Patents

Literature

398 results about "Baryte" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Baryte or barite (UK: /ˈbærʌɪt/, /ˈbɛəraɪt/) is a mineral consisting of barium sulfate (BaSO₄). Baryte is generally white or colorless, and is the main source of barium. The baryte group consists of baryte, celestine (strontium sulfate), anglesite (lead sulfate), and anhydrite (calcium sulfate). Baryte and celestine form a solid solution (Ba,Sr)SO₄.

Water industrial antirust paint and preparation method thereof

InactiveCN101045843AHigh hardnessStrong adhesionAnti-corrosive paintsEmulsion paintsEpoxyALUMINUM PHOSPHATE

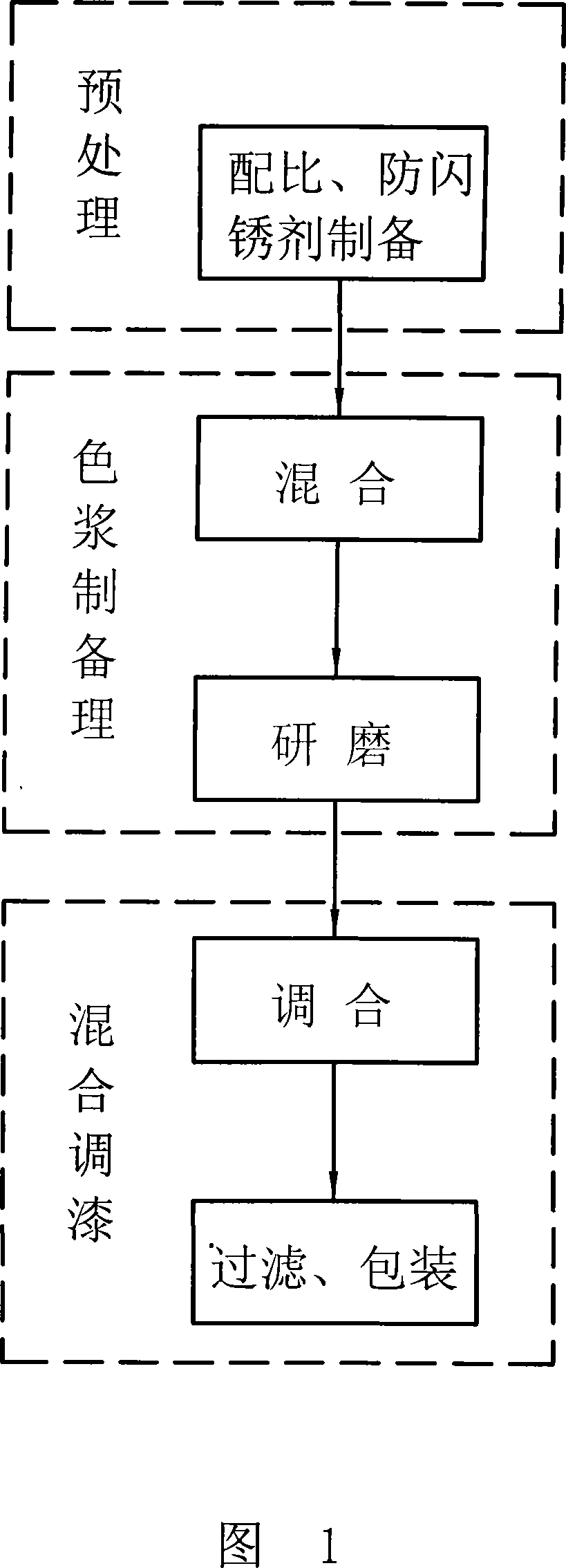

This invention relates to a aquosity industry anti-rust paint and its preparation method. According to weight it includes 8 to 11% aquosity acroleic acid modified epoxy, 33 to 40% acroleic acid latices, 0.1 to 0.3% defoamer, 0.05 to 0.15% wetting agent, 0.3 to 0.5% dispersant, 0.3 to 0.5% rust-resistant agent, 7.5 to 9% iron oxide red, 6 to 8% French chalk, 5 to 10% modified zinc phosphate, 2.5 to 10% trimerization aluminum phosphate, 3 to 3.5% precipitated baryte , 0.5 to 1% zinc oxide, 3 to 5% mica ferric oxide, alcohol ester twelve 1 to 2%, triethanolamine 1 to 2%, thickening agent 0.3 to 0.6%, preservative 0.05 to 0.1%, 5 to 20% de-ionized water, through pretreatment, color paste preparation and blending and adjusting to gain product.

Owner:邹磊

Strong-inhibition anticaving drilling fluid and application thereof

InactiveCN105038737AReduce fluid lossAdjust the flow patternDrilling compositionOrganic chemistryPetroleum engineering

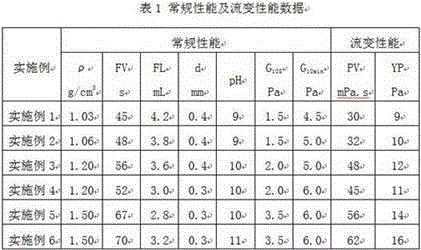

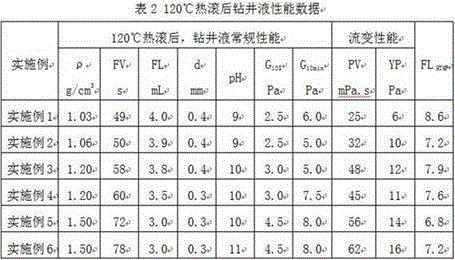

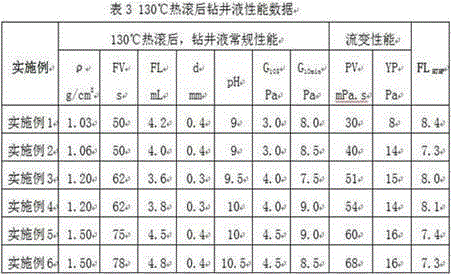

The invention discloses a strong-inhibition anticaving drilling fluid and application thereof. The strong-inhibition anticaving drilling fluid consists of 1000 parts of water, 20 to 60 parts of bentonite for drilling fluid, 5 to 20 parts of sodium carbonate, 5 to 20 parts of alkali, 10 to 20 parts of coating agent, 5 to 20 parts of flow pattern regulator, 5 to 20 parts of shale inhibitor, 10 to 30 parts of borehole stabilizer, 10 to 30 parts of plugging agent, 5 to 30 parts of lubricating agent, 5 to 40 parts of filtrate reducer, 1 to 10 parts of pH regulator, and a proper amount of salts and barite added according to the requirement. The strong-inhibition anticaving drilling fluid has the remarkable characteristics of properties of stabilizing a borehole, protecting an oil layer, improving the drilling speed, and preventing a balled bit and the like from approaching to oil-based drilling fluid.

Owner:北京中科天启油气技术有限公司

Low grade fluorite and barite flotation separation method

A low grade fluorite and barite flotation separation method uses waterglass as the inhibitor for silicious mineral and calcium carbonate mineral; uses oleic acid as the collector for fluorite and barite; and uses starch, sodium sulphate, hydrochloric acid and sodium hexametaphosphate as the inhibitor for barite mineral. The invention can perform flotation separation of low grade fluorite and barite effectively; under the condition that the given fluorite grade is 33.92%-40.41%, and the barite grade is 34.67%-35.33%, by mixing, flotation and separation, can achieves the fluorite concentrate with grade of above 95% and recovery rate of 75.5%-78.5%, and the barite concentrate with grade of 92.3%-93.27% and recovery rate of 75.2%-79.73%.

Owner:GUANGXI UNIV

Friction Material

InactiveUS20070219289A1Improve wear resistanceShort lifeFriction liningActuatorsFiberAlkaline earth metal

A friction material includes a binder, a reinforcement fiber, and a friction modifier which in turn includes flat layered titanate particles and baryte particles, wherein the baryte particles constitute less than 25% by volume of the friction material. The flat layered titanate particle may include alkali metal titanate particles, and more specifically potassium lithium titanate particles. Other flat layered titanates, including alkali metal alkaline earth metal titanates may also be used. The titanate particles may be used in an amount of 3-25% by volume of the friction material, and more specifically 5-15% by volume thereof. They may also have particle sizes ranging from 0.1-500 μm, and more specifically 1-30 μm, and even more specifically 15-30 μm. The friction material may include a binder or binders in an amount of about 8-31% by volume of the friction material. The friction material may also include reinforcement fibers in an amount of about 2-13% by volume of the friction material. These friction material may be used for any friction component including use in industrial machinery and vehicles, but are particularly useful as friction materials for use in various brake and clutch components.

Owner:FEDERAL MOGUL WORLD WIDE

TiO2 complex ore powder and preparation method thereof

InactiveCN101041748AReasonable cooperationGood effectInorganic pigment treatmentKaolin clayPhysical chemistry

The invention discloses a composite powder body with titanium oxide nature and preparing method in paint, plastic and paper making domain, which comprises the following steps: mixing 30-50% ultra-fine heavy calcium carbonate, 5-15% calcining porcelain clay or washing porcelain clay and 5-10% baritic rock; getting coated basal body; adding into organic surface modifier and water; producing slurry; grinding with wet method stripper; adding into inorganic surface modifier; grinding the material to suitable particle diameter; choosing 25-60% titanium dioxide as enveloped material; adding into organic and inorganic surface modifier and water; producing slurry; mixing the titanium dioxide slurry with composite powder body slurry; grinding the composite powder body slurry to demanded fineness with wet method stripper; cooling the slurry directly; disintegrating; getting the product.

Owner:HUBEI PUYUAN CHEM

High-strength ceramic brick and preparation method thereof

The invention discloses a high-strength ceramic brick and a preparation method thereof. The ceramic brick is prepared from the following raw materials in parts by weight: 40-60 parts of yellow sand, 30-50 parts of barite, 15-25 parts of dolomite, 10-20 parts of volcanic rock, 20-30 parts of zirconite, 5-15 parts of mullite, 4-12 parts of blast furnace slag, 16-28 parts of modified clay, 7-14 parts of sea mud, 11-19 parts of a silica micro-powder, 8-16 parts of a waste brick powder, 3-9 parts of tricalcium phosphate, 4-8 parts of barium carbonate, 2-5 parts of nano silicon carbide, and 3-6 parts of nano alumina. The prepared ceramic brick has high strength, has the breaking strength of not less than 1050 N and the rupture modulus of not less than 30 MPa, is anti-knock, anti-cracking and non-friable, and enables the service life to be significantly improved.

