Patents

Literature

71results about How to "Reduce landfill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

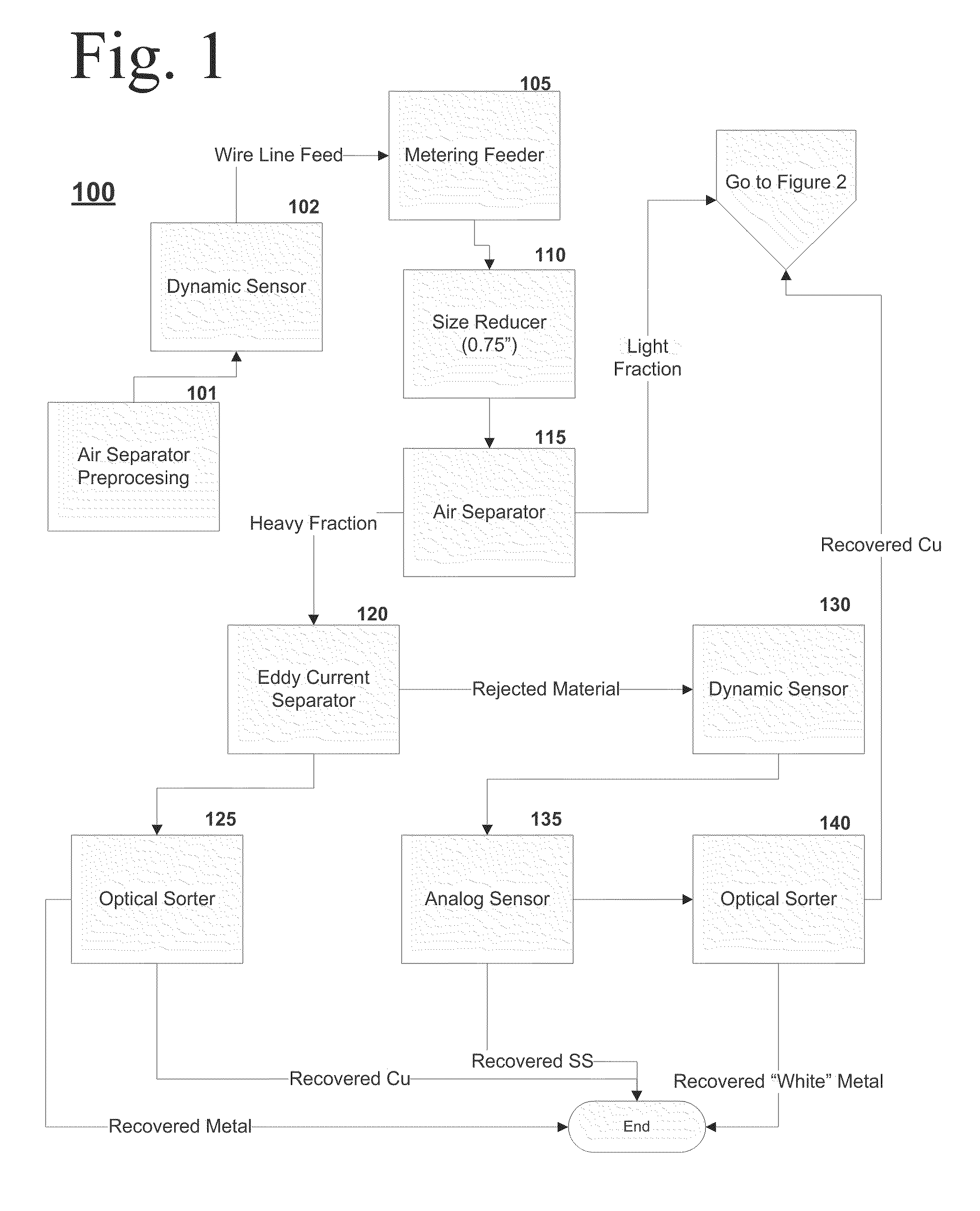

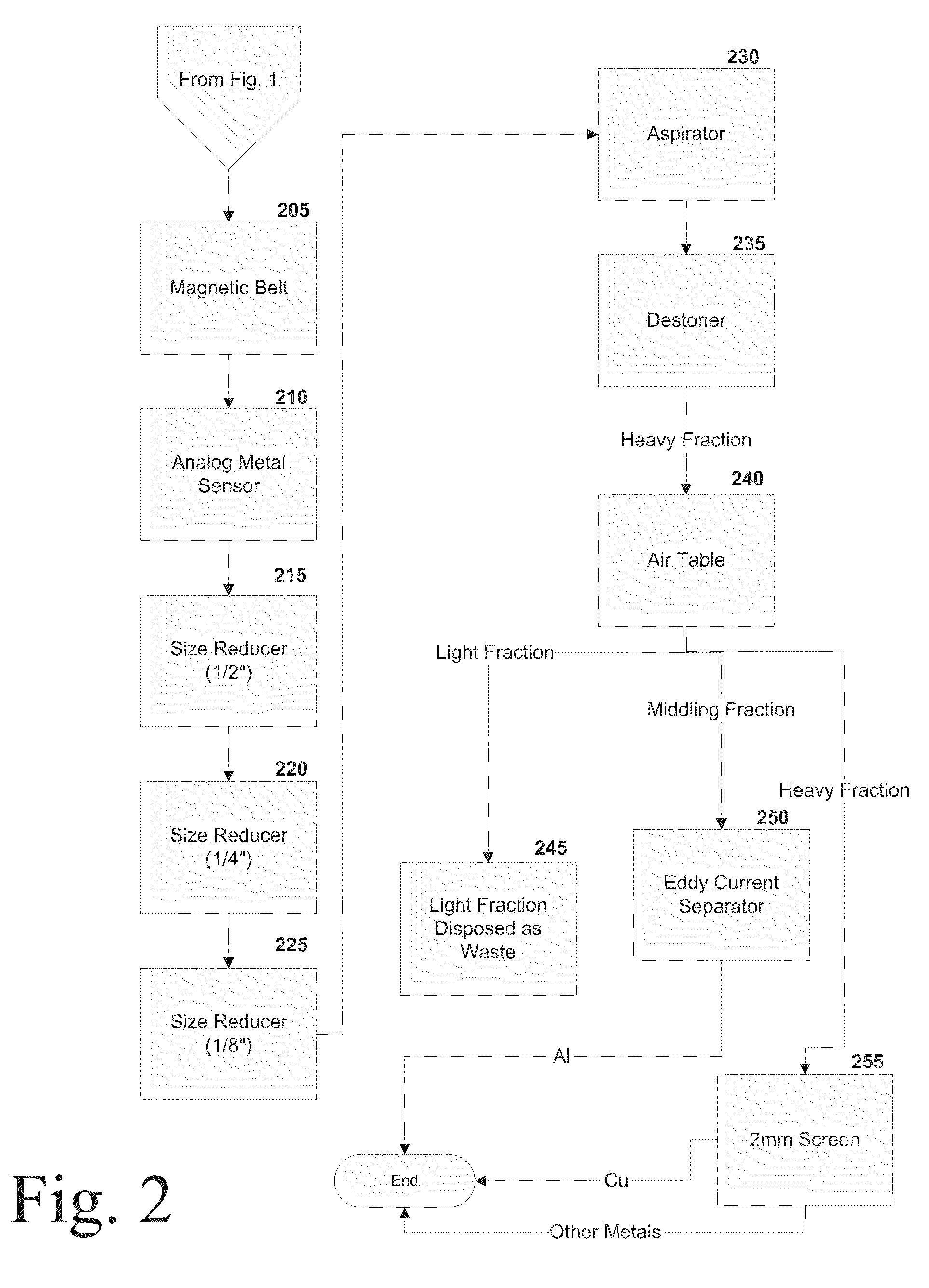

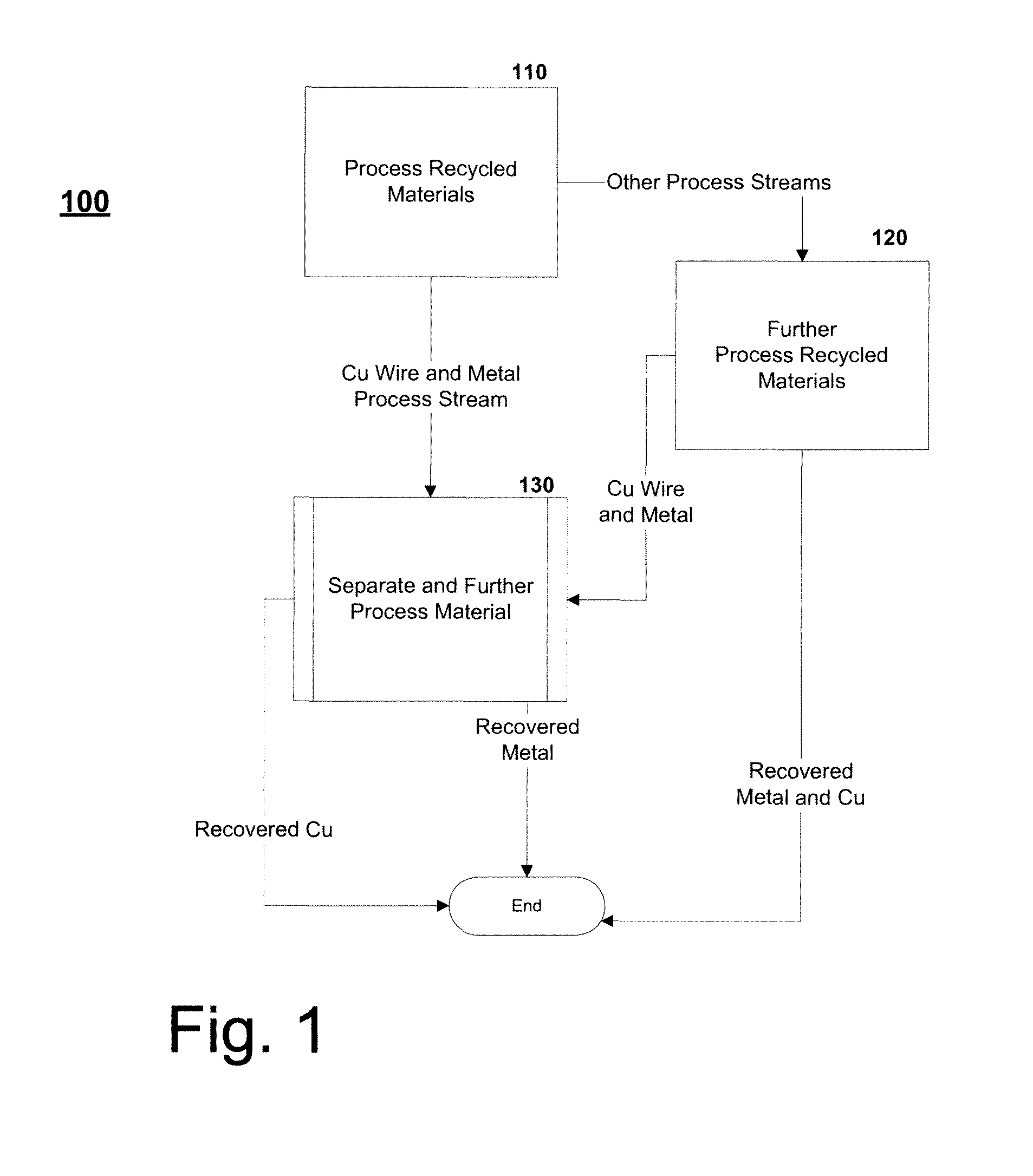

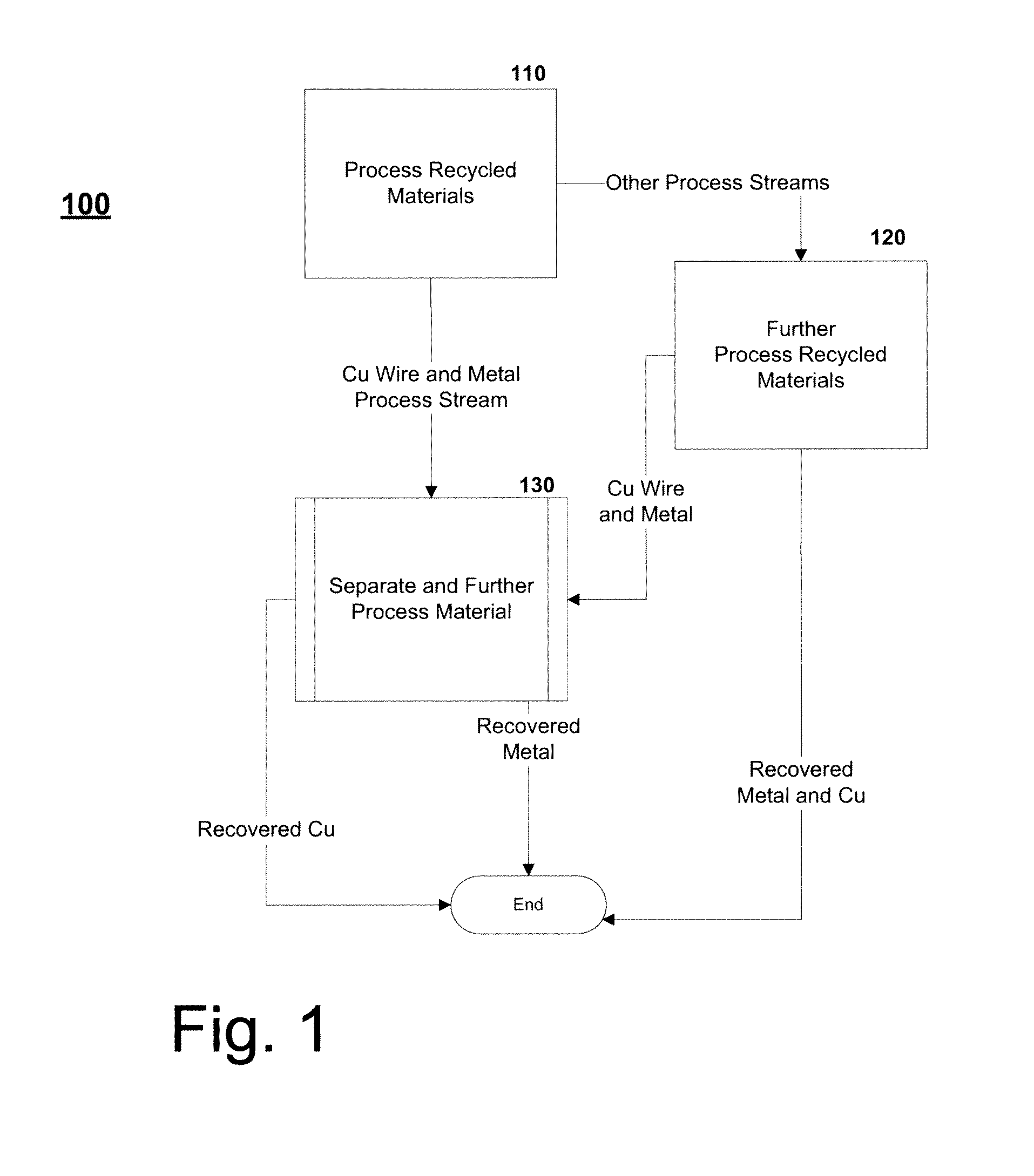

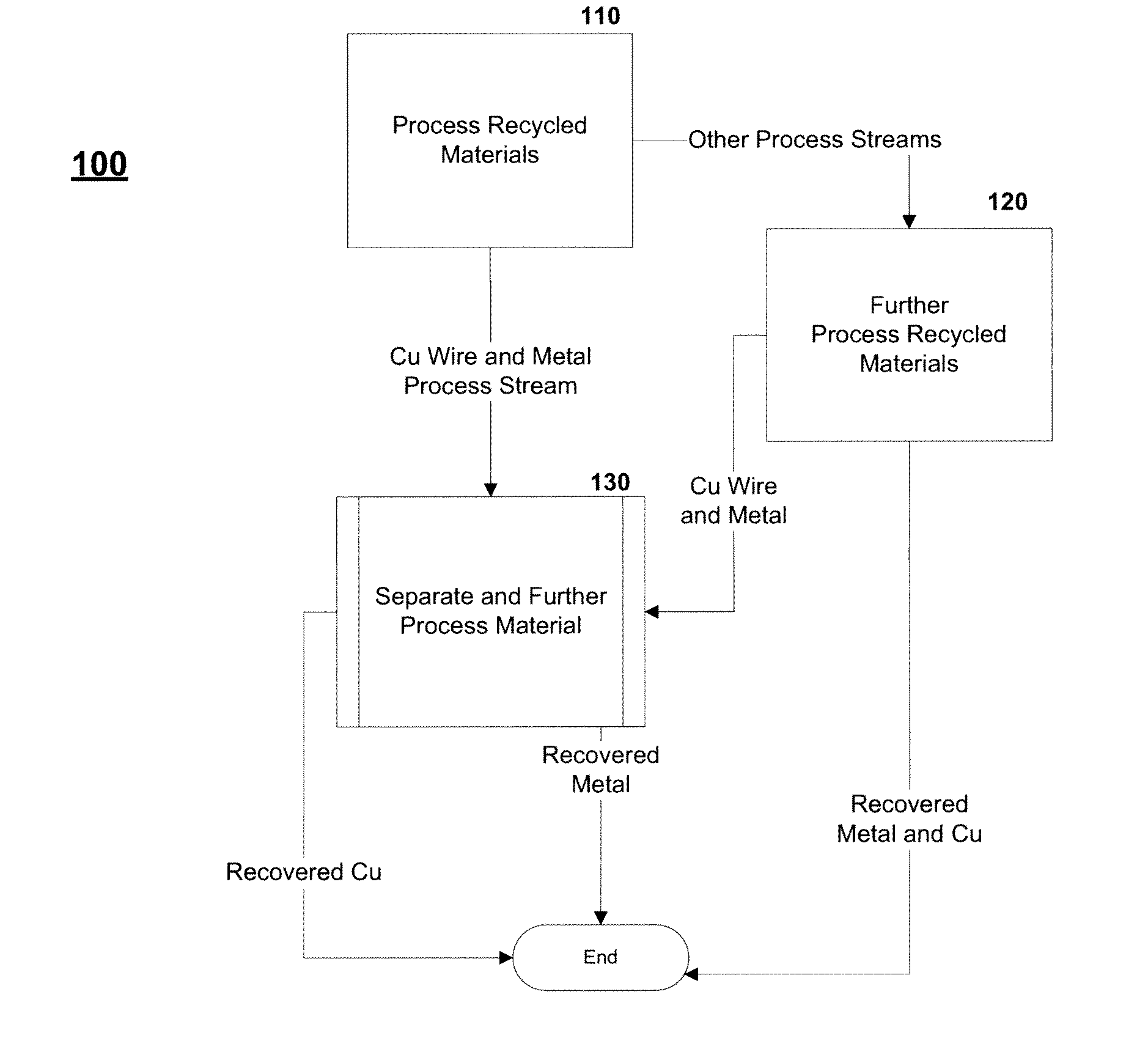

Method and system for recovering metal from processed recycled materials

InactiveUS7786401B2Efficient and cost-effectivePromote incomeGas current separationElectrostatic separationMetallic materialsCopper

