Patents

Literature

535 results about "Magnetic gear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A magnetic gear resembles in part, the traditional mechanical gear. All cogs of each gear component of magnetic gears act as a magnet with periodic alternation of opposite magnetic poles on mating surfaces. Gear components are mounted with a "cushioned" backlash capability similar to other mechanical gearings with no cushioning effect. Although they can exert as much force as a traditional gear, such gears work without touching and so are immune to wear of mating surfaces, have very low noise and can slip without damage, making them very reliable. They can be used in configurations that are not possible for gears that must be physically touching and can operate with a barrier completely separating the driving force from the load. The magnetically coupled gear can transmit force into a hermetically sealed enclosure without using a radial shaft seal, which may leak. Hermetically sealed processes are not contaminated or chemically affected by the magnetic gear. This can be an advantage in explosive or otherwise hazardous environments where leaks constitute a real danger.

Magnetic transmission

Owner:NISSEN EDWARD WILLIAM

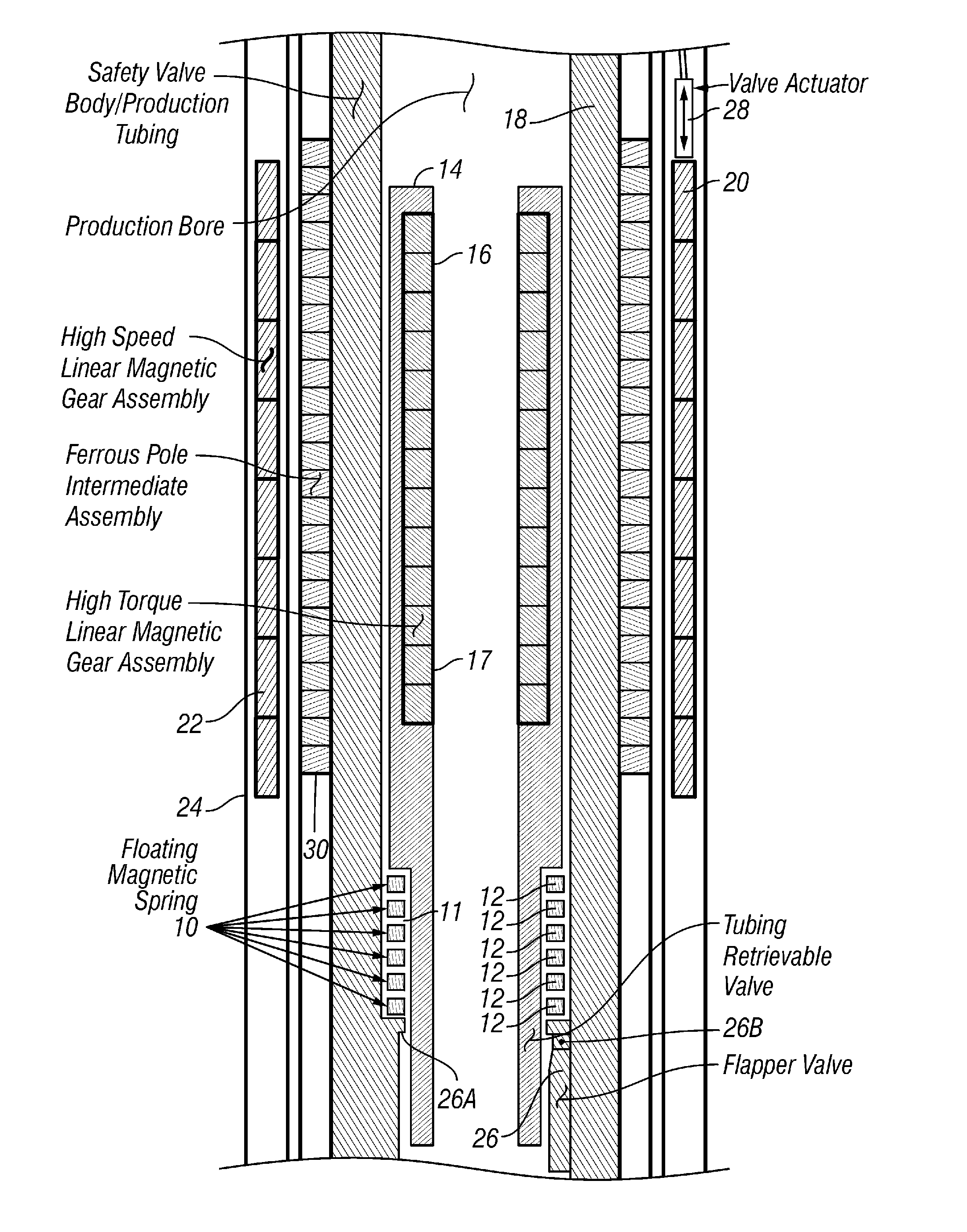

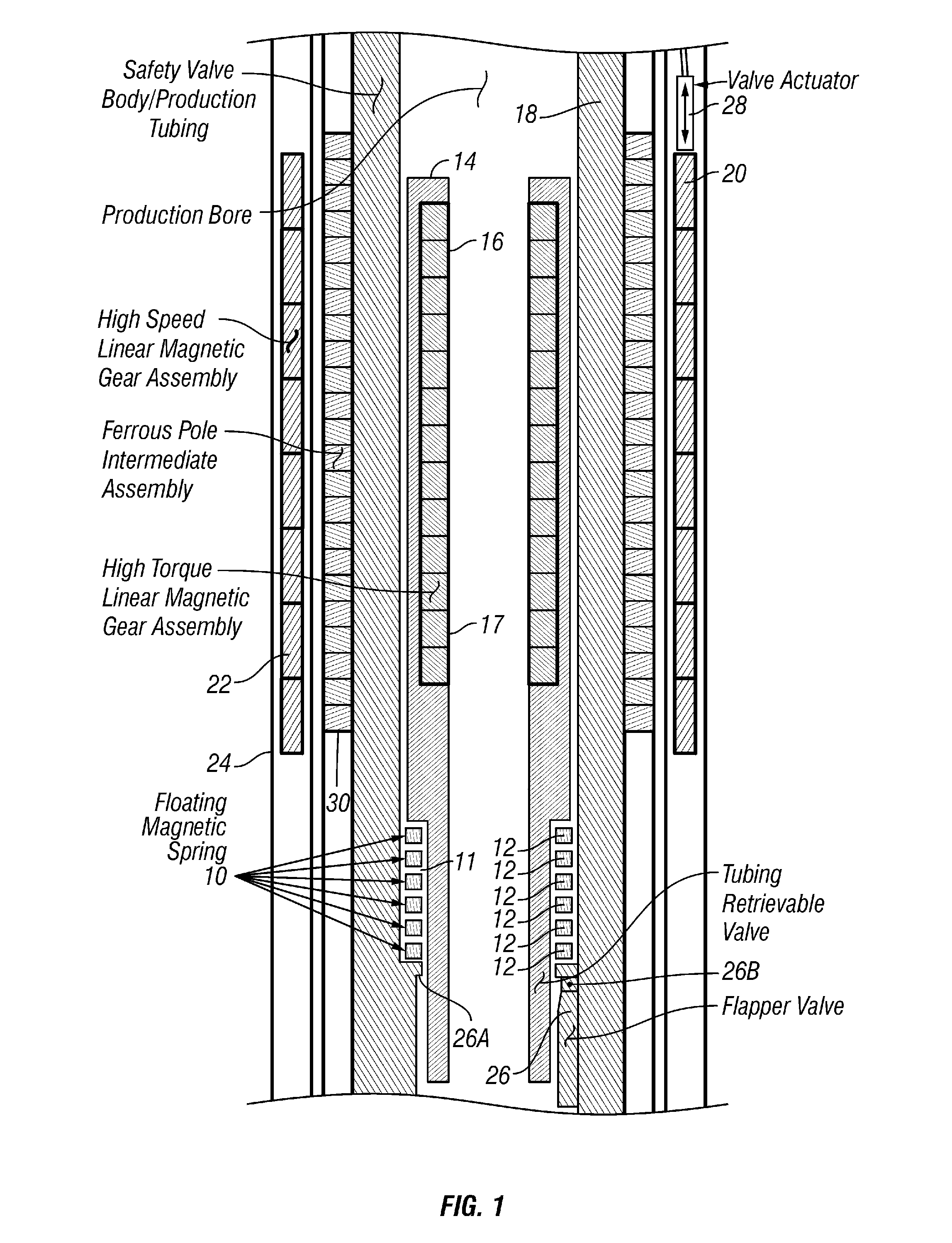

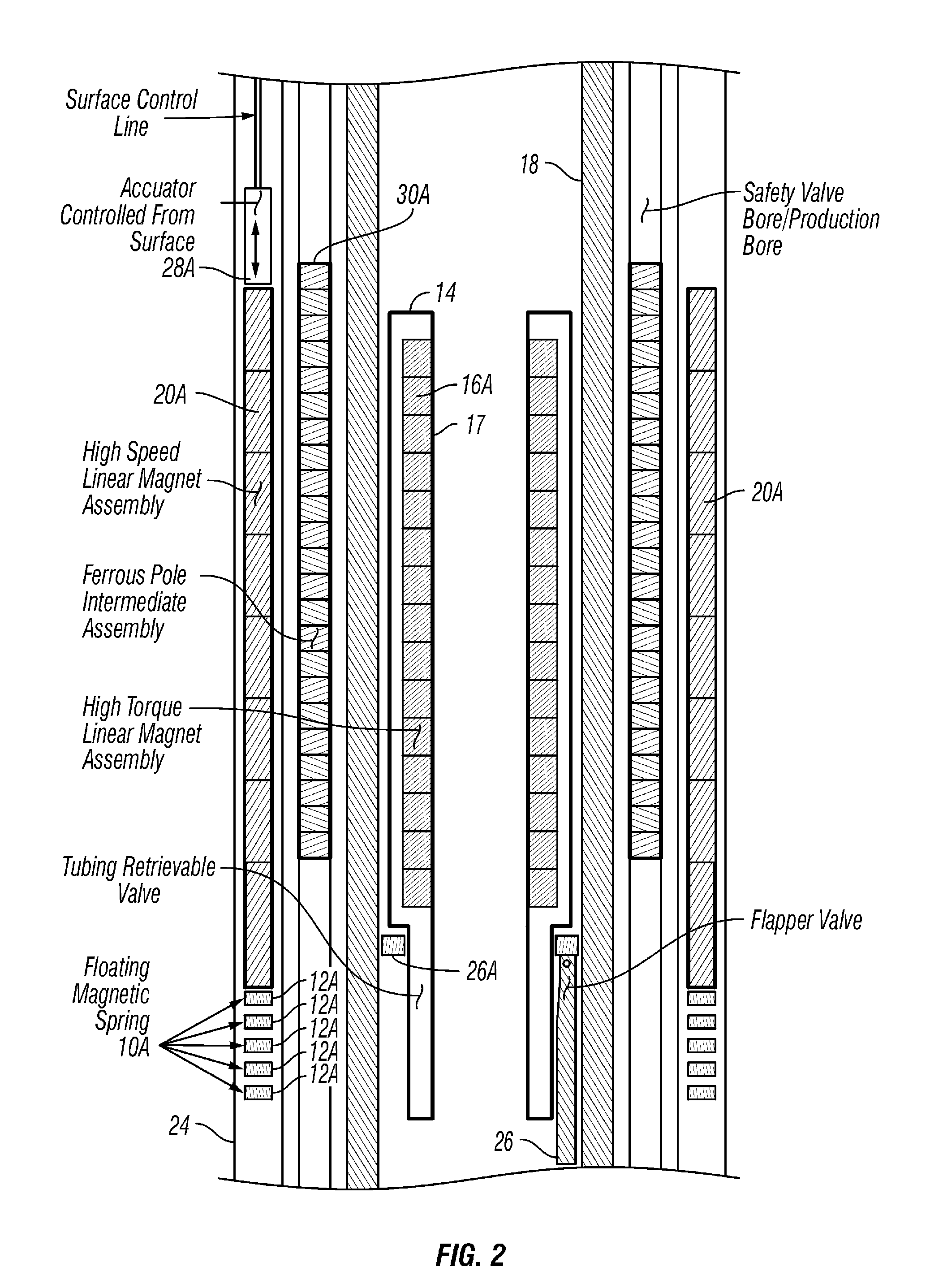

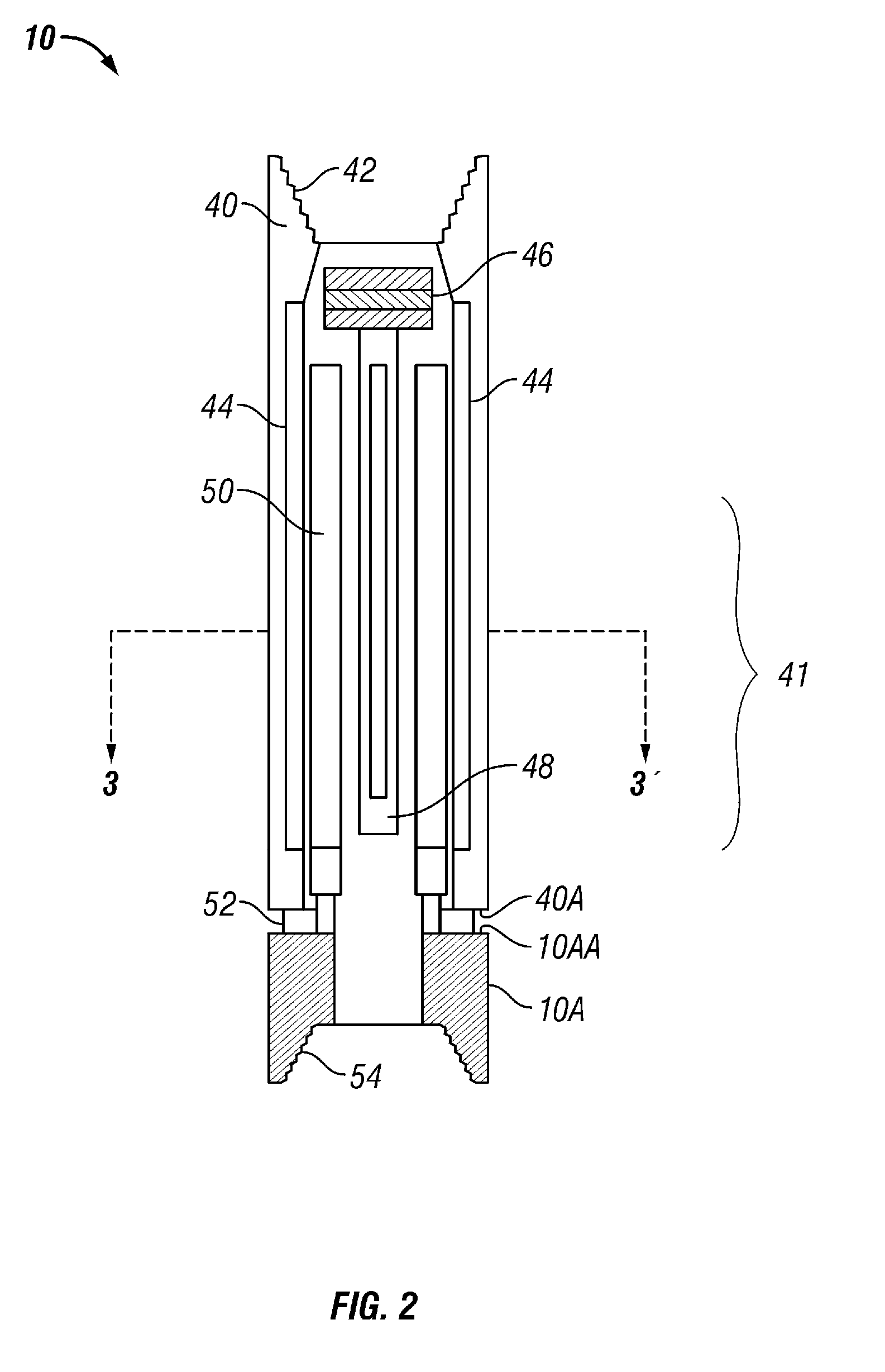

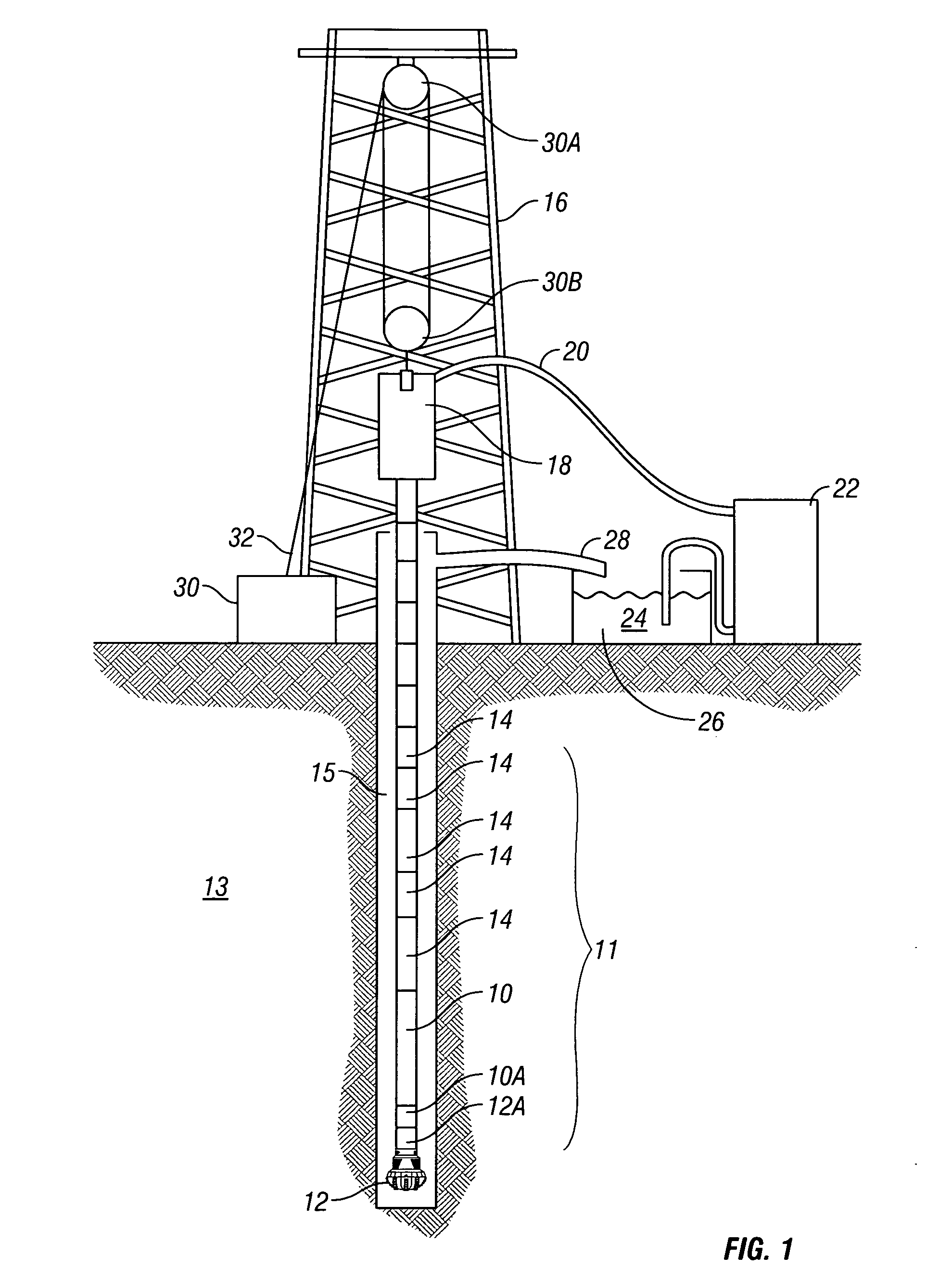

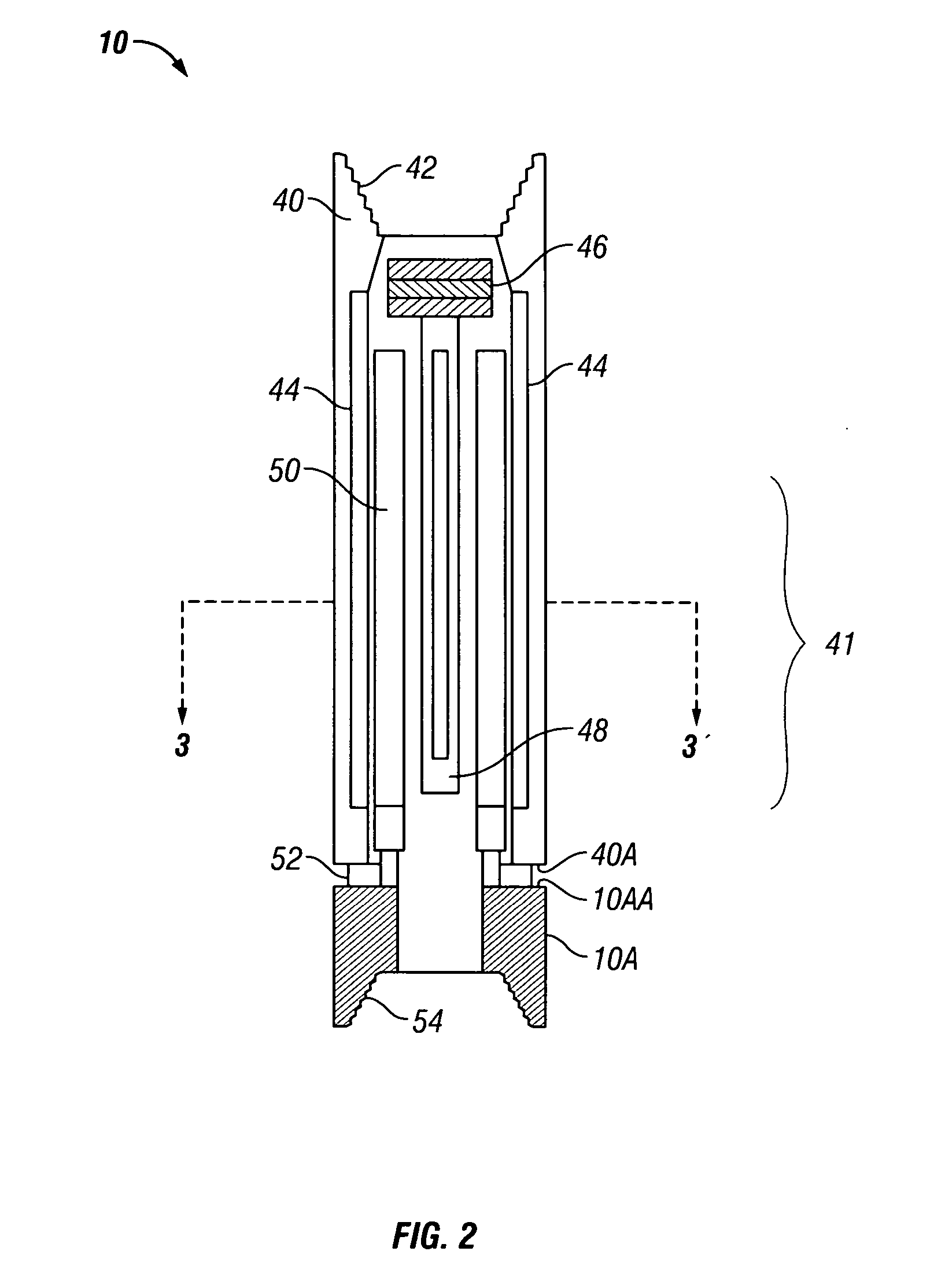

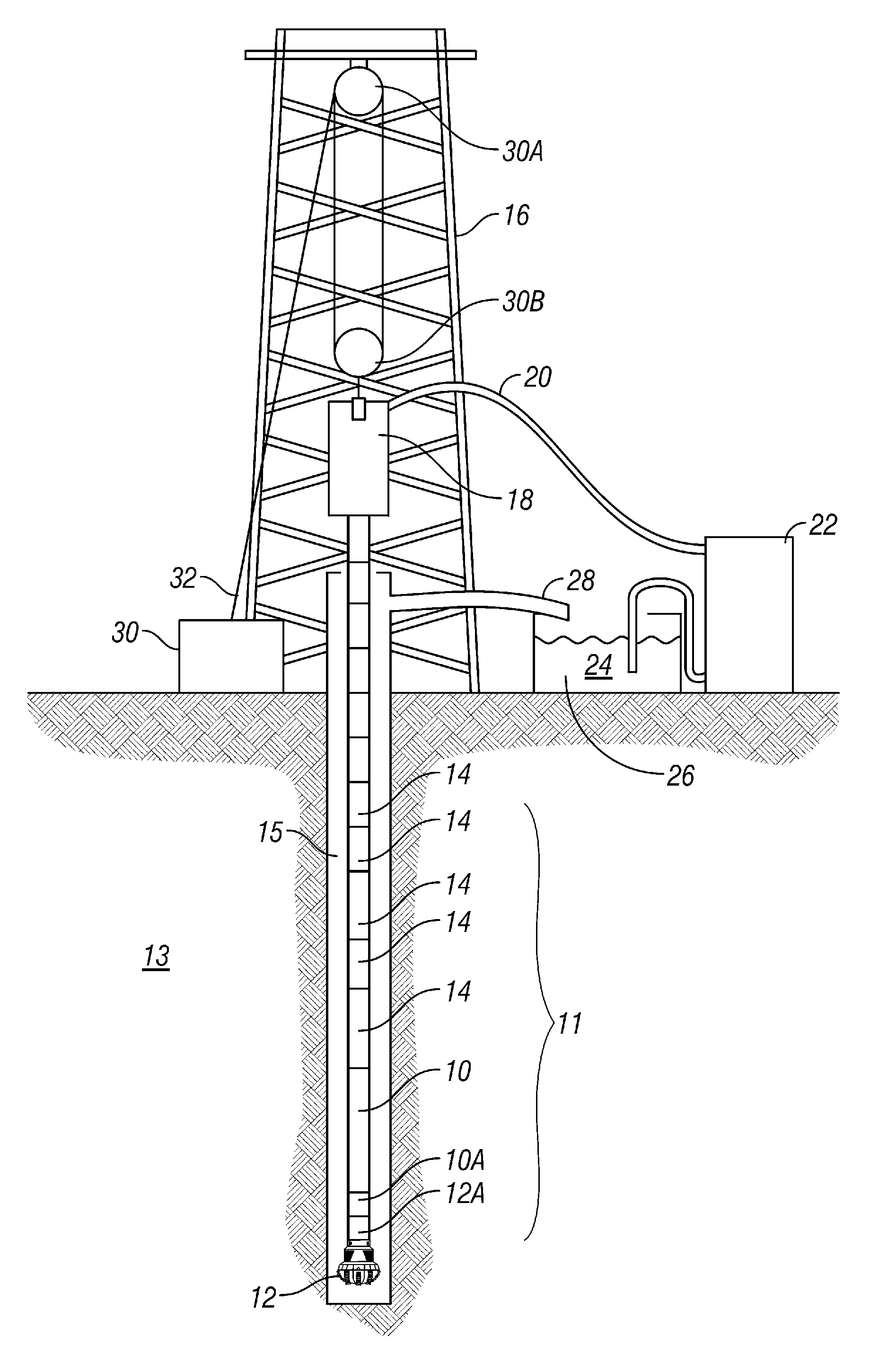

Wellbore Valve Having Linear Magnetically Geared Valve Actuator

InactiveUS20070289734A1Operating means/releasing devices for valvesFluid removalValve actuatorMotion transfer

A wellbore valve includes a valve operator arranged to move axially along an interior of the wellbore, the valve operator arranged to operate a valve. A valve actuator is disposed proximate the valve operator. The valve actuator is arranged to move from one longitudinal position to another. A linear magnetic gear is coupled at an input element thereof to the valve actuator. The gear is coupled at an output element thereof to the valve operator such that motion of the valve actuator is transferred to the valve operator.

