Patents

Literature

1287results about How to "Save steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

600-MPa grade vanadium-containing high-strength hot-rolled steel bar and production method thereof

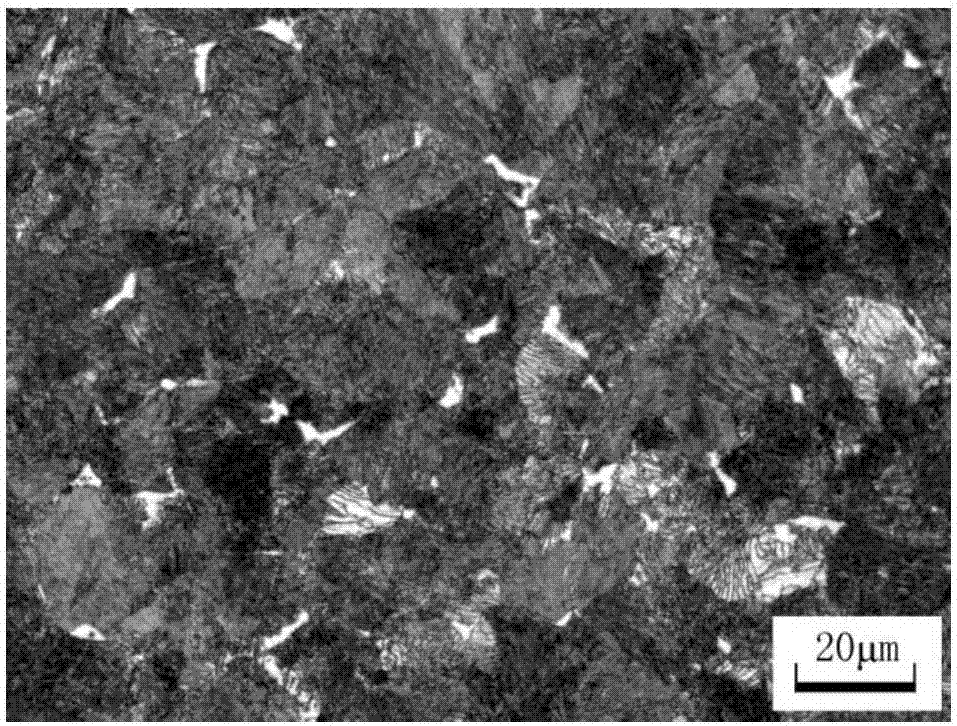

The invention relates to a 600-MPa grade vanadium-containing high-strength hot-rolled steel bar and a production method thereof, and belongs to the technical field of metallurgical steel-making and processing; the technical scheme is that the steel bar is prepared by the following components by mass: 0.21-0.25% of C, 0.35-0.60% of Si, 1.35-1.55% of Mn, 0.08-0.12% of V, 0.005-0.04% of N, not more than 0.040% of S, not more than 0.040% of P, and the balance of Fe and inevitable impurities; by adopting vanadium-increasing, nitrogen-increasing, and nitrogen-fixing processes during the smelting process, and by decreasing the initial rolling temperature and the finish rolling temperature during the rolling process, fine-grain, solid-solution and precipitation strengthening are realized at a lowtemperature and a high pressure, so the strength is increased; the hot-rolled steel bar contains a dual-phase structure of ferrite and pearlite, wherein the pearlite accounts for 25-50%; good cooperation of strength and toughness can be reached by controlling ratios, forms and sizes of the phases.

Owner:HEBEI IRON AND STEEL

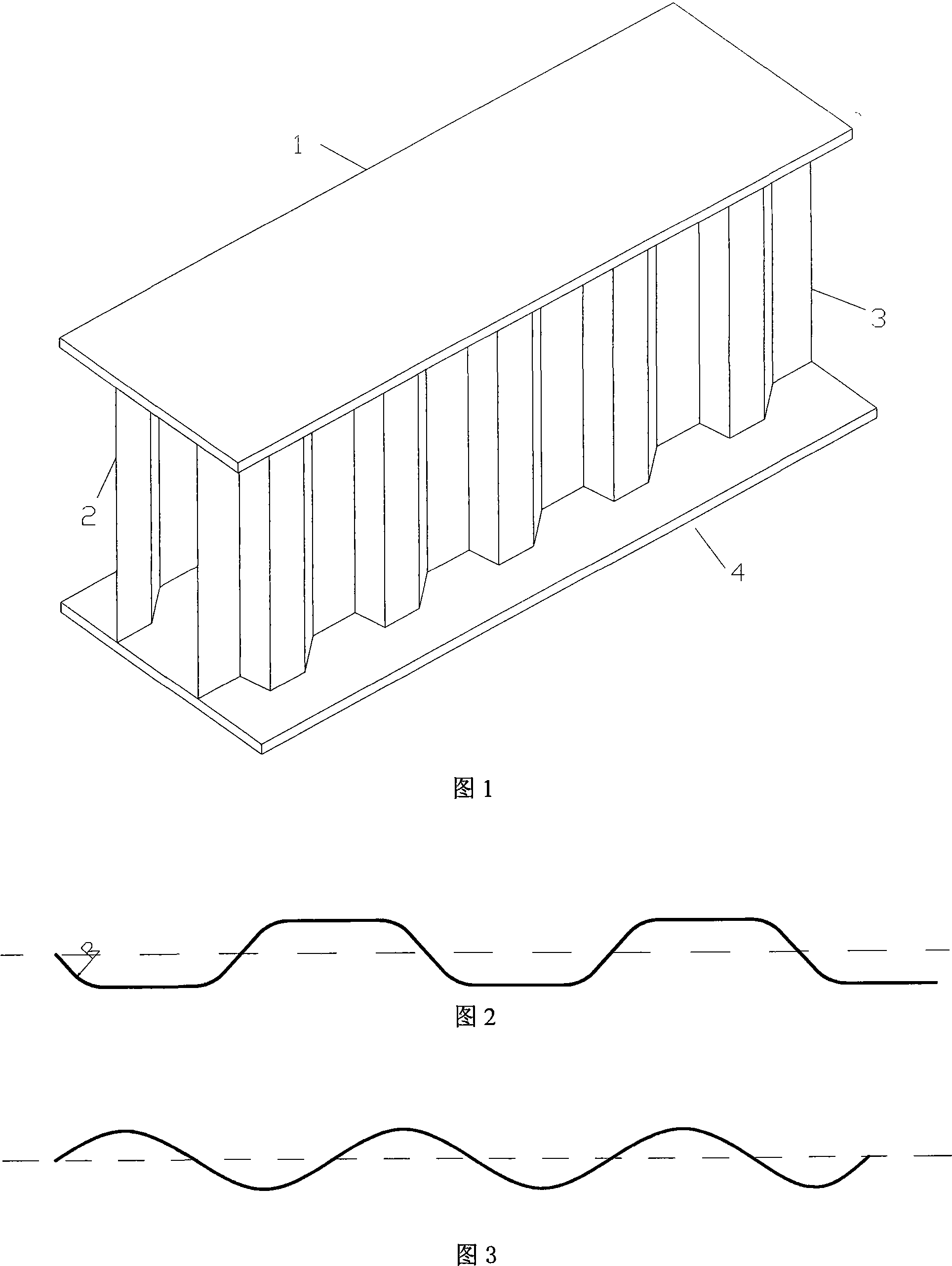

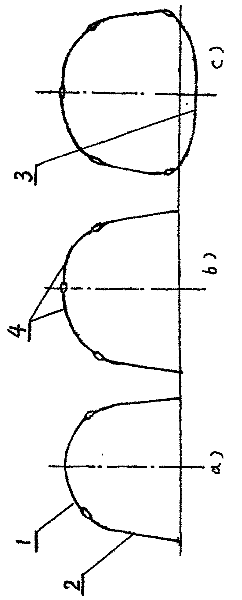

Double corrugated web plate steel box girder

The invention belongs to the technical field of building materials and in particular relates to a double undulated web slab steel box girder. The cross-section fracture shape is composed of a middle web slab, an upper flange and a lower flange which are integrated, wherein the upper flange is parallel to the lower flange, a double web slab is vertically located between the upper flange and the lower flange, the double web slab is arranged symmetrically and takes a honeycomb structure, the web slab and the flange slabs adopt one side fillet weld to connect, the web slab is an undulated web slab whose length direction are periodically repeated evenly or unevenly, and the undulated cross section takes circular arc angle trapezoid and sinusoidal curve. The product can replace products such as normal welded box steel girders, hot rolled H-shaped steel, I-shaped steel and the like, has wider usage compared with the products, and can realize maximization and can be used in the special fields and special places including the building of bridges with large spans, the manufacture of ships and the like.

