Patents

Literature

127results about How to "High compressive and flexural strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Abrasion resistant ceramic coating

The invention discloses a brushing-proof abrasion-proof and erosion-proof ceramic paint, which is characterized by the following: selecting at least one of electric-melting brown corundum, electric-melting subwhite corundum, electric-melting white corundum, carborundum and electric melting mullite with different grain sizes as main material and at least one of compact corundum, electric-melting subwhite corundum, electric-melting white corundum, carborundum, silicon nitride and boron nitride as auxiliary material; using CA50 calcium aluminate cement or pure calcium aluminate cement as binder and nanometer micro-silica powder and active alpha-Al2O3 micropowder as reinforcer; making hyperdrying active high-effective dehydragent, sodium citrate and sodium hexametaphosphate as composite additive; loading in the strength stirrer to stir 12-17min; blending evenly; packing.

Owner:CHONGQING LUOMAN NEW MATERIAL TECH CO LTD

Inorganic composite heat insulation material and preparation method thereof

ActiveCN102093030ADecreased volumetric water absorptionStable physical and chemical propertiesFiberCellulose

The invention relates to an inorganic composite heat insulation material, which is prepared from the following raw materials in part by weight: 100 parts of common silicate cement, 10 to 30 parts of quick hardening sulfate aluminum cement, 10 to 30 parts of gypsum powder, 10 to 40 parts of admixture, 20 to 40 parts of mineral fiber, 150 to 200 parts of vitrified micro bubbles, 4 to 8 parts of re-dispersible latex powder, 2 to 4 parts of cellulose ether, 0.1 to 0.3 part of starch ether, 0.2 to 1.0 part of water reducing agent, 0.2 to 0.6 part of retarder, 1 to 3 parts of early strength agent, 0.5 to 3 parts of water repellent, and 0.02 to 0.06 part of air entraining agent. The raw materials are mixed uniformly to prepare dry powder, and the dry powder and water are mixed in a weight ratio of 1: (0.8-1.2) and stirred to form slurry for use. The inorganic composite heat insulation material has good workability, quick strength development, high construction efficiency, good adhesive property, low drying shrinkage, heat insulation, hydrophobic property, fire resistance and durability.

Owner:辽宁际洲环保节能建材有限公司

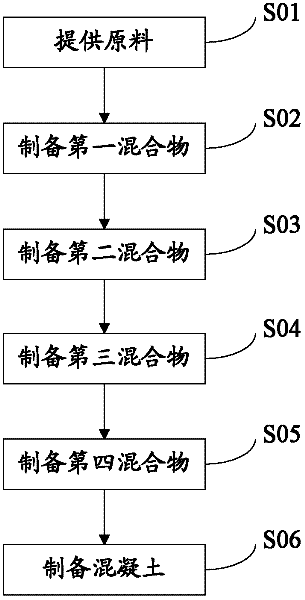

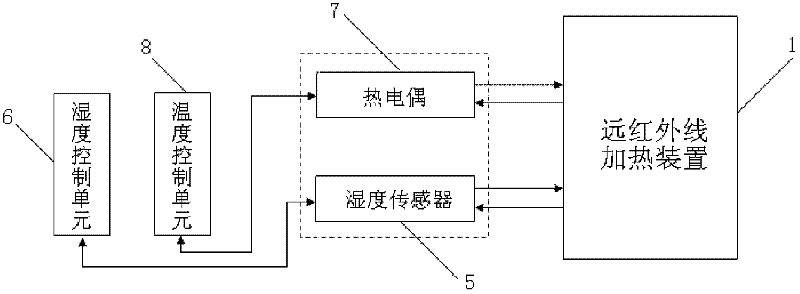

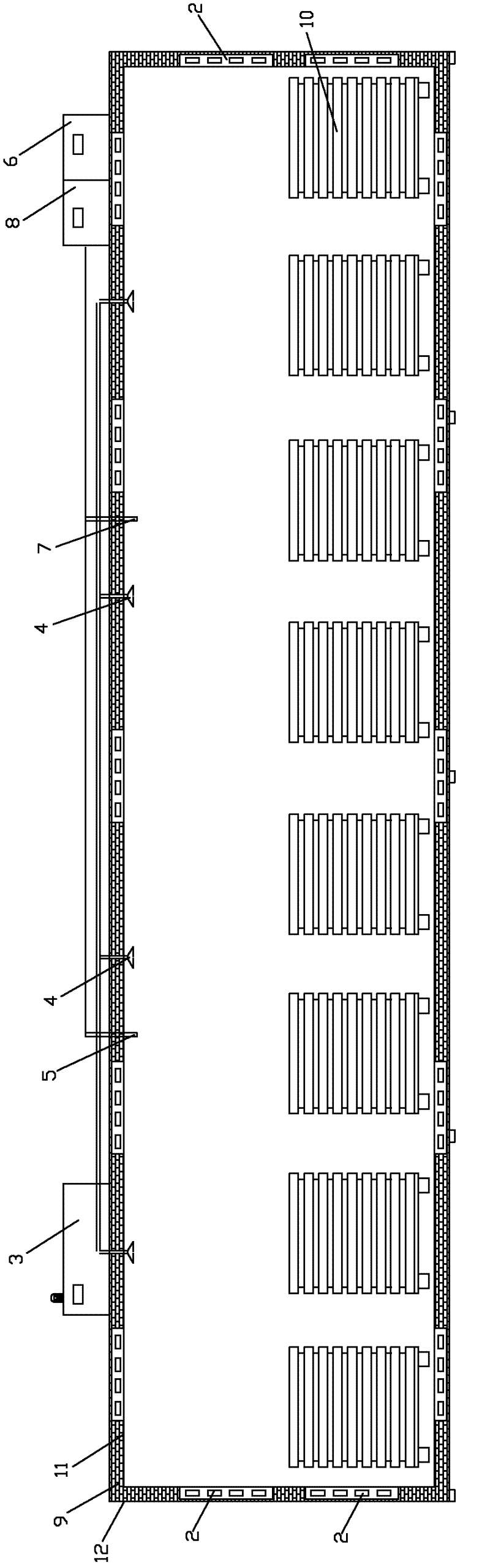

Concrete and preparation method thereof

The invention is applicable to the technical field of building materials, and provides a concrete and a preparation method of the concrete. The concrete comprises a cementing material, river sands, a super plasticizer, water, steel fibers and polypropylene fibers. The concrete of the invention has a gradation synergetic effect by utilizing mixed graded steel fibers, so as to greatly improve compressive strength and bending strength, crack resistance and impact resistance of concrete; and the concrete overcomes early-stage microcrack problem of concrete via fine polypropylene fibers, and mainly improves toughness of concrete via coarse polypropylene fibers, so as to realize the advantages of concrete such as high compressive strength and bending strength, high crack resistance, and good durability. The concrete preparation method is easy in operation and low in cost, and is very suitable for industrial production.

Owner:黄贺明

Wear-resistant cement mortar, wear-resistant floor and preparation method thereof

InactiveCN102910885AHas high strengthNon-shrinkableIn situ pavingsFlooringCalcium silicateWear resistant

