Patents

Literature

535 results about "Calcium lignosulfonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium lignosulfonate - SP/ADJ, REG, GMP, Dispersing agent and stabilizer in pesticides for pre- or post-harvest use on bananas - 172.715 from FDA Center for Food Safety and Applied Nutrition (CFSAN)

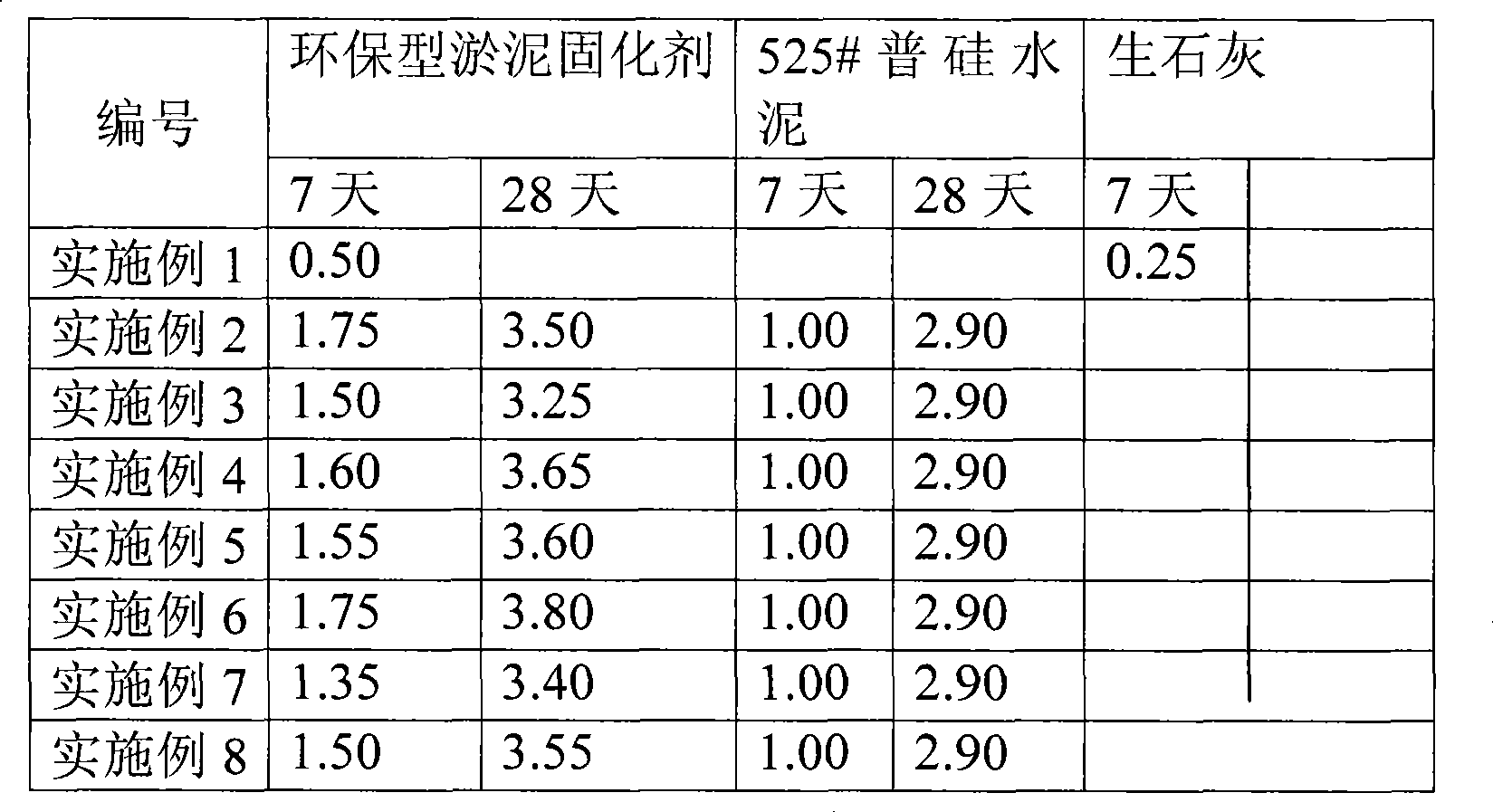

Environment-friendly type sludge firming agent

InactiveCN101381194AImprove curing abilityImprove curing effectSludge treatment by de-watering/drying/thickeningRoad engineeringSlag

The invention provides an environment-friendly silt curing agent, which is manufactured through the following steps: one or two among fly ash, calcium sulfate, sodium sulfate, sodium carbonate and potassium carbonate, one or two among slag, slag combination, potassium hydroxide, calcium oxide, sodium silicate or silicon dioxide, one or two among carbide slag, lime or gypsum, as well as one or two among triethanol amine surfactant, calcium lignosulfonate or sodium lignosulfonate form a plurality of optimal compound formulations according to respective attributes, are optimized, compounded, ground till the Brinell specific surface areas are between 300 and 900 m2 / kg respectively and then mixed, wherein particle sizes are between 0.00040 and 0.5 mm. As a large amount of waste is utilized, the curing agent saves raw materials, solves the problems about waste discharge and environmental pollution, controls waste through waste, and has important significance to environmental protection. The invention aims to provide the environment-friendly silt curing agent which has strong adaptability to a plurality of types of silt and soil, is good in curing effect, good in durability after curing and capable of utilizing industrial waste, and can be widely applied to fill engineering, embanking or embankment reinforcement engineering, road engineering and other fields.

Owner:天津渤海环保工程有限公司 +1

Soft soil curing agent

The invention discloses a soft soil curing agent composed of a main agent and an adjuvant, wherein the main agent is composed of cements, sands, lime, fly ash, slag cement, gypsum, nanometer silicon based oxides and the like, the adjuvant comprises triethanolamine, calcium lignosulfonate, sodium chloride, magnesium chloride, calcium chloride, ferric chloride, light vanadium or water glass, polyacrylamide, calcium sulfate, sodium sulfate, sodium hydroxide and the like. The invention has the advantage of perfect service effect, and is capable of being used as powder (for dry spraying) or pulp agent (for wet spraying) in cement injection pile construction, and further can be used in constructions of cement mixing pile, grouting, chemical churning pile, shallow layer cushion reinforcement, subgrade strengthening, tamping and the like.

Owner:劲桩科技有限公司

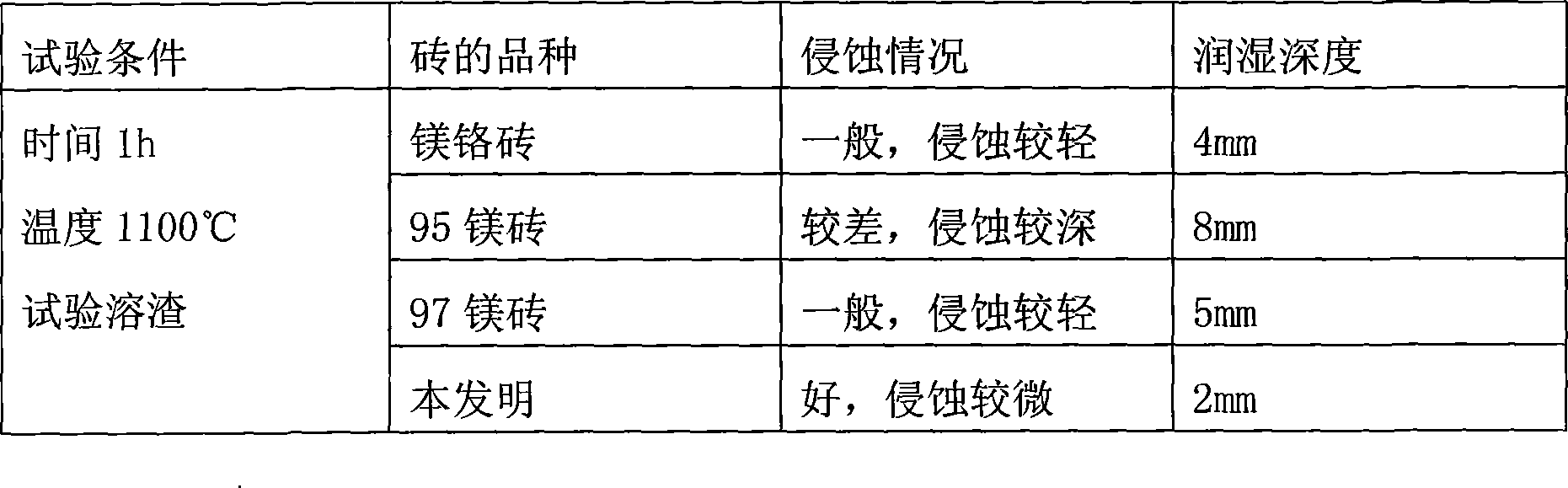

Slag adhesion resistant gunning refractory for converter

The invention provides a slag adhesion resistant gunning refractory for a converter. The gunning refractory comprises the following components in percentage by weight: 35 to 45 percent of magnesia carbon refractory crushed brick recycled aggregate, 5 to 16 percent of magnesite clinker, 18 to 25 percent of fused magnesite, 5 to 8 percent of silicon carbide, 8 to 13 percent of graphite, 1 to 3 percent of alumina cement, 1 to 3 percent of silicon micro powder, 1 to 3 percent of alpha-Al2O3 micro powder, and 3 to 4 percent of sodium hexametahposphate. On the basis of the raw materials, 0.2 to 0.4 percent of calcium lignosulfonate and 0.05 to 0.15 percent of polypropylene fiber are added; the magnesia carbon refractory crushed brick recycled aggregate has two granularities, namely comprises 30 to 40 weight percent of aggregate with the granularity of 3 to 1 mm and 60 to 70 weight percent of aggregate with the granularity of 1 to 0.15mm; the granularity of the magnesite clinker is 1 to 0.15mm; the fused magnesite has two granularities, namely comprises 40 to 60 percent weight percent of fused magnesite with the granularity of 180 meshes and 40 to 60 weight percent of fused magnesite with the granularity of 325 meshes; and the granularity of the silicon carbide is 180 meshes.

