Patents

Literature

304 results about "Shielded metal arc welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shielded metal arc welding (SMAW), also known as manual metal arc welding (MMA or MMAW), flux shielded arc welding or informally as stick welding, is a manual arc welding process that uses a consumable electrode covered with a flux to lay the weld.

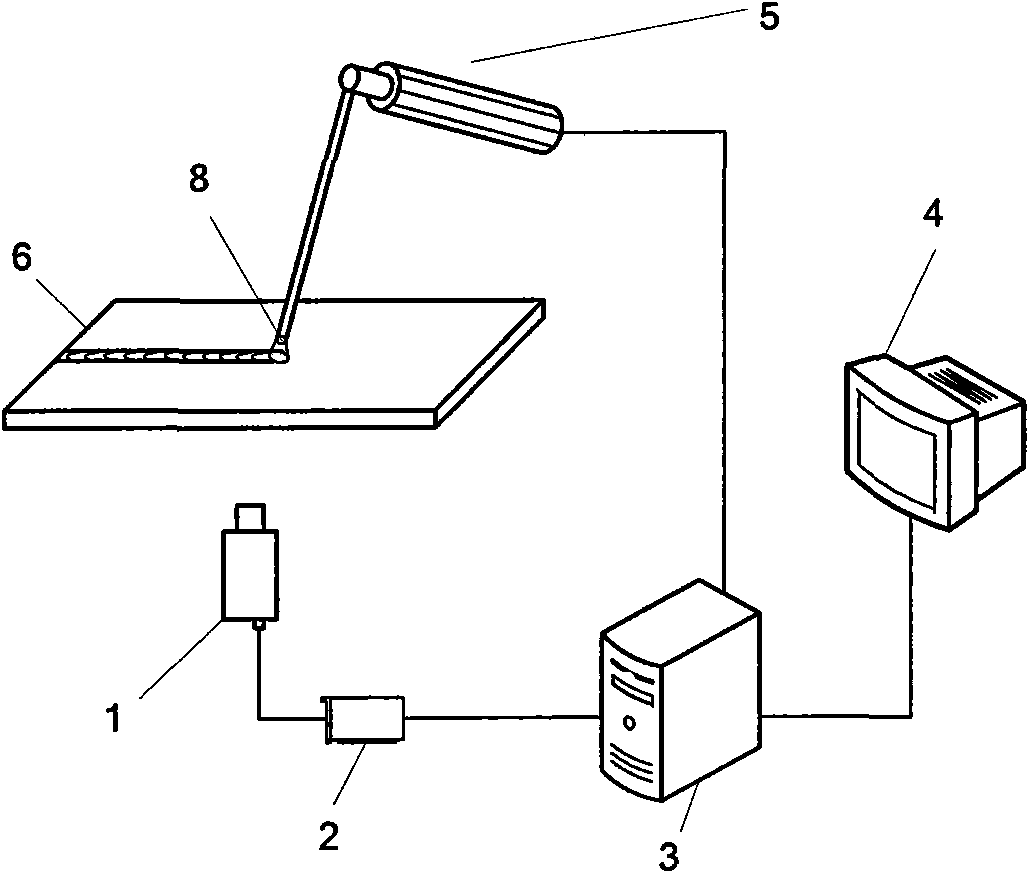

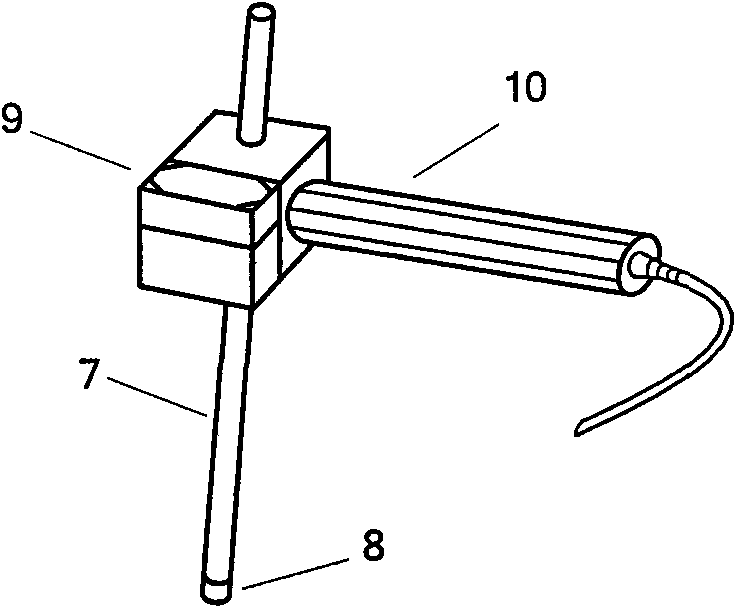

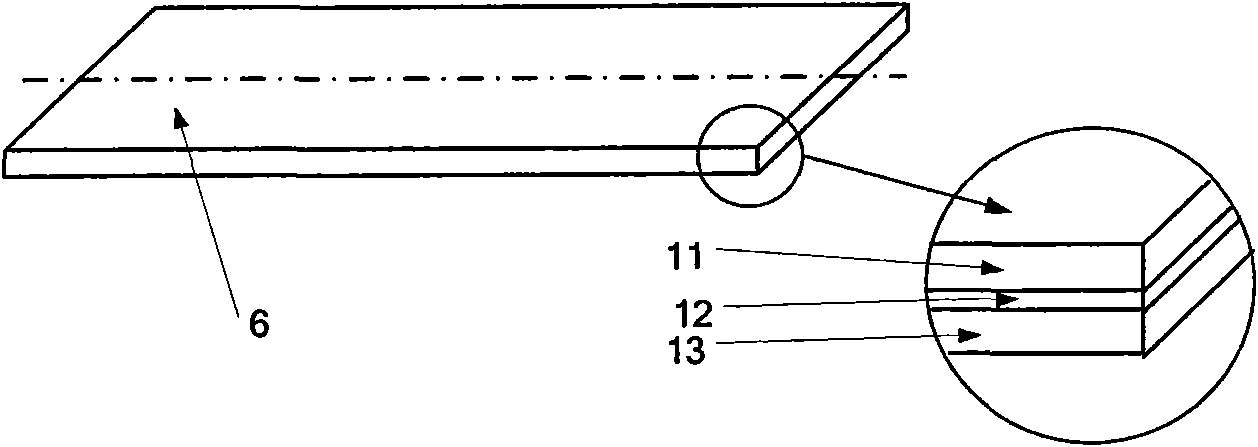

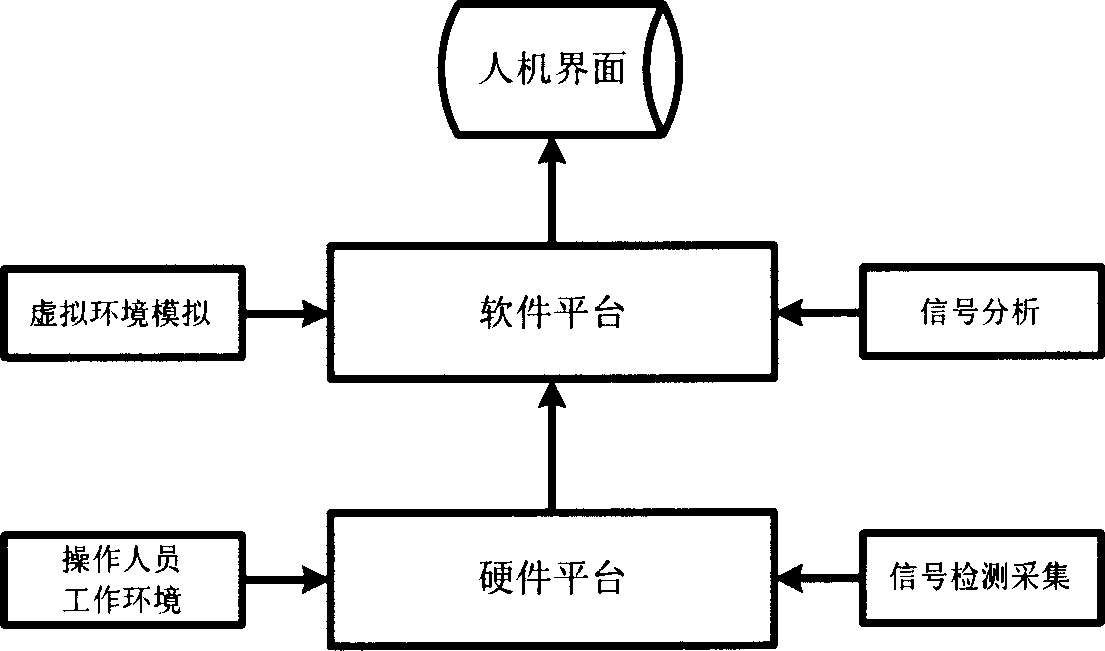

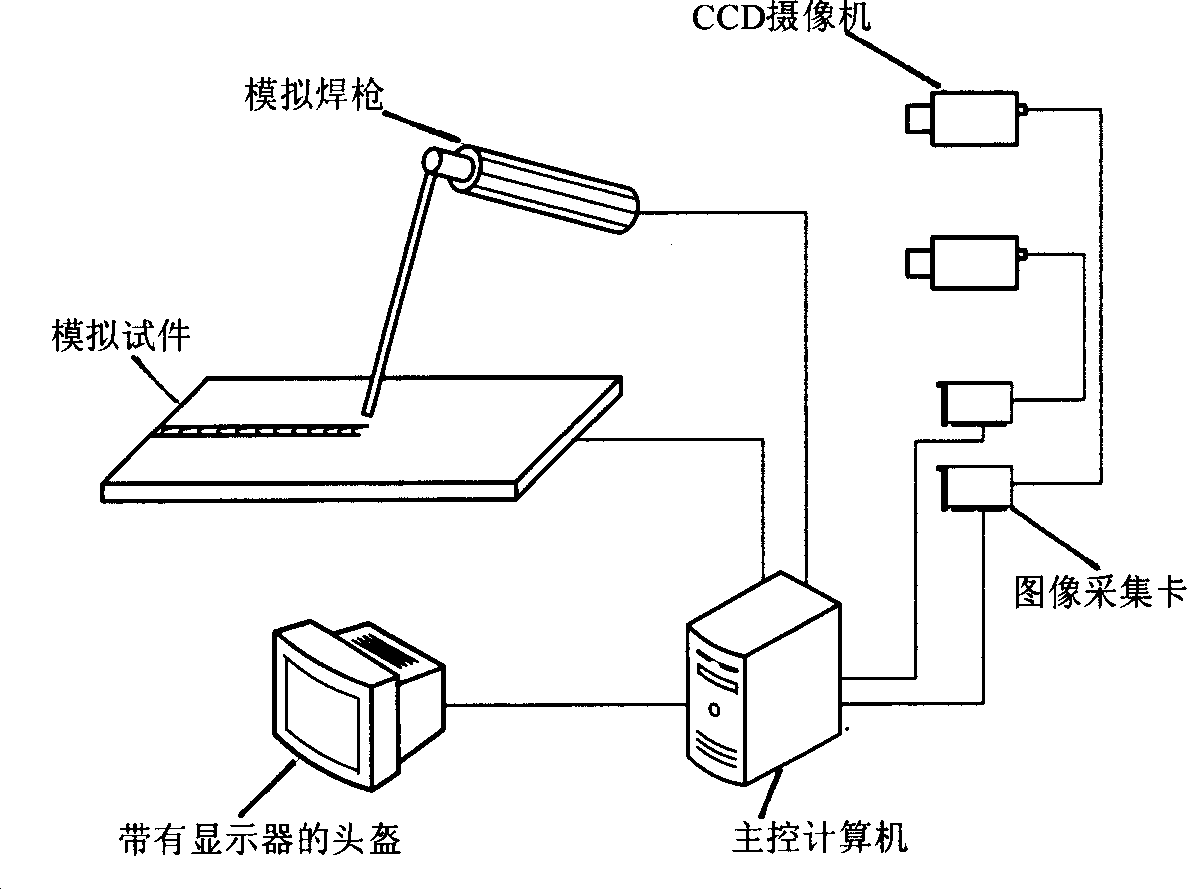

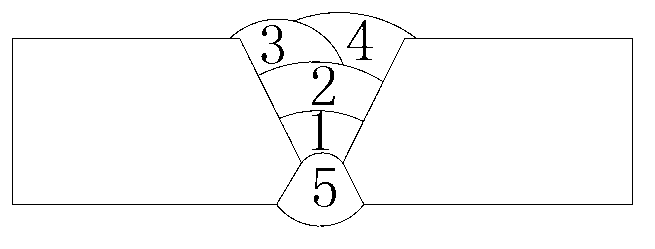

Simulation training device for manual arc welding rod-moving operation, and arc welding rod-moving detection method

InactiveCN101587659ARealize high-precision detectionImprove learning efficiencyUsing optical meansTeaching apparatusShielded metal arc weldingImage detection

The invention provides a simulation training device for manual arc welding rod-moving operation, and an arc welding rod-moving detection method, which is used for the introduction, improvement and enhancement training of welders in welding rod-moving operation. The device comprises a simulated welding torch, a simulated test plate, an image detection module, a dip-angle sensor, a master control computer and an evaluation system. Through the reasonable choice and layout of sensors and efficient data processing, high-precision detection and evaluation of real-time positions of simulated welding rods operated by the welders are realized. The device can record the arc striking, rod moving, ending and a series of operation of welding students during operation, and allows operation tracks to reappear after the operation is completed so as to improve learning efficiency and learning effects.

