Patents

Literature

319results about How to "Good retarding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

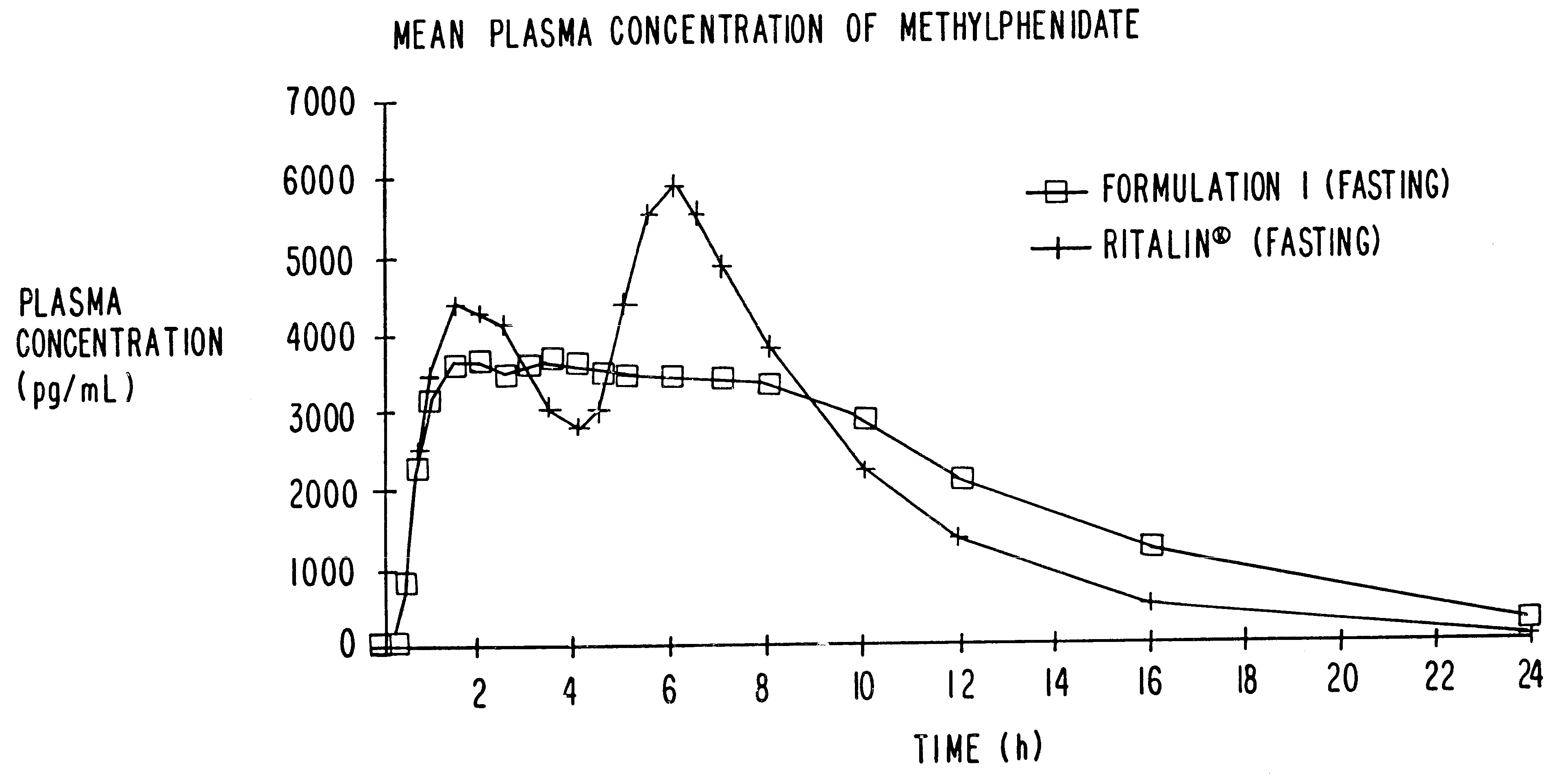

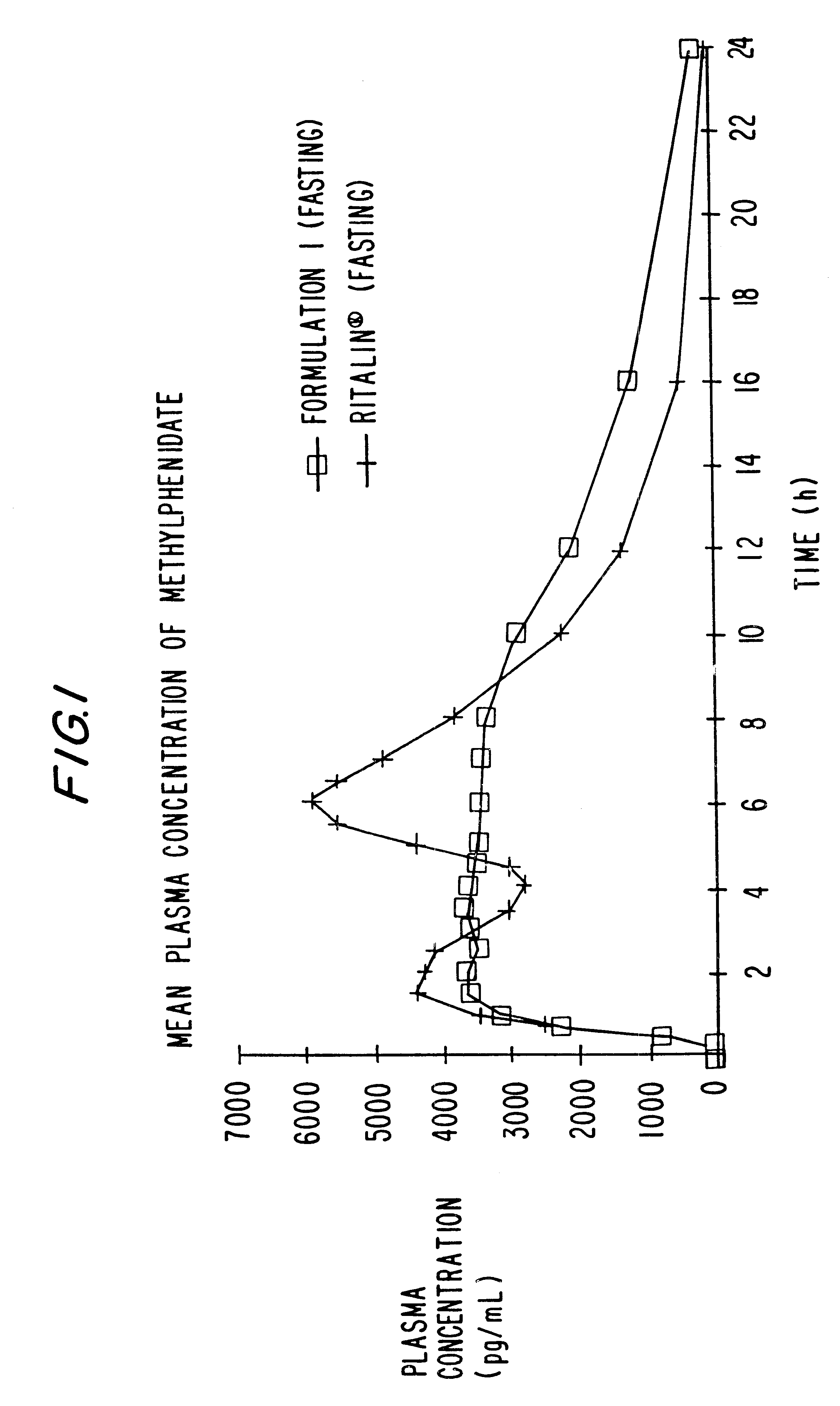

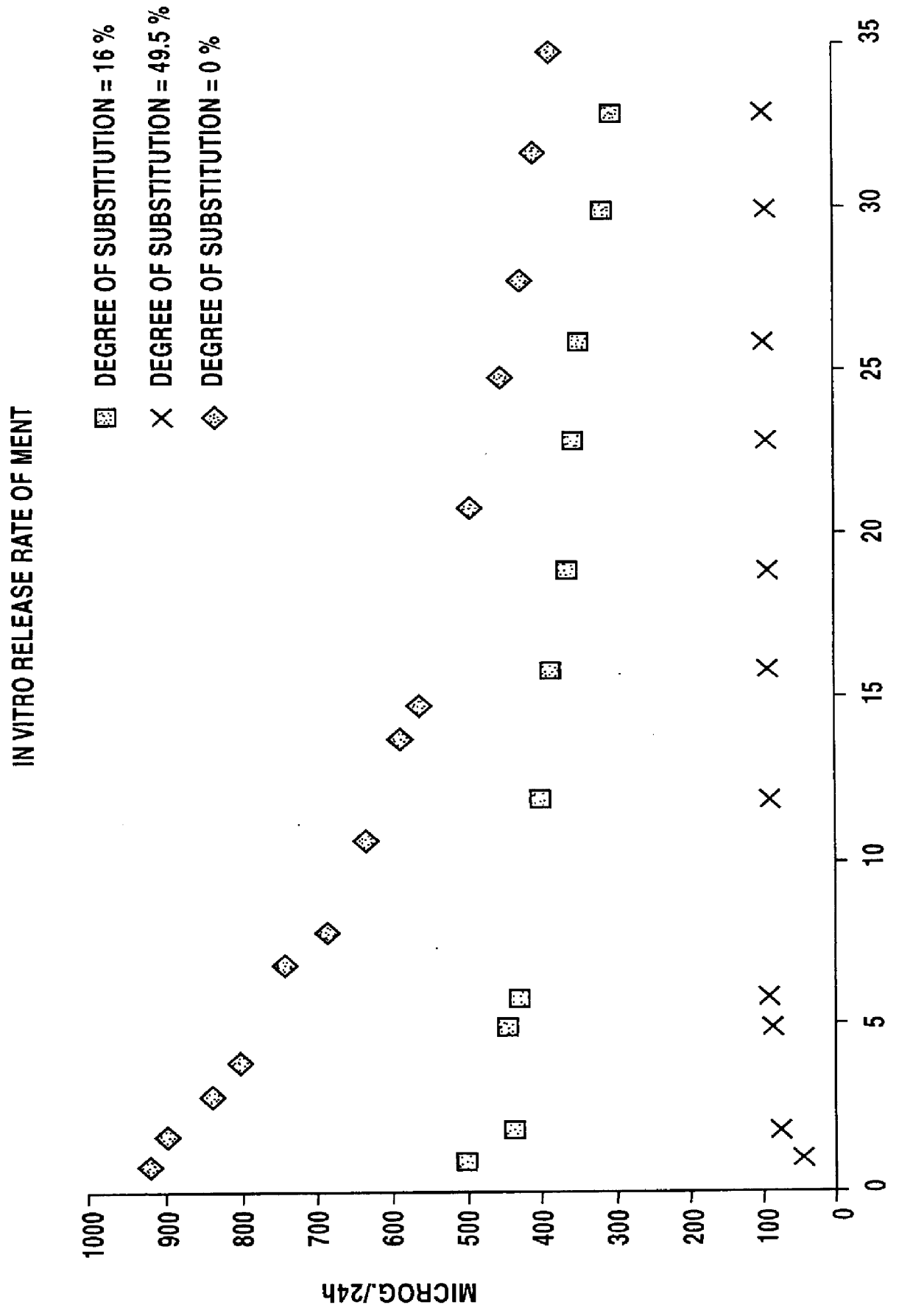

Controlled release formulations having rapid onset and rapid decline of effective plasma drug concentrations

InactiveUS6419960B1Patient compliance is goodGood retarding effectPowder deliveryOrganic active ingredientsImmediate releasePlasma drug concentration

The invention is directed to oral modified / controlled release drug formulations which provide a rapid initial onset of effect and a prolonged duration of effect. Preferably, the peak concentration is lower than that provided by the reference standard for immediate release formulations of the drug, and the duration of effect falls rapidly at the end of the dosing interval.

Owner:RHODES PHARMA LP

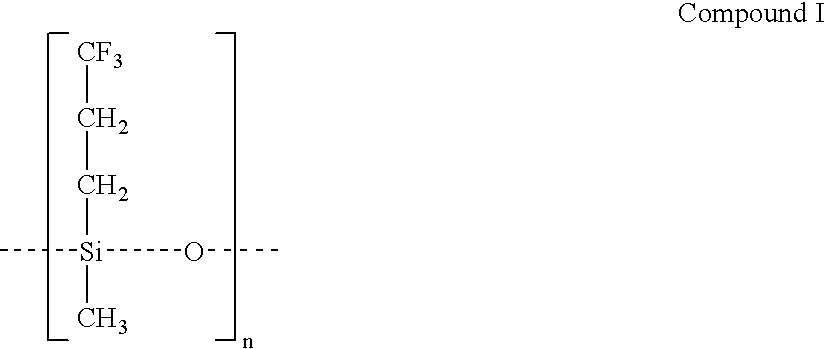

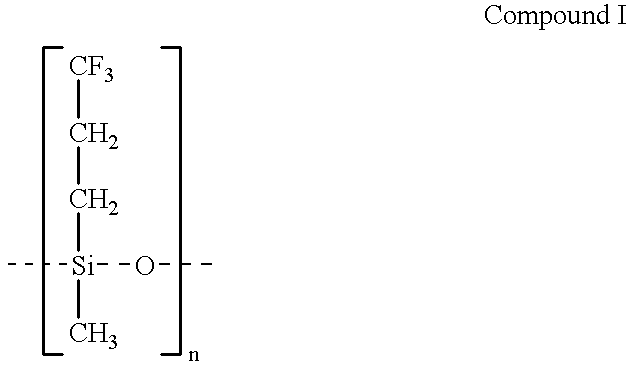

Elastomer, its preparation and use

InactiveUS6056976AEasy to prepareMeet the requirements of mechanical propertiesPowder deliveryPharmaceutical non-active ingredientsElastomerSilicon

The invention relates to a siloxane-based elastomer intended for controlling the permeation of drugs, wherein the elastomer includes 3,3,3,-trifluoropropyl groups attached to the Si-atoms of the siloxane units. The invention relates also to a method for the preparation of a siloxane-based elastomer including 3,3,3,-trifluoropropyl substituents, where the elastomer is intended for controlling the permeation of drugs. In the method either i) a 3,3,3,-trifluoropropyl-substituted vinyl-functional polysiloxane component and a silicon hydride-functional crosslinking agent are crosslinked in the presence of a catalyst, or ii) a 3,3,3,-trifluoropropyl-substituted polysiloxane component is crosslinked in the presence of a peroxide catalyst.

