Filling-hole non-mortar reinforcement building block brickwork shear wall and construction method thereof

A mortar-free, shear wall technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of weakening the wall, many blocks, and inability to construct, and achieves the effect of saving engineering costs, good overall performance, and no need for formwork.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

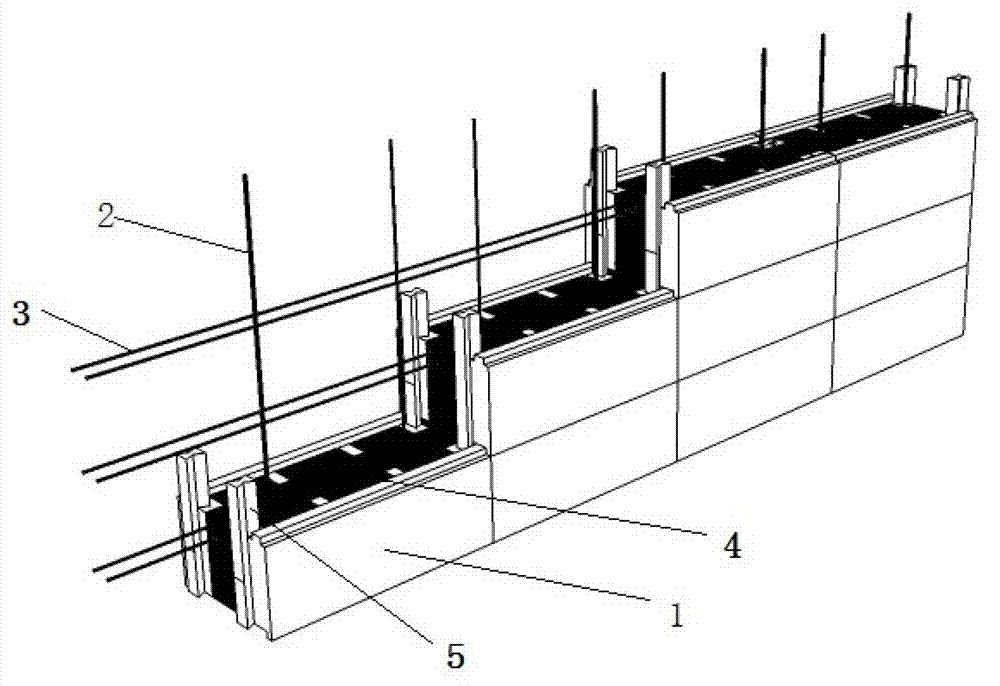

[0028] see figure 1 , a kind of masonry shear wall with no mortar reinforced block with filling holes, the masonry method is joint joint masonry, including formwork blocks, vertical steel bars, transverse steel bars, core-filled concrete and prefabricated connectors; the upper and lower skins The molded blocks are clamped together by the clamp head, and the prefabricated connectors are inserted into the connecting groove to geometrically interlock the left and right, upper and lower sides of the molded blocks; there are vertical steel bars in the holes of the molded blocks, and the upper and lower two leather blocks There are transverse steel bars between them, and the core-filled concrete is poured into the holes to form a masonry shear wall without mortar reinforcement in the holes.

