Welding method of dissimilar steels such as 917 low-magnetic steel and CCSB steel

A welding method and low magnetic steel technology, applied in the direction of welding medium, welding equipment, welding equipment, etc., to achieve the effects of small welding deformation, high production efficiency and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Embodiment 1: Welding method of flat butt joint of 917 low magnetic steel + CCSB steel dissimilar steel.

[0027] (1) Welding requirements for flat butt joints: the inclination angle of the weld seam is 0°, the deviation is ±5°, the weld seam rotation angle is 90°, the deviation is ±10°;

[0028] (2) The welding equipment is: TPS4000 welding machine, equipped with VR4000 wire feeder, using water-cooled automatic welding gun;

[0029] (3) Welding wire: ER309L, Φ1.0mm;

[0030] (4) The protective gas is: Ar+1.5% CO 2 ;

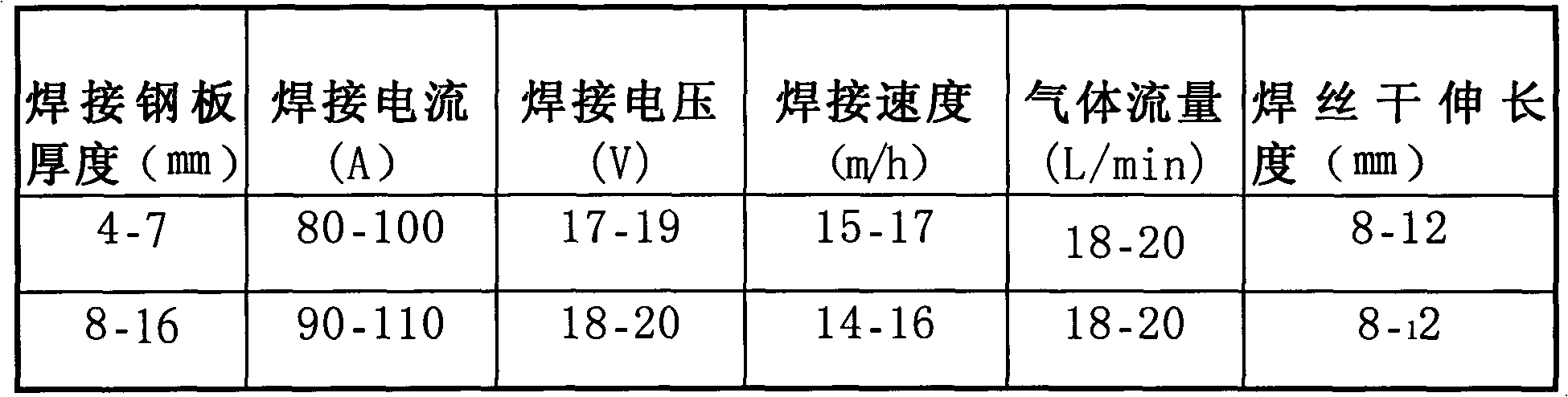

[0031] (5) The welding parameters are:

[0032]

[0033] Welding process: Cooperate with two certified welders, assemble 917 low magnetic steel plate and CCSB steel plate according to the requirements of 70°V-shaped groove, blunt edge of 1-2mm, and assembly gap of 0-1mm, and 917 low magnetic steel plate and The CCSB steel plate is strengthened laterally to prevent deformation after welding; after the assembly of the 917 low magnetic steel plate ...

Embodiment 2

[0034] 2. Embodiment 2: Welding method of horizontal butt joint of 917 low magnetic steel + CCSB steel dissimilar steel.

[0035] (1) Horizontal butt welding requirements: weld inclination angles are 0°, 180°, deviation ±5°; weld seam rotation angles are 0°, 180°, deviation ±10°;

[0036] (2) The welding equipment is: TPS4000 welding machine, equipped with VR4000 wire feeder, using water-cooled automatic welding gun;

[0037] (3) Welding wire: ER309L, Φ1.0mm;

[0038] (4) The protective gas is: Ar+1.5% CO 2 ;

