Patents

Literature

7876 results about "Brown iron oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

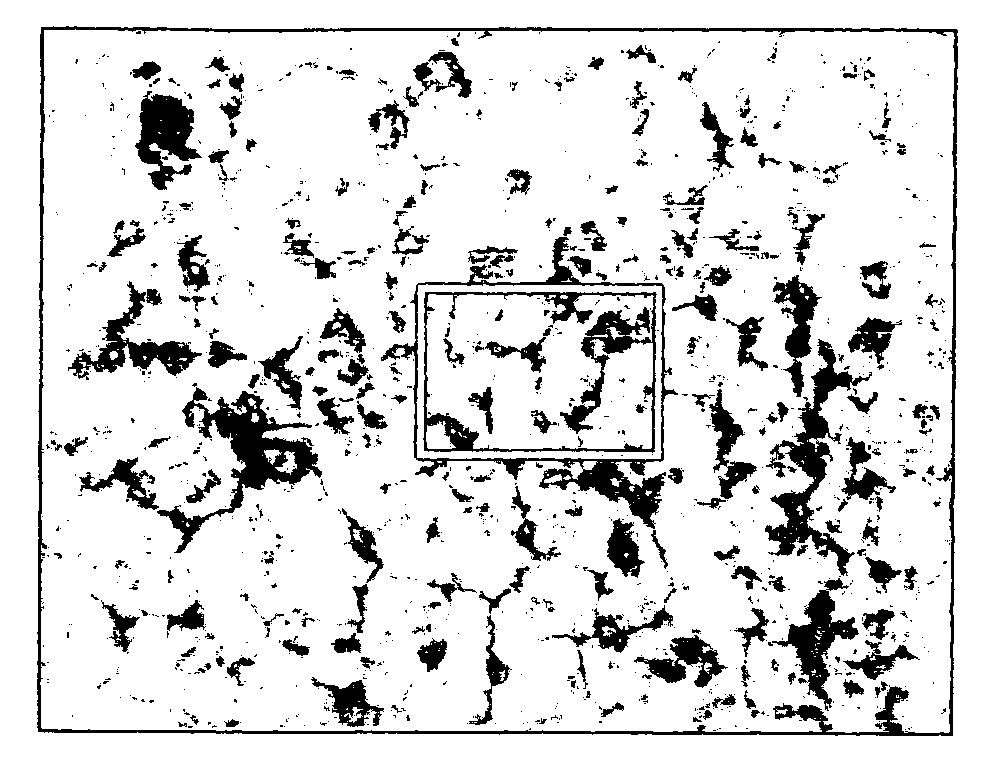

Iron oxide pigment. The brown color indicates that iron is at the oxidation state +3. Green and reddish brown stains on a limestone core sample, respectively corresponding to oxides/hydroxides of Fe2+ and Fe3+.

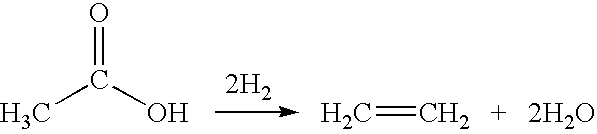

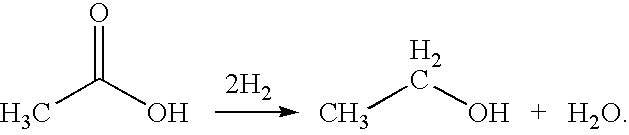

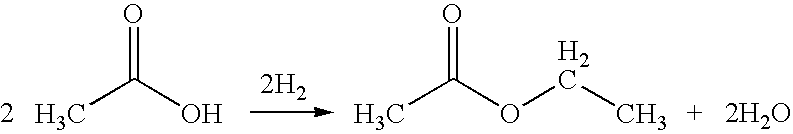

Process for catalytically producing ethylene directly from acetic acid in a single reaction zone

InactiveUS20100030001A1High selectivityHigh yieldHydrocarbonsBulk chemical productionAcetic acidHydrogen

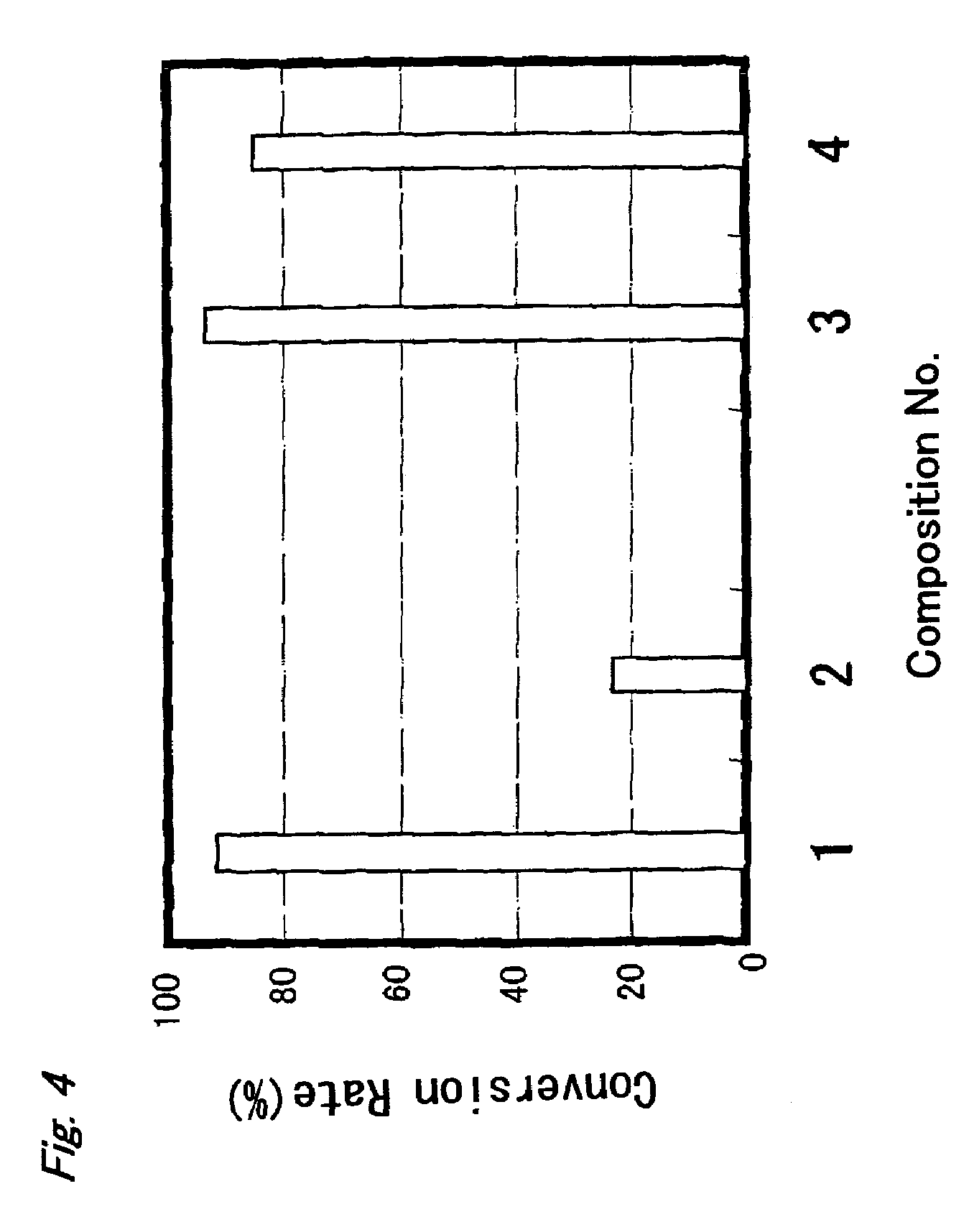

A process for the selective production of ethylene by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form ethylene in a single reaction zone is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over either a copper supported on iron oxide, copper-aluminum catalyst, cobalt supported on H-ZSM-5, ruthenium-cobalt supported on silica or cobalt supported on carbon selectively produces ethylene in a vapor phase at a temperature in the range of about 250° C. to 350° C.

Owner:CELANESE INT CORP

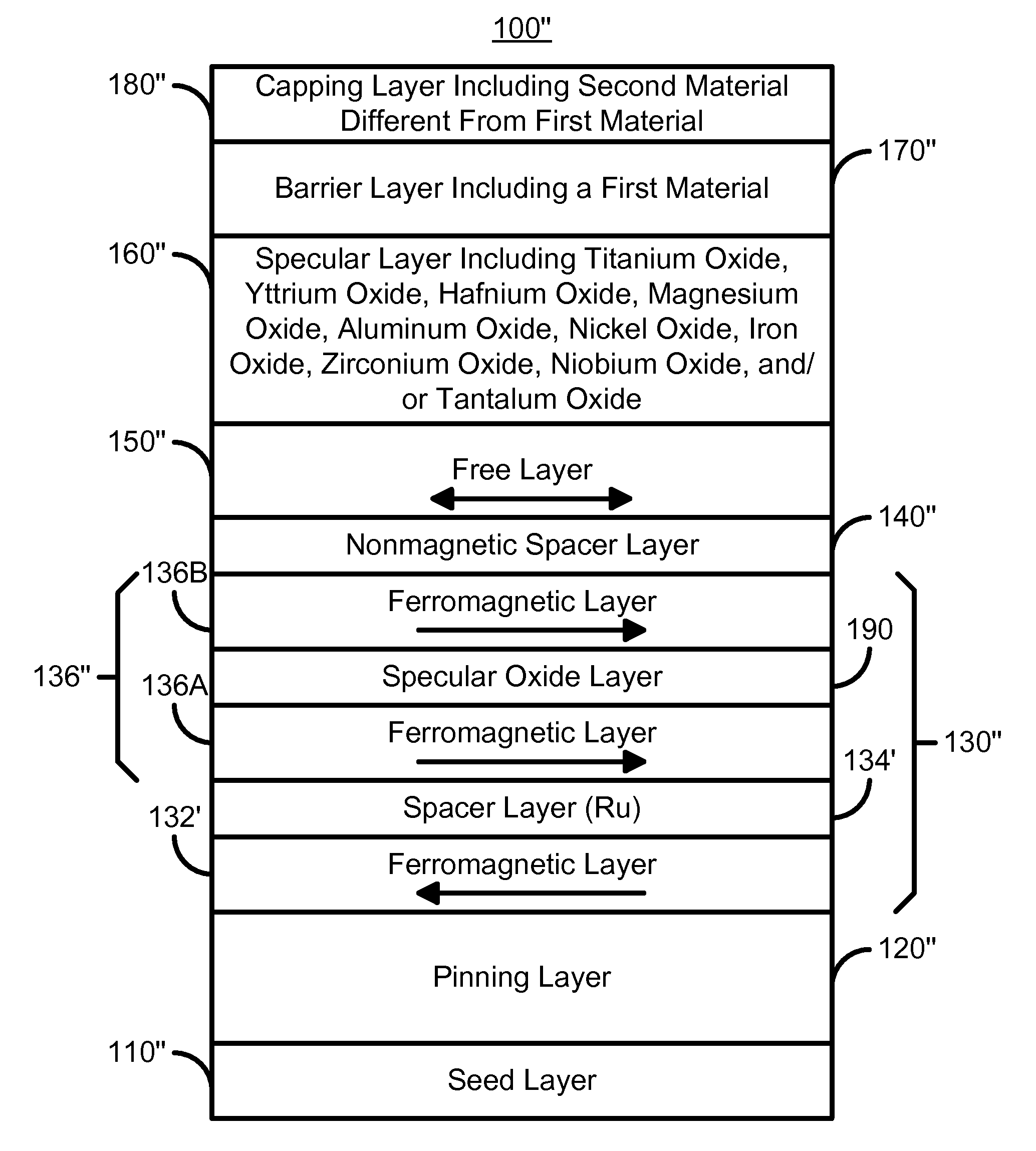

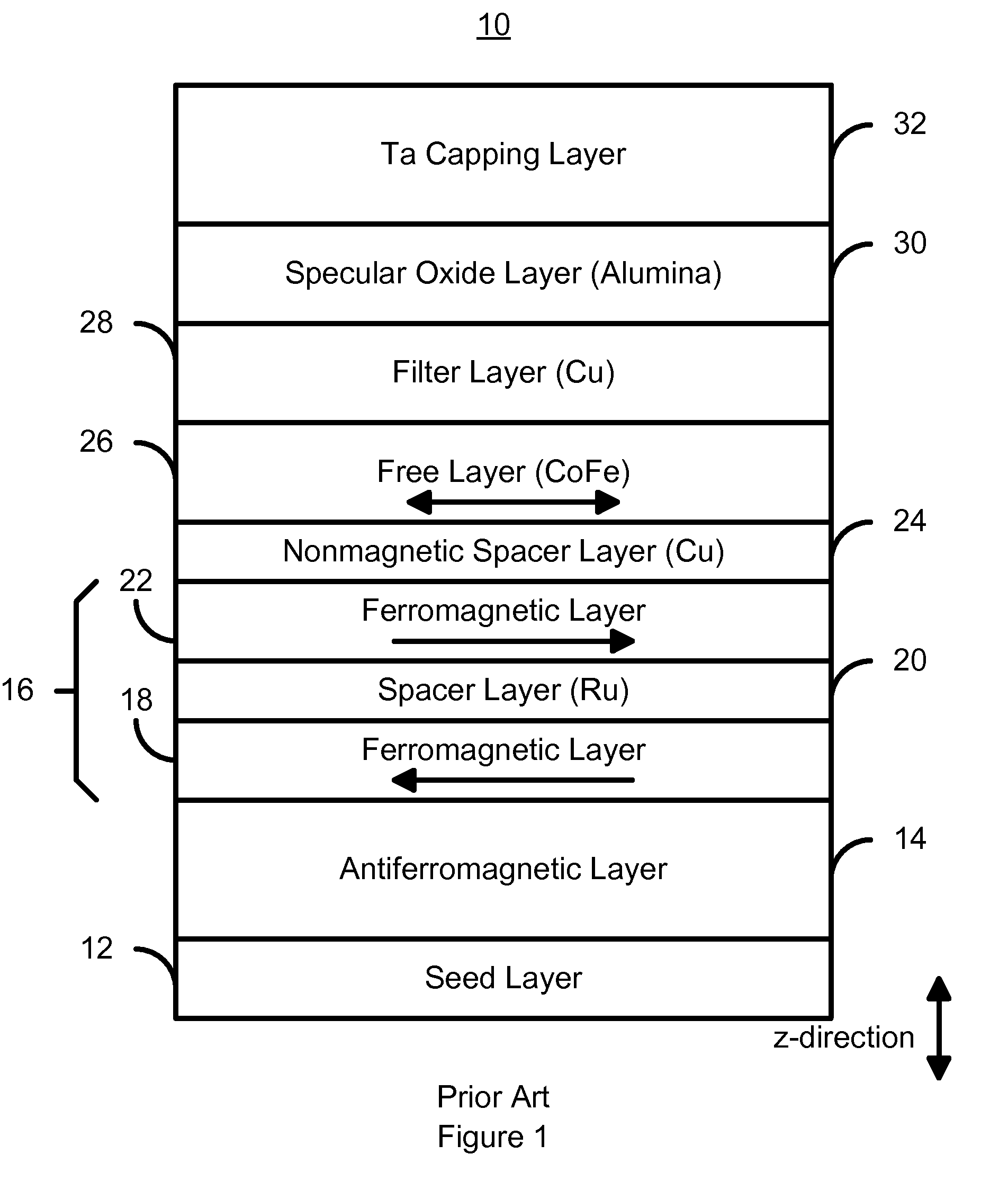

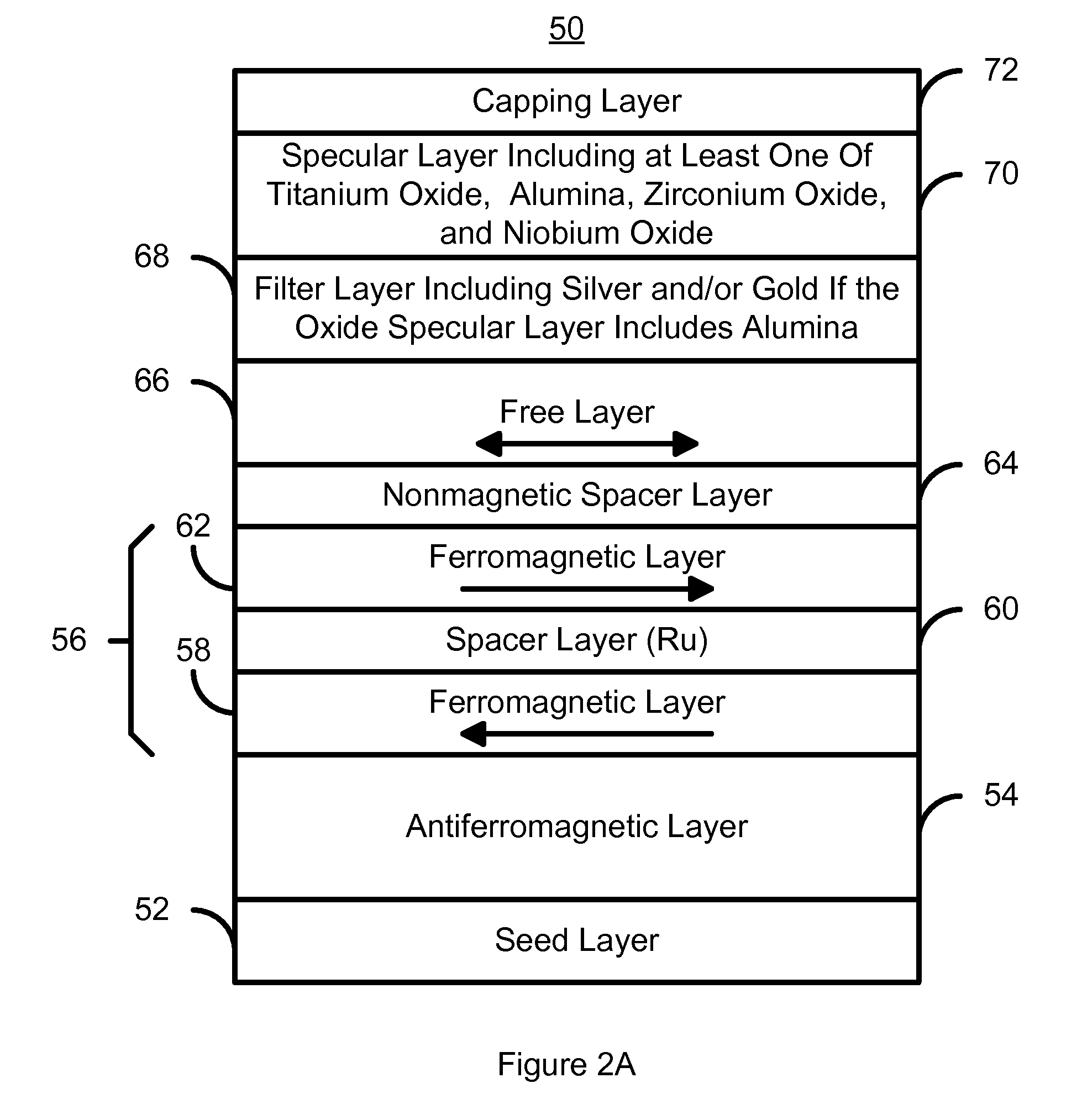

Magnetoresistive structure having a novel specular and barrier layer combination

InactiveUS7684160B1Magnetic-field-controlled resistorsConductive/insulating/magnetic material on magnetic film applicationYttriumTitanium oxide

A method and system for providing a magnetoresistive structure is disclosed. The magnetoresistive structure includes a pinned layer, a nonmagnetic spacer layer, a free layer, a specular layer, a barrier layer, and a capping layer. The spacer layer resides between the pinned layer and the free layer. The free layer is electrically conductive and resides between the specular layer and the nonmagnetic spacer layer. The specular layer is adjacent to the free layer and includes at least one of titanium oxide, yttrium oxide, hafnium oxide, magnesium oxide, aluminum oxide, nickel oxide, iron oxide, zirconium oxide, niobium oxide, and tantalum oxide. The barrier layer resides between the specular layer and the capping layer. The barrier layer is nonmagnetic and includes a first material. The capping layer includes a second material different from the first material.