Owner:TONGJI UNIV +1

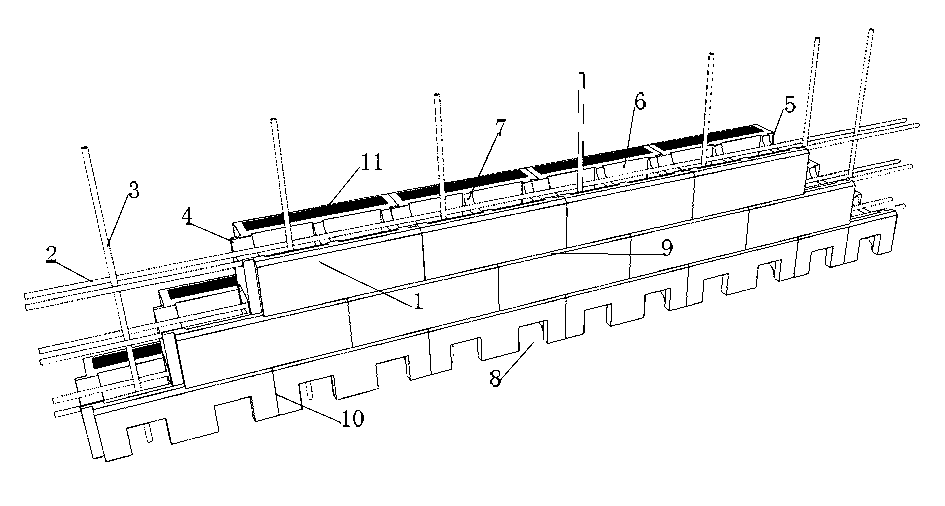

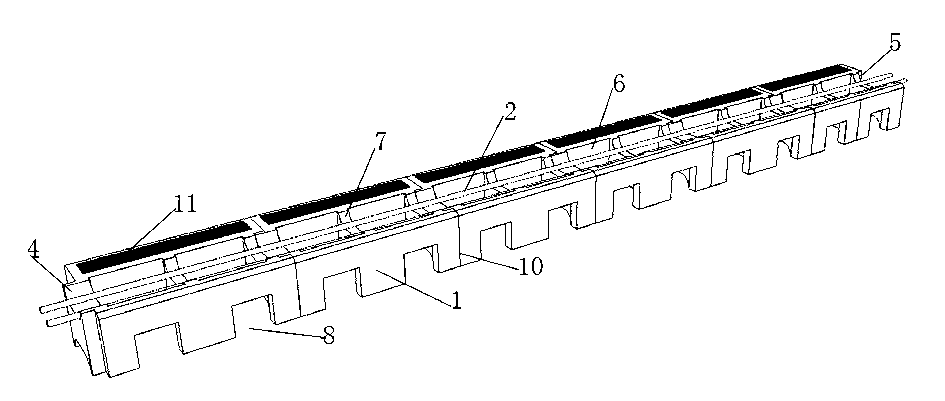

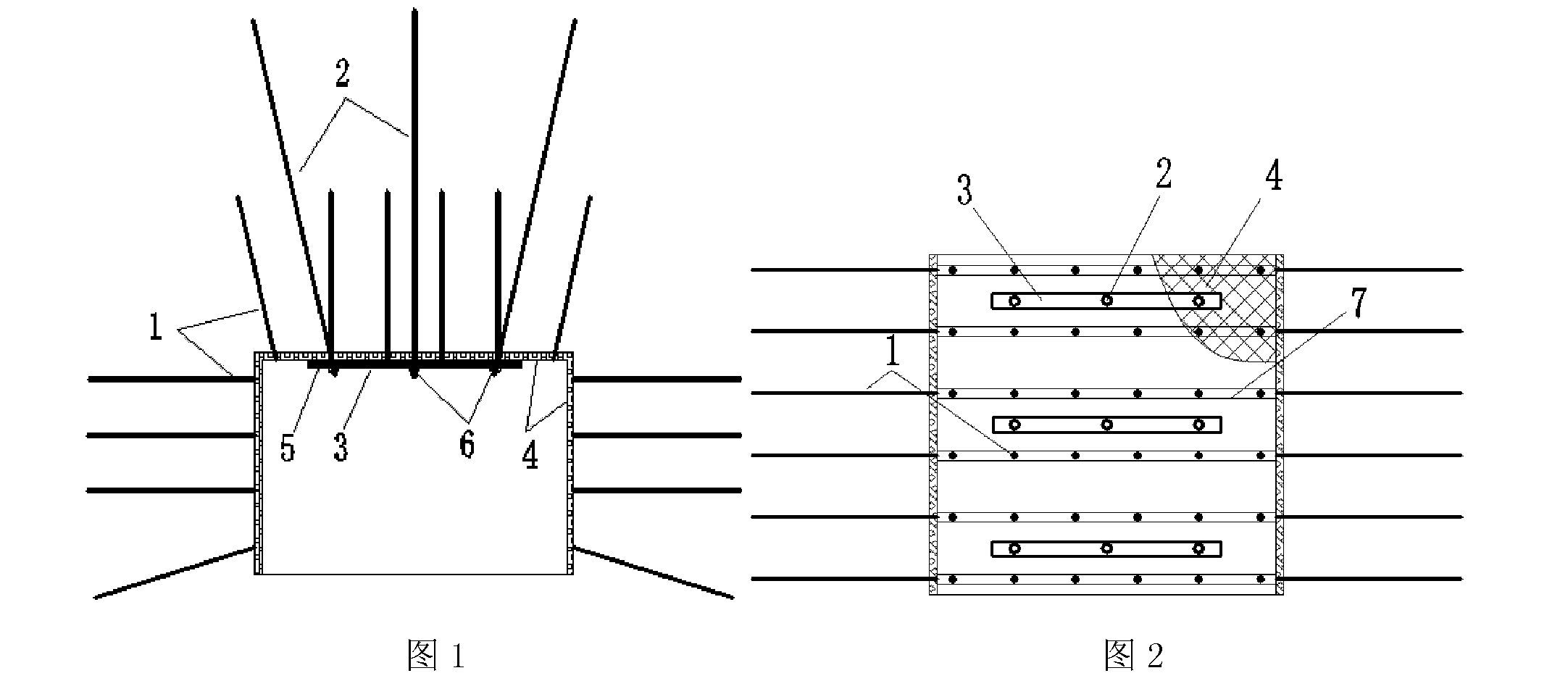

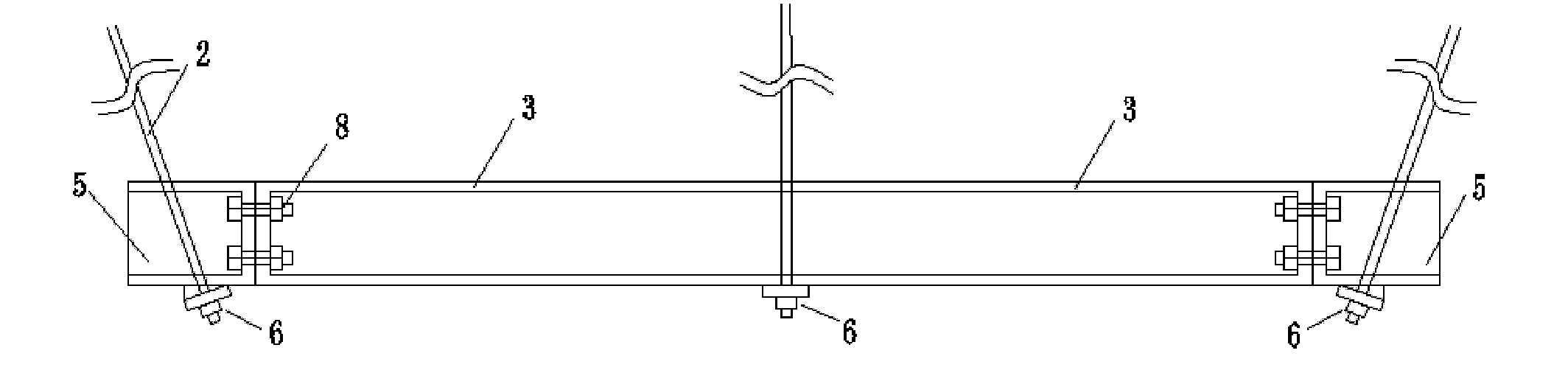

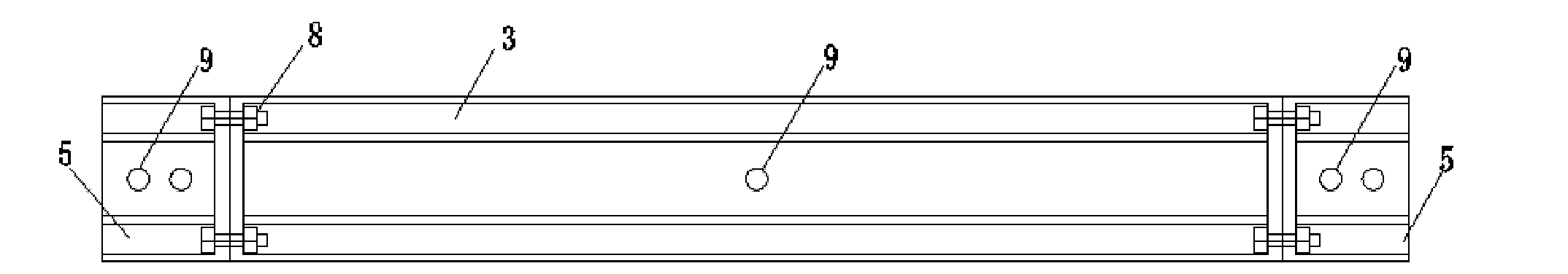

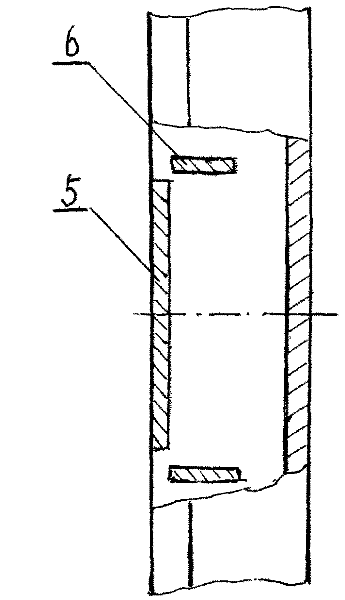

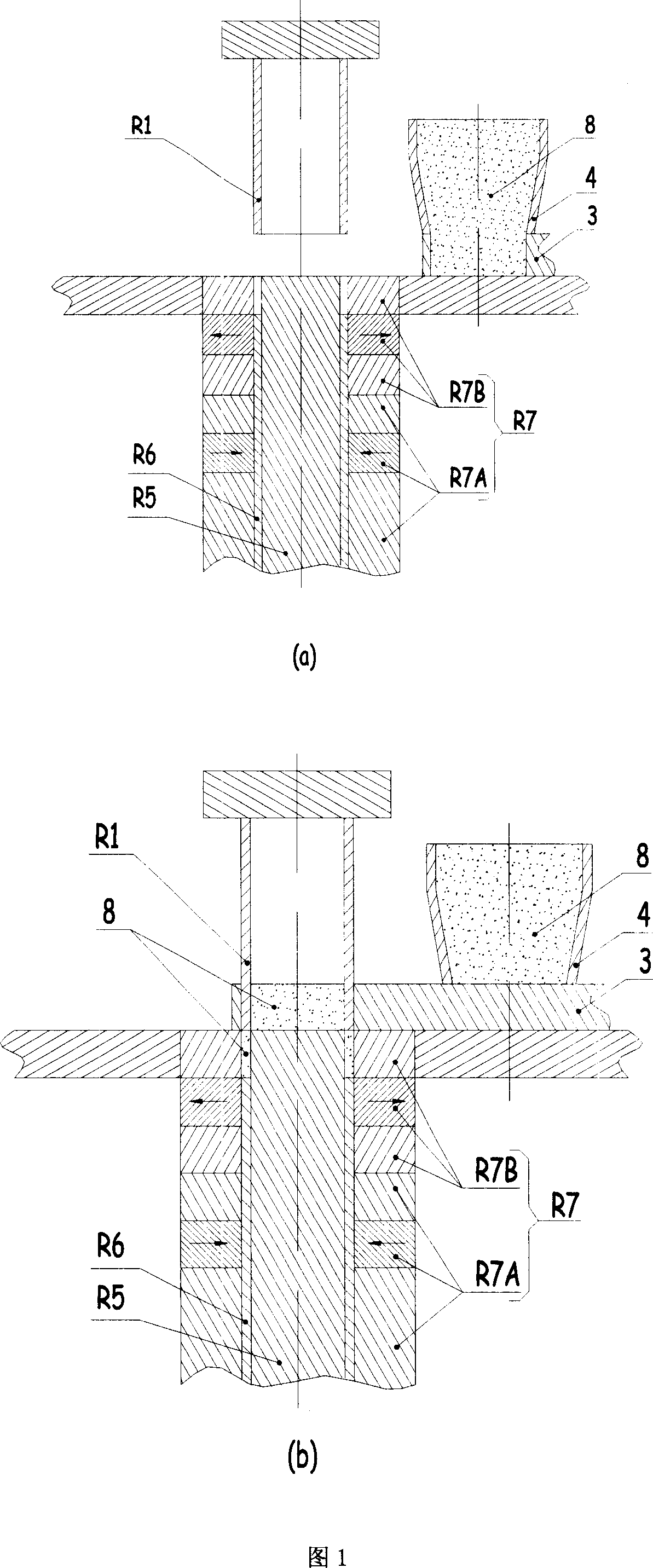

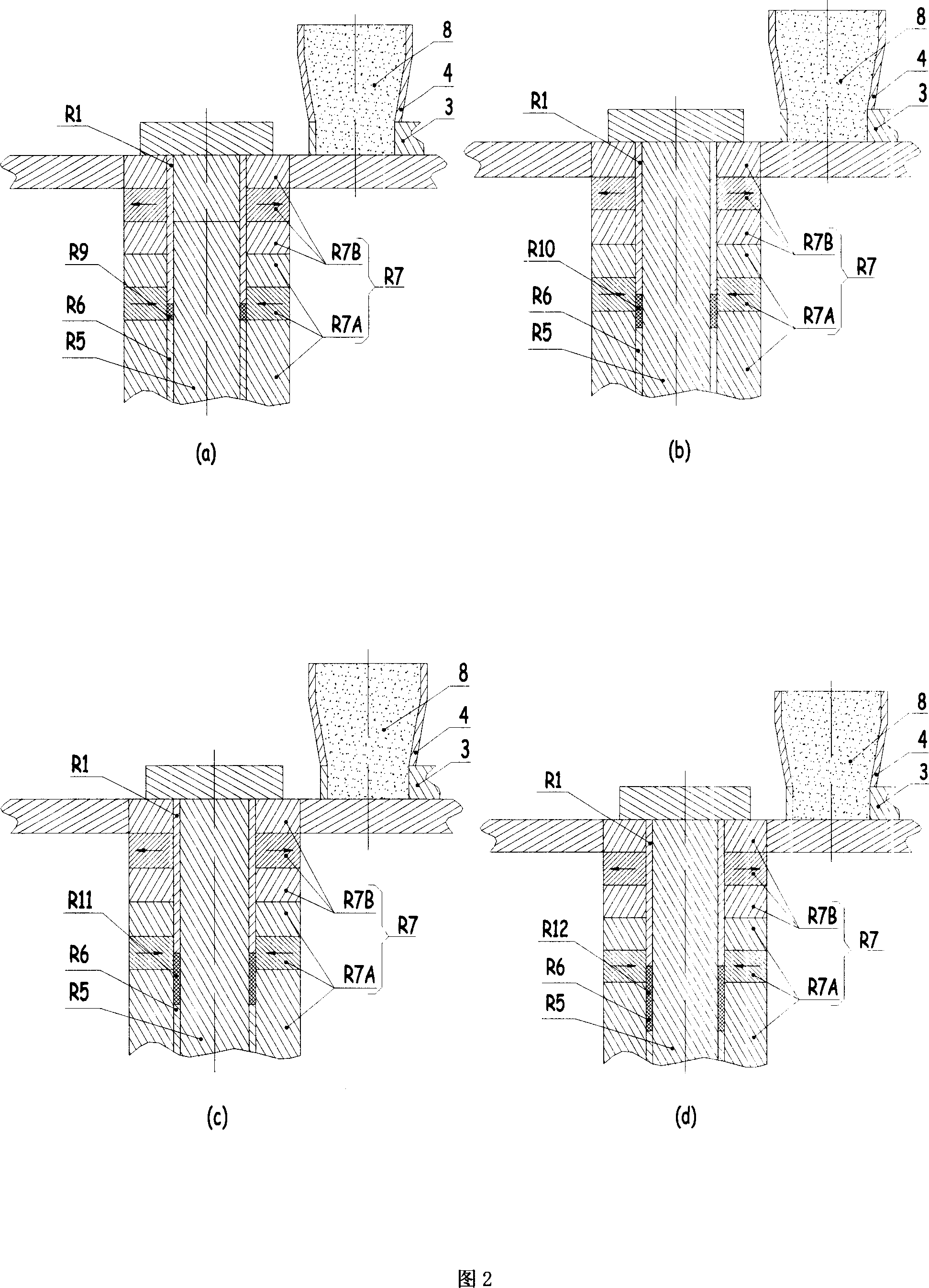

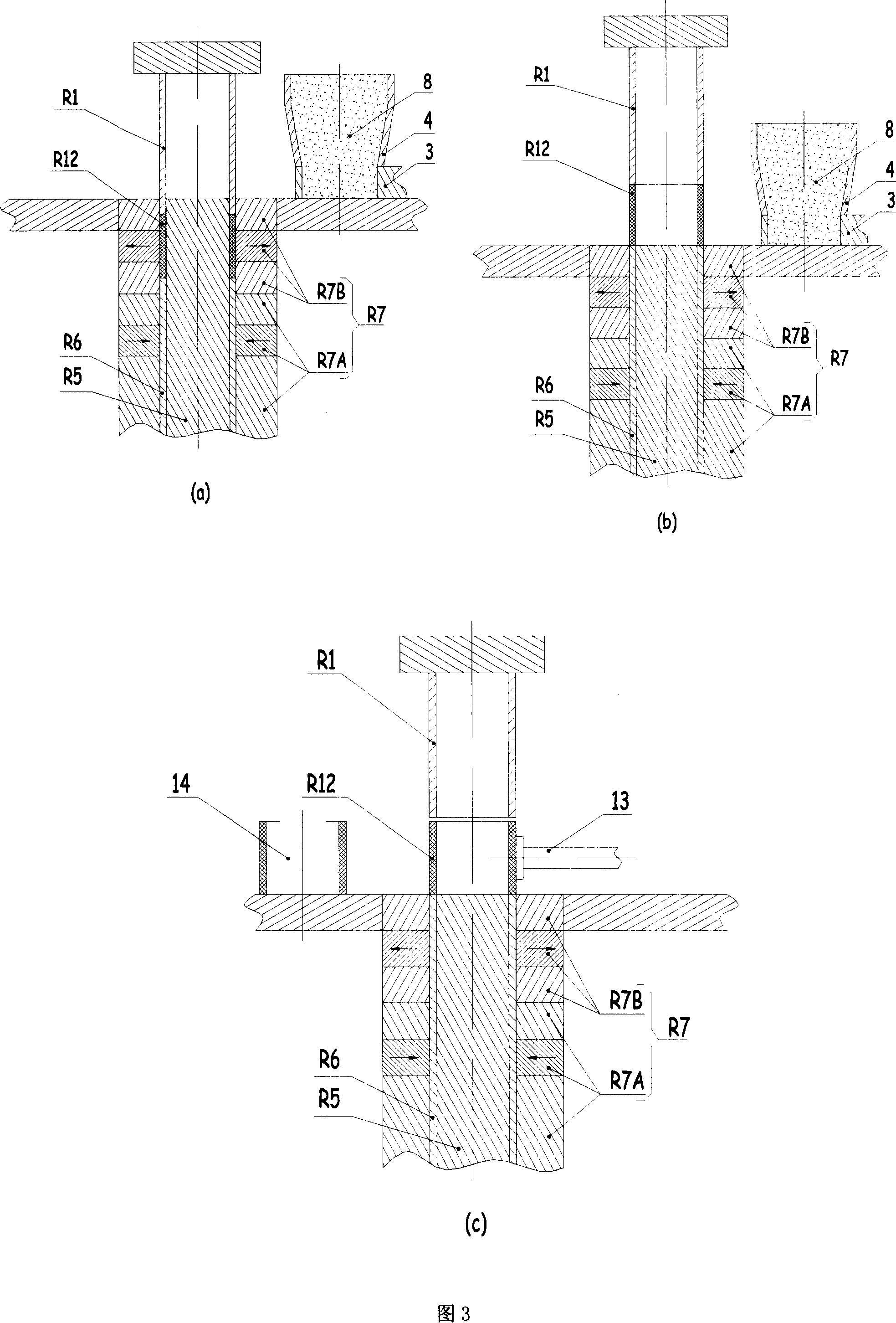

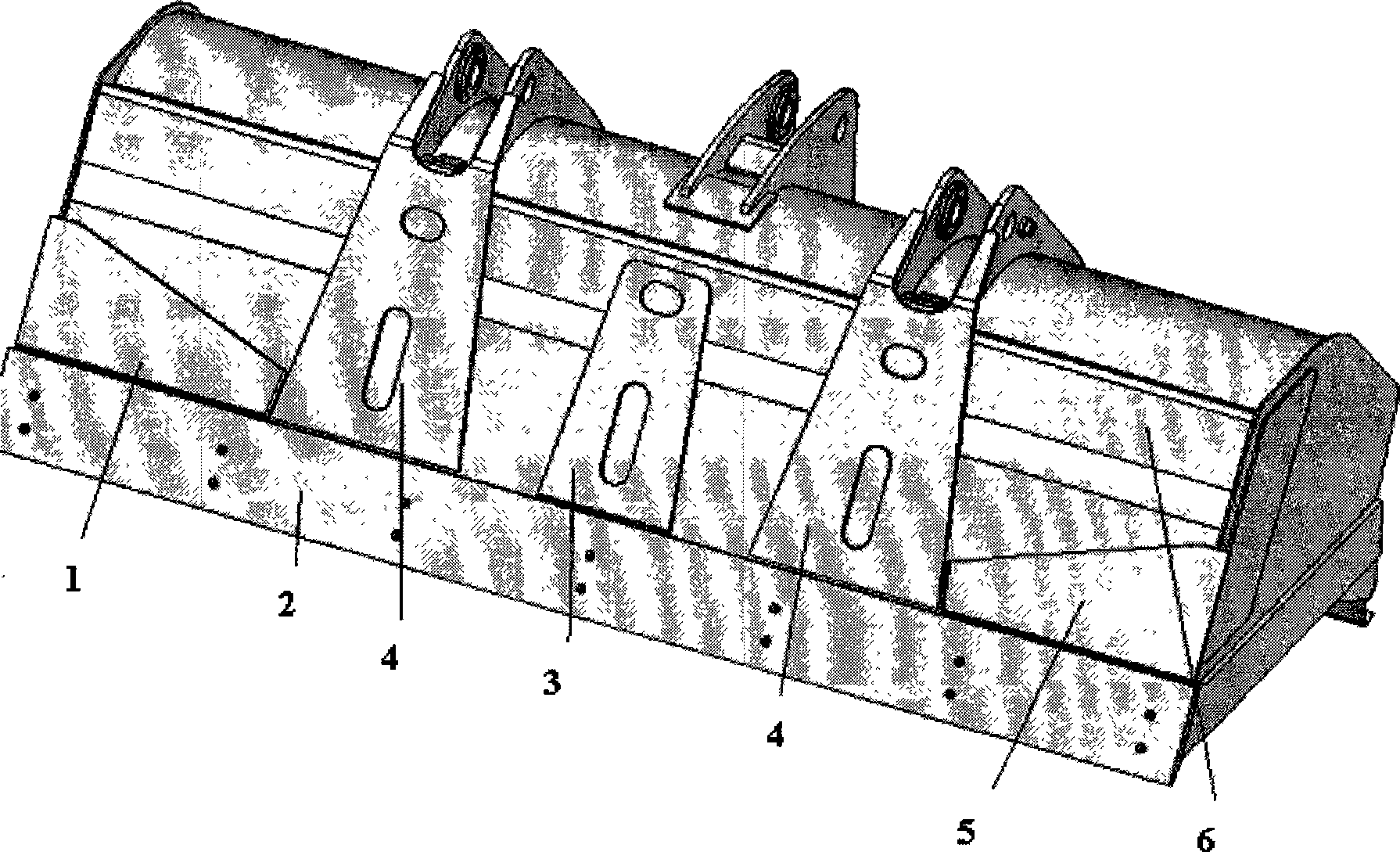

Self-heat-preservation mortar-free block masonry shear wall system and construction method thereof

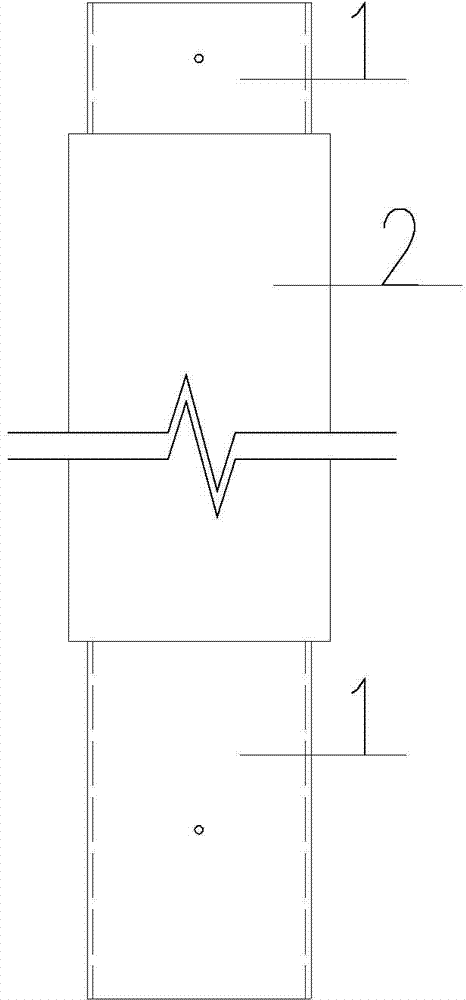

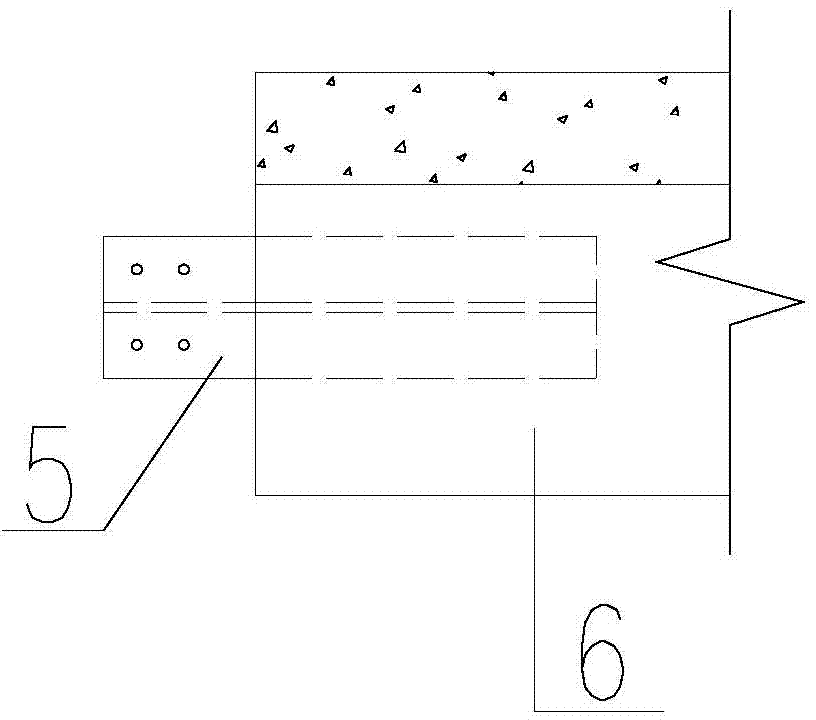

The invention discloses a self-heat-preservation mortar-free distributed steel block masonry shear wall system and a construction method of the self-heat-preservation mortar-free block masonry shear wall system. A self-heat-preservation mortar-free block masonry shear wall is made of self-heat-preservation mortar-free die clamping blocks (1), horizontal reinforcing bars (2), vertical reinforcing bars (3) and grout concrete. The self-heat-preservation mortar-free die card blocks (1) are connected through rabbets (4) and mortises (5) in a die card mode, and the vertical reinforcing bars (3) are arranged into vertical holes (6) formed by the self-heat-preservation mortar-free die card blocks, and the horizontal reinforcing bars (2) are arranged in horizontal holes (7) formed by the self-heat-preservation mortar-free die clamping blocks (1). The grout concrete is finally poured so as to form the self-heat-preservation mortar-free block masonry shear wall. The construction method of the self-heat-preservation mortar-free block masonry shear wall sequentially comprises the following steps of performing preparatory work, building blocks of the bottommost layer, building blocks of other layers, inserting the bars and pouring the concrete.

Owner:ZHUZHOU BOERMAN TECH DEV

Polyether graft poly-carboxylic acid concrete water reducer preparation

Production of polyether graft poly-carboxylic acid concrete water reducer is prepared by sulfonating styrene-anhydride multipolymer with anhydride content 10í½50 mol% and relative molecular mass 2000í½20000 from sulfonating agent of non-destructive acid anhydride group, esterifying grafting polyether side chain on acid anhydride key, and dissolving in water. Its advantages include simple process, no catalyst, higher fluidity of cement concrete and compression strength.