Owner:XI AN JIAOTONG UNIV

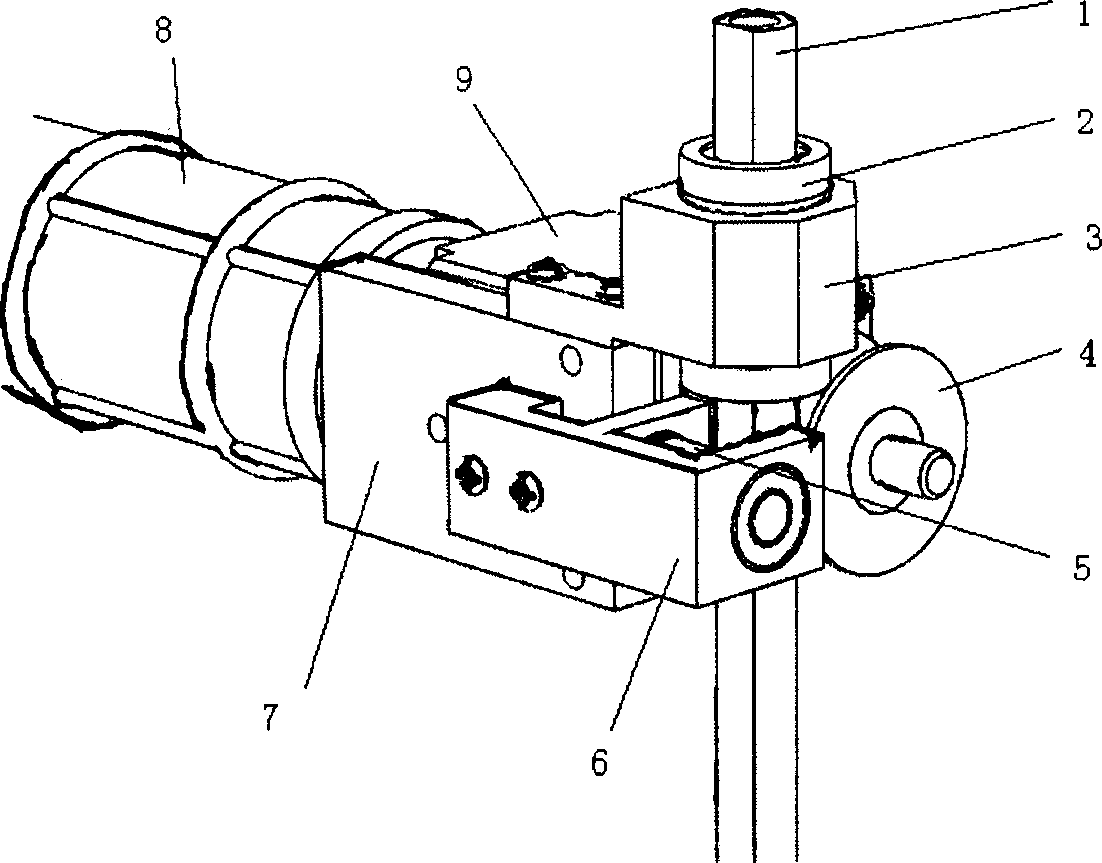

Simulative training device for manual arc welding operation

InactiveCN1866317AChange the melting rateMaster the welding feelEducational modelsTeaching apparatusShielded metal arc weldingElectric machine

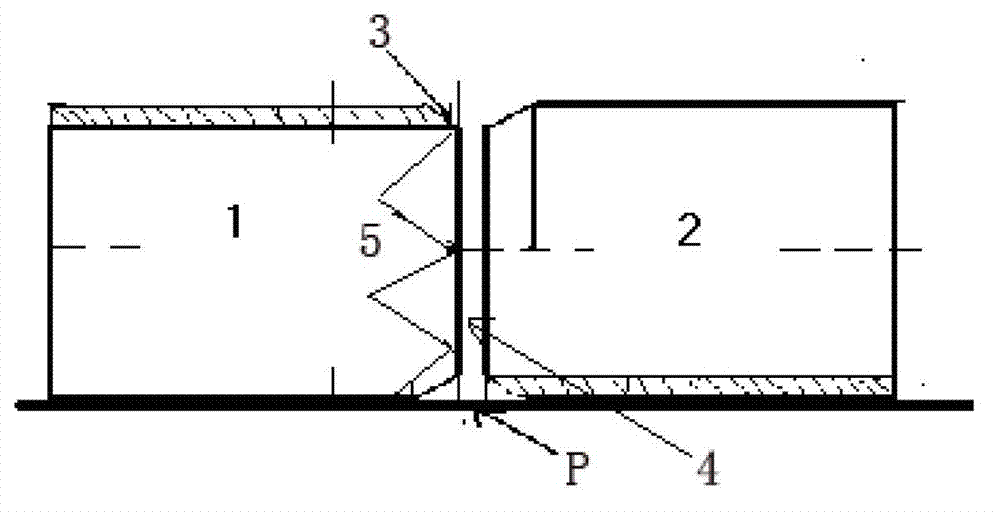

The related training simulator for welding operation comprises: a simulating welding gun with a handle (8) connected to a step motor (9); a controller; and a simulated test piece. Wherein, arranging an active rolling wheel (4) on motor output shaft, a rolling base (6) with a driven rolling wheel on the motor base (7), and a welding rod (1) between (4) and (5). This invention can accelerate training with less consumption.

Owner:XI AN JIAOTONG UNIV

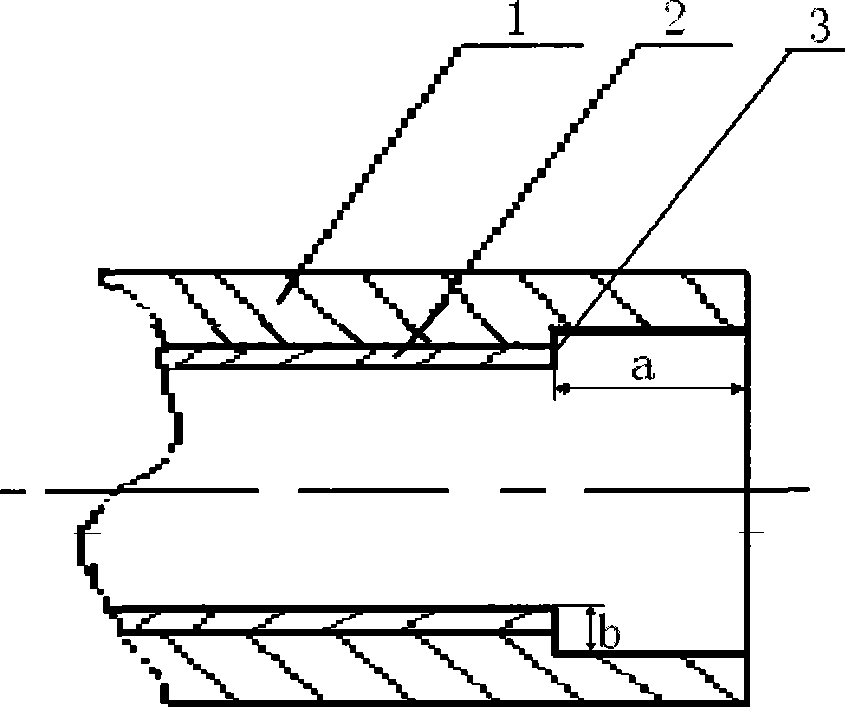

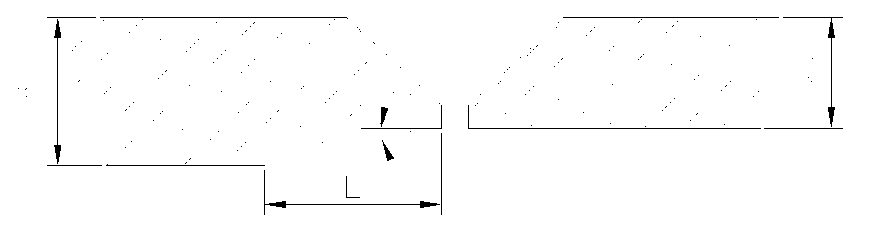

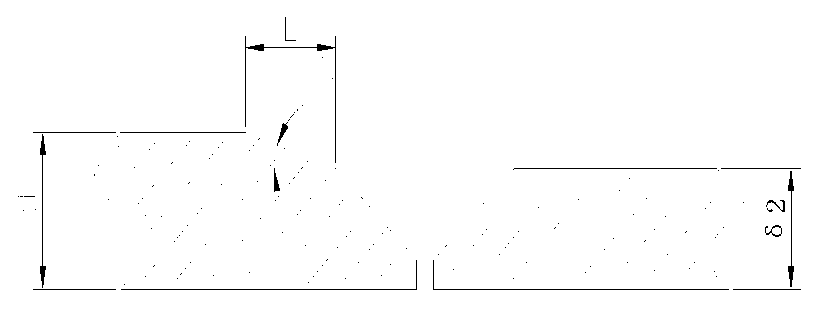

Method for welding thin layer iron nickel base alloy carbon steel composite tube

ActiveCN101462193AIncrease the effective thicknessHigh strengthArc welding apparatusWelding/cutting media/materialsAlloyWeld seam

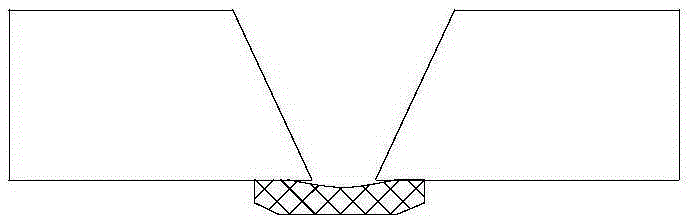

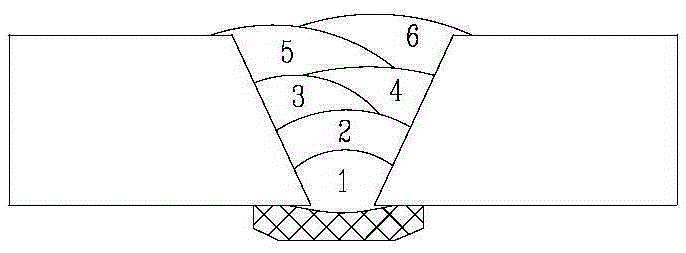

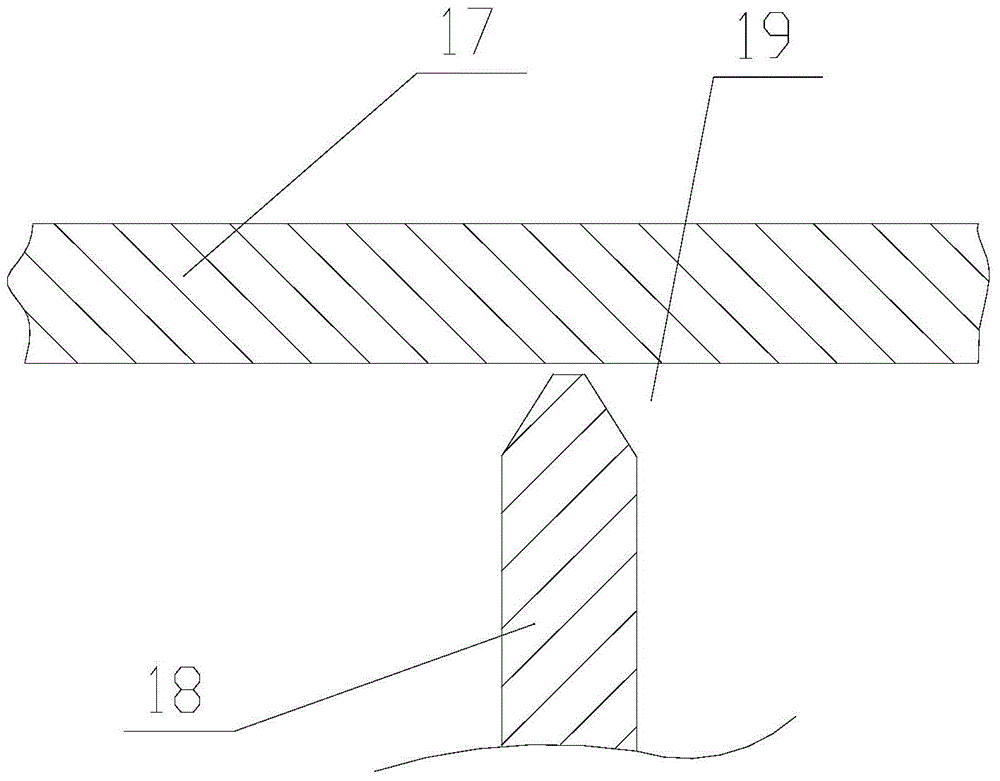

The invention relates to a method for welding a carbon steel composite pipe of a thin iron-nickel-based alloy. The method comprises: processing a step on the end part of the composite pipe; adopting the surfacing of argon arc welding on the surface of the step and trimming the surfacing layer; processing a groove; adopting tungsten electrode argon arc welding to carry out three-point positioning of spot welding evenly around a welding seam, and adopting the tungsten electrode argon arc welding to carry out back welding on the root; and adopting manual electric arc welding to carry out filling welding and overlay welding on the upper part of a second layer of back welding. The chemical compositions of a welding material by weight percentage: 0.02 to 0.1 percent of C, 0.2 to 1.0 percent of Si, 1.0 to 2.2 percent of Mn, 20.0 to 31.5 percent of Cr, 40.0 to 60.0 percent of Ni, 8.0 to 14.5 percent of Mo, 0.5 to 2.5 percent of Cu, 0 to 5.0 percent of Co, 0.3 to 4.2 percent of Nb, and the balance being Fe. The welding seam has the characteristics of no sensitivity to offset, favorable corrosion resistance, high strength and favorable plastic toughness.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

