Patents

Literature

3825results about How to "High calorific value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

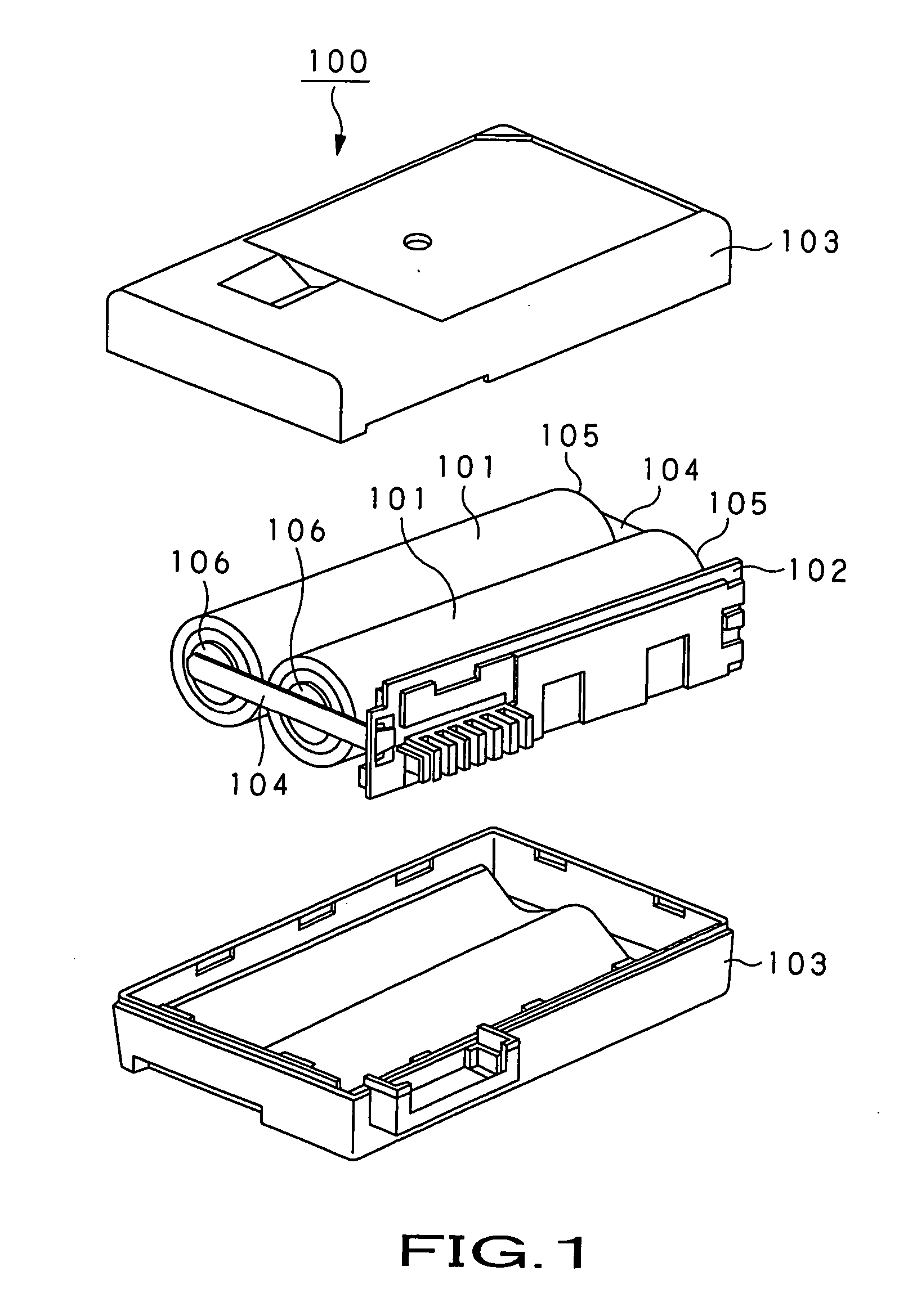

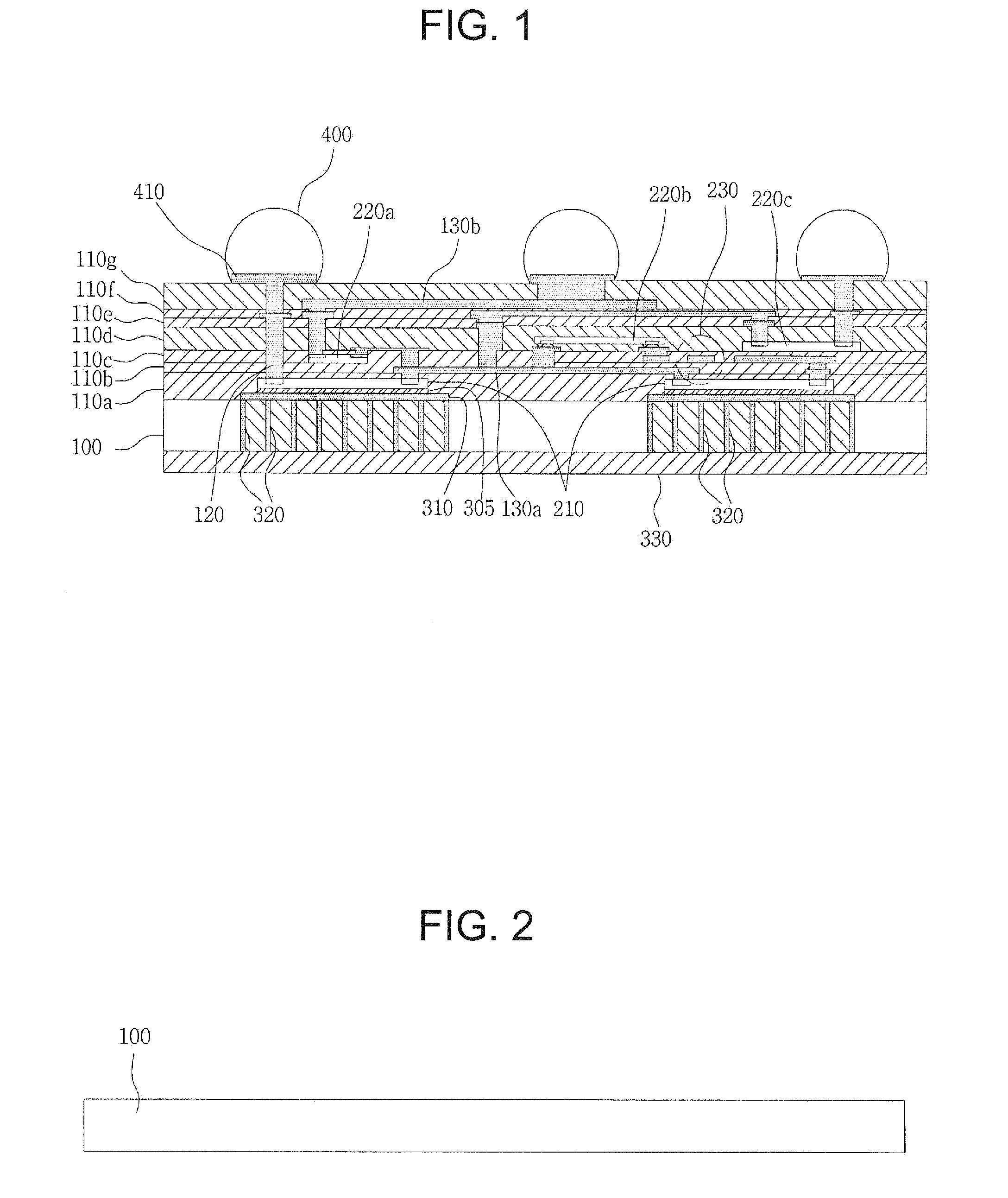

Semiconductor device and manufacturing method of the same

ActiveUS20090309213A1Improve cooling effectImprove manufacturing yieldSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSolder ball

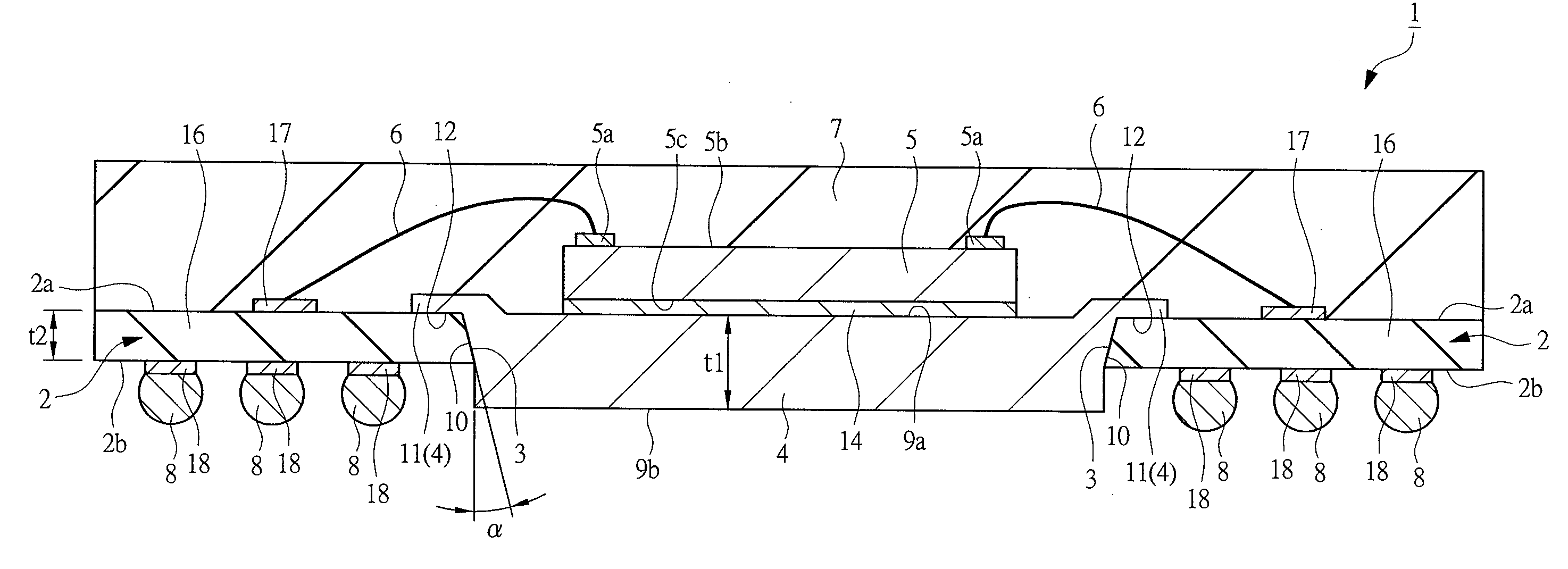

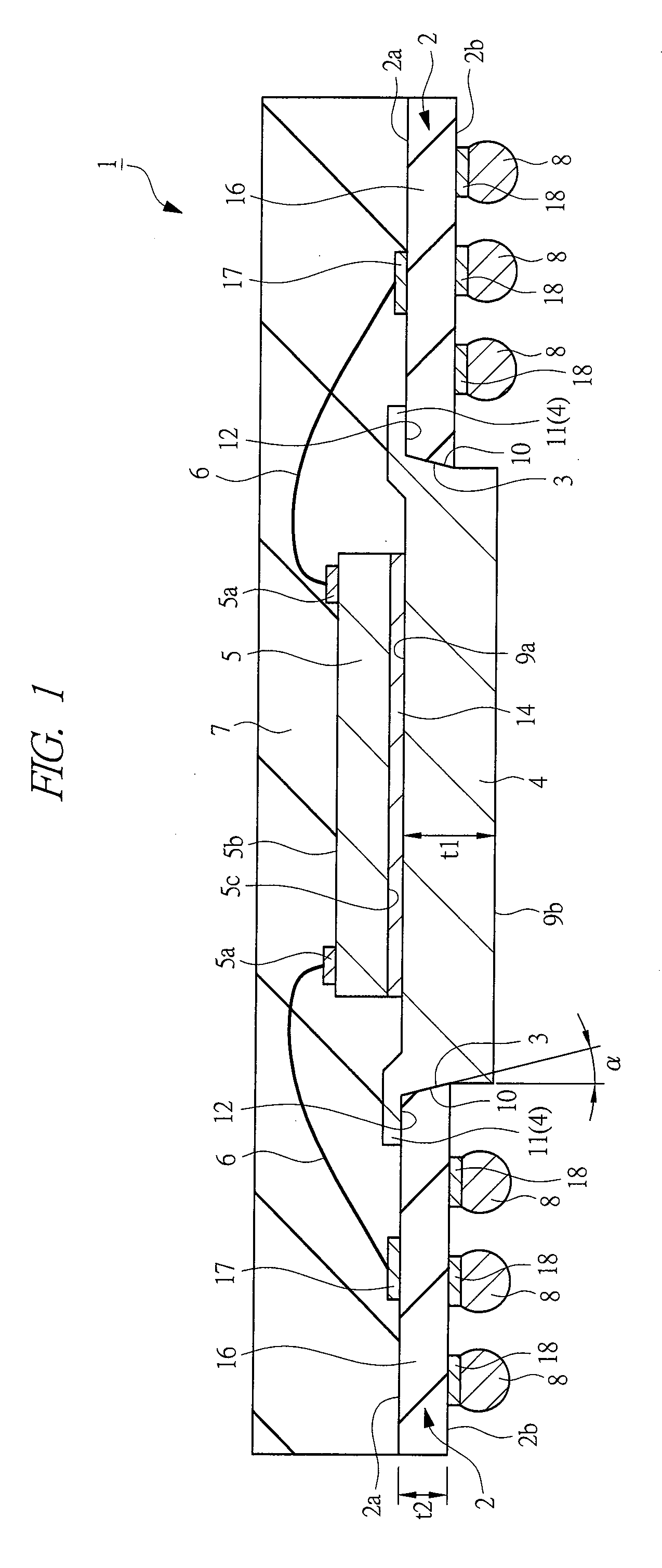

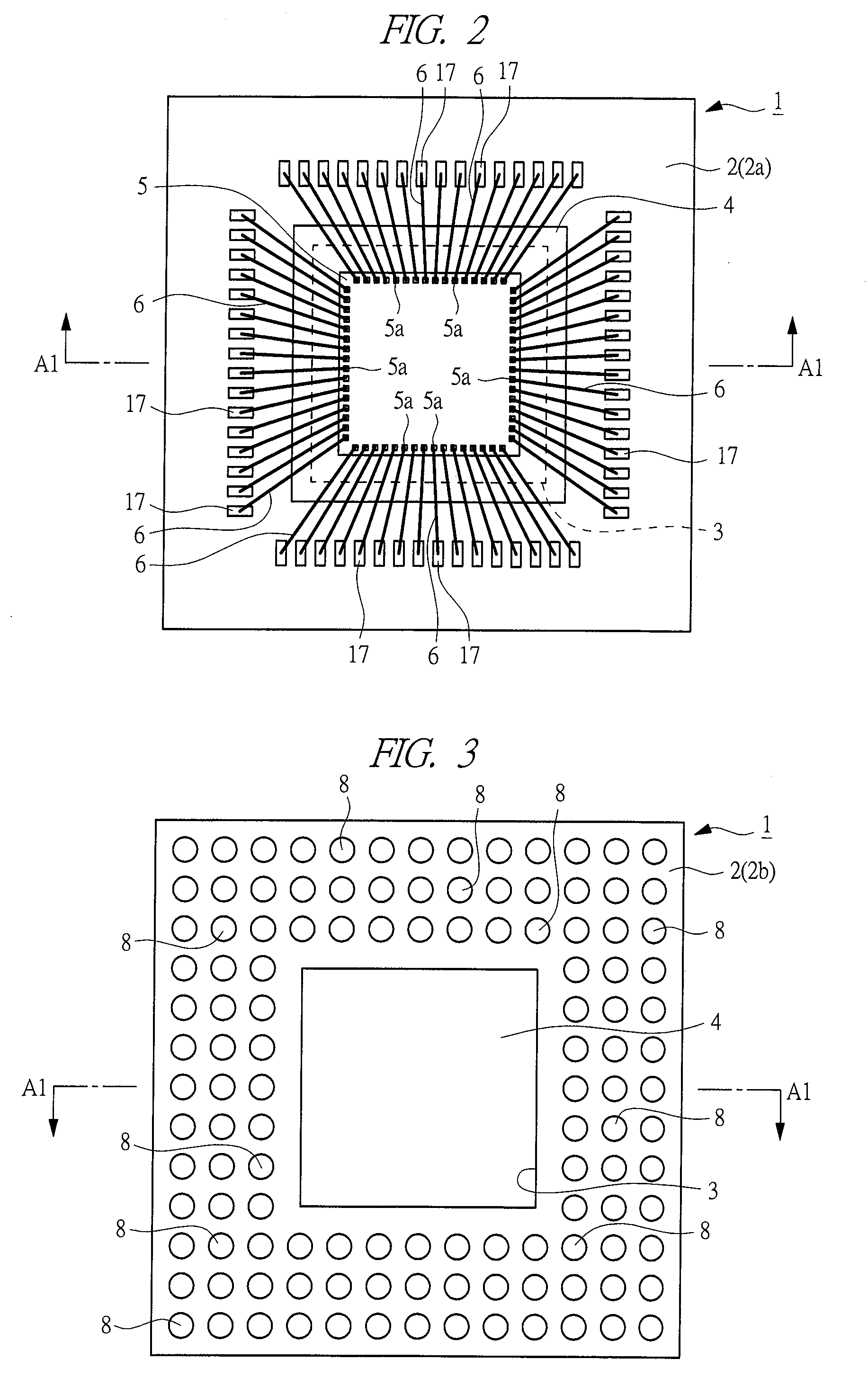

A semiconductor chip is mounted on a heat sink disposed inside a through-hole of a wiring board, electrodes of the semiconductor chip and connecting terminals of the wiring board are connected by bonding wires, a sealing resin is formed to cover the semiconductor chip and the bonding wires, and solder balls are formed on the lower surface of the wiring board, thereby constituting the semiconductor device. The heat sink is thicker than the wiring board. The heat sink has a protruded portion protruding to outside from the side surface of the heat sink, the protruded portion is located on the upper surface of the wiring board outside the through-hole, and the lower surface of the protruded portion contacts to the upper surface of the wiring board. When the semiconductor device is manufactured, the heat sink is inserted from the upper surface side of the wiring board.

Owner:RENESAS ELECTRONICS CORP

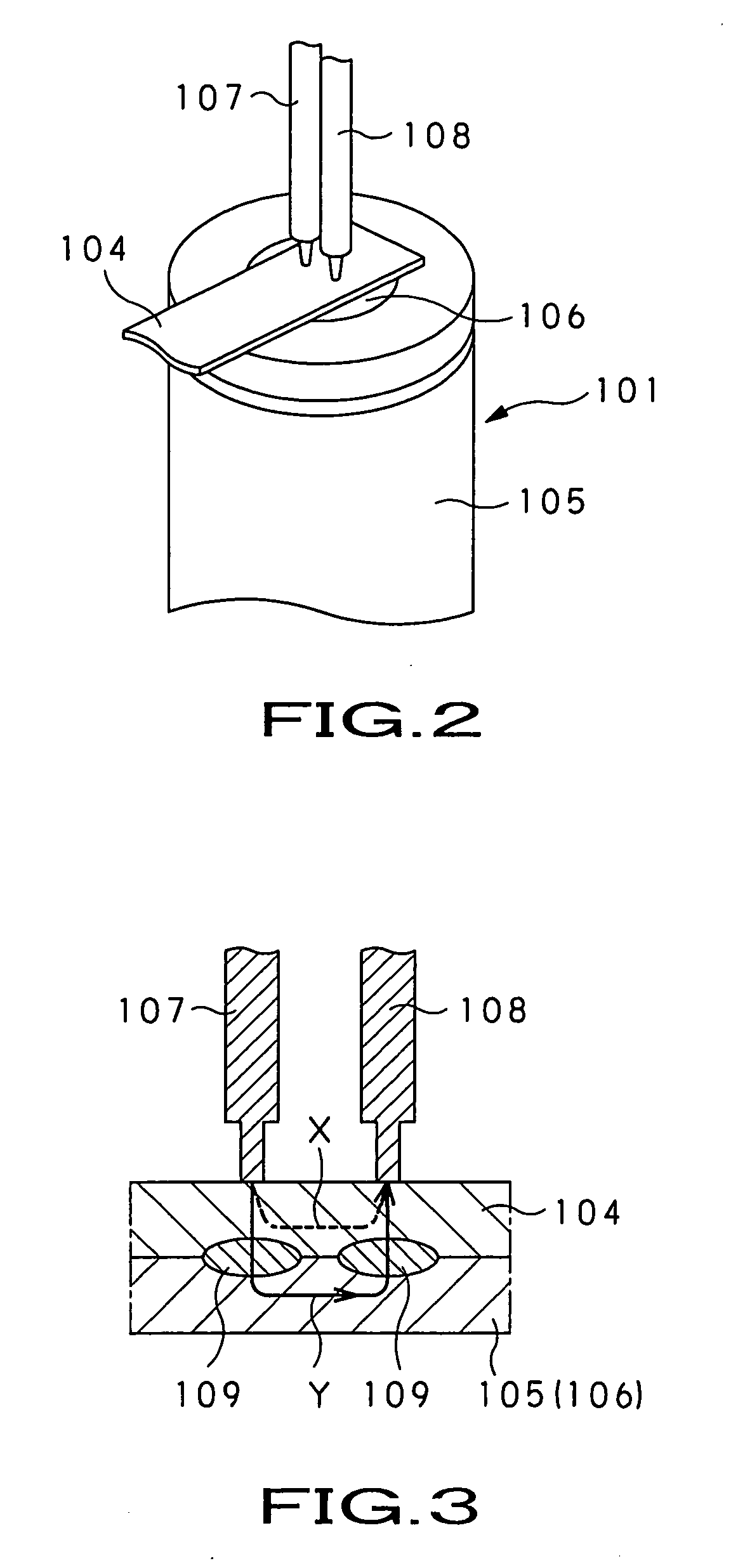

Lead terminal and power supply device

InactiveUS20060032667A1Improve welding strengthImprove electrical resistancePrinted electric component incorporationSoldered/welded conductive connectionsElectricityElectrical resistance and conductance

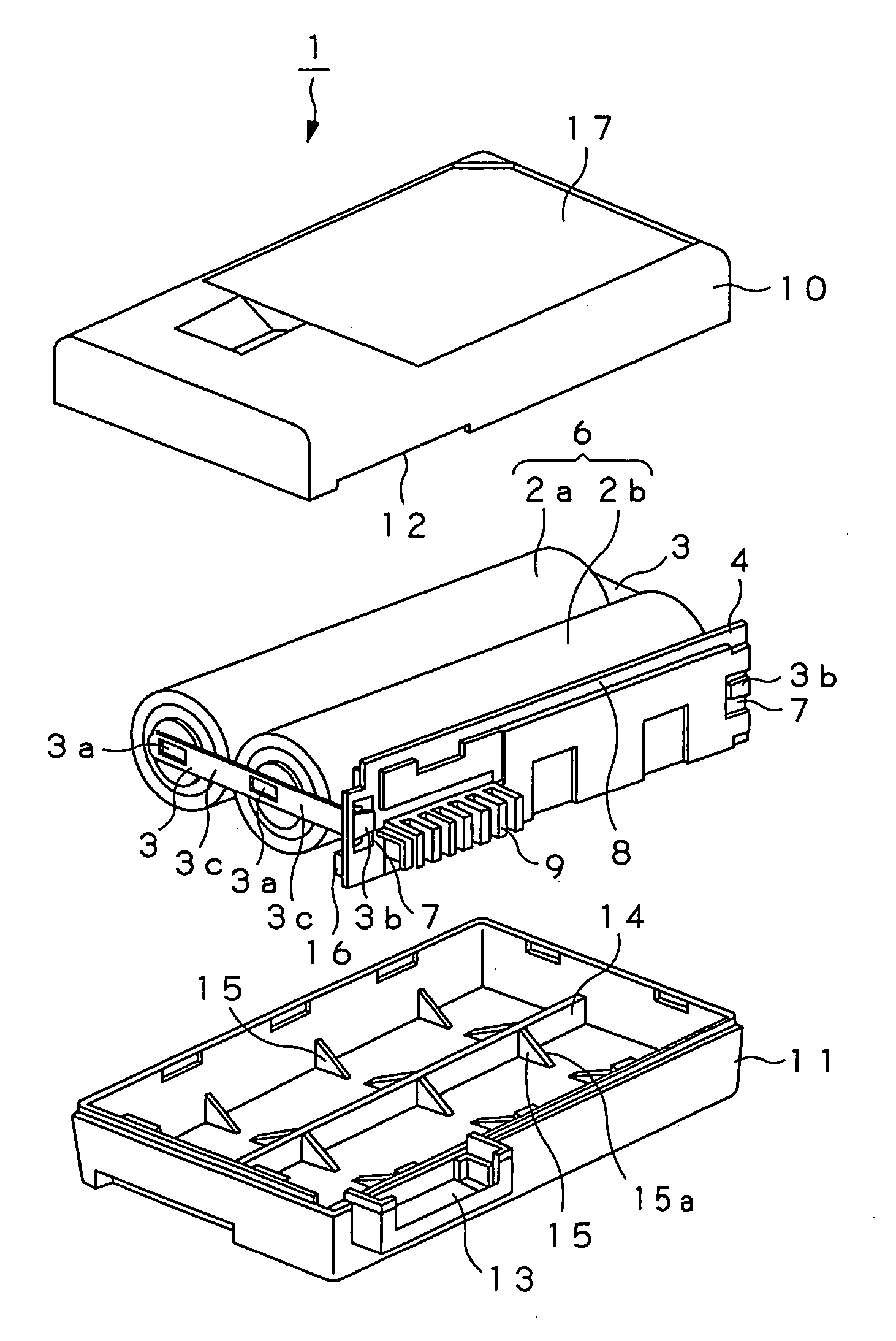

The present invention is directed to a power supply apparatus in which a battery and a circuit wiring board or boards are electrically connected by using lead terminals. The lead terminal (3) is adapted so that thickness of a welding portion (3a) is caused to be thinner than the thickness of a conductive portion (3b). Thus, current for welding flows to much degree in a thickness direction so that electric resistance of the welding portion becomes large, and heat based on the electric resistance also becomes large. From this fact, welding nugget (63) can be enlarged. As the result of the fact that large welding nugget is formed, the lead terminals are welded to terminal portions (37a) of the battery (2) with high reliability.

