Patents

Literature

311results about How to "Physical health effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

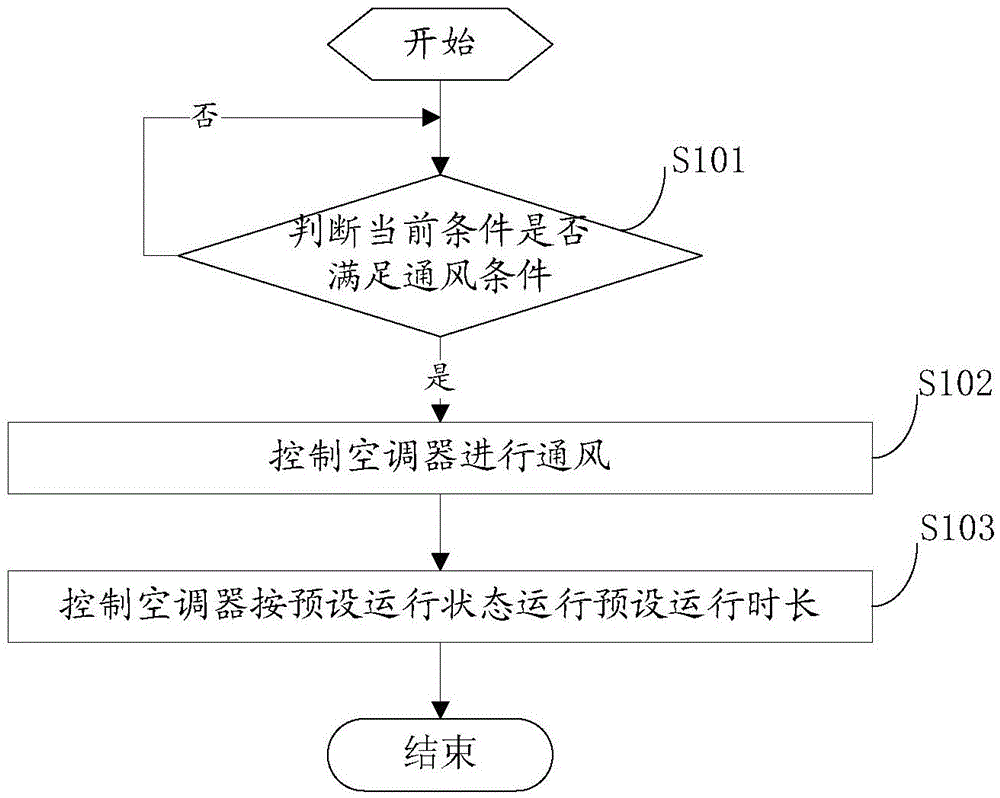

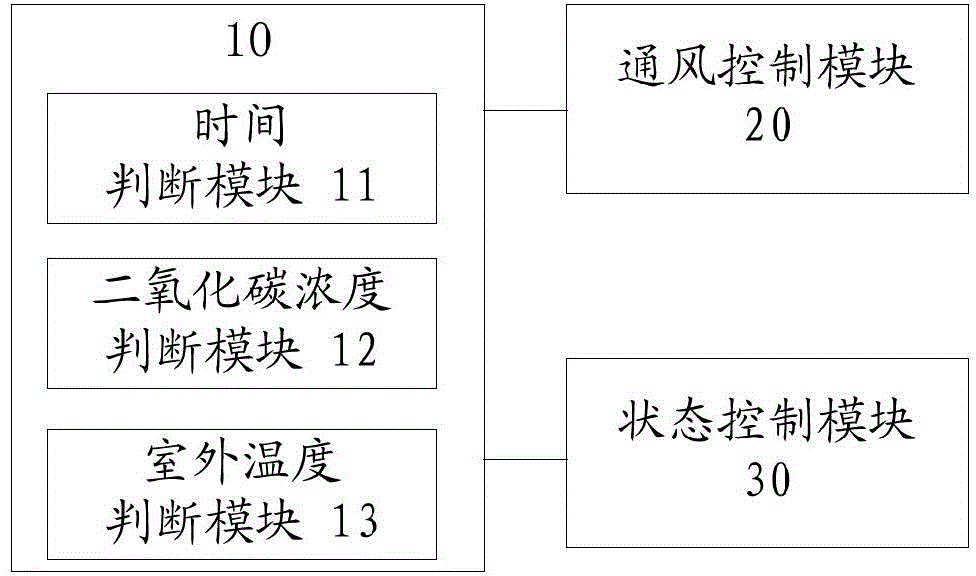

Air conditioner with fresh air function and control method and system thereof

InactiveCN104456735AImprove air qualityAvoid physical fitnessMechanical apparatusSpace heating and ventilation safety systemsIndoor airEngineering

The invention provides an air conditioner with a fresh air function. The air conditioner comprises an indoor unit and an outdoor unit and further comprises a fresh air pipeline, a fan and a controller. An air outlet of the indoor unit and the fresh air pipeline form a passage connecting the indoor and the outdoor. The controller is used for controlling running of the fan so as to deliver outdoor to the indoor, thereby improving the indoor air and preventing adverse influence on physical health of users.

Owner:GREE ELECTRIC APPLIANCES INC

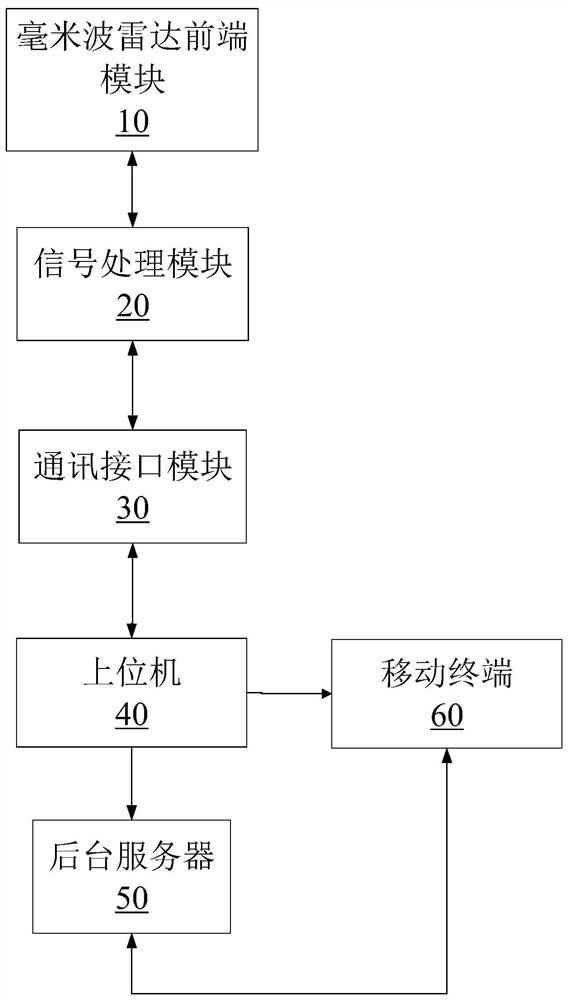

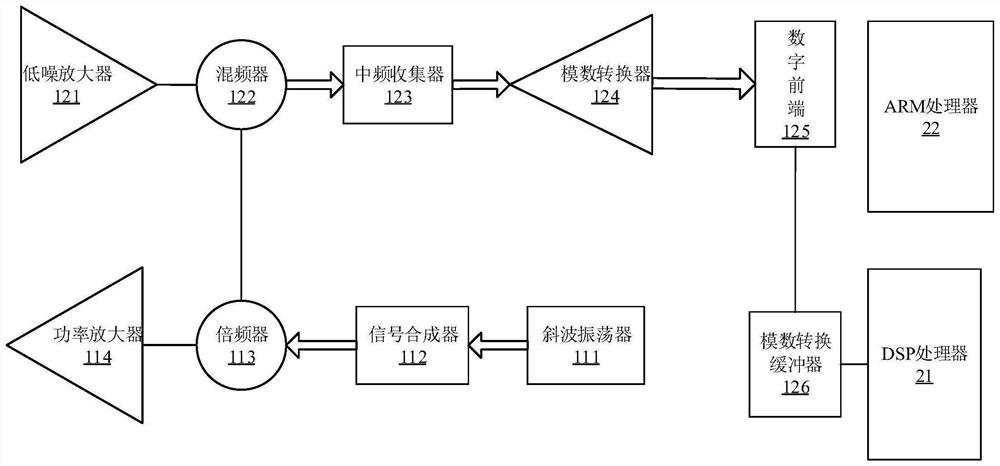

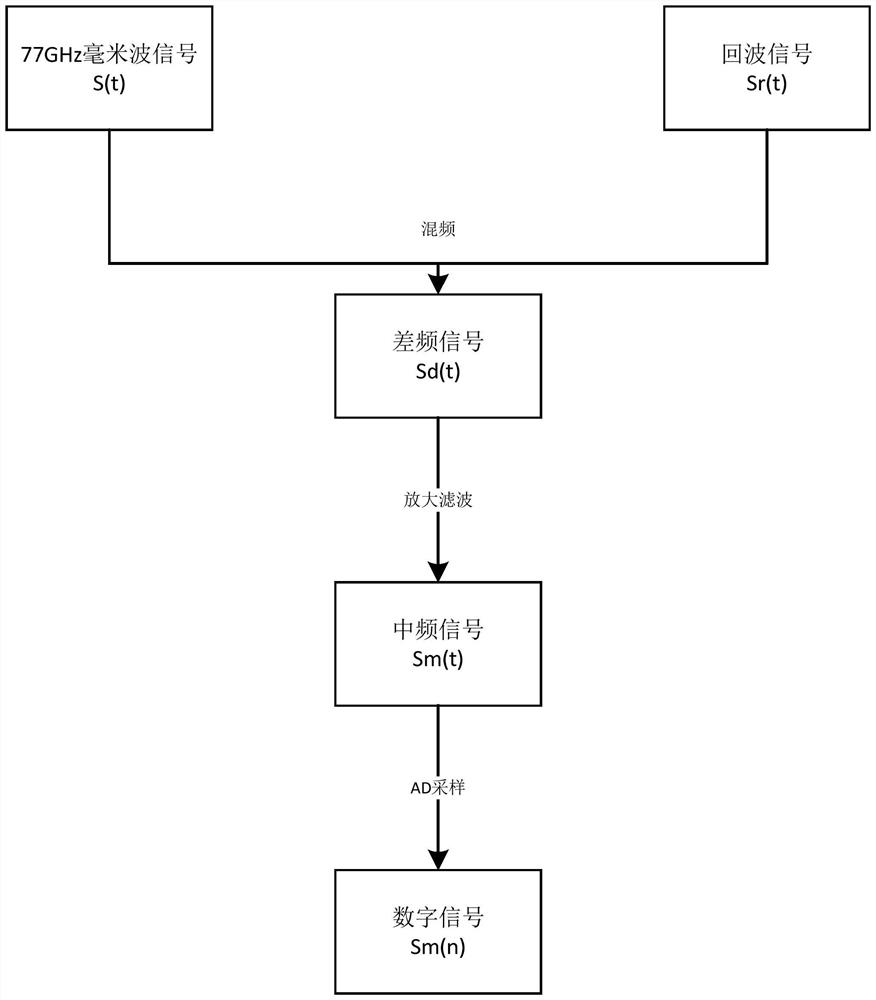

Physical sign non-contact intelligent monitoring system based on millimeter-wave radar

ActiveCN112014837AAvoid cumbersomeAvoid bulkySensorsMeasuring/recording heart/pulse rateCommunication interfaceTelecommunications

The invention discloses a physical sign non-contact intelligent monitoring system based on a millimeter-wave radar. A millimeter-wave radar front-end module transmits and receives a millimeter-wave radar signal, and the millimeter-wave radar front-end module is connected with a signal processing module; a signal processing module is connected with a communication interface module, analyzes the echo signals after sampling quantification to obtain vital sign data, including frequency parameters of respiration and heartbeat, of a tested person, and transmits a processed information result to an upper computer through the communication interface module; and the upper computer compares the received vital sign data with preset data, uploads the data and a comparison result to a background server, gives an alarm to the mobile terminal if the comparison result is abnormal, and automatically gives an alarm when the comparison result exceeds a preset maximum value. According to the invention, the real-time intelligent monitoring of vital signs of indoor old people is realized, including monitoring of breathing and heartbeat parameters, and real-time alarm is carried out in case of abnormality so as to prevent accidents.

Owner:HANGZHOU DIANZI UNIV

Plant fiber reinforced inorganic light composite and preparation method thereof

InactiveCN106747031APrevent shrinkageFast condensationSolid waste managementCeramicwareMagnesium chloride hexahydrateFlexural strength

The invention discloses a plant fiber reinforced inorganic light composite which is mainly prepared from magnesium chloride hexahydrate, magnesium sulfate heptahydrate, light calcined magnesia, water, a water reducer, a reinforcing agent, reinforcing fibers, a foaming agent, an exciting agent, a stabilizer and adjusting admixture. The preparation method comprises steps as follows: magnesium chloride hexahydrate, magnesium sulfate heptahydrate and water are mixed to be made into a saline solution; light calcined magnesia, the water reducer and the reinforcing agent are added to the saline solution, the mixture is stirred at a constant speed, and an inorganic sizing material is obtained; the reinforcing fibers are added to the inorganic sizing material and stirred at a constant speed, the adjusting admixture, the stabilizer and the exciting agent are dropwise added slowly, finally, the foaming agent is added quickly, the mixture is stirred at a high speed, and a foamed inorganic sizing material is obtained; the foamed inorganic sizing material is poured into a die, left to stand for foaming, removed from the die and maintained, and the plant fiber reinforced inorganic light composite is obtained. The composite has the advantages of high pressure resistance, high bending resistance, low density, no formaldehyde, aging resistance, mildew resistance, termite resistance, moisture-proof performance, no deformation, sound and heat insulation, good heat preservation and the like.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

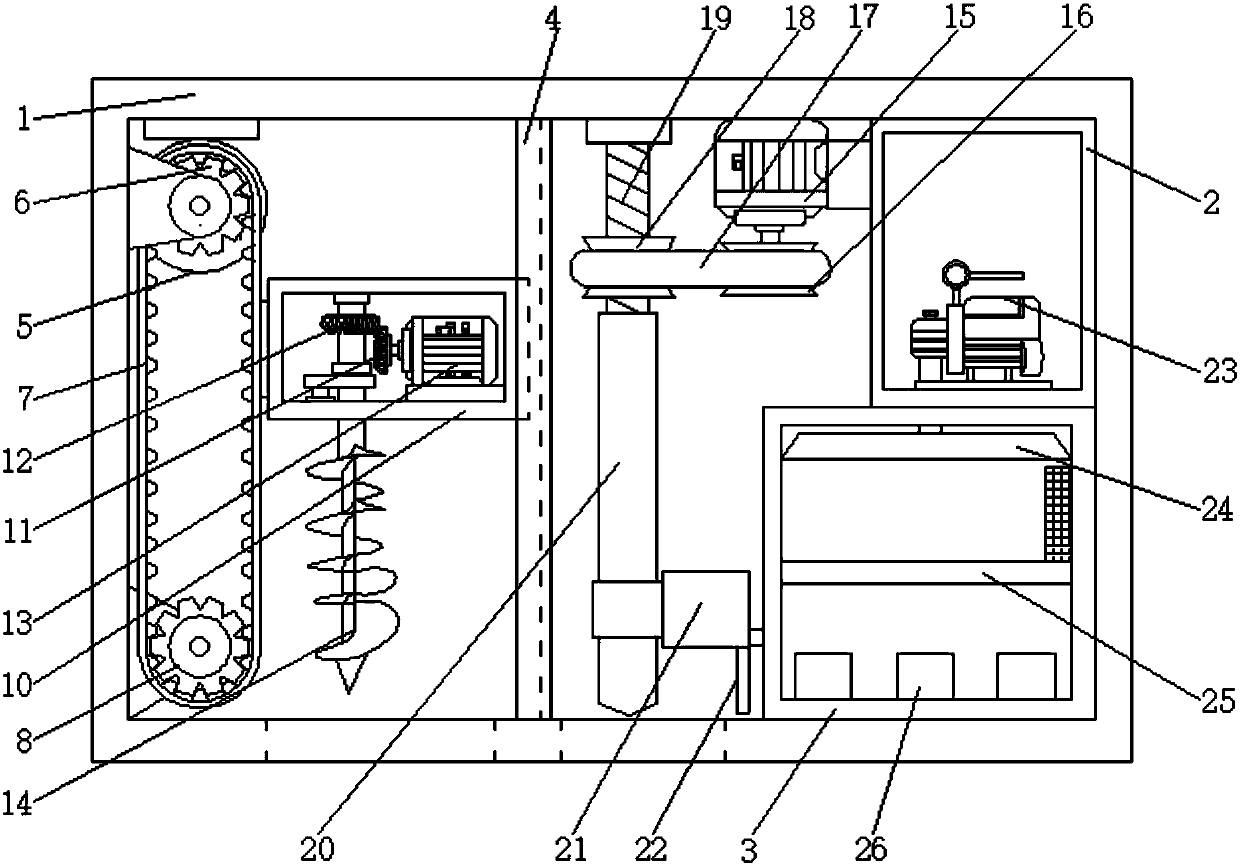

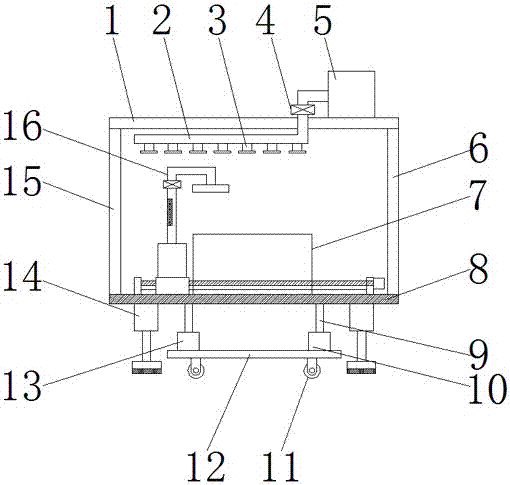

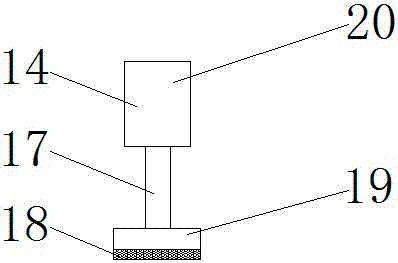

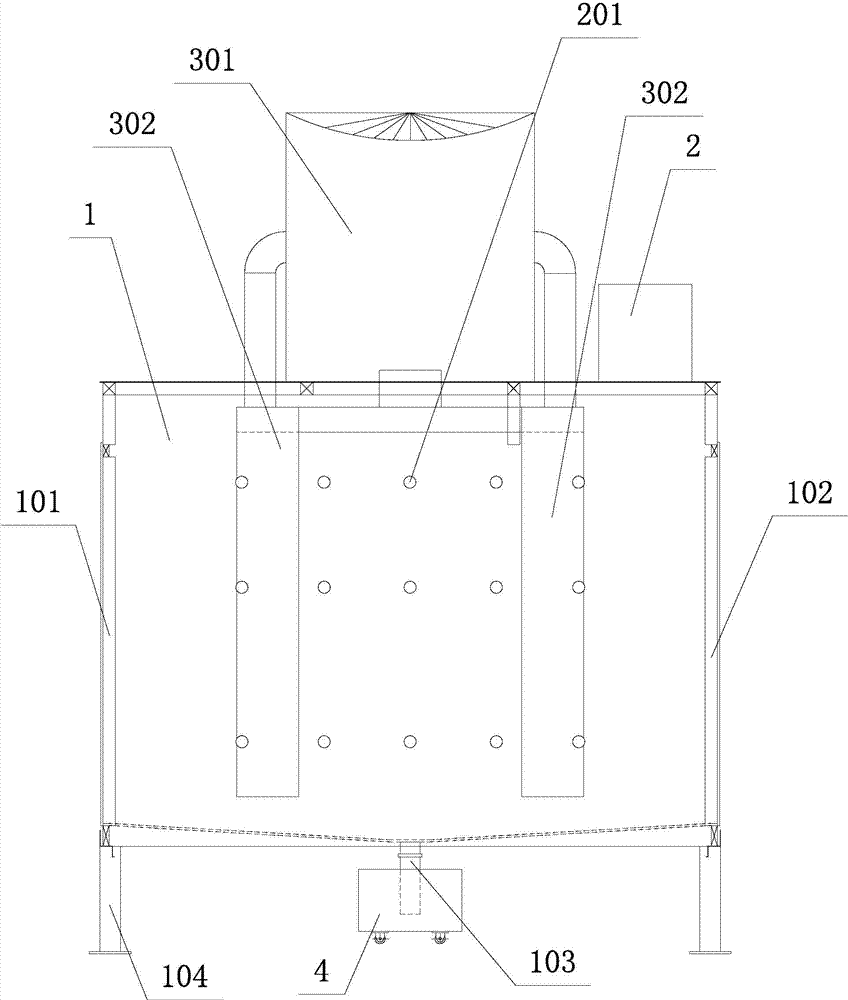

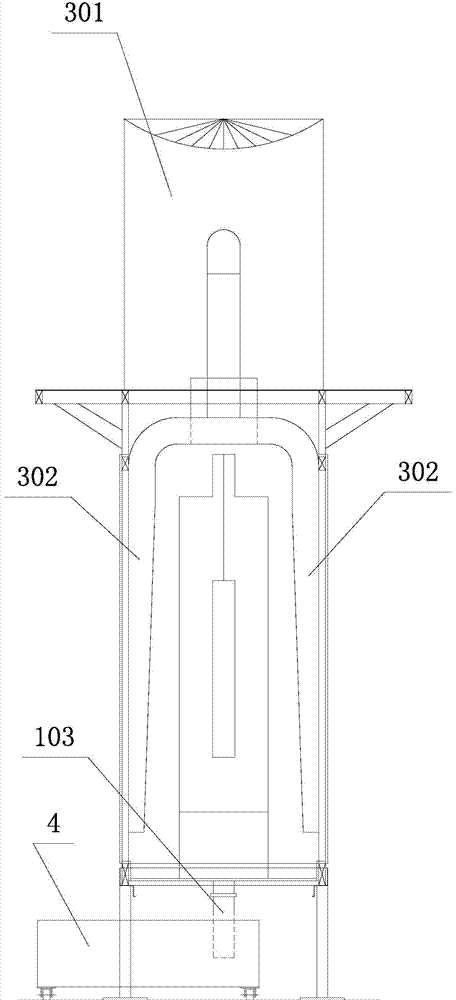

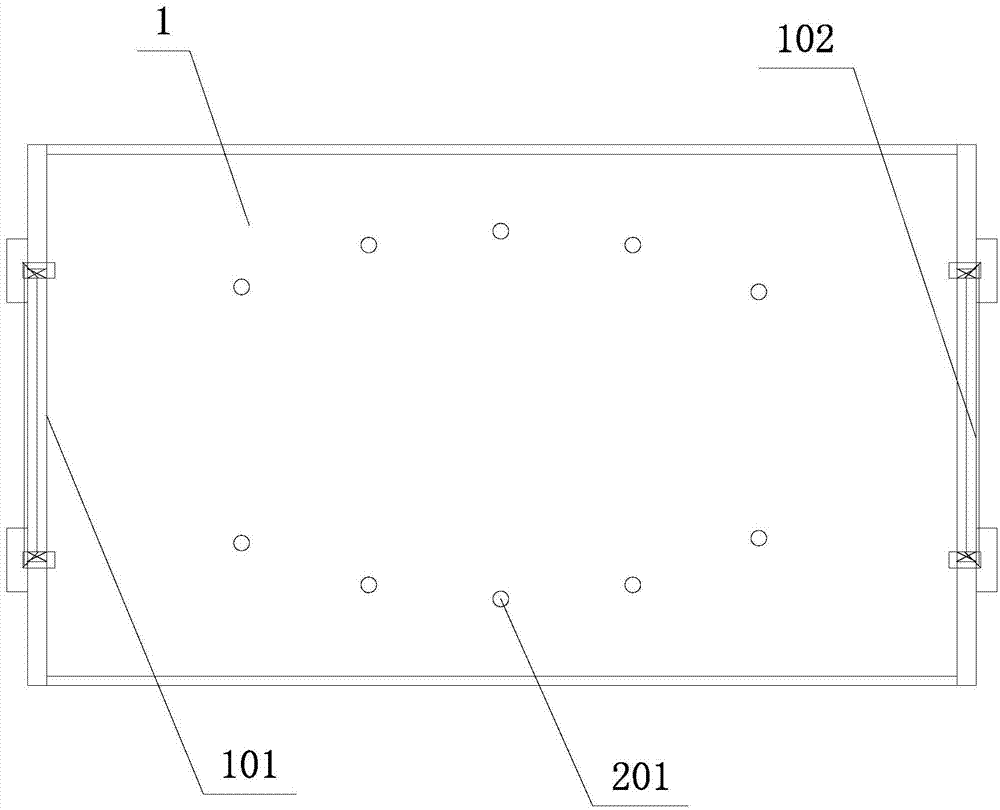

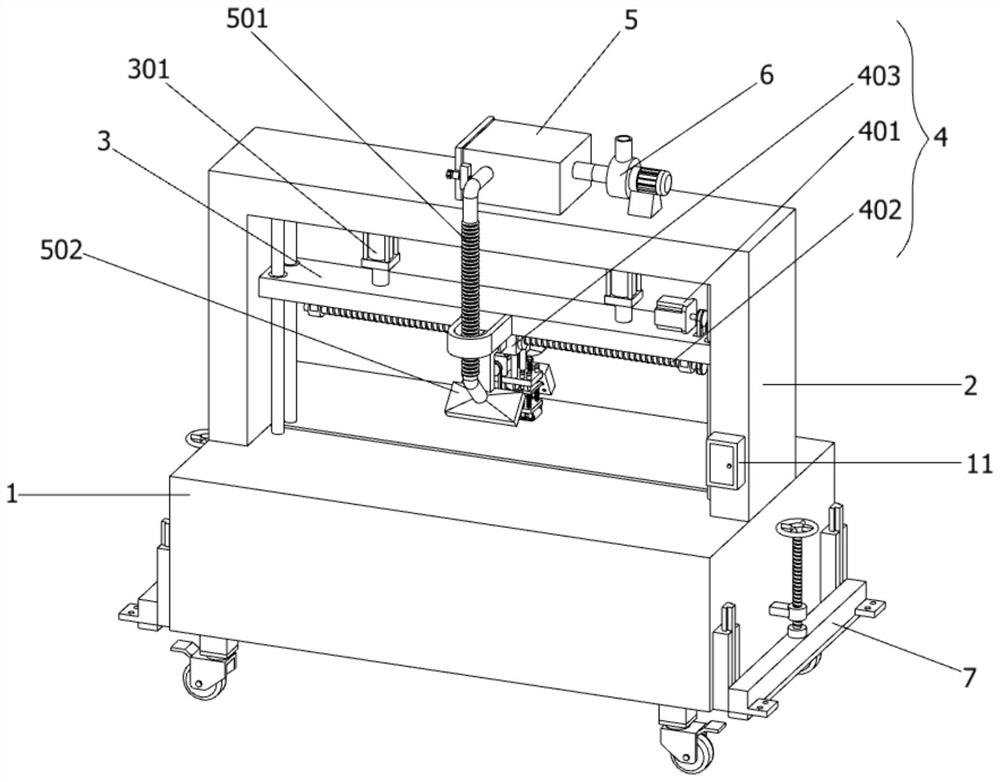

Soil collection device based on geological detection

InactiveCN107588978AHeight adjustableEfficient deliveryWithdrawing sample devicesElectric machineryEngineering

The invention discloses a soil collection device for based on geological detection, which comprises a box body, wherein the right side of the top of the inner wall of the box body is fixedly connectedwith a top box; a bottom box is fixedly connected between the bottom of the top box and the bottom of the inner wall of the box body; a vertical plate is fixedly connected between the top and the bottom of the inner wall of the box body; the left side of the top of the inner wall of the box body is fixedly connected with a first electric motor; an output shaft of the first electric motor is fixedly connected with a first gear; a gear belt is in transmission connection with the surface of the first gear, a second gear is in transmission connection with one side, far from the first gear, of thegear belt; the axes of the first gear and the second gear each are fixedly connected with the left side of the inner wall of the box body through a support plate. The invention relates to the technical field of geology related equipment. The soil collection device based on geological detection can collect soil with different depths according to requirements, thus facilitating the collection of samples and ensuring the normal use of the device, and facilitating the movement of the device at the same time.

