Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3564results about "Waste water treatment from textile industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

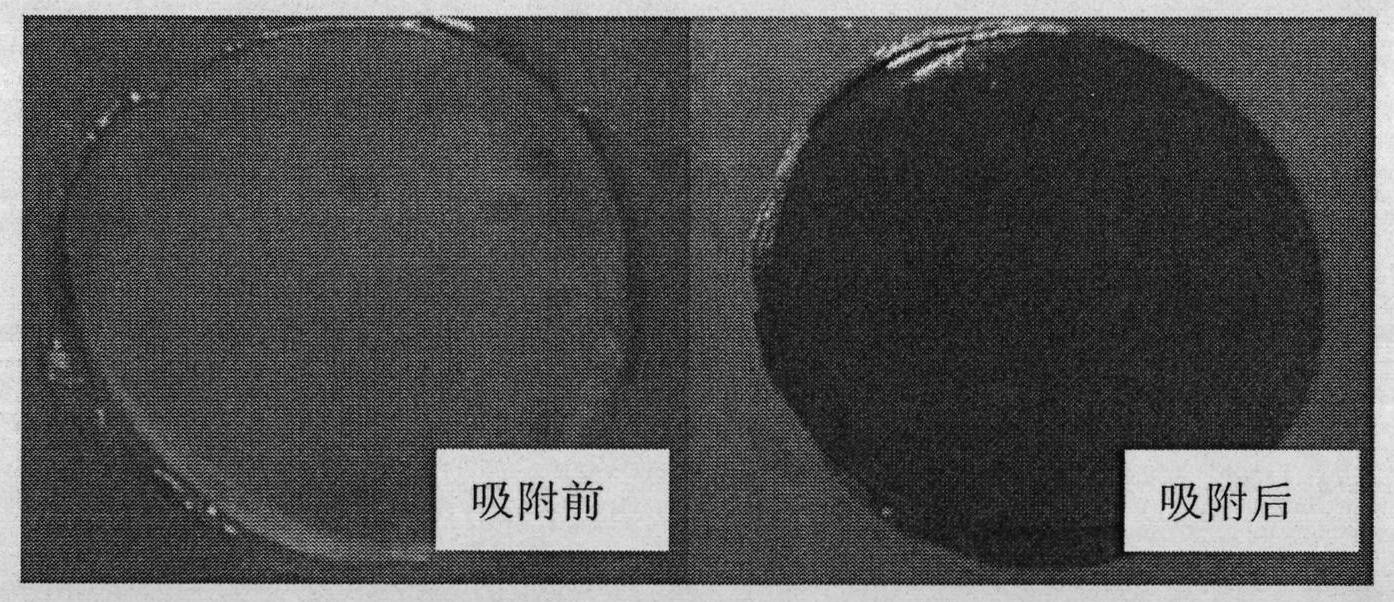

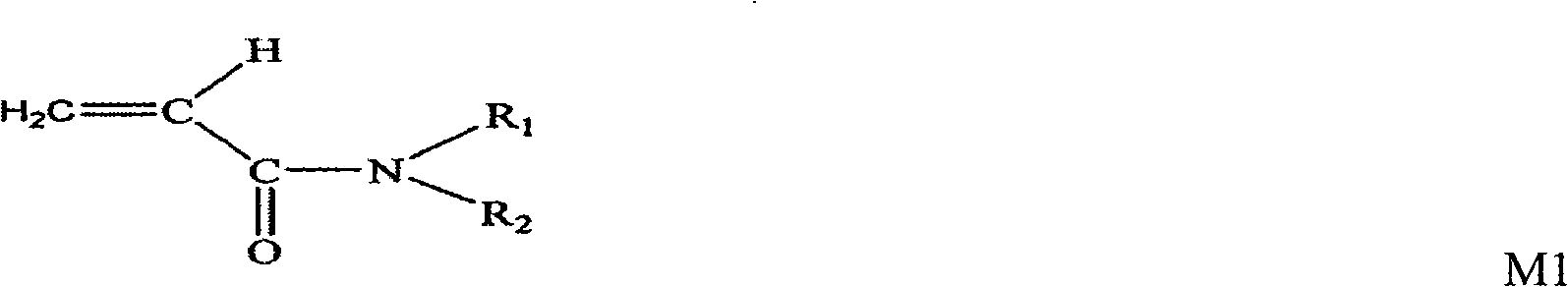

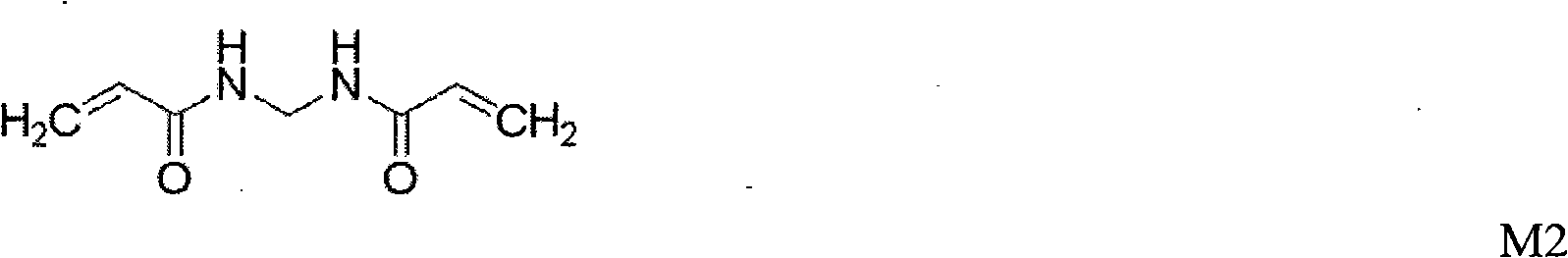

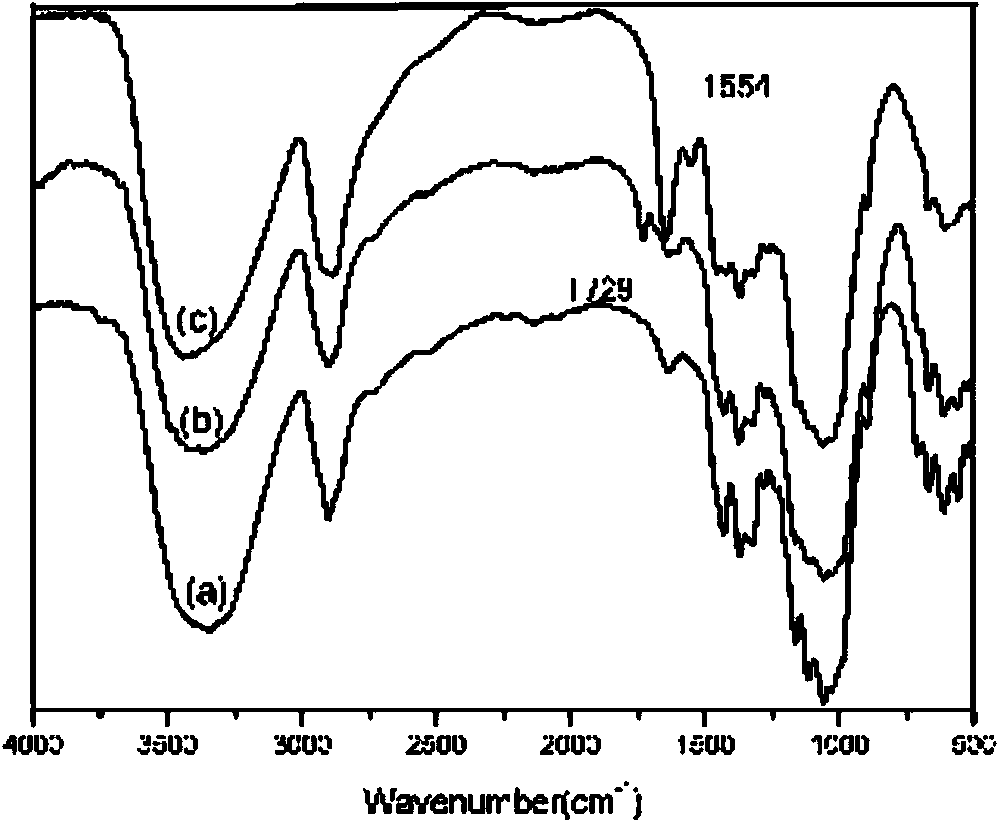

Nanometer clay-containing high absorptive hydrogel as well as preparation method and application thereof

InactiveCN101942167AImprove adsorption capacityImprove mechanical propertiesOther chemical processesWaste water treatment from textile industryBiopolymerWater soluble

The invention relates to a nanometer clay-containing high absorptive hydrogel as well as a preparation method and application thereof. The hydrogel contains an acrylamide monomer M1, a chemical crosslinking agent M2, inorganic nanometer clay M3 and a water soluble biopolymer M4 with use level of 98-50:0-10:2-25:015 in mass percent. The preparation method comprises the following step of: taking M3 as a filler or a reinforcing agent or a physical crosslinking agent and taking M4 as a second component in a water solution to prepare the environmentally-friendly hydrogel with high water soluble dye adsorption property and excellent mechanical property. The method has the advantages of simple and reliable preparation process, no environmental pollution, very strong dye adsorption removal effects and practicability; and the dye adsorption quantity can be adjusted by temperature, pH value, crosslinking degree, dye concentration, nanometer clay or biopolymer variety and use level and a reactant charge ratio. The hydrogel can be used for the fields of weaving and dyeing wastewater treatment, dye adsorption, and the like.

Owner:TIANJIN POLYTECHNIC UNIV

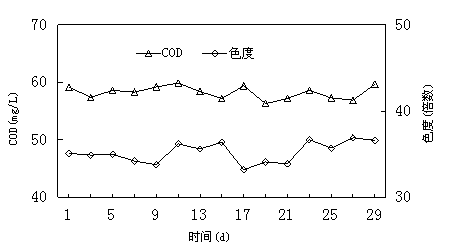

Textile dyeing wastewater advanced treatment recycling technology

InactiveCN102145965AReduce chromaImproved BioprocessingMultistage water/sewage treatmentWater/sewage treatment by neutralisationTextile fiberChemical treatment

The invention discloses a textile dyeing wastewater advanced treatment recycling technology. The technology comprises the following steps: filtering to remove textile fibers; cooling; neutralizing, degrading organic matters and decomposing, replacing or degrading (cracking) the chormophoric groups of the organic matters to reduce the chroma of the wastewater; performing biochemical treatment with the biomembrane; precipitating to ensure that the precipitated sludge enters a sludge treatment system and the supernatant enters a flocculation pool; performing chemical treatment, namely adding a medicament in the flocculation pool to remove the suspended matter (SS), CODcr (chemical oxygen demand), BOD (biochemical oxygen demand) and chroma of the water; performing secondary precipitation to ensure that the free SS is precipitated and the wastewater is decolored further; separating to remove and degrade the chloride ions of the reuse water; performing secondary biochemical treatment to further reduce the concentrations of the SS, CODcr and BOD in wastewater; performing ozone oxidation treatment, decoloring, degrading organic matters; performing chemical treatment to remove insoluble dye materials and SS and reduce the COD and chroma; and performing secondary filtration, and forming an ozone / activated carbon system to ensure that the hydroxyl radicals of activated carbon are used and the organic reaction in wastewater is adopted to decolor and degrade organic matters. The invention overcomes the defects of the existing physical method, chemical method and chemical method treatment technologies; and the technology has been used in many enterprises, and the good treatment effects are obtained.

Owner:李斌 +2

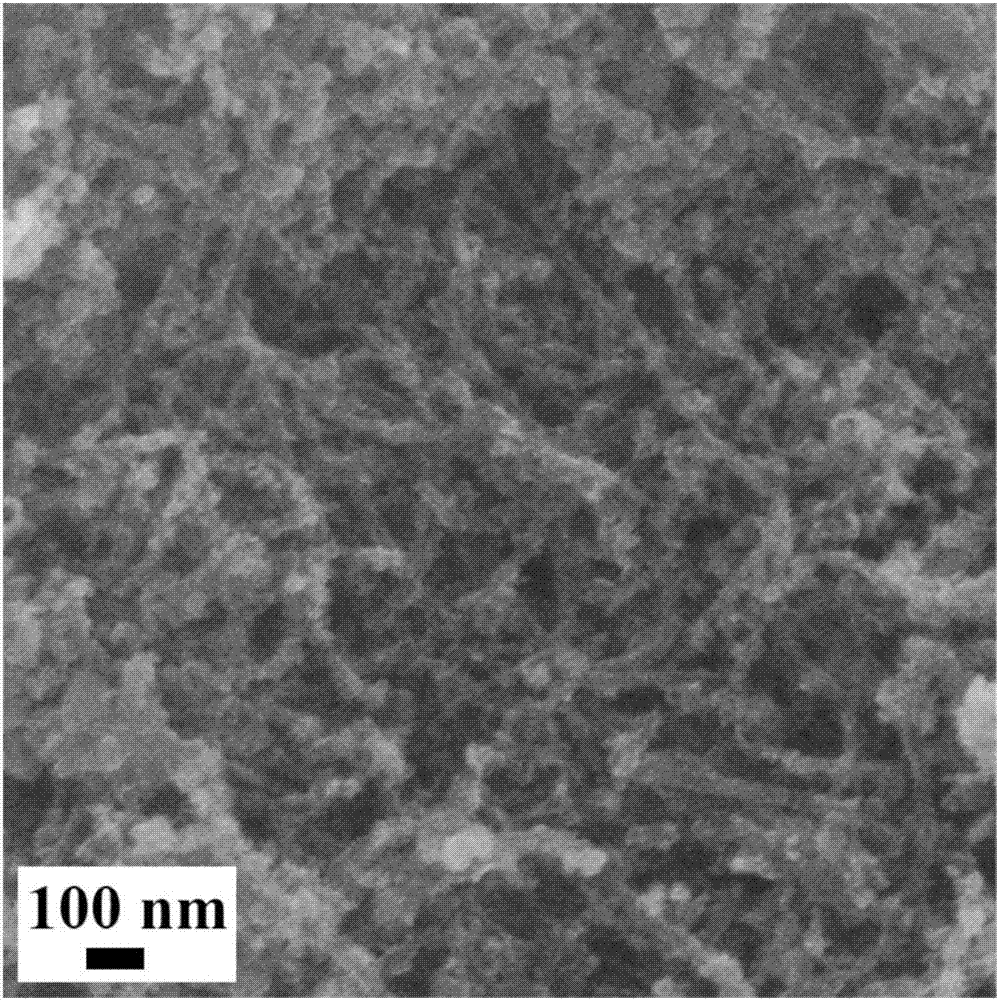

Preparation method and application of graphene oxide-polyurethane foam material

InactiveCN103408718AImprove adsorption capacityGood removal effectOther chemical processesWater contaminantsMalachite greenPolymer science

The invention belongs to the field of high polymer material synthesis, and relates to preparation of a graphene oxide-polyurethane foam material, in particular to a preparation method and application of the graphene oxide-polyurethane foam material. The preparation method of the graphene oxide-polyurethane foam material comprises the following steps: firstly, preparing graphene oxide by adopting an improved Hummers method, then mixing and stirring graphene oxide, polyether glycol NJ-330, foaming agent, foam stabilizer and catalyst at room temperature, adding isophorone diisocyanate, and finally, foaming further to obtain the graphene oxide-polyurethane foam material. The graphene oxide-polyurethane foam material prepared through the method can be applied to absorption of coloring matters or heavy metal ions in waste water, and has better absorption and removal effects as shown in a test by taking a solution containing malachite green and Cd (II) as the absorption object. The application of the foam material to treatment of the coloring matters and the heavy metal ions in sewage has the characteristics of simplicity in operation and high absorption rate, and has a certain practical value.

Owner:JIANGSU UNIV

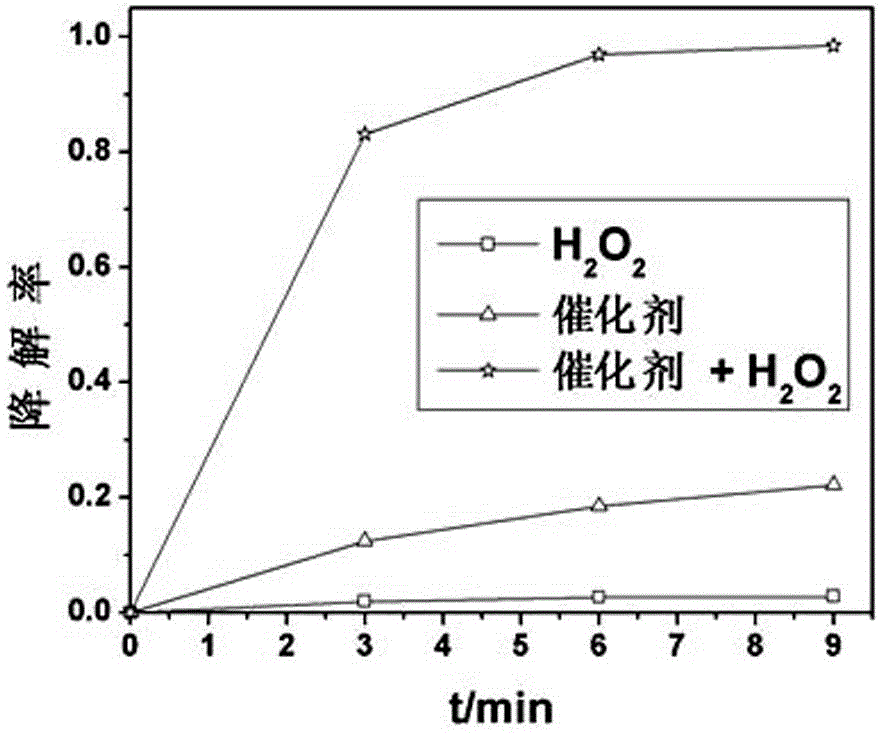

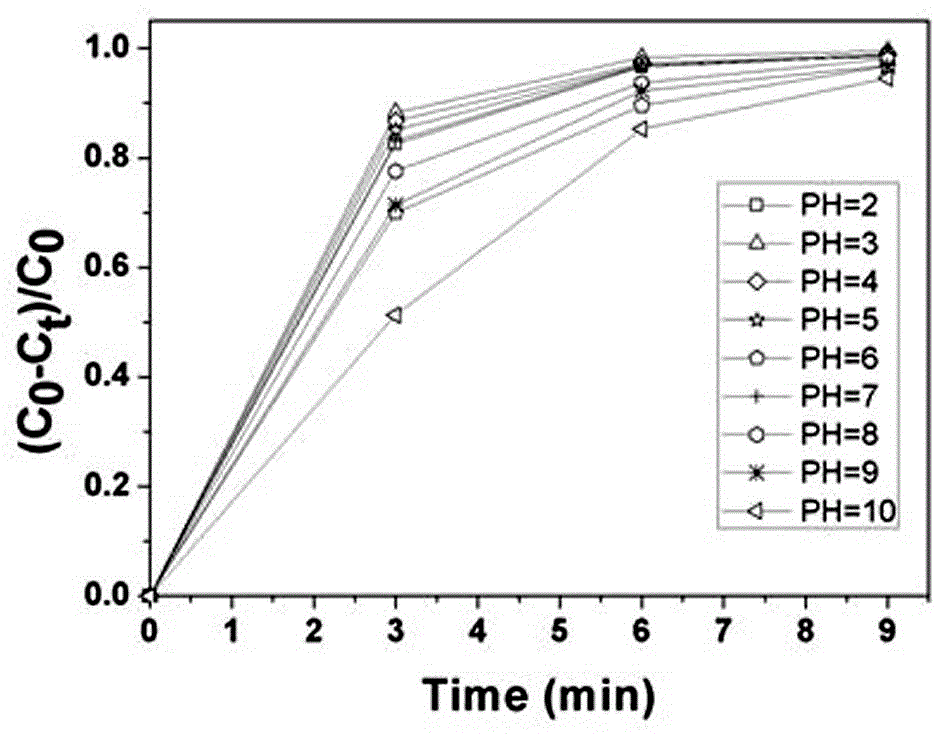

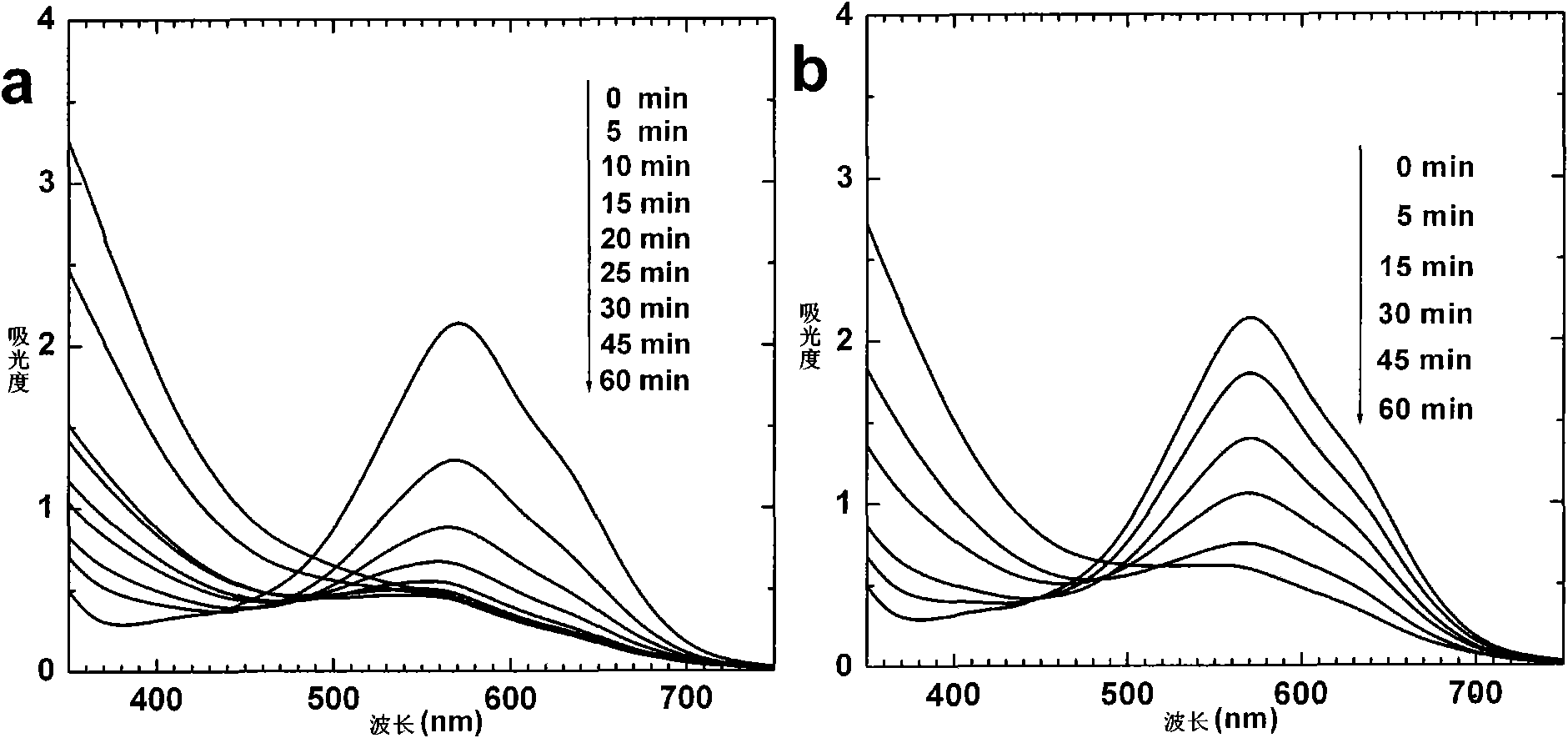

Preparation method and application of heterogeneous Fenton-like catalyst

InactiveCN102909073ALow costEfficient degradationOrganic-compounds/hydrides/coordination-complexes catalystsWaste water treatment from textile industryFiberCarbon fibers