Owner:WESTERN DIGITAL TECH INC

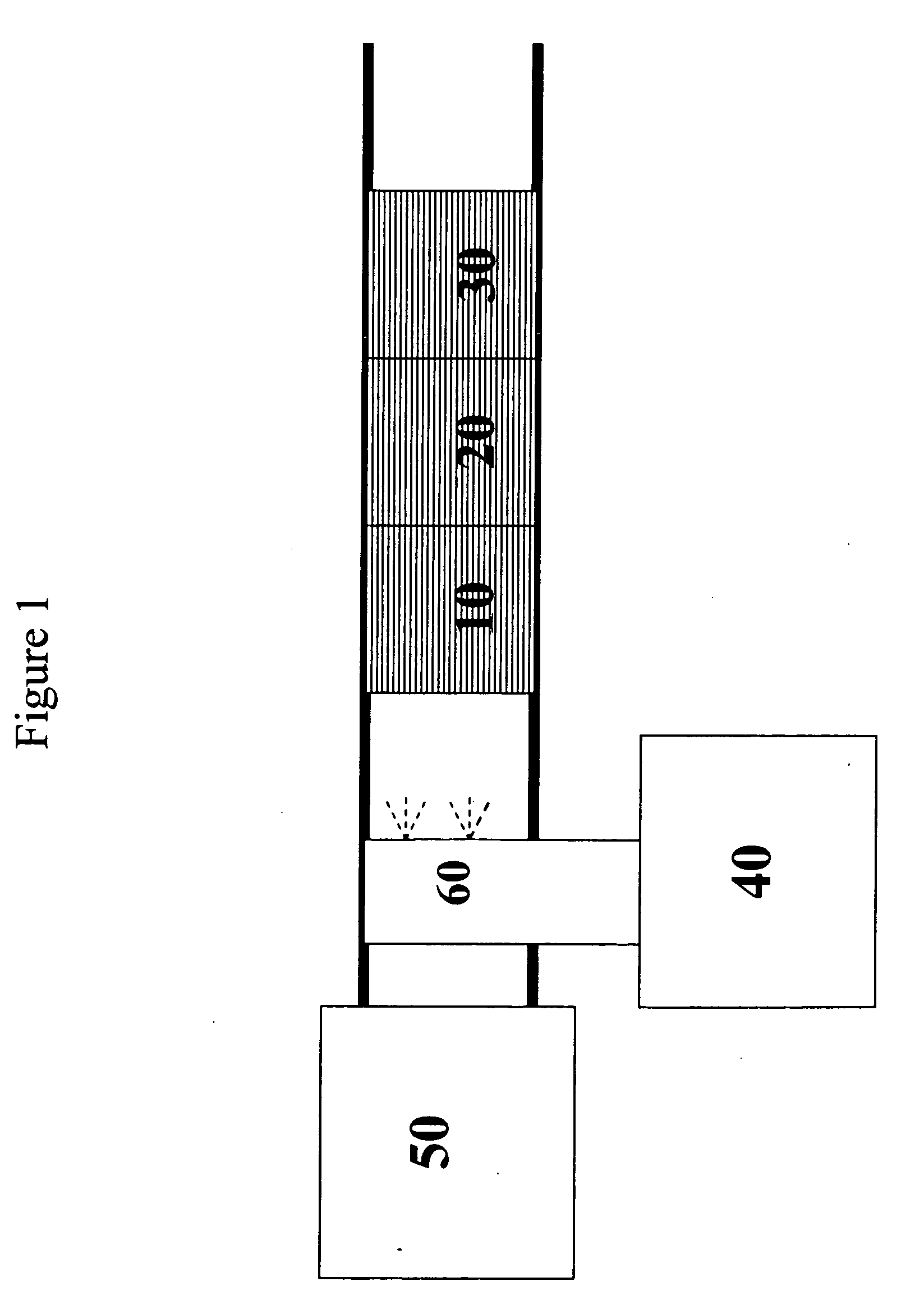

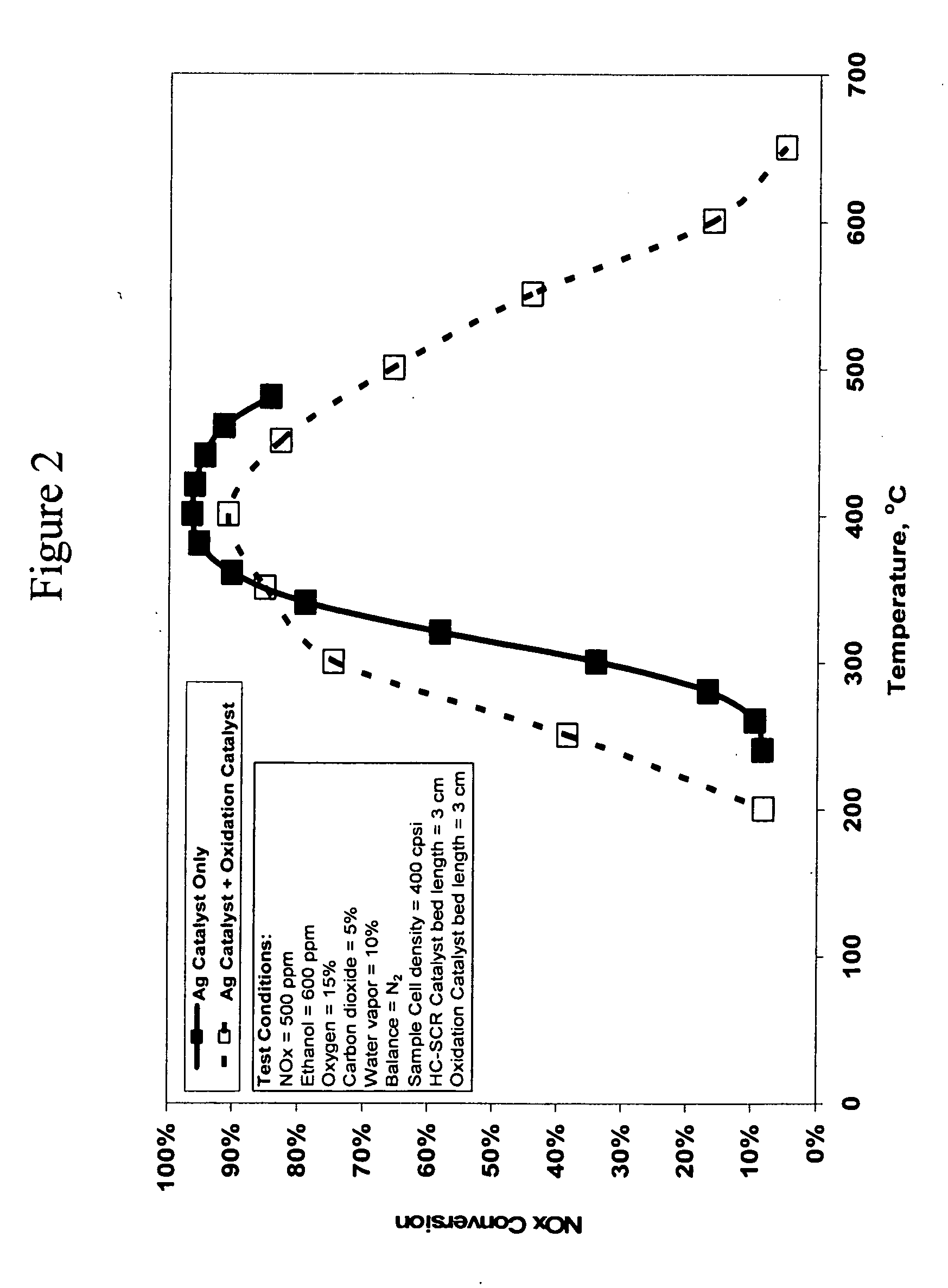

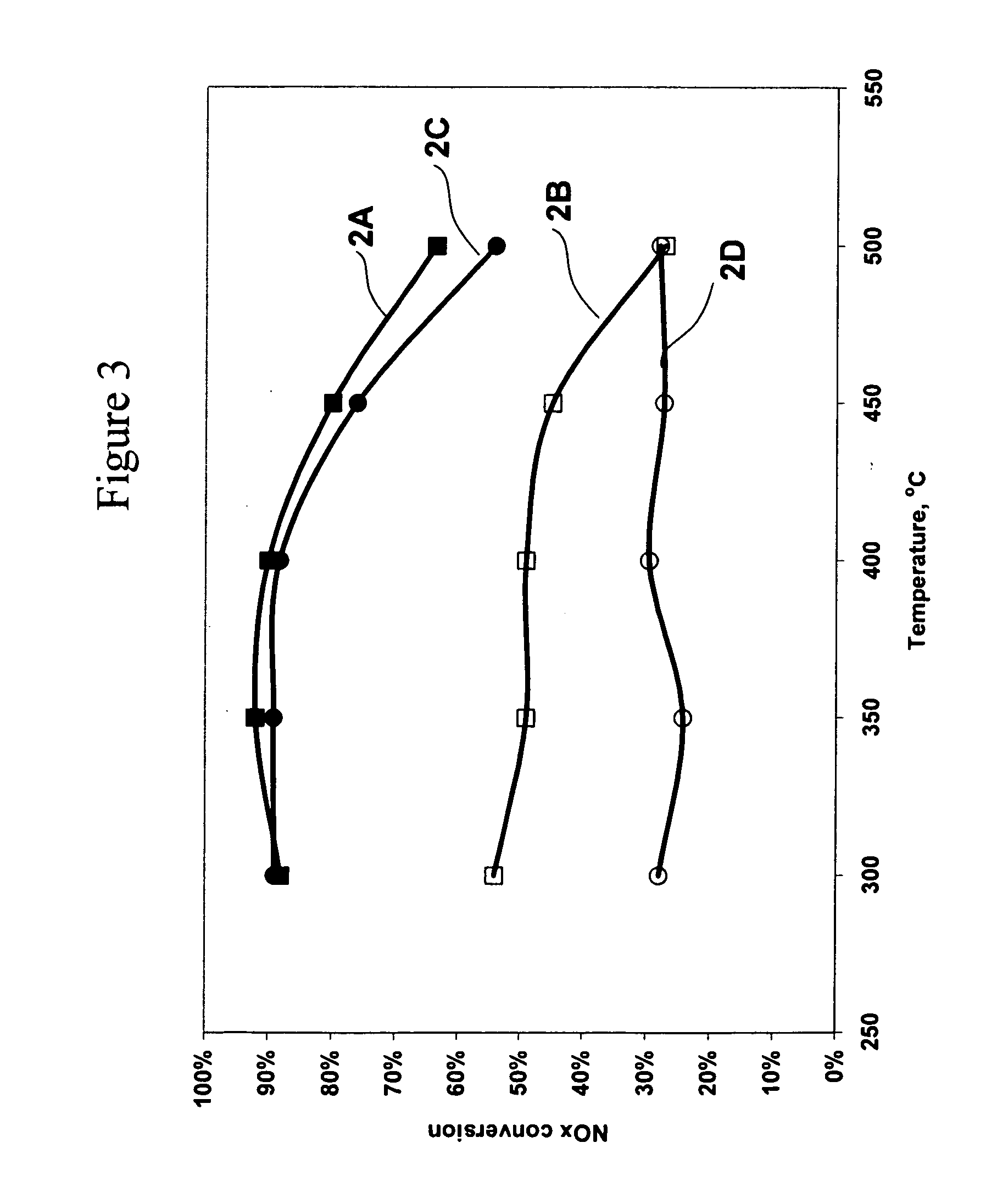

Catalyst and method for reducing nitrogen oxides in exhaust streams with hydrocarbons or alcohols

A catalyst system and a method for reducing nitrogen oxides in an exhaust gas by reduction with a hydrocarbon or oxygen-containing organic compound reducing agent are provided. The catalyst system contains a silver catalyst and a modifier catalyst, where the modifier catalyst contains a modifier oxide, where the modifier oxide is selected from the group consisting of iron oxide, cerium oxide, copper oxide, manganese oxide, chromium oxide, a lanthanide oxide, an actinide oxide, molybdenum oxide, tin oxide, indium oxide, rhenium oxide, tantalum oxide, osmium oxide, barium oxide, calcium oxide, strontium oxide, potassium oxide, vanadium oxide, nickel oxide, tungsten oxide, and mixtures thereof. The modifier oxide is supported on an inorganic oxide support or supports, where at least one of the inorganic oxide supports is an acidic support. The catalyst system of the silver catalyst and the modifier catalyst provides higher NOx conversion than either the silver catalyst or the modifier catalyst alone.

Owner:CATALYTIC SOLUTIONS INC

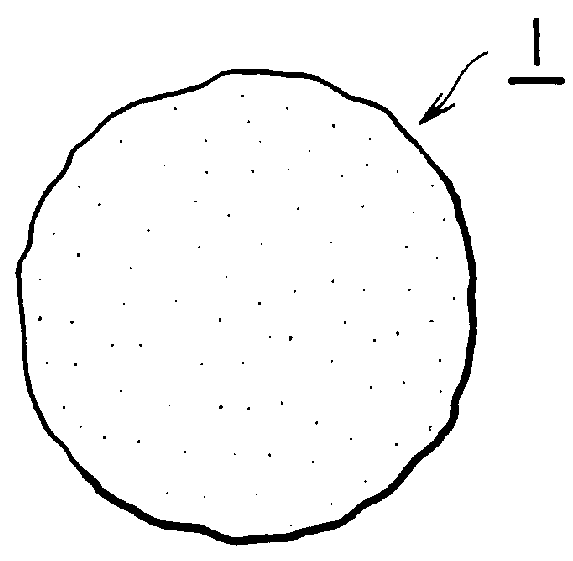

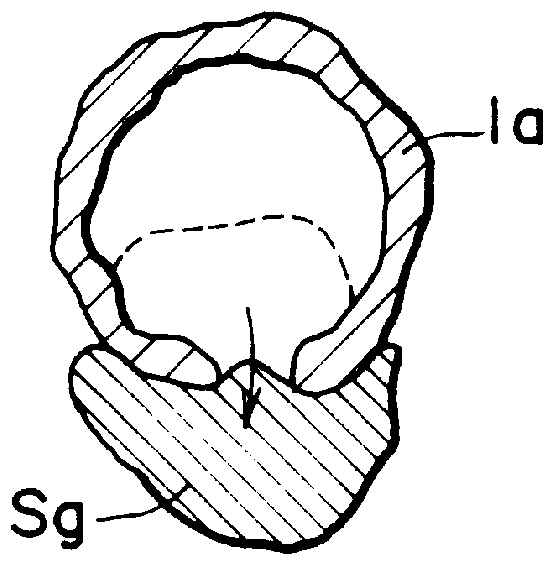

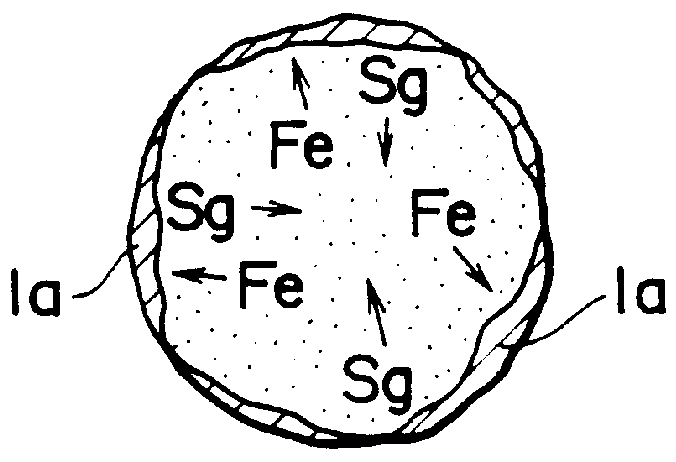

Method and apparatus for making metallic iron

InactiveUS6036744AHigh purityReadily and efficiently madeBlast furnace componentsRotary drum furnacesMolten slagCoal

A method of making metallic iron in which a compact, containing iron oxide such as iron ore or the like and a carbonaceous reductant such as coal or the like, is used as material, and the iron oxide is reduced through the application of heat, thereby making metallic iron. In the course of this reduction, a shell composed of metallic iron is generated and grown on the surface of the compact, and slag aggregates inside the shell. This reduction continues until substantially no iron oxide is present within the metallic iron shell. Subsequently, heating is further performed to melt the metallic iron and slag. Molten metallic iron and molten slag are separated one from the other, thereby obtaining metallic iron with a relatively high metallization ratio. Through the employment of an apparatus for making metallic iron of the present invention, the above-described method is efficiently carried out, and metallic iron having a high iron purity can be made continuously as well as productively not only from iron oxide having a high iron content but also from iron oxide having a relatively low iron content.

Owner:KOBE STEEL LTD

Magnetic biological carrier and preparation method thereof

InactiveCN102225806APromote recoveryRealize dynamic regenerationSustainable biological treatmentBiological water/sewage treatmentResource utilizationEngineering

The invention discloses a magnetic biological carrier and a preparation method thereof. The raw materials of the magnetic biological carrier comprise aggregate, iron oxide, a binder and a reducing agent. The preparation method of the magnetic biological carrier comprises the following steps of: mixing the aggregate, iron oxide and the reducing agent, crushing, screening with a 60-mesh sieve to obtain a mixed material, adding water which is 30-60% of the mixed material by weight to the binder, stirring for dissolving the binder to obtain a binder solution, then mixing the binder solution with the mixed material, uniformly stirring, granulating and shaping to obtain 2-10 mm granules, drying the granules till the water content of the granules is less than 10%, and calcining at the temperature of 350-1100 DEG C for 0.2-10 hours to obtain the magnetic biological carrier. The magnetic biological carrier provided by the invention can be applied to the deep treatment of secondary treatment water of domestic sewage, meets the requirements of landscape water replenishing and circulating cooling water treatment, and can be used for realizing the deep treatment and resource utilization of industrial wastewater.

Owner:HEFEI UNIV OF TECH

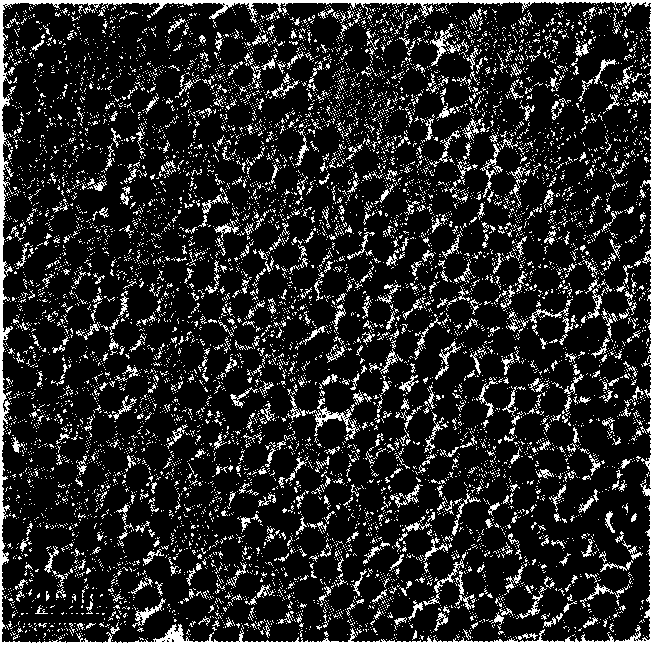

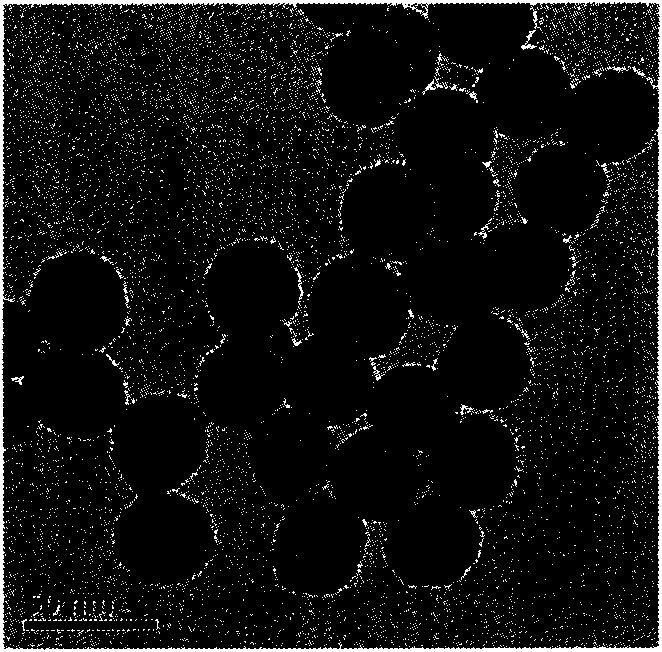

Synthesis of magnetite nanoparticles and the process of forming Fe-based nanomaterials

InactiveUS6962685B2Small sizeNarrow size distributionMaterial nanotechnologyNanomagnetismIron saltsMagnetite Nanoparticles

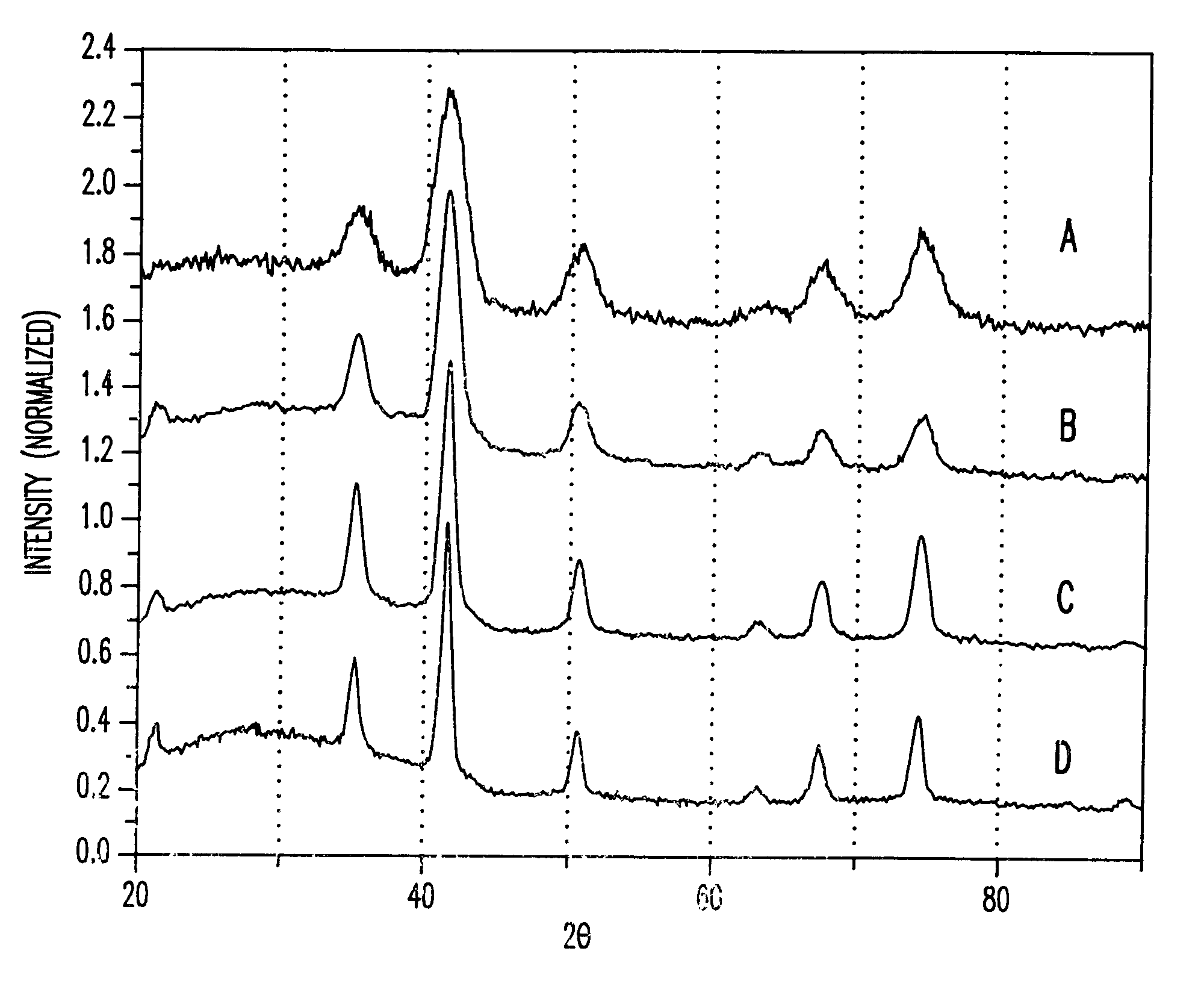

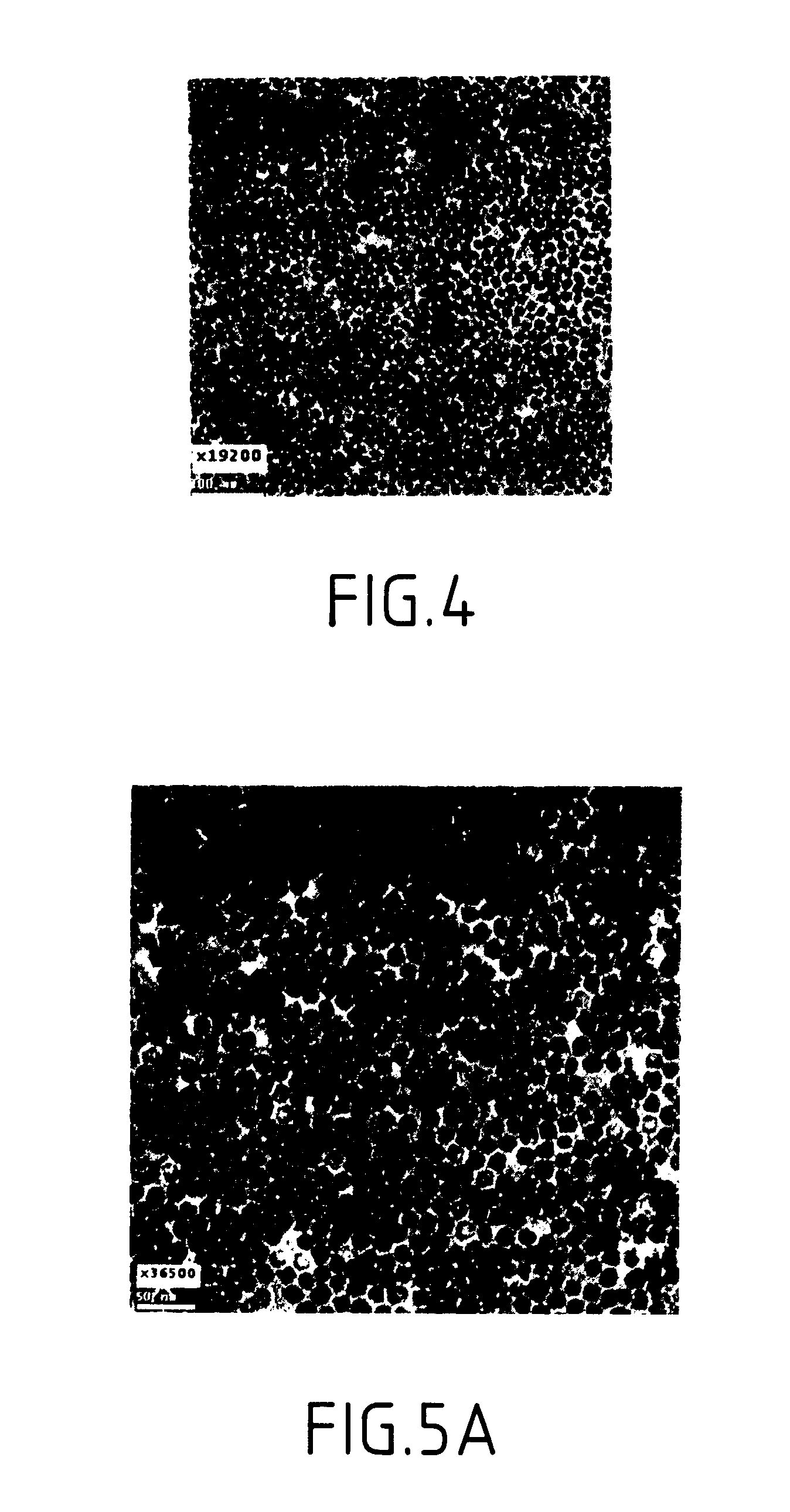

A method and structure for making magnetite nanoparticle materials by mixing iron salt with alcohol, carboxylic acid and amine in an organic solvent and heating the mixture to 200–360 C is described. The size of the particles can be controlled either by changing the iron salt to acid / amine ratio or by coating small nanoparticles with more iron oxide. Magnetite nanoparticles in the size ranging from 2 nm to 20 nm with a narrow size distribution are obtained with the invention. The invention can be readily extended to other iron oxide based nanoparticle materials, including M Fe2O4 (M=Co, Ni, Cu, Zn, Cr, Ti, Ba, Mg) nanomaterials, and iron oxide coated nanoparticle materials. The invention also leads to the synthesis of iron sulfide based nanoparticle materials by replacing alcohol with thiol in the reaction mixture. The magnetite nanoparticles can be oxidized to γ-Fe2O3, or α-Fe2O3, or can be reduced to bcc-Fe nanoparticles, while iron oxide based materials can be used to make binary iron based metallic nanoparticles, such as CoFe, NiFe, and FeCoSmx nanoparticles.

