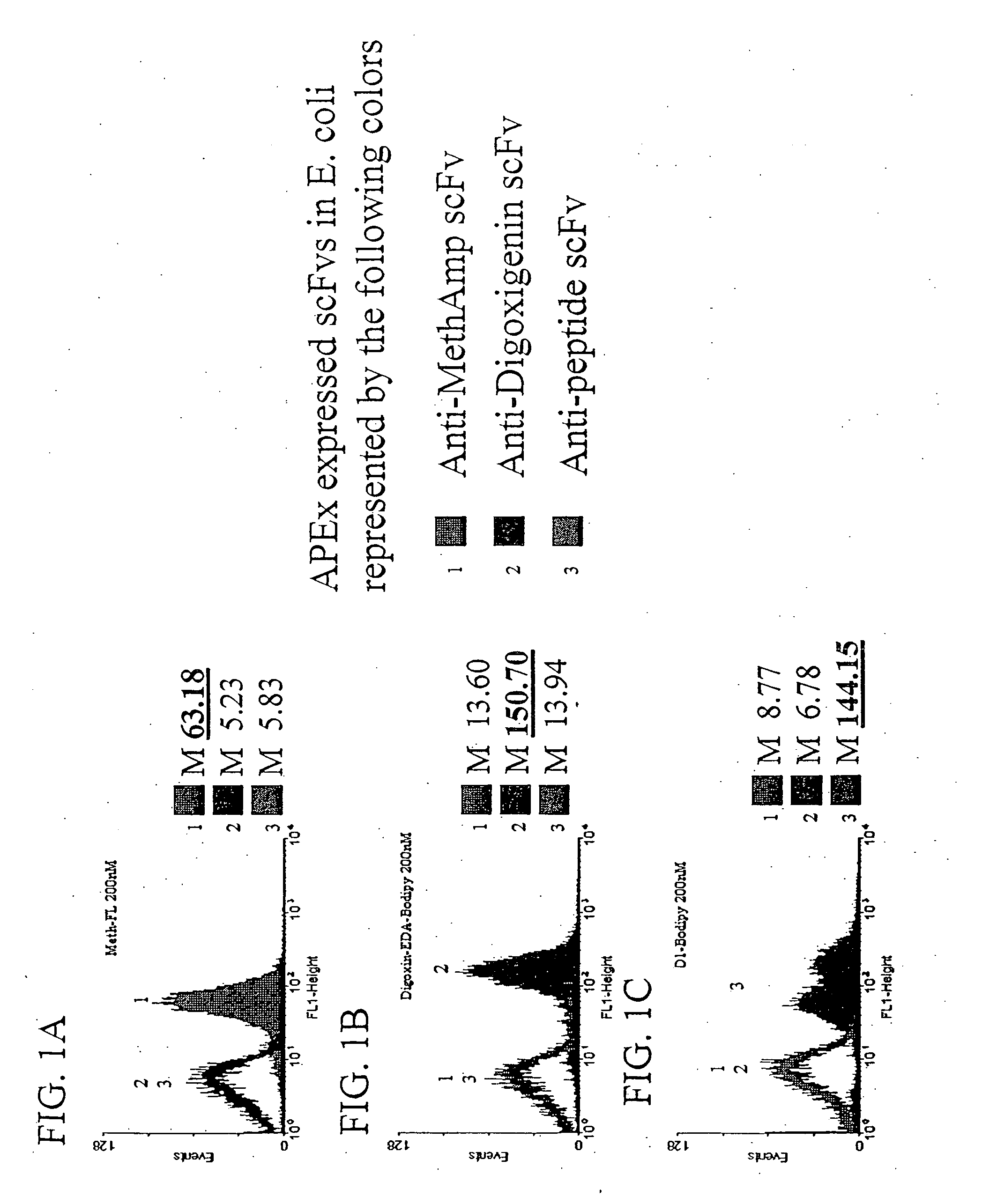

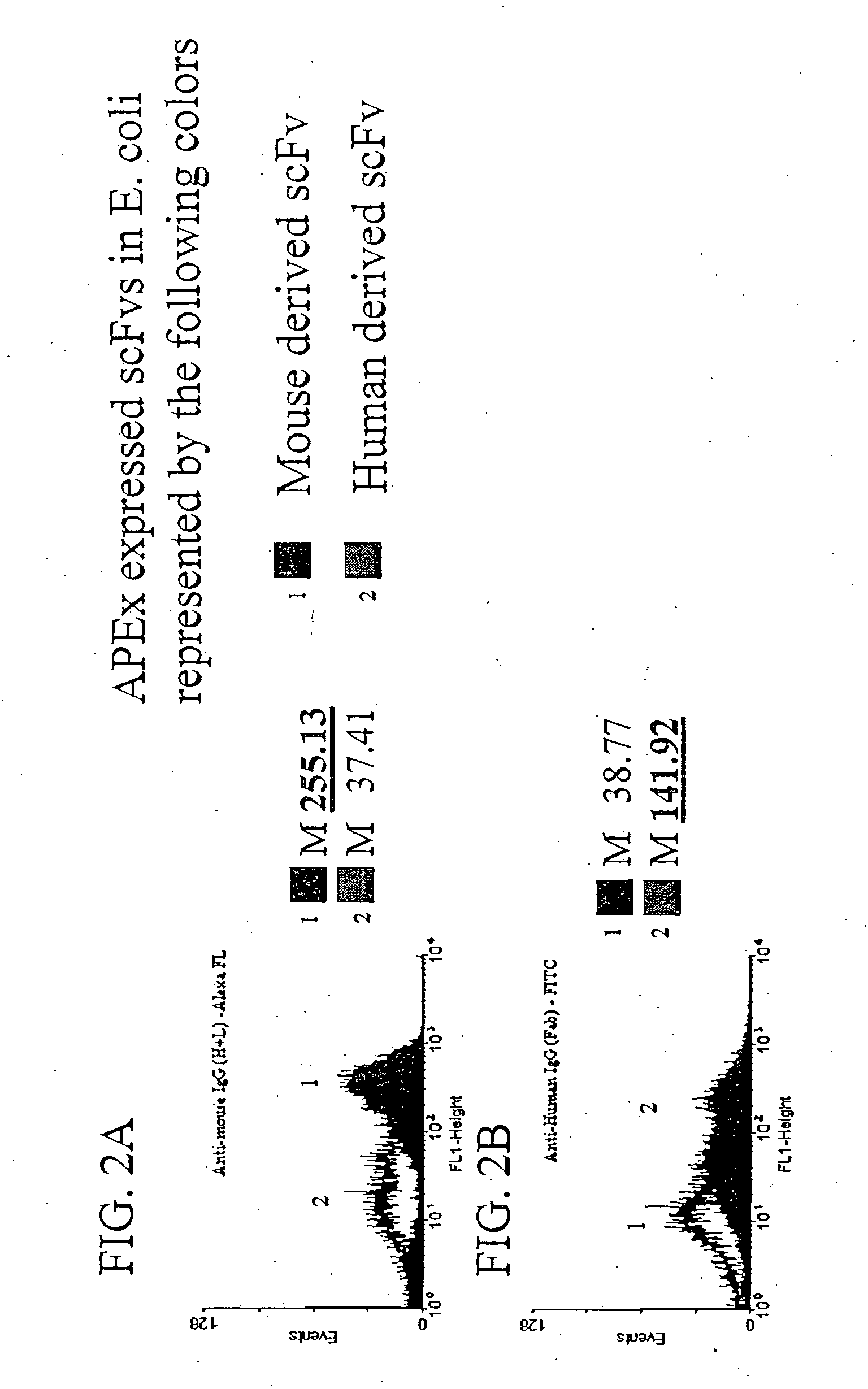

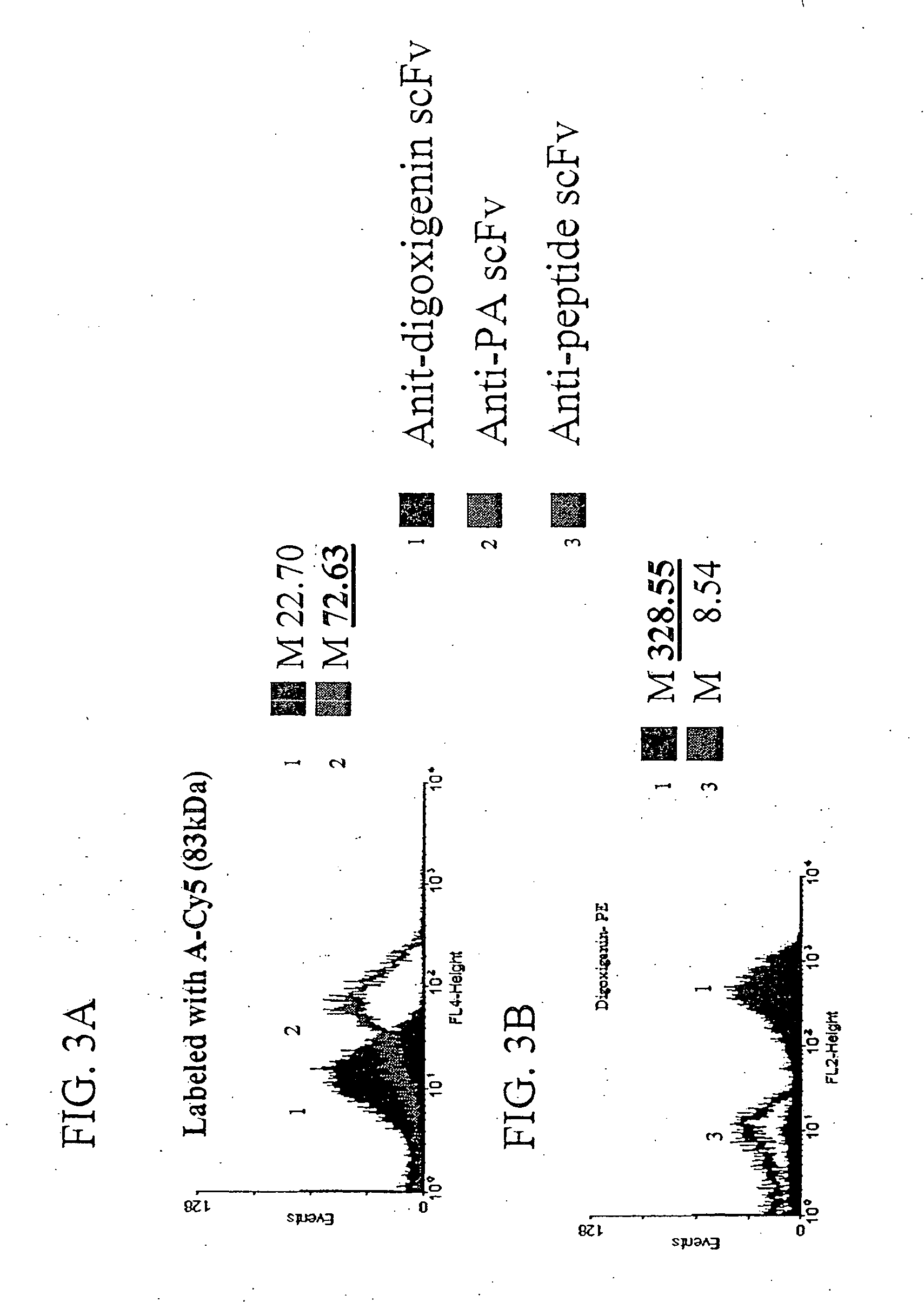

Combinatorial protein library screening by periplasmic expression

InactiveUS20060029947A1Improve breathabilityPolypeptide with localisation/targeting motifBacteriaScreening techniquesSurface expression

The invention overcomes the deficiencies of the prior art by providing a rapid approach for isolating binding proteins capable of binding small molecules and peptides. In the technique, libraries of candidate binding proteins, such as antibody sequences, may be expressed in the periplasm of gram negative bacteria with at least one target ligand. In clones expressing recombinant polypeptides with affinity for the ligand, the ligand becomes bound and retained by the cell even after removal of the outer membrane, allowing the cell to be isolated from cells not expressing a binding polypeptide with affinity for the target ligand. The target ligand may be detected in numerous ways, including use of direct fluorescence or secondary antibodies that are fluorescently labeled, allowing use of efficient screening techniques such as fluorescence activated cell sorting (FACS). The approach is more rapid and robust than prior art methods and avoids problems associated with the outer surface-expression of ligand fusion proteins employed with phage display.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