Owner:OY SCHERING +1

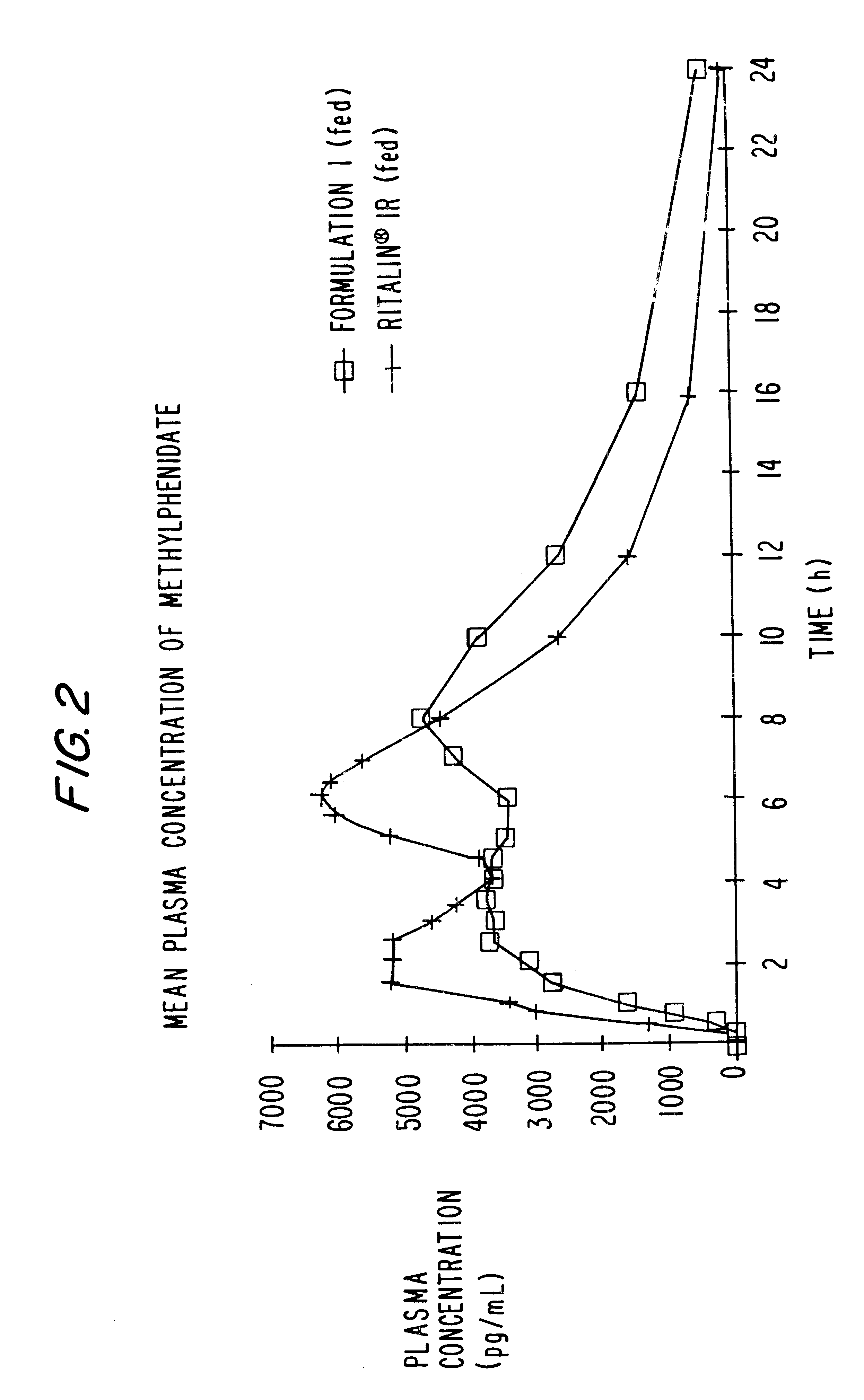

Drug delivery device especially for the delivery of progestins and estrogens

InactiveUS6063395AEasy to adjustSmall sectionOrganic active ingredientsPowder deliveryElastomerControl release

The invention relates to a delivery device for the controlled release of a therapeutically active agent, especially a progestin or an estrogen, over a prolonged period of time, said device including a core which contains the therapeutically active agent, and a membrane encasing the core wherein said membrane is made of an elastomer. According to the invention, the elastomer is a siloxane-based elastomer which includes 3,3,3-trifluoropropyl groups attached to the Si-atoms of the siloxane units.

Owner:OY SCHERING +1

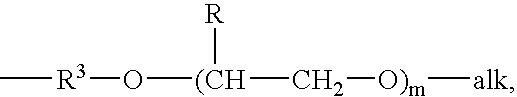

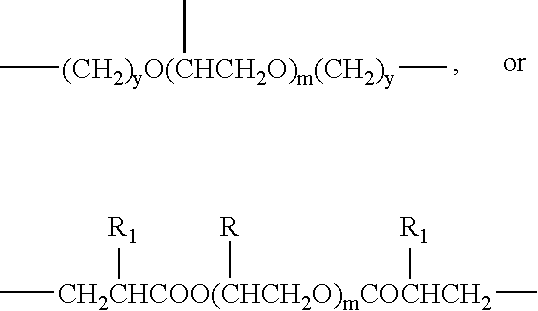

Drug delivery system

InactiveUS20040247674A1Easy and cost-effective to produceEasy to controlOrganic active ingredientsSuppositories deliveryElastomerDimethyl siloxane

A delivery system including at least one core and a membrane. The core and the membrane include an elastomer composition containing, e.g., poly(dimethylsiloxane), a siloxane-based elastomer having 3,3,3-trifluoropropyl groups attached to the Si-atoms of the siloxane units and / or poly(alkylene oxide) groups, present as alkoxy-terminated grafts or blocks linked to the polysiloxane units by silicon-carbon bonds, or as a mixture of these forms. The delivery system is preferably an implant or an interuterine, intracervical or intravaginal system.

Owner:BAYER OY

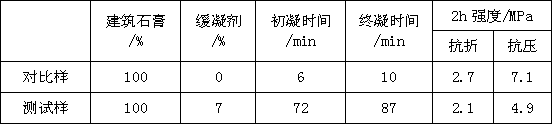

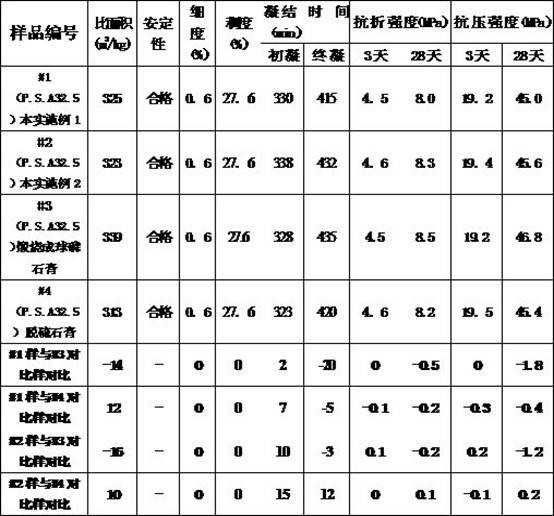

Polycarboxylic retarding high-performance water reducing agent for preparing concrete of middle and low strength grade

InactiveCN101580354AReduce shrinkage ratioGood retarding effectSuperplasticizerUltimate tensile strength

The invention discloses a polycarboxylic retarding high-performance water reducing agent used for preparing concrete of middle and low strength grade. According to the weight percentage of the effective solid content, the water reducing agent comprises 9-15% of low air-entrained mother liquor, 0.5-3.0% of retarder, 0.01-0.03% of foam stabilizer, 0.03-0.10% of air-entraining agent, 0.02-0.08% of thickener, 0.05-0.20% of activator and the balance of water. The preparation method comprises the following steps of: weighing all compositions by the weight percentage of each effective solid content, putting and slowly mixing the compositions in a reaction kettle for 10-30min, thus obtaining the concrete. By adjusting the proportion of all compositions, the polycarboxylic retarding high-performance water reducing agent can meet the usage requirements of the concrete of middle and low strength grade (C15-C40), has the advantages of wide doping range, high water reducing ratio, good retarding effect, low chlorine and alkali content, low concrete shrinkage ratio, greenness, environmental protection and the like, and can prepare the green and economic high-performance concrete.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