Owner:INT BUSINESS MASCH CORP

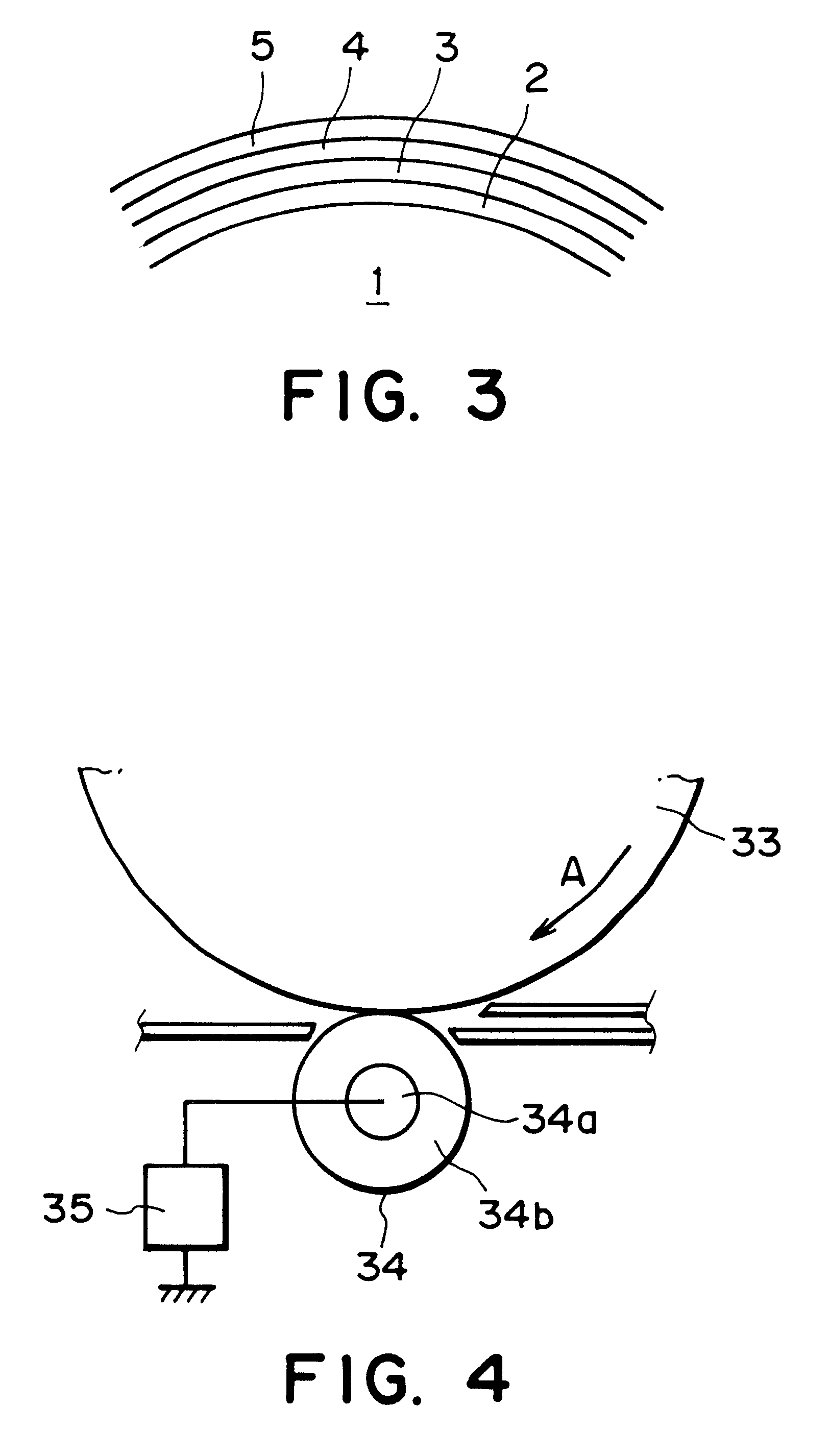

Colored film-coated ultraviolet/infrared absorbent glass plate and window glass of vehicle

InactiveUS6340646B1Reduced durabilityIncrease temperatureCeramic layered productsGlass/slag layered productsTO-18Ultraviolet

A colored film-coated ultraviolet / infrared absorbent glass plate is formed of base glass, colorants, and a colored film. The base glass includes 65 to 80 wt. % SiO2; 0 to 5 wt. % Al2O3; 0 to 10 wt. % MgO; 5 to 15 wt. % CaO; 10 to 18 wt. % Na2O; 0 to 5 wt. % K2O; 5 to 15 wt. % total amount of MgO and CaO; 10 to 20 wt. % total amount of Na2O and K2O; 0.05 to 0.3 wt. % of SO3; and 0 to 5 wt. % B2O3. The colorants includes 0.35 to 0.55 wt. % total iron oxide (T-Fe2O3) expressed as Fe2O3; 0.08 to 0.15 wt. % FeO; 0.8 to 1.5 wt. % CeO2; and 0 to 0.5 wt. % TiO2. FeO expressed as Fe2O3 is equal to or more than 20 wt. % and less than 27 wt. % of T-Fe2O3. The colored film has a red color shade with a thickness between 30 nm and 300 nm and includes fine particles of gold and silicon oxide of more than 50 wt. % and equal to or less than 95 wt. %. The colored film is applied onto a surface of the ultraviolet / infrared absorbent glass plate.

Owner:NIPPON SHEET GLASS CO LTD

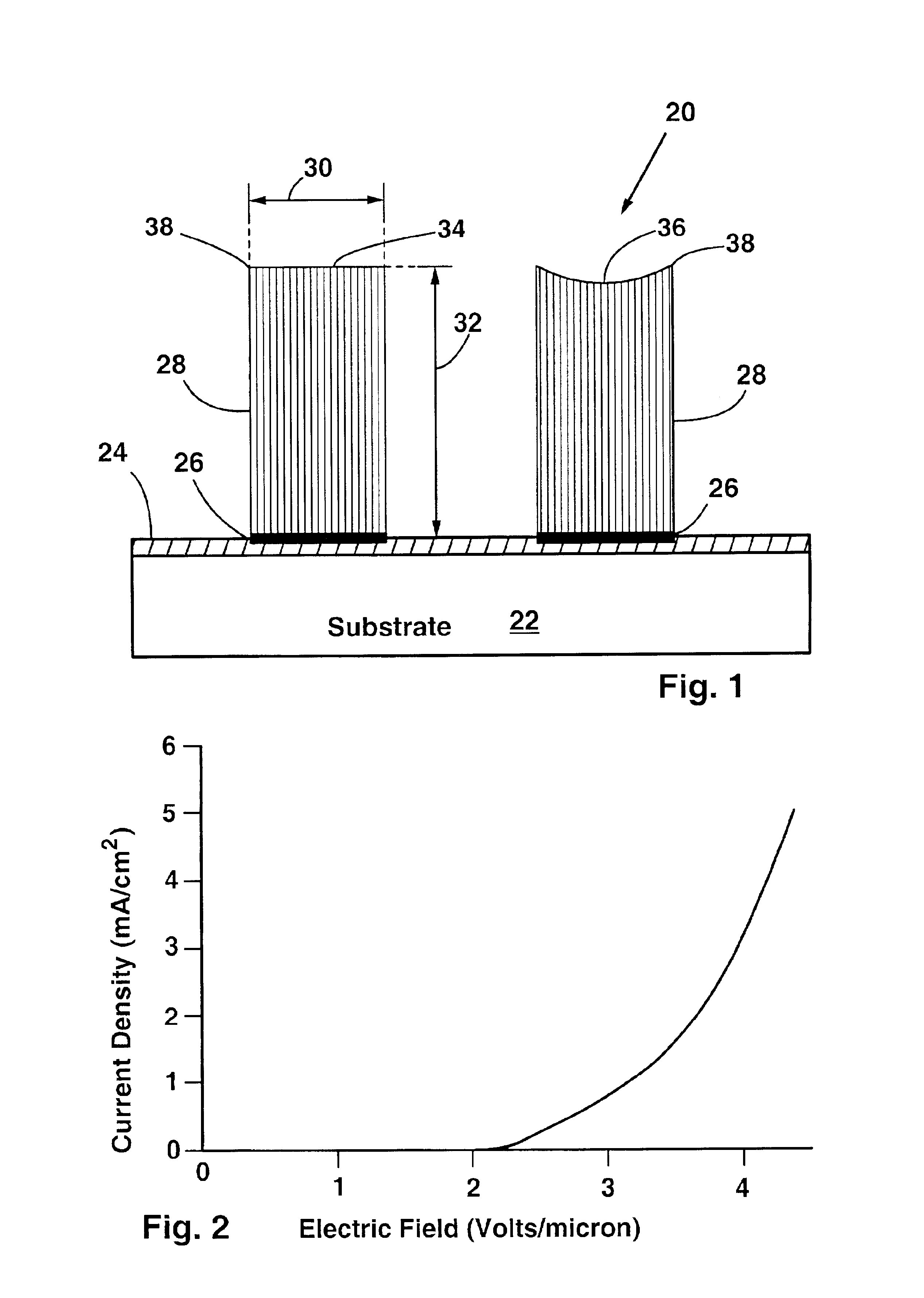

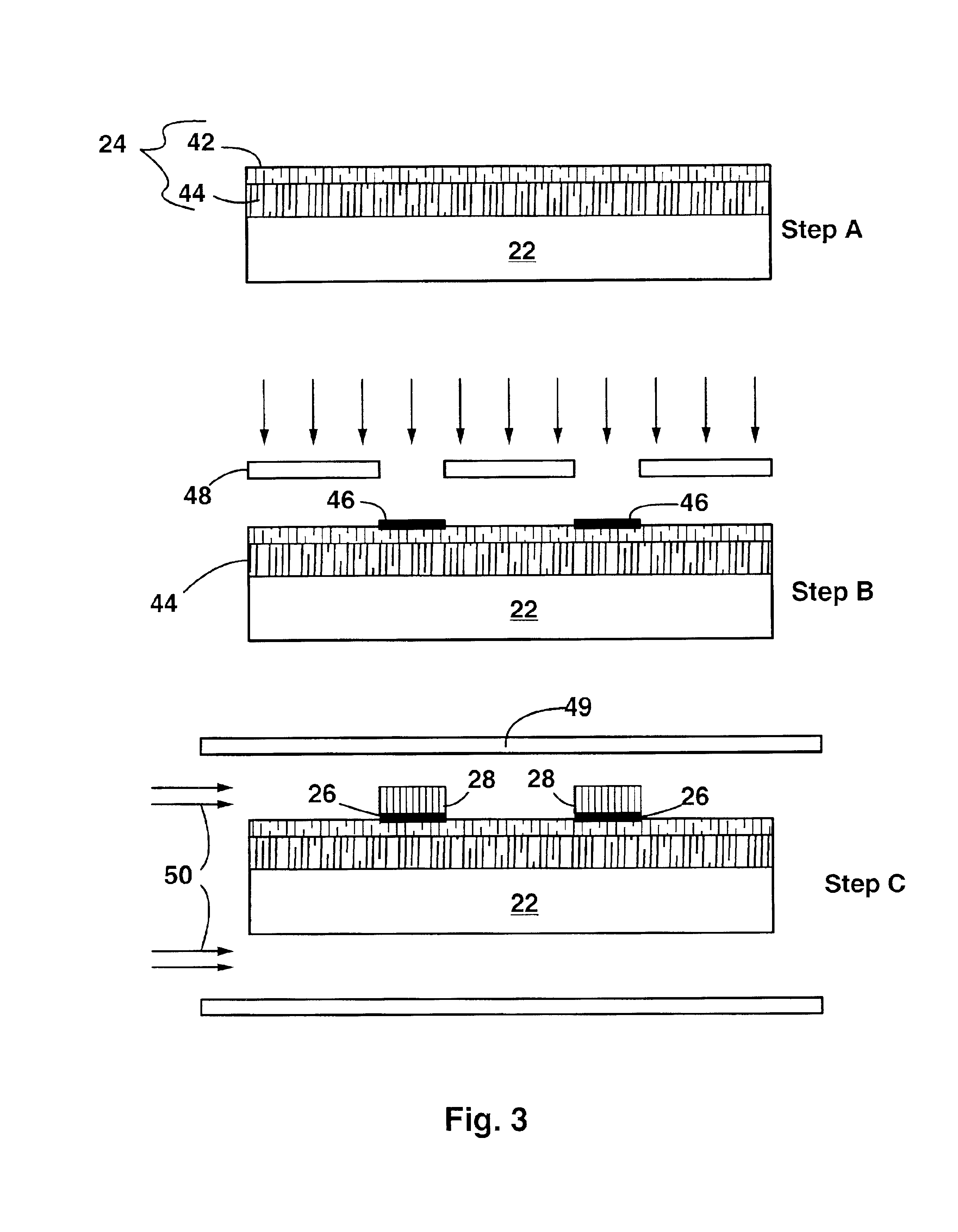

Self-oriented bundles of carbon nanotubes and method of making same

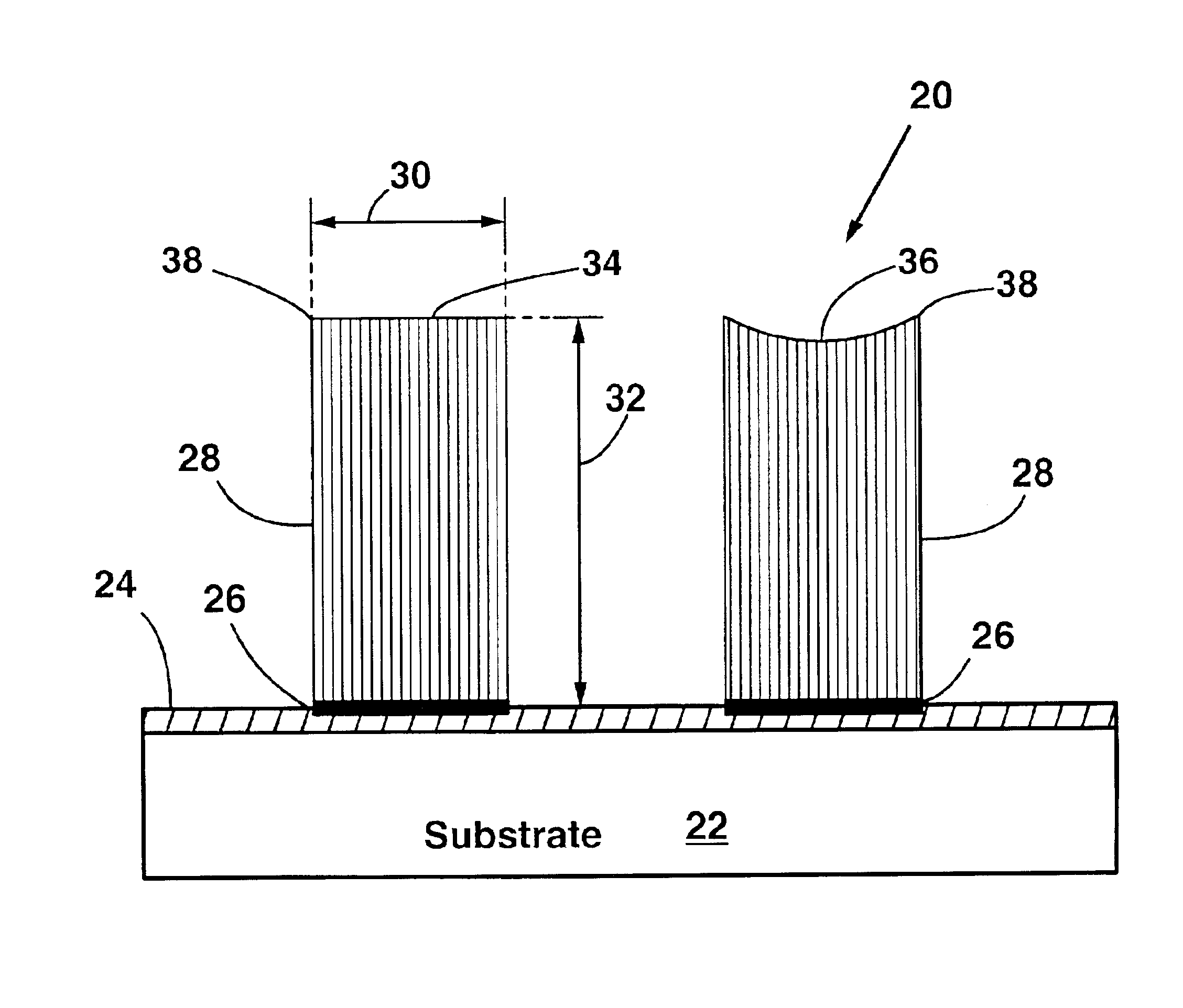

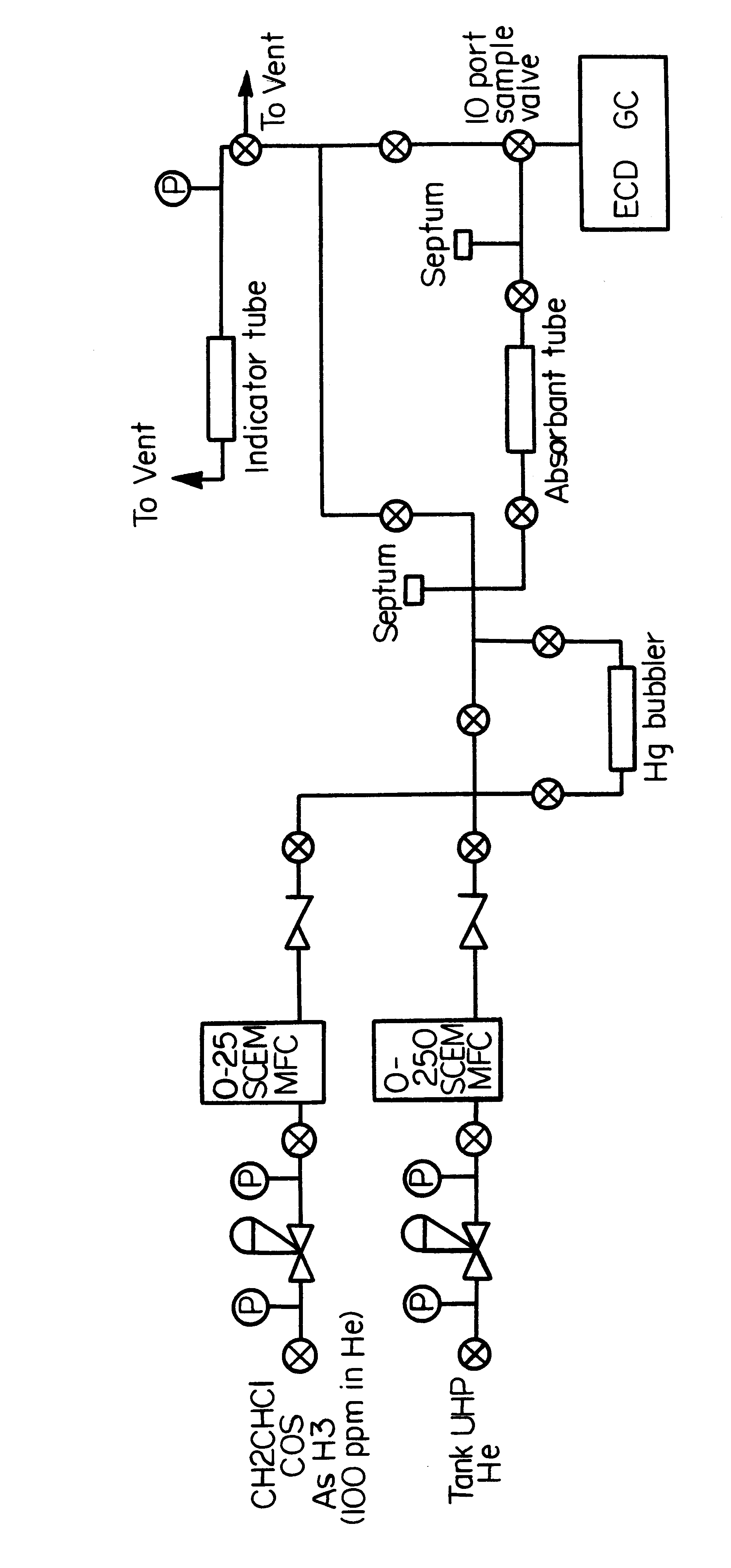

A field emission device having bundles of aligned parallel carbon nanotubes on a substrate. The carbon nanotubes are oriented perpendicular to the substrate. The carbon nanotube bundles may be up to 300 microns tall, for example. The bundles of carbon nanotubes extend only from regions of the substrate patterned with a catalyst material. Preferably, the catalyst material is iron oxide. The substrate is preferably porous silicon, as this produces the highest quality, most well-aligned nanotubes. Smooth, nonporous silicon or quartz can also be used as the substrate. The method of the invention starts with forming a porous layer on a silicon substrate by electrochemical etching. Then, a thin layer of iron is deposited on the porous layer in patterned regions. The iron is then oxidized into iron oxide, and then the substrate is exposed to ethylene gas at elevated temperature. The iron oxide catalyzes the formation of bundles of aligned parallel carbon nanotubes which grow perpendicular to the substrate surface. The height of the nanotube bundles above the substrate is determined by the duration of the catalysis step. The nanotube bundles only grow from the patterned regions.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

