Patents

Literature

1182results about How to "Improve torsion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

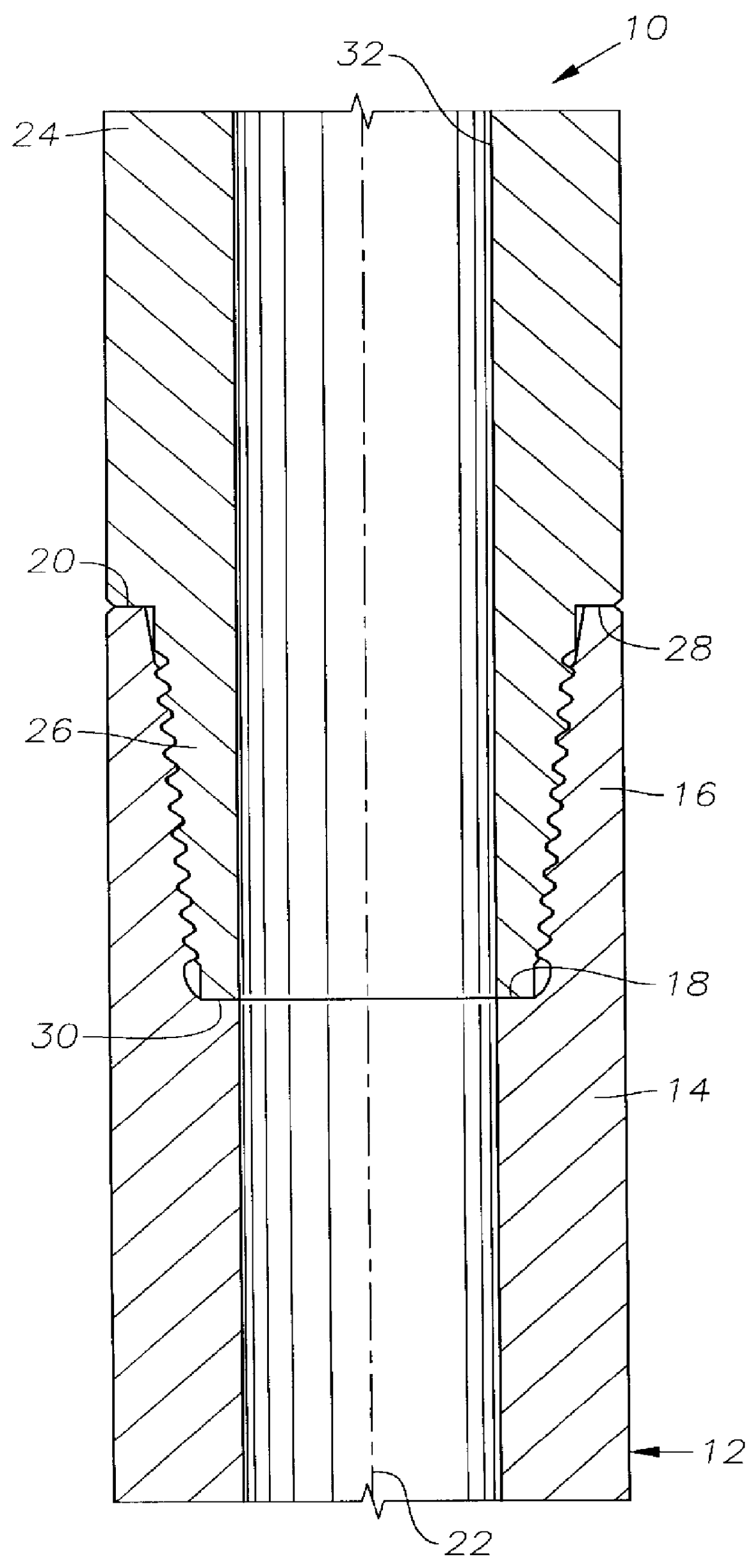

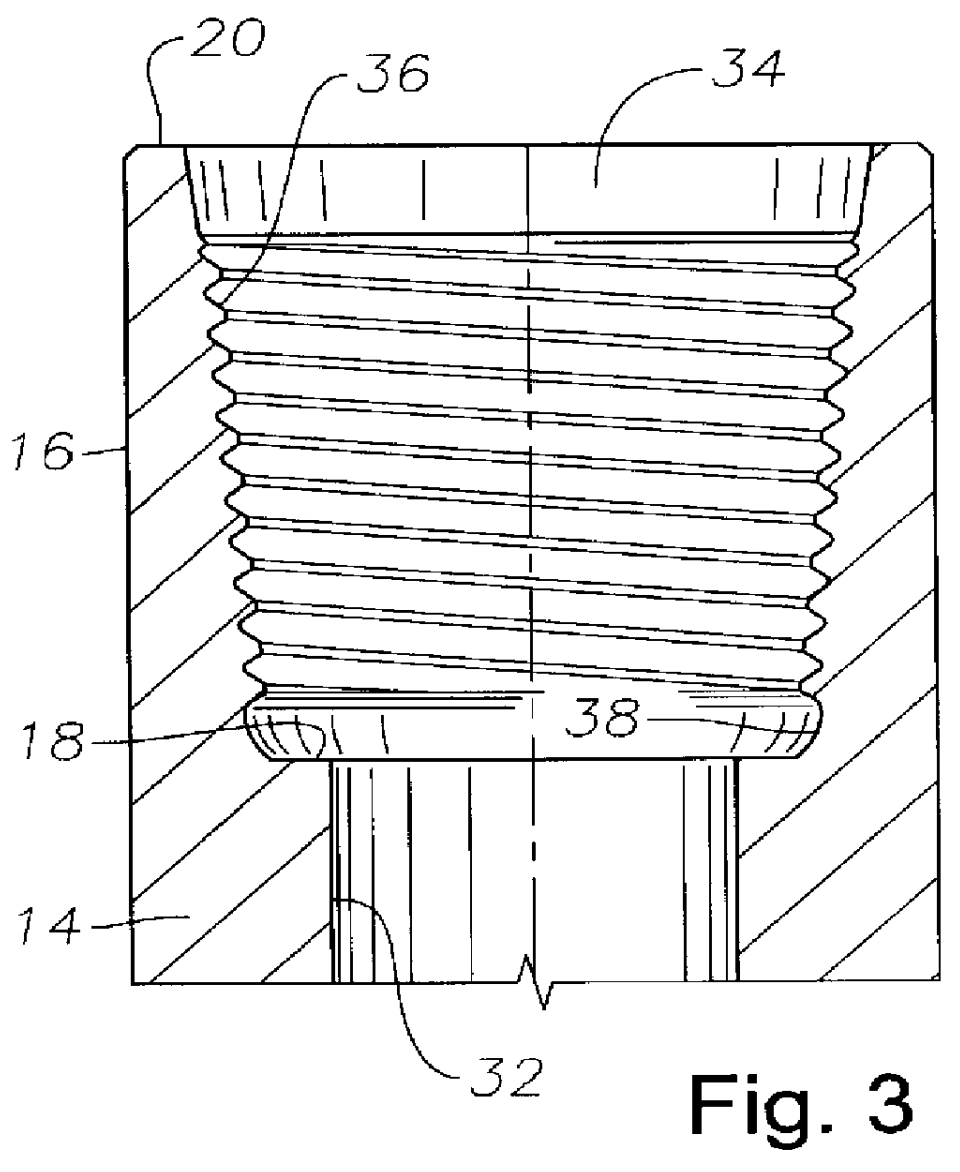

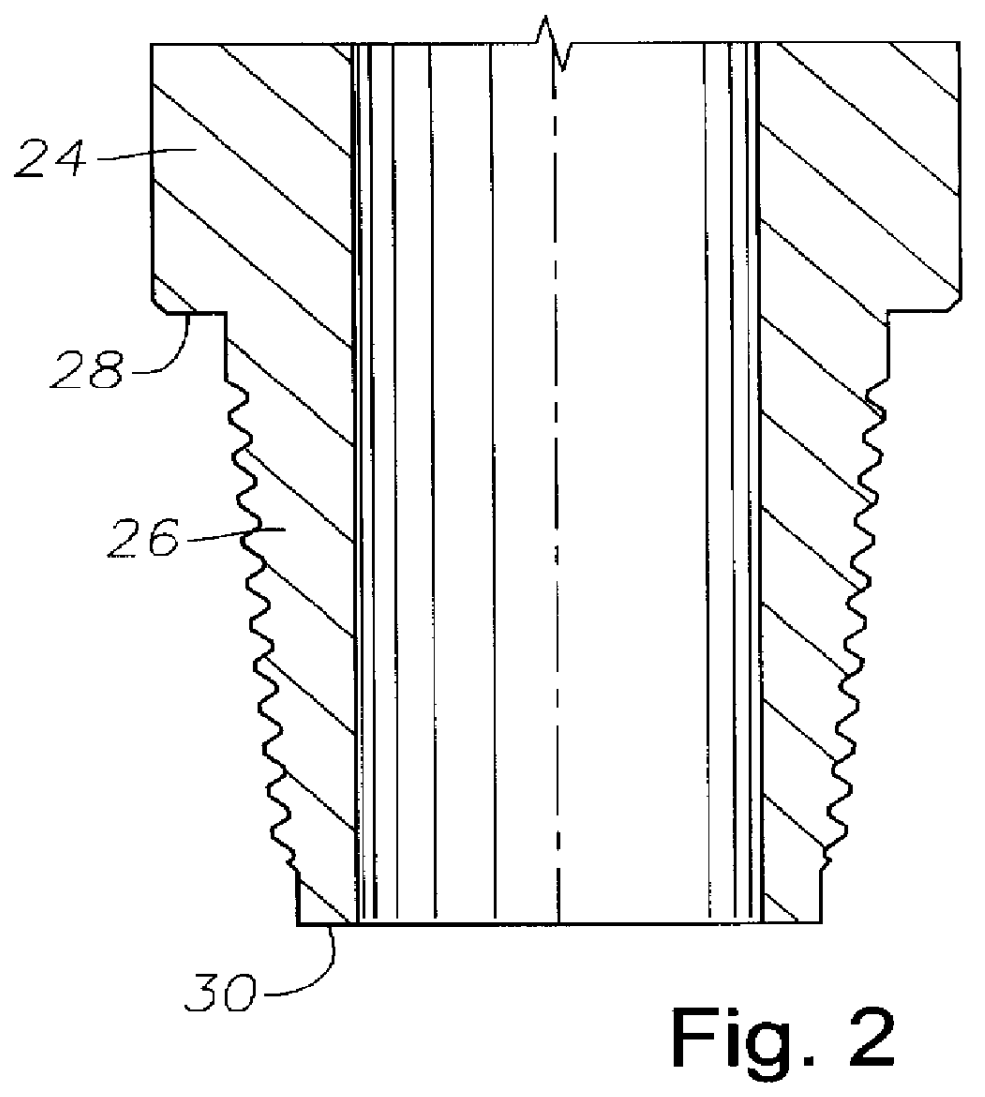

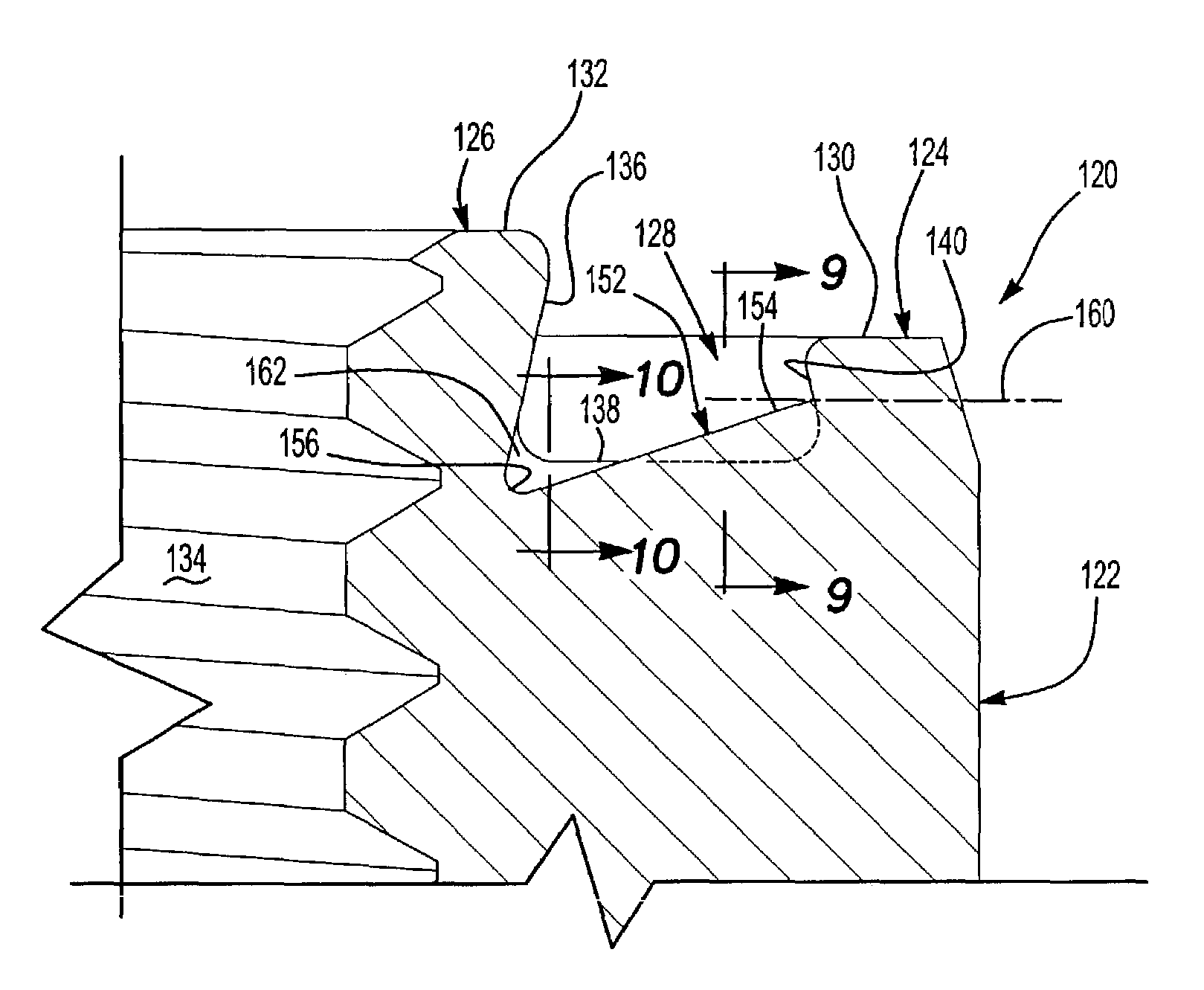

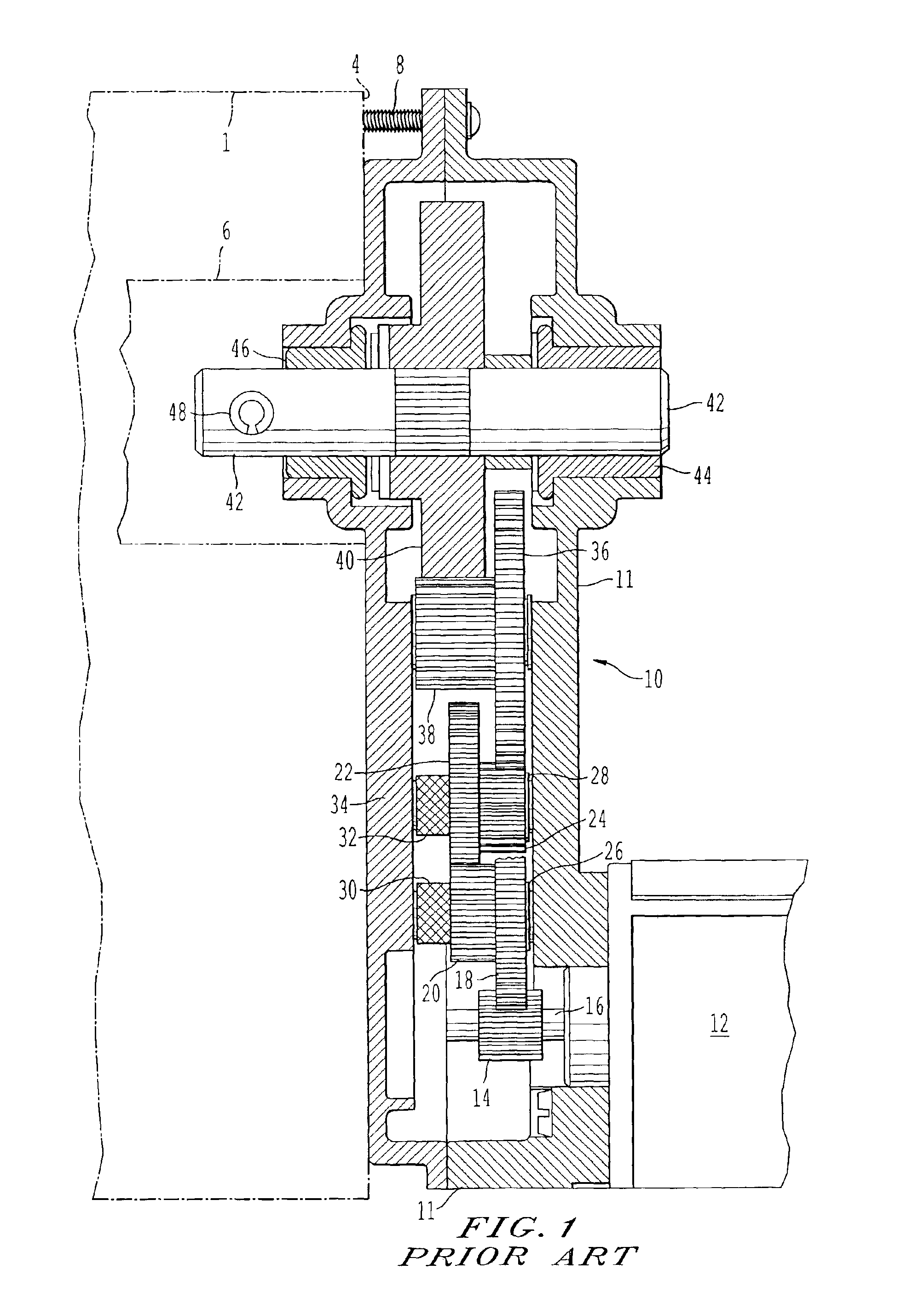

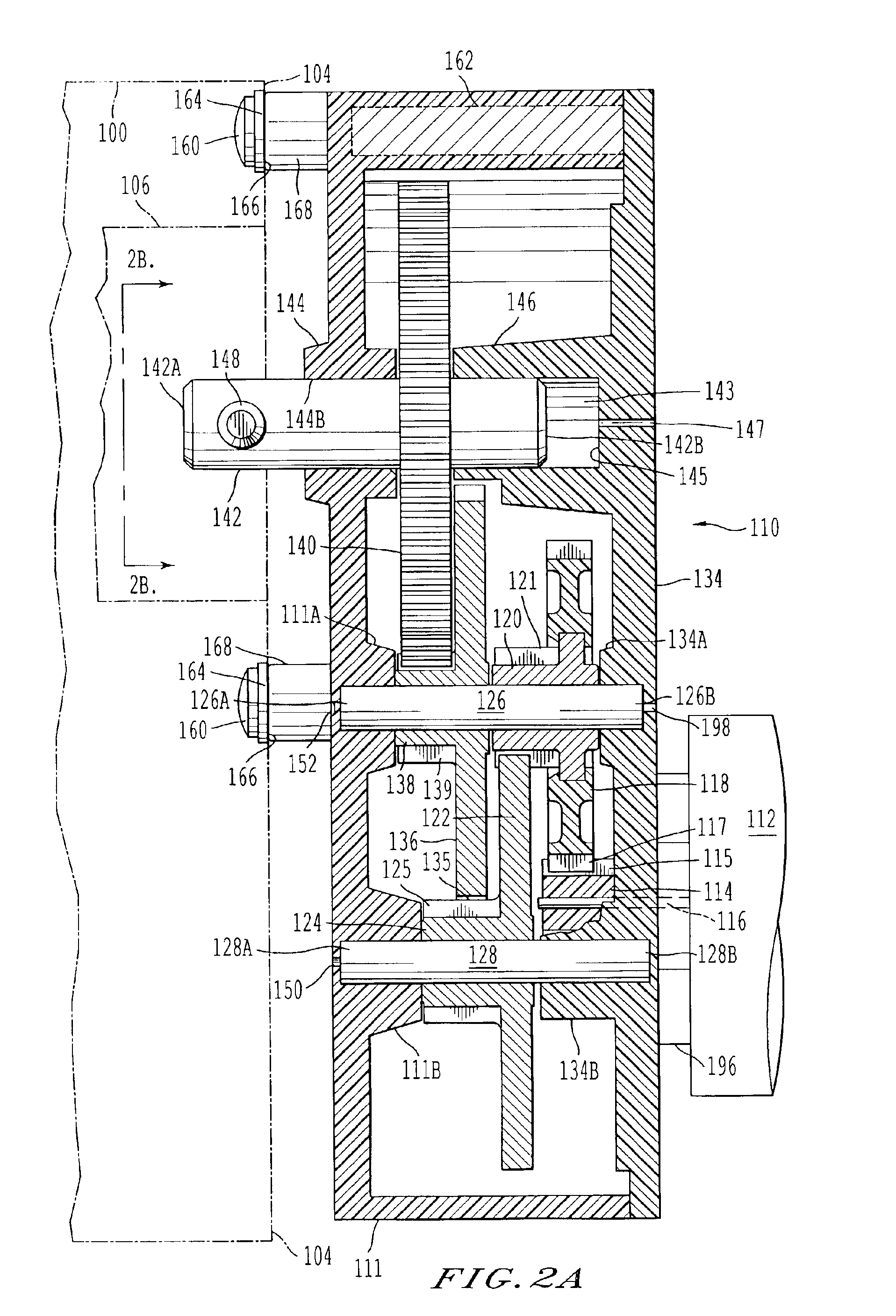

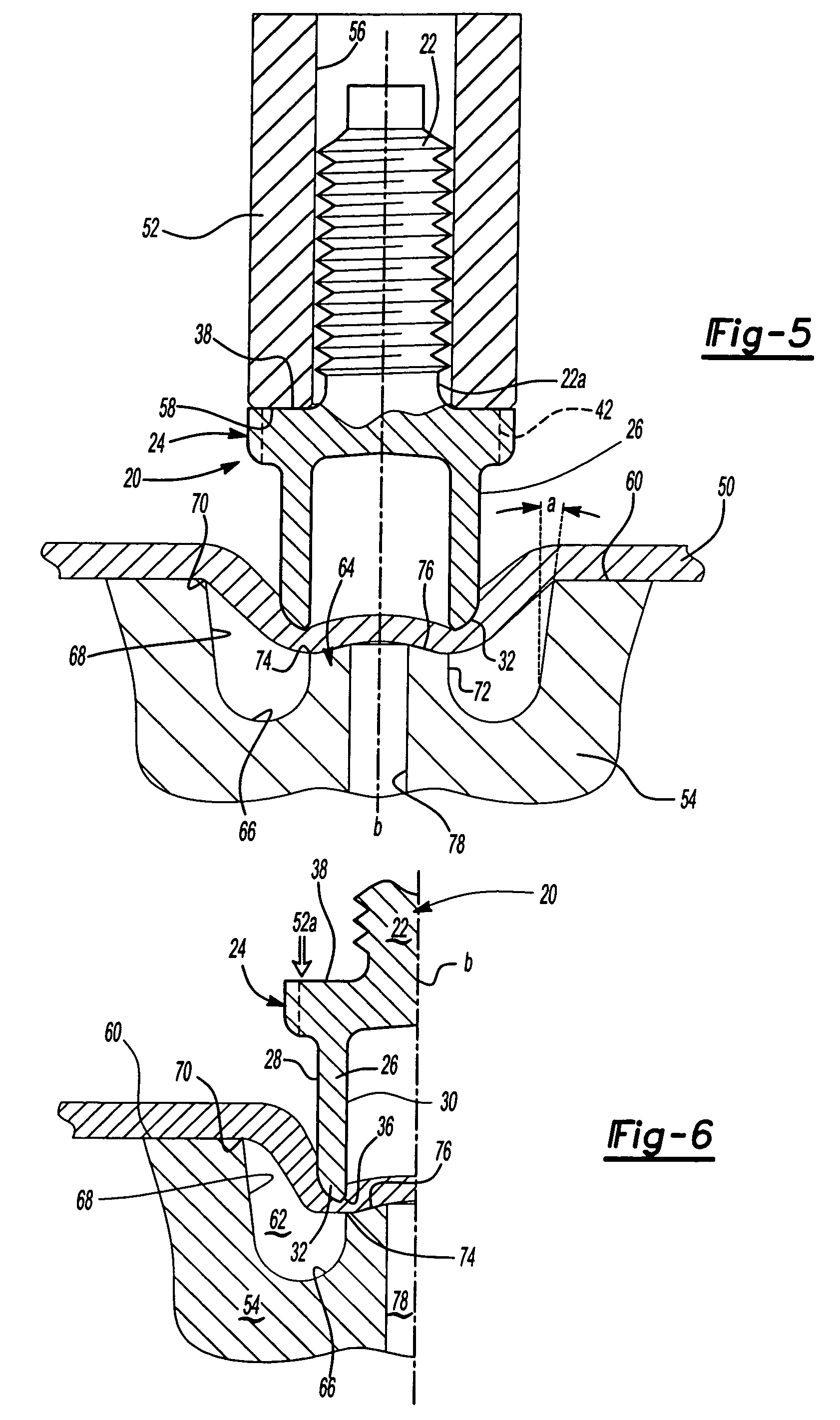

High torque threaded tool joint for drill pipe and other drill stem components

InactiveUS6030004AIncrease torqueEnhancing the torque resisting characteristicsDrilling rodsNutsStress concentrationRoot surface

A double shouldered high torque resistance threaded connection for drill stem components having enhanced resistance to torque forces, tensile loads and material stress and fatigue is disclosed. The tool joint is provided with threads having a 75 DEG included angle between the thread flanks thereof and with generally elliptical root surfaces to minimize material stress and fatigue during operation under high torque and high tensile loads. When made up, the double intrerengaging shoulders of the threaded tool joint are in firm face to face engagement permitting torque forces and tensile loads to propagate through the tool joint in a manner that minimizes bending forces and minimizes high stress concentration so that the resulting service life of the tool joint is significantly enhanced.

