Special high strength grouting material for connecting reinforcement sleeve

A technology for steel bar sleeves and grouting materials, which is applied in the field of high-strength grouting materials for steel bar sleeve connections, which can solve problems such as insufficient performance, and achieve the effects of large fluidity loss, good retarding effect, and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

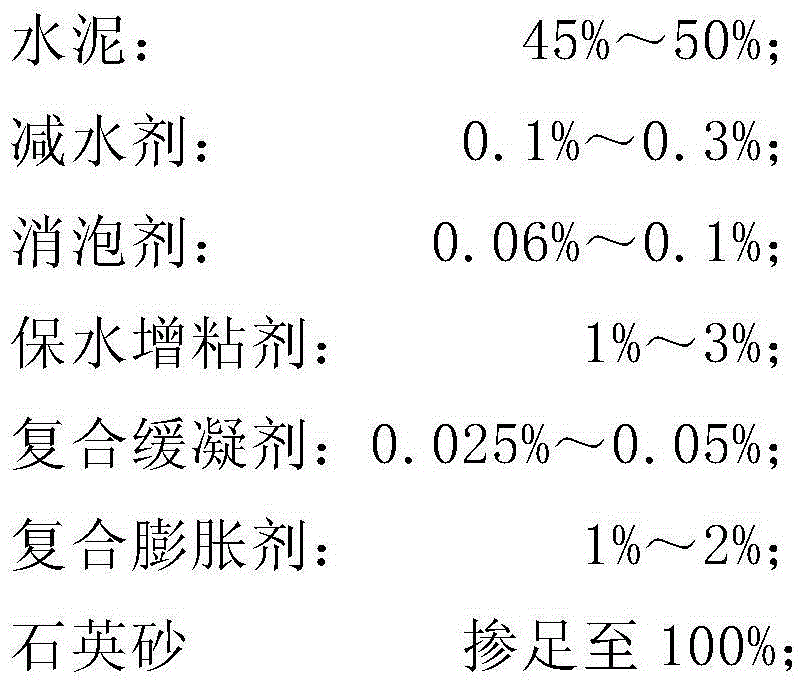

[0045] The formula of special high-strength grouting material for steel bar sleeve connection of this embodiment is shown in Table 1

[0046] Table 1

[0047] raw material

1t production ratio / kg

Sulphoaluminate cement

45

PII52.5

412

Quartz sand

529

2

Methyl cellulose ether 500 viscosity

0.2

Latex powder (vinyl acetate-ethylene copolymerization, Tg=15°C, film-forming temperature 4°C)

1

Analytical pure tartaric acid L+

0.38

sodium gluconate

0.02

0.6

Composite expansion agent

10

water

124

[0048] The special high-strength grouting material for the sleeve connection of steel bars in this embodiment is used for the steel bar connection of large sleeves of bridges, wherein the sleeve length is 800 mm, the diameter is 60 mm, and the diameter of the built-in steel bar is 40 mm.

[0049] The special high-strength grout ...

Embodiment 2

[0054] The formula of special high-strength grouting compound for the connection of steel bar sleeve of this embodiment is shown in Table 3,

[0055] table 3

[0056]

[0057]The special high-strength grouting material for steel bar sleeve connection in this embodiment is used for steel bar sleeve connection in the construction of PC components in a certain substation in Shanghai.

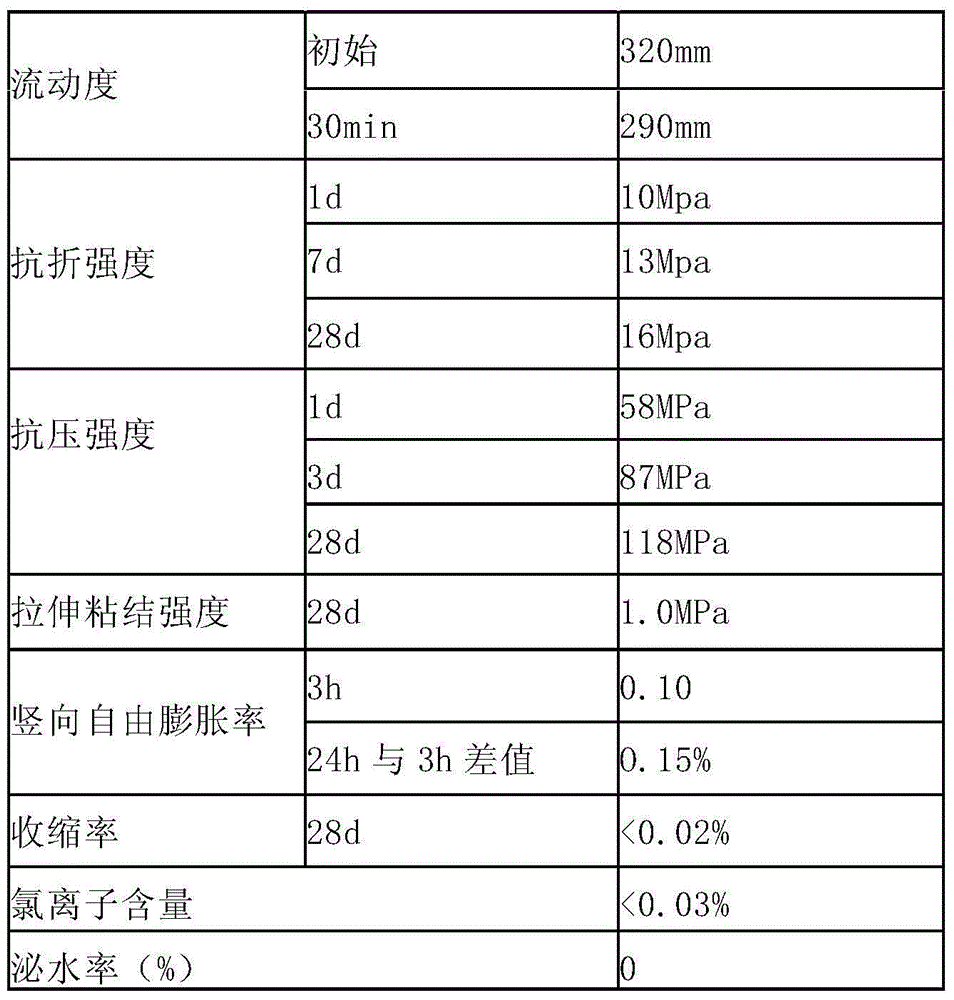

[0058] The special high-strength grout for steel bar sleeve connection in this embodiment is tested according to JGT408-2013 sleeve grout for steel bar connection, and the test results are shown in Table 4.

[0059] Table 4

[0060]

[0061] For the preparation method of the above embodiment, refer to a high-performance grouting material for prefabricated building construction disclosed in CN103265253A and its preparation method.

Embodiment 3

[0063] The special high-strength grouting material formula for the connection of the reinforcement sleeve of this embodiment is shown in Table 5,

[0064] table 5

[0065] raw material

1t production ratio / kg

Shuanghe Sulphoaluminate Cement

23

Onoda PII52.5

433

Quartz sand

529

3

Methyl cellulose ether 500 viscosity

0.2

latex powder

1

Analytical pure tartaric acid L+

0.34

sodium gluconate

0.03

0.6

Composite expansion agent

10

water

122

[0066] The special high-strength grouting material for steel bar sleeve connection in this embodiment is used for steel bar sleeve connection in PC component construction. The sleeve length is 380 mm, the inner diameter is 45 mm, and the built-in steel bar diameter is 32 mm.

[0067] The special high-strength grout for steel bar sleeve connection in this embodiment is tested accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com