Owner:杭州星翼进出口有限公司

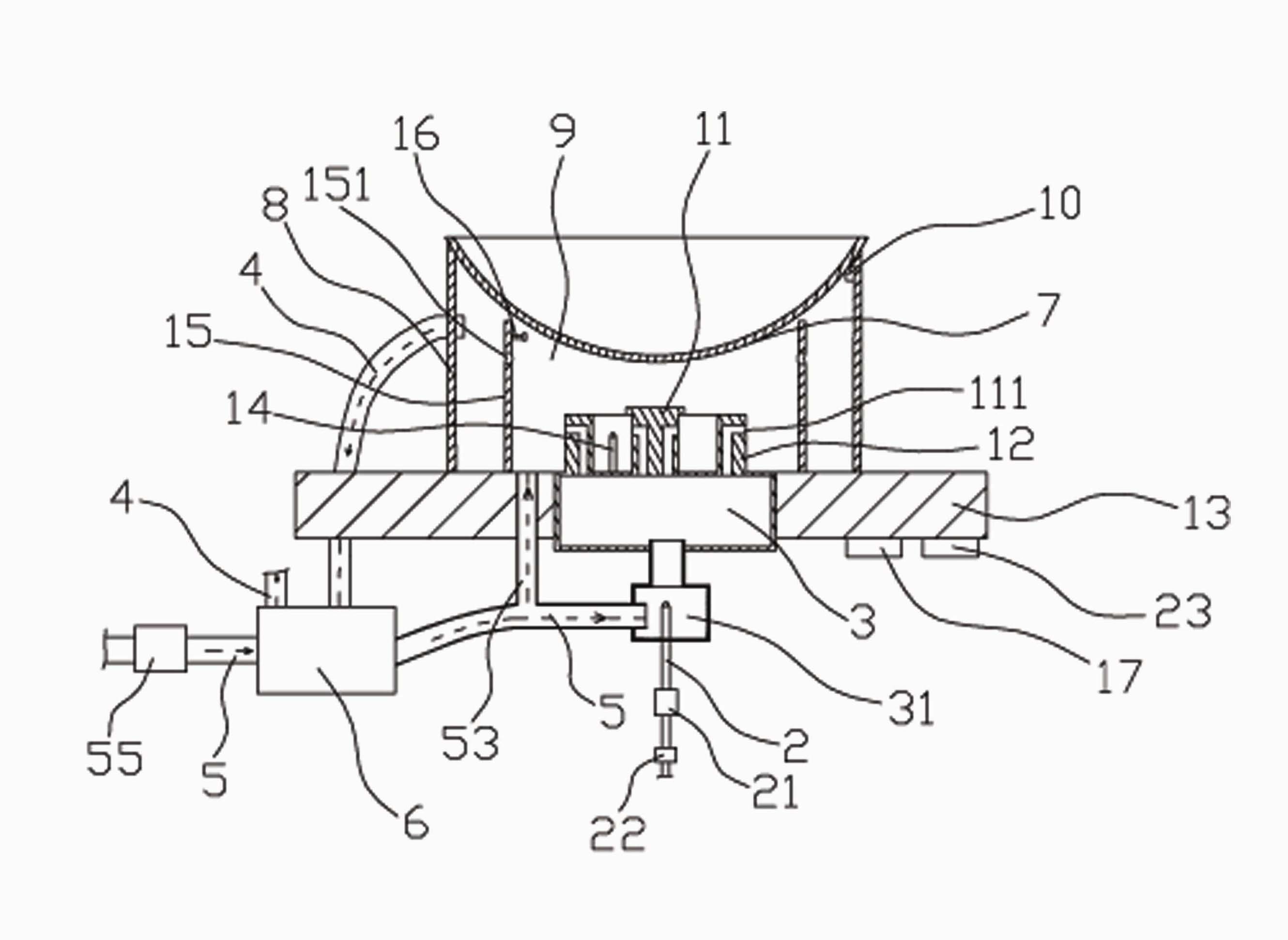

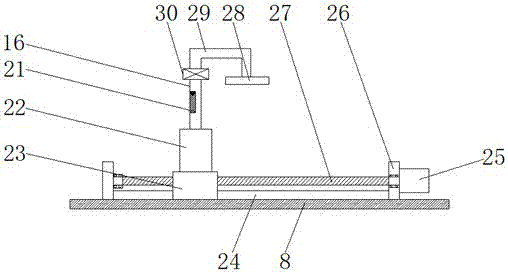

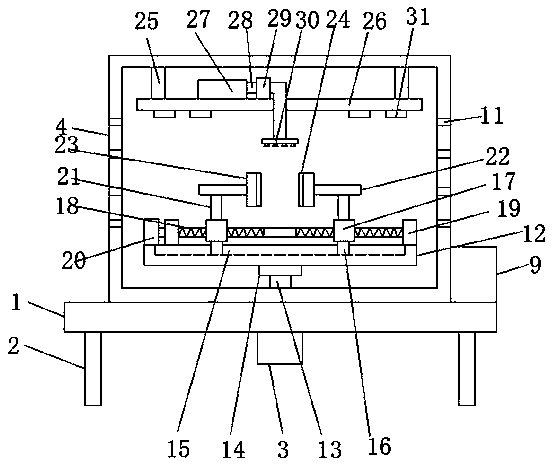

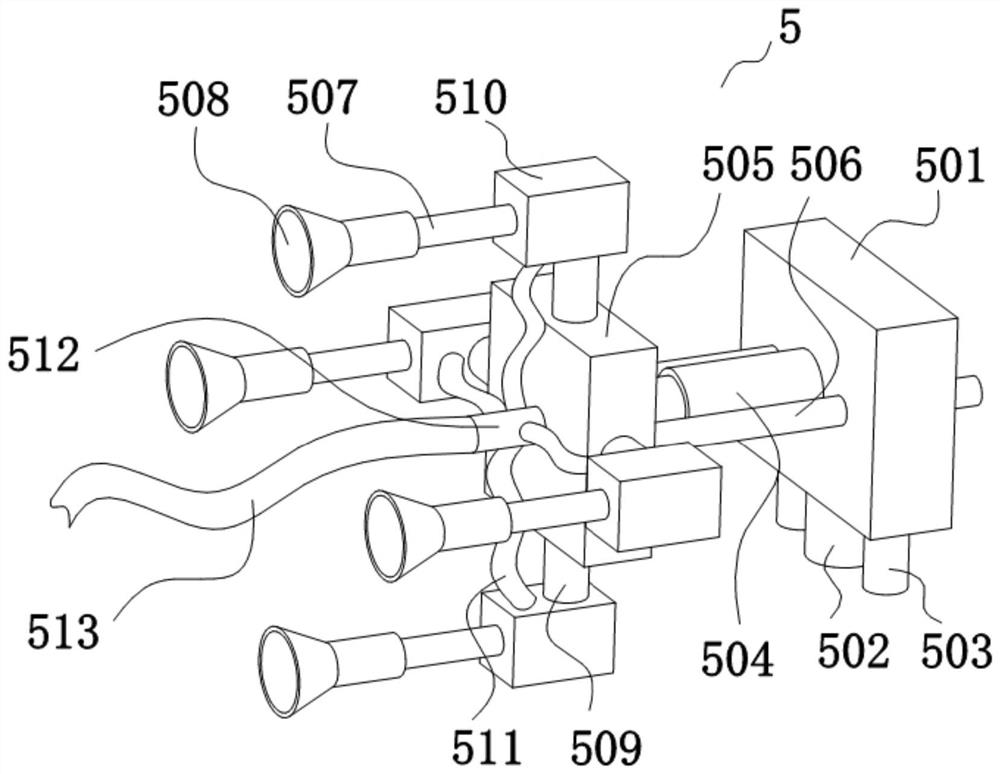

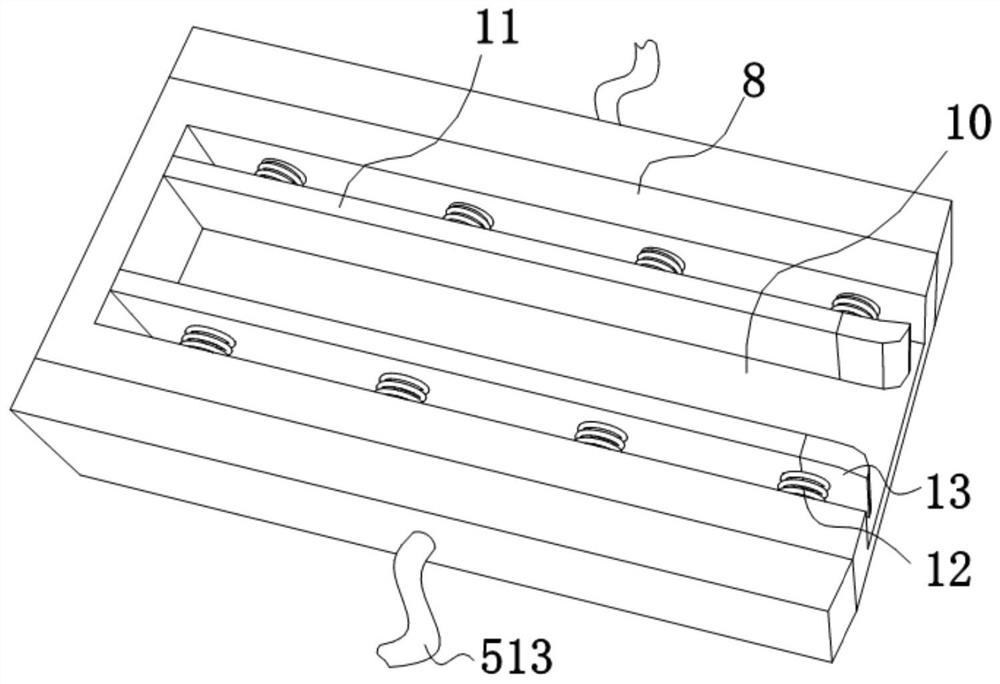

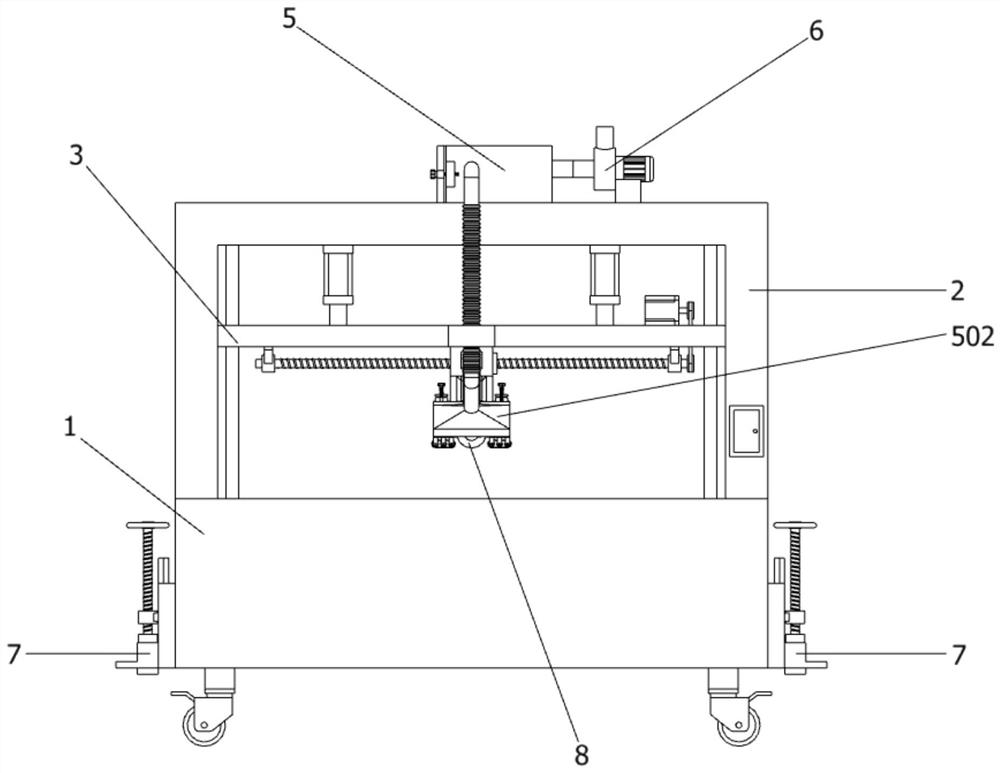

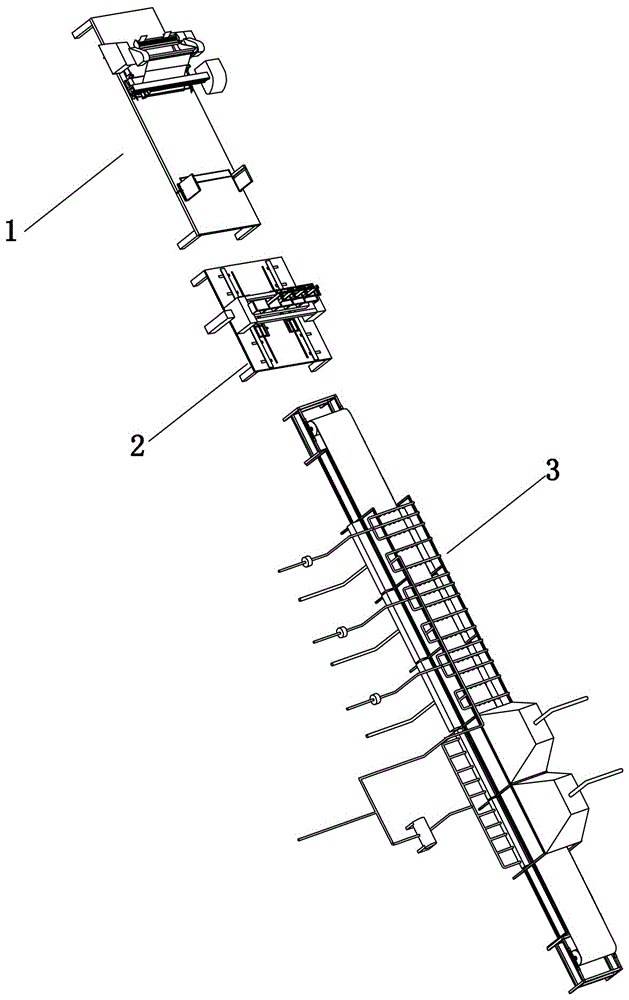

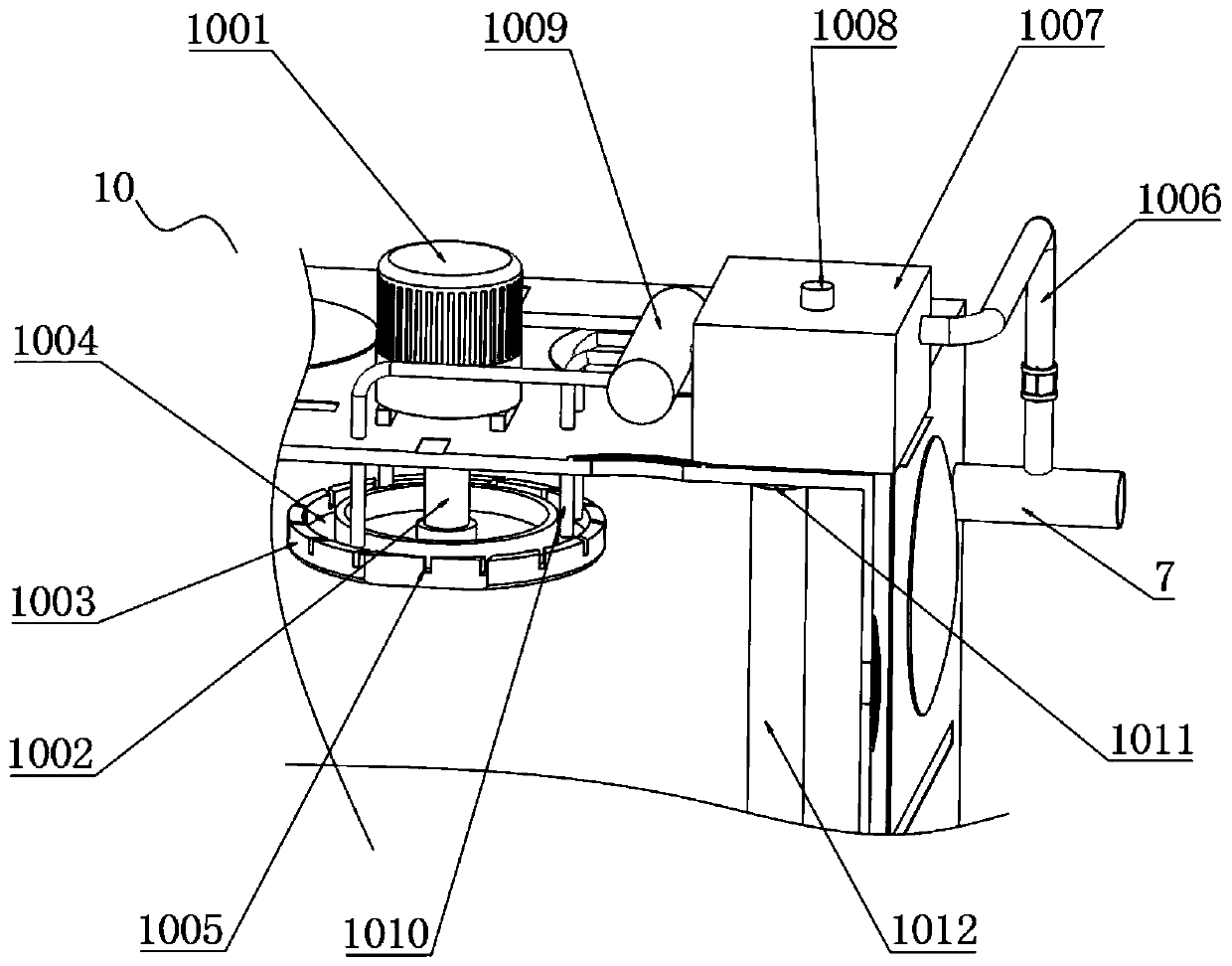

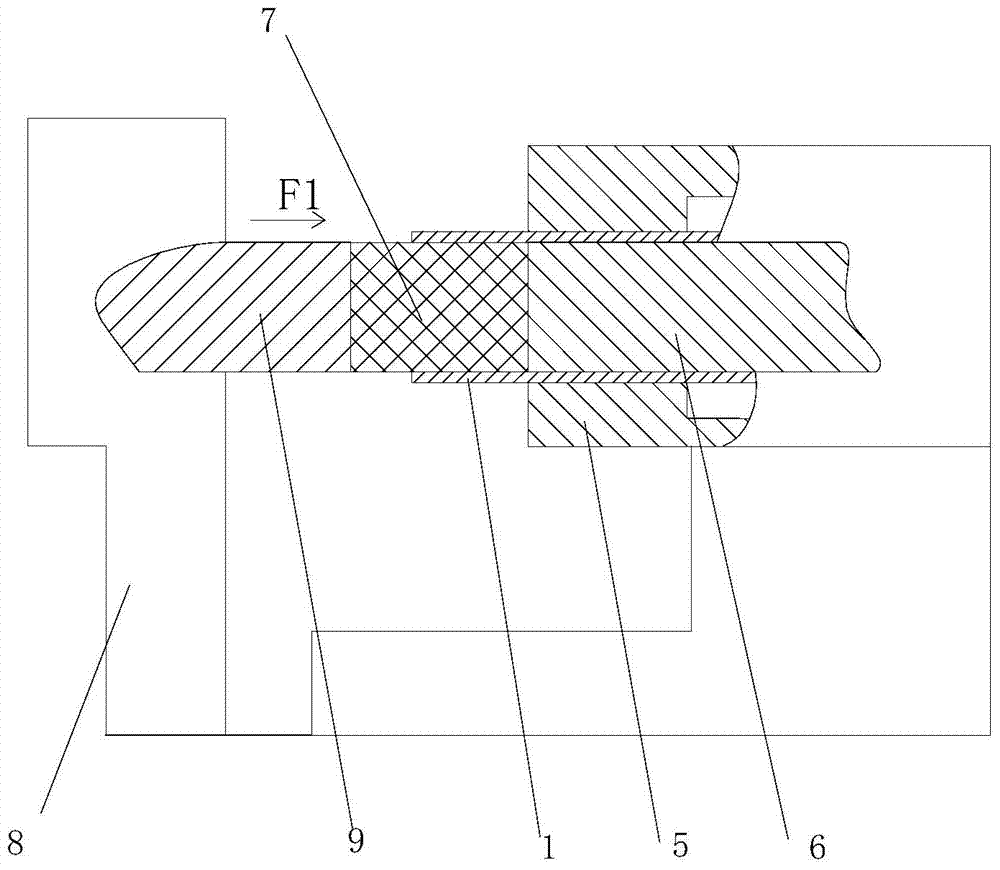

Lithium ion battery end portion grinding device

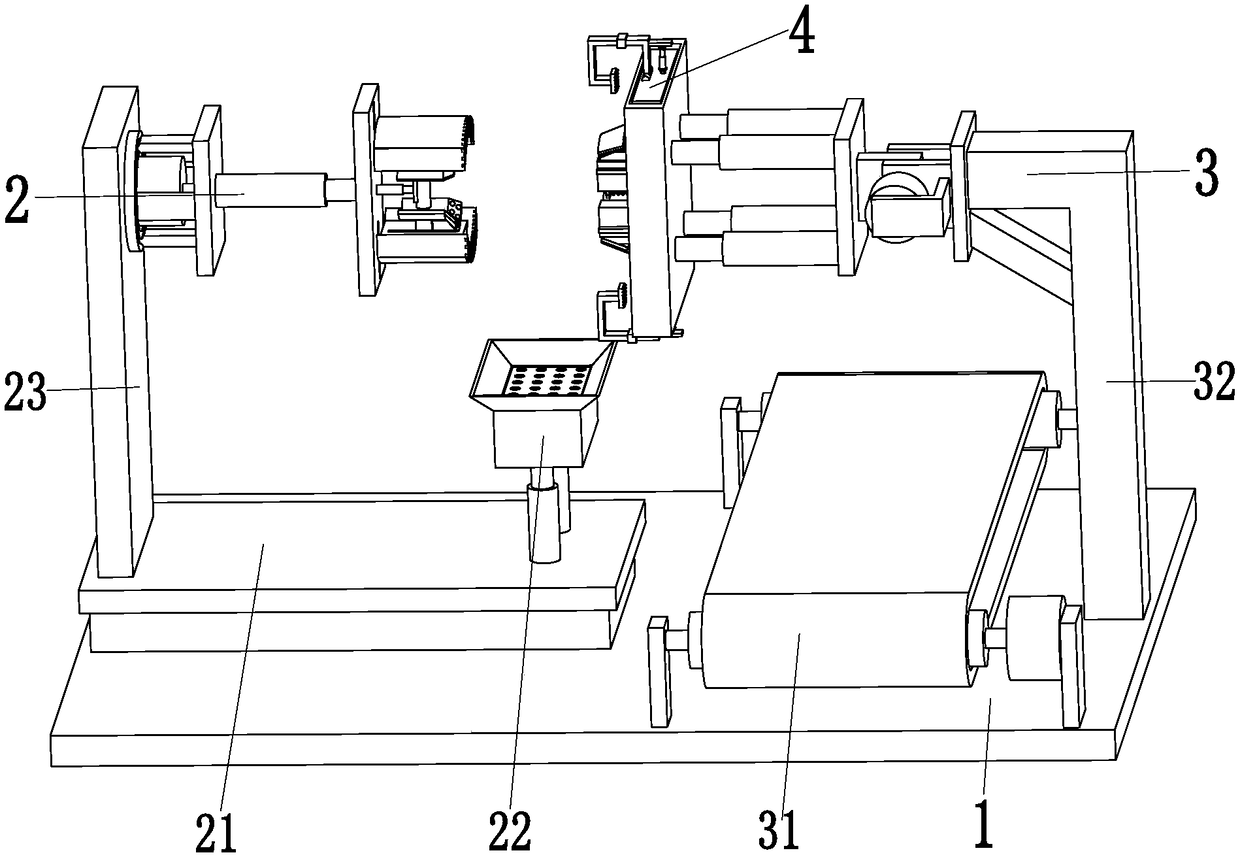

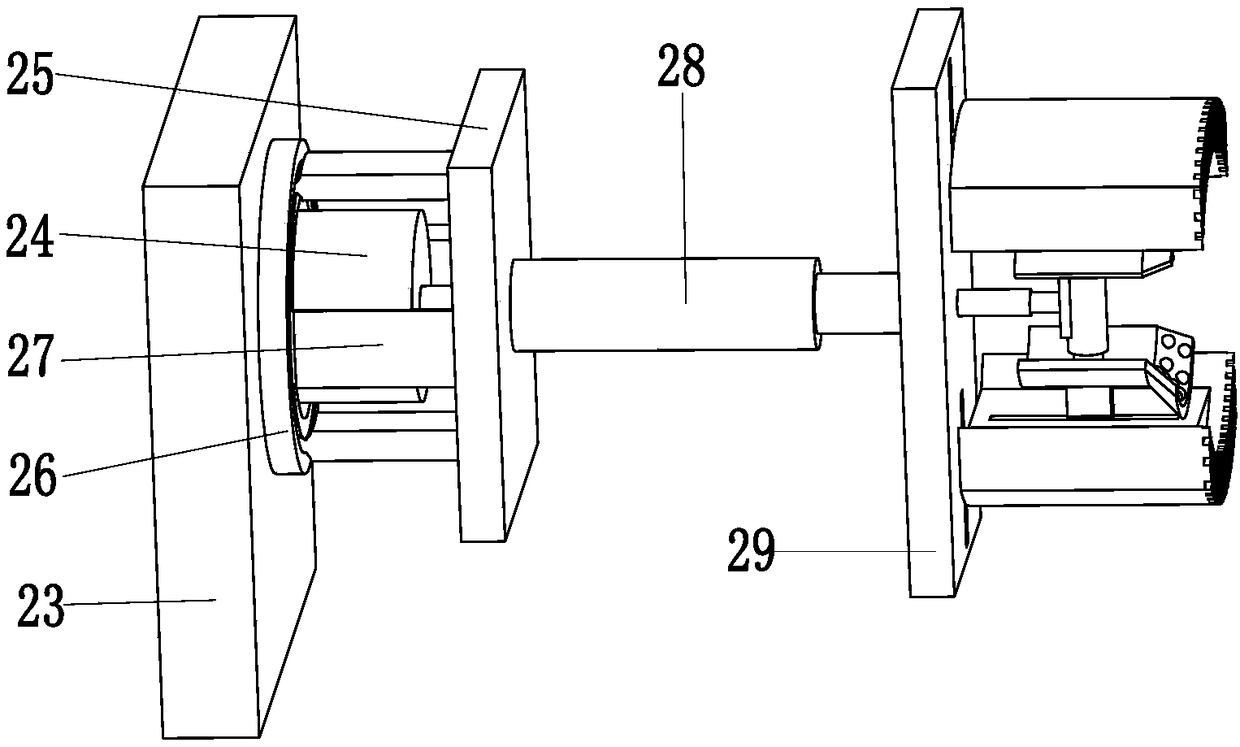

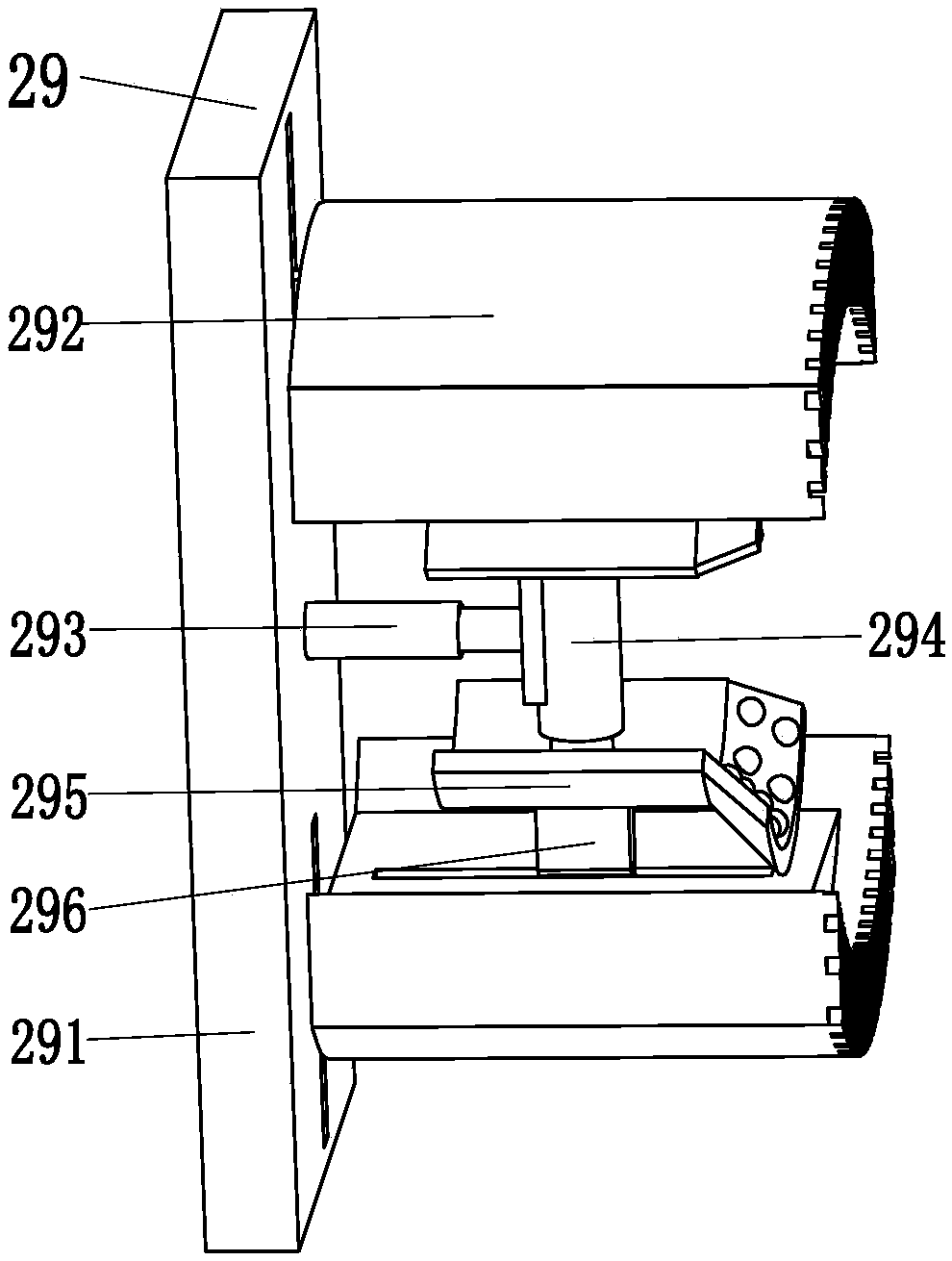

InactiveCN108838776AImprove grinding effectPhysical health effectsGrinding carriagesGrinding work supportsEngineeringLithium-ion battery

The invention relates to a lithium ion battery end portion grinding device. The lithium ion battery end portion grinding device comprises a supporting bottom plate, a grinding device body, a transmission adjusting device and a fixing device. The grinding device body is arranged on the top of the left end of the supporting bottom plate. The transmission adjusting device is arranged on the top of the right end of the supporting bottom plate. The fixing device is connected with the upper end of the transmission adjusting device. The grinding device body comprises a grinding supporting table, a dust suction mechanism, a grinding side plate, a grinding motor, a grinding rotation plate, a grinding sliding groove, a grinding sliding frame, a grinding push rod and a grinding mechanism. The lithiumion battery end portion grinding device can solve the problems that when grinding is conducted on lithium battery end portion cover plates at present, the cover plates cannot be fixed according to the structure characteristics of the cover plates, different clamps are needed for the different types of cover plates, the position of a grinding block needs to be adjusted when the different types ofcover plates are ground, the lithium battery cover plate grinding effect is poor, and dust generated due to grinding cannot be automatically sucked.

Owner:ZHEJIANG GODSEND POWER TECH

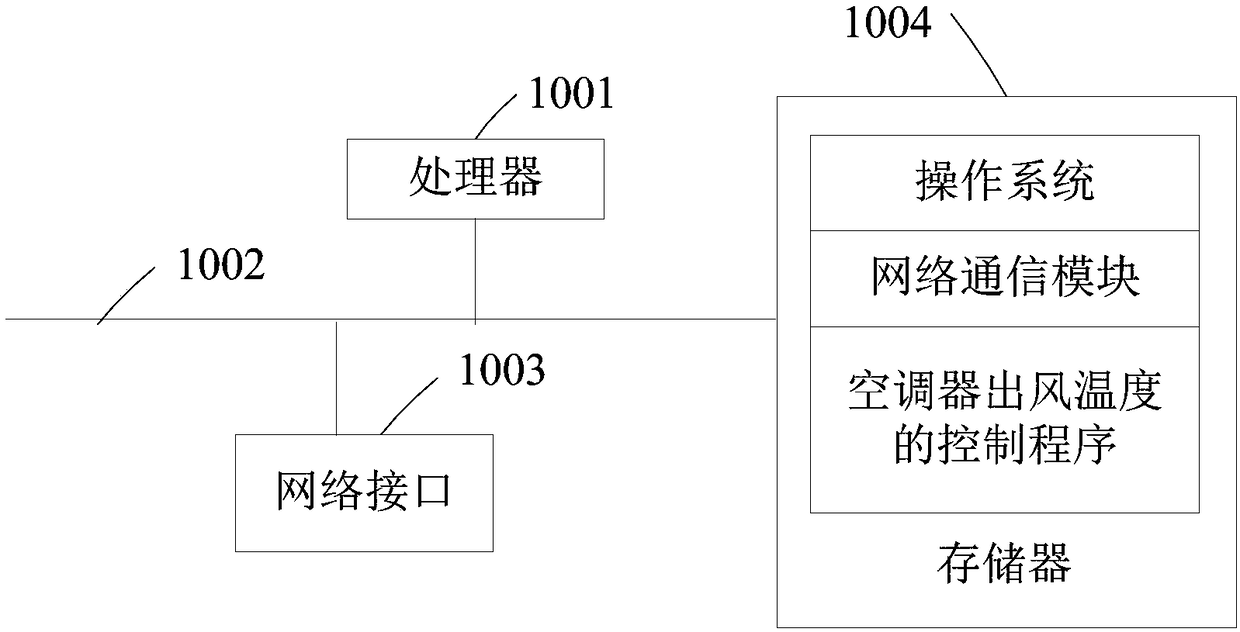

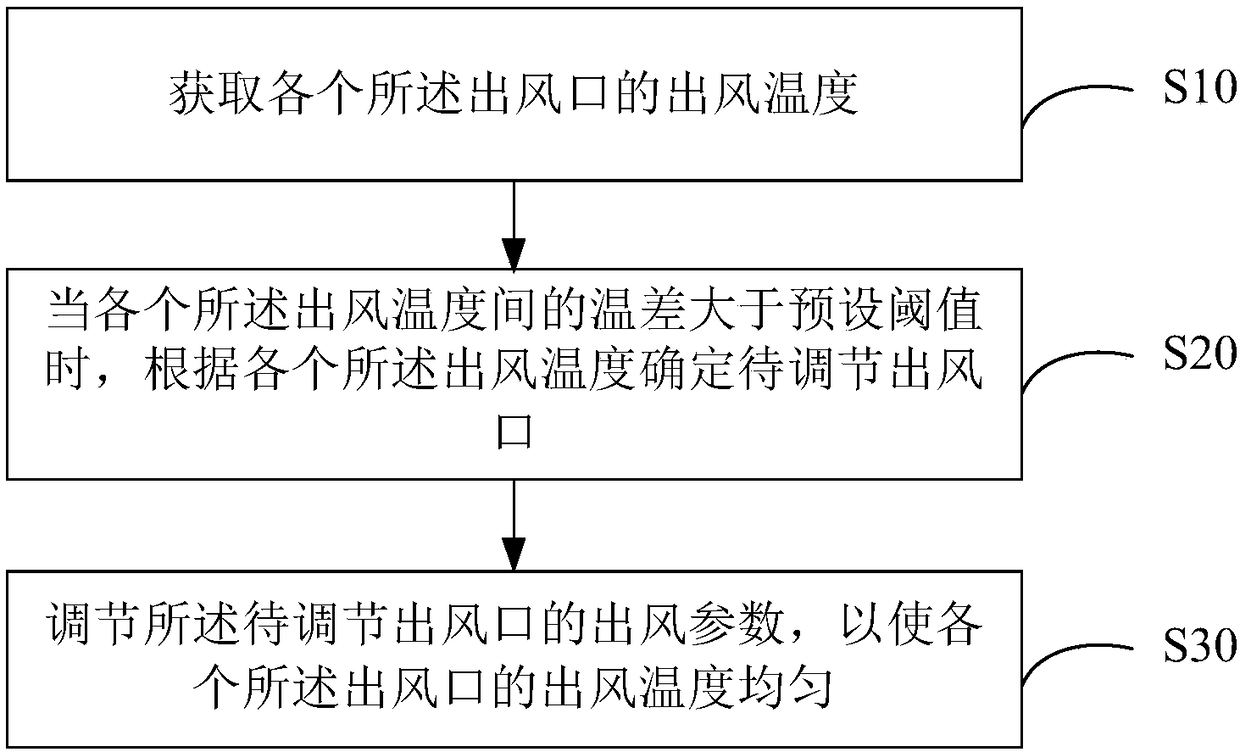

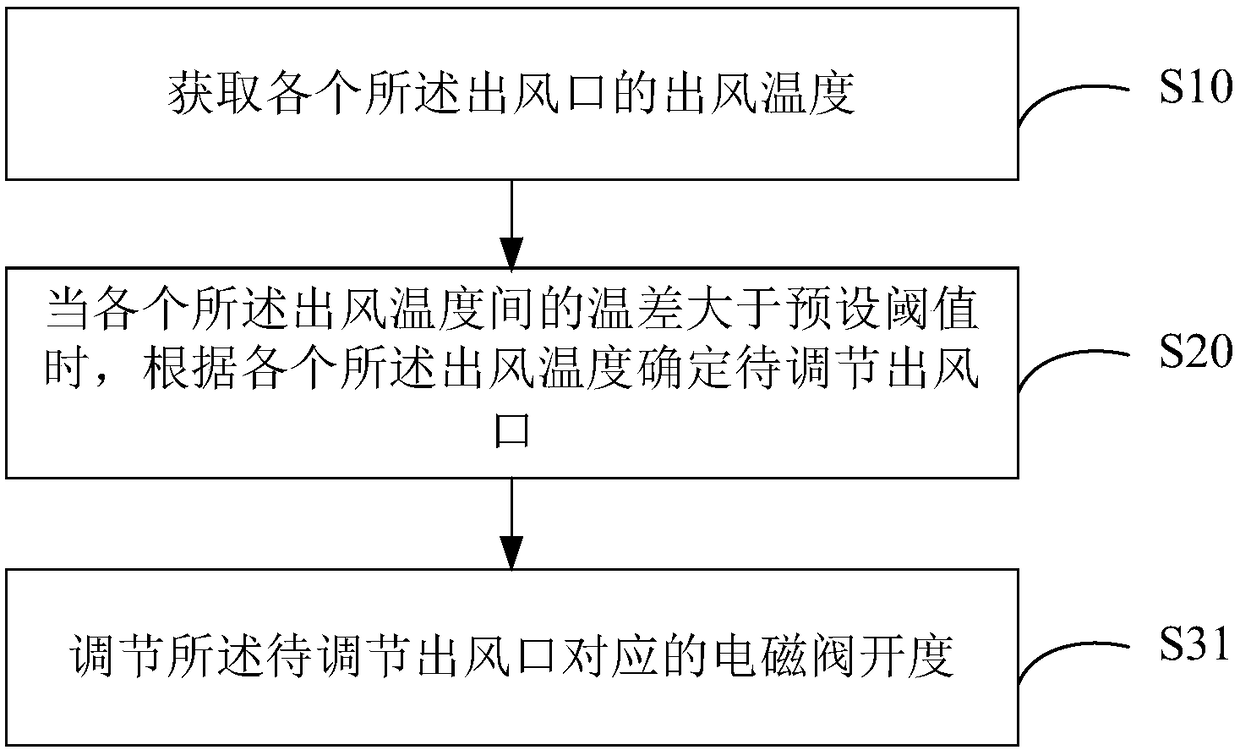

Outlet air temperature control method for air conditioner, and air conditioner

InactiveCN108592328APhysical health effectsImprove comfortMechanical apparatusSpace heating and ventilation safety systemsEngineeringAir temperature