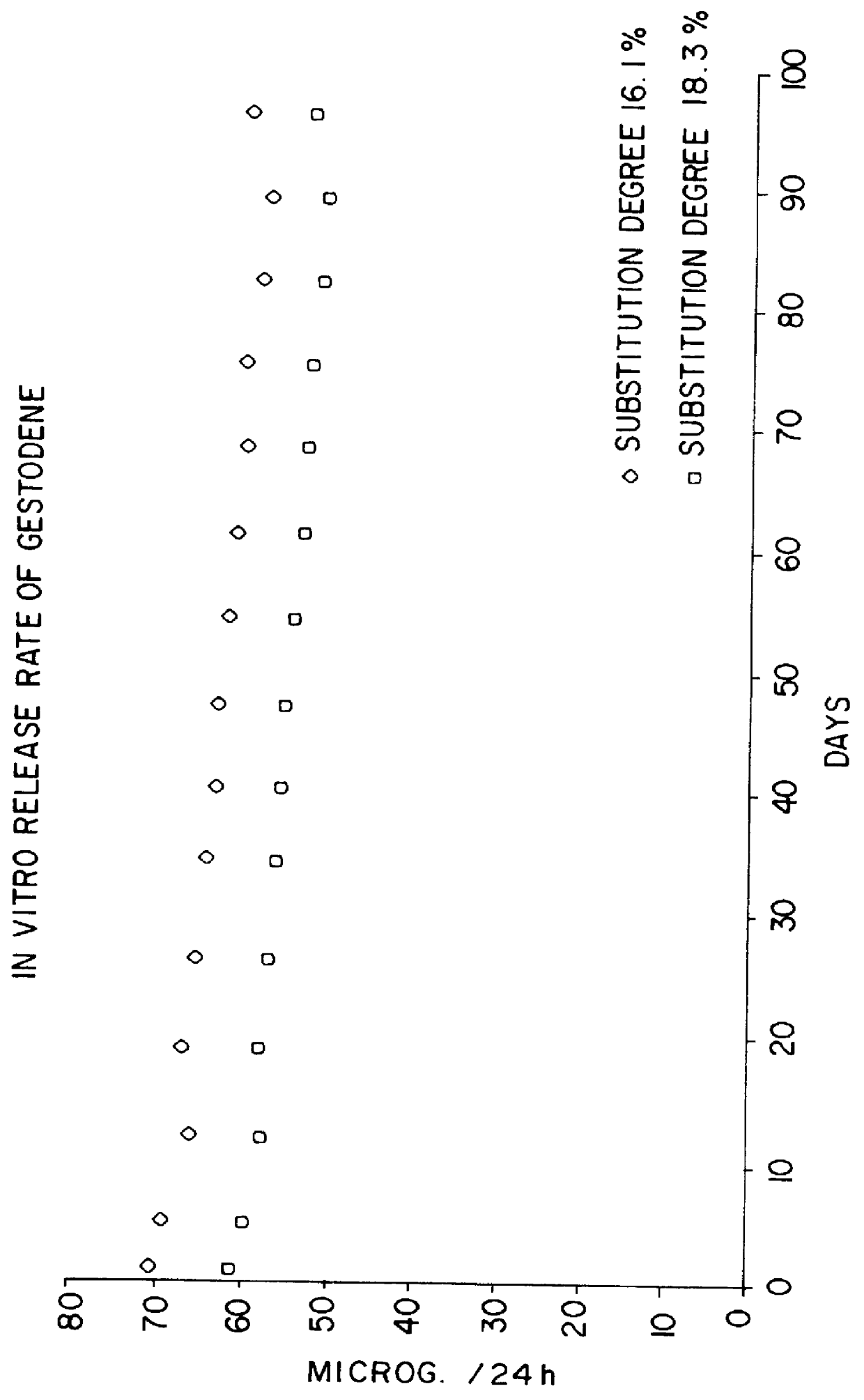

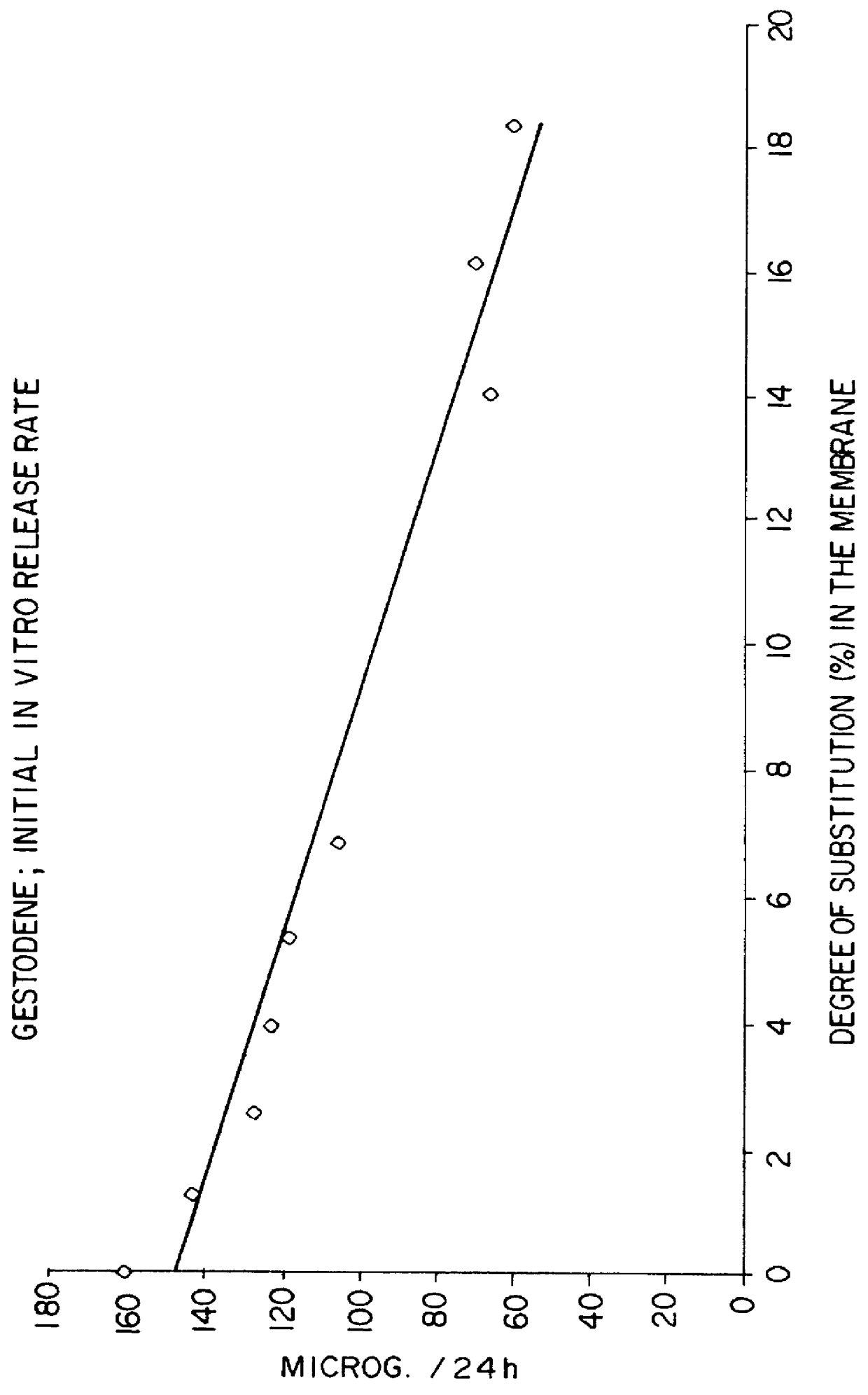

Drug delivery device, especially for the delivery of gestodene

InactiveUS6299894B1Solve low usageGreat permeation retarding effectPowder deliveryFemale contraceptivesElastomerControl release

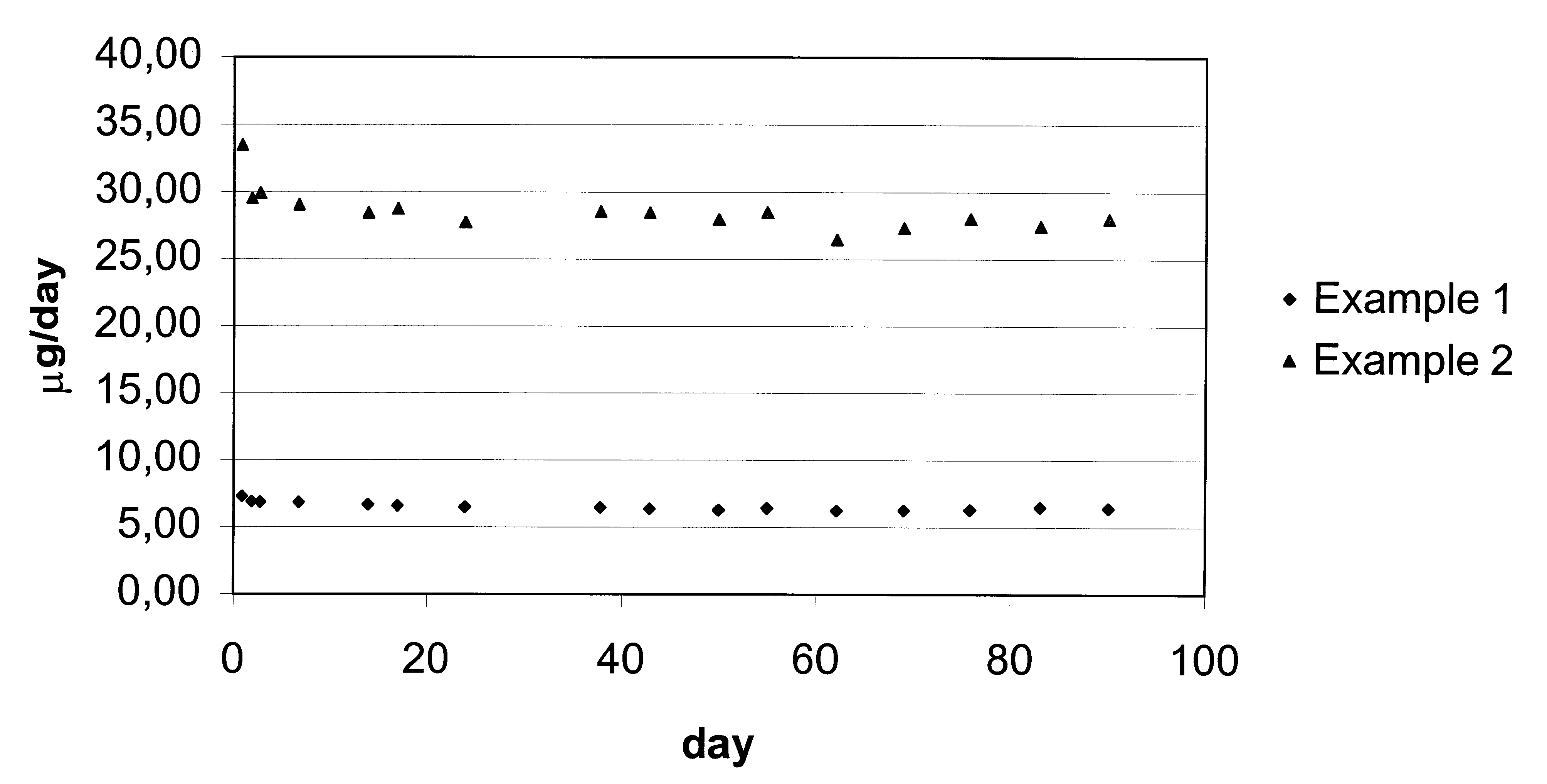

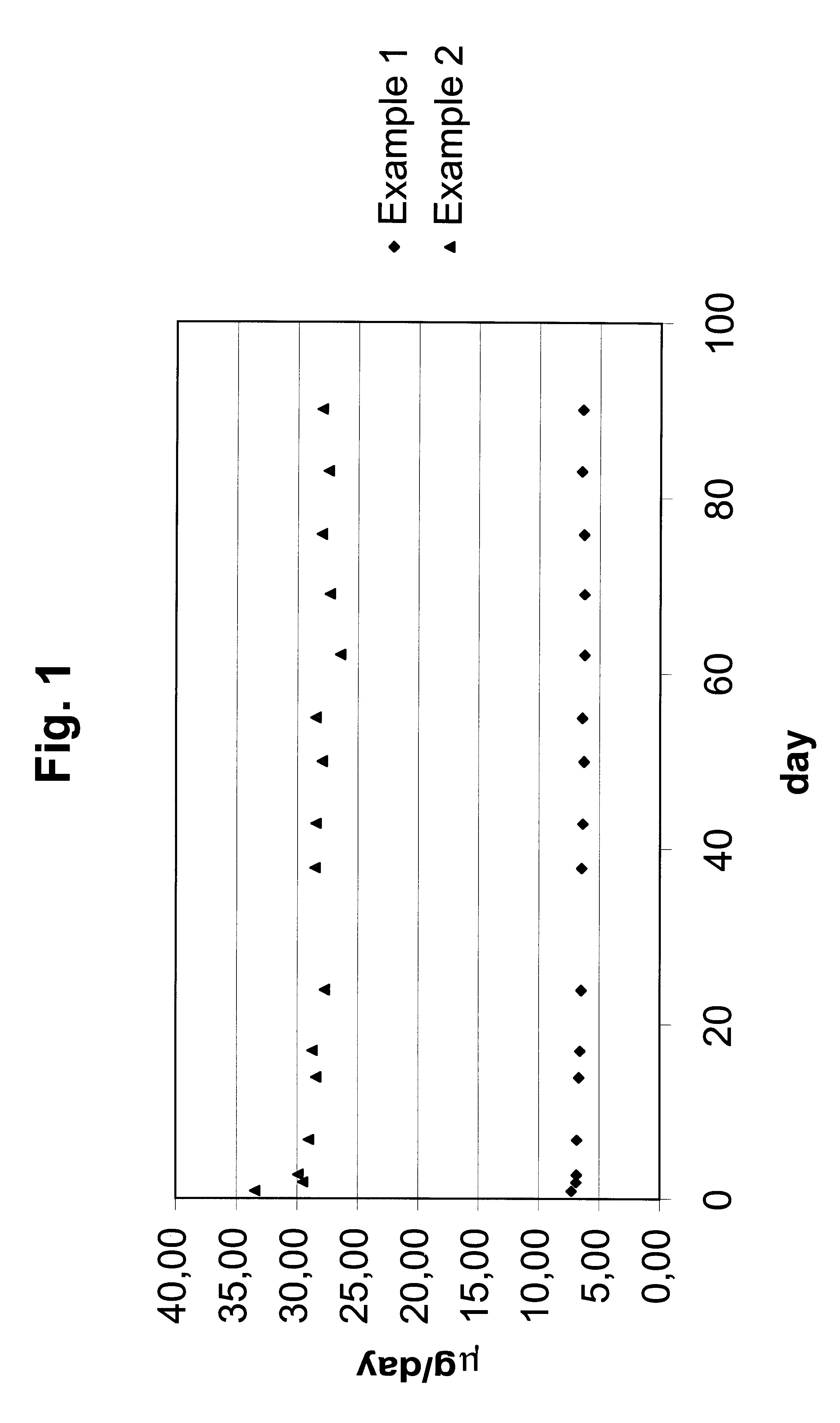

The invention relates to a delivery device for the controlled release of the therapeutically active agent gestodene, over a prolonged period of time, at a release rate of 0,1-300 mug / day, said device comprising a core comprising at least said therapeutically active agent, and a membrane encasing said core wherein said membrane is made of an elastomer. According to the invention, the elastomer is a siloxane-based elastomer comprising 3,3,3-trifluoropropyl groups attached to the Si-atoms of the siloxane units, and the release rate of said therapeutically active agent of said delivery device is regulated by the amount of said 3,3,3-trifluoropropyl groups.

