Ultrasonic detection narrow pulsewidth laser sludge remover and its sludge removing method

An ultrasonic detection and narrow pulse width technology, which is applied in the field of laser technology, can solve the problems of lack of monitoring means, medium denaturation, damage, etc., and achieves high decontamination efficiency, low energy consumption, and good decontamination effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

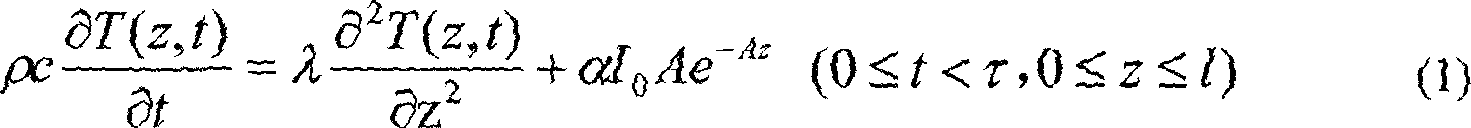

[0045] Embodiment 1: remove the car paint layer on the ferroalloy surface

[0046] Implementation steps:

[0047] (1) According to the specific sample and dirt properties, input the laser working parameters through the automatic control device. The working parameters of the laser are: 1064nmNd: YAG laser or other types of lasers, the pulse width is, for example, 15ns, 10ns, 5ns or other pulse widths suitable for the working process, and the single pulse energy is 500mJ, 200mJ or within the range of 100mJ to 10J according to The specific situation of the dirt is determined; the repetition frequency ranges from 20Hz to 60Hz. For car paint removal on ferroalloy surfaces, the laser operating parameters are: 1064nm Nd:YAG laser, pulse width 15ns, single pulse energy 500mJ, repetition frequency 20Hz. If it is not clear that the required laser pulse energy can also be set to 0J, the automatic control device will use the trial and division method for preprocessing to select the appr...

Embodiment 2

[0054] Embodiment 2: remove the rust layer of medium corrosion degree on the iron plate surface

[0055] This embodiment is basically the same as Embodiment 1, the difference is:

[0056] (1) The energy density required for rust removal is higher than that for paint removal, so the laser energy in the laser working parameters should be increased, which can be 600mJ, and other parameters can remain unchanged.

[0057] (2) For some local rusts whose shapes are not very standard, this device also adds manual control on the basis of automatic control, and the two can be switched at will. In this way, during the laser derusting process, when the automatic scanning of the laser in a certain direction is close to the irregular edge of rust, it can be switched to manual control, so that the laser stops working, and then the mobile platform device is controlled to locate the next decontamination position before starting the laser. Start working and switch to automatic control at the s...

Embodiment 3

[0058]Embodiment 3: remove the paint or other dirt on the object surface with local irregular shape (larger object surface radian)

[0059] According to the specific sample and dirt properties, the laser working parameters are input through the automatic control device. The working parameters of the laser are: 1064nmNd: YAG laser or other types of lasers, the pulse width is, for example, 15ns, 10ns, 5ns or other pulse widths suitable for the working process, and the single pulse energy is 500mJ, 200mJ or within the range of 100mJ to 10J according to The specific situation of the dirt is determined; the repetition frequency ranges from 20Hz to 60Hz. If it is not clear that the required laser pulse energy can also be set to 0J, the automatic control device will use the trial and division method for preprocessing to select the appropriate energy range during the cleaning process; or choose from the parameters given by the feedback control device, control The software of the syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com