Owner:WUHAN IRON & STEEL (GROUP) CORP

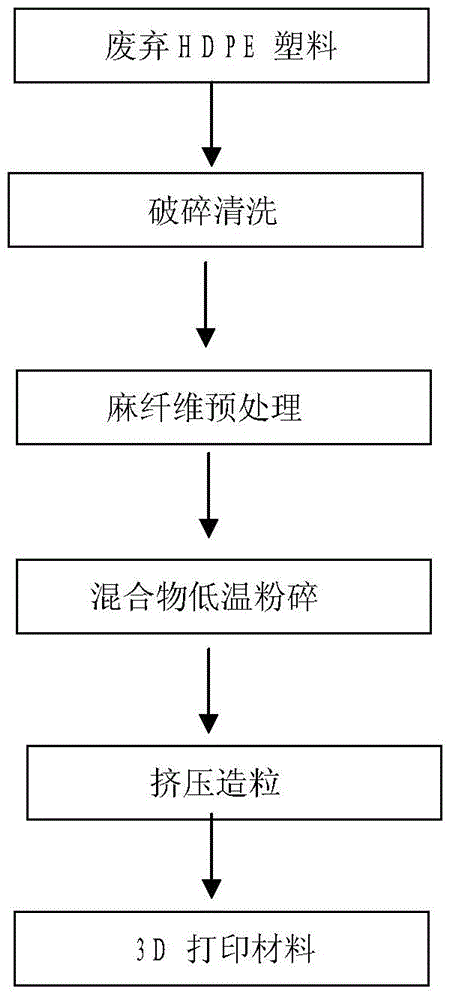

Method for preparing 3D printing material by use of recycled waste high-density polyethylene plastics

ActiveCN104629152AReduce performance lossSmall granularityAdditive manufacturing apparatusPlastic recyclingFiberCalcium silicate

The invention discloses a method for preparing a 3D printing material by use of recycled waste high-density polyethylene plastics. The raw material adopted by method is the waste high-density polyethylene plastics which are prepared from the following components in parts by weight: 100 parts of high-density polyethylene, 10-40 parts of jute fibers, 10-30 parts of calcium lignosulfonate, 10-30 parts of calciumsilicate, 0.8-1.4 parts of a coupling agent, 10 parts of a compatilizer and 20-30 parts of a plasticizer. The method comprises the following steps: 1, breaking and cleaning the waste plastics; 2, preprocessing the jute fibers; 3, adding additives, and grinding at low temperature; 4, extruding and pelletizing. According to the method, the waste high-density polyethylene plastics are recycled, and the additives are added to modify the recycled plastics and enhance the toughness, tensile strength and impact strength of the plastics, so that the plastics can be accepted as a material meeting 3D printing requirements, and the cost of the 3D printing material is greatly reduced.

Owner:康硕(河南)智能制造有限公司

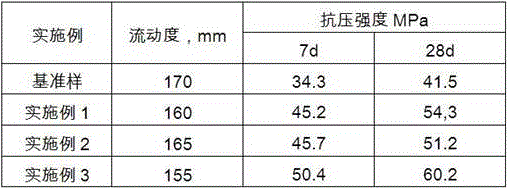

Low slump loss concrete pumping agent

The low slump loss concrete pumping agent has the composition of: naphthalene water reducing agent 35-65 wt%, calcium lignosulfonate 1.0-3.0 wt%, FEA sweller 30-60 wt%, saccharide retarder 1.0-3.0 wt%, sodium gluconate 0.5-4.5 wt% and air entraining agent lower than 0.03 wt%. Adding it in the amount of 3.5-5.0% of cement and other additive at 30-42 deg.c results in concrete solidifying time adjustable in 10-24 hr and 3H slump constant greater than 140 mm pumpable. Its use can avoid cold seam and delayed hydration heat peak. It has important application significence, especially in large volume and large area concrete engineering and concrete conveyance for long distance and at high environment temperature.

Owner:李乃珍

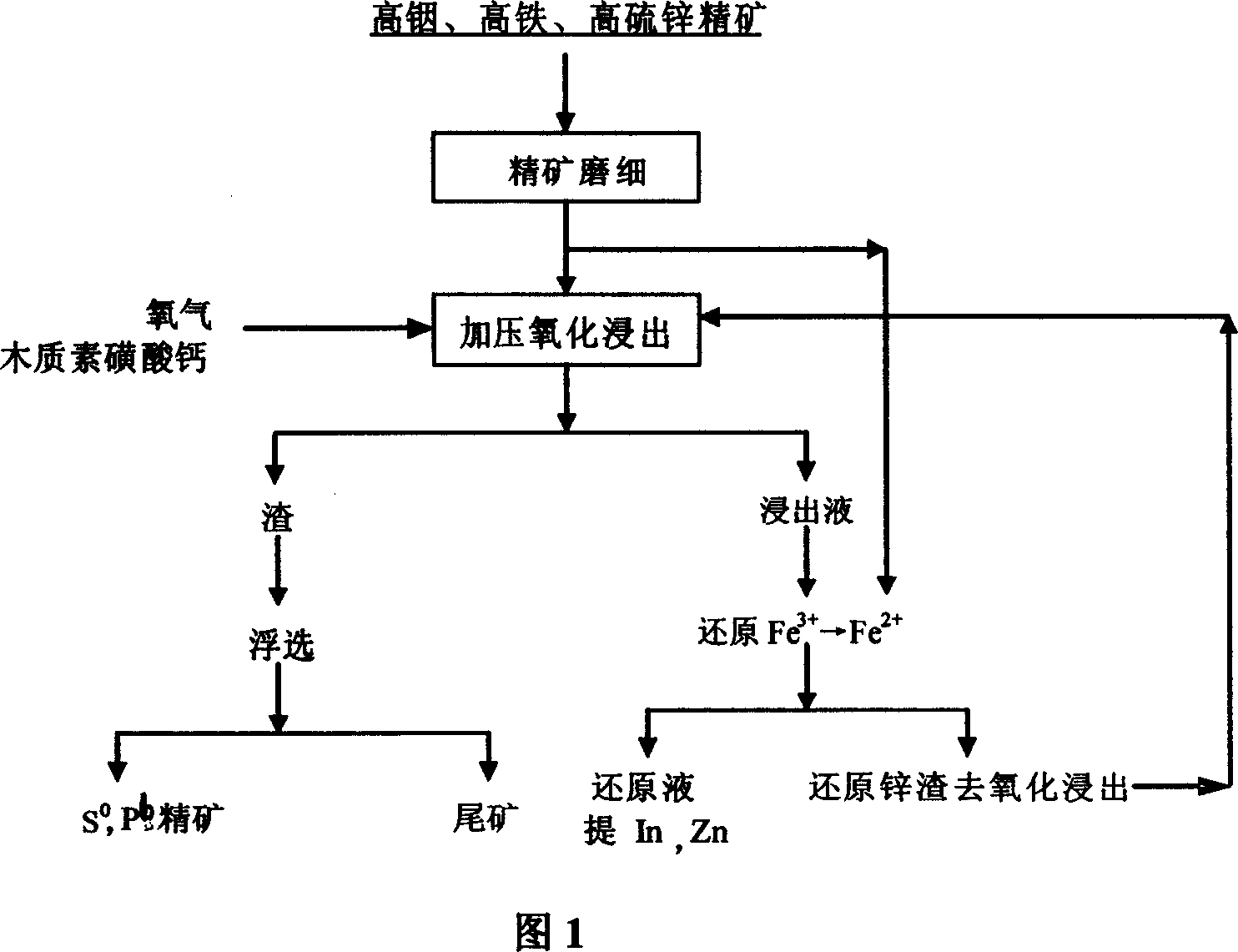

New method for soaking out enriched ores of high indium, high iron, and high sulfur zinc

This invention discloses a wet method for treating high In-Fe-S Zn concentrate by oxidative acid leaching. Compared with traditional high-pressure leaching technique, the method obviously reduces the operation temperature and pressure. Ore slurry composed of Zn concentrate, surfactant and sulfuric acid aqueous solution is operated at 95-105 deg.C under 0.2-0.4 MPa. The surfactant is sodium or calcium lignosulfonate, which can change the hydrophobicity of sulfide and sulfur, raise the leachin speed, and improve the suspension fluidity of the ore slurry. Since the operation temperature is lower than the normal pressure boiling point of the solution system, normal rubber pipe pump can be used to replace oil diaphragm high-pressure slurry pump, and Ti heat exchanger and vacuum flash evaporator are not needed. The leaching rate of Zn and In is up to 95-99%, and the yield of S is higher than 80%. The leaching solution can be treated according to normal method to recover valuable components, with total recovery rate of In up to 90-95%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

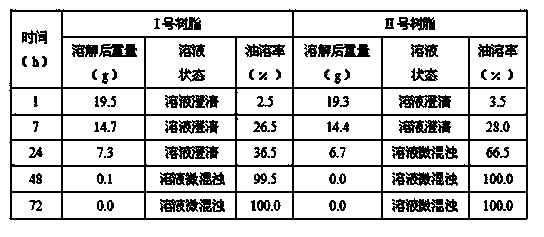

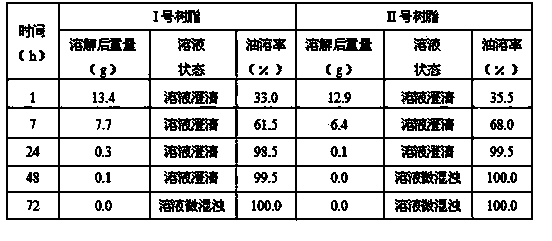

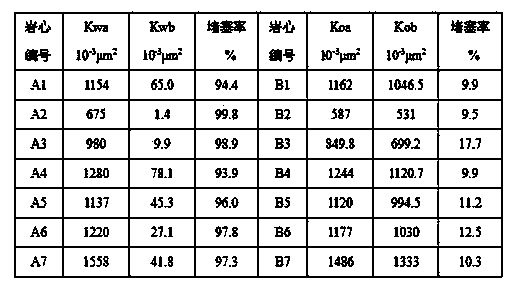

Oil well dual crosslinking selective plugging agent

InactiveCN104250546ATo achieve the effect of blocking waterPrevent another breakthroughDrilling compositionThioureaCross linker

The invention discloses an oil well dual crosslinking selective plugging agent, and solves the problems that the selectivity of selective plugging agents in the prior art is not high, and effective plugging of a water layer and complete unblocking of an oil layer cannot be achieved. The oil well dual crosslinking selective plugging agent comprises the following components by mass: 2% of dispersing agent calcium lignosulfonate, 0.6% of suspending agent polyacrylamide, 0.9% of a cross-linking agent, 8% of oil soluble resin, and balance of water; wherein the 0.9% of crosslinking agent comprises 0.4% of reductant thiourea and 0.5% of oxidizing agent potassium dichromate. Compared with general plugging agents, water phase plugging rate and oil phase recovery rate of the oil well dual crosslinking selective plugging agent are higher, and the selective water plugging performance of the oil well dual crosslinking selective plugging agent is more superior.