Owner:LEIRAS

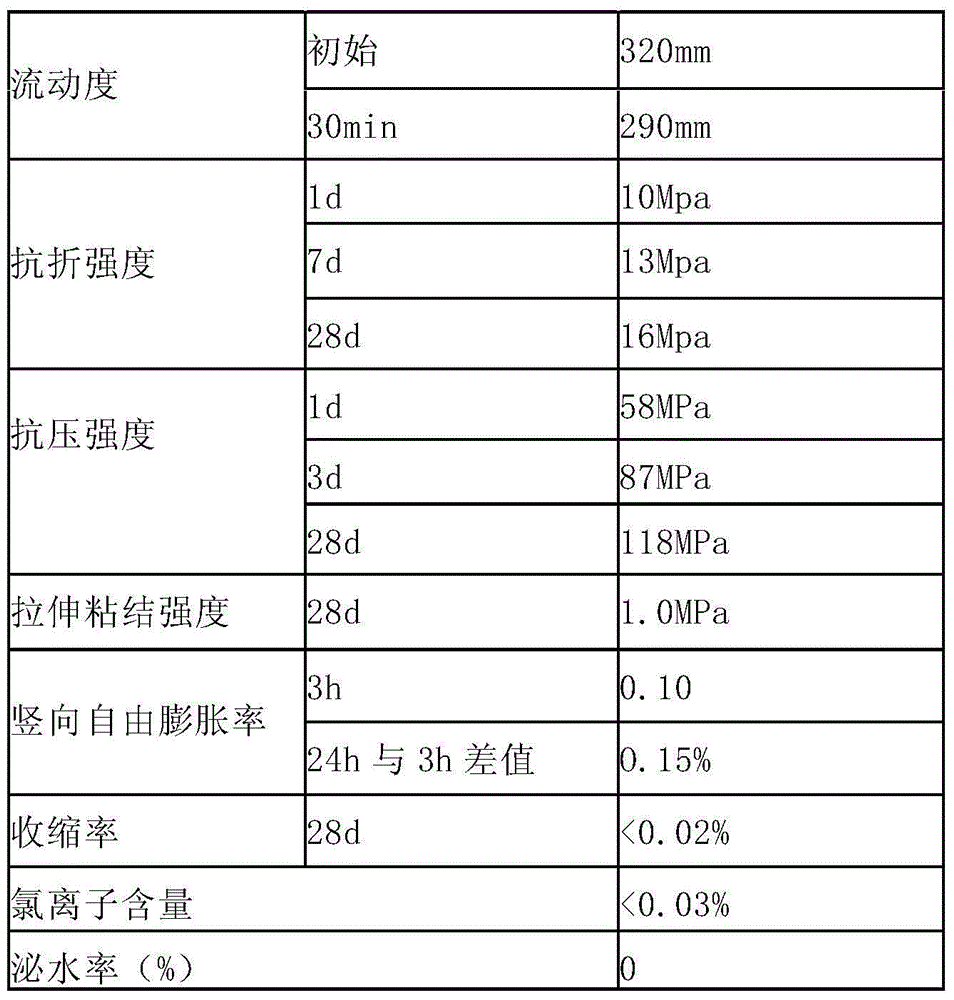

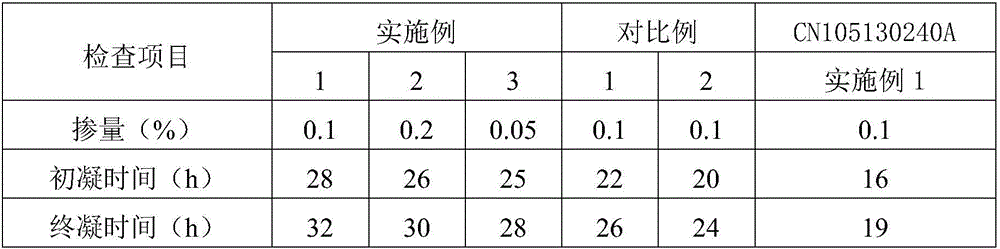

Special high strength grouting material for connecting reinforcement sleeve

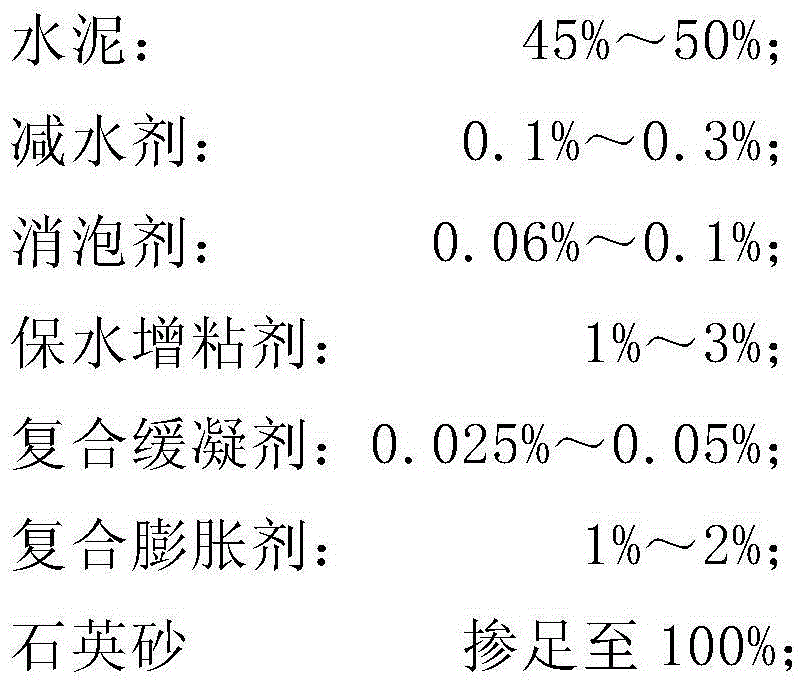

The present invention discloses a special high strength grouting material for connecting a reinforcement sleeve. The special high strength grouting material for connecting the reinforcement sleeve comprises grouting material powder and water, wherein the grouting material powder is prepared from the following raw materials in percentage by weight: 45% to 50% of cement, 0.1% to 0.3% of a water reducing agent, 0.06% to 0.1% of a defoamer, 1% to 3% of a water retention tackifier, 0.025% to 0.05% of a composite retarder, 1% to 2% of a composite expansion agent; and and the balance of quartz sand, totalling 100, wherein the mass ratio of the grouting material powder to the water is 1 to (0.23-0.28). The special high strength grouting material for the connecting reinforcement sleeve provided by the present invention has the characteristics of high strength, high adhesion and slight expansion with no shrinkage; the high strength grouting material can be poured into the reinforcement sleeve to enable fixed connection formed between reinforcements and between the reinforcements and the sleeve, and has excellent durability.

Owner:SHANGHAI URBAN CONSTR MATERIAL CO LTD

Drug delivery device, especially for the delivery of androgens

InactiveUS6117442AEasy to adjustSmall sectionPowder deliveryOrganic active ingredientsControl releaseActive agent

The invention relates to a delivery device for the controlled release of a therapeutically active agent, especially an androgen, over a prolonged period of time, said device including a core containing the therapeutically active agent, and a membrane encasing the core wherein the membrane is made of an elastomer. According to the invention, the elastomer is a siloxane-based elastomer which includes 3,3,3-trifluoropropyl groups attached to the Si-atoms of the siloxane units.

Owner:LEIRAS +1

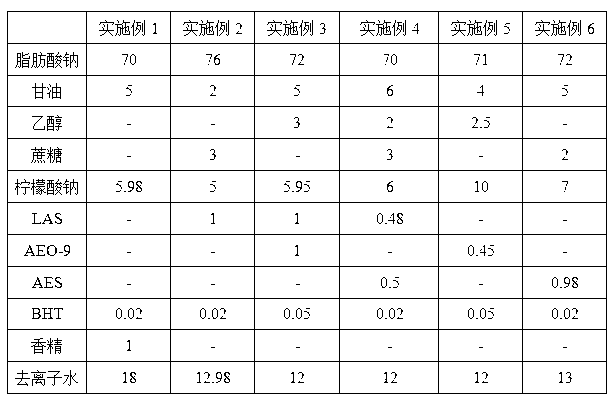

Transparent soap

InactiveCN103013715AHigh transparencyHigh hardnessSoap detergents with organic compounding agentsAlkali/ammonium soap compositionsActive agentFatty acid

The invention discloses a transparent soap, which is mainly prepared by fatty acid, a transparent reagent, sodium citrate, a surfactant and deionized water, wherein the content of sodium citrate based on weight is 0.1-15%. The transparent soap has appropriate hardness and transparency; and the washing capability is not influenced by calcium ions and magnesium ions when in use.

