Patents

Literature

214results about How to "Improve torque performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

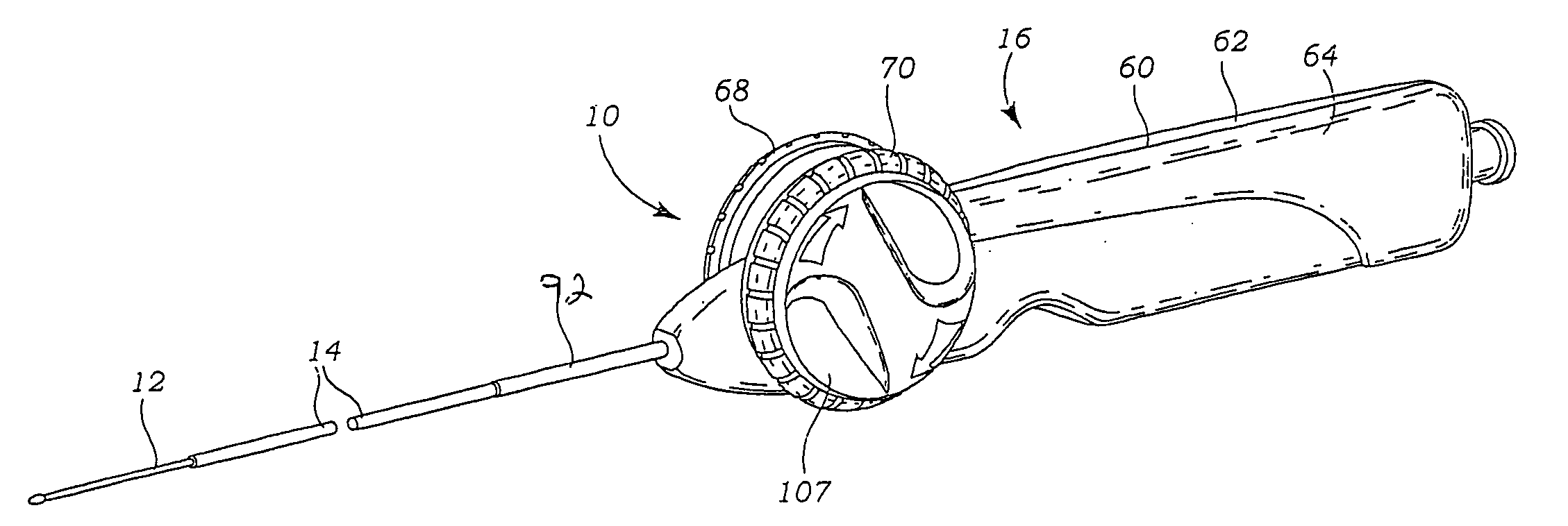

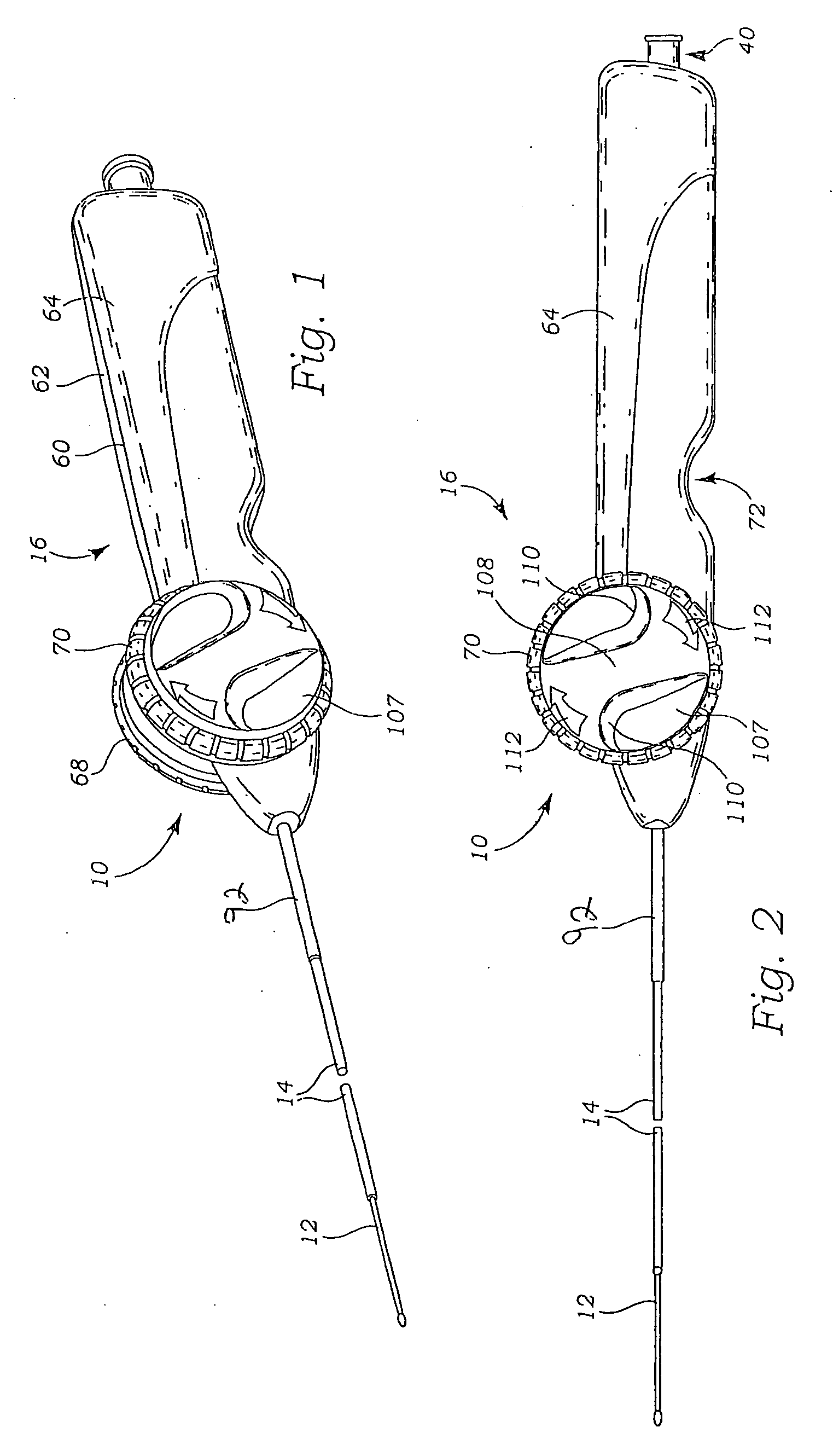

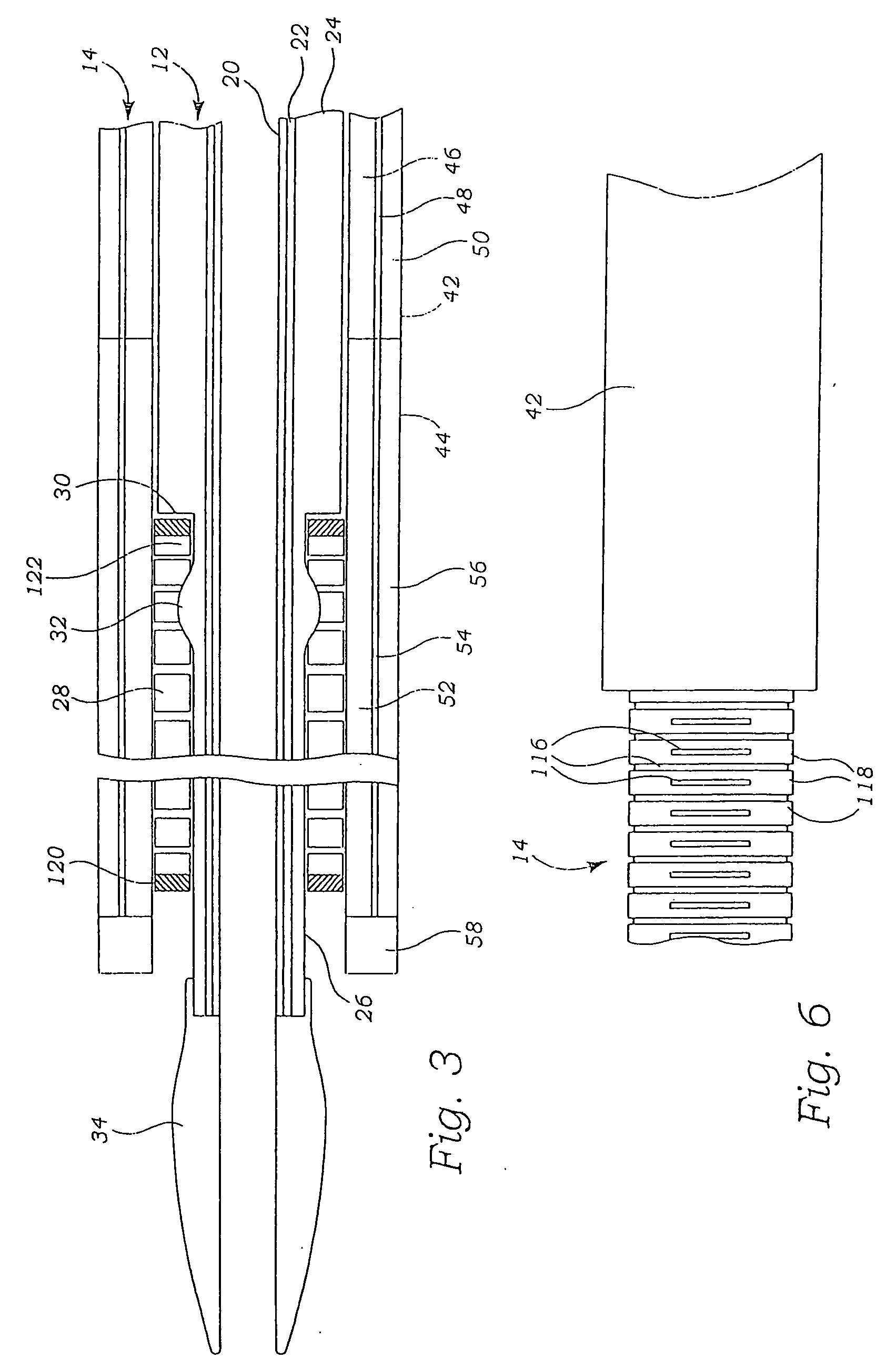

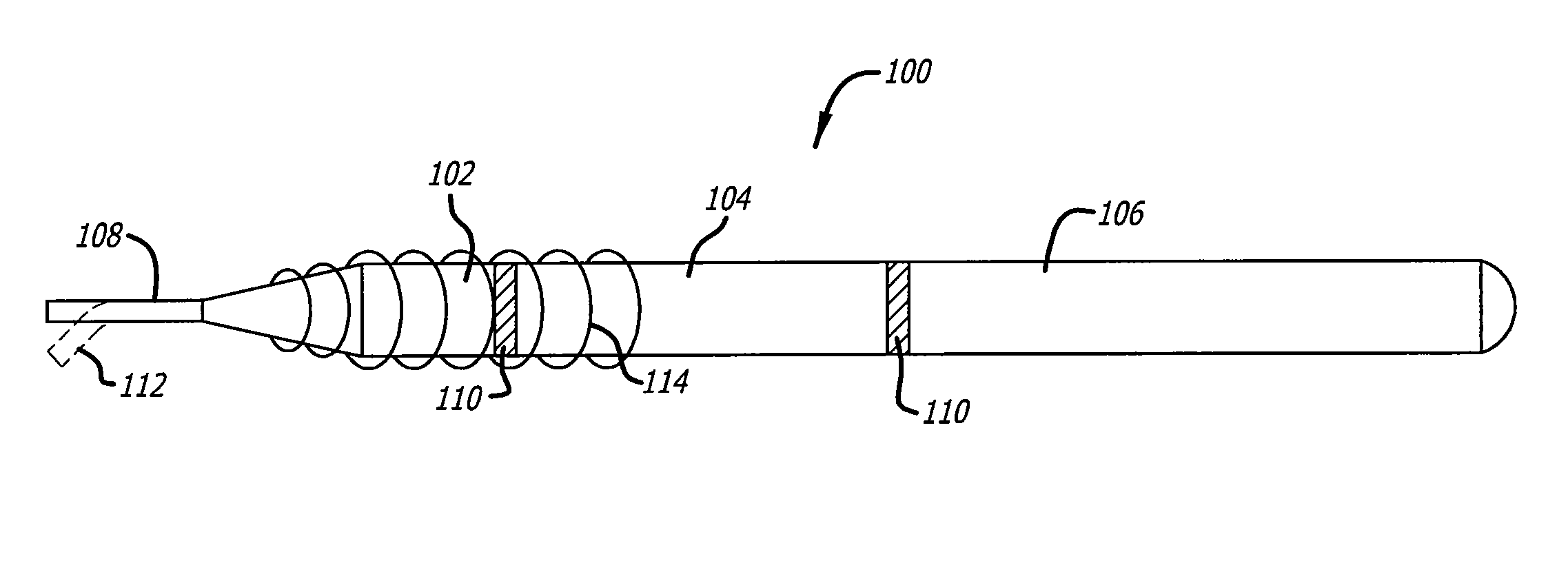

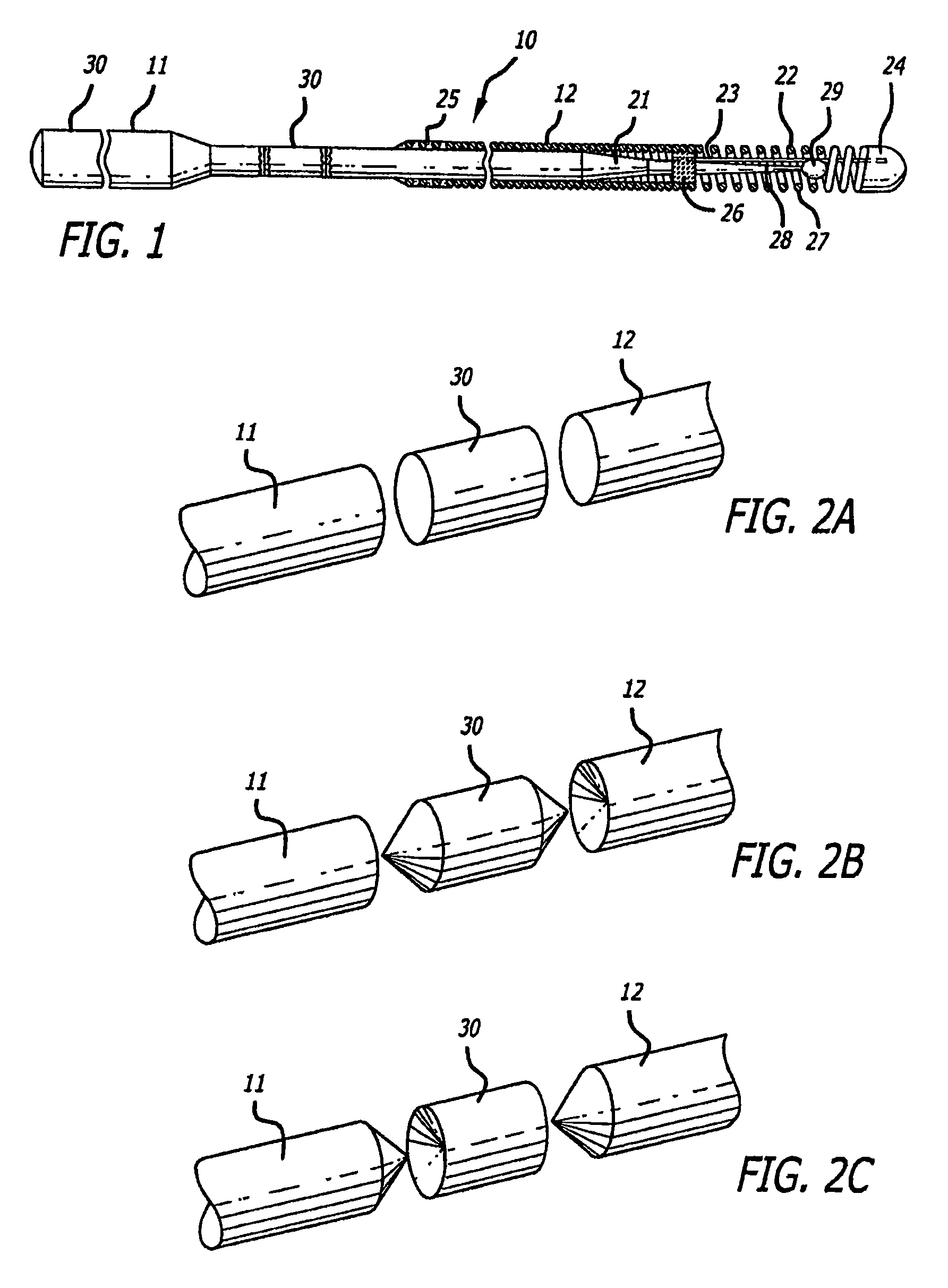

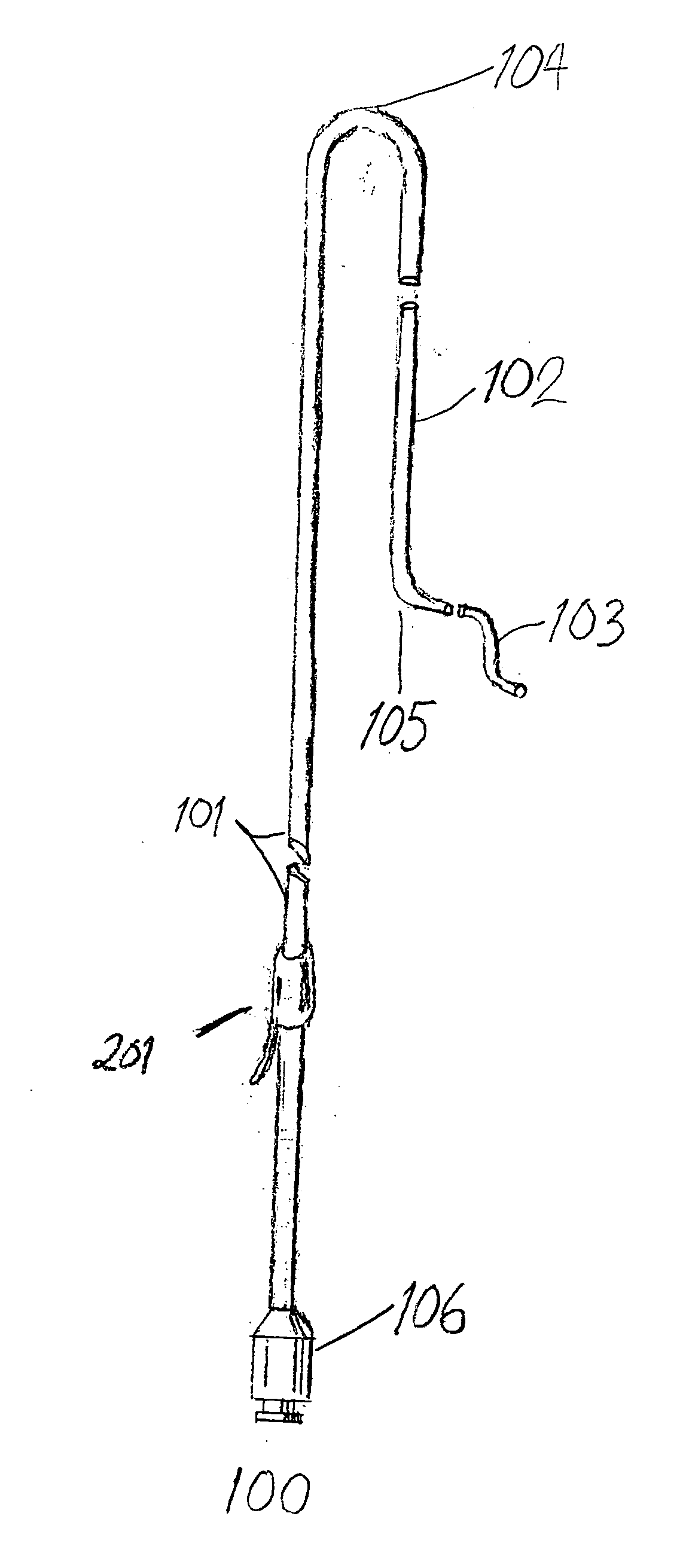

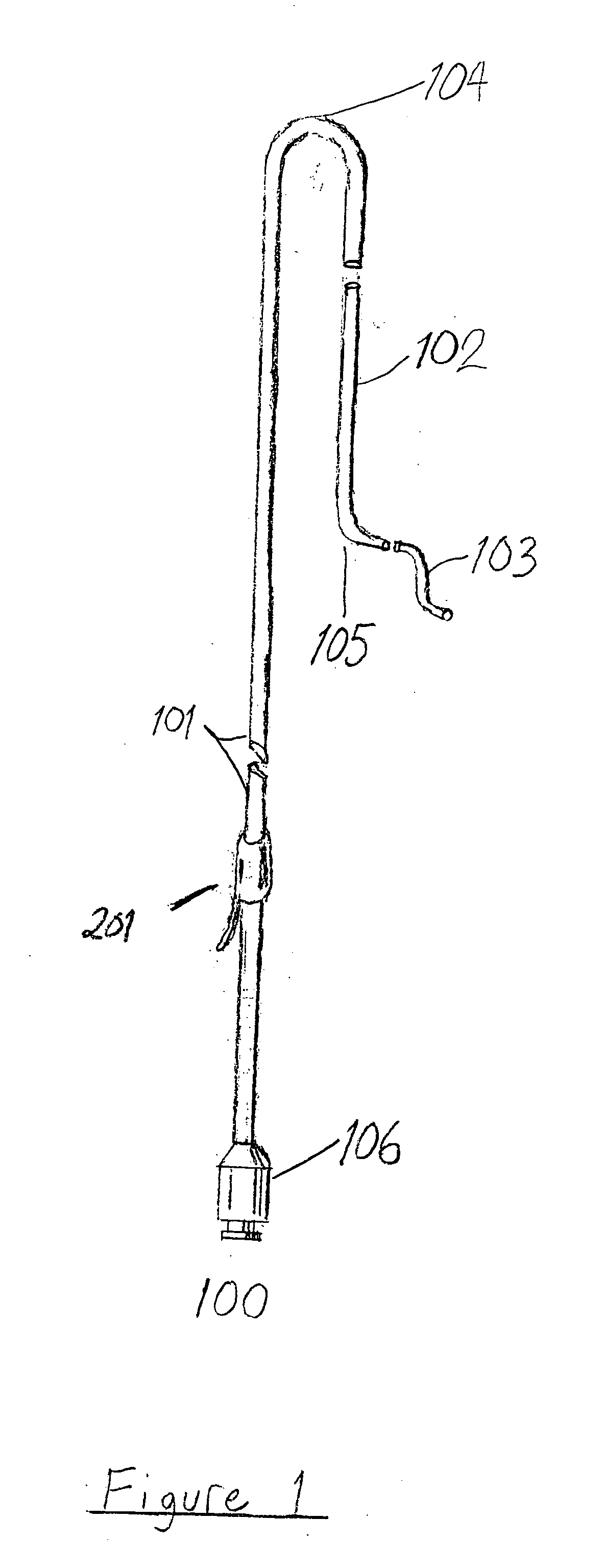

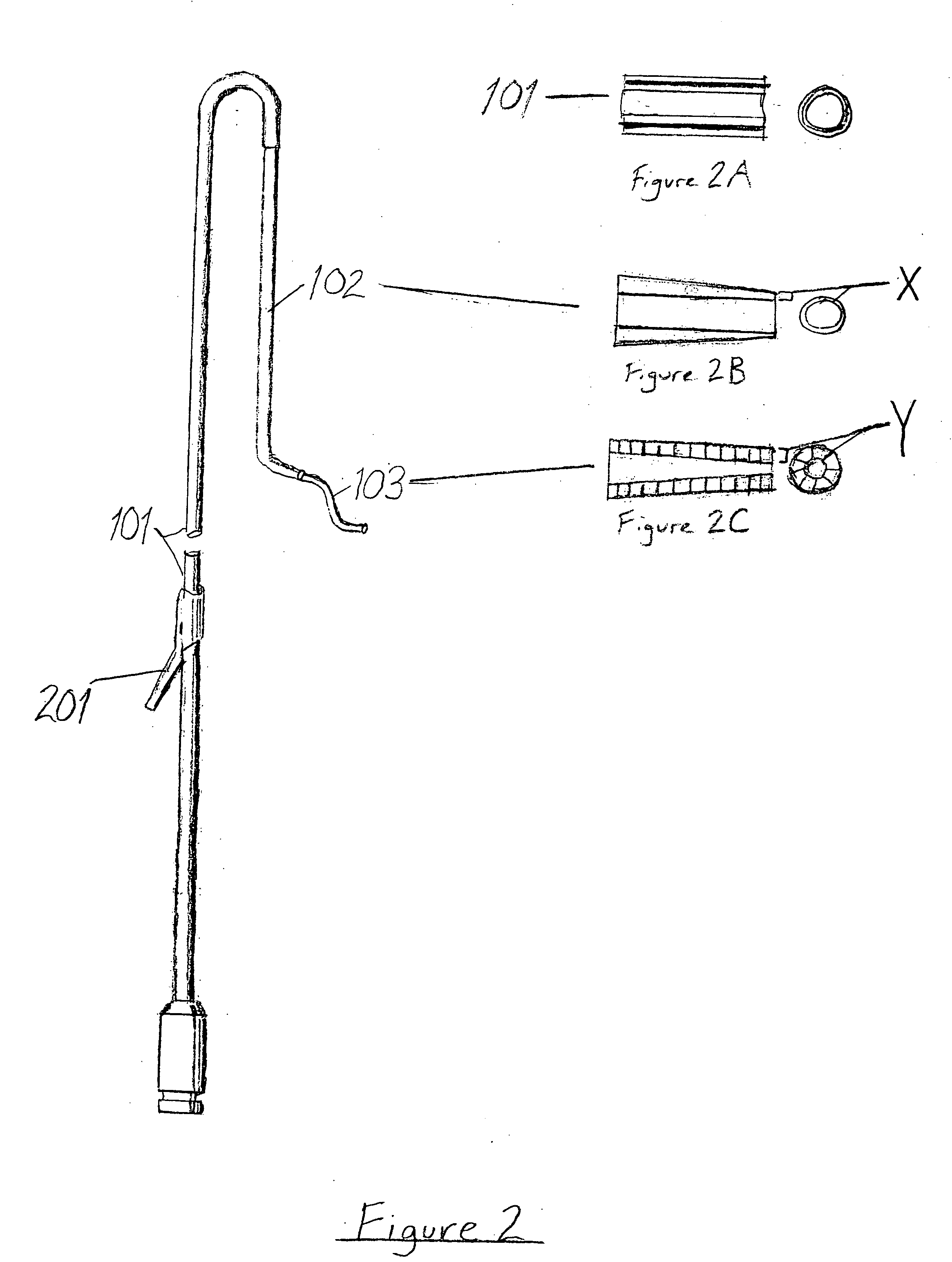

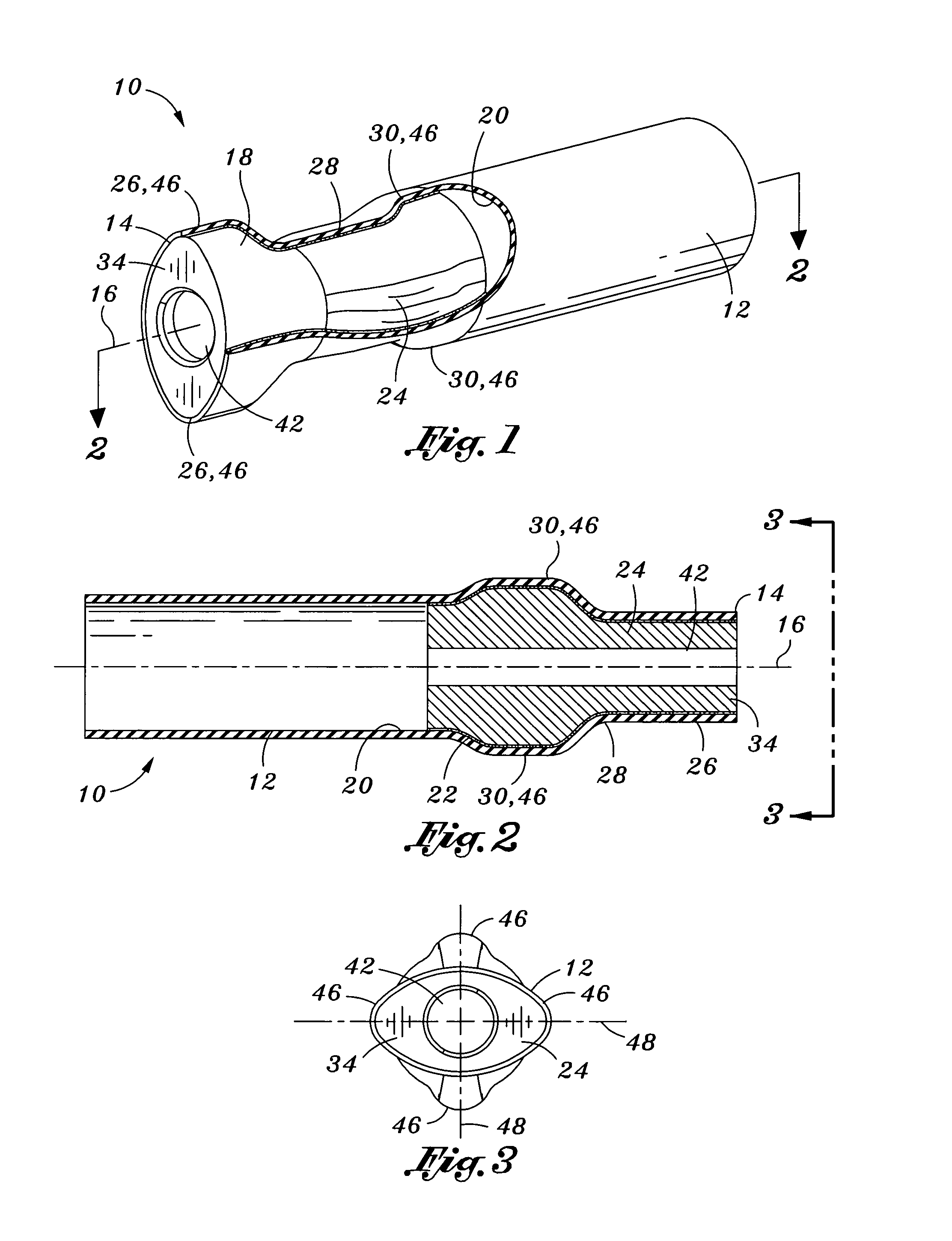

Stent delivery system

InactiveUS20050273151A1High degree of controlEasy to controlStentsBlood vesselsInsertion stentStent deployment

A stent delivery system includes an inner tubular member on which a stent is loaded, an outer jacket extending over said inner tubular member, the retraction of which causes deployment of the stent, and a handle adapted to move the jacket relative to the inner tubular member. The constructions of the inner tubular member and outer jacket and the handle provide increased control of the relative movement of the outer jacket relative to the inner tubular member, and prevention of premature release of the stent from the deployment instrument, and greater control over stent deployment among other advantages.

Owner:CR BARD INC

Translation dilator and stand alone vascular guide catheter

Systems and methods for delivering implantable devices, catheters, or substances in or near and / or restoring flow through body lumens, such as blood vessel lumens are described. A catheter having a proximal portion of a first diameter and a distal portion of a second diameter (smaller than the first diameter) is advanced into a body lumen. The distal portion of the catheter is caused to expand to a diameter that is larger than the second diameter but no larger than the first diameter. A working device is then advanced out of the distal end of the catheter and used to remove obstructive matter, deliver an implantable device or substance and / or restore flow. The distal portion can be reduced in diameter prior to removal from the body. A stand alone, guide catheter is also disclosed possessing high resistance to kinking even with a very thin wall.

Owner:TYCO HEALTHCARE GRP LP

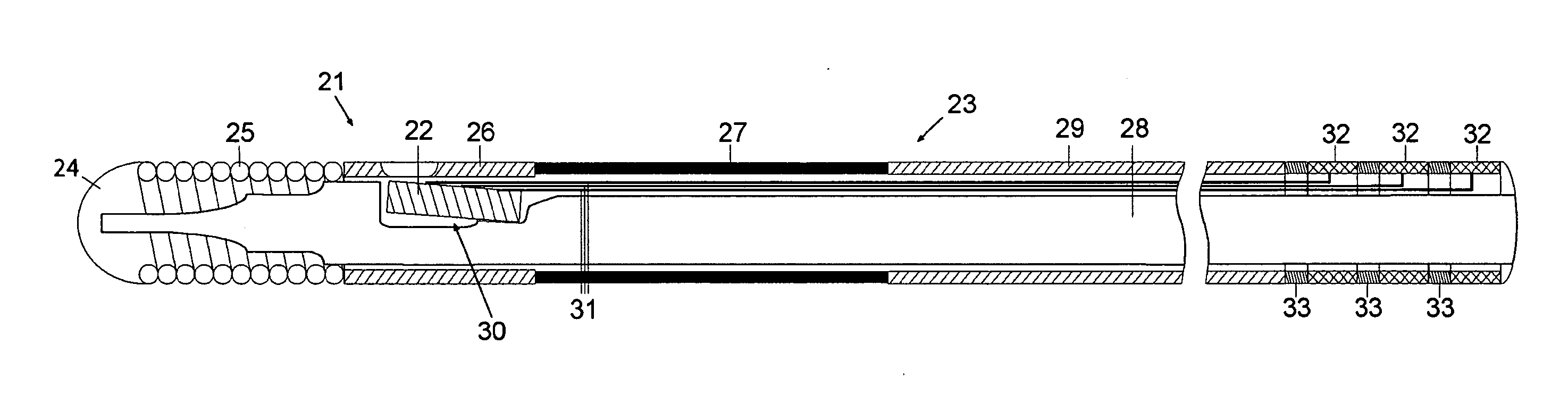

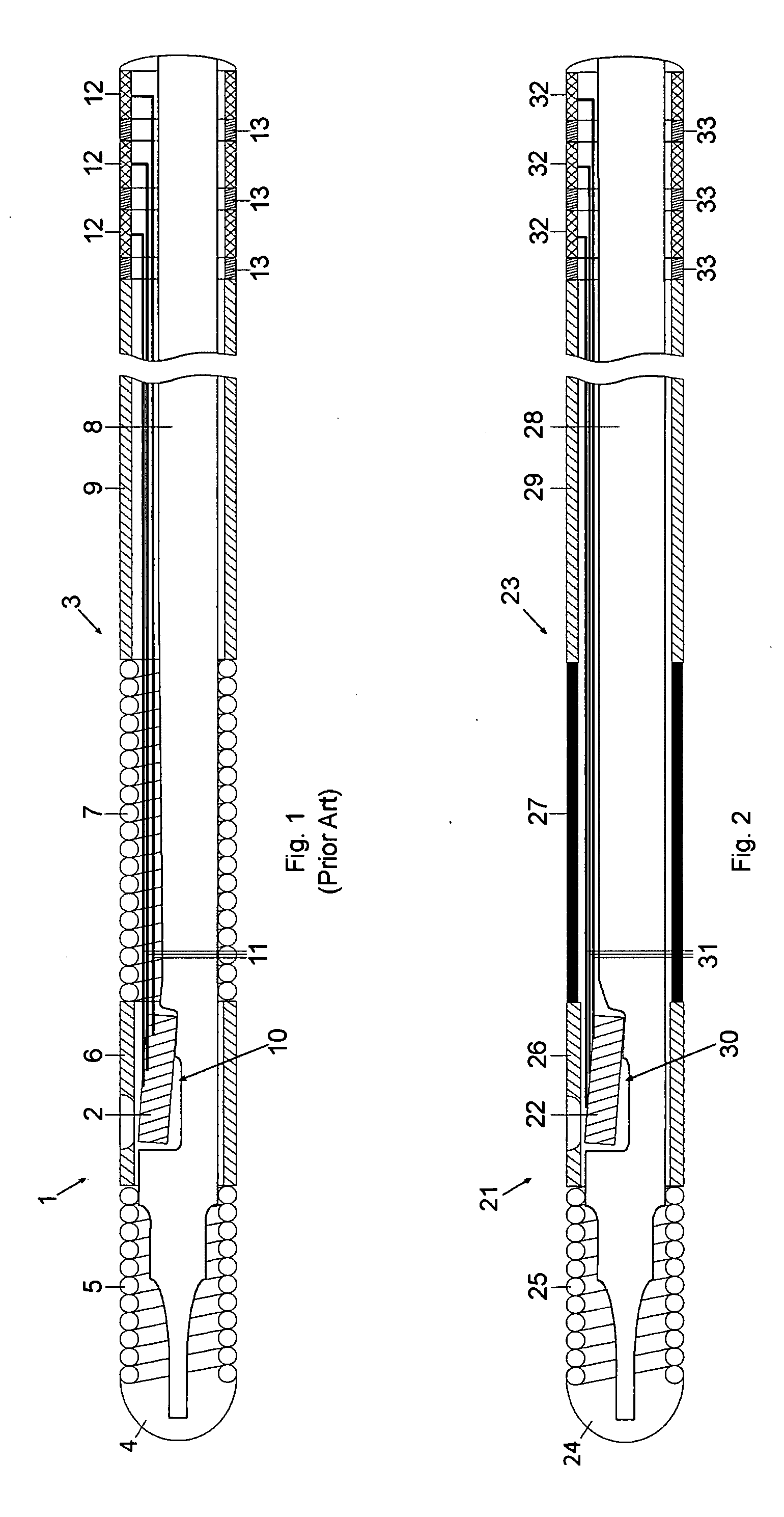

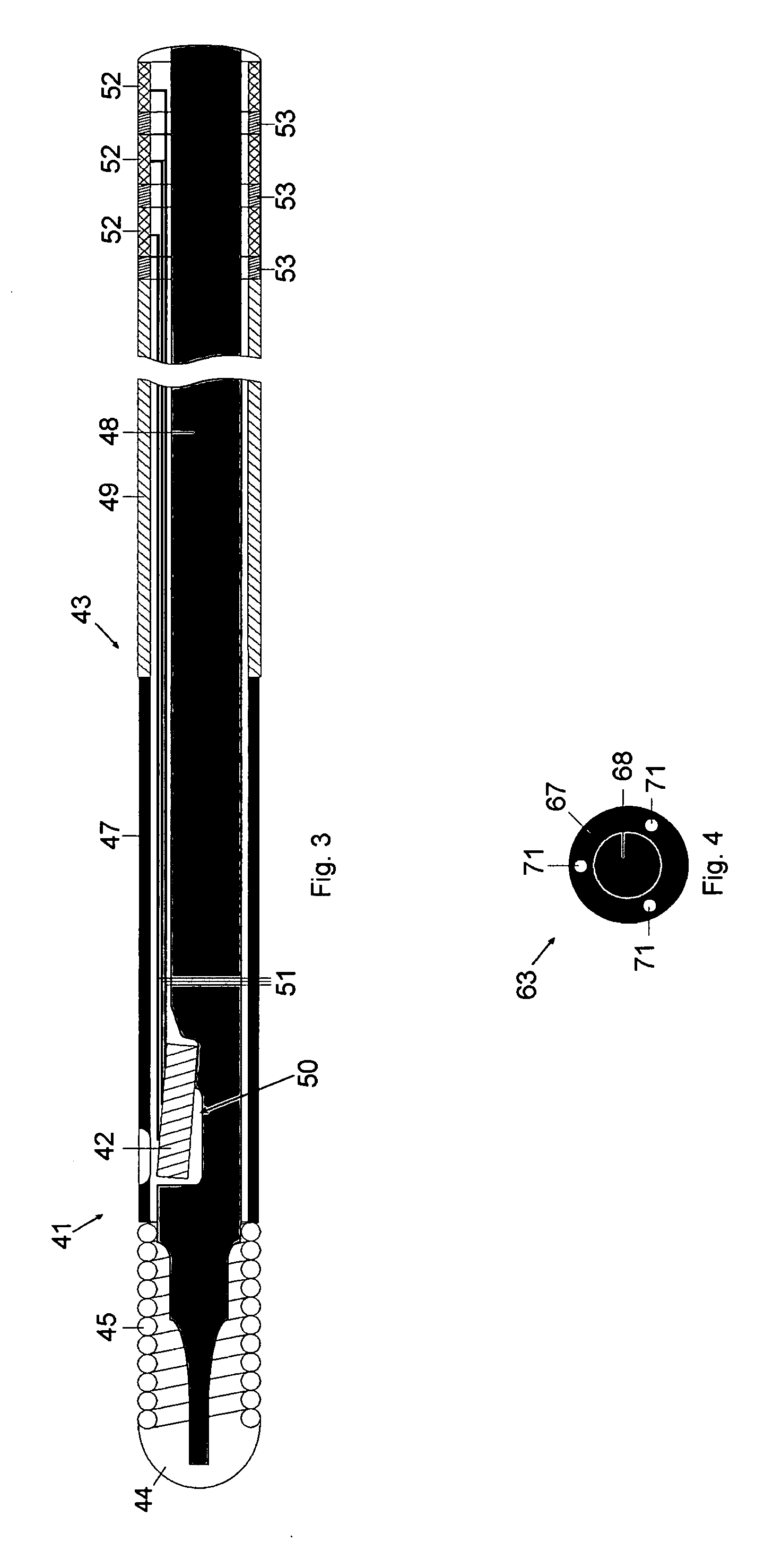

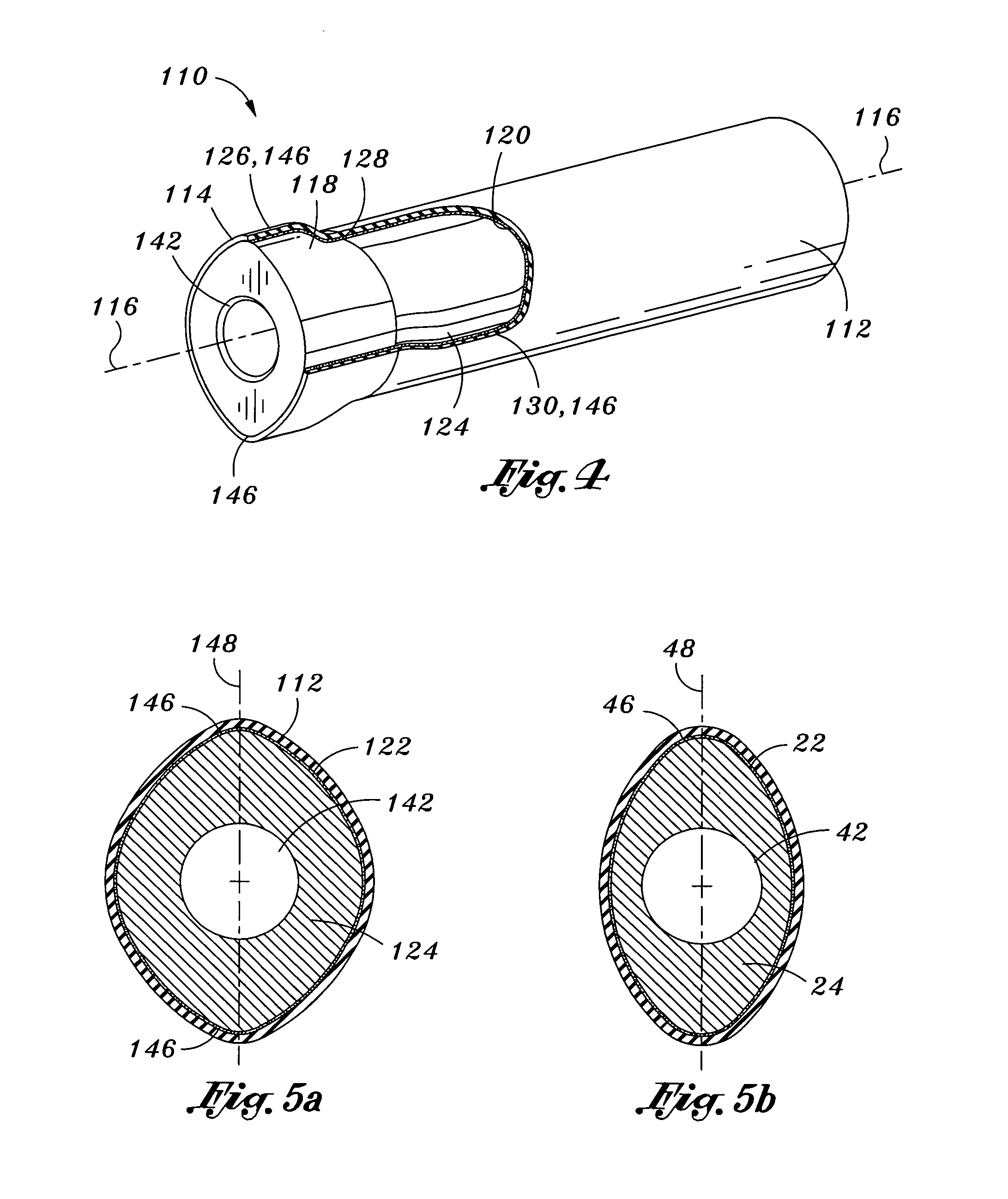

Sensor and guide wire assembly

InactiveUS20070255145A1Improve mobilityReduce riskGuide wiresDiagnostic recording/measuringEngineeringLiving body