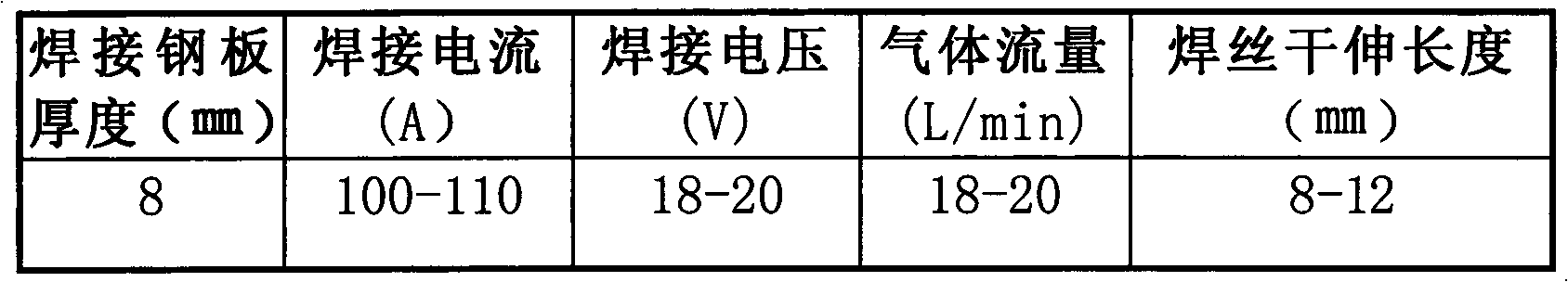

[0039] (5) The welding parameters are:

[0040]

[0041] Welding process: Cooperate with two certified welders, assemble 917 low magnetic steel plate and CCSB steel plate according to the requirements of 70° V-shaped groove, blunt edge 1-2mm, and assembly gap 0-1mm, and make 917 low magnetic steel plate and CCSB steel plate Implement transverse reinforcement to prevent deformation after welding; after the 917 low-magnetic steel plate and CCSB steel plate are asse...

Embodiment 3

[0042] 3. Embodiment 3: the welding method of supine butt joint of 917 low magnetic steel + CCSB steel dissimilar steel.

[0043] (1) Upward butt welding requirements: the inclination angle of the weld is 0°, 180°, the deviation is ±15°, the welding seam rotation angle is 270°, the deviation is ±15°;

[0044] (2) The welding equipment is: TPS4000 welding machine, equipped with VR4000 wire feeder and water-cooled automatic welding gun;

[0045] (3) Welding wire: ER309L, Φ1.0mm;

[0046] (4) The protective gas is: Ar+1.5% CO 2 ;

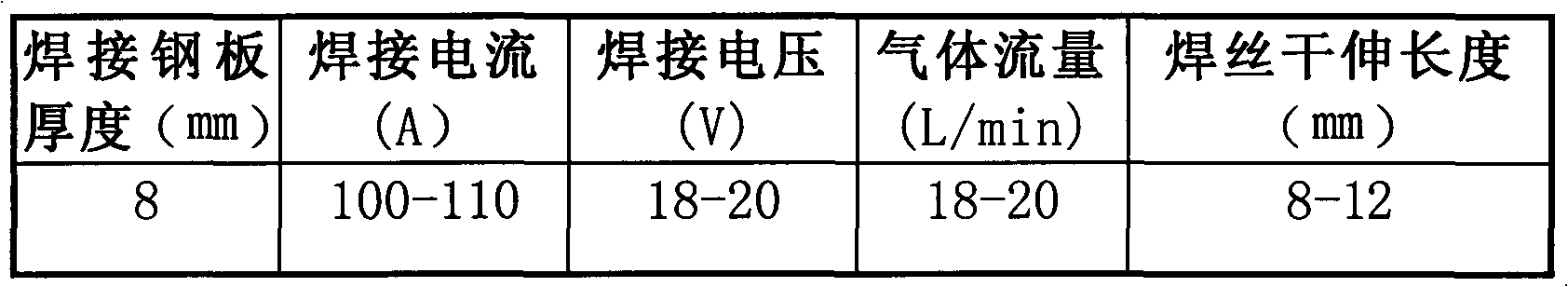

[0047] (5) The welding parameters are:

[0048]

[0049]Operation process: Cooperate with two certified welders, assemble 917 low magnetic steel plate and CCSB steel plate according to 70° V-shaped groove, blunt edge is 1-2mm, assembly gap is 0-1mm, and 917 low magnetic steel plate and CCSB The steel plate shall be strengthened transversely to prevent deformation after welding; after the 917 low magnetic steel plate and CCSB steel plate are asse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com