Patents

Literature

786 results about "Transverse reinforcement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reinforcement bars provided perpendicular to the longitudinal reinforcement are referred to as transverse reinforcements. In a one way RC slab, the reinforcement bars spanning along short direction is referred to as main reinforcement and that spanning along the long direction is referred to as transverse reinforcement.

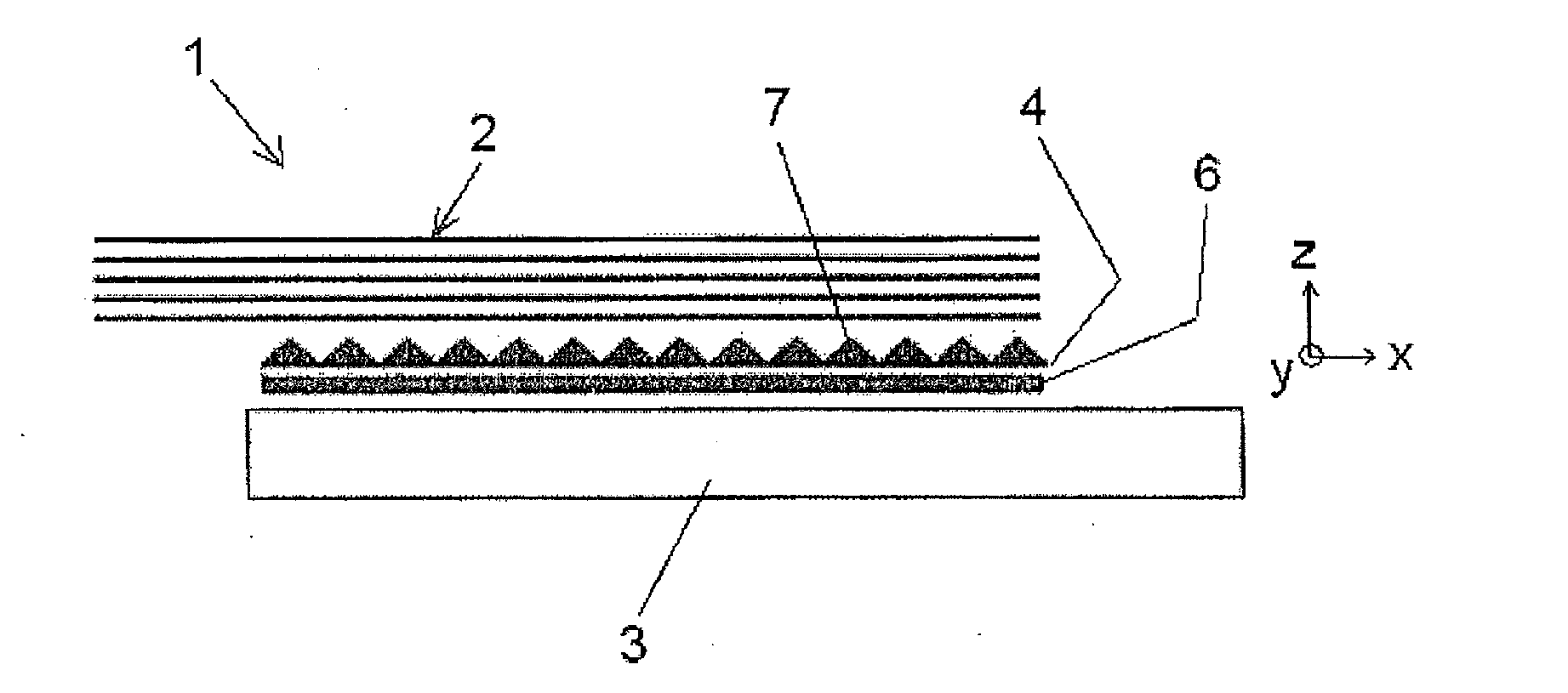

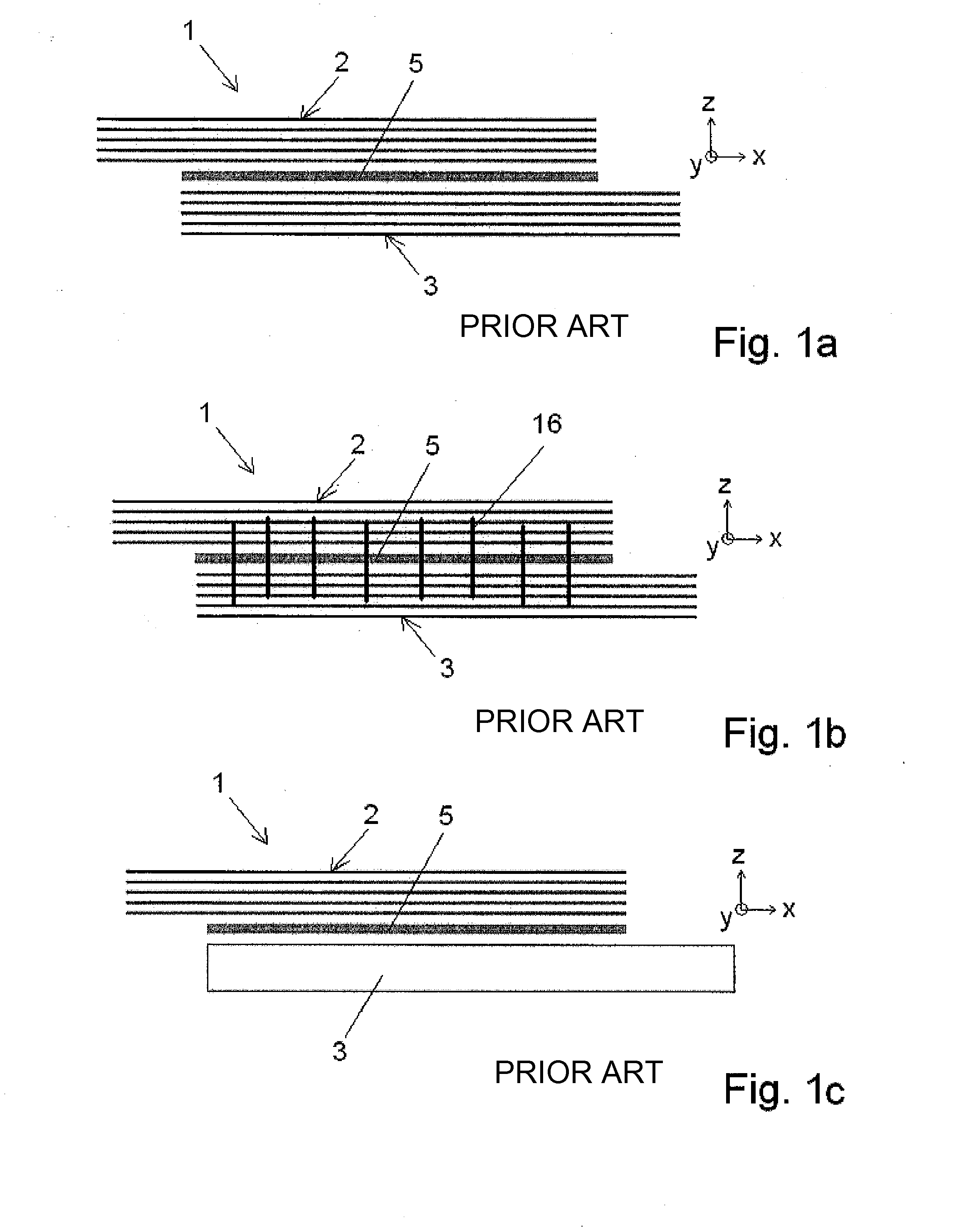

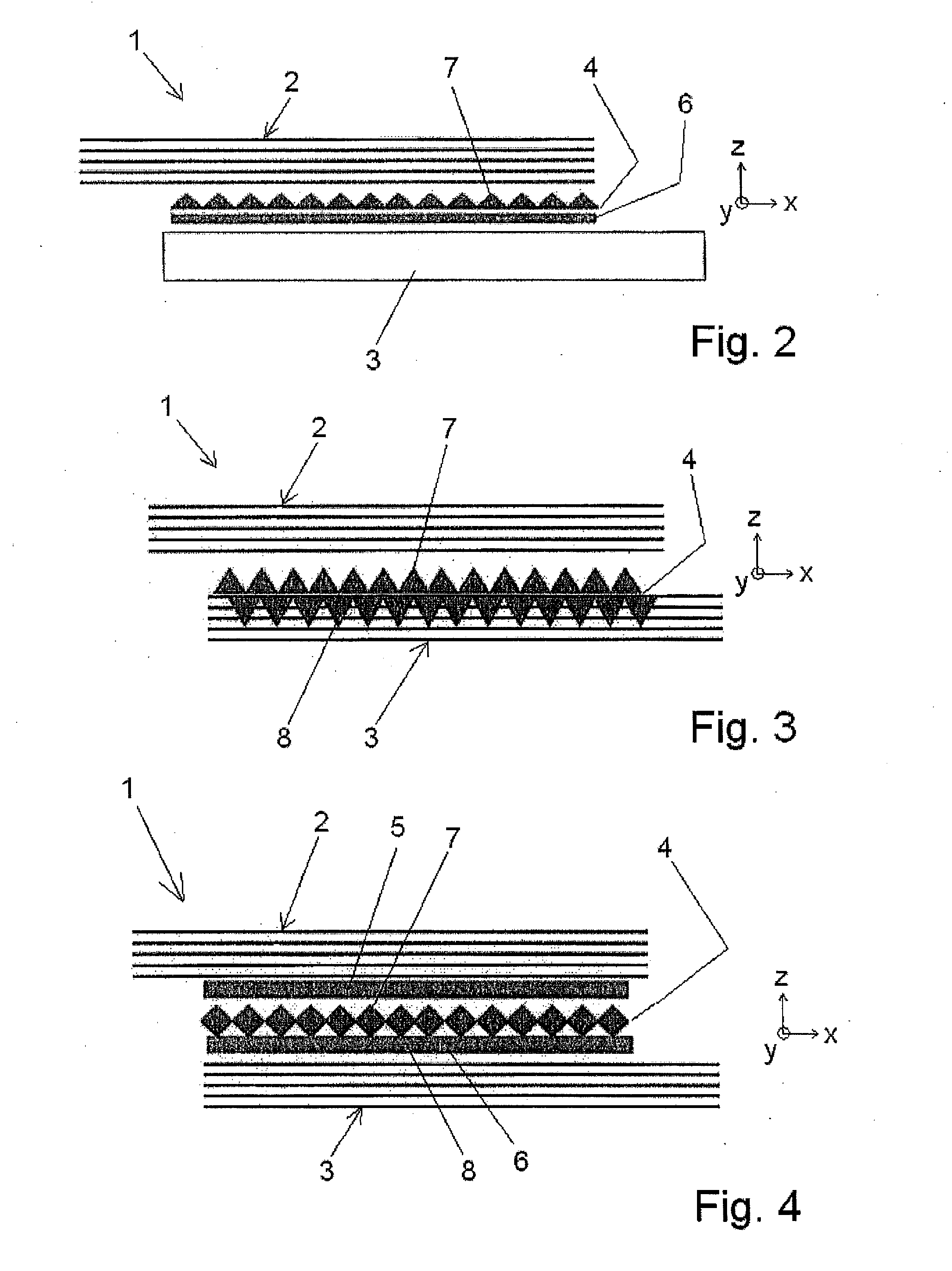

Method for connecting a fibre composite component to a structural component of an aircraft and spacecraft and a corresponding arrangement

InactiveUS20130149501A1High damage toleranceAvoid componentsLayered productsMetal-working apparatusMetal foilFibrous composites

In the case of a method for connecting a fibre composite component to a structural component of an aircraft and spacecraft, a metal foil is provided as a transverse reinforcement element between the fibre composite component and the structural component. It is formed with at least one anchoring portion which protrudes from the surface facing the fibre composite component and is inserted between the fibre composite component and the structural component. A corresponding arrangement is produced in accordance with this method.