The invention discloses an outlet air temperature control method for an air conditioner. The air conditioner comprises a plurality of air outlets; each air outlet is provided with a temperature sensor; the outlet air temperature control method for the air conditioner comprises the following steps: acquiring the outlet air temperature of each air outlet; determining the to-be-regulated air outlet according to each outlet air temperature if the difference of all outlet air temperature values is larger than a preset threshold value; and regulating the air output parameters of the to-be-regulatedair outlet to make sure that the outlet air temperature of each air outlet is uniform. The invention further discloses the air conditioner. According to the air conditioner, the to-be-regulated air outlet is determined according to the outlet air temperature of each air outlet; the air output parameters of the to-be-regulated air outlet are regulated to make sure that the outlet air temperature ofeach air outlet of the air conditioner is uniform, and thus the influences on body health of a user are prevented, and the comfort level of the user is increased.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

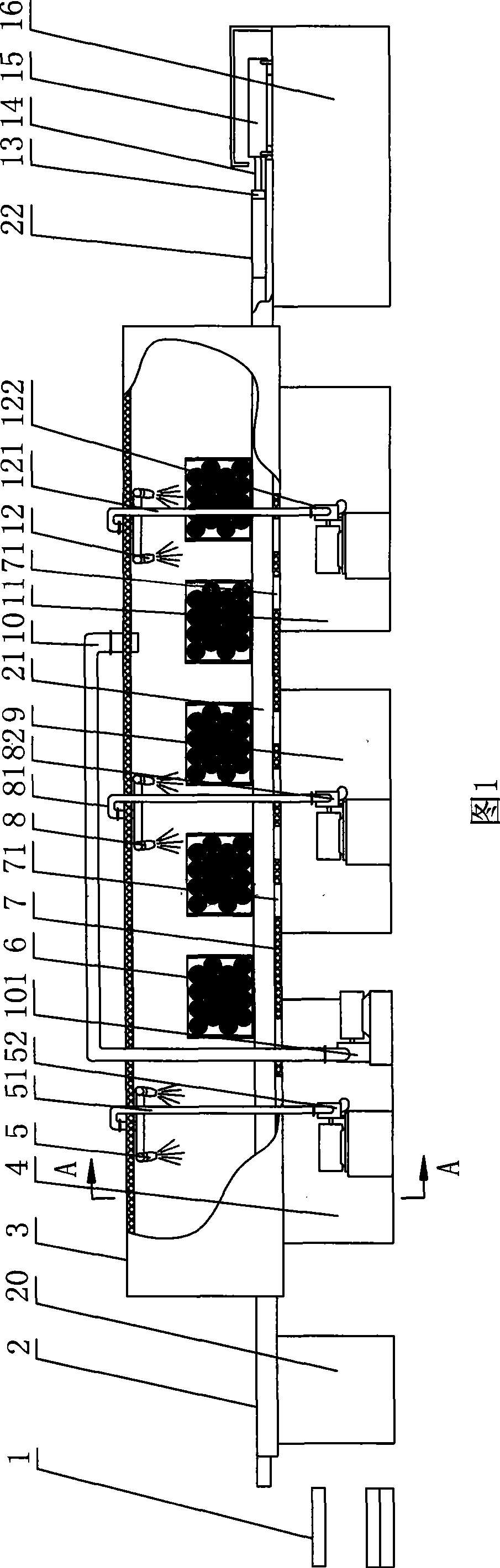

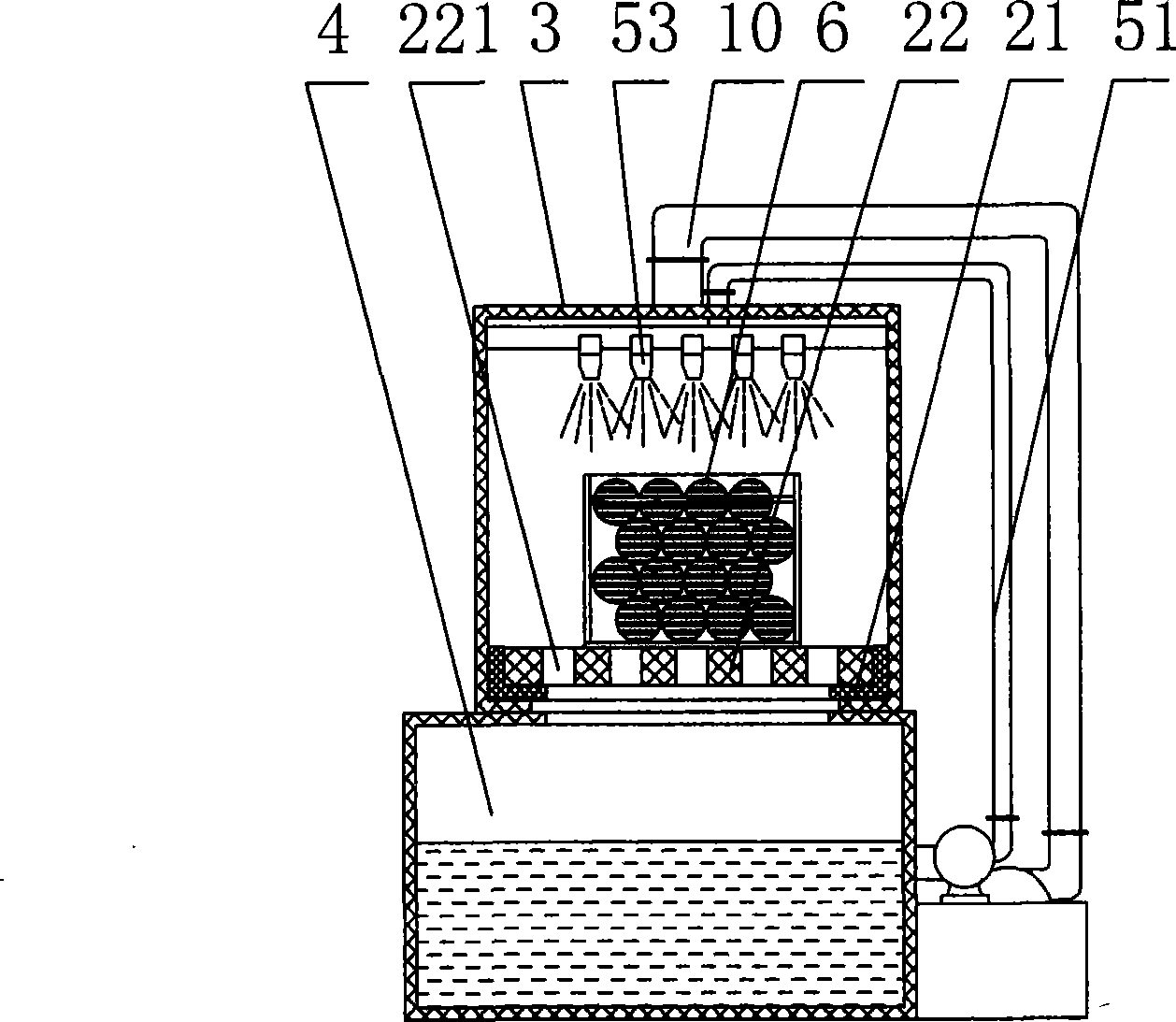

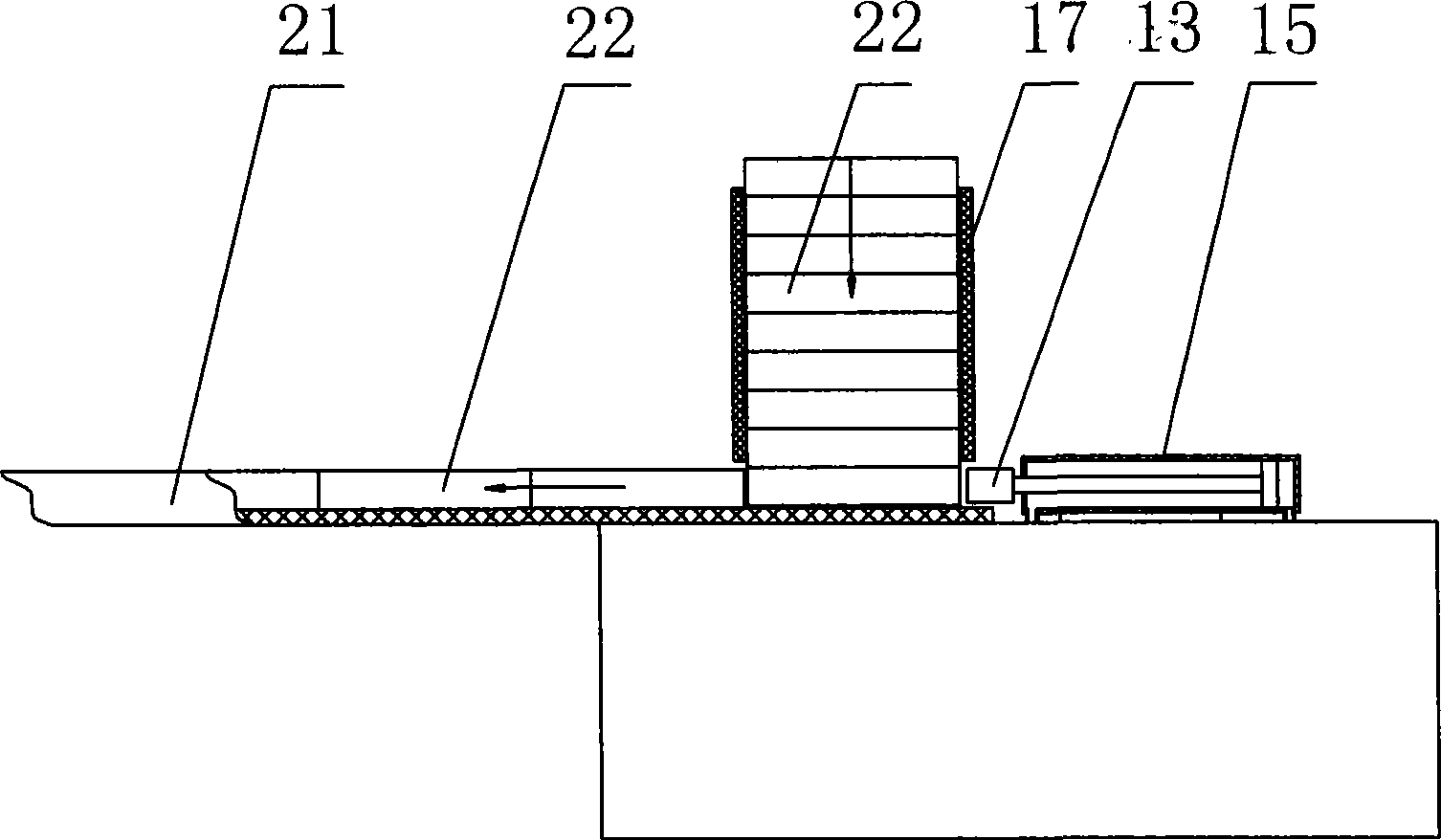

Device for cleaning vanadium-removing copper wire balls

ActiveCN101444781ANo effect on healthPhysical health effectsConveyorsCleaning using liquidsCopper wireSpray nozzle

A device for cleaning vanadium-removing copper wire balls comprises a tunnel, a copper wire ball conveying mechanism which is arranged at the bottom of the tunnel and passes through the entire tunnel, and a suction tube which is arranged at the top of the tunnel and connected with a vacuum pump. An acid cleaning spray nozzle set, a rough cleaning spray nozzle set and a fine cleaning spray nozzle set are sequentially arranged on the inner wall of the tunnel from the inlet of the tunnel, and an acid cleaning liquid storage tank, a rough cleaning liquid storage tank and a fine cleaning liquid storage tank are sequentially arranged below the copper wire ball conveying mechanism in the positions corresponding to the spray nozzle sets. The acid cleaning spray nozzle set, the rough cleaning spray nozzle set and the fine cleaning spray nozzle set are all connected with a high-pressure hydraulic pump via pipelines, and the high-pressure hydraulic pump is correspondingly connected with acid cleaning liquid storage tank, the rough cleaning liquid storage tank and the fine cleaning liquid storage tank. The entire cleaning process is enclosed and mechanized; and during the cleaning process, no irritant gases are discharged and an operator does not directly contact the copper wire balls, so as not to affect the health of the operator.

