Patents

Literature

197results about How to "Avoid flying around" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

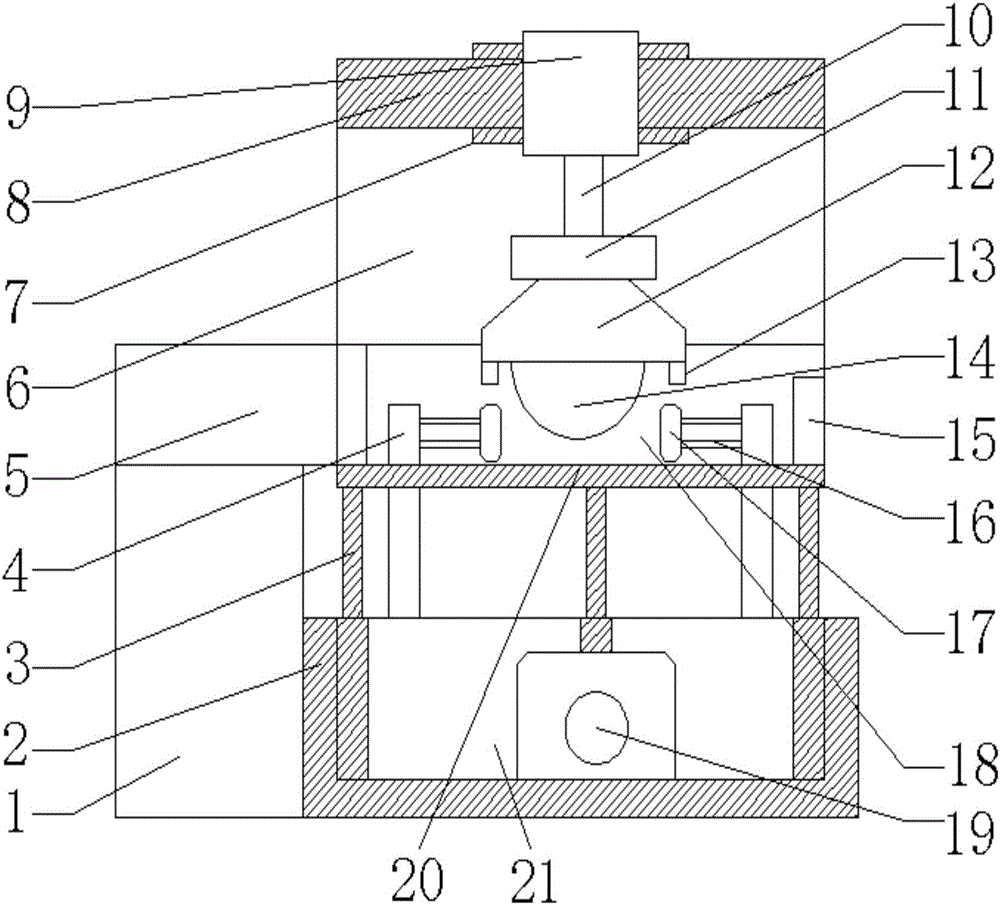

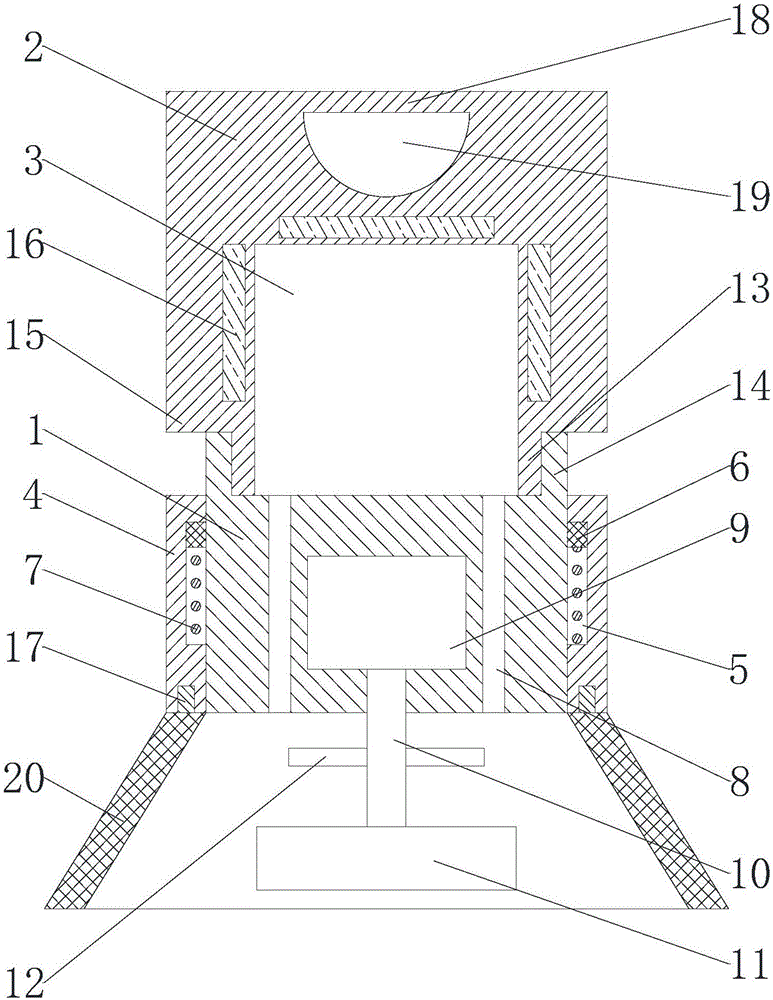

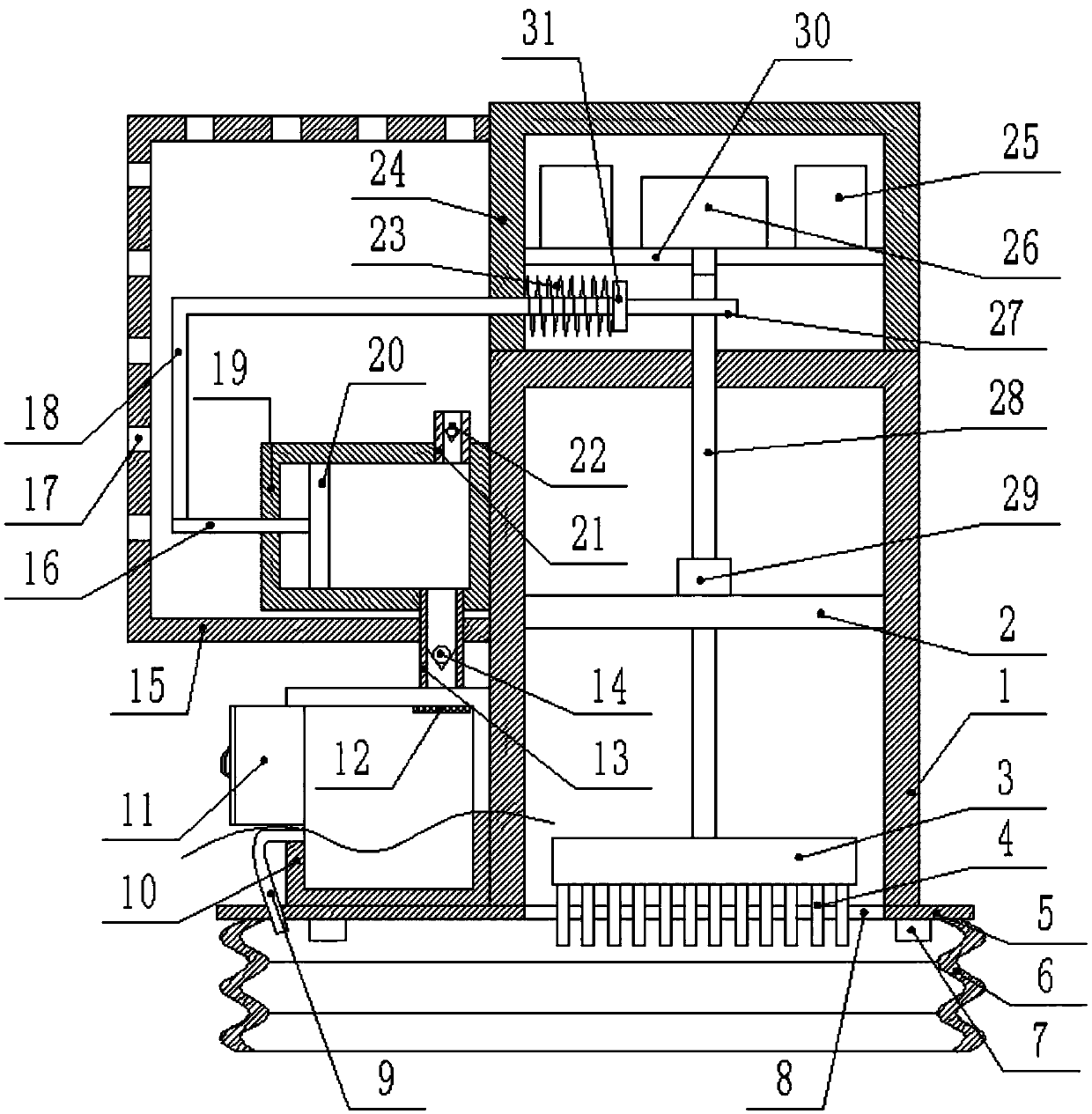

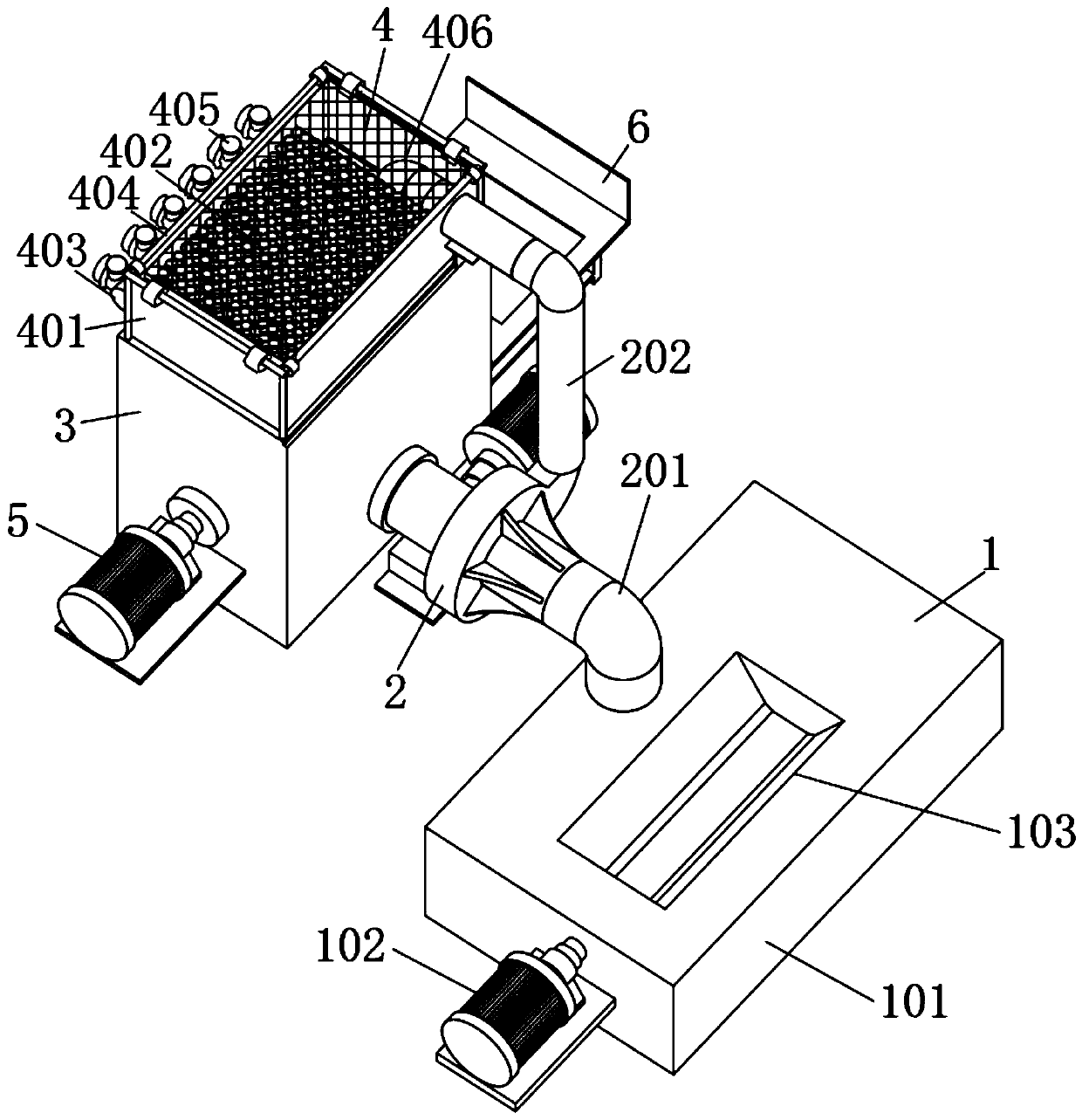

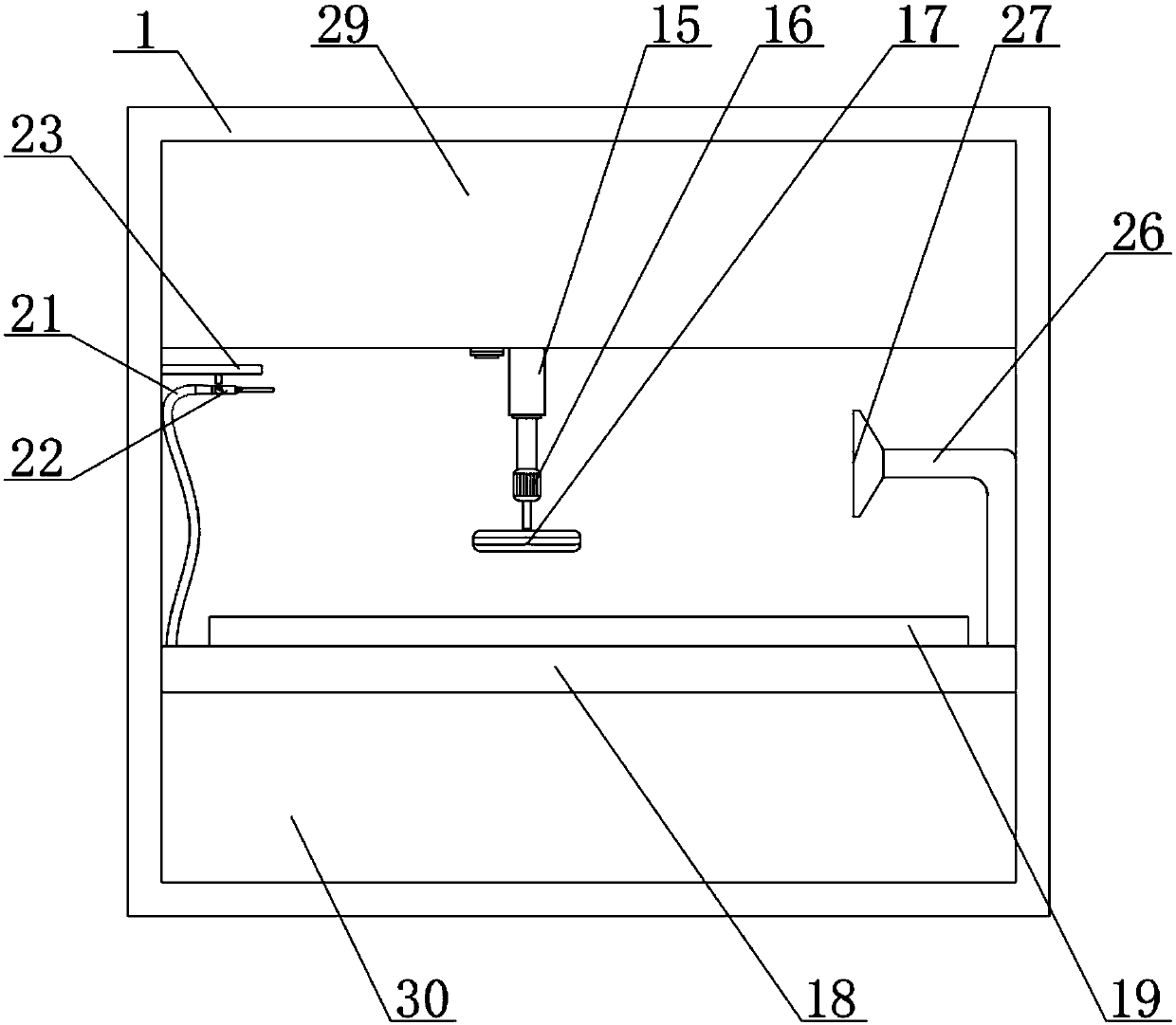

Ore cutting device with dust removal function

InactiveCN106346618AImprove working environmentReduce vibrationWorking accessoriesStone-like material working toolsArchitectural engineeringAir blower

The invention discloses an ore cutting device with dust removal function, which comprises a dust collecting device and a cutting table, a baffle plate and a fixed base are installed above the cutting table, and a dust suction pipe is arranged on the left side of the baffle plate. A blower is arranged on the right side of the baffle, a crossbeam is installed above the fixed base, a mobile frame is installed above the crossbeam, an electric telescopic rod is connected below the mobile frame, and an electric telescopic rod is connected below the electric telescopic rod. A rotating block is installed, a cutting device is installed under the rotating block, a cutting knife is installed inside the cutting device, a supporting plate is installed under the cutting device, and a shock absorbing device is passed between the cutting table and the base connection, a control box is installed above the base, a motor unit is installed inside the control box, a support frame is installed above the control box, and a stone is placed on the right side of the support frame. The invention has the advantages of simple structure, reasonable design and simple operation, and is worth popularizing.