Owner:安徽省亚欧陶瓷有限责任公司

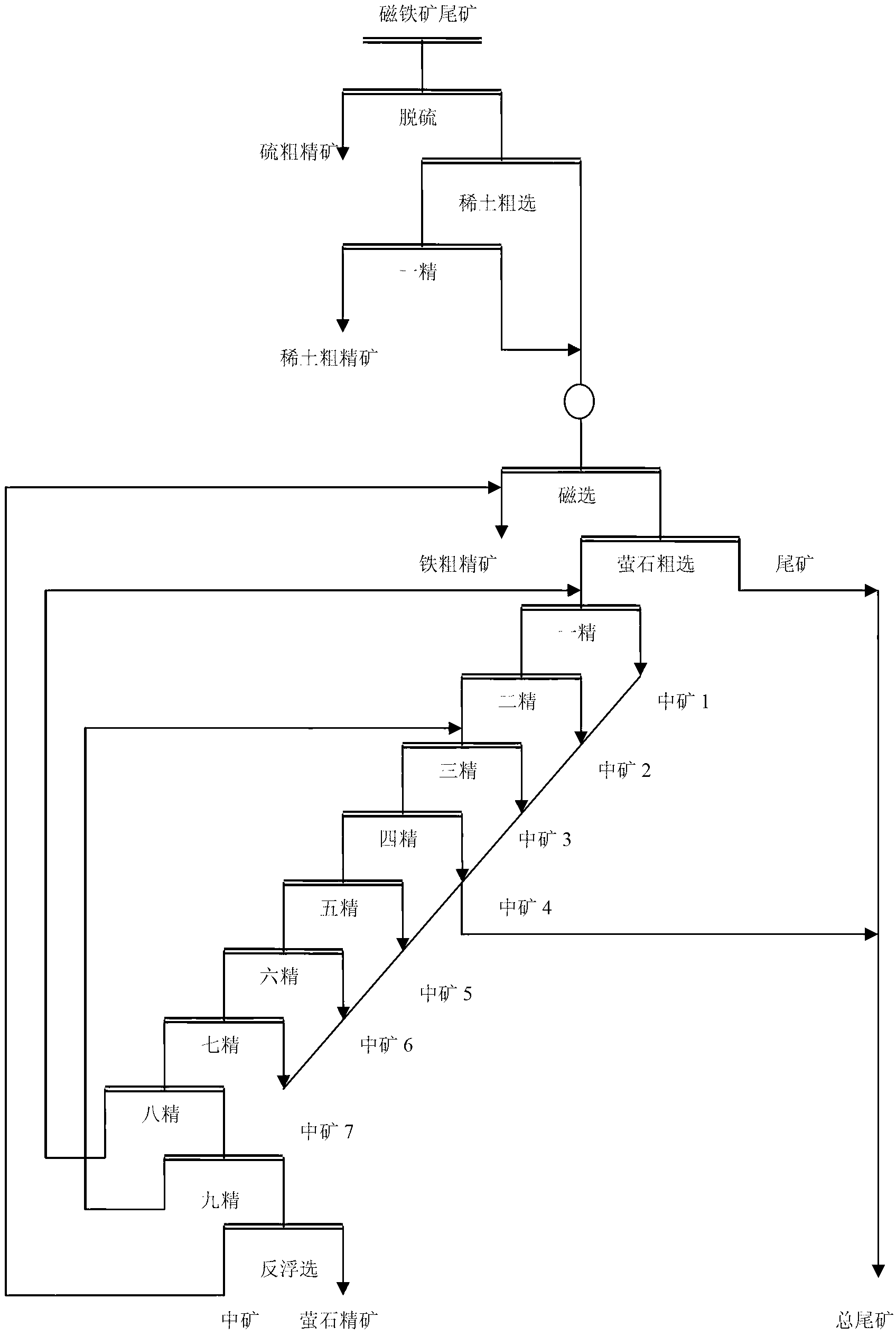

Mineral processing technology for recycling fluorite from baotite, magnetite and tailing

The invention belongs to the technical field of mineral engineering and provides a mineral processing technology for recycling fluorite from baotite, magnetite and tailing. In the tailing, mineral particle size of the fluorite is thin, iron-bearing mineral, rare-earth mineral, gangue mineral and the fluorite mineral are closely symbiotic and floatability of minerals such as rear earth, barite, apatite, calcite and dolomite is close to the fluorite mineral, so that separation of the fluorite mineral is difficult. According to the mineral processing technology for recycling the fluorite from the baotite, the magnetite and the tailing, priority desulfuration, rear earth flotation, ore grinding, iron selection through magnetic separation, fluorite selection through direct flotation and a reverse flotation sorting technology are performed on the magnetite and the tailing to enable pyrite, the rare earth, the iron-bearing mineral and the fluorite to be picked out in sections, efficient, high selective, easy-to-operate inhibitor and collecting agent combination is utilized in sorting of fluorite which is mostly performed monomer separation, so that fine fluorite of high grade and high recovery rate is obtained, a purpose of synthetically recycling valuable minerals is achieved, and effective separation of the fluorite mineral and the gangue mineral is achieved.

Owner:包钢集团矿山研究院(有限责任公司)

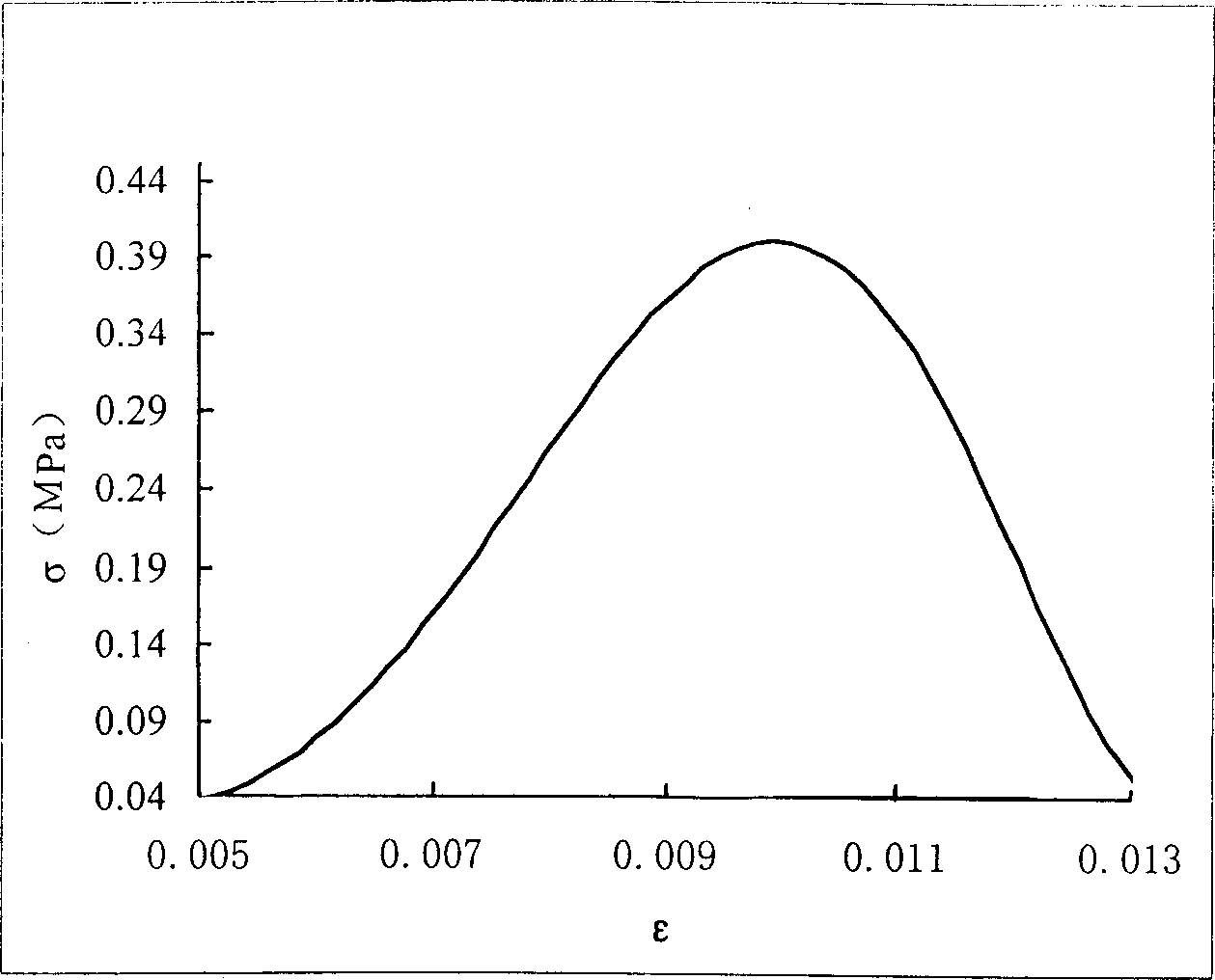

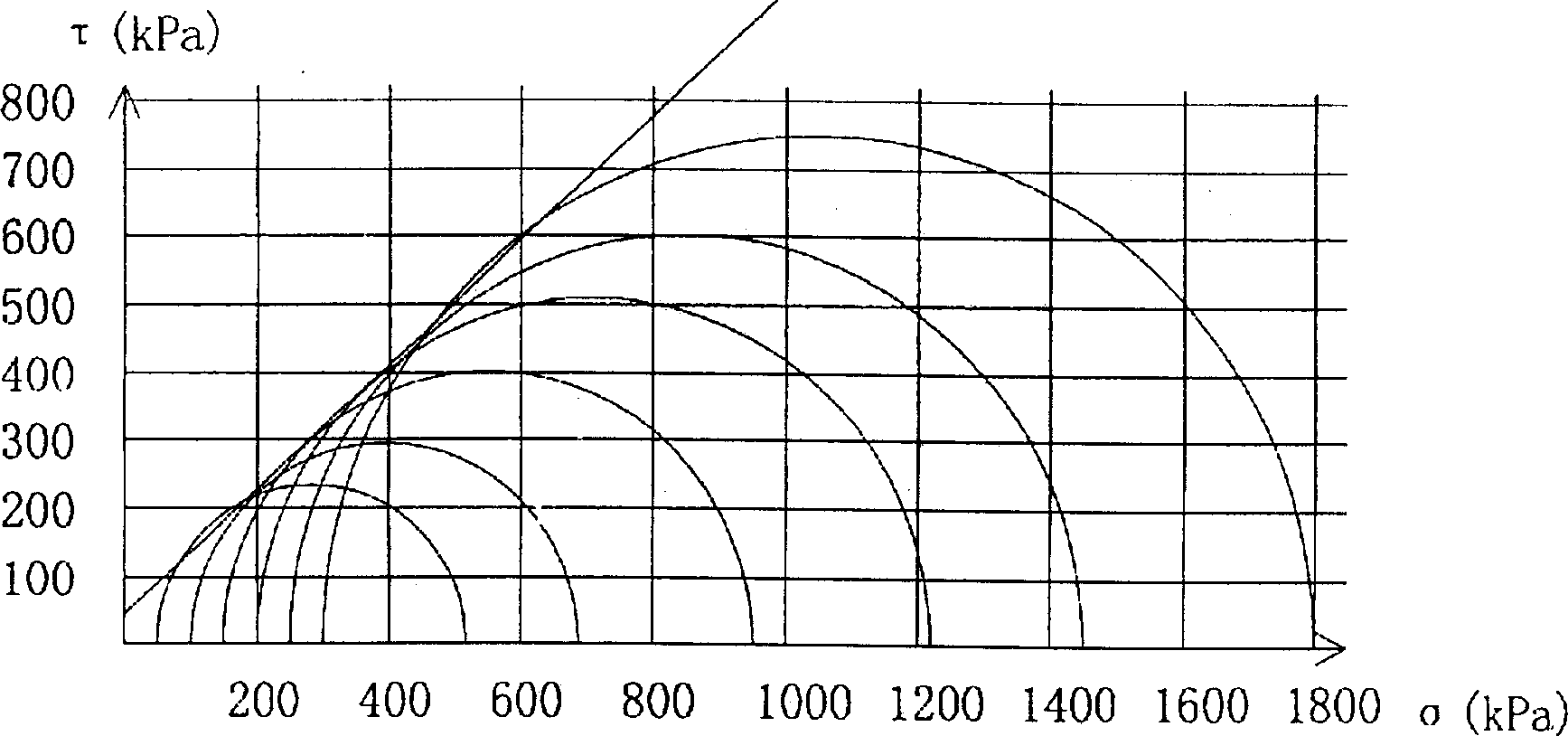

Iron spar powder, guartz sand cement rock-soil similar material and preparation process thereof

The invention relates to a method to produce equivalent material of iron crystal sand cemented rock soil that uses iron ore, barite powder and quartz sand as main aggregate, uses solution that is made up from rosin and alcohol as cementing agent, and uses gesso as regulator. Whisking the iron ore, barite powder and quartz sand, gesso, resin-alcohol solution to equal, pouring into steel mould, pressing the mixture, opening the mould, drying for 2-3 days, the invention could be gained. The invention has the advantages of high unit weight, large range of mechanics parameter, easy to process and low cost.