Owner:SONY CORP

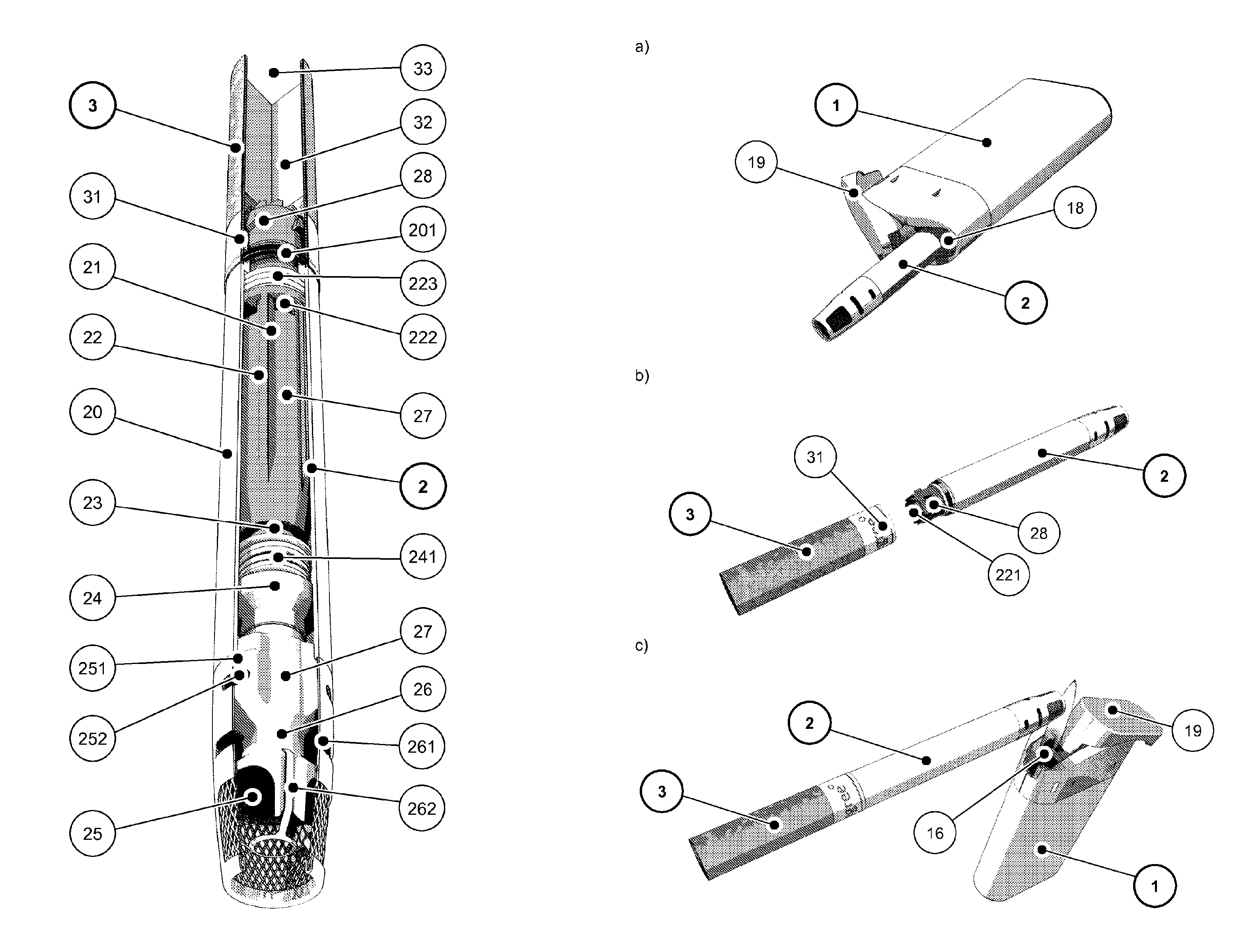

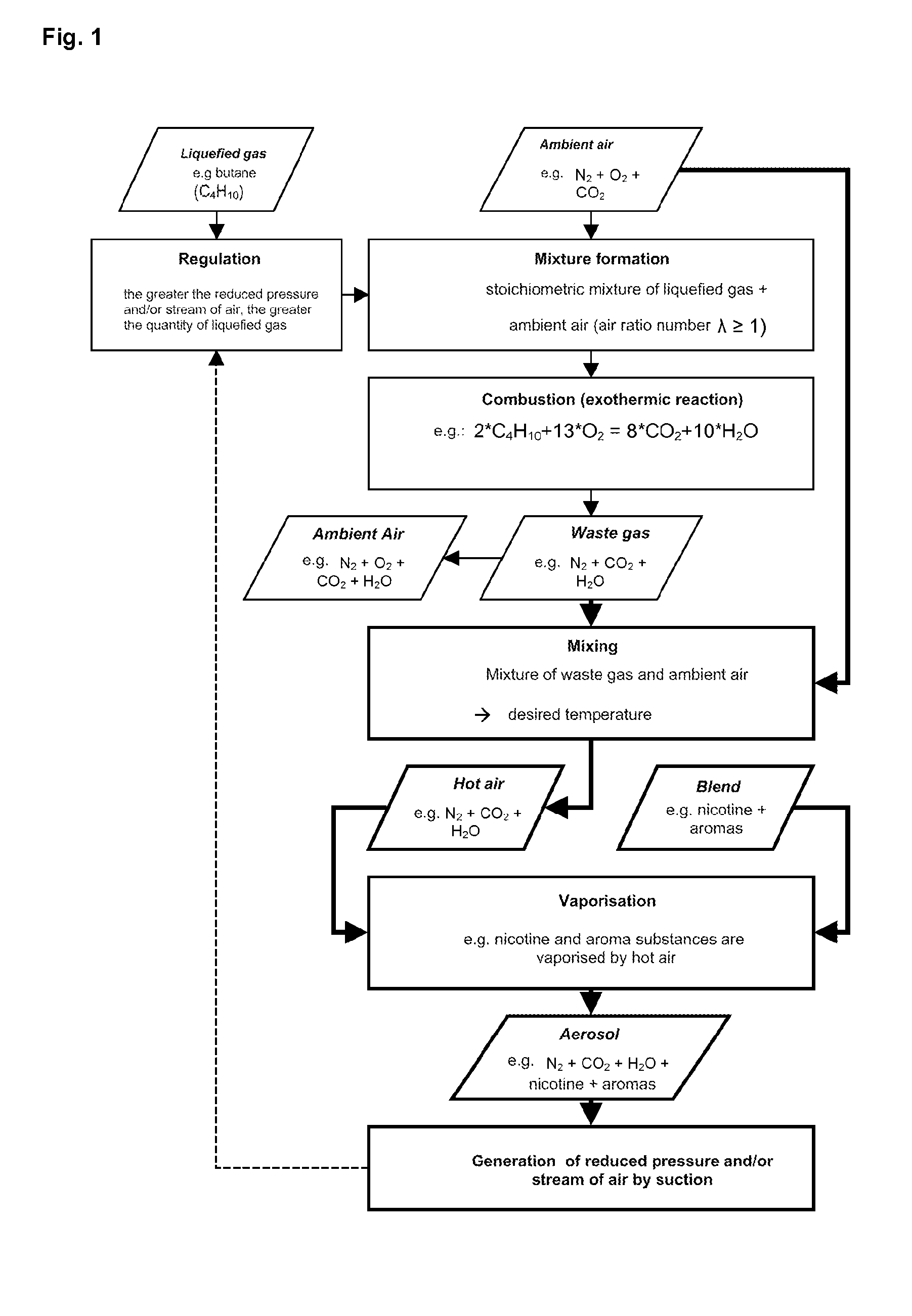

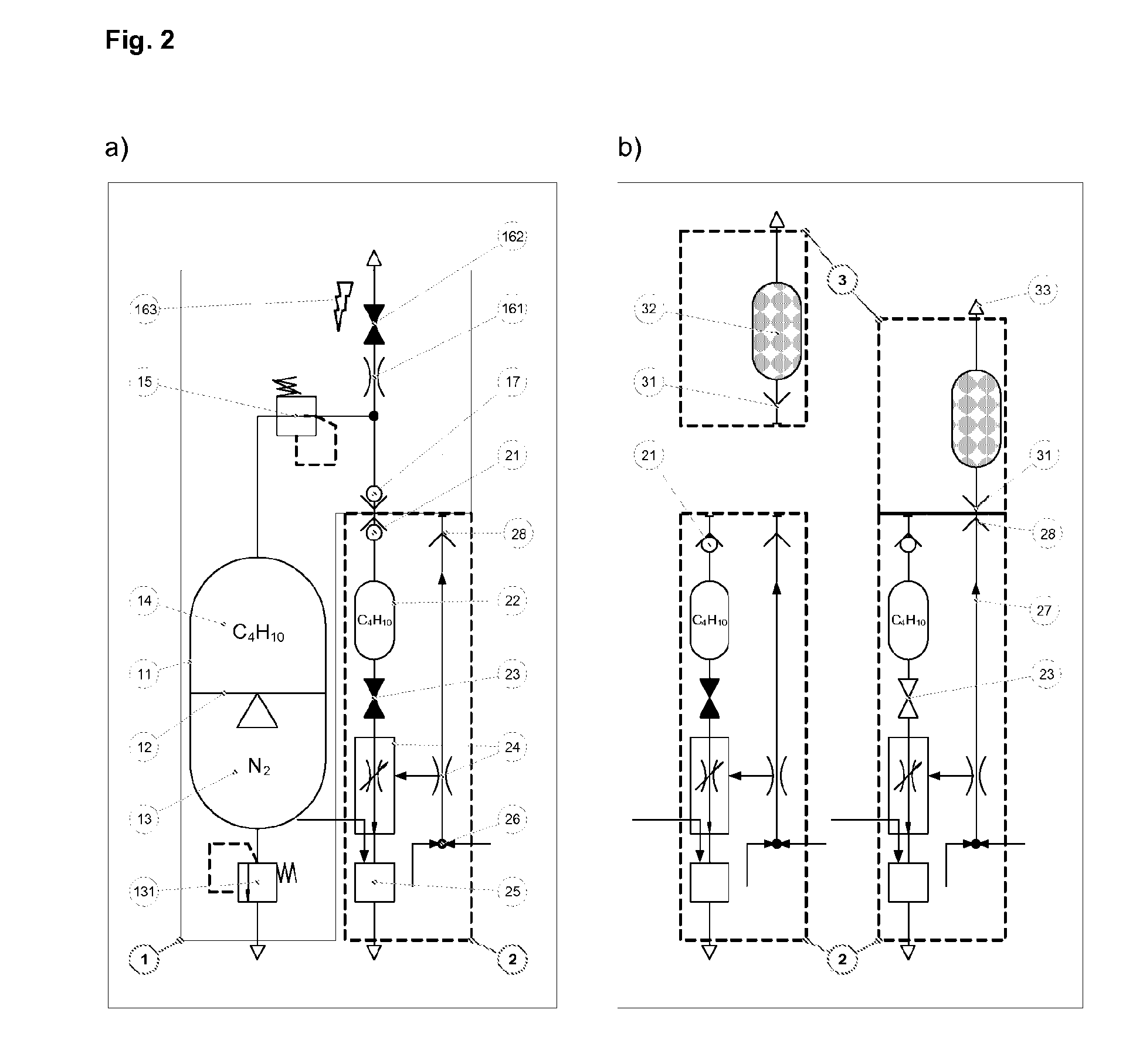

Smoke-free substitute cigarette product

ActiveUS8733346B2High calorific valueGood environmental compatibilityTobacco treatmentTobacco pipesCombustorControl release

An aerosol-releasing inhalation device, fuelling station, and apparatus are provided. The device includes a mouthpiece having a substance depot, and a heating member detachably connected to the mouthpiece for volatilising a substance to release an inhalable aerosol. The heating member includes a housing sleeve having at least one air inlet, and at least one hot air outlet at a mouthpiece end separated from the air inlet; a filling valve at the mouthpiece end to fill a tank with a flammable gas; a premix burner; a regulating valve to control release of the gas to the premix burner by suction on the mouthpiece; and a mass transfer exchanger to heat air by heat generated from the premix burner. The substance depot at least partially passes combustion gases, and a desired inhalation air temperature is selectable by at least a proportion of the combustion gases exiting the mass transfer exchanger.

Owner:PHILIP MORRIS PROD SA

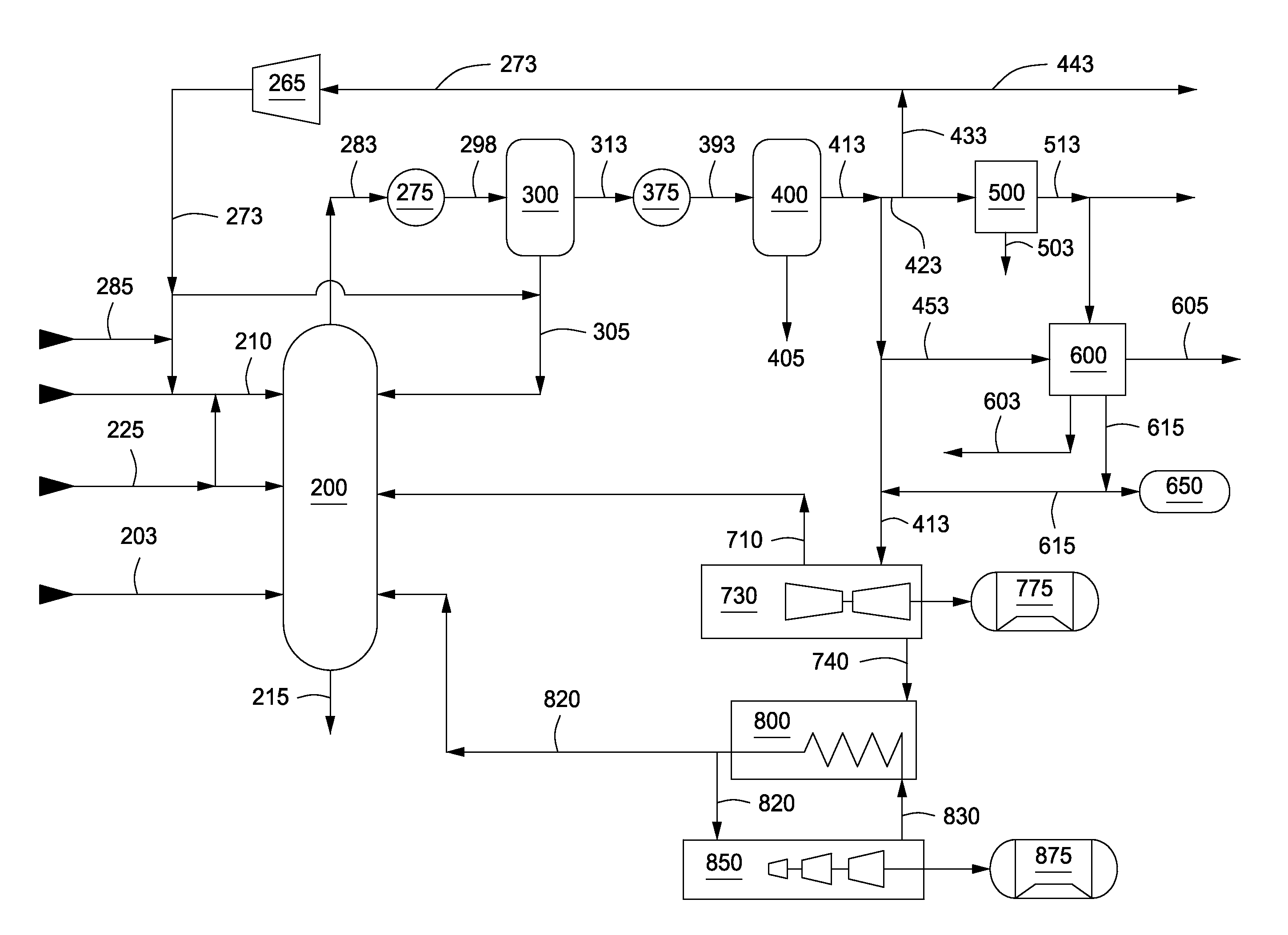

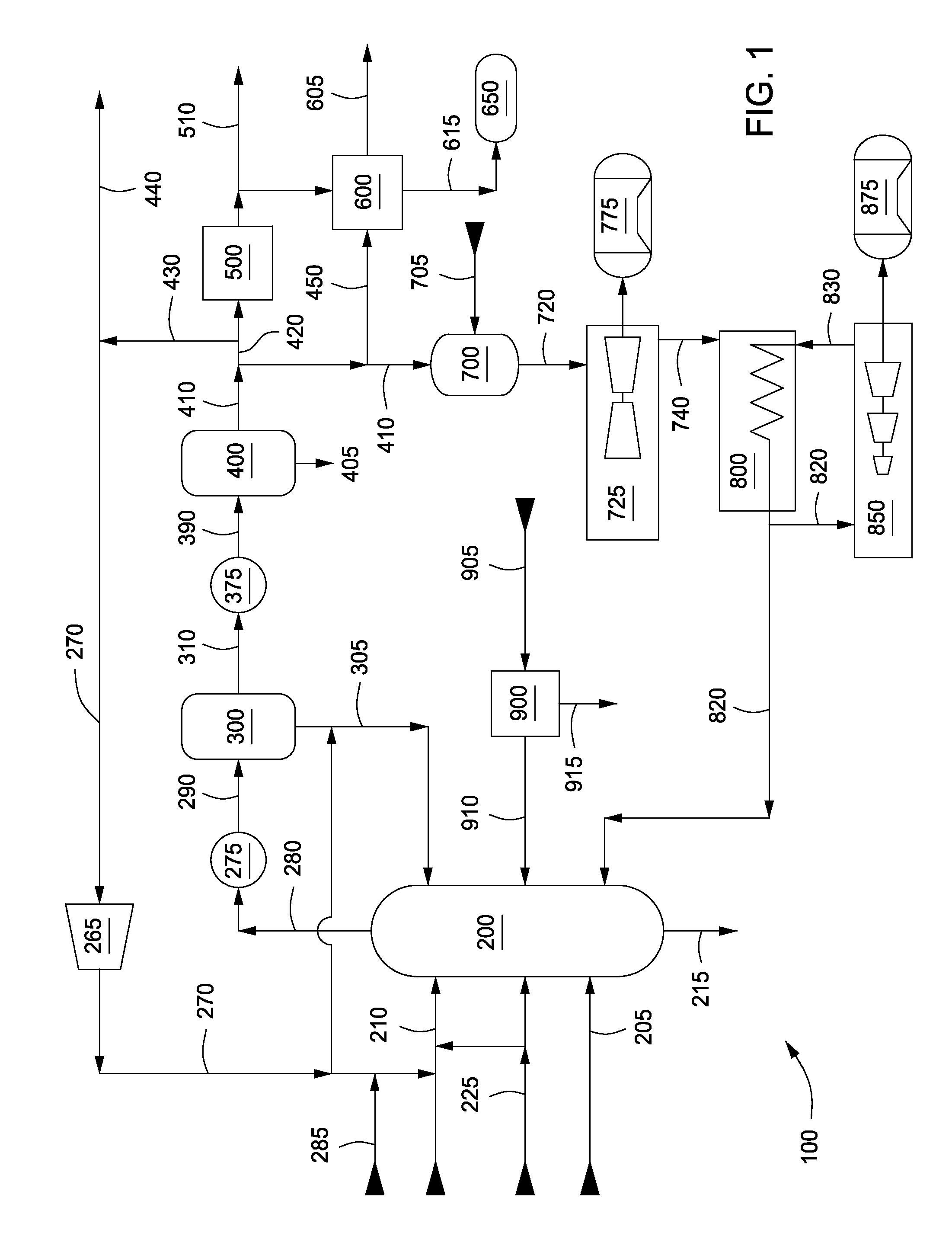

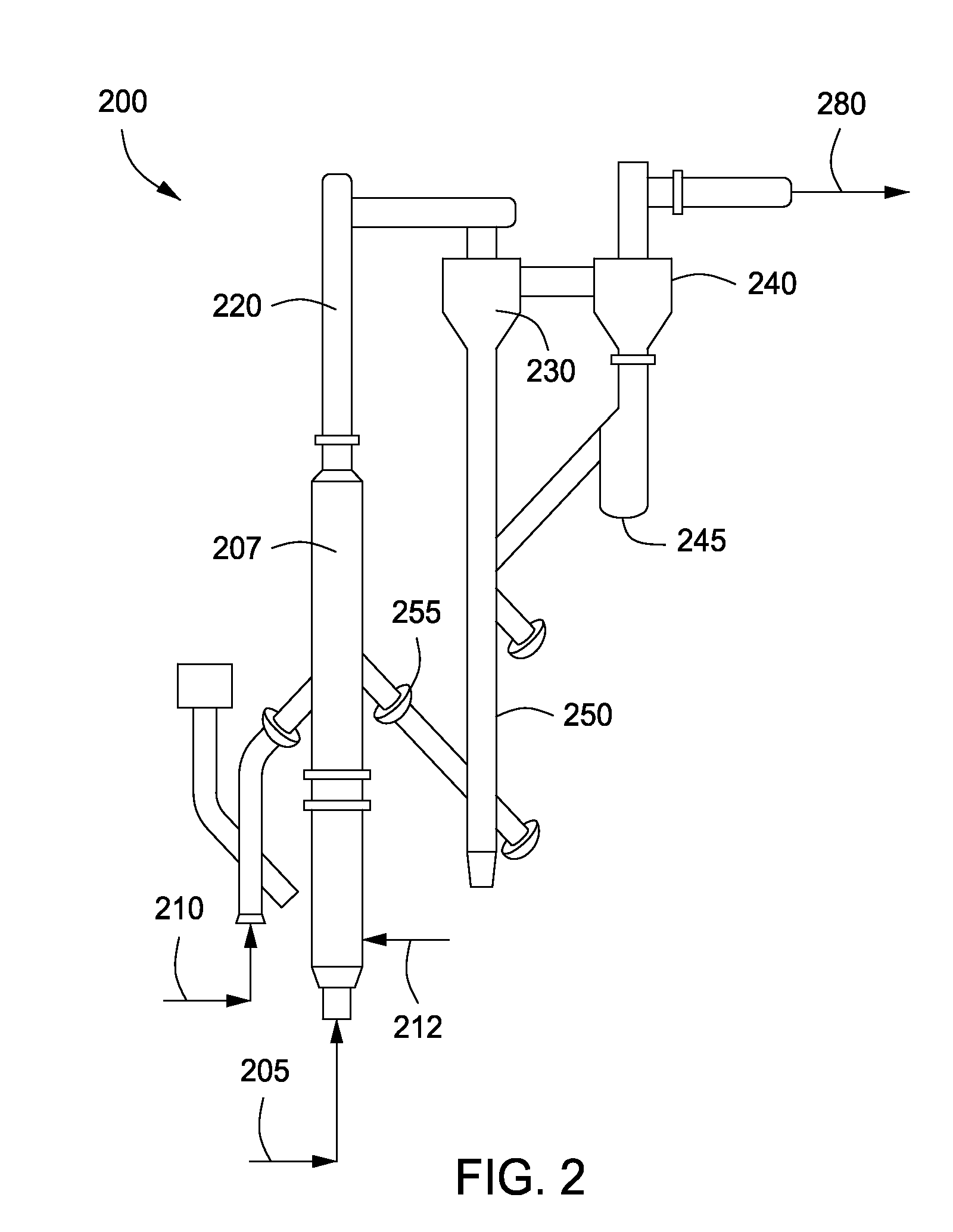

Low oxygen carrier fluid with heating value for feed to transport gasification

ActiveUS20090188165A1Reduce and eliminate partial and complete oxidationReduce and eliminate exothermic conversionMultiple metal hydridesCombustible gas catalytic treatmentCarrier fluidOxidizing agent

Systems and processes for producing synthesis gas. A carbonaceous feedstock can be combined with one or more low-oxygen carrier fluids having a high heating value. The feedstock and carrier fluid, in the presence of one or more oxidants, can be gasified to provide a synthesis gas. In one or more embodiments, at least a portion of the synthesis gas can be recycled for use as the carrier fluid.