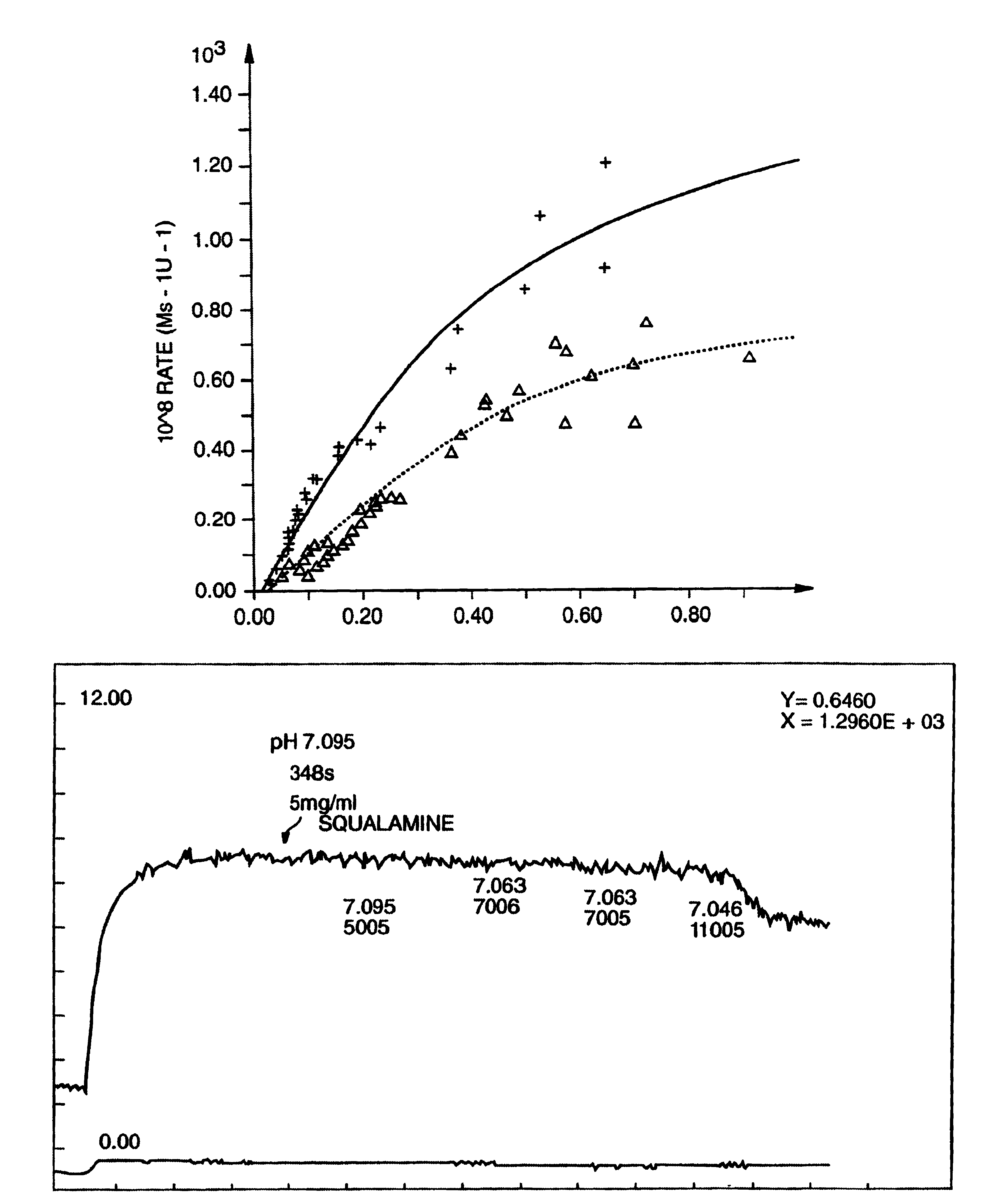

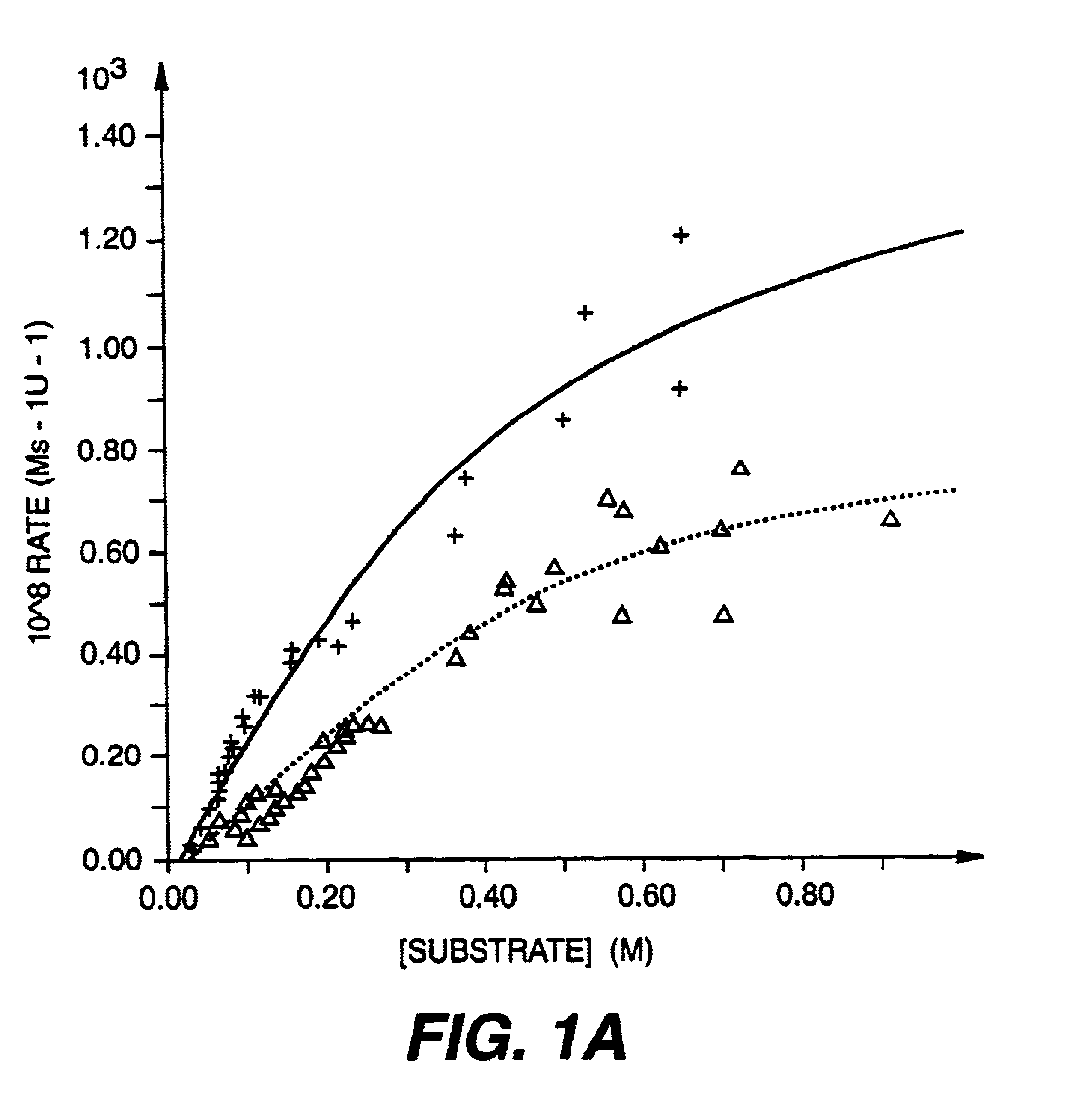

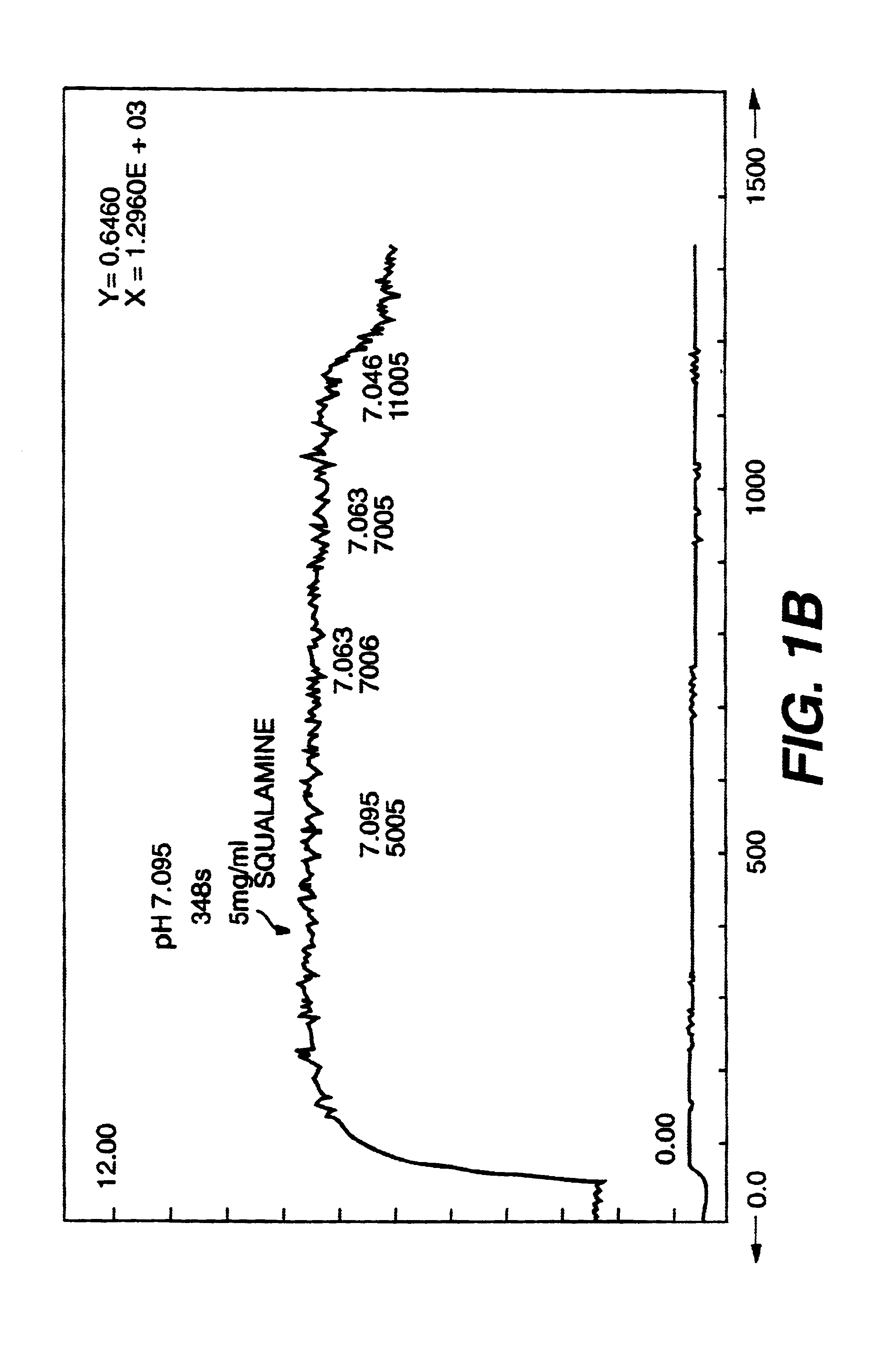

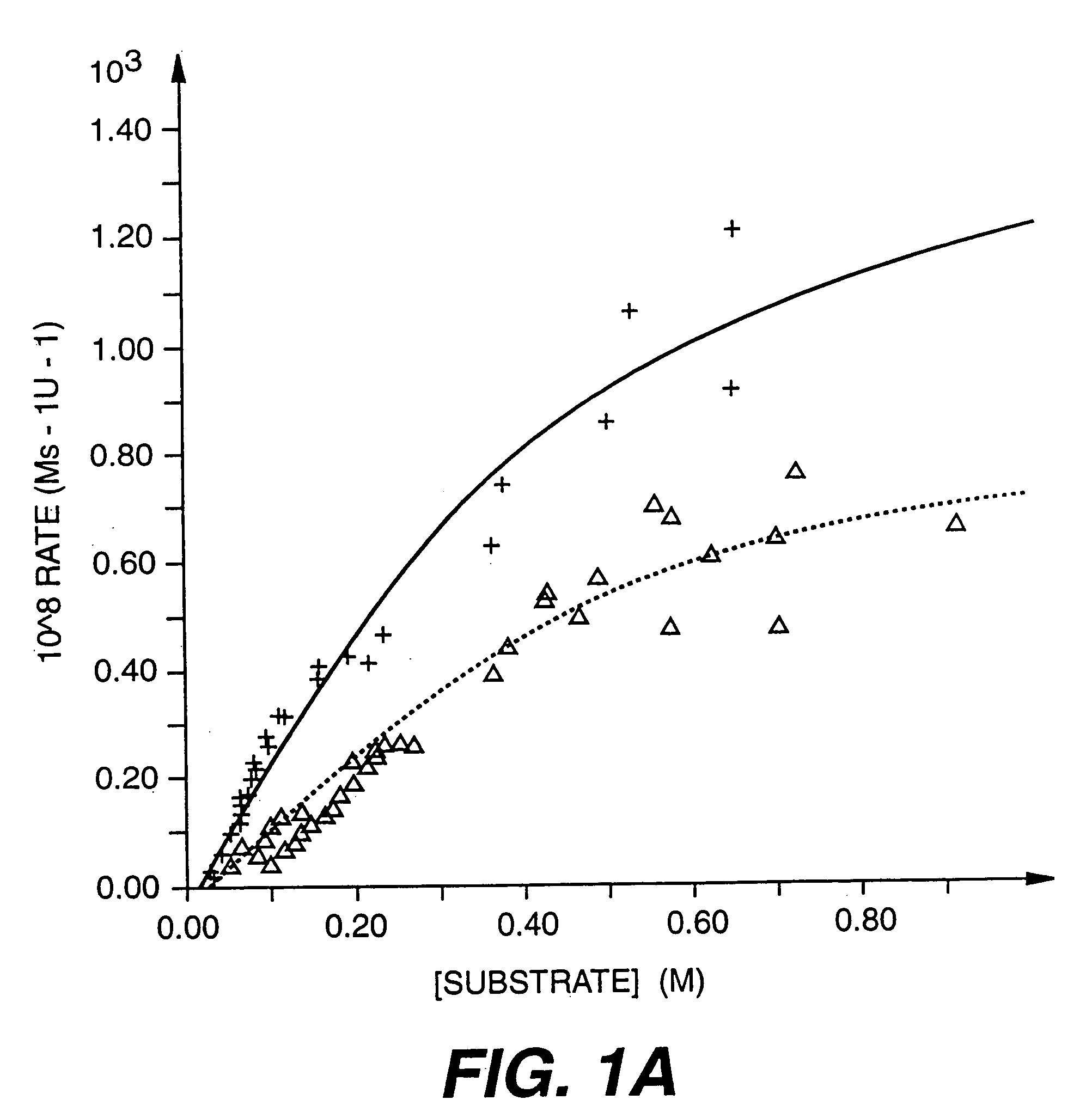

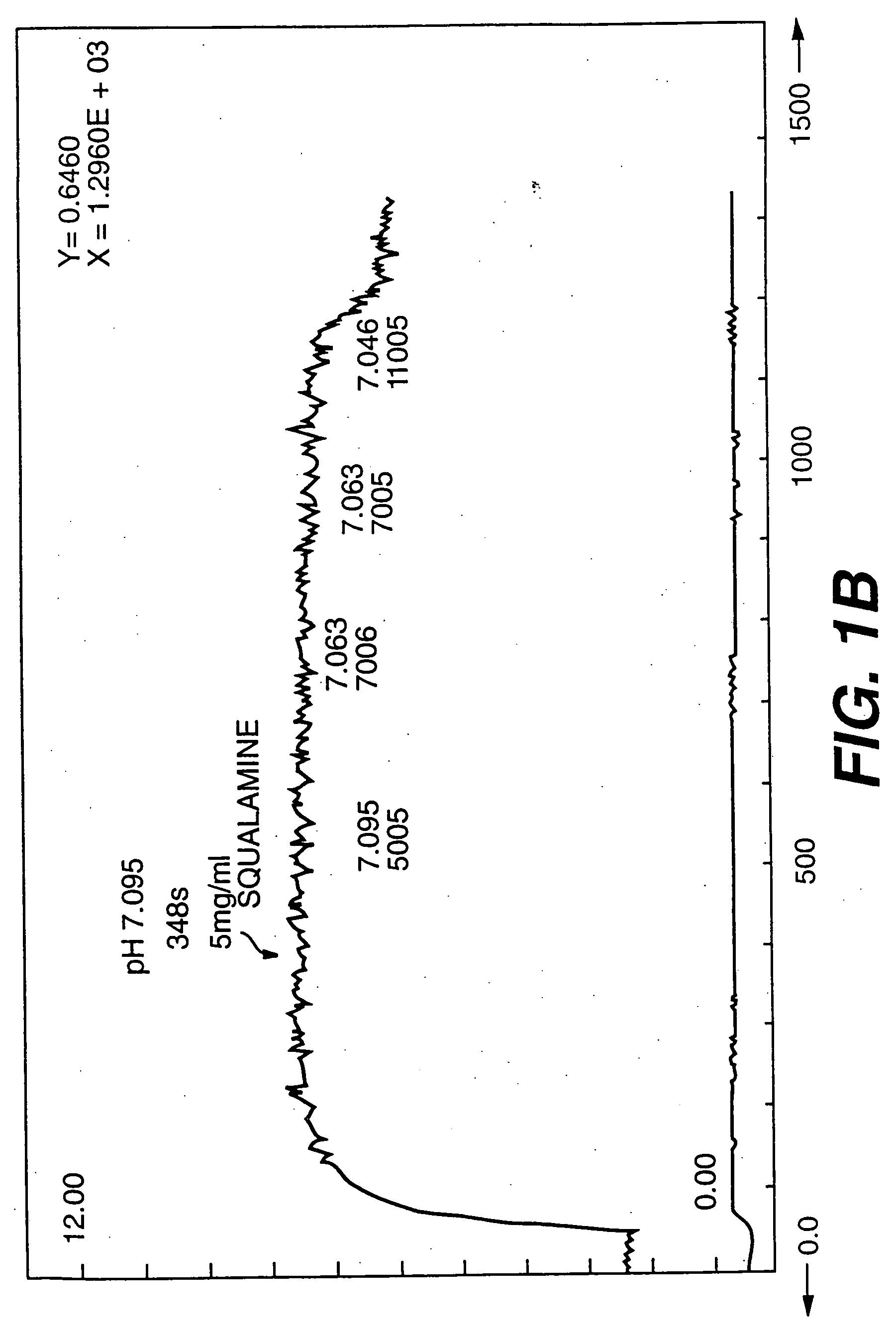

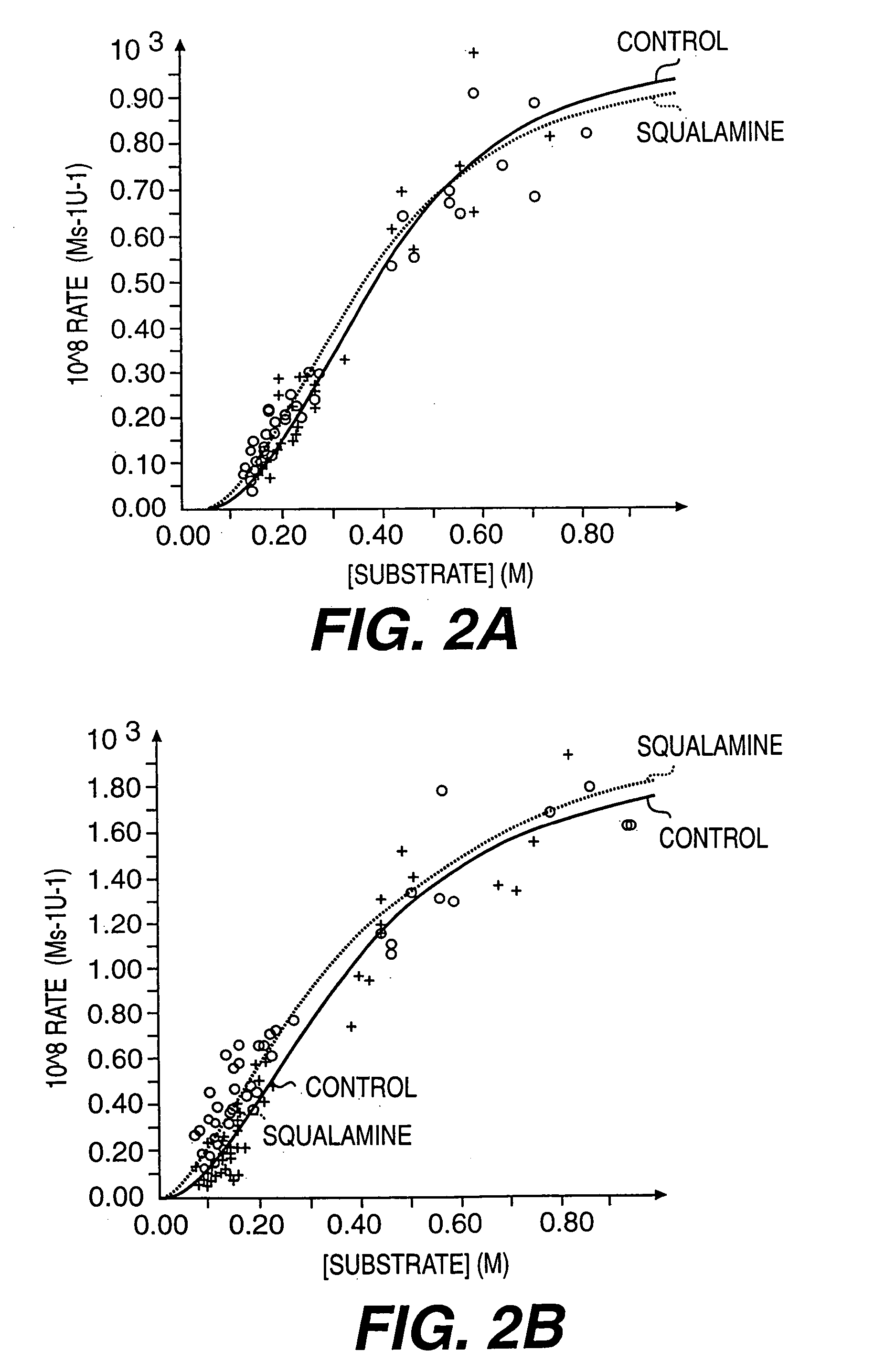

Treatment of neovascularization disorders with squalimine

Aminosterol compounds are described that are useful as inhibitors of the sodium / proton exchanger (NHE). Methods of using such aminosterols compounds are also enclosed, including those employing compounds that are inhibitors of a spectrum of NHEs as well as those using compounds that are inhibitors of only one specific NHE. Advantageous screening techniques and assays for evaluating a compound's therapeutic activity are also disclosed.

Owner:OHR PHARMA +1

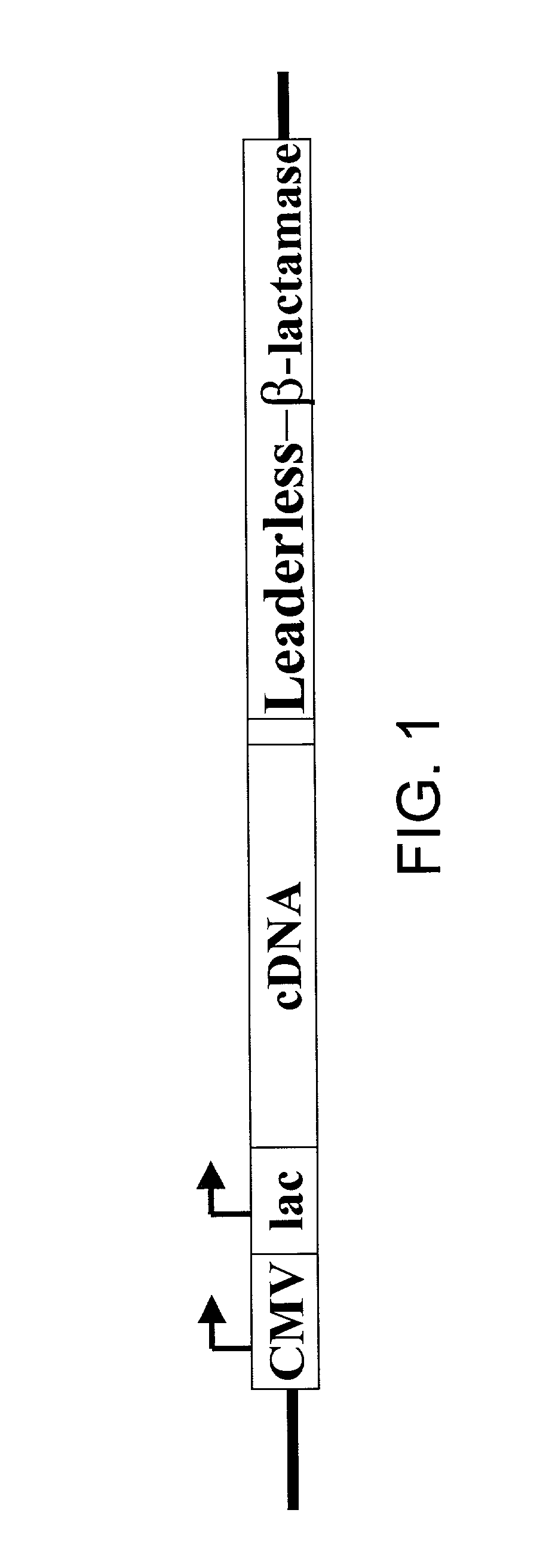

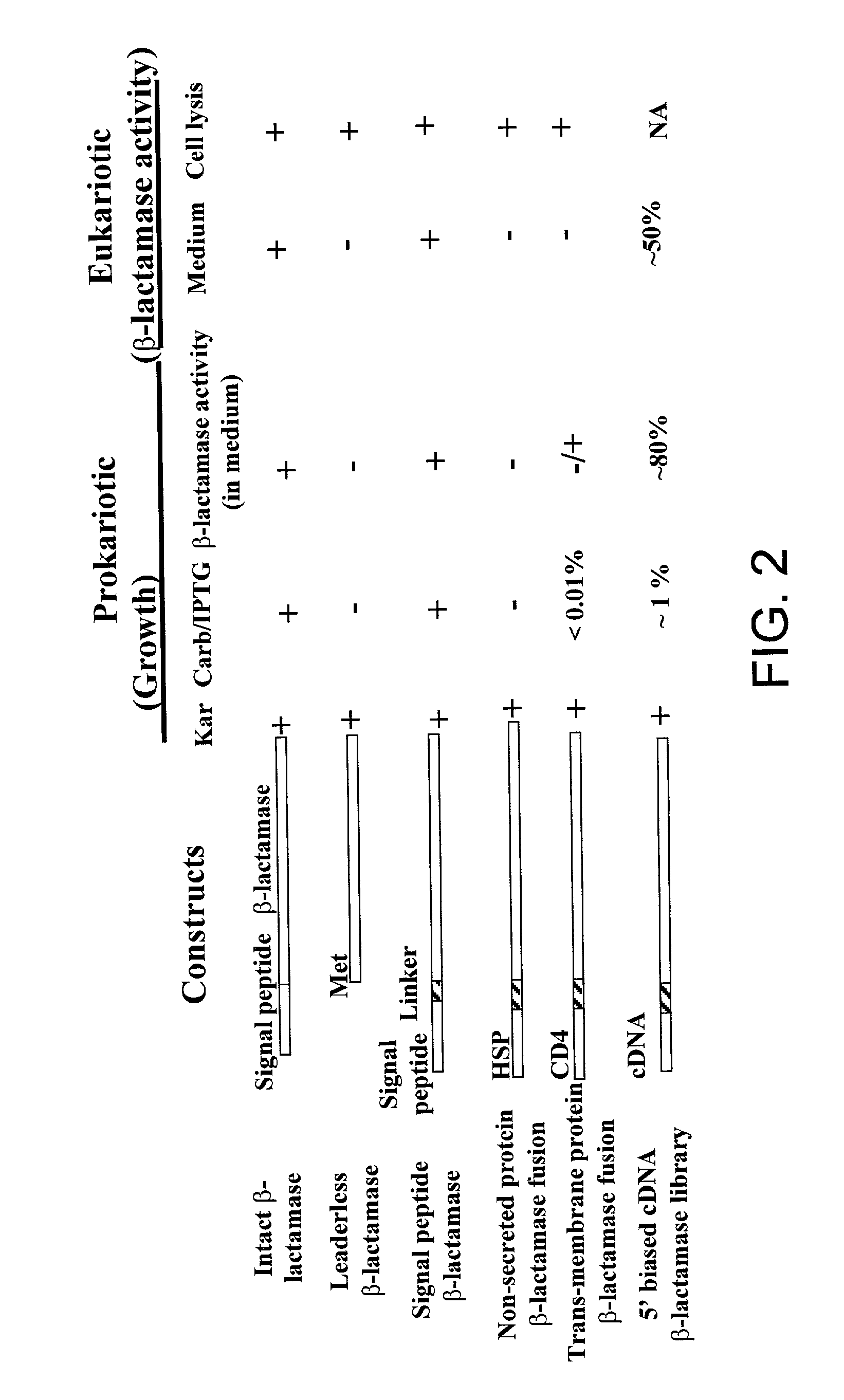

Method for identification of cDNAs encoding signal peptides

InactiveUS20020127557A1Fast wayBacteriaMicrobiological testing/measurementScreening techniquesPresent method

The present invention provides a method in which cDNAs that encode signal sequences for secreted or membrane-associated proteins are isolated using a fusion protein that directs secretion of a molecule that provides antibiotic resistance, e.g., .beta.-lactamase. The present method allows the isolation of signal peptide-associated proteins that may be difficult to isolate with other techniques. Moreover, the present method is amenable to throughput screening techniques and automation, and especially in validating the presence of the signal sequence via expression of the protein in both prokaryotic and eukaryotic cells. This invention provides a powerful and approach to the large scale isolation of novel secreted proteins.