Owner:NORTHEAST GASOLINEEUM UNIV

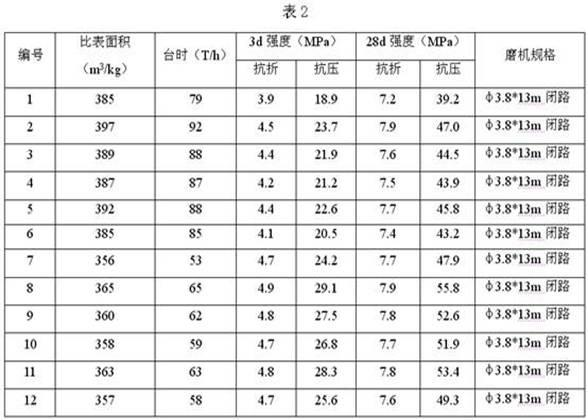

Cement grinding aid and preparation method thereof

ActiveCN102126843AImprove performanceNo adverse side effectsSolid waste managementCelluloseCarbamate

The invention discloses a cement grinding aid. The cement grinding aid comprises the following components in percentage by weight: 8 to 20 percent of triethanolamine, 0 to 10 percent of triisopropanolamine, 8 to 20 percent of diol byproduct, 0 to 10 percent of synthetic glycerine, 0 to 25 percent of molasses, 0 to 5 percent of calcium lignosulfonate, 0 to 15 percent of polyurethane, 0 to 10 percent of cystine, 3 to 5 percent of sorbitol, 5 to 10 percent of sodium carboxymethylcellulose, 0 to 5 percent of citric acid, 0 to 5 percent of silica powder, 0 to 5 percent of fly ash and the balance of water. The invention also discloses a preparation method of the cement grinding aid. The grinding aid can effectively improve the equipment-hour yield of a cement grinding mill, reduce energy consumption and remarkably improve cement performance, does not have adverse side effects on cement, reduces the using amount of cement clinkers by 4 to 10 percent, improves the equipment-hour yield of cement production by 6 to 10 percent, and has a good effect. The method has a unique process, a part of raw materials are treated by ultrasound, and the prepared grinding aid has high performance.

Owner:CHINA UNITED CEMENT LUNAN

Reinforcing and repairing grouting material for construction in minus-temperature environment

The invention provides a reinforcing and repairing grouting material for construction in a minus-temperature environment in the technical field of construction materials, which comprises the following components in percentage by weight: 7 to 13 percent of magnesium oxide, 25 to 35 percent of potassium dihydrogen phosphate, 5 to 45 percent of quartz sand, 15 to 25 percent of fly ash, 1 to 2 percent of boric acid or borax or citric acid, and 1 to 2 percent of calcium lignosulfonate or sodium lignosulphonate. Compared with the prior art, the material has the characteristics of constructing and condensing to become hard to generate strength at the temperature of 18 DEG C below zero, along with high mobility, high early strength and the like.

Owner:SHANGHAI JIAO TONG UNIV

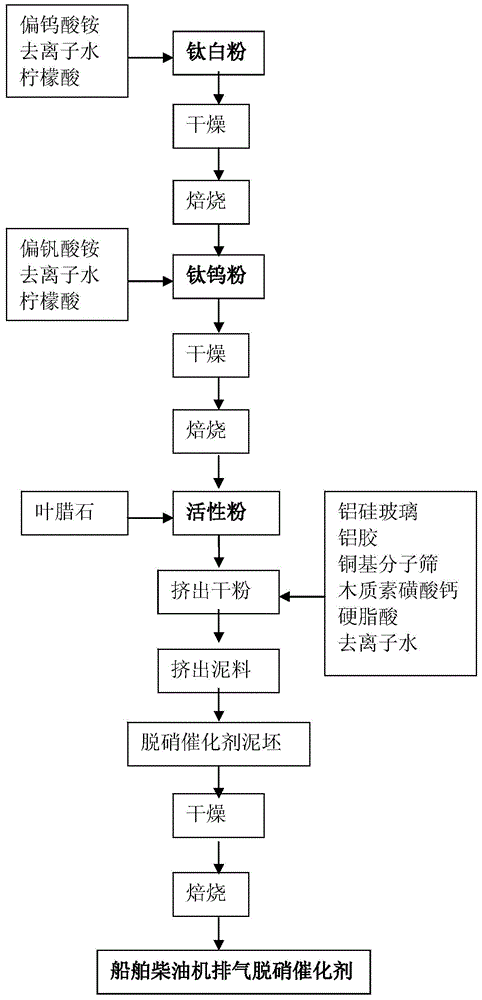

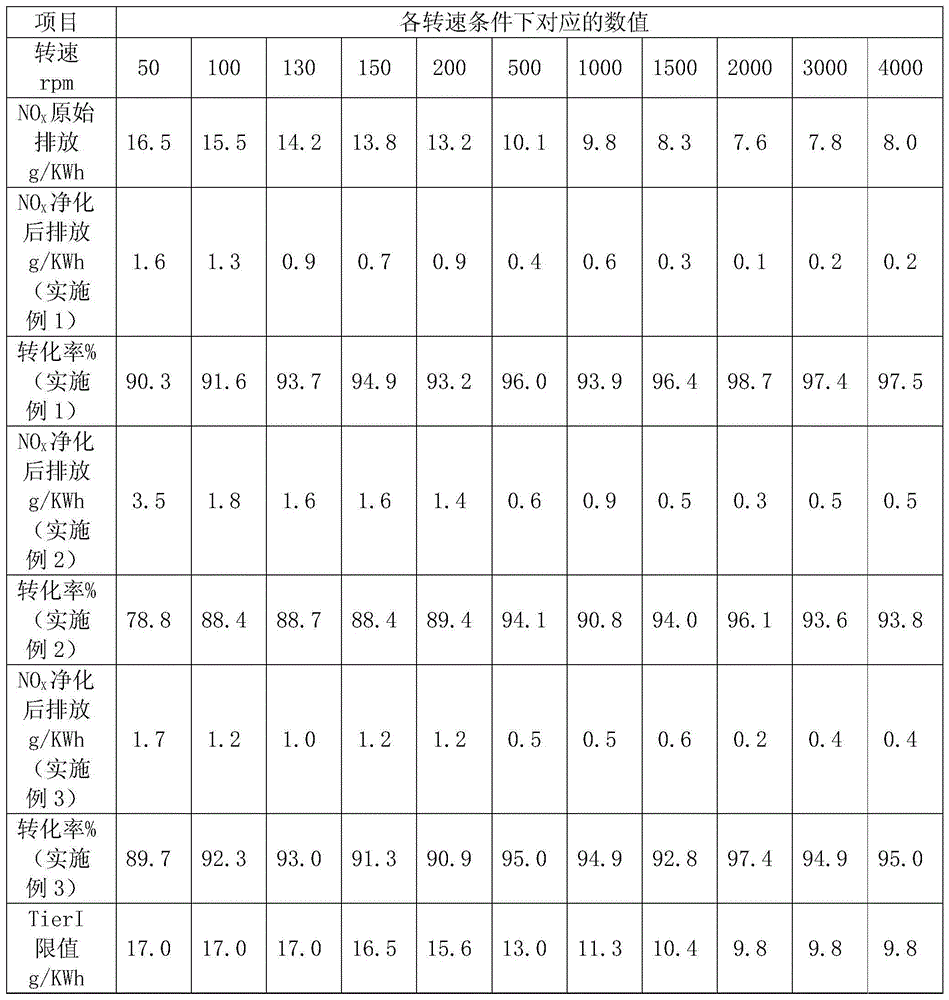

Ship diesel engine gas exhaust denitration catalyst preparation method

InactiveCN104415781AImprove denitrification efficiencyReduced service lifeMolecular sieve catalystsDispersed particle separationPyrophylliteEngineering

The invention relates to a ship diesel engine gas exhaust denitration catalyst preparation method, and belongs to the technical field of denitration catalysts. In the prior art, the denitration catalyst has the short service life and can not meet the denitration requirement under the low rotation speed of the ship diesel engine. With the ship diesel engine gas exhaust denitration catalyst preparation method of the present invention, the problems in the prior art can be solved. According to the present invention, pyrophyllite is adopted as a plasticizer and is added to active powder so as to obtain extruded dry powder, the extruded dry powder, Al-Si glass, an aluminum gel, a copper base molecular sieve, calcium lignosulfonate, stearic acid and a proper amount of deionized water are subjected to a shearing effect to prepare a pug, the pug is subjected to vacuum extruding to obtain a honeycomb-like denitration catalyst green body, and drying and calcination are performed to obtain the finished product, wherein the finished product has characteristics of high NOx harmful gas removal rate and high denitration efficiency.

Owner:SHANGHAI LANGT AUTOCATALYST

Low-temperature hardening scurry-proof cement slurry for well cementing

ActiveCN101126018AImprove anti-channeling abilityStrong volcanic ash effectDrilling compositionSlagPolyvinyl alcohol

The invention relates to a low temperature early strength channeling control cement slurry, comprising portland cement, water, light strengthening agent, low-temperature early strength agent, channeling control agent, rheological performance adjusting agent and defoaming agent; wherein, the light strengthening agent consists of glass beads, fine cement, fine silicon powder and superfine, high-activity slag; the low-temperature early strengthening agent consists of sodium silicate, calcium sulphate and triethanolamine; the channeling control agent consists of polyvinyl alcohol, gypsum, poly naphthalene sulphonic sodium and borax; the rheological performance adjusting agent consists of sodium polystyrene sulfonate and calcium lignosulfonate; the defoaming agent consists of poly glycol dipropionate ether. The invention has the advantages of fast expanding speed of intensity in low temperature, strong channeling control and leakage resistance performance, low water lost and good rheological performance, and can be used as cementing material in low-temperature air layer, activity water layer and leakiness ground layer.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

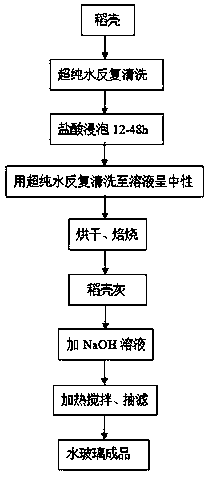

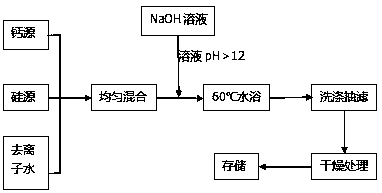

Preparation method of hydrated calcium silicate early strength agent and self-compacting concrete

The invention relates to a preparation method of a hydrated calcium silicate early strength agent, and a steaming-free C30 self-compacting concrete prepared by using the early strength agent. According to the preparation method, acid treated waste rice husks and waste liquid of calcium lignosulfonate production are effectively utilized as raw materials, so that not only is energy saved and is environment protected, but also the production cost of the hydrated calcium silicate early strength agent is reduced; and the hydrated calcium silicate early strength agent prepared by using the acid treated waste rice husks and the waste liquid of the calcium lignosulfonate production has similar properties to a hydrated calcium silicate early strength agent prepared by using a silicon source such assodium silicate and a calcium source such as calcium nitrate, and both can effectively improve early strength and later strength of a cement-based material.