A sensor and guide wire assembly (21; 41) for intravascular measurements of a physiological variable in a living body, comprises a sensor element (22; 42) and a sensor guide wire (23; 43) comprising a core wire (28; 48) and at least one signal transmitting cable (31; 51) connected to the sensor element, wherein a polymer layer (27; 47) is provided which encloses a portion of the core wire and the at least one signal transmitting cable.

Owner:ST JUDE MEDICAL COORDINATION CENT

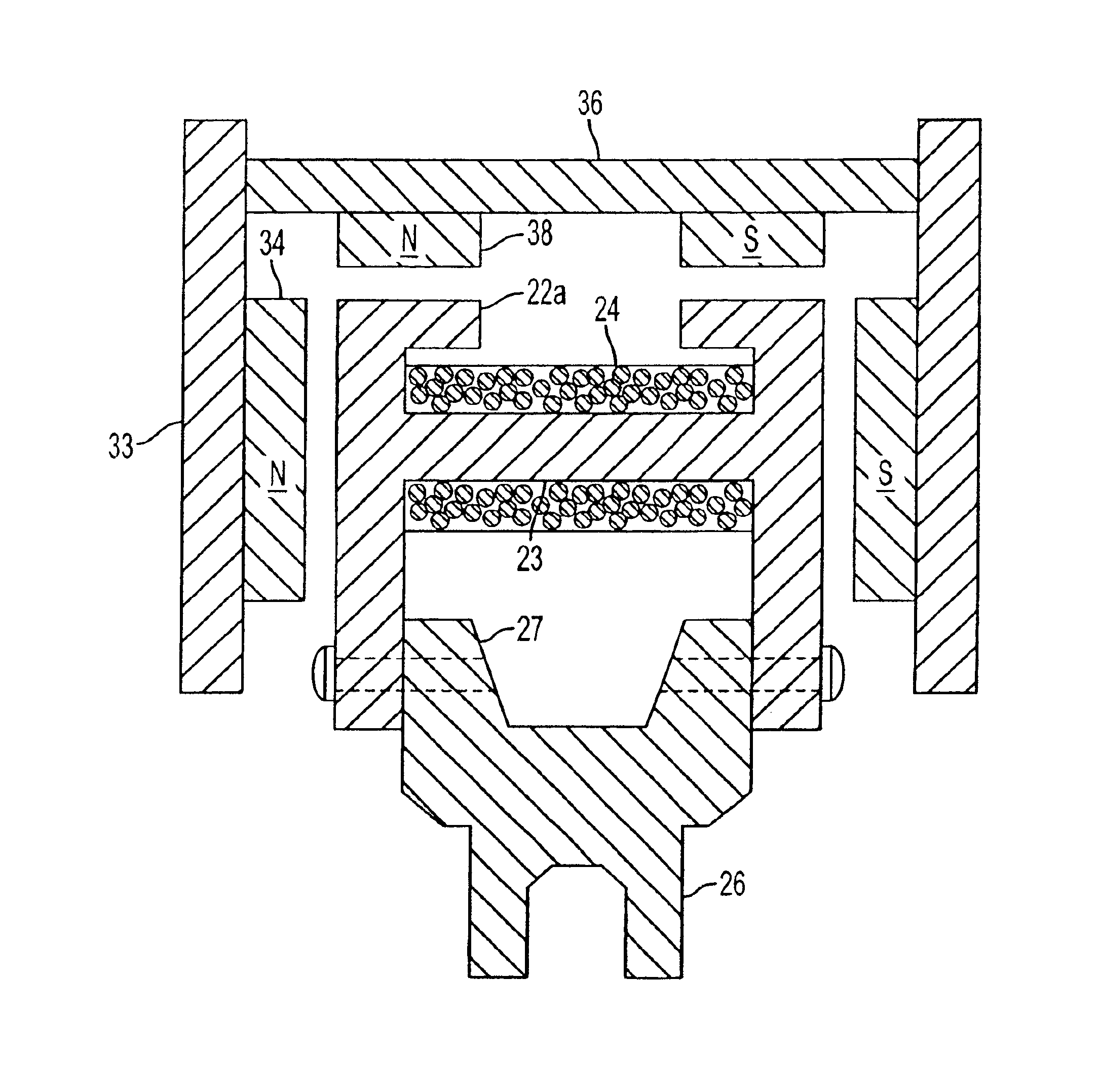

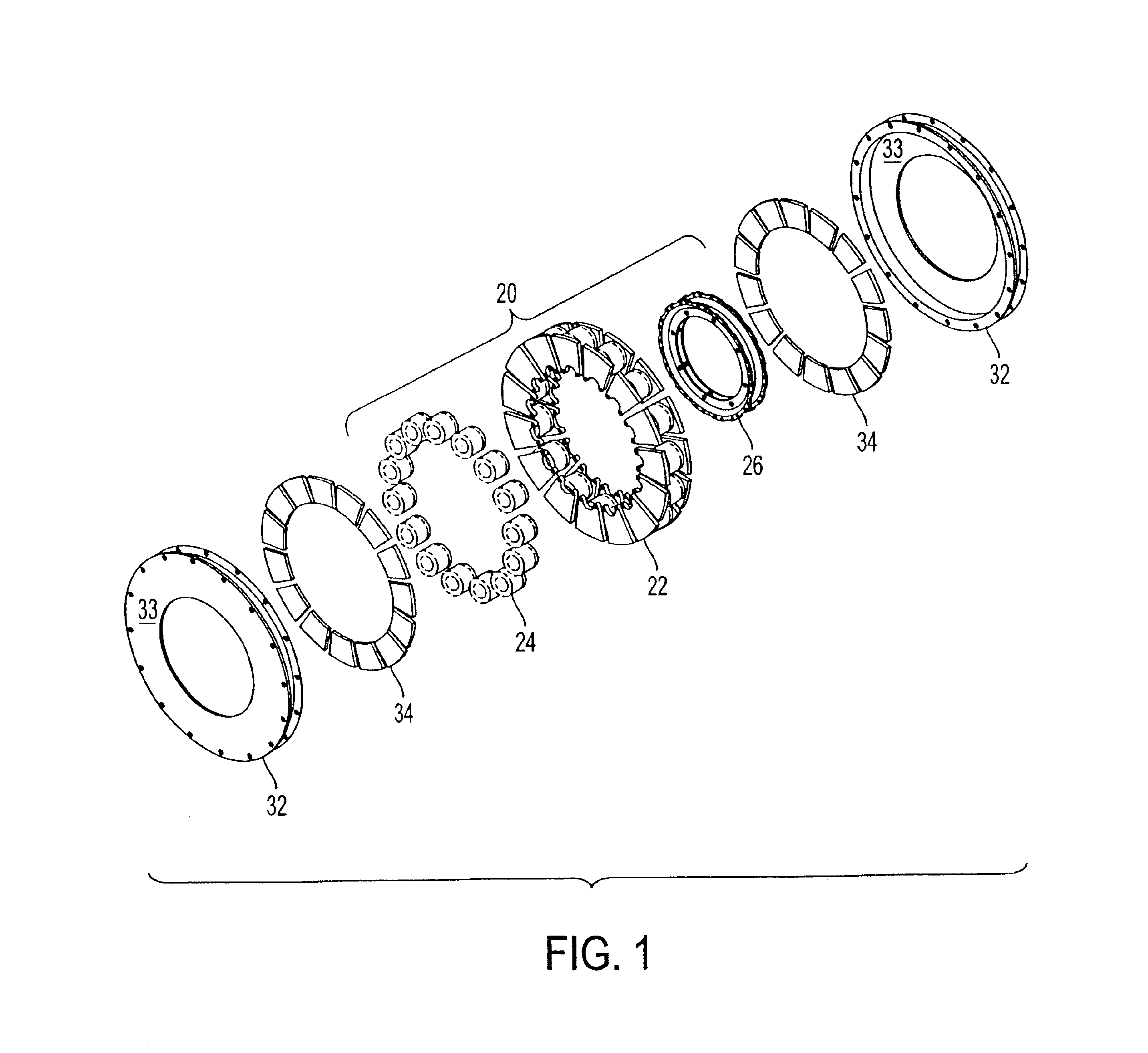

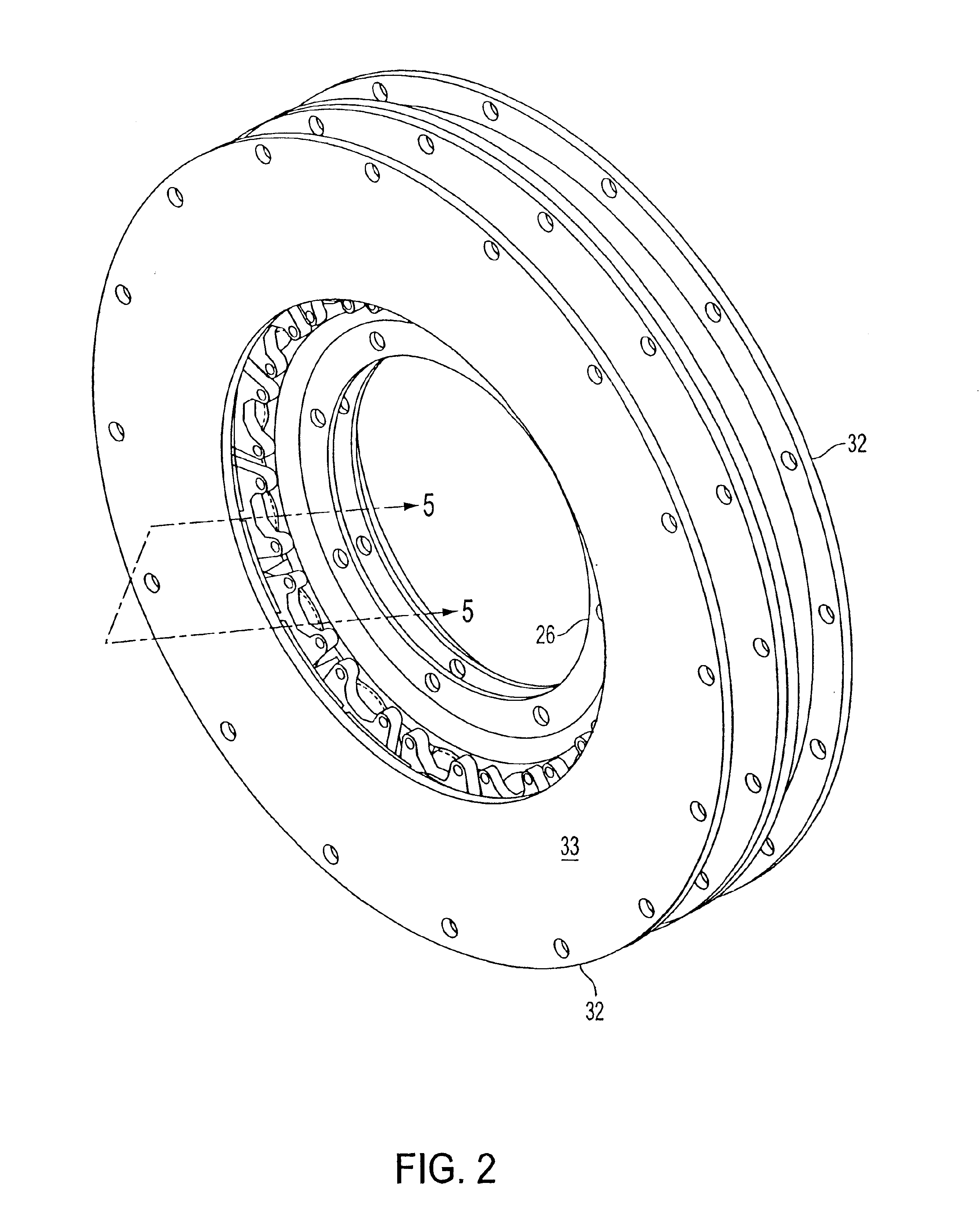

Rotary electric motor having both radial and axial air gap flux paths between stator and rotor segments

InactiveUS6891306B1Low flux lossEliminate the effects ofMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesElectrical polarity

In a rotary electric motor, a stator contains a plurality of separate electromagnet core segments disposed coaxially about an axis of rotation. The core segments are affixed, without ferromagnetic contact with each other, to a non-ferromagnetic support structure. The rotor is configured in a U-shaped annular ring that at least partially surrounds the annular stator to define two parallel axial air gaps between the rotor and stator respectively on opposite axial sides of the stator and at least one radial air gap. Permanent magnets are distributed on each inner surface of the U-shaped rotor annular ring that faces an air gap. A winding is formed on a core portion that links axially aligned stator poles to produce, when energized, magnetic poles of opposite polarity at the pole faces.

Owner:BLUWAV SYST LLC

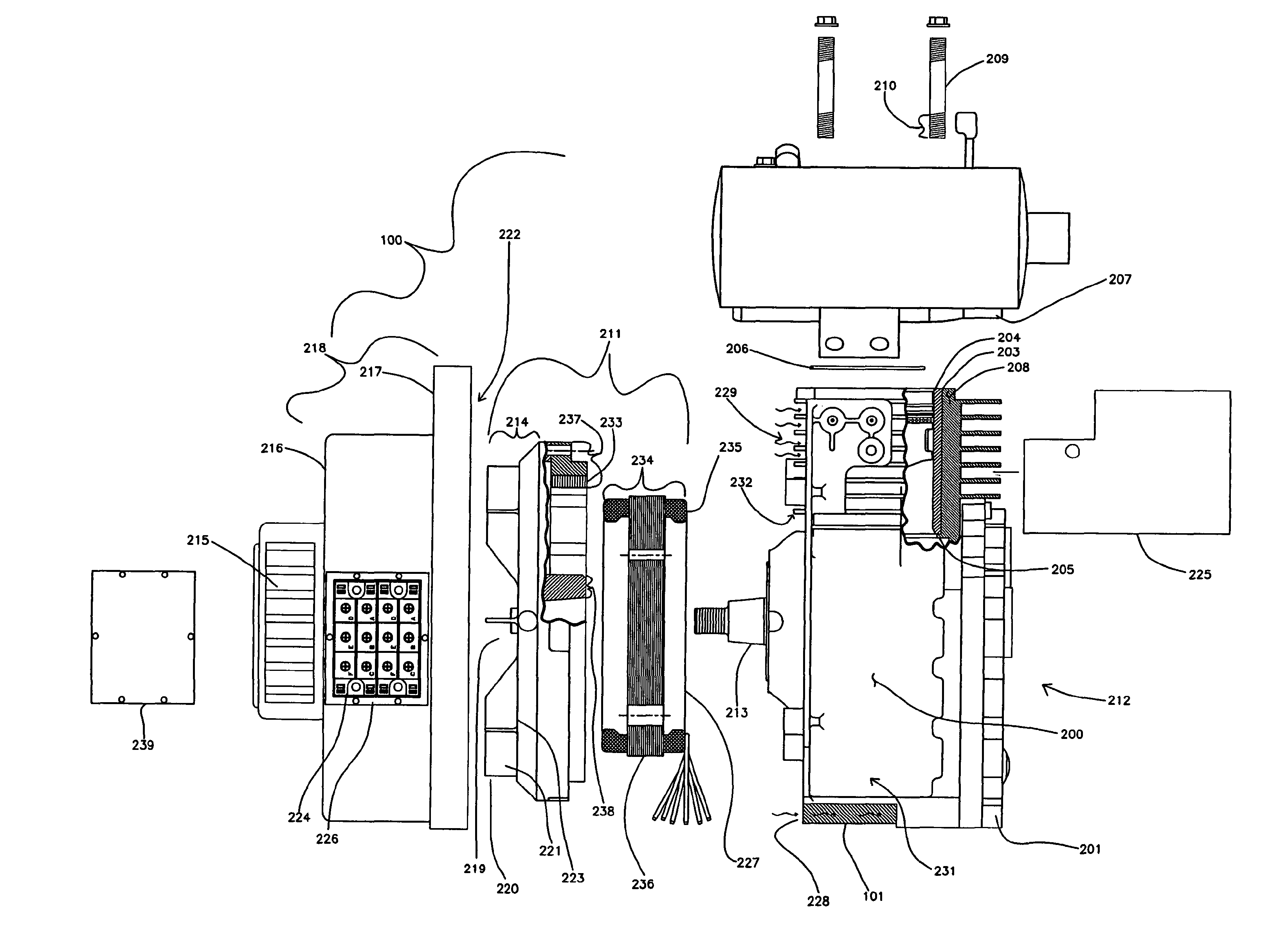

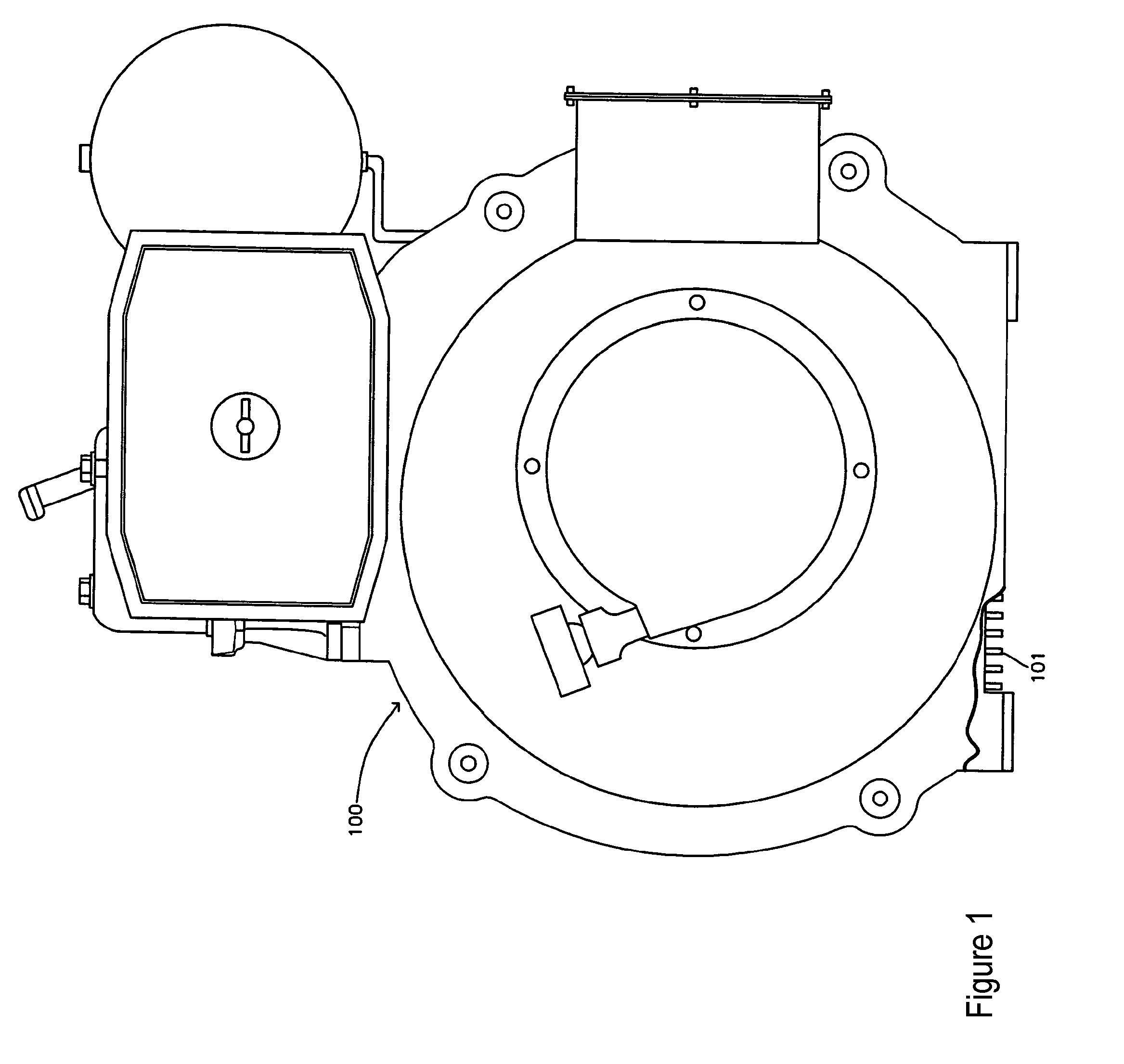

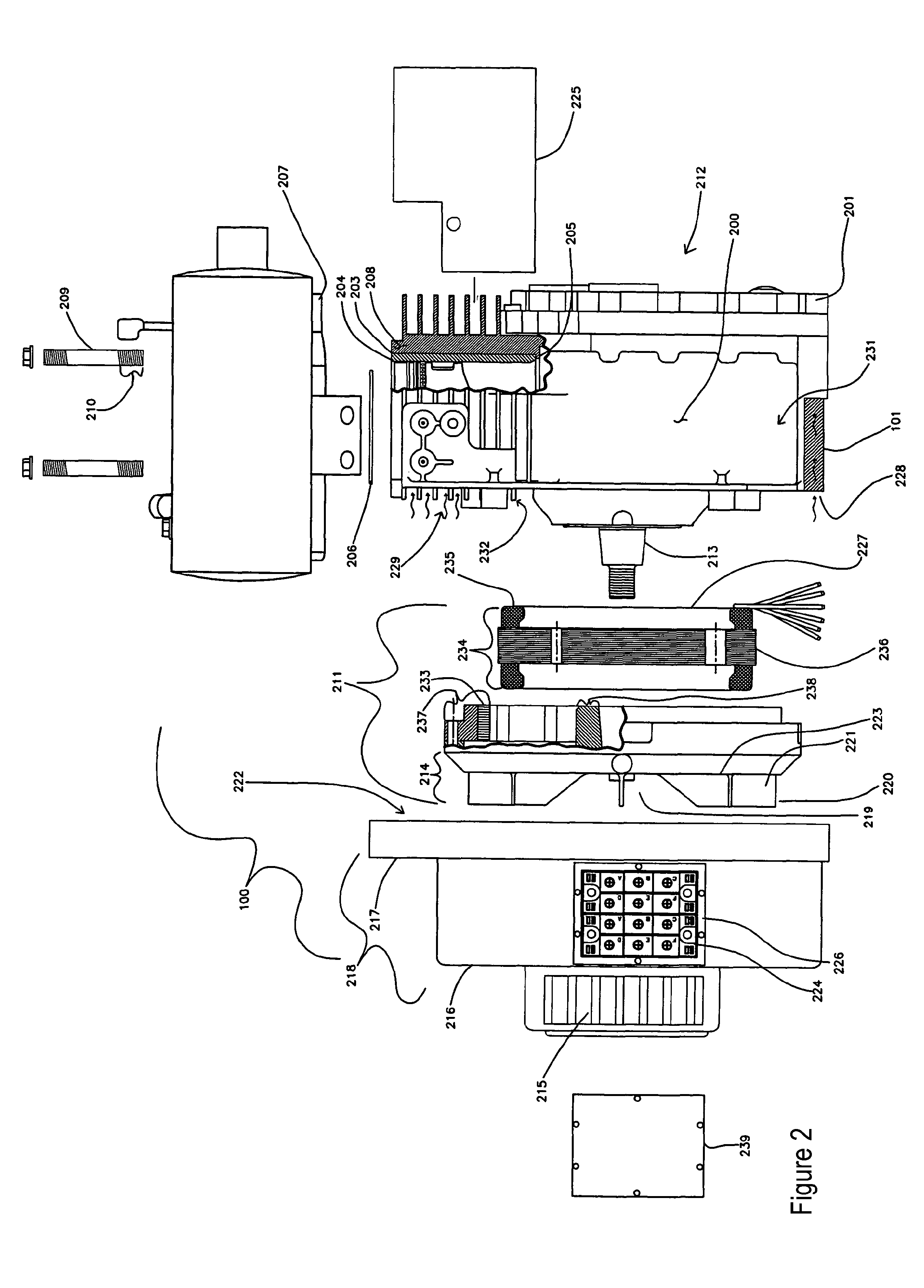

Lightweight Portable Electric Generator with Integrated Starter/Alternator

ActiveUS20070227470A1Improve torque performanceLow costMagnetic circuit rotating partsAir coolingAlternatorFuel efficiency

A compact and lightweight electric generator for portable power applications employs a new engine design and integration approach for reducing engine, generator, and starter weight. A unique flywheel alternator / starter configuration that generates electrical power, rotates the engine for starting, provides inertia for smooth engine operation, pressurized air for cooling, and inertia for the alternator. An engine cowling provides rotating component protection, a fan shroud mechanism, cooling air ducts, and a cooling mechanism for handling large quantities of heat produced by rectified power conversion. An electrical hook up that allows the generator to provide transient surge capacity for starting inductive loads, or improved load leveling and fuel efficiency.