Owner:AIRBUS OPERATIONS GMBH

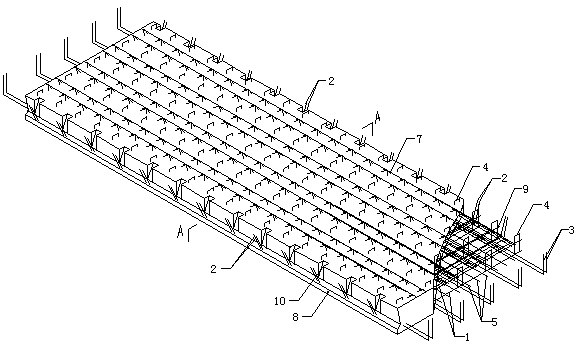

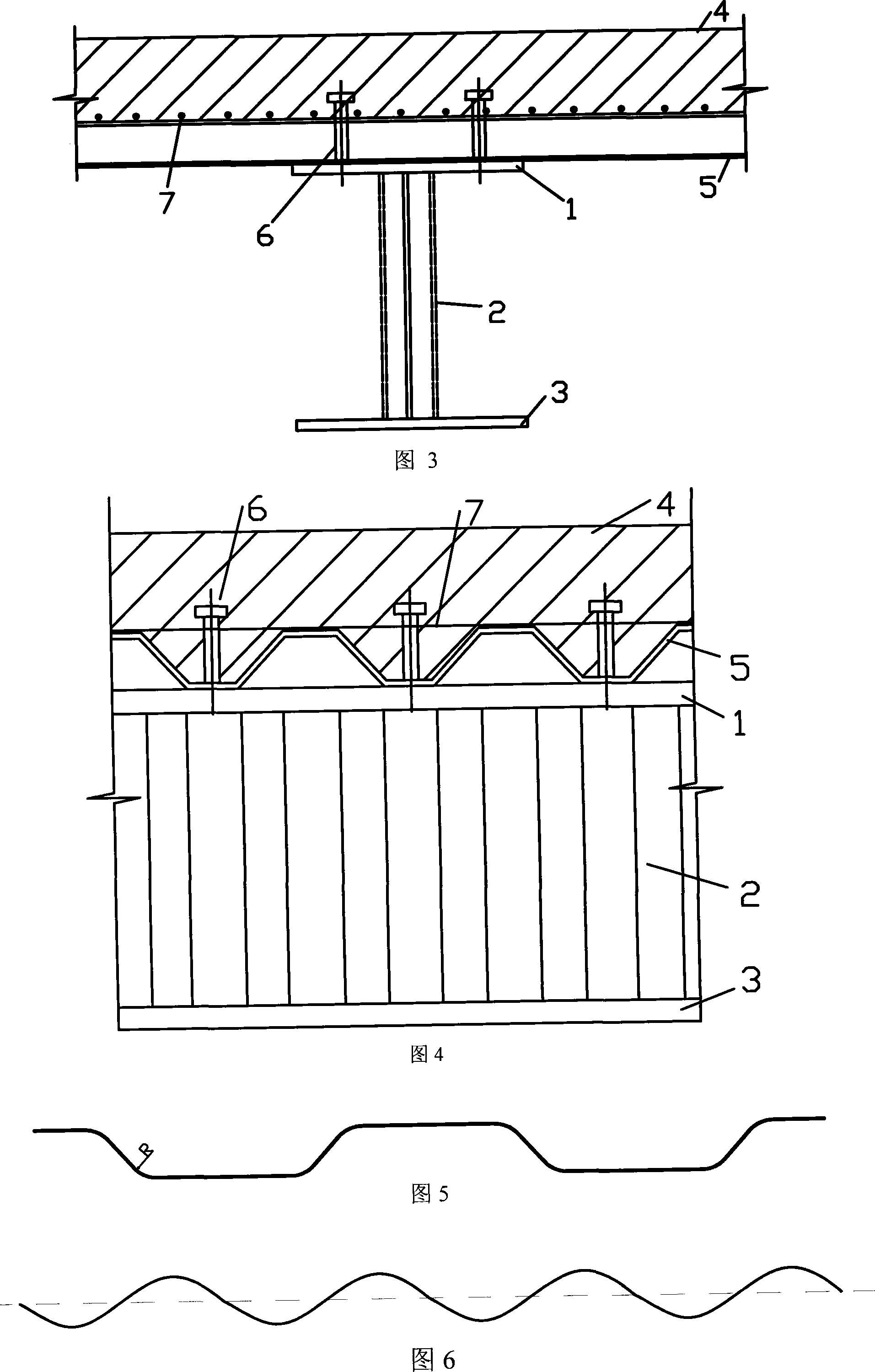

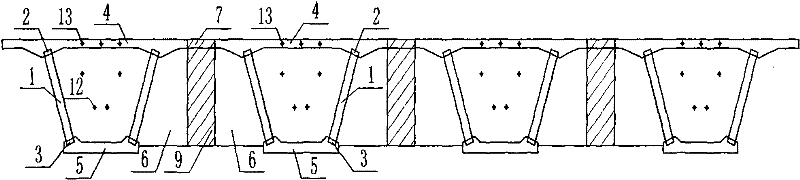

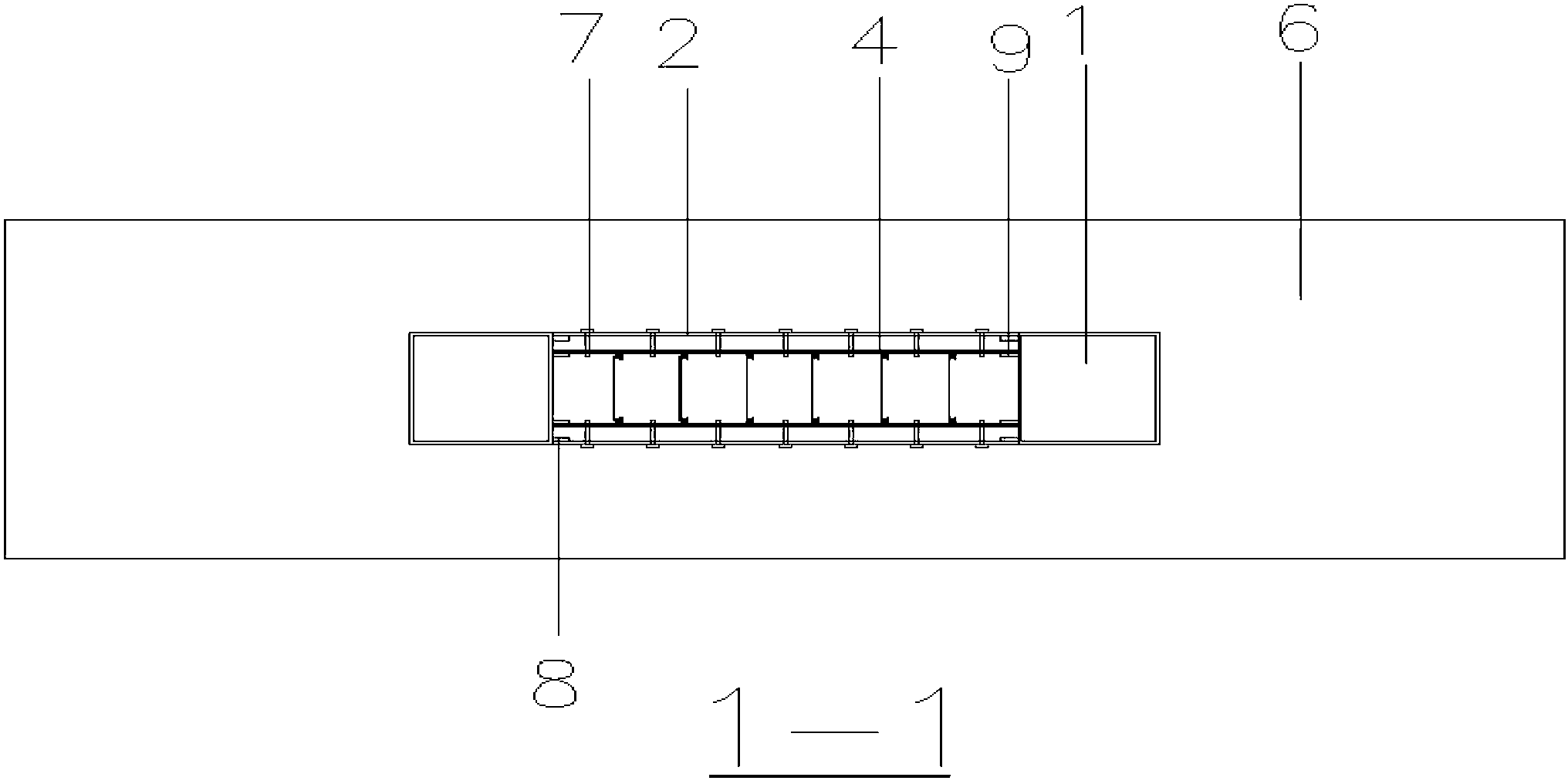

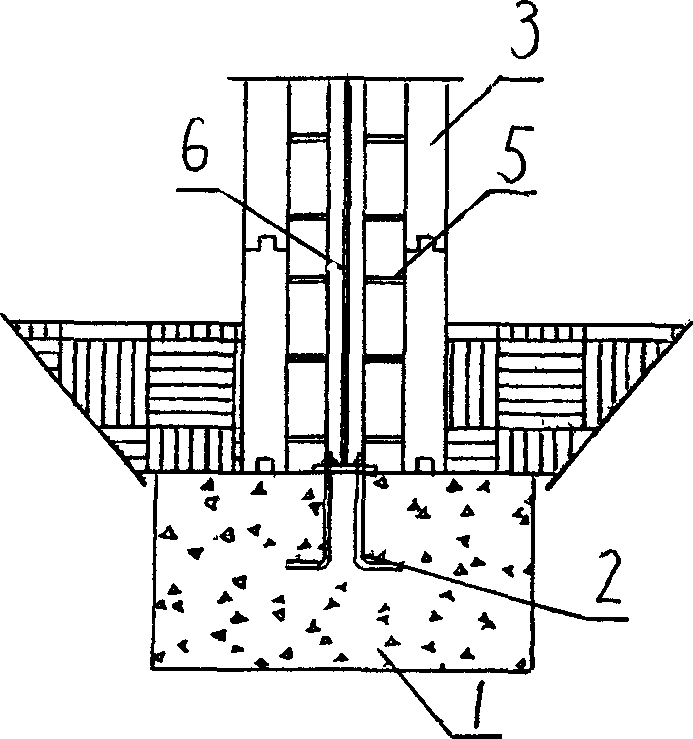

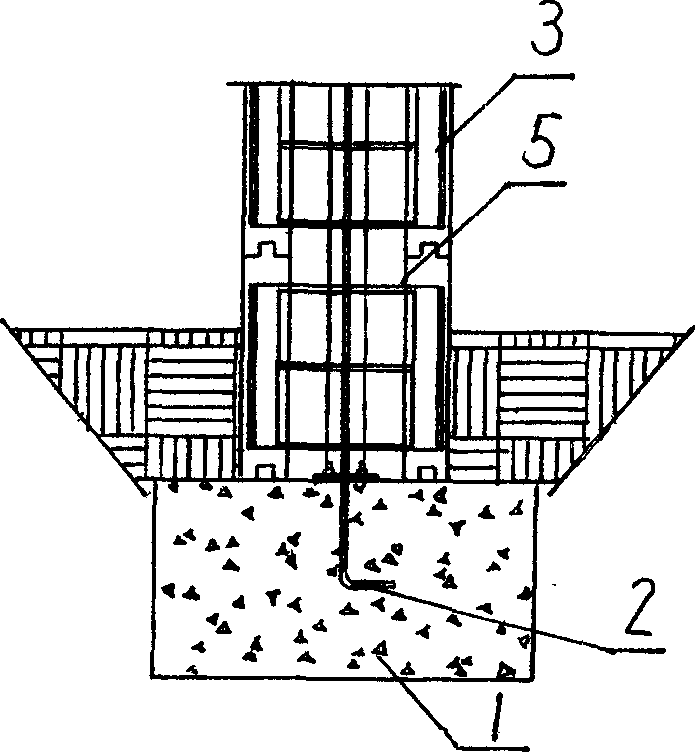

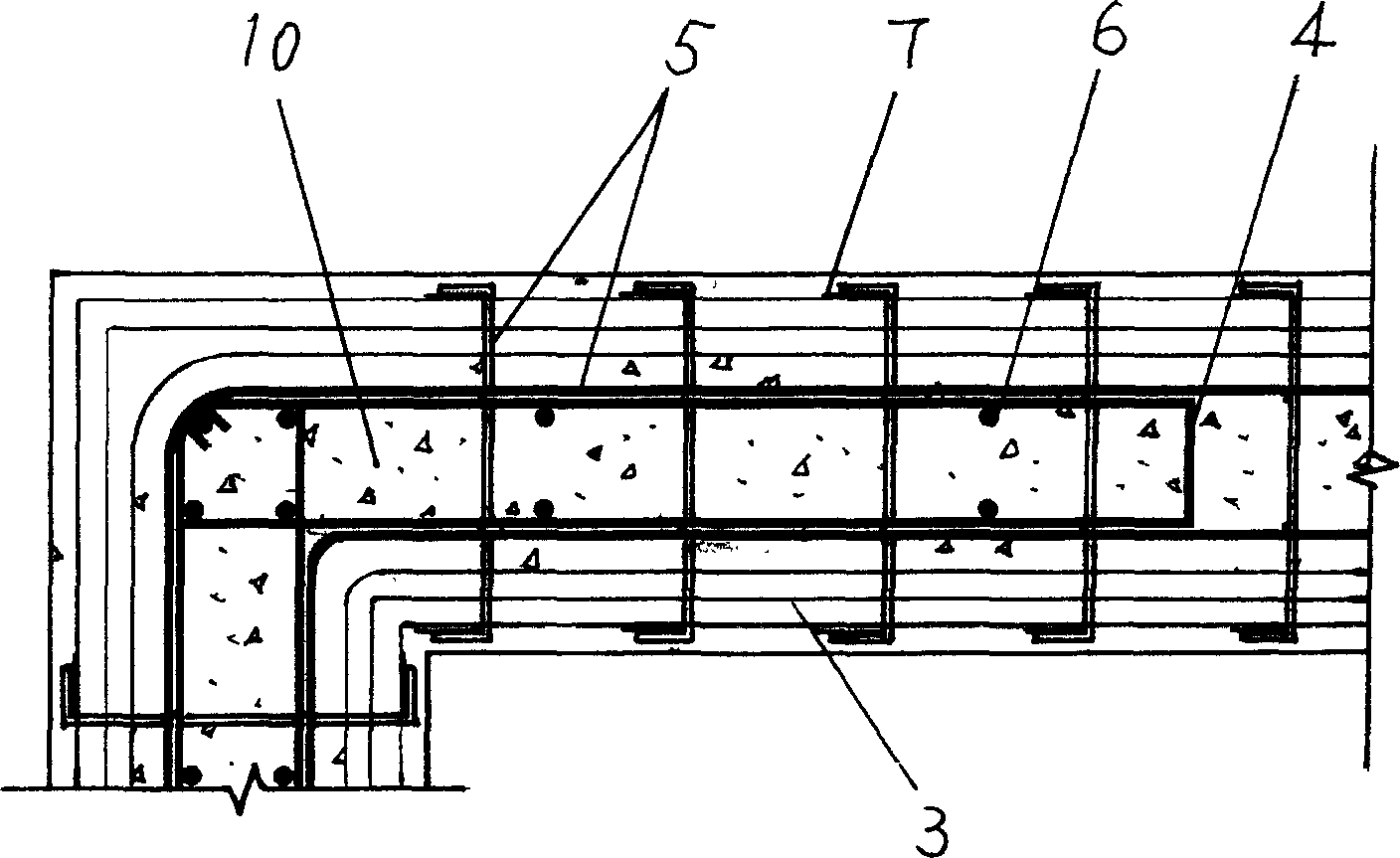

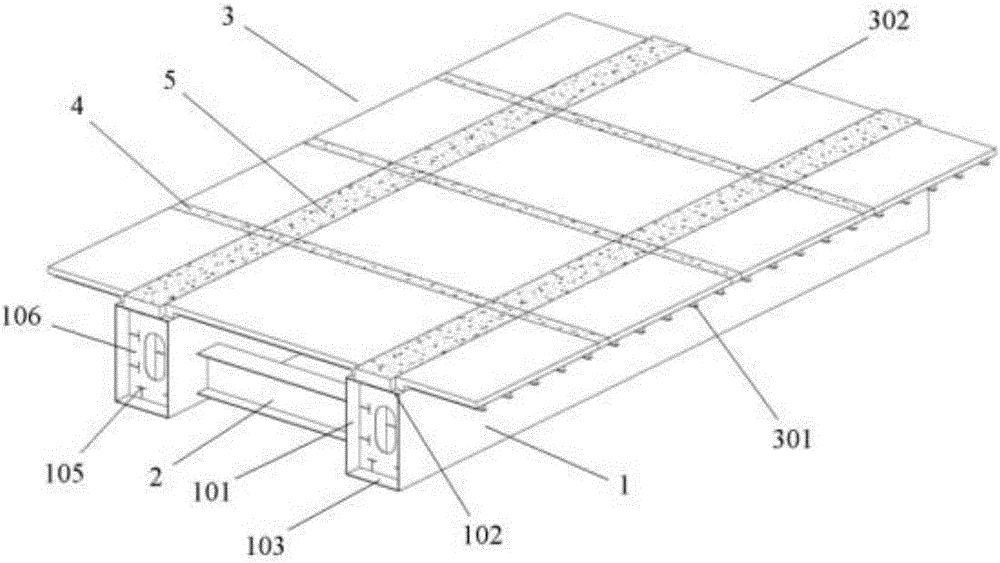

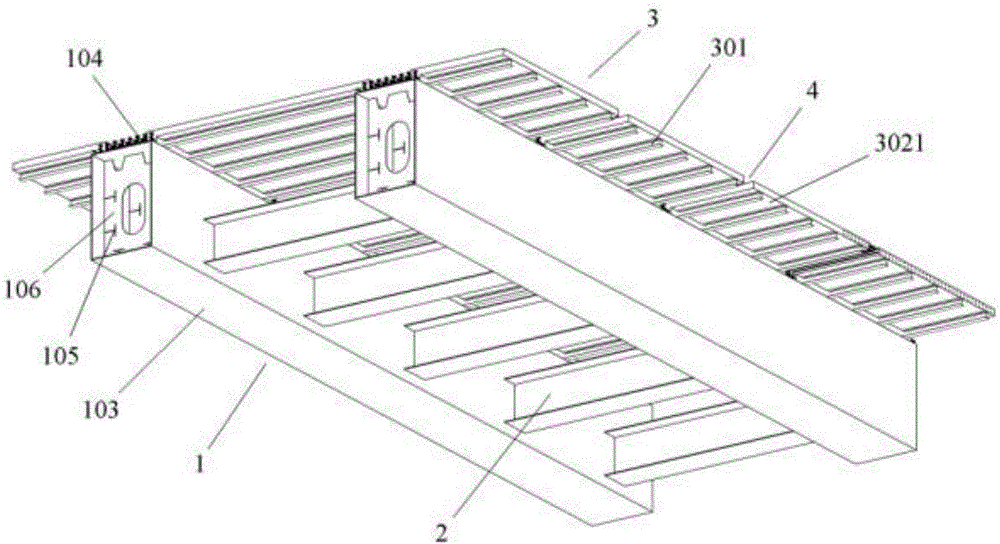

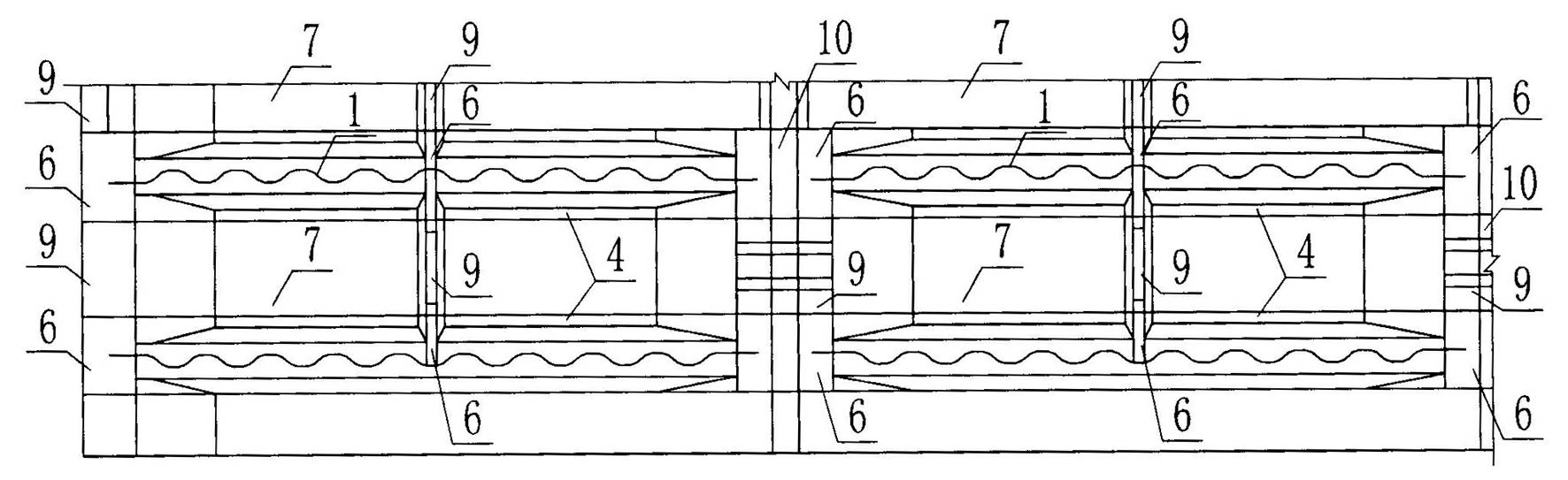

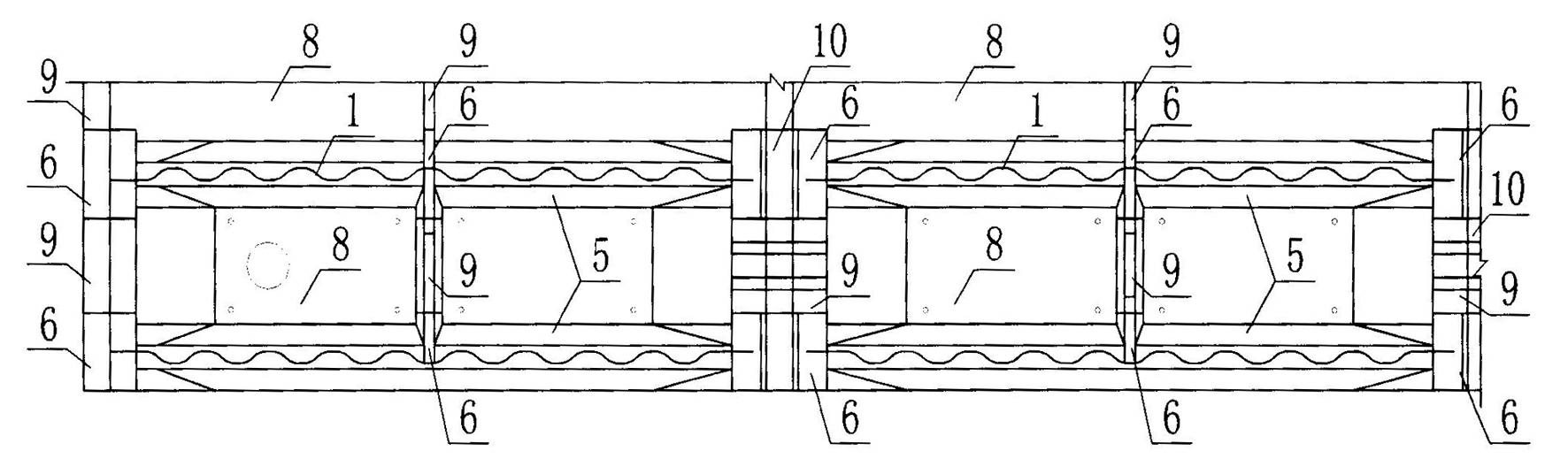

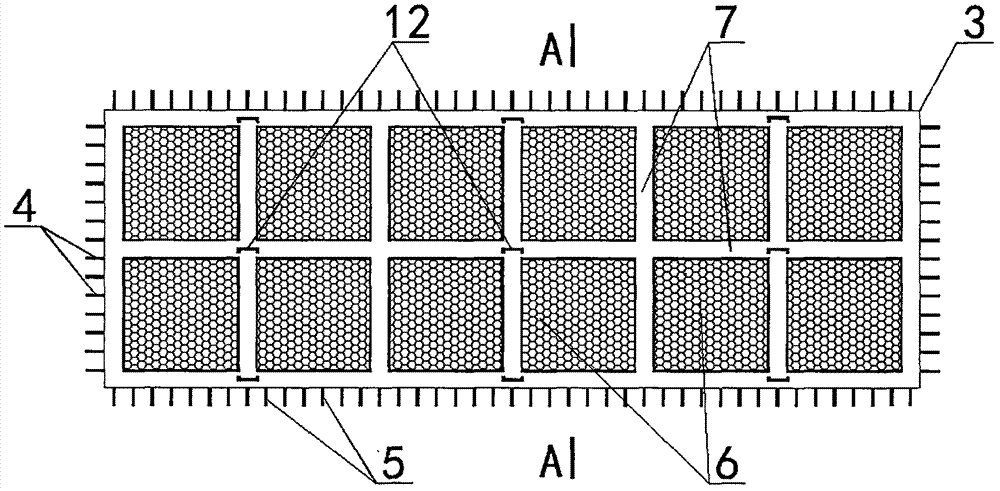

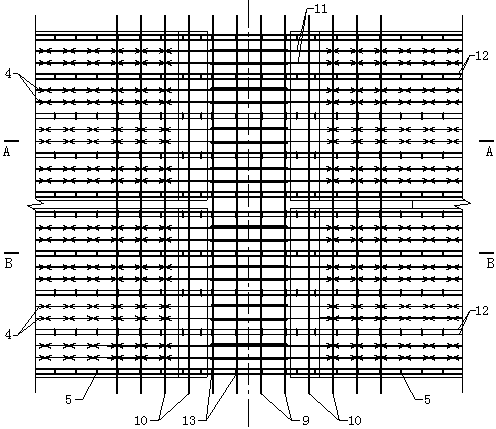

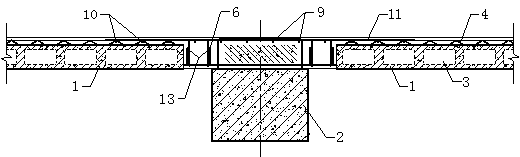

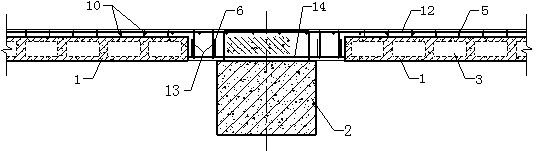

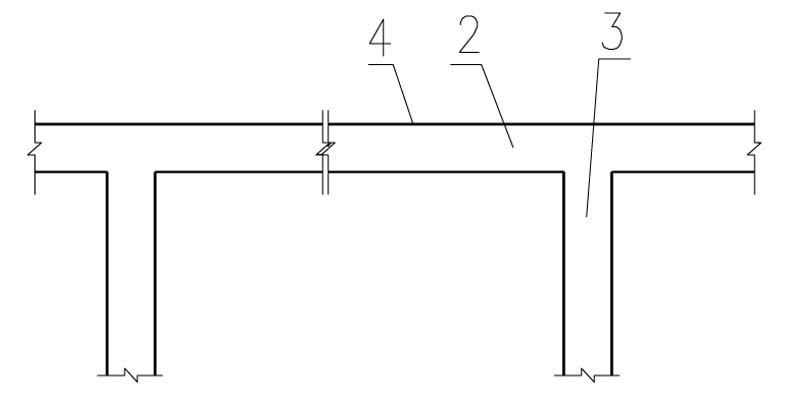

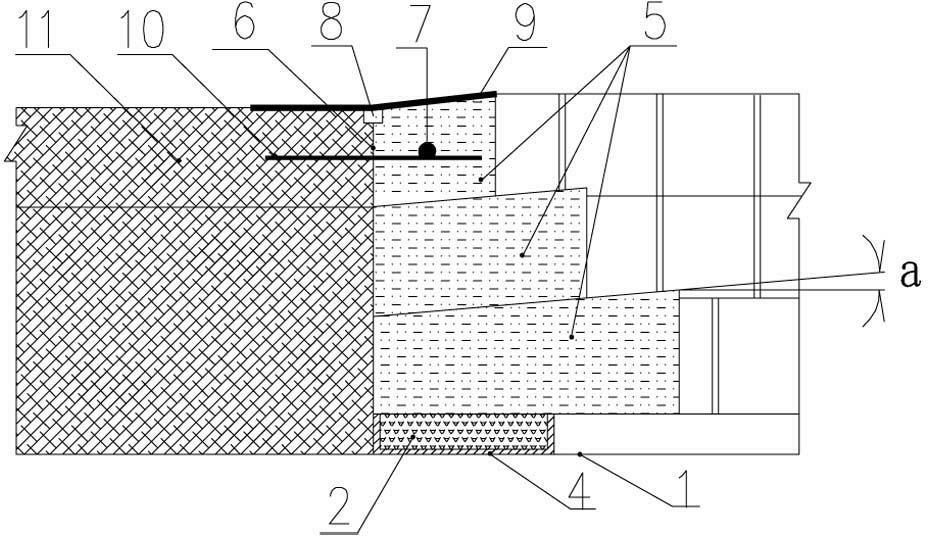

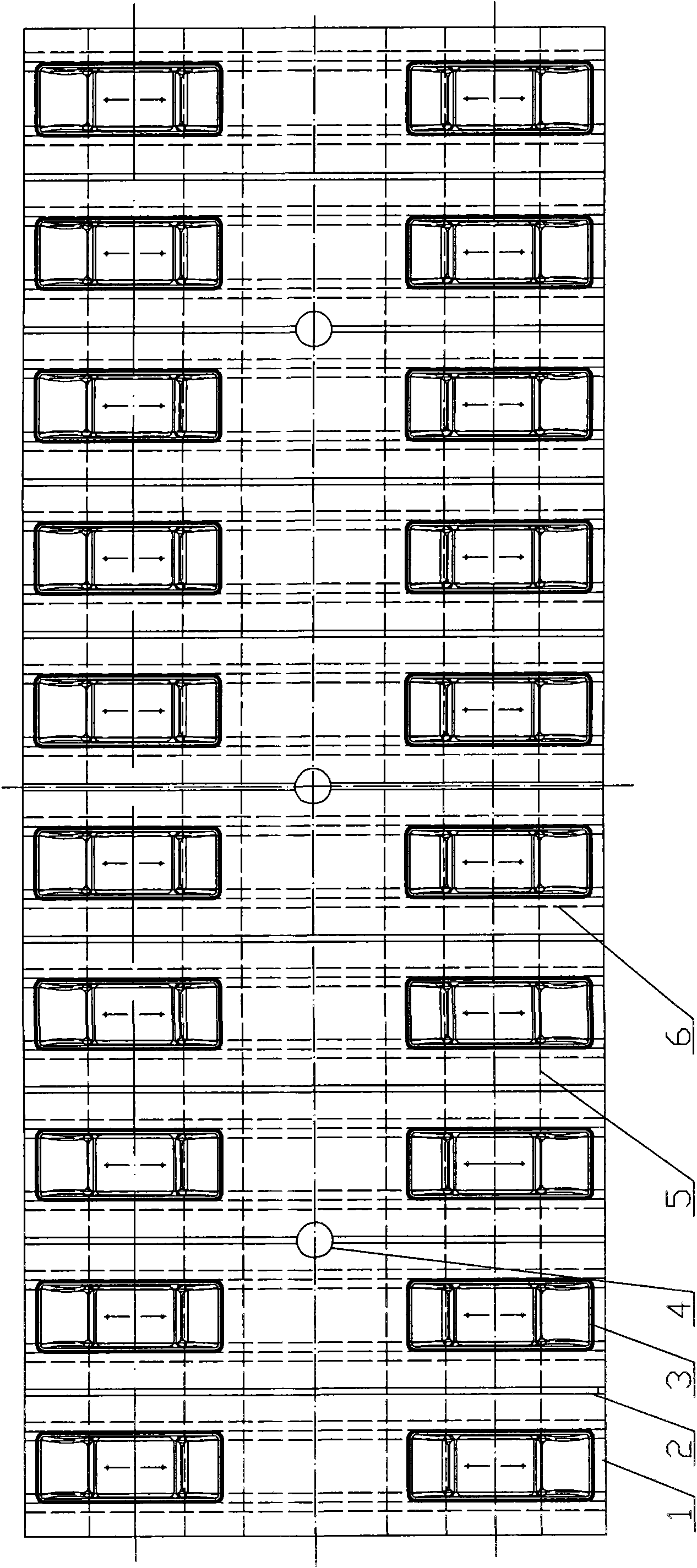

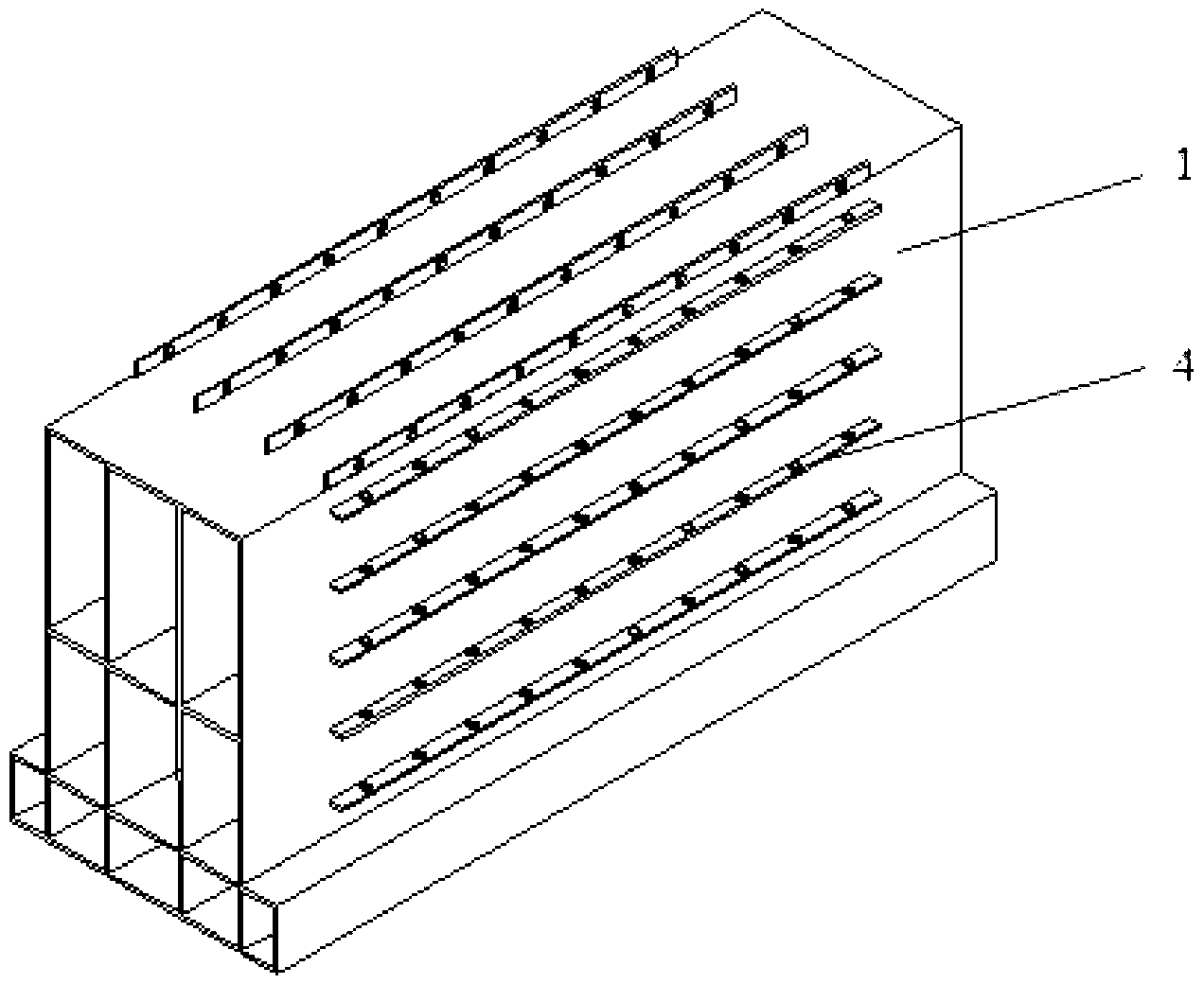

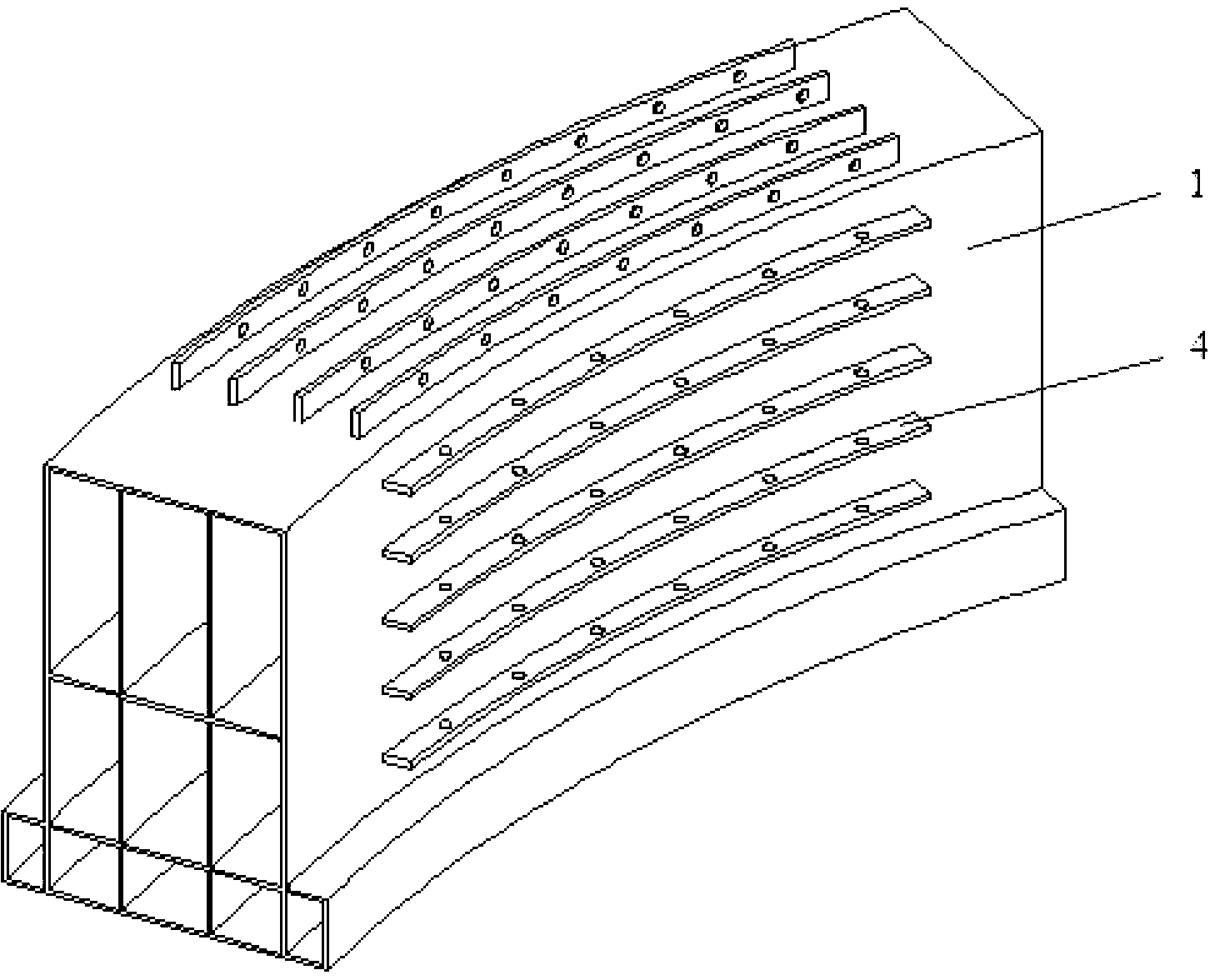

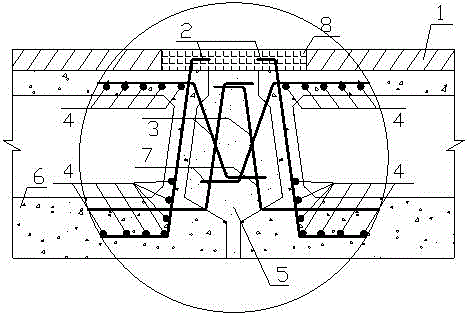

Integrally fabricated box-shaped multi-ribbed composite floor

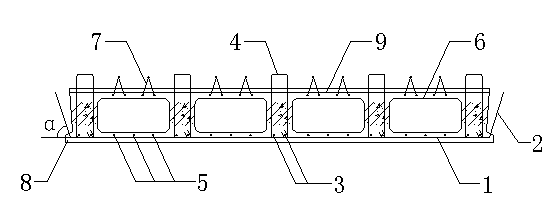

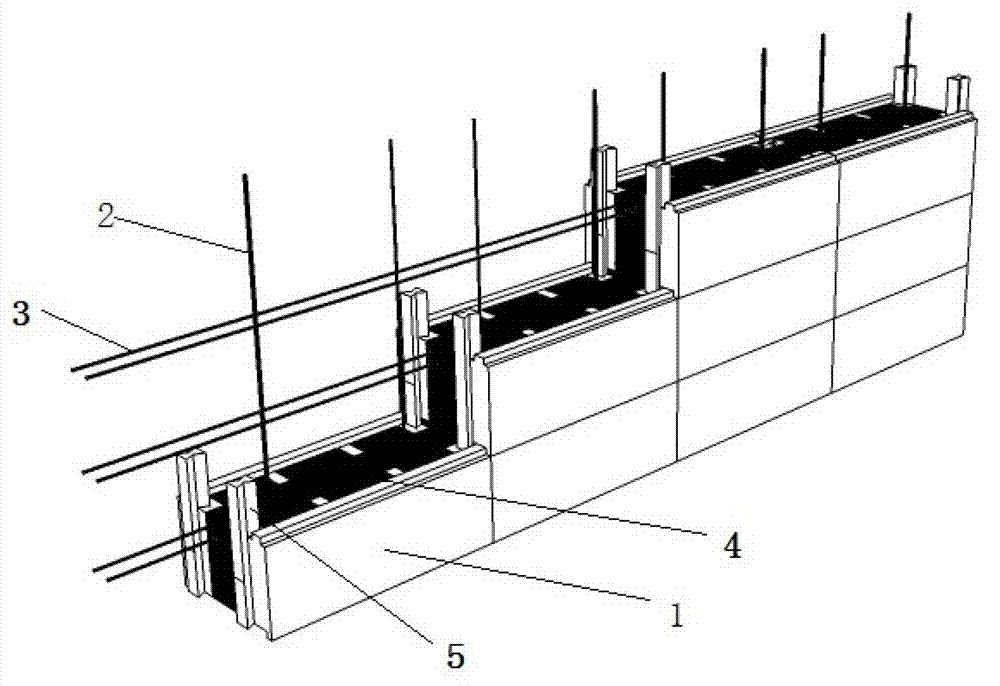

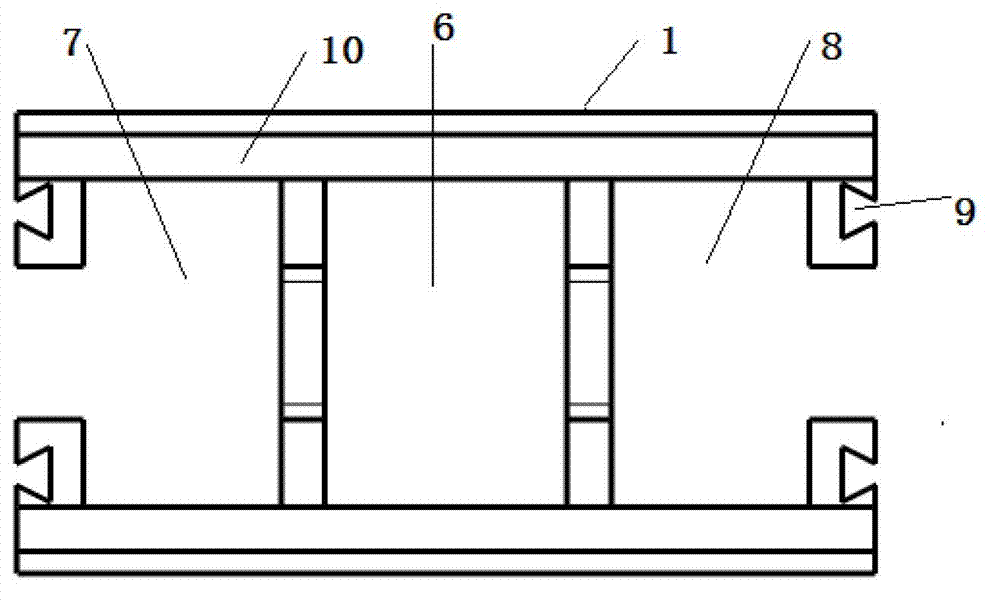

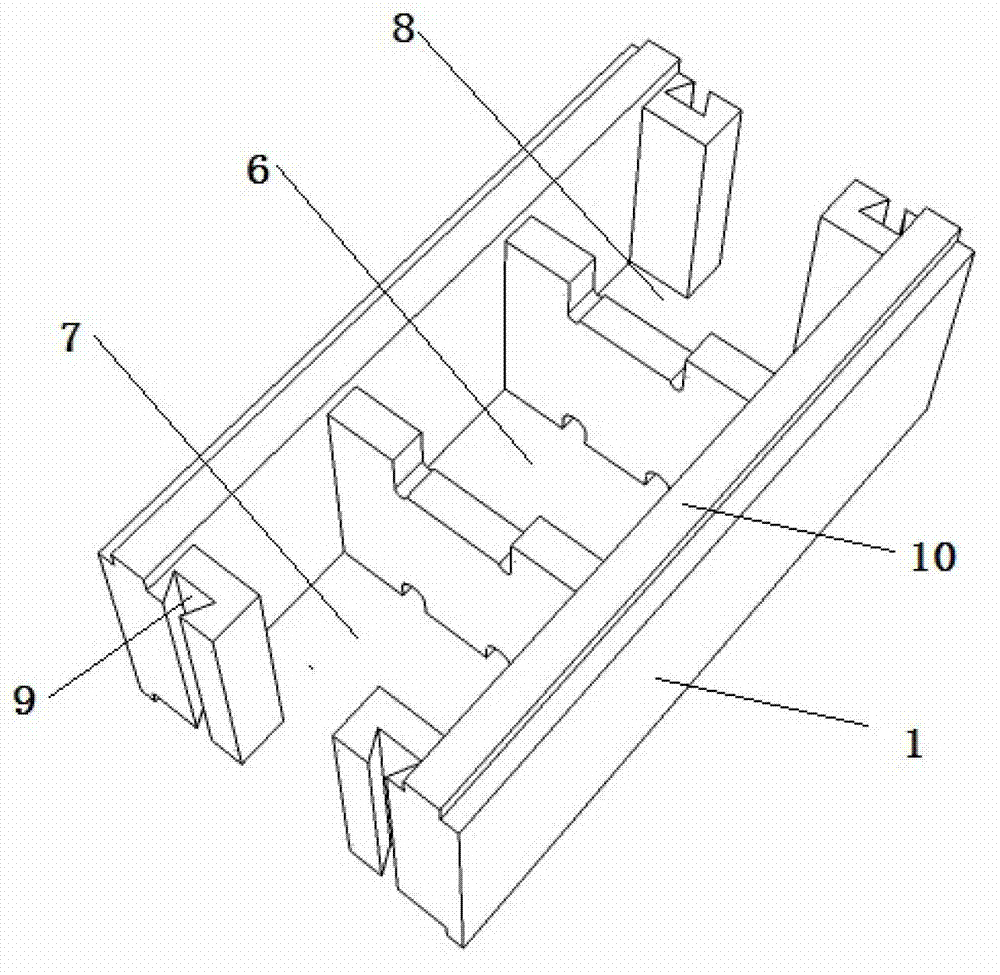

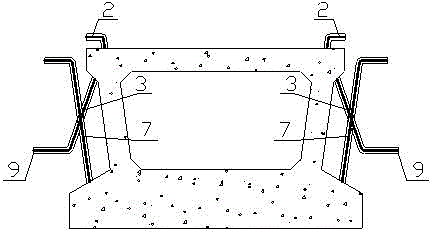

The invention relates to an integrally fabricated box-shaped multi-ribbed composite floor, and belongs to a prefabricated concrete structural component. The integrally fabricated box-shaped multi-ribbed composite floor is characterized in that the composite floor mainly comprises bottom transverse reinforcement bars, bottom linkage reinforcement bars, lower ribbed beam longitudinal ribs, ribbed beam stirrups, bottom longitudinal reinforcement bars, shutterings, truss ribs, flanges, top transverse reinforcement bars, wedge-shaped grooves and a concrete layer, wherein the bottom linkage reinforcement bars, the bottom transverse reinforcement bars, the lower ribbed beam longitudinal ribs, the bottom longitudinal reinforcement bars, the ribbed beam stirrups, the top transverse reinforcement bars and the truss ribs form a steel reinforcement framework of the composite floor; the concrete layer is poured with a conventional concrete pouring method, the flanges are arranged at the bottoms of the front side and the rear side of a concrete slab body, the connecting position of two composite floors forms a U-shaped groove by the flanges, and crack pouring of post-poured concrete is facilitated; and the wedge-shaped grooves are formed in the front side part and the rear side part of the concrete slab body at intervals respectively, the wedge-shaped grooves between every two adjacent composite floors form shear keys, and the shearing resistance between the composite floors is increased.

Owner:CHINA MCC17 GRP

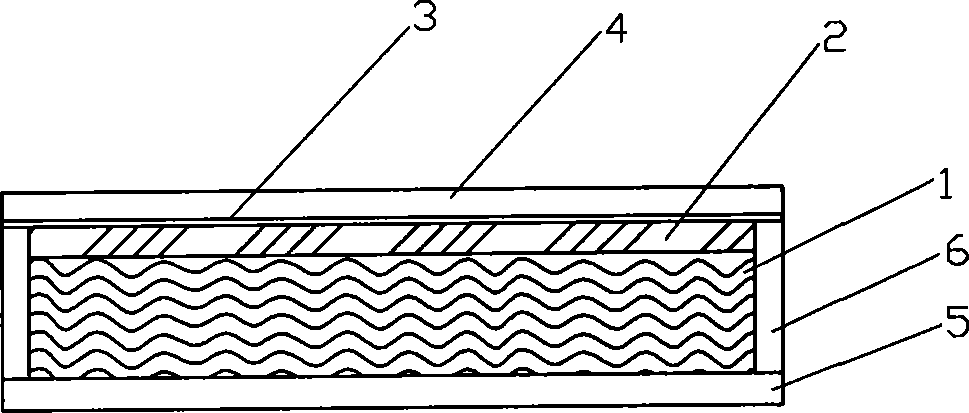

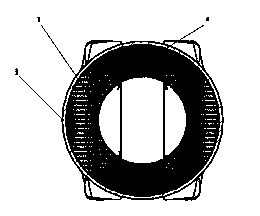

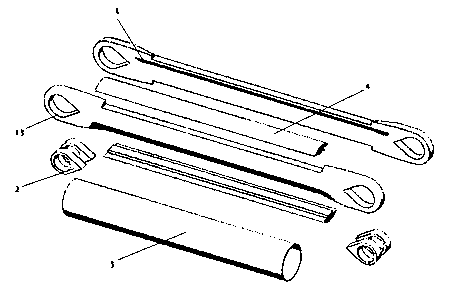

Tearing-proof high temperature resisting conveyer belt