Owner:VALLOUREC OIL & GAS FRANCE SAS

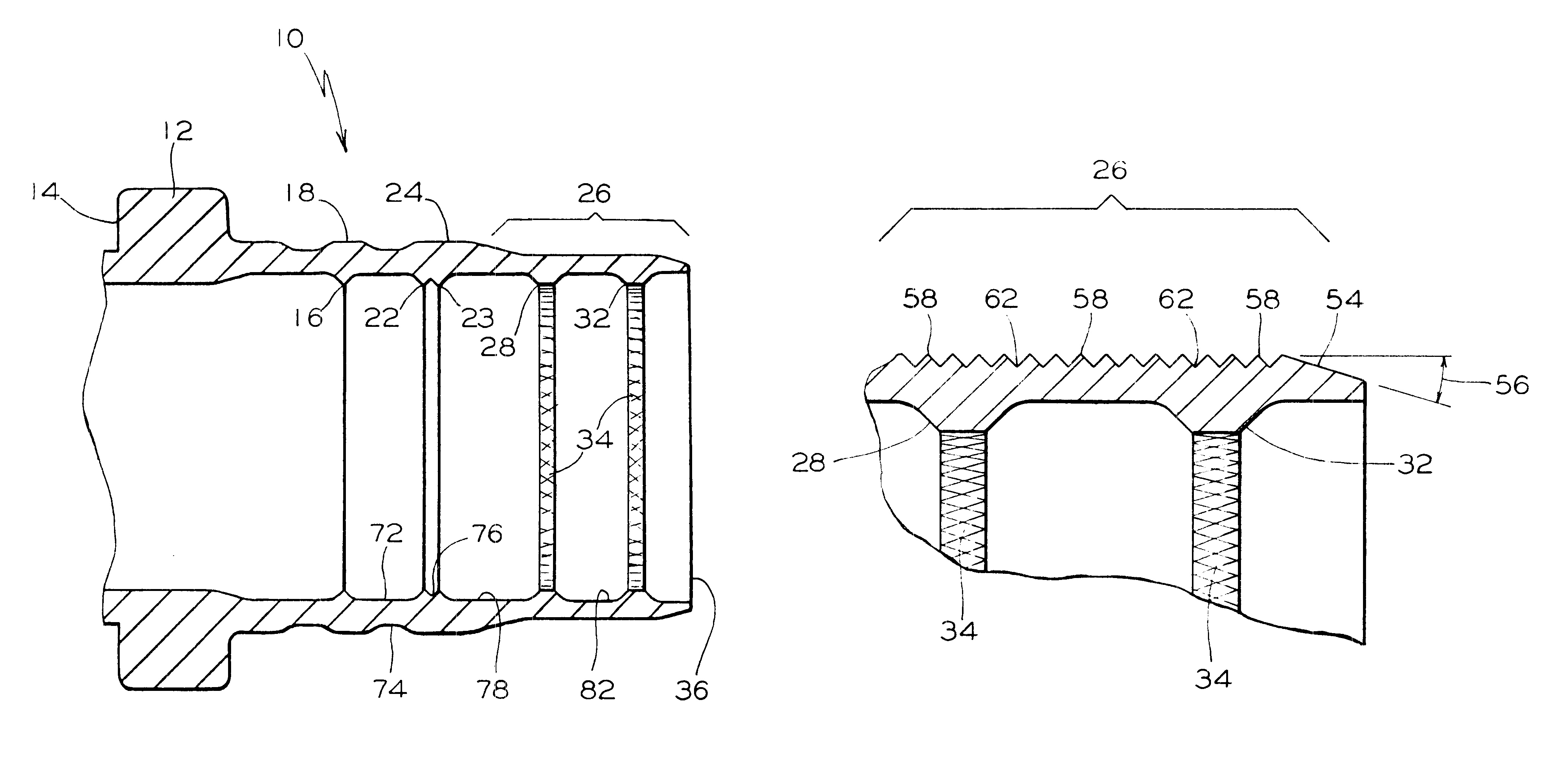

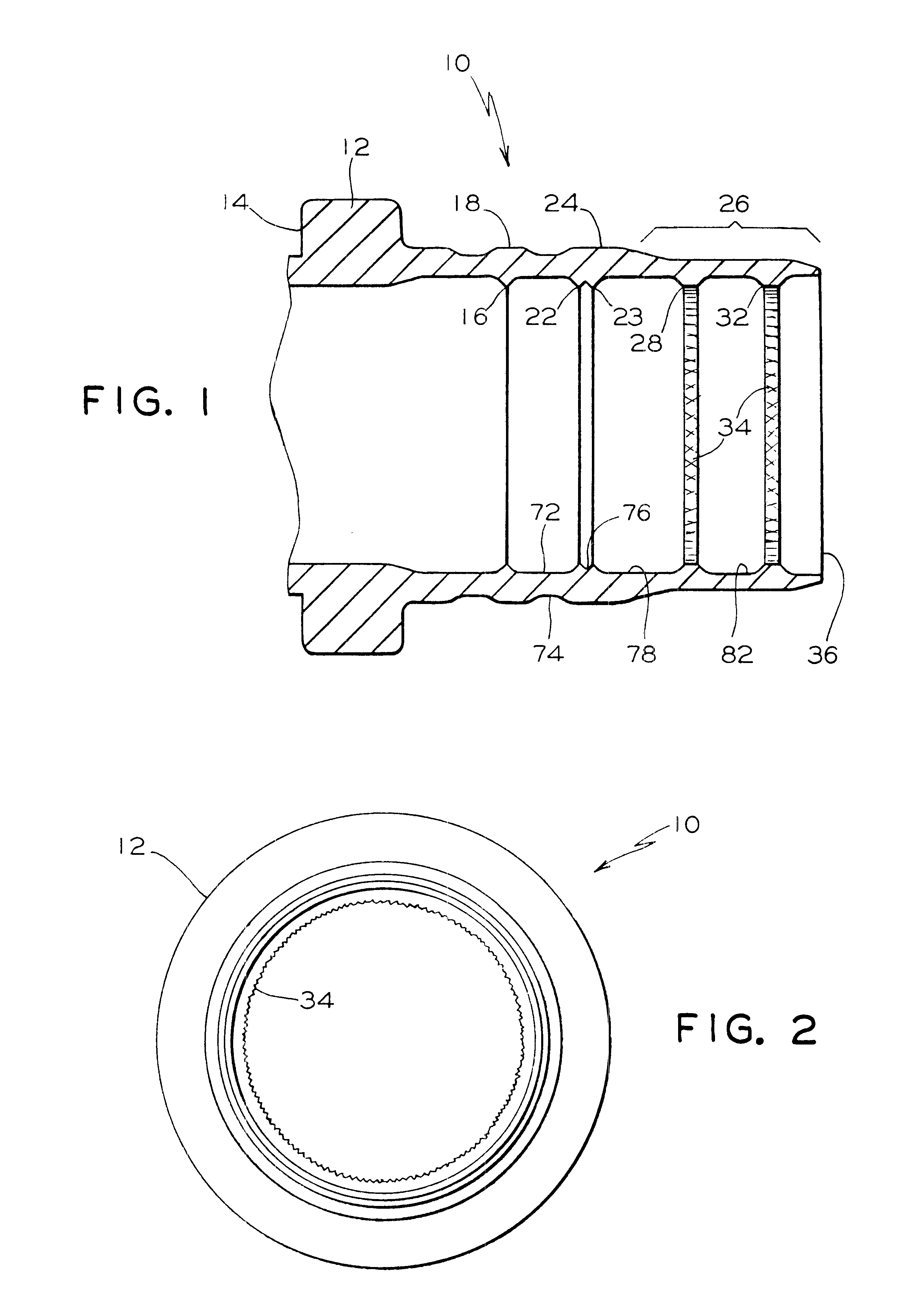

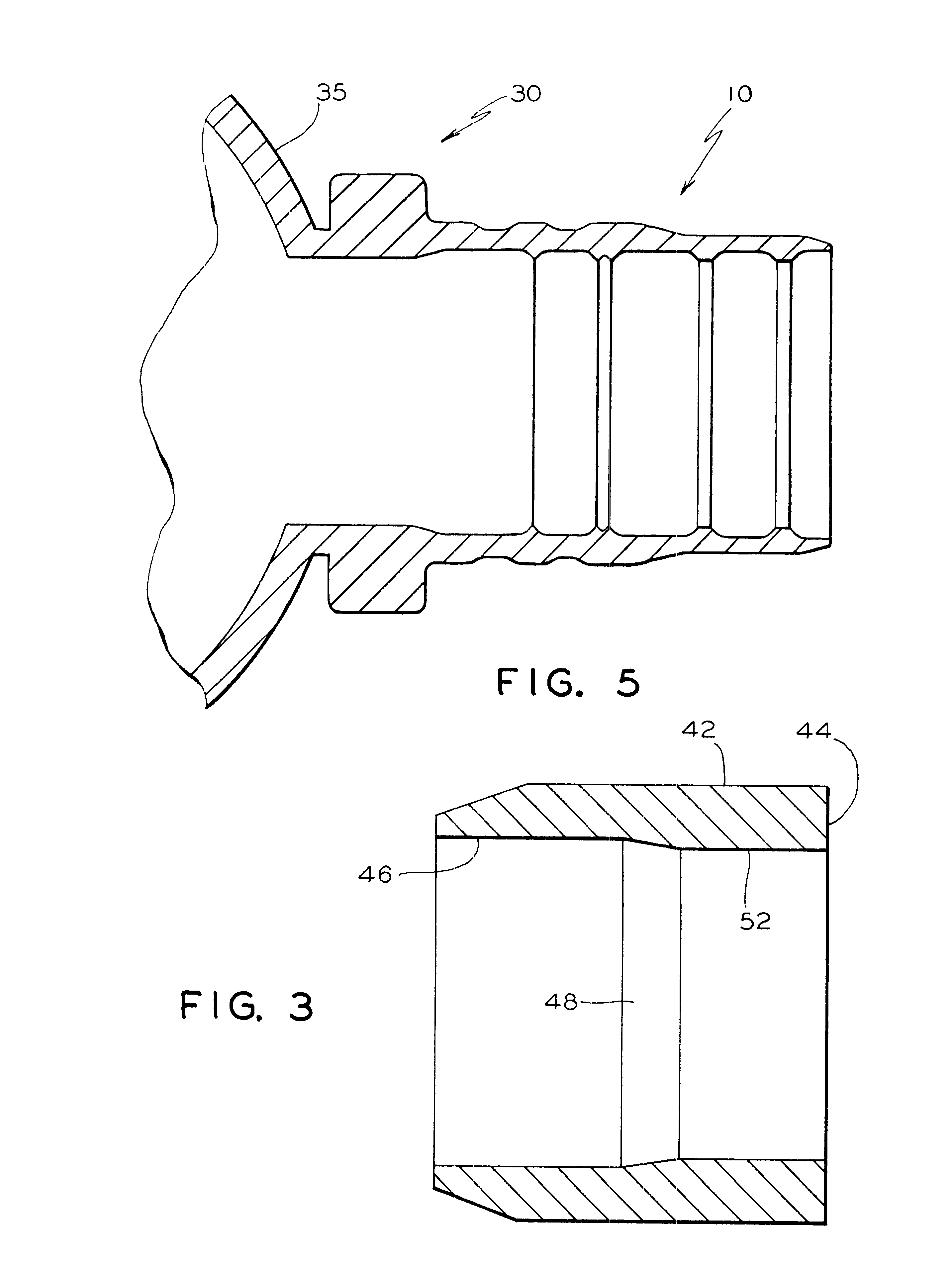

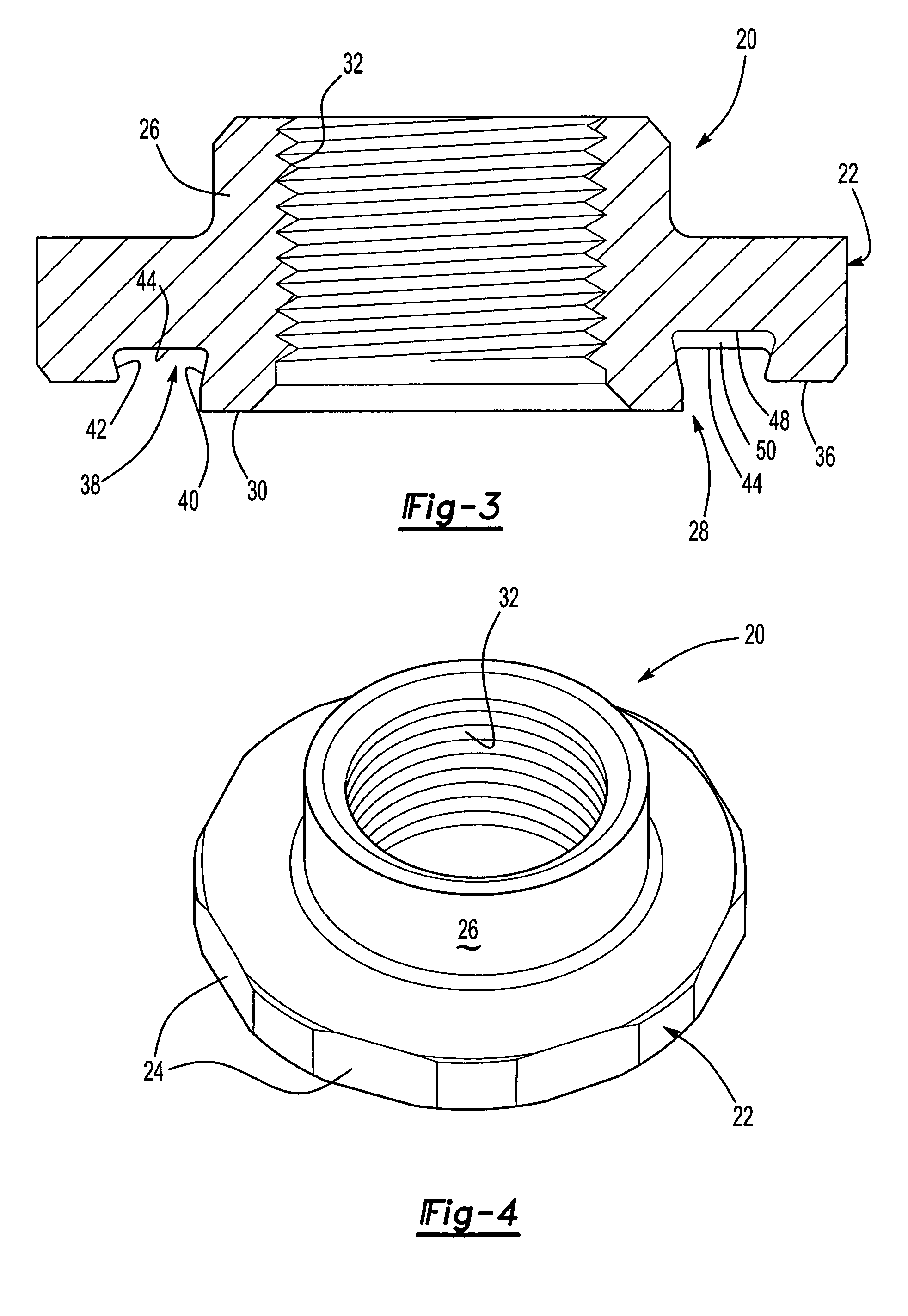

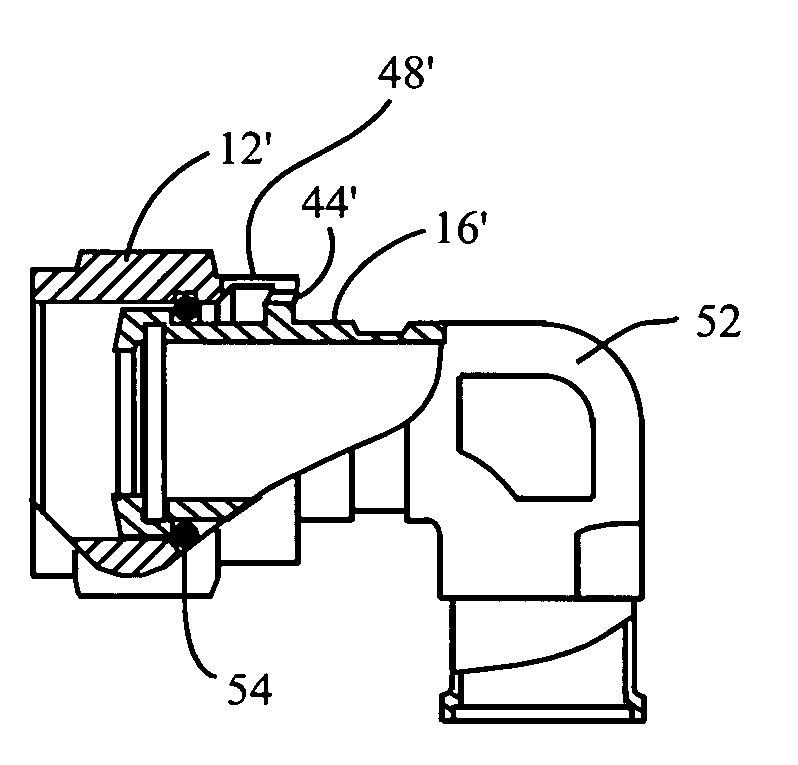

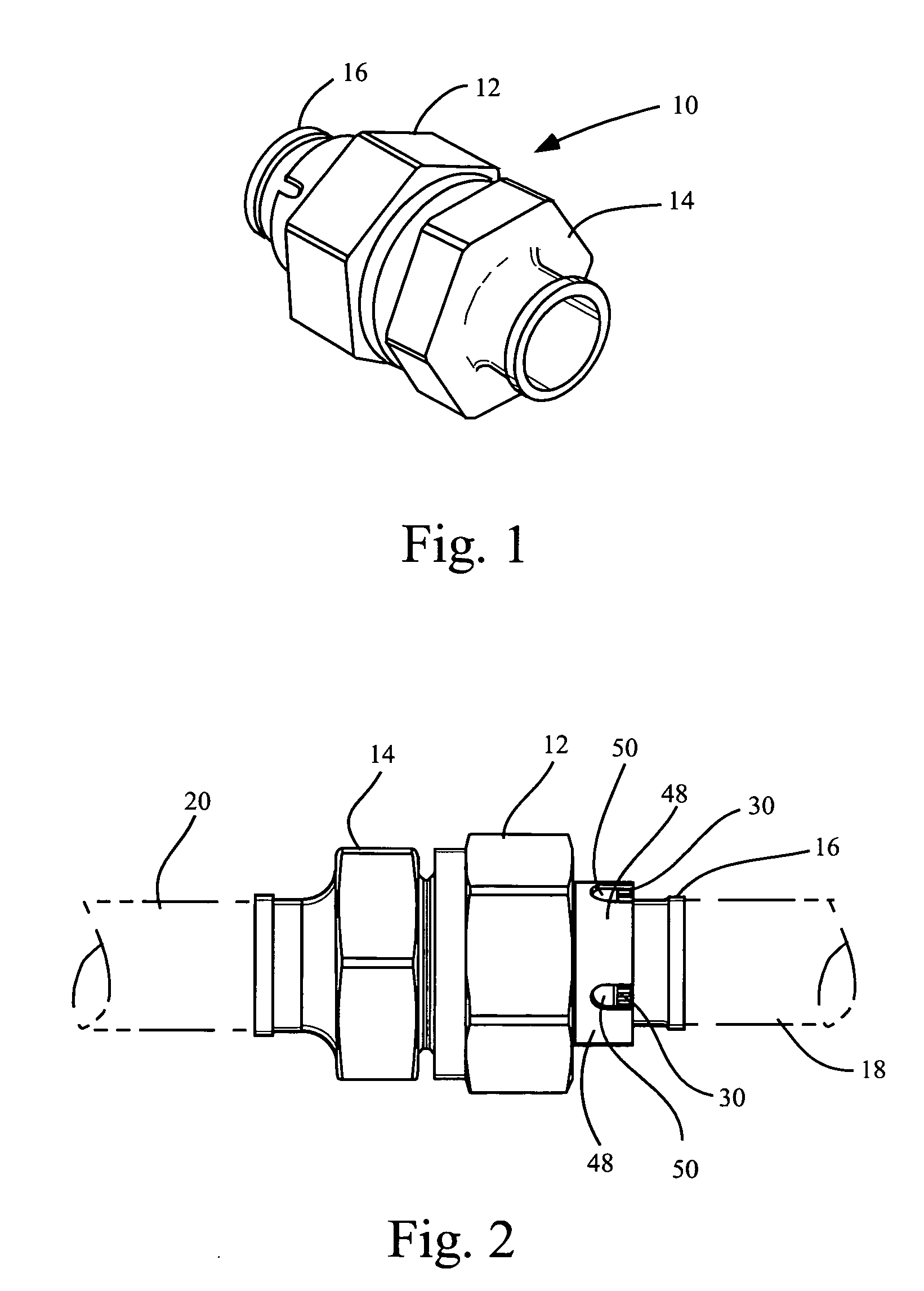

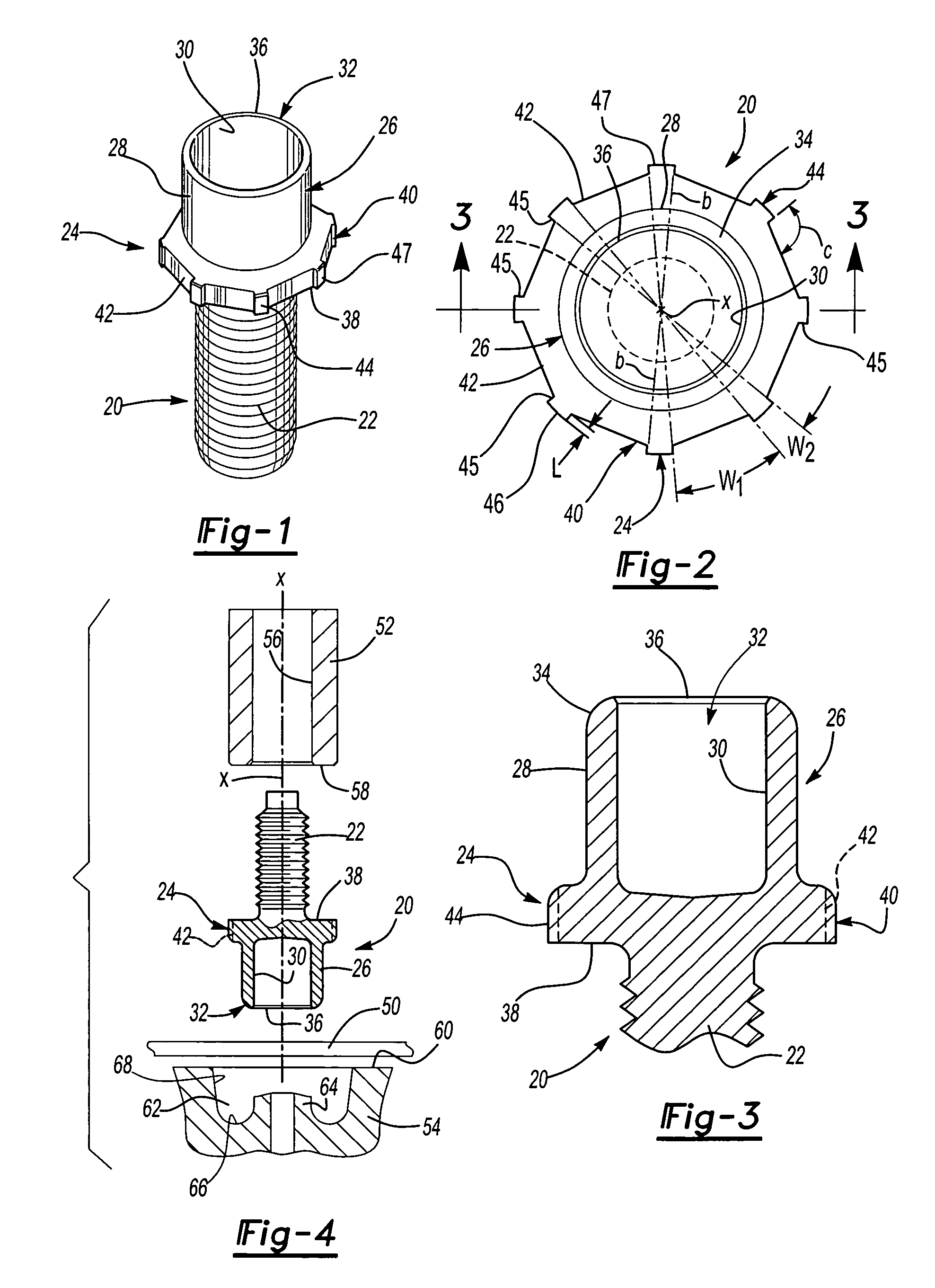

Lokring fitting having improved anti-torsion capability

InactiveUS6692040B1Improve torque performanceImprove torsion resistanceSleeve/socket jointsJoints with sealing surfacesEngineeringTorsion spring

A fitting for a fluid pressure conduit. The fitting includes a coupling body having a substantially axisymmetrical inside surface for engaging an outside surface of the fluid pressure conduit. The inside surface has at least one substantially axisymmetrical seal formed as at least one axisymmetrical ridge on the inside surface of the coupling body. There is at least one seal land on an outside surface of the coupling body adjacent the substantially axisymmetrical seal(s). There are a plurality of anti-torsion ridges on the inside surface of the coupling body, the anti-torsion ridges having friction surfaces for resisting torsion between the fitting and the fluid pressure conduit. Furthermore, there is at least one torsion land formed on the outside surface of the coupling body adjacent the torsion ridges. The fitting also includes a ring for fitting over the coupling body, the ring being for engaging the seal land(s) to force the seal(s) into engagement with the outside surface of the fluid conduit, the ring further being for engaging the torsion land(s) to force the plurality of anti-torsion ridges into engagement with the fluid pressure conduit.

Owner:LOKRING TECHNOLOGY

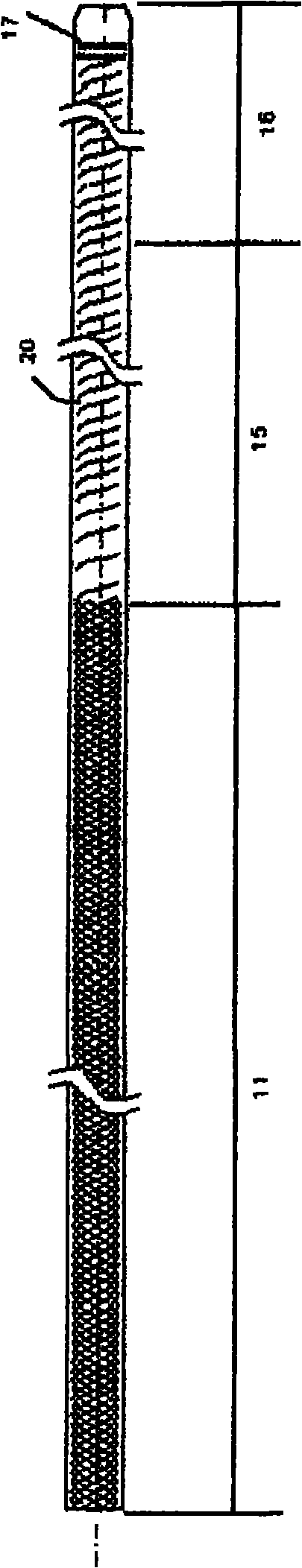

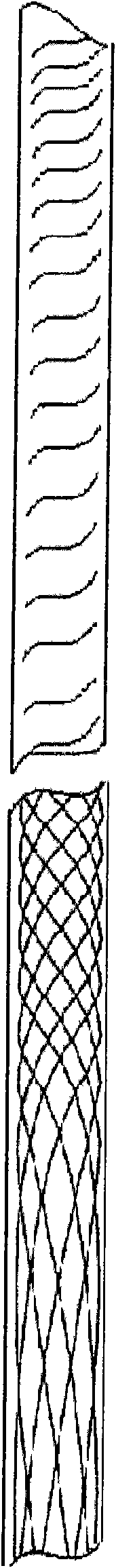

Mciro-catheter

ActiveCN101933821ASafe and smooth crossingImprove flexibilitySurgeryMedical devicesBlood vesselPolymer

The invention relates to a catheter. A catheter wall thereof sequentially comprises a smooth layer, a strengthened layer and a jacket layer from inside to outside, wherein the smooth layer and the jacket layer are both formed by compounding polymer materials, and the strengthened layer is a support layer and is respectively connected with the smooth layer and the jacket layer, therefore, every two layers of the catheter are connected. The catheter also sequentially comprises a proximal end part and an extension part along the direction from the near to the distance. In addition, the strengthened layer is in a braided structure at the proximal end part and is in a spiral structure at the extension part. The invention has the advantages that the structure can enhance the flexibility, the torsional resistance, the tracing property, the supporting property and the anti-fold property of the catheter when reducing the size of the catheter, and therefore, the catheter is suitable for penetrating through a distal vessel in a cranium.

