Non-excess activated sludge discharged printing and dyeing wastewater processing equipment and operation method thereof

A printing and dyeing wastewater and residual activity technology, which is applied in water/sludge/sewage treatment, textile industry wastewater treatment, water/sewage multi-stage treatment, etc., can solve the problems such as difficult to treat biodegradable industrial wastewater, and improve biochemical sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

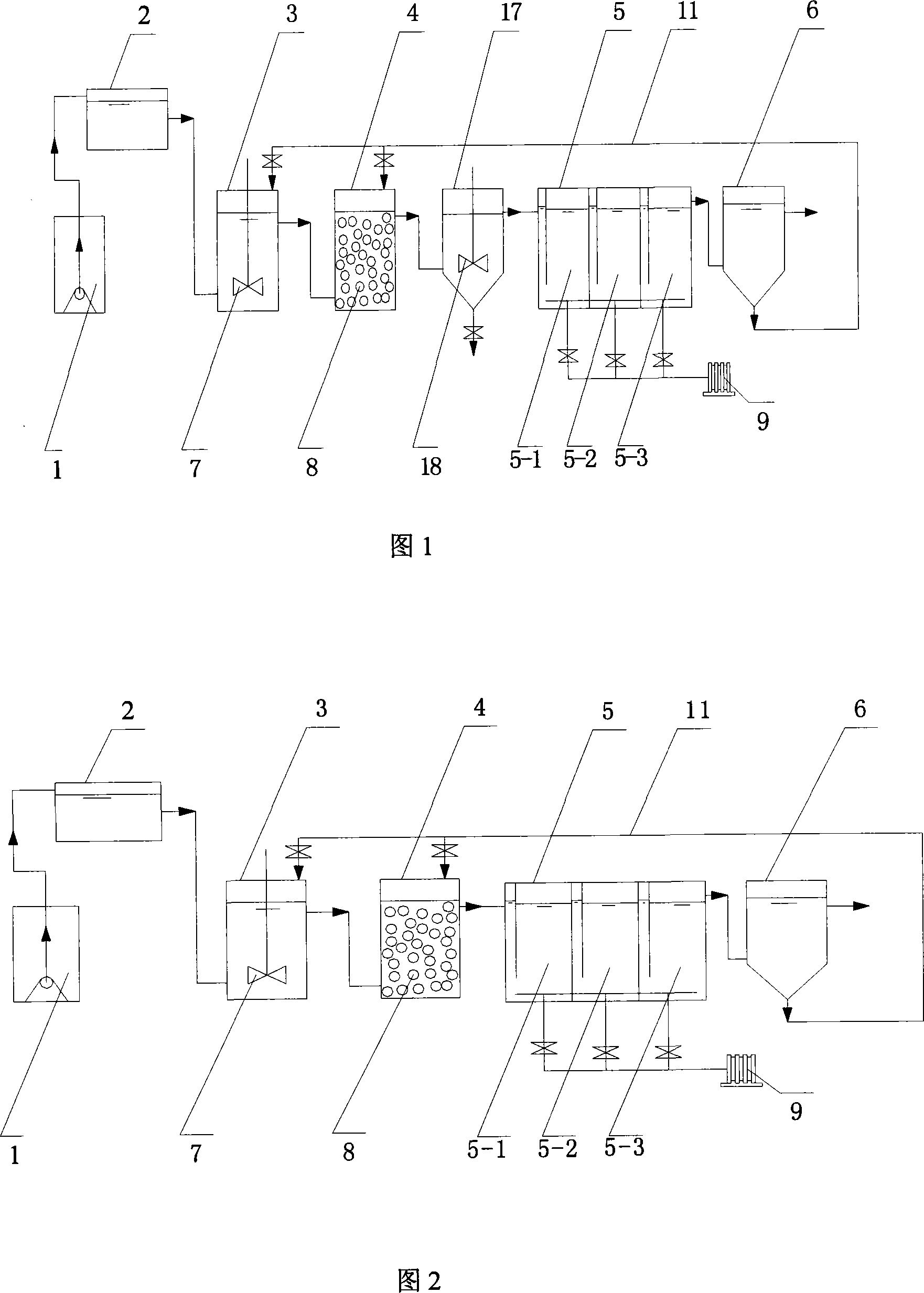

[0034] As shown in Figure 1, the start-up stage: the excess sludge retrieved from the urban sewage plant and a small amount of domestic wastewater are mixed in a ratio of 1:1 into the two-stage hydrolysis acidification reaction tank and the multi-stage oxidation reaction tank, and the MLSS in the control reactor is 4g / L. The reactor was started with a mixture of printing and dyeing wastewater and domestic wastewater with a COD of 1000mg / L. The rotation speed of the slow agitator 7 in the No. 1 hydrolysis acidification reactor 3 is 50 r / min. Keep the water temperature in the multi-stage contact oxidation tank at 20-25° C. and the pH at 6-9 during the whole operation process. After the effluent from the multi-stage contact oxidation tank settles in the solid-liquid separation sedimentation tank 6, the supernatant is discharged, and the remaining sludge at the bottom of the solid-liquid separation sedimentation tank is evenly distributed to each reaction tank. The average sludg...

Embodiment 2

[0040] The start-up phase is the same as Example 1.

[0041] As shown in Figure 1, the continuous operation stage: a small amount of residual sludge at the bottom of the solid-liquid separation sedimentation tank flows back along the return pipe 11 to the No. 1 hydrolysis and acidification reactor 3 and the No. 2 hydrolysis and acidification reactor 4. The sludge distribution ratio of No. 1 hydrolytic acidification reactor 3 and No. 2 hydrolytic acidification reactor 4 is 2:1. The rotation speed of the slow agitator 7 in the No. 1 hydrolysis acidification reactor 3 is 40r / min, and the rotation speed of the agitator 18 in the phosphorus removal tank 17 is 80r / min. Influent COD concentration control increased from 1200-1400mg / L to 3800-4500mg / L. Maintain the total HRT for 35h, the COD removal effect is shown in Table 2, and the COD removal rate is always higher than 94%. The effluent COD index meets the secondary standard of the Textile Dyeing and Finishing Industry Water Poll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com