Patents

Literature

39results about How to "High-strength adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cold mixing color asphalt mixture and preparation method

The invention discloses a cold mixing color asphalt mixture and a preparation method. The preparation method comprises the following steps: selecting aromatic hydrocarbon oil, rubber oil, petroleum resin, epoxy resin, a modifier, a plasticizer, a diluent, diatomite, a pigment and stabilizers, and mixing the materials according to the mass proportion, thus obtaining color asphalt cement; selecting an emulsifier, the stabilizers and a defoamer, and mixing the three materials with the color asphalt cement in proportion, thus obtaining emulsified color asphalt cement; and selecting an aggregate, a filler, cement, a waterborne curing agent, an expansive agent and the emulsified color asphalt cement, and mixing the materials in proportion, thus obtaining the cold mixing color asphalt mixture.

Owner:SHENZHEN TRAFFIC CONSTR ENG TEST & DETECTION CENT

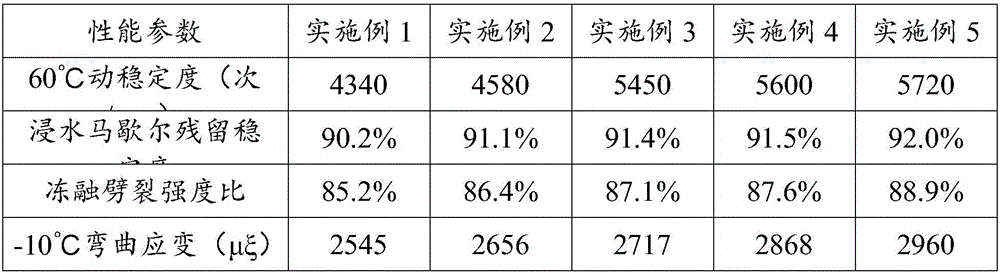

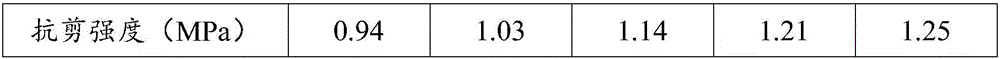

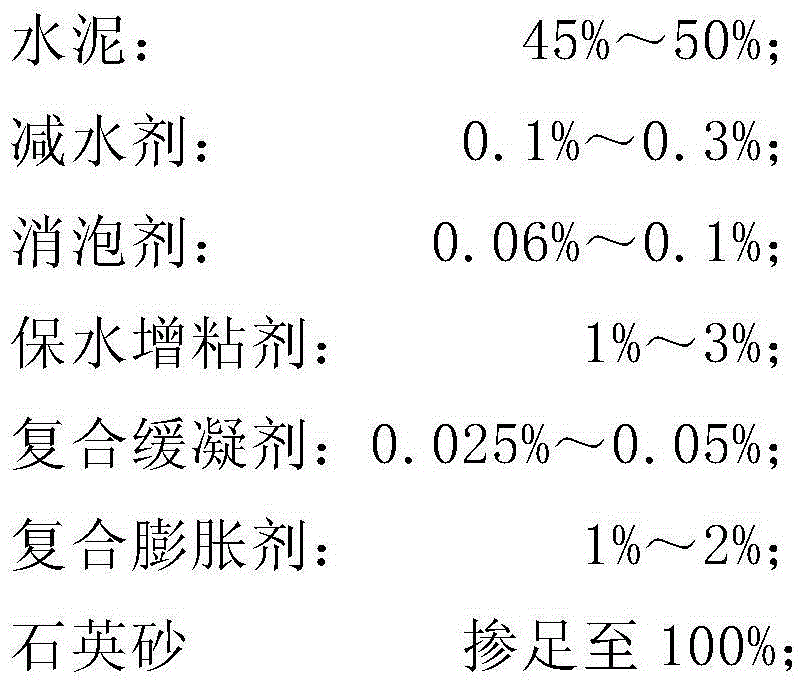

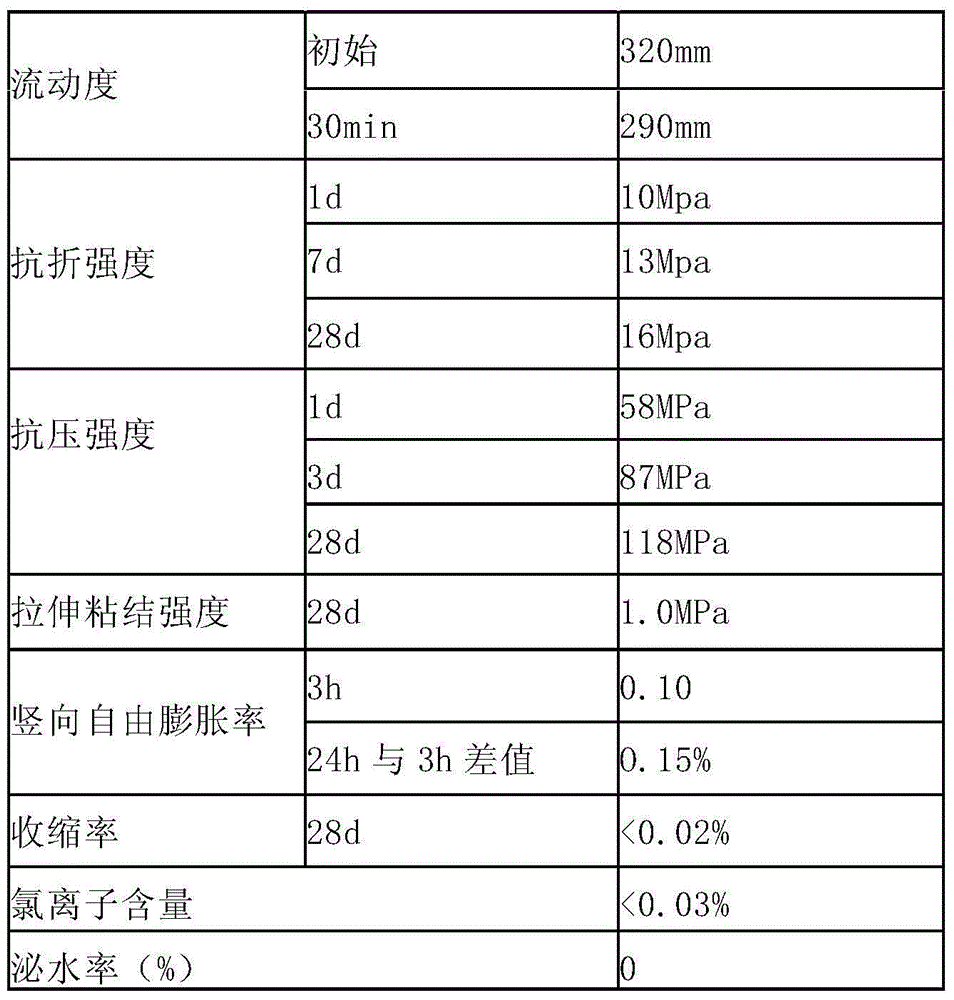

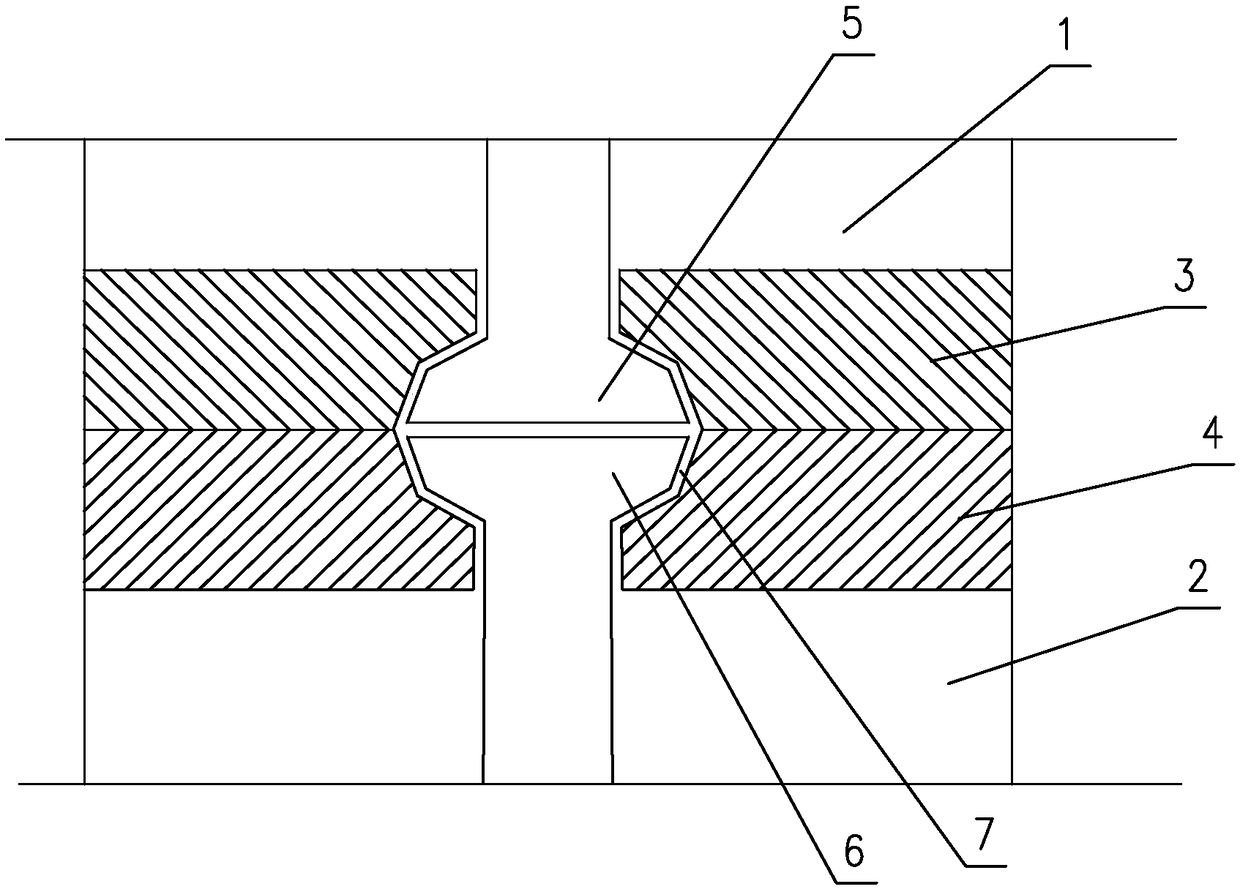

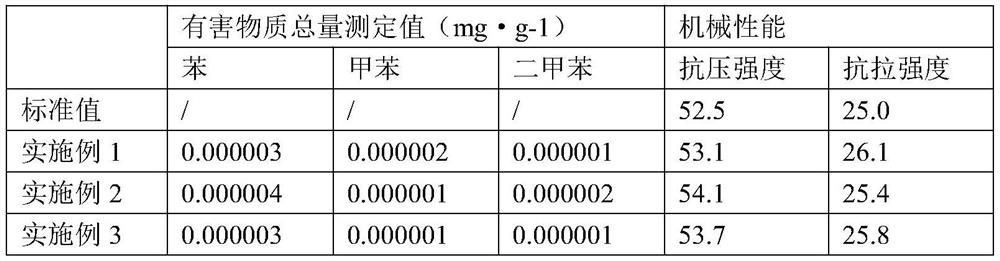

Special high strength grouting material for connecting reinforcement sleeve

The present invention discloses a special high strength grouting material for connecting a reinforcement sleeve. The special high strength grouting material for connecting the reinforcement sleeve comprises grouting material powder and water, wherein the grouting material powder is prepared from the following raw materials in percentage by weight: 45% to 50% of cement, 0.1% to 0.3% of a water reducing agent, 0.06% to 0.1% of a defoamer, 1% to 3% of a water retention tackifier, 0.025% to 0.05% of a composite retarder, 1% to 2% of a composite expansion agent; and and the balance of quartz sand, totalling 100, wherein the mass ratio of the grouting material powder to the water is 1 to (0.23-0.28). The special high strength grouting material for the connecting reinforcement sleeve provided by the present invention has the characteristics of high strength, high adhesion and slight expansion with no shrinkage; the high strength grouting material can be poured into the reinforcement sleeve to enable fixed connection formed between reinforcements and between the reinforcements and the sleeve, and has excellent durability.

Owner:SHANGHAI URBAN CONSTR MATERIAL CO LTD

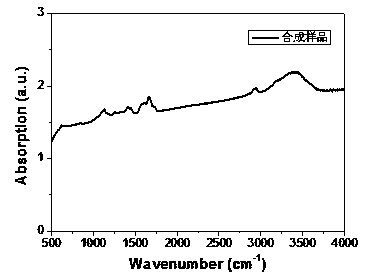

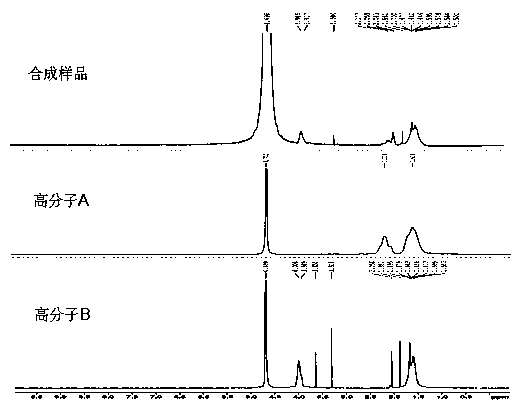

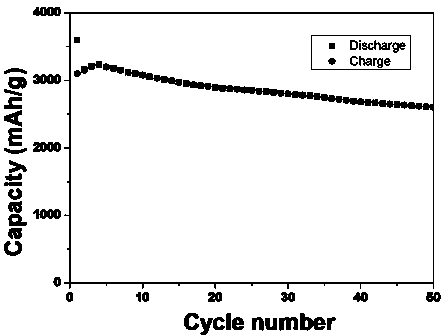

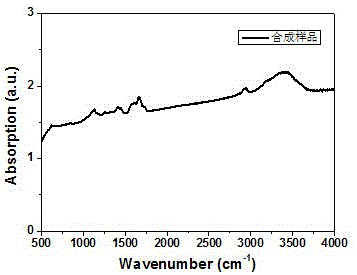

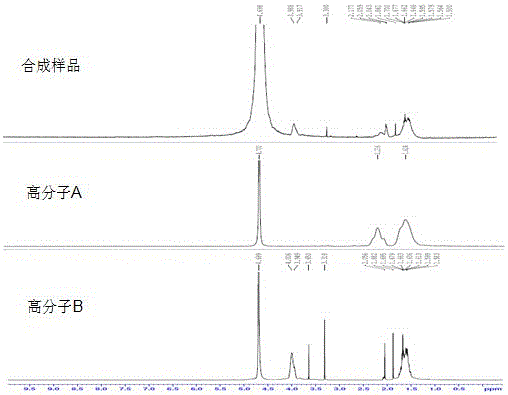

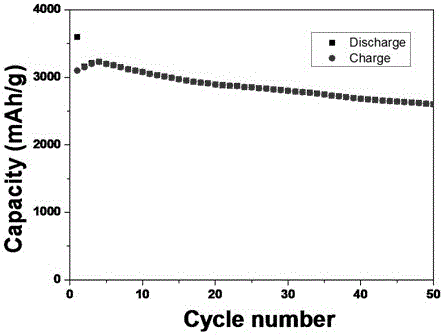

Adhesive for lithium battery and preparation method thereof

ActiveCN103427083APromote circulationImproved high-magnification performanceCell electrodesPolymer scienceAdhesive

The invention relates to adhesive for a lithium battery and a preparation method thereof. The adhesive is aqueous and is prepared through polymer A containing carboxyl functional groups and polymer B containing hydroxyl functional groups. The preparation method includes dissolving and placing the polymer A containing the carboxyl functional groups and the polymer B containing the hydroxyl functional groups in a reactor in proportion, then adding reaction initiator C to stir without a break for 10 to 12 hours at the constant temperature ranging from 40 to 70 DEG C, and cooling to the room temperature to obtain the adhesive. The adhesive has high-strength adhesion and excellent plasticity, prepared slurry can be preserved for long time without phase separation and can be mass produced, so that a battery producing process is easier and more facilitated, and consistence of battery quality can be guaranteed.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