Owner:KELLOGG BROWN & ROOT LLC

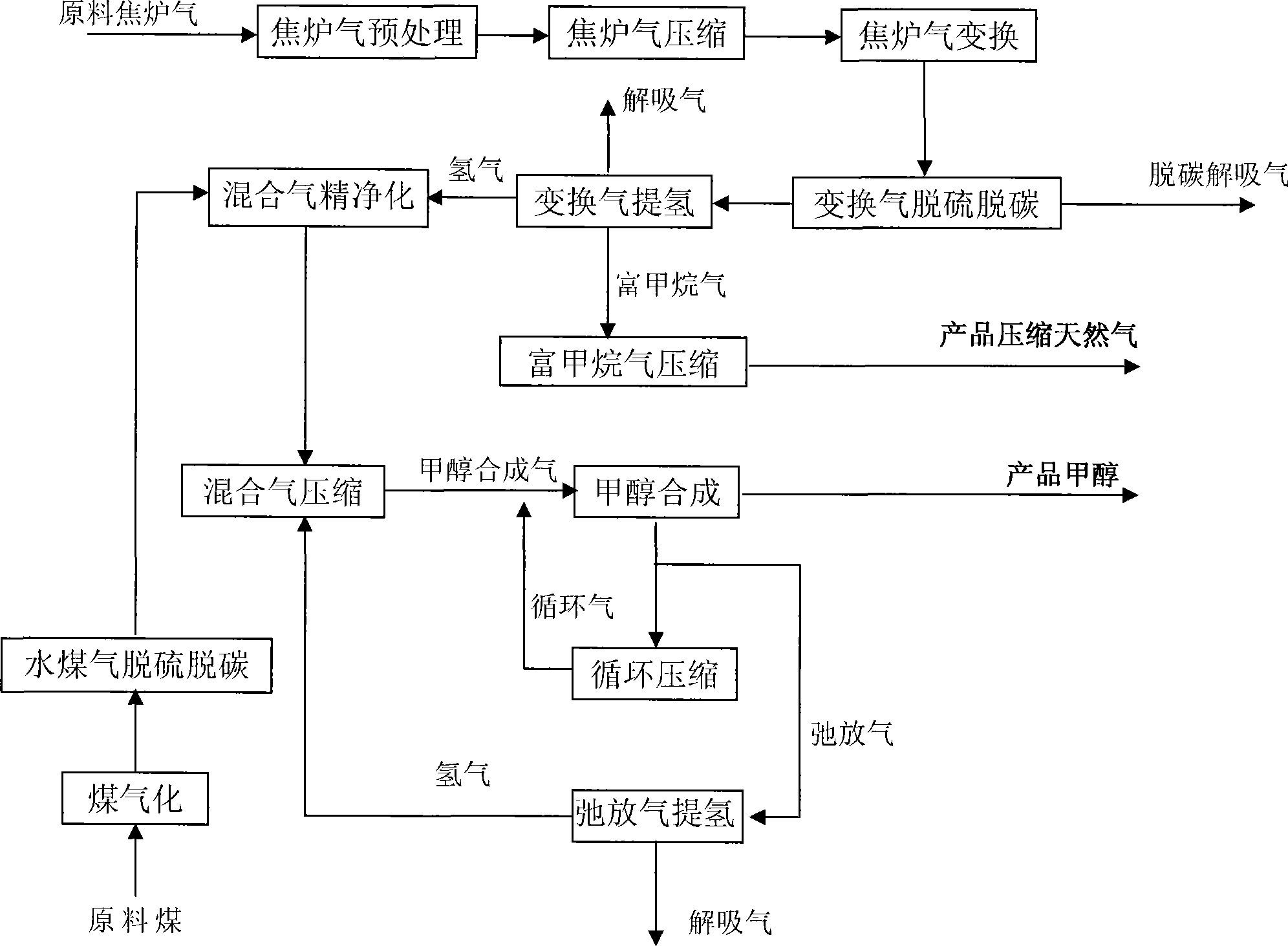

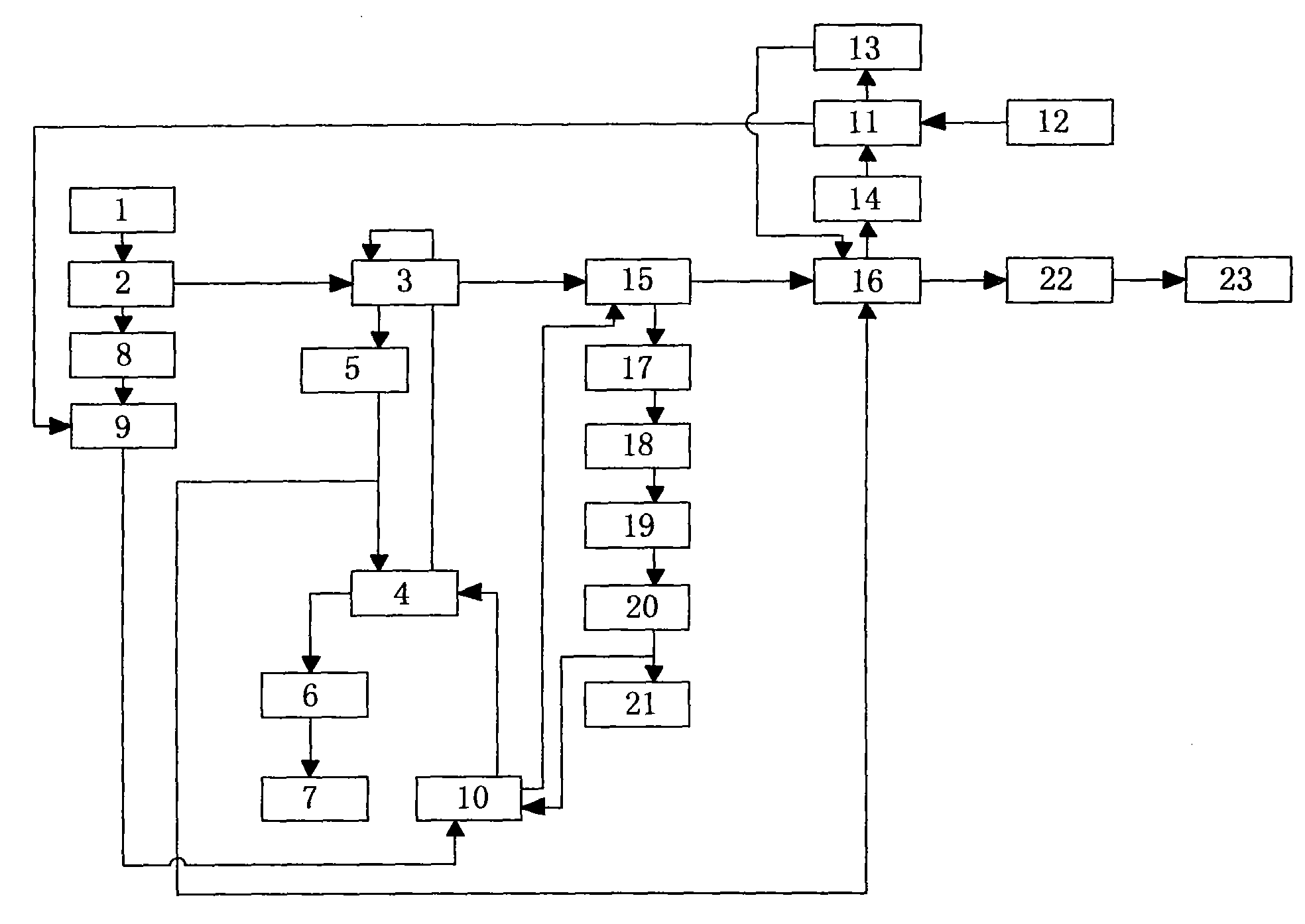

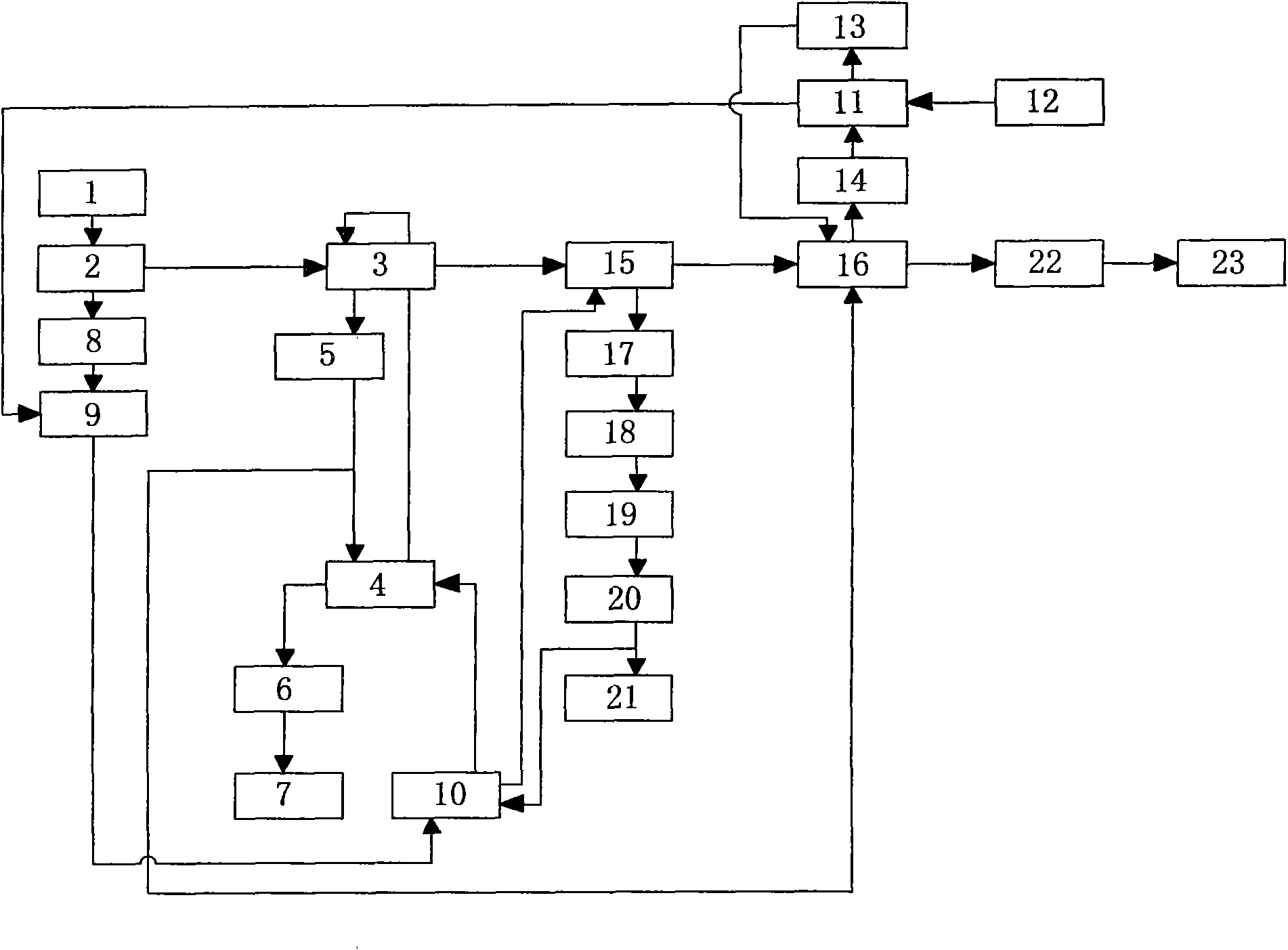

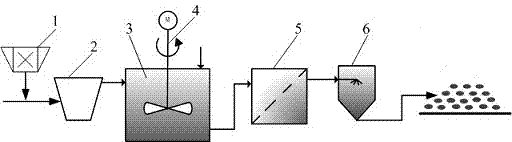

Method for preparing methyl alcohol synthesis gas and compressed natural gas from coke oven gas and coal

The invention discloses a method for producing methanol synthesis gas and compressed natural gas by taking coke oven gas and coal as raw materials, and the main steps comprise that purification treatment, transformation treatment, desulfurizing decarburization, pressure swing absorption separation of methane and hydrogen and methane-rich gas compression are carried out to the coke oven gas to prepare the compressed natural gas; and coal gasification reaction, purification treatment, mixing with the hydrogen and fine desulfurization treatment are carried out to the coal to obtain the methanol synthesis gas. The method is based on the characteristics of more hydrogen and less carbon in the coke oven gas and more carbon and less hydrogen in the coal-made methanol feed gas, transforms CO to H2 and CO2 by the transformation treatment after the effective pretreatment to the coke oven gas, and then the H2 and CH4 are separated effectively by a PSA technology so as to be used as the raw materials with higher values, and therefore the method achieves the purpose of comprehensively utilizing the coke oven gas and the coal as the raw materials for producing the methanol synthesis gas and the compressed natural gas, adopts the effective energy in the coke oven gas and the coal to maximum, saves energy, reduces emission and improves the economic benefits.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

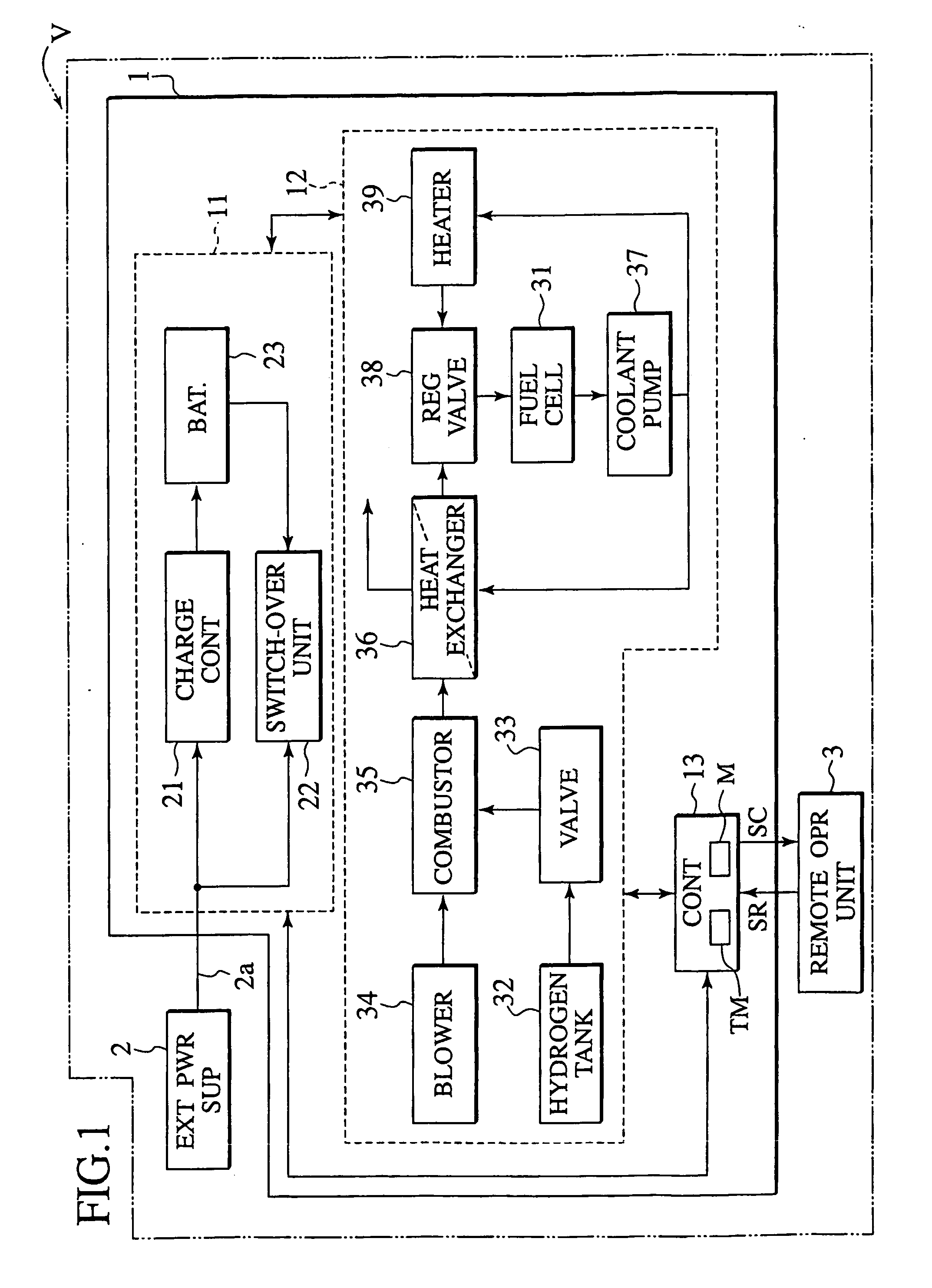

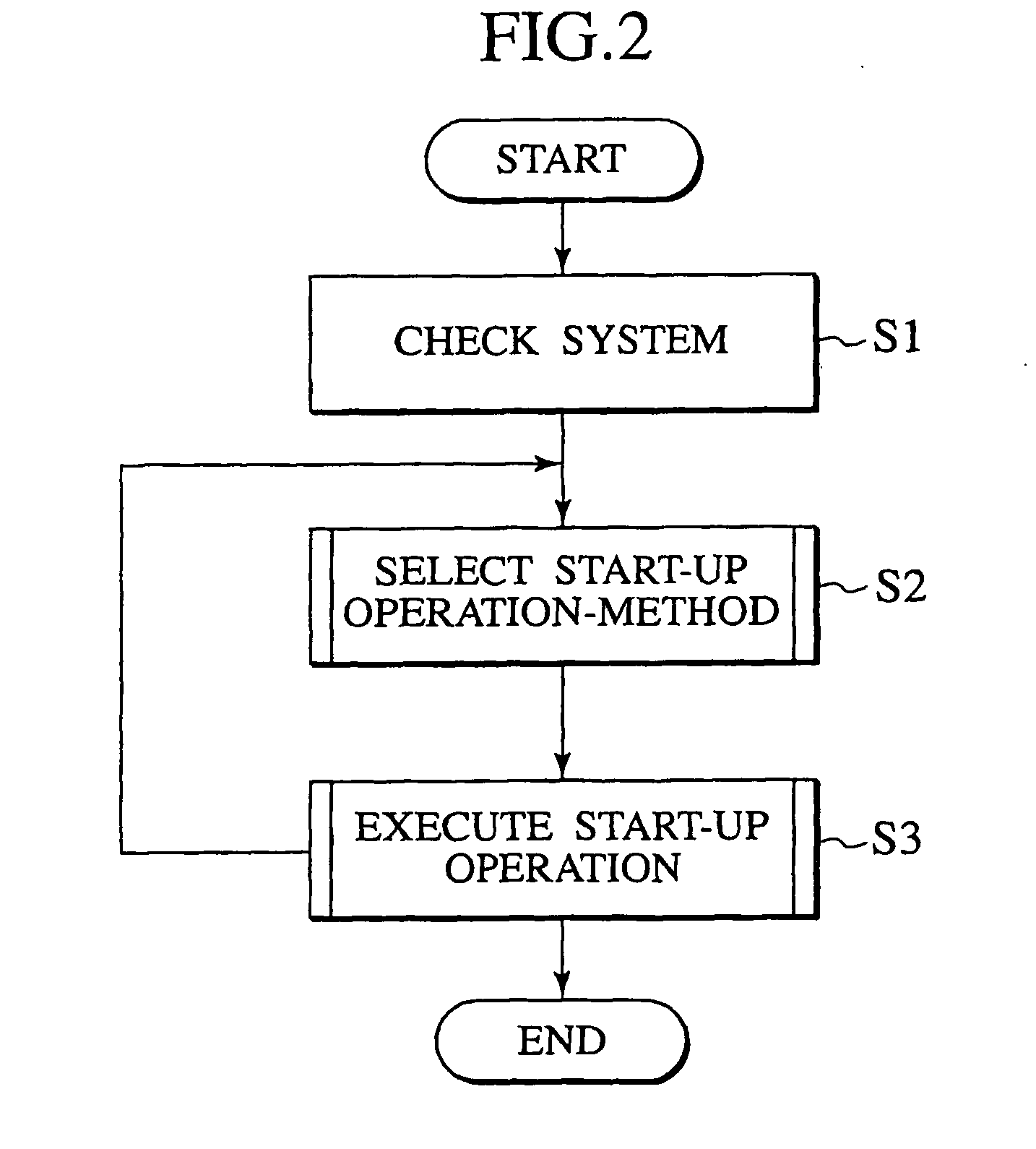

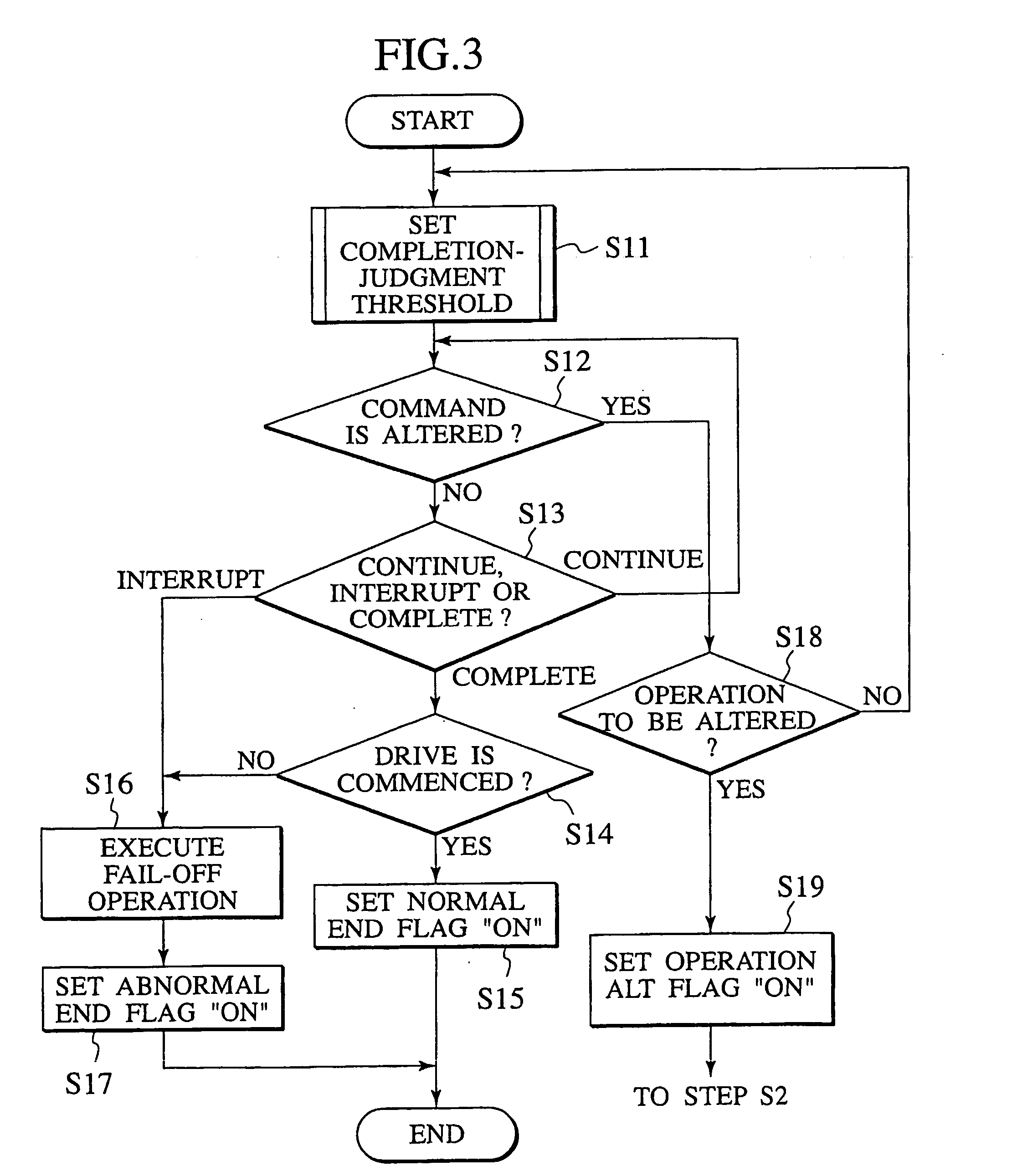

Fuel cell system and related method

ActiveUS20050181246A1High calorific valueIncrease supplyBatteries circuit arrangementsRoad vehicles traffic controlCompletion timeFuel cells

A fuel cell system (1, 100) adapted to be installed on a moving object (V) is provided with an electric power generating element (31, 45) including a fuel cell (31) supplied with fuel gas and oxidizing gas to generate electric power, a warm-up mechanism (21 to 23, 32 to 39, 41 to 50′) enabled to achieve warm up of the electric power generating element, and a controller (13), in response to reception of a control signal transmitted from an external remote operator unit (3) and commanding a start-up completion time at which start-up of the fuel cell system is to be completed through the warm-up of the electric power generating element, controlling the warm-up mechanism to allow the warm-up of at least the electric power generating element to be completed in alignment with the start-up completion time.

Owner:NISSAN MOTOR CO LTD

Compound amino acid organic fertilizer and production method of compound amino acid organic fertilizer

The invention disclose a compound amino acid organic fertilizer, which is characterized in that the compound amino acid organic fertilizer consists of the following ingredients in parts by weight: 5 to 10 of compound amino acid, 0.3 to 0.5 of microbial yeasts, 16 to 29 of inorganic fertilizers, 5 to 10 of humic acid fertilizers and 0.2 to 1 of trace elements. A production method of the compound amino acid organic fertilizer comprises the following steps that: firstly, compound amino acid water solution, the microbial yeasts and the humic acid fertilizers are respectively prepared, then, inorganic compounds containing boron, copper, iron, manganese and zinc are added into the compound amino acid water solution, and the chelation is carried out at a temperature being 80 to 110 DEG C so that the mixture becomes free-state chelated amino acid salt; after the metering, 10 to 50kg of raw materials are added into each ton of farmyard manure to be mixed, then, the mixed materials are placed into a warehouse for natural stacking and curing for 3 to 5 days and can be pelletized and packed to leave factories. The compound amino acid organic fertilizer can be used as a base fertilizer and an additional fertilizer and belongs to a compound organic fertilizer capable of improving the amino acid content of high-quality fragrant rice and fruit and vegetables, improving the fruit and vegetable quality and improving the sugar content of sugarcanes.

