Material for improving mortar coagulating time and operability and use method thereof

A technology of setting time and operability, applied in the field of water-retaining and thickening materials, can solve the problems of low strength grade of building mortar, poor construction operability, and insufficient effect, and achieve extended setting time, adjustable setting time, and good economic benefits. and market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

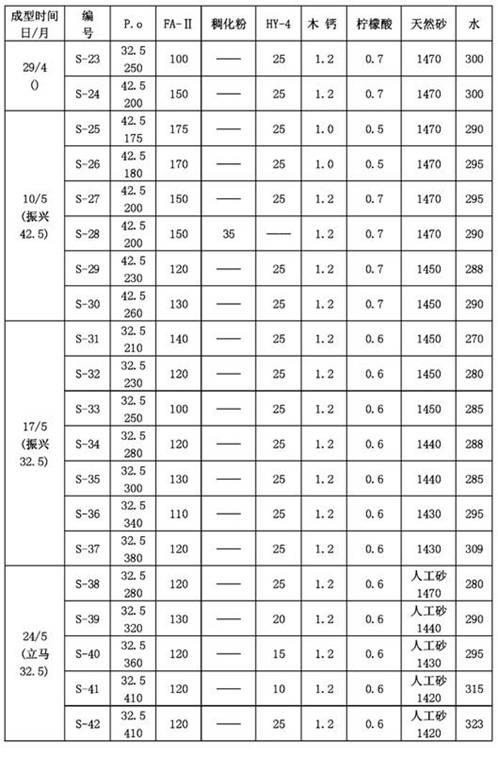

[0026] Embodiment 1, the material used to improve the setting time and operability of mortar, its raw material composition and the consumption per m?? of mortar are as follows:

[0027] Calcium-based bentonite 15kg;

[0028] Sodium bentonite 10kg;

[0029] Calcium lignosulfonate 1.2kg;

[0030] Sodium tripolyphosphate 0.5kg.

[0031]

Embodiment 2

[0032] Embodiment two, the material used to improve the setting time and operability of mortar, its raw material composition and the consumption per m?? of mortar are as follows:

[0033] Calcium-based bentonite 20 kg;

[0034] Sodium bentonite 15 kg;

[0035] Calcium lignosulfonate 1.5kg;

[0036] Sodium tripolyphosphate 1.0kg.

[0037]

Embodiment 3

[0038] Embodiment three, the material used to improve the setting time and operability of mortar, its raw material composition and the amount per m?? of mortar are as follows:

[0039] Calcium bentonite 16 kg;

[0040] Sodium bentonite 13kg;

[0041] Sodium lignosulfonate 1.3kg;

[0042] Sodium citrate 0.8kg.

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| bleeding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com