InactiveCN101214880AImprove tear resistanceImprove high temperature resistanceConveyorsSteelmakingPolyester

The invention discloses an anti-tear and high temperature resistant conveyor belt, including a skeleton layer, a working face glue-covering layer, a non-working face glue-covering layer, a transverse reinforcement layer and a buffer glue layer. The transverse reinforcement layer is arranged between the skeleton layer and the buffer glue layer and is adjacent to the skeleton layer. The buffer glue layer is arranged between the transverse reinforcement layer and the working face glue-covering layer and is adjacent to the working face glue-covering layer. The skeleton layer adopts low hear shrinkage polyester canvas and the transverse reinforcement adopts polyester curtain net or metal wire. The material of the working face glue-covering layer is made by mixing ethylene propylene diene monomer with other filers with proper proportion. The material of the buffer glue layer is made by mixing the blend glue of ethylene-propylene-diene rubber and natural glue with other fillers of proper proportion. The invention improves the anti-tear and high temperature resistant performances and is widely applied to convey high temperature materials in such industrial enterprises as steelmaking plants, thermal power plants, cement plants, etc.

Owner:ZHEJIANG SOUTHEAST RUBBER CORP

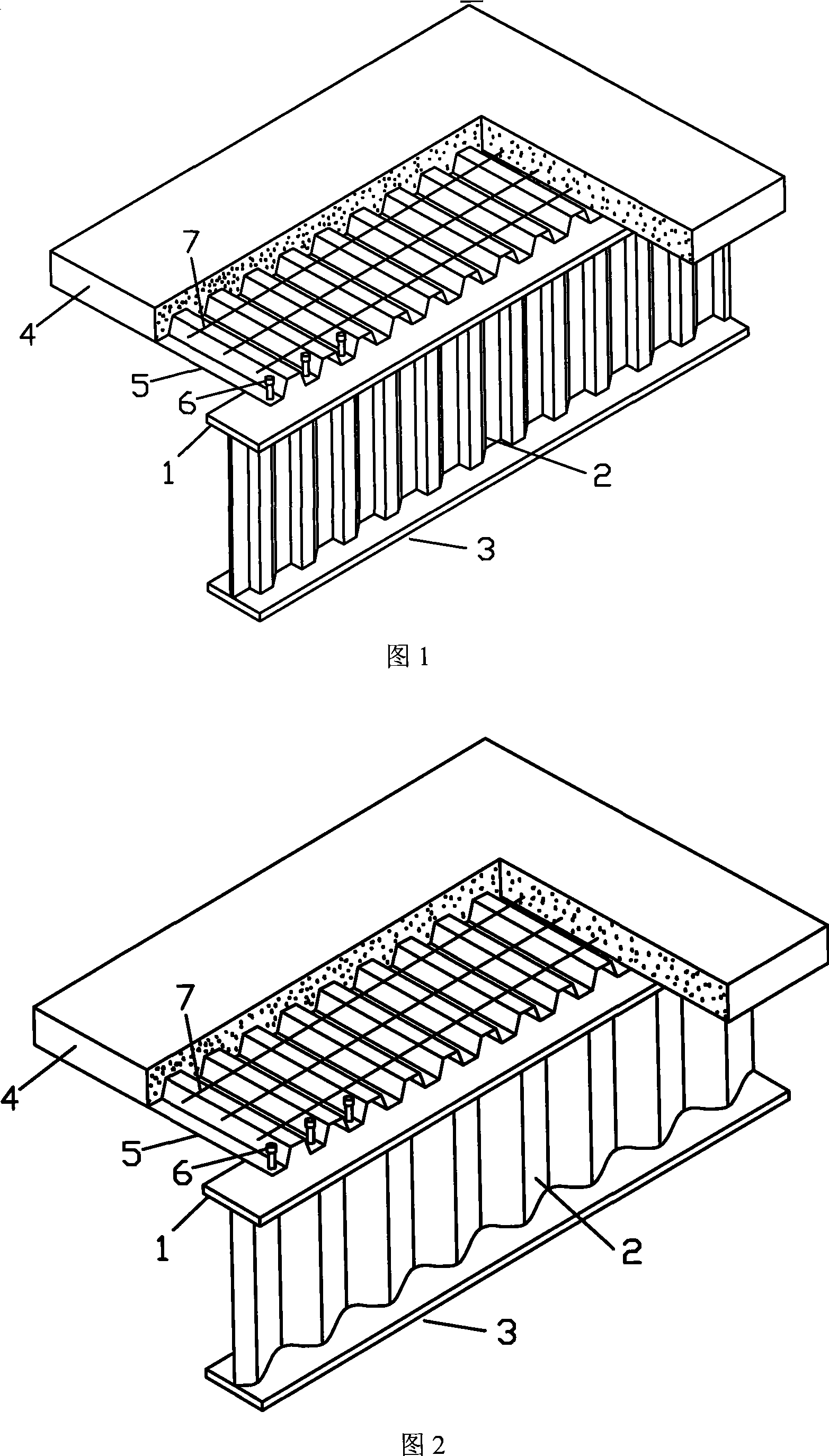

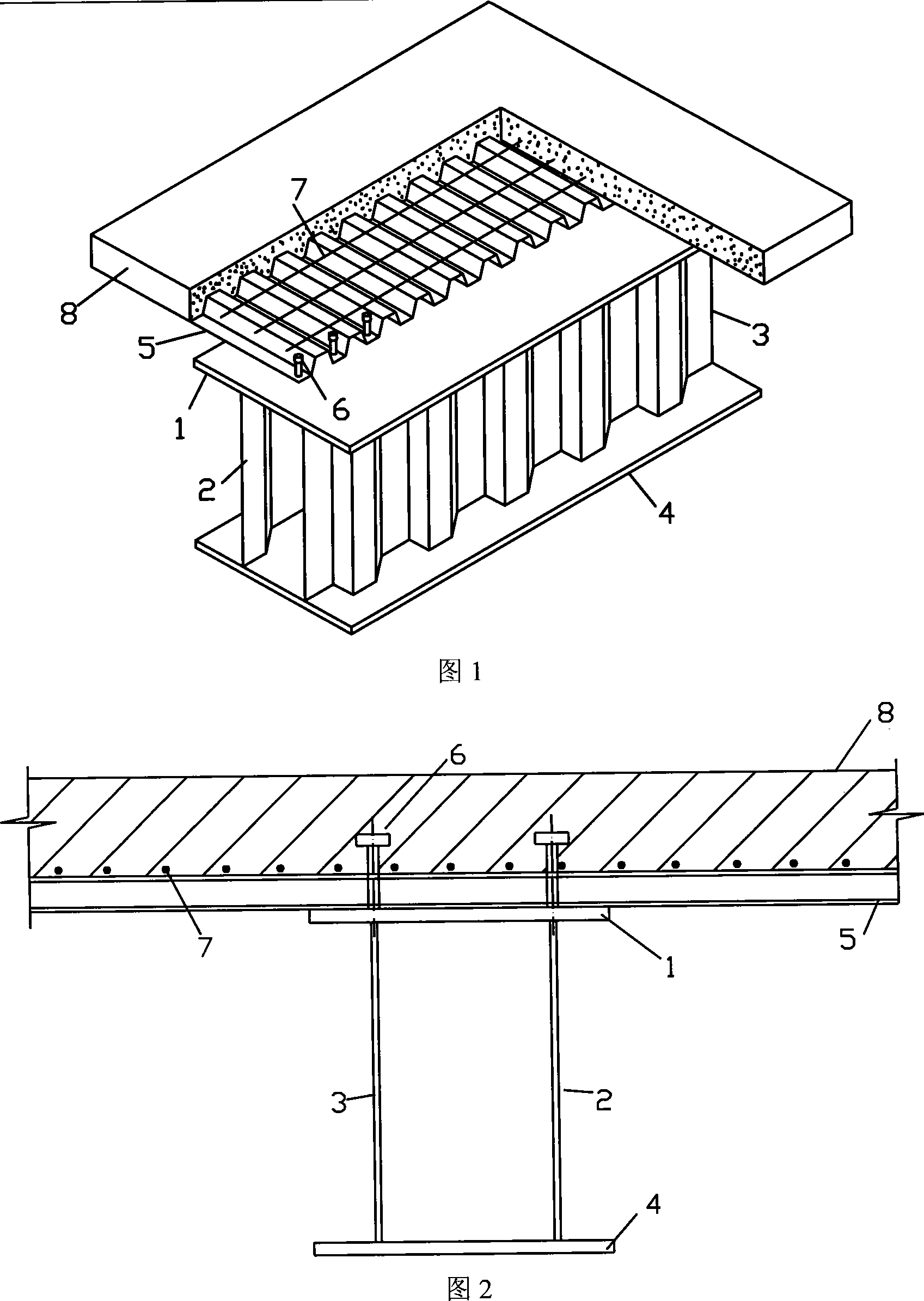

Corrugated sternum H-shaped steel composite beam

InactiveCN101225688APrecise positioningImprove carrying capacityLoad-supporting elementsFillet weldJoist

The invention relates to a corrugated web plate H-shaped profile steel composite bean, belonging to the technical field of building profile materials . The cross section port type comprises a corrugated web plate and an upper and lower flange joints. The upper flange is in parallel with the lower flange; the web plate is vertical to the upper flange and the lower flange; the web plate is connected with the flanges by single-sided fillet weld; the web plate is a trapezoid ripple or a sine curve ripple, wherein the lengthwise direction of the trapezoid ripple is repeated periodically. The upper part of a composite beam is a reinforced concrete swing plate and a profiled steel sheet. The upper flange, the reinforced concrete plate and the profiled steel sheet are connected by a plurality of studs; the reinforced concrete swing plate can be connected with the profiled steel sheet by additional lateral steel bar. The traditional hot-rolling joist steel and H-shaped profile steel composite beam can be replaced by the corrugated web plate H-shaped profile steel composite bean which has the wider application than joist steel and H-shaped profile steel composite beam; the maximization can be realized for special field and special location comprising the construction of large span industrial and civil building and large span bridge.