Owner:镇江建科建设科技有限公司

Preparation method of high-performance gas-filling building block composite material

The invention discloses a preparation method of a high-performance gas-filling building block composite material, belonging to the technical field of building materials. According to the invention, the coal ash, tailings, slag, yellow sand and the like are used as major raw materials, the cement, carbide slag and lime are used as excitants, the aluminum powder paste and hydrogen peroxide are used as gas production agents, the phosphoric acid and water glass are used as foam stabilizers, the ardealite and titanium gypsum are used as retarders, and the calcium lignosulphonate and hydroxylmethylcellulose are used as dispersing agents. The preparation method is characterized in that the coal ash, the tailings, the slag, the yellow sand and the like are subjected to the technologies of PLC system grinding, mixing, pouring, precuring, cutting, steaming and pressing, building block separation, packing and the like; and the technology for preparing the silicate composite material for a building is adopted. Through the invention, the produced building block has the characteristics of stable chemical property, excellent physical performance and the like. The preparation method has a simple technology and high efficiency, can consume a great quantity of solid wastes, prevents the emission of three wastes and the environmental pollution, reduces the environmental pollution caused by other wastes, and creates obvious economic and social benefits.

Owner:安徽建鑫新型墙材科技有限公司

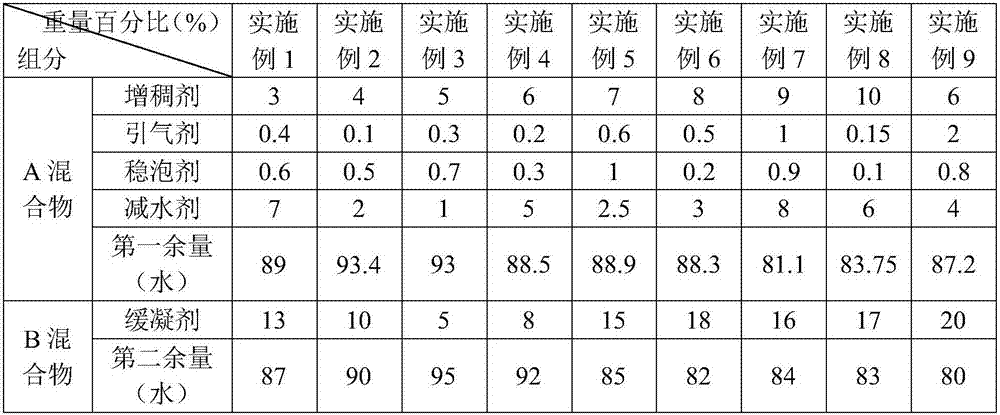

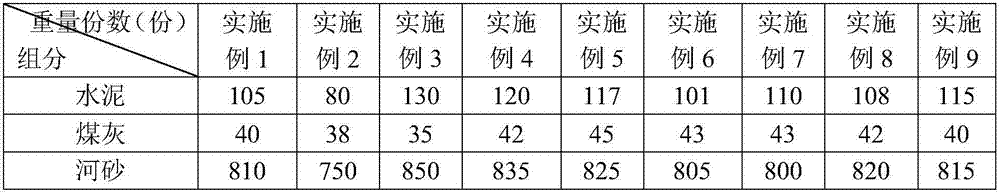

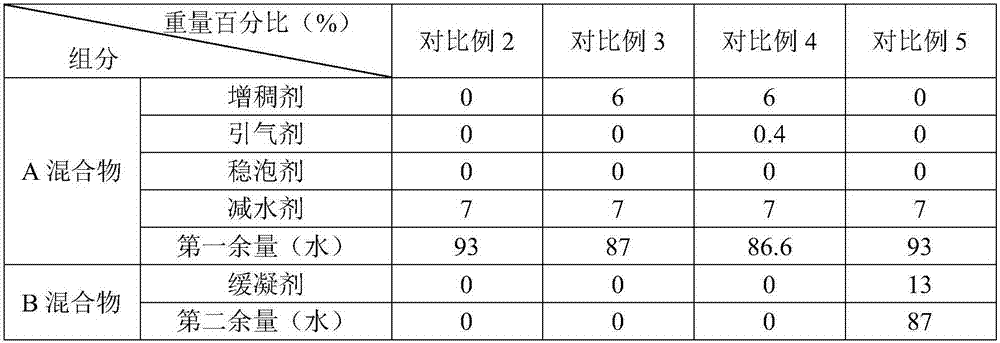

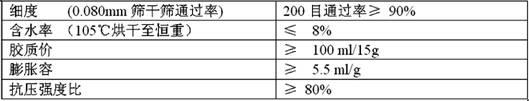

Premixed mortar additive, and preparation technology and applying method thereof

InactiveCN107162459AImprove workability water retentionHigh water reduction ratePolyvinyl alcoholAir content

The invention discloses a premixed mortar additive, and a preparation technology and an applying method thereof. The premixed additive comprises a mixture A and a mixture B, and the mixture A comprises a thickener, an air entraining agent, a foam stabilizer, a water reducer and water; the mixture B comprises, by weight, a retarder and water; the thickener comprises at least one of welan gum, a polyacrylate copolymer emulsion, starch and carboxymethyl cellulose; the air entraining agent comprises one of AE-2, fatty acid sodium sulfate and calcium lignosulfonate; the foam stabilizer includes one of cocoamido propyl hydroxy sulfobetaine (CHSB) and a composite foam stabilizer formed by polyvinyl alcohol and calcium stearate; the water reducer is selected from a polycarboxylic high performance water reducer; and the retarder comprises at least two of sodium gluconate, white sugar and sodium hexametaphosphate. The premixed mortar additive has the advantages of improvement of the workability and the water retention rate of a mortar, increase of the tensile bond strength, increase of the air content, and easiness in realization of the control of the opening time.

Owner:杭州构建新型材料有限公司

Material for improving mortar coagulating time and operability and use method thereof

The invention relates to a material for improving mortar coagulating time and operability and a use method thereof. The material comprises the following raw materials in mortar per cubic meter: 15-20kg of calcium bentonite, 10-15kg of sodium bentonite, 1.2-1.5kg of calcium lignosulfonate, and 0.5-1.0kg of sodium tripolyphosphate. By using the invention, the workable performance of cement mortar can be significantly improved, the mechanical property of the cement mortar is not damaged, the mortar has higher tensile bond strength, and the impermeability of the mortar can be greatly increased. The component of retarder is mingled with products, and therefore, the coagulating time can be adjusted on a large scale. After the retarder is added, the coagulating time of the mortar can be prolonged and adjusted, and the mortar has the advantages of good water retention and little weepage. In addition, when the commercial mortar of the invention is used, environmental pollution can be decreased, and project quality is increased, which is beneficial to increasing construction efficiency. Because of little product amount, obvious effect and low cost, the material is quite suitable for preparing pre-mixed mortar and dry-mixed mortar for ordinary masonry, plaster, ground, cushion and the like.

Owner:北京住总集团有限责任公司 +1

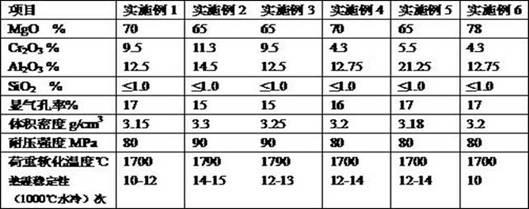

Chromium free refractory material for RH vacuum furnace lining

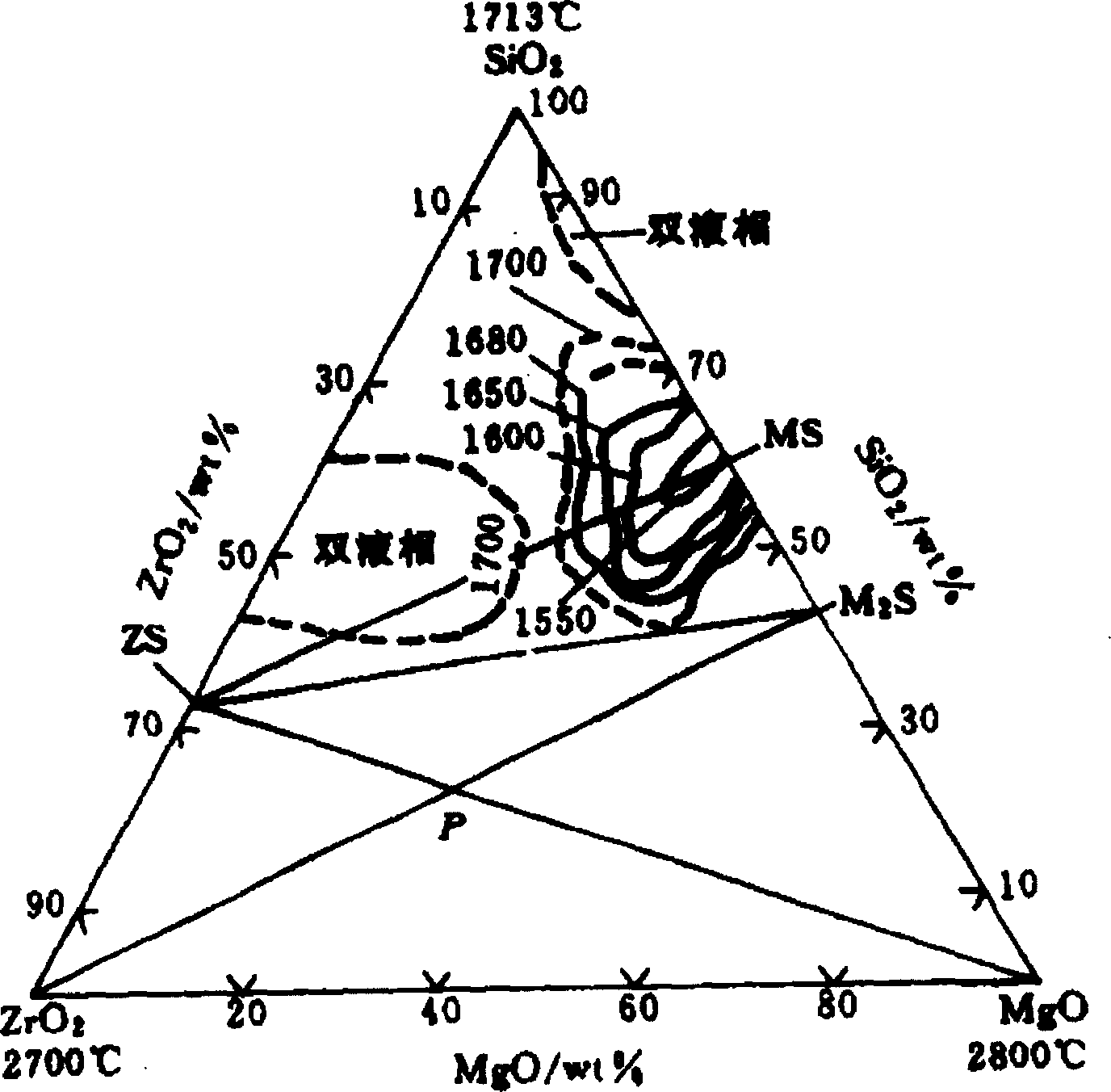

InactiveCN1715246AExtended service lifeStrong slag resistanceBlast furnace componentsBlast furnace detailsChromium freeZirconia silica

The chromium-free refractory material for RH vacuum furnace lining consists of one or several of magnetize, magnesia zirconia and magnesia zirconia silica 88-97 wt%, fine zirconia powder 1-6 wt%, fine zircon powder 0-9 wt%, and organic binding agent 1-3 wt%. It has the chemical composition of MgO 80-90 wt%, SiO2 1-4 wt%, and ZrO2 7-13 wt%. The organic binding agent is binding agent commonly for refractory material, such as sodium humate, calcium lignosulfonate, dextrin and Arabic gum. The MgO-SiO2-ZrO2 chromium-free refractory material has high slagging resistance and is significant for RH vacuum furnace to obtain long service life.