Disclosed are a preparation method and application of heterogeneous Fenton-like catalyst. The preparation method includes the steps of firstly, dissolving complexing agent and metal salt in distilled water to respectively prepare complexing agent and metal salt solutions; secondly dropwise adding the metal salt solution into the complexing agent solution under the action of a magnetic mixer, and mixing for 20-60 after dropwise addition to obtain metal complex solution; and thirdly, impregnating activated carbon fiber in the metal complex solution for 1-24h, and subjecting taken-out activated carbon fiber to distilled water washing and drying to obtain the heterogeneous Fenton-like catalyst. The preparation method is simple, and conditions are mild. Environment-friendly hydrogen peroxide is used as oxidant, no extra ultraviolet light or even visible light is needed, and the heterogeneous Fenton-like catalyst is capable of efficiently degrading organic pollutants such as dye within a wide pH range of 2-10. The heterogeneous Fenton-like catalyst is well repeatable, and secondary pollution of the homogeneous Fenton reagent caused by iron ions is avoided.

Owner:ZHEJIANG SCI-TECH UNIV

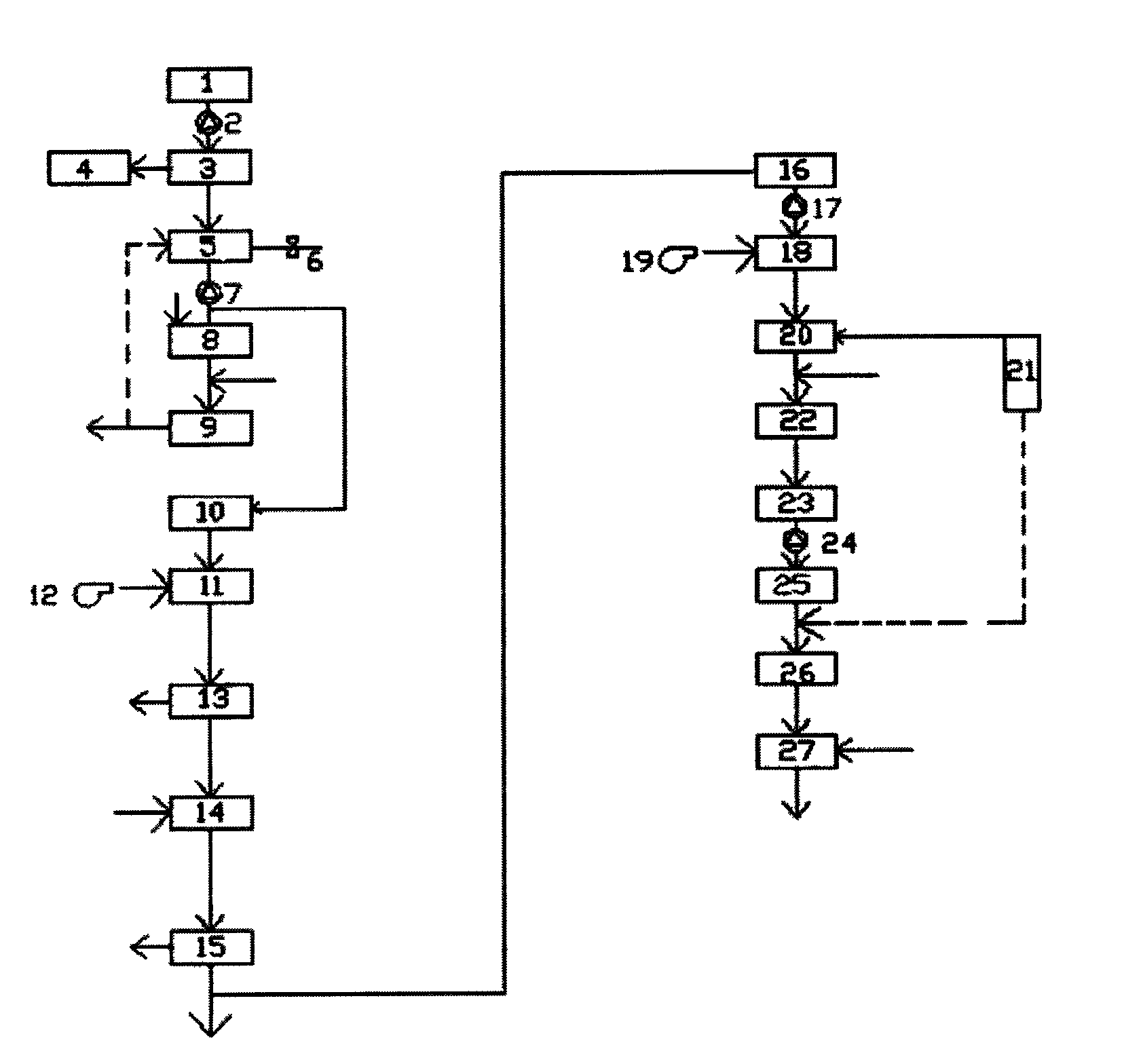

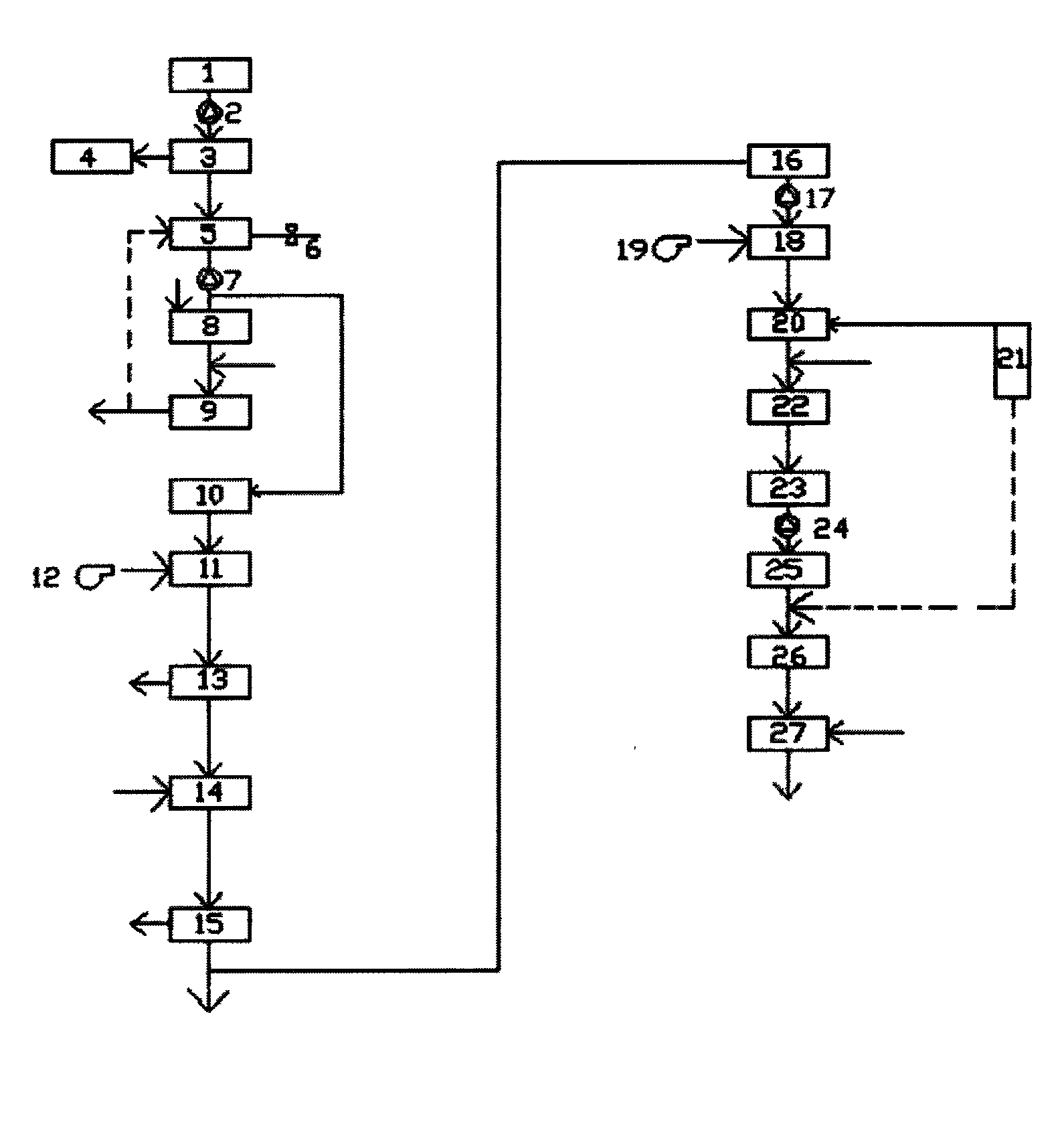

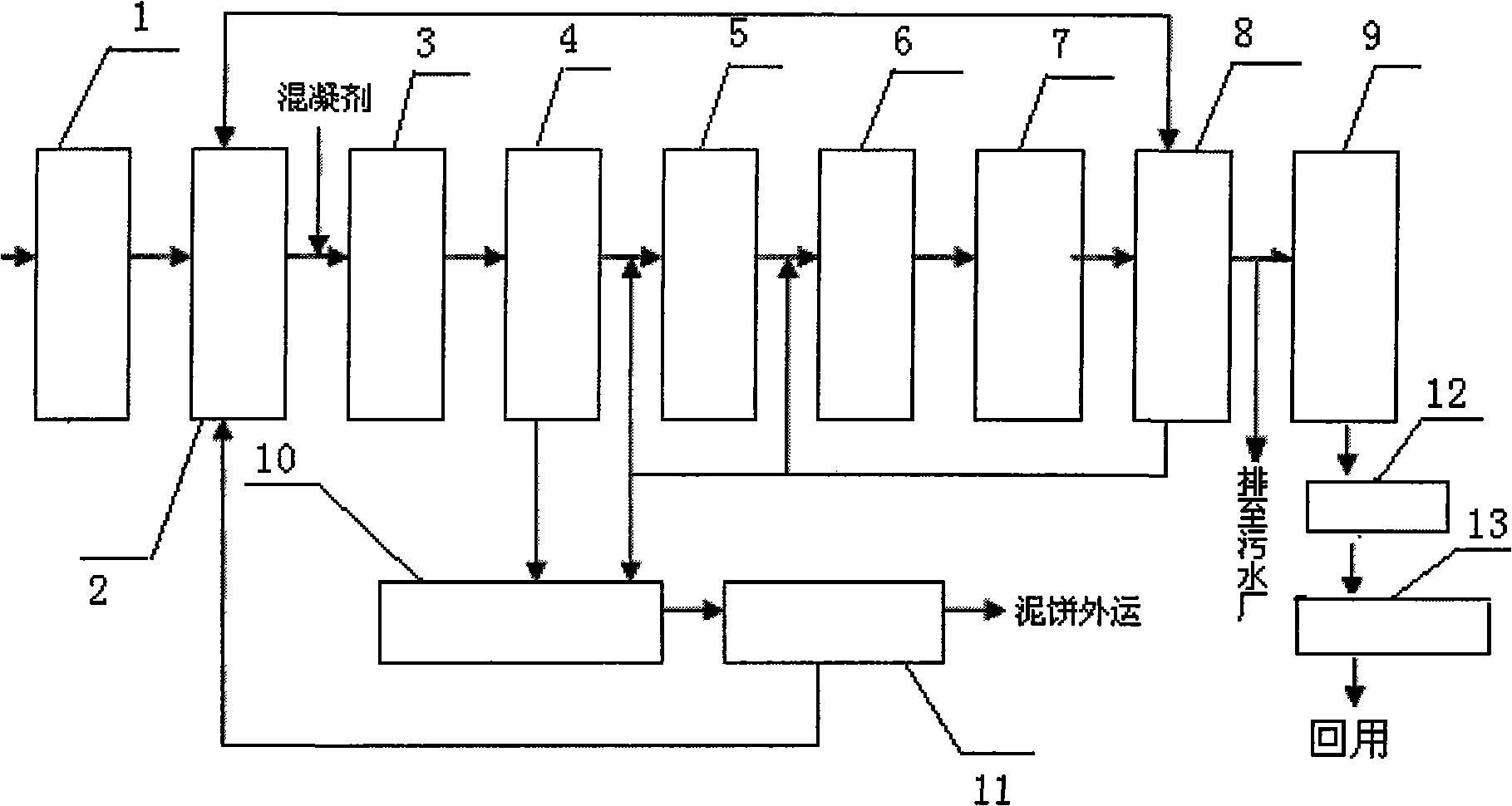

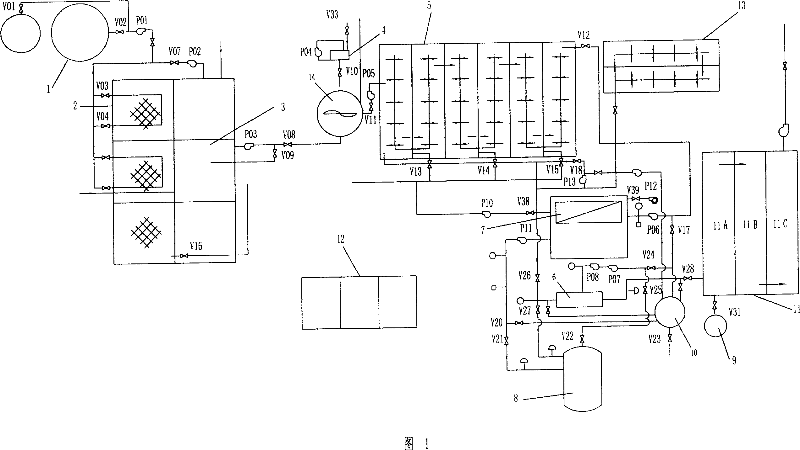

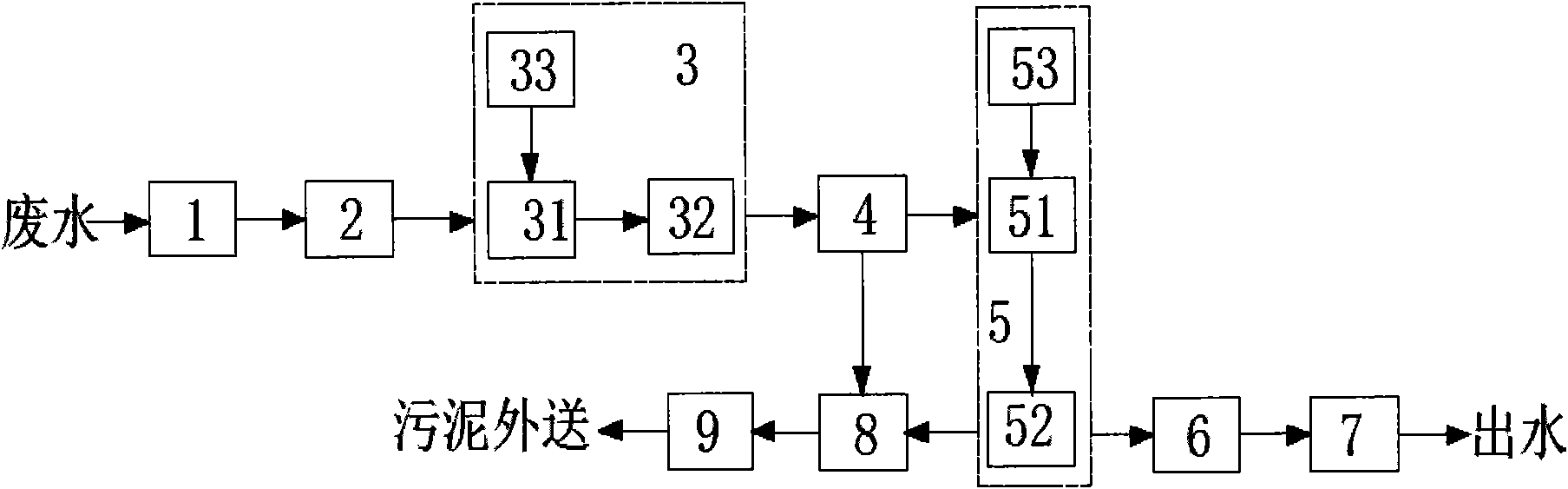

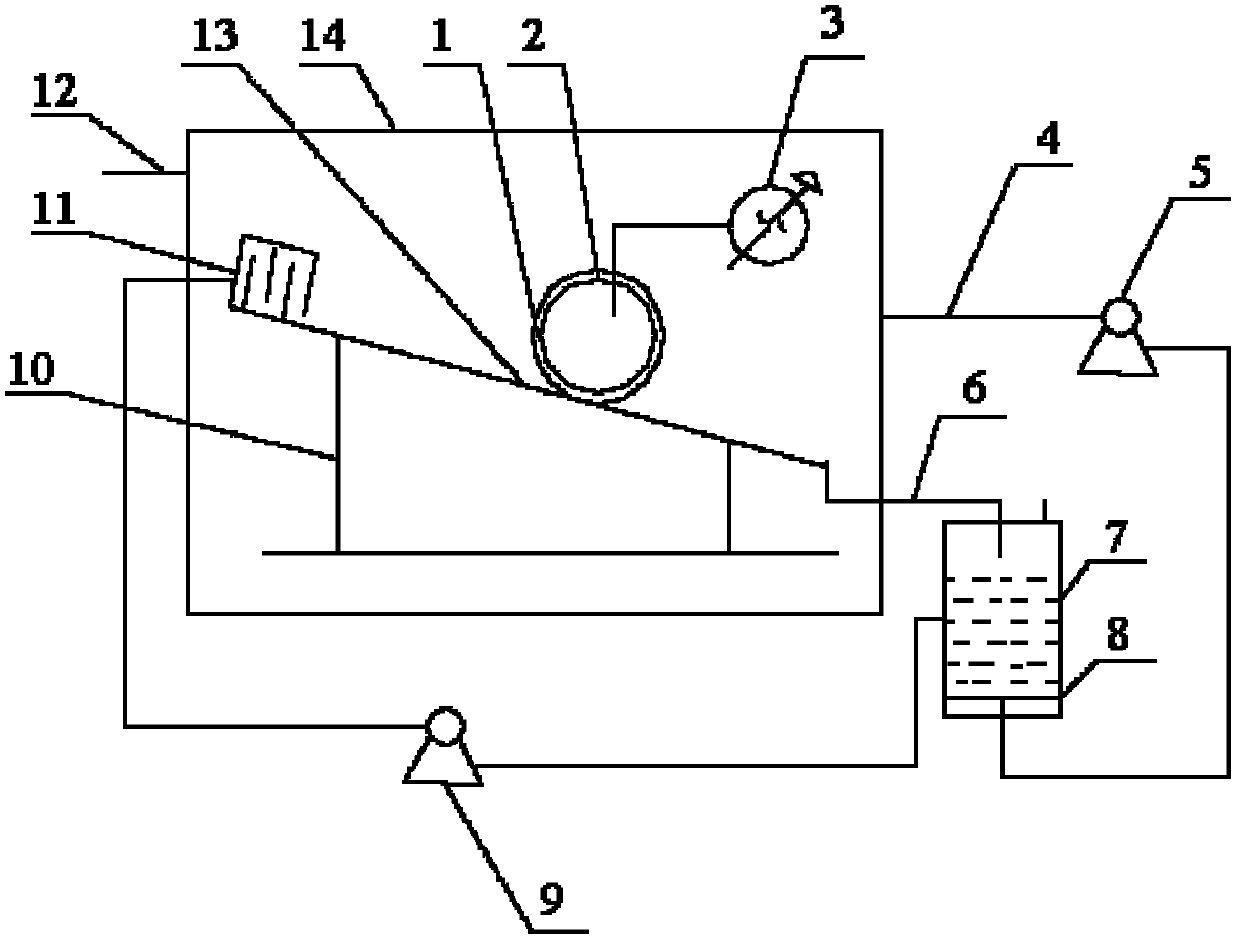

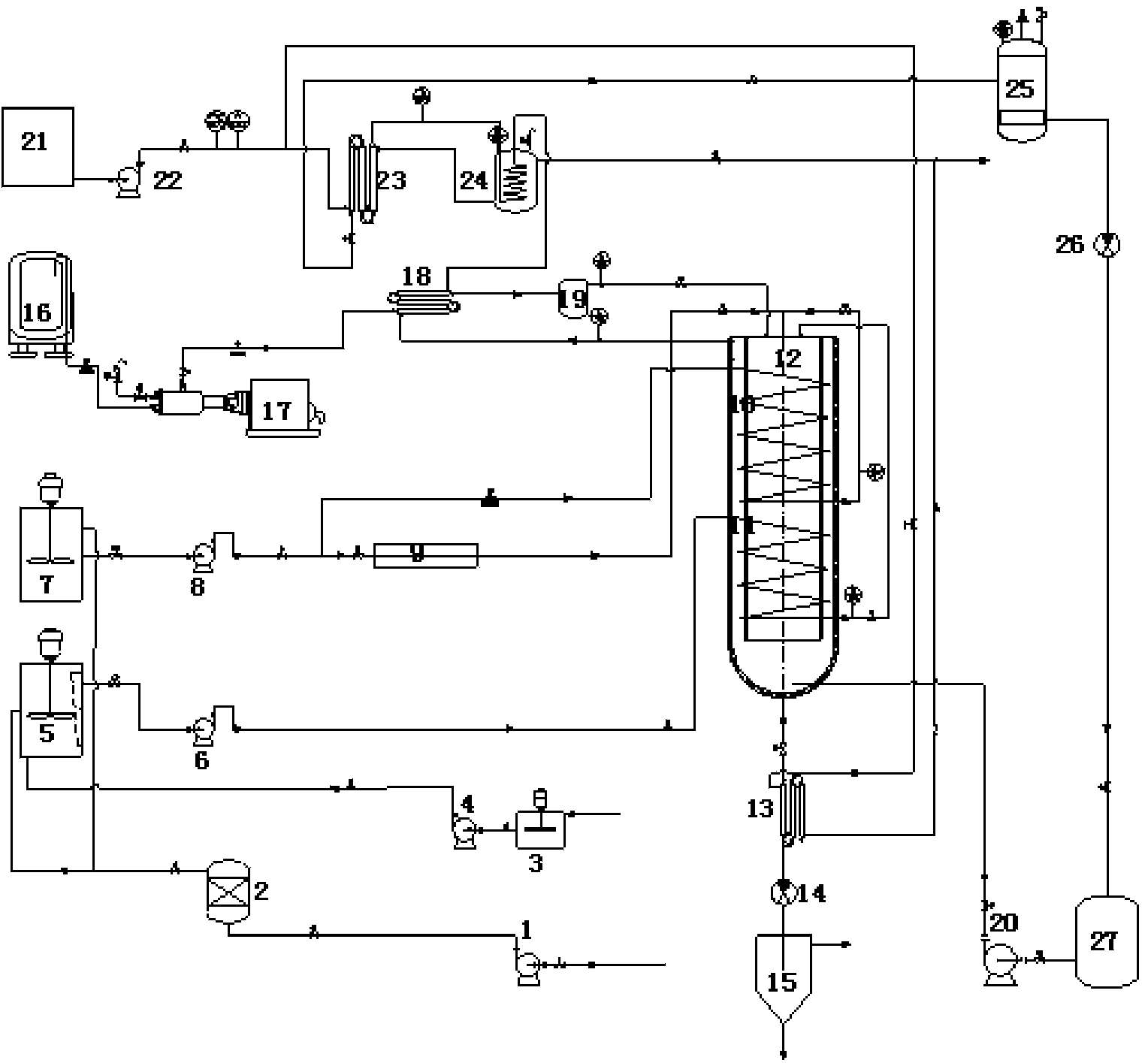

Advanced dyeing wastewater treatment and reclaimed water reuse system and method thereof

InactiveCN101525202ASimple processLow running costSludge treatment by de-watering/drying/thickeningTreatment with aerobic and anaerobic processesBiological activated carbonReclaimed water

The invention relates to an advanced dyeing wastewater treatment and reclaimed water reuse system and a method thereof. The system consists of a regulating tank (2), a coagulation tank (3), a preliminary sedimentation tank (4), an acidification hydrolysis tank (5), a deep well (6), a deaeration tank (7), a secondary sedimentation tank (8), a biological activated carbon tank (9), a sludge concentration tank (10), a sludge dewatering tank (11), a filter tank (12) and an ozone oxidation tank (13). The method comprises the following steps: wastewater is sent to the regulating tank, the coagulation tank and the preliminary sedimentation tank, then sludge is returned to the coagulation tank, excess sludge is discharged to the sludge concentration tank, clarified water flows to the acidification hydrolysis tank, is sent to a deep well aeration tank and then sent to the secondary sedimentation tank; and the obtained clarified water is discharged after meeting the standard, or flows to the biological activated carbon tank and is treated for production. The system and the method have the advantages of simple process, low operating cost, high stability and reliability, convenient operation, and realization of automation control. Most of the wastewater discharged is reused in production after the treated wastewater meets the standard, thus reducing emission of pollutants, being capable of eliminating environmental pollution resulting from the wastewater and protecting environment.

Owner:常州市东霞房地产代理有限公司 +2

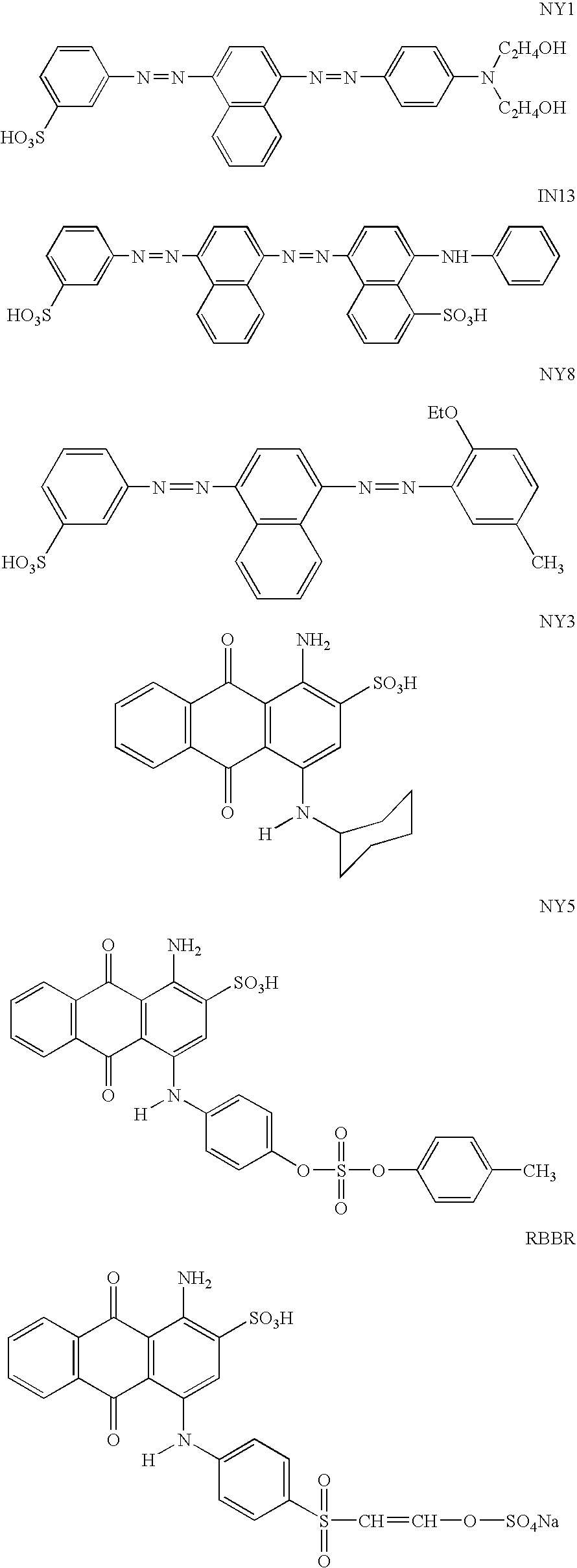

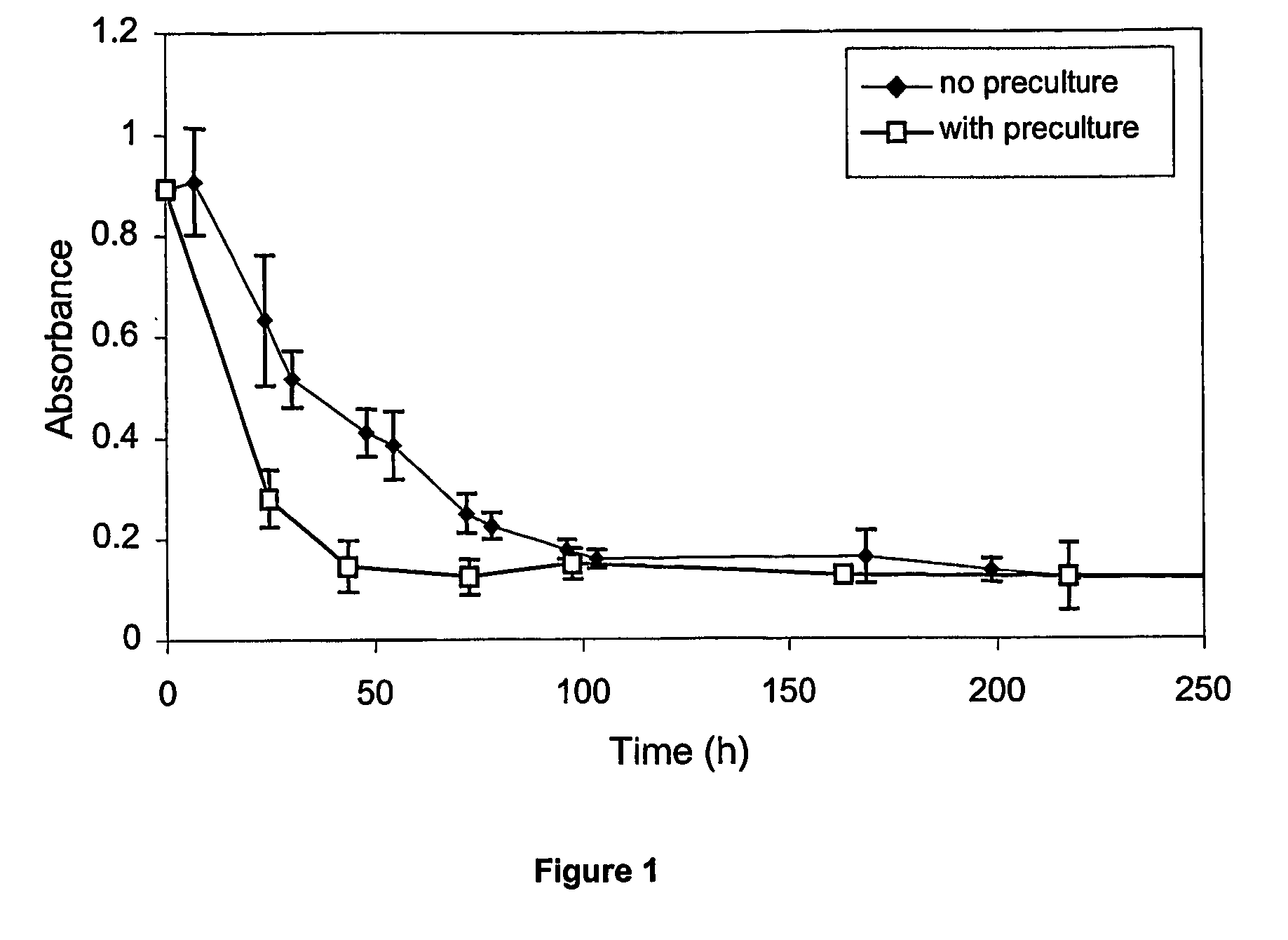

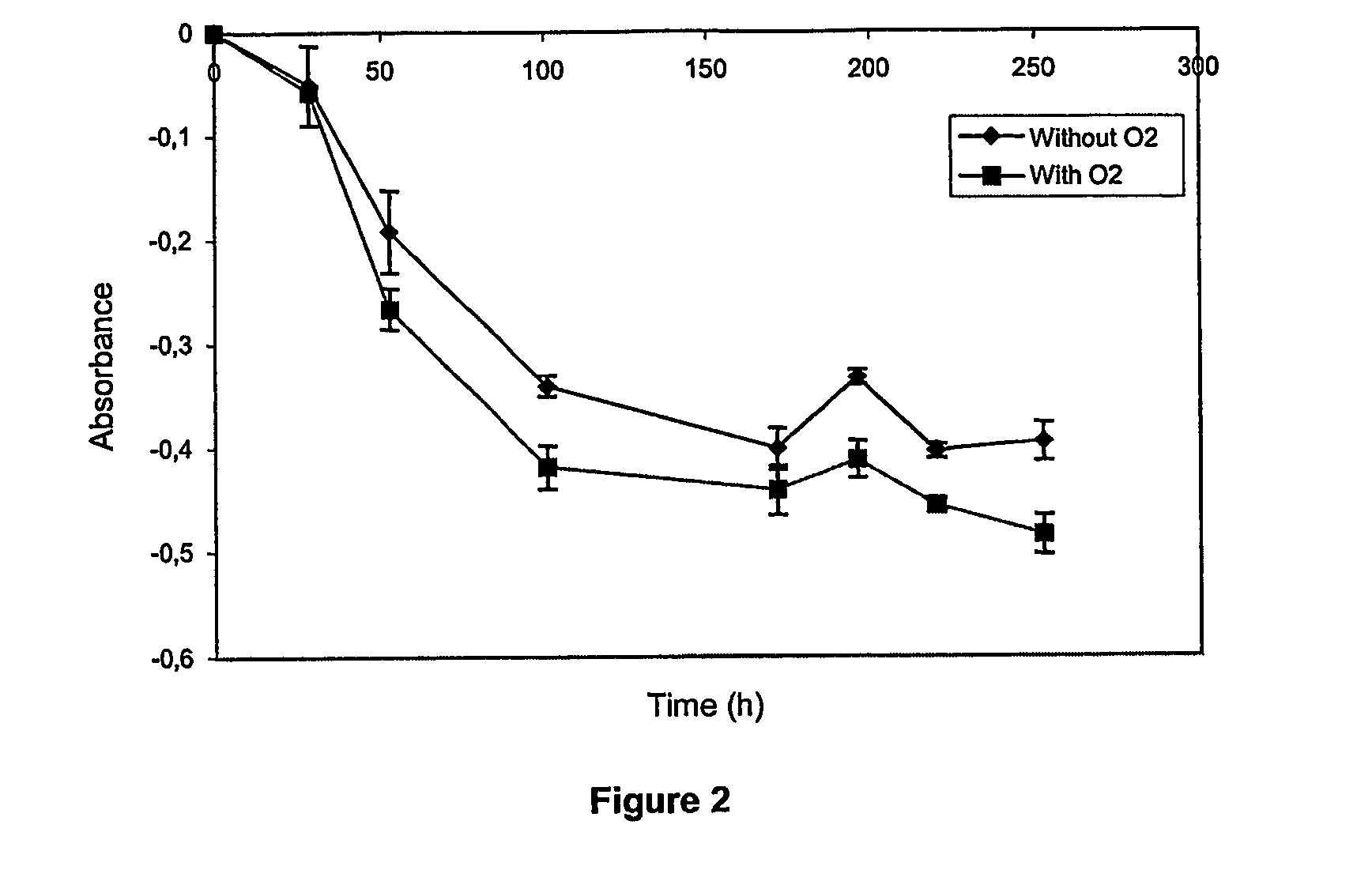

Sustainable process for the treatment and detoxification of liquid waste

InactiveUS20050067347A1Efficient decolorizationEfficiently detoxifyWater contaminantsWaste water treatment from animal processingLiquid wasteFungal microorganisms