Owner:TONGJI UNIV

Double-ripple ventral shield steel case built-up beam

InactiveCN101220697APrecise positioningImprove mechanical propertiesFloorsLoad-supporting elementsSteel barSpandrel

The invention belongs to the technical field of architectural profiles and particularly relates to a double corrugated web steel box composite beam. The sectional shape of the invention is composed of two symmetrically arranged corrugated webs, a top flange and a lower flange. The top flange is parallel with the lower flange, the web is vertical to the top flange and the lower flange, the web and the flange are connected by single-side fillet joint, and the web has periodically repetitive trapezoidal wave or sinusoid wave along the length direction. The top of the composite beam is a reinforced concrete wing plate and a profiling steel plate. The top flange, the reinforced concrete slab and the profiling steel plate are connected each other by male pins, and a transverse reinforcement can be additionally used for the connection between the reinforced concrete wing plate and the profiling steel plate. The invention can replace the traditional hot rolled flange beam, H-beam composite beam and welded steel box composite beam; furthermore, the invention has wider application than the flange beam and the H-beam composite beam, and can realize maximization to be used in special fields and special places, including the construction of wide-span industrial and civilian buildings and wide-span bridges, etc.

Owner:TONGJI UNIV

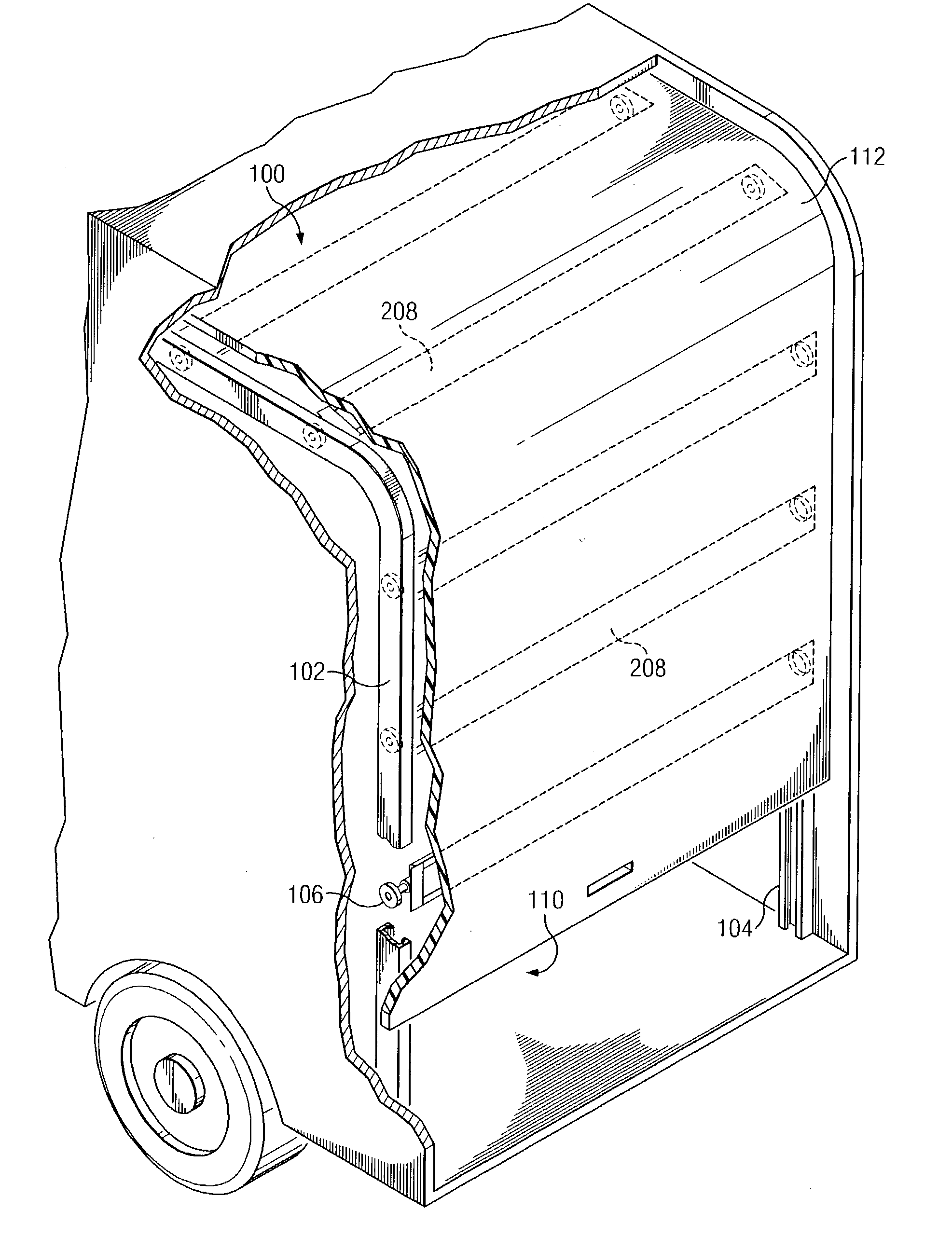

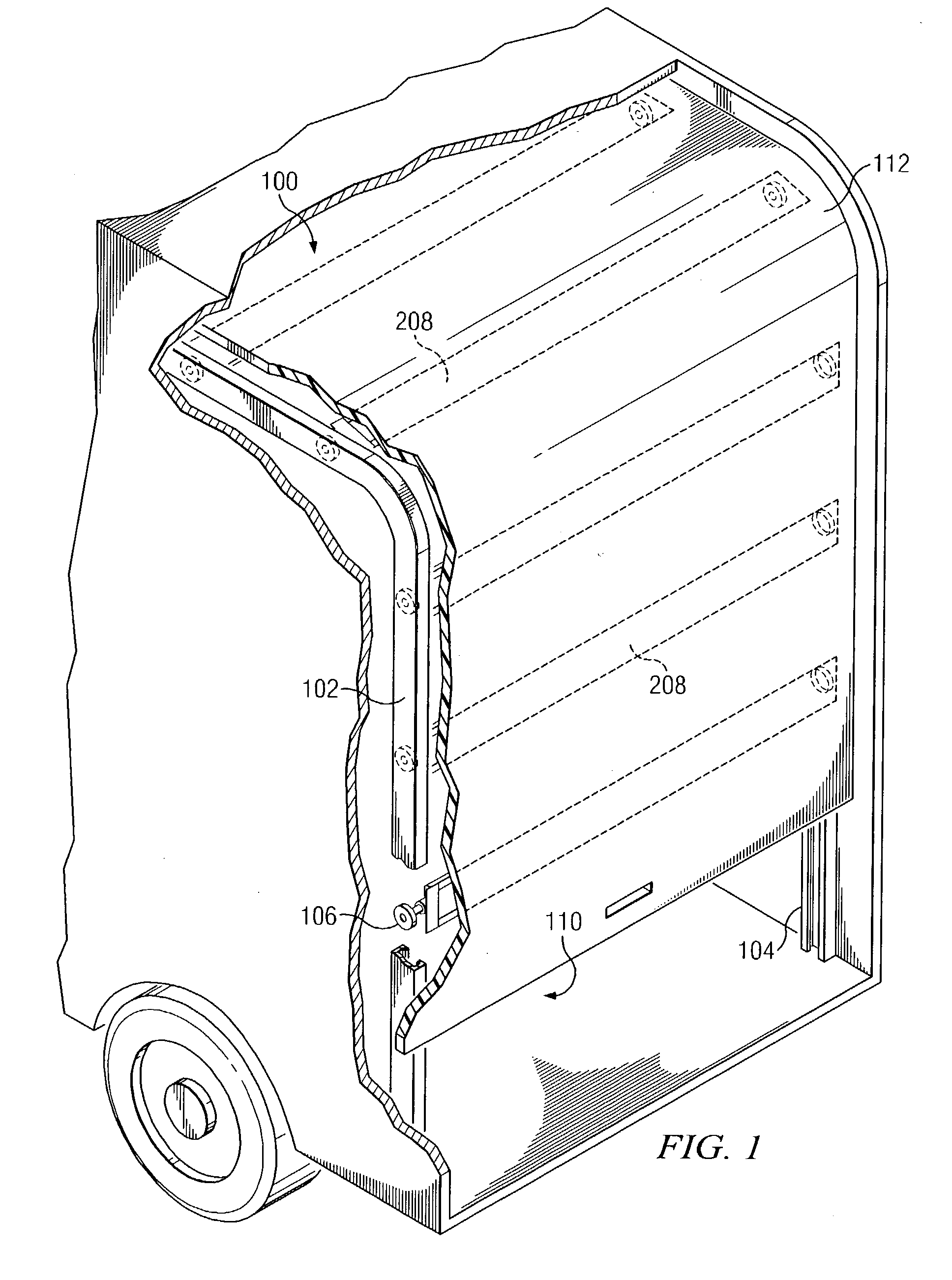

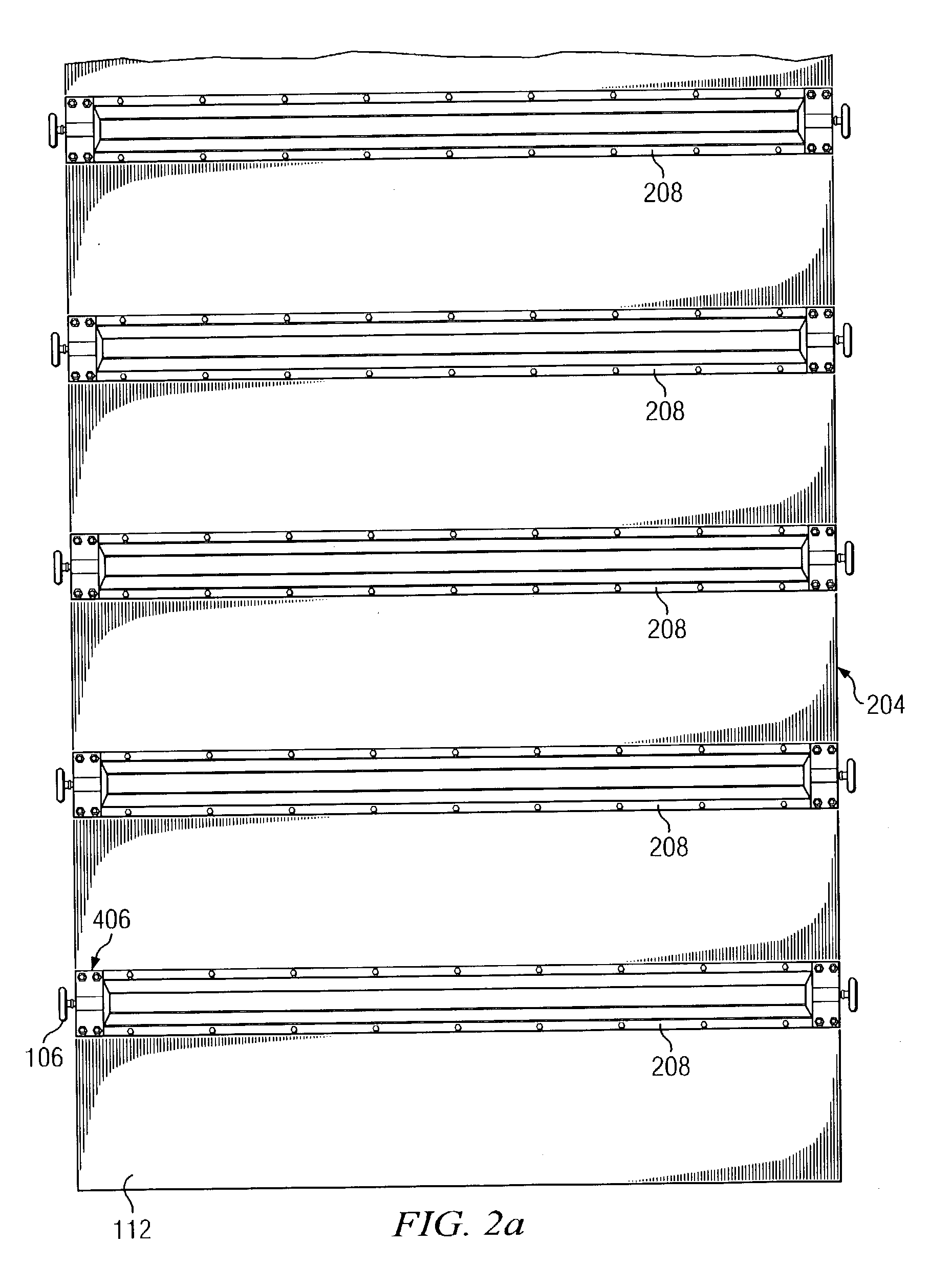

Unitary flexible roll-up door

A roll-up door assembly for a variety of uses for example commercial vehicles, commercial buildings, residential buildings or other suitable purposes. The door assembly includes a flexible unitary panel constructed from a material comprising a fiber and resin composite. A plurality of transverse support bars are affixed to the flexible panel. Rollers are rotably mounted on an axle and are adapted to be received in a track for guided movement of the flexible panel. The axle can be integral with the transverse reinforcement member or part of a roller bracket affixed to the transverse reinforcement member. Alternately, the flexible panel can be provided without rollers and can be received in and guided by a slotted track.

Owner:COURT CALVIN L +1

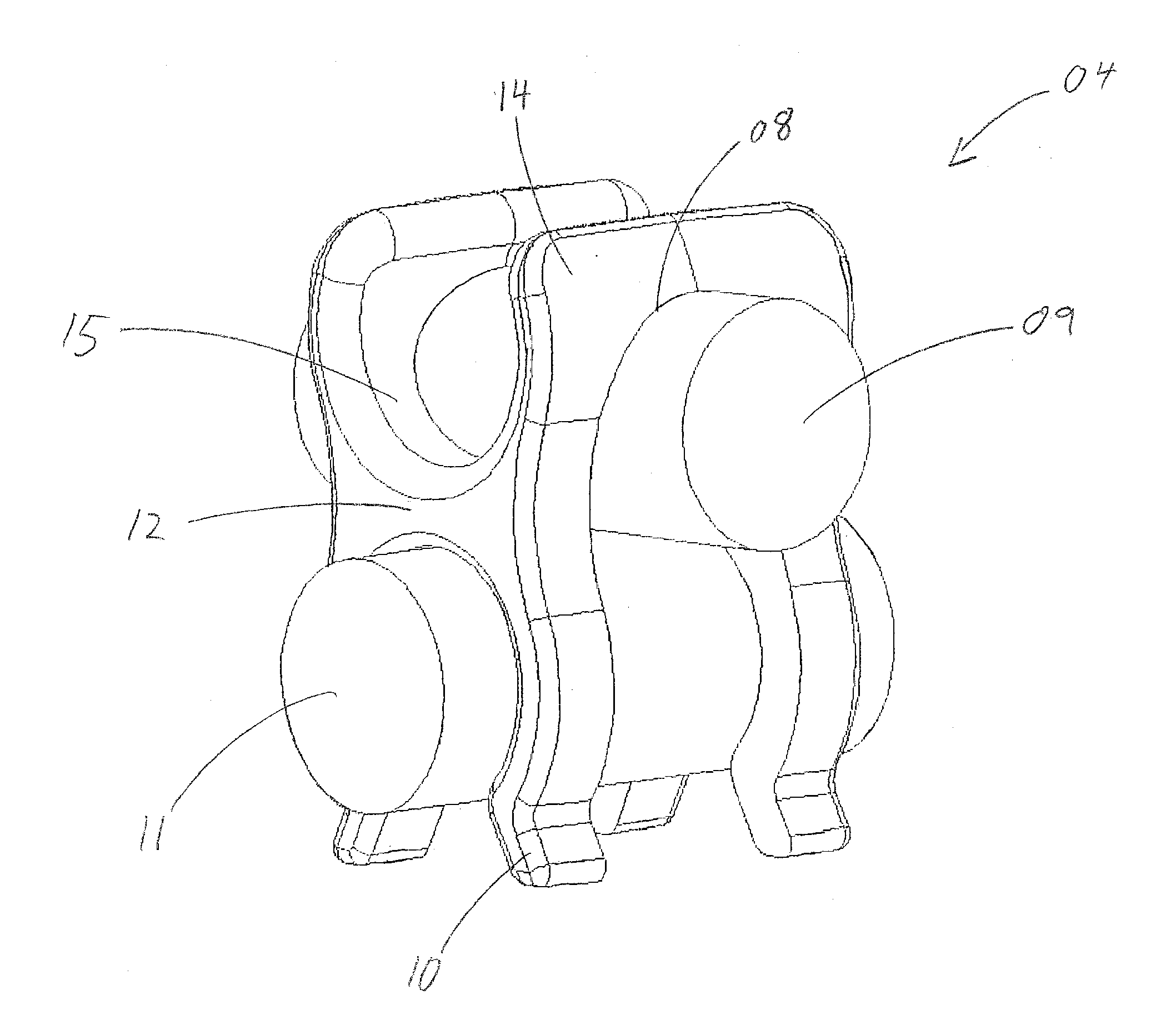

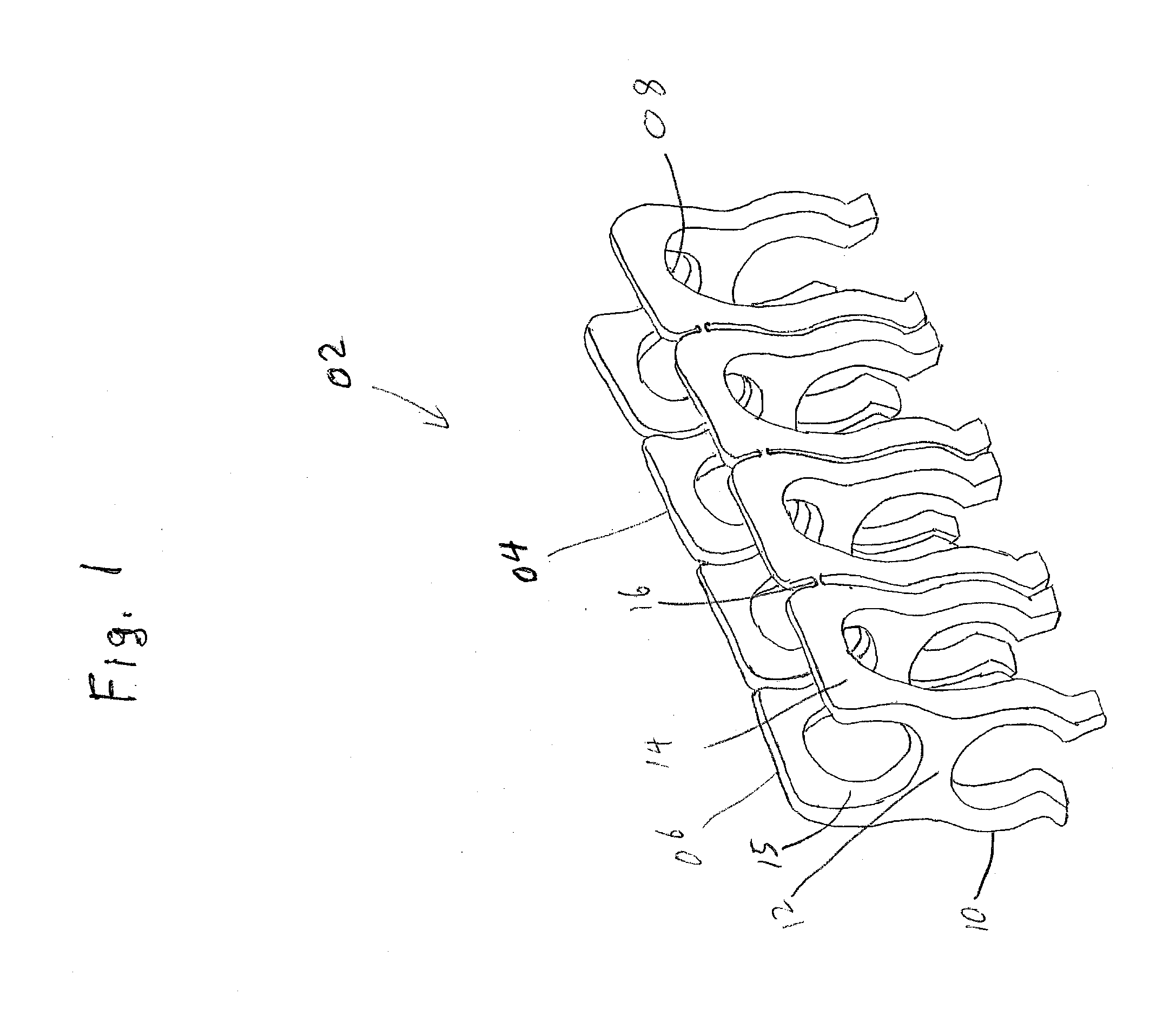

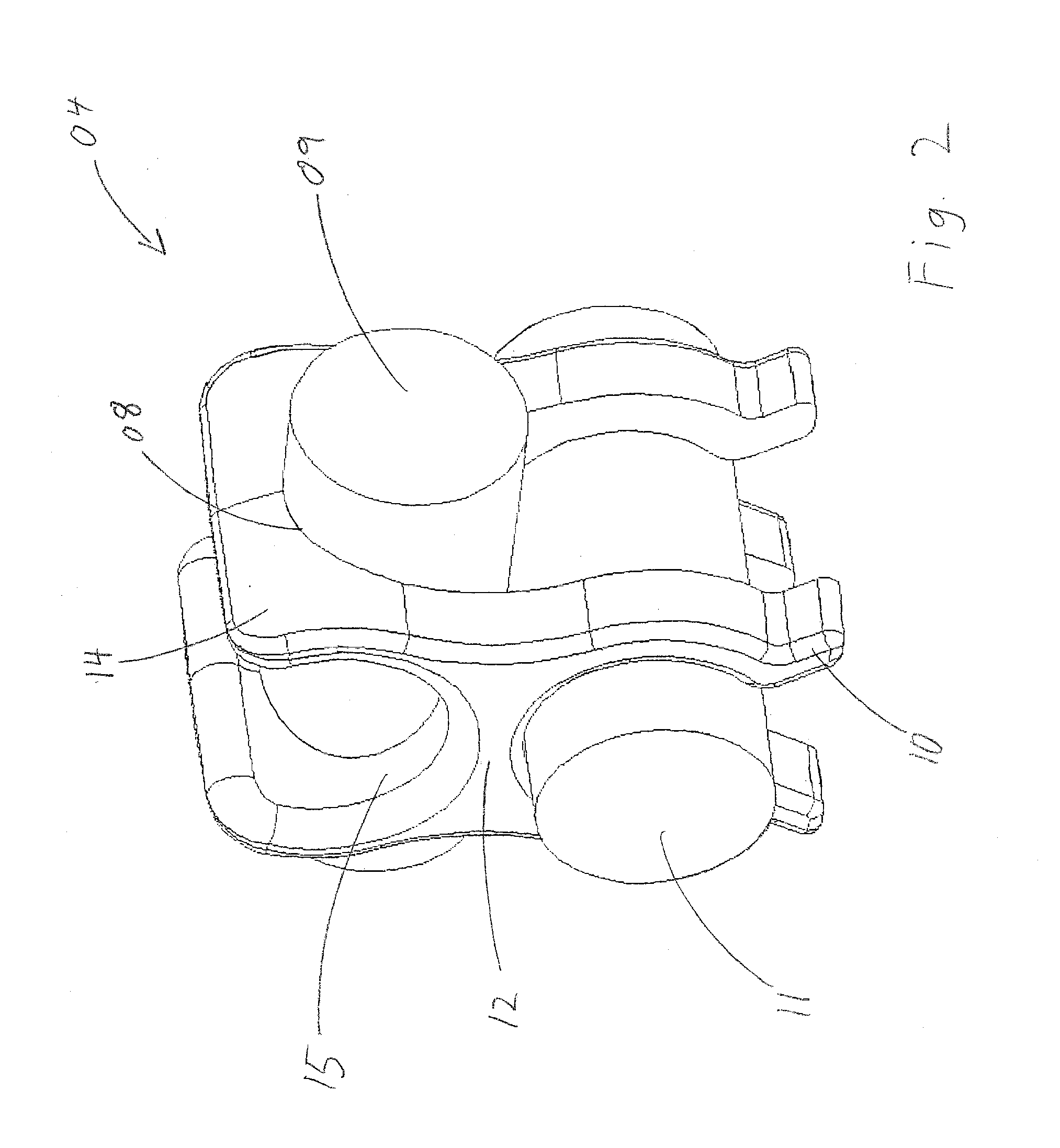

Bar Connecting Apparatus

ActiveUS20080115448A1Building reinforcementsBuilding material handlingReinforced concreteReciprocating motion

A bar connecting apparatus applies clips to connect transverse bars used in reinforced concrete. A clip string is fed into the bar connecting apparatus by a clip feed assembly, so several pairs of transverse bars can be connected in rapid succession. A hammer reciprocates in the barrel of the bar connecting apparatus, and drives a clip from the barrel into engagement with the bars. An alignment head aligns the bar connecting apparatus with the transverse bars so the clips properly engage the bars.