Owner:SHANDONG UNIV

Strong-inhibition efficient shielding temporary plugging protection reservoir drilling fluid and preparation method thereof

InactiveCN102559155AEnhanced inhibitory effectDownhole safetyDrilling compositionCelluloseInorganic salts

The invention discloses strong-inhibition efficient shielding temporary plugging protection reservoir drilling fluid. The drilling fluid comprises the following components by weight percent: 2-5% of new shielding temporary plugging agent, 3-7% of inorganic salt inhibitor, 3-7% of organic inhibitor, 0.3-0.5% of low-viscosity polyanionic cellulose, 0.1-0.3% of high-viscosity polyanionic cellulose, 0.1-0.3% of viscosity enhancer, 0-3% of barite and the balance water, wherein NaOH is added to adjust the pH value to 9-10. The drilling fluid is used to effectively and temporarily plug the micro-cracks of the reservoir, has efficient plugging property and shallow layer property and ensures that some solid particles of the later drilling fluid can not enter the reservoir, thus the reservoir can be protected; and the drilling fluid has very good inhibitory property, and can balance the formation pressure and have the function of stabilizing the well wall.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Strongly inhibitory solid-free polyamine-formate drilling fluid system

ActiveCN102424746AImprove rheologyImprove high temperature resistanceDrilling compositionFormateWell drilling

The invention belongs to the technical field of petrochemical industry well drilling and relates to a strongly inhibitory solid-free polyamine-formate drilling fluid system. The polyamine-formate drilling fluid system contains strongly inhibitory polyamine shale inhibitor and usually comprises necessary finishing agents like filtrate reducer, polymer coating agent, tackifier and lubricant, etc. The system contains no solid phase, and uses formate as a weighting agent. The polyamine-formate drilling fluid system comprises 0.1-5% of shale inhibitor, 0.1-5% of filtrate reducer, 0.1-5% of coatingagent, 0.1-5% of tackifier, 0.1-5% of lubricant, weighting agent formate added according to actual requirement during well drilling and the balance of water for preparing the drilling fluid. And routine drilling fluid finishing agents like plugging agent and pH conditioning agent can be added according to on-site conditions on the well drilling spot. The drilling fluid system of the invention hasstrong inhibition effect on water-sensitive mud shale; besides, as the drilling fluid system contains no solid-phase particles like clay and barite, damage on a hydrocarbon reservoir is reduced substantially.

Owner:CHINA PETROCHEMICAL CORP +1

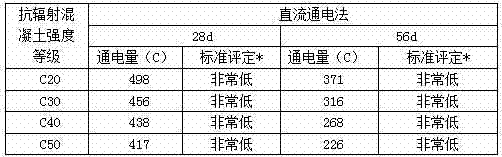

Barite anti-radiation pump concrete

The invention discloses barite anti-radiation pump concrete. The concrete comprises the following components: cement, water, barite powder, barite sand, barite, synergist and admixture according to a ratio of [340-450]:[110-170]:[75-150]:[1000-1400]:[1800-2000]:[2-4]:[7-19]. According to selection of raw materials and design of the ratio, the anti-radiation concrete which is high in density and high in liquidity and can be used for pumping is obtained.

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

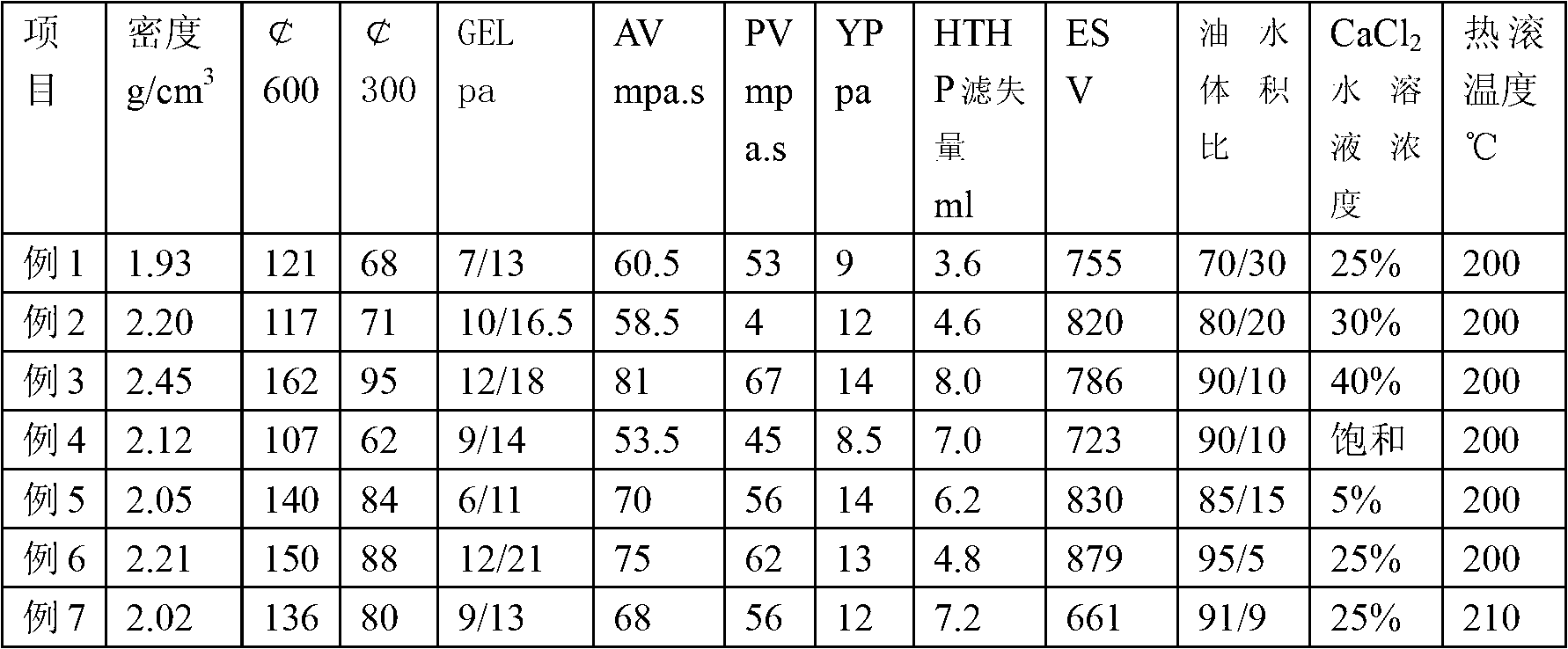

Gas oil base invert oil-emulsion drilling fluid and preparation method

InactiveCN102796497AStrong salt resistanceGood temperature resistanceDrilling compositionTemperature resistanceChemistry

The invention relates to a gas oil base invert oil-emulsion drilling fluid and a preparation method, wherein the total volume of gas oil and calcium chloride aqueous solution is 100 parts: the volume ratio of oil phase to water phase is between 95:5 and 70:30, and the concentration of calcium chloride aqueous solution is 5%-saturation; the required gas oil, primary emulsion, auxiliary emulsion and wetting agent are added into a high speed mixing beaker, and are mixed at high speed for 2-5 minutes; the calcium chloride aqueous solution is added and mixed at high speed for 15 minutes; organic soil, calcium oxide and a fluid loss agent are added and mixed at high speed for 10 minutes; and the required amount of barite is added according to density, and is mixed at high speed for 25 minutes. The gas oil base invert oil-emulsion drilling fluid is used for overcoming the defects of the existing gas oil base drilling fluid and solving the problems of the salt resistance and temperature resistance of the gas oil base drilling fluid, and can resist the temperature above 200 DEG C.

Owner:COSL CHEM TIANJIN +1

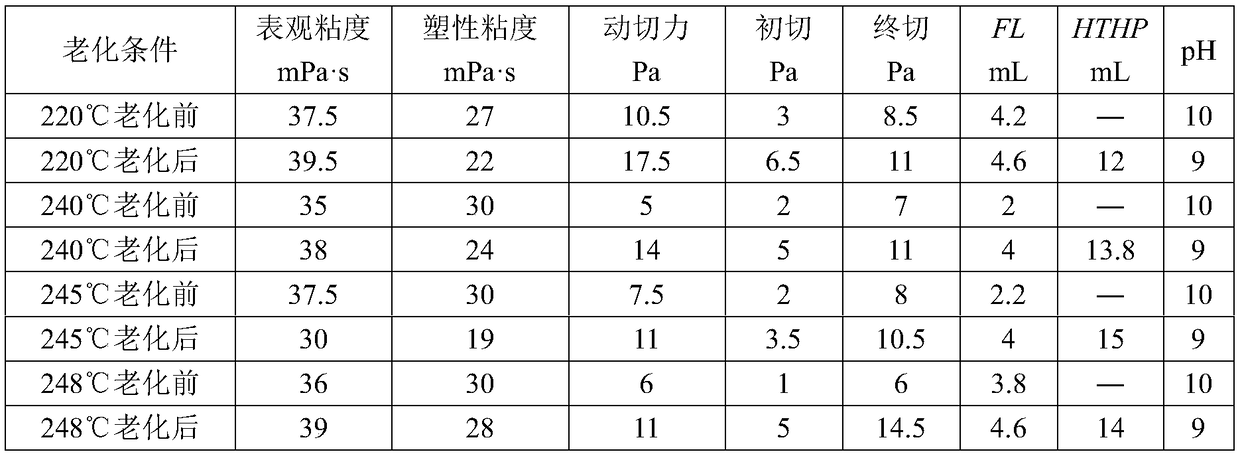

Low-density water base drilling fluid capable of resisting ultra-high temperature of 248 DEG C as well as preparation method and application thereof

ActiveCN108659801AImprove thermal stabilityRheology is easy to controlFlushingDrilling compositionChemistryPetroleum

The invention relates to a low-density water base drilling fluid capable of resisting ultra-high temperature of 248 DEG C as well as a preparation method and application thereof. The drilling fluid isprepared from the following raw materials: 100 parts of pulp blending water, 0.2-0.3 part of sodium carbonate, 1.5-4 parts of sodium bentonite, 0-0.5 part of caustic soda flake, 0.3-0.5 part of deoxidant, 0.3-0.7 part of zwitter-ion hydrophobic associated polymer filtrate reducer, 0.5-1.2 parts of anionic type polymer filtrate reducer, 3-5 parts of sulfomethylation formoldehyde resin type II, 3-5parts of sulfomethylation lignite resin, 2-4 parts of high softening point sulfonated bitumen, 1-3 parts of modified graphitic lubricant, 1-3 parts of polymeric alcohol, 0-6 parts of No.5 white oil,0-1 part of emulsifier, 0-2 parts of polycarboxylate flow type conditioning agent, 3-5 parts of ultra-high temperature blocking agent and 0-20 parts of API (American Petroleum Institute) standard barite. The drilling fluid is suitable for a stratum of which the temperature is 248 DEG C. The ultra-high temperature low-density water base drilling fluid disclosed by the invention has the advantages of high thermal stability under an ultra-high temperature condition, simpleness in performance maintenance and low cost, and the rheological property of the drilling fluid is easy in regulation and control.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

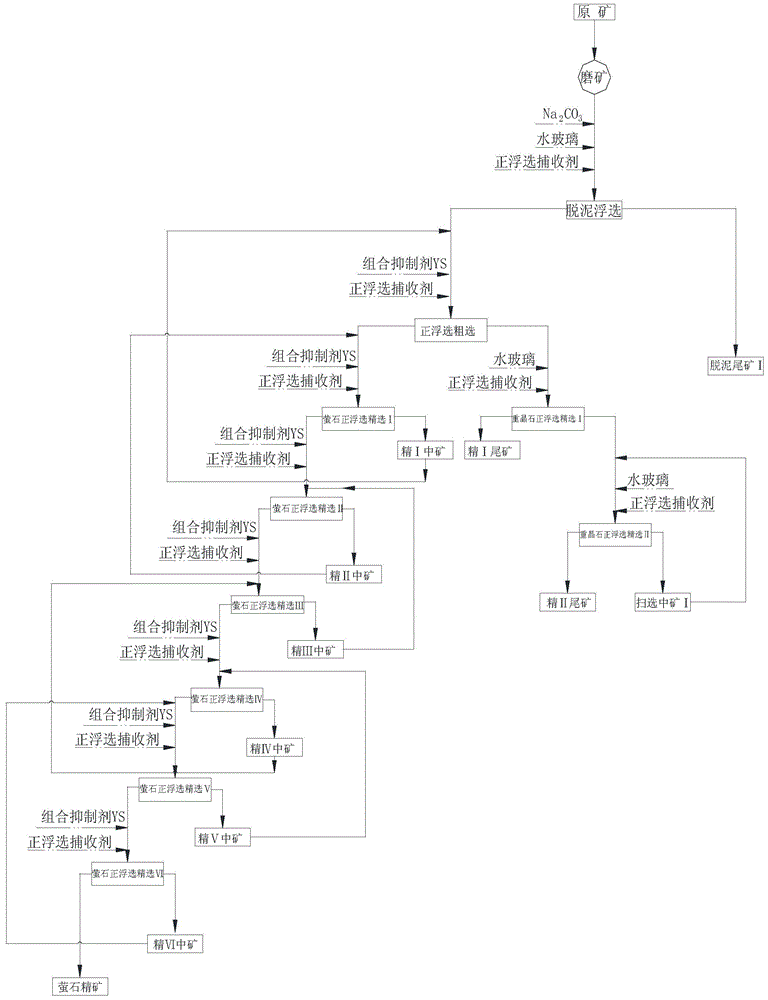

Staged floatation method for separating low-grade calcite-barite-fluorite type ore