A method for treatment of liquid waste is disclosed that includes the steps of (a) submitting the liquid waste to a pretreatment and (b) submitting the pretreated liquid waste to the action of fungi or active agents thereof. In particular, the described process is useful for the effective decoloration and detoxification of dye-containing liquid wastes using white rot fungi or active agents thereof.

Owner:UNIVERSITE CATHOLIQUE DE LOUVAIN

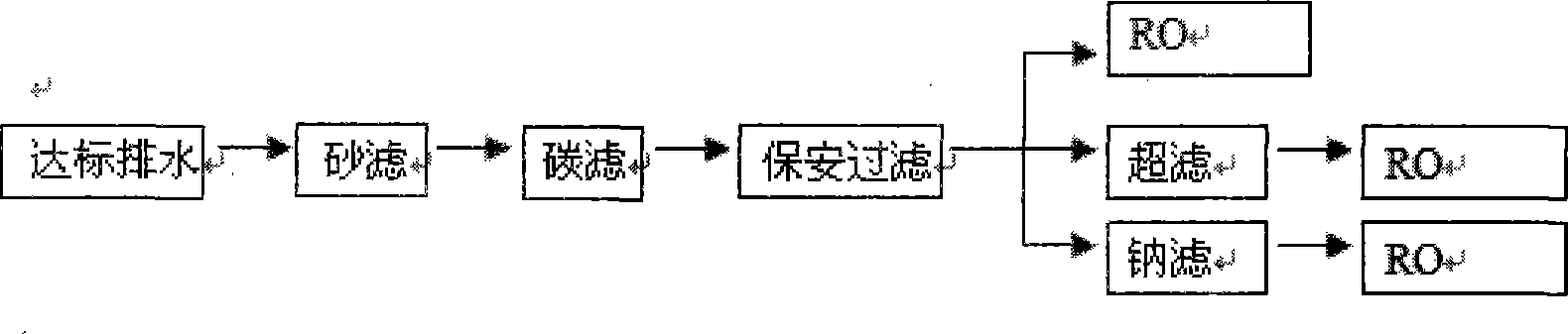

Printing and dyeing waste water treatment method based on film technology

ActiveCN101041532AOvercome costsUnsatisfactory processing effectWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentTextile printerWater based

The invention discloses a disposing method of textile printing waste water based on film technology involving a waste water disposing method, which comprises the following steps: adjusting pH and COD value of integrated waste water; pumping into flocculate tank; adding into flocculant; pumping into flocculating setting vessel; getting clarified solution; pumping into membrane biological reactor; proceeding biological treatment; getting dialysate; pumping into counter osmotic separating system; proceeding counter osmotic separation; getting reverse osmosis dialysate; recycling; making concentrated liquid flow into oxide adsorbing tank; refluxing into flocculating setting disposal process; proceeding twice flocculating setting dispose; reaching to two grade emission standard; discharging the eligible reverse osmosis dialysate; adding ClO2 to oxide ineligible reverse osmosis dialysate; adsorbing with activated char; adjusting pH value with alkali liquor; depositing in storing tank.

Owner:SUNTAR MEMBRANE ENVIRONMENT TECH

Composite reagent for treating recycled water of printing and dyeing wastewater and application method of composite reagent

InactiveCN104108775AAchieve efficiencyAchieve economyWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationSolubilityFlocculation

The invention discloses a composite reagent for treating recycled water of printing and dyeing wastewater and an application method of the composite reagent. The composite reagent comprises the following components by weight percent: 20% to 70% of aluminum salt coagulant, 5% to 30% of iron salt coagulant, 5% to 40% of mineral material and 5% to 45% of activated carbon. The method comprises the following steps: preparing the composite reagent for treating the recycled water of the printing and dyeing wastewater into powder or an aqueous liquid in which the content of effective components accounts for 5% to 30%; regulating a pH value of effluent in a printing and dyeing wastewater biochemical system to be within 3 to 9; adding the powder or the aqueous liquid of the composite reagent into the effluent in the printing and dyeing wastewater biochemical system under the condition that the adding quantity of the effective components is between 20mg / L and 1000mg / L after the pH value of the effluent is regulated; and stirring for 0.2 to 2 hours and then standing so as to obtain the recycled water conforming to the water quality standard in textile industry. According to the method, macromolecular colloidal pollutants in the biochemical effluent of the printing and dyeing wastewater, which are difficult to degrade, can be removed by utilizing the coagulation / flocculation performance of aluminum salts and iron salts in the composite reagent; and meanwhile, soluble inert pollutants in the wastewater are removed by utilizing the adsorbability of the activated carbon and the mineral material in the composite reagent.