Owner:MICROPORT NEUROTECH SHANGHAI

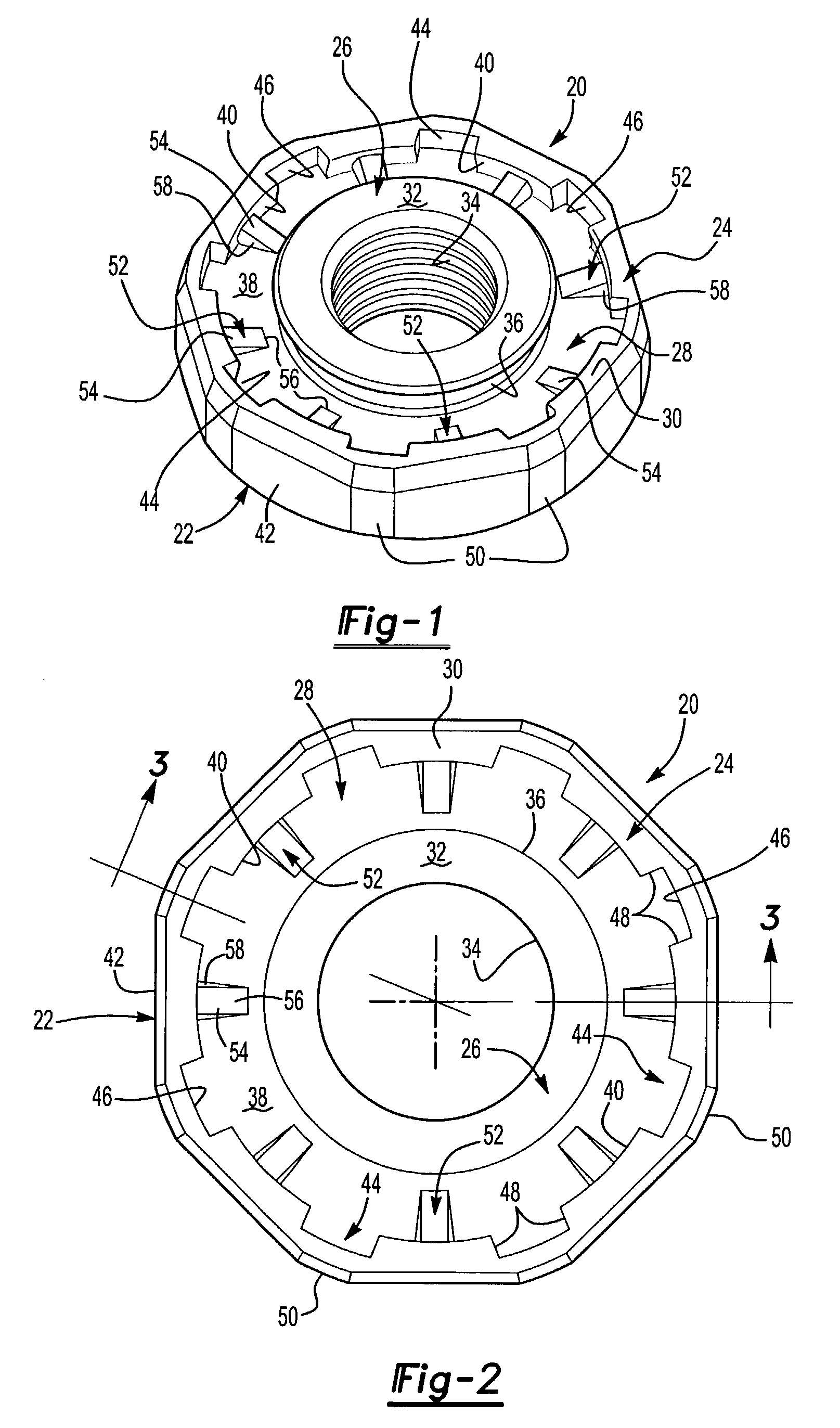

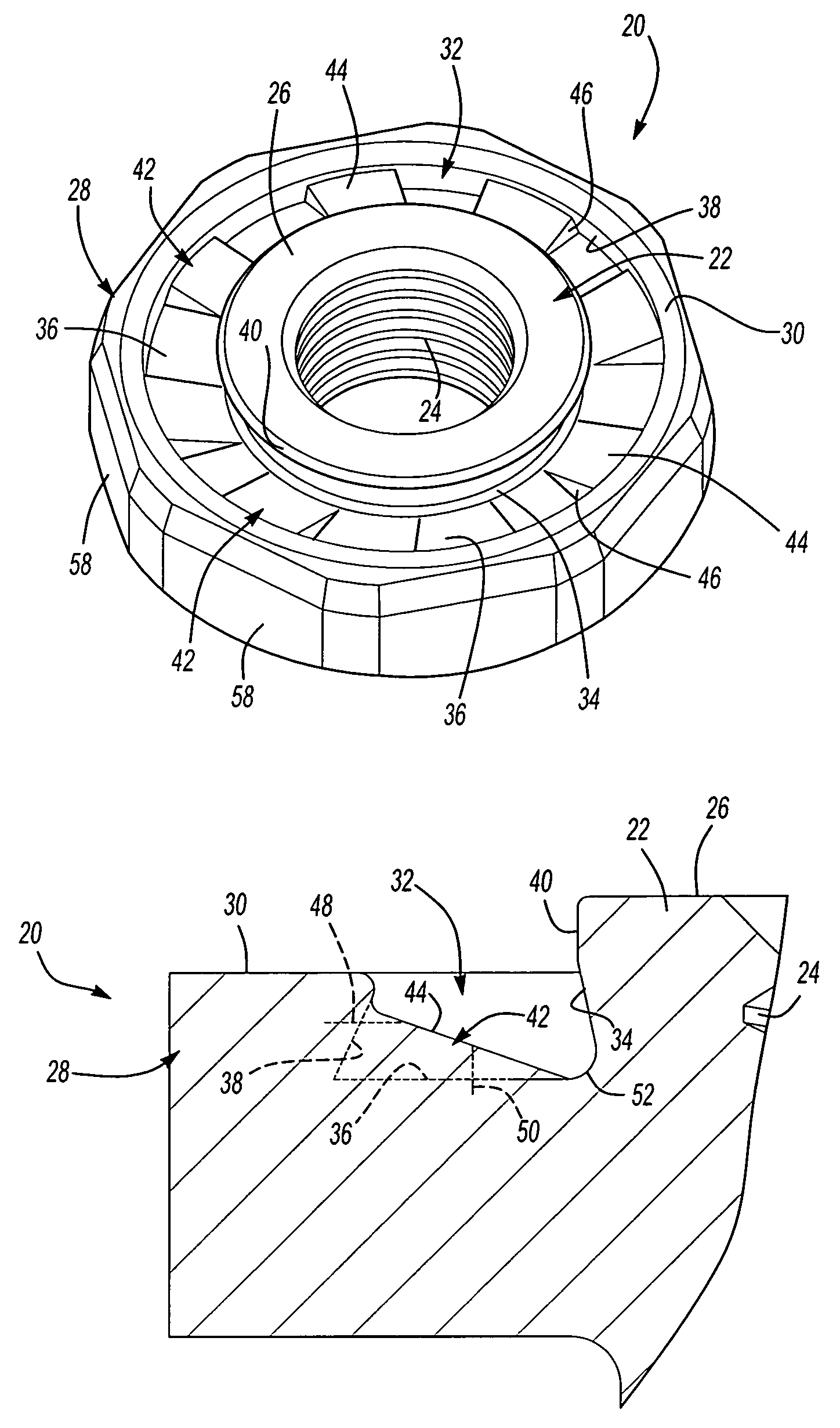

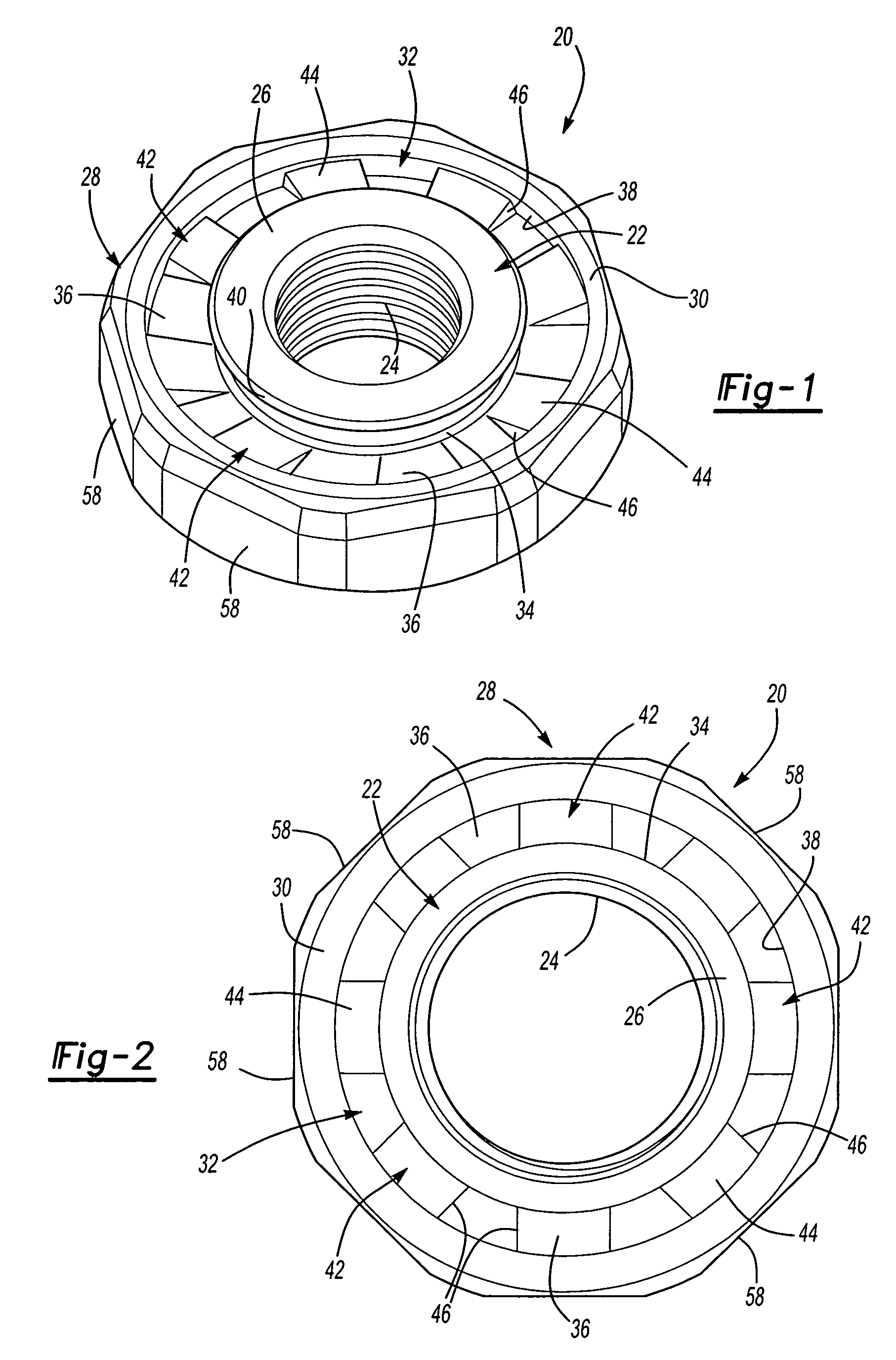

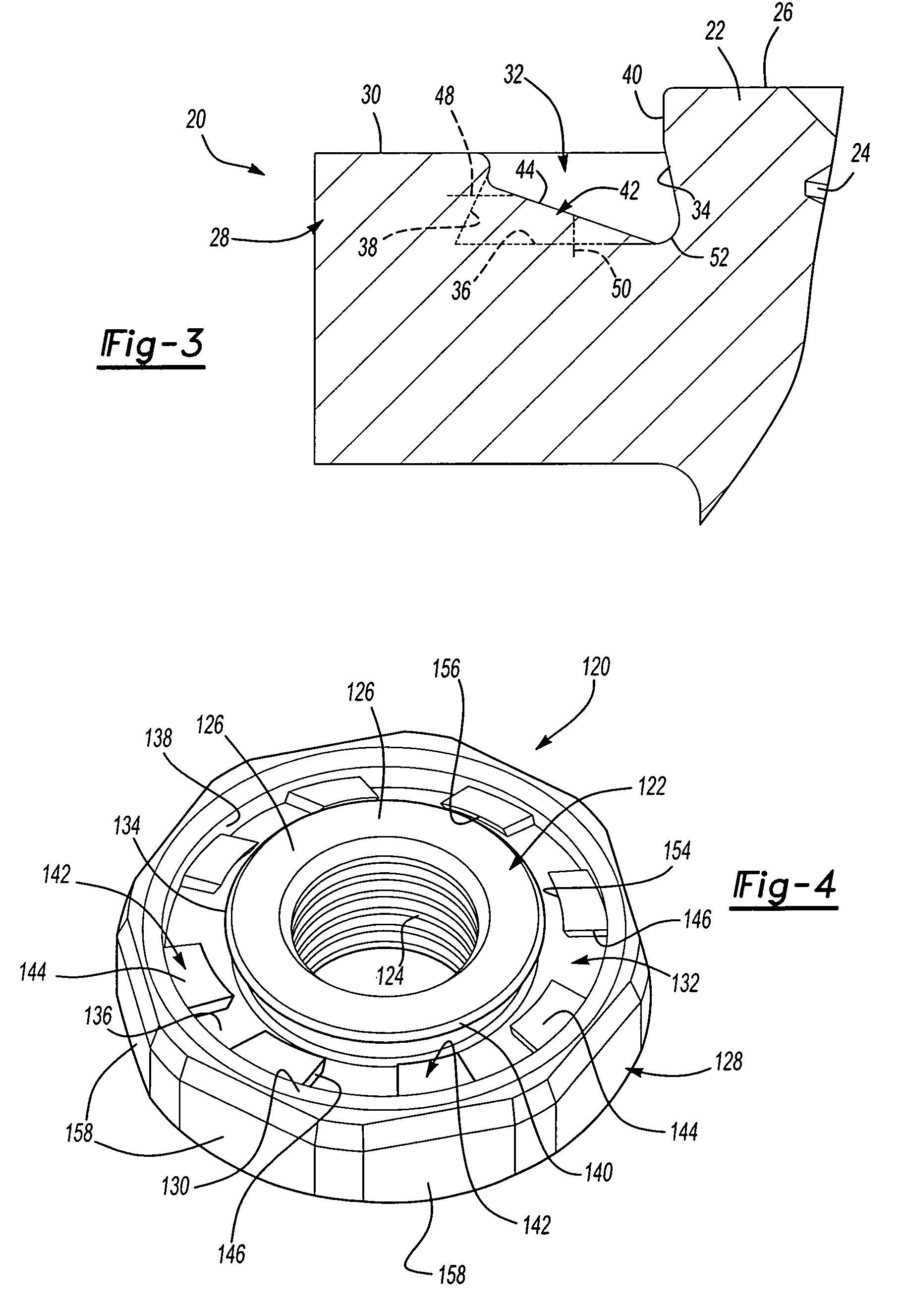

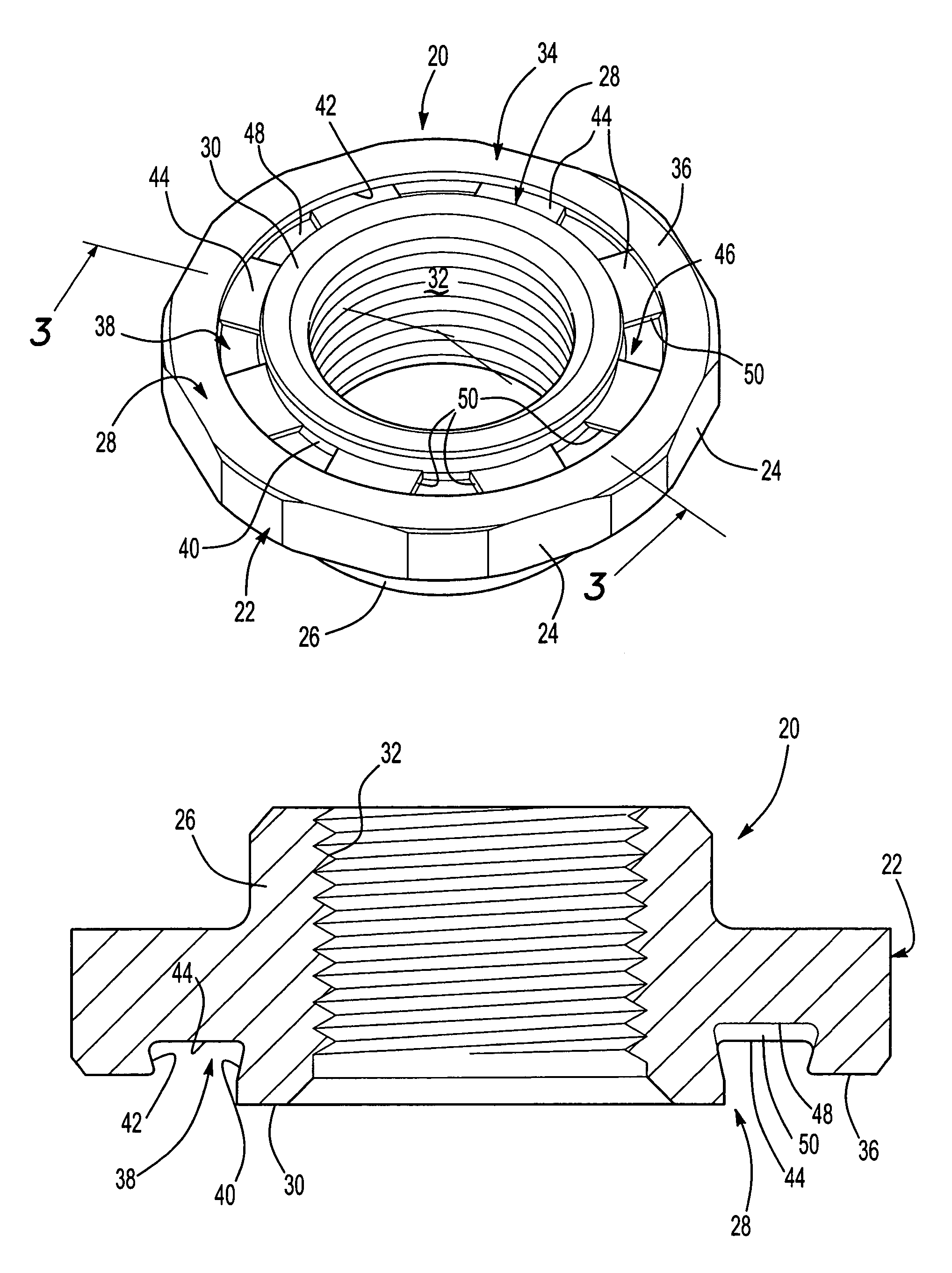

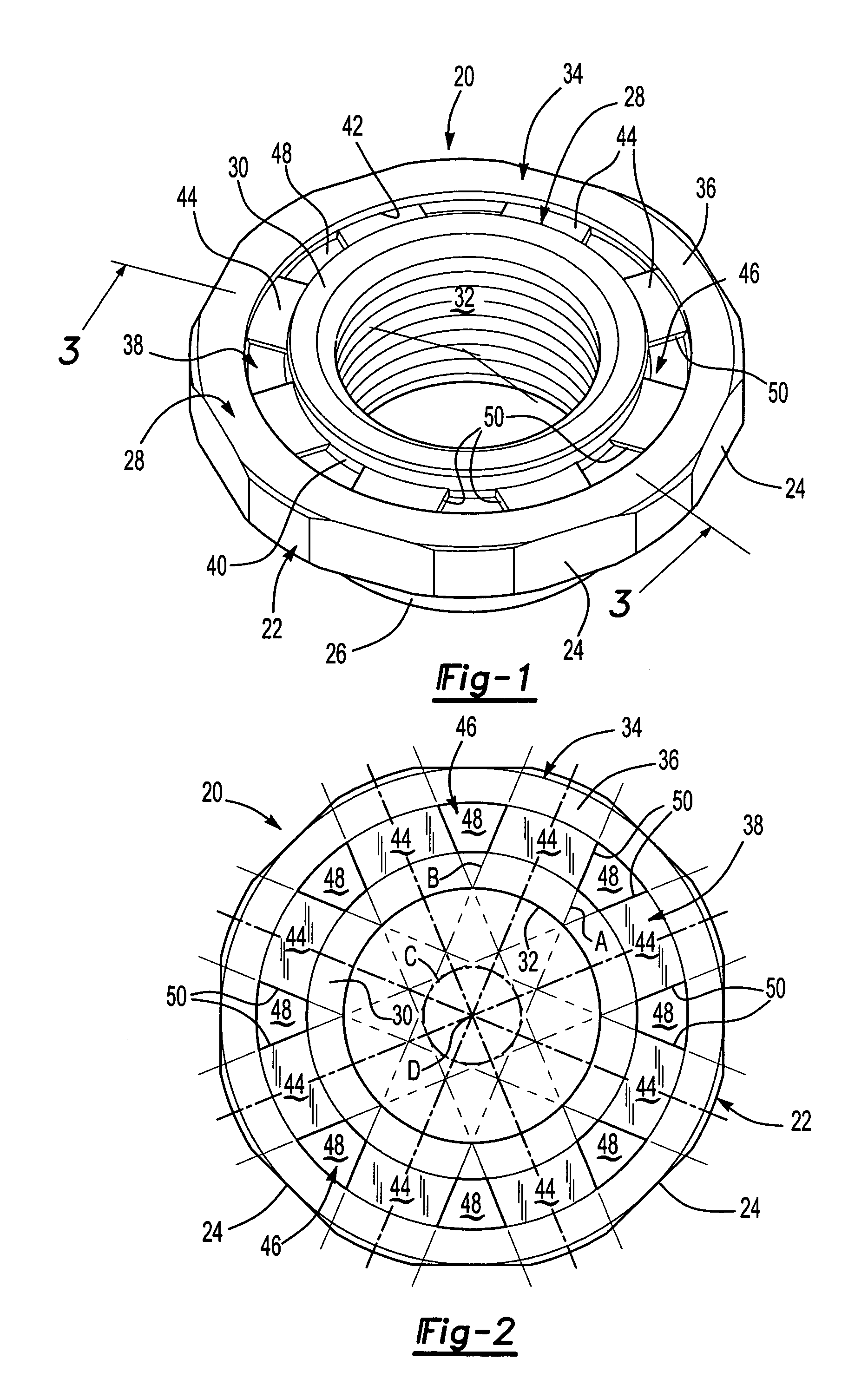

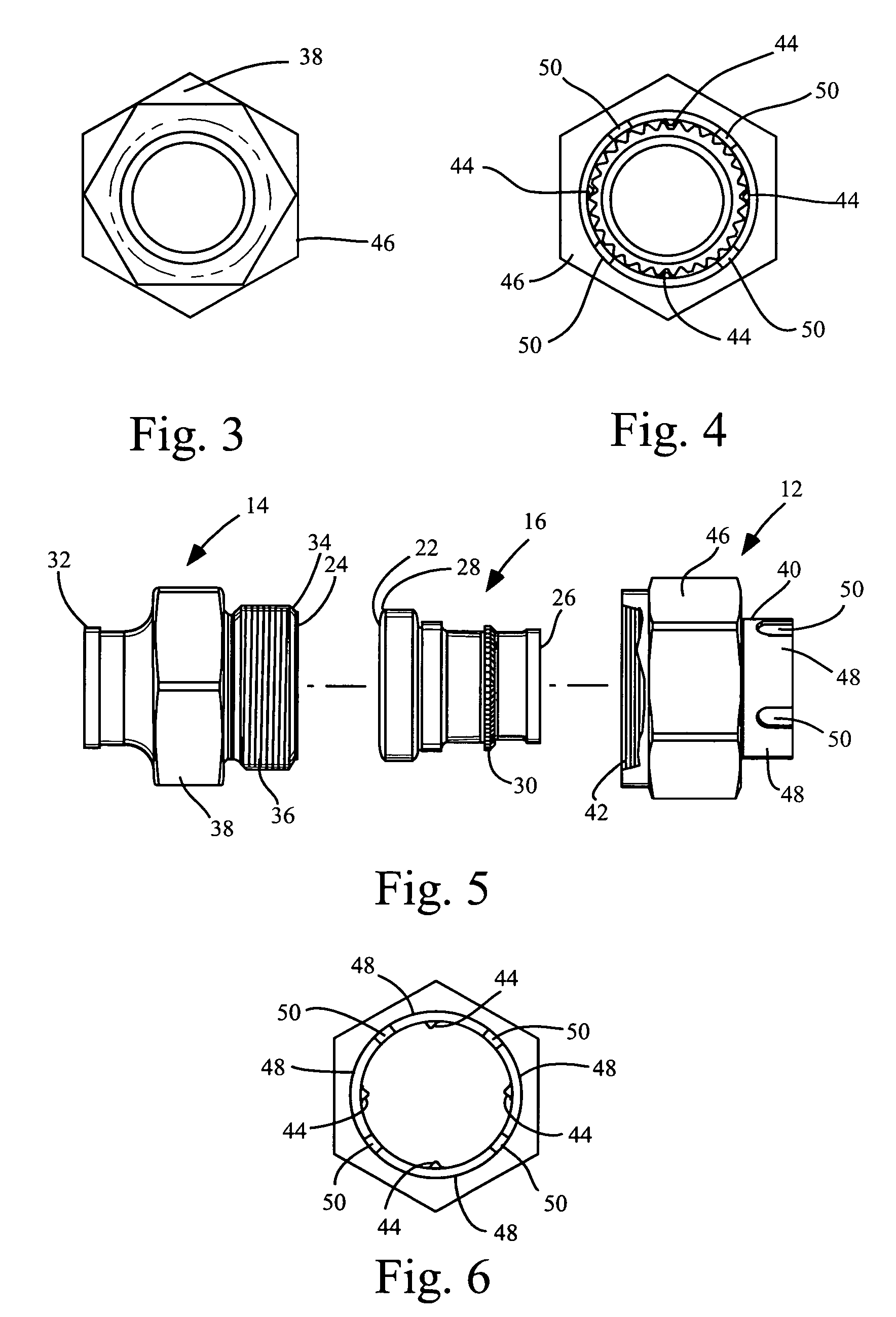

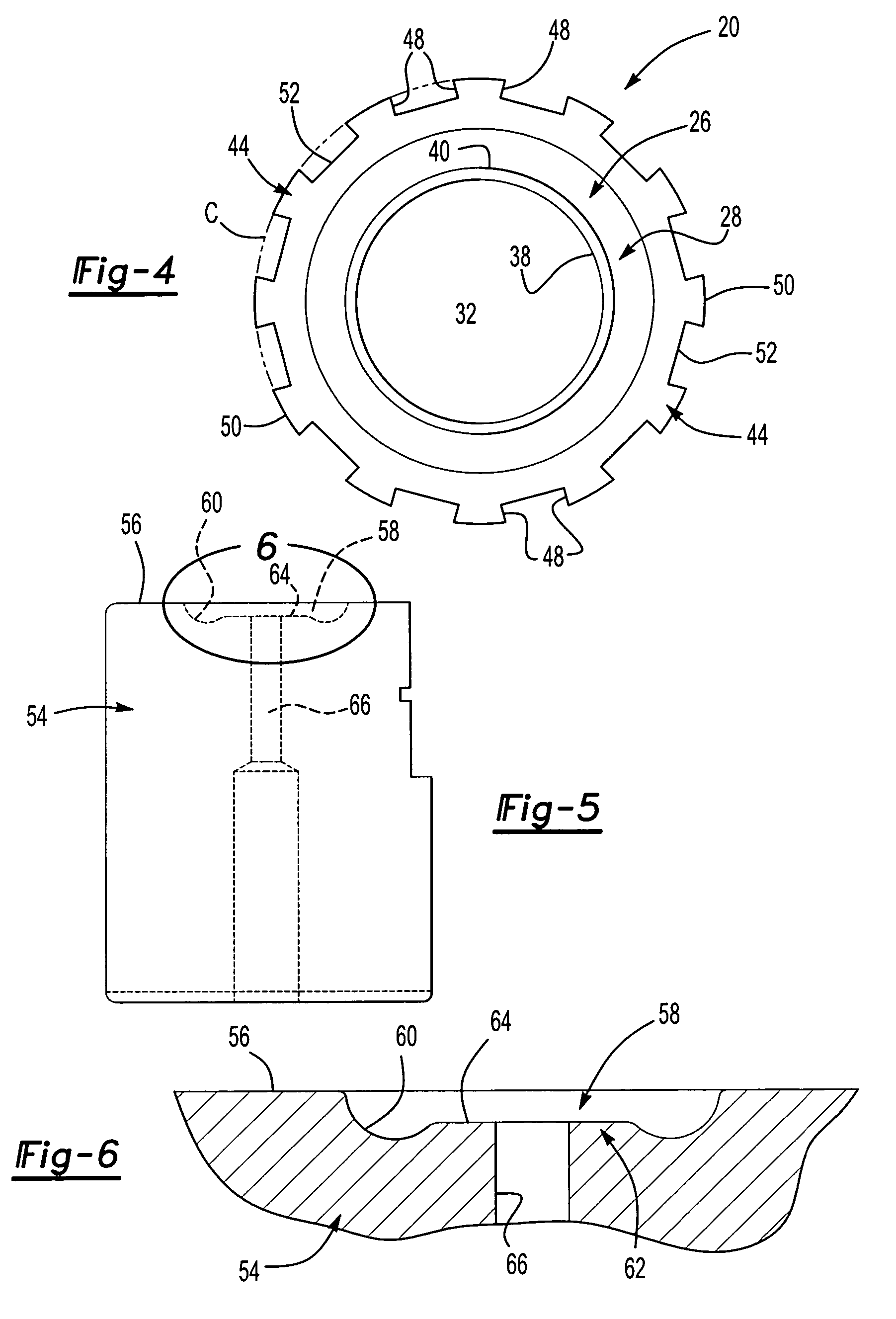

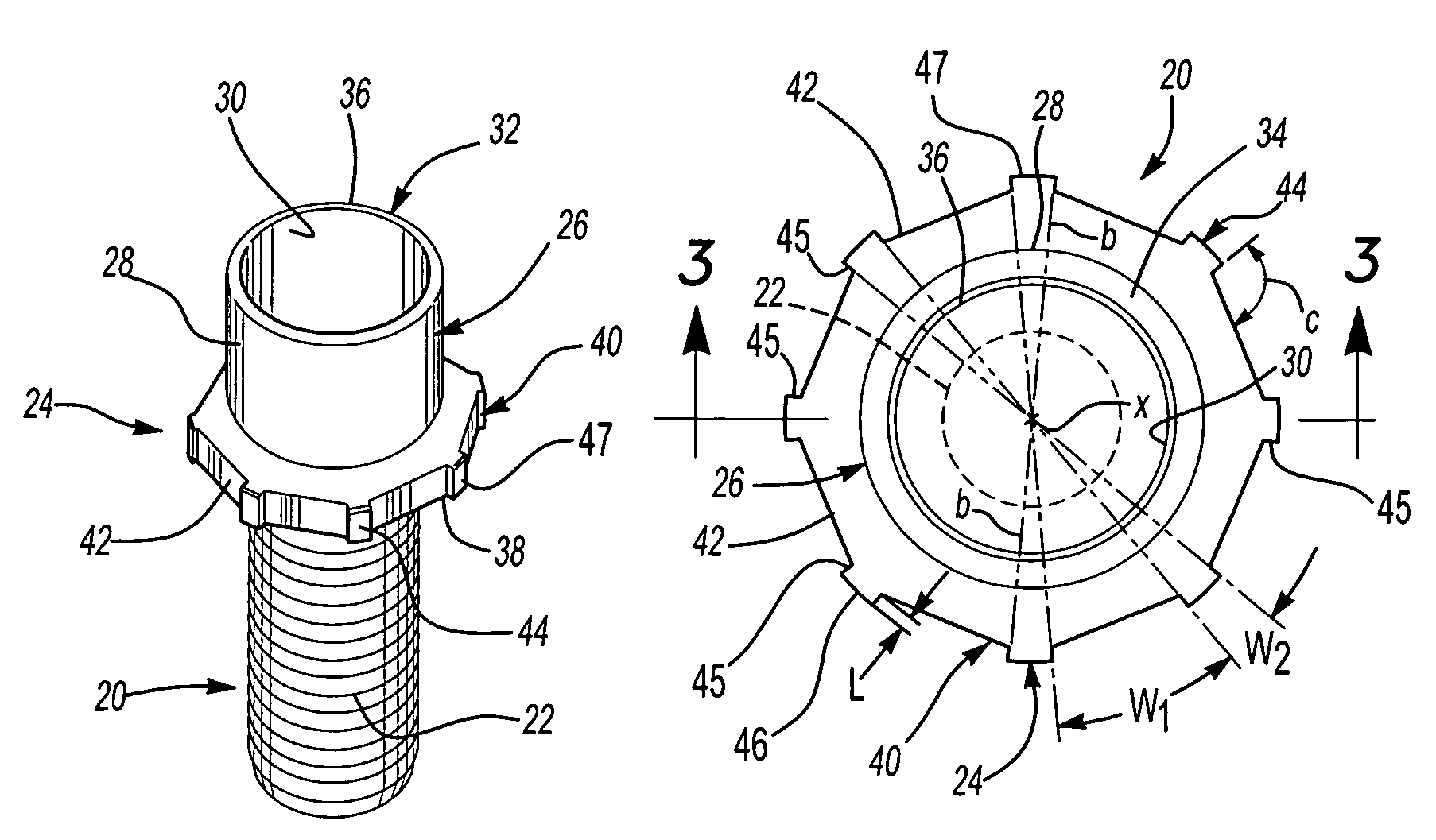

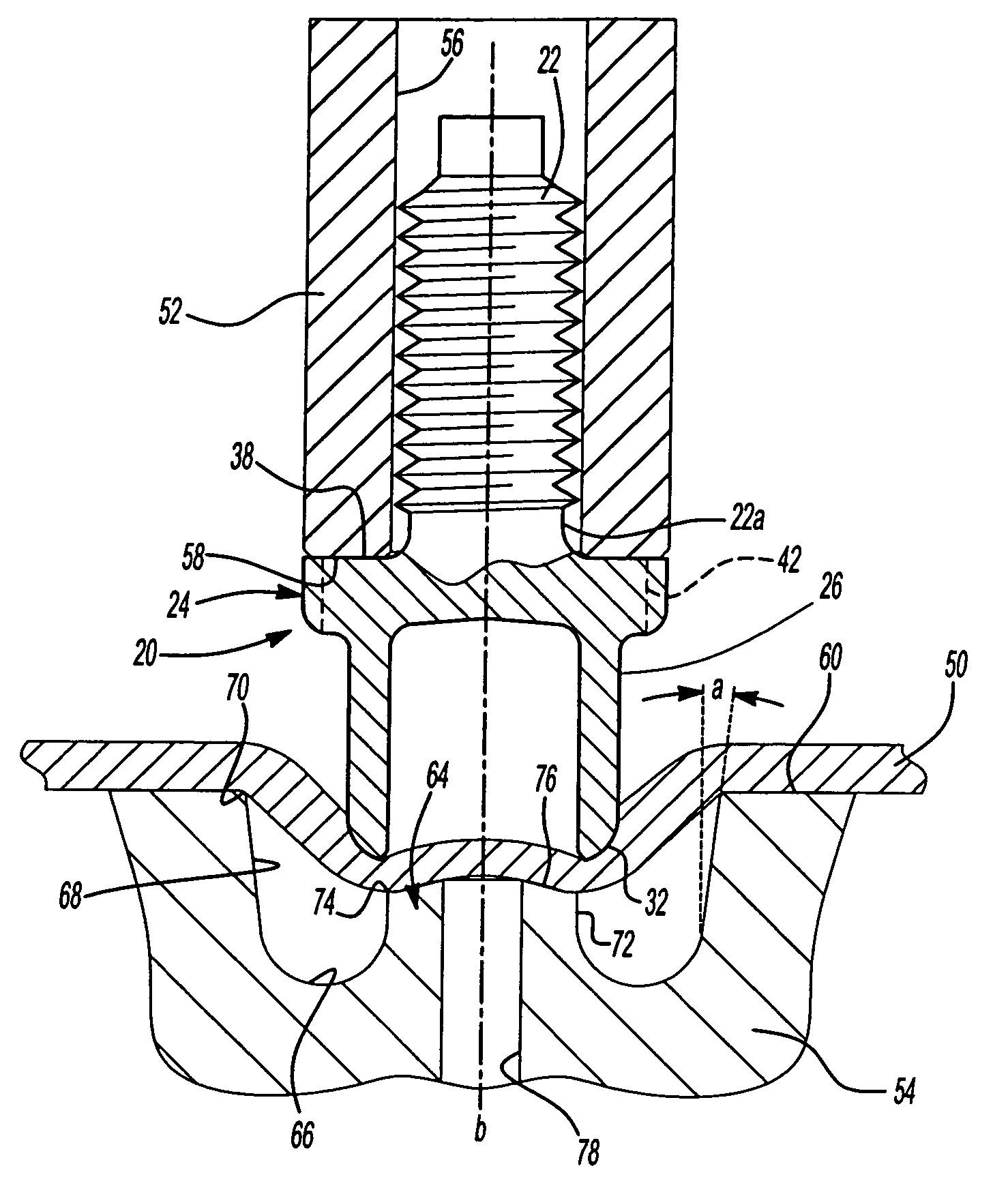

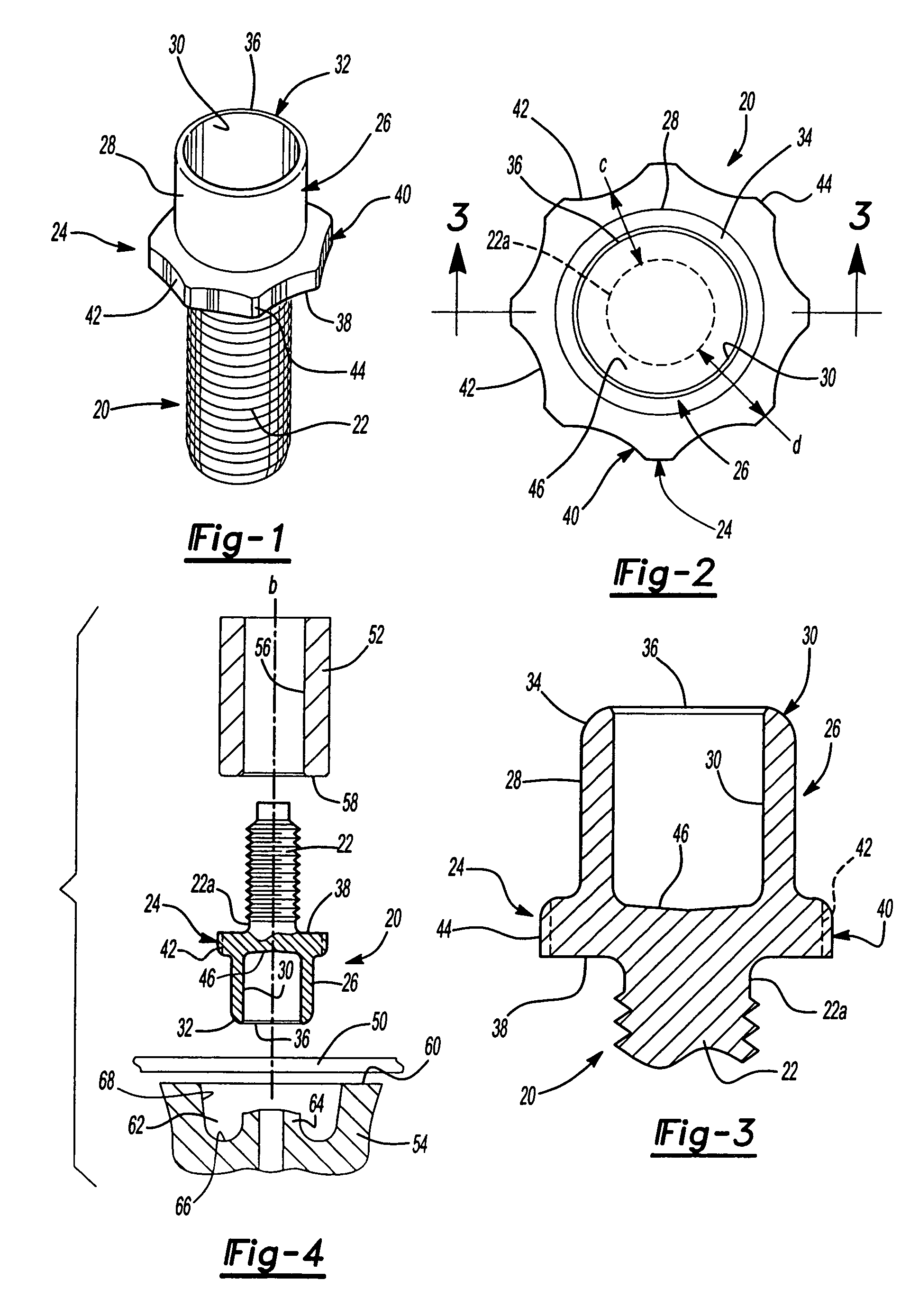

Self-attaching nut

A self-attaching nut having a central pilot projecting from an end face of the body portion, an annular groove surrounding the pilot and an annular panel support face surrounding the groove, wherein the outer side wall includes a plurality of circumferentially spaced notches, each having an outer wall which extends from the bottom wall of the annular groove to the panel support face and the bottom wall of the groove includes a plurality of circumferentially spaced radial ribs integral with either the outer or inner side walls of the annular groove having a radial end spaced from the opposed side wall and a top face inclined toward the bottom wall of the annular groove providing improved torque resistance and push-off strength. Alternating circumferentially overlapping radial ribs integral with the pilot and the outer groove wall and ribs which extend below the bottom wall of the groove are also disclosed.

Owner:PENN AUTOMOTIVE INC

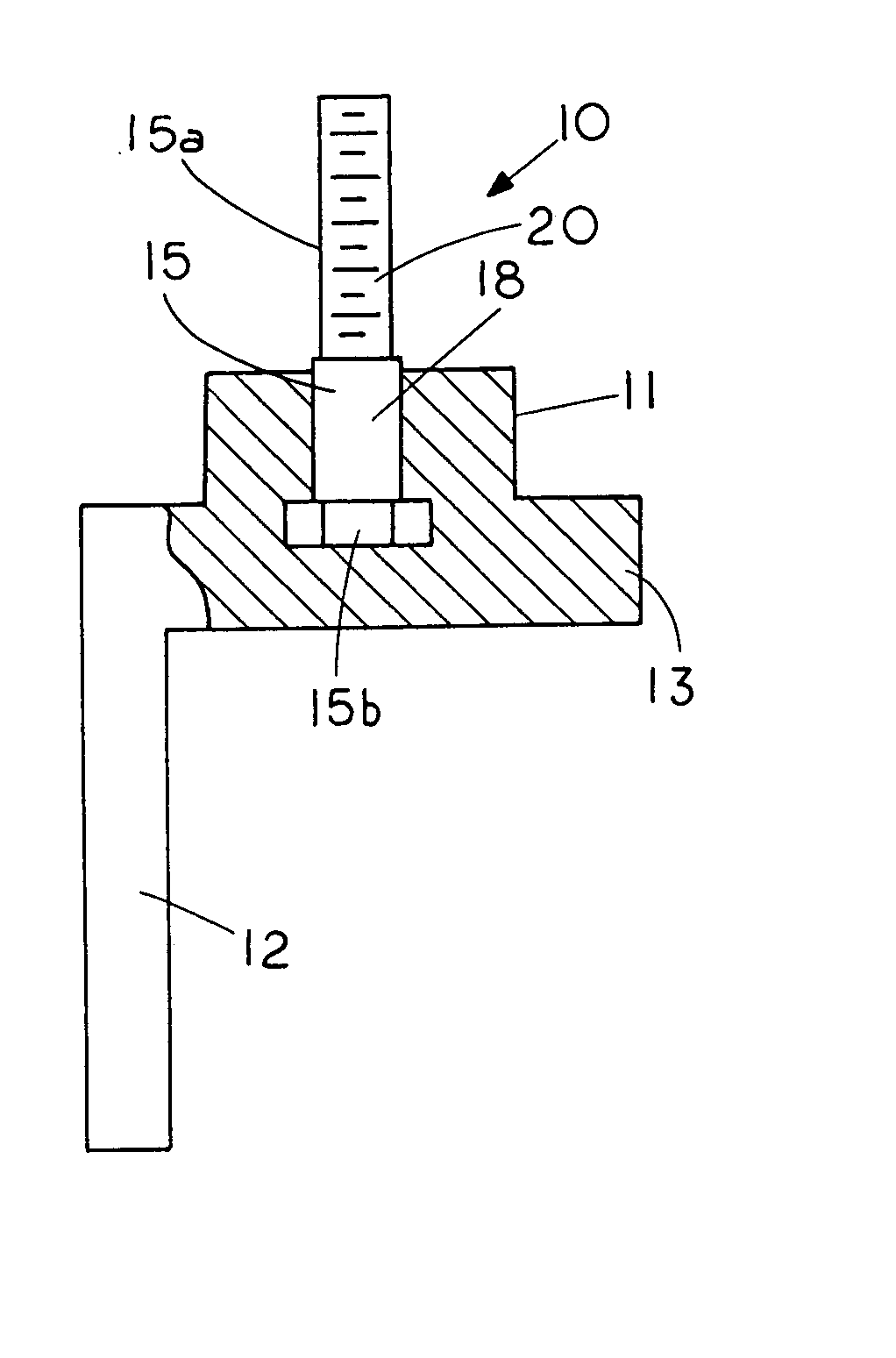

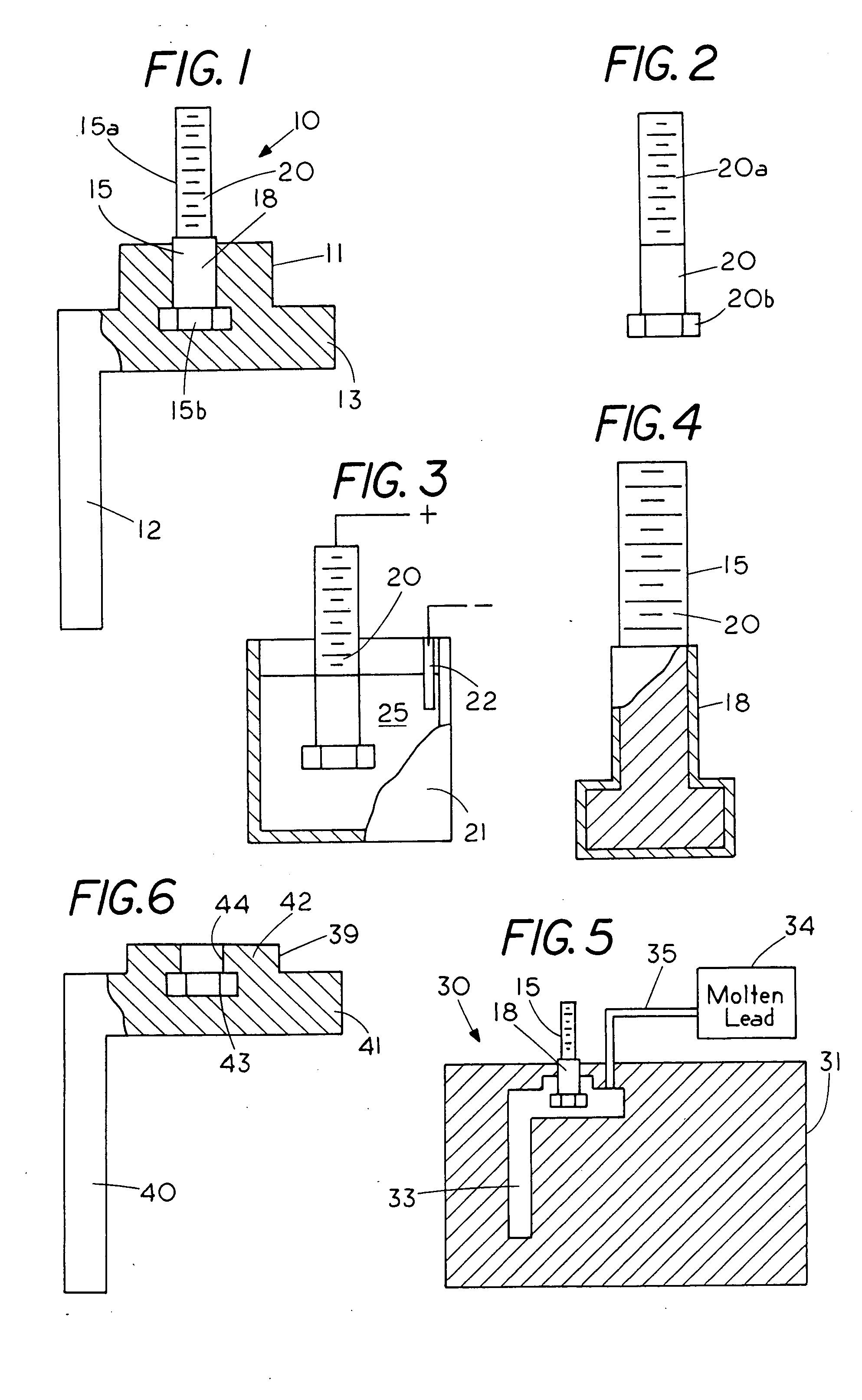

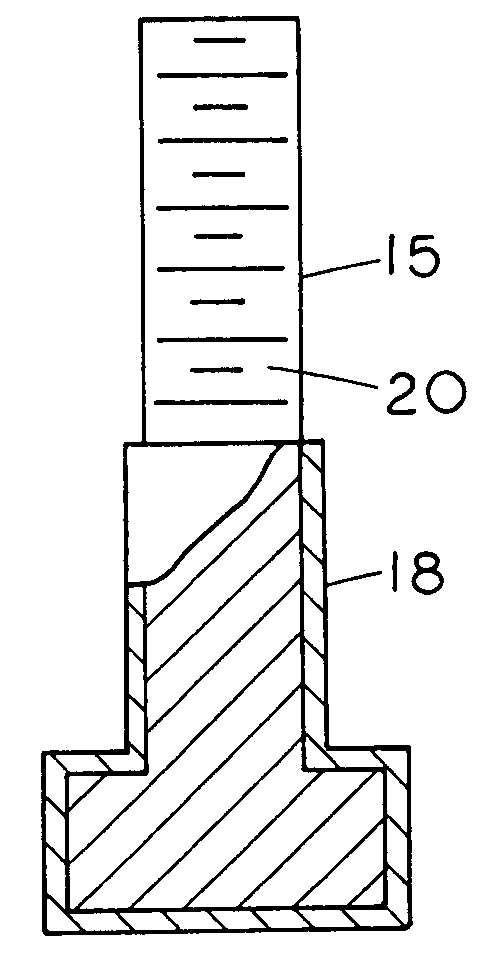

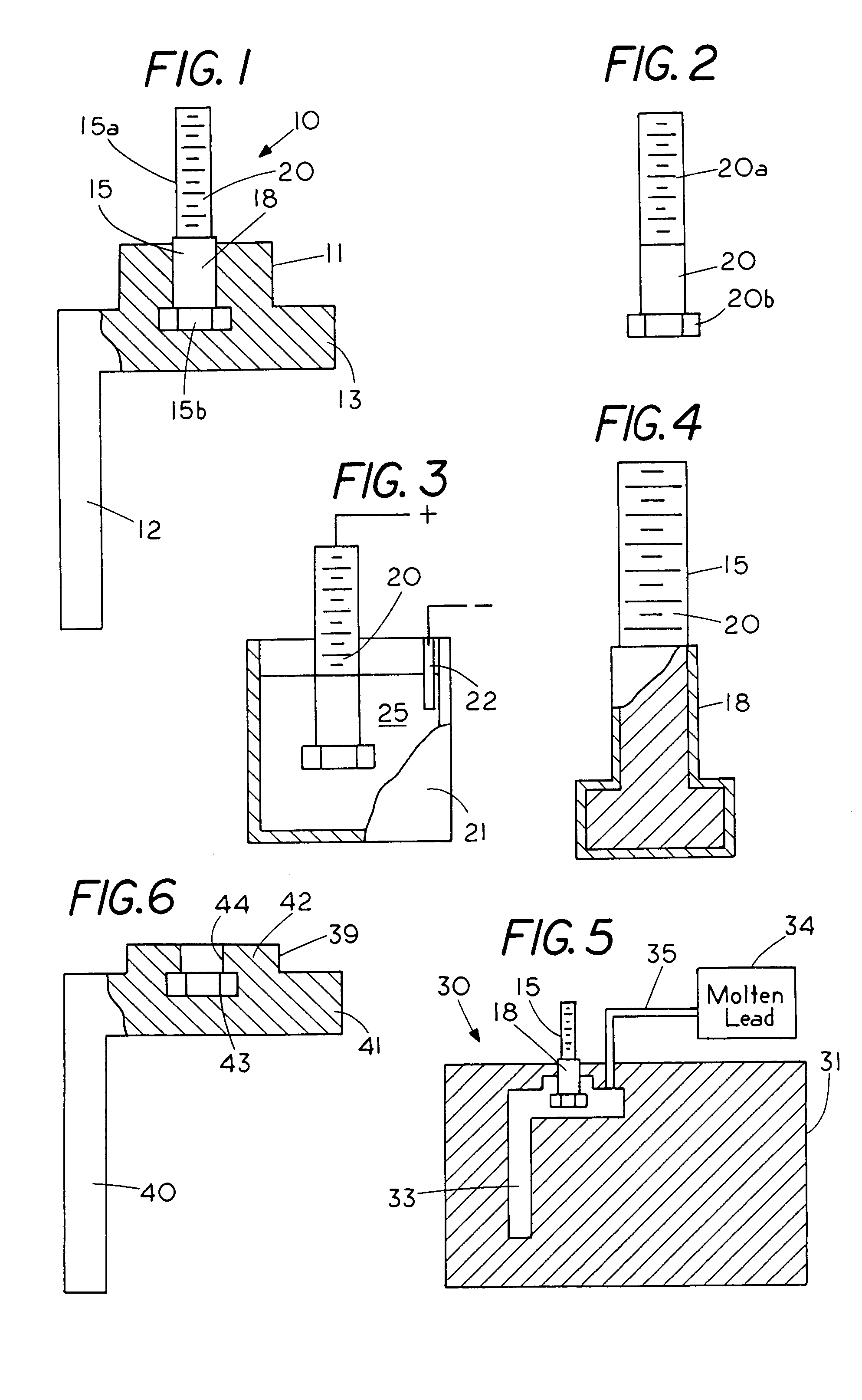

Enhanced torque resistant battery part

ActiveUS20050084751A1Improve torsion resistanceSmall-sized cells cases/jacketsEngineeringElectrical and Electronics engineering

An embedded fastener having enhanced torque resistance and a method of making an embedded fastener with enhanced torque resistance comprising interposing a layer between the lead battery part and the fastener. In one embodiment an electrically conducting layer of a lead adhereable layer is applied to the exterior surface of a fastener. Next, one places the fastener with the layer of lead adhereable material in a mold and injects molten lead into mold and allows the molten lead to solidify around the layer of lead adhereable material on the fastener to thereby secure the solidified lead to the layer of lead adhereable material on the fastener to provide a battery part having a fastener therein with enhanced torque resistance.