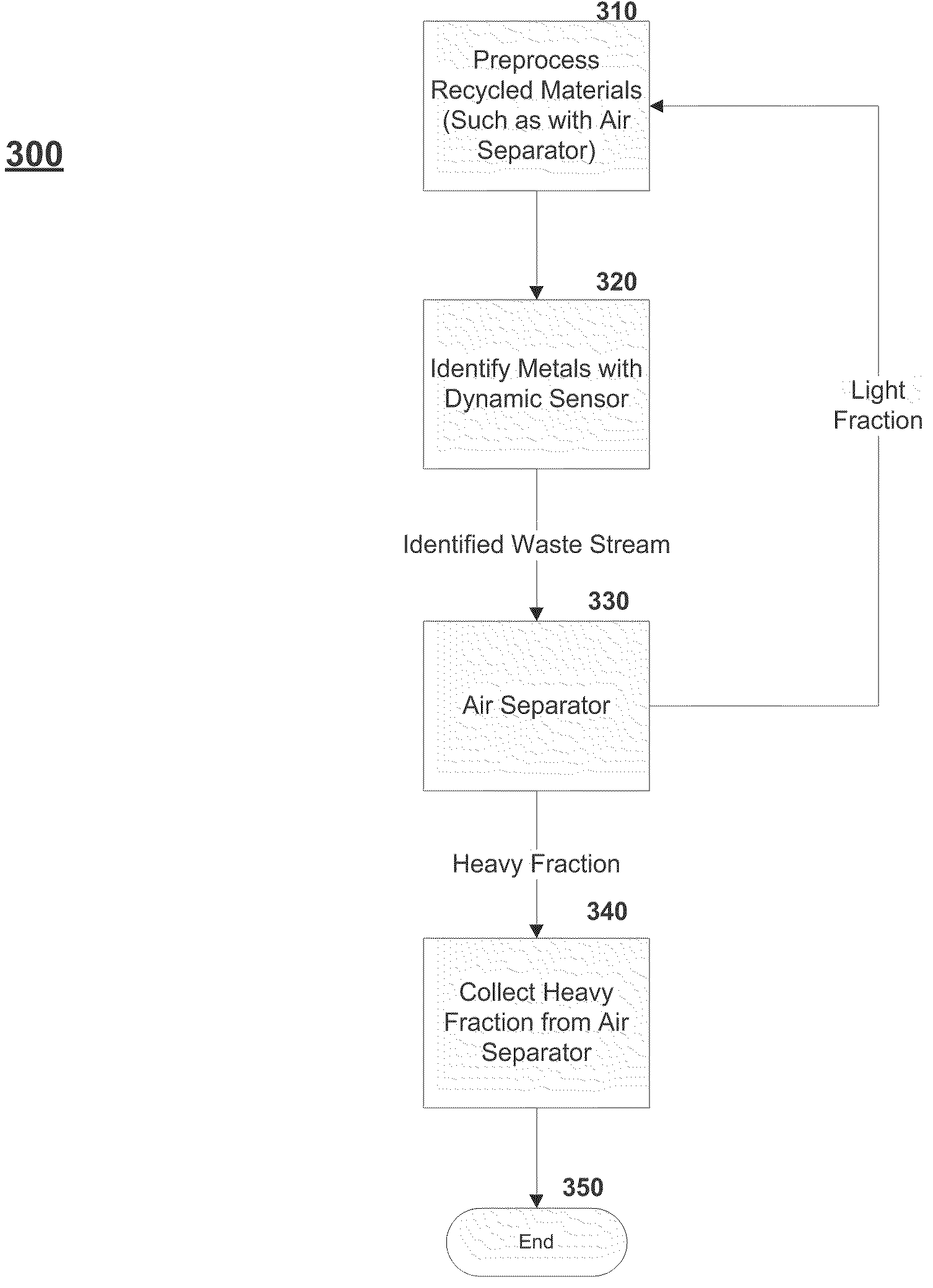

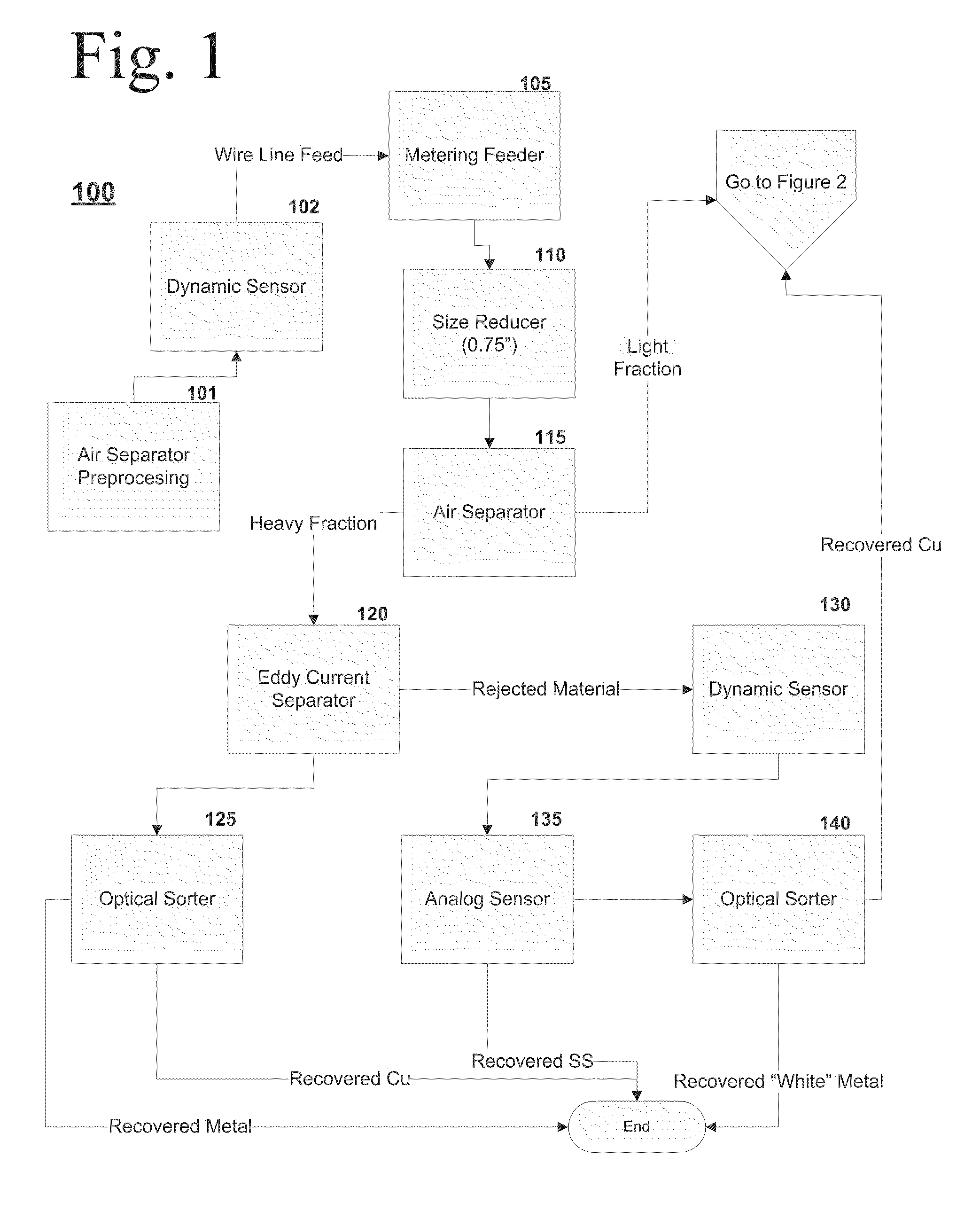

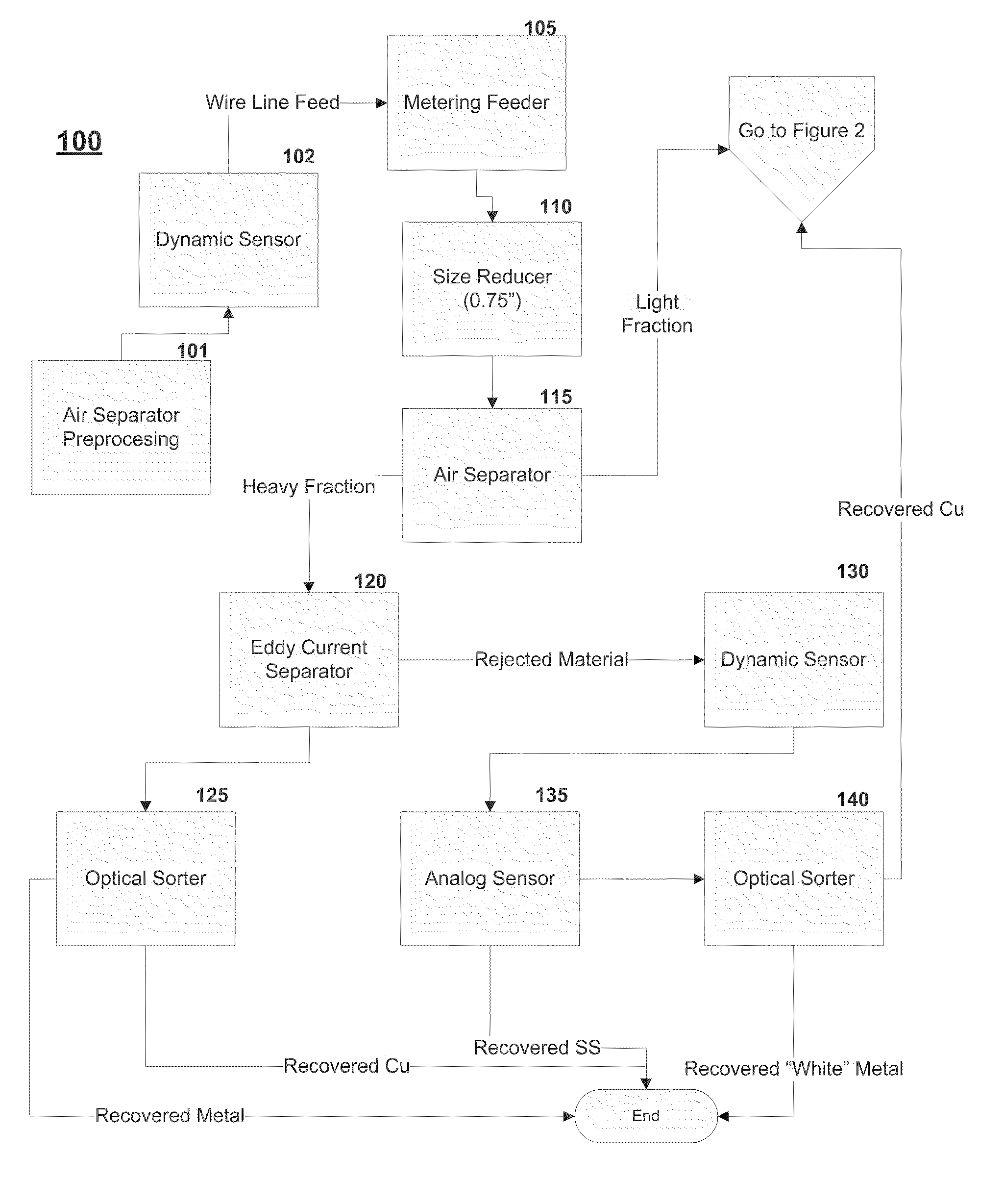

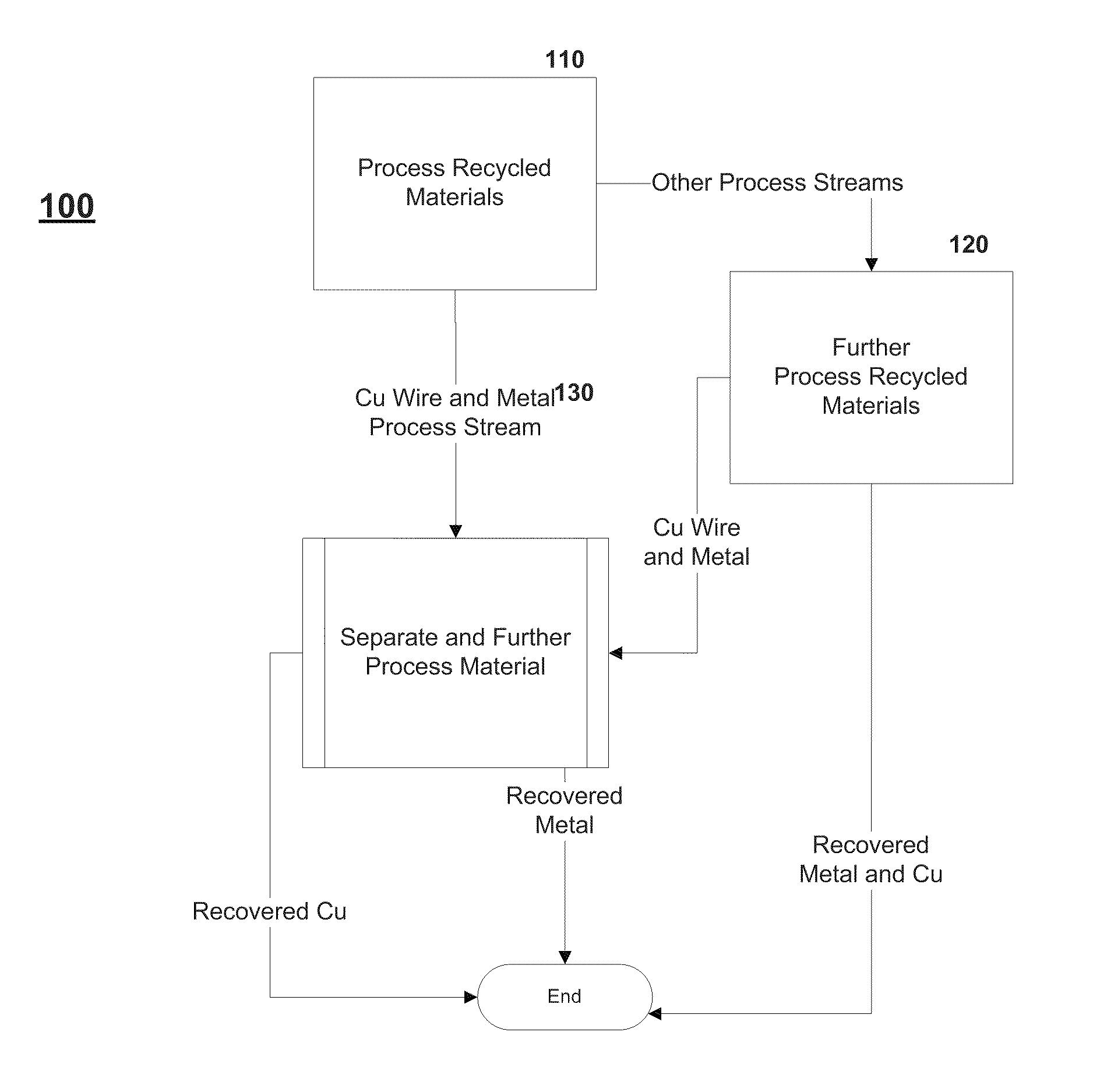

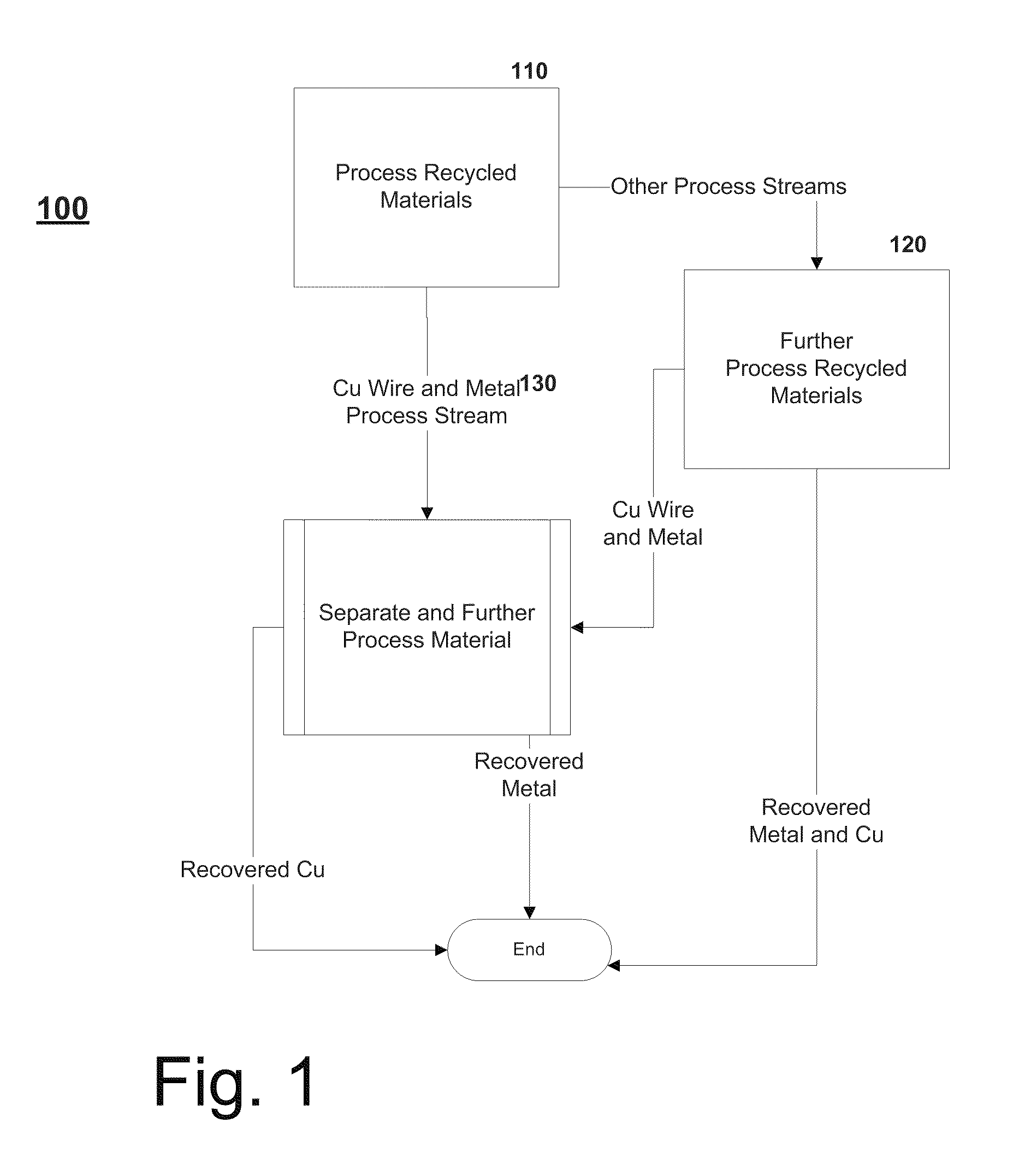

Recovering metallic materials, such as copper, from waste materials. The A dynamic sensor measures the rate of change of current generated by metallic materials in the waste materials. Preprocessing and post processing of the waste materials may be completed to further concentrate the amount the metallic materials recovered from the waste.

Owner:VALERIO THOMAS A

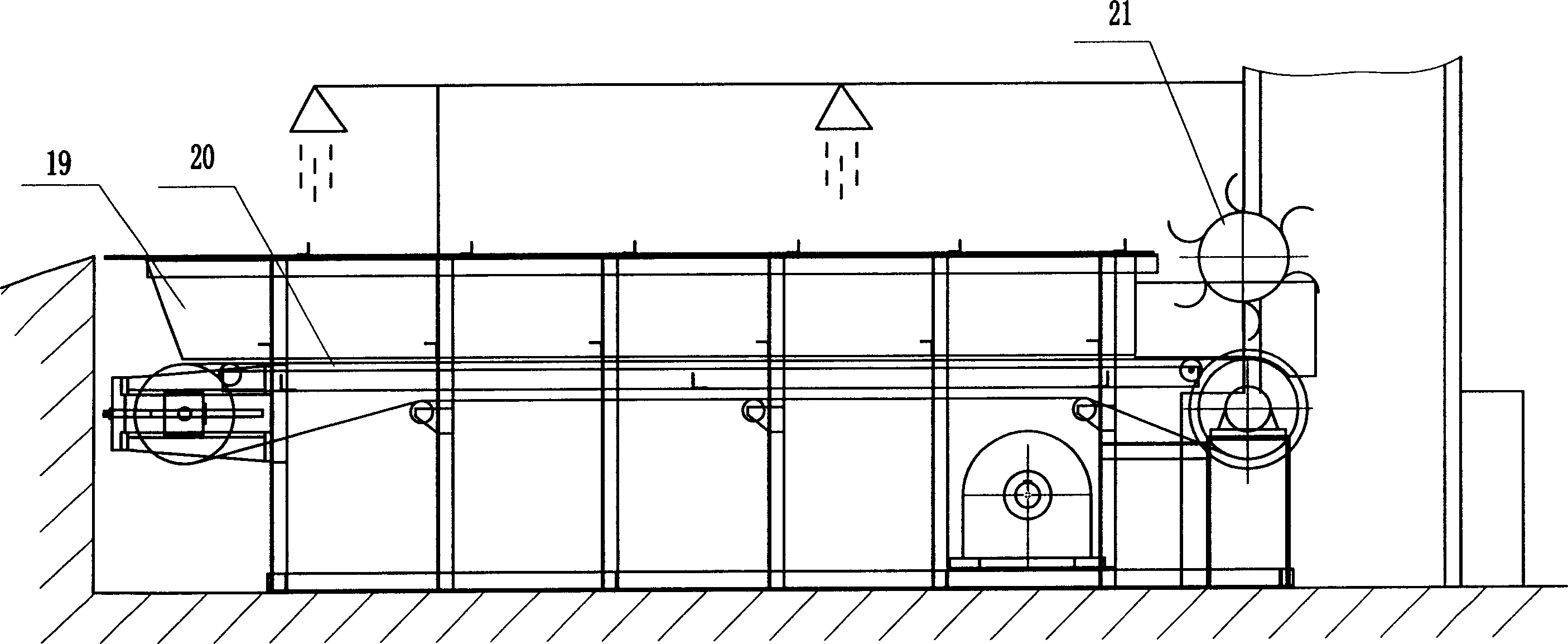

Method And System For Recovering Metal From Processed Recycled Materials

InactiveUS20100005926A1Facilitates revenue recoveryReduce landfillGas current separationElectrostatic separationMetallic materialsCopper

Recovering metallic materials, such as copper, from waste materials. The A dynamic sensor measures the rate of change of current generated by metallic materials in the waste materials. Preprocessing and post processing of the waste materials may be completed to further concentrate the amount the metallic materials recovered from the waste.

Owner:VALERIO THOMAS A

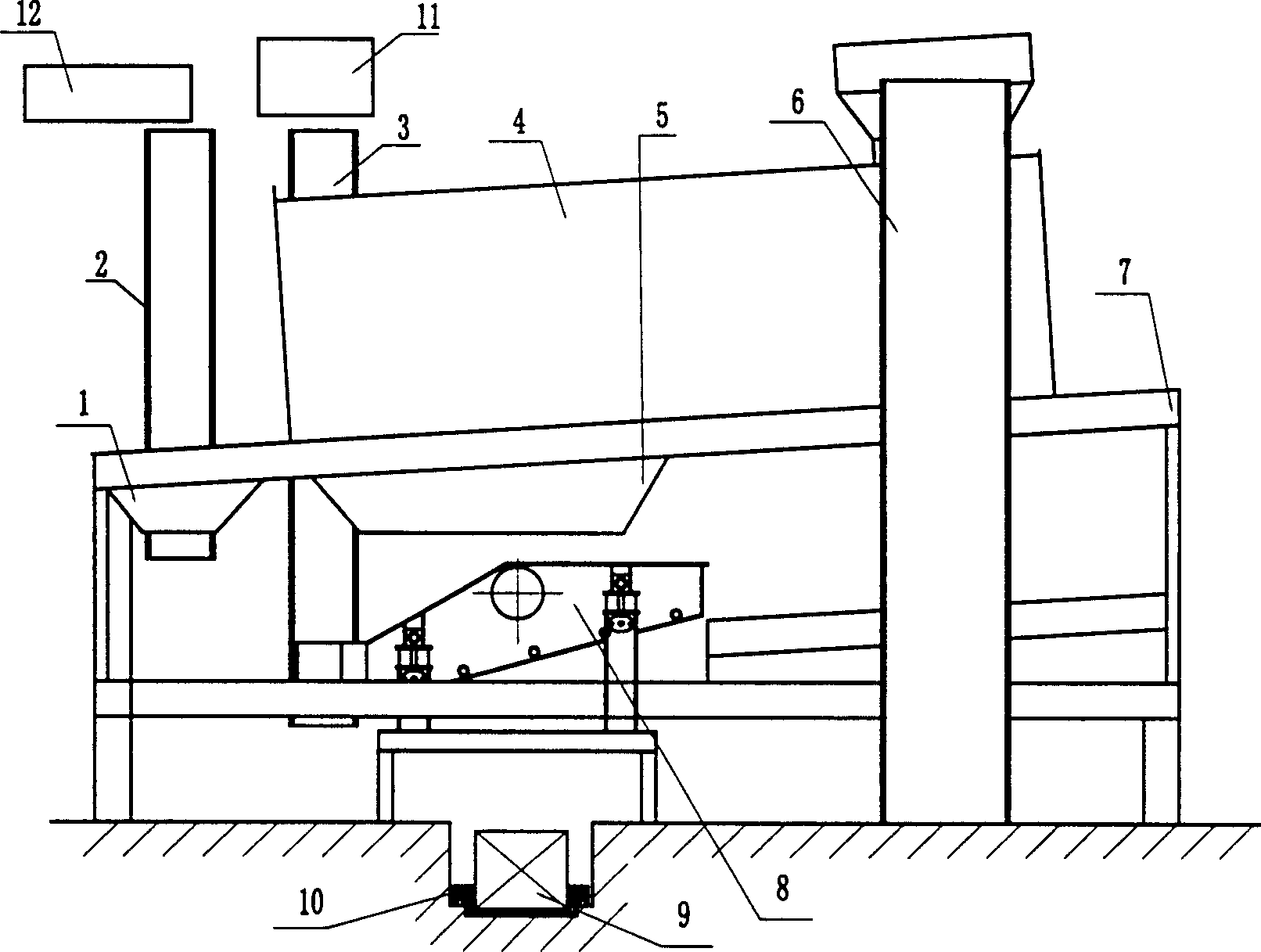

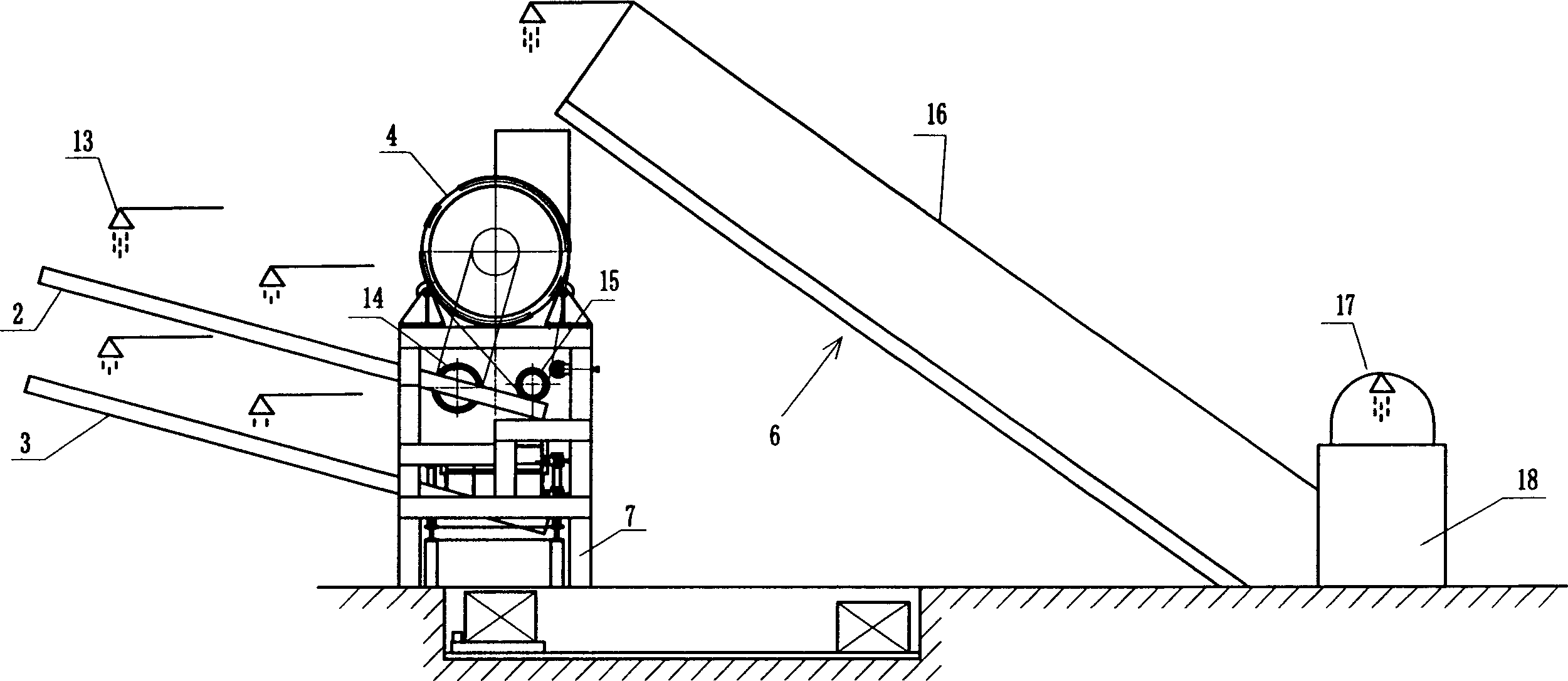

Domestic refuse sorting and treating system and treating process thereof

The invention relates to sorting refuse disposal system and its method. The system comprises distributing device, feeding belt conveyer equipped at outlet of distributing device, sorting device under the outlet of feeding conveyor, two outlets on sorting device, regrading device under the outlet of organic matter, organic matter discharging belt device equipped at discharging side, garbage container under the discharging side, and discharging belt device under the inorganic matter outlet. The invention comprises the following steps: anti-odor treatment, sending garbage to sorting device to complete selective breaking sorting; organic refuse biological treatment or composting process. The invention is adapted to various garbages and sorting garbage at its source.

Owner:北京厨房设备有限公司

Method for improving dehydration performance of residual sludge by assisting oxidization of ferrate by utilizing ultrasonic waves

InactiveCN103359908AImprove dehydration effectFilter specific resistance dropsSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationPotassiumPotassium ferrate

The invention relates to a method for improving dehydration performance of residual sludge by assisting oxidization of ferrate by utilizing ultrasonic waves and belongs to the technical field of sludge processing. The method comprises the following steps of: introducing concentrated sludge into a conditioning tank, and adding dilute sulfuric acid or dilute nitric acid into the conditioning tank while stirring, so as to enable the pH of the sludge to be 2.5-3.5; adding potassium ferrite under the action of the ultrasonic waves, adding calcium hydroxide into the reacted sludge and carrying out stirring, and regulating the pH to 6-7, wherein the adding amount of the ferrate (namely the mass ratio of the ferrate to the residual sludge) is ((0.5-2)*10<3>):1, the ultrasonic frequency is 20-40 kHz, the energy density of sound of a dry basis is 1000-3000 KJ / kg, and the action time is 60-90 seconds; carrying out mechanical dehydration on the processed sludge by utilizing a belt press-filter or centrifugal dehydration method, so as to obtain the dehydrated sludge with the water content of 70-75%. According to the method disclosed by the invention, the filtering specific resistance of the sludge can be reduced, the solid content of a mud cake can be increased, the reaction efficiency can be improved, the reaction time can be shortened, the processing capacity can be improved, and the sludge treatment cost can be lowered.