Owner:海南中科翔新材料科技有限公司

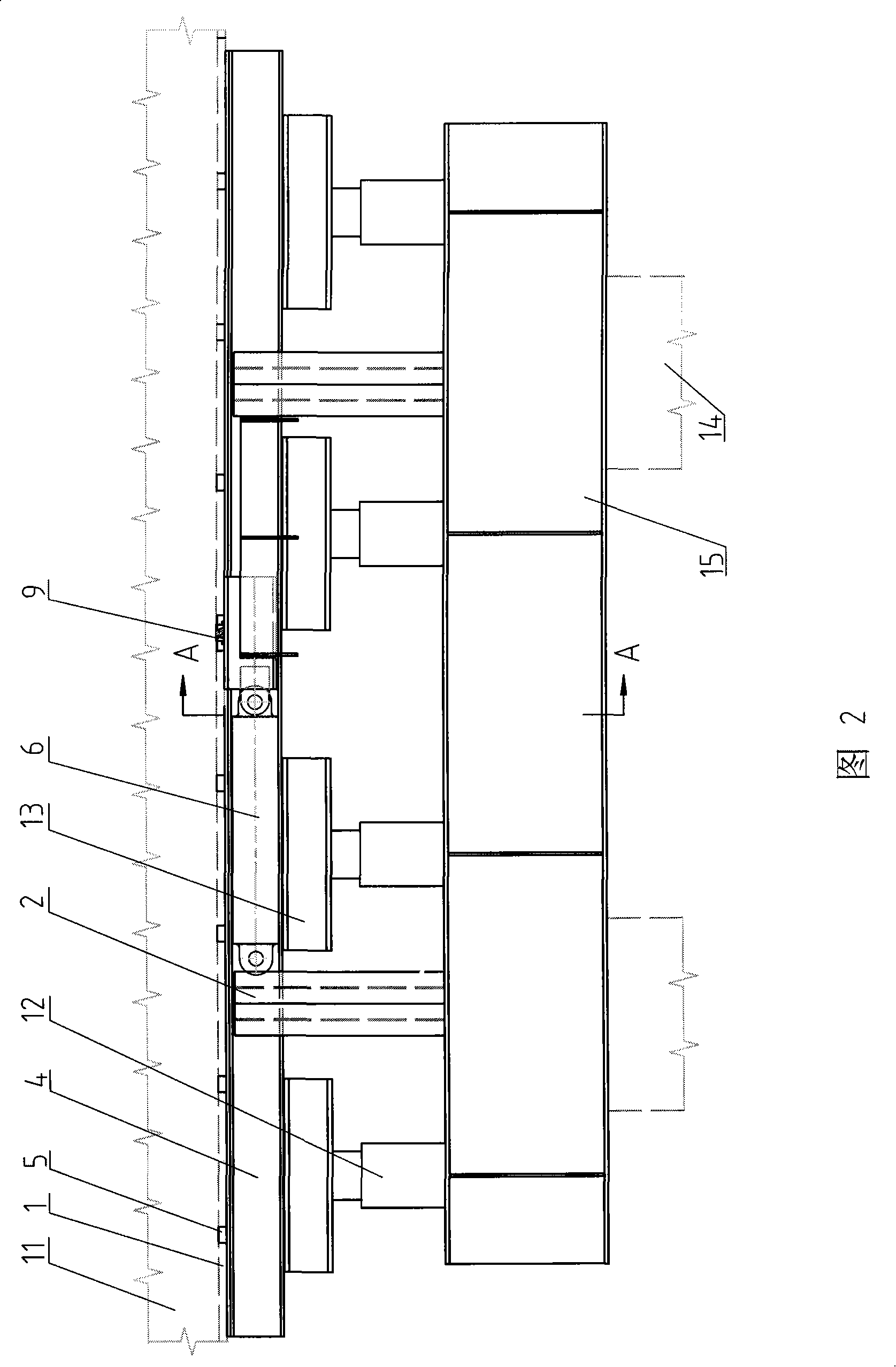

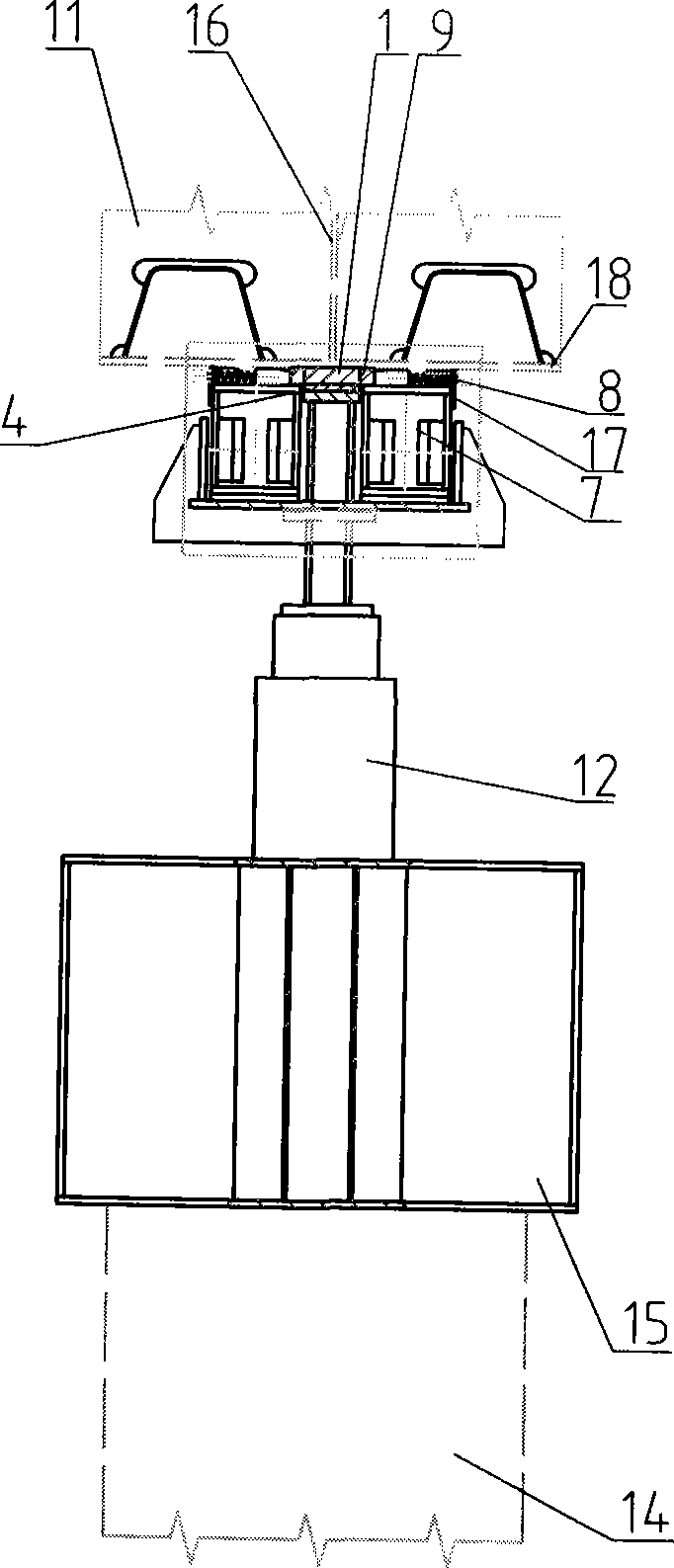

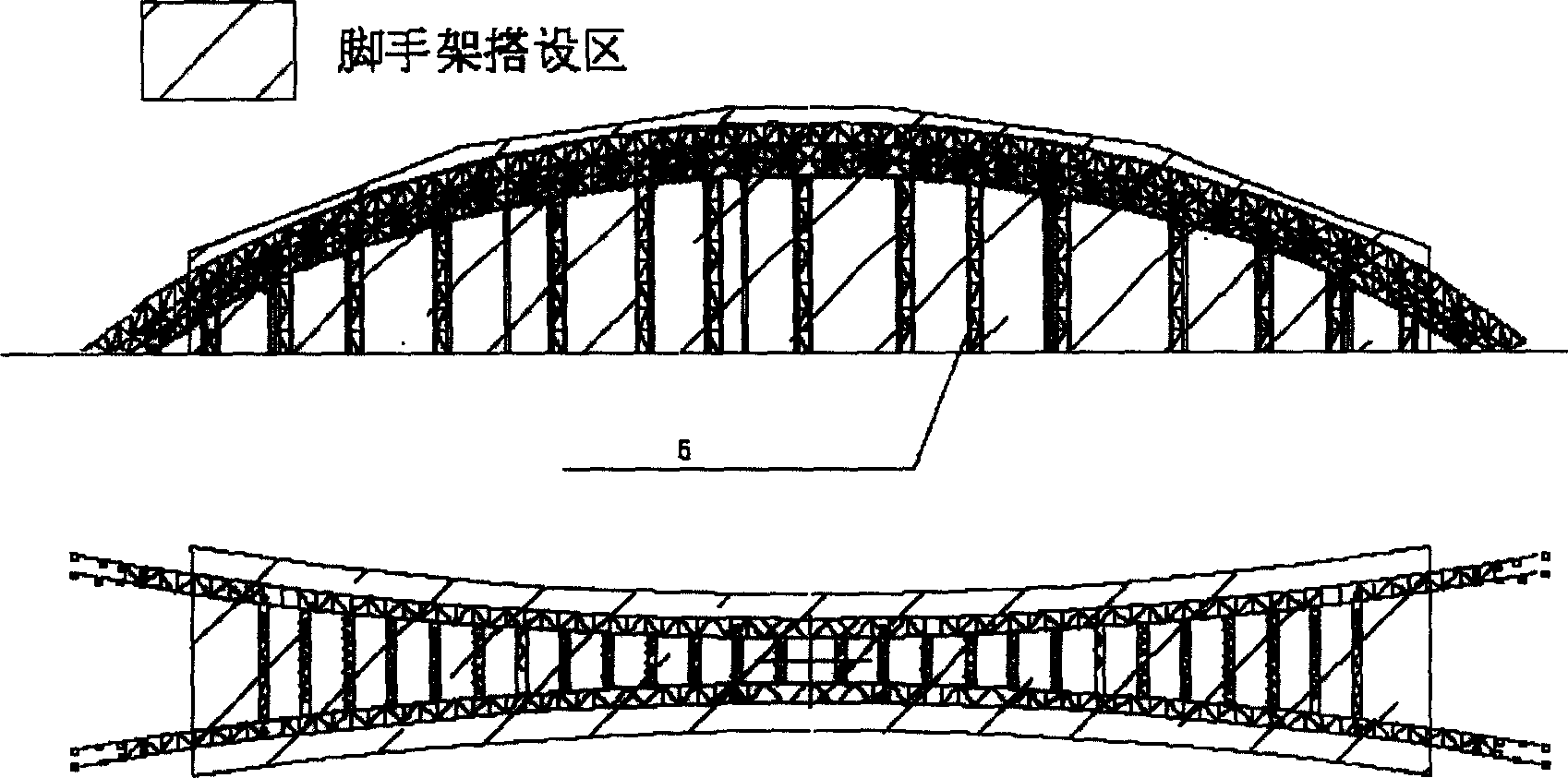

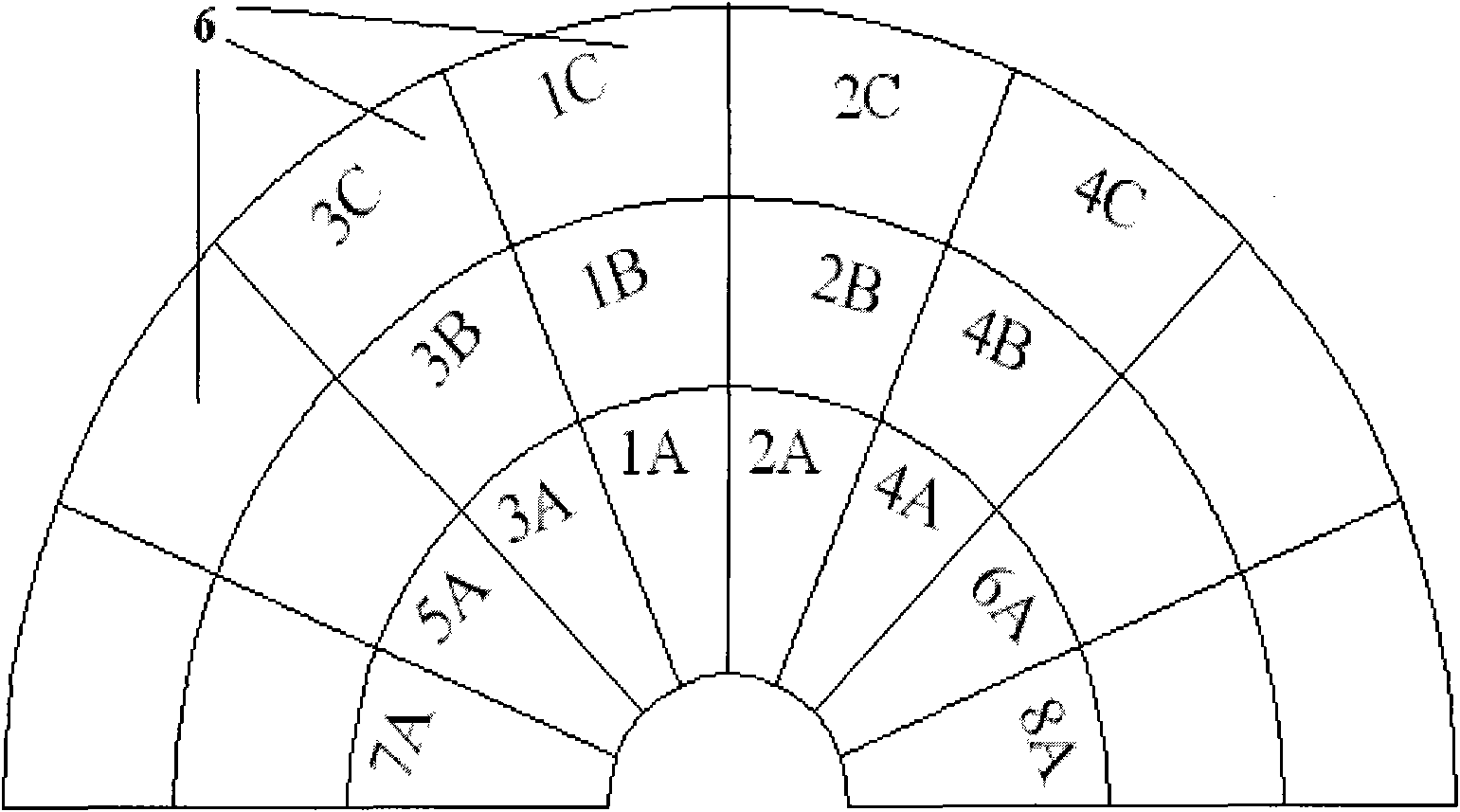

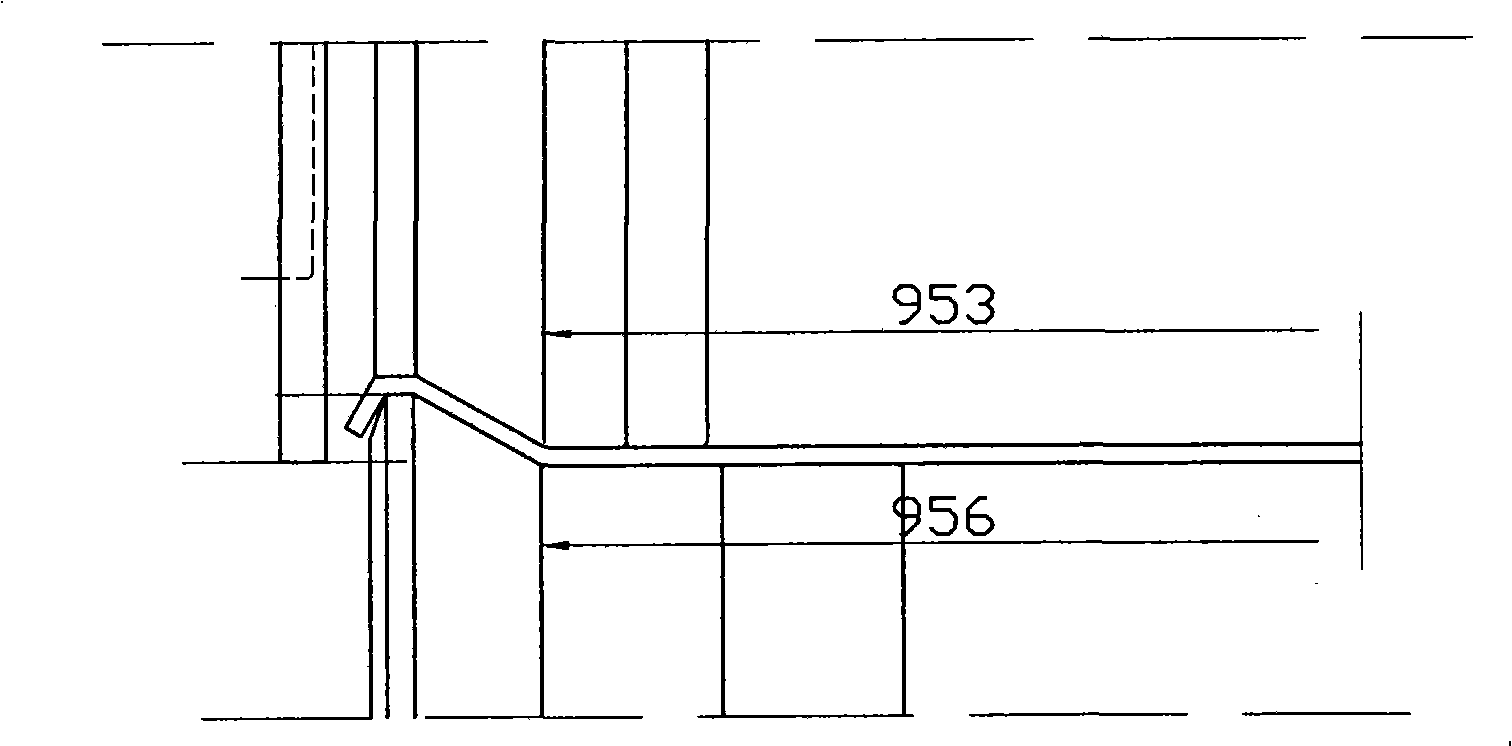

Method for construction of multi-point integral top pulling steel case beam

ActiveCN101250855AReduce width sizeImprove work efficiencyBridge erection/assemblyBridge materialsBridge engineeringPiston rod

The invention discloses a construction method of a multi-point whole incremental launching steel box girder, which belongs to the field of bridge engineering. The construction method uses a dental plate with a tooth socket, which is arranged on a steel box girder and a guiding beam web plate, a jacking force is supplied by an incremental launching jack, wherein a piston rod of the incremental launching jack is equipped with a slider, on which a spinous block with an inclined plane and a control spring are arranged, the inclined plane is arranged on the side of the incremental launching jack, the steel box girder and the guiding beam are applied with the jacking force through the push travel of the incremental launching jack, and the spinous block withdraws from the tooth socket during the return to enter into a next push travel. The construction method also supplies the support and adjusts the elevation of corresponding points through lifting-up the jack, simultaneously the incremental launching jack and the upper portion of the incremental launching jack are all equipped with a displacement sensor and a pressure sensor to collect information, thereby controlling an incremental launching process. The construction method has less consumption of steel material, a support reaction and a thrust force are capable of being controlled, and the problem of the rotation angle of the steel box girder is capable of being excellently solved.

Owner:SHANDONG LUQIAO GROUP

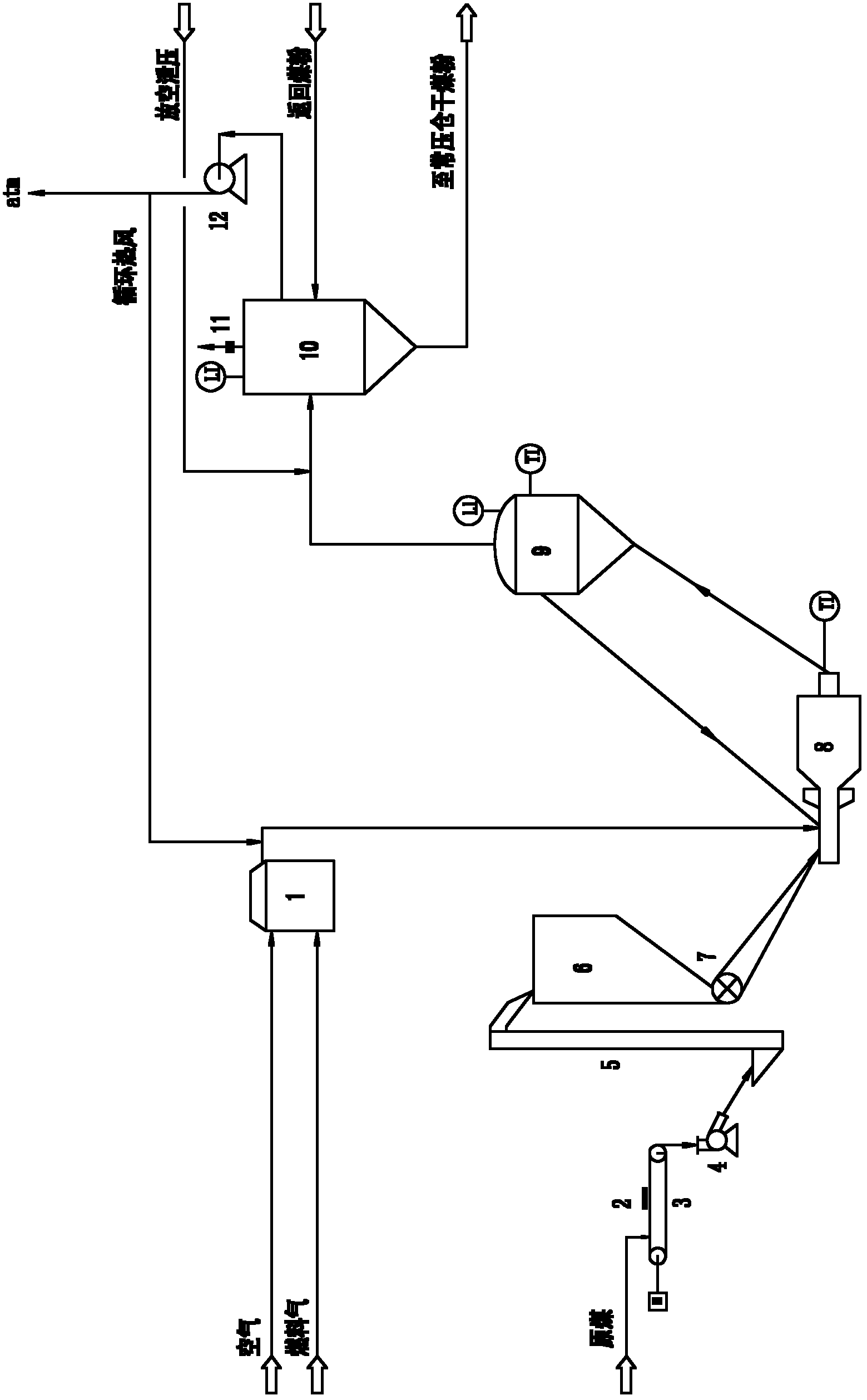

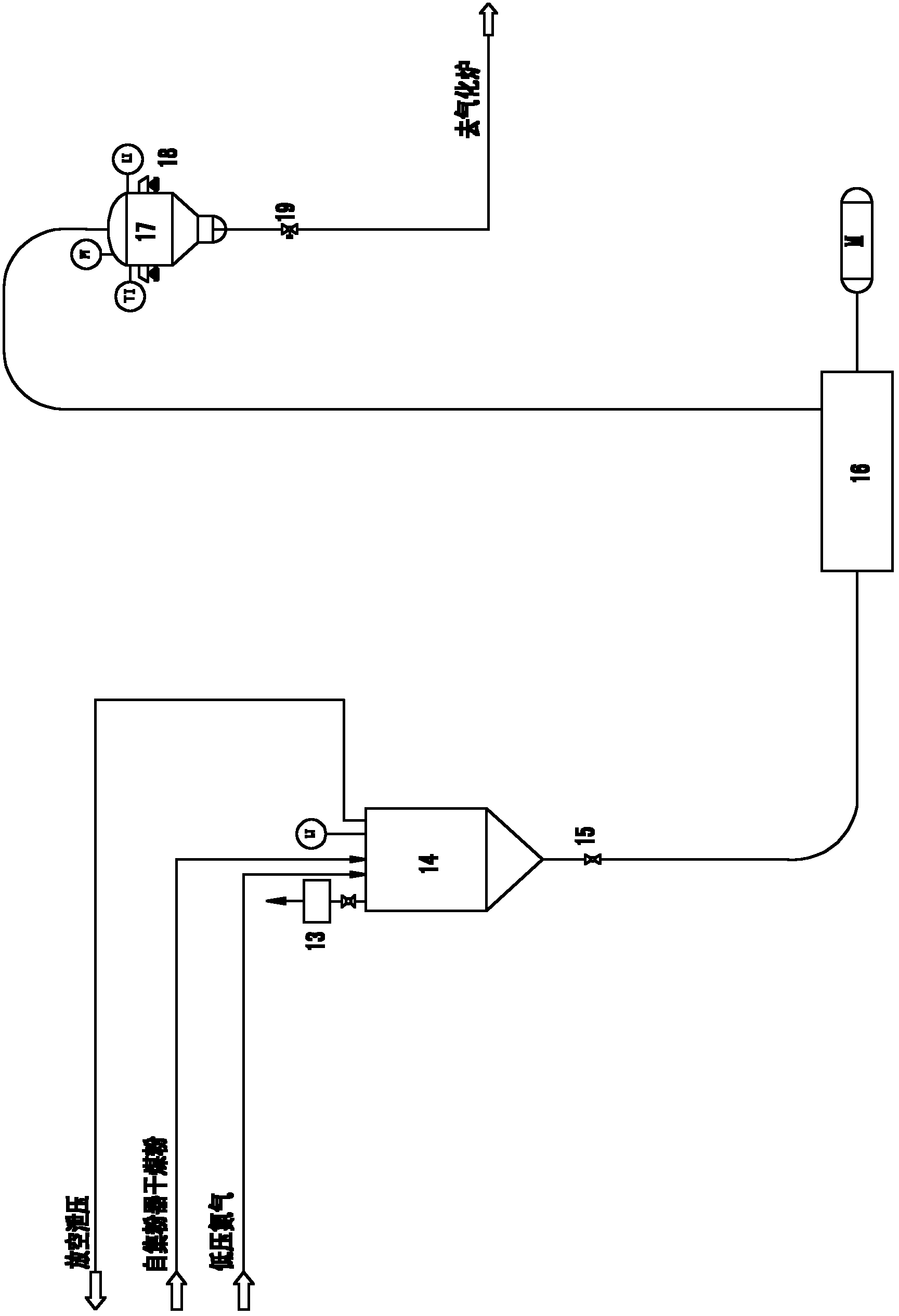

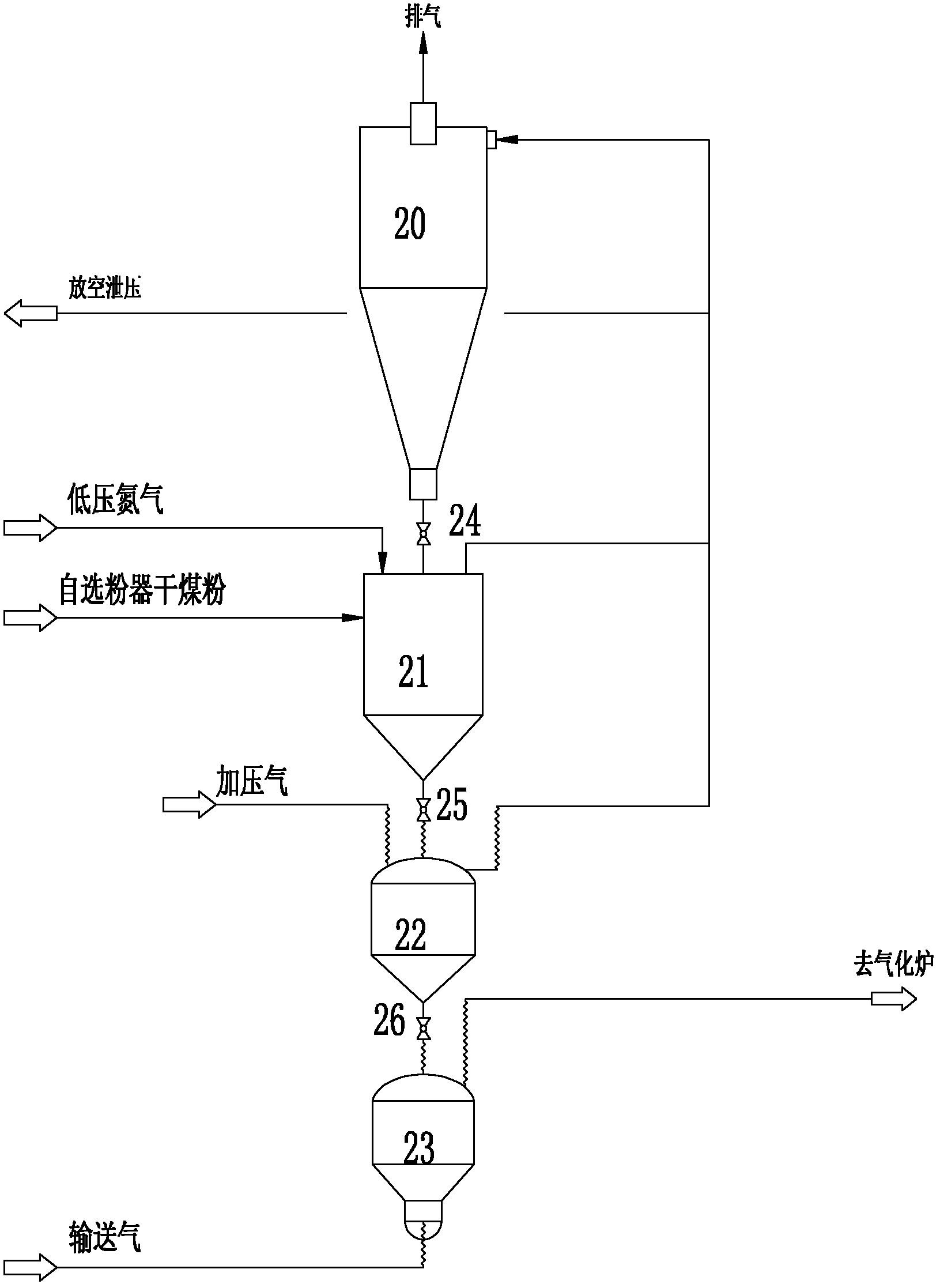

Method for producing synthesis gas by using coal powder as raw material

ActiveCN102352268AImprove utilization efficiencyWon't happenMultistage water/sewage treatmentCombined combustion mitigationProcess configurationAnthracite

The invention discloses a pressurization high temperature gasification method of dry coal powder. The method comprises the following five steps: the preparation of dry coal powder, the pressurization delivery of the dry coal powder, the pressurization and high temperature gasification of the dry coal powder, the cooling of high temperature crude synthesis gas and molten ash and the washing and purifying of the crude synthesis gas, and the treatment of water containing fine ash. The method is suitable for not only the bituminous coal with low ash content and low ash fusion point, but also other types of coal, which widely exist at home and abroad, have different metamorphic degrees and qualities and contain the coal with low ash content and high ash fusion point, the coal with high ash content and low ash fusion point and the anthracite, bituminous coal and lignite with high ash content and high ash fusion point. The method has good gasification index, simple equipment, flexible process configuration, low investment and operation convenience, the large-scale product is easy to realize, and the method has the beneficial effects of wide raw material application range, environmental friendliness and the like.

Owner:THE NORTHWEST RES INST OF CHEM IND

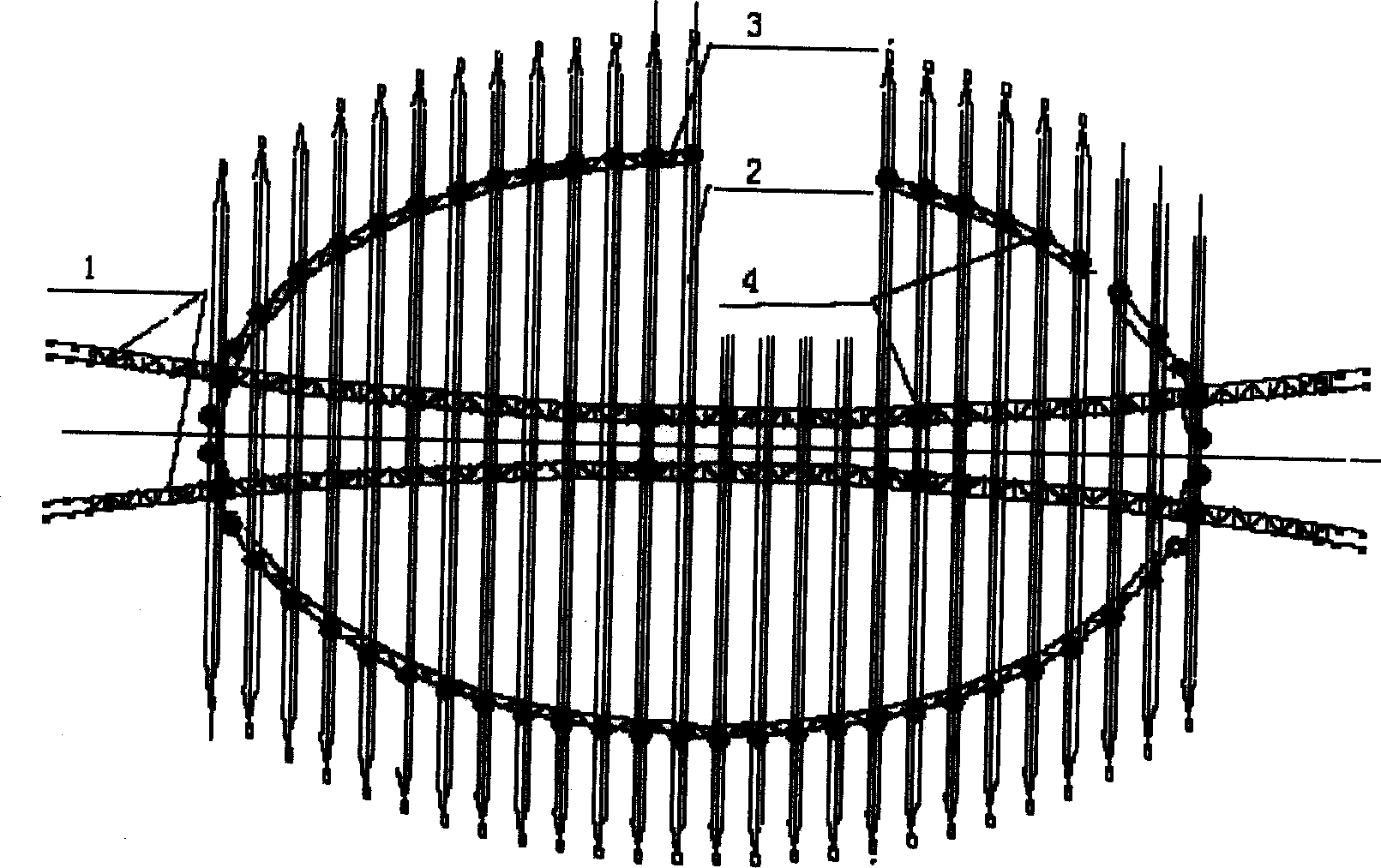

Building truss integral lifting method and equipment thereof

The integral building truss lifting method features that the lifting process includes assembling the main truss on ground in two units; manufacturing and installing corresponding lifting frame; setting cable system on the elevating frame and installing hydraulic elevator in corresponding position; installing the truss ground end shifting units; lifting the two elevated ends of the truss units with the hydraulic elevator synchronously while ensuring the horizontal shift of the ground ends of the truss units under the control of main computer; dismantling the ground end shifting units after the overhead butt joints are in place; elevating and fixing the ground ends; and assembling the overhead butt joints.

Owner:中国机械工业建设总公司

Method of manufacturing technology of ultra-deep large cylinder-shaped drilling platform main hull

The invention discloses a method of a manufacturing technology of an ultra-deep large cylinder-shaped drilling platform main hull, which comprises the following steps: division of construction stage of the cylinder-shaped drilling platform main hull, construction of double bottom total stage, manufacturing folding of a cylinder body, folding of deck section, and carry and hoisting of superstructure. The invention is provided with a platform structure for strengthening the whole resistance, can be applicable to various marine environments, is free from changing navigation bearing with the wind, has better stability, and can achieve the safety level of preventing immeasurable wind waves.