The invention relates to a staged flotation method for separating low-grade calcite-barite-fluorite type ore, belonging to the technical field of mineral processing. The staged flotation method comprises the following steps: crushing raw ore of low-grade fluorite to -1.0mm, feeding the crushed raw ore to a ball grinder, grinding and adding water to prepare raw ore pulp, wherein a part finely ground to -0.074mm accounts for 70-95 percent; putting the ore pulp into a desliming floatation machine, adding sodium carbonate serving as a regulator while stirring, and then adding sodium silicate and a collecting agent CA to adjust the pH value of the ore pulp; feeding foams obtained by desliming floatation to a rougher flotation machine, adding a combined inhibitor YS first and stirring, then adding a direct flotation collecting agent CA and stirring, carrying out direct rougher flotation, and separating barite-containing tailings; carrying out direct fine flotation on rough concentrate obtained by direct rougher flotation to obtain fluorite concentrate, carrying out direct fine flotation on the tailings obtained by direct rougher flotation to obtain barite concentrate. The staged flotation process provided by the invention has a favorable separation effect aiming at barite-fluorite ore, and achieves the purposes of saving energy, reducing emission and easily realizing comprehensive recycling of barite and fluorite.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

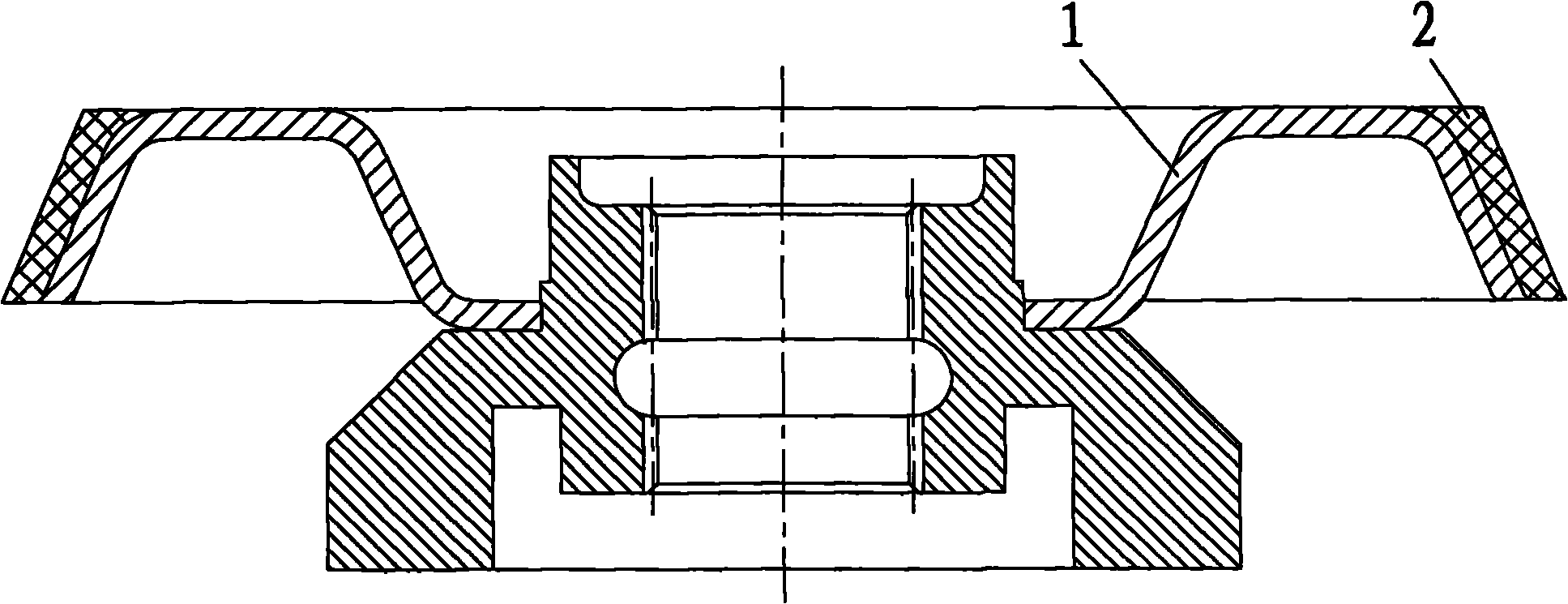

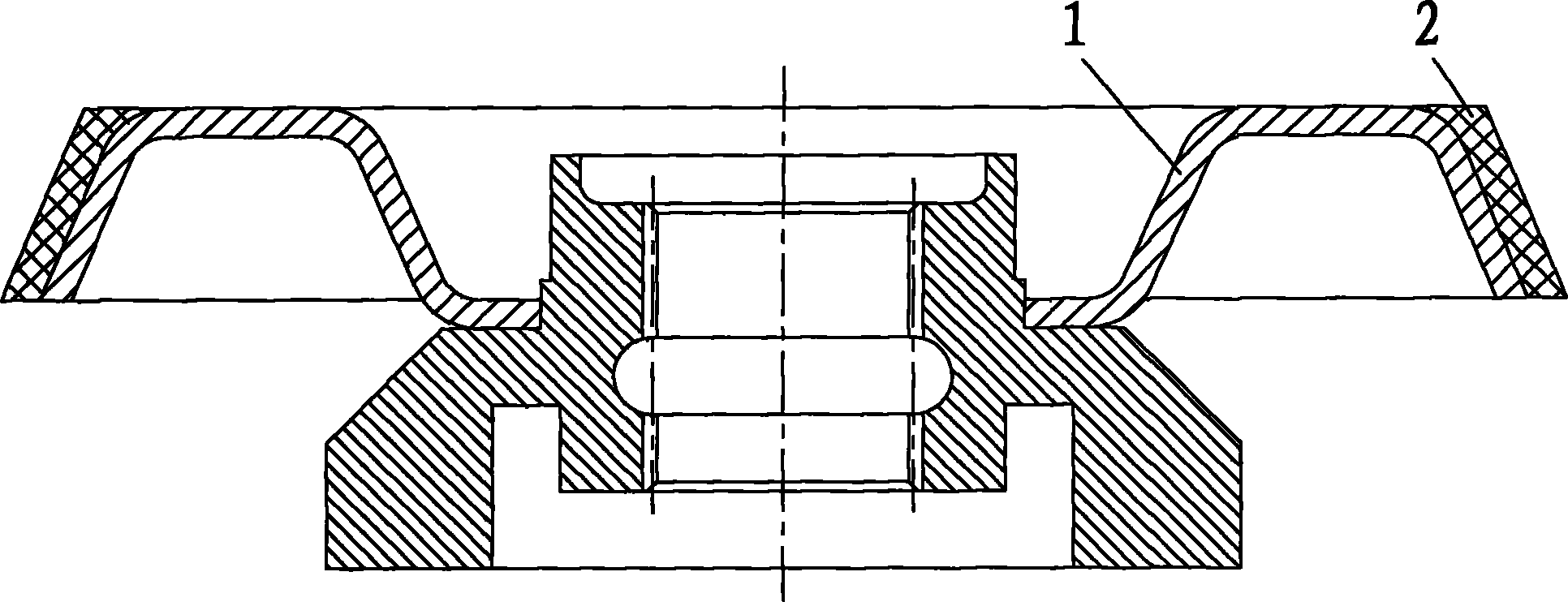

Friction brake disk of double-speed electric-block and preparation method thereof

ActiveCN101870438AIncrease coefficient of frictionIncreased shear strengthOther chemical processesFriction liningMetal fiberLow noise

The invention relates to a friction brake disk of a carbon-base double-speed electric-block and a preparation method thereof, aiming to provide the brake disk which has large brake moment, high shear strength, high temperature resistance, wear resistance, environmental protection and low noise. The preparation method has the advantages of simple technology, convenient manufacture and low cost. The invention has the technical scheme that the friction brake disk of the double-speed electric-block comprises an iron-base frame and a friction material layer which is attached to the brake surface of the iron-base frame, wherein the friction material layer comprises modified phenol-formaldehyde resin, aramid fiber, short carbon fiber, SACF mineral fiber, precipitated baryte, modified bauxite, metal sulfides, hydrogenated nitrile-butadiene rubber, metal fiber, nano calcium carbonate, stearic acid, vulcanization accelerator, medium-carbon frictional property modifier and melamine-cashew nut shell oil. The preparation method comprises the following steps: (1) weighing raw materials; (2) synthetically kneading the raw materials; (3) compression molding; (4) thermocuring; and (5) machining.

Owner:杭州汉乐科新材料科技有限公司

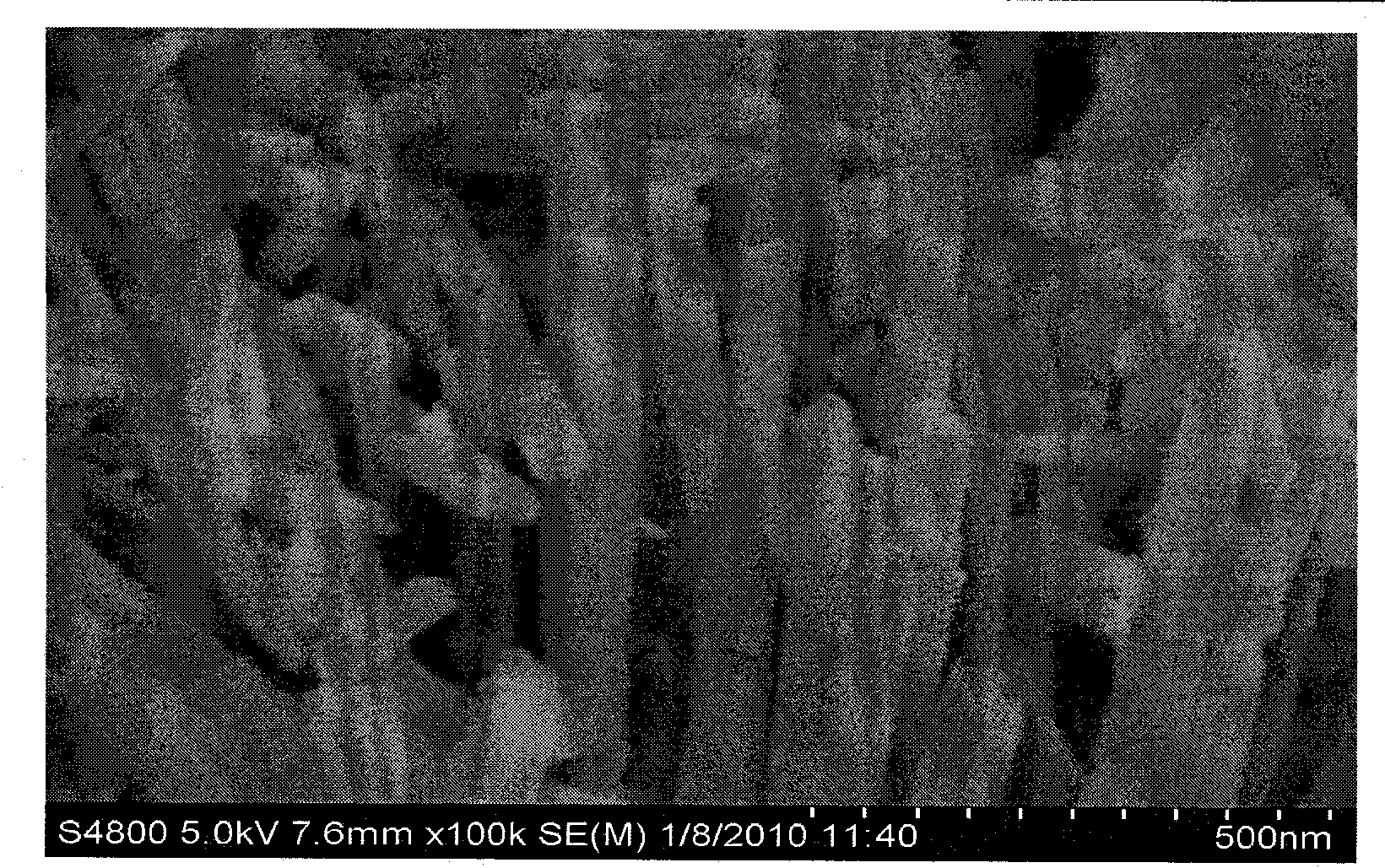

Method for preparing ultrafine high-whiteness active barite powder

ActiveCN102616824AConserve waterFully washedCalcium/strontium/barium sulfatesOXALIC ACID DIHYDRATEHydrogen Sulfate