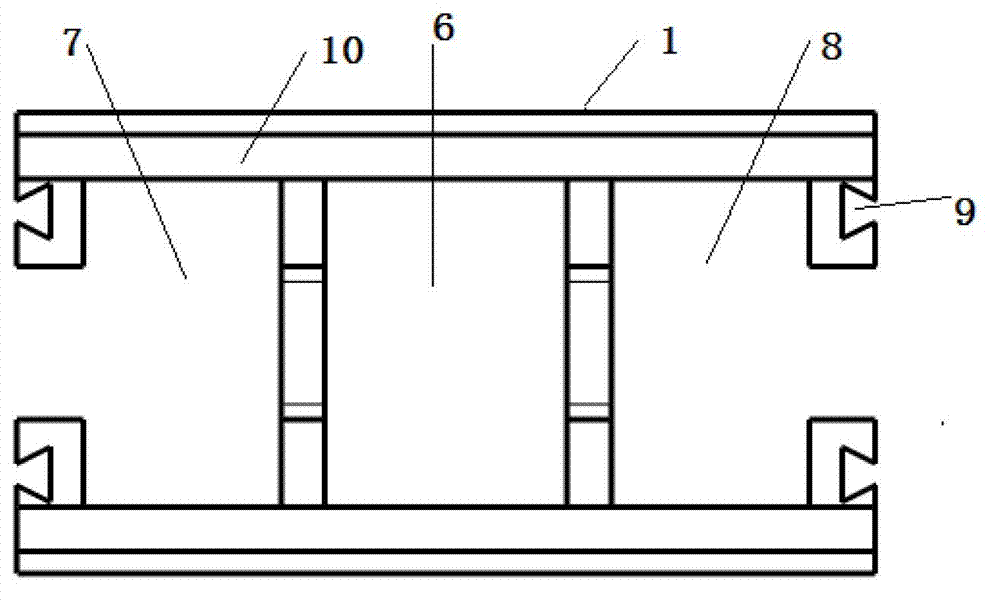

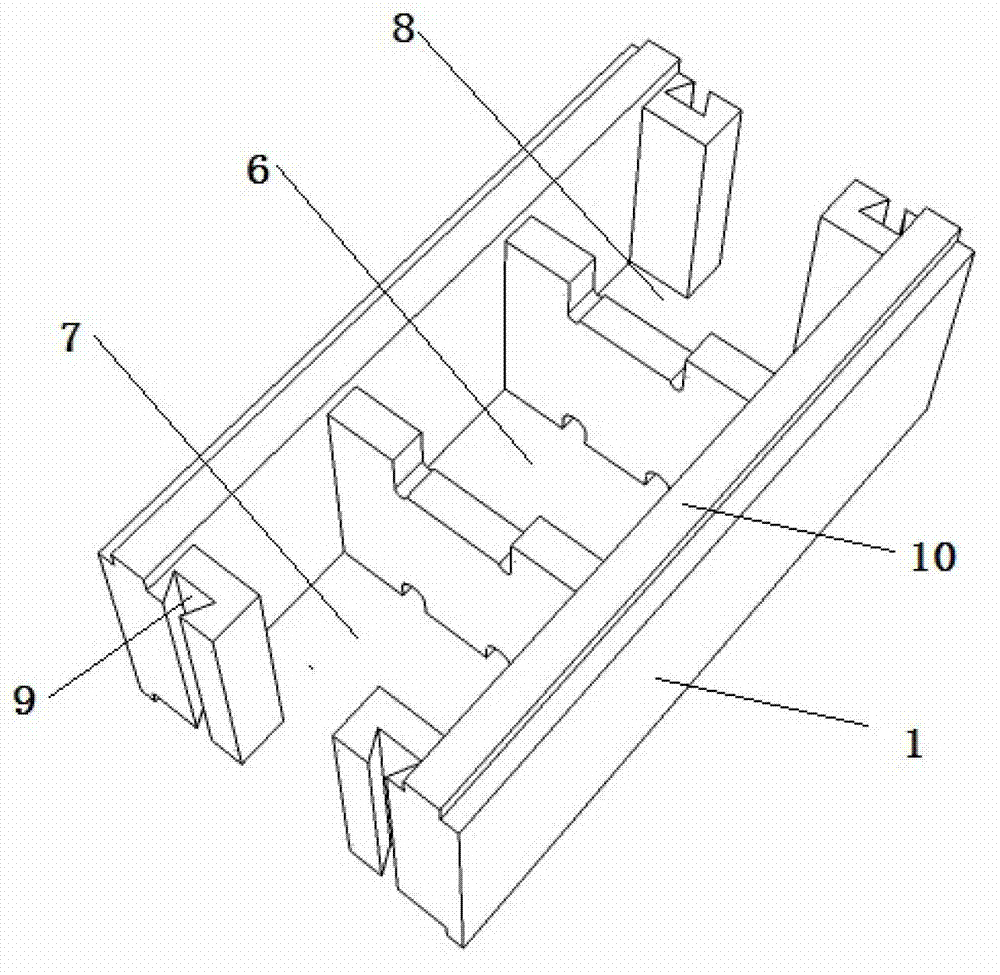

[0029] see figure 2 , image 3 , Figure 4 , insert the prefabricated connecting piece into the connecting groove of the modular block.

[0030] see Figure 5 , the arrangement of the pre...

Embodiment 2

[0040] see Figure 8 , a kind of masonry shear wall with filling holes and no mortar reinforcement blocks, the masonry method is staggered masonry, including formwork blocks, vertical steel bars, transverse steel bars, core-filled concrete and prefabricated connectors; two adjacent The leather molded blocks are clamped together up and down through the card slots, and the connectors are inserted into the reserved connection holes to geometrically interlock the left and right, upper and lower sides of the molded blocks; there are vertical steel bars in the holes of the molded blocks, and the upper and lower two There are transverse steel bars between the skin blocks, and the core-filled concrete is poured into the holes to form a masonry shear wall with no mortar reinforced blocks in the holes.

[0041] see figure 2 , image 3 , Figure 4 , insert the prefabricated connecting piece into the connecting groove of the modular block.

[0042] see Figure 6 , the arrangement of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com