Owner:BAOSHAN IRON & STEEL CO LTD

Magnesium-calcium-zirconium slag non-sticking spraying coating

The invention relates to magnesia-calcium-zirconium non-stick slag spray paint, which effectively solves the problems of high energy consumption and environmental pollution during the use of the paint. The invention is calculated by weight percentage: dolomite 20-80%, zircon sand 2 -10%, corundum powder 5-15%, silicon micropowder 2-10%, bentonite 2-5%, soft clay 5-15%, phosphate 2-6%, calcium lignosulfonate 0.1-1%, boric acid 0.2-2%, the total amount is 100%. The test in the steel-making converter shows that the spray coating of the present invention has good fluidity, can complete the gunning operation within three minutes, can effectively isolate the slag and is easy to clean up the slag, reducing the work Time, the main raw material used in the present invention is non-burning dolomite, which is not hydrated, has a wide range of raw material sources, is convenient to obtain, and because it does not burn raw materials, it saves a lot of energy, which is beneficial to reduce costs and save energy consumption.

Owner:郑州荣达工矿集团有限公司

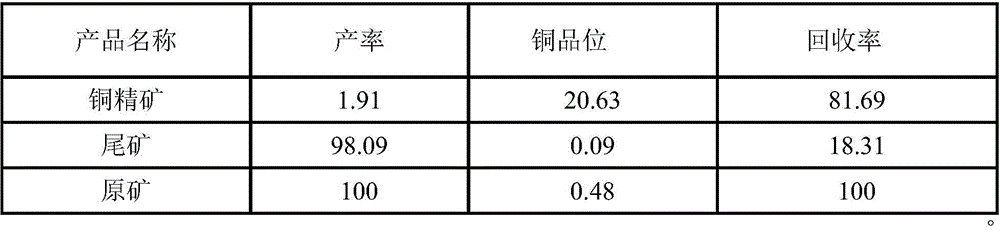

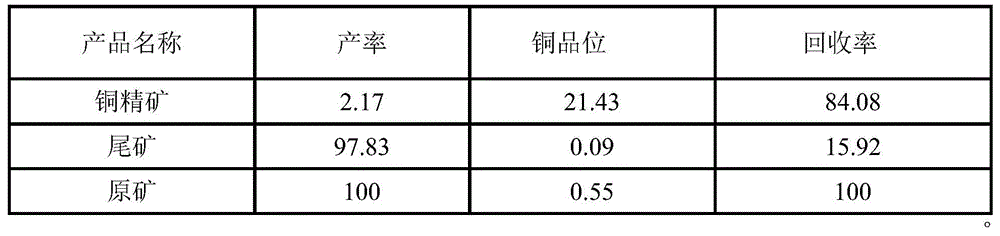

Beneficiation method for improving ore dressing recovery percentage of copper sulfide mineral hard to dispose

ActiveCN106269287AEfficient use ofNo pollution in the processFlotationSulfide mineralsCopper sulfide

The invention relates to a beneficiation method for improving the ore dressing recovery percentage of copper sulfide ore hard to dispose. By applying the method, flotation separation of copper sulfide mineral from hydrophobic silicate gangue talc and ferric sulfide mineral pyrite can be realized, and the preparing technical indexes of copper sulfide mineral can be improved. The method comprises the operations of ore grinding, size mixing, rougher flotation, scavenging and selection. According to the invention, a combined inhibitor TYZ01 has a selective inhibiting effect on talc and pyrite and cannot affect the flotation of copper pyrites, and a combined collecting agent TBS02 has strong collecting capability on copper pyrites; by using the two combined reagents, efficient utilization of copper sulfide mineral containing hydrophobic silicate gang and pyrite can be realized; proved by practices, by using the beneficiation method disclosed by the invention, good selection indexes can be obtained; and the adopted reagents, calcium lignosulfonate and Arabic gum, are organic macromolecule reagents, thus being easy to degrade and having no pollution to the environment.

Owner:苏尼特右旗朱日和铜业有限责任公司

Method for producing baking-free bricks by solidifying construction wastes by utilizing phosphogypsum

The invention provides a method for producing baking-free bricks by solidifying construction wastes by utilizing phosphogypsum, comprising the following steps: taking the construction wastes as a main raw material, adding phosphogypsum solidifying agent, high-temperature calcined or molten activating agents such as industrial residues, water glass and sodium carbonate and the like, water reducer such as polycarboxylic acid or calcium lignosulphonate and the like, and additives such as calcium fluosilicate or sodium fluosilicate and the like; stirring and mixing, shaping, maintaining and the like to obtain the baking-free brick with the advantages of high strength, low softening coefficient, low water absorption, wet and heat resistance, good alternating ability, freeze resistance and no swell and the like. The method of the invention solves the problems that the existing phosphogypsum and the construction wastes have enormous piling quantities and are difficult to be processed, and makes full use of potential activity of construction wastes to prepare a high-quality baking-free brick used for construction at the coaction of phosphogypsum and other additives; the construction waste use amount can reach 99%; the brick not only has low cost and good physical performance, but also effectively utilizes construction and industrial wastes, thus being beneficial for protecting environments, saving energy and lowing energy consumption.

Owner:KUNMING UNIV OF SCI & TECH

Flyash excitant

The flyash excitant has two different compositions. That for no-steel bar concrete consists of mirabilite 10-30 wt%, calcium chloride 10-30 wt%, sodium chloride 10-20 wt%, efficient water reducing agent 10-25 wt%, calcium lignosulfonate 1.5-7.0 wt% and ardealite 5-15 wt% other than carrier material. That for reinforced concrete consists of mirabilite 10-30 wt%, calcium chloride 10-15 wt%, sodium chloride 10-20 wt%, calcium nitrite 20-30 wt% efficient water reducing agent 6-10 wt%, calcium lignosulfonate 2-5 wt% and ardealite 5-15 wt% other than carrier material. The flyash excitant can excite the latent activity of flyash effectively so as to increase the added amount of flyash in concrete and lower the cost of concrete product.

Owner:葫芦岛市辽西混凝土外加剂有限公司

Concrete additive

InactiveCN106810105AImprove stress resistanceImprove deformation abilitySodium BentoniteSilicon dioxide

The invention provides a concrete additive and relates to the technical field of building engineering materials. The concrete additive comprises, by weight, 15-25 parts of modified concrete, 10-15 parts of gypsum, 5-10 parts of carbon black, 10-20 parts of bentonite, 1-3 parts of silicon dioxide, 10-25 parts of polypropylene fiber, 1-5 parts of a high efficiency slushing agent, 2-4 parts of calcium lignosulfonate, 0.3-0.7 part of hexadecylsulfonic acid sodium salt, 1-9 parts of dispersed latex powder, 0.2-0.6 part of a stabilizer, 1-7 parts of a corrosion inhibitor, 0.5-5 parts of a waterproofing agent, 5-15 parts of an acrylic emulsion and 10-25 parts of deionized water. The invention further provides a preparation method of the concrete additive. The concrete additive has high performance, capabilities of water seepage and compressive deformation, good duration and certain anti-rust function.

Owner:苏州泰如新材料科技有限公司

High intensity low conductivity magnesium aluminate spinel brick

The invention relates to a high intensity low conductivity magnesium aluminate spinel brick. The high intensity low conductivity magnesium aluminate spinel brick comprises the following ingredients: 20-25% magnesium aluminate composite material with granularity of 5-3 mm, 20-25% magnesium aluminate composite material with granularity of 3-1 mm, 12-16% fused magnesite with granularity of 1-0 mm, 12-16% fused magnesite with granularity of 180 F, 10-12% magnesium aluminate composite material with granularity of 180 F, 4-8% fused magnesium aluminate spinel with granularity of 180 F, 2-5% Alpha-Al2O3 fine powder, and calcium lignosulphonate which accounts for 3.5-5 weight percentage of the raw material. The high intensity low conductivity magnesium aluminate spinel brick is suitable for cement rotary kiln, has good sintering performance, thermal shock resistance, erosion resistance and permeating resistance, and has good economic and social benefits.

