Patents

Literature

4640results about "Mechanical material recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

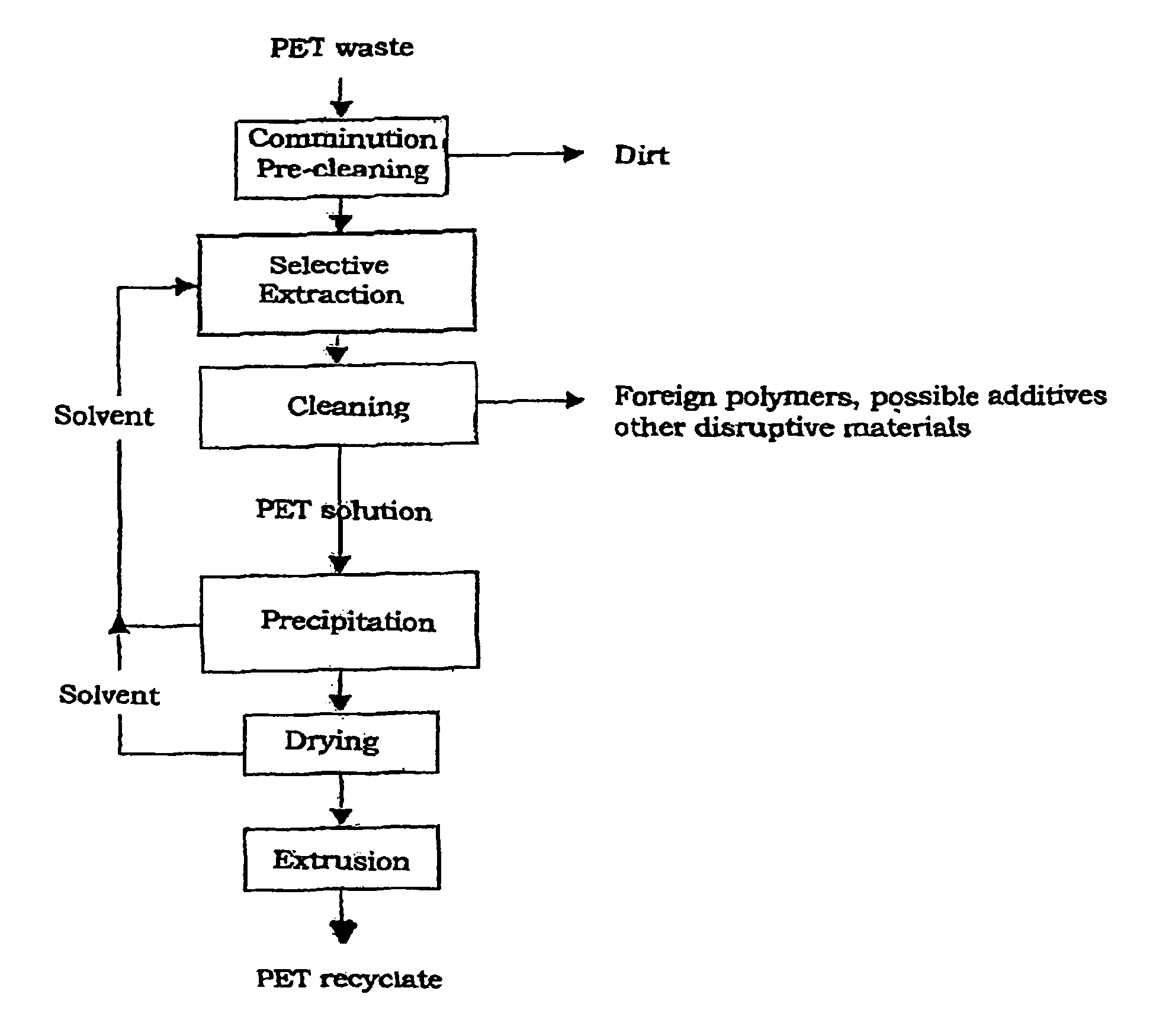

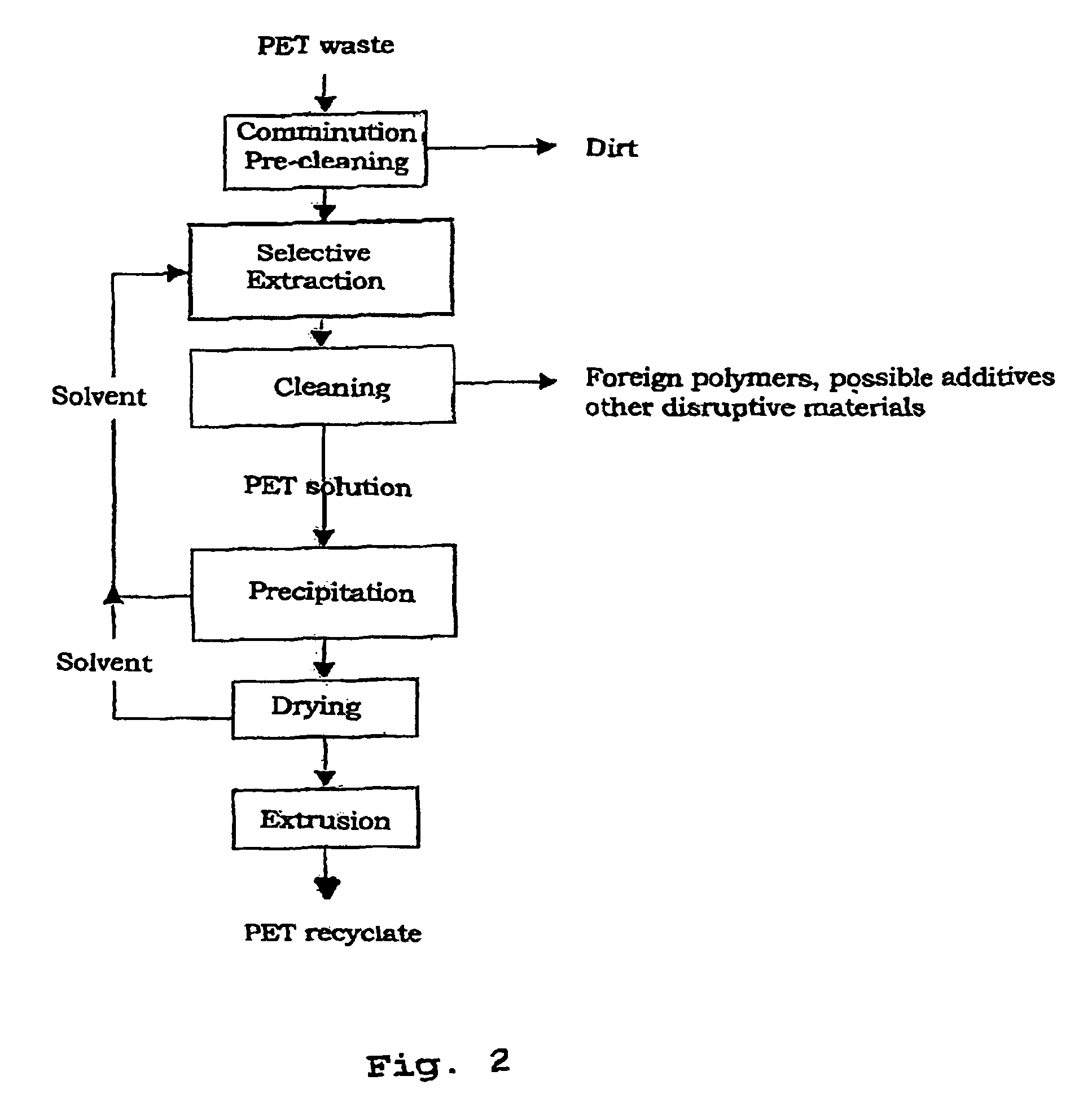

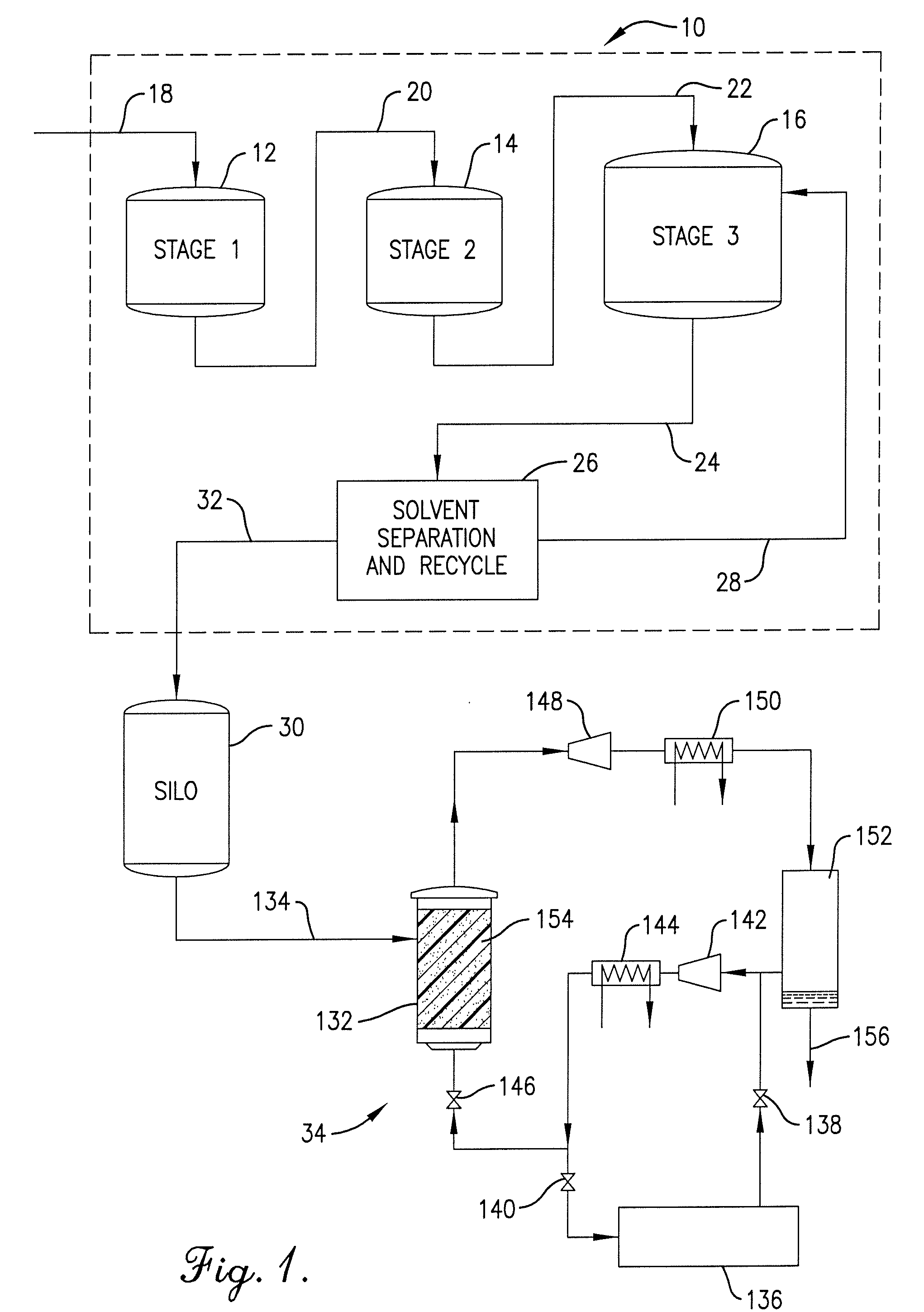

Method for recycling polyesters or polyester mixtures from polyester-containing waste

The invention relates to a method for recycling polyesters or polyester mixtures from polyester-containing waste, in which the polyester or the polyester mixture is dissolved in a solvent and subsequently free-flowing particles are precipitated herefrom with a precipitant. The precipitant is thereby chosen such that subsequent separation of precipitant and solvent is made possible in a simple manner.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

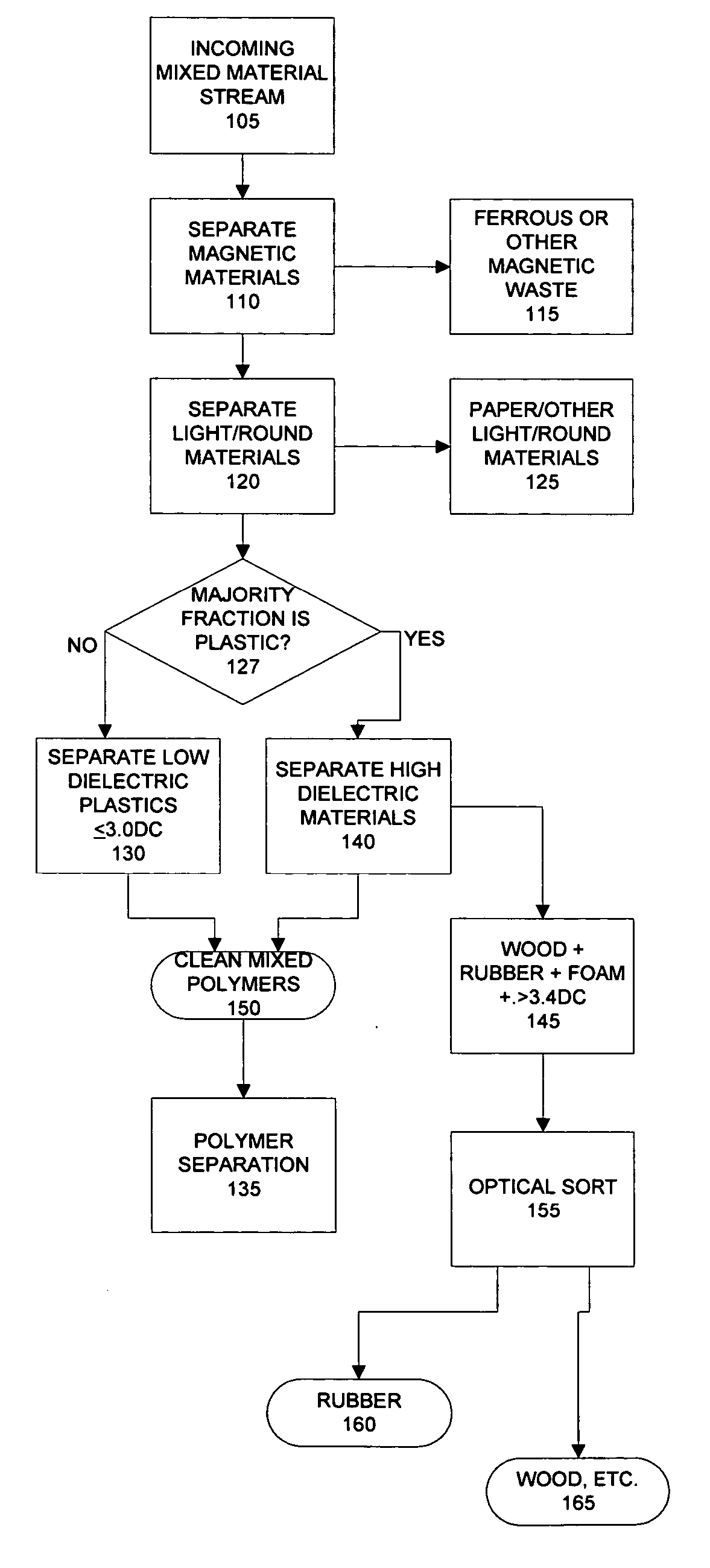

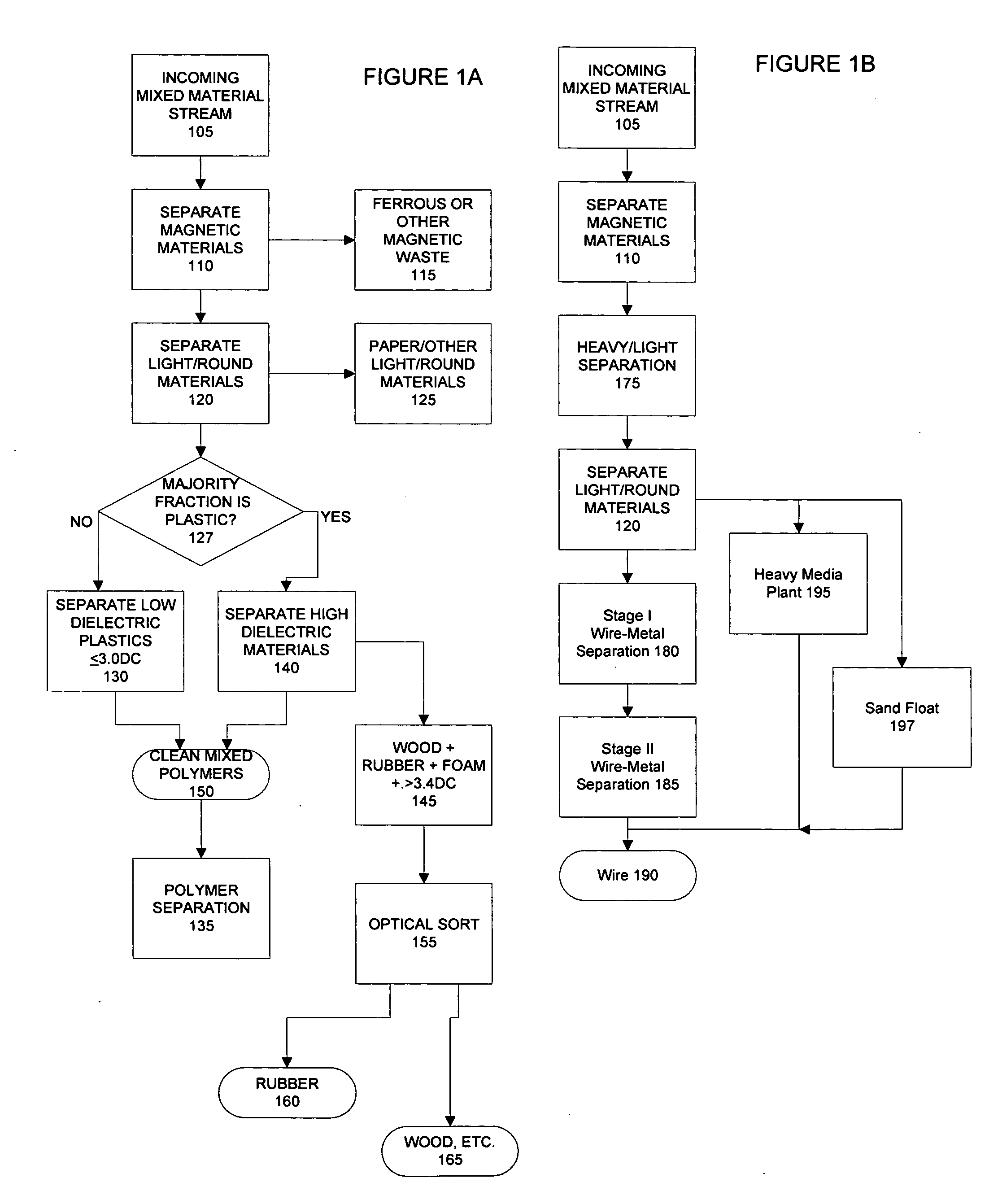

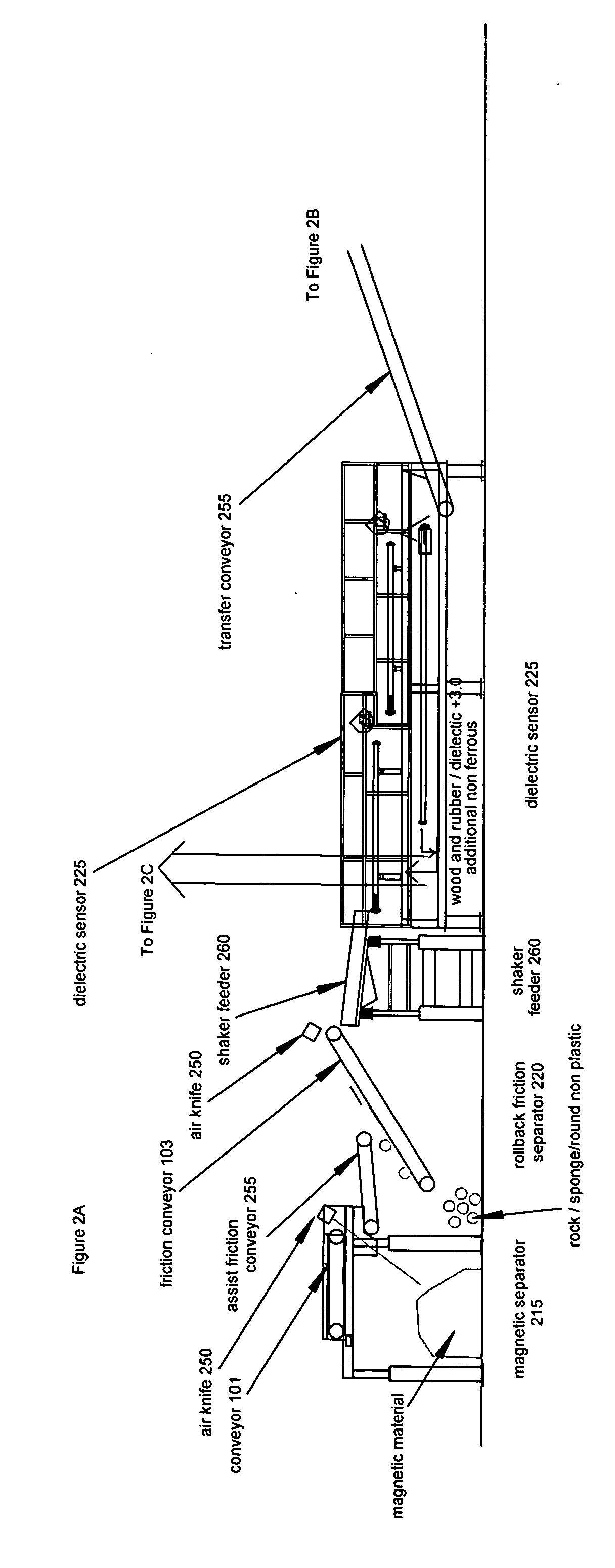

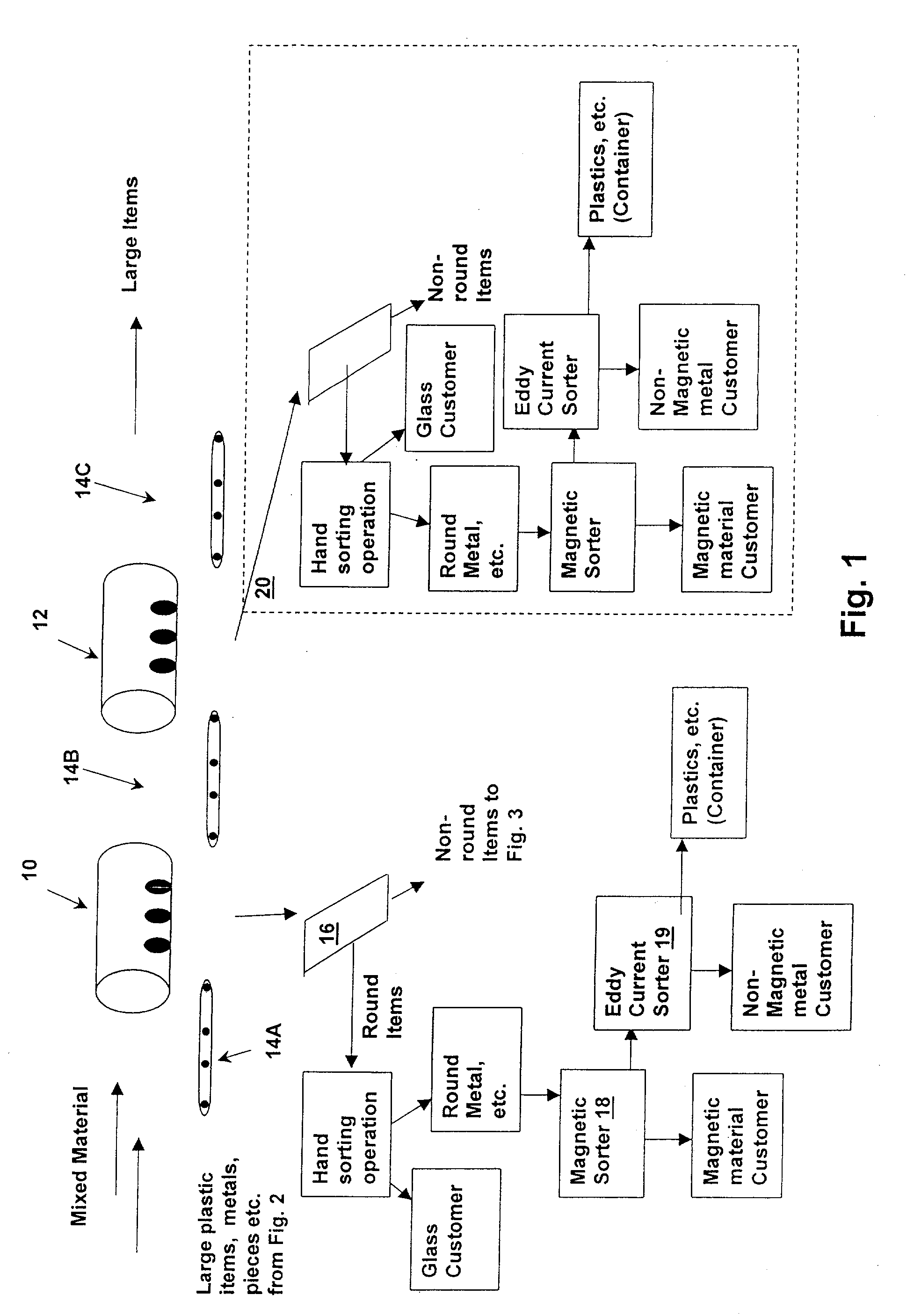

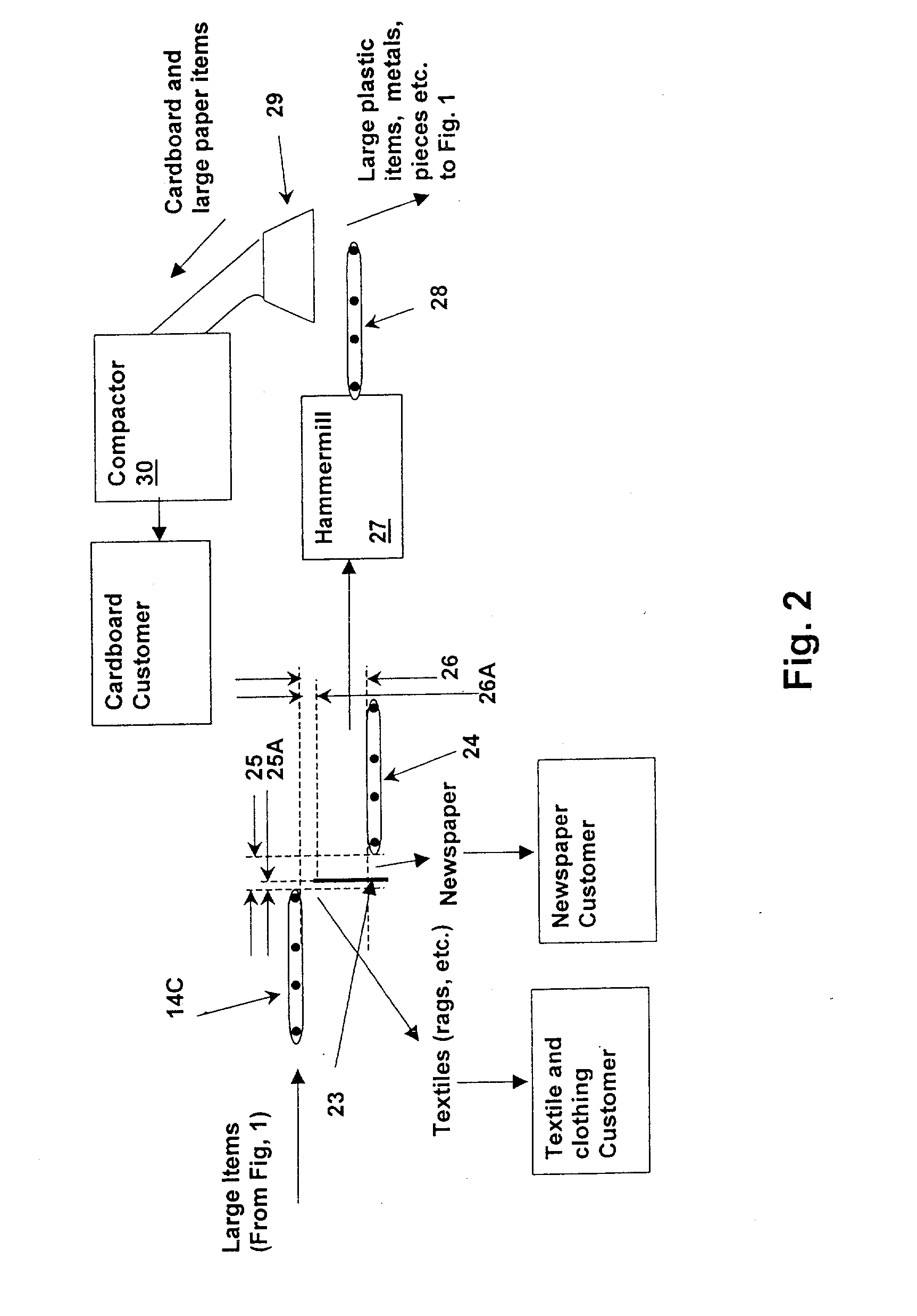

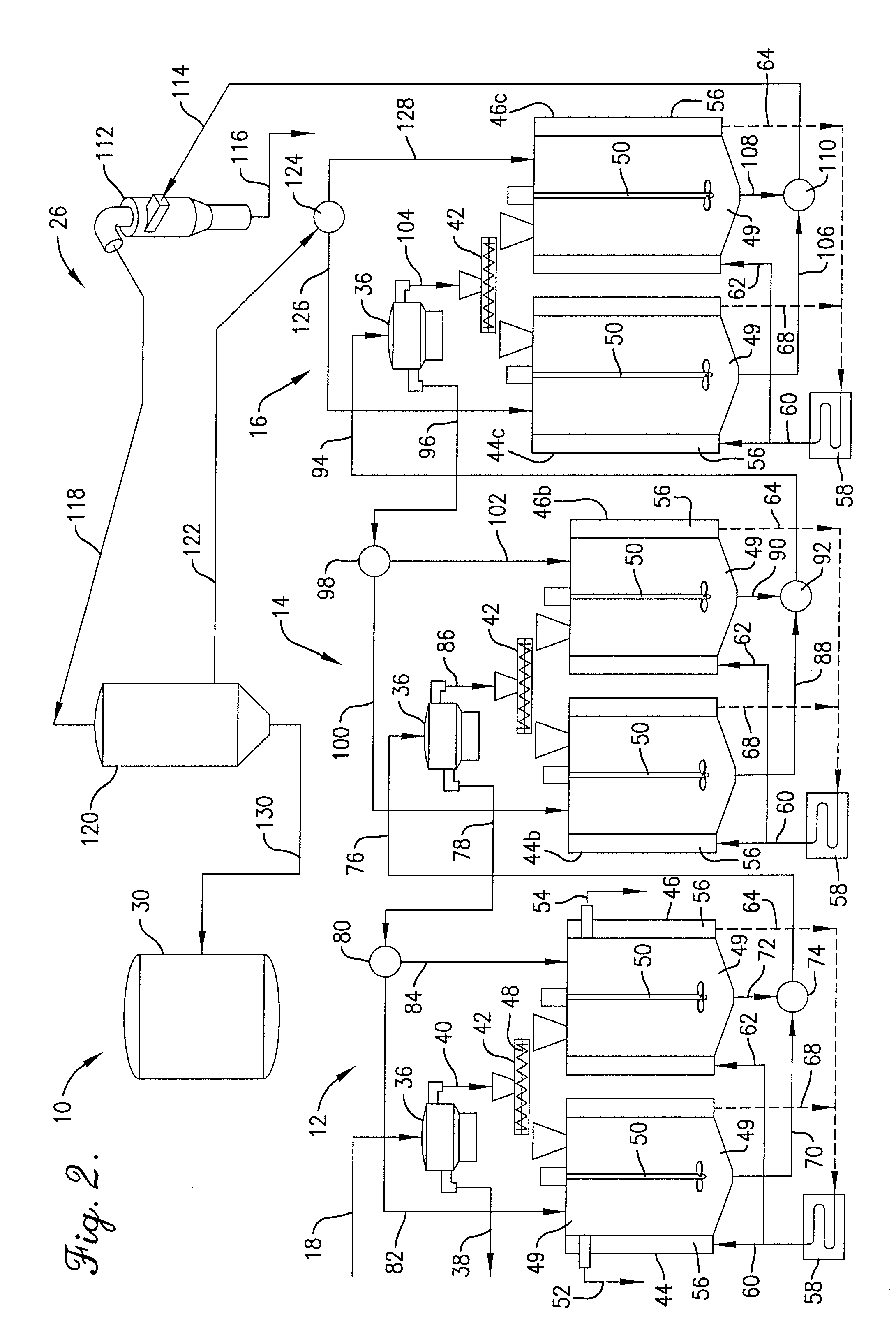

Dissimilar materials sorting process, system and apparata

InactiveUS20070187299A1Improve uniformityUnified operationGas current separationSolid waste disposalElectricityMagnetic separator

An automated system for sorting dissimilar materials, and in particular for sorting plastics from other materials and for sorting different types of plastics from one another comprises, depending upon the embodiment, combinations of a sizing mechanism, a friction separation, an air separator, a magnetic separator, a dielectric sensor sortation bed, shaker screening, a ballistic separator, an inductive sensor sortation system and a float / sink tank. The dielectric sensor sortation system may be either analog or digital, depending upon the particular implementation. One or more float / sink tanks can be used, depending upon the embodiment, each with a media of a different specific gravity. The media may be water, or water plus a compound such as calcium chloride. In addition, multiples of the same general type of module can be used for particular configurations. A heavy media system or a sand float process can be used either alternatively or additionally.