Owner:GUANGXI YUXIN BIOLOGICAL TECH

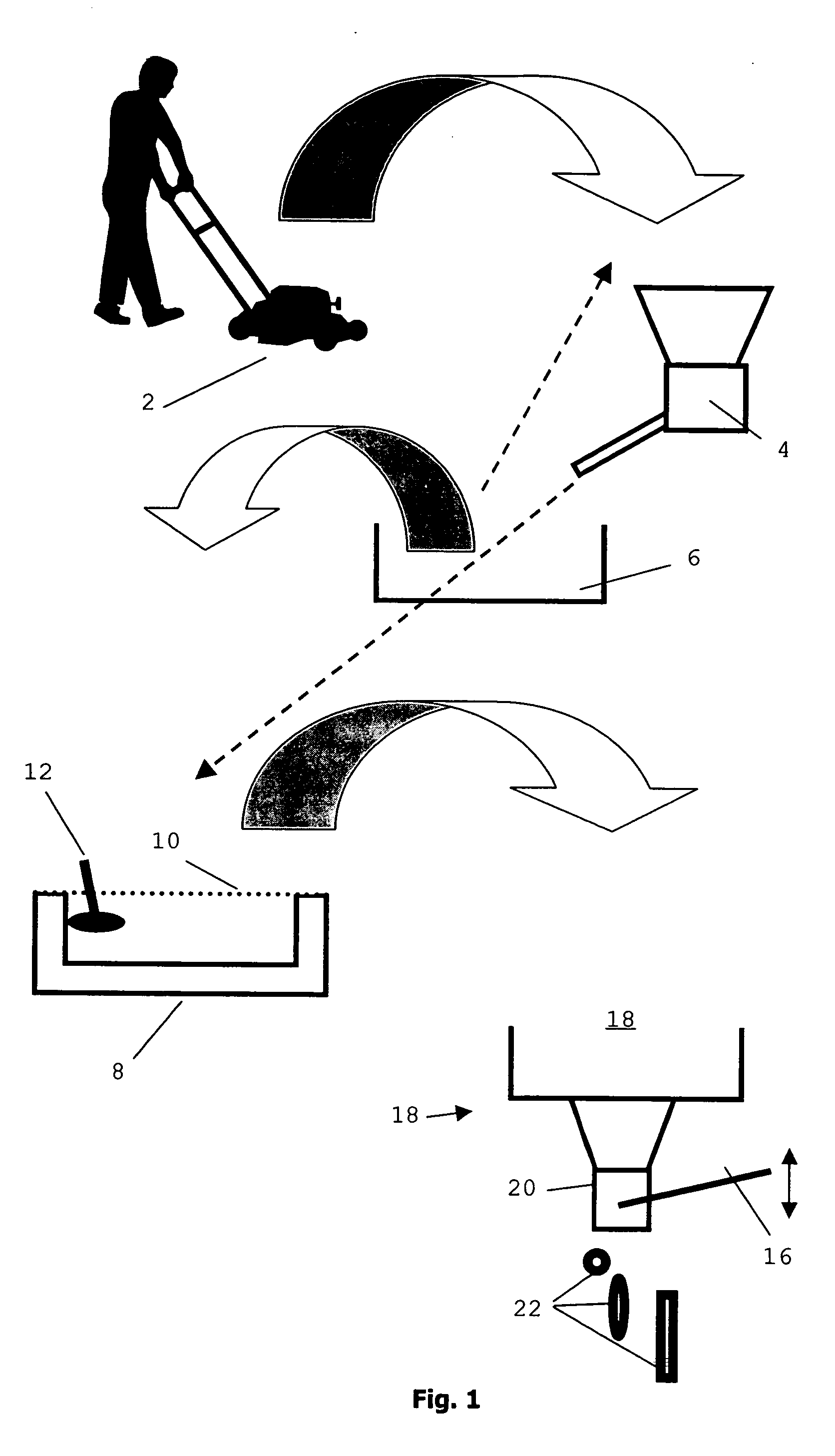

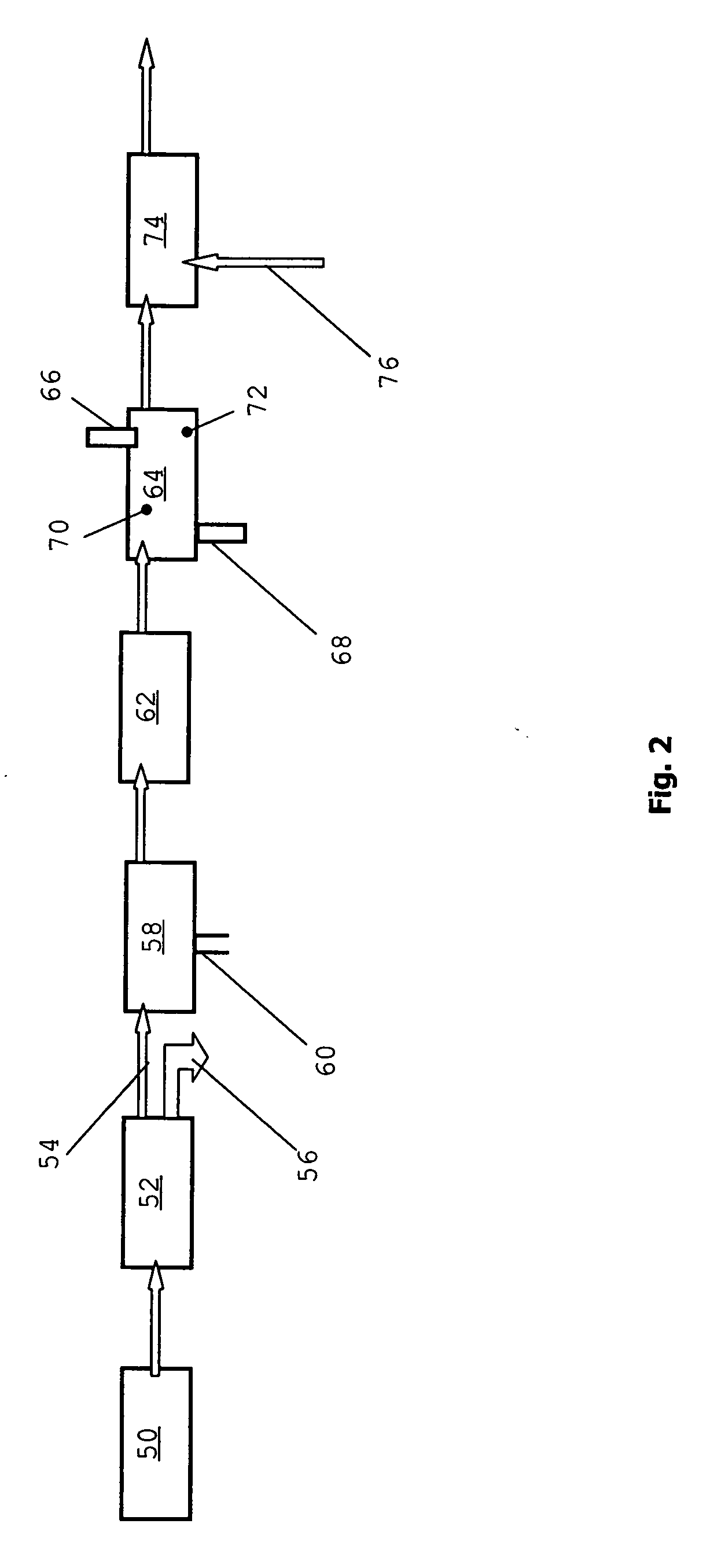

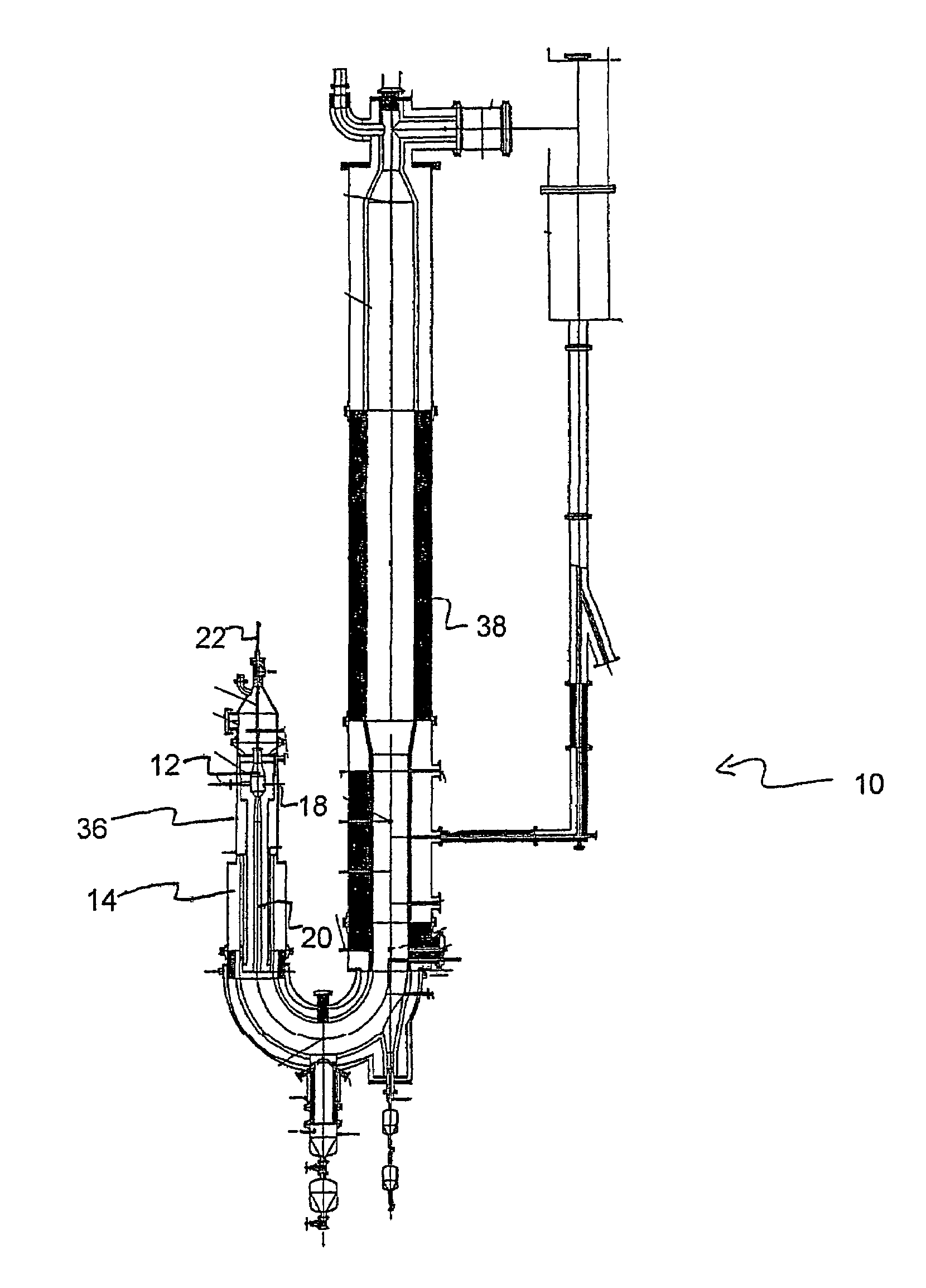

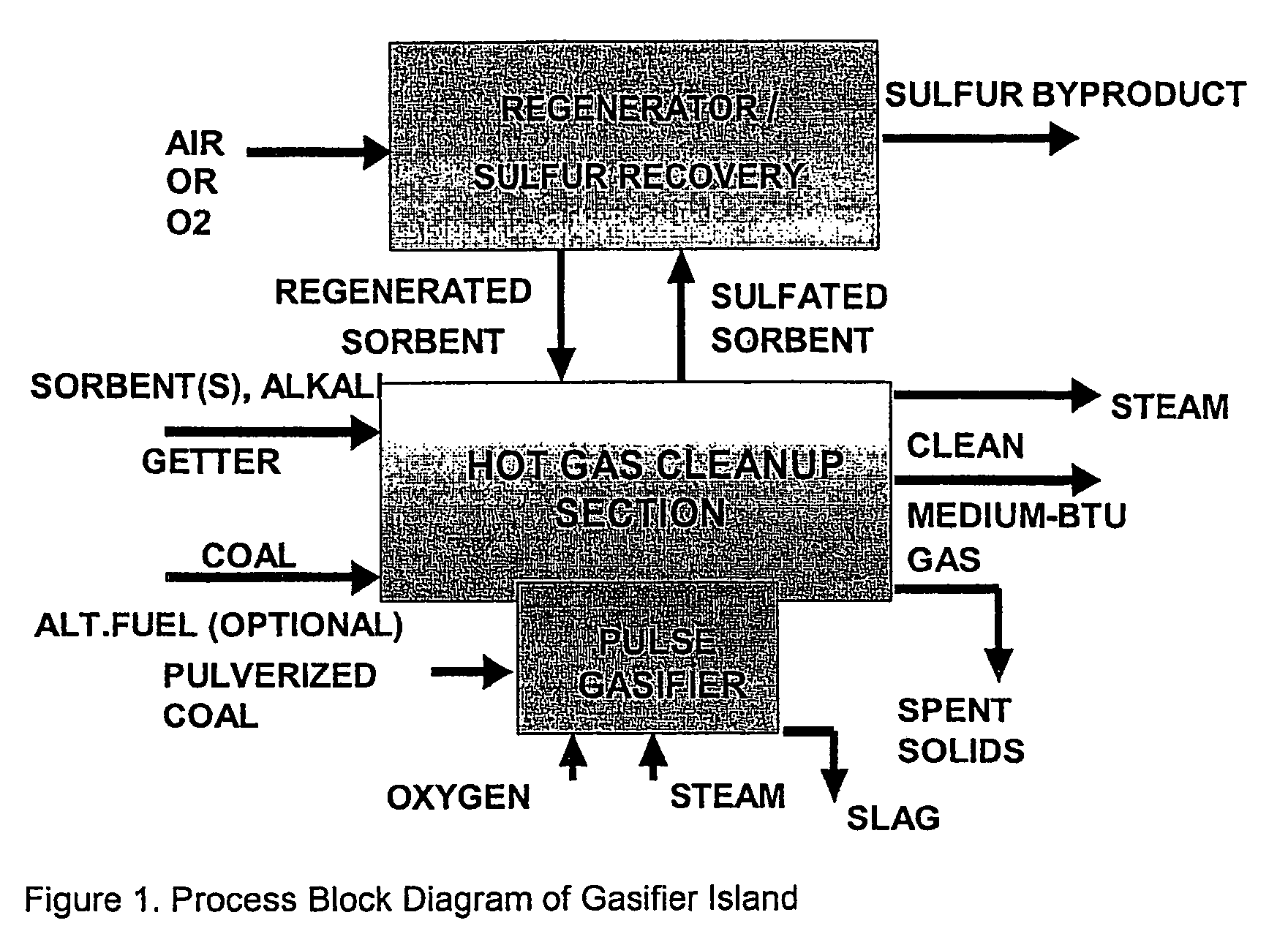

Pulse gasification and hot gas cleanup apparatus and process

InactiveUS6997118B2Easy to useConducive to agglomerationAuxillary pretreatmentGasifier mechanical detailsSteam reformingElectricity

A gasifier system and process comprises a pulse combustion device in communication with a fluid channel for producing a gas stream having heat or fuel value. The pulse combustion device is operated under sub-stoichiometric conditions such that combustion and steam reforming both occur in the fluid channel. The pulse combustion device also produces a pulsating combustion product stream and an acoustic pressure wave. The acoustic pressure wave serves to cause agglomeration of particles contained within the combustion stream for easy removal. In one embodiment, a sulfur capturing agent is injected into the fluid channel for not only removing sulfur from the combustion product stream but for also facilitating particle agglomeration. Ultimately, a gas stream containing hydrogen is produced that may be used in various processes, such as in the production of electricity.

Owner:MFG & TECH CONVERSION INT

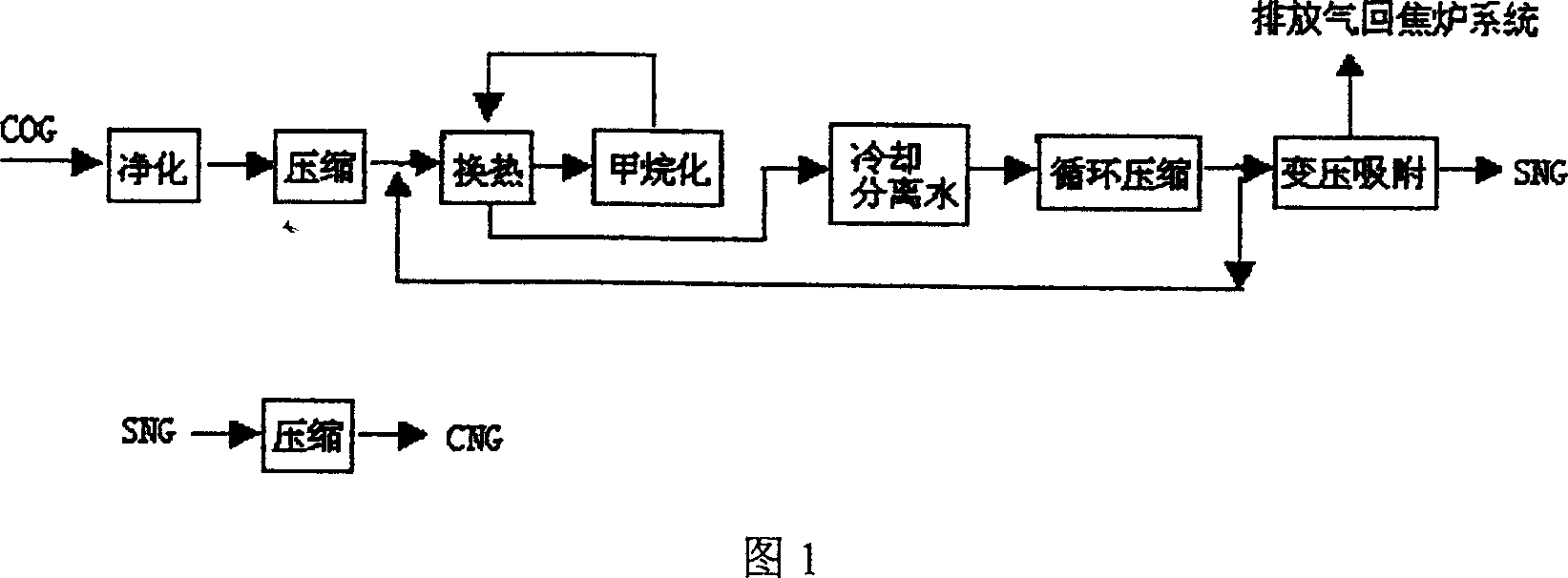

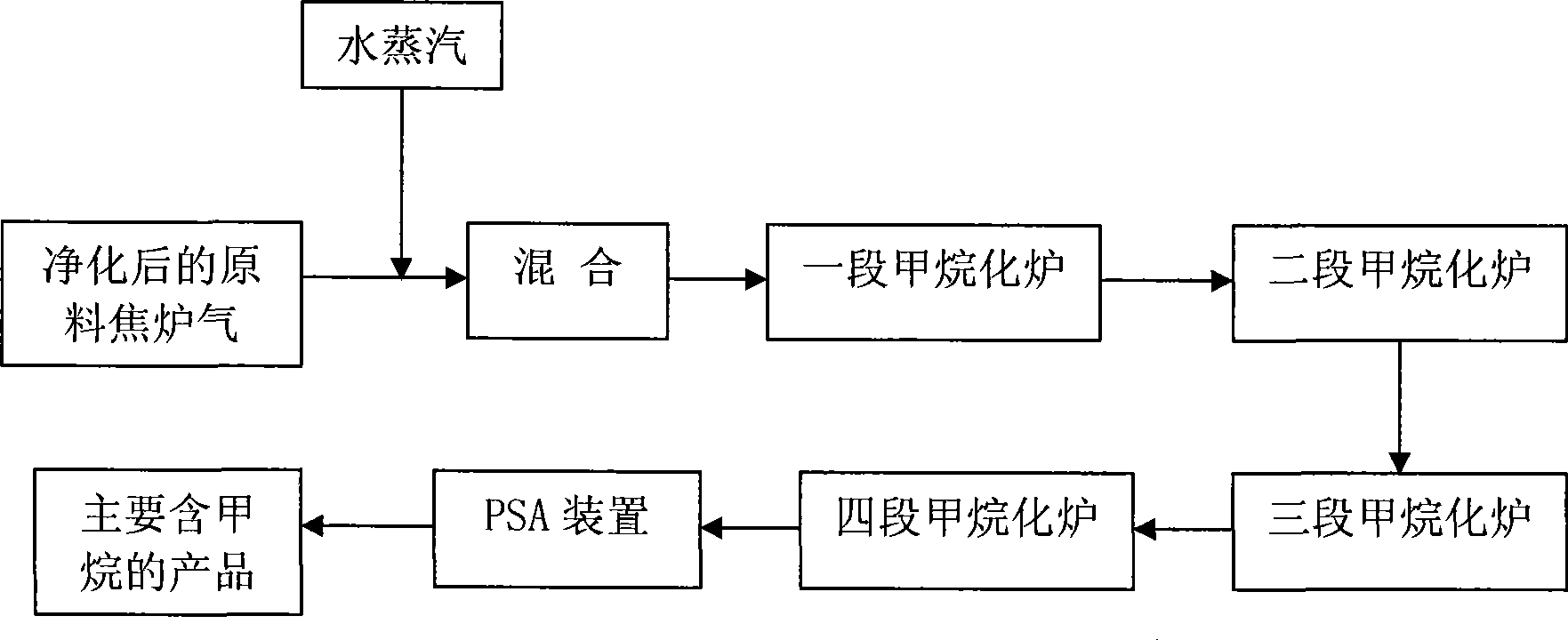

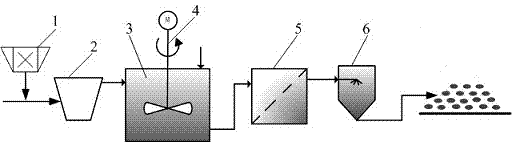

Method of preparing synthetic natural gas by coke oven gas

ActiveCN1919985AHigh calorific valueLow impurity contentGaseous fuelsCompressed natural gasMethanation

The invention discloses the method for producing natural gas with coking gas, comprising the following steps: purifying coking gas and removing benzene, naphthalene, hydrocarbon and sulphide, compressing, heat transferring, carrying out methanation reaction with catalyst, hydrogen in COG reacting with carbonic oxide and carbon dioxide to get methane; putting the mixture gas into pressure swing adsorbing device, and getting natural gas whose concentration is 90%. The natural gas has high caloric value, low impurity content.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

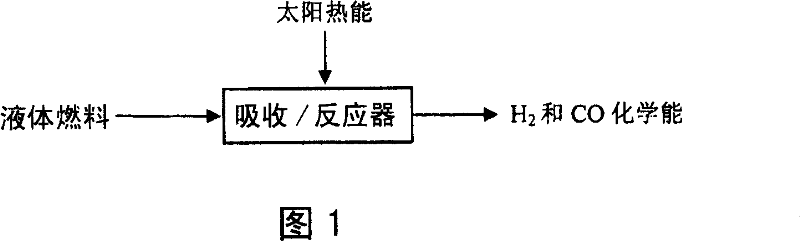

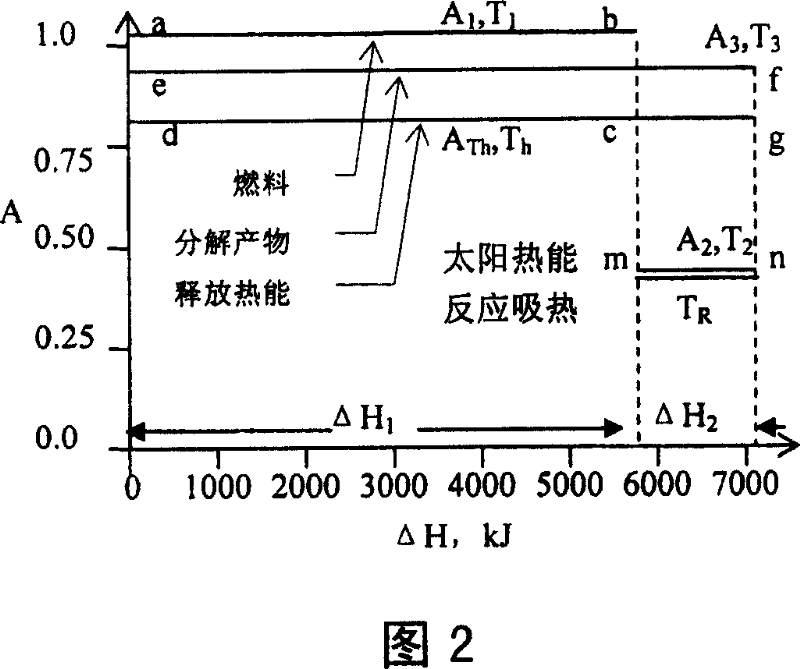

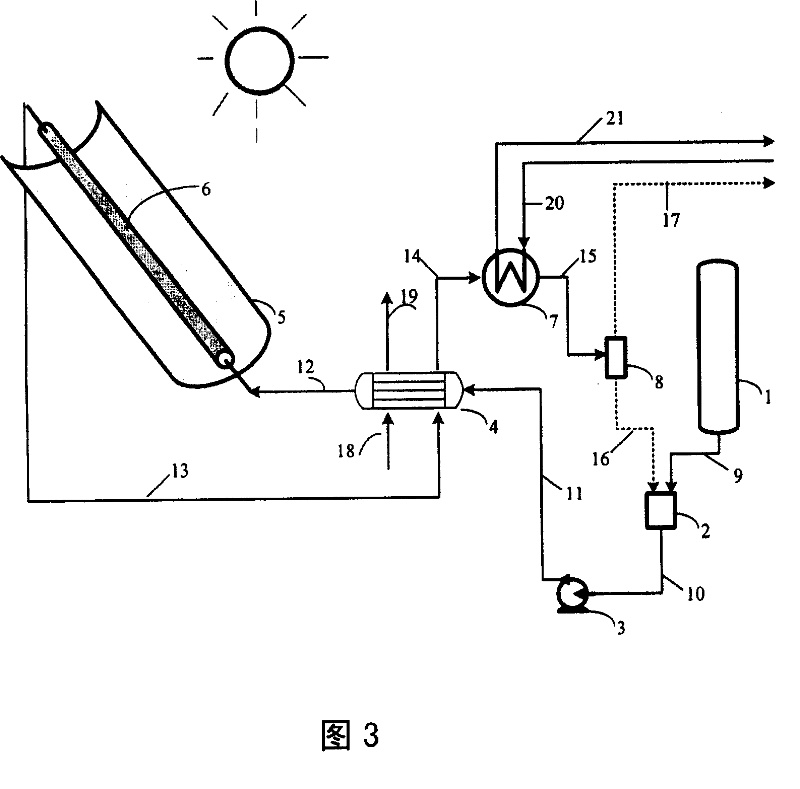

Method and apparatus for converting solar energy into fuel chemical energy

It relates to a method and device of changing solar energy to chemical energy. It accumulates the solar energy and changing it to heat energy ranging from 150deg.C-300deg.C, providing reaction heat for the liquid fuels, allowing the middle and low level solar energy changing and stored into high level chemical energy, with the liquid being carbinol or dimethyl ether synthetic fuel, with the catabolite being hydrogen and monoxide formed gas. It can be used for multi purposes, providing fine synthetic fuel and material for customers.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