Owner:WATER GREMLIN

Self-attaching nut

Owner:PENN AUTOMOTIVE INC

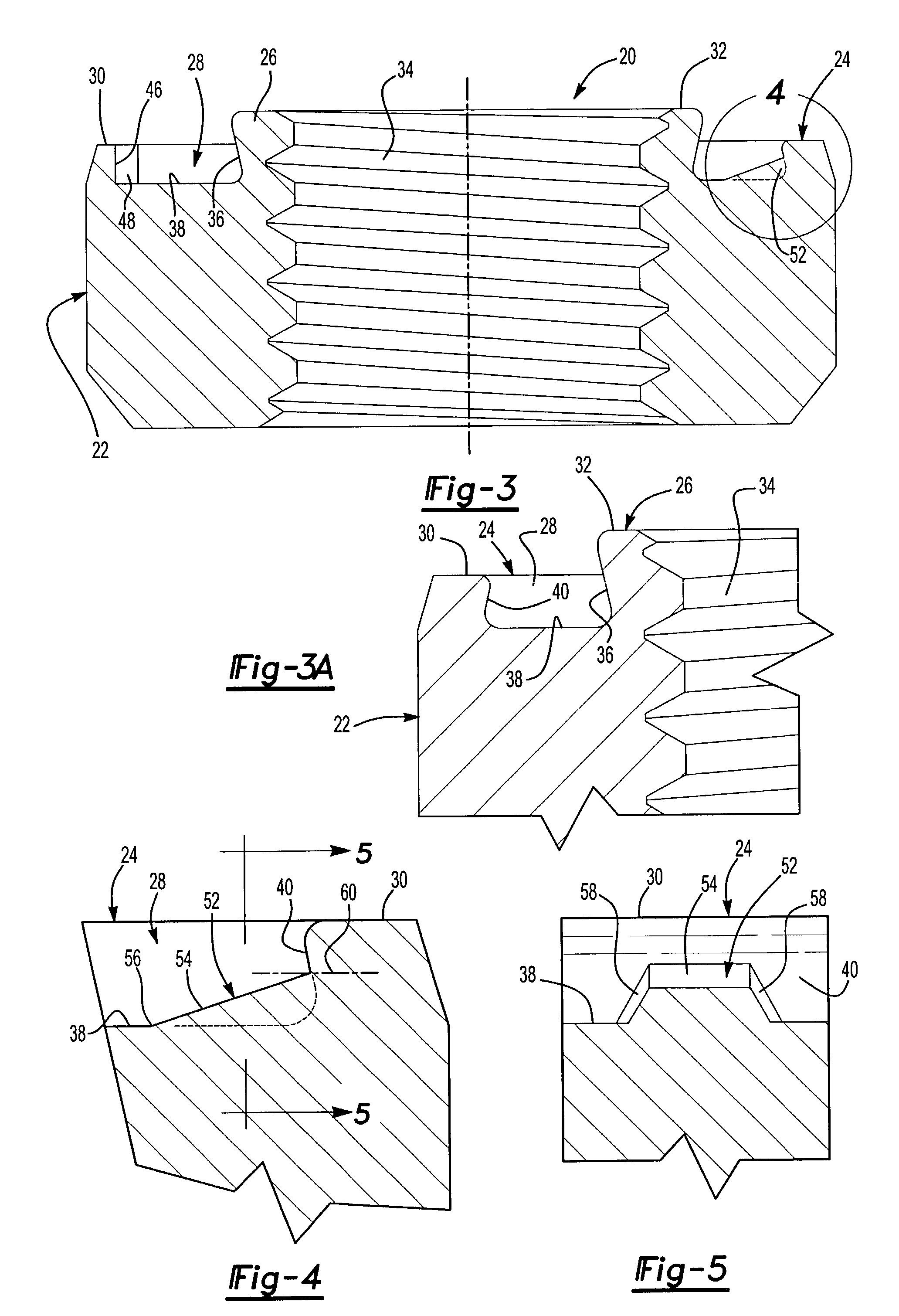

Self-attaching female fastener element, sealed fastener and panel assembly and method of forming same

InactiveUS7001125B2Improve torsion resistanceImproved push-off strengthNutsBoltsBearing surfaceFlange

A self-attaching female fastener such as a pierce nut having an annular pilot, an annular flange surrounding the pilot and an annular groove in the flange bearing surface surrounding the pilot, wherein the bottom wall of the groove includes wedge-shaped recesses dividing the groove bottom wall into segments having parallel sides defined by the adjacent wedge-shaped recesses and the inclined outer wall of the pilot is deformed radially during installation to entrap and compact panel metal in the groove forming a sealed secure installation having improved push-off and anti-rotation strength.

Owner:PENN AUTOMOTIVE INC

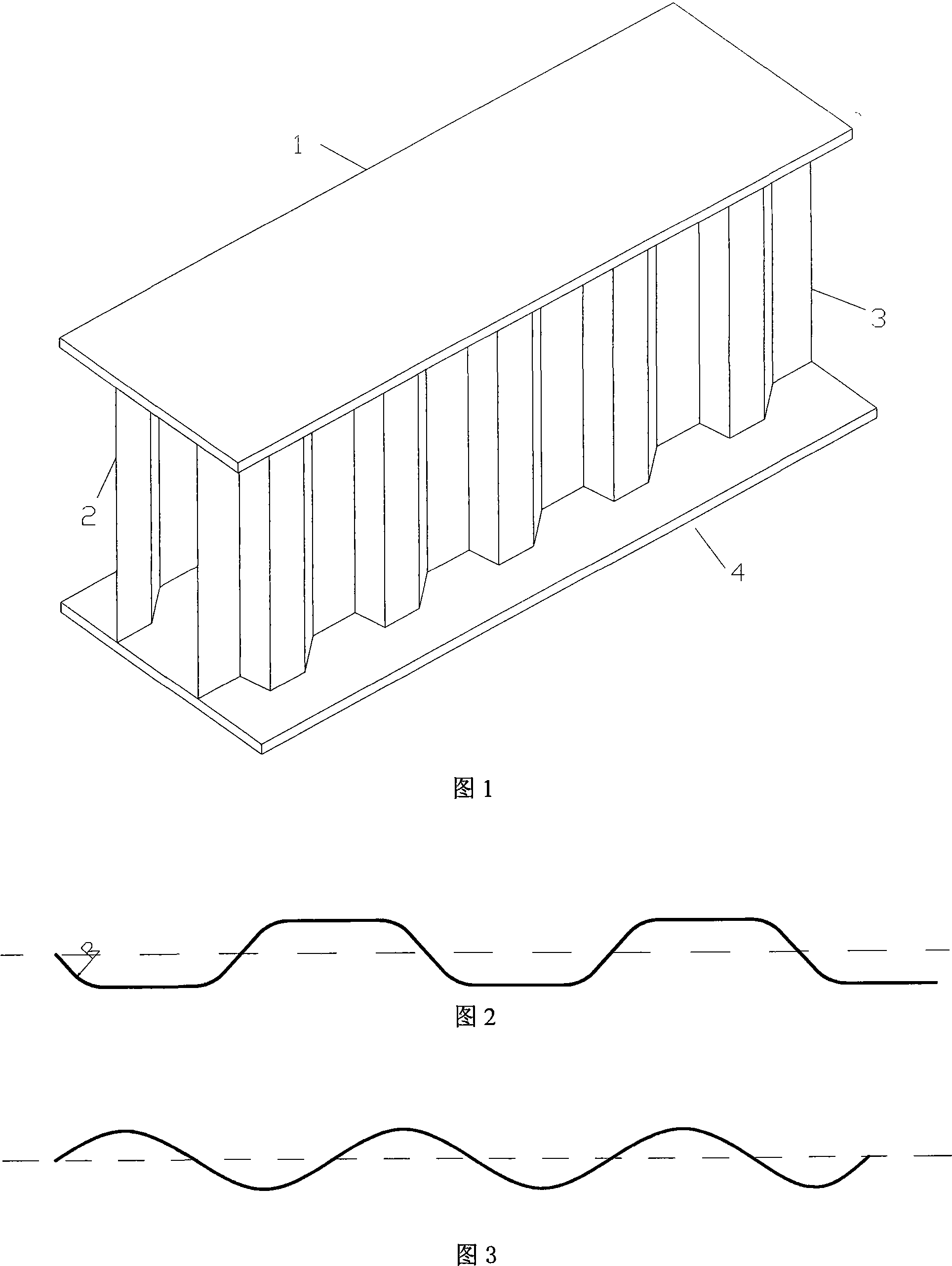

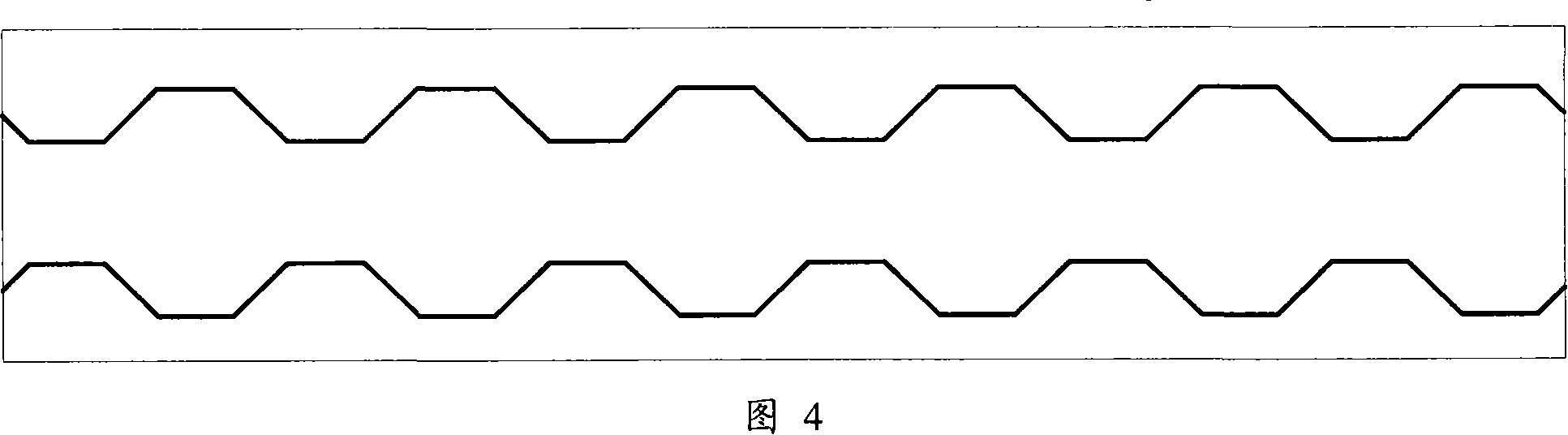

Double corrugated web plate steel box girder

The invention belongs to the technical field of building materials and in particular relates to a double undulated web slab steel box girder. The cross-section fracture shape is composed of a middle web slab, an upper flange and a lower flange which are integrated, wherein the upper flange is parallel to the lower flange, a double web slab is vertically located between the upper flange and the lower flange, the double web slab is arranged symmetrically and takes a honeycomb structure, the web slab and the flange slabs adopt one side fillet weld to connect, the web slab is an undulated web slab whose length direction are periodically repeated evenly or unevenly, and the undulated cross section takes circular arc angle trapezoid and sinusoidal curve. The product can replace products such as normal welded box steel girders, hot rolled H-shaped steel, I-shaped steel and the like, has wider usage compared with the products, and can realize maximization and can be used in the special fields and special places including the building of bridges with large spans, the manufacture of ships and the like.

Owner:TONGJI UNIV +1

Enhanced torque resistant battery part

ActiveUS7163764B2Improve torsion resistanceSmall-sized cells cases/jacketsClamped/spring connectionsEngineeringFastener

An embedded fastener having enhanced torque resistance and a method of making an embedded fastener with enhanced torque resistance comprising interposing a layer between the lead battery part and the fastener. In one embodiment an electrically conducting layer of a lead adhereable layer is applied to the exterior surface of a fastener. Next, one places the fastener with the layer of lead adhereable material in a mold and injects molten lead into mold and allows the molten lead to solidify around the layer of lead adhereable material on the fastener to thereby secure the solidified lead to the layer of lead adhereable material on the fastener to provide a battery part having a fastener therein with enhanced torque resistance.

Owner:WATER GREMLIN

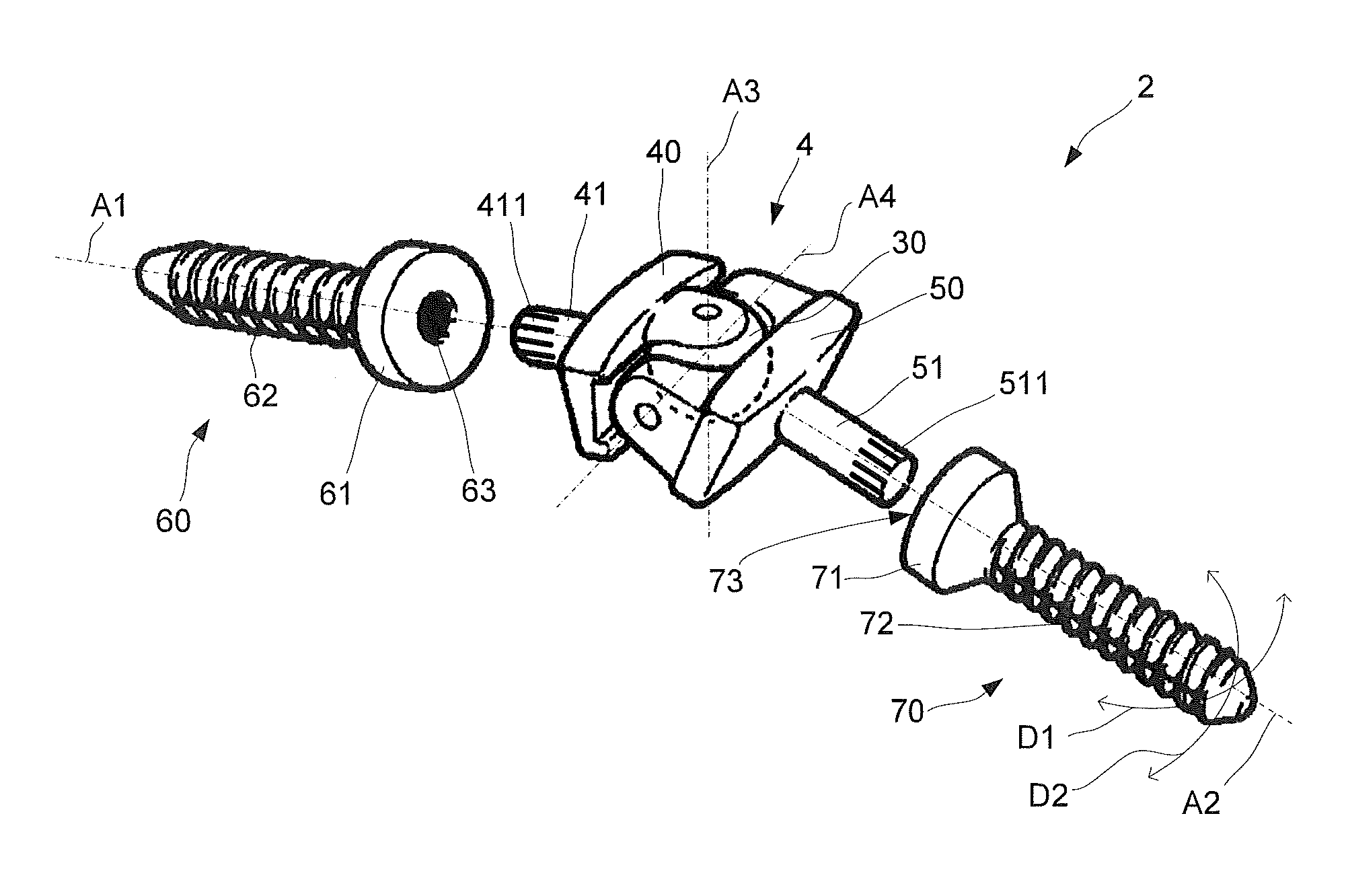

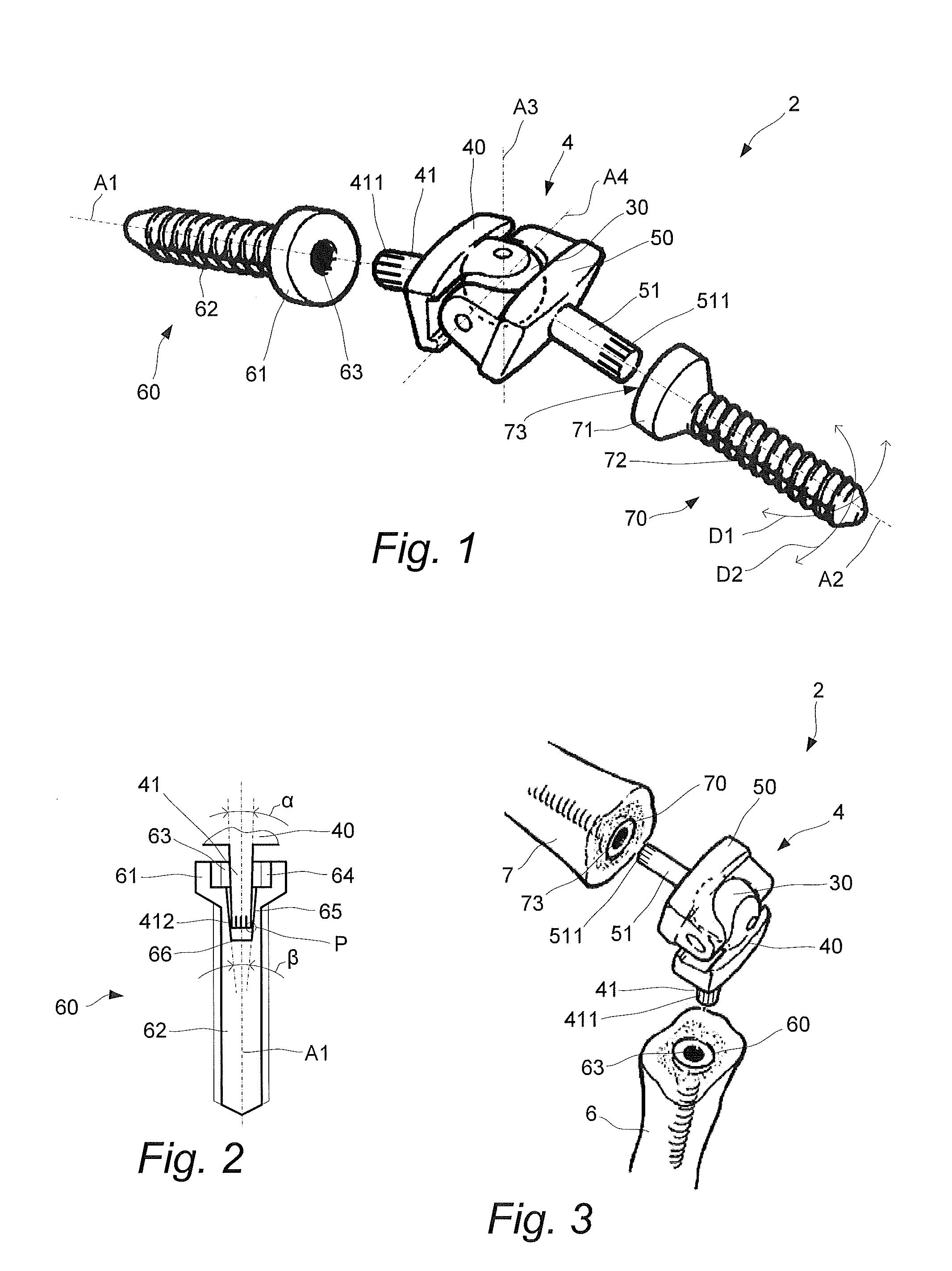

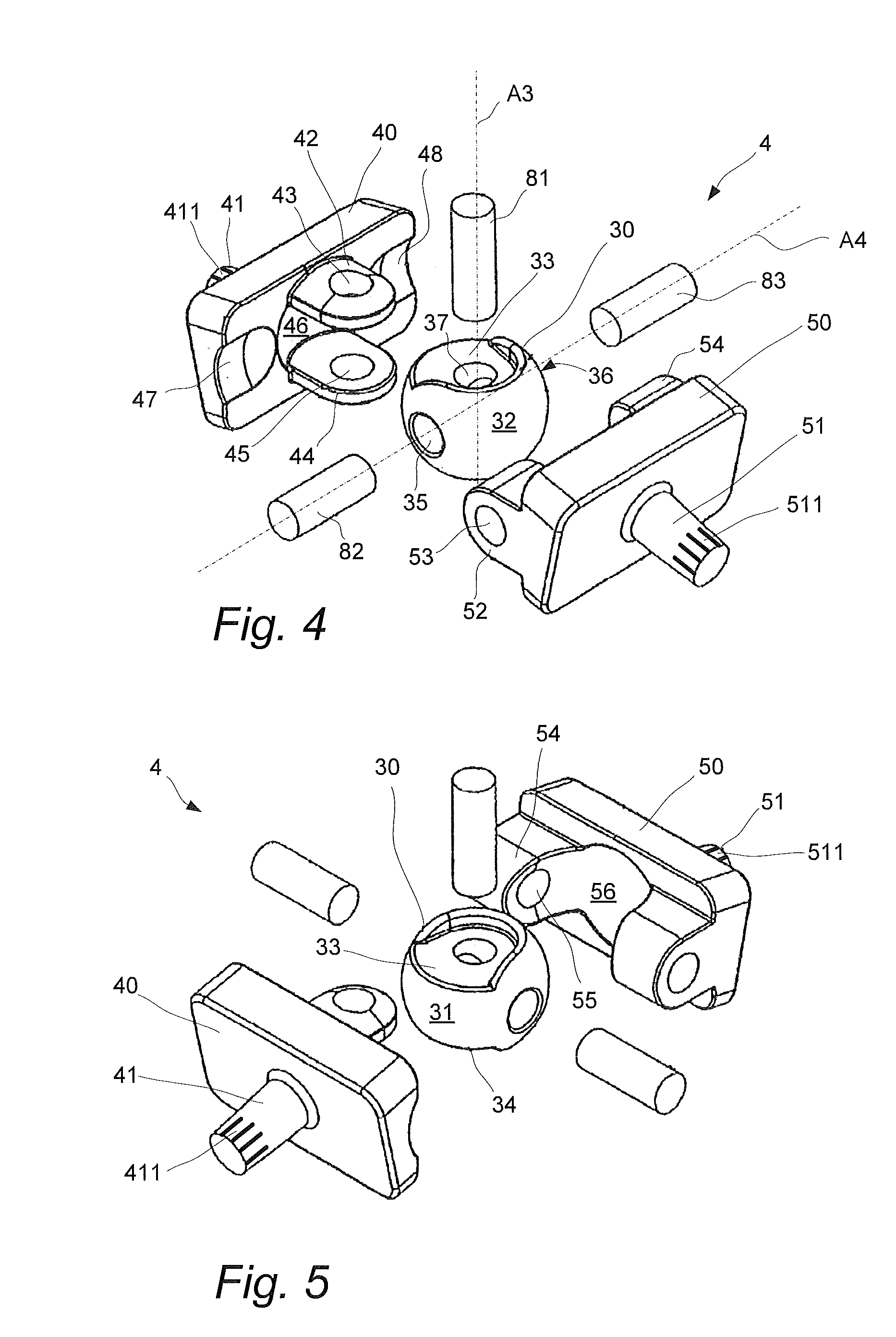

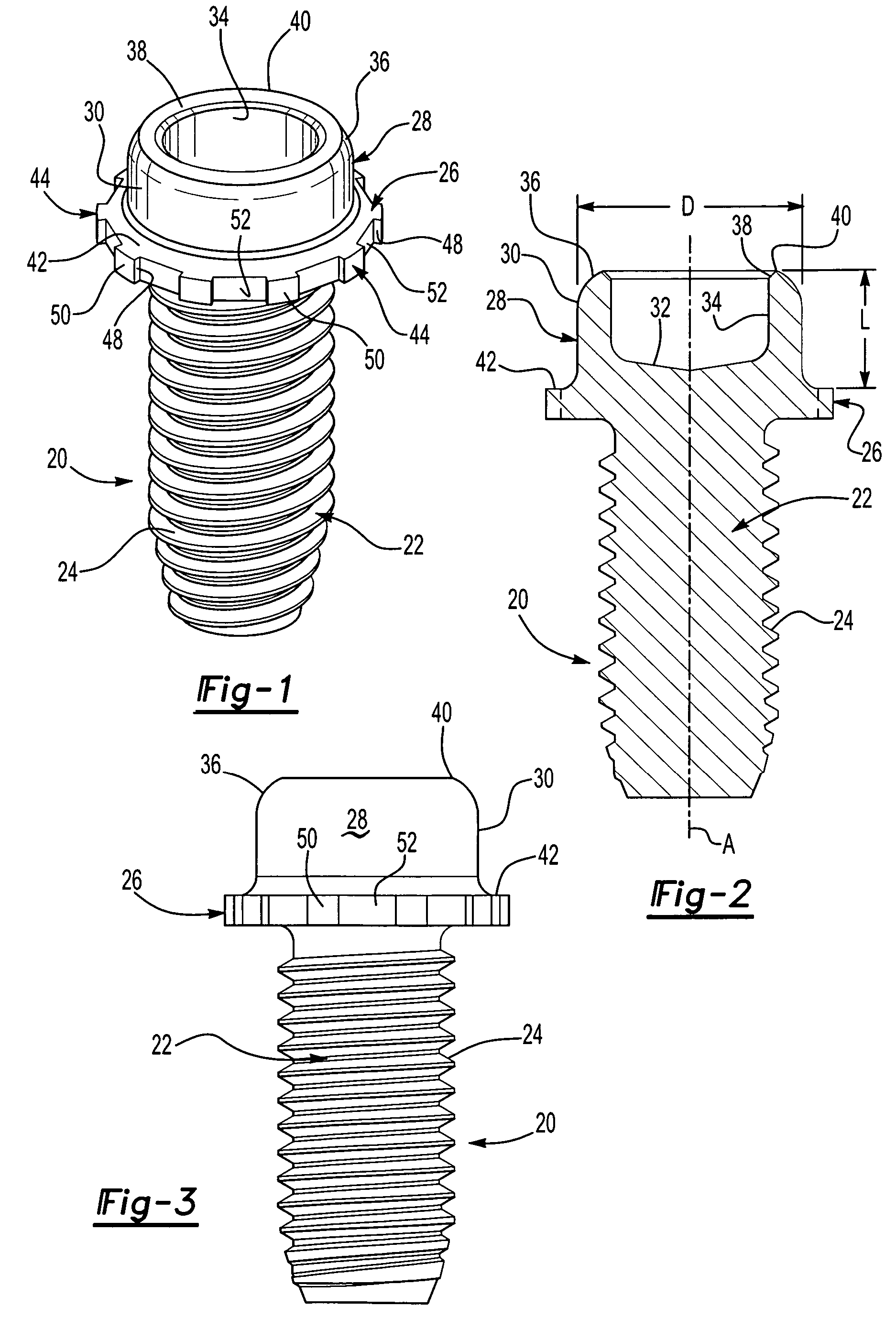

Artificial joint

InactiveUS20130218286A1Overcome limitationsPrevent movementFinger jointsAnkle jointsArtificial jointsEngineering

