Method and device for preparing formed sludge fuel

A sludge and fuel technology, which is applied in the field of preparing sludge briquette fuel and devices, can solve the problems of not meeting the conditions for industrialization promotion, hindering the promotion and application of fuel technology, reducing the calorific value of sludge, etc., and achieving an increase in the addition ratio and an addition ratio Low, the effect of improving the dehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing solid fuel derived from sludge, the steps are as follows:

[0030] Step 1 Add water to the dehydrated wet sludge with a moisture content of 70%~85% and stir evenly to prepare a slurry with a moisture content of about 90%. Add sludge to the tempering kettle with a mass ratio of 20:(1~8) the pre-crushed stalks, and stir the mixture evenly through a mixer;

[0031] Step 2: Add chemical conditioner to the conditioning tank according to 1-6% of the sludge mass, and continue to stir for 2-10 minutes to fully react the chemical conditioner and the mixture;

[0032] Step 3 Send the chemically conditioned mixture into the fuel dehydrator for dehydration;

[0033] Step 4: Granulate the dehydrated fuel mixture and dry it naturally for 24 hours to obtain a sludge-derived solid fuel with a water content of about 35%.

Embodiment 2

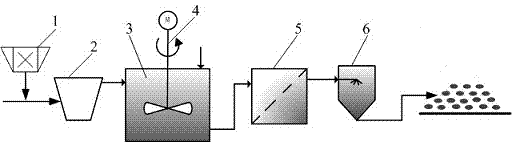

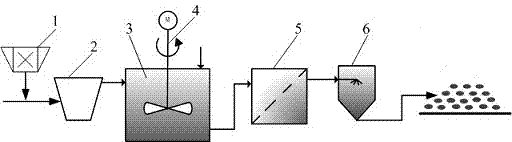

[0035] A device for implementing the above-mentioned method for preparing sludge-derived solid fuel, including a straw crusher 1 , a feeder 2 , a tempering kettle 3 , an agitator 4 , a fuel dehydrator 5 , and a fuel molding machine 6 . The agitator is located at the top of the conditioning kettle, the stirring shaft coincides with the axis of the conditioning kettle and goes deep into the conditioning kettle, the outlet of the straw crusher and the inlet of the feeder, the outlet of the feeder and the inlet of the conditioning kettle, the outlet of the conditioning kettle and the fuel The inlet of the dehydrator, the outlet of the fuel dehydrator are connected with the inlet of the fuel forming machine.

[0036] Below with reference to accompanying drawing, the present invention is described in more detail:

[0037] refer to figure 1 , a device for preparing synthetic fuel from sludge, comprising a straw crusher 1, a feeder 2, a tempering kettle 3, a stirrer 4, a fuel dehydra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com