Owner:MAINSTREAM ENG

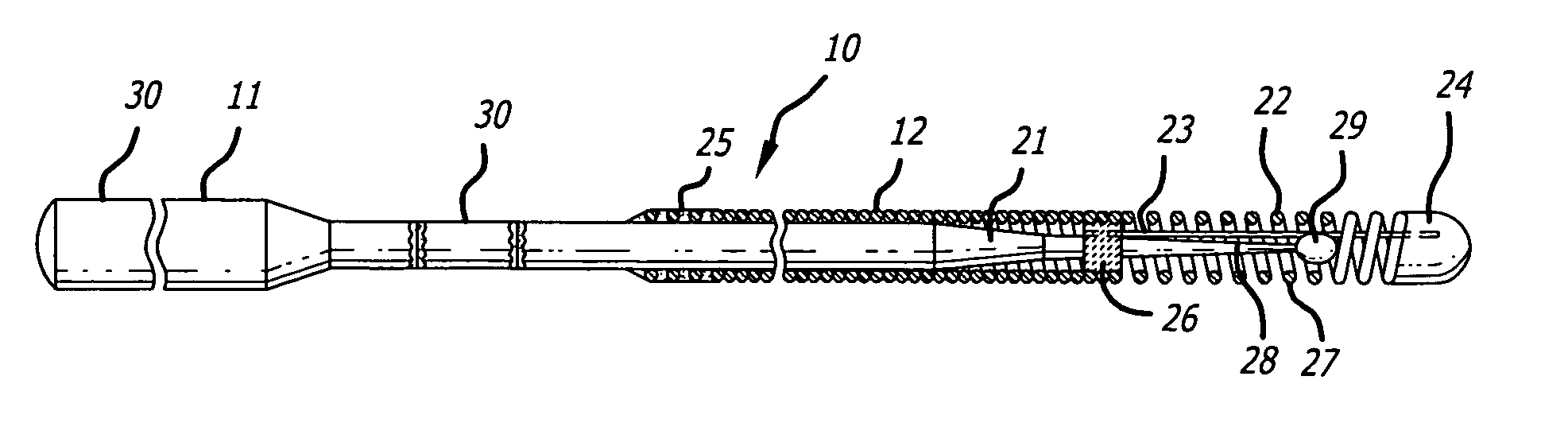

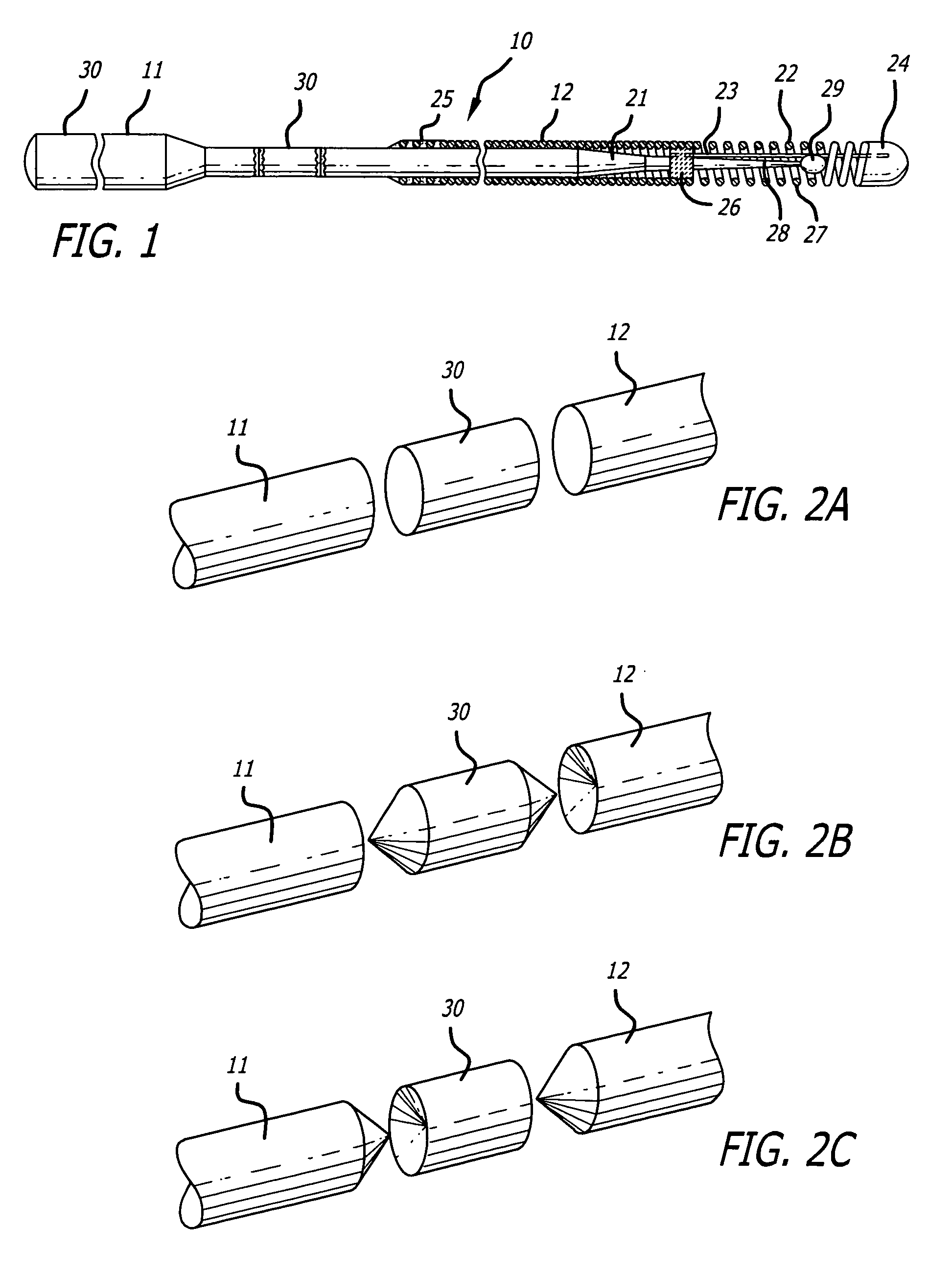

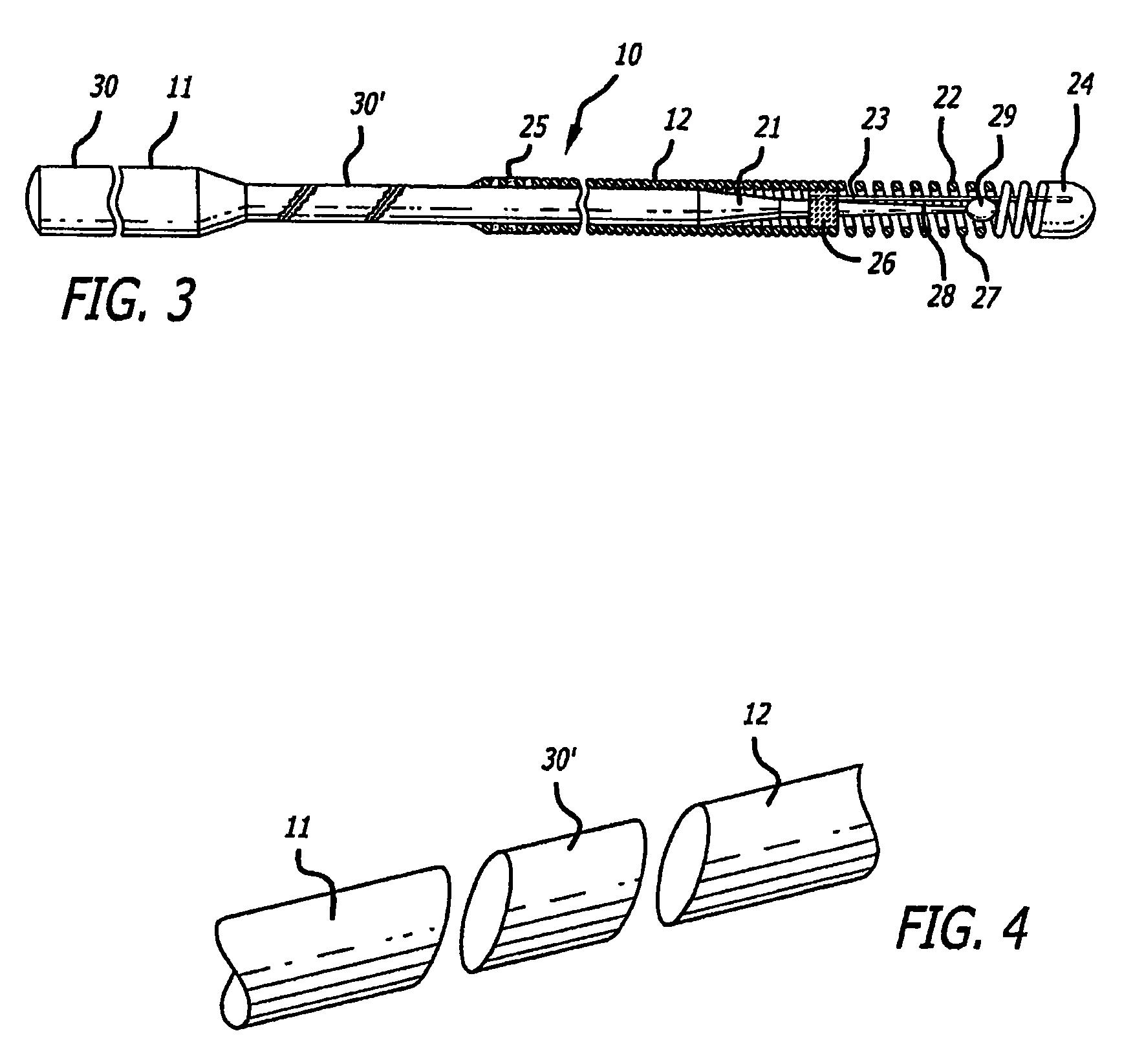

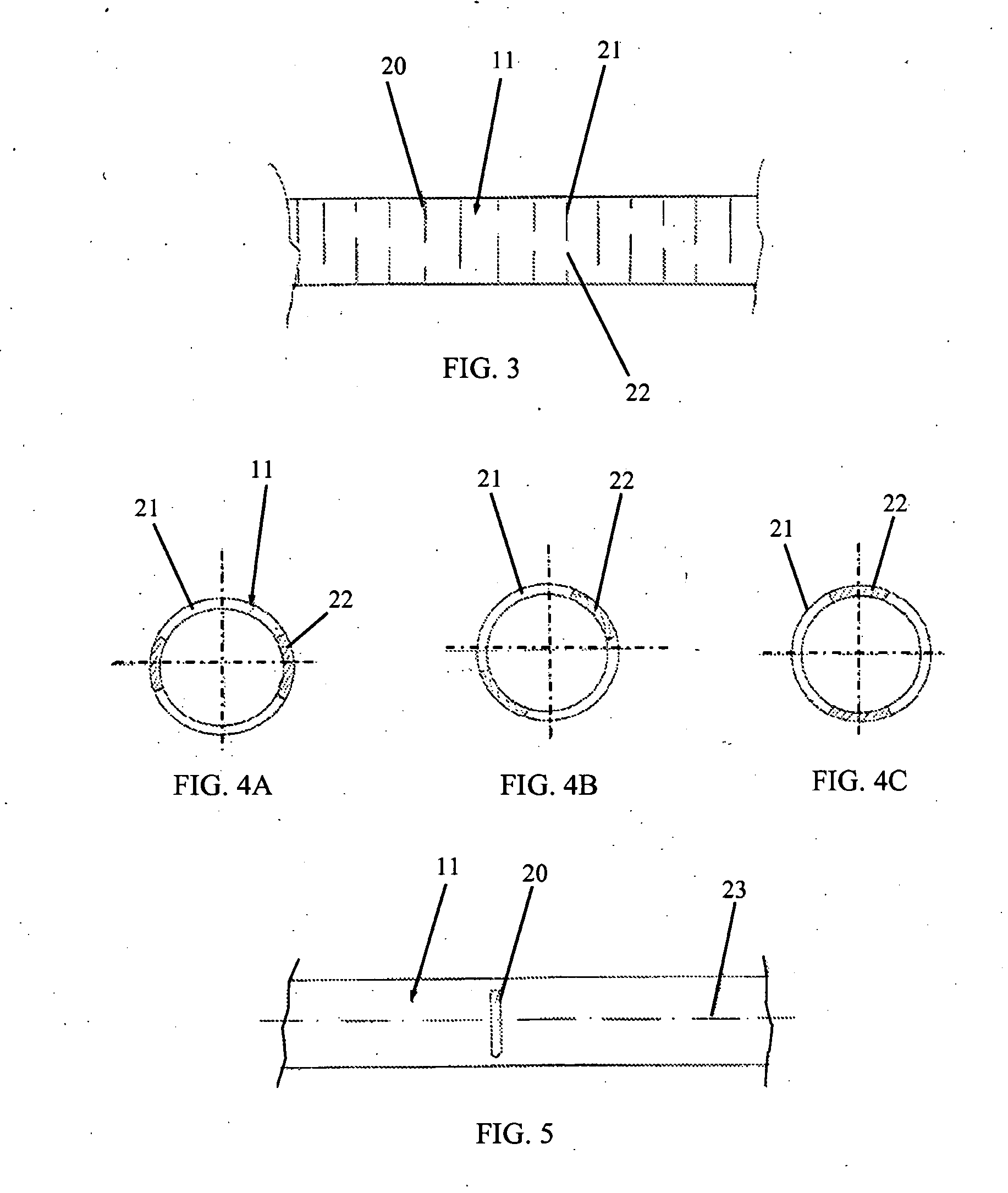

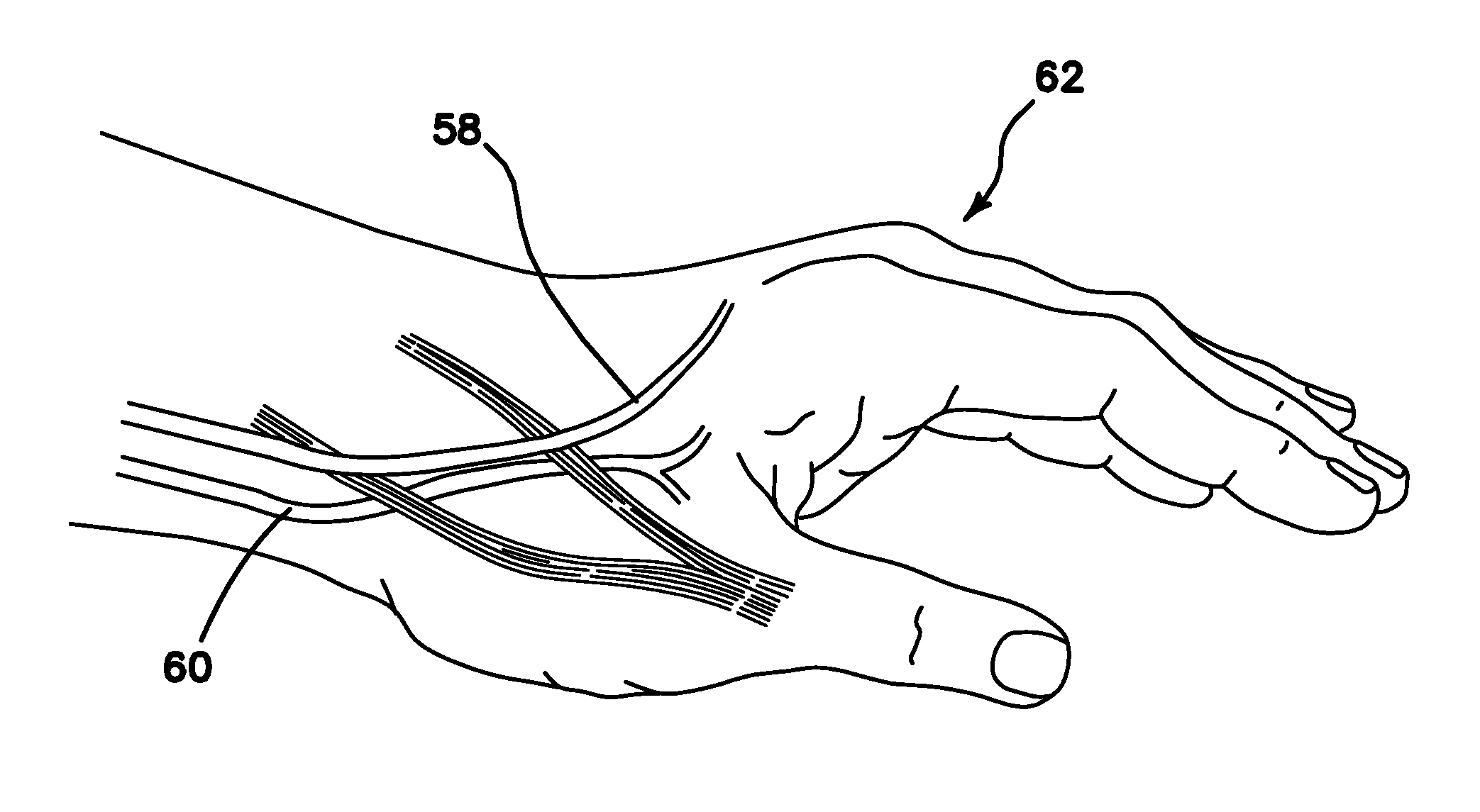

Apparatus and method for joining stainless steel guide wire portion to nitinol portion, without a hypotube

InactiveUS20060047223A1Enhanced compressive and tension and torsion strengthImprovement in torqueabilitySenses disorderGuide wiresMetal alloyMetallic Nickel

An intravascular guide wire having two core materials joined together without the use of a connector tube or sleeve, the core materials being stainless steel and psuedoelastic metal alloy, nitinol. The core materials are joined to each other through an intermediate transition piece made essentially of nickel, which is welded on either side to the two core materials. In alternative embodiments, the intermediate piece may have different shapes to provide different strengths and advantages as may be required.

Owner:ABBOTT CARDIOVASCULAR

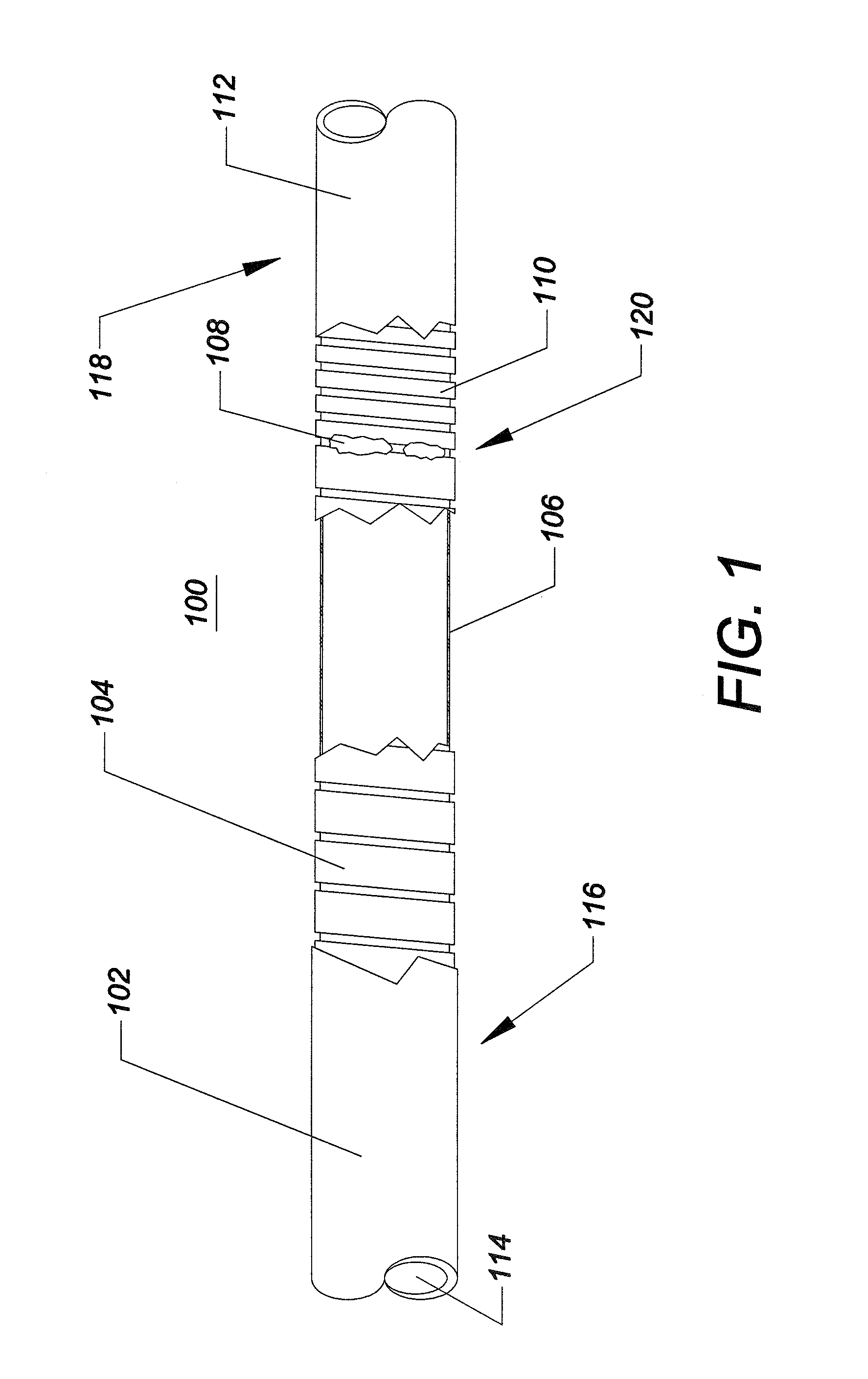

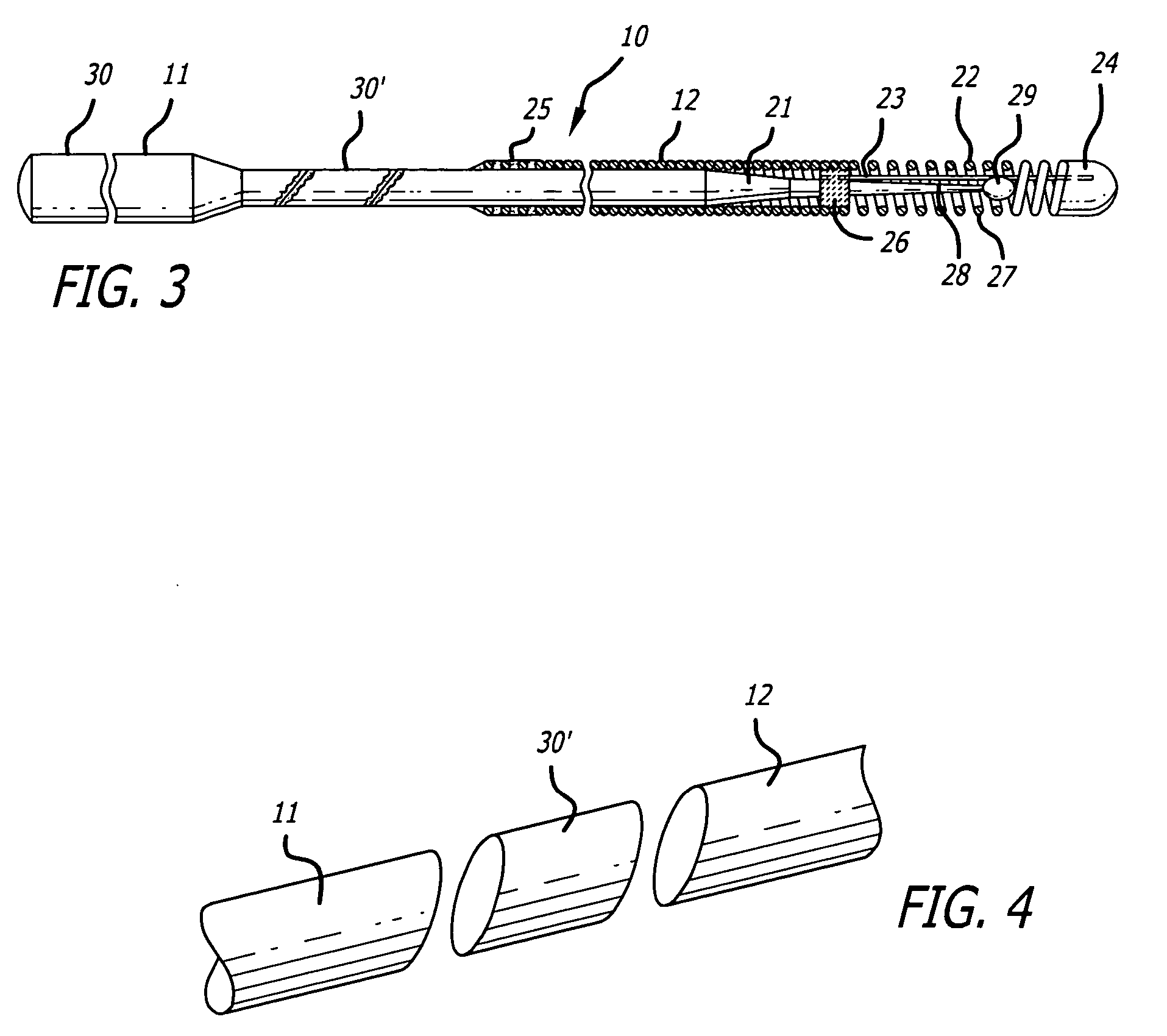

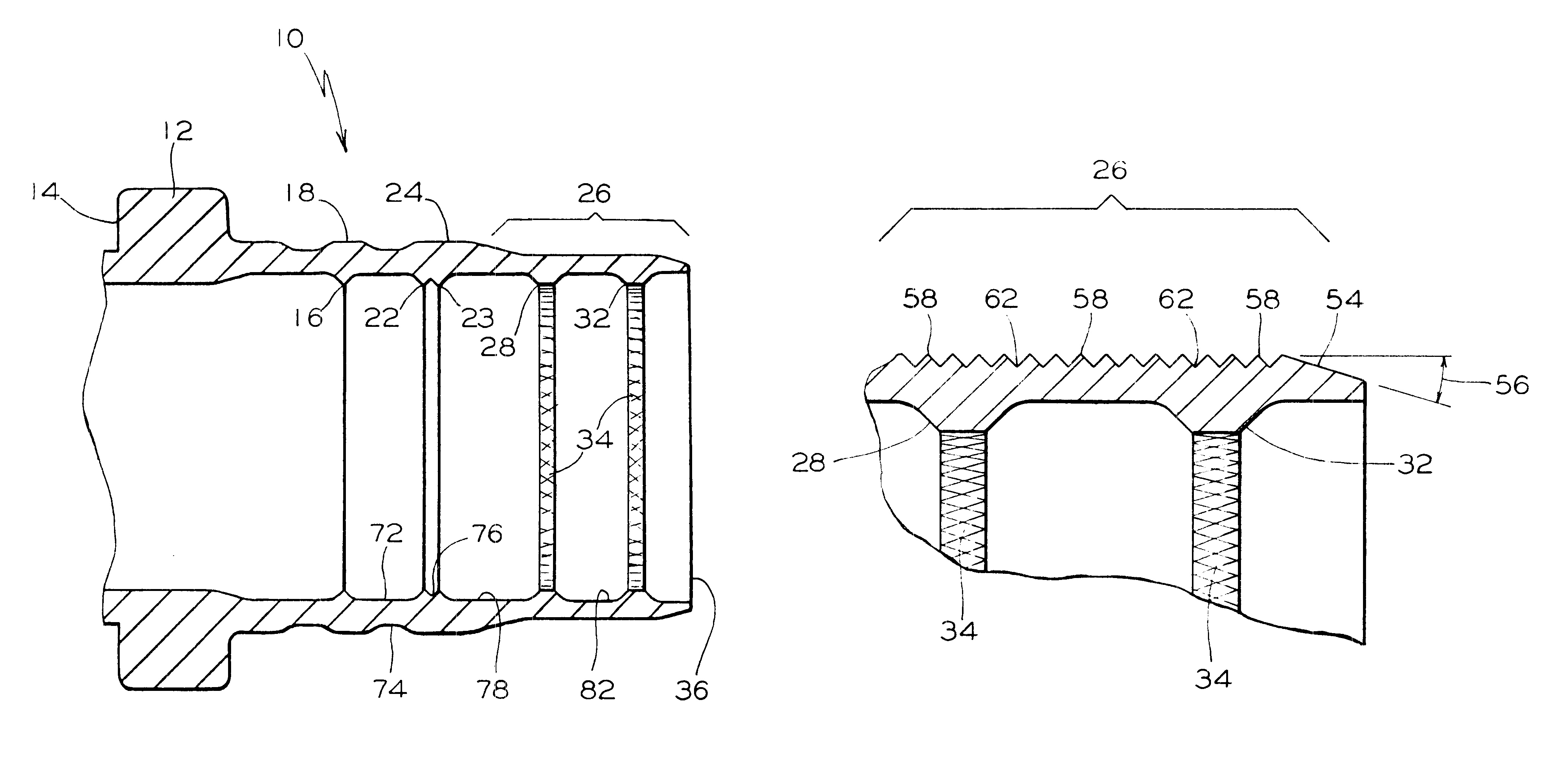

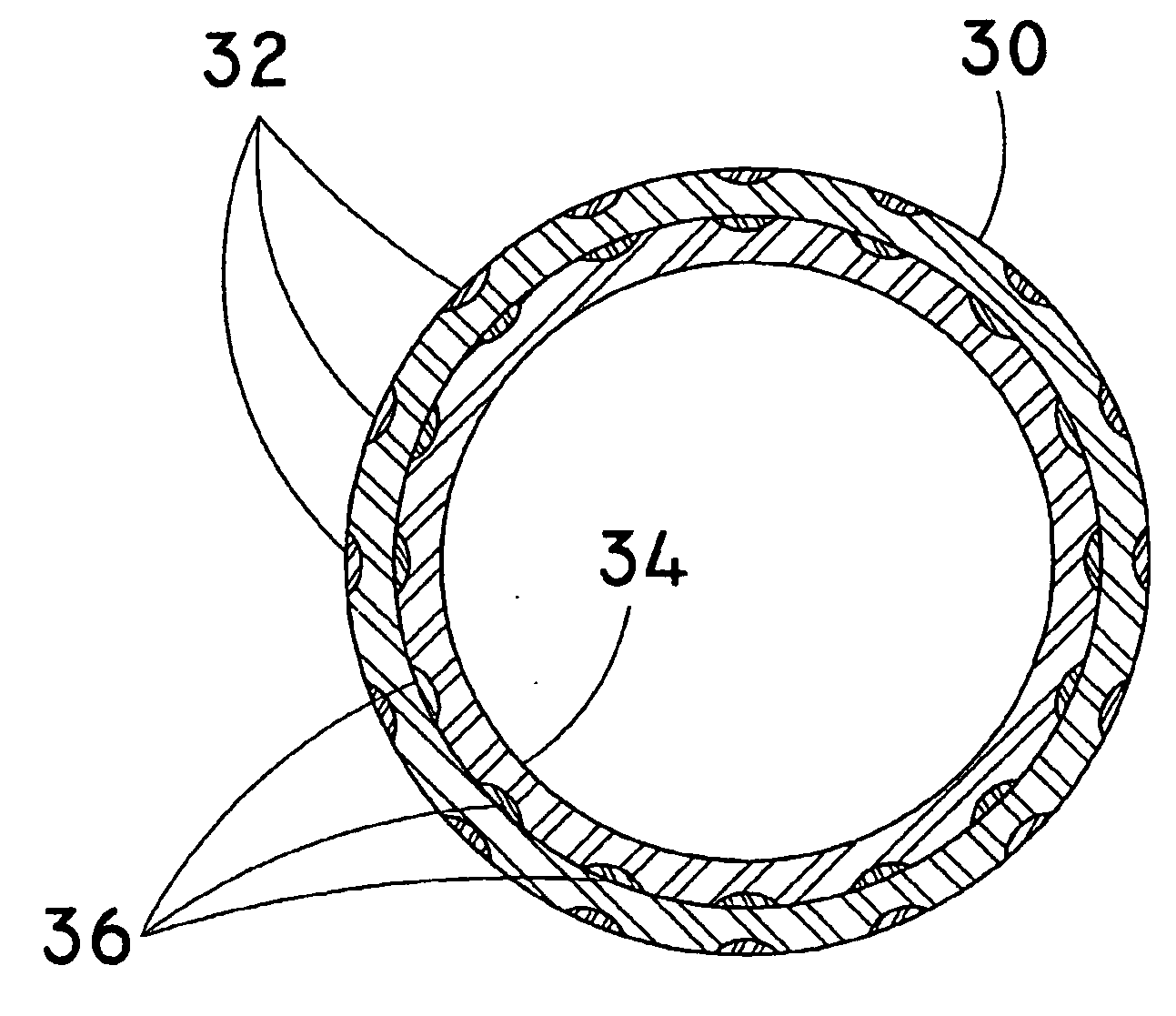

Lokring fitting having improved anti-torsion capability

InactiveUS6692040B1Improve torque performanceImprove torsion resistanceSleeve/socket jointsJoints with sealing surfacesEngineeringTorsion spring

A fitting for a fluid pressure conduit. The fitting includes a coupling body having a substantially axisymmetrical inside surface for engaging an outside surface of the fluid pressure conduit. The inside surface has at least one substantially axisymmetrical seal formed as at least one axisymmetrical ridge on the inside surface of the coupling body. There is at least one seal land on an outside surface of the coupling body adjacent the substantially axisymmetrical seal(s). There are a plurality of anti-torsion ridges on the inside surface of the coupling body, the anti-torsion ridges having friction surfaces for resisting torsion between the fitting and the fluid pressure conduit. Furthermore, there is at least one torsion land formed on the outside surface of the coupling body adjacent the torsion ridges. The fitting also includes a ring for fitting over the coupling body, the ring being for engaging the seal land(s) to force the seal(s) into engagement with the outside surface of the fluid conduit, the ring further being for engaging the torsion land(s) to force the plurality of anti-torsion ridges into engagement with the fluid pressure conduit.