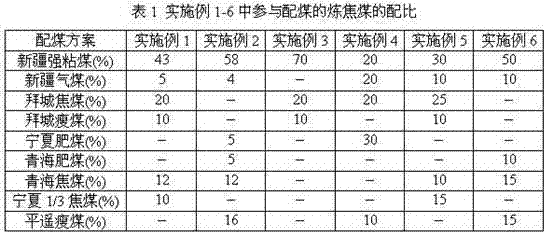

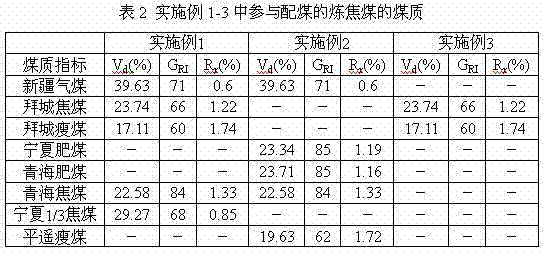

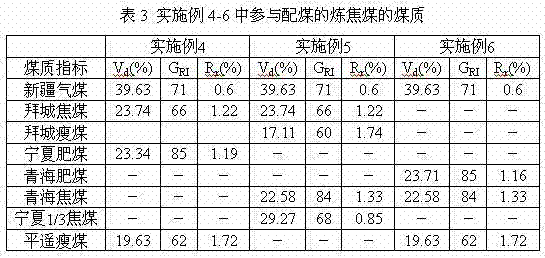

Coal blending method for preparing high-activity high-strength coke

ActiveCN102453490AHigh in Calcium OxideHigh in Iron OxideCoke ovensVitrinite reflectanceHigh availability

The invention discloses a coal blending method for preparing high-activity high-strength coke. The coal blending method comprises a step of blending coking coal, wherein the coking coal participating in coal blending comprises the following components in percentage by weight: 20 to 70 percent of Xinjiang strongly caking coal, and the balance of one or a mixture of more of charred coal, lean coal,fat coal, gas coal and 1 / 3 charred coal; and after blending, the air-dried moisture is 1.0 to 1.7 percent, the dry basis ash is 8 to 12 percent, the dry basis volatile is 22 to 26 percent, the sulfurcontent is less than 0.6 percent, the caking index is 82-100, the maximum value of Gieseler fluidity is 1.9-3.0, the average value of vitrinite reflectance is 1.1 to 1.4 percent, and in the dry basisash, CaO is 10 to 15 percent, Fe2O3 is 9 to 15 percent and MgO is 3 to 5 percent. In the method, the strongly caking coal produced in Xinjiang and considered to be poor traditionally is effectively utilized, the advantages of high caking property, low ash, low sulfur, cheapness and high availability of the strongly caking coal are exerted, and the high-activity high-strength coke is produced at low cost for blast furnaces.

Owner:BAOSHAN IRON & STEEL CO LTD

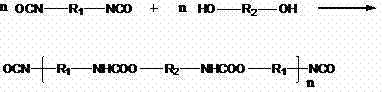

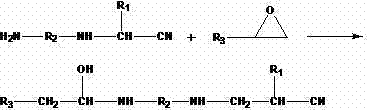

Combination of polyurethane modified epoxy resin and modified secondary amine delayed-hardening agent as primer of polyurea elastomer

InactiveCN102352176AGood environmental adaptabilityGood construction performanceCarboxylic acid nitrile preparationOrganic compound preparationPrepolymerPolyurea

Owner:固克节能科技股份有限公司

Preparation and application of rock salt concrete

The invention belongs to the technical field of chemical engineering, and relates to technology for preparing rock salt concrete by potassium ore tail salts, tailings and waste salts and applications. The invention is characterized in that the raw materials comprises: 30-85% of rock salts, 2.5-15% of magnesium oxide, 2.0-15% of magnesium chloride, 5.5-15% of water, 5-25% of fillers; the production characteristics of the rock salt concrete are that: (1) the production process is simple, and rock salt concrete slurry can be prepared by proportionally mixing magnesium oxide, a magnesium chloride aqueous solution, fillers, and rock salts; (2) the main raw materials required by the production are various halites, tail salts, waste salts or salt-containing slag generated during mining, and the production has low cost and no pollution; (3) the production is energy-saving and environment-friendly, and facilitates three-waste comprehensive utilization and environment protection; (4) the rock salt concrete can be used for backfill of salt mine gob areas, mine pits or roadways; the rock salt concrete can be used for pouring of various building foundations, salt pan pool plates and dam revetment in salt lake regions.

Owner:山发寿

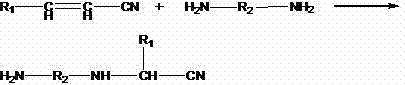

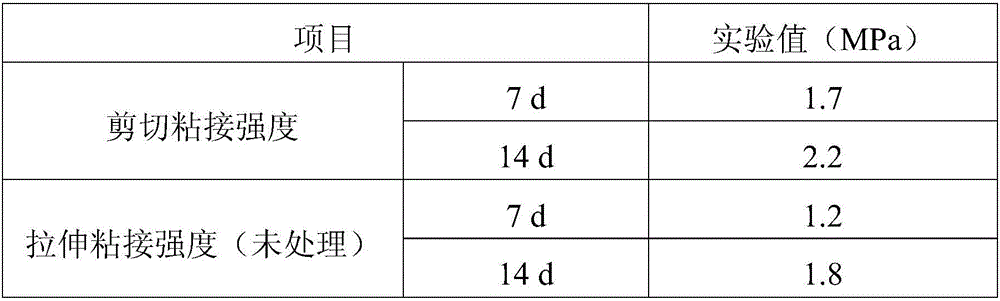

Composite polymer emulsion high-strength interface agent for vitrified brick and preparation thereof

The invention belongs to the technical field of interface agent, and discloses a composite polymer emulsion high-strength interface agent for a vitrified brick and a preparation method thereof. The interface agent comprises the following components by the mass fraction: 45-65% of a small-particle-size styrene-acrylic emulsion, 15-25% of a pure acrylic emulsion, 5-10% of a small-particle-size styrene-butadiene emulsion, 0.2-0.5% of a synergistic agent, 0.1-0.3% of a dispersant, 0.3-1.0% of a wetting agent, and the balance water. With adopting of the small-particle-size styrene-acrylic emulsion, with cooperation of the smaller-particle-size styrene-butadiene emulsion as a penetrating agent, and with collocation use of the water-based synergistic agent, the water solubility of the two kinds of emulsions are effectively improved, the compatibility of the emulsions is improved, the adhesion force and stability of an interface material are increased, the effect of penetrating into the back of a brick with low water absorption rate can be realized, the pulling strength of the material is also increased, the comprehensive effect of an acrylic emulsion is fully played, two-way permeability is achieved, and the adhesion force of a cement-based material is fully played.

Owner:广东亿固壁安粘贴技术有限公司

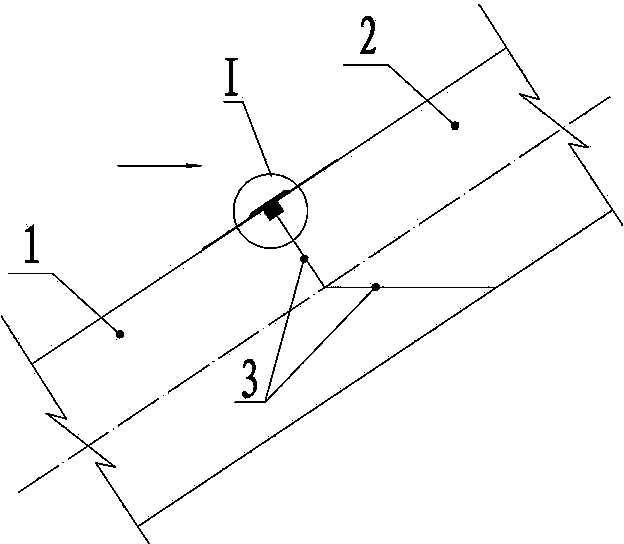

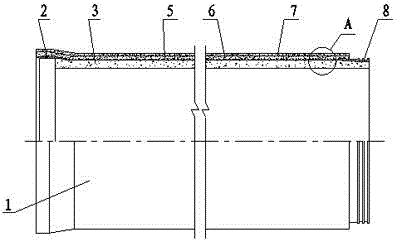

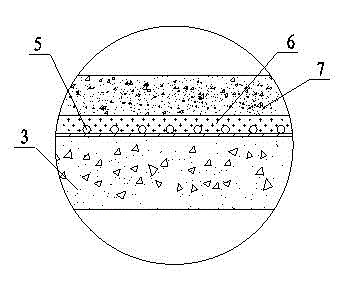

Water stopping construction method for horizontal seam of face rock-fill dam panel

The invention discloses a water stopping construction method for a horizontal seam of a face rock-fill dam panel. The water stopping construction method comprises the following steps: firstly, setting connection seams of first-stage and second-stage concrete panels into the crease line styles; secondly, forming grooves in seam closures of the connection seams on the water attaining surfaces of the first-stage and second-stage concrete panels, perpendicular to the face rock-fill dam inclination and carrying out construction and scabbling treatment; thirdly, filling a polysulfide sealant water stopping filler into the grooves; fourthly, water stop plates of which the width is larger than the groove mouth width of the grooves are attached to the groove mouths of the grooves; fifthly, coating a brushing-type plastic filler protective layer of which the width is larger than that of the water stop plate on the outer surface of each water stop plate. The water stopping construction method has the advantages that as the crease line connection seams are adopted, the first-stage and second-stage panels can be connected more securely, the construction is convenient and the operation is simple; as the polysulfide sealant water stopping filler is filled into the rectangular grooves, embedded into the rectangular seams and kept at the embedding part to perform a water stopping function, and flows into the connection seams from the embedding part under the action of water pressure, the water stopping effect of the connection seams is greatly improved.

Owner:YELLOW RIVER ENG CONSULTING

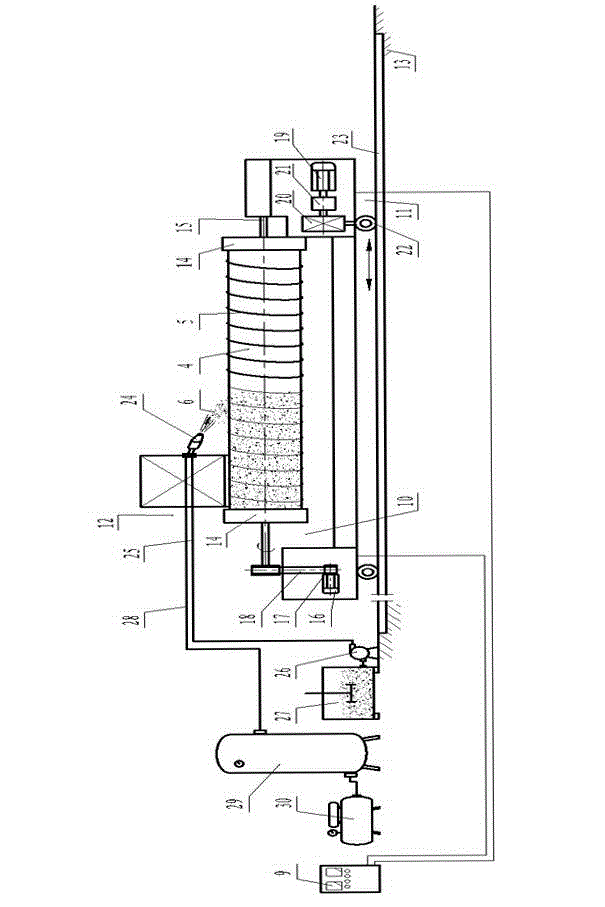

Method and device for producing prestressed concrete cylinder pipe by surfactant

The invention discloses a method and a device for producing a prestressed concrete cylinder pipe by surfactant, and belongs to the technical field of the method and the device for producing the prestressed concrete cylinder pipe. An annular prestressed high-strength steel wire is wound on a cylindrical thin steel plate tube at the outer surface of a pipe core. The method is characterized by also comprising the following steps of: spraying a layer of surfactant of which the thickness is 1.5-2.5mm on the surface after winding the annular prestressed high-strength steel wire on the cylindrical thin steel plate tube at the outer surface of the pipe core; processing the interface bonded between a metallic material and a non-metallic material, and then spraying a dry hard cement mortar protection layer by a roll injection machine. According to the method, the adhesive bonding performance between the surface of a thin steel tube of the pipe core, the surface of the annular prestressed high-strength steel wire and the cement mortar protection layer is enhanced by processing the interface between the metallic material and the non-metallic material; the protection effect of the cement mortar protection layer is enhanced, and the durability and the service life of the prestressed concrete cylinder pipe are improved. The device can finish the method.