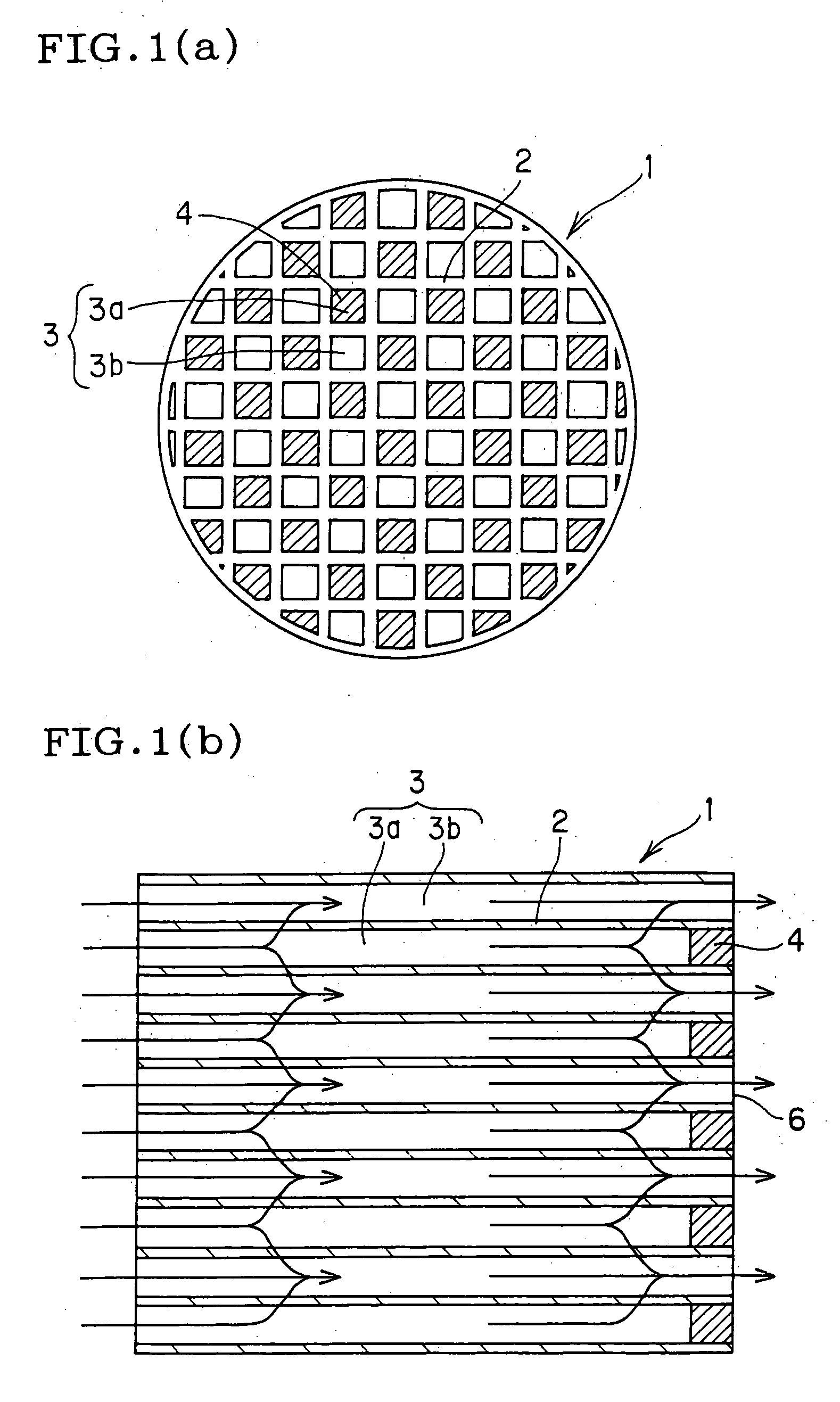

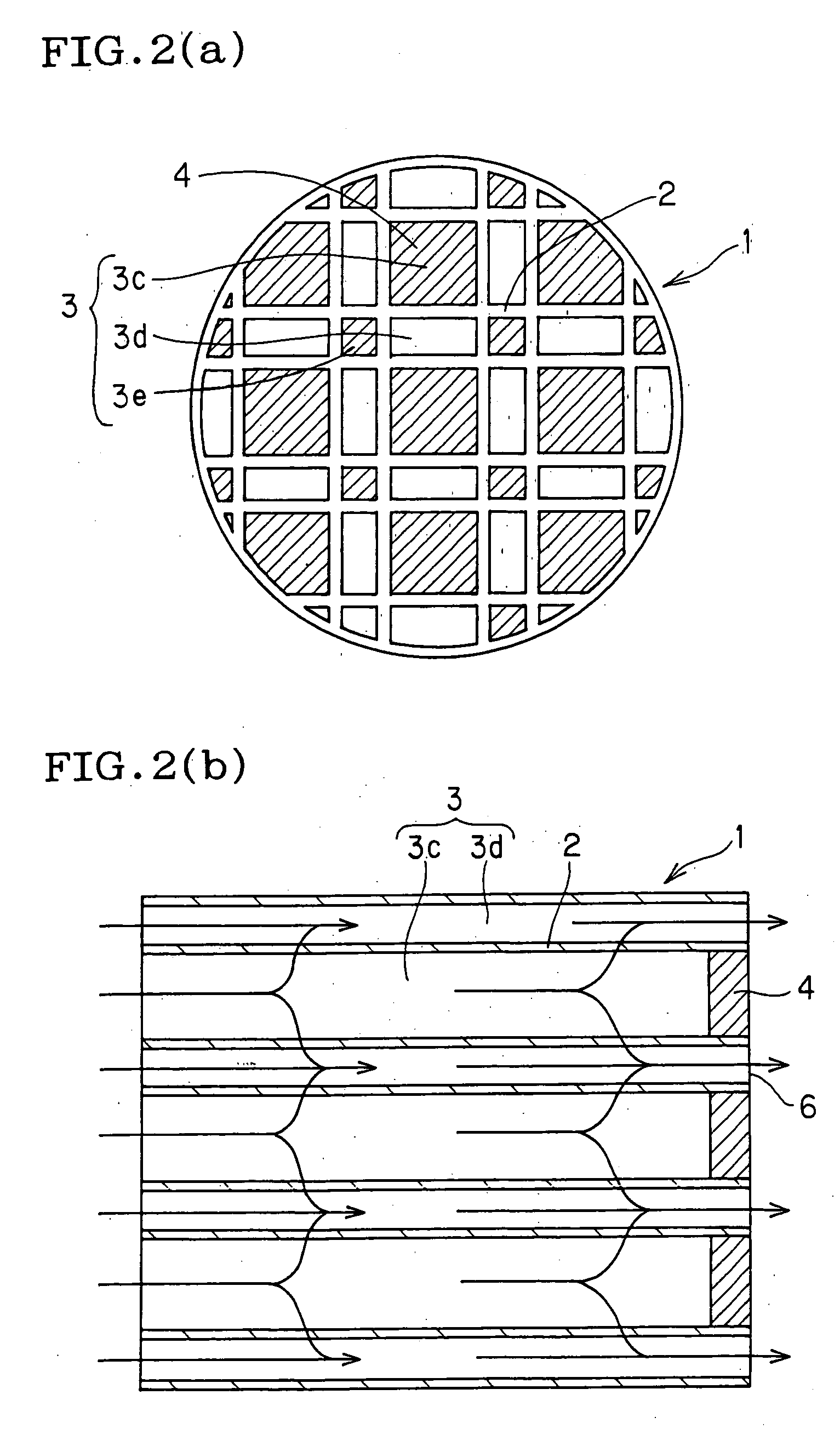

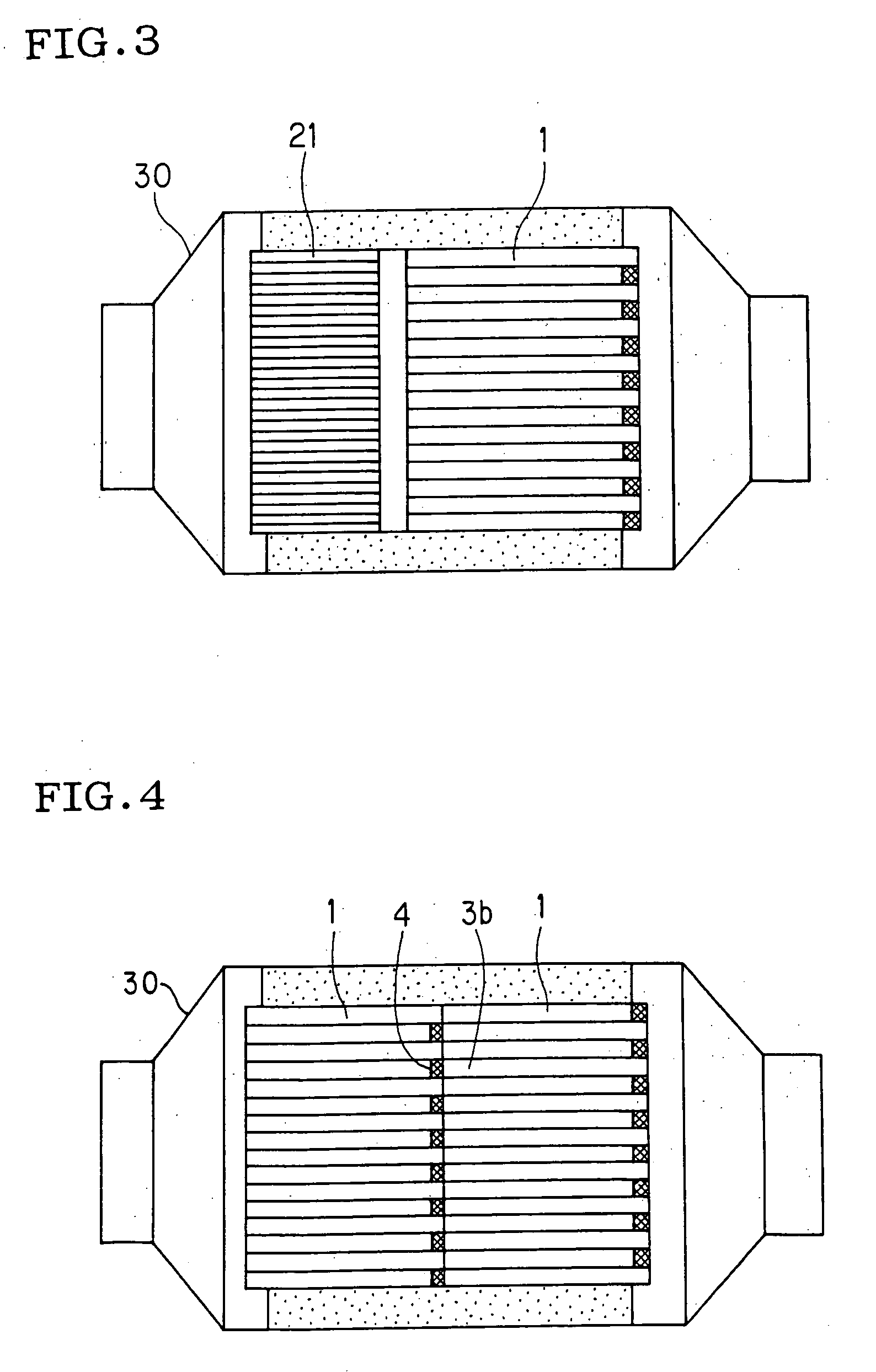

Honeycomb filter and exhaust gas purification system

A honeycomb filter comprises a honeycomb structure having a large number of through channels formed in the axial direction and partitioned by porous partition walls, wherein specified through channels are plugged only on one end face at the same side out of two end faces. This honeycomb filter shows less pressure loss, and is hardly clogged with solids that cannot be extinguished by combustion such as ash, iron oxide, and the like. Furthermore, an unwanted discharge of particulates deposited in through channels of the filter in a larger amount due to pulsation even under conditions that the exhaust gas from an engine greatly pulsates can be effectively suppressed. This filter is also usable as an element for exhaust gas purification system, or a part of composite filter in addition to the use for an exhaust gas purification filter for gasoline engines. The production method therefor is also disclosed.

Owner:NGK INSULATORS LTD

Method of making iron and steel

InactiveUS6149709AEasy to getLess impurity contentProcess efficiency improvementElectric furnaceHigh energyRefractory

Molten iron is prepared by (1) providing iron oxide and a carbonaceous reducing agent, (2) preparing a shaped product from the carbonaceous reducing agent and the iron oxide, (3) preparing solid reduced iron from the shaped product, wherein the solid reduced iron has a metallization of at least 60%, a specific gravity of at least 1.7, and a carbon content of at least 50% of the theoretical amount required for reducing the iron oxide remaining in the solid reduced iron, and, (4) before substantial cooling occurs, heating the solid reduced iron in an arc heating-type melting furnace at a high temperature. The molten iron can be prepared efficiently from iron ores of relatively low iron content without causing erosion of refractories, at high energy and high reduction efficiencies, and by a simple operation in a simple facility.

Owner:KOBE STEEL LTD

Nuclear shell nanometer catalyst packaged with noble metal nanometer grains and method thereof

InactiveCN101623634AShape controllableControllable shapeCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNano catalystHeterojunction

The invention relates to a nuclear shell nanometer catalyst packaged with noble metal nanometer grains and a method thereof, which relate to a nanometer catalyzing material. The invention provides a nuclear shell nanometer catalyst packaged with noble metal nanometer grains, which has a size of the noble metal grains less than 10nm, and higher contact level among noble metal grains and stability of the catalyst, can be reused and is adaptive to different using conditions by multi-level derivation, and also provides a preparation method thereof. The catalyst has a formula of NMP@X, NMP is nanometer grains such as Pd, AgPd or Au, and the like, and X is spherical SiO2, hollow SnO2 ball or hollow C ball. The method comprises the following steps: synthesizing noble metal nanometer grains and adorning the surface to obtain noble metal-iron oxide nanometer heterojunction; coating a silicon dioxide to obtain noble metal iron heterojunction oxide @ silicon dioxide nuclear shell nanometer material, growing porous pores on the surface, removing the silicon dioxide, and removing iron oxide on the noble metal nanometer grains so that the noble metal nanometer grains are located in a nanometer capsule of the hollow porous pores to obtain the product.

Owner:XIAMEN UNIV

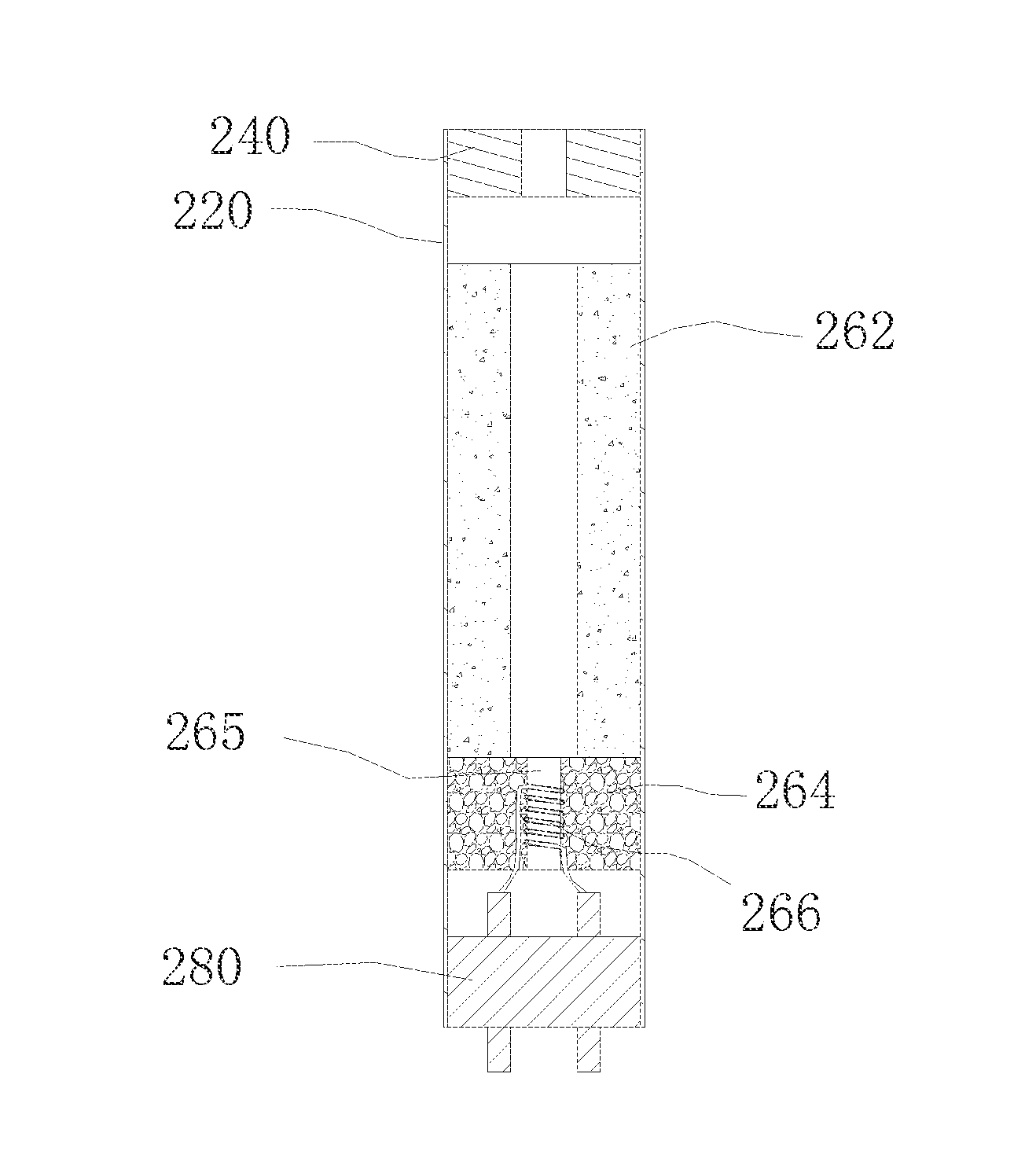

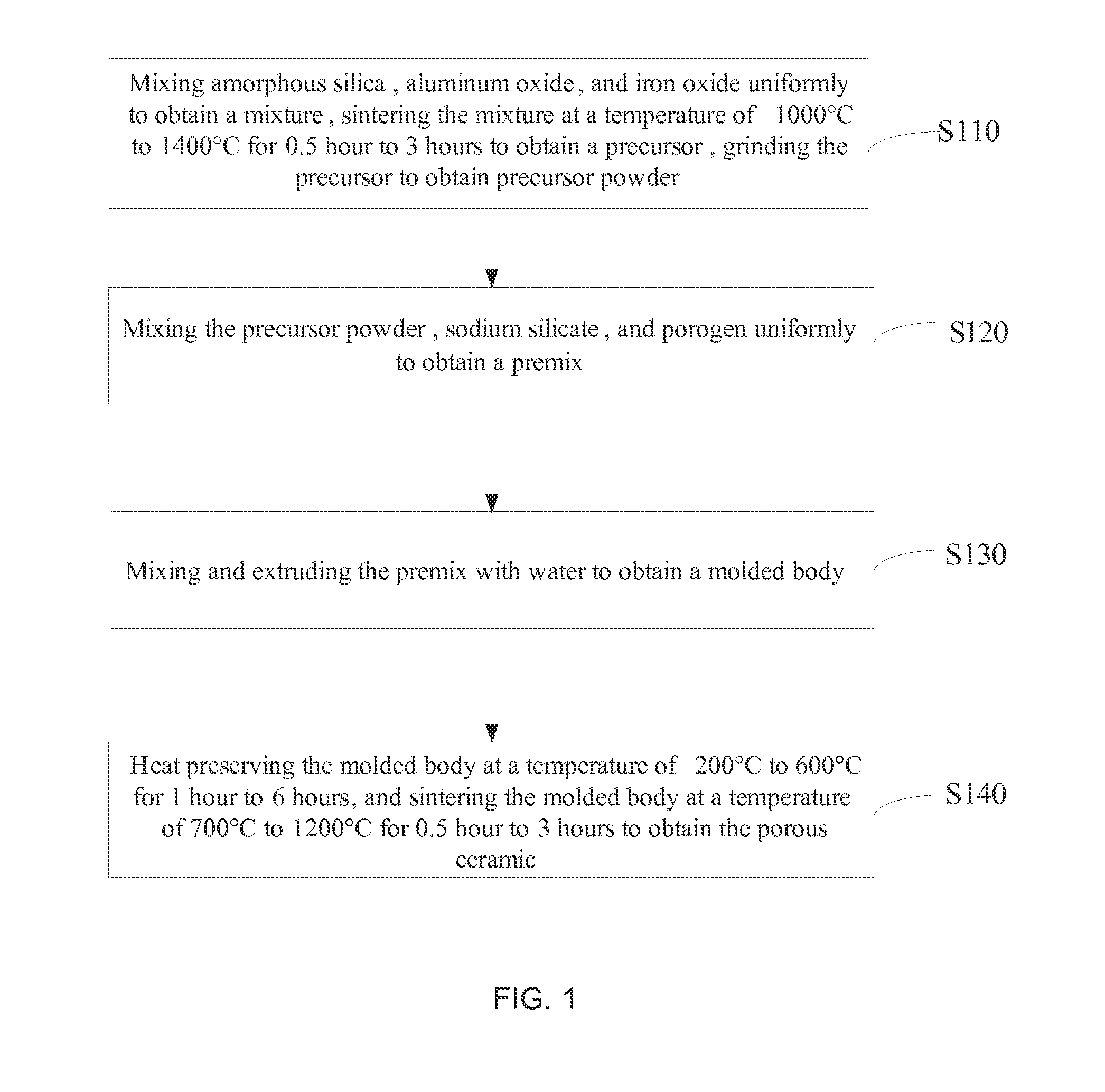

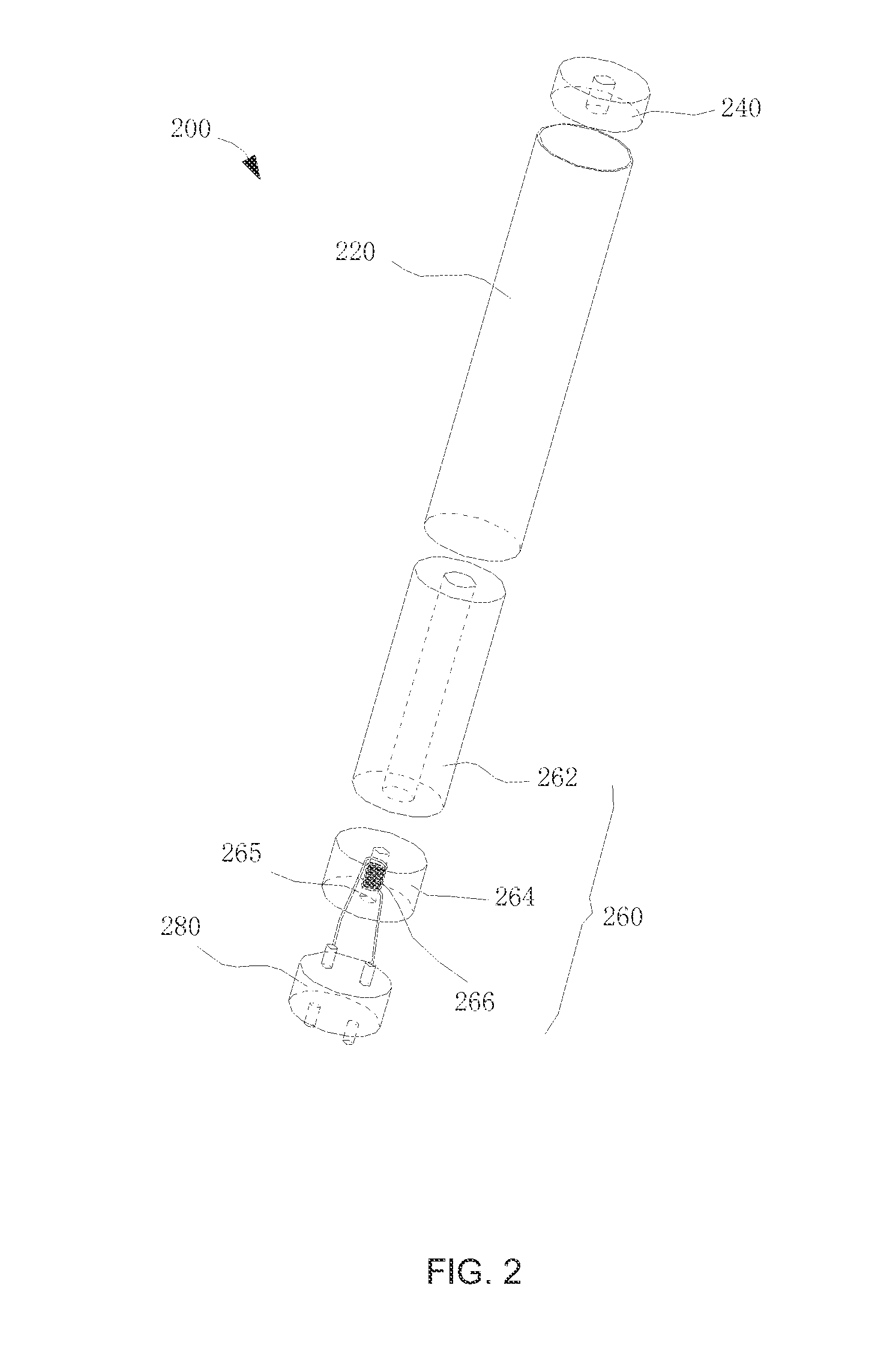

Preparation method of porous ceramic, porous ceramic, and electronic cigarette

ActiveUS20150359262A1Stable structureHigh strengthMedical devicesTobacco pipesElectronic cigaretteSodium silicate