Owner:SUN YAT SEN UNIV

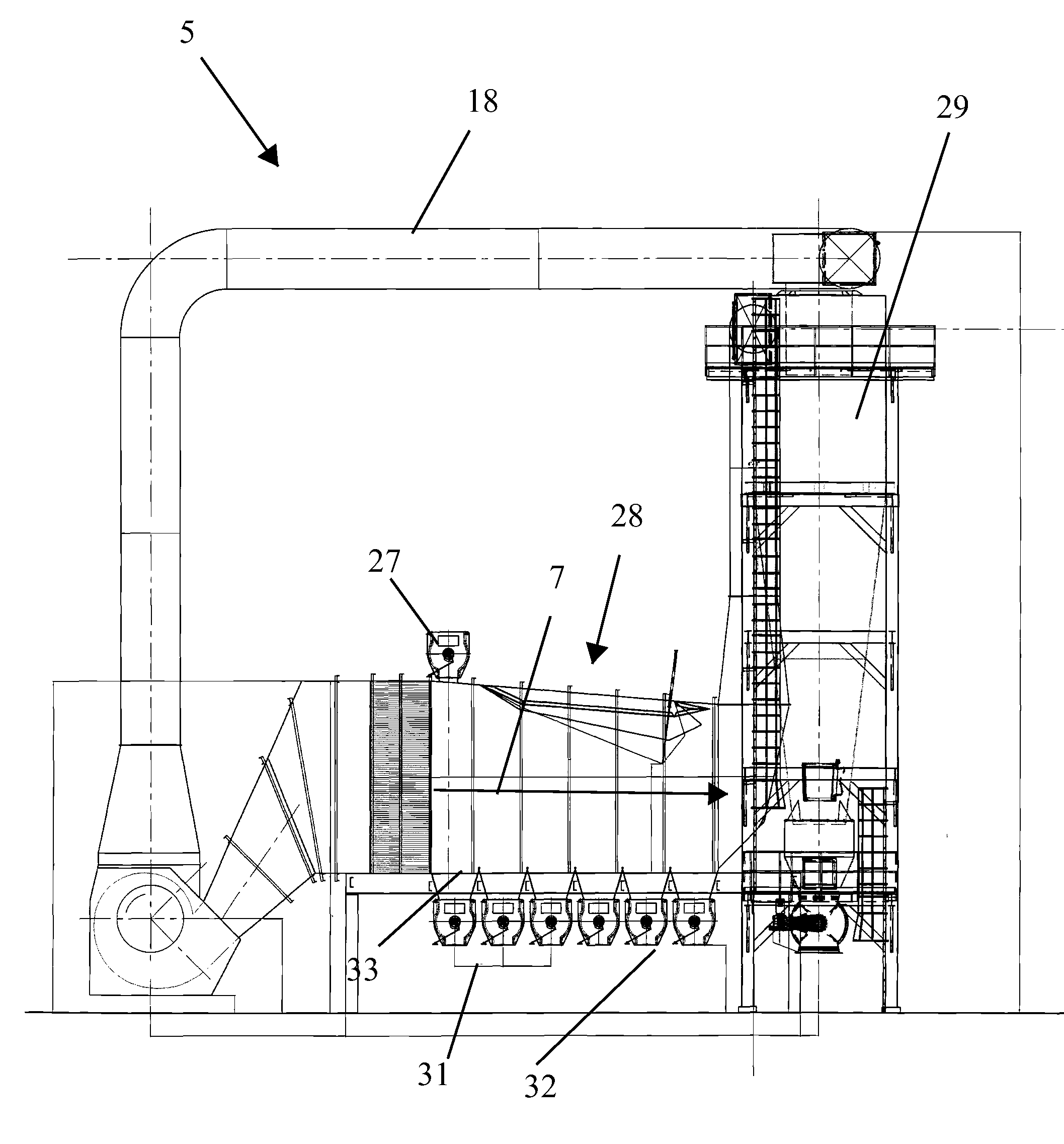

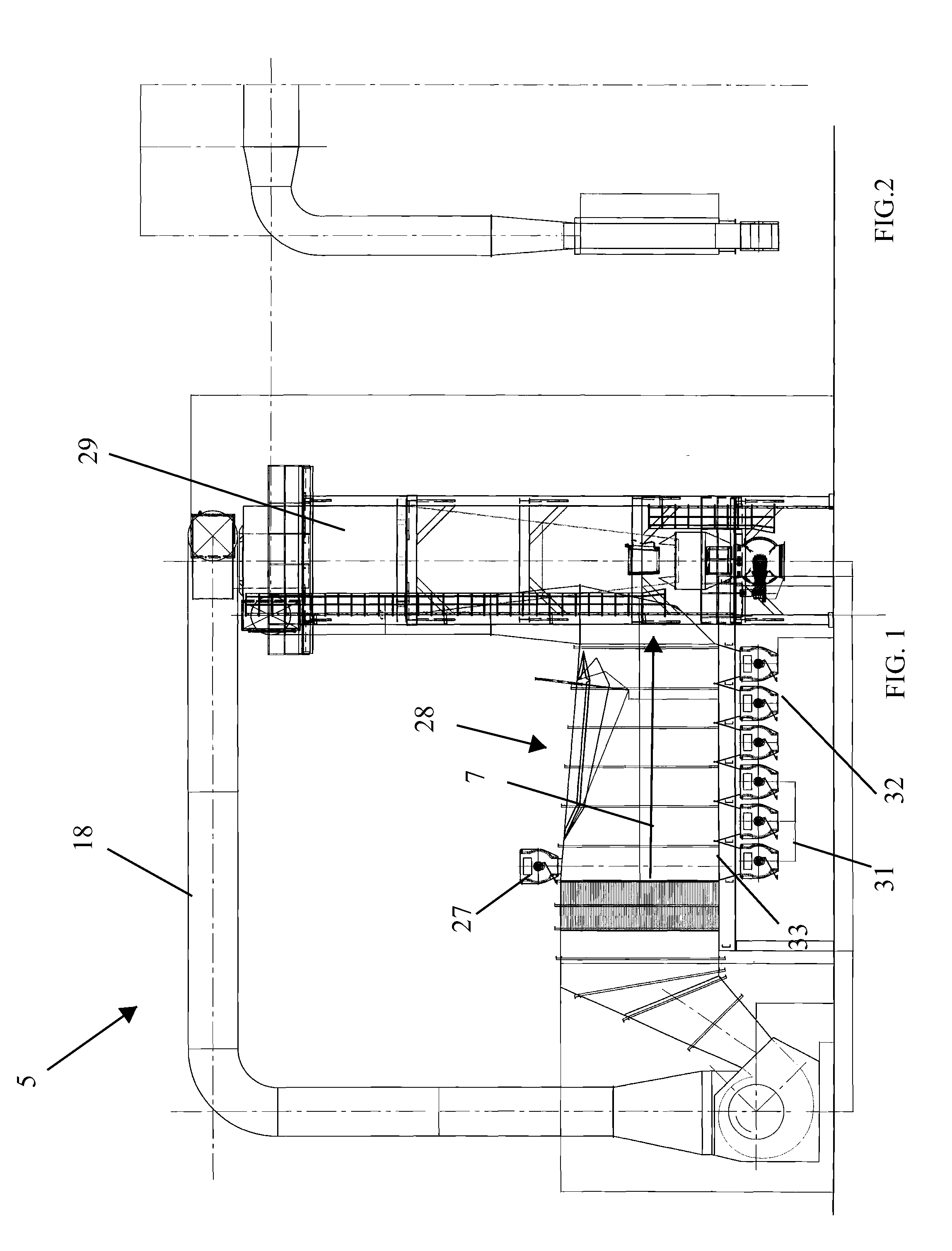

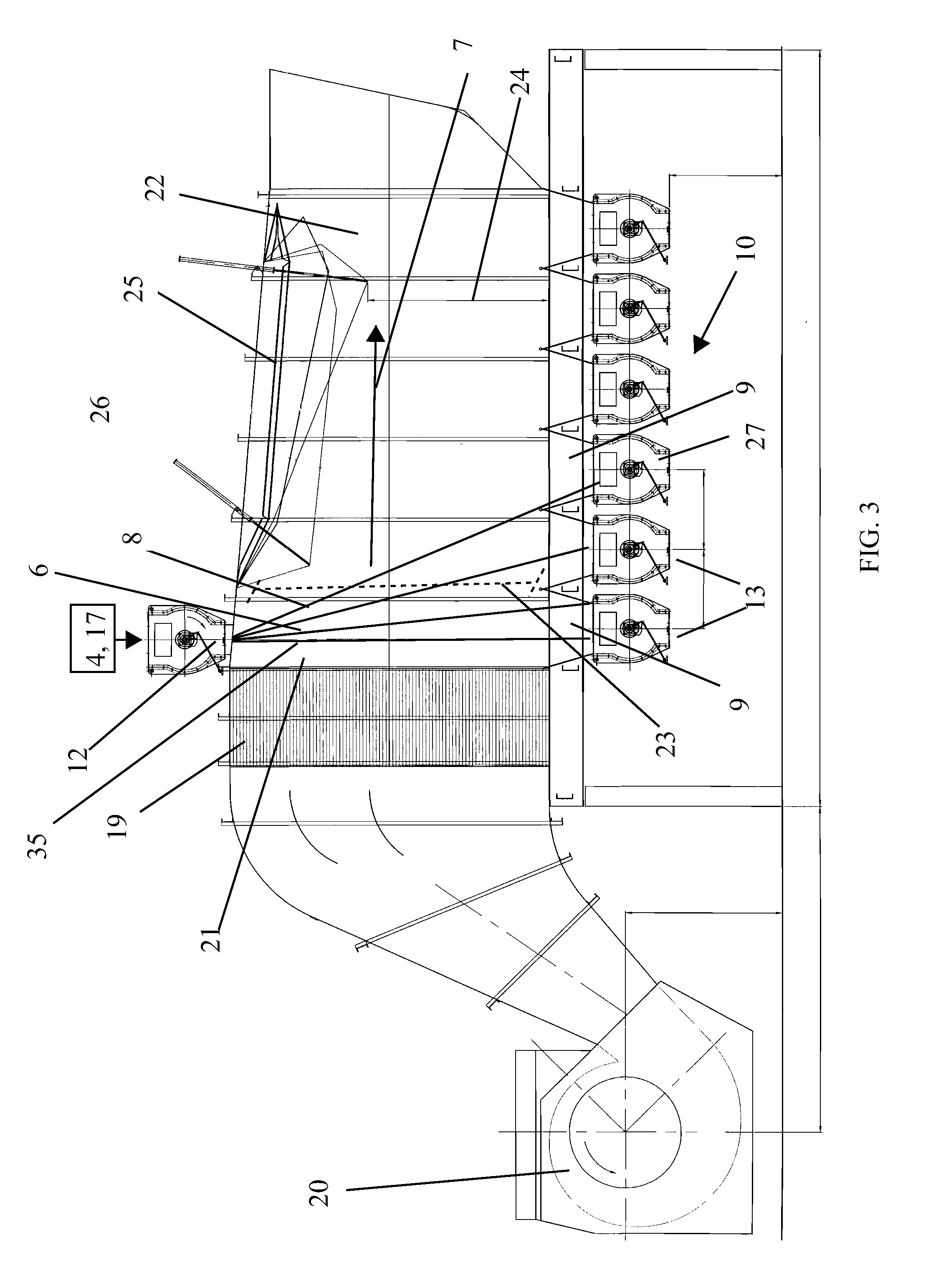

Isotropic Quantization Sorting Systems of Automobile Shredder Residue to Enhance Recovery of Recyclable Materials

ActiveUS20130092609A1Easy to sortReduce wasteGas current separationPlastic recyclingNonferrous metalMicroparticle

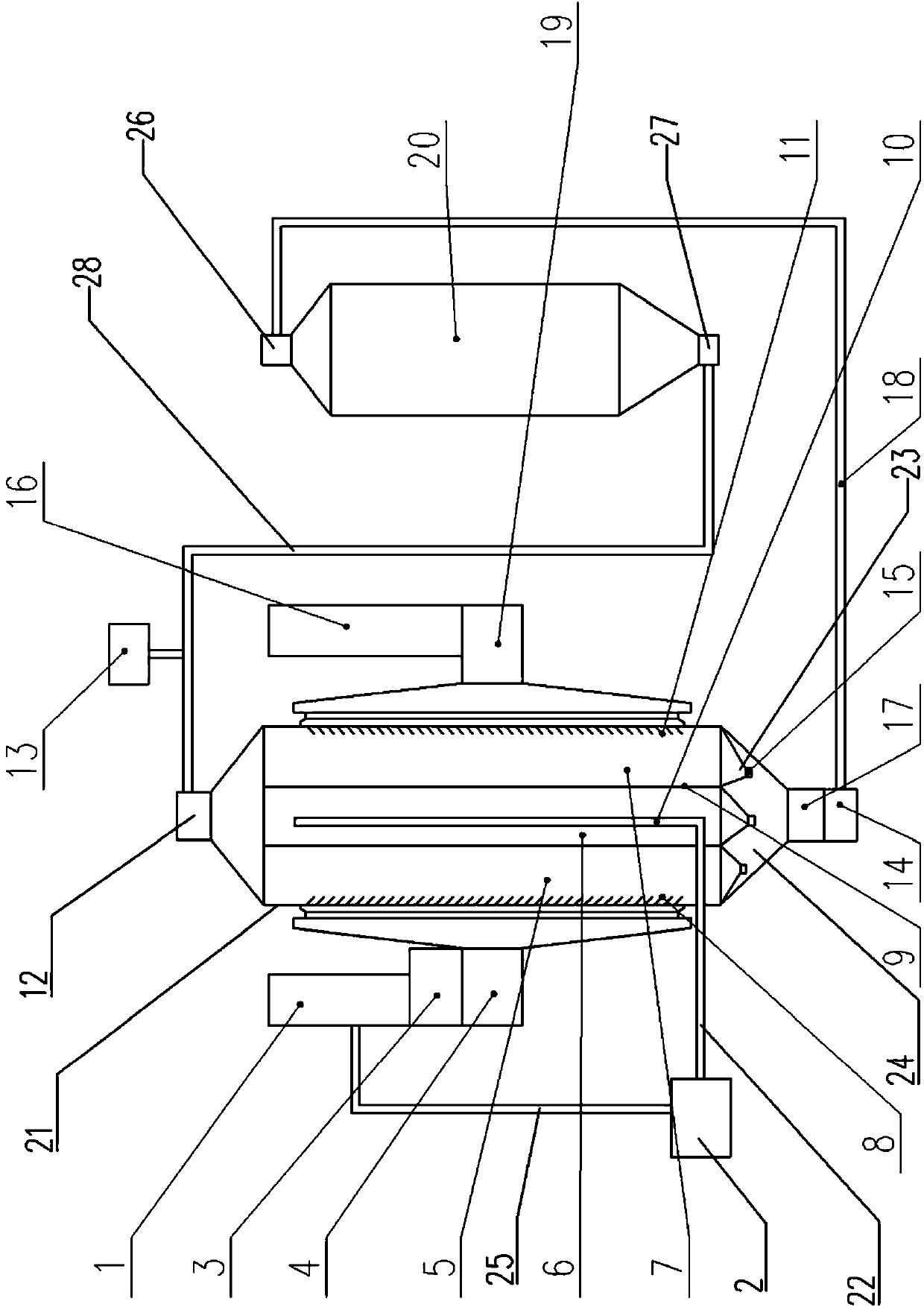

Systems and methods for increasing recyclable material recovery from automobile shredder residue (4). Embodiments include separation of automobile shredder residue with a sorting system (5) such as an air sorting system, a non-ferrous automobile shredder residue air sorter, an air-locked automobile shredder residue sorting system, a non-magnetic magnetic sorter, a substantially isotropic quantization sorting system, an air-locked Z-box air classifier, low susceptance microparticle separator, a magnetic fuzz separator, a wind tunnel system, or the like perhaps with substantially horizontal laminar air flow (7) and can be used with or without out other traditional automobile shredder residue sorting systems (16) or (15) perhaps creating additional recyclable quantities and even better separated results such as with zorba and zurik and the like.

Owner:IQASR

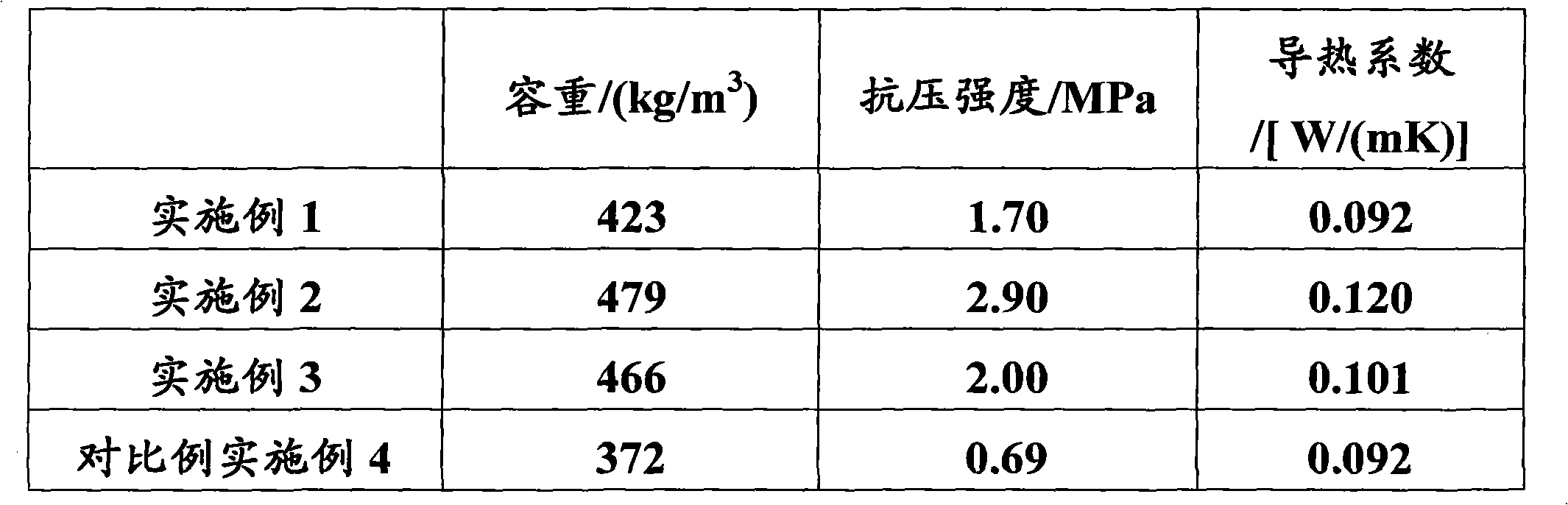

Lightweight gypsum plaster mortar

The invention belongs to building mortar, and particularly relates to lightweight gypsum plaster mortar which is the secondary development of gypsum plastered product technology. The lightweight gypsum plaster mortar is used for leveling inner sides of outer walls, inner partition walls and ceilings of buildings, and the heat-insulated effect is good. Because the flue gas desulphurized building gypsum of power plants is used, the problem of disposing and using the desulphurized gypsum is solved, and the circulating economy is developed. The method for preparing the plaster mortar comprises the following steps of: accurately weighing up the following materials in part by weight: 70 to 80 parts of flue gas desulphurized gypsum of power plants, 15 to 25 parts of vitreous hollow microsphere, 0.2 to 0.4 part of cellulose ether, 0.3 to 0.6 part of air entraining agent and 0.2 to 0.5 part of retarding agent; and putting the materials into a container, adding 60 to 120 parts of water into the container, and uniformly stirring the mixture at the normal temperature to obtain the lightweight gypsum plaster mortar. The lightweight gypsum plaster mortar has the advantages of moderate strength, unnecessary additional making of protective covering, direct leveling after plastering, high performance cost, high workability, short construction period, functions of preventing fire, absorbing sound, and adjusting air humidity and no emission of CO2 in the production process.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

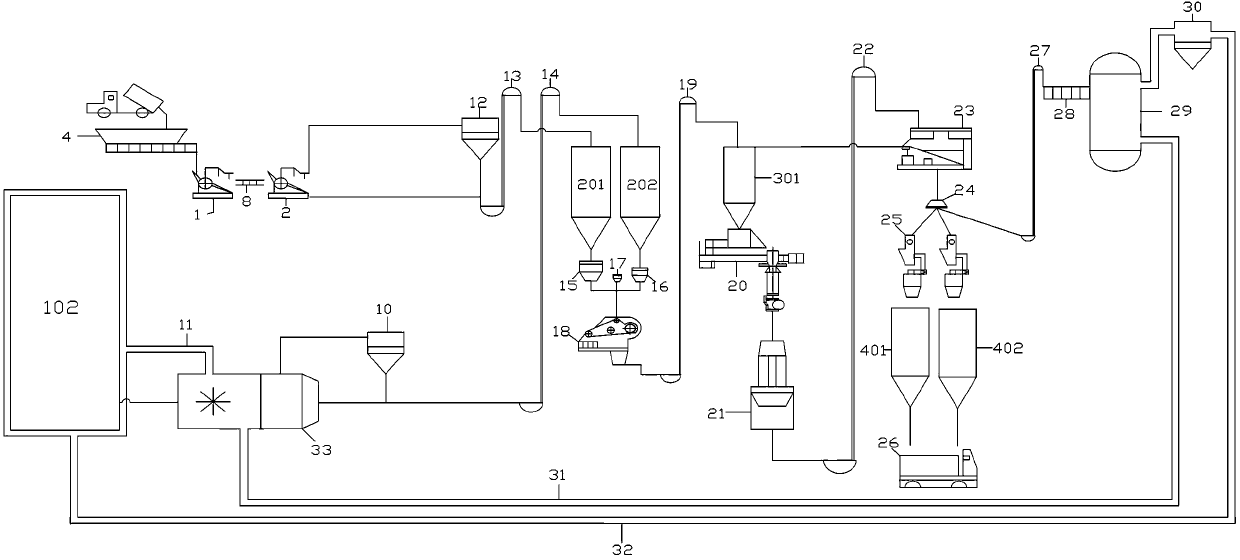

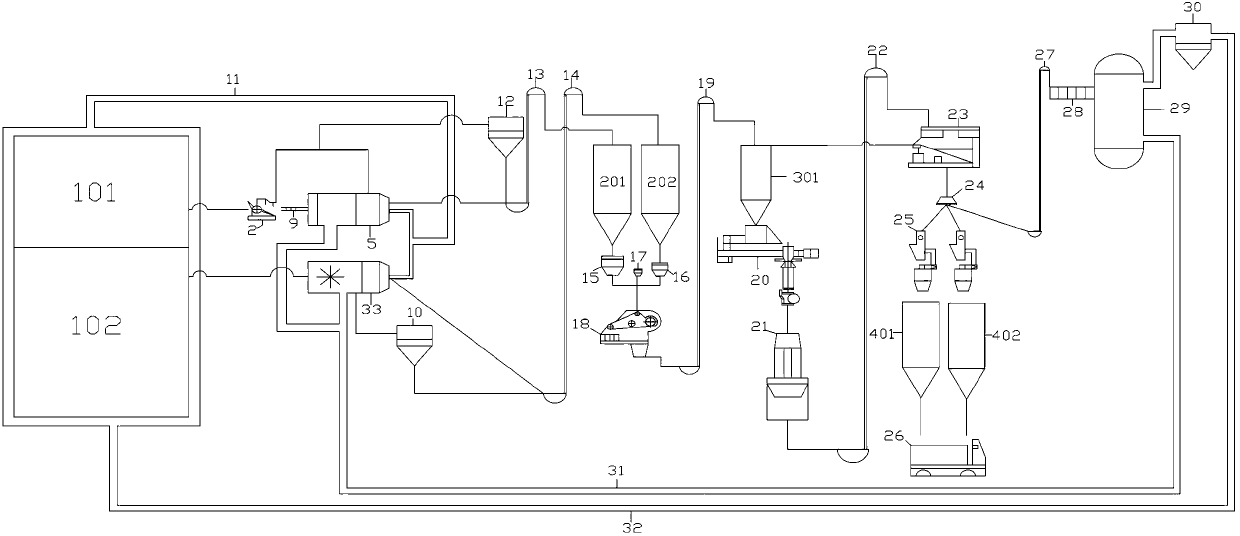

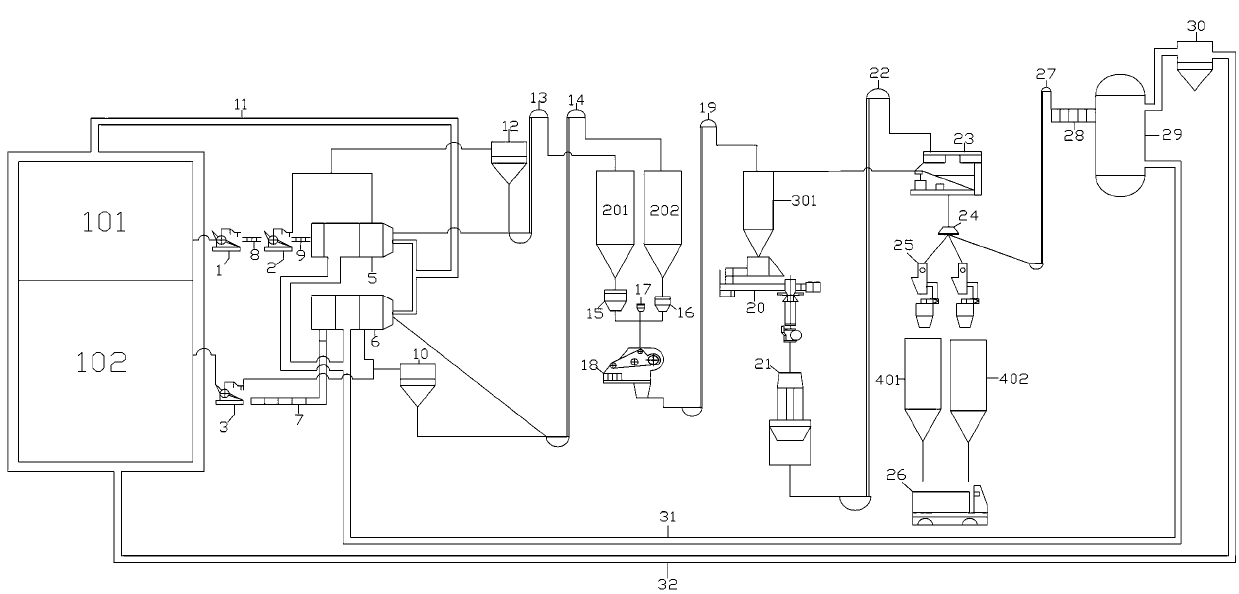

Process method and process system for preparing solid fuel through biomass and sludge

The invention discloses a process method and a process system for preparing solid fuel through biomass and sludge. The method comprises the step of mixing biomass dried raw materials with sludge dried raw materials which are aired, ground and dried to obtain the solid fuel, wherein sludge airing energy is one or the combination of any two or three of solar energy, waste gas generated by drying sludge raw materials and high-temperature fume generated by combusting the solid fuel, and sludge raw material drying energy is high-temperature and high-pressure steam generated by combusting the solid fuel. The system comprises a raw material treatment system, a molding system and a boiler system, wherein the raw material treatment system and the boiler system transfer heat energy to each other through first, second and third gas delivery pipelines. According to the method, the cost is low, the effect is good, environmental protection is realized and the solid fuel is suitable for large-scale production. The system is resource-saving and stable to operate.