Owner:LOKRING TECHNOLOGY

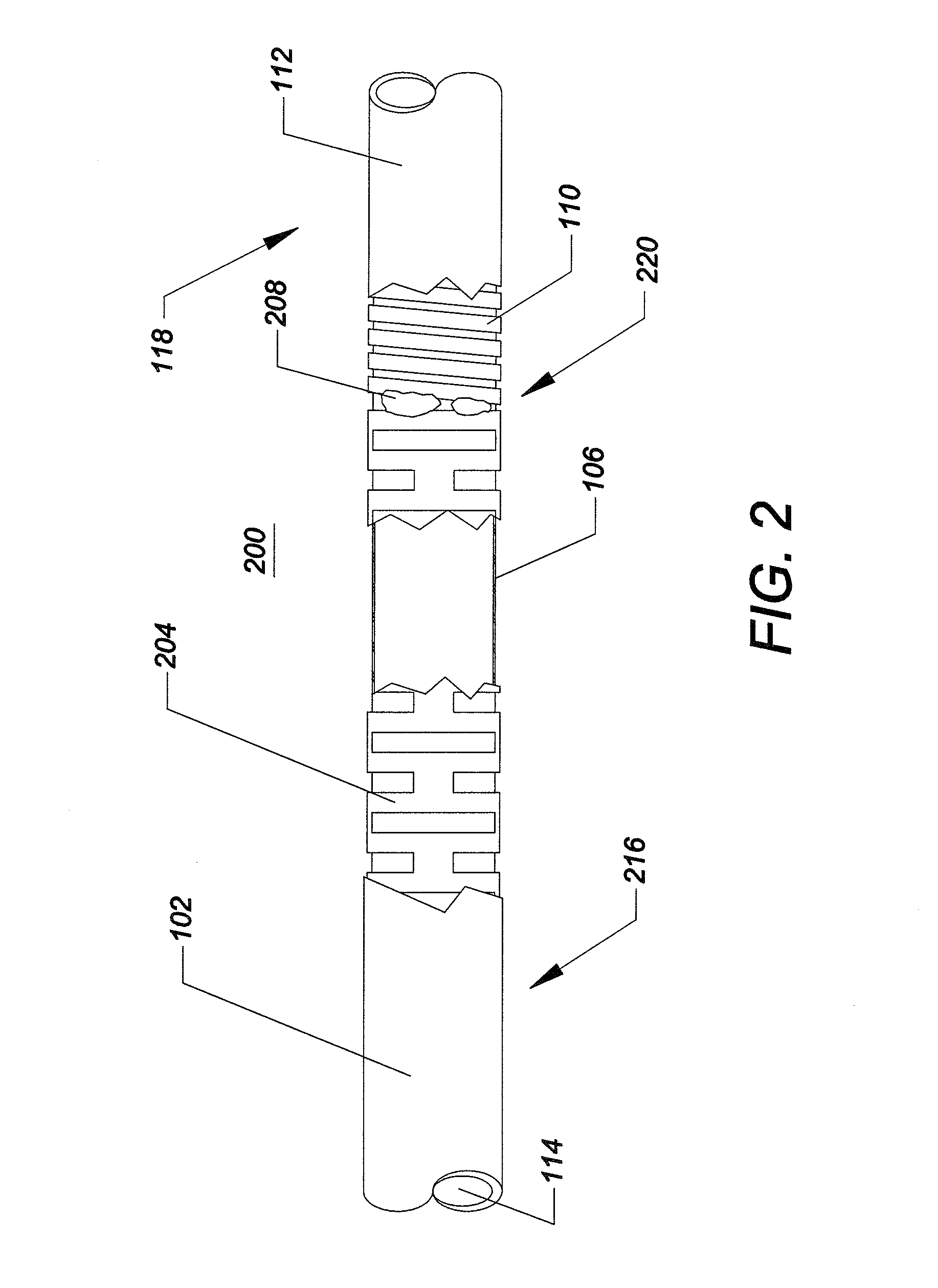

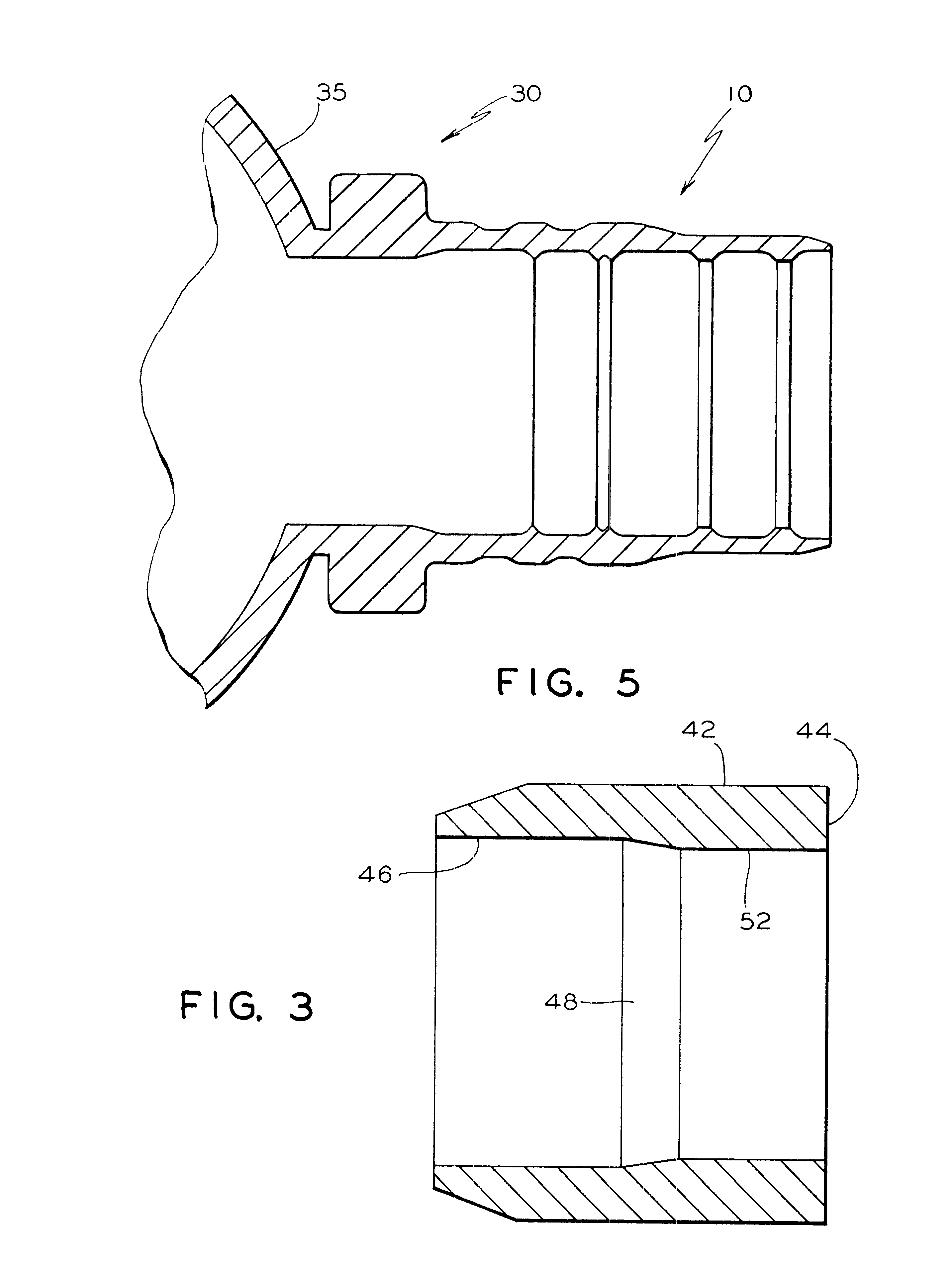

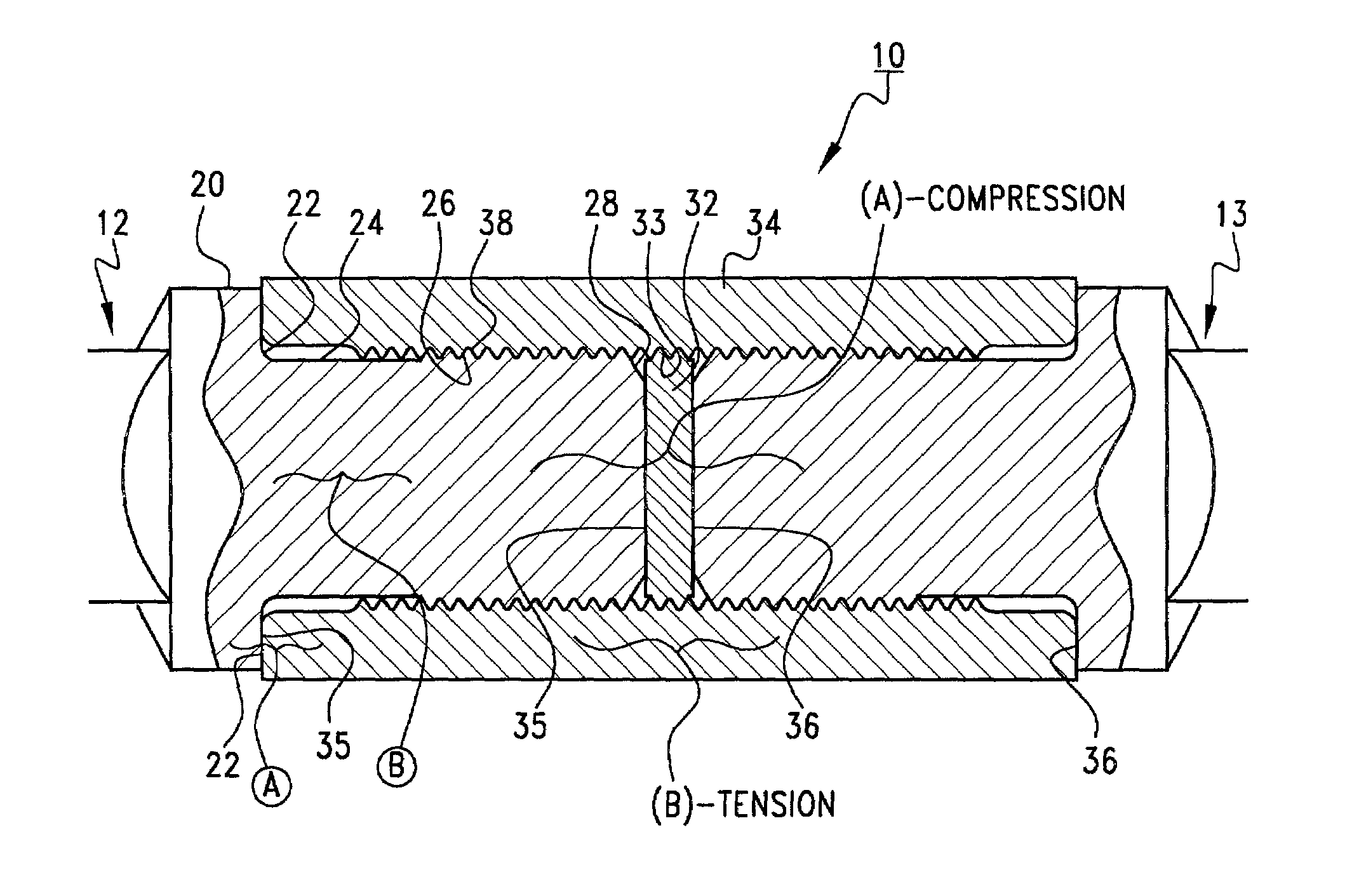

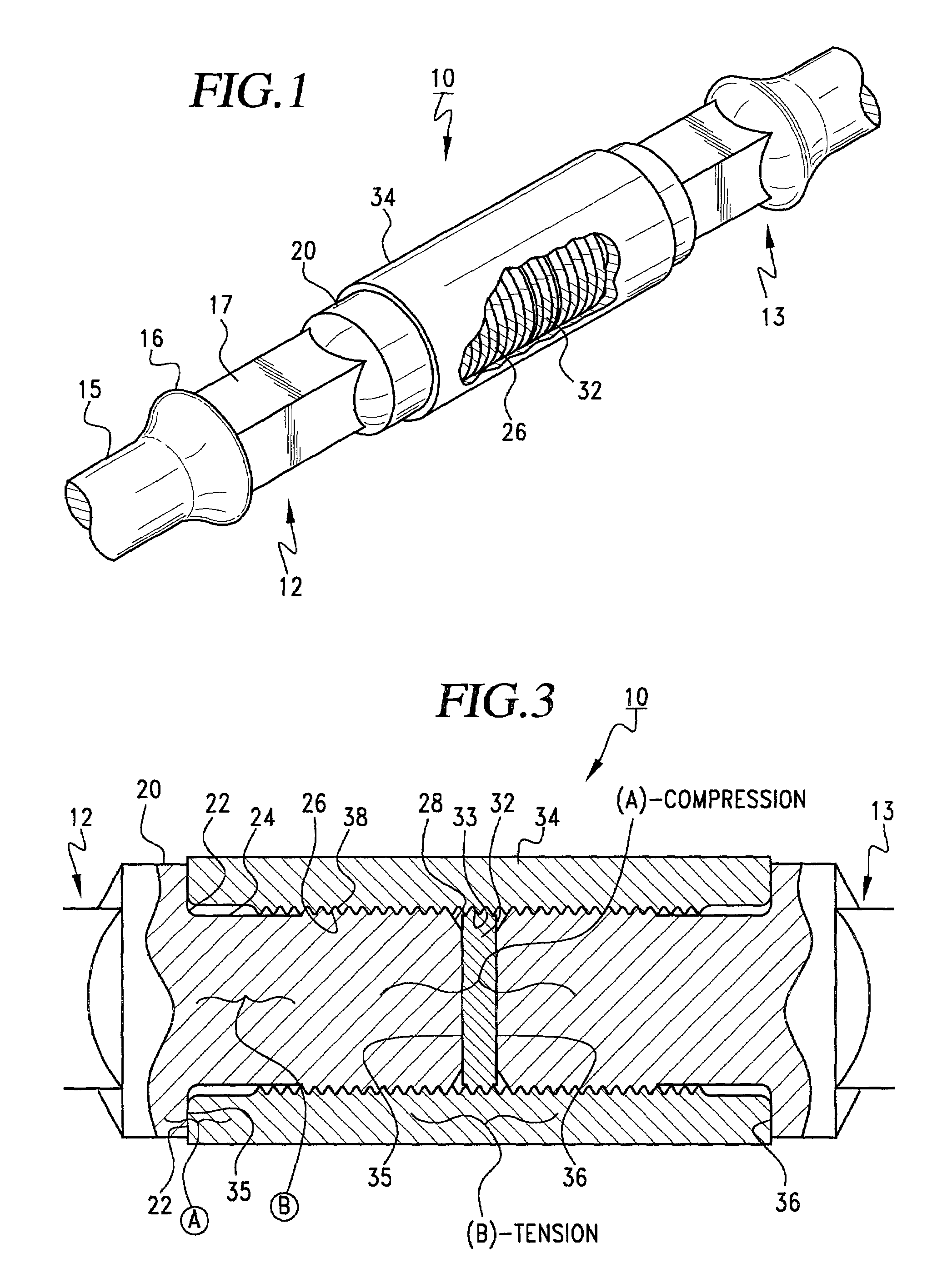

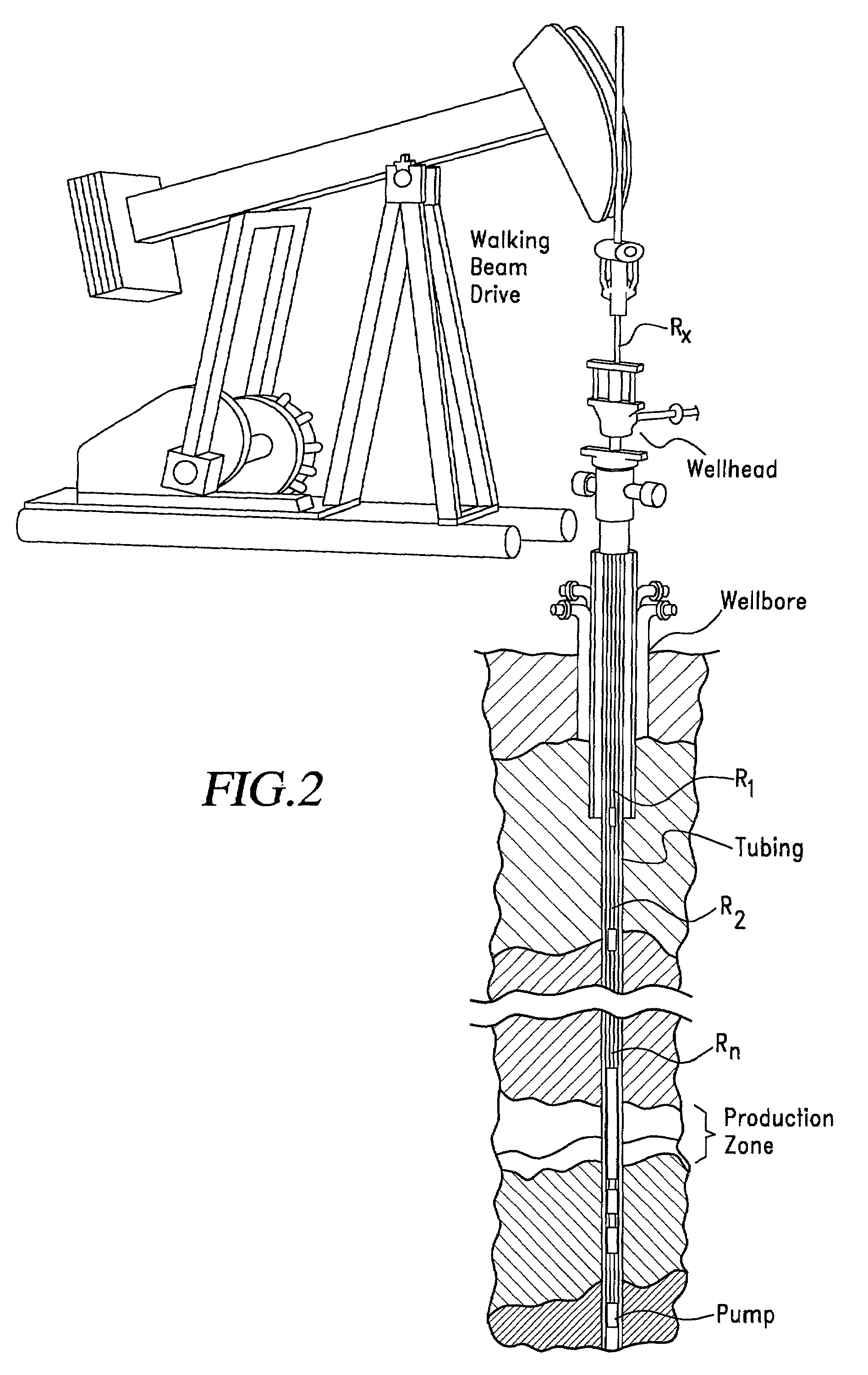

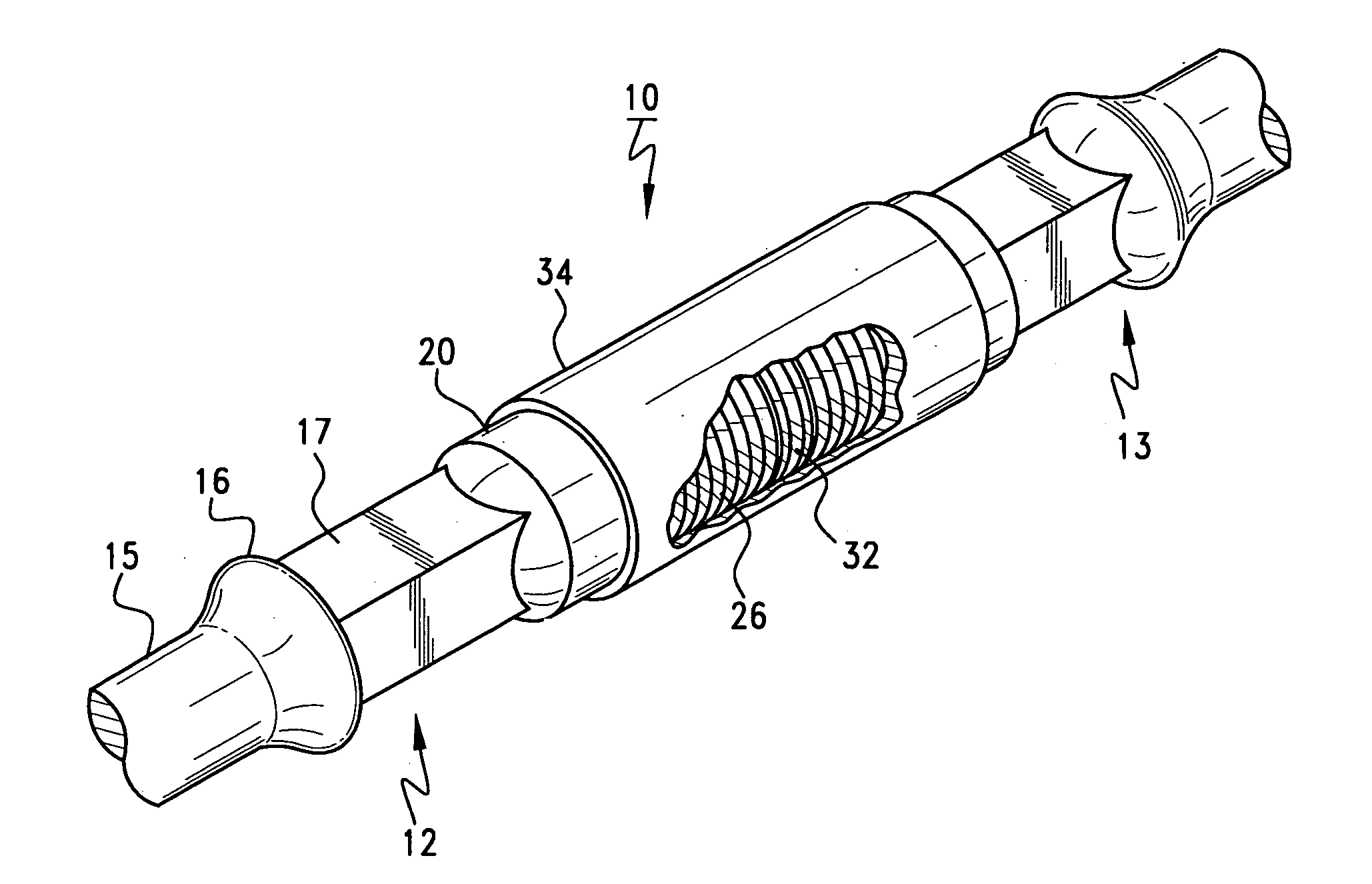

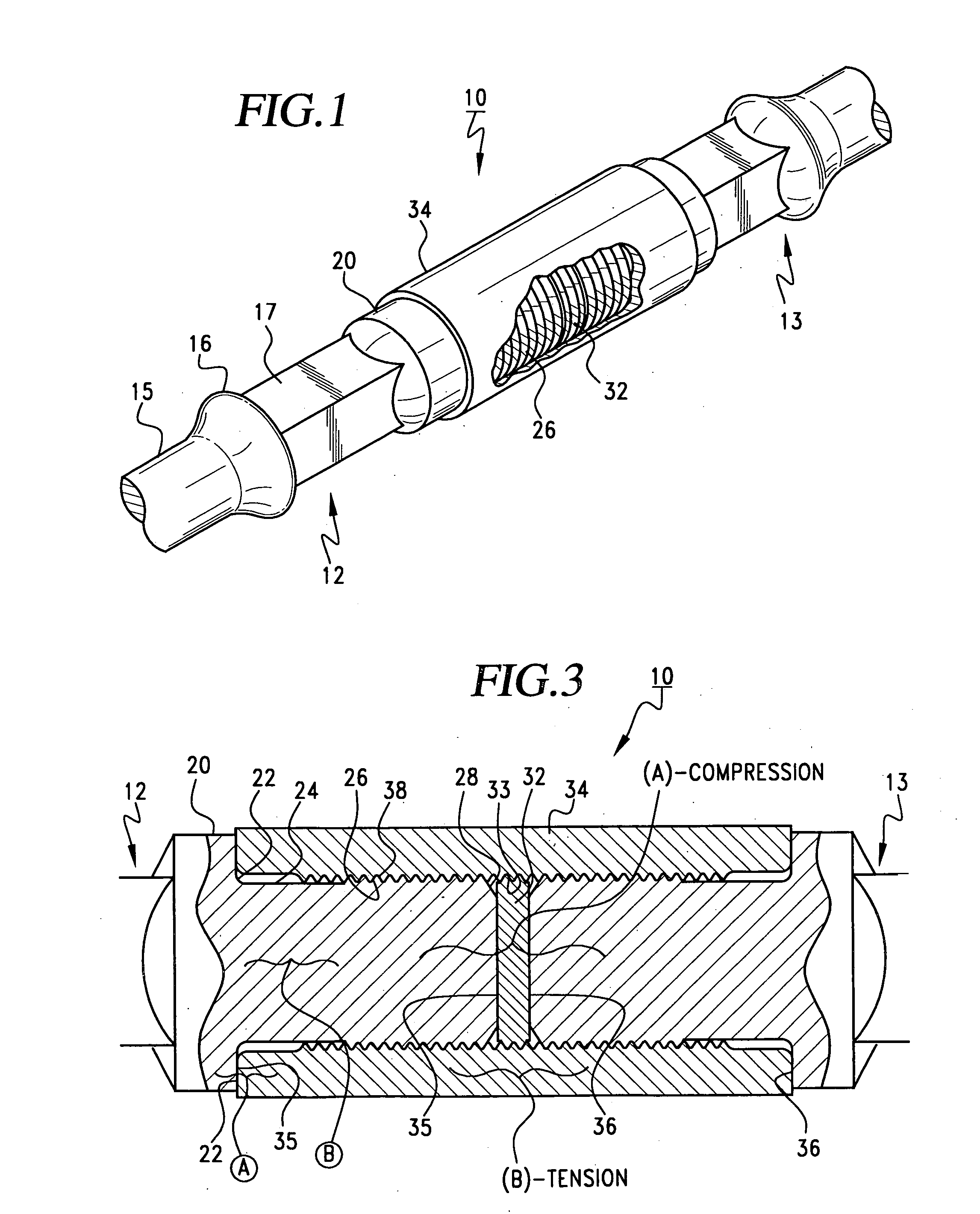

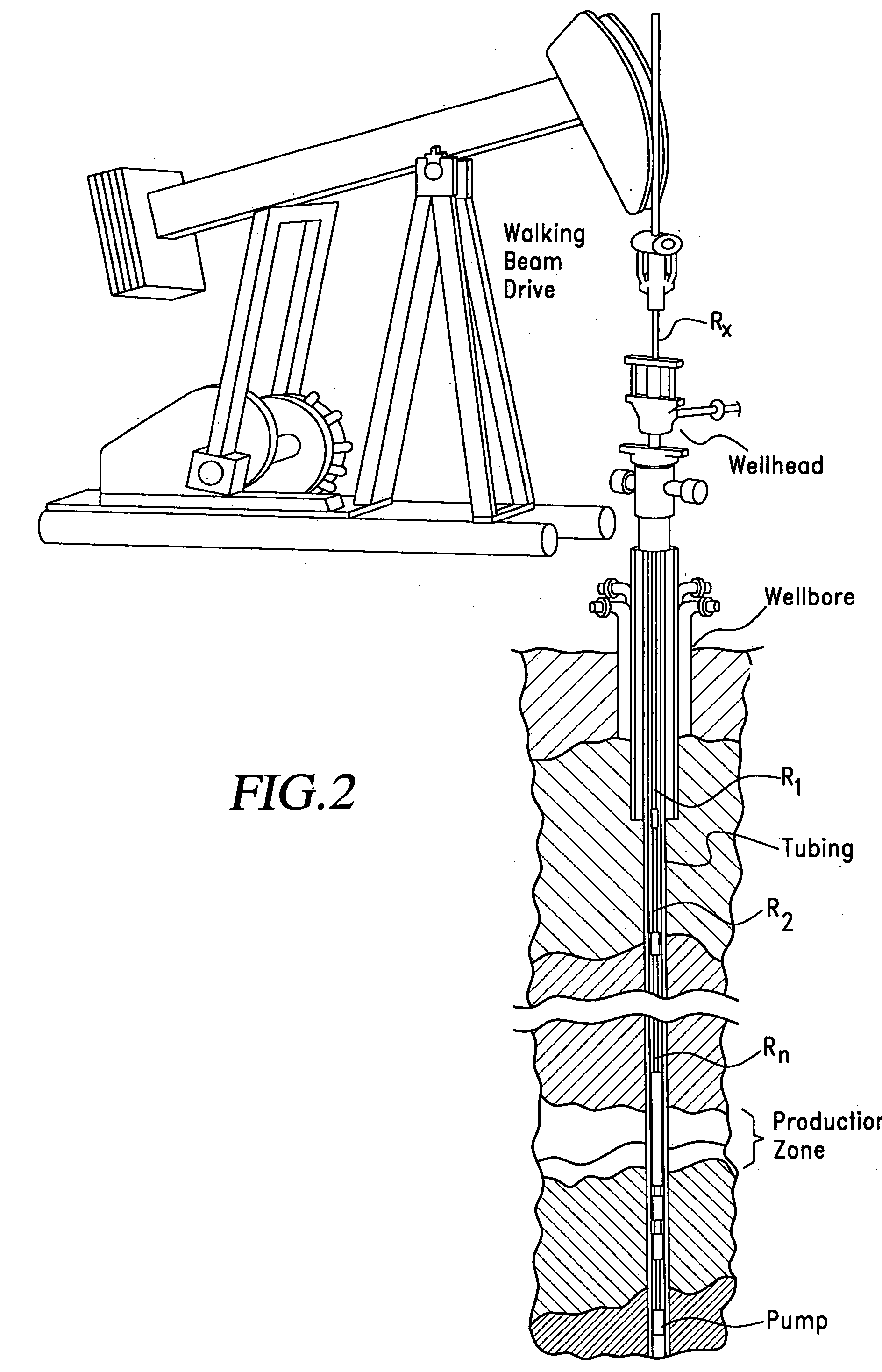

Connectable rod system for driving downhole pumps for oil field installations

InactiveUS7108063B2Strong in tensionImprove torque performanceDrilling rodsDrilling casingsTorsional ForcesMaterial fatigue

Improved sucker rod joints for down hole petroleum pumping applications are provided within the form factor of standard API sucker rods, such that existing inventory in suitable condition is fully usable in more demanding applications. The pin ends are selected or processed such as to provide preselected axial distance between a flat pin end and at least one reference surface, such as a threaded region or reference shoulder or both. The coupler is dimensioned such that the pin ends are in abutment either with each other or with opposite sides of an intervening torque washer in the central region, when the connection is made to a selected level of thread engagement. Furthermore, the engagement is such as to put the pin ends in compression and the coextensive length of coupler in tension. This increases frictional restraints and locks the elements together to resist fatigue failure upon cycling and to insure together with an anaerobic adhesive sealant, against back threading. This arrangement enables standard quality sucker rods to be employed in a configuration which is mechanically secure and highly resistant to tensile, bending and torsional forces, thus assuring a greater strength at the joint than in the rod itself, and resisting the effects of material fatigue arising from long term and stressful cycling operations.

Owner:CARSTENSEN KENNETH J

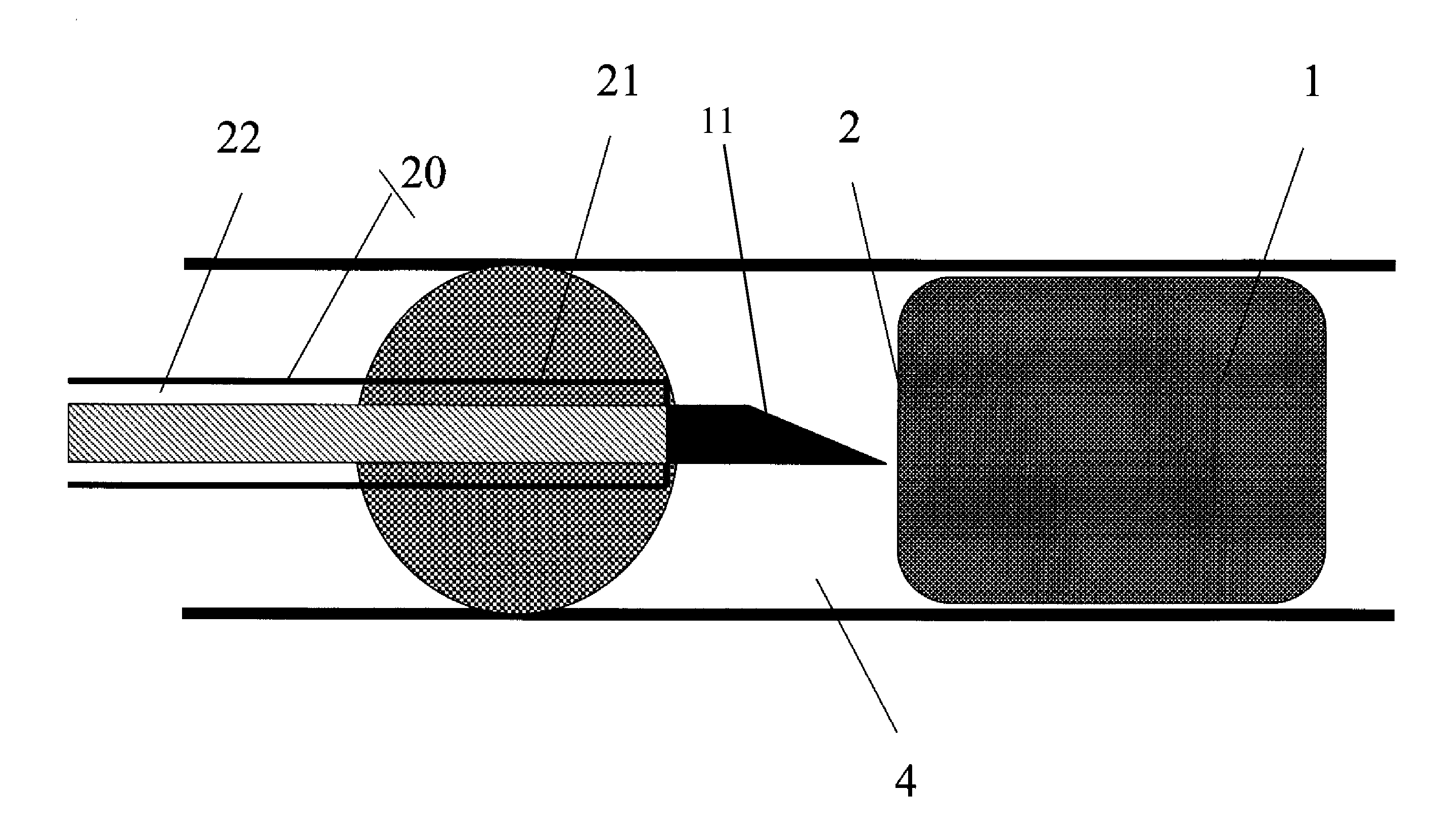

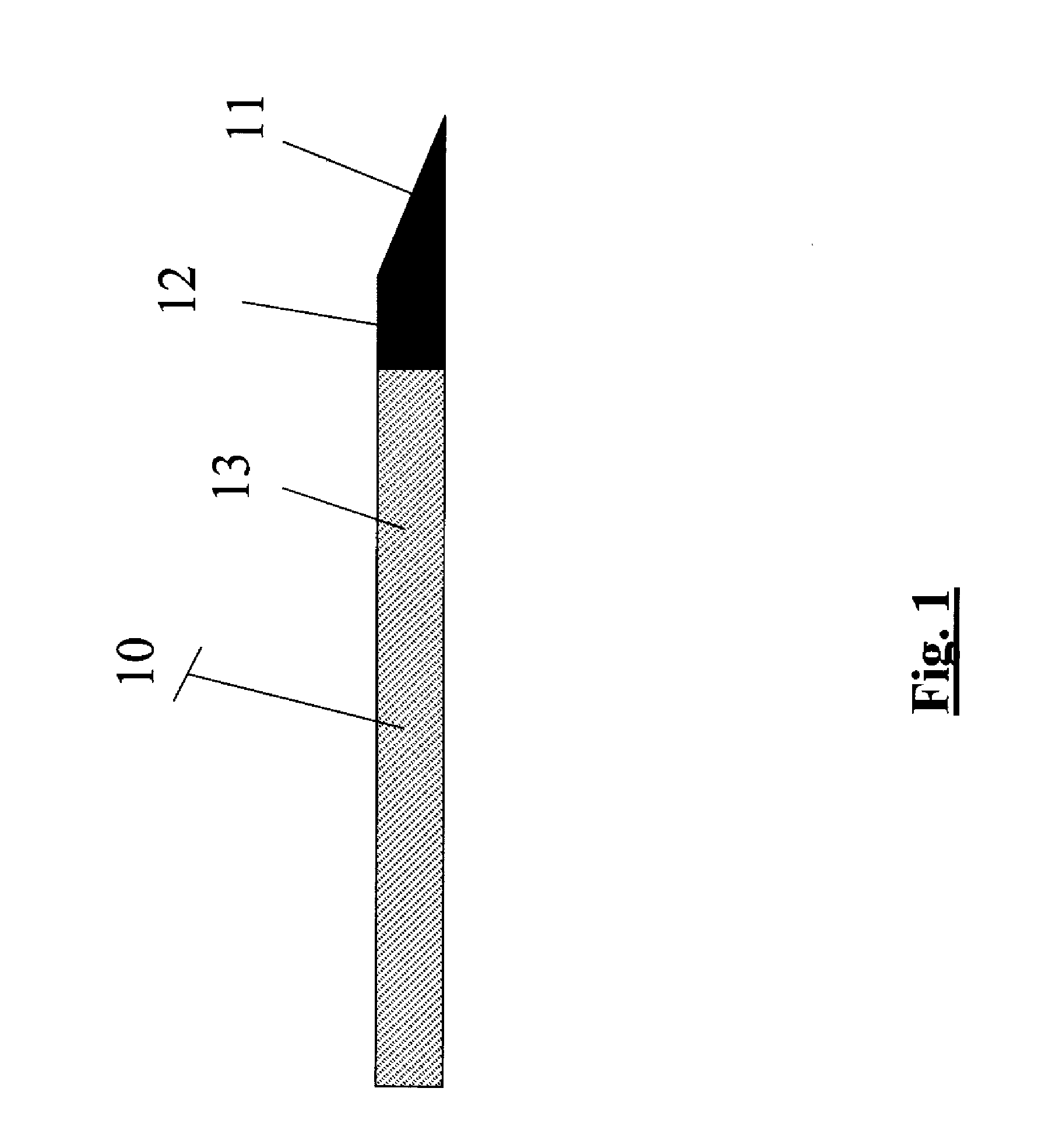

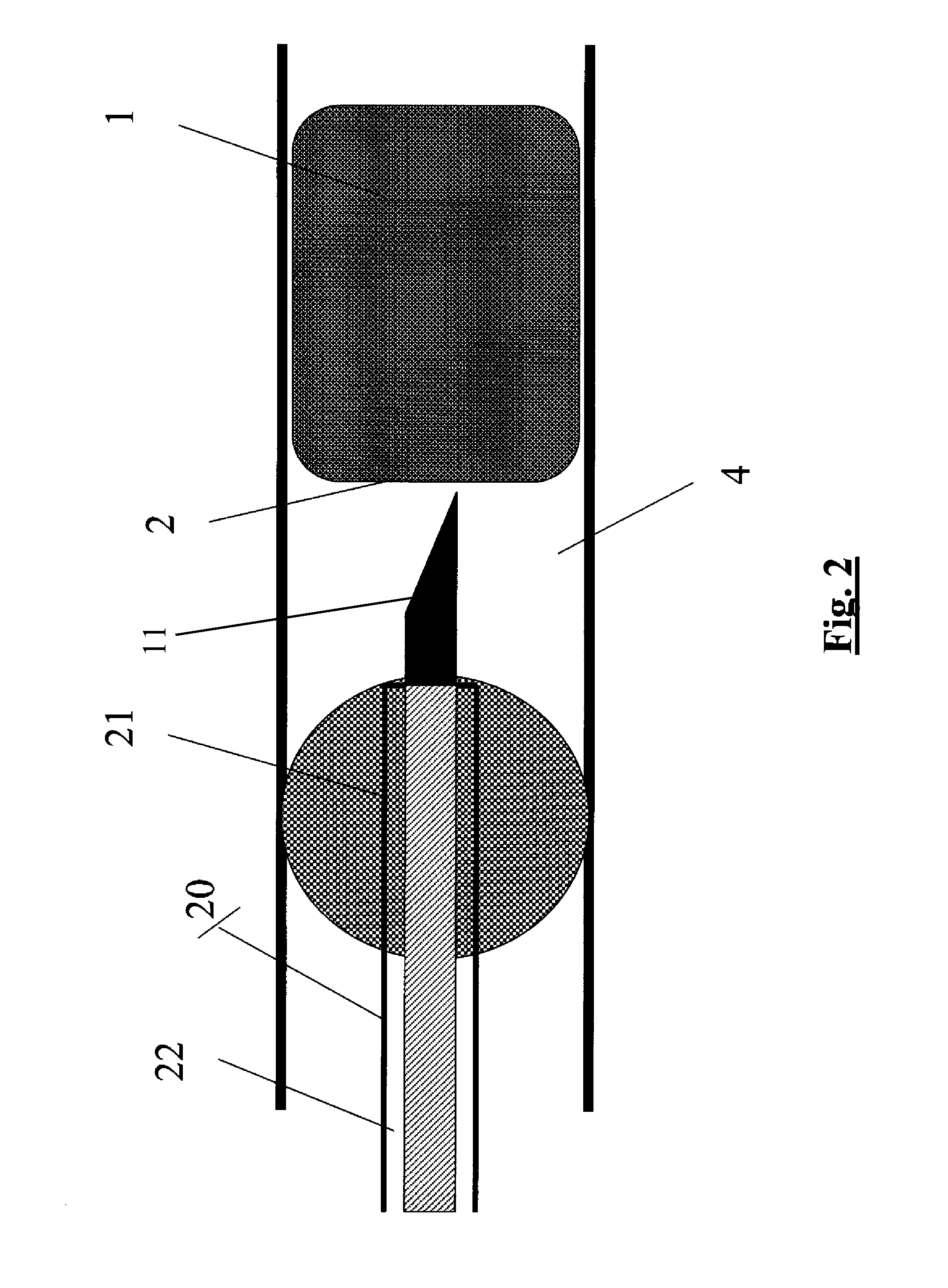

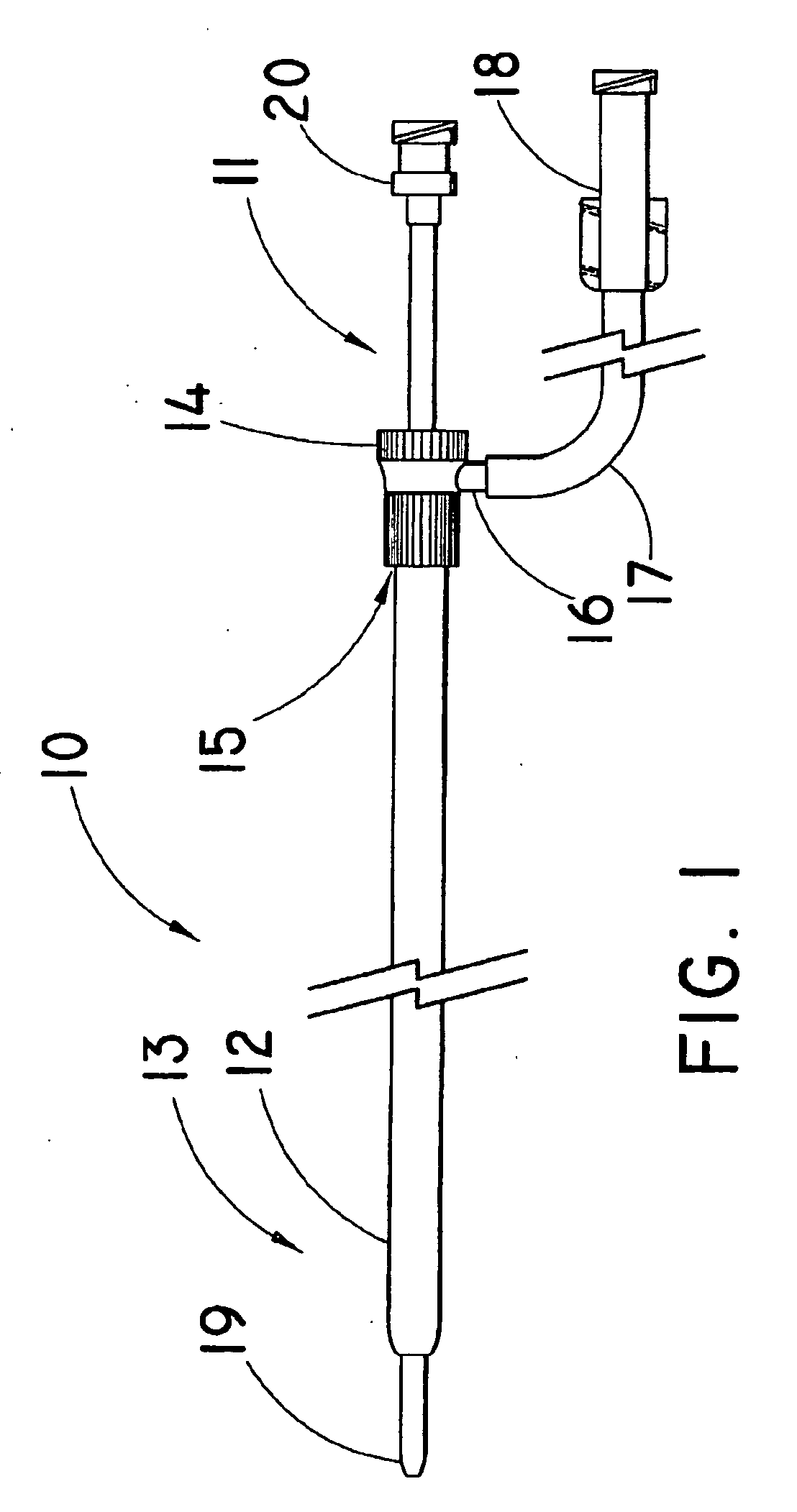

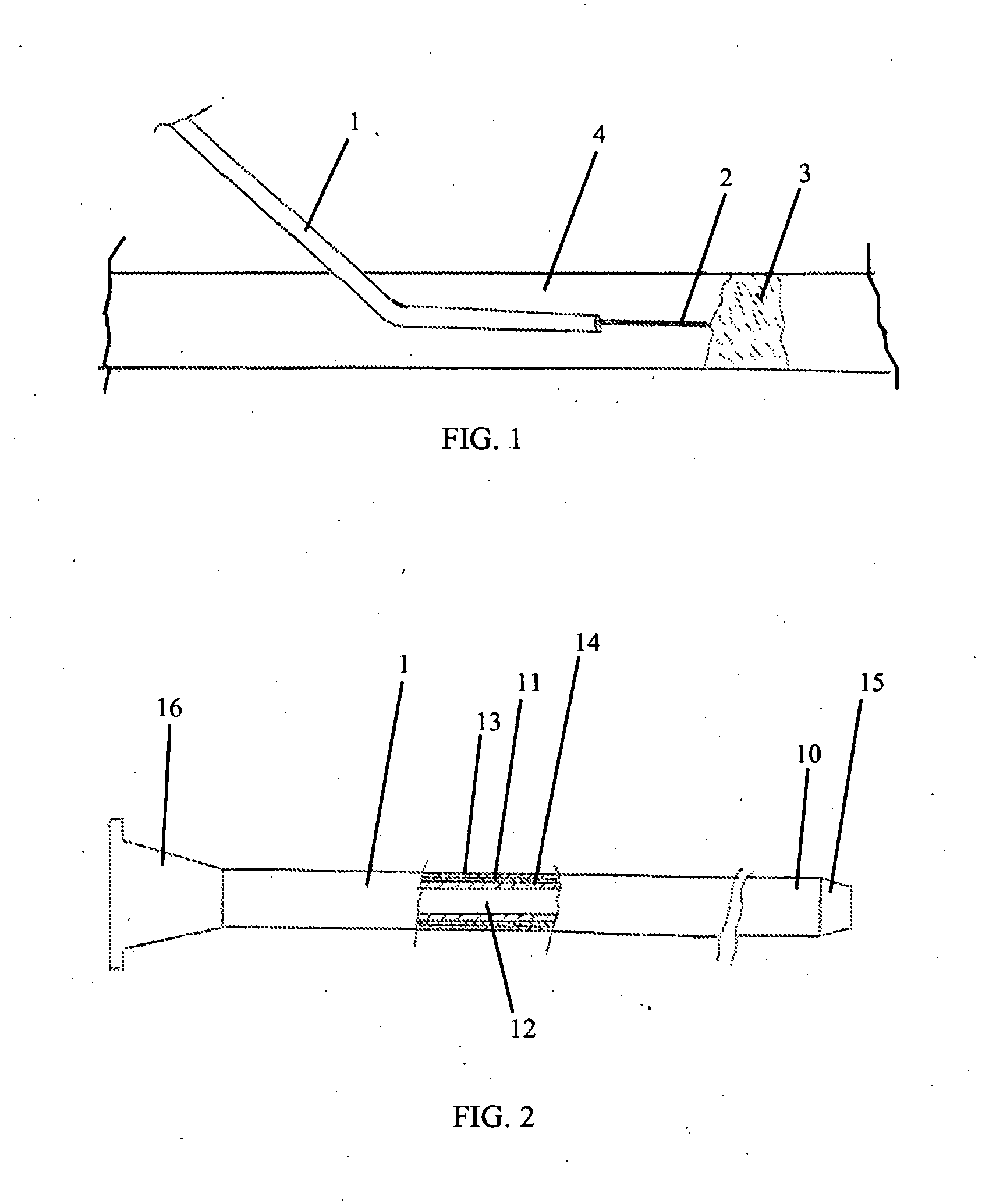

Lancet micro-catheter

InactiveUS20120265229A1Reducing device wall-thicknessIncrease flexibilityBalloon catheterSurgical needlesMedicineCatheter device

A micro-catheter (10) including a hypo-tube including a proximal section (13) and a distal section (12) and a sharp tip (11) formed at a distal end of the distal section (12), characterized in that the proximal section (13) of the micro-catheter (10) is formed with a plurality of cuts (23) which are not perpendicular to a longitudinal axis of the proximal section (13), the cuts (23) being made partially around a circumference of the proximal section (13) with uncut portions separating the cuts (23) from one another.

Owner:BOSTON SCI SCIMED INC

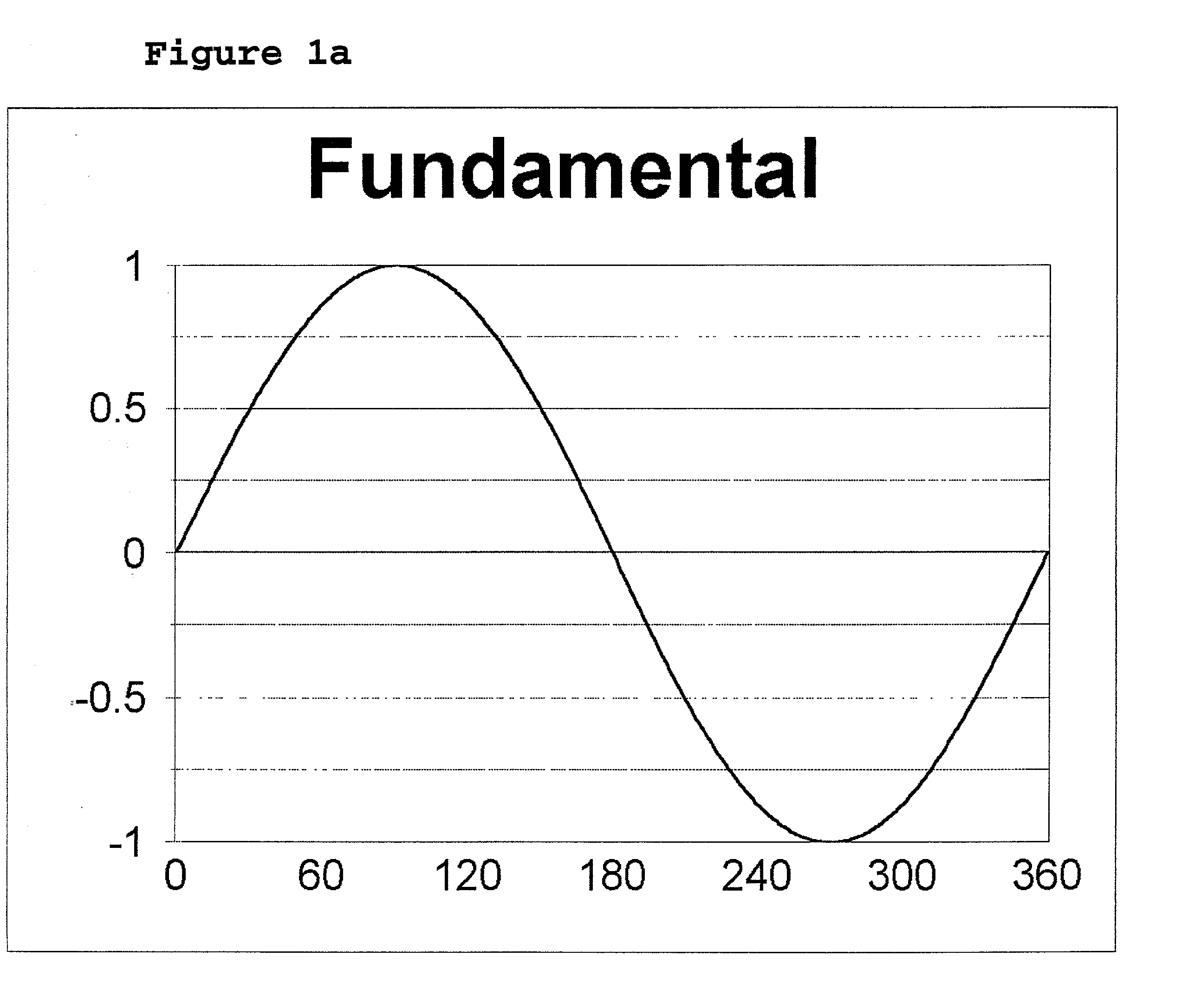

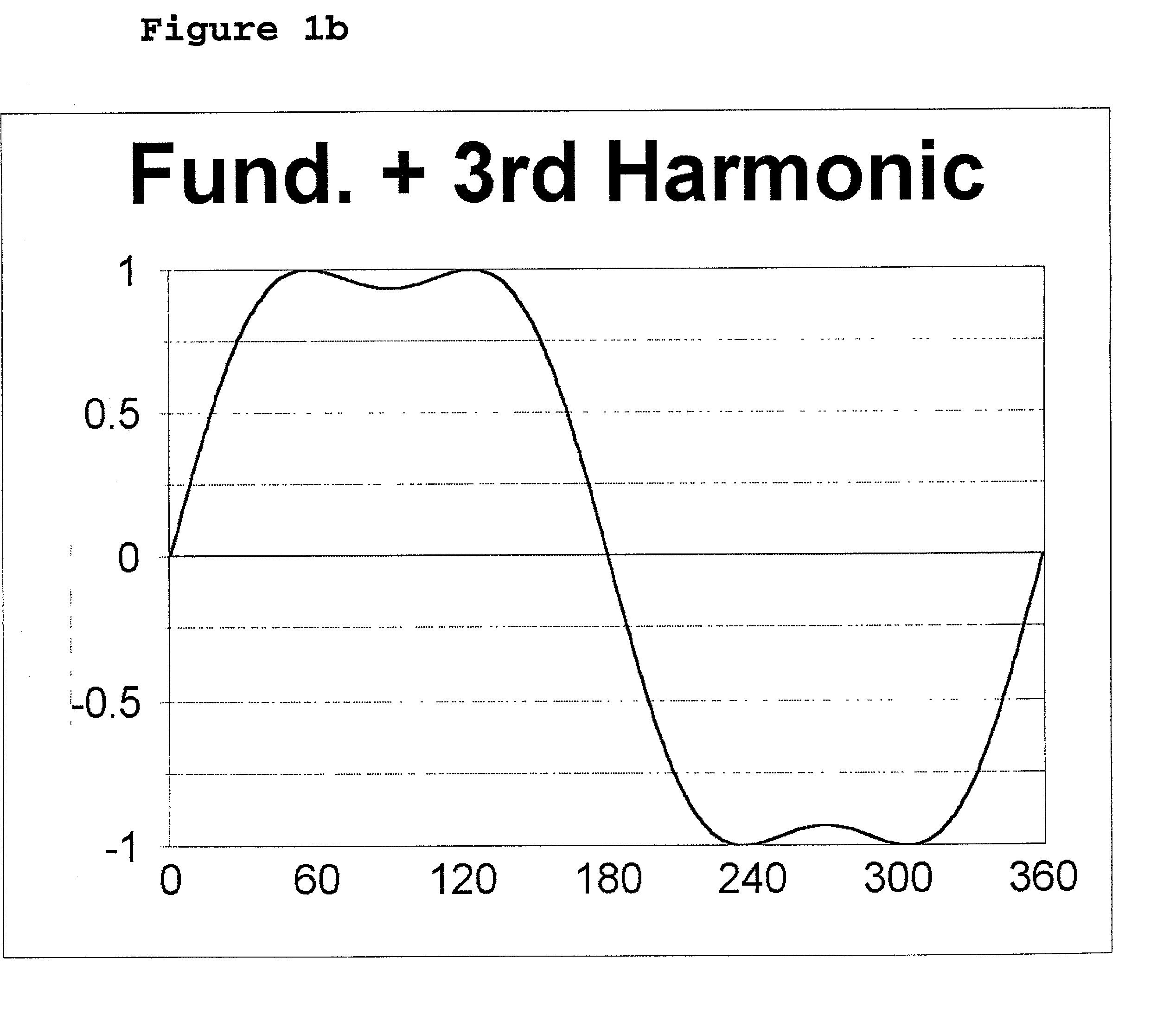

PWM motor drive apparatus with increase of low speed capability

InactiveUS20020074969A1Increases torque and speedIncrease output voltage capacitySingle-phase induction motor startersMotor/generator/converter stoppersPower inverterMotor drive

Maximizing current from a given power inverter in an electrical rotating machine and maintaining the speed of an electrical rotating machine which has more turns of the winding.