Owner:DAYTON SUPERIOR CORP

Corrugated steel web prestressed concrete continuous box girder and construction method thereof

ActiveCN102220739AHigh section stiffnessImprove carrying capacityBridge structural detailsBridge erection/assemblyConcrete beamsPre stress

The invention discloses a corrugated steel web prestressed concrete continuous box girder. In the box girder, after being fixedly connected with a corresponding steel bar in a cast-in-place member, transverse steel bars of a precast concrete top plate, a precast concrete bottom plate and a precast concrete beam or a precast concrete diaphragm plate of two adjacent corrugated steel web prestressed concrete flanged beam units which are erected are connected by a cast-in-place concrete top plate between the adjacent precast concrete top plates, a cast-in-place concrete bottom plate between the adjacent precast concrete bottom plates and a cast-in-place concrete beam or a cast-in-place concrete diaphragm plate between the adjacent precast concrete beams or precast concrete diaphragm plates to form closed box girders; and external prestressed bars in the closed box girders are pulled and anchored, the closed girders corresponding to two adjacent holes are connected by pouring cast-in-place concrete longitudinal beams, hogging moment prestressed bars on pillar tops are pulled and anchored, and temporary supports are removed to form the continuous box girder. The corrugated steel web prestressed concrete continuous box girder has the characteristics of high stressed performance, high utilization rate of materials and obvious economic benefit, and is easy and convenient to construct.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

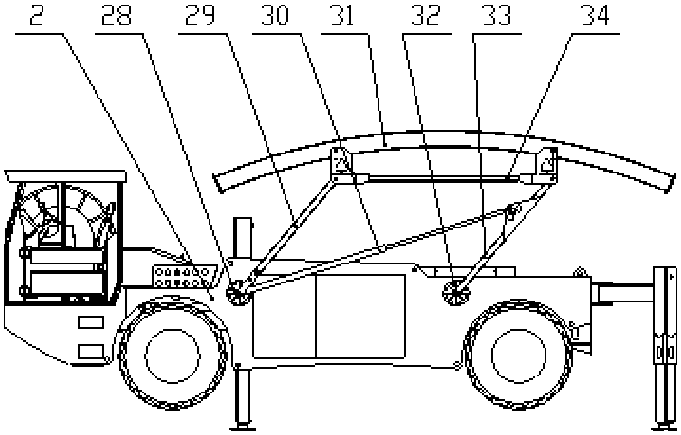

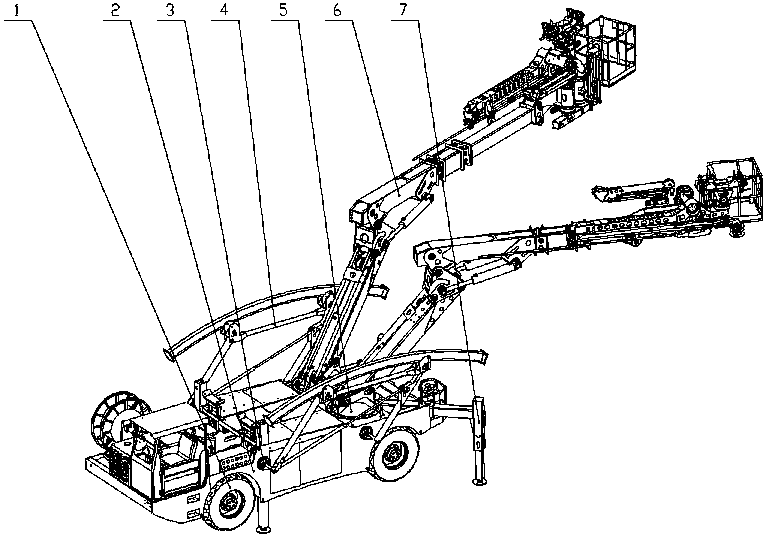

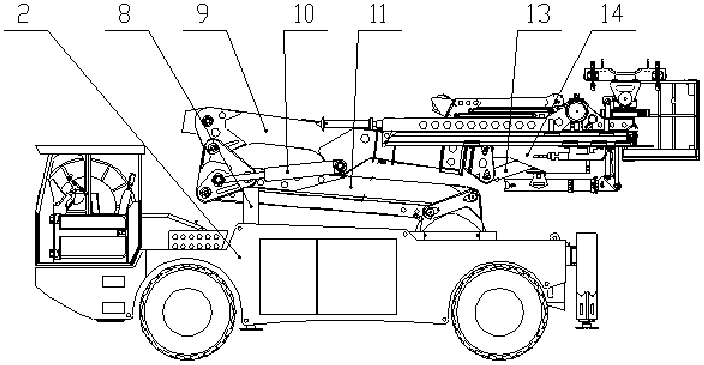

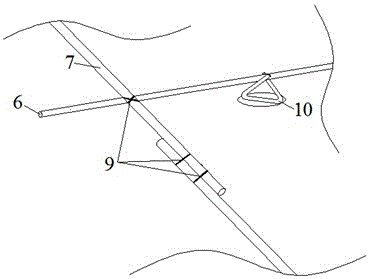

Multi-function tunnel rock drilling and arching all-in-one machine

PendingCN107842311AGrow fastSolve the problem that the vehicle cannot be retracted and the vehicle is too long and has a large turning radiusUnderground chambersDerricks/mastsEngineeringDrilling machines

A multi-function tunnel rock drilling and arching all-in-one machine comprises a host platform (2) which is arranged on a basal disc (1); two arm frames (6) are arranged at the rear portion of the host platform by a rotation seat (5), and the arm frames can be folded and stored in a driving or static state; the front end of a forearm is rotationally provided with an arch grabbing device (18), a rock drilling device (19), a manned platform (24), and a truck crane (23). The multi-function tunnel rock drilling and arching all-in-one machine can perform the arch support operation during full section, two-step and three-step excavating of a tunnel. Through the coordination of the two arm frames and the above working devices, the arch frame transported by car, the installation of the arch, the hanging of the reinforcing mesh, the welding of the transverse reinforcement and the installation of a bolt and a drill hole of leading small tube can be realized; the efficiency is far higher than that of the manual operation.

Owner:CHANGSHA KEDA INTELLIGENT EQUIP INC CO

Composite shear wall with concrete-filled steel tube frames and double steel plates with concealed bracings and construction method thereof

InactiveCN102704598AAct as a constraintImprove binding abilityWallsBuilding material handlingSteel frameSteel bar

A composite shear wall with concrete-filled steel tube frames and double steel plates with concealed bracings and a construction method thereof relate to the field of construction. According to the invention, the composite shear wall is formed by combining reinforced concrete frames, a double steel plate shear wall and steel plates with concealed bracings. The reinforced concrete frames are formed by pouring concrete into steel tubes; then, the double steel plates are placed, the double steel plates are welded to the reinforced concrete frames, and the steel plates are perforated and are connected through studs; oblique crossing concealed bracings are placed between the double steel plates, and the oblique angle of the concealed bracings is between 45 degrees and 60 degrees; tie bars are threaded through the interspace between the concealed bracings; a reinforcing mesh composed of transverse steel bars in horizontal arrangement and longitudinal steel bars in vertical arrangement is arranged between the concealed bracings and the steel plates; and concrete is poured between the double steel plates. The composite shear wall has the advantages that the bearing capability is enhanced, the bearing capacity and the rigidity attenuate slowly, the ductility and the energy dissipation of the shear wall are enhanced due to multi-defenses, and the earthquake resistant capability is more excellent. The composite shear wall also has the advantage of convenience in steel structure construction, and can be used in high-rise or large complex multi-storey buildings.

Owner:BEIJING UNIV OF TECH

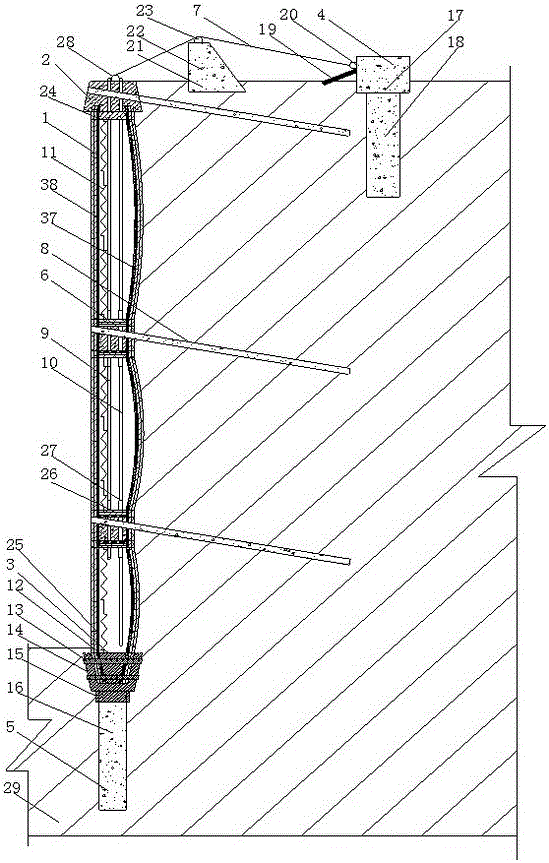

Pressure compensation type foundation pit supporting structure and construction method

ActiveCN105155551AControl deformationChange stressExcavationsArchitectural engineeringMechanical engineering

The invention relates to a pressure compensation type foundation pit supporting structure and a construction method. The pressure compensation type foundation pit supporting structure is characterized in that a multi-cavity back-pressure bag composed of a plurality of continuous airtight cavities is arranged on the base foundation supporting side; a bag top beam and a bag bottom beam connected with the bag in an airtight manner are arranged on the top and at the bottom of the multi-cavity back-pressure bag respectively; the bag top beam and the bag bottom beam are connected with a transverse counterforce structure and a vertical counterforce structure respectively; transverse counterforce beams and vertical counterforce beams are arranged at partitions of the airtight cavities; transverse reinforcement bodies are arranged at the crossed parts of the transverse counterforce beams and the vertical counterforce beams; cavity pressurizing pipes and cavity grouting pipes are arranged in the cavities of the multi-cavity back-pressure bag; and a tension steering structure is arranged between the transverse counterforce structure and the side wall of a foundation pit. According to the pressure compensation type foundation pit supporting structure, the change of the stress state of a soil body due to excavation of the foundation pit can be avoided, in addition, an airtight seeping-preventing structure can be formed on the supporting side, and deformation of the soil body on the outer side can be dynamically controlled. The invention further provides the construction method for the pressure compensation type foundation pit supporting structure.

Owner:华泰建设工程有限公司

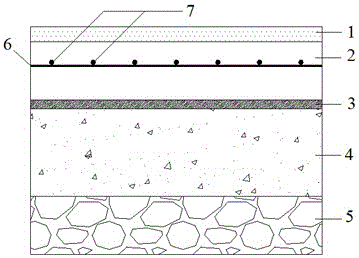

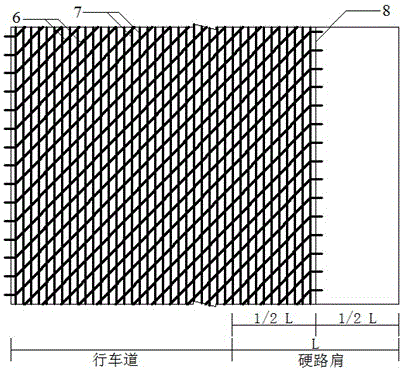

Cement concrete pavement structure provided with continuous steel bars

ActiveCN104988823AReduce maintenance and repair costsGood driving comfortPaving reinforcementsIn situ pavingsRoller-compacted concreteCrushed stone

The invention discloses a cement concrete pavement structure provided with continuous steel bars. The pavement structure comprises a base layer. Roller compacted concrete is adopted in the base layer. A broken stone hardcore is laid below the base layer. Cement concrete surface layers are laid on the base layer. The cement concrete surface layers include the upper surface layer and the lower surface layer. Rubber cement concrete is adopted in the upper surface layer. A transverse induction kerf is arranged on the edge of the upper surface layer on the left side of the driving direction. The continuous transverse steel bars, the continuous longitudinal steel bars and a slidable support are arranged at the portion, within the range of a carriageway and one half of the width (L) of a hardened verge, of the lower surface layer. Plain concrete is formed at the portion, within the other half of the width (L) of the hardened verge, of the lower surface layer. A longitudinal joint is arranged at the portion one half of the width of the hardened verge. A bituminous concrete anti-scouring layer is arranged between the base layer and the surface layers. The pavement structure can solve the problems of existing cement concrete pavements and continuous reinforced concrete pavement structures and can be widely applied to high-grade highways, tunnel pavements and the like on the heavy-duty traffic condition.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

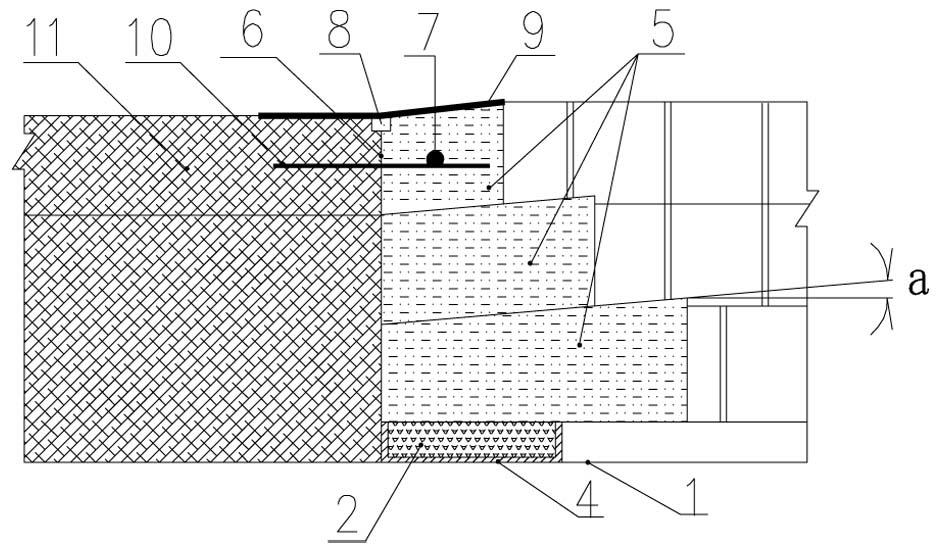

Composite heat insulation concrete shear wall and its construction method

InactiveCN1603538AImprove insulation effectImprove insulation performanceWallsHeat proofingNew energyPolystyrene

One kind of compound heat preservation heat insulation concrete shearing force is strong and the job practice, in the concrete foundation connects the prefabricated polystyrene heat preservation wall template, the prefabricated polystyrene heat preservation wall template interconnection has the steel bar skeleton, the steel bar skeleton by along the board length and along the board widely spaced establishment transverse steel, the embedment steel disk permanent connection becomes along in the board high establishment vertical steel bar and the board. Outside the prefabricated polystyrene heat preservation wall board template the side permanent connection cement tile, the prefabricated polystyrene heat preservation wall template compound constructs with the cast-in-place concrete wall is a body. The invention provides a kind of new energy conservation construction wall, reduced the construction working procedure, reduced the time limit for a project, reduced the construction cost, has solved the energy conservation construction craft complex problem. Is suitable for the multilayer and the small high-rise construction.

Owner:朱秦江

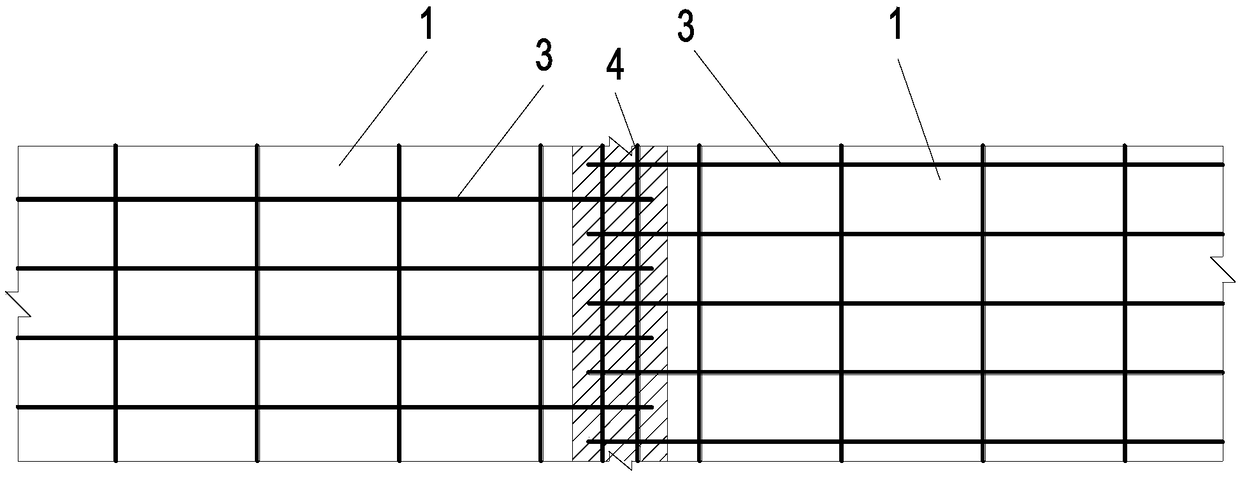

Assembled bridge deck transverse joint using UHPC grouting material

PendingCN109487686AImprove crack resistanceGood wet seam joining performanceBridge structural detailsBridge materialsBridge deckTongue and groove

The invention provides an assembled bridge deck transverse joint using a UHPC grouting material. The transverse joint comprises two precast concrete bridge decks with tongue-and-grooves and the UHPC grouting material cast between the two precast concrete bridge decks in place. Each precast concrete bridge deck is internally provided with a steel frame formed by splicing a plurality of transverse steel bars and longitudinal steel bars. Each longitudinal steel bar is of a double-layer U-shaped steel bar structure with a U-shaped structure at the tongue-and-groove end, and U-shaped steel bars arearranged in the staggered mode at the tongue-and-groove position between the two precast concrete bridge decks. The two precast concrete bridge decks are connected into a whole by cast-in-place of the UHPC grouting material on the tongue-and-grooves arranged oppositely. The assembled bridge deck transverse joint using the UHPC grouting material enhances the durability and the stability of a wet joint of the bridge decks, a bottom mold is not needed during the cast-in-place of the UHPC, the precast bridge deck structure is simplified, and the long-term performance of a precast bridge deck system is improved.

Owner:WUHAN UNIV OF TECH

Concrete prefabricated panel, prefabricated building formed by same and construction method

PendingCN106499116AShorten the lengthReduce workloadDischarging arrangementWallsEngineeringBuilding design

The invention discloses a concrete prefabricated panel and a prefabricated building formed by the same. A nonpenetrating transverse hole is formed in the panel. The panel adopts a structure that the transverse hole is preserved in the edge rib of the panel, a horizontal steel bar meeting the splicing length required by codes for architectural and structural design is inserted into the hole, a transverse hole penetrating the whole panel is not required to be formed, the splicing of a horizontal steel bar between prefabricated panels can be achieved, the transverse transfer requirement is met, and the requirement of an earthquake resistant code of architectural design is met. The length of the inserted horizontal steel bar is greatly shortened, the cost is lowered, the workload and construction difficulty for penetrating the penetrating transverse steel bar are reduced, and the method is simple to implement, simple and effective, an excellent earthquake resistant effect can be achieved, and meanwhile the prefabricated panel is more convenient to produce and manufacture and higher in quality.

Owner:BEIJING EVEREST GREEN BUILDING TECH

Pre-cast concrete column and method of fabrication

Owner:BAUMANN HANNS U

Secondary main beam composite beam bridge using prefabricated composite bridge deck slabs and construction method of secondary main beam composite beam bridge

ActiveCN106638254ALose weightIncrease horizontal spanBridge structural detailsBridge deckEngineering

The invention discloses a secondary main beam composite beam bridge using prefabricated composite bridge deck slabs and a construction method of the secondary main beam composite beam bridge. The secondary main beam composite beam bridge includes steel box beams, steel cross beams and the prefabricated composite bridge deck slabs, a horizontal wet joint is formed between every two adjacent bridge deck slabs, the prefabricated composite bridge deck slabs include a plurality of pieces of structural steel and prefabricated concrete layers cast on the structural steel, the bottom of the structural steel is welded to the steel box beams, longitudinal wet joints are formed in the prefabricated composite bridge deck slabs and in the range of the top of the steel box beams, a plurality of through holes are formed in the structural steel and in the range of the longitudinal wet joints, perforated steel bars connected with the structural steel pass through the through holes, and vertical and horizontal direction steel bar meshes are arranged in the prefabricated concrete layers, stretch out of the prefabricated range of the prefabricated composite bridge deck slabs and are connected with the perforated steel bars; wet joint concrete is cast in situ in the horizontal wet joints and the longitudinal wet joints. The secondary main beam composite beam bridge is light in dead weight, large in bearing capacity, reasonable in loading, good in integrality and large in adaptation width.