Owner:GUANGDONG PENGJIN INDUSTRY CO LTD

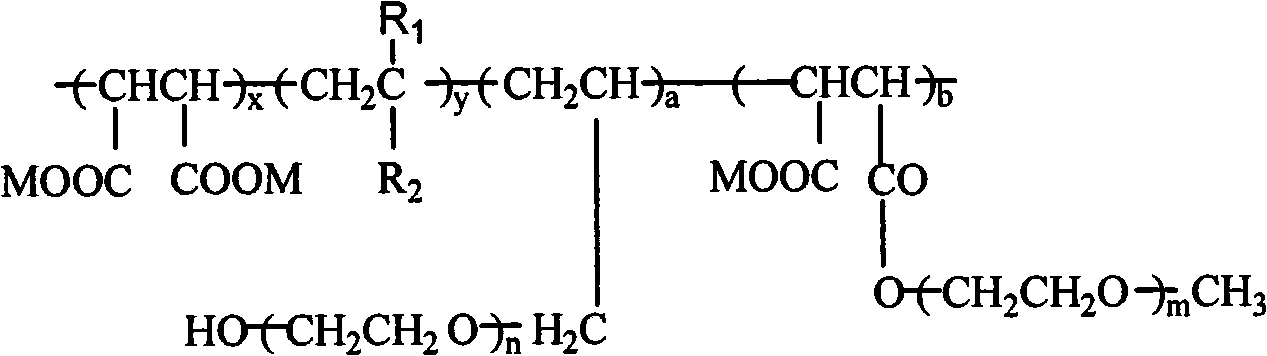

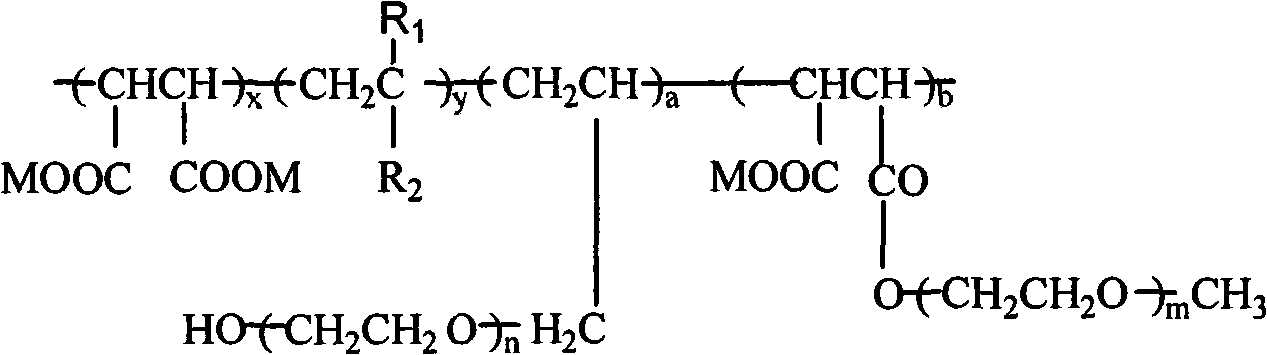

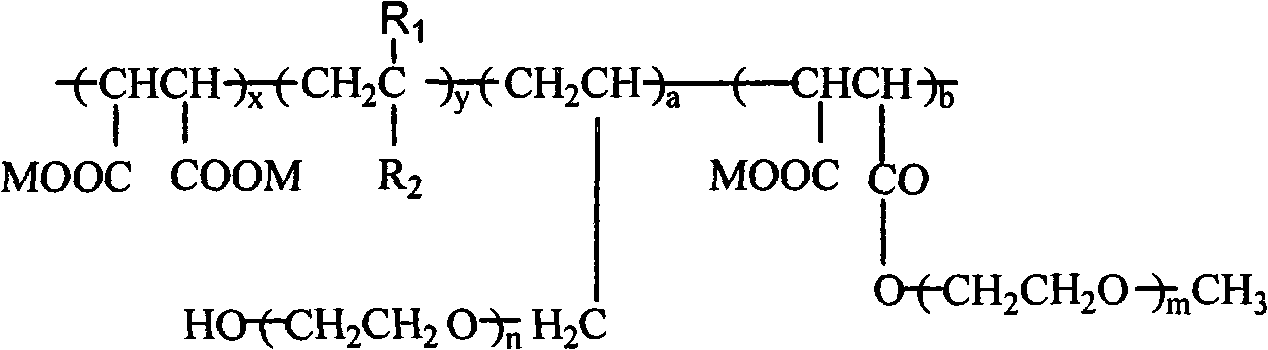

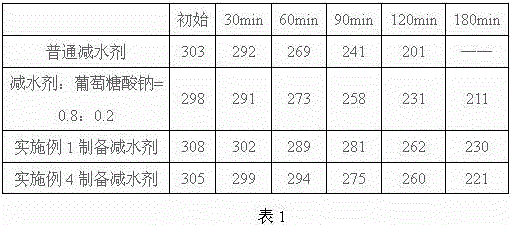

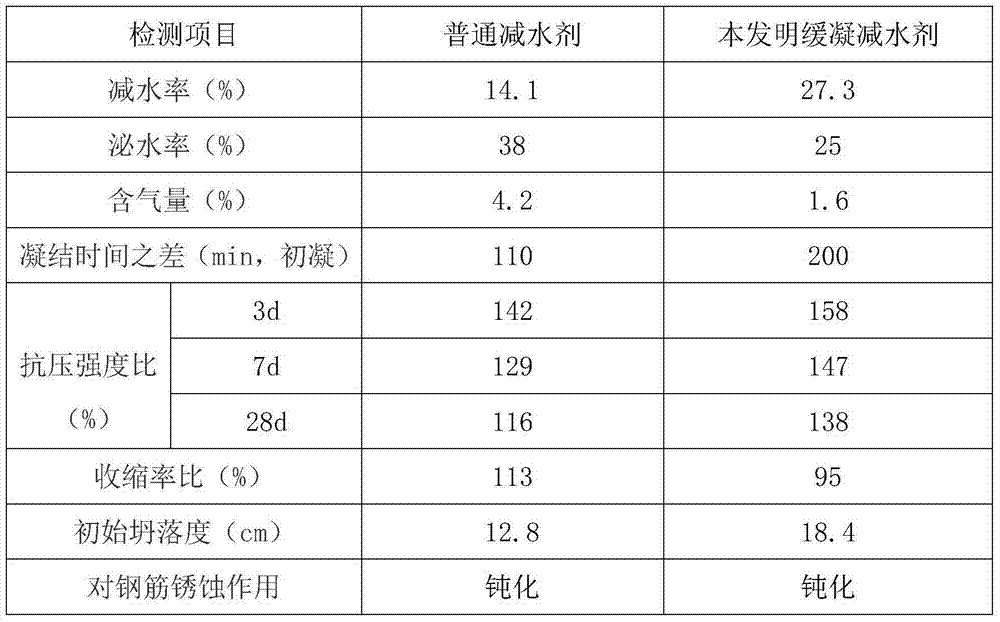

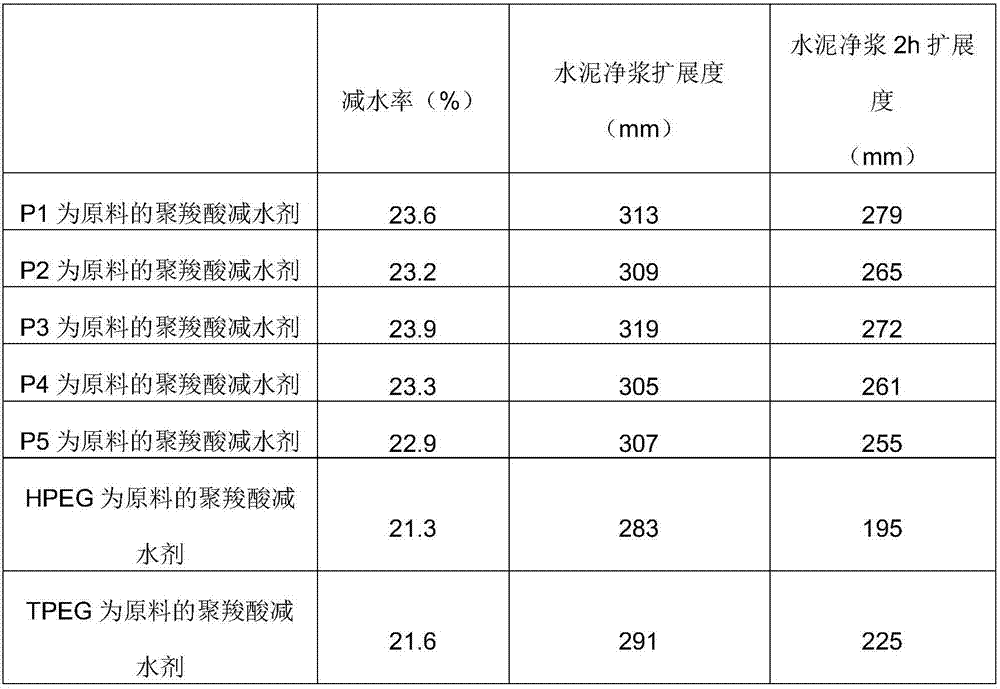

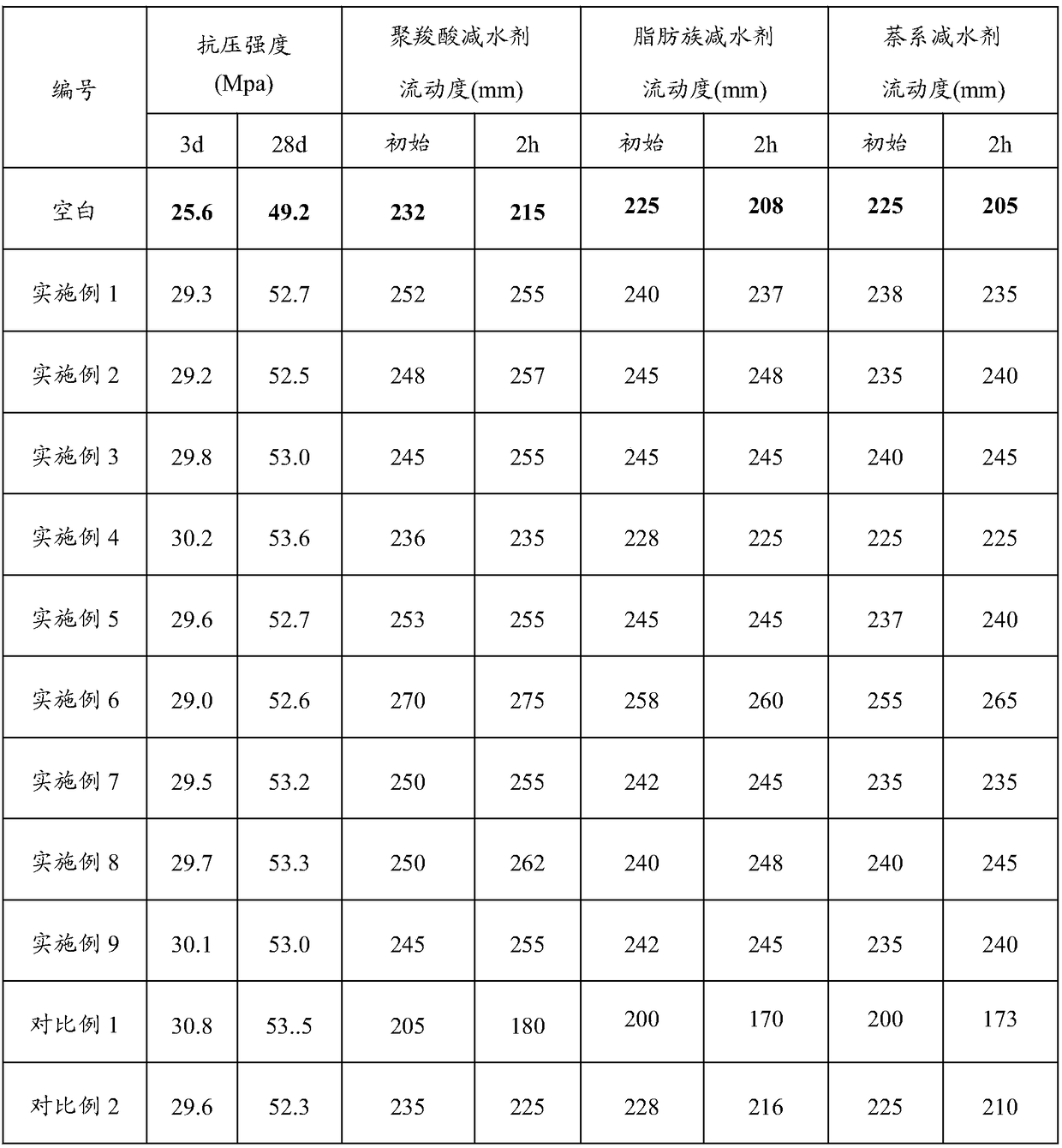

Carbohydrate ester modified polycarboxylate superplasticizer and preparation method thereof

InactiveCN106279559ALow raw material costGood retarding propertiesChemistrySaturated carboxylic acid

The invention provides a carbohydrate ester modified polycarboxylate superplasticizer and a preparation method thereof. The preparation method comprises the following steps of adding unsaturated carboxylic acid and dried polyhydroxyl saccharide compounds, performing an esterification reaction under a concentrated sulphuric acid catalysis condition, wherein a certain proportion of a polymerization inhibitor also needs to be added so as to prevent the unsaturated carboxylic acid from self-polymerization in a reaction process, and after the esterification reaction is finished, enabling esterification products, the unsaturated carboxylic acid and unsaturated alcohol polyether to be subjected to a copolymerization reaction so as to prepare a delayed coagulation type polycarboxylate superplasticizer containing polyhydroxyl functional groups.

Owner:SHANGHAI TAIJIE CHEM

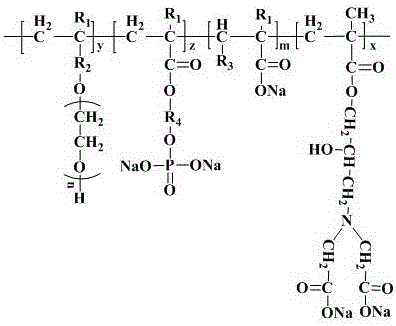

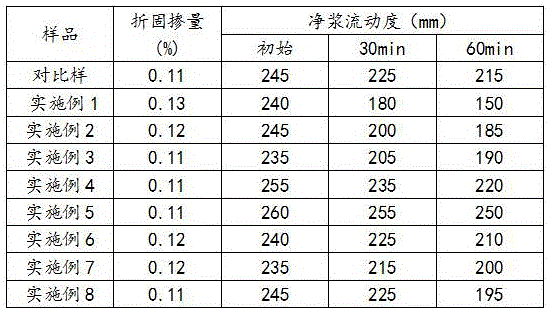

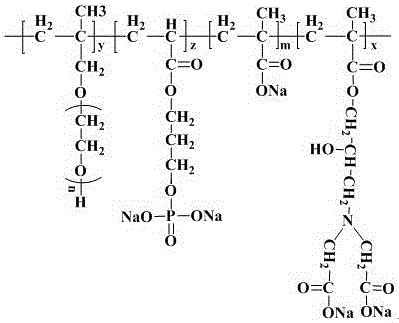

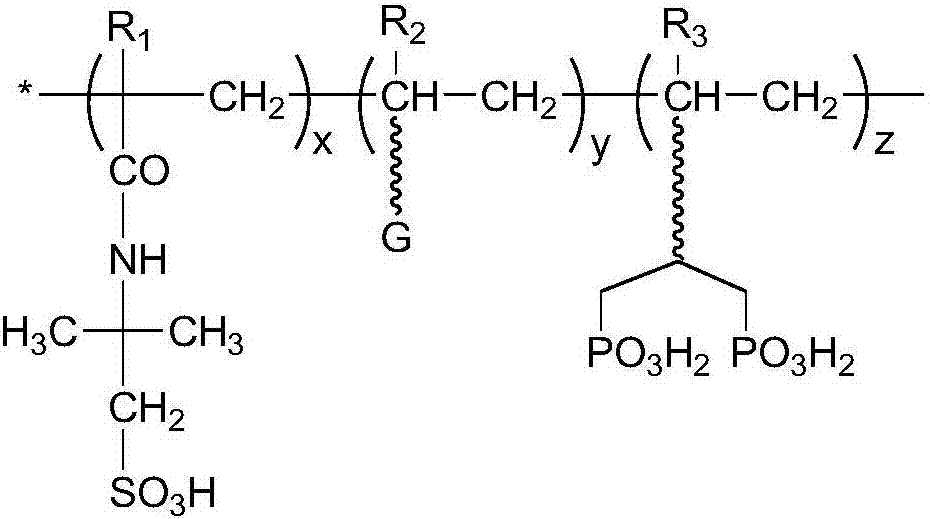

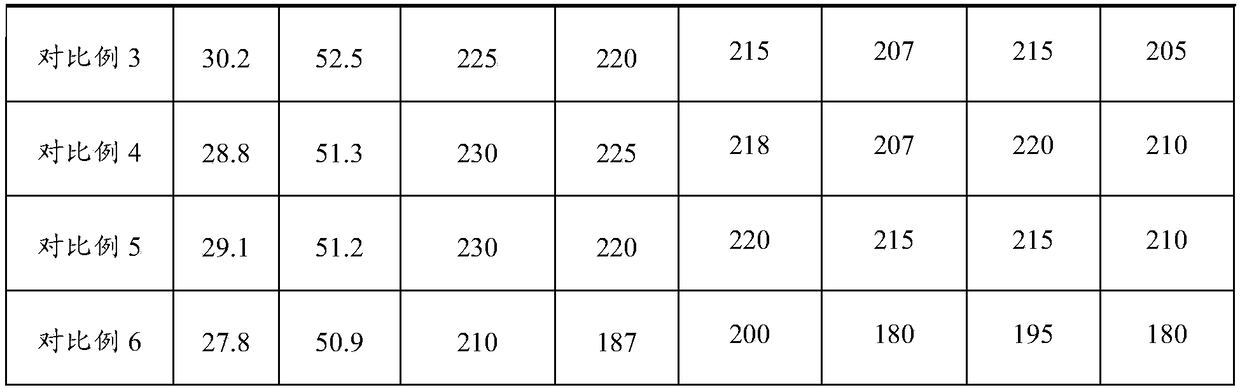

Phosphate containing high-adaptability polycarboxylate superplasticizer and preparation method thereof

The invention discloses a phosphate containing high-adaptability polycarboxylate superplasticizer and a preparation method thereof.The phosphate containing high-adaptability polycarboxylate superplasticizer is prepared through the steps that unsaturated polyether macromonomers, micromonomers, unsaturated phosphate monomers, 2-methacrylic acid-3(N,N-oxalic acid amine)-2 hydroxy propyl ester, an initiator and a chain transfer agent react with water at the temperature of 50-80 DEG C for 3-6 hours, a copolymer is obtained, then the pH value is adjusted to range from 6.0 to 7.0 with alkaline matter, and a settled solution is obtained.Compared with a polycarboxylate superplasticizer, the phosphate containing high-adaptability polycarboxylate superplasticizer has higher adsorption capacity, sulfate in cement can be effectively resisted, the dispersing power of polycarboxylate is greatly improved, the phosphate structure can change the crystal morphology formed at the initial stage of ettringite, and then collapse protecting performance is improved.

Owner:GUIZHOU TIEJIANHENGFA NEW MATERIAL TECH CO LTD

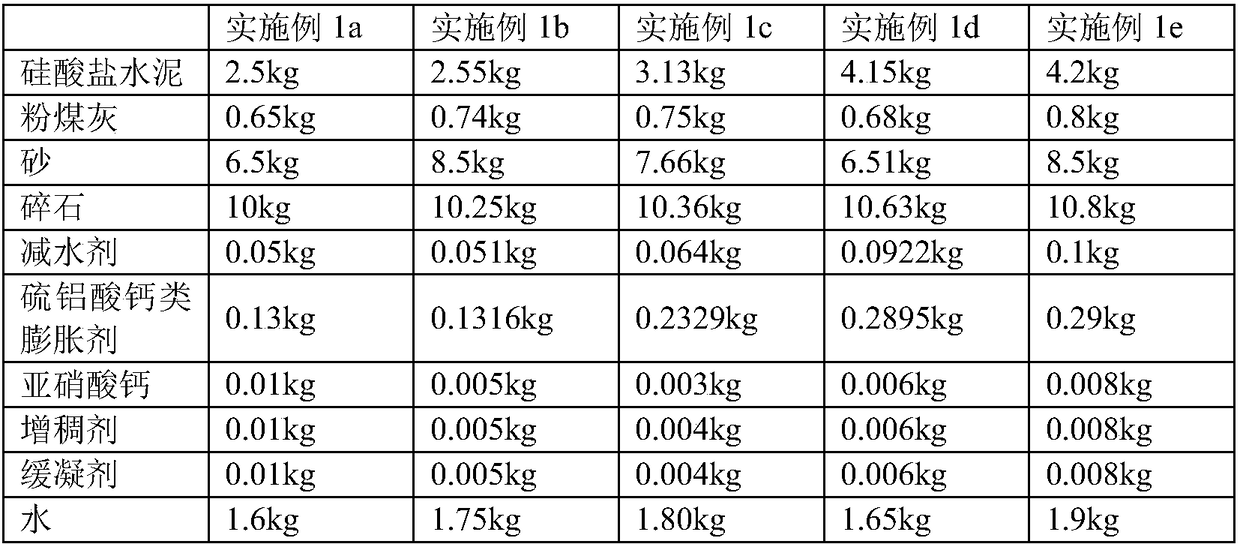

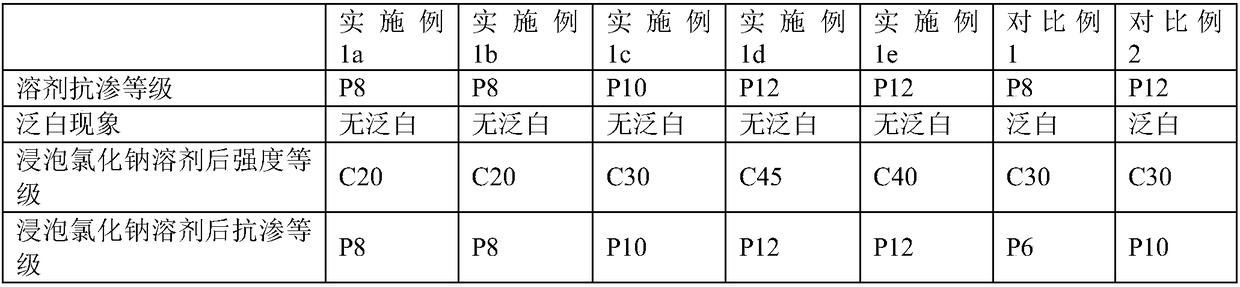

Anti-permeation concrete mixture and construction method thereof

The invention discloses an anti-permeation concrete mixture and a construction method thereof, aiming at solving the problems that an ocean environment contains a lot of chlorine ions, damages to steel bars in concrete and the concrete are caused and the use effect of anti-permeation concrete is influenced. According to technical scheme, the anti-permeation concrete mixture is prepared from the following raw materials in parts by weight: 250 to 420 parts of portland cement, 65 to 80 parts of fly ash, 650 to 850 parts of sand, 1000 to 1080 parts of crushed stones, 5 to 10 parts of a water reducing agent, 13 to 29 parts of a calcium sulfoaluminate expanding agent, 1 to 3 parts of other auxiliary agents and 160 to 190 parts of water; after the anti-permeation concrete mixture is cured, obtained concrete has a relatively good tolerance capability.