Owner:BOREALIS TECH LTD

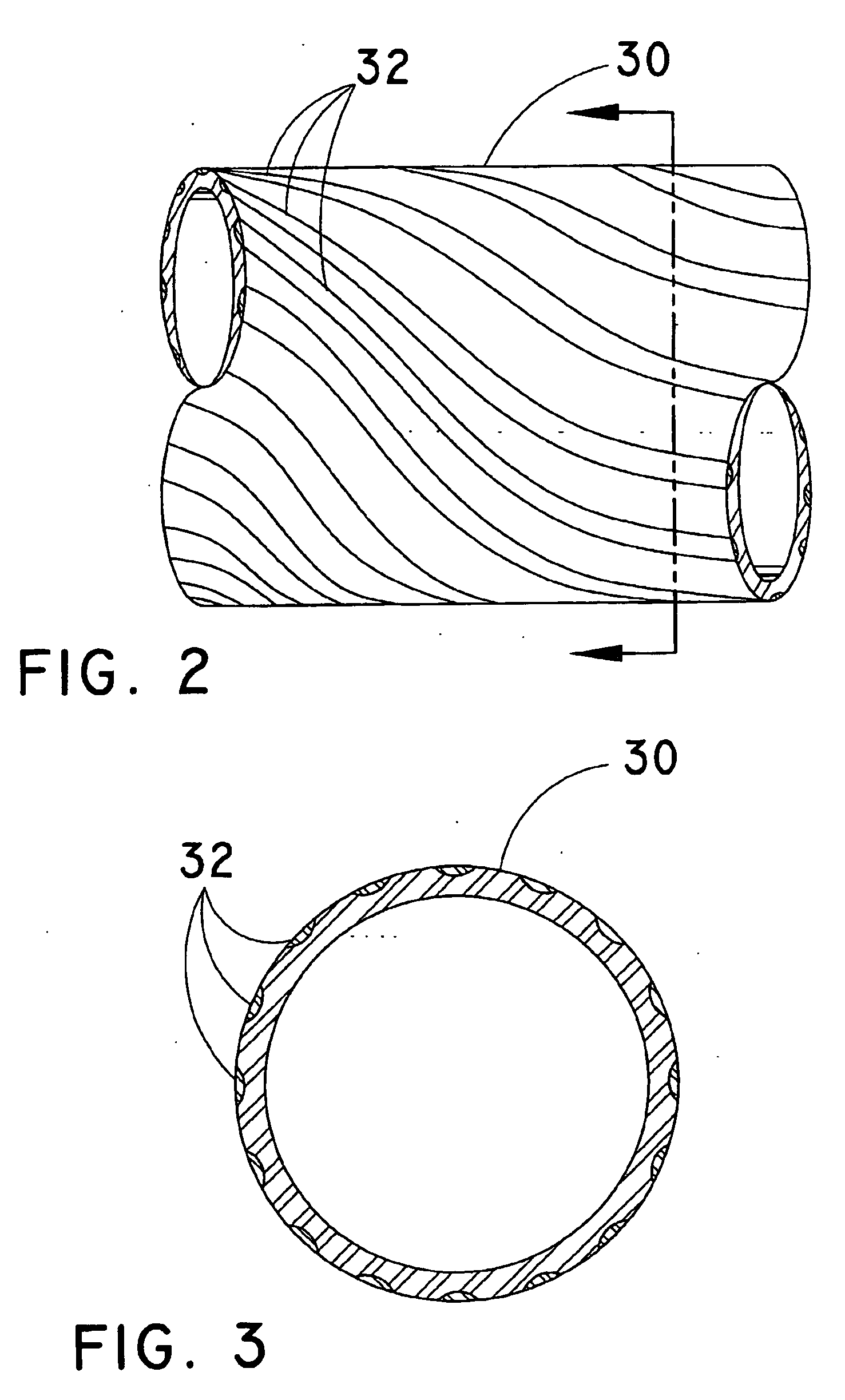

Introducer Sheath and Method for Making

An introducer sheath and a method of manufacturing an introducer sheath. The introducer comprises a first polymeric sleeve having a first striped extrusion arranged in a generally helical pattern along the first sleeve. A second polymeric sleeve is positioned over and bonded to the first polymeric sleeve, the second polymeric sleeve comprising a second striped extrusion that is arranged in a generally helical pattern along the second sleeve. The first and second polymeric sleeves are axially aligned such that the second striped extrusion is superposed over the first striped extrusion to define a generally braid-like configuration. The introducer sheath can optionally include an inner liner disposed within a lumen of the first polymeric sleeve, and / or a coil fitted over the inner liner, such that the first polymeric sleeve is bonded to the inner liner between turns of the coil.

Owner:COOK INC

Connectable rod system for driving downhole pumps for oil field installations

InactiveUS20060273601A1Improve torque performanceUnique and useful tensionDrilling rodsDrilling casingsEngineeringAxial distance

Improved sucker rod joints for down hole petroleum pumping applications are provided within the form factor of standard API sucker rods, such that existing inventory in suitable condition is fully usable in more demanding applications. The pin ends are selected or processed such as to provide preselected axial distance between a flat pin end and at least one reference surface, such as a threaded region or reference shoulder or both. The coupler is dimensioned such that the pin ends are in abutment either with each other or with opposite sides of an intervening torque washer in the central region, when the connection is made to a selected level of thread engagement. Furthermore, the engagement is such as to put the pin ends in compression and the coextensive length of coupler in tension. This increases frictional restraints and locks the elements together to resist fatigue failure upon cycling and to insure together with an anaerobic adhesive sealant, against back threading. This arrangement enables standard quality sucker rods to be employed in a configuration which is mechanically secure and highly resistant to tensile, bending and torsional forces, thus assuring a greater strength at the joint than in the rod itself, and resisting the effects of material fatigue arising from long term and stressful cycling operations.

Owner:CARSTENSEN KENNETH J

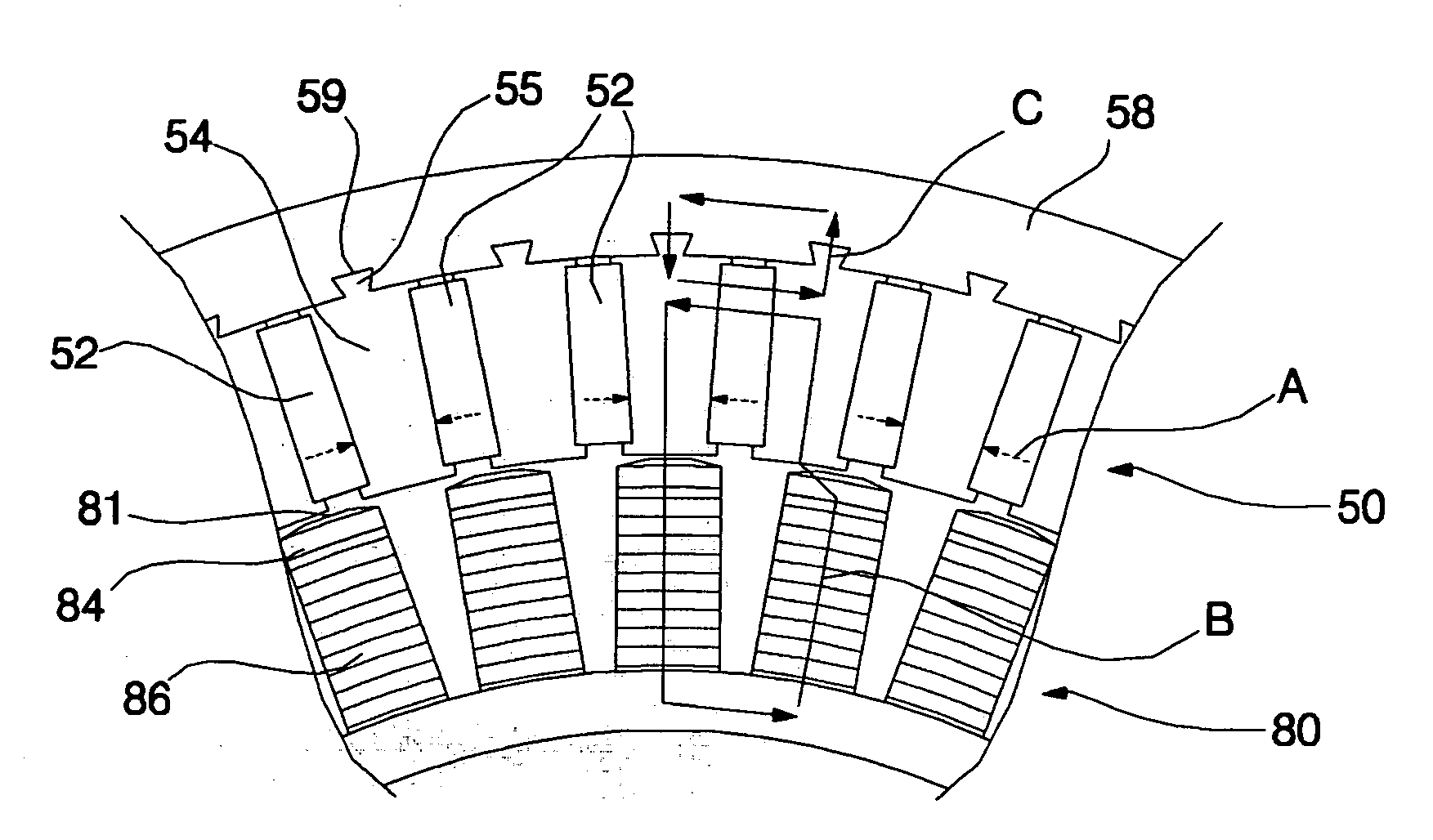

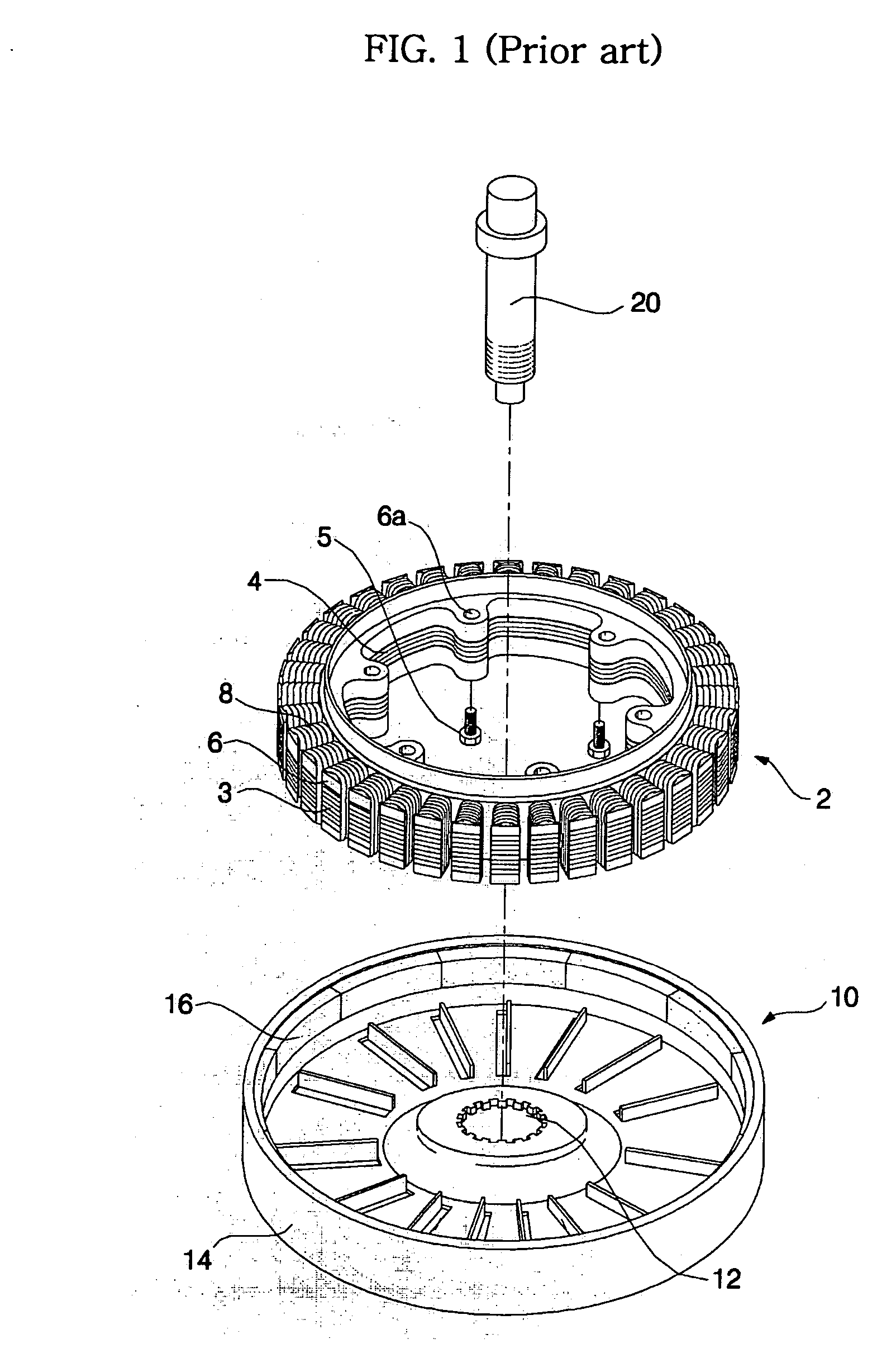

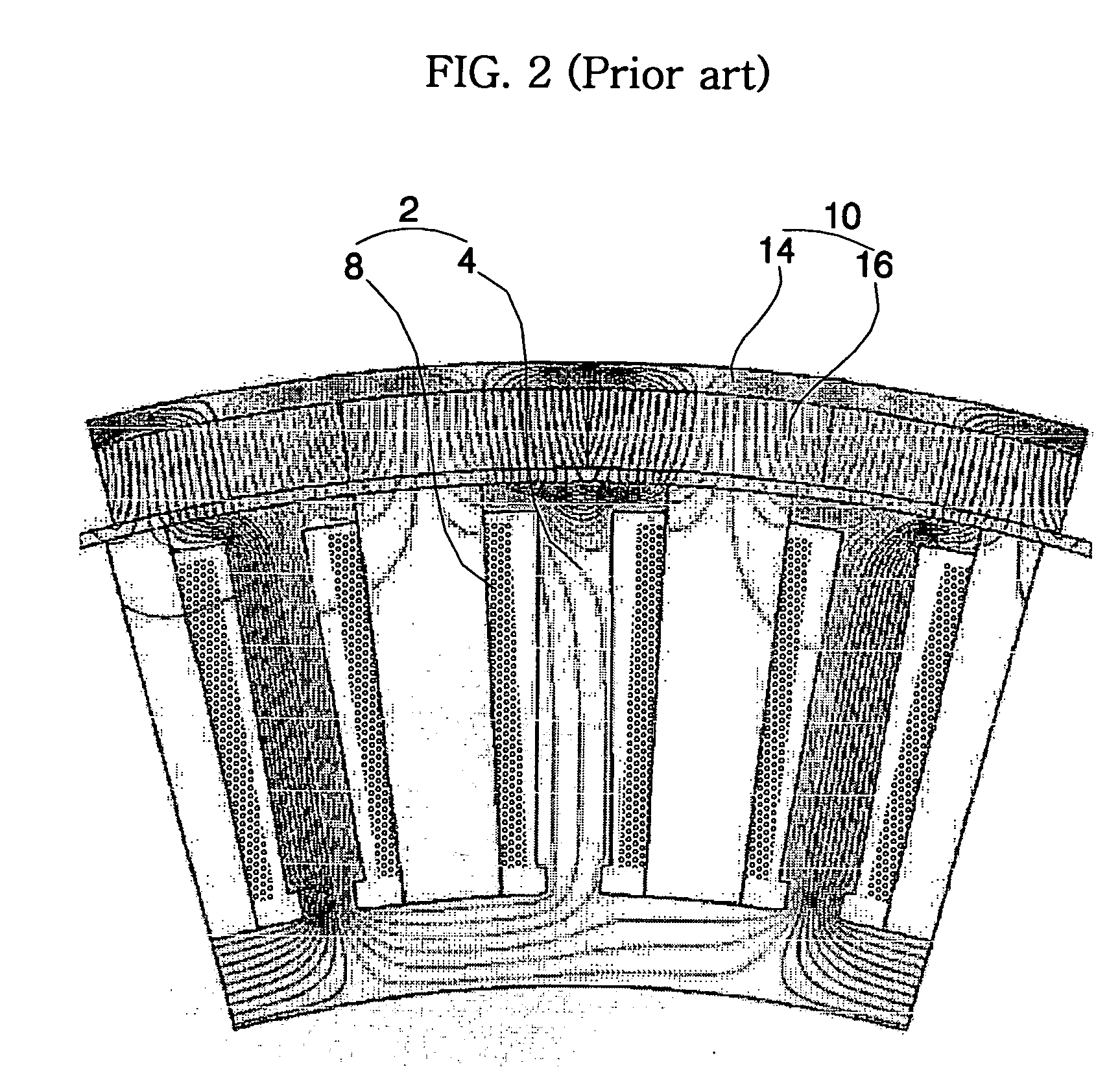

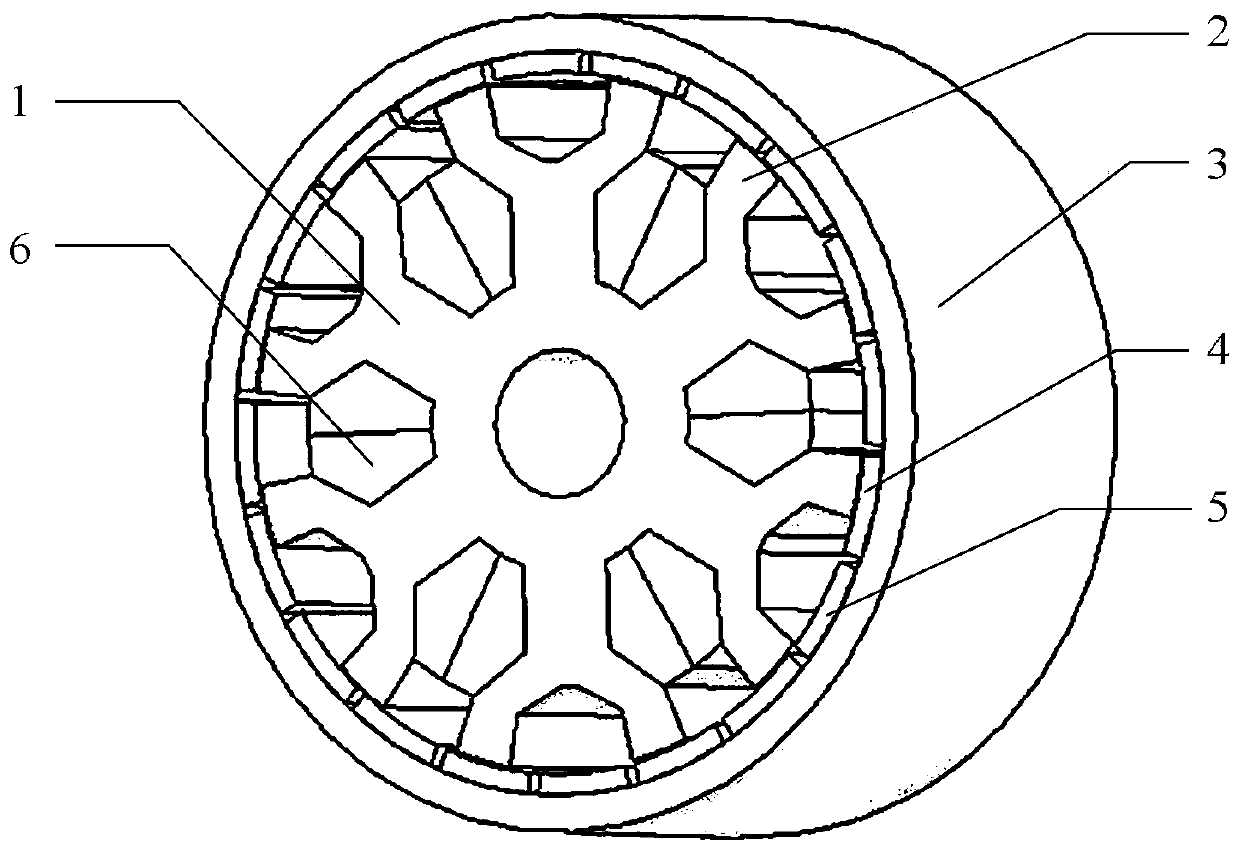

Motor, method for manufacturing field magnet assembly of the same, and washing machine with the same

InactiveUS20060091754A1Minimizing magnetic flux leakageIncrease torqueManufacturing dynamo-electric machinesMagnetic circuit characterised by magnetic materialsElectrical polarityEngineering

A motor has a field magnet assembly comprising a plurality of magnets arranged in the circumferential direction of the field magnet assembly such that like polarities face each other, and a plurality of magnet spacers disposed between the magnets, respectively. Consequently, leakage of magnetic flux of the field magnet assembly is minimized, and torque is improved as compared to a conventional motor having the same stacking and capacity. In a washing machine with the motor, the magnets and the magnet spacers are integrally attached to the outer tub of the washing machine. Consequently, the size of the washing machine is minimized. The sizes of the inner and outer tubs are increased when the washing machine according to the present invention has the same size as the conventional washing machine. Consequently, the capacity of the washing machine is increased.

Owner:LG ELECTRONICS INC

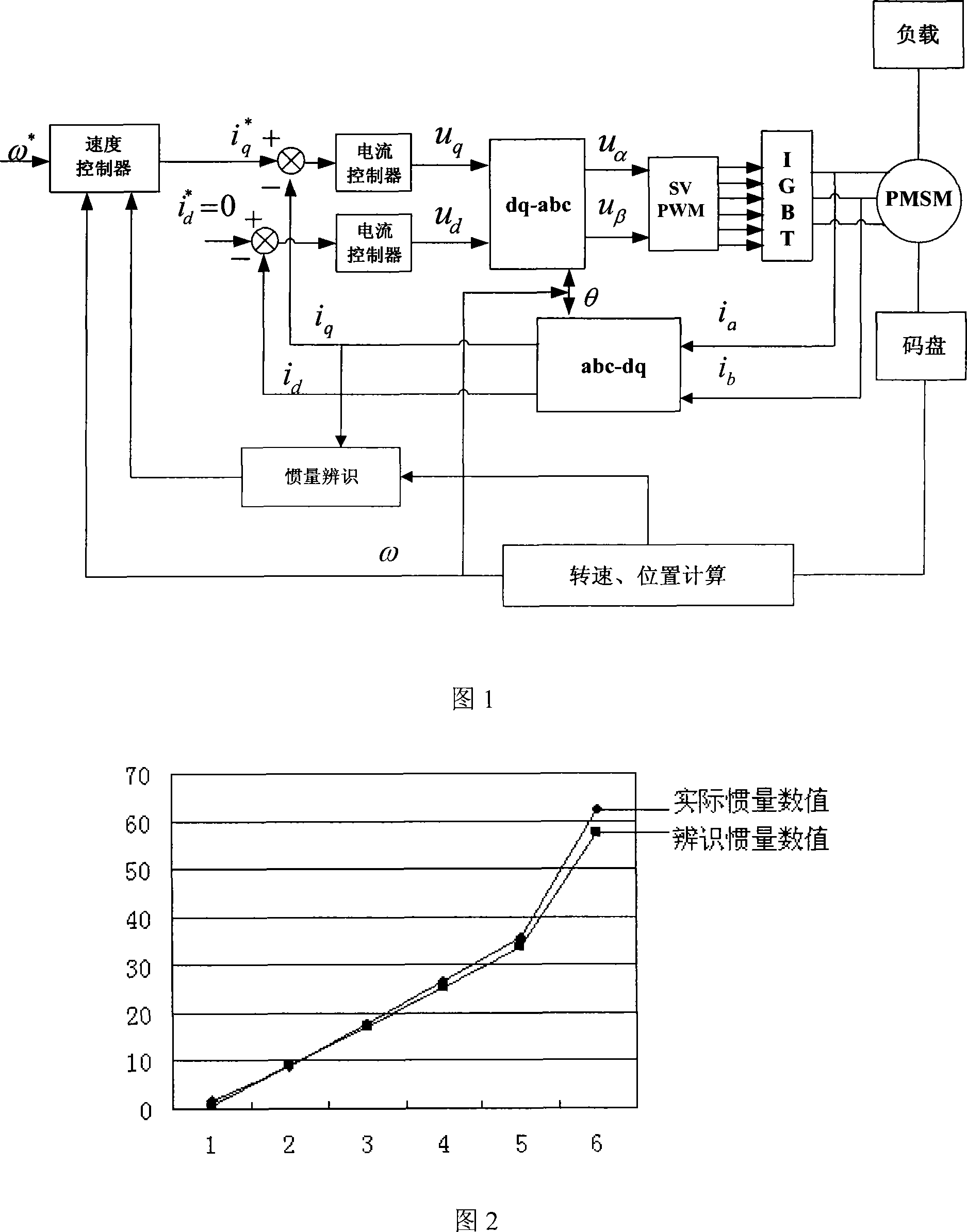

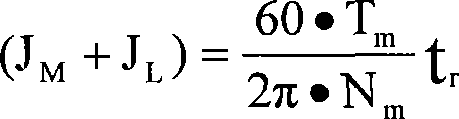

Method for identification of rotational inertia of AC servo

InactiveCN101231207AImprove torque performanceGood dynamic responseStatic/dynamic balance measurementElectric controllersServo actuatorLoad torque

The invention relates to a rotary inertia identification method of an alternating-current servomechanism, the load inertia and the rotor inertia of a motor are regarded as a whole inertia, a servo system does an accelerated motion and a decelerated motion, so as to obtain the system output torque and the motor average rotate speed for a period of time. The average torque of the servo system can be obtained by the system output torque, the value of the whole inertia can be obtained according to the motor average rotate speed, the average torque of the servo system, and the total operation time of the accelerated motion and the decelerated motion of the system, that is, the rotary inertia of the alternating-current servomechanism can be identified. The invention does not need to singly identify the load inertia or the load torque for identifying the system rotary inertia, but causes the load inertia and the motor rotary inertia to be regarded as an inertia, and the identification of the system rotary inertia can be realized by combining the system output torque. The implementation of the method is simple, the use is convenient, the identified inertia precision is higher, and the method can be applied to the servo system inertia detection of a permanent magnetism synchronous servo-actuator.

Owner:ESTUN AUTOMATION TECH

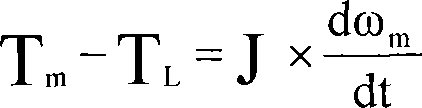

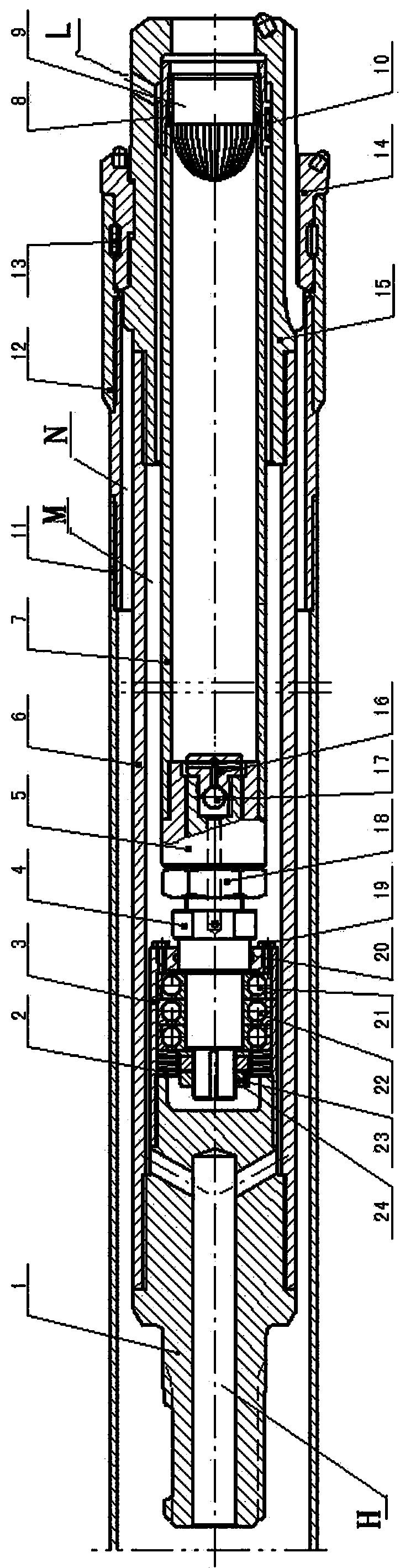

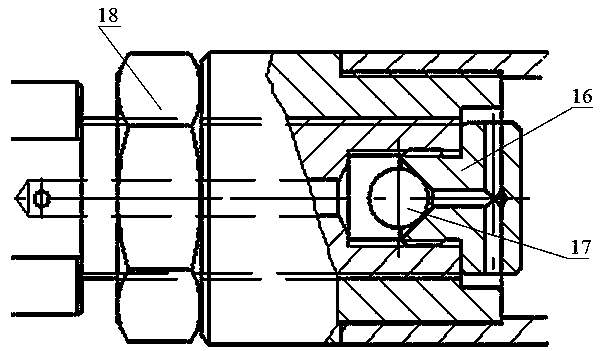

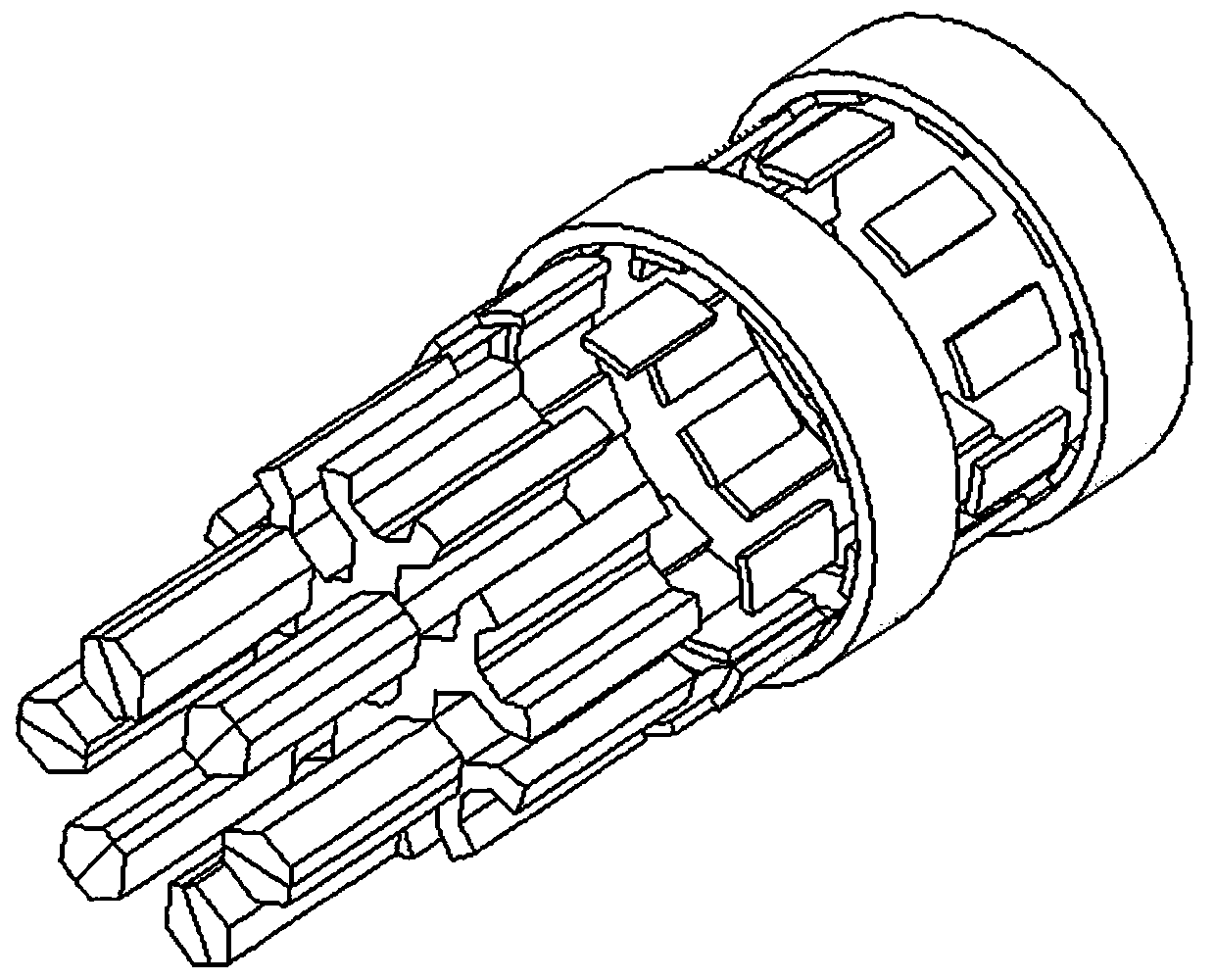

Single-action double-pipe coring overburden drill tool for air down-the-hole hammer

InactiveCN104295232AEliminate disadvantagesReduce frictional resistanceBorehole drivesCore removalBall bearingGeological survey

The invention relates to a single-action double-pipe coring overburden drill tool for an air down-the-hole hammer. The single-action double-pipe coring overburden drill tool comprises a central coring drill tool and an overburden drill tool. The central coring drill tool is a single-action double-pipe coring drill tool and comprises a single-action vibration reduction mechanism, an inner pipe adjusting mechanism and a coring mechanism with a bayonet device; the single-action vibration reduction mechanism comprises an impact connector, a disc spring, a bearing block, a connecting shaft, a thrust ball bearing and a radial ball bearing; the inner pipe adjusting mechanism comprises a connecting shaft, a core pipe connector, an inner pipe and a nut; the coring mechanism with the bayonet device comprises an outer pipe, an inner pipe, a connecting shaft, a core pipe connector, a coring drill bit, a rolling needle, a pawl spring seat and a pawl spring; the overburden drill tool comprises a casing, a casing connector, a casing shoe, a clamp ring and a casing drill bit. The single-action double-pipe coring overburden drill tool for the air down-the-hole hammer is applicable to relevant fields such as geological mineral exploration and engineering geological survey for complex formation with loose sand, cobbles, gravel, fracture, breakage and the like.