Owner:HANGZHOU DIANZI UNIV

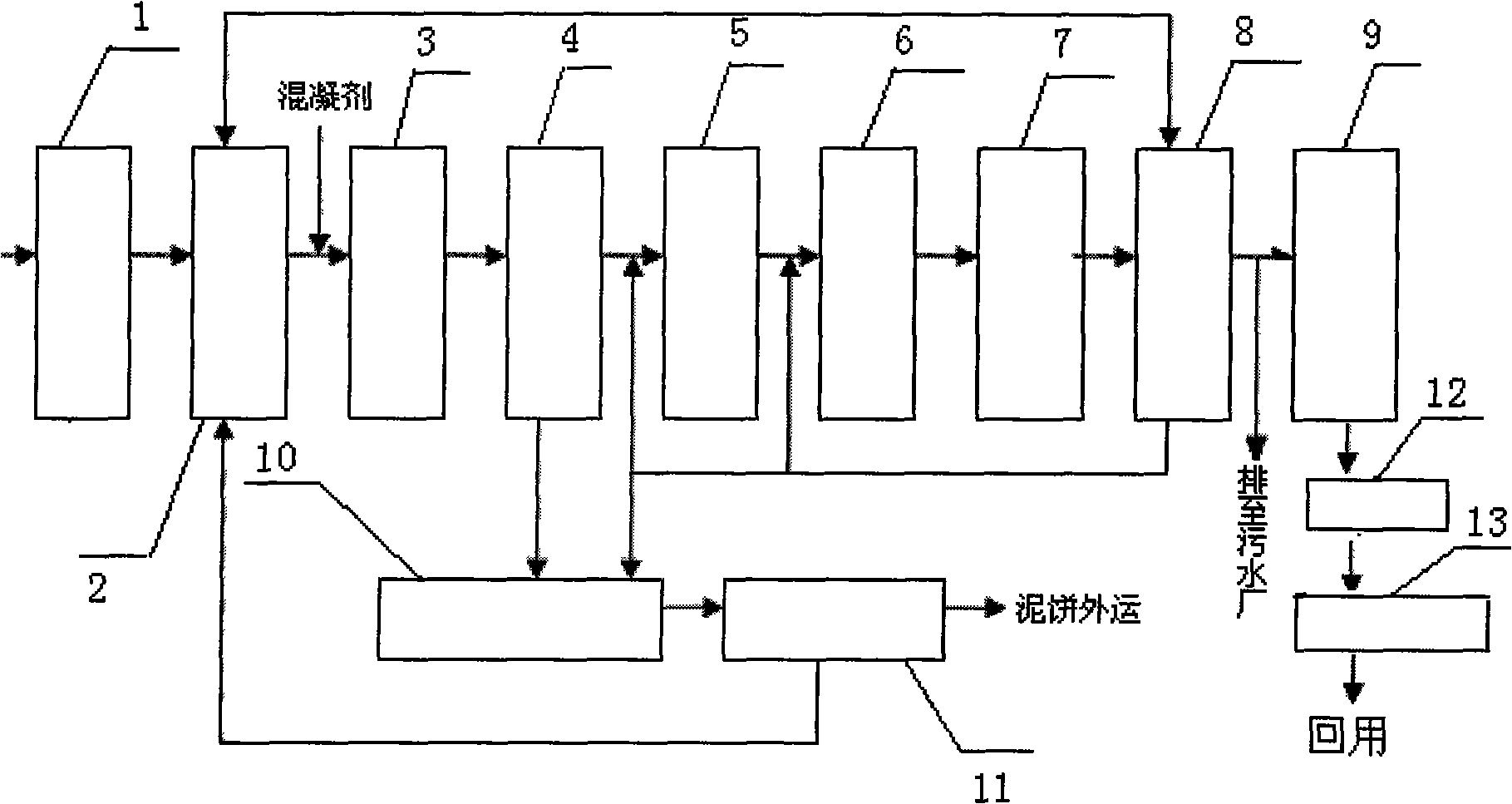

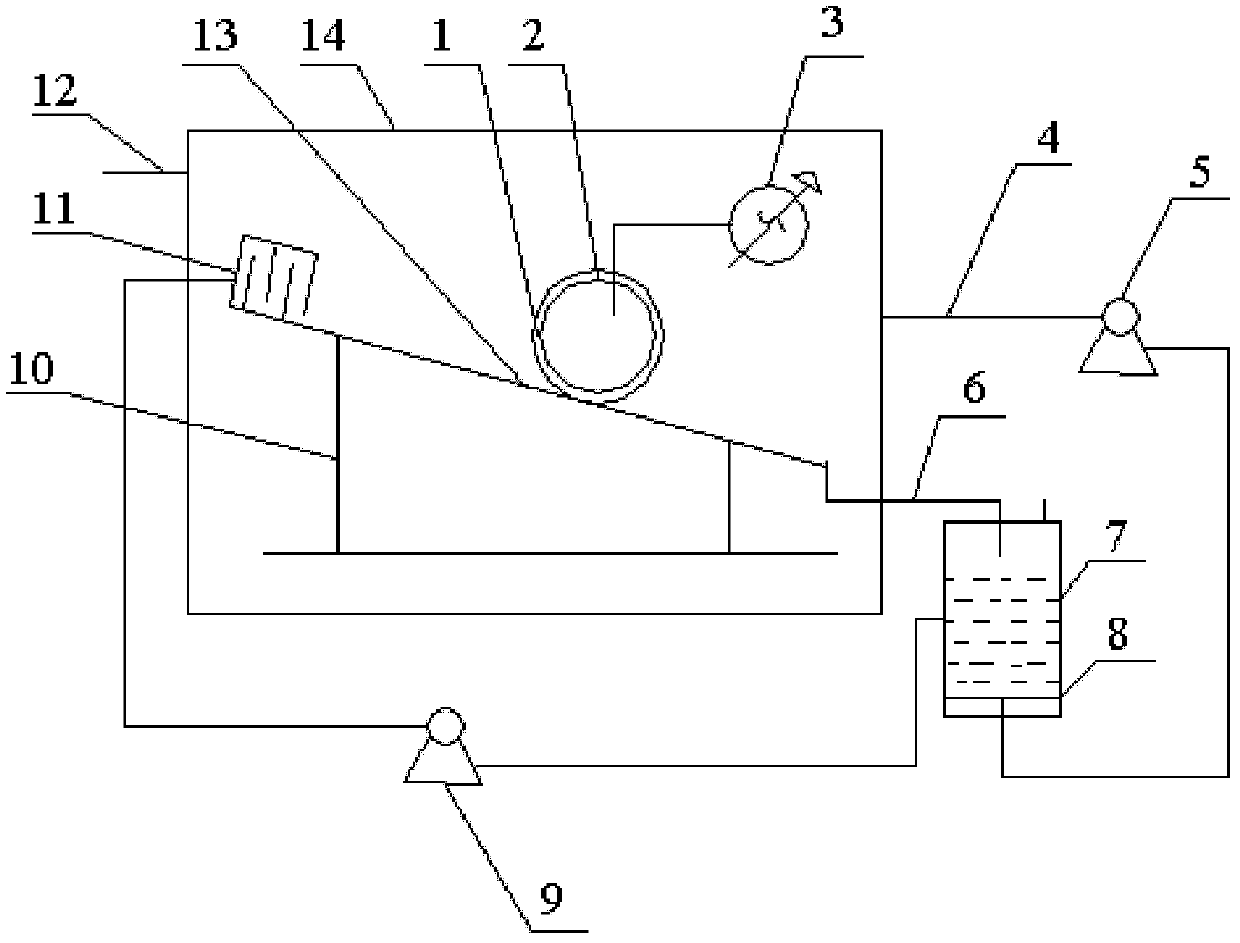

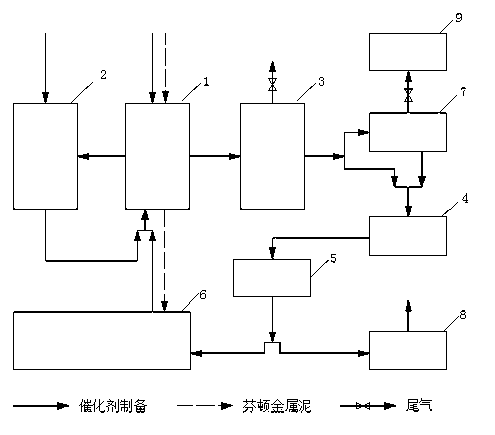

Printing and dyeing wastewater treatment system

InactiveCN101591123ACompact structureSmall footprintSludge treatment by de-watering/drying/thickeningTreatment with aerobic and anaerobic processesSludgeWater quality

The invention relates to a printing and dyeing wastewater treatment system, and belongs to the technical field of printing and dyeing wastewater treatment. The system consists of nine parts, namely an adjusting tank 1, a lift pump 2, a coagulating system 3, a primary sedimentation tank 4, a contact oxidation sediment system 5, a sand filtering tank 6, an active carbon adsorbing tank 7, a sludge pump 8 and a sludge concentrating tank 9. The printing and dyeing wastewater treatment system adopts the combined process of coagulation, contact oxidation, sand filtration and active carbon adsorption, and adds the deep treatment processes of the sand filtration and the active carbon adsorption after the physical-chemical treatment coagulation process and the biochemical treatment contact oxidation process. The printing and dyeing wastewater treatment system can be designed and manufactured respectively according to the wastewater quantities of printing and dyeing enterprises, and has the advantages of good treatment effect of printing and dyeing wastewater, stable operation, high degree of automation, simple operation, convenient maintenance, good and stable outlet water quality, superior level to the national emission primary standard and the like. The system particularly has good treatment effect of the printing and dyeing wastewater with high density and high chromaticity.

Owner:JIANGSU UNIV

Method for preparing catalyst for treating high-concentration organic wastewater through catalytic oxidation

InactiveCN101601998AChange adsorptionIncrease the number ofWater contaminantsCatalyst activation/preparationHigh concentrationActivated carbon

The invention discloses a method for preparing a catalyst for treating high-concentration organic wastewater through catalytic oxidation, which comprises the following steps: 1) drying a cocoanut active charcoal at a temperature of between 100 and 120 DEG C for 8 to 15 hours, taking out and adding the cocoanut active charcoal into 2 to 10 percent sulfuric acid solution to perform soakage for 12 to 36 hours, adding the cocoanut active charcoal into a 1 to 10 percent oxydol solution to perform soakage for 12 to 36 hours, taking the cocoanut active charcoal out, and draying the cocoanut active charcoal in shade to obtain an activated charcoal for standby; and 2) soaking constant volume of the activated charcoal into transition metal salt solution for 12 to 36 hours, drying the activated charcoal at a temperature of between 100 and 120 DEG C for 8 to 15 hours, and calcining the activated charcoal at a temperature of between 300 and 650 DEG C for 3 to 8 hours to obtain the catalyst for treating the high-concentration organic wastewater through the catalytic oxidation. The service life of an active charcoal catalyst bed prepared by the method can reach over 0.5 to 1 year. After the treatment of the wastewater, compared with a Fenton reagent, the treatment efficiency of the catalyst is improved obviously, and the treatment cost is reduced by about 20 percent.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

Rhodococcus erythropolis and microbial inoculum and application thereof

ActiveCN101857846AReduce production and use costsStrong resistanceBacteriaWater contaminantsPetrochemicalCoking wastewater

The invention discloses a rhodococcus erythropolis (rhodococcus sp.) BZ-9 which is preserved in the China General Microbiological Culture Collection Center with the accession number of CGMCC No.3695. The invention also discloses a microbial inoculum, the active component of which is the rhodococcus erythropolis BZ-9. The rhodococcus erythropolis BZ-9 and the microbial inoculum thereof have high-efficient degradation performance on various toxic organic substances as well as high degradation ability even under the condition of chromium (VI), and are applicable to treatment on coking wastewater, tanning wastewater, printing and dying wastewater and other organic wastewater containing phenol, pyridine and other toxic organic substances produced in the process of the production of the petrochemical industry.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Device for treating dye wastewater by dielectric barrier discharge technology and method thereof

InactiveCN102603029AEfficient degradationEasy to operateWater/sewage treatment by irradiationWaste water treatment from textile industryHigh energyUltraviolet lights

The invention relates to a device for treating dye wastewater by a dielectric barrier discharge technology and a method thereof. Uniform grooves are processed on a surface of a metal negative plate to make dye wastewater formed into a uniform liquid film on the surface of the negative plate; a metal column closely clings to a dielectric barrier inner wall to form a sleeve structure, the distance between the sleeve and the negative plate is adjusted to form dielectric barrier discharge between the negative plate and a high-voltage electrode, and pollutants are degraded by O3, .OH, H2O2, high-energy electrons, ultraviolet light and the like generated in the discharge process; unused ozone and other active substances generated in reaction are injected into a container through a micropore aeration device so as to further degrade organic matter in the dye wastewater; and in addition, Mn2+, Cu2+, Zn2+, Co2+ and other metal ions or MnO2, FeOOH, TiO2, active carbon and other heterogeneous catalysts are added into the reaction container to strengthen a treatment effect.

Owner:DONGHUA UNIV

Carbon material-supported copper-cobalt bimetallic sulfide composite material and its preparation method and application in waste water treatment

ActiveCN106944098ARegulatory TopographyPromote degradationPhysical/chemical process catalystsWater contaminantsMetallic sulfideCobalt

The invention discloses a carbon material-supported copper-cobalt bimetallic sulfide composite material and its preparation method and application in water treatment. In the composite material, the copper-cobalt bimetallic sulfide (CuCo2S4) micrometer or nanometer particles are loaded on the carbon material. Through a one-step method or a multi-step method, the composite material is prepared. In water treatment or waste water treatment, through synergistic effects between the copper-cobalt bimetals and synergistic effects between the sulfide and carbon material, the composite material has good catalytic degradation and degradation pollutant adsorption performances.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI +1

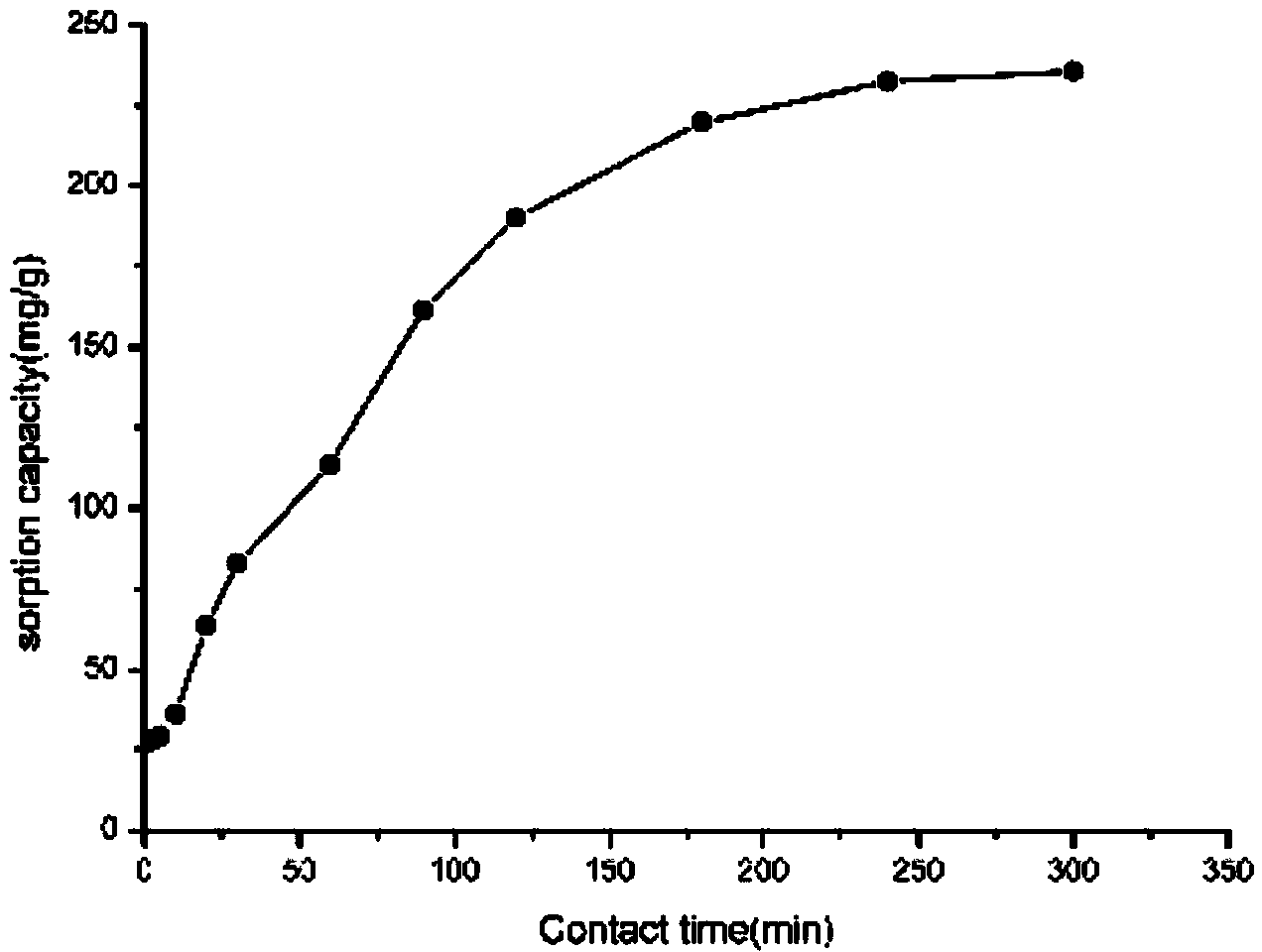

Preparation method for adsorbent for treating dye wastewater

InactiveCN103551124ALow costWide variety of sourcesOther chemical processesWaste water treatment from textile industryFiberCongo red

The invention discloses a preparation method for an adsorbent for treating dye wastewater, and particularly discloses a preparation method for a biomass adsorbent for treating anionic dye wastewater. The adsorbent is prepared by pretreating sugarcane bagasse, performing alkali activation and oxidization treatment, and then grafting a hyperbranched polyamidoamine polymer. The preparation method comprises the following steps: (1) performing pretreatment, alkali activation and oxidization treatment on sugarcane bagasse fiber; (2) grafting the oxidized sugarcane bagasse fiber with the hyperbranched polyamidoamine to obtain the polyamino-modified sugarcane bagasse-based adsorbent. The prepared adsorbent has the characteristics of being good in stability, good in adsorption effect, wide in application range and the like, and can be used for treating the anionic dye wastewater. Taking Congo red dye wastewater for example, the Congo red adsorption capacity and adsorption efficiency of the adsorbent respectively achieve 240mg / g and 97%. The prepared adsorbent is wide in raw material source, low in price and easily available, low in cost, convenient to operate when being applied to wastewater treatment, and simple in technology.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