Owner:倪志权

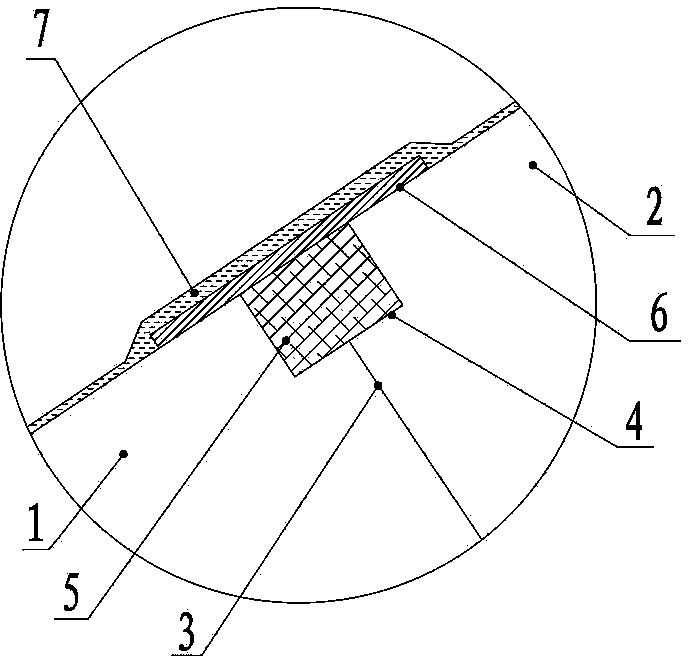

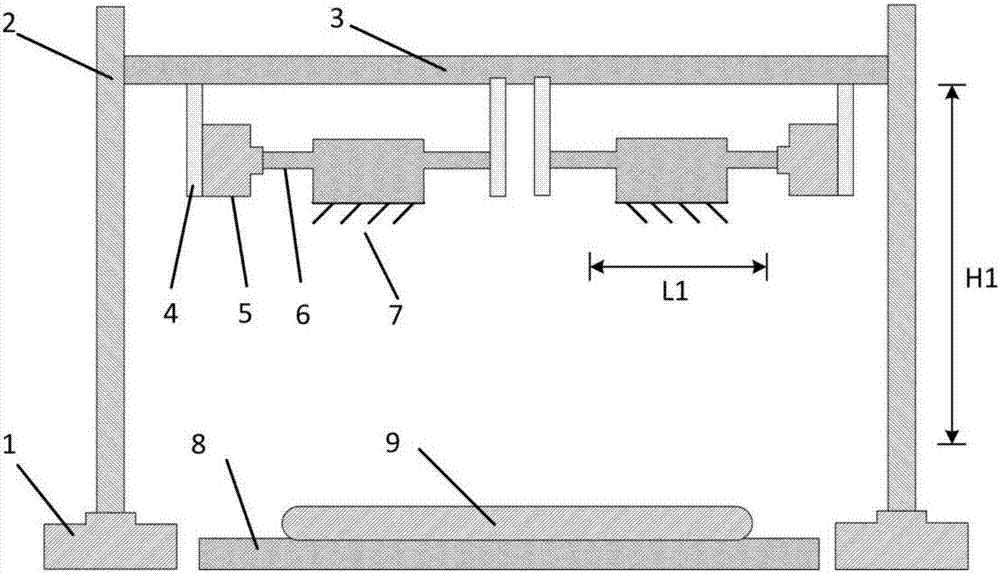

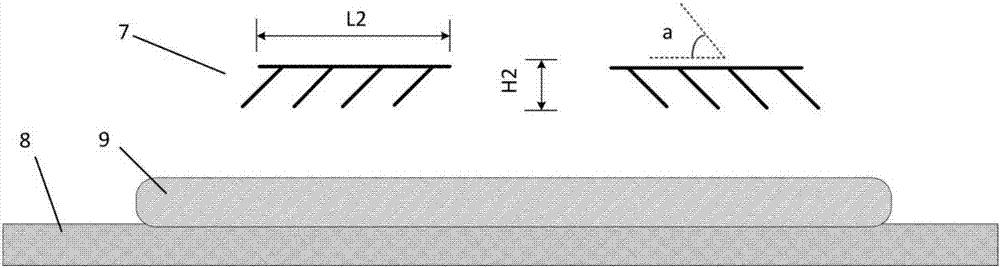

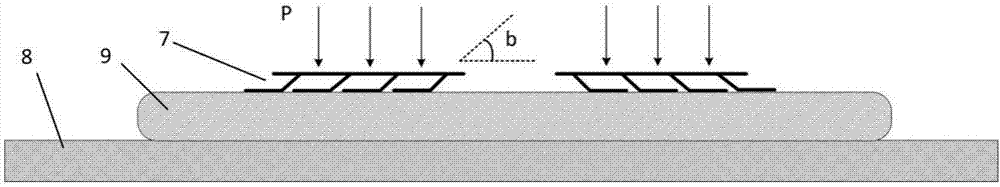

Motion based stripping dry adhesion mechanism and implementation method

The invention discloses a motion based stripping dry adhesion mechanism and an implementation method. The mechanism comprises two dry adhesion structures which are each formed by an inclined flaky structure. The inclination directions of the two dry adhesion structures are opposite, and the two dry adhesion structures are arranged symmetrically. Each dry adhesion structure is mounted on a sliding block of a horizontal ball screw, each horizontal ball screw is driven by a horizontal motor, and horizontal left-and-right motion of each dry adhesion structure is achieved. The horizontal motors are connected to a cross beam through supports. The two ends of the cross beam are mounted on sliding blocks of vertical ball screws, each vertical ball screw is driven by a vertical motor, and vertical up-and-down motion of the cross beam can be achieved under drive of the vertical motors. An adhered object is put on a horizontal platform below the dry adhesion structures. When the two dry adhesion structures are controlled to horizontally move in the inclination directions, object adhesion grabbing is achieved. When the two dry adhesion structures are controlled to horizontally move in the directions opposite to inclination directions, efficient and fast stripping and releasing of the adhered object are achieved. The motion based stripping dry adhesion mechanism can be widely used for the field of dry adhesion of belt conveyors, mechanical arms, micro suction cups and the like.

Owner:XI AN JIAOTONG UNIV

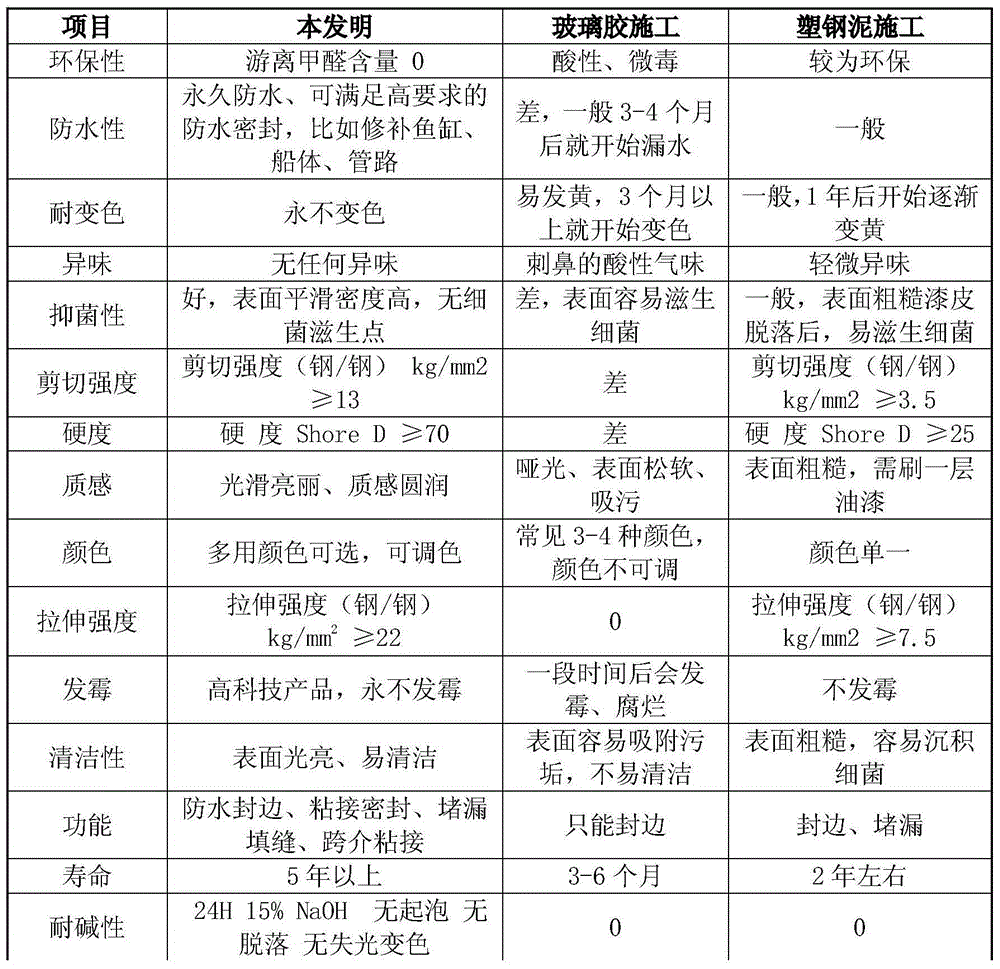

Water-proofing material for adhesive joint between solid objects

InactiveCN101284979AHigh strengthHigh strength adhesionOther chemical processesEpoxy resin adhesivesEpoxyPolyamide

The invention relates to a waterproof material for bonding solids, namely plastic-steel mud, which is characterized in that: the waterproof material for bonding solids, namely the plastic-steel mud, comprises an A component and a B component; the A component comprises the following contents in percentage by mass: 25 to 45 percent of epoxy resin, 1 to 5 percent of phthalic acid ester, and the rest additive being the combination or one of calcium carbonate, CCR, talcum powder and extra fine talc powder; the B component comprises the following contents in percentage by mass: 20 to 35 percent of polyamide curing agent, and the rest additive being the combination or one of calcium sulphate, calcium carbonate and talcum powder. The plastic-steel mud has waterproof and mildewproof performance, high adhesive force and tough structural strength, applies to the bond of ceramics, metal, rigid plastics, glass, concrete, stone and various materials, as well as the water prevention of lines, hides no dirt, and is resistant to wear, acid, alkali, corrosion and high-low temperature. In construction process, the plastic-steel mud has no pollution source or pungent odor, and does no harm to human body, which is a novel waterproof material for indoor decoration design.

Owner:张建杉

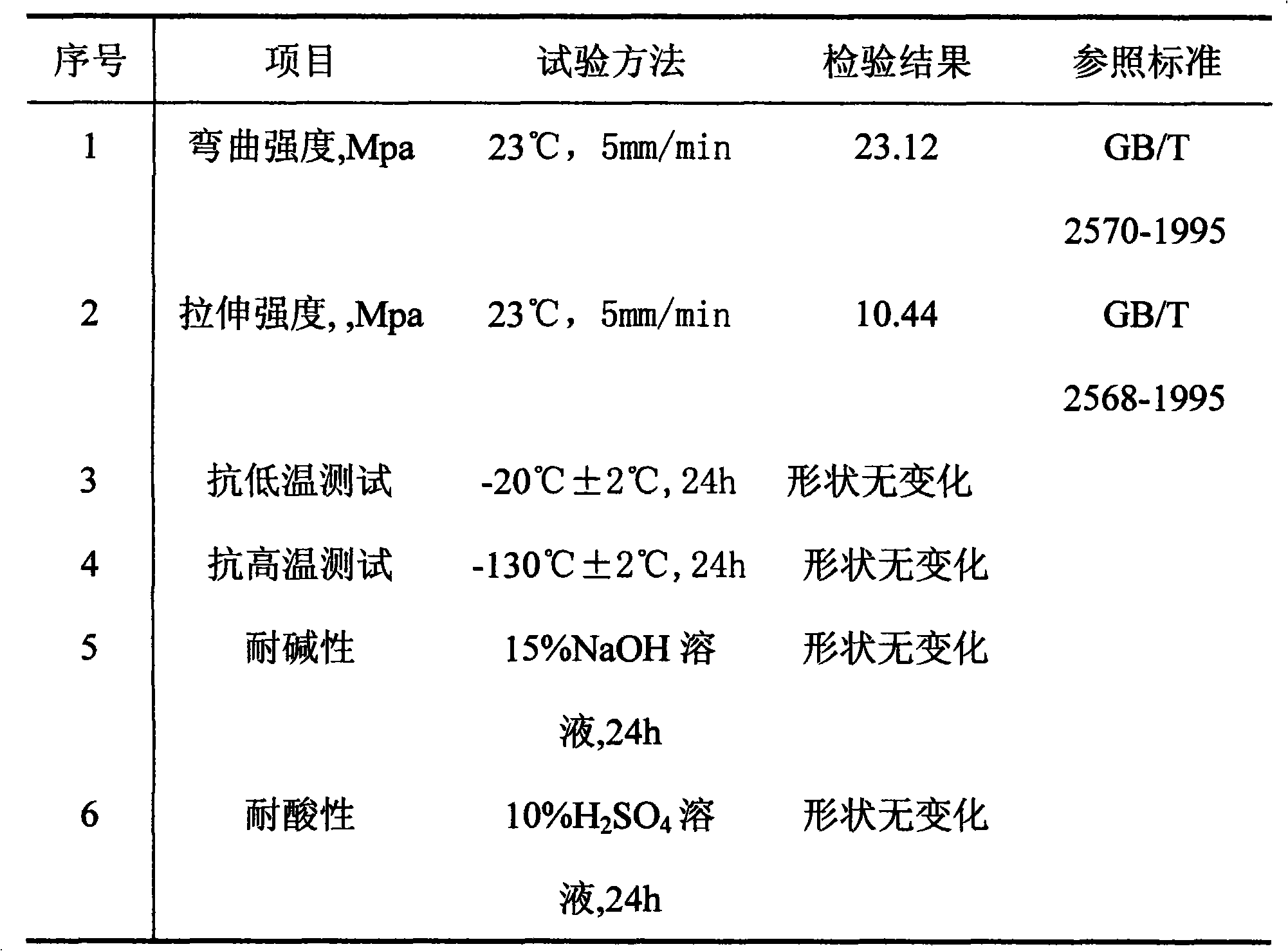

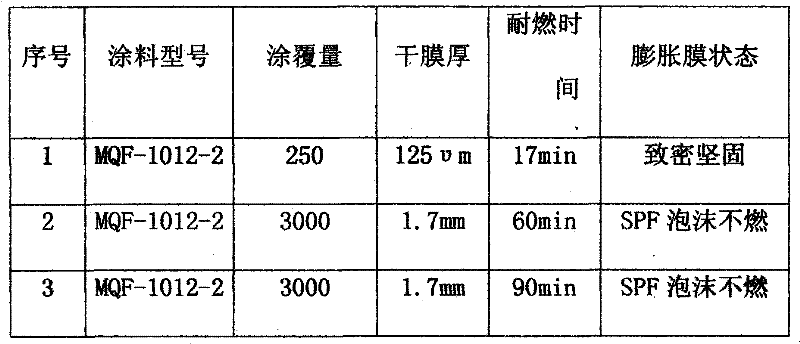

Rigid polyurethane foam insulation material with fireproof and anticorrosion function and preparation method thereof

InactiveCN102296710APaste firmlyContains a lot of solid matterFireproof paintsCovering/liningsThermal insulationPreservative

The invention is a rigid polyurethane foam insulation material with fireproof and anticorrosion function and its preparation method, which is composed of rigid polyurethane foam, penetrating primer, fireproof intermediate paint and anticorrosion sealing topcoat, and is characterized in that the surface of rigid polyurethane foam is sprayed A layer of penetrating primer, spray a layer of fireproof intermediate paint on top of the penetrating primer; finally spray a layer of anti-corrosion sealing topcoat on the dried substrate. The manufacturing process of the rigid polyurethane foam insulation material is as follows: spray a layer of penetration primer with a thickness of 30-40 μm on the polyurethane foam, and spray a fireproof intermediate paint with a thickness of 1-3 mm on the penetration primer; finally spray a layer of thickness 30-40μm anti-corrosion sealing topcoat. According to the polyurethane rigid foam fireproof and anticorrosion paint of the present invention, it has the properties of firm adhesion to the base layer, corrosion resistance, and can be sprayed and formed on any curved surface. The special paint has the advantages of thin coating, long flame resistance time, less smoke generation, and low toxicity.