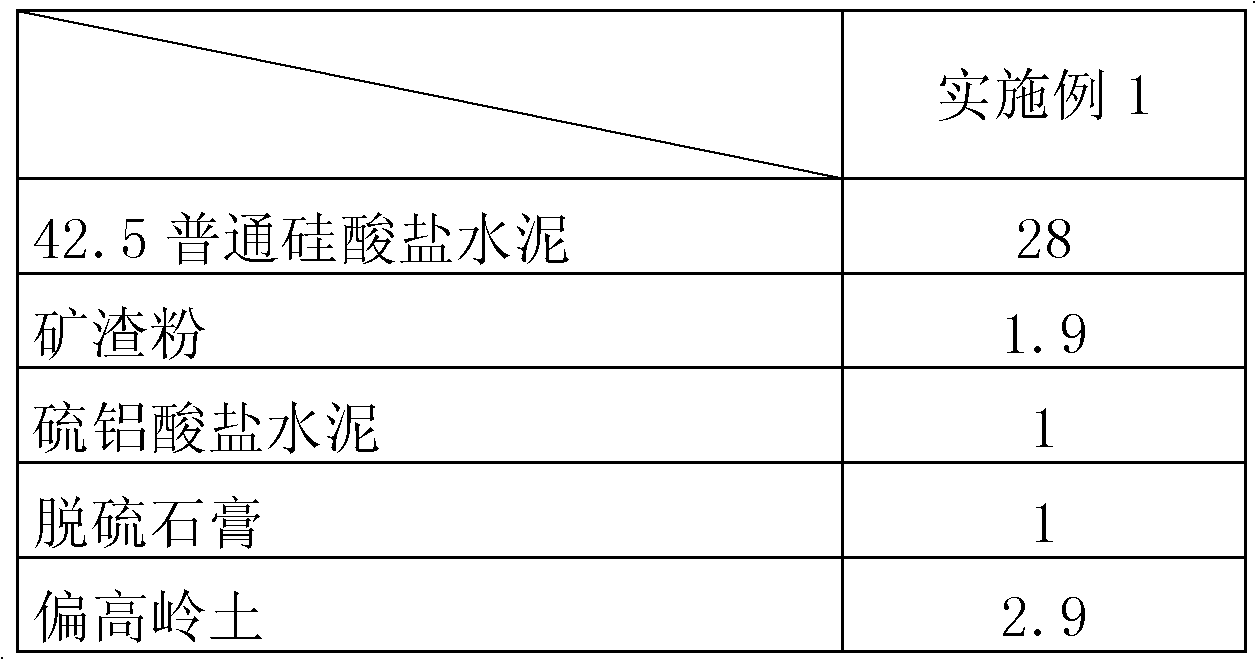

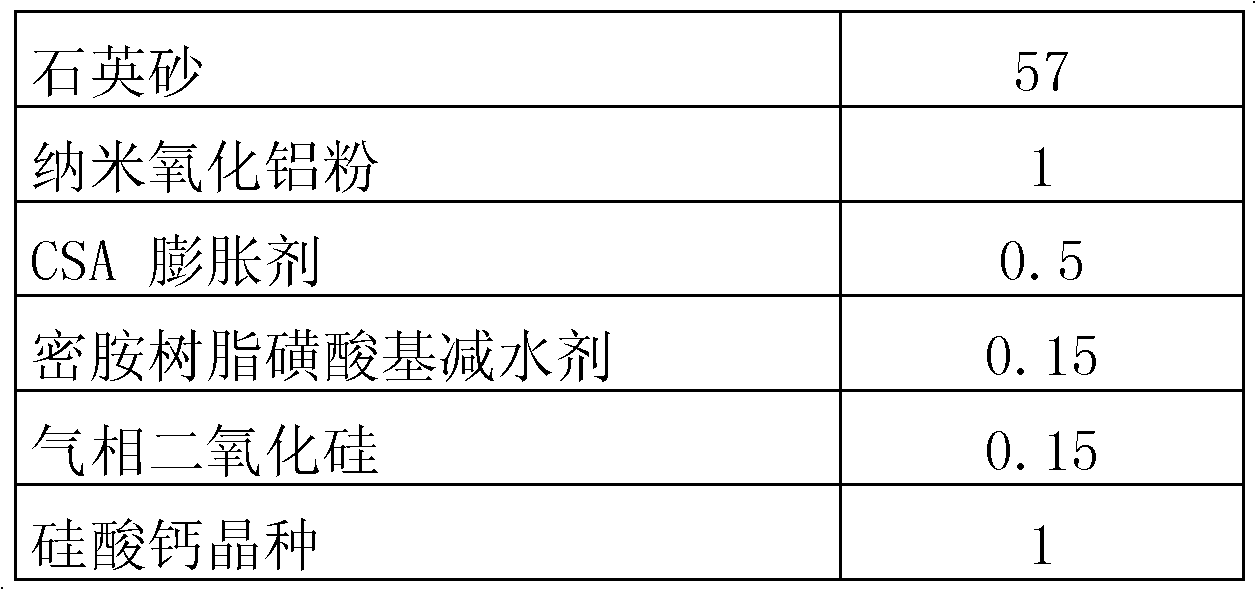

The invention discloses wear-resistant cement mortar, a wear-resistant floor and a preparation method thereof, wherein the wear-resistant cement mortar is composed by mixing the following components according to a normal method, by weight, 22-40 parts of ordinary portland cement, 1.9-7.5 parts of slag powder, 1-5 parts of special cement, 1-5 parts of metakaolin, 1-5 parts of gypsum, 40-60 parts of quartz sand, 1-3 parts of calcium silicate seed crystal; 1-7 parts of nano alumina powder and 0.1-0.3 part of a water reducing agent, wherein the special cement is sulphoaluminate cement or aluminate cement. The wear-resistant cement mortar has the advantages of excellent hardness and strength. The wear-resistant floor prepared by the wear-resistant cement mortar has no micro-cracks on the surface after being grinded; good smoothness and various fresh brilliant colors can be obtained; color ordonnance can be realized on the surface with extremely high compactness; and aesthetic patterns with paint effects can be obtained.

Owner:MINGLUN BUILDING MATERIALS IND SUZHOU CO LTD

Manufacture method of silicon carbide refractory ceramics material

The invention discloses a preparing method of carbofrax fireproof ceramic material combined by beta-Sialon host phase, which comprises the following steps: adopting predisposal clay mineral raw material, industrial carbon powder and gas with nitrogen as main raw material to form beta-sialon hose combining phase; adding reacting accelerating addictive; adding different particle grades to allocate SiC particle; blending evenly with organic adhesive; moulding biscuit through ceramic moulding method; drying; loading in the high-temperature kiln-furnace with nitrogen; setting the reacting temperature under 1300-1550 deg.c for 3-36h; proceeding carbon heat-nitrogenizing reaction; setting each reacting sintering period at 10-100h; synthesizing the product.

Owner:QINGDAO UNIV

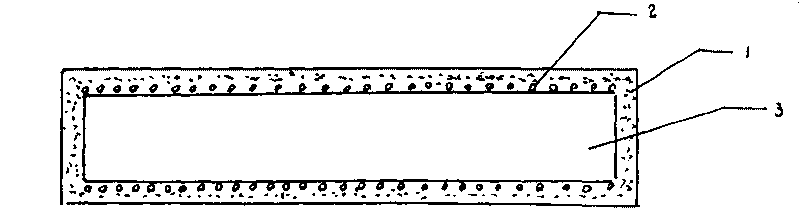

Fireproof foam concrete door core plate and preparation method thereof

InactiveCN103089118ASmall shrinkagePrevents cracking and water absorptionFireproof doorsCeramicwareFilling materialsEmulsion

The invention relates to a fireproof foam concrete door core plate and a preparation method thereof. A foam concrete base plate of the door core plate is prepared from cement paste and foam used for concrete in a volume ratio of 1:(5-12); the cement paste comprises the following raw materials in part: 80 to 100 parts of Portland cement, 10 to 30 parts of filling material, 30 to 50 parts of water, 2 to 7 parts of EVA emulsion, 2 to 6 parts of waterproof agent, 0.5 to 1.0 part of water repellent, 1.5 to 2.5 parts of water reducing agent, and 1 to 3 parts of early strength agent; and the volume weight of the foam used for the concrete is 70g / L to 90g / L, and the foam is prepared by adding water into a high-quality foaming agent for foaming. The fireproof foam concrete door core plate has the advantages of light weight, high strength, low heat conductivity coefficient, good fireproof and waterproof performance, long service life and the like, the preparation process is simple, and the cost is low.

Owner:河南永立建材有限公司

Enhanced magnesium oxysulfate cement, and method for making sheets by using cement

The invention relates to an enhanced magnesium oxysulfate cement, and a method for making sheets by using the cement. The formula of the enhanced magnesium oxysulfate cement comprises, by weight, 100 parts of light calcined magnesia, 30-70 parts of magnesium sulfate heptahydrate, 30-70 parts of water and 10-200 parts of a fiber. The method for making sheets by using the enhanced magnesium oxysulfate cement comprises the following steps: mixing 100 parts of light calcined magnesia with 30-70 parts of magnesium sulfate heptahydrate and 30-70 parts of water, uniformly stirring to form a clear paste, adding 50-200 parts of the fiber into the clear paste, uniformly stirring, carrying out roll forming, or transferring the obtained mixture into a die with a required shape and carrying out press forming, and curing. The formula of the cement does not contain free chloride ions, so the phenomena of scum, moisture absorbing, warpage, iron piece corrosion and poor weather ability of products formed by using the cement are avoided; and the reduction and residue sieving of raw materials are in favor of improving the compactness of the products and improving the compression and bending resistance of the products in the product formation process.

Owner:NG TERASUN AIR DUCT

Epoxy resin concrete material and microwave-coagulation preparation method thereof

InactiveCN102584109AFast curing rateSimple preparation processCeramic shaping apparatusEpoxyMicrowave

The invention relates to an epoxy resin concrete material and a microwave-coagulation preparation method thereof and comprises the composition of raw materials, the mix proportion, the preparation method, the mechanics performance testing and the like of the epoxy resin concrete material. The epoxy resin concrete material can be coagulated in a few minutes under the condition of microwave and has the advantages of even coagulation, high strength of condensate, good interface cohesiveness and excellent road performance, thus the concrete material can be used for rapid mending of concrete road surface.

Owner:雷运波

High performance cement-base sealing up leading stoppage material

InactiveCN1560171AImprove adhesionShort setting timeOther chemical processesBuilding insulationsRebarWater reducer

The invention relates to a high-performance cement-based water and leakage stopping material, composed of general Portland cement, high alumina cemen, 0.16-2.5 mm-sized quartz sand, fibrin, water reducer, plaster, and calcined lime powder. It can be mixed into quick-hardening cement, completely efficiently stopping the water and leakage in water- permeable positions of the buildings (structures) such as roofs, walls, floors, dams, tunnels, ponds, etc, thus thoroughly controlling the leakage, and improving living environments by a large margin, prolonging the service life of concrete buildings (structures). It is applied to the constructions (structures) of reinforced concrete, light aggregate concrete, industrial and civil architectures, basements, dams, tunnels, etc.