Owner:东莞市图美环保科技有限公司

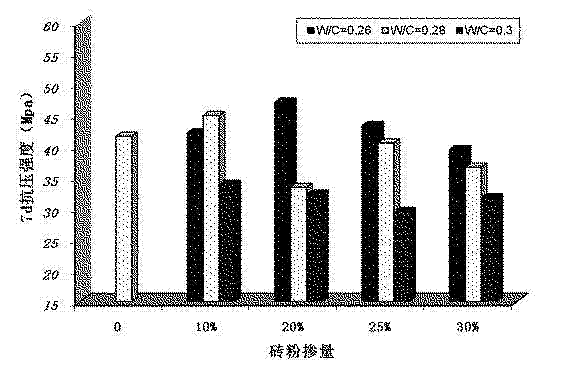

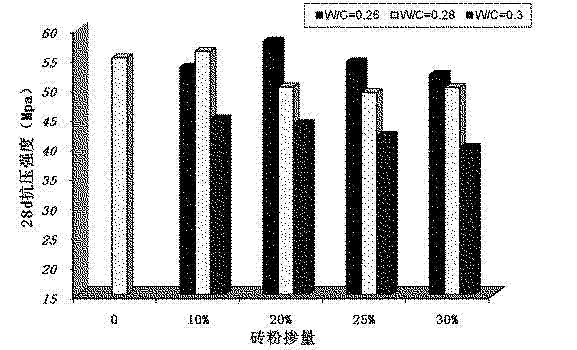

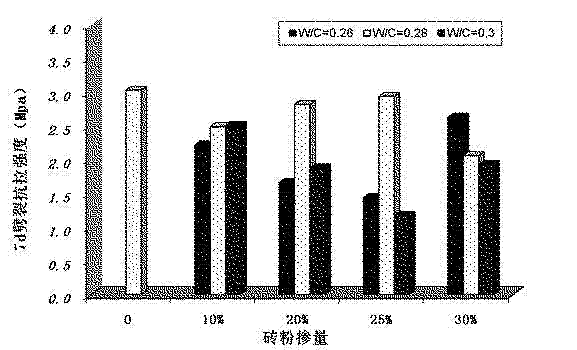

Waste chamotte brick regeneration and utilization method, and concrete doped with waste chamotte brick powder

InactiveCN102363575AReduce landfillEasy to handleConstruction waste recoverySolid waste disposalPollutantSulfur oxide

The invention discloses a waste chamotte brick regeneration and utilization method. The method comprises steps that: waste chamotte bricks are crushed and sieved; and the waste chamotte brick powder is doped into cement, such that a cementing material of concrete is prepared. An addition amount of the waste chamotte brick powder is 0-30wt% of that of the cementing material, wherein 0% is not included. The invention also discloses a concrete doped with the waste chamotte brick powder. The price of the waste chamotte brick powder is generally lower than that of cement. Therefore, when cement ispartially replaced by waste chamotte brick, the cost of concrete is reduced. Meanwhile, the production of cement is reduced, such that natural clay, limestone resources and coal resources can be saved. Also, discharge of environmental pollutants such as carbon dioxide and sulfur dioxide caused by cement production can be reduced from the source. The waste chamotte bricks are recycled and utilized, such that landfill and treatment of the waste chamotte bricks can be reduced, and treatment cost of construction wastes can be reduced. Therefore, the method and the concrete provided by the invention assist in protecting the environment, and satisfy the sustainable development strategy.

Owner:SHANDONG UNIV

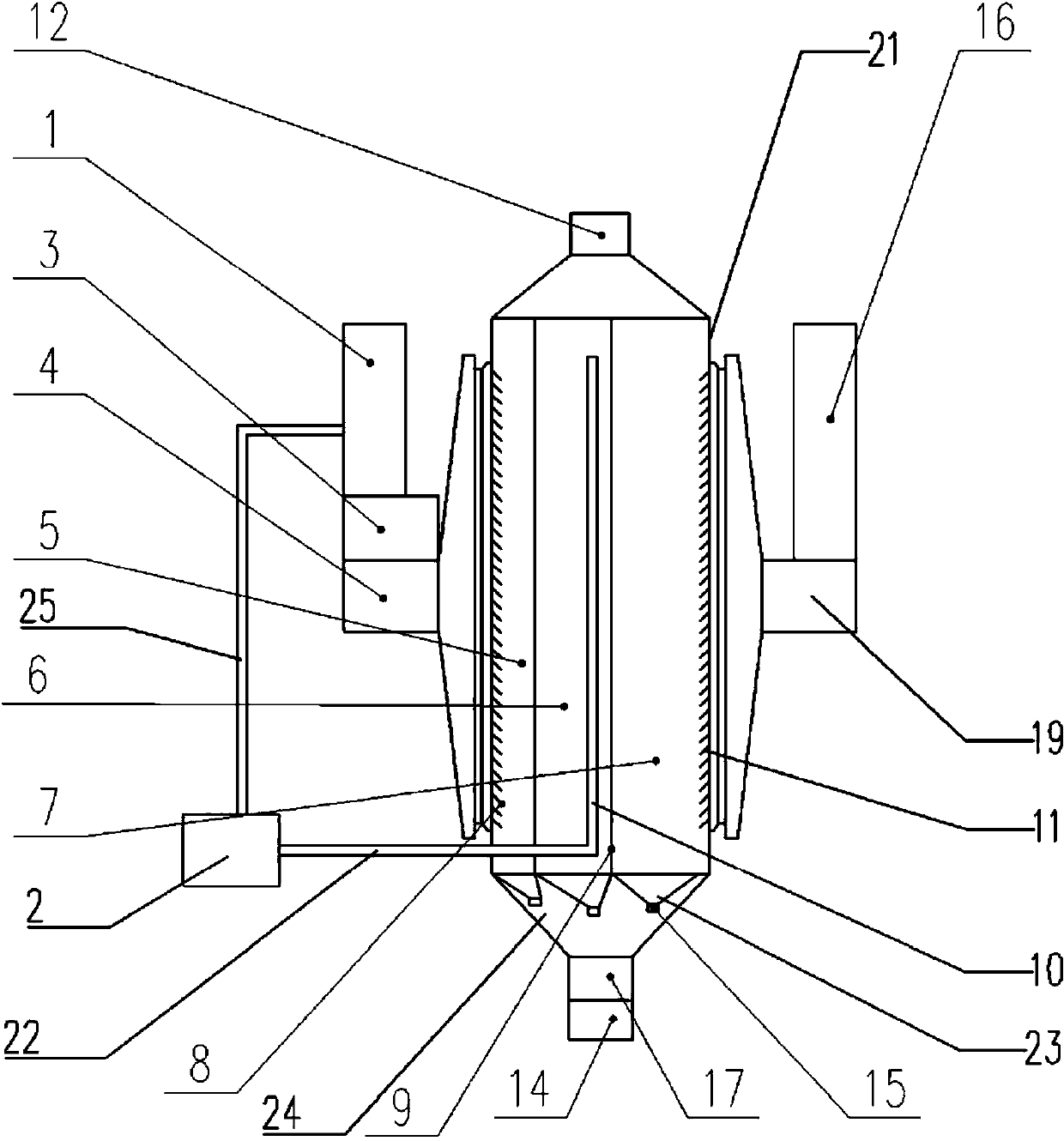

Flue gas treating device capable of synchronously removing sulfur, saltpeter, mercury and dedusting and its method

The invention discloses a flue gas treating device capable of synchronously removing sulfur, saltpeter, mercury and dedusting and its method, the flue gas treating device comprises a reactor case, an flue gas inlet and a flue gas outlet are provided on the reactor case, two parallel porous isolation devices are provided on a vertical direction in the reactor case, the isolation devices divides the inner part into a front chamber, a middle chamber and a rear chamber; a first shutter guide plate is provided at a communication part of the flue gas inlet and the front chamber, a second shutter guide plate is provided at the communication part of the flue gas outlet and the rear chamber, a feed inlet is provided at the top of the reactor case, and is communicated with the front chamber, the middle chamber and the rear chamber; a feed outlet is respectively provided at the bottom of the front chamber, the middle chamber and the rear bottom; and an ammonia gas distribution apparatus is provided in the middle chamber. The flue gas treating device has the advantages of small equipment volume and high treating efficiency, and can reach the flue gas treating effect with characteristics of removing sulfur, saltpeter, mercury and dedusting; has the characteristics of simple structure, energy saving and high efficiency, has advantages of agility, stabilization, high efficiency and low operation cost, and has wide application prospect.

Owner:张博 +1

Desulfurized gypsum thermal-insulation material

The invention relates to a desulfurized gypsum thermal-insulation material belonging to thermal-insulation materials. The waste pollutant desulfurized gypsum in the existing heat power plants is piled and filled in land, thereby polluting the ecological environment and influencing the safe operation of the power plants. The desulfurized gypsum thermal-insulation material provided by the invention comprises the following components in parts by weight: 80-85 parts of desulfurized building gypsum, 15-20 parts of vitrified microbead, 0.1-0.25 part of cellulose ether, 0.2-0.4 part of air entraining agent, 0.01-0.015 part of retarder and 70-100 parts of water. The components are added into water and evenly mixed to obtain the desulfurized gypsum thermal-insulation material. The desulfurized gypsum thermal-insulation material has the advantages of low coefficient of heat conductivity, thermal insulation and heat-shielding performance, energy saving, moderate strength, favorable workability and short construction cycle, has the functions of fire resistance, sound absorption, air humidity conditioning and the like, and reduces the piling and landfilling of the desulfurized waste residues as well as environmental pollution; and no CO2 is emitted in the production process.