Owner:天津派尔尼尔科技发展有限公司

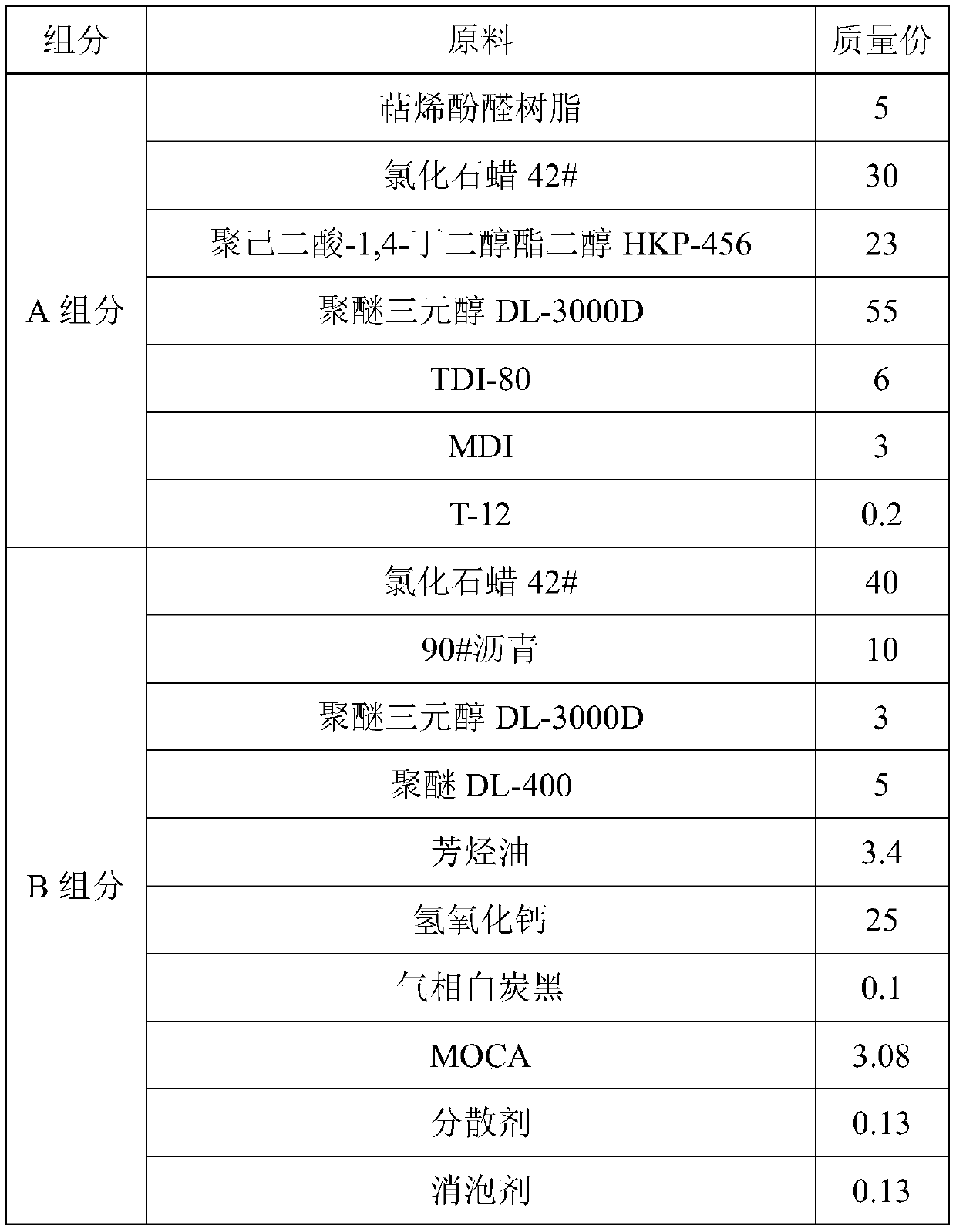

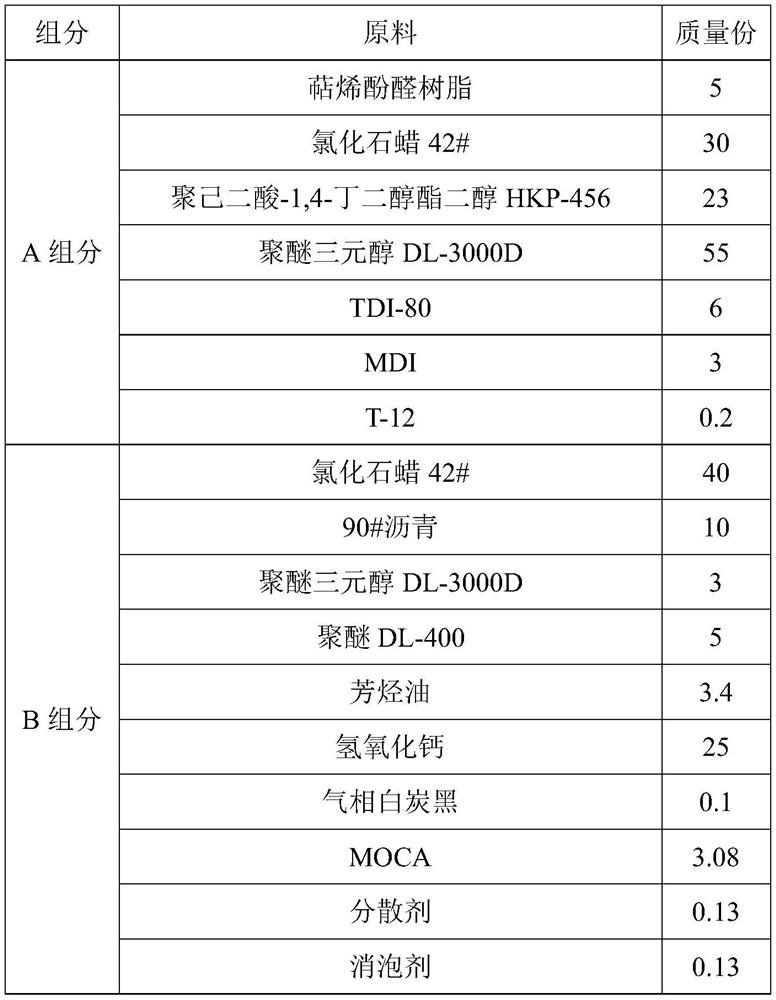

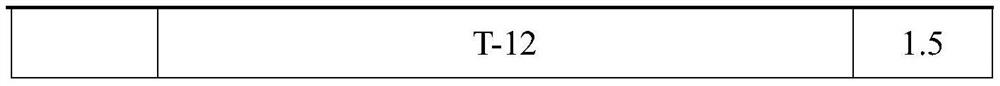

Self-healing polyurethane waterproof coating and preparation method thereof

ActiveCN111073491AHas tensile strengthAdhesiveWax coatingsPolyurea/polyurethane coatingsPolyesterPolymer science

The invention discloses self-healing polyurethane waterproof coating and a preparation method thereof. The self-healing polyurethane waterproof coating comprises a component A and a component B, wherein the component A comprises terpene phenolic resin, a plasticizer, polyester polyol, polyether polyol A, diisocyanate and a catalyst; the component B is prepared from the following components: a plasticizer, asphalt, polyether polyol A, polyether polyol B, filling oil, a filler, a thixotropic agent, a dispersing agent, a chain extender, a defoaming agent and a catalyst; the number-average molecular weight of the polyether polyol A is 2,000 to 4,000; the number-average molecular weight of the polyether polyol B is 300 to 500; the filler is alkaline earth metal hydroxide; the mass ratio of thecomponent A to the component B is 1:(2-4). The self-healing polyurethane waterproof coating disclosed by the invention has the tensile strength of polyurethane coating and the self-healing property ofnon-cured rubber asphalt waterproof coating, and also has the characteristics of excellent adhesion with the existing waterproof coiled material and the like.

Owner:大禹九鼎新材料科技有限公司

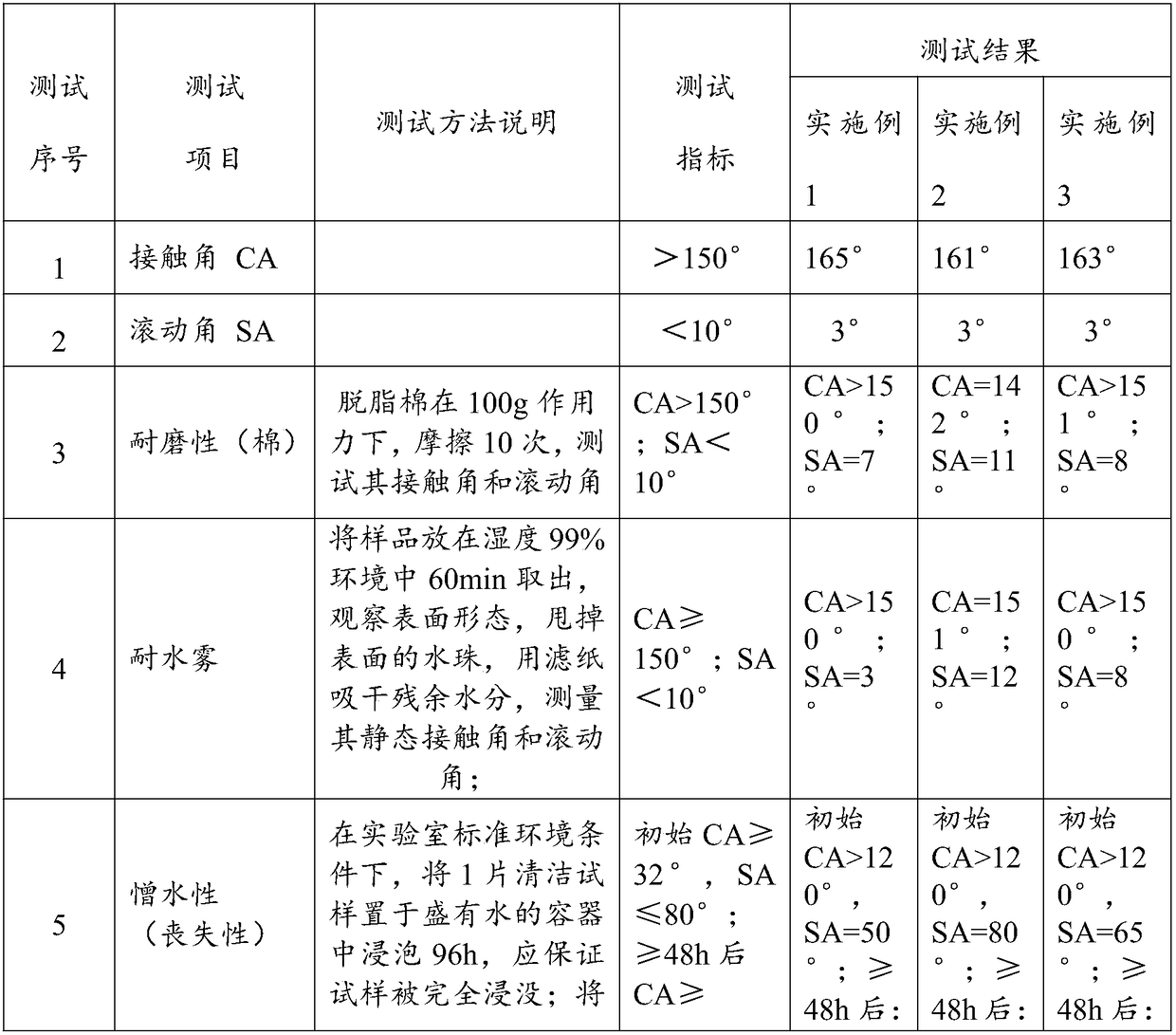

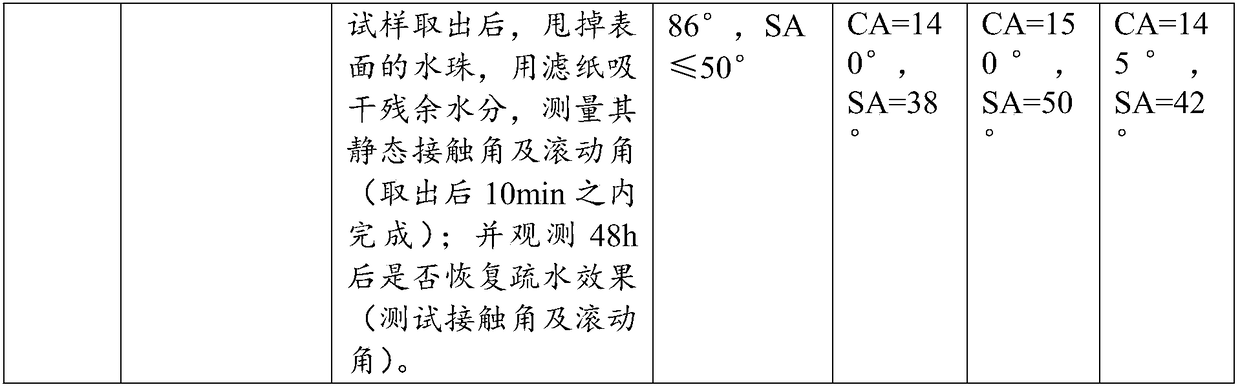

Super-hydrophobic and super-selfcleaning composite coating and preparation method thereof as well as selfcleaning insulator used by super-hydrophobic and super-selfcleaning composite coating

InactiveCN108250858AExcellent resistance to water mistExcellent rain and snow protectionAntifouling/underwater paintsPaints with biocidesMicro nanoWear resistant

The invention relates to a super-hydrophobic and super-selfcleaning composite coating and a preparation method thereof as well as a selfcleaning insulator used by the super-hydrophobic and super-selfcleaning composite coating. The super-hydrophobic and super-selfcleaning composite coating is prepared from the following raw materials in parts by weight: 10 to 15 parts of a nano hydrophobing agent,2 to 6 parts of polytetrafluoroethylene powder and 0.3 to 0.8 part of a polysilazane coating. The super-hydrophobic and super-selfcleaning composite coating provided by the invention is prepared by combining an organic material with an inorganic material, namely combining a polytetrafluoroethylene wax packing with a nano silicon dioxide modified-hydrophobing agent, so that a lotus leaf-similar multiple-micro-nano-surface structure is formed, and super-hydrophobic and super-wear-resistant functions are realized by correspondingly using low surface energy and the micro-nano structure of the lotus leaf-similar multiple-micro-nano-surface structure. A coating layer formed by curing the super-hydrophobic and super-selfcleaning composite coating provided by the invention has a static hydrophobicangle larger than 160 degrees and a rolling angle smaller than 5 degrees, has excellent water fog resisting, dew prevention and snow and rain prevention functions, is high in adhesive force, and is still super-hydrophobic after being scraped.

Owner:武汉疏能新材料有限公司

Antistatic polyester powder coating and preparation method thereof

InactiveCN112778882AAvoid it happening againImprove conductivityPowdery paintsElectrically-conductive paintsPolymer scienceWeather resistance

The invention provides an antistatic polyester powder coating. The antistatic polyester powder coating comprises the following components in parts by mass: 50-80 parts of polyester resin, 10-20 parts of conductive filler, 0.2-0.6 part of conductive carbon black, 8-12 parts of auxiliaries, 2-4 parts of pigment and 15-30 parts of inorganic filler. According to the antistatic polyester powder coating provided by the invention, the conductive filler and the conductive carbon black are added on the basis of mixing the polyester resin, the auxiliary agent, the pigment and the filler, and the other components are reasonably proportioned, so that the prepared polyester powder coating has excellent conductive performance, and can prevent static electricity from being generated on the surface of a coating film, and the polyester powder coating also has high leveling property, excellent toughness, strong binding power and high weather resistance, so that the polyester powder coating is widely applied to the field of powder coatings.

Owner:SHANGHAI BANGZHONG NEW MATERIAL

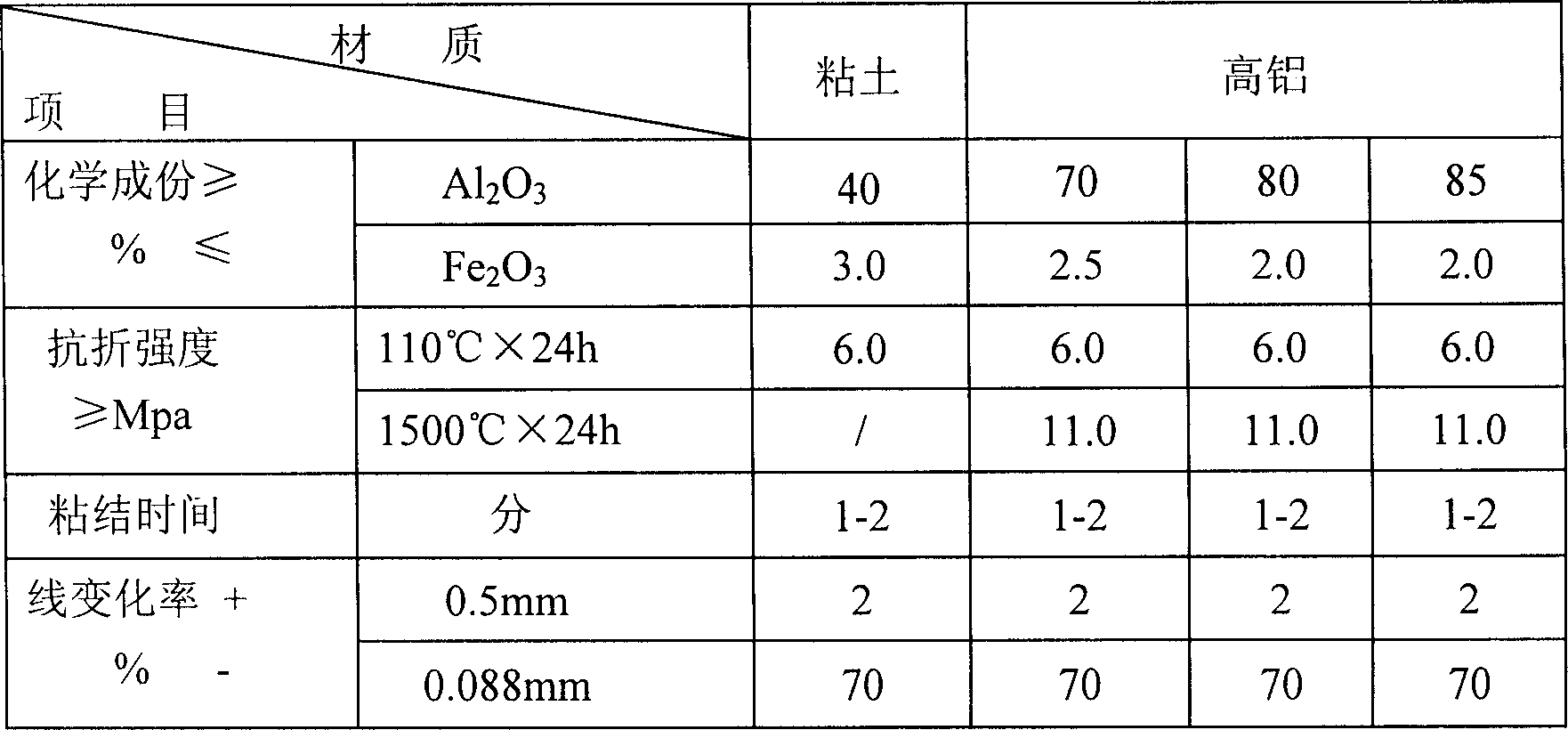

High-strength quick-solidifying refractory adhesive

A refractory adhesive for repairing the liner of blast furnace or spraying it on the liner contains high-aluminium powder (30-75 portions), Guangxi clay (5-15), superfine powder (2-10), sodium hexametaphosphate (1-1.5) and water glass (15-50). Its advantages include high refractory temp up to 1800 deg.C, high adhesion, high compression strength, not shrinking and cracking at high temp, high resistance to wear and chemical corrosion, and quick solidification.