Owner:TONGDA REFRACTORY TECH CO LTD +1

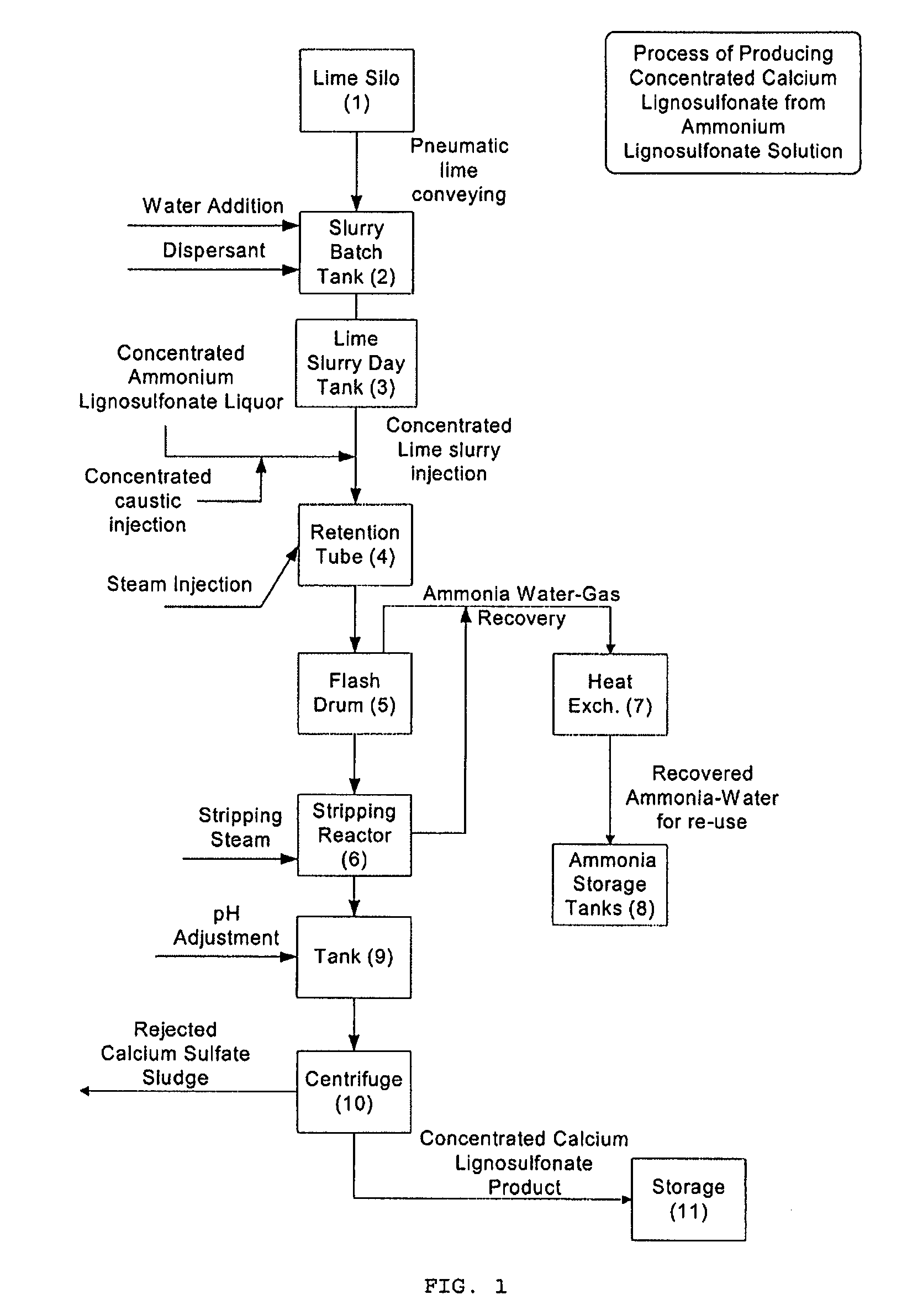

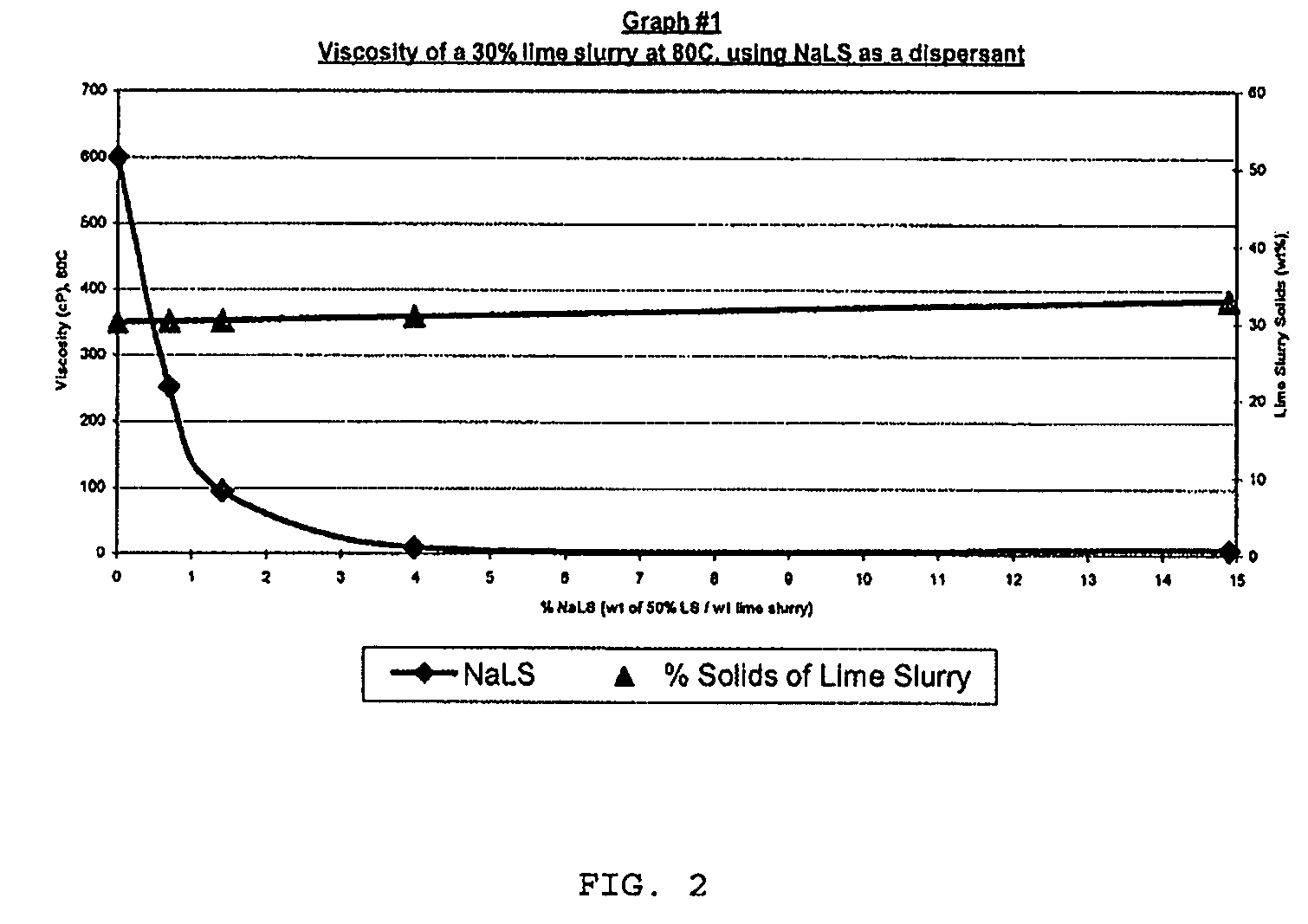

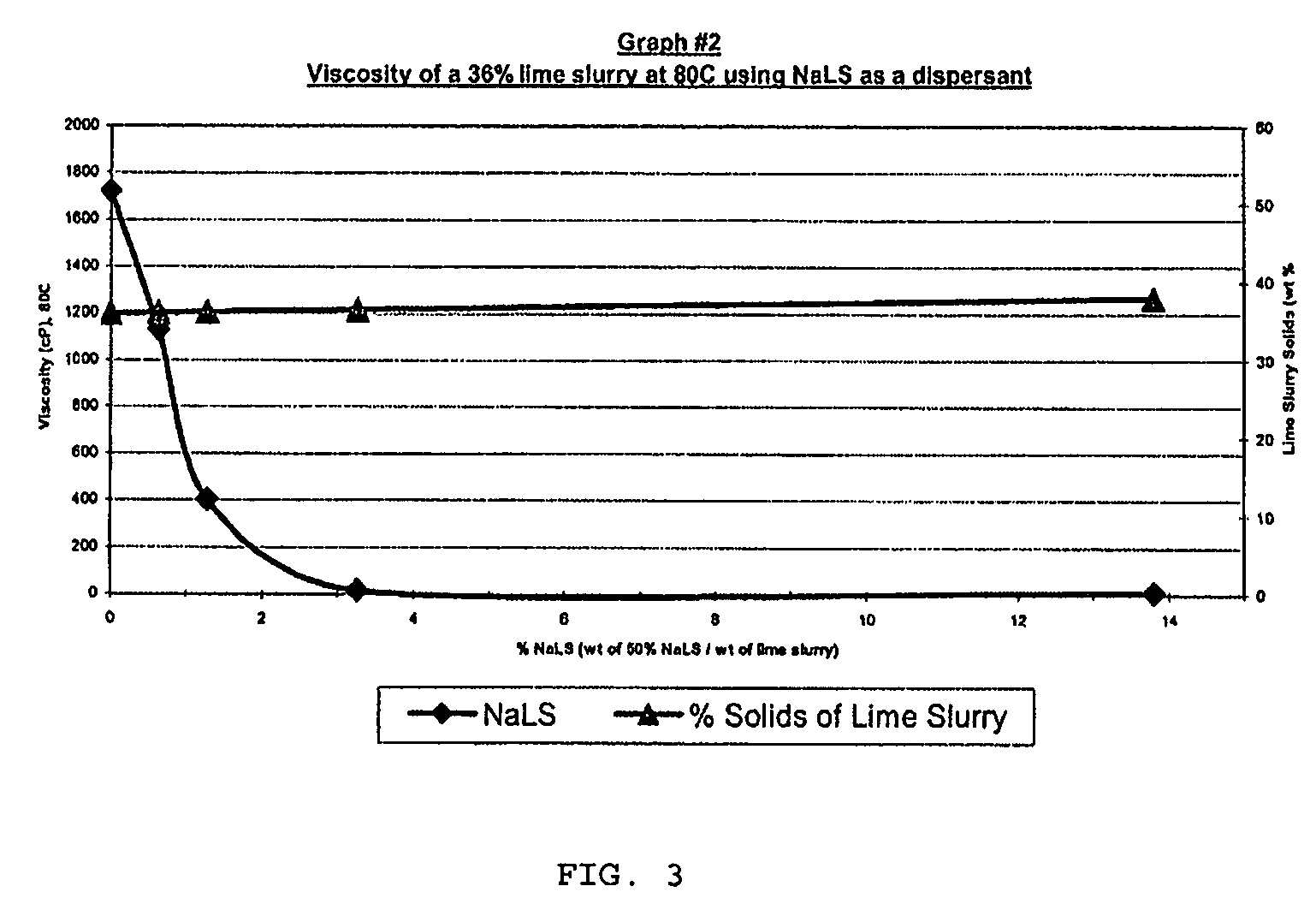

Higher than 30% concentration lime slurries, preparation and uses thereof

InactiveUS20080206126A1Reduced final product viscosityEliminate processingNon-fibrous pulp additionNatural cellulose pulp/paperCalcium hydroxideSulfate

The present invention relates to a composition comprising water, more than 30% w / w of calcium hydroxide, and >0.2% w / w dispersant. A process for preparing such a composition is also disclosed. The composition which can be in the form of a 45-55% concentration lime slurry is particularly useful for converting concentrated ammonium lignosulfonate into calcium lignosulfonate, for converting ammonium lignosulfonate into low sulfate calcium, potassium, sodium, or magnesium lignosulfonate and mixtures thereof, for removing soluble sulfate from concentrated sodium, potassium, ammonium or magnesium lignosulfonate or for treating a weak liquor obtained from the pulp and paper industry.

Owner:TEMBEC INC

Method for producing water reducer of cement concrete

The present invention relates to the production process of water reducer for cement and concrete, and belongs to the field of building material technology. The water reducer consists of calcium lignosulfonate, p-aminobenzenesulfonic acid, phenol, alkali and formaldehyde, and is produced into water preparation via adding water in 1-3 times. The production process includes heating water to 85-100 deg.c, adding the said materials successively via stirring, cooling to room to form water preparation, or further drying to form powder preparation. The present invention has the advantages of low temperature and normal pressure production, easy control of technological process, no environmental pollution, high function of controlling flowability loss of cement slurry and concrete and no harm to concrete durability.