The invention relates to the field of mineral materials, in particular to a method for preparing ultrafine high-whiteness active barite powder. The method comprises the following steps of: (1) preparing pulp from 325-mesh barite powder, and performing wet ultrafine grinding until the particle size is less than 10mu m; (2) filtering the barite pulp subjected to wet ultrafine grinding, and drying; (3) adding mixed acid into the dried ultrafine barite powder, and performing oxidation leaching reaction with stirring, wherein the mixed acid is a mixed solution of sulfuric acid, hydrofluoric acid and oxalic acid; (4) filtering the barite powder subjected to oxidation leaching reaction by the mixed acid, and washing until the pH is 6 to 7; and (5) performing pressure filtration, and drying to obtain the ultrafine high-whiteness active barite powder. The preparation method is simple and controllable and easy to popularize, equipment can be localized completely, over 99 percent of prepared barite product has the particle size of -10mu m, and the whiteness is over 90 percent.

Owner:WUHAN UNIV OF TECH

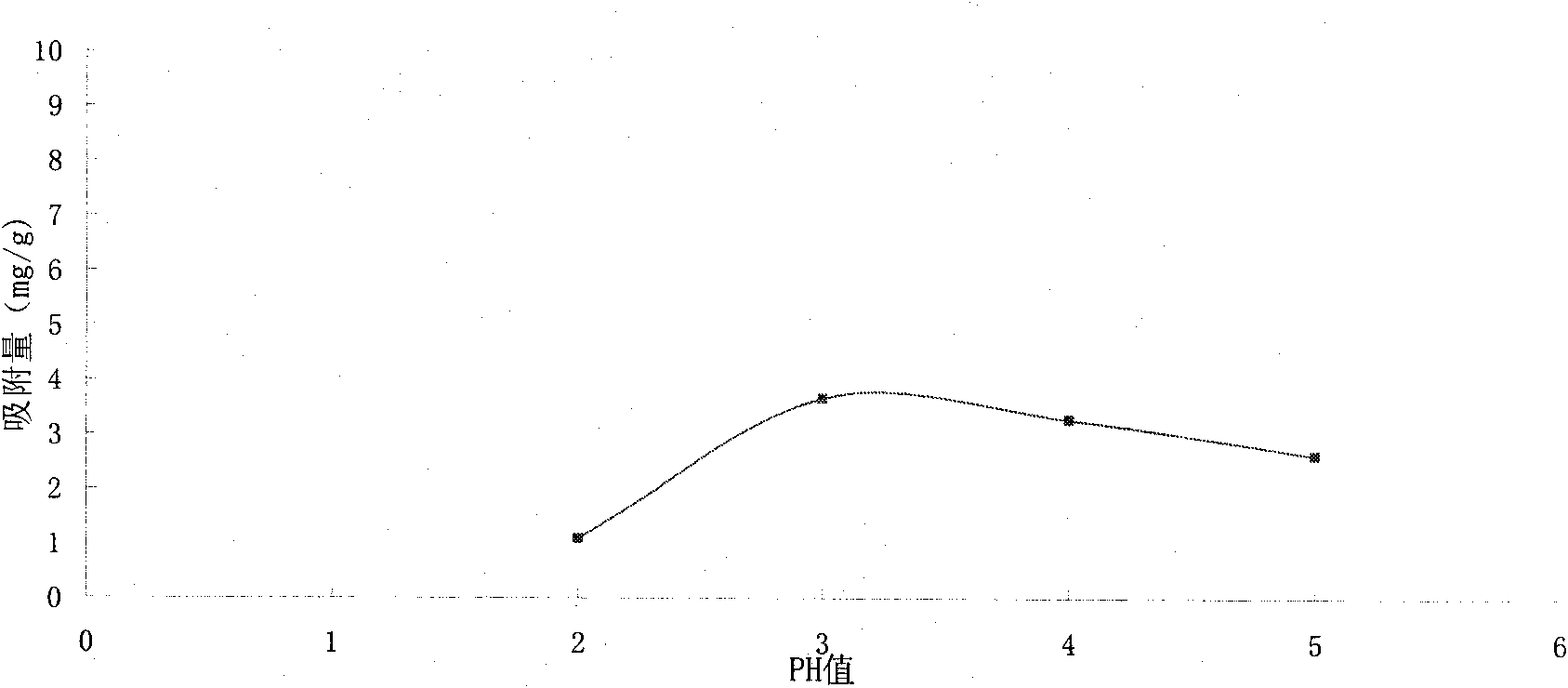

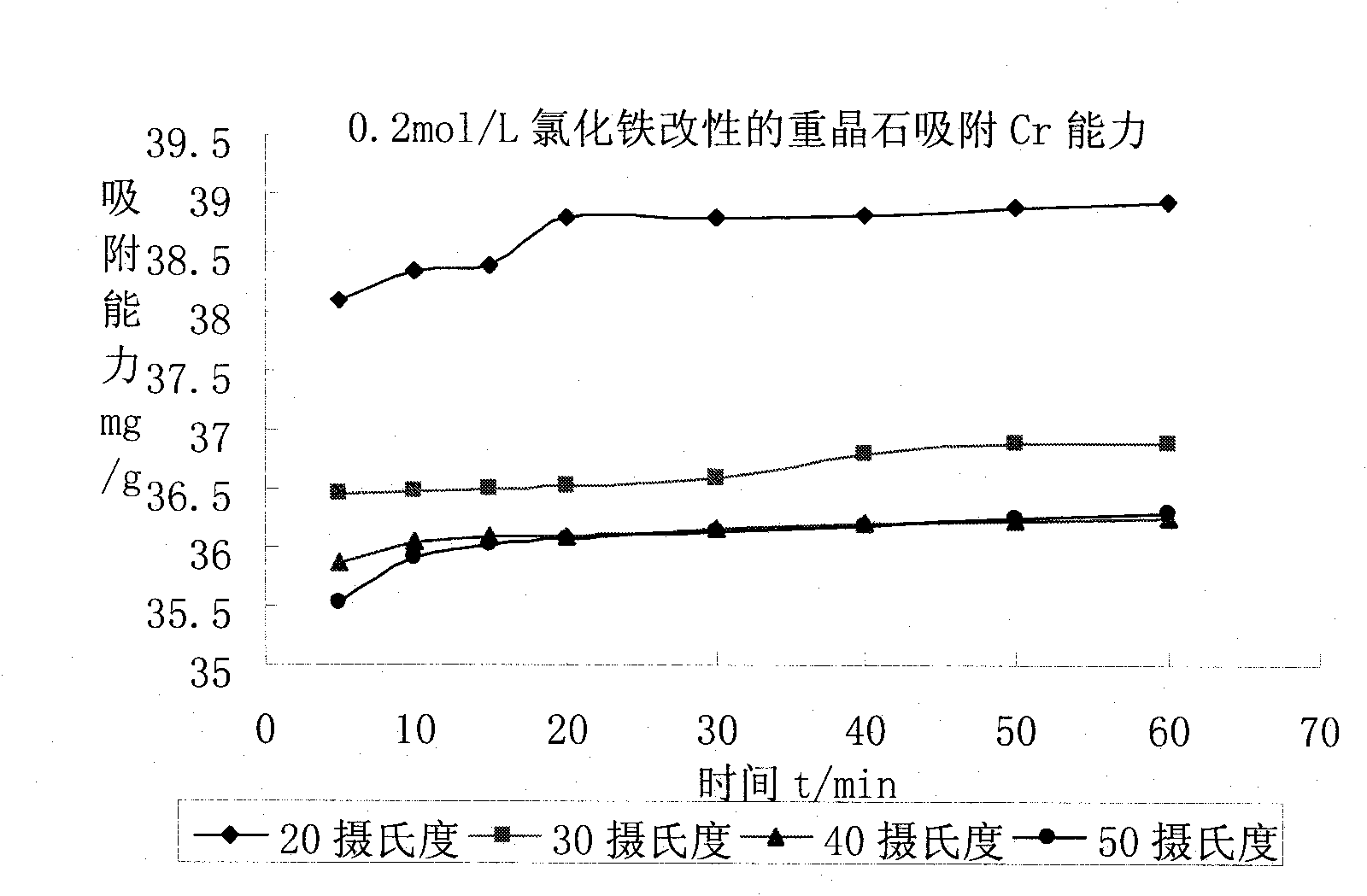

Method for treating chromium-containing wastewater by using barite adsorbent

InactiveCN101898107AAbundant resourcesLow priceOther chemical processesWater contaminantsChromium CompoundsWater baths

The invention discloses a method for treating chromium-containing wastewater by using barite adsorbent. The method comprises the following steps of: fusing, crushing and screening a barite mineral material, reacting the barite mineral material by using ferric chloride solution to generate the barite adsorbent for removing chromium ions from sewage containing 50 to 150 mg / L of chromium compound, and shaking the barite adsorbent for 1 hour in a 20 DEG C water bath thermostatic oscillator when the pH is 3 to 4, wherein the removal rate of the chromium ions in the sewage is over 99 percent; and adding a proper amount of barium chloride powder into the barite adsorbent for treating the high chromium content sewage so as to improve the removal rate of the chromium ions. The method has the advantages that: the barite is a most common barium-rich sulfate mineral, the globe surface has rich resources and the cost is low, so the method is convenient for popularization and application; and the barite adsorbent has simple preparation process, convenient operation and high adsorption rate of the chromium ions in the wastewater, can be repeatedly regenerated and recycled, and meets the energy conservation and emission reduction requirements.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