Owner:GUANGZHOU DANJUE COMM TECH CO LTD

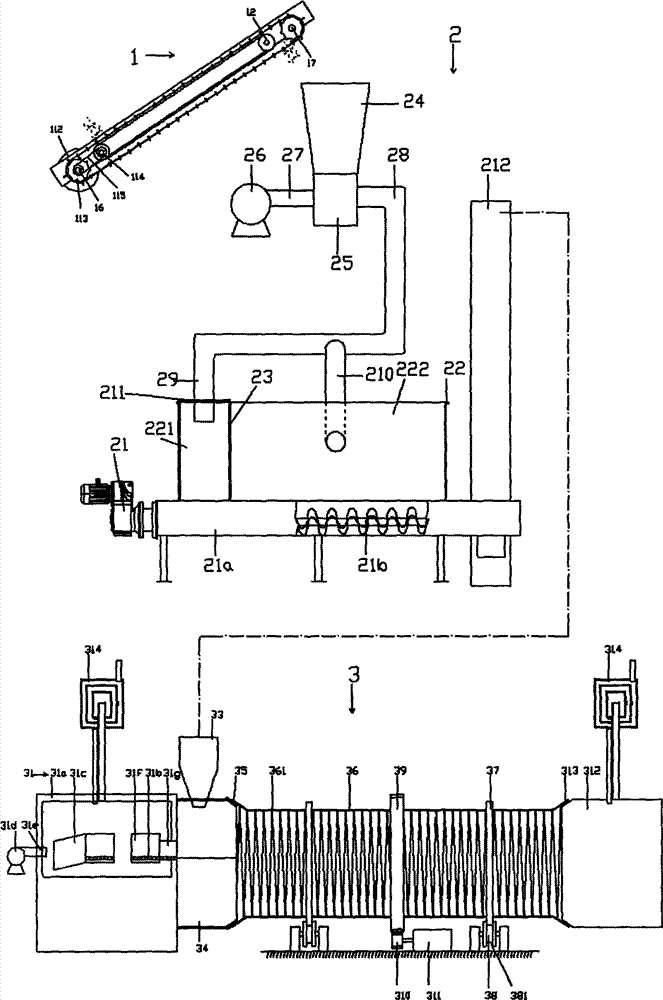

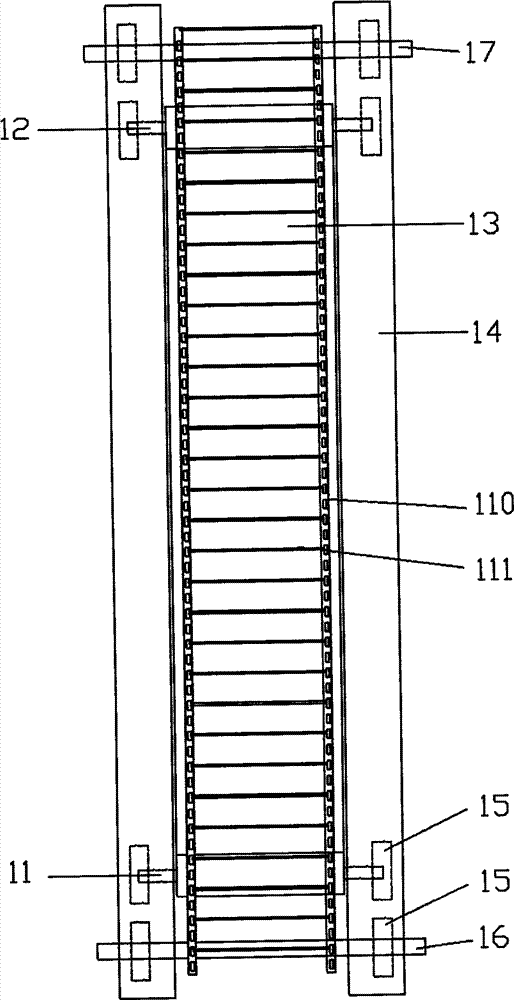

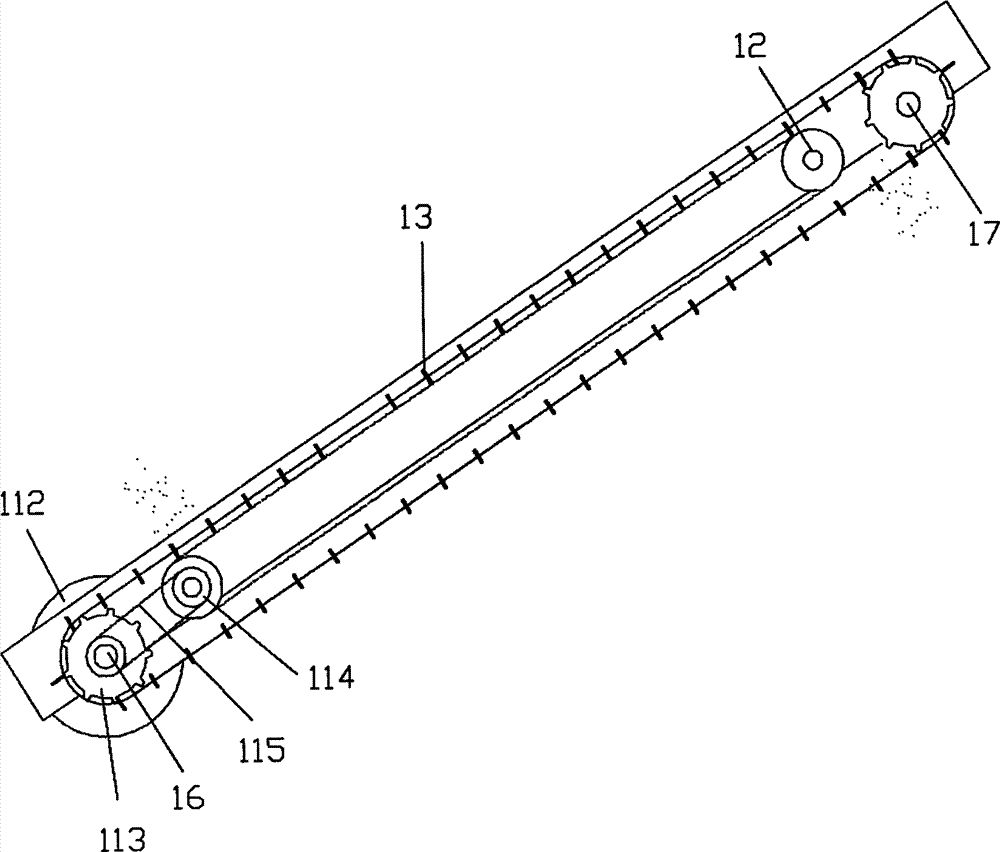

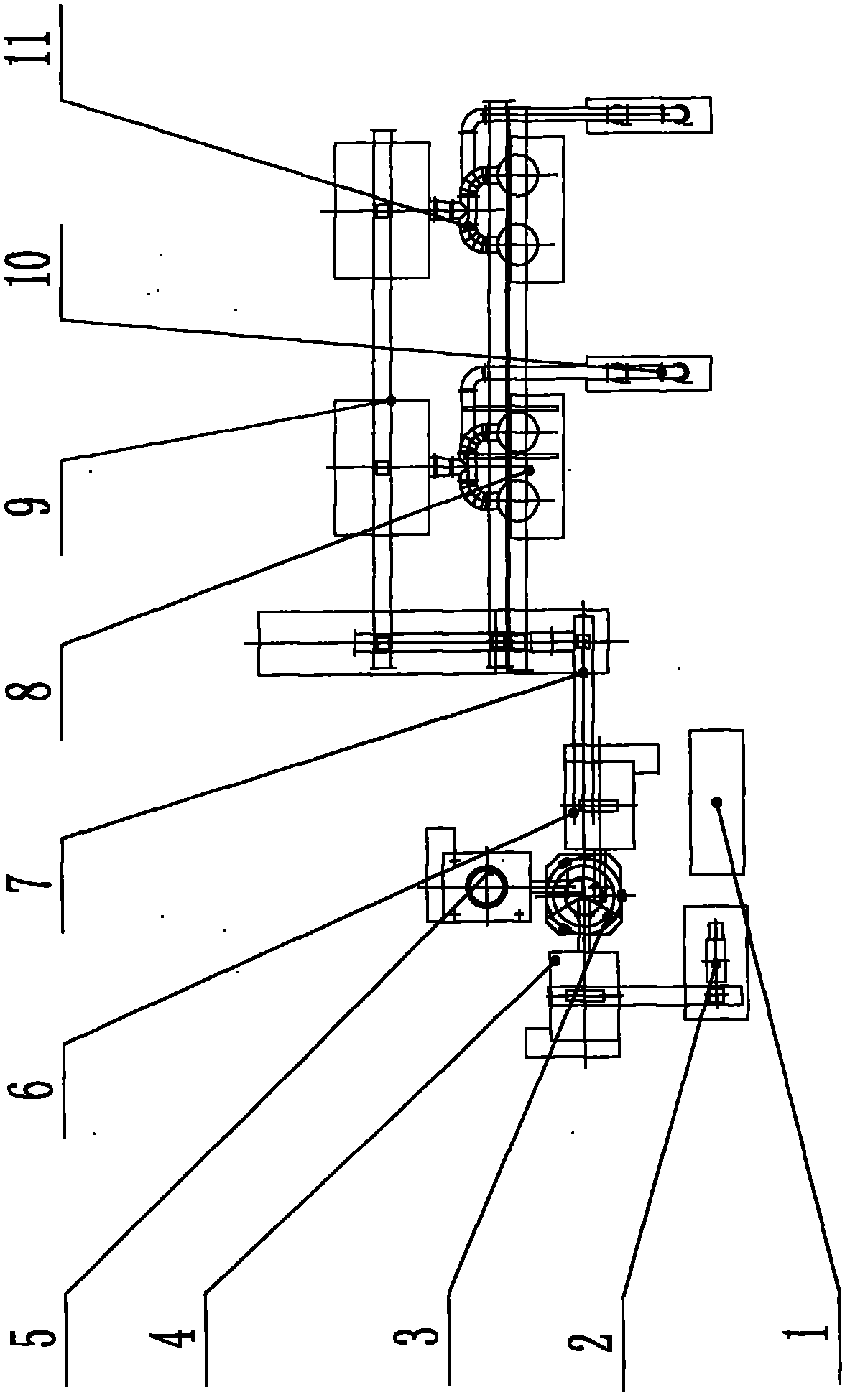

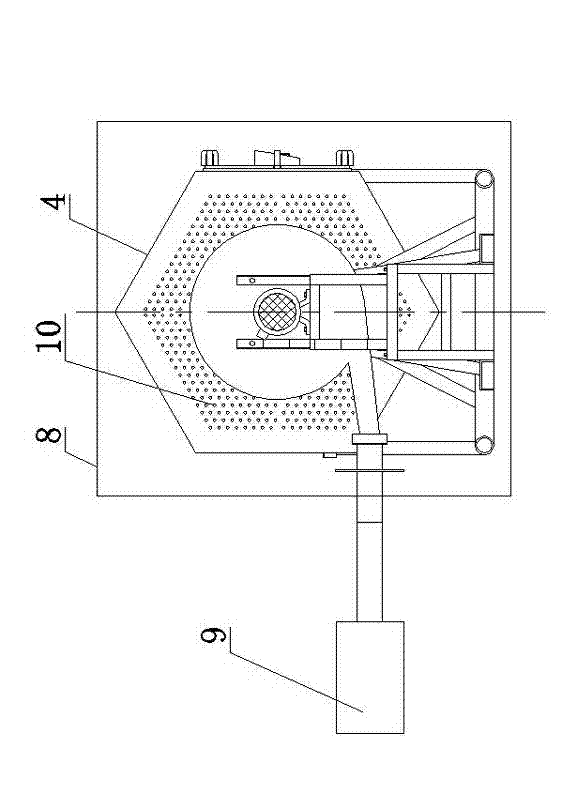

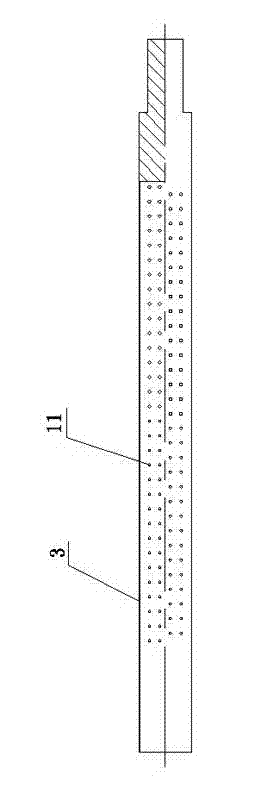

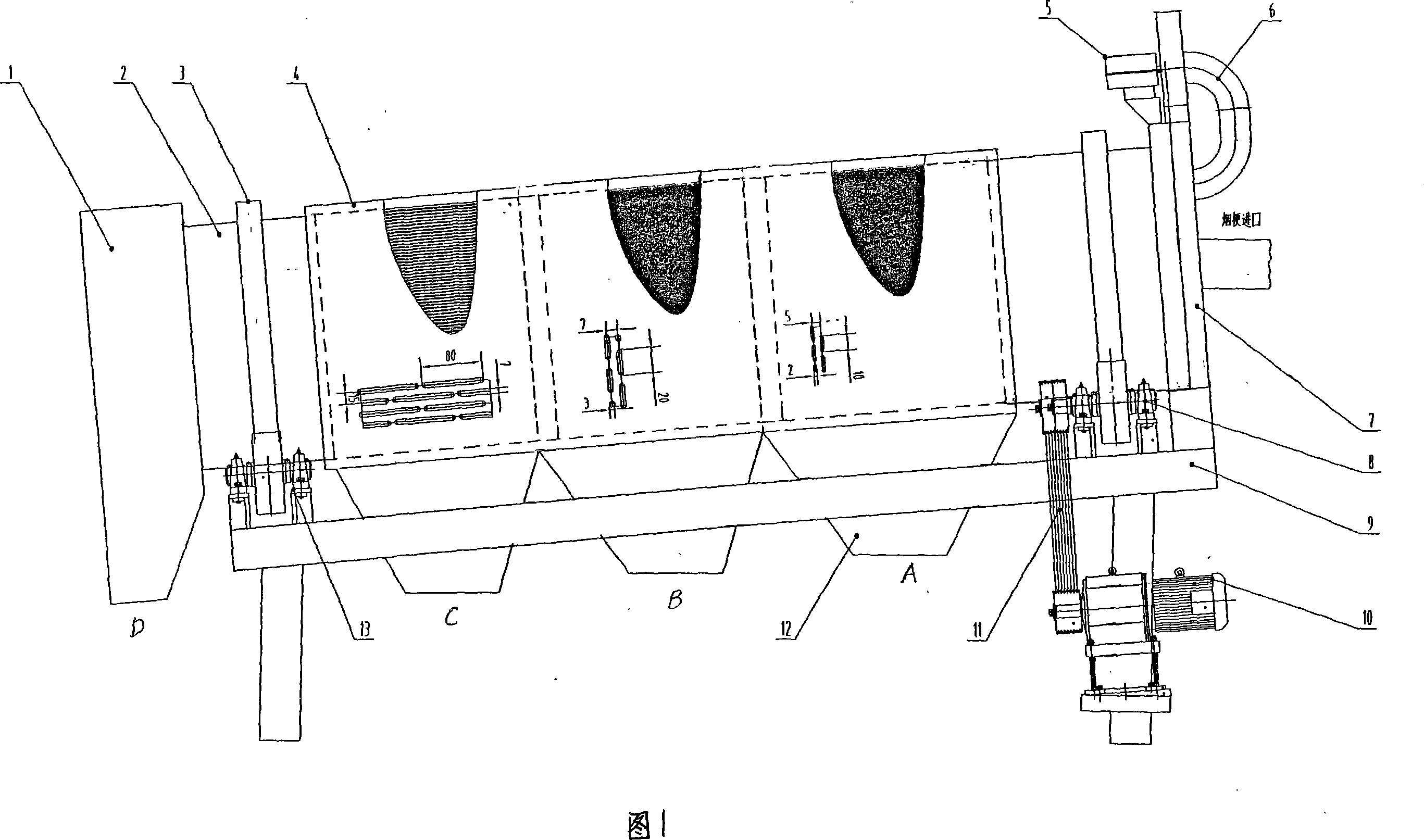

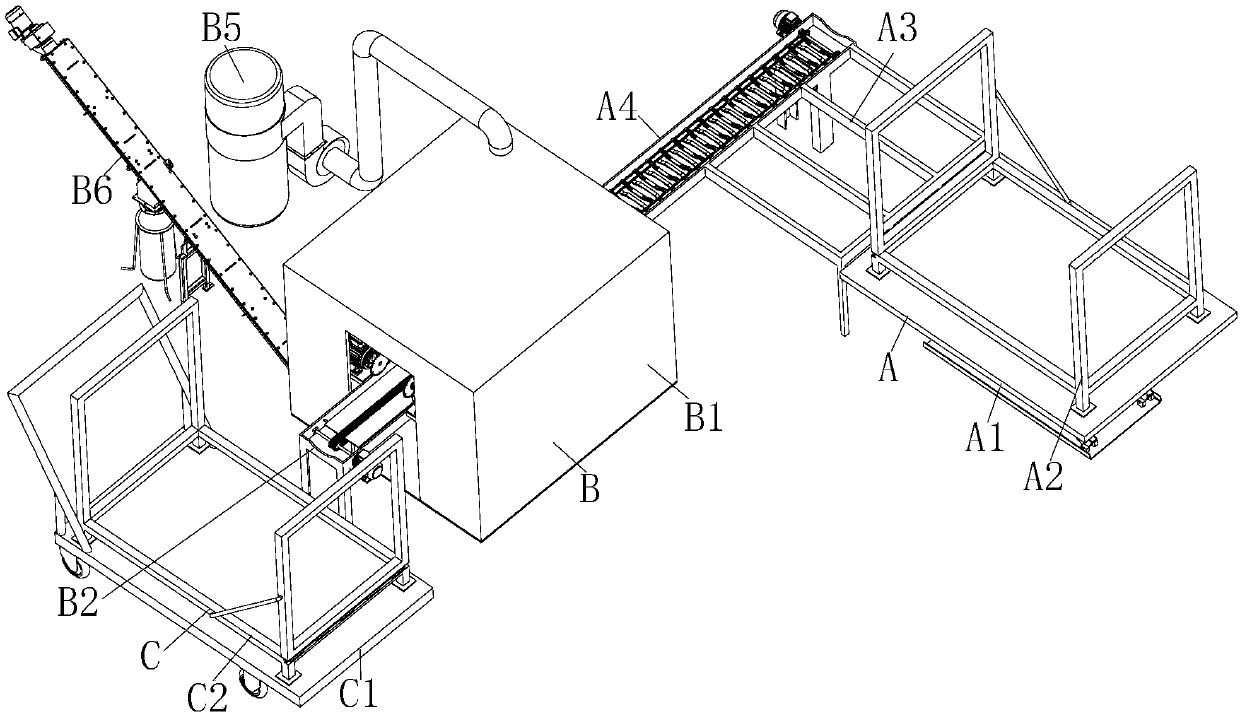

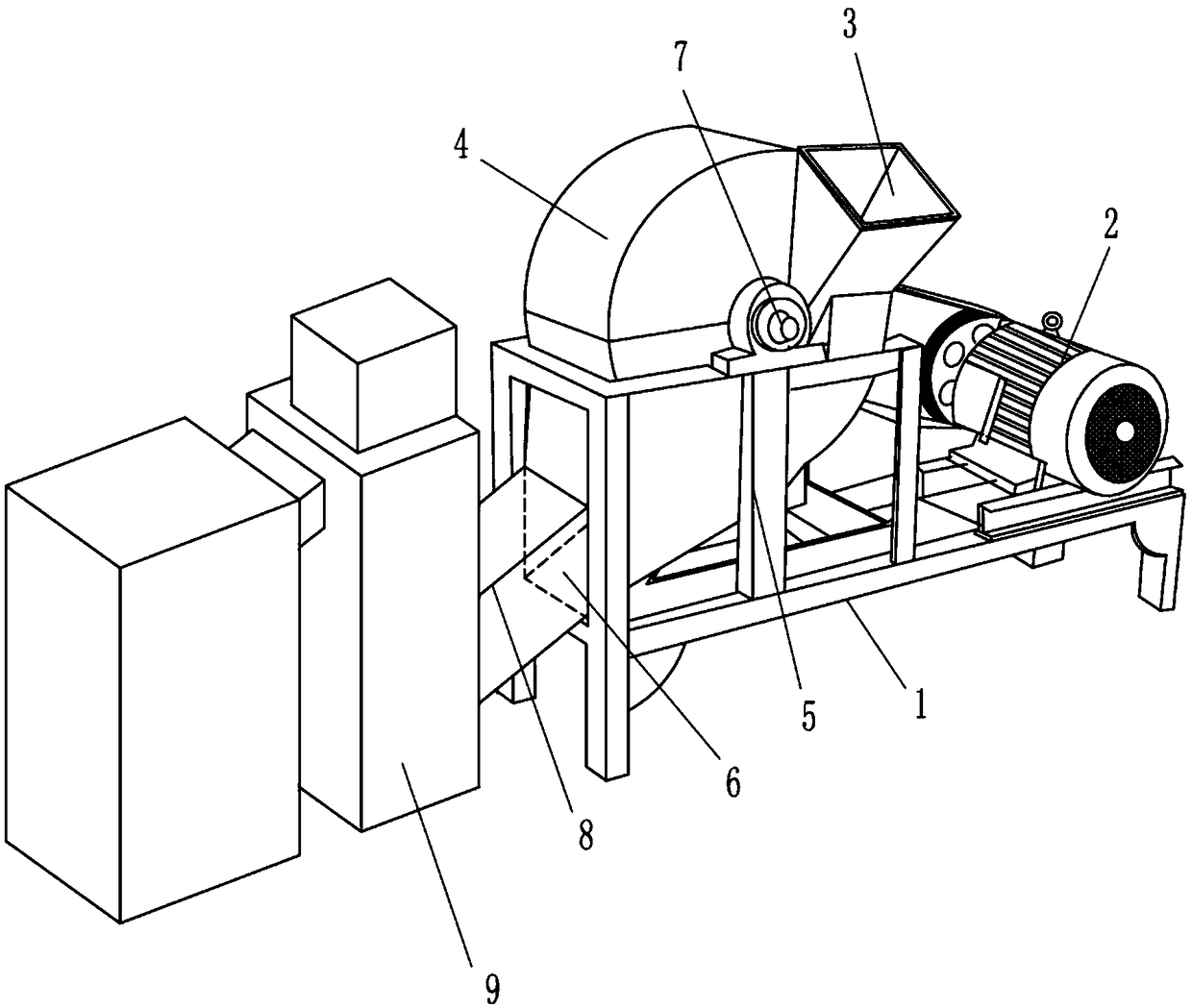

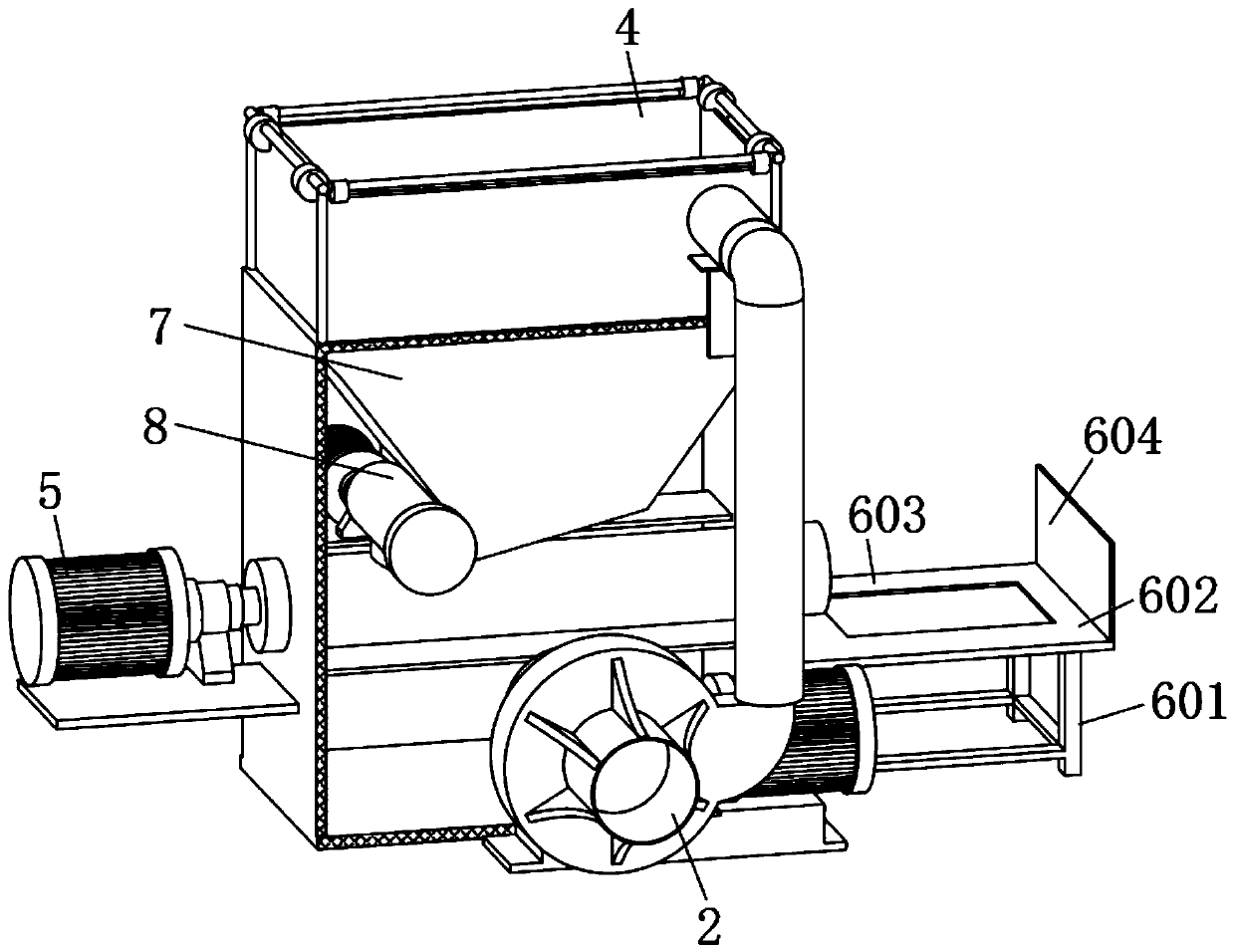

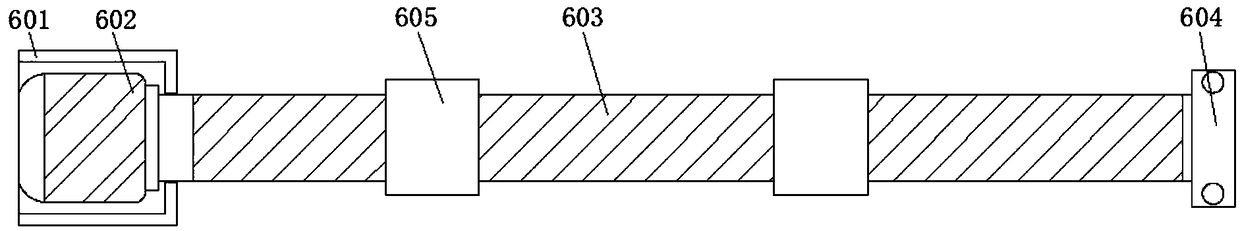

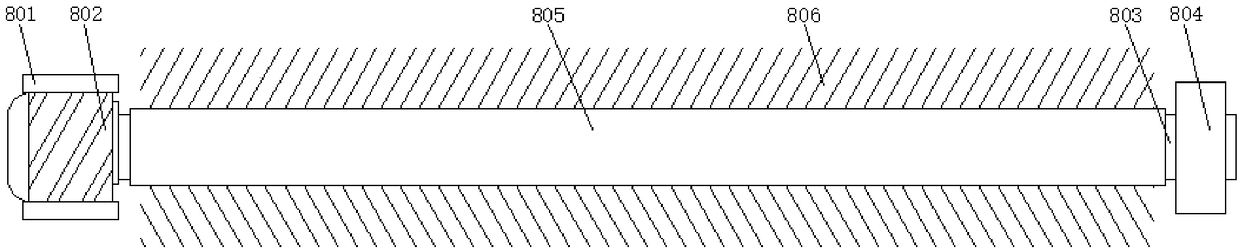

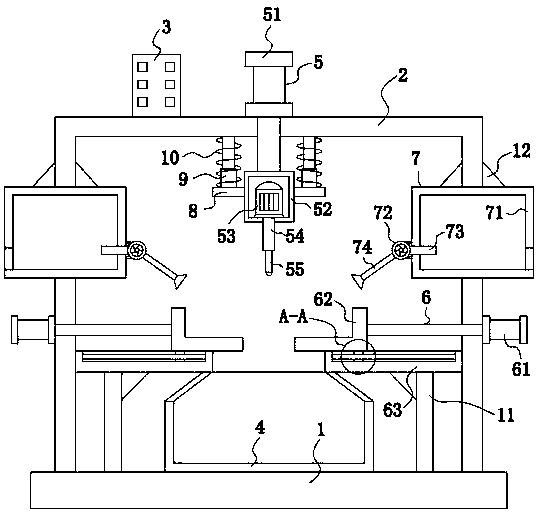

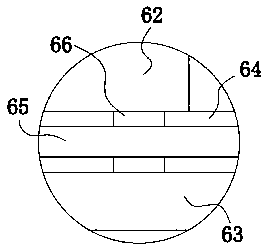

Organic fertilizer production line

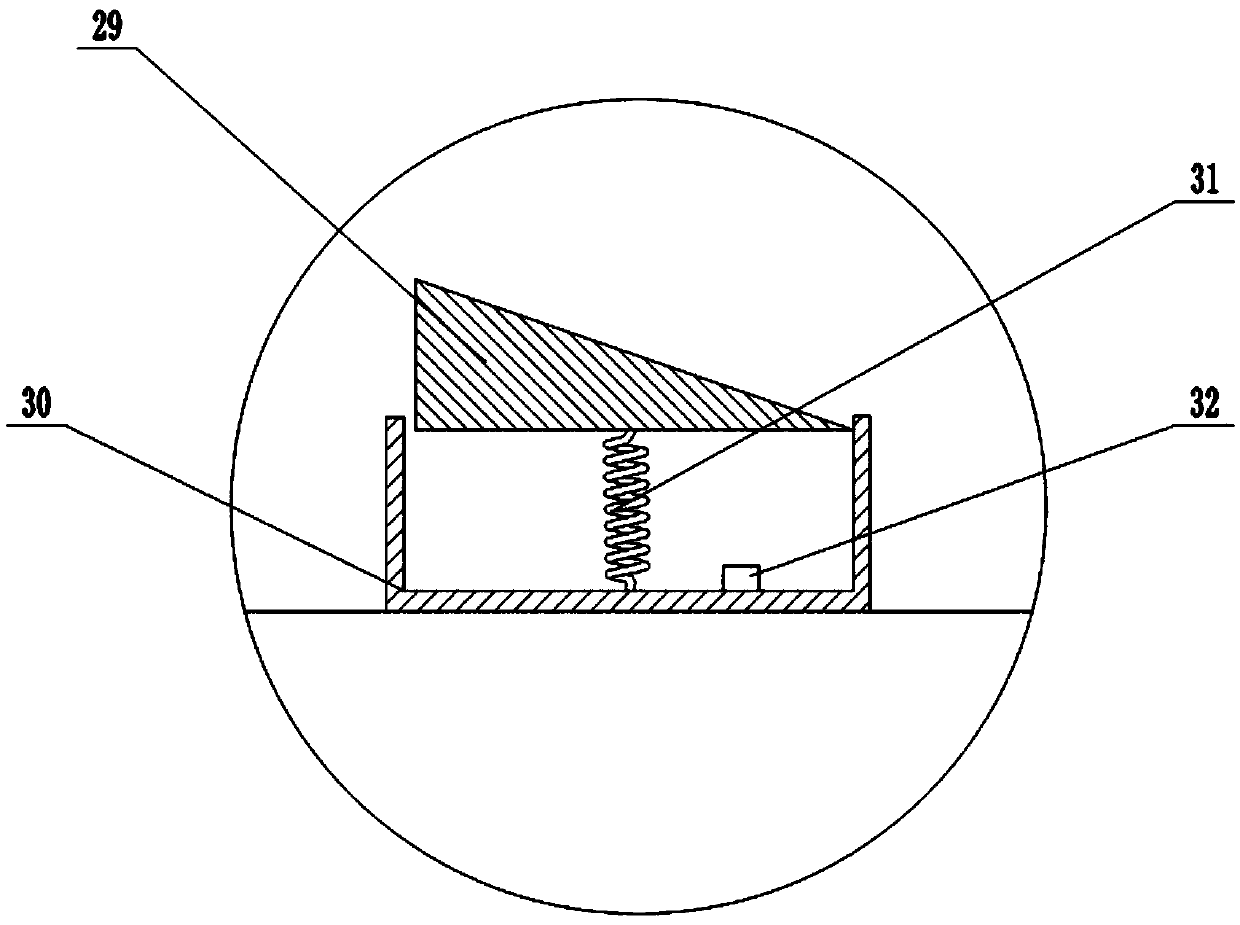

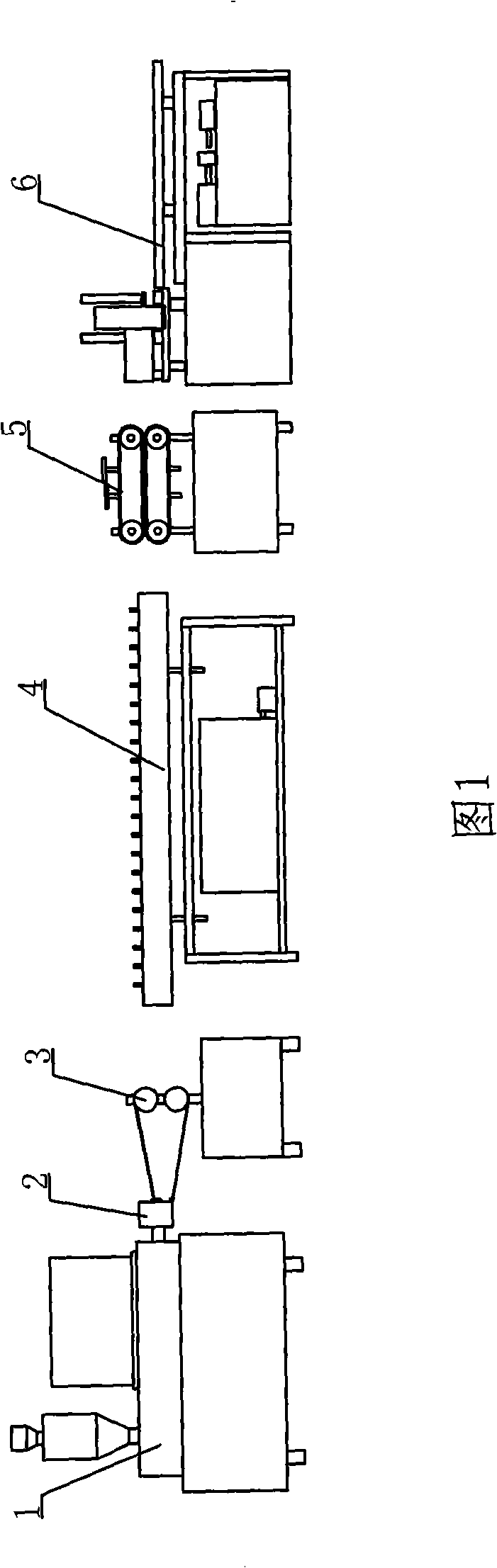

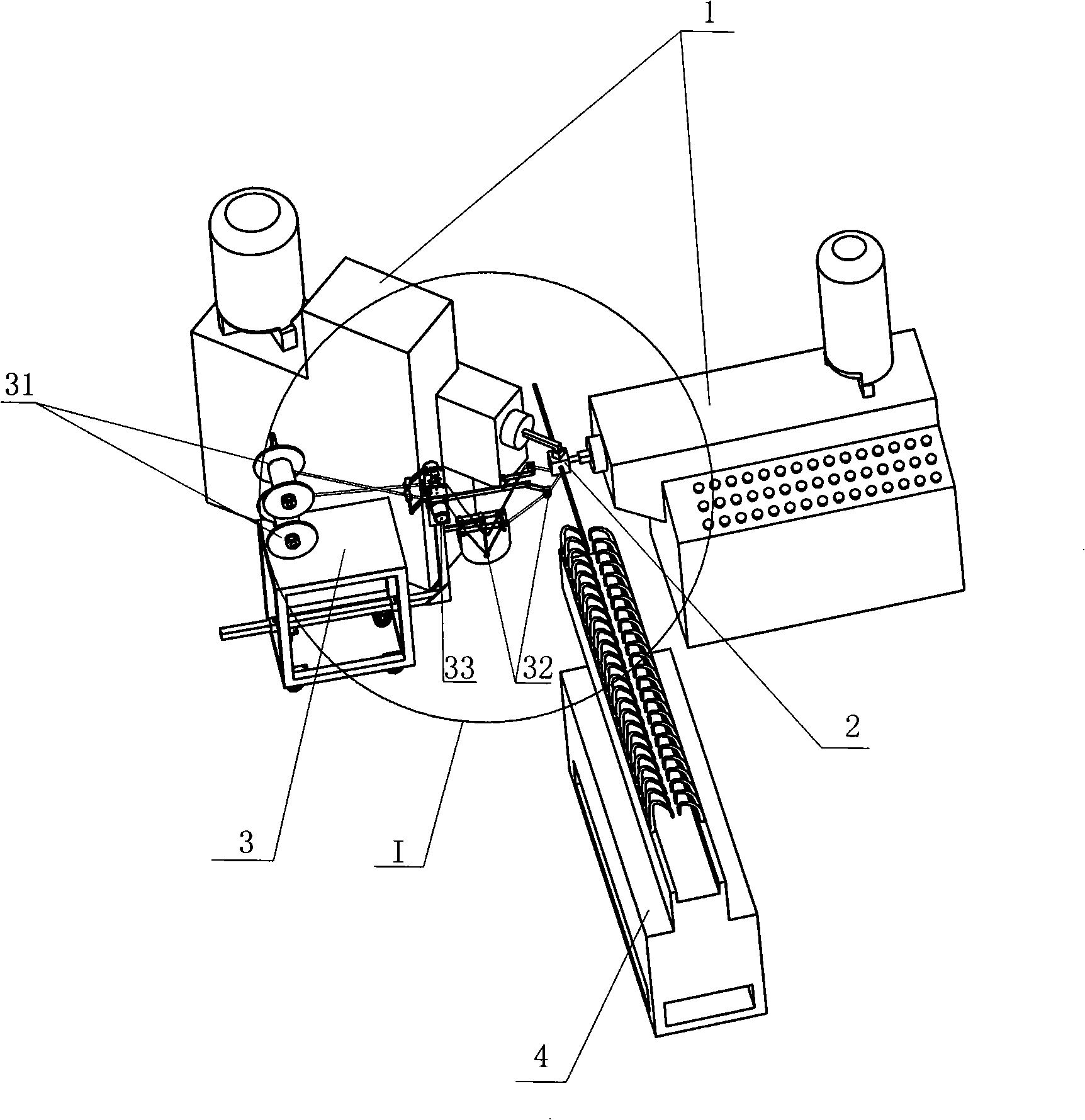

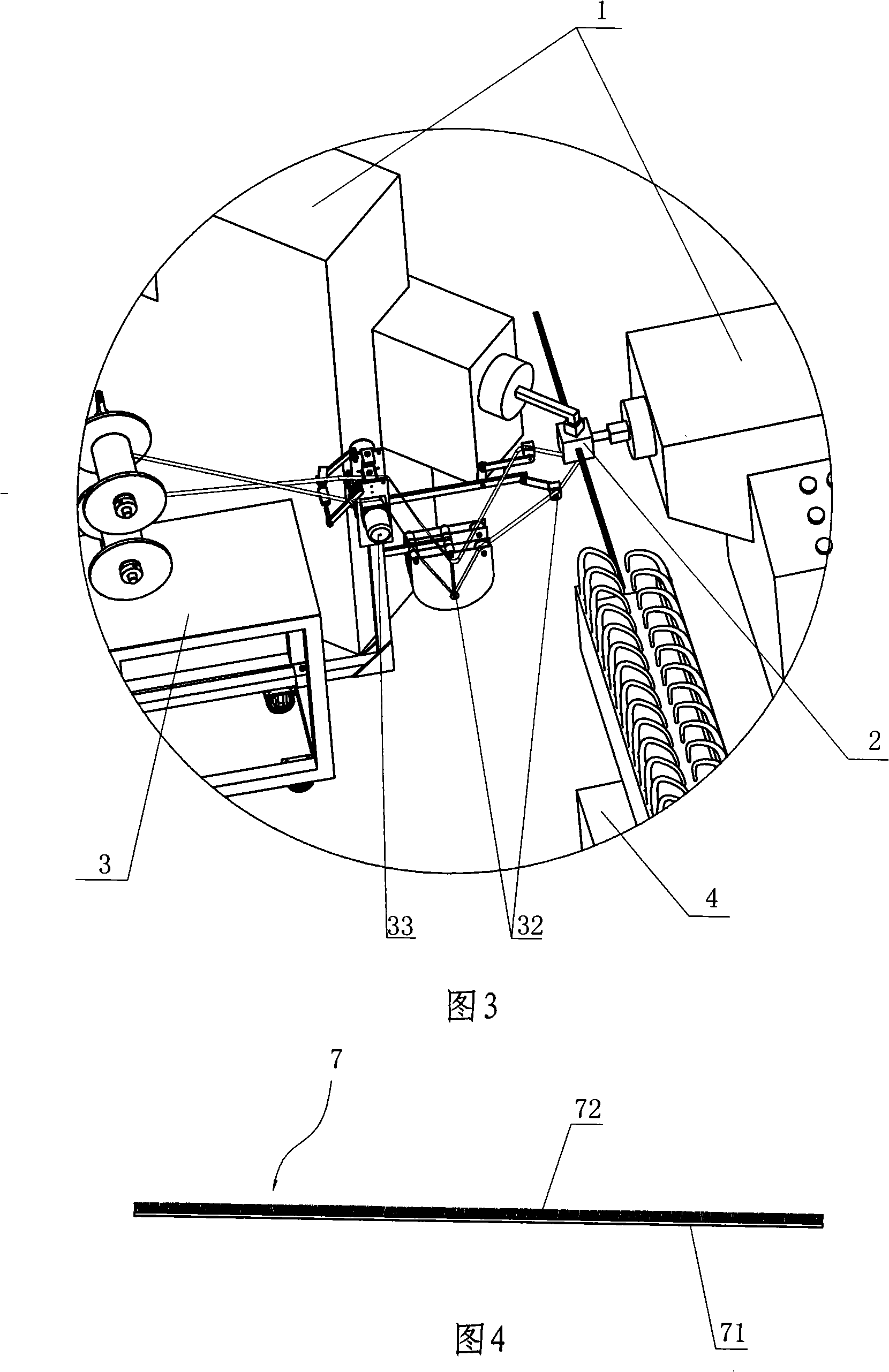

InactiveCN104728850AReduce drop outAvoid flying aroundConveyorsMixer accessoriesProduction lineCombustion

An organic fertilizer production line is composed of a saw dust lifting conveying belt, a saw dust and sludge mixing device and a combustion device. According to the structure of the saw dust lifting conveying belt, the two ends of a roller shaft of a rubber belt lower roller and a rubber belt upper roller are installed on a shaft seat, and the shaft seat is fixed to a baffle. According to the structure of the saw dust and sludge mixing device, a feeding hopper is fixed to a conveying groove of a spiral conveyer, a separating plate is fixed in the feeding hopper and divides the feeding hopper into a saw dust feeding chamber and a sludge feeding chamber, and a discharging port of the saw dust feeding chamber is located in the upper portion of the initial end of a spiral shaft of the spiral conveyer. According to the structure of the combustion device, an electric heating plate is fixed in a hearth of a furnace body, the hearth is provided with a feeding door, an air outlet of an air blower of the combustion device is communicated with an air blowing pipe of the combustion device, the air blowing pipe of the combustion device is communicated with the hearth, and a hearth air outlet is formed in the right side of the hearth. The organic fertilizer production line can reduce saw dust falling off a rubber belt and improves the work environment. Exhaust dust smoke meets the national standards, and has no pollution to the surroundings basically.

Owner:LINAN XINNENG BIOTECH

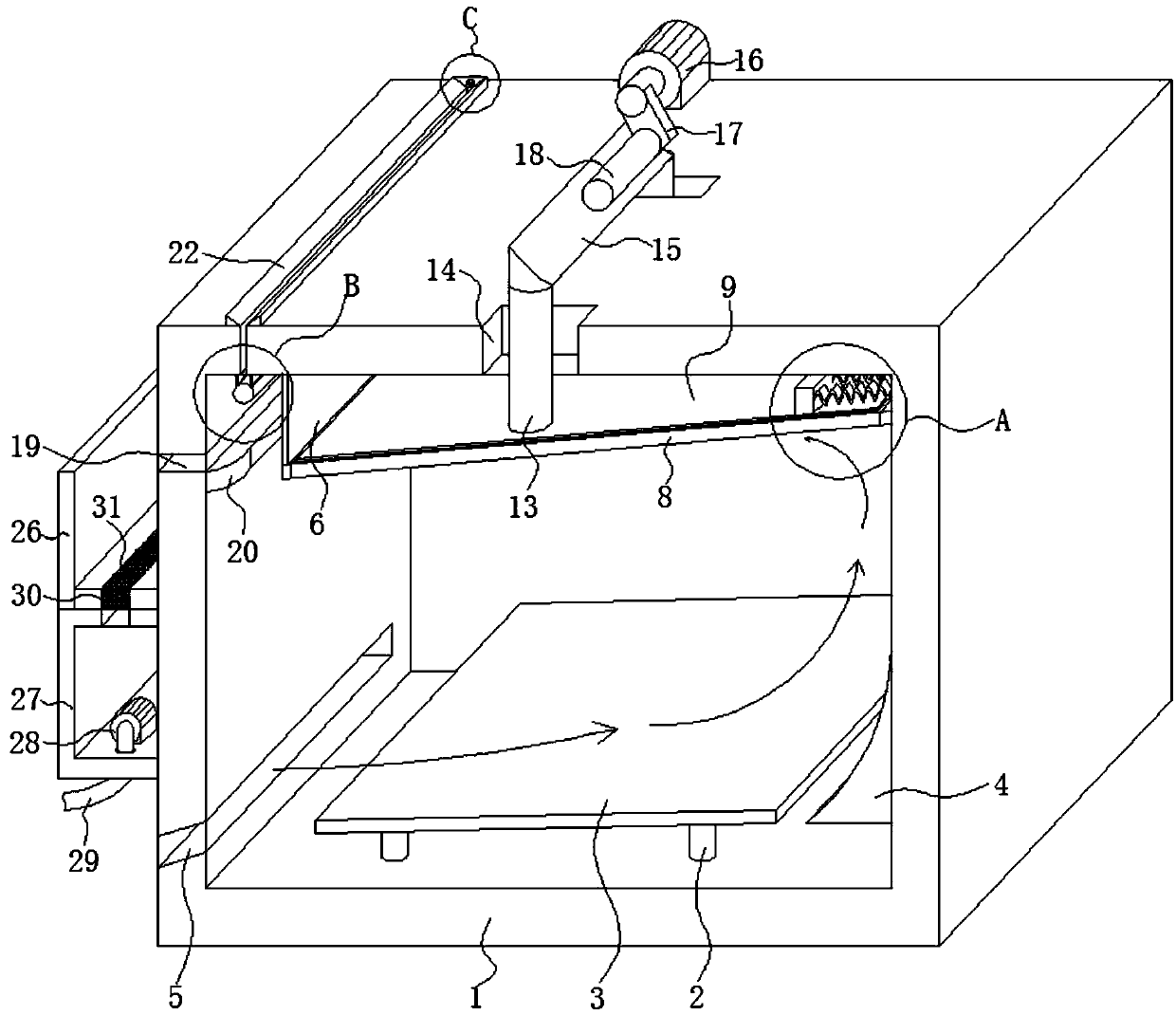

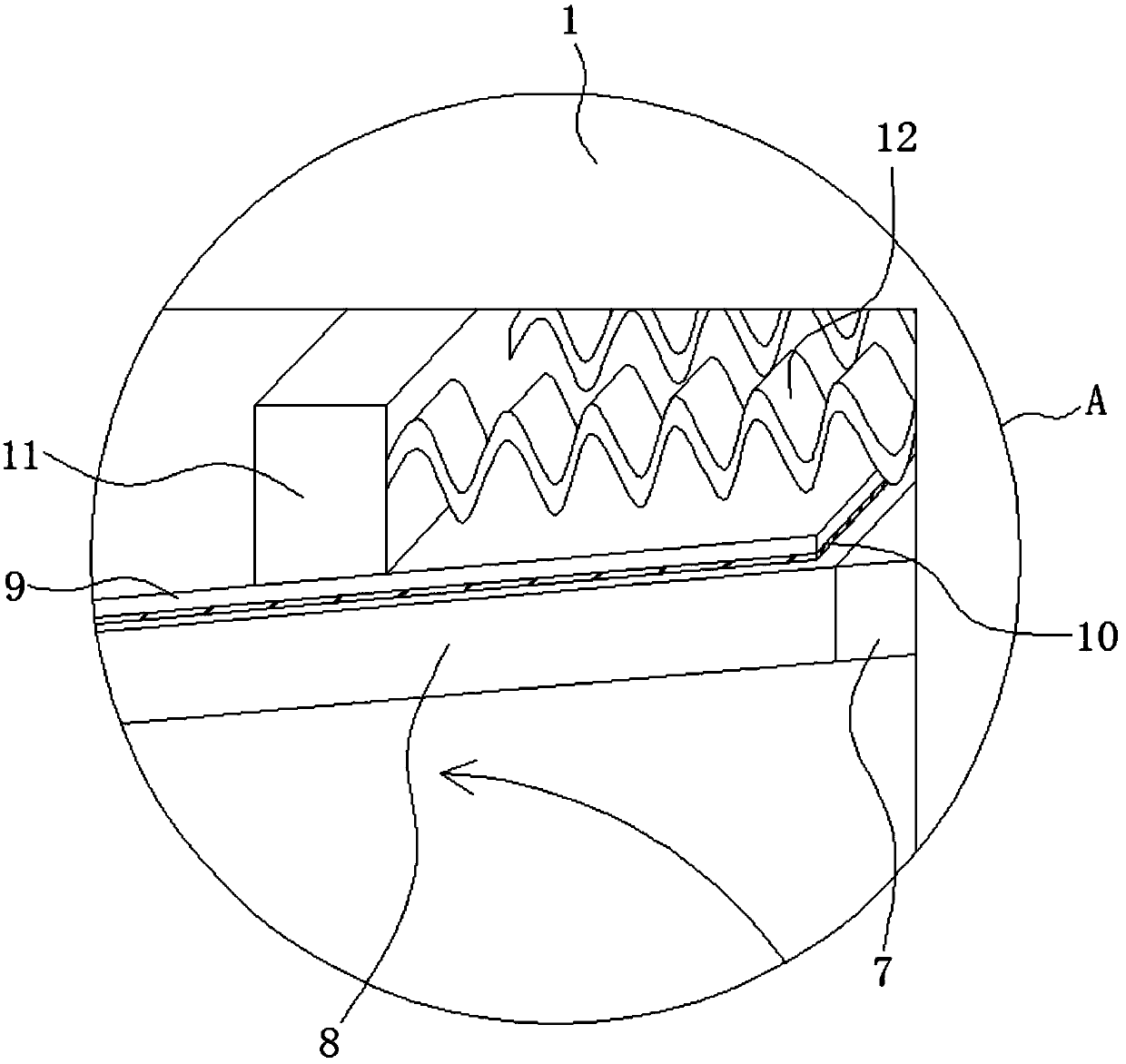

Polishing and spraying integrated paint spraying equipment

InactiveCN108097490AEvenly paintedReduce deliveryGrinding carriagesPolishing machinesWorking environmentPollution