Owner:TONGJI UNIV

Energy-saving and light quick-setting waterproof mortar for outer wall

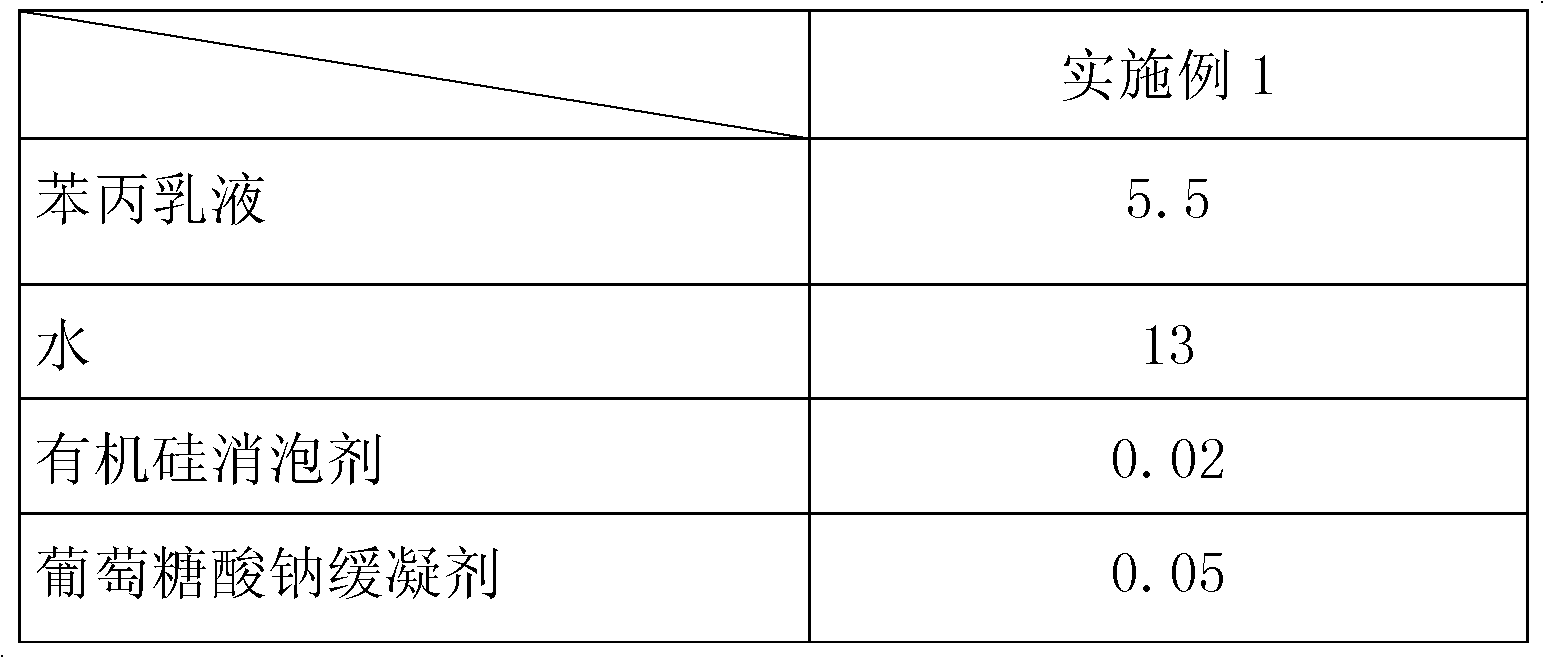

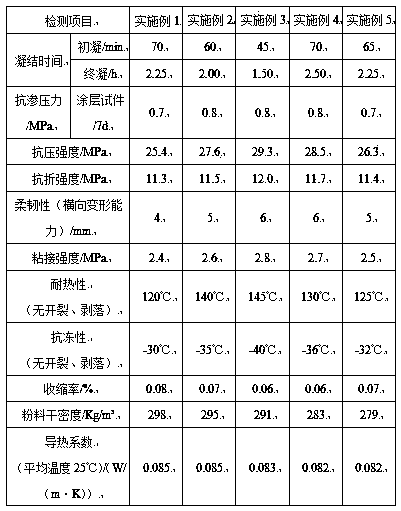

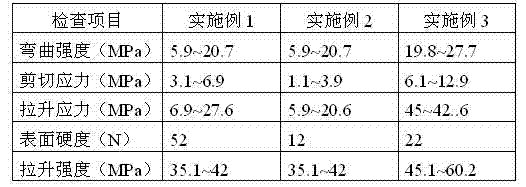

The invention provides energy-saving and light quick-setting waterproof mortar for an outer wall. The waterproof mortar is prepared from liquid materials and powder materials. The weight ratio of the liquid materials to the powder materials is 1:2.77-1:3.33. The liquid materials include styrene-butadiene latex, cellulose ether, water, a defoaming agent and a preservative. The powder materials include portland cement, hollow glass beads, coal ash, quartz sand, a cement expansion agent, a water reducing agent, a dispersing agent, a setting accelerator and a thixotropic agent. The waterproof mortar is short in setting time, the initial setting time is 45-70 min, and the final setting time is 1.50-2.50 h; besides, the waterproof mortar is strong in seepage resistance and good in compressive strength and flexural strength.

Owner:WEIFANG HONGYUAN WATERPROOF MATERIAL

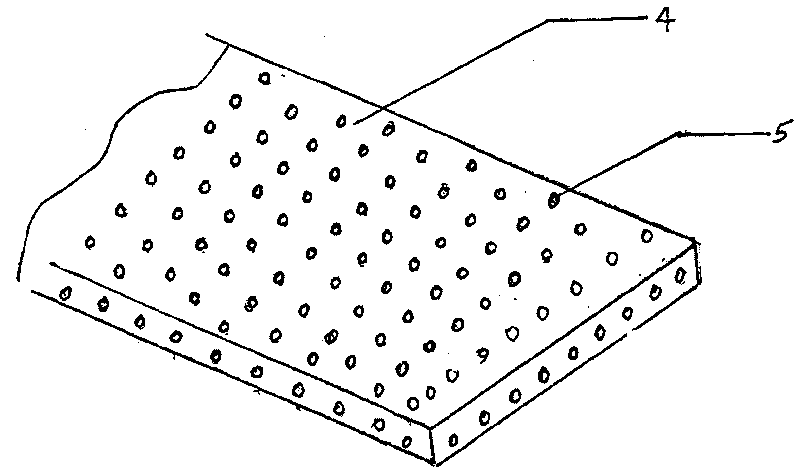

Method for producing paperboards and paper tubes

InactiveCN102248562AImprove adhesionHigh compressive and flexural strengthWood compressionGrain treatmentsFiberAnimal fiber

The invention relates to a method for producing paperboards and paper tubes, comprising the following steps of: (1) carrying out steam blasting and fluid energy milling on plant waste materials to obtain a raw material A; (2) carrying out the steam blasting on waste and old textiles and animal fibers to obtain a raw material B; (3) preparing a sodium silicate solution with the mass concentration of 12-15% to obtain a raw material C; (4) uniformly mixing the raw material A with the mass percent of 84-86%, the raw material B with the mass percent of 6-9%, the raw material C with the mass percent of 6-8% and thermosetting resin with the mass percent of 0-4%, putting the mixture into a paper pressing machine to prepare the paperboards and the paper tubes; and (5) carrying out air drying and curing on the obtained paperboards and paper tubes or curing by adopting a drying machine or a blast blower. The invention has the advantages that: process is simple, raw materials are available; manpower and energy are saved, production efficiency is improved, production cost is reduced; and the obtained paperboards and the paper tubes have good and stable quality, thus the method is applicable topopularization and application and is environment-friendly for papermaking.

Owner:强光初

Oxide ceramics multiple phase refractory material

InactiveCN1919796AIncrease temperatureHigh compressive and flexural strengthOxide ceramicsClay minerals

The invention discloses an oxide ceramic composite phased fireproof material based on clay as raw material, which is characterized by the following: adopting clay minerals, industrial carbon powder and nitrogen as main raw material to form beta-sialon connecting phase; adding reacting accelerant, alumina or mullite particle to blend evenly; moulding; drying; aerating nitrogen in the high-temperature kiln to proceed carbon heat reducing-nitrogenizing reaction to sinter into combined beta-sialon alumina or mullite fireproof ceramic product with 10-30% beta-sialon continuous base phase and 70-90% alumina or mullite particle dispersing phase.

Owner:QINGDAO UNIV

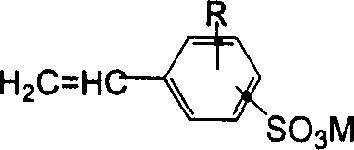

Polymer emulsion for cement base material water reducing and its preparing method

The present invention relates to a kind of polymer emulsion for water reducing of cement base material and its preparation process. The present invention features that the stable polymer emulsion for reducing water of cement base material is prepared through the emulsion polymerization in water of reactive non-ionic emulsifier hydroxyl or alkyl polyalkoxylate glyucol acryl acrylic ester with double bond capable of being polymerized, matter containing sulfo radical or sulfate radical and vinyl radical as ionic emulsifier, methyl acrylate, etc. The emulsion has high water reducing and strengthening effect on cement base material and can greatly raise the work performance, physical mechanical performance and waterproof endurance of composite cement base material.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

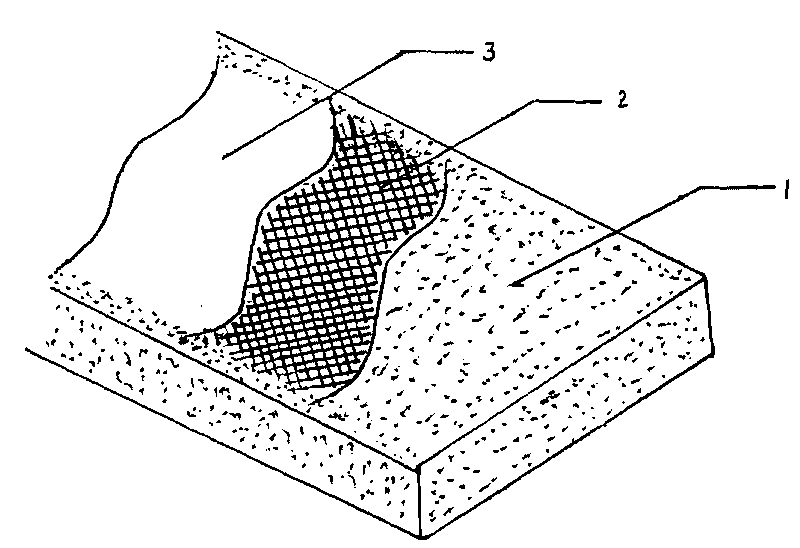

Aerated concrete composite external wall insulation block without autoclaving and production method thereof

InactiveCN101748816AImprove thermal insulationIncreased durabilityCeramic shaping apparatusHeat proofingSurface layerUltimate tensile strength

The invention relates to an aerated concrete composite external wall insulation block without autoclaving and a production method thereof. The method comprises the following steps: casting uniformly stirred aerated concrete material into a die where organic insulation boards are well fixed, and covering all the organic insulation boards inside when the cast material expands; the volume of the cast material after completely expanding is two thirds of the total volume of the aerated concrete composite external wall insulation block without autoclaving. The insulation block has the following advantages: firstly, because the surface layer of the external wall insulation block is made of aerated concrete material, the compression strength, the folding strength and the shock strength thereof are superior to those of the prior external wall insulation block, the insulation block can be strongly bound with cement mortar, is convenient for construction and has extremely strong fire resisting property; secondly, in order to improve the insulating property of the external wall insulation block, polyphenylene boards or polyurethane boards with extremely good insulating property are covered in aerated concrete, thereby not only greatly improving the insulating property of the external wall insulation block, but also overcoming various defaults due to the exposed use of the polyphenylene boards or polyurethane boards. Therefore, the aerated concrete composite external wall insulation block without autoclaving has a very broad application prospect.