Owner:COSCO SHIPPING (QIDONG) OFFSHORE CO LTD +2

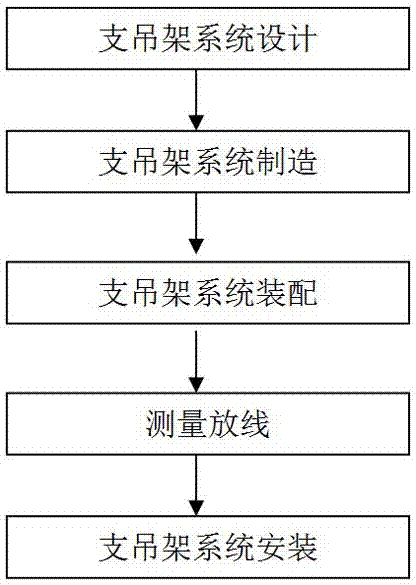

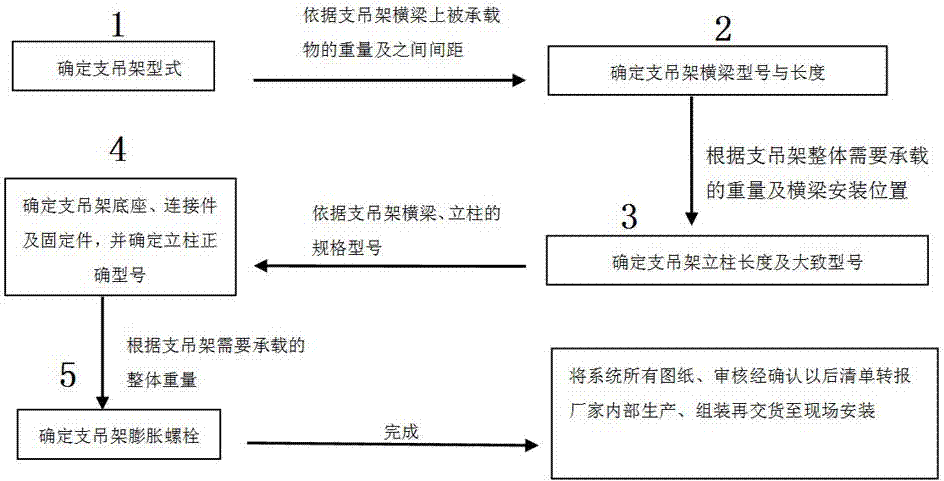

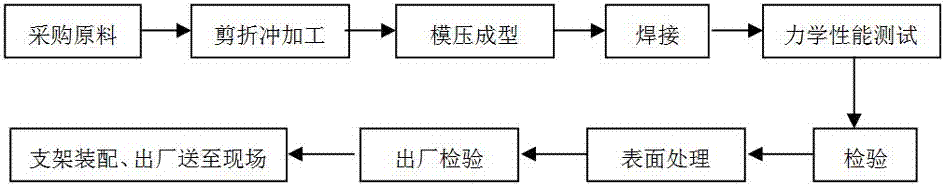

Assembly type building pipeline supporting and lifting frame system installation method based on BIM

ActiveCN106989211AReduce work intensityEnsure site safetyGeometric CADPipe supportsPunchingLight pollution

The invention discloses an assembly type building pipeline supporting and lifting frame system installation method based on a BIM. The installation method includes the steps that supporting and lifting frame design and stress analysis are conducted, the supporting and lifting frame connecting and fixing manner is determined, and a supporting and lifting frame design drawing is obtained; the drawing is guided into BIM software, and three-dimensional modeling is conducted; adjustment optimization is conducted on supporting and lifting frame arrangement, arrangement design, stress calculation and product model selecting of supporting and lifting frames are completed; part drawings and assembling drawings of all assemblies are generated, and factory production of the assemblies is achieved accordingly; measuring paying-off of the supporting and lifting frame system is conducted on the spot, and structure punching operation is conducted accordingly; and the supporting and lifting frames are formed through assembling, and installation is completed. By means of the assembly type building pipeline supporting and lifting frame system installation method based on the BIM, energy can be obviously saved, steel is saved, air pollution, noise pollution and light pollution brought by field feeding, cutting, welding, drilling and the like are avoided during installation, the manufacturing cost is reduced, meanwhile, the field safety of a constructor is ensured, and the work intensity of a laborer is effectively lowered.

Owner:ZHONGYIFENG CONSTR GRP

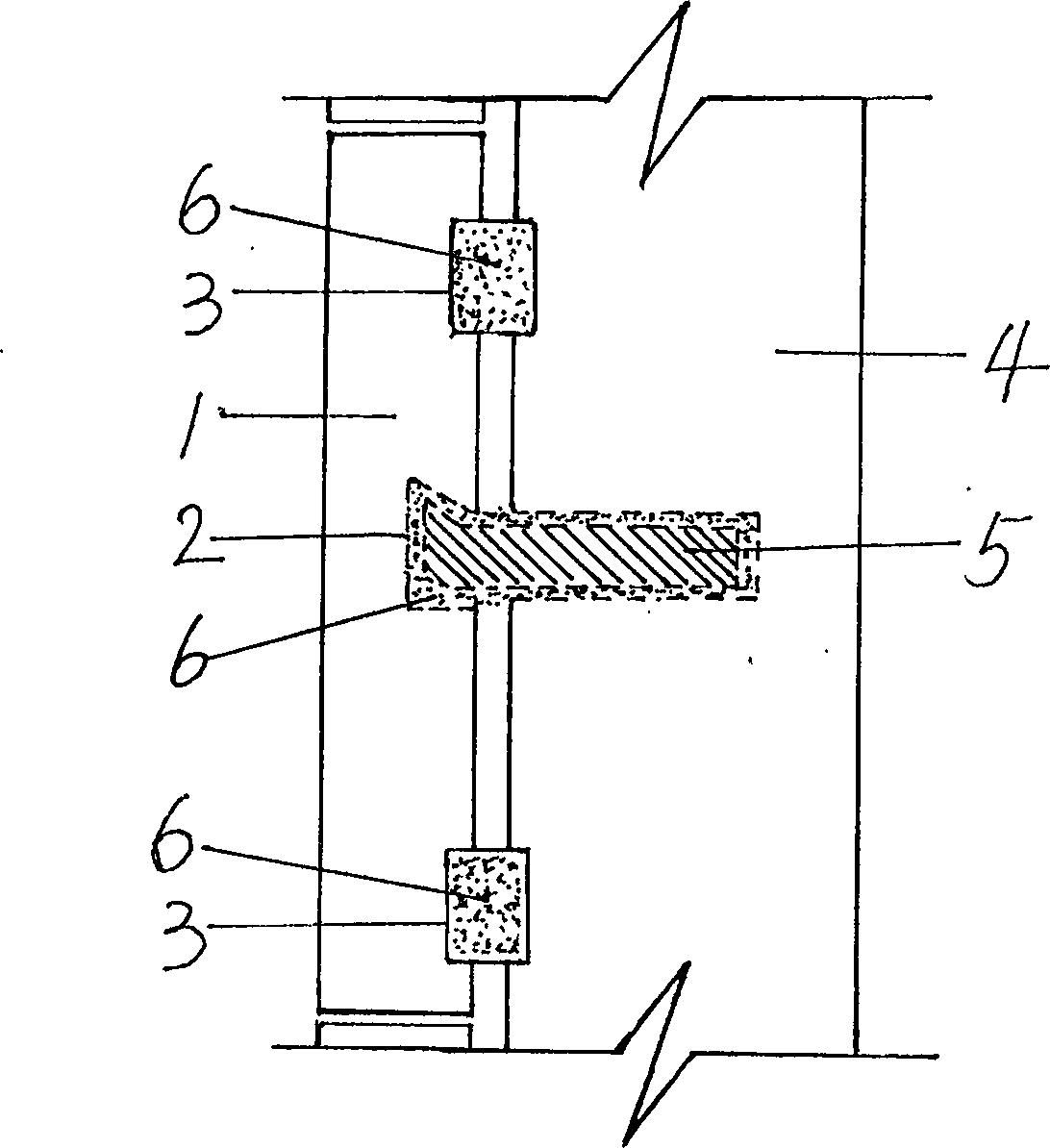

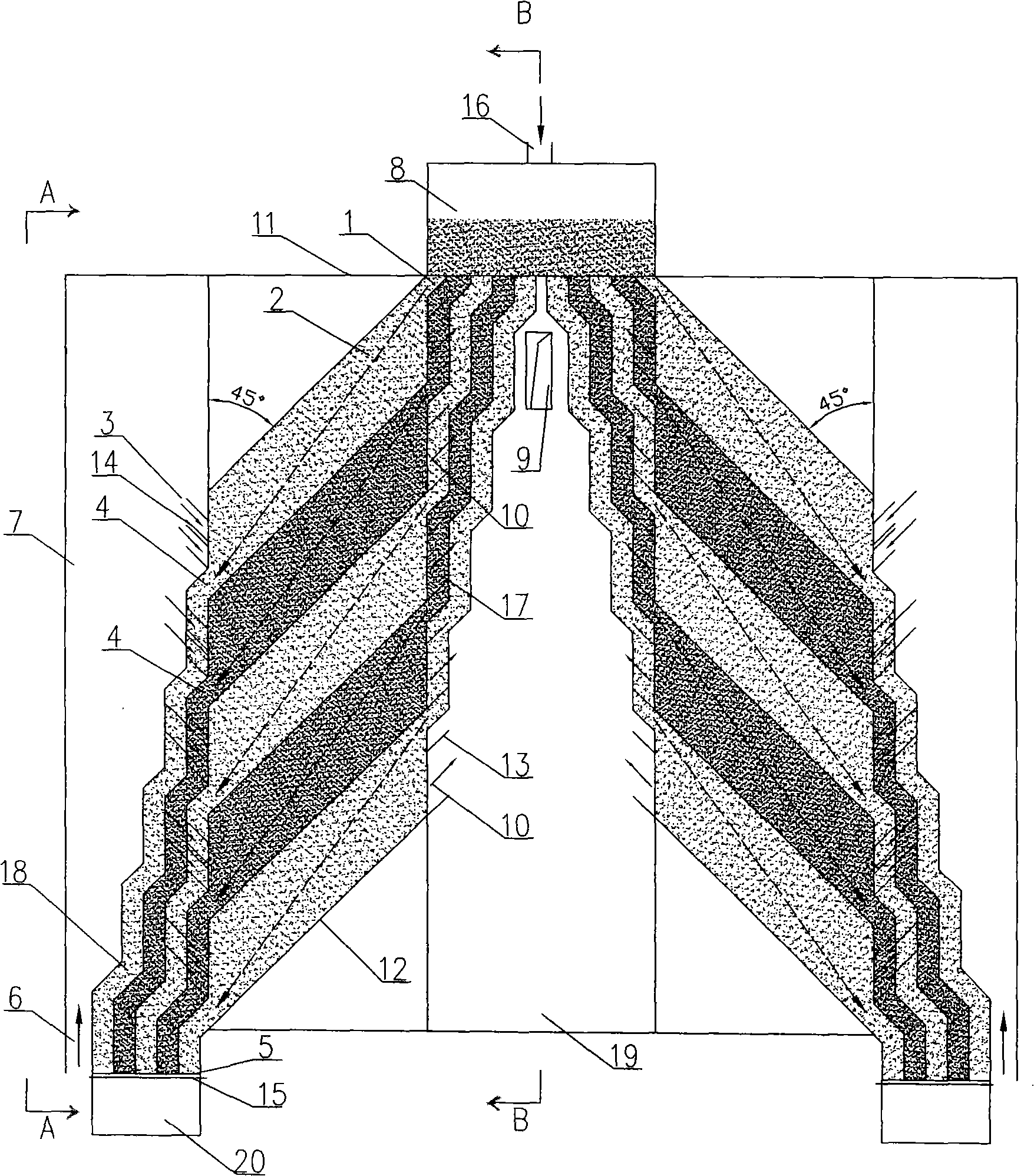

Semi-rigid abnormal beam anchor cable truss roadway supporting system

InactiveCN102182483AGuaranteed integrityEfficient deliveryMine roof capsAnchoring boltsSupporting systemRock bolt

The invention relates to a semi-rigid abnormal beam anchor cable truss roadway supporting system. A metal net is paved on the surface of a roadway, a semi-rigid abnormal beam anchor cable truss is arranged at a coal-rock roof or a roadway side, the semi-rigid abnormal beam anchor cable truss is formed by abnormal beams with semi-rigid nodes and anchor cables or anchor rods, and each abnormal beam is provided with a plurality of anchor cables or anchor rods; the anchor cables and anchor rods are anchored into a rock layer by passing through the abnormal beams and the metal net and apply a prestress to form an extrusion and annular protection function on surrounding rocks; and outer anchor ends of the anchor cables and anchor rods are provided with trays and locks, the trays and the locks make the end heads of the anchor cables or anchor rods tightly matched with the abnormal beams. The invention has the advantages that: (1), the protective surface area is large, the rigidity is high, stability is not easy to loss, and the integrality of the supporting system is ensured; (2), a steel material is saved, the cost is reduced, and the efficiency is increased; (3), the strength is high, and the regulation space of the whole supporting performance is large; and (4) the semi-rigid nodes can play a role of better flexible yield, and the stability and the safety of the whole supporting system are ensured.

Owner:SHANDONG UNIV

Paste arts and crafts by planting nails and anchors on facesheet of surface of wall

InactiveCN1873158ANo wasted spaceThere is no large loadCovering/liningsBuilding reinforcementsAdhesiveEngineering