Owner:MAGNOMATICS LTD

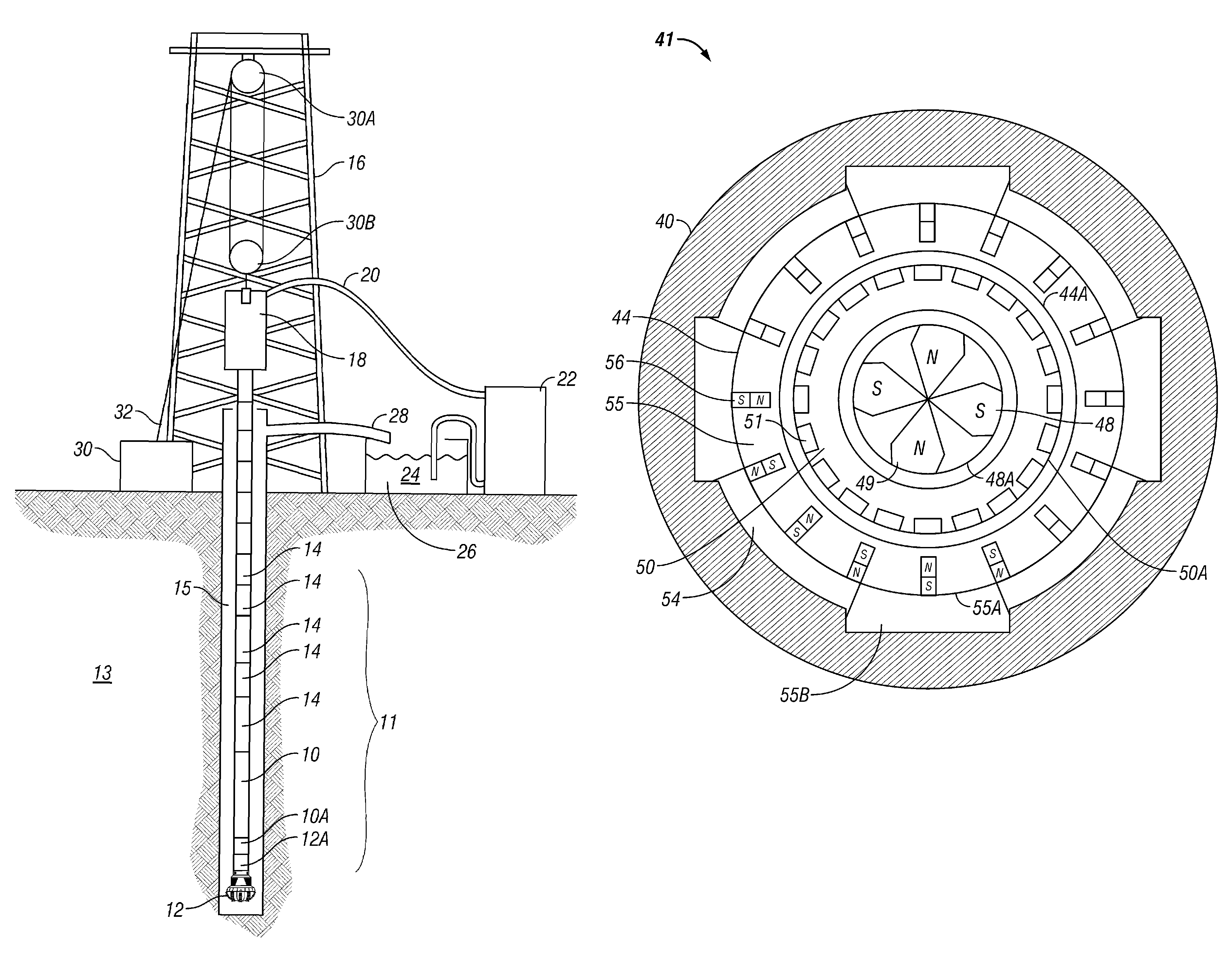

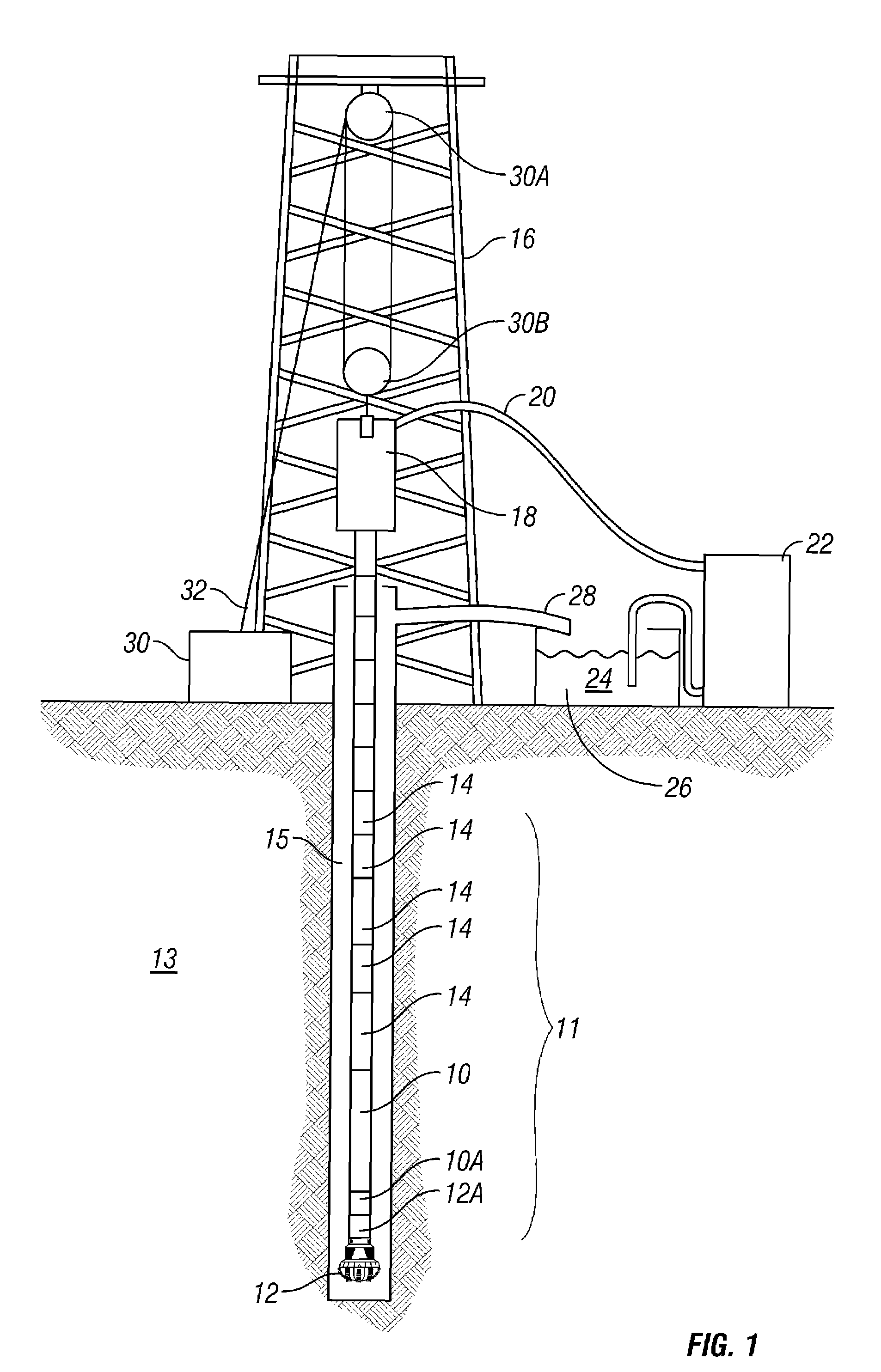

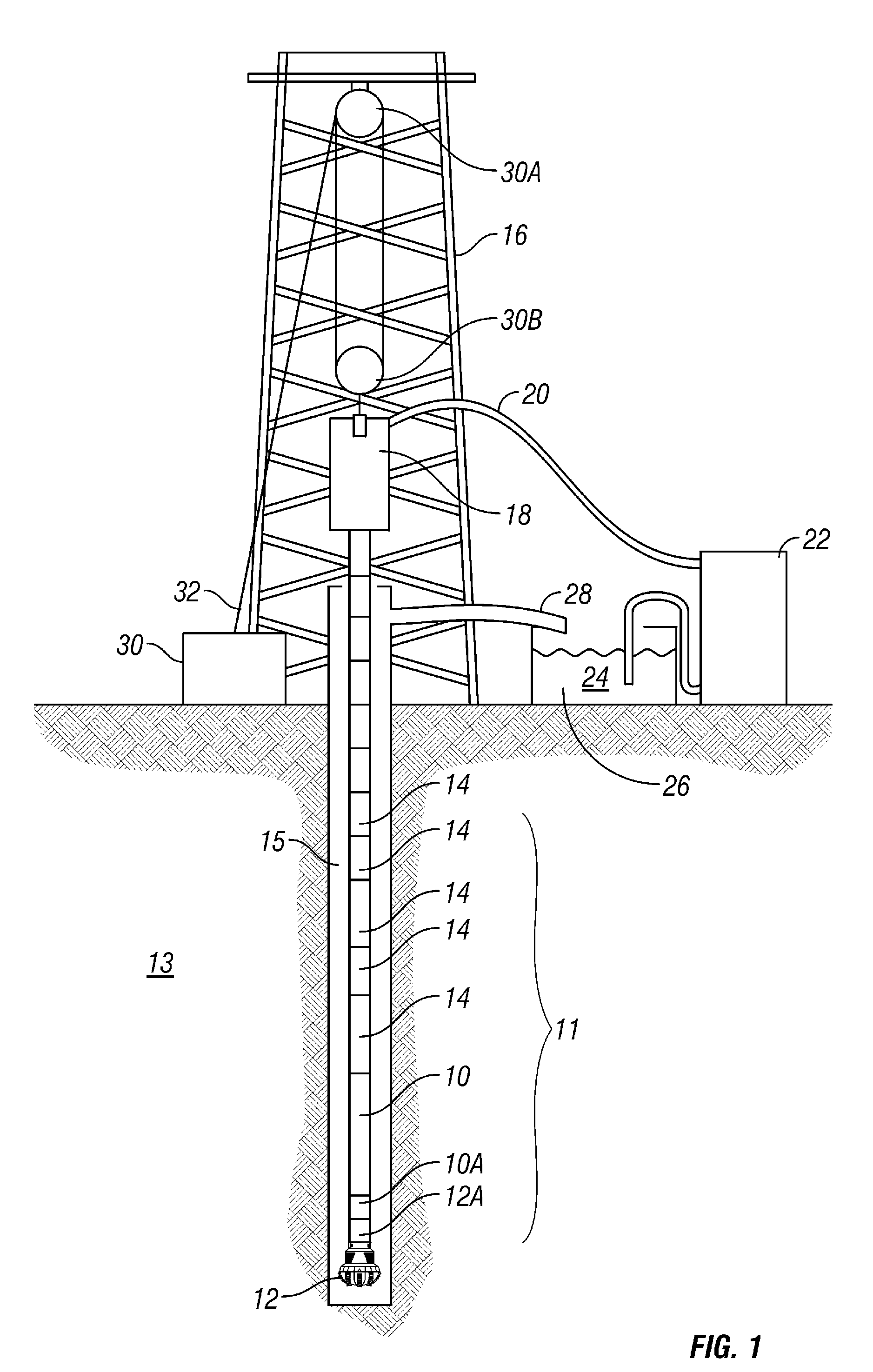

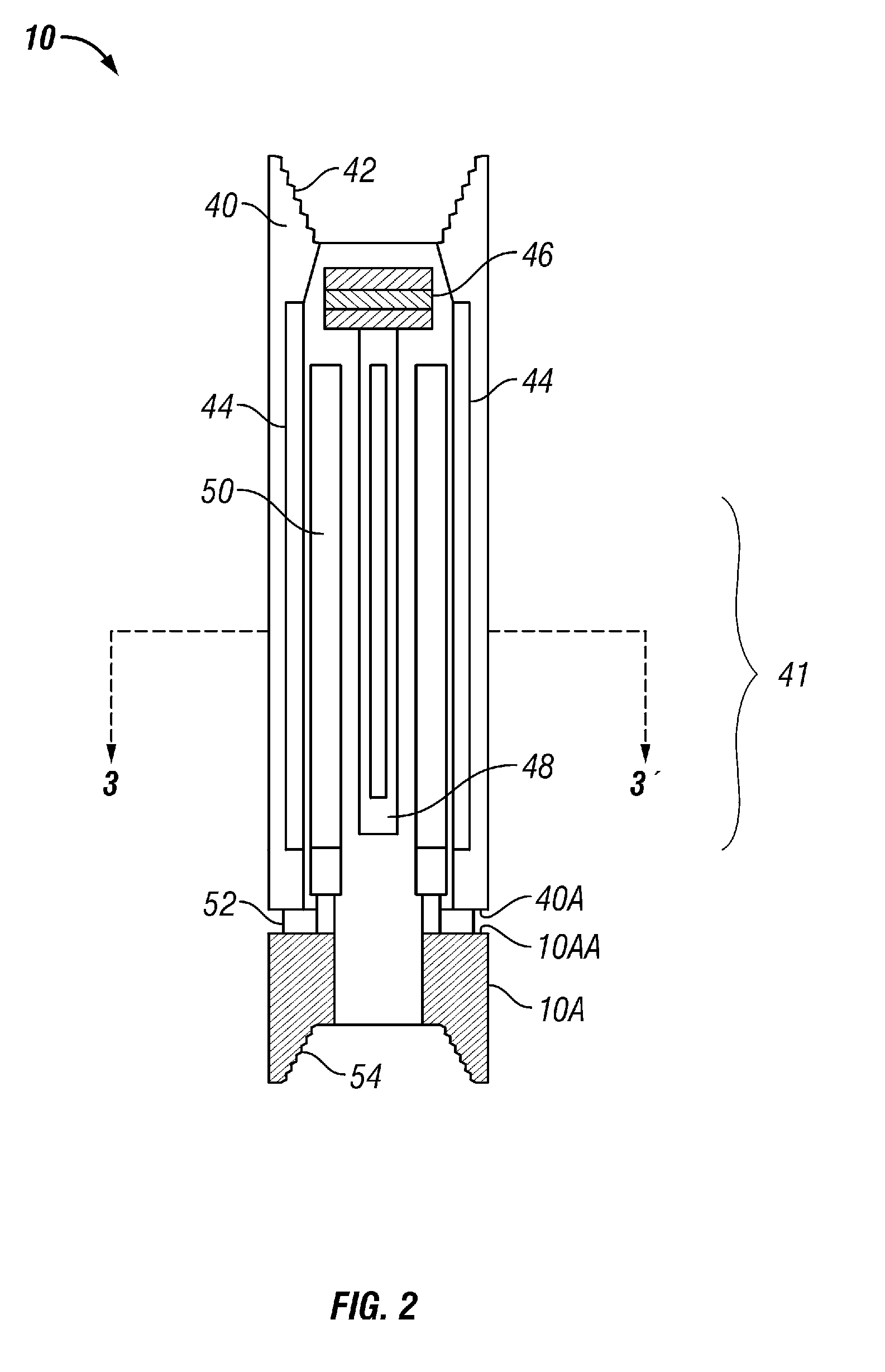

Wellbore motor having magnetic gear drive

A wellbore motor includes a source of rotational motive power disposed in a wellbore, a magnetic gear member operatively coupled at an input thereof to the source; and a magnetic gear member output coupled rotationally to a rotary wellbore tool.