Owner:江苏省南京工程高等职业学校

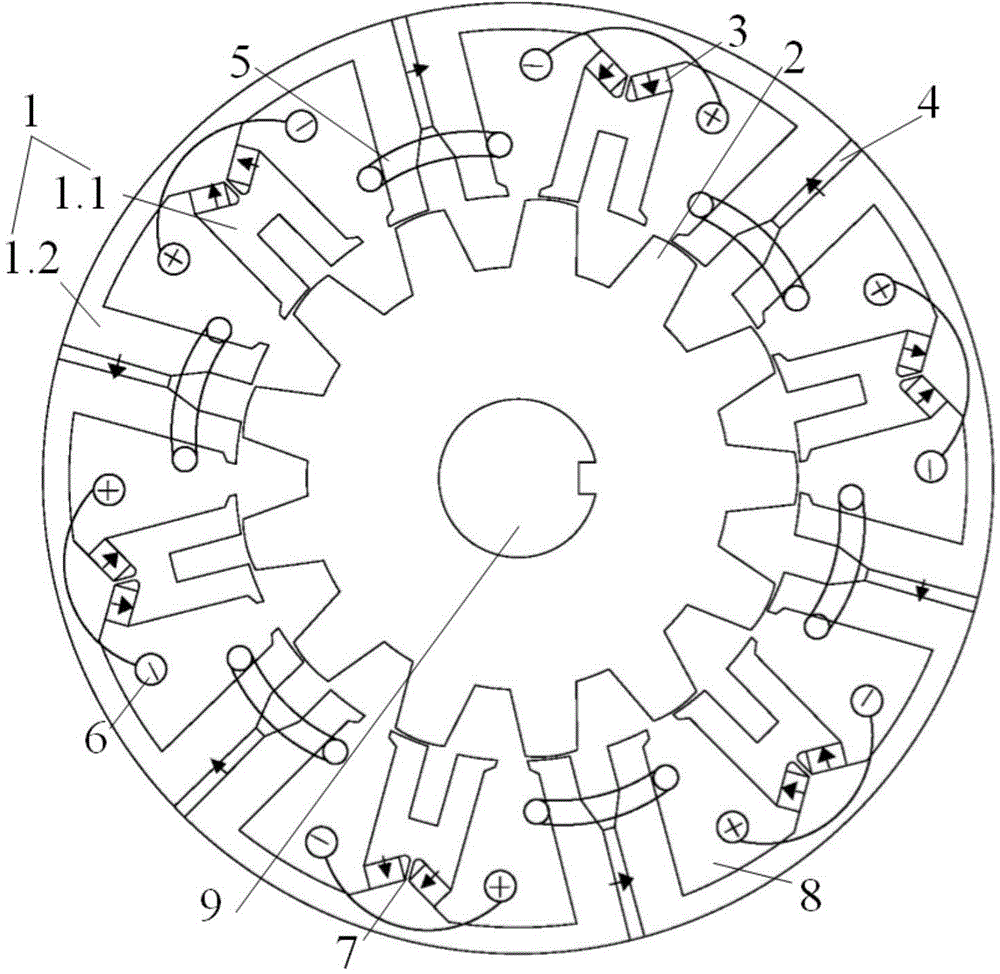

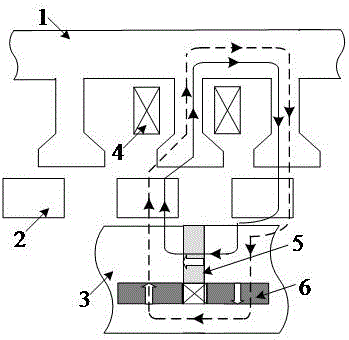

Mixed permanent magnetic pole-alternating and magnetic flux-switching memory motor and winding switching magnetism-weakening control method thereof

ActiveCN104578477ASimple structureImprove space utilizationAC motor controlMagnetic circuit stationary partsLow speedMagnetic poles

The invention discloses a mixed permanent magnetic pole-alternating and magnetic flux-switching memory motor and a winding switching magnetism-weakening control method thereof. The mixed permanent magnetic pole-alternating and magnetic flux-switching memory motor comprises a salient rotor and a stator, wherein the stator contains stator cores, aluminium-nickel-cobalt permanent magnets, neodymium-iron-boron permanent magnets, centralized armature windings and pulsed magnetism-adjusting windings; iron core edges of two adjacent outer U-shaped units and tangentially-magnetized long-stripped neodymium-iron-boron permanent magnets form a first permanent magnetic pole, while the circumferentially-inward (outward) and parallel-magnetized V-shaped embedded aluminium-nickel-cobalt permanent magnets and inner U-shaped units form a second permanent magnetic pole; mixed magnetic poles are in alternating polarity distribution; when the motor runs at a low speed, the pulsed magnetism-adjusting windings are in direct-current pulsed working state, while in a high-speed weak-magnetism area, the pulsed magnetism-adjusting windings are converted into alternating-current armature windings. Requirements on performance in a low-speed area and in the high-speed area can be met at the same time; influence of an armature reaction field on the aluminium-nickel-cobalt permanent magnets with low coercivity is small; the utilization rate of permanent magnetism, the torque density, and the reliability of system operation are high.

Owner:SOUTHEAST UNIV

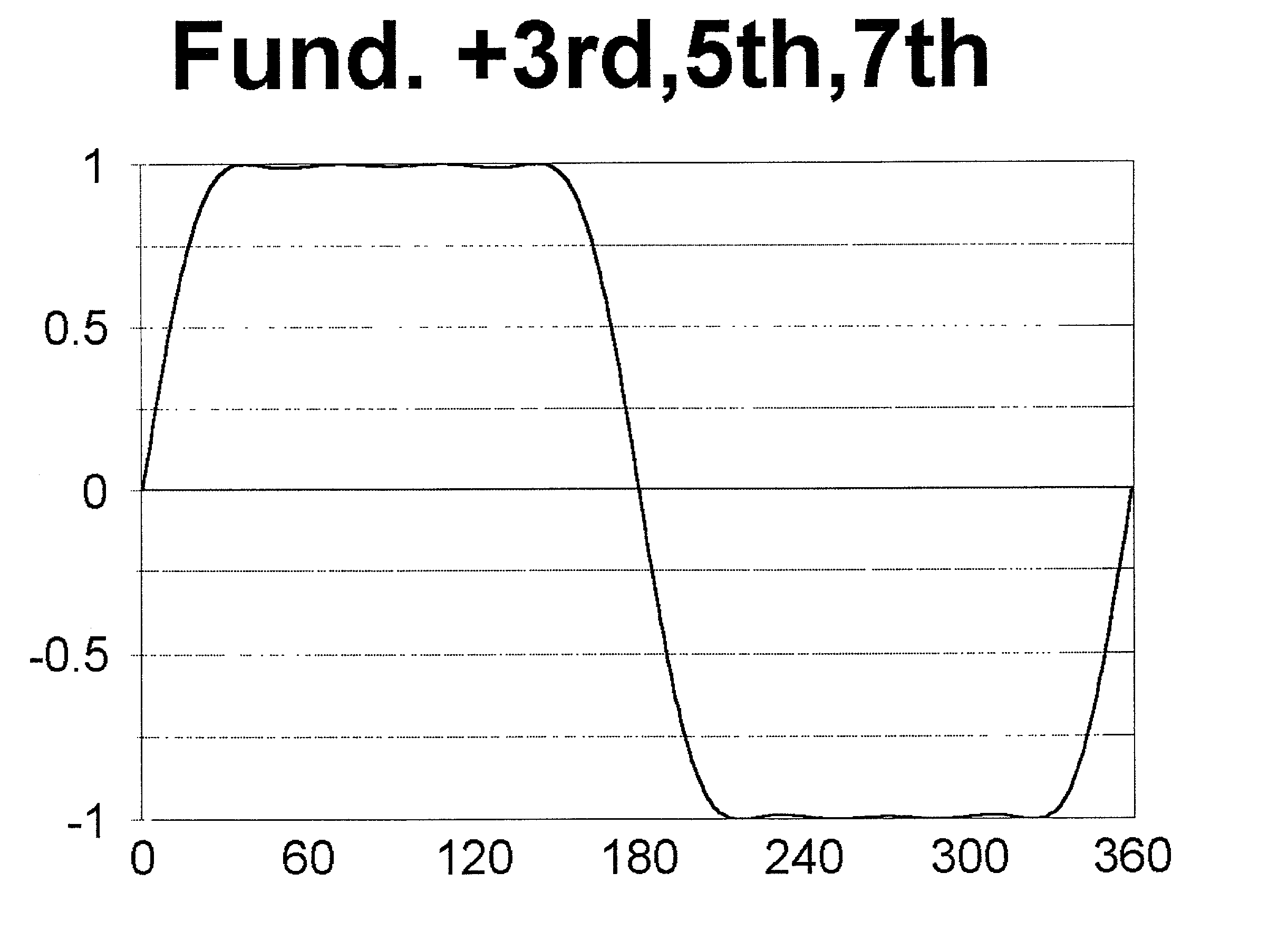

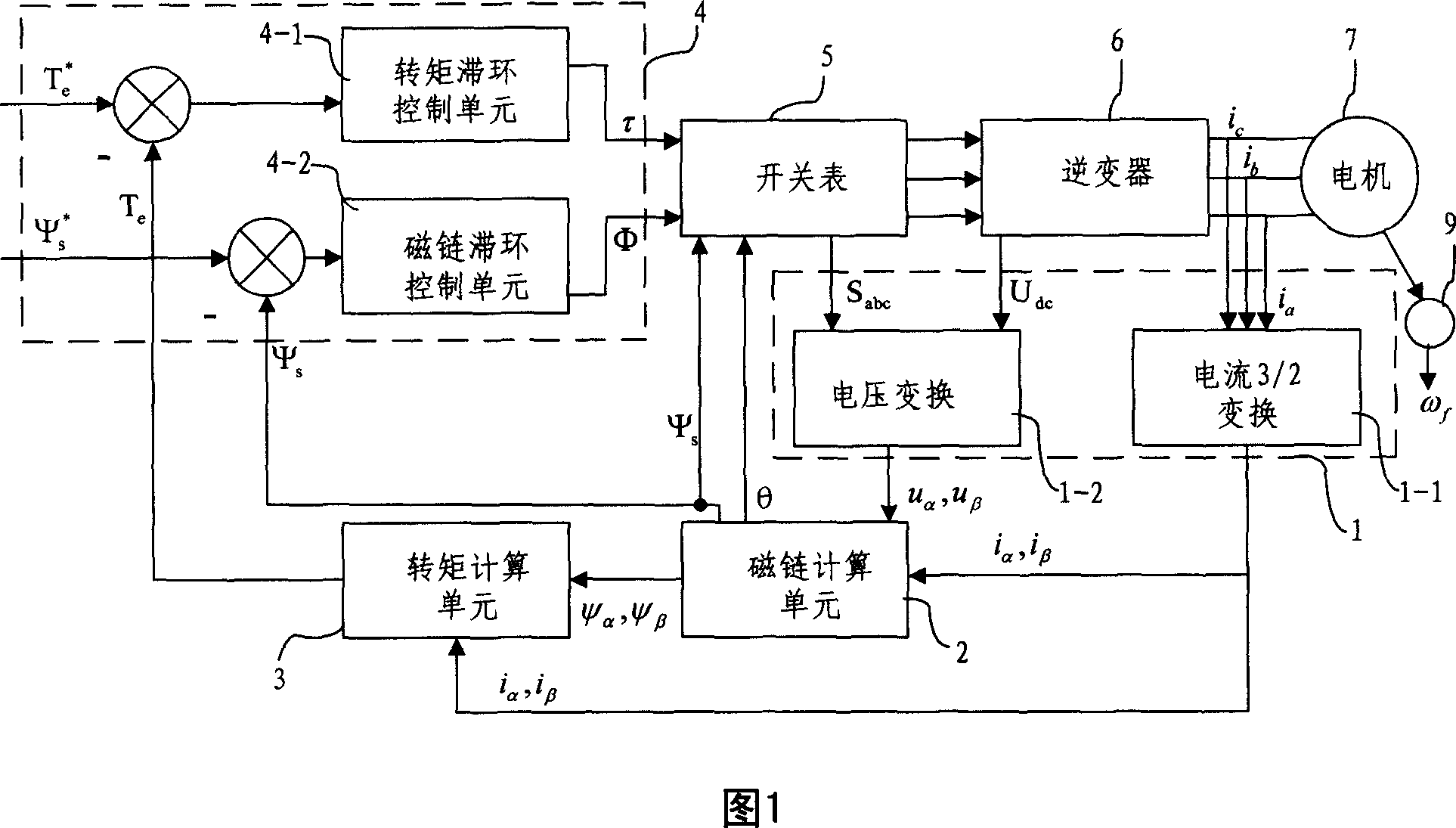

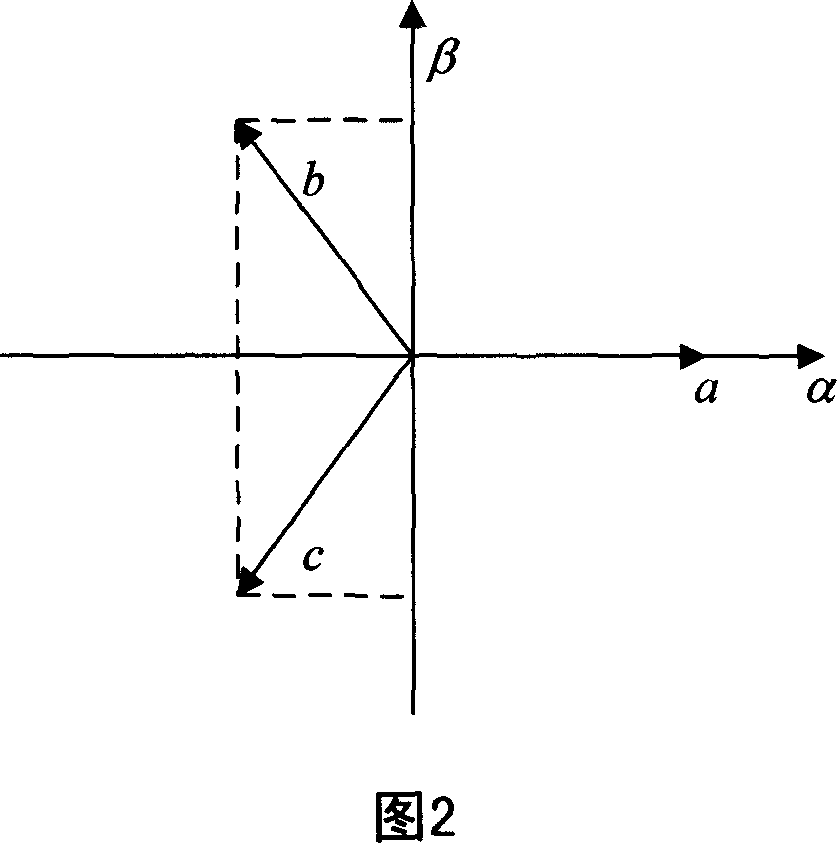

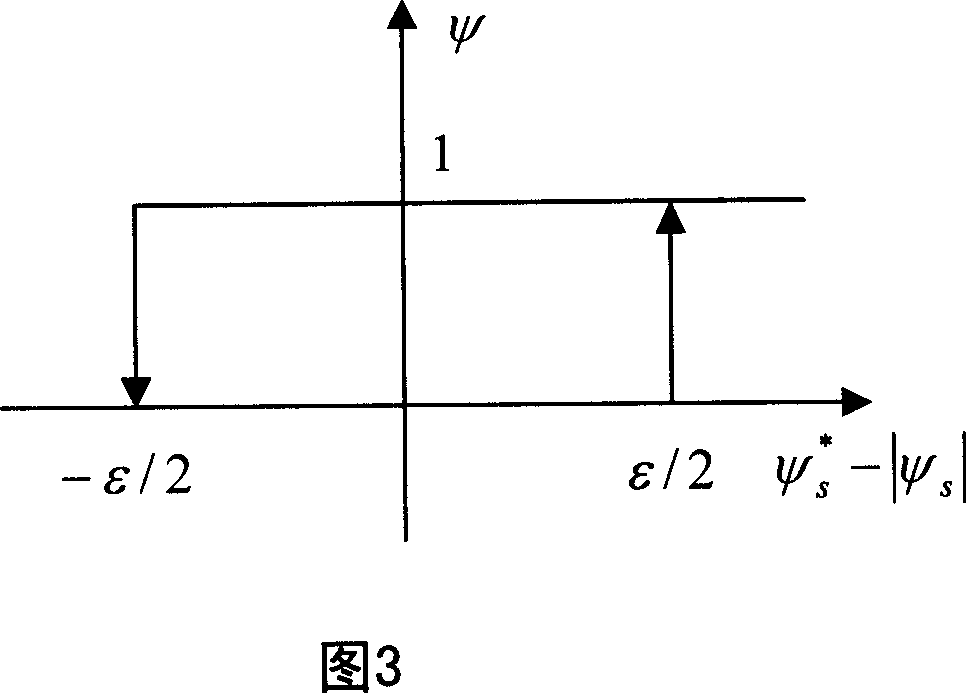

Direct torque brushless DC servo control system and its working method

ActiveCN101056084AImprove control effectQuick responseElectronic commutation motor controlVector control systemsSwitching frequencyTransformation unit

The present invention relates to a direct-torque brushless DC servo-control system and the working method thereof. The controller includes a coordinate transformation unit, a magnetic linkage computing unit, a torque computing unit, a magnetic linkage and a torque hysteresis control unit, a switch watch and an inverter unit; in the direct-torque brushless DC servo-control system in the present invention, the magnetic linkage and torque hysteresis control unit are used for comparing the stator magnetic linkage Psi s from the magnetic linkage computing unit and the stator torque Te from the torque computing unit respectively with the reference value Psi s * and T*e, and for outputting the magnetic linkage adjusting signal Tau and torque adjusting signal Phi having the corresponding frequency of 4-8kHz according to the compared result to improve the switch frequency of the inverter and reduce the torque pulsation. The system in the present invention has a good control effect to the torque and a quick response, and the problem of the torque pulsation of the brushless DC electric motor is solved.

Owner:常州今创电工有限公司

Guide wire with core having welded wire segments

InactiveUS7998090B2Enhanced compressive and tension and torsion strengthDifferent advantagesGuide wiresDiagnostic recording/measuringFriction weldingMetal alloy

An intravascular guide wire having two core materials joined together without the use of a connector tube or sleeve, the core materials being stainless steel and pseudoelastic metal alloy, nitinol. The core materials are joined to each other through an intermediate transition piece made essentially of nickel, which is welded on either side to the two core materials. In a multi-segment intravascular guide wire, discrete, high modulus and medium modulus core portions of different materials are welded to a shapeable, low modulus distal core portion made of a third material having a flattened, shapeable section at a most distal end that is not welded to but made from the distal core portion, so the flattened, shapeable section can be deformed to create a steerable tip. Processes such as simultaneous resistance and friction welding can be used to join the core portions.

Owner:ABBOTT CARDIOVASCULAR

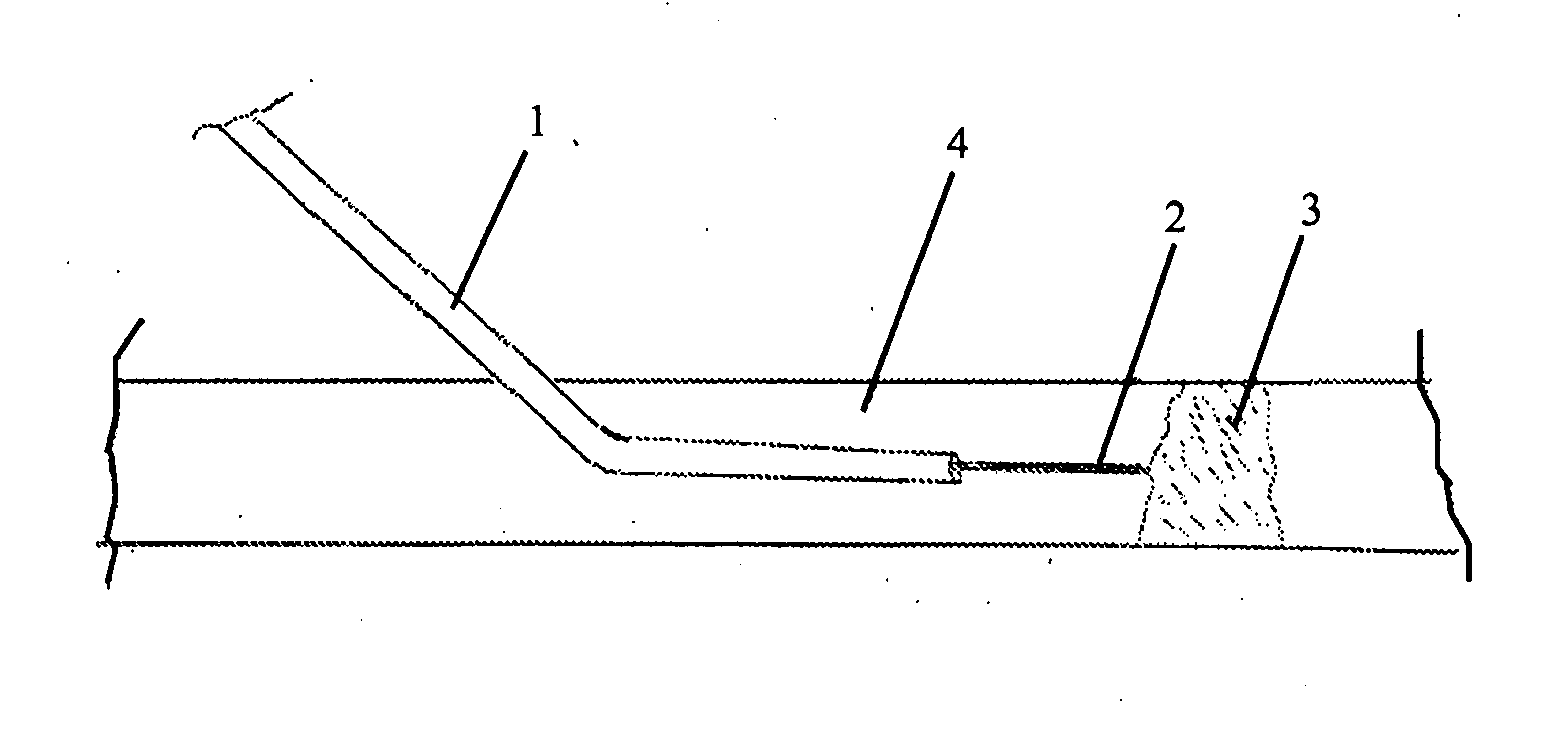

Hypotube based support catheter

ActiveUS20140031843A1Increase successImprove techniqueCannulasGuide wiresPercutaneous angioplastyBlood vessel

Hypo-tube based support catheter (1) for treating blood vessels, such as below the knee (BTK) blood vessels and other blood vessels (e.g., coronary, pediatric), which are partially or totally occluded. The tip of the support catheter (1) of the invention is shapeable to any desired shape before the insertion of the device into the blood vessel. The disclosed device enables improved angioplasty treatment of blood vessels, especially with a retrograde approach.

Owner:SPECTRANETICS

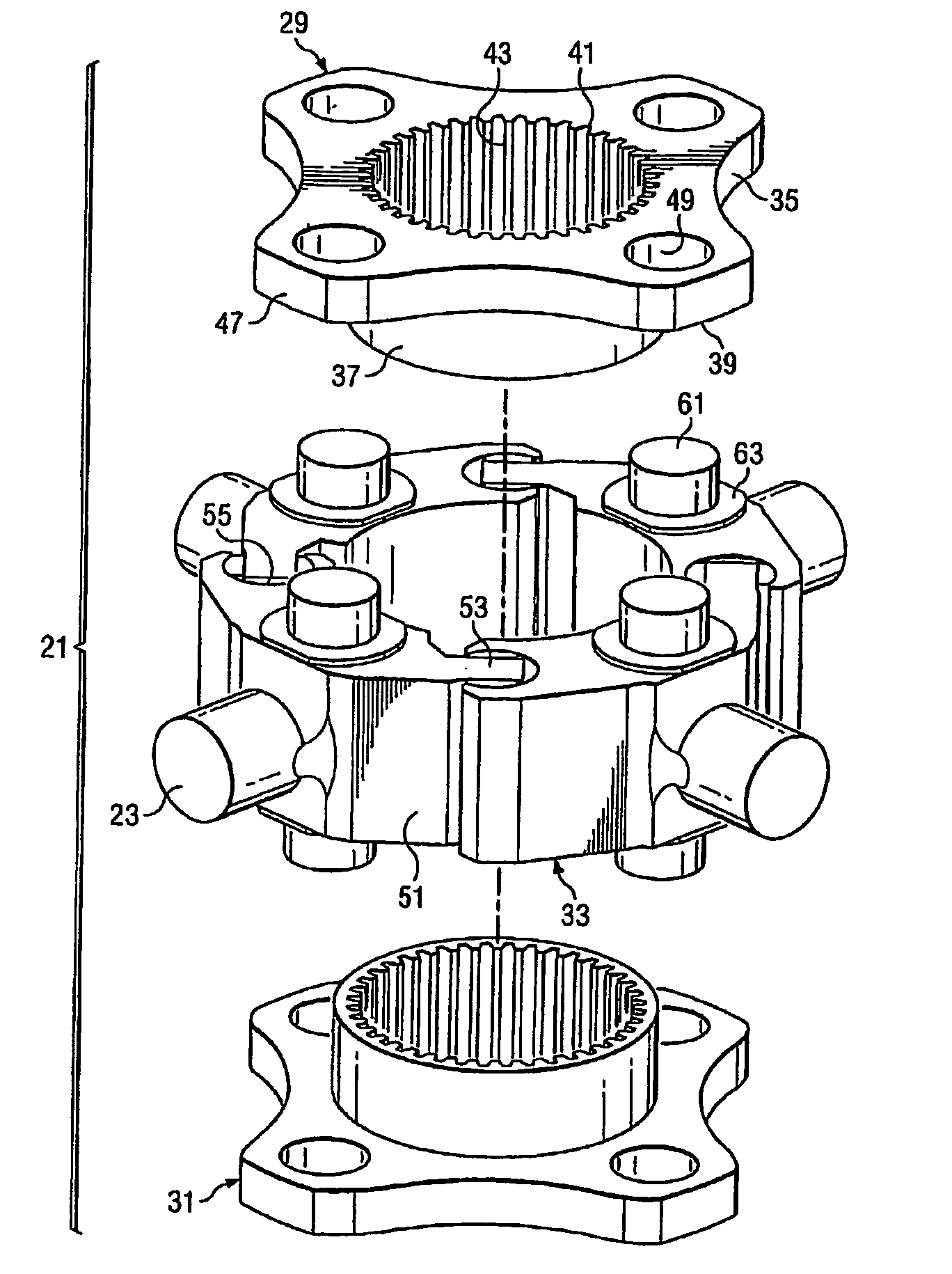

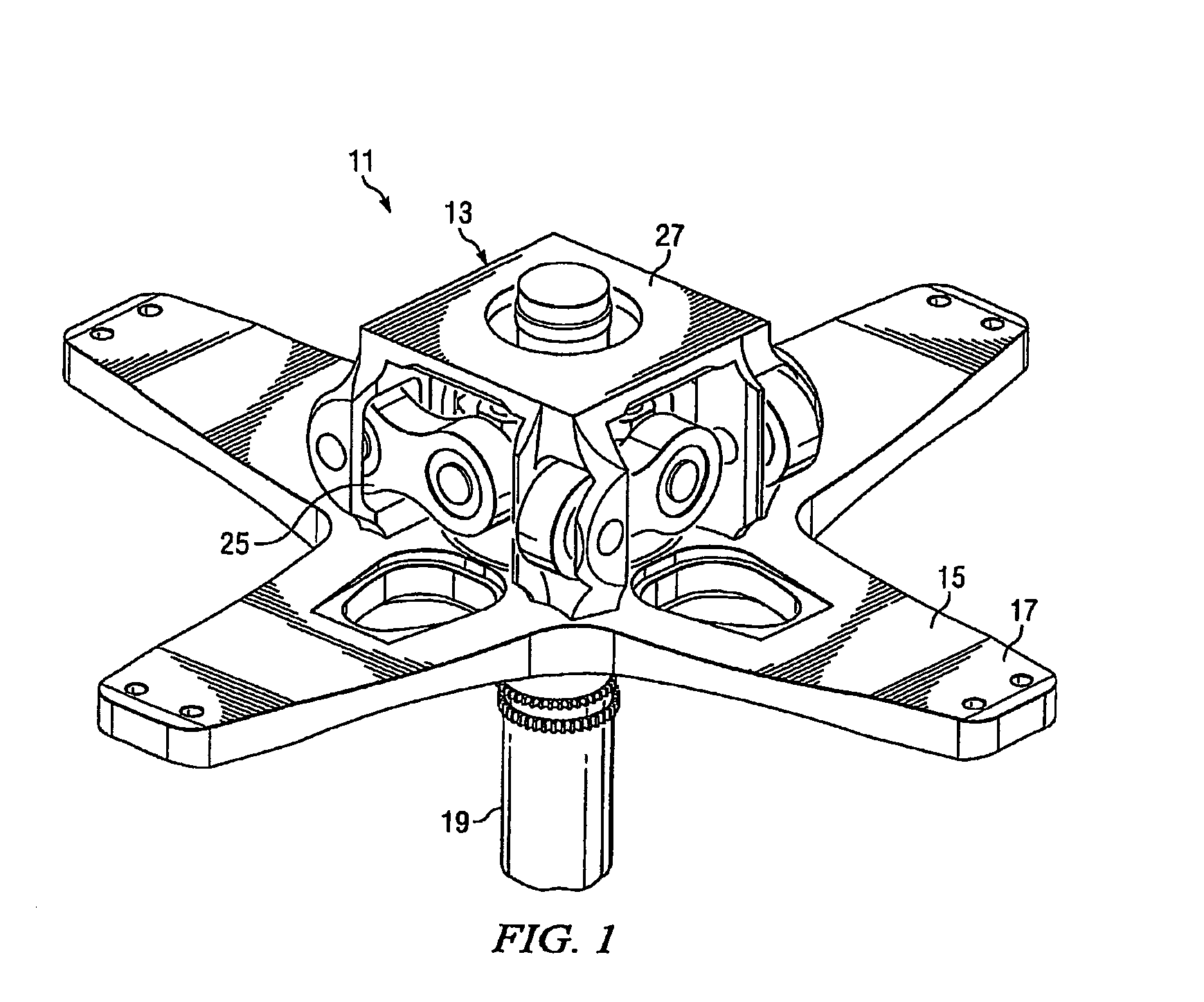

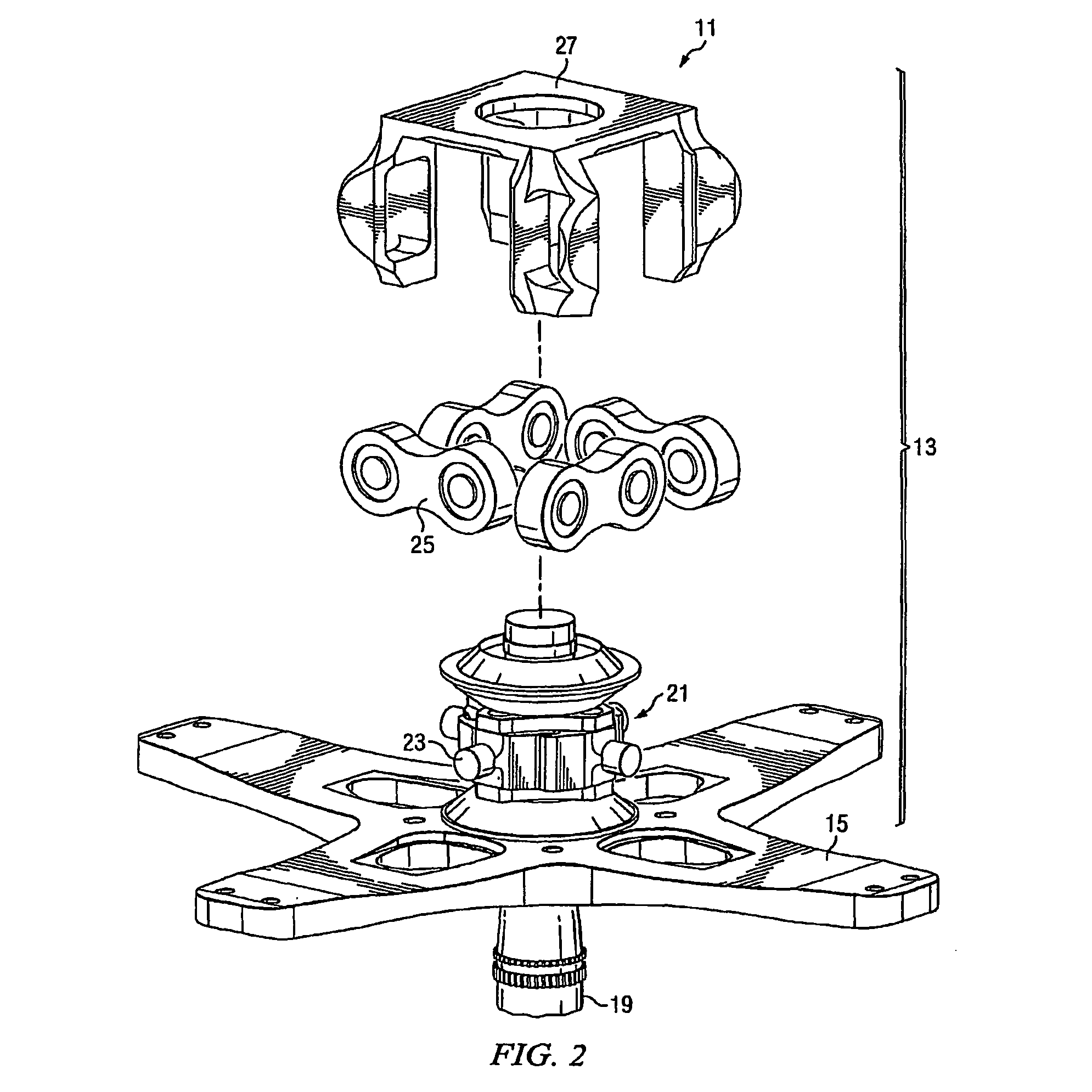

Torque coupling for rotary-wing aircraft

ActiveUS8226355B2Relieve kinematic bindingEnhanced couplingPump componentsBlade accessoriesCouplingUniversal joint

A torque coupling (13) for a rotor head (11) of a rotary-wing aircraft has upper and lower plates (29, 31) configured for rotation with a rotor mast (19). Drive links (33) pivotally connected to the upper and lower plates (29, 31) pivot about a pivot axis generally parallel to and radially offset from an axis of rotation of the plates. Each link (33) is engaged with adjacent drive links (33) to form a continuous ring of links, such that motion of one link (33) about its pivot axis causes motion in an opposite direction of each adjacent link (33) about its pivot axis. Drive elements (25) connect the drive links (33) to an assembly configured to receive rotor blades. The drive elements (25) may be components of a universal joint, a multiple trailing-link configuration, a pad-bearing configuration, or another type of articulating assembly.

Owner:TEXTRON INNOVATIONS

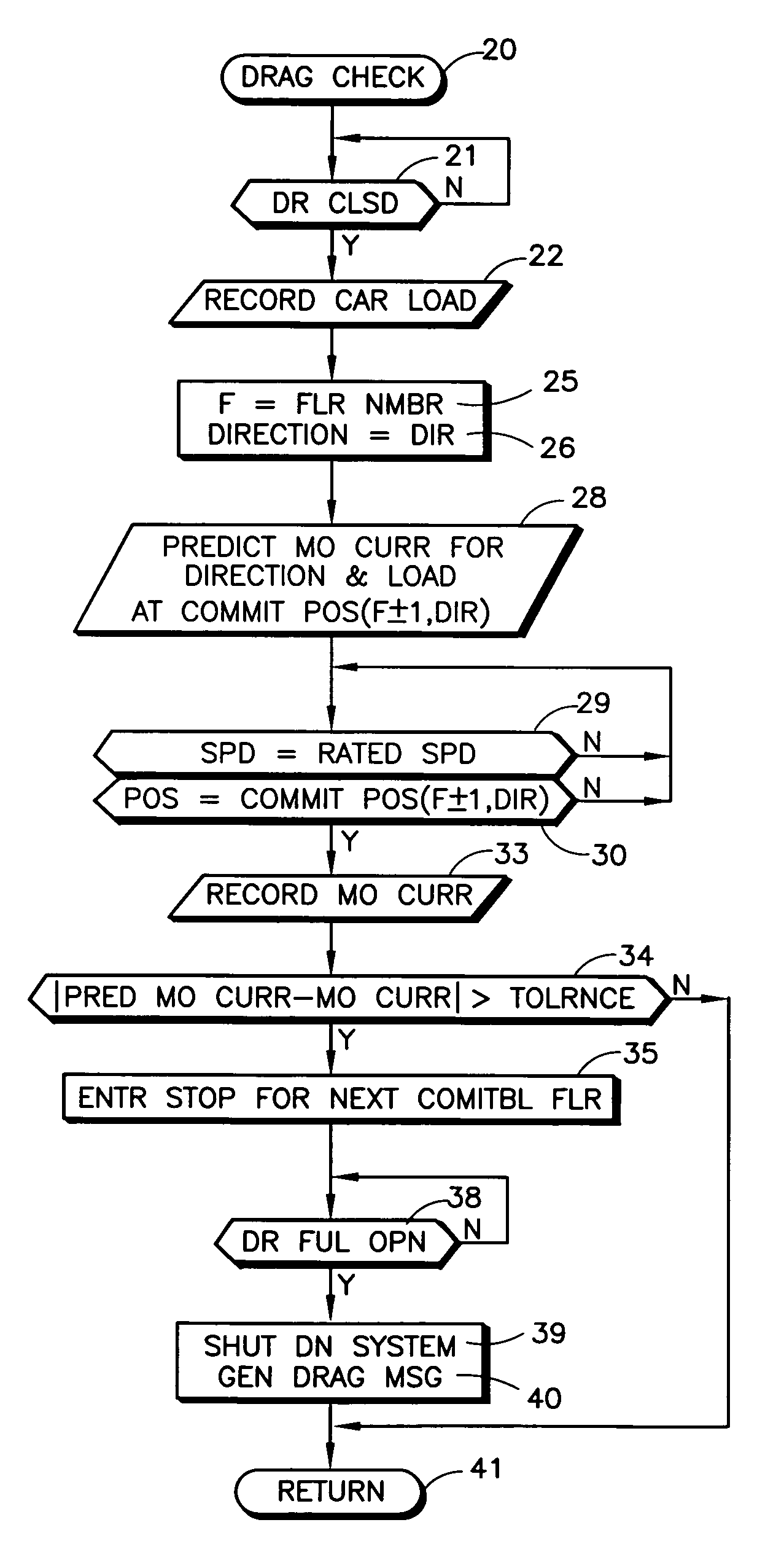

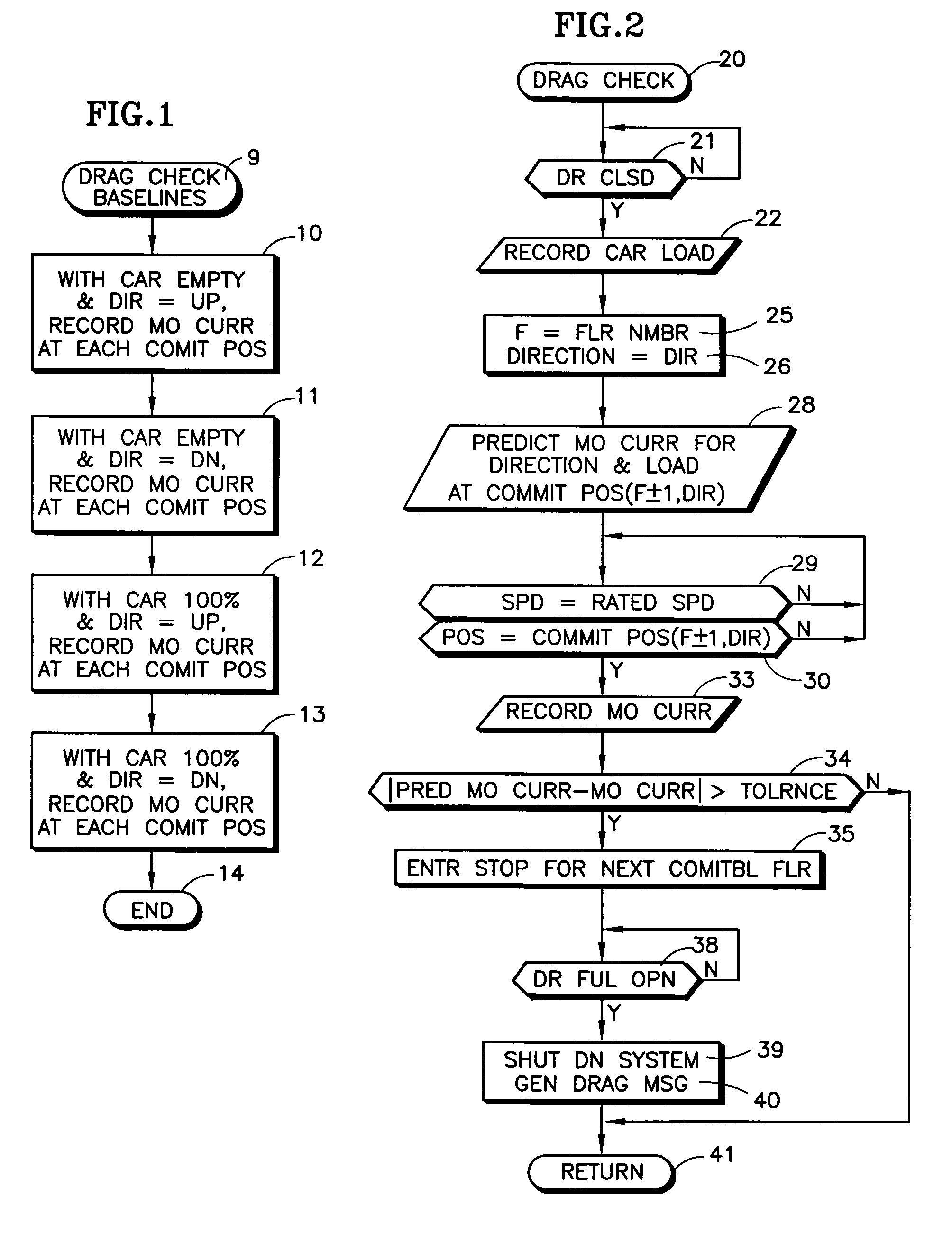

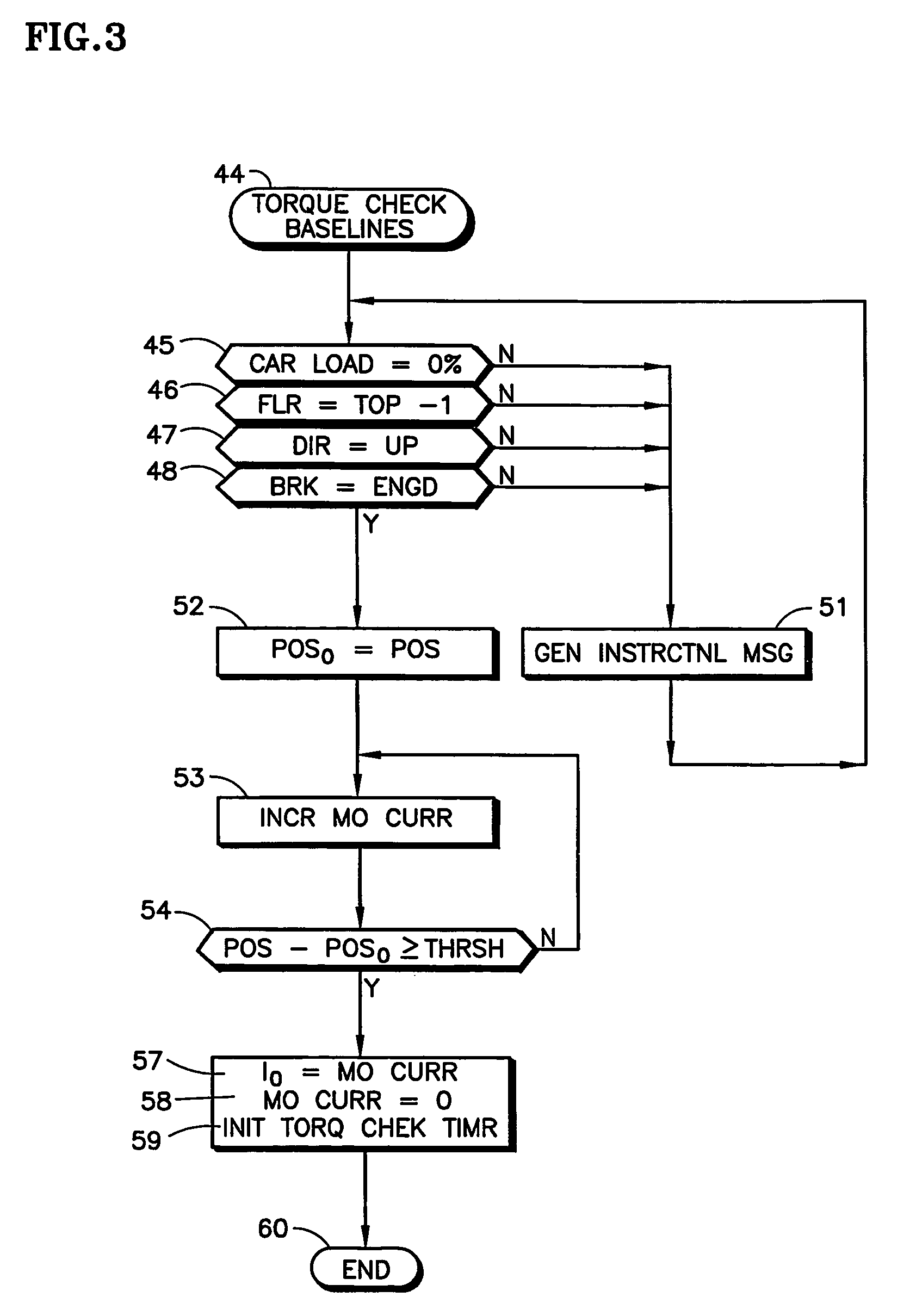

Detecting elevator brake and other dragging by monitoring motor current

Elevator brake or other drag is checked by establishing (10-13) baseline motor currents at plural determined positions as the car is moved up and down both empty and with full load. In a normal run (21), the load is recorded (22) and the motor current required to drive the load at rated speed at the next determined position is both predicted (28) and measured. If the difference between the predicted and actual current exceeds a tolerance (33, 34), the car stops at the next floor (35), the system is shut down (39) and a message generated (40). When the brake is in proper operating condition, baseline motor current required to move a car with the brake engaged is recorded. Thereafter, a high fraction (such as 90%) of baseline motor current is applied to attempt to move the car. If the car moves, the system is shut down (101) and a message generated (102).