Owner:SHENZHEN SMOORE TECH LTD +1

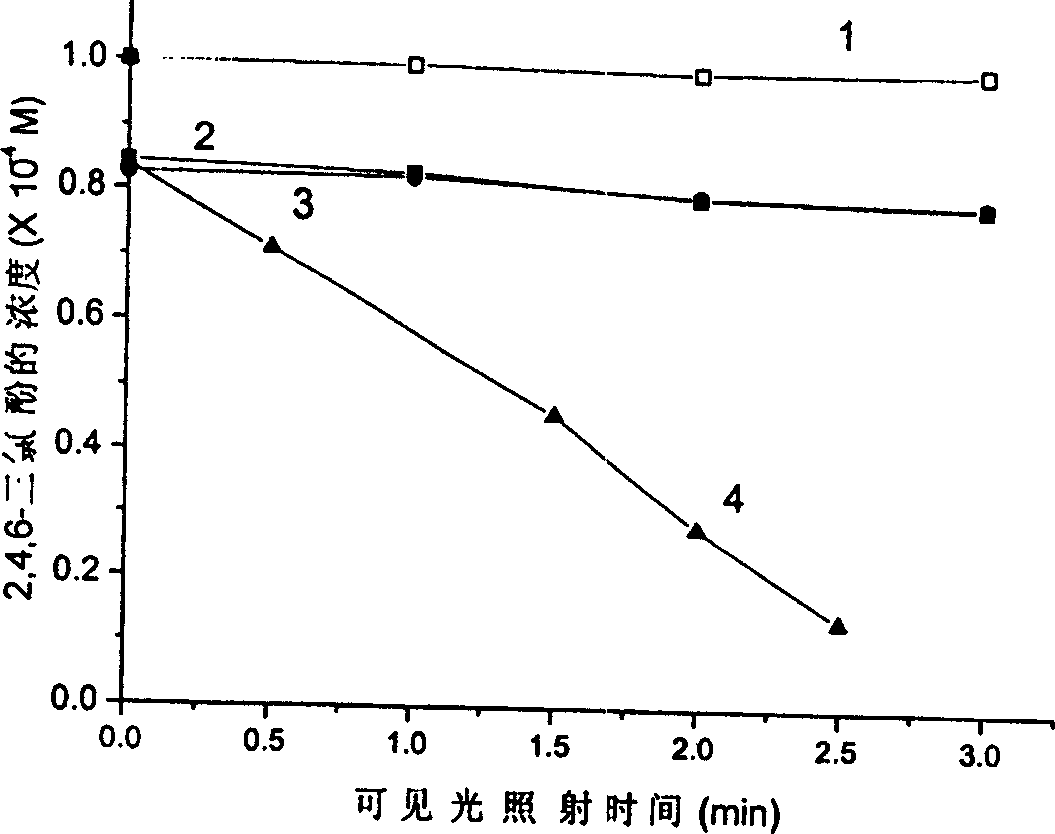

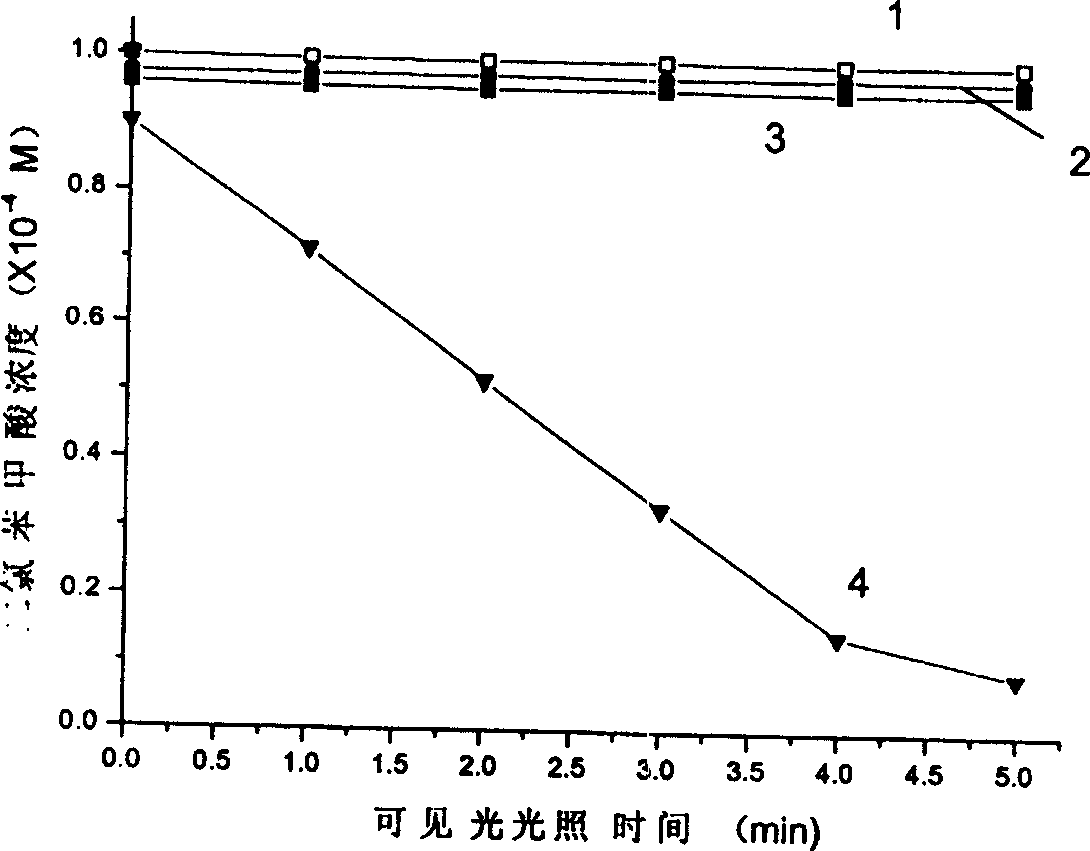

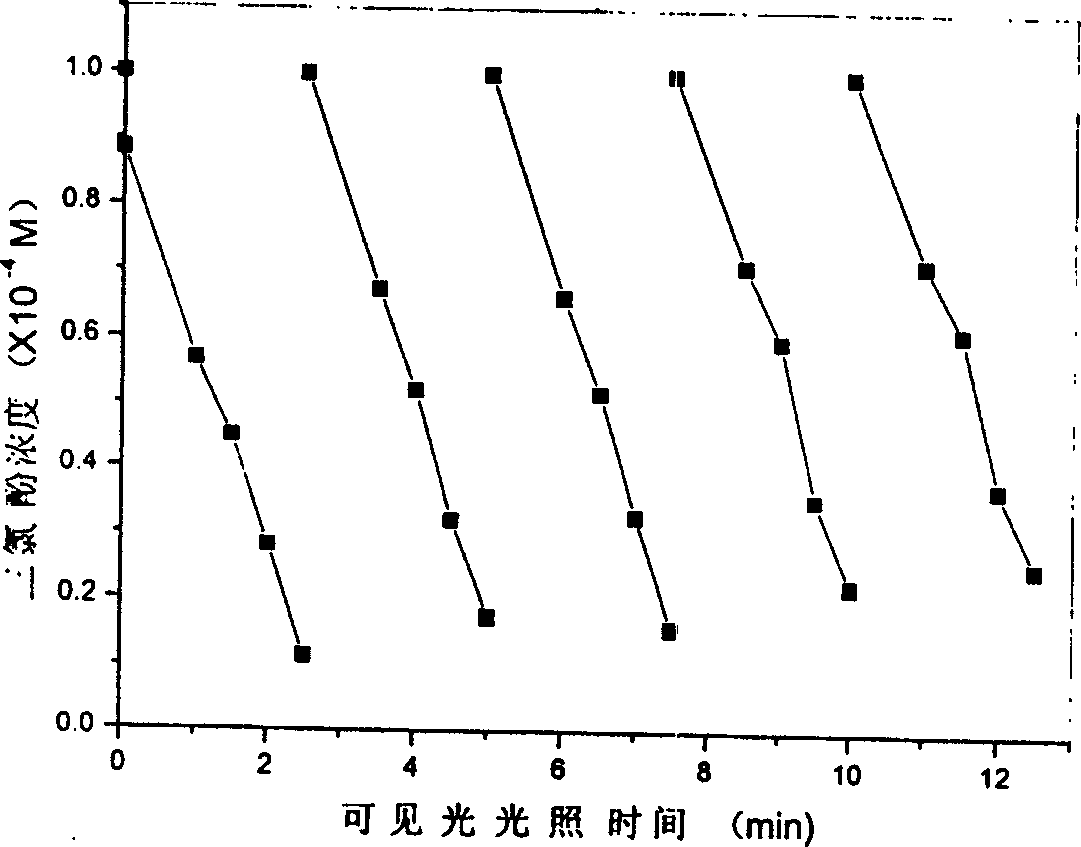

Photocatalyst responding to visible light, and preparation method and application

ActiveCN1600424ASimple preparation processLow costWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsPhotocatalytic reactionCopper oxide

A semiconductor photocatalyst responsive to visual light is composed of the particles of metallic oxide chosen from iron oxide, nickel oxide, cabolt oide, copper oxide, etc, the non-metal element chosen from N, C, S, B and P and semiconductor nanoparticles chosen frmo TiO2, SnO2, ZnO, CdS and WO3.

Owner:INST OF CHEM CHINESE ACAD OF SCI

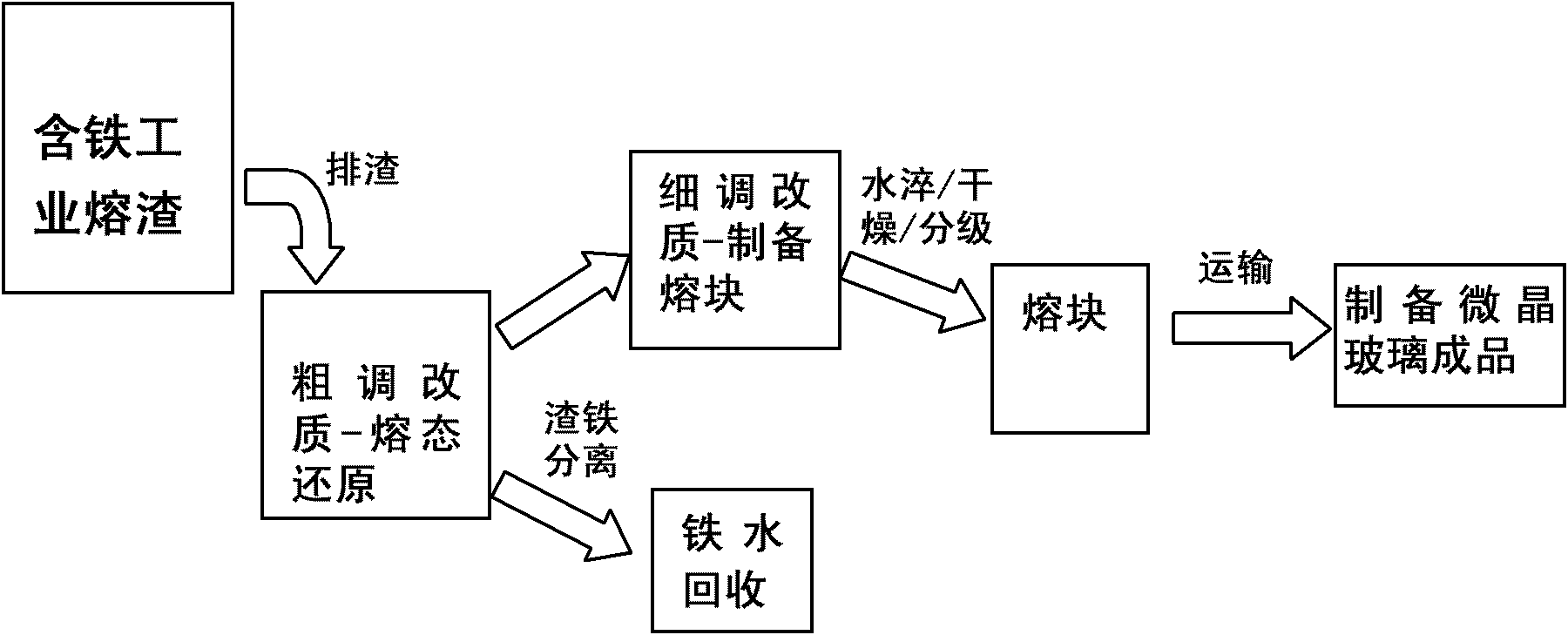

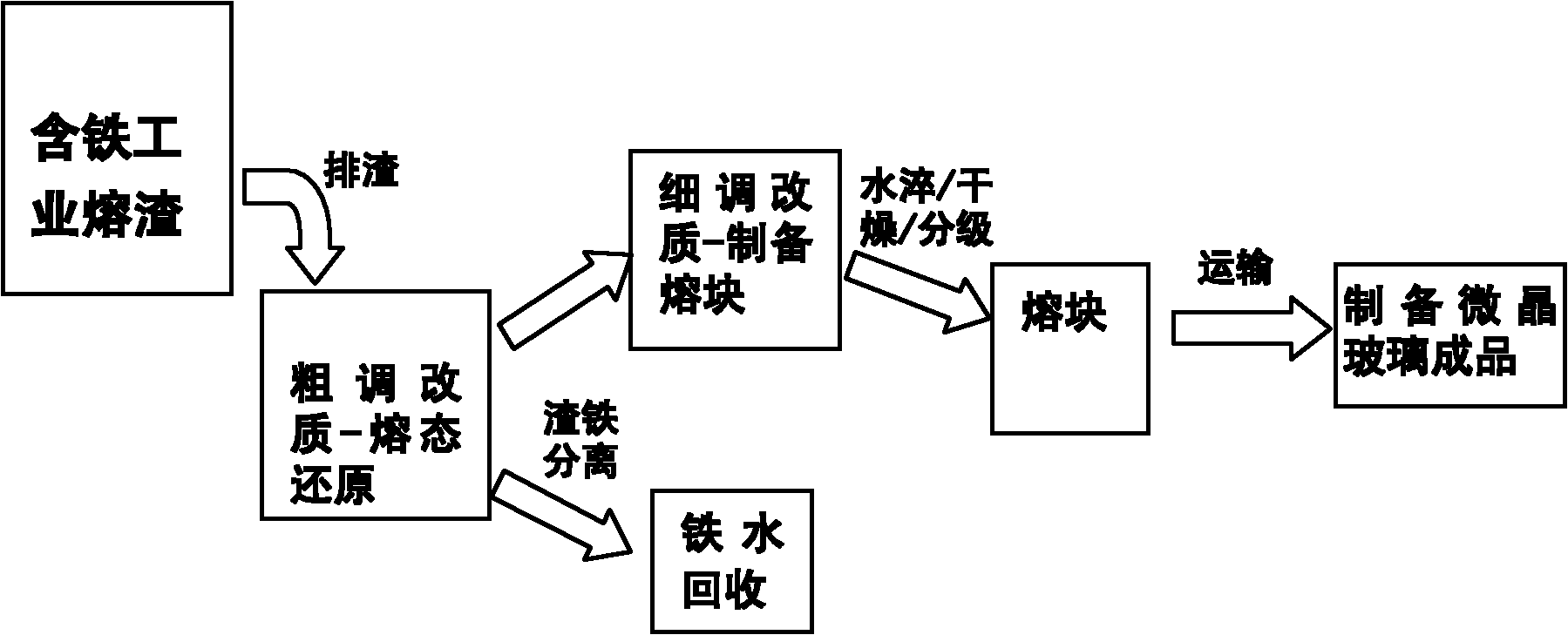

Method for recycling iron on line from iron-containing industrial slag and preparing glass ceramics frit

InactiveCN101914639AGuaranteed slag compositionRecycling and recovery technologiesProcess efficiency improvementMaterials preparationSlag

The invention relates to a method for recycling iron on line from iron-containing industrial slag and preparing a glass ceramics frit, belonging to the technical field of resource comprehensive utilization and material preparation and mainly comprising a two-step method process of iron-containing industrial slag online rough adjustment and modification for reducing iron and fine adjustment and modification for preparing the frit. The method comprises the steps of: discharging high-temperature iron-containing slag into a high-temperature furnace device, and simultaneously adding a reducing agent and a modifying agent to ensure that slag components are adjusted to reach the optimal component point in which iron oxide is reduced; after fully reacted, separating reduced molten iron from the slag, and recycling to obtain high-temperature molten iron; further adding a modifying agent and an adjusting agent into the slag remained after the separation to ensure that the slag components are adjusted to achieve the quality requirement of slag glass ceramics on the frit; and water-hardening, drying and grading the qualified slag to prepare the glass ceramics frit. The invention realizes multiple purposes that the heat of the slag is directly utilized and metal iron is recycled to prepare a high addition value product as well as solid wastes are massively utilized, and the like.

Owner:UNIV OF SCI & TECH BEIJING

Adsorbent for the removal of trace quantities from a hydrocarbon stream and process for its use

An adsorbent product for the adsorption of trace elements of sulfur, arsenic, mercury, compounds which contain these elements or metal hydrides from a hydrocarbon gas stream, preferably an olefinic or paraffinic stream, wherein the adsorbent product is iron oxide and manganese oxide placed on a support material, preferably aluminum oxide. Also disclosed is a process for the use of this adsorbent product for the removal of trace elements of arsenic, mercury and sulfur or compounds containing those elements or metal hydrides from a hydrocarbon gas stream, preferably an olefinic or paraffinic gas stream.

Owner:UNITED CATALYSTS INC

Catalyst support and method of producing the same

ActiveUS7618919B2Improve adhesionImprove reforming performanceHydrogenCatalyst activation/preparationRare-earth elementAlkali metal oxide

A method of producing a catalyst support comprising a substrate, and coating formed on the surface of the substrate and including powder of a first metal oxide of at least one member selected from the group consisting of alumina, zirconia, titania, iron oxides, oxides of rare earth elements, alkali metal oxides and alkali earth metal oxides, wherein the coating is obtained by heat treating the substrate after applied with a coating composition obtained by mixing the first metal oxide powder together with a fluid raw material composition containing raw material of a second metal oxide of at least one member selected from the group consisting of alumina, zirconia, titania, iron oxides, oxides of rare earth elements, alkali metal oxides and alkali earth metal oxides, at a shear rate of 1000 sec−1 or higher.

Owner:TOYOTA CENT RES & DEV LAB INC

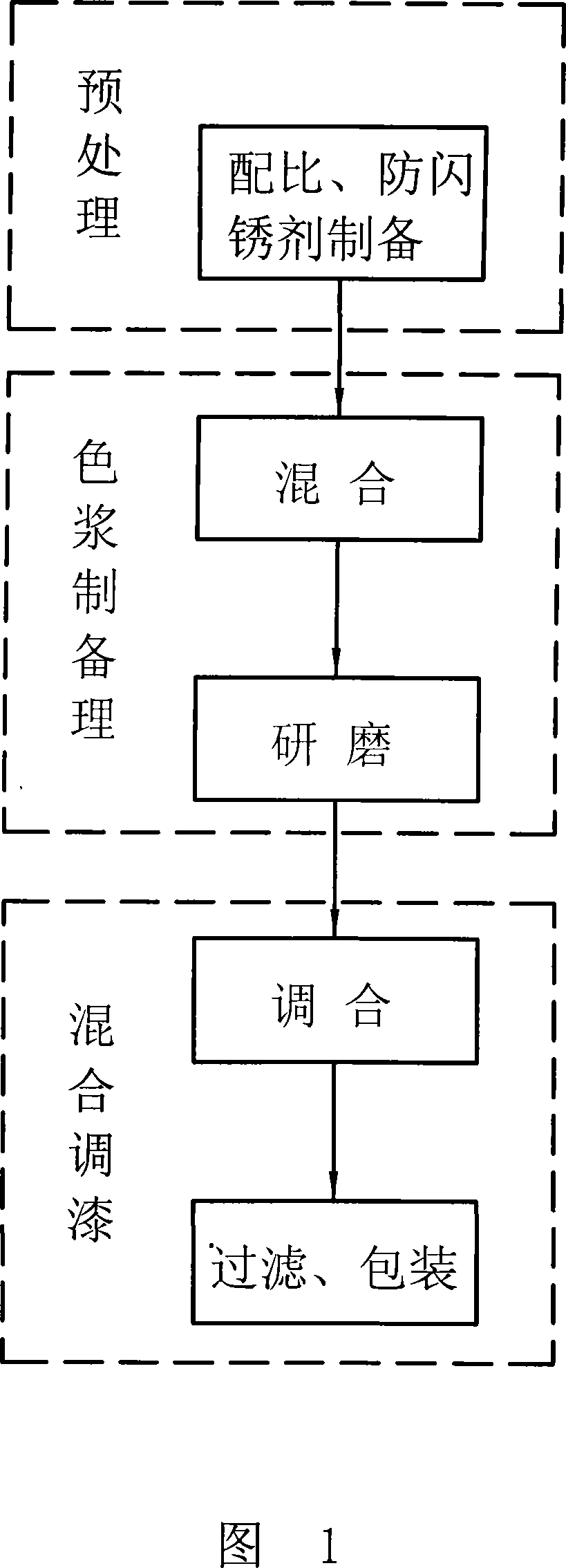

Water industrial antirust paint and preparation method thereof

InactiveCN101045843AHigh hardnessStrong adhesionAnti-corrosive paintsEmulsion paintsEpoxyALUMINUM PHOSPHATE

This invention relates to a aquosity industry anti-rust paint and its preparation method. According to weight it includes 8 to 11% aquosity acroleic acid modified epoxy, 33 to 40% acroleic acid latices, 0.1 to 0.3% defoamer, 0.05 to 0.15% wetting agent, 0.3 to 0.5% dispersant, 0.3 to 0.5% rust-resistant agent, 7.5 to 9% iron oxide red, 6 to 8% French chalk, 5 to 10% modified zinc phosphate, 2.5 to 10% trimerization aluminum phosphate, 3 to 3.5% precipitated baryte , 0.5 to 1% zinc oxide, 3 to 5% mica ferric oxide, alcohol ester twelve 1 to 2%, triethanolamine 1 to 2%, thickening agent 0.3 to 0.6%, preservative 0.05 to 0.1%, 5 to 20% de-ionized water, through pretreatment, color paste preparation and blending and adjusting to gain product.

Owner:邹磊

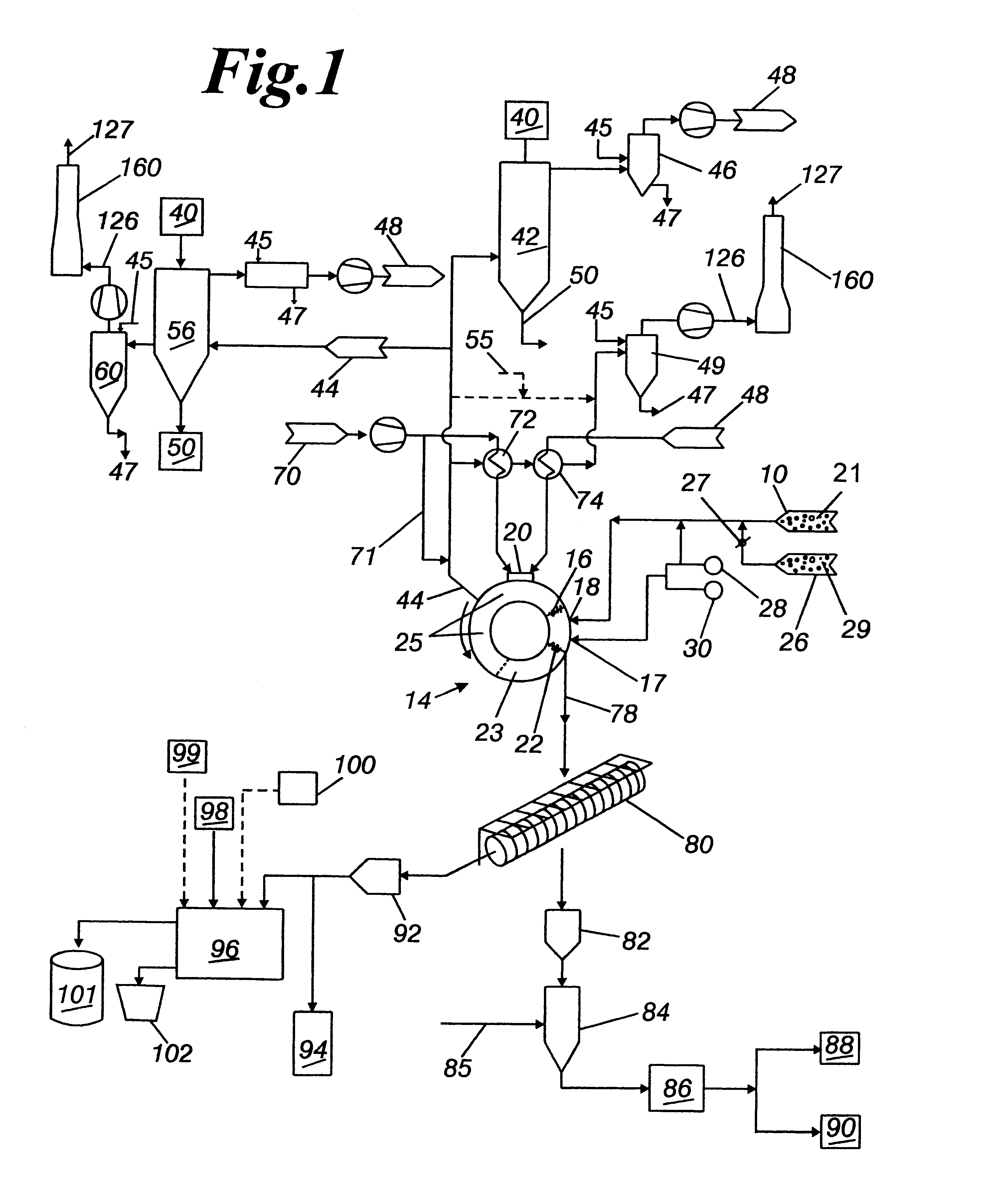

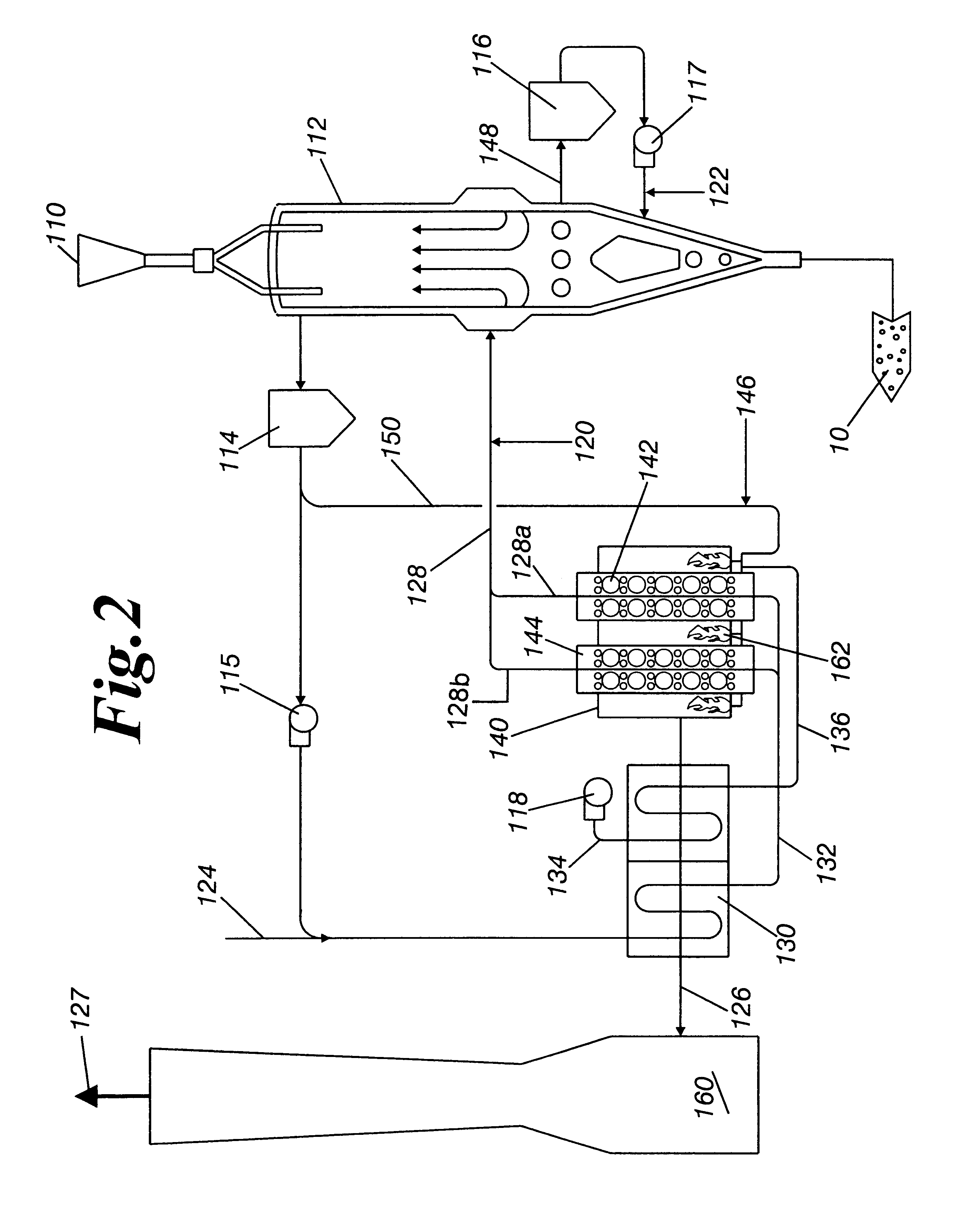

Method of direct iron-making / steel-making via gas or coal-based direct reduction and apparatus

The invention is a method and apparatus for iron-making / steel-making using a modified rotary hearth furnace, that is a finisher-hearth-melter (FHM) furnace. In the method the refractory surface of the hearth is coated with carbonaceous hearth conditioners and refractory compounds, where onto said hearth is charged with pre-reduced metallized iron. The pre-reduced metallized iron is leveled, then heated until molten, and then reacted with the carbon and reducing gas burner gases until any residual iron oxide is converted to iron having a low sulfur content. Nascent slag separates from the molted iron forming carburized iron nuggets. The nuggets are cooled, and then the iron nuggets and the hearth conditioners, including the refractory compounds, are discharged onto a screen, which separate the iron nuggets from the hearth conditioner. The hearth conditioner is recycled, and the iron nuggets are either prepared for sale or for additional treatment, such as alloying, in a final melter, where the final melter is preferably an electric furnace. Exhaust gases from the FHM furnace are recovered for calcining coal into fuel gases and coke.