Owner:上海城建置业发展有限公司 +1

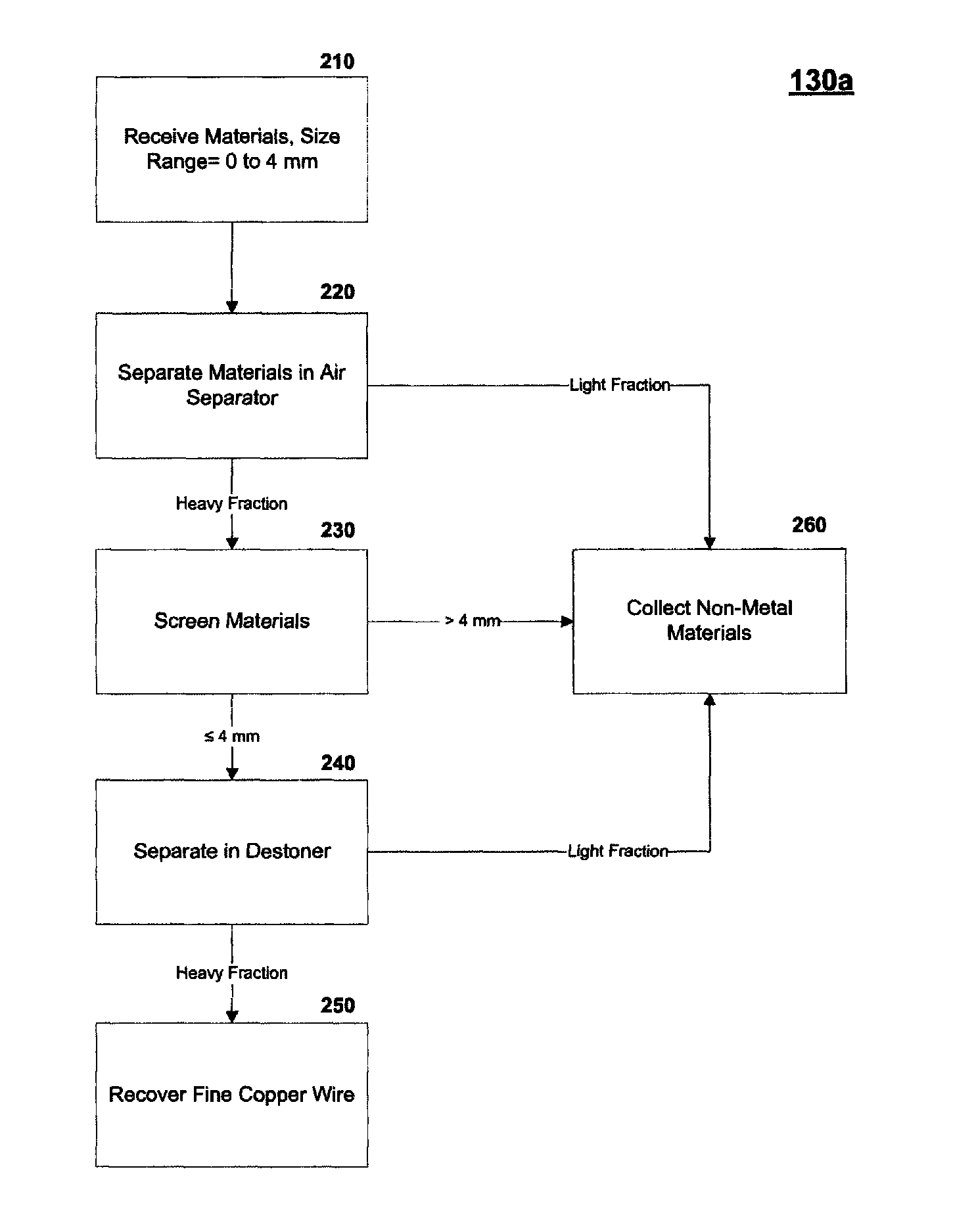

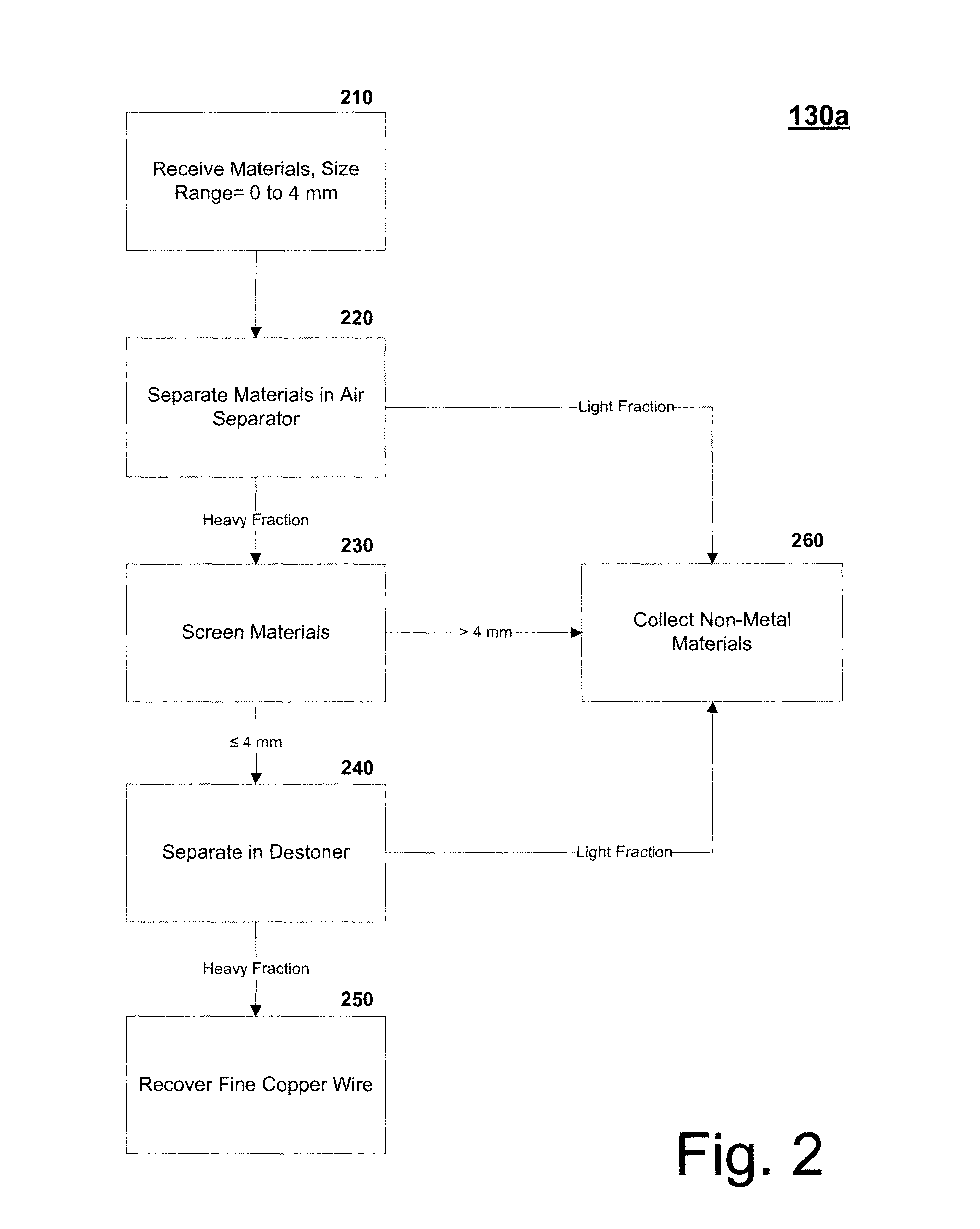

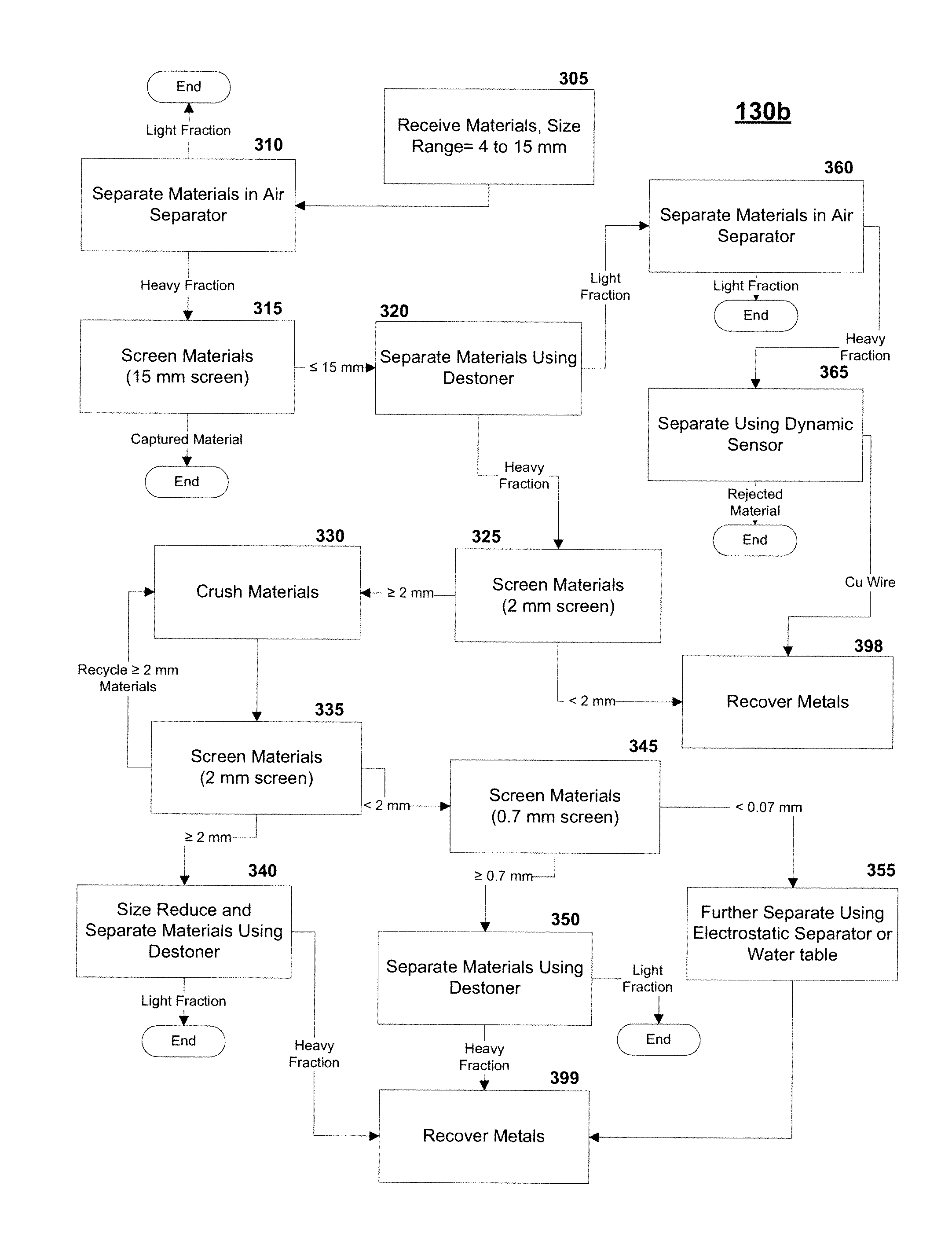

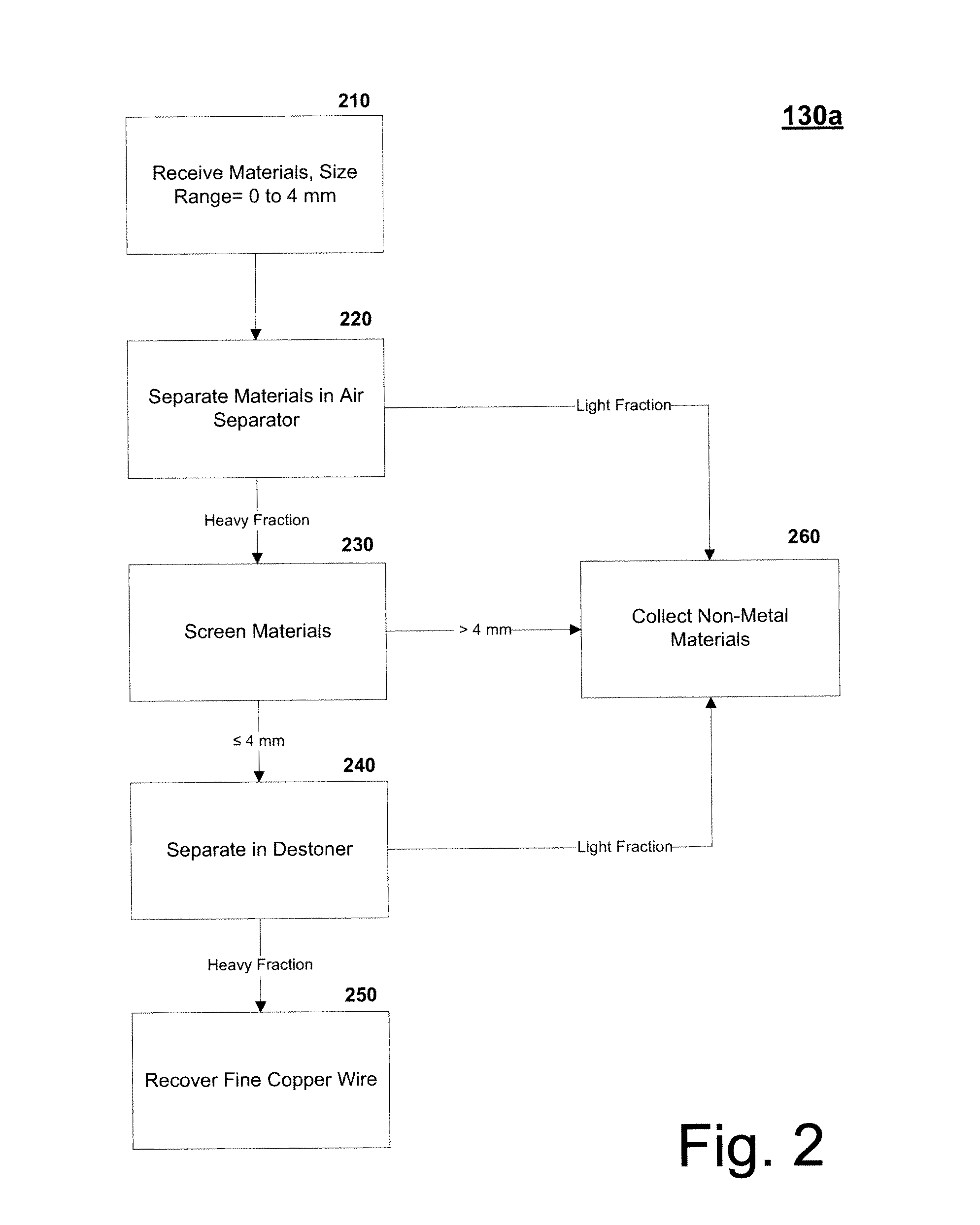

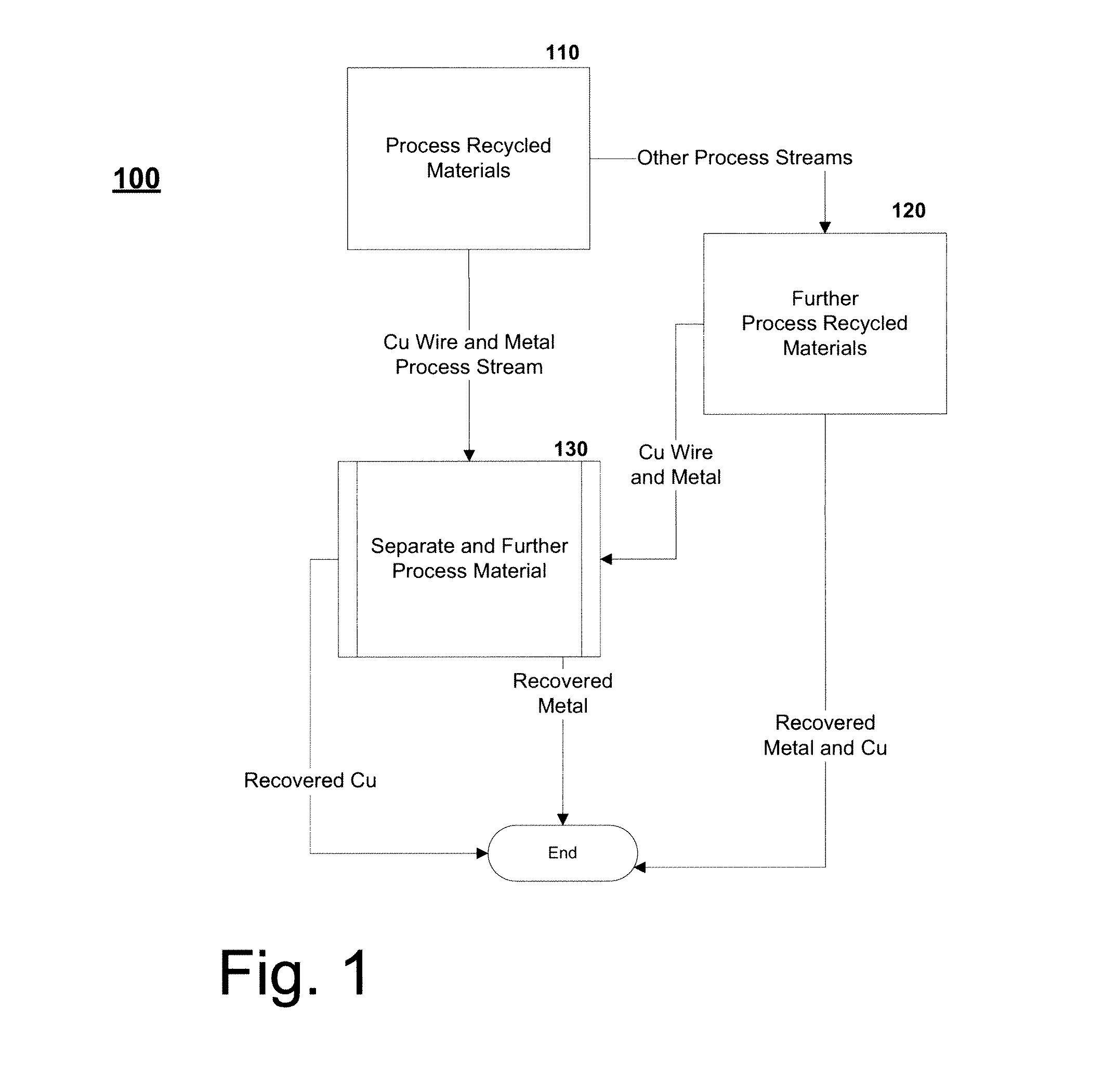

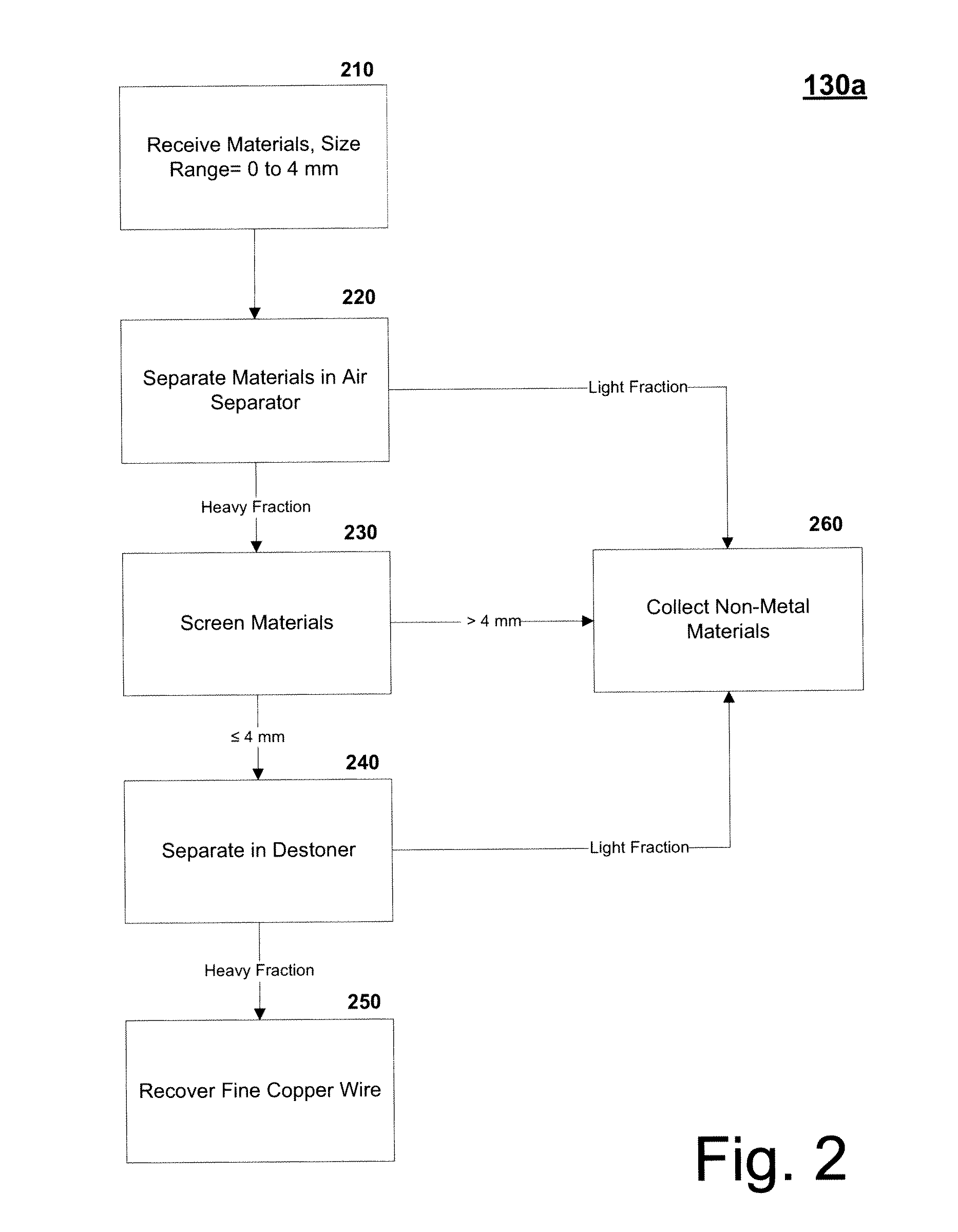

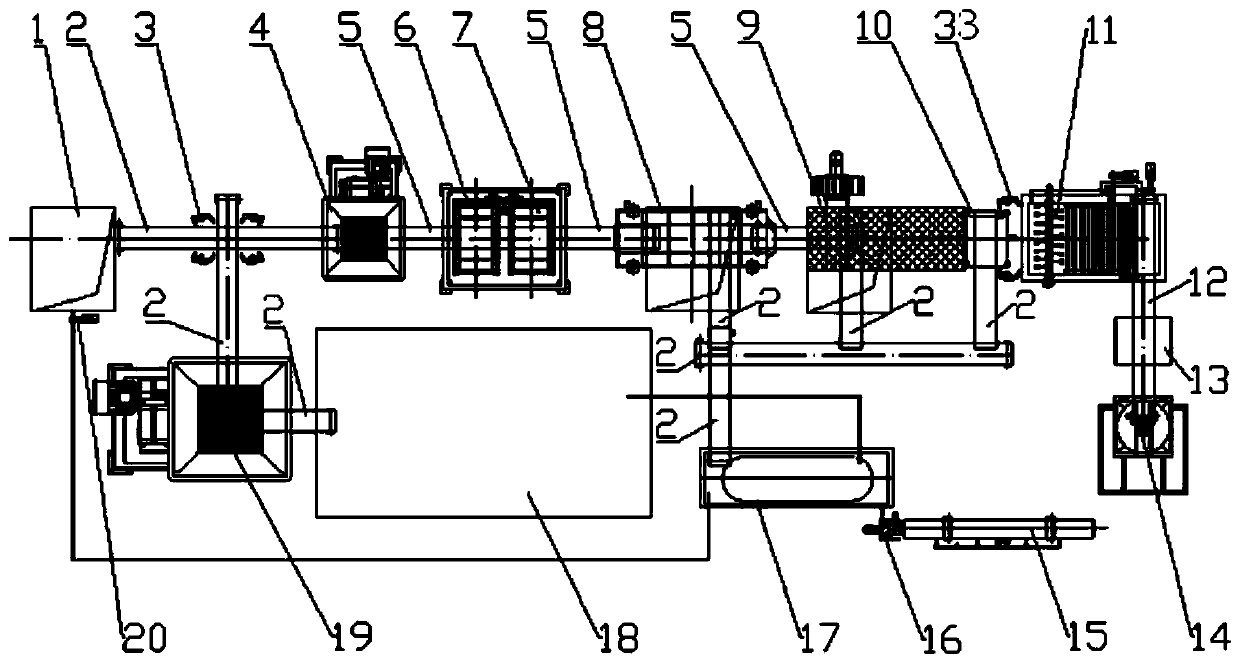

Method and System for Separating and Recovering Wire and Other Metal from Processed Recycled Materials

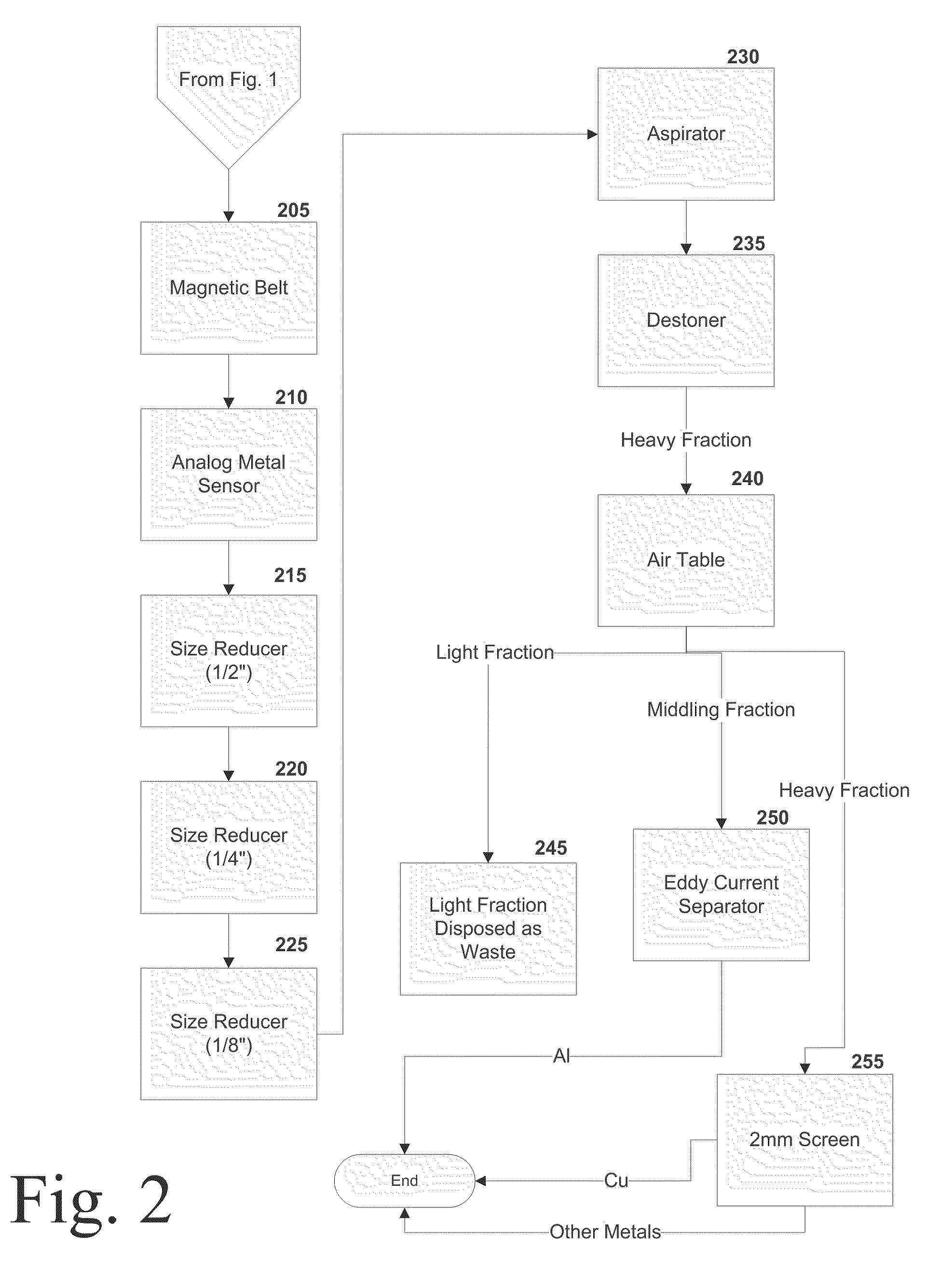

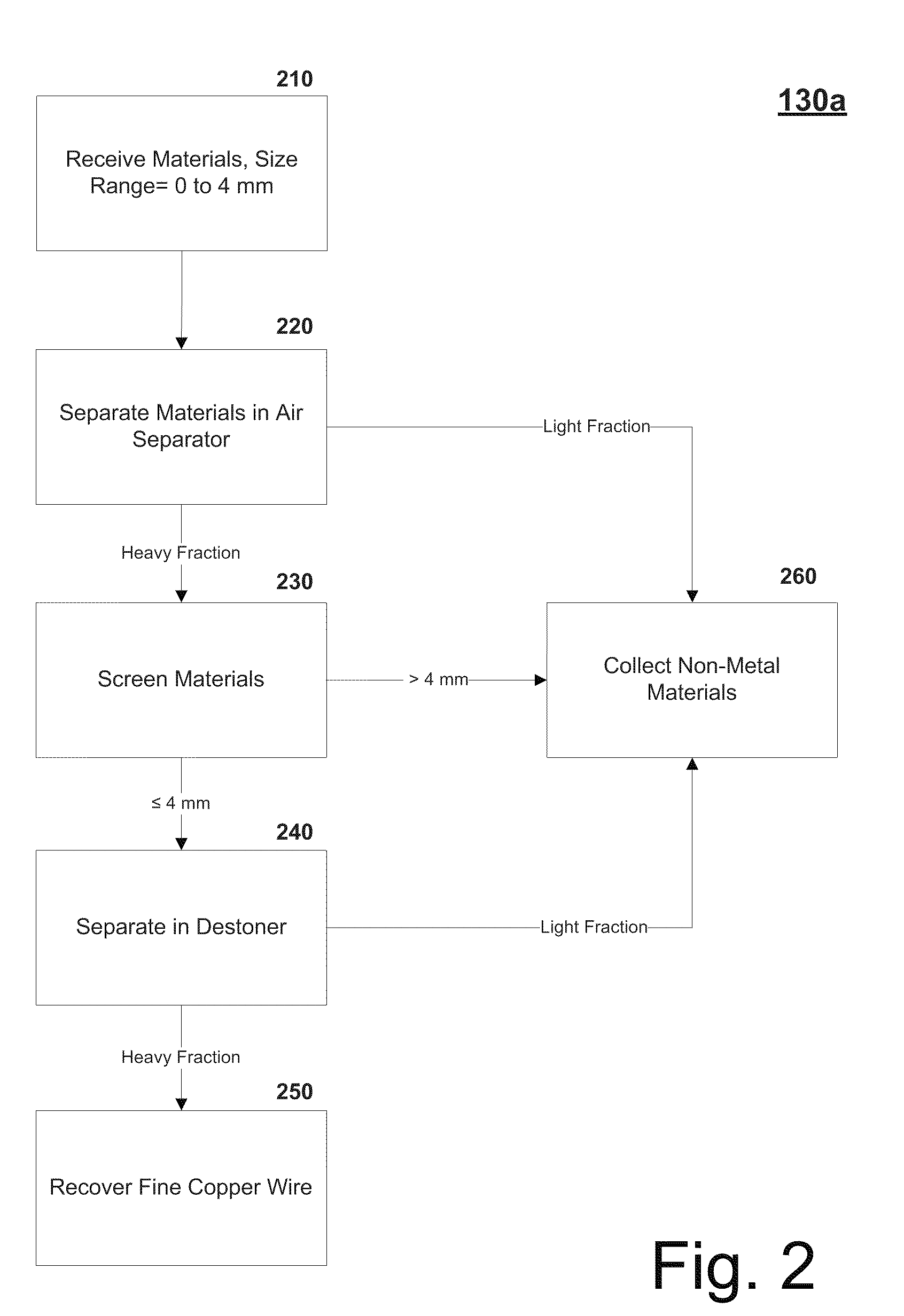

InactiveUS20110147501A1Efficient and cost-effectivePromote incomeGas current separationCocoaVacuum pressureAir separation

Processing waste materials to recover valuable metals, such as copper, from the materials. The disclosed systems and methods employ processes that further refine the waste materials to concentrate the metallic material after the waste materials are initially processed. Processes include employing air separation and screening. Processes also include employing a dynamic sensor and a vacuum pressure separator to separate metals from other materials. A central processing facility may process metal concentrate from multiple concentration facilities.

Owner:VALERIO THOMAS

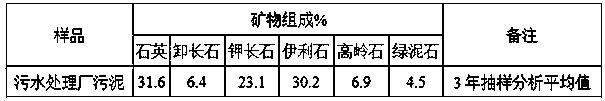

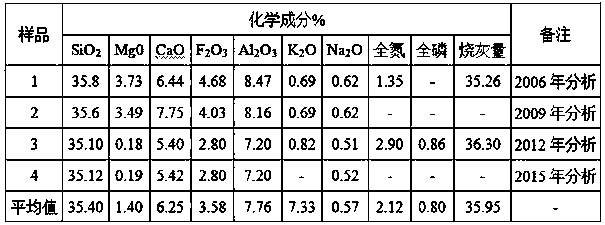

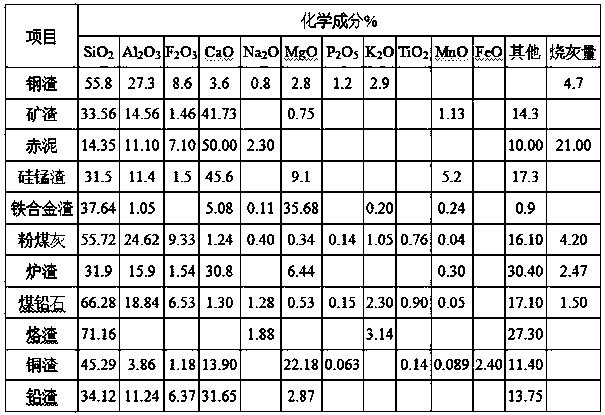

Method for pressing steaming-free and baking-free wall body block from dehydrated sludge in sewage treatment plant

The invention discloses a method for pressing a steaming-free and baking-free wall body block from dehydrated sludge in a sewage treatment plant. The method specifically comprises the following steps:dehydrating sludge of the sewage treatment plant, modifying the dehydrated sludge by virtue of seashell dust, ferrous sulfate and calcium hydroxide, so as to obtain modified sludge; mixing the modified sludge, the seashell dust, calcium sulfate, silica fume, slag charge, an F14 liquid activating agent and water, so as to obtain a mixture; digesting the mixture, so as to obtain a digested material; mixing the digested material, a solidifying agent and a YW-type surfactant, so as to obtain a blank preparing material; preparing a product workblank from the blank preparing material by virtue of apunching system; and carrying out pre-maintenance on the product workblank, and carrying out thermal air circulating reaction maintenance on the product workblank, so as to obtain the wall body block. The method has the beneficial effects that the problems in the effective treatment and resource utilization of the dehydrated sludge and industrial waste residue or engineering muck in the sewage treatment plant are solved, the cost is low, an obtained baking-free brick has excellent compressive strength, has no radioactivity, can be used for producing multiple specifications of wall body blocksand can be manufactured into building components for various uses.

Owner:宁波纯恒固废科技有限公司

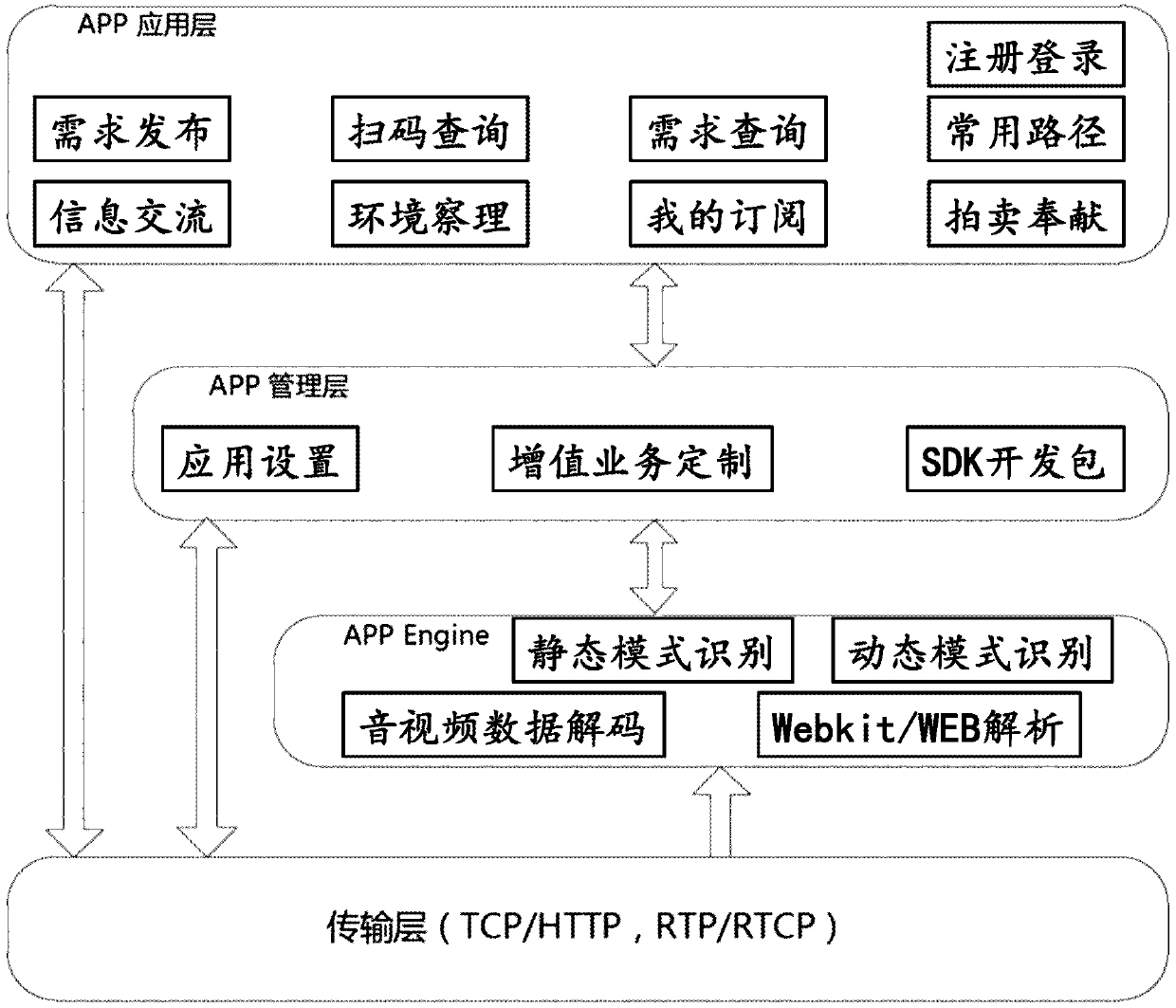

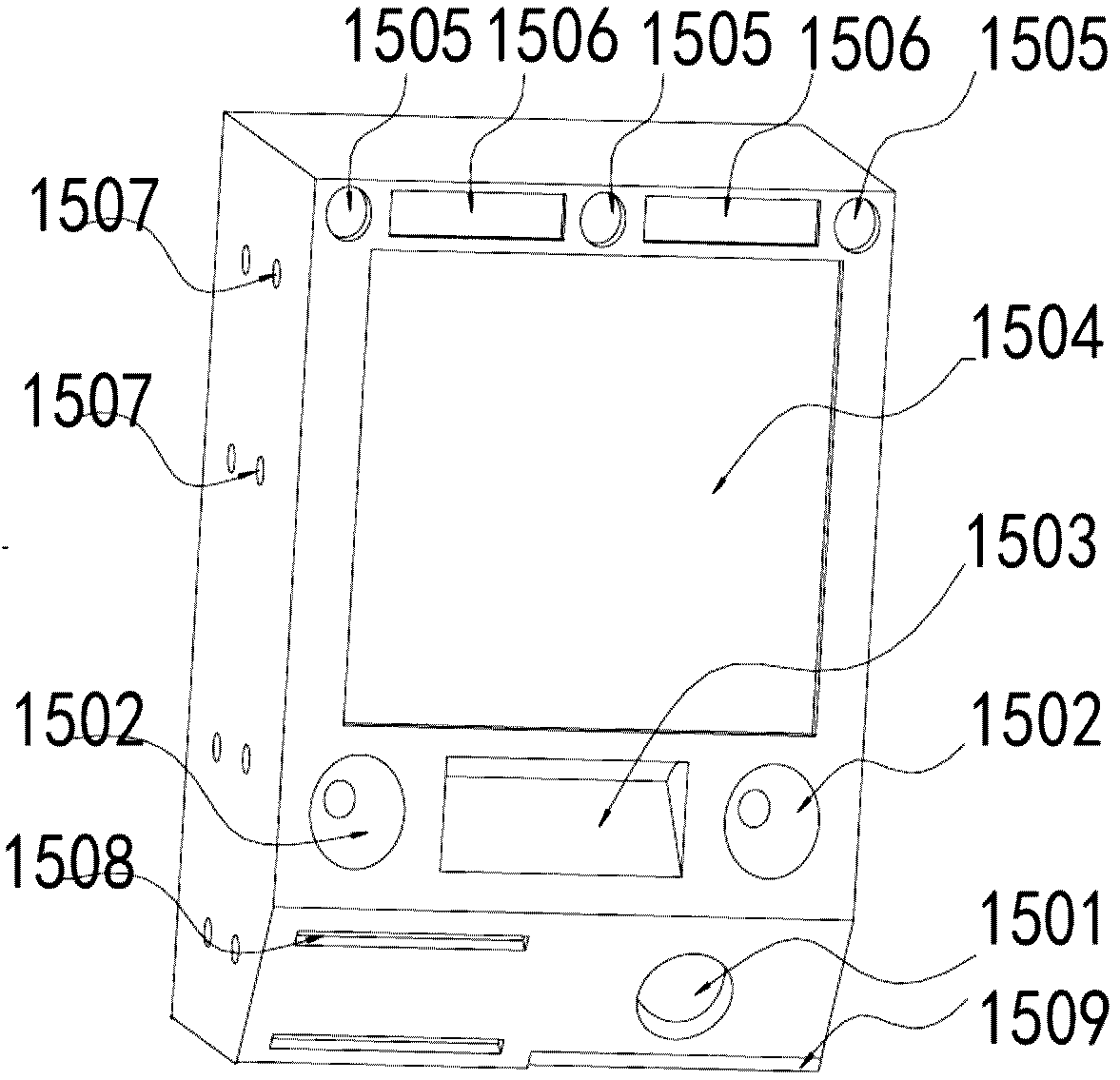

Identification code-containing device and device system and method for recycling identification code-containing device

PendingCN110135540ALow costImprove efficiencyData processing applicationsCo-operative working arrangementsRelevant informationManagement process

The invention provides an identification code-containing device and device system and a method for recycling the identification code-containing device. The invention sets articles or services to be managed in parallel with at least one device with a unique identification code or a device with a unique identification code, and scans or receives the identification code with the intelligent terminalbefore and after, and combines the relevant information in the system. The server generates a unique transaction ID in the system, and uses the unique identification code and the intelligent terminal,and its management device and system to manage the material or service data, and realizes the goods, services and exchange resources without printing the waybill or bill. The transfer and managementprocess, and the identification code form or the identifier-containing device can be recycled to the management process including the identification, classification, merging, transfer, transmission and reception, evaluation, statistics, and settlement. The program is applicable to various scenarios of commodity distribution, catering and take-out, second-hand item transfer sharing, transmission maintenance and repair, garbage classification and clearing and receiving, product life cycle management, volunteer management, and precision poverty alleviation.