Owner:四川通德商品混凝土有限公司

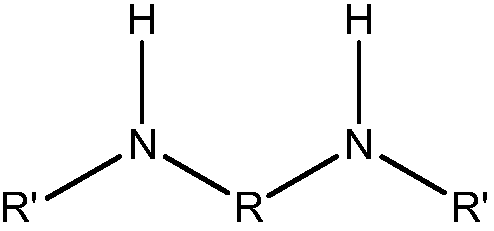

Preparation method and application of novel anti-clay phosphate superplasticizer

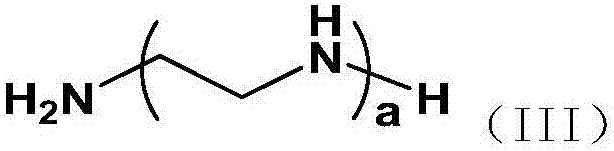

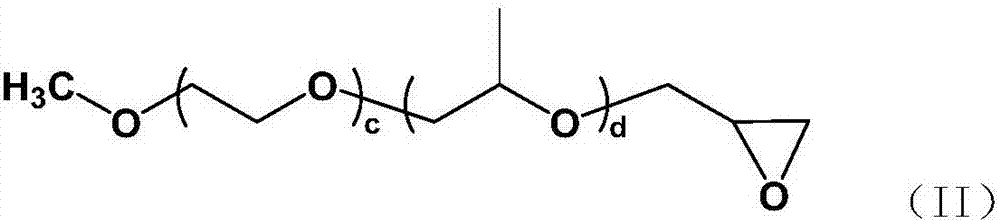

The invention discloses a preparation method of a novel anti-clay phosphate superplasticizer. The preparation method comprises steps as follows: (1) polyamine A and epoxyalkane are subjected to a ringopening polymerization reaction, and a branched polyether polyamine intermediate I is obtained; (2) the branched polyether polyamine intermediate I and epoxy chloropropane are subjected to a reaction, and an epoxypropyl ammonium chloride intermediate is obtained; (3) the epoxypropyl ammonium chloride intermediate and polyamine B react, and a branched polyether polyamine intermediate II is obtained; (4) the branched polyether polyamine intermediate II is taken as a substrate, a catalyst C, phosphorous acid and aldehyde monomers are added, the mixture reacts, and the phosphate superplasticizeris obtained. The prepared superplasticizer solves the problem about adaptability of current water reducers and clay, also has excellent retarding effect and slump retaining performance and improves the adaptability of various sand aggregates; raw materials selected in the process are low in cost, the reaction efficiency is advantageously improved, the reaction time is shortened and large-scale industrial production is realized.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

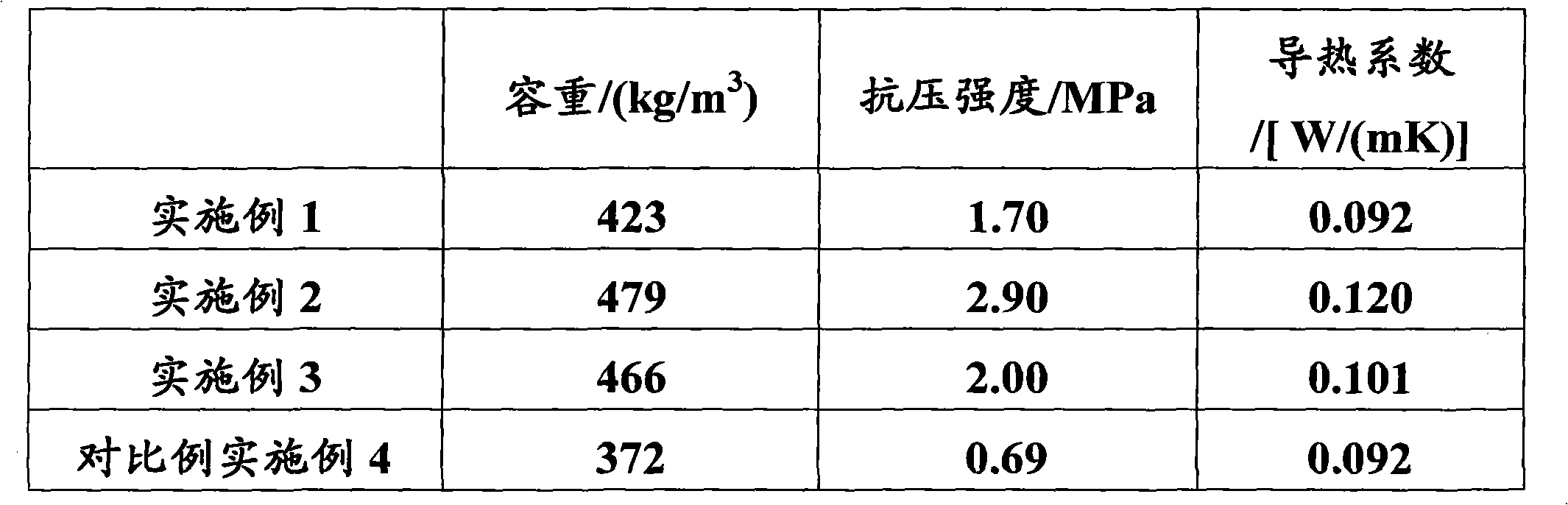

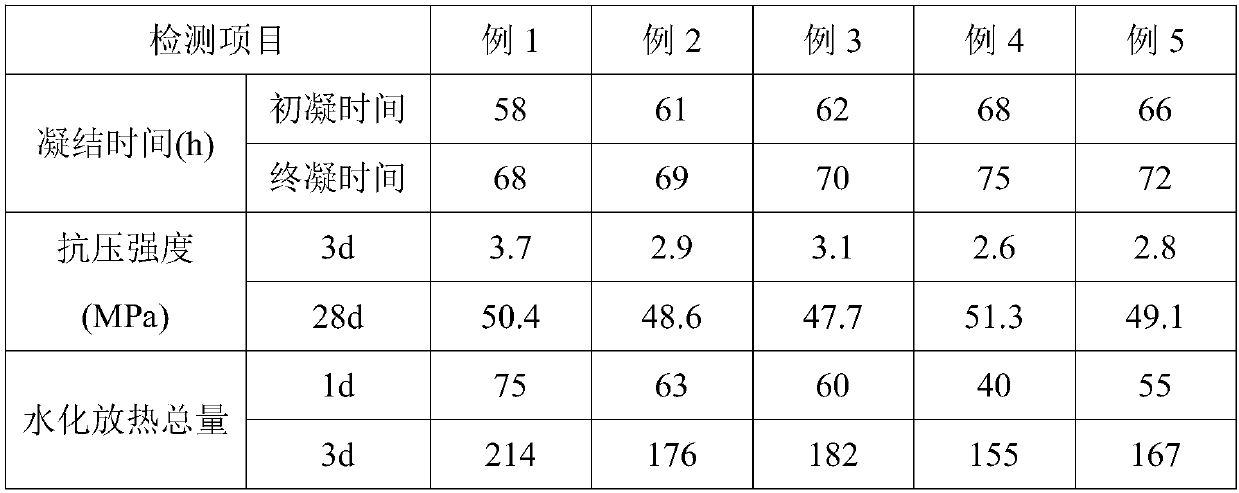

Lightweight gypsum plaster mortar

The invention belongs to building mortar, and particularly relates to lightweight gypsum plaster mortar which is the secondary development of gypsum plastered product technology. The lightweight gypsum plaster mortar is used for leveling inner sides of outer walls, inner partition walls and ceilings of buildings, and the heat-insulated effect is good. Because the flue gas desulphurized building gypsum of power plants is used, the problem of disposing and using the desulphurized gypsum is solved, and the circulating economy is developed. The method for preparing the plaster mortar comprises the following steps of: accurately weighing up the following materials in part by weight: 70 to 80 parts of flue gas desulphurized gypsum of power plants, 15 to 25 parts of vitreous hollow microsphere, 0.2 to 0.4 part of cellulose ether, 0.3 to 0.6 part of air entraining agent and 0.2 to 0.5 part of retarding agent; and putting the materials into a container, adding 60 to 120 parts of water into the container, and uniformly stirring the mixture at the normal temperature to obtain the lightweight gypsum plaster mortar. The lightweight gypsum plaster mortar has the advantages of moderate strength, unnecessary additional making of protective covering, direct leveling after plastering, high performance cost, high workability, short construction period, functions of preventing fire, absorbing sound, and adjusting air humidity and no emission of CO2 in the production process.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

Ground floor plastering gypsum

The invention discloses a preparation method of a ground floor plastering gypsum, which is improvement of the ground floor plastering gypsum. The ground floor plastering gypsum is prepared mainly by the following ingredients according to weight percentage: 30-50% of desulfurization building gypsum, 50-70% of fine sand, 0.01-0.04% of binder, 0.015-0.05% of water retaining agent and 0.01-0.05% of retarder. The ground floor plastering gypsum is strong in cohesive force, good in water resistance and low in cost, and does not crack, thus being an ideal choice for replacing traditional plastering materials.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Retarder suitable for quick set and rapid hardening of magnesium phosphate cement system and method of application thereof

InactiveCN102923986AProlong clotting timeGood retarding effectMagnesium orthophosphateRepair material

The invention discloses a retarder suitable for quick set and rapid hardening of a magnesium phosphate cement system and a method of application thereof, wherein the retarder is composed of one chlorine salt or more compound chlorine salts; and the retarder comprises four methods of applications; the first method is to prepare solution fresh; the second method is to prepare solution in advance; the third method is to stir modified magnesium phosphate cement fresh; and the fourth method is to pre-stir modified magnesium phosphate cement. The four methods of application are simple and quick in operation when being used for preparing a magnesium phosphate cement repair material; different retarders have different effects; and the status quo of long-term use of the solid retarder for the magnesium phosphate cement system is changed. The retarder provided by the invention is excellent in retarding effect; on the one hand, the retarder is capable of greatly prolonging the solidification time of the magnesium phosphate repair system at normal temperature and still has strong retarding effect in the high temperature environment; and on the other hand, the retarder is capable of ensuring the early strength of the magnesium phosphate cement sample and also improves the long-term strength thereof to a certain extent.

Owner:SOUTHEAST UNIV

Super-weather resistant alkali-activated-fly ash-slag bicomponent outer wall inorganic coating

InactiveCN101880151AGood flexibilityHigh activitySolid waste managementPliabilityPulverized fuel ash

The invention provides a super-weather resistant alkali-activated-fly ash-slag bicomponent outer wall inorganic coating. In the coating, sodium water glass and water are selected as base materials, and pulverized fuel ash, high-aluminum cement, slag, titanium white powder, pigment, talcum powder, redispersable latex powder, hydroxyethylcellulose, a naphthalene-based water reducing agent and a powdery antifoaming agent are used as padding. By testing the washing resistance of the coating of the invention, a specimen is washed 25,000 times without bubbling or cracking or dropping; by testing the water resistance, the specimen is soaked for 4,320 hours without bubbling or cracking or dropping; by testing acid rain resistance, the specimen is soaked in a solution, of which the pH is equal to 3 and is adjusted every day to be maintained to be 3, for 960 hours without bubbling or cracking or dropping; by testing salt resistance and alkali resistance, the specimen is soaked in 0.2mol / L of KOH solution of 5 percent of NaCl for 960 hours without bubbling or cracking or dropping; by testing bonding strength, the specimen has the bonding strength of 1.14MPa; and by testing flexibility, the specimen is qualified by 100 percent by being inspected through a grid scoring method of 1mm.

Owner:王建华 +1

Retarded cement grinding aid and preparation method thereof

ActiveCN103193415AImprove early strengthIncrease late strengthCarboxymethyl celluloseCement grinding

The invention discloses a retarded cement grinding aid and a preparation method thereof. The retarded cement grinding aid comprises 0.01-0.02wt% of sodium carboxymethyl cellulose, 25-30wt% of molasses calcium, 5-10wt% of citric acid and the balance of water, wherein the total percent is 100%. The retarded cement grinding aid provided by the invention has the beneficial effects that the molasses calcium is used instead of the molasses and cane sugar commonly used at present, is a powdery product prepared by neutralizing the molasses with lime, has better water reducing and retarding effects than the molasses and saves the cost; and the hydration and hardening time of the cement is effectively lengthened so that the freshly mixed cement concrete can maintain the plasticity in a longer time, thus adjusting the setting time of the freshly mixed cement concrete.