Owner:湖南省交通水利建设集团有限公司 +1

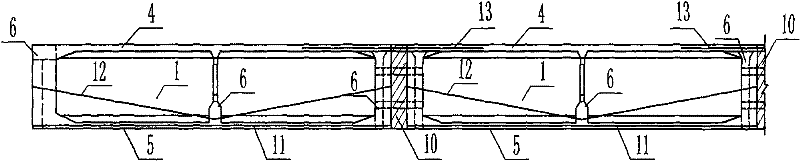

Continuous box girder made of corrugated steel web pre-tensioned prestressed concrete and construction method

InactiveCN102691257AImprove mechanical performanceLarge amount of workBridge erection/assemblyBridge materialsShaped beamPre stress

The invention discloses a continuous box girder made of corrugated steel web pre-tensioned prestressed concrete. A plurality of I-shaped beam elements precast by a plurality of corrugated steel web pre-tensioned prestressed concrete are erected and installed on an abutment, precast concrete top plates, precast concrete bottom plates, and transverse reinforcements of precast concrete beams or diaphragm plates of each two adjacent I-shaped beam elements are fixedly connected with reinforcing steel bars in corresponding cast-in-place members, and then a cast-in-place concrete top plate between each two adjacent precast concrete top plates, a cast-in-place concrete bottom plate between each two adjacent precast concrete bottom plates and a cast-in-place concrete beam or transverse diaphragm plate between each two adjacent precast concrete beams or transverse diaphragm plates are connected with one another to form closed box girders. Each two adjacent closed box girders are connected with each other by pouring cast-in-place concrete longitudinal beams, thus forming the continuous box girder. Pre-tensioned prestressed tendons are arranged in bottom plate bodies of the precast I-shaped beam elements; and pier top hogging moment prestressed tendons are arranged in the cast-in-place concrete top plates of the closed box girders.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