Owner:仙桃市中星电子材料有限公司

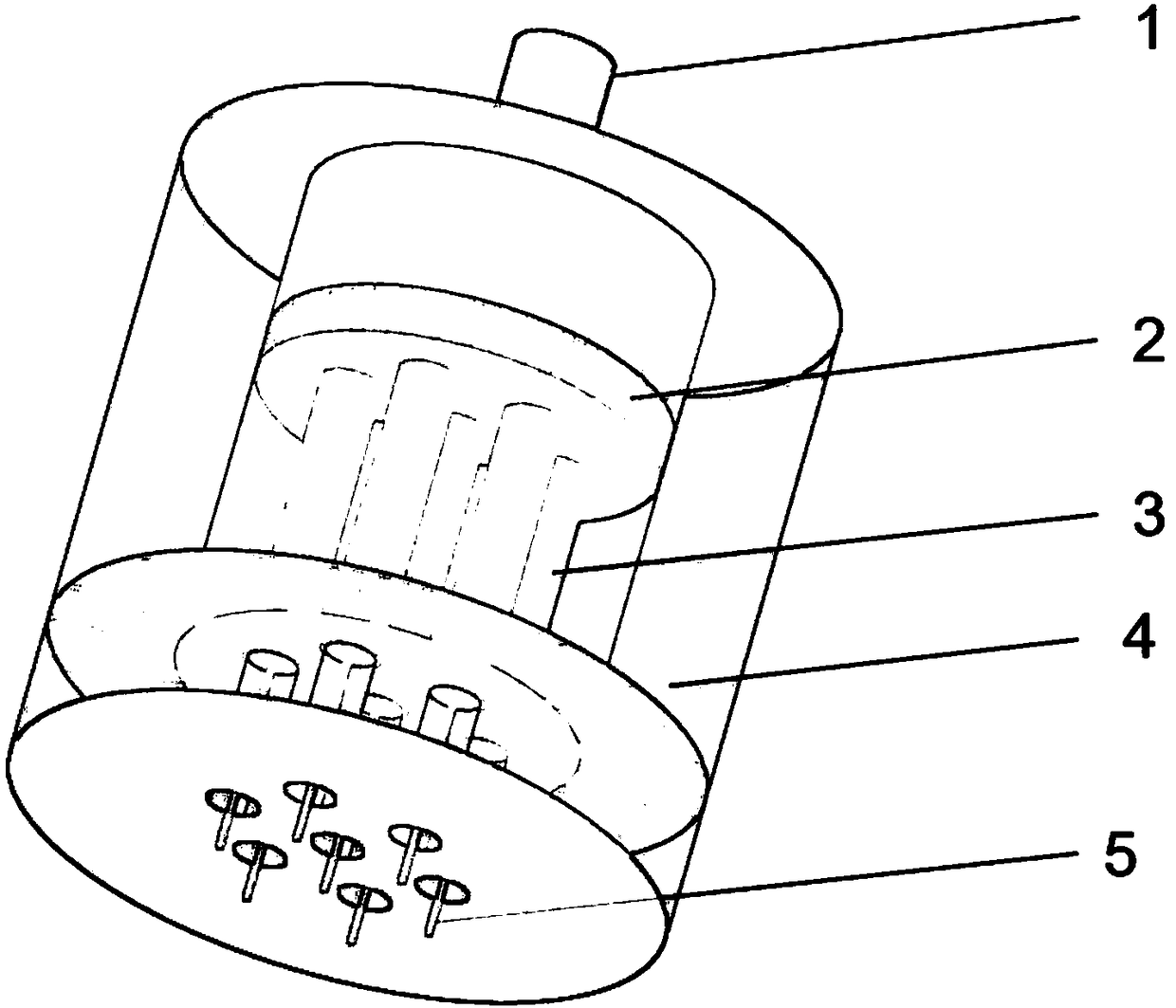

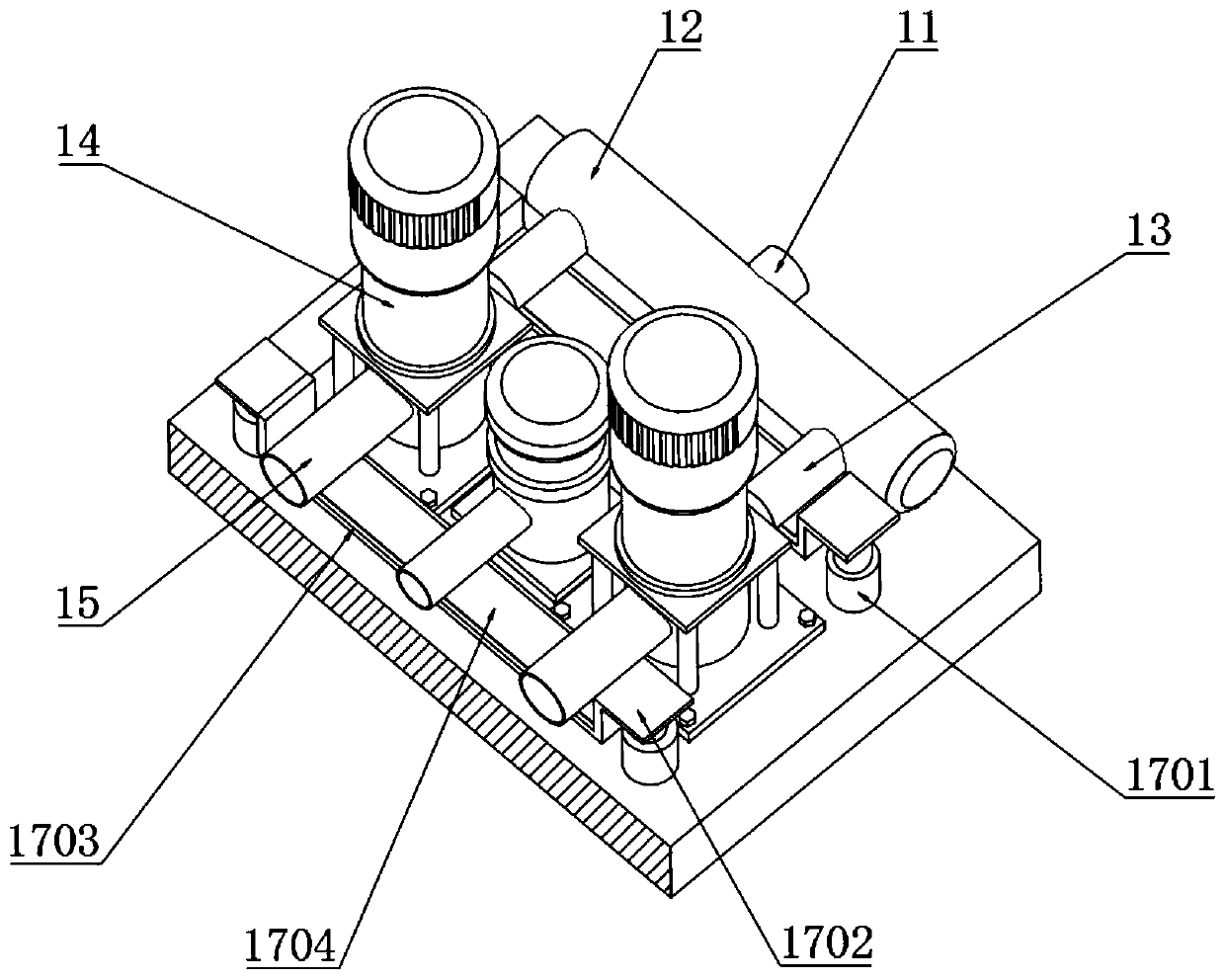

Plasma activated oil treatment device

InactiveCN109121278AHigh active oxygen contentImprove disinfection and sterilizationPlasma techniqueCurrent limitingNeedle electrode

The invention discloses a device for preparing plasma activated oil. The device comprises a discharge module and an annular grounding device which are oppositely arranged in the axial direction from the top to the bottom. A gap is arranged between the discharge module and the annular grounding device. The annular grounding device is internally provided with a cavity for storing the oil liquid. Thegap is communicated with the cavity. The discharge module comprises a metal base, multiple current limiting resistors and multiple corresponding metal needle electrodes from the top to the bottom. The first ends of the current limiting resistors are arranged on the bottom surface of the metal base, and the second ends are connected with the rear ends of the metal needle electrodes. The front endsof the metal needle electrodes are opposite to the annular grounding device. The device can produce low temperature plasma at the atmospheric pressure, and the plasma can directly process the activated oil so that the required time is shorter, the power consumption is lower and the device more environment-friendly.

Owner:HUAZHONG UNIV OF SCI & TECH

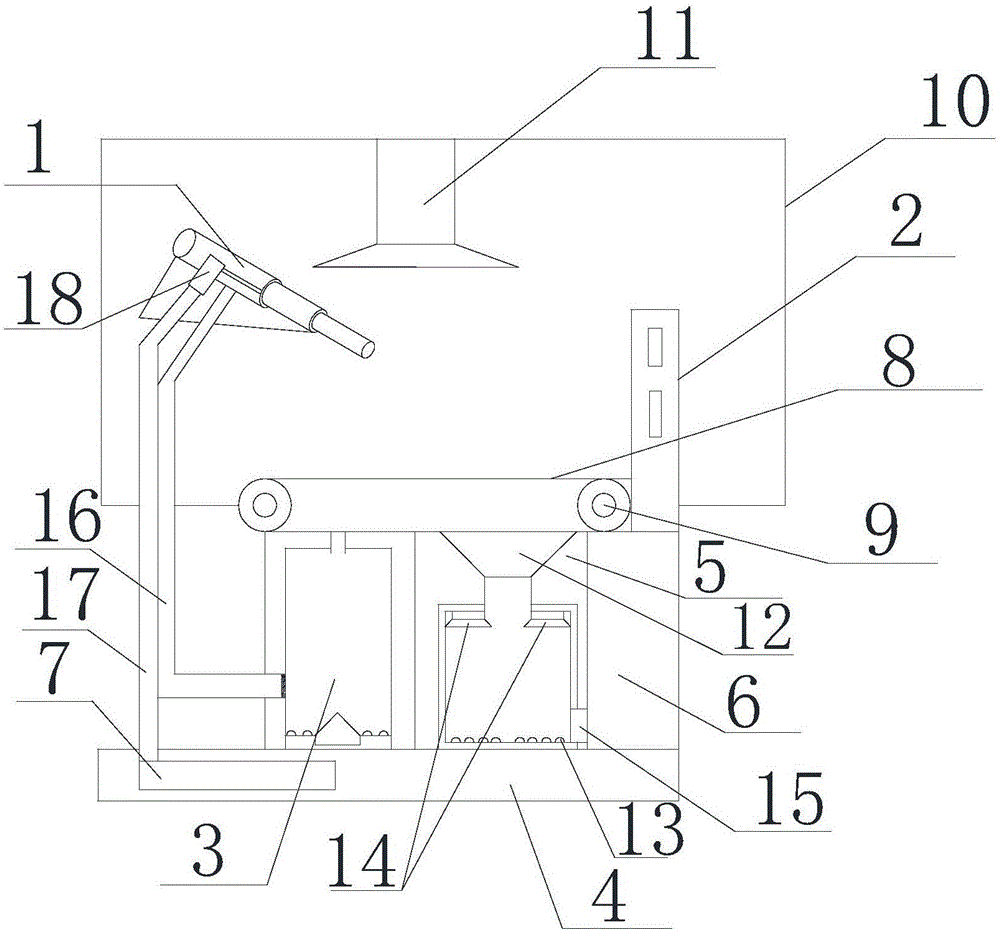

Energy-saving gas stove

ActiveCN101825295AImprove combustion efficiencyImprove efficiencyDomestic stoves or rangesCombustion processExhaust fumesProcess engineering

The invention discloses an energy-saving gas stove, which comprises a gas stove body, a combustor, a gas guide pipe and a gas mixing chamber, wherein the gas guide pipe is communicated with the gas mixing chamber and the combustor is communicated with the upper part of the gas mixing chamber. The gas stove additionally comprises an isolation hood, a waste gas exhaust pipe, an air guide pipe and a heat exchange device, wherein the isolation hood isolates combustion hot gas from the outside and the heat exchange device is used for heat exchange between incoming cold air and exhausted hot waste gas. The invention has the advantages that not only the gas is combusted more fully but also the thermal efficiency is effectively improved because heat contained in the waste gas produced during combustion is used for preheating the cold air participating in combustion, and the impact on body health caused by the waste gas is effectively avoided because the waste gas is fully exhausted. Moreover, since the heat generated by the gas in the closed gas combustion chamber is not rapidly dissipated around, the thermal efficiency of the gas stove is promoted.

Owner:GUANGDONG DEHE TECH CO LTD

Powder spraying device

InactiveCN106391348AReduce pollutionAvoid spreadingLiquid spraying plantsLiquid surface applicatorsHigh pressureFeeding tube

The invention provides a powder spraying device. The powder spraying device includes a spraying gun, a controller, a powder storage room and a base; the power storage room, a recovery device, and a power supply device are successively arranged on the base from left side to right side; a high voltage static device is arranged in the base; the powder storage room, the recovery device and the power supply device are fixedly connected to an operation table; two rolling wheels are arranged in the operation table; the controller is arranged on the right end of the operation table; the tops of the spraying gun and the controller are connected to a shielding cover; a fan is arranged on the top of the inner side of the shielding cover; the recovery device consists of a powder suction device, pulse blowing nozzles, air blast tubes and a residue powder outlet; a powder feeding tube and a gun tube are connected to the inner part of the spraying gun. The beneficial effects of the invention are that the shielding cover can be fully utilized to effectively prevent powder from spreading outside; the recovery device can effectively recover the spread powder to be reused; and the pollution to an environment can be effectively relieved.

Owner:TIANJIN YUERUN PLASTIC PROD CO LTD

Environmentally-friendly textile machine with functions of shock absorption and cotton flock absorption

PendingCN107575718AImprove practicalityAvoid excessive vibrationNon-rotating vibration suppressionDirt cleaningWater diversionWater pipe

The invention discloses an environmentally-friendly textile machine with functions of shock absorption and cotton flock absorption. The environmentally-friendly textile machine with the functions of shock absorption and cotton flock absorption comprises a hydraulic expansion link, an exhaust fan, a booster pump, a shock absorption device, a baseplate and a base, wherein the hydraulic expansion link is used for adjusting the height of the baseplate and further realizes the adjustment of the height of a textile machine body, thereby meeting the using requirements of operators with different height; the exhaust fan is used for causing cotton flocks generated in the working process of the textile machine body to enter a pipeline through an absorption cover and further enter a cotton flock collecting tank, thereby avoiding the problem that the cotton flocks generated in the working process of the textile machine body float in the air to cause pollution and affect the physical health of bodies of operators in the workshops; the booster pump is used for causing water in a water storage tank to pass through a water diversion pipe and then be sprayed from an atomizing spray head so as to humidify the cotton flocks floating in the air in the workshops, thereby causing the cotton flocks floating in the air in the workshops to fall on the ground under the action of gravity.

Owner:长兴宝诺纺织科技有限公司

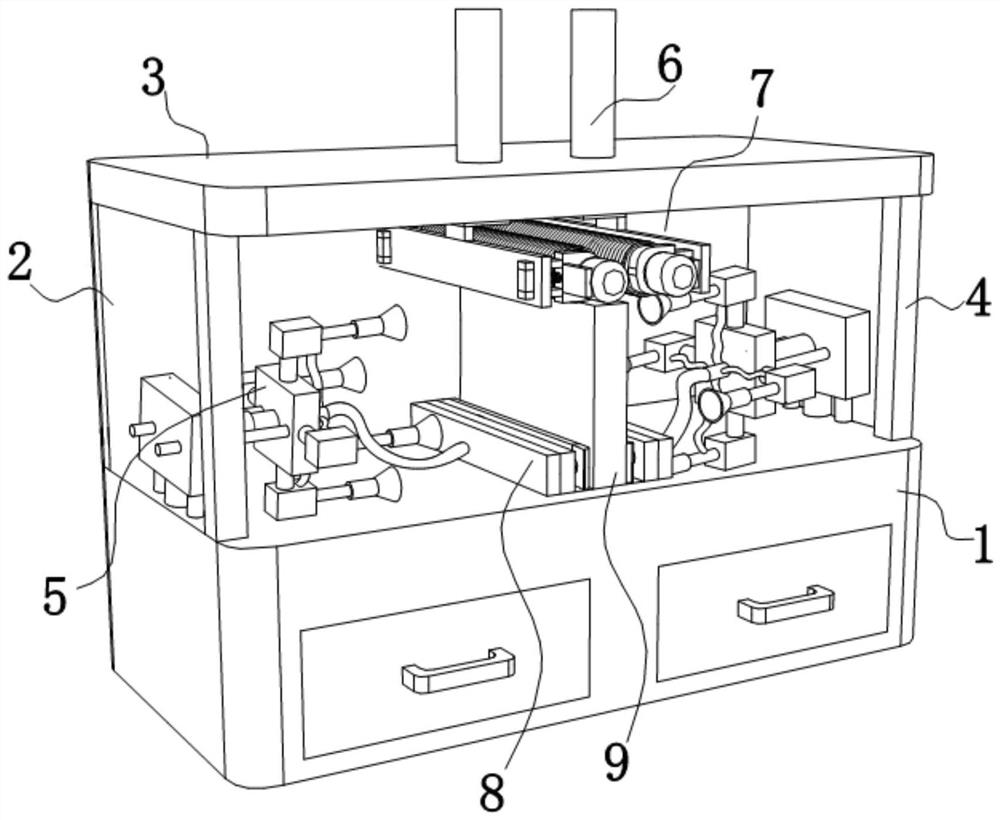

Plasma paint spraying and machining electromechanical equipment

InactiveCN108970884APhysical health effectsImprove work efficiencyMolten spray coatingLiquid spraying apparatusPhysical healthEngineering

The invention discloses plasma paint spraying and machining electromechanical equipment. The plasma paint spraying and machining electromechanical equipment comprises a base; a plurality of supportingrods are arranged at the bottom of the base; a first driving motor is arranged at the bottom of the base; a paint spraying box is arranged at the top of the base; a display screen is arranged on thesurface of the paint spraying box; a box door is arranged below the display screen; an observation port is formed in the box door; a handle is arranged on one side of the observation port; a control box is arranged on one side of the paint spraying box; a rotating plate is arranged at the inner bottom of the paint spraying box; a rotating shaft is arranged at the bottom of the rotating plate; anda sliding rail is arranged at the middle position of the top of the rotating plate. The plasma paint spraying and machining electromechanical equipment has the beneficial effects that the plasma paintspraying and machining electromechanical equipment is reasonable in design and convenient to use; compared with traditional paint spraying and machining, the impact on physical health of staff from paint spraying is lowered, and the working efficiency of the plasma paint spraying and machining electromechanical equipment is improved effectively; and through intelligent machining, human resourcesare saved greatly.

Owner:安徽阳露新型建材有限公司

Aluminum alloy metal part grinding and polishing device

ActiveCN112775777AEffectively fixedEasy to polishGrinding carriagesGrinding drivesStructural engineeringMechanical engineering

The invention belongs to the technical field of aluminum alloy machining equipment, and discloses an aluminum alloy metal part grinding and polishing device which comprises a grinding table and an aluminum alloy plate. Two symmetrically-distributed fixing assemblies are arranged at the top of the grinding table. Each fixing assembly comprises a first hydraulic rod, wherein the mounting end of the first hydraulic rod is arranged at the top of the grinding table, a fixing plate is arranged at the output end of the first hydraulic rod, a first electric telescopic rod is arranged on one side of the fixing plate, a first moving plate is arranged at the output end of the first electric telescopic rod, second electric telescopic rods are arranged on the end face of the periphery of the first moving plate, second moving plates are arranged at the other ends of the second electric telescopic rods, first air guide pipes are arranged at one ends of the second moving plates, and suckers are arranged at the other ends of the first air guide pipes. According to the aluminum alloy plate polishing device, through the arrangement of a polishing assembly, the fixing assemblies and a containing plate, the two side faces of an aluminum alloy plate can be ground at a time, the aluminum alloy plate can be ground and pre-cleaned, and the grinding precision is controlled.

Owner:JIANGXI DONGYANG ALUMINUM CO LTD

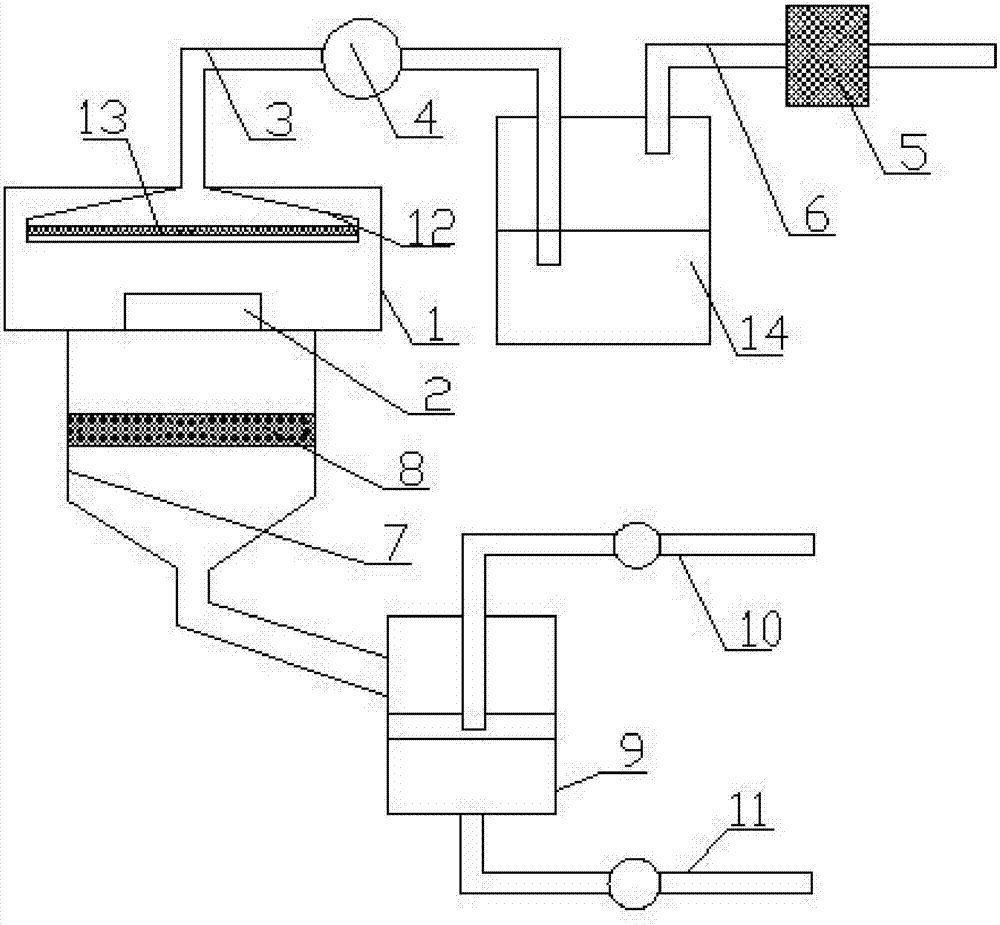

Electrostatic spray coating system

InactiveCN104759368AAvoid runningPrevent overflowLiquid spraying plantsLiquid surface applicatorsSpray nozzleSpray coating

The invention provides an electrostatic spray coating system. The electrostatic spray coating system comprises a working shed, a spray coating system, an electrostatic generator, a recovery system and a carrying device; a spray coating chamber is formed in the working shed, and a feeding hole and a discharge hole are formed in the two sides; the spray coating system comprises an atomizing box; the inlet end of the atomizing box is connected with a liquid inlet pipe, while the outlet end of the atomizing box is connected with a nozzle in the spray coating chamber; the electrostatic generator is located at the outlet end of the nozzle; the recovery system comprises a recovery box and an exhaust tube; an exhaust fan is arranged on the exhaust tube, and the outlet end of the exhaust tube is communicated with the recovery box; the carrying device is located in the spray coating cavity and grounded. The electrostatic spray coating system is capable of realizing quick and even coating, high in coating quality, high in raw material utilization rate, environmental friendly and pollution-free.

Owner:互美方向(江苏)环保科技有限公司

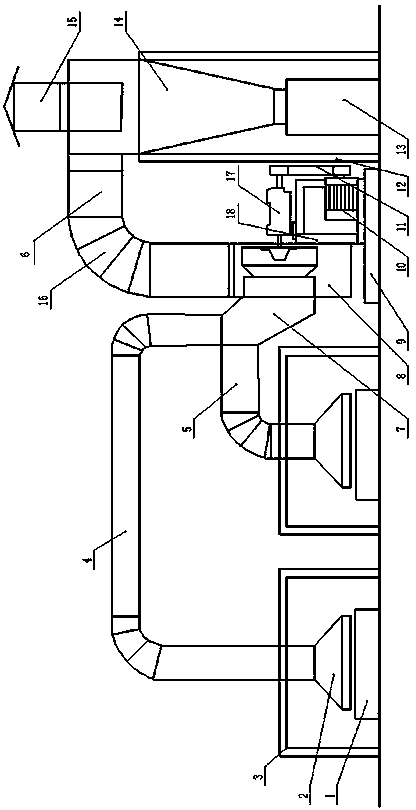

Recycling and disassembling equipment for new energy power battery

InactiveCN106876821AReduce concentrationPhysical health effectsDispersed particle separationWaste accumulators reclaimingLiquid wastePower battery

The invention discloses recycling and disassembling equipment for a new energy power battery. The recycling and disassembling equipment comprises a power battery separation room and a cutting platform which is arranged in the power battery separation room and used for disassembling a new energy power battery; an air exhausting pipeline is arranged on the top of the power battery separation room; the air exhausting pipeline is provided with a pumping fan; the exterior of the air exhausting pipeline is connected with a waste gas dissolving room; an alkali liquid is placed in the waste gas dissolving room; the waste gas dissolving room is connected with an active carbon adsorption room through a drainage connecting pipe; a collecting cabin used for collecting waste slag and waste liquid is arranged below the cutting platform; a filtering net is arranged in the collecting cabin; the collecting cabin is connected with a waste liquid disposal tank through a connecting pipe; an alkali liquid is put in the waste liquid disposal tank; an upper drainage pipe used for extracting an organic phase from the waste liquid disposal tank is arranged on the upper part of the waste liquid disposal tank; and a lower drainage pipe used for extracting an aqueous phase from the waste liquid disposal tank is arranged on the lower part of the waste liquid disposal tank.