Owner:INCYTE CORP

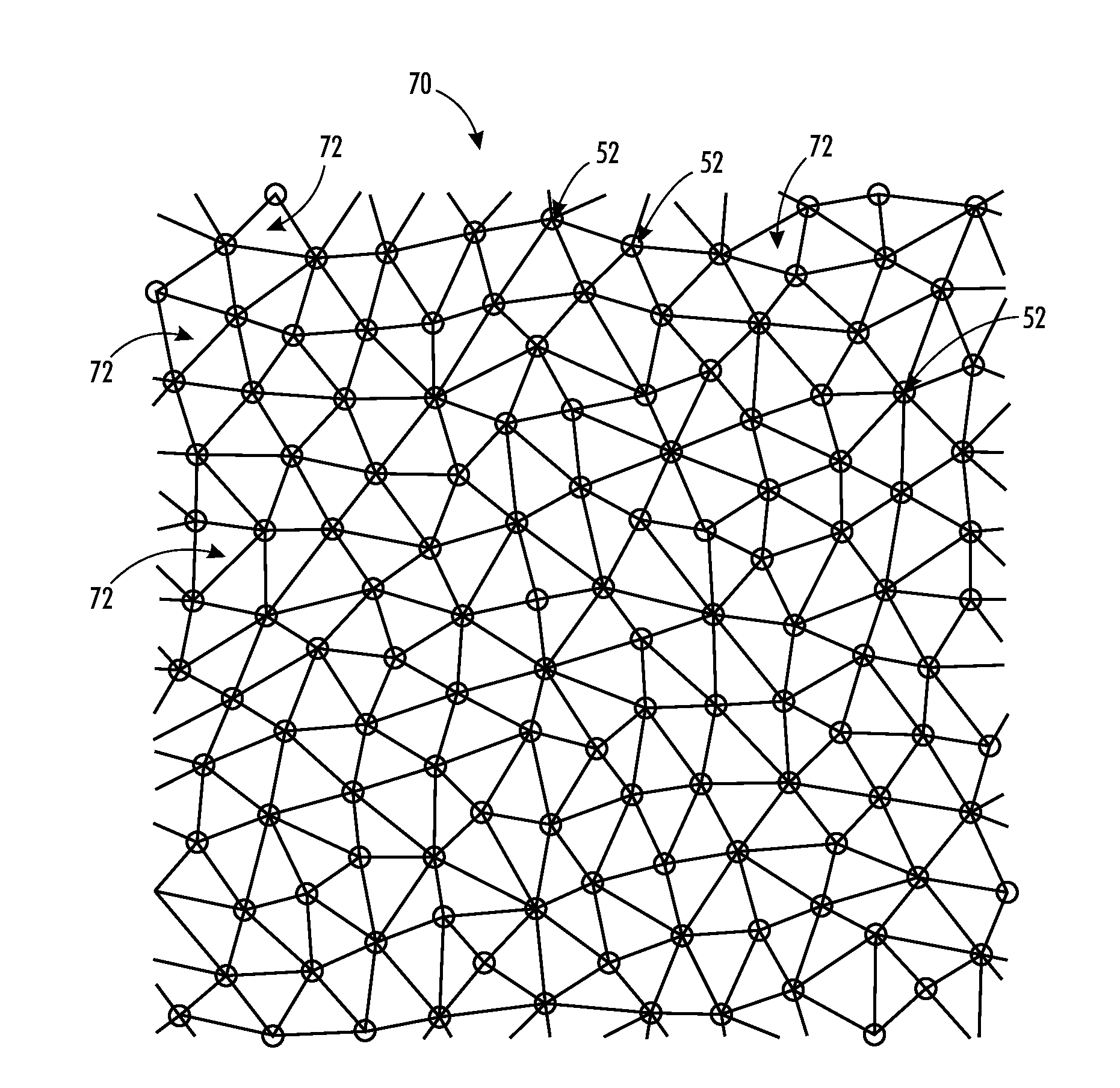

Method and Apparatus to Visualize the Coronary Arteries Using Ultrasound

ActiveUS20120116226A1Improved three dimensional imageReduce noiseImage enhancementImage analysisBLOOD FILLEDScreening techniques

A non-invasive screening technique for visualizing coronary arteries which overcomes the problems of visualizing the curved arteries by projecting the three dimensional volume of the arteries onto a two dimensional screen. Blood-filled areas such as the coronary arteries and veins, are highlighted to contrast with other nearby tissues using non-linear classification and segmentation techniques. Data is gathered as a sequence of 2D slices stored as a 3D volume. Software interpolates voxels intermediate to the slices. Wiener filtering or LMS spatial filtering can be implemented on each 2D scan to improve lateral resolution and reduce noise prior to the use of the scan data with the classification and segmentation algorithms. A traditional handheld ultrasound probe is employed to enable the technician to locate the area of interest, but a gyroscopic stabilizer is added to minimize unwanted variation on two axes of rotation.

Owner:MAUI IMAGING

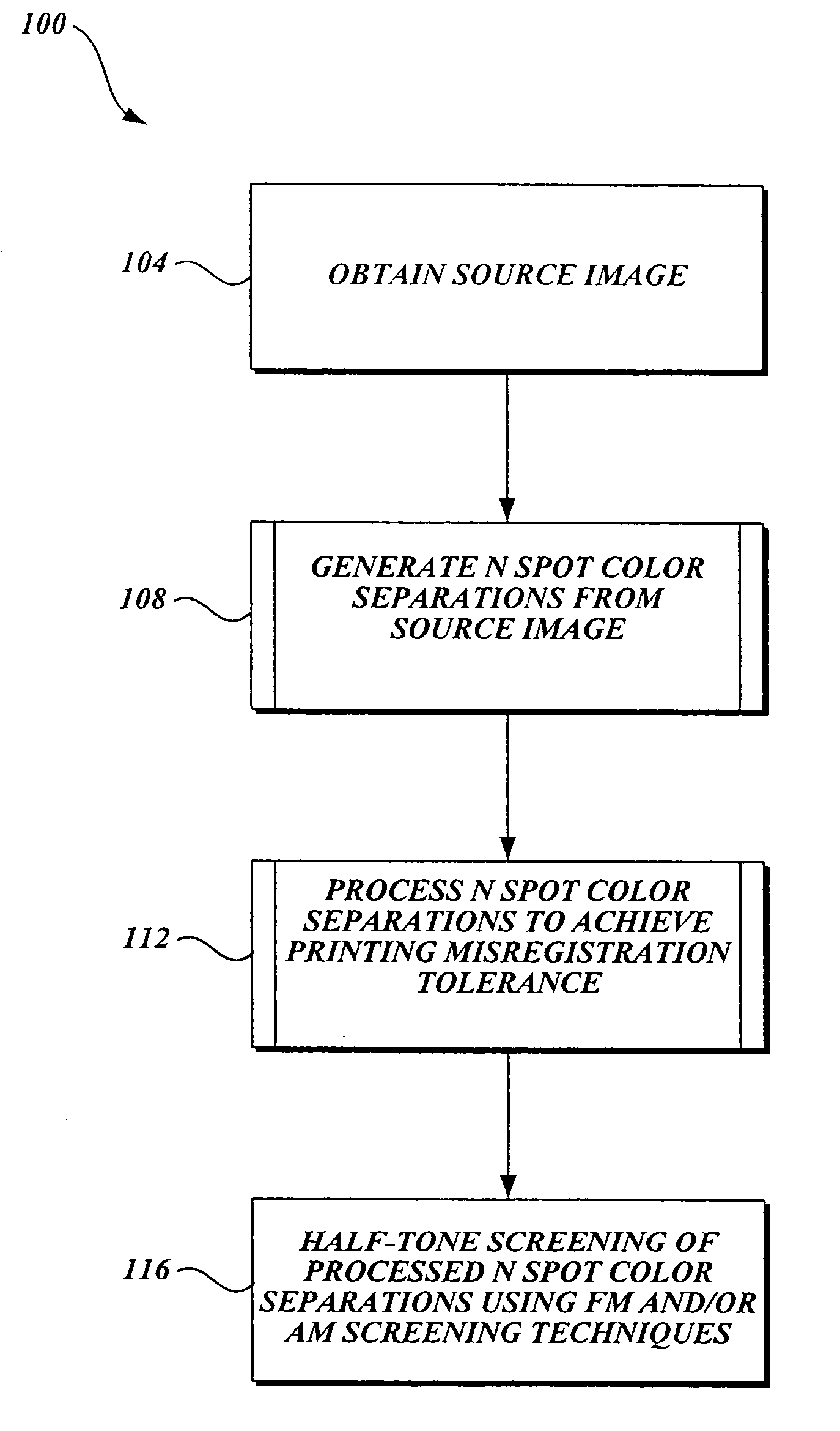

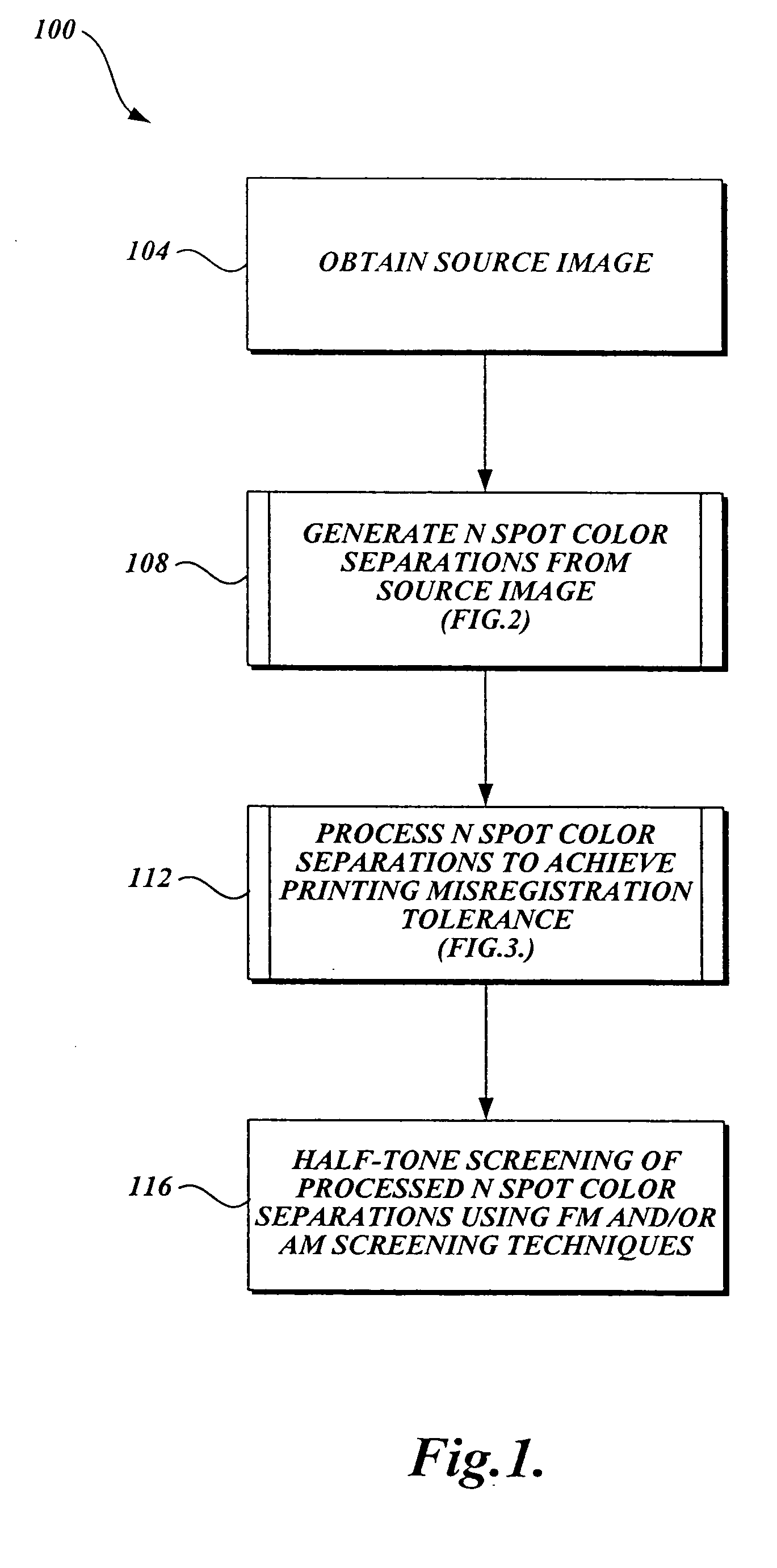

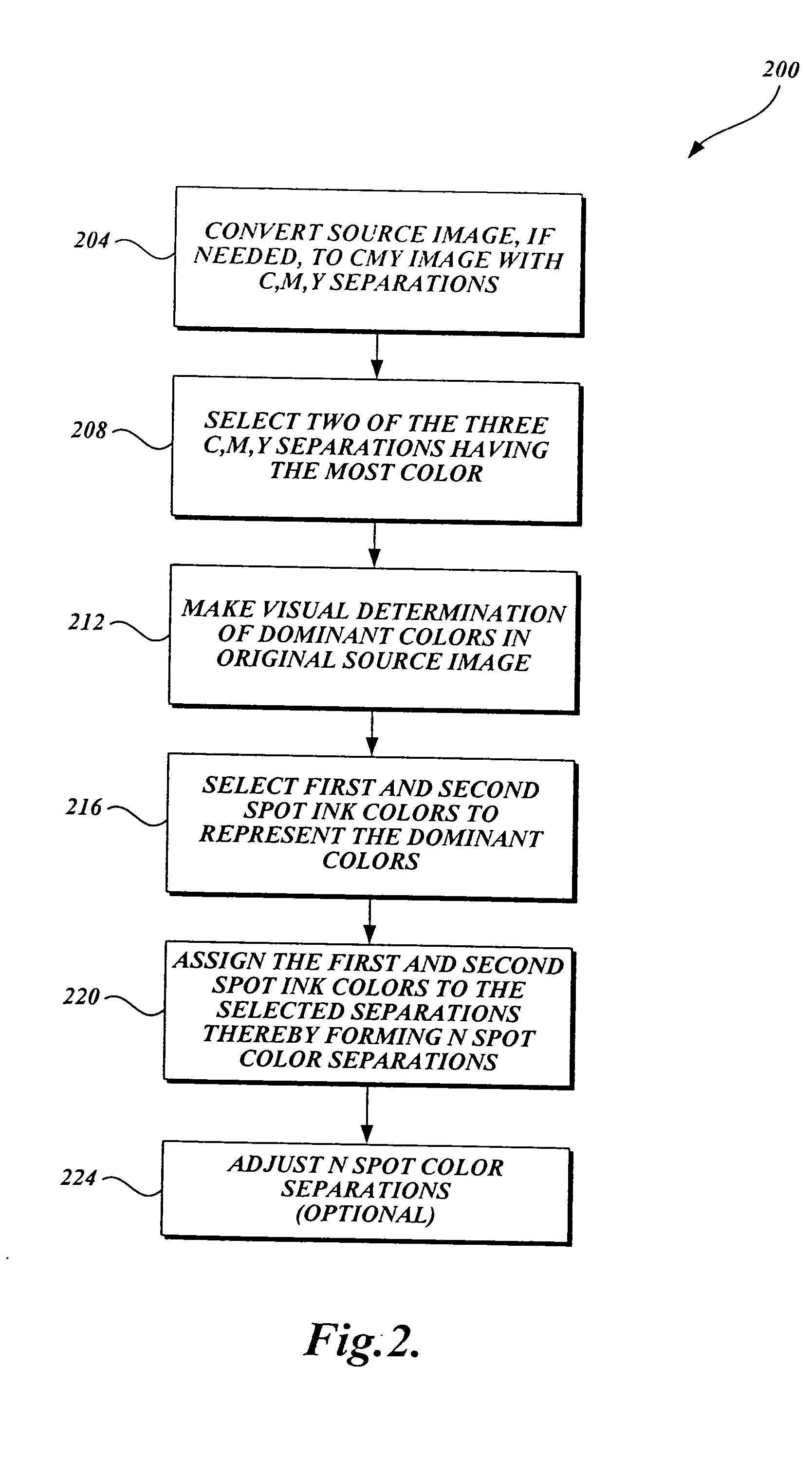

Prepress workflow process employing frequency modulation (FM) screening techniques

InactiveUS20050226498A1Character and pattern recognitionVisual presentationPattern recognitionScreening techniques

Embodiments of the present invention include prepress workflow methods. The prepress workflow methods include generating N spot color separations from the color source image, wherein N is less than four. The N spot color separations, when superimposed, form a reproduction composite image similar in color to the source image. Alternatively, N non-process color separations obtained from Duotone, Tritone, or Quadtone images may also be employed. The methods may optionally include processing the generated N digital spot color separations to achieve misregistration tolerant printing prior to screening. The methods further include screening the N spot color separations, wherein at least one of the N spot color separations is screened using frequency modulation (FM).