Owner:林文新

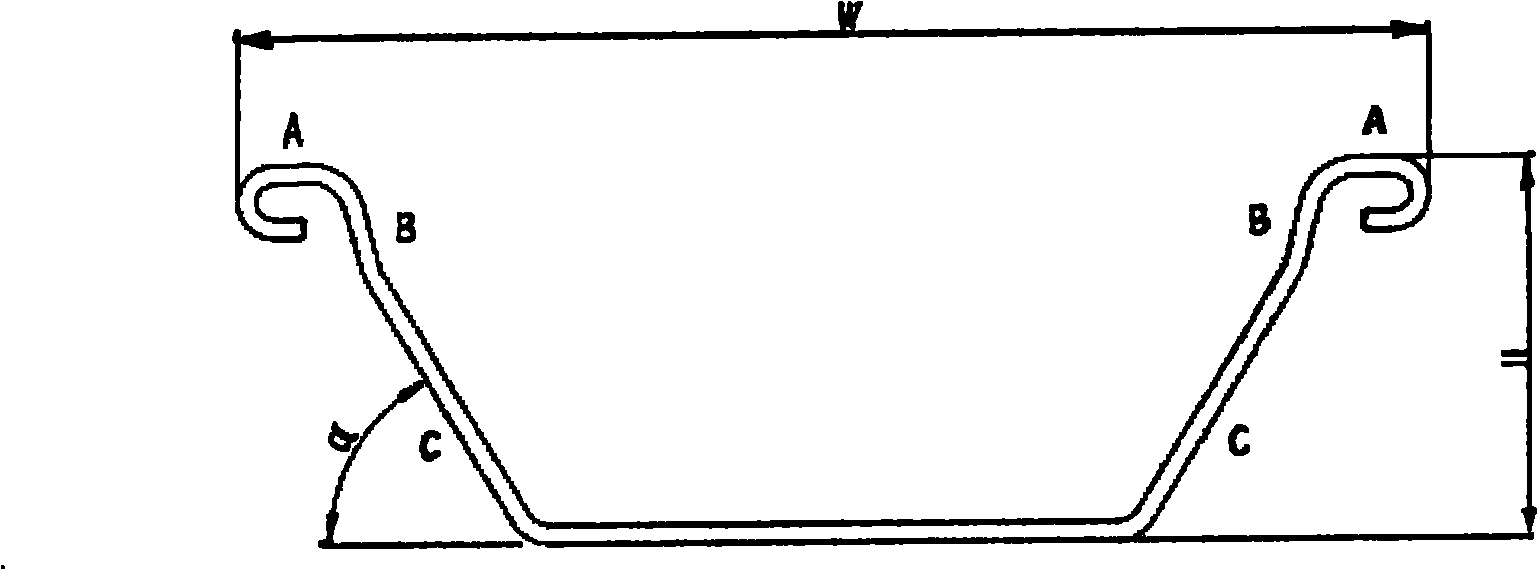

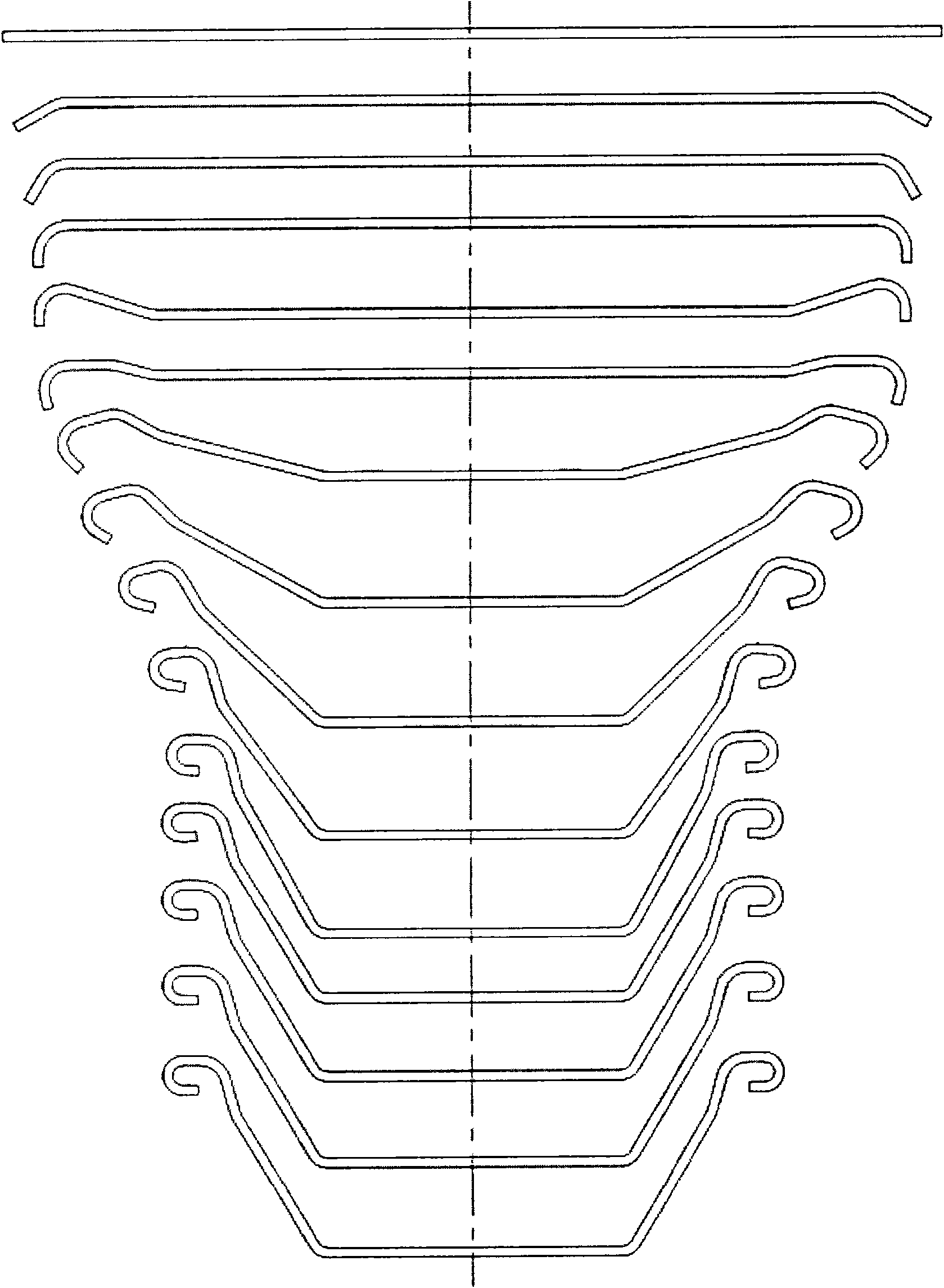

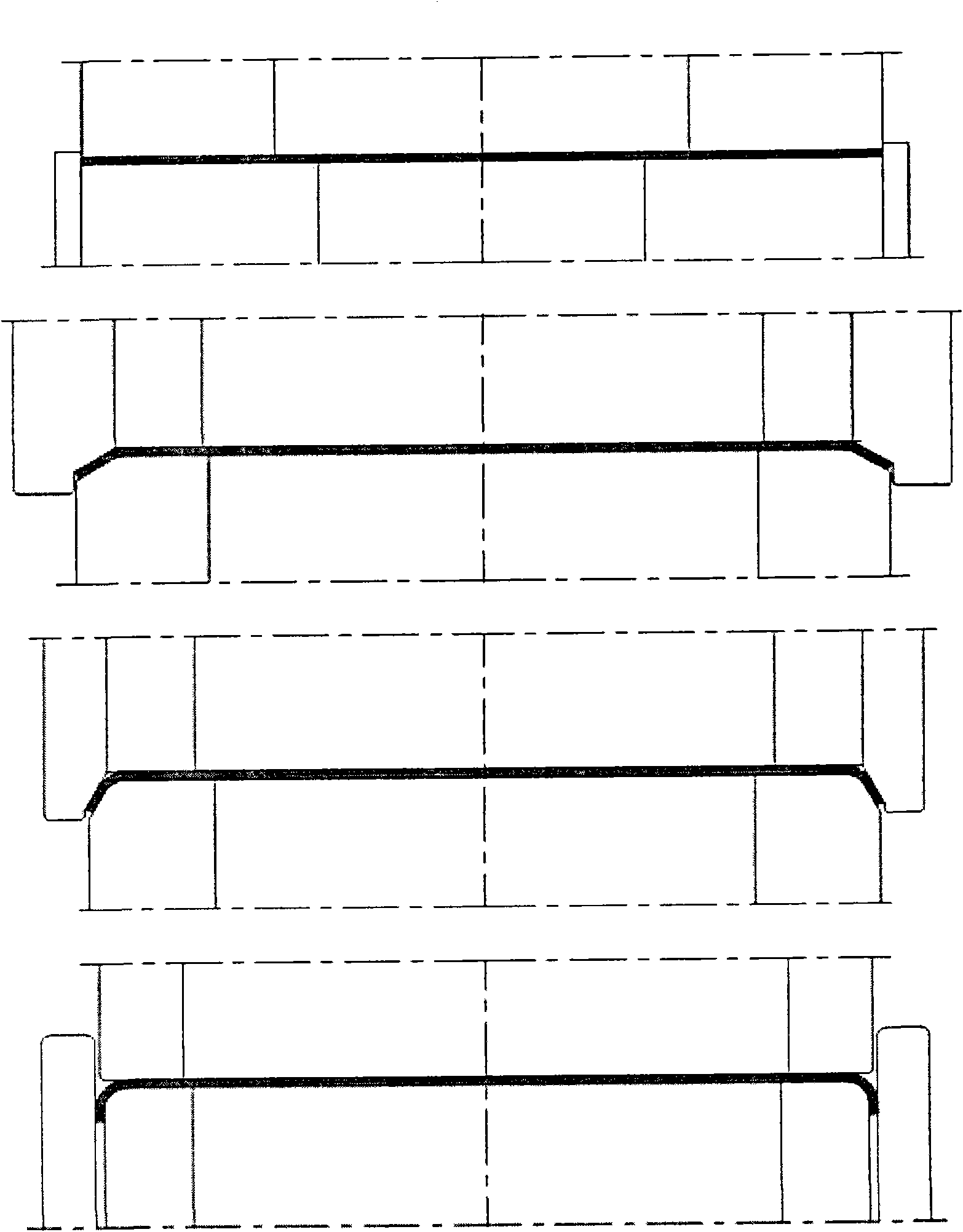

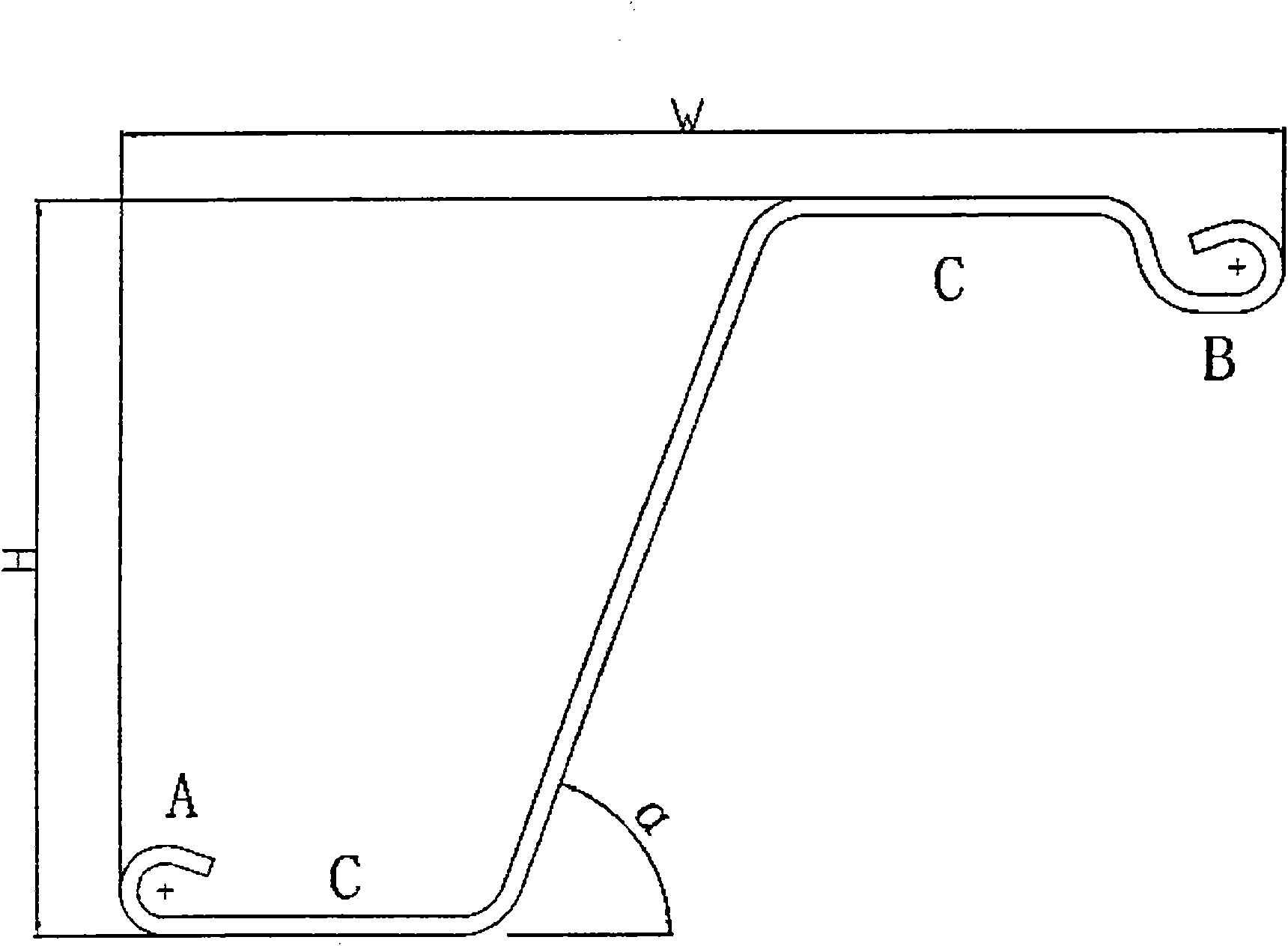

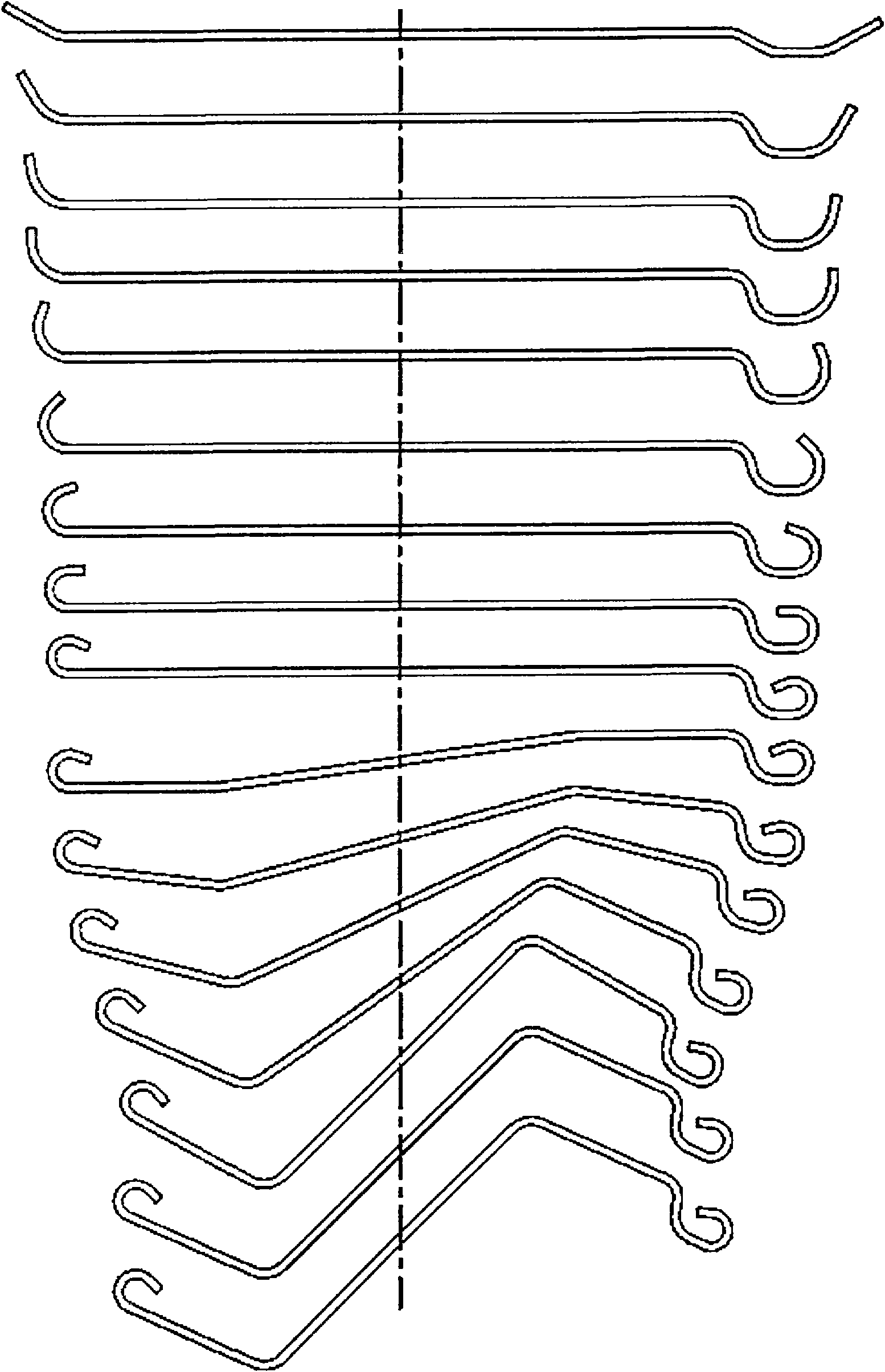

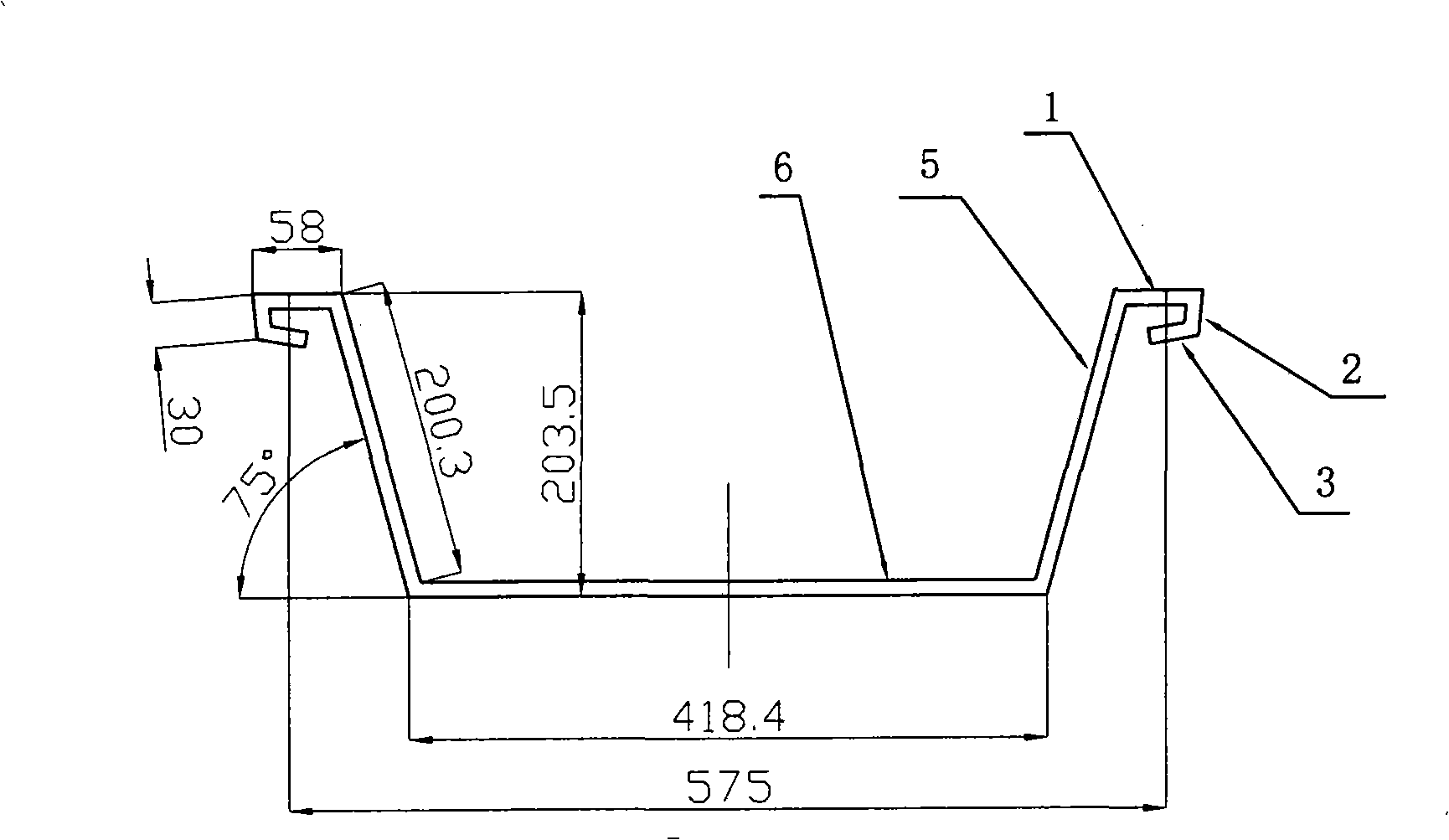

Roll type continuous cold-bending forming fabricating method for U-shaped steel sheet pile

The invention discloses a roll type continuous cold-bending forming fabricating method for a U-shaped steel sheet pile, which comprises the steps of: carrying out continuous rolling and forming by using a cold-bending machine unit and continuously overlapping lateral fore shafts to form a steel structure of sheet pile walls. The process plays an important role in controlling the product quality and improving the mate precision and the connection strength of the fore shafts of the steel sheet pile. The U-shaped steel sheet pile has rich specifications and models, and the most economical and reasonable cross section can be selected according to the actual situation of a project to realize the optimization of engineering design; and compared with a hot rolled steel sheet pile with the same performance, the U-shaped steel sheet pile saves materials of 10% to 15%, which greatly reduces the construction cost.

Owner:NANJING WANHUI STEEL SHEET PILING

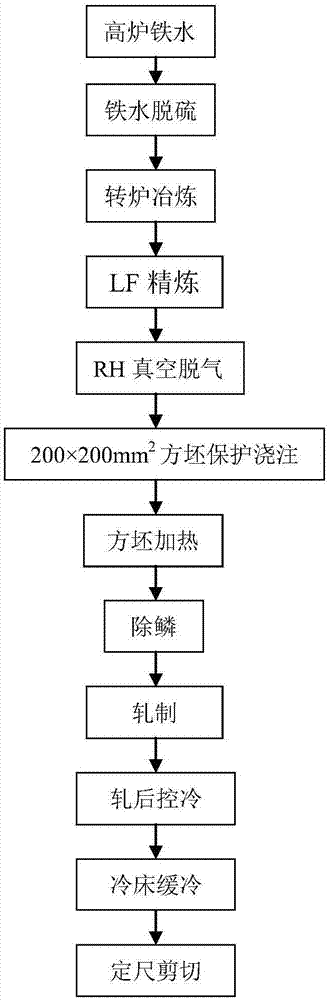

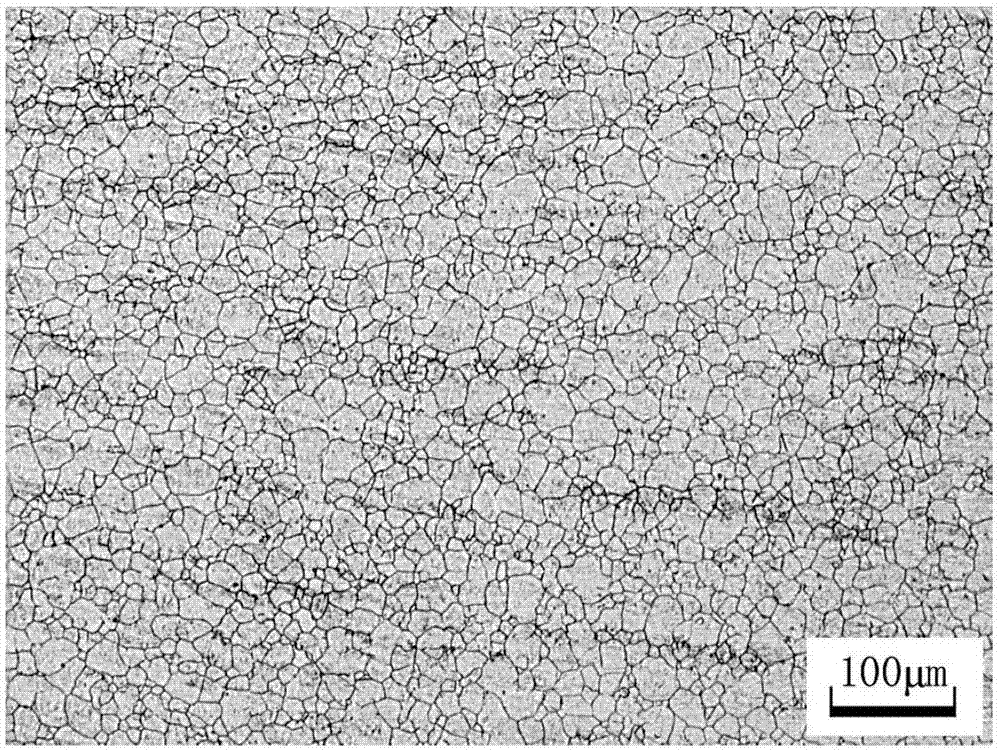

HRB600E vanadium-containing high-strength hot-rolled earthquake-resistant reinforced bar and production method thereof

The invention discloses an HRB600E vanadium-containing high-strength hot-rolled earthquake-resistant reinforced bar and a production method thereof. The reinforced bar comprises the following chemical components in percentage by weight: 0.23-0.30% of C, 0.5-0.8% of Si, 1.20-1.60% of Mn, 0.15-0.20% of V, no more than 0.035% of P, no more than 0.030% of S, 0.015-0.025% of N and the balance of Fe and inevitable impurities. The production method comprises the following steps: performing converter or electric furnace smelting, performing external refining, performing continuous casting, heating a casting blank, rolling and performing air cooling on a cooling bed. According to the invention, the V and N contents in steel are controlled, thereby promoting formation and precipitation of V (C, N) fine particles; steel making and steel rolling process parameters are strictly controlled, thereby obviously enhancing the strength of the reinforced bar and having certain hydrogen corrosion resistance; indicators of the reinforced bar meets the requirements of an earthquake-resistant reinforced bar; and the reinforced bar has the practical meanings of energy saving, emission reduction, high safety and environment friendliness.

Owner:HEBEI IRON AND STEEL

Multiple anti-corrosive controllable expansion extrusion soil anchor and construction method

InactiveCN101550696AEasy constructionFast constructionExcavationsBulkheads/pilesSlurryExpansion joint

Multiple anti-corrosive controllable expansion extrusion soil anchor, including anchorage segment, free-tensioned segment, outer anchor, grouting pipe, at least one power transmission member and more than one loading plates, the anchorage segment includes controllable expansion extrusion soil apparatus for geotechnical engineering use, which includes upper sleeve components, lower sleeve components and expansion extrusion barrel which is filled of cement-based slurry or cement-based slurry containing expansion agent inside. The construction method of the multiple anti-corrosive controllable expansion extrusion soil anchor includes inject the cement-based slurry or cement-based slurry containing expansion agent into the expansion extrusion barrel of deep anchor hole. The objective is to provide a multiple anti-corrosive controllable expansion extrusion soil anchor and construction method which is suitable for complicated, flaccidity, corrosivity stratum, being capable of repressing anchorage slurry loss and controlling expansion size of anchorage segment, high bearing capacity, good durability, low cost.

Owner:CHINA JINGYE ENG TECH CO LTD +1

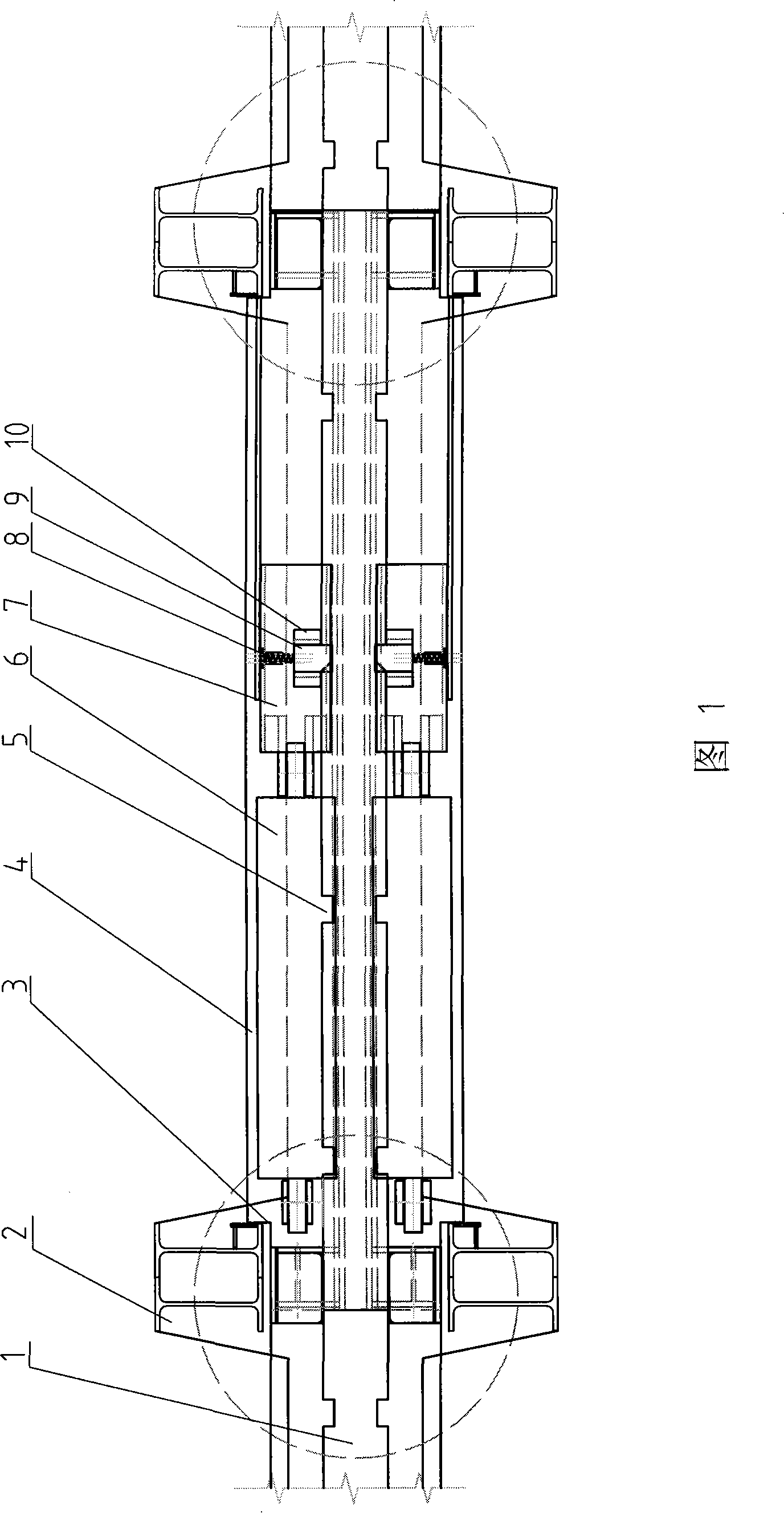

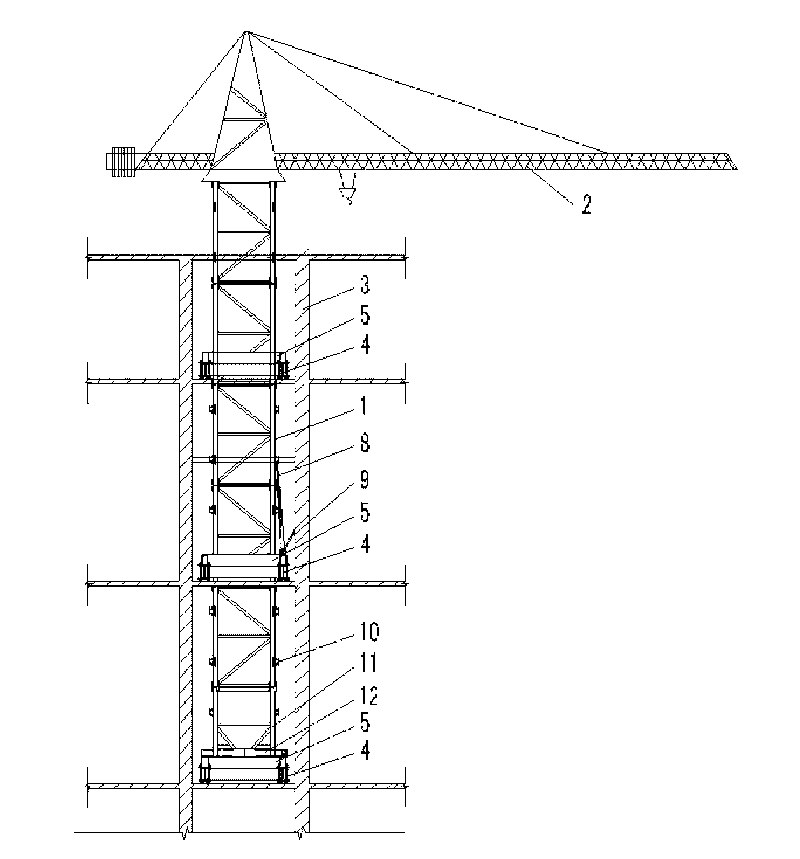

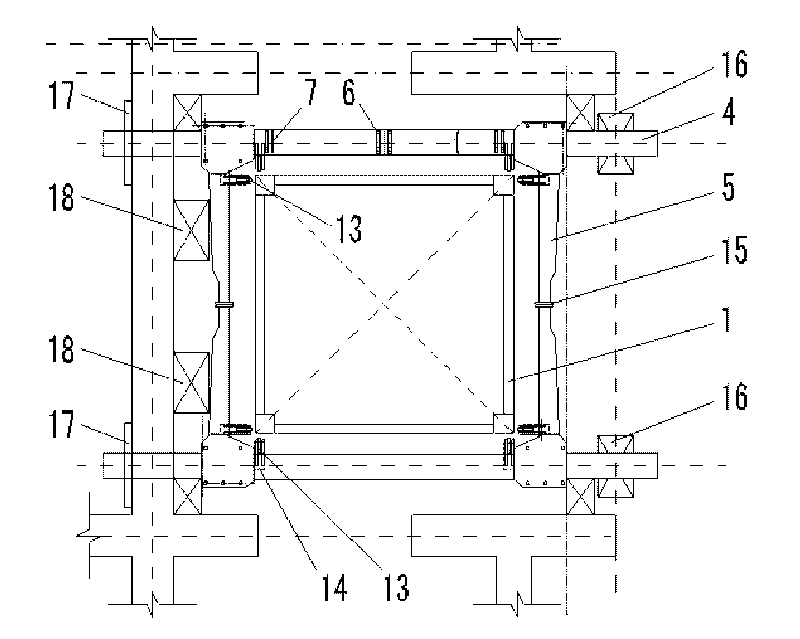

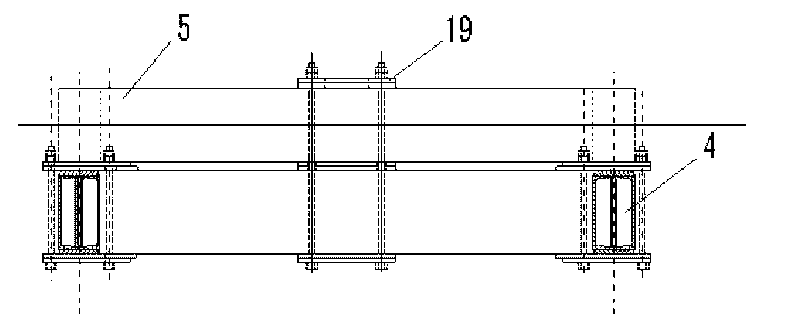

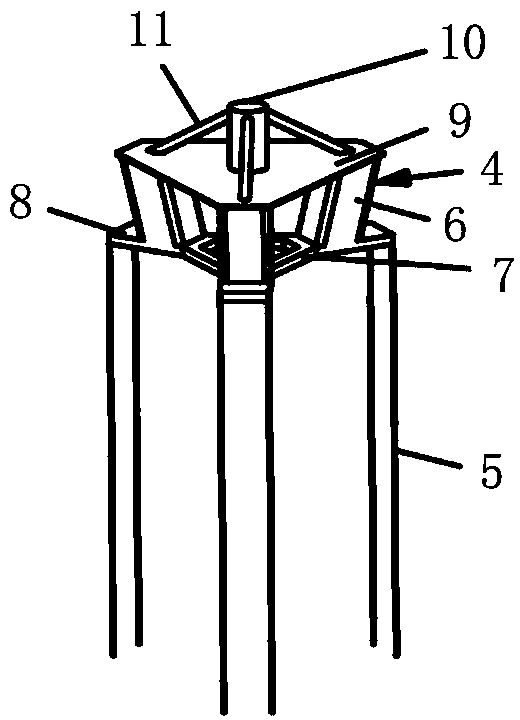

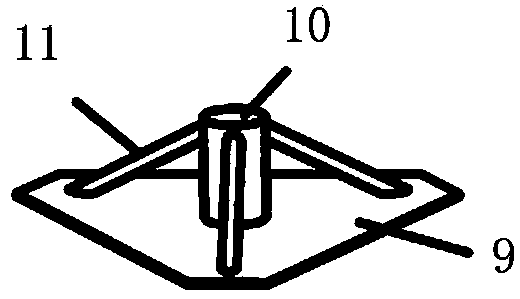

Self-climbing tower crane

InactiveCN101691191AHave vertical transportation requirementsMeet vertical transportation requirementsCranesSocial benefitsTower crane

The invention discloses a self-climbing tower crane, which comprises a tower body (1), a hoisting arm (2) and a climbing mechanism, wherein the climbing mechanism comprises a main stressed supporting steel beam (4) and a steel structure climbing attached frame (5); the steel structure climbing attached frame (5) is fixedly connected on the main stressed supporting steel beam (4) and is provided with a jacking cylinder (8) and a supporting steel beam (9); and a tower body supporting tread (10) is arranged on a tower body (1), and the bottom of the tower body (1) is provided with a climbing base section (11). The self-climbing tower crane can climb upward along a constructed structure by using the constructed building structure as a support, meet the requirements of superhigh-rise and out-of-code tall buildings on vertical transportation at the whole construction height, contribute to construction efficiency, construction period reduction, steel conservation and energy conservation and create obvious economic and social benefits.