Owner:广东纳玛逊科技有限公司

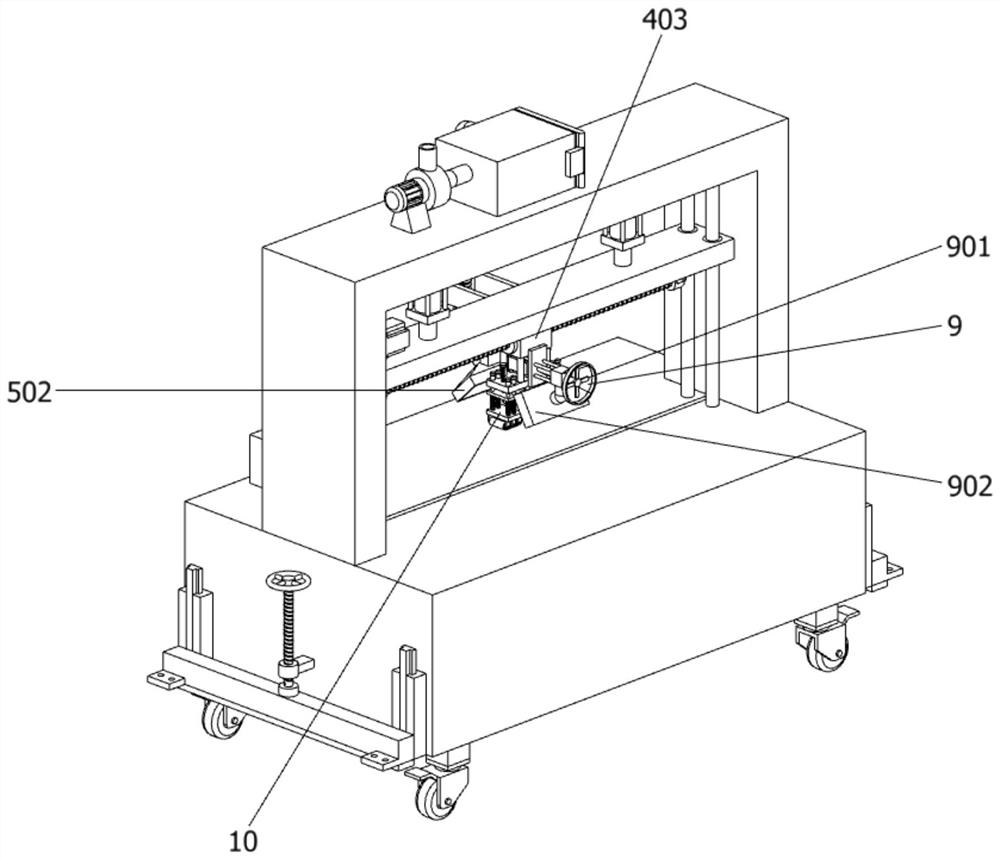

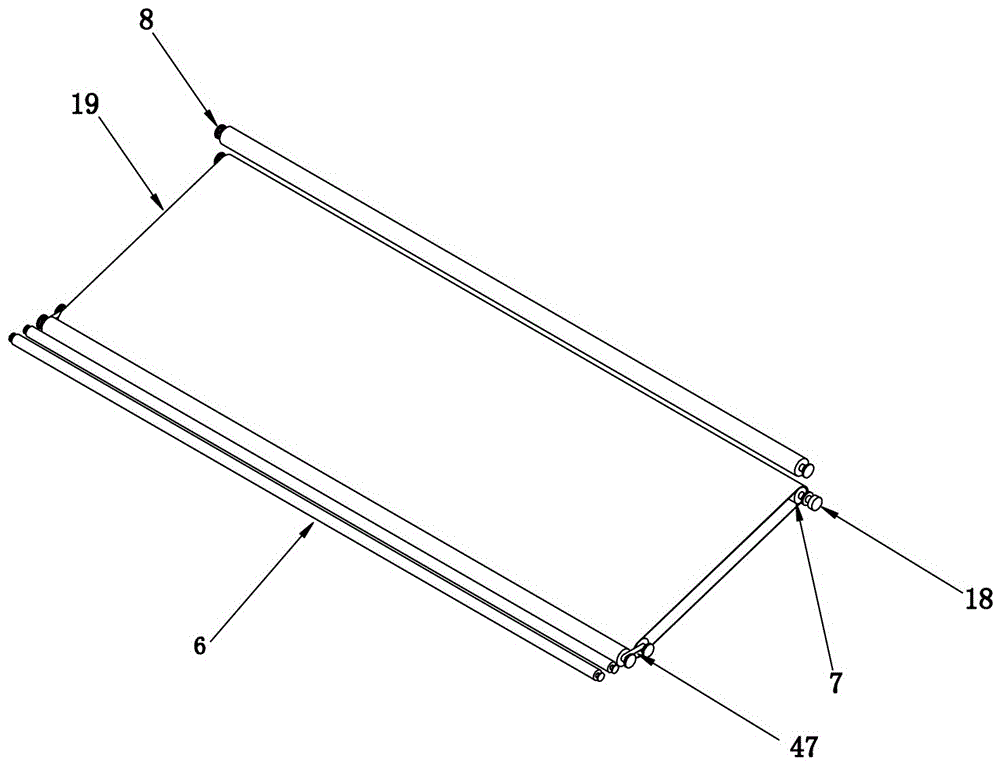

Intelligent new textile material cutting device for spinning

The invention provides an intelligent new textile material cutting device for spinning, belongs to the technical field of textile cutting devices, and aims to solve the problem that when a new textilematerial is cut by the cutting device, the middle of the new textile material is still wrinkled during cutting, so that the cutting quality of the cutting device during cutting is reduced. The cutting device comprises a base; a C-shaped support is fixedly connected to the middle of the upper end face of the base; and a lifting mechanism is arranged at the top of the inner side of the C-shaped support. Through the arrangement of pressing mechanisms, in the cutting process, when a circular cutting blade makes contact with the new textile material, and pressing belts on the two pressing mechanisms make close contact with the upper surface of the new textile material, so that a cutting area of the new textile material is effectively pressed; and when the circular cutting blade moves leftwardsand rightwards, the pressing belts can be driven on the peripheral surfaces of pressing rollers, so that the new textile material cannot be wrinkled during cutting, and the cutting quality of the cutting device during cutting is improved.

Owner:宿州市悦然纺织有限公司

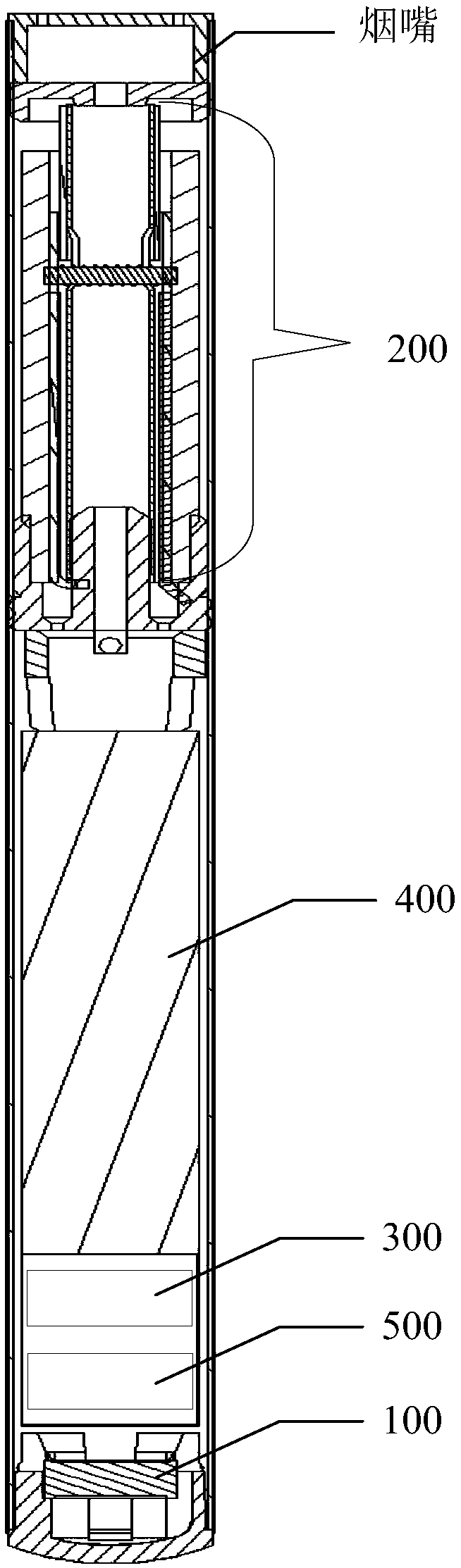

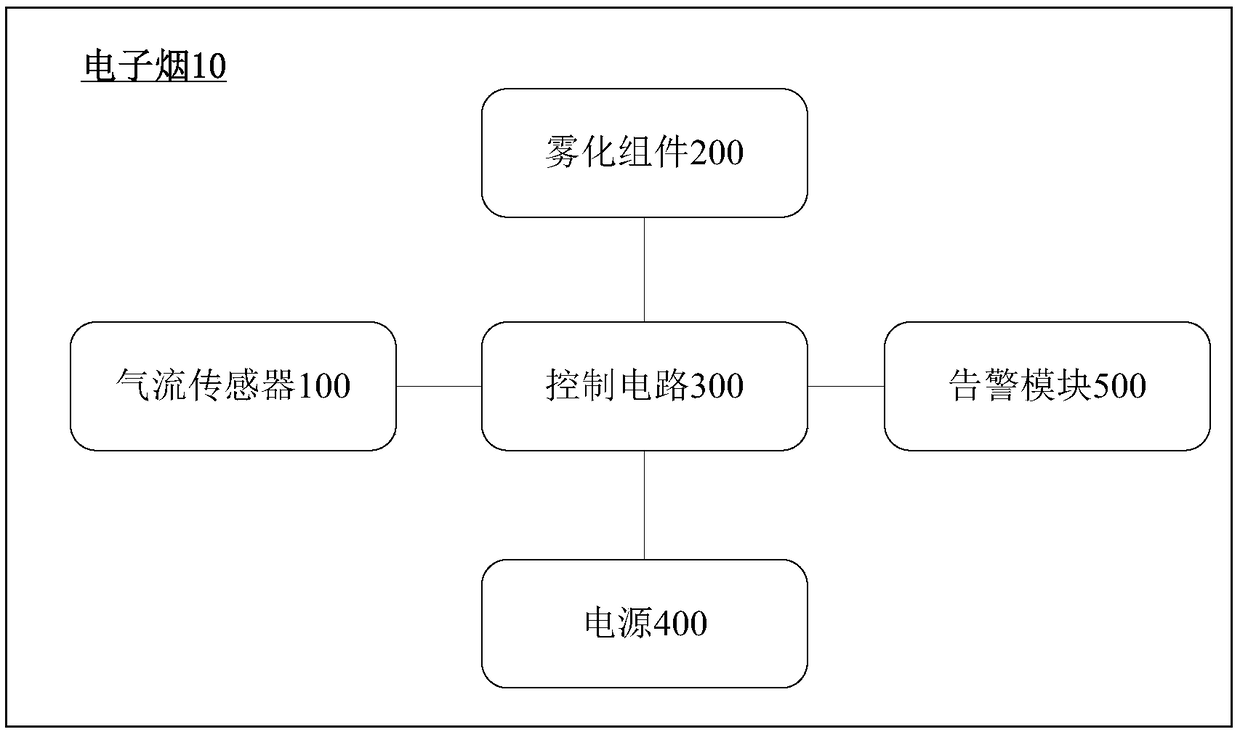

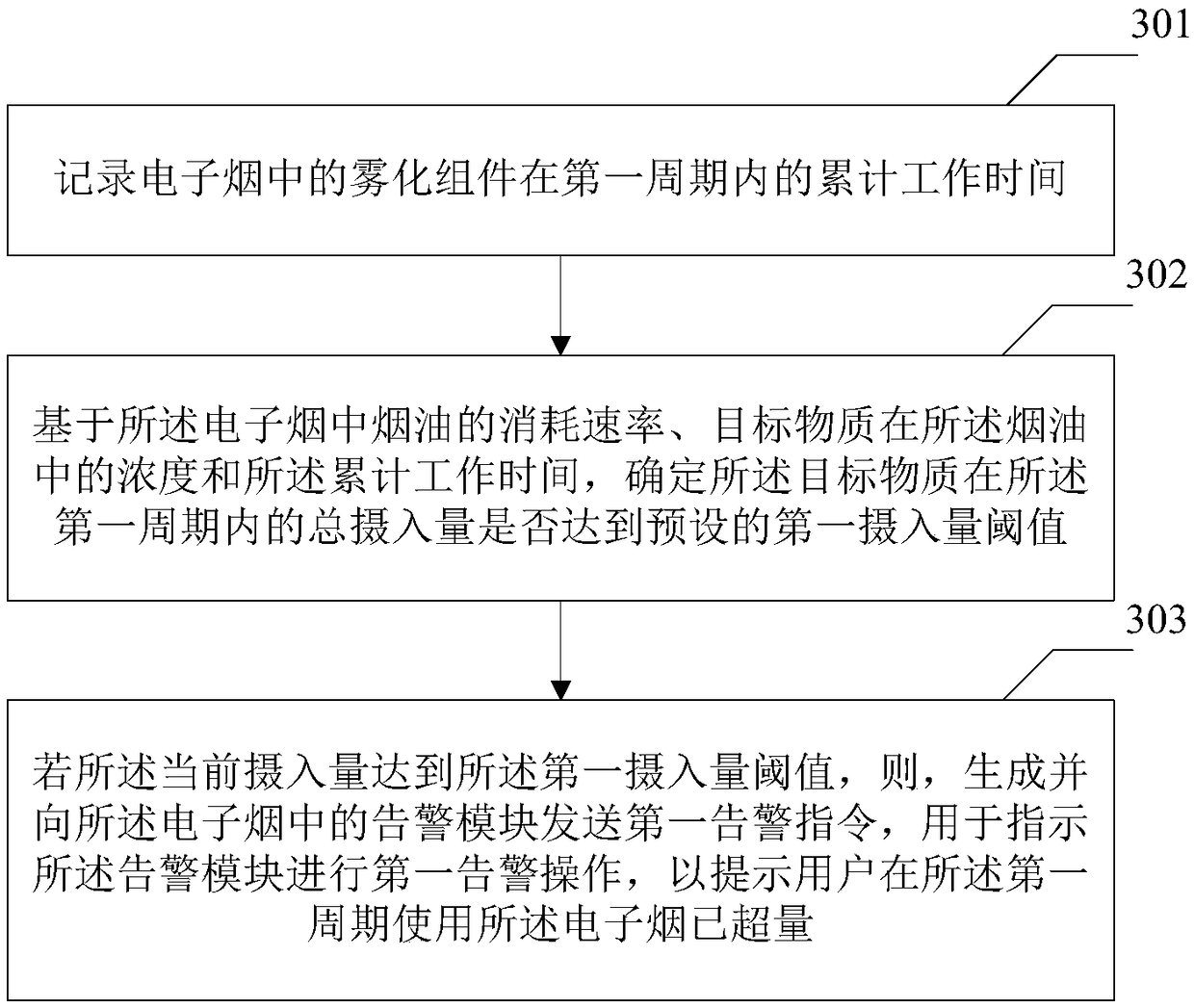

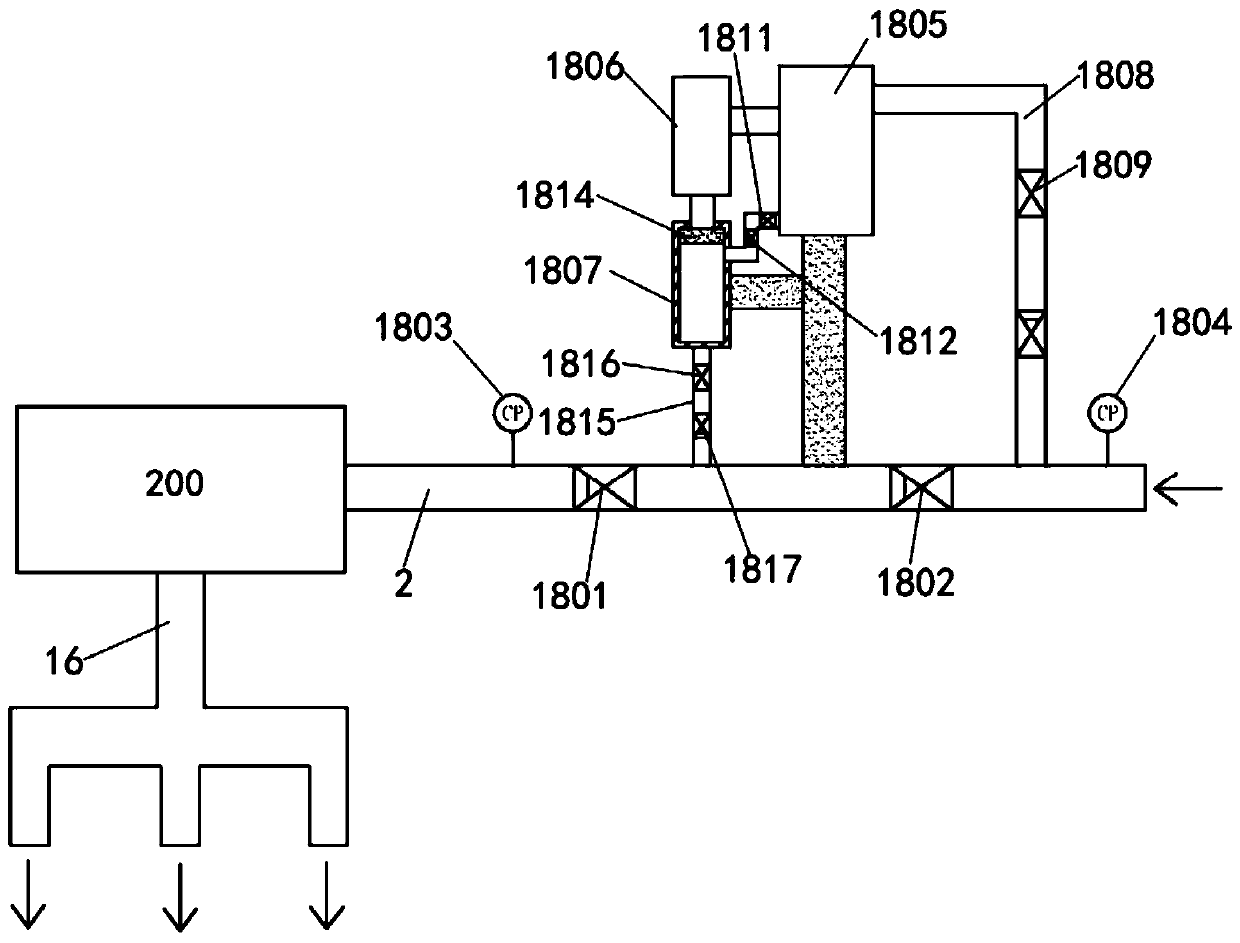

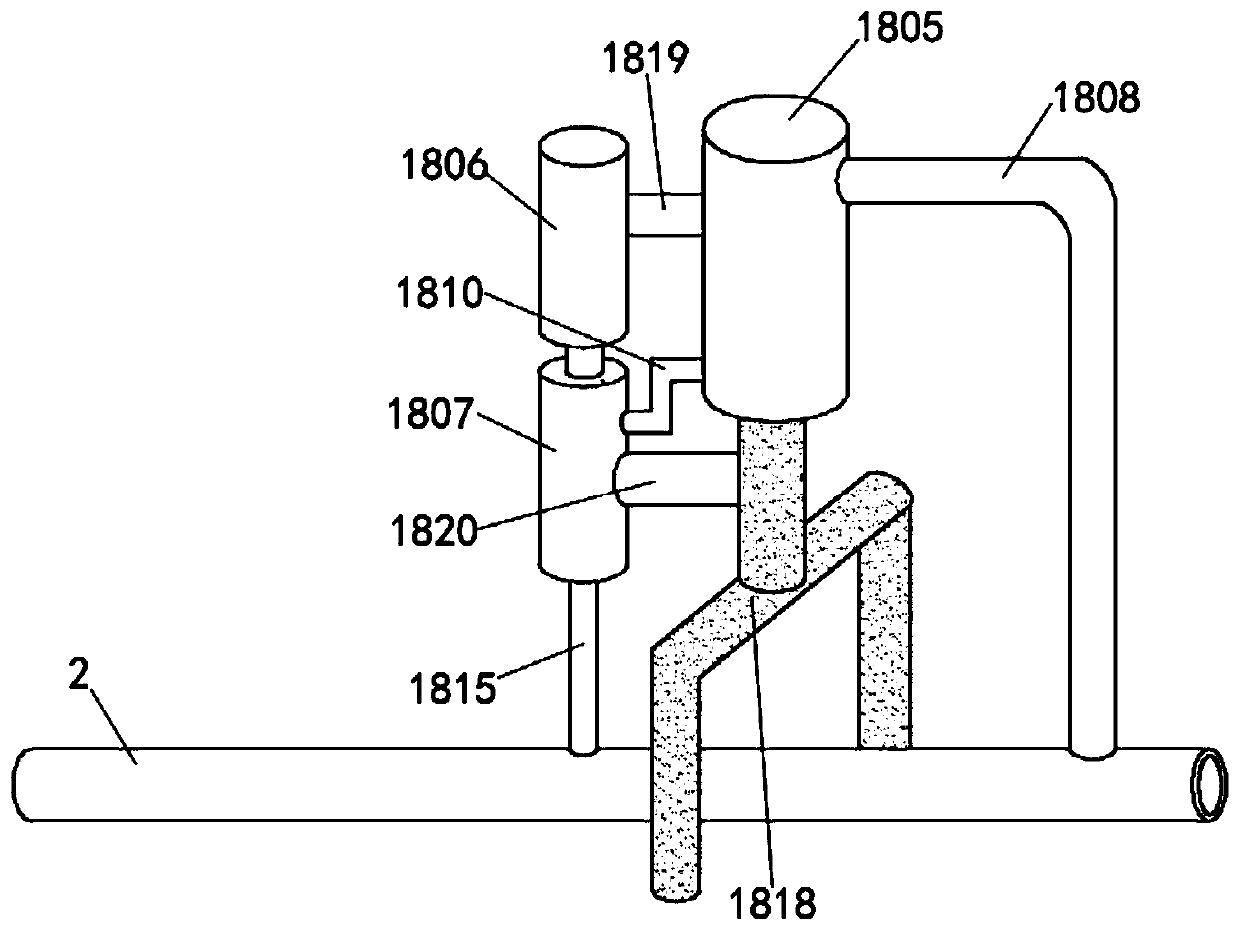

Electronic cigarette and control method and control device thereof

InactiveCN109430947APhysical health effectsImprove experienceTobacco devicesAcceptable daily intakeEngineering

An embodiment of the invention discloses an electronic cigarette and a control method and a control device thereof. The control method includes recording cumulative working time of an atomizing assembly of the electronic cigarette within one week; determining whether the total acceptable daily intake of a target substance reaches the preset first acceptable daily intake or not according to consumption rate of tobacco tar of the electronic cigarette, concentration of the target substance in the tobacco tar and the cumulative working time; if reaching, then generating a first warning instructionand sending the same to a warning module of the electronic cigarette to indicate the warning module to do first warning, thereby reminding users of excessive use of the electronic cigarette in the first period. Therefore, if users smoke too much harmful substance through the electronic cigarette and physical health of the users are affected severely, the warning module can remind the users of theexcessive use of the electronic cigarette within the period in a manner such as vibrating when the acceptable daily intake reaches the preset acceptable daily intake, and accordingly, users' experience in using the electronic cigarette is improved, and excessive use of the electronic cigarette to the users is reduced.

Owner:北京羽衣科技有限公司

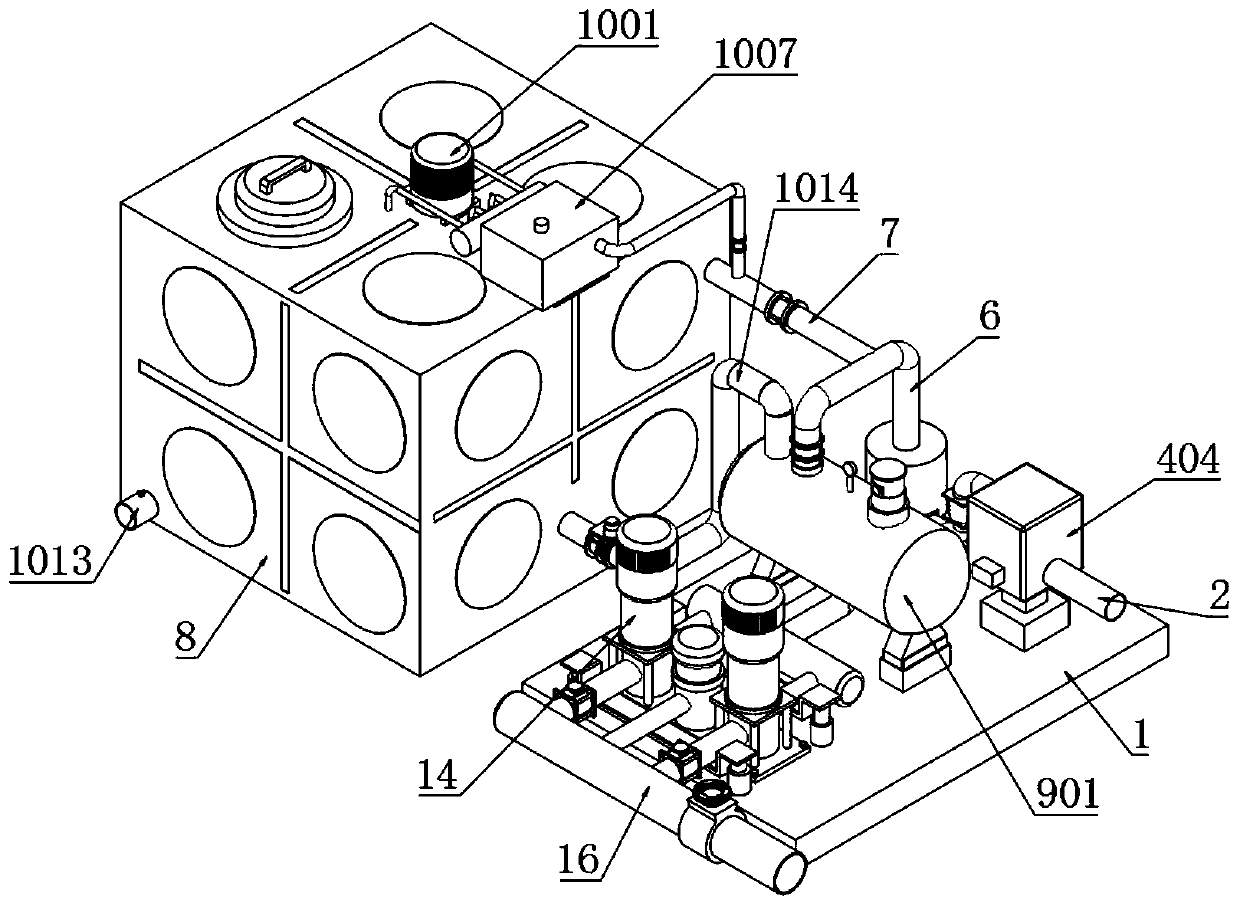

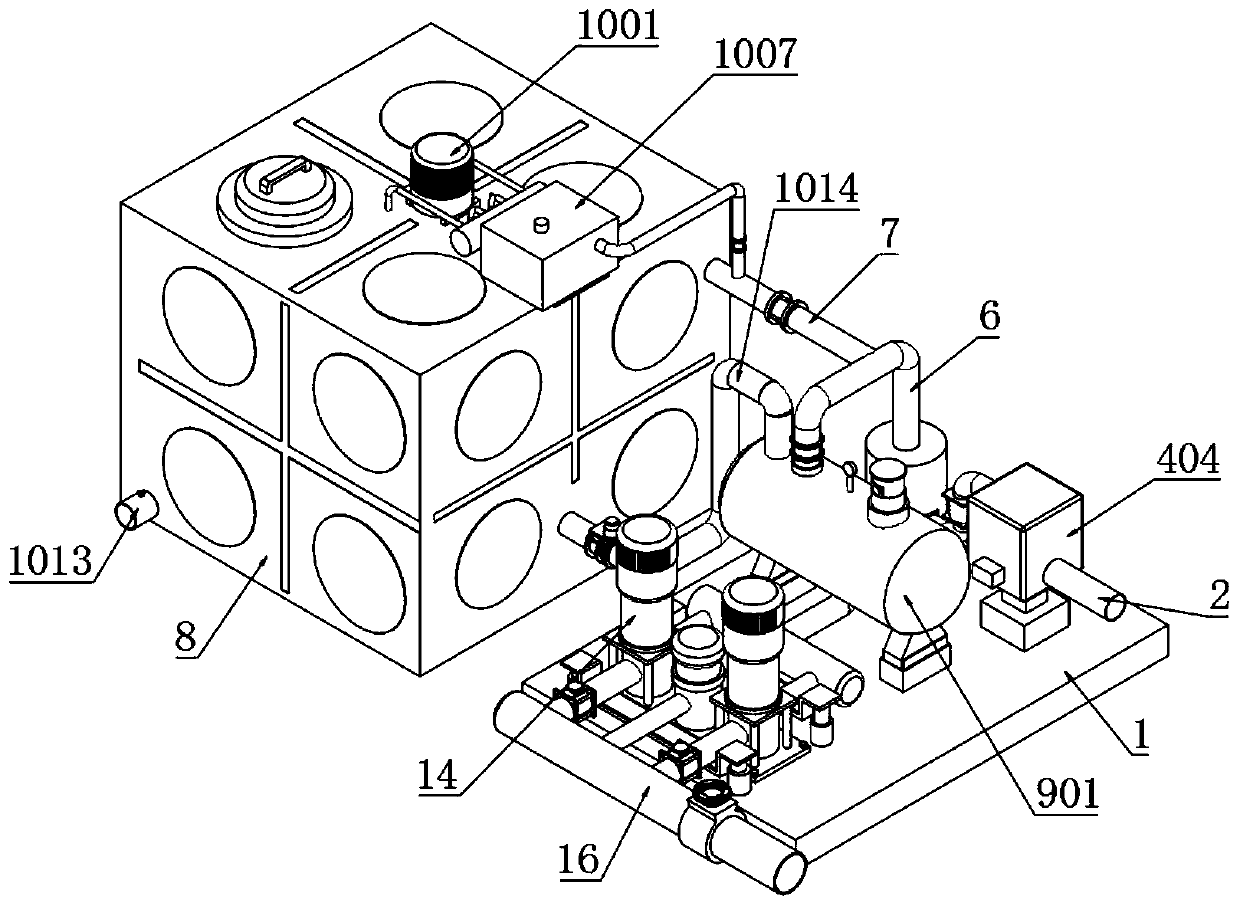

Pressure stabilizing type non-negative pressure water supply system

ActiveCN111561023AScientific and reasonable structureSafe to useWater/sewage treatment by irradiationGeneral water supply conservationWater supply networkPiston

The invention discloses a pressure stabilizing type non-negative pressure water supply system which comprises a water inlet pipe, a water inlet pipe pressure stabilizing device, a water supply power combination device and a water supply pipe. The water inlet pipe pressure stabilizing device is integrally arranged on the water inlet pipe communicated with a municipal tap water pipe, and the water inlet pipe is supplied to all users after being treated and pressurized by the water supply power combination device; the water inlet pipe pressure stabilizing equipment comprises a high-level water tank, a hydraulic cylinder and a pressurizing barrel, the high-level water tank is communicated with the water inlet pipe through an L-shaped pipe, a water replenishing valve is arranged on the L-shapedpipe, the bottom of the high-level water tank is communicated with the pressurizing barrel through a folding pipe, a first electromagnetic control valve and a third check valve are arranged on the folding pipe, and a liquid level sensor is arranged in the high-level water tank; and an output shaft of the hydraulic cylinder is fixedly connected with a piston in the pressurizing barrel, the bottomend of the pressurizing barrel is communicated with the water inlet pipe through a pressurizing pipe, and a second electromagnetic control valve and a fourth check valve are arranged on the pressurizing pipe.