Owner:TIANJIN NORMAL UNIVERSITY

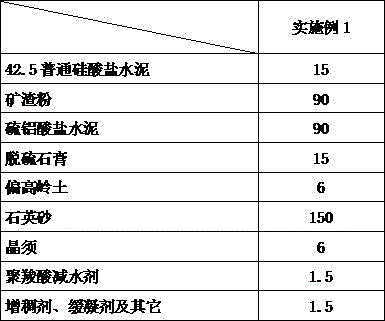

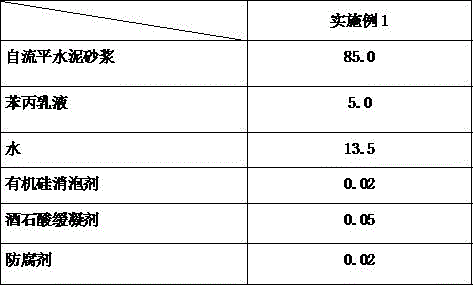

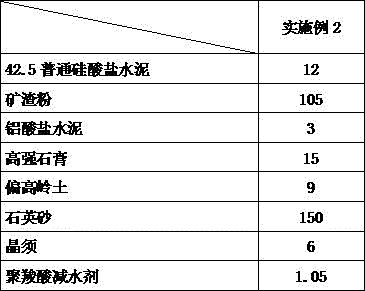

Whisker reinforcement-based self-leveling cement mortar and application thereof

The invention discloses whisker reinforcement-based self-leveling cement mortar. The whisker reinforcement-based self-leveling cement mortar comprises the following components in parts by weight: 10 to 20 parts of ordinary Portland cement, 50 to 150 parts of slag powder, 3 to 20 parts of special cement, 10 to 20 parts of gypsum, 5 to 10 parts of metakaolin, 100 to 160 parts of quartz sand, 1 to 10 parts of a crystal whisker and 1 to 1.5 parts of a water-reducing agent, wherein the special cement adopts sulphoaluminate cement or aluminate cement; the gypsum adopts one of or a mixture of more than two of high-strength gypsum, fluorgypsum, desulfurized gypsum and citric acid gypsum; and the crystal whisker adopts one of or a mixture of more than two of gypsum crystal whiskers, a magnesium hydroxide crystal whisker, a magnesium oxide crystal whisker, an ettringite crystal whisker and a calcium carbonate crystal whisker. A terrace prepared from the whisker reinforcement-based self-leveling cement mortar has high surface hardness and high anti-compression and anti-bending strength, and can meet the wear-resistant requirement of most occasions.

Owner:江苏蓝圈新材料股份有限公司

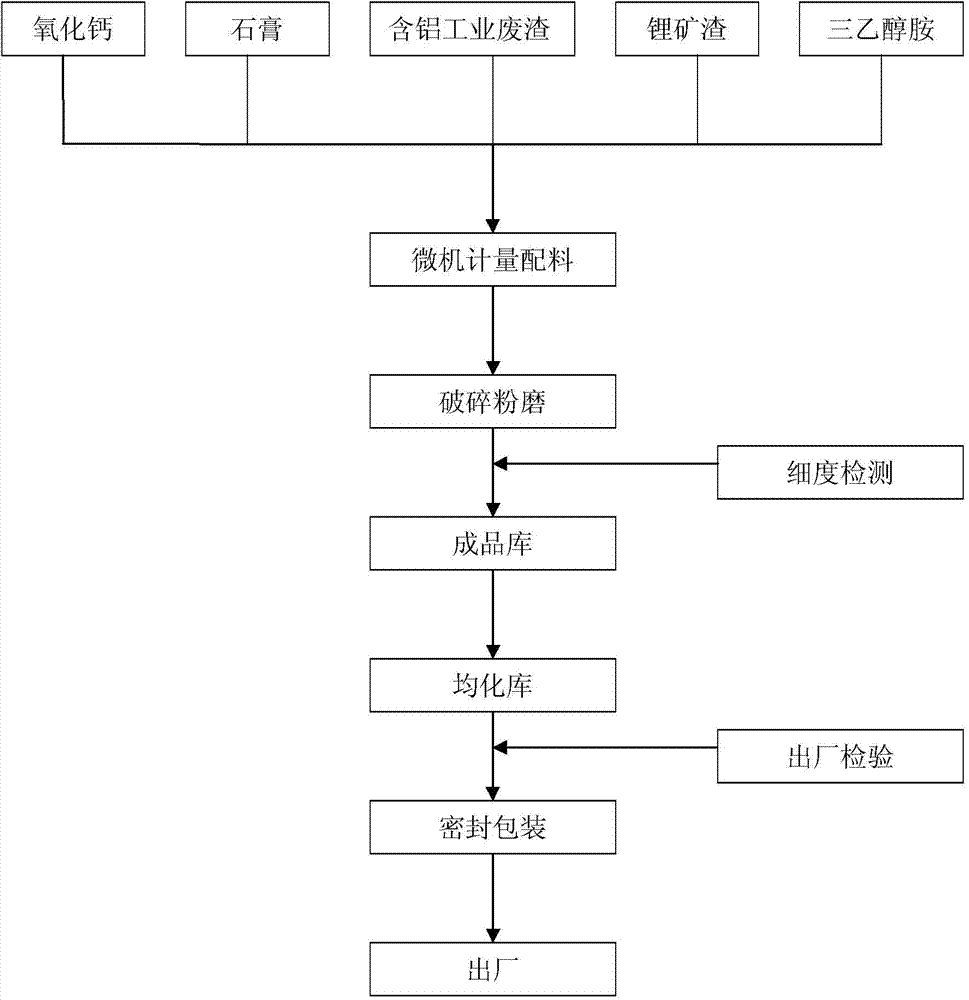

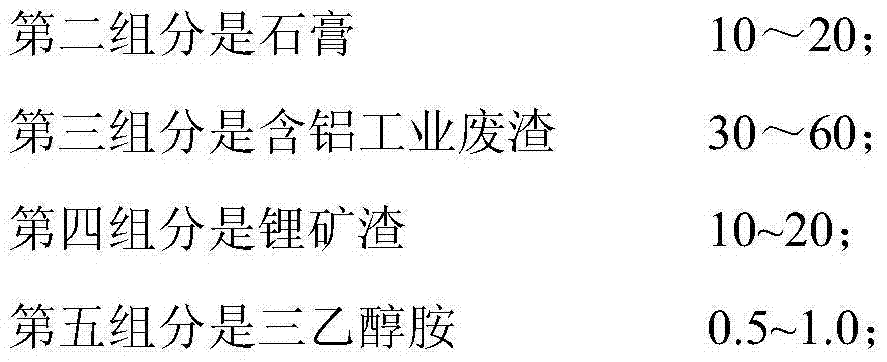

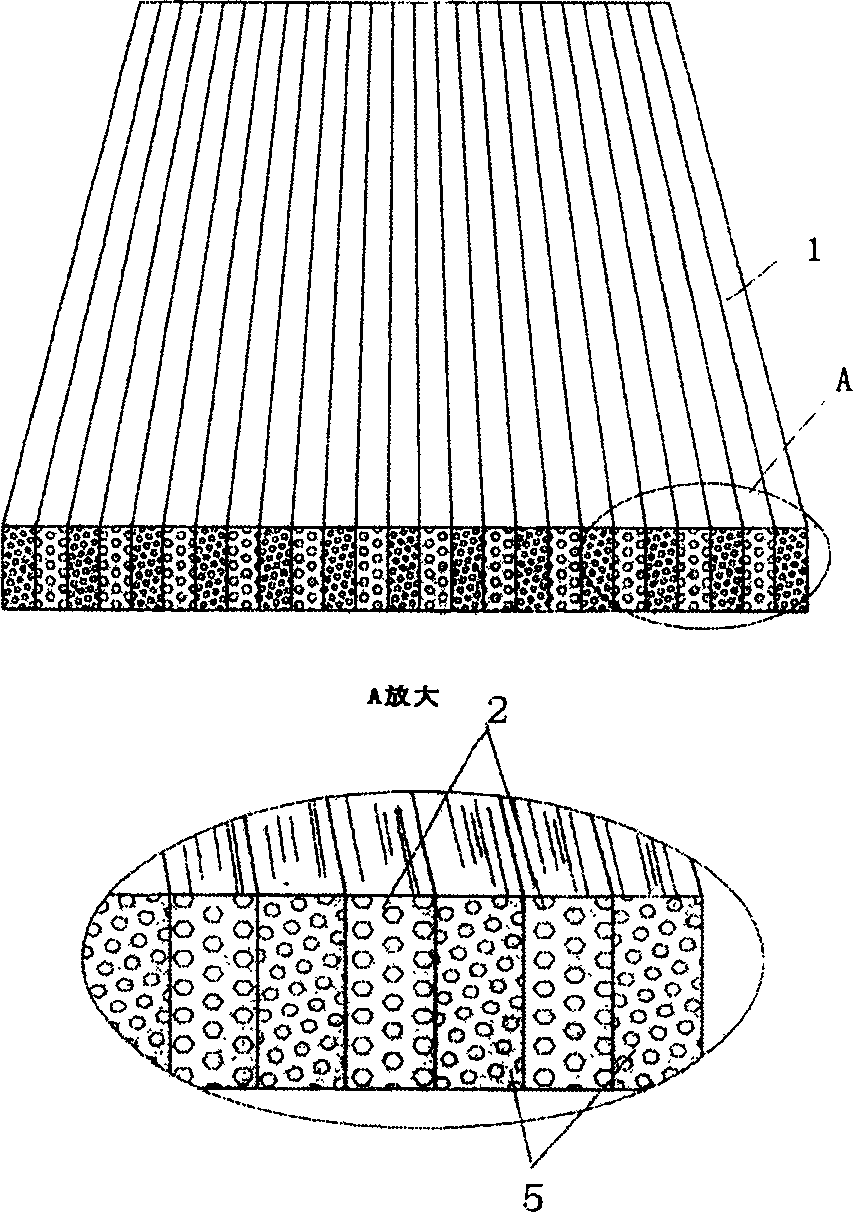

Concrete efficient expending agent employing aluminum-containing industrial waste residues as well as preparation method and application of concrete efficient expending agent

ActiveCN104761172ALarge limit expansion rateHigh compressive and flexural strengthIndustrial wasteSolubility

The invention provides a concrete efficient expending agent employing aluminum-containing industrial waste residues as well as a preparation method and an application of the concrete efficient expending agent. According to the concrete efficient expending agent employing the aluminum-containing industrial waste residues, the solubility of active Al2O3 in the aluminum-containing industrial waste residues is increased by employing multiple excitation effects of calcium oxide, gypsum, lithium slag and triethanolamine; and the obtained expending agent can generate two expending sources, namely calcium hydroxide and ettringite through hydration reaction. The expending agent has the characteristics of calcium oxide expending agents and calcium sulphoaluminate expending agents, and has relatively large restrained expansion rate, relatively high compression resistance and breaking strength.