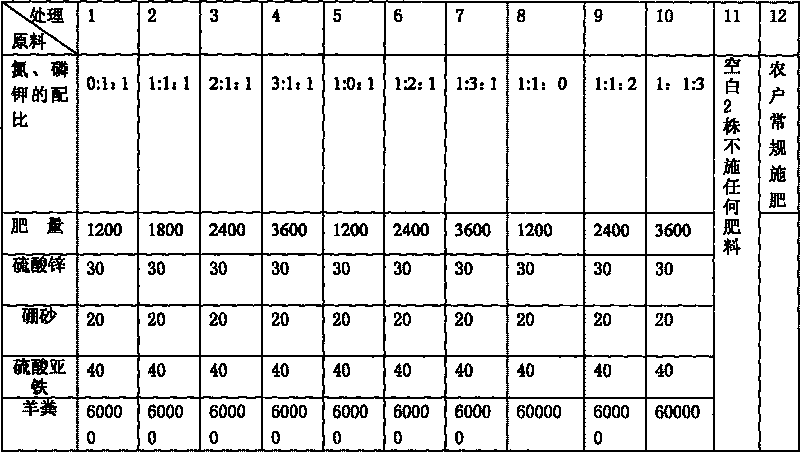

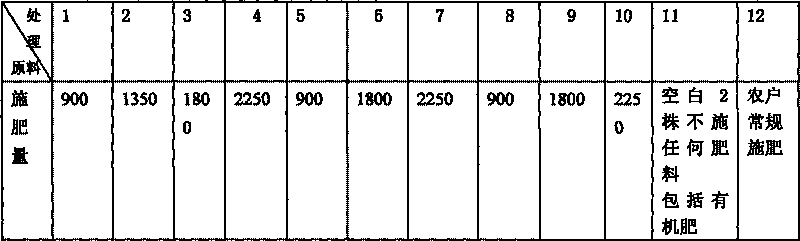

Preparation method and application method of grape special fertilizer

ActiveCN101693639AIncrease productionImprove qualityClimate change adaptationAlkali orthophosphate fertiliserSodium BentoniteAdditive ingredient

The invention relates to preparation method and application method of a grape special fertilizer, wherein the preparation method comprises the following steps: preparing an I-type fertilizer by taking the following ingredients in parts by weight: 30-40 parts of urea, 20-30 parts ammonium phosphate, 15-30 parts of potassium sulphate, 1-3 parts of humic acid, 1-3 parts of excrement, 1-5 parts of synergist, 0.1-1.0 part of ferrous sulphate, 0.1-0.8 part of zinc sulfate, 0.1-0.6 part of manganese sulphate, 0.1-0.6 part of borax, 0.1-0.4 part of copper sulfate, 3-7 parts of plaster and 3-13 parts of bentonite; preparing an II-type fertilizer by taking the following ingredients in parts by weight: 7-15 parts of urea, 25-35 parts ammonium phosphate, 35-45 parts of potassium sulphate, 1-3 parts of humic acid, 1-5 parts of excrement, 2-5 parts of synergist, 0.1-1.0 part of ferrous sulphate, 0.1-0.8 part of zinc sulfate, 0.1-0.6 part of manganese sulphate, 0.1-0.6 part of borax, 0.1-0.4 part of copper sulfate, 3-7 parts of plaster and 3-13 parts of bentonite; and blending, spraying, pelleting and drying at lower temperature to obtain the product. The application method of the fertilizer comprises the following steps: taking an organic fertilizer and the II-type fertilizer as a base fertilizer; applying the I-type fertilizer before blossom, applying the II-type fertilizer in the young fruit development period, and meanwhile, respectively spraying monopotassium phosphate and rare earth mixed liquid once on the leaf surfaces; and spraying calcium nitrate or calcium acetate to enhance the storage resistance property before picking.

Owner:新疆满疆红农资化肥科技有限公司

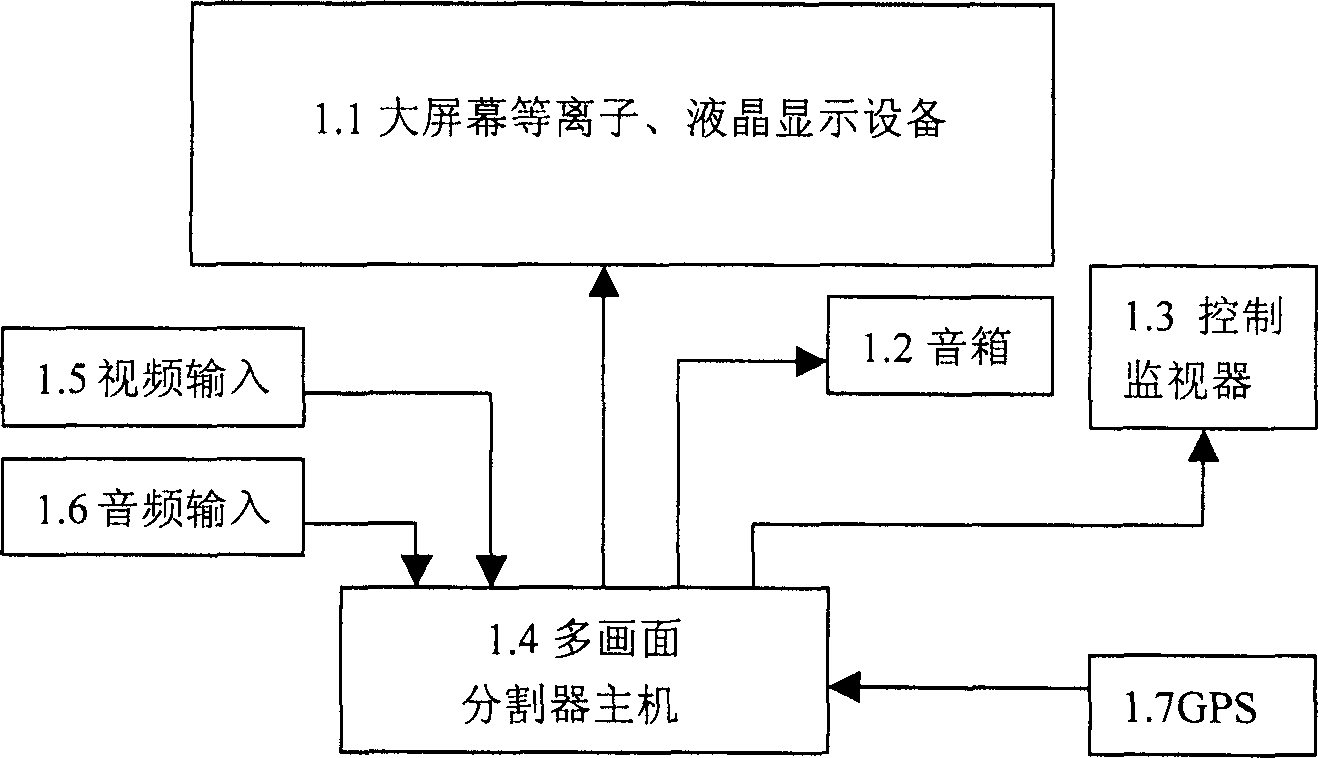

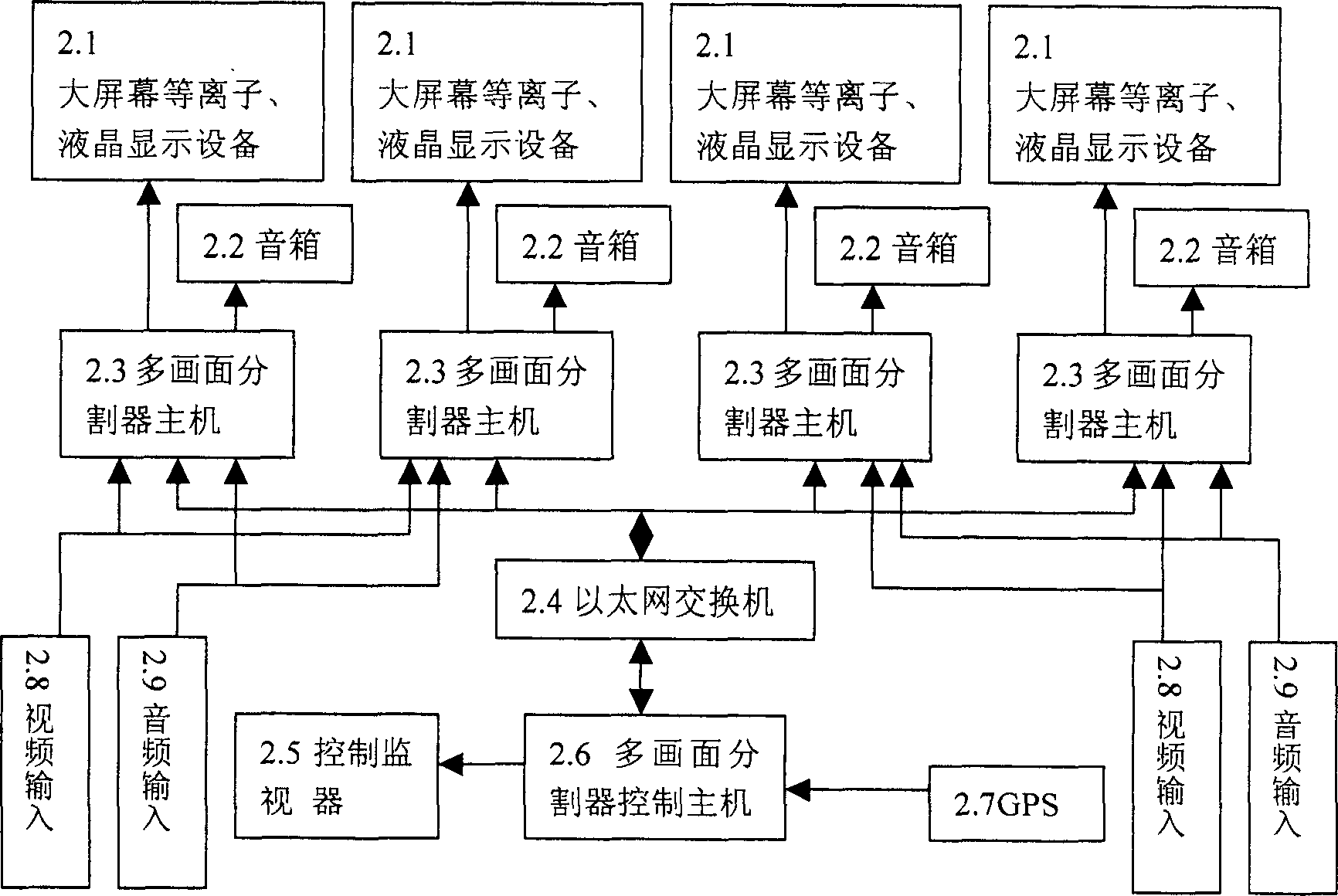

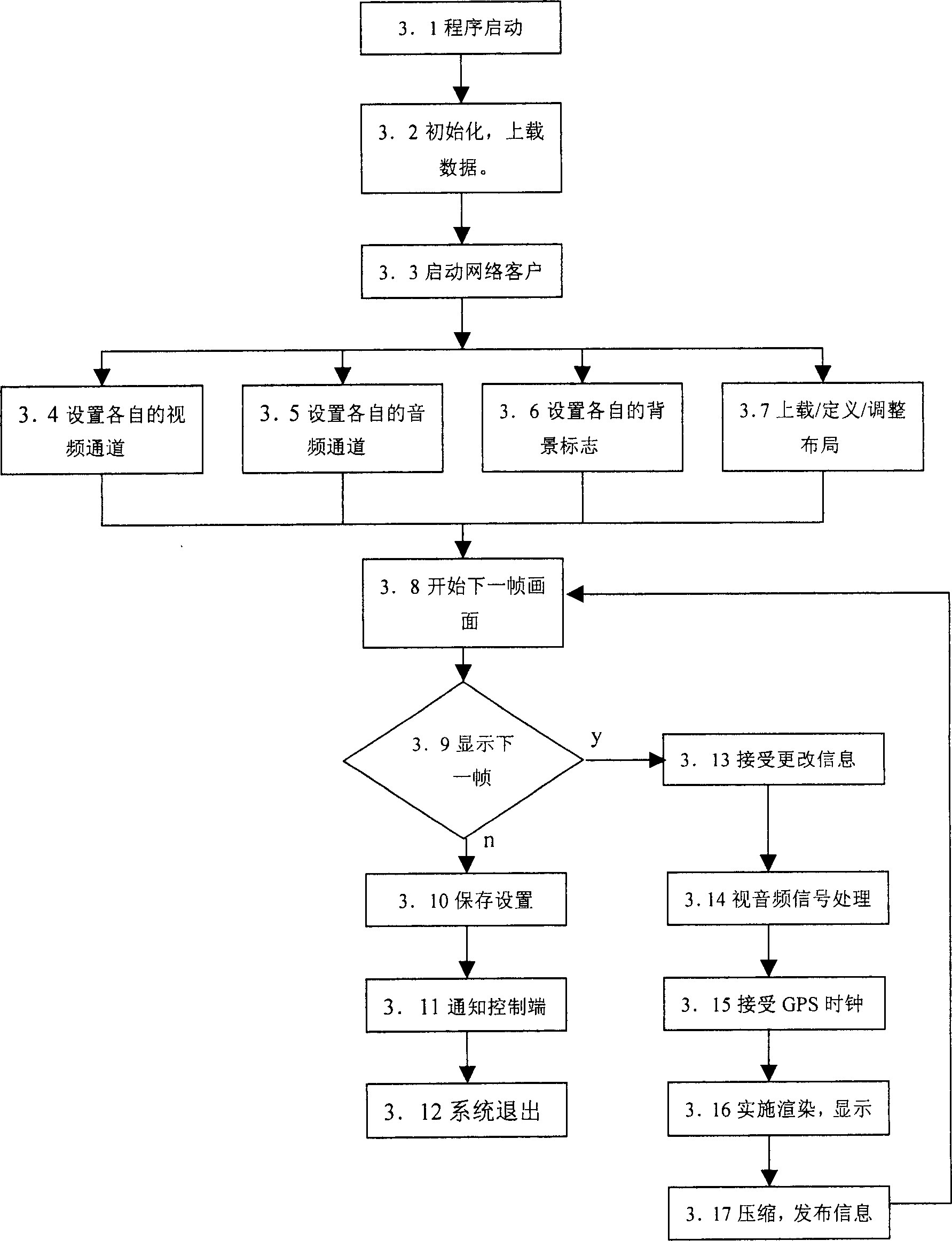

Multiple picture frame splitting system

InactiveCN1782984AAchieve arbitrary scalingLess investmentTelevision systemsDigital output to display deviceLarge screenDigital image

The multiple picture frames decollating system belongs to the field of video digital image treating technology, and is especially multiple picture frame great screen TV wall decollating display system. The present invention consists of two parts, including multiple picture frame decollator and large screen display equipment. The multiple picture frame decollator consists of a computer with video and audio treating card, operation system and control software, a control monitor and sound box. The large screen display equipment is large screen liquid crystal screen, plasma screen or large screen rear projecting TV with VGA / DVI interface. The present invention may be used in multiple picture frame monitoring in different fields. The present invention may be controlled in different modes.

Owner:BEIJING DAYANG TECH DEV

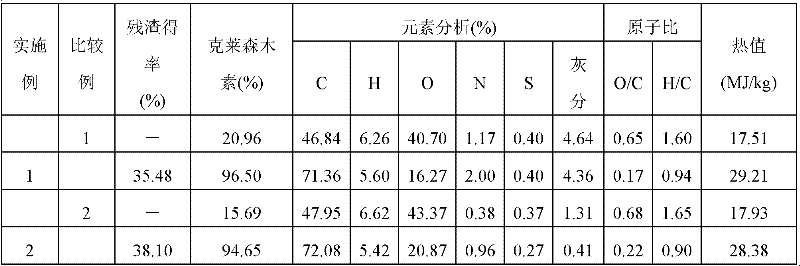

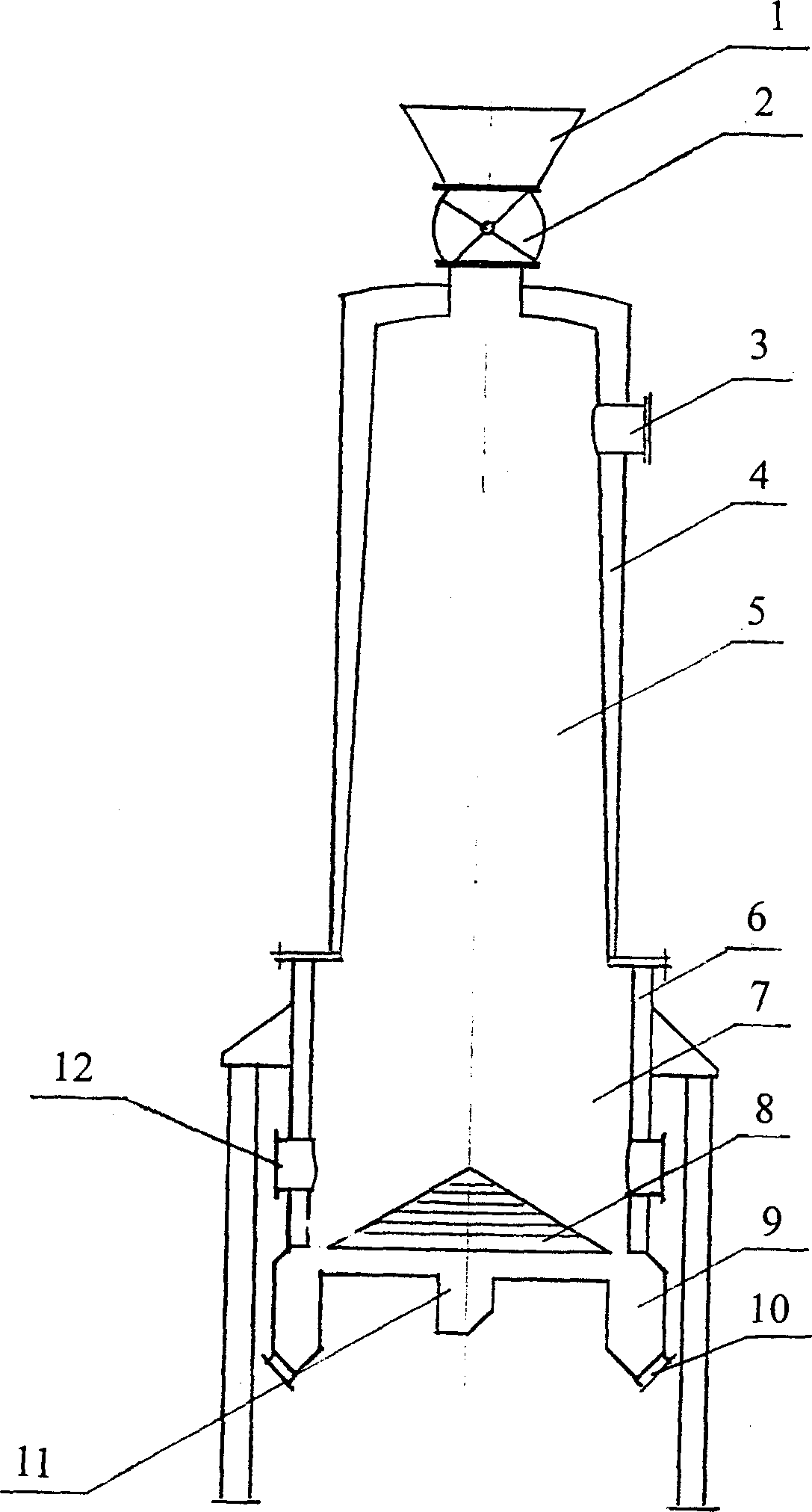

Method for preparing biomass carbon by utilizing agricultural and forestry waste

InactiveCN102583311AImprove protectionRaw materials are easy to getSolid waste disposalCarbon preparation/purificationBiomass carbonSorbent

The invention relates to a method for preparing biomass carbon by utilizing agricultural and forestry waste, belonging to the technical fields of preparation of carbon materials and utilization of biomass resources. The method comprises the following steps of: adopting agricultural and forestry waste as raw materials; under the condition of subcritical water, fully mixing dried biomass materials and deionized water according to the proportion of 1:(10-30); under the protection of inert atmosphere, carbonizing for 2-6 hours at the temperature of 220-250 DEG C; and then carrying out vacuum filtration and hot-water cleaning, and drying to obtain the biomass carbon. The biomass carbon prepared by the invention is coaly carbon material with an aromatic-ring structure, is high in carbon content and calorific value and large in specific surface area, and can be used as a soil conditioner or an absorbent. The method has the advantages that the materials are low in cost and easy to obtain, the process is simple, the operation is convenient, the manufacturing cost is low, the industrial promotion is convenient, and the application range and the application value of biomass resources are further expanded in the aspect of carbon materials.