The invention discloses polishing and spraying integrated paint spraying equipment. The polishing and spraying integrated paint spraying equipment structurally comprises a body, a paint box, a polishing and spraying transmission device, a pump, a material pipe, a reverse motor, a column, a paint spraying controller, a lifting rod, a paint spraying head, a transfer platform, a limiting plate, a support frame and a dryer, wherein the column is welded to the left side of the body; the paint box is mounted on the left side of the body and is arranged on the bottom of the column; the polishing andspraying transmission device is arranged on the right side of the paint box and is movably connected with the body; the pump is mounted in the column and is connected with the material pipe; and the material pipe is connected with the paint box and the pump at the position of the paint spraying head. The polishing and spraying integrated paint spraying equipment has the beneficial effects that while polishing of a polisher through the reverse motor, dust is blown out of a box and is treated, the purpose of uniformly spraying paint is achieved by rotation of a rotary rack connecting rod with different lengths, baffles are arranged at two ends of a treatment box to prevent paint molecules from scattering in all directions, paint pollution of a working environment is relieved, the equipment is simple in framework and easy to operate, the working efficiency is improved, and the equipment is convenient to use.

Owner:江门市蓬江区辛欣摩托车配件有限公司

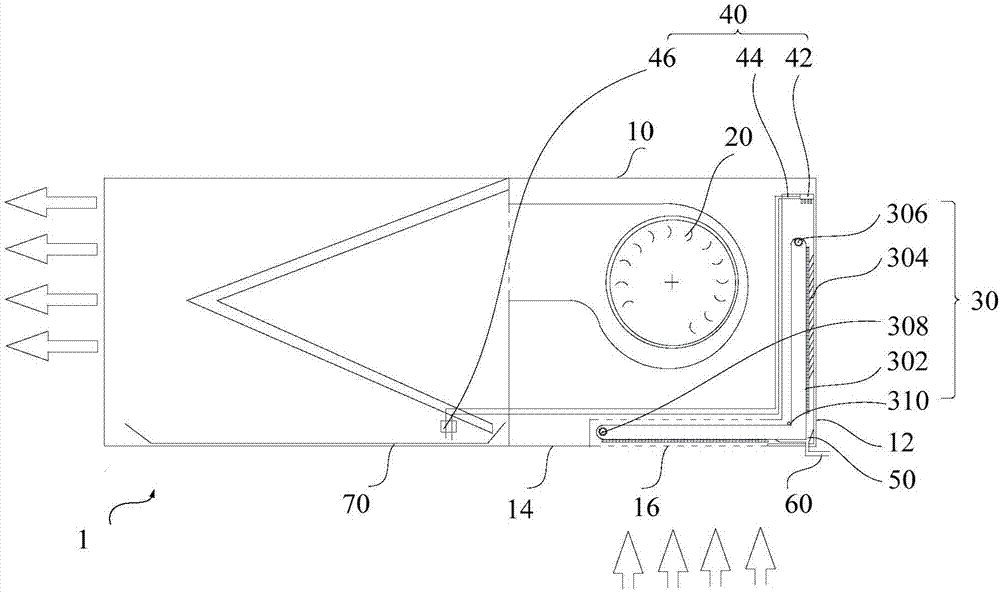

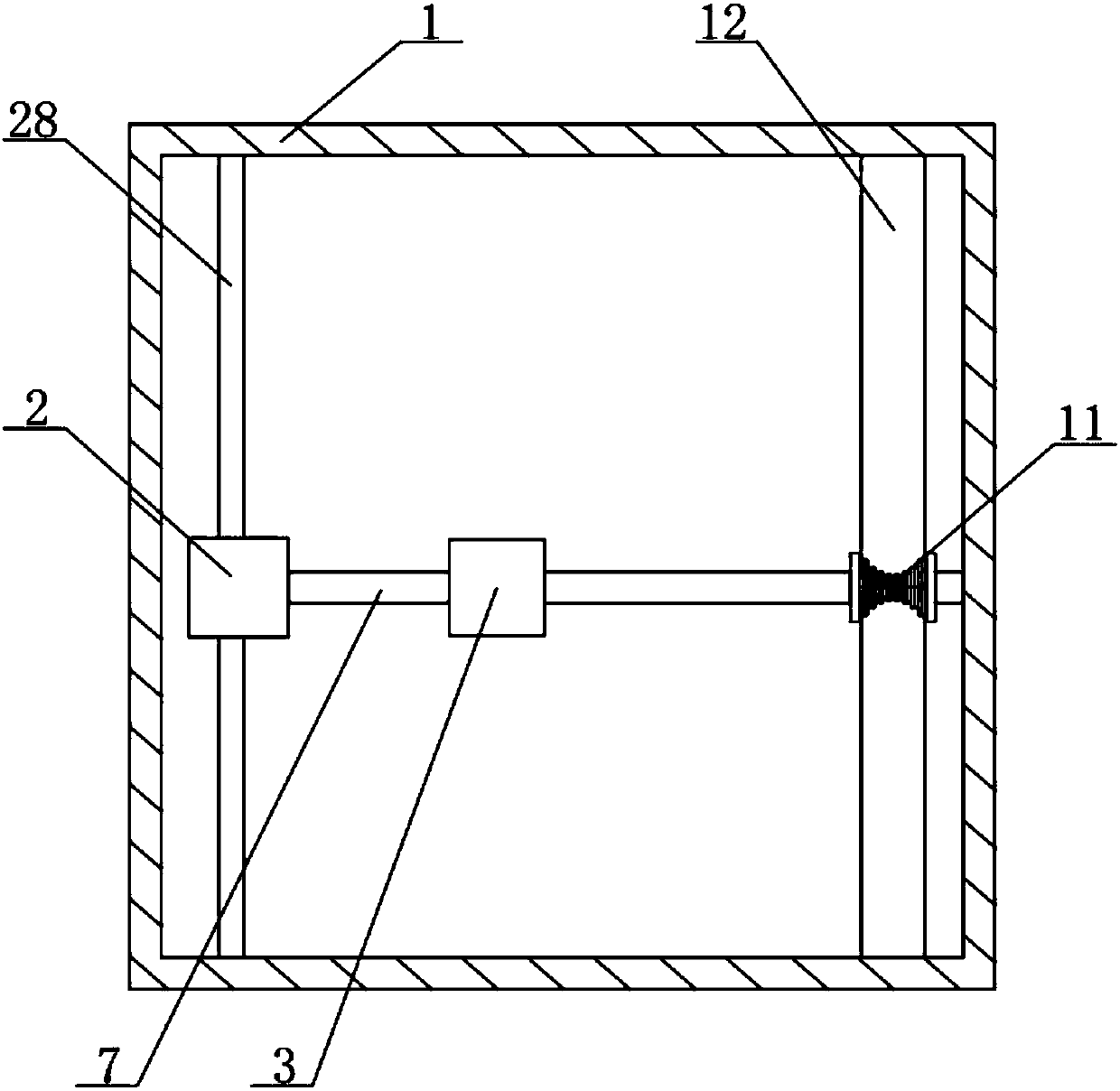

Indoor unit and air-conditioner

InactiveCN107192015AAffecting workInfluence structureCondensate preventionLighting and heating apparatusAir conditioningReturn channel

The invention provides an indoor unit and an air-conditioner. The indoor unit is used in the air-conditioner and comprises a shell, a fan and a filter screen assembly. The filter screen assembly comprises a filter screen, a hairbrush, a first transmission device, a second transmission device and a first drive device. The two ring-shaped ends of the filter screen are arranged on the first transmission device and the second transmission device in a sleeving manner correspondingly. The first drive device drives the first transmission device or the second transmission device to rotate around the self axis to drive the filter screen to rotate around the first transmission device and the second transmission device, and the filter screen covers a wind return opening in the rotating process and / or makes interference contact with the hairbrush. In the working process, the filter screen can cover the wind return opening and has a function of filtering impurities and dust, it is ensured that air entering an air-conditioning room is clean, the hairbrush can clean the dust on the filter screen automatically, and the filter screen does not need to be manually disassembled to be cleaned. An interval is reserved between the hairbrush and the wind return opening, it is effectively ensured that the filter screen assembly does not occupy a wind return channel, and the wind return efficiency is ensured.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