Owner:INT PAPER CO

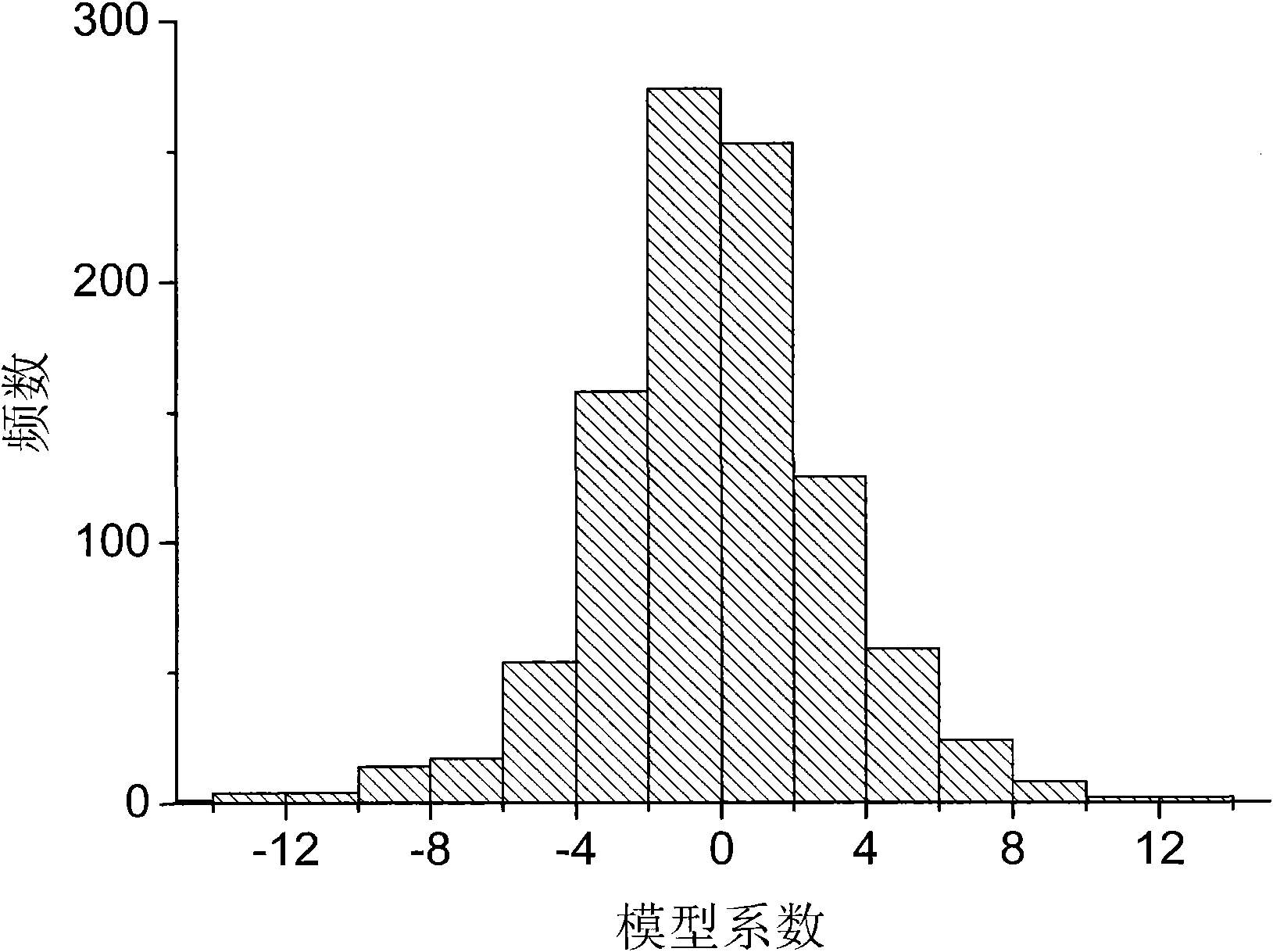

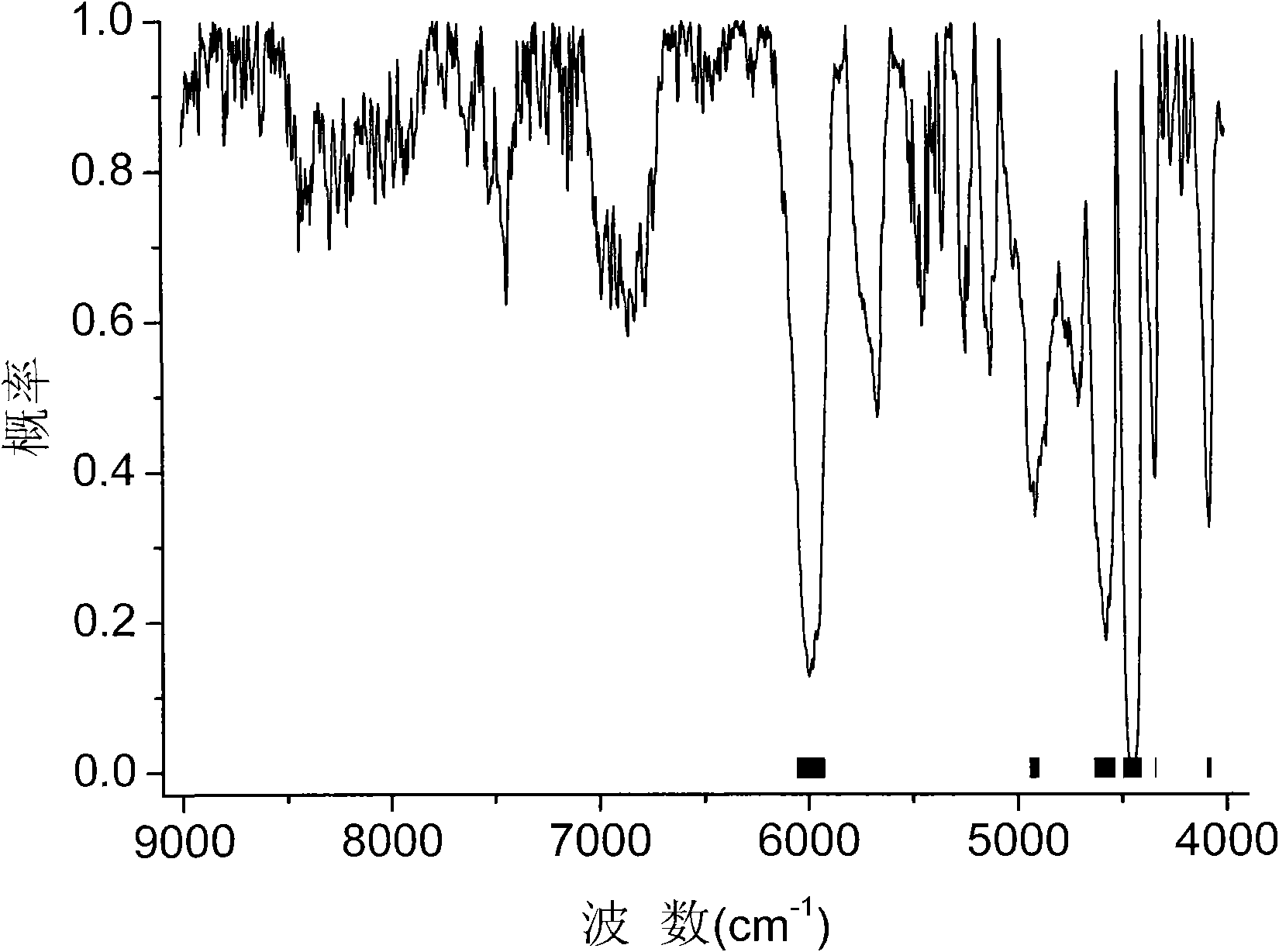

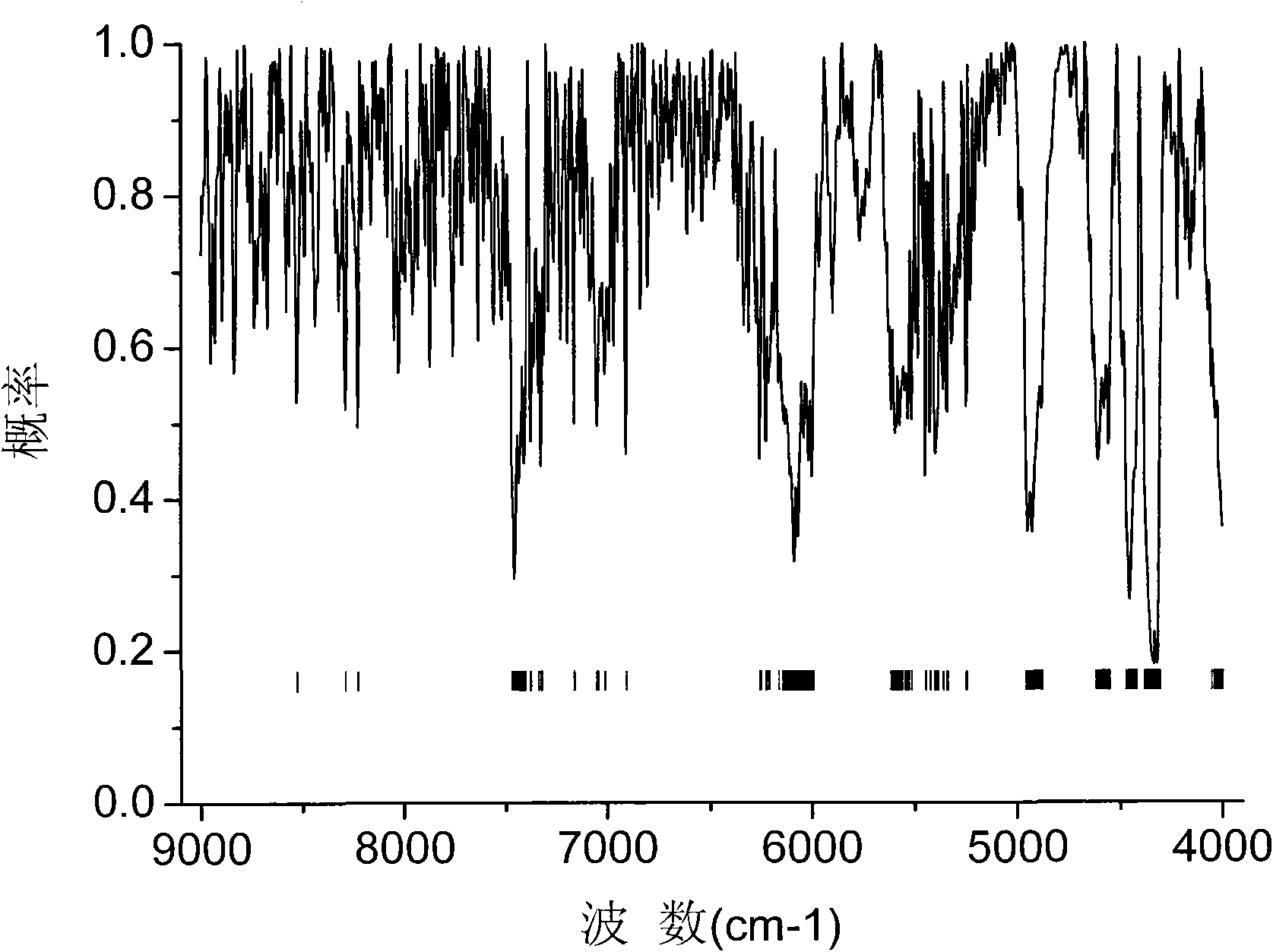

Screening method for near infrared spectrum wavelength and Raman spectrum wavelength

InactiveCN101825567AImprove forecast accuracyAccurate extractionComputing modelsRaman scatteringInfraredScreening techniques

The invention relates to a screening method for near infrared spectrum wavelength and Raman spectrum wavelength. The method comprises that acquired near infrared spectrum or Raman spectrum and data of concentration of corresponding composition to be detected are divided into a training set, a check set and a prediction set; a PLS model is established by using original spectrum and the concentration of the composition to be detected to obtain a real PLS model coefficient; the concentration of the composition to be detected is ordered randomly and a great number of PLS models are established by using the vectors of the concentration of the composition to be detected and original spectrum matrices; according to the models, the times that a single model coefficient is larger than the real PLS model coefficient are respectively calculated to obtain a corresponding probability value; the wavelength that the probability value is less than a threshold value is reserved; an optimum model is established by using the reserved wavelength to predict the concentration of the composition to be detected of a sample in the prediction set. By adopting the method, the invention has the advantages that the wavelength containing spectral information can be accurately extracted, the quantitative analysis model is simplified, the prediction accuracy of the quantitative analysis model is improved and the new wavelength screening technique is provided for the multivariate calibration analysis of the near infrared spectrum and the Raman spectrum.

Owner:NANKAI UNIV

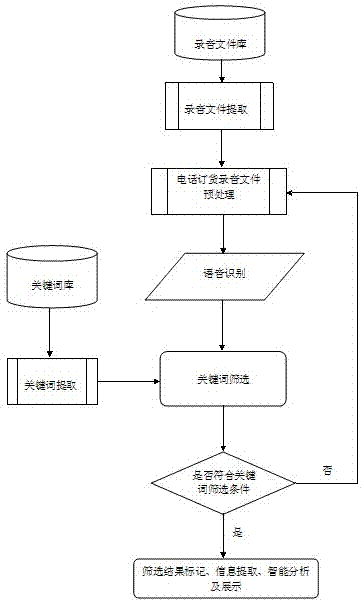

Voice lexicon screening method

InactiveCN102760436AAddressing Content Monitoring NeedsEasy to useSpeech recognitionSpecial data processing applicationsScreening techniquesScreening method

Owner:河南省烟草公司开封市公司

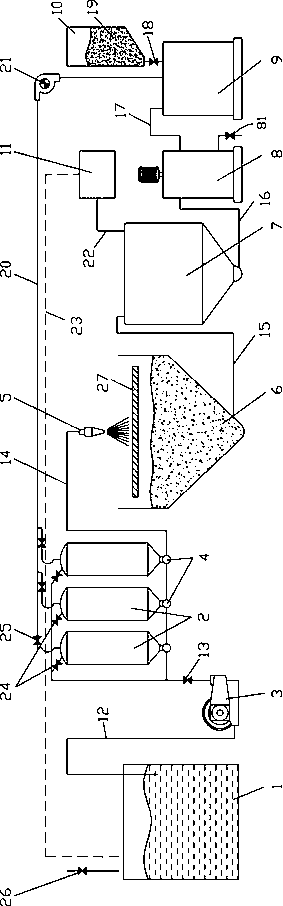

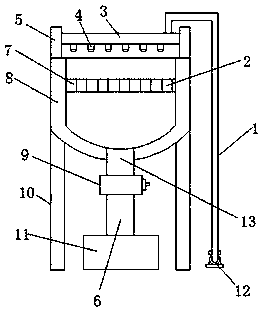

Continuous jet descaling system for cold-state metal part surface

ActiveCN102756003AGood environmental protectionReduce the cost of daily useWork treatment devicesMetal rolling arrangementsScreening techniquesEngineering

A continuous jet descaling system for cold-state metal part surface comprises a water tank, prepressing sand tanks, sand water mixers, an injection system, a collecting pool, a settling pool, a filter sifter and a sand mixing pool. The prepressing sand tanks are connected with the water tank through a pipeline and a pressurizing device, the sand water mixers are arranged at outlets of the prepressing sand tanks, the injection system is used for directly removing scale, inlets are connected with the sand water mixers through the pipeline, the collecting pool is used for collecting various mixtures after descale and is arranged below the injection system, the settling pool is connected with the bottom of the collecting pool through the pipeline, the filter sifter is connected with the bottom of the settling pool through the pipeline, a discharging outlet and a control valve are arranged at the bottom of the filter sifter, the sand mixing pool is connected with the upper part of the filter sifter through the pipeline, the sand mixing pool is connected with a sand box for storing sand through the pipeline and is connected onto the prepressing sand tanks through a mortar pipeline and a mortar pump. The continuous jet descaling system for the cold-state metal part surface can realize high-efficient and continuous surface descaling, and fine recycling of various media in the whole system is realized by making full use of washing technique of front mixed jet, filter recycling technique of the mixtures, vibrating screening technique and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

Real-time detection method and system for identifying individual aerosol particles

InactiveUS7260483B2Reduce activationTime-of-flight spectrometersMaterial analysis by optical meansScreening techniquesDesorption

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Aminosterol compounds useful as inhibitors of the sodium/proton exchanger (NHE), pharmaceutical methods and compositions employing such inhibitors, and processes for evaluating the NHE-inhibitory efficacy of compounds

Aminosterol compounds are described that are useful as inhibitors of the sodium / proton exchanger (NHE). Methods of using such aminosterols compounds are also enclosed, including those employing compounds that are inhibitors of a spectrum of NHEs as well as those using compounds that are inhibitors of only one specific NHE. Advantageous screening techniques and assays for evaluating a compound's therapeutic activity are also disclosed.