Owner:安徽海沃特水务股份有限公司

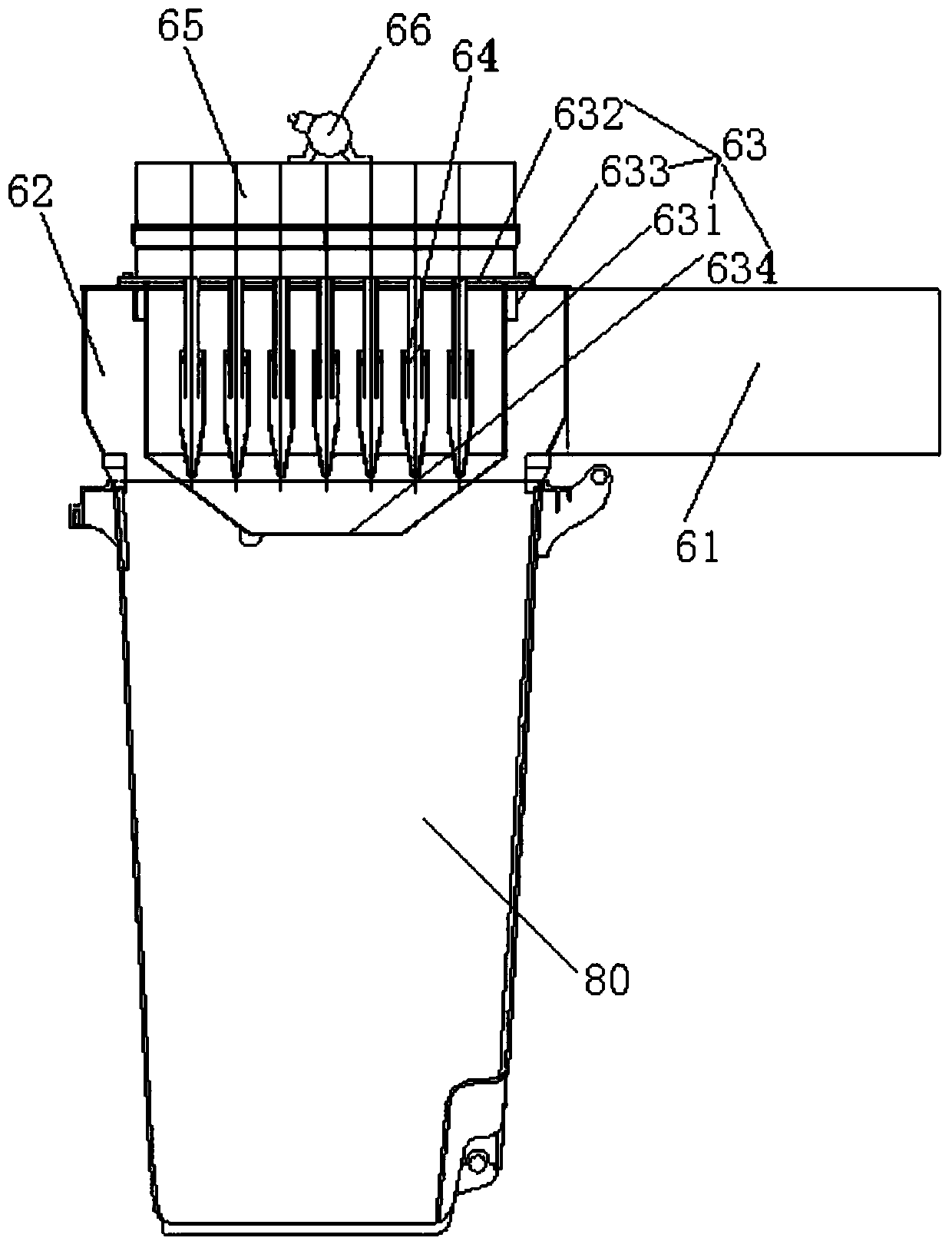

Efficient textile machine dust removing plant

InactiveCN104353287AEnsure cleanlinessImprove efficiencyGas treatmentDispersed particle separationMachine toolTextile

Owner:SUQIAN CITY SUYU DISTRICT ZHUOWEI SILK

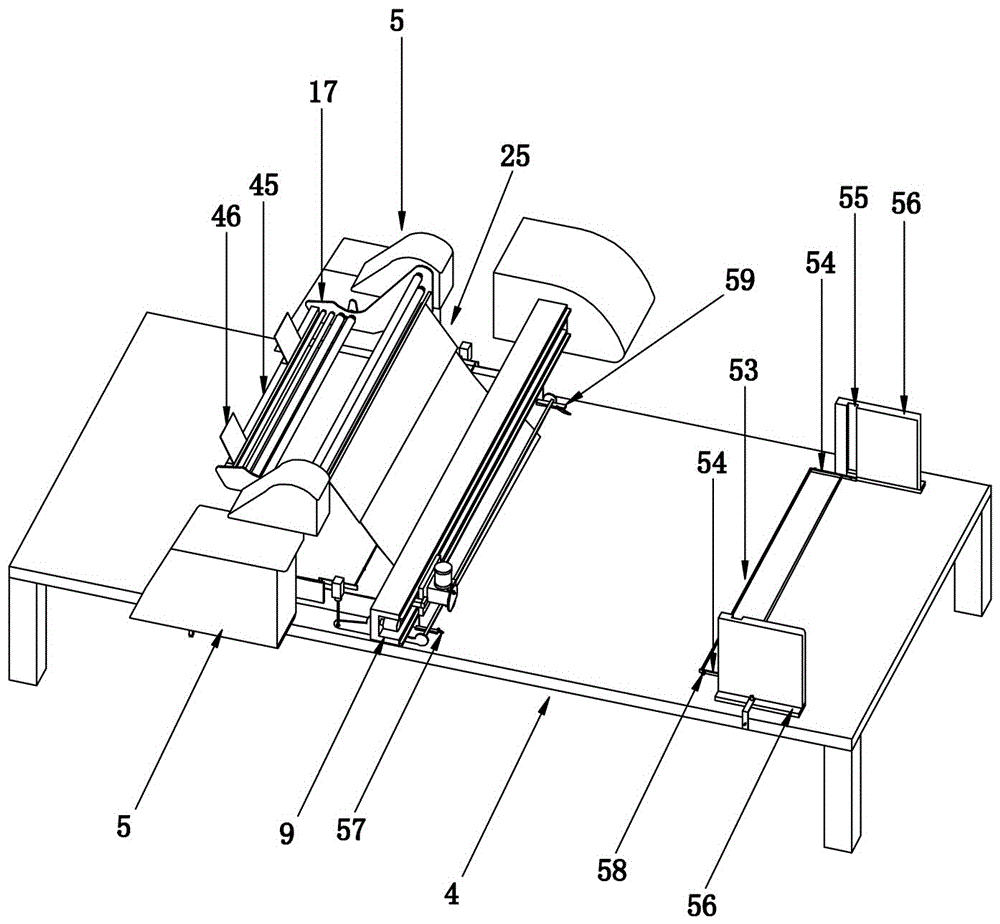

3D polyester fiber mattress production line and mattress production method thereof

ActiveCN106809794AIncrease productivityImprove breathabilityUpholstery manufactureFiberProduction line

The invention provides a 3D polyester fiber mattress production line and a mattress production method thereof. The mattress production line comprises a material laminating machine, a multi-needle quilting machine and a washing and drying machine, wherein the material laminating machine comprises a moving device, a group of conveying rollers, an output roller, a pressing roller, a discharging plate, a pressing device, a cutting assembly, a lifting device and a photoelectric sensor; the multi-needle quilting machine comprises a gantry, a quilting frame, needles, a longitudinal guide rail, a transverse guide rail, a control frame, a control board, a first driving device, a second driving device and a numerical control system; a washing mechanism and a jet drying mechanism are arranged on the washing and drying machine. The mattress production line disclosed by the invention has the beneficial effects that the manual production manner is replaced with a mechanized production manner, and the production efficiency is improved; the traditional glue fixing manner is replaced with a quilting manner, so that the gas permeability of 3D polyester fiber mattresses is enhanced, and any influence to the human body health is avoided. Moreover, with the adoption of the quilting manner, patterns can be formed on the surface of the 3D polyester fiber mattress, and the attractive appearance of the mattress is improved.

Owner:三明通用科技孵化有限公司

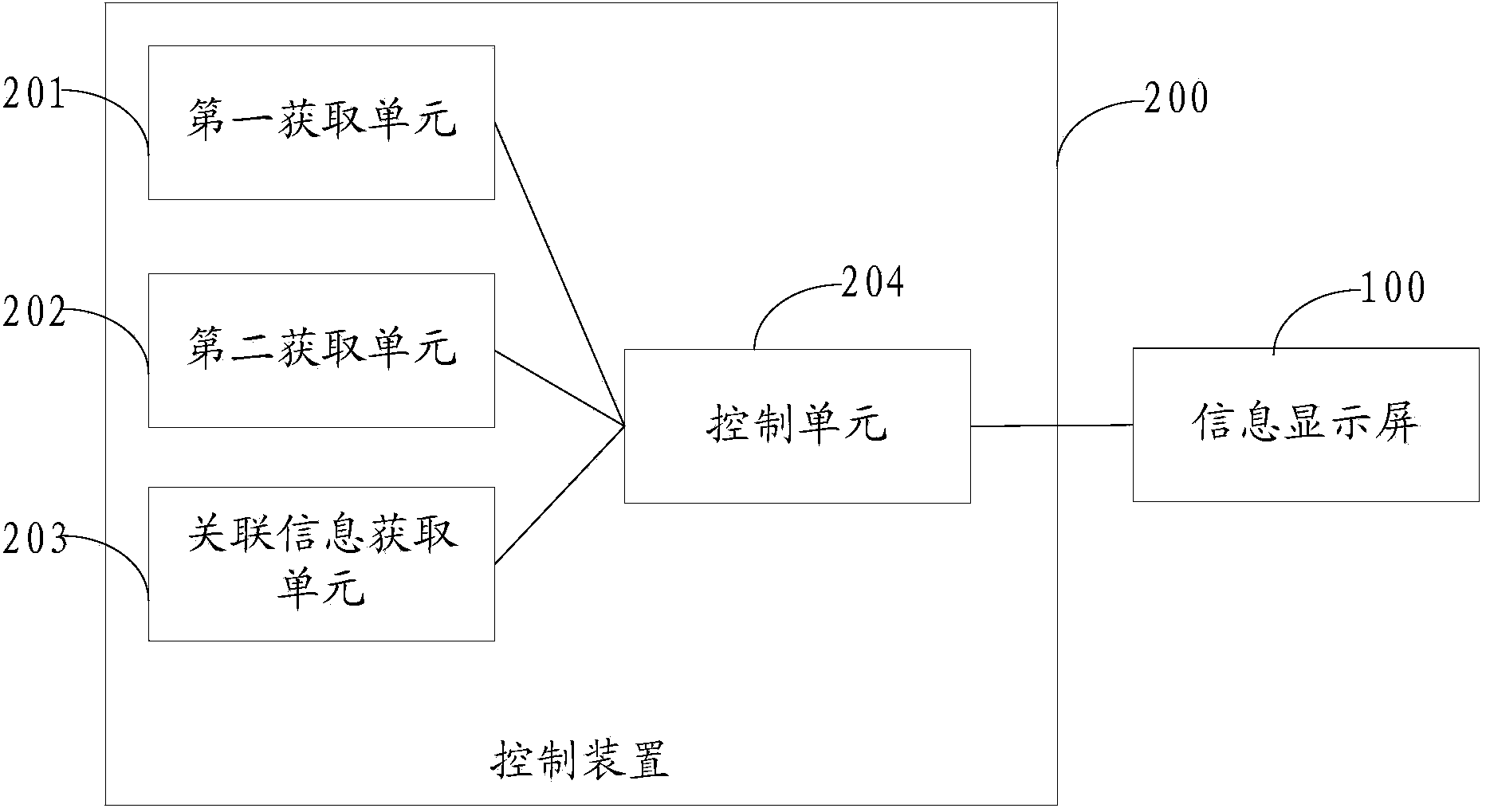

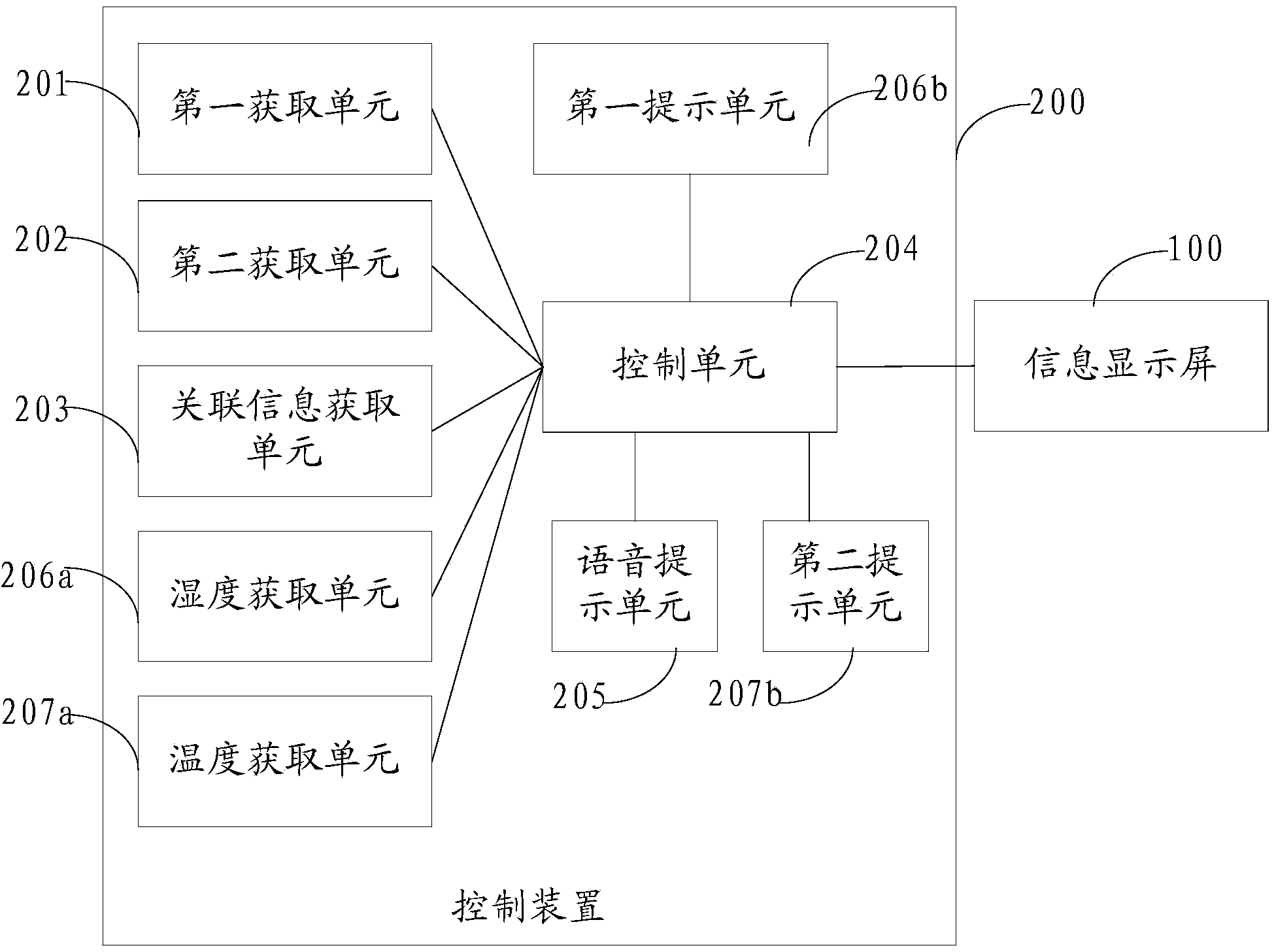

Control method and control device of air conditioner and air conditioner

ActiveCN104296327AEasy to operateAvoid misuseMechanical apparatusSpace heating and ventilation safety systemsEngineeringTime information

The invention discloses a control method and a control device of an air conditioner and the air conditioner. The control method comprises the following steps: obtaining an old man mode opening command, controlling an information display screen to display according to a symbol with preset size; in an old man mode, obtaining a starting command, controlling the air conditioner to enter a low wind mode and controlling the output temperature of the air conditioner to be within the preset temperature; obtaining associated information for controlling the operation of the air conditioner in real time in the working process of the air conditioner and controlling the air conditioner to do corresponding action according to the associated information, wherein the associated information includes time information and a turn-off command; controlling the turn-on of a silent mode and a sleep mode of the air conditioner when the time information reaches a first preset time point and controlling the turn-off of the silent mode and the sleep mode of the air conditioner until the time information reaches a second preset time point; according to the turn-off command, controlling the turn-off of the air conditioner. The control method and the control device of the air conditioner and the air conditioner have the benefits that the user's operation is greatly facilitated, the user's misoperaiton is avoided, and the effect on user's physical health is avoided.

Owner:GREE ELECTRIC APPLIANCES INC

Anti-corrosion secondary water supply non-negative pressure equipment

InactiveCN111547929AScientific and reasonable structureEasy to useWater/sewage treatment by irradiationSpecific water treatment objectivesIon exchangeIon-exchange resin

The invention discloses anti-corrosion secondary water supply non-negative pressure equipment. One end of a water conveying pipe is connected with a treatment tank; a granular activated carbon filterscreen is fixedly mounted at the top of a treatment tank; an annular fixing frame is fixedly connected to a position, which is located below the granular activated carbon filter screen, in the treatment tank; an annular fixing groove is formed in the bottom end of the annular fixing frame; an ion exchange resin filter element is mounted in the middle of the treatment tank; and the top end of the ion exchange resin filter element is fixedly connected with an upper mounting block. The structure is scientific and reasonable, the equipment is safe and convenient to use, by using the ion exchange resin filter element, free anions and cations in the water are removed, the pH value of water is reduced, corrosion of water to the equipment is reduced, water in the equipment will not be polluted bythe rusts, chlorides in the water can be absorbed by using the granular activated carbon filter screen, and the probability that the equipment is corroded is further reduced.

Owner:罗显容

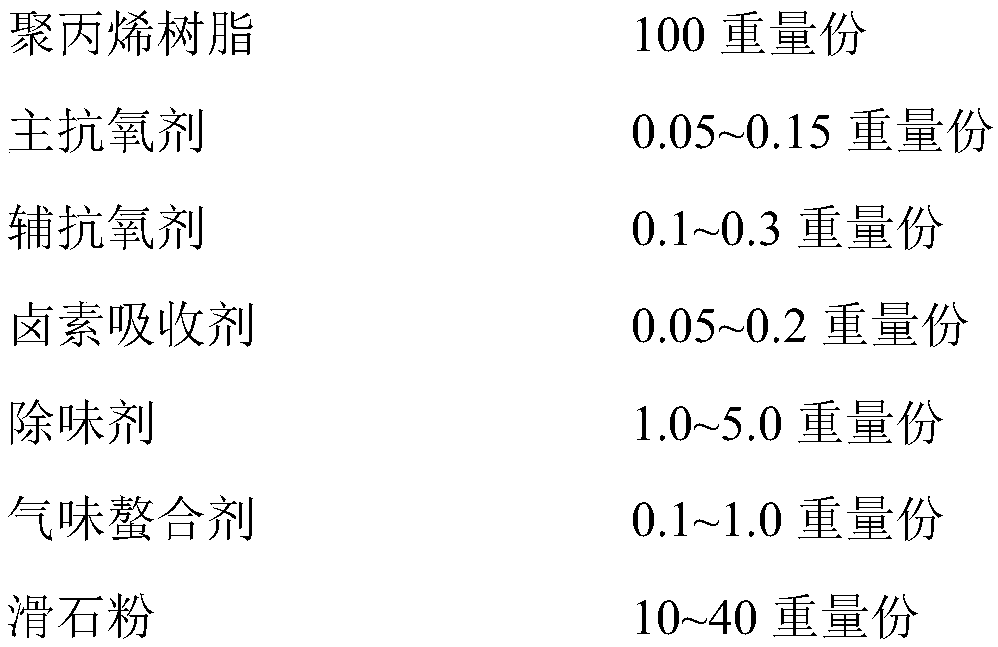

Preparation method of polypropylene composition

InactiveCN108727683AInhibits thermal and oxygen degradationPromote dissolutionBulk chemical productionHalogenPolypropylene

The invention discloses a preparation method of a polypropylene composition and belongs to the technical field of materials. The composition at least comprises 100 parts of polypropylene, 0.05-0.15 part of a primary antioxidant, 0.1-0.3 parts of an auxiliary antioxidant and 0.05-0.2 parts of a halogen absorbent. Supercritical carbon dioxide is used for assisting in extrusion; heat and oxygen degradation of polypropylene is effectively inhibited in an extrusion process; at the same time, dissolution of micromolecular volatile matters is greatly accelerated; and the micromolecular volatile matters are removed in a pressure release extraction manner in front of a neck mold of an extruder. The method is simple in technology, wide in application scope and low in production cost.

Owner:SINOPEC YANGZI PETROCHEM +1

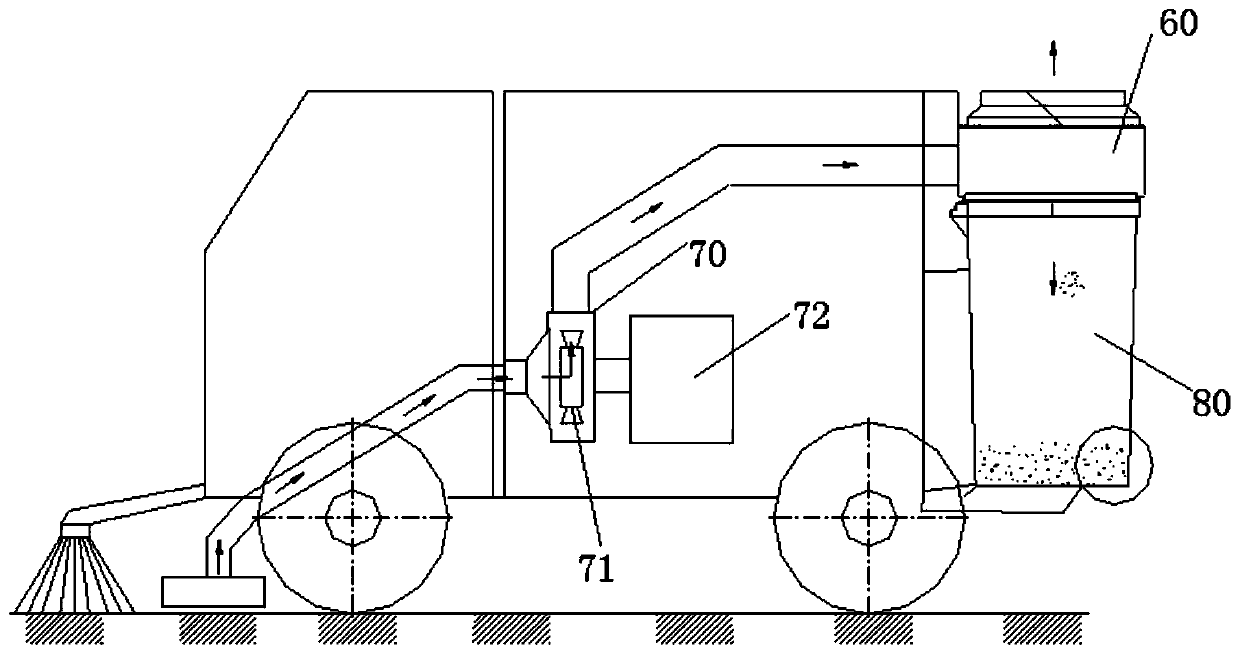

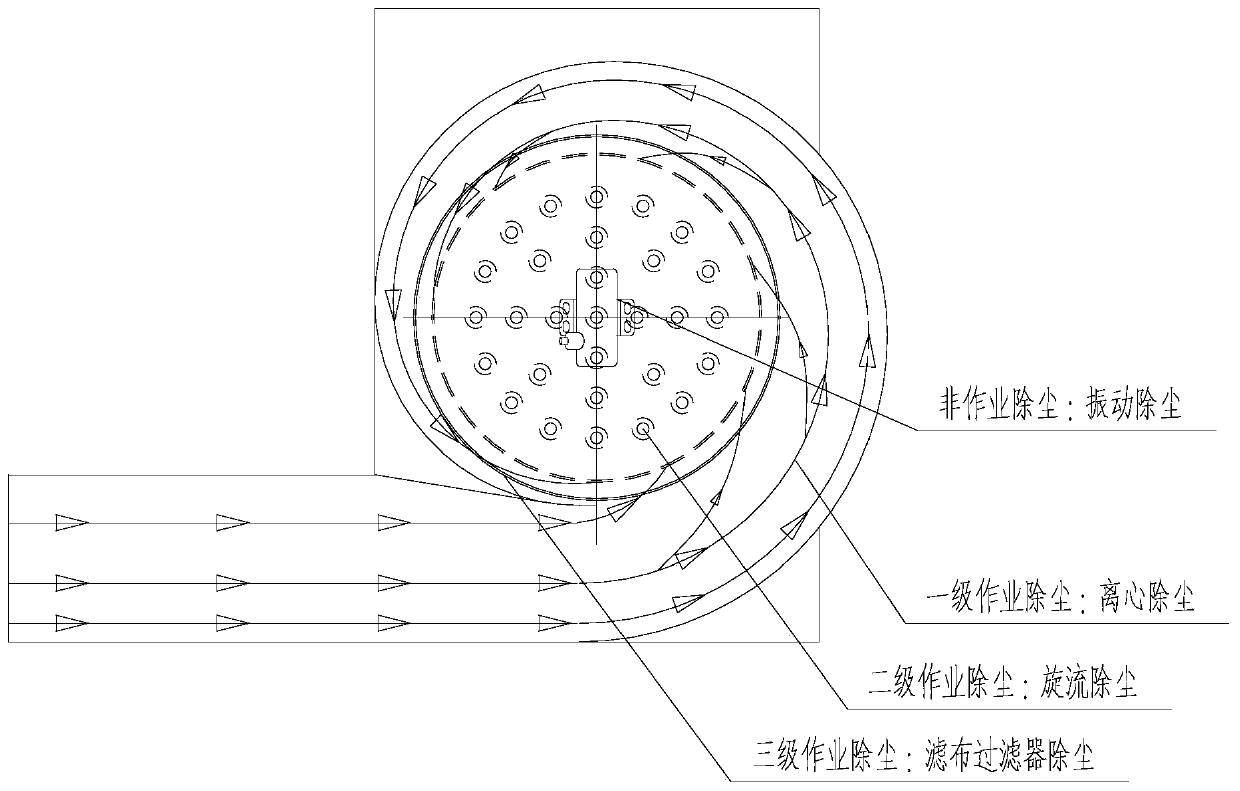

Garbage dust removal system and cleaning vehicle with same

ActiveCN110258398AEasy to separatePhysical health effectsCombination devicesRoad cleaningDust controlProcess engineering