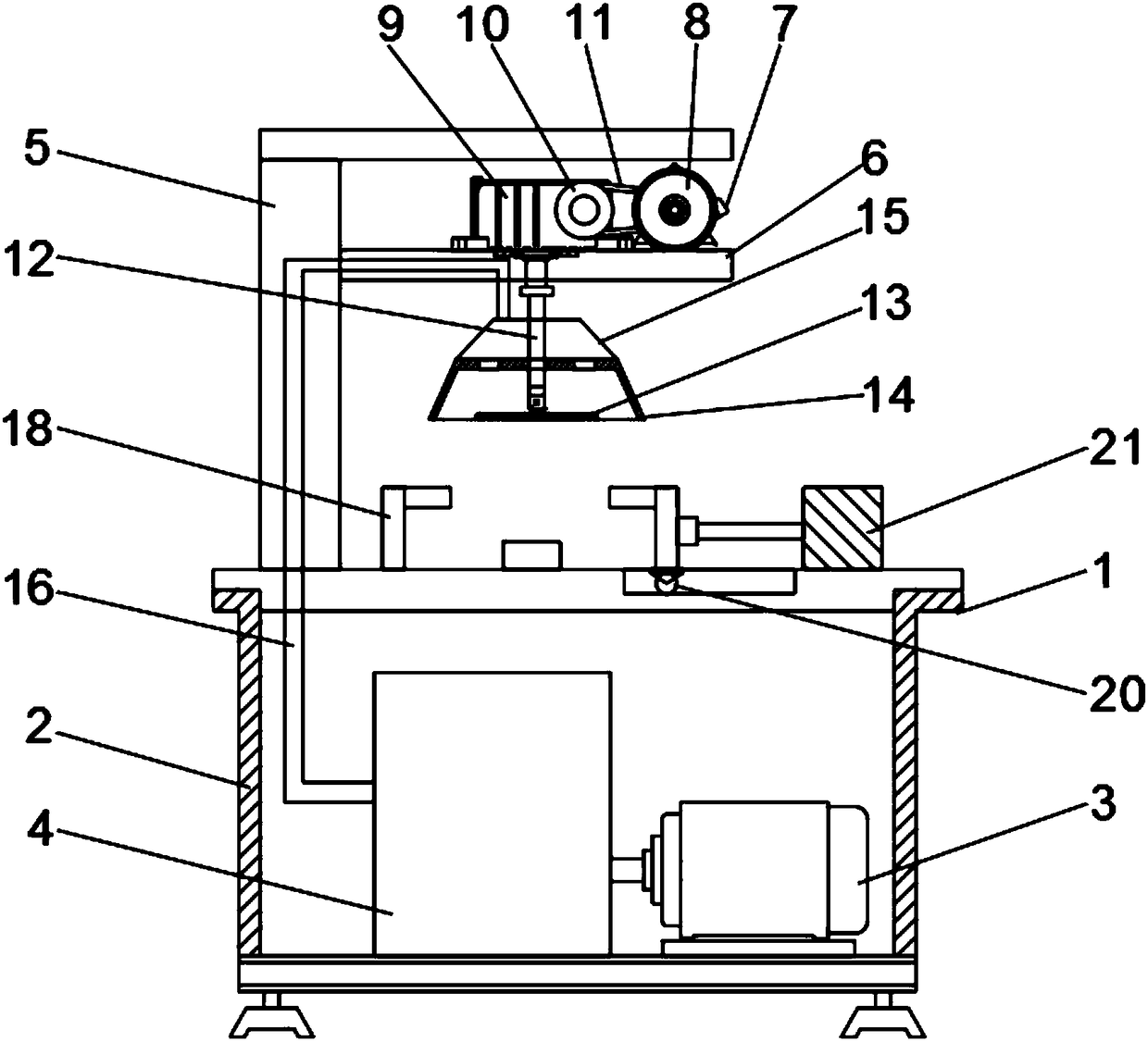

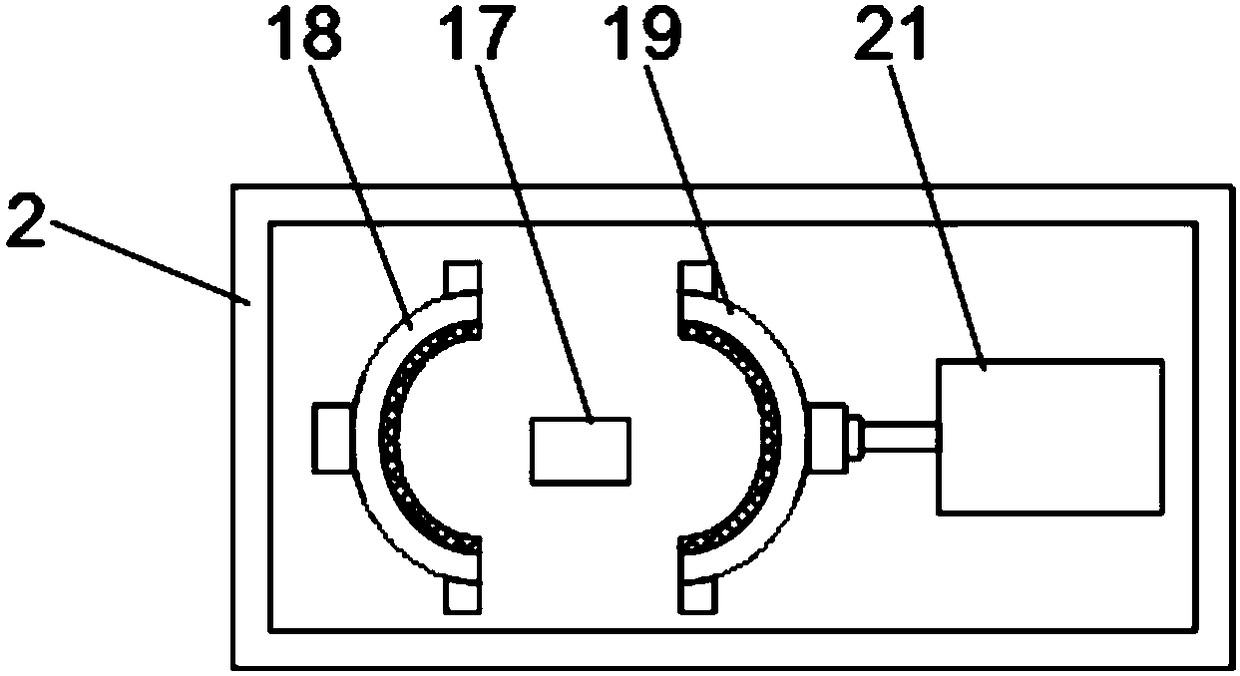

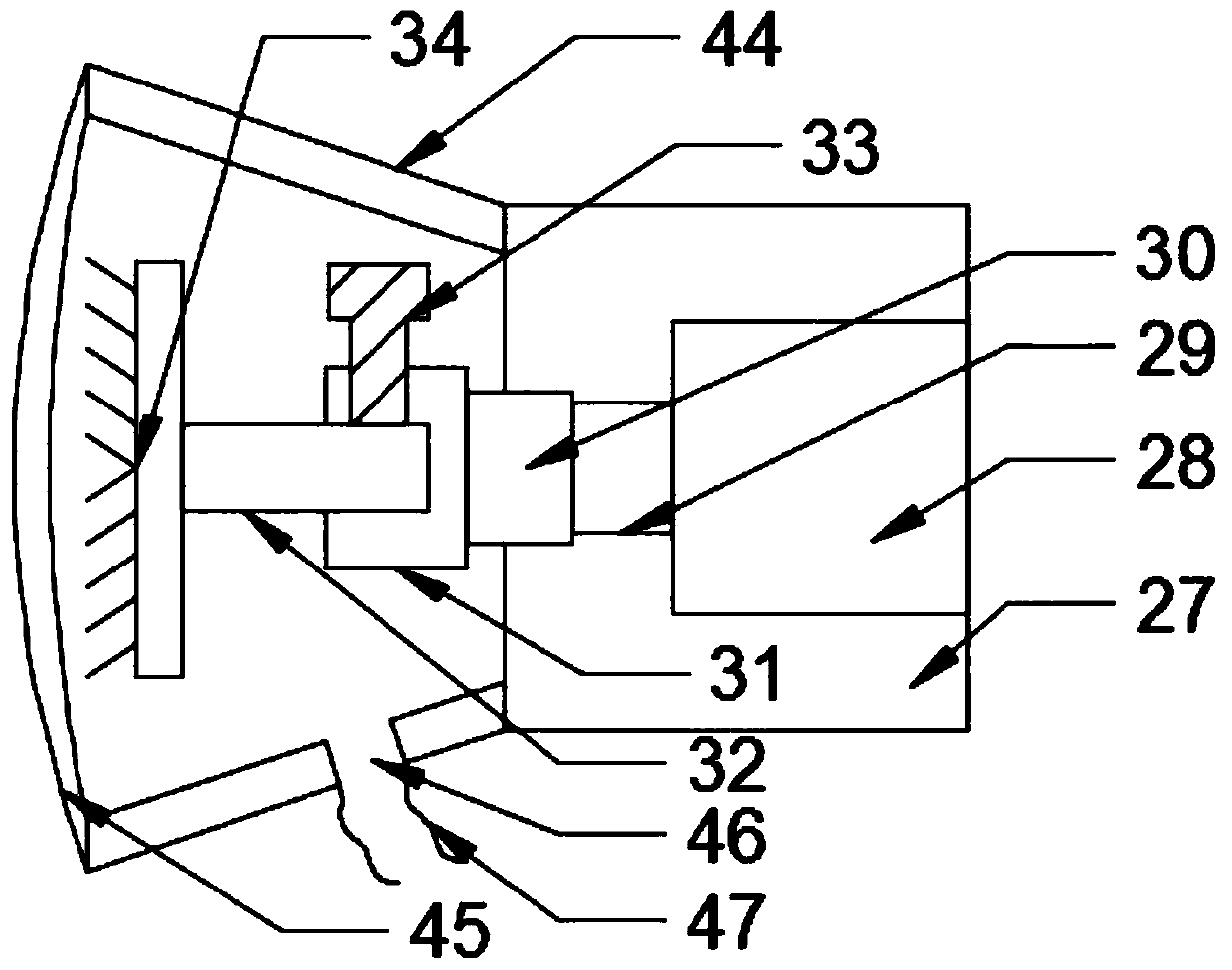

Polishing device for lighting lamp cover

InactiveCN108161663AAvoid flying aroundReduce the impactGrinding carriagesGrinding machinesSuction stressEngineering

The invention discloses a polishing device for a lighting lamp cover. The polishing device for the lighting lamp cover comprises a device body, a box body, an suction fan, a collecting box, an electromotor, a rotating shaft, a grinding wheel, a dust suction hood, a dust suction pipe, a support seat, fixed blocks, moving blocks, a pulley and an air cylinder; the bottom of the device body is provided with the box body, one side inside the box body is provided with the suction fan, and one side of the suction fan is provided with the collecting box; the lighting lamp cover polishing device is reasonable in structure, suction is produced by the suction fan, dust particles produced by the lighting lamp cover in the process of grinding and polishing can be inhaled into the collecting box throughthe dust suction hood to avoid the dust particles flying around, so that the impact on the surrounding environment is reduced, and the health of an operator is ensured; and rubber gaskets are installed at the inner sides of both the fixed blocks and the moving blocks to prevent a workpiece from being crushed and damaged and to prevent slipping, one sides opposite to the fixed blocks and the moving blocks are arranged in the shape of an arc, and the clamping area is increased, thus the fastness of clamping is further increased.

Owner:海宁双迪电子照明有限公司

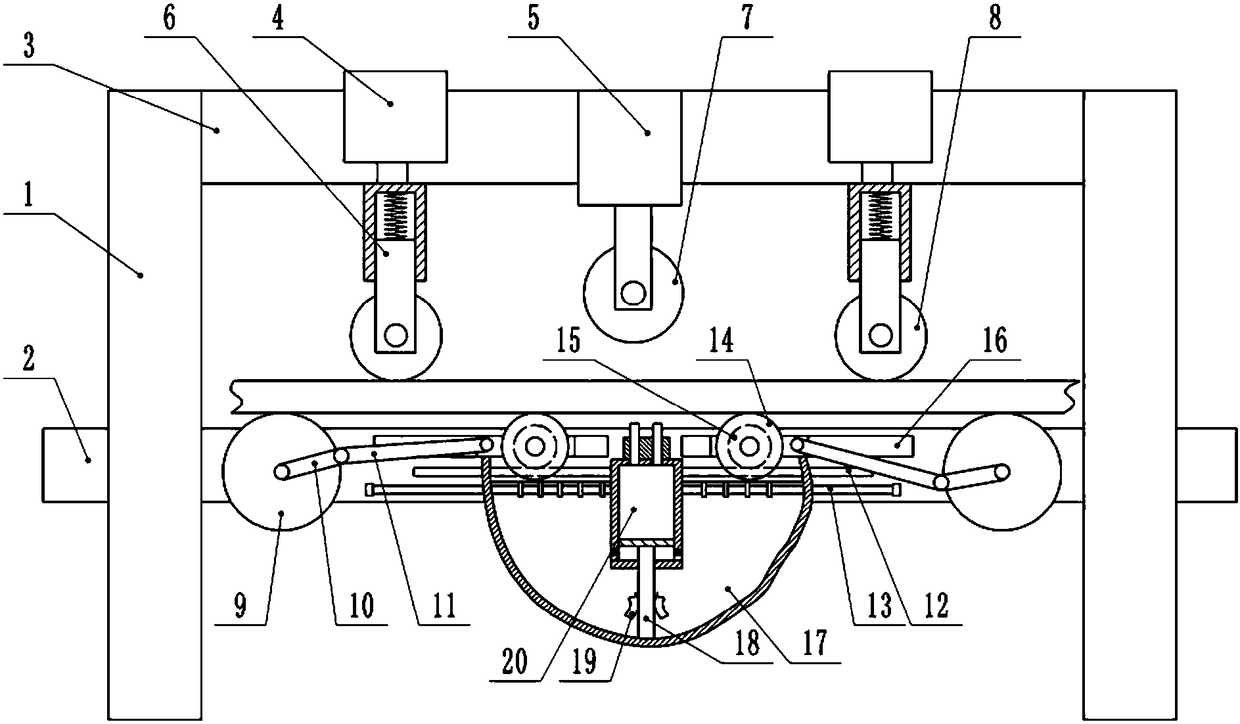

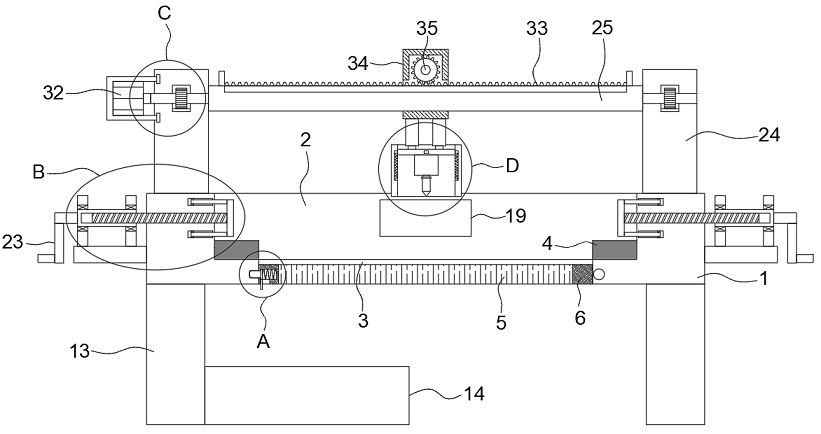

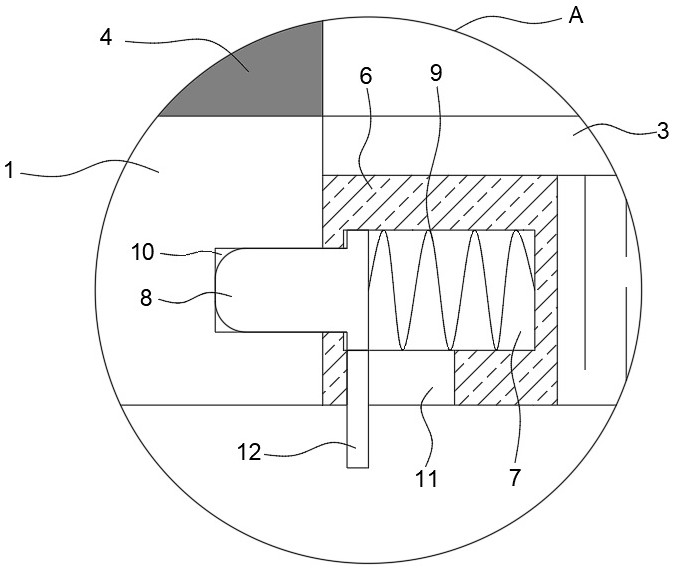

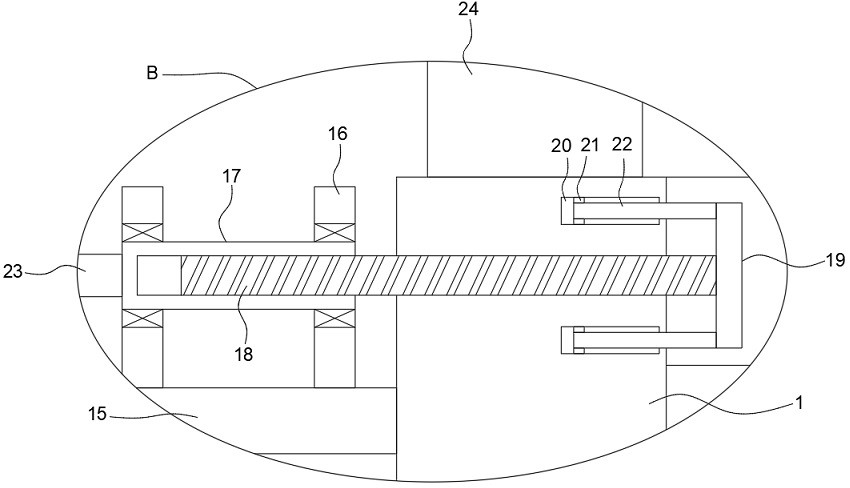

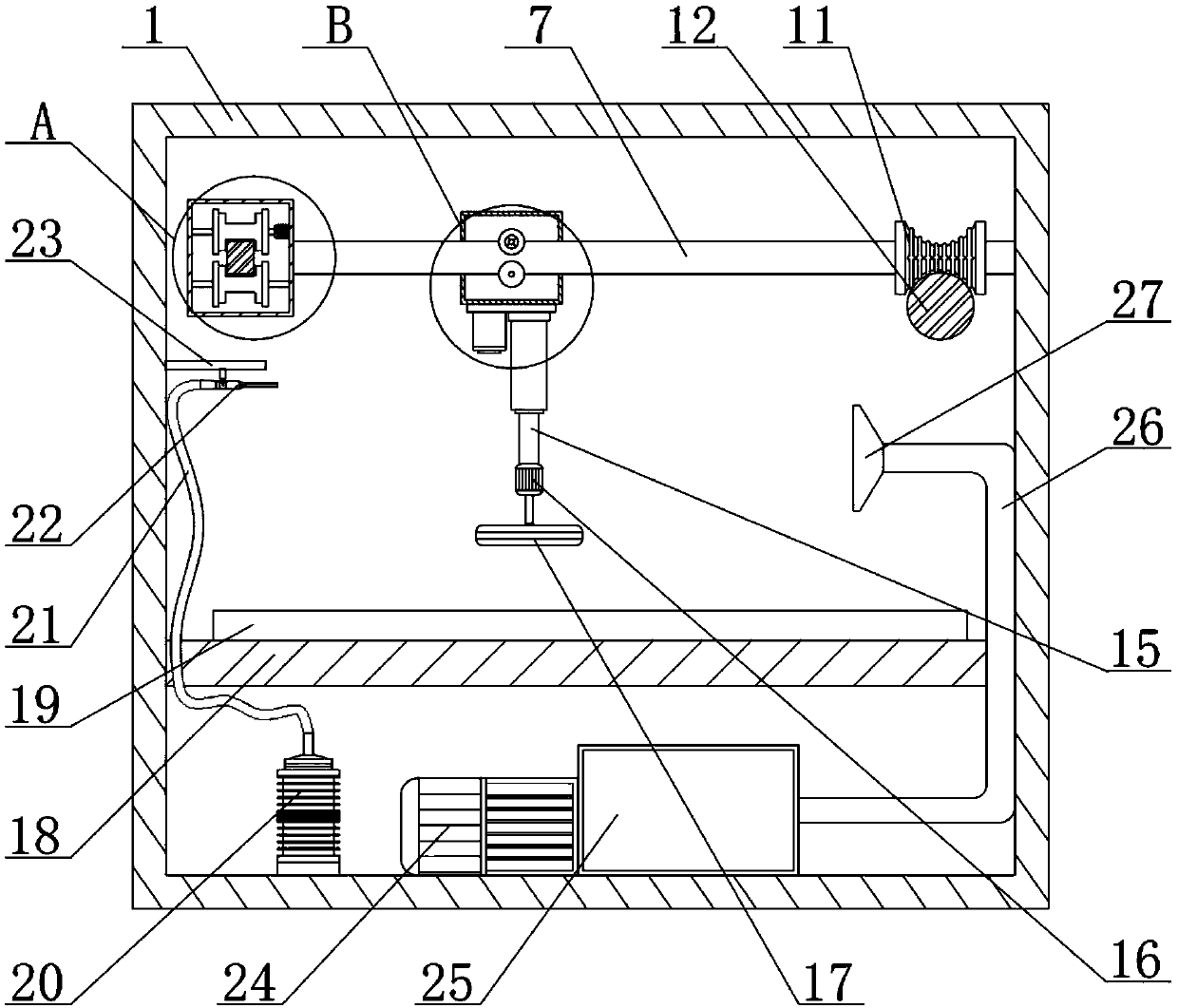

Automobile sealing strip punching and cutting integrated equipment

The invention relates to the technical field of automobile sealing strip processing and discloses automobile sealing strip punching and cutting integrated equipment. The automobile sealing strip punching and cutting integrated equipment comprises a rack and a conveyor belt. The conveyor belt is horizontally arranged on the rack. A punching mechanism is arranged above the conveyor belt. The punching mechanism comprises a first rotary shaft arranged horizontally. The first rotary shaft is rotatably connected to the rack. The first rotary shaft is coaxially provided with a hollow cylinder and a box. The bottom of the hollow cylinder is provided with an opening. A tapered bar is arranged at the opening. The tapered bar is vertically and slidably connected to the rack. The portion, located in the box, of the first rotary shaft is sleeved with a shaft sleeve. The side face of the shaft sleeve is uniformly and fixedly connected with a plurality of blades. A cutting platform is arranged in theposition, at the tail end of the conveyor belt, of the rack. A cutting mechanism is arranged above the cutting platform. The cutting platform is provided with a slot. A translational block is slidably connected to the interior of the slot. The top surface of the translational block is provided with a groove. A square block is slidably connected to the interior of the groove. The bottom surface ofthe groove is provided with a switch. Through the automobile sealing strip punching and cutting integrated equipment, the problems that the distance between holes cannot be adjusted and fixed-lengthcutting cannot be implemented in the prior art can be solved.

Owner:象山权友机械有限公司

Suede plastering method for decorative strip of vehicle

InactiveCN101318487AImprove the quality of pastingEasy to cleanLiquid surface applicatorsVehicle componentsWorking environmentEngineering

The invention relates to a velvet sticking method for a decorative strip of a vehicle which conducts flocking after coating glue on a film surface which can carry out thermal bonding with the body of the decorative strip; then the flocked film is cut into the flocked glue belts with needed width; after leading one end of the flocked glue belts to pass through a channel on an extruding die, the one end of the flocked glue belts is exposed out of the extruding opening of the extruding die and the back surfaces of the back ends of the flocked glue belts are caused to be just corresponding to the part needed to be stuck with the velvet of the body of the decorative strip extruded from the extruding opening; with the body of the decorative strip extruded from the extruding opening of the extruding die, the back parts of the flocked glue belts are thermally bonded on the part needed to be stuck with the velvet of the body of the decorative strip. After the scheme is adopted, not only can the device investment and the operation personnel be obviously reduced, the production period is shortened, the production cost and the risk of batch production are reduced, but also the flocking efficiency and the flocking quality of the film can be greatly improved; besides, the working environment is amended, the health of the operation personnel is protected and the machine is avoided from being polluted by the velvet.