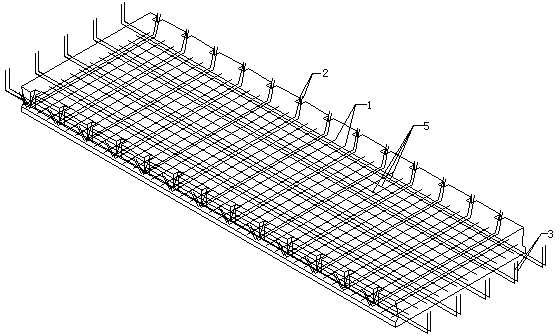

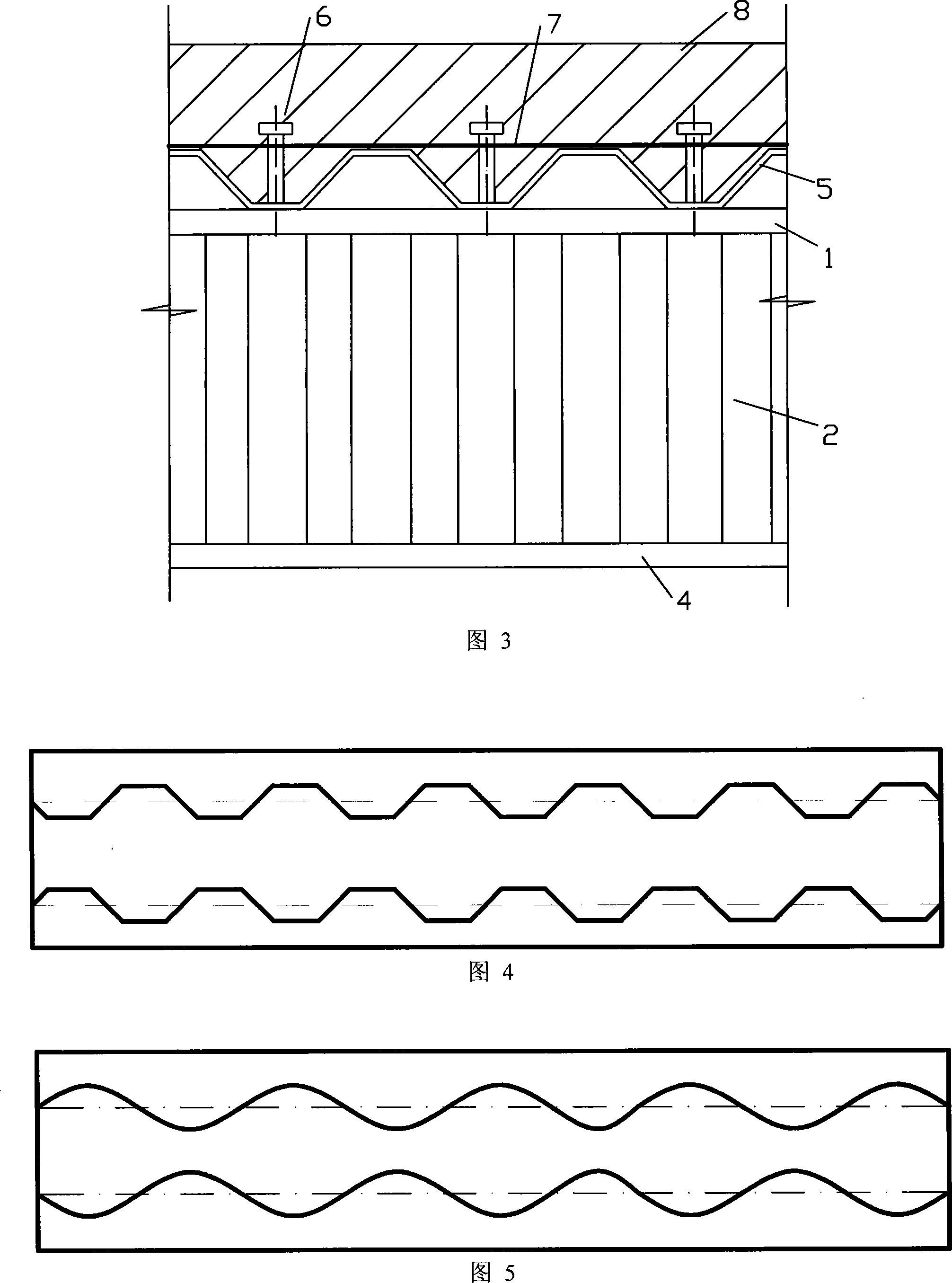

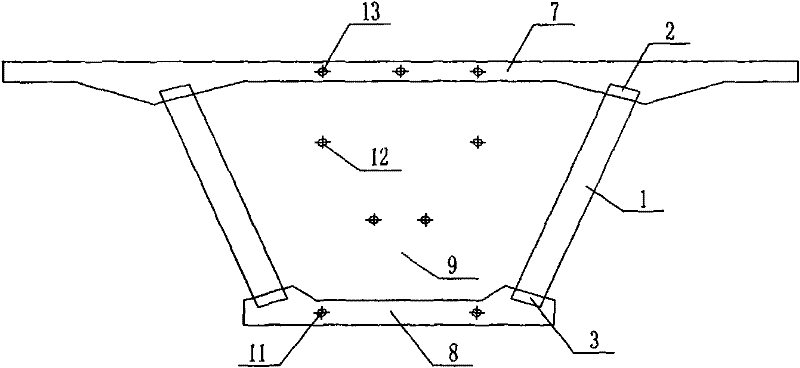

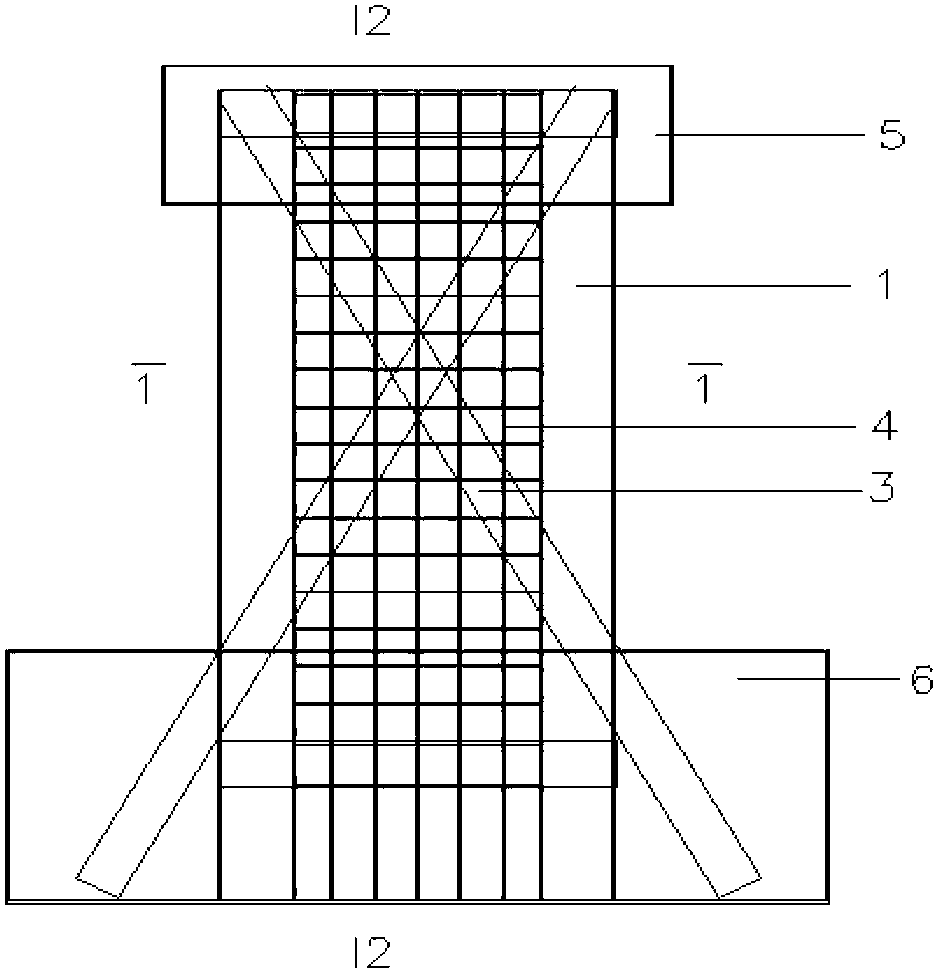

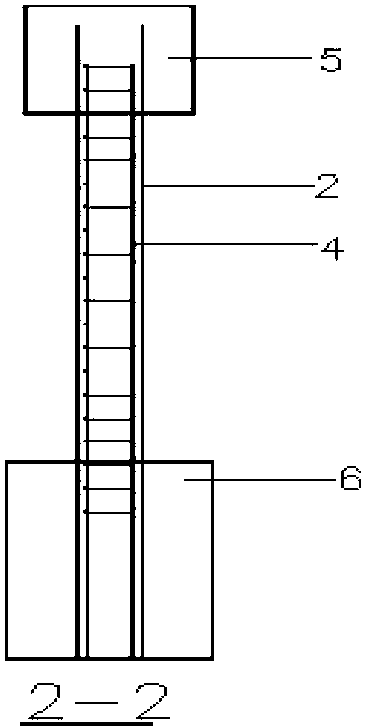

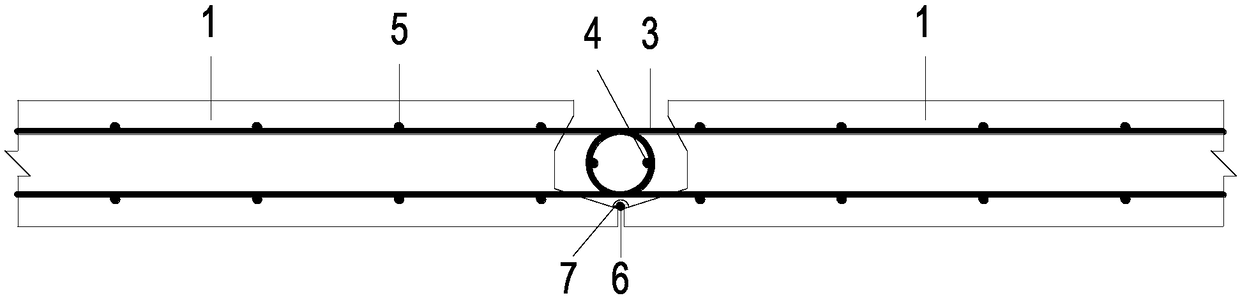

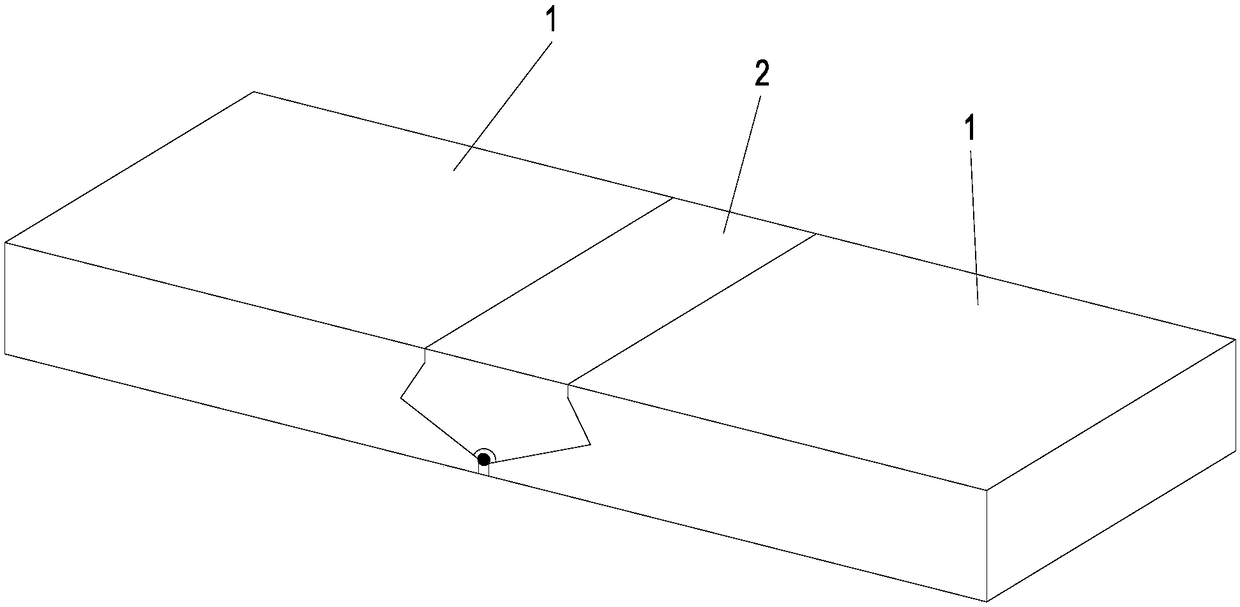

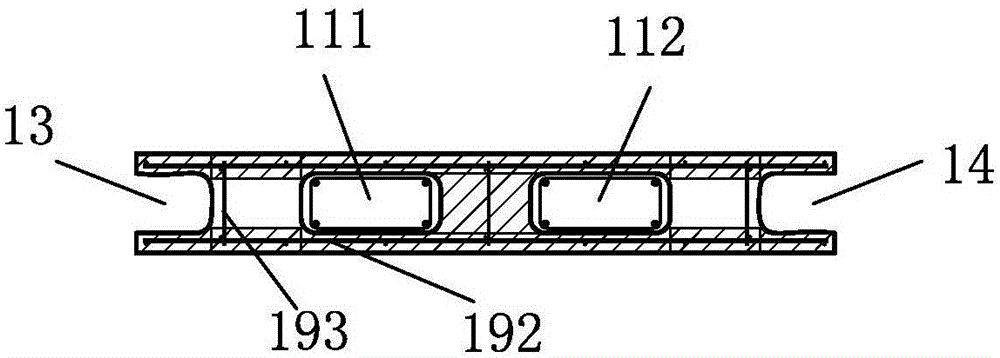

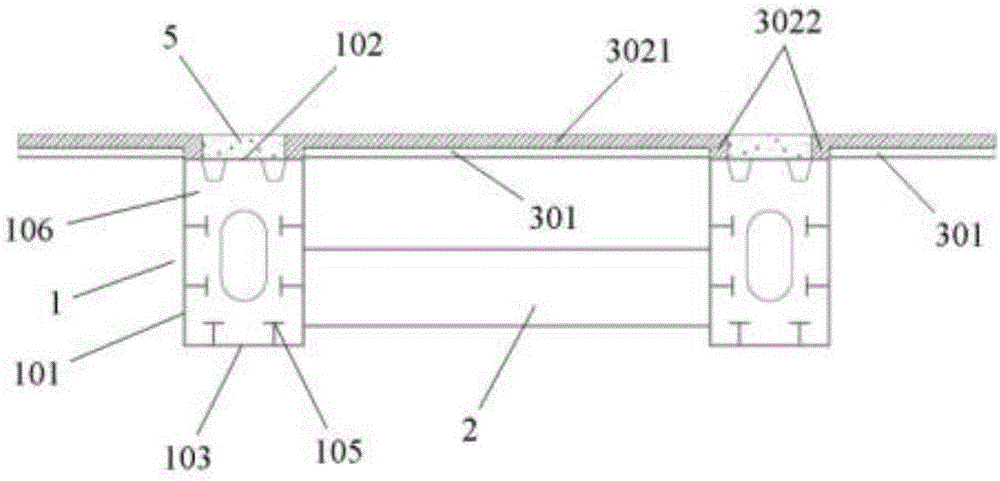

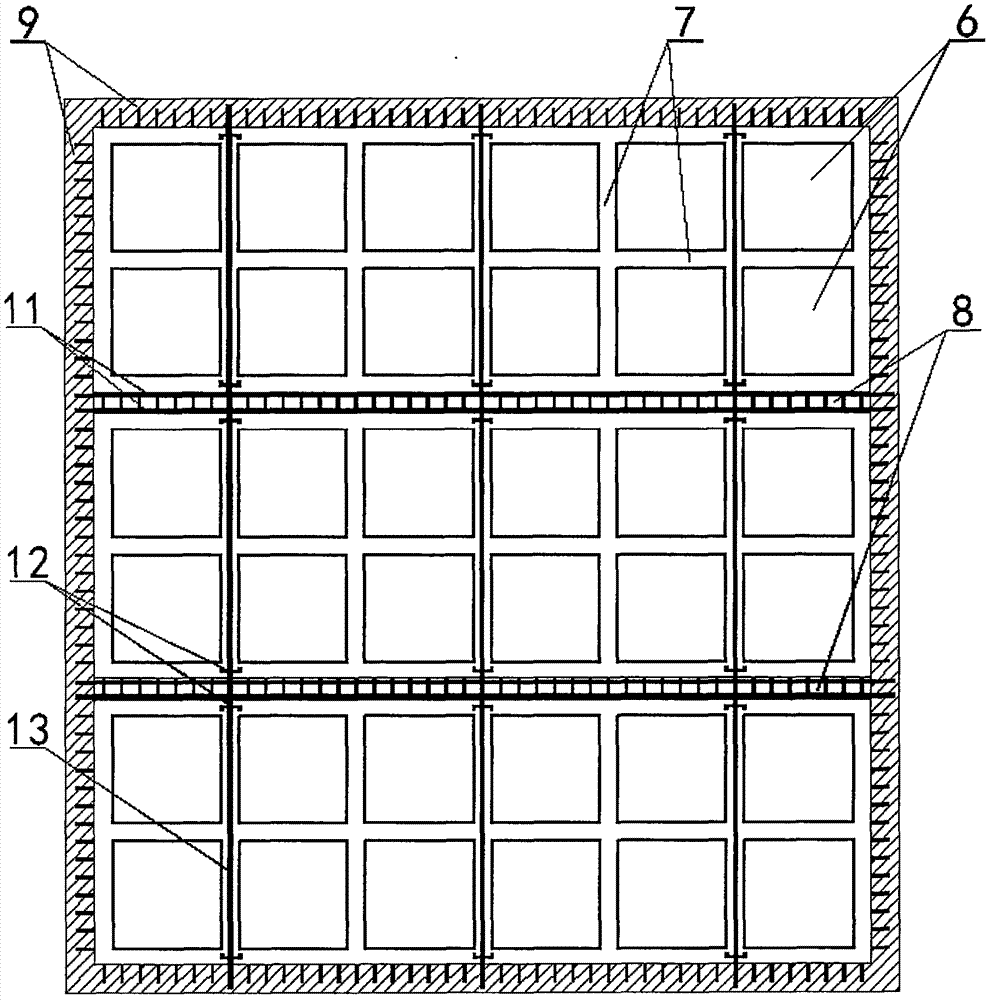

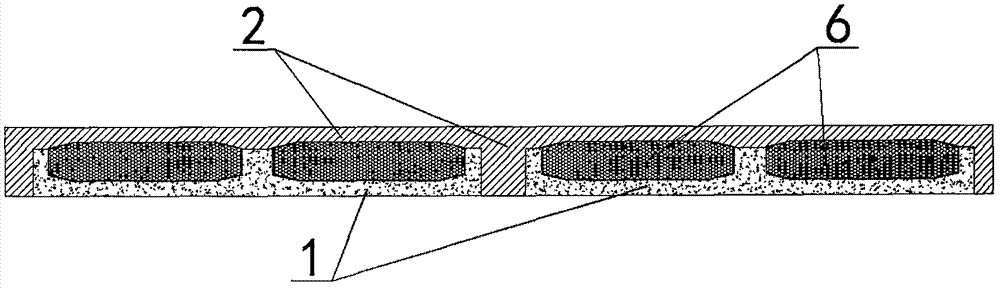

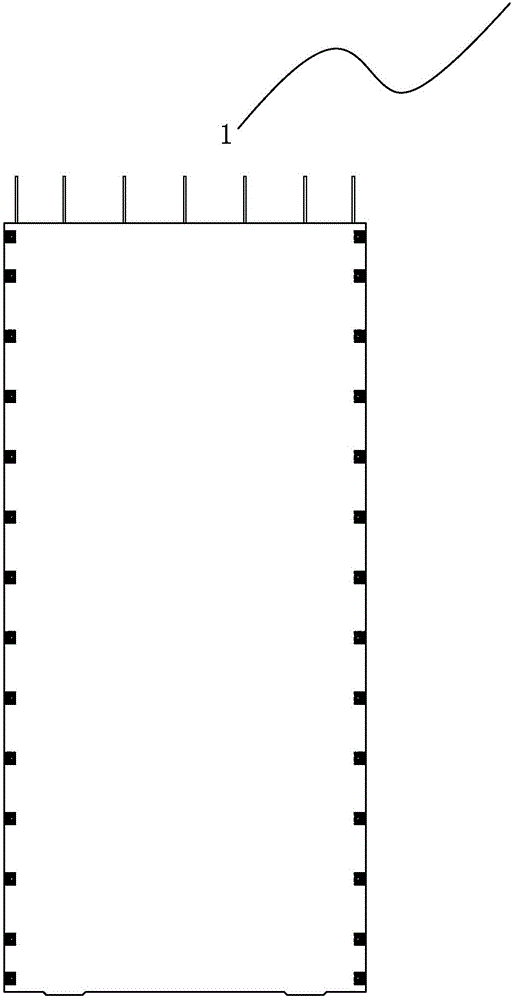

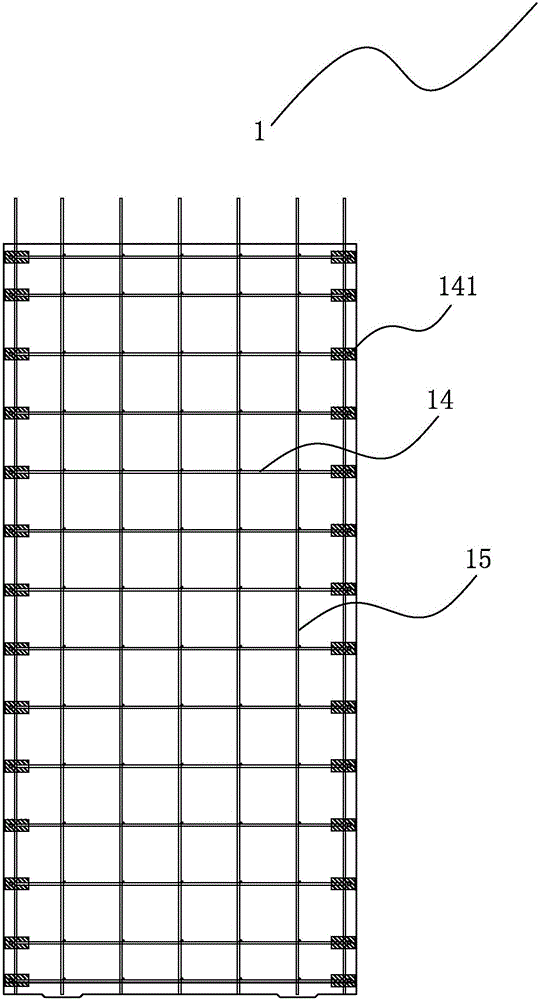

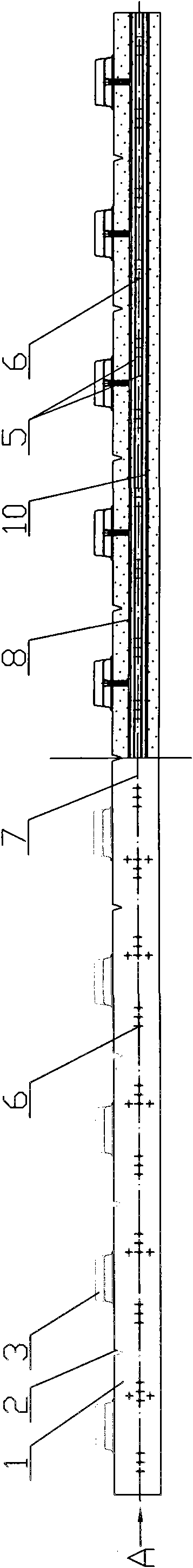

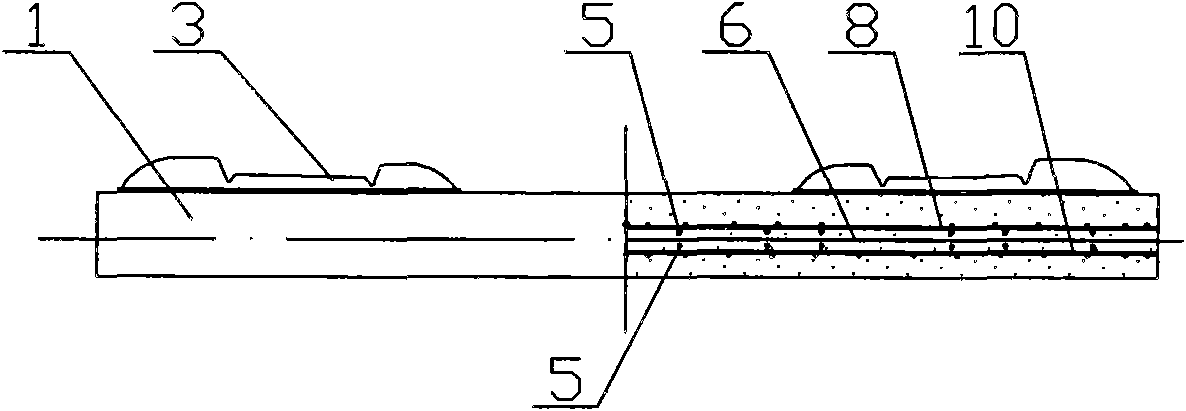

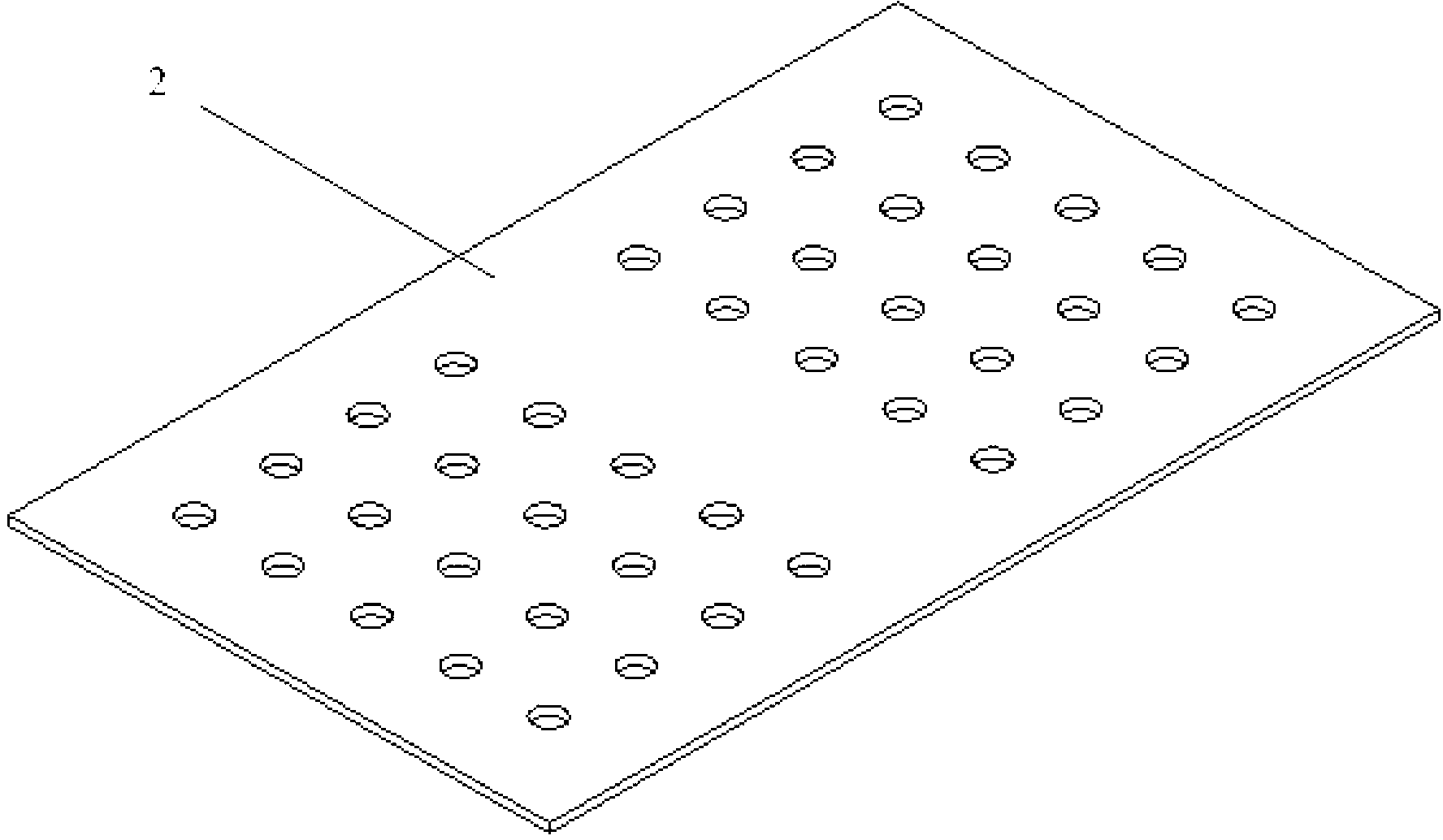

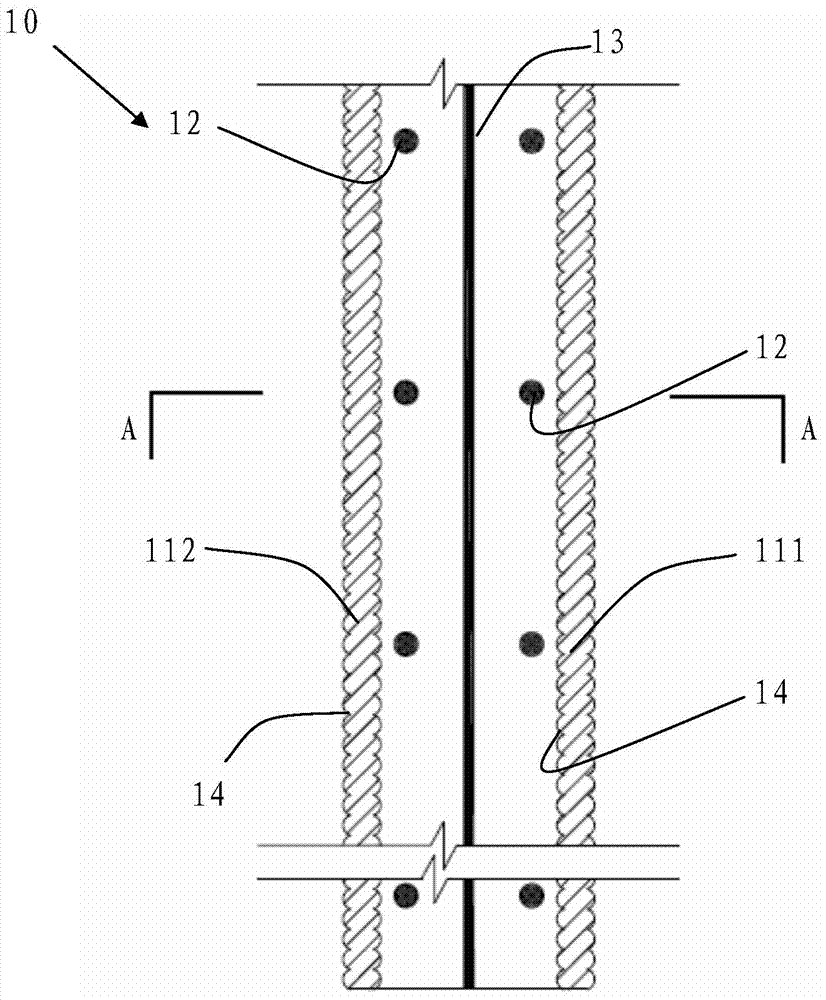

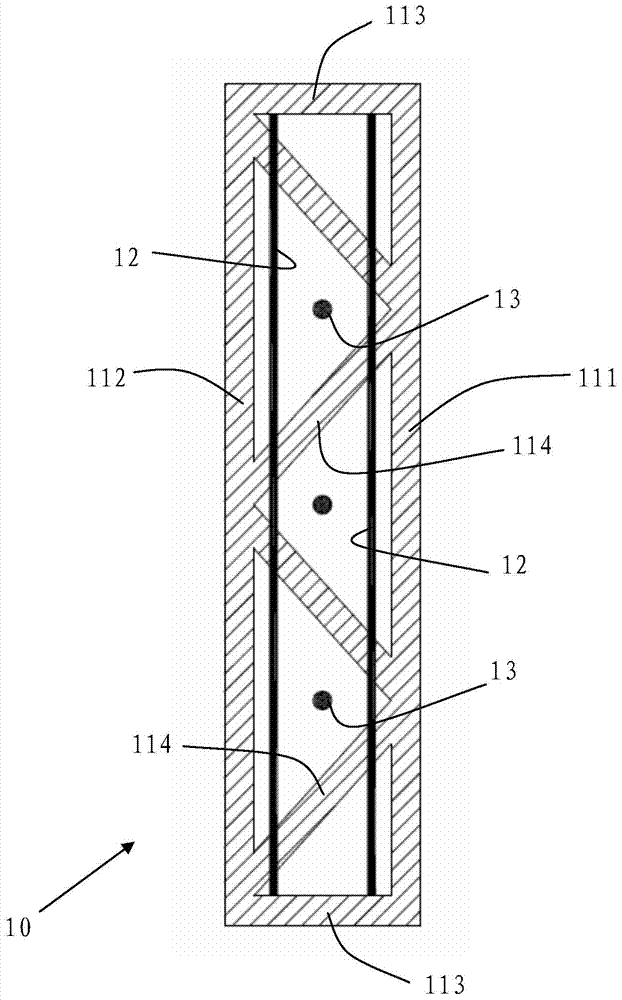

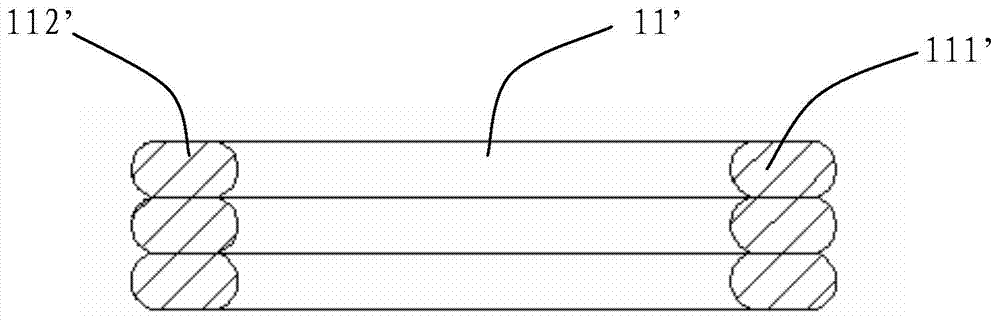

Prestressed hollow composite slab

ActiveCN107313539ALight weightApplicable span is largeFloorsBuilding reinforcementsPre stressComposite slab

The invention relates to a prestressed hollow composite slab and a manufacturing method thereof, and belongs to the field of normal building construction. The composite slab comprises prefabricated pieces (1) and composite layers (2). Thickness of a bottom plate (3) of each prefabricated piece (1) is greater than or equal to 35 mm and less than or equal to 60 mm, prestressed steel wires (4) in the bottom plate are located at the upper parts of transversal steel bars (5), and the length of each prestressed steel wire (4) and each transversal steel bar (5) extending out of the corresponding bottom plate (3) is greater than or equal to 50 mm; the width of each prefabricated piece is greater than or equal to 1500 mm, light-weight material filling pieces (6) are arranged at the upper part of each prefabricated piece (1); the heights of concrete solid ribs (7) between adjacent filling pieces are greater than or equal to 50 mm; the transversal steel bars (5) between adjacent prefabricated pieces (1) are overlaid in a joint area (8), upper part steel bars (10) of the composite slab are bound, composite layer concrete is poured, and the composite slab is formed. According to the prestressed hollow composite slab and the manufacturing method thereof, the self-weight of the composite slab is light, the stiffness in the longitudinal direction and the transversal direction is high, the application range is large, and transportation and installation are convenient. The prestressed hollow composite slab and the manufacturing method thereof have good economic efficiency and applicability, and play a role on promoting the development of building technology.

Owner:徐焱

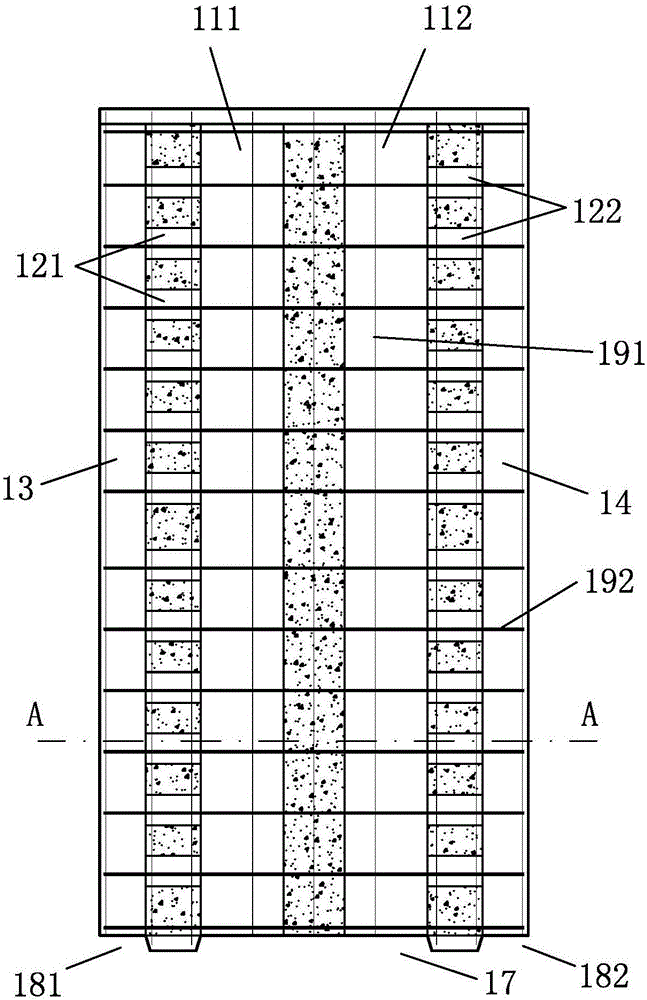

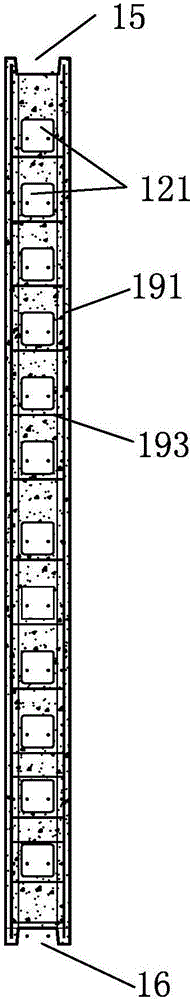

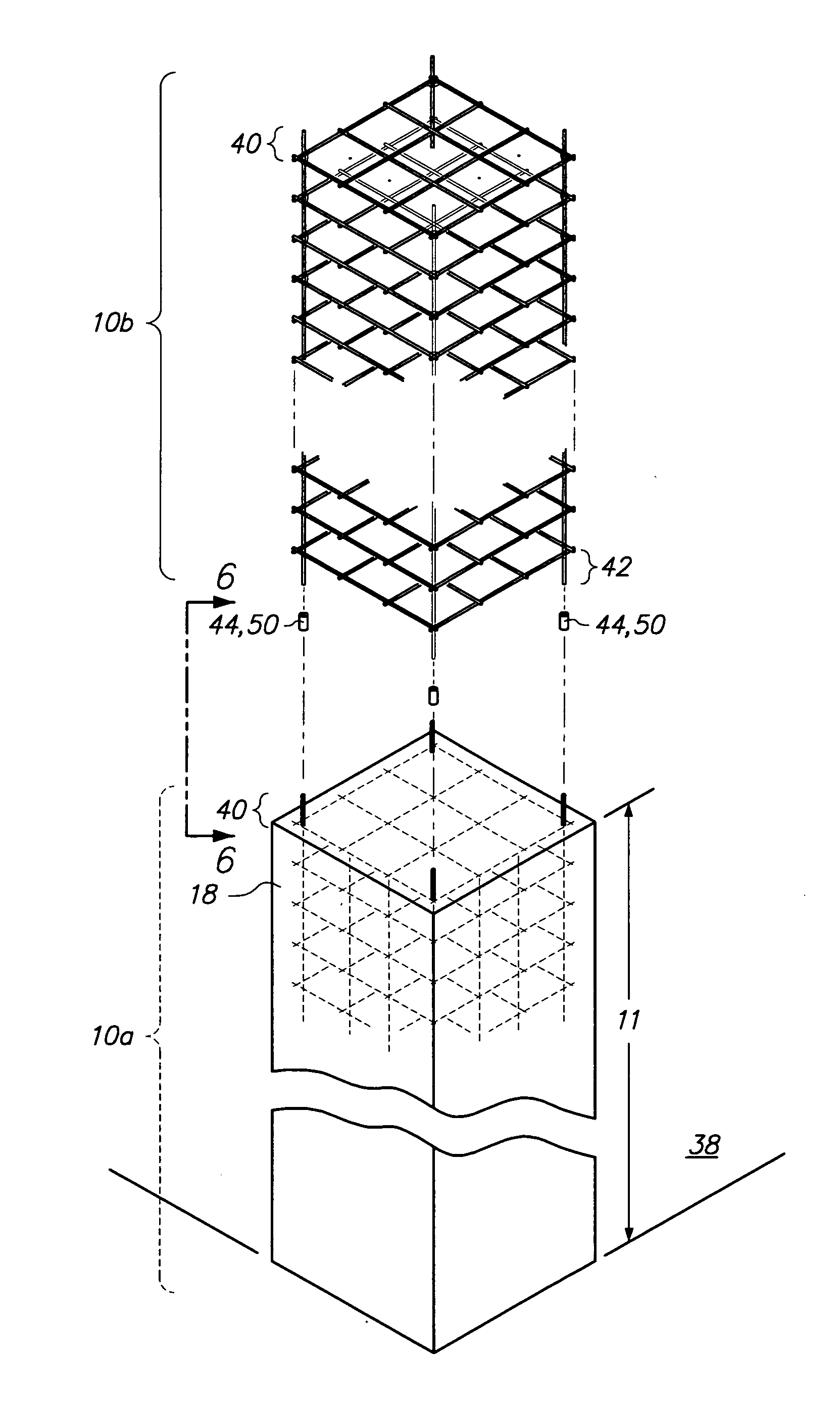

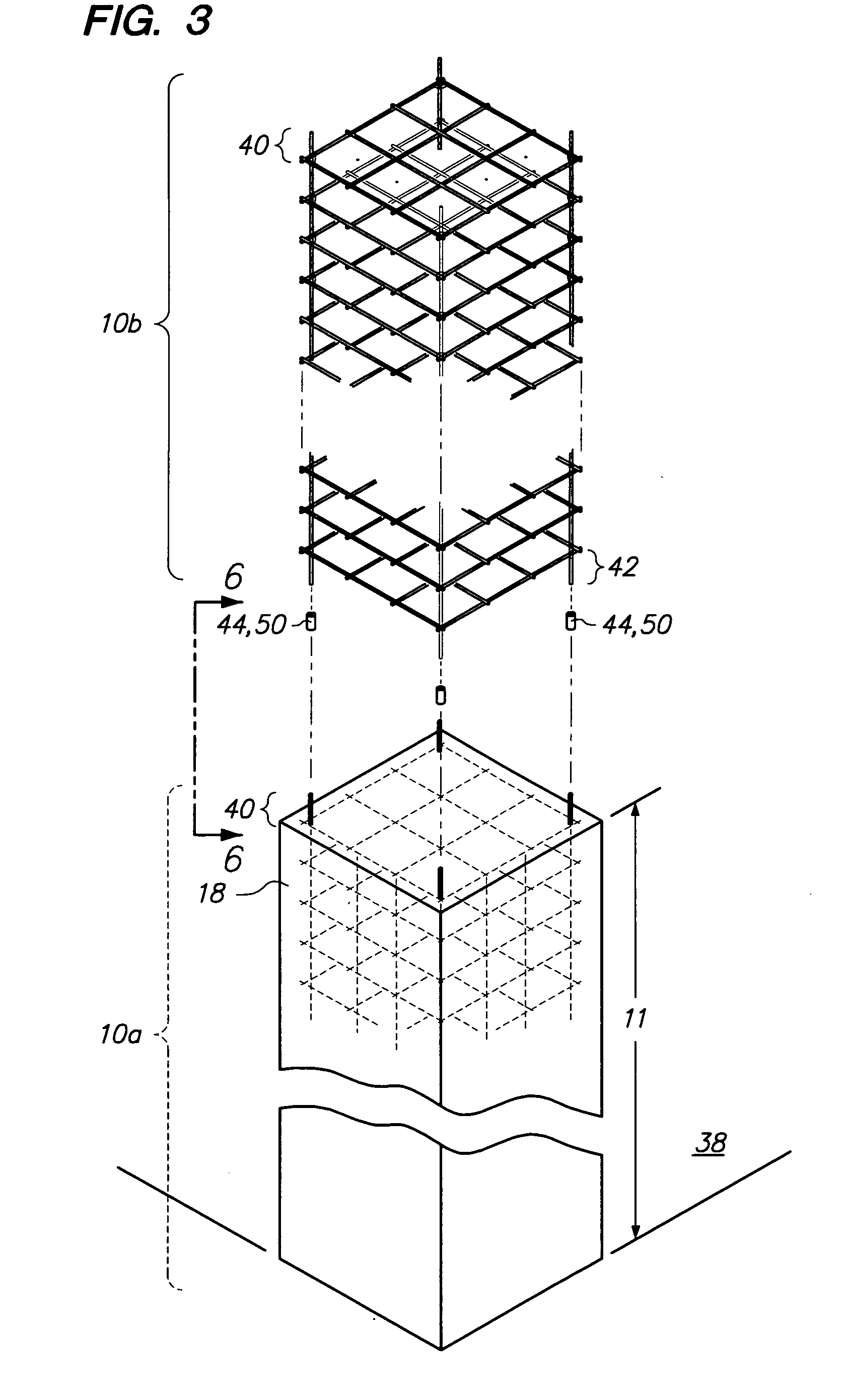

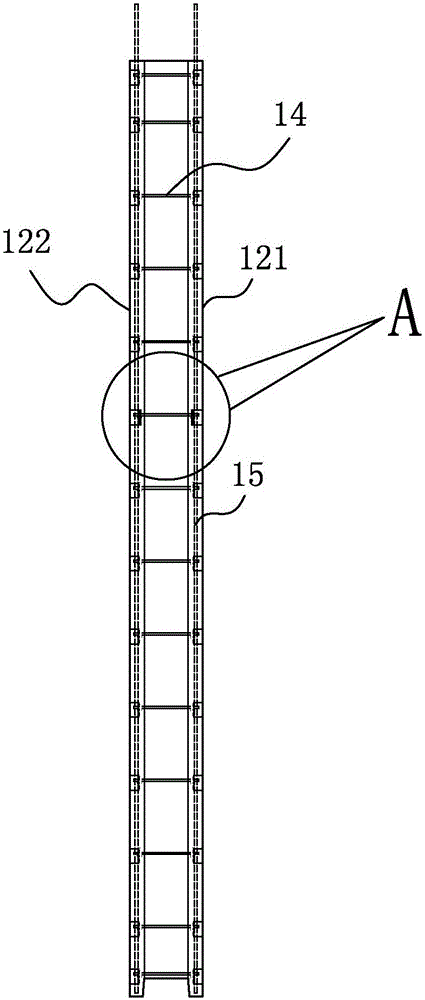

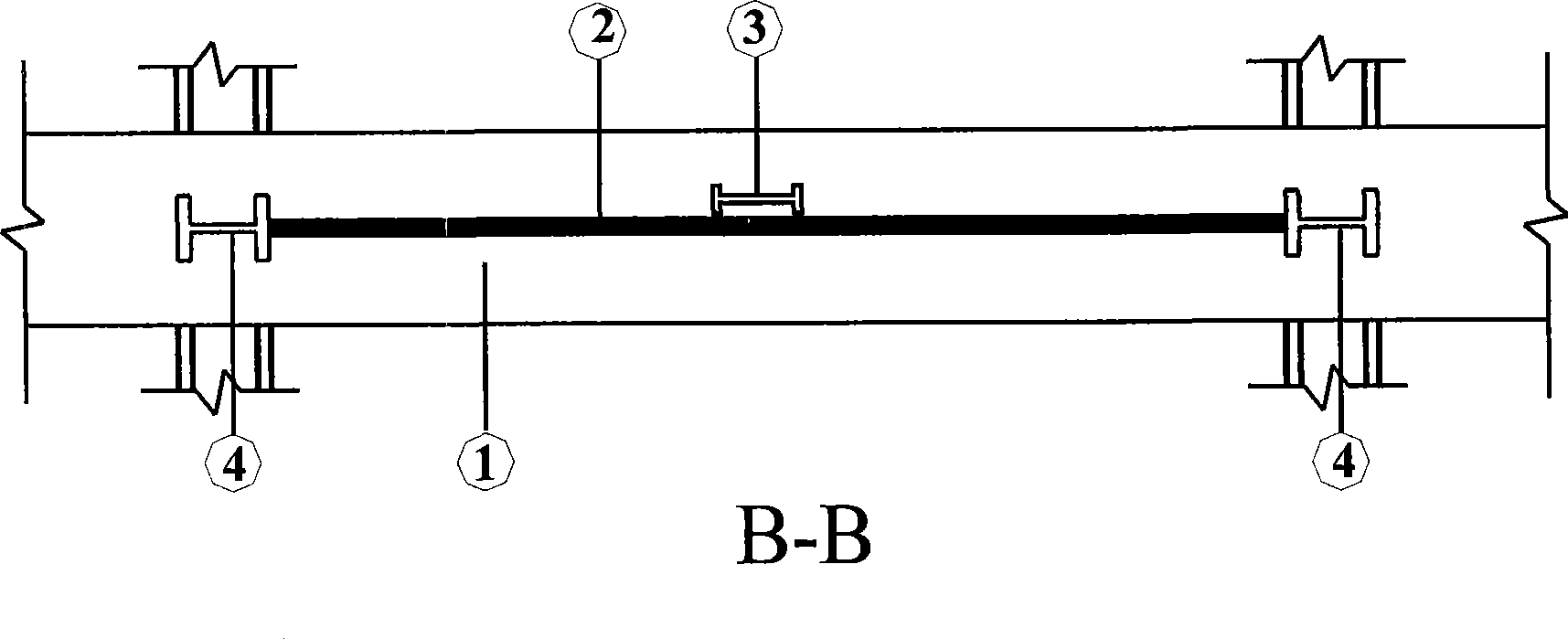

Assembling type plate-beam connecting joint and construction method thereof

The invention discloses an assembling type plate-beam connecting joint and a construction method thereof. The joint comprises a dense rib box type composite floors and a superposed beam which are preformed by concrete. Each dense rib box type composite floor is provided with a die shell, a truss rib, a floor rib beam stirrup, a floor extending-out bending steel rib and a floor extending-out flange. The superposed beam is provided with a superposed beam horizontal reserved rib and a superposed beam longitudinal reserved rib. When the dense rib box type composite floors on the left side and the right side of the beam are placed in position and supported, the longitudinal-horizontal steel ribs of a joint zone are bound, finally later-placing concrete is placed, and construction of the plate-beam connecting joint is completed. The joint can be widely used in an assembling integral type structure of large space, and wide engineering application prospect is achieved. The assembling type plate-beam connecting joint has the advantages that an outer stand face is smooth and attractive, joint integrity is good, anti-seismic property is good, the technology is simple, construction is convenient, and manufacturing cost is not obviously improved.