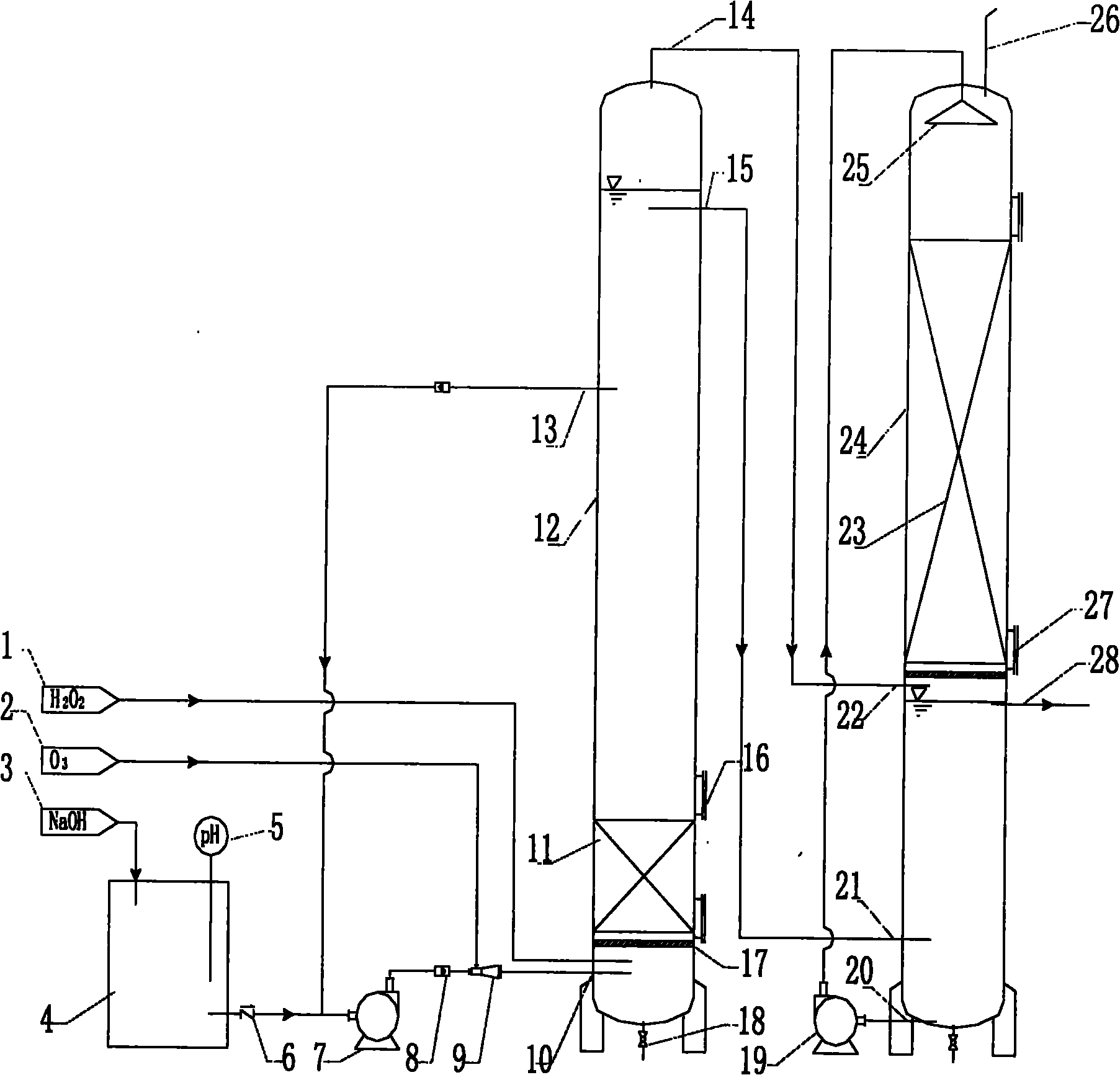

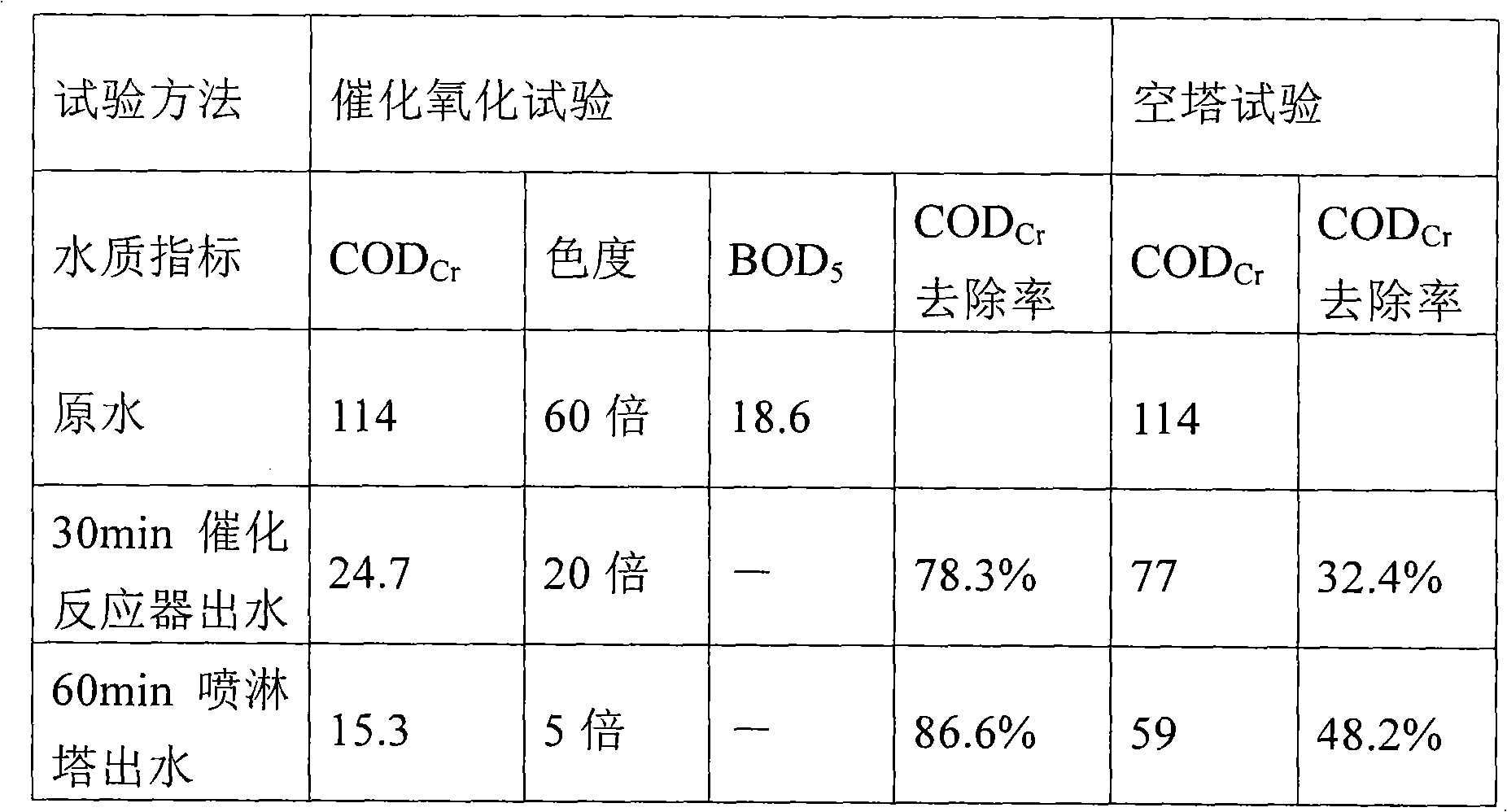

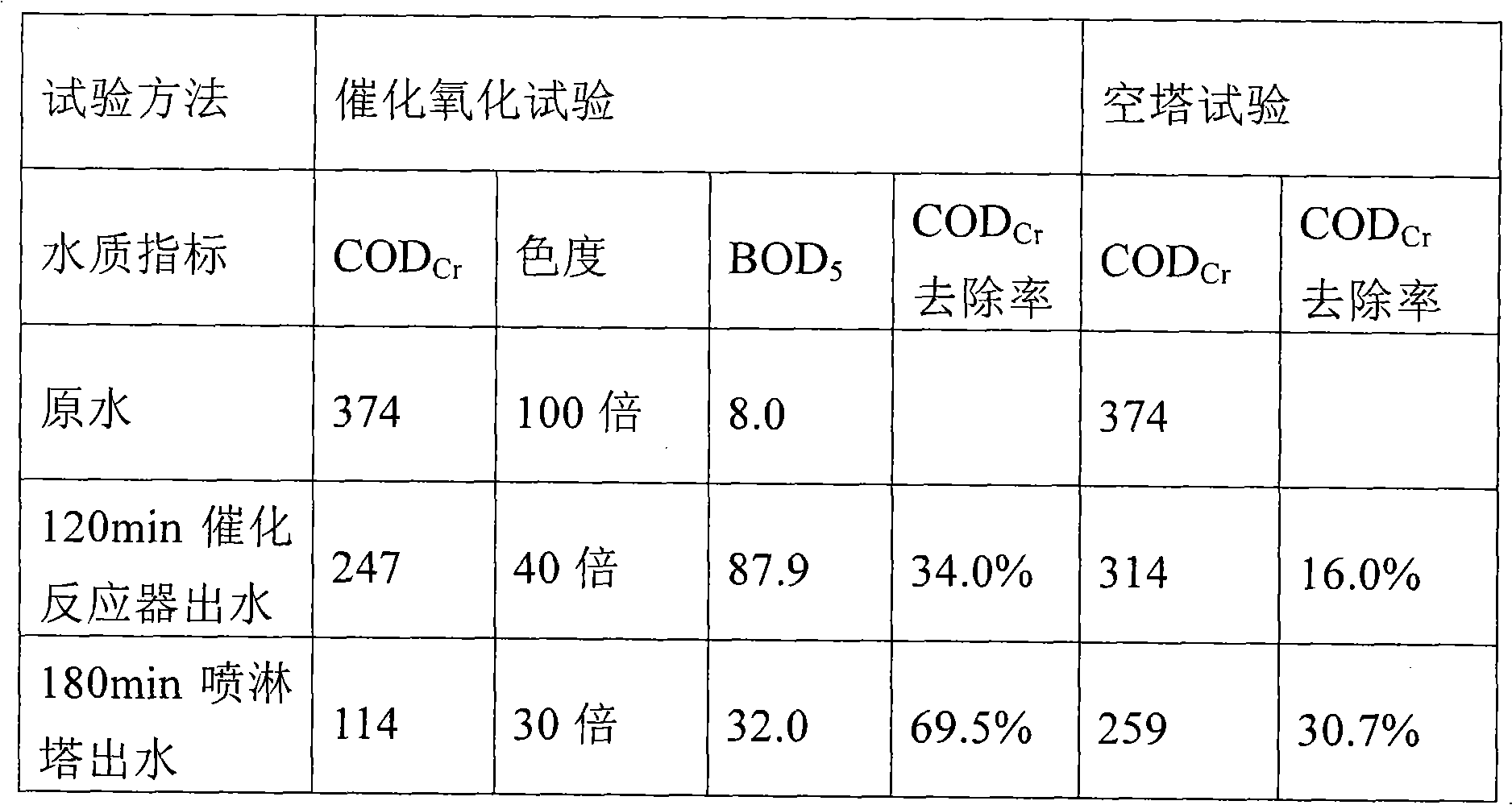

Equipment and method for treating nondegradable wastewater by utilizing catalytic oxidation of ozone

ActiveCN101781036AIncrease contact areaImprove biodegradabilityWater contaminantsMultistage water/sewage treatmentWastewaterPh regulation

The invention provides equipment and a method for treating nondegradable wastewater by utilizing catalytic oxidation of ozone. The equipment comprises a feeding system, an ozone catalytic reaction tower and a spray absorbing tower; the feeding system comprises a wastewater pH regulation device, a wastewater feeding pipeline, a hydrogen peroxide aqueous solution feeding pipeline, an ozone feeding pipeline and a pH regulator feeding pipeline; the wastewater pH regulation device is communicated with the wastewater feeding pipeline and the pH regulator feeding pipeline respectively; the ozone feeding pipeline is communicated with the wastewater feeding pipeline; the ozone catalytic reaction tower is communicated with the wastewater feeding pipeline and the hydrogen peroxide aqueous solution feeding pipeline respectively so that wastewater undergoes once catalytic reaction in the presence of a first catalyst to generate a liquid flow and an ozone tail gas flow which are subjected to initial treatment; and the spray absorbing tower is communicated with a catalytic reaction system, is used for spraying at least one part of the liquid flow which is subjected to the initial treatment, and is contacted with the ozone tail gas flow in the presence of a second catalyst to undergo second catalytic reaction.

Owner:ENN ENVIROTECH CO LTD

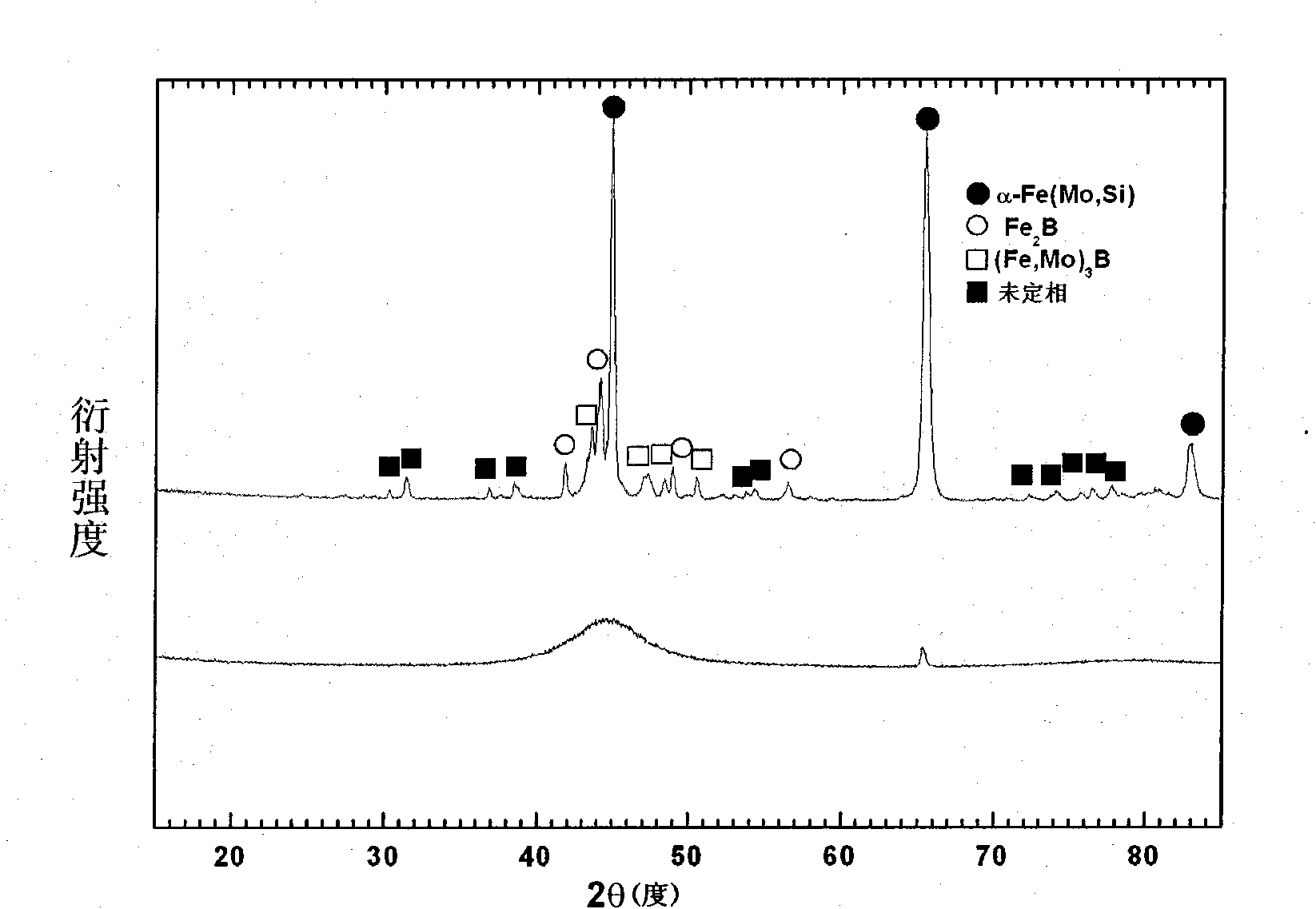

Ferrum-based amorphous alloy strip for treating printing and dyeing wastewater and preparation method thereof

ActiveCN102070236AAchieve amorphizationRetain color removal abilityWaste water treatment from textile industryWater/sewage treatment by reductionIron powderDyeing wastewater

The invention relates to a ferrum (Fe)-based amorphous alloy material, in particular to a Fe-based amorphous alloy strip for treating printing and dyeing wastewater and a preparation method thereof. According to the conventional literatures and technical data, an alloy component with Fe-based amorphous alloy strip forming capacity is selected; and general requirements show that the selected alloy component comprises more than 50 percent of Fe atoms, preferably 60 to 85 percent, so the reduction decoloring capacity of the Fe atoms is exerted. The amorphous alloy strip is obtained by adding a small amount of other elements and performing rapid solidification by using melt spinning equipment. The decrystallization of zero-valent Fe is realized by preprocessing technology; the decoloring capacity of the Fe atoms is kept; the rusting consumption of the Fe in the wastewater treatment process is effectively reduced; the strip is repeatedly and persistently utilized on the premise of guaranteeing the decoloring rate; the technical defects and the application defects in the conventional method for treating the printing and dyeing wastewater by using reducing Fe powder or waste cast Fe scraps are overcome; and the Fe-based amorphous alloy strip relates to the field of potential application of decrystallization technology in the industrial field, and has an extremely high application prospect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