Owner:JIANGSU SOBUTE NEW MATERIALS

Thermal conductive graphite blocks for blast-furnace bottom and hearth

InactiveCN101993246AReduce porosityImprove thermal conductivityBlast furnace componentsBlast furnace detailsPorosityHearth

The invention provides thermal conductive graphite blocks for a blast-furnace bottom and a hearth, belonging to the technical field of carbon refractory. The raw materials of the graphite blocks comprise the following components in parts by weight: 11-15 parts of petroleum coke with grain size of more than 2mm and less than or equal to 4mm, 10-14 parts of petroleum coke with grain size of more than 1mm and less than or equal to 2mm, 53-60 parts of petroleum coke with grain seize of more than 0.075mm and less than or equal to 0.15mm, 34-40 parts of petroleum coke with grain seize of less than or equal to 0.075mm, and 22-25 parts of mesothermal asphalt. In the formula of the thermal conductive graphite blocks for the blast-furnace bottom and the hearth, high-quality needle cokes with higherintensity and easy graphitization are used, a small grain formula is adopted, and a high-pressure multi-soaking and multi-baking method is adopted, so that an impregnant can penetrate through the holes of the graphite blocks, thus reducing the porosity of the graphite blocks, improving the compactness, volume density and intensity of the products, improving the coefficient of heat conductivity and alkali-resistant corrodibility of the graphite blocks greatly, fundamentally solving the problem of low coefficient of heat conductivity of the graphite blocks, and meeting the requirement on quality of the graphite blocks with high thermal conductivity for large blast furnaces.

Owner:HENAN FANGYUAN CARBON GRP

Water permeable brick and preparation method thereof

InactiveCN105174811AGood water permeabilityHigh compressive and flexural strengthSolid waste managementSlagCoal gangue

The invention provides a water permeable brick and a preparation method thereof. The water permeable brick is prepared from the following raw materials in parts by weight: 60-80 parts of blast furnace slag, 5-15 parts of polished slag, 10-20 parts of coal gangue, 15-25 parts of redware ore soil, 8-15 parts of a flux, 0.8-1.2 parts of an adhesive. The preparation method comprises the following steps of (1) material preparing; (2) crushing; (3) ball milling and wet mixing; (4) drying; (5) molding; and (6) burning. According to the preparation method, the water permeable brick which is prepared by adopting the blast furnace slag and the polished slag as main raw materials and adding the coal gangue and the redware ore soil has a relatively good water permeability, and the tensile structure and bending strength of the water permeable brick can be further improved.

Owner:FOSHAN HECAI TECH SERVICE

Tenon jointed artificial reconstructed bamboo furniture

InactiveCN1807042AHigh hardnessHigh densityFurniture joining partsWood treatment detailsTongue and grooveEngineering

The invention relates feather joint manual reconstructed bamboo furniture, comprising the following steps: using bamboo clappers to make furniture parts, making different shapes tenon, tenon hole and tongue-and-groove, assembling and gluing the parts to make furniture. The said manual reconstructed bamboo is made by high-pressure bonding the bamboo which is high temperature boiled, dried, carbonized and dewatered. The manual reconstructed bamboo made by high pressure bonding comprises side pressure manual reconstructed bamboo, flat clamp manual reconstructed bamboo, I-shaped pressure manual reconstructed bamboo and many I-shaped pressure manual reconstructed bamboo. The tenon, tenon hole and tongue-and-groove are square, trapezoid, round, long round and trapezoid with circular arc.

Owner:MARIA YEE

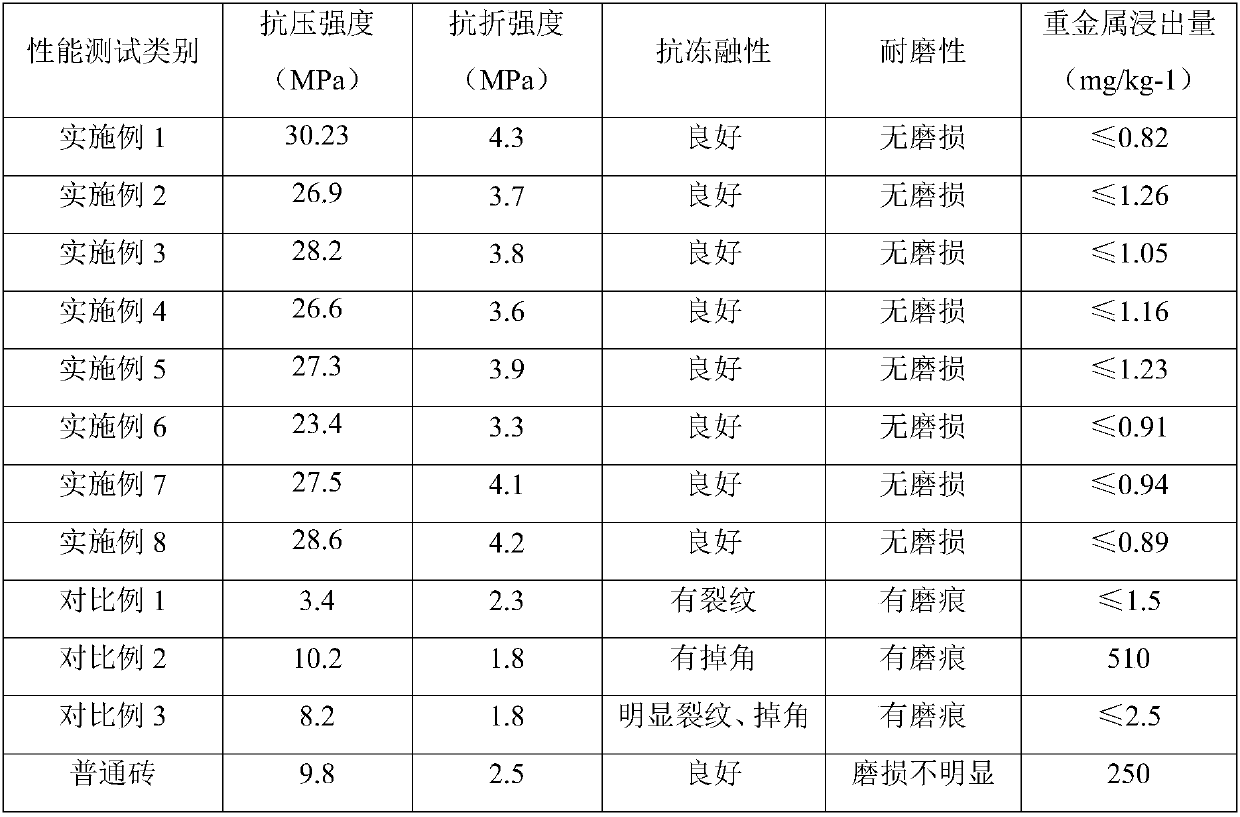

Sludge/mud environment-friendly type baking-free bricks and preparation method thereof

ActiveCN107602041AReduce manufacturing costImprove production efficiencySolid waste managementCoal gangueBrown iron oxide

The invention discloses sludge / mud environment-friendly type baking-free bricks. The sludge / mud environment-friendly type baking-free bricks are prepared from the following raw materials in percentageby weight: 30 percent to 60 percent of waste mud, 5 percent to 25 percent of rough sand, 5 percent to 25 percent of silicon aluminum calcium iron oxide, 2 percent to 20 percent of mountain flour, 2 percent to 20 percent of quicklime and 2 percent to 20 percent of gypsum, wherein the waste mud is sludge or / and mud; the silicon aluminum calcium iron oxide is one or a mixture of more of fly ash, fine coal slag, mineral slag powder and coal gangue. According to the sludge / mud environment-friendly type baking-free bricks disclosed by the invention, resource utilization of the sludge / mud can be realized; the raw material composition is simple and the cost is low; the product has the characteristics of high bending strength and compressive strength, good wearing resistance, strong freezing and thawing resisting capability and the like through the optimization of the raw material ratio; the leaching rate of heavy metal in the baking-free bricks is relatively low, and the baking-free bricks have no odor and are environmentally friendly and safe, so that large-scale batch production is easy to realize; the baking-free bricks can be applied to the fields of engineering construction includingmunicipal plaza pavement, sidewalk pavement, hydraulic engineering protection slopes and the like.