Owner:MAGNOMATICS LTD

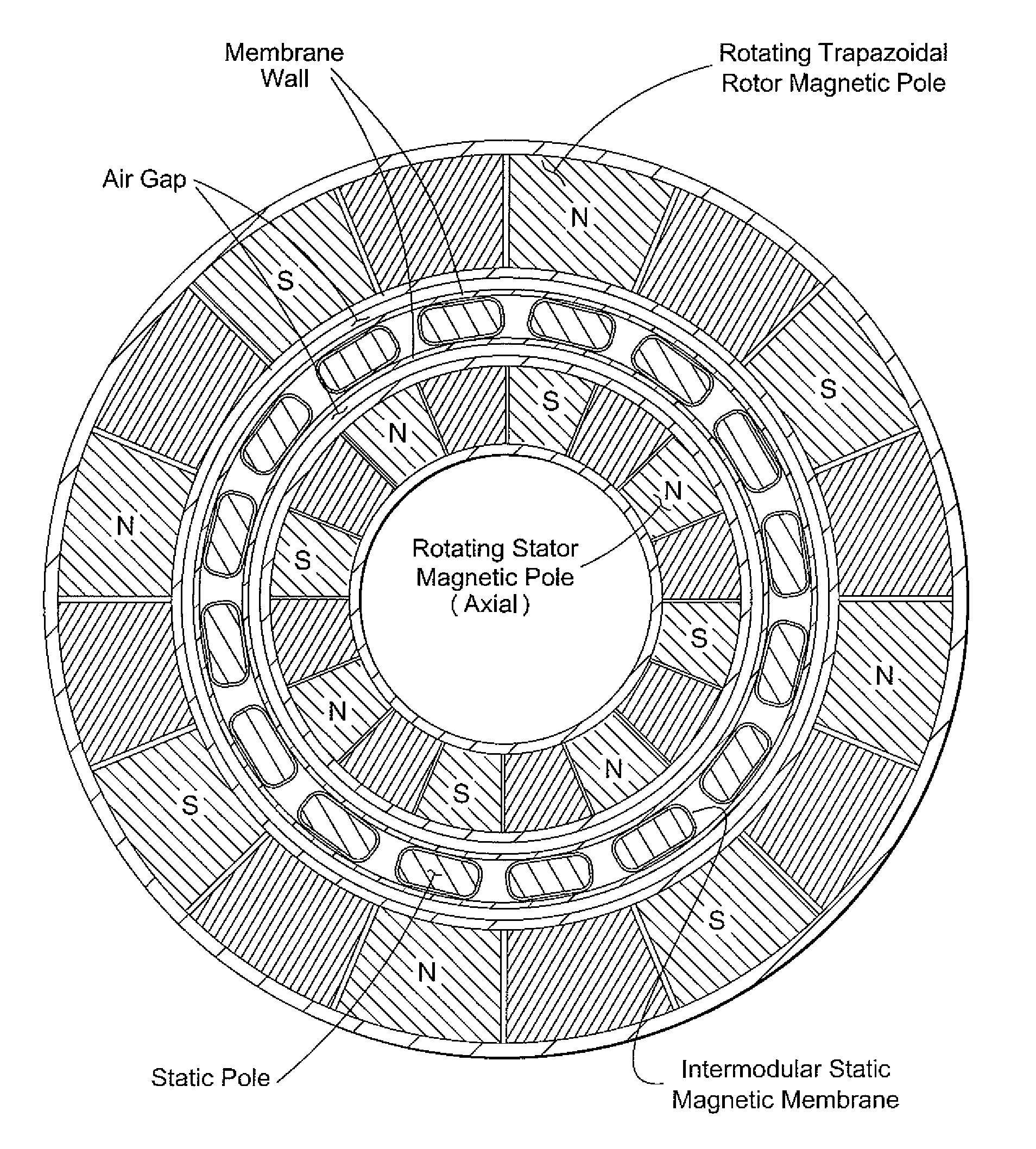

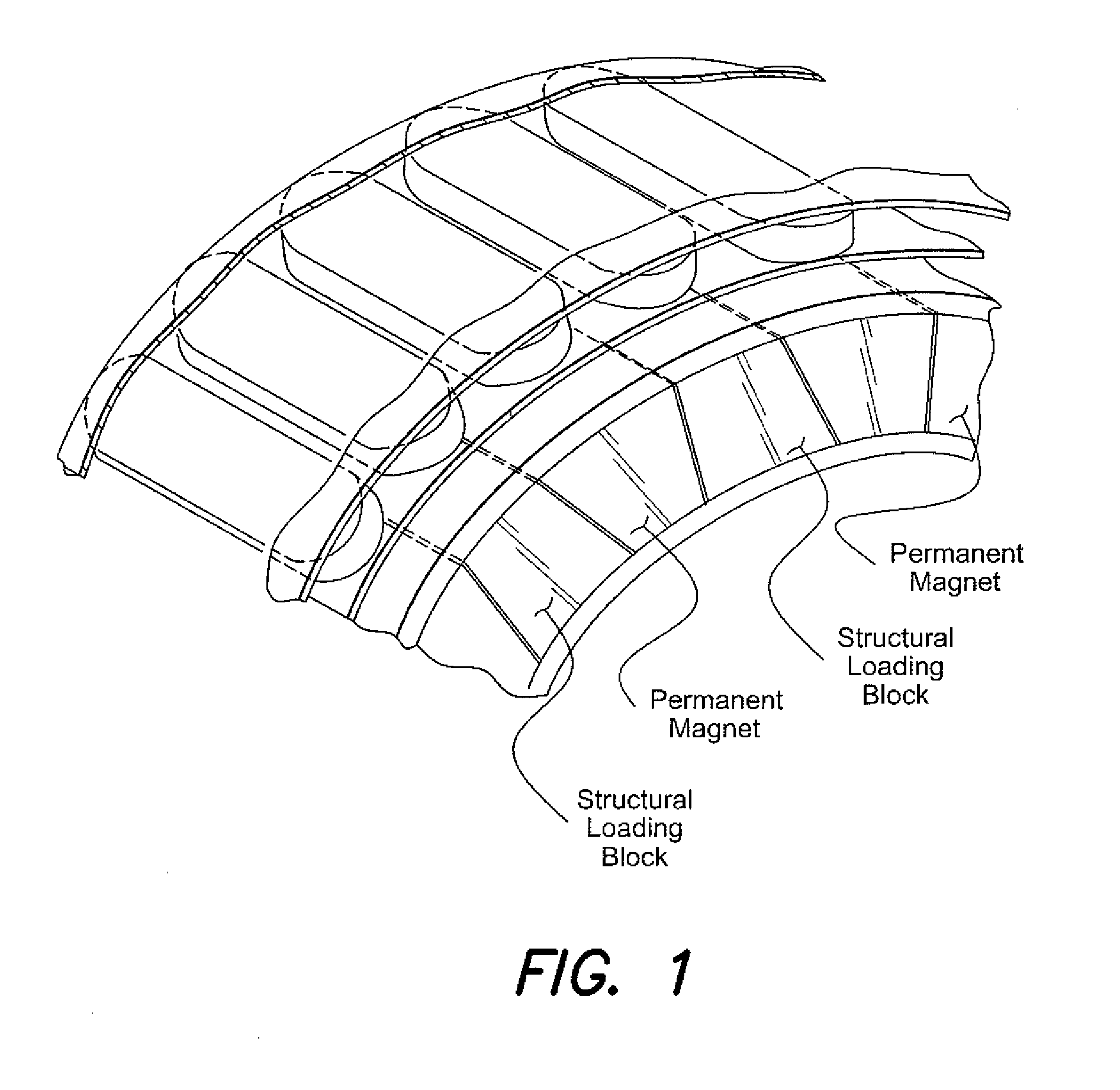

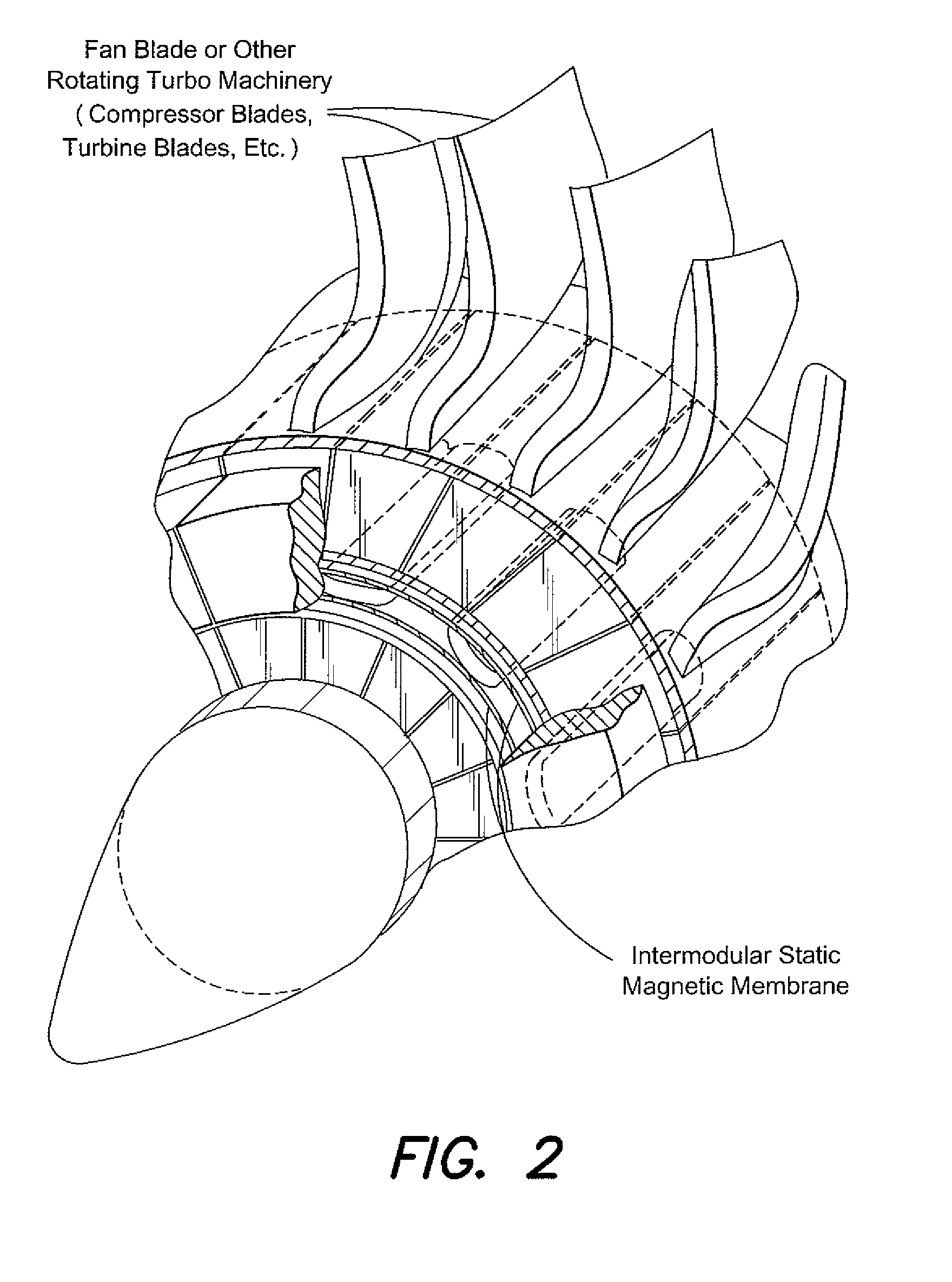

Magnetic advanced gas-turbine transmission with radial aero-segmented nanomagnetic-drive (MAGTRAN)

ActiveUS8446060B1Performance maximizationMaximizing extractionDynamo-electric brakes/clutchesEngine fuctionsElectric machineRotation velocity

An electrical machine apparatus having magnetic gearing embedded therein includes a moveable rotor having a first magnetic field associated therewith, a stator configured with a plurality of stationary stator windings therein, and a magnetic flux modulator interposed between the moveable rotor and the stator windings. The magnetic flux modulator is configured to transmit torque between the first magnetic field associated with the moveable rotor and a second magnetic field through a movable stator, through a plurality of magnetic flux gates arranged axially in the modulator with the field excited by, and controlled by, eddy currents normal to the field through the plurality of stationary stator magnets governed by the position of the modulator rotating in reference to the rotating (at different speeds, hence flux paths) stator and rotor and their magnetic field poles, than the speed of the modulator and its interfering referenced field poles, with the eddy currents existing flux gate arrays with open or closing sequencing governing rotational speeds of the movable rotor, and enabling magnetic gear ratios, in respect to the driving movable stator, intermediate magnetic flux modulator, methods of a continuously variable, high torque, aero gas turbine transmission which allows for complete segmentation of turbomachinary stages (in respect to the bypass fan, compressor and power of the aero gas turbine.

Owner:SONIC BLUE AEROSPACE

Magnetic gear

InactiveUS20110127869A1Total current dropDynamo-electric gearsSynchonous clutches/brakesPole pieceConductor Coil