Owner:NANJING YONGNENG MATERIALS

Method for preparing large-admixture-amount wet-milled phosphorus solid waste super-retarding cementing material

The invention discloses a method for preparing a large-admixture-amount wet-milled phosphorus solid waste super-retarding cementing material. The method comprises the following steps: putting phosphorus slag and desulfurized fly ash into a wet-milling machine, and performing mixing and wet milling so as to obtain mixed slurry A; grinding caustic dross, ardealite and coal ash in a dry-milling machine so as to obtain a mixed powder material B; and mixing the mixed slurry A with the mixed powder material B so as to obtain a mixed material C, adding cement, a water reduction agent, a retarder, tailing sand and macadam into the mixed material C, and performing stirring for 4 minutes, so as to obtain super-retarding concrete. Wastes such as the phosphorus slag, desulfurized fly ash, caustic dross, ardealite, coal ash and tailings are adopted to prepare concrete, wastes are turned into wealth, and the amount of cement can be also reduced; due to a mixed wet-milling mode of the phosphorus slagand the desulfurized fly ash, phosphorus dissolution of the phosphorus slag can be promoted, the initial setting time and the final setting time of the concrete can be greatly prolonged, early-stagehydration heat can be reduced, cracks can be reduced, later strength can be ensured, and large-admixture-amount efficient application of the phosphorus slag can be achieved; and the prepared super-retarding concrete can be applied to large-size concrete, drilling bitten piles, and the like.

Owner:HUBEI UNIV OF TECH

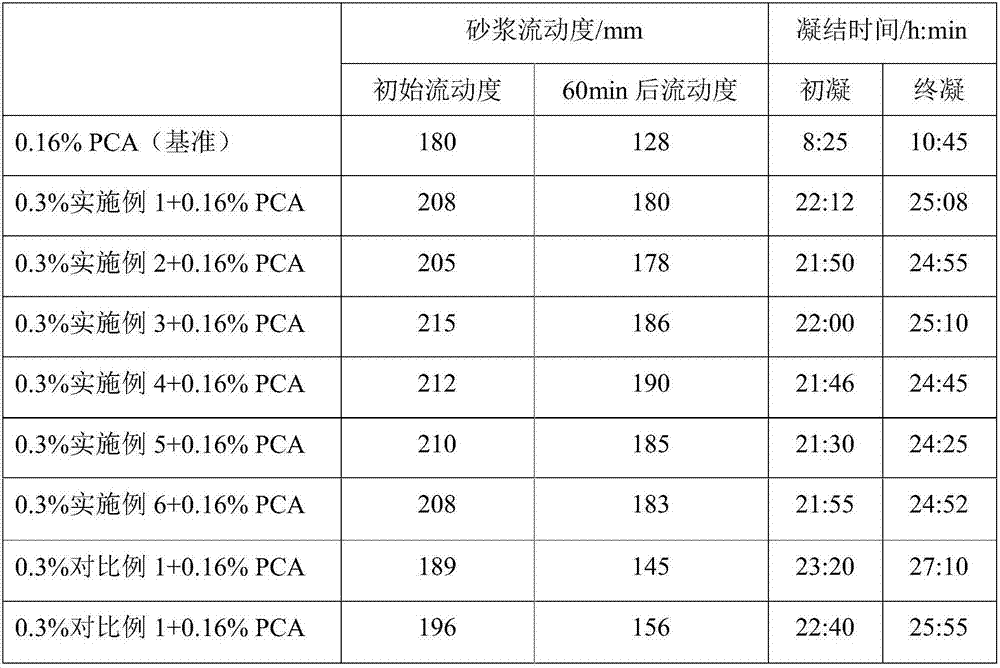

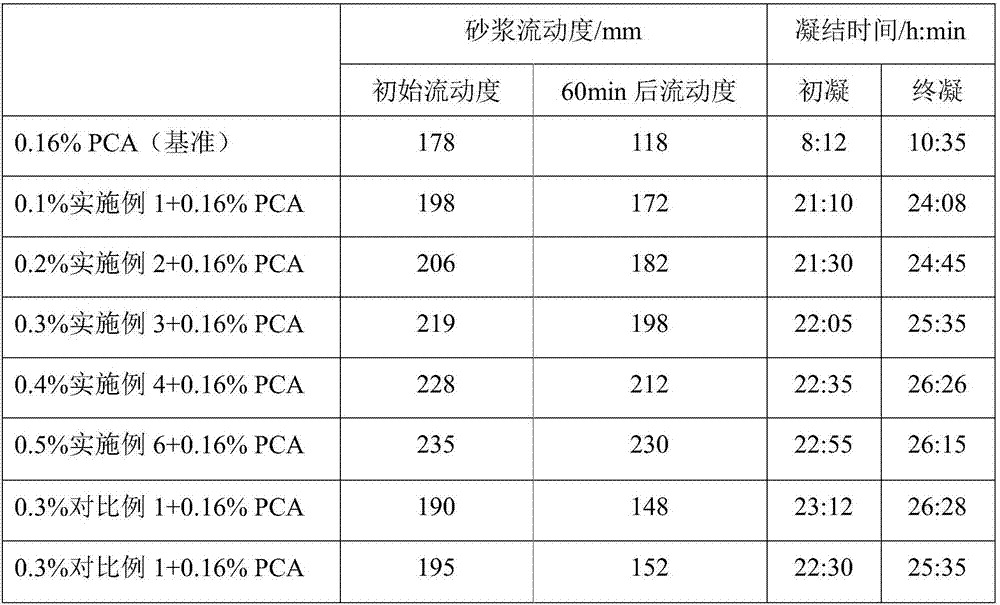

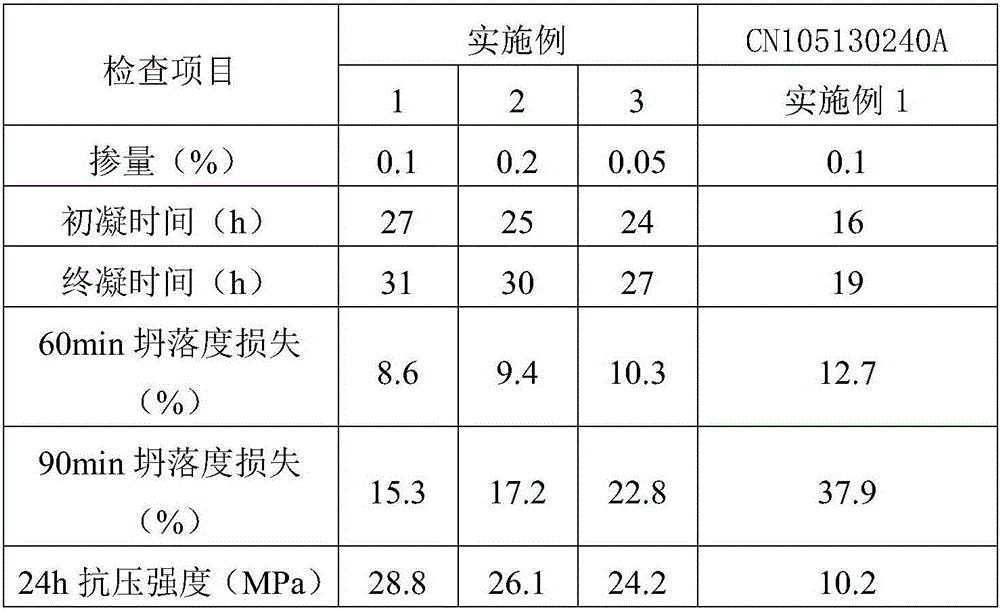

High-temperature-resistant phosphono-containing concrete retarder and preparation method thereof

The invention provides a high-temperature-resistant phosphono-containing concrete retarder and a preparation method thereof. The phosphono-containing concrete retarder has the advantages of high temperature resistance and excellent setting retarding effects, can enhance the adaptability of a polycarboxylic acid water reducing agent to machine-made sand and low-activity admixtures, lowers the sensitivity to cement, temperature and water consumption, and enhances the sulfate and clay tolerance. Under the synergic action of the polycarboxylic acid water reducing agent, the concrete retarder obviously improves the concrete workability, and is suitable for preparing concrete under harsh working conditions, such as low sandstone material quality, high-temperature environment, long-time transportation and the like. The preparation technique is simple, and has high feasibility for industrial production and broad market application space. The concrete retarder has important technical support effects on promoting the market application of the polycarboxylic acid water reducing agent and enhancing the rheological properties, mechanical properties and durability of the concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Concrete retarder

The invention discloses a concrete retarder which is prepared from the following components in parts by weight: 4-6 parts of ammonium phosphate, 5-7 parts of ammonium sulfate, 6-8 parts of sodium tripolyphosphate, 10-15 parts of amino trimethylene phosphonic acid, 3-7 parts of gelatin, 1-3 parts of glycerol, 2-4 parts of sodium citrate, 10-15 parts of zeolite powder, 10-15 parts of pumice powder, 3-5 parts of water reducer, 1-3 parts of dispersant and 0.4-0.6 part of surfactant. The concrete retarder has the advantages of good retarding effect, high strength, no pollution and the like, and is a concrete additive with developing future.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Concrete retarder

The invention discloses concrete retarder. The concrete retarder comprises, by weight, 2-4 parts of sodium borate, 3-7 parts of monopotassium phosphate, 4-8 parts of calcium sulfate, 6-8 parts of etidronic acid, 3-5 parts of ethylene diamine tetraacetic acid, 1-4 parts of sorbitol, 25-30 parts of bentonite, 10-15 parts of vermiculite powder, 4-6 parts of a water reducing agent, 1-3 parts of a dispersing agent and 0.4-0,8 part of a surface active agent. The concrete retarder has the advantages of good retarding effect, high strength, free of pollution and the like, and is a concrete additive which is quite promising.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

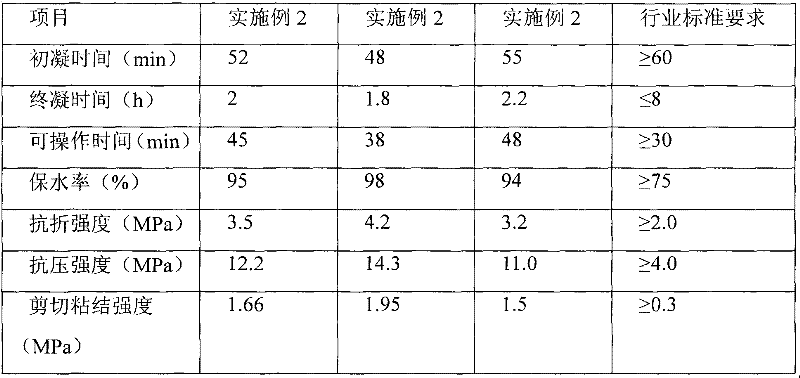

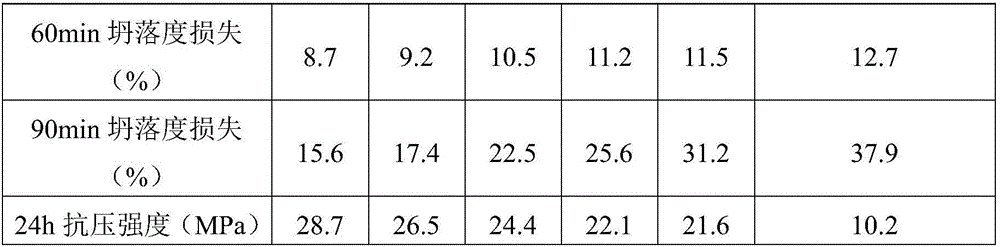

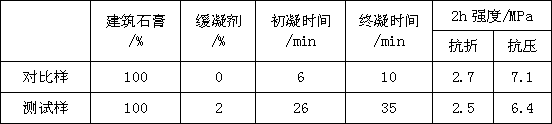

Novel gypsum retarder and preparation method thereof

The invention relates to a novel gypsum retarder and a preparation method thereof. The novel gypsum retarder consists of the following components in parts by weight: 150-180 parts of penicillin mycelium, 0.2-0.4 part of disodium hydrogen phosphate, 0.3-0.6 part of sodium hydroxide, 0.05-0.08 part of polydimethylsiloxane, 0.04-0.06 part of potassium sorbate, 10-20 parts of alkaline calcium bentonite, 0.01-0.03 part of beta-phenethyl alcohol and 350-450 parts of water. Modification condition: modification is performed at the temperature of 40-50 DEG C for 3-5 hours; and a modified material is prepared into a solid gypsum retarder by spray drying. The retarder has the characteristics of low cost, good retarding effect and small strength loss.

Owner:邯郸市潘仁新能源科技有限公司

Retarding and water reducing agent

The invention discloses a retarding and water reducing agent prepared by mixing the following raw materials in parts by weight: 35-45 parts of beta-naphthalene sulfonated formaldehyde condensates, 20-30 parts of sulfonated acetone-formaldehyde condensates, 10-15 parts of hydroxypropyl methyl cellulose, 6-12 parts of casein, 3-6 parts of mirabilite, 4-8 parts of sulfonated coal tar, 2-4 parts of borax, 5-10 parts of slaked lime, 8-14 parts of activated sludge, 5-10 parts of sodium fluosilicate, 2.5-4.5 parts of oil foot, 2-3 parts of tartaric acid, 3-5 parts of zinc molybdate, 4-6 parts of triethyl phosphate, 2-4 parts of maltodextrin, 4-8 parts of sodium methallyl sulfonate and 3-6 parts of auxiliary. The water reducing agent disclosed by the invention is good in retarding effect, good in adaptability to various kinds of cement, free of corrosion to reinforcing steel bars and capable of prolonging the setting time by 2-4h, achieving the water reducing rate of 15-20%, greatly improving the workability of concrete and improving various mechanical properties of the concrete, and can be used for various reinforced concrete works.