Owner:VALERIO THOMAS A

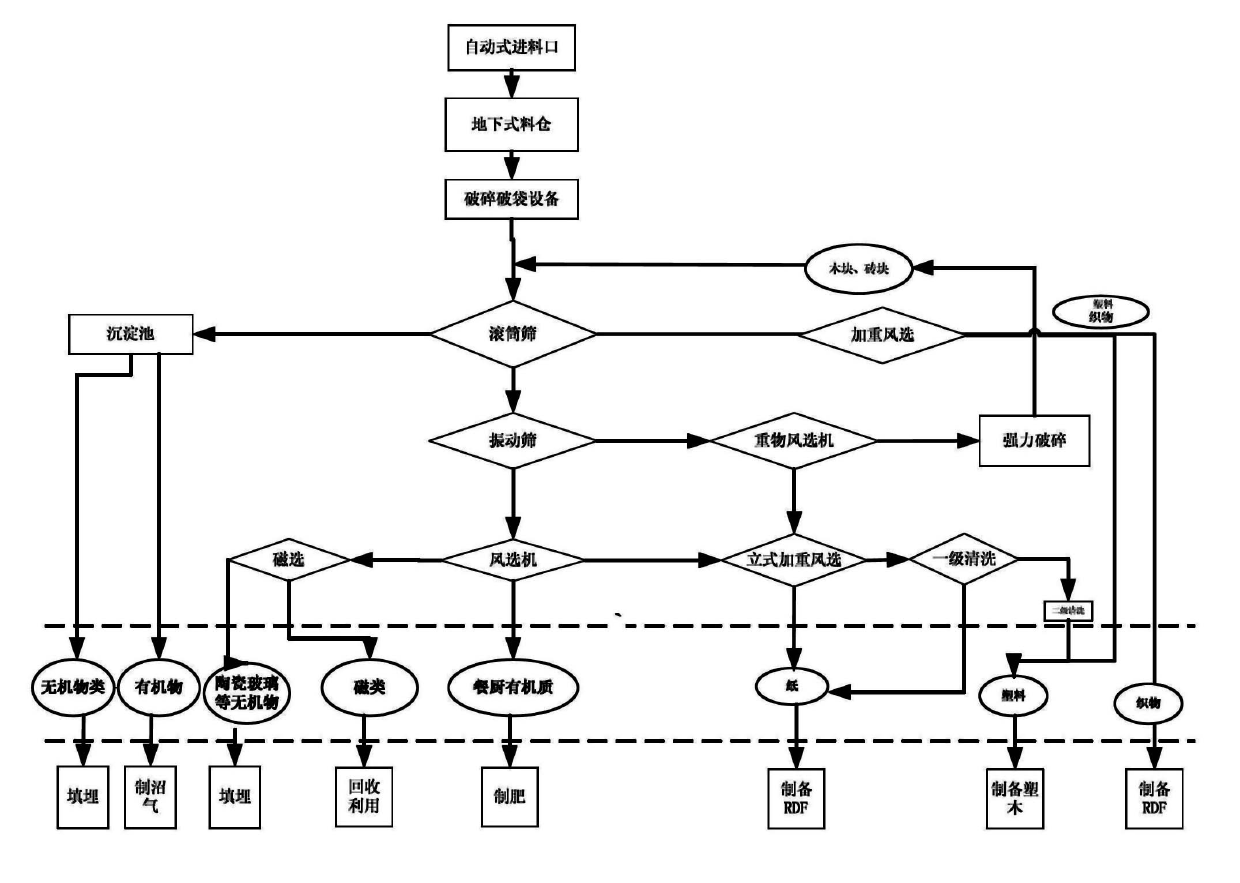

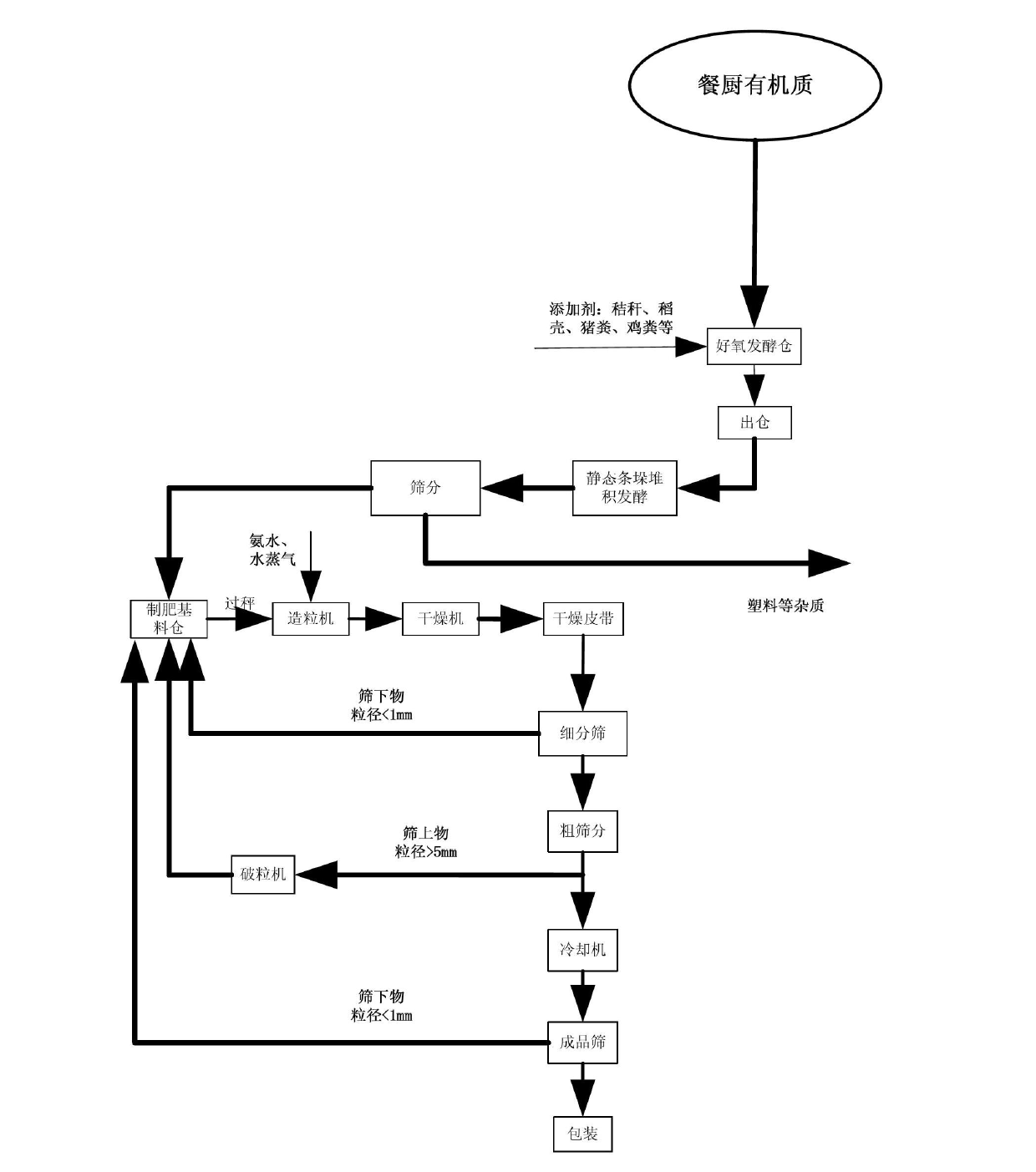

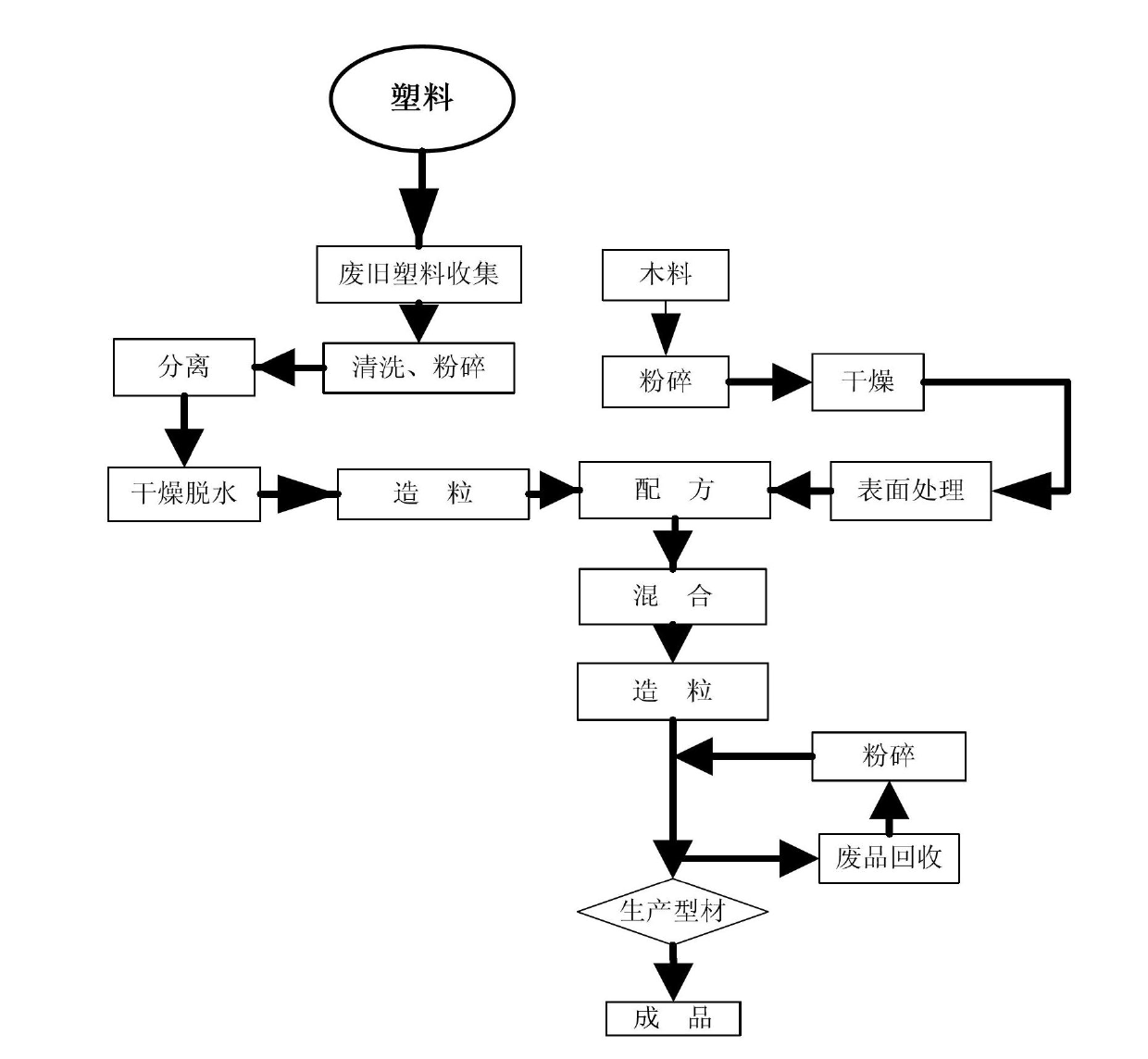

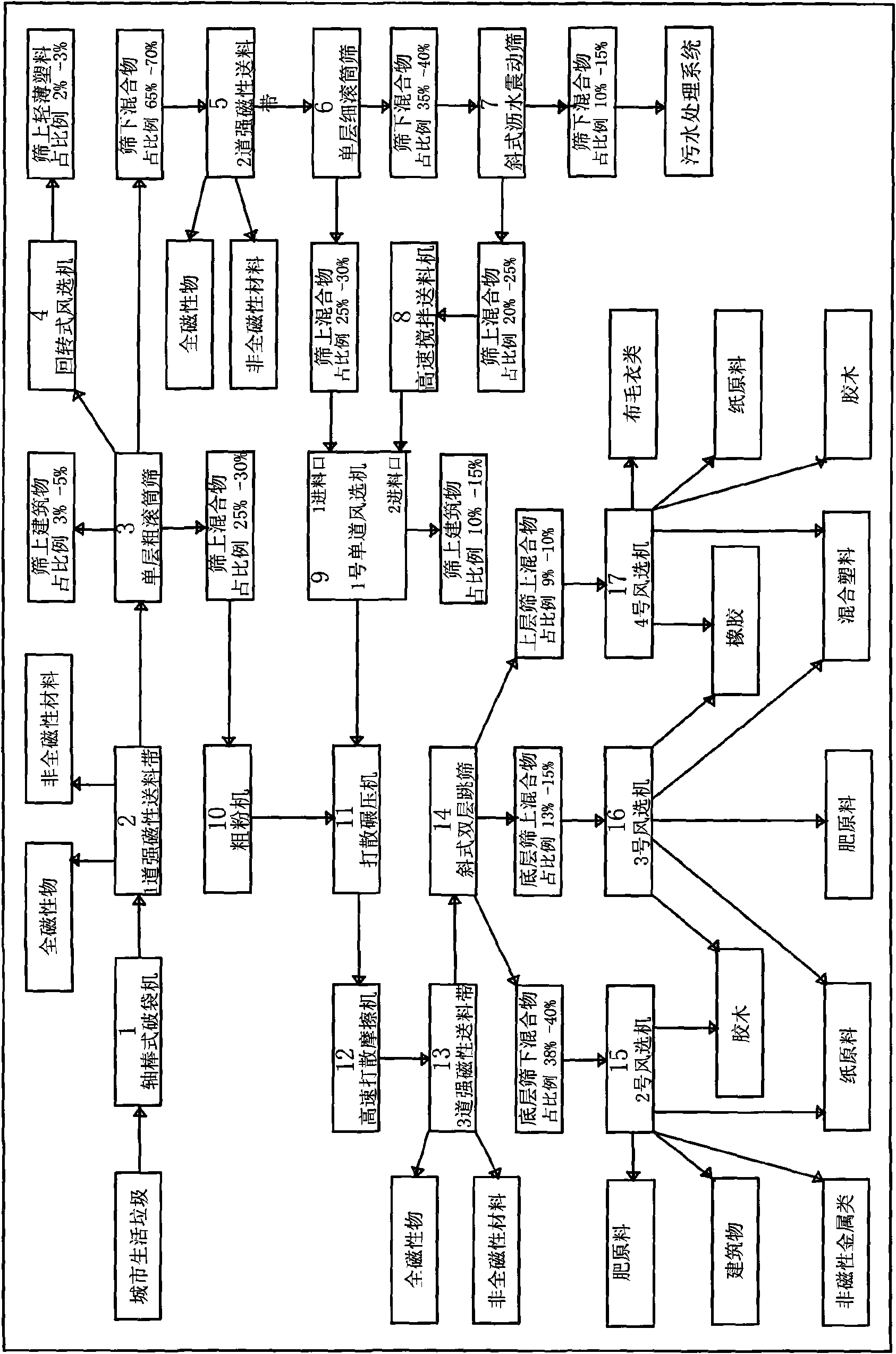

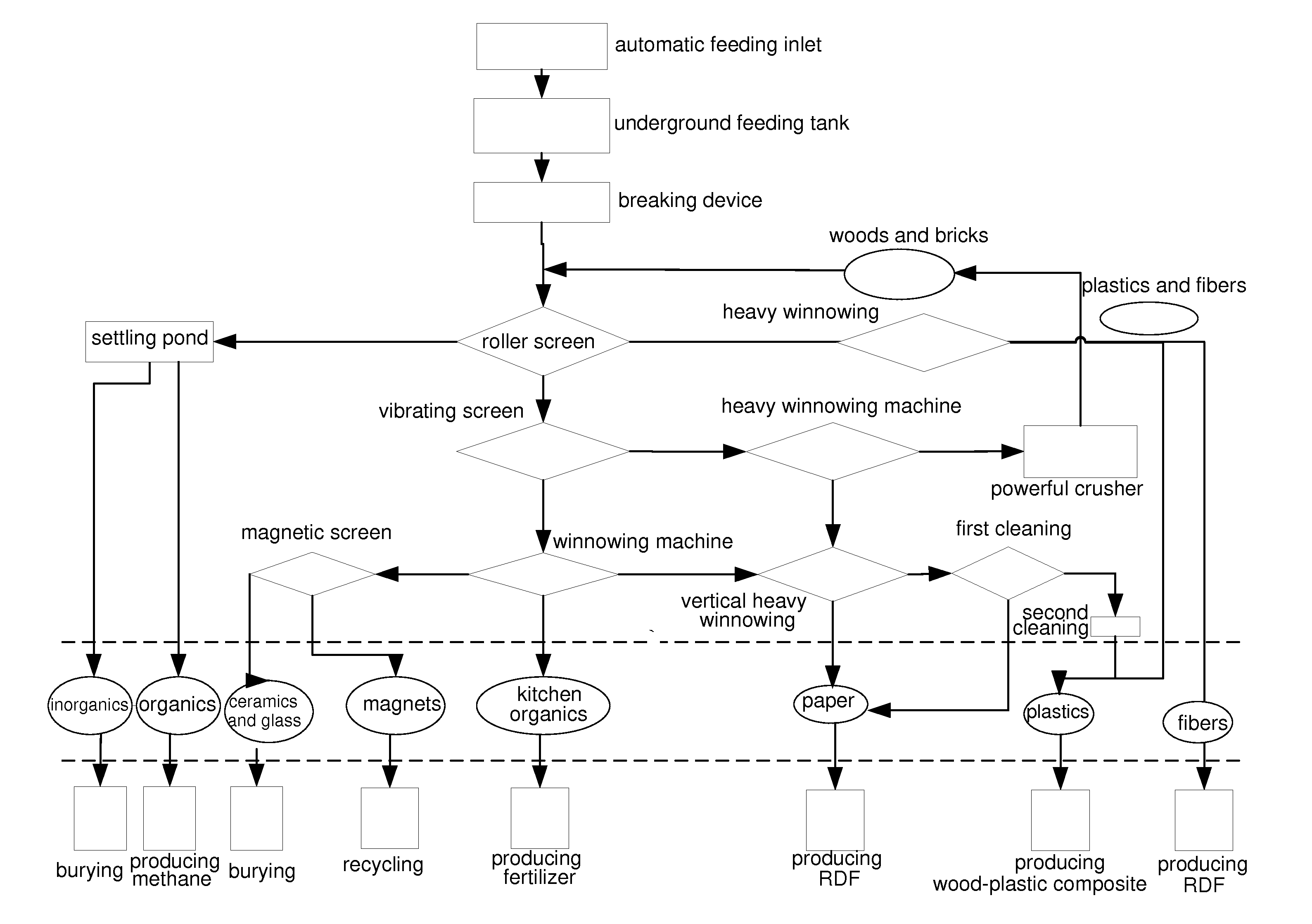

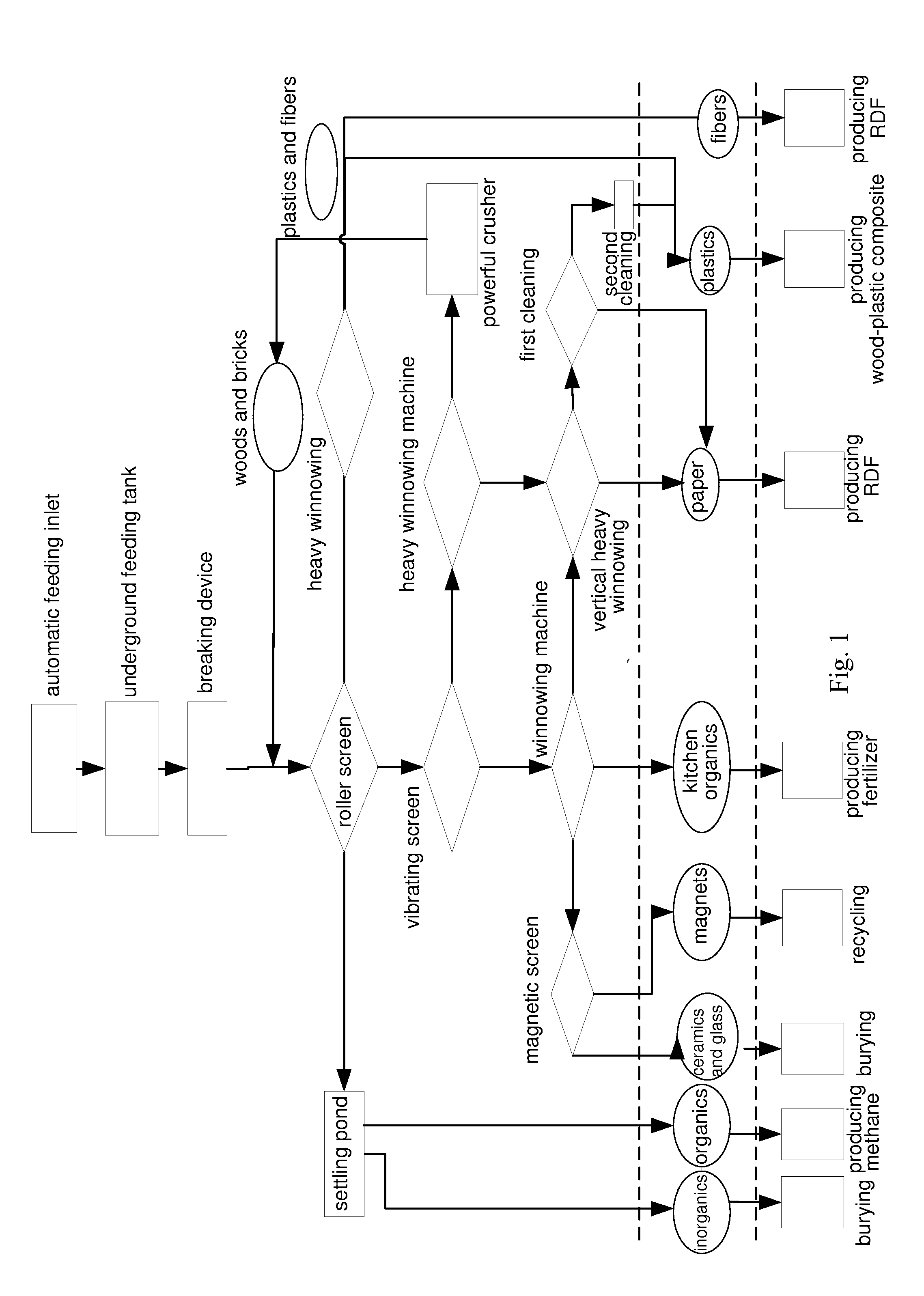

Method for sorting and comprehensively using urban mixed garbage

InactiveCN102671928AStructural innovationRealize full mechanizationBio-organic fraction processingSolid waste disposalRefuse-derived fuelPulp and paper industry

The invention discloses a method for sorting and comprehensively using urban mixed garbage. The method comprises the following steps: 1) allowing the urban mixed garbage to enter a feed bin through a feeding hole, discharging, and introducing into crushing and bag breaking equipment; 2) breaking garbage bags and crushing block garbage by using the crushing and bag breaking equipment; 3) feeding the garbage subjected to crushing and bag breaking into a two-stage rotary screen, screening out dust of which the grain size is less than 3mm, and picking out strip substances; and 4) feeding the mixed garbage into a vibration screen, separating inorganic cakes, large-sheet plastics and paper from an oversize material by using a heavy winnowing machine, and winnowing heavy substances, light substances and intermediate substances from an undersized material in a double-wind chamber multifunctional winnowing machine. Sorting equipment is effectively combined, so that the mixed garbage is efficiently sorted and recycled; and the sorted paper and textiles, plastics and kitchen organics are respectively used for preparing garbage derived fuel, plastic wood and fertilizers.

Owner:SICHUAN CRUN ENVIRONMENTAL PROTECTION ENERGY TECH CO LTD +1

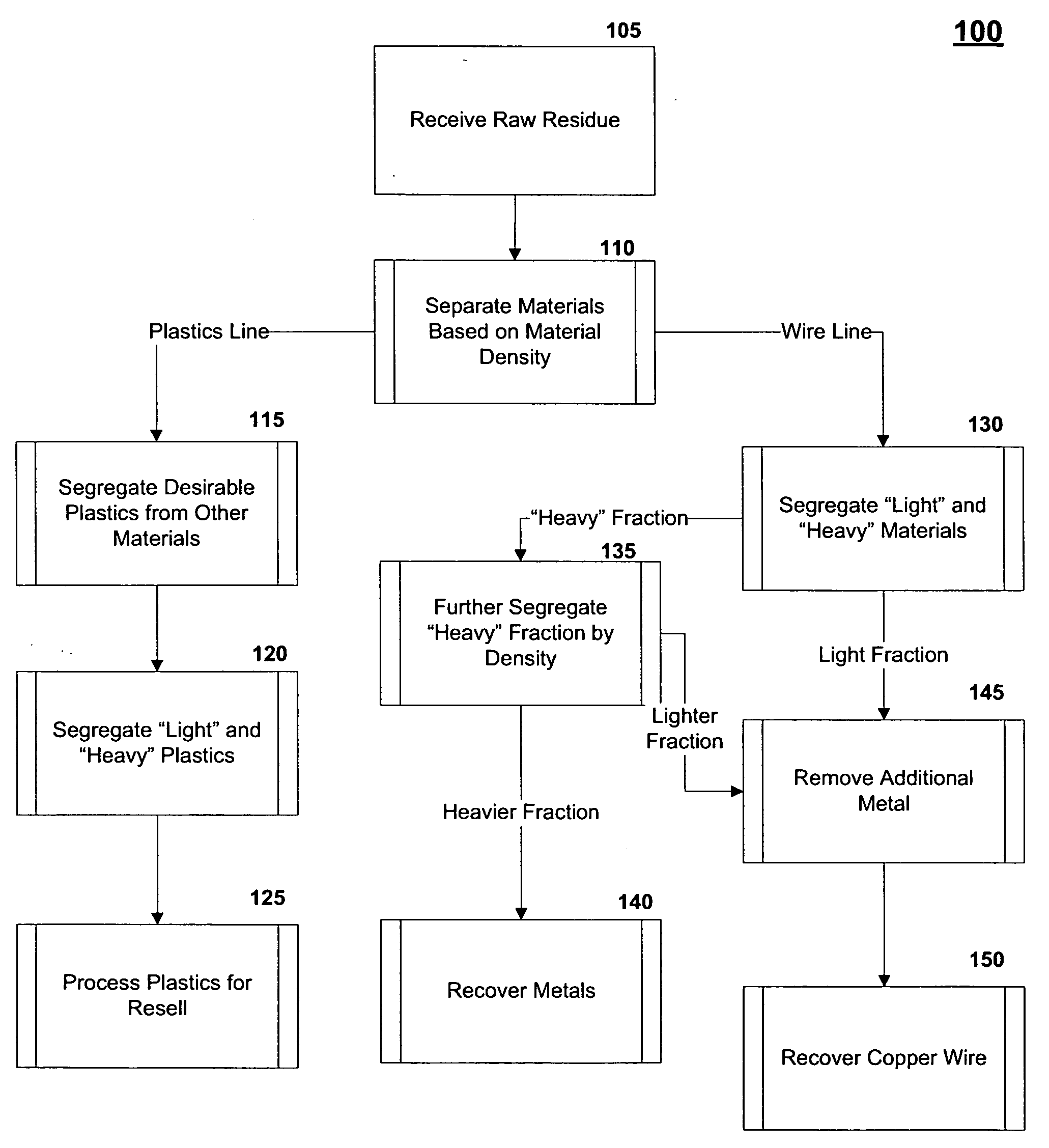

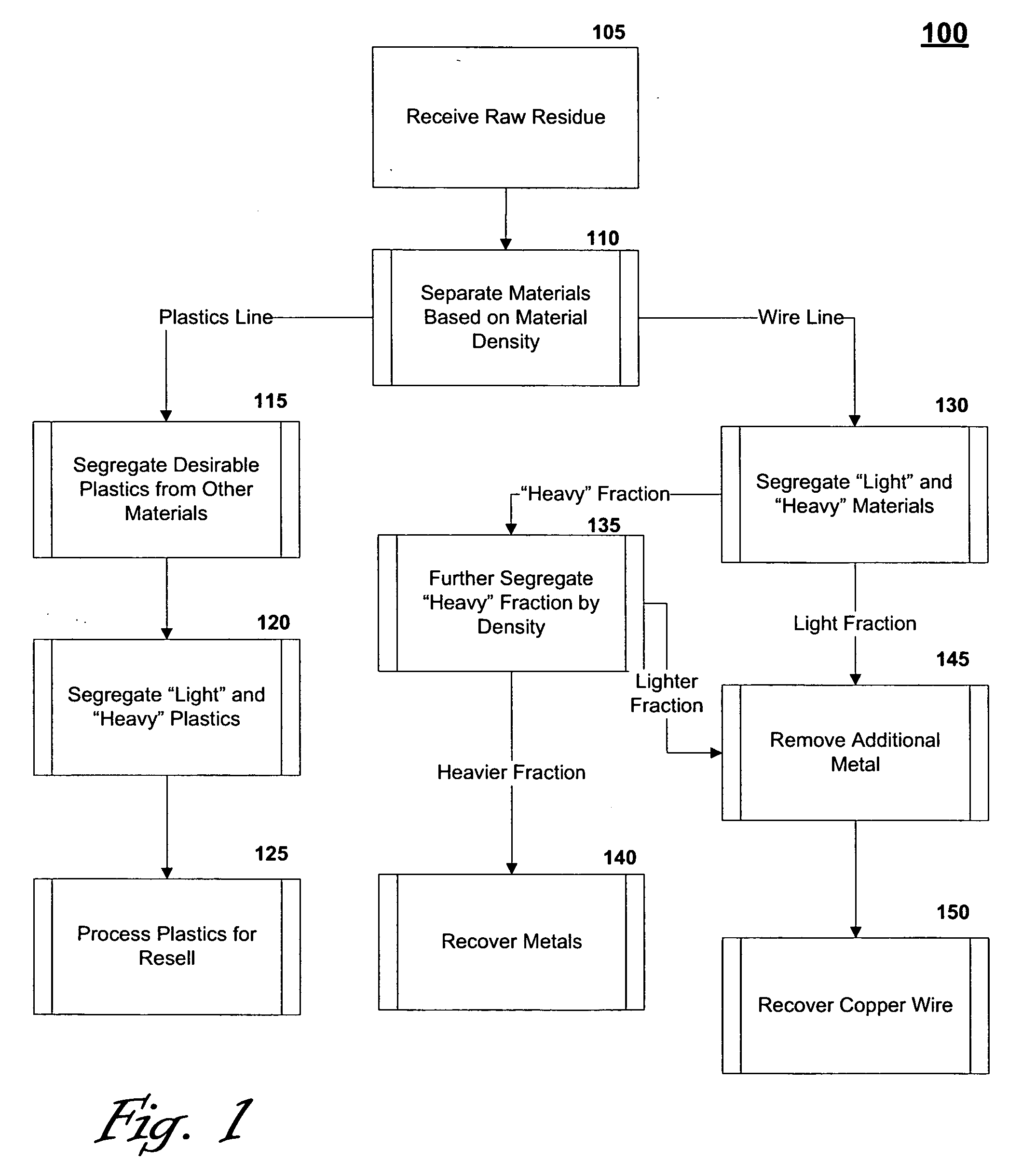

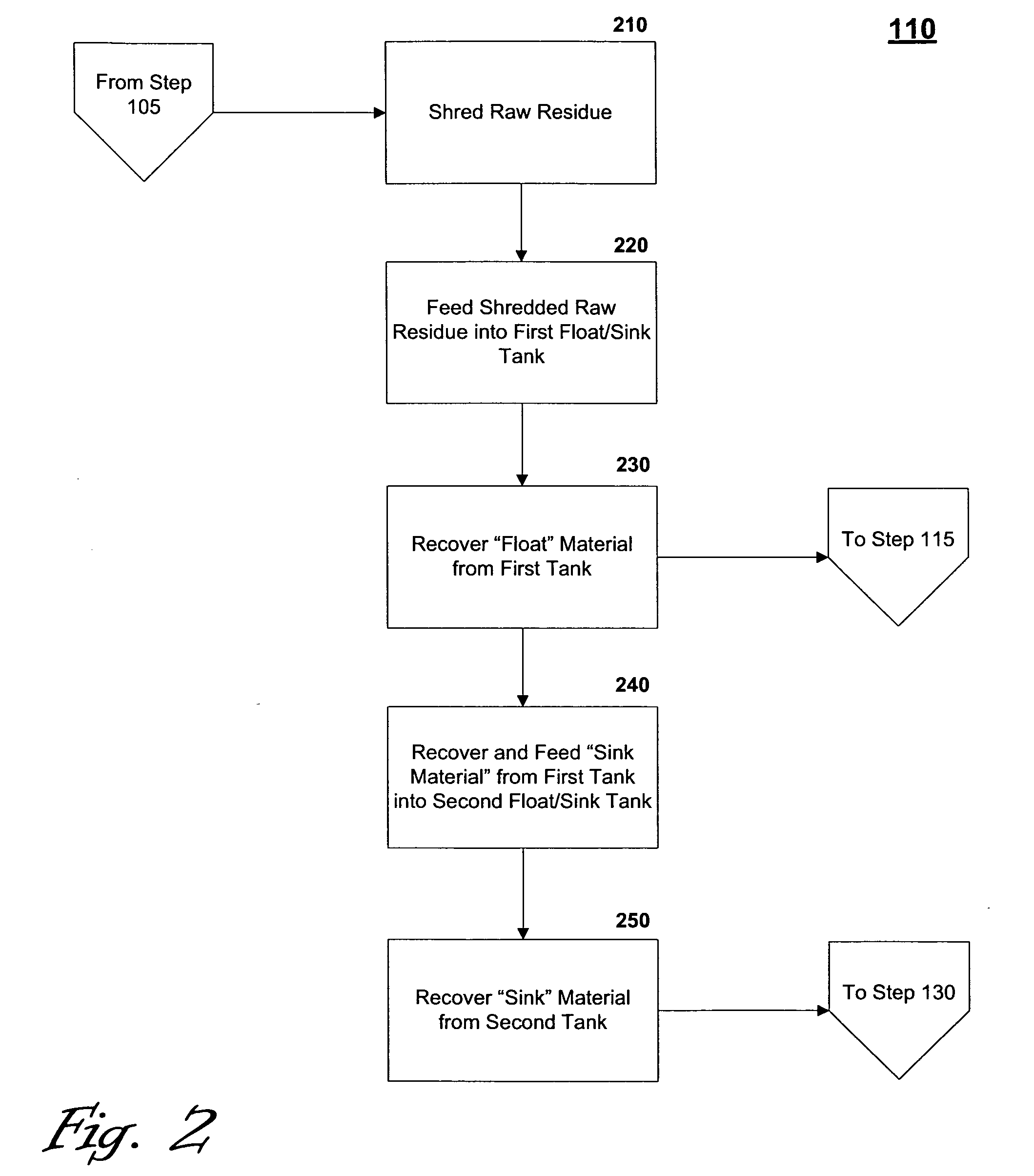

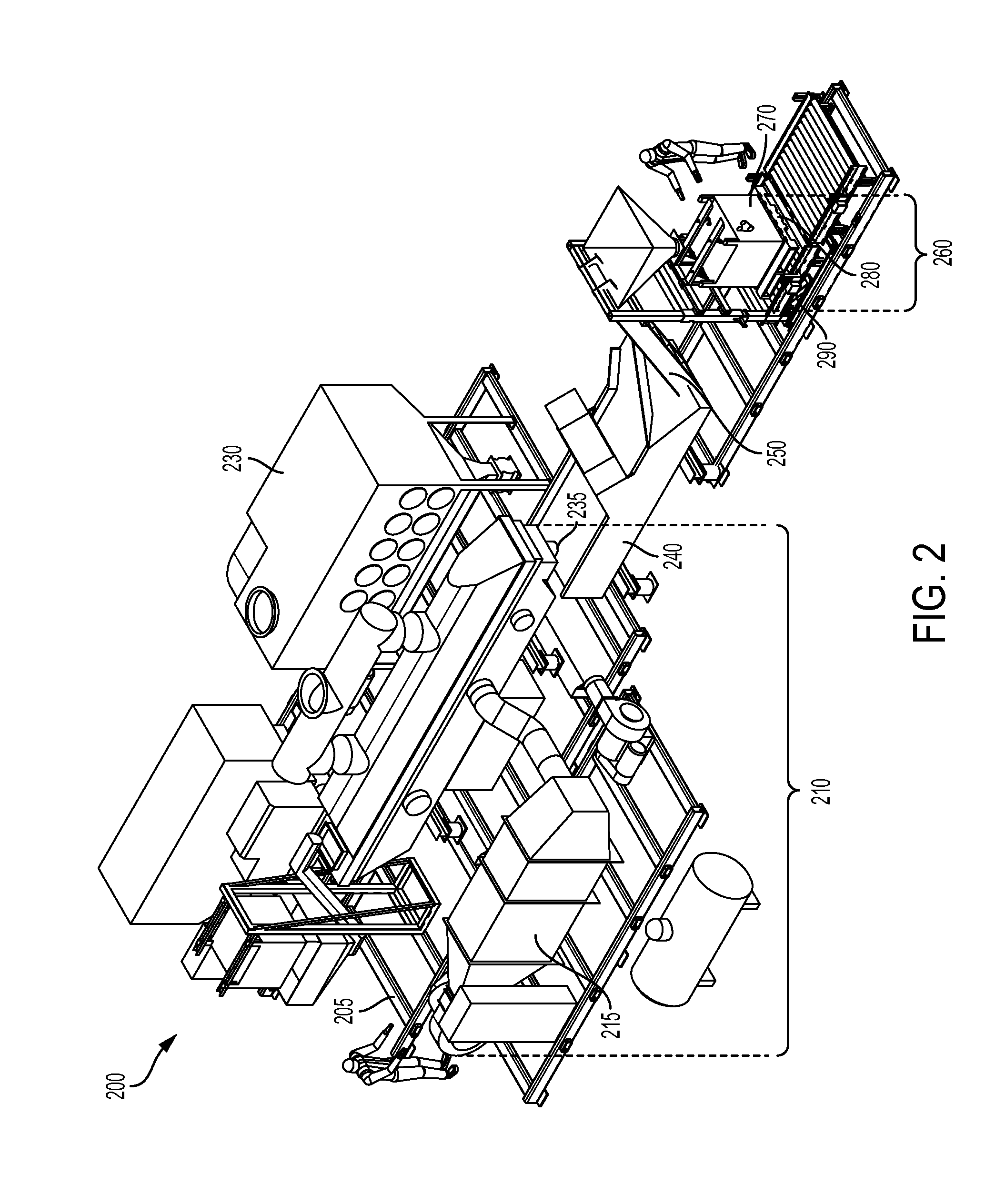

Method and system for sorting and processing recycled materials

InactiveUS20080257794A1Small sizePlastic recyclingAuxillary shaping apparatusCopper wireNonferrous metal

Processing recycled materials to recover plastics, copper wire, and other non-ferrous metals. Aspects of the invention employ density separation to separate plastic-bearing materials from copper-bearing materials. Plastic-bearing materials are further separated to separate light plastics from heavy plastics. Plastics are concentrated, extruded, and palletized. Copper and other valuable metals are recovered from copper-bearing materials using a water separation table.