Owner:GS DEVMENT

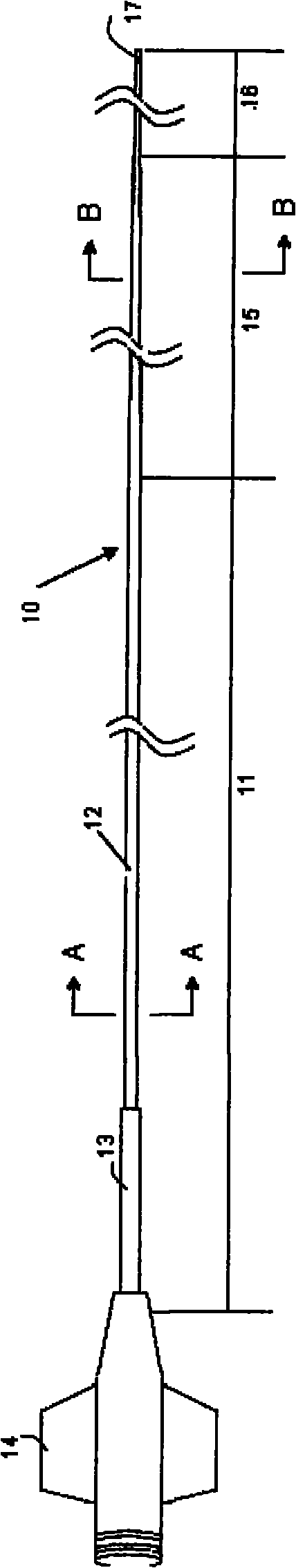

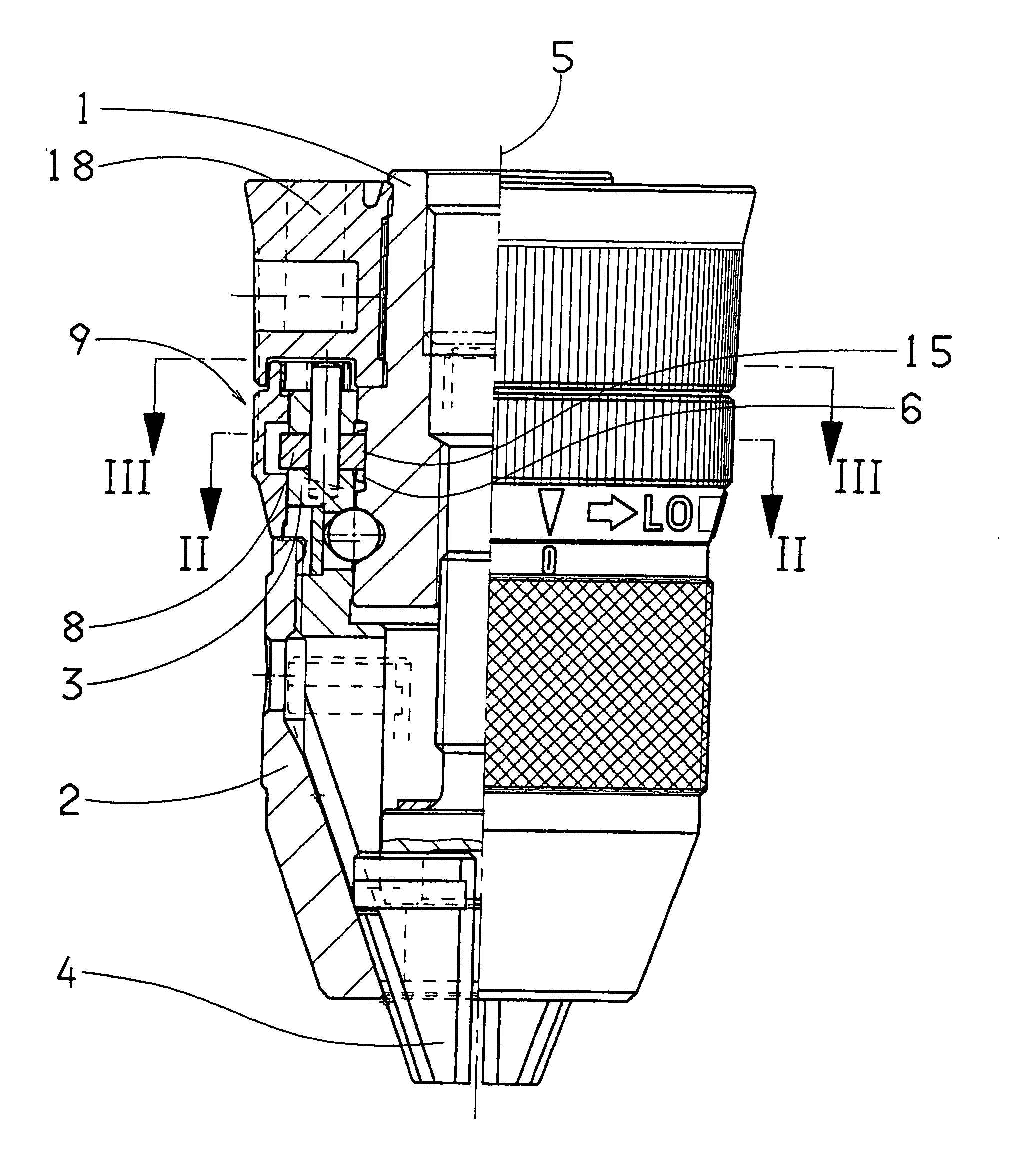

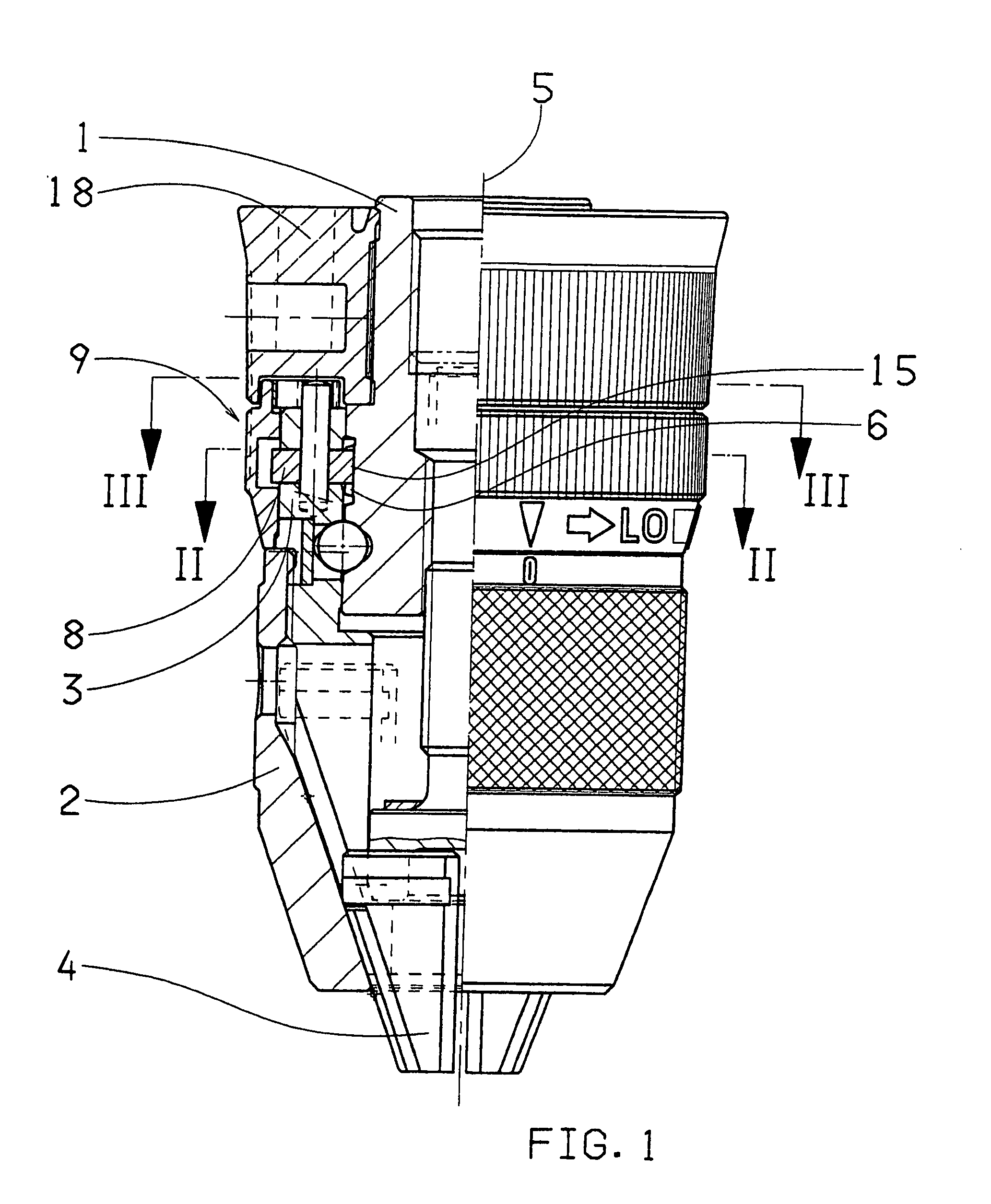

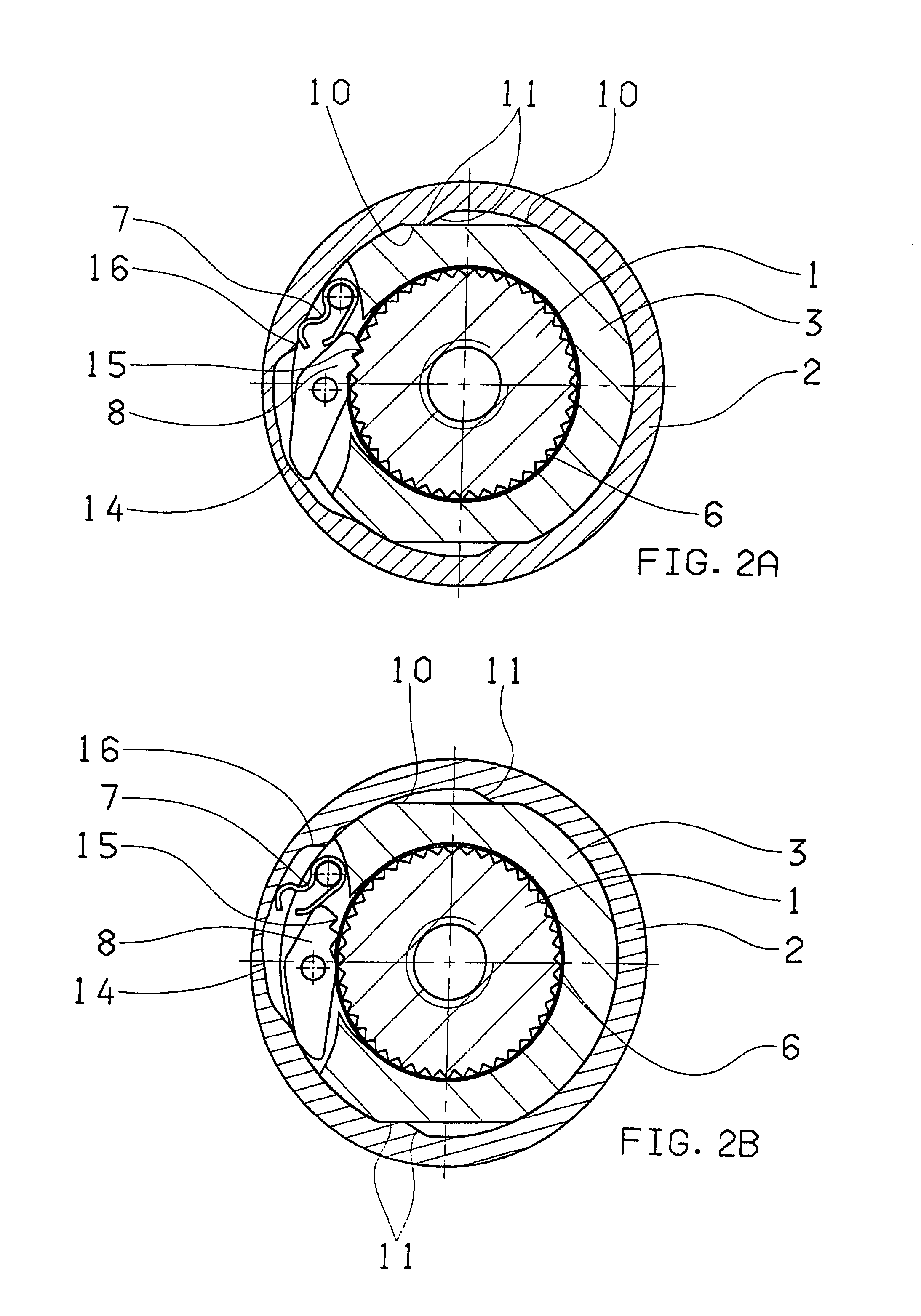

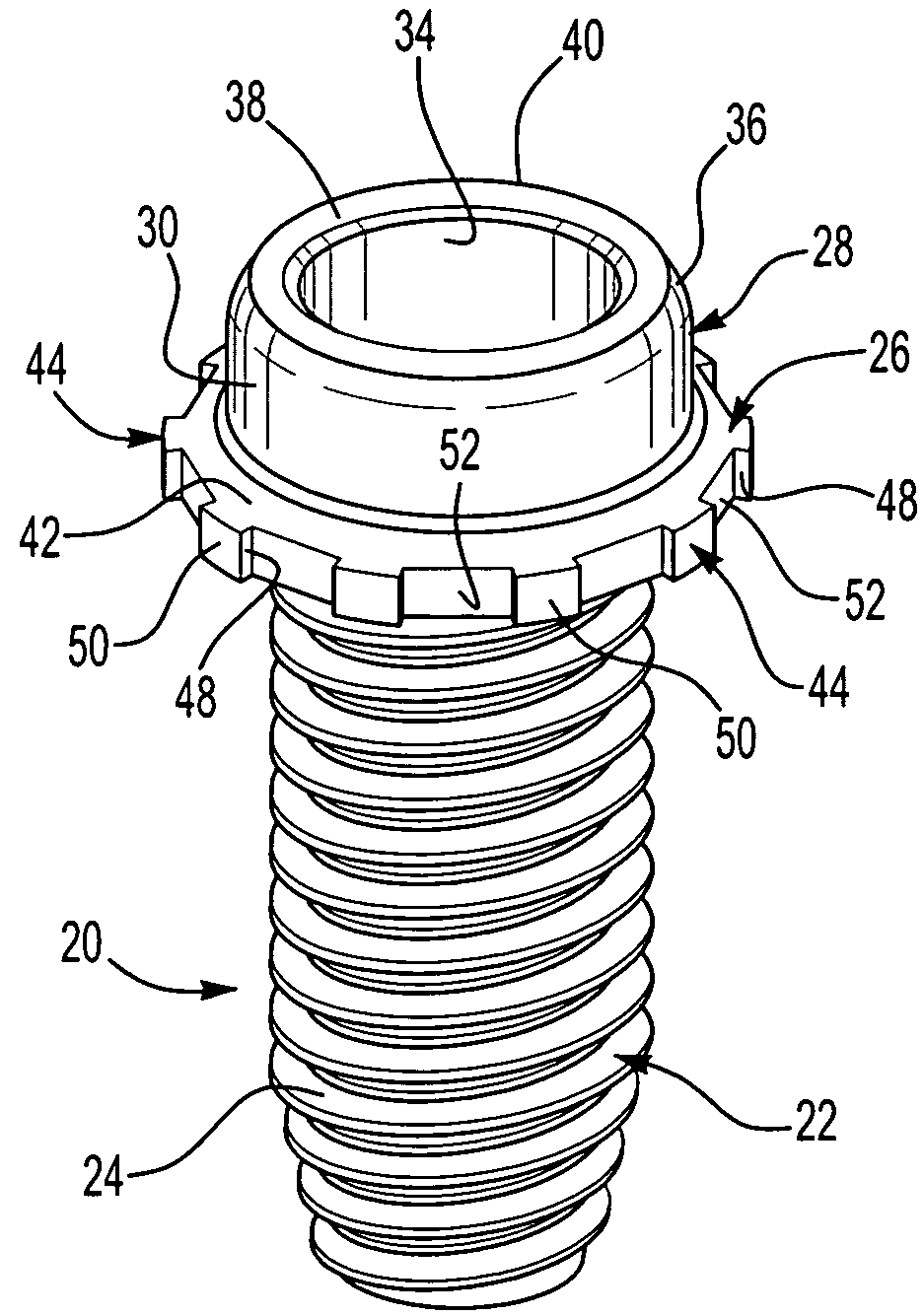

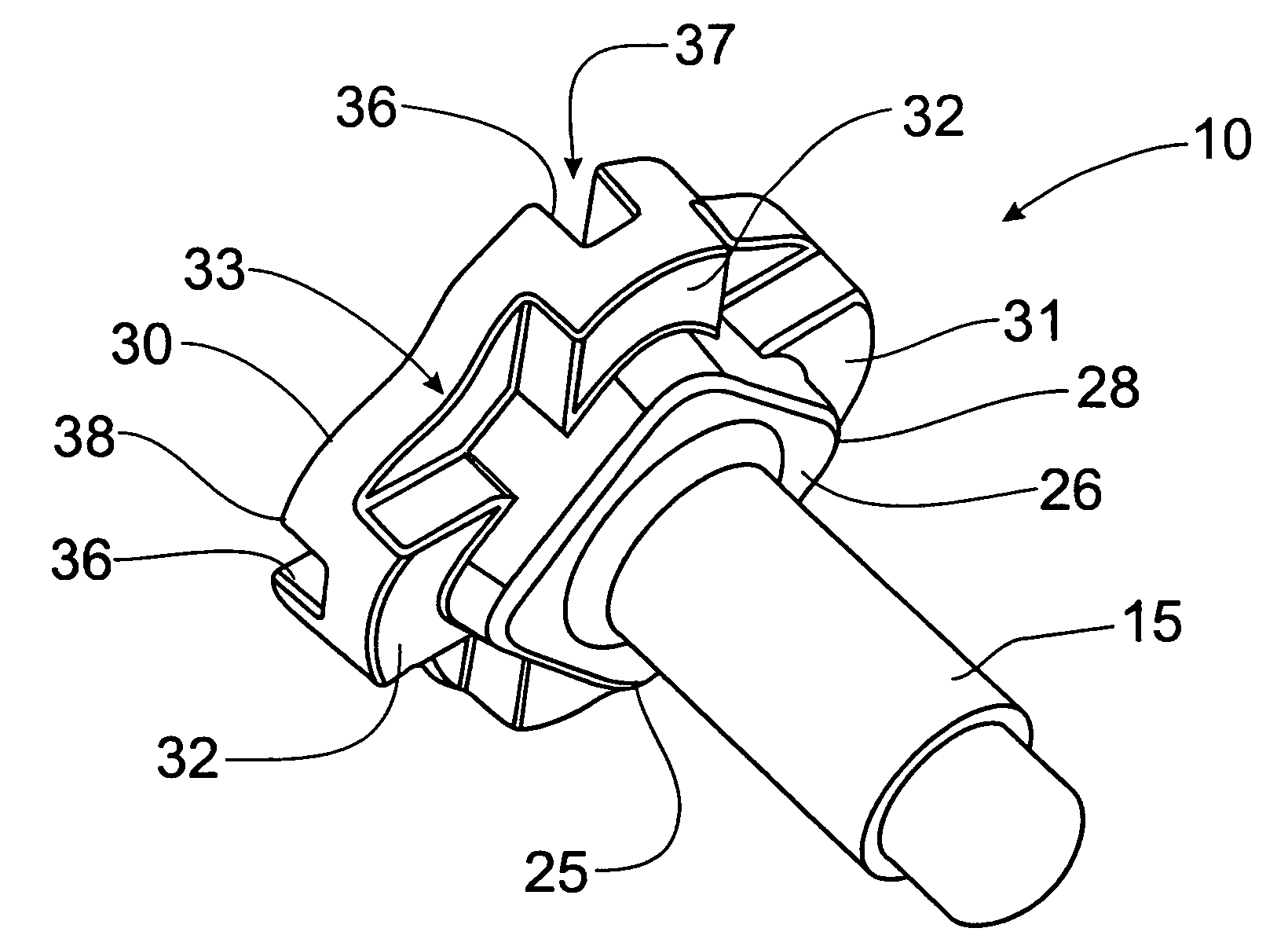

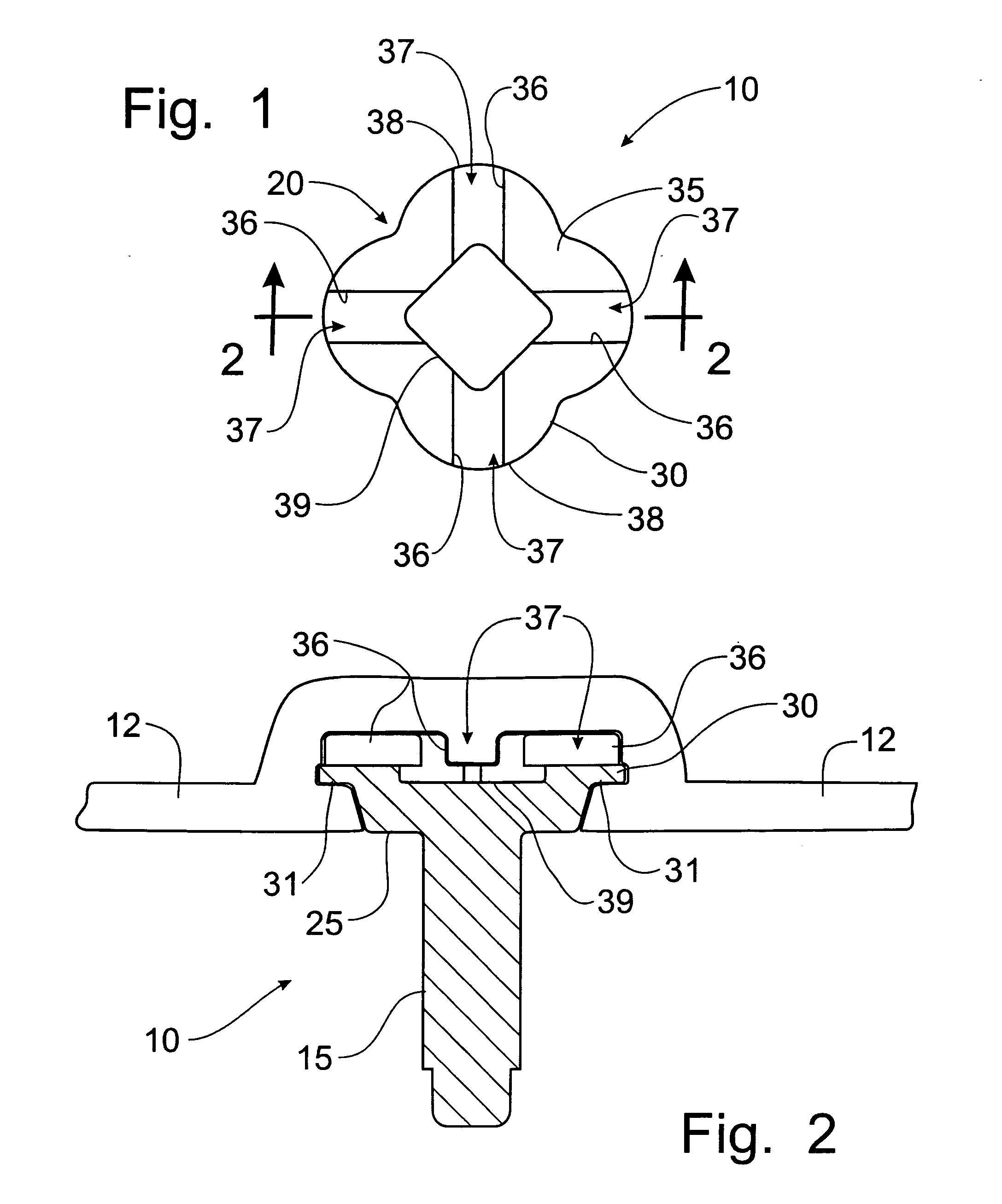

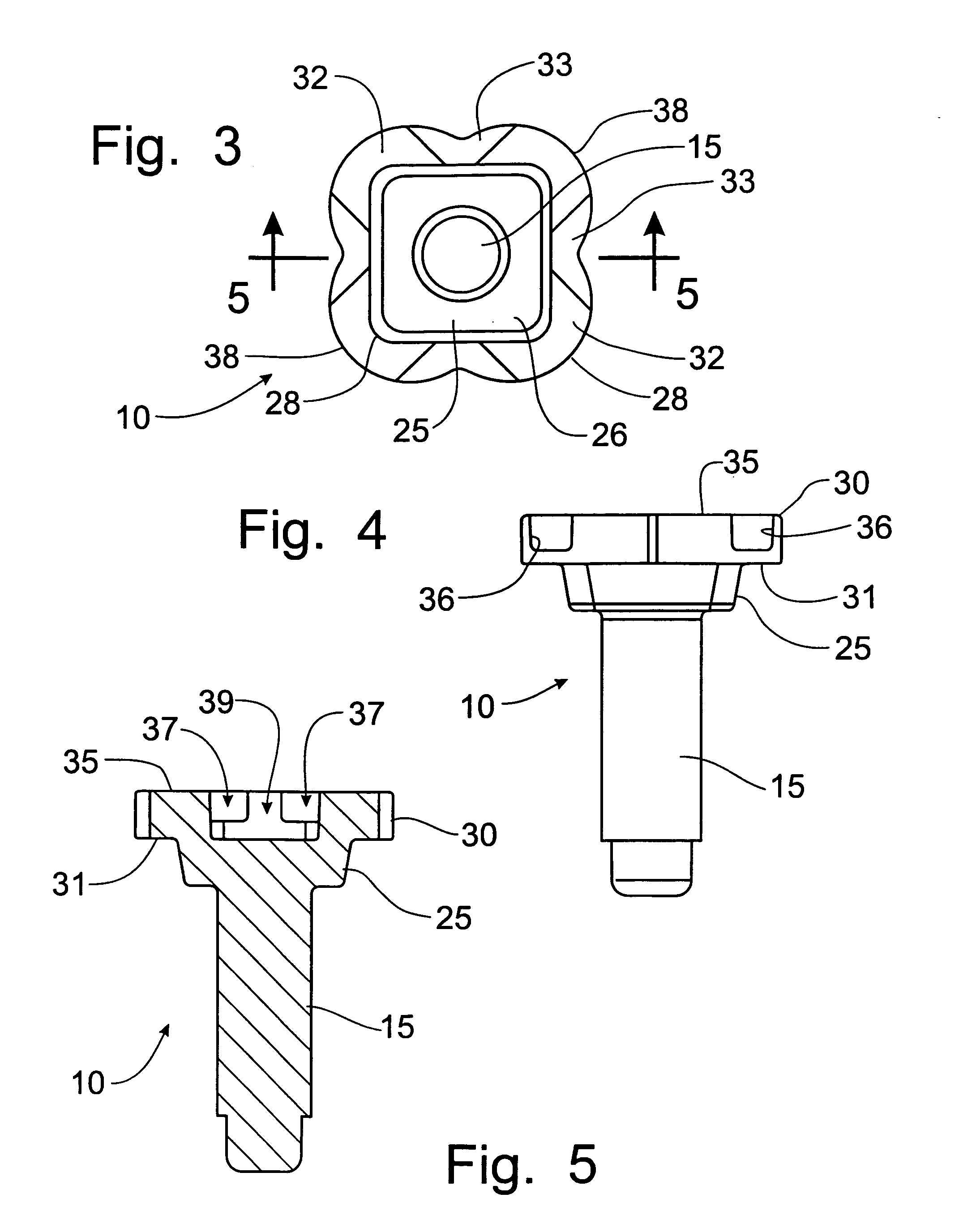

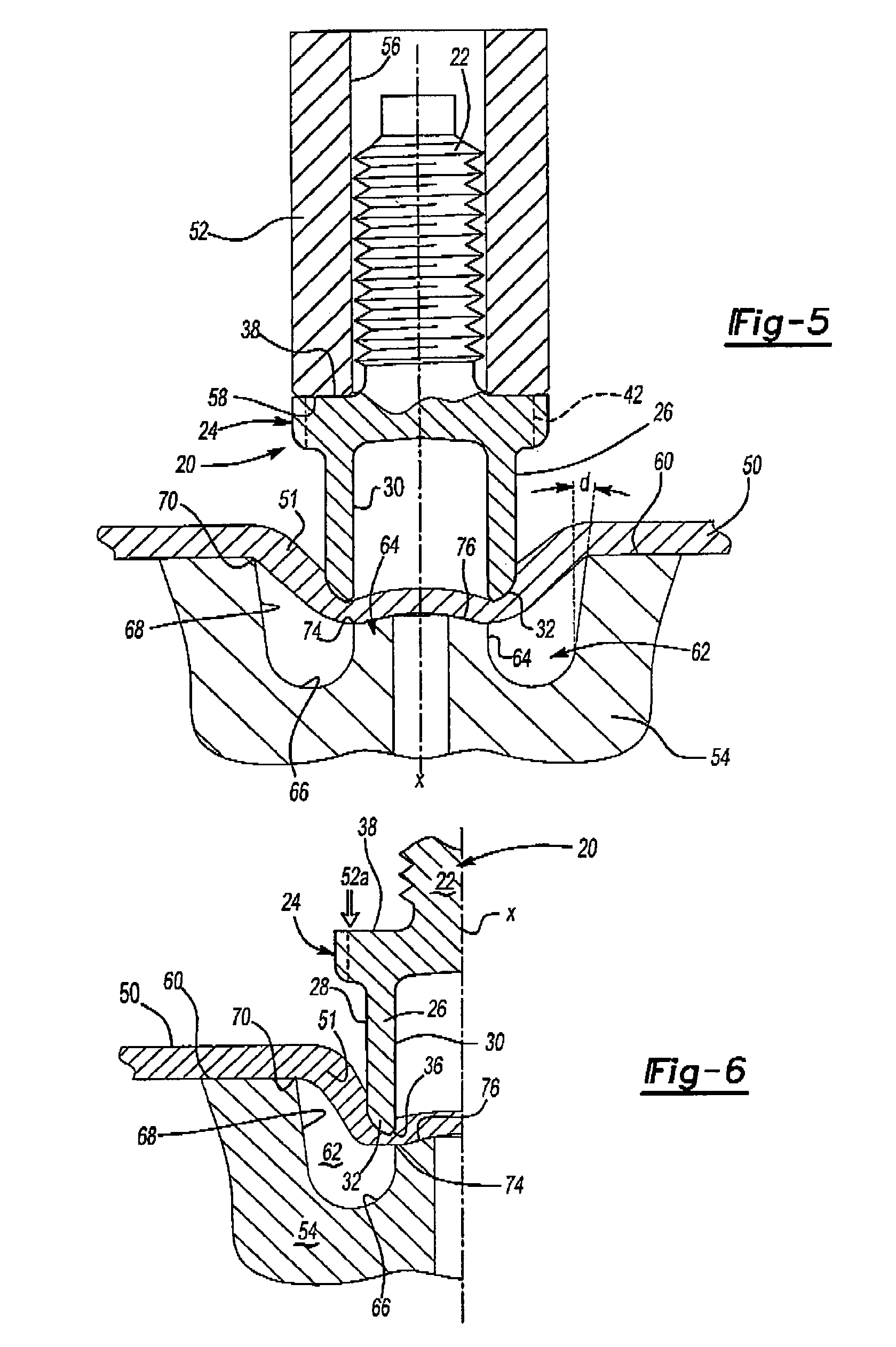

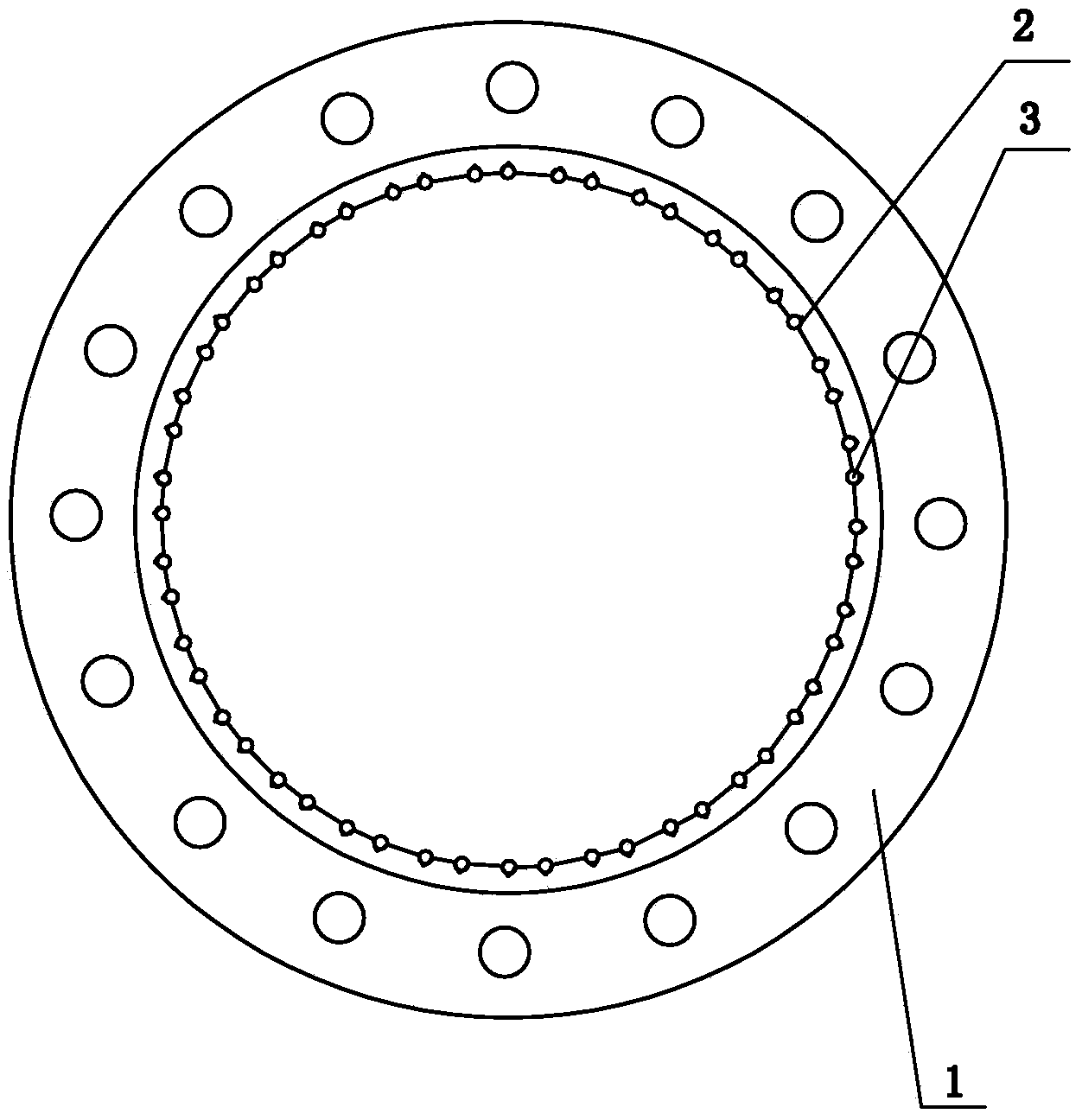

Drill chuck

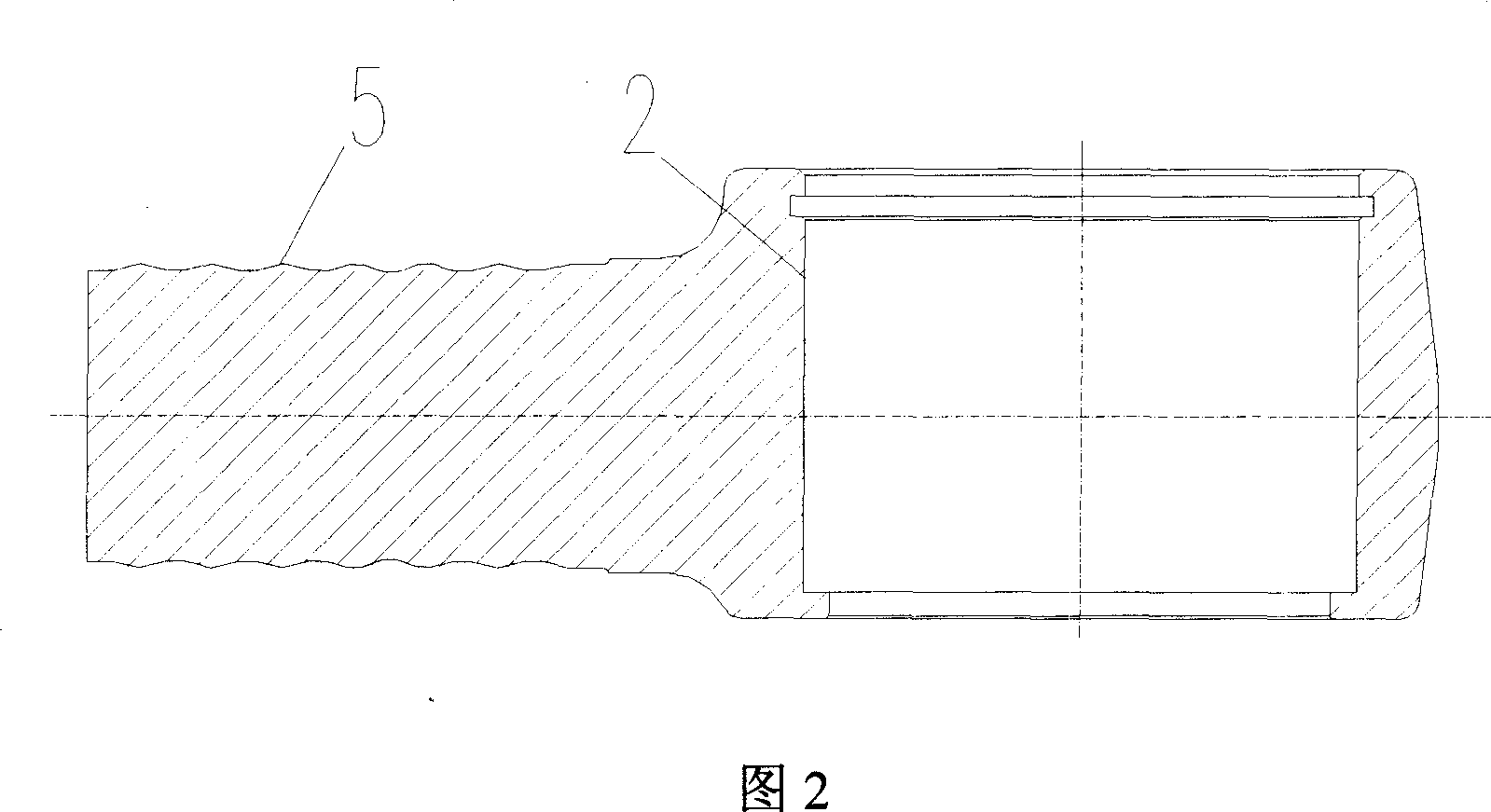

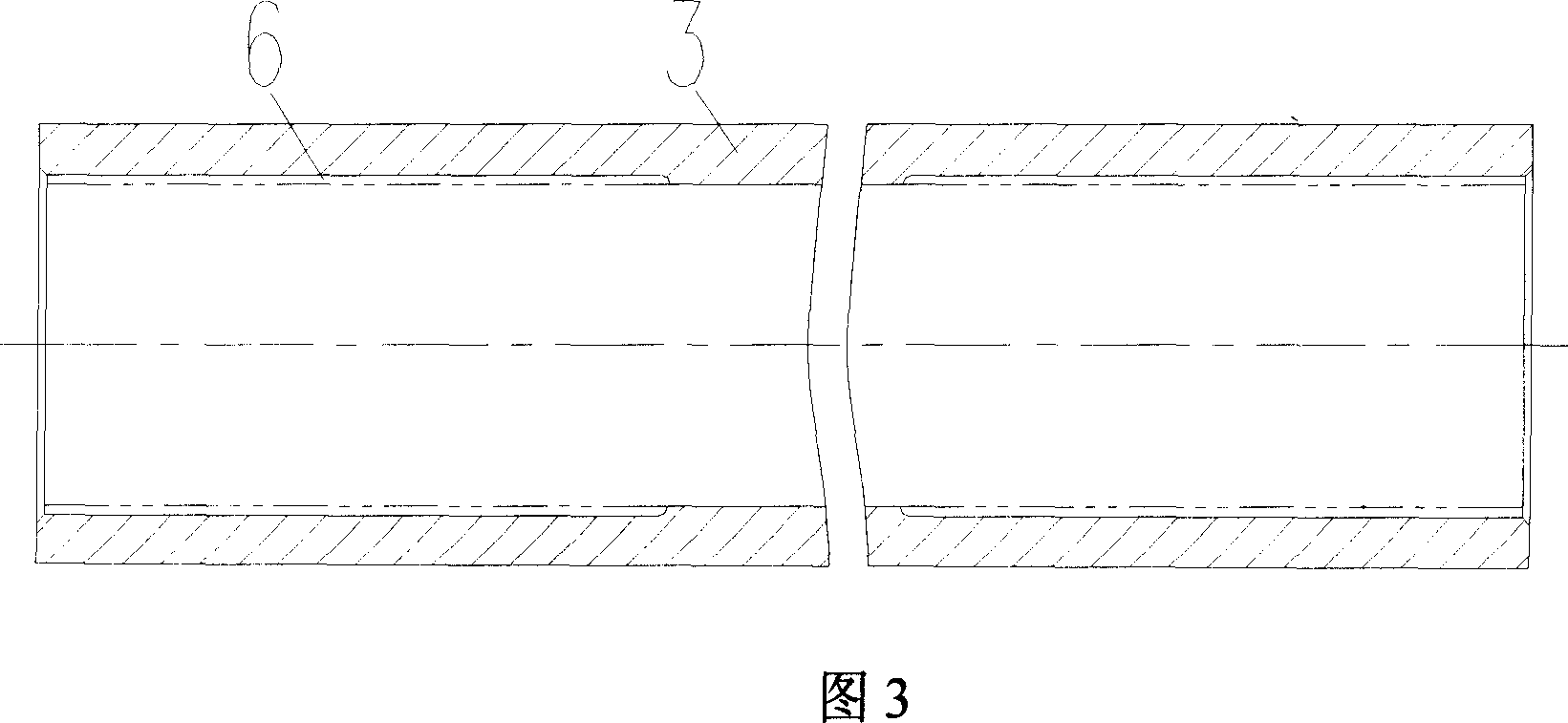

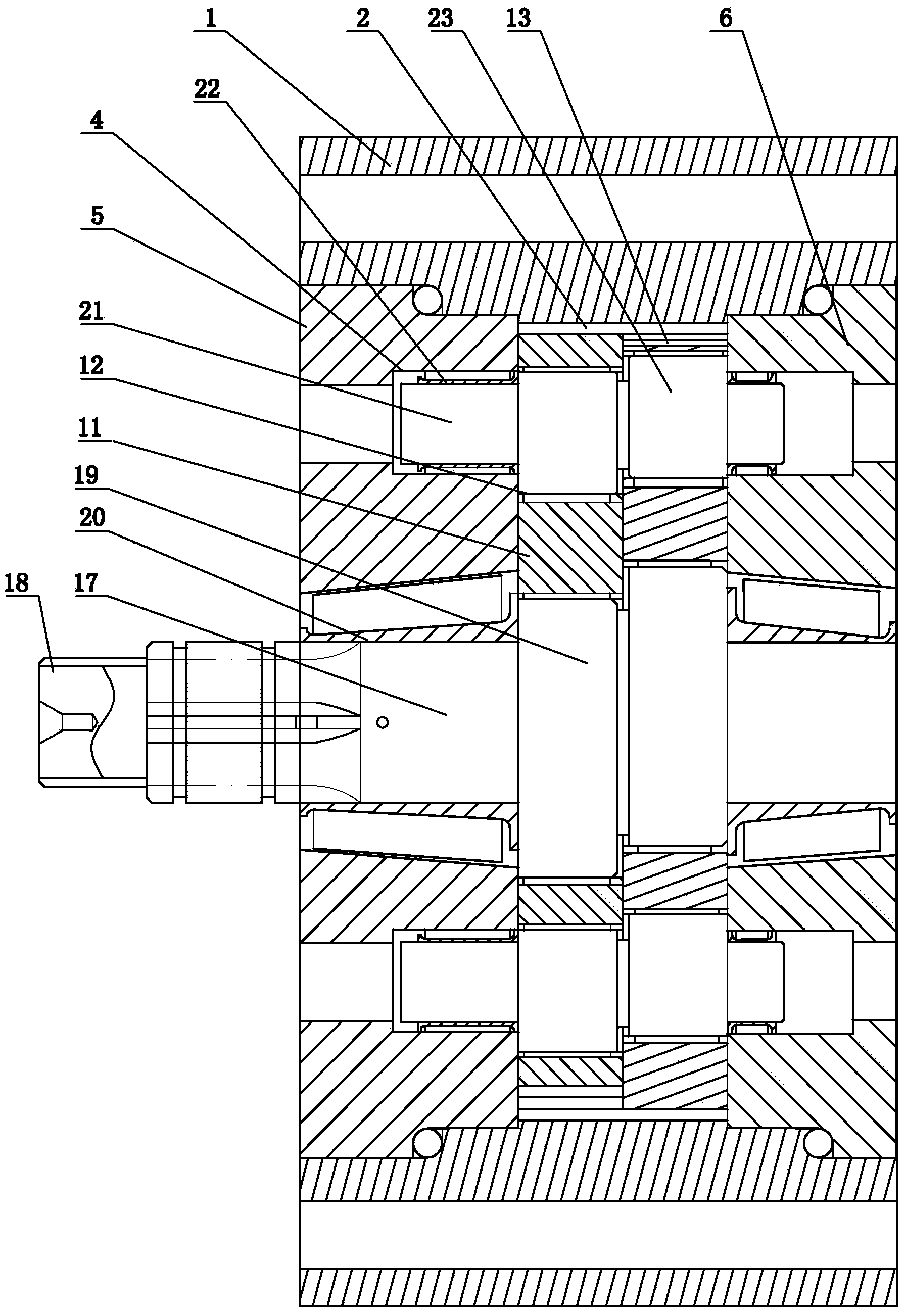

ActiveUS8070168B2High degree of reliabilityImprove torsion resistanceSleeve/socket jointsChucksEngineeringDrill

The invention relates to a clamping drill chuck including a chuck body (1), a clamping cone (2) that can be rotated coaxially in relation to the chuck body (1) and is axially supported on a jaw holder (3) mounted on the chuck body (1) and in which clamping jaws (4) are guided in guiding slits, said clamping jaws being adjustable, by means of the jaw holder (3), for the clamping and releasing action by a relative rotation between the chuck body (1) and the clamping cone (2). The drill chuck also includes a locking device (9) provided with a toothed ring (6) which is coaxial to the chick axle (5), in addition to a latch mechanism (8) which is mounted on the jaw holder (3) and engages in the toothed ring (6) when subjected to the force of a spring (7).

Owner:ROHM GMBH & CO KG

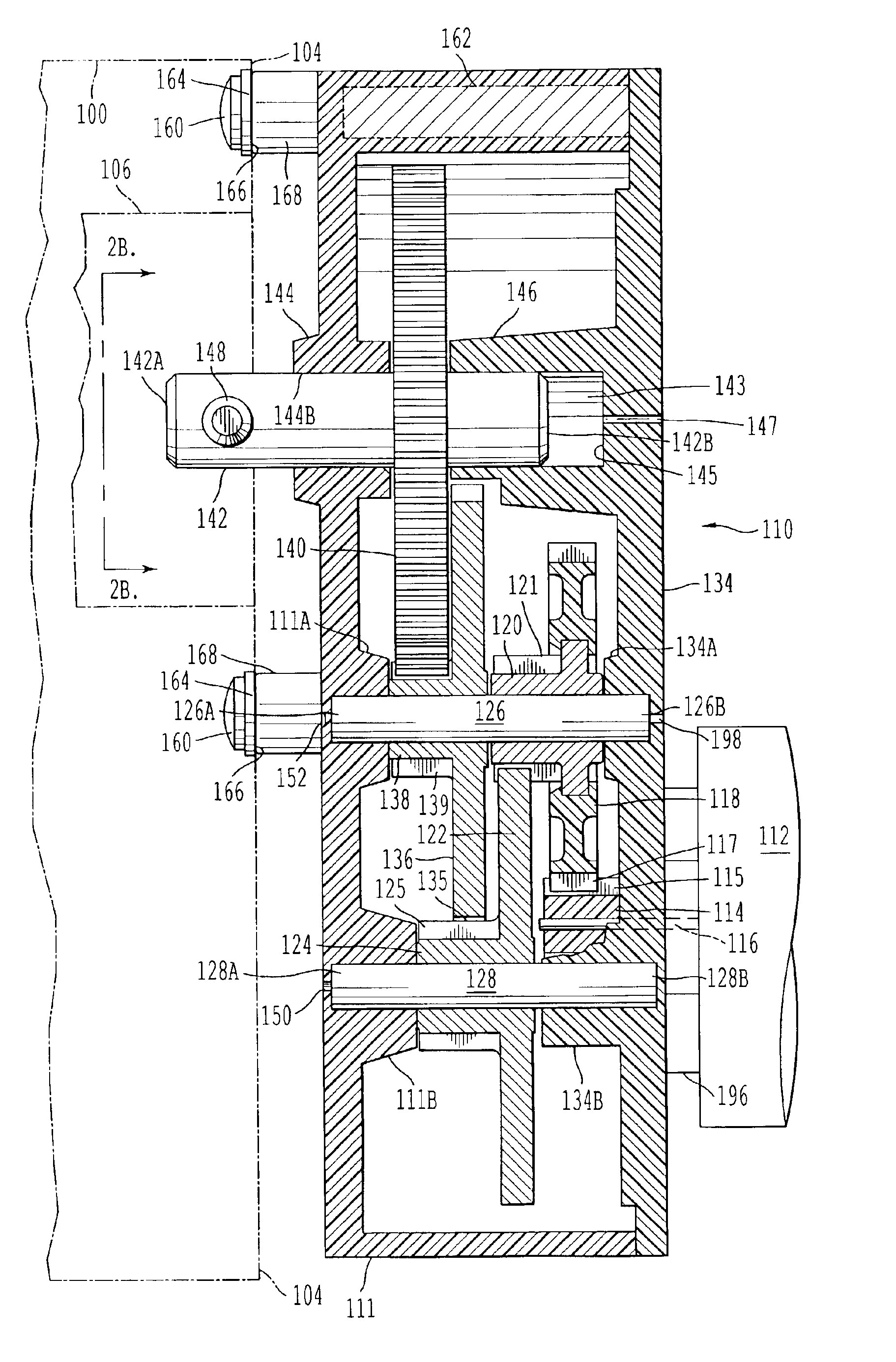

High torque resistant and strong screwless plastic gear box

InactiveUS6857338B2Improve torsion resistanceReduce thicknessGearboxesToothed gearingsHigh torqueEngineering

A high torque resistant and strong screwless plastic gear box has a reduced thickness at its output shaft. The gear box and a reduction drive assembly therein may be used particularly, but not exclusively, in a slot machine with a spinning drum or hopper which holds coins or tokens to be released therefrom. The gear box includes a main body and a cover which is ultrasonically welded thereto. Locating posts, holding tubes, inner welding pads, outer surrounding tubes, and locating ribs are provided to weld the cover to the main body. Acoustical chambers are formed between outer walls and inner arcuate walls of the main body. The inner arcuate walls surround all of the shafts and gears inside the main body. This double-walled construction reduces noise and provides surprising mechanical strength. All of the gears are mounted on only three shafts secured between the main body and the cover. Four of the gears are stacked on a single central shaft and rotate in two pairs independently of each other.

Owner:MOLON MOTOR COIL

Construction method for super-long high-precision horizontal drilling

ActiveCN101158268AImprove stabilityImprove airtightnessDirectional drillingTunnelsConstruction planSlurry pump

The invention discloses a super-long and high-accurate horizontal boring construction plan. The plan is that a proper horizontal borer is used for driving a bit connected with a bore rod to turn to take cores and cut holes; a guiding device is used for controlling a decline rate; a slurry pump is used for pumping out the bore scraps generated in a boring process, so as to form a set-caliber super-long and high-accurate horizontal boring. The invention adopts a compound connection measure of combining a screw connection and a welding connection to connect the bore rod, guaranteeing the concentricity and sealing of the bore rod. When in a horizontal boring process, a freezing cut sealing and a freezer sealing are adopted. An area ranging from 8cm to 10cm is preserved as a safety layer in a tube-boring process on a concrete wall. And a strict deviation measuring and a deviation controlling are adopted to guarantee the construction safety. The form and improvement of the construction plan of the invention experiences many tests, researches and improvements, and a horizontal frozen boring bored through the construction plan of the invention can be provided with a high accuracy even when a construction horizontal length is too long.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

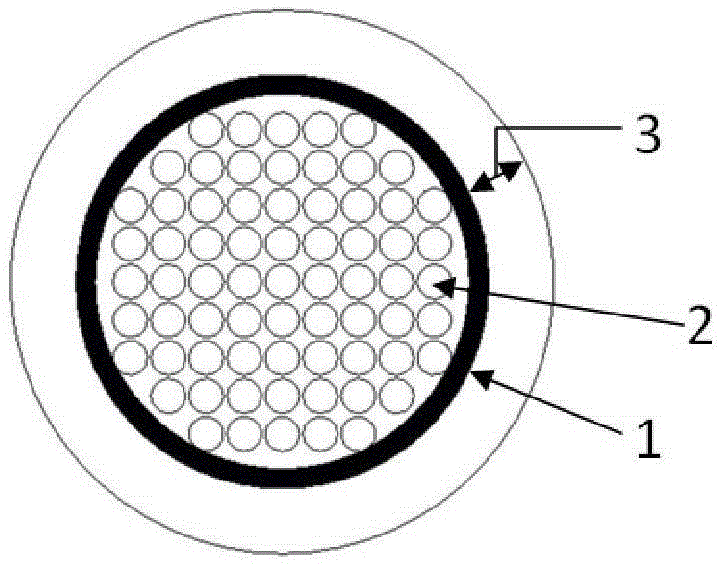

Low temperature resistant anti-crack rubber sleeve flexible cable used for wind power generation

ActiveCN101221836AMeet the torsion resistance requirementsImprove mechanical propertiesRubber insulatorsFlexible cablesPlasticizerFlexion Test

The invention relates to a low-temperature resistant and anti-crack cabtyre flexible cable for the wind power generation and is characterized in that a plasticiser inside a rubber insulation and sheath is a low-temperature resistant plasticizer and is added with 2 to 5 portions of pine tar oil and / or cylinder oil and 3 to 8 portions of coupling agent; the pitch of flexible conductor strands is intertwisted by 8 to 14 times; in the situation of a multiple-core cable, the cable pitch of insulating core is 8 to 10 times. Compared with the prior art, the invention improves the flexility at a low temperature, the anti-crack performance, the mechanical performance at a low temperature and the torsibility of the cable of the rubber insulation and sheath and can satisfy the torsibility requirements of a wind energy cable. The cable of the invention is not cracked in an impact test at a low temperature of 40 DEG C below zero and a flexion test, can maintain the flexility at a very low temperature, satisfies the requirement of the cable used at a low temperature or a maritime climate environment, and can be applicable to the use in the environmental conditions of big difference in environmental temperature, salt mist, moist heat, mould fungus, etc. In addition, an environment-friendly auxiliary material is used and the cable insulation as well as the sheath environment are good; therefore, the invention can satisfy the environment-friendly requirements of PAH such as ROHS and RAHS of the EU.

Owner:JIANGSU ZHONGMEI CABLE

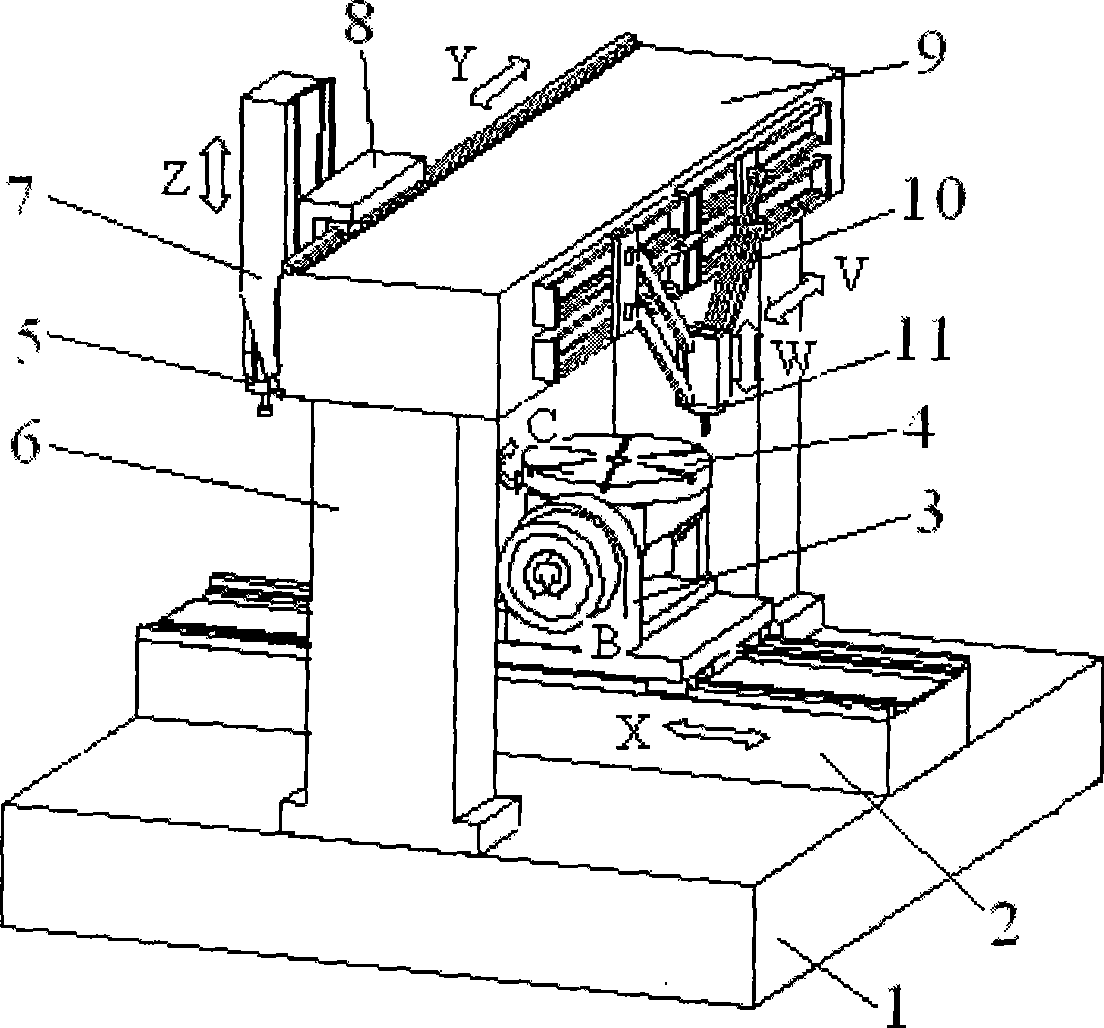

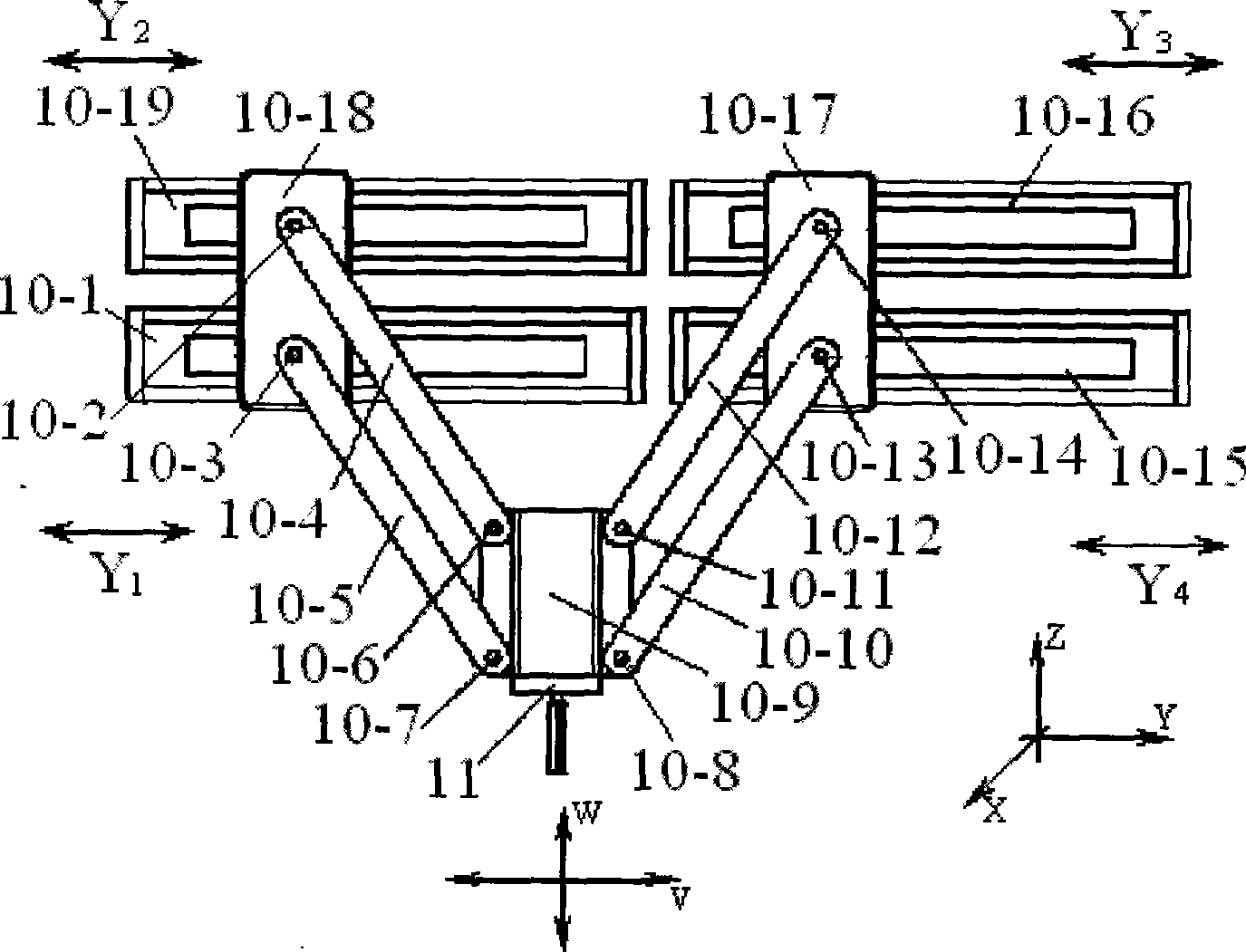

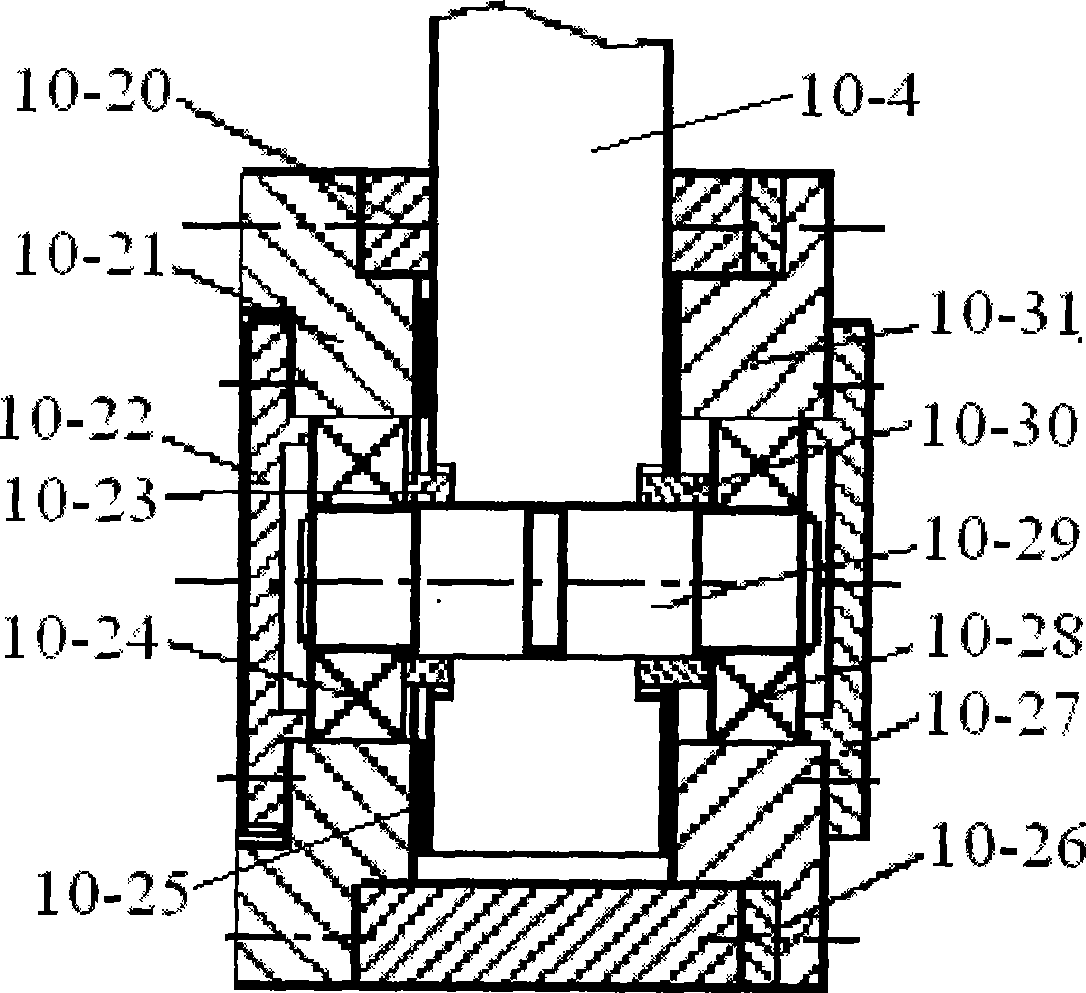

Composite machining center with hot displacement constraint skid revolving joint portion macro/micro drive

InactiveCN101480734AImprove torsion resistanceImprove processing efficiencyMilling machinesActuatorThermal displacement