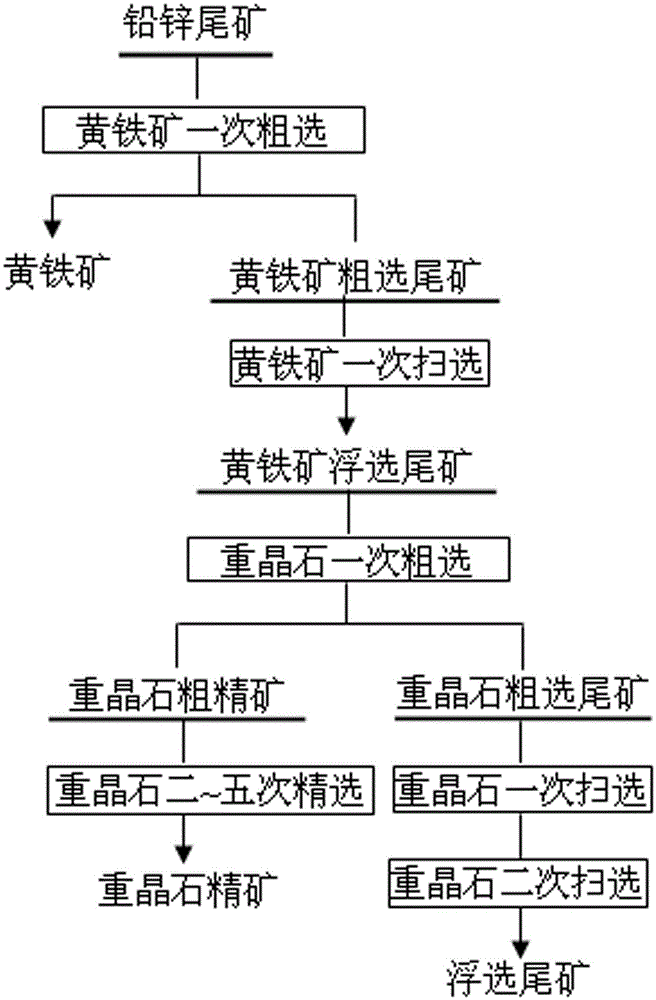

Method for recovering barite from lead and zinc tailings

The invention relates to a method for recovering barite from lead and zinc tailings. The method includes the following steps: pyrite flotation is carried out to obtain pyrite flotation tailings; barite rougher flotation is carried out to obtain barite rough concentrates and barite rougher flotation tailings; scavenging is carried out on the barite rougher flotation tailings to obtain flotation tailings; and barite rough concentrate selection is carried out to obtain barite concentrates. The method is a beneficiation method which is relatively lower in medicament cost and processing cost and small in environmental pollution, and can use tailing water repeatedly; and the method is suitable for low-grade barite ore with the dolomite content ranging from 55% to 65% and the barite grade ranging from 10% to 15%.0

Owner:广东省资源综合利用研究所

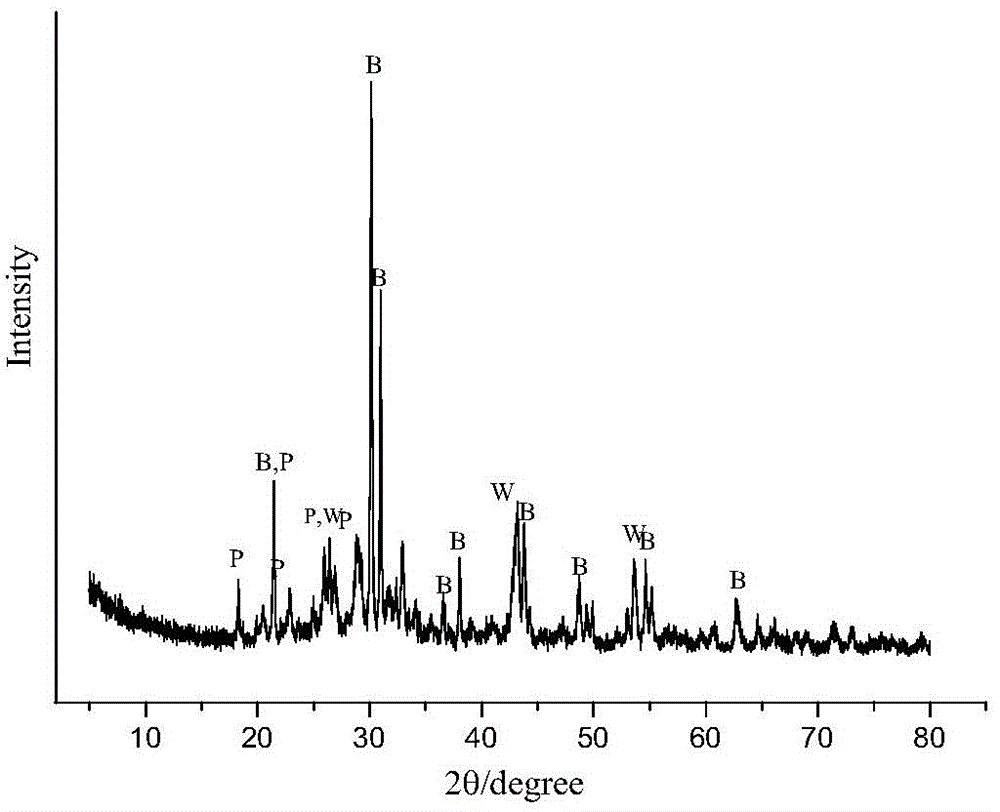

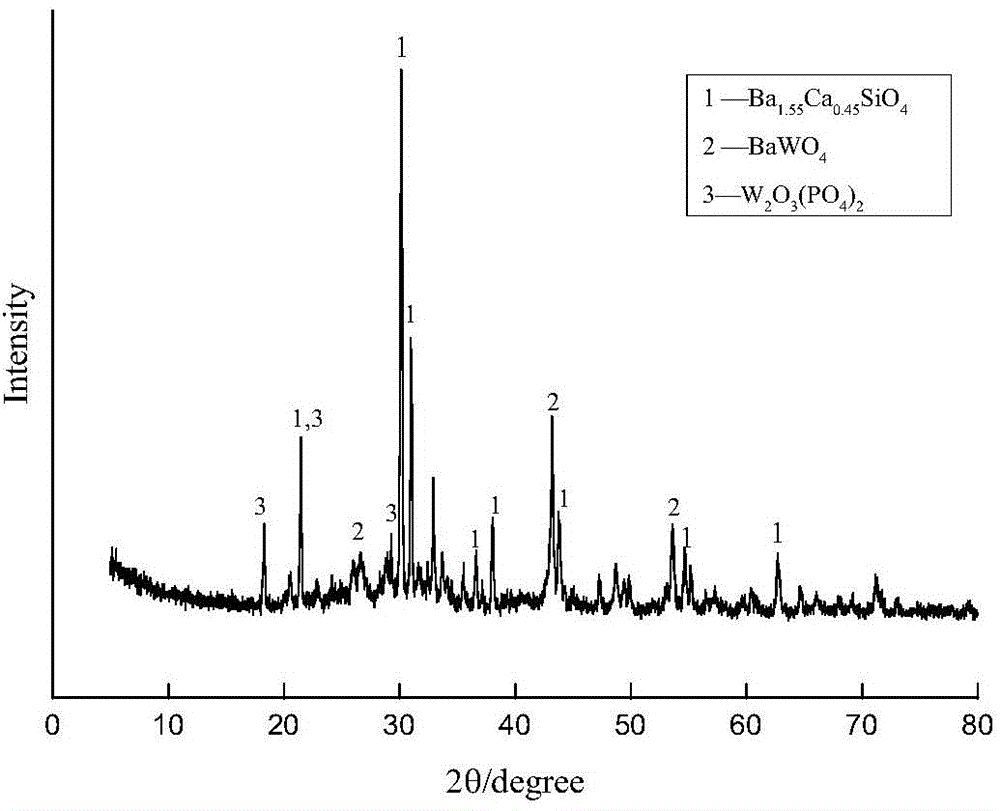

Method of extracting tungsten from high-barium tungsten ore

InactiveCN104372169ASolve the low leaching ratePrevent precipitationProcess efficiency improvementHigh concentrationSlag

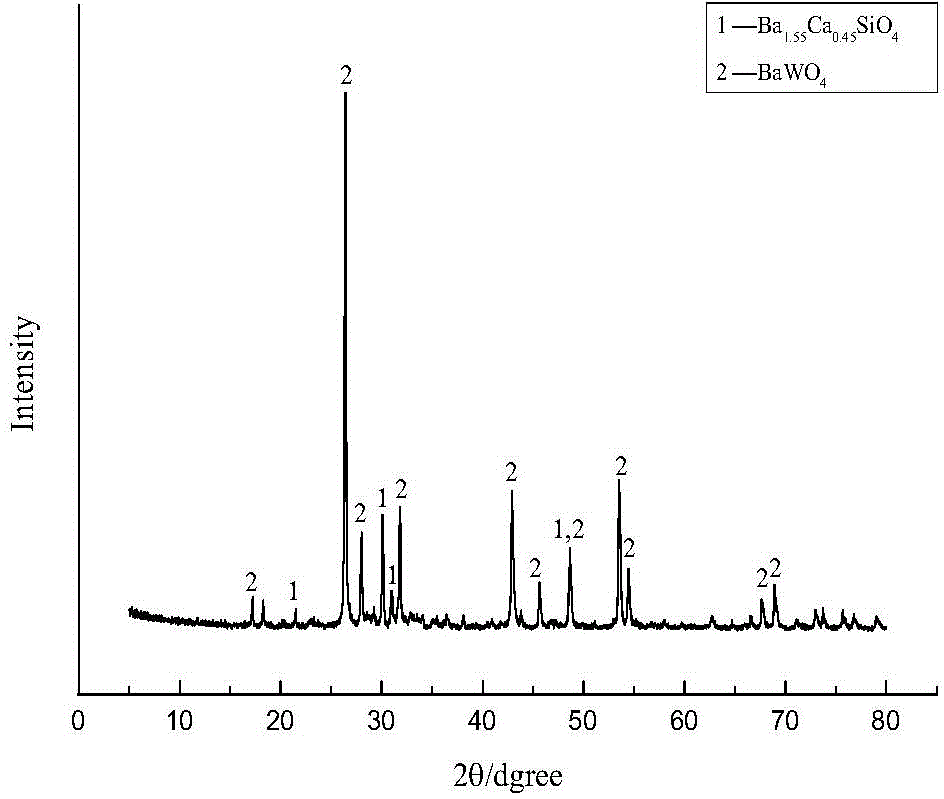

The invention discloses a method of extracting tungsten from high-barium tungsten ore. The method includes: mixing the high-barium tungsten ore and a certain amount of SiO2 and Na2CO3 to obtain mixture, roasting the mixture at the high temperature, and leaching roasting slag with Na2CO3 to obtain tungsten. By roasting the Na2CO3 and SiO2, the structure of the high-barium tungsten ore is fully broken to obtain stable (Ba or Ca)2SiO4 slag which is leached with high-concentration Na2CO3, water-soluble calcium and barium ions in roasting material are deposited, deposition of tungsten ions is prevented, leaching rate of the tungsten is greatly increased, reaching greater than 95%, and the problem that the high-tension alkaline leaching methods of the prior art fail to break the barite structure, leading to low leaching rate, is solved. The method according to the technical scheme is simple to operate, raw materials are cheap, processing can be performed with traditional equipment, and the method fully satisfies industrial production.

Owner:CENT SOUTH UNIV

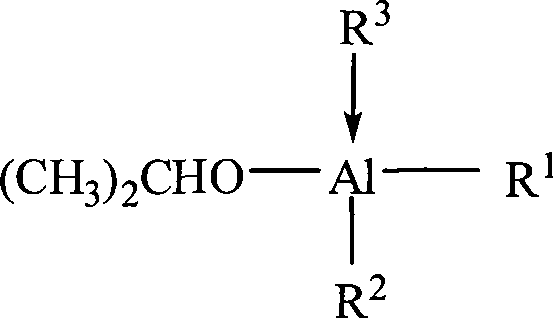

Grinding-aid coupling agent and preparation thereof

InactiveCN101503577AGood effectReduce pollutionGroup 3/13 element organic compoundsPigment physical treatmentPolymer scienceCoupling

The invention discloses a grinding promoting coupling agent and a preparation method thereof. The grinding promoting coupling agent contains 30 to 35 weight percent of grinding aid and 41 to 51 weight percent of aluminic acid ester coupling agent. The preparation method is simple. The grinding promoting coupling agent has dual functions of grinding promotion and coupling and remarkable effects, and is applied to various inorganic powders such as heavy calcium carbonate, barite, talc powder and kaolin which are produced by a dry method. The grinding promoting coupling agent simplifies the dry method production process and synchronously completes the grinding and modification, thereby improving the production efficiency, saving the investment, the labor and the energy consumption, reducing the production cost and environmental pollution, and having wide application prospect.