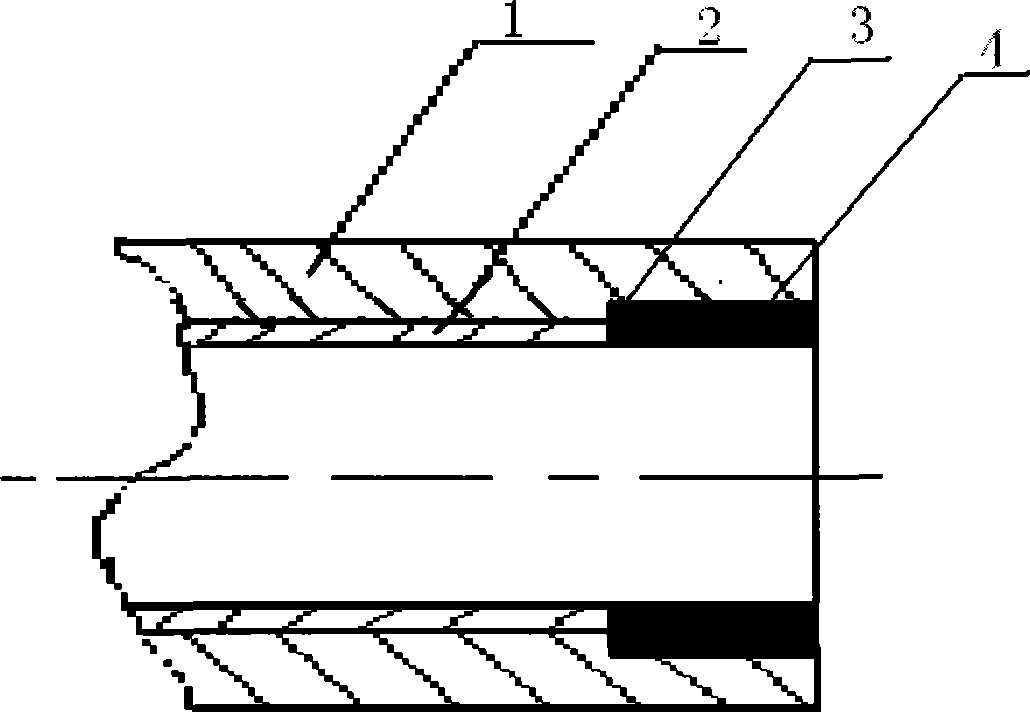

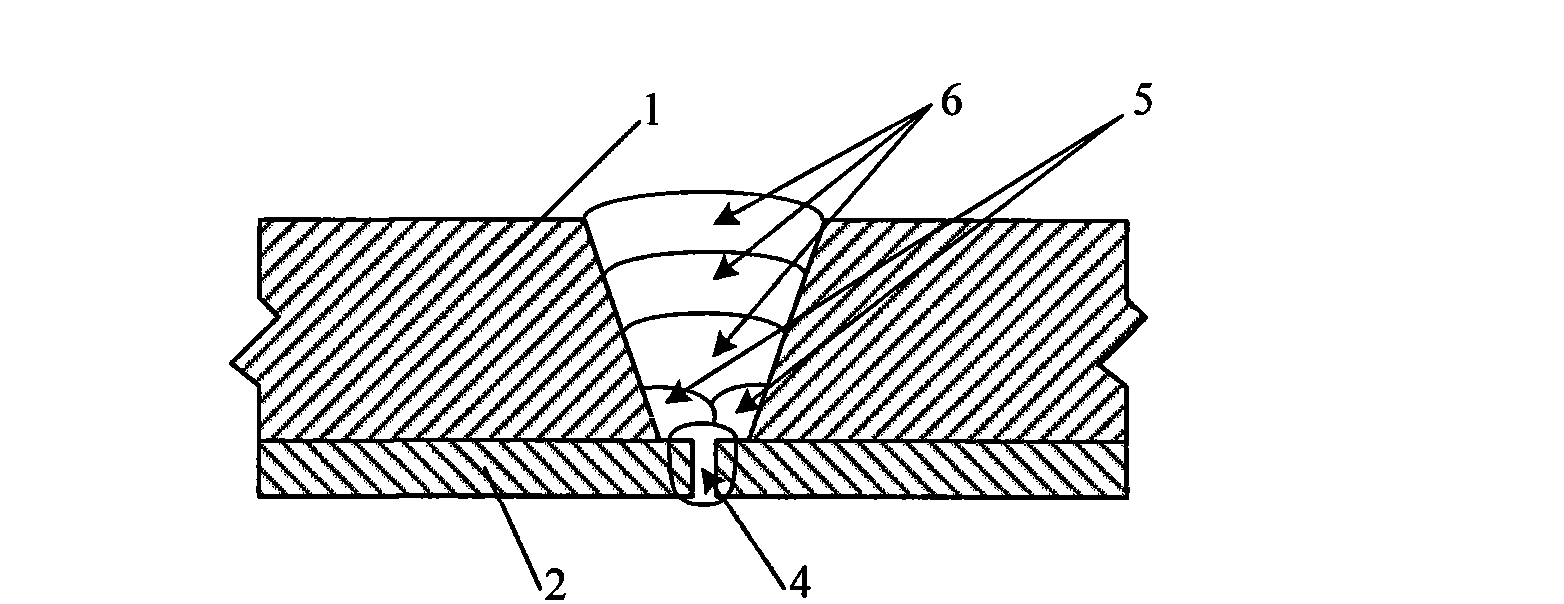

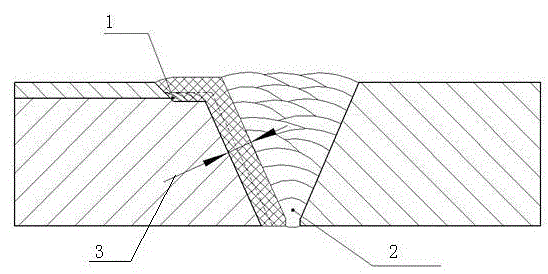

Welding method of girth weld of inner cladding thin-walled stainless steel composite tube

InactiveCN101633074AResolving ingredient matchesSolve the corrosion resistanceWelding/cutting auxillary devicesAuxillary welding devicesChemical industryWeld seam

The invention relates to a welding method of a girth weld of an inner cladding thin-walled stainless steel composite tube. The welding method comprises the following steps: girth welds of the inner cladding stainless steel composite tube are respectively and gradually welded by three welding seams, an inner cladding layer welding seam and a transition layer welding seam are welded by argon tungsten-arc welding, the stainless steel inner cladding layer welding seam adopts welding wires with the same quality thereof, the transition layer welding seam adopts ER309 welding wires, and the base layer is welded by shielded metal arc welding or CO2 gas shielded welding and adopts a welding material matched with the strength of the base layer; and the inner cladding layer, the transition layer and the first layer of the base layer are welded under back argon gas protection. The welding method guarantees corrosion resistance of a joint of the inner cladding layer and mechanical property of a welding joint of the base layer; and the method plays an important role in promoting wide application of the inner cladding stainless steel composite tube in businesses such as oil-gas delivery, chemical industry, oil refining and the like, improving corrosion resistance of an inner wall of a pipe, and solving the problems of high cost and the like caused by adopting a full wall-thickness stainless steel pipe.

Owner:XI AN JIAOTONG UNIV

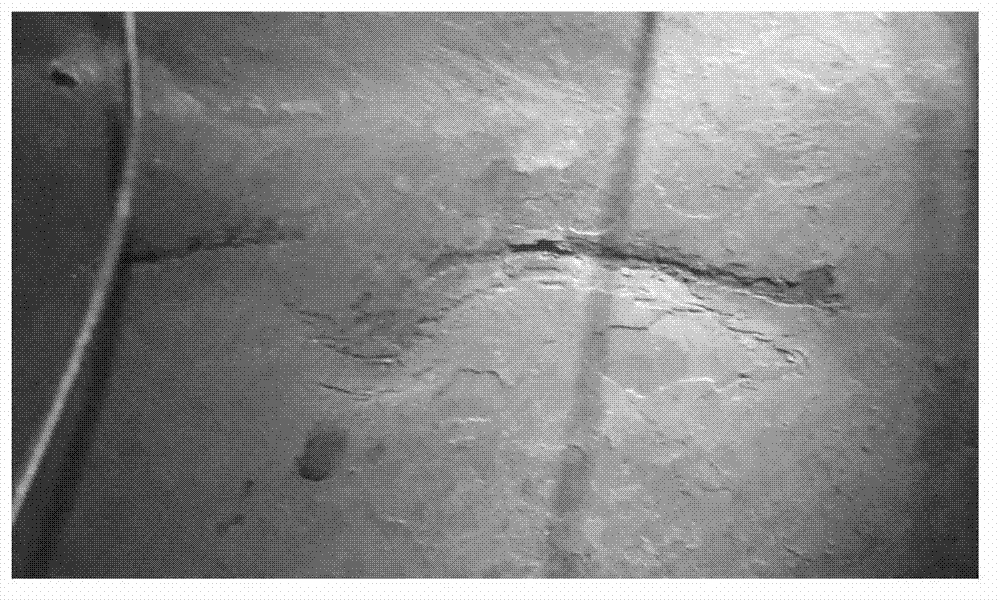

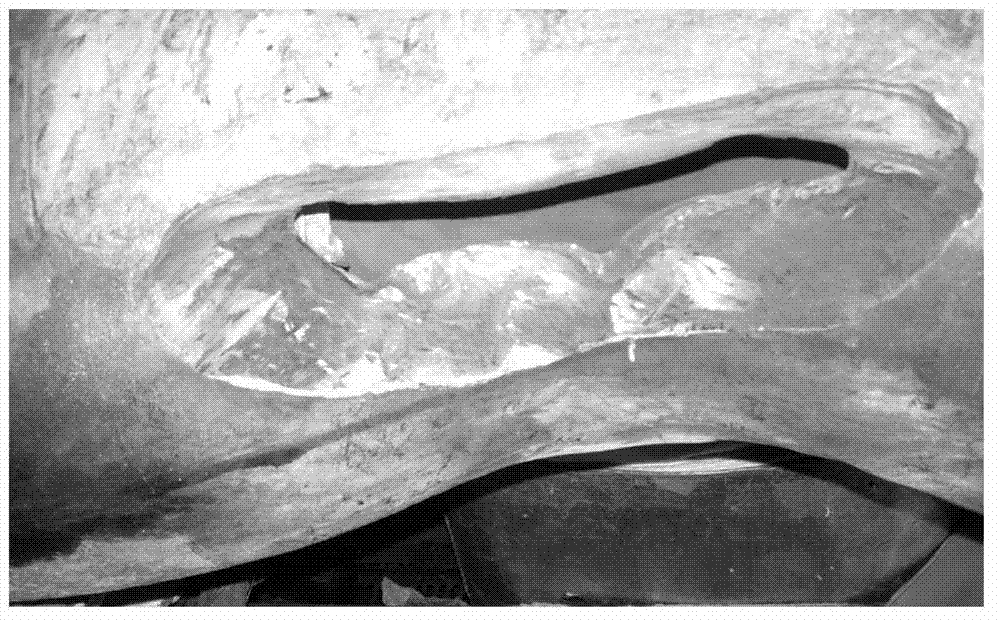

Field welding repair method especially for larger and penetrating defects in steel casting with heavy wall thickness

The invention relates to a field welding repair method especially for larger and penetrating defects in a steel casting with heavy wall thickness. The method comprises a pre-welding preparation process, a welding repair process and a post-welding quality inspection process, wherein the welding repair process comprises the steps of (1) preheating; (2) carrying out 1 to 2 layers of backing weld for all positions of a groove by adopting TIG weld, and filling the whole bottom of the groove with solid wire materials; (3) warming up to 220 to 330 DEG C, carrying out constant thermal insulation for 3 to 8 hours, adopting manual arc welding to implement the filler welding for the groove, hammering the welded bead immediately with an air hammer, and ensuring the dense and uniform traces of the hammer; (4) carrying out dehydrogenation heat treatment; (5) carrying out post-welding treatment: carrying out stress annealing at the temperature of 500 to 550 DEG C, then carrying out high tempering at the temperature of 700 to 750 DEG C, and finally, cooling at the speed of 65 to 150 DEG C / h to the room temperature. After welding repair, a welding seam is tested to be good in quality, and have low possibility of cracking again.

Owner:SUZHOU NUCLEAR POWER RES INST +4

Welding repair method for large-sized heat-resistant steel castings

ActiveCN103962791AEliminate Large Area DefectsRelieve welding stressArc welding apparatusShielded metal arc weldingCrazing

The invention relates to a welding repair method for large-sized heat-resistant steel castings, and solves the problems that the welding stress is difficultly removed, the defects of incomplete fusion, incomplete penetration, delayed crack and slag inclusion are easily caused in a repair process and the repair quality is difficultly guaranteed as the heat-resistant steel castings are poorer in welding performance, complicated in defect position and large in workpiece in an existing manual arc welding type surfacing welding mode for repairing large-sized castings. The method mainly comprises the following steps: 1, removing the defects; 2, performing heat treatment; 3, performing dye check; 4, performing statistics on the repair welding quantity; 5, preheating before welding; 6, performing repair welding on defect parts; 7, cleaning and repairing; 8, performing post-welding heat treatment; 9, performing nondestructive inspection. According to the method, the large-area defects of the castings can be effectively repaired, the repair quality is guaranteed, the processing and use requirements of the castings can be met after repair, and the economic loss of scrapped important or major castings is reduced. The method is used for repairing the large-area defects of the large-sized heat-resistant steel castings.

Owner:HARBIN JIANCHENG GRP

900MPa high-strength steel preheating-free combined welding method

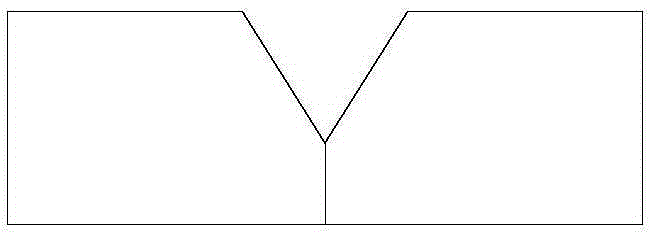

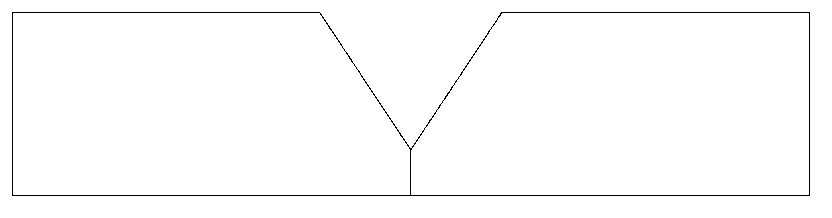

The invention discloses a 900MPa high-strength steel preheating-free combined welding method. 700-800 MPa low-hydrogen type high-tenacity shielded metal arc welding is adopted for backing welding, then a 900MPa high-tenacity solid wire is matched with Ar+CO2 mixed gas shielded welding for implementing filling welding, and a 800MPa flux-cored wire is matched with CO2 gas shielded welding for cosmetic welding. A crack-free welding joint can be obtained by welding 900MPa high-strength steel through adopting a preheating-free and postweld heat treatment free combined welding process, and a joint region is smooth and clean, and can meet operating requirements on a high-strength steel welding structure for higher bearing capacity because the room temperature tensile strength of weld metal is more than 860MPa and the damping power of a V-shaped notch of the weld metal with the test temperature of 0 DEG C is more than 90J; and meanwhile, the method has welding cost reduced by about 25 percent, simple and convenient operation and easy popularization.