The invention discloses a garbage dust removal system and a cleaning vehicle with the same. The garbage dust removal system comprises a dust removal device, the dust removal device comprises a flow inlet pipeline, the flow inlet pipeline communicates with a mounting box, and the mounting box communicates with a garbage can. A filter bucket is arranged in the mounting box, the filter bucket is matched with the mounting box so as to form a vortex-shaped flow channel between the filter bucket and the mounting box, then garbage-containing airflow can be subjected to primary separation under the action of centrifugal force, separated heavy garbage, large-grain-size garbage and a part of medium-and-small-particle-size medium garbage are enabled to fall into the garbage can, and the left medium-and-small-particle-size medium garbage enters an inner cavity of the filter bucket after passing through the filter bucket. The garbage dust removal system further comprises a filter element set, wherein the filter element set is used for enabling the garbage-containing airflow to form the rotational flow to separate out the medium-and-small-particle-size light garbage, and the filter element set communicates with the inner cavity of the filter bucket. The garbage dust removal system further comprises a filter which is connected to a top plate of the mounting box and correspondingly communicates with the filter element set and the atmosphere, so that the garbage-containing airflow discharged by the filter element set enters the filter to be separated, and the separated clean airflow is discharged into the atmosphere.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

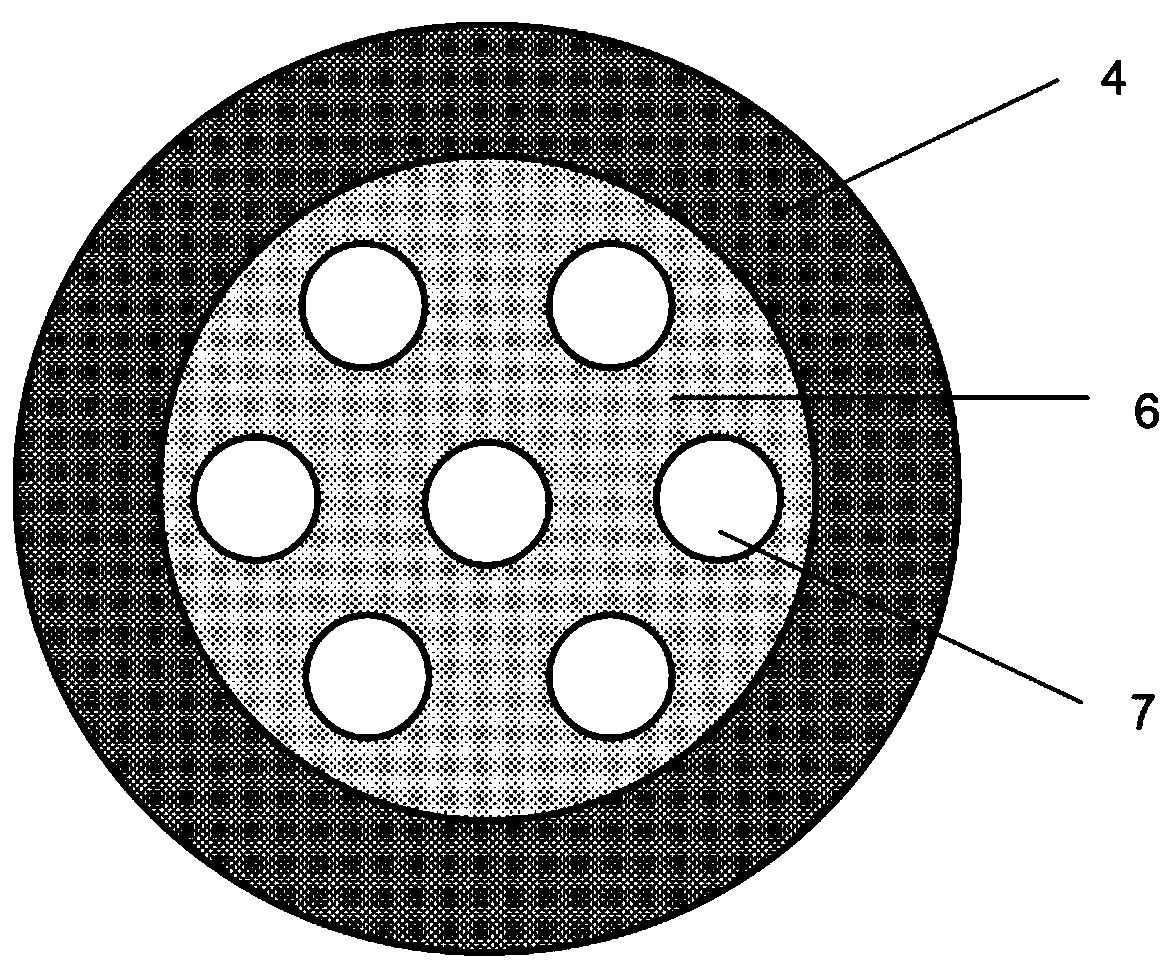

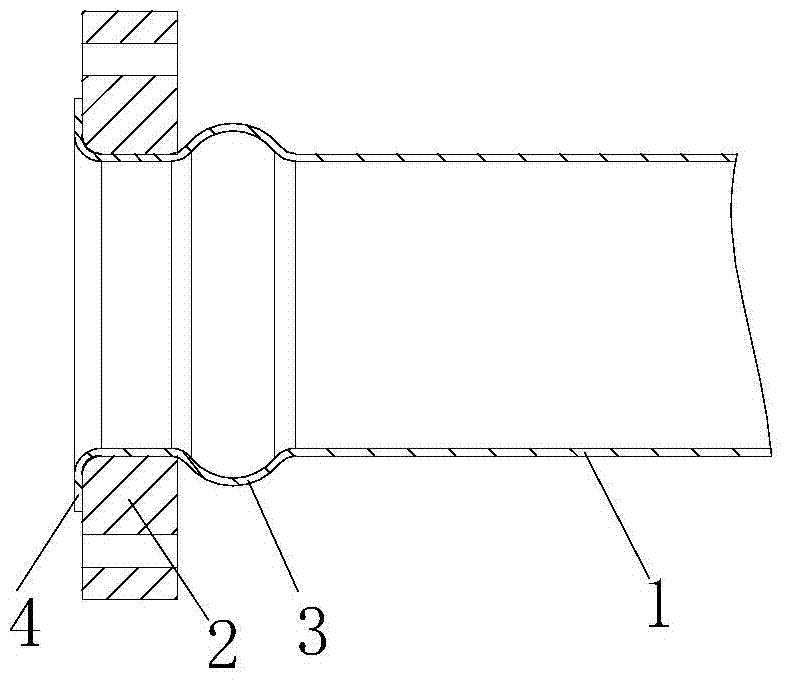

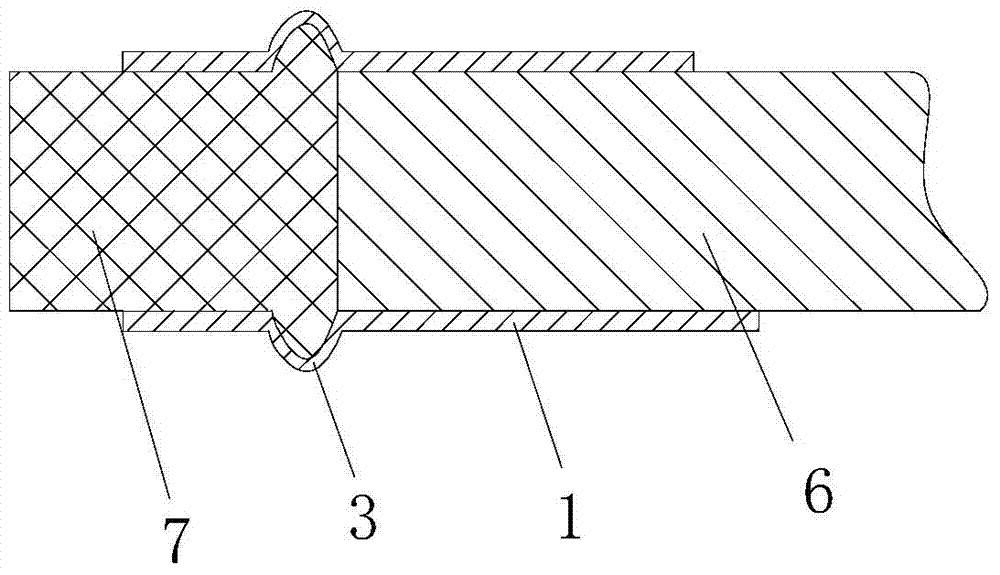

Pipe and flange connection structure and processing method thereof

The invention discloses a pipe and flange connection structure and a processing method thereof. The pipe and flange connection structure comprises a pipe (1) and a flange (2) sleeving the end of the pipe, the pipe (1) inside the flange (2) is provided with a convex ring (3) expanding outwards radially, the pipe (1) outside the flange (2) is provided with a flanging (4) expanding outwards radially, and the flange (4) is tightly pressed onto the convex ring (3) by the flanging (4). The pipe and flange connection structure is low in production cost, and the processing method of the pipe and flange connection structure is low in harms to bodies of operators, simple in manufacturing process and short in production cycle.

Owner:NINGBO T ERRE AUTOMOTIVE COMPONENTS

Cutting waste material collecting device for machining and manufacturing

InactiveCN107791315AAvoid touchingAvoid damageUsing liquid separation agentMetal working apparatusManufacturing technologyPulp and paper industry

The invention provides a cutting waste material collecting device for machining and manufacturing, and relates to the technical field of machining and manufacturing. The cutting waste material collecting device for machining and manufacturing comprises a base. The top of the base is fixedly connected with the bottom of a supporting pillar. The top of the supporting pillar is fixedly connected withthe bottom of an installing plate. The bottom of the installing plate is fixedly provided with an electric telescopic rod. The side, far away from the mounting plate, of the electric telescopic rod is fixedly connected with the top of a stand. A motor is fixedly installed at the top of the stand. A blade is fixedly installed at an output shaft of the motor. According to the cutting waste materialcollecting device for machining and manufacturing, damage to the blade is prevented, collection of leftover materials is facilitated due to the arrangement of a storage box, and collection treatmentfor the leftover materials is more convenient. A fan is arranged, so that dust generated during cutting is collected conveniently and prevented from flying into air to affect the body health of operators. A water draining pipe is arranged, so that water inside a water tank is replaced conveniently, and continuous collection treatment of the dust is facilitated.

Owner:于浩

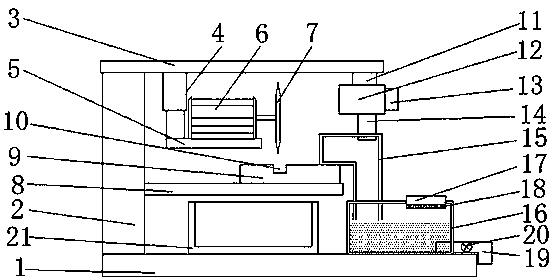

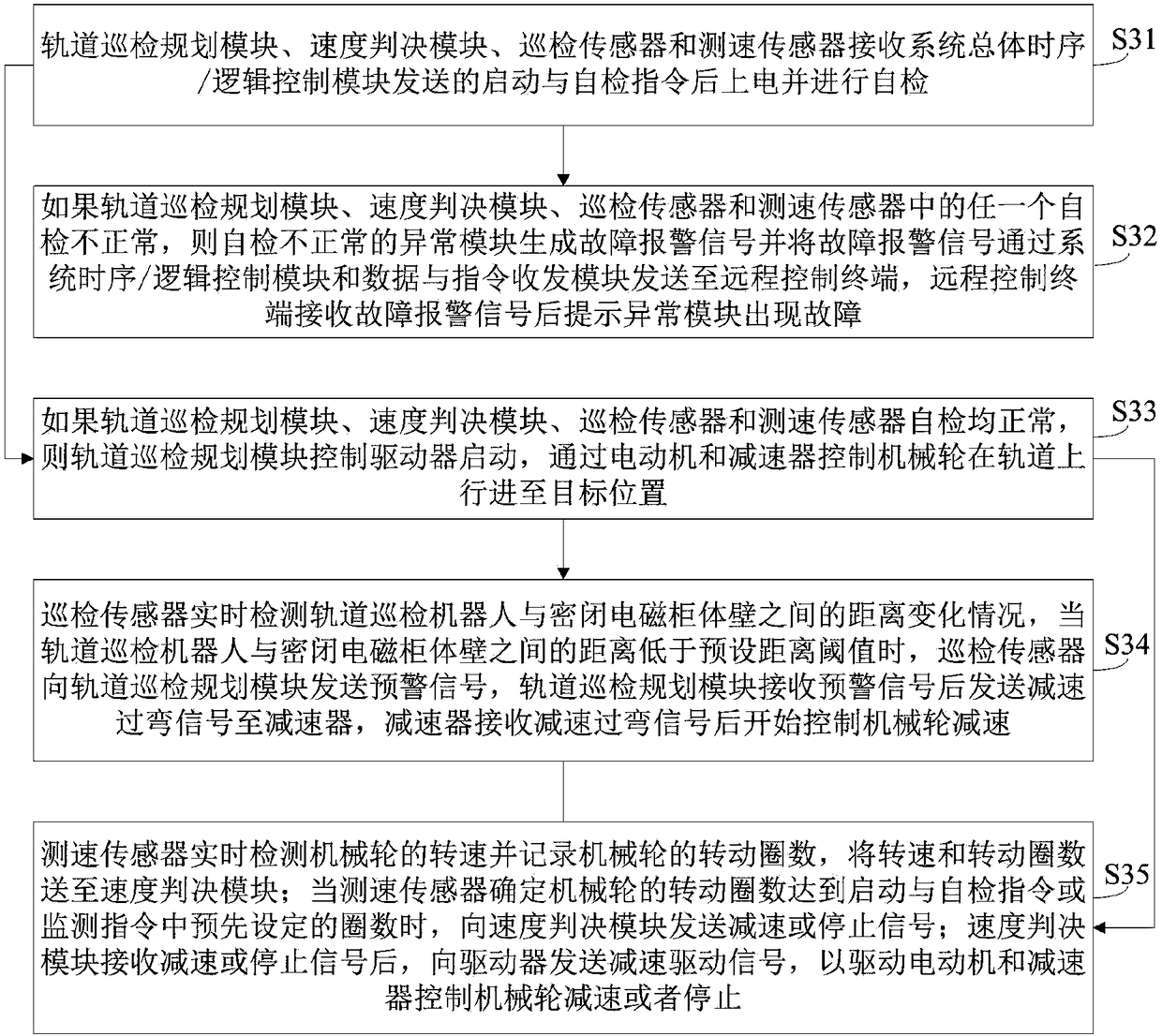

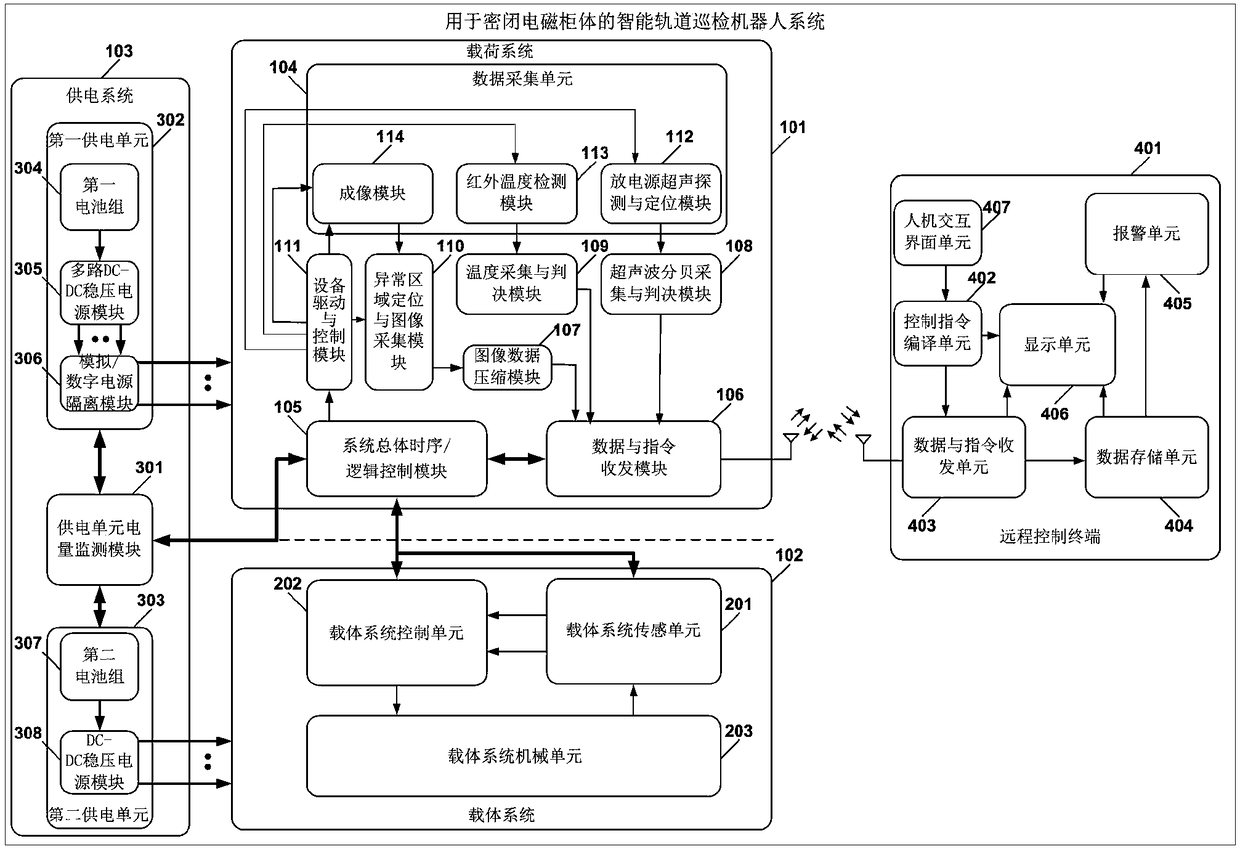

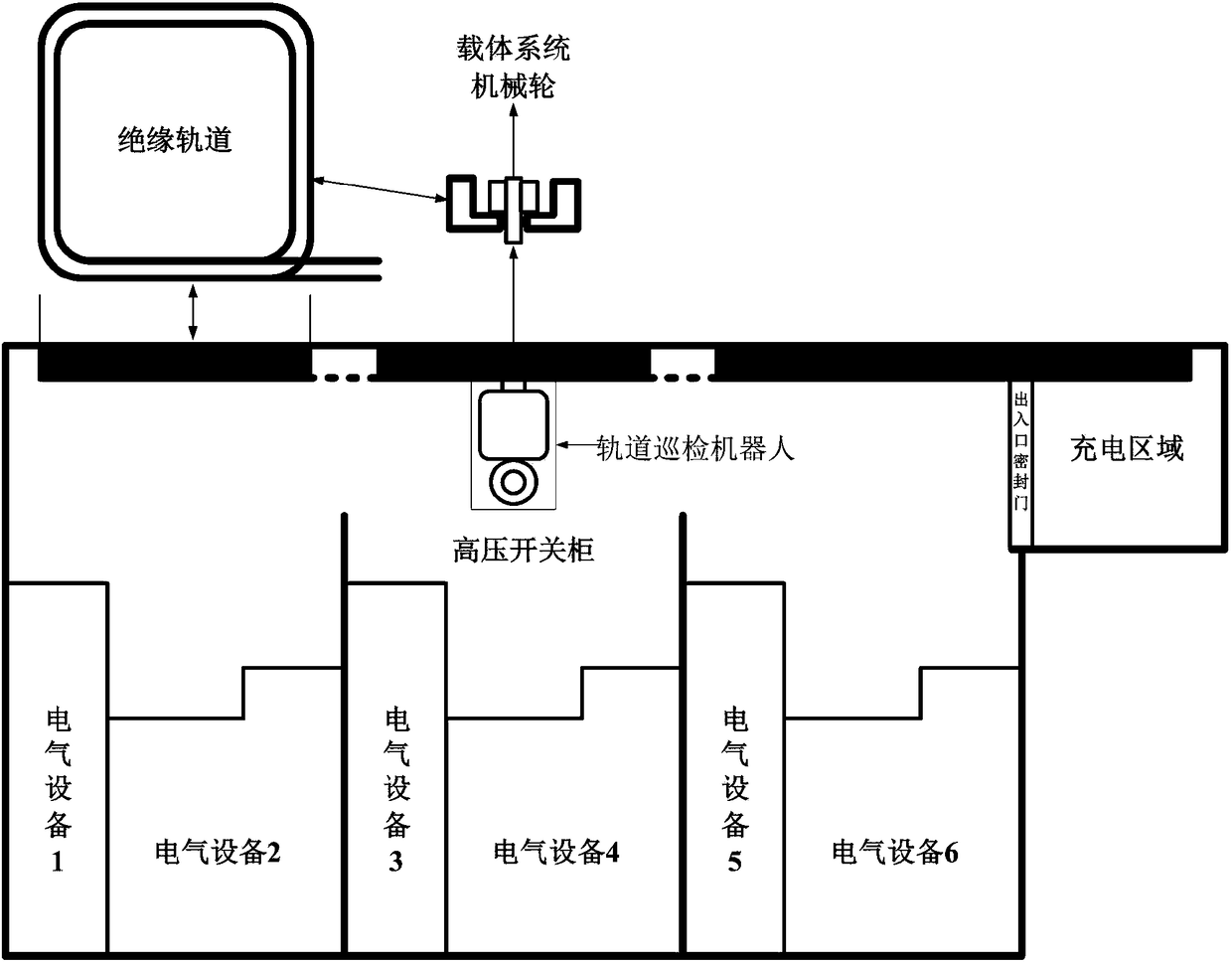

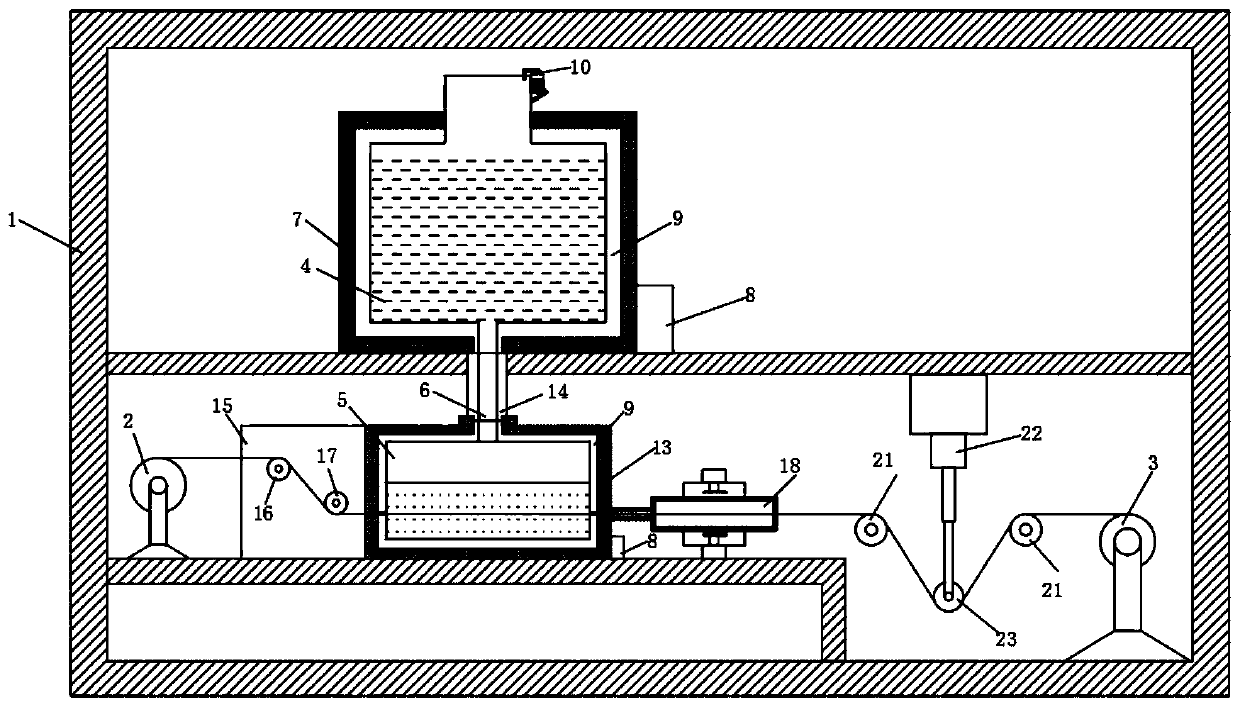

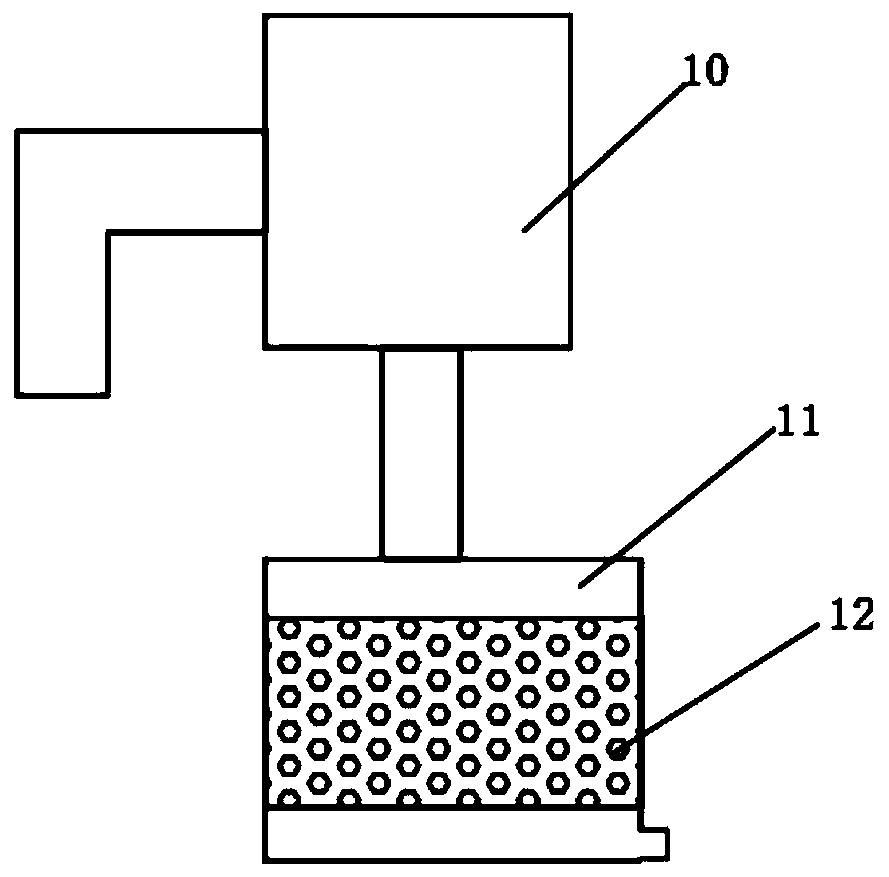

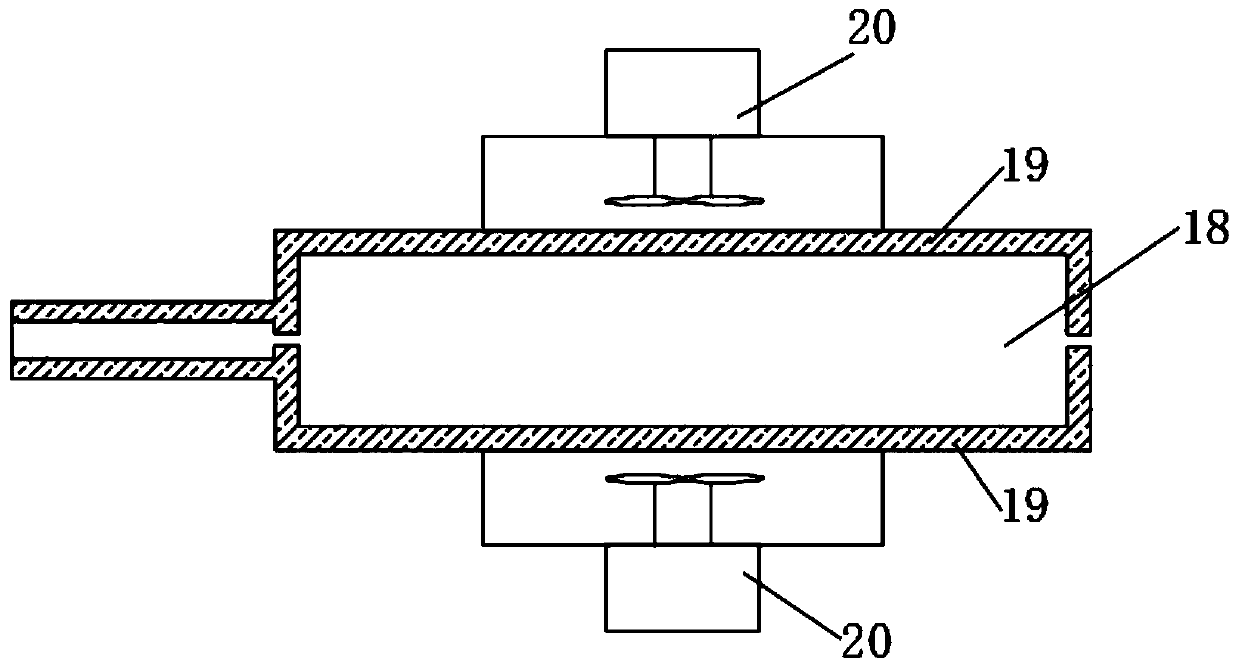

Smart track routing inspection robot system and control method for closed electromagnetic cabinet