Owner:重庆市嘉世泰化工有限公司

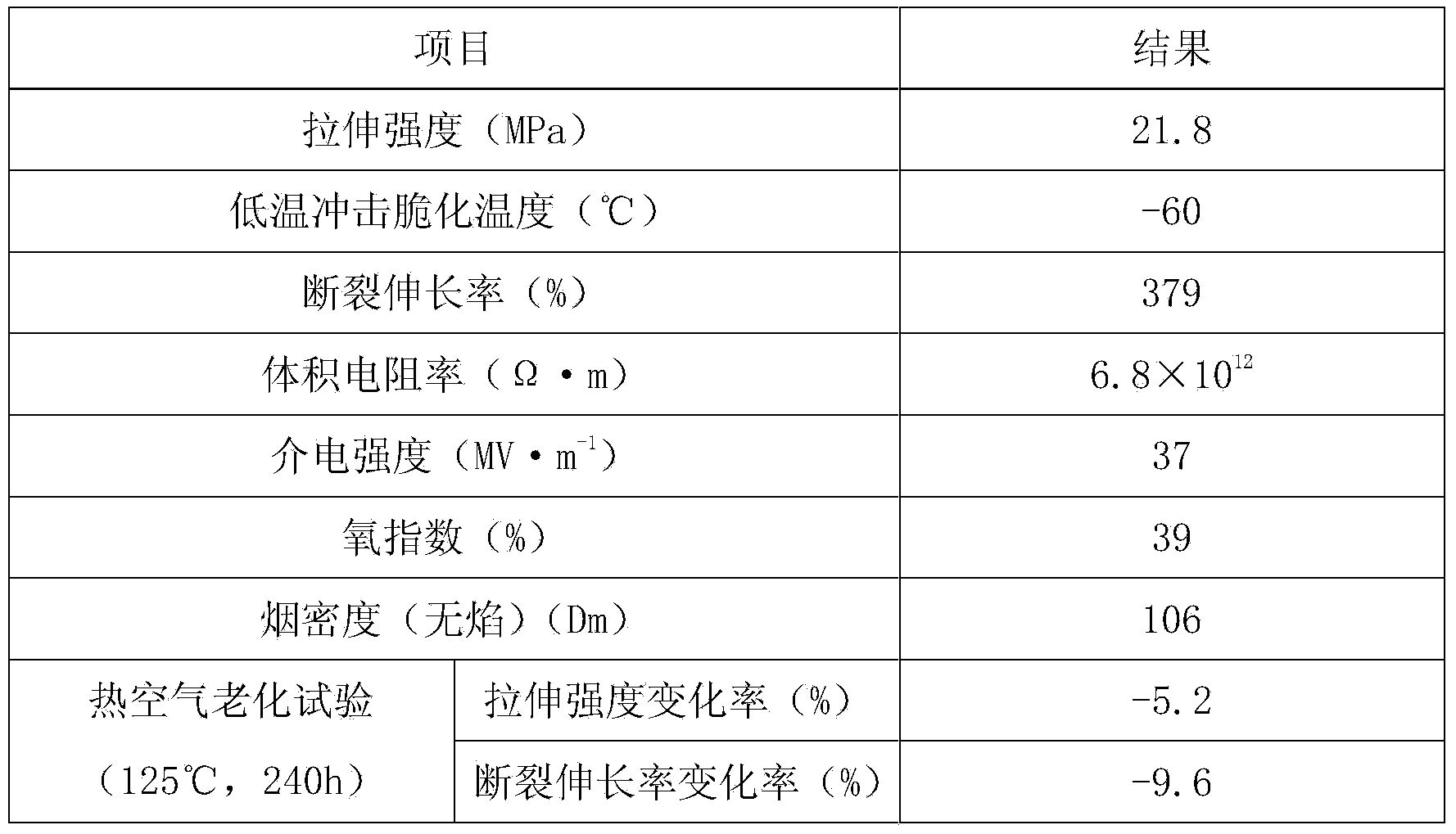

High and low temperature-resistant insulating sheath material for transformer and preparation method thereof

ActiveCN103509353AGood high and low temperature resistanceImprove insulation performanceRubber insulatorsInsulated cablesTransformerBrucite

The invention discloses a high and low temperature-resistant insulating sheath material for a transformer and a preparation method thereof. The high and low temperature-resistant insulating sheath material is prepared from 70-90 weight parts of fluorosilicone rubber, 20-30 weight parts of SG-3-type PVC, 10-15 weight parts of dioctyl maleate, 5-10 weight parts of nylon acid diisobutyl ester, 15-20 weight parts of magnesium hydroxide, 10-15 weight parts of ammonium polyphosphate, 4-8 weight parts of molybdenum trioxide, 30-40 weight parts of fumed silica, 4-6 weight parts of zinc oxide, 2-3 weight parts of stearic acid, 1-2 weight parts of nano-cerium oxide, 1-2 weight parts of bis(P,P-bis-ethylhexyl diphosphato)ethanediolato titanate, 3-6 weight parts of oxidized polyethylene wax, 10-15 weight parts of brucite powder, 15-20 weight parts of nano-barite, 8-12 weight parts of nano-wollastonite and 4-6 weight parts of a composite filling material. The high and low temperature-resistant insulating sheath material has excellent high and low temperature resistance, good insulating properties, good physical and mechanical properties, good weathering aging resistance, acid and alkali resistance, radiation resistance and oil resistance, can be used in a temperature range of -60-180 DEG C for a long time, does not deform, embrittle and crack, and is durable.

Owner:ANHUI KELIN ELECTRONICS

Process adopting barite-fluorite paragenic ore for preparing barite powder

A process adopting barite-fluorite paragenic ore for preparing barite powder comprises the steps of (1), after crushing, screening and classifying the raw barite-fluorite paragenic ore, carrying out classification and gravity concentration; (2), dehydrating and drying the concentrate subjected to classification and gravity concentration in the step (1) so as to obtain barite rough concentrate; (3), separately carrying out photoelectric separation on the barite rough concentrate with the size fraction of 1-3 mm and 3-6 mm obtained in the step (2) so as to obtain barite concentrate with the whiteness classified; (4), grinding the barite rough concentrate with the size fraction smaller than 1 mm obtained in the step (2), the barite concentrate with the whiteness smaller than 88% obtained in the step (3) and the barite concentrate with the whiteness greater than or equal to 88% obtained in the step (3) so as to obtain the barite powder. The process has the advantages that the procedures are simple, the investment is small, the energy consumption is low, and gravity concentration waste water can be reused after being clarified so that environmental friendliness can be achieved. The yield of the barite concentrate with the whiteness greater than or equal to 88% is high, and the barite concentrate can be used in the high-end fields such as coatings, oil paint, rubber and the national defense industry after being ground to form powder.

Owner:湖南楚天钡业有限公司

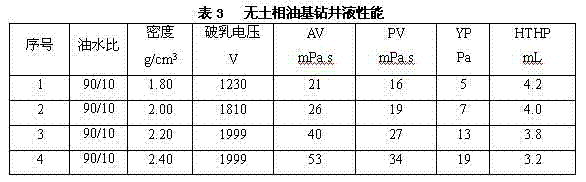

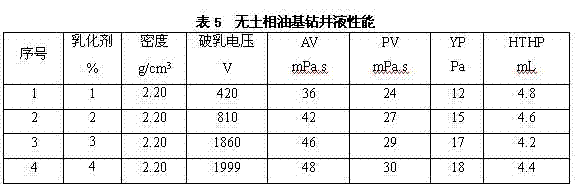

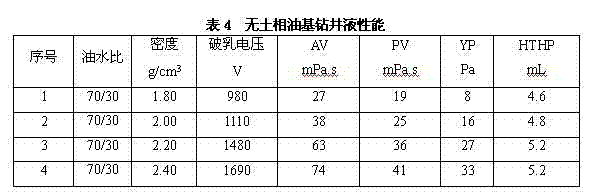

Soil-phase-free oil-based drilling fluid

ActiveCN103788934AStrong electrical stabilityHigh breaking voltageDrilling compositionSoil scienceHigh density

The invention relates to a soil-phase-free oil-based drilling fluid. The soil-phase-free oil-based drilling fluid is prepared from the following raw materials in percentage by weight: 50-85 percent of base oil, 5-30 percent of CaCl2 saline, 1-4 percent of composite type emulsifier G326-HEM, 1-5 percent of filtrate reducer G328, 0.5-3 percent of alkalinity conditioning agent, 0.5-3 percent of tackifier, 0.2-2 percent of viscosifier and the balance of barite. According to the soil-phase-free oil-based drilling fluid, the demulsification voltage is higher than 800V, and the temperature resistance of higher than 180 DEG C is achieved; the formula is simple, the field operation and maintenance are convenient, and the soil-phase-free oil-based drilling fluid has good rheological property in the absence of a wetting agent under the condition of high density; the system is widely applicable to the base oil and can be used in mineral oil or gaseous oil; and a novel method is provided for lowering the well leakage loss of the oil-based drilling fluid, the cost of the drilling fluid is also remarkably lowered, good economic and social benefits are obtained, and thus the soil-phase-free oil-based drilling fluid is worthy of popularization and application.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

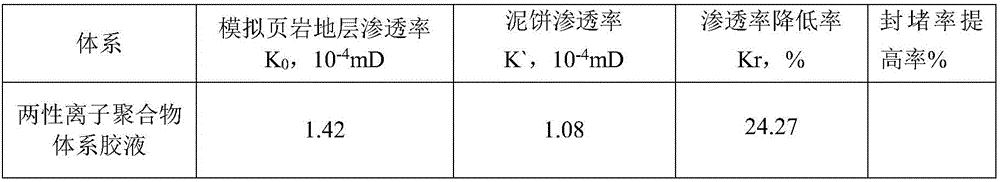

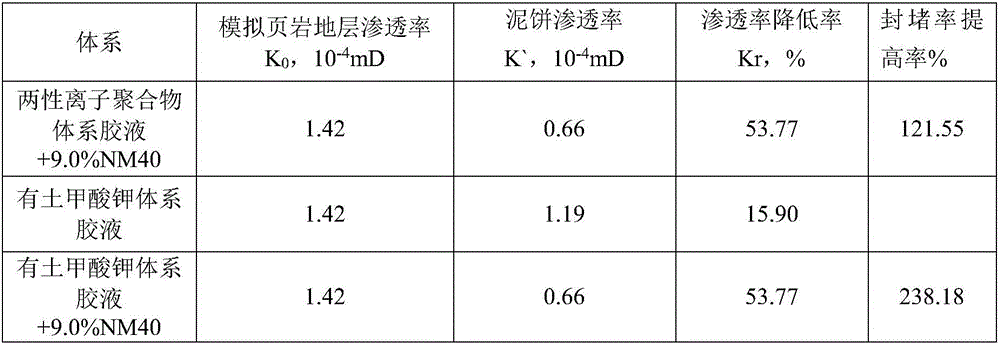

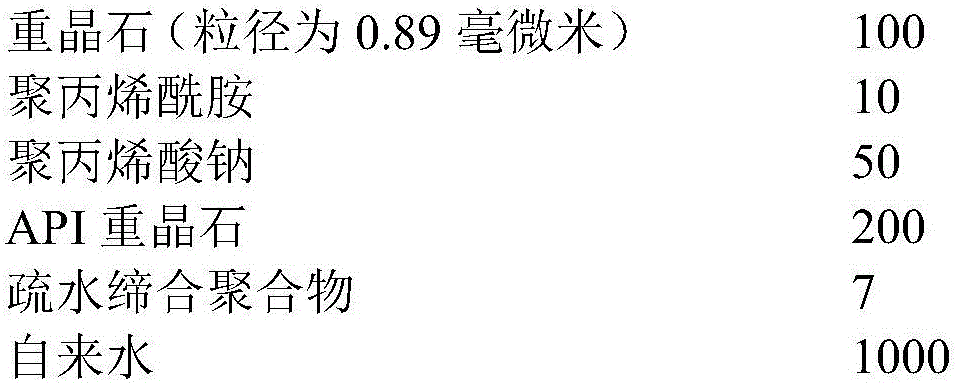

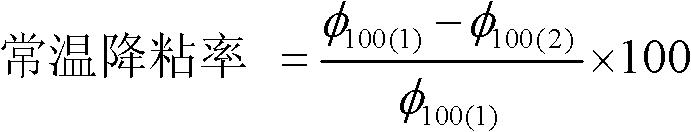

Evaluation mud cake for shale water-based drilling fluid blocking performance and preparation method

ActiveCN105866339AConvenient physical and chemical propertiesPhysicochemically stablePermeability/surface area analysisPhysical chemistryPolypropylene

The invention relates to an evaluation mud cake for shale water-based drilling fluid blocking performance and a preparation method. An effective blocking agent can be preferentially selected to evaluate shale well water-based drilling fluid blocking performance. According to the technical scheme, the evaluation mud cake is prepared from 100 g of barite, 10 g of polyacrylamide, 50 g of sodium polyacrylate, 200 g of API barite, 7 g of a hydrophobic associated polymer and 1000 g of tap water. The preparation method includes the steps that firstly, 1000 g of tap water is weighed, 100 g of barite is added under low-speed stirring, and high-speed stirring is carried out for 30 min; then, 10 g polyacrylamide is added, and high-speed stirring is carried out for 30 min; 50 g of sodium polyacrylate is added, and high-speed stirring is carried out for 30 min; 200 g of API barite is added, and stirring is carried out for 30 min; finally, 7 g of the hydrophobic associated polymer is added, stirring is carried out for 30 min, the mixture is put into a vessel of a water loss meter, pressing is carried out for 2 h at the pressure of 3.5 Mpa and the normal temperature, and the evaluation mud cake is obtained. Only a few kinds of raw materials are used at a low dose for preparing the evaluation mud cake, and the evaluation method is simple and efficient.

