Double corrugated web plate steel box girder

A steel box girder, double corrugated technology, applied in joists, girders, trusses, etc., can solve the problem that the lateral deformation capacity and overall torsional resistance of components are not significantly improved, the processing workload is increased, and it is difficult to achieve automated production, etc. problems, to achieve the effect of beautiful welding seam without spatter, excellent fatigue resistance, excellent weight and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

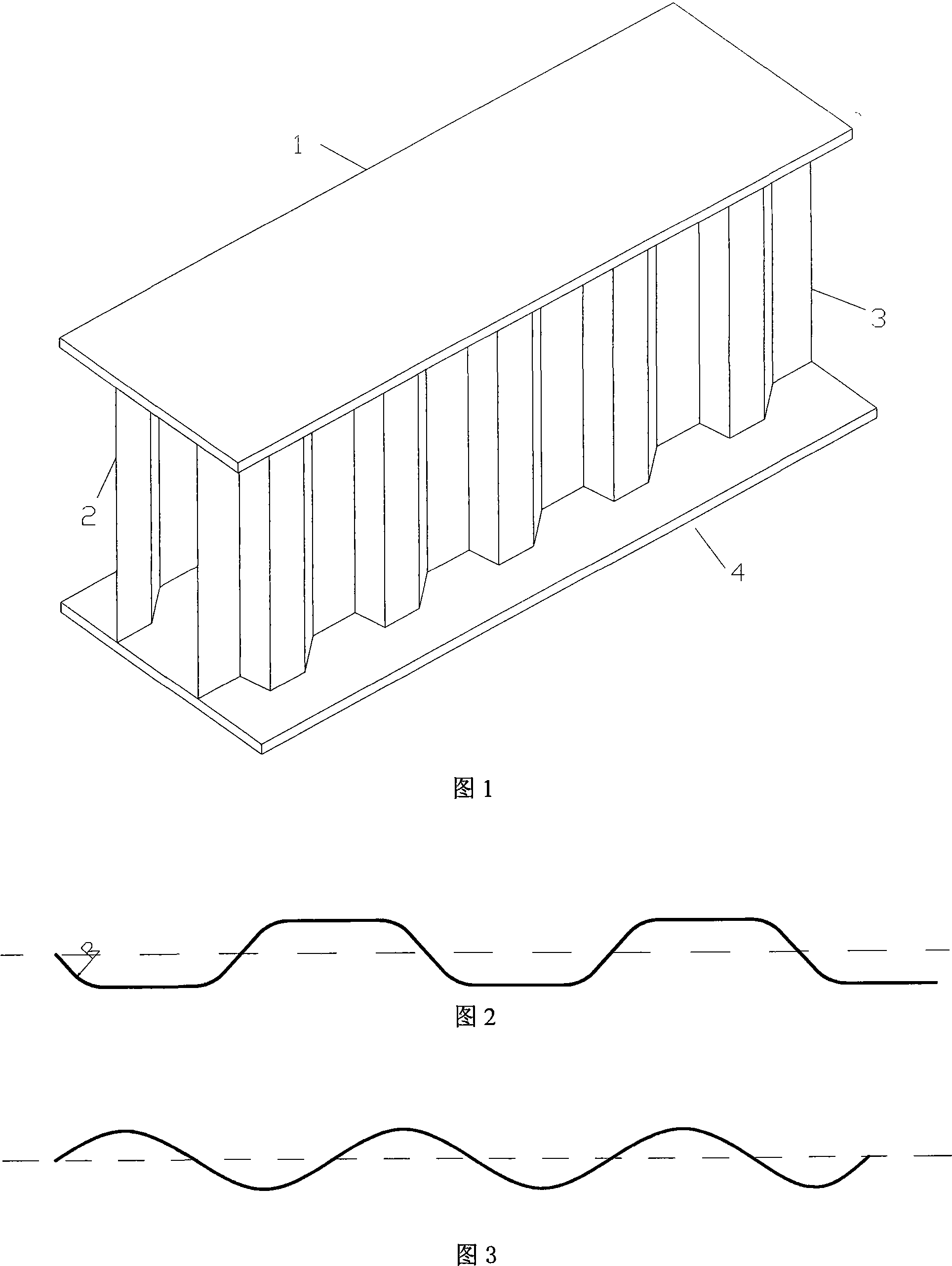

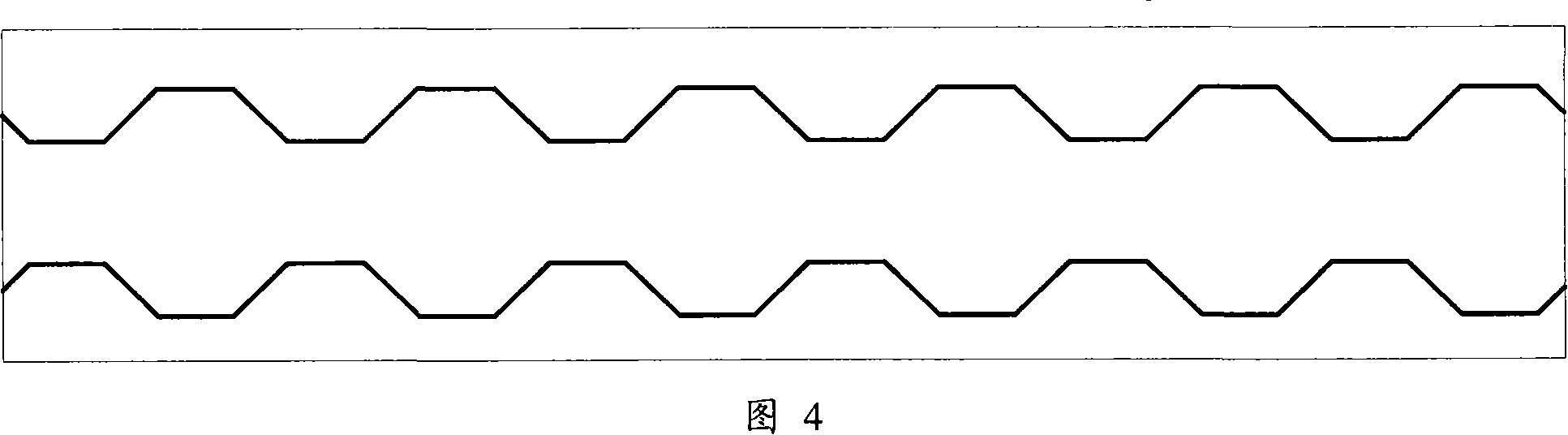

[0034] Example 1: The cross-section shape of a double-web steel box girder is composed of the middle web 2, web 3, upper flange 1, and lower flange 4. The upper flange 1 is parallel to the lower flange 4, and the web 2 and 3 are vertically located between the upper flange 1 and the lower flange 4. Web 2 and web 3 are corrugated webs with uniform or uneven periodic repetition in the length direction. The corrugated section is trapezoidal or sinusoidal with arc angles curve.

[0035] In order to verify the performance of the product, a test piece was made for research. The material of the test piece is Q235 steel, the thickness of flange 1 and flange 4 of the test piece is 10mm, the width is 500mm, the thickness of web 2 and web 3 is 2mm, the height is 1000mm, the corrugation height is 50mm, and the wavelength is 240mm. mm, and the radius of the transition arc at the corner is 30 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com