InactiveCN108508902AContinuous monitoringAccurate monitoringMeasurement devicesTransmission systemsRobotic systemsRemote control

The invention provides a smart track routing inspection robot system and a control method for a closed electromagnetic cabinet, belonging to the technical field of Internet of Things, and aiming at solving the current problem that electrical equipment in a closed electromagnetic cabinet requires artificial participation and easily influences physical and psychological health of staff when being used for inspecting. A track is laid at the top inside a closed electromagnetic cabinet, and the smart track routing inspection robot system comprises a track routing inspection robot and a remote-control terminal, and the track routing inspection robot is used for performing routing inspection for the closed electromagnetic cabinet on different positions of the track. The smart track routing inspection robot system and control method can be used for monitoring closed electrical equipment in a complicated electromagnetic environment to reduce manual operation, combining spontaneous control and remote control and performing real-time continuous accurate monitoring and data collection for the closed electromagnetic cabinet through interaction of the track routing inspection robot and the remote control terminal.

Owner:SHANXI UNIV

Yarn waxing device

InactiveCN110592845AReduce heat lossReduce energy wasteFibre cleaning/openingTextile treatment machine arrangementsWaxYarn

The invention provides a yarn waxing device which comprises a pay-off roller, a wind-up roller, a wax block storage box arranged between the pay-off roller and the wind-up roller, and a yarn waxing chamber arranged under the wax block storage box and communicated with the wax block storage box. A first heating box is installed outside the wax block storage box. A second heating box is installed outside the yarn waxing chamber. The outer side of the first heating box and the outer side of the second heating box are each provided with a constant-temperature controller. The heating temperature ofthe second heating box is lower than the heating temperature of the first heating box. The yarn waxing device is simple in structure; by using the first heating box and the second heating box in cooperation, wax liquid is converted into wax oil low in temperature and easy to apply, and therefore the breakage of yarn at the too high temperature in the waxing process can be effectively avoided, andthe yarn quality is ensured.

Owner:宿迁至诚纺织品股份有限公司

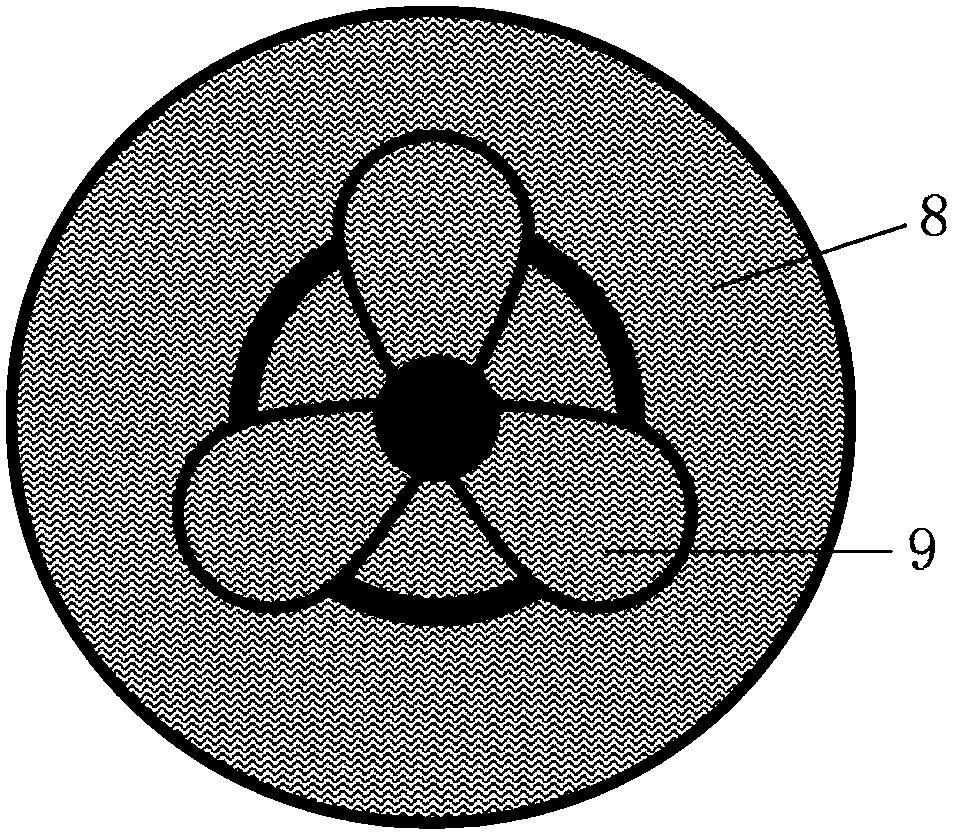

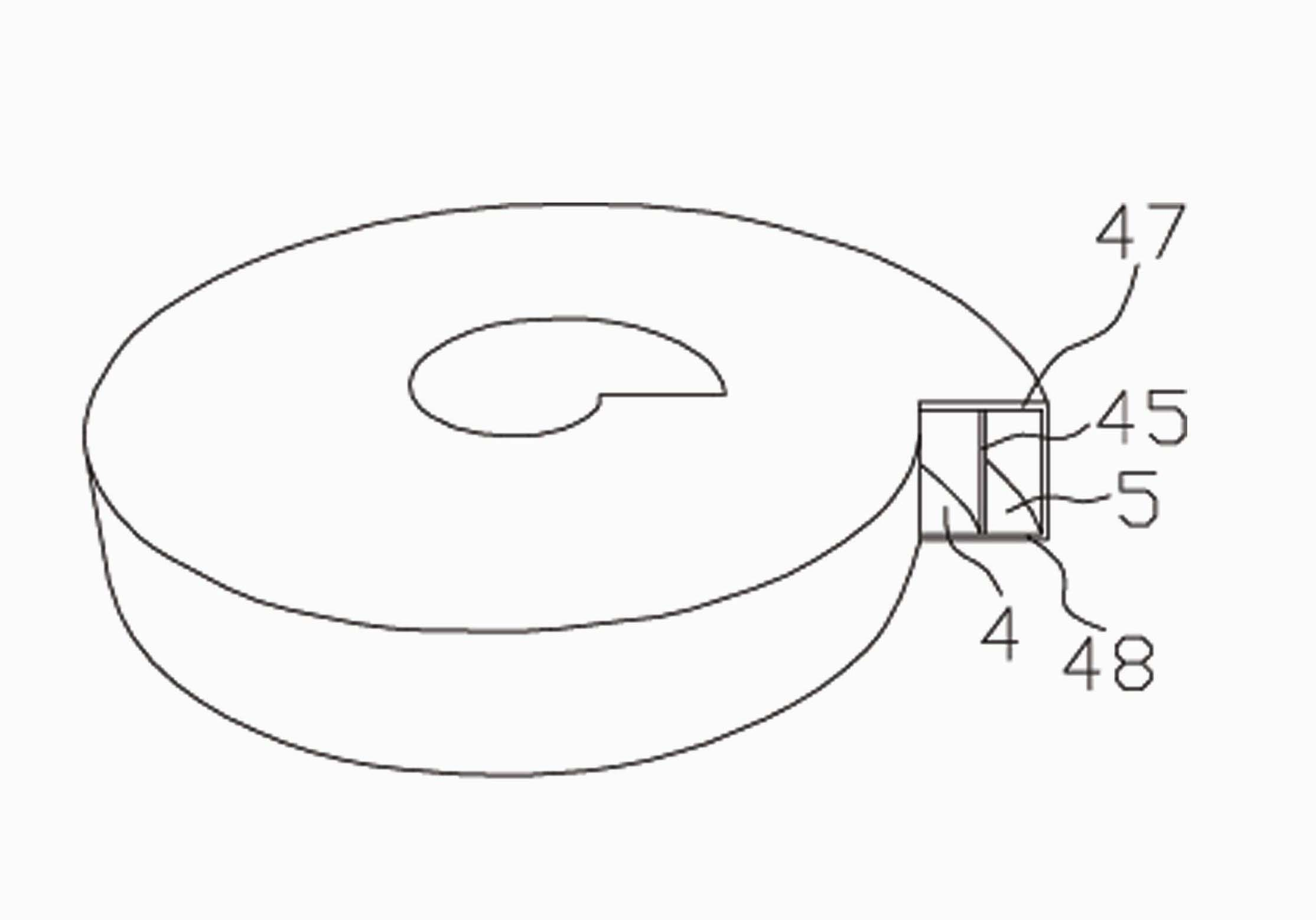

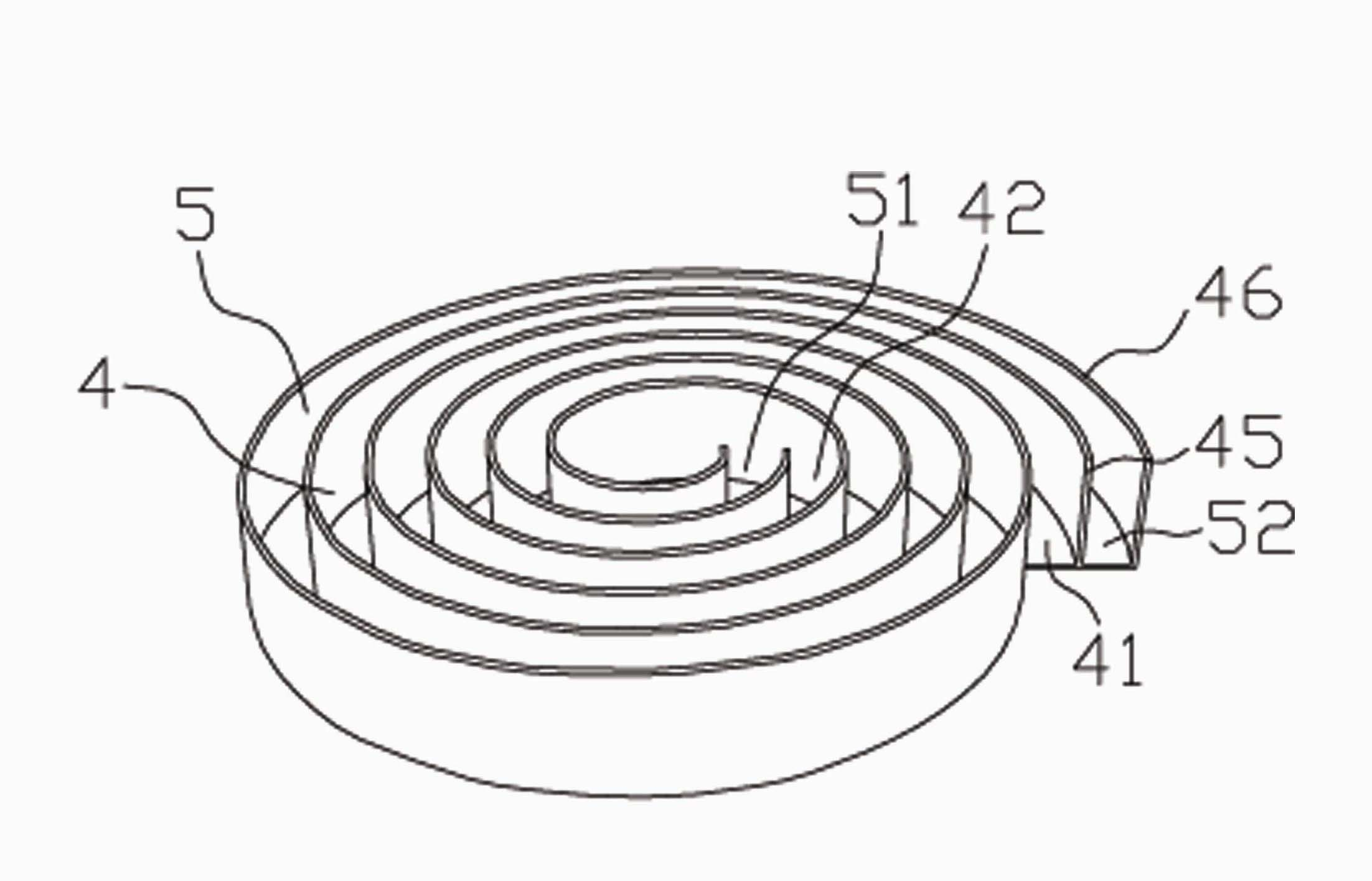

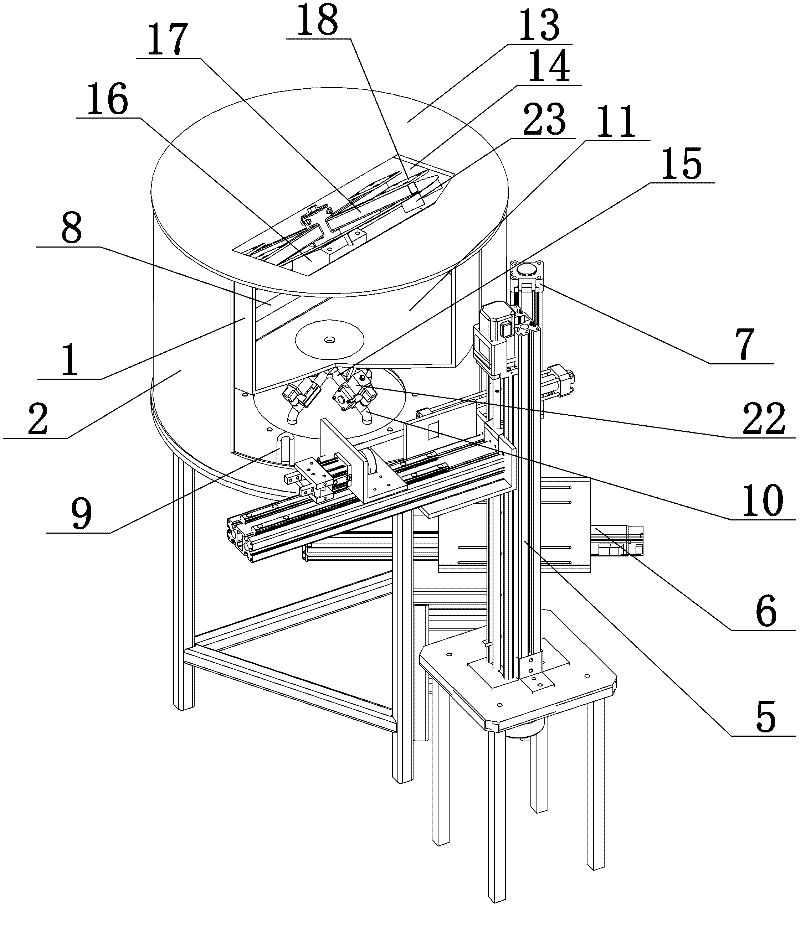

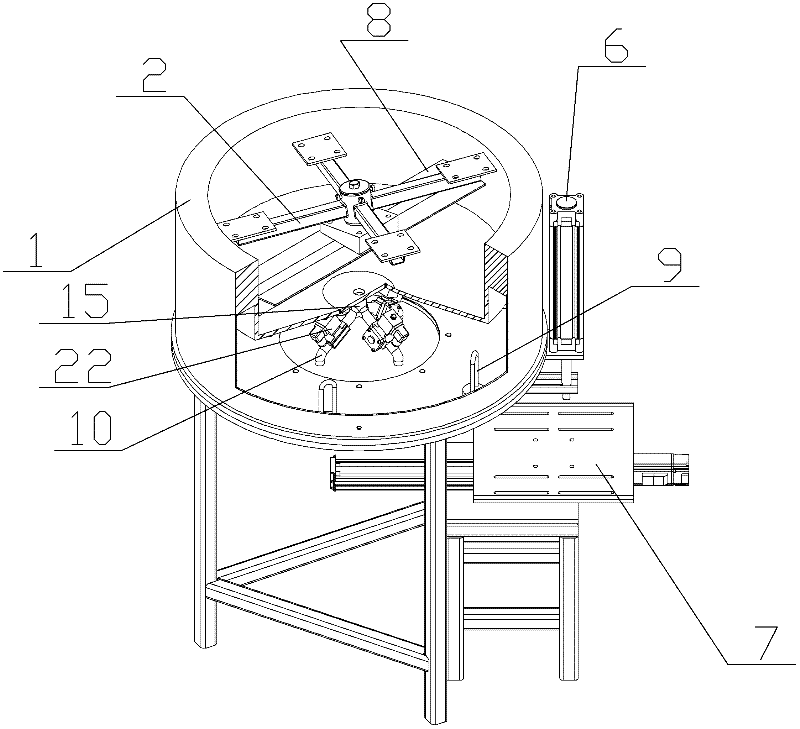

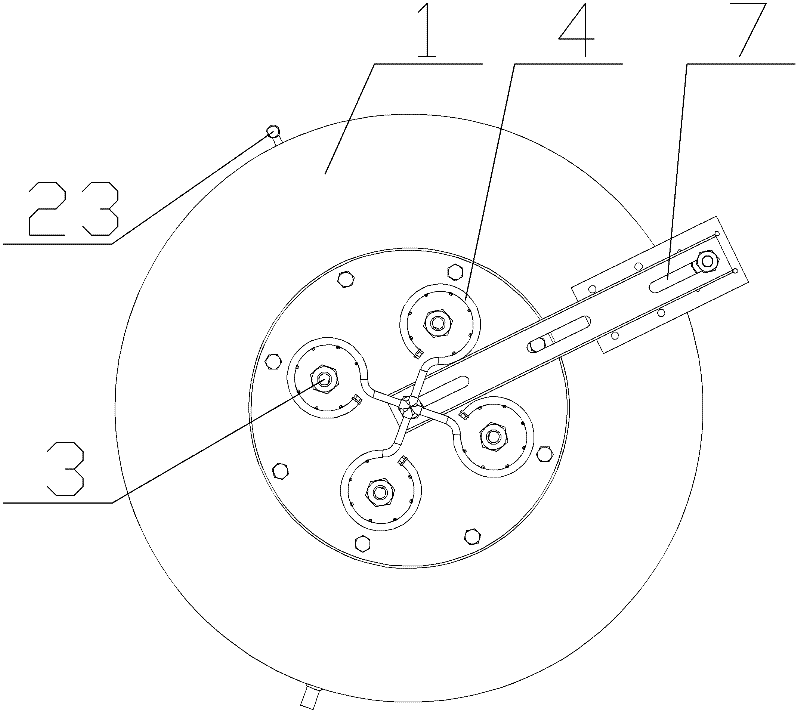

Filling and recovering device for low-melting-point alloy

The invention discloses a filling and recovering device for low-melting-point alloy, which can automatically fill and recover the low-melting-point alloy. The filling and recovering device comprises a water tank, a turntable, a pouring gate (3), a cooling shower nozzle (4), a first manipulator (5), a second manipulator (6) and a third manipulator (7), wherein the first manipulator (5) is used for taking and placing a workpiece from and onto the turntable; the second manipulator (6) is used for taking and placing the workpiece from and onto the pouring gate (3); the third manipulator (7) can drive the cooling shower nozzle (4) to move along the filling direction of the low-melting-point alloy in the workpiece; a mounting base (8) and a water temperature keeping unit (9) are arranged in the water tank; the turntable is in rotatable connection with the mounting base (8); a rotating plane of the turntable is intersected with a horizontal plane; an openable and closed connecting pipe (10) for communicating the pouring gate (3) with the water tank is arranged between the pouring gate (3) and the water tank; one end of the connecting pipe (10) is connected with the bottom of the water tank; the other end of the connecting pipe (10) is connected with the pouring gate (3); and the cooling shower nozzle (4) is located under the pouring gate (3) and is of an annular shape encircling the outer wall of the workpiece.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

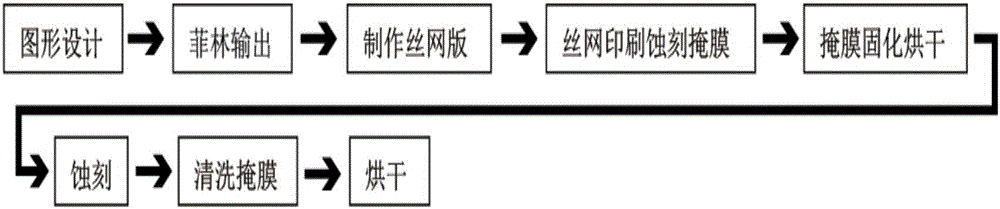

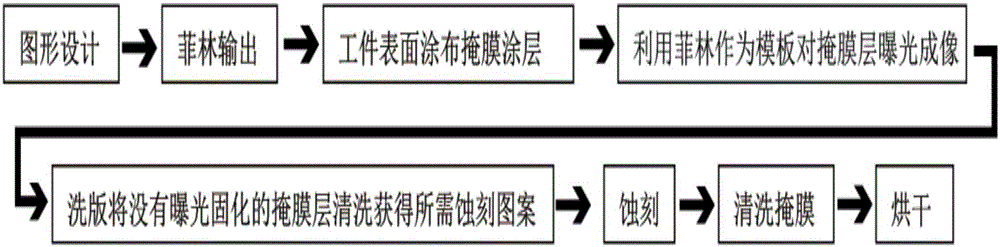

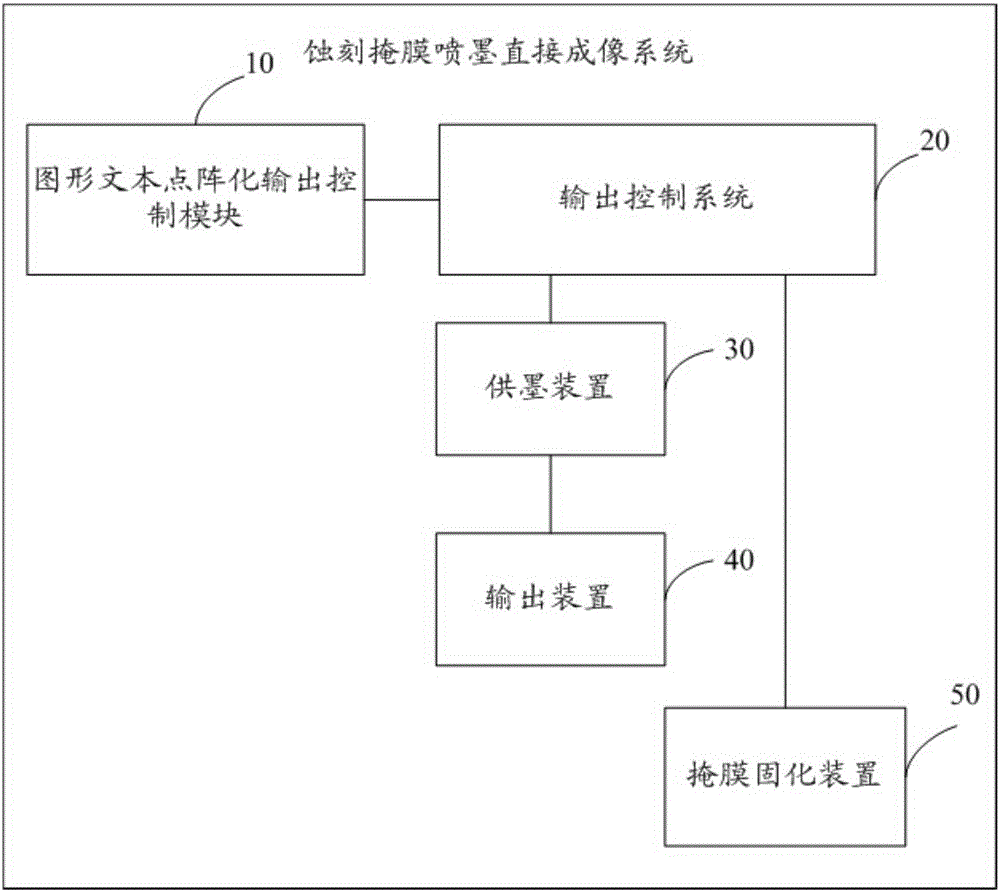

Etching mask ink-jet direct imaging system and process

The invention discloses an etching mask ink-jet direct imaging system and process. The etching mask ink-jet direct imaging system comprises an ink-jet printer, a graph text rasterizing output control module and etching mask ink. According to the etching mask ink-jet direct imaging system and process, compared with a traditional etching process, the operating steps of the process are simplified, and production efficiency is improved; moreover, more labor cost and more labor force are saved.

Owner:数印通科技河北有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com