Owner:MAGAININ PHARMA INC

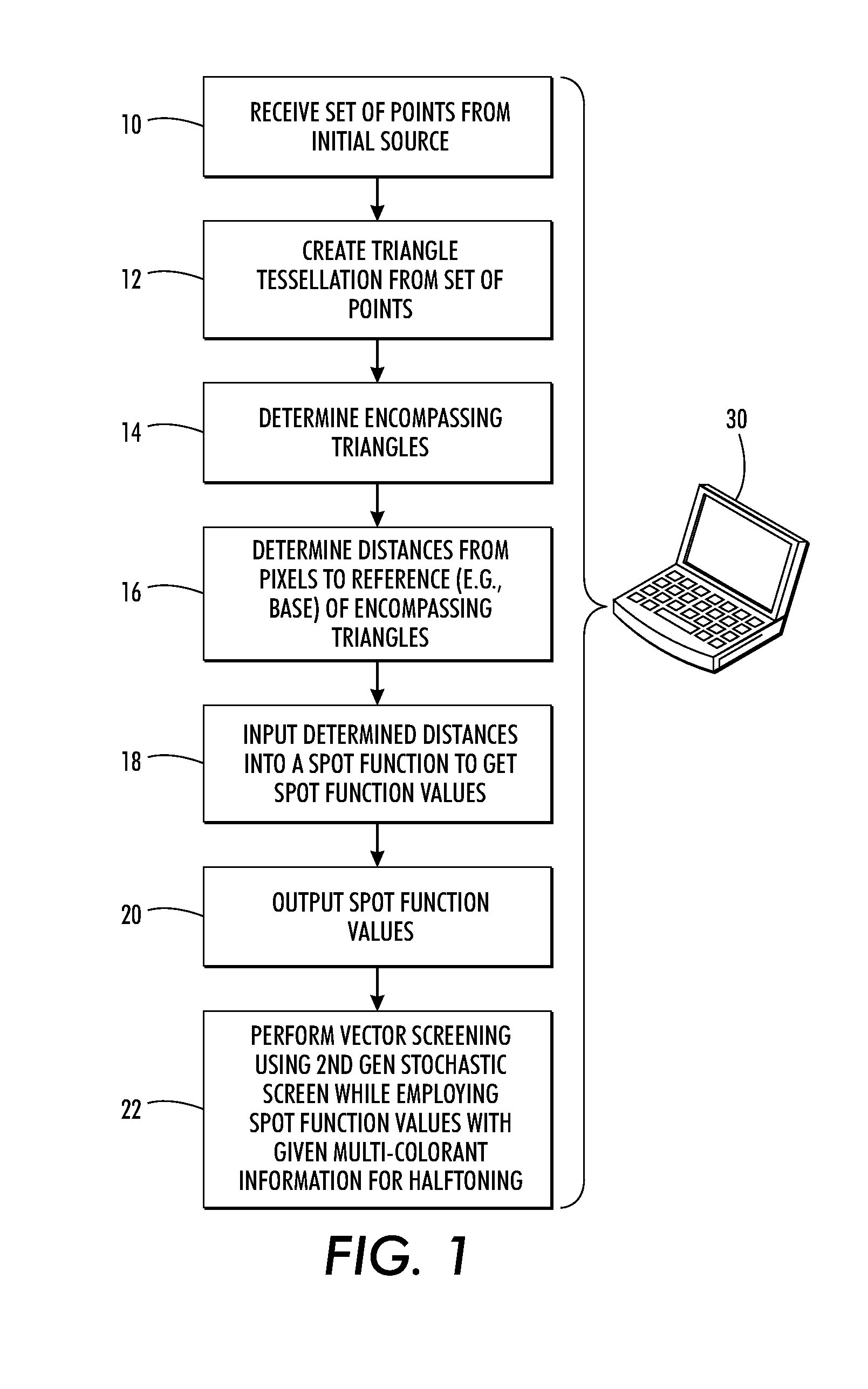

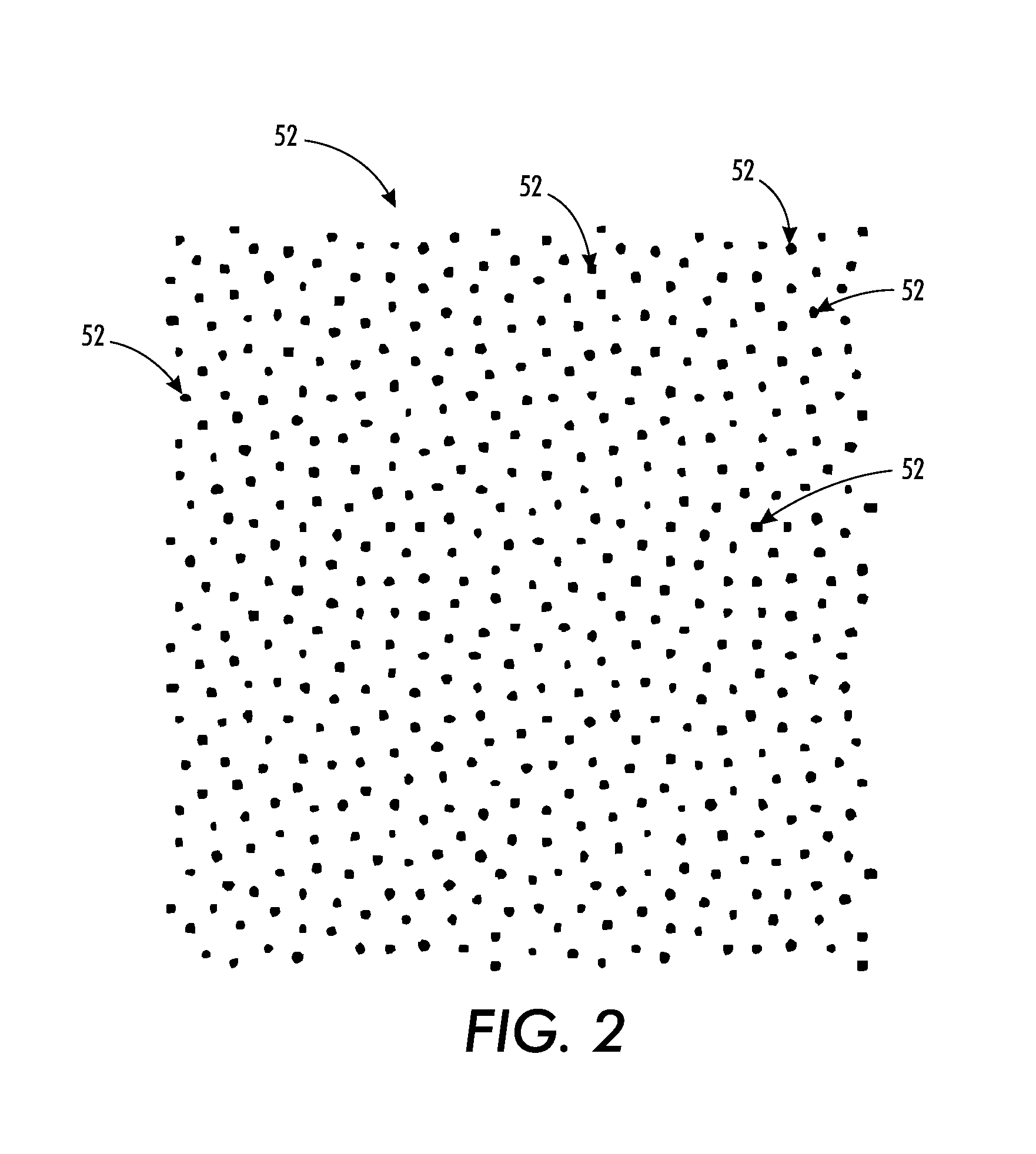

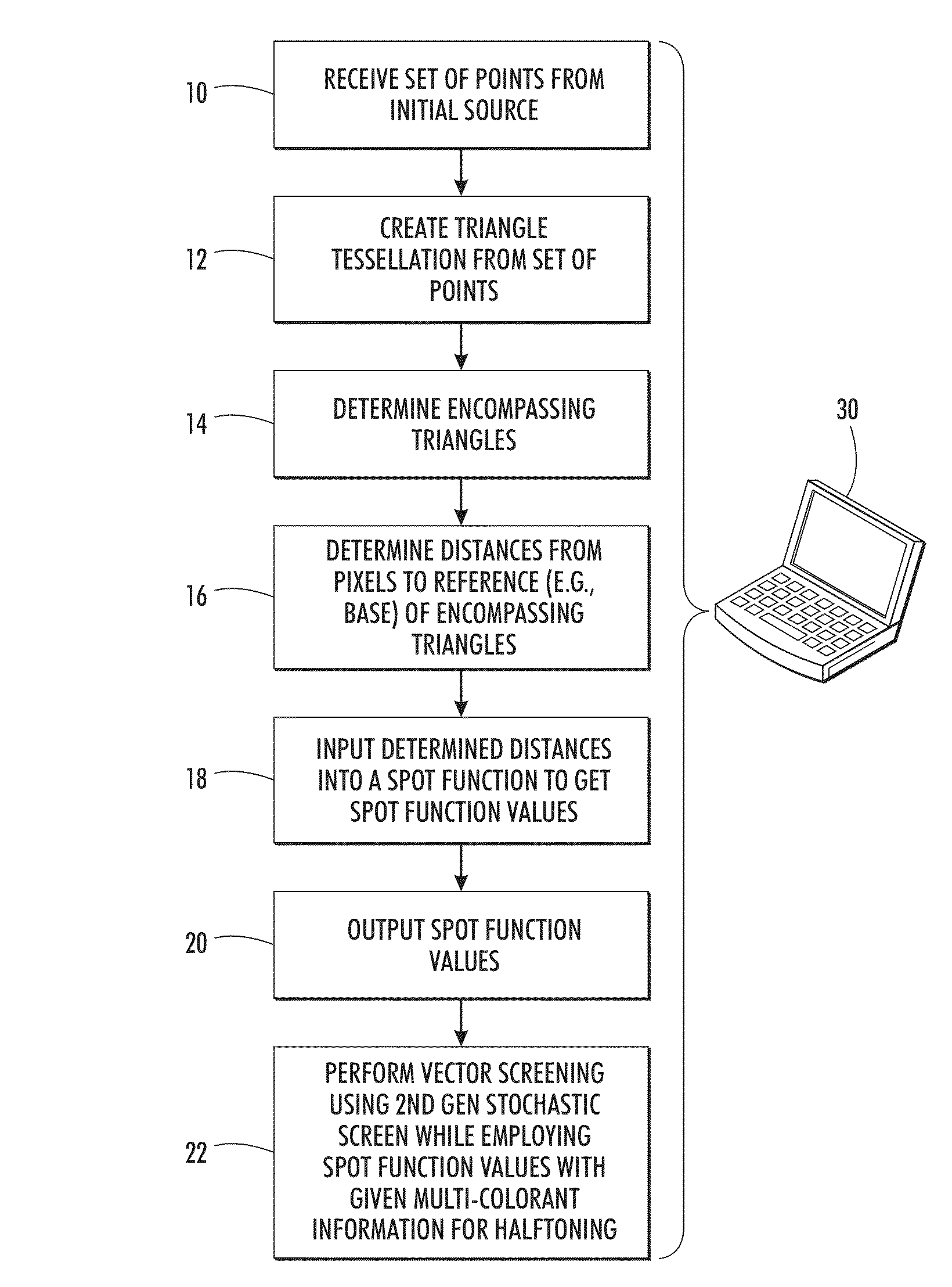

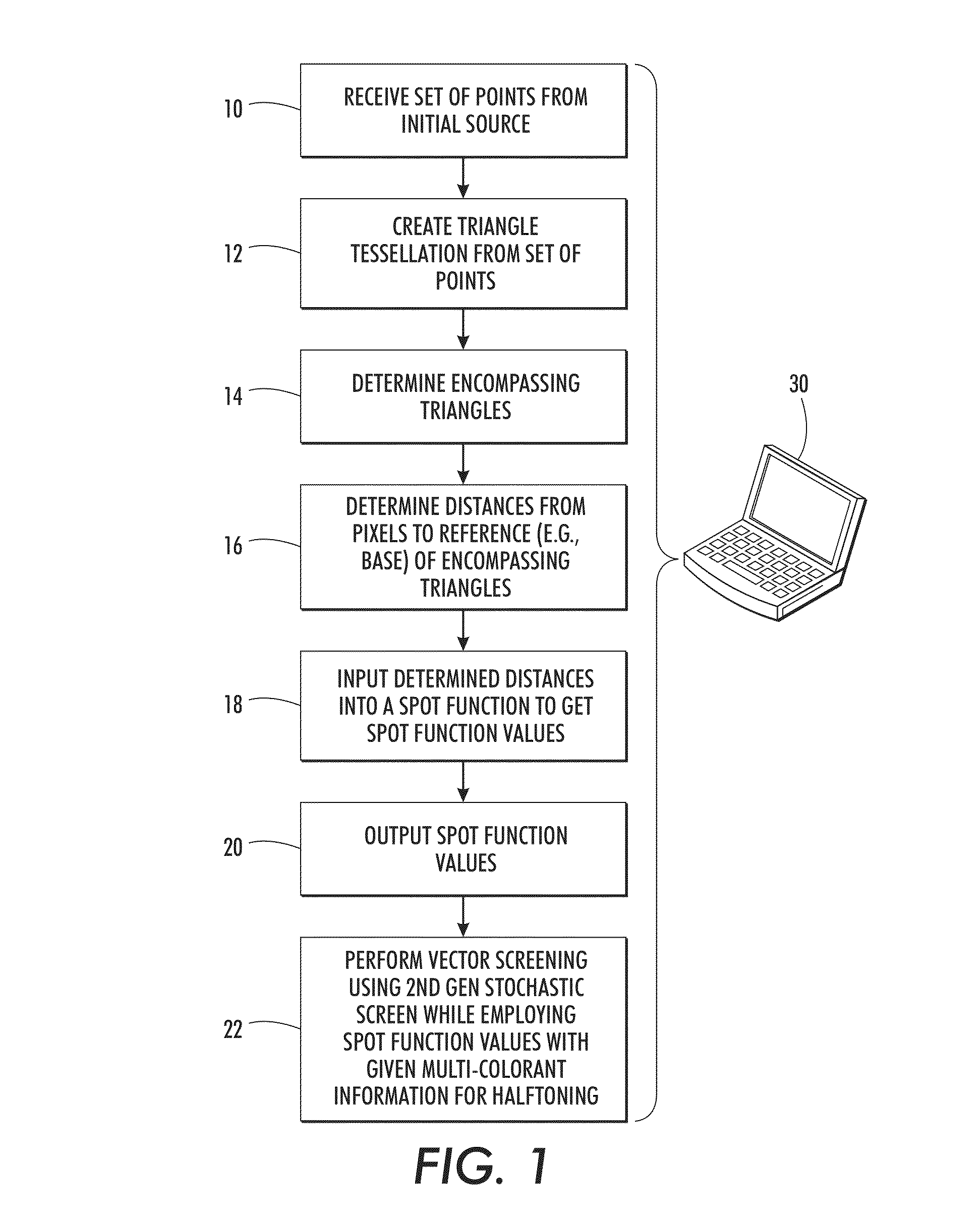

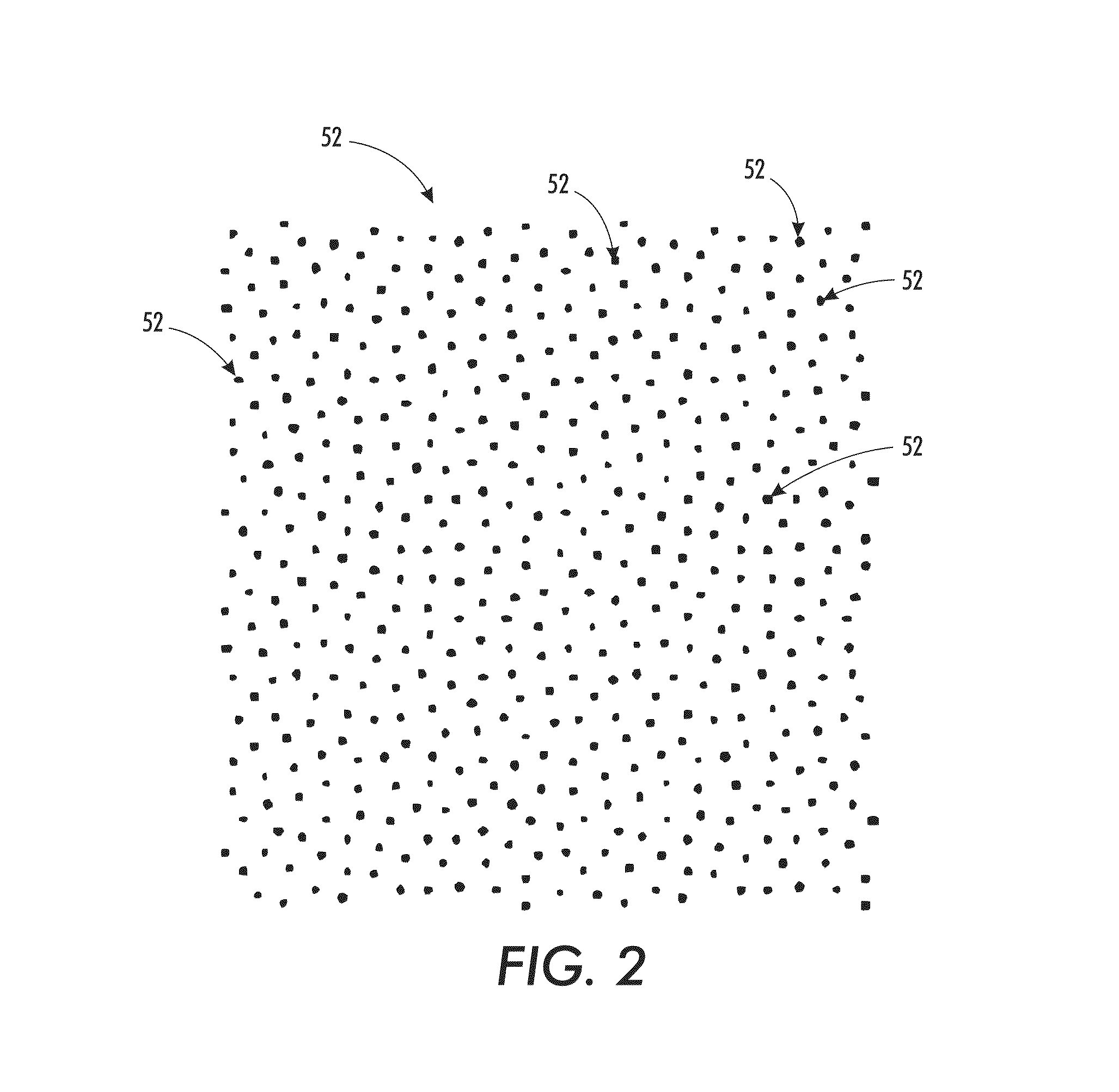

2nd GENERATION DOT-OFF-DOT STOCHASTIC HALFTONE

InactiveUS20130163053A1Promote generationVisual presentationPictoral communicationScreening techniquesColor shift

As set forth herein, computer-implemented methods and systems facilitate employing a single stochastic screen defined up to a specified transition level. The dots at the specified level are connected to form a triangle tessellation with an associated spot function. For up to three colorants, a vector screening technique is employed, which involves a first colorant dot being grown from the vertices, second colorant dot grown from the triangle center, and a third colorant dot grown from the side midpoints. Growth in this manner ensures separation of colorants up to a certain density level. In cases where fourth colorant is to be used at a given pixel, the fourth colorant can be added using methods typically used for clustered screens, such as stochastic screening of the lightest colorant, in order to mitigate color shift sensitivity issues.

Owner:XEROX CORP

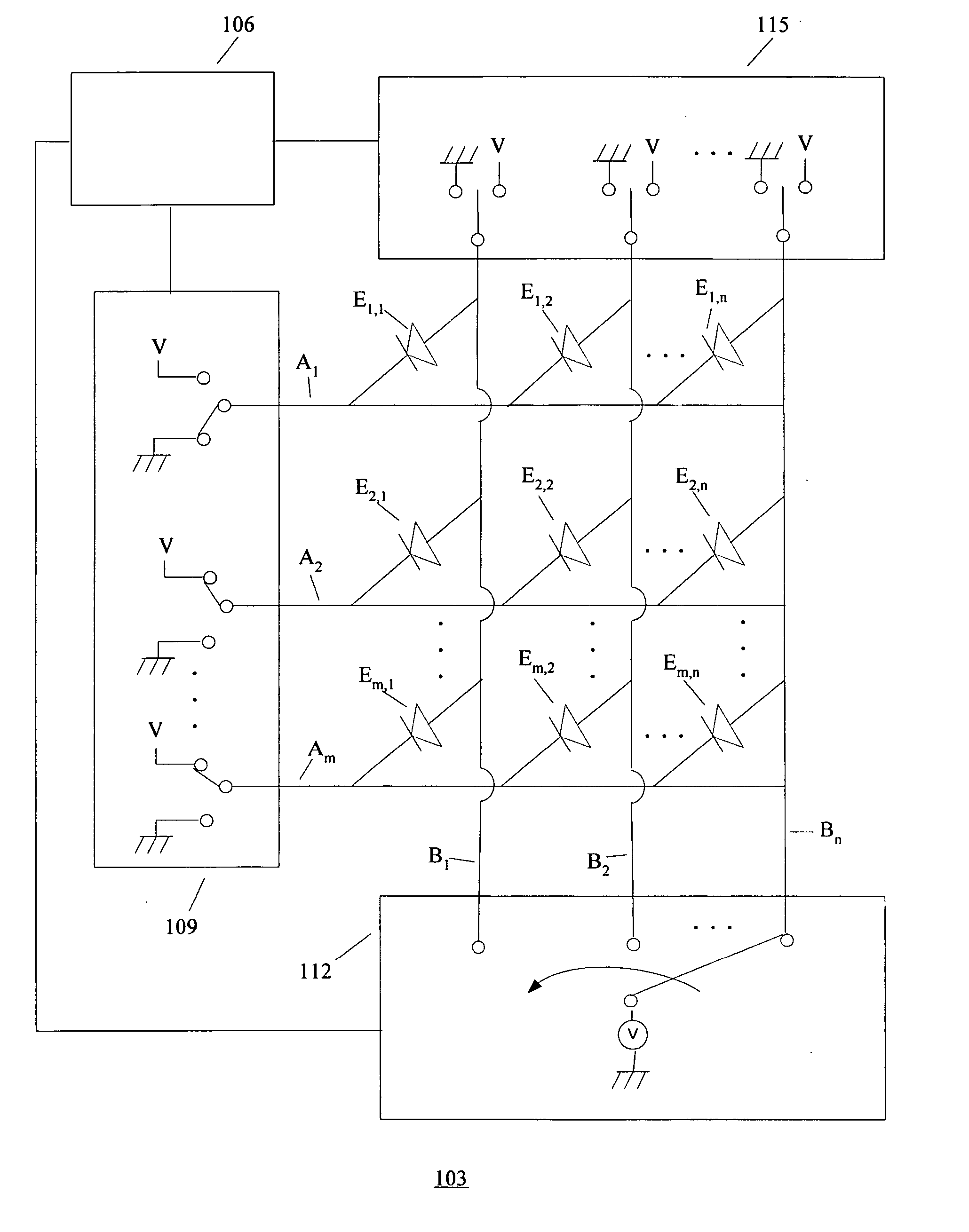

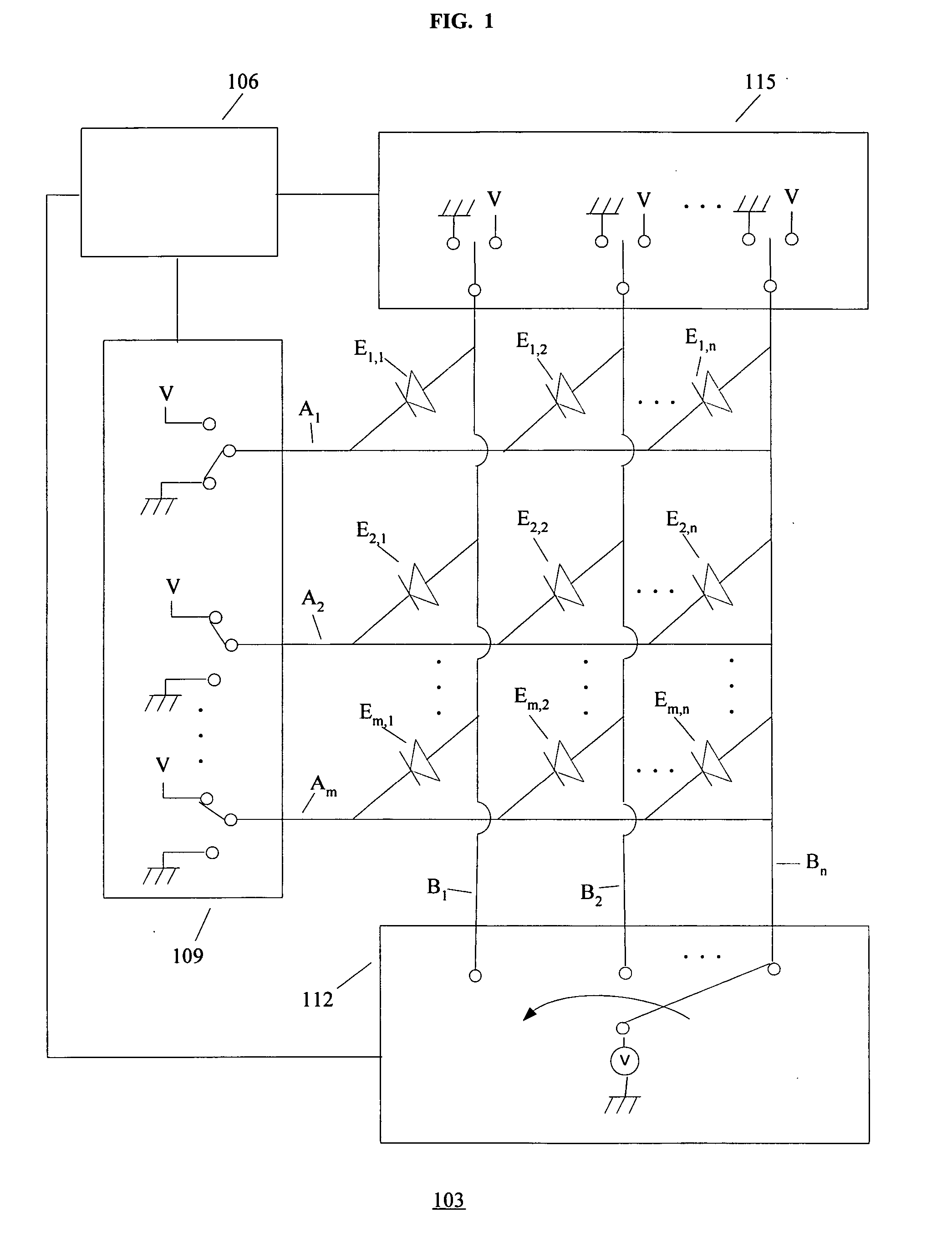

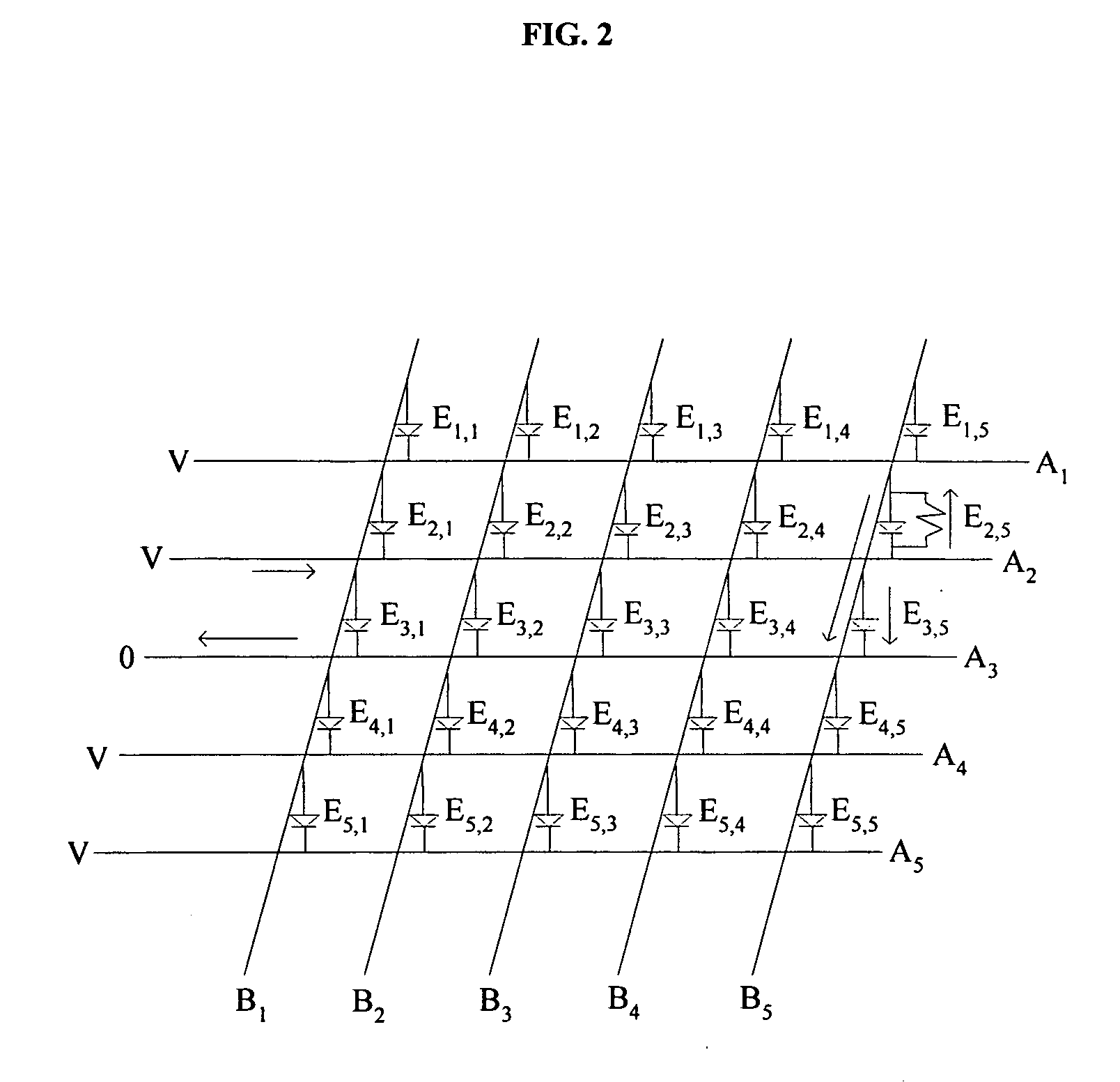

Determining leakage in matrix-structured electronic devices

One embodiment of this invention pertains to a high throughput screening technique to identify current leakage in matrix-structured electronic devices. Because elements that are likely to develop a short have relatively high leakage current at zero operation hours, by identifying elements with the relatively high leakage current, the electronic devices that are more likely to later develop a short can be differentiated. The screening technique includes performing the following actions: selecting one of multiple first lines; applying a first voltage to the selected first line; applying a second voltage to the one or more of the first lines that are not selected; floating the multiple second lines; and measuring the voltages on the second lines, either sequentially one line at a time or measuring all the lines at the same time.