Owner:蒋德奎

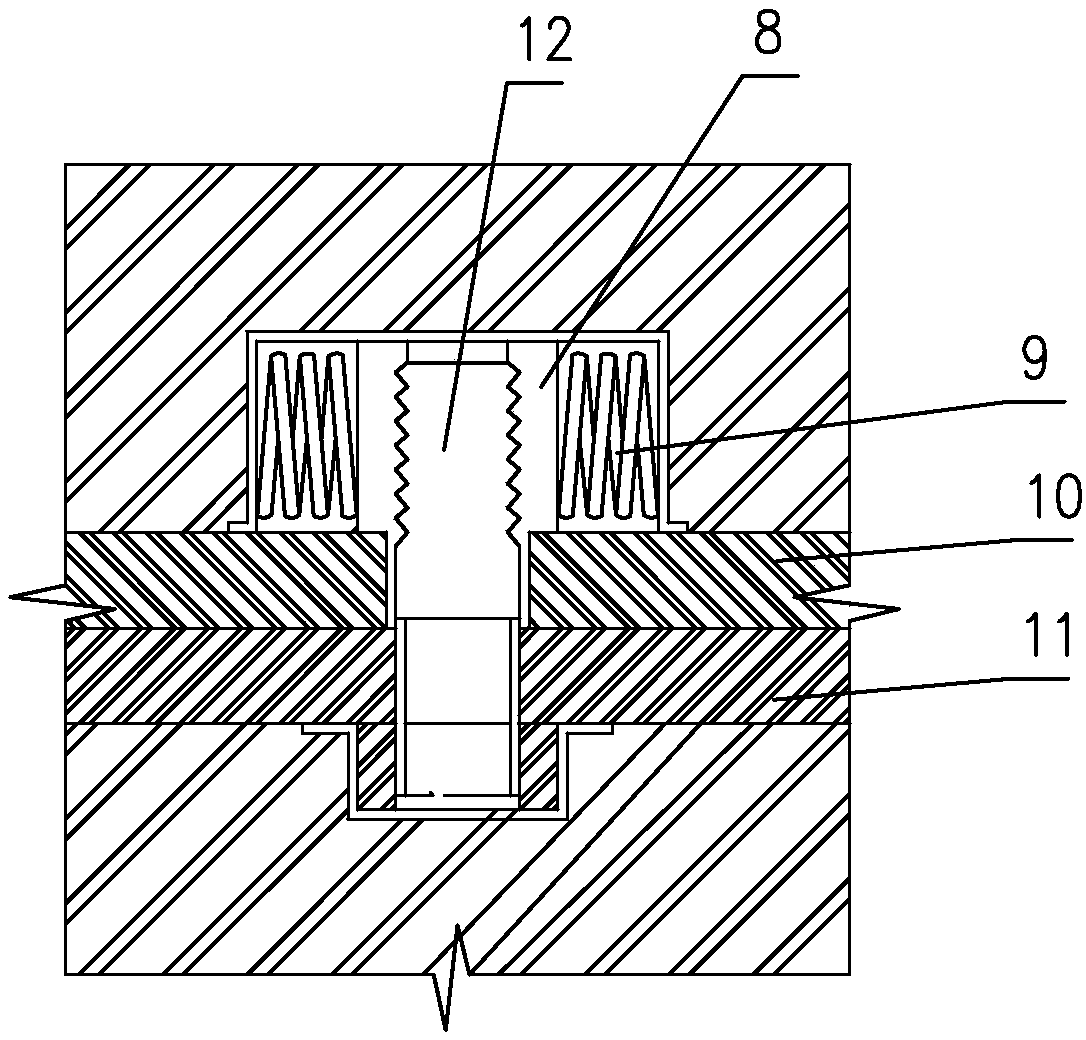

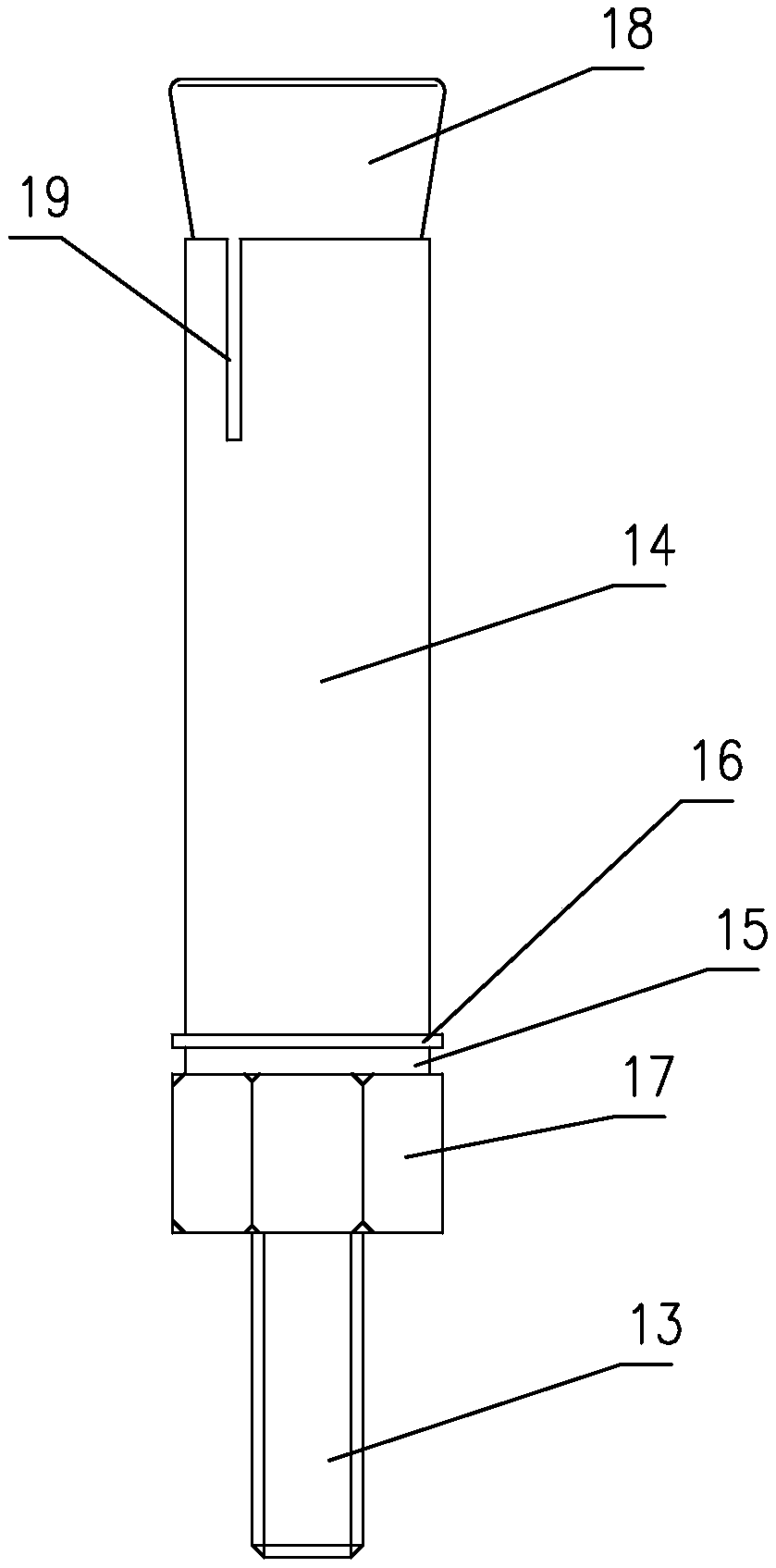

Prestressed concrete pipe pile internal expansion quick end lengthening device and construction method thereof

InactiveCN109056714AImprove the efficiency of extension constructionAvoid defectsBulkheads/pilesStructural engineeringPrestressed concrete

The invention discloses a prestressed concrete pipe pile internal expansion quick end lengthening device. The device comprises a long screw rod, an opening expansion sleeve, an elastic gasket and a fastening nut; the middle upper section of the long screw rod is a smooth section; the upper end of the smooth section is an expansion end gradually expanding; the lower section of the long screw rod isa thread section; the fastening nut sleeves the thread section; the opening expansion sleeve sleeves the smooth section; a longitudinal breakage opening is formed in the upper pipe wall of the opening expansion sleeve; and the elastic gasket is positioned between the lower end of the opening expansion sleeve and the fastening nut. The device mainly applies an internal expansion bolting principleand a rib lengthening principle, improves the pile body lengthening construction efficiency under the precondition of guaranteeing the lengthening quality, and is not influenced by the rain and snow weathers; and as the device is simple in structure and reliable in connection, and saves implanted steel parts, the single pile lengthening construction cost is reduced. In addition, through a drawingtest on end lengthening test pieces before construction, the quality hidden troubles of inspection lots can be reduced.