Owner:VALERIO THOMAS A

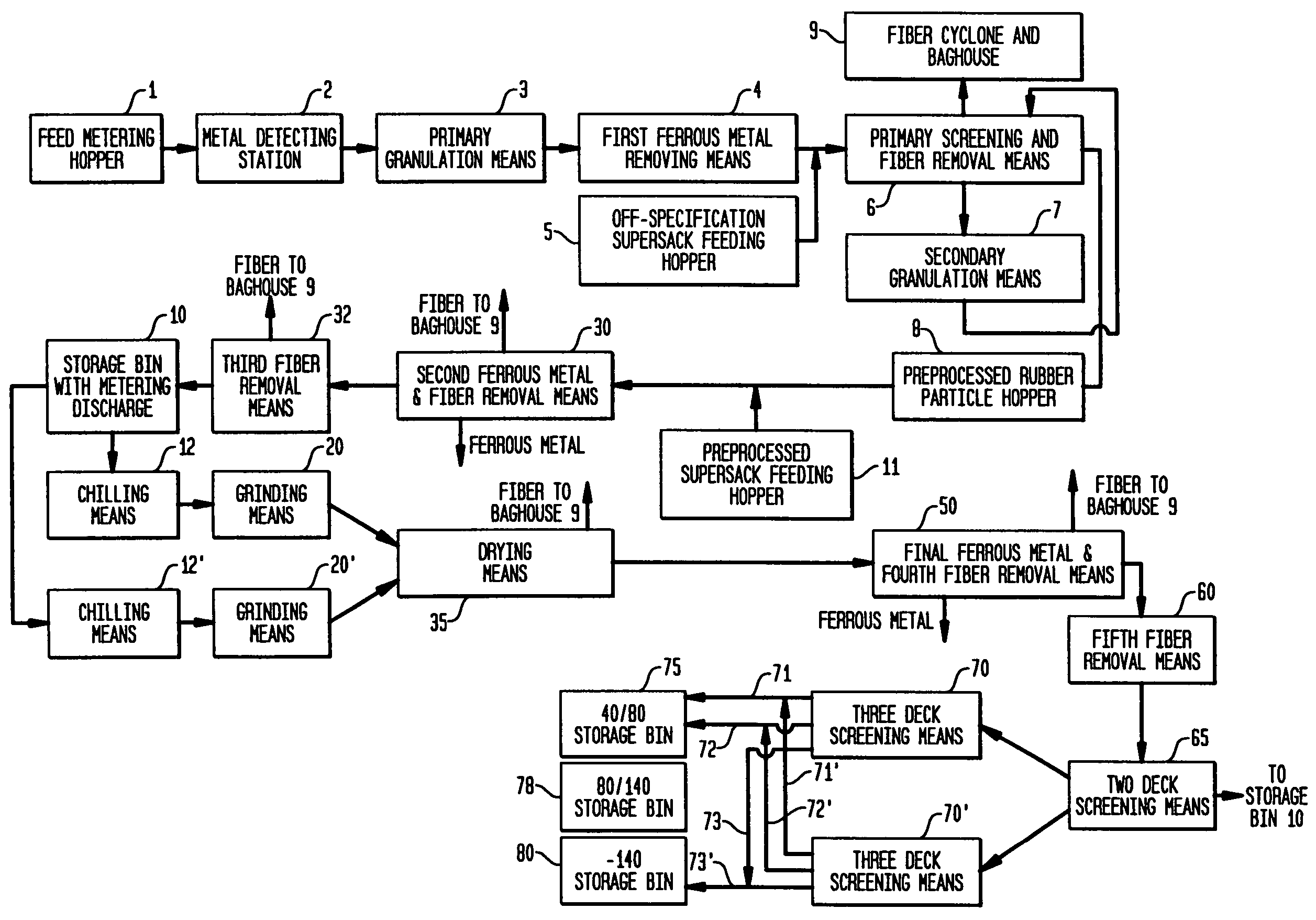

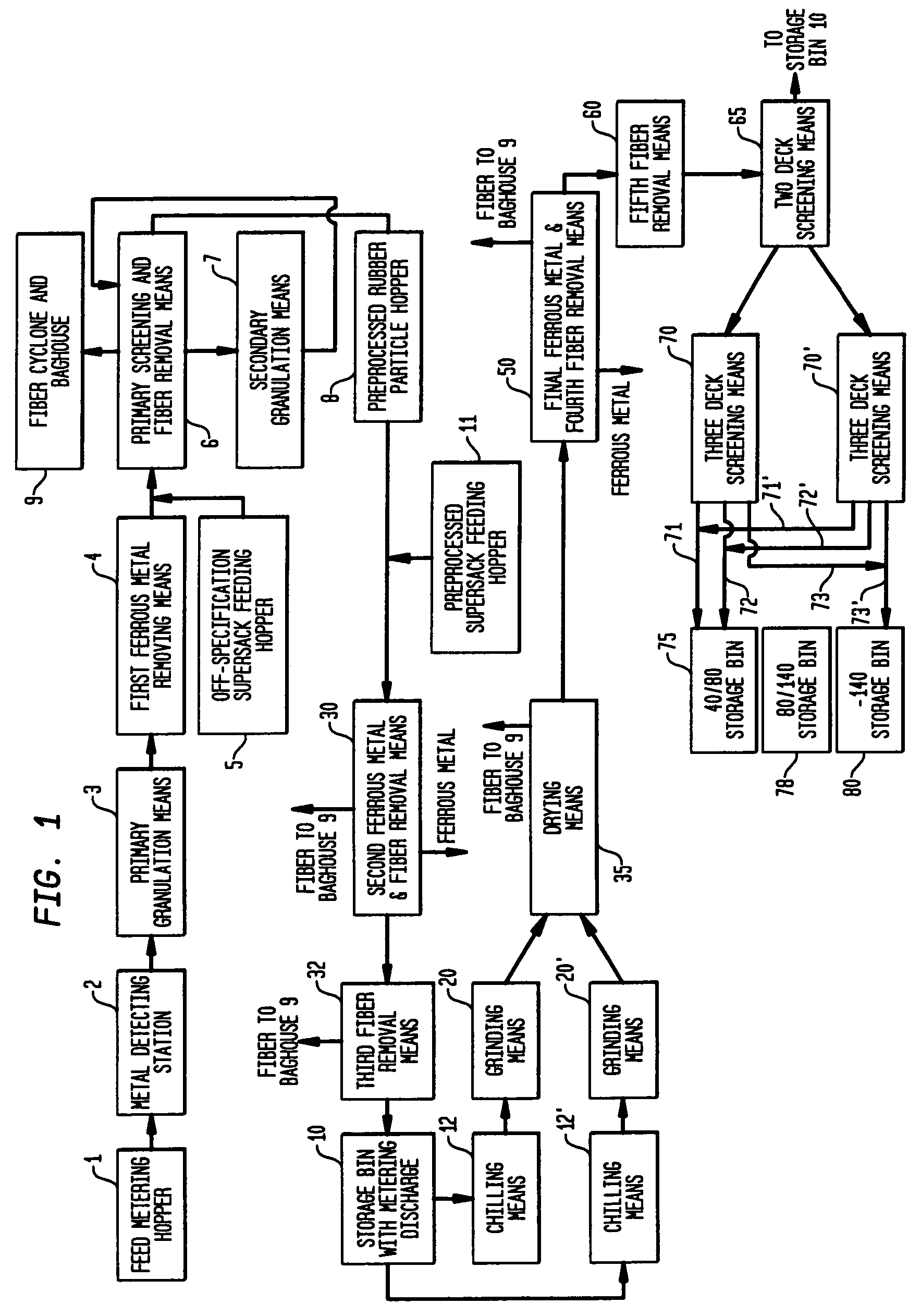

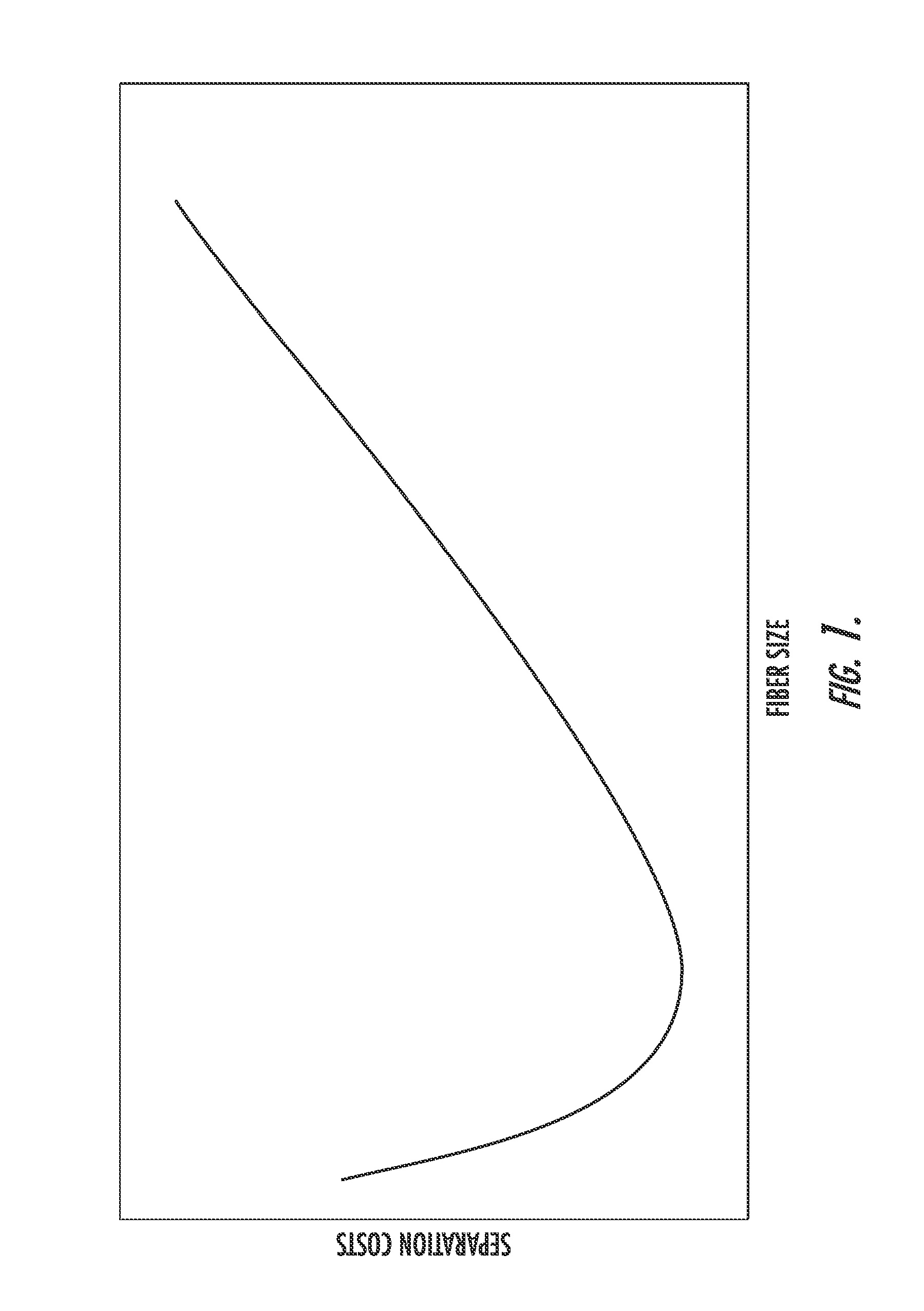

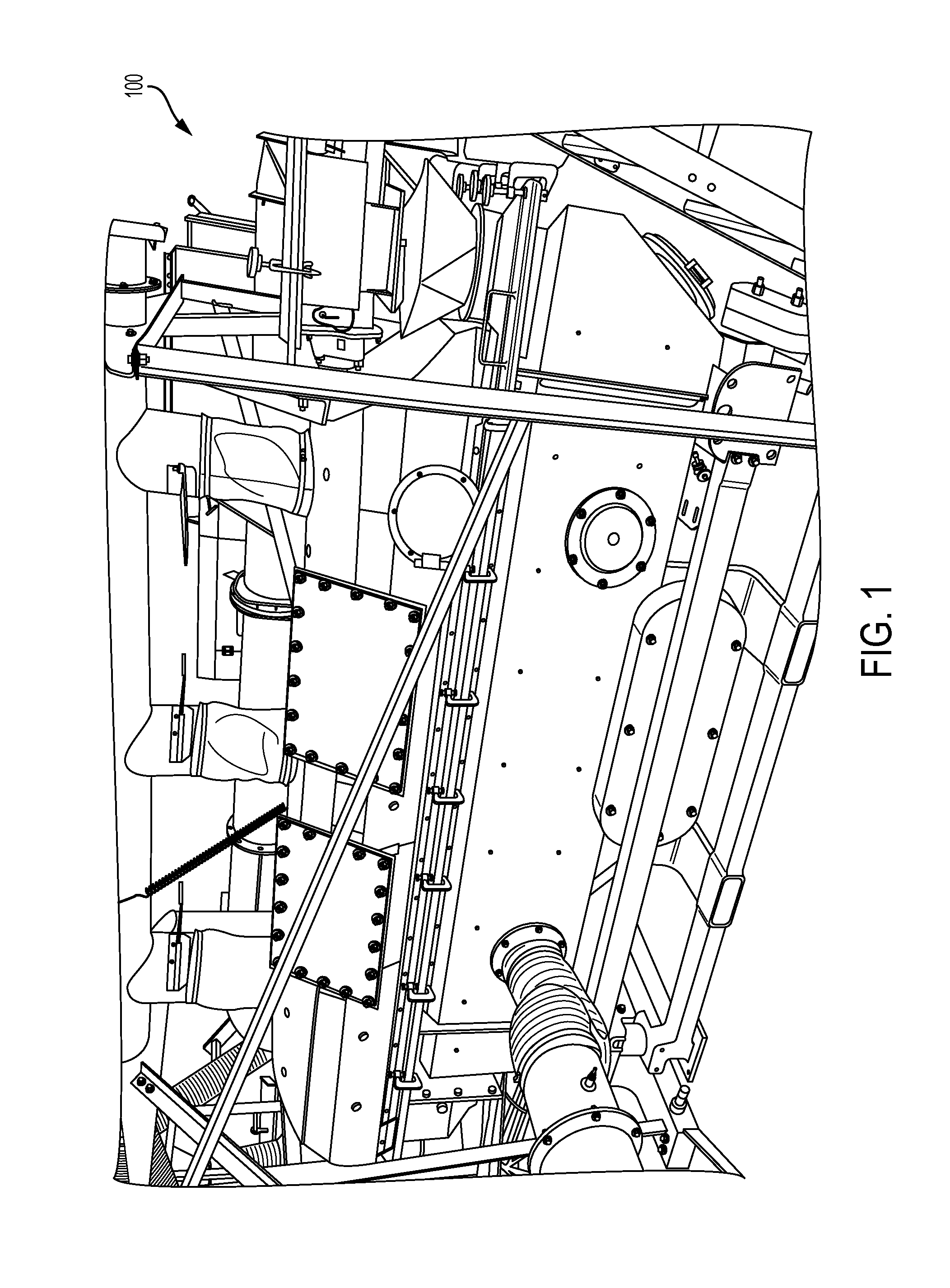

Process and apparatus for manufacturing crumb and powder rubber

A process and apparatus for manufacturing crumb and powder rubber. The process and apparatus include a cooling step, effectuated by cooling means, wherein the temperature of cryogenically cooled preprocessed rubber particles is controlled. The process and apparatus also include a grinding step, effectuated by grinding means, in which the degree of grinding, and thus the product particle size range, is controlled.

Owner:LEHIGH TECH INC

Systems and methods for sorting, collecting data pertaining to and certifying recyclables at a material recovery facility

Systems and methods for collecting data pertaining to glass, plastic and / or paper composition within an input stream that includes recyclable material. The data collected can pertain, for example, to the weight and / or volume of the glass, plastic and / or paper within the input stream. The data can be certified for use a third party.

Owner:THE CLOROX CO +1

Plastic reclamation process

A plastic article or plastic container reclamation process if provided in which plastic containers are divided into relatively large pieces, then washed, agitated and separated using an aqueous solvent to remove residual materials. The residual materials such as motor oil are reclaimed for reuse and the aqueous solvent is regenerated for reuse in the process. Residual materials such as dirt, labels and adhesives from the plastic containers is recovered for recycling or passed to waste for disposal or reuse.

Owner:DOONAN BILLIE ODELL

Methods of recycling post-consumer carpet

ActiveUS7784719B1Efficient and cost-effectiveCost-effective methodSolid waste disposalPlastic recyclingPolyesterFiber

Owner:WELLMAN ADVANCED MATERIALS LLC

Systems and methods for sorting, collecting data pertaining to and certifying recyclables at a material recovery facility

Systems and methods for collecting data pertaining to glass, plastic and / or paper composition within an input stream that includes recyclable material. The data collected can pertain, for example, to the weight and / or volume of the glass, plastic and / or paper within the input stream. The data can be certified for use a third party.

Owner:THE CLOROX CO +1

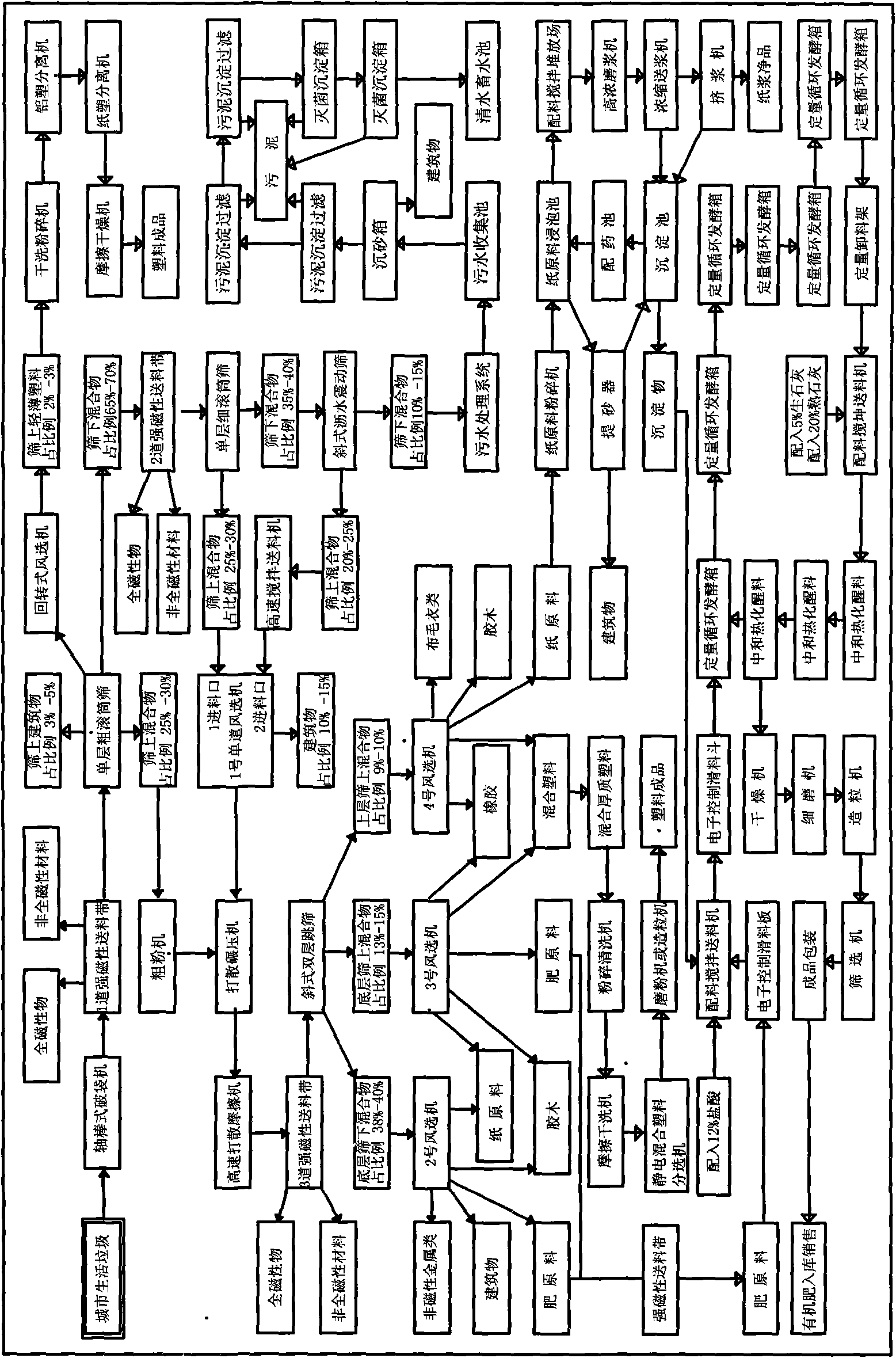

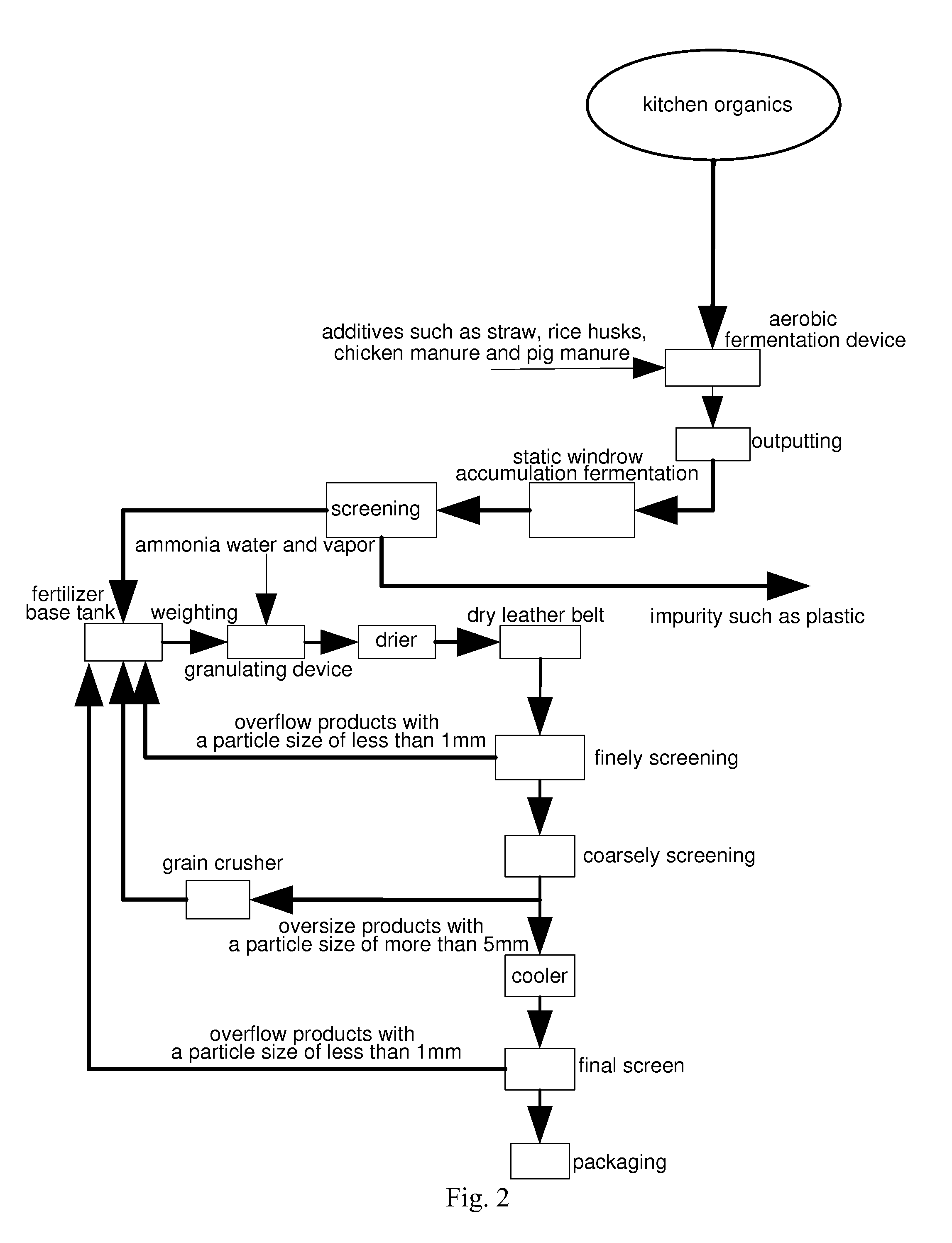

Complete system of recycling treatment of city household garbage and a method thereof

InactiveCN101579689ASolve the fragile problemSolve hanging problemsSievingGas current separationControl systemSewage treatment

The invention relates to a complete system of recycling treatment of city household garbage and a method thereof. The invention is characterized in that an electronic screen control system controls mechanical transmission and treatment condition of a garbage mechanical classification system, a fertilizer-making system, a plastic classification system, a pulping system and a sewage treatment system by a contact screen and a circuit, the recycling treatment of day treatment for day garbage, closed operation, automatic sorting, no secondary pollution and fully treatment of resources is realized finally, the city household garbage is divided into 48 types, which are combined into 15 types and seven sorts, the classification rate reaches 100 percent, the recycling rate reaches over 99 percent and the whole-range treatment needs 60 to 80 minutes.

Owner:邵道德

Method for sorting and comprehensively utilizing municipal solid waste

InactiveUS20150135785A1Maximize resource utilizationEfficient combinationBio-organic fraction processingSolid waste disposalRefuse-derived fuelFiber

A method for sorting and comprehensively utilizing municipal solid waste includes steps of: 1) feeding the municipal solid waste into a feeding tank through a feeding inlet, then outputting into a breaking device; 2) breaking refuse bags and large blocks by the breaking device; 3) transporting broken refuse into a two-stage roller screen for screening out dusts with a particle size of less than 3 mm, and hanging strips; and 4) transporting mixed refuse screened by the two-stage screen into a vibrating screen; screening oversize products by a heavy winnowing machine for separating inorganic blocks, large plastics and paper; transporting underflow products into a two-room multi-functional winnowing machine for dividing into heavy materials, light materials and medium materials. By effectively combining sorting devices, effective sorting and reutilization of mixed refuse are achieved. Thereafter, paper, fibers, plastics and kitchen organic refuse are respectively for producing refuse derived fuel, wood-plastic composite and fertilizer.

Owner:XI AN JIAOTONG UNIV

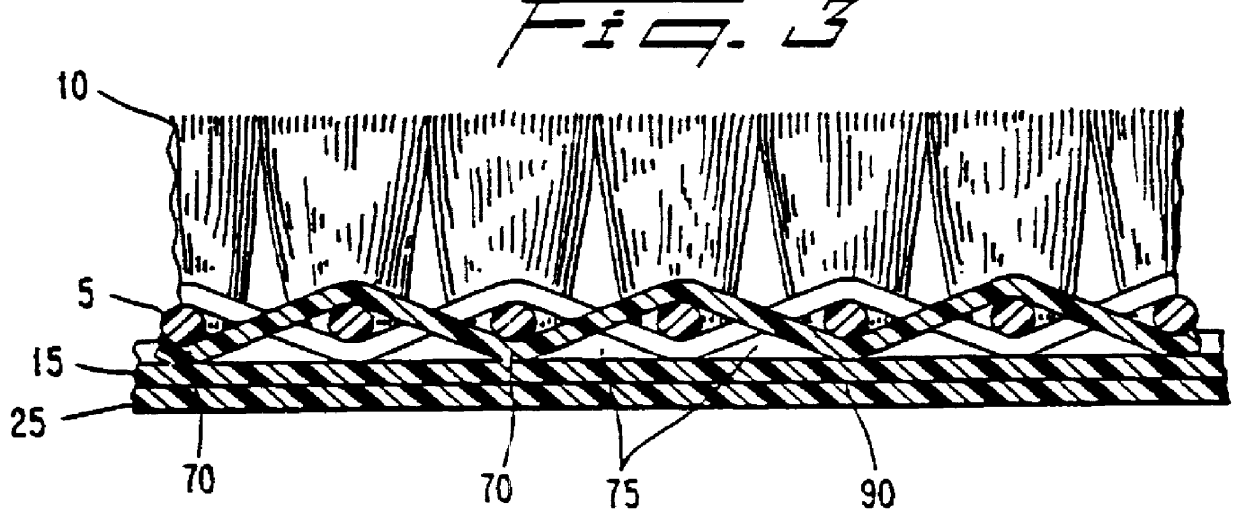

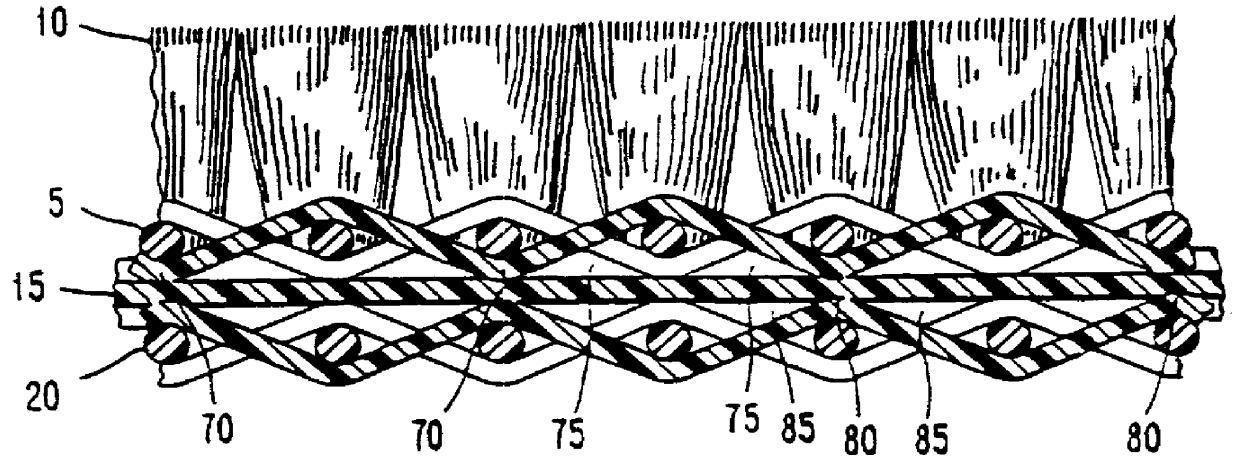

Carpet and techniques for making and recycling same

InactiveUS6051300AAlters performanceAlters processibilityCoatingsThin material handlingFiberPolyolefin

The disclosure relates to a carpet, a process for manufacturing a carpet and a method for recycling a carpet. The carpet of the present disclosure includes a primary backing having tufts of synthetic carpet fibers protruding from a top surface and, optionally, a secondary backing, with an extruded sheet of an isotactic polyolefin polymer between and integrally fused to a bottom surface of the primary backing and an upper surface of the secondary backing. The process for manufacturing the recyclable carpet includes contacting the extruded sheet with the primary backing and, optionally, the secondary backing, at a temperature sufficiently high to integrally fuse the extruded sheet to the respective backing. The method for recycling synthetic carpet of the type described includes manufacturing the carpet, collecting portions of the carpet, and melting the collected portions to make a feedstock.