Owner:SHANDONG UNIV

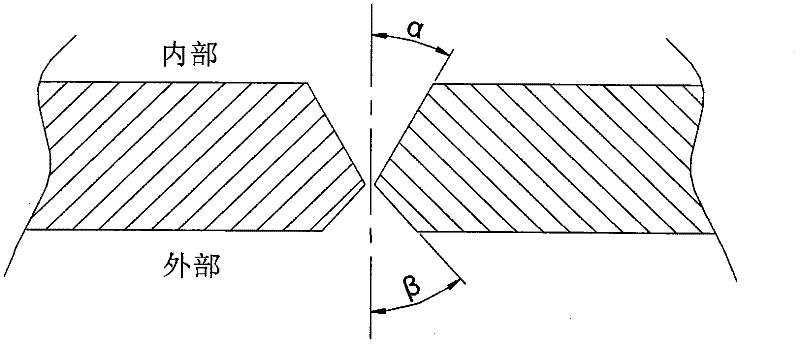

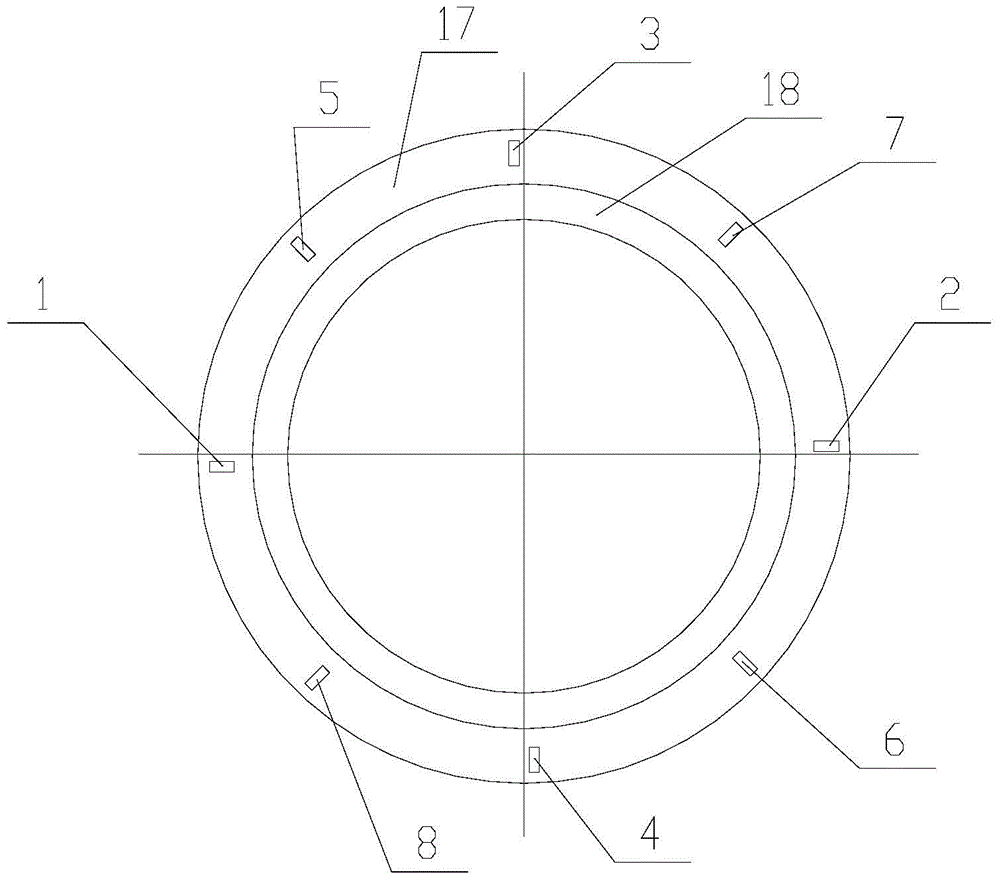

Girth welding technology for vacuum container

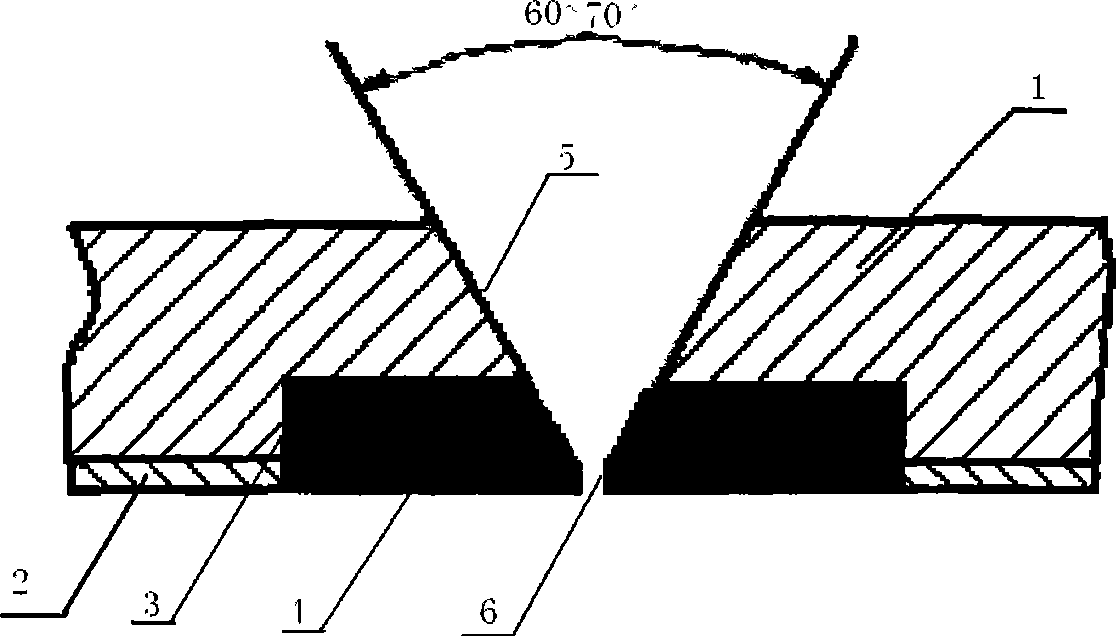

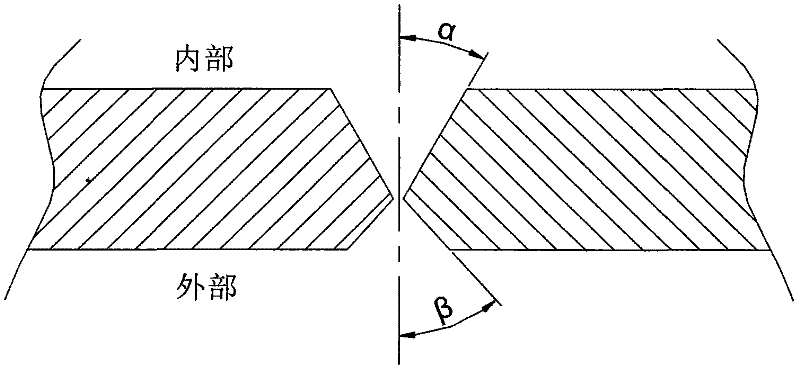

ActiveCN102357741AGuaranteed absolute penetrationAvoid the phenomenon of localized high temperatureArc welding apparatusWorkpiece edge portionsShielded metal arc weldingButt welding

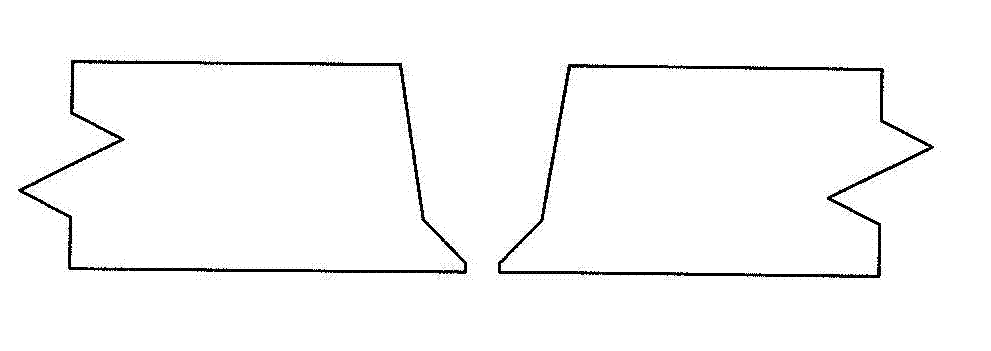

The invention discloses a girth welding technology for a vacuum container, which comprises the following steps: processing beveled edges, assembling and welding. In the step of processing the beveled edges, a 14mm thick 0Cr18Ni9 austenitic stainless steel material is selected as a cylinder base material, X-shaped beveled edges are adopted, an inside beveled edge is processed for 10mm with a single-side angle of 32.5 degrees, an outside beveled edge is processed for 4mm with a single-side angle of 35 degrees, and no truncated edge is left. In the step of assembling, reserved clearances of 2.0-2.5mm are assembled, argon tungsten-arc welding is adopted to position, a positioning welding length is 10-15mm, an interval is 200mm, and then a 'strut having a shape of Chinese character 'mi' which is used for adjusting the roundness of a cylinder is welded in the cylinder. In the step of welding, an argon arc welding double-gun butt-welding method is used for bottoming the interior of the cylinder, two layers are filled in an inner welding bead of the cylinder in the manner of manual arc welding, an external welding bead is covered in the manner of submerged-arc welding, and finally, the inner welding bead is covered in the manner of manual arc welding. The girth welding technology can be used for controlling the welding deformation and has the advantages that the method is simple and is easy to realize.

Owner:无锡市创新低温环模设备科技有限公司

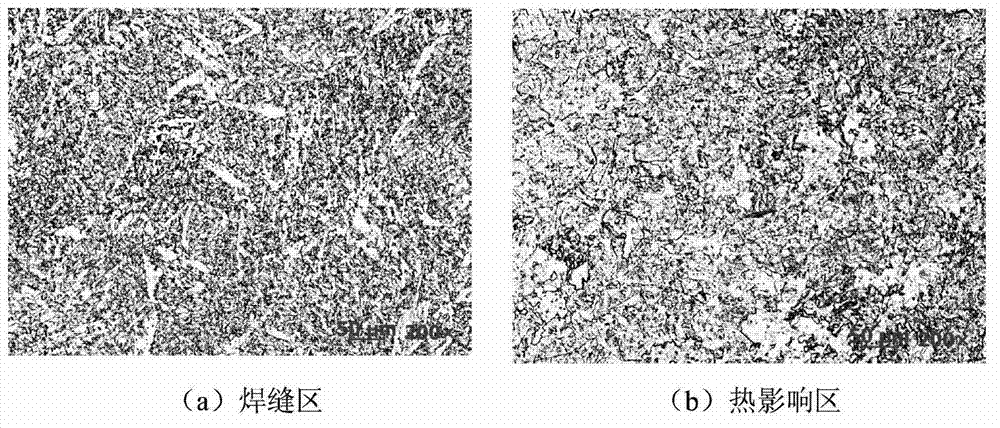

Welding technology of super martensitic stainless steel

InactiveCN101596640AImprove performanceHigh hardnessArc welding apparatusWelding/soldering/cutting articlesShielded metal arc weldingMartensitic stainless steel

The invention provides a welding technology of super martensitic stainless steel, which comprises the processes of a preweld preparatory process including bevel preparation of super martensitic stainless steel, splicing and assembly of bevel and weld material choosing, a backing welding process and a filling welding and facing welding process, wherein the preweld preparatory process is provided with a preweld preheating step for preheating a welding part at the temperature of 50-70 DEG C; the welding material chosen in the preweld preparatory process comprises two phase stainless steel welding sticks and two phase stainless steel welding rods; the backing welding process adopts manual argon tungsten arc welding; and the filling welding and facing welding process adopts manual argon tungsten arc welding or shielded metal arc welding. The invention improves the performance of welded splices, in particular the rigidity and the decay resistance, omits the heat treatment process after welding, reduces processes, enhances the welding efficiency and reduces the production cost.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Welding method for Q345qDNH weather-resisting steel for bridge

ActiveCN102837105AGood mechanical propertiesEasy to upgradeArc welding apparatusWelding/soldering/cutting articlesShielded metal arc weldingButt joint

The invention discloses a welding method for Q345qDNH weather-resisting steel for a bridge. According to the welding method provided by the invention, specific to the special chemical components, suitable technical conditions and different slab thickness of the Q345qDNH weather-resisting steel for the bridge, a welded joint is jointed in a butt-jointed or T-shaped corner jointed form. According to the welding method, submerged-arc welding, drug core CO2 gas shielding semi-automatic welding or shielded metal arc welding is adopted and the weld preheating temperature is confirmed according to the different slab thickness. According to the welding method provided by the invention, the joint form and the thickness size of a bridge structure are completely covered; the technical scheme is simple and the applicability is strong; the implementing effect meets the technical demands of the present related standard for the construction of the bridge steel and the bridge structure; and the welding method can be practically applied to the welding of the Q345qDNH weather-resisting steel bridge structure.

Owner:CHINA RAILWAY SHANQIAO GRP CO LTD

Welding method for high-performance weather-resistant steel which is at Q345qENH-Q420qENH level and used for bridges

InactiveCN105252122AGood mechanical propertiesImprove corrosion resistanceArc welding apparatusWelding/cutting media/materialsShielded metal arc weldingChemical composition

The invention discloses a welding method for high-performance weather-resistant steel which is at the Q345qENH-Q420qENH level and used for bridges. Welding connectors selected according to specific chemical components, mechanical properties, welding connector corrosion-resistant indexes, applicable technological conditions and different plate thickness specifications of the high-performance weather-resistant steel which is at the Q345qENH-Q420qENH level and used for bridges are in the type of a butt joint and a T-shaped connector (including a corner connector); a welding method includes submerged automatic arc welding, solid wire argon-rich gas protection semi-automatic welding, flux-cored wire CO2 gas protection semi-automatic welding and shielded metal arc welding; and preheating temperature before welding is determined according to different plate thicknesses. The welding method comprehensively covers the connector types and the plate thickness specifications of the bridge steel structure; the technical scheme is high in practicability; the implementation effect totally meets the technological requirements of structural steel for existing bridges and relevant standards in the steel bridge manufacturing field; and the welding method can be used for welding the high-performance weather-resistant steel which is at the Q345qENH-Q420qENH level and has a great effect on prompting popularization of high-level weather-resistant bridge steel.