The invention discloses a macro-micro dual-drive combined machining center which has a skid and rotation joint portion with thermal walking constraint, comprising a lathe body, upright posts, beams, X-axis parts, swing B-axis parts, rotation C-axis parts, a two-axes paralleling mechanism, a milling electro-spindle, Y-axis parts, Z-axis parts and a lapping-polishing electro-spindle, wherein the two-axes paralleling mechanism realizes the movement of a virtual W axis and a virtual V axis by adopting dual drive, a micro-drive actuator deforming guide way is adopted between a macro-micro dual-drive macro-motion table and a macro-micro dual-drive micro-drive table, the X-axis parts, the Y-axis parts and the two-axes paralleling mechanism movement pairs adopt combined slide seats which are combined by a cast iron working slide seat, a thermal walking constraint joint portion and a granite bearing slide seat, and the B-axis, the rotation C-axis and the two-axes paralleling mechanism rotation pairs adopt skid and rotation joint portion mechanisms. The combined machining center has a combined machining function that the five axes of X, B, C, V and W are interlinked so as to mill the complex moulding surfaces of hard parts at high speed and the five axes of X, B, C, Y and Z are interlinked so as to lap and polish the complex moulding surfaces of hard parts with high accuracy.

Owner:XIAN UNIV OF TECH

Ethylene-propylene-diene monomer rubber used for manufacturing wind energy cable and preparation method thereof

ActiveCN102617942AImprove mechanical propertiesEasy to stretchPolymer scienceDecabromobiphenyl ether

The invention discloses an ethylene-propylene-diene monomer rubber used for manufacturing a wind energy cable and a preparation method thereof. The ethylene-propylene-diene monomer rubber comprises the following components: 90-110 parts of ethylene-propylene-diene monomer rubber, 1-4 parts of anti-aging agent, 0.2-0.5 part of stearic acid, 2-9 parts of paraffin oil, 2-5 parts of lead sulfate tribasic, 1-4 parts of zinc oxide, 80-120 parts of activated kaolin, 0.3-1.5 parts of coupling agent, 0.5-2.6 parts of cross-linking agent, 0.5-2.0 parts of assistant crosslinker, 1-3 parts of semi-reinforcing carbon black, 1-4 parts of plasticizer, 0.5-2 parts of antimonous oxide, 0.5-2 parts of zinc borate, 1-5 parts of basic magnesium carbonate, 1-4 parts of antioxygen, 0.1-0.5 part of sulphur, 2-5parts of epoxidized soybean oil, 5-15 parts of decabromodiphenyl ether, 12-30 parts of antimony oxide and 2-5 parts of organic modified bentonite. The material has the advantages of wide applicable temperature range, god performance and long service life.

Owner:无锡市远登电缆有限公司

Lockwireless coupling assembly

InactiveUS20070164566A1Prevent leakageEasy to confirmJoints with sealing surfacesFluid couplingLocking mechanism

A self-locking fluid coupling, utilized to connect two fluid conduits together, does not require the lockwiring of the coupling nut to prevent the rotation of the coupling nut. The locking mechanism comprises a rotational locking means on a ferrule member. The rotational locking means engage one or more inwardly protruding engagement members of the B-nut. The engagement of the rotational locking means of the ferrule with the engagement members of the B-nut creates resistance to circular motion, thereby resisting rotation of the B-nut and eliminating the requirement for lockwire to resist rotation of the B-nut.

Owner:SHUR LOK CORP

Self-riveting male fastener and panel assembly

A male fastener formed of heat treated carbon steel for high performance applications, including a shank portion, radial flange and tubular barrel, wherein the barrel has an axial length of 60% or less than the outside diameter and a fastener and panel assembly, wherein the distal open end of the barrel is deformed into an L-shape and the panel is deformed by the radial flange into an L-shape having an inwardly projecting portion deformed between the radial flange and the outwardly deformed distal end of the barrel.

Owner:PENN AUTOMOTIVE INC

Waffle stud for insert molded plastic members

ActiveUS7156598B2Maximum spin-out torque and pull-out force valueEasy to moveTravelling carriersHoldersPlastic materialsMaterials science

A fastener is configured for use in the manufacture of molded plastic components that will be subsequently attached to other components by the fastener. The low profile head portion of the fastener has a rounded contoured and convoluted top surface to facilitate the flow of plastic material around the head portion during the molding process. The underside of the head portion is formed with a square face surrounded circumferentially by circumferential land surfaces that provides a high pull-out force resistance for the fastener. The square face on the underside and convoluted top surface of the head portion provides a high spin-out torque resistance without sacrificing the pull-out force resistance. The rounded edges of the head portion are compatible with molding processes to allow the flow of plastic material to fully encapsulate the head portion within the molded plastic component.

Owner:FORD GLOBAL TECH LLC

Torque resistant fastening element

A torque resistant self-attaching fastener having a tubular barrel portion and a radial flange portion including a plurality of circumferentially spaced radial projections each having opposed planar generally radial side faces with the outer surface of the radial flange between the radial projections having a greater circumferential width than a circumferential width of the radial projections and a radial length less than the circumferential width. The side faces may be aligned with a radius, the side faces may be parallel or the side faces of adjacent radial projections may be parallel.

Owner:PENN AUTOMOTIVE INC

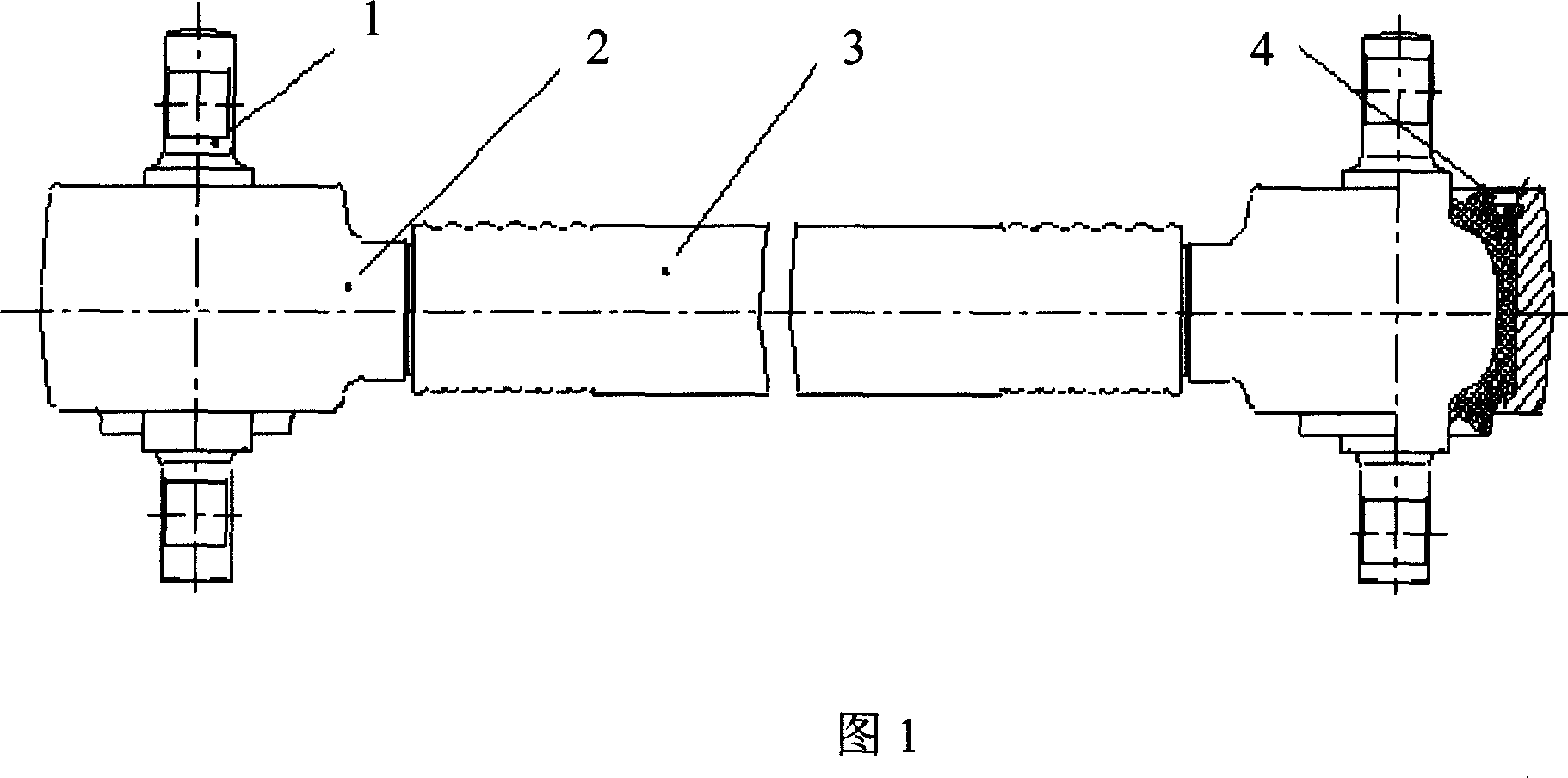

Subassembly of buttonhead of car distance rod and sheath, and assembling technique

ActiveCN1958319AMeet the connection strengthImprove torsion resistancePivoted suspension armsMetal working apparatusHeating furnaceHeating power

A thrust ball head-sleeve pipe assemblage for car is composed of a ball head of thrust rod and a sleeve pipe, which are coupled in corrugated mode. Its assembling technology includes such steps as corrugating the coupled part of said ball head of thrust rod, machining the coupled part of sleeve pipe to become thin wall, setting up the pressing parameters of hydraulic press, setting up the heating power and time of MF heater, heating the thin-wall part of sleeve pipe, inserting it in a dedicated riveting apparatus, turning on hydraulic press to rivet the sleeve pipe with the ball head of thrust rod, and cooling.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Method of attaching a self-piercing element in a panel and die member

A self-piercing element including a shank, a radial flange and a tubular barrel. The flange includes spaced concave surfaces and the annular bearing surface has an area at least four times the concave surfaces. The element is installed in a panel supported on a female die including a central die post, wherein the outer side wall is a frustoconical having an included angle between five and twelve degrees. During installation, the tubular barrel pierces an opening in the panel and the panel is drawn against the outer surface of the tubular barrel and the barrel is deformed into a U-shape. The flange is simultaneously received in the die cavity and the panel is incrementally deformed radially into the concave surfaces between the frustoconical side wall and the flange portion providing improved torque resistance.