Owner:KOBE STEEL LTD

Method of producing fatty acid lower alkylester from fat and oil

InactiveUS6090959AImprove reaction efficiencySimplify eliminate needFatty acid esterificationFatty acids production/refiningAlcoholTransesterification

In a method of producing a fatty acid lower alkylester according to the invention, a fat & oil and a lower alcohol are caused to react with each other in the presence of a catalyst, in which triglyceride contained in the fat & oil undergoes a transesterification. The catalyst to be used in the reaction is a solid basic catalyst consisting essentially of a potassium compound and iron oxide, of a calcium compound and iron oxide, or of a potassium compound and zirconium oxide. It is possible to produce the fatty acid lower alkylester at a high reaction efficiency by this method as well as to simplify or eliminate the need of catalyst separation and recovery processes.

Owner:GREENTECH SOLUTION

Thermal protective coating for ceramic surfaces

ActiveUS6921431B2Extended shelf lifeConvenience to workFireproof paintsOther chemical processesColloidal silicaSodium Bentonite

A coating admixture, method of coating and substrates coated thereby, wherein the coating contains colloidal silica, colloidal alumina, or combinations thereof; a filler such as silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides, copper chromium oxides, cerium oxides, terbium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide is also added.

Owner:WESSEX

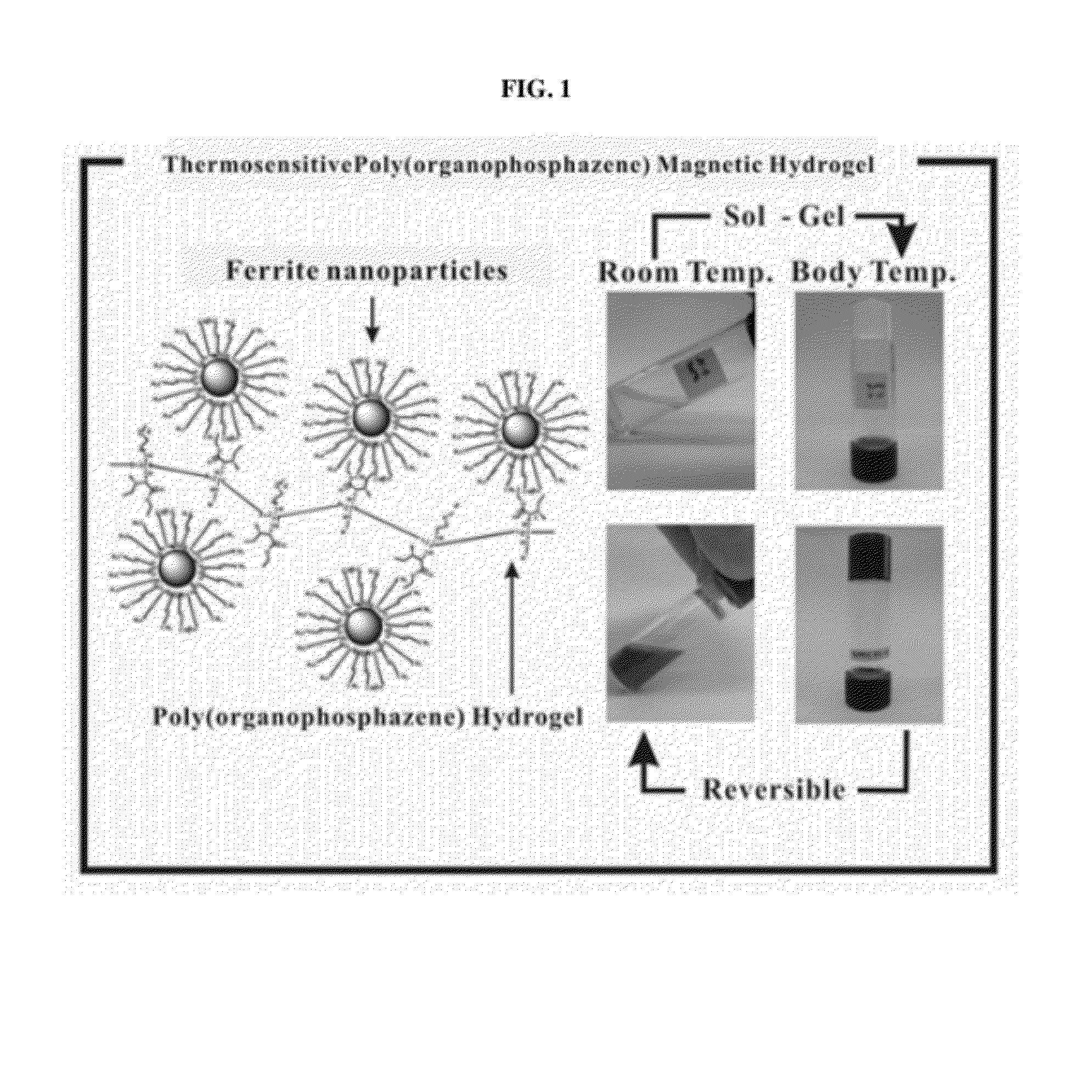

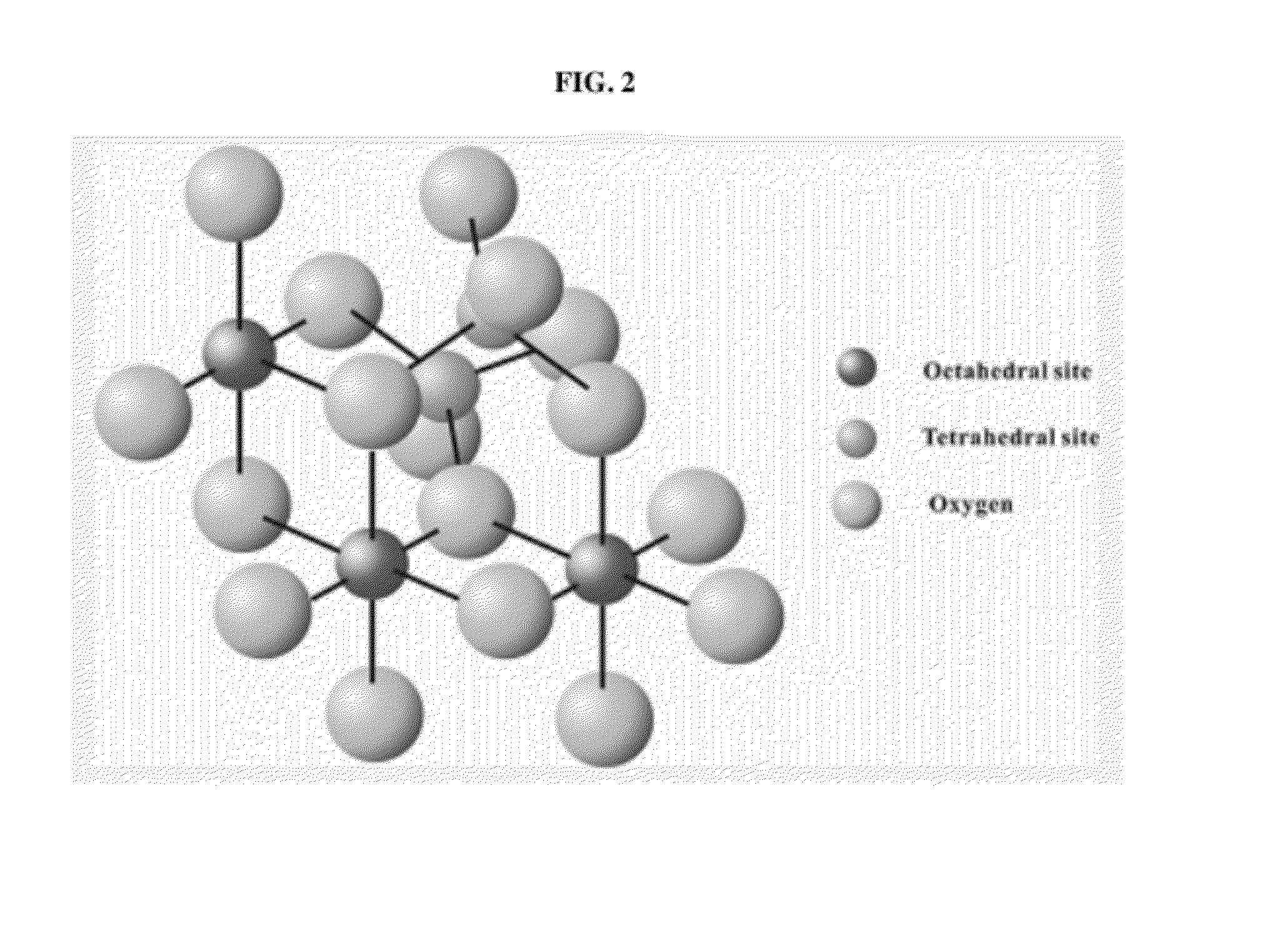

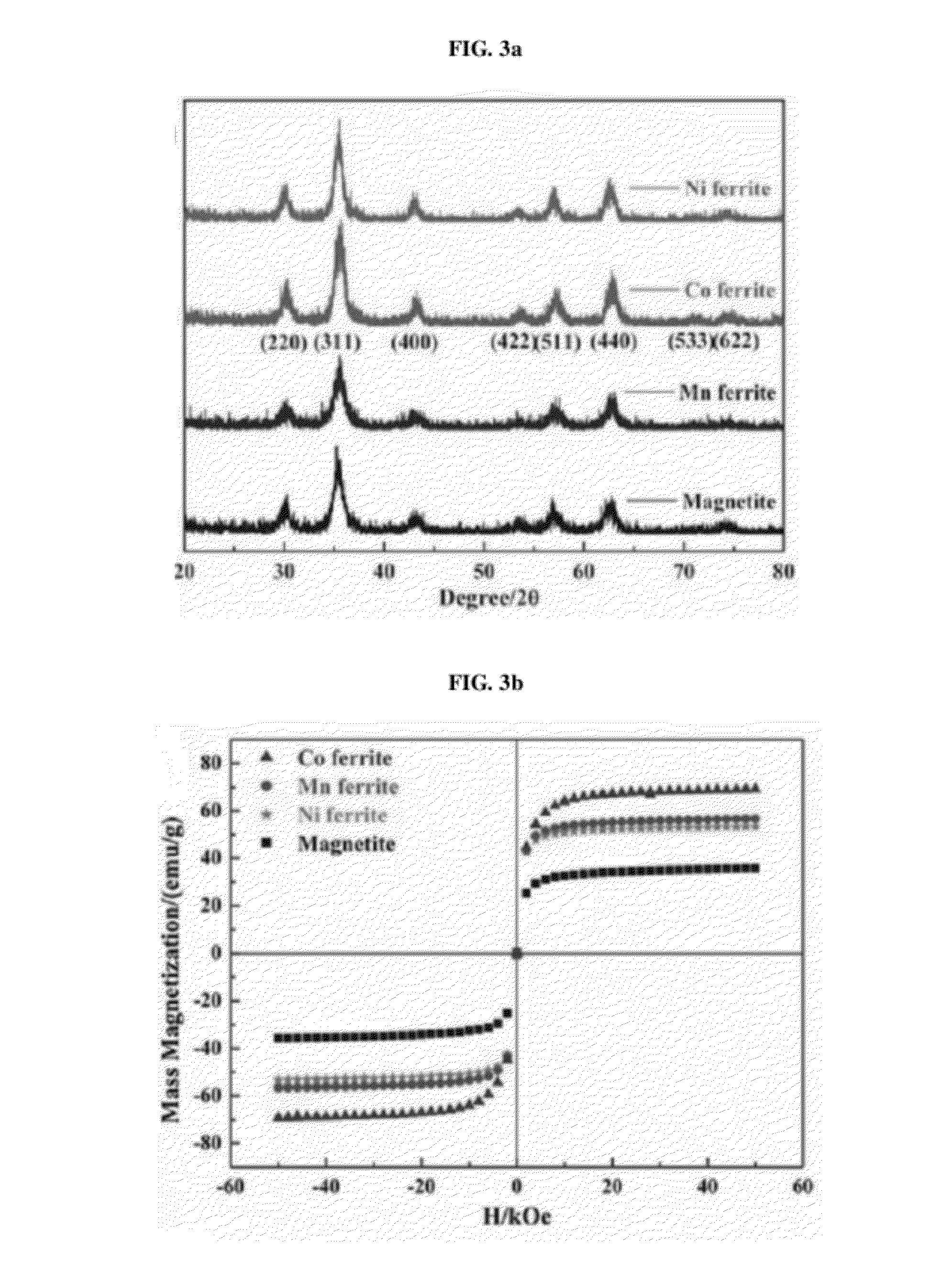

Biodegradable and thermosensitive poly(organophosphazene)-superparamagnetic nanoparticle complex, preparation method and use thereof

ActiveUS20120121517A1Facilitated releaseImprove load effectMaterial nanotechnologyBiocideMRI contrast agentFerrite nanoparticles

The present invention relates to a poly(organophosphazene)-superparamagnetic nanoparticle complex including a biodegradable and thermosensitive poly(organophosphazene) and a iron oxide (Fe3O4, Magnetite)-series ferrite superparamagnetic nanoparticle, a preparation method, and uses of carrying a physiologically-active material, a bio-material and a biomaterial for cancer hyperthermia. The iron oxide is used as a MRI contrast agent for T-2 and T2* weighted image, and the poly(organophosphazene) shows a sol-to-gel behavior depending upon the temperature change. The complex is a bound-type where the superparamagnetic ferrite nanoparticle is bonded to phosphazene-based polymer via hydrophobic binding, and a mixed-type where the superparamagnetic ferrite nanoparticle is physically mixed with the phosphazene-based polymer.

Owner:KOREA INST OF SCI & TECH

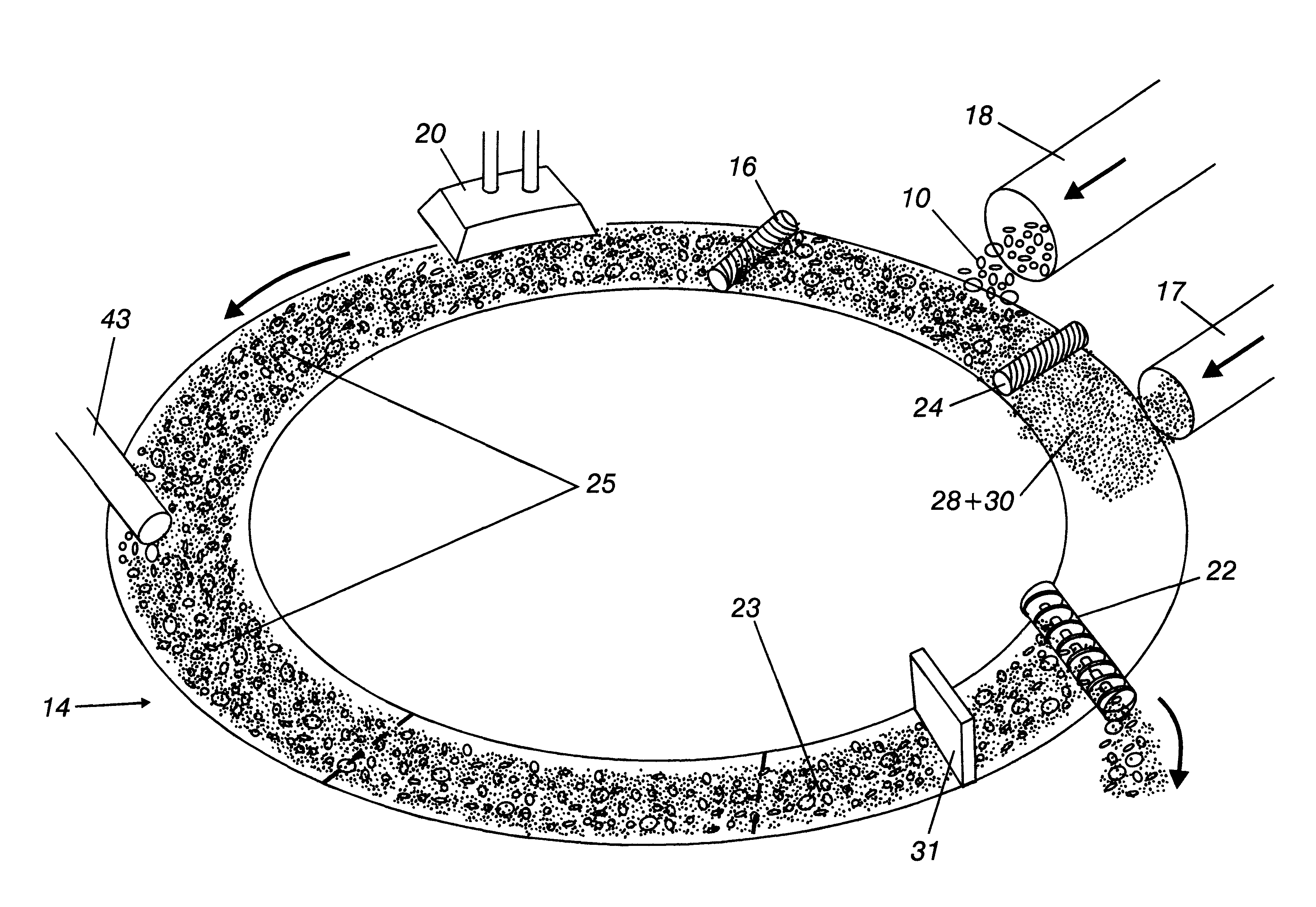

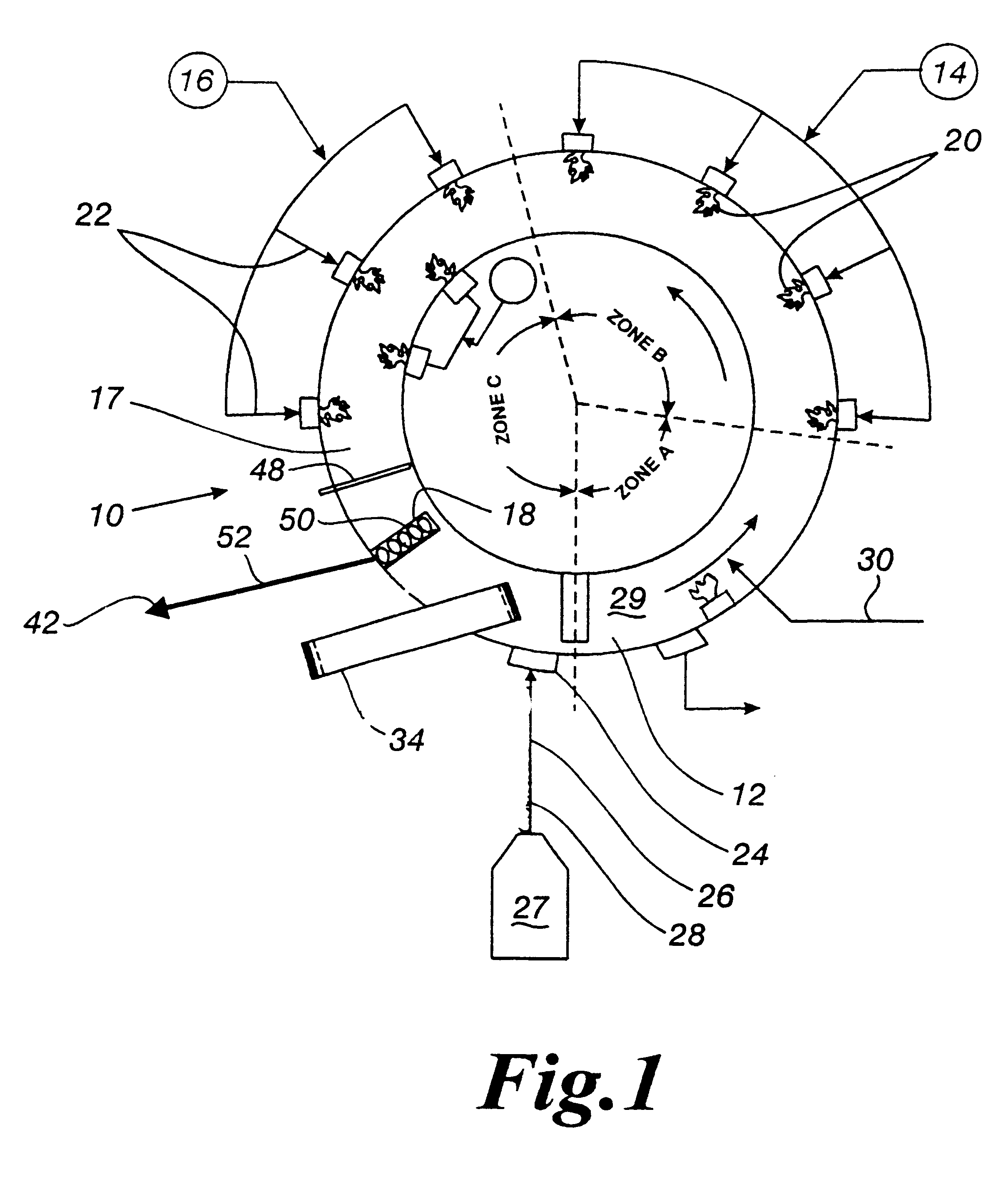

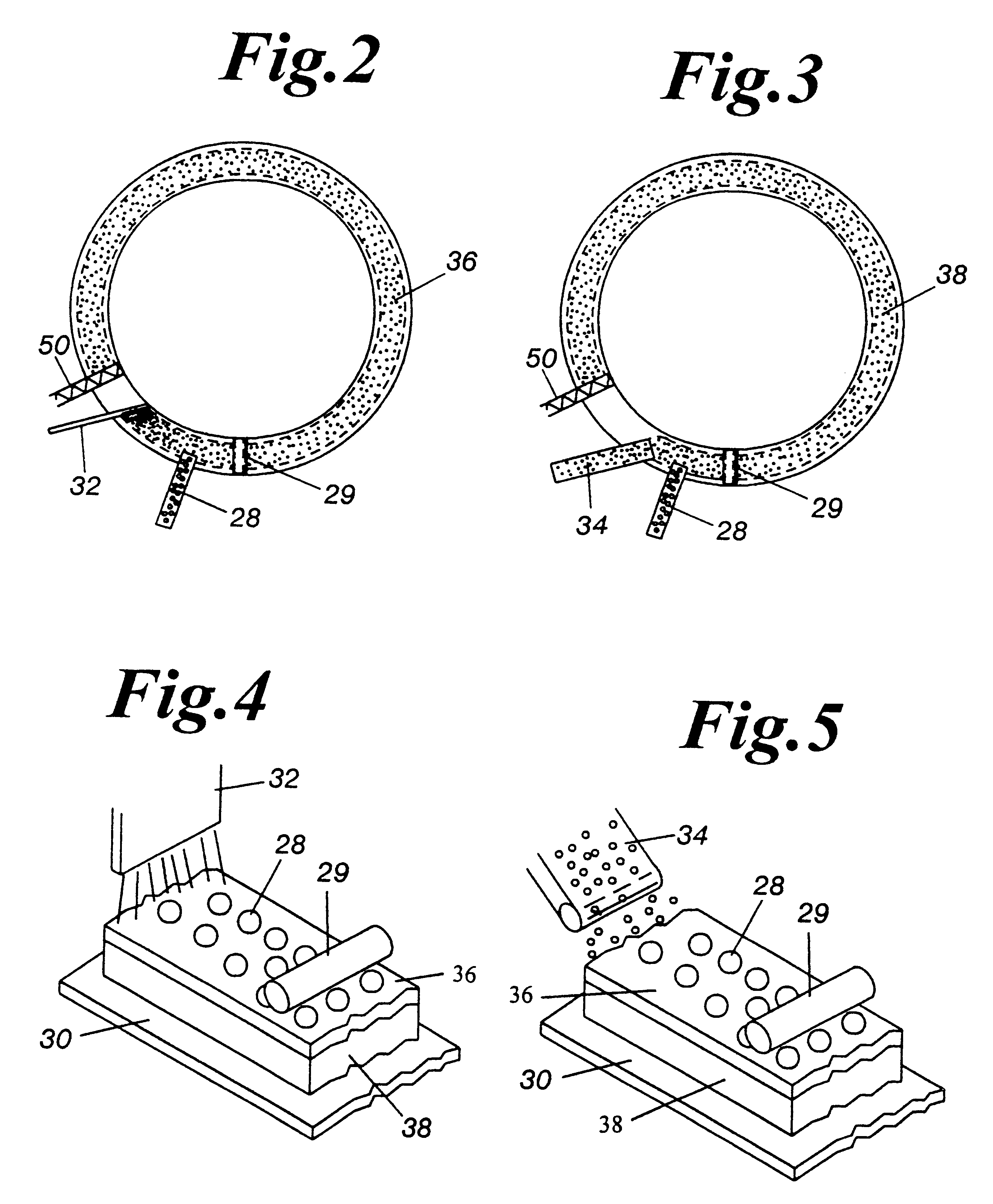

Iron production method of operation in a rotary hearth furnace and improved furnace apparatus

The present invention is an apparatus and method for the direct reduction of iron oxide utilizing a rotary hearth furnace to form a high purity carbon-containing iron metal button. The hearth layer may be a refractory or a vitreous hearth layer of iron oxide, carbon, and silica compounds. Additionally, coating materials may be introduced onto the refractory or vitreous hearth layer before iron oxide ore and carbon materials are added, with the coating materials preventing attack of the molten iron on the hearth layer. The coating materials may include compounds of carbon, iron oxide, silicon oxide, magnesium oxide, and / or aluminum oxide. The coating materials may be placed as a solid or a slurry on the hearth layer and heated, which provides a protective layer onto which the iron oxide ores and carbon materials are placed. The iron oxide is reduced and forms molten globules of high purity iron and residual carbon, which remain separate from the hearth layer. An improved apparatus includes a cooling plate that is placed in close proximity with the refractory or vitreous hearth layer, cooling the molten globules to form iron metal buttons that are removed from the hearth layer. The improvements due to the present apparatus and method of operation provide high purity iron and carbon solid buttons, which are separate from slag particulates, and discharged without significant loss of iron product to the interior surfaces of the furnace.