Owner:MAGNOMATICS LTD

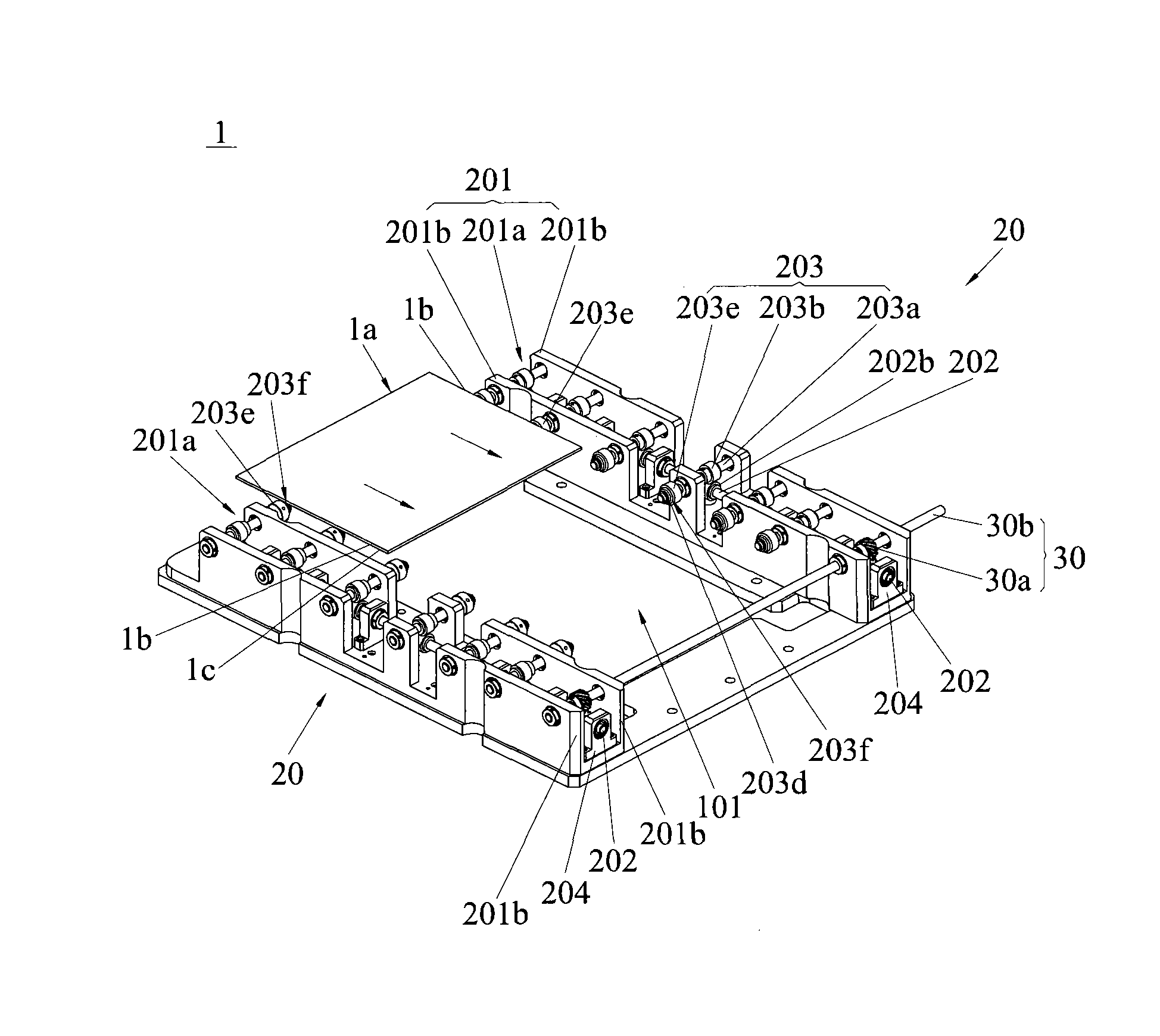

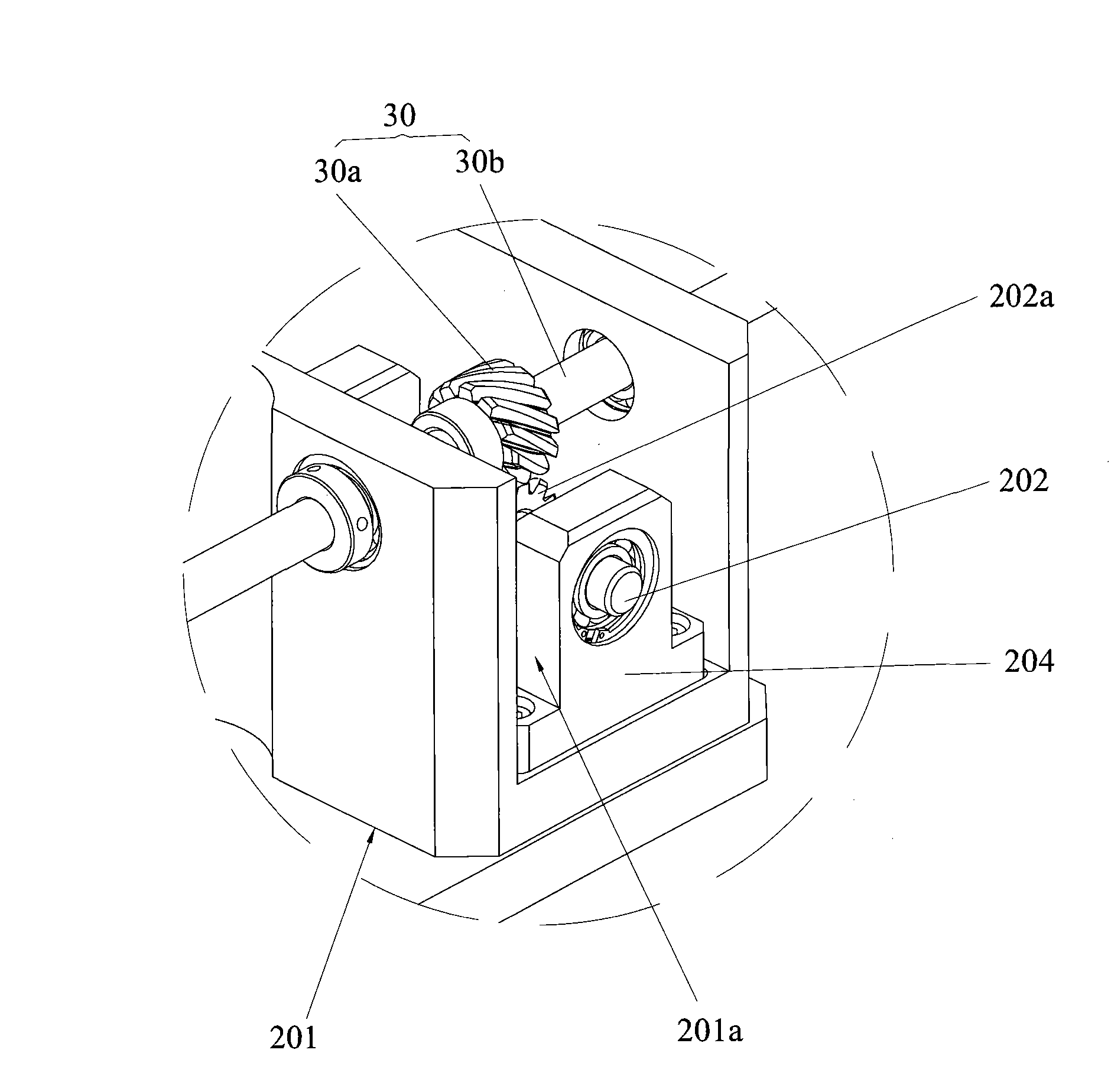

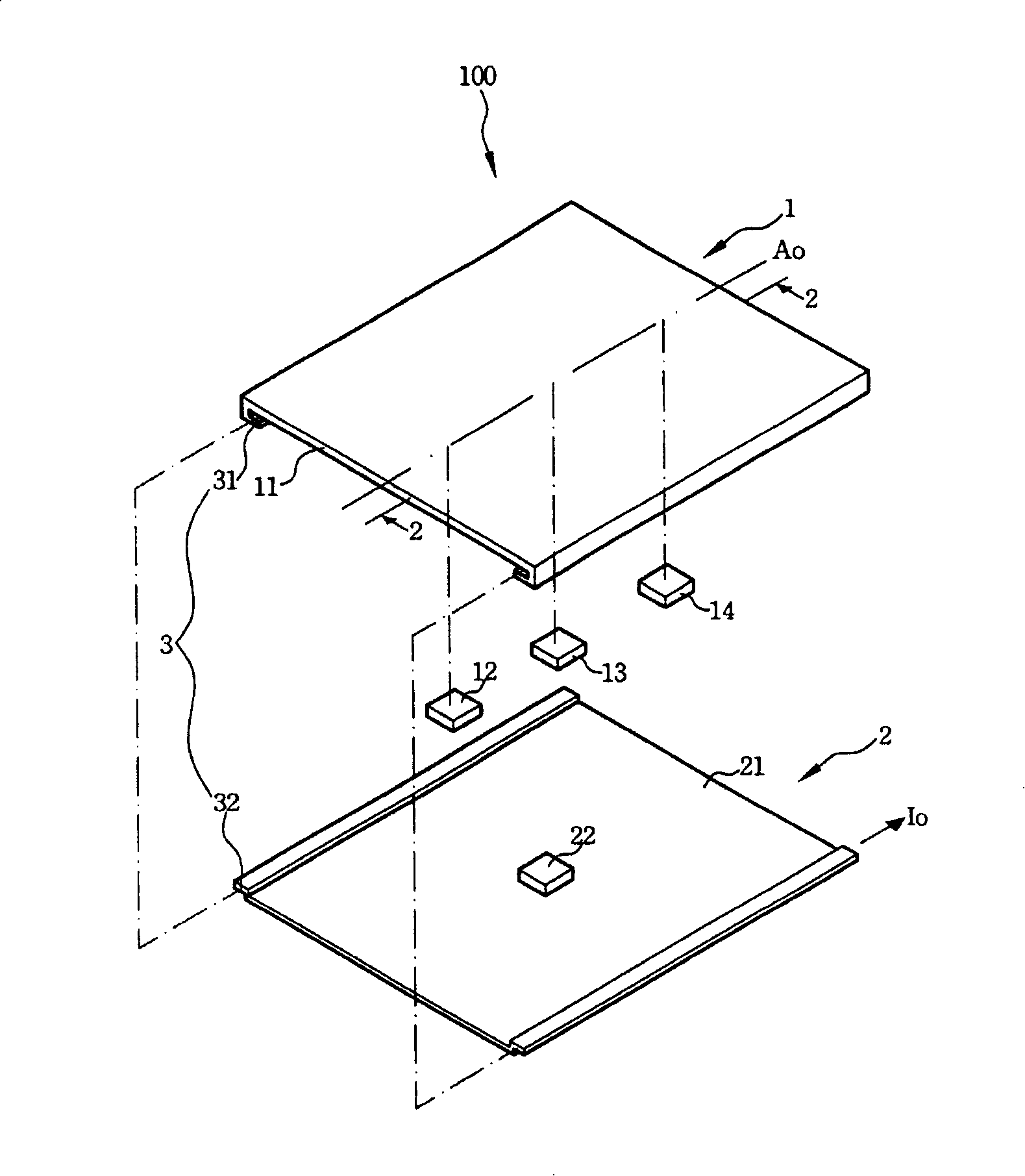

Substrate transmission mechanism

InactiveCN101580179AImprove cleanlinessReduce noiseConveyorsSolid-state devicesLow noiseTransfer procedure

The invention discloses a substrate transmission mechanism, which comprises an actuating device, a primary transmission gear, a soleplate and two secondary transmission gears, wherein each secondary transmission gear comprises a bearing box, a magnetic transmission shaft, a first helical gear, and a plurality of first permanent magnetic gears and magnetic transmission units which correspond mutually; the bearing box is connected with the soleplate, the magnetic transmission units are parallelly pivoted with the bearing box, and are provided with roller wheels; the first helical gear is fixed on the magnetic transmission shaft, the primary transmission gear is provided with a second helical gear engaged with the first helical gear, and the first helical gear and the second helical gear are axially and mutually vertical; and the first permanent magnetic gears are fixed on the magnetic transmission shaft, the magnetic transmission units are provided with second permanent magnetic gears corresponding to the first permanent magnetic gears, the first permanent magnetic gears and the second permanent magnetic gears are axially and mutually vertical, and the first permanent magnetic gears drive the second permanent magnetic gears through a magnetic field. The substrate transmission mechanism realizes low noise and high cleanness in the process of transmitting substrates, and has simple structure and low production cost.