Owner:CHINA CONSTR FOURTH ENG DIV

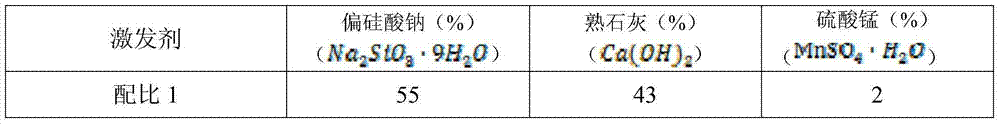

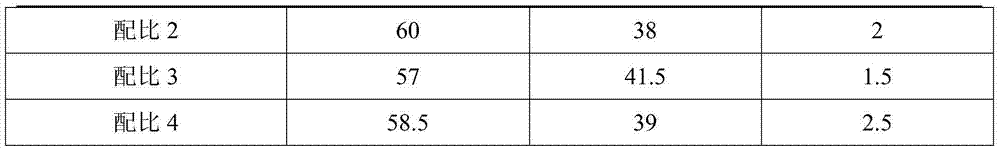

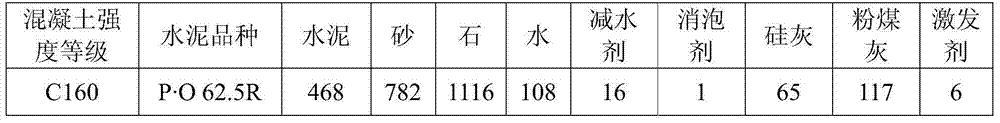

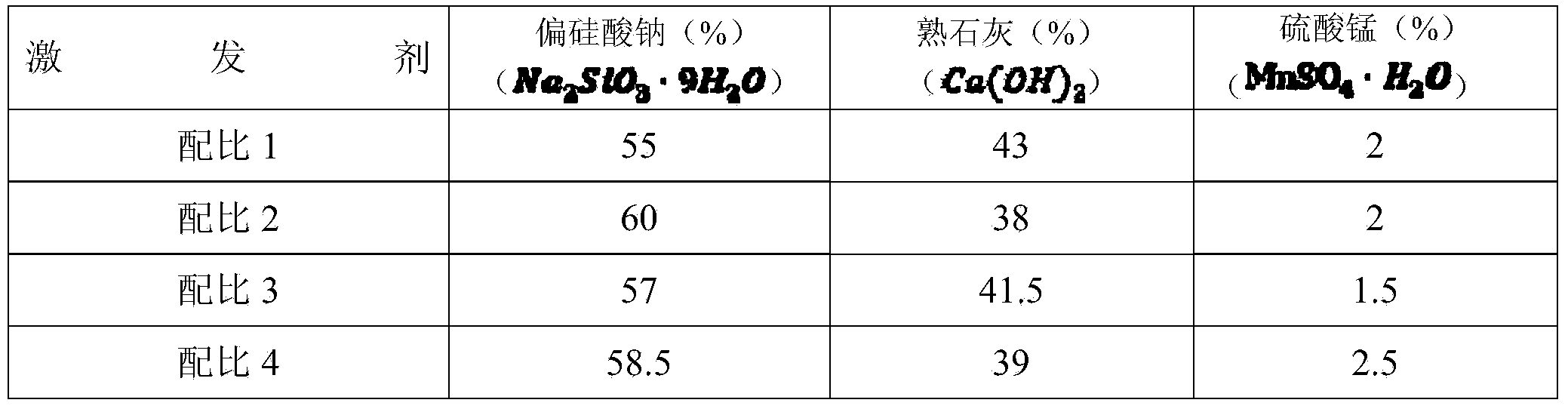

Concrete for steel reinforced concrete combined structure with C160 strength level

InactiveCN103539407AIncreased durabilityHigh strength and durabilityCarrying capacityReinforced concrete

The invention discloses concrete for a steel reinforced concrete combined structure with C160 strength level. The concrete is composed of cement, fine aggregate, coarse aggregate, water, a concrete super plasticizer, a defoaming agent, silica fume, fly ash and an activator according to a ratio of 468:782:1116:108:16:1:65:117:6. The preparation method is as follows: firstly, uniformly mixing the concrete super plasticizer and the activator in weighed water to obtain a mixture, sequentially adding 1 / 3 of total dosage of the fine aggregate and the mixture in a stirring machine according to a weight ratio, and stirring; adding 1 / 3 of total dosage of the coarse aggregate and the mixture and stirring; and adding the cement, the silica fume and the fly ash, and stirring; and adding the defoaming agent and the rest mixture, stirring and discharging. The concrete can greatly perfect the adhesive property between section steel and the concrete under a natural state, effectively play the respective mechanical properties and mutual cooperative working performance of the steel and the concrete and greatly improve the carrying capacity, application performance and durability of the structural member, thereby having good high-volume stability and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

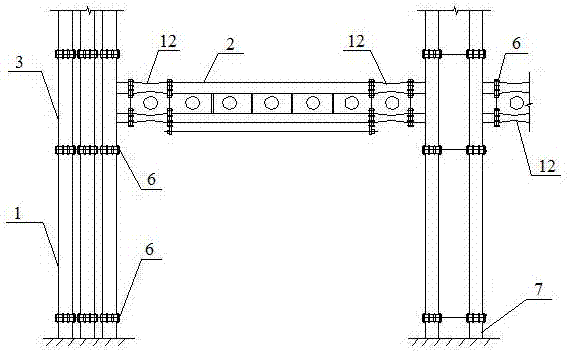

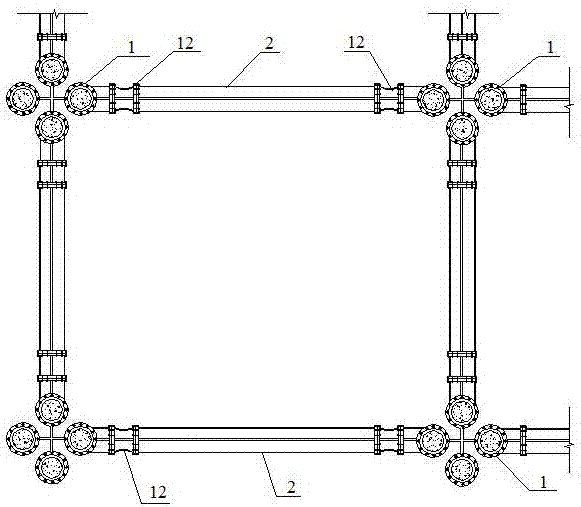

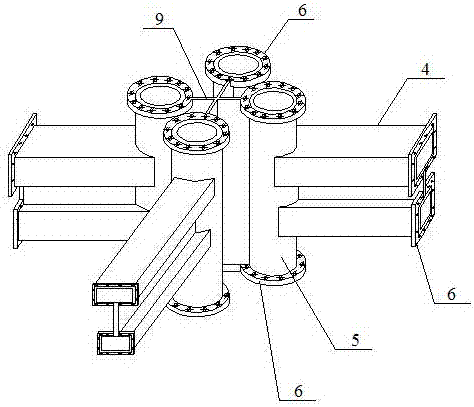

Composite frame system with beam column flanges being made of steel pipe concrete and construction method

ActiveCN106869316ASimplify the construction processLabor savingStrutsPillarsComposite beamsBeam column

The invention relates to a composite frame system with beam column flanges being made of steel pipe concrete and a construction method. The composite frame system with the beam column flanges being made of the steel pipe concrete is formed by connecting composite columns with composite beams through joints. The composite beams are horizontally arranged among the composite columns. The joints are steel pipe concrete integral type joints. The composite columns are cross-shaped or I-shaped composite columns with the flanges being made of the circular steel pipe concrete. The composite beams are I-shaped honeycombed beams with the flanges being made of the steel pipe concrete. The joints and the composite columns are fixedly connected at respective connecting plates through high-strength bolts. The joints and the composite beams are connected through buffer sections which are I-shaped honeycombed beams with the flanges being made of the steel pipe concrete. The cross sections of the buffer sections are variable cross sections gradually diminished from the two ends to the centers, and the cross sections of the buffer sections are smallest at the midpoints. The problems that according to an existing steel-concrete composite structure, construction is complex, connection and stability between the composite structure are poor, and the joints are liable to damage under the earthquake effect are solved.

Owner:青岛义和钢构集团控股有限公司

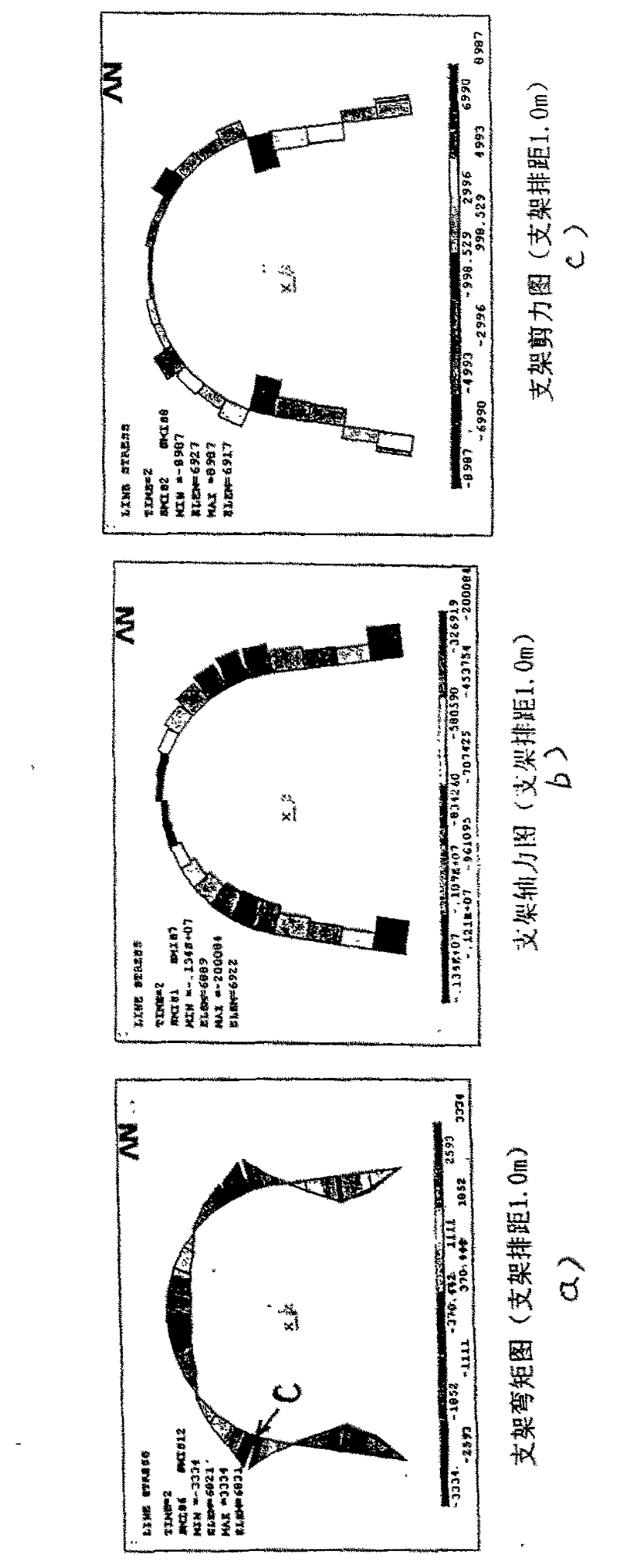

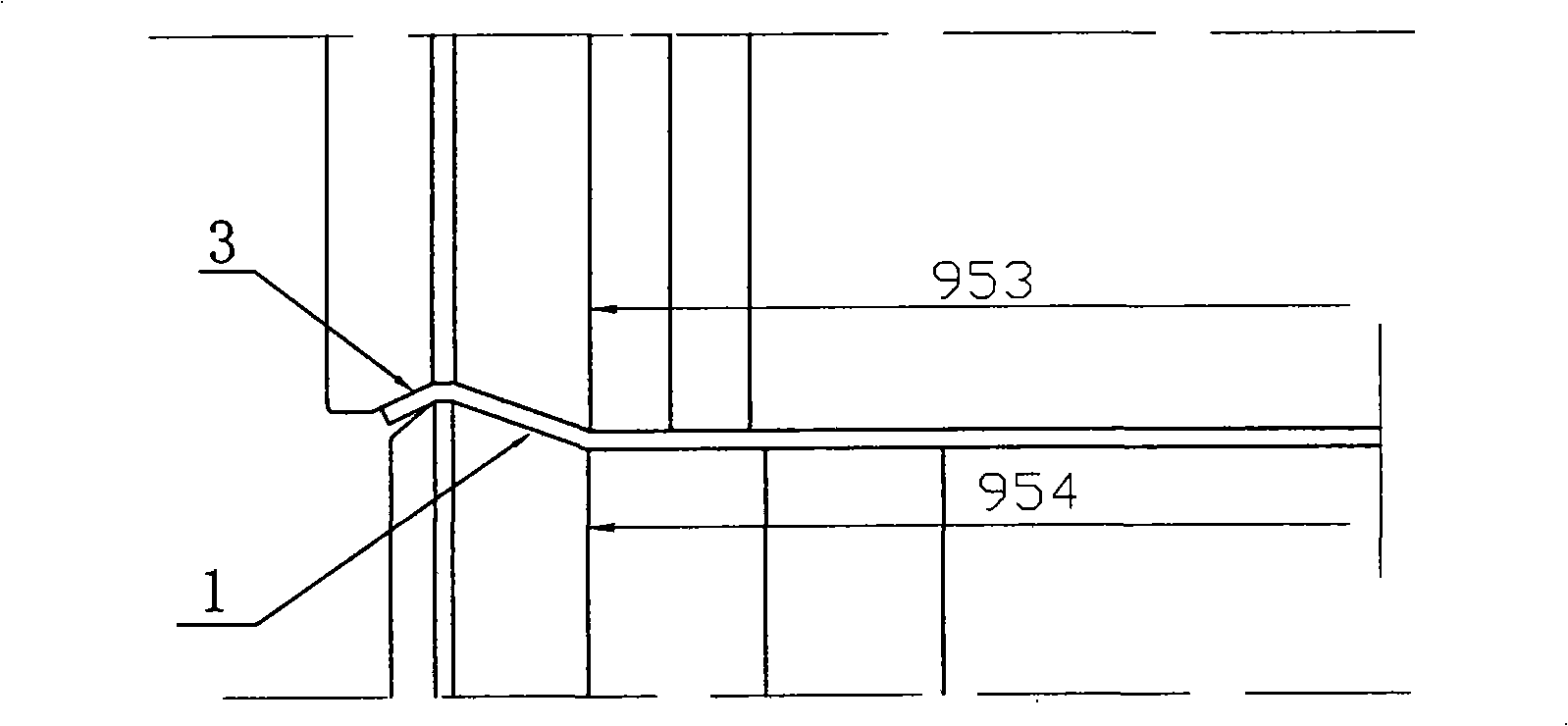

A method for improving the stability of U-shaped steel arch support and connecting components

InactiveCN102268999AIncrease spacingNo wasteUnderground chambersTunnel liningGreenhouseCritical load

A method for improving the stability of U-shaped steel arch support and a connecting component, which are used in the field of roadway excavation support. The retractable support must rely on the friction of the overlapping section to conduct the support, and the failure of the card to loosen accounts for 50% of the accident rate. According to the principle of mechanics, any roadway section, regardless of whether the shape of the arch frame is closed or not, when the steel section is determined, the longer the connection with the card, the more complete, the lower the critical load, and even the overall strength of the material fails due to local weakness. Steady and crumbling. The new method enhances the critical load and support through comprehensive measures such as local reinforcement with moderately variable cross-section to increase the moment of inertia of the weakest part, effective fractured top-to-top connection at the part with large curvature, and mutual pulling between the supports. overall stability. Based on this method, technology and the internal force characteristics of the arch under pressure, several sets of special connecting components are designed. The new method can reduce support accidents, increase shed spacing, reduce support strength and greatly reduce steel consumption.

Owner:颜曙光

Manufacture method of Z-shaped steel sheet pile through continuous cold roll forming

The invention discloses a manufacture method of a Z-shaped steel sheet pile through continuous cold roll forming by continuously rolling and forming with a cold bending unit and distributing preliminary shafts at both sides of a central shaft. Web plates are continuous so as to greatly improve the modulus and the flexible rigidity of a cross section and fully exert the mechanical characteristic of the cross section. The manufacture process takes great effects in aspects, such as controlling the quality of the cold-bent Z-shaped steel sheet pile, improving the matched accuracy and the connection strength of the preliminary shafts of the steel sheet pile, and the like. The invention controls the product size and overcomes the defects generated in the processing process by performing the preliminary shafts of the cold-bent Z-shaped steel sheet pile and wholly forming the Z-shaped steel sheet pile.

Owner:NANJING WANHUI STEEL SHEET PILING

The method of the orientation profiling of the lanthanide permanent magnet and preparation device for the same

InactiveCN1996514AReduce volumeReduce consumptionPermanent magnetsInorganic material magnetismHead pressingRare earth

This invention relates to one rare each permanent part pressing and shaping method and its magnetic adding device and taking device, wherein, the shaping method comprises the following steps: top head presses the material case into magnetic powder into mode; top and down heads unmoved and negative mode elevates to fill powder into magnetic field; top head and negative mode unmoved, the top head presses into magnetic part; the negative mode drops till whole magnetic part outside negative mode; the top head elevates to push pull bar into finally product area; the materials add devices comprises materials case and barrel with changeable height.

Owner:姚燕 +1

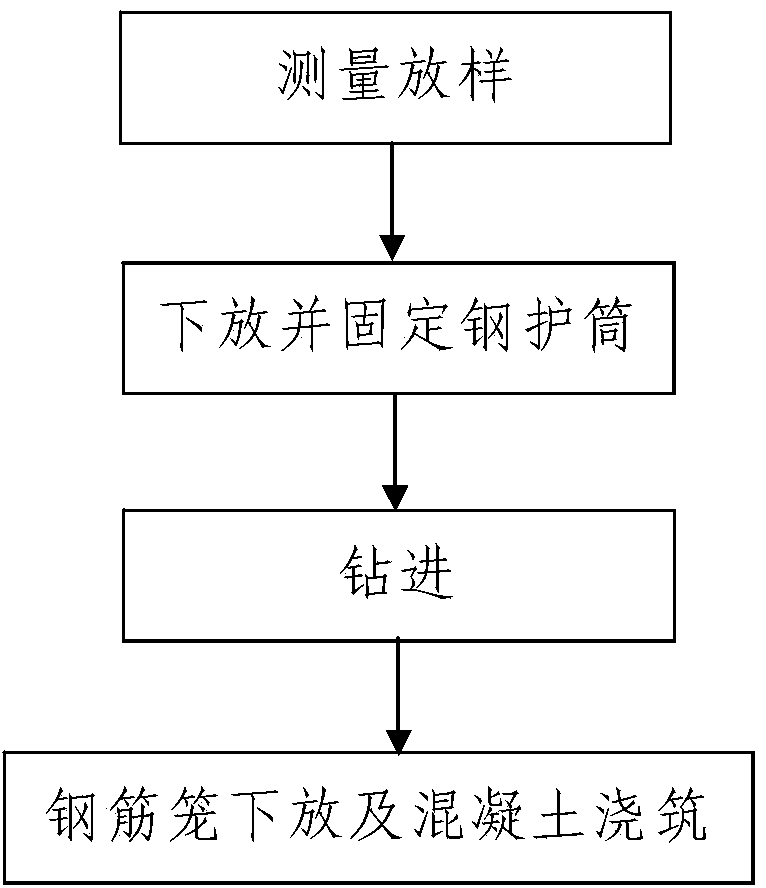

Karst-area underwater bridge pier drilled pile construction method

ActiveCN103469789AThe method steps are simpleReasonable designDrill bitsEmbankmentsEnergy transferUnderwater

The invention discloses a karst-area underwater bridge pier drilled pile construction method. The construction drilled pile passes through one or more karst caves from top to bottom according to the following steps that (1) measuring staking-out is conducted; (2) a steel protection barrel is put downwards and fixed; (3) drilling is carried out, namely, the steel protection barrel is put downwards and drilled from top to bottom through a percussion drill until the designed depth is reached, a slurry breast wall is adopted in the drilling process, when the drilled pile is drilled to enter the karst caves needing passing from top to bottom in the drilling process, an energy transfer method is firstly adopted to process the karst caves needing passing under the current state, then downward drilling is continuously carried out through the percussion drill; (4) a steel reinforcement cage is put downwards and concrete pouring is conducted. The karst-area underwater bridge pier drilled pile construction method is simple in step, reasonable in design, low in input cost, convenient to achieve, good in construction effect and capable of simply, conveniently and fast finishing the karst-area drilled pile construction process at a low cost in a high-quality mode.

Owner:中铁建安工程设计院有限公司 +1

Square steel pipe fabricated column-prefabricated superposed beam integrally-fabricated frame and construction method

InactiveCN104499568ALabor savingImprove product qualityClimate change adaptationBuilding material handlingSteel tubeHigh performance concrete

The invention discloses a square steel pipe fabricated column-prefabricated superposed beam integrally-fabricated frame and a construction method. The frame comprises a square steel pipe with inner and outer ribs, a square steel pipe casing with connecting wing plates and a prefabricated superposed beam. The square steel pipe is formed by rolling once, a thin centrifugally-produced concrete protective wall is arranged inside the square steel pipe, and high-performance concrete wraps the square steel pipe, so that a square steel pipe fabricated column is formed. The square steel pipe casing with the connecting wing plates is used for vertical connection between one upper square steel pipe fabricated column and one lower square steel pipe fabricated column as well as connection between the prefabricated superposed beam and the square steel pipe fabricated column. Short I-beams are arranged at the ends of the prefabricated superposed beam, and the prefabricated superposed beam is connected with the connecting wing plates on the square steel pipe casing through high-strength bolts. An engineered cementitious composite or fiber reinforced cement composite is poured in beam-column joint connection areas. The concrete fabricated superposed beam is connected with prefabricated floor slabs as well as the prefabricated floor slabs are connected both through fiber reinforced composite plastic boards. A prefabricated house has the advantages of reasonable stress, convenience in construction, high joint ductility, good endurance and anti-seismic performance and the like.

Owner:SOUTHEAST UNIV

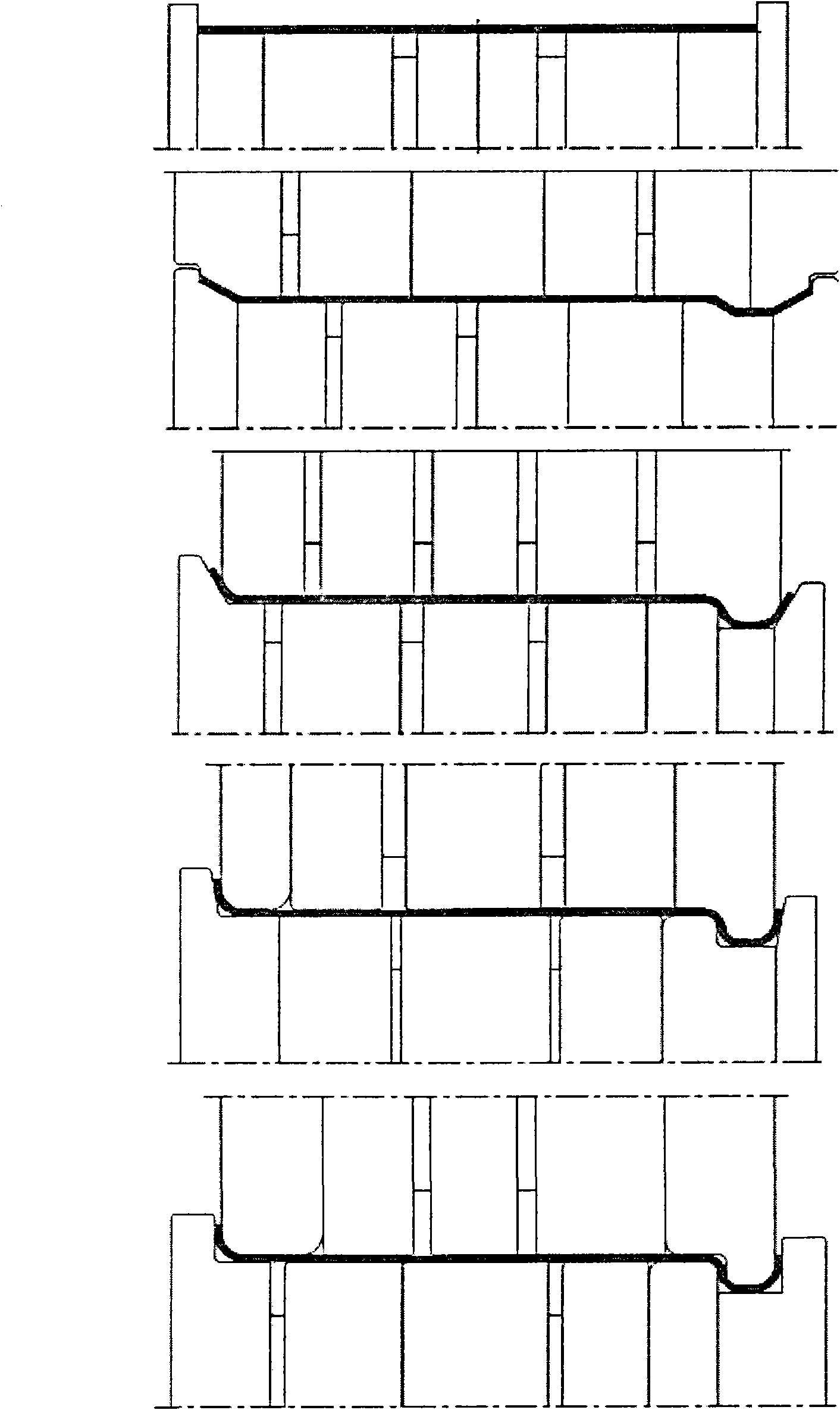

Continuous roller type cold bending shaping method for metal sheet pile

The invention relates to a continuous roll type cold-bending forming method for a steel sheet pile, including scrolling, continuous cold-bending forming and cutting; the method is characterized in that the continuous cold-bending forming refers to that the scrolled steel band is fed into a production line of a multi-pass continuous roll type cold-bending forming machine set for multi-pass continuous roll type cold-bending forming, a frame at each pass is provided with an upper rotation axis and a lower rotation axis which are equipped with inosculated dies, the upper rotation axis and the lower rotation axis rotate oppositely, one rotates along the clockwise direction, while the other rotates along anticlockwise direction; in this way, a scrolled steel plate moves forwards depending on friction force in the roll gap of rotation dies inosculated up and down after being well adjusted and enters the next pass for continue forming, when entering each pass for forming, the steel plate is forced to deform under the action of the inosculated dies, each pass completes setting forming amount, and the forming of the steel sheet pile is finally completed through a plurality of passes, thus rolling the products of the steel sheet pile in line with requirements. The method has the advantages of energy saving, environmental protection, high production efficiency and complete specification, length and size of products.