Owner:冯乃谦

High strength silicon nitride combined silicon carbide material and method for preparing same

The invention relates to the technical field of refractory materials, in particular to a high strength silicon nitride combined silicon carbide material and a method for preparing the same. The material comprises the following raw materials by weight percentage: 76 to 86 percent of SiC, 10 to 20 percent of Si, 0.1 to 1 percent of mixture of La2O3 and Y2O3 and 2 to 4 percent of calcium lignosulfonate paper pulp. The preparation method comprises the following steps of: weighing up the raw materials; mixing the raw materials into pug; pressing the pug into a green body; drying the green body the green body in a resistance furnace at a temperature of between 100 and 150 DEG C to obtain a biscuit; and baking the biscuit at a temperature of between 1,400 and 1,480 DEG C for 8 to 16 hours under nitrogen atmosphere to obtain the finished product. Compared with the prior art, the generation of beta-Si3N4 is promoted by means of rare earth oxides; and simultaneously, the ultrafine powder can promote the sintering so as to improve the performance of the product, in particular, the strength of the product reaches 300MPa which is 1.5-time higher of that of the similar product and is 3 times of that of the conventional silicon carbide similar product.

Owner:宜兴新威利成耐火材料有限公司

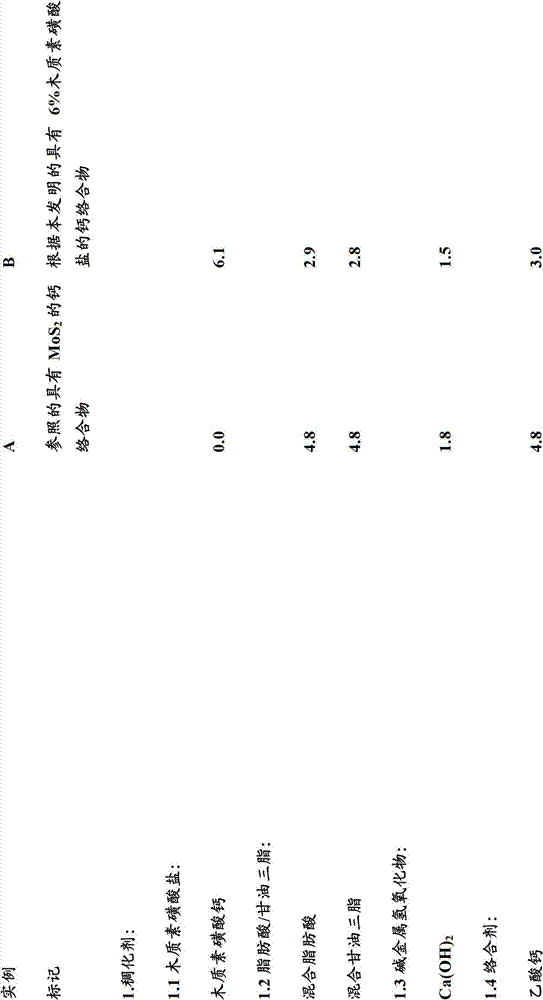

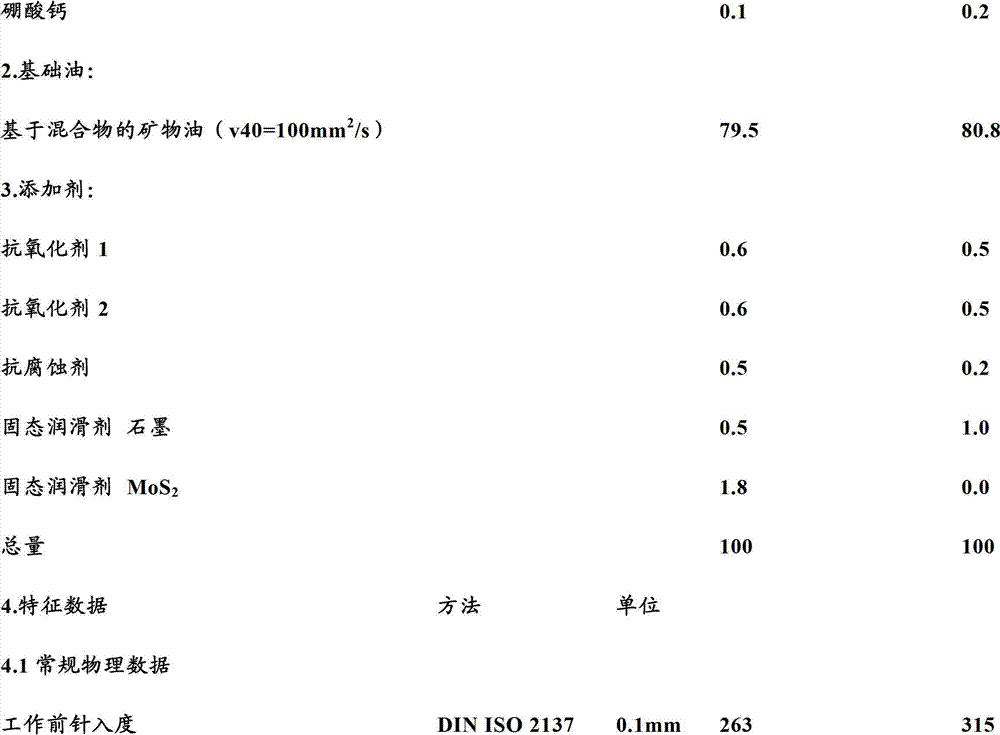

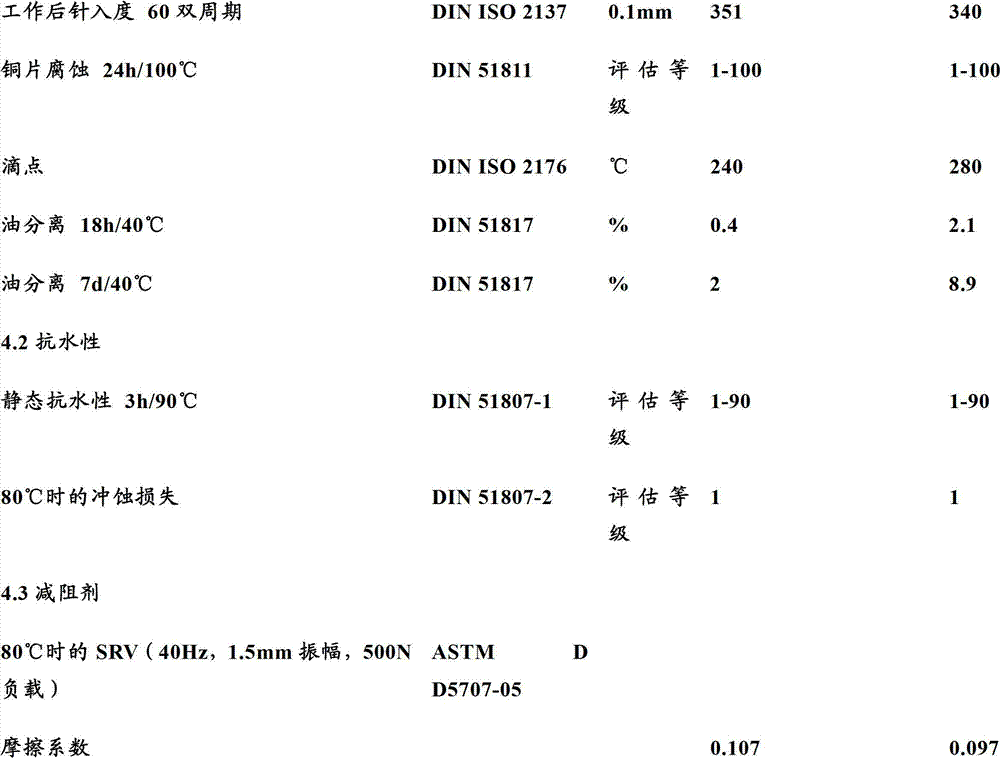

Lubricating greases containing lignosulfonate, the production thereof, and the use thereof

ActiveCN102770513AImprove waterproof performanceReduce frictionAdditivesAlkaline earth metalBoiling point