Owner:TENNESSEE VALLEY PATENT DEV

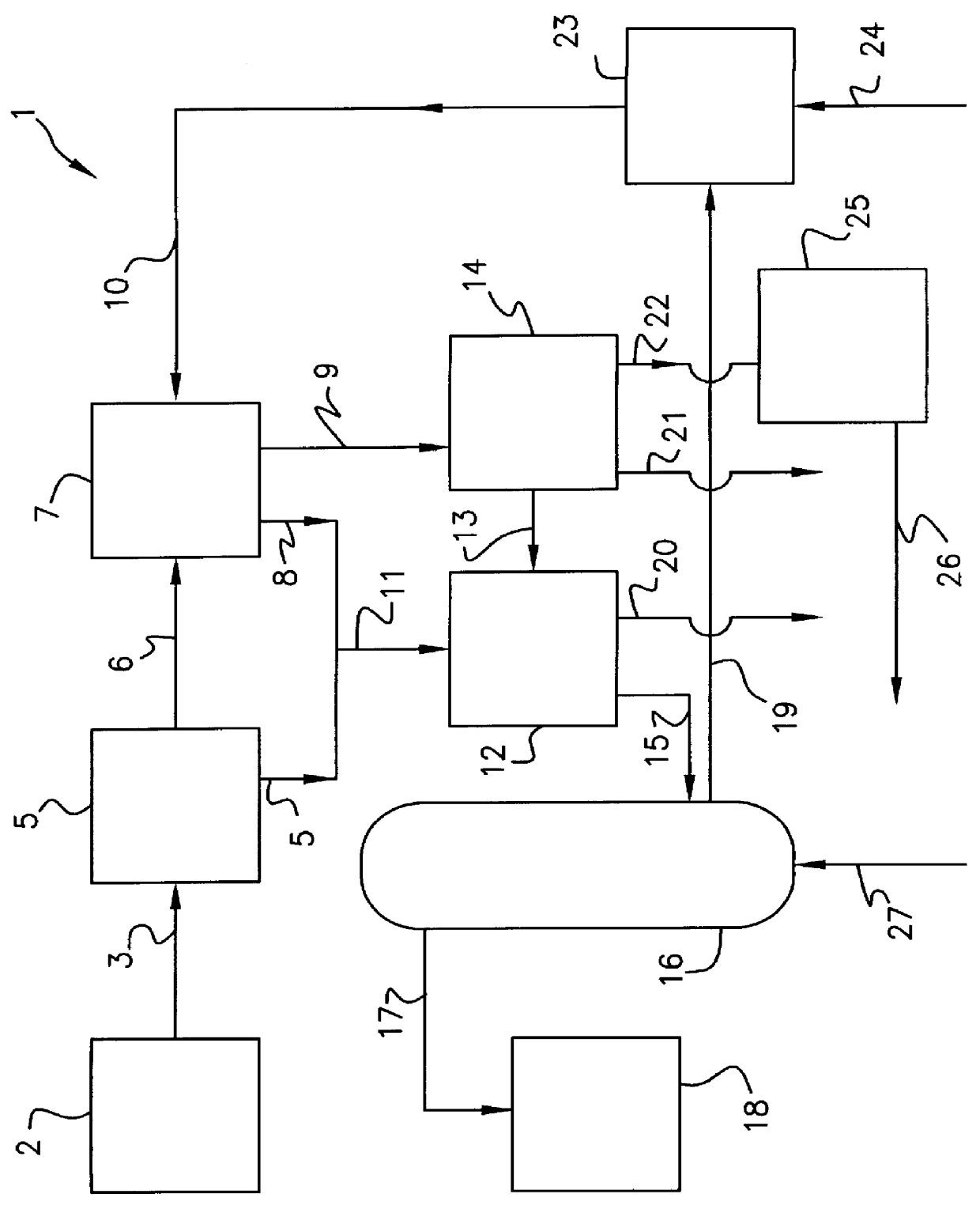

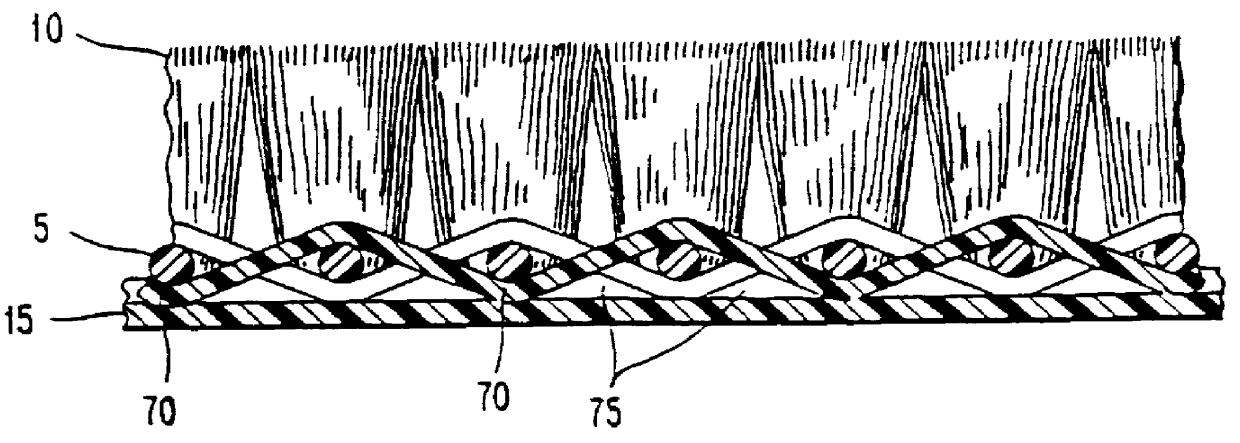

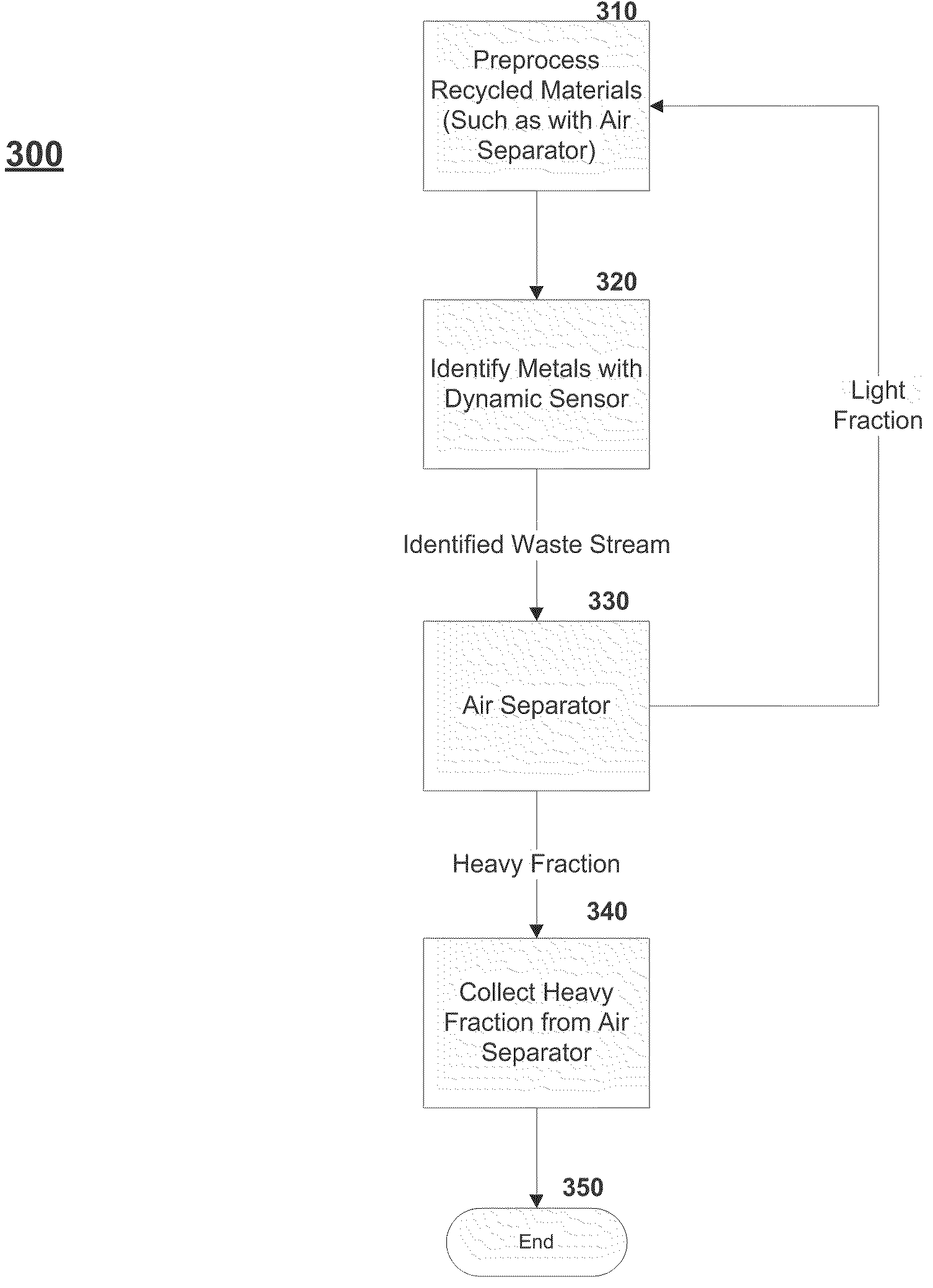

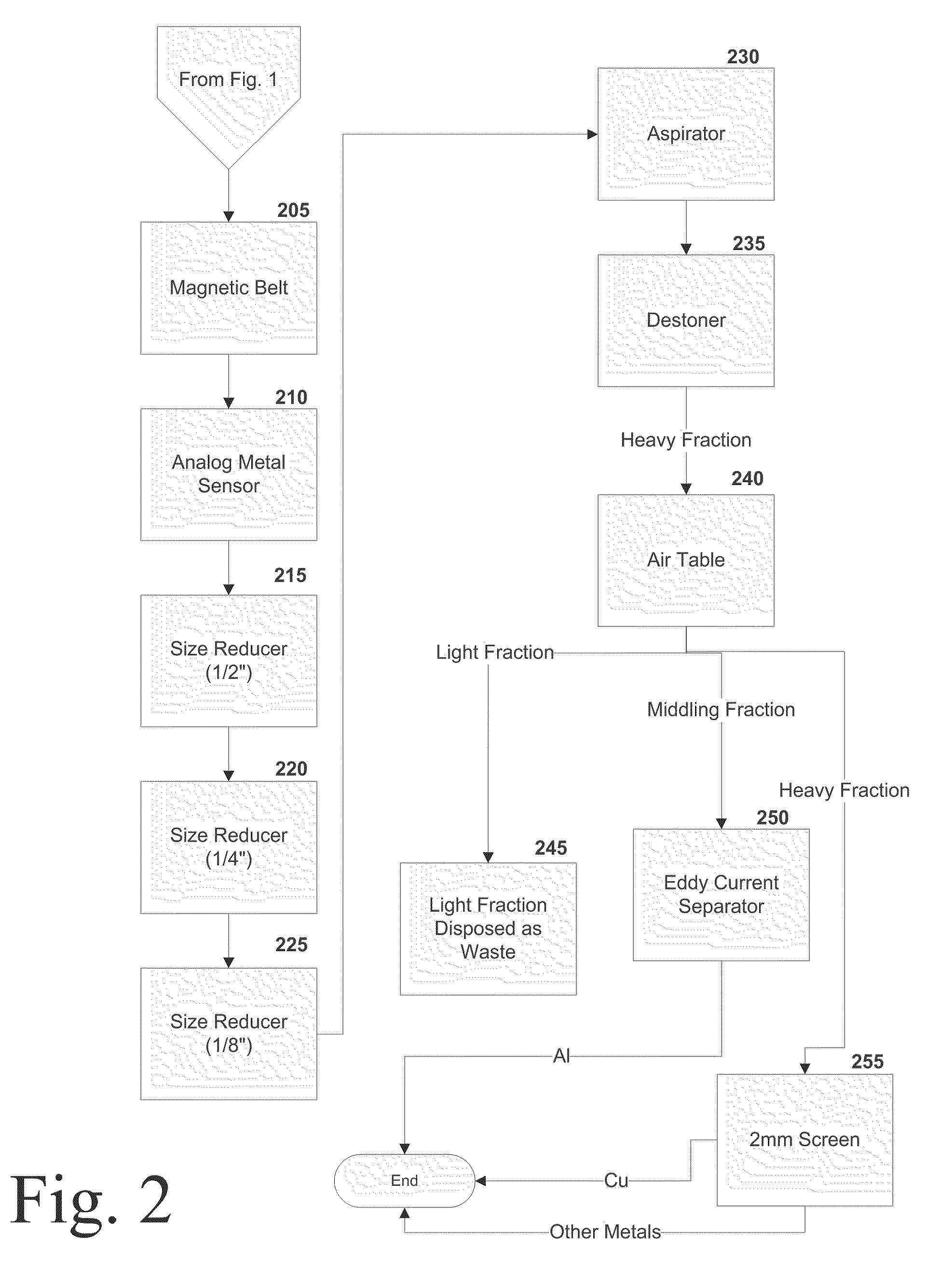

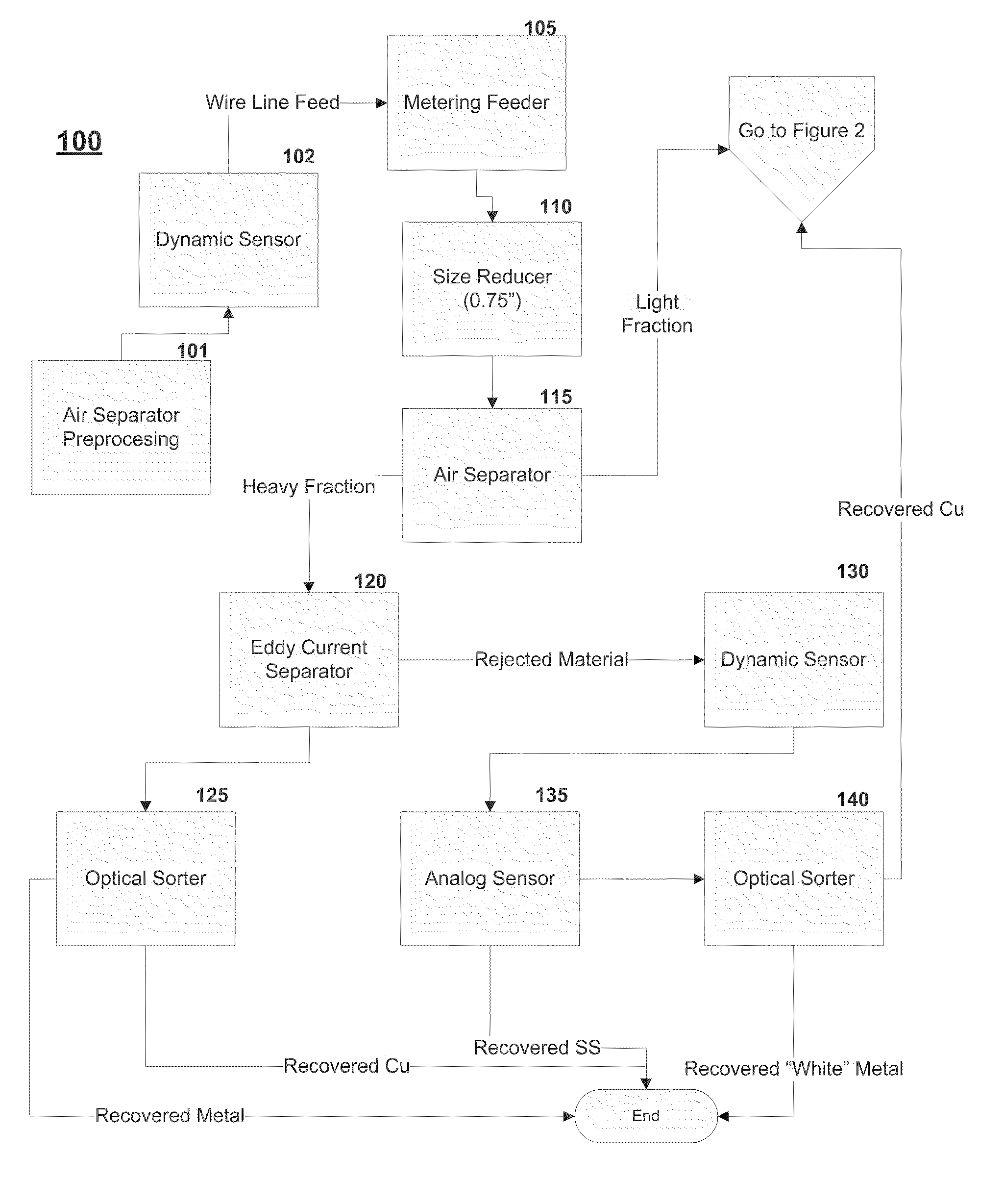

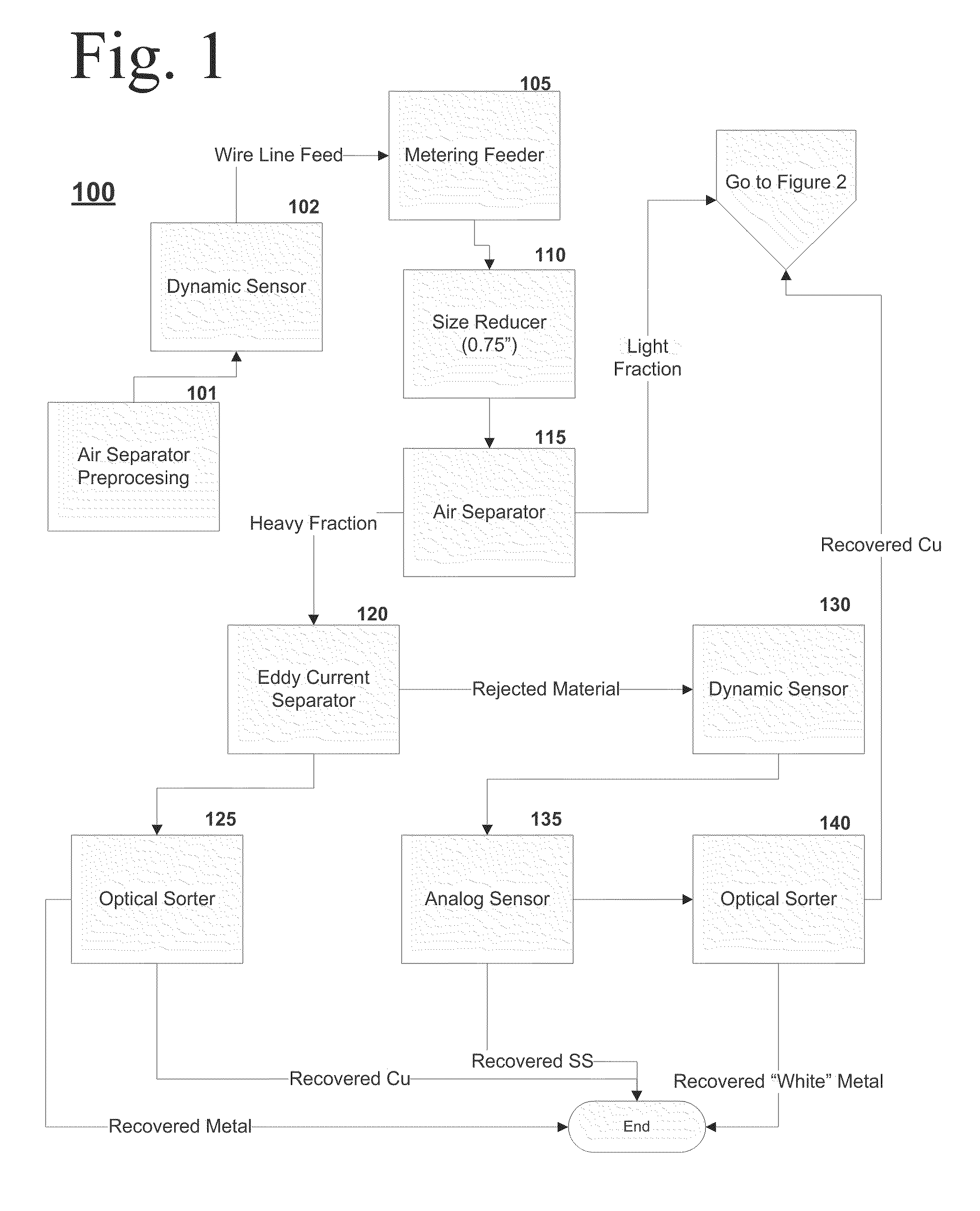

Method and system for recovering metal from processed recycled materials

InactiveUS7786401B2Efficient and cost-effectivePromote incomeGas current separationElectrostatic separationMetallic materialsCopper

Recovering metallic materials, such as copper, from waste materials. The A dynamic sensor measures the rate of change of current generated by metallic materials in the waste materials. Preprocessing and post processing of the waste materials may be completed to further concentrate the amount the metallic materials recovered from the waste.