Owner:DOLYA HOLDCO 5 LTD

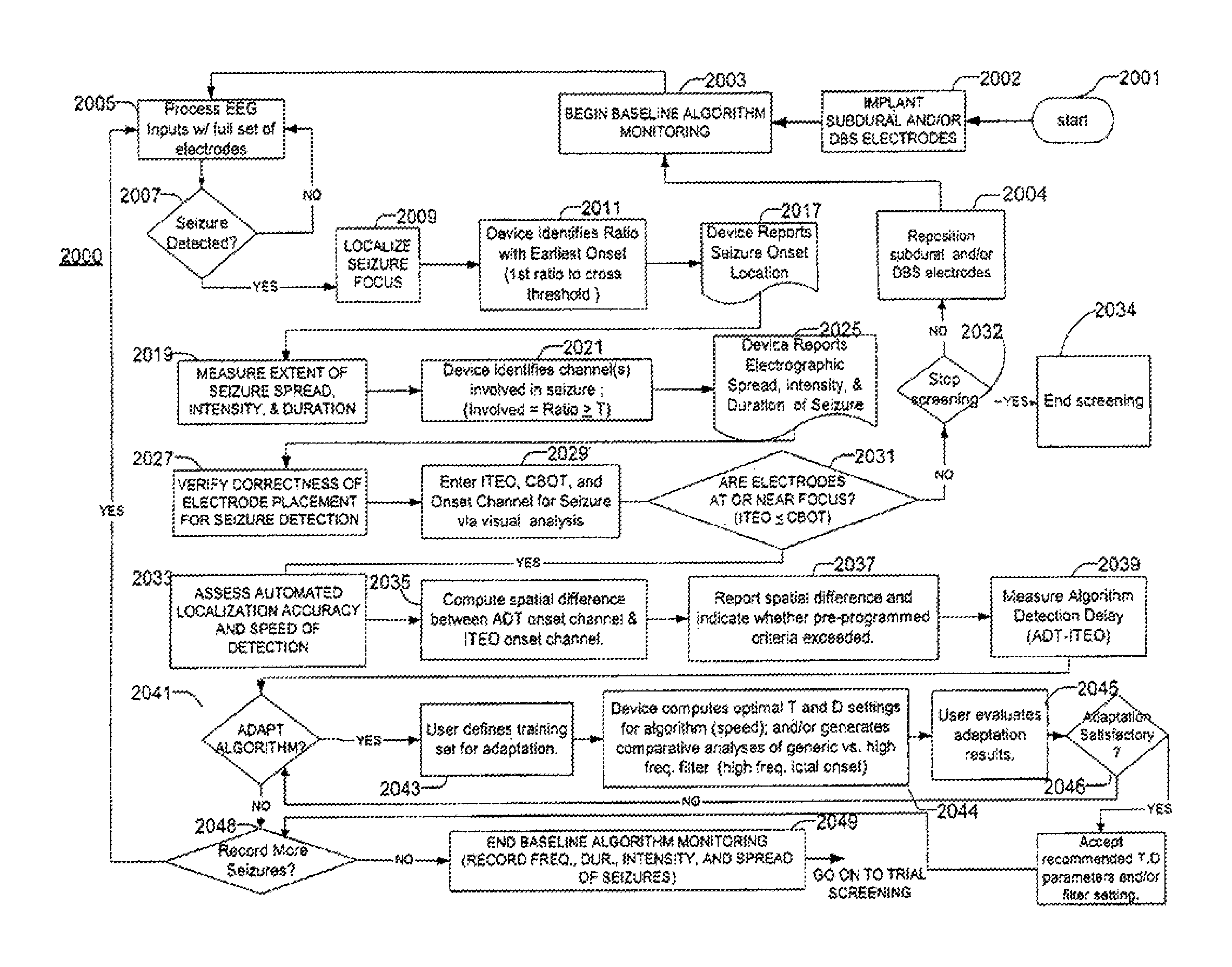

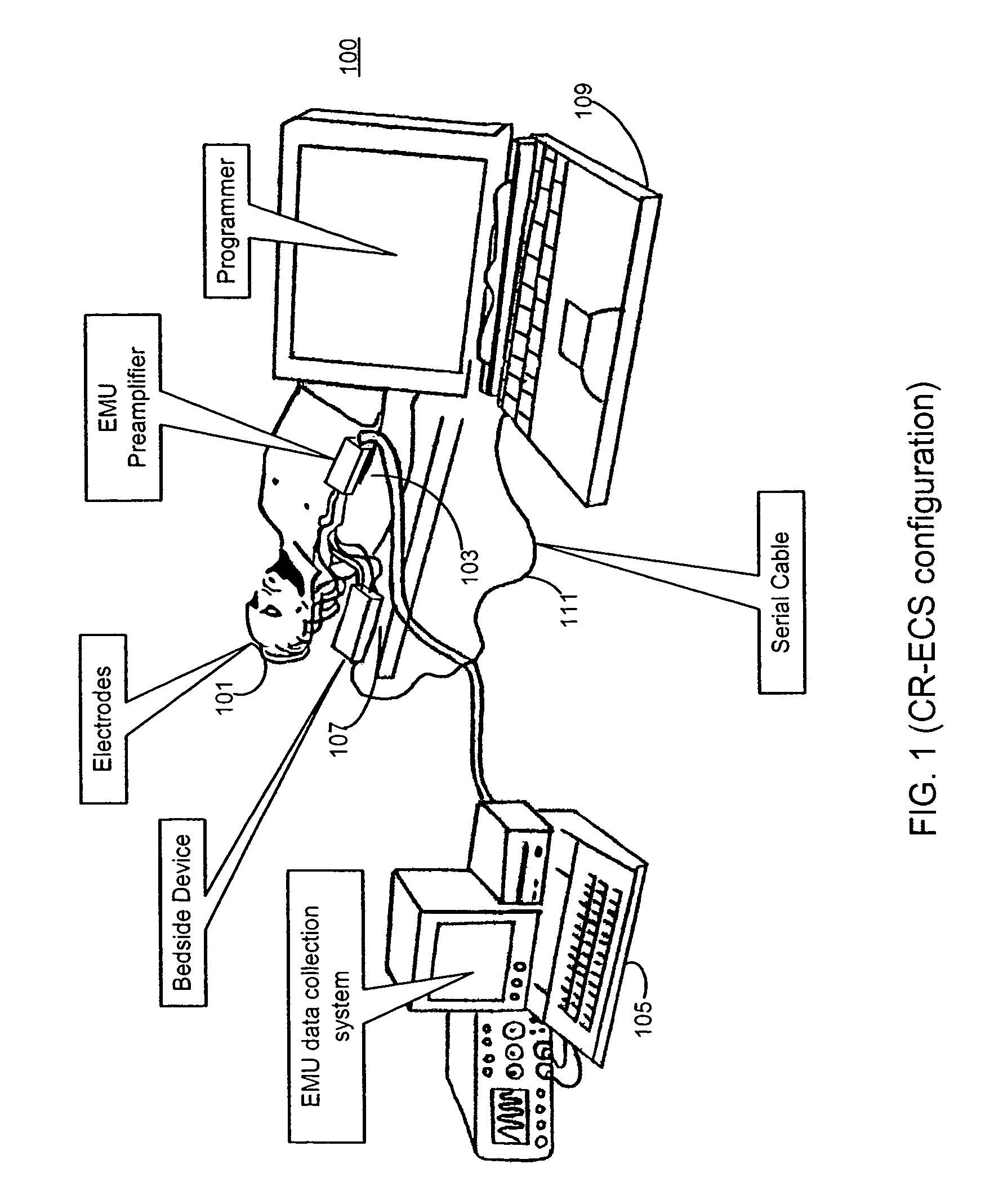

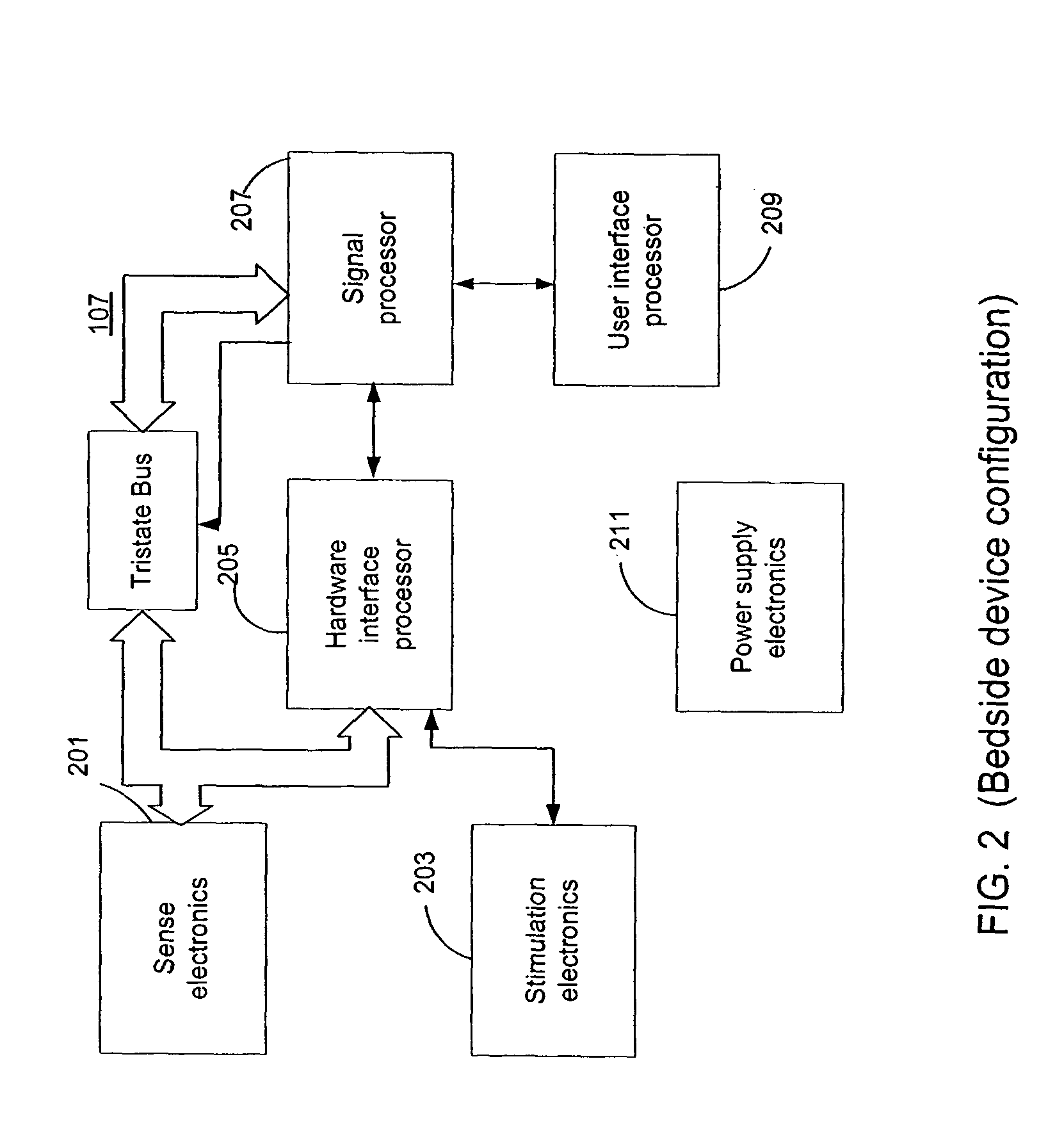

Screening techniques for management of a nervous system disorder

Apparatus and method support a neurological event screening for a medical device. The medical device assists a user in determining a configuration of the medical device for delivering an effective treatment for a nervous system disorder. The medical device detects a neurological event, such as a seizure, and reports a neurological event focus location and a neurological event spread to the user. The user may use the information to provide a configuration of a therapeutic delivery unit and associated therapy parameters. Therapeutic treatment is delivered to the patient, and the medical device is provided an indication of the patient's acceptance to the treatment. The user may modify the configuration and therapy parameters in order to achieve efficacy and acceptance. Depending upon the patient's acceptance, therapy is applied in either an open loop mode or a closed loop mode. The medical device determines whether the treatment is successful in accordance with a criterion.

Owner:MEDTRONIC INC

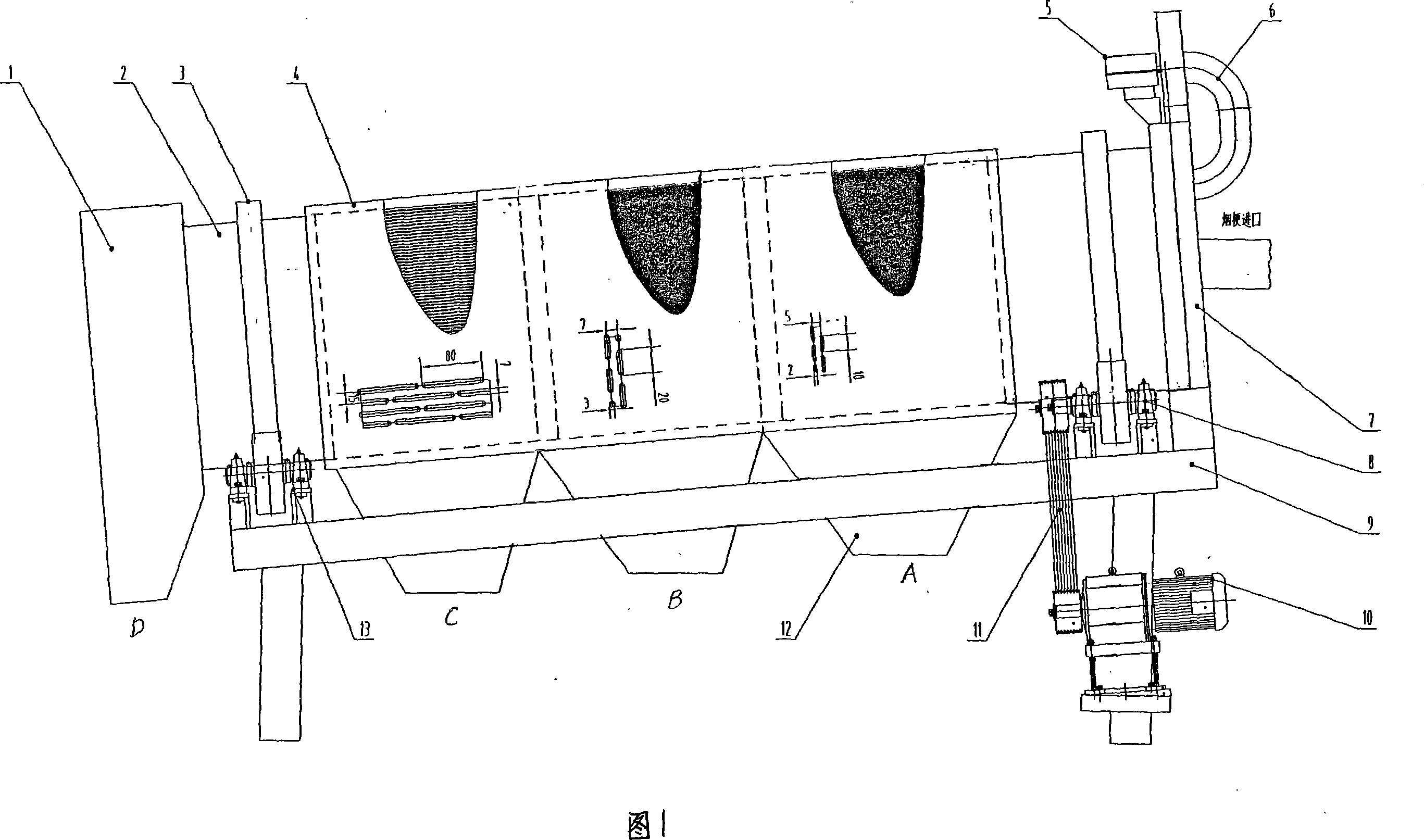

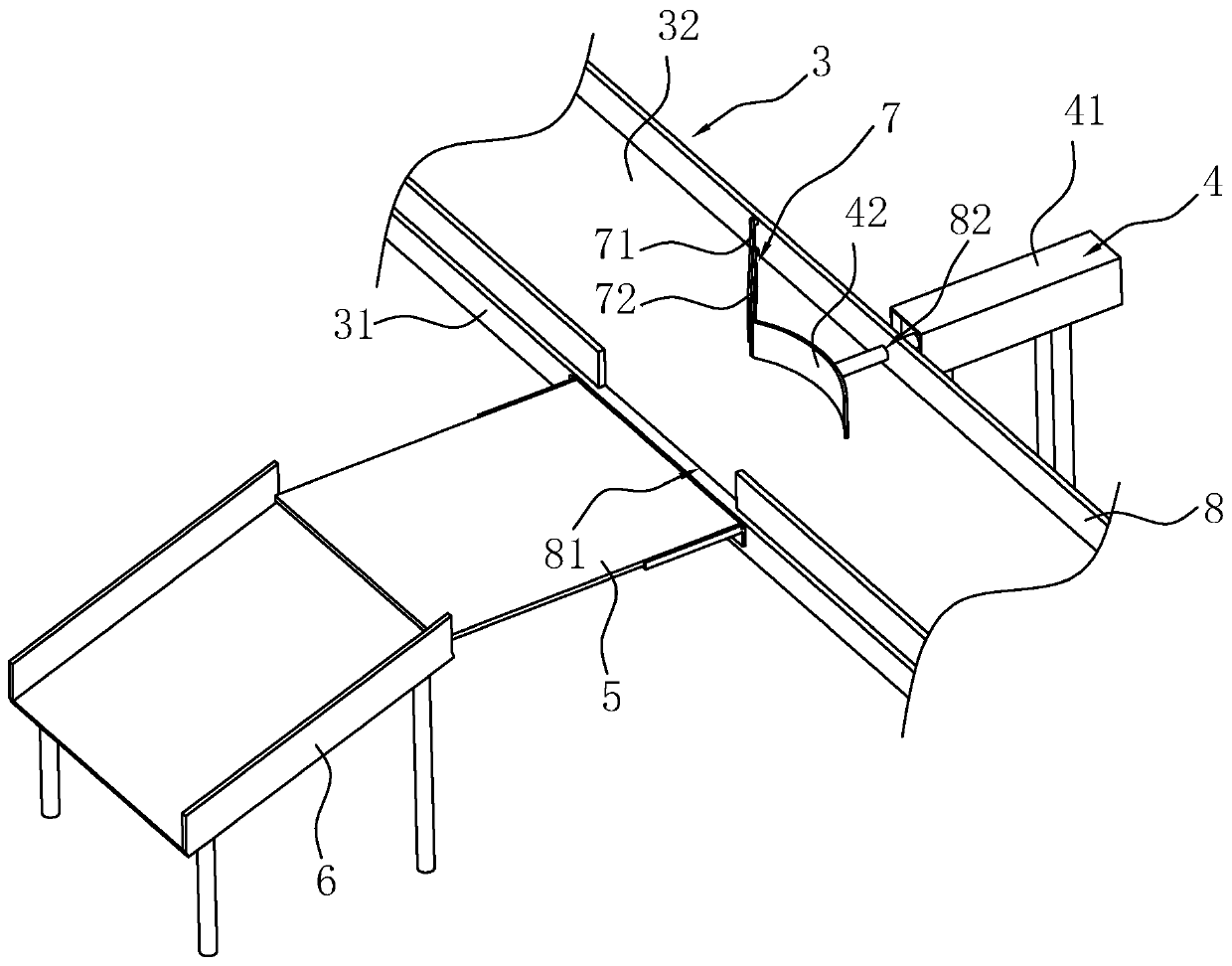

Cabo sifting barrel

InactiveCN101218988AOptimizing the screening processAvoid flying aroundSievingTobacco treatmentScreening techniquesScreening effect

The invention relates to a tobacco stem screening tube which is characterized by consisting of a screening tube device, a transmission device and a dust removing mechanism. The screening tube device essentially consists of a screening tube body, a rolling ring on the tube body, a sealing housing and a discharging port and a feeding cover and a discharging cover at two ends of the tube body; the screening tube body is welded by a feeding port section, a tobacco dust screen tube section, a short stem screen tube body, a middle and long stem screen tube body and a stem head outlet tube section. The dust removing system consists of a dedusting fan and a dedusting pipe that are installed on the feeding cover. The invention optimizes the stem screening technique and is integrated with stem screening and dust removing, thus solving the problems of poor screening effect and product quality resulting from manual screen cleaning due to screen blockage by tobacco stem, ensuring good product quality, preventing dust from flying through dust collecting, maintaining cleanness of the on-site production environment and saving energy and equipment occupation area as a plurality of original devices are integrated into one device.

Owner:玉溪市浩森工贸有限公司

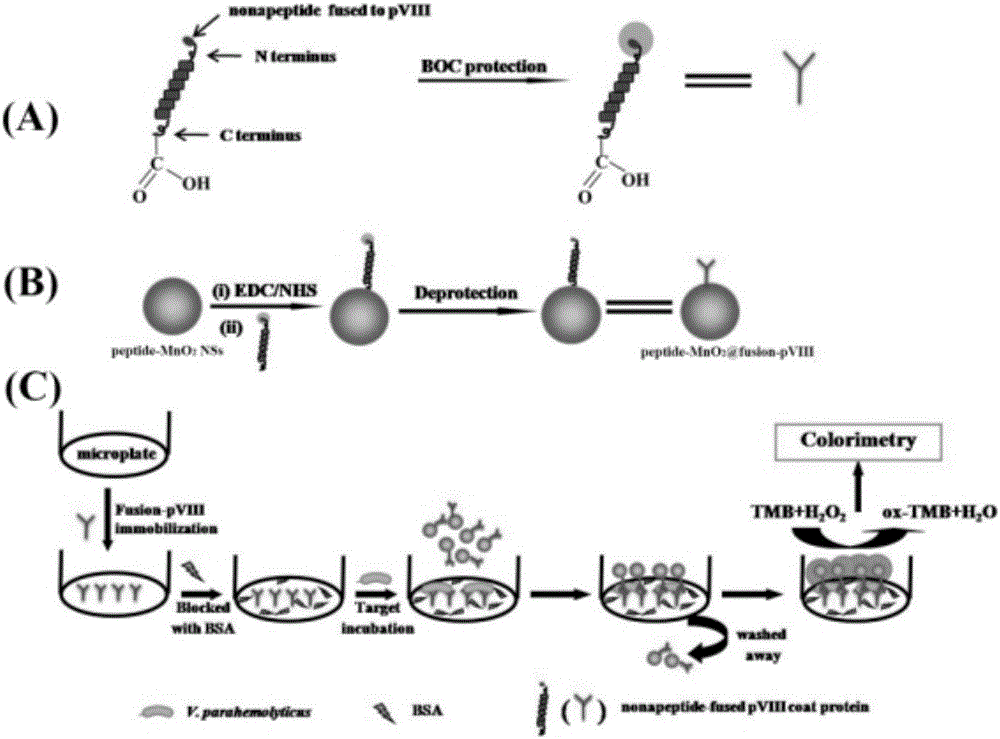

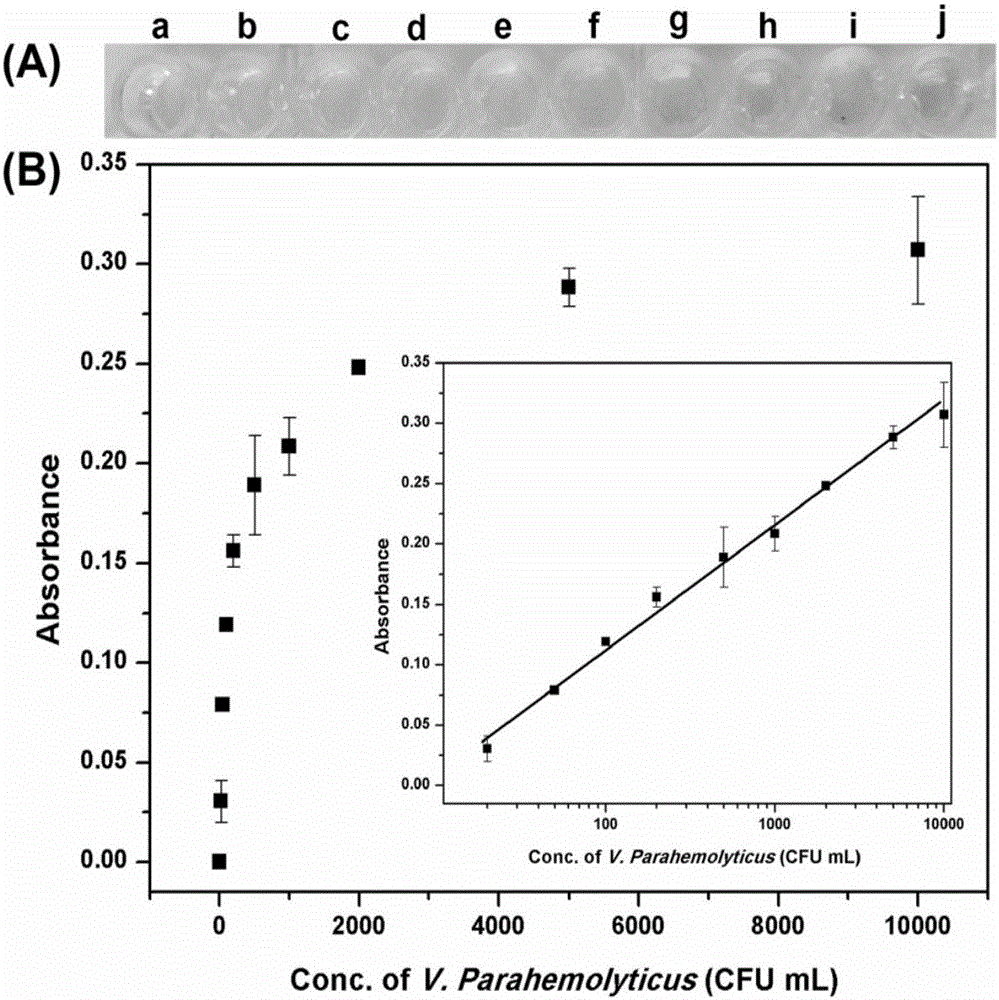

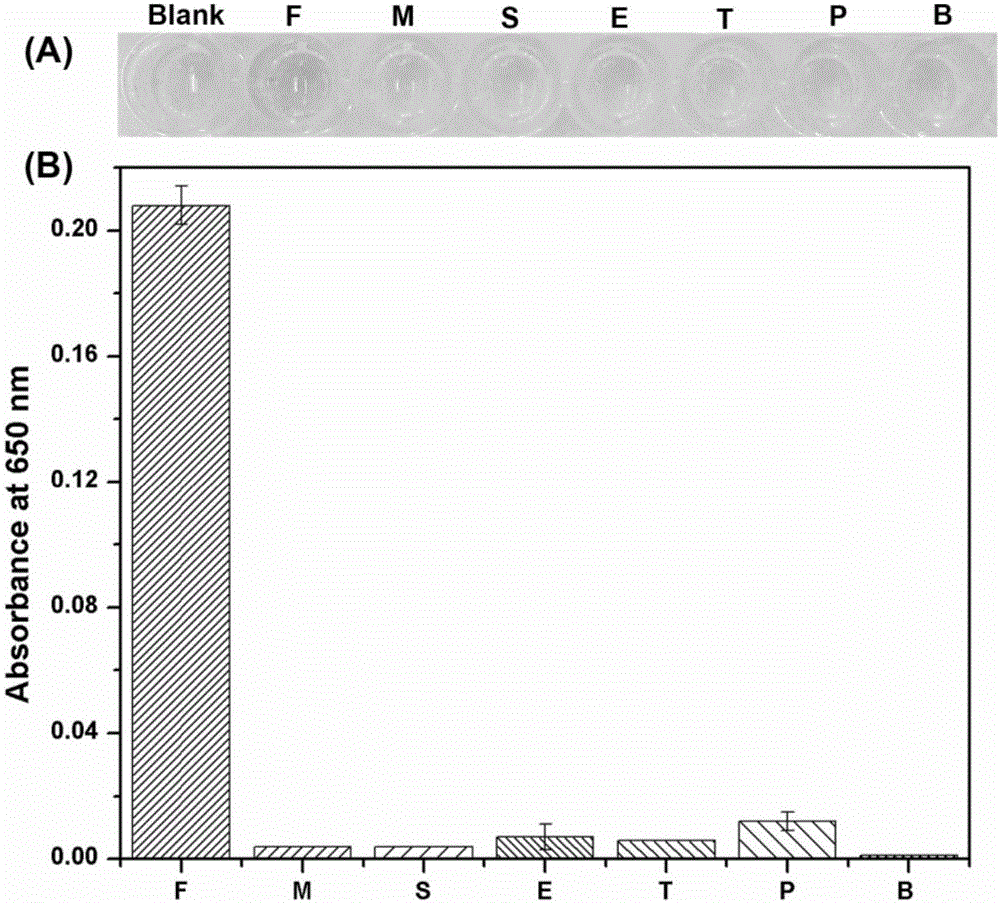

Method for detecting pathogenic microorganism

InactiveCN106771194AAchieving sensitive and specific detectionAchieve signal amplificationMaterial analysisScreening techniquesSurface display

The invention belongs to the field of nanometer biological technical detection, in particular to a method for detecting pathogenic microorganism based on phage surface display peptide ligands and biomimetic nanometer material. The method comprises the following steps of using a multifunctional biological nanometer probe and to-be-detected target pathogenic microorganism to incubate, and detecting under a chromogenic system, wherein the multifunctional biological nanometer probe uses a biological screening technique to screen phage monoclone specifically combined with the pathogenic microorganism from a scenery phage library, and further separate and purify to obtain protein at the corresponding site of the phage which displays specific peptide; assembling the capsid protein of the phage displaying specific peptide onto the biomimetic nanometer material. The method has the advantages that the probe can specifically identify and combine with the target microorganism, the signal can be amplified by the biomimetic activity, and then the immune colorimetric quantitative detection of vibrio parahaemolyticus is realized; the operation is simple, the cost is low, the specificity and sensitivity are higher, and an effective path is provided for the sensitivity detection of the pathogenic microorganisms.