Owner:中铁宝桥(扬州)有限公司

Method for welding Q500qE ultralow-carbon bainite steel for bridge

ActiveCN103286427ASolve welding process problemsAvoid cold cracksArc welding apparatusWelding/cutting media/materialsShielded metal arc weldingChemical composition

The invention provides a method for welding Q500qE ultralow-carbon bainite steel for a bridge. The method is excellent in joint mechanical performance and high in welding efficiency and specifically includes that aiming at specific chemical components, applicable technical conditions and different plate thicknesses of the Q500qE ultralow-carbon bainite steel for the bridge, preheating temperature before welding, groove types and welding process parameters are determined; a welding joint type adopts butt joint, penetration angle joint or ship position T-shaped angle joint; a welding method adopts submerged arc welding, CO2 gas shielded semiautomatic welding or shielded metal arc welding. By the welding method, the joint type and thickness specifications of a bridge structure are comprehensively covered, the technical scheme is simple, convenient and high in adaptivity, all implementing effects meet technical requirements of standards related to building of bridge steel and the bridge structure, and the method is of great significance in promoting upgrading of the bridge steel and development of large-span steel bridge building technology. The method can be applied to building of the bridge structure, can also be applied to welding of other ultrathin-carbon bainite steel and is high in adaptivity.

Owner:CHINA RAILWAY SHANQIAO GRP CO LTD

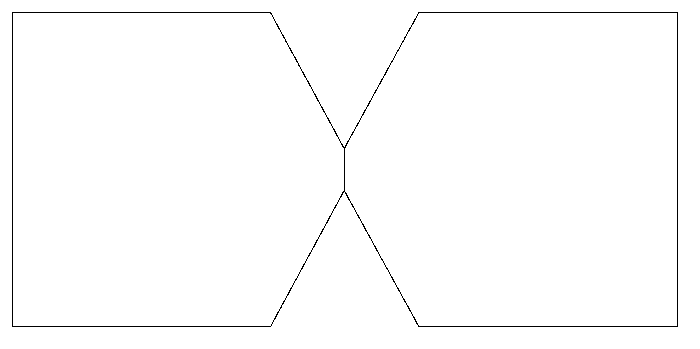

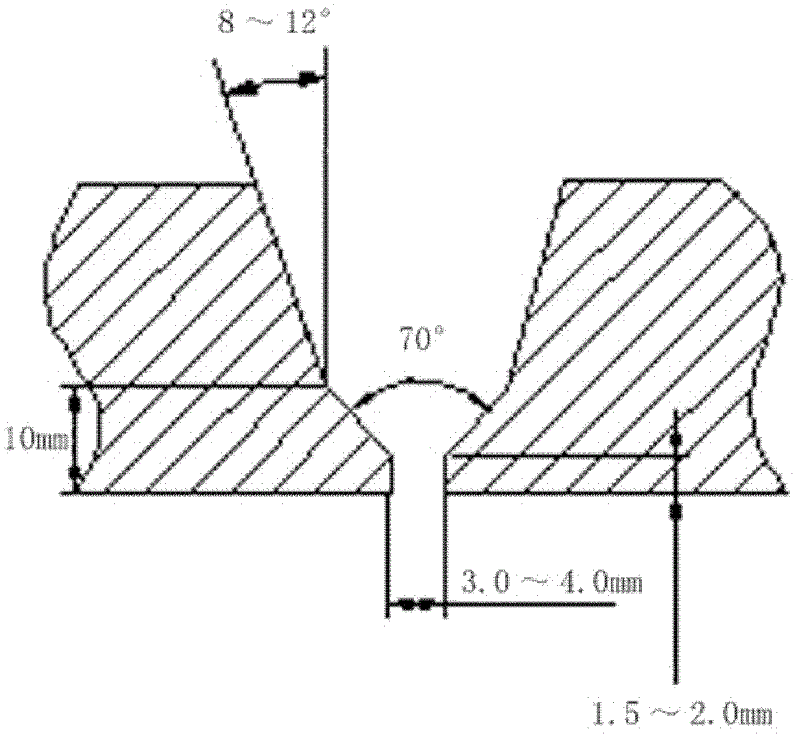

Welding process of ultra-supercritical fossil power unit for welding SA335-P91/P92 steel

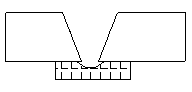

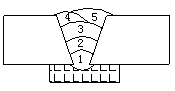

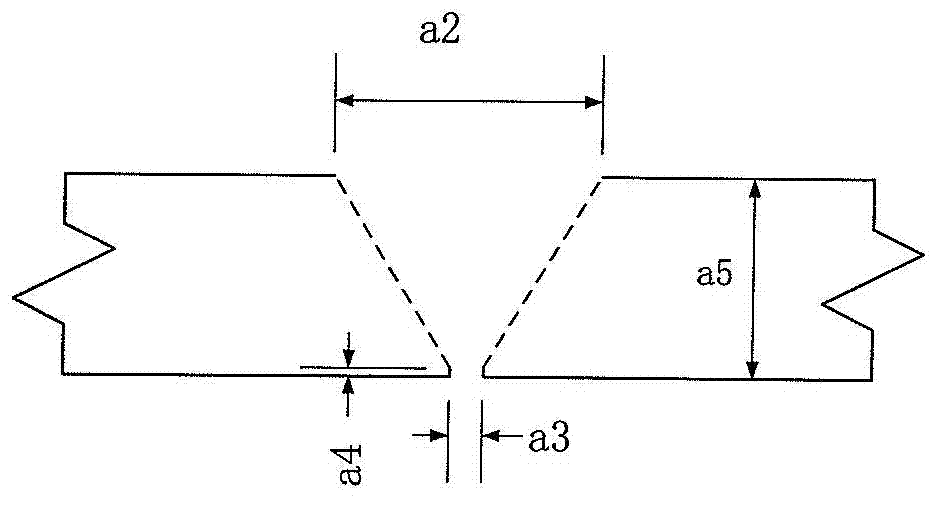

InactiveCN102615380AImprove the first pass rate of weldingImprove accuracyArc welding apparatusWorkpiece edge portionsShielded metal arc weldingPower flow

The invention relates to a welding process of an ultra-supercritical fossil power unit for welding SA335-P91 / P92 steel. The process is characterized by comprising three aspects of preparation before welding, welding parameter optimization and welding process optimization. In workpiece selection, a manual arc welding electrode is used as a welding workpiece; in welding bead arrangement, a welding bead is arranged in a double V-shaped or U-shaped groove shape, and the surface of the groove is cleaned; contra-aperture assembly is carried out, pipelines to be welded are arranged in the welding bead, each section of pipeline is propped firmly after contra-aperture connection, and the requirements on the contra-aperture of each section of pipeline are that: the staggered joint is 0.1-1.0mm, the gap is 3.0-4.0mm, and the truncated edge is 1.5-2.0mm; a large-diameter thick-wall pipe is fixed in the groove by a positioning block; and a welding area is preheated before welding, and then multi-layer welding bead welding is carried out in a GTAW (gas tungsten arc welding) and SMAW (shielded metal arc welding) combined welding method. According to the welding process disclosed by the invention, a multi-layer welding bead welding technology with a small-dimension electrode, a small current parameter and small swing is adopted, the impact toughness of a weld joint is improved, and the first-pass yield of welding can be greatly improved.

Owner:GUANGDONG SHAOGUAN YUEJIANG POWER GENERATION

Method for welding dissimilar material welded joint of composite plate

ActiveCN105127562AEasy to operateAvoid welding cracks etc.Arc welding apparatusWelding/soldering/cutting articlesButt weldingComposite plate

The invention provides a method for welding a dissimilar material welded joint of a composite plate, belongs to the field of dissimilar material welding of composite plates of pressure vessels, and aims to solve the problems that the corrosion resistance at the welded joint part is reduced, welding cracks easily occur in the joint face of a composite plate and the like. According to the technical scheme, the method mainly comprises the following steps: processing a groove, removing the clad layer and oil rust on the periphery of the groove until the periphery of the groove has metal luster; surfacing from the bottom of the groove, surfacing the insulating layer on the side of the composite plate, and performing stress relieving annealing thermal treatment on the composite plate; welding by adopting small-sized welding rods in a multi-layer and multi-pass welding manner; and performing butt welding on the composite plate and an austenitic stainless steel material, performing manual tungsten argon arc welding for the backing weld, filling the weld pass by adopting shielded metal arc welding, small-size, small thermal input, short arc quick welding and multi-layer multi-pass welding. The method can be used for welding a dissimilar material welded joint between a Cr-Mo low-alloy steel / carbon steel-austenitic stainless steel composite plate and austenitic stainless steel, has excellent welded joint quality, and can be used for overcoming the defect of the prior art.

Owner:青岛兰石重型机械设备有限公司

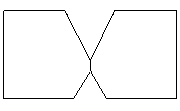

Welding method of ultra-thick and high-strength water-power steel

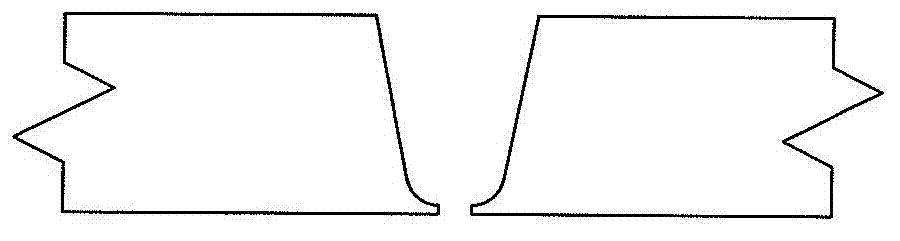

ActiveCN101905365ATo achieve the welding effectReduce fillingArc welding apparatusWorkpiece edge portionsEngineeringWelding defect

The invention relates to a welding method of ultra-thick and high-strength water-power steel, belonging to the welding field. Welding is realized by adopting a mixed welding mode, i.e. hand welding is adopted as a basis for filling the bottom, and gas shielded welding is adopted for a middle layer and a cover part, multilayer and multi-pass welding are adopted, a carbon arc is cropped out after a single side is filled, and the input of welding heat is controlled within 65 kJ / cm. A welding bevel adopts an asymmetric U-shaped bevel, a thick steel plate of 145-155 mm is preheated to 100 DEG C before welding, the inter-layer temperature is kept between 100 DEG C to 160 DEG C, and heat treatment stress is not carried out after welding, and the problem of reheat embrittlement of a welding joint of the high-strength water-power steel is solved. The invention needs simple welding equipment, realizes welding through a combined welding process on the basis of the traditional equipment, reduces the filling amount of welding metal, and achieves the welding effect of a narrow gap. Compared with the hand arc welding, the invention greatly improves the welding efficiency of the thick steel plate and lowers the possibility of welding defects easily generated on the hand arc welding of an ultra-thick steel plate, such as cold cracks, incomplete fusion, crisp fusion, and the like.

Owner:SHOUGANG CORPORATION +1

Pipeline welding method

ActiveCN102848048AInhibition of crack tendencyGuaranteed StrengthArc welding apparatusPipeline systemsShielded metal arc weldingEngineering

The invention discloses a pipeline welding method which includes the steps: firstly, processing and assembling a weld joint to form a correct welding joint form; secondly, selecting a GTAW (gas tungsten arc welding) and SMAW (shielded metal arc welding) combined welding method for welding; and thirdly, performing post-weld heat treatment for the finished weld joint. The root is made of welding materials fine in anti-cracking performance, and the GTAW method is selected to effectively inhibit the cracking tendency of the root. The strength of the weld joint is guaranteed by the combined strength of two kinds of welding materials, and the overall strength of the joint is higher than the strength of a base material.

Owner:LONGKOU CIMC RAFFLES OFFSHORE +2

Welding method for furnace top flange of blast furnace

ActiveCN104439740AGuaranteed levelnessReduce welding distortionArc welding apparatusShielded metal arc weldingMarking out

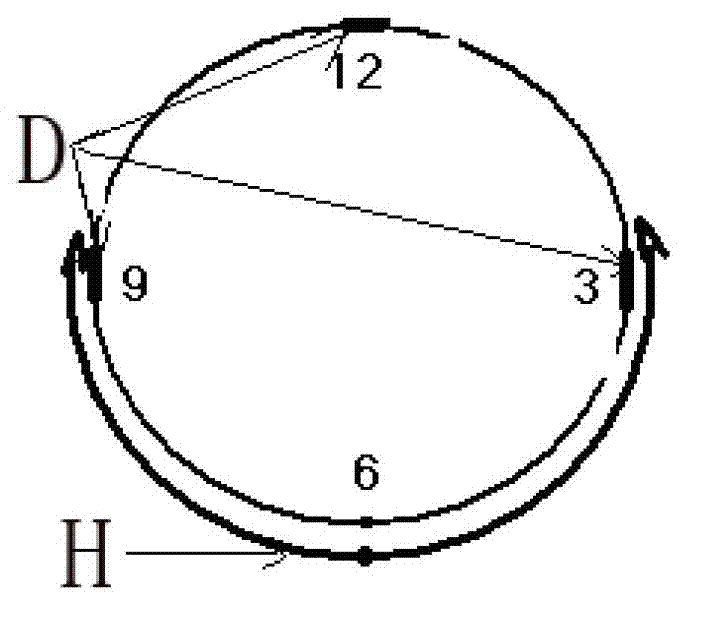

The invention discloses a welding method for a furnace top flange of a blast furnace. The method mainly comprises the following steps that checking and accepting; measuring and paying off; groove preparation; hoisting in position; leveling and centering; scale division and marking out, wherein even scale division and marking out are carried out on the furnace top flange through two or more diameter lines, pitch circles of rib plates arranged on the furnace top flange are equally divided into a plurality of small circular arcs, pitch circles, crossing with a furnace top steel ring, of the furnace top flange are equally divided into a plurality of small circular arcs, and pitch circle face, crossing with the furnace top steel ring, of the furnace top flange are equally divided into a plurality of congruent small sectors; rib plate welding, wherein the two sides of the rib plates are fixedly connected from the inner ends to the other ends through a symmetric welding method, and the welding speed is the same; flange welding, wherein backing weld and layered continuous bead welding are included; according to backing weld, the symmetric welding method is adopted, in the manual electric-arc welding manner, same-direction symmetric welding begins to be carried out on two sides of grooves in the centered and segmented symmetric segments at the same time, and according to the layered continuous bead welding, the number of welding layers is determined according to the thickness of the furnace top steel ring and the thickness of the furnace top flange, and the symmetric welding method is adopted, and same-direction continuous bead welding begins to be carried out on the two sides of the grooves in the centered and segmented symmetric segments at the same time.