Owner:MIDREX INT B V ROTTERDAM

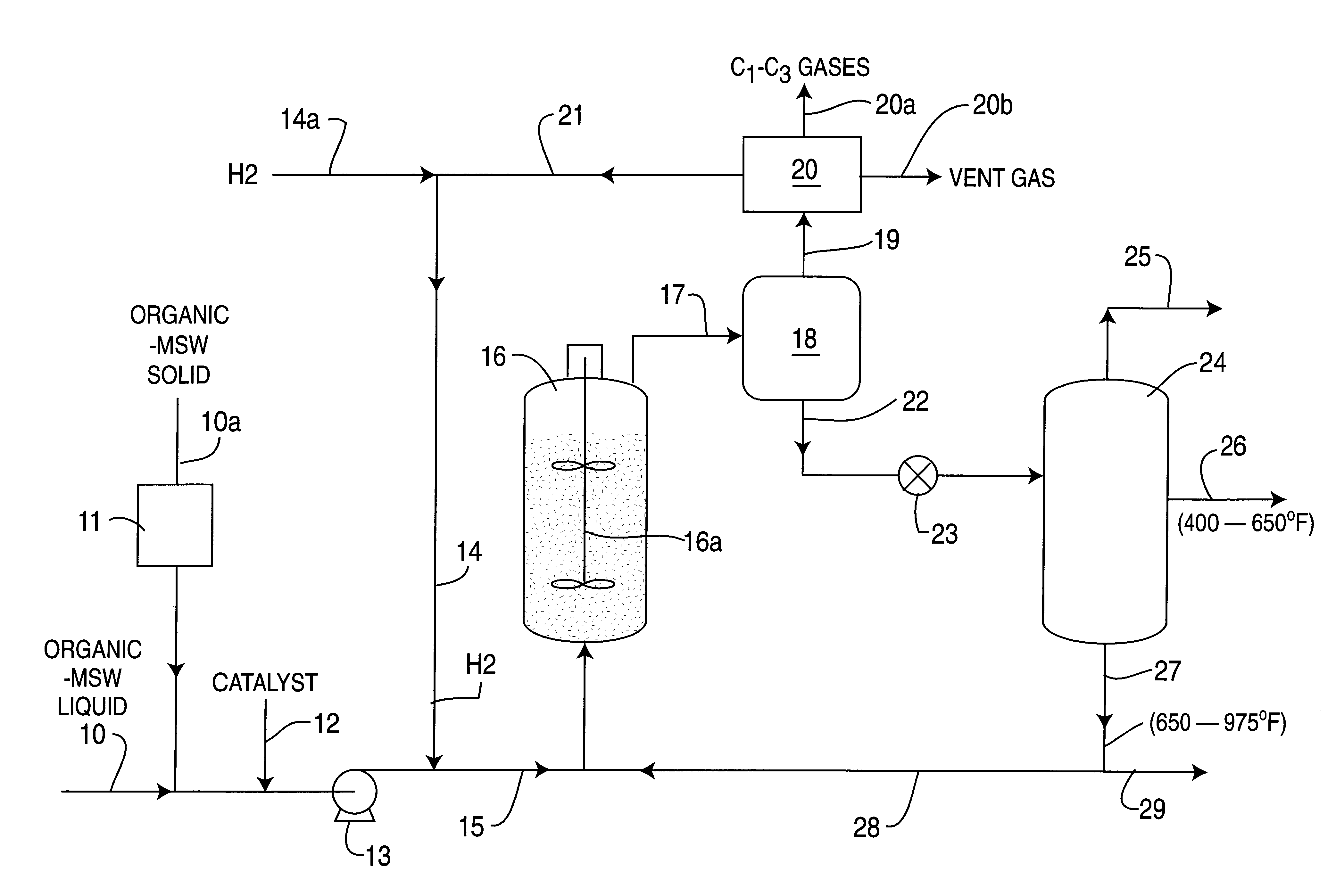

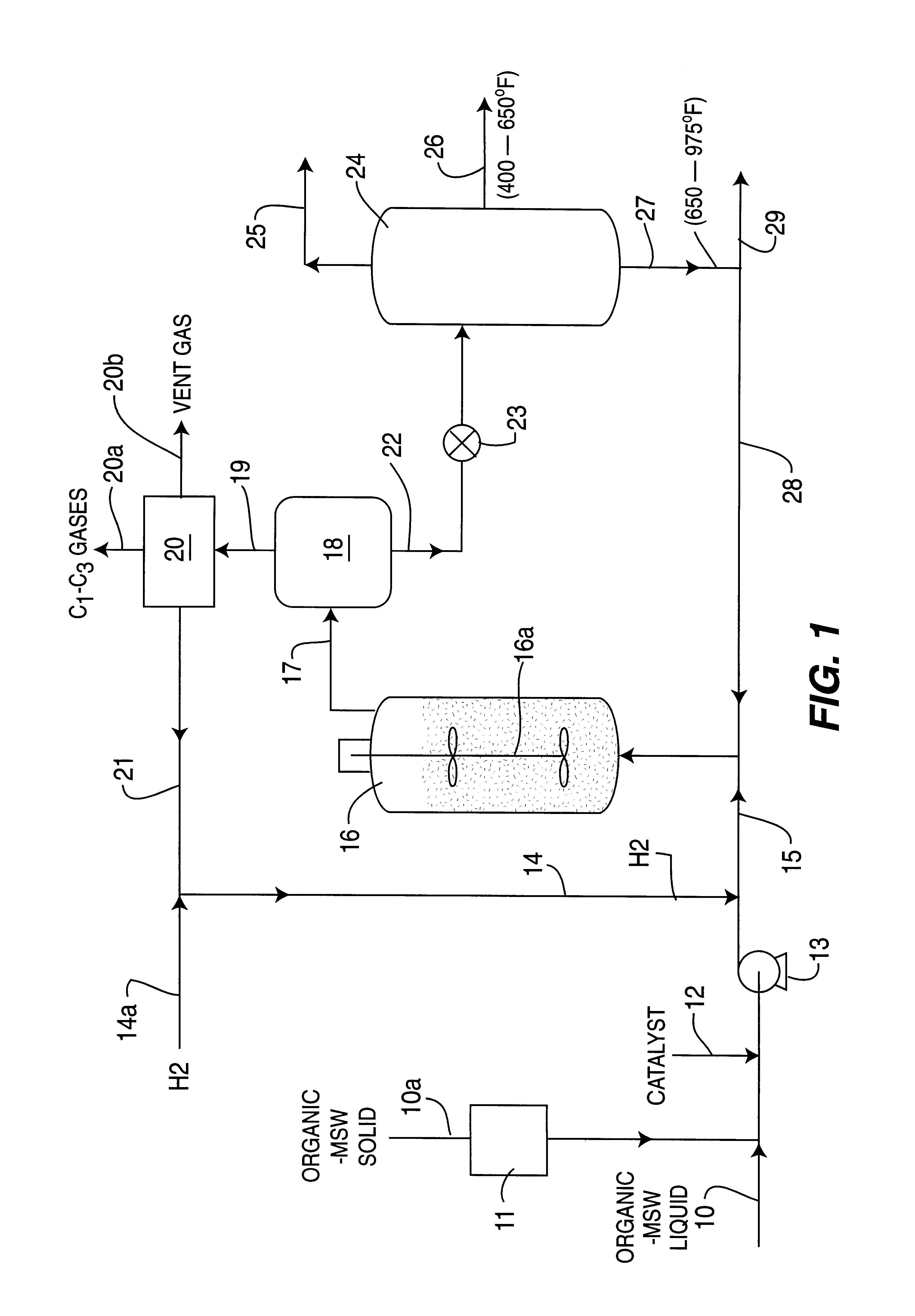

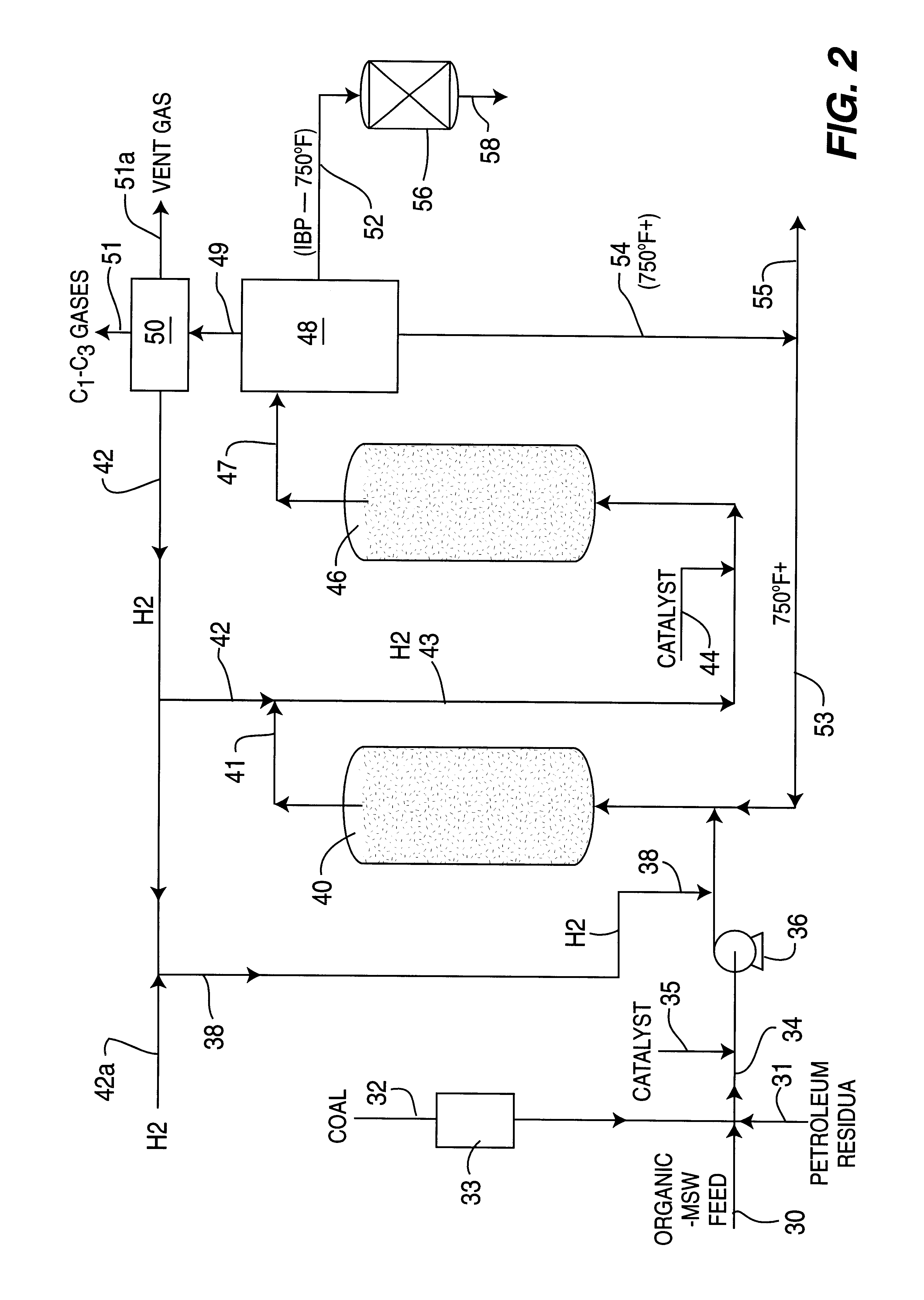

Catalytic hydroconversion of chemically digested organic municipal solid waste materials

InactiveUS6270655B1Increase surface areaReduce total nitrogenLiquid hydrocarbon mixture productionHydrocarbon oil crackingParticulatesLiquid product

A hydrocarbon liquid feedstock containing at least 50 wt. % chemically digested organic-MSW material is catalytically hydroconverted utilizing either a single stage or two-stage catalytic reaction process to produce desirable lower-boiling hydrocarbon liquid products. The catalyst can be either a particulate supported type catalyst such as containing cobalt and / or molybdenum and / or nickel on alumina support, or a dispersed slurry type catalyst containing mainly iron oxide with anions of molybdate, phosphate, sulfate or tungstate, and combinations thereof. Broad useful reaction conditions are 600-860° F. (315-460° C.) temperature, 1000-3000 psi hydrogen partial pressure, and fresh feed rate of 20-60 pounds / hr / ft3 reactor volume. Effluent material from the final stage catalytic reactor is phase separated and the resulting liquid portion is fractionated to produce the desired low-boiling hydrocarbon liquid products particularly useful as transportation fuels. If desired, the chemically digested organic-MSW feedstock can be blended with petroleum residua and / or particulate coal and / or mixed waste plastics and the blended feed material processed in catalytic two-stage reactors to produce similar desirable low-boiling hydrocarbon liquid products.

Owner:HYDROCARBON TECH

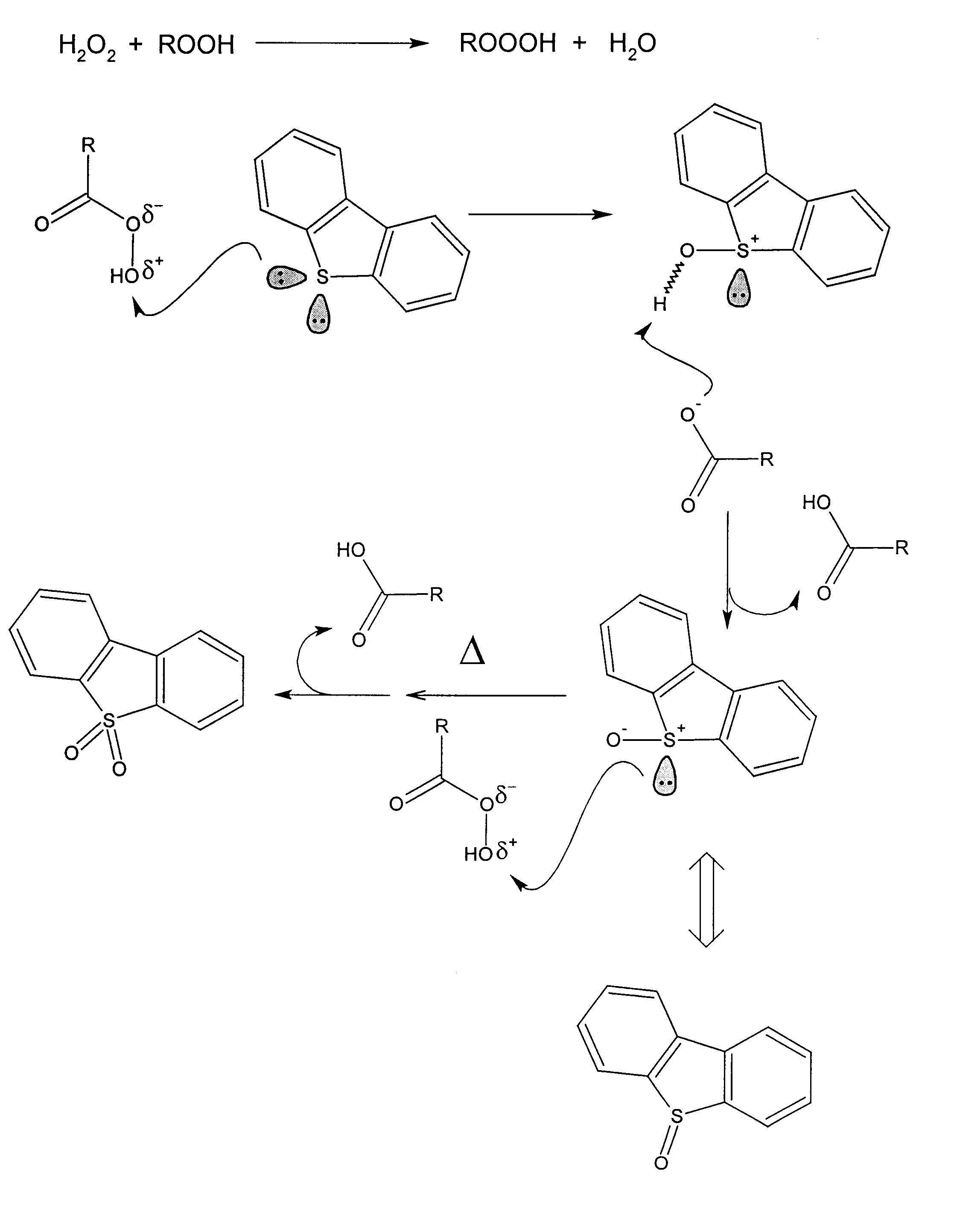

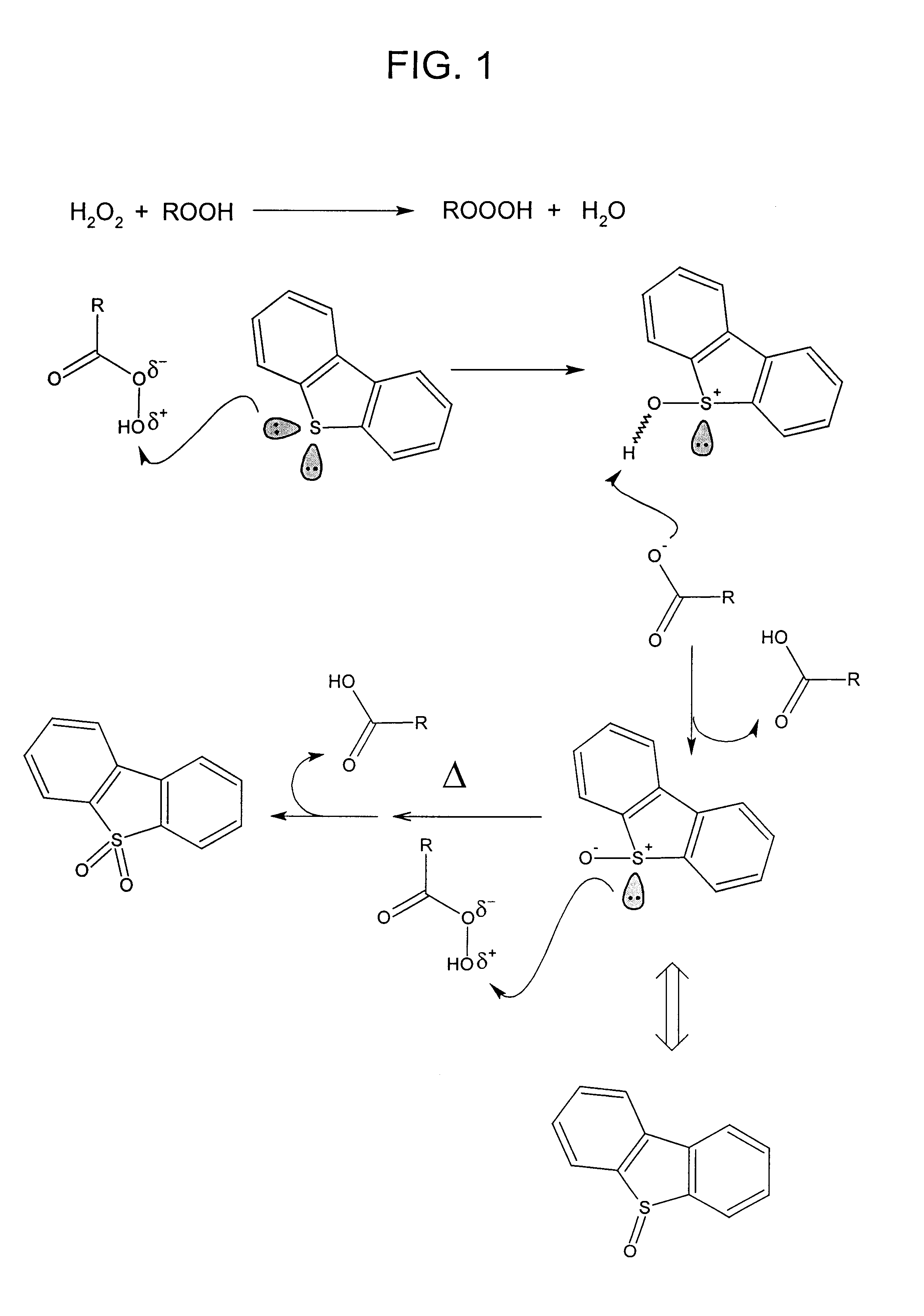

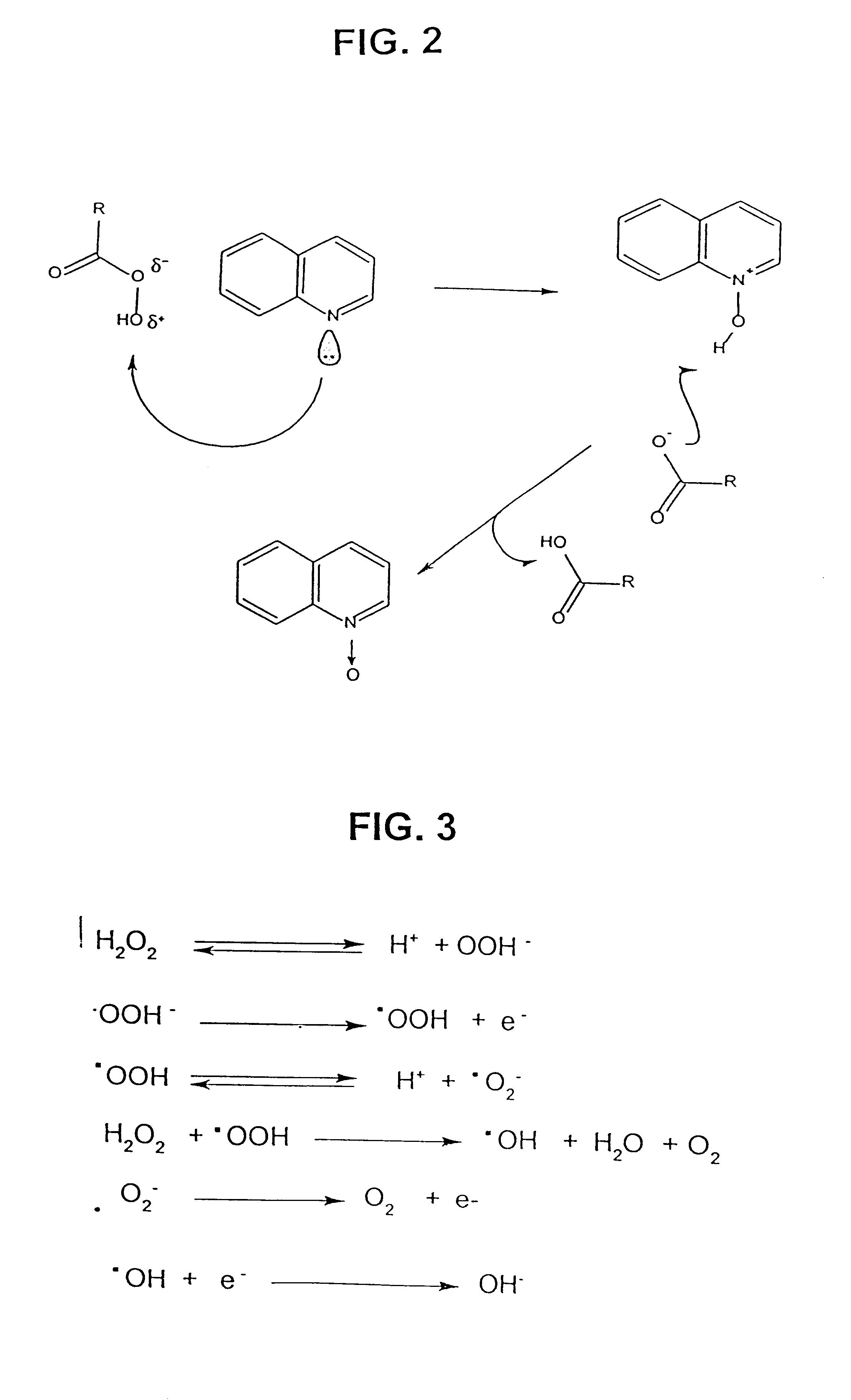

Process for the catalytic oxidation of sulfur, nitrogen and unsaturated compounds from hydrocarbon streams

A process for the catalytic oxidation of sulfur and nitrogen contaminants as well as unsaturated compounds present in a hydrocarbon fossil oil medium is described, the process comprising effecting the oxidation in the presence of at least one peroxide, at least one acid and a pulverized raw iron oxide. The process shows an improved oxidation power towards the contaminants typically present in a fossil oil medium, this deriving from the combination of the peroxyacid and the hydroxyl radical generated in the reaction medium due to the presence of an iron oxyhydroxide such as a limonite clay, which bears a particular affinity for the oil medium. The process finds use in various applications, from a feedstock for refining until the preparation of deeply desulfurized and deeply denitrified products.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Reduction of oxides of nitrogen in a gas stream using high-silics molecular sieve CHA

A process for the reduction of oxides in a gas stream (e.g., automotive exhaust) uses a catalyst comprising a molecular sieve having the CHA crystal structure and having a mole ratio of greater than 50 to 1500 of (1) an oxide selected from silicon oxide, germanium oxide or mixtures thereof to (2) an oxide selected from aluminum oxide, iron oxide, titanium oxide, gallium oxide or mixtures thereof.