Owner:QINGDAO UNIV

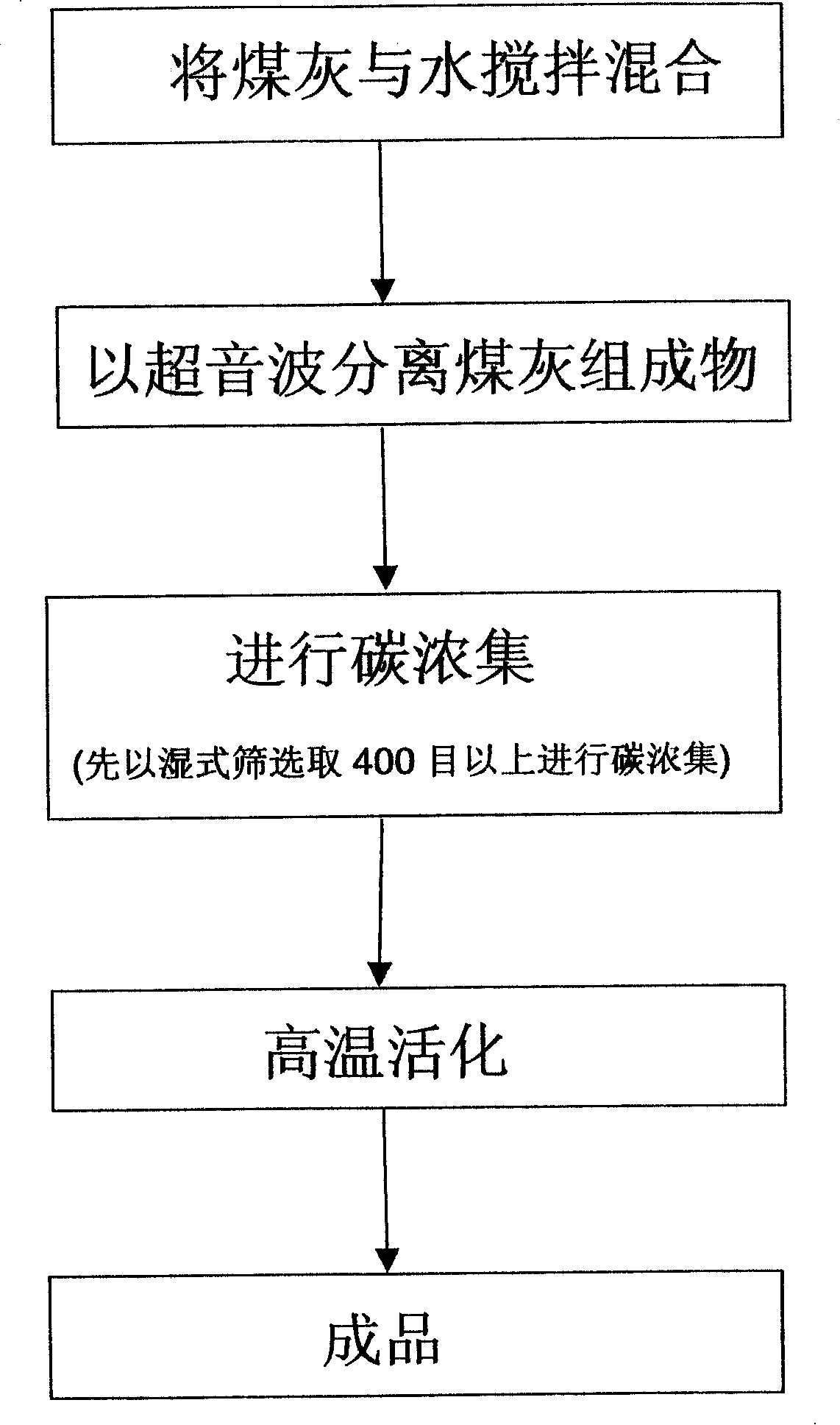

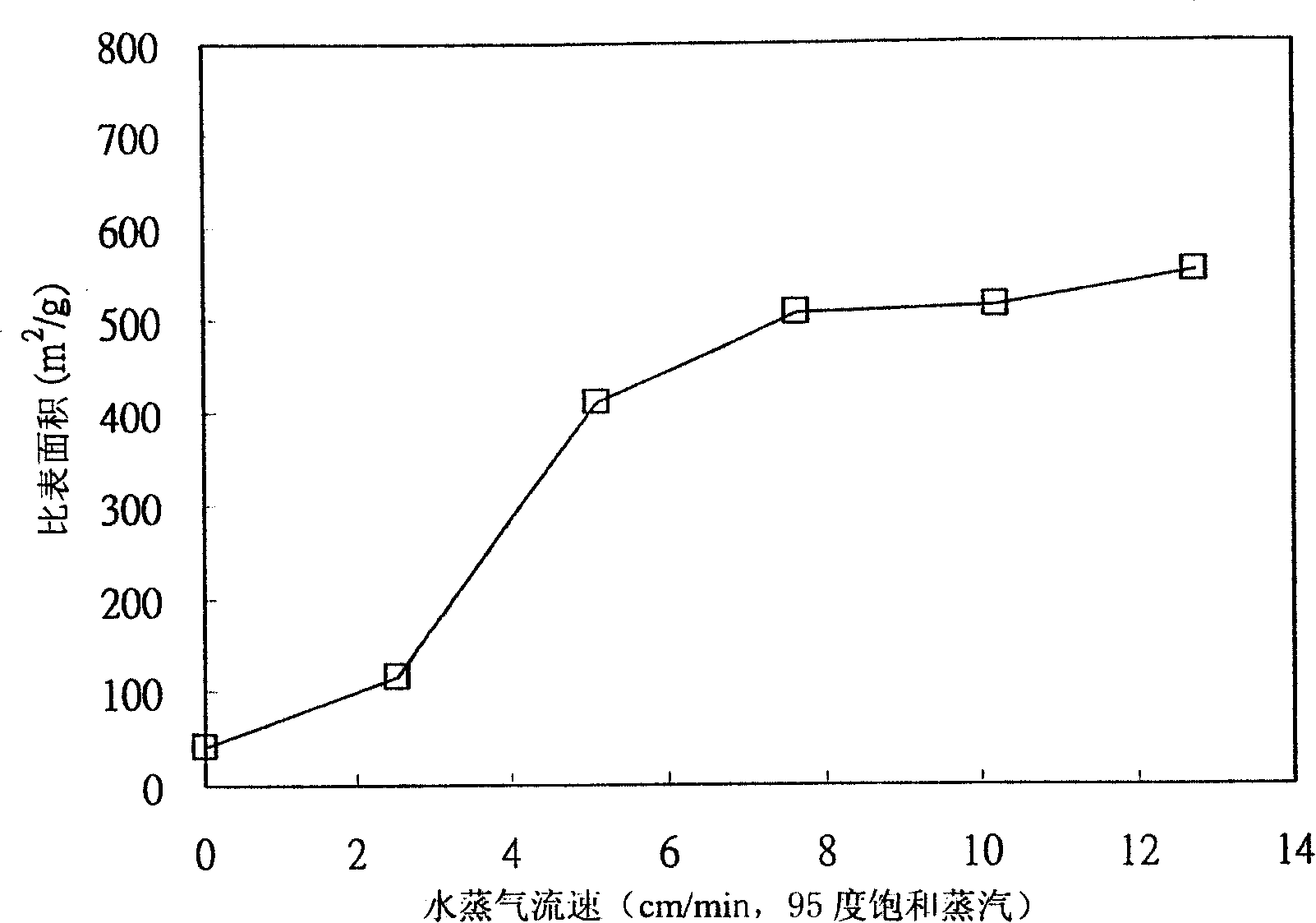

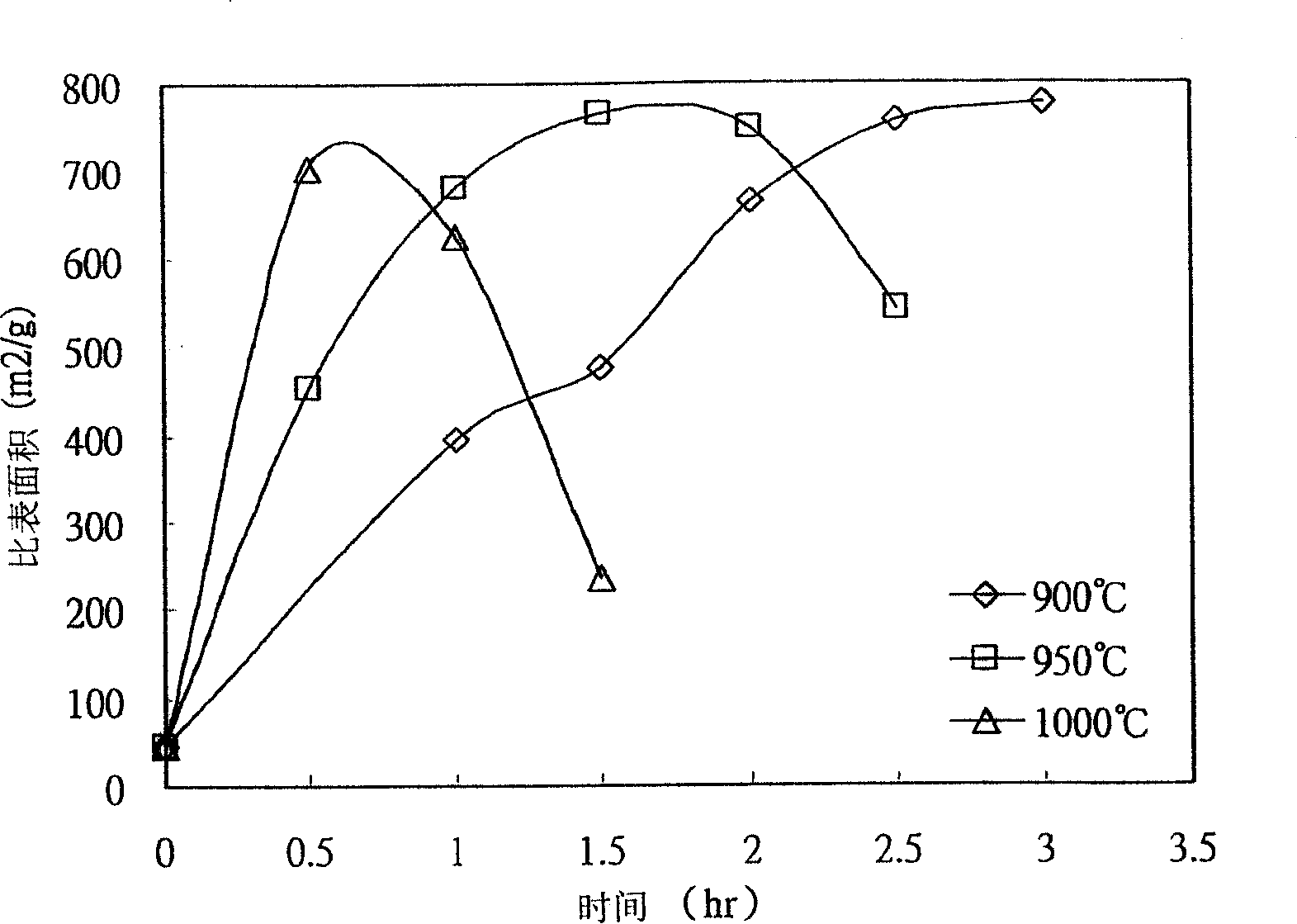

Process for sorbing material using soot

InactiveCN101204646AQuality improvementImprove adsorption capacityOther chemical processesPorosityScreening techniques

A method of preparing a sorbing material by coal ash is provided by the invention, which mainly utilizes the screening technique to separate unburned carbon from coal ash; the unburned carbon is then processed by vapor or carbon dioxide to cause a plurality of micro-holes forming on surface of the unburned carbon and becoming absorbing space that can contain micro-substance; the sorbing material thus prepared has high porosity, large adsorbance, high adsorbance efficiency and low cost, and can be used as a sorbing material for processing wastewater.

Owner:谢雅敏 +5

2nd generation dot-off-dot stochastic halftone

Owner:XEROX CORP

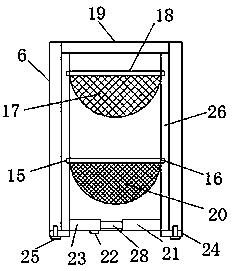

Soil restoration screening device

InactiveCN107755231AImprove filtering effectEasy to separateSievingScreeningScreening techniquesSoil remediation

The invention relates to the technical field of soil restoration screening, in particular to a soil restoration screening device which comprises a tank. A plurality of supporting legs are mounted at the bottom of the tank, a drainage mechanism penetrates the bottom of the tank, a spraying device is arranged at the top of the tank and comprises two first mounting plates, a spraying pipe is arrangedbetween the two first mounting plates, a plurality of sprayers are arranged at the bottom of the spraying pipe in a penetrating manner, a connecting water pipe is arranged at the top of the sprayingpipe in a penetrating manner, one end, far away from the spraying pipe, of the connecting water pipe is connected with a water pump, and a filtering mechanism is mounted at the bottom of the drainagemechanism and is in sleeve connection with a water storage tank. The soil restoration screening device is simple in structure and convenient to use, large and small particles in soil are convenientlyclassified and screened, and a first screen mesh and a second screen mesh can be conveniently maintained or replaced.

Owner:成都酷爱睿工业产品设计有限公司

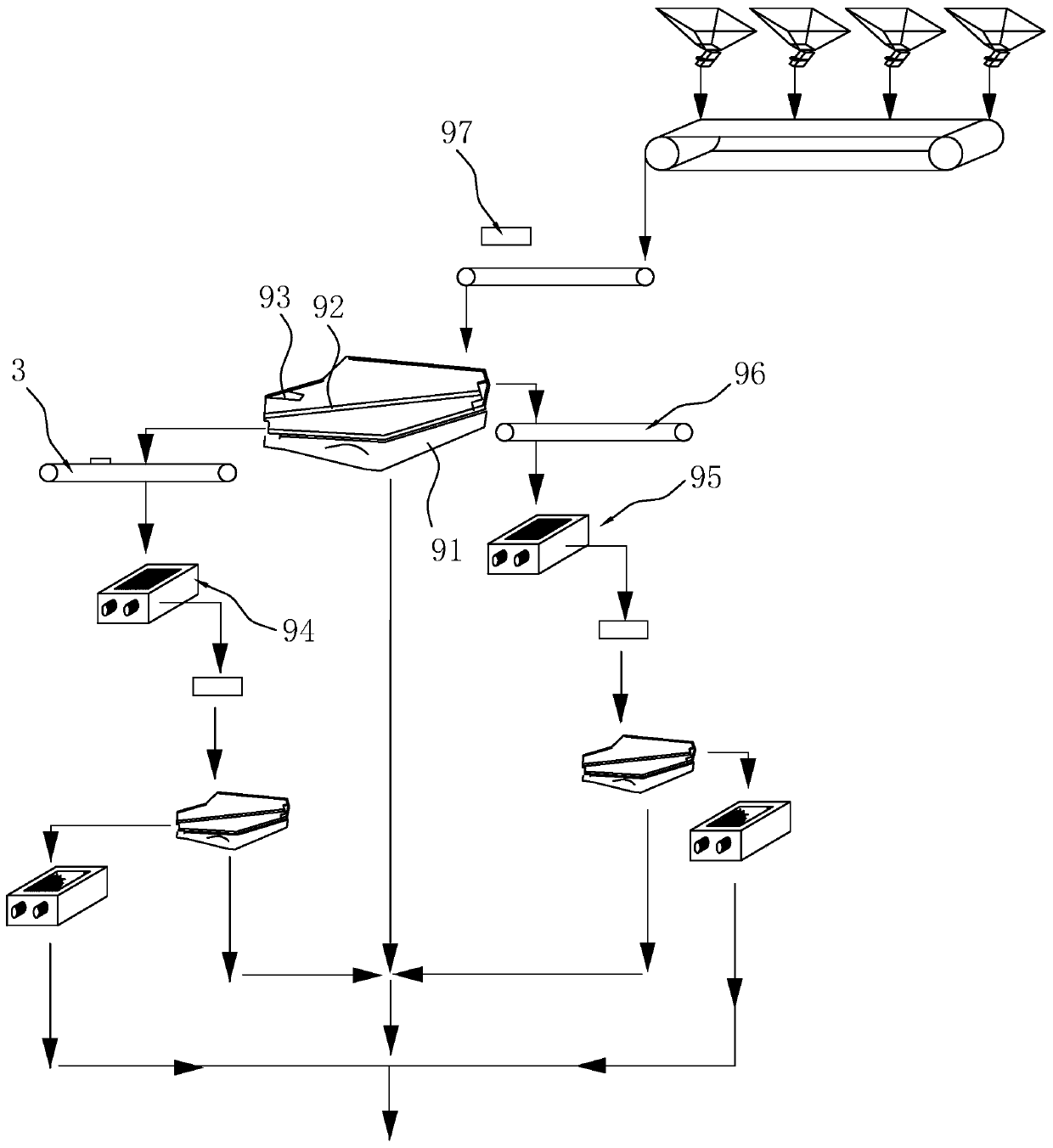

Raw coal feeding and screening technique

ActiveCN109701715ARealize selectionAchieve separationSievingGas current separationScreening techniquesCrusher

The invention discloses a raw coal feeding and screening technique, and relates to the field of raw coal processing. The raw coal feeding and screening technique comprises the following steps that 1,raw coal feeding is carried out; 2, primary raw coal magnetic screening is carried out; 3, primary raw coal classification is carried out, wherein the raw coal is screened through a first screening device (9) to obtain coarse undersize, gangue contained heavy substances and light substances; 4, primarily crushing is carried out, wherein the gangue contained heavy substances in step 3 is conveyed to a first-stage crusher for crushing through a first-stage conveyor belt device, and the light substances in step 3 is conveyed to a second-stage crusher for crushing through a second-stage conveyor belt device; 5, the magnetic screening and the classification are carried out again; and 6, crushing is carried out again. The raw coal feeding and screening technique has the advantages that in the raw coal treatment technique, gangues can be screened conveniently, labor is saved and labor intensity of workers is reduced; and the raw coal with different particle sizes in the process is subjected to multiple times of iron removing and crushing, and iron impurities in the raw coal are removed more completely, so that the quality of finally crushed raw coal is improved and subsequent fine processing is promoted.

Owner:乌拉特中旗浩通清洁能源有限公司

Method for recycling metal iron from slag magnetic separation powder

ActiveCN106311728AEasy to recycleHigh iron oxide contentSolid waste disposalScreening techniquesSlag

The invention belongs to the technical field of metal iron recycling and particularly relates to a method for recycling metal iron from slag magnetic separation powder. The method for recycling metal iron from slag magnetic separation powder provided by the invention comprises the following steps: taking the slag magnetic separation powder with grain size less than 15mm and MFe less than 25% as the main raw material and crushing; performing low intensity magnetic separation after crushing, thereby acquiring the magnetic separation powder with MFe more than or equal to 25%; grinding the magnetic separation powder and then grinding, thereby screening the part above 20 mesh and the part below 20 mesh; performing high intensity magnetic separation on the part above 20 mesh, thereby acquiring the iron grain with TFe more than or equal to 90%; performing twice low intensity magnetic separation on the part below 20 mesh, thereby acquiring the iron fine powder with TFe more than or equal to 55%. The reasonable crushing technique, screening technique, grinding technique and magnetic separation technique are adopted, so that the metal iron in the slag magnetic separation powder can be more effectively recycled; the ferric oxide content of the tailings is higher; the method can be more effectively applied to the cement irony correcting material.