Owner:NINGBO XINTAI MACHINERY

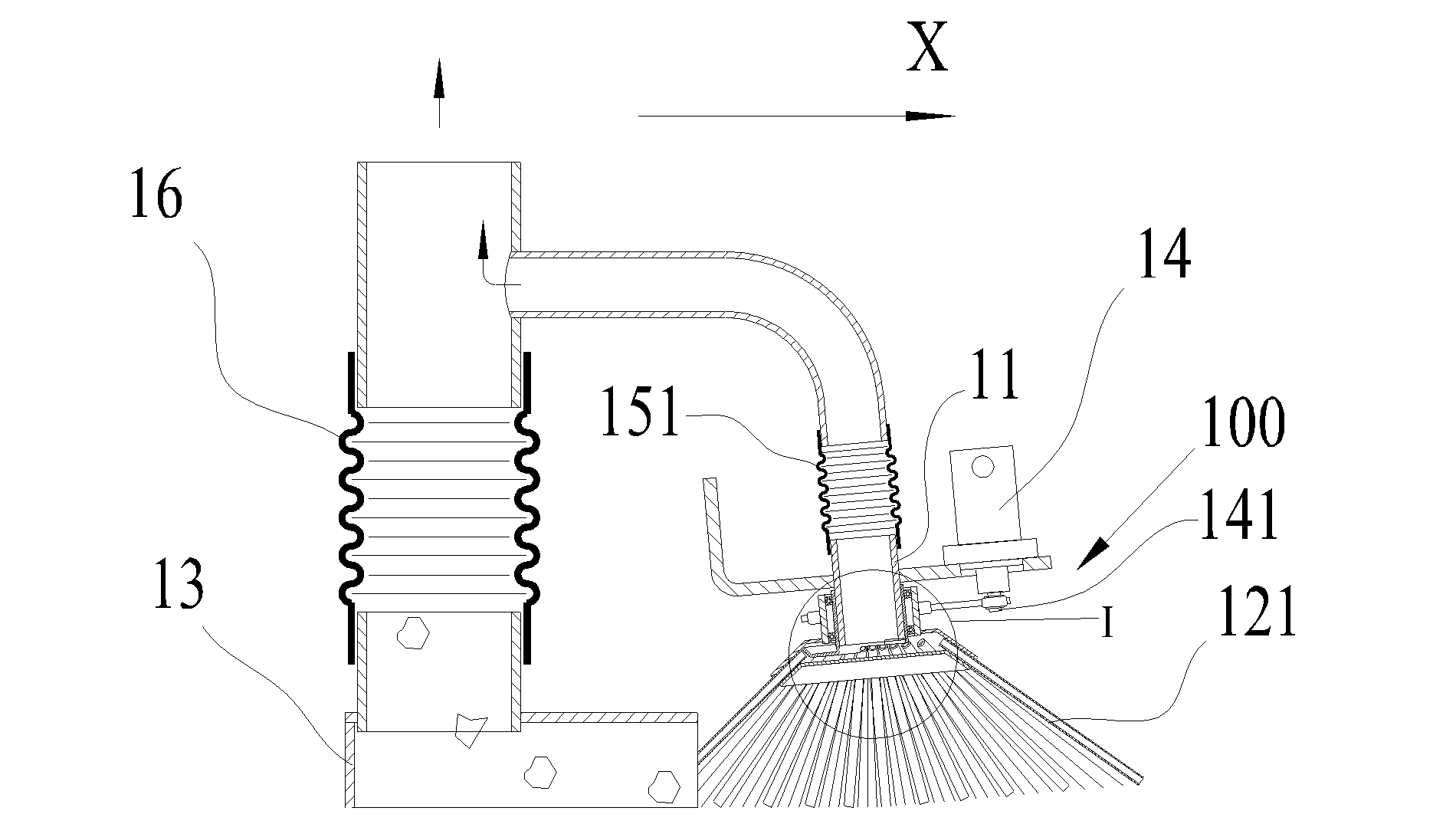

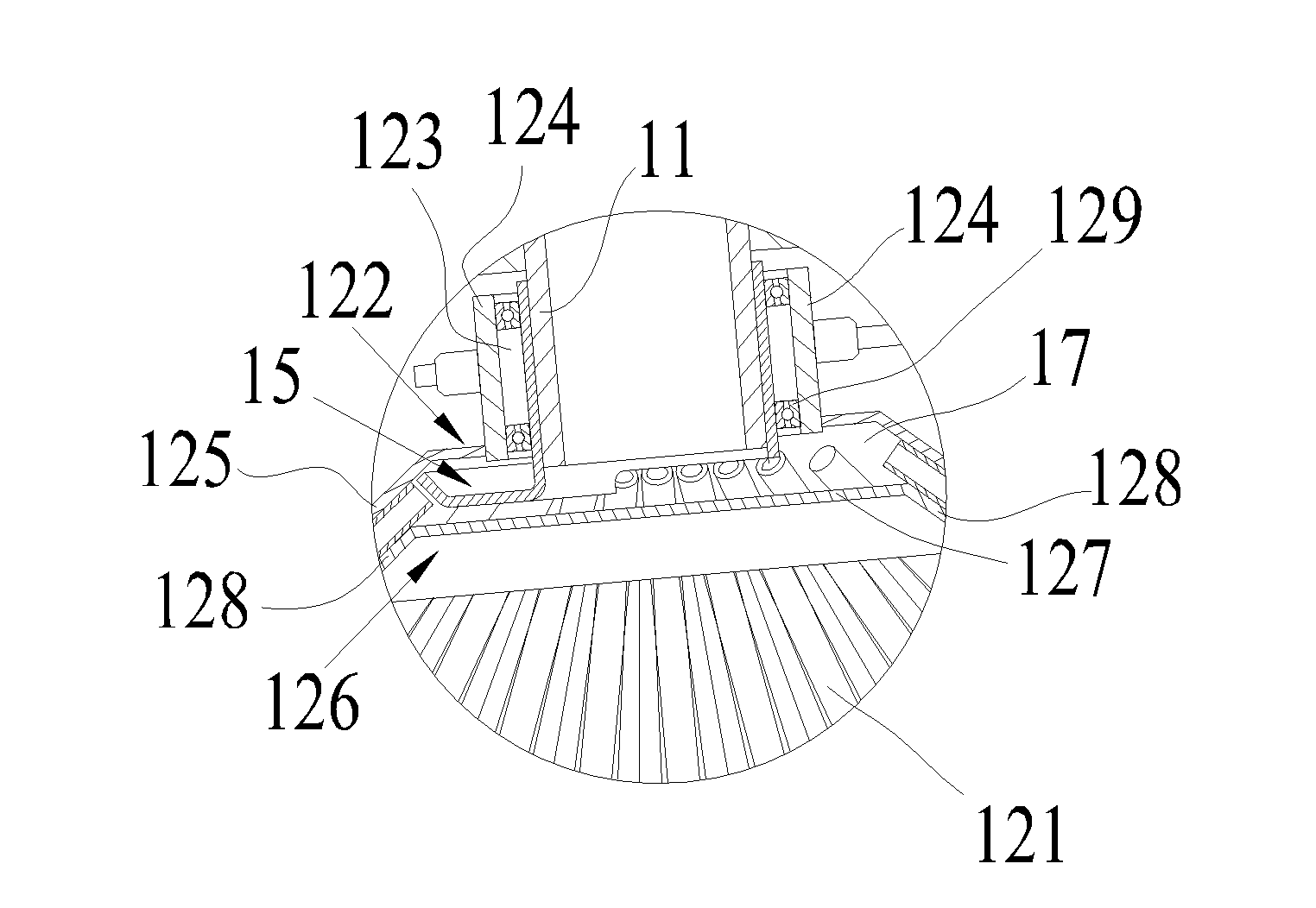

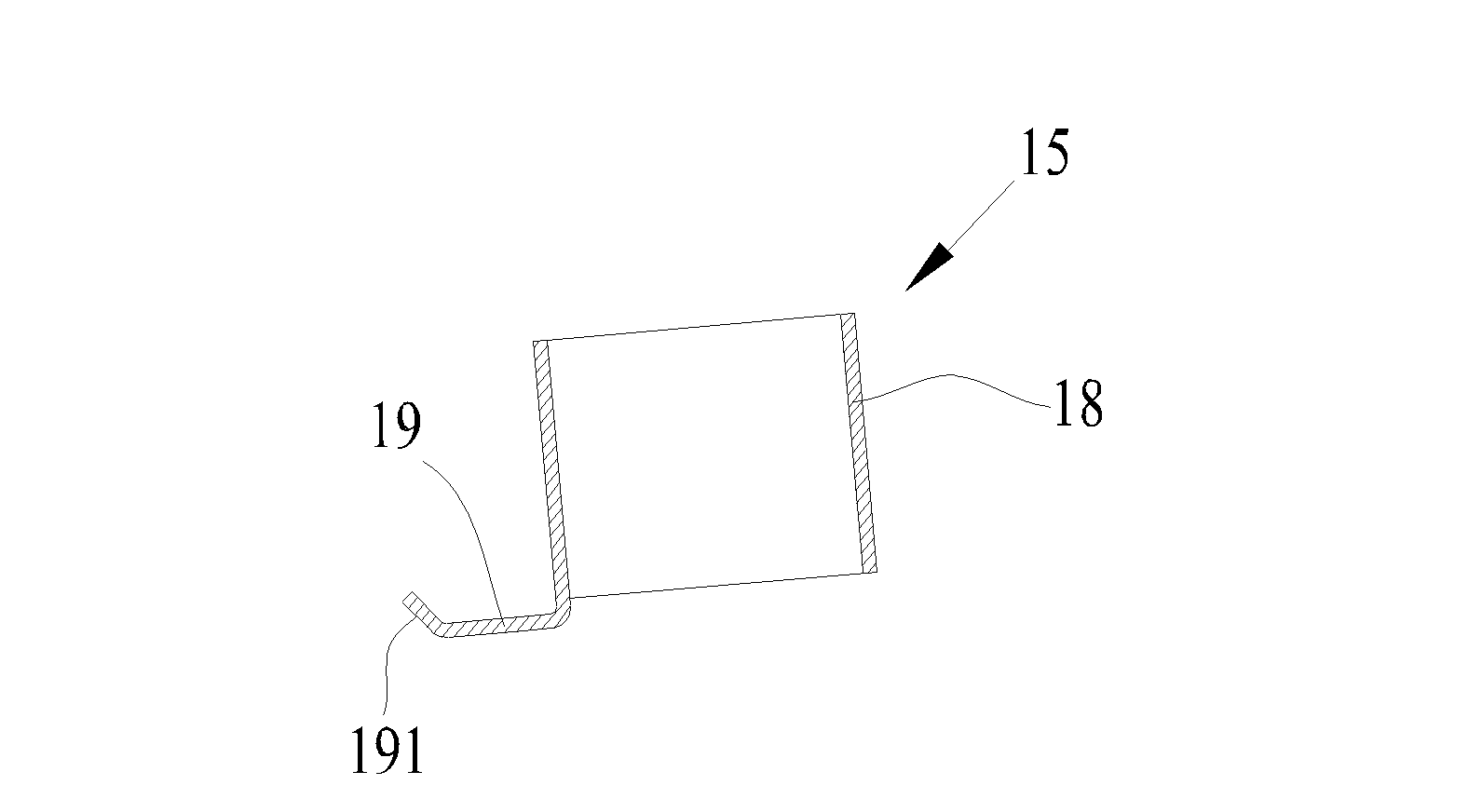

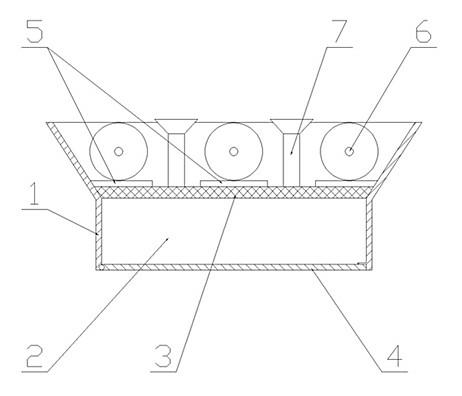

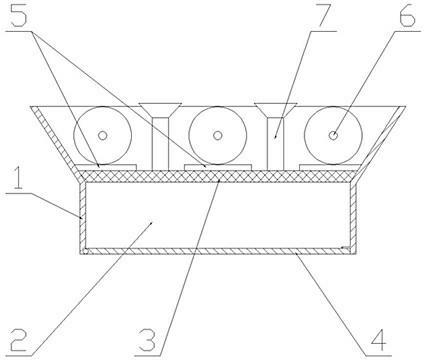

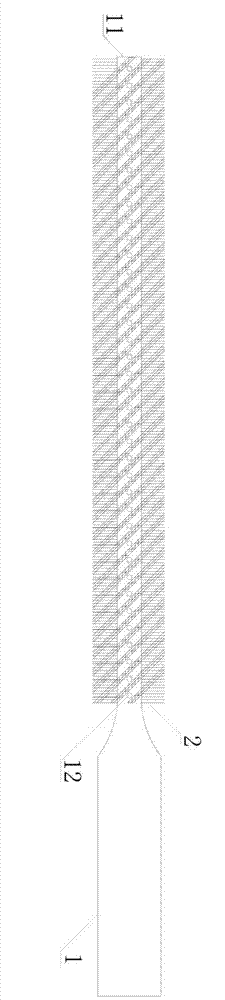

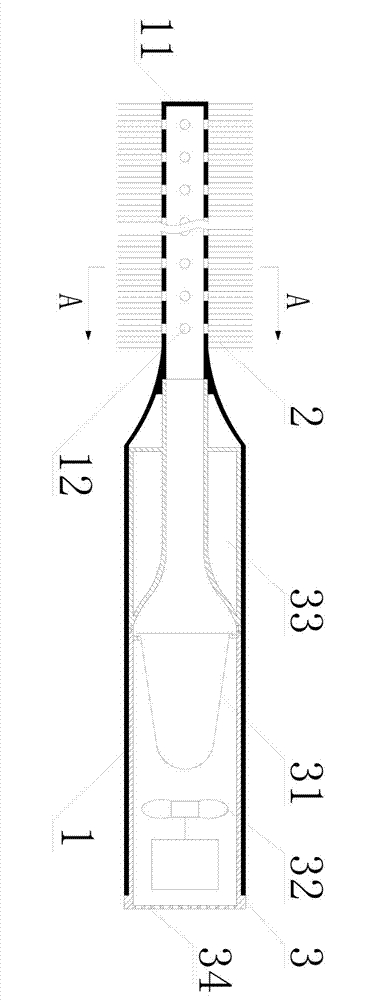

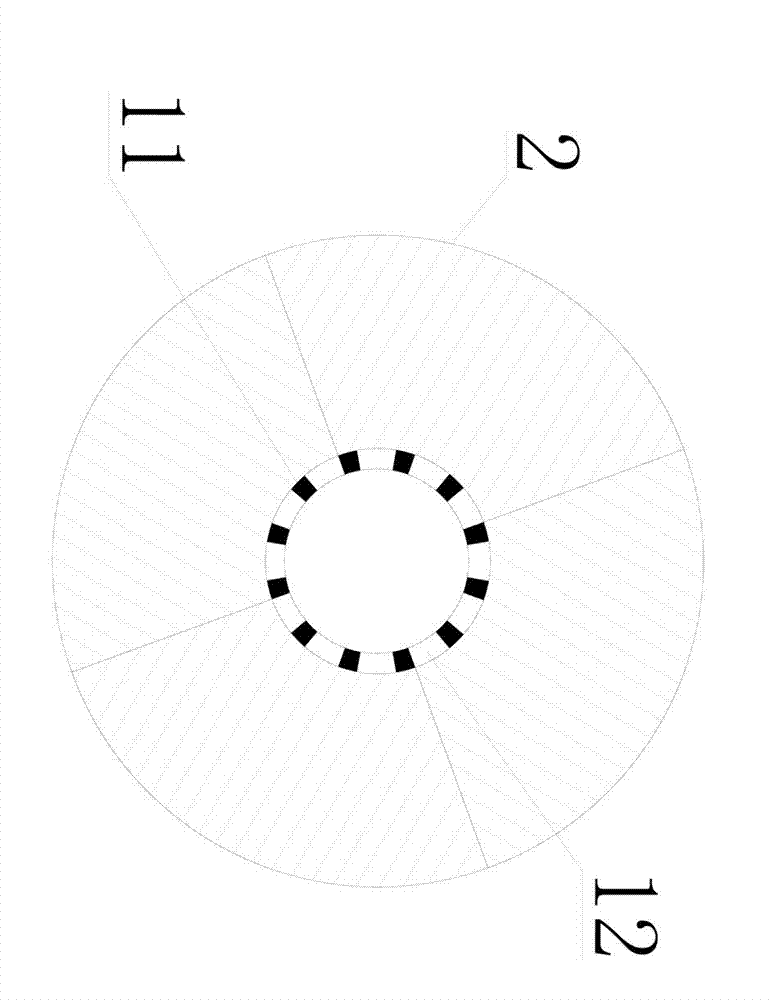

Sweeping operational head, sweeping device and road sweeping vehicle

The invention discloses a sweeping operational head, a sweeping device comprising the sweeping operational head, and a road sweeping vehicle. The sweeping operational head (100) comprises a support (11), a rotary supporting part (122) and a plurality of bristles (121), wherein the rotary supporting part (122) is rotatably mounted on the support, and the bristles (121) are mounted on the rotary supporting part. The support comprises a hollow supporting pipe, the rotary supporting part is hermetically mounted on the supporting pipe, an opening, adjacent to the bristles, of the supporting pipe is closed, at least part of the bristles comprises hollow bristle tubes, and each hollow bristle tube is communicated with the hollow supporting pipe. During sweeping, a suction source can be connectedto the other end of the support and peripherally communicated with the bristles through the bristle tubes communicated with the inside of the support, so that dust raised by the bristles can be sucked away. Using the sweeping operational head can effectively reduce flying dust and needs no water.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

Dustless blackboard eraser

The invention discloses a dustless blackboard eraser which comprises a blackboard eraser body (1) and is characterized in that a dust collection cavity (2) is arranged inside the blackboard eraser body (1), a metal static filter screen (3) is arranged above the dust collection cavity (2), a flip-open cover (4) at the rear end of the blackboard eraser body (1) is communicated with the dust collection cavity (2), a ground-glass plate (5) is fixedly arranged on the metal static filter screen (3), a roller (6) supported in a rotating manner is arranged inside the blackboard eraser body (1), a silk layer is arranged on the outer surface of the roller (6), when the roller (6) rolls, the roller (6) and the ground-glass plate (5) are in mutual friction, and an erasing strip (7) is arranged inside the blackboard eraser body (1). The dustless blackboard eraser has a simple structure, is unique in design, can prevent chalk ash from flying by using the principle of electrostatic adsorption, and can uniformly collect the chalk ash.

Owner:DALIAN OCEAN UNIV

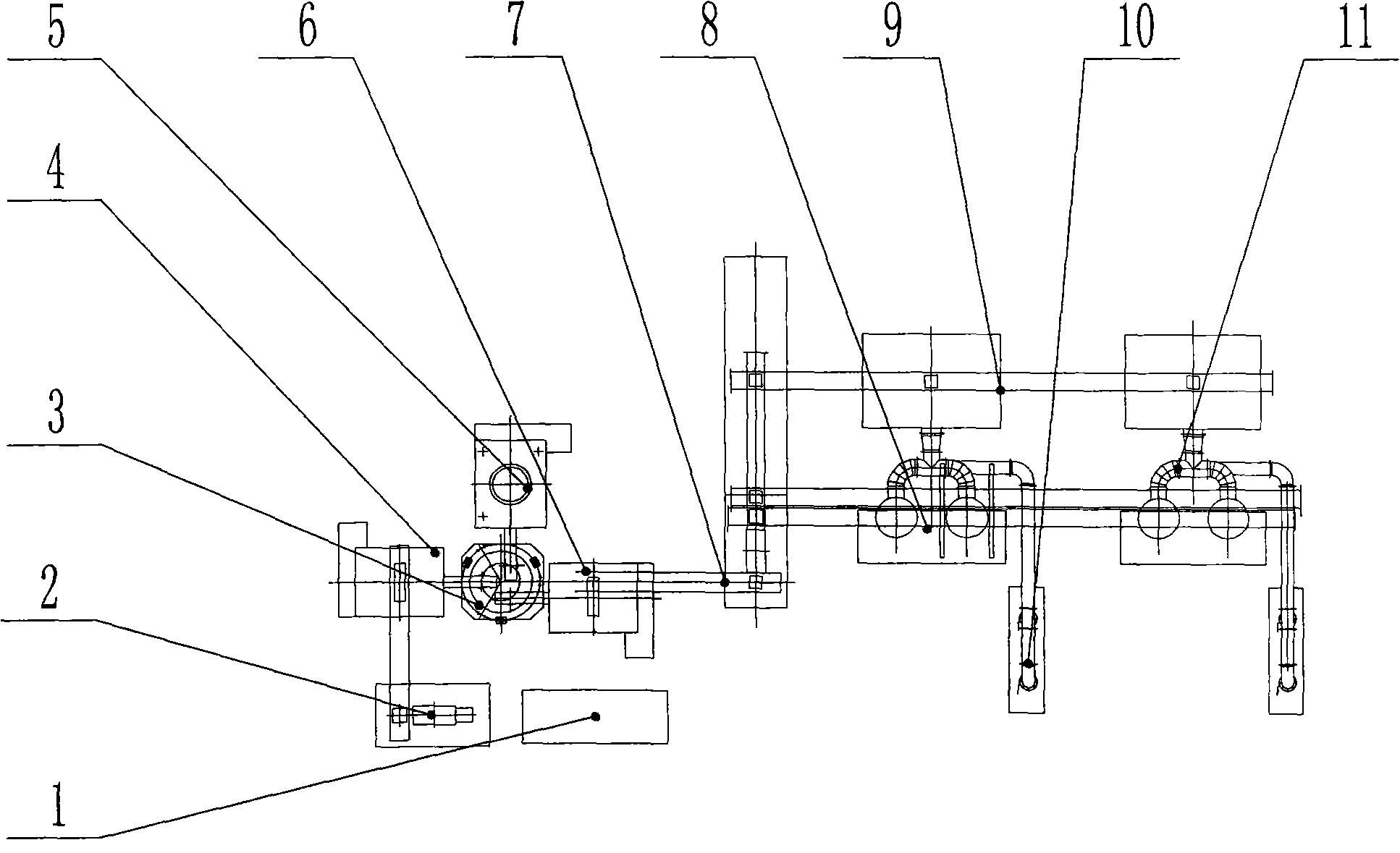

Fully automatic rapid powder filling system

ActiveCN102136578AGuaranteed powder filling requirementsAvoid flying aroundElectrode carriers/collectorsAutomatic controlProgrammable logic controller

Owner:山东鑫旭集团有限公司

Device for removing surface attachment of steel shovel

ActiveCN102814722AAvoid flying aroundAvoid harmEdge grinding machinesPolishing machinesIron powderCoupling

The invention relates to a device for removing the surface attachment of a steel shovel; the device comprises a frame, and a transmission motor and a reducing gear which are arranged on the frame and are connected together; a barrel is arranged at the middle part of the frame; one end which penetrates through the barrel shaft of the barrel is connected with the reducing gear through a bearing and a coupler; the barrel shaft is in a hollow structure; dust removal holes are uniformly distributed on the side wall of the barrel shaft; a draught fan is arranged on the frame; the air inlet of the draught fan is communicated with the other end of the barrel shaft; and the outer side of the frame is provided with a cyclone separator which is communicated with the air outlet of the draught fan. According to the device for removing the surface attachment of the steel shovel, the structure is simple, the surface attachment of the steel shovel is removed, meanwhile iron powder does not fly everywhere, the removed iron powder can be recovered in time, and a role of protecting the environment is played. The device is arranged in a sound-proof room with sound-proof boards, so that an operator is not harmed by the noise, the environment is not polluted, the product cost is reduced, and the economic benefits are improved.

Owner:TANGSHAN YANNAN SHOVEL MAKING

Dryer capable of removing lint for cotton wool textile fabrics

ActiveCN109520223AKeep clearingAvoid flying aroundMechanical cleaningPressure cleaningEngineeringCOTTON WOOL

The invention provides a dryer capable of removing lint for cotton wool textile fabrics and relates to the field of textile. The dryer comprises a textile drying box. Supporting feet are welded to theinner bottom wall of the textile drying box. The surfaces of the supporting feet are fixedly connected with a textile drying plate. A lint guide plate is welded to the surface of the textile drying box. A hot air inlet is formed in the surface of the textile drying box. A lint collecting supporting partition is welded to the inner top wall of the textile drying box. A glass supporting frame is welded to the surface of the lint collecting supporting partition. The surface of the glass supporting frame is fixedly connected with the inner wall of the textile drying box. The dryer capable of removing the lint for cotton wool textile fabrics utilizes electrostatic adsorption and breeze to push the lint to be collected in a timely and orderly manner while drying, so that the problems that ordinary textile dryers cannot remove the lint orderly and quickly when drying cotton wool products, and flying lint not only affects the health of processing workers, but also has potential production safety hazards to a certain extent are solved effectively.