Owner:江苏顺力冷弯型钢实业有限公司

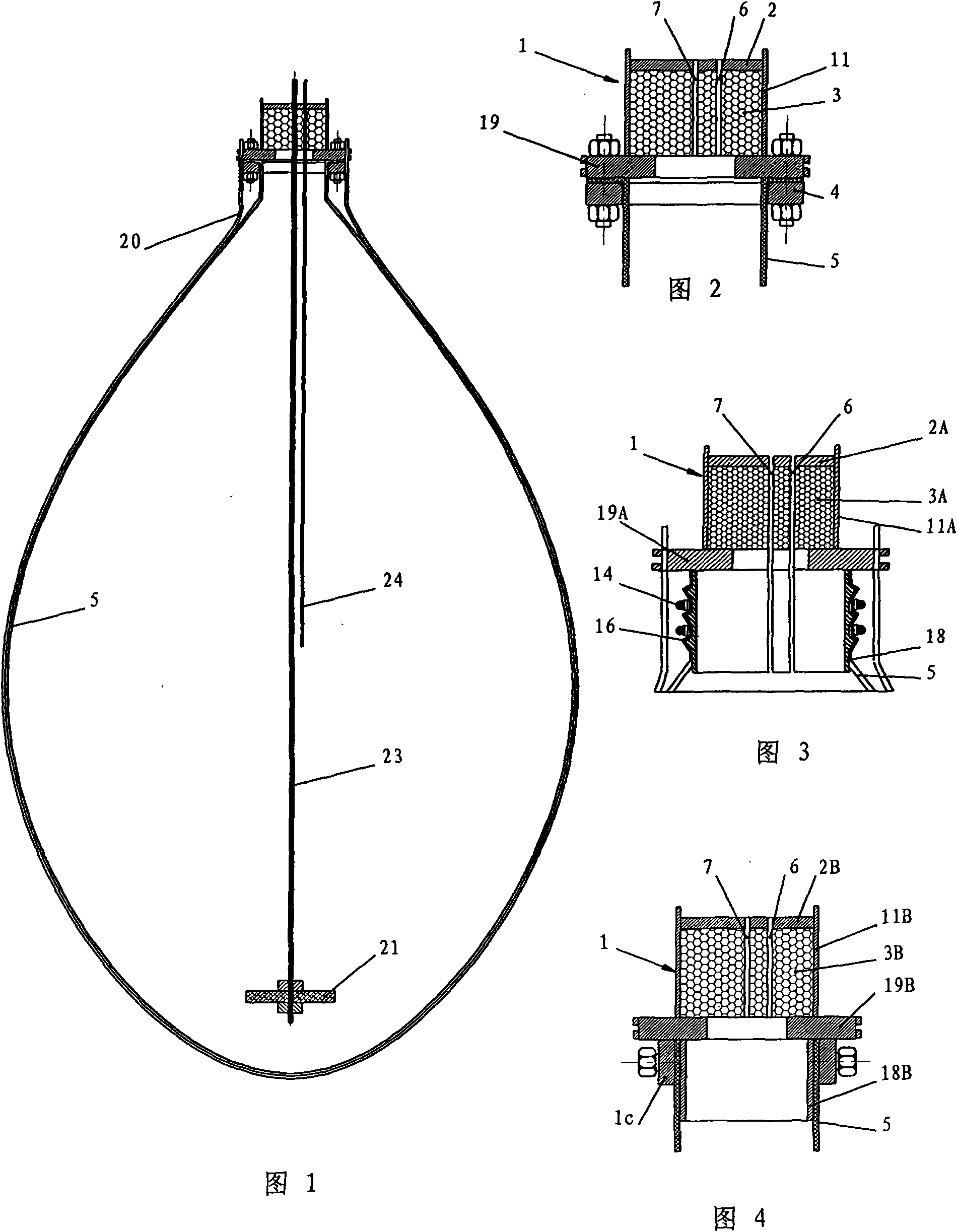

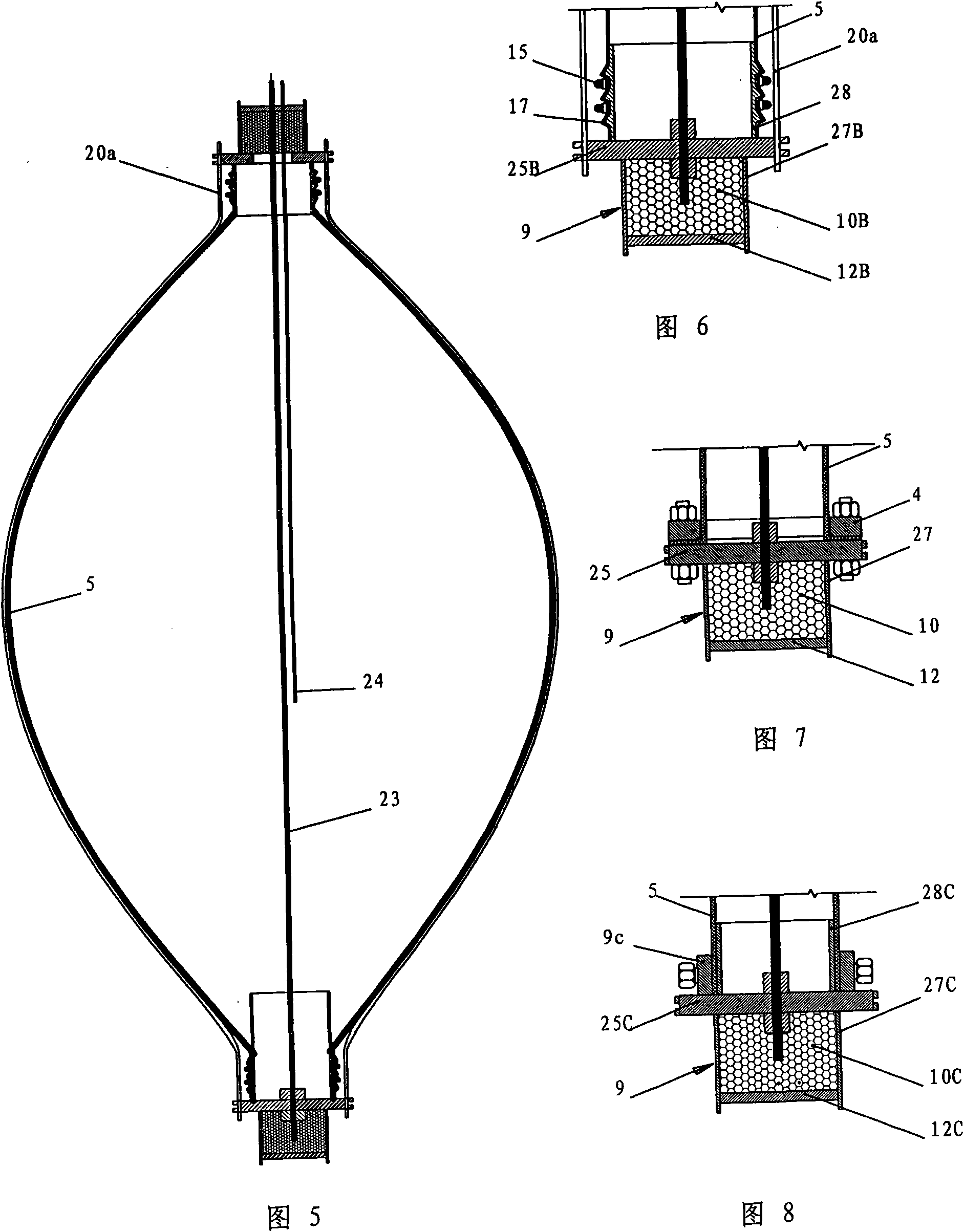

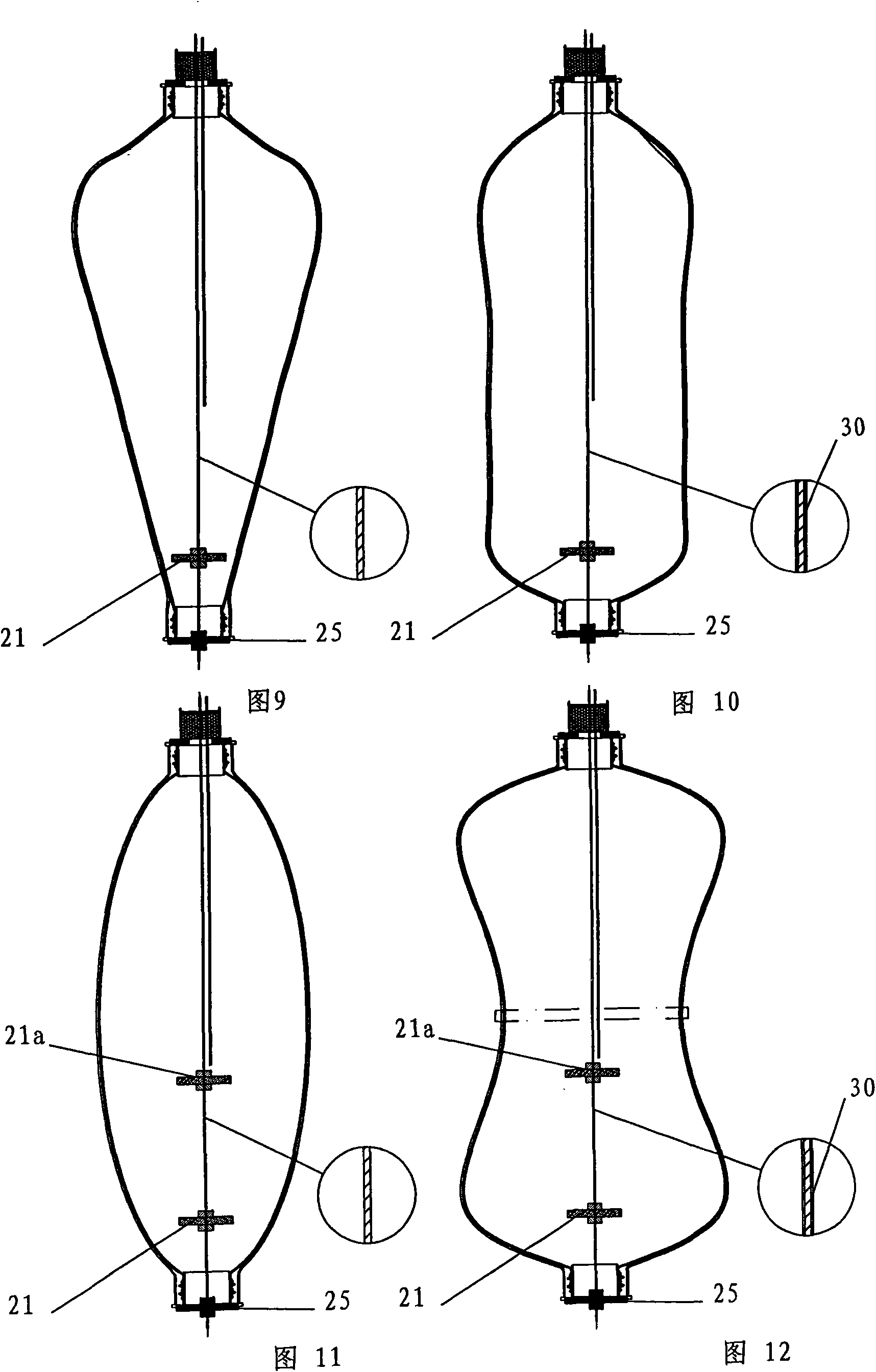

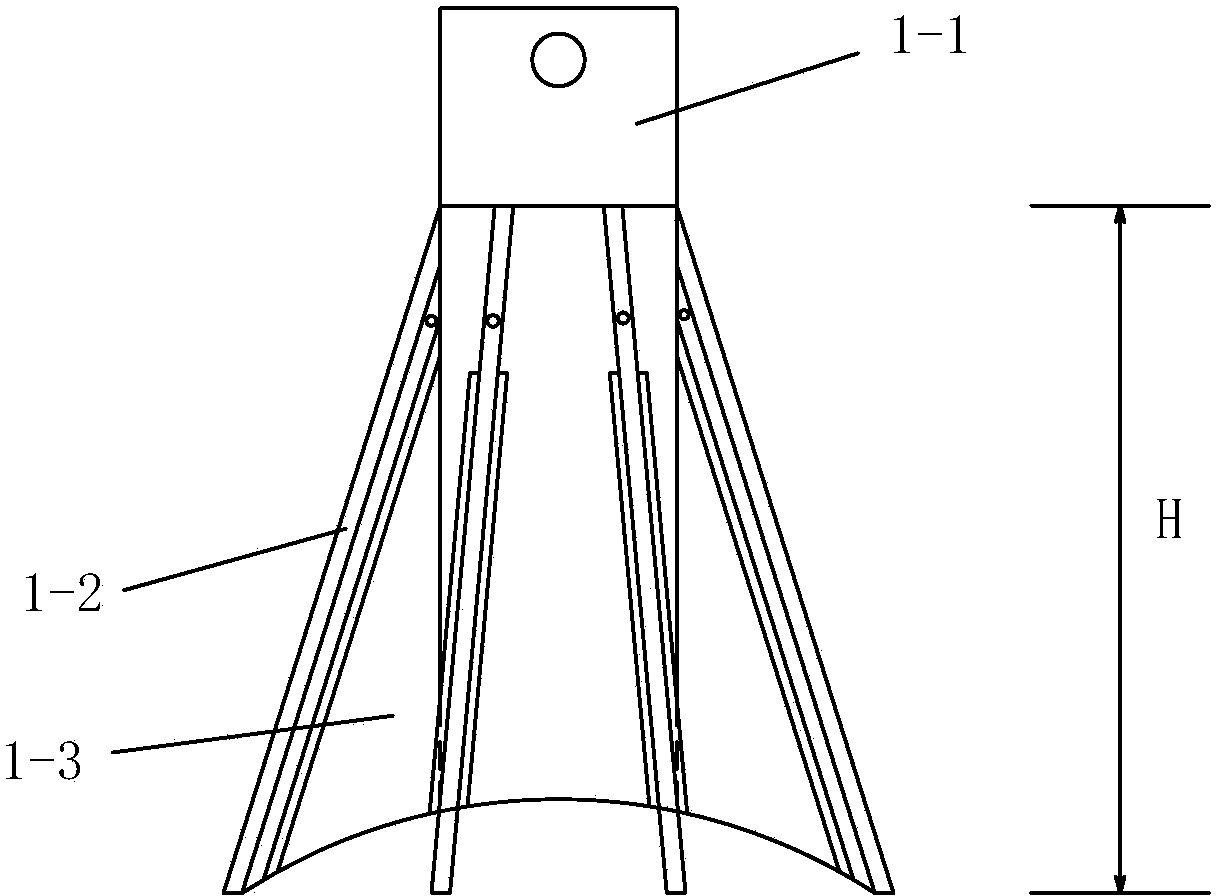

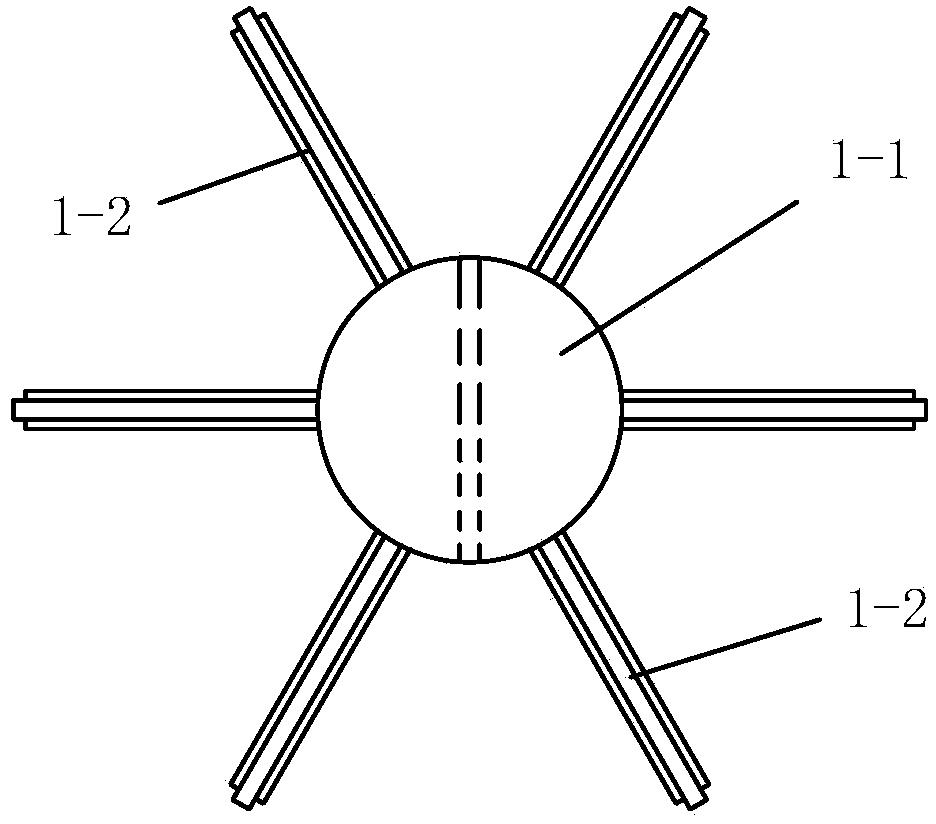

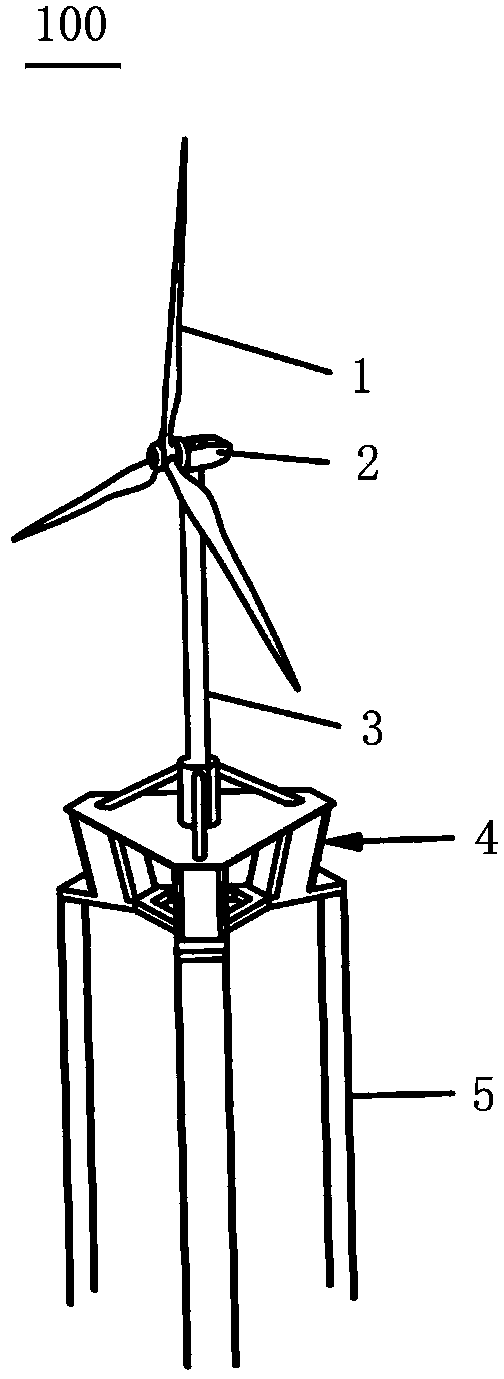

Floating fan base with flare type tension legs, marine wind-driven generator and construction method

ActiveCN103818523AStable stateOvercome the defect of excessive horizontal movementFinal product manufactureWind motor supports/mountsWind drivenEngineering

The invention discloses a floating fan base with flare type tension legs, a marine wind-driven generator and a construction method. The floating fan base comprises a top supporting platform, a bottom supporting structure, at least three hollow stand columns and a ballast regulating system, wherein the top supporting platform is used for supporting a pylon, blades and a wind-driven generator set; the bottom supporting structure is connected with multiple tension legs; the top supporting platform is connected with the bottom supporting structure via the hollow stand columns, the hollow stand columns are arranged around the vertical center line of the floating fan base, and each stand column inclines outwards from a lower end to an upper end relative to the vertical center line of the floating fan base; the ballast regulating system is arranged in the stand columns and / or the bottom supporting structure. The marine wind-driven generator of the base with the structure has excellent movement performance, integral wet towing can be performed, and the floating fan base and the marine wind-driven generator are convenient to manufacture, assemble and mount.

Owner:XINJIANG GOLDWIND SCI & TECH

Spring steel and surface decarbonization control process thereof

The invention discloses spring steel which is prepared from the following components in percentage by weight: 0.56-0.64% of C, 1.5-2.0% of Si, 0.70-1.00% of Mn, less than or equal to 0.035% of P, less than or equal to 0.035% of S, 0.10-0.35% of Cr, 0.01-0.04% of Nb and the balance of Fe and impurity elements. High-end spring steel which is uniform in structure, stable in performance, high in strength, good in plasticity, and especially has excellent controlled performance of a surface decarburized layer can be developed by adopting a niobium micro-alloying method and integrating a proper clean steel smelting process, a continuously-cast blank surface defect control technology, a heating furnace fuel and in-furnace atmosphere optimization technology, and the problems such as a complex production process, high alloy cost and low production efficiency in an existing spring steel preparation method are effectively solved.

Owner:武汉钢铁有限公司

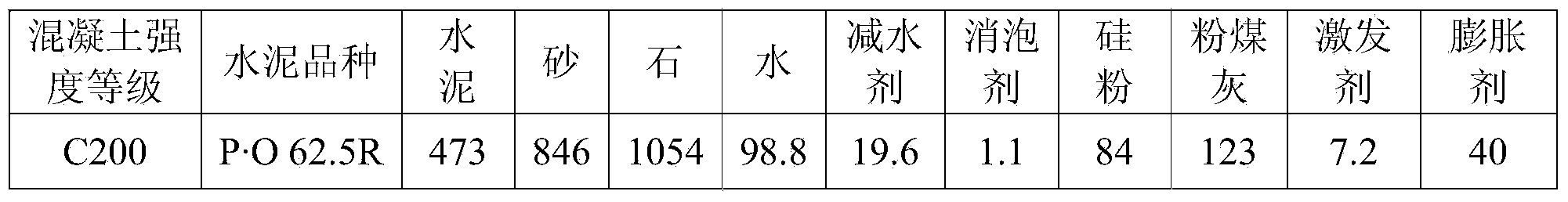

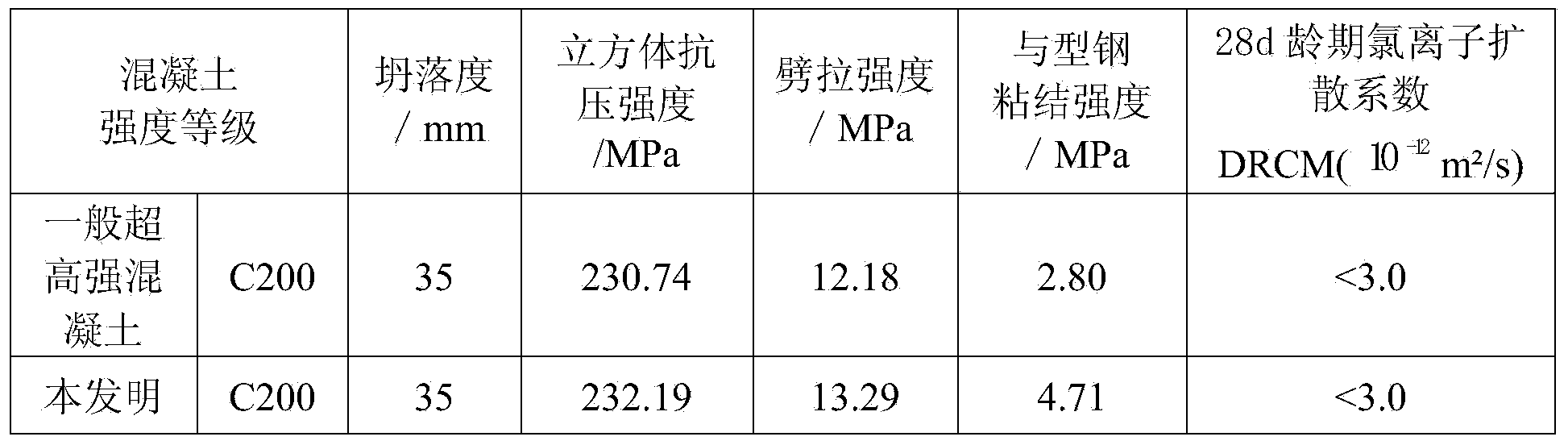

C200 strength-grade concrete for formed steel concrete composite structure

InactiveCN103553460AIncreased durabilityHigh Strength and DurabilitySolid waste managementNatural stateSuperplasticizer

The invention discloses a C200 strength-grade concrete for a formed steel concrete composite structure, which is composed of 473 parts of cement, 846 parts of fine aggregate, 1054 parts of coarse aggregate, 98.8 parts of water, 19.6 parts of concrete superplasticizer, 1.1 parts of defoaming agent, 84 parts of silicon powder, 123 parts of expanding agent, 7.2 parts of activator and 40 parts of expanding agent. The preparation method comprises the following steps: blending the concrete superplasticizer and activator into weighed water to obtain a mixture, sequentially adding the fine aggregate and 1 / 3 of the mixture into a stirrer according to parts by weight, and stirring; adding the coarse aggregate and 1 / 3 of the mixture, and stirring; adding the cement, expanding agent, silicon powder and fly ash, and stirring; and adding the defoaming agent and the rest of mixture, stirring and discharging. The concrete can obviously improve the bonding property between the formed steel and the concrete in a natural state, effectively displays the respective mechanical properties and the synergic working performance of the steel and concrete, greatly enhances the loading capacity, service performance and durability of the structural member, and has high volume stability and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for realizing abrasion proof treatment to loader hopper and special welding wire thereof

InactiveCN101456123AImprove efficiencySuitable for mass productionArc welding apparatusWelding/cutting media/materialsIsosceles trapezoidSheet steel

The invention discloses a method for performing anti-wear treatment on a hopper of a loading machine, which comprises the following steps: using a low-carbon steel or low-alloy steel plate as a base plate, selecting a build-up welding flux-cored soldering wire of which the diameter is between 2.0 and 4.0 millimeters special for the hopper of the loading machine, and welding a wear-resisting layer of which the thickness is between 3.5 and 8.0 millimeters on the base plate by adopting a visible arc build-up welding or gas coverage build-up welding process to prepare a wear-resisting composite steel plate; by adopting a plasma cutting device, cutting out a left wear-resisting plate and a right wear-resisting plate in a right trapezoid shape respectively, a middle wear-resisting plate in an isosceles trapezoid shape, and two bottom plates in isosceles trapezoid shapes on the wear-resisting composite steel plate; leveling the plates; and putting the cut wear-resisting layers of the left wear-resisting plate, the middle wear-resisting plate, the two bottom plates and the right wear-resisting plate outwards, and welding the wear-resisting layers on the outside surface of the hopper bottom of the main cutting board side of the hopper respectively through gas shielded arc welding or welding rod arc welding so that the wear-resisting layers are integrated with the original hopper bottom into a whole. After the treatment by the method, the service life of the hopper is greatly improved, the frequent maintenances are avoided, the working efficiency of the loading machine is improved, and steel materials are saved.