Owner:FUCHS PETROLUB SE

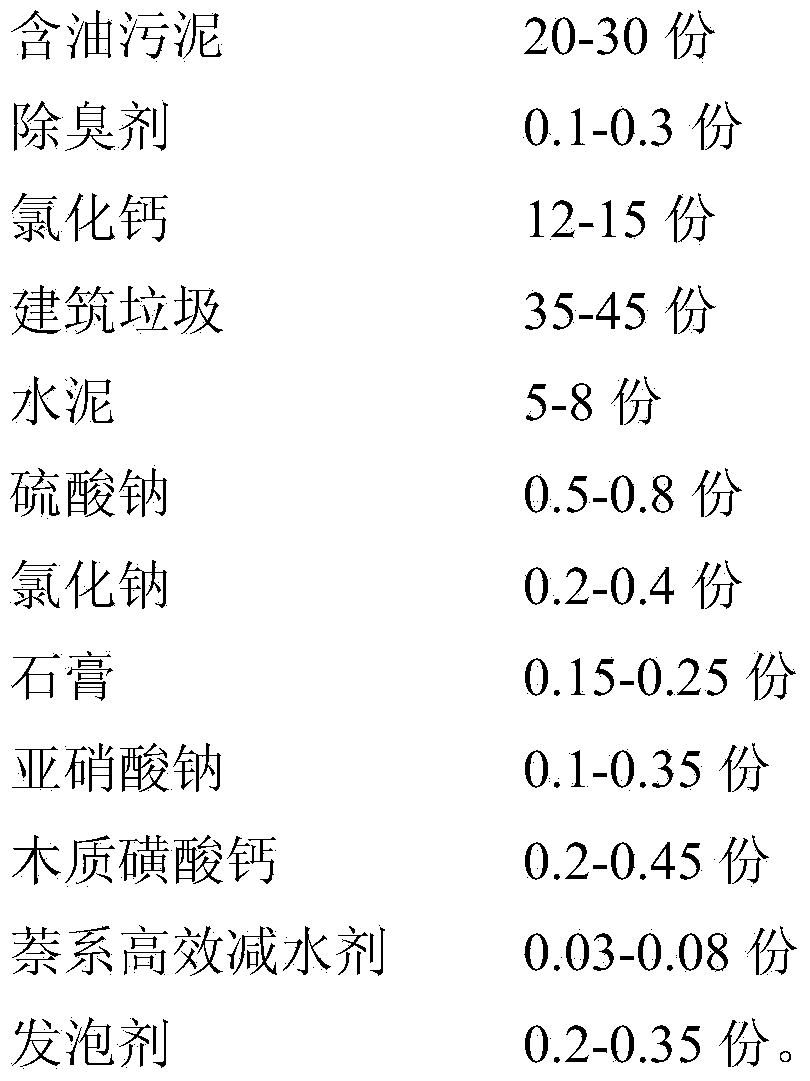

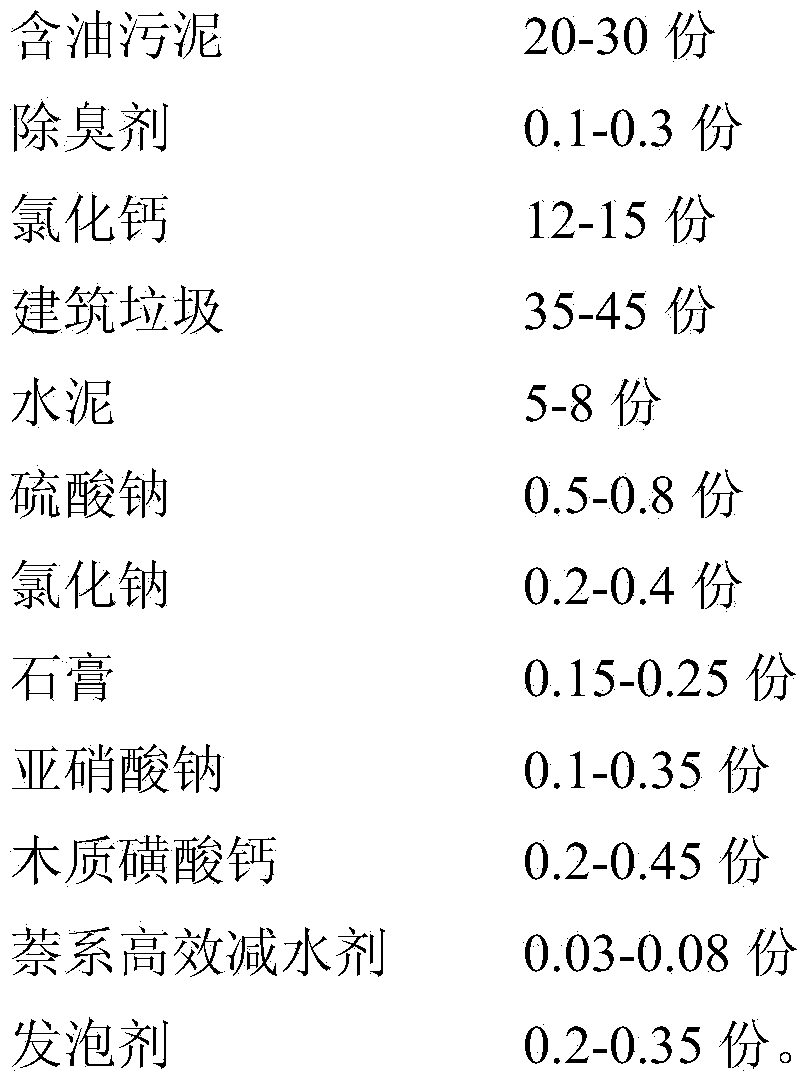

Method for producing environment-friendly baking-free hollow brick from oil-containing sludge and construction wastes

InactiveCN103708847AHarmlessSolve resource problemsSolid waste managementCeramicwareBrickResource utilization

The invention relates to a method for producing an environment-friendly baking-free hollow brick from oil-containing sludge and construction wastes, which comprises the following step: by taking oil-containing sludge, construction wastes, calcium chloride and cement as main raw materials, adding deodorizer, foaming agent, sodium sulfate, sodium chloride, gypsum, sodium nitrate, calcium lignosulfonate, naphthalene high-efficiency water reducing agent and other additional reagents to perform deodorization, heavy metal removal and curing treatment on the raw materials, thus preparing the environment-friendly baking-free hollow brick. According to the invention, the problem on the harmless, recycling and minimization treatment of oil-containing sludge and construction wastes is solved; the prepared environment-friendly baking-free hollow brick is high in strength, low in cost and favorable in sound insulation effect and causes no pollution, and the appearance quality, compression strength, relative water content, impermeability and freezing resistance conform to various indices. The resource utilization rate is increased on the one hand, and the landfill burden is reduced on the other hand, thus having predominant environmental benefits.

Owner:DALIAN DONGTAI INDAL WASTE TREATMENT

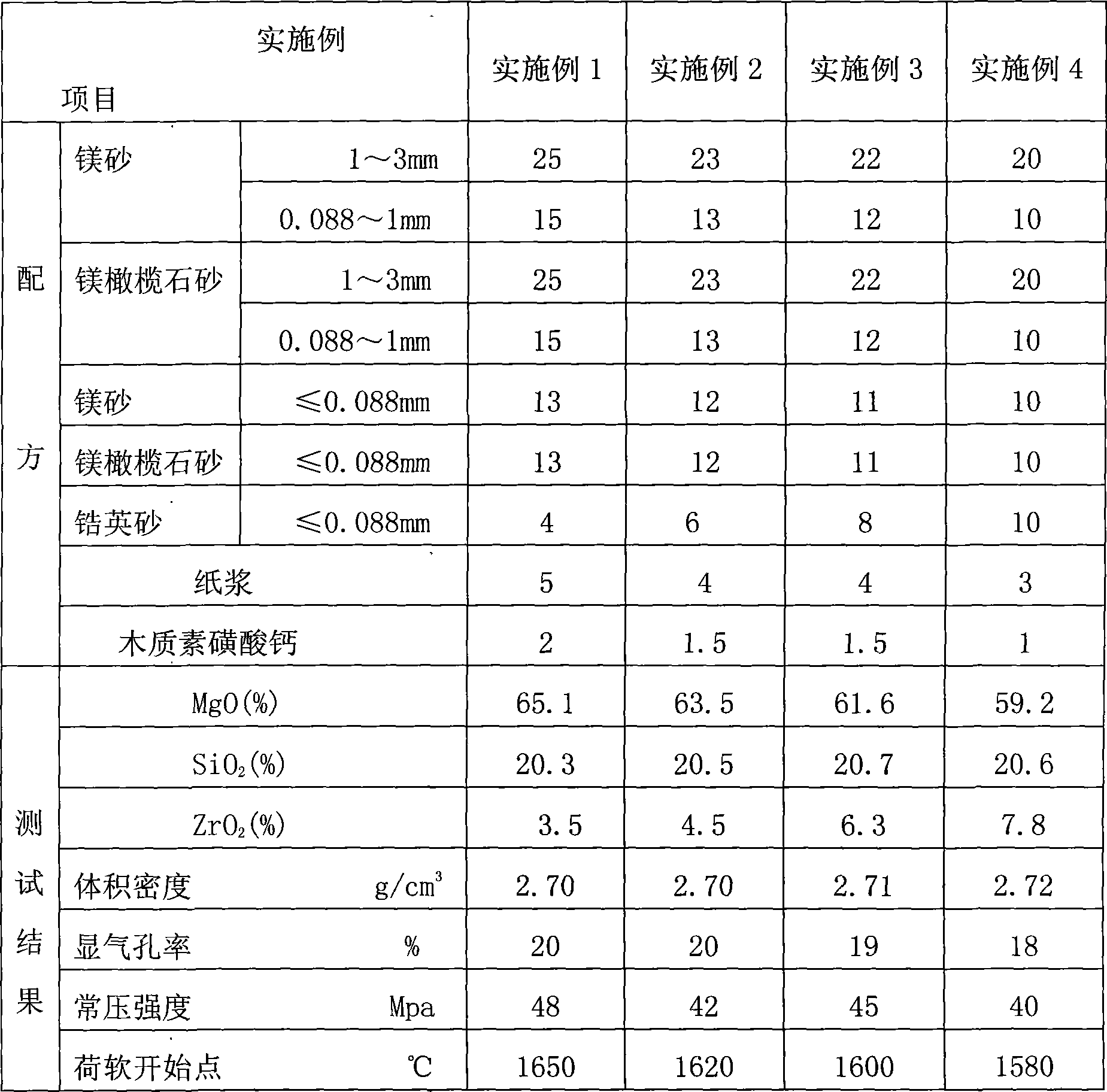

Forsterite zirconia brick and producing method thereof

The invention relates to a forsterite zirconia brick and a producing method thereof. Magnesium sand, forsterite sand, zircon sand, sulphite liquor and calcium lignosulphonate are mixed according to the weight part. The producing method of the forsterite zirconia brick is as follows: granule materials of the magnesium sand and the forsterite sand are added to a sand mixer to be mixed without water for 3 to 5 minutes; the sulphite liquior and the calcium lignosulphonate are added to be mixed with water for 3 to 7 minutes, and then the fine powder of the magnesium sand, the forsterite sand and the zircon sand is added to be mixed for 8 to 12 minutes; the mixed material is added to a mould to be pressed into a brick body; the shaped brick body is dried in a drying kiln at 70-110 DEG C no less than 12 hours until the water content in the dried brick body is not higher than 8 percent; the dried brick body is sent into a tunnel kiln to be fired at 1580-1680 DEG for 3 to 5 hours. The forsterite zirconia brick has no toxin or harm and is the fireproof alkali brick suitable for the middle part and the upper part of the glass kiln.

Owner:中国建筑材料科学研究院大石桥镁砖厂

Regenerative magnesium-aluminium-chromium brick and preparation method

The invention relates to a regenerative magnesium-aluminium-chromium brick and a preparation method. The regenerative magnesium-aluminium-chromium brick comprises the following components in parts by weight: 65 to 80 parts of waste magnesite brick particles and powder; 15 to 25 parts of alumina-chrome slag powder; 5 to 15 parts of chrome ore powder; 0 to 5 parts of chrome green powder and 0 to 5 parts of zirconium oxide powder. The preparation method comprises the following steps of: removing etching layers of waste magnesite bricks, crushing and sieving into particles with particle sizes of below 1mm, 1 to 3mm and 3 to 5mm; respectively crushing alumina-chrome slags, chrome ores, chrome green, zirconium oxide and part of waste magnesite brick particles with the particle size of below 1mm into powder with the particle size of less than or equal to 0.088mm; adding the powder into a mixing rolling mill and adding calcium lignosulphonate solution to carry out mixing rolling; after mixing rolling, carrying out compression moulding in a press; and drying and firing to obtain the regenerative agnesium-aluminium-chromium brick. According to the invention, the alumina-chrome slags and the waste magnesite bricks are used as raw materials, the price is low, waste slags and waste bricks are timely processed and the problems of space occupation and environmental pollution are solved; the prepared regenerative magnesium-aluminium-chromium brick has good bonding strength, strong wear resistance, good anti-erosion ability and high thermal shock resistance.

Owner:JINZHOU YINGMING REFRACTORY MATERIALS

Preparation method of adding agent for controlling concrete collapse loss

The invention relates to a method of making additive for controlling concrete collapsing loss, belonging to building material technical field. The composition of said additive is: zeolitic powder, water reducing agent, calcium lignosulfonate and water. Its making method is: mix water reducing agent and calcium lignosulfonate in definite proportions, stir the mixture thoroughly; add natural zeolitic powder to the mixture in proportions and stir it; spray said mixture and add water to it in proportions, stir it at the same time, dry at the room temperature, and crush to get said additive.The additive making method in said invention is characterized by: there is only physical adsorption and desorption process without chemical reaction, therefore, it is friendly to environment without releasing of waste liquid, waste gas, waste slag, etc; it only needs strong mixing at normal temperature during the production process with simple production facilities, and the technique is easy to control. The additive is capable of diminishing and controlling collapsing loss, which could not only control collapsing loss of common concrete, but also control collapsing loss of high-intensity high fluidized form concrete.

Owner:INNER MONGOLIA XINGTAI CONSTRAL GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com