Owner:GUANGZHOU CITY CONSTR COLLEGE

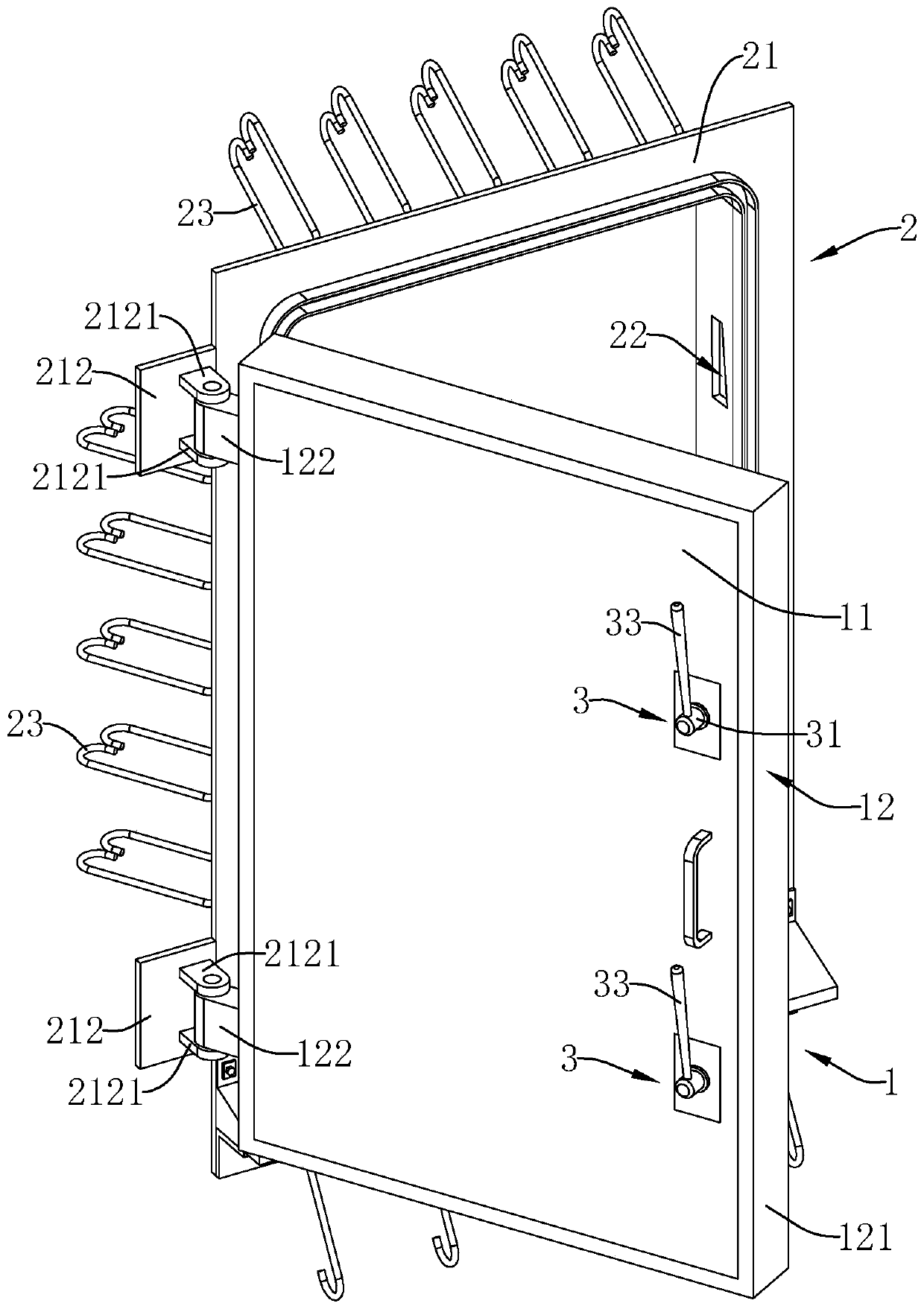

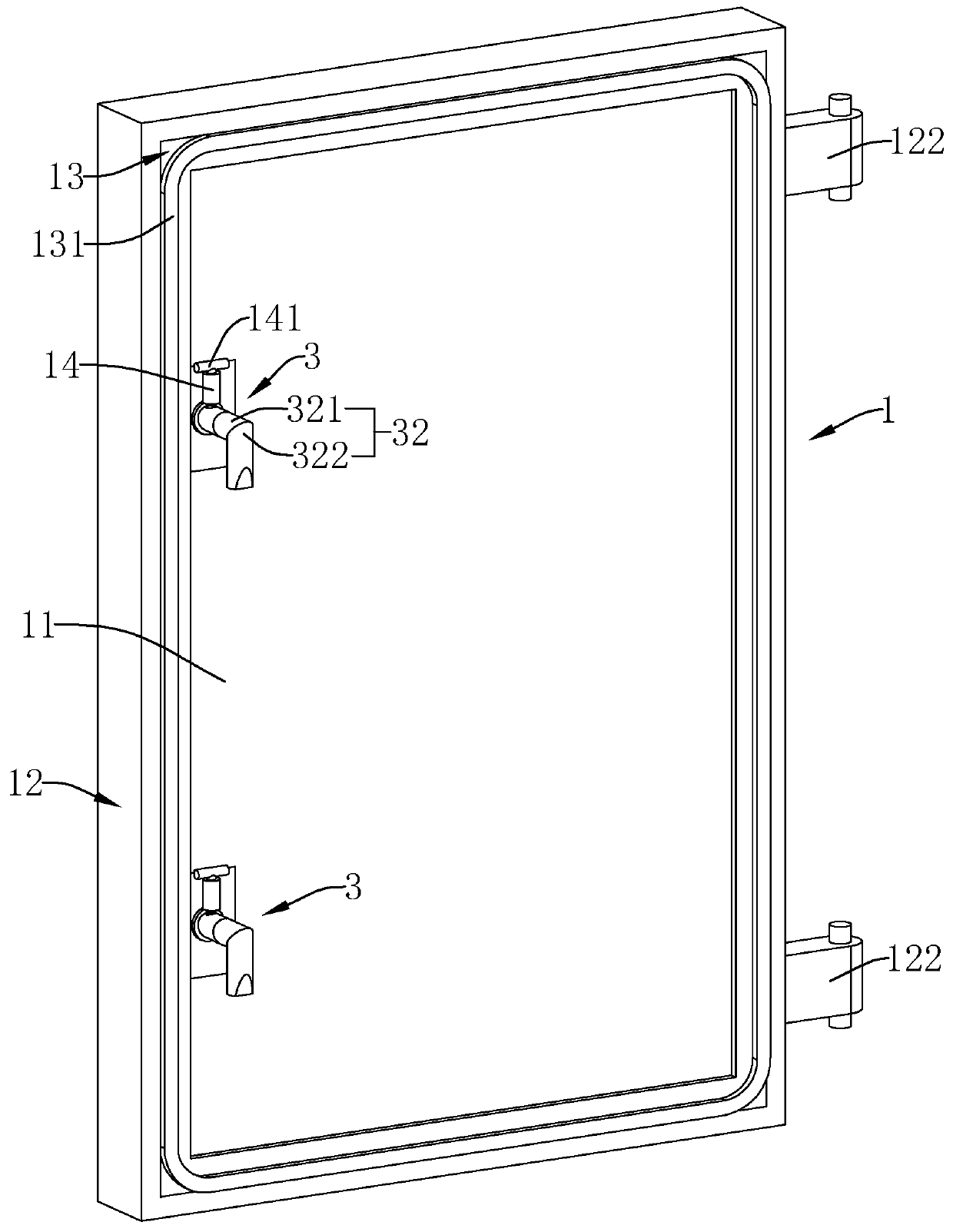

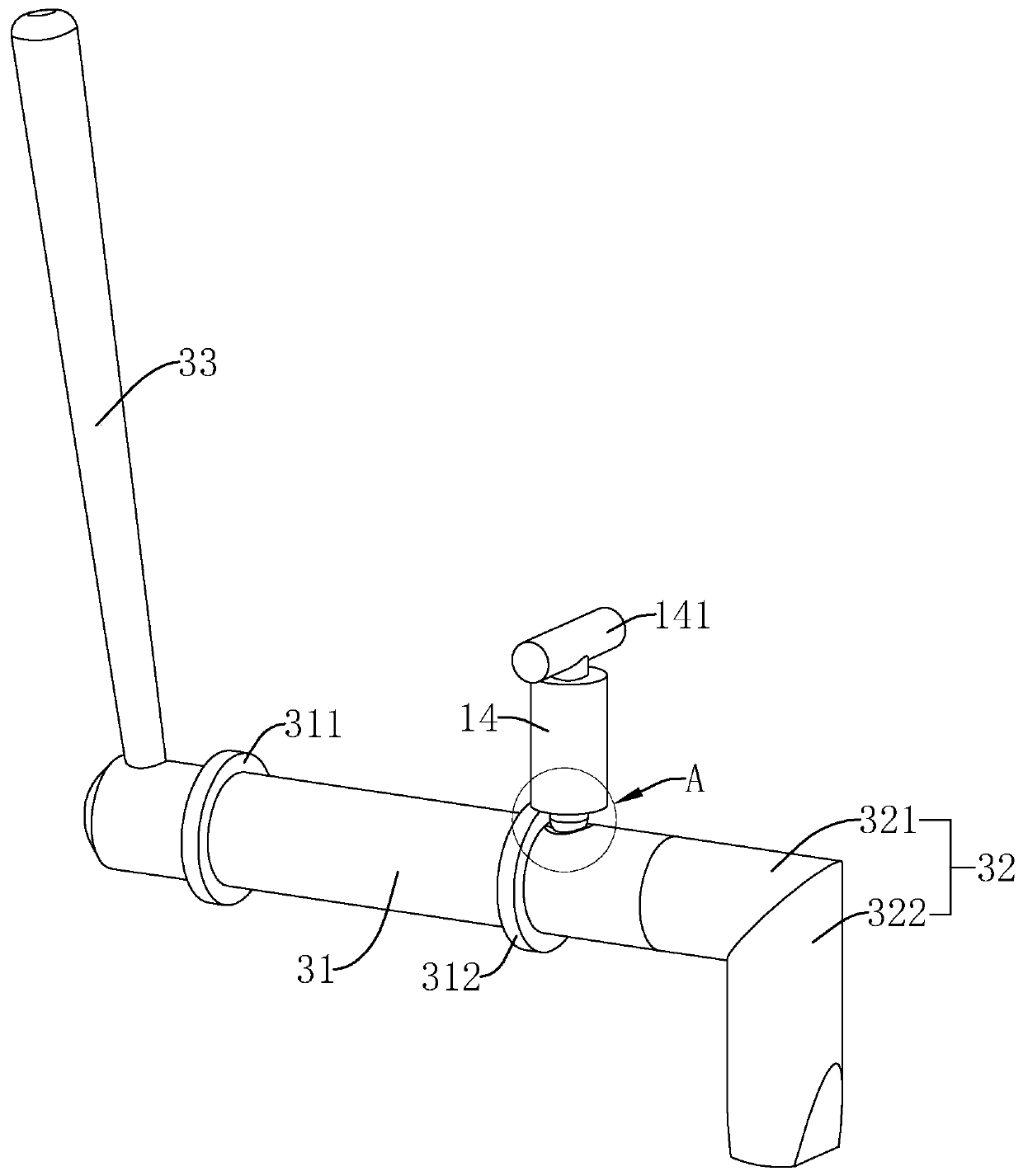

Moulding processing technology for reinforced concrete airtight door and reinforced concrete airtight door

ActiveCN109854145AImprove sealingAssembly precisionWing handlesWing accessoriesReinforced concreteEngineering

The invention relates to a reinforced concrete airtight door and a moulding processing technology thereof, which relate to the technical field of human defense equipment processing. A technical schemecomprises the following steps: step A: making a frame; step B: welding hinge ears on the side wall of the frame; step C: pouring concrete in the frame to form a prefabricated door leaf; step D: performing maintenance treatment on the door leaf; step E: prefabricating angle steel; step F: performing calibration and straightening treatment on the angle steel, and making a door frame; step G: assembling between a door sill and the door frame; and step H: performing hinged assembly between the door leaf and the door frame. The reinforced concrete airtight door and the moulding processing technology thereof are advantageous in that calibration and straightening can be performed on the door frame, so that the airtightness between the door frame and the door leaf is better in a process of usage,and matching is more precise.

Owner:北京华予人防设备有限公司

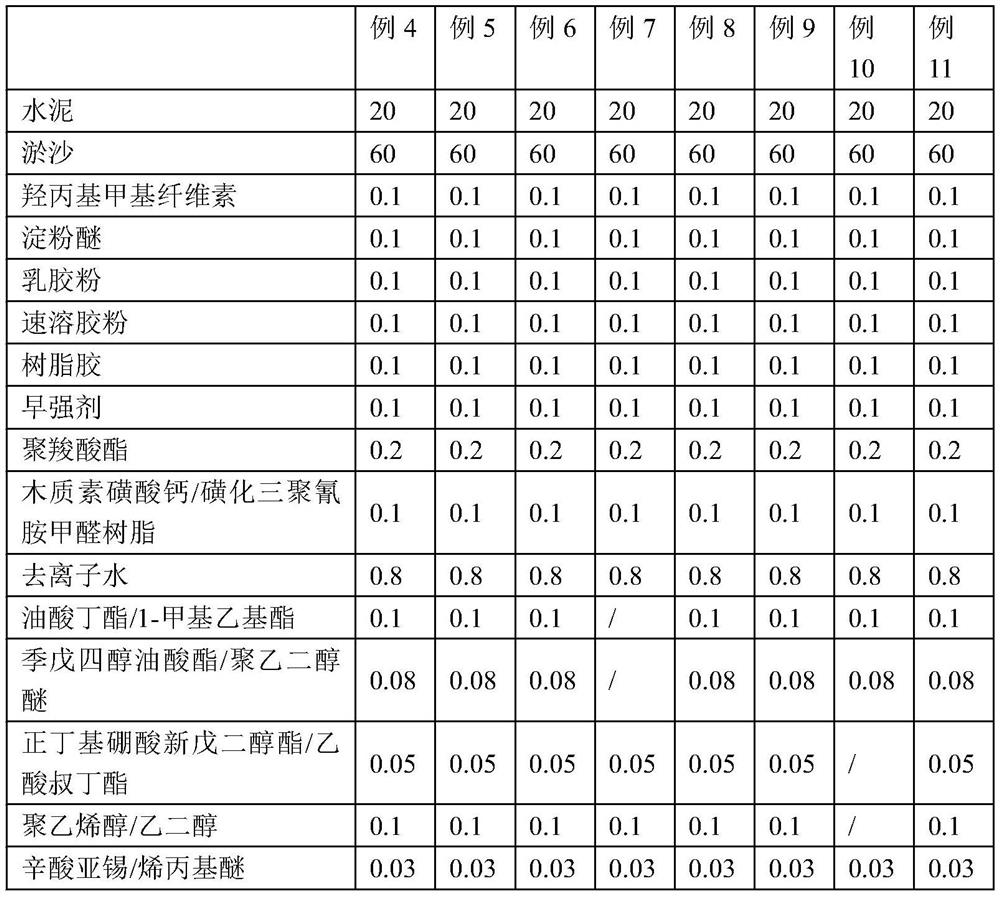

Benzene-free ceramic tile mortar

The invention relates to the field of building materials, and discloses benzene-free ceramic tile mortar which comprises the following raw materials in parts by weight: 20-40 parts of cement; 60-80 parts of silt; 0.1-0.5 part of hydroxypropyl methyl cellulose; 0.1-0.5 part of starch ether; 0.1-0.6 part of latex powder; 0.1-0.6 part of instant glue powder; 0.1-0.6 part of a resin adhesive; 0.1-0.6part of an early strength agent; and a water reducing agent. The invention has the following advantages and effects: polycarboxylate molecules are directionally adsorbed on the surfaces of cement particles, so that the surfaces of the cement particles are negatively charged to form an electrostatic repulsion effect, and calcium lignosulphonate and polycarboxylate are mixed to further promote mutual dispersion of the cement particles, destroy a flocculation structure and release part of wrapped water to participate in flowing; and therefore, the flowability of the ceramic tile mortar is effectively improved, and the bonding performance is improved.

Owner:温州明远新型建材有限公司

Binder for lithium battery and preparation method thereof

ActiveCN103427083BPromote circulationImproved high-magnification performanceCell electrodesPolymer scienceAdhesive

The invention relates to adhesive for a lithium battery and a preparation method thereof. The adhesive is aqueous and is prepared through polymer A containing carboxyl functional groups and polymer B containing hydroxyl functional groups. The preparation method includes dissolving and placing the polymer A containing the carboxyl functional groups and the polymer B containing the hydroxyl functional groups in a reactor in proportion, then adding reaction initiator C to stir without a break for 10 to 12 hours at the constant temperature ranging from 40 to 70 DEG C, and cooling to the room temperature to obtain the adhesive. The adhesive has high-strength adhesion and excellent plasticity, prepared slurry can be preserved for long time without phase separation and can be mass produced, so that a battery producing process is easier and more facilitated, and consistence of battery quality can be guaranteed.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

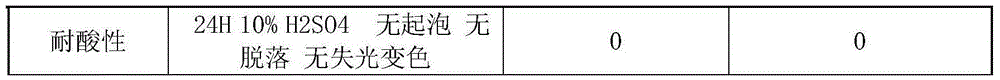

Multipurpose high temperature resistant ceramization agent, and preparation method thereof

The invention relates to a multipurpose high temperature resistant ceramization agent. The multipurpose high temperature resistant ceramization agent comprises an ingredient A and an ingredient B; the ingredient A is composed of nano aluminium oxide, nano ceramic powder, a color matching agent, and a resin; and the ingredient B is composed of a resin, a curing agent, and a modifying agent. In applications, the two ingredients are mixed to be uniform, and tools such as an electric glue gun are used for smearing, so that bonding and repairing of joints and damaged parts are realized. After curing, a ceramic-similar surface is obtained, and possesses lifelong water resistance and mildew resistance, high strength, adhesive force, toughness, and structure strength. The multipurpose high temperature resistant ceramization agent is suitable to be used for bonding of a plurality of materials such as ceramic, metal, rigid plastic, glass, concrete, and stone, and possesses water resistance, stain resistance, wear resistance, acid and alkali resistance, corrosion resistance, high temperature resistance, and low temperature resistance. In construction, no pollution source or pungent smell is generated, the multipurpose high temperature resistant ceramization agent is nontoxic for human body, is a novel water resistance material used for interior decoration, and can be used for replacing conventional glass cement and water-proofing agent.

Owner:TIANJIN BOHOU HONGDE TECH CO LTD

Quality inspection nitro putty used for coating of glass reinforced plastic base material and preparation method thereof

The invention relates to the technical field of paint and manufacturing thereof, in particular to a quality inspection nitro putty used for coating of a glass reinforced plastic base material and a preparation method thereof. The nitro putty is prepared from, by mass percentage, 5%-10% cellucotton, 15%-25% mixed solvent, 45%-65% pigments and fillers, 5%-10% alkyd resin and 2%-5% additive, and thetotal mass percentage of each component above is 100%. The prepared quality inspection nitro putty is one-component nitro putty, wherein the alkyd resin greatly enhances the adhesion of the nitro putty, so that the nitro putty can be attached to the glass reinforced plastic base material, besides, no harmful additives are added to the nitro putty, and the nitro putty is environmentally friendly and safe.

Owner:上海一田涂料有限公司

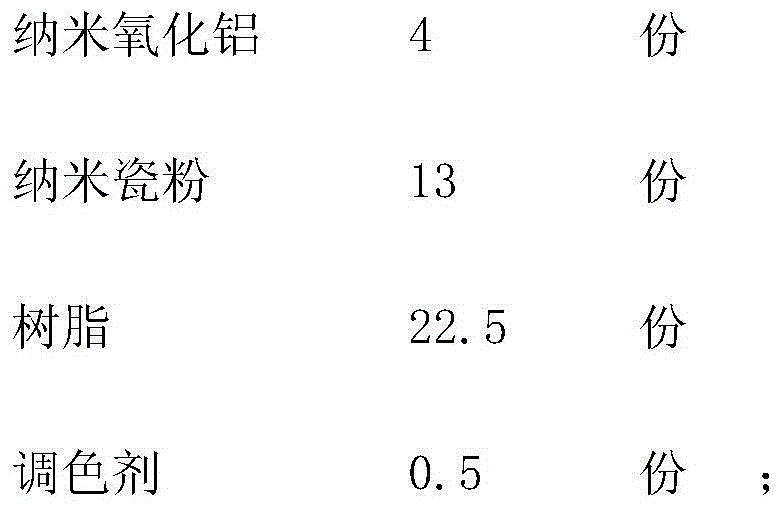

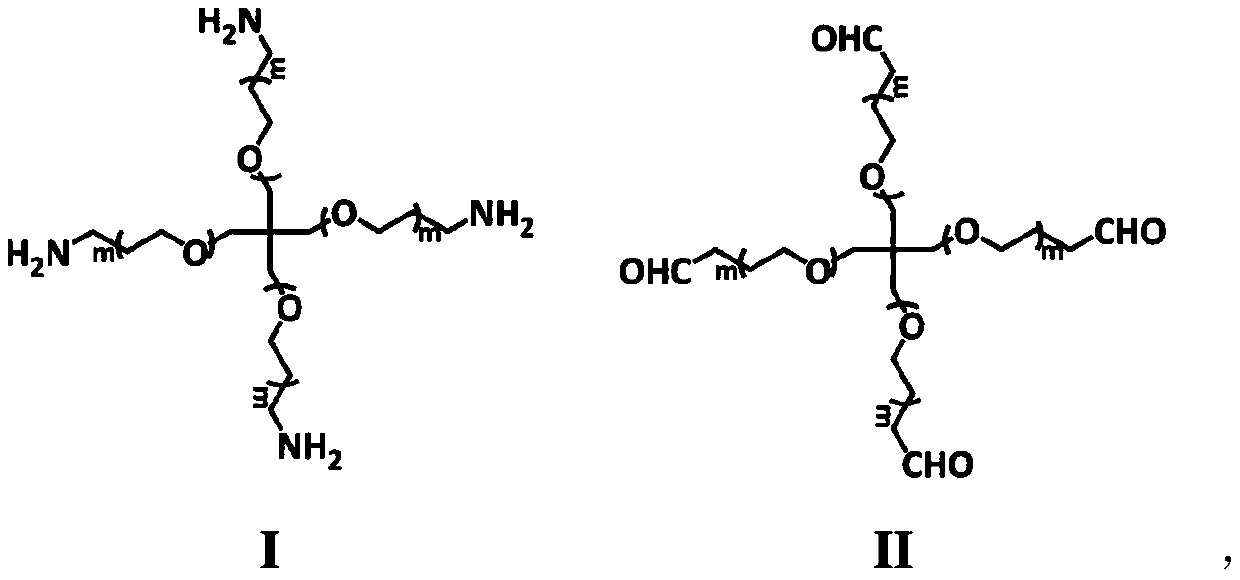

Preparation method of injectable polyethylene glycol hydrogel loaded with alendronate sodium and application thereof

InactiveCN111557902ARegular structureGood mechanical propertiesOrganic active ingredientsAerosol deliveryPolymer scienceCollagenan

The invention discloses a preparation method of an injectable polyethylene glycol preparation loaded with alendronate sodium and an application thereof. The preparation at least comprises two independent solutions, wherein a solution 1 is prepared from four-arm-polyethylene glycol-aldehyde group; a solution 2 containsg four arms-polyethylene glycol-amino groups; the hydrogel is dissolved in the solution 1 or the solution 2, or is independently dissolved to form a solution 3; wherein the pH value of the mixed solution of the preparation obtained by mixing the solutions is 4.0-9.0. The four-arm-polyethylene glycol-aldehyde groups and four-arm-polyethylene glycol-amino groups are adopted for in-situ gelling through Schiff base bonds, intraoperative operation is convenient, and the gelling speed is high. Meanwhile, amino on collagen on the surface of the tissue and alendronate sodium in the solution can be quickly and chemically bonded with the four-arm-polyethylene glycol-aldehyde group through a Schiff base bond.

