Lightweight gypsum plaster mortar

A technology for plastering mortar and gypsum, which is applied in the field of construction mortar to achieve the effect of shortening the construction period, satisfying anti-aging, and having remarkable retarding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

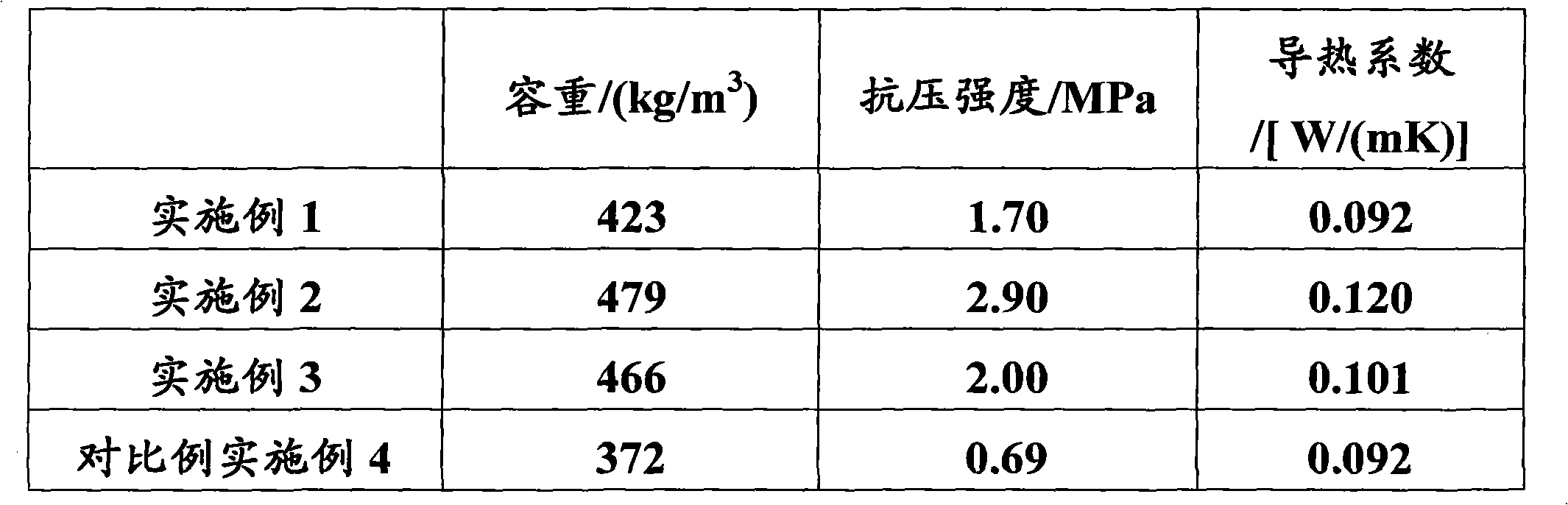

Examples

Embodiment 1

[0038] Take the following substances in weight ratio:

[0039] 75.8 kg of desulfurized gypsum, 22.7 kg of vitrified hollow microbeads, 0.2 kg of 20,000-viscosity cellulose ether, 0.5 kg of air-entraining agent, 0.1 kg of retarder, and 98 kg of water were slowly stirred evenly to obtain the lightweight gypsum mortar of the present invention .

Embodiment 2

[0041] Take the following substances in weight ratio:

[0042] 78.6 kg of desulfurized gypsum, 20.6 kg of vitrified hollow microbeads, 0.2 kg of 15,000 cellulose ether, 0.3 kg of air-entraining agent, 0.1 kg of retarder, and 86 kg of water were slowly stirred evenly to obtain the lightweight gypsum mortar of the present invention.

Embodiment 3

[0044] Take the following substances in weight ratio:

[0045] 79.0 kg of desulfurized gypsum, 20.8 kg of vitrified microbeads, 0.4 kg of 15,000-viscosity cellulose ether, 0.3 kg of air-entraining agent, 0.08 kg of retarder, and 92 kg of water were uniformly stirred to obtain the lightweight gypsum mortar of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com