Owner:武汉鹏森环境科技有限公司

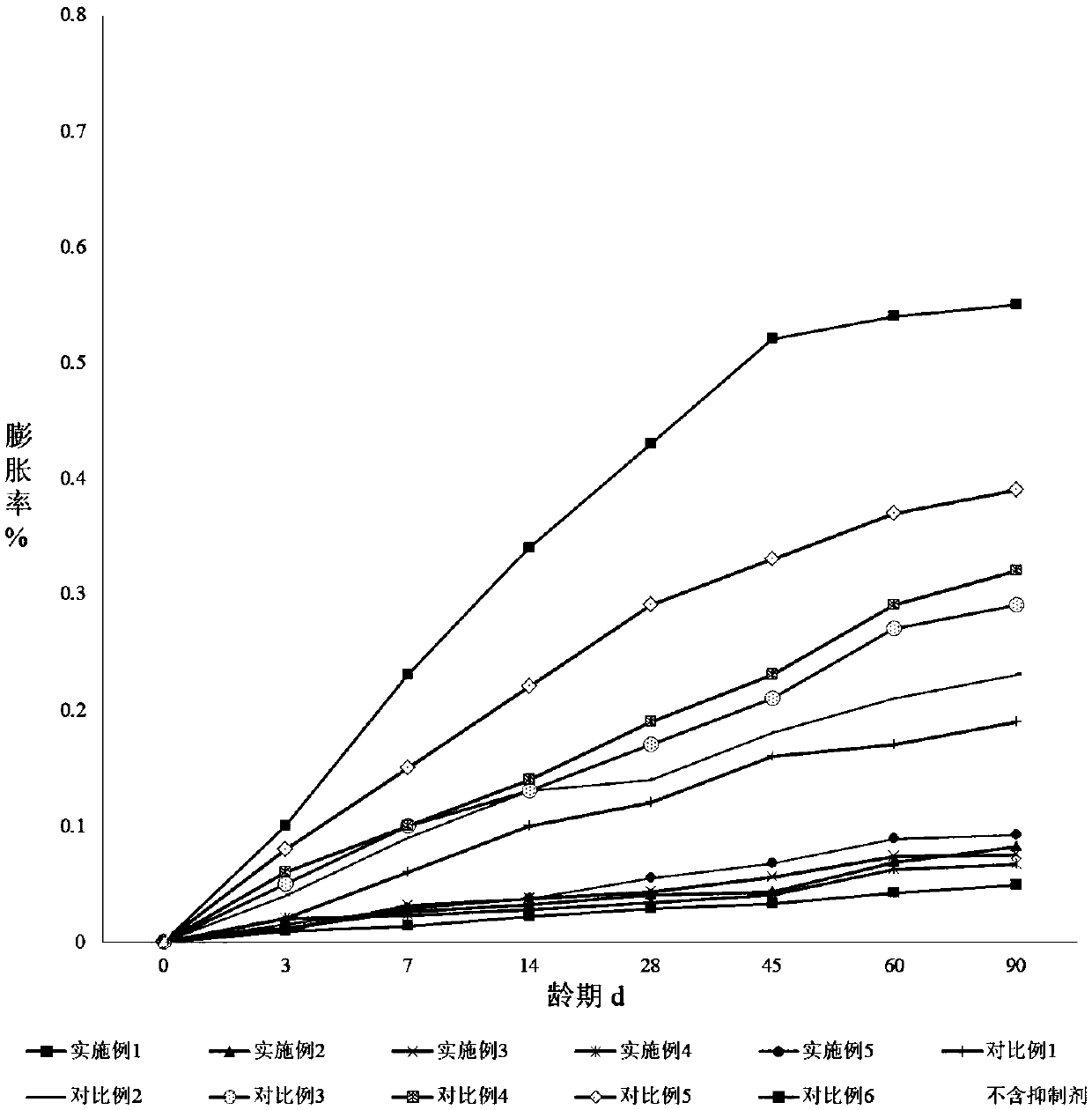

Alkali aggregate reaction inhibitor

The invention belongs to the field of concrete auxiliary materials, and particularly relates to an alkali aggregate reaction inhibitor. The inhibitor comprises quaternary ammonium salt, a nonionic surfactant, rice hull ash, soybean meal, lactic acid and lithium carbonate. The invention further discloses a preparation method of the inhibitor. The inhibitor is simple in preparation method and can effectively inhibit the alkali aggregate reaction after being mixed with cement mortar, and the method is an economical and efficient alkali aggregate reaction inhibition technology.

Owner:内蒙古自治区水利水电勘测设计院 +1

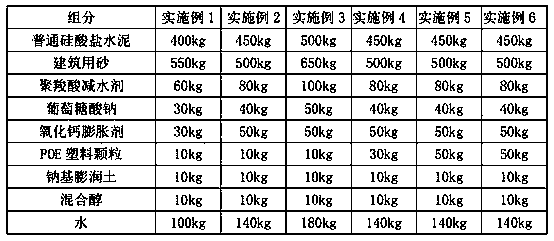

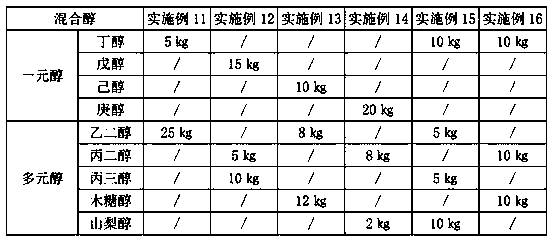

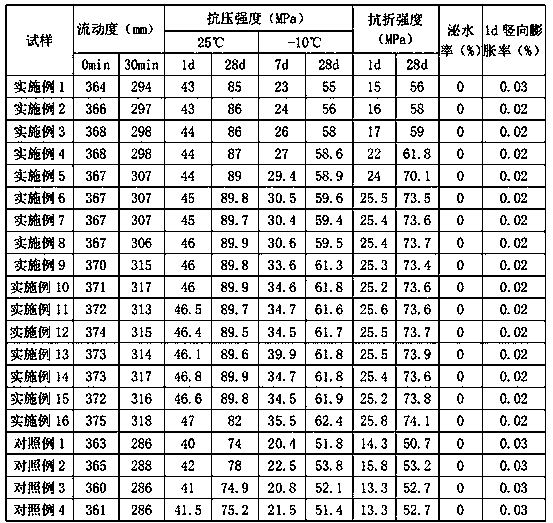

Grouting material for connection of prefabricated concrete member sleeves for prefabricated construction and preparation method thereof

ActiveCN109824320AImprove compression and impact resistanceAvoid crackingHigh intensityCompressive strength

The invention discloses a grouting material for the connection of prefabricated concrete member sleeves for prefabricated construction, and belongs to the technical field of cement based grouting materials. The grouting material comprises following components in parts by weight: 40 to 50 parts of silicate cement, 55 to 65 parts of building sand, 6 to 10 parts of water reducer, 3 to 5 parts of early strength agent, 3 to 5 parts of expanding agent, 1 to 5 parts of damping particles, 1 to 3 parts of bentonite, 1 to 3 parts of mixed alcohol, and 10 to 18 parts of water. The grouting material has the characteristics of excellent fluidity, high compressive strength and high rupture strength, maintains high strength at a low temperature, and is suitable for low temperature construction. The invention also discloses a preparation method of the grouting material. The preparation method has the advantages of simple steps and low raw material cost, and is suitable for popularization and application.

Owner:南京华致建设集团有限公司

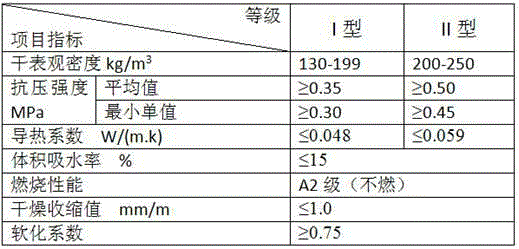

Foaming magnesium cement EPS particle grade A noncombustible board and preparation method thereof

InactiveCN104671822AIncrease tensile toughnessHigh compressive and flexural strengthCeramicwareFiberThermal insulation

The invention discloses a foaming magnesium cement EPS particle grade A noncombustible board. The foaming magnesium cement EPS particle grade A noncombustible board is characterized by being prepared from the following raw materials by weight: 80Kg of magnesium oxide, 5Kg of magnesium sulfate heptahydrate, 500g of nekal, 500g of calcium stearate, 10Kg of silicified straw fiber, 20Kg of hydroxyl mineral fibers, 18Kg of EPS particles, 500g of borax, 10Kg of nanofiber gypsum, 20Kg of sepiolite powder and 20Kg of magnesium chloride, wherein the silicified straw fiber is formed by spraying the mixed emulsion of sodium silicate and sodium chloride on the surface layer of the straw fibers for permeating. The preparation method comprises the steps of firstly adding water to the raw materials and stirring, secondly adding the nekal and stirring for foaming, and finally adding the EPS particles and stirring, injecting into a mold for molding, and curing at the normal temperature of 25 DEG C. The foaming magnesium cement EPS particle grade A noncombustible board prepared from the following raw materials is fireproof and thermal insulating, and reaches the fire protection glade A2. Besides, the board is good in thermal insulation properties, high in compressive strength and strong in adhesion stress.

Owner:南阳中兴银通建材科技有限公司

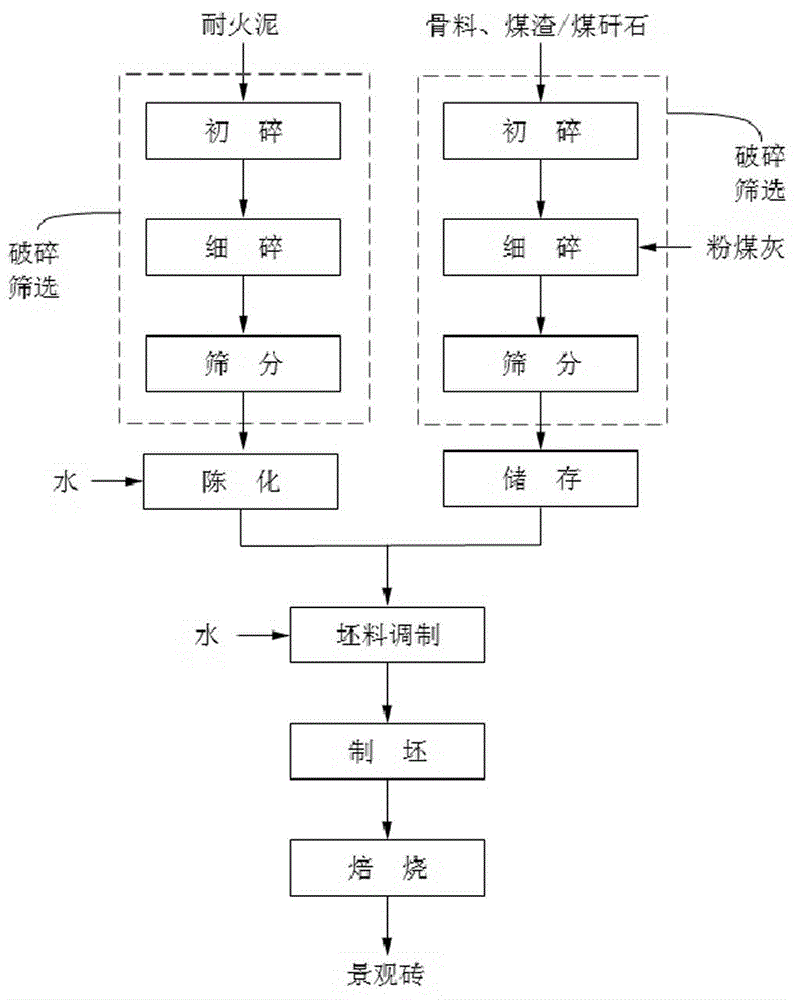

Yellow sintered landscape brick and production method thereof

InactiveCN104556962AImprove firing performanceReduce deformation of finished productFire clayHigh pressure

The invention discloses a yellow sintered landscape brick and a production method thereof. The yellow sintered landscape brick comprises 30 to 50 percent of fire clay and 50 to 70 percent of aggregate, wherein the sum of mass percent of all raw materials is not more than 100 percent. The production method comprises the steps of crushing, screening, blank mixing, blank preparation and roasting. According to the yellow landscape brick, aggregate is adopted as a main material, fire clay is adopted as an auxiliary material, and particularly hard fire clay and / or half-hard fire clay is adopted, so that the plasticity of the aggregate can be realized, and the blank is good in moldability; meanwhile, the raw materials are sintered at a high temperature of a specific range, the fire clay is thermally decomposed and toughened and covers and is bonded to the aggregate to present in faint yellow color and yellow color effects, so that the landscape brick has the characteristics of pure yellow color, relatively high pressure resistance and bending resistance and small deformation. The production method is pure in color, simple in process and stable in product quality.