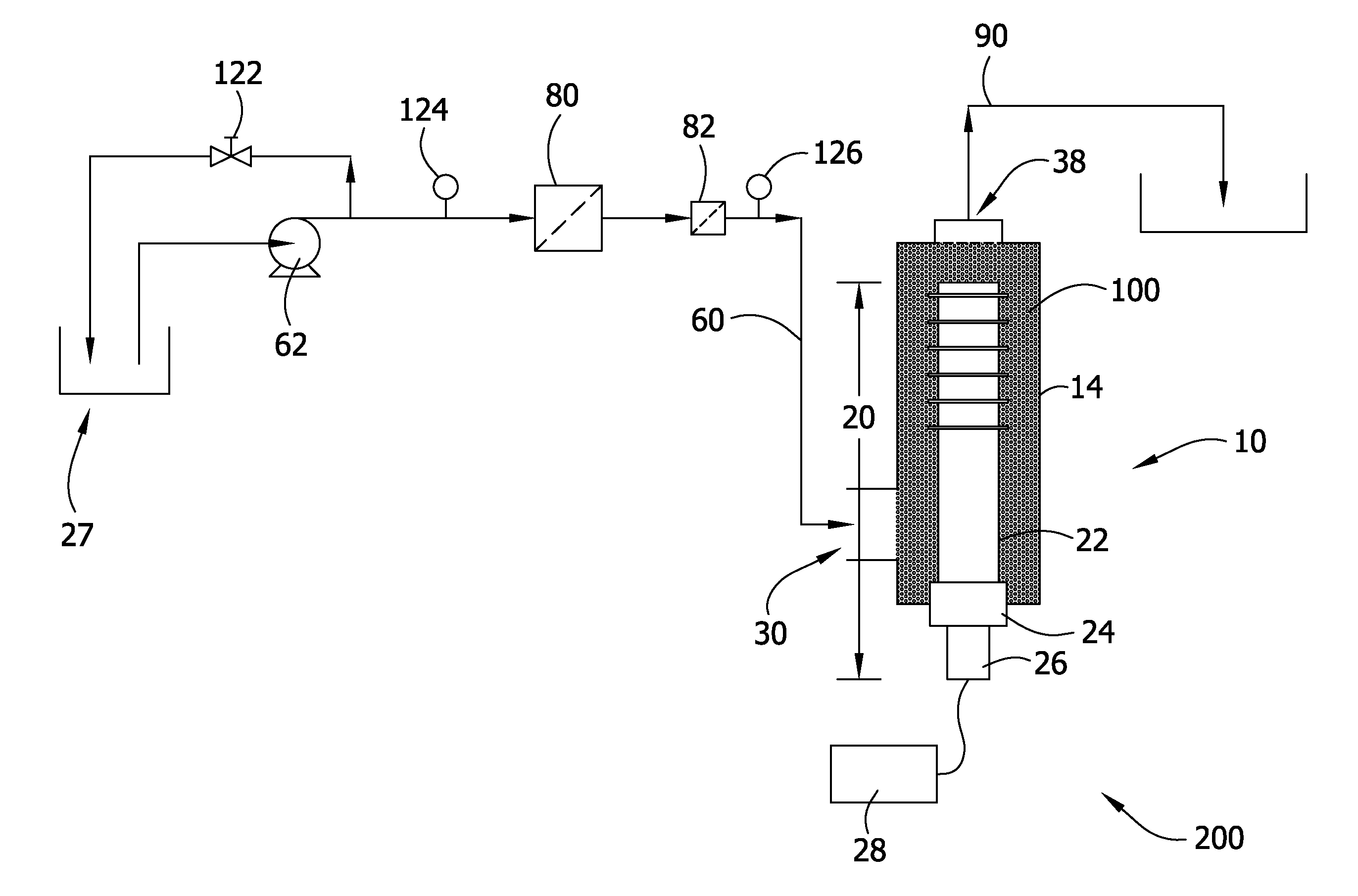

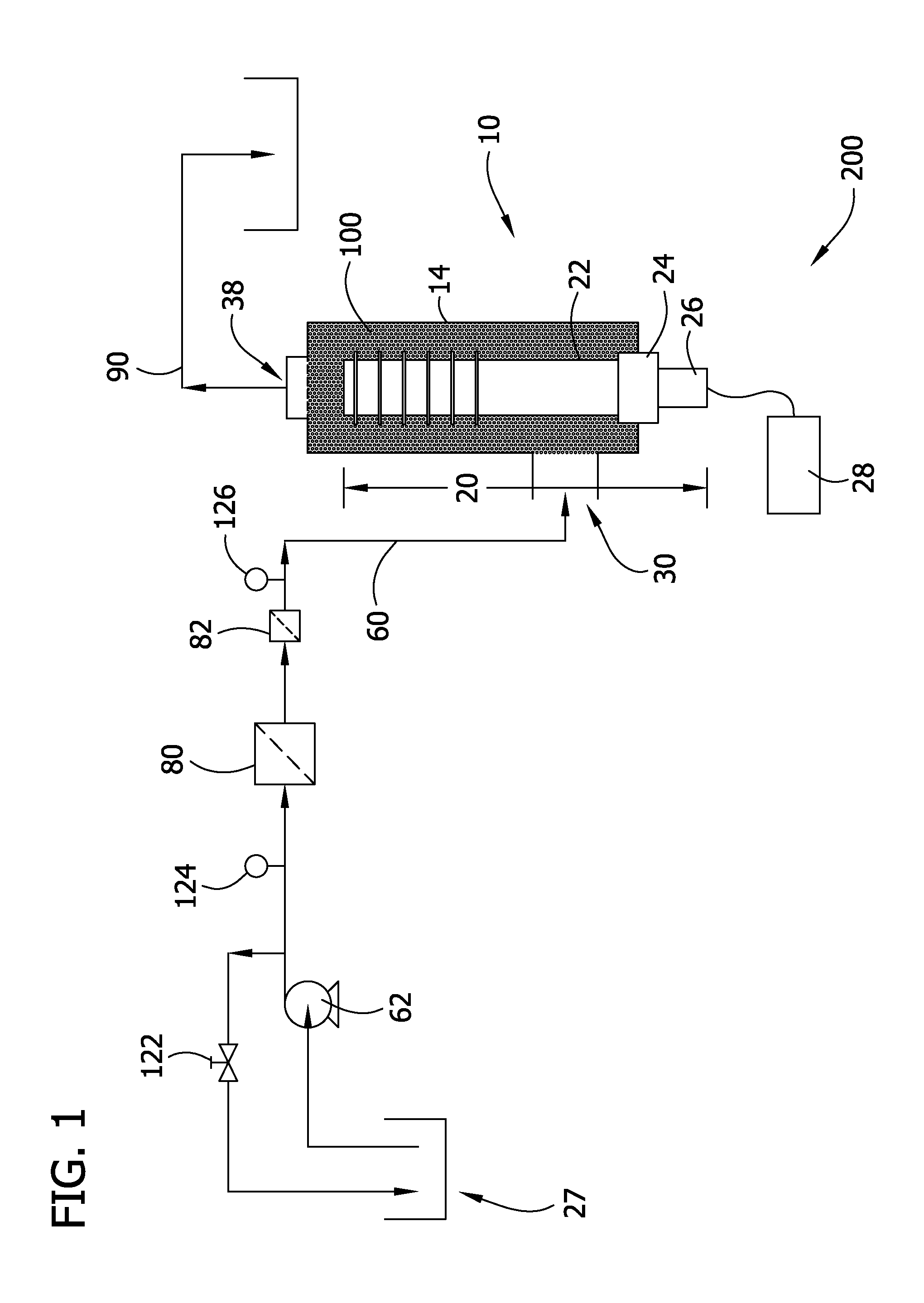

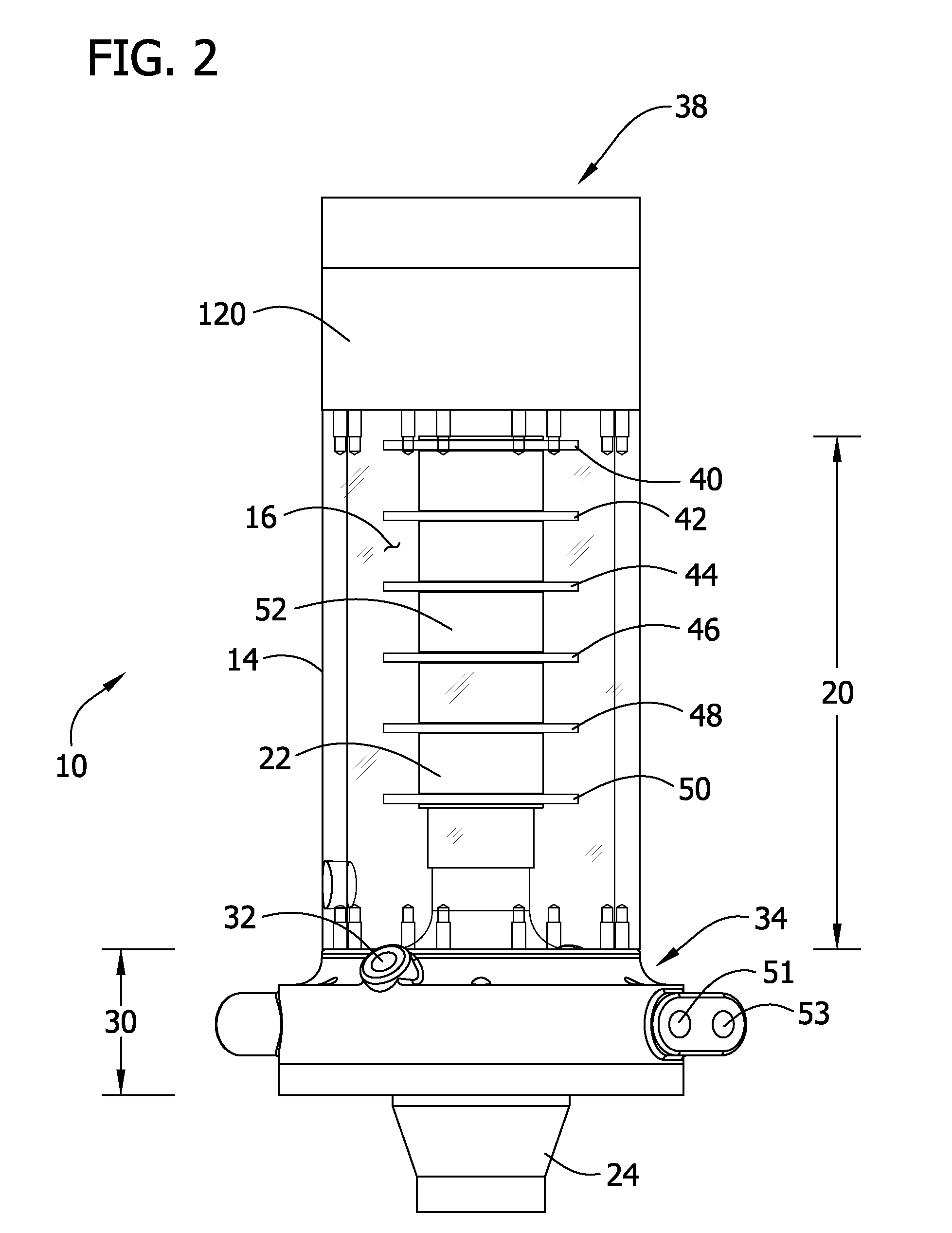

Ultrasonic Treatment System For Separating Compounds From Aqueous Effluent

ActiveUS20080061000A1Improve abilitiesThinner hydrodynamic boundary layerPaint waste treatmentSolid sorbent liquid separationSorbentTreatment system

Novel ultrasonic treatment systems for separating compounds in an aqueous effluent and processes for using the ultrasonic treatment systems are disclosed. More particularly, the ultrasonic treatment systems use ultrasonic energy to energize adsorbent to provide efficient and effective removal of compounds from aqueous effluents, such as textile effluents.

Owner:KIMBERLY-CLARK WORLDWIDE INC

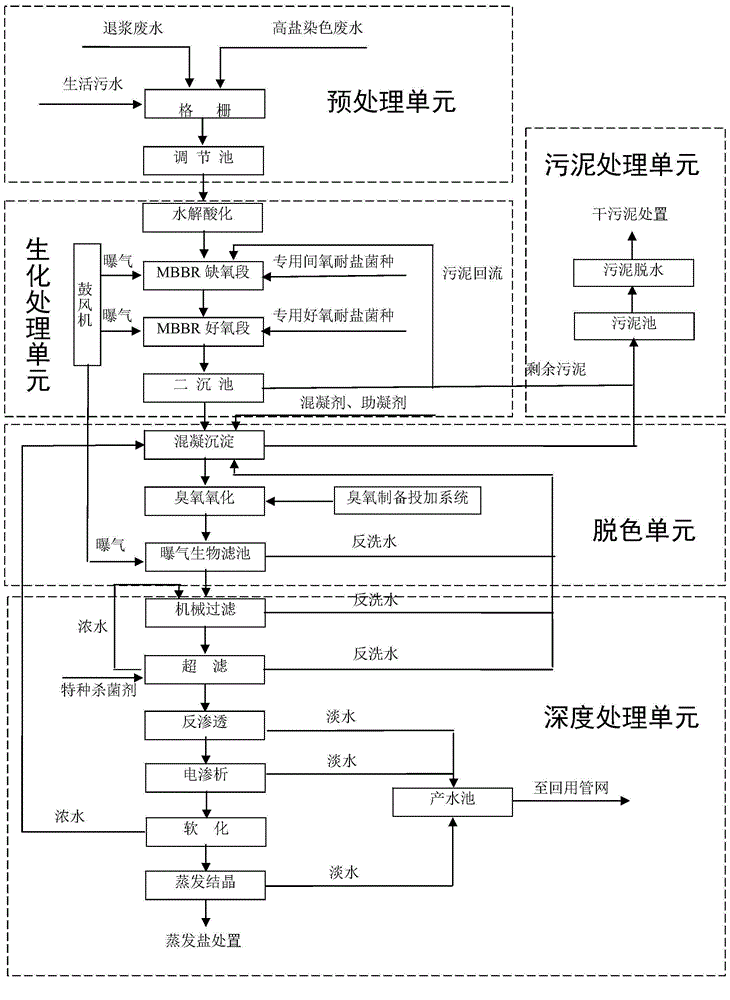

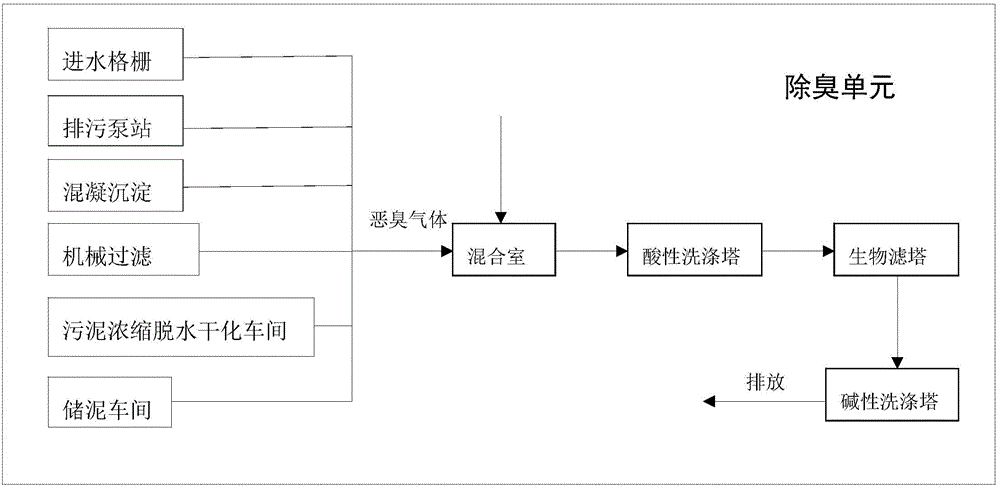

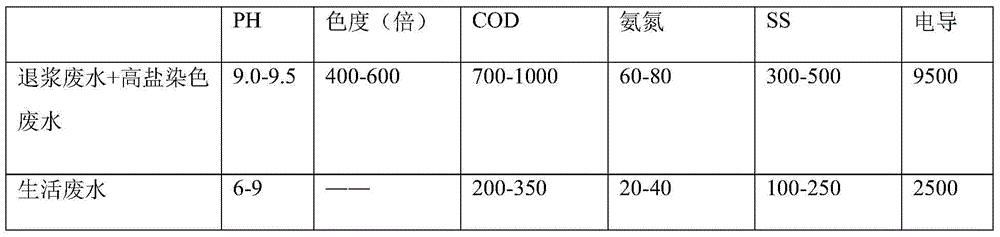

High-salt-content dyeing wastewater treatment recovery zero discharge integration method

ActiveCN104478174APromote growthAvoid emissionsSludge treatment by de-watering/drying/thickeningTreatment using aerobic processesTextile printerSalt content

The invention belongs to the technical field of sewage treatment, and particularly discloses a high-salt-content dyeing wastewater treatment recovery zero discharge integration method. The method can perform deep treatment recovery on the high-salt-content dyeing wastewater to obtain production water for textile printing industry, thereby achieving the goal of zero discharge. The integration method is composed of a pretreatment unit, a biochemical treatment unit, a decolorization unit, an advanced treatment unit, a sludge treatment unit and a deodorizing deodorization unit. The integration method is mainly used for treating high-salt-content dyeing wastewater.

Owner:XINJIANG ENVIRONMENTAL ENG TECH

Application and preparation method of nanometer Fe(0)-porous sludge carbon material

InactiveCN106076256AGood dechlorination and detoxification effectSolve pollutionOther chemical processesWaste water treatment from textile industryToxicity reductionIron salts

The invention discloses a preparation method of a nanometer Fe(0)-porous sludge carbon material. The method includes: taking iron salt as an iron source of nanometer Fe(0), taking sludge as a precursor for thermal reduction of porous carbon and iron salt, taking an organic matter capable of generating a great quantity of gas by thermal decomposition at 300-500 DEG C as a pore forming agent, taking waste organics as a carbon regulating agent (in order to solve the problem of difference of organic carbon composition of sludge different in source), taking water as a harmonizing agent, and performing pyrolysis carbonization and thermal reduction at 500-900 DEG C to obtain the nanometer Fe(0)-porous sludge carbon material being 0.01-100micron in pore diameter, wherein Fe(0) average particle size is 30-80mm. The nanometer Fe(0)-porous sludge carbon material is effective in dechlorination and toxicity reduction and has a promising application prospect in various environmental pollution control fields including dehalogenation reduction, soil remediation, heavy metal wastewater treatment, printing and dyeing wastewater treatment and / or anaerobic wastewater treatment and the like, and sludge recycling and 'using waste to treat waste' are realized.

Owner:SUN YAT SEN UNIV

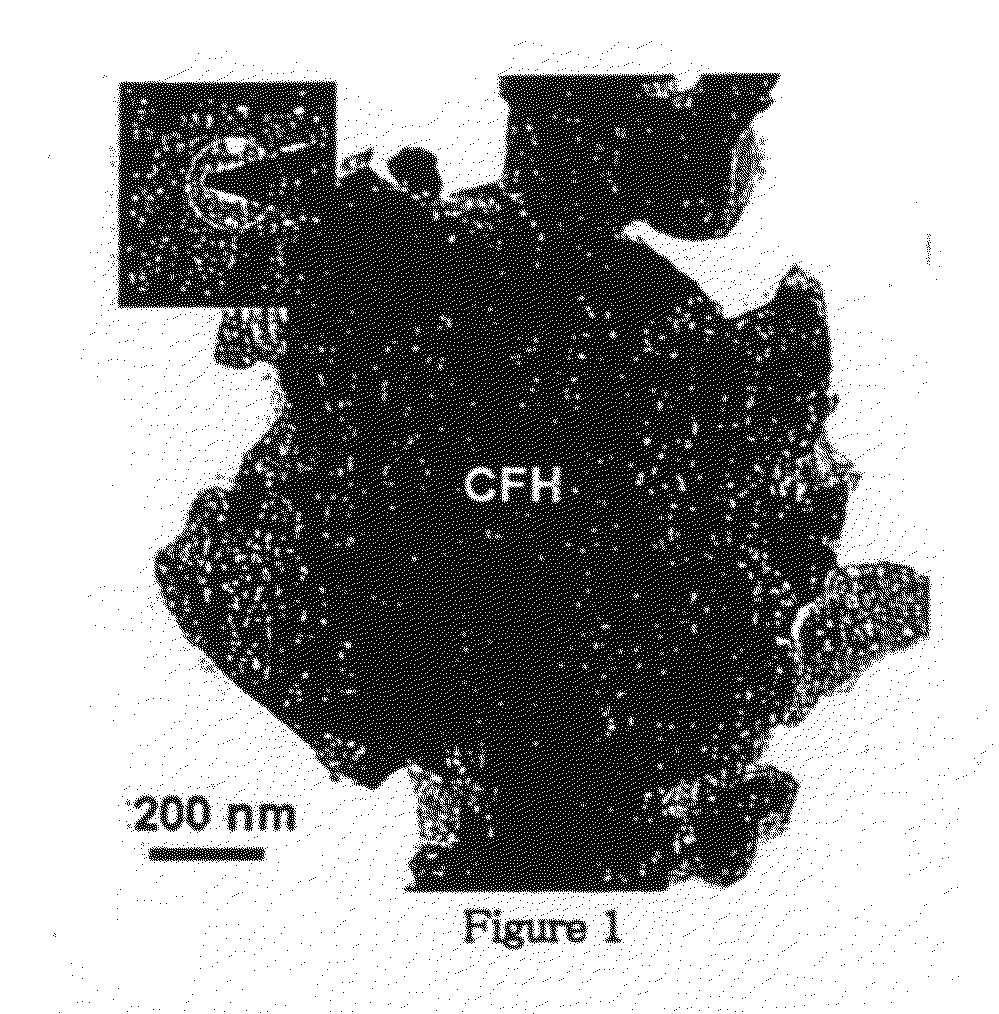

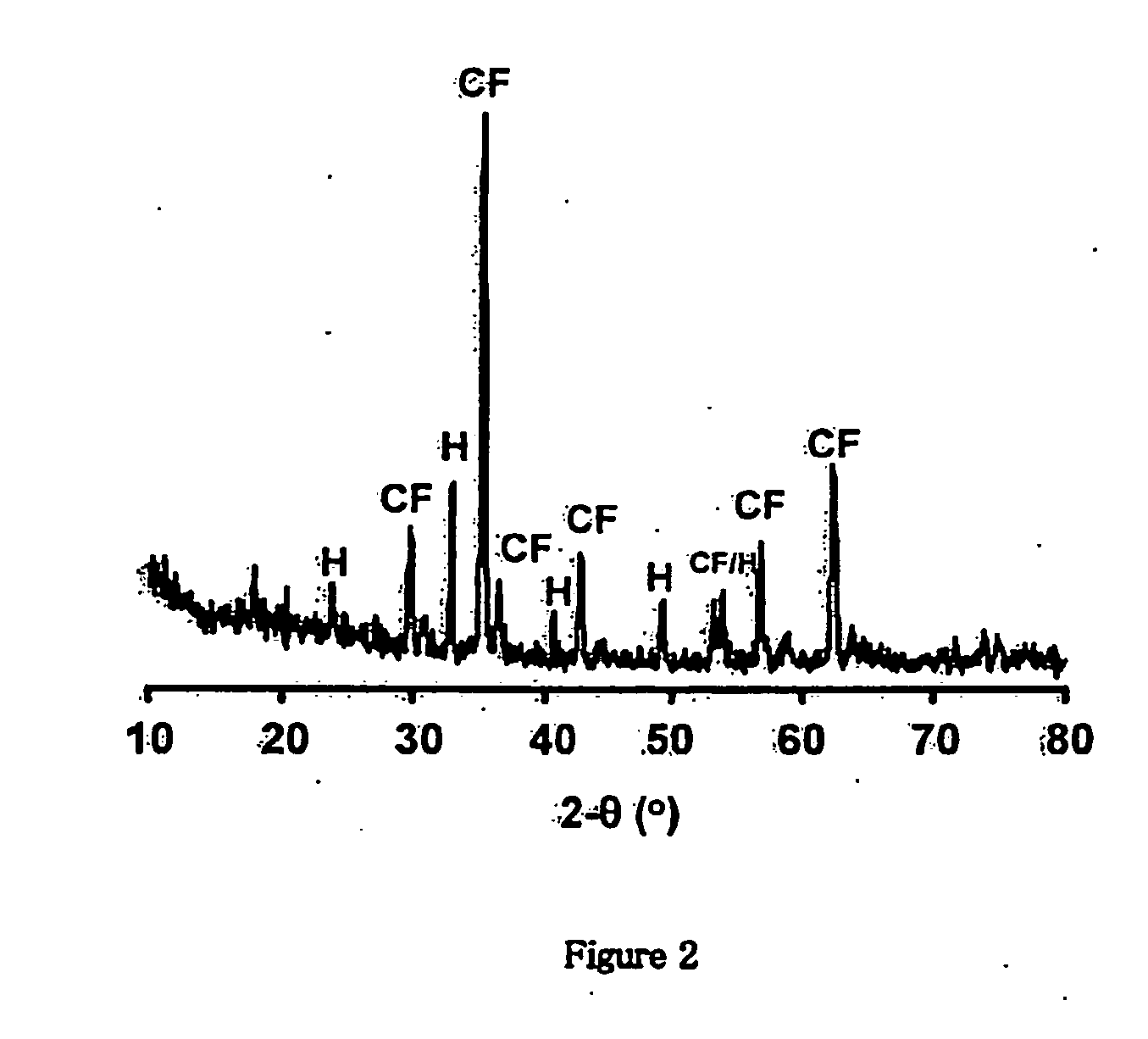

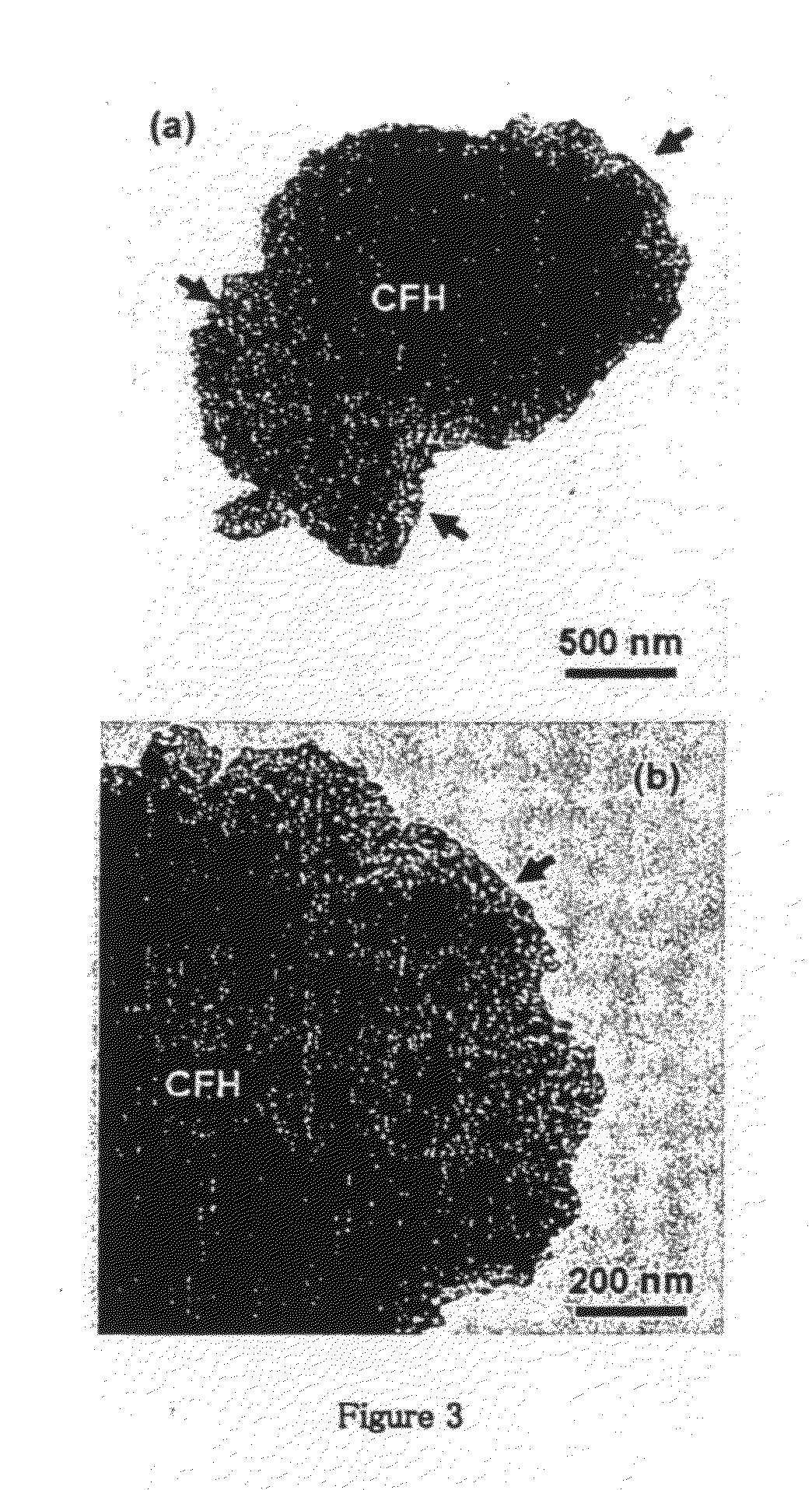

Magnetic dye-adsorbent catalyst

InactiveUS20130105397A1Easy to removeEnhancing its specific surface-areaMaterial nanotechnologySolid sorbent liquid separationOrganic dyeSorbent

New magnetic dye-adsorbent catalyst has been described in this invention, which is the modification of conventional magnetic photocatalyst. The catalyst consists of a composite particle having a core-shell structure, with a magnetic particle as a core and a dye-adsorbent (which may also exhibit photocatalytic activity) as a shell. The shell is made up of 1-dimensional (1-D) nanostructure, which enhances the specific surface-area of the conventional magnetic photocatalyst. The new magnetic dye-adsorbent catalyst removes an organic dye from an aqueous solution via surface-adsorption mechanism; while, the conventional magnetic photocatalyst uses the photocatalytic degradation mechanism.