Owner:GENERAL HOSPITAL OF PLA

Oil filter adhesive

InactiveCN109628035AIncrease roughnessIncrease contact areaNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyAdhesive

The invention discloses an oil filter adhesive. The adhesive is prepared from 3-4 parts of a sulfonated modified graphite powder / silicon micropowder composite, 15-25 parts of silane modified epoxy resin, 5-8 parts of butyl rubber, 1-2 parts of diaminodiphenyl methane, 0.5-1 part of bis(2-ethylhexyl) phthalate, 1-1.5 parts of a silane coupling agent KH-550, 0.4-0.7 part of an initiator, 0.3-0.5 part of a stabilizer and 0.4-0.6 part of an emulsifier. The prepared oil filter adhesive has the advantages that the adhesive has high adhesion performance through the synergistic effect of all components; meanwhile, the corrosion resistance is high, the high-temperature resistance is excellent, after curing, the surface is flat, the toughness is good, the service life is long, and the sealing performance of a filter is ensured.

Owner:BENGBU CITY MINGWEI FILTER CO LTD

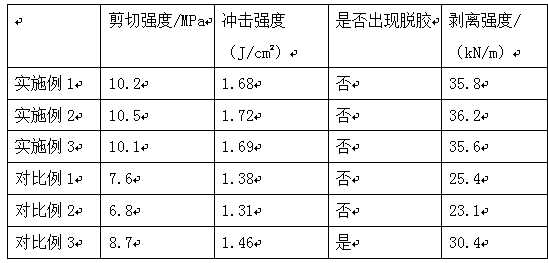

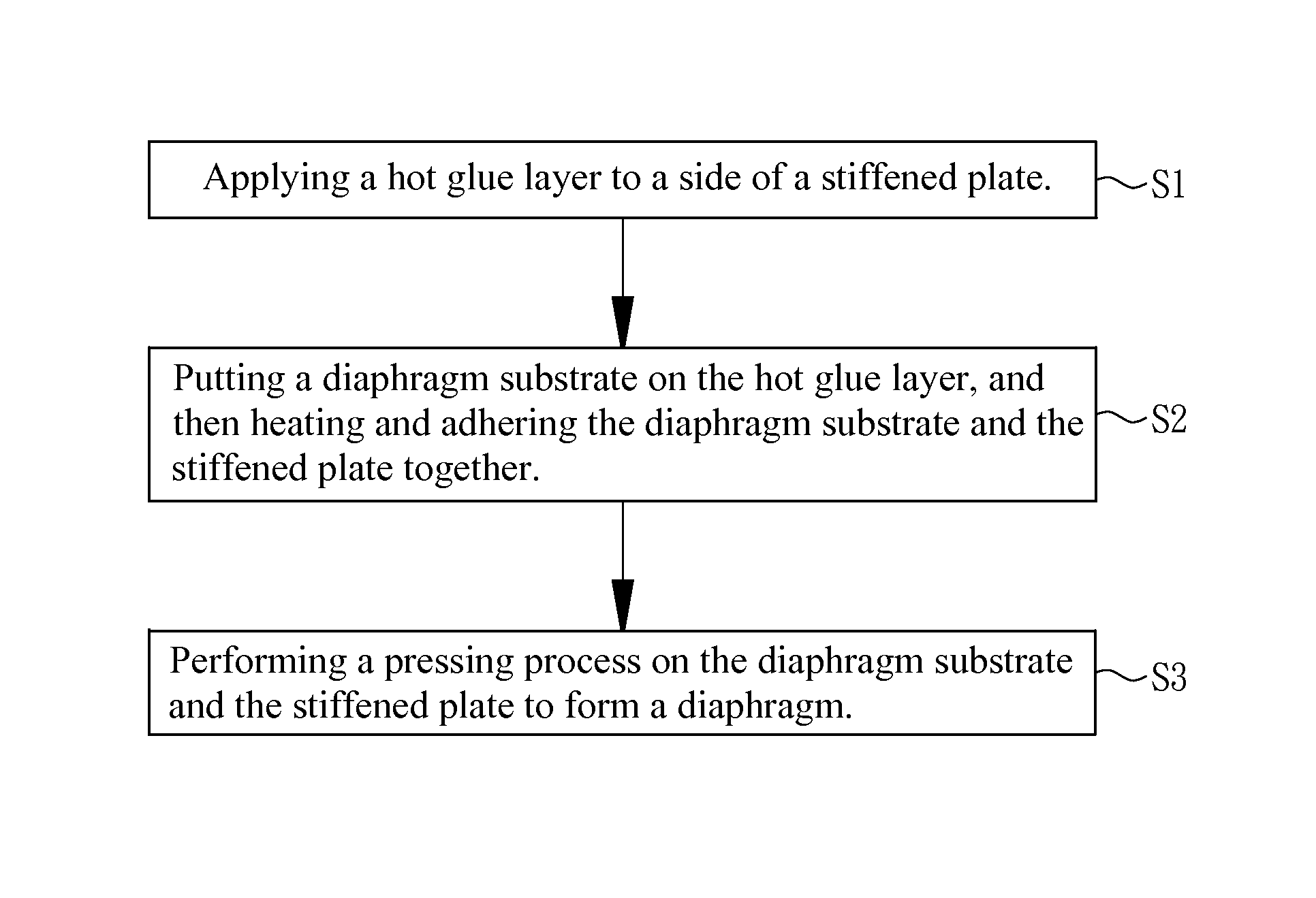

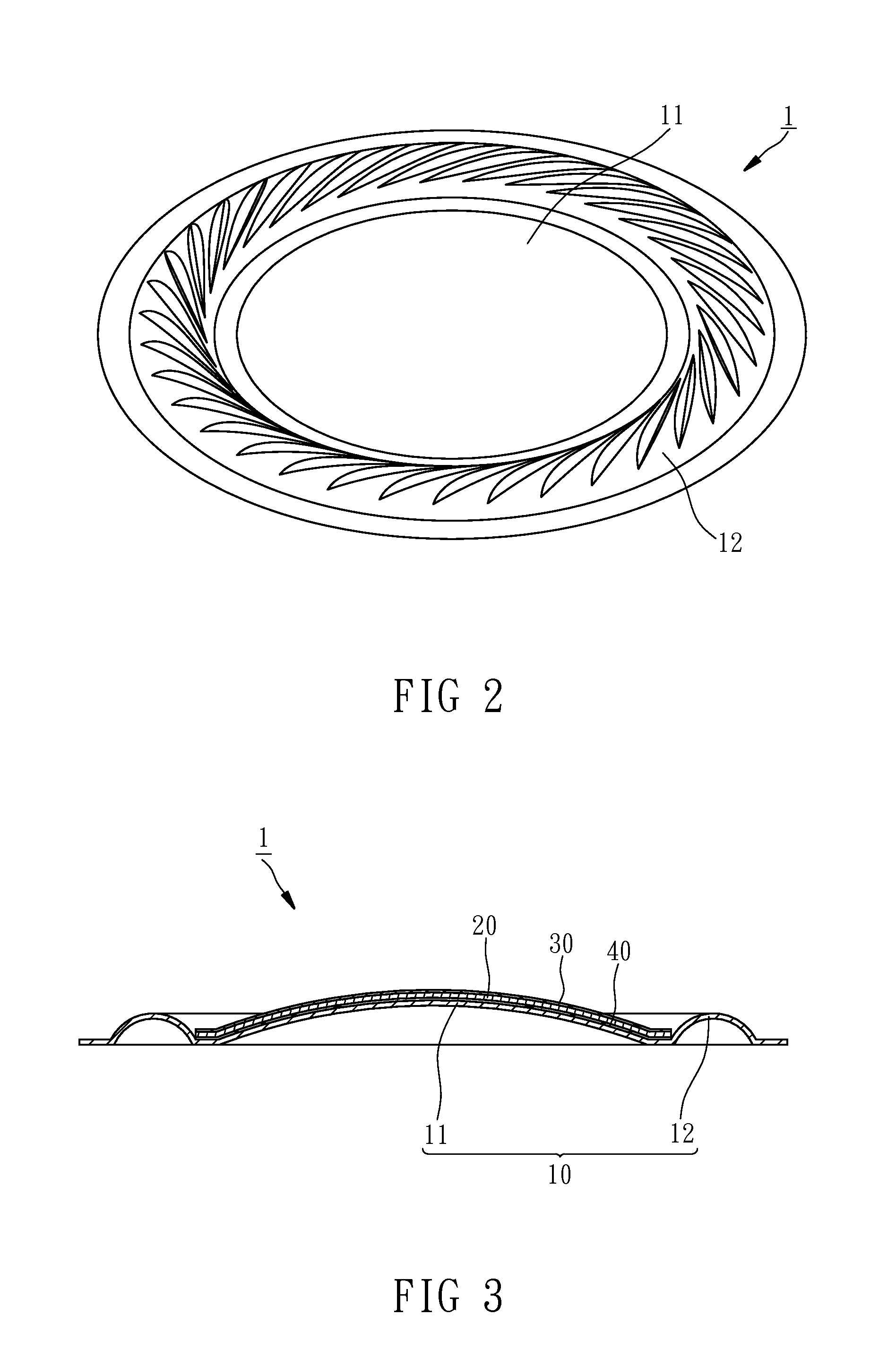

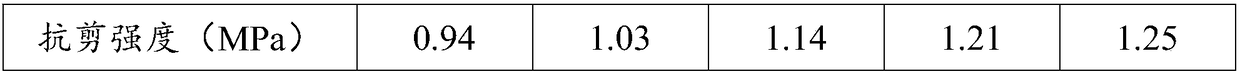

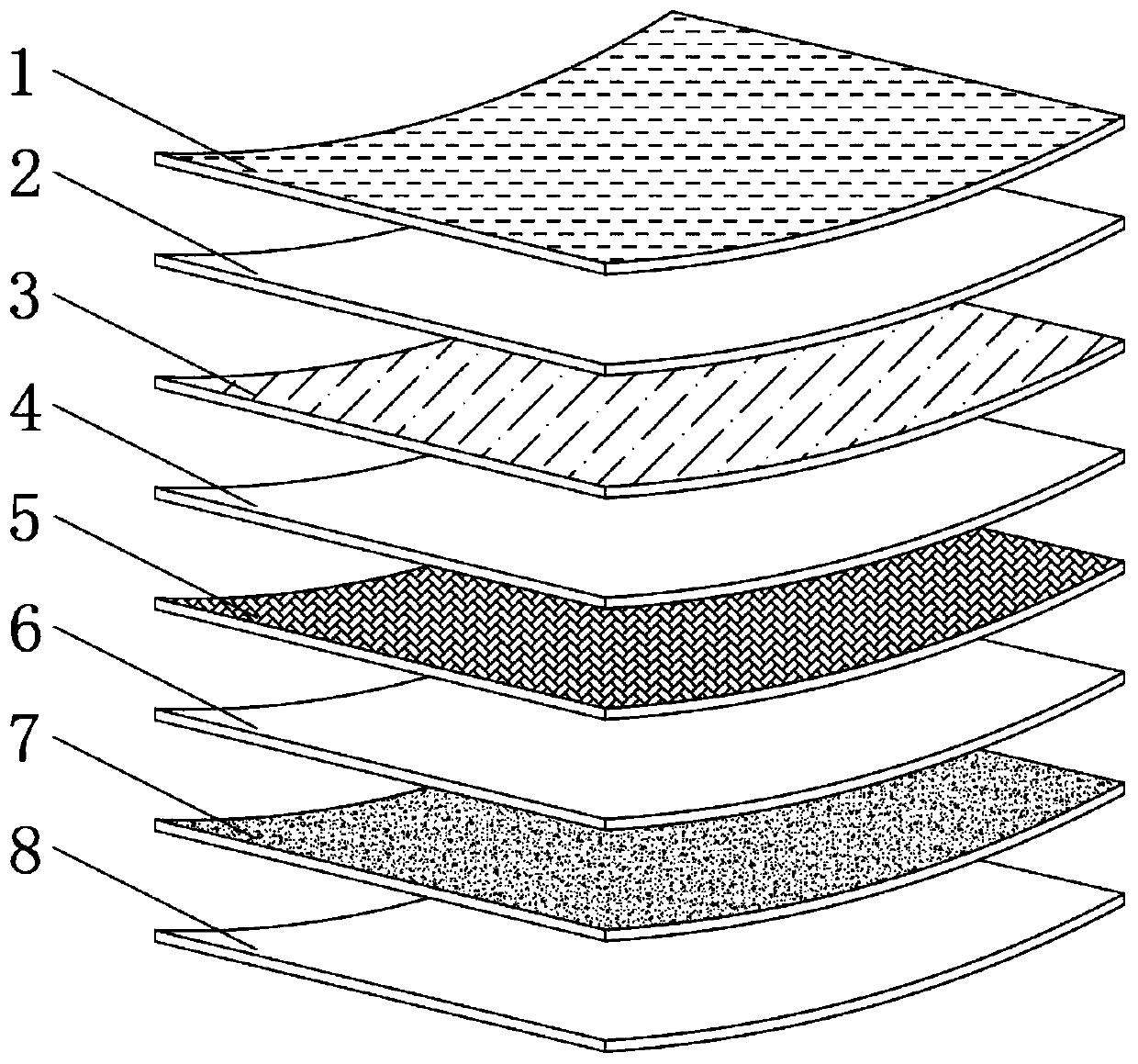

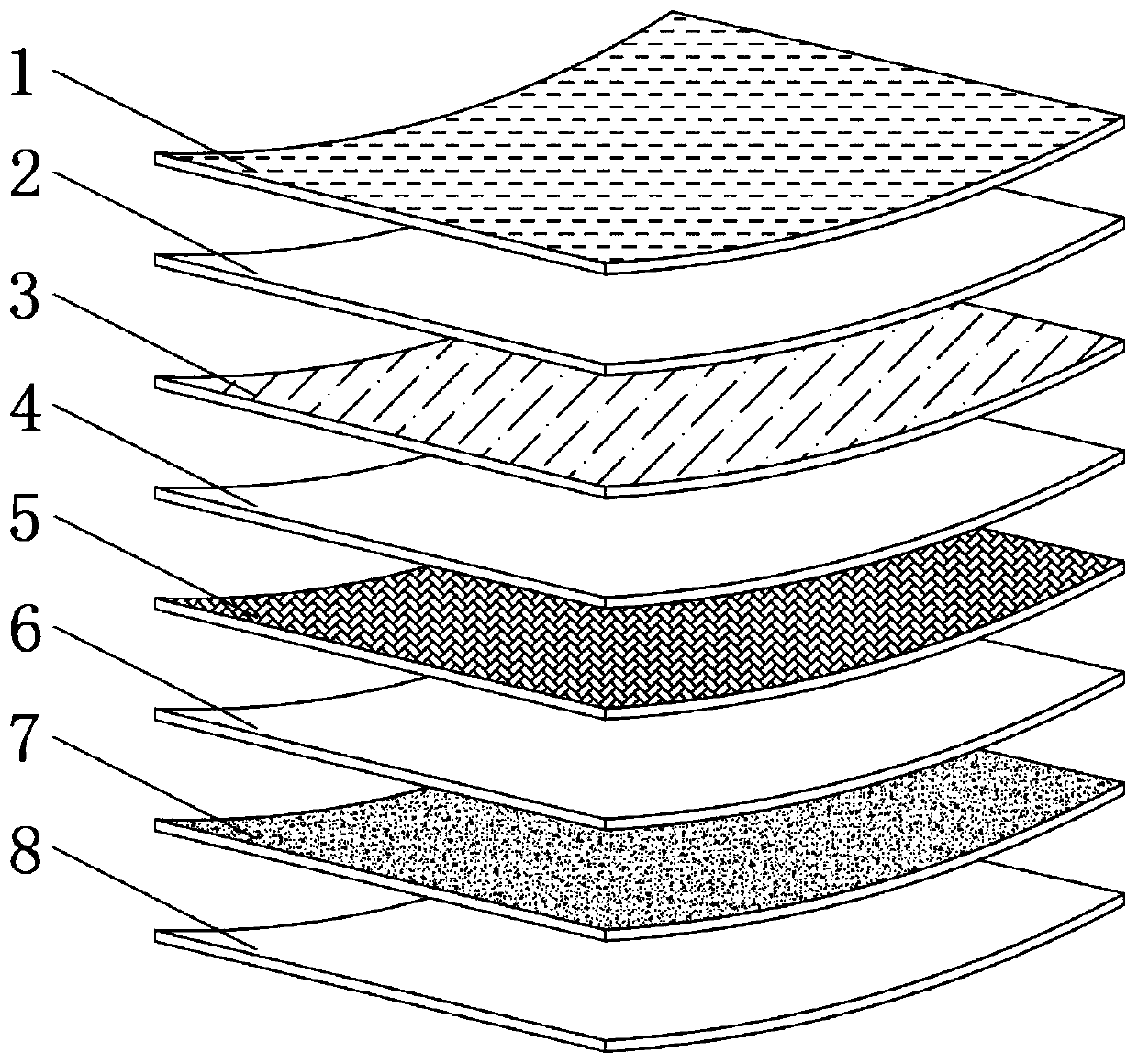

Manufacturing method for stiffened diaphragm and the manufactured diaphragm using same

InactiveUS9402134B2High strength adhesionSimple manufacturing processPlane diaphragmsDiaphragm mounting/tensioningHigh intensityEngineering

Owner:MERRY ELECTRONICS (SUZHOU) CO LTD

A kind of cold-mix colored asphalt mixture and preparation method thereof

The invention discloses a cold mixing color asphalt mixture and a preparation method. The preparation method comprises the following steps: selecting aromatic hydrocarbon oil, rubber oil, petroleum resin, epoxy resin, a modifier, a plasticizer, a diluent, diatomite, a pigment and stabilizers, and mixing the materials according to the mass proportion, thus obtaining color asphalt cement; selecting an emulsifier, the stabilizers and a defoamer, and mixing the three materials with the color asphalt cement in proportion, thus obtaining emulsified color asphalt cement; and selecting an aggregate, a filler, cement, a waterborne curing agent, an expansive agent and the emulsified color asphalt cement, and mixing the materials in proportion, thus obtaining the cold mixing color asphalt mixture.

Owner:SHENZHEN TRAFFIC CONSTR ENG TEST & DETECTION CENT

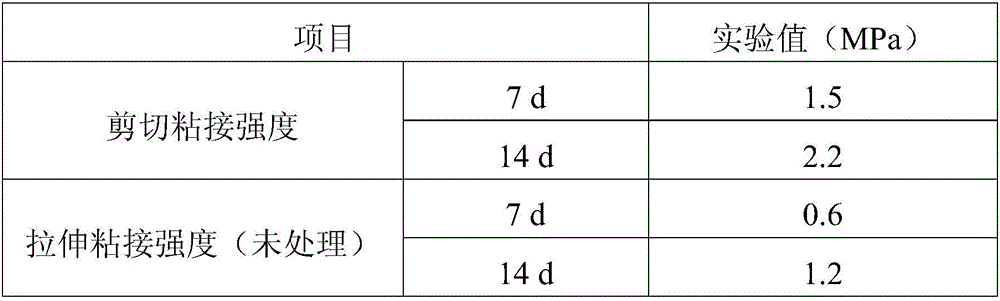

Graphene modified assembled high strength sleeve connecting mortar

The invention provides graphene modified assembled high strength sleeve connecting mortar. The graphene modified assembled high strength sleeve connecting mortar includes graphene modified magnesium oxychloride cement, portland cement, fly ash with moisture content less than 0.2%, mineral powder with particle size less than 3.5 micrometers, mineral admixture consisting of alumina powder with particle size less than 10 micrometers and silica with particle size less than 0.3 micrometer, aggregate consisting of river sand with the particle size of 0.05-2.5 millimeters and sea sand with the particle size of 0.5-5 millimeters, polycarboxylate high performance water reducer and water, wherein preparation method of graphene modified magnesium oxychloride cement clinker includes the steps of conducting pretreatment of graphene oxide solution by hydrophilic modification of alkaline substances, adding the pretreated graphene oxide solution to magnesium oxychloride cement raw meal to be mixed evenly firstly and then conduct heating reaction, high temperature calcination and fully grinding to obtain the graphene modified magnesium oxychloride cement. With the graphene modified magnesium oxychloride cement and Portland cement as main raw materials, the prepared assembled sleeve connecting mortar has the advantage of having excellent engineering properties and mechanical properties.

Owner:浙江省通用砂浆研究院

A kind of self-healing type polyurethane waterproof coating and preparation method thereof