Owner:DONGGUAN ANWELL DIGITAL MASCH CO LTD

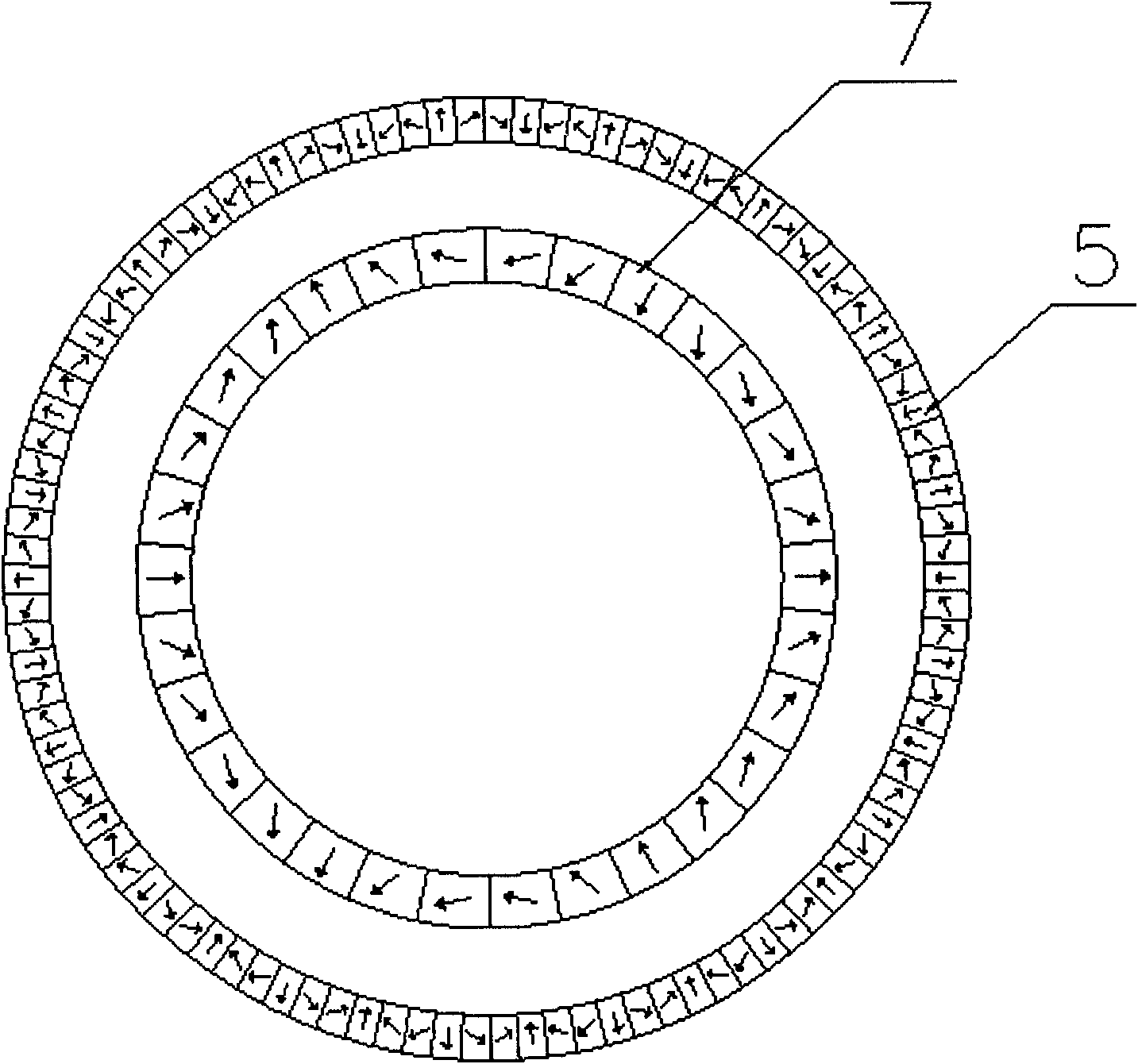

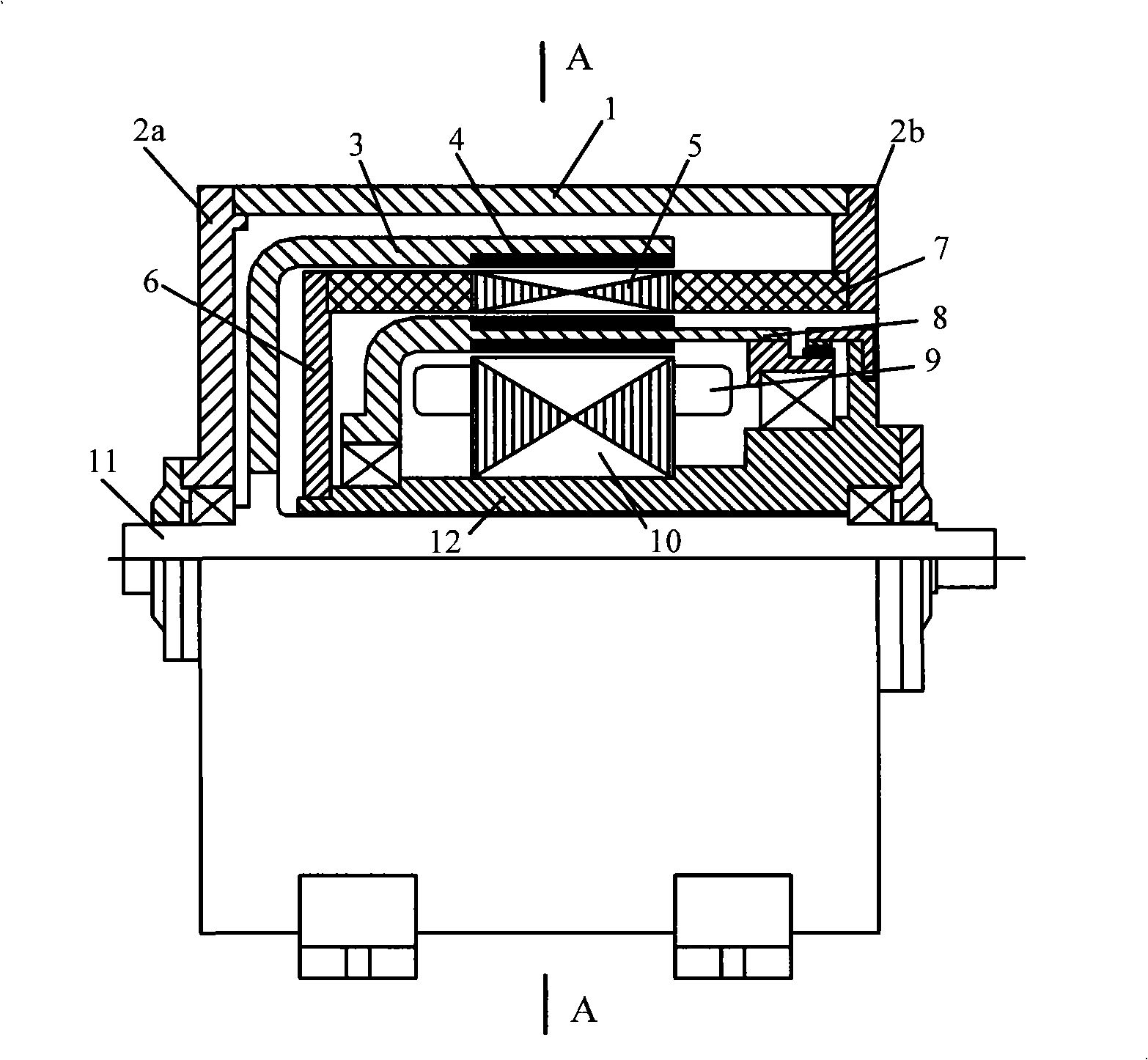

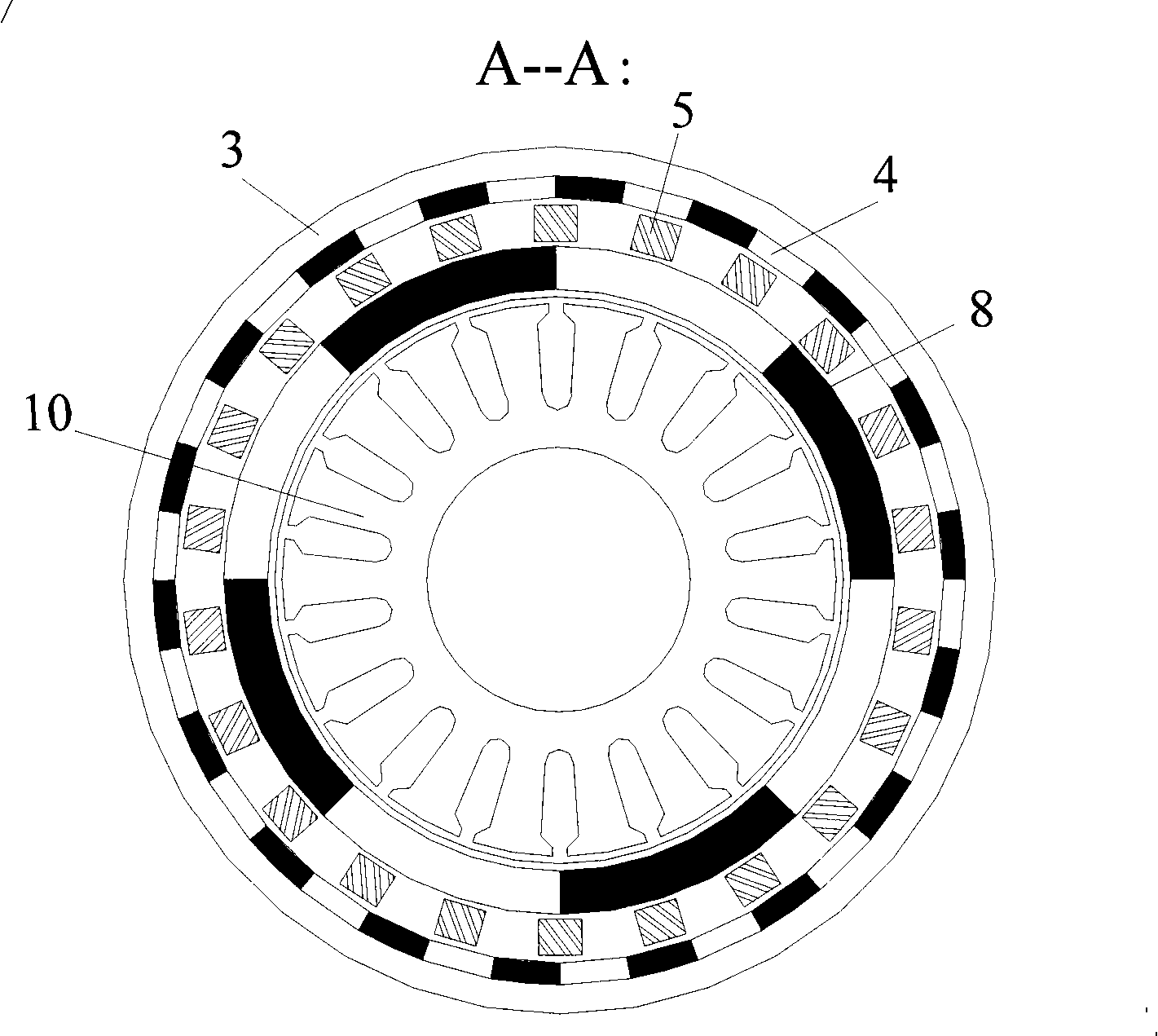

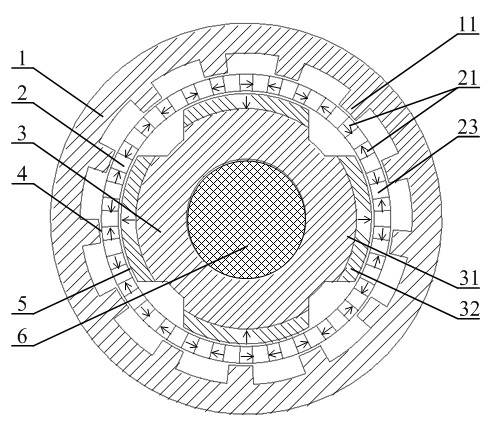

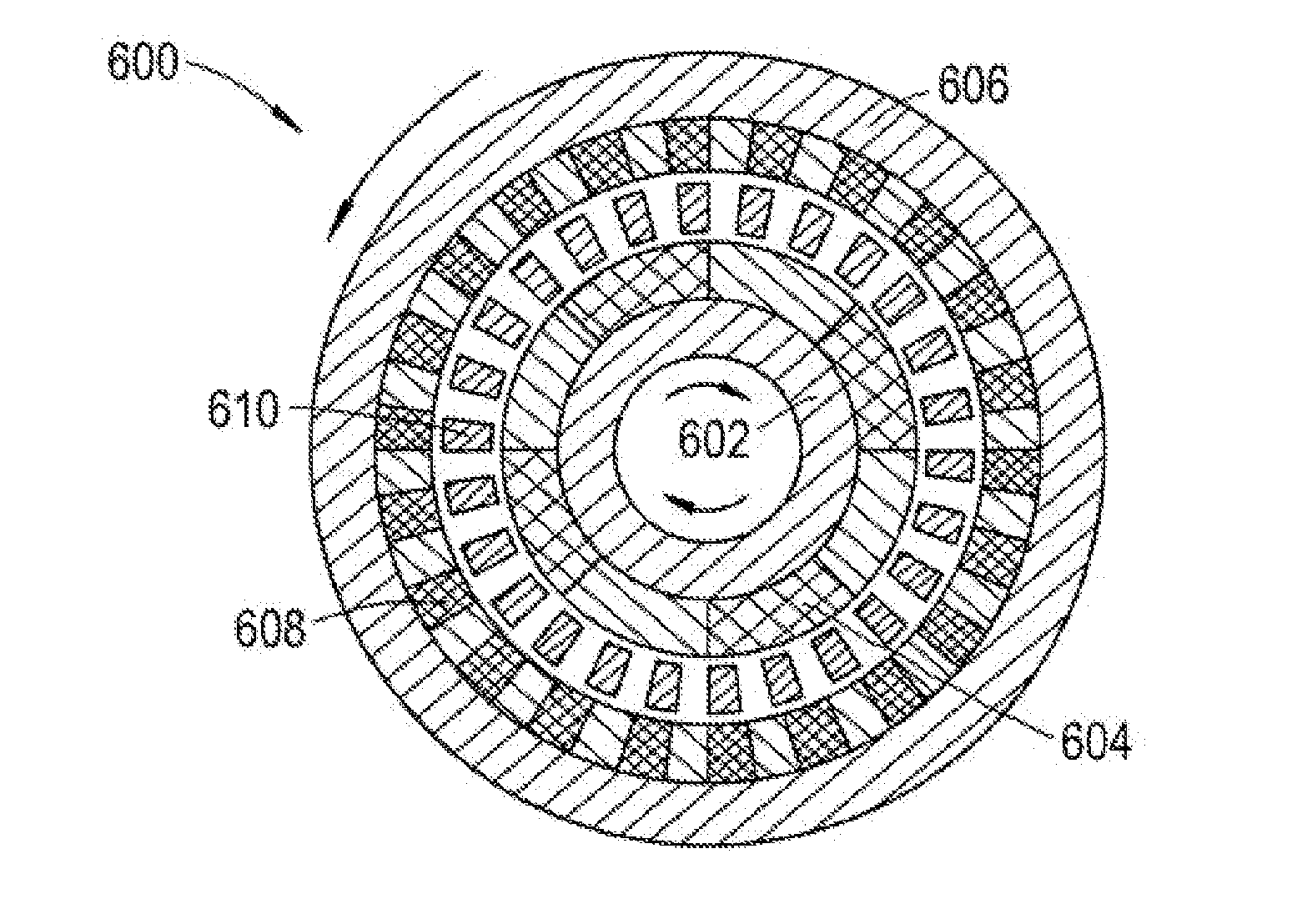

Magnetic field modulating type concentric magnetic gear transmission device in Halbach magnet structure

InactiveCN101662202AHarmonic reductionReduce harmonic lossDynamo-electric gearsDensity distributionDetent

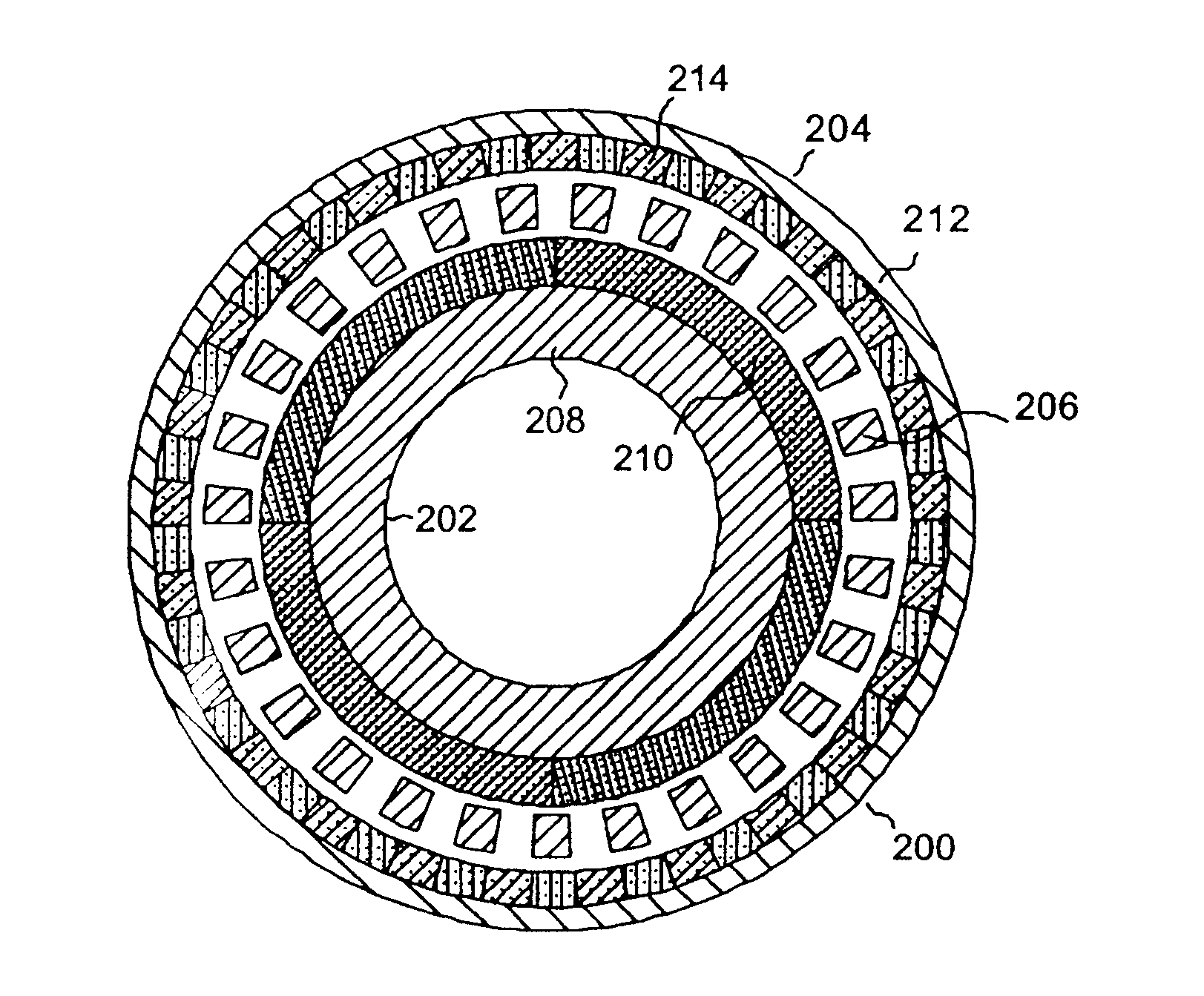

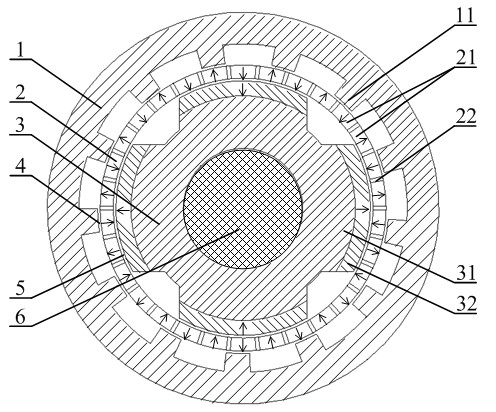

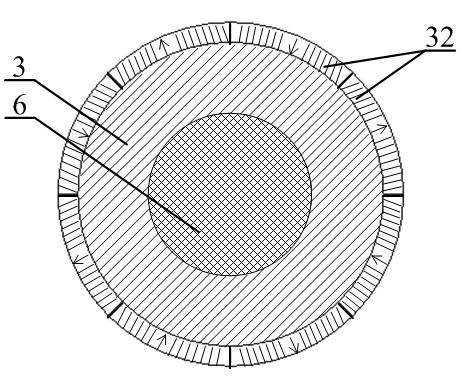

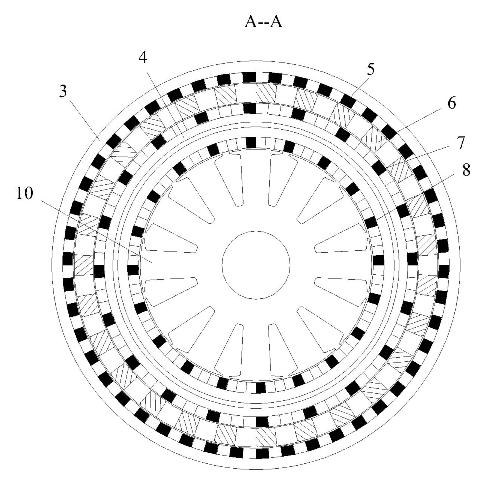

The invention provides a magnetic field modulating type concentric magnetic gear transmission device in a Halbach magnet structure, which comprises a shell, an outer rotor and an inner rotor, whereinthe outer rotor and the inner rotor are installed in an inner cavity of the shell and are in a cantilever type; the inner rotor comprises an inner rotor iron core and a permanent magnet, which are installed on an output shaft of the inner rotor; the outer rotor comprises an outer rotor iron core and a permanent magnet, which are installed on an output shaft of the outer rotor; a magnetic modulation ring is arranged between the permanent magnet of the inner rotor and the permanent magnet of the outer rotor; and the magnetic modulation ring comprises an iron core block and is fixed on an end plate of the shell. The magnetic gear transmission device comprises two layers of air gaps, wherein an inner-layer air gap is formed between the inner rotor and the magnetic modulation ring, and an outer-layer air gap is formed between the outer rotor and the magnetic modulation ring. The magnet structure uses a Halbach array to replace the conventional radial structure, thereby improving the magnetic density distribution of the air gaps of the magnetic gear transmission device. Because the magnetic density of the air gaps approaches to sinusoidal distribution, the detent torque of the magnetic gear transmission device in the structure is greatly reduced, thereby decreasing the vibration and noise of the magnetic gear transmission device and improving the running efficiency.