Owner:COUNCIL OF SCI & IND RES

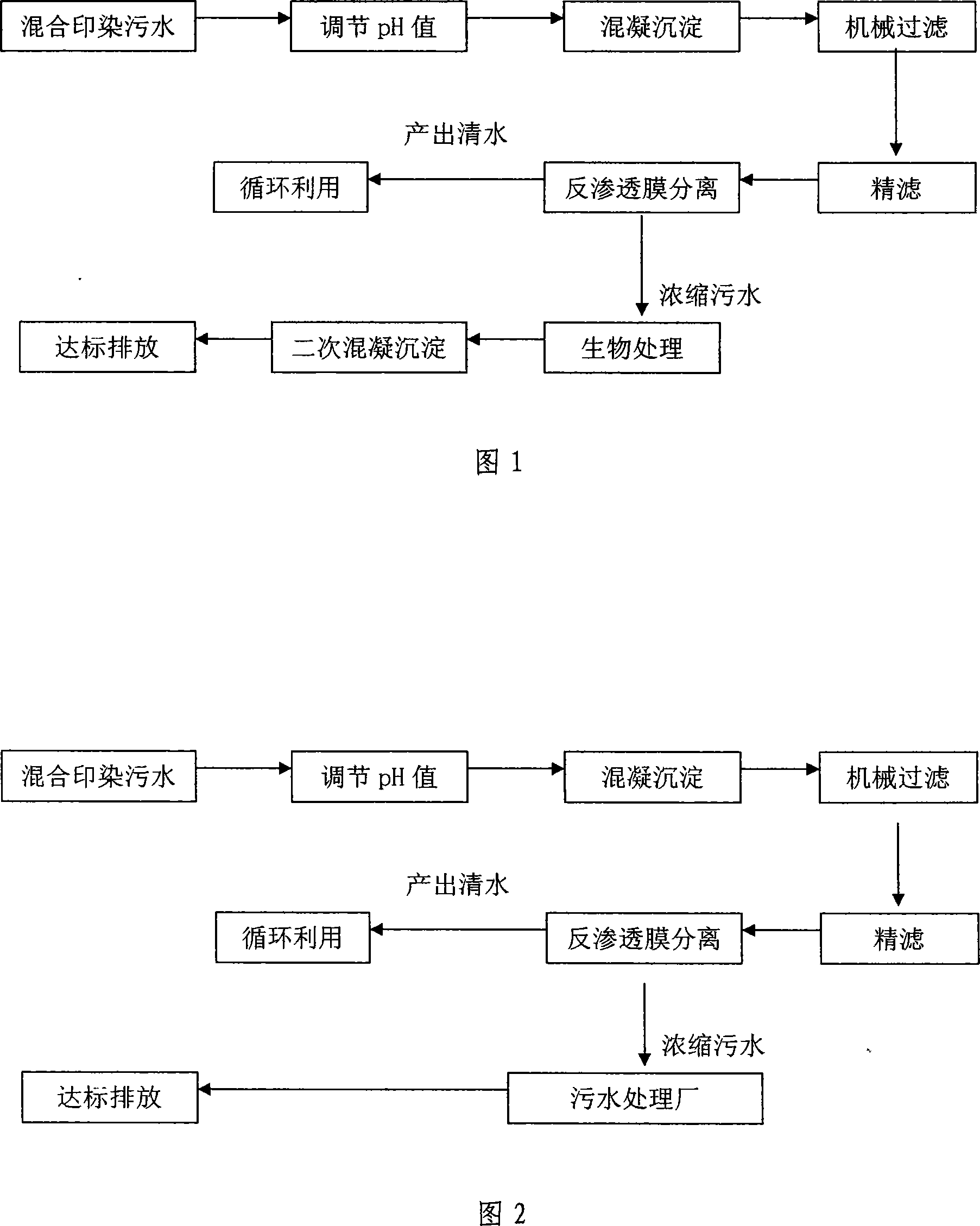

Regeneration treatment and cyclic utilization method of printing and dyeing wastewater

InactiveCN101205105AReduces problems with separation operating pressure increasesGood effectWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentSuspended particlesFiltration

The invention relates to a method for reproducing, treating, cycle using dyeing sewage, which is characterized in that the method comprises that: (1) adjustment of pH value: the pH value of the mixed dyeing sewage is on-line real-time detected and adjusted by automatically adding acid or alkali to a best pH value corresponding to adopted coagulant; (2) coagulation sedimentation: the coagulant is added to stirring reaction and gravity sedimentation; (3) mechanical filtration: supernatant is filtered by the mechanism to remove a little plurality of suspended particles in the water; (4) fine filtration: by adopting security filter, residual micro particles are caught; (5) reserve osmosis membrane separation: by using the reserve osmosis membrane to carry out membrane separation, output clear water is cycled for use; (6) biological treatment: by adopting the biological treatment to membrane separate concentrated sewage, organic pollutants in the sewage are removed; (7) secondary coagulation sedimentation: bio-chemical effluent adding with the coagulant is reacted and precipitated again, and discharged after reaching the national first class discharge standard.The biological treatment and the secondary coagulation sedimentation can be replaced by sewage treatment plant for centralized treatment.The method is characterized by small occupied area, little investment and low operating cost.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

Supercritical water oxidation treatment system for printing and dyeing wastewater and sludge

InactiveCN104030427AReduce volumeReduce secondary pollutionSludge treatment by oxidationWaste water treatment from textile industryLiquid wasteHigh concentration

The invention discloses a supercritical water oxidation treatment system for printing and dyeing wastewater and sludge. The system comprises a concentration pretreatment device, a supercritical water oxidation device, an oxidizing agent supply device and a wastewater recycling system, wherein the concentration pretreatment device comprises a waste liquid storage tank, a nanofiltration membrane concentration module and a printing and dyeing sludge storage pool, the oxidizing agent supply device comprises a liquid oxygen storage tank, a liquid oxygen gasifier and a buffer tank, and the supercritical water oxidization device comprises an auxiliary heating supercritical water oxidization reactor, a methyl alcohol starting preheater, a methyl alcohol preheater and a waste liquid preheater. The system can be used for realizing efficient, clean and harmless treatment of high-concentration printing and dyeing wastewater and sludge at low cost.

Owner:山川丽(苏州)环保科技有限公司

Biological modified straw adsorbent, and reparation method and application thereof

InactiveCN102847516ARaw materials are cheap and easy to getWide variety of sourcesOther chemical processesWaste water treatment from animal processingSorbentDyeing wastewater

The invention discloses a biological modified straw adsorbent, and a preparation method and application thereof. The method comprises the steps of: crushing the straw to prepare a straw powder; mixing the straw powder with a synergistic agent and water, and inoculating microbial strain for modification to conduct fermentation; and after the fermentation, taking out the modified straw powder and drying to prepare the adsorbent. The microbial strain is Trichoderma viride CGMCC3.5455, Trichoderma koningii CGMCC3.2774, Aspergillus niger CGMCC3.4309, Rhizopus stolonifer CICC40317, and Trichoderma koningii CICC 40108. The invention uses straw powder as a carbon source to conduct solid fermentation, so as to produce the adsorbent. The production process does not produce wastewater, waste gas or waste residue, and is energy-saving and environment-friendly. The prepared adsorbent has strong capacity, and can be used for treatment of tanning wastewater and dyeing wastewater.

Owner:JIAXING UNIV

Organic-inorganic in-situ composite flocculant and preparation method thereof

InactiveCN101717141ALow costSimple methodWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationFully developedIn situ polymerization

The invention discloses an organic-inorganic in-situ composite flocculant and a preparation method thereof. The organic-inorganic in-situ composite flocculant is prepared by the steps of taking inorganic powder as a disperse phase, adding acrylamide, initiating agent and solvent to form a mixed solution system and carrying out in-situ polymerization reaction for 10 to 24 hours at 40 to 70 DEG C, wherein the mass percentage of the inorganic powder in the solution system is 1 to 60 percent, the mass percentage of the acrylamide in the solution system is 1 to 50 percent, and the mass ratio between the initiating agent and the acrylamide is 0.5 to 2: 100. The invention integrates the advantages of organic flocculant and inorganic flocculant and fully develops the flocculating effects of the acrylamide and the inorganic powder; and the organic-inorganic flocculant prepared by utilizing an in-situ composite technology can ensure that the decoloration ratio of dyeing wastewater can reach more than 90 percent. The flocculant has wide application range, low cost, simple and convenient method, mild synthesis conditions, strong practicability and easy industrial production.

Owner:JINAN UNIVERSITY

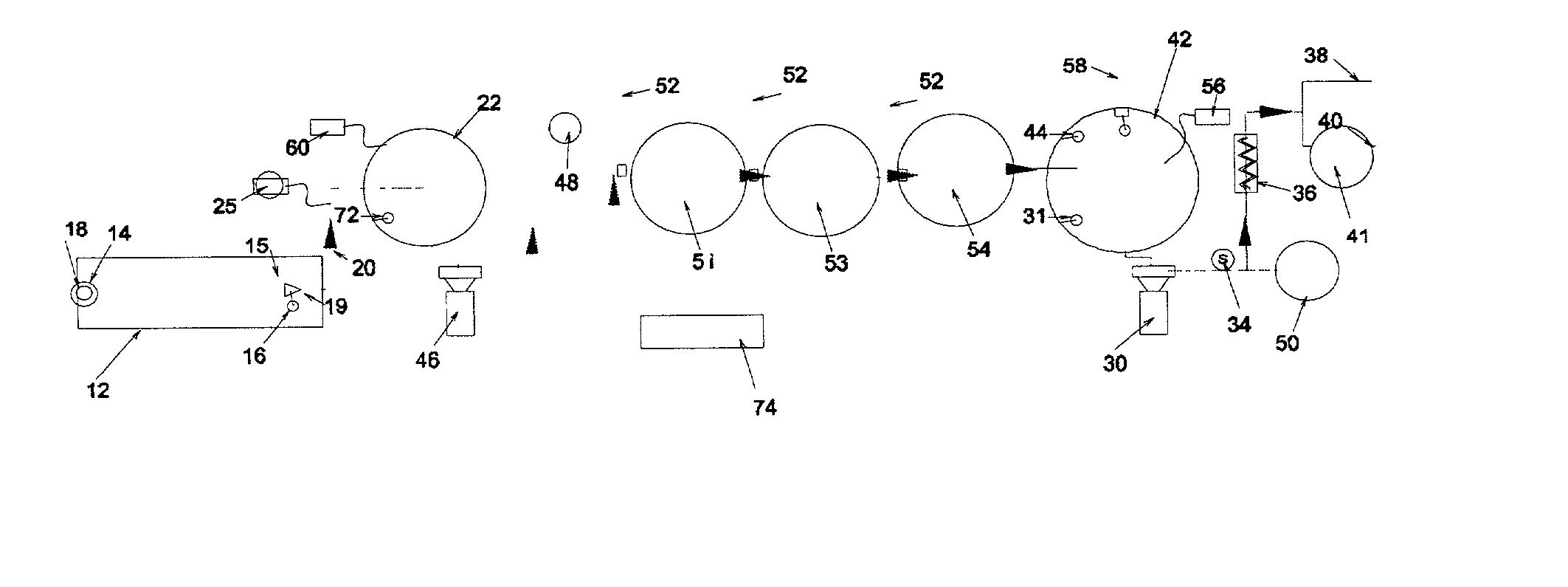

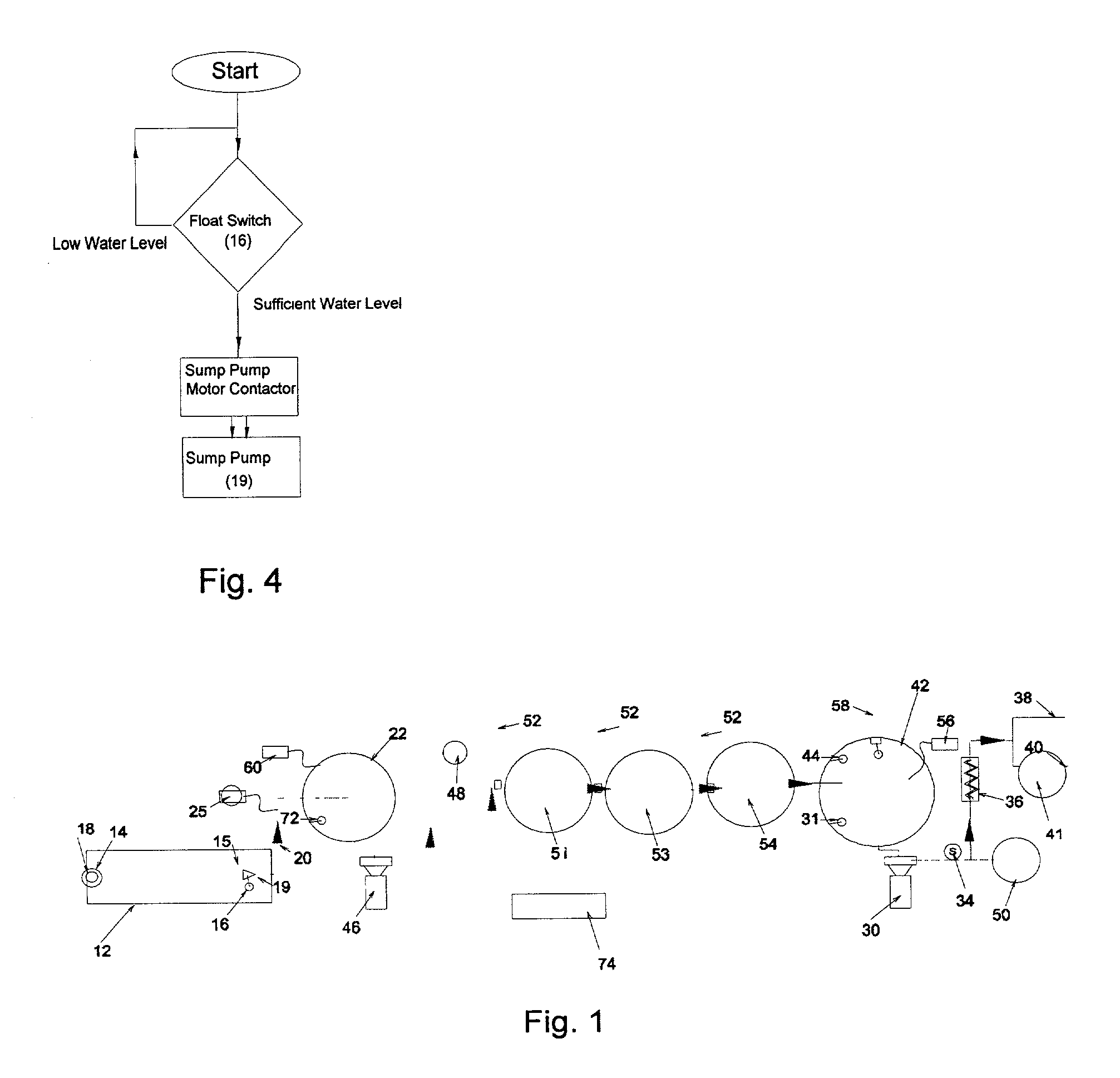

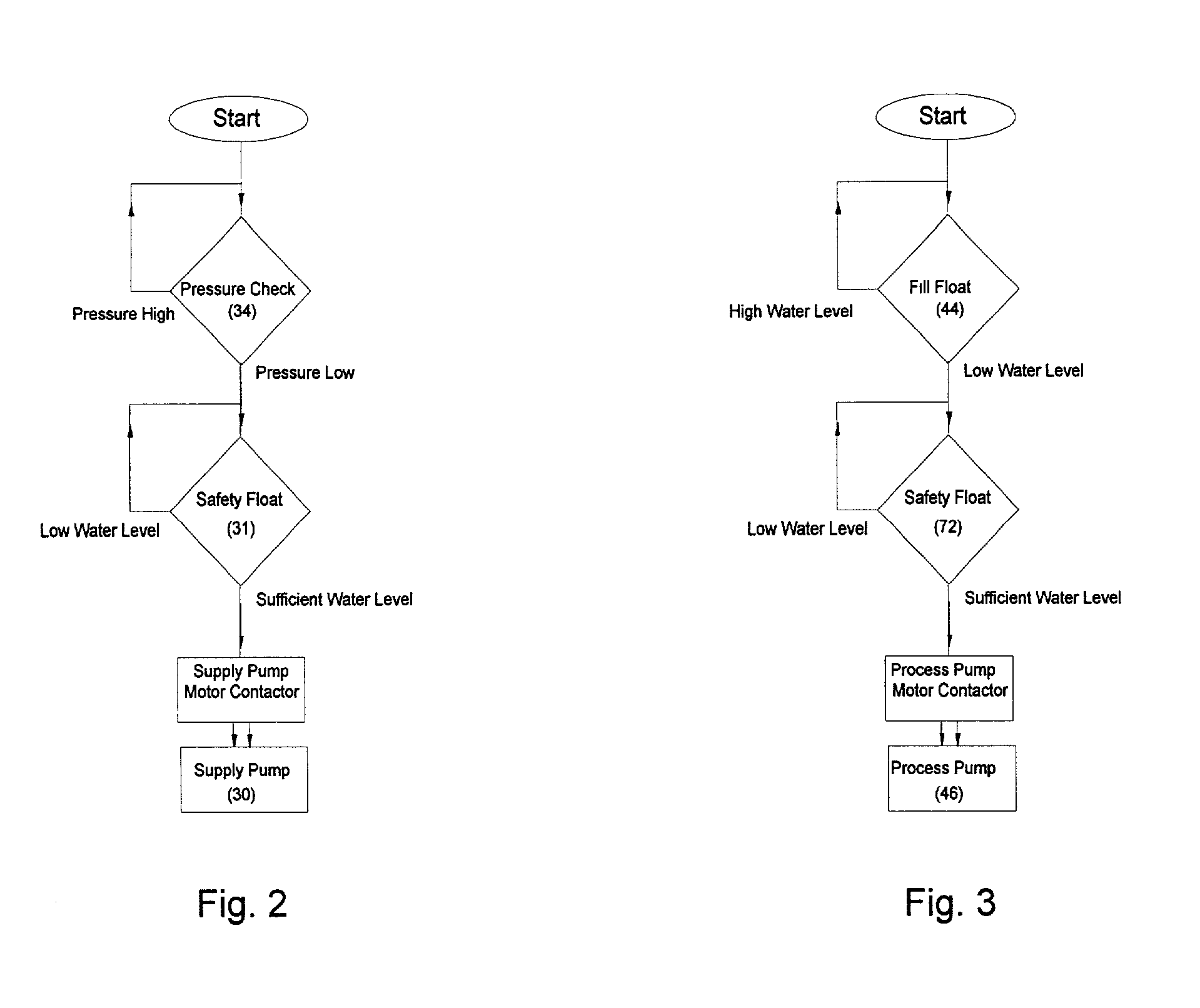

Method and apparatus for recovery of waste water

InactiveUS20020179514A1Minimize releaseMaximize recoveryTreatment involving filtrationSolid sorbent liquid separationUv disinfectionUltraviolet lights

An apparatus and method for recovering wastewater from laundry operations. A substantially closed loop series of tanks, conduits and pumps hold and transfer water output from a wash machine through a series of filters, including a lint pulloff filter, a multimedia pressure filter, a clay filter, and a carbon filter. The water is ozonated to coagulate suspended solids and to disinfect and is subjected to ultraviolet light to disinfect and to reduce residual ozone.