Owner:CHINA 19TH METALLURGICAL CORP

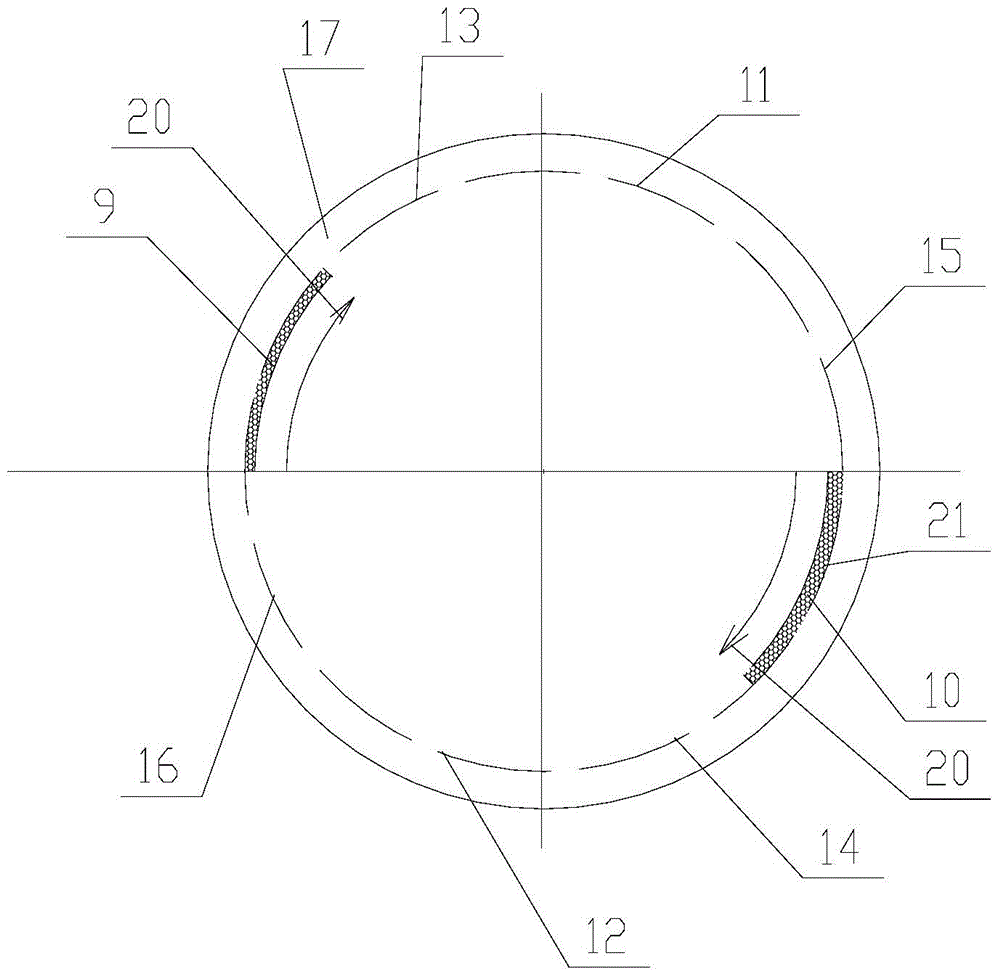

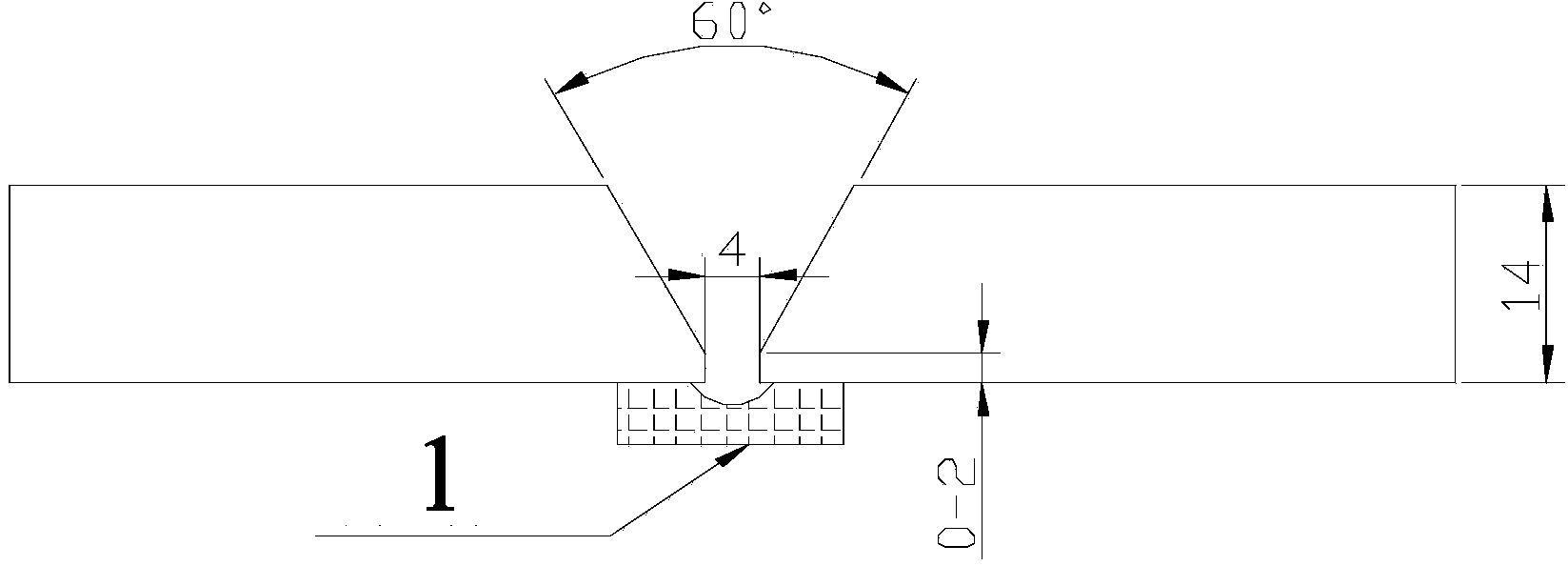

Welding method for stainless steel one-side welding double-side forming

ActiveCN103521886AImprove low temperature toughnessReduce welding distortionArc welding apparatusWelding/cutting media/materialsShielded metal arc weldingEngineering

The invention provides a welding method for stainless steel one-side welding double-side forming. The welding method includes steps that 1) a stainless steel groove is a one-side V-shaped groove, groove angle is 60 degrees, and a groove gap is 4mm; a ceramic liner is attached on the back of the groove; 2) the front side of the groove is bottomed by self-protection argon arc welding wires with coating through argon arc welding and the cover surface is filled by shielded metal arc welding; the technical parameters of the argon arc welding include 125-130A welding current, 12-14V arc voltage, 14cm / min welding speed and 8KJ / cm welding heat input; the technical parameters of the shielded metal arc welding include 150-160A welding current, 22-24V arc voltage, 8cm / min welding speed, 25KJ / cm welding heat input and 350 DEG CX2h shielded metal roasting system. The back of welding joints is good in forming, and various areas of the welding joints have high impact toughness storage and safety richness degree.

Owner:WUHAN YIYE STEEL STRUCTURE

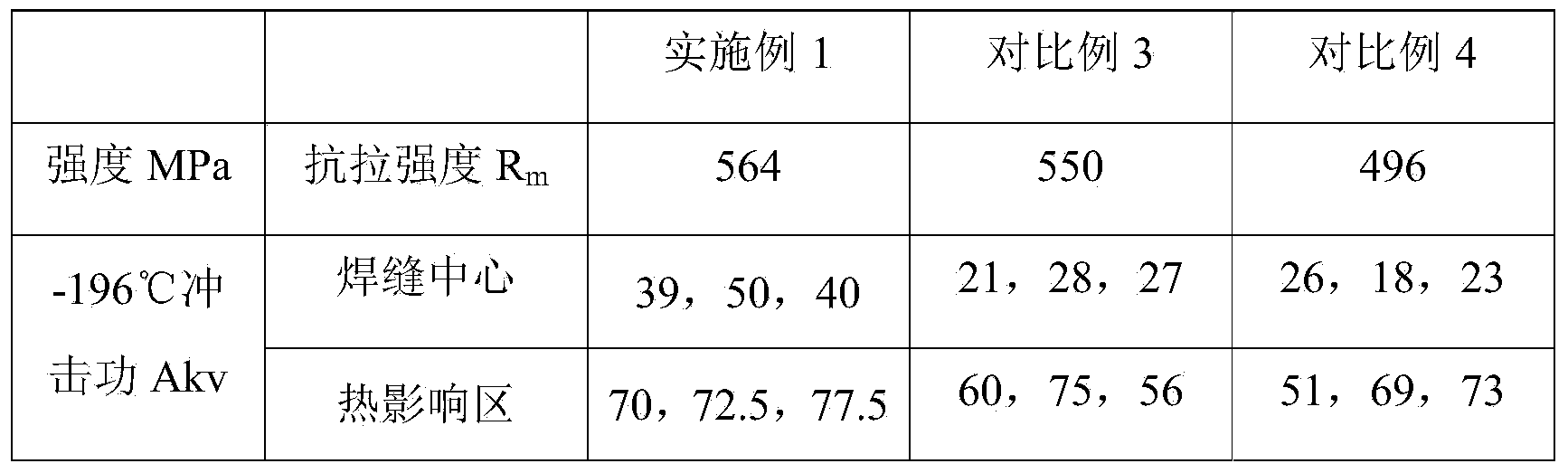

Low-hydrogen welding rod for ultra-low-temperature high-manganese steel manual arc welding

InactiveCN109623194AReduce manufacturing costAvoid microstructureWelding/cutting media/materialsSoldering mediaRare earthFerrosilicon

The invention discloses a low-hydrogen welding rod for ultra-low-temperature high-manganese steel manual arc welding. The low-hydrogen welding rod for the ultra-low-temperature high-manganese steel manual arc welding comprises a welding rod core and a coating, wherein chemical components of the welding rod core comprise 0.30-0.75 wt% of C, 20-26 wt% of Mn, 6.5-8.5 wt% of Ni, 3.0-5.5 wt% of Cr, 2.5-4.0 wt% of W, less than or equal to 0.002 wt% of P, less than or equal to 0.001 wt% of S, and the balance Fe and inevitable impurities; and chemical components of the coating comprise 35-40 wt% of marble, 16-22 wt% of fluorite, 3-5 wt% of quartz sand, 3-6 wt% of zircon sand, 4-10 wt% of titanic schorl, 5-10 wt% of ferrotitanium, 5-8 wt% of low carbon ferromanganese, 3-6 wt% of silicon iron, 1-2 wt% of rare earth ferrosilicon, 2-3 wt% of synthetic mica, and 1-2 wt% of sodium carbonate, wherein the sum of the weight percentages of all the components is 100%. The low-hydrogen welding metal has excellent low-temperature toughness and the strength which is matched with the ultra-low-temperature high-manganese steel, and can meet the technical requirements for the strength and the ultra-low-temperature toughness of the ultra-low-temperature high-manganese steel to be welded.

Owner:NANJING IRON & STEEL CO LTD +1

Low-hydrogen alkaline welding rod for 25Cr2Ni4MoV alloy steel manual arc welding

ActiveCN101898286AThe smelting process is stableEasy to implementWelding/cutting media/materialsSoldering mediaShielded metal arc weldingHydrogen

The invention provides a low-hydrogen alkaline welding rod for 25Cr2Ni4MoV alloy steel manual arc welding, comprising a core wire and a coating, wherein the core wire is composed of the following components by weight percent: 0.030-0.070% of C, 0.10-0.50% of Si, 1.0-2.0% of Mn, 3.0-5.0% of Ni, 0.10-0.50% of Mo, 0.50-2.0% of Cr, 0.10-0.30% of Ti, 0.002-0.009% of B, 0.10-0.30% of Re, less than 0.005% of S, less than 0.005% of P and the balance of Fe, and the total weight of all components is 100%. The welding rod prepared by the invention has favorable arc stabilizing performance, good weld pool flowability, fine droplet spatters, easy slag detachability after welding, evenly covered slag, delicate and beautiful moulded welding line and controllable content of deposited metals of welding rod diffusible hydrogen.

Owner:SERVICE CENT OF COMMLIZATION OF RES FINDINGS HAIAN COUNTY

Method for welding narrow-gap butt-joint connector of pipeline with large pipe diameter and thick wall

ActiveCN102653022ASolve the costReduce the difficulty of dockingArc welding apparatusShielded metal arc weldingButt joint

The invention relates to a welding method of a butt-joint connector of a pipeline. The invention provides a method for welding a narrow-gap butt-joint connector of a pipeline with a large pipe diameter and a thick wall to solve the problems of a TIG+SMAW (Tungsten Inert Gas+Shielded Metal Arc Welding) welding method in the prior art that the working amount is great, a welding effect is poor and the welding period is long; and a TOCE welding method cannot weld the butt-joint connector with the assembling gap which is more than 1.0 mm so that the working period is prolonged and the cost is high. The diameter of the pipeline is more than 700 mm and the wall thickness is more than 30 mm; test pieces are assembled and are protected by back argon; TIG bottoming welding is carried out on the inner wall of the pipeline to be welded; bottoming original filling welding is carried out and a partial welding path is adjusted according to requirements; and TOCE filling welding and capping covering are carried out, so that the welding is finished. With the adoption of the welding method, the butt-joint connector with the assembling gap which is more than 1.0 mm can be welded and the pipeline butt-joint difficulty is reduced; a TIG manual welding method is used for welding when tack welding and bottoming welding are carried out; other welding work adopts a TOCE automatic welding method to weld; and the welding speed and the welding effect are improved, the working period is shortened and the cost is reduced.