Owner:PANZHIHUA GANGCHENG GROUP

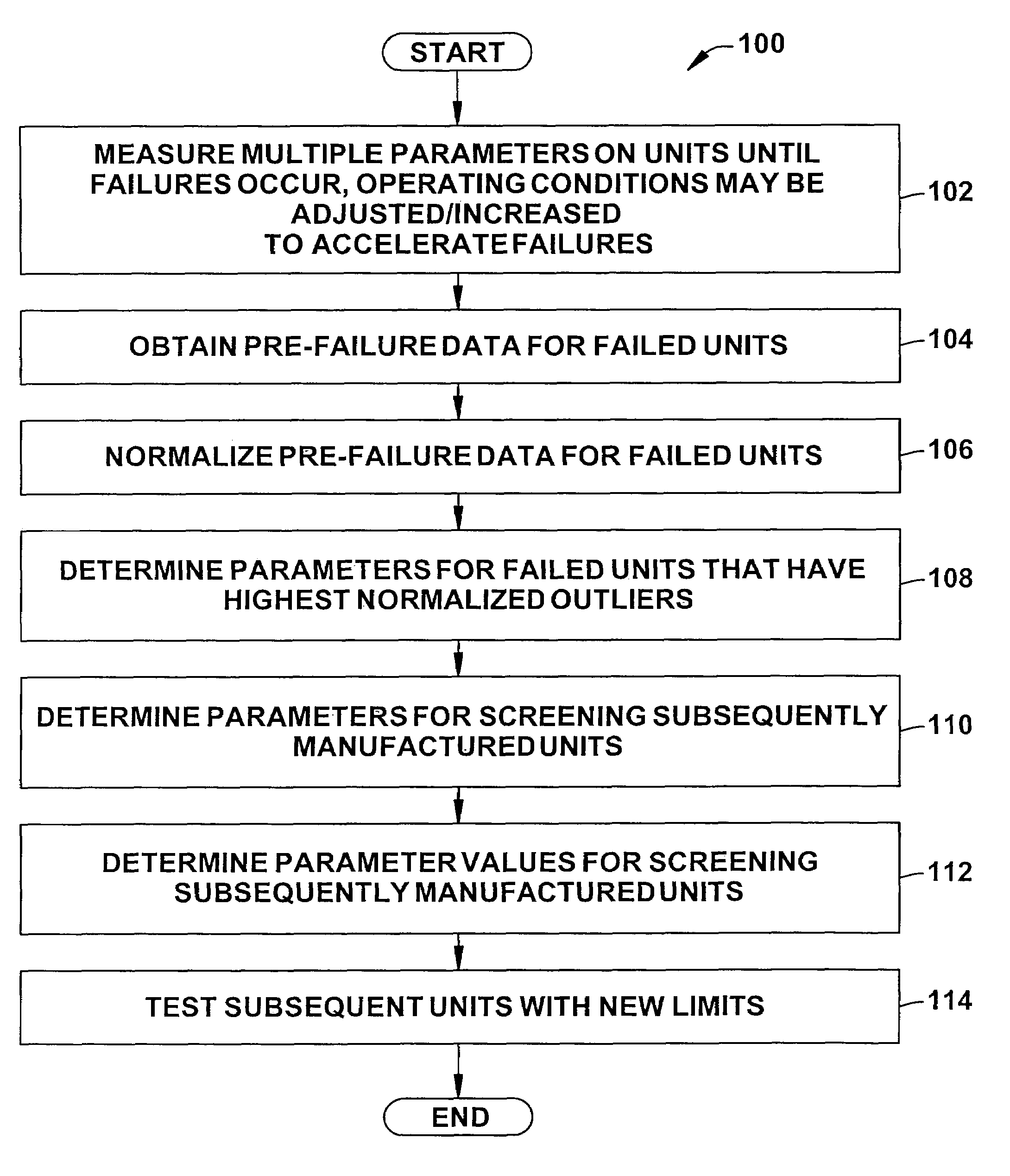

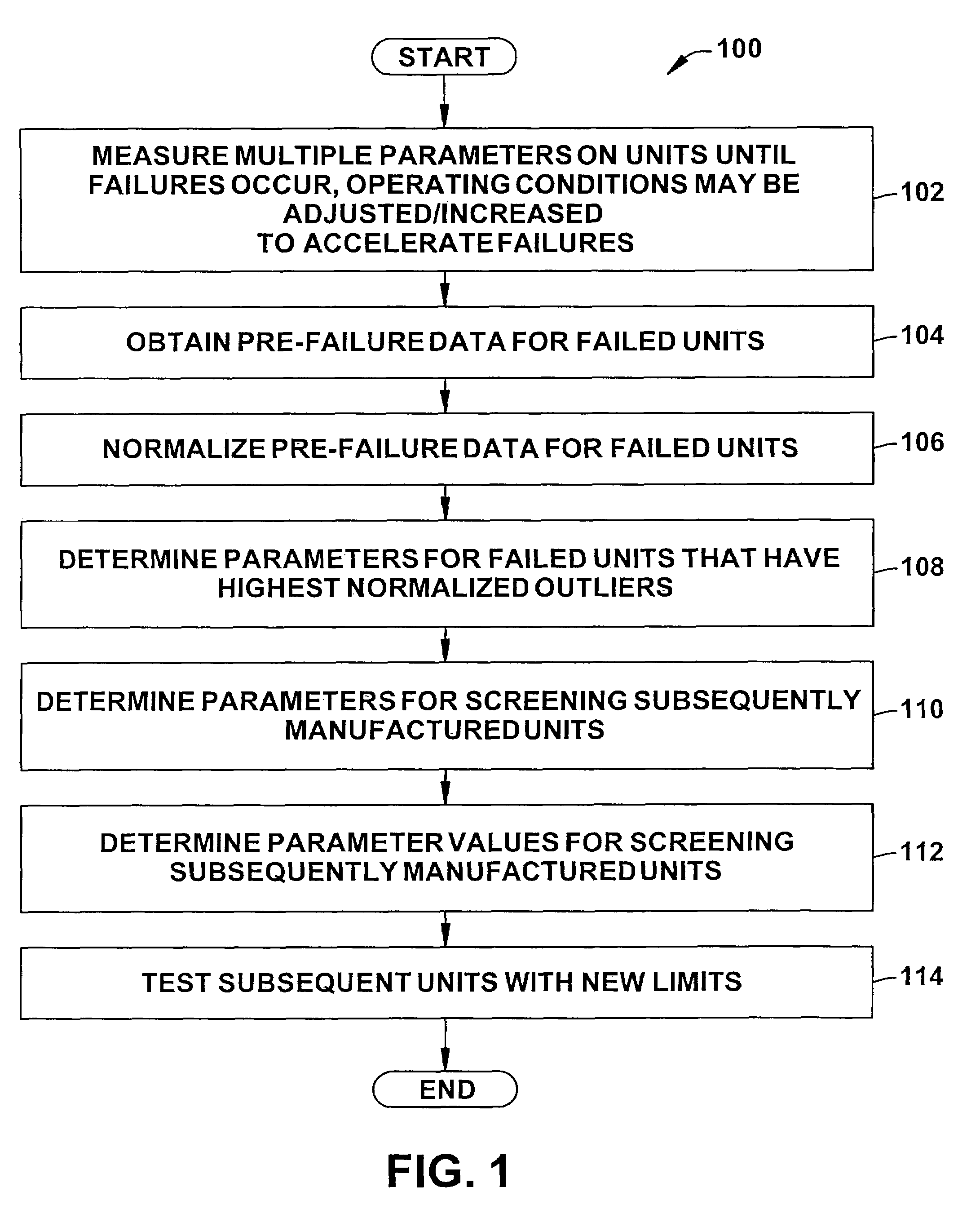

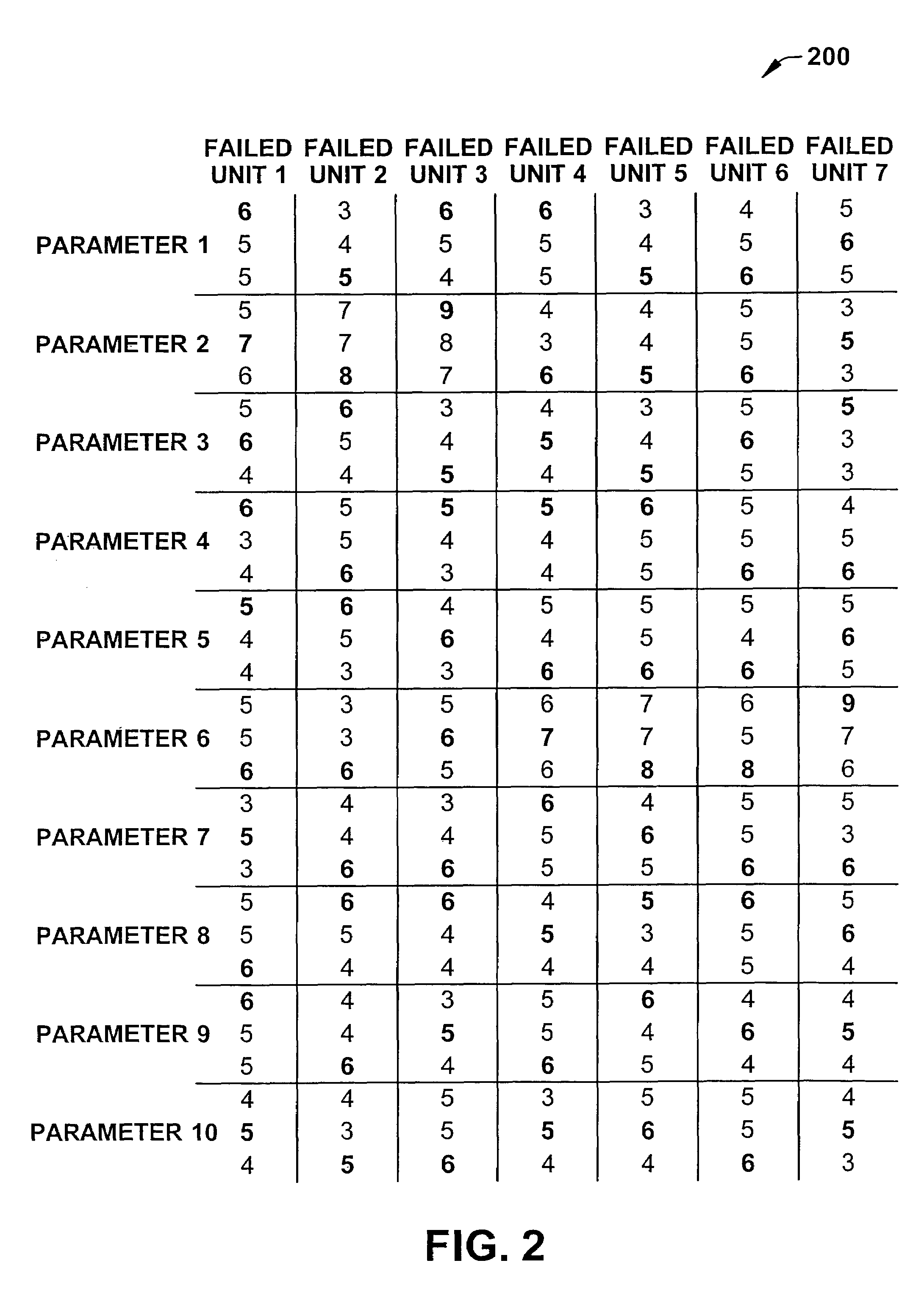

Outlier screening technique

ActiveUS7359813B2Reduce in quantityReduce the valueAmplifier modifications to reduce noise influenceDigital computer detailsScreening techniquesContinuous measurement

Multiple parameters of manufactured units are continually measured until some of the units fail, where failure can be accelerated by adjusting operating conditions. Pre-failure data is then examined to find outliers or aberrant parameter values that may have contributed to the failures. The data is normalized to allow different parameters to be compared to one another. The parameters producing the highest outlier values are then used to screen subsequently manufactured units, thus significantly reducing the number of measurements that have to be taken to screen the units. Lower outlier values for these parameters are, however, used in screening subsequently manufactured units to “catch” potentially defective units.

Owner:TEXAS INSTR INC

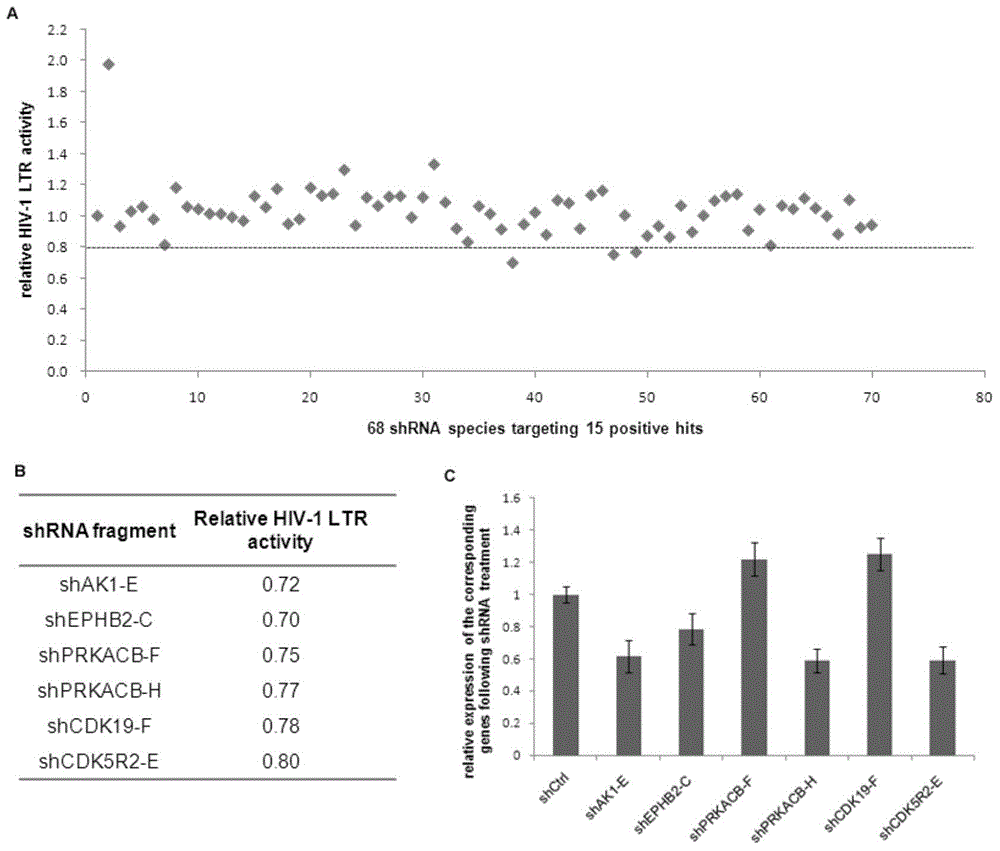

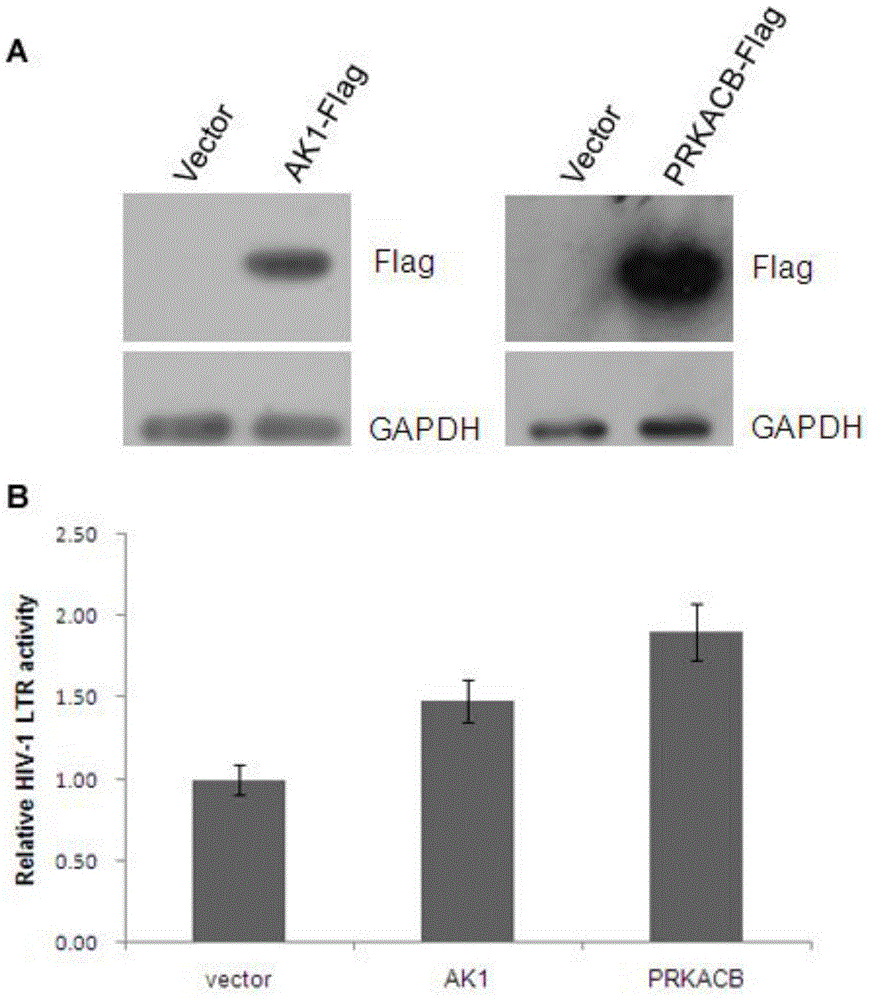

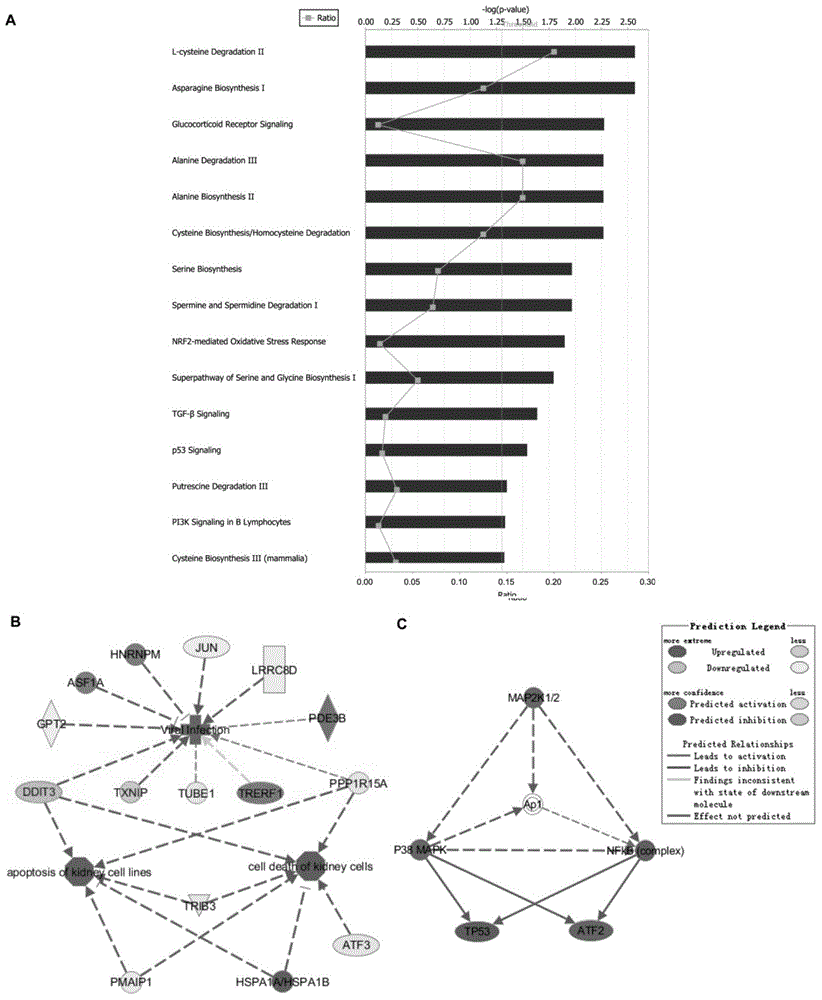

A method of screening an HIV-1 activity determinative factor based on high-throughput RNAi

InactiveCN106032550AMicrobiological testing/measurementGenetic engineeringScreening techniquesHost factors

The invention relates to the technical field of molecular biology, and particularly relates to a method of screening an HIV-1 activity determinative factor based on high-throughput RNAi. Aiming at shRNA libraries of 474 kinases, and through a high-throughput RNAi screening technique, HIV-1 LTR-hRluc / HSVTK-hLuc luciferase double reporter plasmids are stably expressed in HEK293T, and kinase-involved HIV-1 LTR regulatory transcriptional activity is obtained by dividing HIV-1 LTR relative transcriptional activity of hRluc expression fluorescence intensity by hLuc fluorescence intensity. The method aims at human kinase genes, performs functional silence screening, searches HIV replication related host factors, and provides valuable reference basis for further understanding interactions between HIV and hosts and for searching HIV-infection resisting potential treatment targets.

Owner:SHANGHAI PUBLIC HEALTH CLINICAL CENT

Methods and pharmaceutical formulations for the treatment of pulmonary hypertension

Owner:CHILDRENS HOSPITAL OF LOS ANGELES

Saccharomycetes used for making wine, screening technique of the saccharomycetes and application of the saccharomycetes in blueberry red wine fermentation

ActiveCN108865910AStrong fermentation abilityImprove fermentation performanceFungiMicroorganism based processesScreening techniquesAdditive ingredient

The invention relates to a saccharomycetes used for making wine, with the preservation number of CGMCC NO.15931, which relates to the screening technique of the saccharomycetes and the application ofthe saccharomycetes in blueberry red wine fermentation. The blueberry red wine made by fermentation of the saccharomycetes has high quality, clearness and transparency orange red color and classic redwine flavor. The production of blueberry fruit creates a good development opportunity for the red wine industry, fermented wine contains a large amount of nutritional ingredients such as amino acids,vitamins and minerals and the like, and a certain physiological activator, which mainly plays a role of relaxing muscles, stimulating blood circulation and boosting metabolism, and is suitable for drinking.

Owner:贵州凯缘春酒业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com