Owner:VALERIO THOMAS A

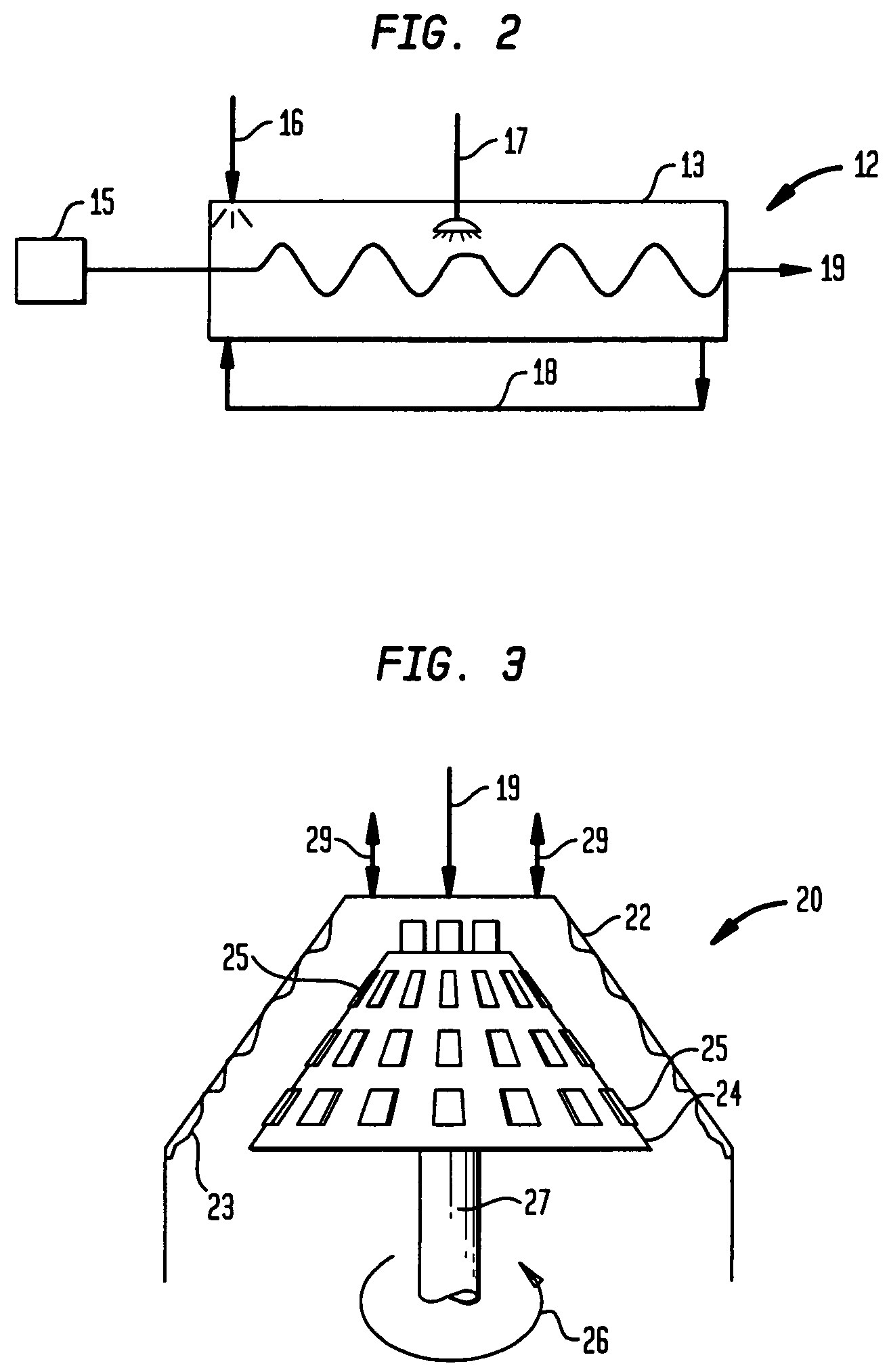

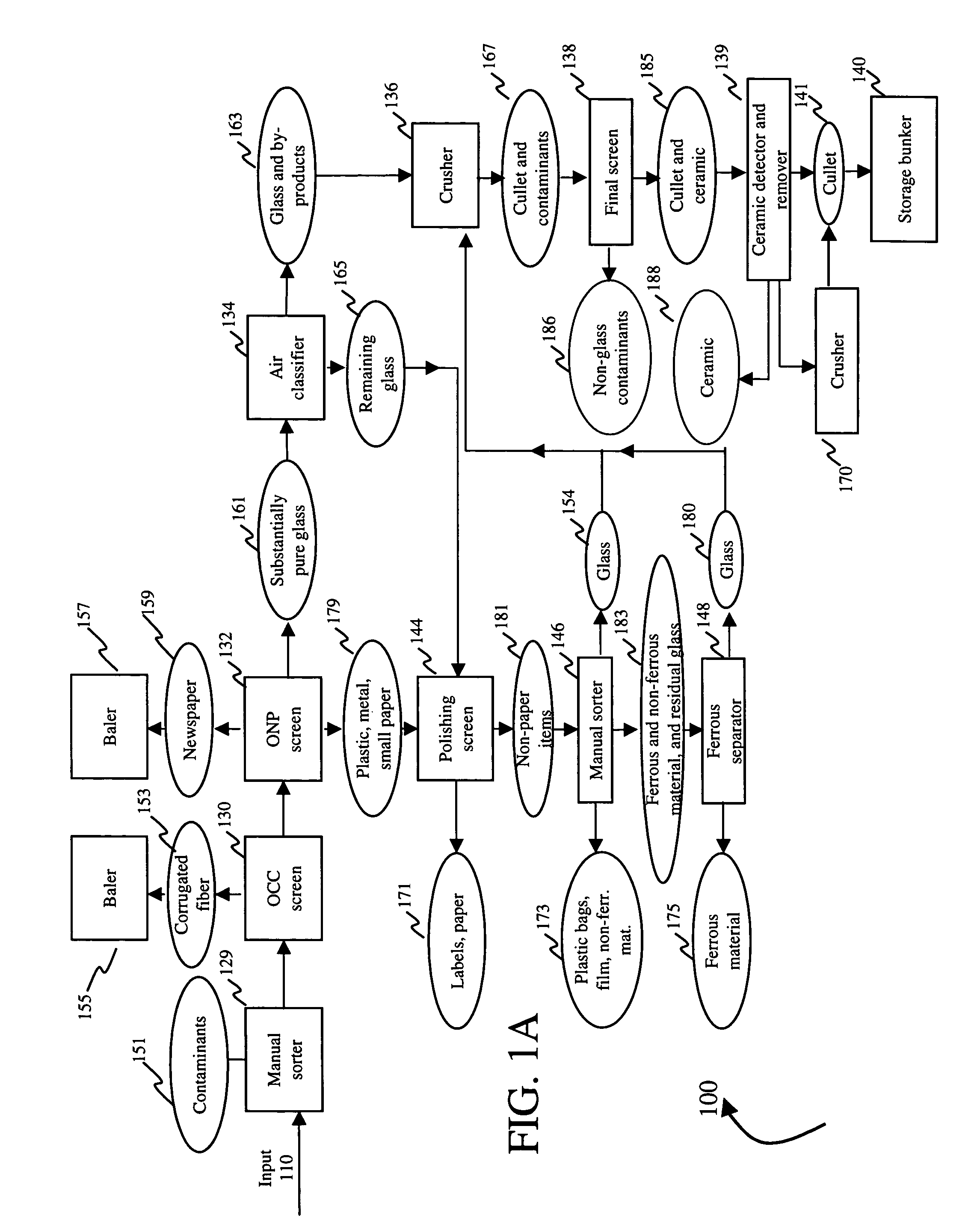

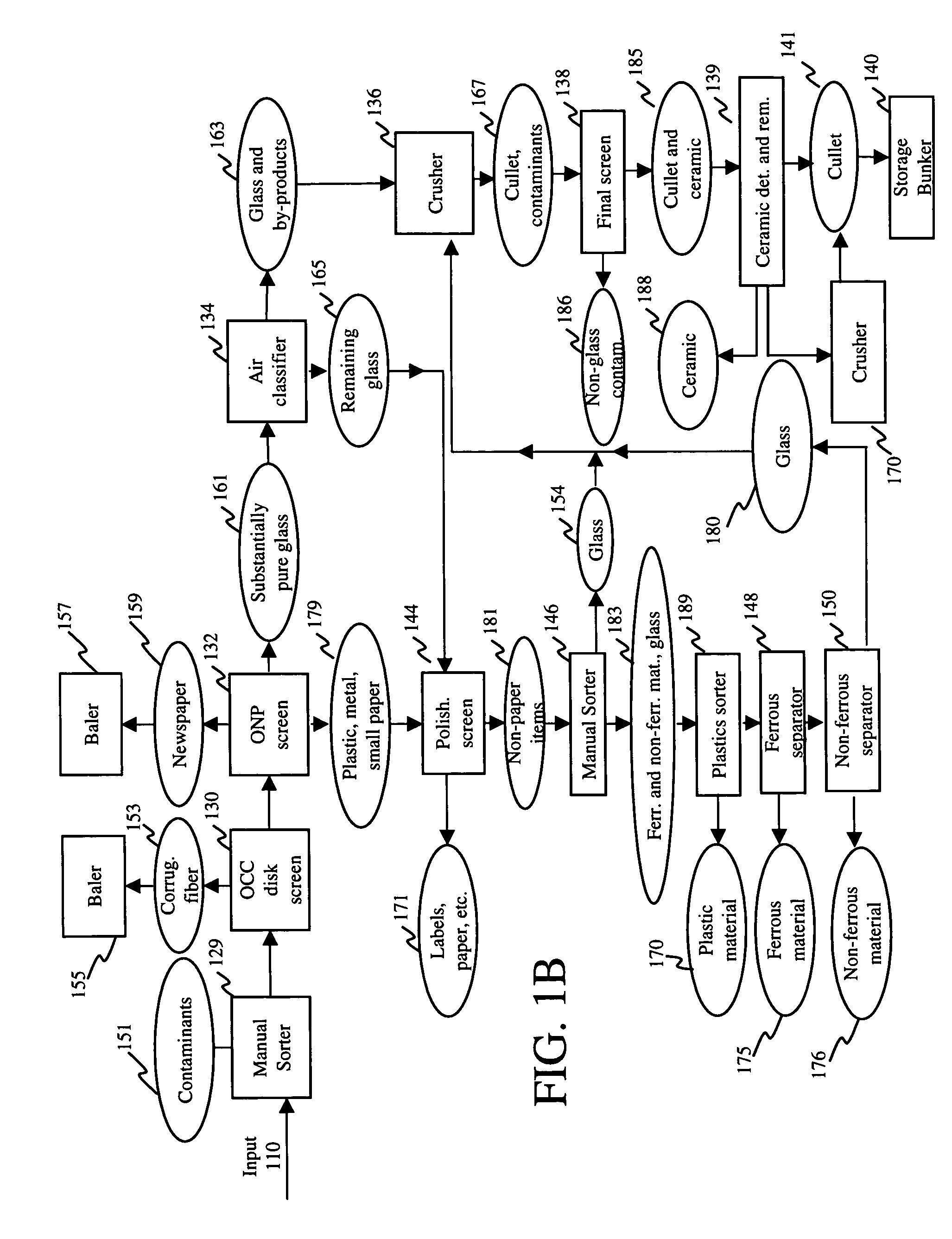

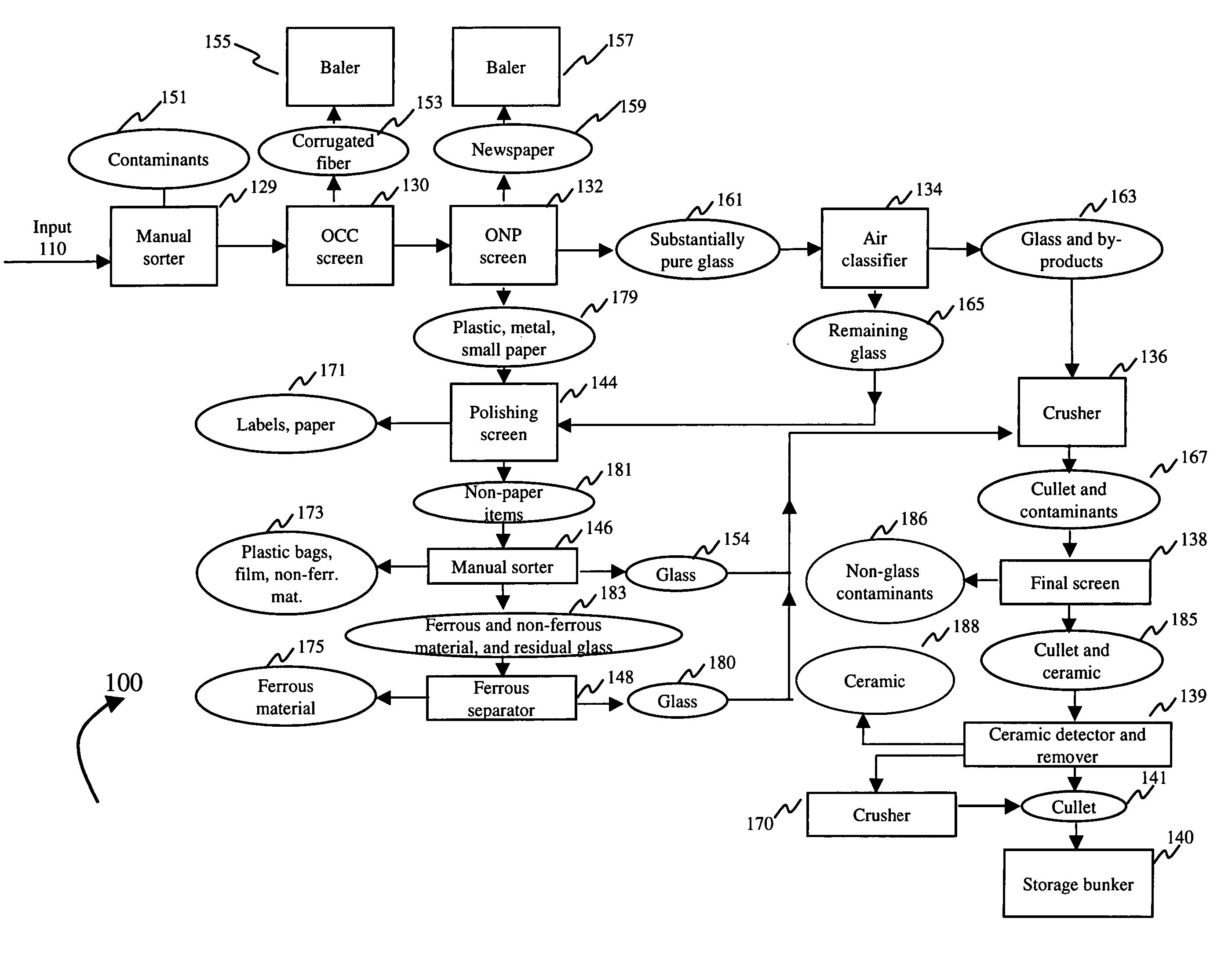

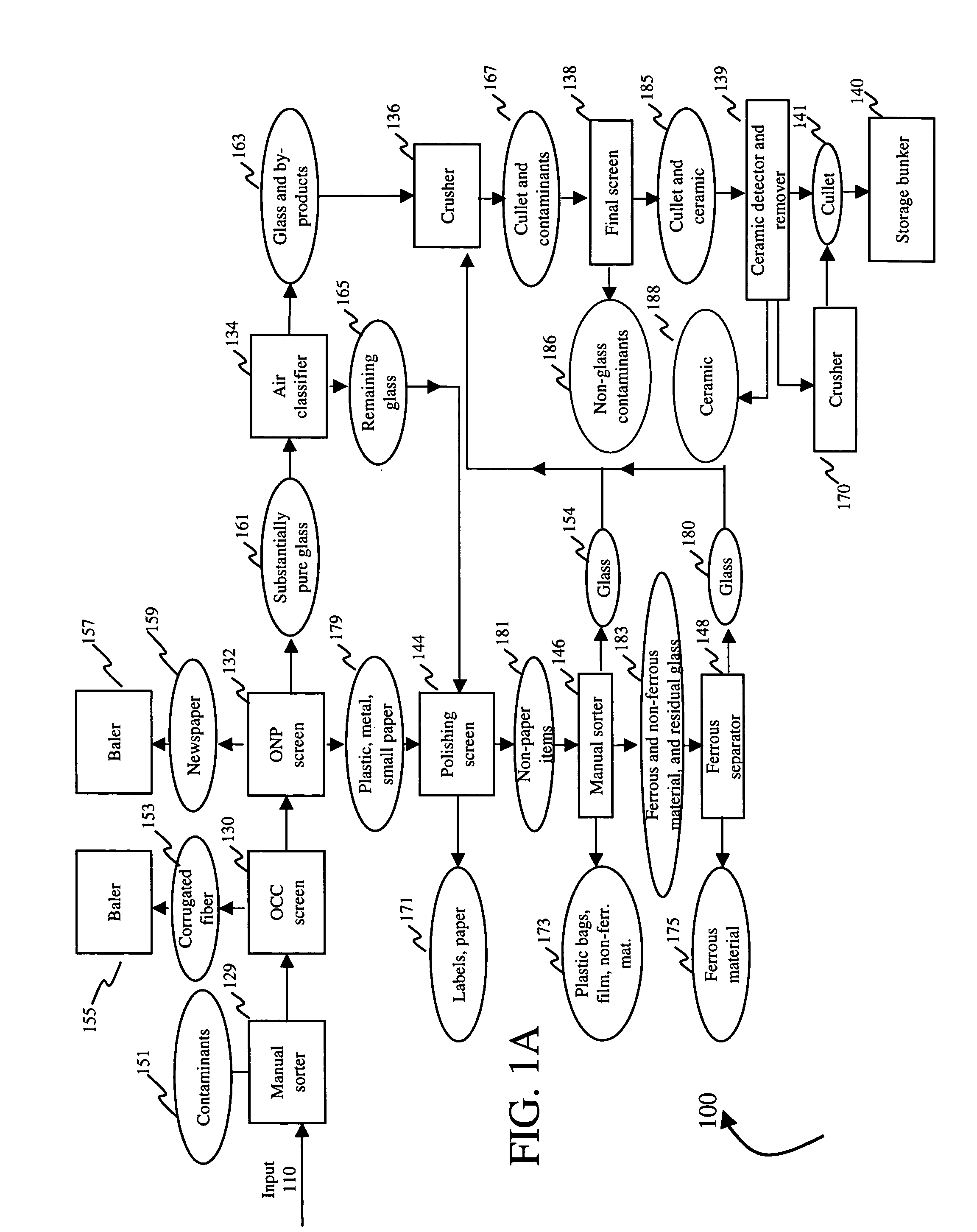

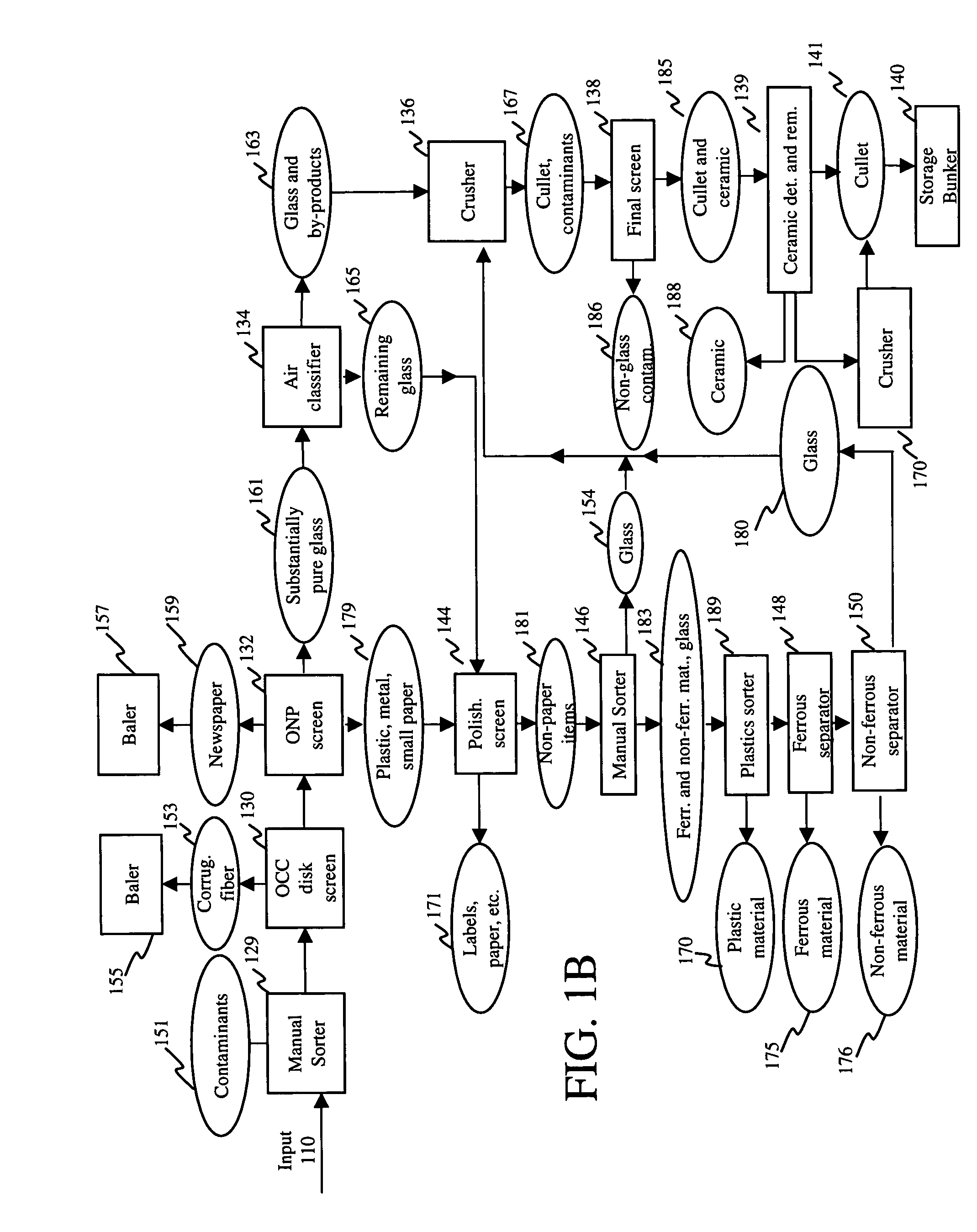

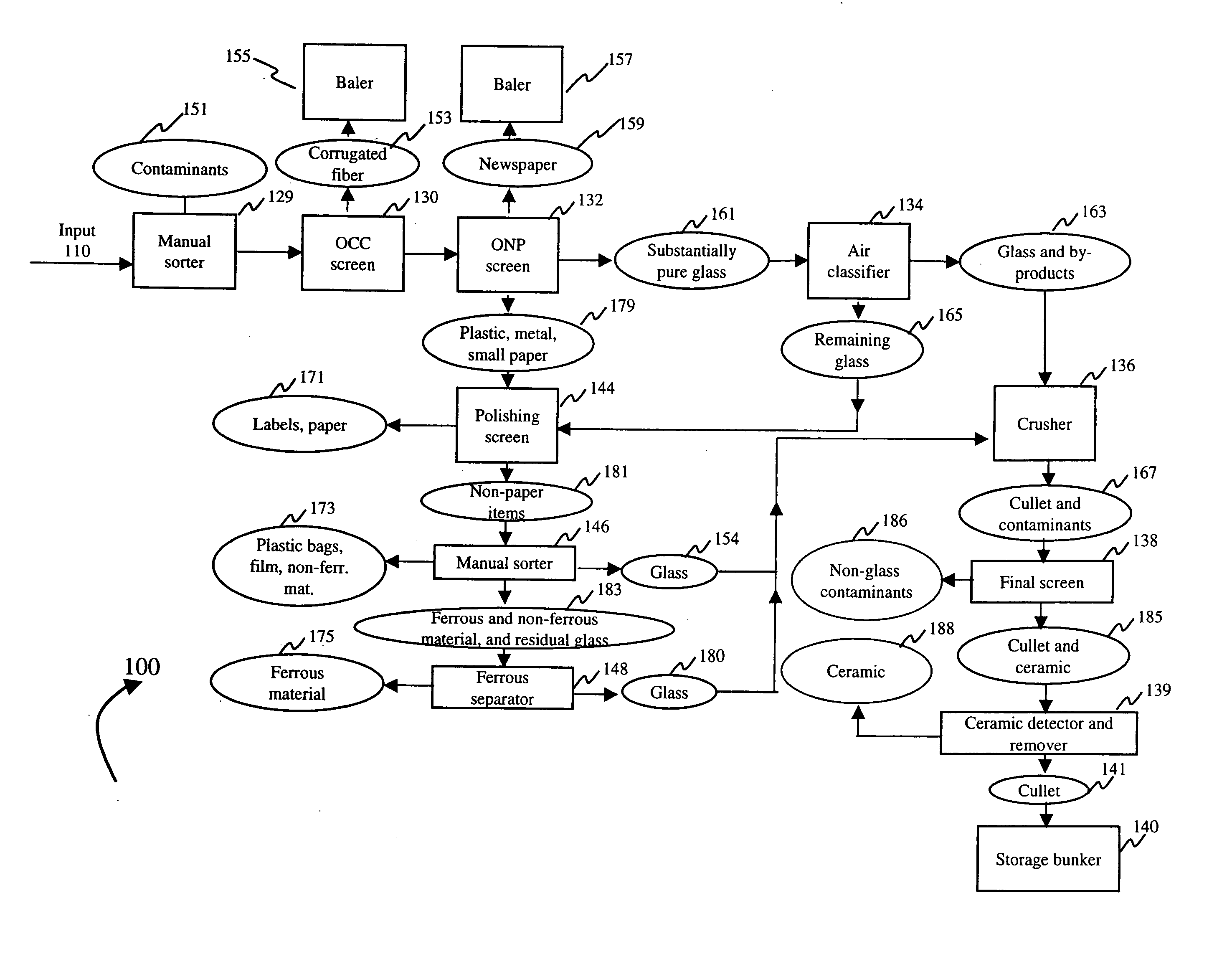

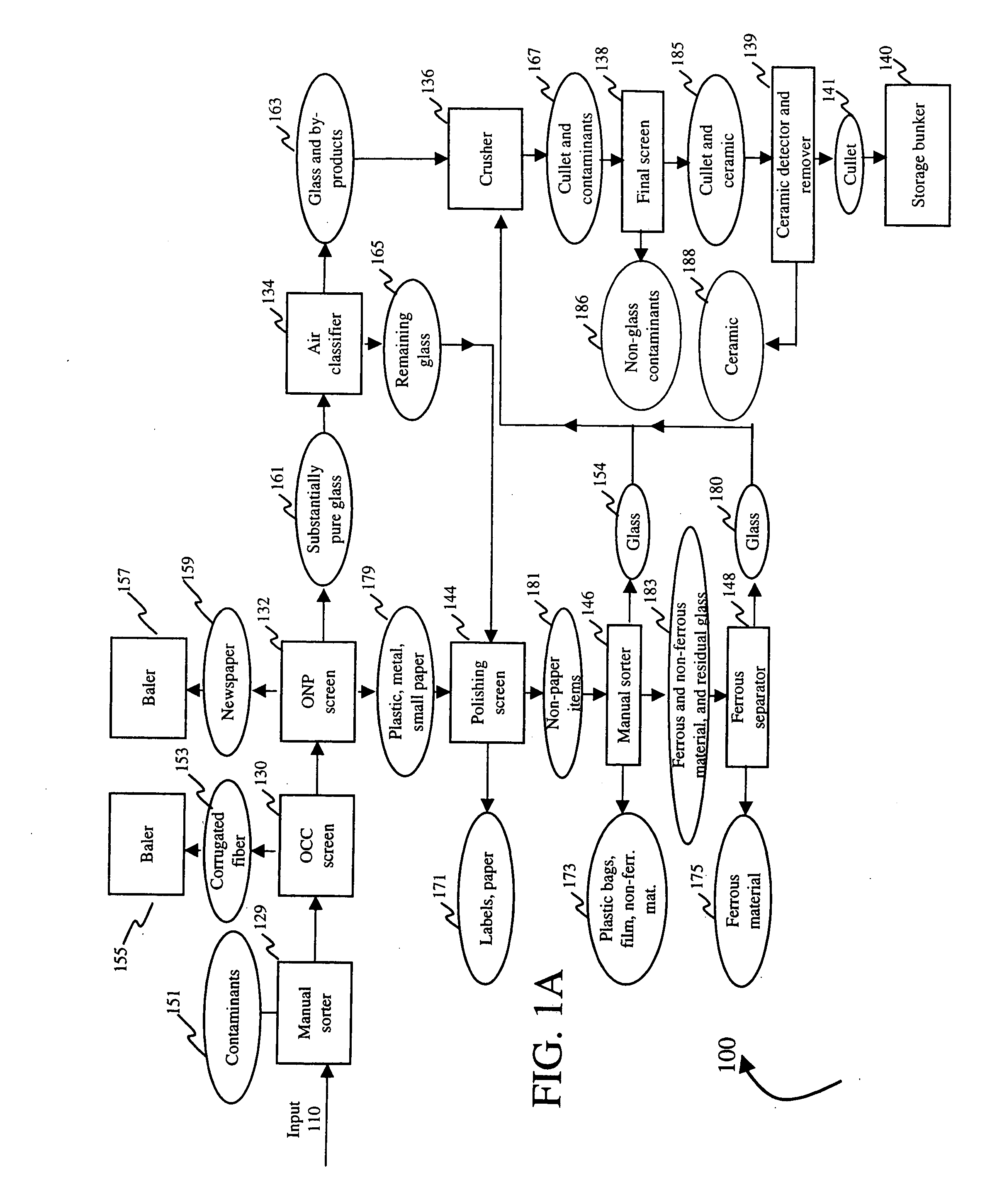

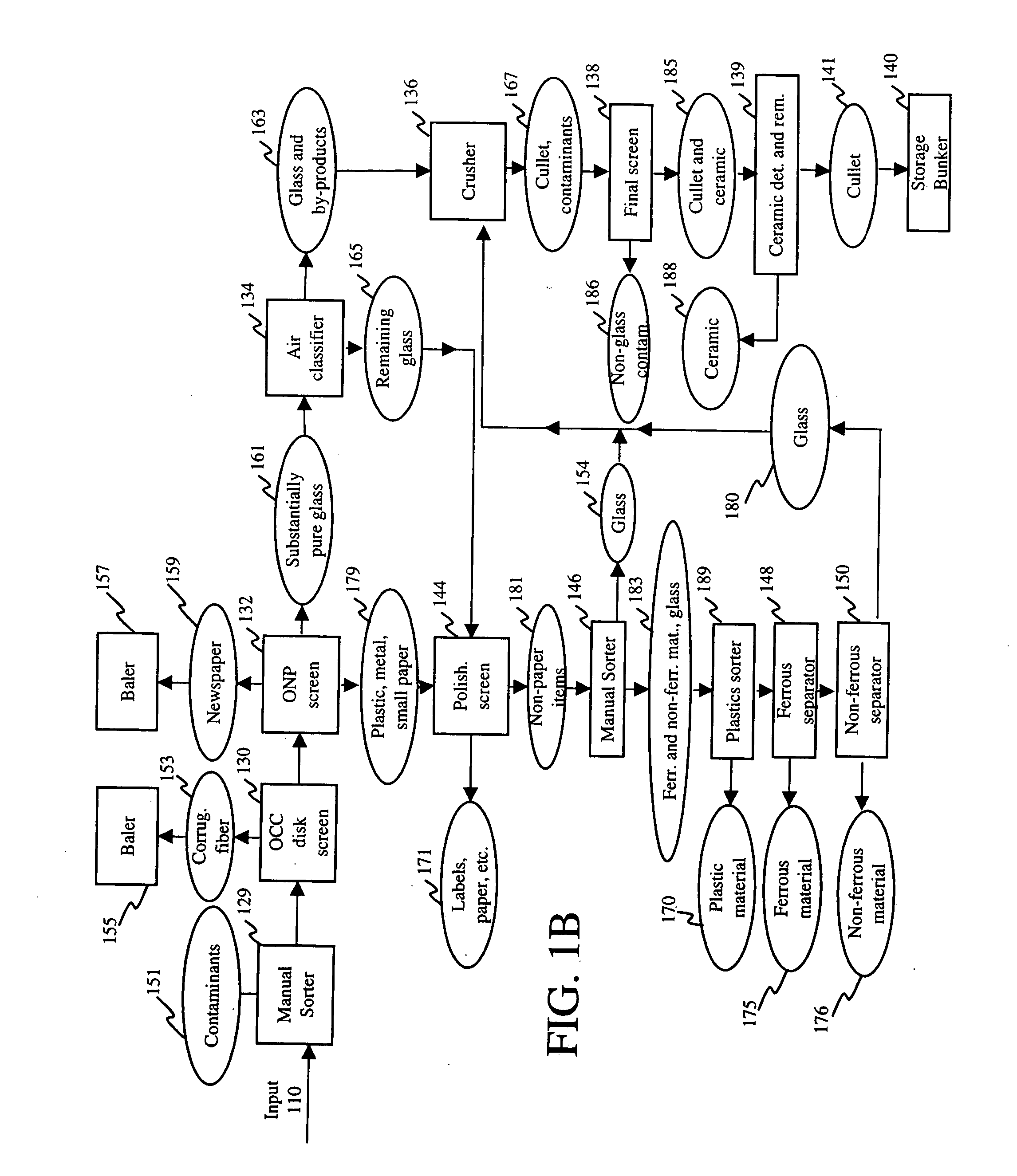

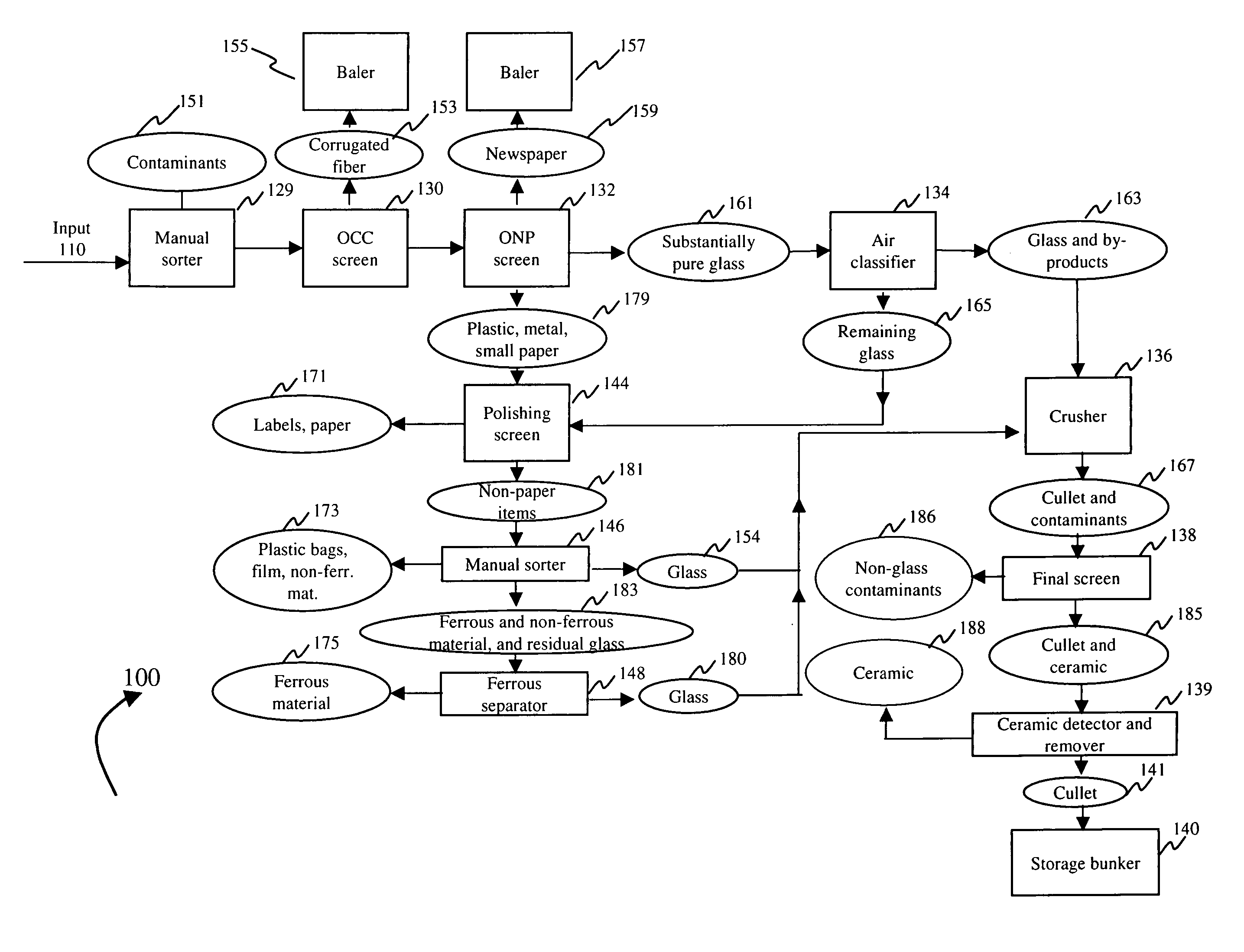

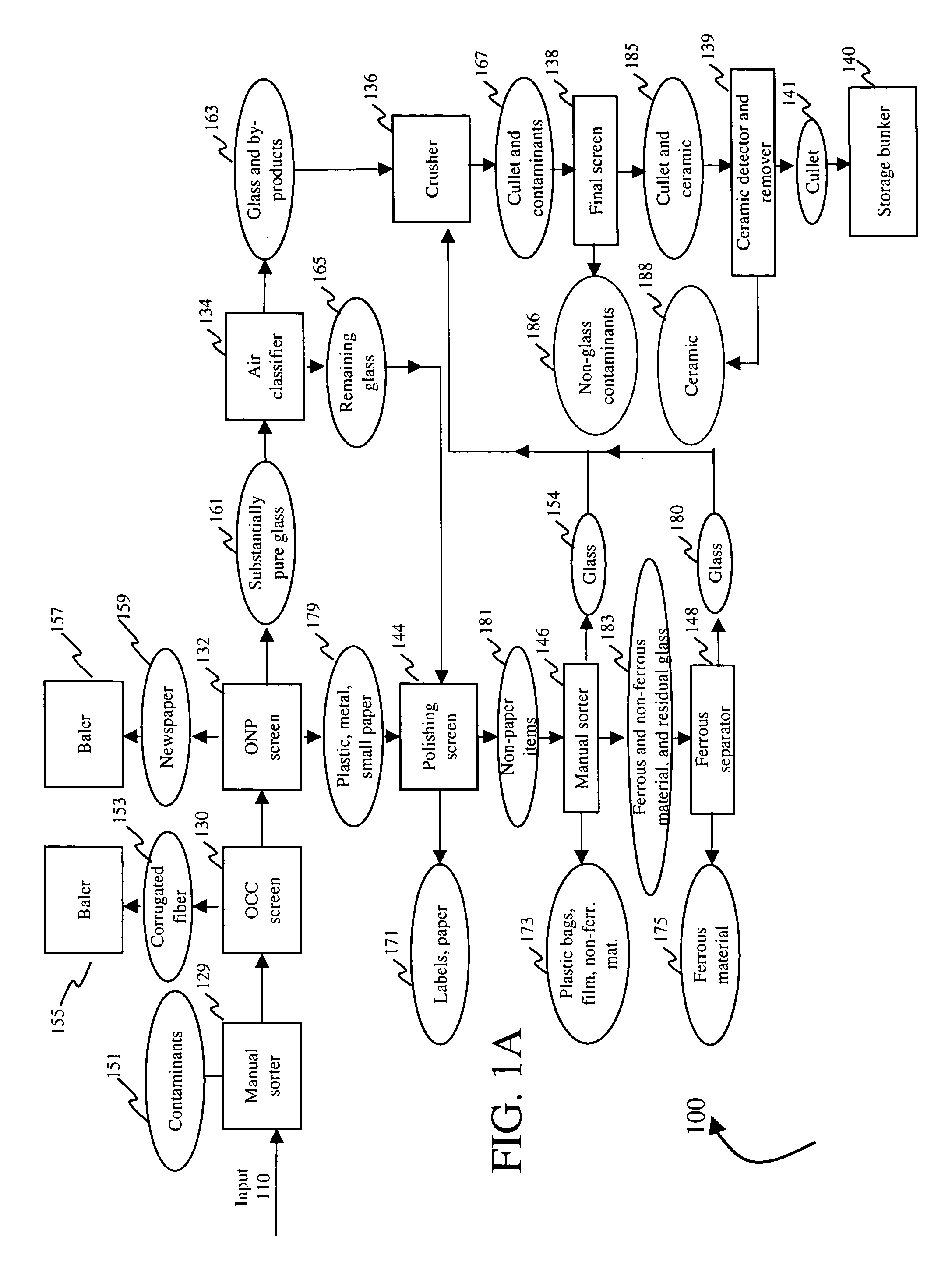

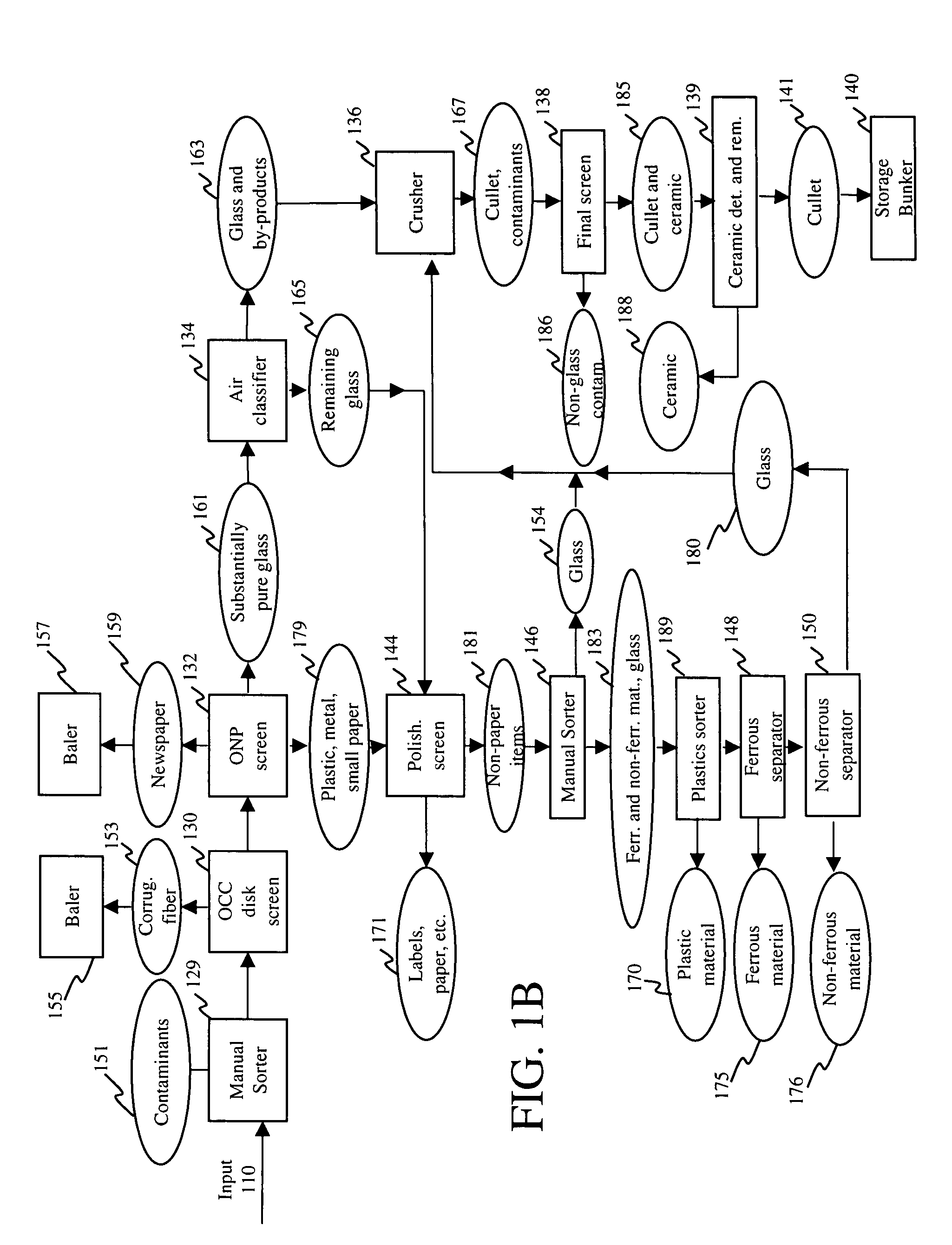

Systems and methods for sorting recyclables at a material recovery facility

InactiveUS20060254957A1Glass recyclingDigital data processing detailsProcess engineeringAir classifier

Owner:RE COMMUNITY HLDG II INC

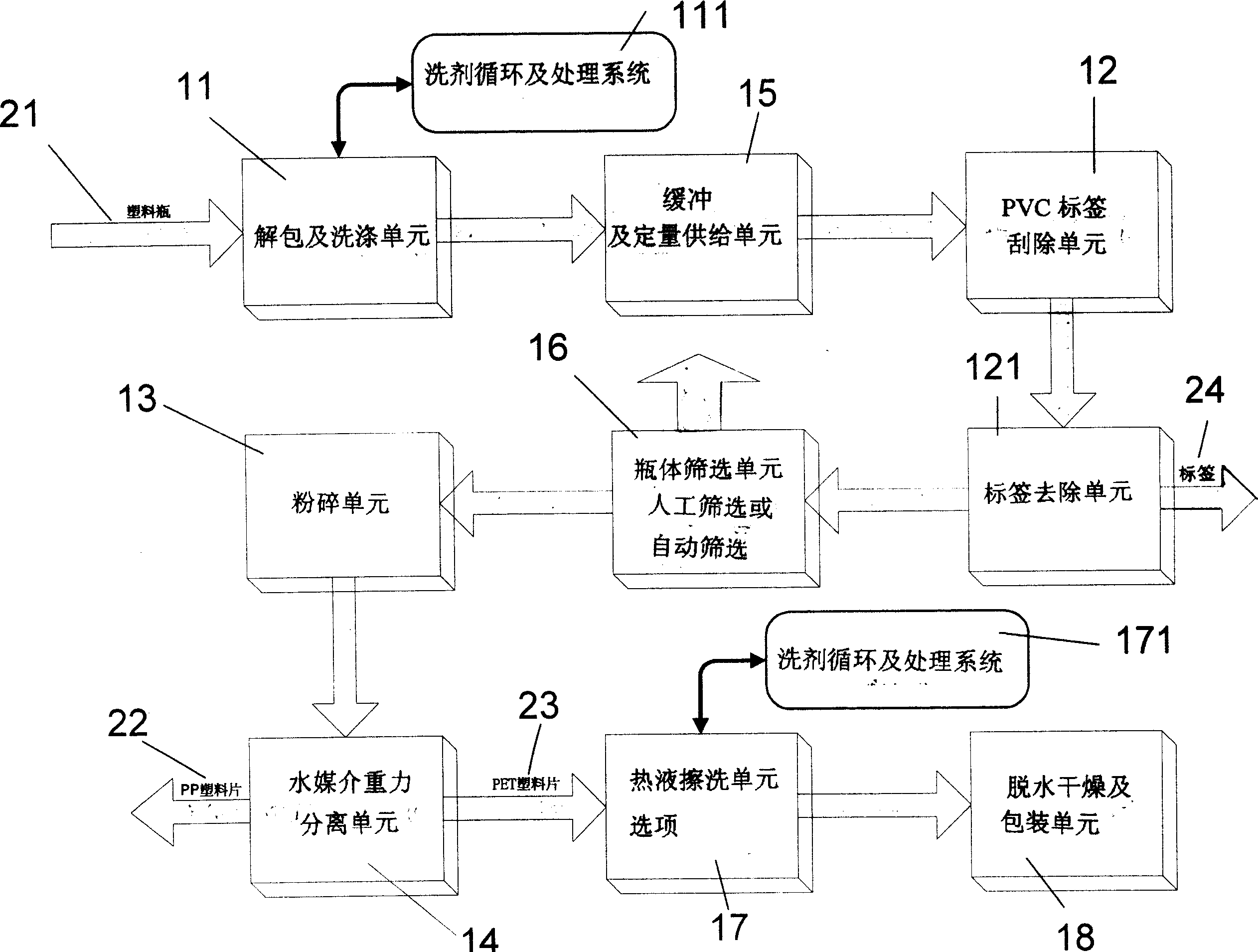

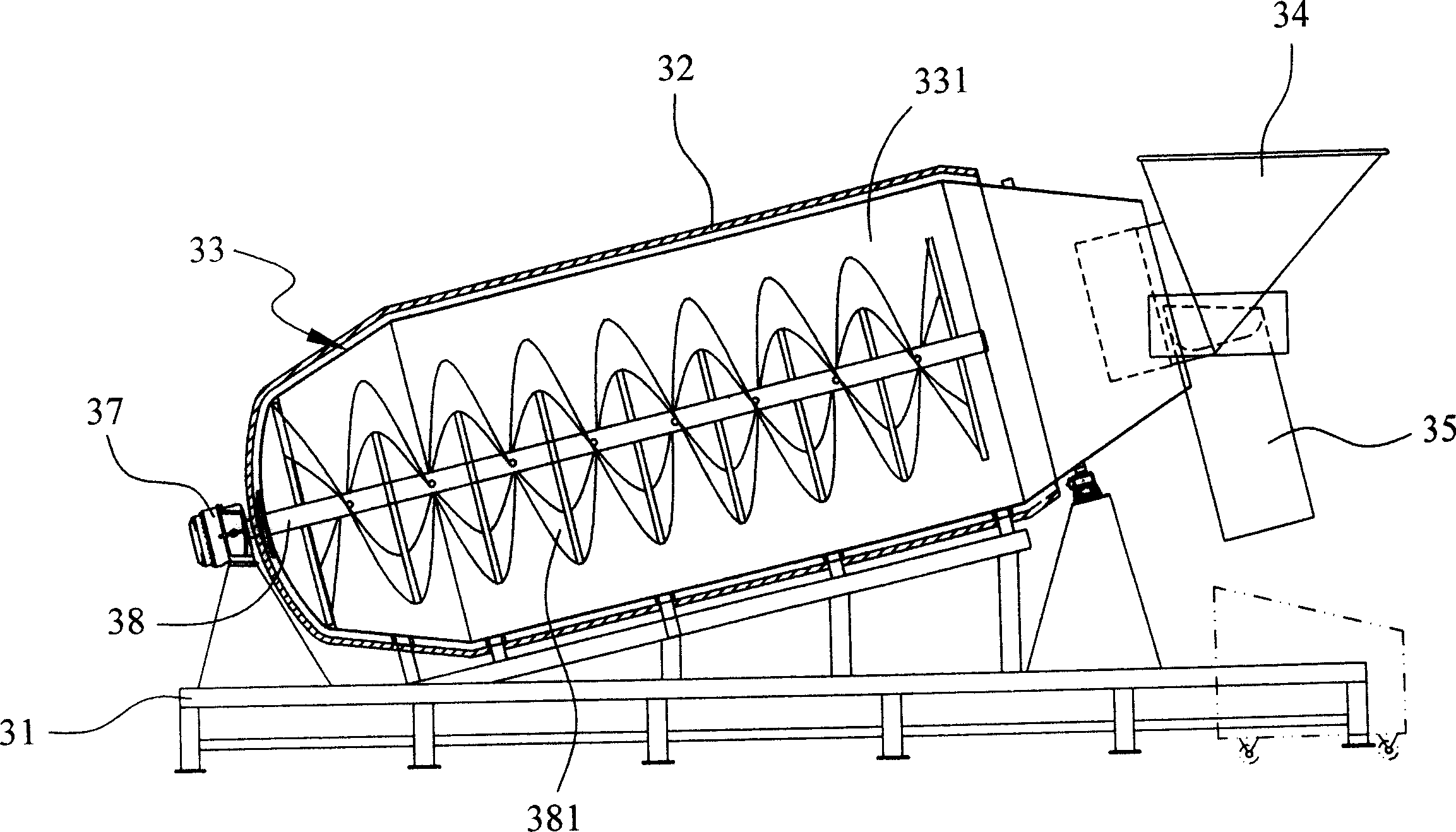

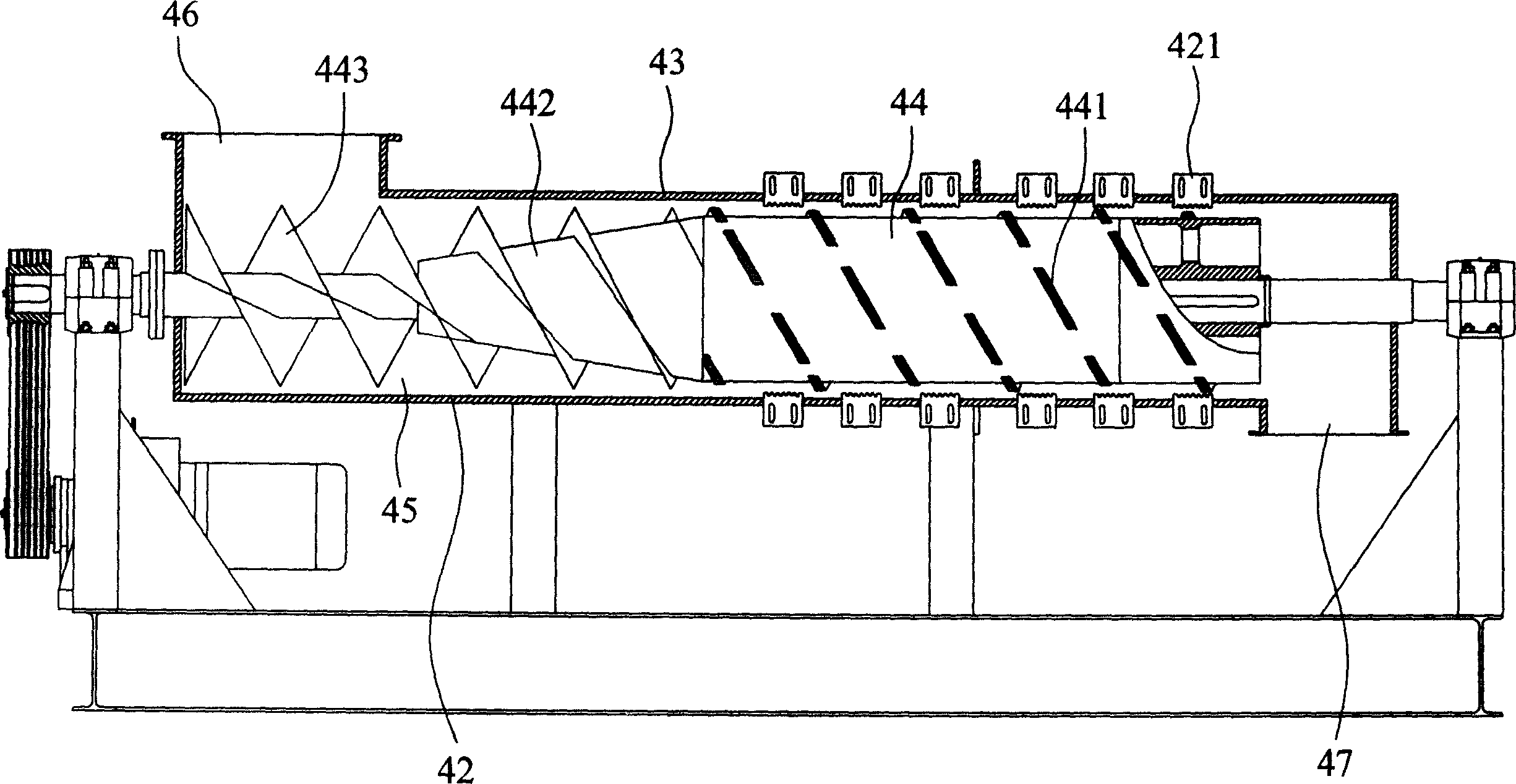

Plastic bottle reclaim treatment system

InactiveCN1765602ASimple structureEasy to operateSolid waste disposalPlastic recyclingEngineeringGravity separation

The invention relates to a plastic-bottle recovery processing system, belonging to the waste recovery system. The invention comprises: an open-washing unit; a PVC label-removing unit connected with open-washing unit; a crush unit connected to the PVC label-removing unit; and a water-medium gravitational separation unit connected to the crush unit. The invention has simple structure, easy operation, lower labor, automation recovery, and better benefits.