Owner:重庆砼磊高新混凝土有限公司

Oxidation-sulfonation starch water reducing agent preparation method

The invention discloses an oxidation-sulfonation starch water reducing agent preparation method, which comprises: adding water to a reaction kettle, adding 20-40% of corn starch while stirring, adjusting the pH value of the starch milk to 9-11 with an alkaline substance, adding an oxidizing agent while stirring, continuously carrying out the stirring reaction for 3-5 h at a temperature of 30-45 DEG C, adjusting with an acid to achieve a neutral state, filtering, and drying to obtain oxidation starch; and adding an organic solvent to a reaction kettle, adding 10-15% of the oxidation starch while stirring, controlling the temperature at 0-60 DEG C, slowly adding an acidic substance and organic solvent mixture in a dropwise manner, stirring for 1-2 h, terminating the reaction, filtering, and drying so as to obtain the oxidation-sulfonation starch. According to the present invention, the process of the preparation method is simple; after the product is added to cement, the cement slurry has good fluidity and good retardability; after the product is added to mortar, the advantages of fluidity increasing, water consumption reducing, compressive strength increasing and bending strength increasing can be provided; and after the product is added to concrete, the slump of the concrete can be increased, and the strength is improved.

Owner:MIANYANG MOSHI TECH CO LTD

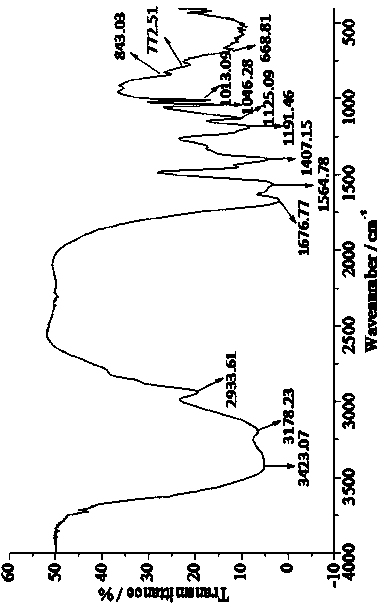

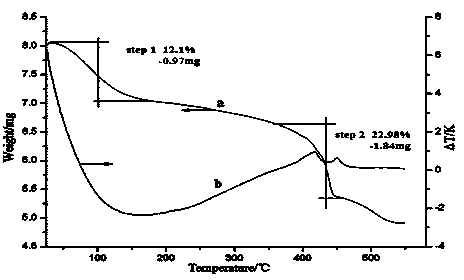

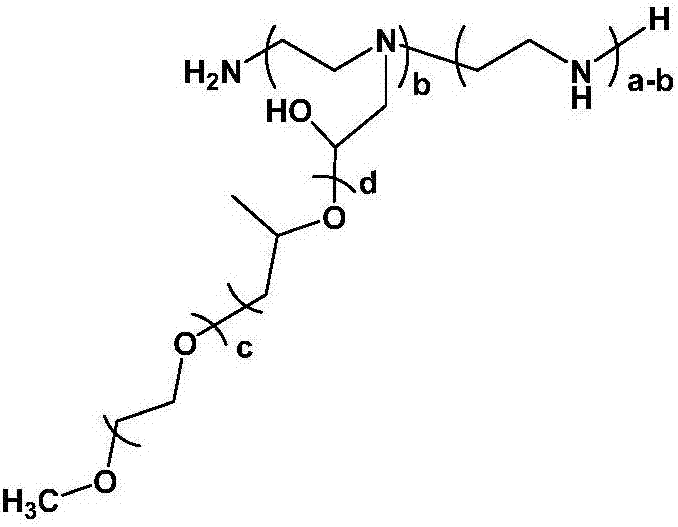

Synthesis method of hyperbranched unsaturated polyoxyethylene ether as well as product and application thereof

The invention provides a synthesis method of hyperbranched unsaturated polyoxyethylene ether, hyperbranched unsaturated polyoxyethylene ether obtained by adopting the synthesis method and application thereof. The synthesis method mainly comprises the steps of firstly, carrying out esterification reaction on a polyhydroxy compound and unsaturated carboxylic acid, wherein massive hydroxyls are reserved in the obtained ester intermediate; then in presence of an anionic ring opening polymerization catalyst, carrying out anionic ring opening polymerization on the ester intermediate and ethylene oxide, thus obtaining the target product. A polycarboxylic acid water reducer which has higher polyoxyethylene ether molecular chain density and is prepared by taking the hyperbranched unsaturated polyoxyethylene ether as a raw material shows higher water reducing rate, higher cement paste expansion degree and then shows more excellent retarding effect. Therefore, the provided synthesis method and the hyperbranched unsaturated polyoxyethylene ether obtained by adopting the synthesis method have broad application prospect and great market potential.

Owner:SHANGHAI TAIJIE CHEM

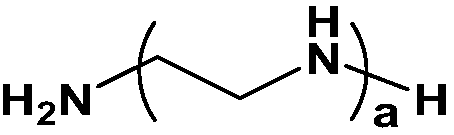

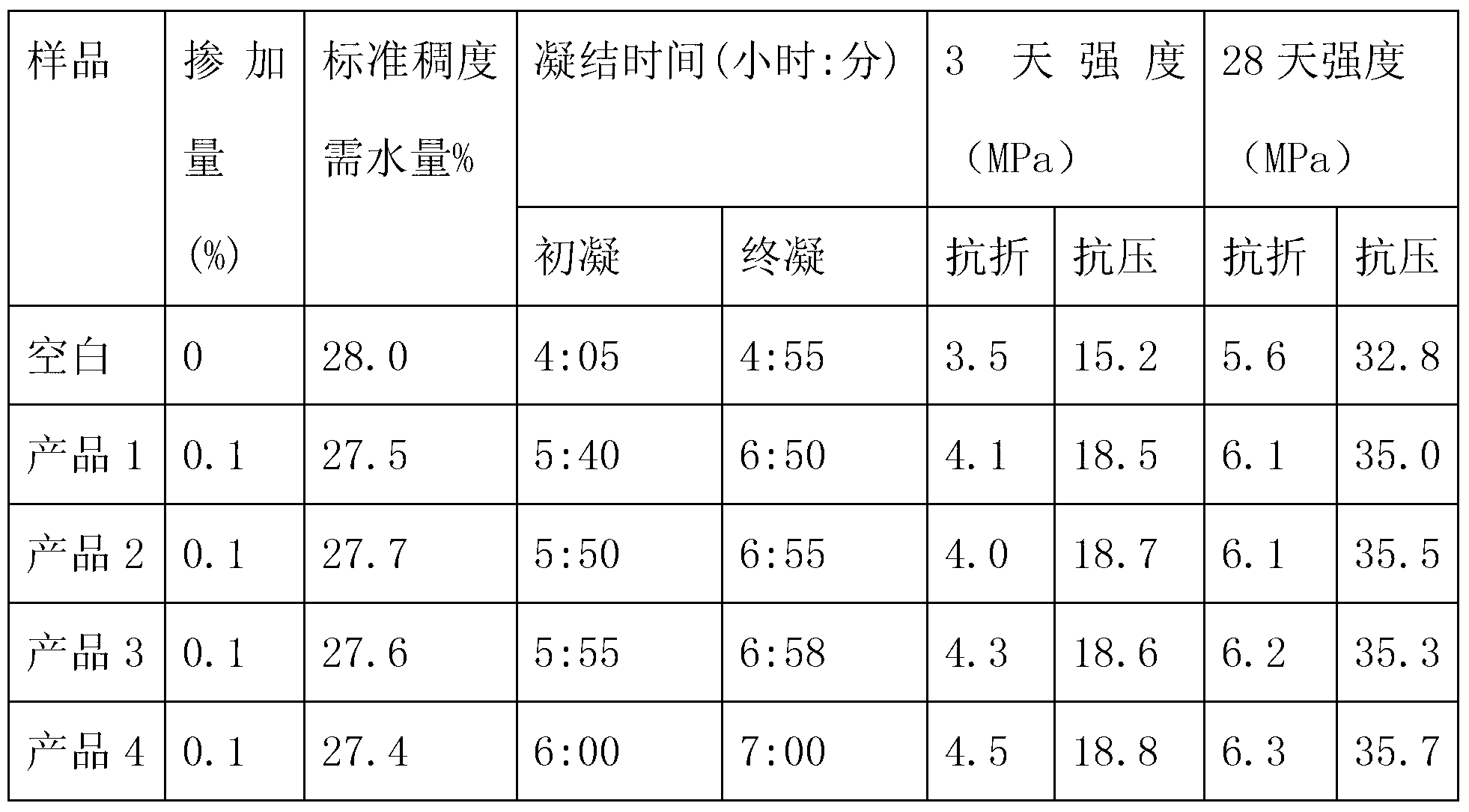

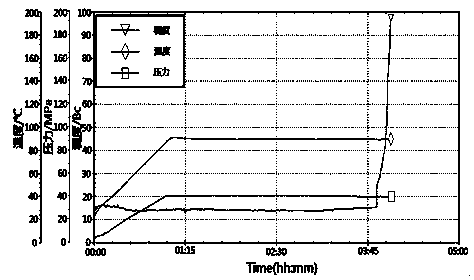

Polymer wide-temperature-zone retarder for oil-gas well cement and preparation method thereof

InactiveCN103740350ADoes not affect engineering performanceConstruction safetyDrilling compositionPolymer scienceMass ratio

The invention discloses a polymer wide-temperature-zone retarder for oil-gas well cement and a preparation method thereof. The preparation method of the retarder comprises the following processes: (1) dissolving itaconic acid, acrylamide and sodium p-styrenesulfonate with deionized water and mixing the solutions, and adjusting the pH value of the solution to be 6-7, wherein the mass ratio of itaconic acid to acrylamide to sodium p-styrenesulfonate is (1-2):(2-4):(2-4), and the total mass concentration of monomers in the solution is 10-20%; (2) heating the mixed solution to 40-60 DEG C, and adding an initiator to carry out polymerization reaction in a nitrogen environment for 4-6 hours to obtain a polymer solution; (3) extracting the polymer solution with absolute ethyl alcohol, drying the extract, and grinding the extract into powder. The retarder can effectively avoid super-retarding or under-retarding of oil-gas well cement paste in a low temperature zone, can effectively lengthen the thickening time of the oil-gas well cement paste in a high temperature zone, can be matched with various admixture systems, does not affect the overall performance of the cement paste, and has extensive market prospects.

Owner:SOUTHWEST PETROLEUM UNIV

Production method and product of cement retarder from ardealite

InactiveCN102531441AGood retarding effectGood modification effectO-Phosphoric AcidProcess engineering

The invention relates to a novel cement retarder prepared from ardealite and a production method thereof. The production method comprises the following steps of: 1, analyzing the mass percentage content of fluorine and free phosphoric acid in the ardealite; 2, adding the weighed ardealite in a mixer, adding quick lime powder the weight of which is 3-8 times that of the ardealite, adding cement kiln ash the weight of which is 5-15% of the ardealite, and adding a grinding aid the weight of which is 5-10% of the ardealite; 3, controlling the mixing time of materials in the mixer to 10-30 minutes to obtain a mixed material; 4, feeding the mixed material into a smashing machine with a belt transportation machine for smashing the mixed material, and uniformly distributing the material layer by layer in a storeroom; 5, standing and curing the distributed material for 3-10 days in the storeroom to obtain the modified ardealite; and 6, continuously turning over the modified ardealite through a double-beam grab bucket crane and further naturally drying so as to obtain the cement retarder prepared from the ardealite. The obtained product is powdery and contains more than or equal to 38% of SO3, less than or equal to 0.1% of free phosphoric acid (based on P2O5), more than or equal to 15% of crystal water and less than or equal to 18% of adhered water.

Owner:云南新龙矿物质饲料有限公司

Chloride-free enhanced slump-retaining cement grinding aid and preparation method thereof

The invention provides a chloride-free enhanced slump-retaining cement grinding aid which comprises, by weight, 2-8 parts of diethanolisopropanolamine, 6-20 parts of triethanolamine, 10-25 parts of sodium formate, 0.5-2 parts of organic phosphonate retarders, 0.5-2 parts of polymeric dispersing agents, 2-4 parts of green syrup and the rest water. The grinding aid has the advantages that the diethanolisopropanolamine, the triethanolamine and the sodium formate are used in a matched manner, the early strength and the later strength of cement are remarkably improved, the organic phosphonate retarders and the polymeric dispersing agents are used in a matched manner, so that the cement has excellent slump-retaining performance, adaptability between the cement and a concrete additive is good, the early strength and the later strength of the cement are improved by 3-5MPa in actual use process, adaptability among the cement, a naphthalene water reducer, an aliphatic water reducer and a polycarboxylic acid water reducer is good, the cement paste fluidity cannot be lost within 2 hours, and the grinding aid does not contain any chloride ions and sulfate ions, is free from toxicity and corrosiveness, green and environmentally friendly and cannot damage to human bodies, buildings and the like.

Owner:UNIV OF JINAN

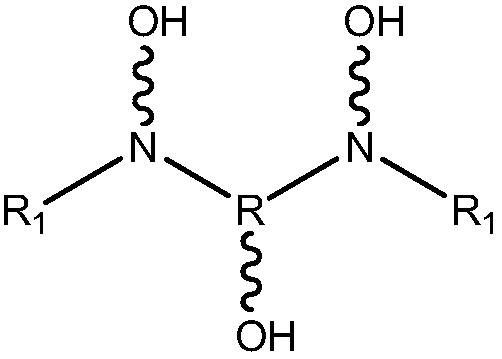

Aminated polyether intermediate, preparation method and application

The invention discloses an aminated polyether intermediate, a phosphorylation product utilizing the aminated polyether intermediate and application of the phosphorylation product as a water reducer. The aminated polyether intermediate is structurally characterized in that a main chain is formed by amine monomers, a side chain with certain steric hindrance and hydrophilic and hydrophobic propertiesis formed by polyether glycidyl ether, and meanwhile, newly-generated hydroxy groups are located on the side chain. A process for preparing the phosphorylation product from the aminated polyether intermediate is simple, and the obtained phosphorylation product can be used as the water reducer and has an excellent delayed coagulation effect and clay tolerance.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com