Owner:北京联博达科技有限公司

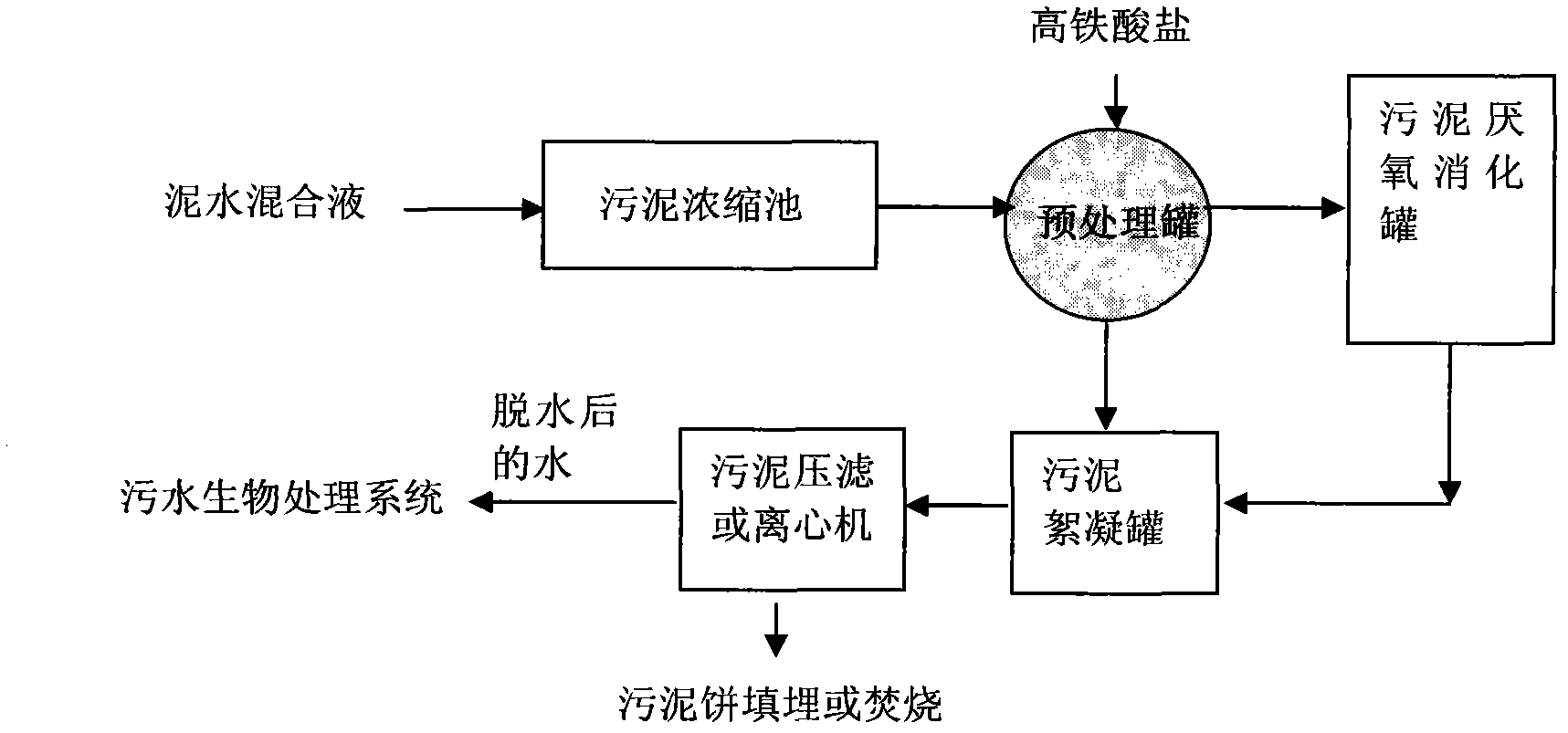

Method for treating sludge and promoting reduction of sludge by using ferrate

InactiveCN102531313AReduce bound water contentReduce filter specific resistanceSludge treatment by de-watering/drying/thickeningSludge processingMethane yieldEconomic benefits

The invention relates to a method of using ferrate for treating sludge and promoting dewatering and anaerobic digestion of excess sludge in sewage treatment plants so as to reduce sludge. The technical scheme of the method is that: after excess sludge is concentrated for 24 hours, concentrated sludge is firstly performed with oxidation treatment through ferrate and then is divided into two lines: one line is to directly add flocculating agent in sludge for dewatering, burying or burning, and the other line is to lead the sludge to enter an anaerobic digestion device so as to lead most of organic matter in sludge to be degraded, and then flocculating agent is added for dewatering, and finally sludge is buried or burned. The method can improve sludge dewatering performance, reduce excess sludge volume, enhance sludge anaerobic digestion performance, greatly improve methane yield, shorten anaerobic digestion time and greatly reduce expanse for sludge treatment and disposition, has the advantages of being simple in device, small in investment, free of pollution, convenient to operate and manage, high in economic benefit and the like, and is applicable to the industry and town sewage treatment plants.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

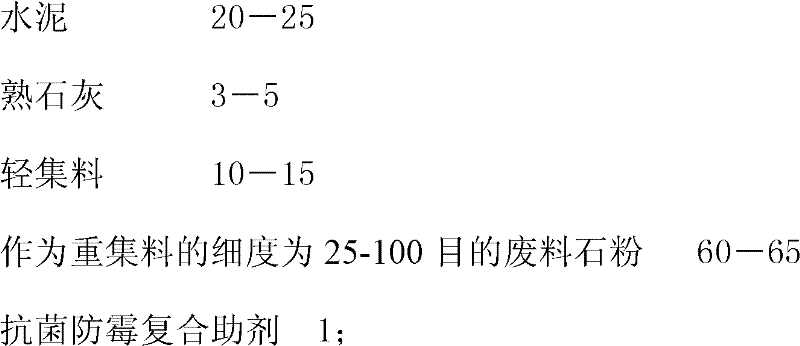

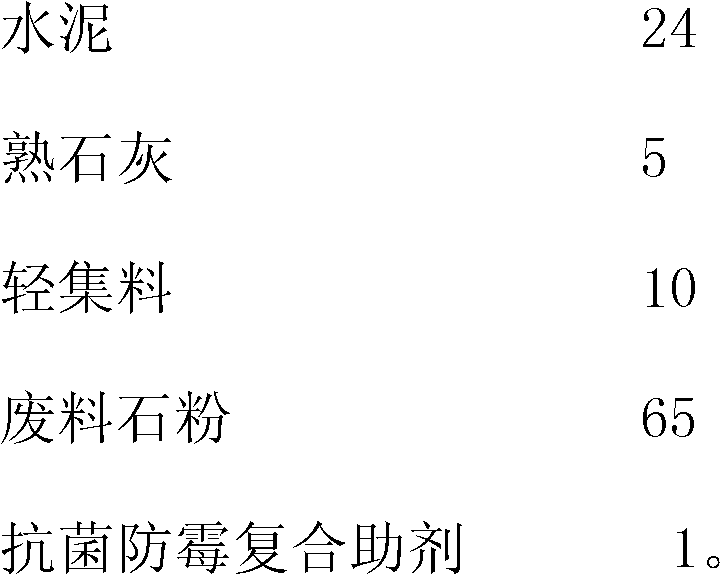

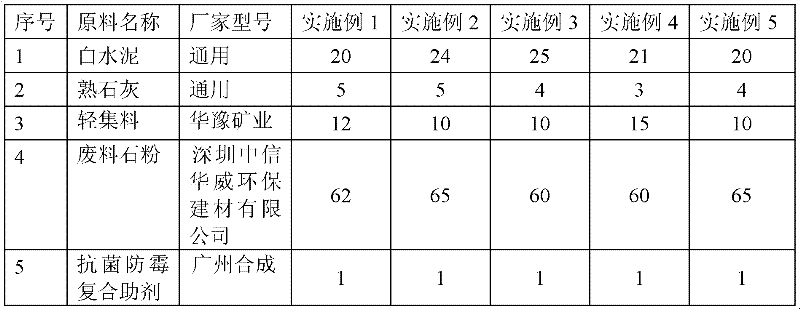

Light and environment-friendly leveling putty and construction method thereof

InactiveCN102250502AReduce stackingReduce landfillFilling pastesEnvironmental resistanceCrack resistance

The invention discloses light and environment-friendly leveling putty, which is prepared by mixing the following components in part by weight: 20 to 25 parts of cement, 3 to 5 parts of hydrated lime, 10 to 15 parts of light aggregate, 60 to 65 parts of waste stone powder of fineness of 25 to 100 meshes and 1 part of antibacterial and mildewproof composite assistant, wherein the light aggregate is inorganic vitreous hollow microporous material of which the fineness is lower than 100 meshes; and each kilogram of the antibacterial and mildewproof composite assistant is prepared by mixing 0.4 kilogram of antibacterial and mildewproof component, 0.1 kilogram of water-retaining agent, 0.3 kilogram of redispersible polymer powder and 0.2 kilogram of air entraining agent. The waste stone powder made of building waste can be recycled, so the comprehensive utilization of building waste can be promoted and the economic, ecological and social benefit can be improved. The putty is light and improved in cracking resistance; being well compatible with a basic layer, the putty makes the leveling easy and can improve the construction efficiency and construction effect; and the putty is more suitable for molded and mechanical construction and can make the construction process simple and reduce construction price per unit square meter. The light and environment-friendly leveling putty also has the functions of reducing growth of mould and bacteria and is suitable for all indoor decorative surface leveling and polishing projects.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

Method and system for separating and recovering wire and other metal from processed recycled materials

InactiveUS8360347B2Efficient and cost-effectivePromote incomeGas current separationSolid waste disposalVacuum pressureMetallic materials

Processing waste materials to recover valuable metals, such as copper, from the materials. The disclosed systems and methods employ processes that further refine the waste materials to concentrate the metallic material after the waste materials are initially processed. Processes include employing air separation and screening. Processes also include employing a dynamic sensor and a vacuum pressure separator to separate metals from other materials.

Owner:VALERIO THOMAS A

Method and System for Separating and Recovering Wire and Other Metal from Processed Recycled Materials

InactiveUS20110024531A1Facilitates revenue recoveryReduce landfillGas current separationSolid waste disposalVacuum pressureMetallic materials

Processing waste materials to recover valuable metals, such as copper, from the materials. The disclosed systems and methods employ processes that further refine the waste materials to concentrate the metallic material after the waste materials are initially processed. Processes include employing air separation and screening. Processes also include employing a dynamic sensor and a vacuum pressure separator to separate metals from other materials.

Owner:VALERIO THOMAS A

Low-impedance automobile wire harness connecting terminal crimping technology

InactiveCN104701706ATo achieve the effect of densificationClosely arrangedLine/current collector detailsVehicle connectorsEngineeringCable harness

The invention relates to the technical field of automobile wire harness manufacture, in particular to an automobile wire harness crimping technology. A low-impedance automobile wire harness connecting terminal crimping technology is implemented by crimping a connecting terminal and an automobile wire harness body together by stamping equipment, and includes the technological steps of wire harness splitting, die debugging, crimping, tension test and performance detection. By the aid of the technical scheme, the low-impedance automobile wire harness connecting terminal crimping technology has the advantages of easiness in control of equipment input and improvement cost, good generated effects and capability of enabling wire harnesses to have low impedance characteristic and meet more demands of the market.

Owner:SHANGHAI MANKASON IND

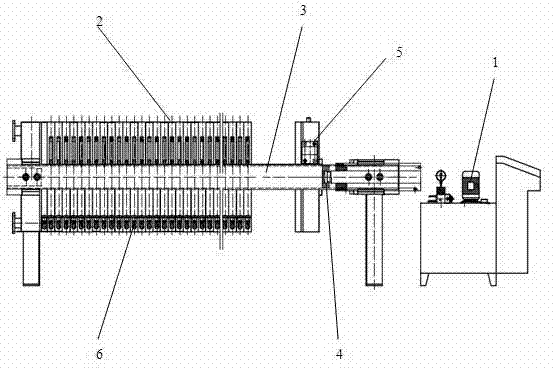

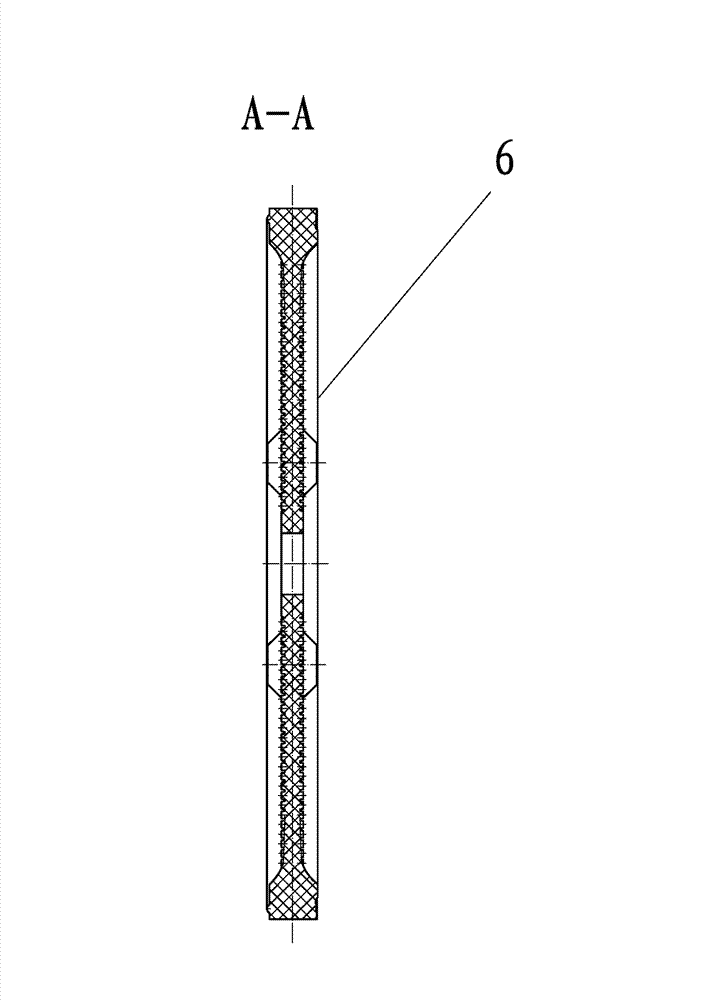

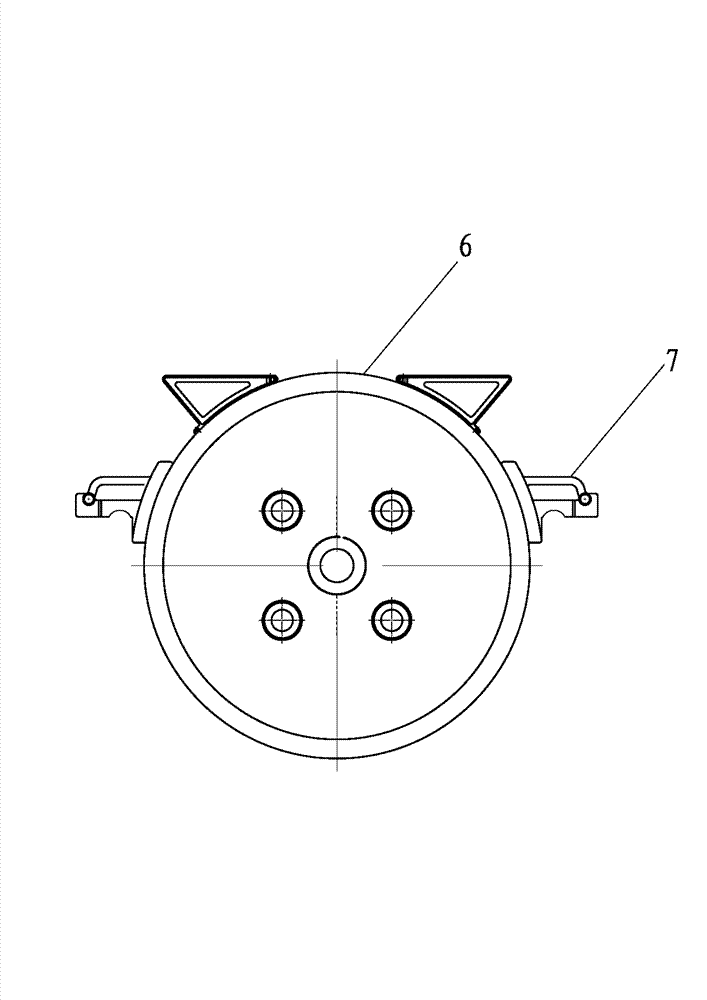

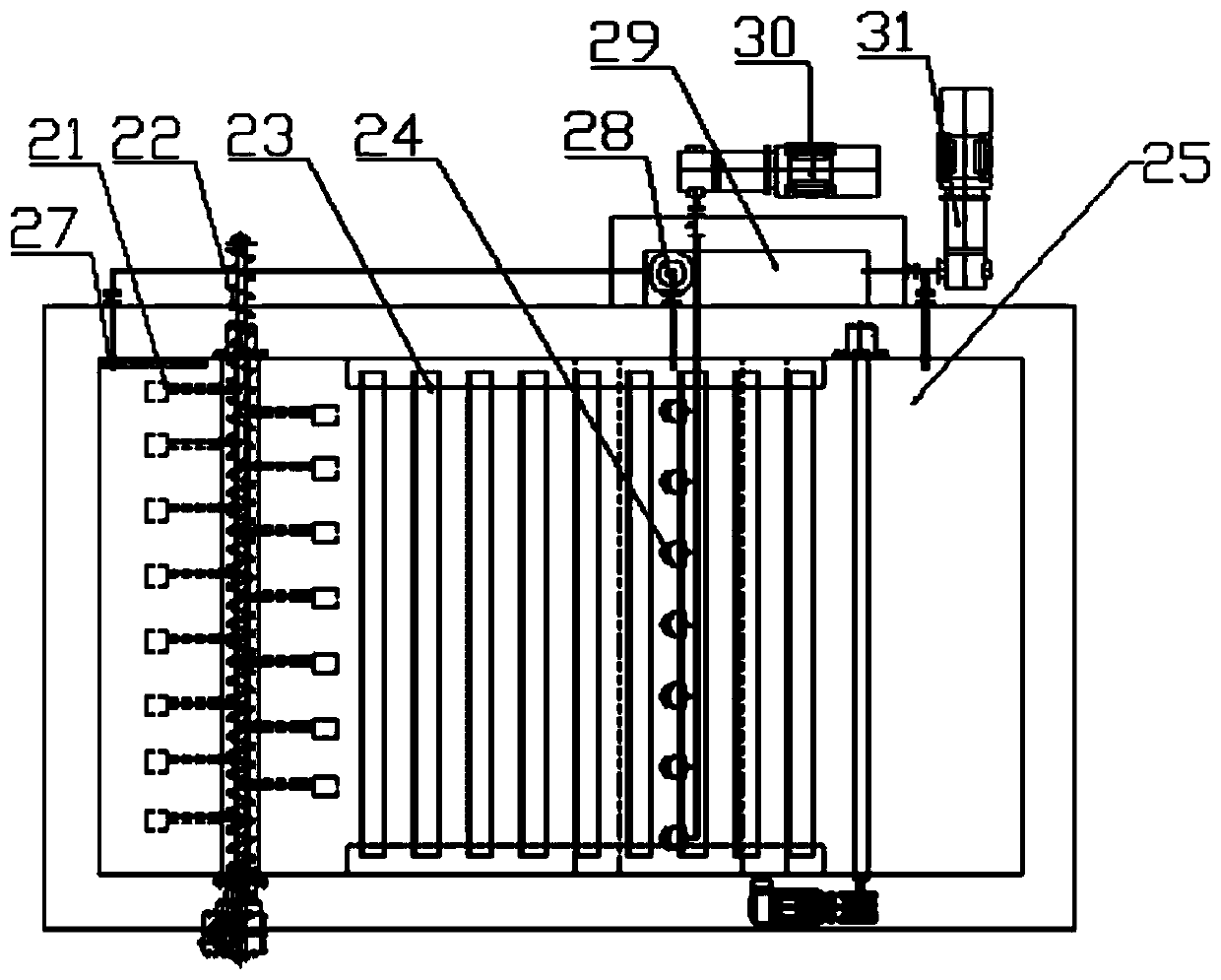

Ceramic filter pressing plate, manufacturing method thereof and filter press using same

InactiveCN102701643ASave energyHigh pressure resistantCeramic shaping apparatusFiltration separationFilter pressPolypropylene

The invention relates to the technical field of the filter pressing plate of a filter press, in particular to a ceramic filter pressing plate, a manufacturing method thereof and a filter press using the ceramic filter pressing plate. The ceramic filter pressing plate is formed by pressing the mixture of ceramic waste residues and polypropylene. Compared with the prior art, the ceramic filter pressing plate and the filter press using the ceramic filter pressing plate are characterized in that: the ceramic waste residues are reused so that no pollution is caused to the environment, in addition, the energy consumption of polypropylene or polyethylene material is lowered, and the cost is saved.