Owner:CITY RECYCLING

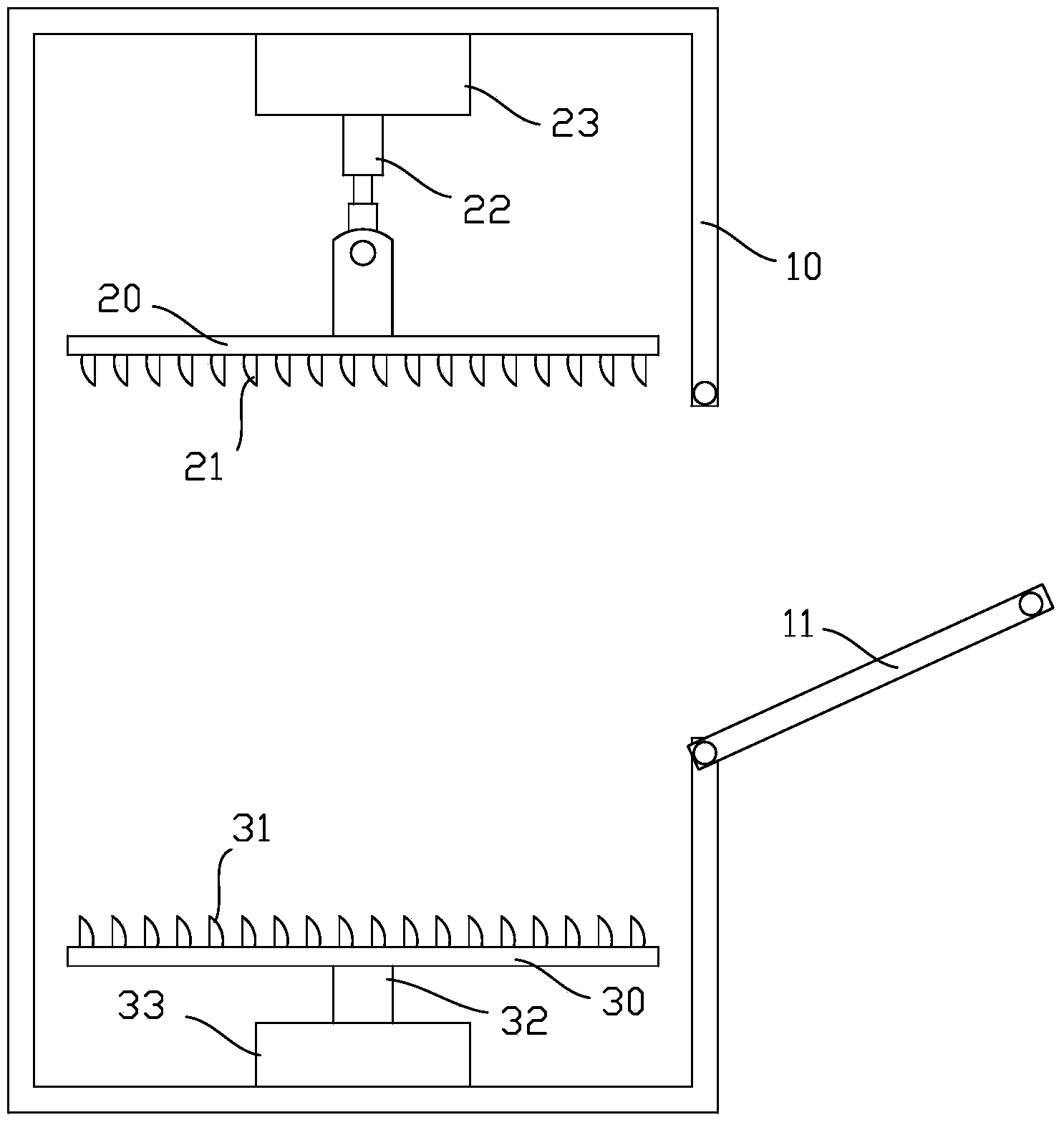

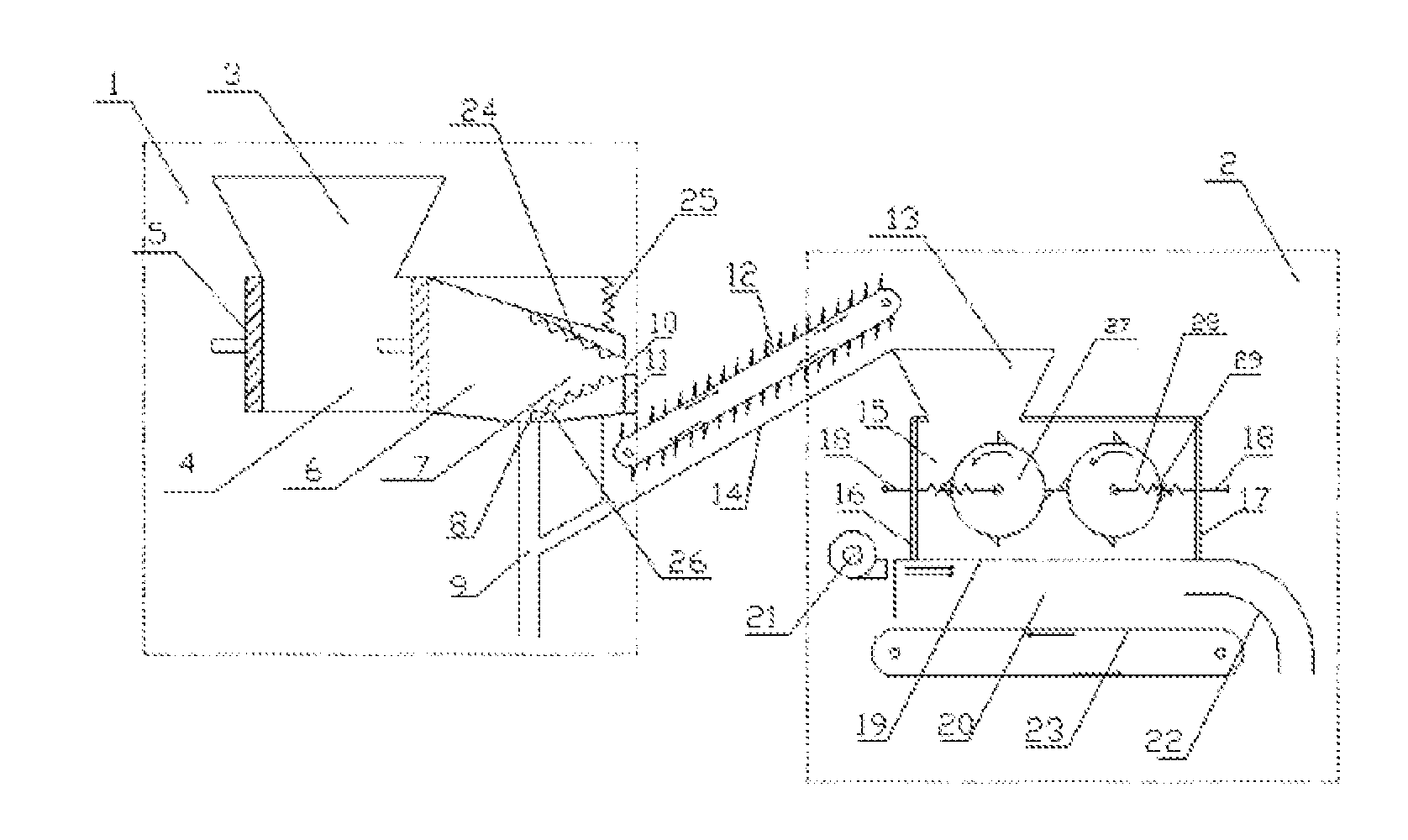

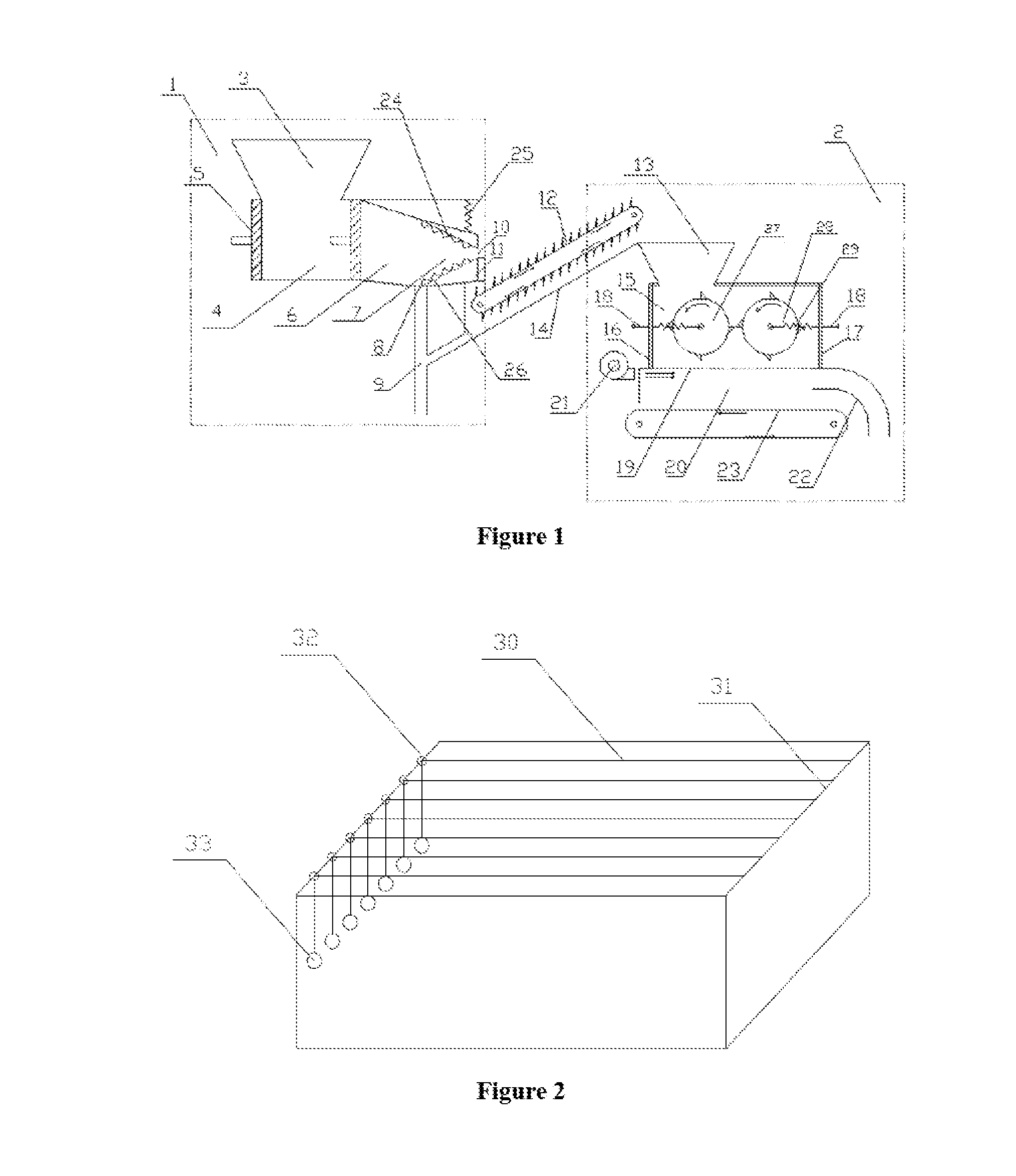

Waste and old mixed plastic recovery and separation device and method

ActiveCN103934923AEffective classificationRealize resource utilizationPlastic recyclingMechanical material recoveryPlastic forming machineMolten state

The invention discloses a waste and old mixed plastic recovery and separation device and method, and belongs to the field of resource recycling of waste and old mixed plastic. The waste and old mixed plastic recovery and separation device comprises a crushing device and a melting, sorting and recovering device, wherein a material feeding mechanism, a crushing mechanism and a material discharging mechanism are arranged in a crushing box body of the crushing device; a heating device, a screening mechanism and a plastic molding mechanism are arranged in a melting box body of the melting, sorting and recovering device; the heating mechanism is used for heating crushed granular materials to a molten state in a staged way; the screening mechanism is used for separating the materials in the molten state and un-melted granular materials; the plastic molding mechanism is placed on the bottom of the melting box body and recycling the separated materials in the molten state. The recovery and separation device can effectively classify the waste and old plastic generated in daily life and industrial production; different plastics are separated and are made into a single plastic which is relatively pure, so that the resource utilization of the waste and old plastic is realized; the post-processing process is omitted; energy resources are saved; the operation is simple; the automation degree is high; the sorting degree is high; the sorting range is wide.

Owner:ANHUI UNIV OF SCI & TECH

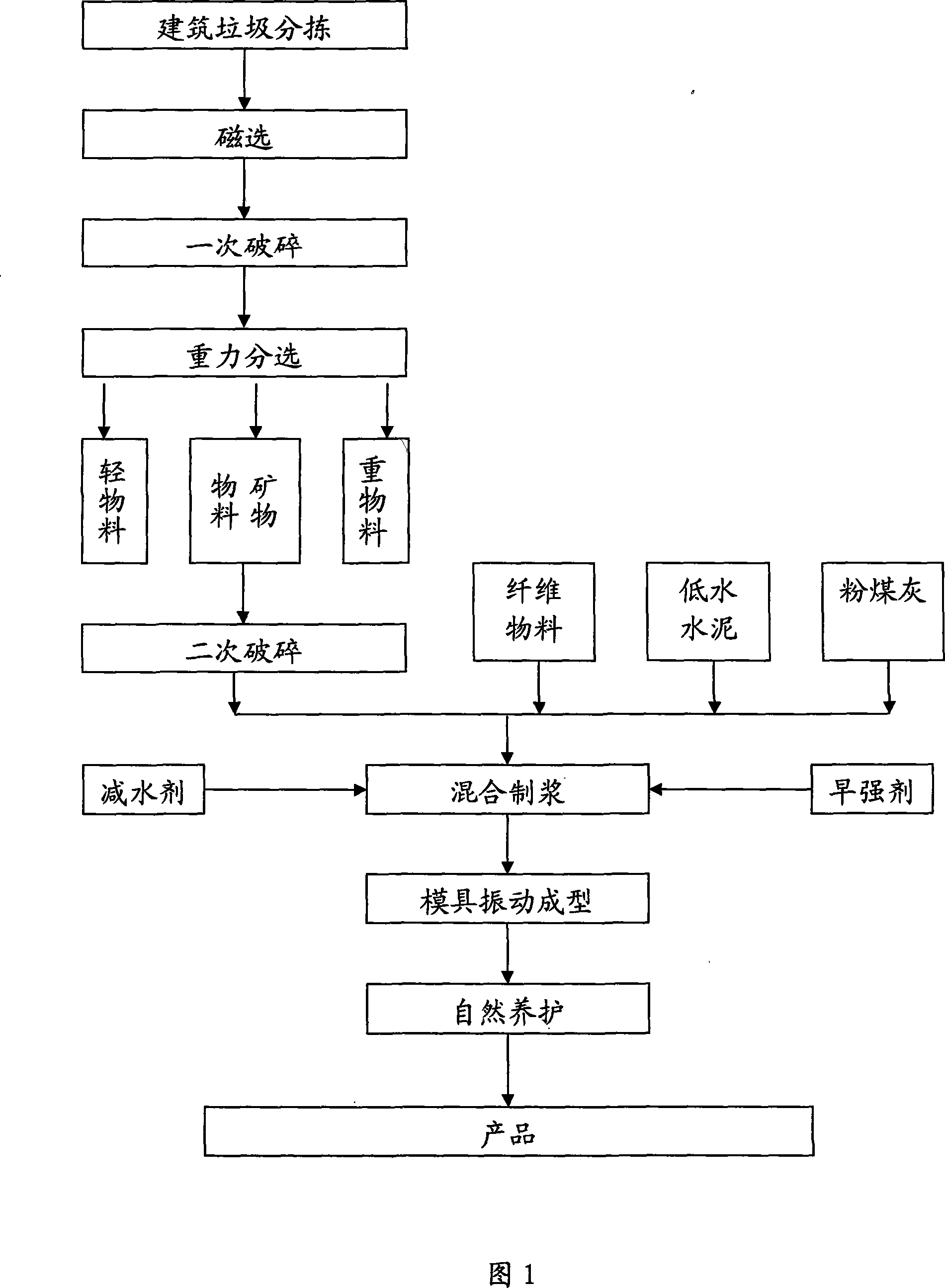

Method for manufacturing building material from building garbage

InactiveCN101239804AReduce final emissionsReduce dosageConstruction waste recoveryTransportation and packagingFiberBrick

The present invention relates to a method for manufacturing the building material with the building garbage, the method executes sorting, magnetic separation, primary crushing and gravity sorting to the city building material, and the building material is separated to heavy material, light material and mineral material, the mineral material is used for manufacturing the building material after the secondary crushing, and the raw material of the building material comprises the following components: fiber material 5-10 parts, mineral material 40-60 parts, low-water cement 20-30 parts and other material 0-30 parts, the production process of the building material comprises the steps of mixing the fiber material, mineral material and other material to uniform, then adding the low-water cement for mixing to uniform, adding water and stirring to slurry, placing into the mold for jolt molding or extrusion molding, and forming the building used sheet material after natural curing. The method of the invention has the advantages of full utilization of the mineral material comprising the major component of the building garbage, saving the material resource, reducing the final discharging amount of the building garbage, and the method can be used for manufacturing the building materials such as hollow brick, hollow block, partition plate and the like.

Owner:BEIJING HENGYECUN S&T

Method And System For Recovering Metal From Processed Recycled Materials

InactiveUS20100005926A1Facilitates revenue recoveryReduce landfillGas current separationElectrostatic separationMetallic materialsCopper

Recovering metallic materials, such as copper, from waste materials. The A dynamic sensor measures the rate of change of current generated by metallic materials in the waste materials. Preprocessing and post processing of the waste materials may be completed to further concentrate the amount the metallic materials recovered from the waste.

Owner:VALERIO THOMAS A

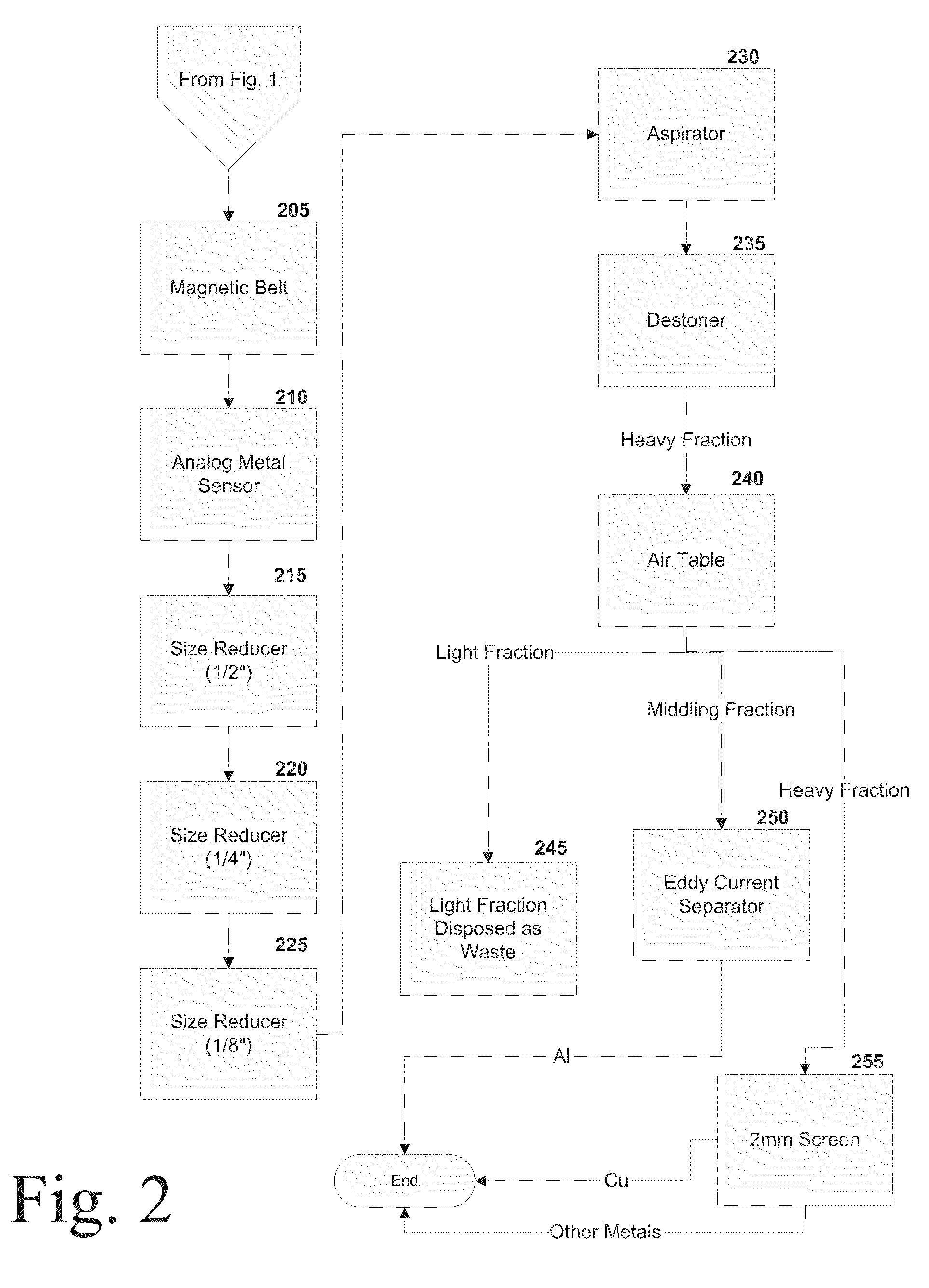

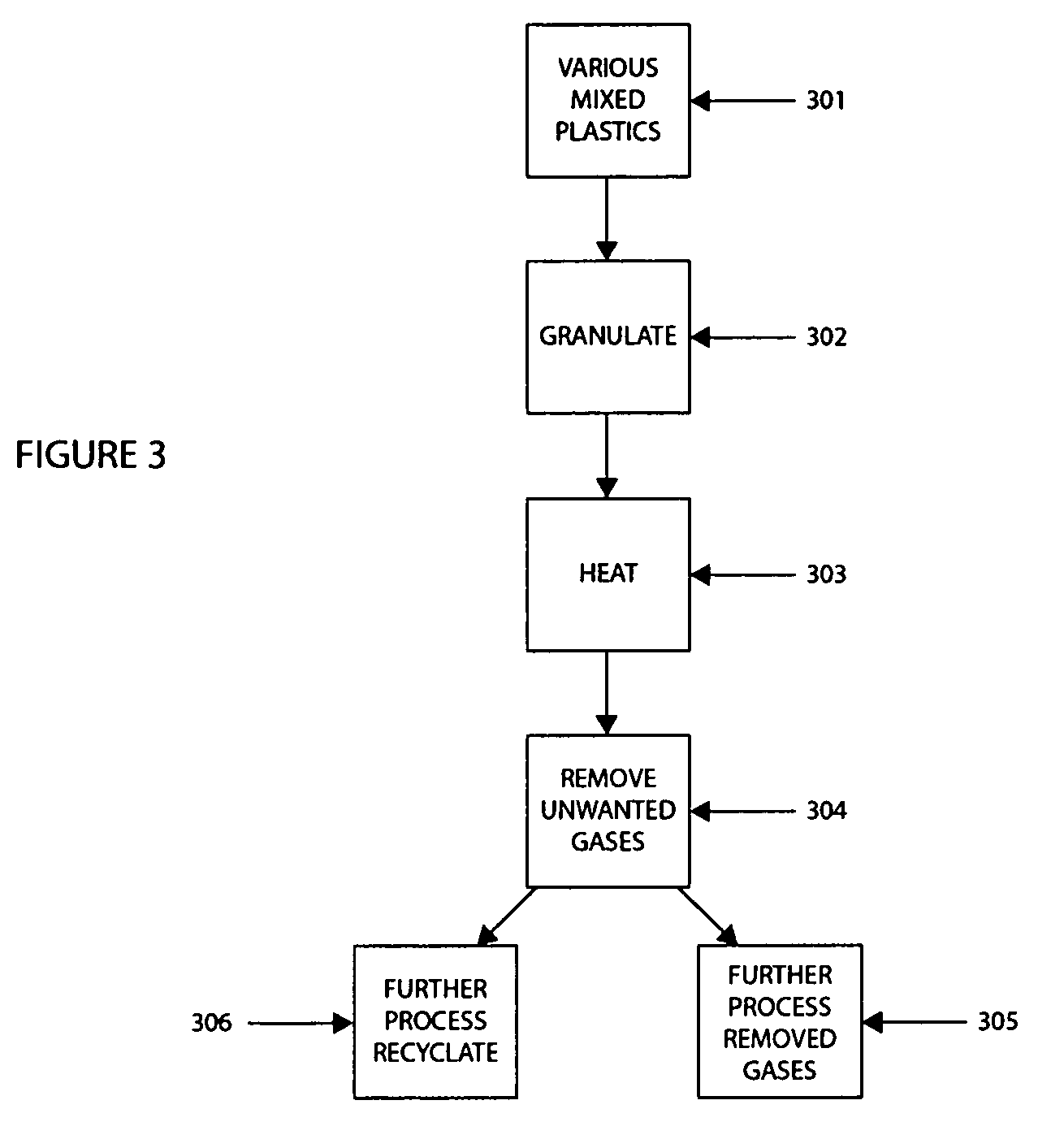

Method of recycling mixed streams of ewaste (WEEE)

The present invention relates to the recycling of waste electrical and electronic equipment (WEEE). Preferably, the present invention relates to the substantial recycling of all material forming the WEEE, thus providing substantially zero landfill. In yet another form, the invention relates to an additive and / or method of providing an additive. In still another form, the invention relates to recycling ink, toner, and / or PU foam from imaging consumables, forming part of the WEEE. In another form, the invention relates to the recycling of plastic materials containing flame retardants, including the recycling of plastics materials, such as plastics materials containing brominated flame retardants generally based on styrenics (e.g. PS, HIPS, ABS, PPO / PS, PPE / PS, ABS / PC) and polyamides (Nylon 6, nylon 6,6, nylon 12) and other engineering plastics such as polyacetal, polycarbonate, PET, PBT, liquid crystal polymers.

Owner:CLOSE THE LOOP TECH

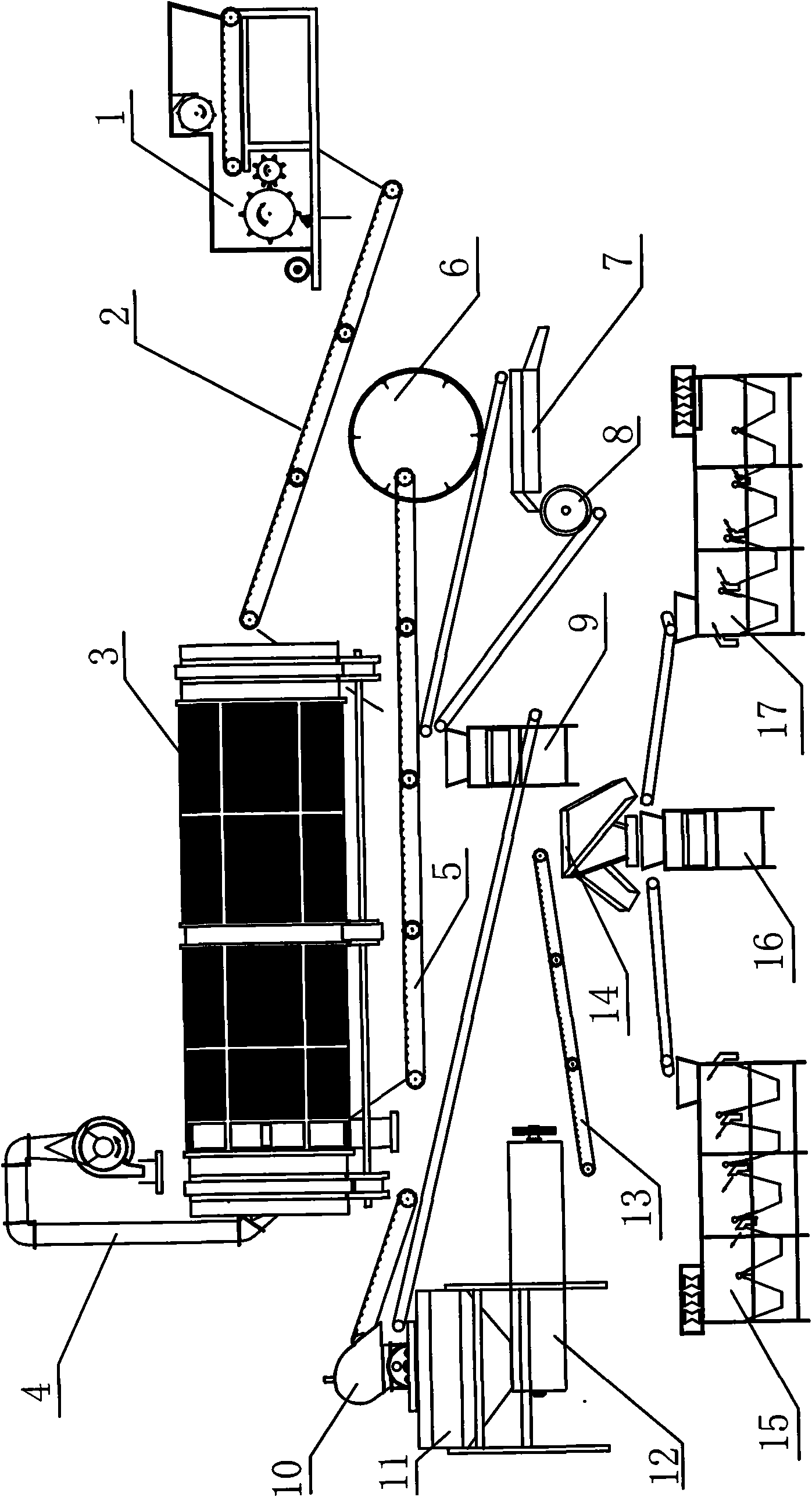

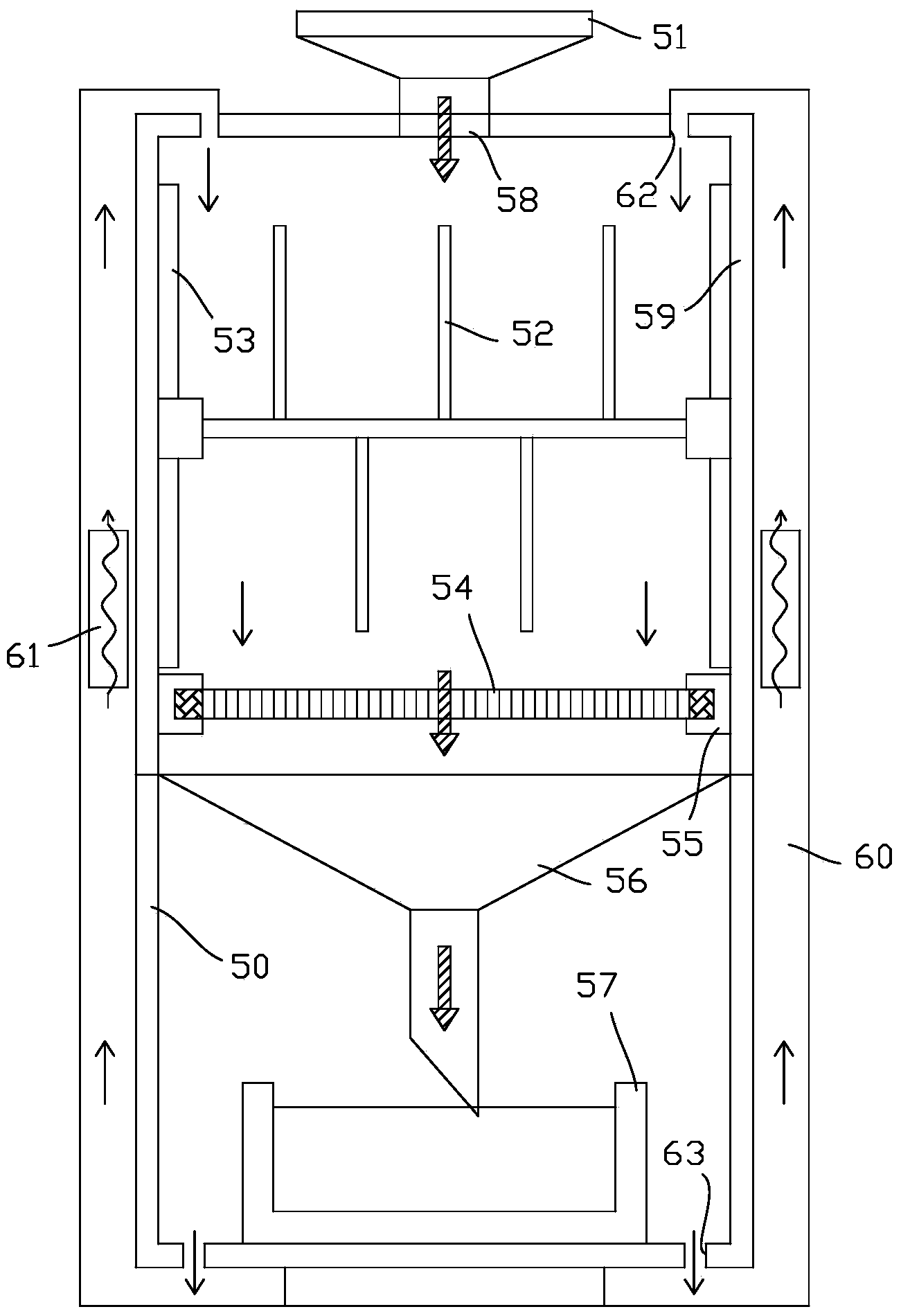

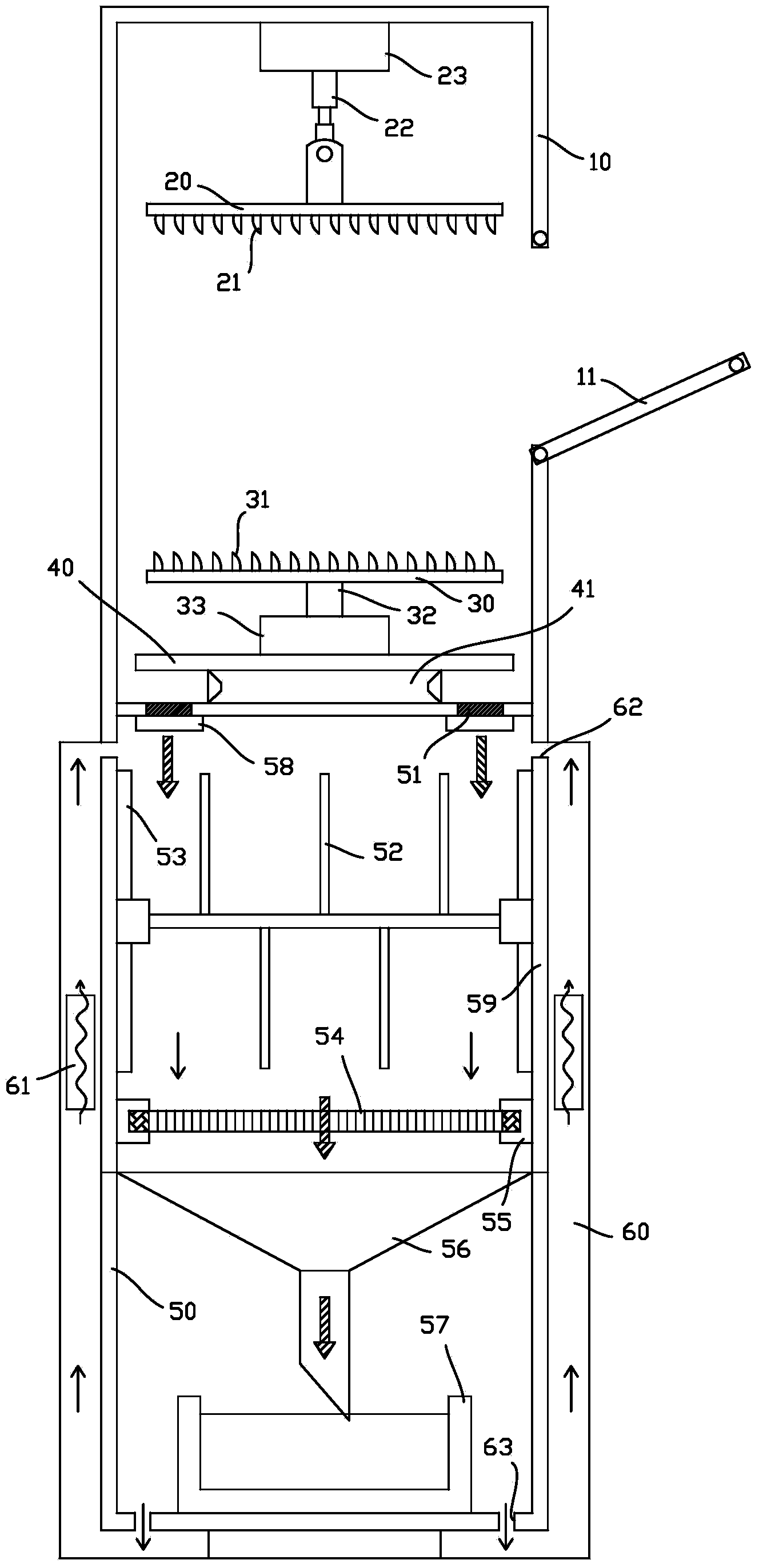

System for squeezing, smashing and winnowing municipal solid waste

ActiveUS20160250648A1Good effect in squeezingGood effect in smashingSievingGas current separationLitterCrusher

The invention discloses a system for squeezing, smashing and winnowing municipal solid waste (MSW). The system comprises a primary squeezing and smashing, device and a secondary smashing and winnowing device. The system of the invention has good effect m squeezing, smashing and winnowing, can greatly reduce the water content of MSW and efficiently separate the MSW into combustible matters and non-combustible matters, so as to facilitate further subsequent utilization of the municipal waste; moreover, an upper jaw of a jaw crusher is connected with a spring device, so that the squeezing pressure, smashing effect and processing capacity of the jaw crusher can be adjusted according to the amount of the MSW. In addition, the system of the invention is further provided with emergency brake switches, spring protection devices and a sieve, so as to ensure the stability and the reliability of the system.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

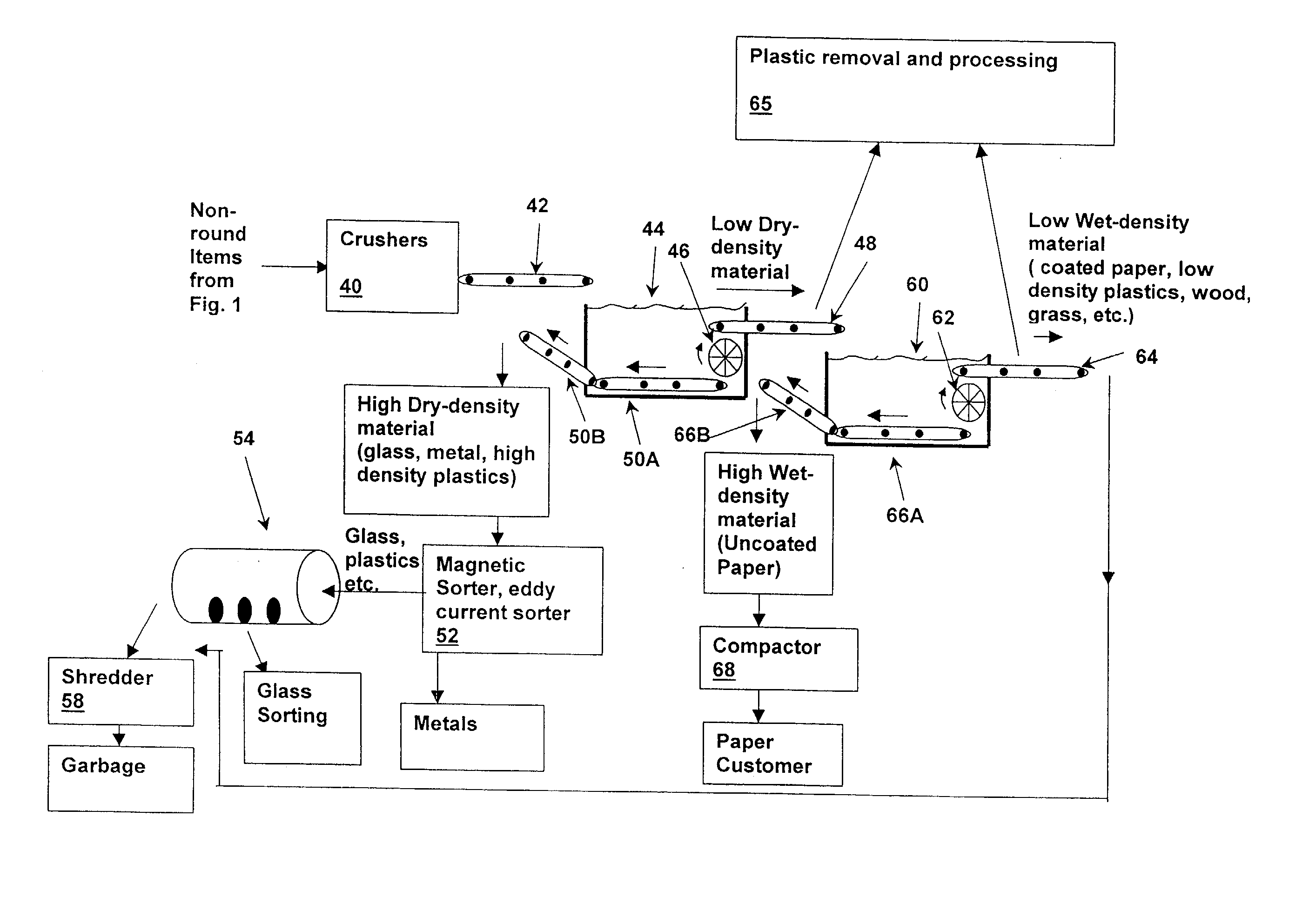

Method and system for separating and sorting recyclable materials from mixed waste streams

A method and system for separating and sorting recyclable materials from mixed waste streams provides improved separation and reduced cost in trash and recyclable material processing systems. A low surface-current bath is used within the sorting system to separate materials having a low wet-density, such as plastics and coated paper, from materials having a high wet-density, such as uncoated paper. A novel newspaper separation device using an appropriately-sized gap in a conveying system provides separation of newspaper from other large pieces of recyclable material or trash, while leaving heavier materials on the conveying system for further sorting. An improved plastics separator is included for separating plastics by melting-point range.

