Benzene-free ceramic tile mortar

A technology of tile adhesive and cement, applied in the field of building materials, can solve the problems of inability to fill the gap with tiles, affecting the effect of tile paving, poor application performance, etc., to reduce the unit water consumption, excellent friction and lubrication characteristics, and improve the paving effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

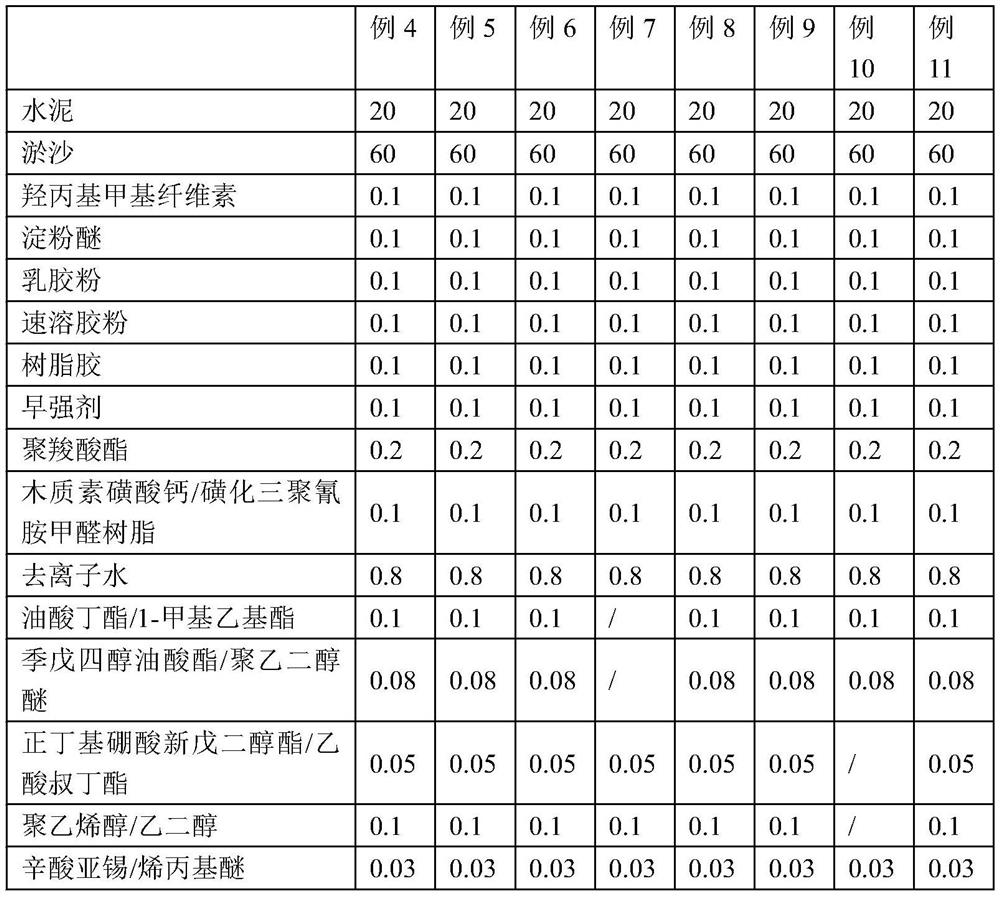

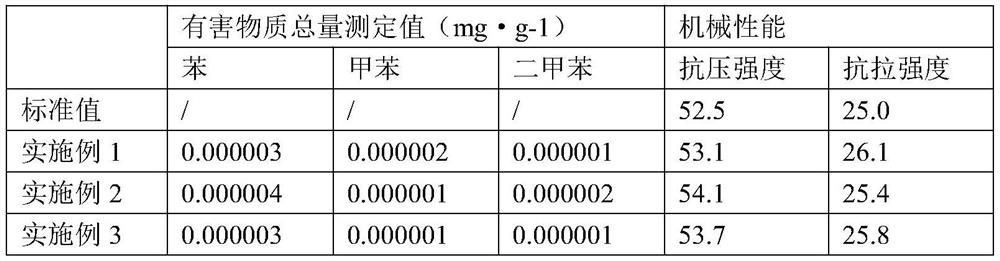

[0042] This application discloses a benzene-free tile cement, which includes the following raw materials: cement, silt, hydroxypropyl methylcellulose, starch ether, latex powder, instant rubber powder, resin glue, early strength agent triethanolamine, and water reducer .

[0043] The preparation method of the water reducer is as follows: firstly, at 85°C, mix polycarboxylate and deionized water, stir and add calcium lignosulfonate dropwise at a rate of 1 drop / s, and stir at constant temperature for 1 hour; then add oil The product of butyl ester and pentaerythritol oleate was stirred at 50°C for 20 minutes. After stirring for 10 minutes, continue to add n-butyl borate neopentyl glycol and stir for 5 minutes. Finally, add polyvinyl alcohol and stannous octoate, and stir at constant temperature for 1 hour. , cooled to room temperature to obtain a water reducer.

[0044] The content of each component is shown in Table 1 below.

Embodiment 2

[0046] This application discloses a benzene-free tile cement, which includes the following raw materials: cement, silt, hydroxypropyl methylcellulose, starch ether, latex powder, instant rubber powder, resin glue, early strength agent triethanolamine, and water reducer .

[0047] The preparation method of the water reducer is as follows: firstly, at 90°C, mix polycarboxylate and deionized water, stir and add calcium lignosulfonate dropwise at a rate of 1 drop / s, and stir at constant temperature for 2 hours; then add oil The product of butyl ester and pentaerythritol oleate was stirred at 60°C for 30 minutes. After stirring for 15 minutes, continue to add n-butyl borate neopentyl glycol ester and stir for 8 minutes. Finally, add polyvinyl alcohol and stannous octoate, and stir at constant temperature for 2 hours. , cooled to room temperature to obtain a water reducer.

[0048] The content of each component is shown in Table 1 below.

Embodiment 3

[0050] This application discloses a benzene-free tile cement, which includes the following raw materials: cement, silt, hydroxypropyl methylcellulose, starch ether, latex powder, instant rubber powder, resin glue, early strength agent triethanolamine, and water reducer .

[0051] The preparation method of the water reducer is as follows: firstly, at 88°C, mix polycarboxylate and deionized water, stir and add calcium lignosulfonate dropwise at a rate of 1 drop / s, and stir at constant temperature for 2 hours; then add oil Butyl butyl borate and pentaerythritol oleate were stirred at 55°C for 25 minutes. After stirring for 12 minutes, continue to add n-butyl borate neopentyl glycol and stir for 7 minutes. Finally, add polyvinyl alcohol and stannous octoate, and stir at constant temperature for 1 hour. , cooled to room temperature to obtain a water reducer.

[0052] The content of each component is shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com