Owner:SHANDONG LINGONG CONSTR MACHINERY

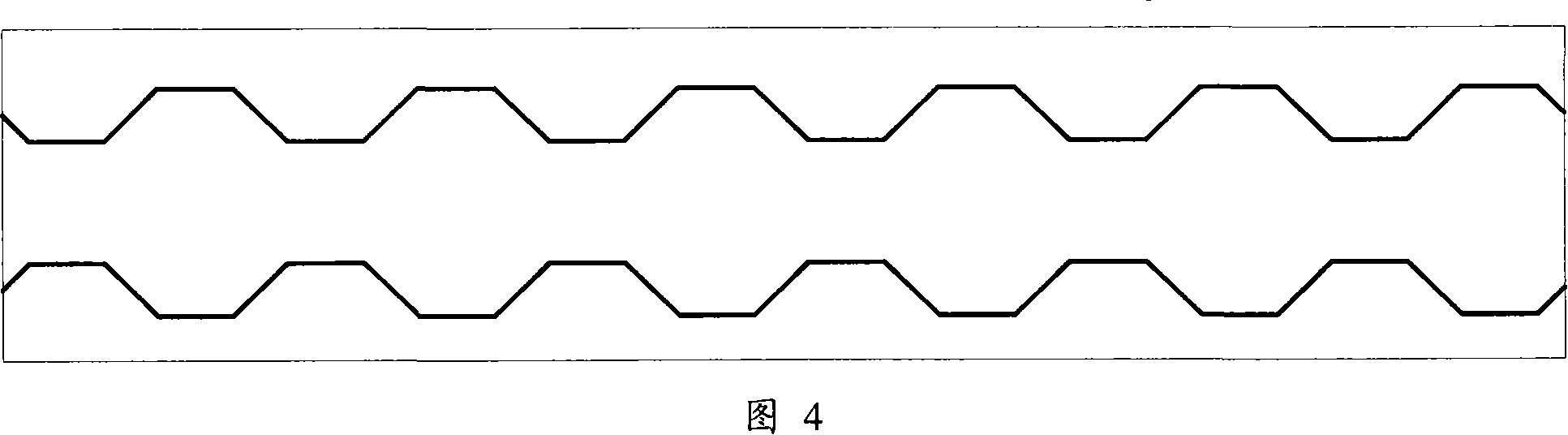

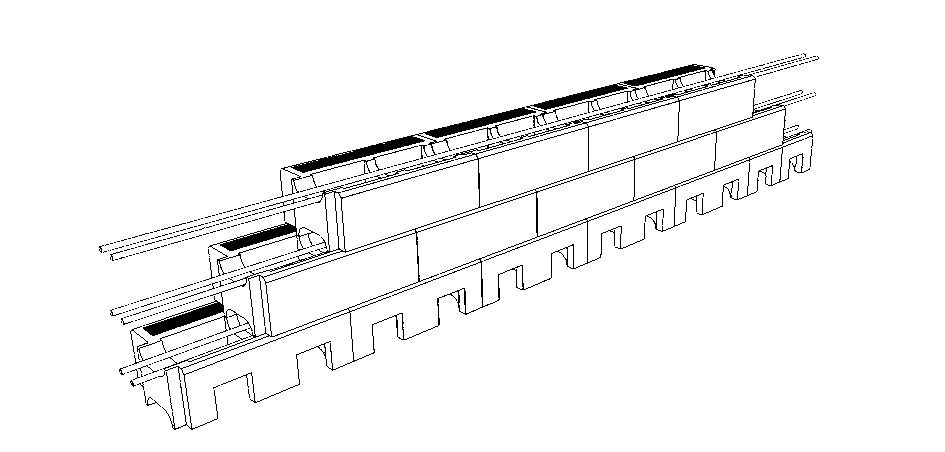

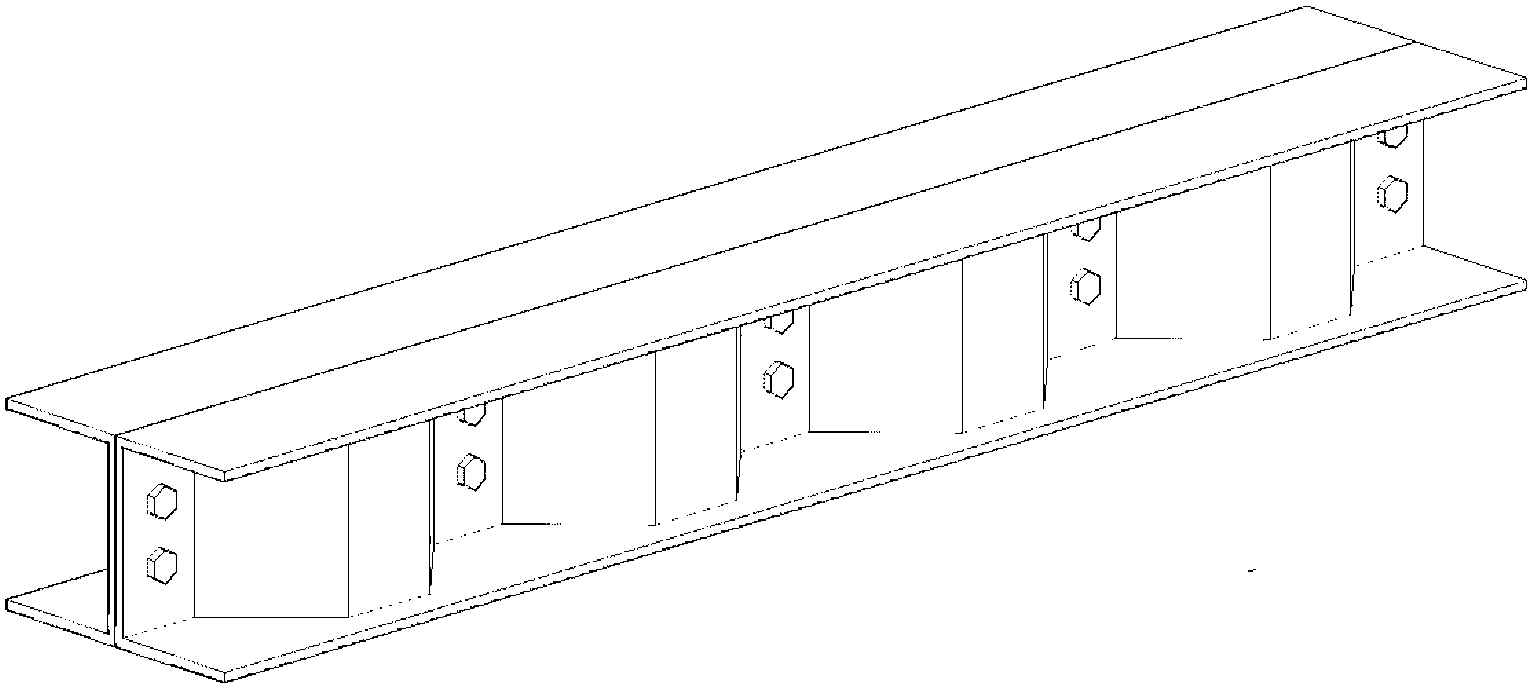

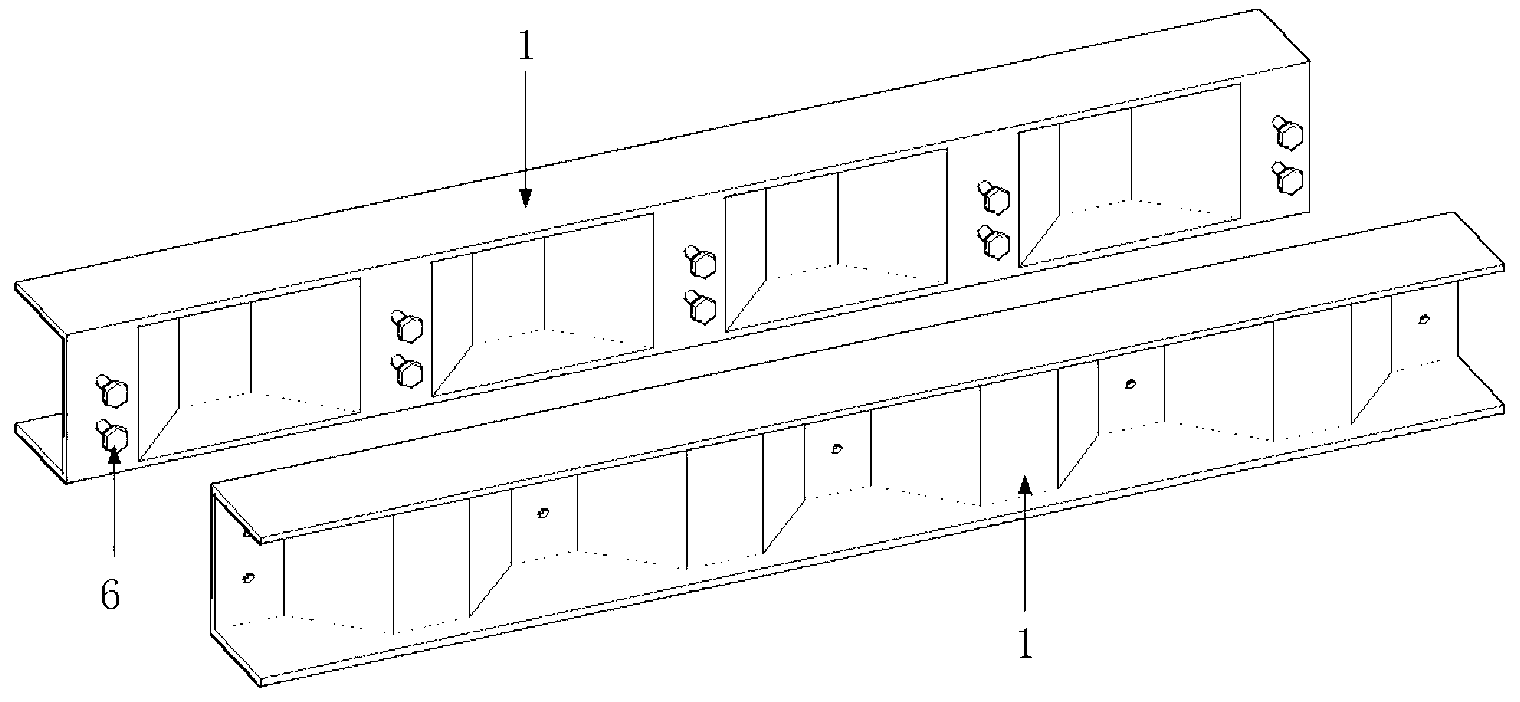

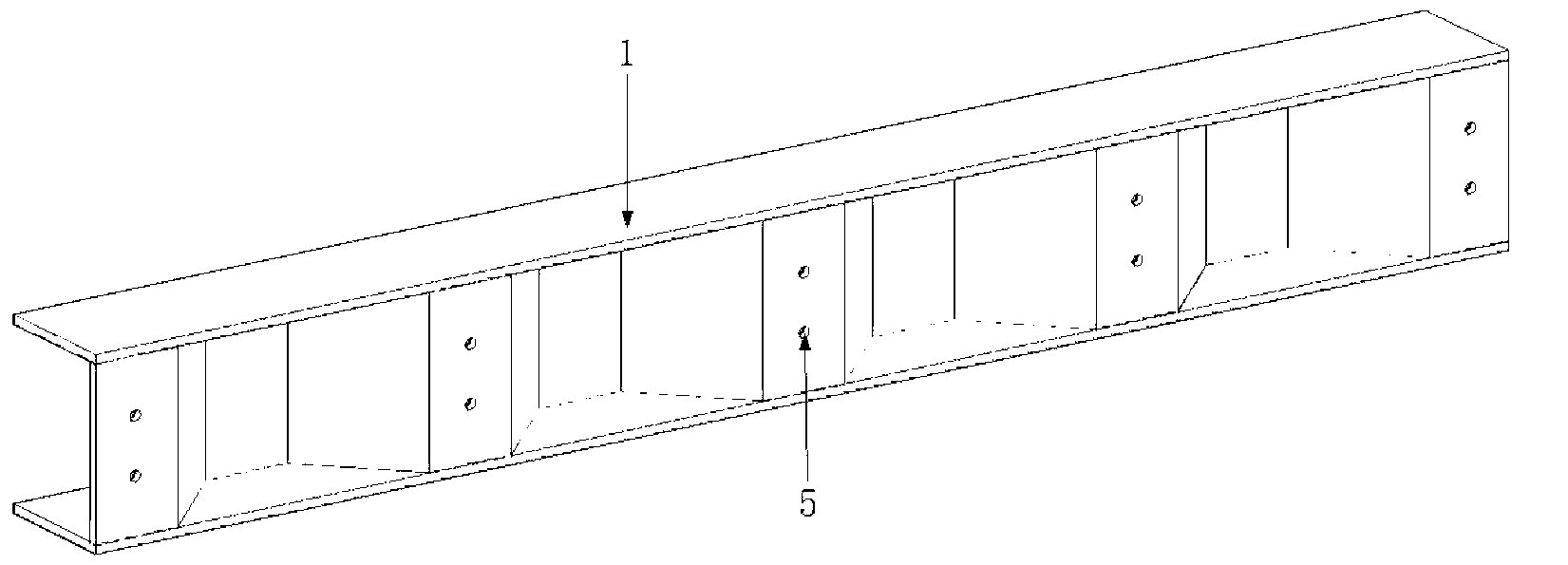

Fabricated honeycomb web steel beam

ActiveCN103233551AImprove mechanical performanceReduce thicknessGirdersJoistsRepeating waveformsSheet steel

The invention relates to a fabricated honeycomb web steel beam, and belongs to the technical field of building profiles. The fabricated honeycomb web steel beam is formed by web plates of two corrugated web steel channel beams, which are butted and assembled through a bolt. The section opening of each corrugated web steel channel beam is formed by an upper flange, a lower flange and a web plate; the sections of the web plates form even or uneven periodic repeated waveforms; the corrugated sections are rectangular curves, or arc angle rectangle curves, or trapezoidal curves or arc angle trapezoidal curves, or wedge curves, or arc angle wedge curves, or sine curves; the flanges are plain plates; each upper flange is parallel to each lower flange; the web plates are vertically located between the flanges as a whole; the outer sides of the corrugated curves of the web plates along the length direction are flush to a side boundary of each flange along the length direction; and the web plates are connected with the flanges by a single-side angle welding line. The fabricated honeycomb web steel beam is an innovation-type steel beam suitable for the fabricated steel structure system. Compared with the traditional fabricated beam, the fabricated honeycomb web steel beam has the advantages of light dead load, high carrying capacity, and good mechanical behavior.

Owner:BEIJING UNIV OF TECH +1

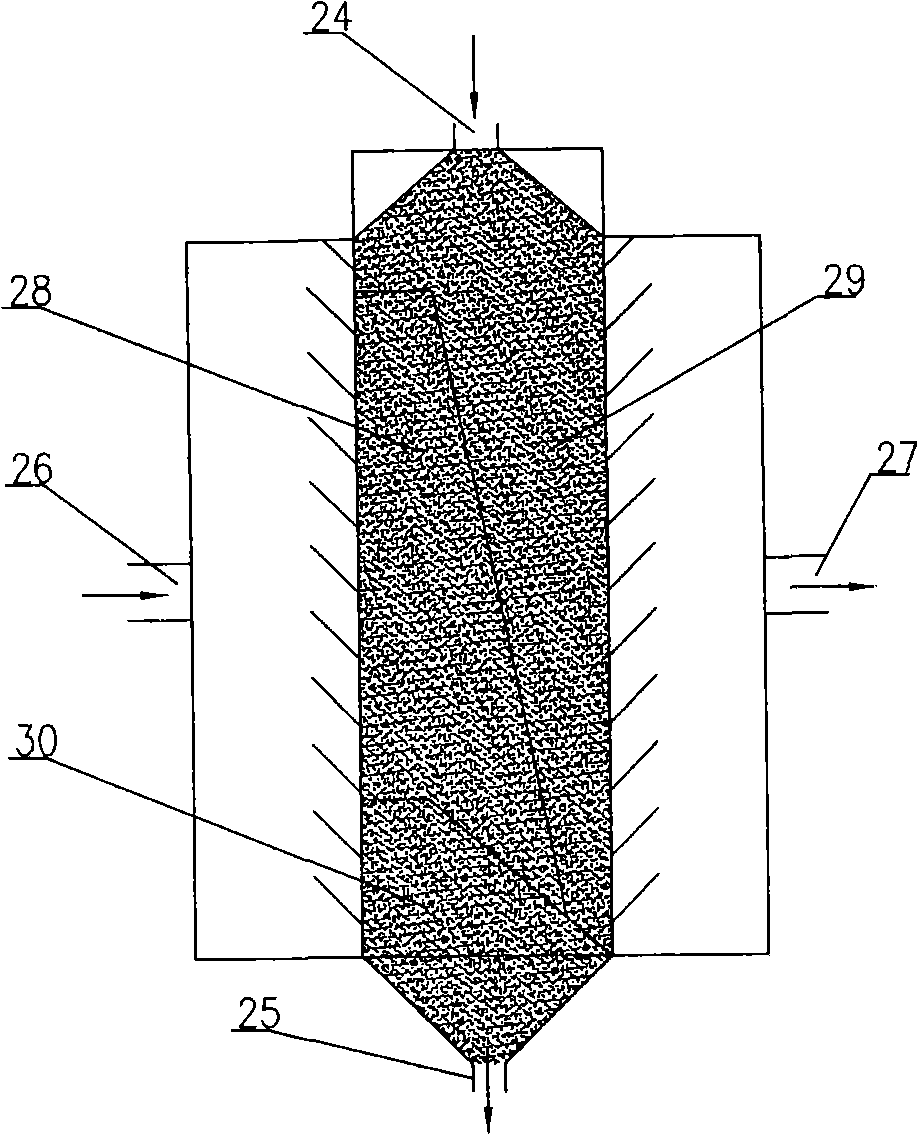

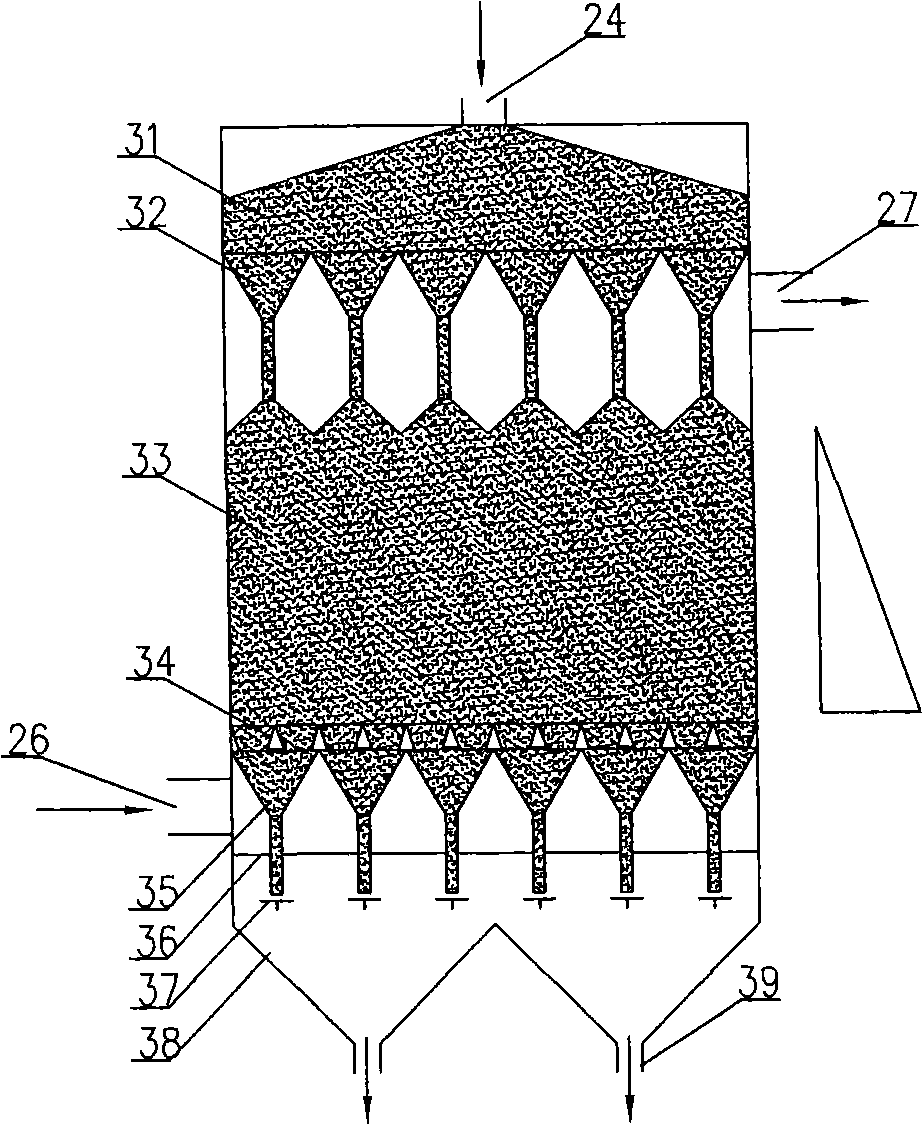

Activated charcoal gas cleaning method and device thereof

ActiveCN101310827AImprove adsorption efficiencySave steelOther chemical processesDispersed particle separationProcess engineeringProduct gas

The invention provides an active coke gas purifying method and a device thereof with high desulfurization and denitrification efficiency, energy conservation, little resistance of a bed layer, high utilization rate of the space in an absorption tower and low construction cost. The device comprises a main feed inlet and a gas main outlet which are arranged at the upper part of the absorption tower, a main discharge outlet and a gas main inlet which are arranged at the lower part of the absorption tower and an active coke bed layer which is positioned in the absorption tower, and the active coke bed layer is tilted and has an included angle Alpha with the vertical line. The method has the following steps: gas enters the active code bed layer from the gas main inlet, gas in the tilted bed layer is flowed to the top from the bottom; active coke simultaneously enters the active coke bed layer from the main feed inlet, the active coke in the tilted bed layer is flowed to the bottom from the top; the gas is exhausted from the gas main outlet after the fully tilted convection contact is formed between the gas and the active coke, and the active coke after the saturation by absorption can be discharged from the main discharge outlet.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

High-strength full-thread equal-strong resin bolting reinforcing bar and production method thereof

The invention provides a high-strength full-thread equal-strong resin bolting reinforcing bar and a production method thereof. The high-strength full-thread equal-strong resin bolting reinforcing bar comprises the following chemical components: 0.18-0.27wt% of C, 0.30-0.75wt% of Si, 1.35-1.60wt% of Mn, 0.06-0.09wt% of V, less than or equal to 0.035wt% of P, less than or equal to 0.035wt% of S and the balance of Fe and inevitable impurities. During a smelting process, a vanadium nitrogen alloy is micro-alloyed, so as to increase the strength and toughness of the reinforcing bar. Due to the high strength of the high-strength full-thread equal-strong resin bolting reinforcing bar according to the invention, the steel material can be saved, the shoring cost is lowered, the structure strength is enhanced and the safety storage is increased.

Owner:LAIWU IRON & STEEL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com