Owner:3R SYST L L C

Systems and methods for sorting recyclables at a material recovery facility

Systems and methods for providing a quantity of cullet having at least two colors of glass from an input stream of recyclable material and non-recyclable material. In an embodiment, the system includes a sortation station, a screening apparatus, an air classifier, and a crushing apparatus to provide as output substantially pure cullet having at least two colors.

Owner:RE COMMUNITY HLDG II INC

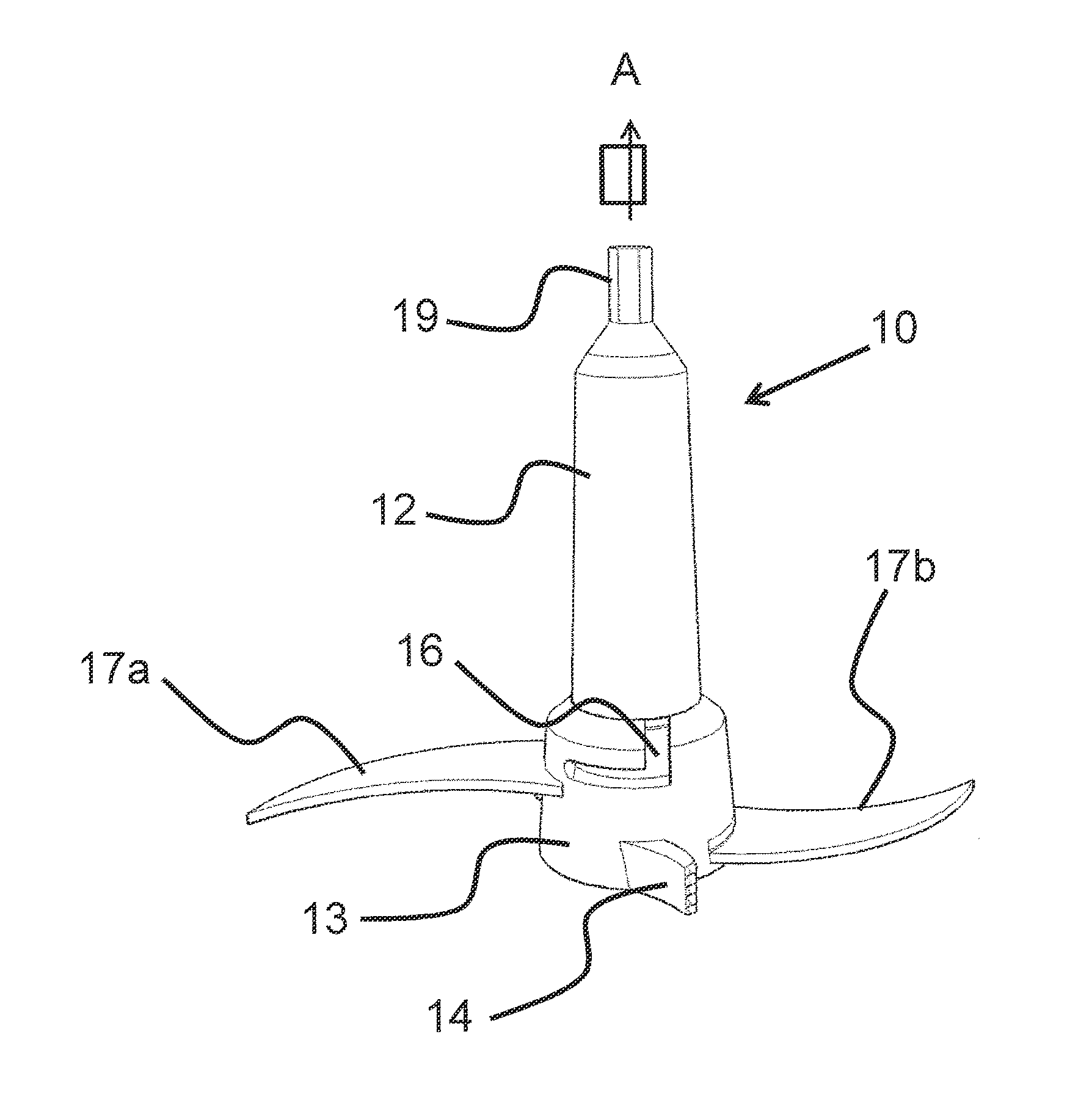

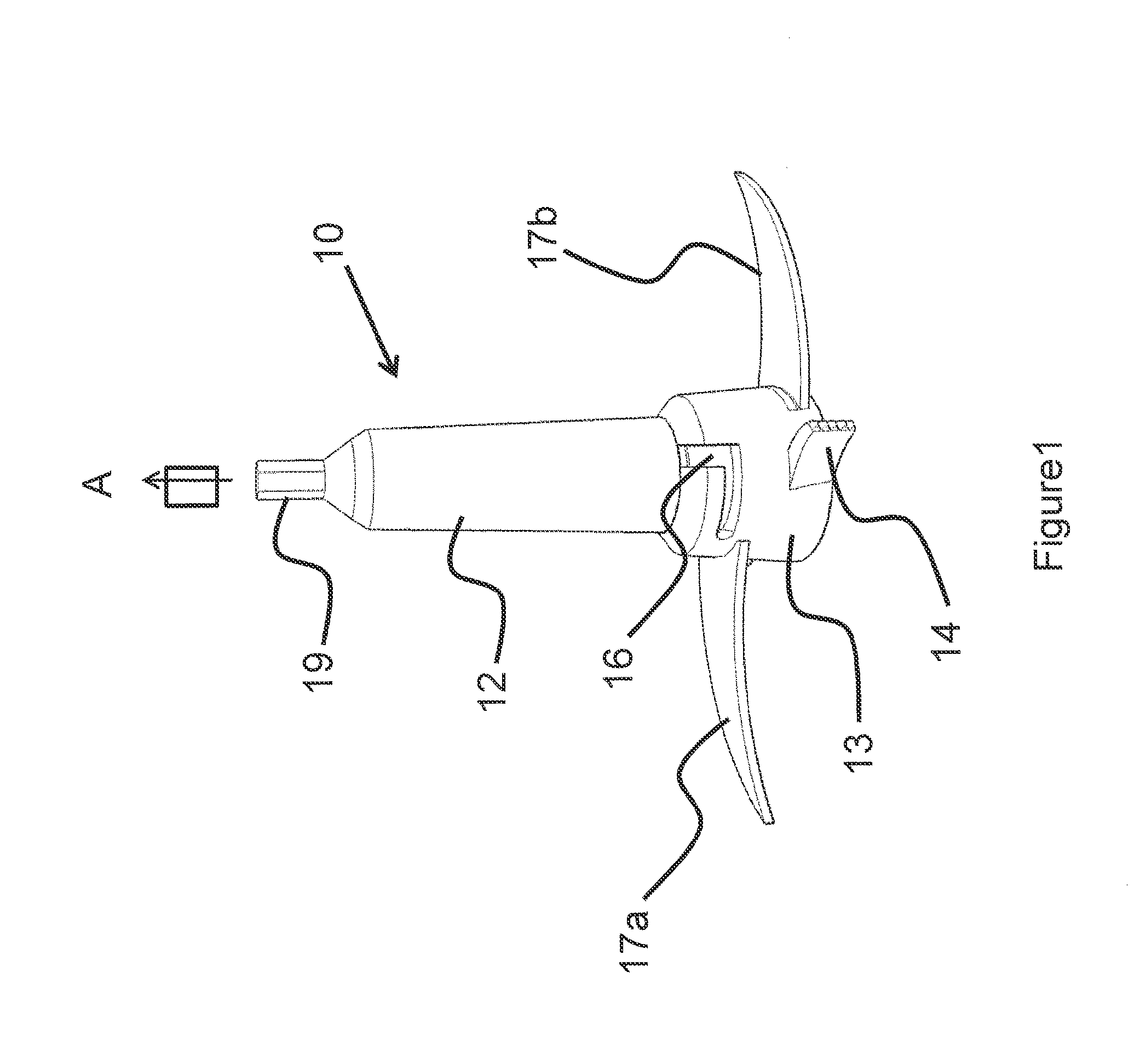

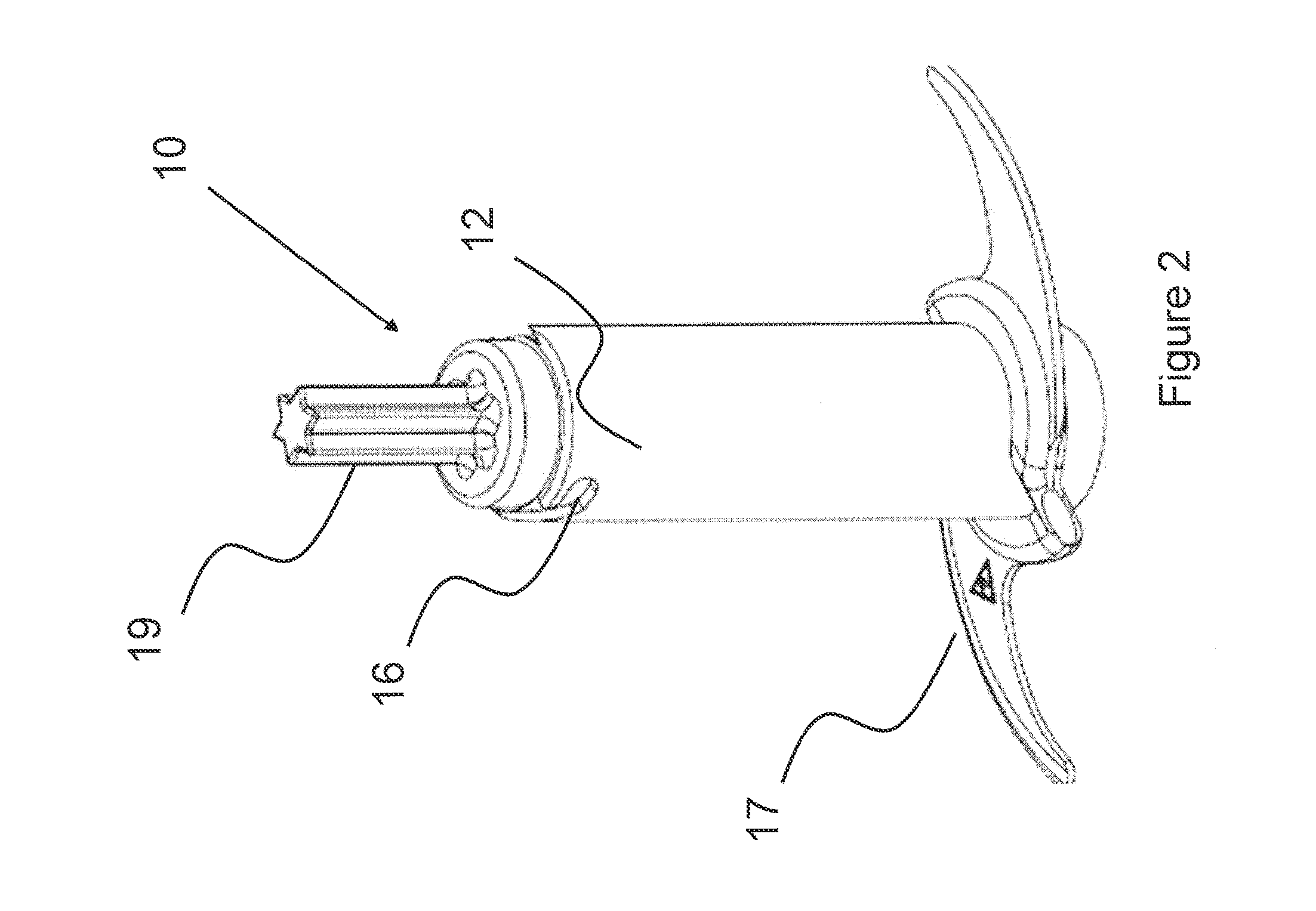

Universal blades and accessories for food processors

ActiveUS20120091245A1Promote sheddingBig liftSolid waste disposalKitchen equipmentEngineeringFood processing

Food processing utensil comprising: paddles, central utensil comprising: shaft coupleable to food processor motor, and connected to base coupleable to food processor bowl, and cutting blades, the paddles coupled to the central utensil and the blades configured to allow uniform cutting of food, providing paddles are not on blades.

Owner:MENASHES DAVID

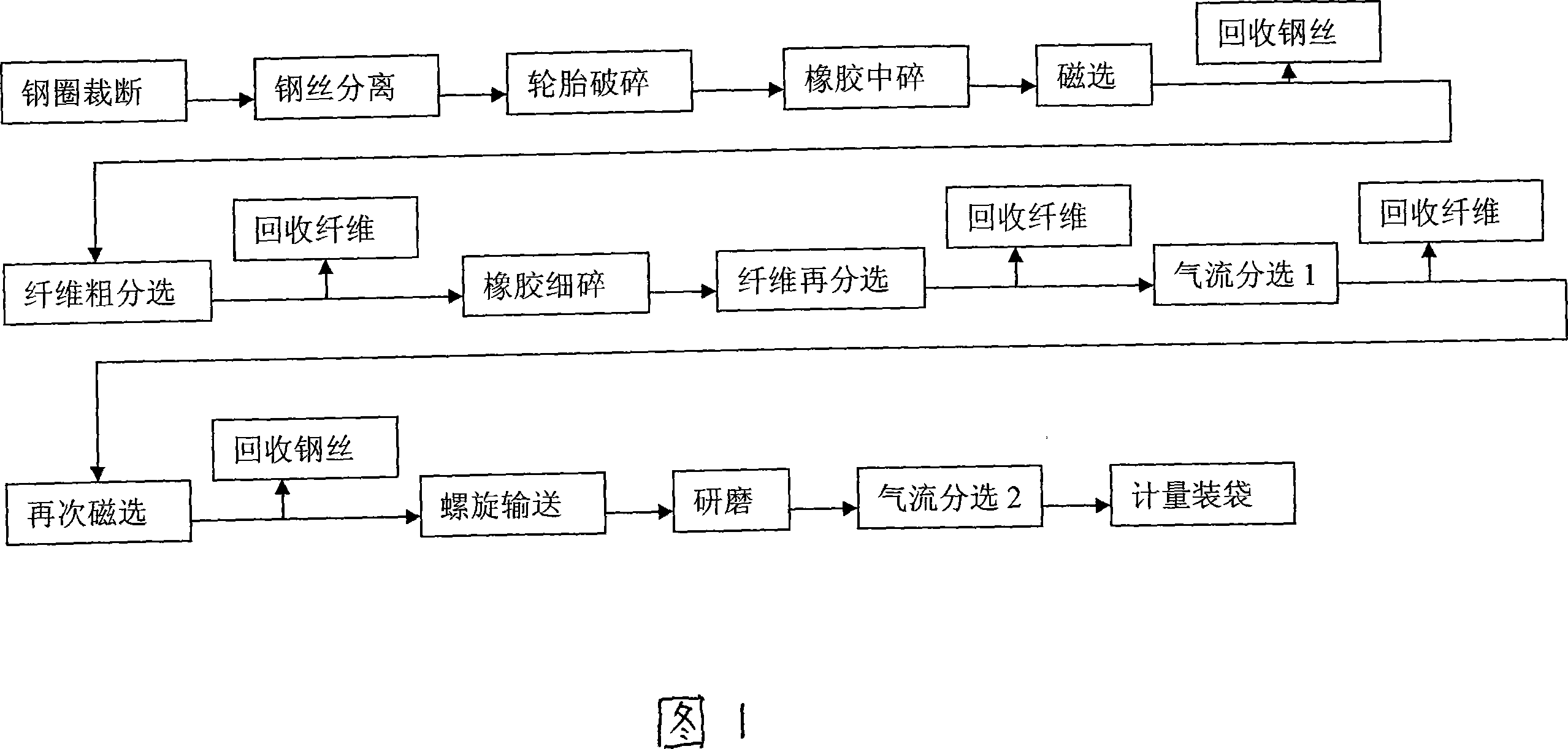

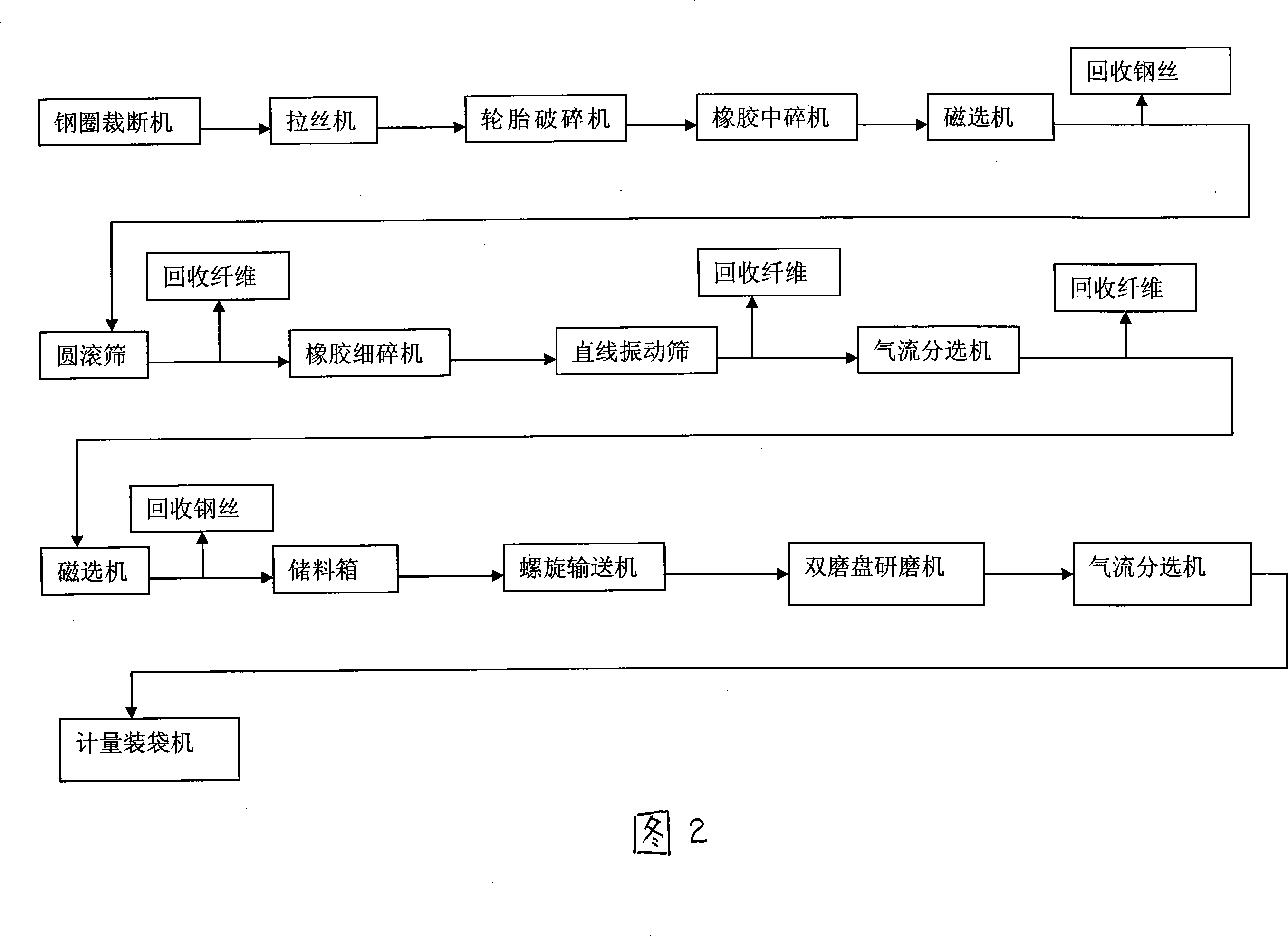

Method for crushing producing fineness rubber powder under normal temperature

InactiveCN101234517ACompact structureEasy to install and maintainSievingGas current separationProduction lineLow noise

The invention relates to a method for producing fine rubber powder by grinding under normal temperature, which adopts the following processes: trimming of steel rings, separation of steel wires, crushing of tires, grinding in the rubber, magnetic selection and separation, rough selection of fibers, finely grinding of the rubber, reselection of the fibers, magnetic reselection, spiral transportation, grinding and airflow selection. The industrial method initiates the precedent of the production of the fine rubber power in batch and the investment of equipment in a whole production line is a half investment of the traditional grinding method under the normal temperature while the investment of the equipment is one eighth of the investment of freezing grinding production line under low temperature. The industrial production line has the advantages of compact structure, convenient arrangement and maintenance of the equipment, long service, life, high rate of rubber output, low power consumption and low noise. Compared with rubber powder index of the freezing grinding production method under the low temperature, each technical index excels current the advanced technology for producing the rubber powder by expansion cooling of air turbines.

Owner:邓裕潮

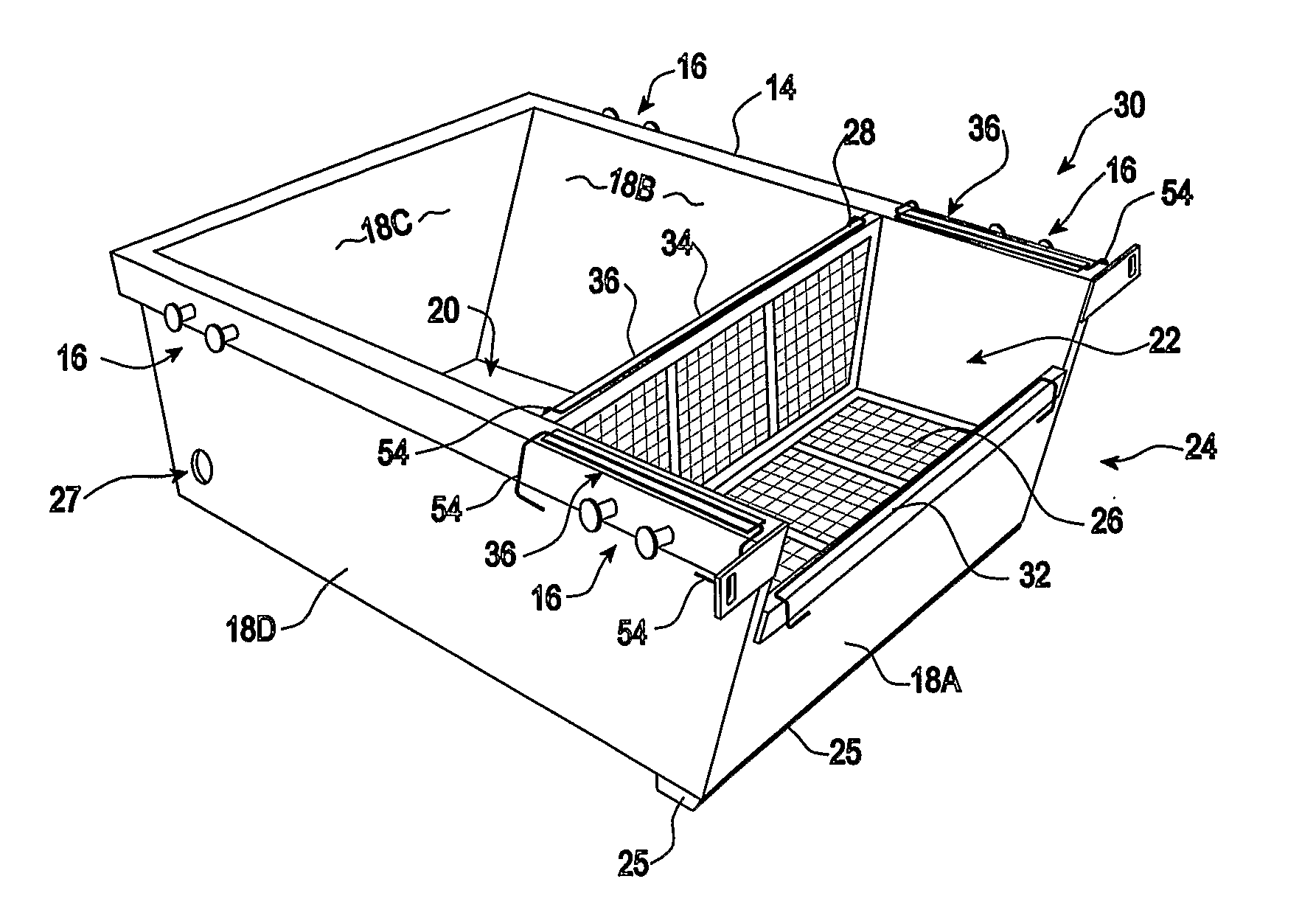

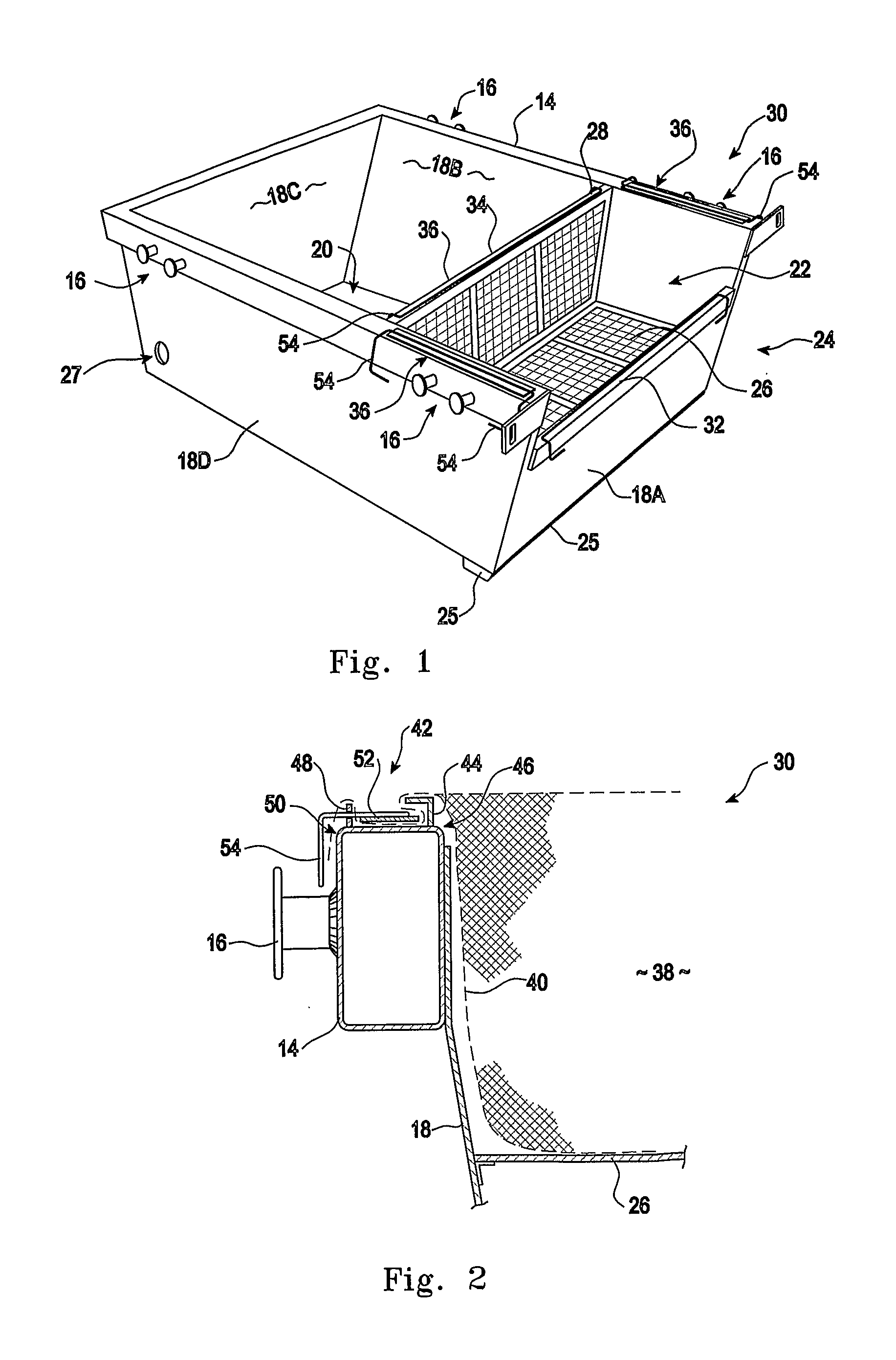

Waste bin

A slurry handling and disposal system is provided for waste slurry and particulates. The system includes a waste bin provided with support structures for retaining a flexible removable filter element with a filter element supported above a floor of the waste bin. The particulate matter component of a volume of the waste slurry and particulates deposited in the filter element is retained in said filter element while the liquid component of the waste slurry and particulates are collected in a base portion of the waste bin.