Owner:浙江越剑机电科技有限公司

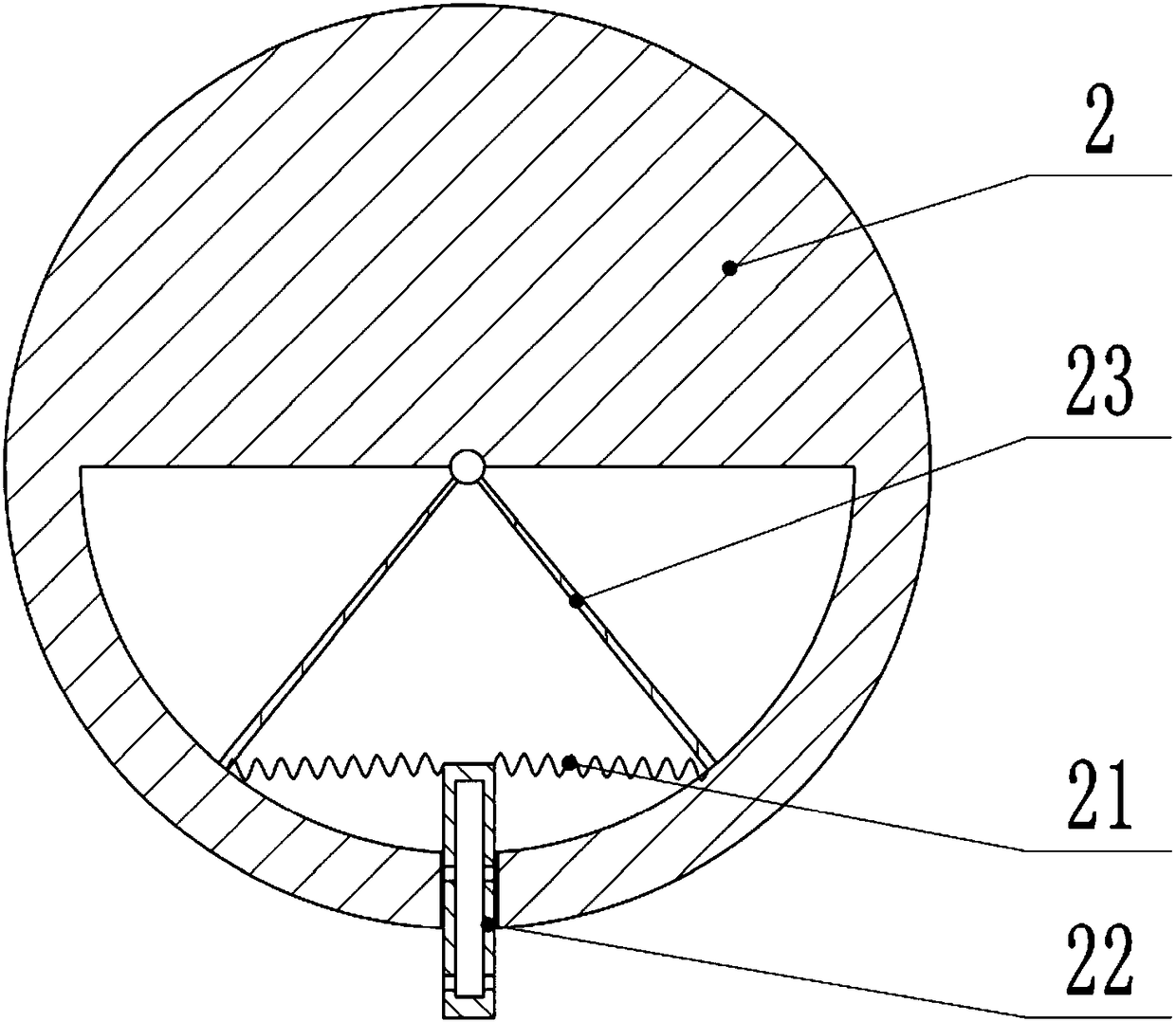

Paint powder mixing device

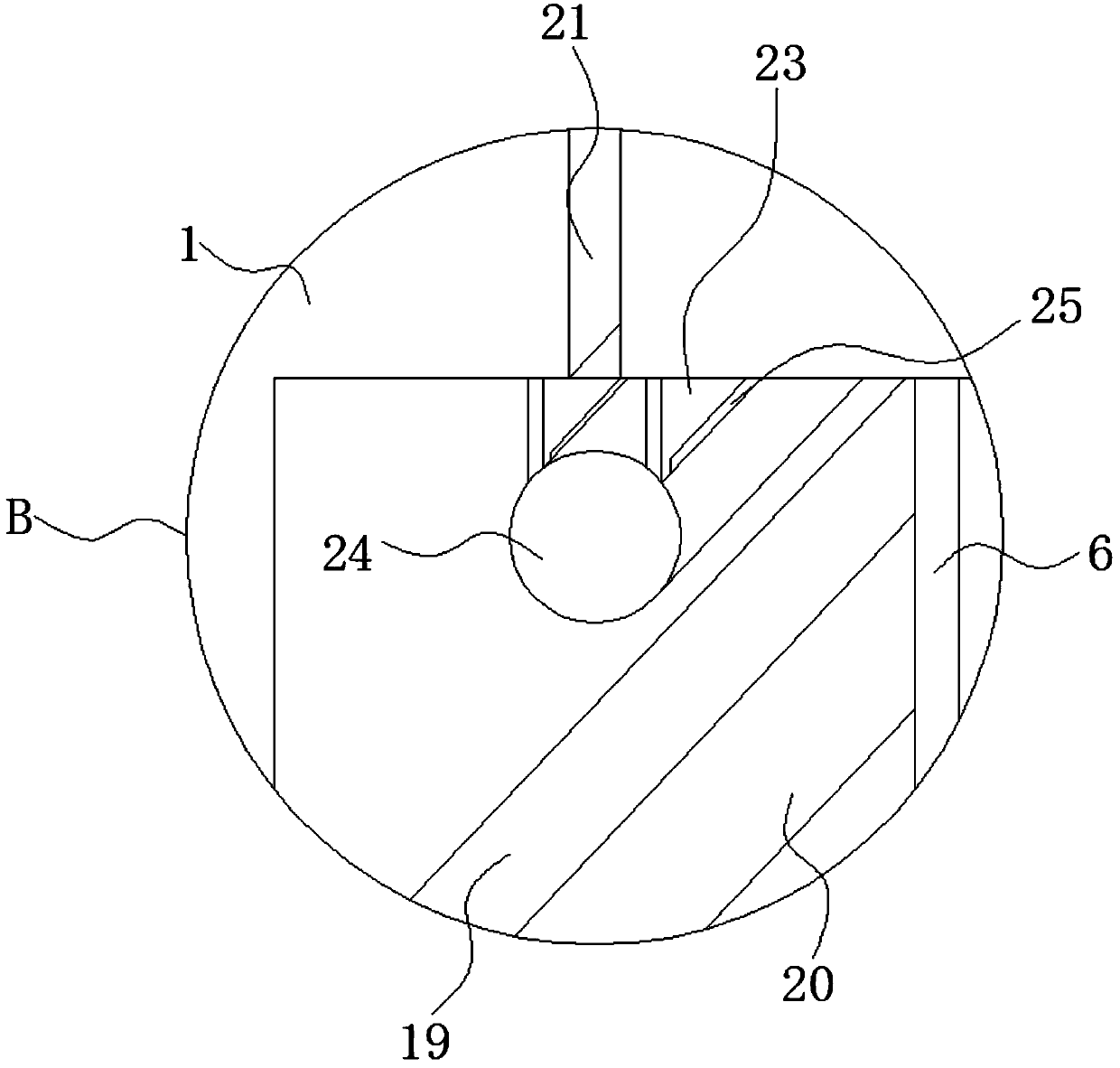

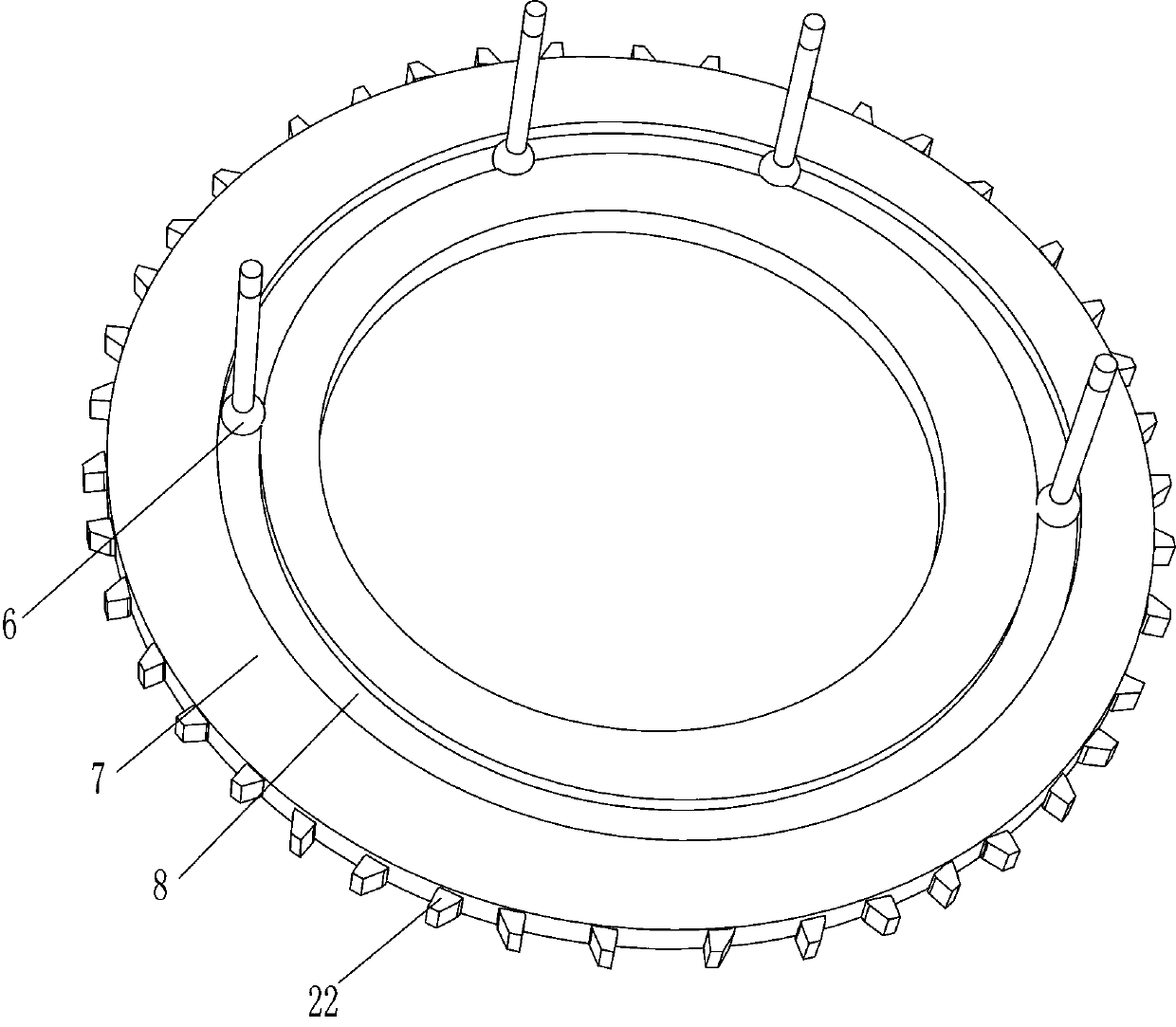

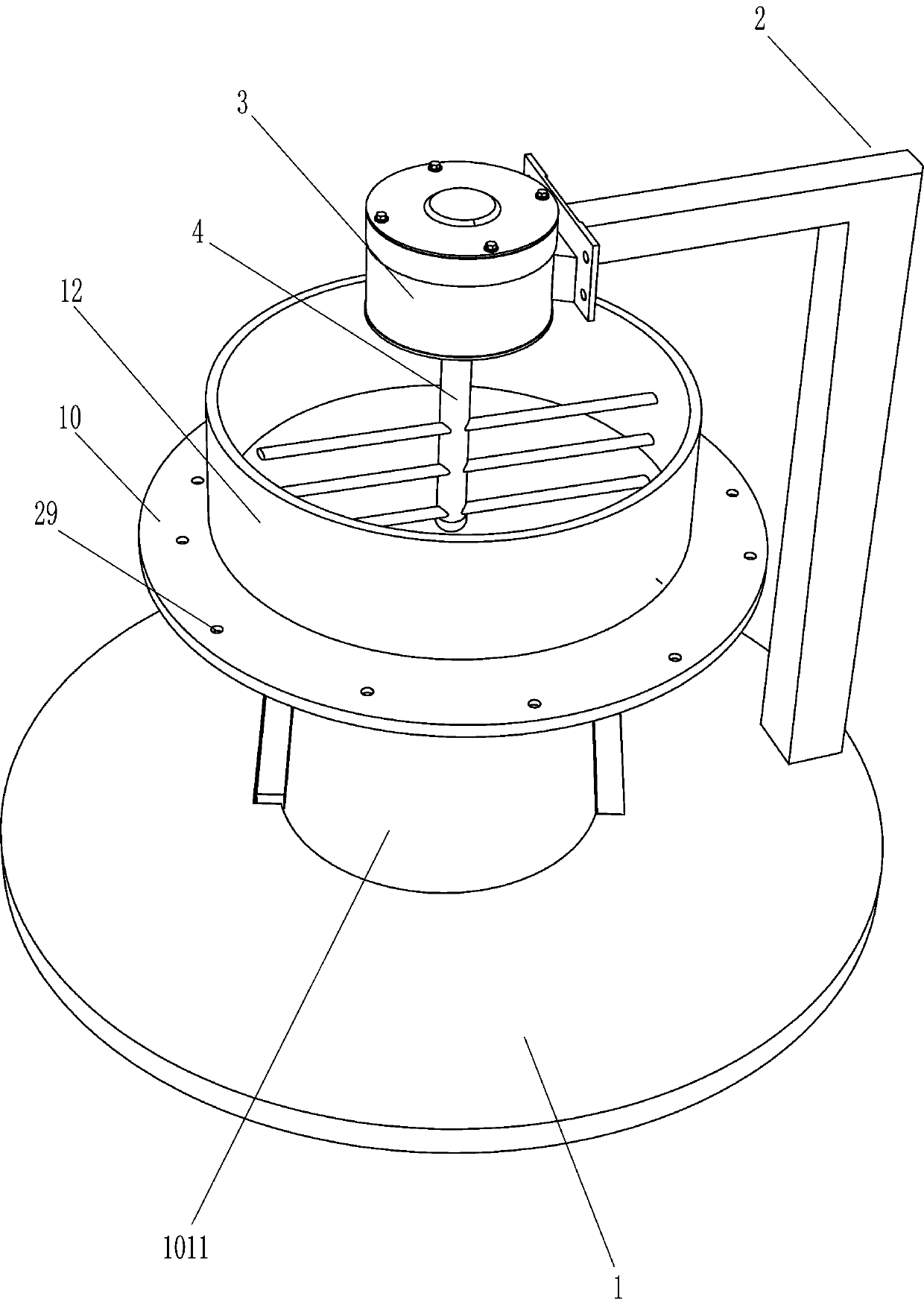

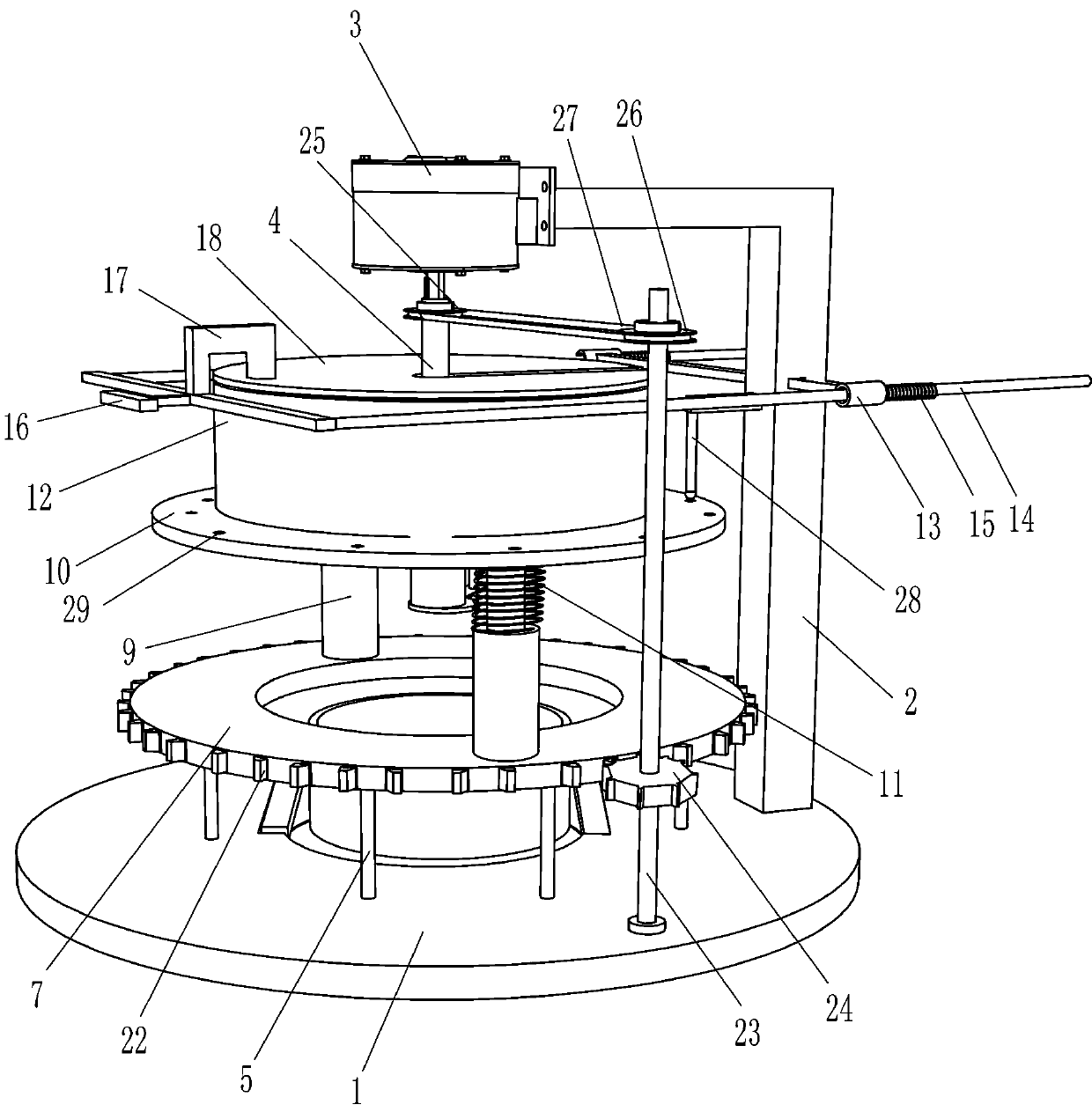

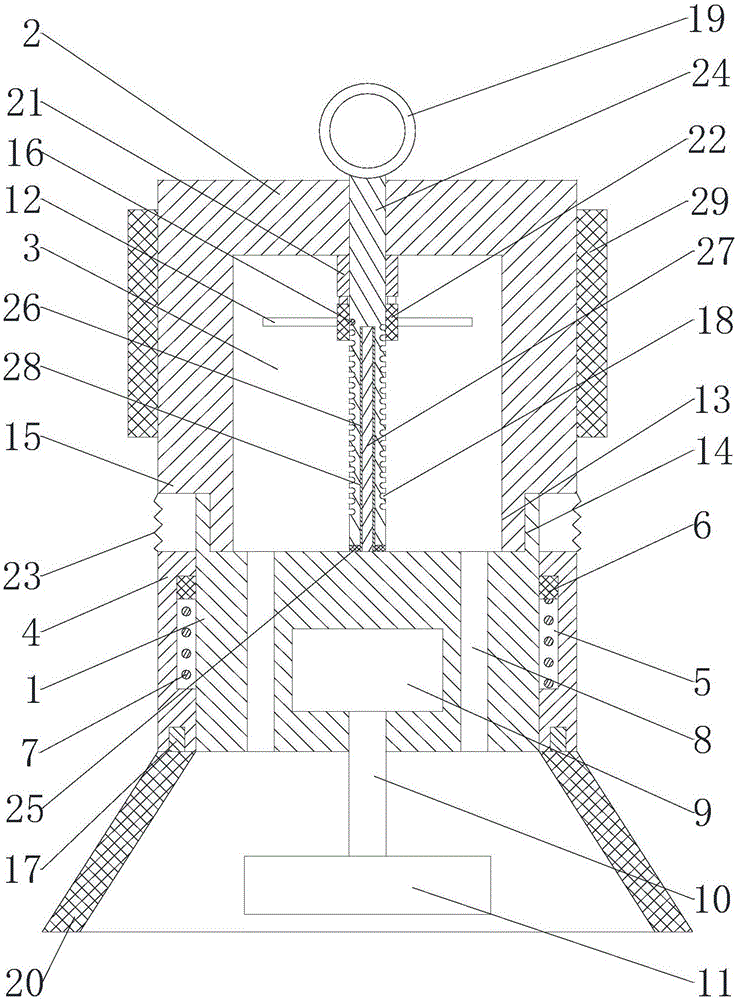

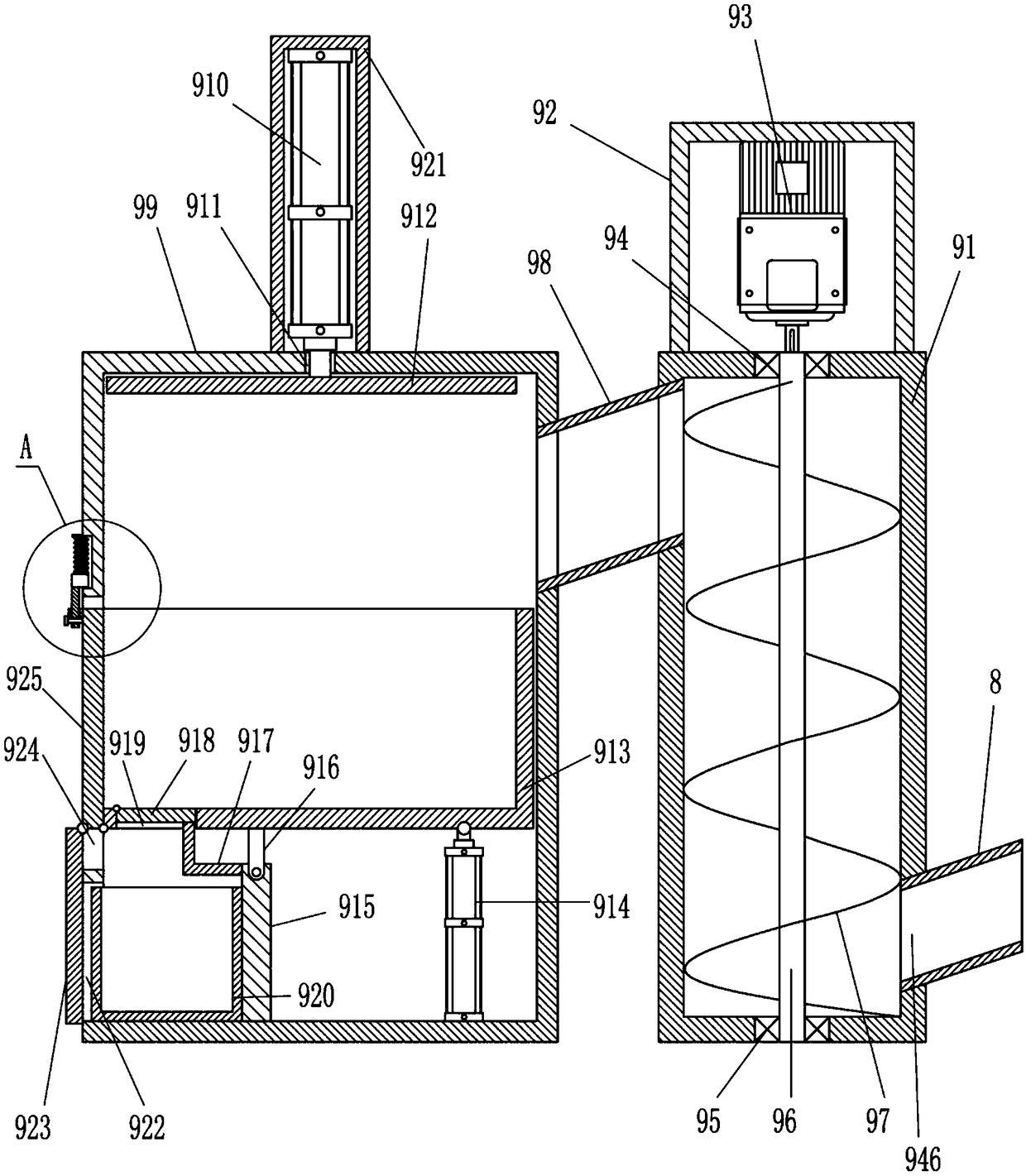

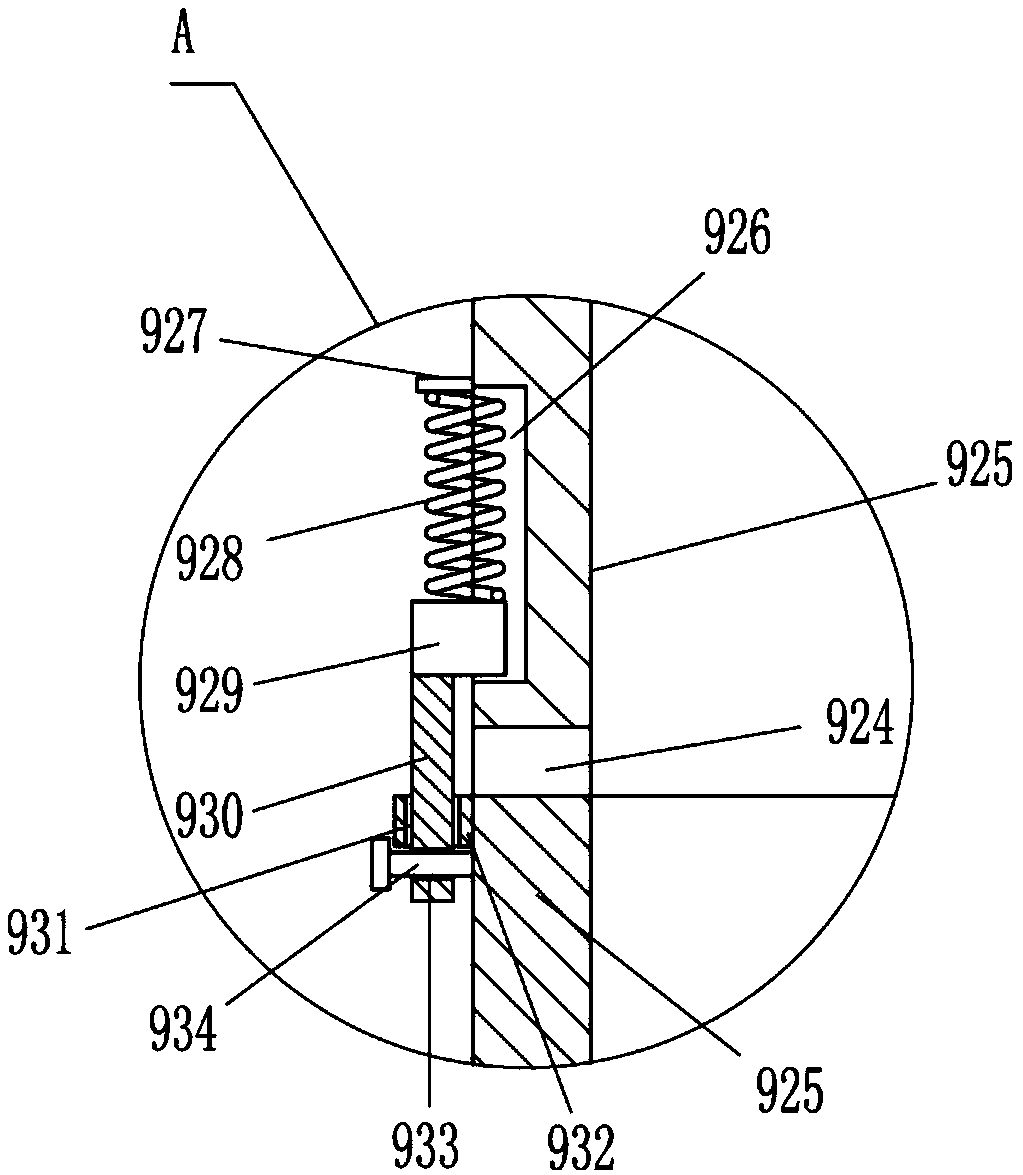

ActiveCN111530343AWell mixedImprove uniformityRotating receptacle mixersSolid waste managementElectric machineMechanical engineering

The invention relates to a mixing device, in particular to a paint powder mixing device. The technical problem to be solved by the invention is to provide the paint powder mixing device capable of effectively preventing paint powder from flying everywhere. The paint powder mixing device comprises a bottom plate used for installing the whole device, a mixing assembly mounted on the bottom plate andpowered by a motor to perform rotary mixing, a storage assembly installed on the bottom plate and used for containing paint powder, a closing assembly mounted on the mixing assembly and opened and closed in a sliding manner, a discharging assembly installed on the storage assembly and conducting discharging in a pushing and rotating mode, and a rotating assembly mounted on the mixing assembly androtating in a rotating manner. Through cooperation of the gear motor and a stirring rod, paint powder can be automatically mixed, labor consumption is reduced, through cooperation of a ball and a rotary disc, a large amount of paint powder can be placed, and the working efficiency is improved.

Owner:浙江慧琳工贸有限公司

Cabo sifting barrel

InactiveCN101218988AOptimizing the screening processAvoid flying aroundSievingTobacco treatmentScreening techniquesScreening effect

The invention relates to a tobacco stem screening tube which is characterized by consisting of a screening tube device, a transmission device and a dust removing mechanism. The screening tube device essentially consists of a screening tube body, a rolling ring on the tube body, a sealing housing and a discharging port and a feeding cover and a discharging cover at two ends of the tube body; the screening tube body is welded by a feeding port section, a tobacco dust screen tube section, a short stem screen tube body, a middle and long stem screen tube body and a stem head outlet tube section. The dust removing system consists of a dedusting fan and a dedusting pipe that are installed on the feeding cover. The invention optimizes the stem screening technique and is integrated with stem screening and dust removing, thus solving the problems of poor screening effect and product quality resulting from manual screen cleaning due to screen blockage by tobacco stem, ensuring good product quality, preventing dust from flying through dust collecting, maintaining cleanness of the on-site production environment and saving energy and equipment occupation area as a plurality of original devices are integrated into one device.

Owner:玉溪市浩森工贸有限公司

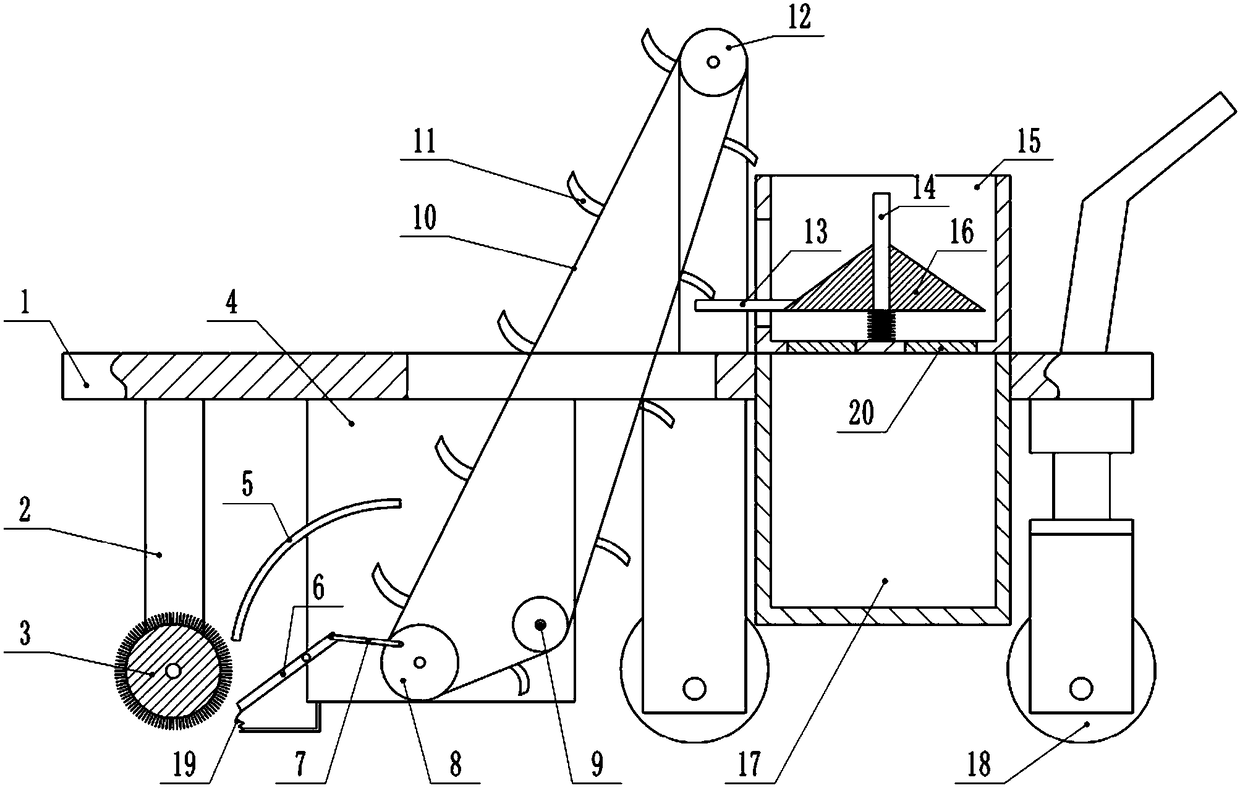

Dust-removal sweeping device

ActiveCN108201419APlay a protective effectAvoid flying aroundCarpet cleanersFloor cleanersDrive wheelEngineering

The invention belongs to the technical field of environmental protection equipment, and specifically discloses a dust-removal sweeping device. The device comprises a trolley, and the front end of thetrolley is provided with a sweeping roller. The upper end of the middle of the trolley is provided with a driving wheel, and the lower end of the middle of the trolley is rotatably connected with a first driven wheel and a second driven wheel. A conveying belt is connected among the driving wheel, the first driven wheel and the second driven wheel. A plurality of clapboards are connected to the conveying belt. A material throwing plate is hinged to a lower bracket, a connecting rod is hinged to the material throwing plate, and the other end of the connecting rod is hinged to the eccentric portion of the end face of the first driven wheel. The upper portion of the trolley is provided with a compression box, the compression box is internally and fixedly connected with a central shaft, the central shaft is slidingly connected with a conical material pressing plate, and a spring is connected between the material pressing plate and the bottom wall of the compression box. A pressing rod is fixedly connected to the lower portion of the material pressing plate, and the end portion of the pressing rod is located below the driving wheel. A garbage box is arranged below the compression box, and a pressure door is connected between the compression box and the garbage box. The dust-removal sweeping device cleans away garbage and compresses the garbage at the same time.

Owner:宁波梦居智能科技有限公司

Wood cutting machine

PendingCN108527533AAvoid flying aroundReduce space occupancyFeeding devicesCircular sawsPulp and paper industryEngineering

The invention belongs to the technical field of wood processing equipment, and particularly discloses a wood cutting machine. The wood cutting machine comprises a rack and a cutting mechanism, the rack is rotationally provided with two driving rollers and a driven roller, the rack is provided with two sliding grooves, two polishing rollers slide and are rotationally connected between the two sliding grooves, transmission mechanisms are arranged between the driving rollers and the polishing rollers, a collecting bag is connected between the two polishing rollers, a gear rack is connected to therack, gears meshed with the gear rack are arranged on the polishing rollers, two cylinder blocks are fixedly connected to the rack, pistons are arranged in the cylinder blocks, elastic pieces are arranged between the pistons and the top walls of the cylinder blocks, push rods are connected to the lower ends of the pistons, the lower ends of the push rods are fixed to the middle portion of the collecting bag, air blowing openings facing the cutting mechanism are formed in the upper portions of the cylinder blocks, air outlets are formed in the side walls of the lower positions of the cylinderblocks and are provided with filter nets, dust sucking openings are formed in the side walls of the cylinder blocks and are provided with one-way doors. According to the scheme, wood polishing can becarried out while wood cutting is carried out, the number of wood processing procedures is decreased, and the working efficiency is improved.