Owner:BEIJING FORESTRY UNIVERSITY

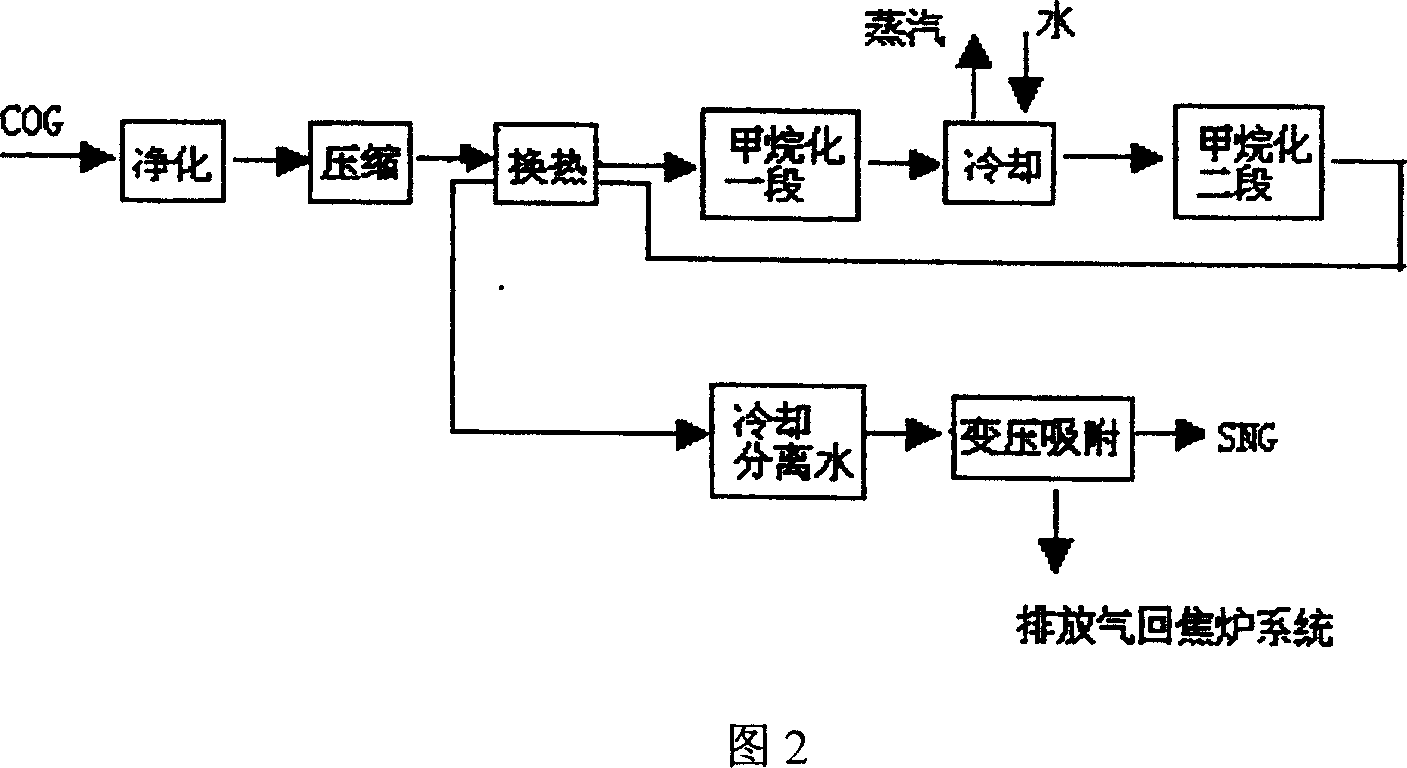

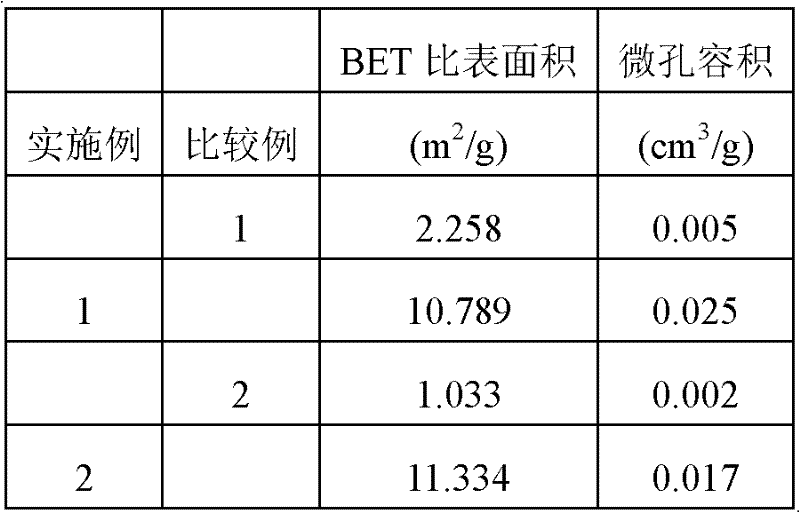

Method for synthesizing methane by using coke-oven gas

ActiveCN101391935AHigh methane contentHigh calorific valueHydrocarbon from carbon oxidesChemical industryWater vaporMethanation

The invention discloses a method for synthesizing methane by utilizing oven gas. Product gas with methane concentration of more than 90 percent is obtained through the main steps of purifying to remove impurities, compressing to exchange heat, adding water vapor, first stage of methanation reaction, second stage of methanation reaction, third stage of methanation reaction, PSA methane separation and the like. By adopting the method and utilizing the oven gas as raw materials, synthetic natural gas with high content of methane, low content of impurities and high heating value can be obtained, which is favorable to protecting the environment, saving energy and developing new energy; in addition, in the method, the addition of appropriate water vapor in the raw materials of oven gas before the fist sage of reaction properly inhibits the depth of the methanation reaction, reduces the heat amount released in the whole reaction process, conduces the cooling of the gas after the reaction and prevents the occurrence of carbon deposition reaction to devitalize the activity of a catalyst, thus being beneficial to the continuous normal operation of the whole synthesizing process.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

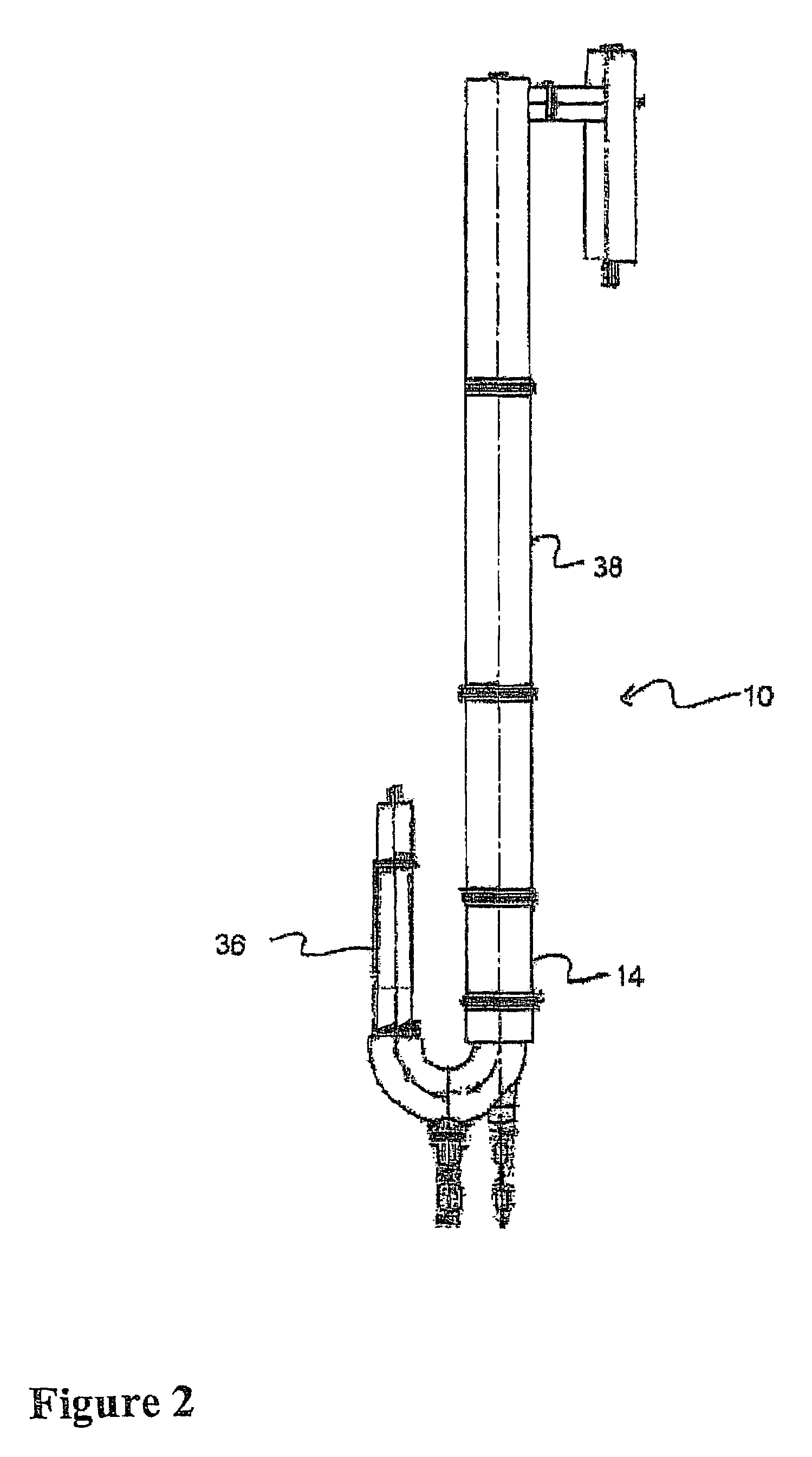

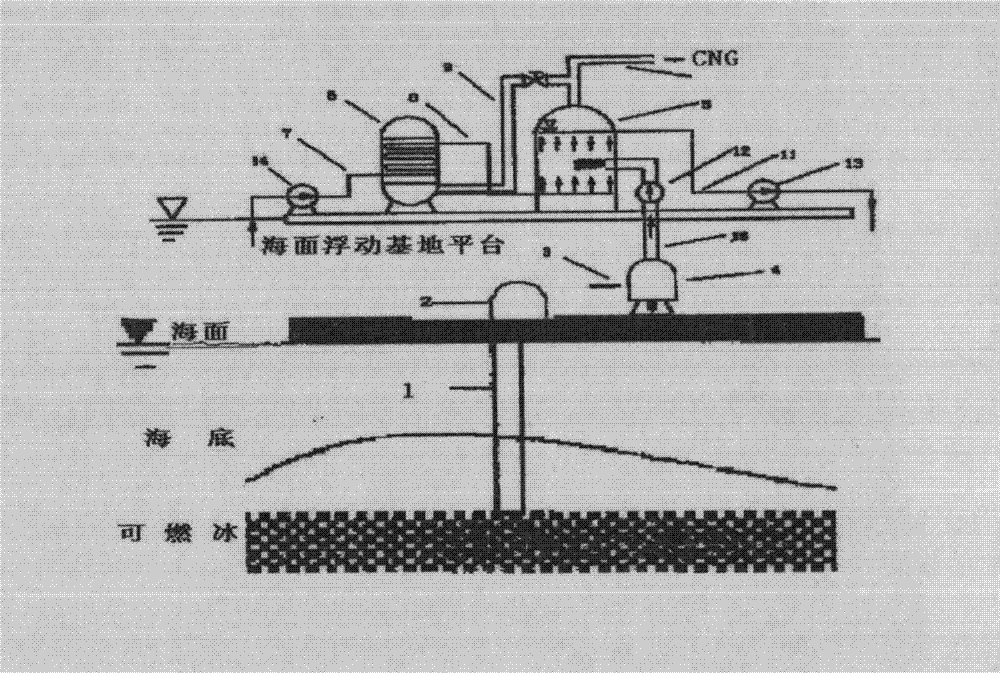

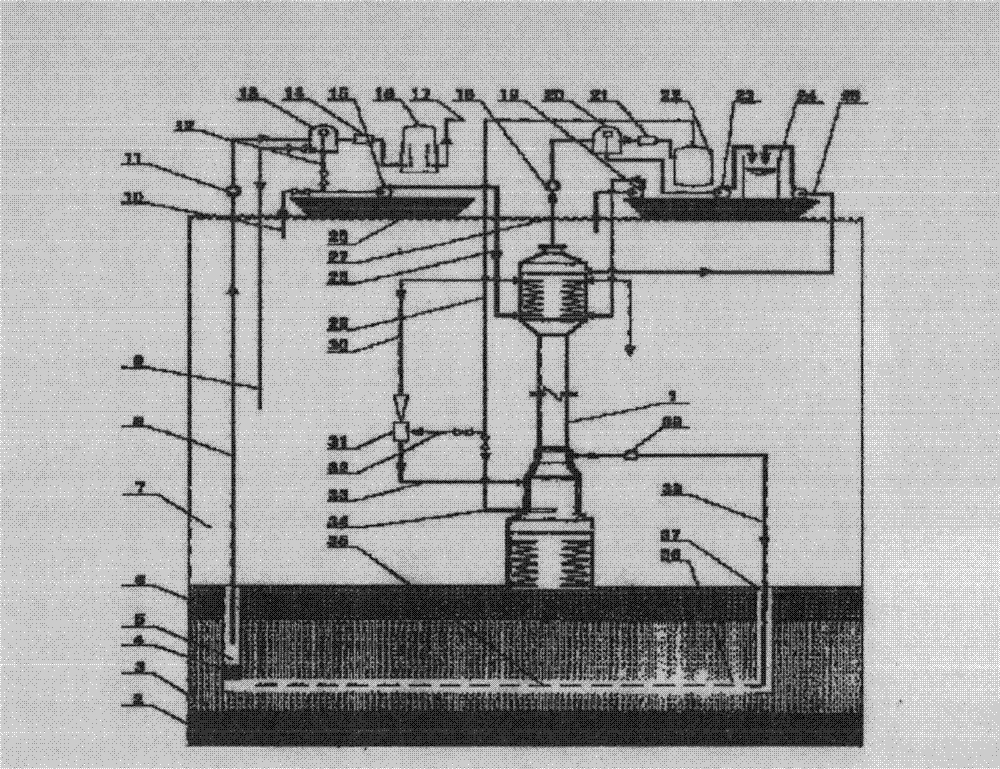

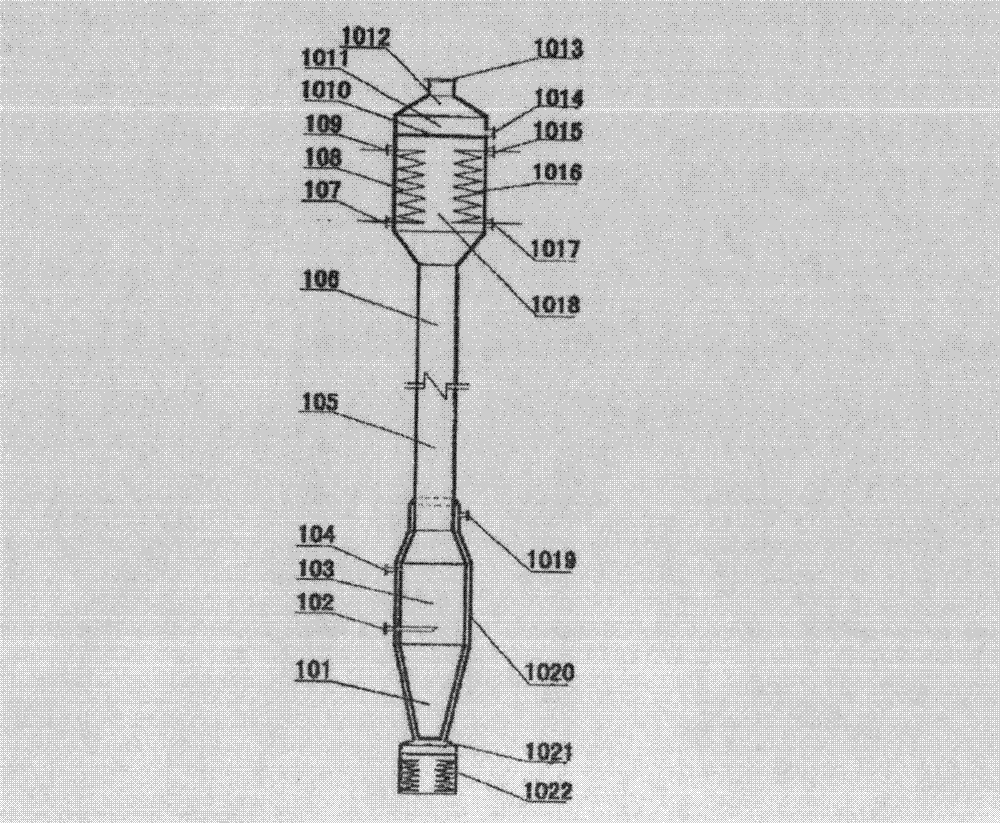

Ocean combustible ice mining device and method

The invention discloses an ocean combustible ice mining method and a mining device adopted by the same. According to the ocean combustible ice mining method, a device for mining combustible ice through heating concentrated saline water is adopted, and heat for heating a combustible ice storage layer is provided by heating the concentrated saline water. The ocean combustible ice mining method is energy-saving and environment-friendly, remarkable in economic benefit, is free from emission and pollution in a mining process, energy-saving and consumption-reducing; and the ocean combustible ice mining device is relatively sample in structure, convenient to use, lower in production cost and convenient for popularization.

Owner:韩中枢

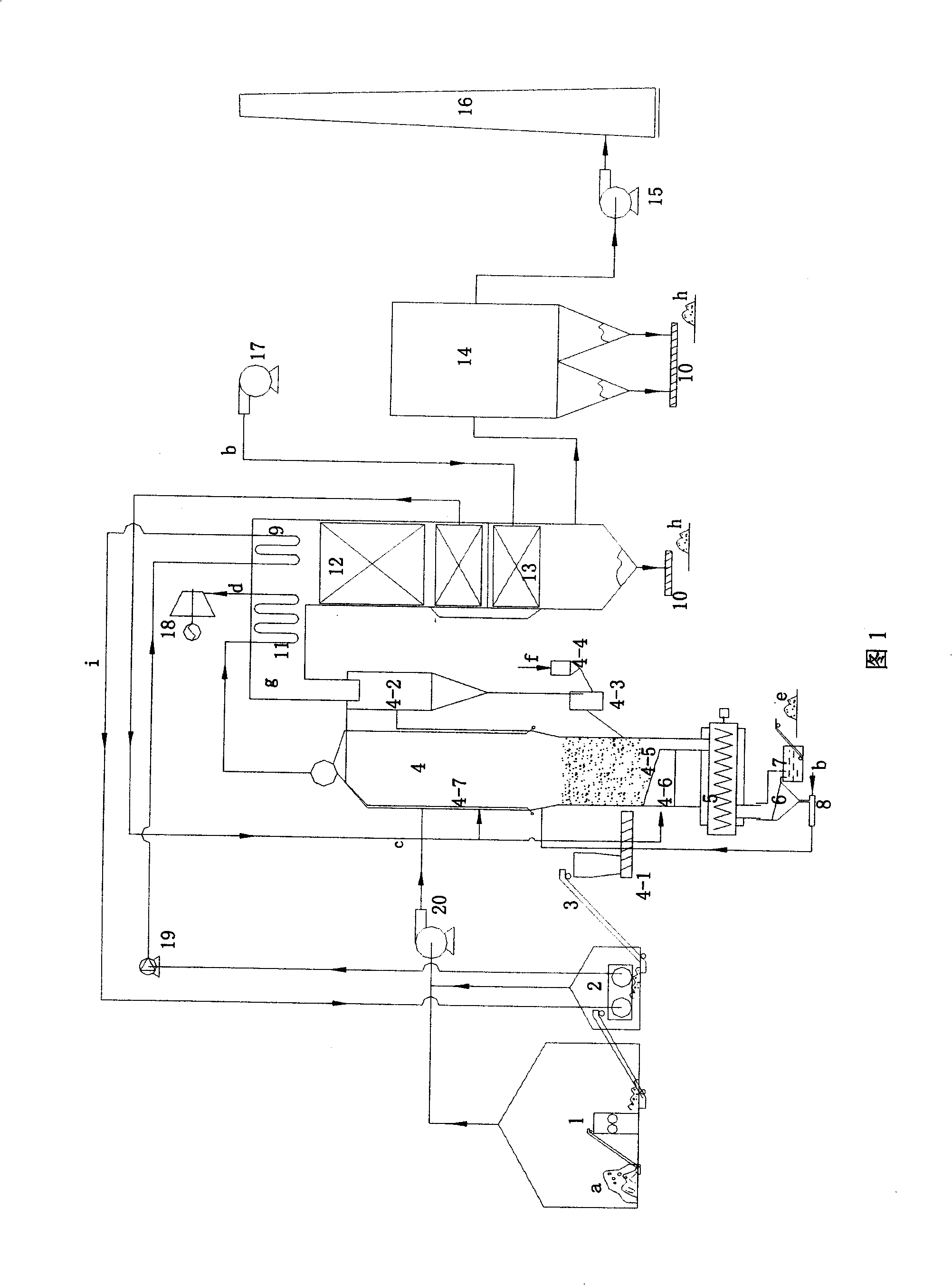

City life rubbish fluidized bed gasification combustion processing method

InactiveCN101294708ASafe and stable operationImprove securityAir supply regulationIndirect carbon-dioxide mitigationSlagHearth

The invention is a fluid bed gasification and combustion processing method for urban garbage. The hearth of a fluid bed garbage furnace (4) is composed of two parts of a low temperature gasification area and a high temperature combustion area, additives (f) such as limestone, kaolin, etc. are added to the garbage furnace (4); acid gases such as chlorine, sulfur, nitrogen, etc. are removed in the furnace; and the generation of dioxin is controlled in the furnace. A water cooling spiral slag cooler (5) and a vibration sieve (6) can be utilized to efficiently reduce heat loss of slag and recycle bed materials. The whole system requires no addition of auxiliary fuel, and has the characteristics of safe reliability, no odor emission, low investment and operating cost, less secondary pollutant discharge, high power generation efficiency, etc.

Owner:SOUTHEAST UNIV +1

Alcohol-based biological fuel oil for boiler and preparation method thereof

InactiveCN101948702ALow costRaw materials are cheap and easy to getBiofuelsLiquid carbonaceous fuelsBiodieselAlcohol

The invention provides a biodiesel-based alcoholic fuel oil, which consists of the following substances in percentage by mass: 20 to 50 percent of refined biodiesel, 40 to 80 percent of industrial methanol and 5 to 30 percent of additive, wherein the additive comprises 5 to 20 percent of solvent aid, 1 to 15 percent of cosurfactant, 0.2 to 2 percent of stabilizer and 0.1 to 1 percent of corrosion inhibitor. A preparation method comprises the following steps of: mixing the substances in percentage by mass, and stirring the mixture uniformly at normal temperature to obtain the fuel oil. The fuel oil has the advantages of low cost, high heat value and stable performance; the preparation method has the advantages of simple process, convenience and safety of use and good adaptability to the boiler; and compared with diesel oil, the fuel oil is economic and energy-saving, has low environmental pollution, is regenerative energy, and can be used as commercial oil for great popularization and use.

