Cabo sifting barrel

A technology for screening cylinders and tobacco stems, which is used in screen, tobacco, solid separation, etc., can solve problems such as poor production environment, affecting screening effect, and clogging of screen holes, reducing equipment footprint and avoiding four Flying, the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

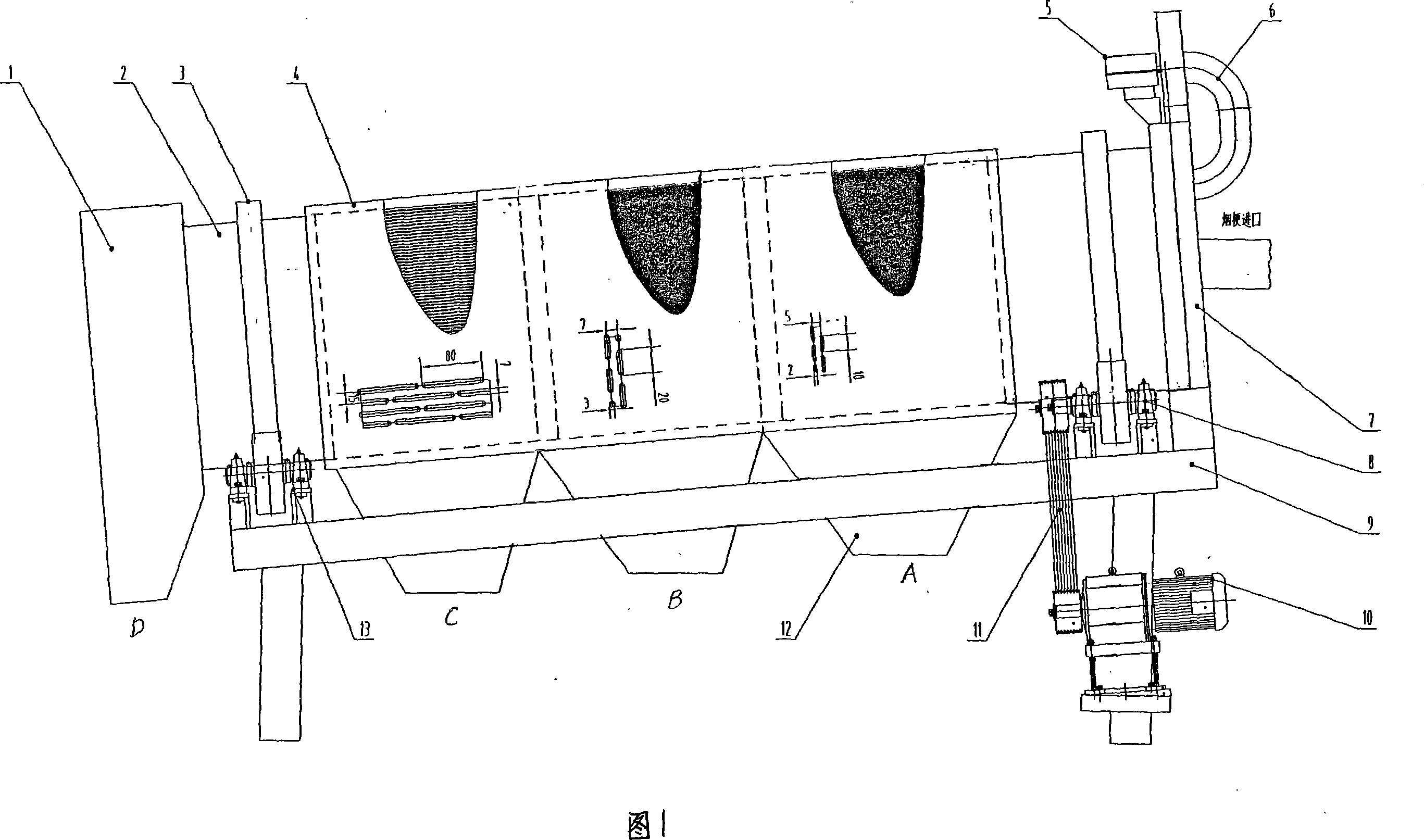

[0012] As shown in Figure 1, the tobacco stem screening cylinder of the present invention consists of the following parts:

[0013] (1) The screening cylinder device is mainly composed of the screening cylinder body 2, the rolling ring 3, the sealing cover 4, the discharge port 12, the feed cover 7, and the discharge cover 1. The screening barrel is divided into an inlet barrel section, a tobacco dust screen barrel section (A), a short stem screen barrel section (B), a medium and long stem screen barrel section (C), and a stem head outlet barrel section (D). The perforations of the tobacco dust screen tube section (A) are 2mm×10mm, the short-stem sieve tube section (B) is 3mm×20mm, and the medium-long-stem sieve tube section (C) is 7mm×80mm. The length direction of the mesh cylinder eyelet is horizontal to the direction of material movement, or the length direction of the mesh cylinder eyelet is perpendicular to the direction of material movement, or the length direction of the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com