Owner:CHINA NUCLEAR IND 23 CONSTR +2

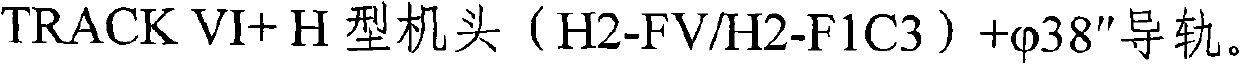

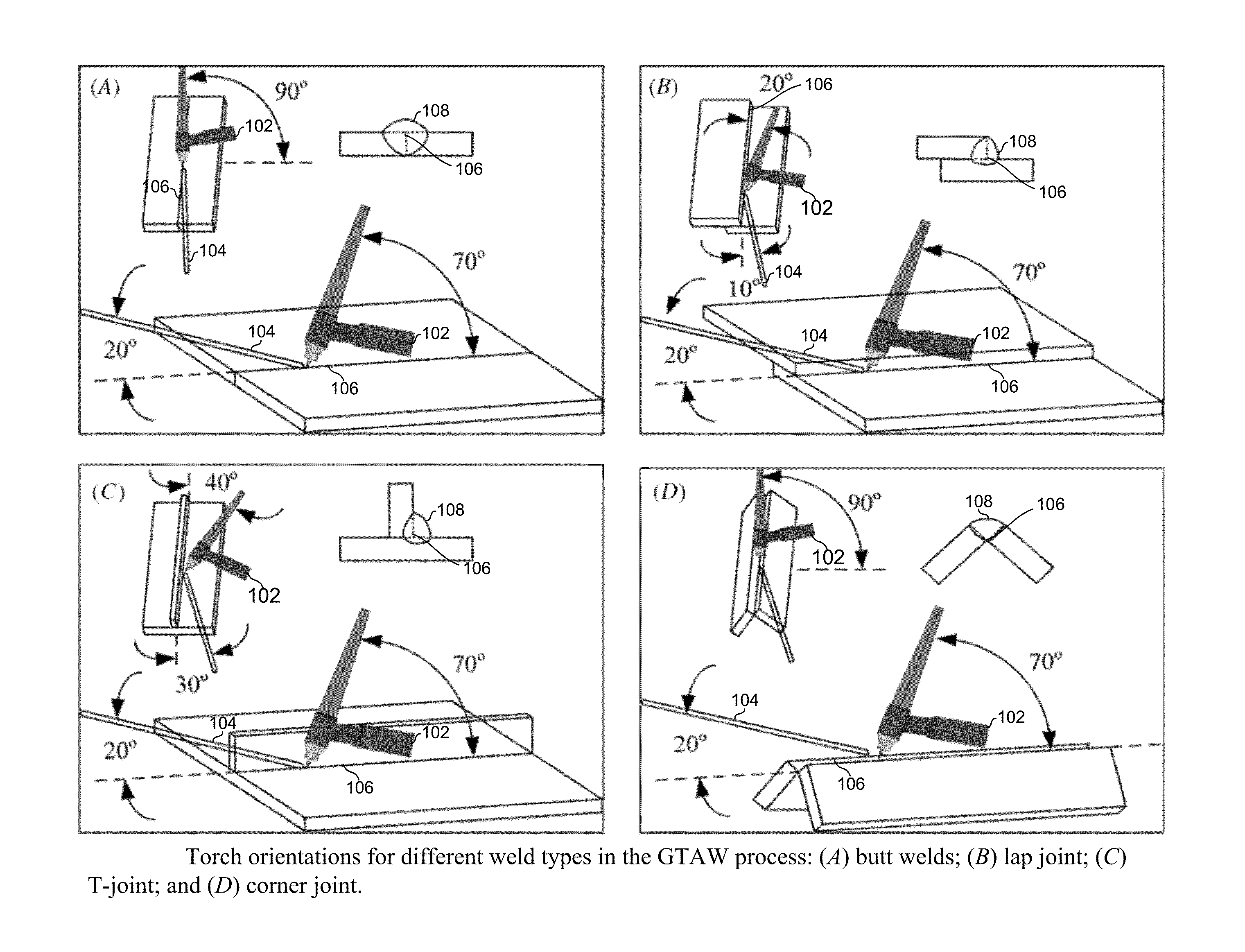

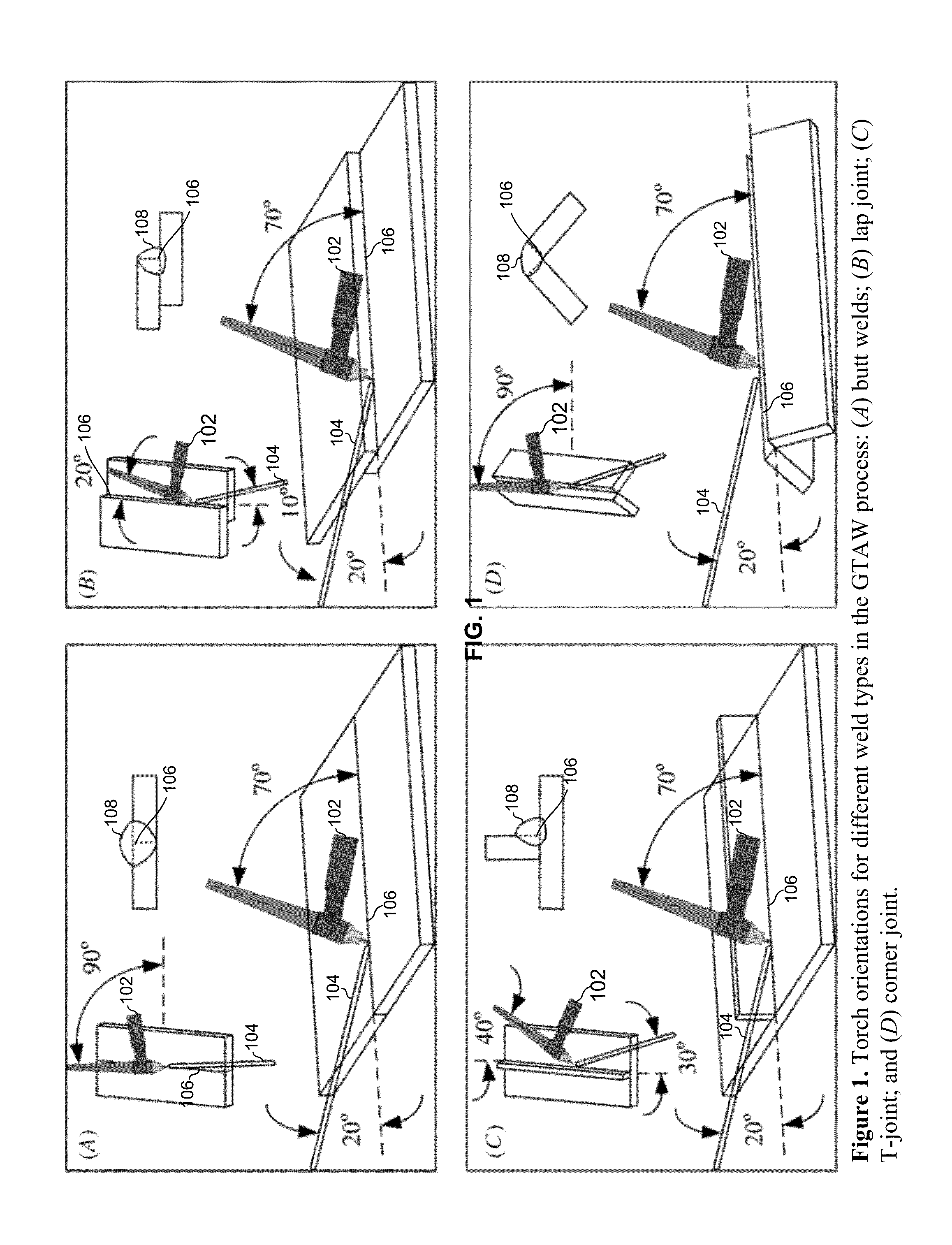

Measurement of three-dimensional welding torch orientation for manual arc welding process

ActiveUS20160193679A1Arc welding apparatusNavigation instrumentsKaiman filterShielded metal arc welding

Methods and systems are provided herein for measuring 3D apparatus (e.g., manual tool or tool accessory) orientation. Example implementations use an auto-nulling algorithm that incorporates a quaternion-based unscented Kalman filter. Example implementations use a miniature inertial measurement unit endowed with a tri-axis gyro and a tri-axis accelerometer. The auto-nulling algorithm serves as an in-line calibration procedure to compensate for the gyro drift, which has been verified to significantly improve the estimation accuracy in three-dimensions, especially in the heading estimation.

Owner:UNIV OF KENTUCKY RES FOUND

Welding method of dissimilar steels such as 917 low-magnetic steel and CCSB steel

ActiveCN102357720AGood mechanical propertiesSimple and fast operationArc welding apparatusWelding/cutting media/materialsStructural deformationShielded metal arc welding

The invention discloses a welding method of dissimilar steel such as 917 low-magnetic steel and CCSB steel, belonging to the welding field of material processing engineering. The welding method is used for manufacturing the welding structures of low magnetic conductivity used for ship manufacture, parts of special vehicles, military equipment and the like. In the invention, a stainless steel solid welding wire ER309L ([Phi]=1.0 mm) suitable for the welding of dissimilar steel, welding equipment and a walking device are adopted; binary mixed gas (Ar+1.5%CO2) is used for protection; flat butt welding, horizontal butt welding and upward butt welding of dissimilar steel such as 917 low-magnetic steel and CCSB steel are performed according to corresponding welding parameters; and full-automatic vertical butt welding is performed by using a full-position automatic welding trolley. Through the welding method disclosed by the invention, the problems of difficult operation, low production efficiency, low welding seam quality, great structural deformation and the like caused by magnetic blow in the traditional shielded metal arc welding method are effectively solved; and the welding method is convenient to operate, has high production efficiency, and realizes the forming of uniform and beautiful welding seams, small welding deformation; moreover, welding joints have good mechanical performances.

Owner:中船桂江造船有限公司

Plug welding repair technology for mammoth converter shell perforation

InactiveCN102717171AEasy to operateEasy to implementArc welding apparatusShielded metal arc weldingSlag

The invention discloses a plug welding repair technology for a mammoth converter shell perforation, the technological method is that rust, greasy dirt, slag oxide and other sundries within the 200-millimeter scope at the periphery of a plug welding area are completely cleared up; a welding line back plate is welded at the outer part of a converter shell plug welding opening, and meanwhile, a heating sheet is hung for weld preheating; the inner part of a converter body is subjected to welding, the manual arc welding is firstly used for plug welding 1 / 3 depth, and then, the CO2 gas shield welding is used for plug welding; and postheat treatment is instantly carried out after completing the seam welding. The repair technology is simple to operate, and easy to carry out; and the production efficiency is high, and the welding quality is reliable.

Owner:ANHUI MASTEEL ENG & TECH GRP

Welding process for red copper and stainless steel dissimilar materials

ActiveCN102962543AMeet the use requirementsImprove mechanical propertiesArc welding apparatusFurnace typesForeign matterDehydrogenation

The invention discloses a welding process for red copper and stainless steel dissimilar materials. The welding process comprises the following steps of: (A) machining grooves on the opposite sides of a red copper component and a stainless steel component, cleaning foreign matters on the edges of the grooves, placing the red copper component and the stainless steel component on the same plane for pairing, and reserving a gap; (B) performing before-welding preheating on one side of the red copper component at 600 to 680 DEG C; (C) tackingperforming point fixing in a plurality of positions between the red copper component and the stainless steel component according to a tacking sequence; (D) welding the red copper component and the stainless steel component by adopting shielded metal arc welding direct current electrode positive; (E) heating a welding joint to 130 to 180 DEG C after the red copper component and the stainless steel component are welded, cooling the welding joint to room temperature, and performing dehydrogenation treatment to reduce hydrogen content in a welding seam; and (F) after the dehydrogenation treatment and cooling, performing stabilization treatment on one side of the stainless steel component at 840 to 890 DEG C, and quickly cooling the stainless steel component to reduce the formation of chromium carbide and improve the plasticity and toughness of the welding seam.

Owner:PETROCHINA CO LTD

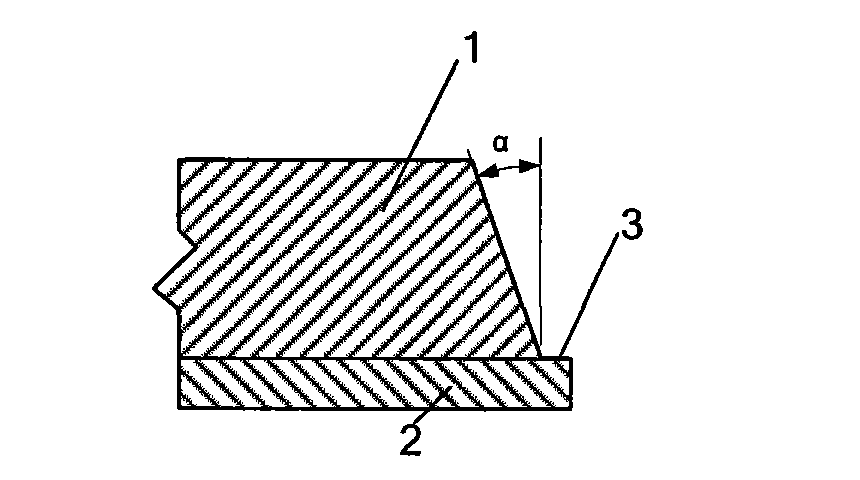

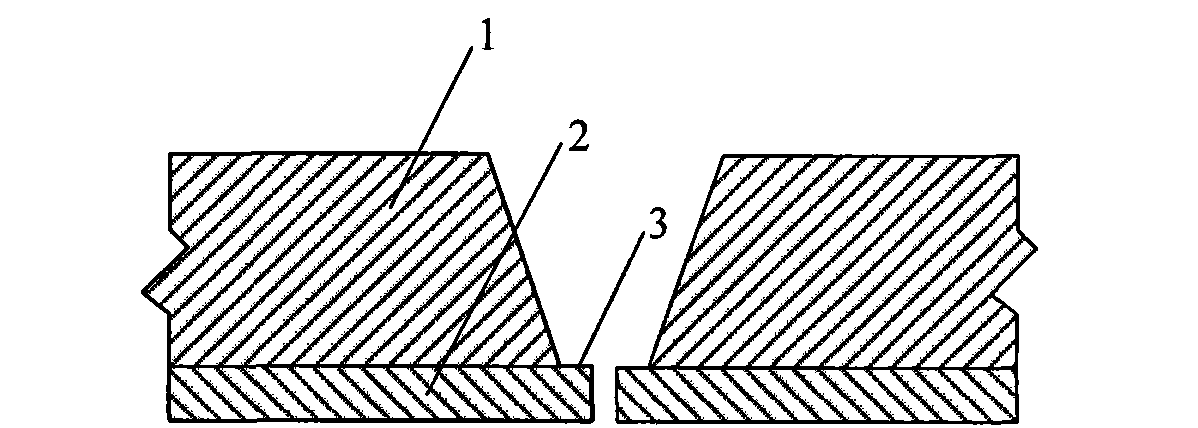

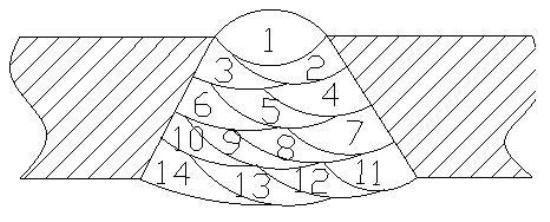

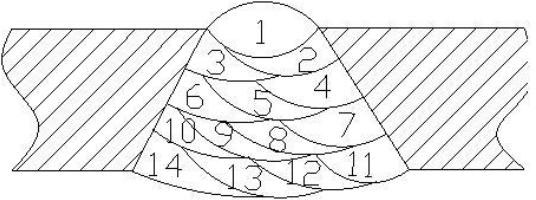

Method for welding butt-jointed seam of upward plate through manual arc welding

The invention relates to a method for welding a butt-jointed seam of an upward plate through manual arc welding, which comprises the following steps of: (1) burnishing the groove and 10-15 mm range of the surface of a test piece to have metallic luster, assembling and pairing the test piece, wherein the included angle between the groove face and the central vertical face is 30-35 DEG, the length of a root gap is 3.0-4.0 mm, the length of the truncated edge is 1.5-2.0 mm, and the unfitness of butt joint is less than 0.5 mm; (2) performing positioned welding on both ends of the test piece, wherein the length of the welding spot is 10-15 mm; and (3) adopting a layered lane welding process for the welding sequence. In the method, a linear or lateral small swing electrode manipulation manner is adopted for welding, therefore, the operation is simple and easy to master; welding joints are reduced, and the defects of porosity, slag inclusion, incomplete fusion and the like at the joints are prevented; the temperature of the molten bath is effectively controlled, and weld beading formed by the burnthrough of the root layer is prevented; the heat input of the weld seam is reduced, and the plasticity and the tenacity of the weld seam are effectively increased.