Owner:FOSHAN JINKAIDI FILTRATION EQUIP CO LTD

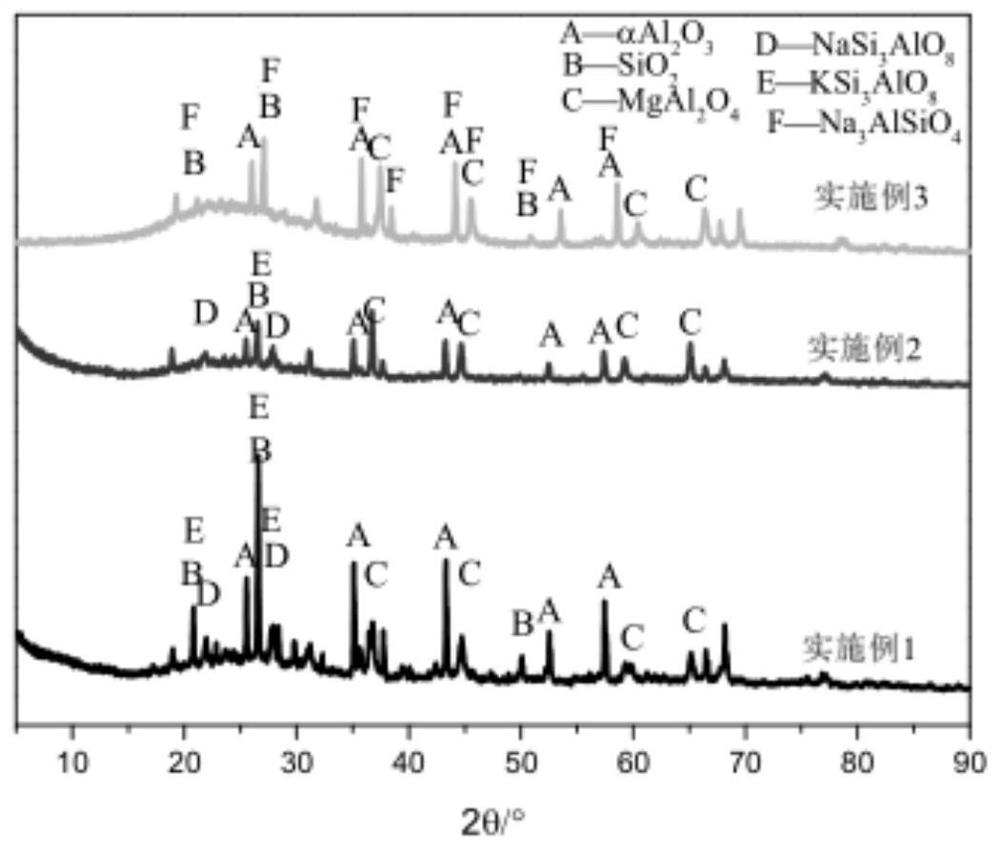

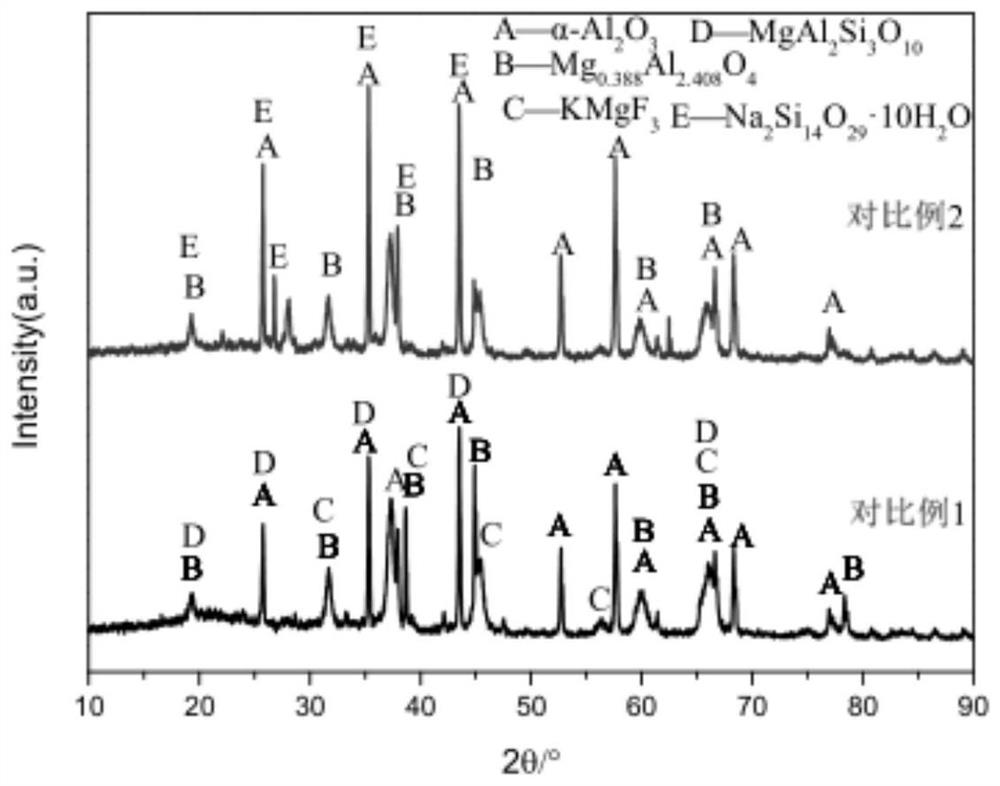

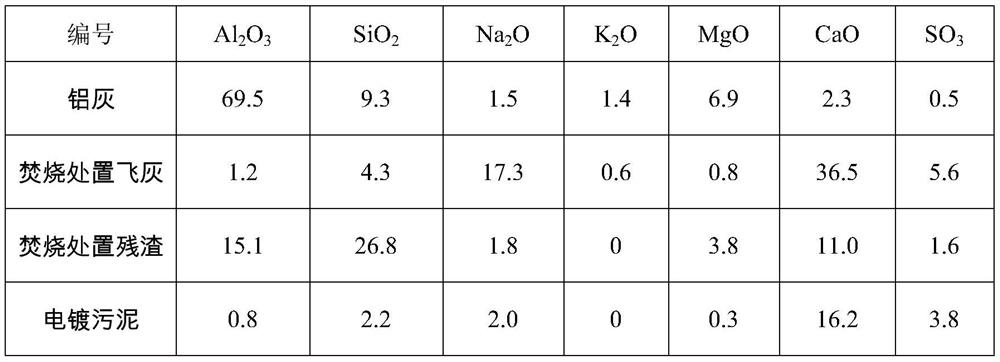

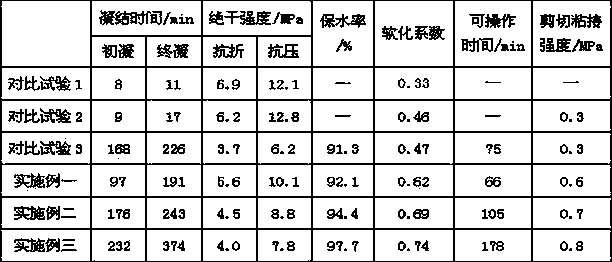

Aluminum ash-based porous ceramic material and preparation method thereof

The invention discloses an aluminum ash-based porous ceramic material and a preparation method thereof, raw materials including secondary aluminum ash, incineration treatment fly ash, incineration treatment slag, electroplating sludge and silicon-containing solid waste are sequentially subjected to mixing ball milling, high-pressure dry forming and firing, and the aluminum ash-based porous ceramic material is obtained. The method is simple to operate, no water participates in the preparation process, harmful gas released by reaction of aluminum ash with water is avoided, all the raw materials adopt solid waste, no additional commercial chemical reagent is needed, the cost is low, and the prepared porous ceramic material is small in volume weight, high in strength, good in heavy metal curing effect and free of secondary pollution.

Owner:武汉大学(肇庆)资源与环境技术研究院

Waste feather regenerated pure keratin fiber and preparation method thereof

ActiveCN111910282AGood molecular weightGood yieldMonocomponent protein artificial filamentPeptide preparation methodsSodium bicarbonateFiber

The invention discloses a waste feather regenerated pure keratin fiber and a preparation method thereof. The preparation method of the waste feather regenerated pure keratin fiber comprises the stepsthat performing high-temperature flash explosion treatment on waste feathers and then performing treatment with urea to obtain feather keratin; dissolving the feather keratin, and adding an antibacterial agent while dissolving; adding sodium hexadecyl sulfonate, performing aging, and heating to obtain a spinning solution; and preparing the regenerated keratin fibers by using the spinning solution.The waste feather keratin with excellent molecular weight and yield is obtained by adopting a high-temperature flash explosion and low-concentration urea synergistic treatment method, the antibacterial regenerated keratin fibers with high additional values are developed on the basis, a new solvent system of sodium carbonate, sodium bicarbonate and hexadecyl sodium sulfonate is developed, and thespinnability of a keratin solution is improved.

Owner:NANTONG UNIVERSITY +1

Water-resistant gypsum base wall repair material

The invention relates to a water-resistant gypsum base wall repair material. The water-resistant gypsum base wall repair material comprises, by weight, 100 parts of desulfurated building gypsum, 5.1-10.5 parts of compound additive A, 10-20 parts of manganese slag powder, 5-10 parts of cement, 0.1-0.6 part of water-retaining agents and 0.3-0.7 part of water reducing agents. The compound additive A has delayed coagulation, water resistance and adhesion enhancement effects, and the acquired gypsum base wall repair material is reasonable in operation time and good in water resistance, adhesion performance, mechanical property and construction performance. Due to the fact that a lot of industrial by-products and waste are used, the water-resistant gypsum base wall repair material has the advantages that environment friendliness is achieved and the ecological environment is protected.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

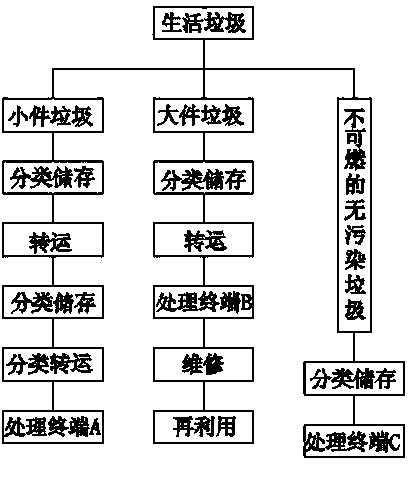

Environment-friendly separate garbage collection, transferring and processing method

InactiveCN103567215AEasy to handleImprove processing efficiencySolid waste disposalFurniture waste recoveryPaper millPollution

The invention provides an environment-friendly separate garbage collection, transferring and processing method. The method comprises the following steps: determining and sorting processing ways, and transferring and processing garbage in different processing ways, and the method is characterized by comprising the following specific steps: dividing the garbage into small garbage, large garbage and incombustible non-pollution garbage; processing the small garbage, namely separately putting, separately storing in a transfer station and separately transferring to all processing terminals; processing the large garbage, namely separately storing, separately transferring to all processing terminals and reusing after processing; and processing the incombustible non-pollution garbage, namely storing and transferring to all processing terminals. The processing terminals include paper mills, plastic prilling factories, glass treatment plants, metal smelting factories, waste incineration power plants, electronic product recovery factories, furniture recycle maintenance factories and the like. The method provided by the invention has the beneficial effects that the recovery rate is high, healthy and environment-friendly effects can be achieved, and the landfill and waste incineration can be reduced.

Owner:杨华

Method and System For Separating and Recovering Wire and Other Metal from Processed Recycled Materials

InactiveUS20130008832A1Efficient and cost-effectivePromote incomeGas current separationSolid waste disposalVacuum pressureMetallic materials

Processing waste materials to recover valuable metals, such as copper, from the materials. The disclosed systems and methods employ processes that further refine the waste materials to concentrate the metallic material after the waste materials are initially processed. Processes include employing air separation and screening. Processes also include employing a dynamic sensor and a vacuum pressure separator to separate metals from other materials.

Owner:VALERIO THOMAS A

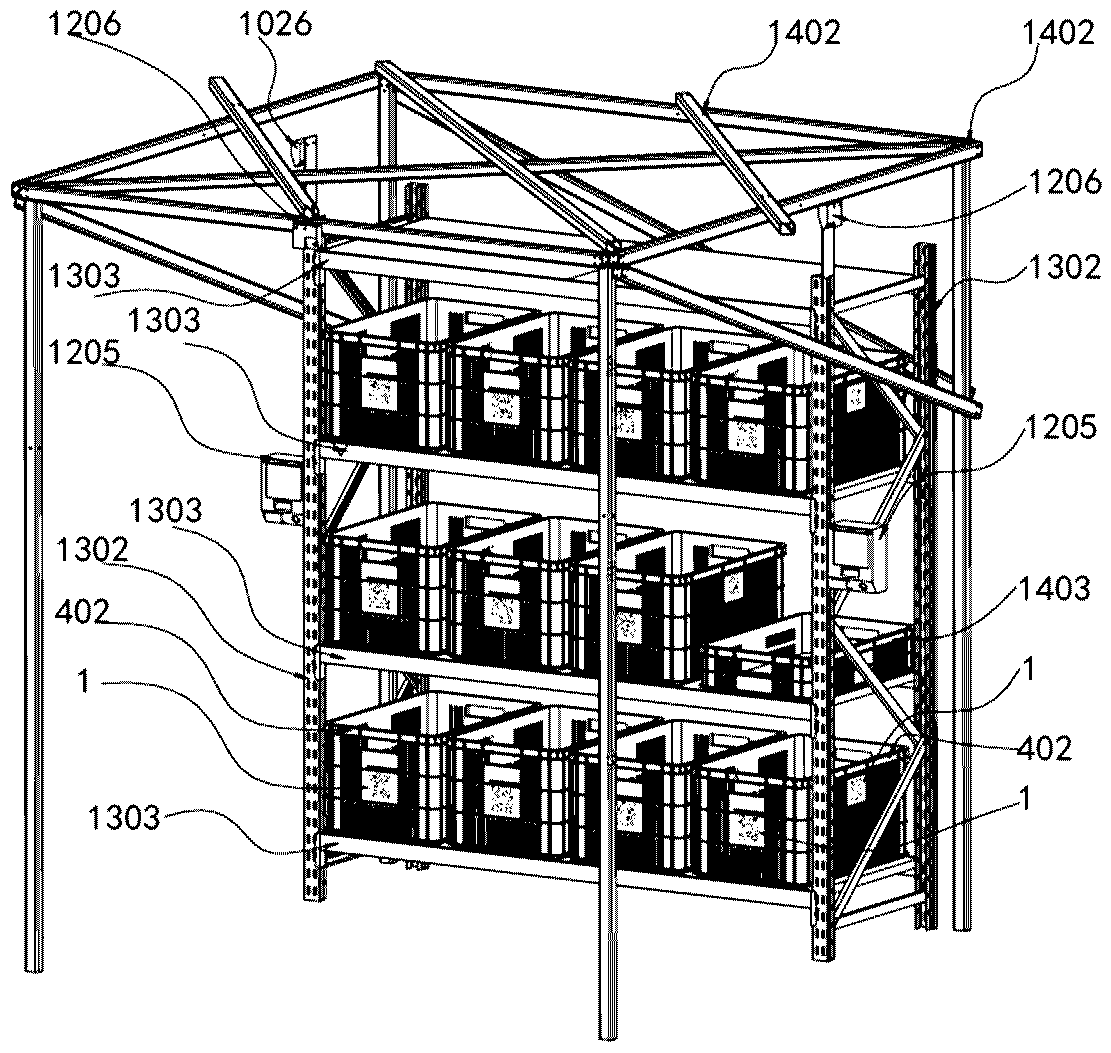

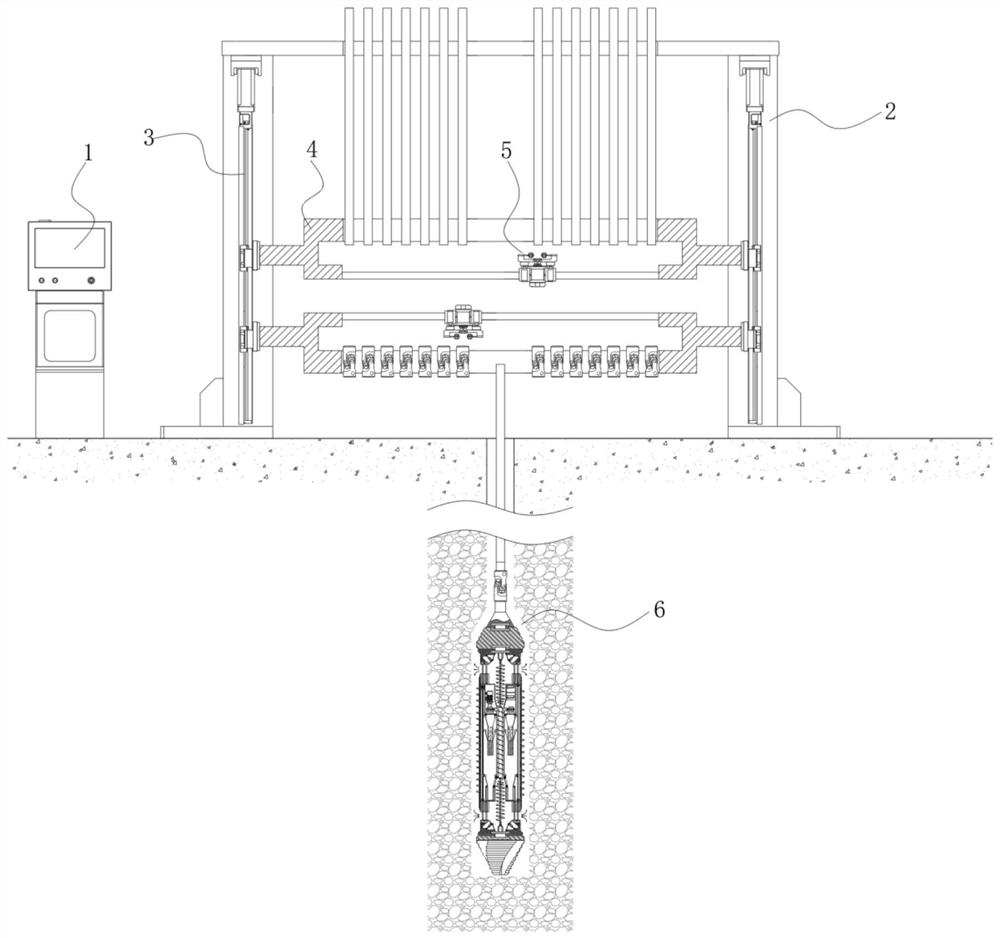

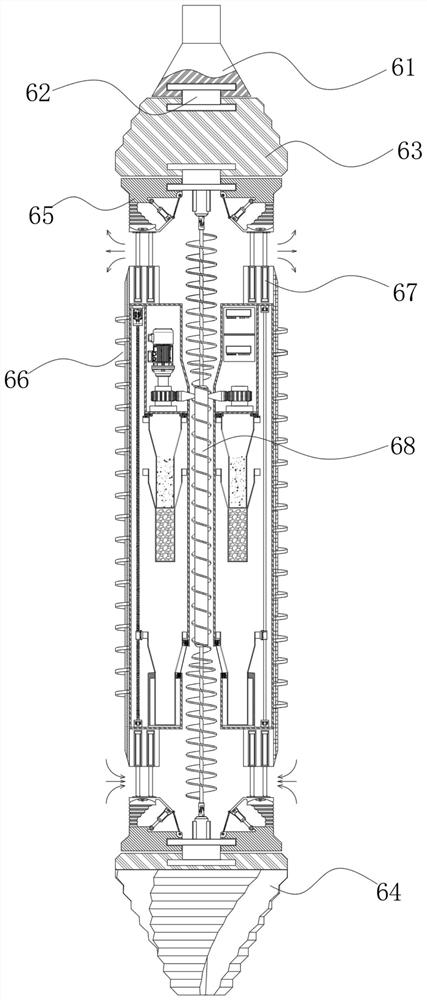

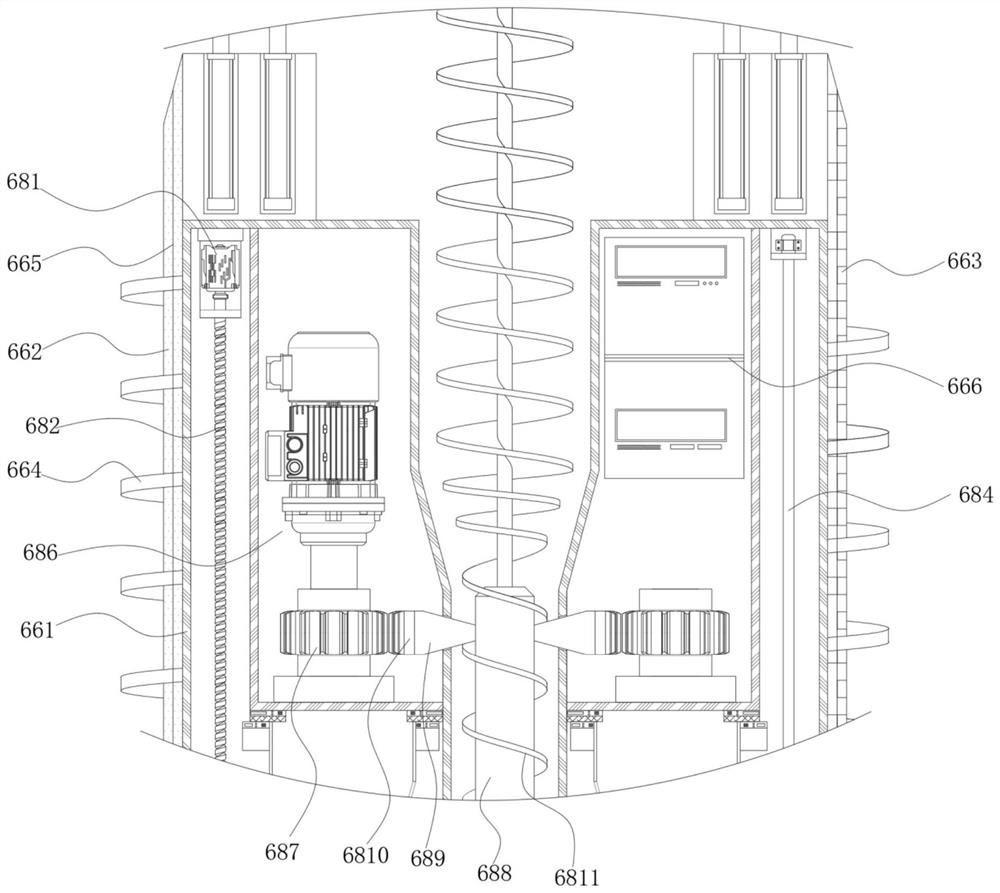

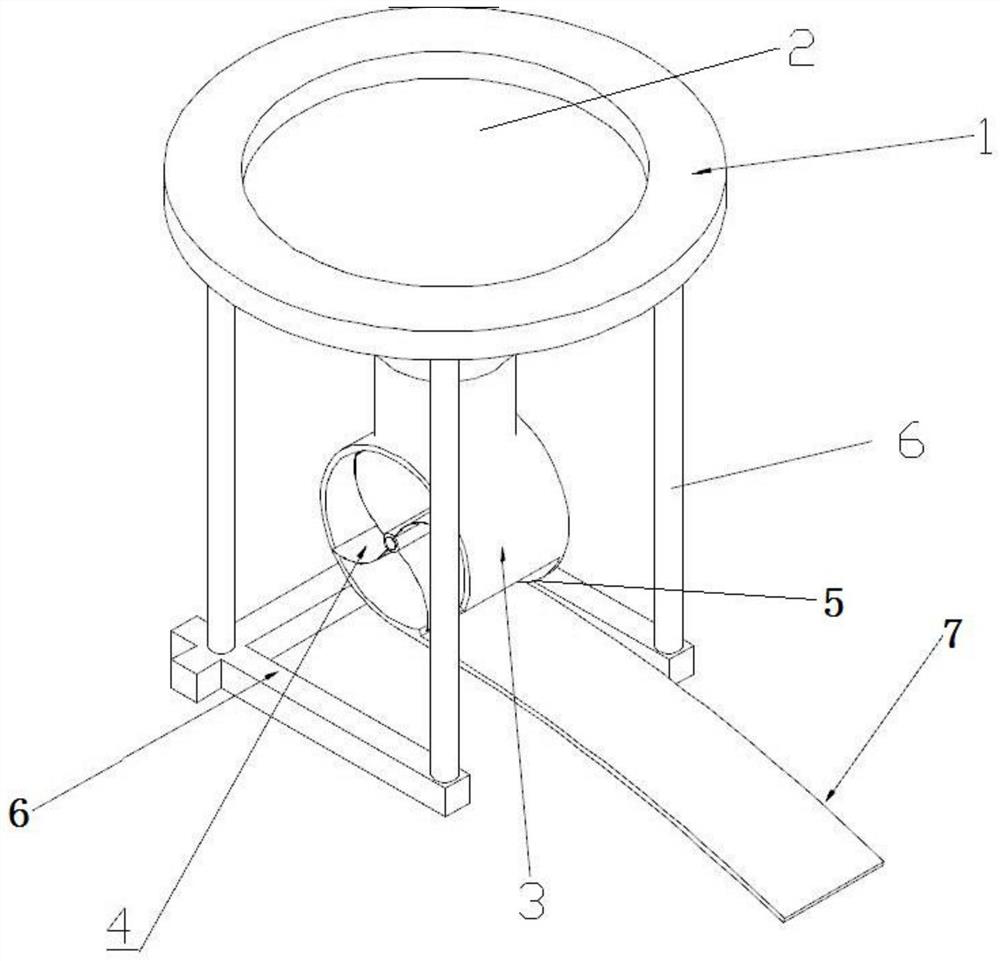

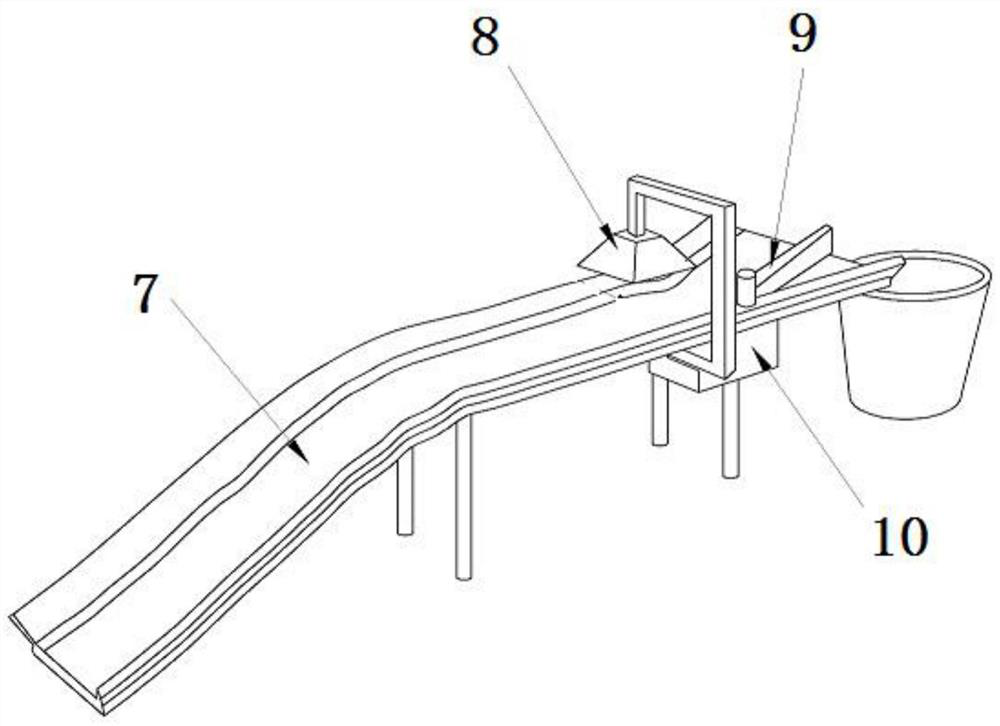

Sampling device for repairing heavy metal contaminated soil by biochar

InactiveCN113654832AReduce the amount of backupReduce landfillWithdrawing sample devicesEarth material testingEngineeringStructural engineering

The invention discloses a sampling device for repairing heavy metal contaminated soil by biochar, which comprises: a frame fixed at a fixed point to be sampled, one side of which is provided with an intelligent screen for monitoring and regulation; two groups of lifting frames which are longitudinally mounted on the left side plate and the right side plate of the building frame; two sets of placing plate frames which are transversely installed on the lifting frame on the left side and the lifting frame on the right side and are arranged in an upper-line parallel mode, longitudinal splicing rods are placed on the upper placing plate frame, and first longitudinal couplings are placed on the lower placing plate frame and used for splicing of the splicing rods; driving clamping seats which are arranged into two groups, are respectively mounted on the corresponding placing plate frames, and are used for taking and placing the corresponding splicing rods and the couplings I; and a sampling device which is mounted at the lower end of the first group of coupling I.