Owner:KUNMING UNIV OF SCI & TECH

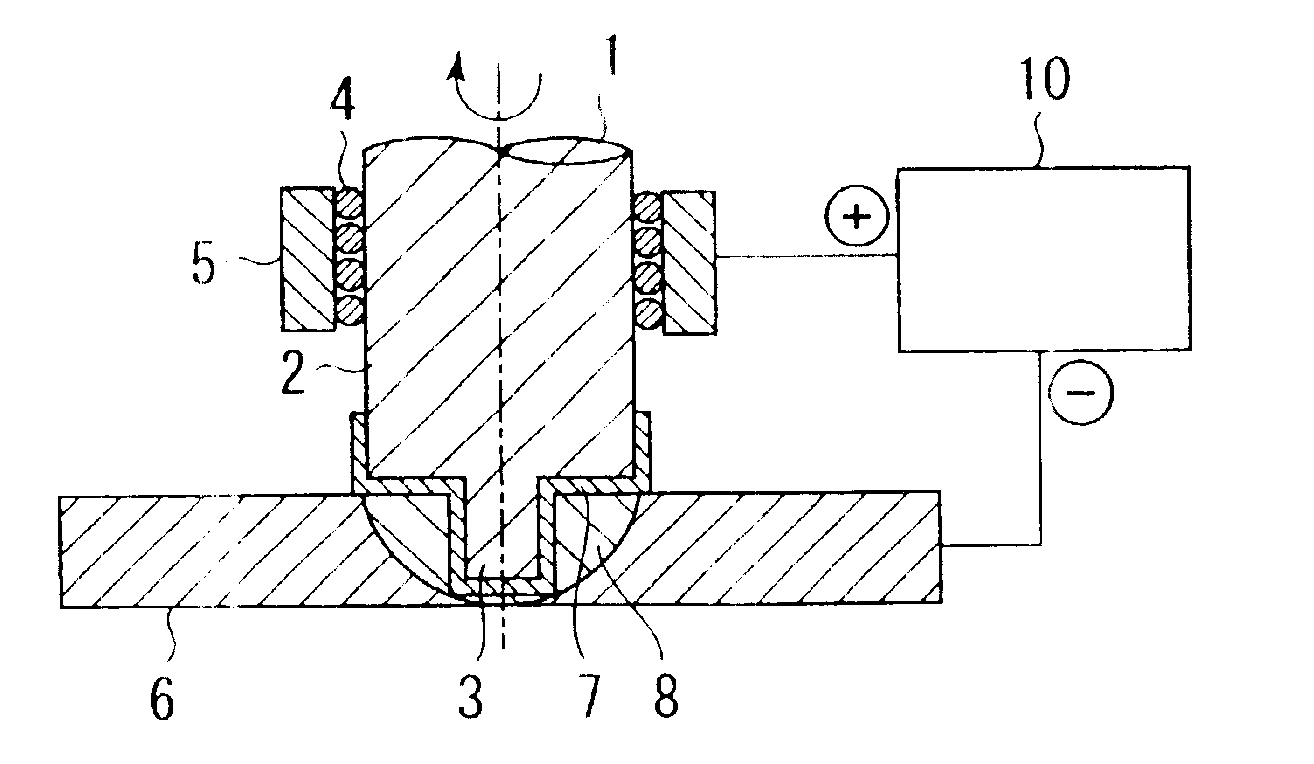

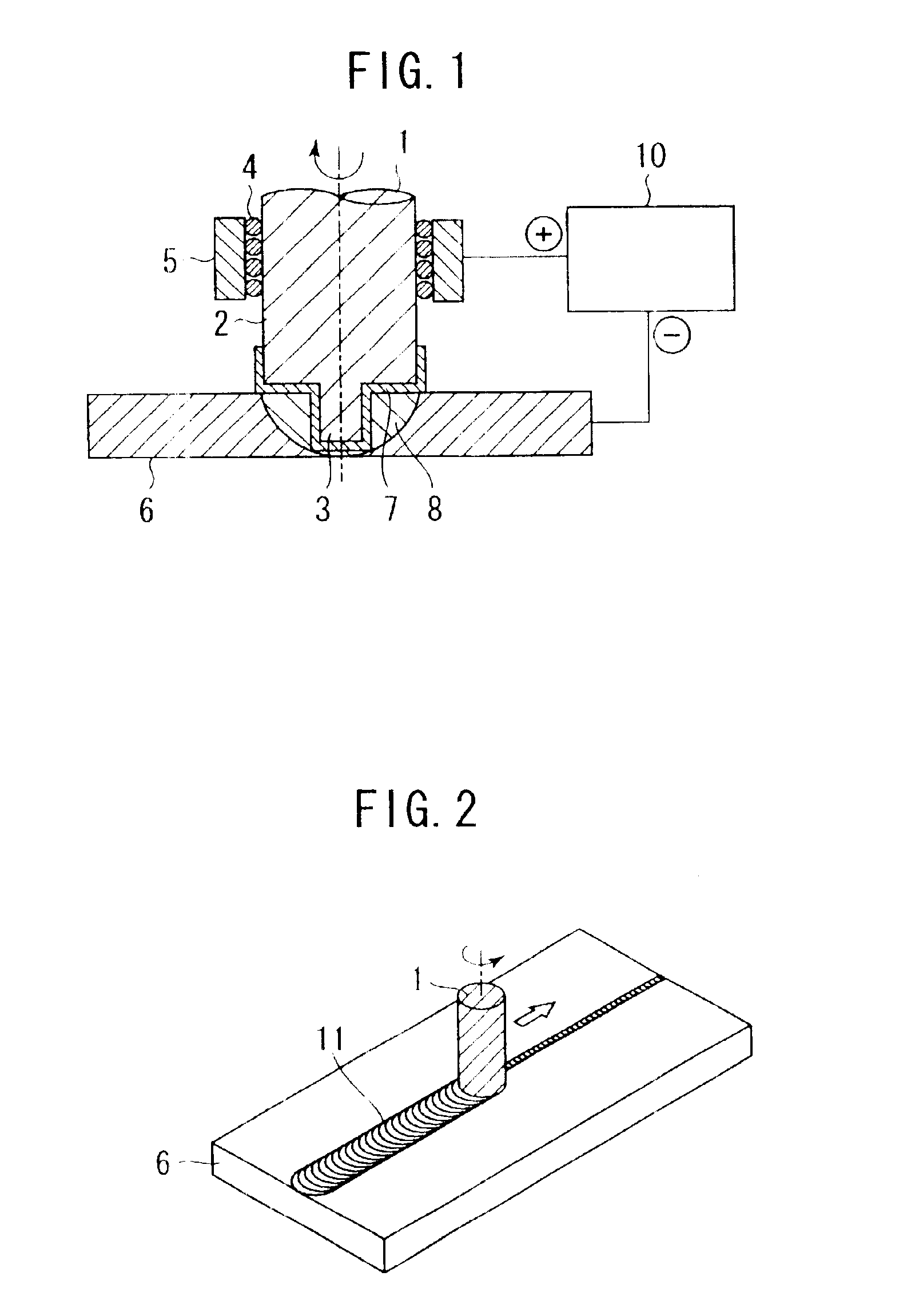

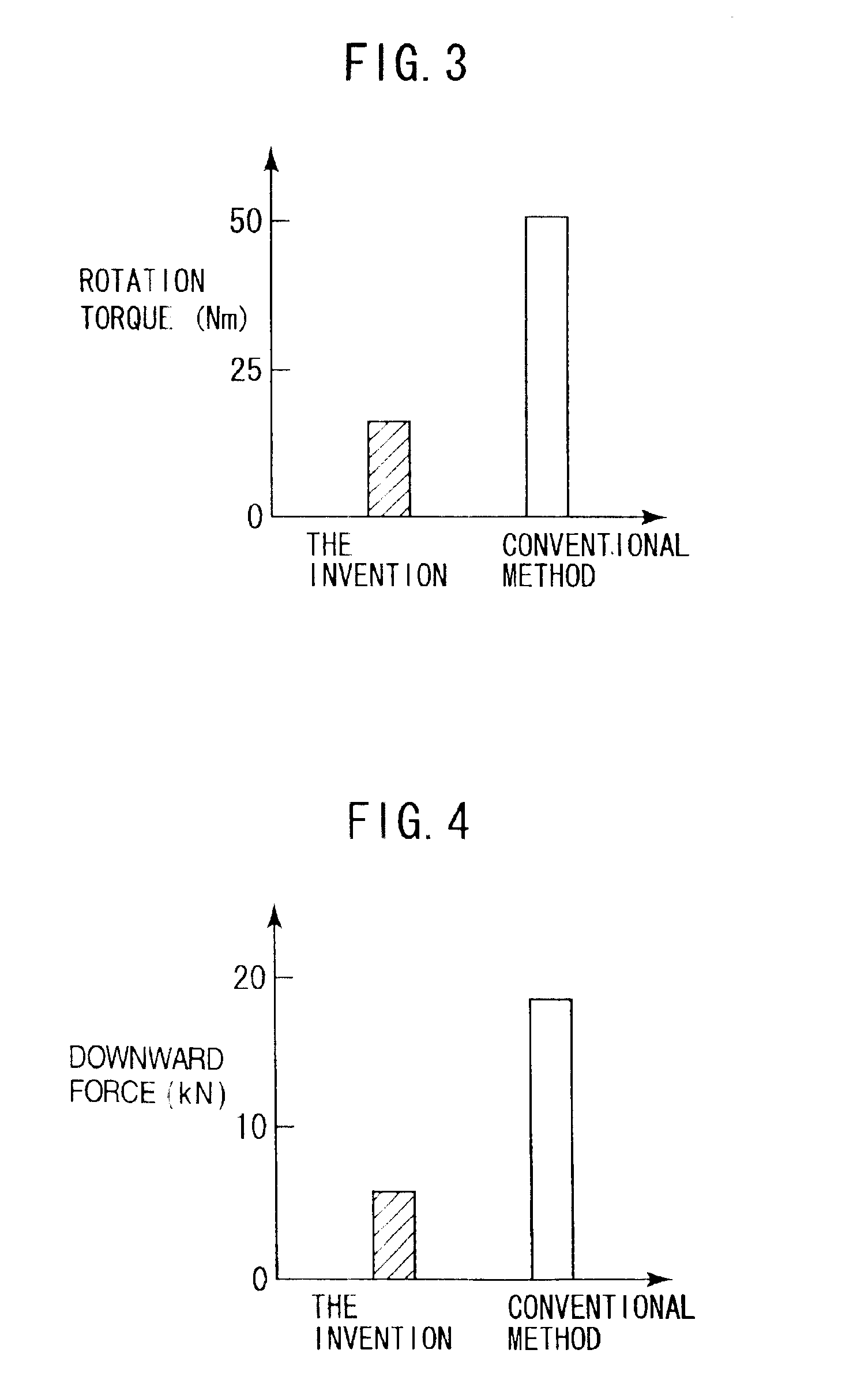

Friction stir welding method

InactiveUS6866181B2Suppress generation of friction forceHeat resistantElectric discharge heatingWelding/cutting auxillary devicesElectrical resistance and conductanceFriction welding

There is provided a method capable of decreasing a friction force in friction stir welding, in which a welding tool is used. In a method of friction stir welding workpieces together by rotating and pressingly plugging a welding tool, formed from a harder material than the workpieces, into a weld zone of the workpieces and moving the welding tool relatively in a welding direction, a power supply device allows a current to flow between the welding tool 1 and the workpieces to cause resistance heating of the welding tool. Combined use of resistance heating makes it possible to decrease a friction force. Preferably, a conductive ceramic is coated on surfaces of the welding tool to cause resistance heating.

Owner:HITACHI LTD

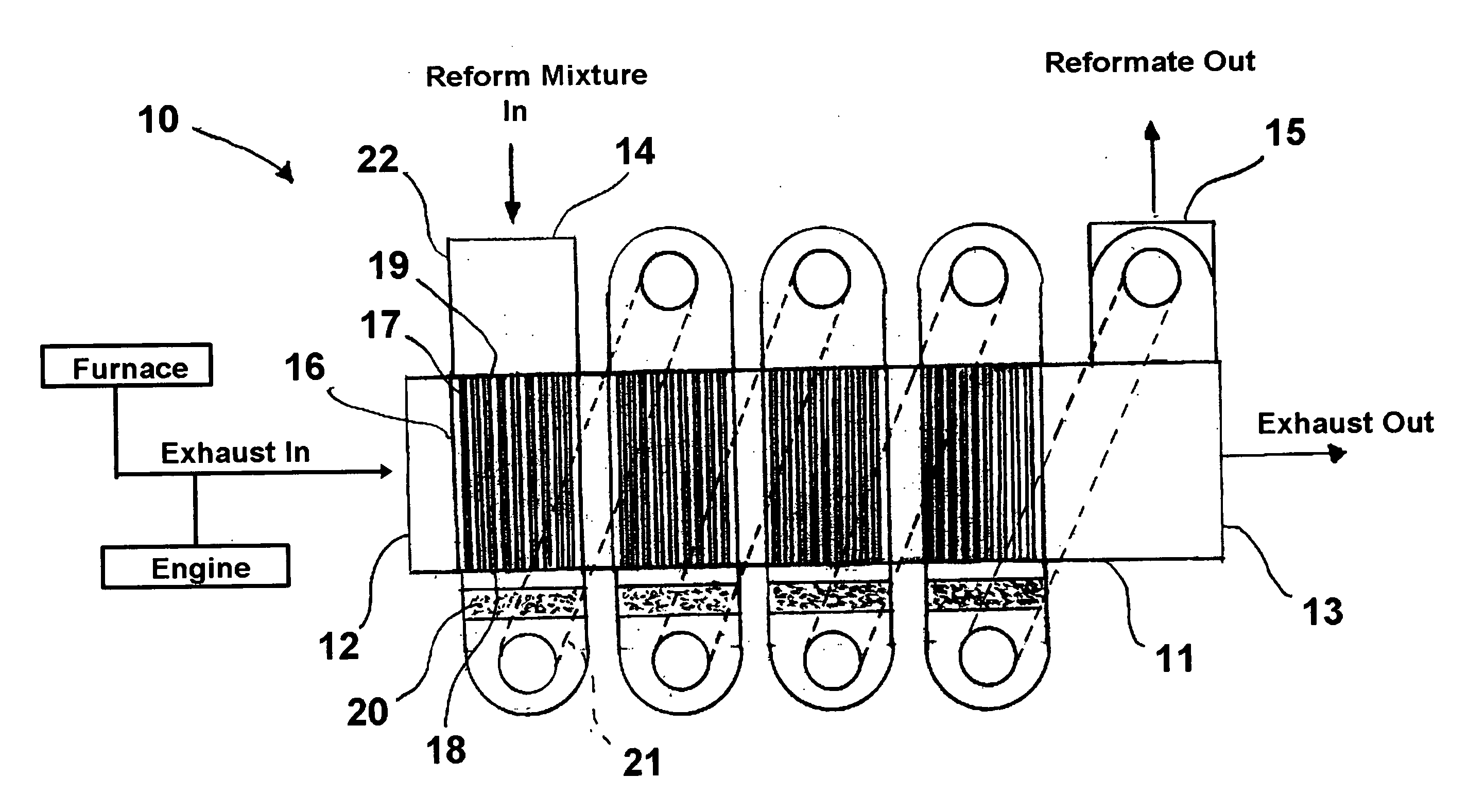

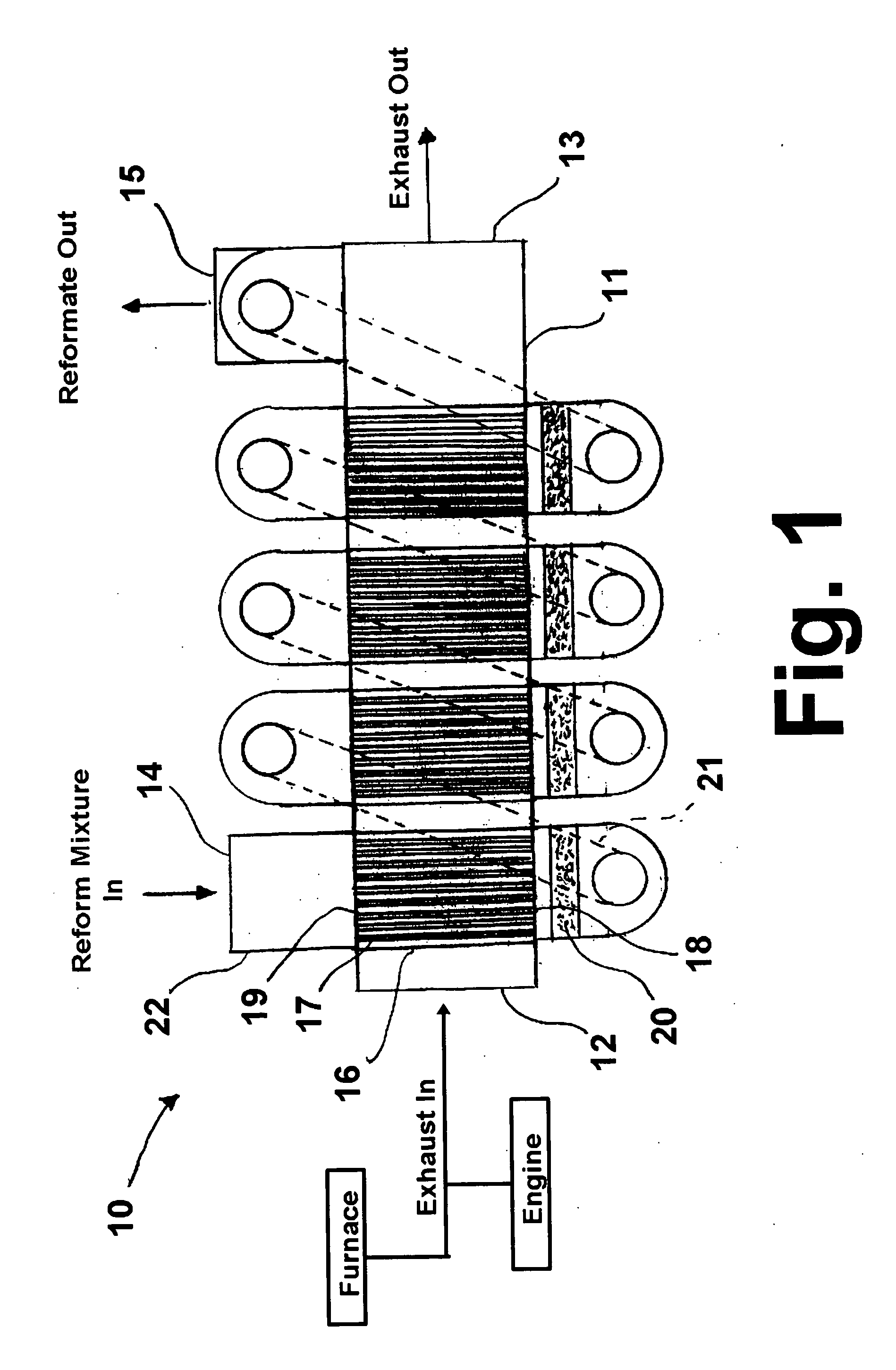

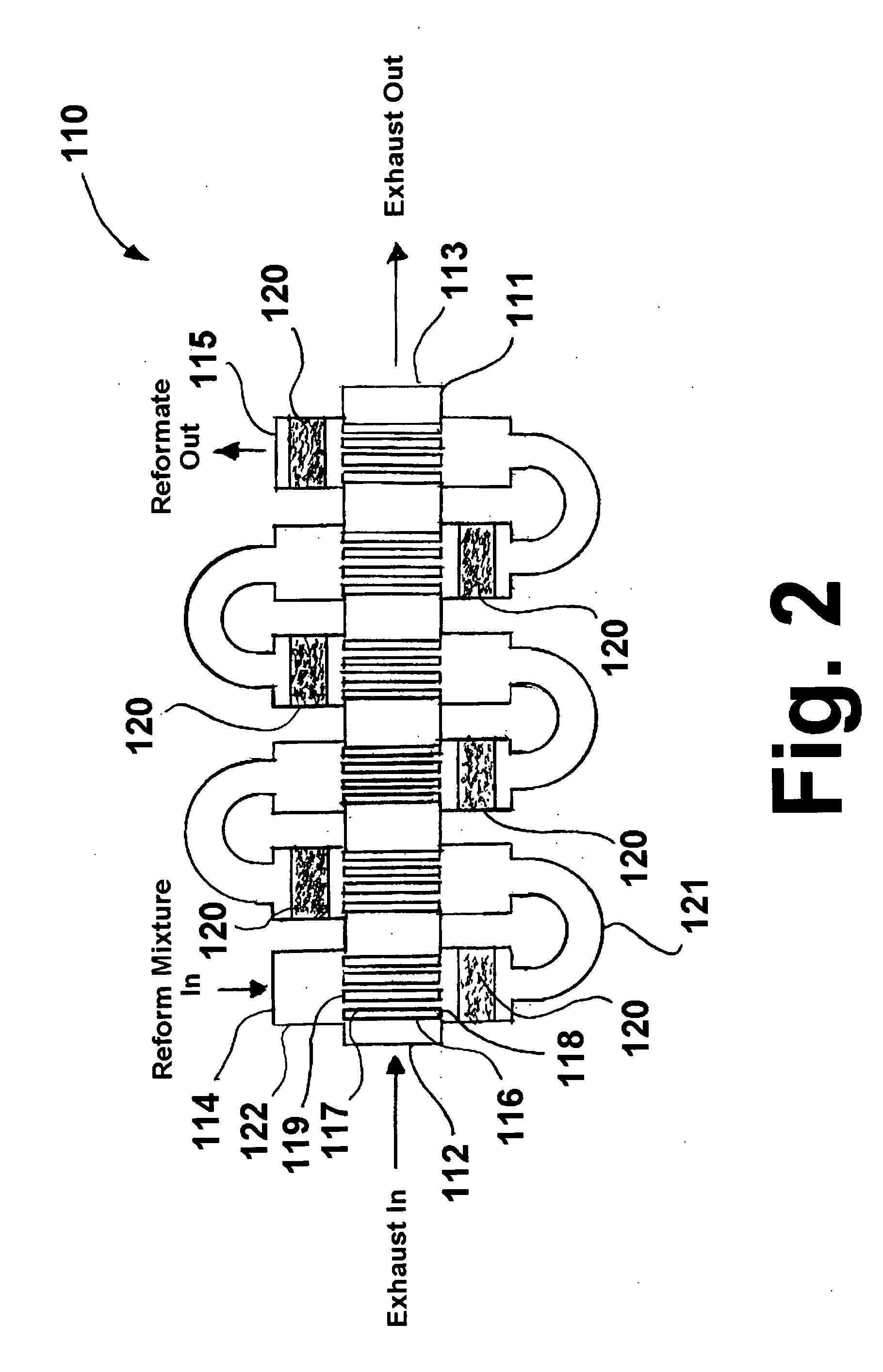

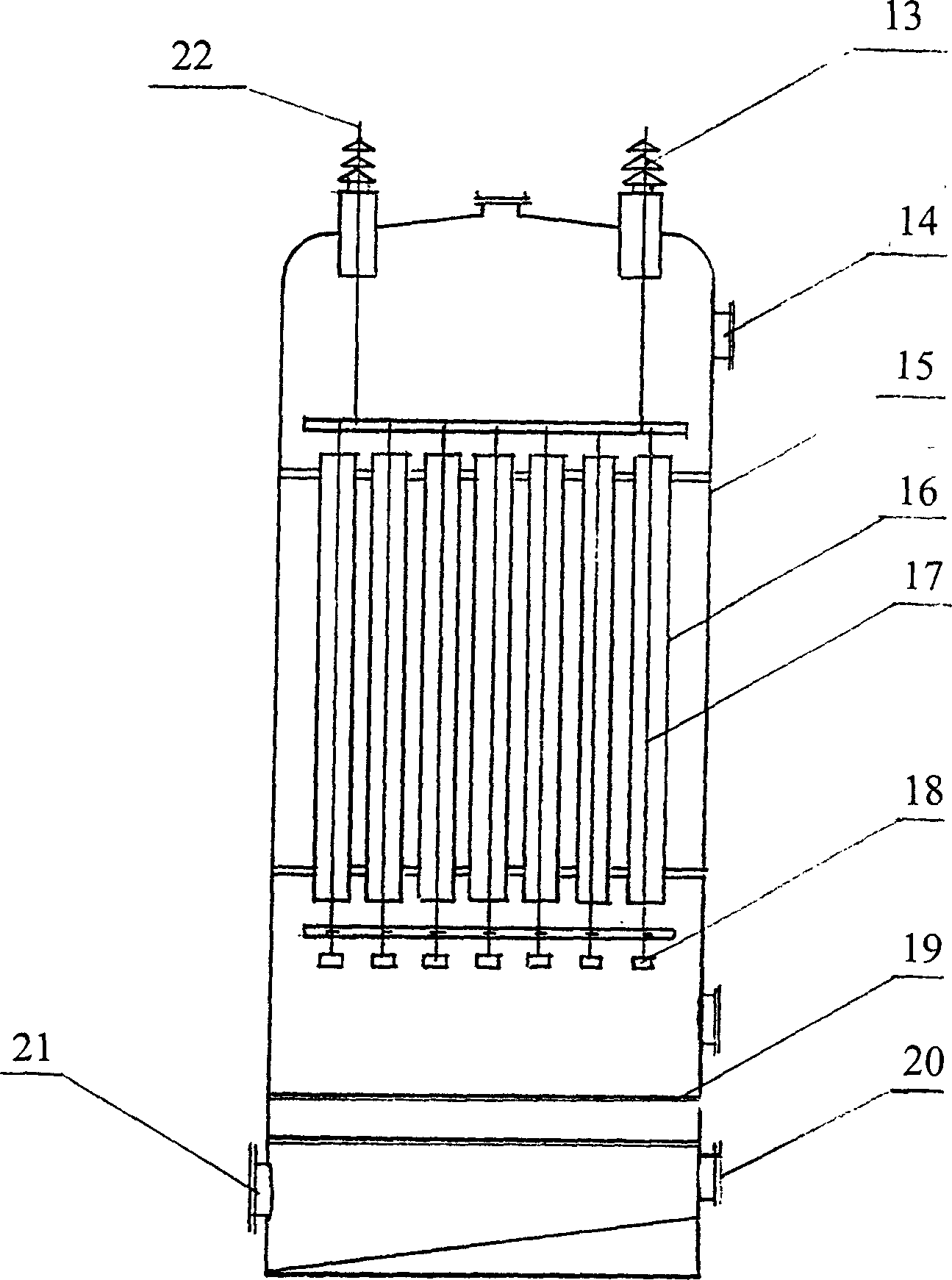

Recuperative reforming reactor

InactiveUS20070028860A1Facilitate catalyzed reforming reactionHigh calorific valueHydrogenCombustion-air/fuel-air treatmentProcess engineeringInternal combustion engine

A method and apparatus for fuel reforming using the exhaust gases from internal combustion engines and high temperature combustion processes in which a fuel for reforming and steam mixture is introduced into a tube bundle having a plurality of heat exchange tubes and heat from the exhaust gases is transferred into the heat exchange tubes, thereby increasing the temperature of the mixture. The heated mixture is reformed by contact with a reforming catalyst external to, but proximate to the exit of, the tube bundle, forming a reformed fuel. To remove substantially all of the heat from the exhaust gases, a plurality of tube bundles and associated reforming catalyst arranged in series are provided.

Owner:UTILIZATION TECH DEV NFP

Boiler coal combustion-improving desulfurizing and denitrifying agent composition and preparation method thereof

The invention provides a boiler coal combustion-improving desulfurizing and denitrifying agent composition. The composition comprises the following raw materials in parts by weight: 2-7 parts of sodium carbonate, 1-3 parts of alumina, 2-8 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 2-6 parts of ferric oxide, 3-10 parts of potassium permanganate, 3-10 parts of potassium chlorate, 10-35 parts of activated attapulgite clay, 15-30 parts of urea, 2-4 parts of ammonium formate, 2-4 parts of ammonium chloride, 6-23 parts of ammonium acetate, 3-9 parts of manganese oxide, 9-12 parts of copper chloride, 1-3 parts of copper oxide, 2-4 parts of zinc sulfate, 1-3 parts of zinc nitrate, 7-18 parts of potassium dichromate, 1.0-1.5 parts of titanium dioxide, 0.5-1.0 part of barium molybdate, 0.5-1.5 parts of cobalt sulfate, 0.5-1.5 parts of vanadium pentoxide, 0.3-0.7 part of cerium oxide, 0.1-0.2 part of sodium dodecyl benzene sulfonate and 0.1-0.2 part of alkyl glyceryl ether. The composition is convenient to use, has stable properties, plays roles of combustion improving, desulfurization and denitrification, has coal saving rate of 8-25% and can remove fixed sulfur by 50-70%.

Owner:兰州熙瑞化工科技有限公司

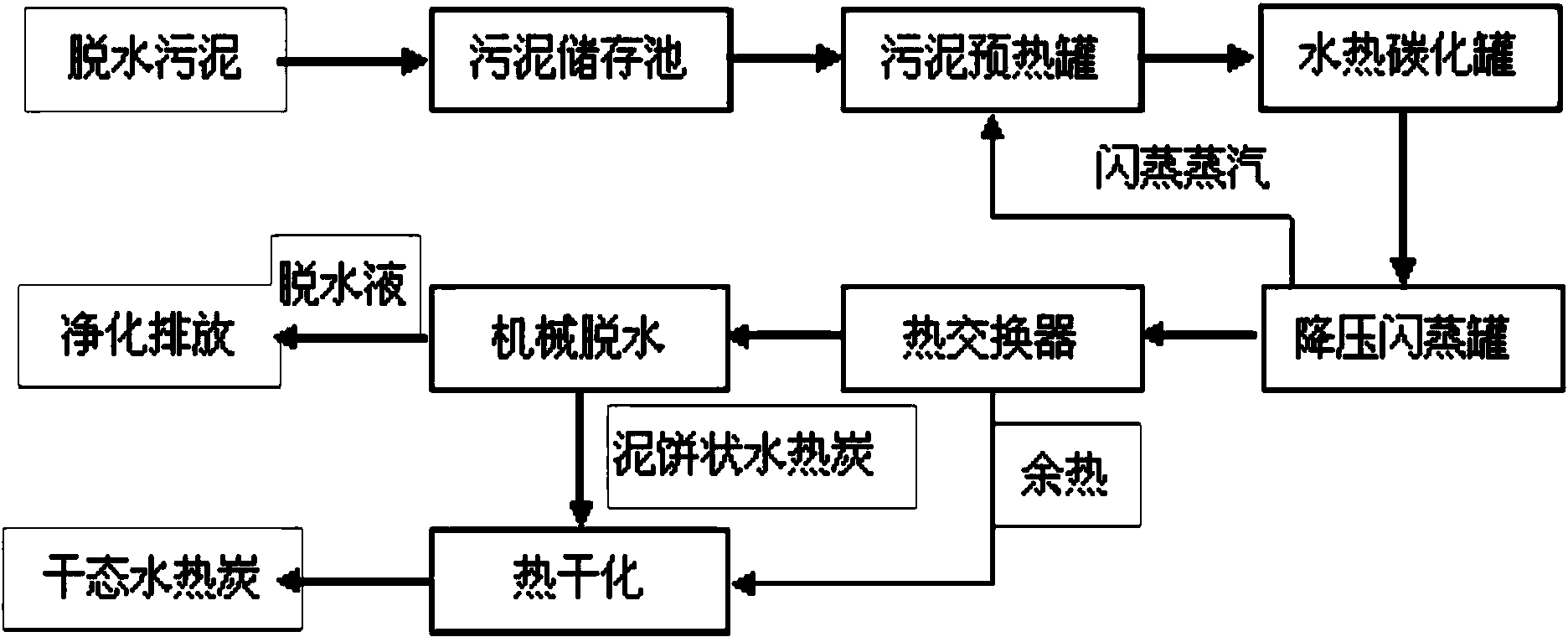

Sludge treatment method based on hydrothermal carbonization

InactiveCN103755124AEmission reductionIncrease organic carbon contentSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeToxic material

The invention relates to a treatment method of sludge generated by urban sewage treatment plant and industrial sludge and discloses a sludge treatment method based on hydrothermal carbonization. The sludge treatment method comprises four steps: sludge preheating treatment, hydrothermal carbonization, waste heat recovery and dehydration desiccation. By adopting the sludge treatment method, as the sludge is converted to hydrothermal carbon by adopting a hydrothermal carbonization technology, pathogenic microorganisms in the sludge are completely killed, most heavy metal pollutants in the sludge are dissolved out, and organic toxic substances in the sludge are effectively decomposed, so that the energy recovery utilization rate is high, and the sludge treatment method is clean, environment-friendly, rapid and effective and has high product additional values.