Owner:重庆草衣木食文化传播有限公司

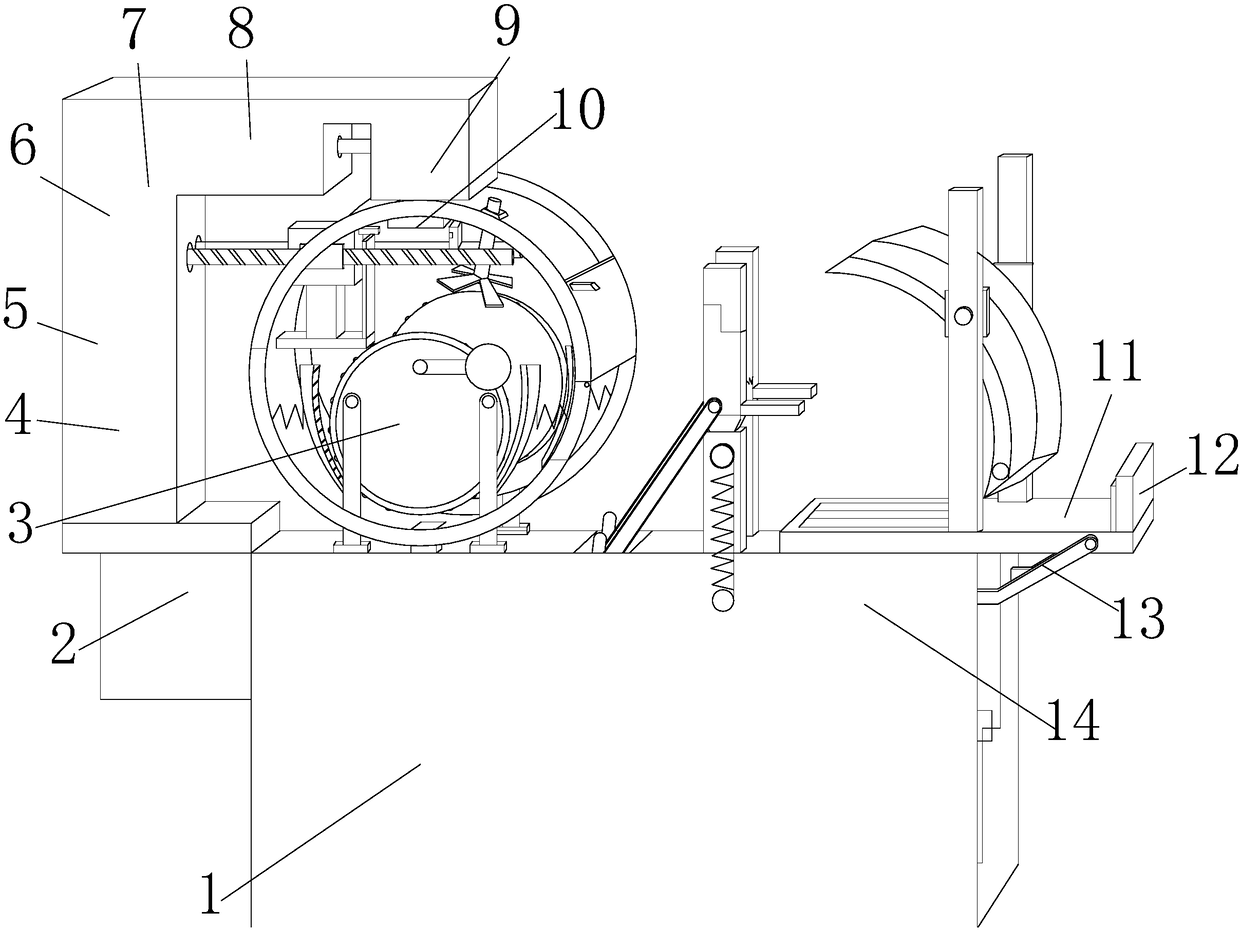

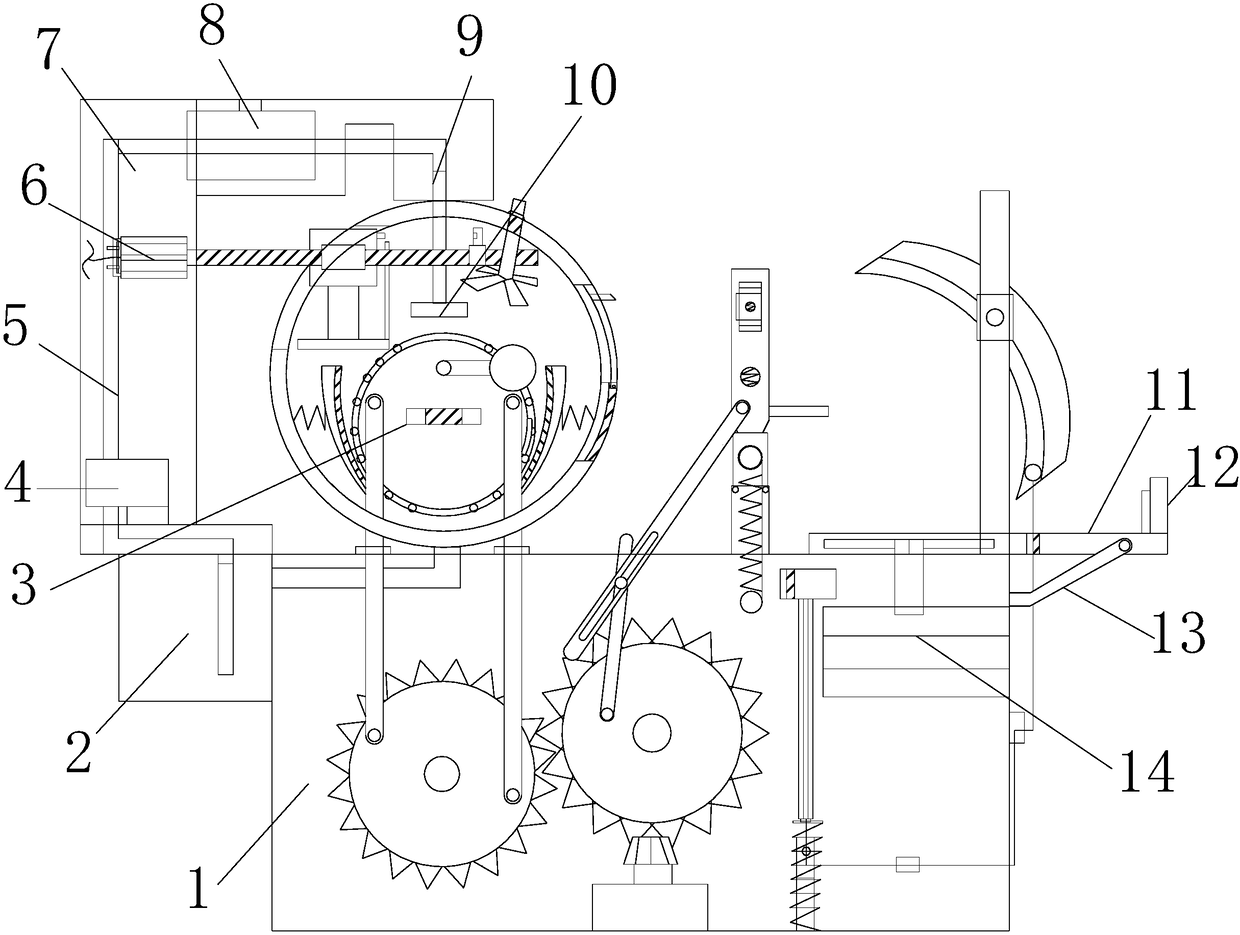

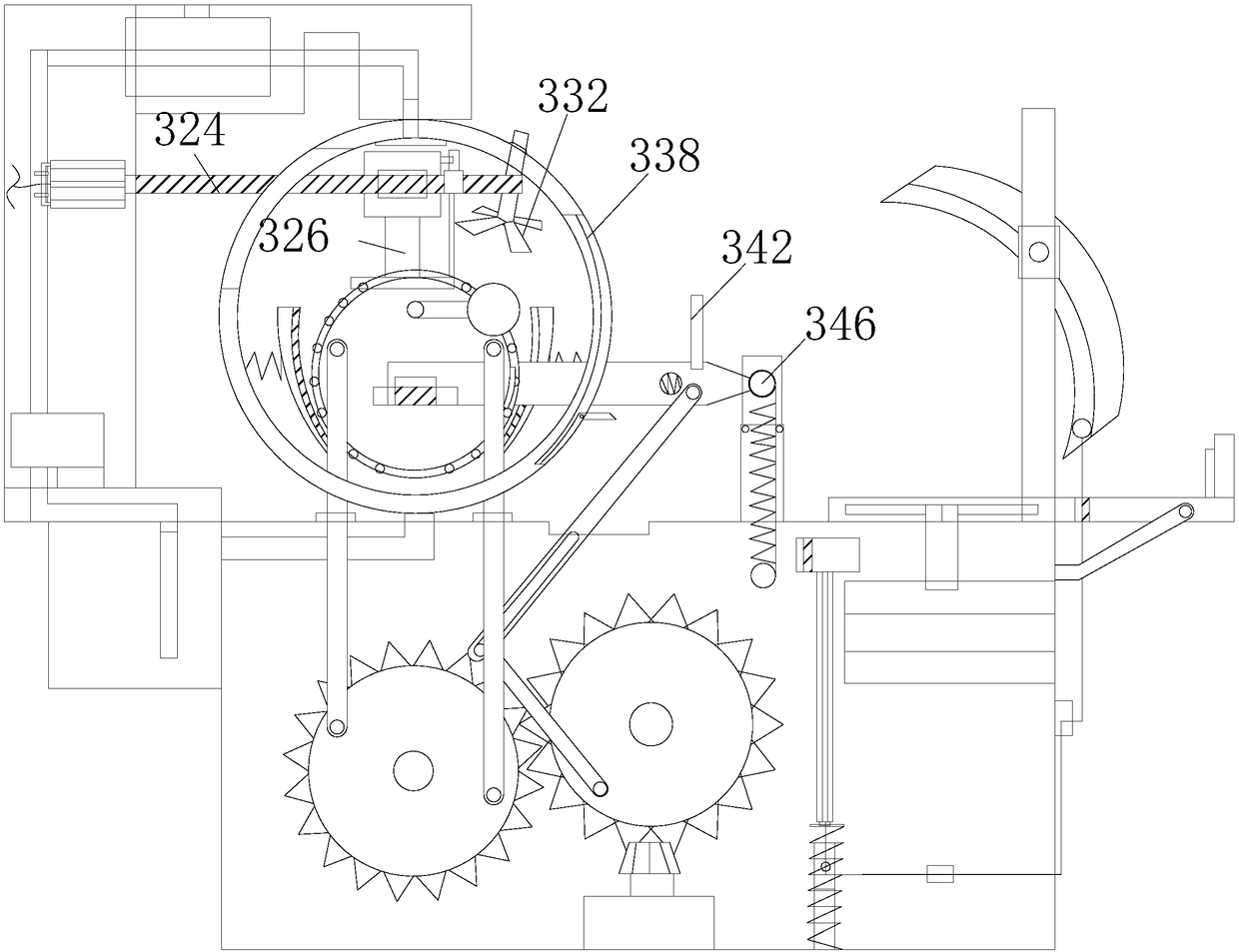

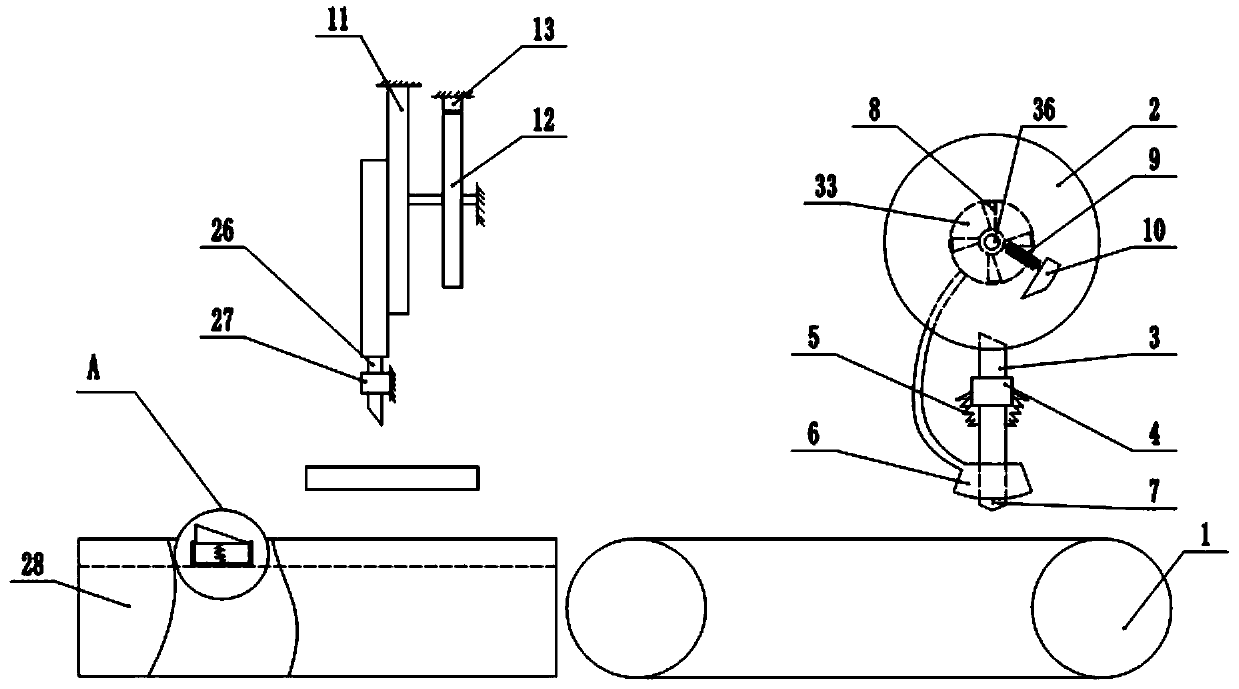

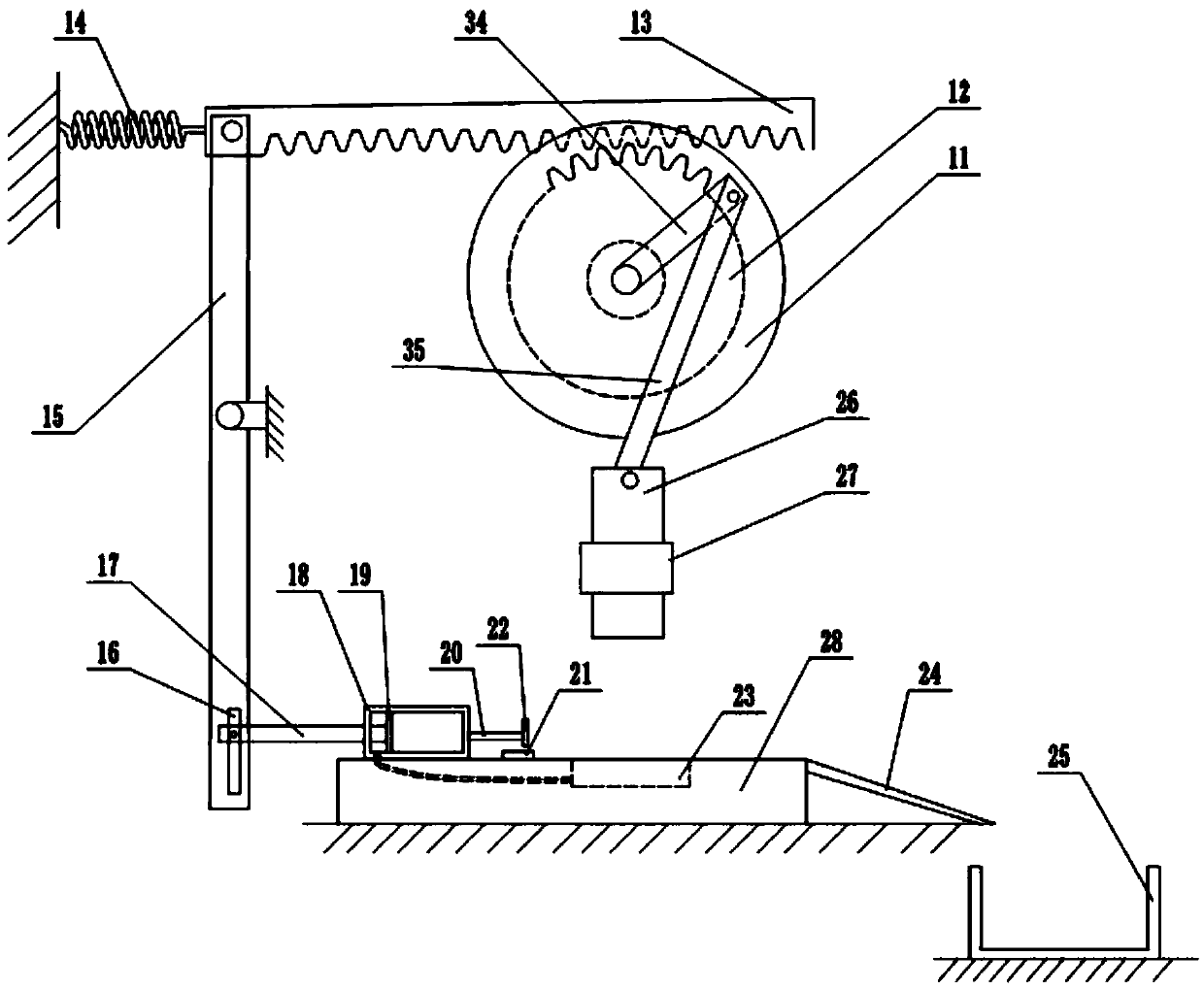

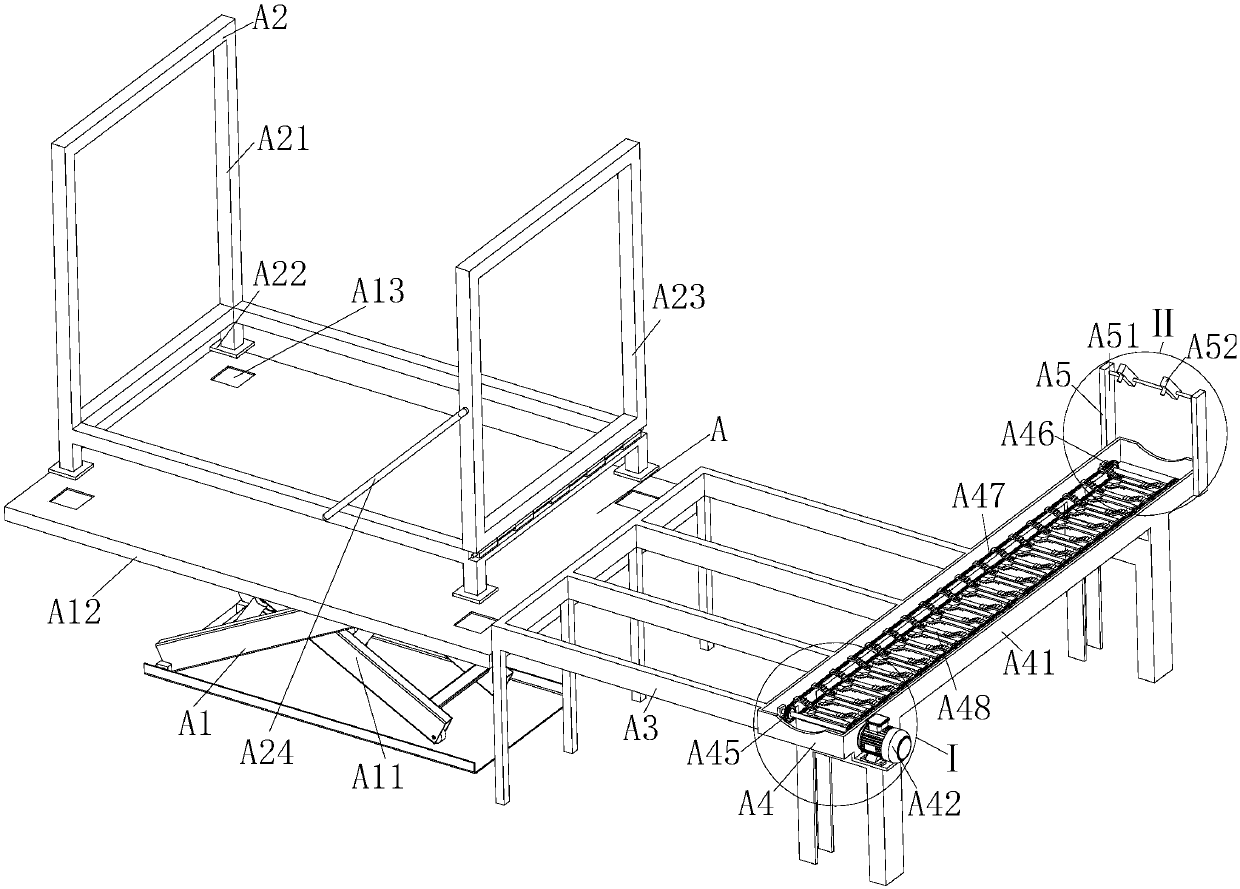

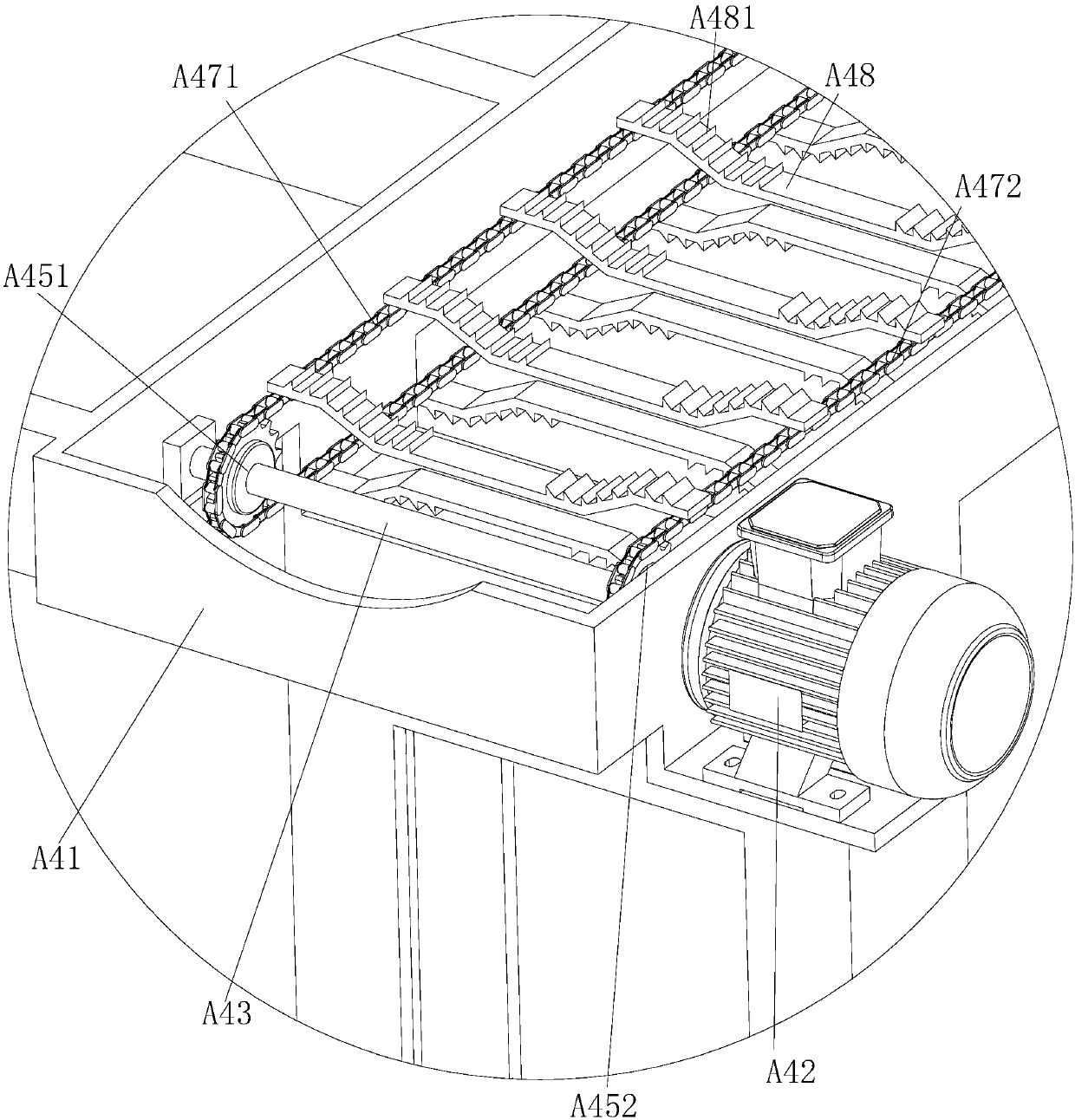

Automatic multifunctional raw wood cutting machine and cutting method

InactiveCN107627398AIncrease productivityReduce manufacturing costCircular sawsBark-zones/chip/dust/waste removalEngineeringManual handling

The invention relates to an automatic multifunctional raw wood cutting machine and a cutting method, which belong to the field of wood processing. The automatic multifunctional raw wood cutting machine is usually applied to wood processing, and in the prior art, a single wood to be processed is carried to the cutting machine so as to be cut, dust produced during a cutting process flies about, woodbits are hard to collect, the environment is polluted, and the health of workers is influenced. The automatic multifunctional raw wood cutting machine comprises a feeding device, a cutting device anda conveying device, wherein the feeding device is connected with one side of the cutting device; and the conveying device is placed at the other side of the cutting device. Manual handling is not needed, and multiple woods to be processed can be loaded every time, so that the production efficiency is improved; and the humidity of the woods to be processed is increased, so that the dust produced during the cutting process cannot fly about, and the environment cannot be polluted.

Owner:浙江林达包装科技股份有限公司

Handheld polishing device

InactiveCN106425781AAvoid flying aroundReduce the impactPortable grinding machinesGrinding/polishing safety devicesDrive motorEngineering

The invention discloses a handheld polishing device. The handheld polishing device comprises a fixed body, a movable cylinder and a collecting cylinder, wherein the collecting cylinder is connected to the upper end of the fixed body, a channel is formed on the fixed body; a driving motor is mounted in the fixed body, an output end of the driving motor is connected with a rotating shaft, the lower end of the rotating shaft is connected with a sand wheel, a plurality of blades are further arranged on the rotating shaft; an annular groove is formed in the inner wall surface of the movable cylinder, a positioning ring is arranged on the outer wall surface of the fixed body, an elastic part is arranged in the annular groove, the inner wall surface of the top of the annular groove is propped against the upper end surface of the positioning ring by the aid of the elastic part; a protective cover surrounding the sand wheel is arranged at the bottom end of the movable cylinder. With the arrangement of the protective cover and the blades, dust can be effectively prevented from flying apart all around, the influence on the surroundings is reduced, and the body health of an operator is guaranteed.

Owner:重庆新缔欧机械制造有限公司

Metal part grinding machine

InactiveCN106425780AAvoid flying aroundKeep healthyPortable grinding machinesGrinding/polishing safety devicesDrive motorPulp and paper industry

The invention discloses a metal part grinding machine. The metal part grinding machine comprises a fixing body, a connecting cylinder and a collecting cylinder, wherein the collecting cylinder comprises a collecting chamber; a driving motor is mounted inside the fixing body; an output end of the driving motor is connected with a rotating shaft; the lower end of the rotating shaft is connected with a grinding wheel; the connecting cylinder sleeves the outer surface of the fixing body; a protective cover is arranged at the bottom end of the connecting cylinder; a supporting cylinder is mounted at the top of the inner wall of the collecting cylinder; a movable cylinder is rotationally arranged at the lower end of the supporting cylinder; a guide column is vertically arranged at the upper end face of the fixing body; a positioning protruding bar is arranged on the sidewall of the guide column; an adjusting rod is also vertically arranged inside the collecting chamber; the inner wall surface of the adjusting rod is provided with a positioning groove; the outer wall surface of the adjusting rod is provided with a helical groove; the inner wall of the movable cylinder protrudes outwards to form a transmission column. By coordination between the adjusting rod and the movable cylinder, the metal part grinding machine disclosed by the invention is capable of realizing forward rotation or reverse rotation of a plurality of blades so as to realize collection and emission of iron scraps and dust.

Owner:重庆新缔欧机械制造有限公司

Suction feather duster

InactiveCN103705181AAvoid flying aroundAvoid flyingSuction filtersCarpet cleanersEngineeringEnvironmental geology

The invention discloses a suction feather duster which comprises a main rod and feathers. The suction feather duster has the advantages that air suction ports which are communicated with airflow channels in the main rod are formed in the peripheries of the feathers, a dust suction device is inserted into the main rod from an opening in the tail end of the main rod and is communicated with the airflow channels in the main rod, and dust on the surfaces of articles is wiped down by the feathers, is sucked into a dust bag by the dust suction device which is operated, and accordingly is prevented from flying around and polluting surrounding environments.