Owner:OTIS ELEVATOR CO

Pelvic arterial catheter

ActiveUS20050113801A1Minimal traumaHigh trafficCatheterRadiation diagnosticsArterial catheterTherapeutic intent

An improved angiographic catheter that allows selective catheterization of the bilateral pelvic arteries via a unilateral single common femoral arterial entry site for the purpose of introducing radioopaque iodinated contrast solutions for both diagnostic and therapeutic purposes. The catheter has an optimal length, specific tapered and curved regions, and a progressively tapering diameter along its length. The catheter is made from a hybrid of soft, flexible hydrophilic and reinforced materials to allow for conformational changes in order to accommodate to the variety of vascular anatomy encountered in clinical angiographic practice.

Owner:VASCULAR SOLUTIONS LLC

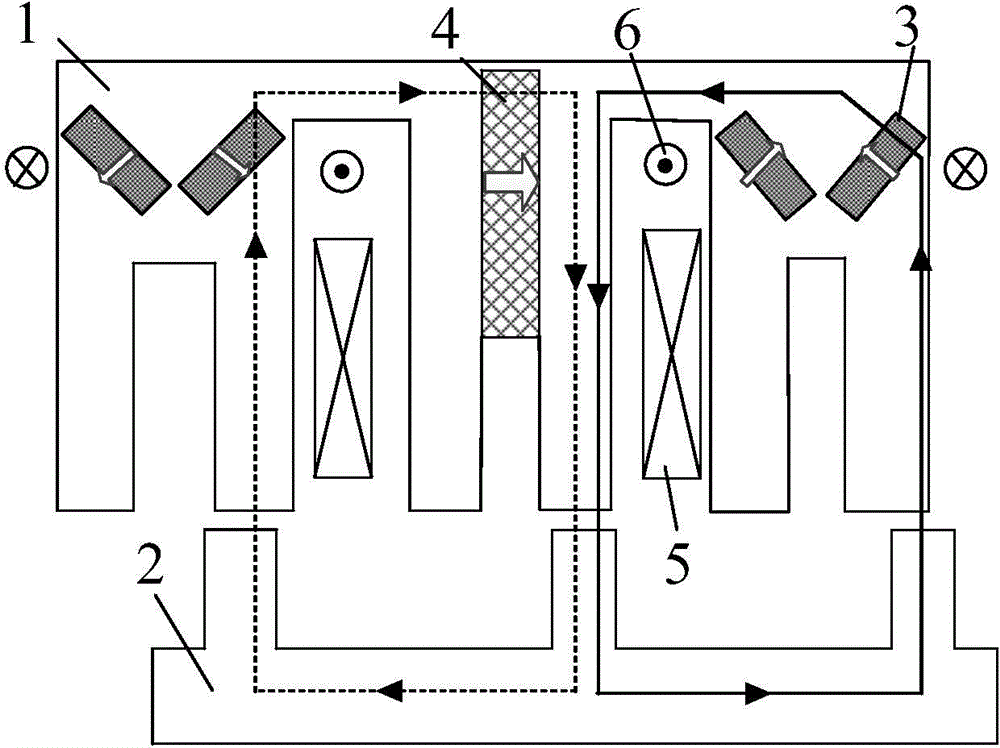

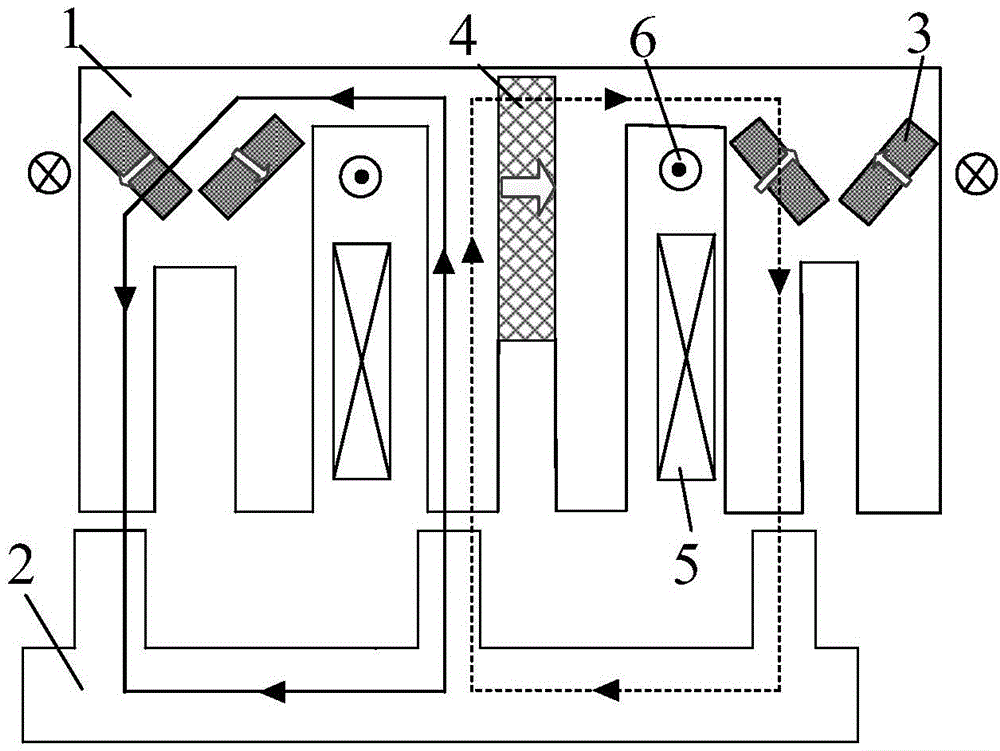

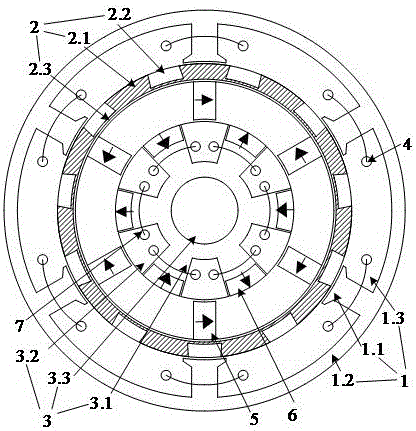

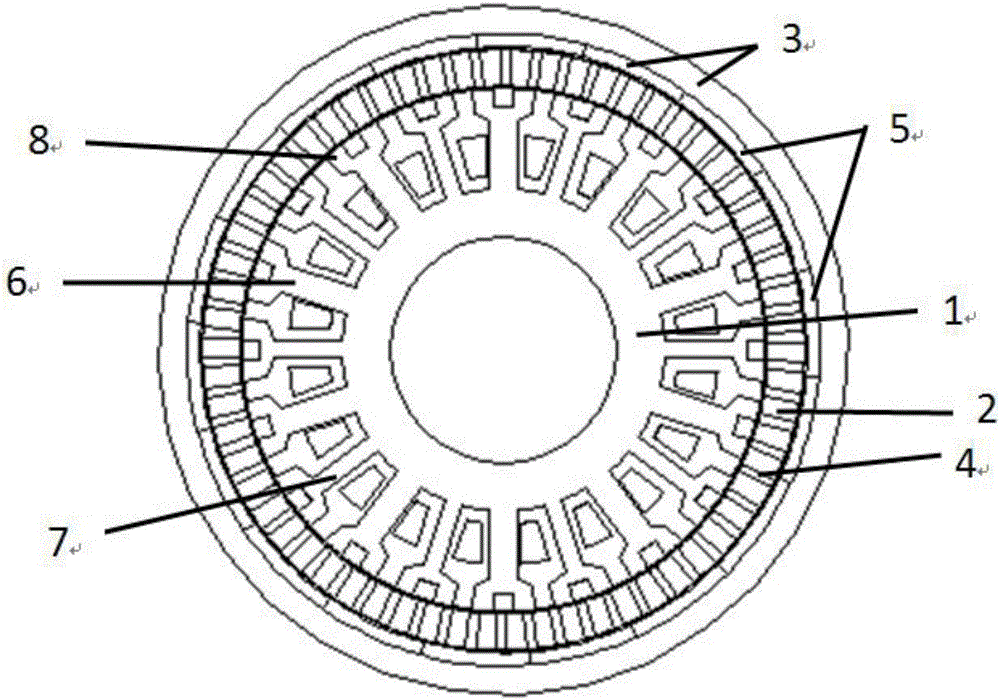

Magnetic gear type double-stator hybrid permanent magnet memory motor

InactiveCN105141092ASimple structureImprove space utilizationMagnetic circuit rotating partsMagnetic circuit stationary partsEpoxyElectric machine

The invention discloses a magnetic gear type double-stator hybrid permanent magnet memory motor. The motor comprises an external stator, a rotor and an internal stator which are coaxially arranged and sleeved from outside to inside in turn. The external stator comprises armature iron core teeth, stator yokes and armature windings which are arranged on the armature iron core teeth. The internal stator comprises an internal stator iron core provided with internal slots, neodymium iron boron permanent magnets, aluminum nickel cobalt permanent magnets and pulse magnetic regulating windings which are arranged in the internal slots of the internal stator. The two types of co-excitation permanent magnets are arranged in a "U" shape. The number of single permanent magnets on the internal stator is equal to that of external stator armature teeth. The whole rotor has an annular cup-shaped structure. Rotor iron blocks are fixed in a non-magnetic-conductive epoxy resin sleeve. The rotor iron blocks are connected via magnetic conductive bridges. Disadvantages that a conventional single stator has multiple internal excitation sources which are mutually hindered in space and torque density is relatively low can be solved. Besides, high power density is realized by arrangement of double-stator hybrid permanent magnets, and residual magnetization intensity and magnetization direction of the permanent magnets are regulated by applying pulse current so that motor magnetic field high-efficiency regulation is realized, and rotating speed operation range is enhanced.

Owner:SOUTHEAST UNIV

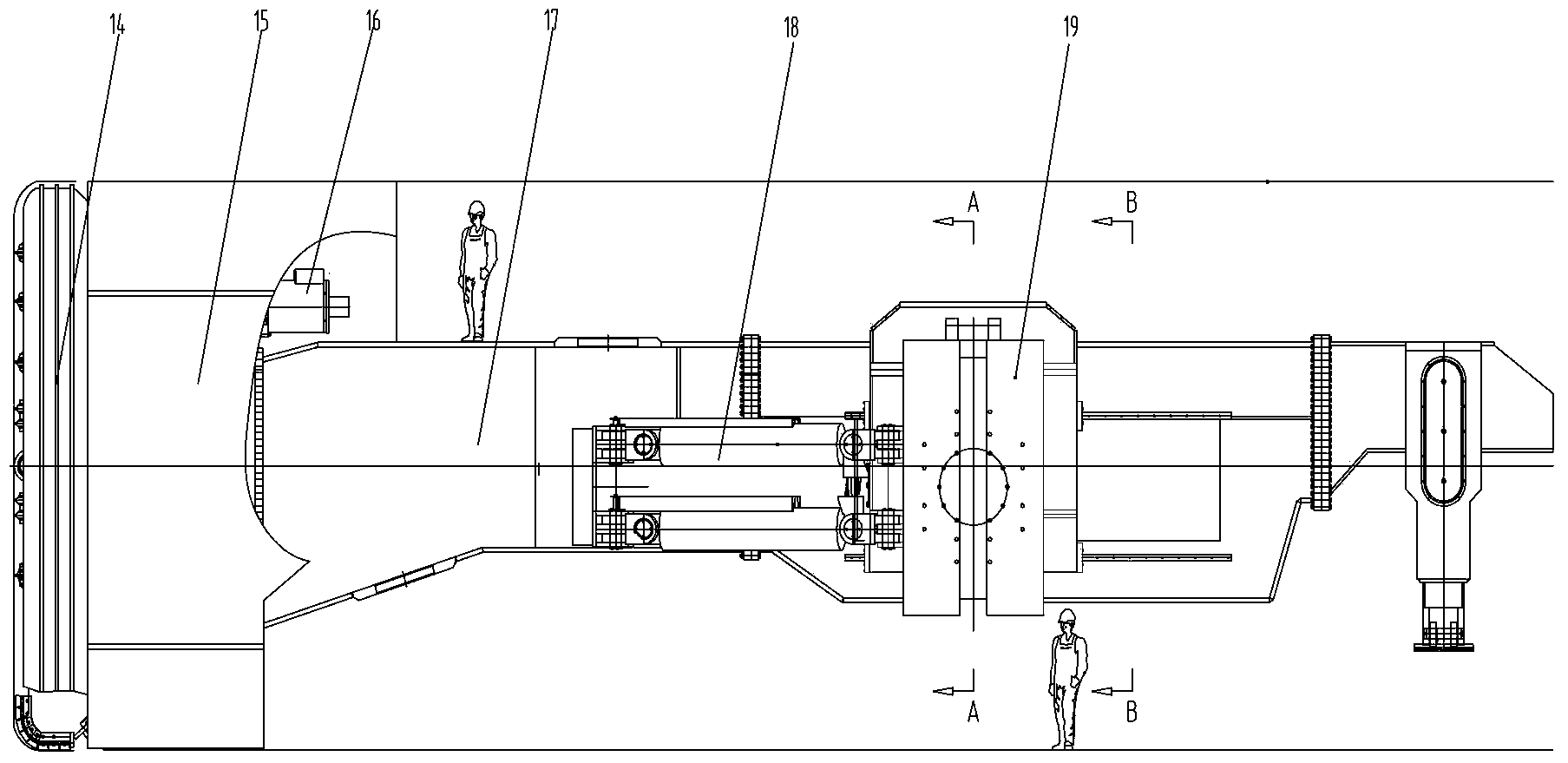

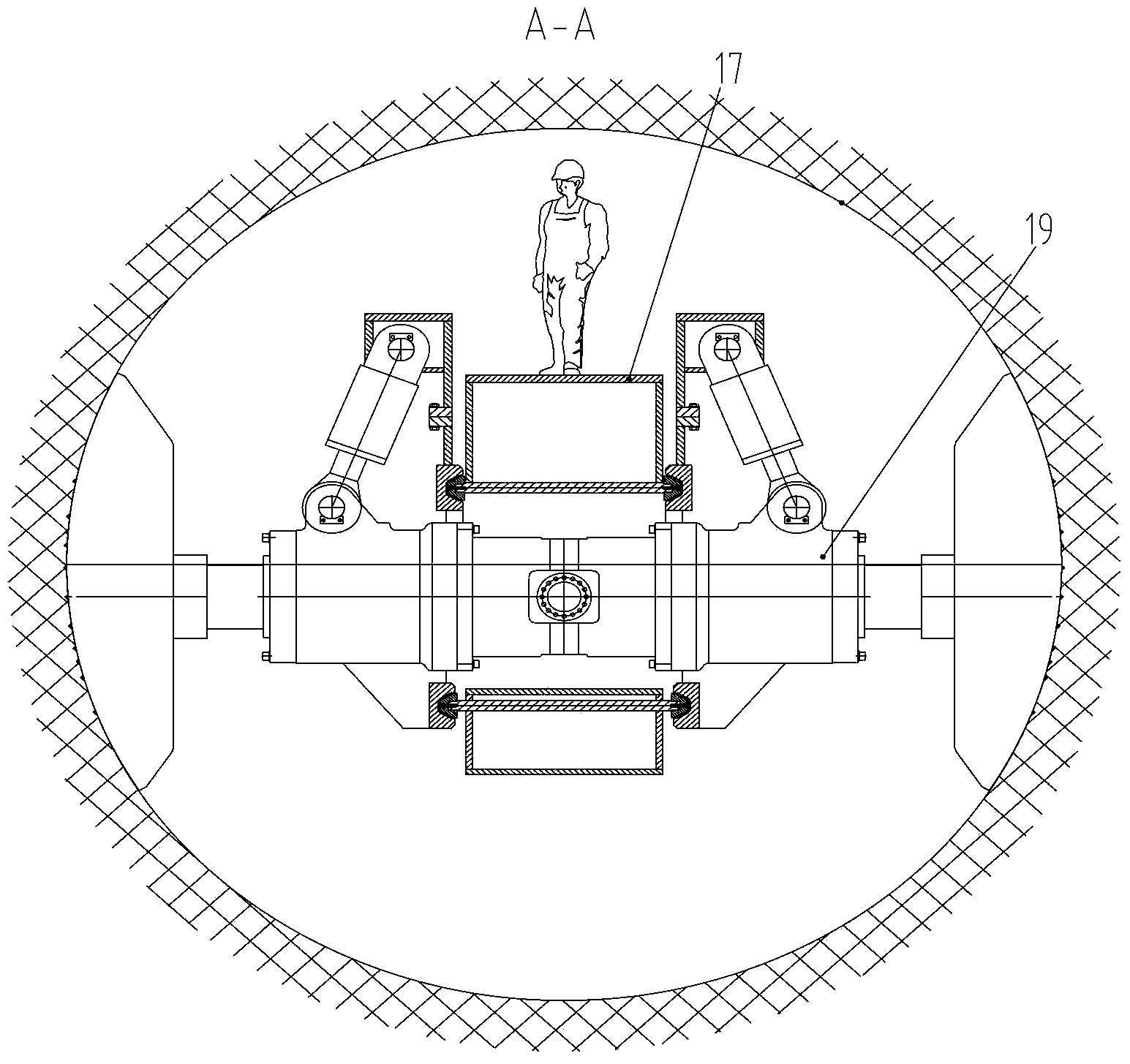

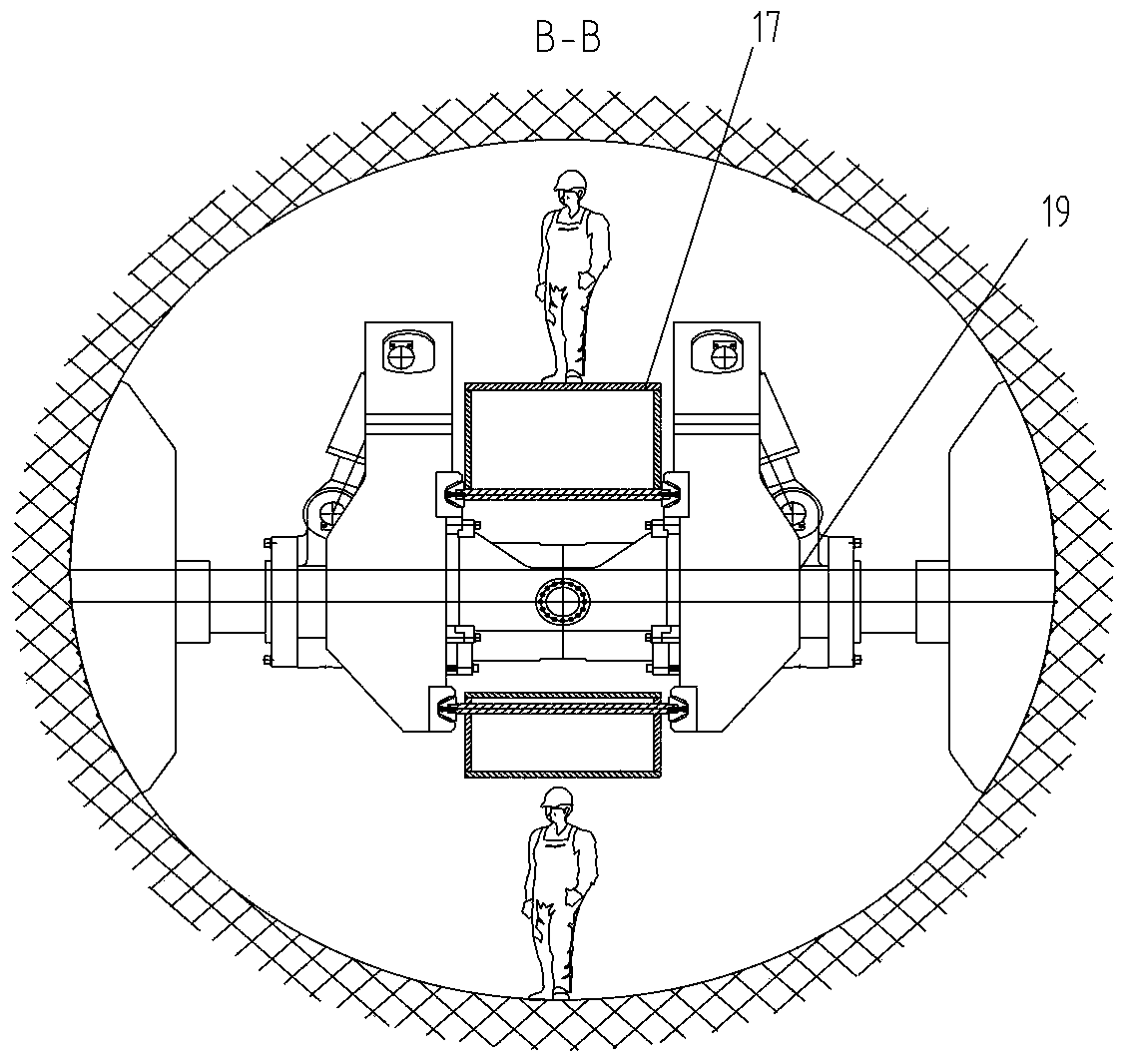

Open-type full-face rock ripper

The invention provides an open-type full-face rock ripper, comprising a cutterhead (14), a shield (15), a driving component (16), a girder (17), a thrust cylinder (18), a support boot and a saddle rack system (19), wherein the girder (17) comprises a first girder (2), a second girder (6), a rear support (9) and a lead rail (7); the first girder (2), the second girder (6) and the rear support (9) are connected through a bolt. By adopting the open-type full-face rock ripper, the height of the upper plane of the girder is reduced; an upper work space of the girder is expanded; the stress of the section of the girder is reduced by the open-type full-face rock ripper under the same load; the capacity of the girder for resisting bending moment and torque is improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

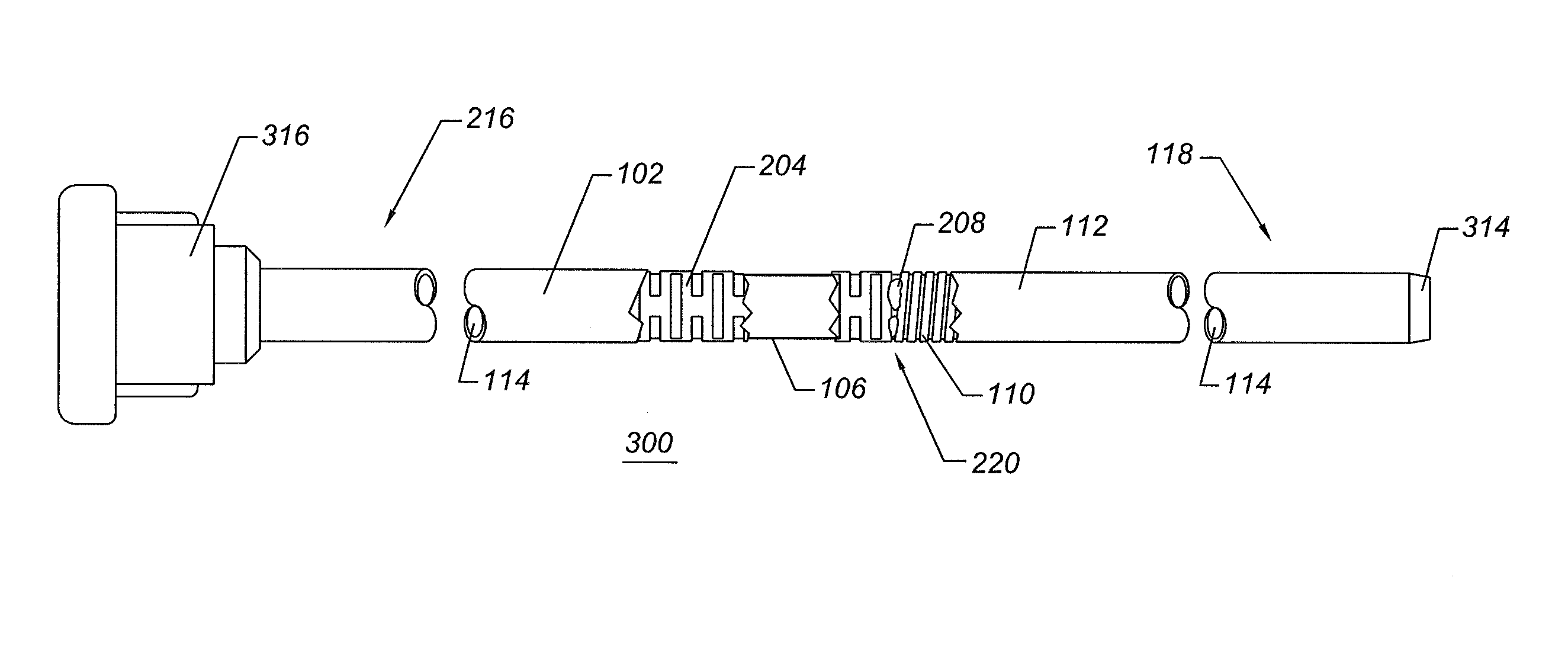

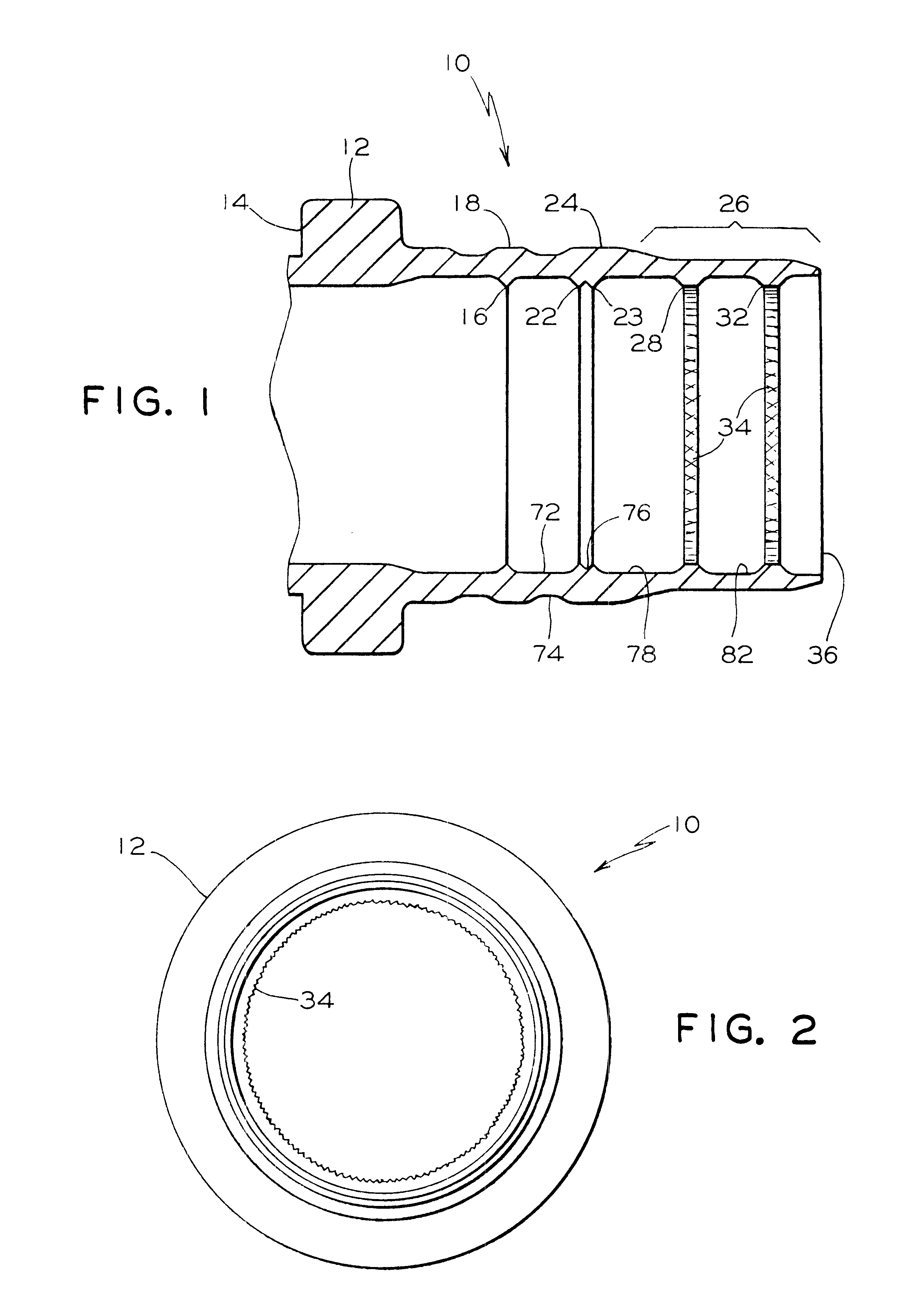

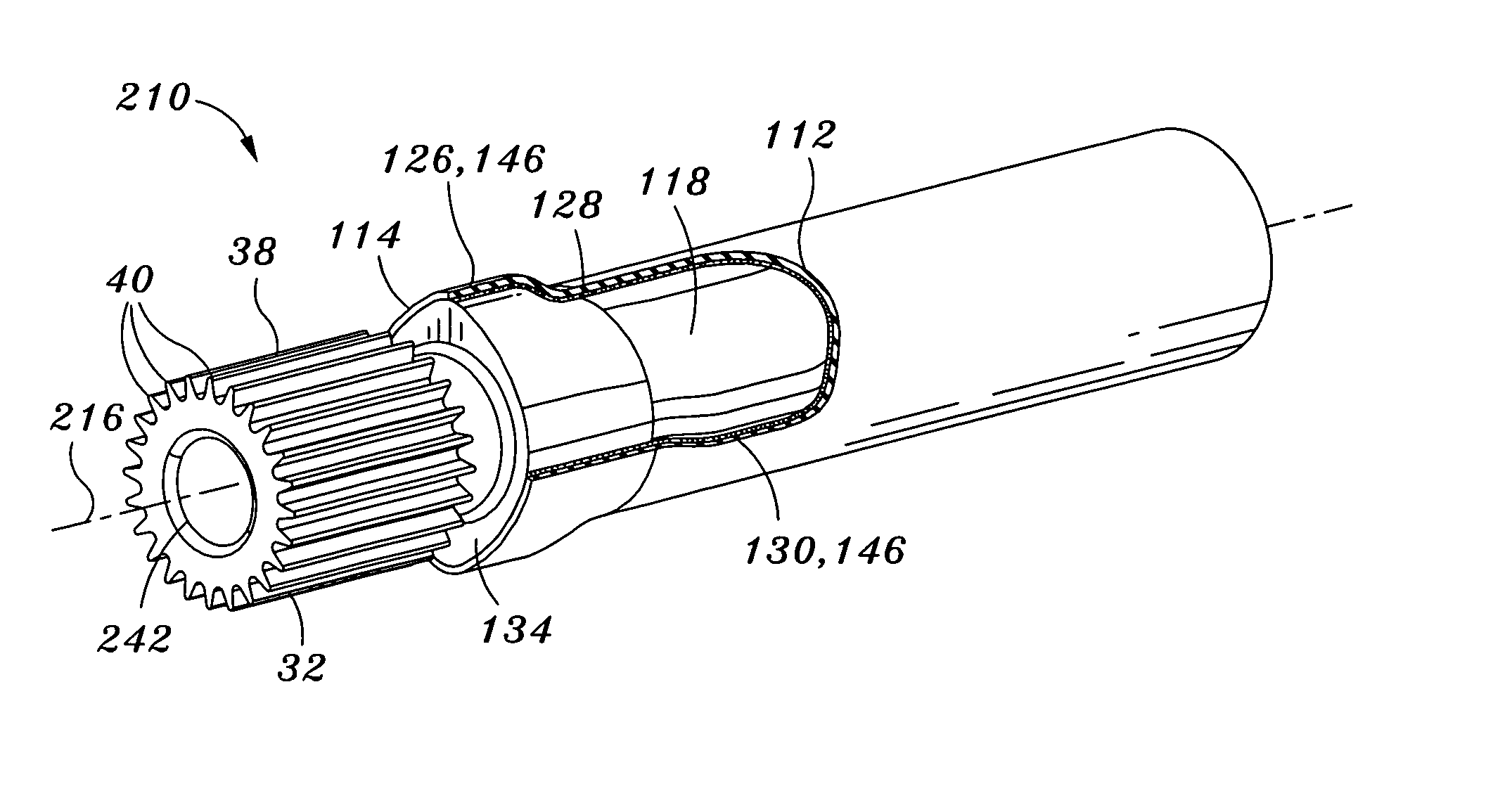

Composite torque tube captured end fitting

ActiveUS7419435B2Improve rendering capabilitiesImprove torque performanceShaft for rotary movementMechanical engineeringTorque tube

A torque tube assembly includes a hollow composite member and an end fitting. The composite member has at least one end portion divided into a forward section and an aft section. The forward section is disposed adjacent a free end of the composite member. Each one of the forward and aft sections has at least one lobe extending radially outwardly along a lobe axis. The lobe axis of the forward section is preferably angularly offset from the lobe axis of the aft section. The end fitting is formed complementary to the composite member and is at least partially enclosed by the forward and aft sections.