Owner:楚雄诚鑫工贸有限公司

Heat insulating material for flume and its preparation method

The invention relates to a heat insulating material used for an aqueduct and a preparation method thereof. The heat insulating material used for the aqueduct is characterized in that the material is made by mixing and stirring dry mixture and water, the mass ratio of the water to the dry mixture is between 1.1:1 and 1.2:1; the dry mixture consists of cement, vitrified hollow beads, sepiolite fiber, siliceous dust, cement-based capillary crystalline material, waste rubber powder, re-dispersible emulsion powder and hydroxypropyl methyl cellulose; and the mass percentage of the raw materials of the dry mixture are: 35 to 54.9 percent of the cement, 35 to 54.9 percent of the vitrified hollow beads, 2 to 8 percent of the sepiolite fiber, 3 to 6 percent of the siliceous dust, 1 to 4 percent of the cement-based capillary crystalline material, 3 to 6 percent of the waste rubber powder, 1 to 5 percent of the re-dispersible emulsion powder and 0.1 to 0.5 percent of the hydroxypropyl methyl cellulose. The heat insulating material has the characteristics of low water absorbing rate, high cohesional strength and compressive strength, good anti-cracking ability and good stability.

Owner:WUHAN UNIV OF TECH

High-performance heat-insulation wear-resistant material and preparation method thereof

InactiveCN102815954AHigh compressive and flexural strengthLow thermal conductivitySodium triphosphateWear resistant

The invention relates to a high-performance heat-insulation wear-resistant material and a preparation method thereof, and is used for solving the problems of high incineration and shedding tendency at the high temperature region, short service life and the like in the heat-insulation material of the blast-furnace air supply device. The technical scheme is as follows: the material is prepared from the following raw materials in parts by weight: 40.5-45.5 parts of flint clay, 15.3-20.5 parts of sintered mullite, 3.2-4.5 parts of floating bead, 5.5-7.4 parts of aluminum oxide hollow sphere, 7.2-8.5 parts of aluminum oxide micropowder, 3.3-5.6 parts of silicon micropowder, 4.3-6.5 parts of spodumene, 3.5-4.5 parts of kyanite, 0.1-0.3 part of sodium tripolyphosphate and 1.5-3.2 parts of dispersant. The method comprises the following steps: mixing the materials, pouring, curing at normal temperature, curing at high temperature and the like. The technique provided by the invention is suitable for preparation and technical pouring of the heat-insulation material of which the heat-insulation layer structure is 25-30mm; and the heat-insulation material has the characteristics of high compaction and folding strength, small heat conductivity coefficient and the like, and can satisfy the technical requirements for heat-insulation materials of blast-furnace air supply devices.

Owner:QINGHUANGDAO NORTH METAL HOSE

Reinforced foaming ceramic inorganic heat-preserving board and preparation method thereof

The invention discloses a reinforced foaming ceramic inorganic heat-preserving board. The reinforced foaming ceramic inorganic heat-preserving board comprises the following components in parts by weight: 60 to 120 parts of nanometer silica fume, 5 to 30 parts of cement, 5 to 14 parts of lime, 0.3 to 3 parts of foaming agent and 0.8 to 3.4 parts of reinforcing element, wherein the reinforcing element is titanium or boric reinforcing substance. The invention also provides a preparation method of the reinforced foaming ceramic inorganic heat-preserving board. The product is obtained by foaming and steaming the raw materials. The heat conduction coefficient of the nanometer silica fume is low, so that the convection movement of the air molecules can be effectively prevented, a purpose of heat preservation and flame retardance can be realized, and the cold-hot bridge is unlikely to form. By adding the reinforcing element, the mullite with high strength is formed, so that the compression-resisting strength and the bending-resisting strength are higher. The reinforced foaming ceramic inorganic heat-preserving board has the advantages that the strength is high, the density is low, and the heat conduction coefficient is low.

Owner:CHONGQING LONGZHE HIGH TECH MATERIAL

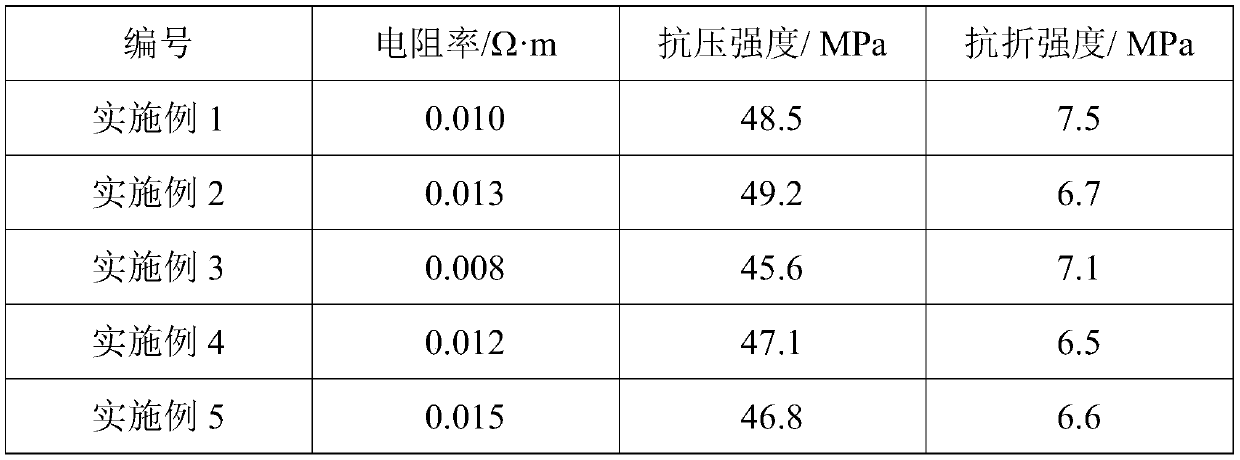

Conductive concrete for tower grounding and preparation method thereof

The invention provides conductive concrete for tower grounding. The conductive concrete is prepared from, by weight, 100-150 parts of cement, 100-150 parts of aggregate, 50-120 parts of water, 40-65 parts of graphite, 2-8 parts of stainless steel fiber, 1-5 parts of a polyaniline / bentonite composite material and 0.5-3 parts of an auxiliary. The graphite and the stainless steel fiber are compoundedinto a main conductive doping phase, and the polyaniline / bentonite composite material and the auxiliary are added so that the conductive performance and mechanical strength of the conductive concretecan be effectively improved, the electrical resistivity of the conductive concrete is smaller than or equal to 0.015 ohm.m, the compressive strength is 45-50 MPa, and the bending strength is 6.5-7.5MPa.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO LTD RES INST +3

Coal slime tailings, sintered brick prepared from coal slime tailings and preparation method thereof

PendingCN110153143AFast sintering speedIncrease productionSolid waste disposalCeramic shaping apparatusBrickCoal

The invention belongs to the field of wall material production, and particularly relates to a coal slime tailings, a sintered brick prepared from coal slime tailings and a preparation method thereof.The raw material of the sintered brick is the tailings separated by a separation column; the tailings comprises the following, by mass 40%-55% of SiO2, 16%-30% of Al2O3, 1%-5% of Fe2O3, 1%-5% of CaO,and the balance other elements; and the calorific value of the coal slime tailings is less than or equal to 2.5 MJ / kg. The sintered brick has high compressive strength and light weight, and has the characteristics of frost resistance, sound absorption, corrosion resistance, water permeability and air permeability; the brick has uniform size and no deviation; the brick surface is clean and smooth,and edges and corners are distinct; the color is uniform; and the preparation method has simple process, so that the energy waste is reduced.