Owner:HANGZHOU HUHUI ENVIRONMENTAL PROTECTION TECH

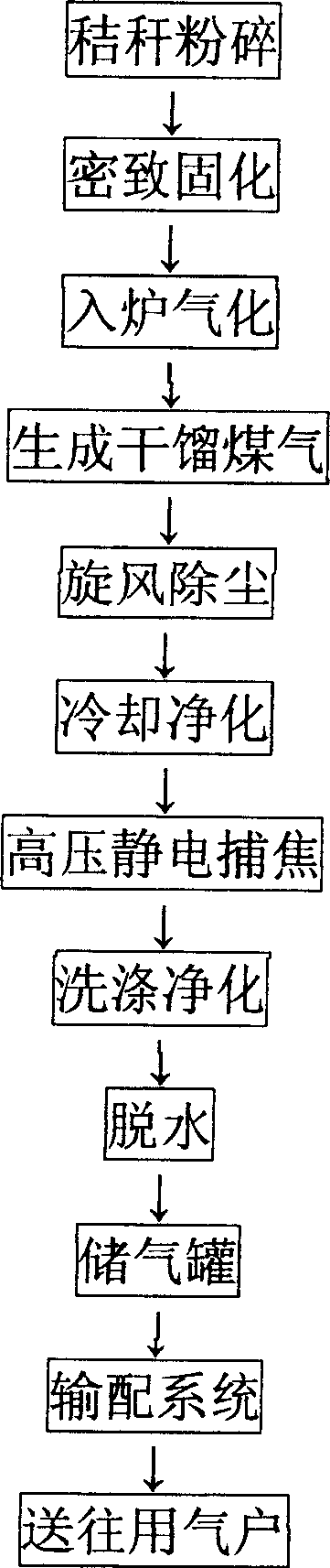

Biomass pyrogenation gasification and purification method

InactiveCN1730609AHigh calorific valueHigh hydrogen contentBiofuelsCombustible gas purificationCyclonePurification methods

The invention provides a biological mass thermal decomposition, gasification and purification method which comprises, disintegrating the biological mass, gasifying in a furnace, obtaining retort gas, cyclone dedusting, cooling down and purifying, high voltage static coke trapping, making the coke tar bubbles and dust in the coal gas deposit onto the coke collection poles, thus purifying the coal gas, finally washing and dewatering.

Owner:MIANYANG TONGMEI ENERGY SCI & TECH CO LTD

Straw densification briquetting fuel preparation method for biomass power generation and boiler combustion

InactiveCN101768494ARaise the ash melting pointImprove combustion effectBiofuelsSolid fuelsSolid fuelPotassium ions

The invention provides a straw densification briquetting fuel (SDBF) preparation method for biomass power generation and boiler combustion, solving problems of low ash fusion point, easily coking, serious corrosion to boilers and the like of direct straw combustion. In the invention, straw is pre-processed through steam explosion or with diluted acid then is subjected to enzyme hydrolysis with cellulose, and the enzyme hydrolysis residue is briquetted to be used as fuel for biomass power generation or boiler combustion. The pre-processed and enzyme-hydrolysis straw can be briquetted easily; cellulose and hemicellulose in the pre-processed and enzyme-hydrolysis straw are removed basically, lignin content and calorific value increase, potassium ion, sodion and chloridion are removed, thereby improving ash fusion point of straw, reducing coking and boiler corrosion in combustion process, and improving combustion performance of straw. The straw solid fuel prepared by the invention can be used as fuel for common domestic boilers. Sugar produced by enzymolysis can be used as a fermentation carbon source for large-amount fermented products, so as to improve comprehensive utilization value of straw.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

High-efficiency lignite low-temperature dry distillation quality-enhancing process by using dry distillation coal gas as heat-carrying medium

InactiveCN101812310AReduce in quantityEfficient use ofCoke quenchingChemical industryEconomic benefitsTar

The invention relates to a low-temperature dry distillation process for coal, in particular to a high-efficiency lignite low-temperature dry distillation quality-enhancing process by using dry distillation coal gas as a heat-carrying medium. The process comprises a coal-preparing flow, a drying flow, a dry distillation flow, a heat source flow, a coal gas and tar processing flow and a semicoke cooling transfer flow; in the process, vapor self-generated by a drying tower is used as a drying medium, the coal gas of a generator is taken as a heat source to heat the self-generated dry distillation coal gas, and serves as a dry distillation medium, and the coal gas of the generator is used as fuel of a hot air furnace; the dry distillation semicoke is cooled in a cooling mode of drying fume exhaust plus semi water spraying; and condensation water is used for coke-quenching water, a gasifier of the coal gas of the generator and a tar cooling agent. The process has the advantages of producing high-index dry coal and dry semicoke, high-heating value coal gas and high-quality tar, having a flawless and high-efficiency energy recycling system, not using outside nature water, hardly discharging water to the outside, saving huge cost for sewage treatment, creating the maximum economic benefits for customers and having quite strong competitive power on economy, technology and market.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Biomass curing-forming fuel and preparation method thereof

The invention discloses a biomass curing-forming fuel. The biomass curing-forming fuel consists of straws, saw dust, coal dust, a combustion improver, a sulfur-fixing agent and a dust-falling agent according to parts by weight, wherein the straw is one or combination of the straw of crops such as rice, wheat, soybean, corn, sorghum, cotton, rape and tobacco, a branch and a bark of trees and shrubs, rice hull, chaff and peanut coat; the combustion improver is one or more of table salt, sodium nitrate, potassium permanganate, potassium oxide, sodium nitrite and sodium hypochlorite and capable of realizing decomposition and combustion supporting at different temperatures; the sulfur-fixing agent is in a manner that sodium carbonate, calcium hydroxide and alkyl alcohol amine compounds are synergistically used and is capable of reducing discharging of sulfur dioxide; and the dust-falling agent is selected from iron sesquioxide and capable of lowering a melting point of ash and reducing dust volume. The biomass curing-forming fuel has the advantages that the combustion efficiency is high, the slag bonding and the soot formation are not generated, the black smoke is little, the fire power strong, the combustion is sufficient, the ash does not fly, the biomass curing-forming fuel is clean and sanitary and the like. The invention further discloses a preparation method of the biomass curing-forming fuel.

Owner:JINAN SANNONG ENERGY TECH

Method of modifying biomass, modified biomass aqueous biomass sluryy and method of producing the same, modified biomass gas and method of gasifying biomass

InactiveUS20060112638A1Reduce the amount of oxygenImprove efficiencyPressurized chemical processSolid waste disposalCelluloseSolid component

This method of upgrading a biomass comprises: an upgrading step for performing upgrading treatment of a cellulose based biomass with an oxygen / carbon atomic ratio of at least 0.5, in presence of water and under a pressure of at least saturated water vapor pressure, and reducing said oxygen / carbon atomic ratio of said biomass to no more than 0.38, and a separation step for separating an upgraded reactant obtained from said upgrading step into a solid component and a liquid component.

Owner:JGC CORP +1

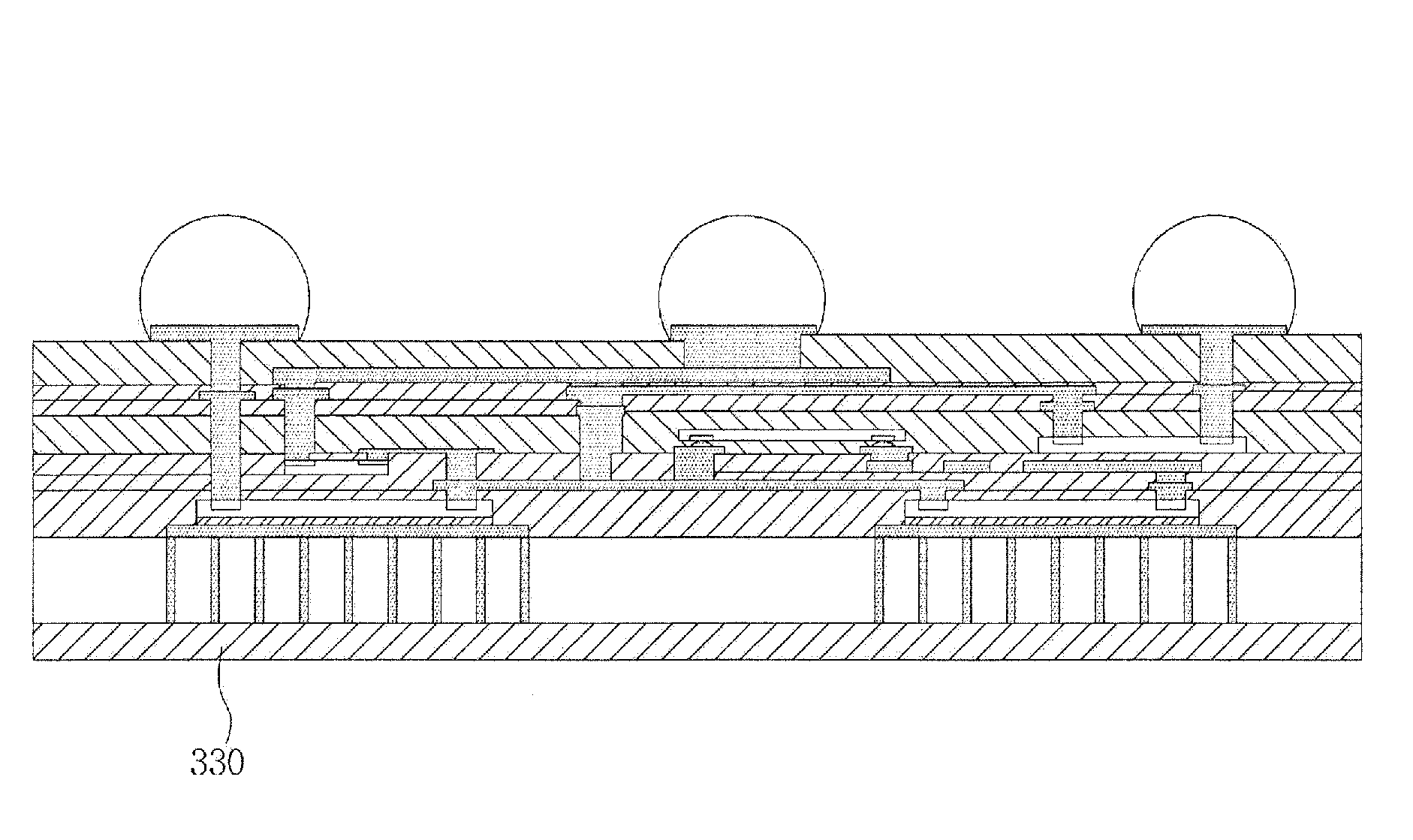

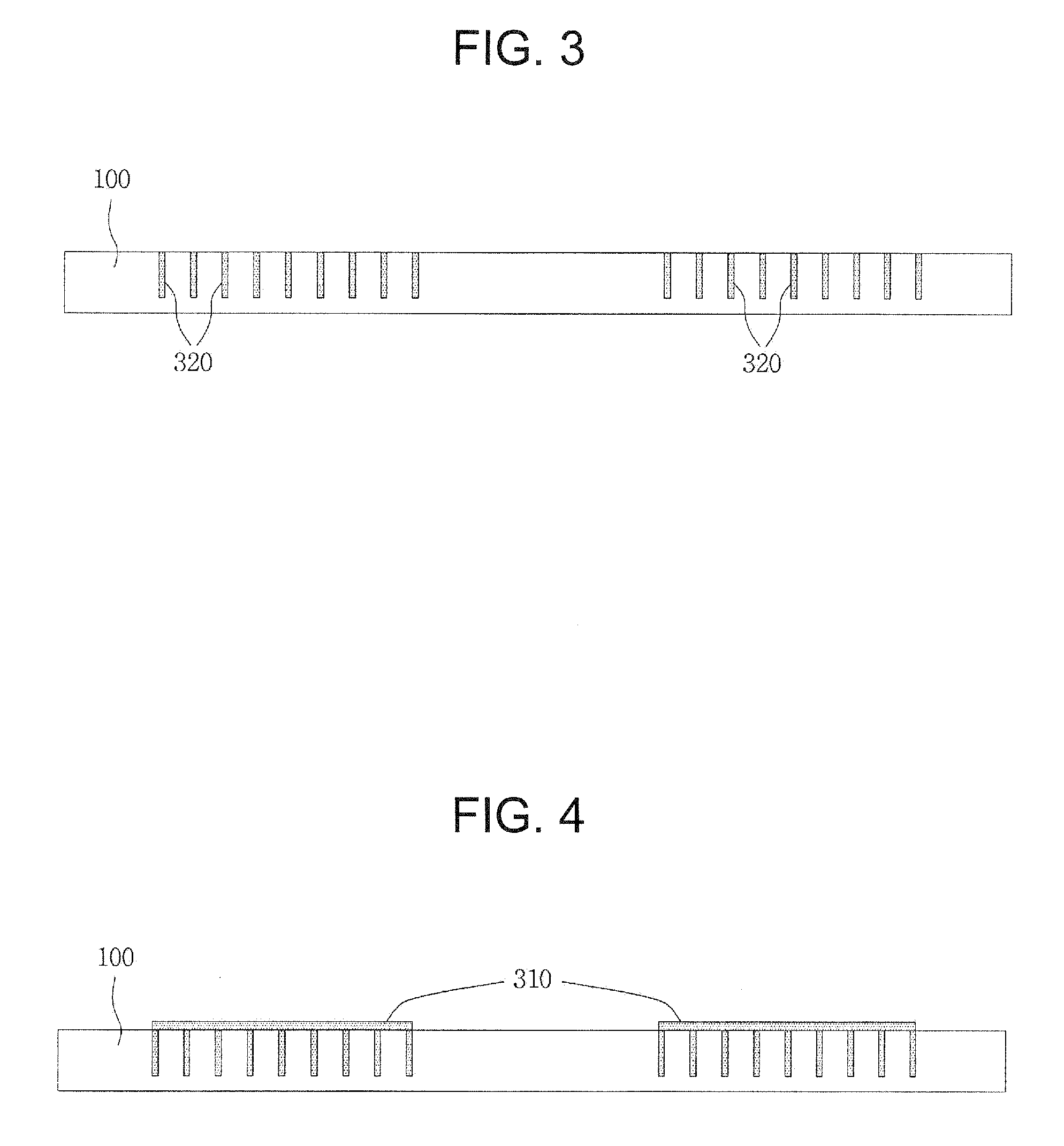

Wafer level system in package and fabrication method thereof

ActiveUS20080290496A1Easy to integrateEasily radiatedSemiconductor/solid-state device detailsSolid-state devicesDielectricUnit system

There is provided a system-in-package (SiP), which includes a substrate obtained by cutting a wafer for each unit system; one or more first electronic devices mounted on the substrate by a heat radiation plate; a plurality of interlayer dielectrics sequentially formed on the substrate; and one or more second electronic devices buried between or in the interlayer dielectrics on the substrate. A heat sink may be additionally attached to the bottom surface of the substrate. In this case, a thermal conduction path including heat pipes connecting the heat radiation plate on the substrate and the heat sink is formed. In the SiP, various types of devices are buried at a wafer level, so that a more integrated semiconductor device is implemented corresponding to demand for a fine pitch. Further, the heat radiation of a device required in high-speed operation and high heat generation is maximized due to the multi-stepped heat radiation structure, and thus the operation of the device is more stabilized.

Owner:NEPES CO LTD

Method and device for preparing formed sludge fuel

InactiveCN102212403AImprove dehydration effectImplement resourcesSludge treatment by de-watering/drying/thickeningBiofuelsSludgeSolid fuel

The invention discloses a process method for preparing a derived solid fuel by using sludge, and the method comprises the following steps: feeding dehydrated wet sludge with the moisture content of 70-85% and biomass at a weight ratio of 50:(1-10) into a tempering kettle, introducing less water, evenly stirring, adding a tempering agent the mass of which is 0-20% of that of dried solid sludge, stirring for 2-10 minutes continuously, removing most of water by a dehydrator, forming, and naturally drying for 24 hours, thus obtaining the derived sludge solid fuel. The invention also discloses a device for preparing a formed sludge fuel. The device comprises a straw crusher, a feeder, the tempering kettle, the stirrer, the fuel hydrator and a fuel forming machine, wherein the stirrer is positioned at the top of the tempering kettle, a stirring shaft is coincident with the axis of the tempering kettle and inserted into the tempering kettle, the outlet of the straw crusher is connected with the inlet of the feeder, the outlet of the feeder is connected with the inlet of the tempering kettle, the outlet of the tempering kettle is connected with the inlet of the fuel dehydrator, and the outlet of the fuel dehydrator is connected with the inlet of the fuel forming machine.

Owner:JIANGSU XINFA ENVIRONMENTAL PROTECTION TECHCO

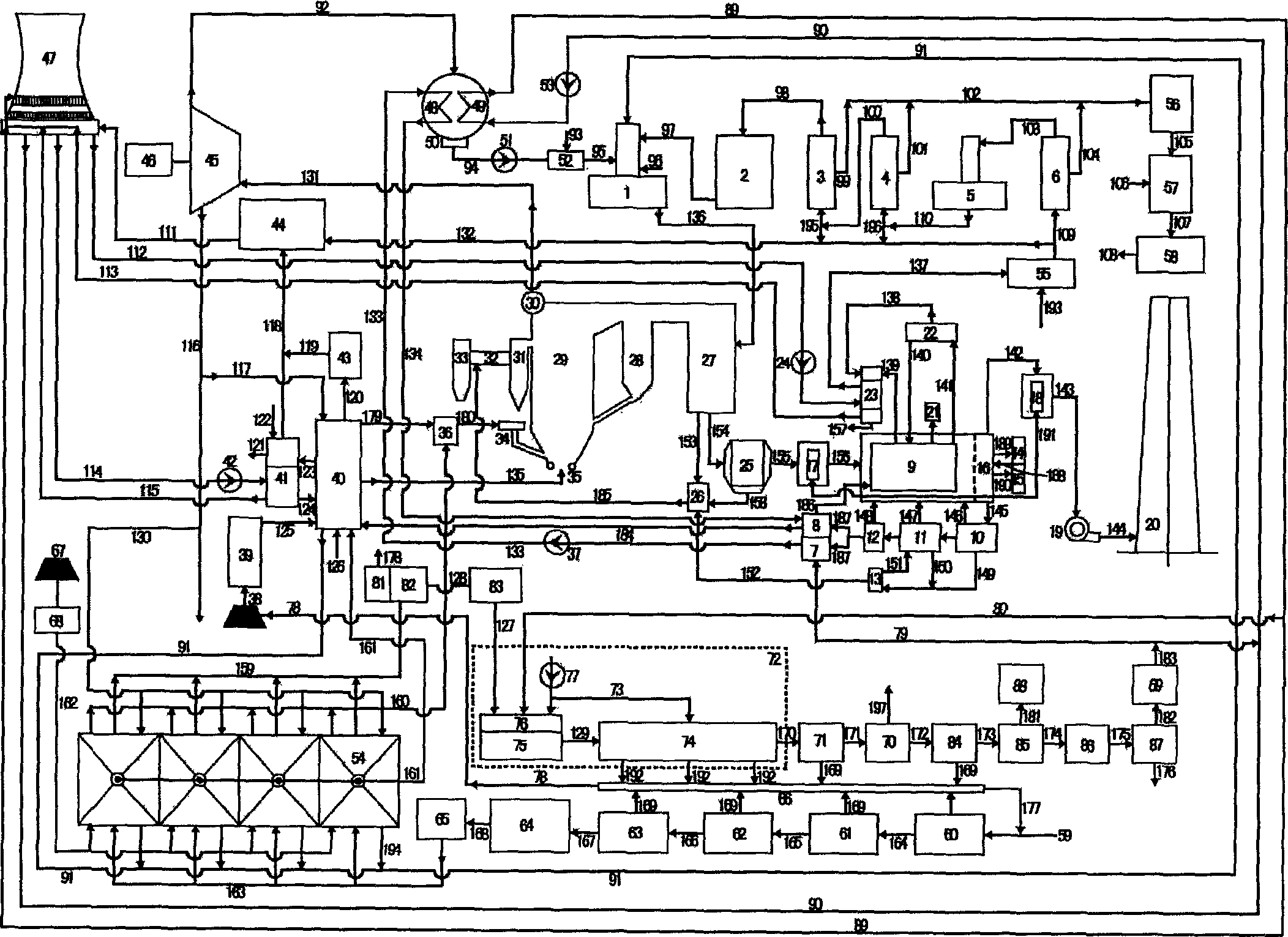

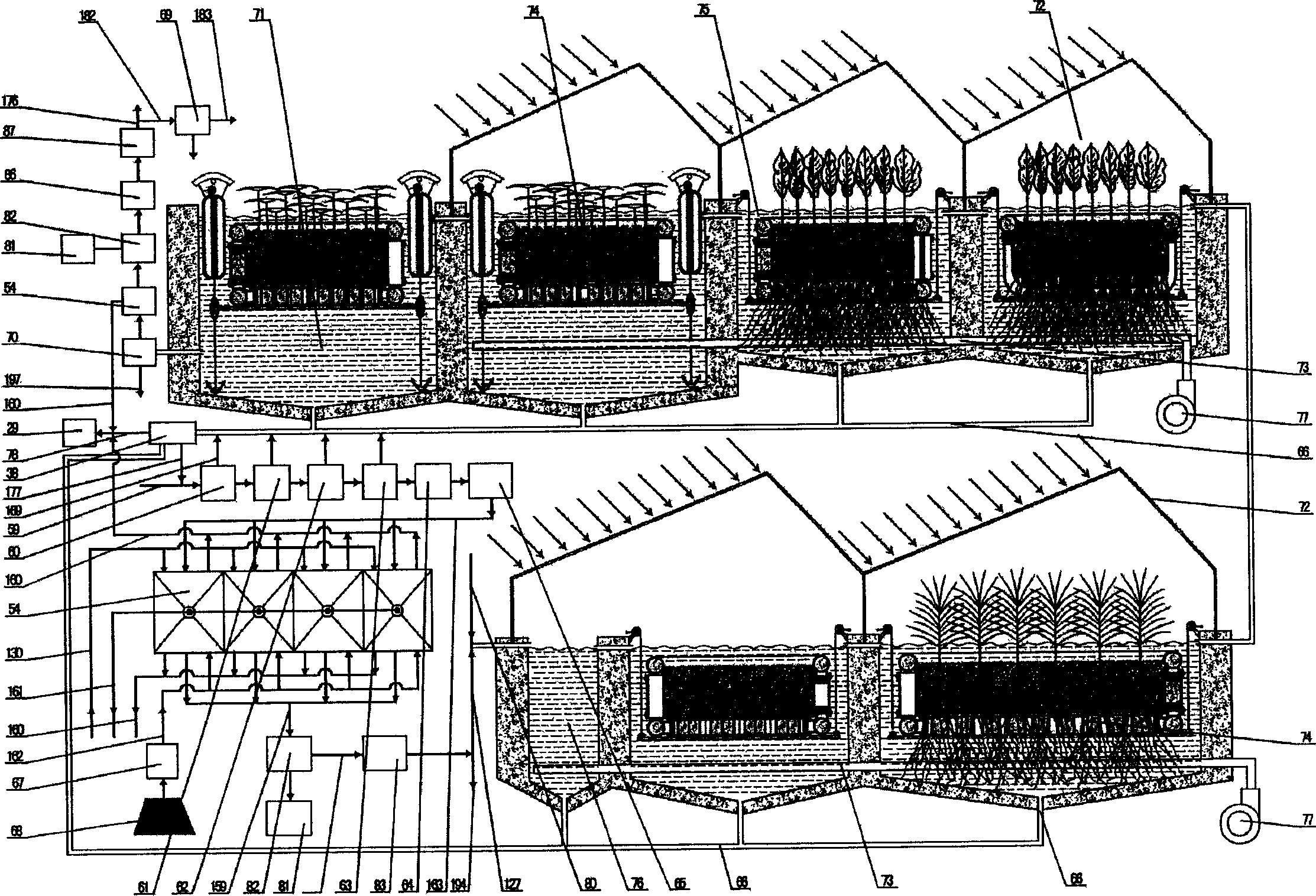

Sewage-refuse treatment clean-production system at the center of generating plant

InactiveCN1743284AImprove efficiencyComplete desulfurizationWater/sewage treatment by irradiationSolid waste disposalSteam condensationCoal

This sewage and garbage treatment system centrally designed for power plant includes sewage treatment unit, fuel processing unit, garbage combustion boiler, fly ash processing unit, smoke processing unit, the de-oxygenating draining steam of turbine steam-extraction heat-supply boiler and circulated water cooling unit. The effluent of sewage treatment unit with coal as filter is led into magnetic water strainer, and condensed water from the domestic garbage dehydration-drying condensed water-recovering combustion-supporting device is cleared by the coal filtration and normal water treatment system to feedback the circulated water-cooling system, the steam condensed water is heated and delivered into the de-oxygenating device. Treated sewage is introduced into multi-medium condenser and the distillation-desalination device; discharged smoke from fly ash incineration device is led into garbage combustion boiler; acid water discharged from distillation unit and alkaline water from coal filter are neutralized and discharged. Water distillation system and the circulation cooling water of the steam turbine condensator are led to the air- water cooling tower.

Owner:徐宝安

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com