Owner:NORTHROP GRUMMAN SYST CORP

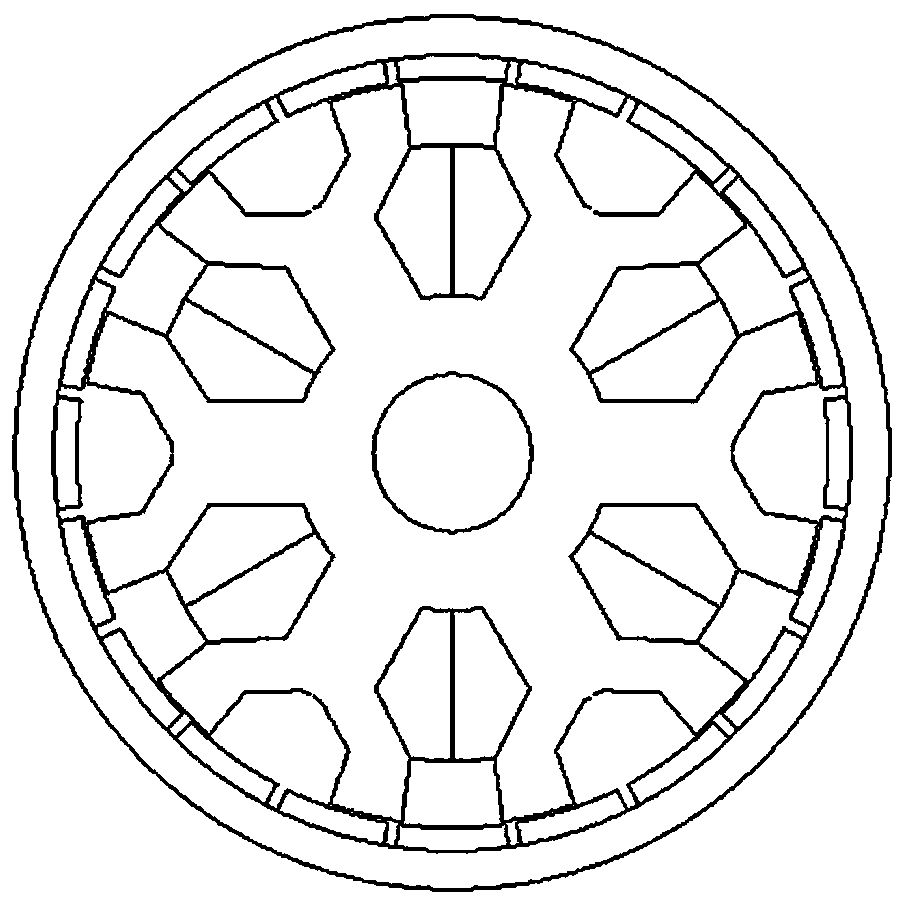

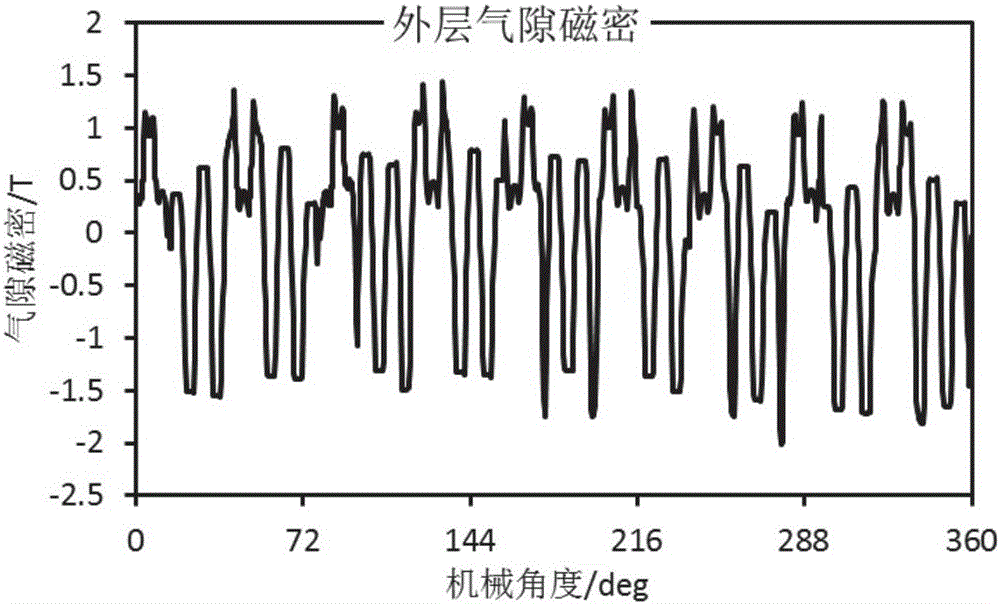

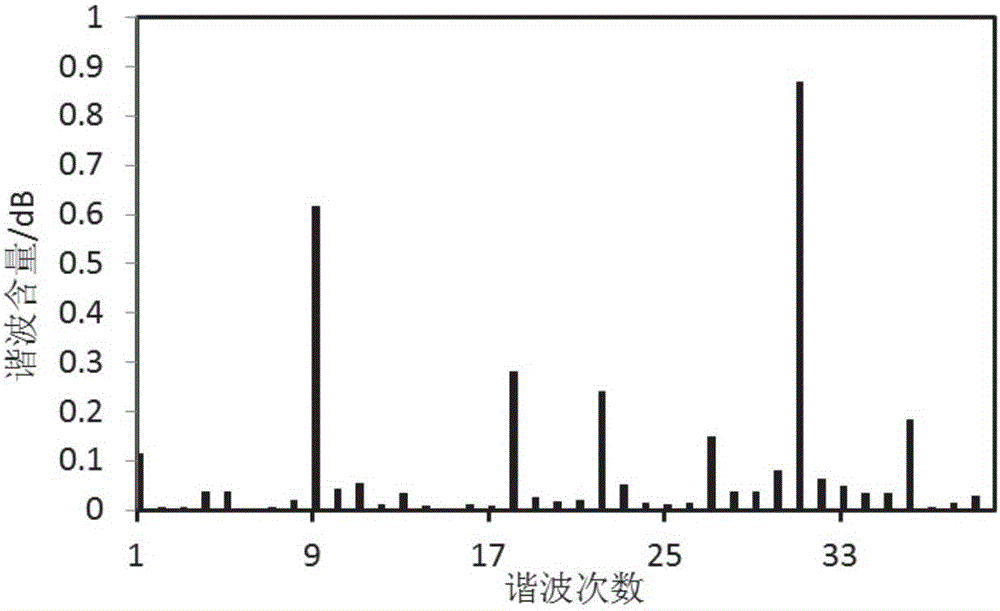

Torque ripple weakening method for concentrated winding outer rotor magnetic field modulation motor

ActiveCN111525713AIncrease sineIncrease the reduction ratioElectronic commutation motor controlMagnetic circuit rotating partsElectric machineTorque density

The invention discloses a torque ripple weakening method for a concentrated winding outer rotor magnetic field modulation motor, and the method employs a method of building a target function to adjusta modulation polar coefficient combination and rotor axial segmentation for inhibition for main odd harmonics and even harmonics in the counter electromotive force of the motor. According to the method, the reduction of motor torque ripple is taken as an objective function, and an optimal modulation polar coefficient combination is obtained through a method of combining analytical calculation anda finite element method so as to suppress the influence of main odd harmonics. A rotor of the concentrated winding magnetic field modulation motor is divided into two sections in the axial direction,permanent magnets of the two sections are magnetized with N polarity and S polarity respectively, and the upper permanent magnet and the lower permanent magnet are arranged in a staggered mode by thedistance of one pole so as to restrain the influence of even harmonics. The torque ripple suppression method is easy to operate and obvious in effect, and the concentrated winding outer rotor magnetic field modulation motor has the advantages of being high in torque density and low in torque ripple.

Owner:SOUTHEAST UNIV

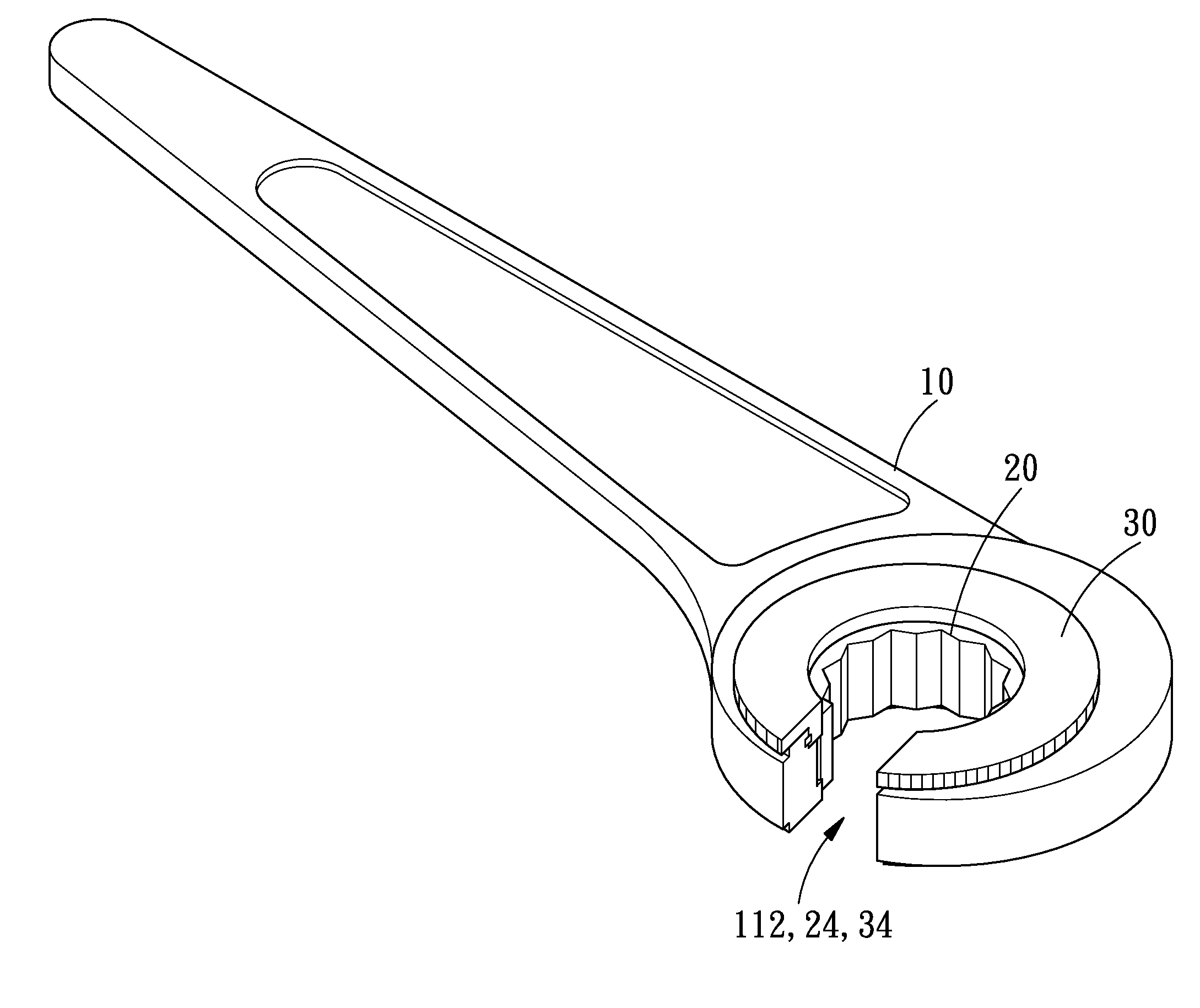

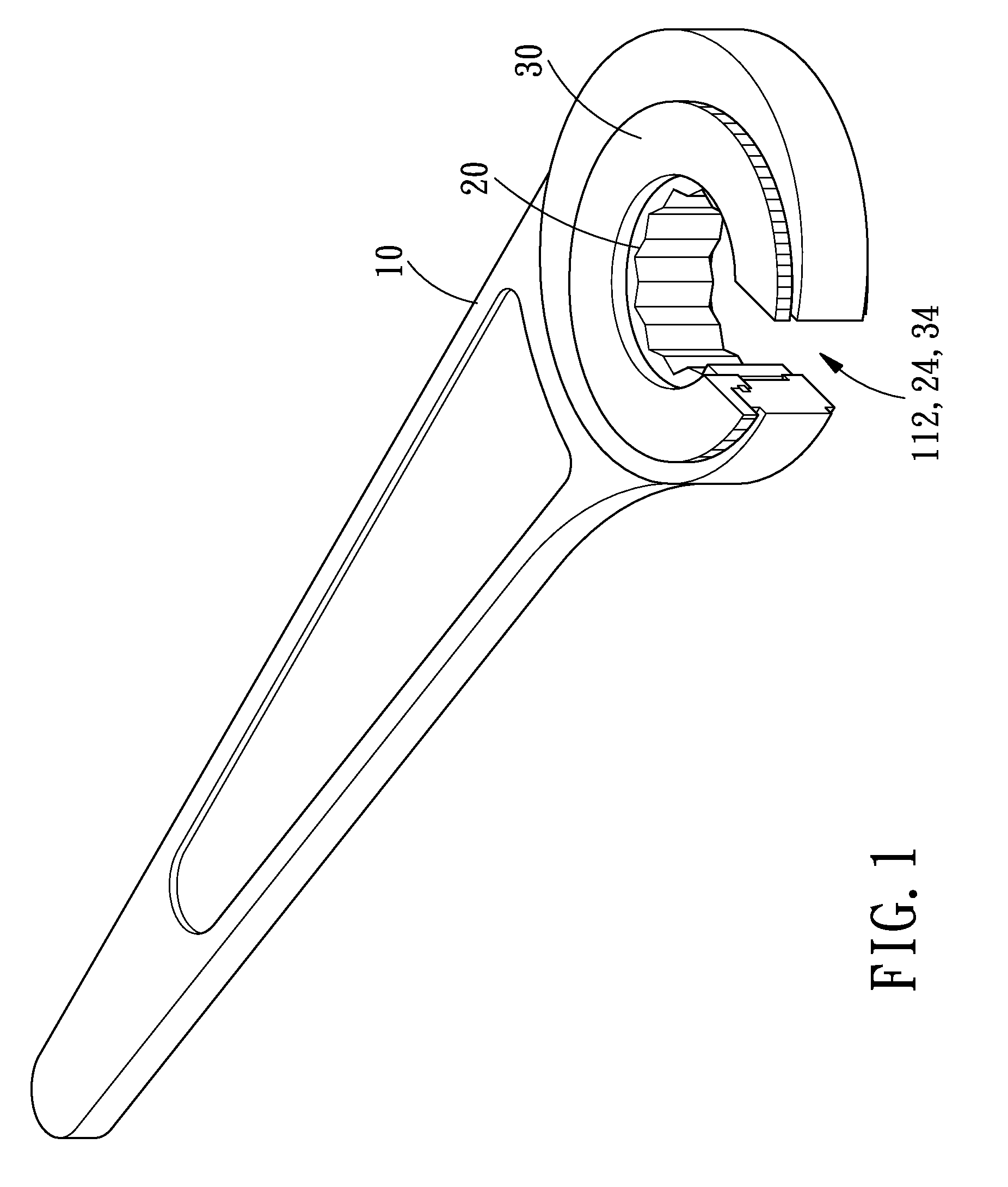

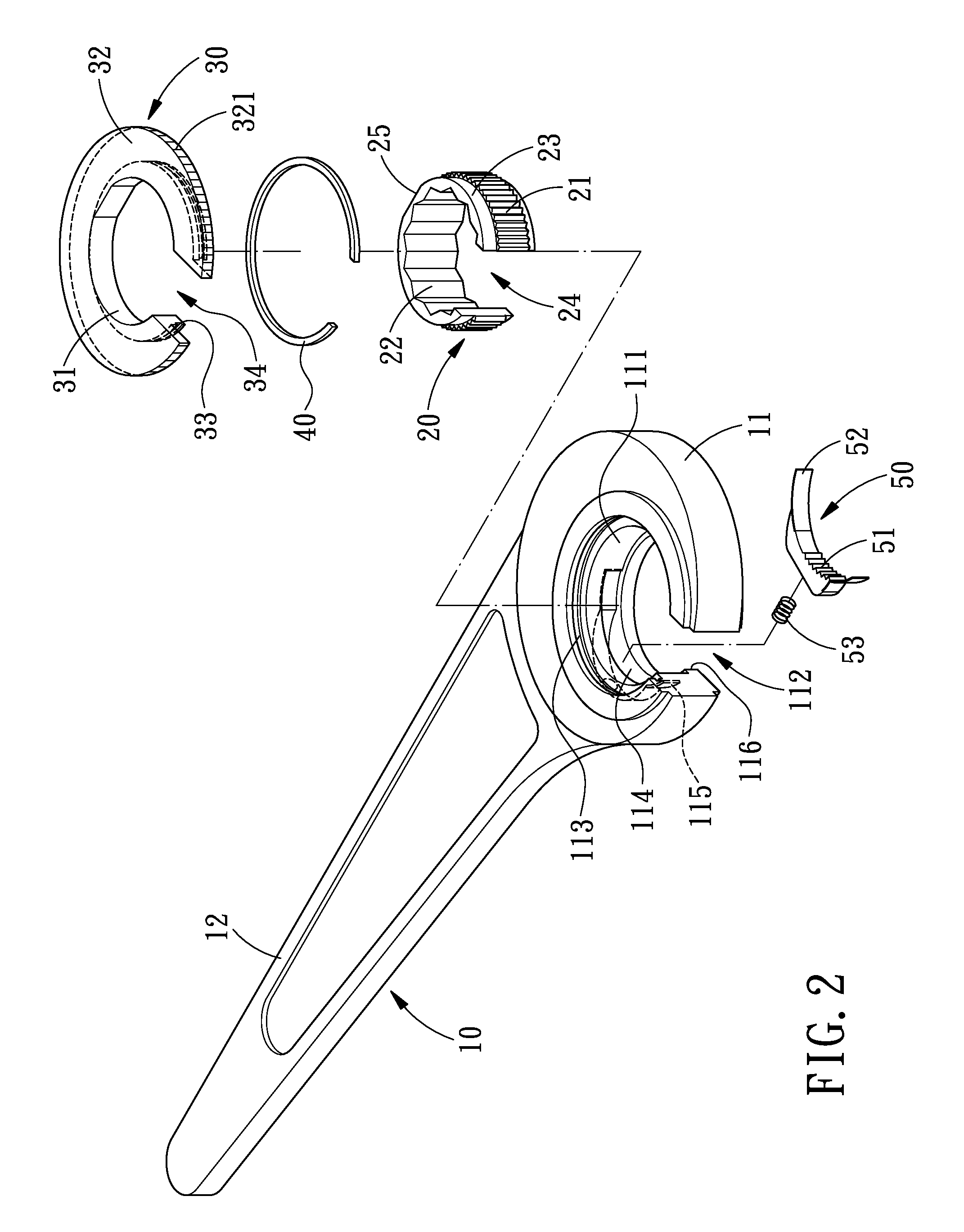

Open End Ratchet Wrench

An open end ratchet wrench is defined with a gap which allows the ratchet wrench to pass through a pipe or obstacle to carry out rotation, thus improving the operability and convenience of the wrench. Both ends of the open end ratchet wrench extend outward to form a stopping piece, respectively. The stopping pieces allow the toothed pawl to be well positioned and prevent it from disengaging, thus maintaining a stable torque and making the ratchet wrench easy to use.

Owner:CEO TOOL

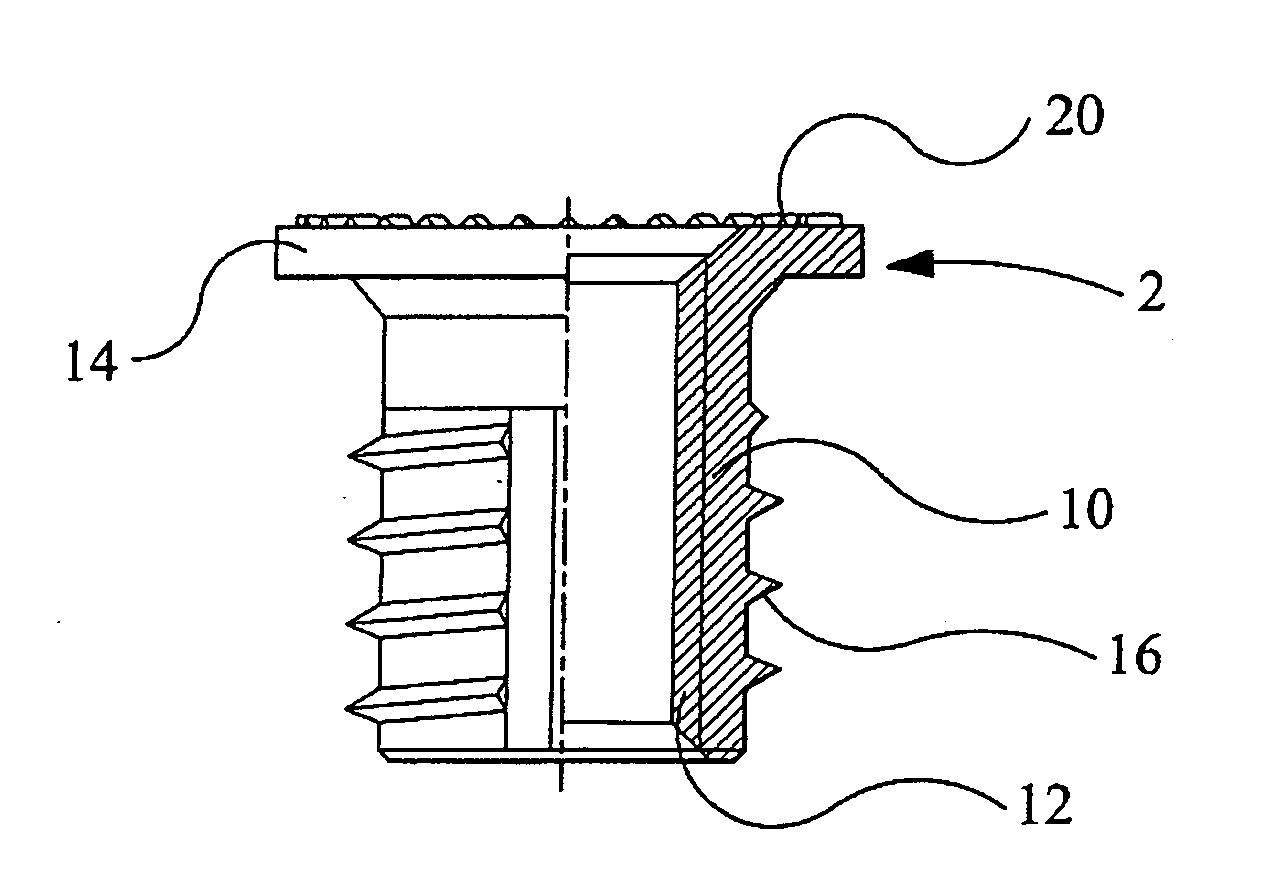

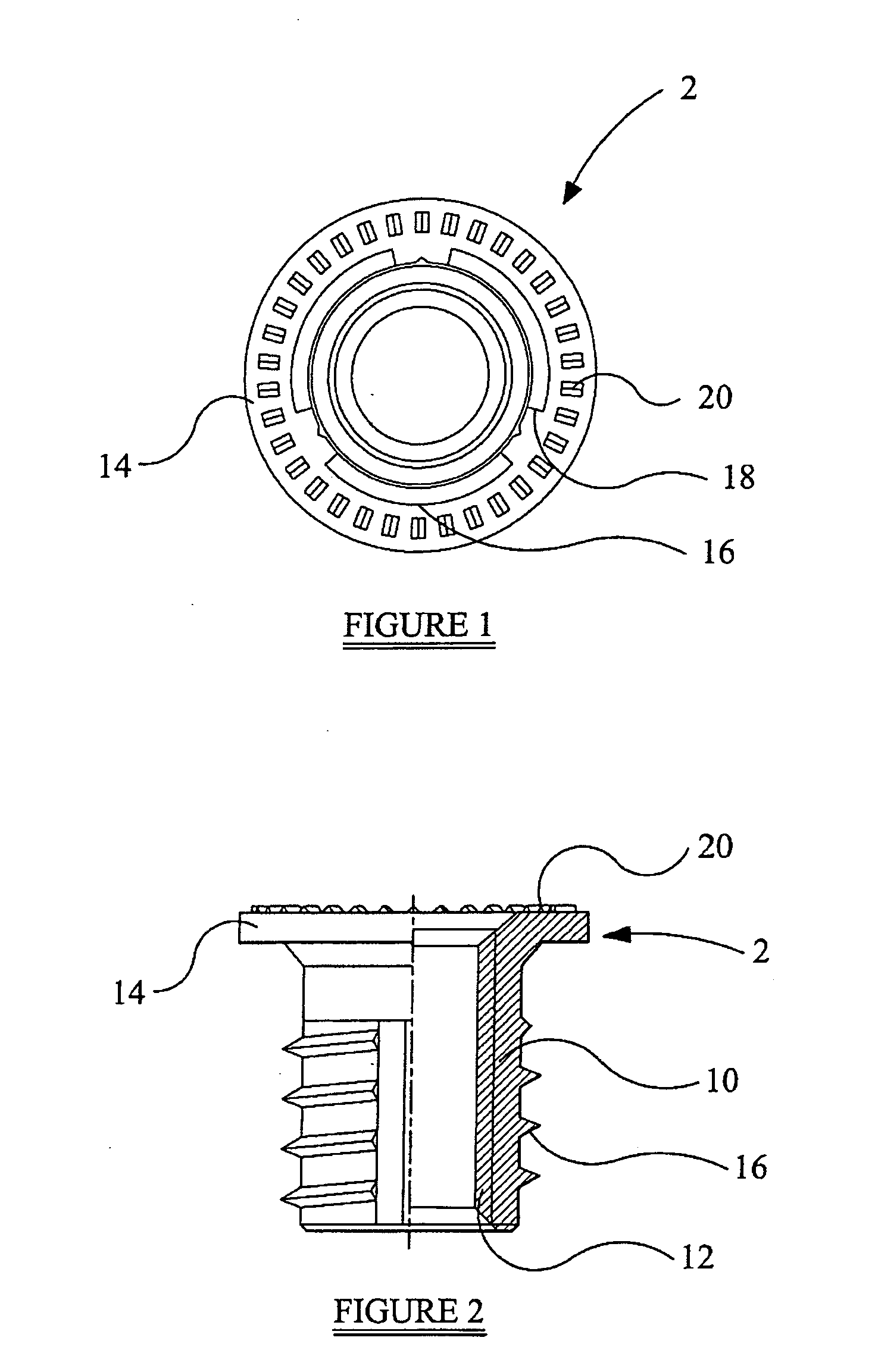

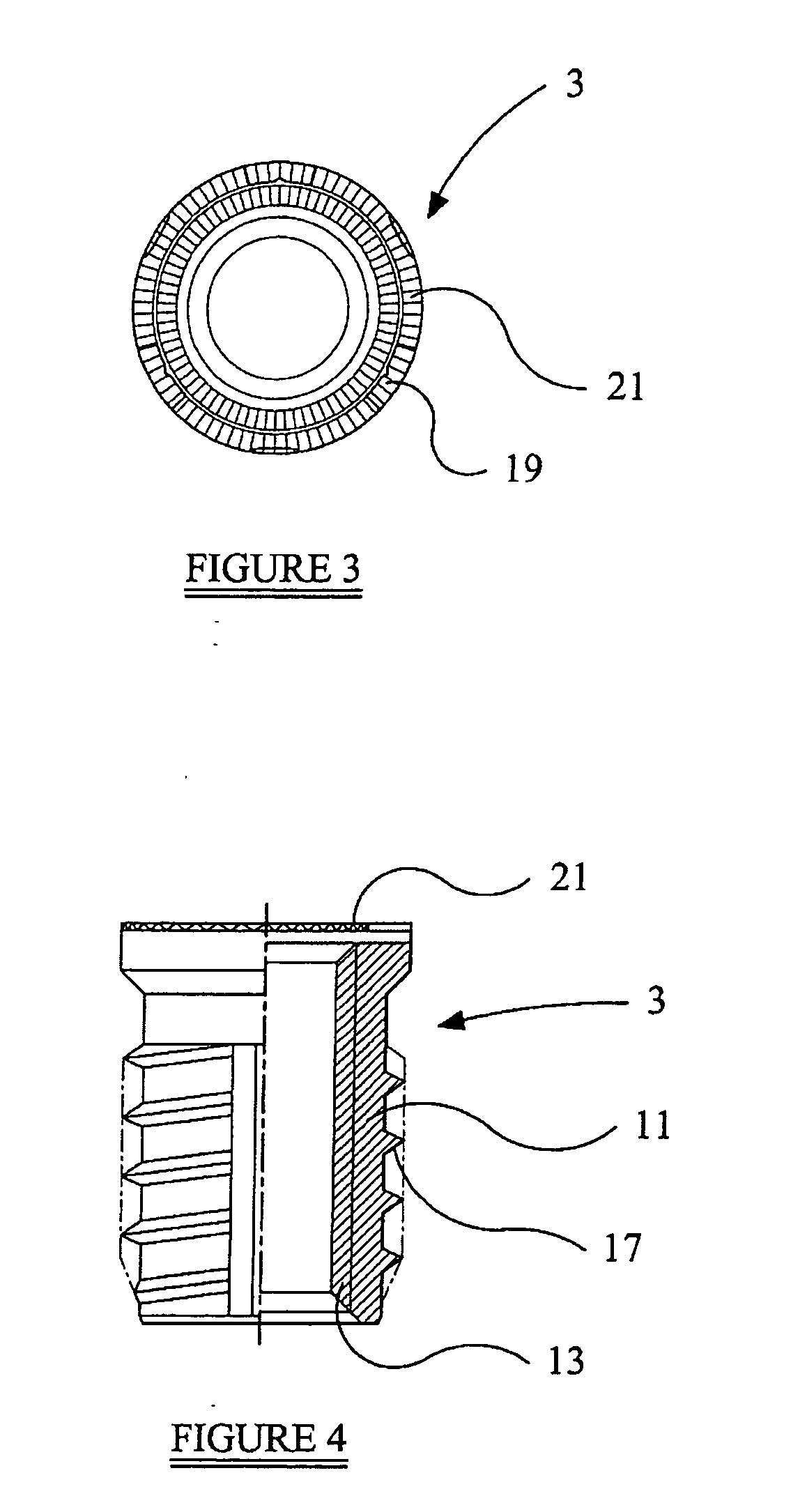

Fastener

The present invention relates to fasteners and in particular to fasteners, such as threaded inserts, arranged in use to be self-threaded into a parent material of a workpiece. A threaded insert may fail due to a number of mechanisms, including I) due to rotation caused by the threaded insert being partially jacked out and compressing the parent material if the material of the parent material is weaker than the material of the threaded insert thereby destroying the joint or ii) by rotation where the thread formed by the threaded insert as it is inserted in the parent material becomes stripped and the threaded insert then continues to turn. A fastener (2,3) is disclosed comprising a generally cylindrical body (10,11) about which is formed a thread (16,17), the fastener having a first end and a second end, in which a first end of the fastener is provided with a knurled surface (20,21). This has the advantage that an insert having improved torque performance is provided.

Owner:TAPPEX THREAD INSERTS

Novel high torque density high power factor fault tolerant permanent magnet vernier machine and its modulation method

ActiveCN105958762AImprove winding factorImprove torque performanceElectronic commutation motor controlMagnetic circuit rotating partsHigh torquePower factor

The invention discloses a novel high torque density high power factor fault tolerant permanent magnet vernier machine and its modulation method. The vernier machine structure comprises a coaxial stator, an inner rotor and an outer rotor, wherein the permanent magnets of the inner rotor are distributed in a radial arrangement with their magnetization directions being tangential and their N poles and the S poles arranged in alternation. The permanent magnets of the outer rotor are arranged in a face embedding manner with their magnetization directions pointing to the center of circle. Ten smaller fault-tolerant teeth and ten bigger armature teeth are alternately arranged on the stator. The tops of each fault-tolerant tooth and the armature tooth are provided with a virtual slot, forming two virtual teeth. The armature windings adopt a single-layer concentrated winding manner in their winding. The invention utilizes the combination of a vernier machine, a magnetic gear and a fault-tolerant performance to further increase the motor torque outputting capacity on the basis of the vernier machine to achieve a more efficient utilization of the motor. This motor, with fault-tolerant performance, is ensured to provide reliable operations. Structured with a magnetic gear, the vernier machine can greatly enhance the motor power factor. The invention can increase the reliability of the motor operation and has great application prospects.

Owner:JIANGSU UNIV

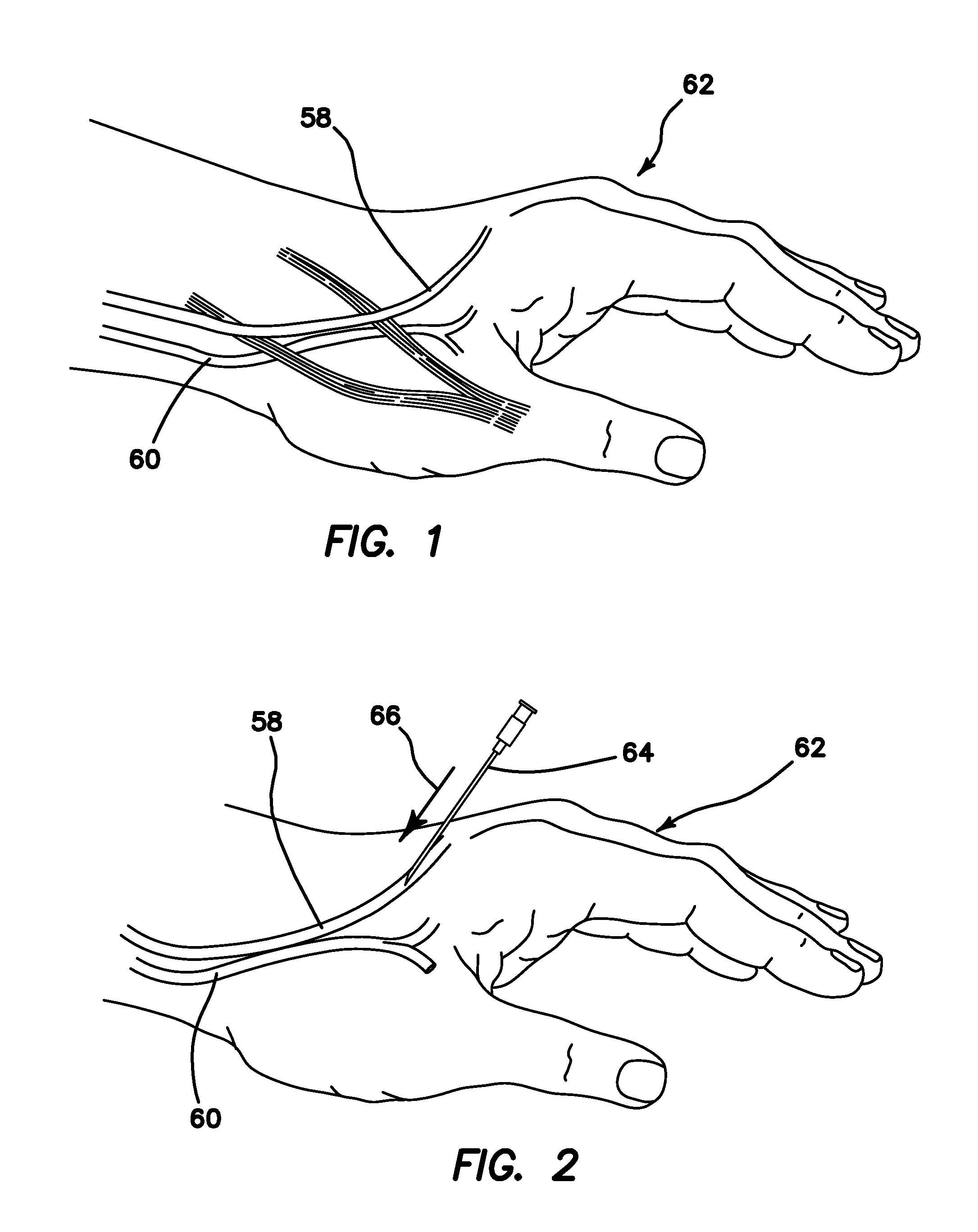

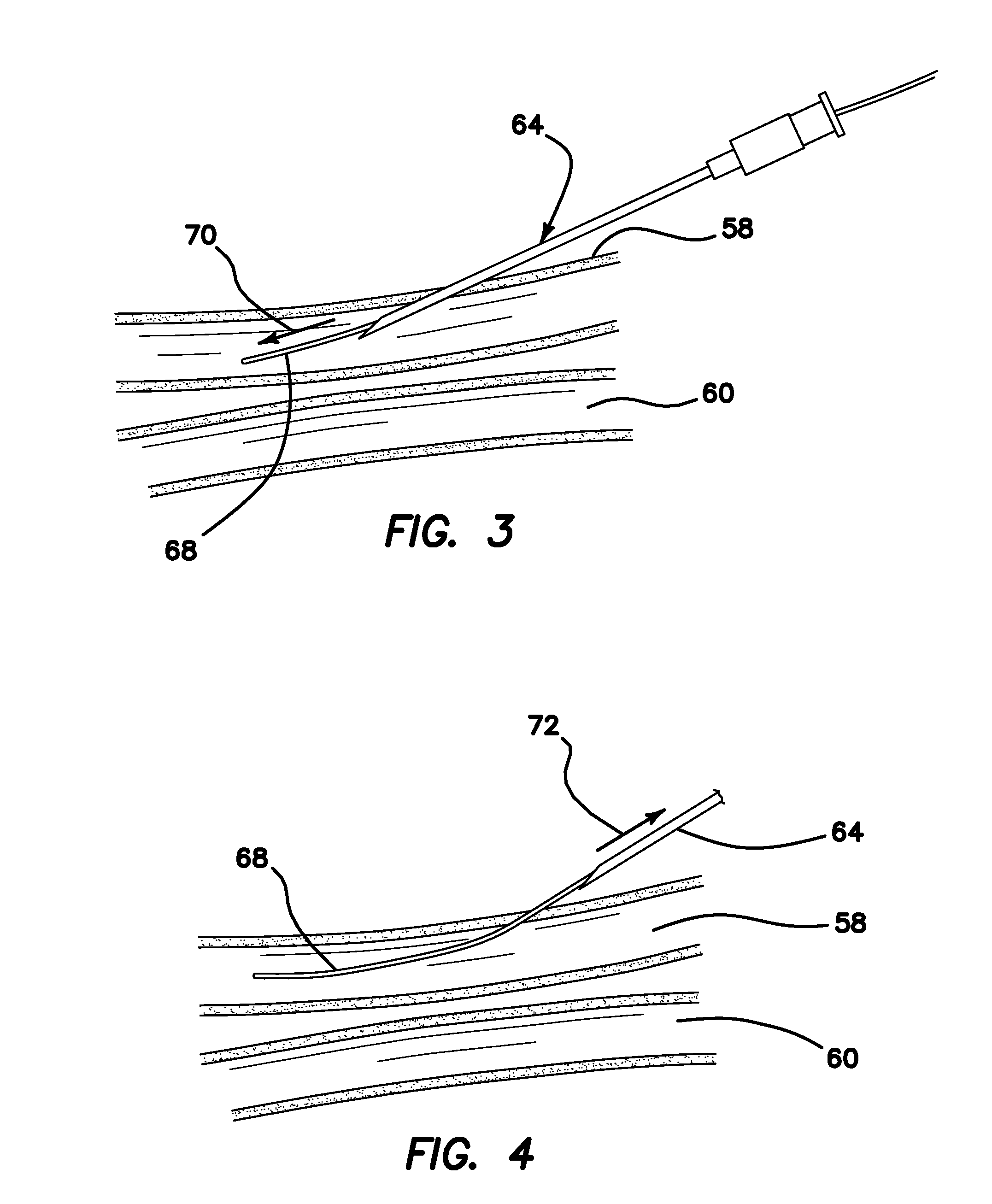

Systems and methods for creating arteriovenous (AV) fistulas

ActiveUS9138230B1Shorten operation timeStop the bleedingSurgical needlesSurgical instrument detailsAv fistulasBlood vessel

An AV fistula between first and second blood vessels is created by forming a hole through adjacent walls of the vessels and inserting a welding catheter into the first vessel, and through the hole into the second vessel, so that a distal end of the catheter is disposed within the second vessel. A portion of wall defining the welding catheter is then expanded radially outwardly, and the expanded wall portion is pulled proximally to engage the wall of the second blood vessel and to pull it toward the wall of the first blood vessel. A portion of wall proximal to the first expanded wall portion and disposed in the first blood vessel is expanded radially outwardly, thereby capturing the walls of each of the second and first blood vessels between the two expanded wall portions. Cutting elements are energized to create a tissue welded elongate aperture between the blood vessels.

Owner:AVENU MEDICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com