Owner:SHANGHAI UNIV

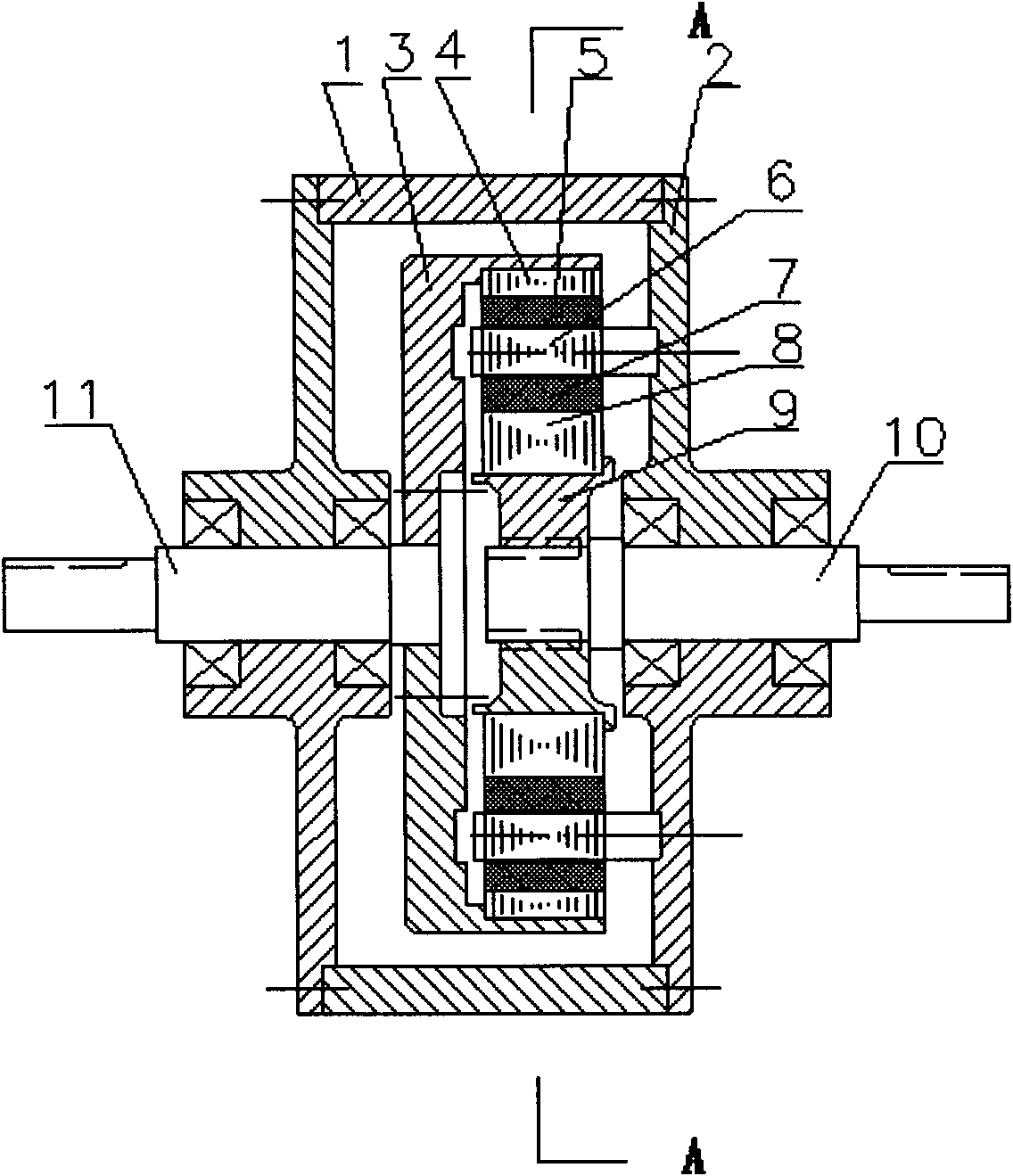

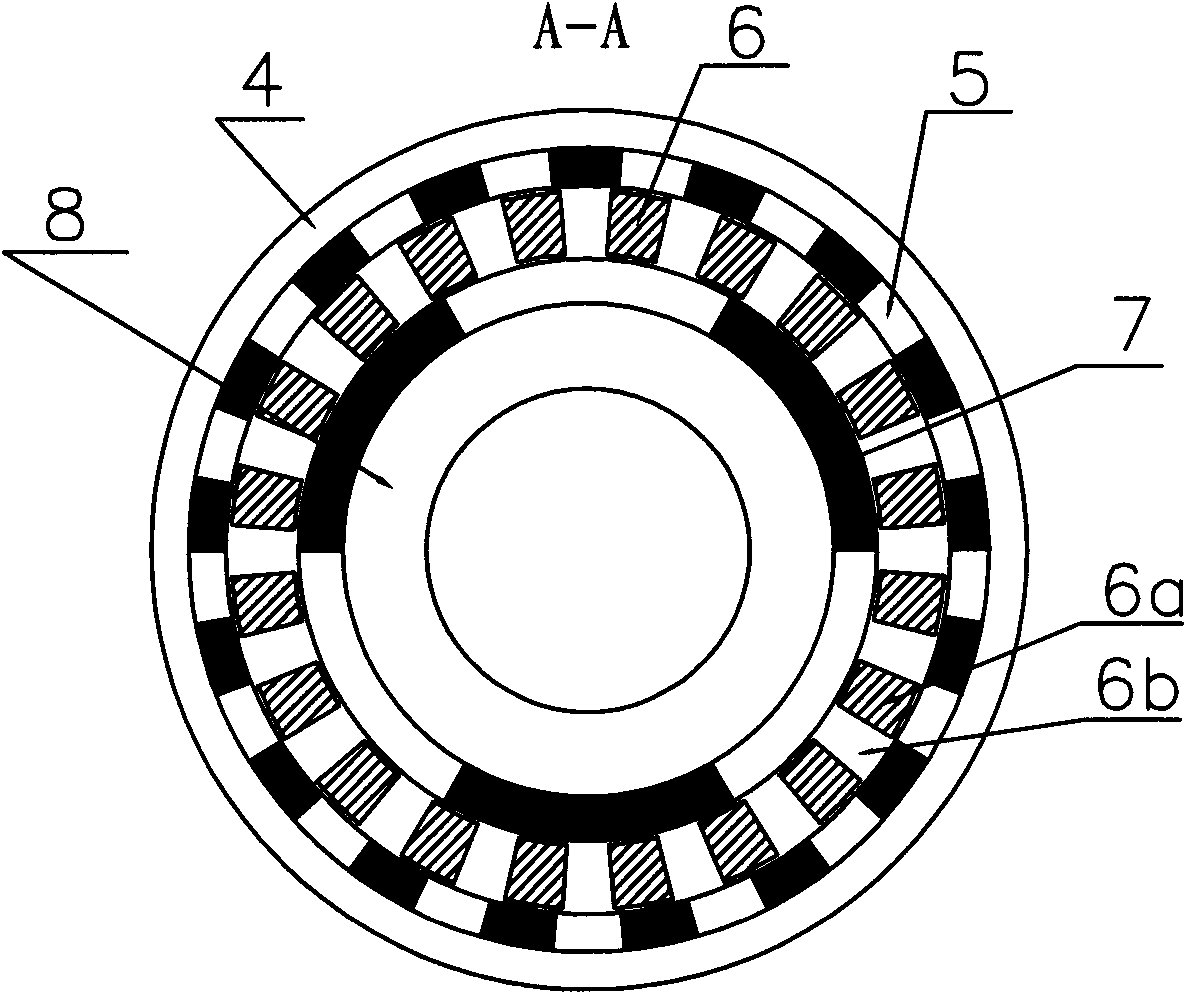

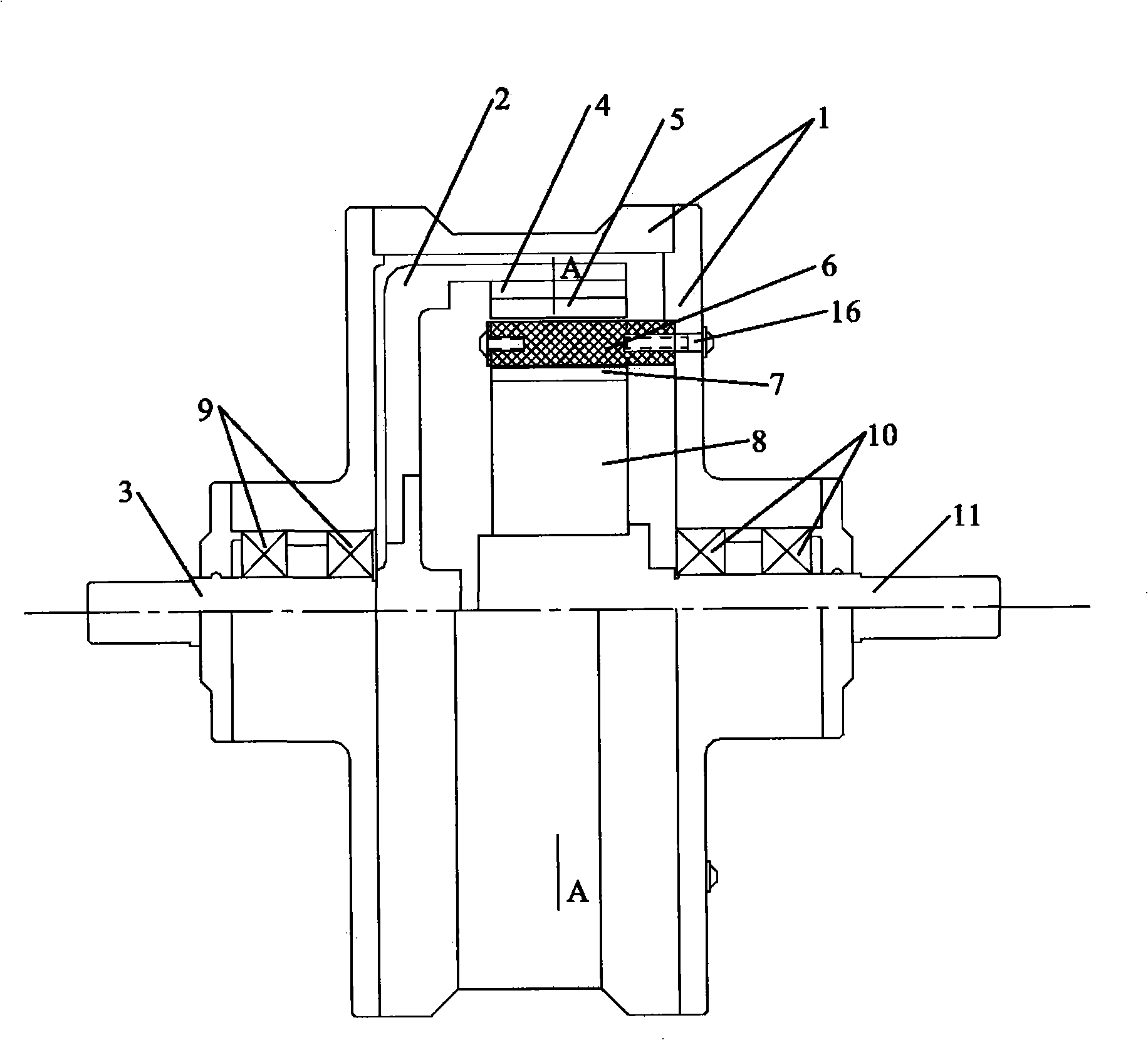

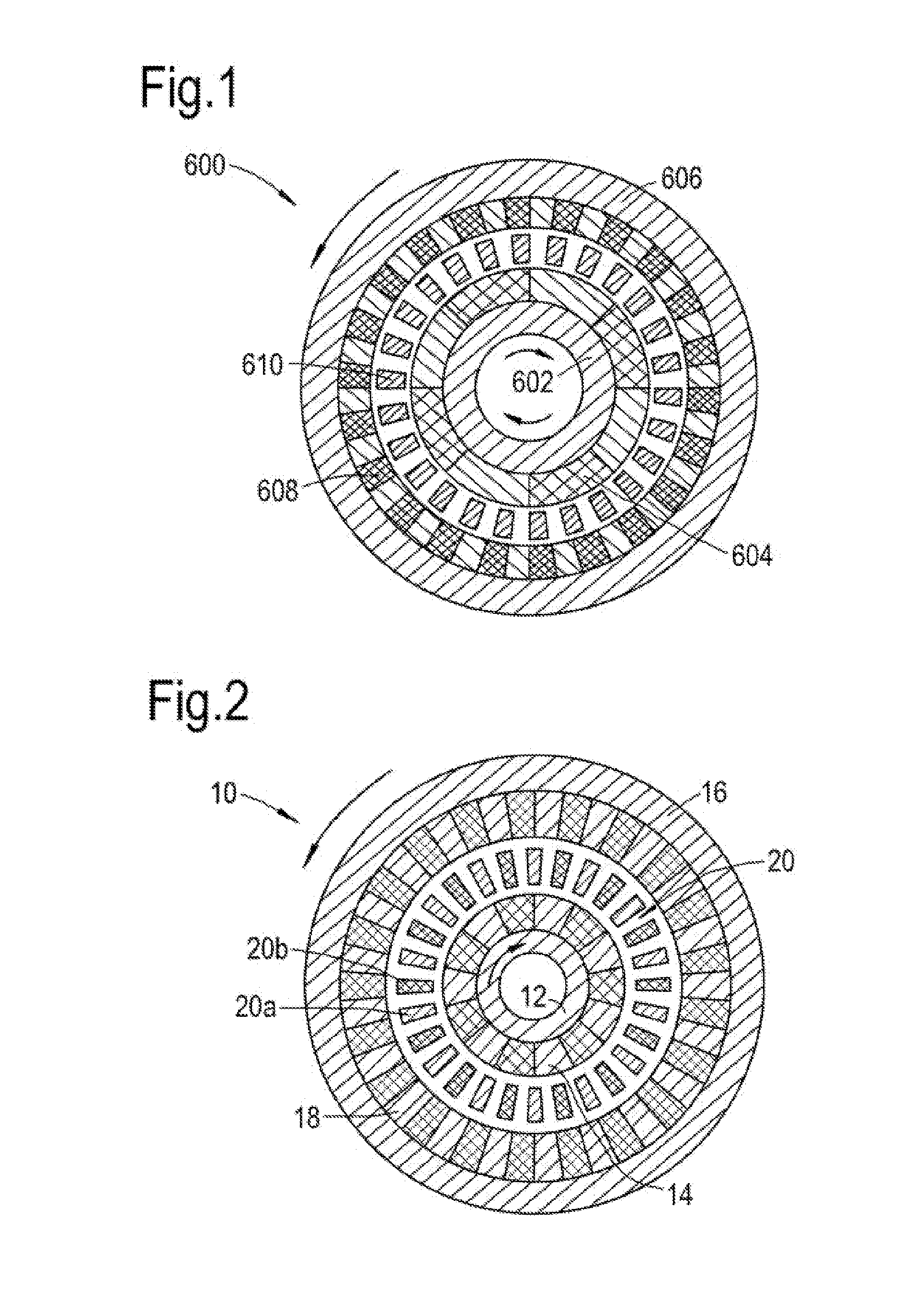

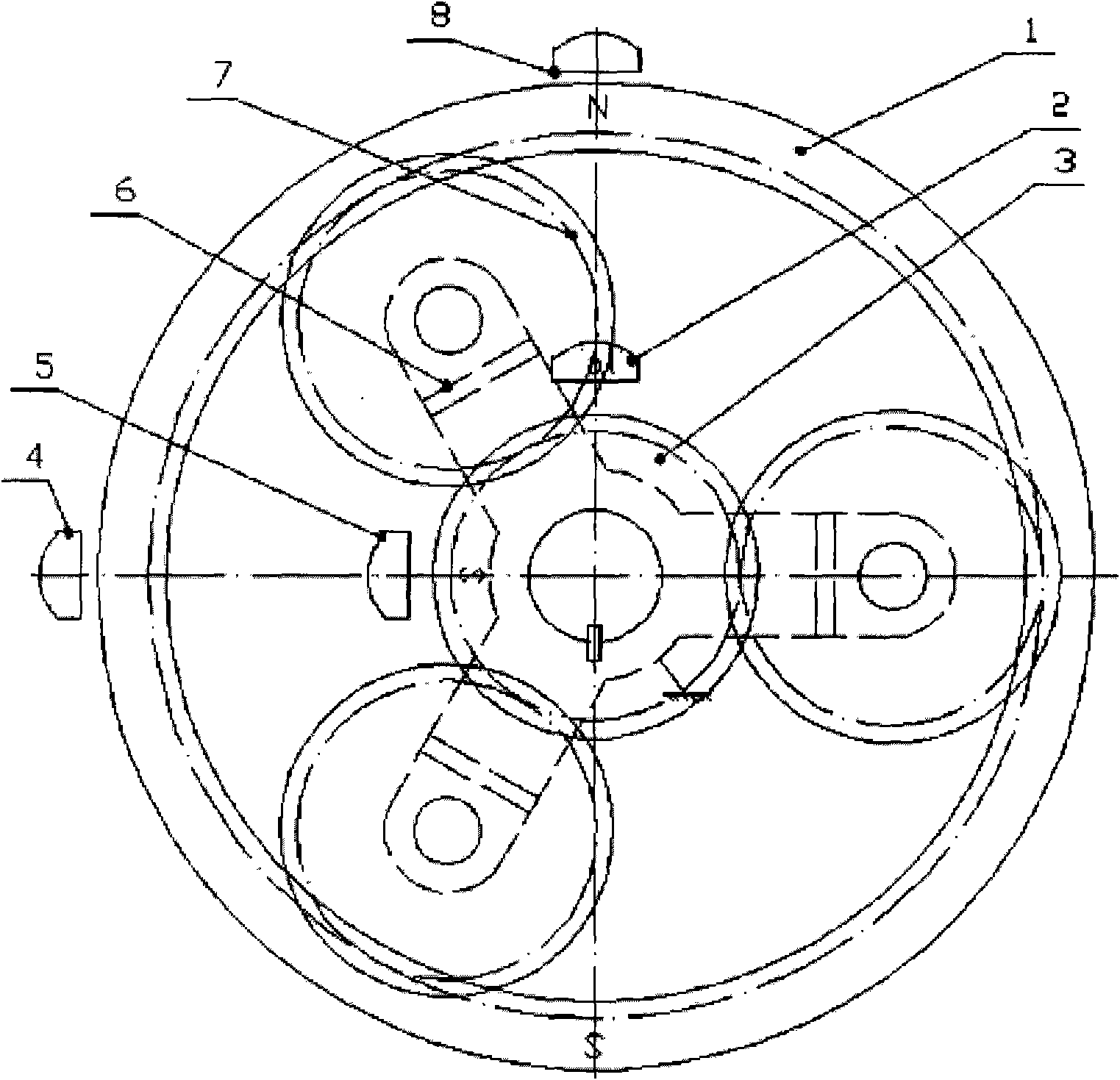

Magnetic field modulation magnetic gear

InactiveCN101267152AReduce dosageImprove reliabilityDynamo-electric gearsElectrical polarityHigh torque

The present invention provides a magnetic field modulated magnetic gear, including a casing, an outer rotor and an inner rotor mounted in the casing chamber, the inner rotor is composed of an inner rotor core, 2N1 permanent magnets, and the polarity of the adjacent permanent magnets are different, the inner rotor is mounted on the output shaft of the inner rotor; the outer rotor is composed of a cup type sleeve, an outer rotor core, N2 permanent magnets, and the polarity of all N2 permanent magnets are identical, the cup type outer rotor is mounted on the output shaft of the outer rotor; the magnetic field regulating ring is composed of N1+N2 core blocks and N1+N2 epoxy blocks, the magnetic field regulating ring is fixed on the end plate of the casing; the magnetic gear has two layers air gap, the inner air gap is between the inner rotor and the magnetic field regulating ring, the outer air gap is between the outer rotor and the magnetic field regulating ring. The invention has advantages of high torque transmitted per volume; and the outer rotor adopts a staggered distribution structure of the permanent magnets and the stator core, saving quantity of the permanent magnets, improving the credibility, simplifying the structure, reducing the cost.

Owner:SHANGHAI UNIV

Wellbore motor having magnetic gear drive

ActiveUS20070125578A1RotationPrevent rotationDynamo-electric brakes/clutchesGearingEngineeringRotational energy

A wellbore motor includes a means for converting flow of fluid in the wellbore into rotational energy. A magnetic gear member is operatively coupled at an input thereof to the means for converting. A wellbore rotary tool is coupled to an output of the magnetic gear member.