Owner:CHINA ENERGY ENG GRP TIANJIN ELECTRIC POWER CONSTR CO LTD

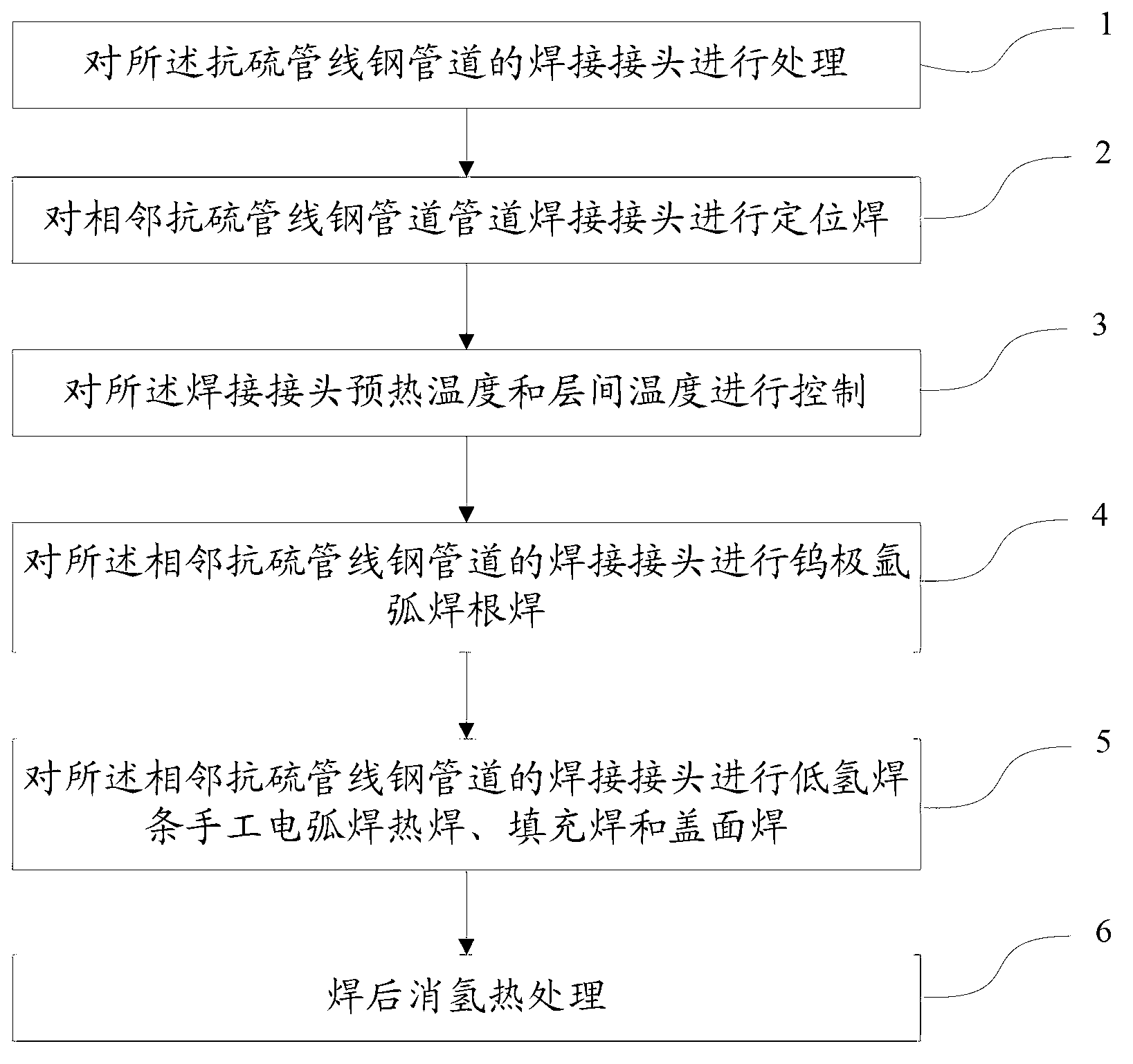

Welding method of oil gas transmission antisulphour steel pipelines

InactiveCN103286414AExcellent corrosion resistance and crack resistanceSafe and stable operationArc welding apparatusTubular articlesCrack resistanceSteel pipeline

The invention discloses a welding method of oil gas transmission antisulphour steel pipelines, which comprises the steps of: 1, treating welding joints of the antisulphour steel pipelines, 2, conducting positioned welding on the welding joints of the adjacent antisulphour steel pipelines, 3, controlling preheating temperature and interlayer temperature of the welding joints, 4, conducting argon tungsten-arc root welding on the welding joints of the adjacent pipelines, 5, conducting manual arc hot welding, filling welding and cosmetic welding on the welding joints of the adjacent pipelines with low-hydrogen electrodes, and 6, conducting post-welding hydrogen removal heat treatment on the welding joints. According to the welding method, since the argon tungsten-arc root welding is combined with the manual arc hot welding, filling welding and cosmetic welding with the low hydrogen electrode, the welding joints with good corrosion resistance and crack resistance can be obtained by effectively controlling the welding parameters, preheating temperature and post-welding heat treatment temperature; the oil gas pipelines can operate stably and safely in service under a sulphated working condition; and the welding method has an active significance in the development of a sulphated oil and gas field.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Welding repair method for large nodular iron castings

InactiveCN105414709AEfficient repairSimple methodArc welding apparatusWelding/cutting media/materialsShielded metal arc weldingWeld seam

The invention discloses a welding repair method for large nodular iron castings. A technical solution of the welding repair method is specifically as follows: adopting a shielded metal arc welding method; carrying out preheating before welding; adopting low linear energy and narrow bead welding operations; adopting such measures as short segment welding, intermittent welding and dispersed welding, and immediate hammering on welding seams after welding; selecting reasonable welding direction and order; employing an insert repair welding method; and applying a screw drilled welding method on a welding groove surface. The welding repair method for large nodular iron castings provided by the present invention is simple, high in operability, and capable of effectively repairing large nodular iron castings, thereby reducing economic losses.

Owner:HANSHAN DALI PRECISION MACHINERY

Method for preventing overlaying sealing surface from cracking

InactiveCN103934544AAvoid crackingSimple processArc welding apparatusShielded metal arc weldingGrinding wheel

The invention relates to an overlaying method, in particular to a method for preventing an overlaying sealing surface from cracking. The method includes the following steps that a direct current arc welding machine is selected as a welding device, the surface of a steel member is polished before overlaying, and no oil stain or water is left on the surface of the steel member; after overlaying of each layer is finished, an overlaying layer needs to be cleaned carefully through a wire brush; when welding is carried out, the steel member is connected with the negative electrode of a power source, and a welding stick is connected with the positive electrode of the power source; angle wrapping weld beads are arranged on the two sides of an overlaying transition layer; the surface of the transition layer is polished; overlaying of the sealing surface is carried out; the quality of the surface of the overlaying layer is detected according to a PT method, if cracks are found, the cracks are polished and removed through a grinding wheel, and then the welding stick of the sealing surface is used for repairing. The sealing surface materials are overlaid on the steel member, shielded metal arc welding is adopted, the welding stick of the A307 type is used as the transition layer, the sealing surface materials are overlaid on the transition layer, welding is carried out in a cold state without preheating, and welding cracks are avoided.

Owner:SHENYANG UNIV

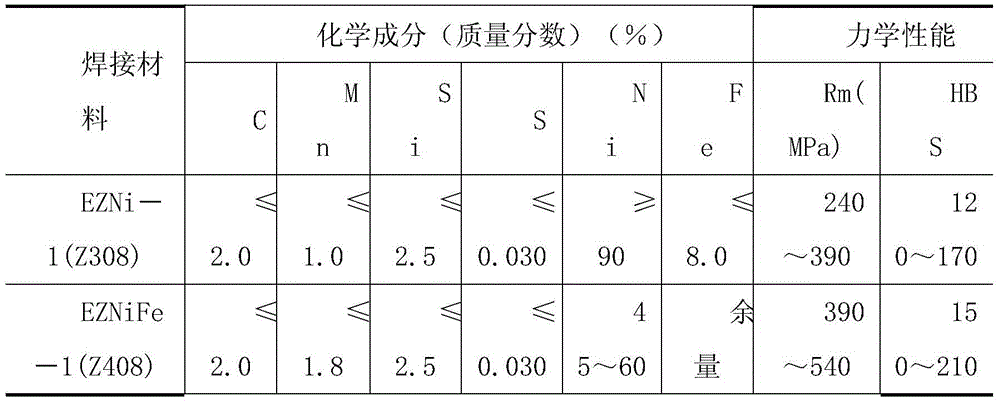

Bearing steel welding repairing method

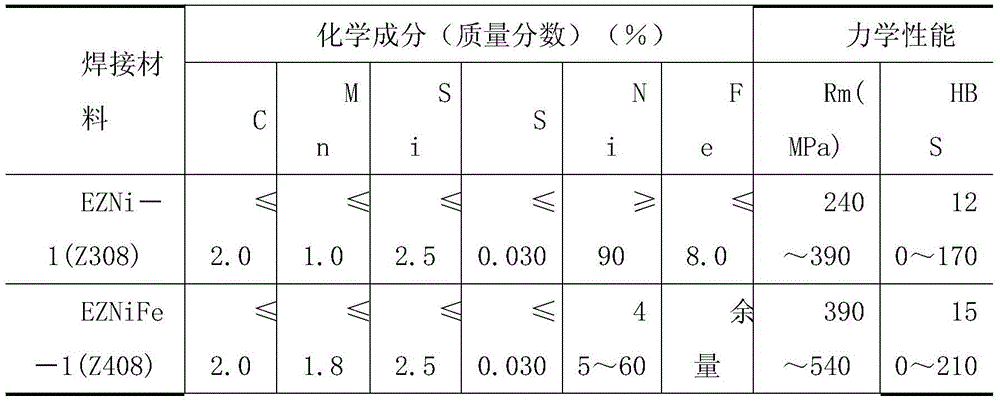

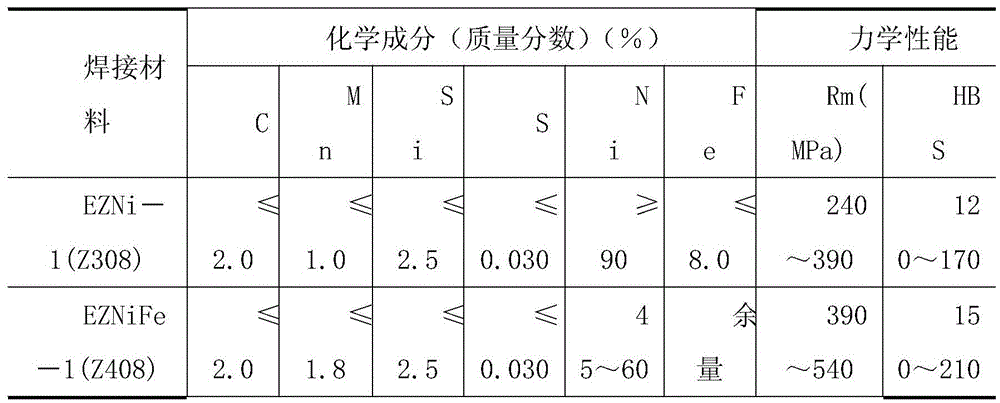

InactiveCN104668880AHigh working reliabilityEasy to operateArc welding apparatusShielded metal arc weldingNickel alloy

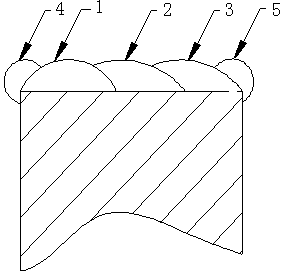

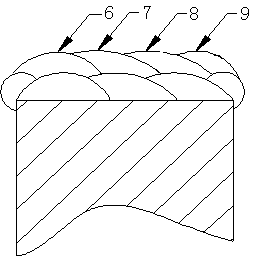

The invention provides a bearing steel welding repairing method. The method comprises the steps of 1, performing the shielded metal arc welding method; 2, selecting a nickel-based welding rod EZNi-1(Z308) or ferro-nickel alloy welding rod EZNiFe-1(Z408) as the welding material; 3, preheating to be 100 to 150 DEG C or stopping preheating before welding; 4, welding with small wire energy through a narrow welding channel; 5, performing short section welding, discontinuous welding, dispersed welding and hammering a weld joint immediately after welding and other measures; 6, performing sectional welding in the welding direction from the closed crack tail end to the crack opening end during repairing the crack; 7, performing the embedded lump welding repairing method, namely, removing the crack dense part or the part with relatively large welding filling quantity, embedding a low carbon steel plate or other materials with high performance, and changing the distribution position of the weld joint; 8, performing the cutting silk welding method for the welding groove surface, namely, drilling and tapping the groove surface of a base material, pinching a low-carbon-steel screw, and welding with the screw as the center. With the adoption of the method, the obtained weld joint is high in quality and less in defect; the work reliability is high, the operability is high, the welding is stable, and the good weld joint can be obtained.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com