Owner:中山市玫瑰园环境电器有限公司

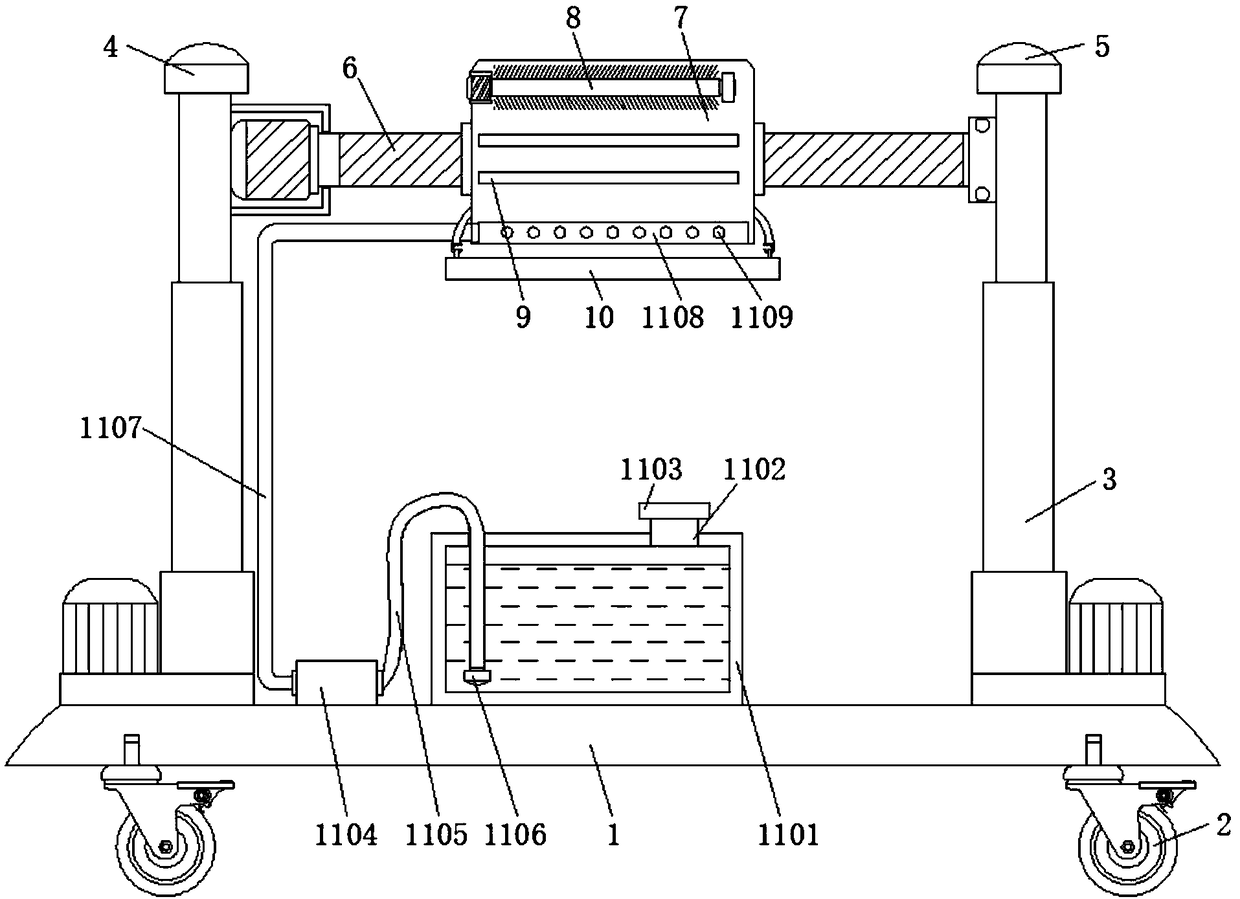

Automatic wall polishing device for building field

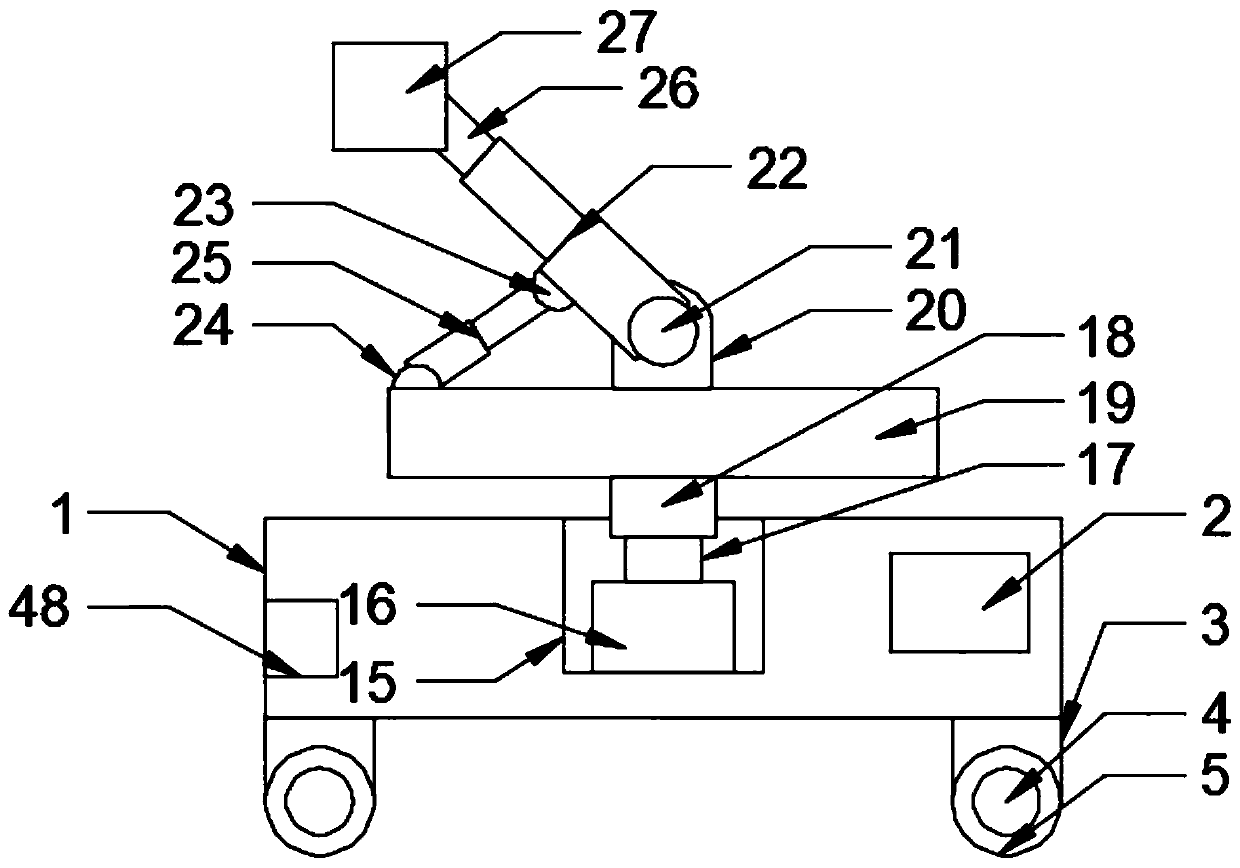

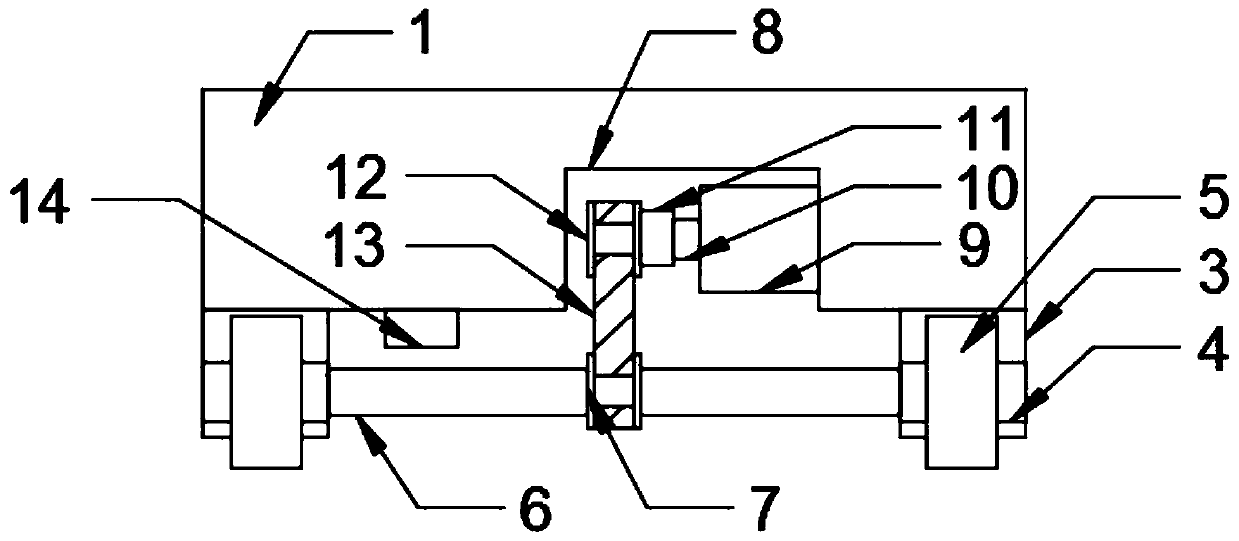

InactiveCN109848778AReduce work intensityImprove work efficiencyGrinding drivesPlane surface grinding machinesControl signalEngineering

The invention discloses an automatic wall polishing device for building field. The automatic wall polishing device for building field comprises a mobile base body. A mobile power-assisted mechanism isarranged below the mobile base body, a rotary telescopic fixing mechanism is arranged above the mobile base body, a wall polishing mechanism is arranged on the rotary telescopic fixing mechanism, a dust collecting mechanism is arranged on the mobile base body, a controller is arranged on the mobile base body, and the control signal output end of the controller is electrically connected to a smallrotary motor I, a distance inductor, a small rotary motor II, a hydraulic telescopic rod I, a hydraulic telescopic rod II, a small rotary motor III, a dust collector and a small rotary motor IV. Theautomatic wall polishing device disclosed by the invention has the beneficial effects of simple structure and high practicality.

Owner:邯郸百世创联电子科技有限公司

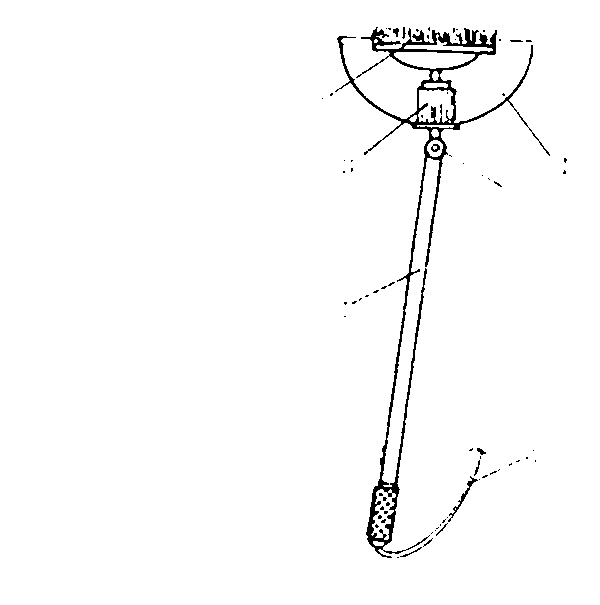

Ceiling sweeper

The invention provides a ceiling sweeper. An upper portion of a handle of the ceiling sweeper is connected with a hair brush driven by an electromotor through a cardan joint. An ash collecting cover is arranged below the hair brush. An external power line penetrates from a tail end of the handle, wherein the external power line is connected with the electromotor. When people use the ceiling sweeper, people can hold the handle with a hand to start the hair brush to sweep a ceiling above the head of the people through a motor-driven mode. The ceiling sweeper is easy, convenient and fast. In addition, due to the fact that the ash collecting cover is mounted, dust can be avoided flying everywhere, so the ceiling sweeper is a good helper for a household and a unit to do some cleaning.

Owner:XIANGYANG HIGH TECH DEV ZONE SHENGLI ELECTRONICS TECH BUSINESS DEPT

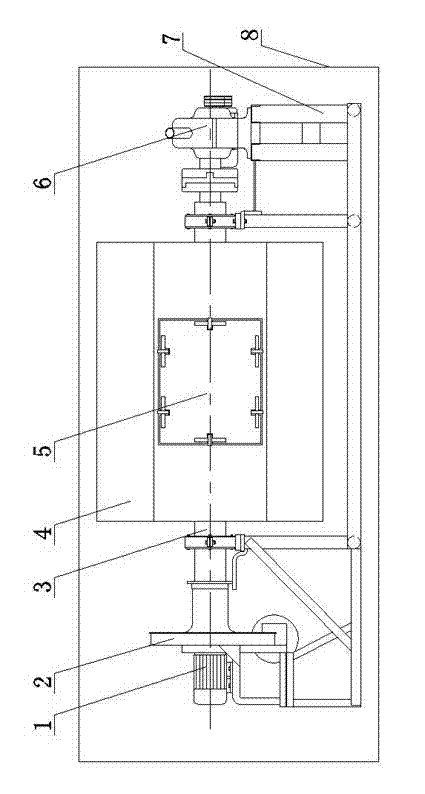

Sweeping device for underground lamp

InactiveCN111215418AAvoid flying aroundAvoid flyingDirt cleaningFlexible article cleaningElectric machineGas passing

The invention discloses a sweeping device for an underground lamp. The sweeping device comprises a cylinder, wherein a first fixing plate is fixedly connected to the interior of the cylinder, a secondcover body is fixedly connected to the top face of the cylinder, a second fixing plate is fixedly connected to the interior of the second cover body, and a motor is fixedly connected to the top faceof the second fixing plate. When the sweeping device is in use, through running of the motor, the output end drives a rotary shaft to rotate, then a hairbrush is utilized for sweeping dust on the underground lamp, and the first fixing plate can prevent the dust generated during sweeping from flying upward; and in the rotary process of the rotary shaft, a cam is driven to intermittently beat a stopdog under the effect of a spring, then a slide block is driven to slide in a box body, and the dust generated through sweeping is sucked into a dust settling box through a dust inlet pipe, and is stopped by a filtering net to be effectively settled in the dust settling box. In the meanwhile, gas is sucked into the box body through a first one-way valve, and then discharged through a second one-way valve, and then the settled dust is cleaned within a certain time through a door.

Owner:黎桃玲

Waste processing device for wood pulverizer

ActiveCN109227865AEasy to cleanSave time and effortWood working apparatusFlat articlesWaste processingWood processing

The invention belongs to the field of wood processing equipment, and particularly relates to a waste processing device for a wood pulverizer. The waste processing device for the wood pulverizer achieves the technical purposes that wood waste can be conveniently cleaned away, wood bits in the wood waste can be restrained from flying, time and labor are saved during wood waste processing, the efficiency is high, and waste is thoroughly processed. The waste processing device for the wood pulverizer comprises a bottom frame, a driving mechanism, a feeding hopper, a pulverizing box, a support, a smashing mechanism, a waste processing device and a first discharging pipe; the driving mechanism is installed at the top of the bottom frame, the pulverizing box is fixedly connected to the top of thebottom frame through the support, the smashing mechanism is installed inside the driving mechanism, and the smashing mechanism is in transmission connection with the output end of the driving mechanism. The device achieves the effects that wood waste can be conveniently cleaned away, wood bits in the wood waste can be restrained from flying, time and labor are saved during wood waste processing, the efficiency is high, and waste is thoroughly processed.

Owner:浙江久安绿色智能家居有限公司

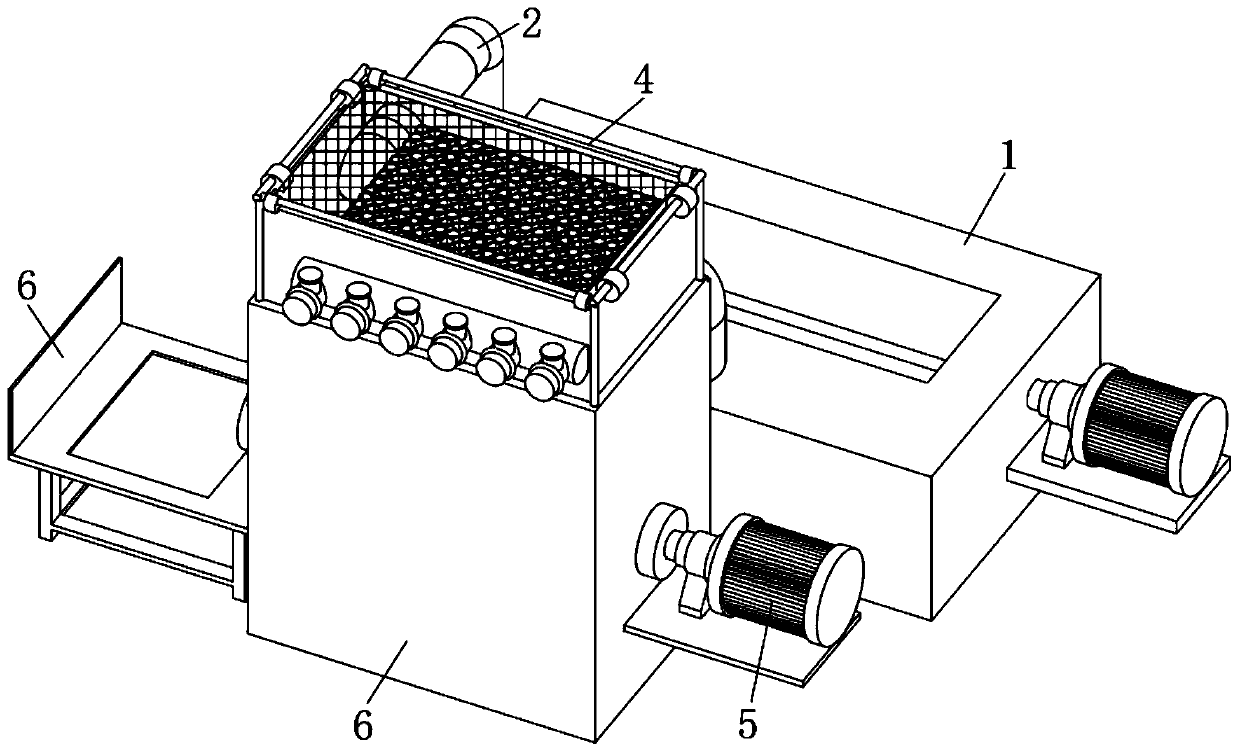

Shredded paper processing and collecting device capable of reducing dust greatly

PendingCN110404655AImprove processing efficiencyReduce pollutionCombination devicesDispersed particle filtrationPulp and paper industryScrew conveyor

The invention discloses a shredded paper processing and collecting device capable of reducing dust greatly, and belongs to the field of waste paper processing. The shredded paper processing and collecting device capable of reducing the dust greatly comprises a crushing mechanism, a blower, a shell, a side jet pulse dust removal device and a screw conveyor. The crushing mechanism is connected withthe side jet pulse dust removal device through the blower, and the top of the shell is fixedly connected with the side jet pulse dust removal device. According to the shredded paper processing and collecting device, after waste paper is crushed and ground, the waste paper is conveyed to an inner cavity of a collection funnel through the blower, dust removal is performed through the side jet pulsedust removal device, then the waste paper and dust are discharged through the screw conveyor for collection, so that the pollution caused by the dust in the process of treating waste paper is greatlyreduced, the environment can be protected, meanwhile, the adverse effect of dust on the bodies of workers is reduced; and the degree of automation is high, the device is simple and convenient to use so that the working efficiency of the workers can be improved, and meanwhile, the efficiency of waste paper treatment is improved.

Owner:浏阳市奥斯特烟花制造有限公司

Wall face finishing coat scraping device for building decoration

InactiveCN109281485ARealize scraping operationRealize the collectionBuilding repairsEngineeringCivil engineering

The invention relates to the technical field of building decoration, and discloses a wall face finishing coat scraping device for building decoration. The wall face finishing coat scraping device comprises a bottom plate. Omnidirectional wheels are fixedly mounted at four corners of the bottom of the bottom plate. Electric hydraulic push rods are fixedly mounted on two sides of the top of the bottom plate. Top blocks are fixedly mounted at the tops of the two electric hydraulic push rods. Rubber pads are fixedly mounted at the tops of the top blocks. A power executing mechanism is fixedly mounted at the top of the position between the two electric hydraulic push rods. A wall face wet by a wall face soaking mechanism, wet finishing coat is scraped with a finishing coat scraping mechanism. Dust and little residual finishing coat on the wall face are swept by a wall face leveling mechanism. Waste falls in a dust collecting mechanism, and therefore dust collecting is achieved, and dust influence on persons is prevented. The power executing mechanism can drive the wall face leveling mechanism and the finishing coating scraping mechanism to move left and right, and therefore continuous wall face finishing coat scraping operation is realized, and scraping working efficiency is improved.

Owner:张日胜

Drilling device for industrial automation

InactiveCN110711873AReduce labor intensityAvoid flying aroundWork clamping meansPositioning apparatusThermodynamicsDust control

The invention discloses a drilling device for industrial automation. The drilling device for the industrial automation comprises a bottom plate, a frame body, a control box, a collection box, a drilling mechanism, a clamping mechanism and a dust removal mechanism, wherein the frame body is installed at the top of the bottom plate, and the control box is installed at the top of the frame body. Thedrilling device for the industrial automation controls the drilling mechanism, the drilling mechanism and the dust removal mechanism through the control box, and performs drilling work for workpiecesby adopting an automatic mode, and compared with manual operation, the drilling device for the industrial automation reduces labor intensity of workers, reduces manual cost, and improves production efficiency. By arranging the clamping mechanism, when the drilling device for the industrial automation processes the workpieces of different quantities or different sizes, clamp customization is not needed, and therefore not only is cost input reduced, but also manual work is not needed for fixing the workpieces, labor intensity is reduced, and work efficiency is improved. The drilling device for the industrial automation can prevent chippings generated in drilling from flying apart in all directions, prevents potential safety hazard from being caused, and brings great convenience to drilling work.

Owner:XIAN YONGXIN TECH CO LTD

Drilling auxiliary device for wooden furniture machining

InactiveCN112428354AAvoid dangerHigh degree of automationStationary drilling machinesBark-zones/chip/dust/waste removalElectric machineryStructural engineering

The invention discloses a drilling auxiliary device for wooden furniture machining. The device comprises a square machining table, wherein a square machining groove is formed in the upper end of the machining table, a square scrap opening is formed in the inner bottom wall of the machining groove, a square buffer gasket is fixedly connected to the position, on the outer side of the scrap opening,of the inner bottom wall of the machining groove, a sound insulation plate is arranged in the scrap opening, the outer side of the periphery of the sound insulation plate is fixedly sleeved with a mounting frame, and the right end of the mounting frame is rotatably connected with the inner wall of the right side of the scrap opening. The device has the advantages that a wooden plate is clamped through a mechanical structure without the need of manual supporting, the safety of workers is guaranteed, drilling operation can be automatically conducted on any position of the wooden plate through cooperative use of a first motor and a second motor, the automation degree is high, the precision is high, chipping splashing is avoided during drilling, and centralized clearing of chippings is facilitated.

Owner:张硕

Mold maintenance device

InactiveCN107717694AEasy to useReduce direct contactGrinding carriagesGrinding drivesEngineeringVacuum pump

The invention relates to the technical field of mold equipment, in particular to a mold maintenance device, which comprises a first shell. An upper baffle plate and a lower baffle plate are fixedly connected to the upper end and the lower end of a front end face of the first shell; a first slide rod and a third slide rod are fixedly connected to rear end faces of the upper baffle plate and the first shell; a second shell is arranged on the first slide rod; a second slide rod is fixedly connected to a right end face of the second shell and is slidably connected with a third shell; a clapboard is fixedly connected into the first shell; a non-slip mat is fixedly connected to an upper end face of the clapboard; and an air pump, a vacuum pump and a dust storage tank are sequentially and fixedlyconnected to the bottom end of the inner part of the first shell from left to right. The mold maintenance device provided by the invention is novel in design and complete in functions, and has no need to be manually polished for a long time so as to be time and labor saving and convenient to use, the direct contact between the device and a mold can be reduced during a mold cleaning process, the risk of damaging the mold is reduced, and the occurrence of the phenomenon that dust flies in all directions to pollute the environment is prevented.

Owner:WUXI BOJIN PRECISION MACHINERY MFG

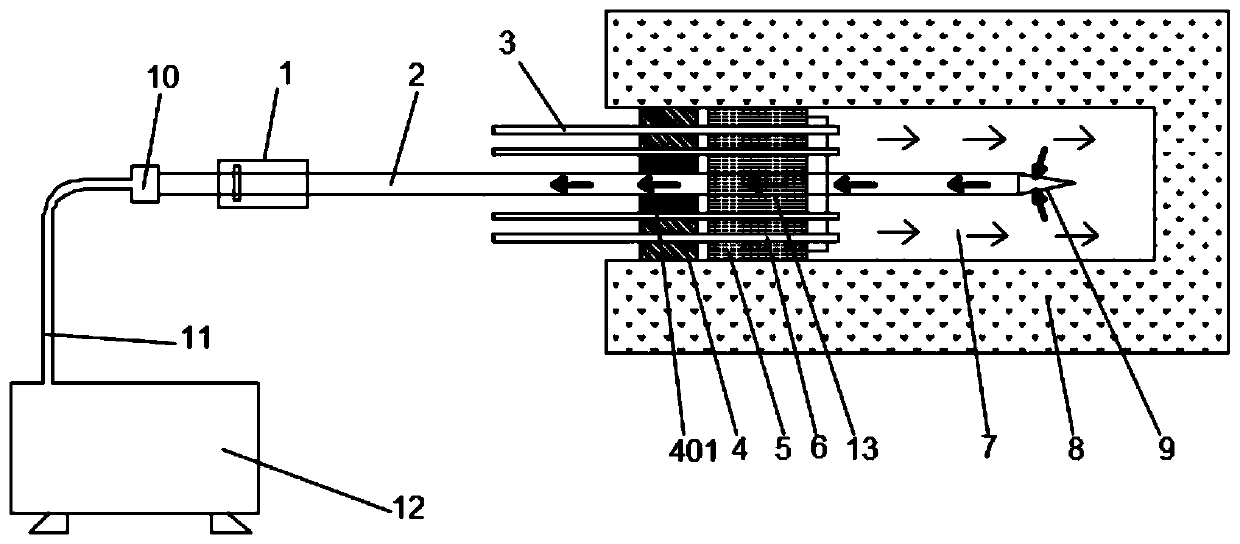

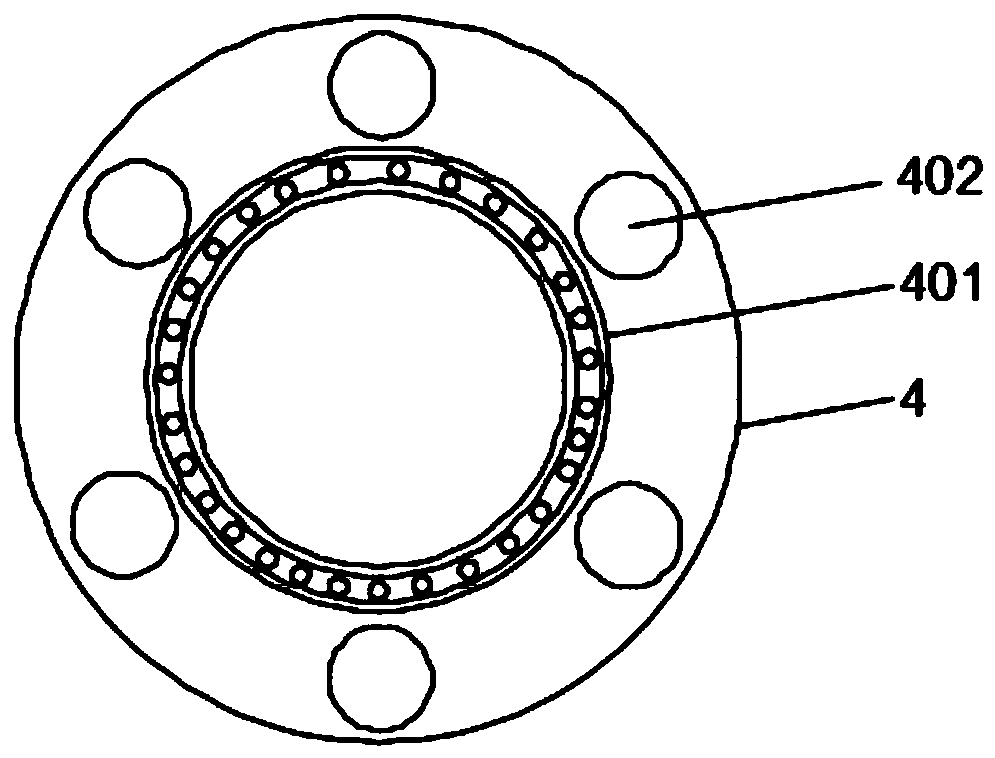

Underground coal mine drilling closed dust removal system and method

The invention discloses an underground coal mine drilling closed dust removal system and method. The system comprises a drilling device, a dust removing device and a hole sealing device; the drillingdevice comprises a drilling machine, a drilling pipe and a drilling bit, the dust removal device comprises a compressed air pipe; Sealing ring and gas-solid separator, Powder discharging hose and dustremover, Bearing is arranged in the middle of the sealing ring, A plurality of round holes are evenly distributed in the edge of the sealing ring in the circumferential direction of the bearing. thehole sealing device is next to the right side of the sealing ring; a central hole corresponding to the bearing inner ring is formed in the hole sealing device; the compressed air pipe holes correspondto the circular holes; The drill rod sequentially penetrates through the bearing and the center hole and then stretches into the drill hole, the drill rod is in running fit with the bearing, the compressed air pipe sequentially penetrates through the round hole and the compressed air pipe hole and then stretches into the drill hole, the compressed air pipe is in sealed connection with the round hole, the gas-solid separator is communicated with the tail end of the drill rod, one end of the powder discharging hose is communicated with the gas-solid separator, and the other end is in sealed connection with the dust remover. Closed dust removal in a drill hole is achieved, dust is prevented from flying all around during drilling, and the environment of a workplace is improved.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com