Owner:TONGREN UNIV

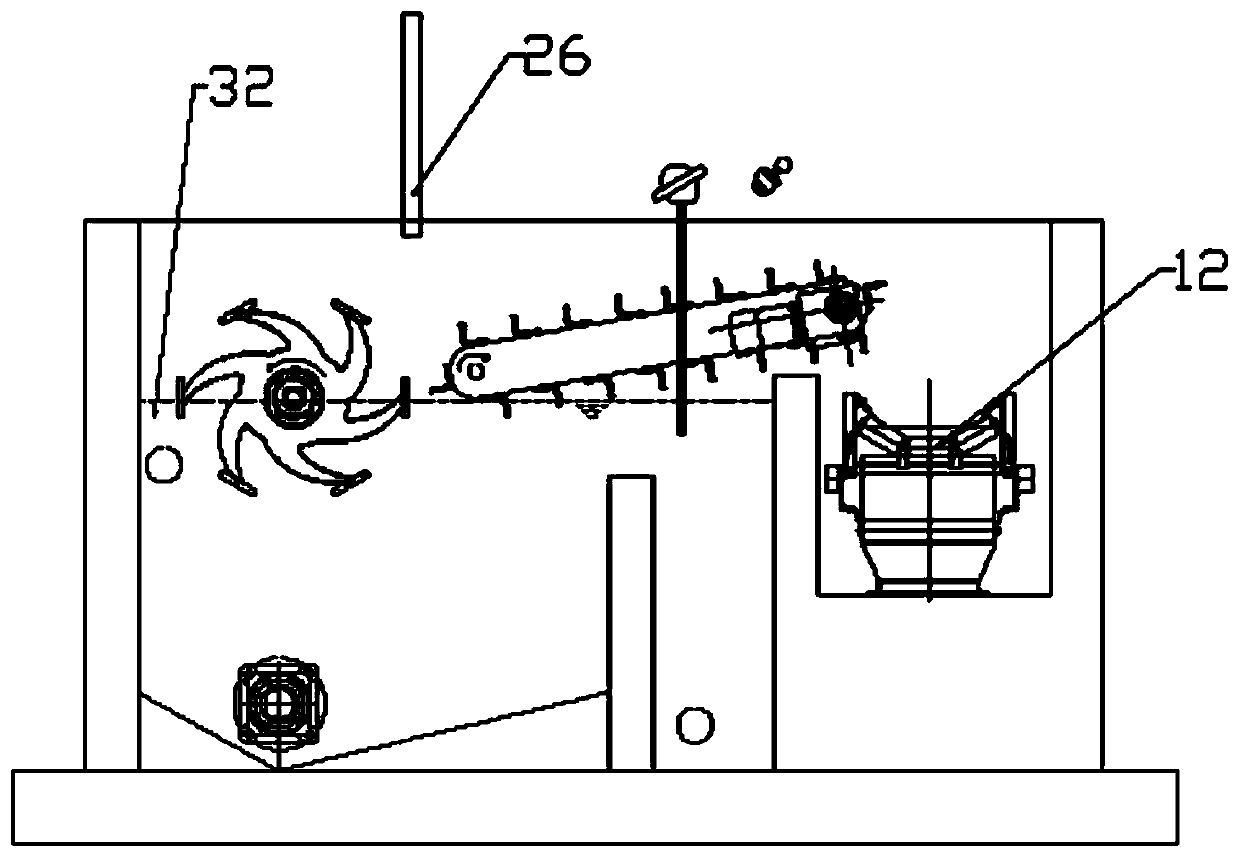

Household garbage resource utilization treatment system

InactiveCN111589848AIncrease solid contentReduce pollutionSolid waste disposalTransportation and packagingProcess engineeringEnvironmental engineering

The invention discloses a household garbage resource utilization treatment system. The system comprises a feeding subsystem, a first conveying mechanism, a sorting subsystem, a dry anaerobic fermentation subsystem, a high-calorific-value garbage pyrolysis subsystem and a plastic purification treatment subsystem. Through organic connection of the feeding subsystem, the first conveying mechanism, the sorting subsystem, the dry anaerobic fermentation subsystem, the high-calorific-value garbage pyrolysis subsystem and the plastic purification treatment subsystem, and the treatment system capable of combining multiple modes of biochemical reaction treatment, chemical reaction treatment, physical treatment, manual treatment and the like to comprehensively treat the household garbage so as to achieve recycling is formed; and due to the fact that landfill and incineration are reduced, and environmental pollution is reduced. The treatment system can make full use of organic fertilizer and biogas generated by garbage fermentation, waste heat and ash are generated by garbage pyrolysis, and in addition, plastic and leachate can be effectively recovered and utilized.

Owner:北京中持绿色能源环境技术有限公司

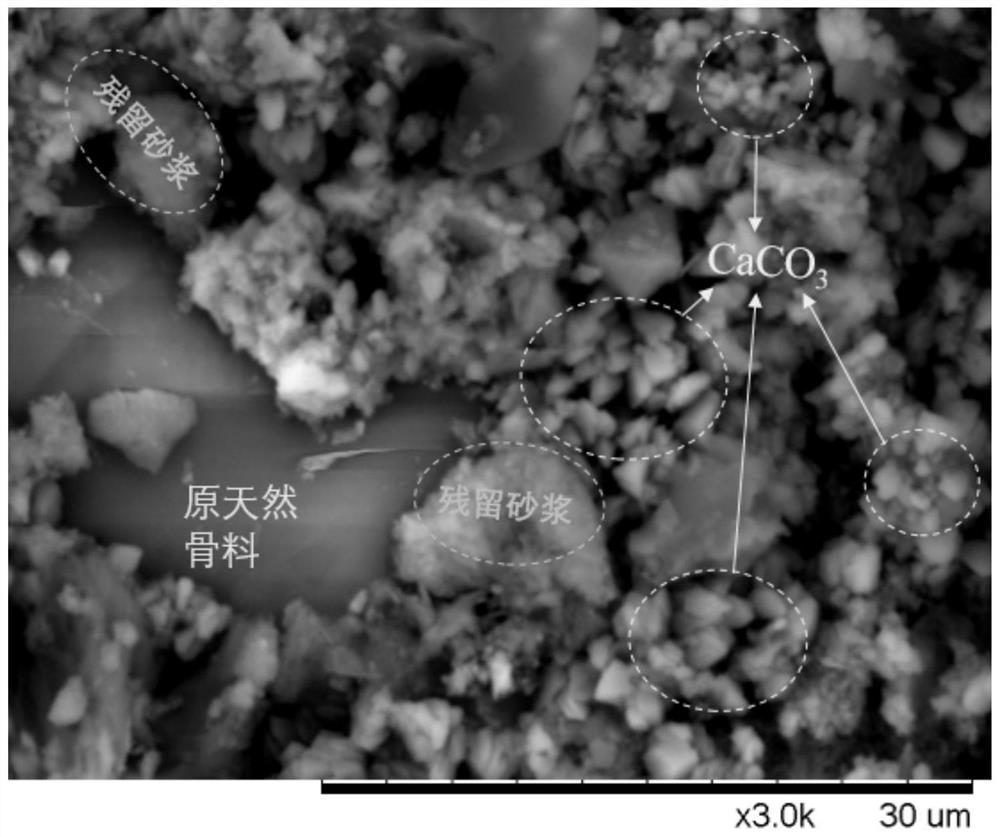

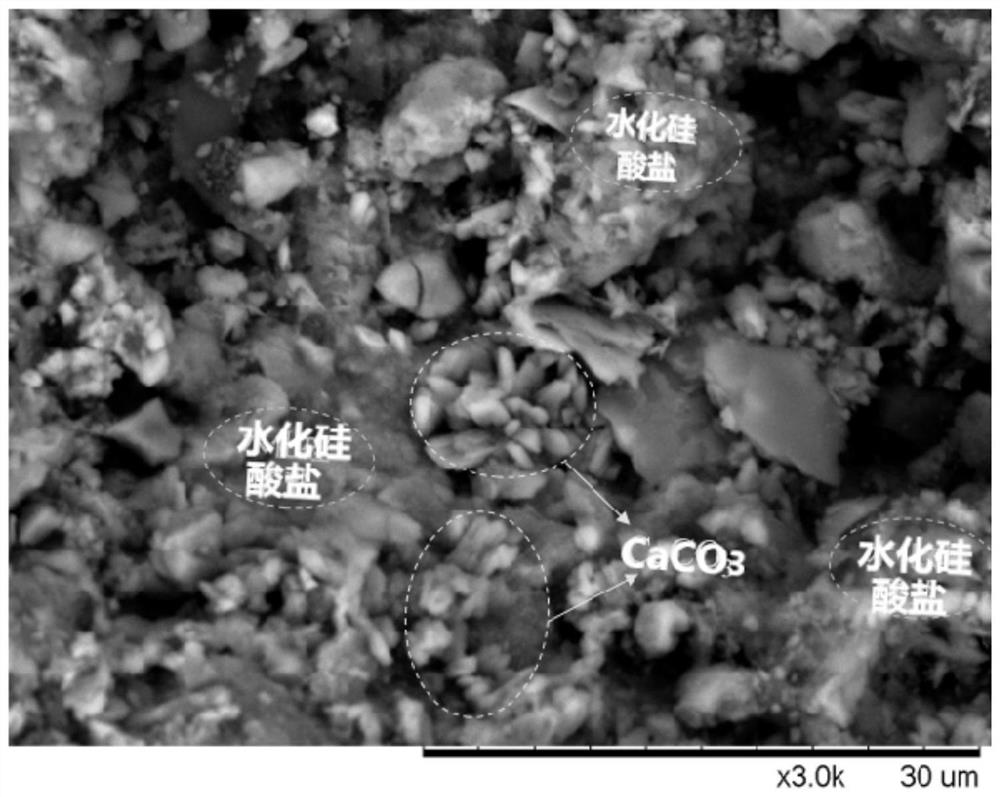

Method for strengthening recycled aggregate concrete by utilizing microbial denitrification phenomenon and recycled aggregate concrete

ActiveCN112851170AReduce landfillReduce miningSolid waste managementMicroorganismDenitrifying bacteria

The invention provides a method for strengthening recycled aggregate concrete by utilizing a microbial denitrification phenomenon and the recycled aggregate concrete. The method for strengthening the recycled aggregate concrete by utilizing the microbial denitrification phenomenon comprises the following steps: (1) soaking recycled aggregate in a bacteria solution of denitrifying bacteria to obtain the recycled aggregate attached with the denitrifying bacteria; (2) soaking the recycled aggregate attached with the denitrifying bacteria obtained in the step (1) in a calcium salt solution and / or spraying the calcium salt solution on the surface of the recycled aggregate attached with the denitrifying bacteria obtained in the step (1); and (3) concrete mixing: mixing the recycled aggregate treated in the step (2) instead of natural aggregate to obtain the recycled aggregate concrete. The method disclosed by the invention well overcomes the defects of low apparent density, high water absorption rate, high crushing value and the like of the recycled aggregate and the defect of low mechanical property of the recycled aggregate concrete.

Owner:XIAN JIAOTONG LIVERPOOL UNIV

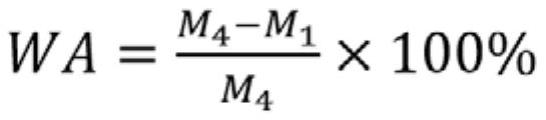

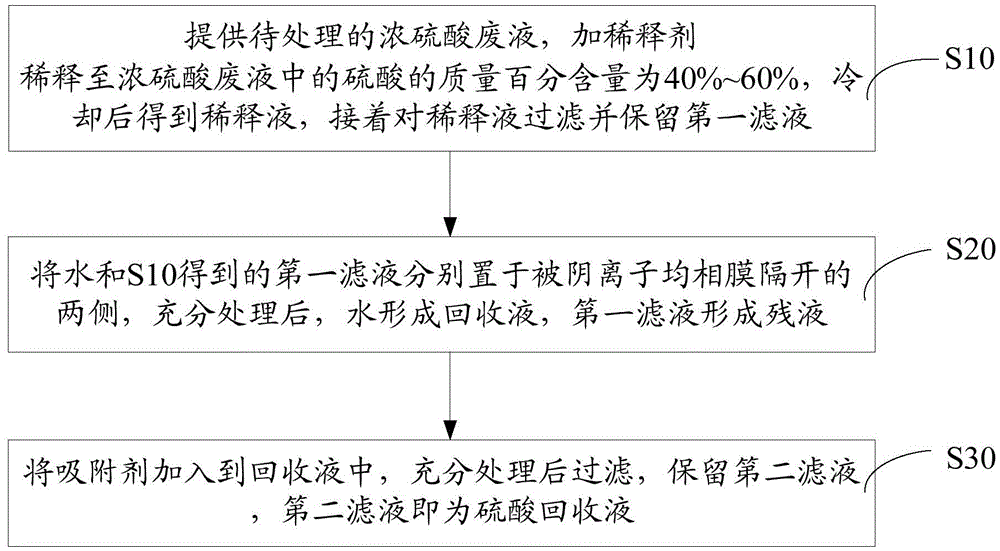

Advanced treatment method of concentrated sulfuric acid waste liquor

InactiveCN105565527AReduce landfillLow costTreatment involving filtrationWater/sewage treatment bu osmosis/dialysisSorbentTreatment costs

The invention discloses an advanced treatment method of concentrated sulfuric acid waste liquor, which comprises the following steps: providing concentrated sulfuric acid waste liquor to be treated, adding a diluter for dilution until the mass percent of sulfuric acid in the concentrated sulfuric acid waste liquor is 40-60%, cooling to obtain a dilute solution, filtering the dilute solution, and maintaining a first filtrate, wherein the mass percent of sulfuric acid in the diluter is 3-15%; respectively putting water and the first filtrate on two sides which are divided by an anionic homogeneous membrane, and carrying out sufficient treatment, wherein the water forms a recovery solution, and the first filtrate forms a residual liquid; and adding an adsorbent into the recovery solution, carrying out sufficient treatment, filtering, and maintaining a second filtrate which is the sulfuric acid recovery solution. The advanced treatment method disclosed by the invention is simple in technique; and after the residual liquid is recovered three times, more than 95% of sulfuric acid in the concentrated sulfuric acid waste liquor can be recovered. Compared with the traditional treatment technique by direct neutralization, only less than 5% of the sulfuric acid residual liquid is subjected to neutralizing treatment in the technique disclosed by the invention, thereby greatly lowering the treatment cost.

Owner:DONGJIANG ENVIRONMENTAL

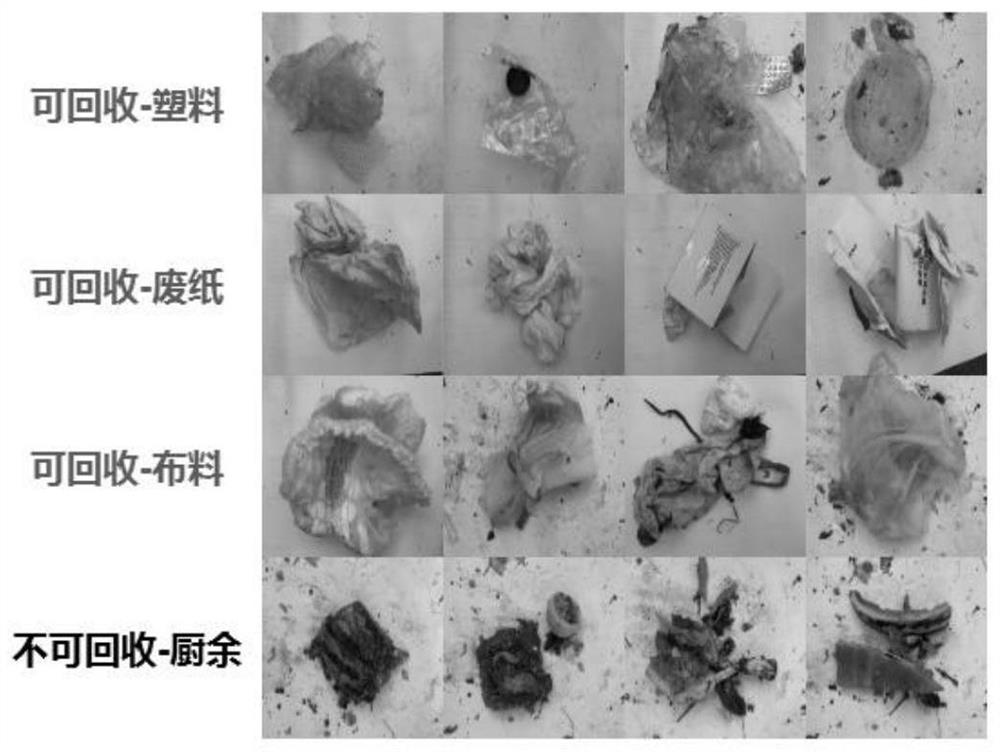

Industrial-grade garbage classification method and device

The invention discloses an industrial-grade garbage classification method and device, and belongs to the technical field of garbage classification. The method includes the steps that garbage classification images are collected from a garbage environment, and a garbage classification image database is established; a pre-treatment device scatters the garbage, an image recognition model is adopted torecognize an image of scattered garbage, and the scattered garbage image is compared with an image in a classification image database, and thus garbage classification is achieved; and according to signals transmitted by the image recognition model, a garbage conveying track is intervened, and finally different types of garbage are conveyed into different garbage cans. Compared with a traditionalgarbage classification method depending on people participation, the method is based on an artificial intelligence method, machines are used for replacing manpower to achieve automatic classificationof industrial-grade household garbage, and the device can replace manpower, is suitable for dirty, disordered and poor environments, and has the advantages of higher operability, lower cost and bettereffect.

Owner:DALI UNIV

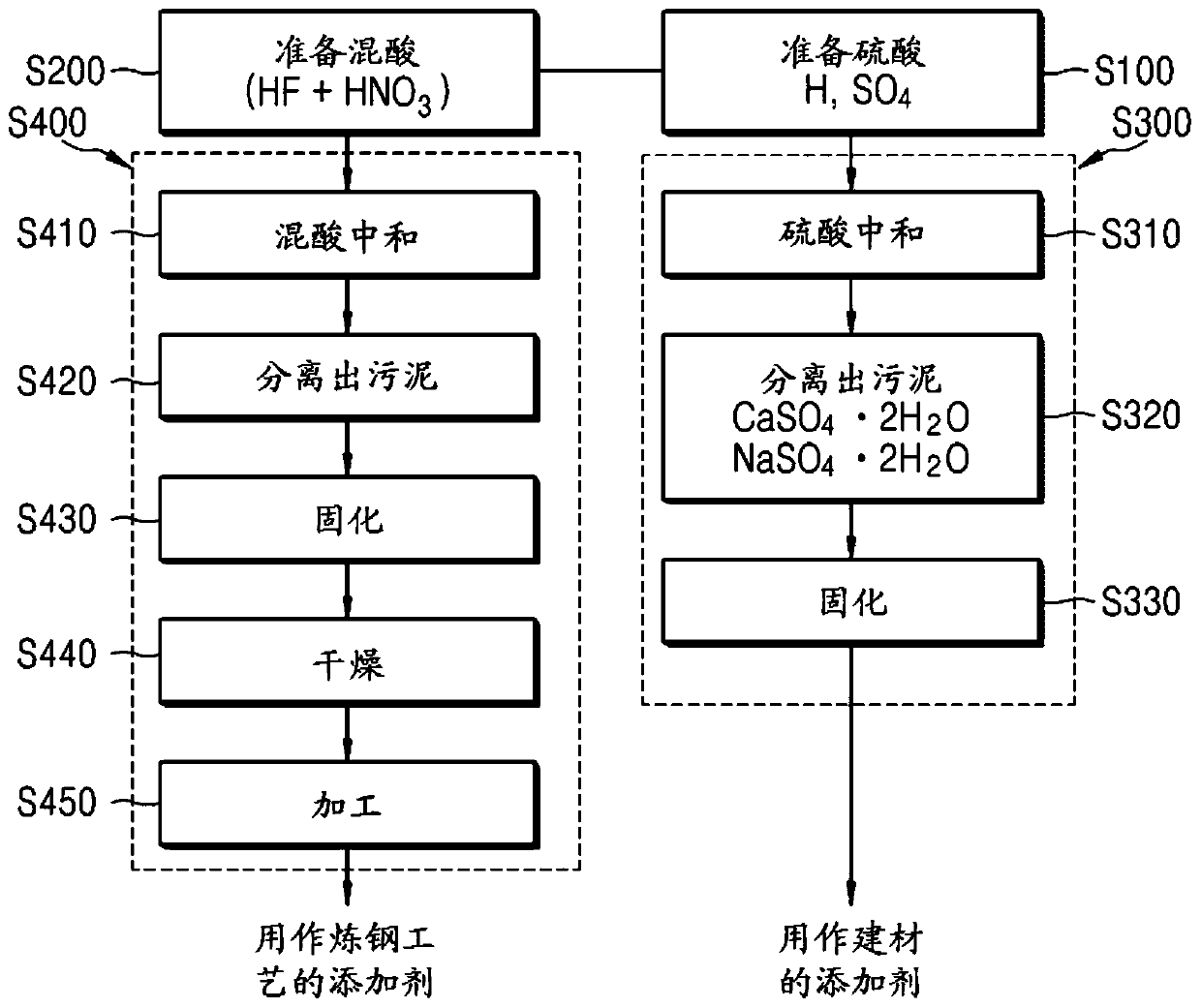

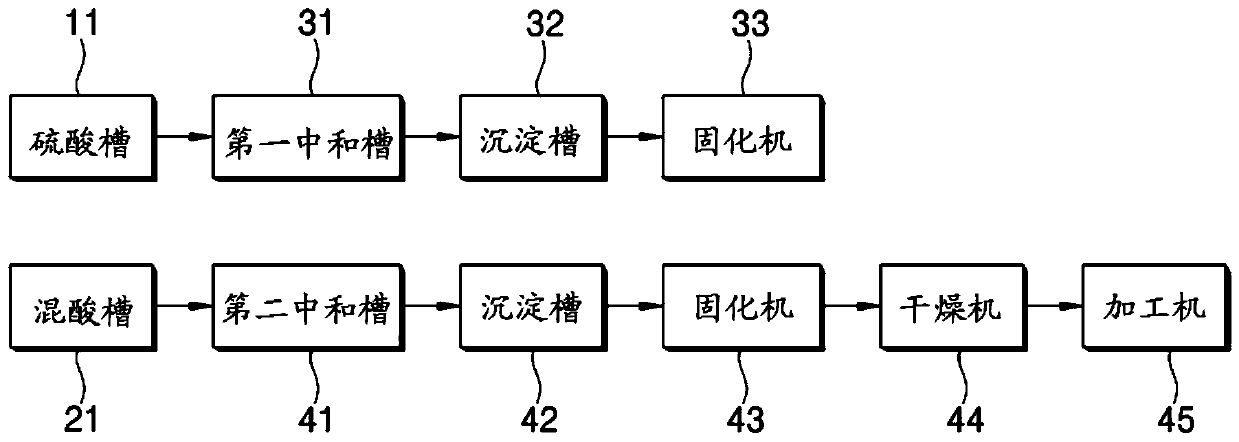

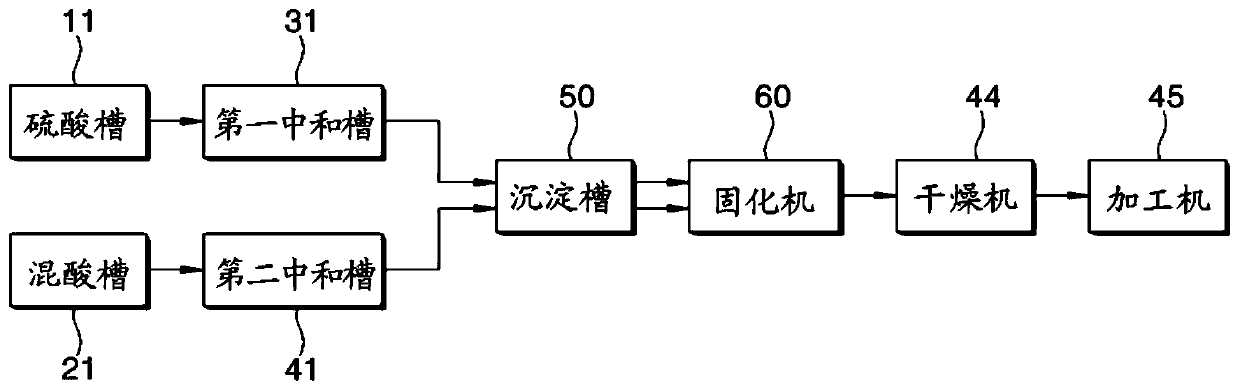

Method for manufacturing additives and method for refining molten steel using the same

InactiveCN109988878ANo sulfur increaseReduce the amount addedProcess efficiency improvementHydrofluoric acidSteelmaking

The invention relates to a method for manufacturing additives and a method for refining molten steel using the same. The method for manufacturing the additives according to embodiment includes a stepof recovering sulfuric acid (H2SO4) after a pickling process of a steel plate; a step of recovering an acid mixture containing hydrofluoric acid (HF) and nitric acid (HNO3) after a pickling process ofa steel plate. A step of preparing a first additive includes a step of neutralizing the sulfuric acid. A step of preparing a second additive includes a step of neutralizing the acid mixture besides the sulfuric acid. According to embodiments, sludge prepared from the waste acid mixture is free of S (sulfur) and can be used for manufacturing any one of a slag former, a dephosphorization agent anda desulfurizing agent during refining in a steelmaking process, namely, even if sludge prepared by reutilization of waste acid is utilized as an additive, sulfur (S) in molten iron will not increase.

Owner:POHANG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com