Owner:WHITESELL FORMED COMPONENTS

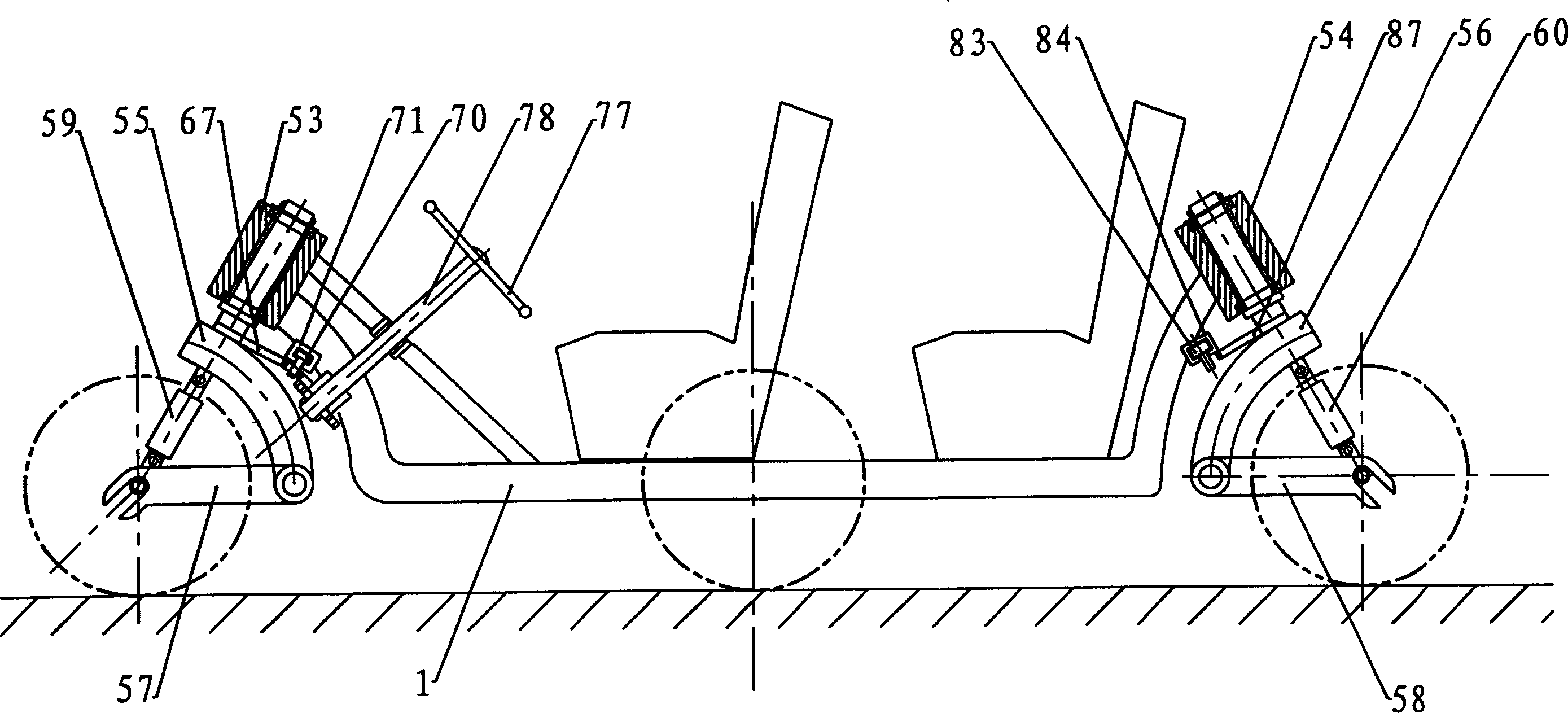

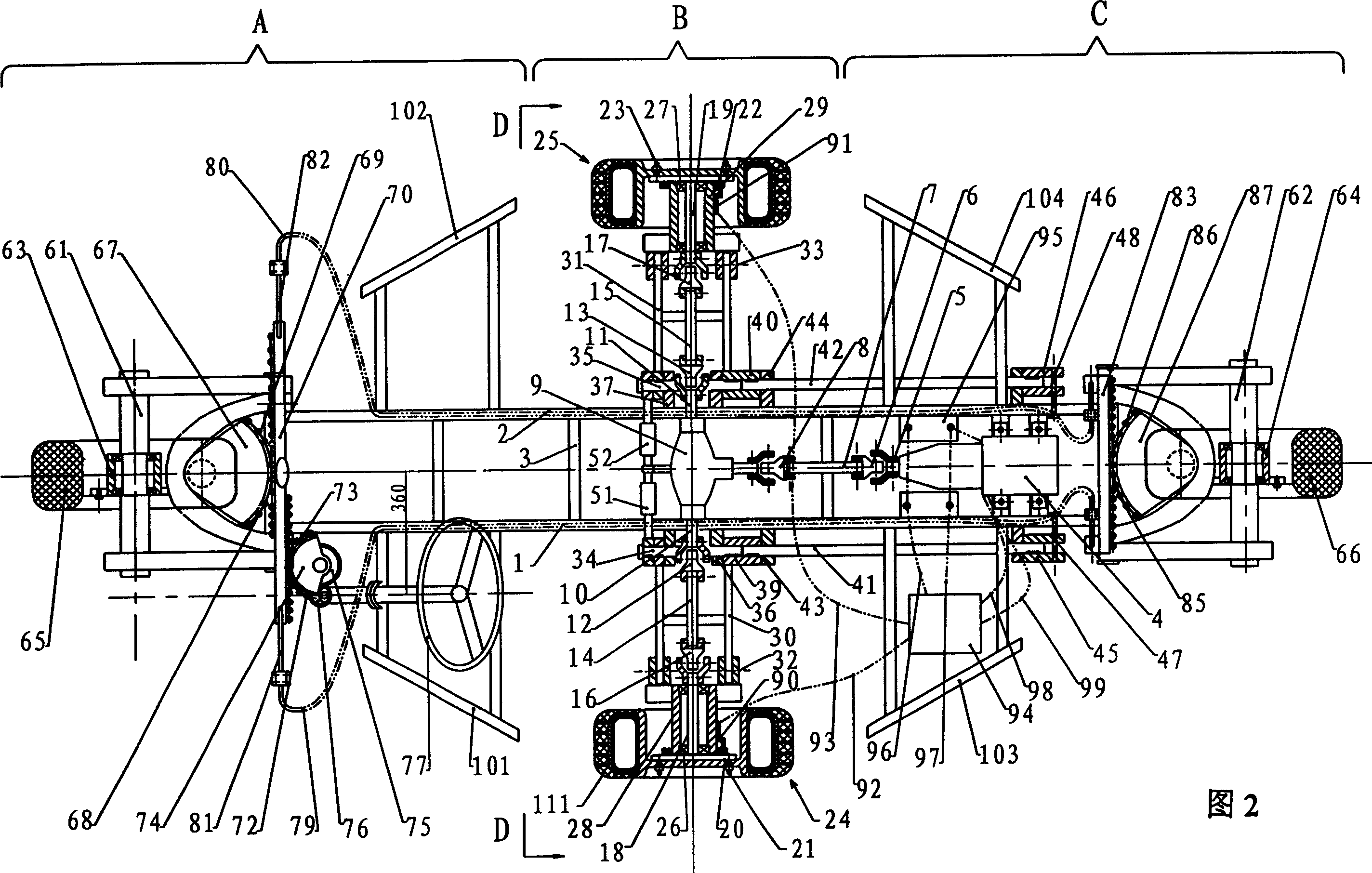

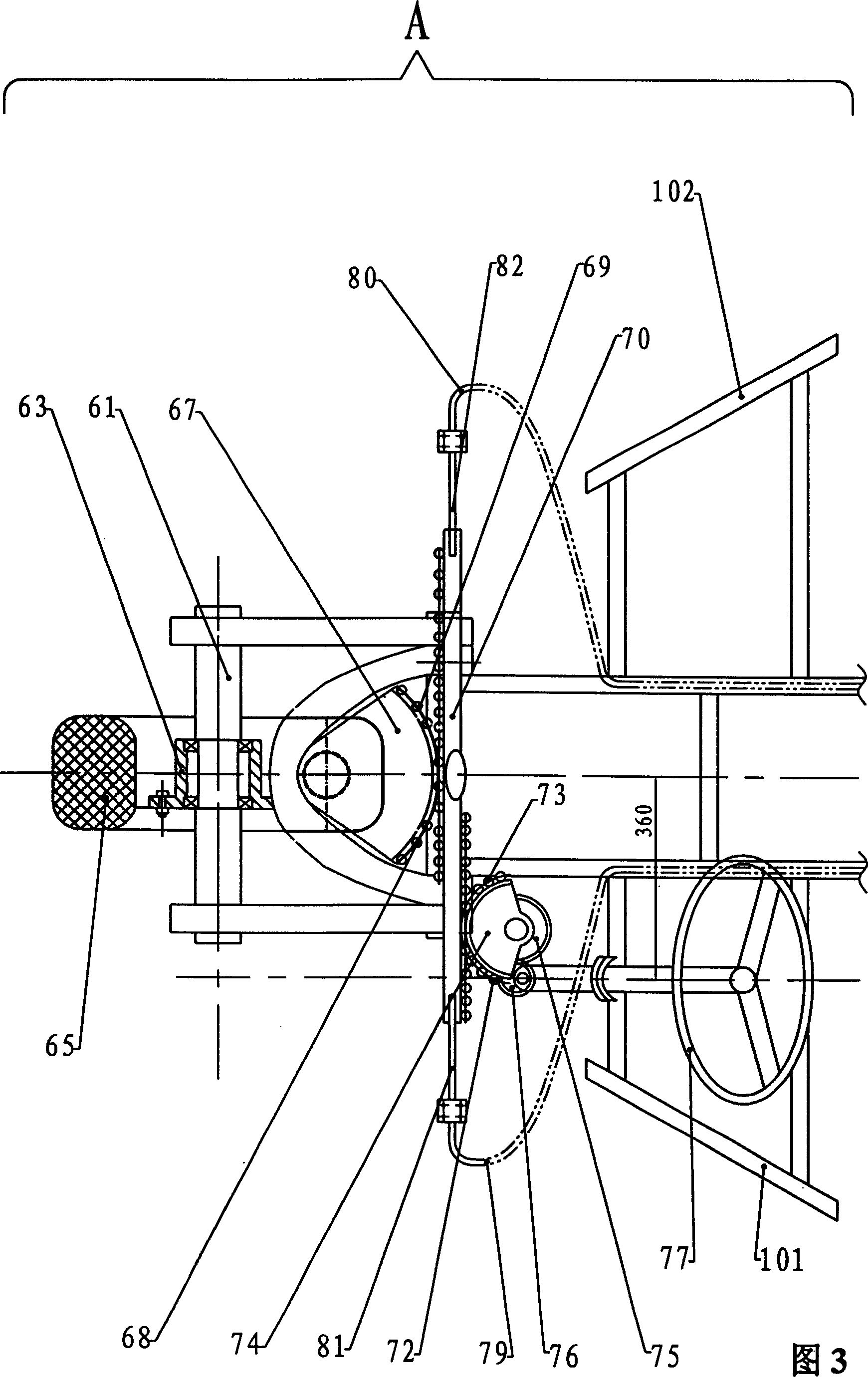

Rhombic electric vehicle

InactiveCN1634737AImprove crash safetyLower performance requirementsElectric propulsion mountingUnderstructuresDrive wheelVehicle frame

This invention relates to lozenge automobile, whose chassis comprises main rack and level swing, wherein, the main rack comprises left and right carlings and several beams with motor located behind; the motor main axis drives the two driving wheels through gimbal, transmission shaft, differential gear and left and right axis; the left and right wheels are imbedded with nail gear connected to the conductive ring connected to the brush panel; the brush contacts the brush panel and is connected to the electric control carbine through wires and the carbine is connected to battery set and motor through wires; the car has one wheel in front and back for turning by connection.

Owner:HUNAN UNIV

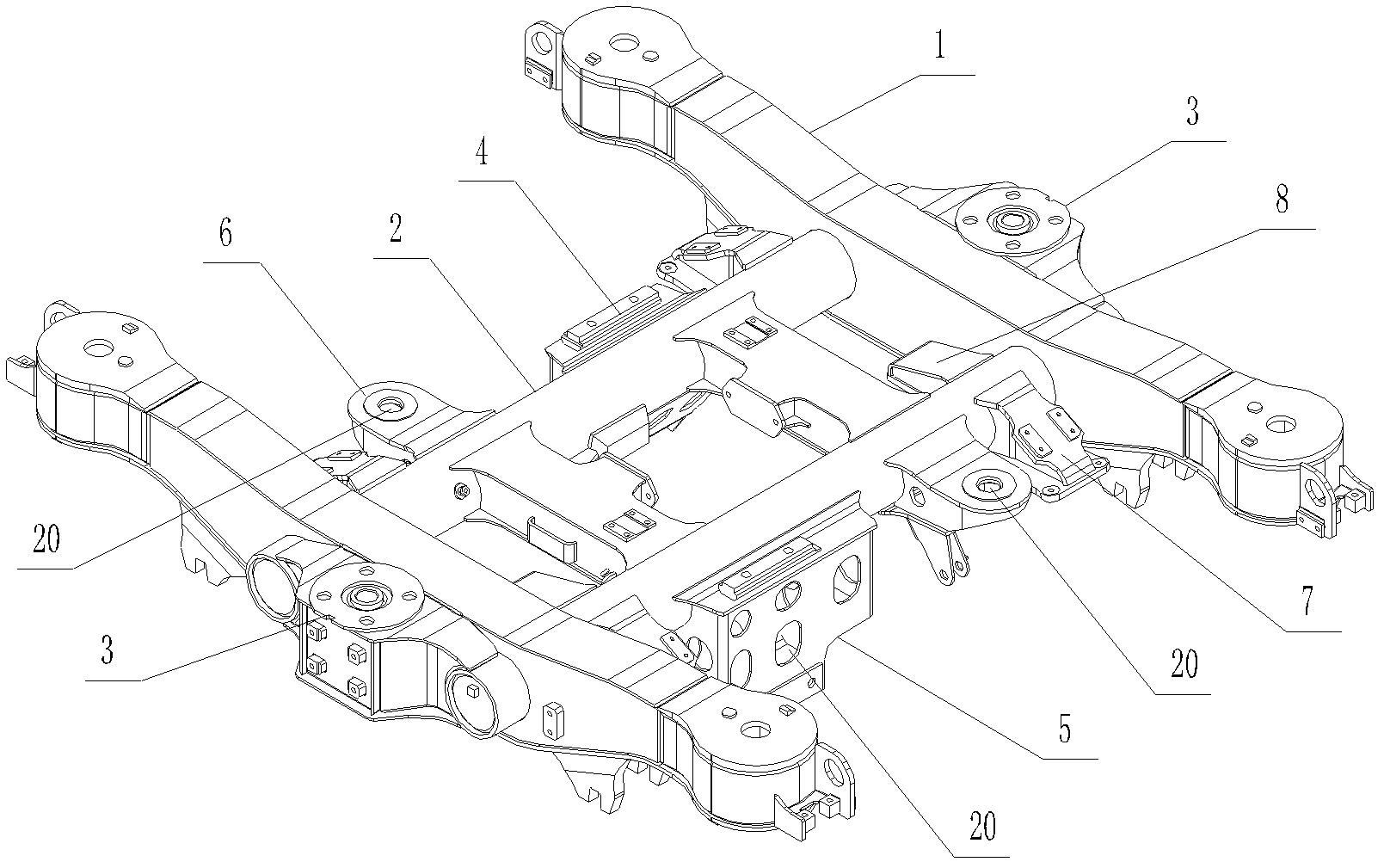

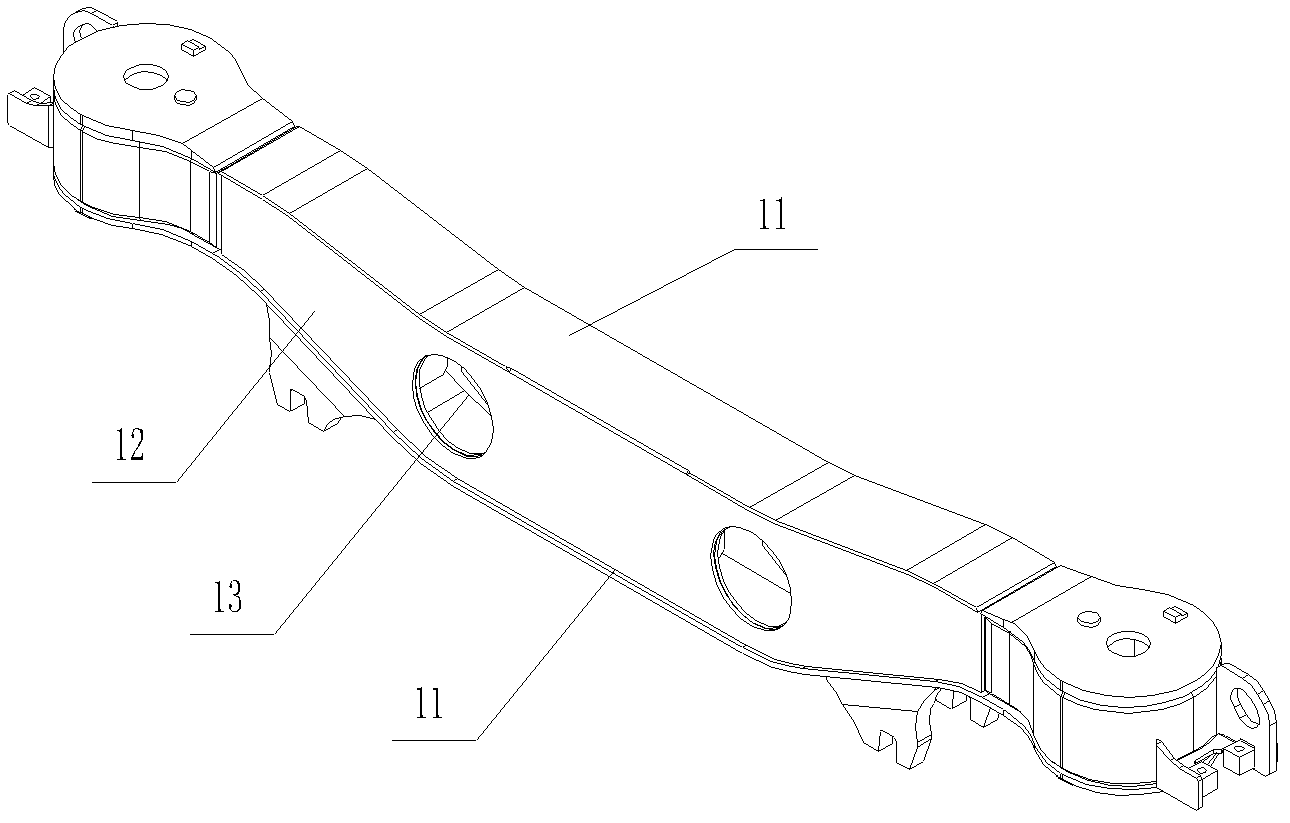

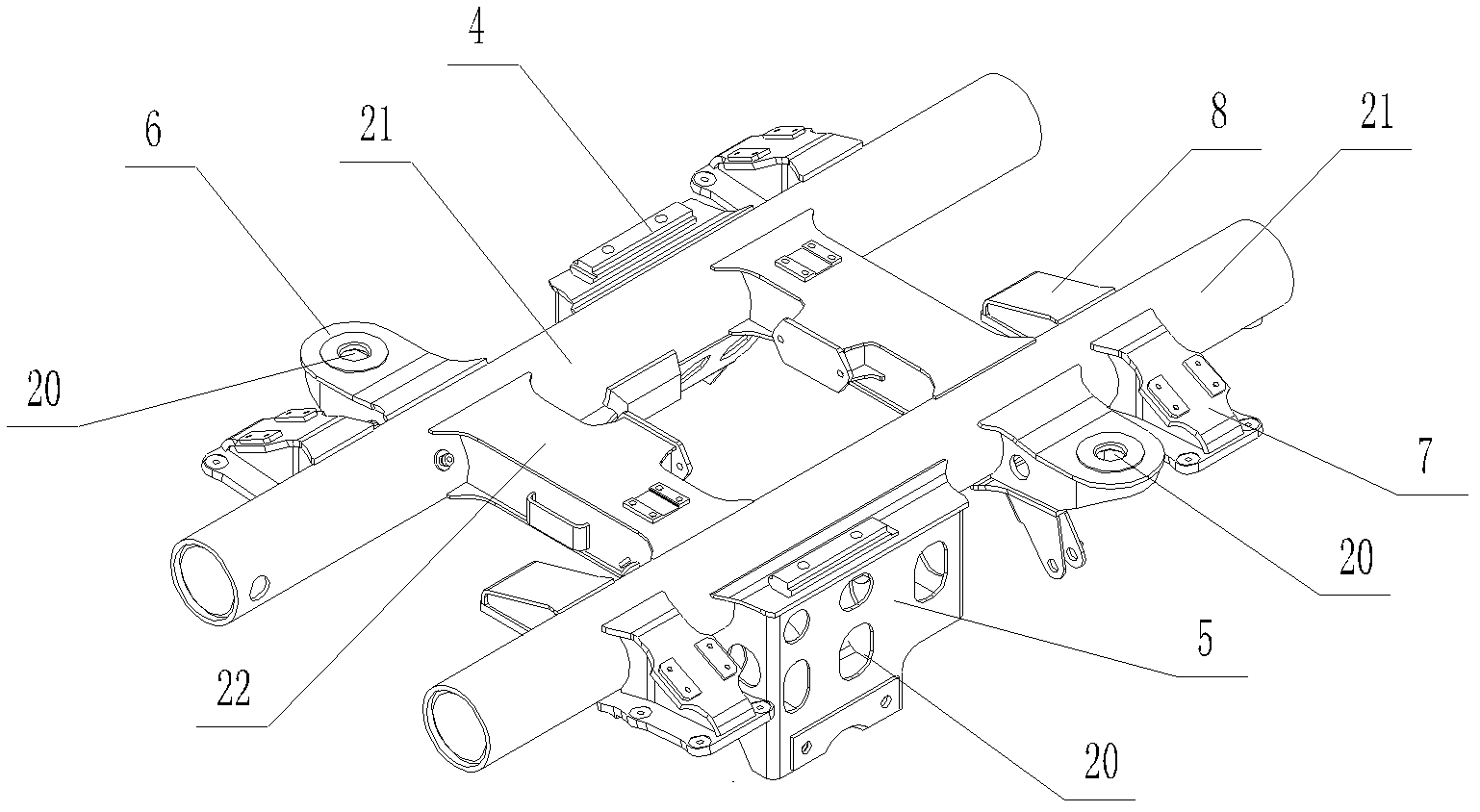

Light bogie welding framework and welding method thereof

The invention discloses a light bogie welding framework and a welding method thereof. The design of further simplifying a structure and reducing the weight of the structure is adopted, and a modularized welding method is adopted simultaneously, so that the aim of the light structure and the aim of improving the whole processing and production efficiency are fulfilled. The framework comprises a pair of side beam assemblies and a pair of cross beam assemblies which are connected with each other; each side beam assembly has a hollow box body structure and comprises a pair of upper and lower cover plates and a pair of side web plates which are welded; the cross beam assemblies comprise a pair of hollow steel pipes which penetrate through the side web plates and are welded with the side web plates; and a pair of air spring supporting beams are welded at the ends of two sides of the steel pipes and outside the side web plates and have a hollow box body structure.

Owner:CRRC QINGDAO SIFANG CO LTD

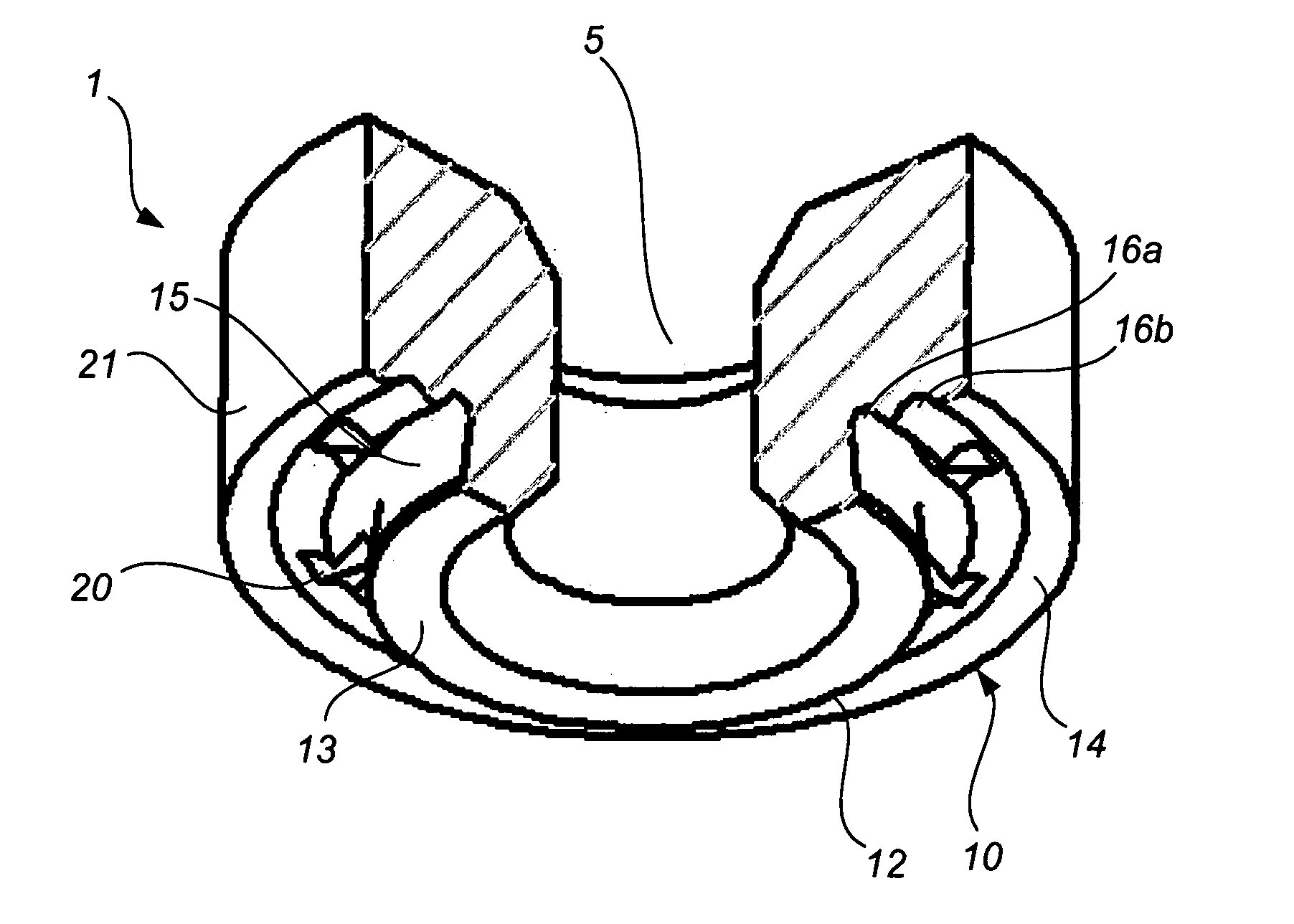

Pierce nut and use thereof

ActiveUS20070258788A1Eliminates and reduces problemImprove joint strengthNutsBoltsMetal sheetBiomedical engineering

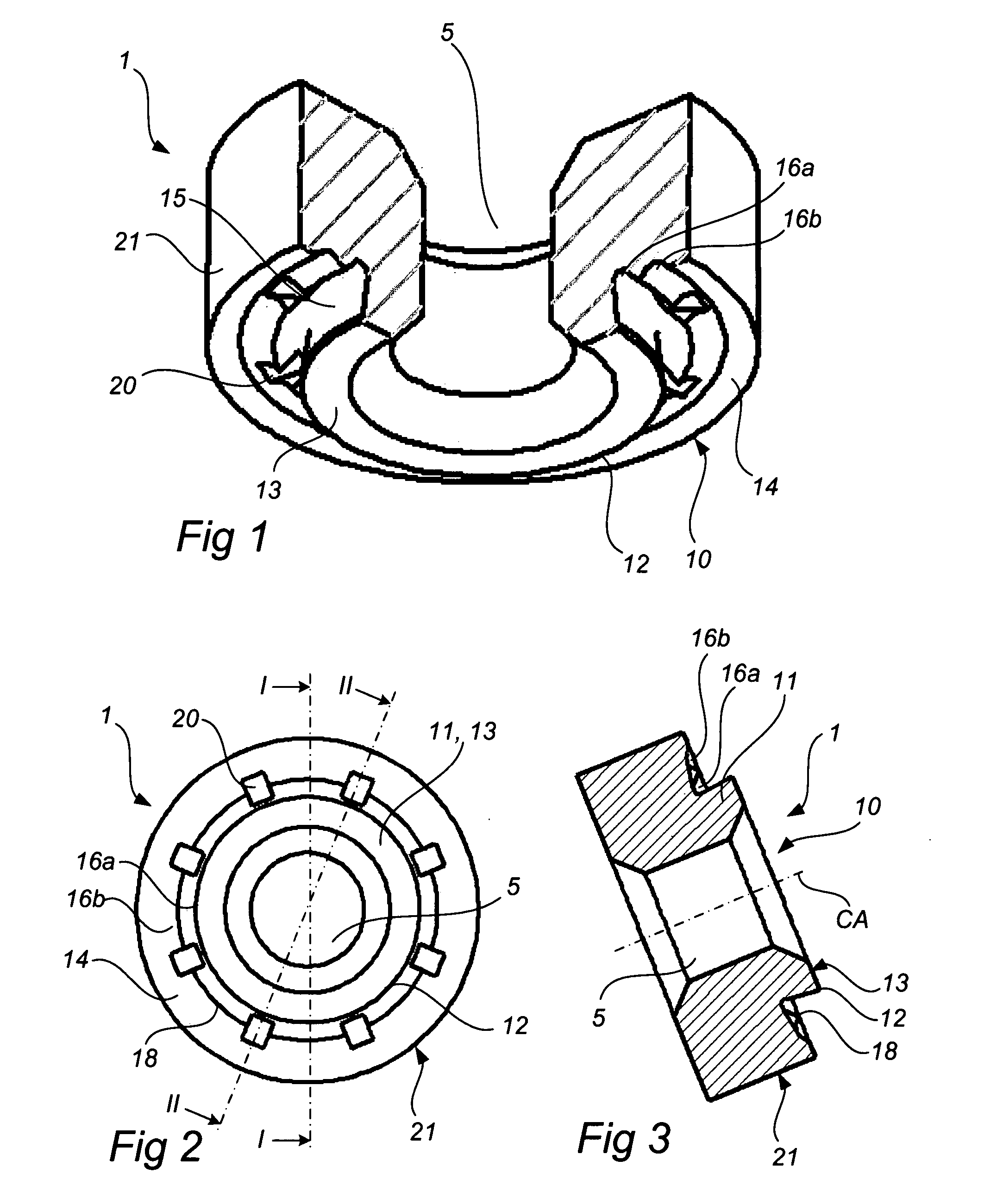

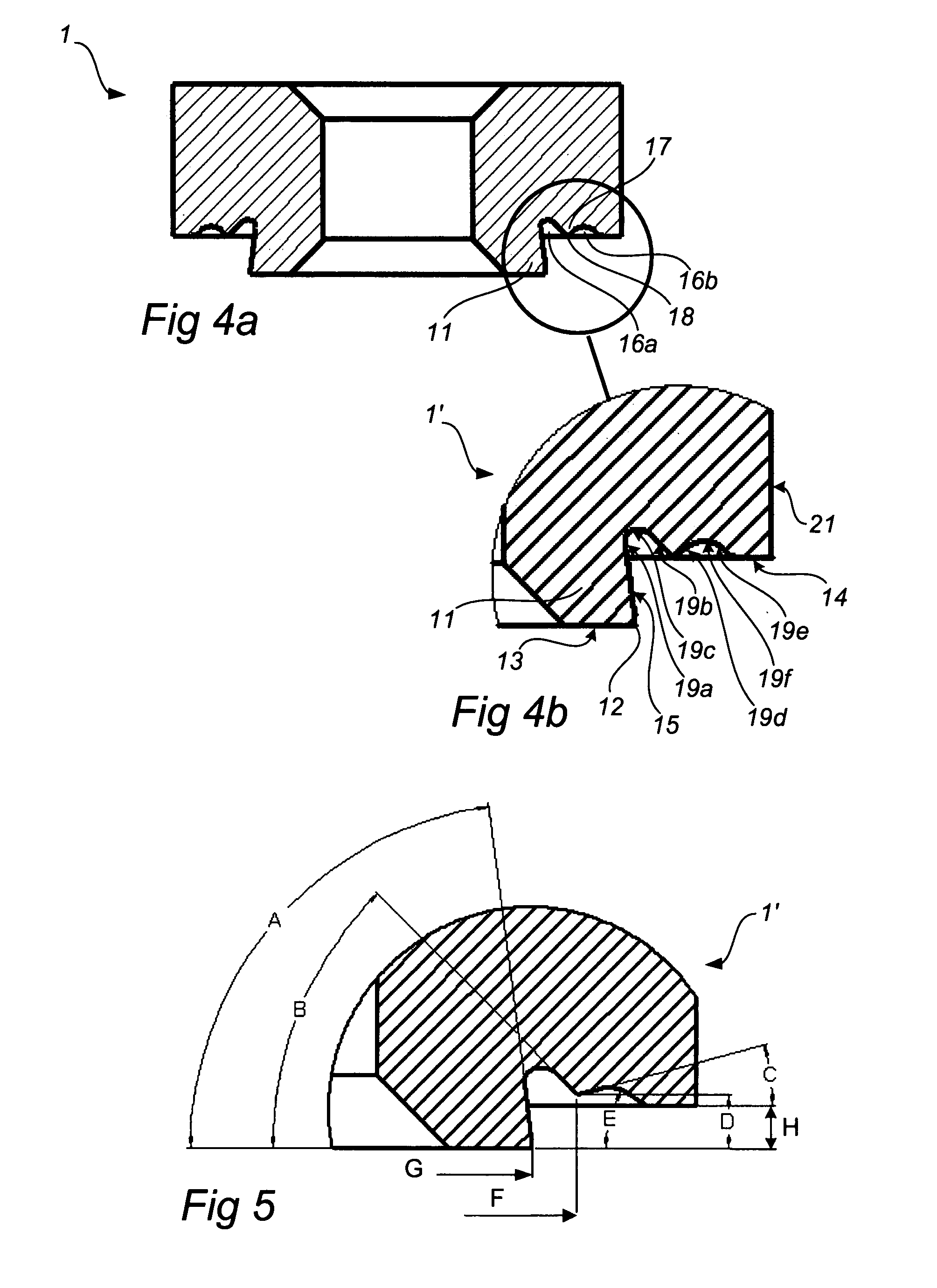

A pierce nut (1) for attachment to a plastically deformable metal sheet (4) has an abutment surface (14) adapted to abut against the metal sheet (4), an undercut pilot (11) protruding relatively to the abutment surface (14), and a countersunk groove (16a, 16b) which is formed in the abutment surface (14) and at least partly surrounds the pilot (11). The groove (16a, 16b) is without active undercuts facing the pilot (11). The groove comprises an inner groove (16a) and an outer groove (16b) and a ridge (17) located therebetween.

