Automatic wall polishing device for building field

A technology in the field of walls and fields, applied in the field of automatic wall grinding devices, can solve the problems of physical injury, time-consuming and labor-intensive, etc., and achieve the effects of reducing work intensity, improving the working environment and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

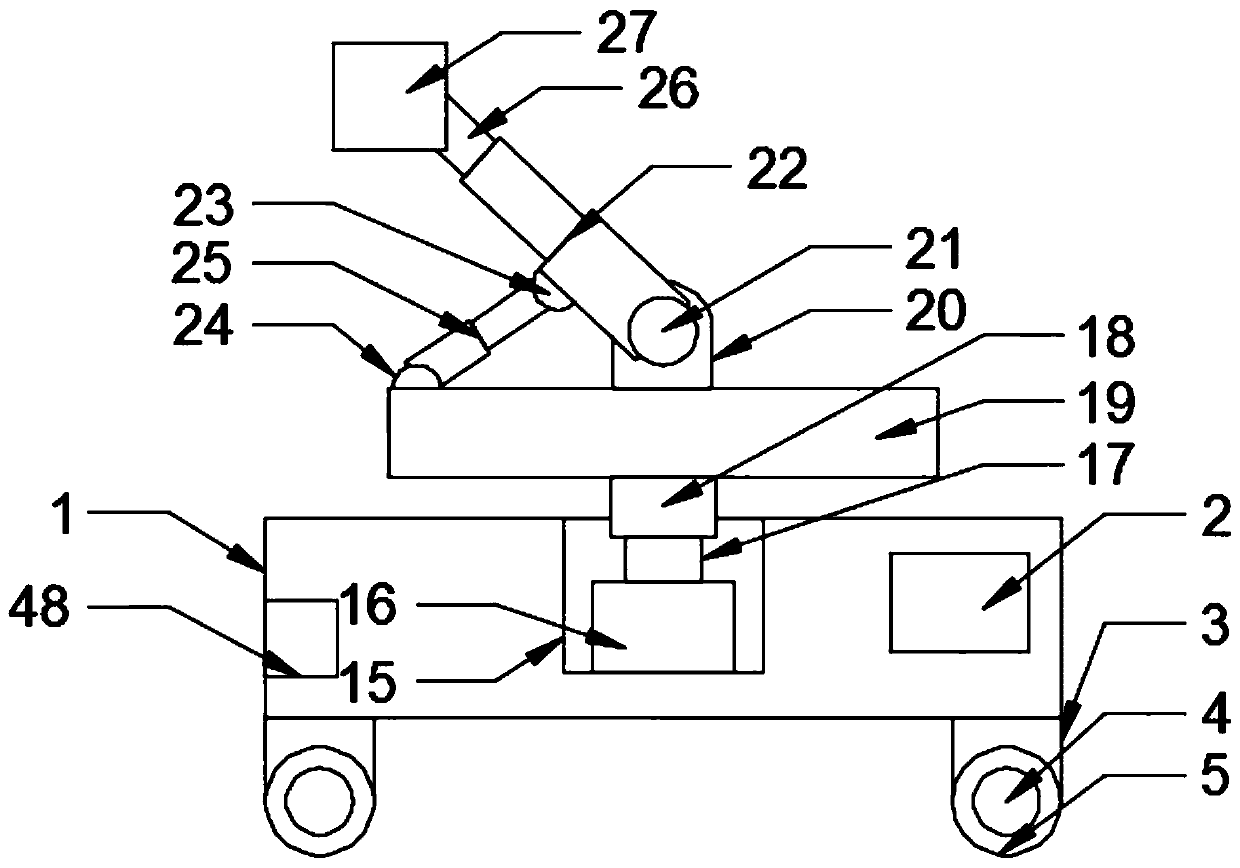

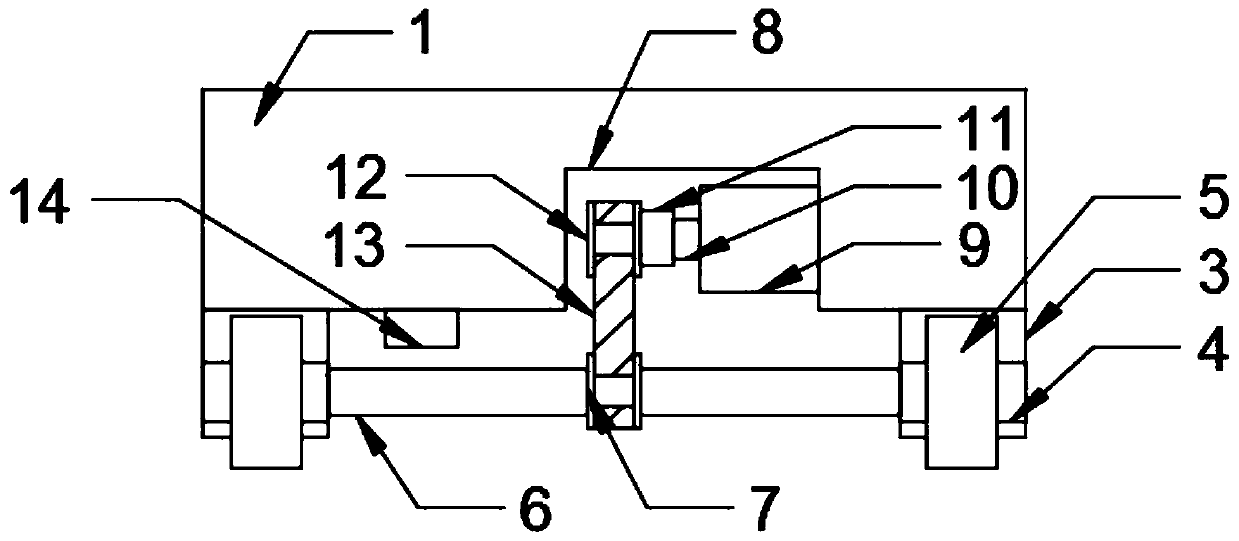

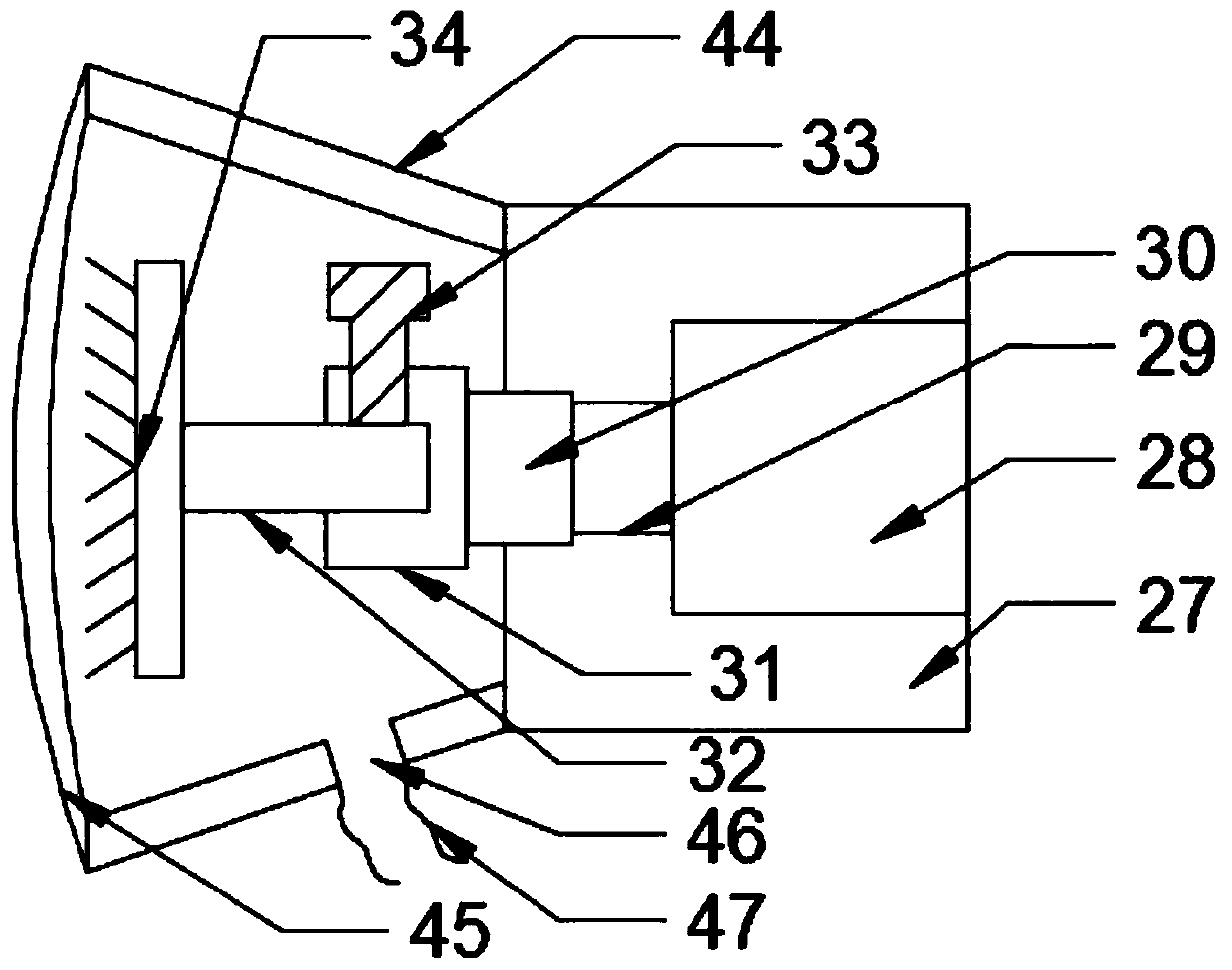

[0022] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6 shown.

[0023] In this embodiment, the first step, when the wall is polished, the staff moves the mobile base body 1 to one side of the wall, the staff touches the grinding key on the capacitive display screen 49 on the controller 2, and the small rotating motor 2 16 Start, the rotating end of the small rotating motor 2 16 drives the coupling 2 17 to rotate, and the coupling 2 17 drives the fixed bearing 2 18 and the rotating fixed plate 19 to rotate, and the position of the hydraulic telescopic rod 1 22 is adjusted by rotating the fixed plate 19. After the adjustment, the hydraulic telescopic rod-22 starts, and the telescopic end of the hydraulic telescopic rod-22 stretches into the drive motor fixed box 27 to move, and the telescopic end of the hydraulic telescopic rod-22 stretches into the top of the motor fixed box 27, and at the same time The hydraulic t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com