Owner:CHINA MCC17 GRP

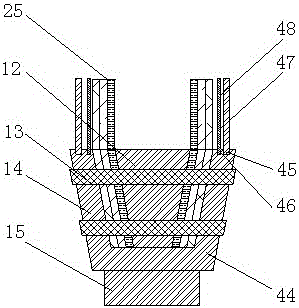

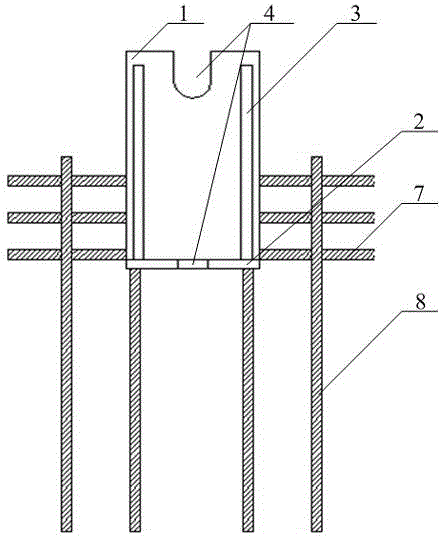

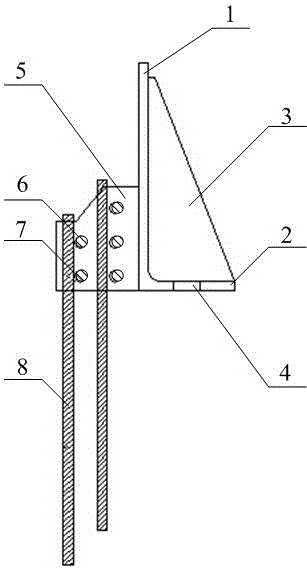

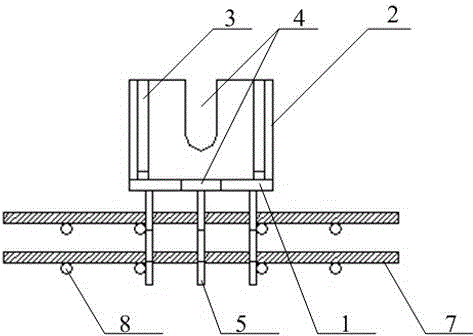

Prefabricated assembly-type concrete outer-hanging wallboard fixing device and installation method

ActiveCN104652671AImprove bearing capacityReduce load capacityWallsCross connectionArchitectural engineering

The invention discloses a prefabricated assembly-type concrete outer-hanging wallboard fixing device, which belongs to the field of the building construction. The prefabricated assembly-type concrete outer-hanging wallboard fixing device comprises a wall top pendant and a board embedded part, wherein the board embedded part can be connected with the wall top pendant; the wall top pendant comprises an L-shaped steel plate, openings are respectively formed in a transverse plate and a vertical plate of the steel plate, and a reinforced steel plate is connected between the transverse plate and the vertical plate; the back surface of the vertical plate is at least fixedly connected with two wing plates which are consistent in direction, and a plurality of through holes are formed in each wing plate; a plurality of transverse reinforcing steel bars penetrate through each wing plate, and the transverse reinforcing steel bars are connected with a plurality of vertical reinforcing steel bars in an intersecting manner; the board embedded part comprises a soleplate, the top of the soleplate is fixedly connected with a bolt, and the bolt can be inserted into an opening on the end of the transverse plate of the steel plate; the bottom of the soleplate is fixedly connected with a plurality of anchoring bars. The prefabricated assembly-type concrete outer-hanging wallboard fixing device is simple in structure, fewer in connection nodes, high in strength, convenient to install and construct and capable of greatly improving the installation stability of an outer-hanging wallboard. The invention also discloses a prefabricated assembly-type concrete outer-hanging wallboard installation method.

Owner:龙信集团江苏建筑产业有限公司

Construction method for joining new and old pavements in road widening project

ActiveCN102409589AReduce the difficulty of millingImprove construction progressPaving detailsLap jointRoad surface

The invention discloses a method for joining new and old pavements in a road widening project. The method comprises the following steps: 1. milling the edge of a bituminous pavement layer of an old road to form lapped steps, and manually clearing away loose aggregates on a side surface; 2. retaining the original cement concrete slabs for sections of the old road with high-quality cement concrete slabs on the bituminous pavement; 3. arranging a drainage system below lap seams, wherein the drainage system is positioned on the top surface of a roadbed of the new-built widened road; 4. casting stepped structures with internal tilt angles in situ by three layers from top to bottom at the base layer and sub-base layer of the pavement of the new-built road and at the lap joint between the new and old pavements; 5. before the top-layer structures of the stepped structures are cast, drilling holes on the side surface of the old road for planting transverse steel bars, arranging longitudinal steel bars at the top layers of the structures, and welding the longitudinal steel bars with the transverse steel bars to form a meshed whole; 6. longitudinally carving grooves at the joining seam on the top surface of the spliced new and old roads, pouring hot asphalt into the grooves, and longitudinally paving an anti-crack paster at the joining seam; and 7. texturing the top surfaces of the stepped structures.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

Prefabricated reinforced concrete component and assembly type building comprising same

The invention provides a prefabricated reinforced concrete component. A through hole which penetrates in the components in the length direction is formed in the component; a groove is formed in a side plate of the component; when two components are in butt joint with each other, the two grooves are in butt joint with each other to form a long hole; a plurality of longitudinal reinforcing steel bars which extend along the length direction of an external wall plate of the component is arranged in the external wall plate of the component along the width direction; a plurality of longitudinal reinforcing steel bars which extend along the length direction of an internal wall plate of the component is arranged in the internal wall plate of the component along the width direction; a plurality of transverse reinforcing steel bars which extend along the width direction of the external wall plate is arranged in the external wall plate along the length direction; a plurality of transverse reinforcing steel bars which extend along the width direction of the internal wall plate is arranged in the internal wall plate along the length direction; the transverse reinforcing steel bars and the longitudinal reinforcing steel bars are intersected to form a reinforcing mesh; an embedded piece is fixedly arranged at one end of each transverse reinforcing steel bar; and when the two components are spliced with each other, two side plates with grooves are spliced together through a connecting piece B. The prefabricated reinforced concrete component is simple in structure, convenient to connect and easy to operate; extra lap joint reinforcing steel bars are not required; construction is facilitated greatly; working efficiency is improved; and moreover, stress conversion does not exist during component connection, and the connection strength of the component is greatly improved.

Owner:BEIJING EVEREST GREEN BUILDING TECH

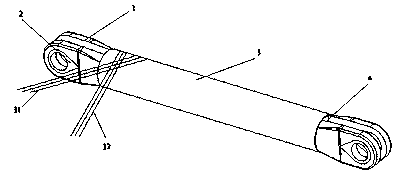

Aerial tube-shaped carbon fiber composite rod piece and manufacturing method thereof

The invention discloses an aerial tube-shaped carbon fiber composite rod piece and a manufacturing method thereof. The rod piece is a tube-shaped structure made from a composite material formed by mixing and weaving high-modulus and low-modulus fibers, wherein the fiber weaving manner is longitudinal arrangement in bearing direction and transverse reinforcement in nonbearing direction. The rod piece comprises two bearing components and metal shaft sleeves, wherein the two bearing components are arranged fixedly, closely adjacently and side by side; the two ends of each bearing component are respectively provided with an ear part; the metal shaft sleeves are embedded in the ear parts; the metal shaft sleeves are in shape of a water drop. According to the rod piece disclosed by the invention, the water-drop-shaped metal shaft sleeves are beneficial to tensile loading and also beneficial to compression-resistance unloading, so that a pull rod can greatly uniformly distribute the load on the carbon fiber composite material when bearing the pressure. The manufacturing method disclosed by the invention is simple and convenient, the provided rod piece has the characteristics of resistance to high-altitude low temperature of -55 DEG C, resistance to ground high temperature of 45 DEG C, resistance to huge tension / pressure of 100 tons, vibration resistance, large torque resistance, no deformation, ultra high rigidity and strength, light dead weight and the like, and the provided rod piece can be taken as key bearing parts on spacecrafts.

Owner:莫凡

Dual-direction pre-tensioning system prestressed concrete track slab

InactiveCN101806024AReasonable structureSimple structureBallastwayBuilding reinforcementsPre stressRebar

The invention discloses a dual-direction pre-tensioning system prestressed concrete track slab, which comprises a rectangular track slab body, wherein the track slab body is provided with a reservation structure, an upper layer steel wire net, a longitudinal reinforced bar layer, a transverse reinforced bar layer, a longitudinal reinforced bar layer and a lower layer steel wire net are sequentially arranged at intervals inside the track slab body along the thickness direction from top to bottom, steel bars inside the longitudinal reinforced bar layer extend in the length direction of the track slab body, steel bars inside the transverse reinforced bar layer extends in the width direction, the steel bars both in the longitudinal and the transverse reinforced bar layers are arranged at intervals, the transverse reinforced bar layer is arranged on a neutral axis of a cross section of the track slab body, and the two longitudinal reinforced bar layers and the upper and the lower steel wire nets are symmetrically and horizontally arranged relatively to the neutral axis of the cross section; and the prestressed concrete track slab is pre-tensioned along the length direction and the width direction, and the steel bar is of a prestressed steel bar. The dual-direction pre-tensioning system prestressed concrete track slab has simple structure and can strengthen the strength of the track slab.

Owner:欧阳炎

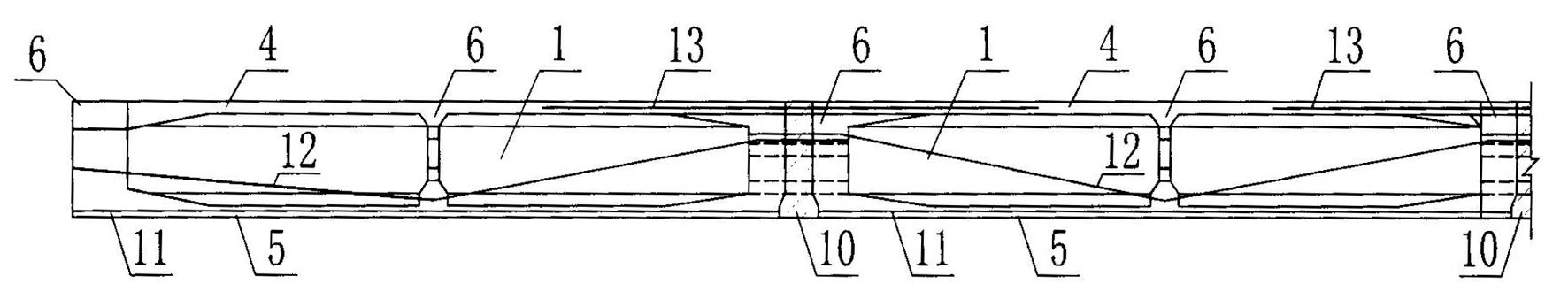

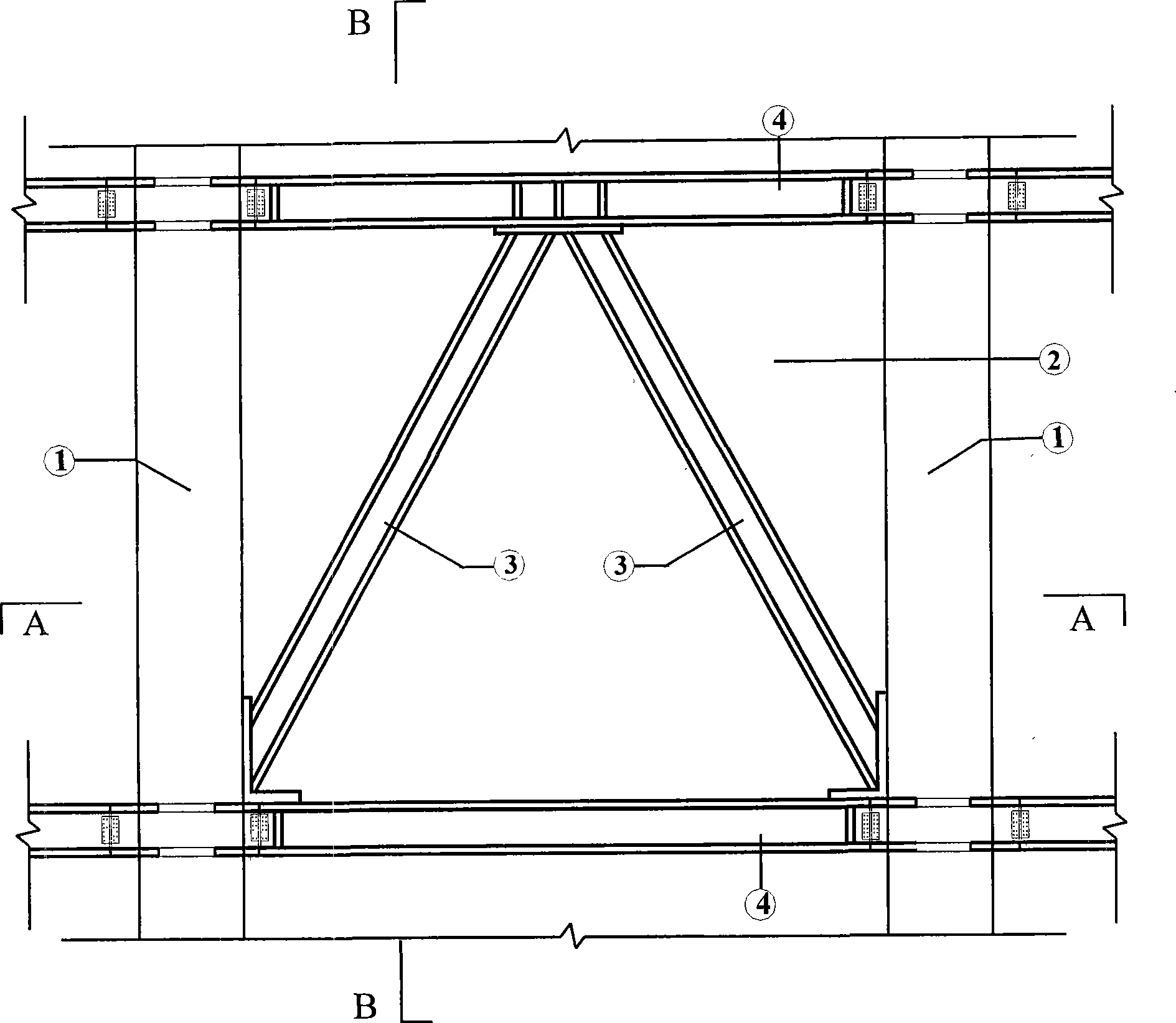

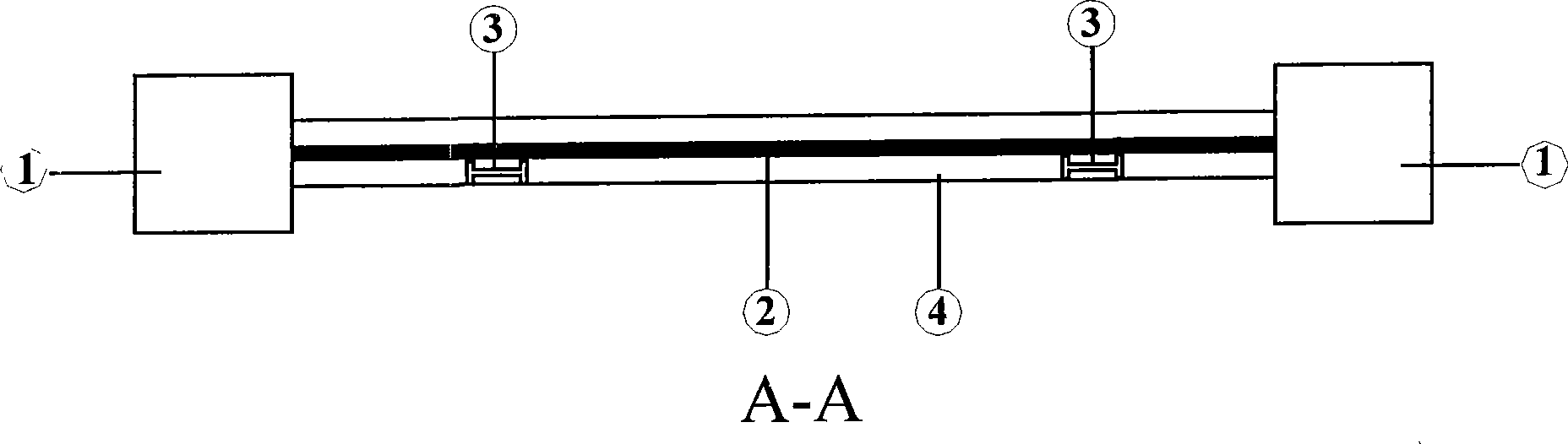

Novel short segment steel box-concrete combined beam

The invention relates to a novel short segment steel box-concrete combined beam, which belongs to the technical field of bridge engineering. The novel short segment steel box-concrete combined beam comprises a steel box beam, anti-shearing connecting elements (4) and three-side outer covering reinforced concrete structures, wherein the steel box beam is formed by short segment steel boxes (1) through split joint via split joint plates (2), the anti-shearing connecting elements (4) are arranged on the two side surfaces and the top surface of the steel box beam, the three-side outer covering reinforced concrete structures consist of concrete (3), vertical steel bars and transverse steel bars and are arranged on the two side surfaces and the top surface of the steel box beam. The novel short segment steel box-concrete combined beam has the beneficial effects that the steel box-concrete combined beam is adopted, the tensile performance of the steel boxes and the pressing resistance performance of the concrete are sufficiently utilized, the steel materials are saved, the cost is reduced, and the obvious economic performance is realized. The steel box beam adopts the segment split joint, the short segment steel boxes and the split joint plates can realize the mass production, the construction progress is fast, and the construction period is short. The combined beam adopts the three-side outer covering reinforced concrete, and adapts to the characteristic of variation of the straddle type monorail traffic rail beam line change, i.e. the three-side stress and line type variation requirement is met.

Owner:BEIJING JIAOTONG UNIV

Steel tube concrete - steel support - concrete combined shear wall and manufacturing method thereof

InactiveCN101435234AIncreased shear capacityImprove ductilityWallsShock proofingSheet steelShock resistance

The invention discloses a steel pipe concrete-steep support-steel plate combine shear wall and making method thereof, belonging to the field of building construction. The steel pipe concrete-holed steel plate-concrete combine shear wall is characterized in that: the shear wall is composed of steel pipe concrete frame columns (1) and steel plate concrete shear wall boards, and the frame beam is provided with a section steel beam (3). A steel plate (2) embedded in the shear wall is provided with an opening, the two sides of the steel plate (2) are provided with steel bar nets composed of transverse steel bars (4) and longitudinal steel bars (5), and the steel bar nets at two sides of the steel plate (2) are tied by steel tie bars (7) at the opening on the steel plate (2). Compared with the conventional shear wall, the shear wall of the invention has large initial rigidity, high bearing ability, slow attenuation for bearing force and rigidity, good whole shock resistance and energy consumption performance, stable shock resistance performance, and reduced bottom shearing sliding destroy.

Owner:BEIJING UNIV OF TECH

3D printing reinforcement masonry shear wall structure and construction method thereof

ActiveCN104264862ASimplify on-site construction laborReduce construction proceduresAdditive manufacturing apparatusWallsRebarTransverse reinforcement

The invention discloses a 3D printing reinforcement masonry shear wall structure and a construction method thereof. The construction method includes the following steps that a, the 3D printing technology is used for manufacturing a first layer of masonry outer shell to the pre-buried elevation position of transverse reinforcement; b, the transverse reinforcement is arranged on the top of the first layer of masonry outer shell; c, the 3D printing technology is used for manufacturing a second layer of masonry outer shell on the top of the first layer of masonry outer shell, and thus the transverse reinforcement can be laid in the masonry outer shell; d, the step b and the step c are executed repeatedly, so that the masonry outer shell is obtained; e, the step a and the step d are executed repeatedly, so that a plurality of masonry outer shells are obtained, and the masonry outer shells are stacked to the designed elevation of a shear wall; f, vertical reinforcement is mounted in each masonry outer shell; g, concrete is poured, and accordingly the shear wall can be constructed. By the adoption of the 3D printing technology, the masonry outer shells of reinforcement masonry can be integrally formed, original concrete small hollow blocks are replaced, the site construction labor force is greatly reduced, the construction procedures are omitted, the building quality is guaranteed, and thus building industrialization can be facilitated.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Filling-hole non-mortar reinforcement building block brickwork shear wall and construction method thereof

InactiveCN103161241AImprove performanceFast constructionWallsBuilding material handlingEngineeringRebar

The invention discloses a filling-hole non-mortar reinforcement building block brick shear wall and a construction method of the shear wall. The shear wall comprises a die card block, a vertical reinforcement; a transverse reinforcement, core-filling concrete and a prefabricated connecting piece, an upper die card block and a lower die card block are engaged together through a clamping head. The right portion, the left portion, the upper portion and the lower portion of the die card block are locked together in a geometrical mode by inserting the precut connecting piece into a connecting groove. The vertical reinforcement is installed inside a hole of the die card block and the transverse reinforcement is installed between the upper die card block and the lower die card block. The entire wall is formed by filling the core-filling concrete into a hole. The method of the shear wall comprises a step of preparation work; a step of arranging the vertical reinforcement; a step of paving building blocks; a step of connecting the connecting piece; a step of arranging the transverse reinforcement; a step of grouting; a step of maintaining and protecting.

Owner:ZHUZHOU BOERMAN TECH DEV

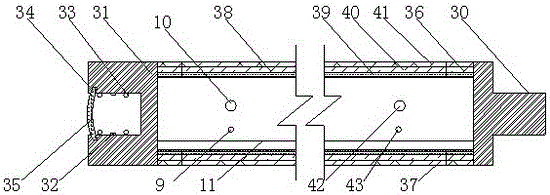

Novel articulated prefabricated hollow slab girder bridge hinge joint connector and construction method thereof

InactiveCN103981798AWith bending abilityReduce stressClimate change adaptationBridge erection/assemblyBridge deckRebar

The invention relates to a novel articulated prefabricated hollow slab girder bridge hinge joint connector and a construction method thereof. The hinge joint connector comprises a plurality of prefabricated hollow slab girders; a hinge joint is formed between every two adjacent hollow slab girders; cement paste fills in the hinge joints; a bridge deck pavement layer is poured above the hollow slab girders and the hinge joints; upper transverse reinforcements are embedded in the upper parts of the hollow slab girders; lower transverse reinforcements and reinforcing reinforcements which are located at the upper sides of the lower transverse reinforcements are embedded in the lower parts of the hollow slab girders; the outer ends of the upper transverse reinforcements stretch out of the side faces of the hollow slab girders and are downwards bent to stretch into the hinge joints; the outer ends of the reinforcing reinforcements stretch out of the side faces of the hollow slab girders and are upwards bent to stretch into the hinge joints; the stretching sections of the upper transverse reinforcements and the stretching sections of the reinforcing reinforcements intersect in the hinge joints; the outer ends of the lower transverse reinforcements are upwards bent to stretch out of the top surfaces of the hollow slab girders and stretch into the bridge deck pavement layer above the hinge joints. The novel articulated prefabricated hollow slab girder bridge hinge joint connector and the construction method thereof have the advantage that the shear resisting performance, the anti-cracking performance and the resistance to bending of the hinge joints are improved.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com