Owner:EMI LLC

Catalytical ozonization catalyst utilizing multi-source sludge to prepare and application thereof

ActiveCN103007937ANo pollution in the processReduce manufacturing costOther chemical processesCarbon compoundsActivated carbonIndustrial waste water

The invention discloses a catalytical ozonization catalyst prepared by utilizing multi-source sludge and an application thereof, and establishes a method for preparing a sludge group active carbon catalyst for catalytical ozone oxidation organic industrial waste water. The method comprises the following steps of: utilizing multi-source sludge such as surplus sludge generated by urban sewage factory biochemical treatment and a metal sludge generated by a Fenton oxidation method, preparing a skeleton which is a sludge group active carbon through steps such as organic substance adding, actification, dehydration, drying, mixing, roasting and screening, wherein a surface layer contains a solid catalyst of metallic oxide, and the ratio of the sludge group active carbon and the metallic oxide in parts by weight is 1:(0.3-0.5). The catalyst is used for catalyzing ozone oxidation treatment organic industrial waste water and has higher catalytic activity and stability, the processing range is wide, the realization and popularization and application are easy, and the economic benefits are improved in an organic industrial waste water processing procedure.

Owner:TIANJIN UNITED ENVIRONMENTAL ENG DESIGN

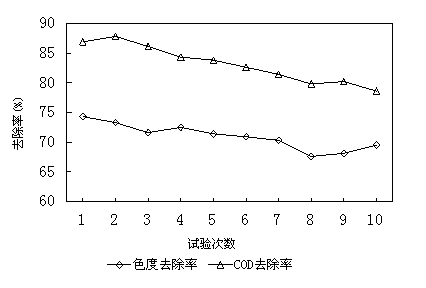

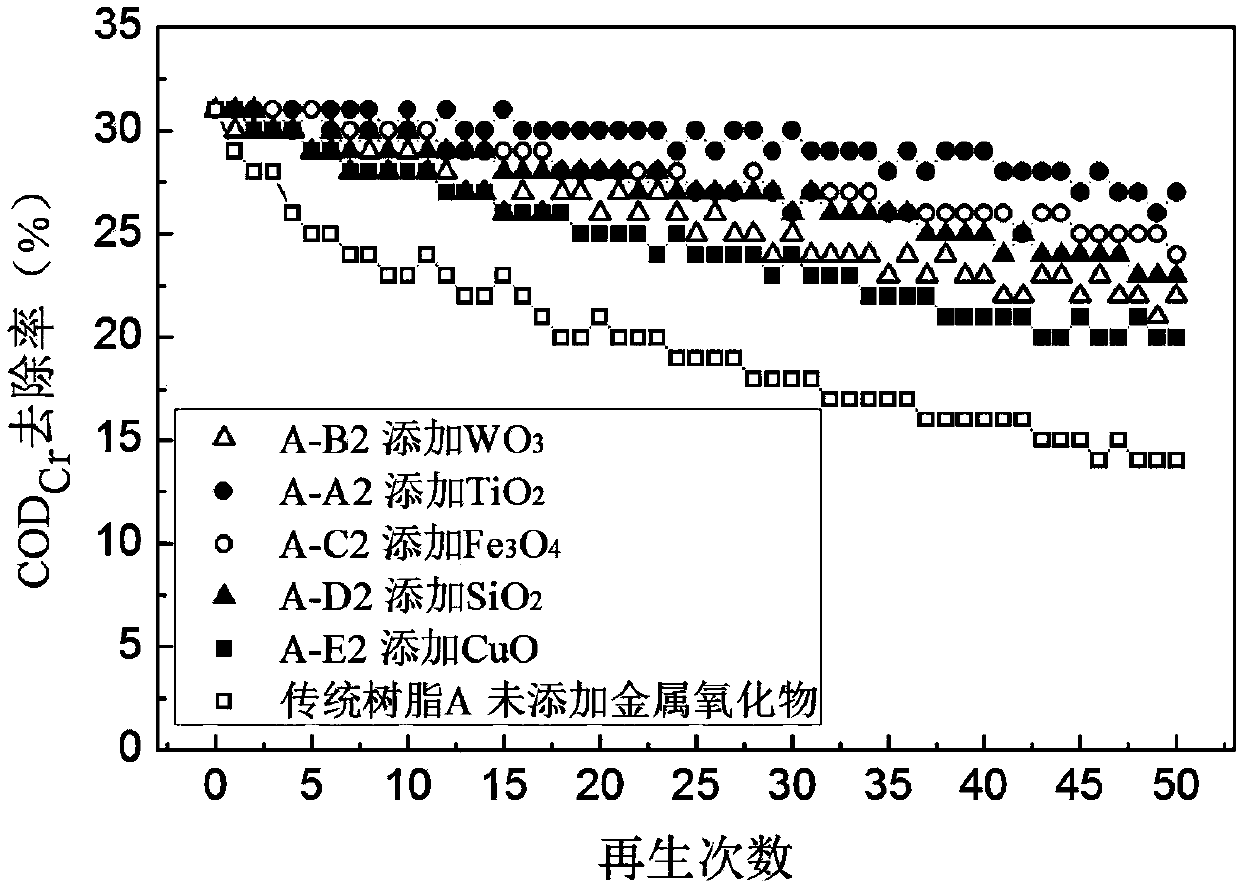

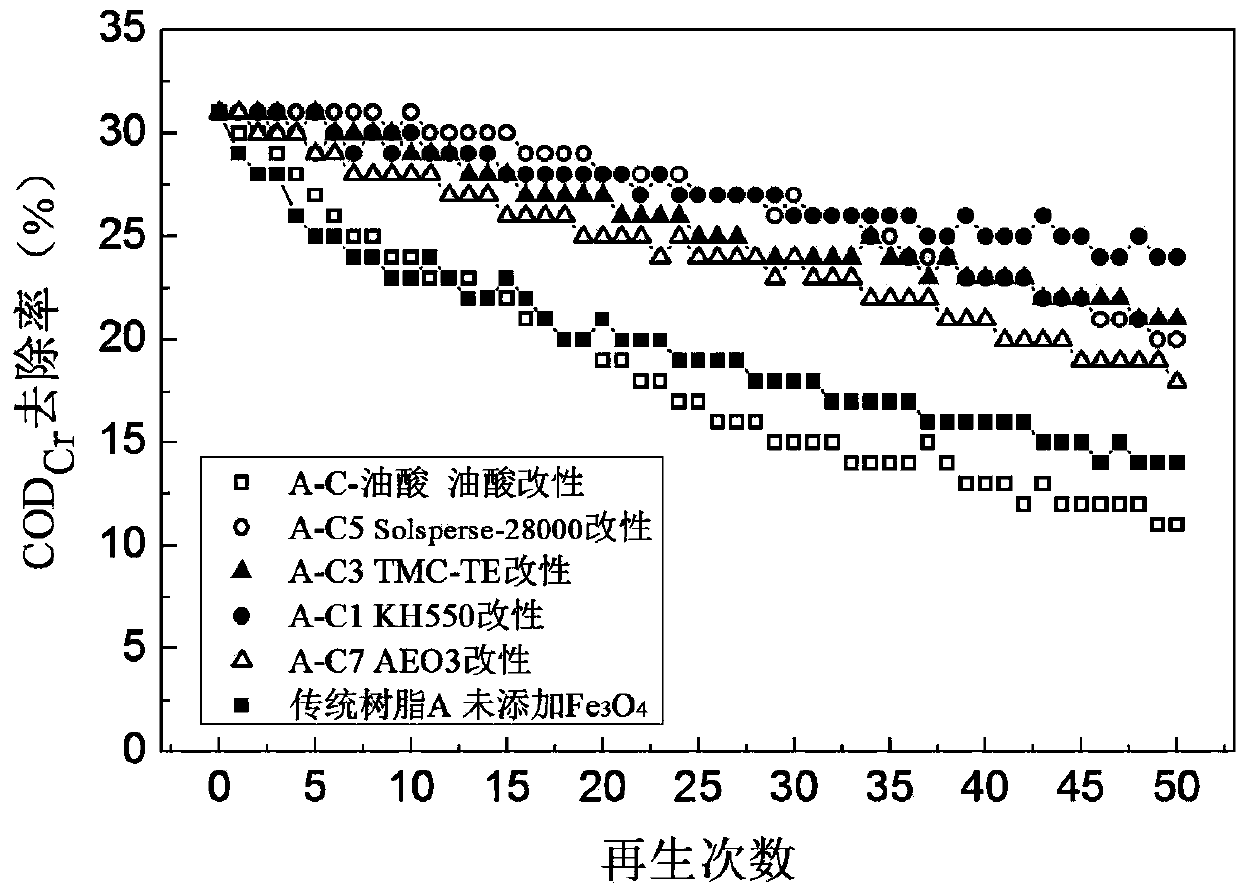

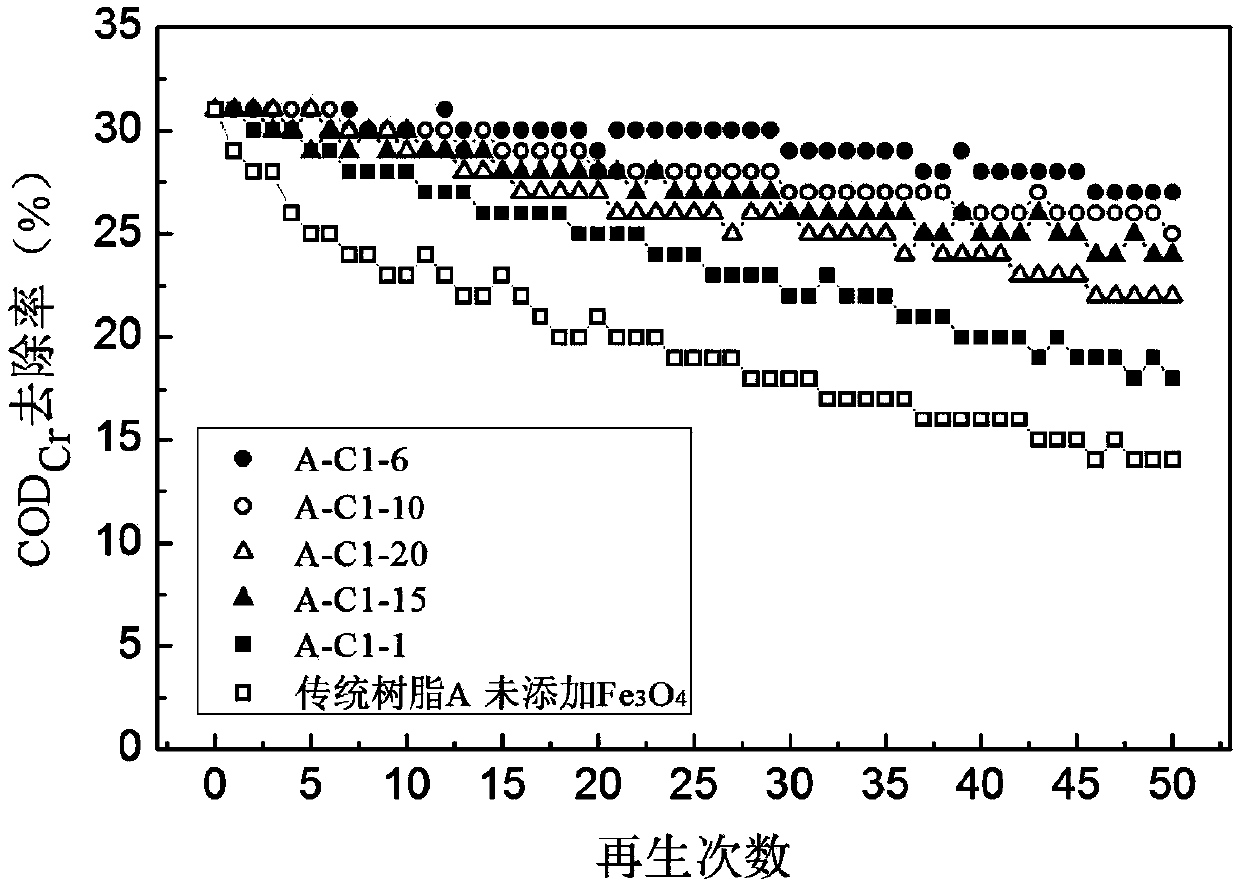

Organic pollution resistance ion exchange resin, and preparation method and application of resin

ActiveCN103467645AExtended service lifeGuaranteed treatment effectCation exchanger materialsWater contaminantsInorganic particleInorganic particles

The invention discloses organic pollution resistance ion exchange resin, and a preparation method and an application of the resin, and belongs to the technical field of improving performances of the ion exchange resin. During preparation of the ion exchange resin, an inorganic particle which is wrapped with a modifier and is equivalent to 0.1-30% of mass of the resin is added to increase a water content of the resin by 3-30%, so that a resin structure is improved, and the regeneration efficiency of the resin is improved by 0.4-70%. The organic pollution resistance of the ion exchange resin in the water treatment application can be improved, the service life of the ion exchange resin is prolonged, the ion exchange resin can be regenerated and used stably for a long term in the water treatment application, ensure a water treatment effect and avoid complicated operation and cost pressure caused by frequent resin replacement, and the method is simple, effective and low in cost.

Owner:NANJING UNIV

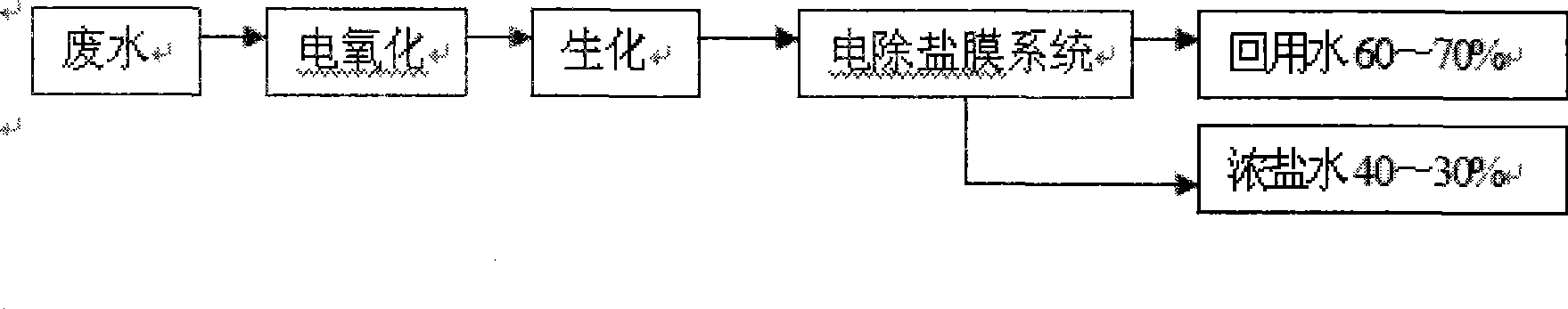

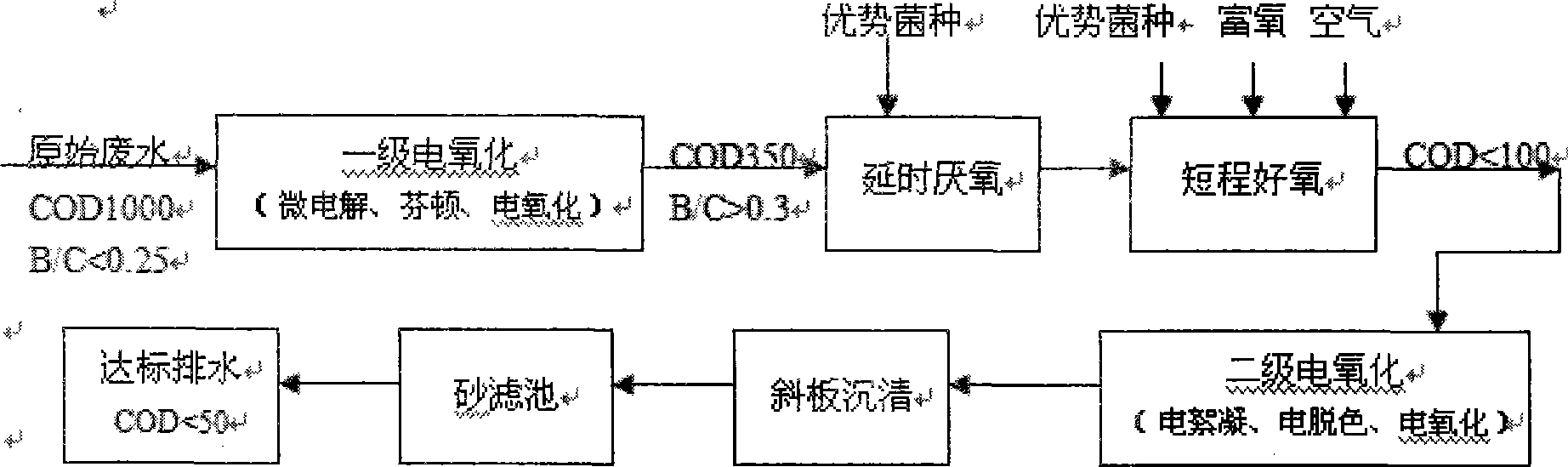

Zero discharge processing EBM method for dyeing waste water

InactiveCN101503268AReduce the load of purification and reuseSolve the blockageGeneral water supply conservationTreatment with aerobic and anaerobic processesFiberElectrolysis

The invention provides an EBM method for zero drainage treatment of dyeing wastewater. The method comprises that: step 1, a centrifuge dripping counter current washing process is carried out in a dyeing rinsing process; step 2, dyeing initial wastewater is subjected to standard-reaching treatment, step 2a, primary electro-oxidation is carried out, comprising micro-electrolysis, electro-oxidation, Fenton action and microwave, step 2b, biochemical treatment is carried out, comprising time delay anaerobism and short time aerobism, and superior bacteria is added in the same time, and step 2c, secondary electro-oxidation is carried out again after the biochemical treatment, comprising electrolytic flocculation, electric de-colorization and electro-oxidation; step 3, standard-reaching drainage water is subjected to deep purification treatment, which is to enter an electric desalination film system for treatment, plain water flows out after the standard-reaching drainage water is subjected to sand leach, fiber filtration, electric desalination and RO film in sequence, and can be recycled, and high concentrated water flows out from electric desalination. The treatment method saves water and energy, reduces COD drainage of the dyeing wastewater, and improves the de-colorization rate, the turbidity and the removal rate of ammonia nitrogen.

Owner:东莞市珠江海咸水淡化研究所

Nano titanium dioxide composite material applicable to wastewater treatment

InactiveCN105709687AEasy to handleQuick breakdownWater/sewage treatment by irradiationOther chemical processesMischmetalRare earth

The invention discloses nano titanium dioxide composite material applicable to wastewater treatment. The nano titanium dioxide composite material comprises nano titanium dioxide, absorptive porous material and nano titanium dioxide-modified material, wherein the nano titanium dioxide-modified material comprises inert metal Ag, Au and Pt or / and transition metal ions Cr, Mn, Fe, Co, Ni and Cu or / and rare earth metal ions La3+, Y3+ and Eu3+ or / and Fe-Sn and Fe-La. The nano titanium dioxide composite material has the advantages that the composite material is composited by the nano titanium dioxide-modified material, the nano titanium dioxide and the absorptive porous material, the photocatalytic activity and light utilization rate of the nano titanium dioxide are increased, the utilization rate of the nano titanium dioxide is increased, and the composite material can evidently decompose pollutants in wastewater.

Owner:GUANGXI UNIV

Wash water maintenance for sustainable practices

ActiveUS20120046211A1Quality improvementReduce the amount of waterWater treatment compoundsDetergent mixture composition preparationWater sourceWash water

Methods for use of enzymes for sustainable wash water maintenance are disclosed. The invention relates to use of enzymes for removing soils from wash water sources in a variety of cleaning applications. The invention cleans wash water sources, prevents the re-deposition of soils on treated surfaces and enhances detergency. Methods of wash water maintenance according to the invention provide sustainable practices by improving water quality and minimizing water and energy consumption in wash systems.

Owner:ECOLAB USA INC

Popular searches

Water/sewage treatment by sorption Water/sewage treatment by oxidation Water/sewage treatment by degassing Sustainable biological treatment Water/sewage treatment using germicide/oligodynamic-process Biological water/sewage treatment Metal/metal-oxides/metal-hydroxide catalysts Microorganism based processes Disinfection Cation exchangers

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com