Owner:西安煤科动力科技有限公司

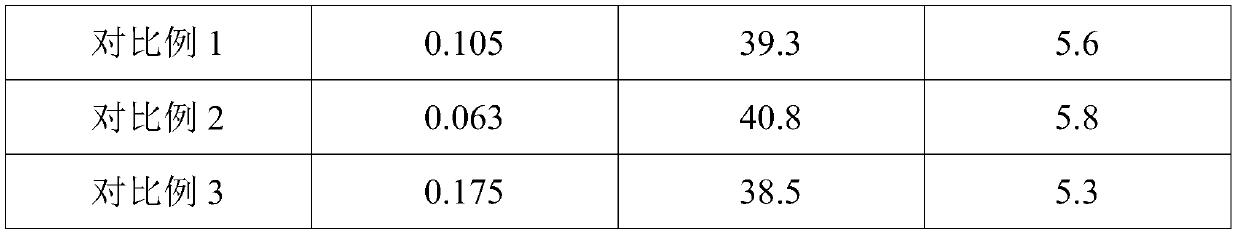

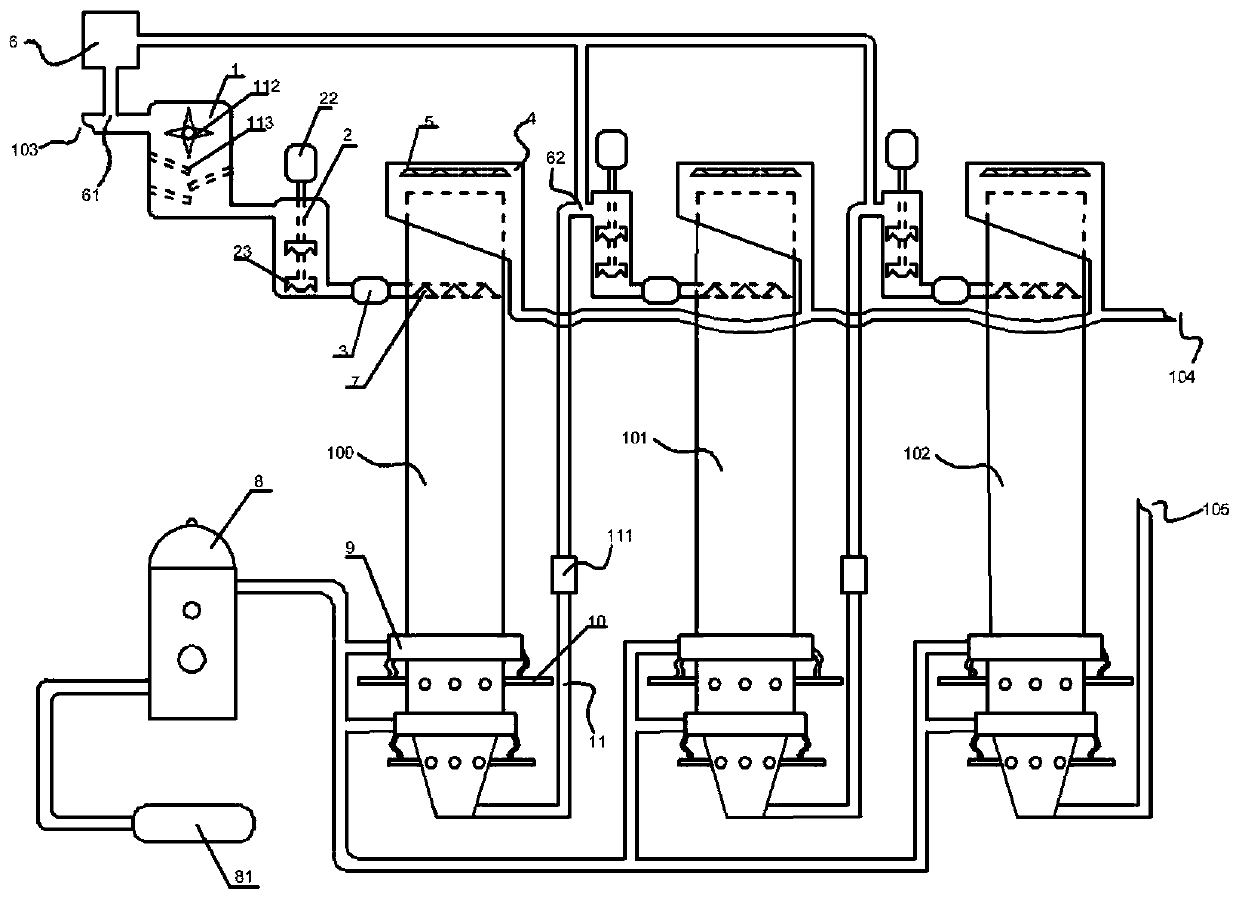

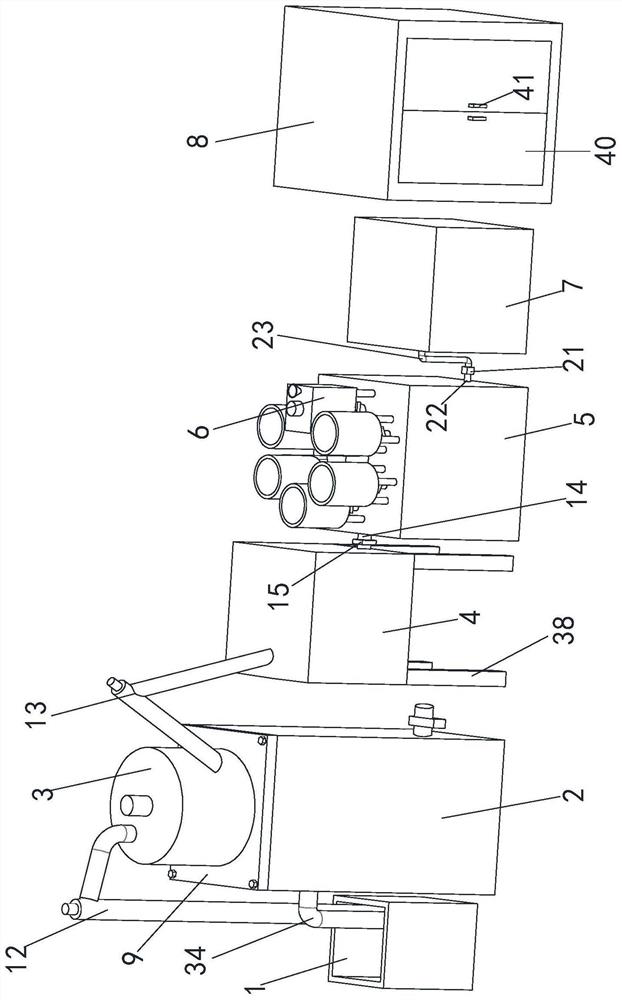

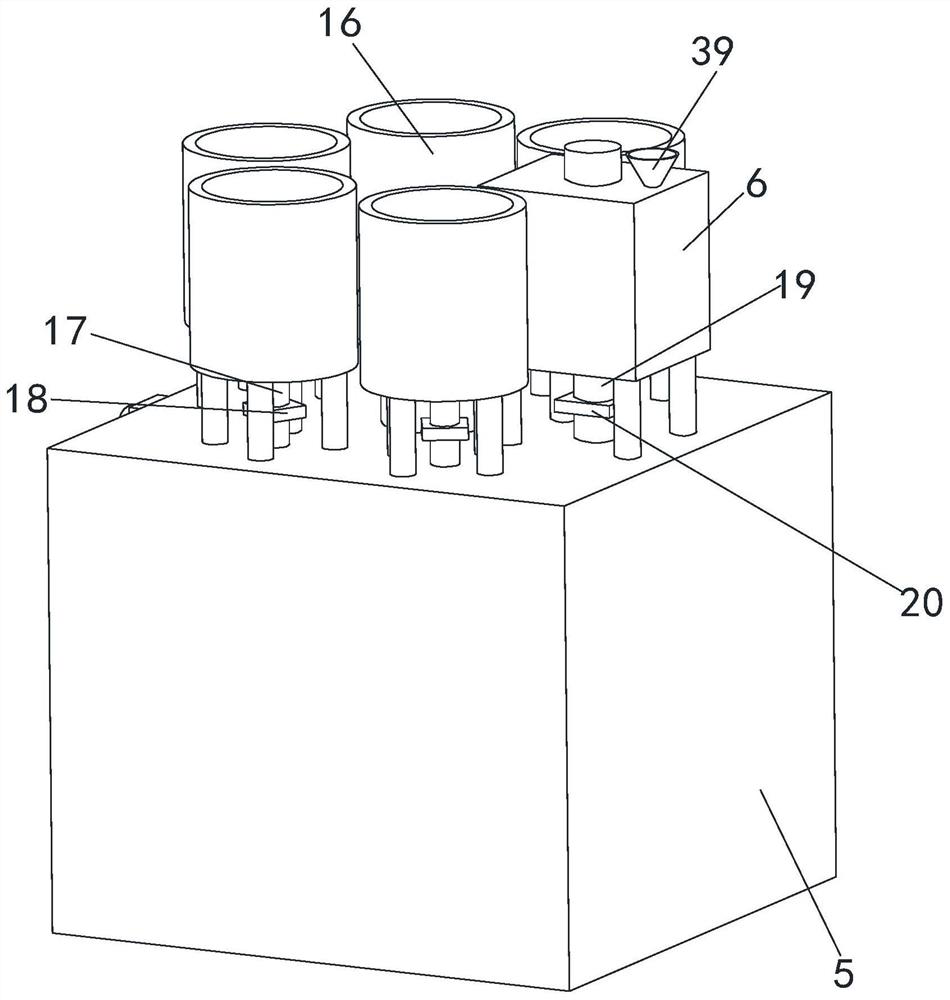

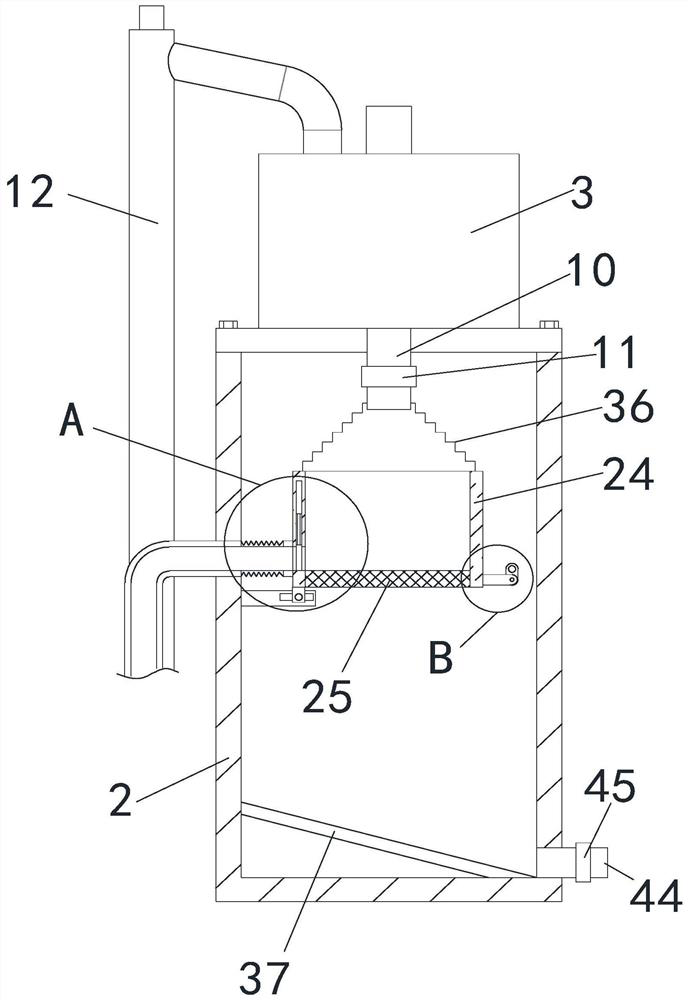

Production line for preparing concrete blocks

PendingCN112476751AAvoid cloggingExtended service lifeCeramic shaping plantsFeeding arrangmentsProduction lineFoaming agent

The invention relates to the technical field of solid waste comprehensive utilization, in particular to a production line for preparing concrete blocks. The production line comprises a feeding box, ascreening box, a crushing and magnetic separation device, a dehydration instrument, a first stirring box, a second stirring box, an injection molding device and a heat preservation chamber; a top plate is mounted at the top end of the screening box; a screening device is arranged in the screening box; the bottom end of the crushing and magnetic separation device is fixedly connected with the top end of the top plate; the bottom end of the crushing and magnetic separation device communicates with the interior of the screening box through a feeding pipe; a first electromagnetic valve is mountedon the feeding pipe; and the feeding box is located on the left side of the screening box. On the premise that the performance of the aerated concrete blocks is guaranteed, the problem of accumulationof waste residues of enterprises is solved, meanwhile, the production cost of the aerated concrete blocks is greatly reduced, the compressive and flexural strength of the concrete blocks is improved,the aerated concrete is prepared from steel slag tail mud, steel slag fine sand, composite foaming agents and alkali excitants without autoclaving, and the relatively-high strength can be developed in a room-temperature environment.

Owner:HUBEI POLYTECHNIC UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com