Owner:CHEVROU USA INC

Catalyst, its preparation and use

A process for preparing a catalyst which process comprises preparing a mixture comprising iron oxide and at least one Column 1 metal or compound thereof, wherein the iron oxide is obtained by heating a mixture comprising an iron halide and at least 0.05 millimoles of a Column 6 metal per mole of iron; a catalyst made by the above described process; an iron oxide composition; a process for the dehydrogenation of an alkylaromatic compound which process comprises contacting the alkylaromatic compound with the catalyst; and a method of using an alkenylaromatic compound for making polymers or copolymers, in which the alkenylaromatic compound has been produced by the dehydrogenation process.

Owner:SHELL OIL CO

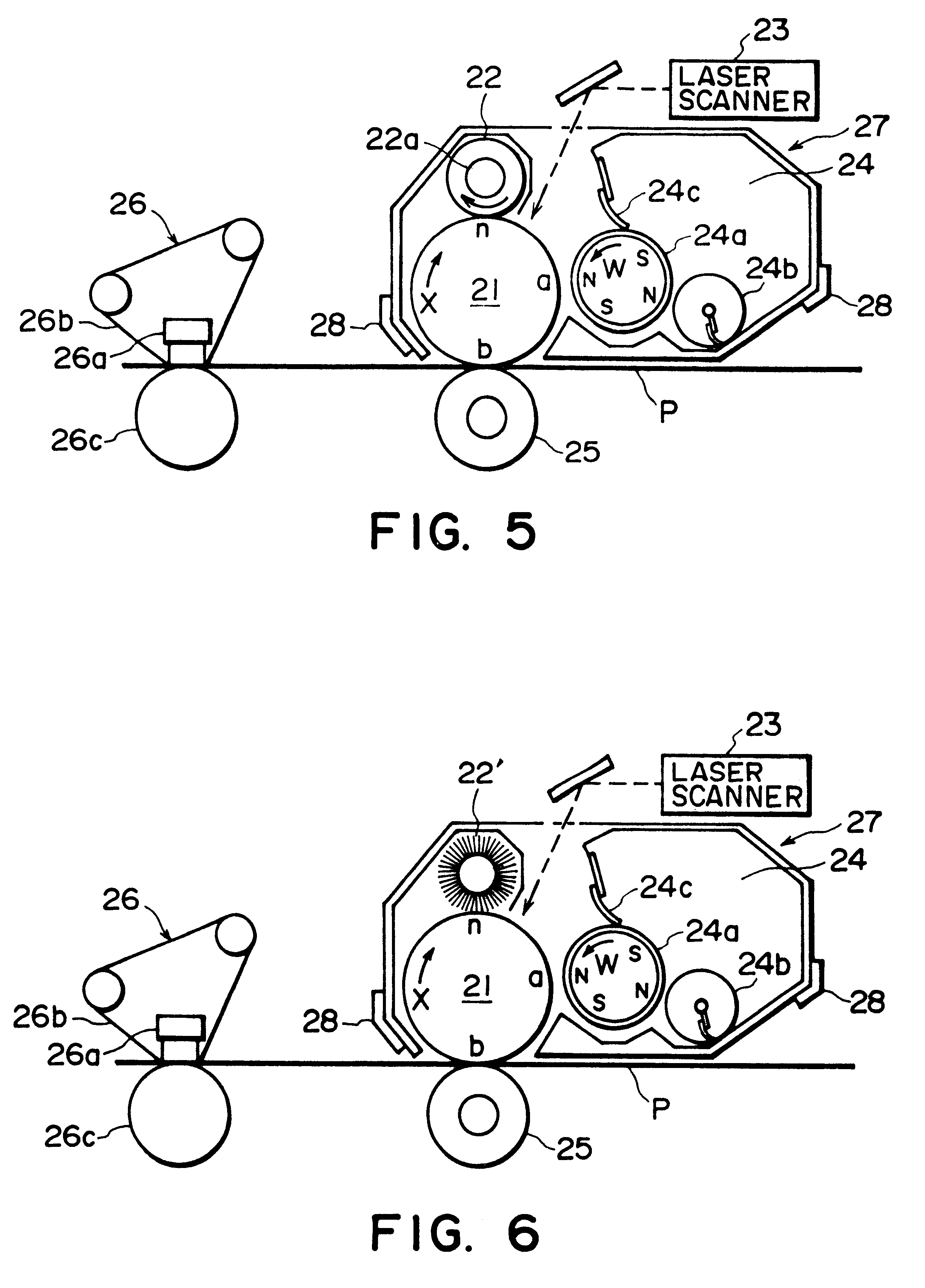

Toner

ActiveUS8084174B2Excellent in ability to prevent electrostatic offset and fixation tailingExcellent charge rise performanceDevelopersWaxIron oxide

Owner:CANON KK

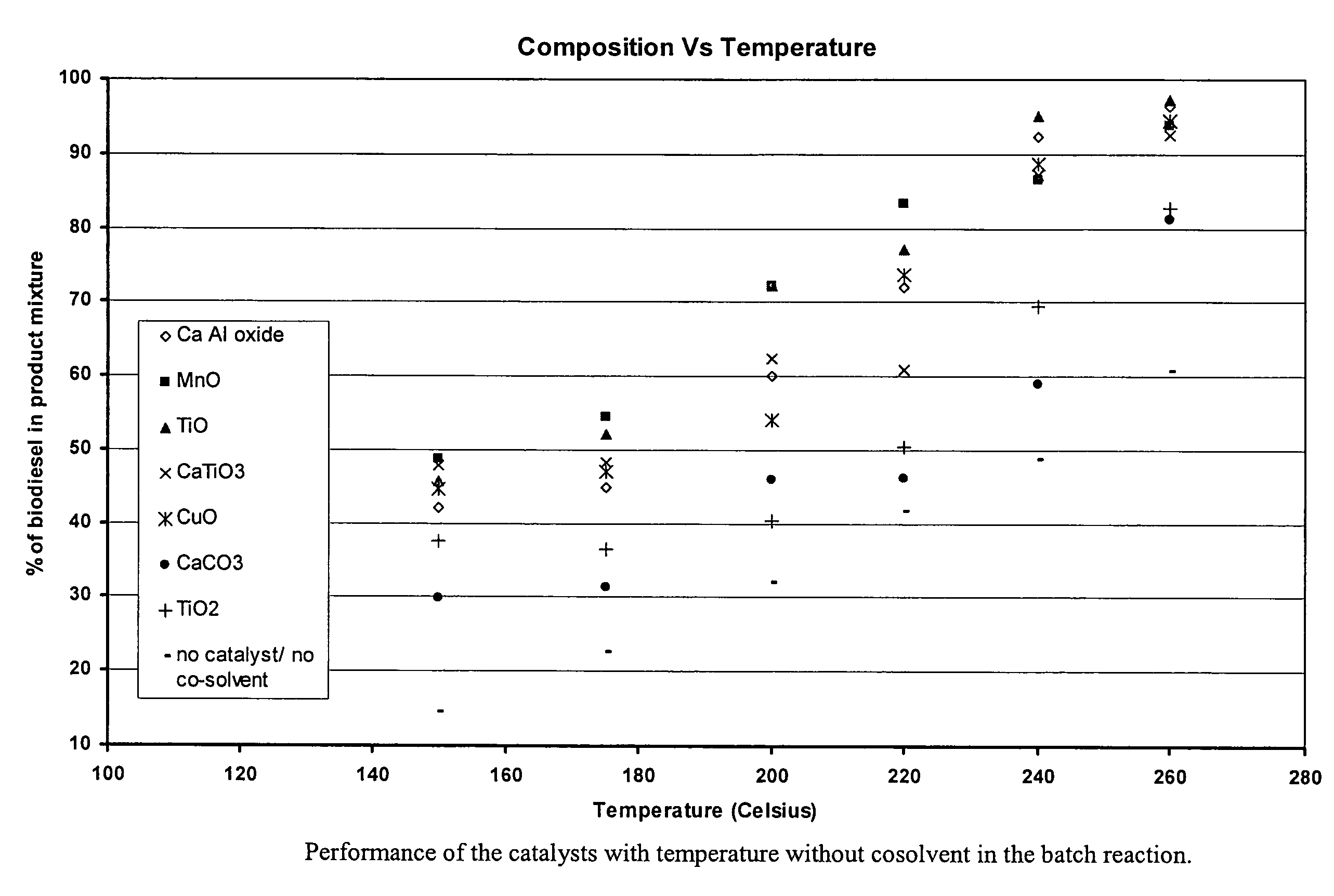

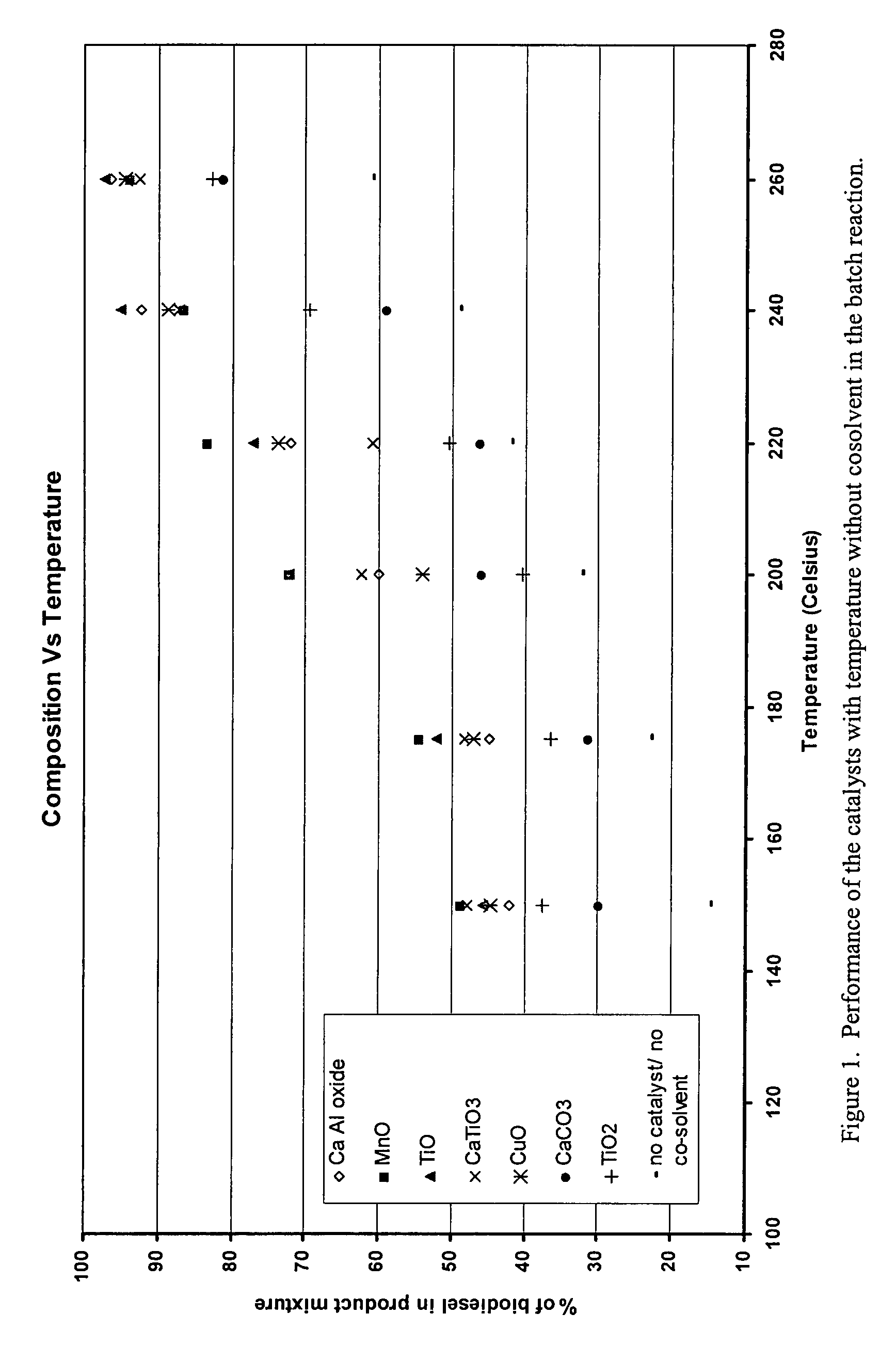

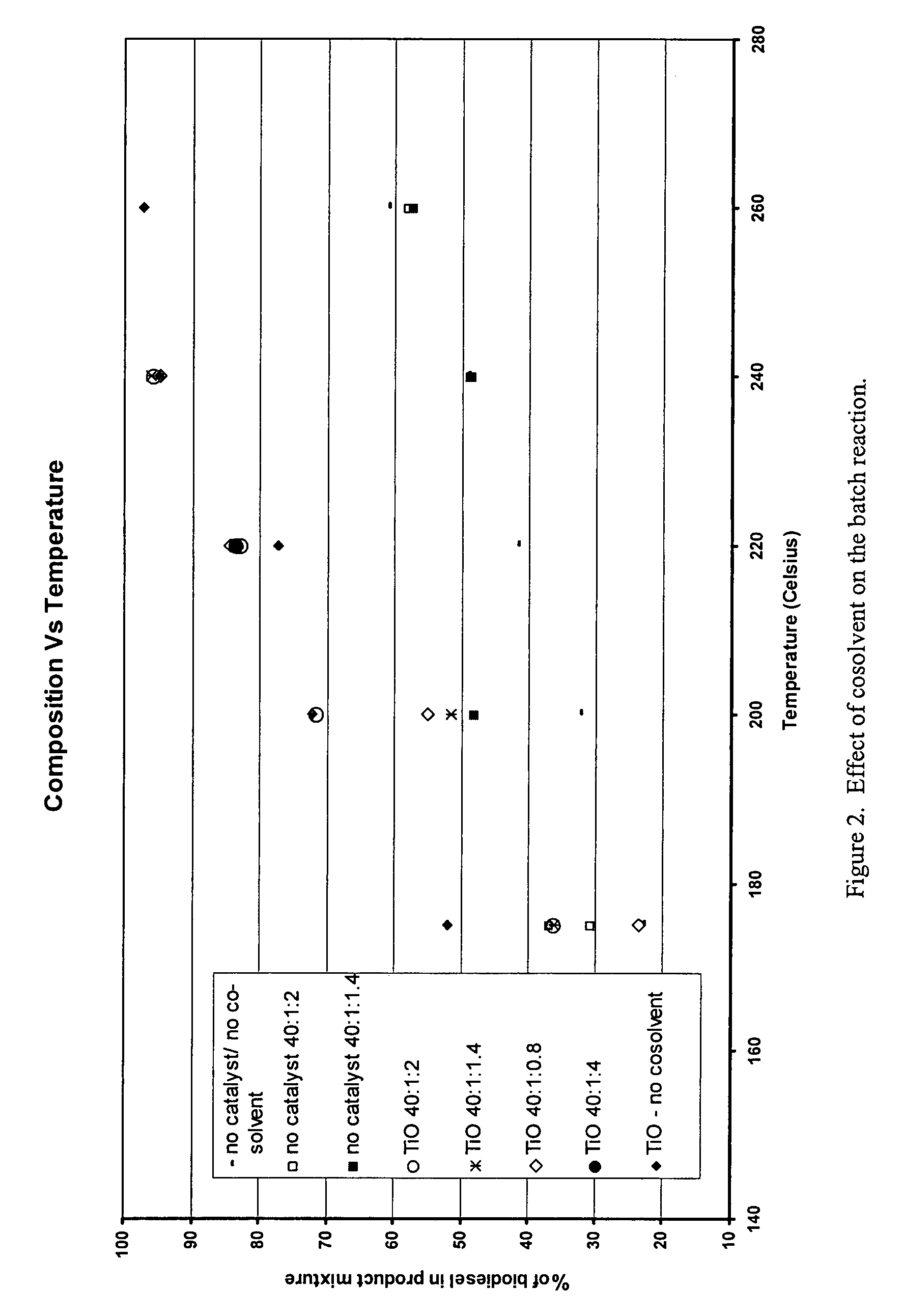

Green biodiesel

InactiveUS7563915B2Reduce wasteSignificant energyFatty oils/acids recovery from wasteFatty acid esterificationCalcium silicateBiodiesel

Methods for improved manufacture of green biodiesel focus on the selection and use of one or more solid metallic oxide base catalyst(s) selected from the group consisting of calcium oxide (CaO), calcium aluminum oxide (CaO—Al2O3), calcium titanate (CaTiO3), barium titanate (BaTiO3), magnesium aluminum oxide (MgO—Al2O3), zinc oxide (ZnO), copper (II) oxide (CuO), nickel oxide (NiO), manganese oxide (MnO), titanium oxide (TiO), vanadium oxide (VO), cobalt oxide (CoO), iron oxide (FeO), chromite (FeCr2O4), hydrotalcite (Mg6Al2(CO3)(OH)16.4(H2O), magnetite (Fe3O4), magnesium silicate and calcium silicate.

Owner:PENN STATE RES FOUND

Thermal protective coating for ceramic surfaces

ActiveUS20050051057A1Extend working lifeReduce surface temperatureFireproof paintsOther chemical processesColloidal silicaSodium Bentonite

A coating admixture, method of coating and substrates coated thereby, wherein the coating contains colloidal silica, colloidal alumina, or combinations thereof; a filler such as silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides, copper chromium oxides, cerium oxides, terbium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide is also added.

Owner:WESSEX

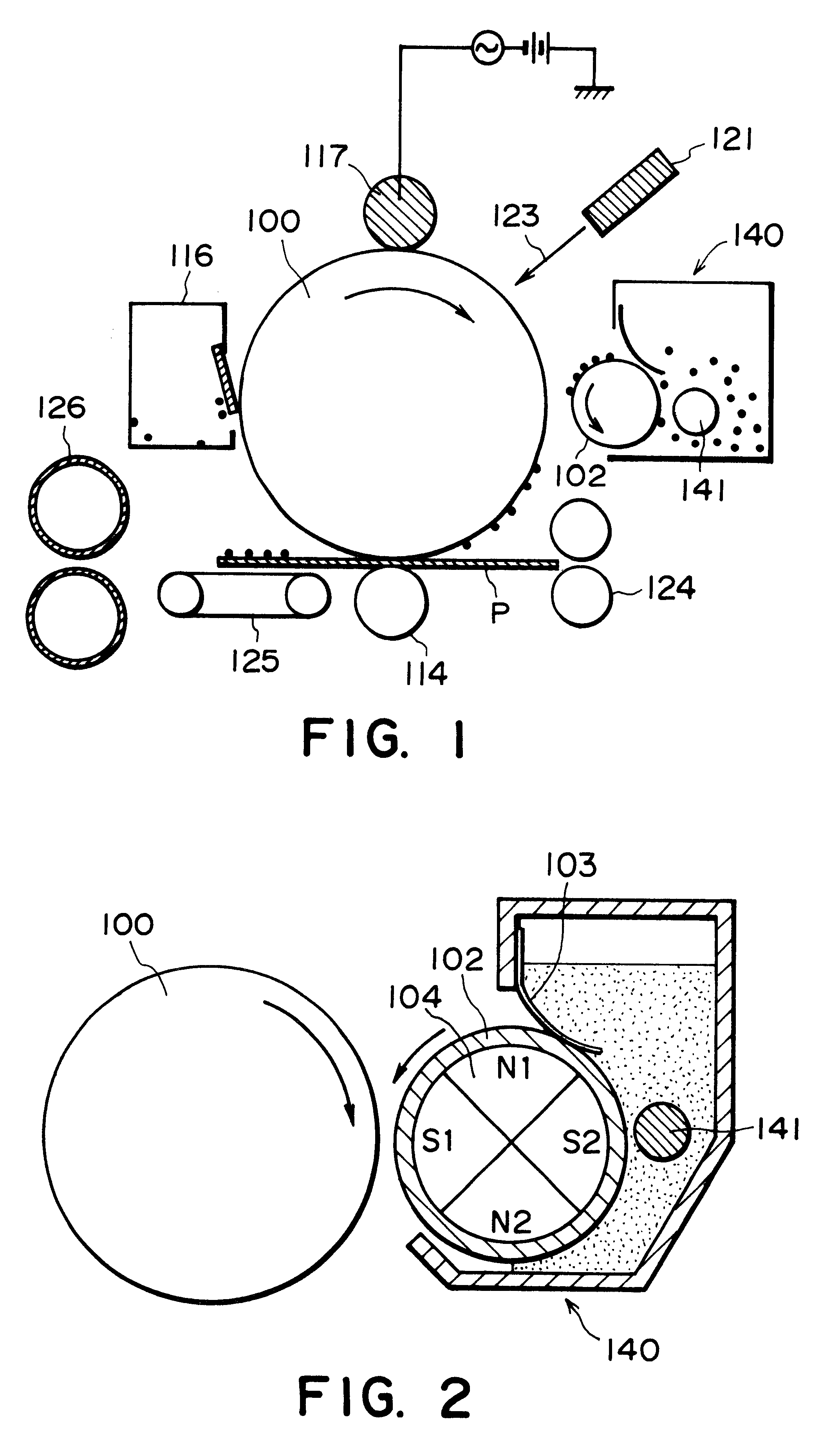

Magnetic toner, process for production thereof, and image forming method, apparatus and process cartridge using the toner

InactiveUS6465144B2Reduce wastePerformance and recoveryDevelopersElectrographic process apparatusMagnetizationX-ray

A magnetic toner includes: magnetic toner particles each comprising at least a binder resin and magnetic toner, and inorganic fine powder. The magnetic toner has an average circularity of at least 0.970, and a magnetization of 10-50 Am2 / kg at a magnetic field of 79.6 kA / m. The magnetic powder comprises at least magnetic iron oxide. The magnetic toner particles retain carbon in an amount of A and iron in an amount of B at surfaces thereof as measured by X-ray photoelectron spectroscopy, satisfying: B / A<0.001. The binder resin comprises a resin formed by polymerization of a monomer comprising at least styrene monomer. The magnetic toner has a residual styrene monomer content of less than 300 ppm, and contains at least 50% by number of toner particles satisfying a relationship of: D / C<=0.02, wherein C represents a volume-average particle size of the magnetic toner, and D represents a minimum distance between the surface of a magnetic toner particle and magnetic powder particles contained in the magnetic toner particle. Owing to the above features, the magnetic toner can exhibit good electrohotographic performances, including excellent chargeability and little transfer-residual toner, even in a cleanerless-mode image forming system.

Owner:CANON KK

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com