Catalytical ozonization catalyst utilizing multi-source sludge to prepare and application thereof

An ozonation and solid catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, oxidized water/sewage treatment, etc., can solve the problem of high operation and maintenance costs, accelerated ozone decomposition, metal Problems such as difficulty in recycling ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

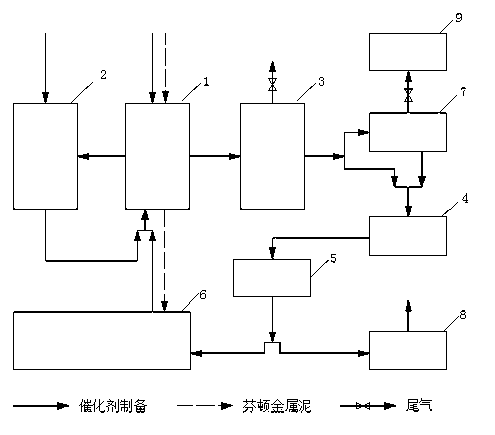

Method used

Image

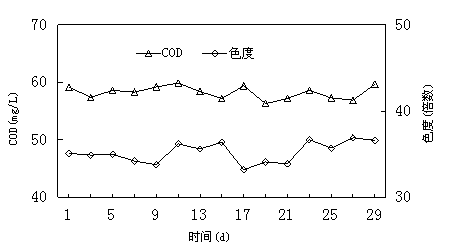

Examples

Embodiment 1

[0054] The solid catalyst has a skeleton of sludge-based activated carbon, and the surface layer is rich in iron oxides; wherein the ratio of weight and number of sludge-based activated carbon to iron oxides is 1:0.5; the sludge-based activated carbon is composed of sludge, Crushed corn cob, activator ZnCl 2 Composition, sludge: crushed corn cob: ZnCl 2 The ratio of parts by weight is 1:3:0.5.

[0055] Its preparation method is as follows:

[0056] Dehydration: The remaining sludge from the biochemical treatment of the urban sewage plant is dehydrated by a centrifuge to make the water content at 50%; after Fenton oxidation, the iron sludge is dehydrated in a centrifuge to make the water content at 30%;

[0057] Activation: dehydrated sludge, crushed corncobs (100g of corncobs per Kg of water-containing sludge), activator 1.5mol / L ZnCl 2 Solution (add ZnCl per Kg of aqueous sludge 2 The solid content is 50g) into the activation kettle with stirring equipment in turn, st...

Embodiment 2

[0066] A solid catalyst whose skeleton is sludge-based activated carbon and oxides of copper on the surface; the sludge-based activated carbon is composed of sludge, pulverized corncobs, and activator KOH, and sludge: pulverized corncobs: parts by weight of KOH solids The ratio is 1:3:0.5.

[0067] Dehydration: The remaining sludge from the biochemical treatment of the urban sewage plant is dehydrated by a centrifuge to make the water content 40%; after Fenton oxidation, the iron sludge is dehydrated in a centrifuge to make the water content 40%;

[0068] Activation: Mix the dehydrated sludge and crushed corncobs (the amount of corncobs per Kg of water-containing sludge is 200g), and the activator 2moL / L KOH solution (the amount of KOH solids per Kg of water-containing sludge is 150g) in sequence. In an activation kettle with stirring equipment, stir and activate for 8 hours;

[0069] Drying: After activation, the sludge enters the centrifuge for dehydration, so that th...

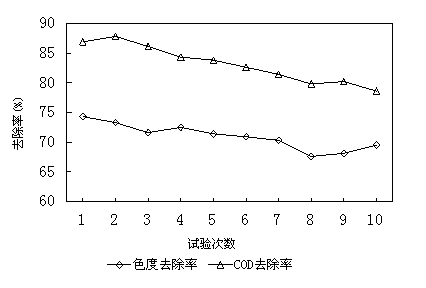

Embodiment 3

[0075] Solid catalyst regeneration:

[0076] Add the deactivated catalyst to the washing tank, wash it several times with 5% (w / w) NaOH solution, wash it with water until it is neutral, and dry it in the air;

[0077] Then proceed to implement Case 1 Steps to obtain the regenerated catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com