ActiveCN111073491BHas tensile strengthAdhesiveWax coatingsPolyurea/polyurethane coatingsPolyesterPolymer science

The invention discloses a self-healing polyurethane waterproof coating and a preparation method thereof. This self-healing polyurethane waterproof coating includes A component and B component; wherein, A component includes the following components: terpene phenolic resin, plasticizer, polyester polyol, polyether polyol A, diisocyanate , catalyst; B component includes the following components: plasticizer, asphalt, polyether polyol A, polyether polyol B, extender oil, filler, thixotropic agent, dispersant, chain extender, defoamer, Catalyst; the number average molecular weight of polyether polyol A is 2000-4000; the number average molecular weight of polyether polyol B is 300-500; the filler is alkaline earth metal hydroxide; the mass ratio of component A and component B is 1 : (2~4). The self-healing polyurethane waterproof coating of the present invention has the tensile strength of the polyurethane coating and the self-healing property of the non-cured rubber asphalt waterproof coating, and also has the characteristics of excellent bonding with the existing waterproof coiled material.

Owner:大禹九鼎新材料科技有限公司

Novel nano energy-saving film

PendingCN111154423AImprove barrier propertiesImprove protectionFilm/foil adhesivesHigh concentrationReaction layer

The invention relates to the technical field of glass films, and in particular, relates to a novel nano energy-saving membrane. The novel nano energy-saving membrane comprises a negative ion reactionlayer, an HC anti-glare layer, a glass substrate, an HC nano anti-infrared barrier layer, a nano UV-resistant layer, a pressure-sensitive adhesive layer and a release layer, wherein the HC anti-dazzlelayer covers the top surface of the glass substrate, the top surface of the HC anti-dazzle layer is fixedly connected with the negative ion reaction layer, and an HC nano anti-infrared barrier layer,the nano UV-resistant layer, the pressure-sensitive adhesive layer and the release layer are sequentially arranged on one side, deviating from the HC anti-dazzle layer, of the glass substrate outwards. The HC anti-infrared barrier layer is arranged, so heat energy invasion can be blocked to the maximum extent, the temperature balance in the relative space is maintained, the real effects of energyconservation, consumption reduction and emission reduction are achieved, and the environment is well protected; through the arrangement of the negative ion reaction layer, the negative ion reaction layer can be decomposed and release high-concentration negative oxygen ions when meeting light, and air in the space can be kept fresh at any time.

Owner:厦门悦客乐家网络科技有限公司

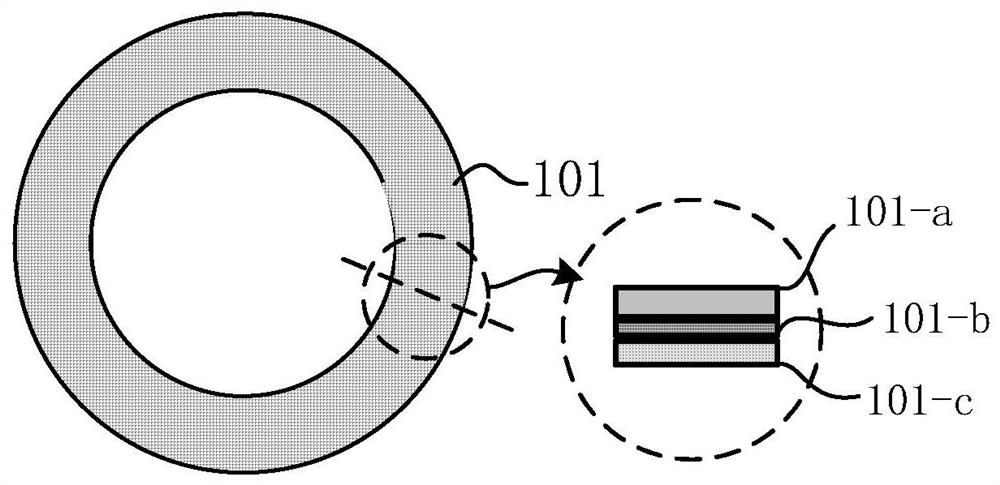

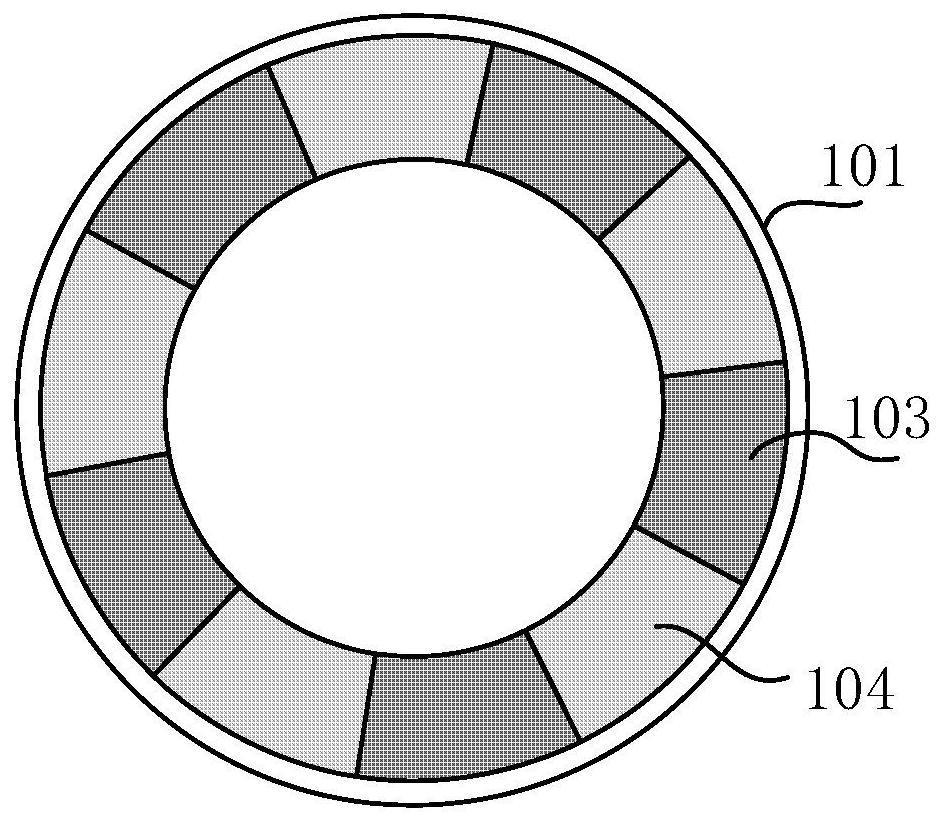

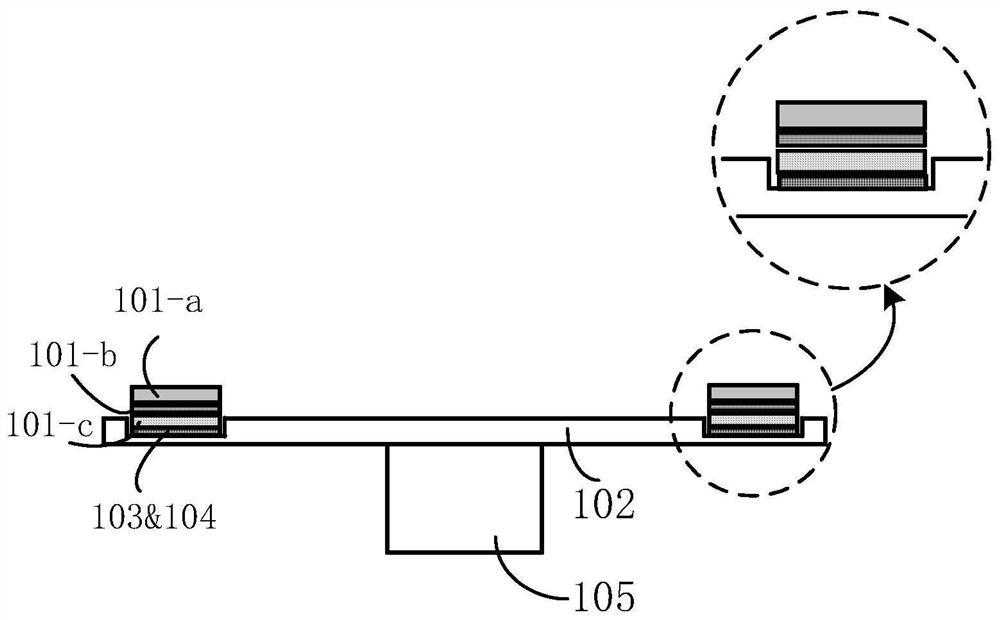

A light-emitting device, packaging method, and projection system

ActiveCN108134000BImprove reliabilityHigh strength adhesionSolid-state devicesRadiation controlled devicesAdhesive glueThermal adhesive

Provided are a light emitting device, a packaging method and a projection system, wherein the light emitting device comprises at least two components that are adhesively packaged together, and an interface of a bonded substrate of the components is divided into at least a first functional zone coated with a high thermal conductivity glue (103) and a second functional zone coated with a low thermal conductivity glue (104), wherein the thermal conductivity of the high thermal conductivity glue (103) is greater than the thermal conductivity of the low thermal conductivity glue (104), but the low thermal conductivity glue (104) has a higher adhesiveness than the high thermal conductivity glue (103). The light emitting device meets the requirement of high thermal conductivity bonding while ensuring high-strength adhesive performance, thereby achieving high reliability of the light emitting device.

Owner:APPOTRONICS CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com