Owner:STROMSHOLMEN

Bearing type RV speed reducer

InactiveCN103527719AReduce processing difficultyHigh transmission reliabilityToothed gearingsGearing detailsDrive wheelReduction drive

The invention discloses a bearing type RV speed reducer, and belongs to the technical field of speed reducers. The speed reducer comprises a pin wheel housing, an installation frame is arranged in the pin wheel housing in a rotary mode, the installation frame is provided with two cycloid gears in transmission connection with the pin wheel housing through needle rollers, the installation frame is rotatably provided with a power input shaft, the power input end of the power input shaft extends out of the installation frame, the power input shaft is provided with two eccentric drive wheels which penetrate through the centers of the two cycloid gears respectively and are matched with the corresponding cycloid gears, the installation frame is rotatably provided with at least two positioning shafts which are symmetric to the rotation center of the power input shaft, and each positioning shaft is provided with two eccentric transmission wheels which penetrate through the two cycloid gears respectively and are matched with the cycloid gears. Power center input and first speed reduction are achieved. Compared with the prior art, the bearing type RV speed reducer reduces the number of power input shafts and use of sun gears and planetary gears, manufacturing cost is low, transmission is reliable, machining and installation are convenient to achieve, and service life is prolonged.

Owner:SHANDONG SHKE MACHINERY MFG

Prestress-reinforced light high-strength controllable-degradation medical composite material and preparation method thereof

InactiveCN103330959AMake full use of the strengthening effectReduce dosageSurgeryAbsorbable polymersProtection layer

The invention relates to a prestress-reinforced light high-strength controllable-degradation medical composite material and a preparation method thereof. The medical composite material is characterized in that a magnesium alloy wire subjected to prestress processing is taken as a reinforced phase to improve strength and stiffness of the composite material, an absorbable high polymer material is taken as a matrix, and meanwhile, the early-stage degradation velocity of the composite material can be further regulated and controlled by regulating the thickness of a shell protection layer formed by the high polymer material of the matrix. According to the composite material, bars or plates are manufactured by utilizing methods of thermal die pressing, extrusion or drawing or the like, and various degradable high-toughness bone repairing and fixing instruments such as bone nails and bone plates can be obtained by carrying out subsequent machining; and compared with the conventional absorbable polymer bone surgery instruments, the composite material has the advantages that the mechanical fixing effect is relatively good, and furthermore, the problems that the degradation speed of the absorbable magnesium alloy bone surgery instruments is difficult to control and the hydrogen release quantity during degradation is large and the like can be overcome.

Owner:SOUTHEAST UNIV

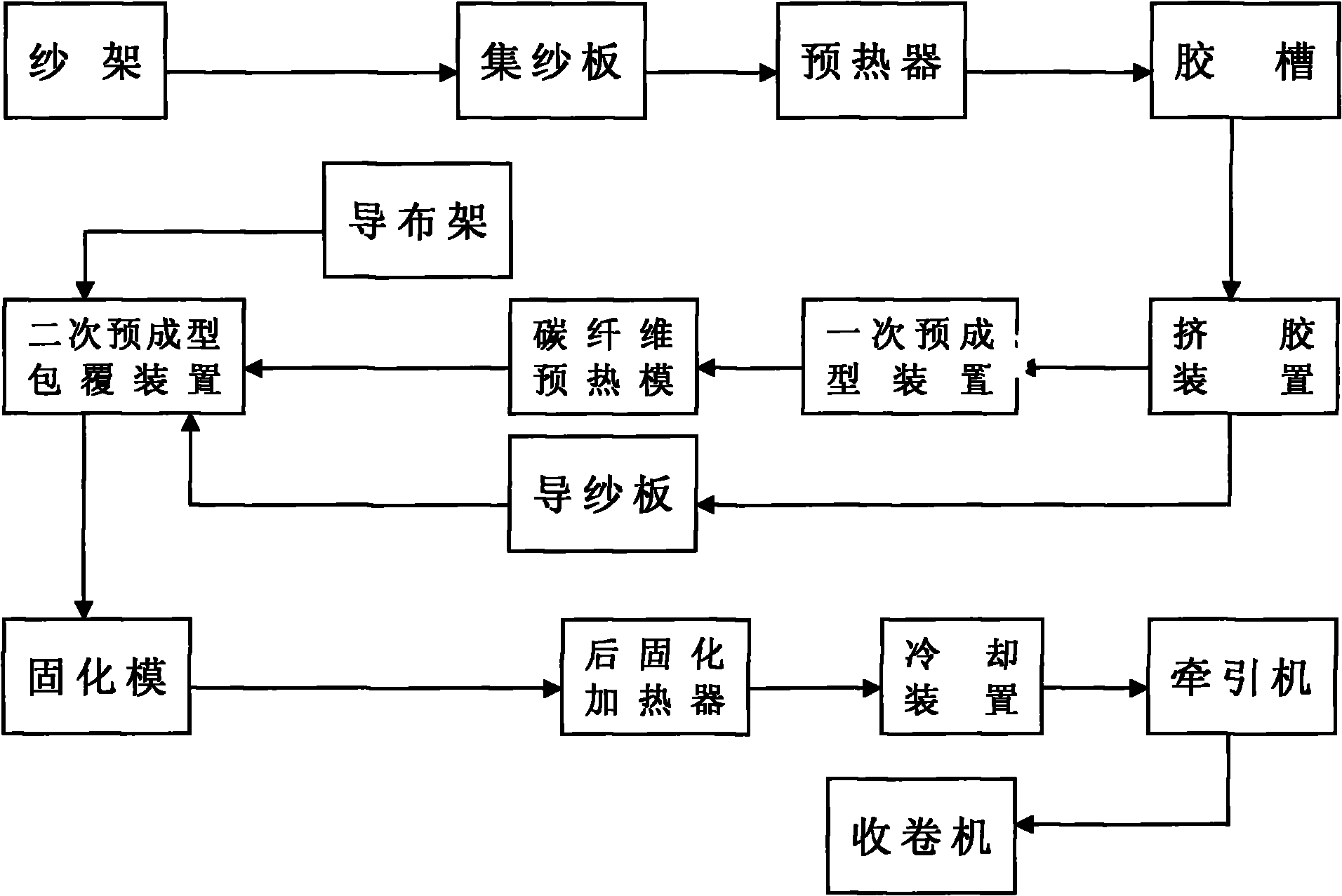

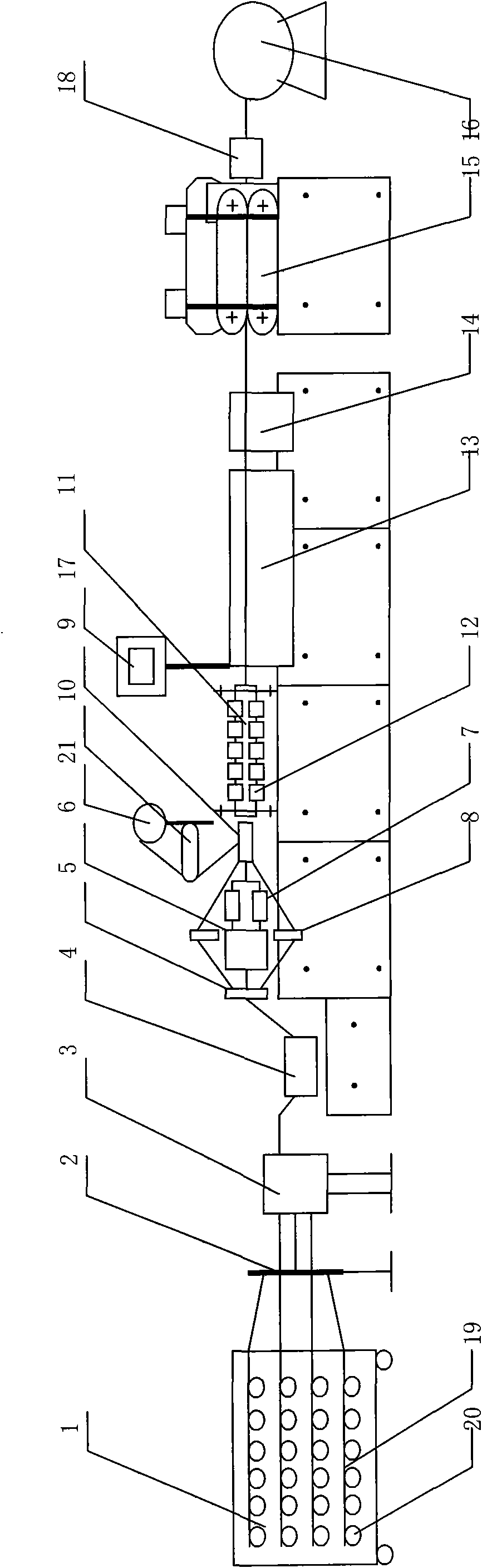

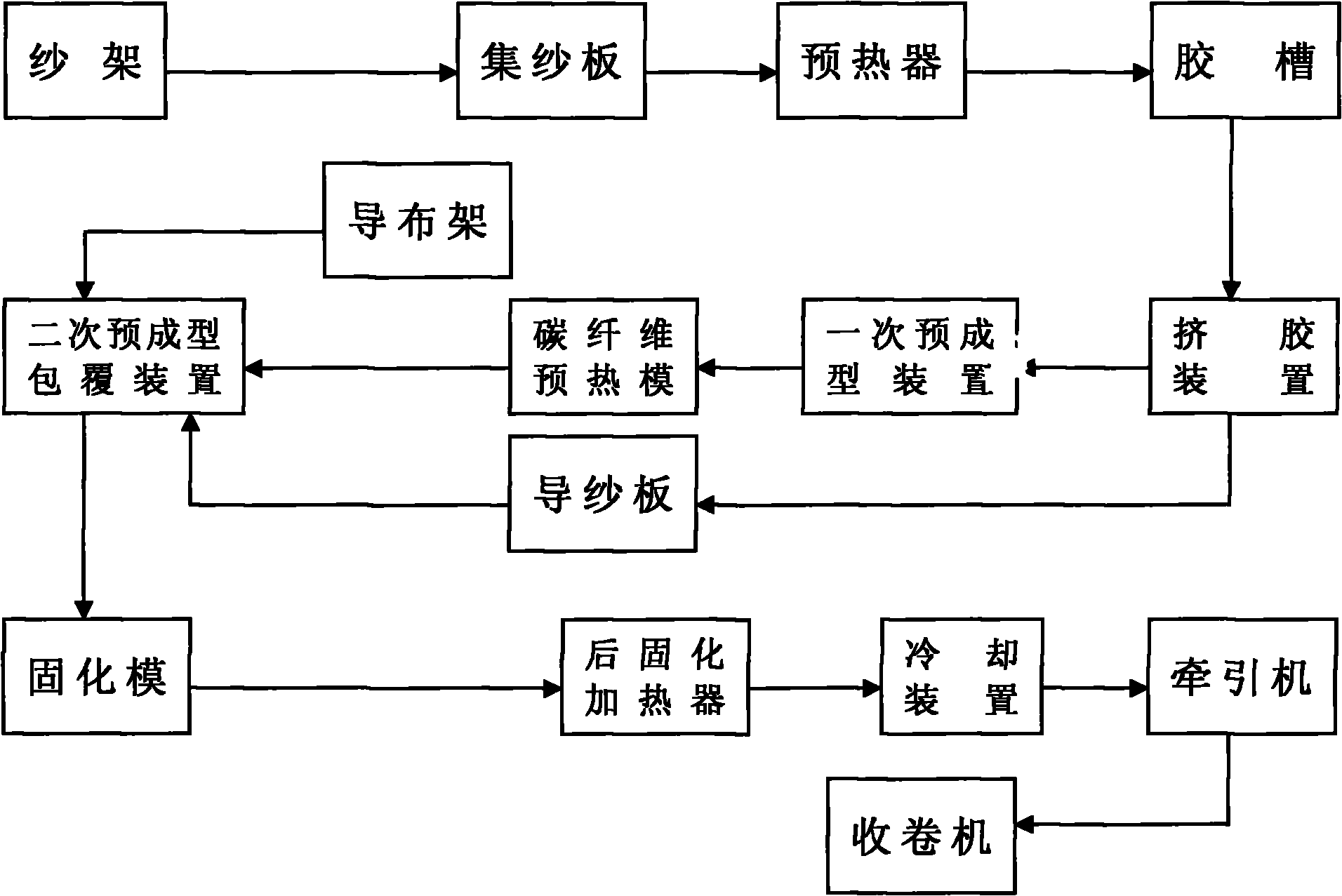

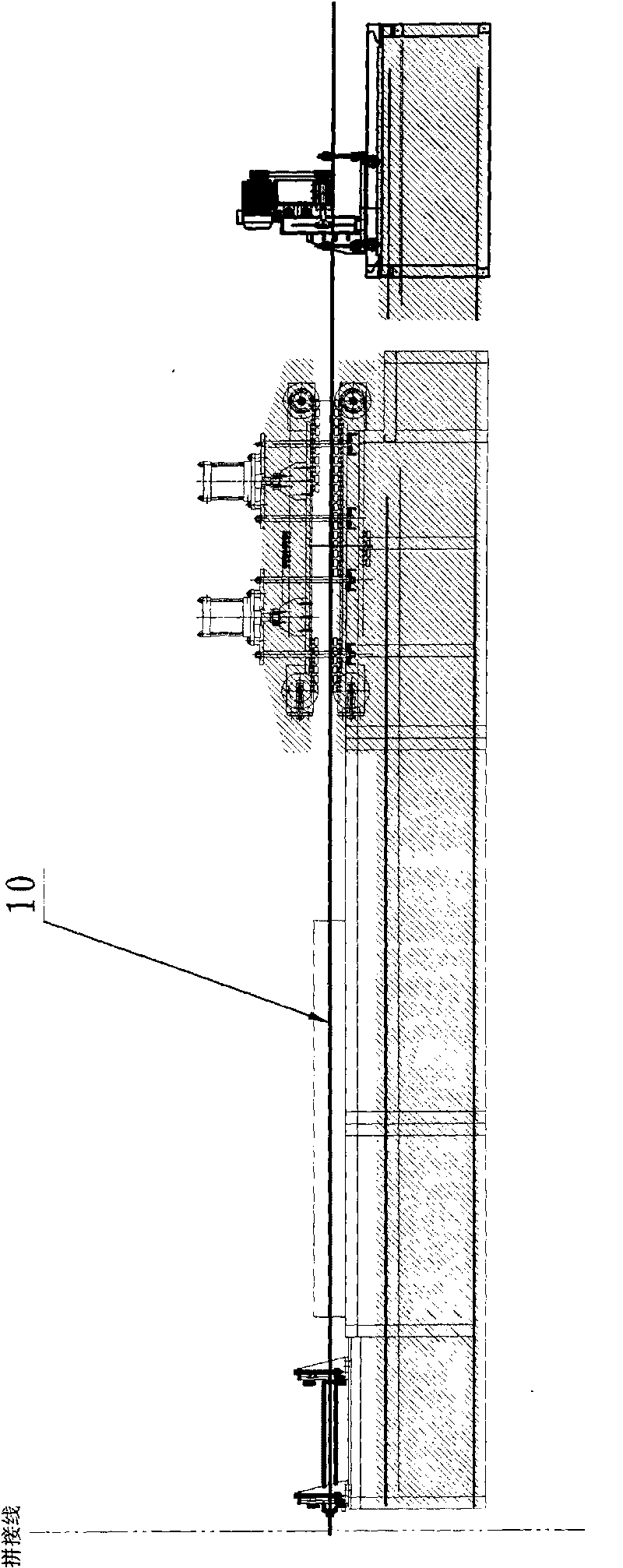

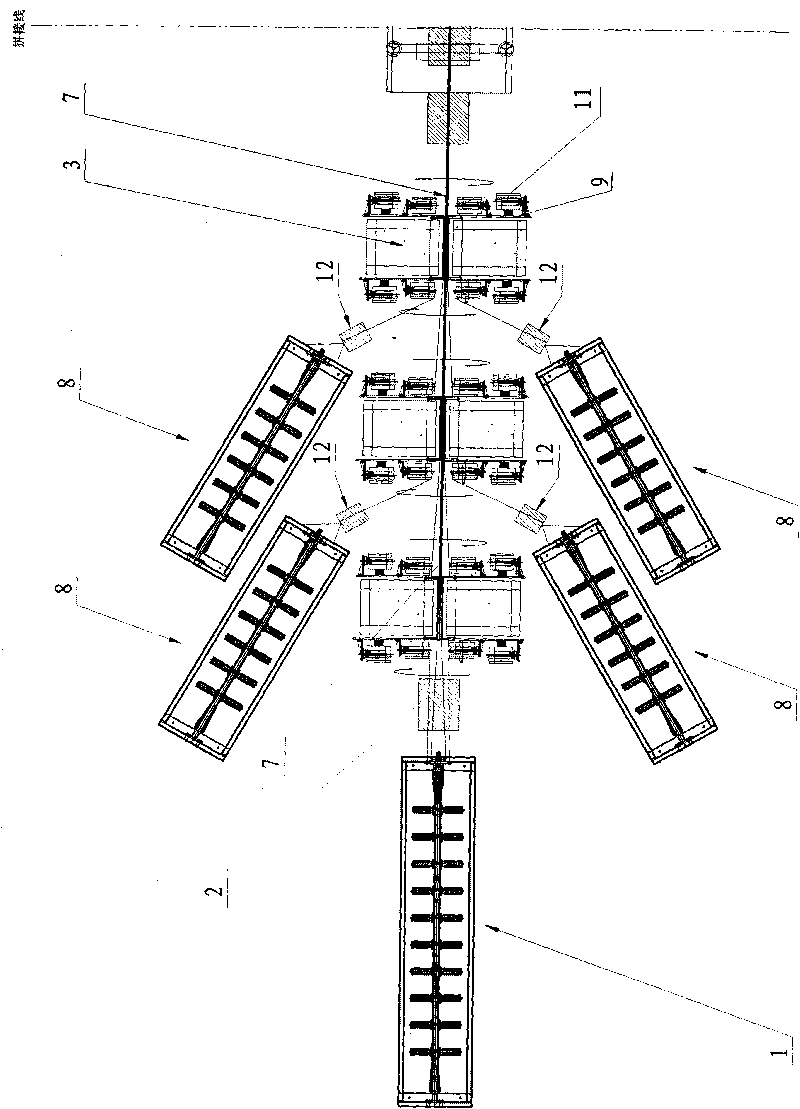

System and process for manufacturing carbon fiber composite core of electric transmission line

InactiveCN102039681AQuality improvementSolve the difficult problem of pultrusionFiberWinding machine

The invention relates to a system and process for manufacturing a carbon fiber composite core of an electric transmission line. The invention is characterized in that the system comprises a yarn frame, a yarn-collecting board, a preheater, a double-roller constant-temperature replaceable glue tank, a glue-squeezing device, a primary preforming device, a carbon fiber preheating mold, a secondary preforming and coating device, a curing mold, a postheating oven, an air cooling device, a tractor and a winding machine which are sequentially connected, wherein a cloth guide frame is mounted above the secondary preforming and coating device, the carbon fiber preheating mold and the curing mold are respectively sheathed with a heater, and both sides of the carbon fiber preheating mold are provided with glass fiber yarn guide boards. In the preparation method provided by the invention, repeated experiments are carried out on the high-performance resin system, and the outermost layer is coated with the glass fiber cloth by fully considering characteristics of carbon fibers and high-strength glass fibers, thereby enhancing the transverse strength of the product, improving the cracking resistance of the product and realizing the feasibility of the process. Thus, the invention solves the problem that high-performance resin is difficult to pultrude.

Owner:西安联瑞科技实业有限责任公司

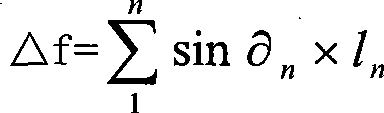

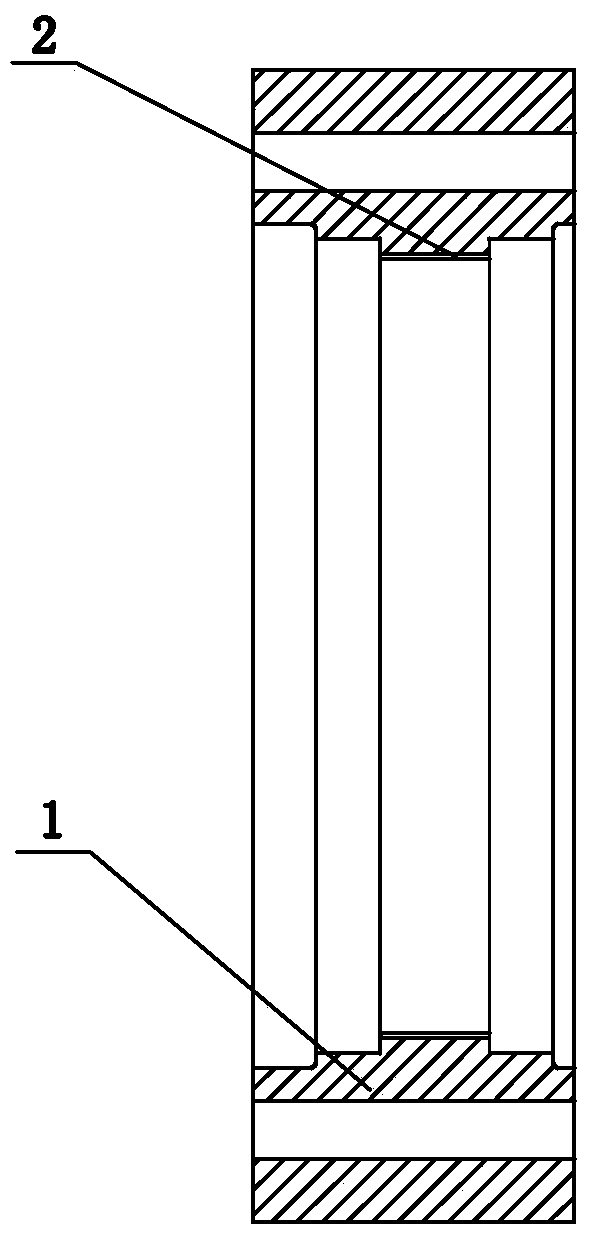

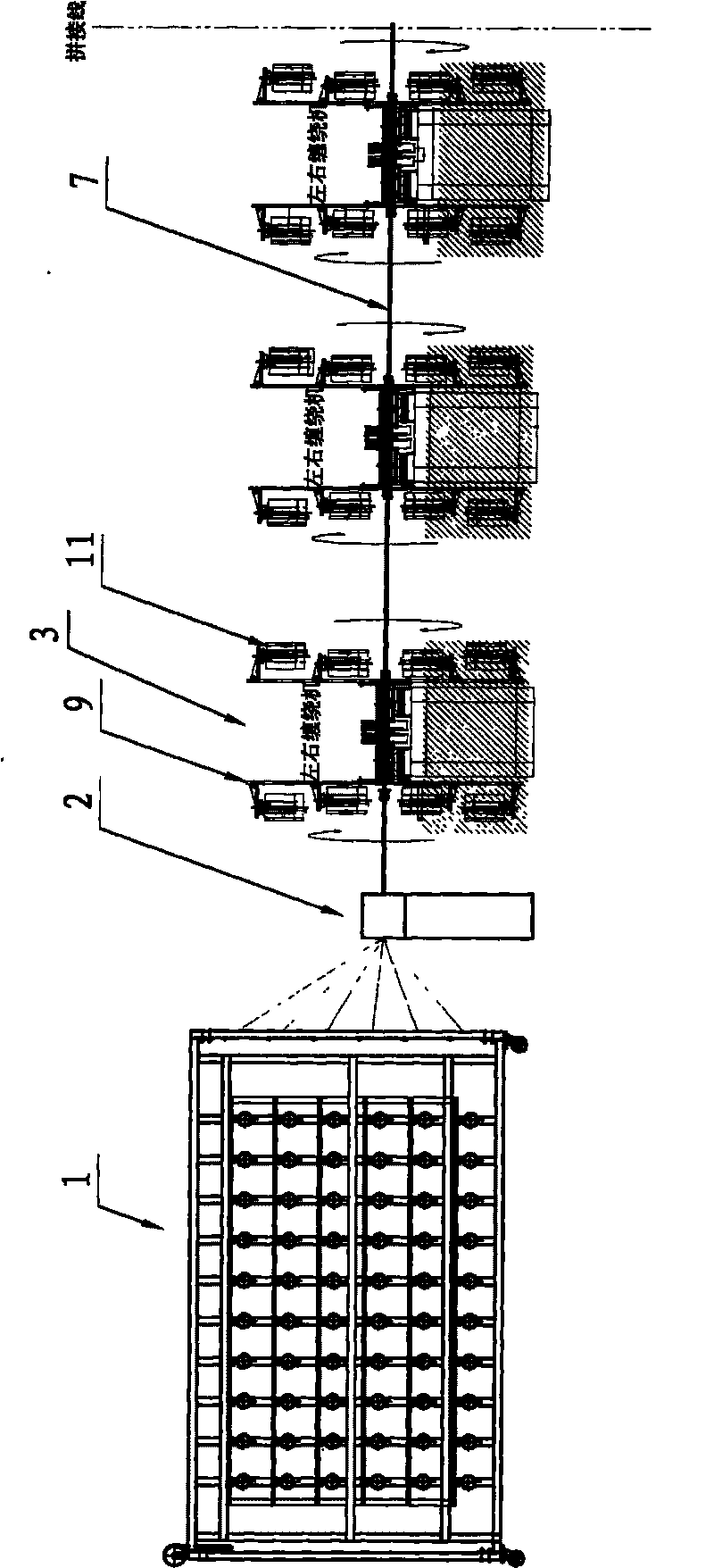

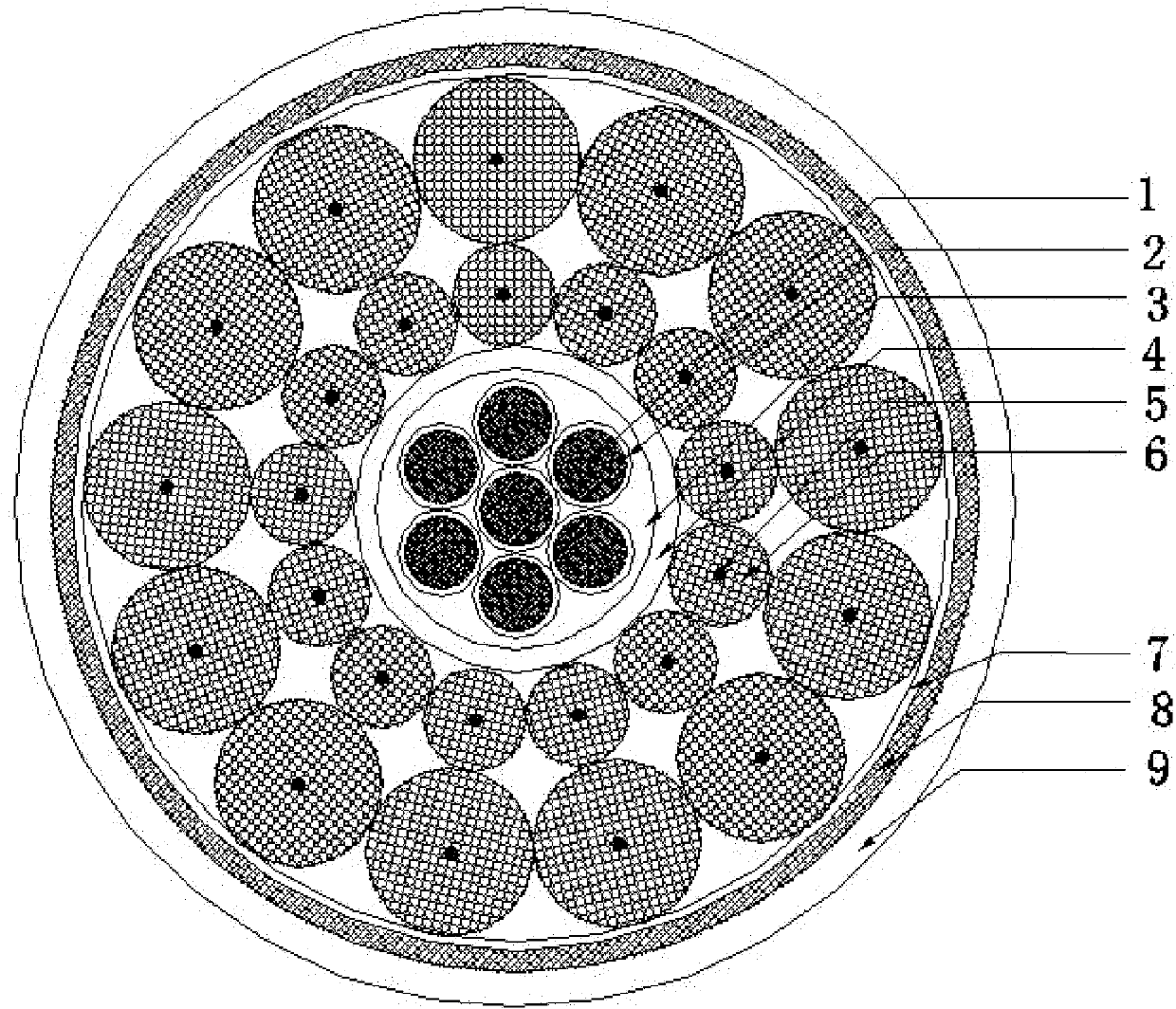

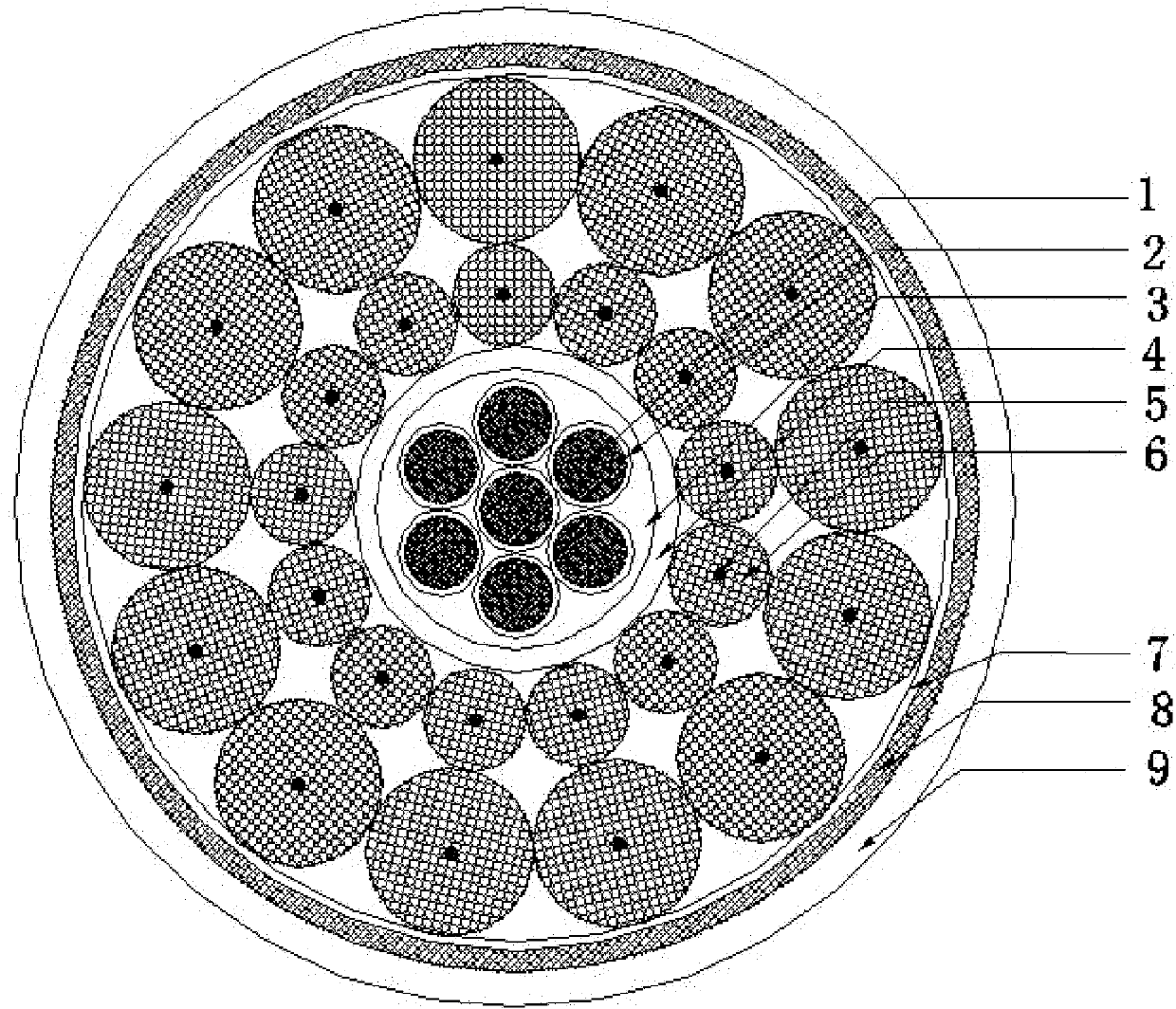

Production method of composite material by multilayer diagonal winding and production line

ActiveCN101708657AIncreased resistance to lateral (perpendicular to axis) forcesImprove torsion resistanceTubular articlesFiberProduction line

The invention relates to a production method and a production line of a composite hollow pipe with transverse winding fibers. Transverse winding layers winded on the surfaces of the fibers in opposite positive and negative directions are pulled and extruded in a longitudinal direction. Therefore, the invention enhances the bending resistant capability of the composite hollow pipe, eliminates a lamination phenomenon caused by using a single longitudinal composite hollow pipe, largely enhances the performance of the composite hollow pipe, and widens the application field of the composite hollow pipe.

Owner:南京诺尔泰复合材料设备制造有限公司

Offshore floating wind power generation cable

ActiveCN101996708AImprove electrical performanceImprove mechanical propertiesNon-insulated conductorsFloating cablesPolyolefinElectrical conductor

The invention discloses an offshore floating wind power generation cable, which comprises conductors, insulating layers, an inner lining layer, an inner protection layer, tensile components, floating components, a waterproof layer, protective layers and an outer sheath, wherein the conductor is coated with the insulating layer by way of extrusion so as to form insulating wire cores, and a plurality of insulating wire cores are stranded into a cable core; the cable core is respectively coated with the inner lining layer and the inner protection layer by way of extrusion; two protective layers are wound outside the inner protection layer, each protective layer consists of a plurality of protective elements which are arranged in the shape of circle, and each protective element is formed by coating the tensile component with the floating component by way of extrusion; the two protective layers are respectively coated with the waterproof layer, the protective layer and the outer sheath by way of outward extrusion; the insulating layers and the inner lining layer are made of thermoplastic elastomeric materials by way of extrusion; and the insulating layer is made of thermoplastic polyolefin (TPO) materials in thermoplastic elastomer (TPE), and the inner lining layer is made of toughened polystyrene (TPS) materials in TPE. The wind power generation cable of the invention has the advantages of low temperature resistance, bending resistance, torsion resistance, abrasion resistance, water blocking, corrosion resistance, weather fastness, high tensile strength, and capability of effectively preventing the damages of stormy waves and other floaters over the sea to the cables.

Owner:FAR EAST CABLE +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com