Owner:SOUTHWEST PETROLEUM UNIV

Environment-friendly noise-free brake block and processing method thereof

InactiveCN103351844ANo pollutionSuitable for useOther chemical processesFriction liningFiberEnvironmental resistance

The invention discloses an environment-friendly noise-free brake block and a processing method thereof. The brake block is produced from resin, a resin flexibilizer, tire powder, glass fibers, composite fibers, graphite, granules, frictional powder, baryte powder, mica powder, vermiculite, coke blacking, carbon black, diatomite and high-temperature aluminium oxide. The environment-friendly noise-free brake block has the advantages that no asbestos, heavy metals and compounds are contained so that no dust falls after braking and no asbestos dust is generated to pollute environment and result in cancer, lots of soft raw materials such as flexible granules, and moreover, organic frictional powder and organic rubber powder are added, and simultaneously, inorganic packing such as coke and vermiculite of porous loose structure is added, so that the brake block is comfortable to brake without noise and thereby especially suitable for urban buses.

Owner:耿琪国

Cement of barium dregs

InactiveCN1539776AAvoid radiationWith radiation protection abilityCement productionRadiation resistantSlag

Owner:许汉兴

Composition for treating sewage and preparation method thereof

InactiveCN105858836AEfficient governanceReduce COD valueWater/sewage treatment by flocculation/precipitationChemistryWollastonite

The invention discloses a composition for treating sewage and a preparation method thereof, belonging to the field of sewage treatment. The composition is prepared from the following raw materials in parts by weight: 25-35 parts of ground calcium carbonate, 5-15 parts of light calcium carbonate, 15-25 parts of bentonite, 5-15 parts of wollastonite, 10-20 parts of sodium borate, 5-15 parts of glauber salt, 5-15 parts of zeolite powder, 10-20 parts of barite powder, 35-45 parts of diatomite powder and 4-6 parts of barium sulfate powder-chitosan mixture. The weight ratio of the barium sulfate powder to the chitosan is (3-5):1. The composition disclosed by the invention can efficiently treat sewage, and the COD (chemical oxygen demand) value and total nitrogen content in the sewage are obviously lowered. The method for preparing the sewage treatment accelerator is simple and practical, can easily implement large-scale preparation, and is suitable for popularization.

Owner:陈斌

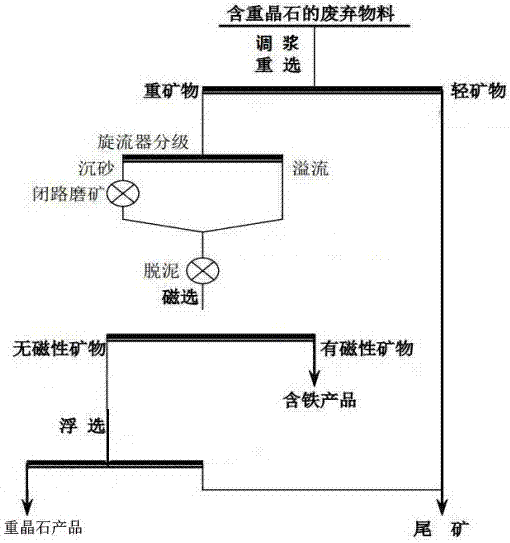

Combined ore dressing method for waste materials containing low-grade barite

InactiveCN106944249AEfficient separationFull recoveryMechanical material recoveryWet separationMagnetic separatorLower grade

The invention discloses a combined ore dressing method for waste materials containing low-grade barite. The method comprises the following steps that 1, powdery materials are prepared into ore pulp by adding water; 2, the ore pulp obtained in the step 1 is fed into gravity dressing equipment for dressing; 3, pulp mixing is conducted on heavy ore obtained in the step 2, obtained heavy ore pulp is fed into a hydrocyclone for classifying to obtain a sand setting product and an overflow product, and the sand setting product enters ore grinding equipment for ore grinding; 4, mixing and desliming are conducted on the ore grinding product and the overflow product which are obtained in the step 3, and pulp mixing is conducted after desliming; 5, ore pulp obtained in the step 4 is fed into a magnetic separator for separation; 6, pulp mixing is conducted on a non-magnetic product obtained in the step 5, and obtained ore pulp is fed into a flotation machine for 4-6-segment grading flotation; 7, filtering, reagent removing and whitening are conducted on a barite powder product obtained in the step 6, and a barite product is obtained. According to the method, the qualified barite powder product can be obtained from the waste materials, the method is applied to the industries of chemical engineering, petroleum drilling, medicine and the like, and the economical efficiency of secondary resource utilization is improved.

Owner:JIUQUAN IRON & STEEL GRP

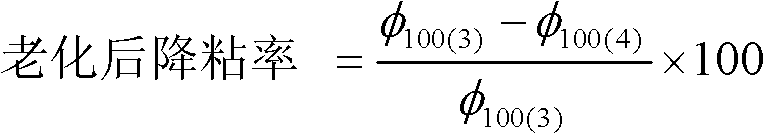

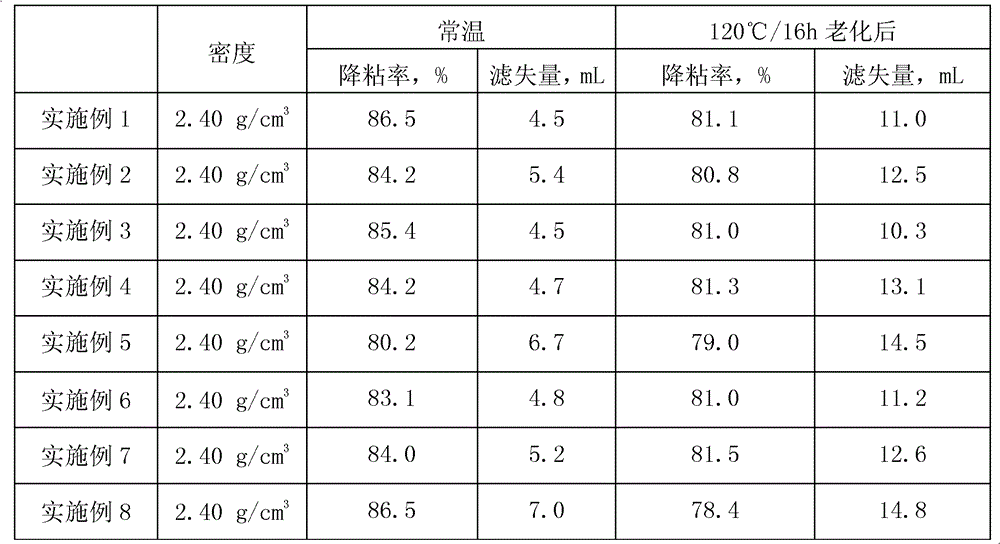

Dispersant for ultra-high density drilling fluid, preparation method and application

The invention discloses a dispersant for ultra-high-density drilling fluid, a preparation method and application thereof. The dispersant is prepared through the reaction of raw materials containing the following components in parts by weight: 10-40 parts of lignin, 1.5-20 parts of phenols, 2.5-15 parts of sulfonating agent, 0.5-5 parts of telomerization agent, 0.5-4 parts of catalyst and 100 parts of water. The method comprises the steps of mixing the components uniformly, carrying out reaction for 6-10 hours at the temperature of 160-180 DEG C, and then obtaining the dispersant for the ultra-high-density drilling fluid. The dispersant disclosed by the invention is applied to the ultra-high-density drilling fluid, and the surface properties of solid-phase weighting agents, such as barite and the like, can be remarkably improved; the hydration film formation for the surfaces of weighting agent particles is prompted, and the agglomeration role and frictional resistance among the weighting agent particles are reduced, so that the viscosity and shearing force of the prepared high-density drilling fluid are reduced, and the fluidity of the high-density drilling fluid is improved; and the dispersant is non-toxic and efficient, and the preparation method is simple and easy in operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

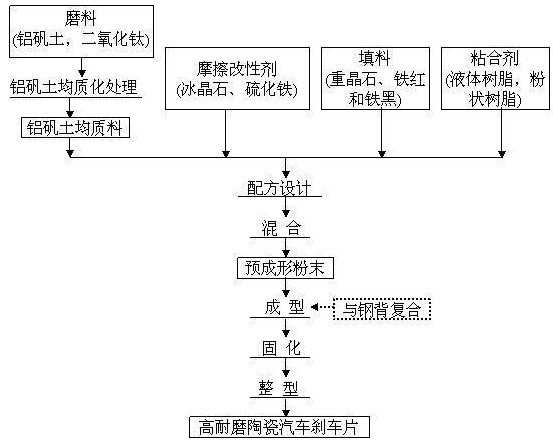

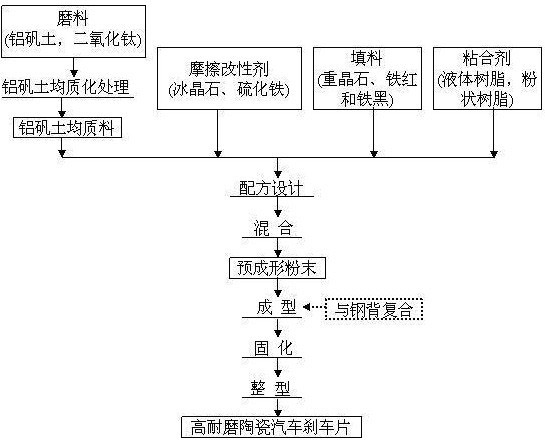

Material of high-wear-resistance ceramic automobile brake block and preparation method thereof

InactiveCN102634320AImprove toughnessImprove shear resistanceOther chemical processesFriction liningIron oxide blackIron sulfide

The invention discloses a material of a high-wear-resistance ceramic automobile brake block, and preparation and molding methods of the material. The material of the high-wear-resistance ceramic automobile brake block comprises the following components in percentage by weight: 7-10% of cryolite, 1.5-2% of ferric sulfide, 1-3% of iron oxide red, 2.5-4% of iron oxide black, 9-12% of barite, 16-18% of binding agent, and the balance of high-titanium bauxite homogenized material composed of bauxite and titanium dioxide. According to the material disclosed by the invention, a multi-component friction modifying agent and a filler are added, the adding amount of each component is optimized and the grain diameter of powder is optimized, so as to adjust friction and abrasion behaviors; and a resin bonding agent is used for compounding a plurality of the functional components with a steel back to sufficiently express the synergistic effect of each component. The high-wear-resistance ceramic automobile brake block prepared by the material and the method disclosed by the invention is an environment-friendly friction material and has the advantages of low noise, high friction coefficient, small heat fading, long service life, small damages to mating plates and the like.

Owner:龚亚云

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com