Owner:WESTON OWEN CHARLES

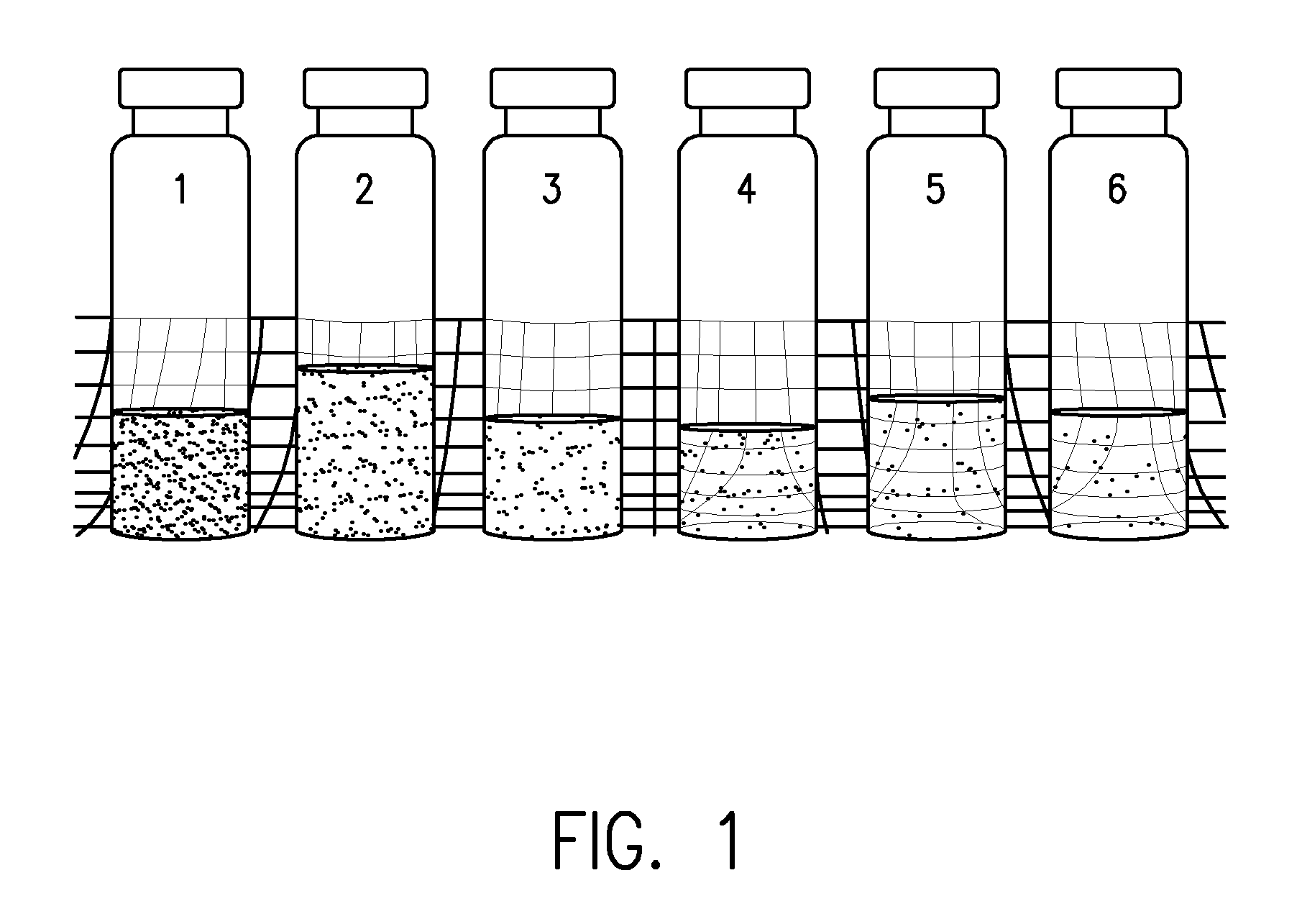

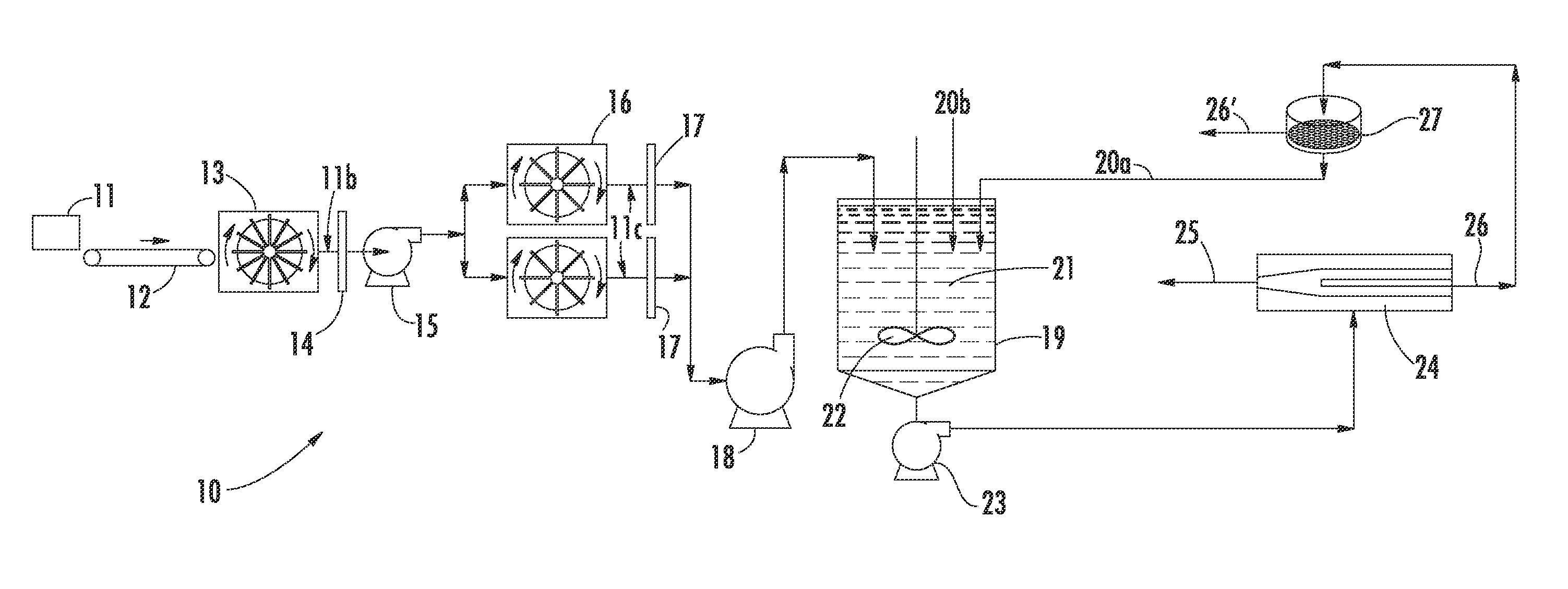

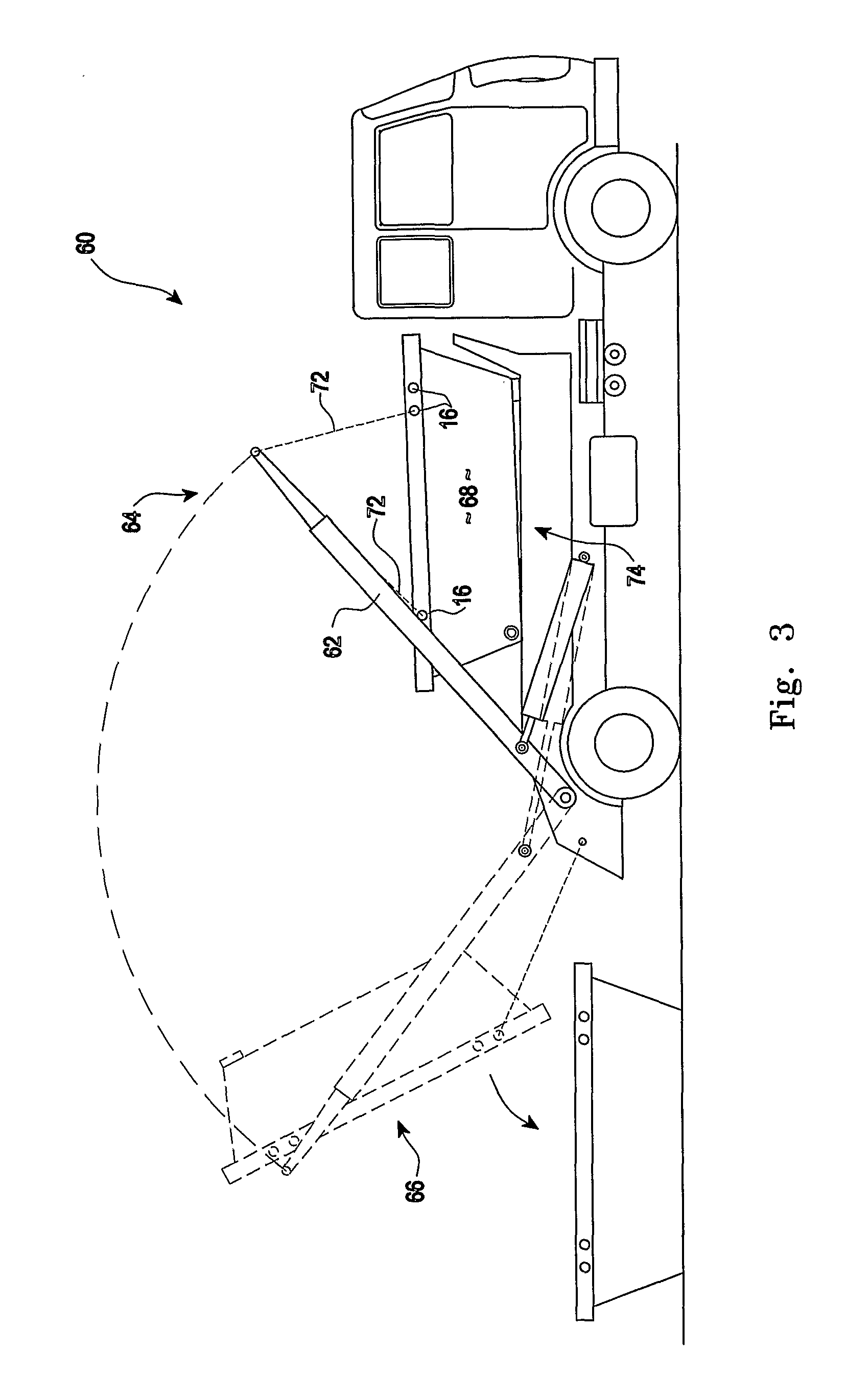

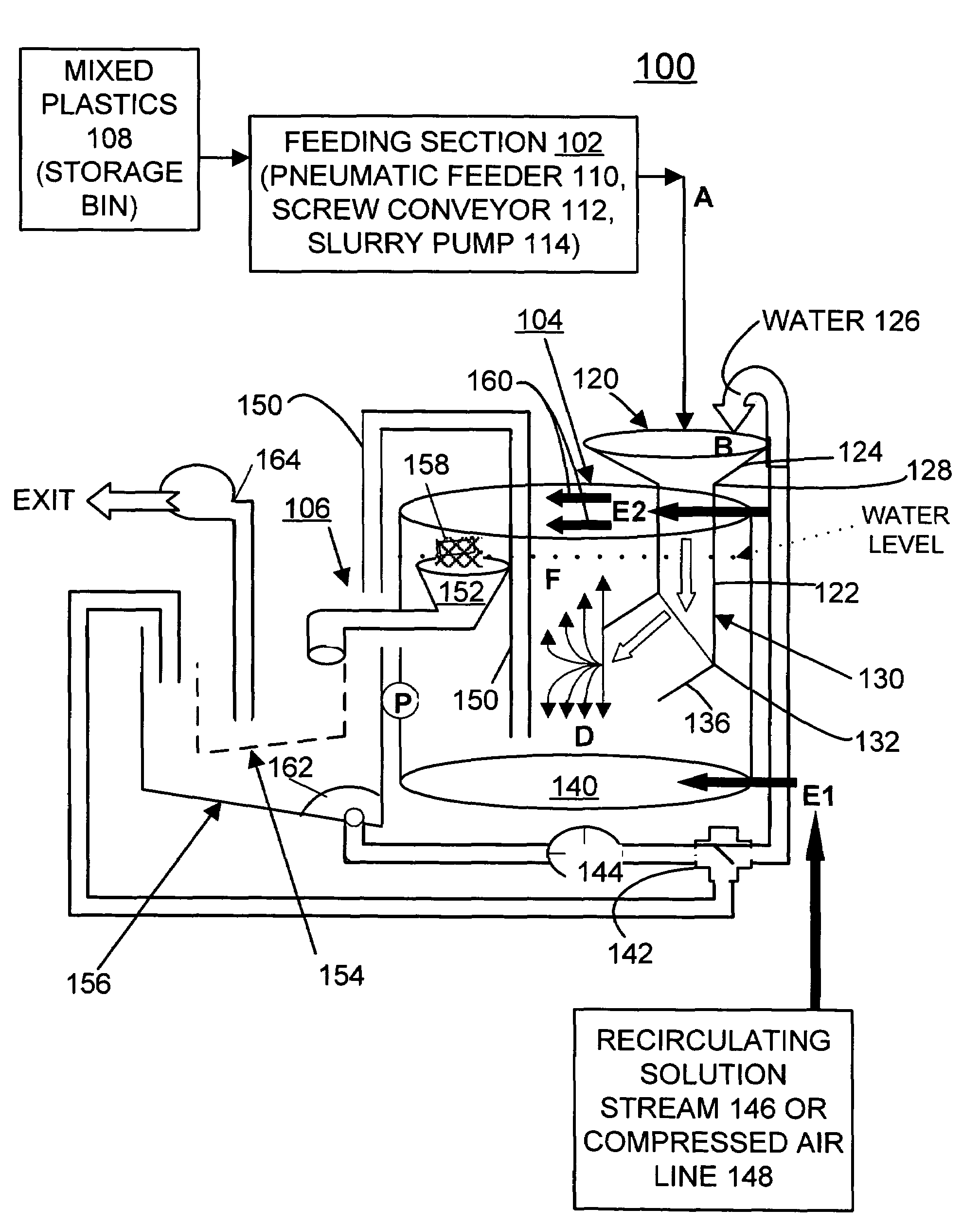

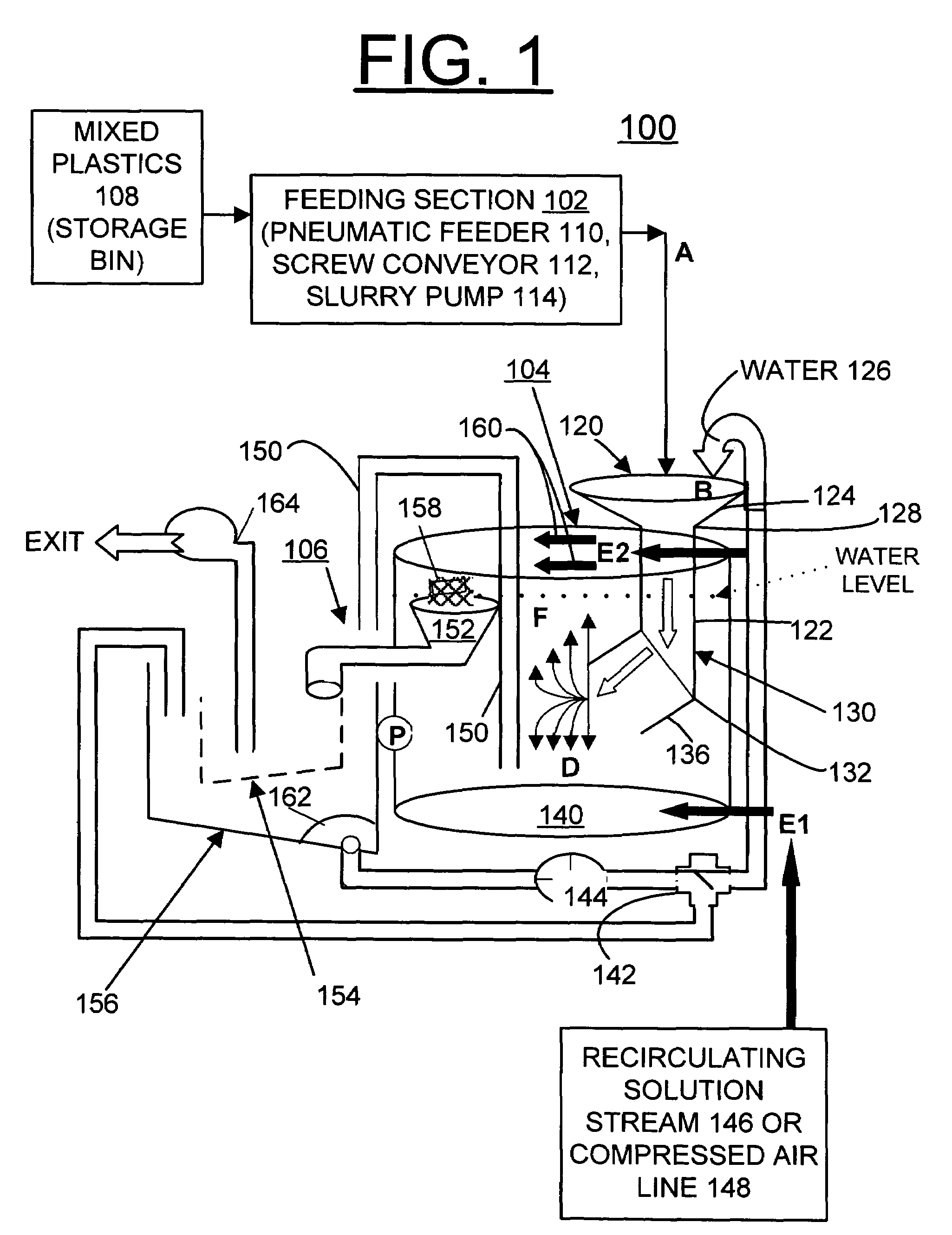

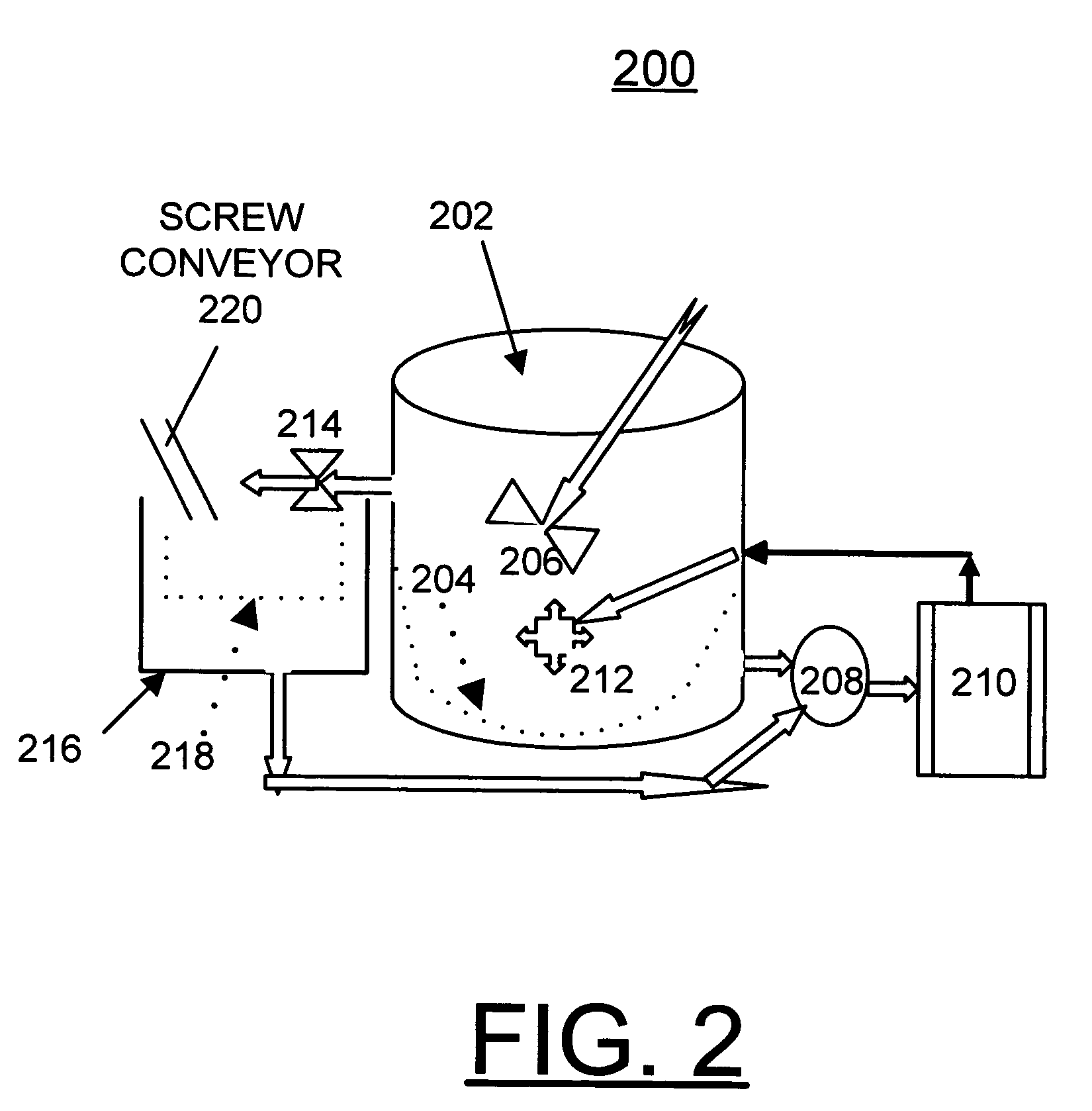

Method and apparatus for separating mixed plastics using flotation techniques

InactiveUS7255233B2Increase upward movementPlastic recyclingSeparation devicesOff the shelfBatch processing

A method and apparatus are provided for separating mixed plastics using flotation techniques including a first stage initial washing tank for washing of incoming plastics and providing a first separation process and at least one separation module. The first stage initial washing tank includes a perforated basket to hold heavy materials, such as metals, glass, and the like. Each separation module includes a separation tank, a feeding section for feeding of mixed stream into the separation tank; and a collecting section for collecting of the separated mixed plastics including floaters and sinkers from the separation tank. The separation tank has no moving parts. Each separation tank and the first stage initial washing tank is a standard off-the-shelf circular tank with a flat bottom. Washing and drying steps are eliminated between separation stages. Batch processing is replaced with generally continuous operation. An integrated vibrating screen and air classification system is provided.

Owner:UCHICAGO ARGONNE LLC

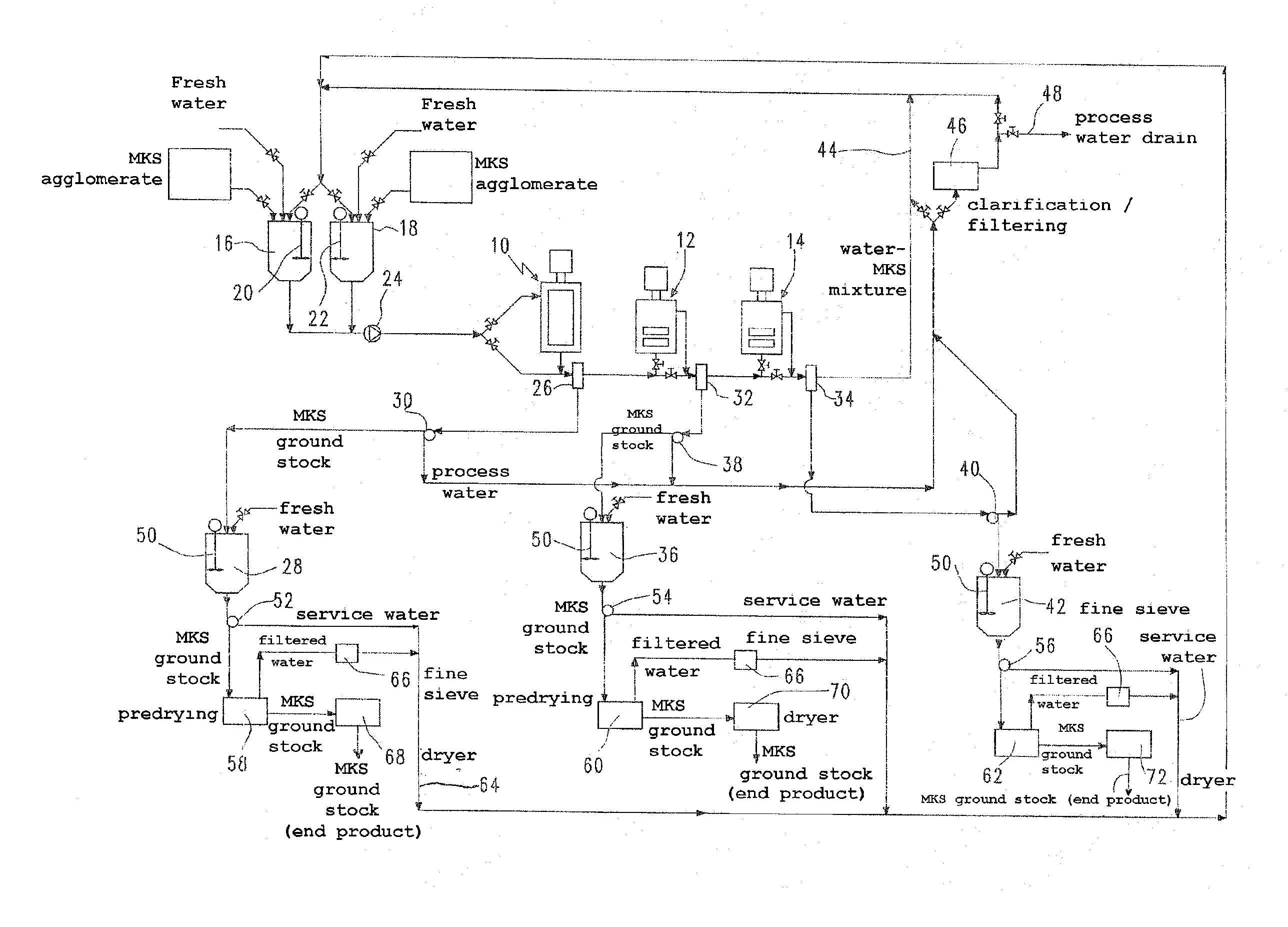

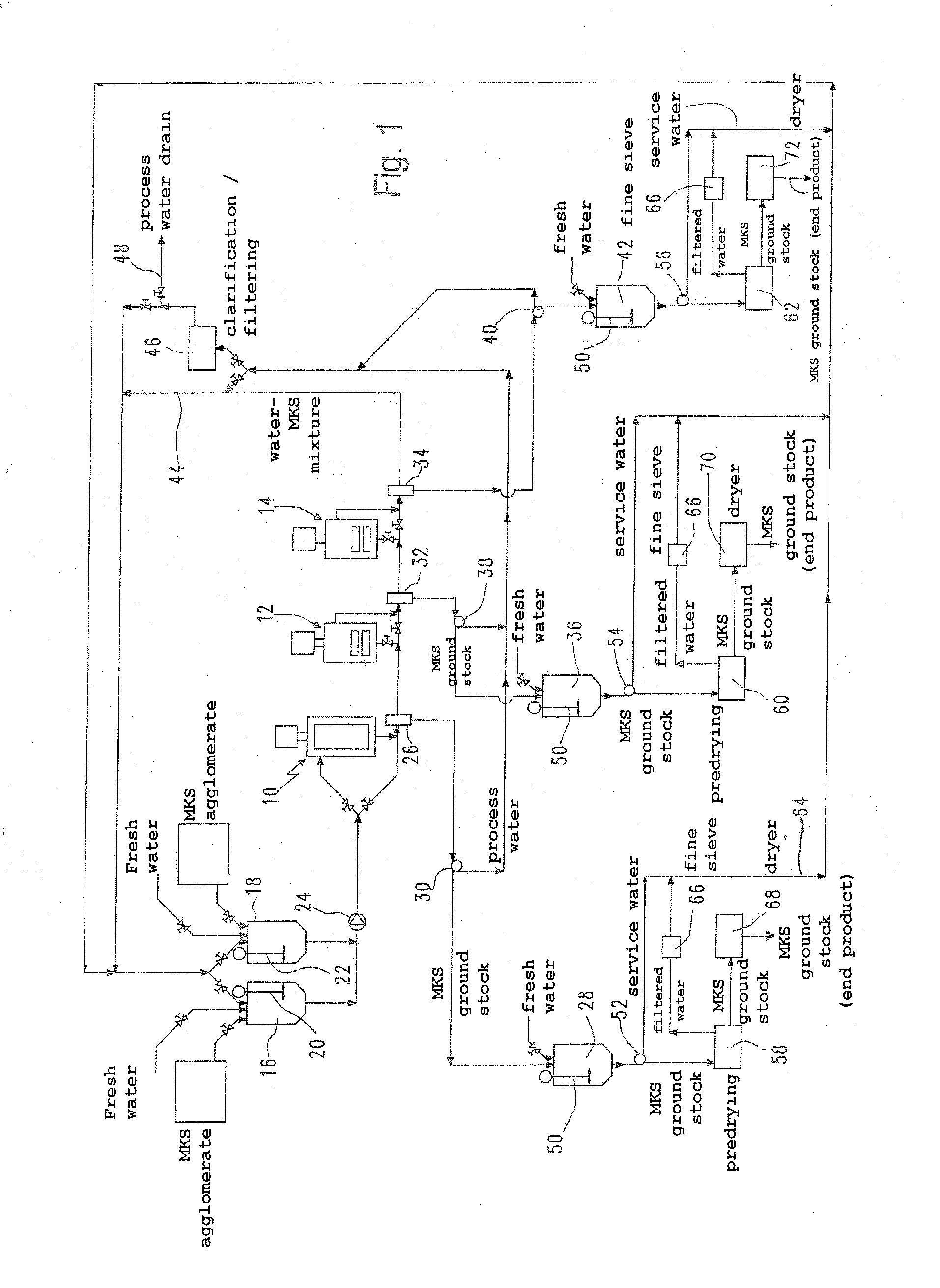

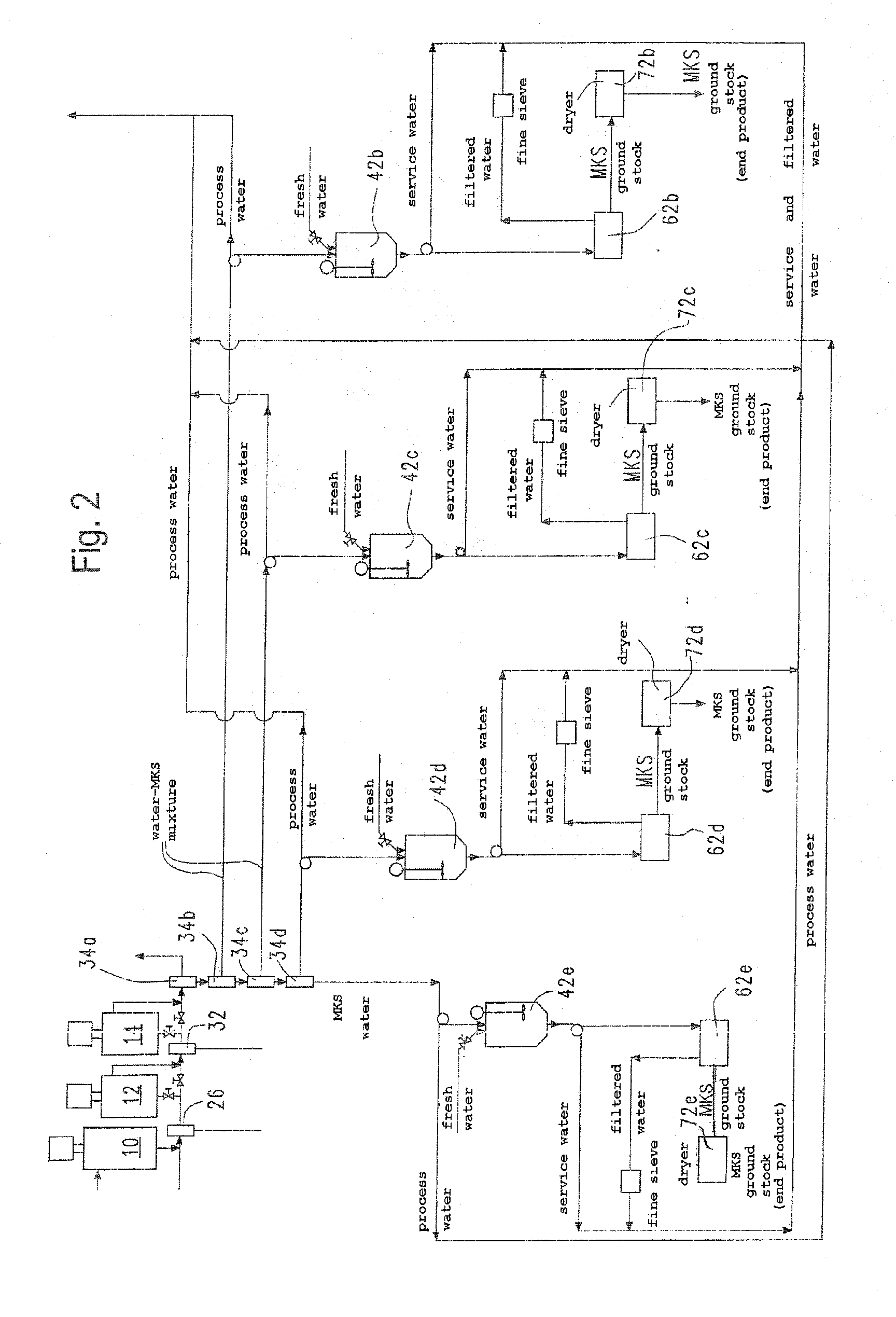

Method and Apparatus for Comminuting and Cleaning of Waste Plastic

InactiveUS20080191069A1Improve consistencyHigh material yieldSolid waste disposalWood working apparatusThick wallFine grain

Method for comminuting and cleaning waste plastic, in particular, mixed plastic (MKS) with the following steps: a compacted material, especially, an agglomerate is produced from film scraps or film remnants comminuted into flakes and / or thick-walled plastic parts chopped up into chips, the compacted material is introduced into a disc or drum refiner and is ground therein in the presence of water, wherein the portion of compacted material of the goods located in the refiner amounts to at least 10 percent by weight, a fine grain fraction is removed from the ground stock exiting from the refiner, the remaining ground stock is washed and either mechanically dewatered and dried, or pulverized again in a further refiner stage in the presence of water, and subsequently dewatered and dried.

Owner:CVP CLEAN VALUE PLASTICS GMBH

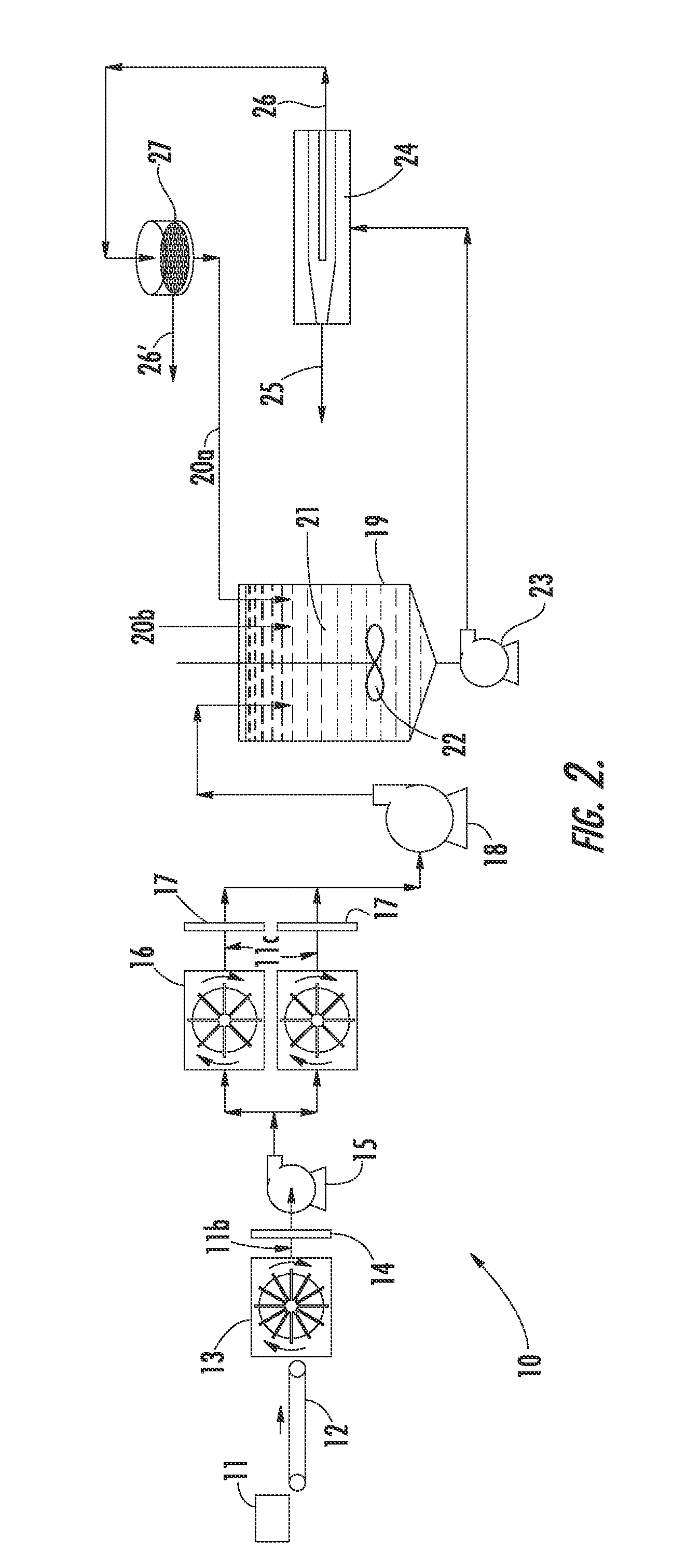

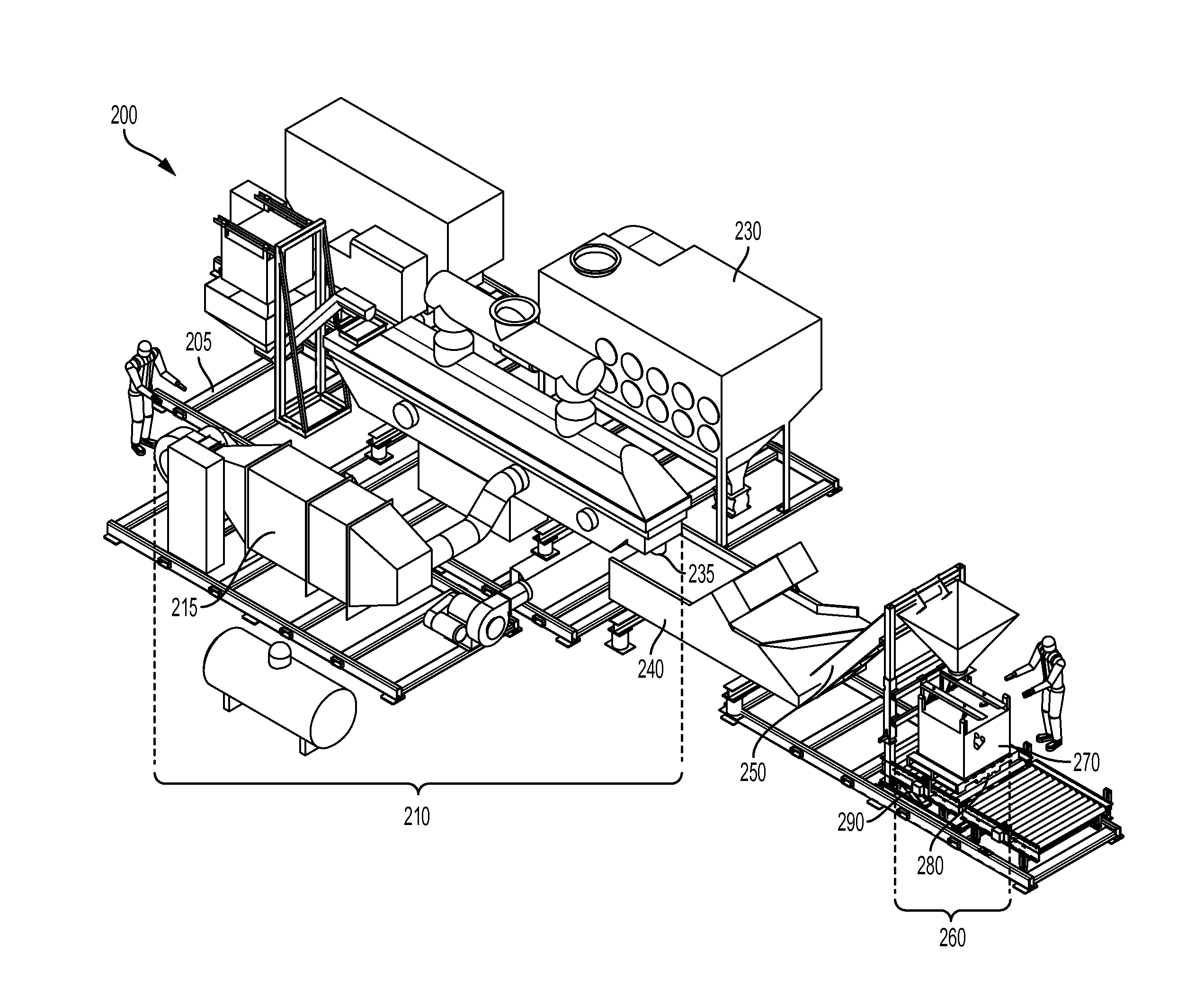

Method and system for processing and recycling infill material of artificial turf

ActiveUS20150209830A1High strengthEasy to set upDrying solid materials with heatGas current separationFluidized bed dryingEngineering

A method and system for processing and recycling infill material of artificial turf. The invention includes drying extracted infill material through a fluid bed dryer, the fluid bed dryer passes a process gas through a bed of solids via a perforated plate. The dried infill material is processed using a plurality of vibrating screens to remove excessively large or small particles from the infill material. The plurality of vibrating screens may be a set of progressively finer mesh screens. The processed infill material is separated by density. The density of the infill material may be determined by a high intensity, uniform sheet of laminar airflow. The separated infill material is discharged and is ready to be used again in another artificial turf. In one embodiment, the infill material includes at least one of graded sand, granulated styrene-butadiene rubber, cork, organic infill, thermoplastic elastomers, or ethylene propylene diene monomers.

Owner:TARKETT INC

Improved method to separate and recover oil and plastic from plastic contaminated with oil

A method for removing contaminants from synthetic resin material containers using a first organic solvent system and a second carbon dioxide system. The organic solvent is utilized for removing the contaminants from the synthetic resin material and the carbon dioxide is used to separate any residual organic solvent from the synthetic resin material.

Owner:HONEYWELL FED MFG & TECHNOLOGI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com