Owner:MAGNOMATICS LTD

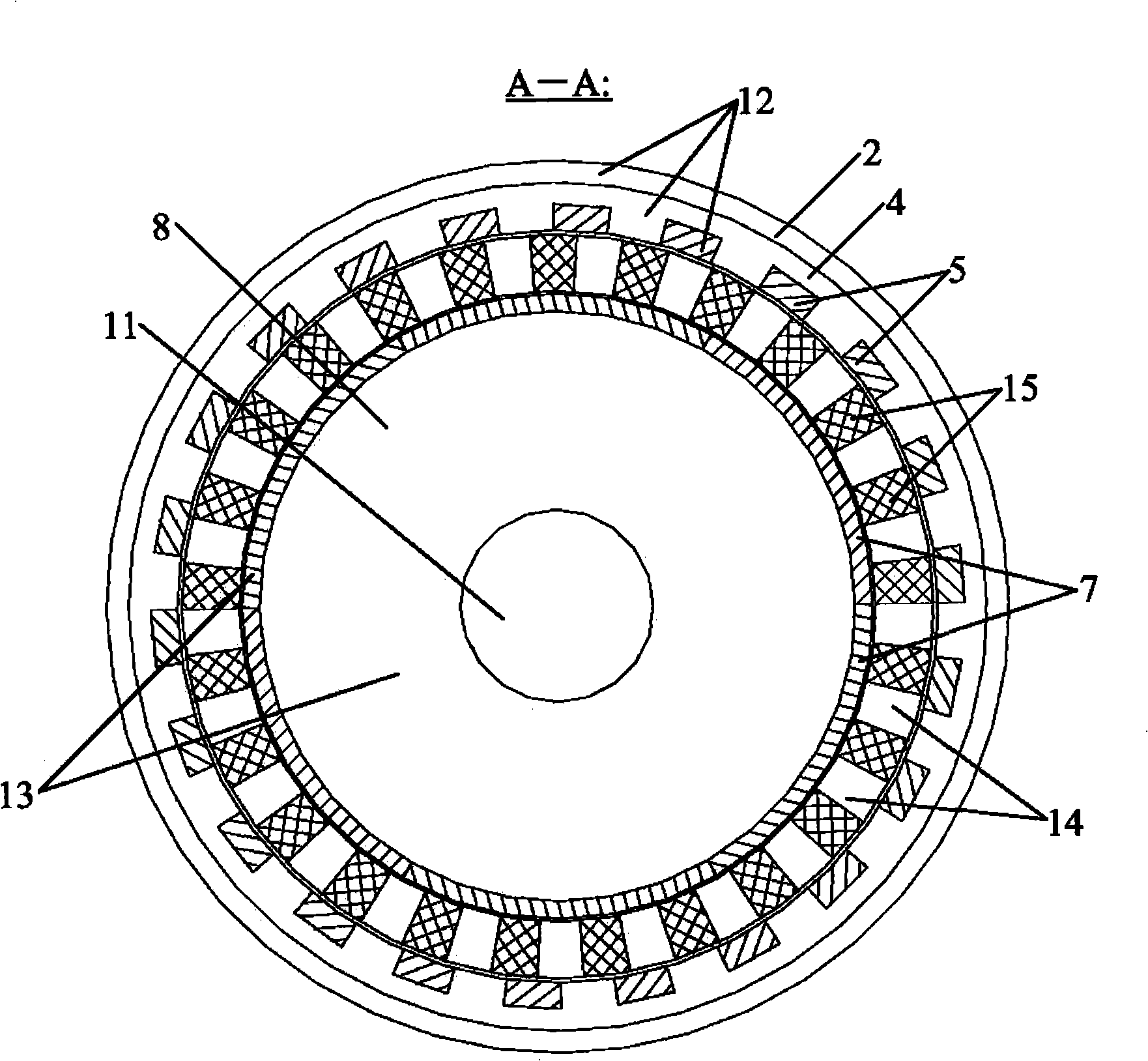

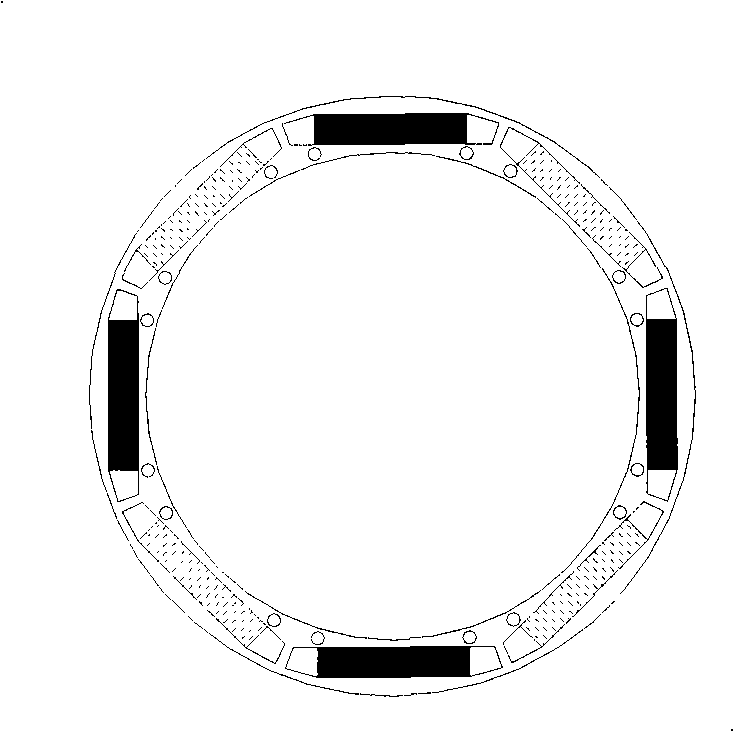

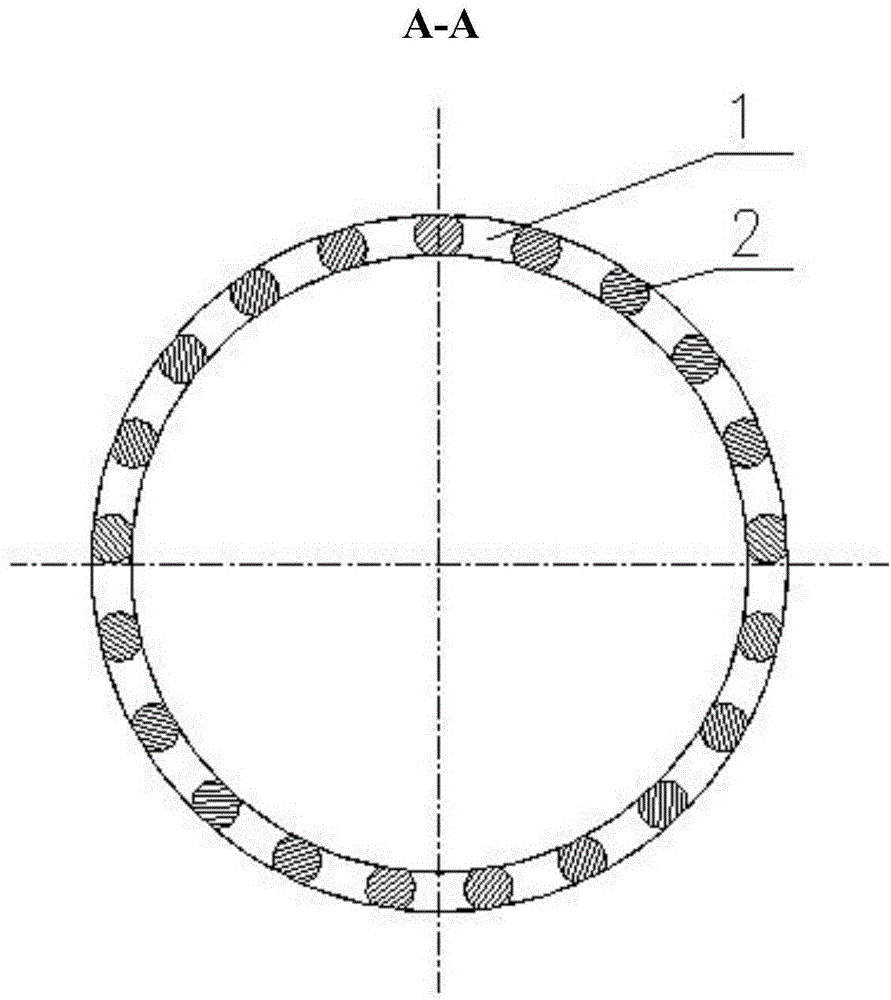

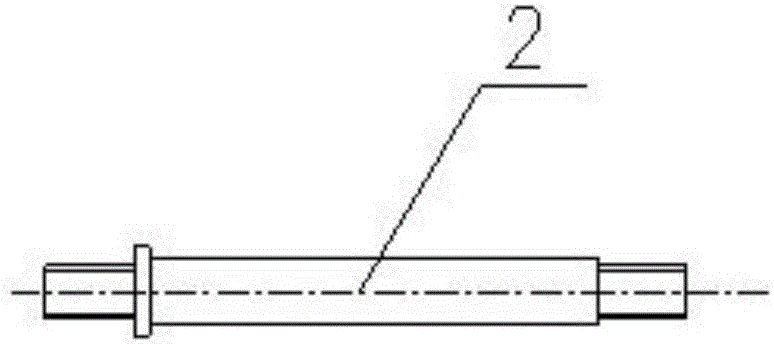

Concentric magnetic gear using squirrel cage type magnetic field regulating device

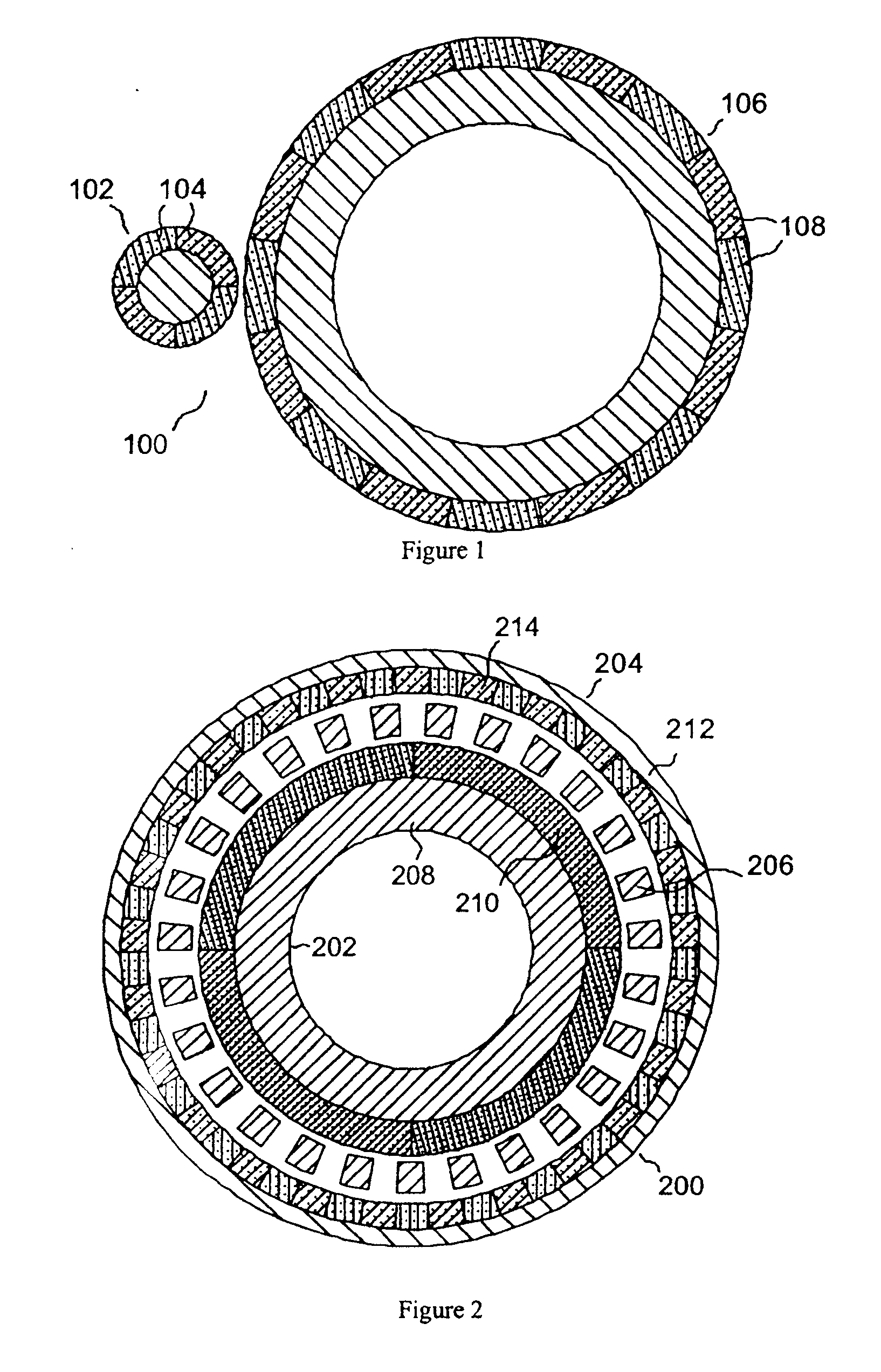

InactiveCN101841280AEasy to processImprove structural rigidityGenerators/motorsMagnetic tension forceMagnetic poles

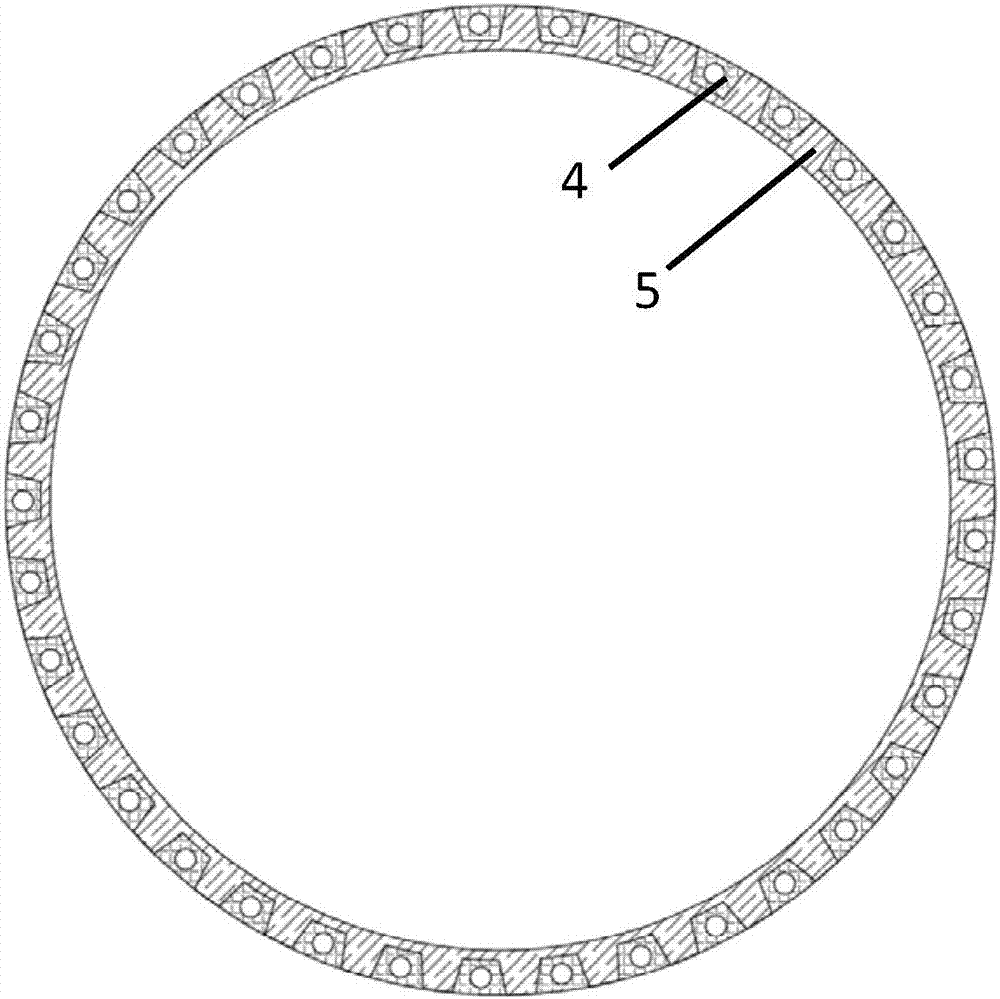

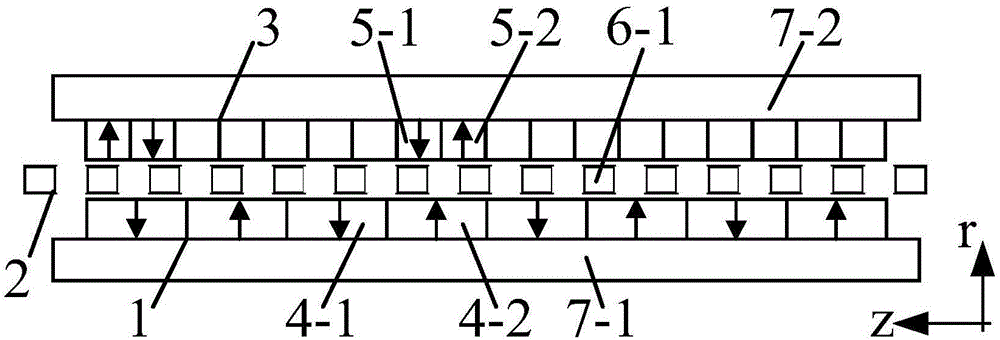

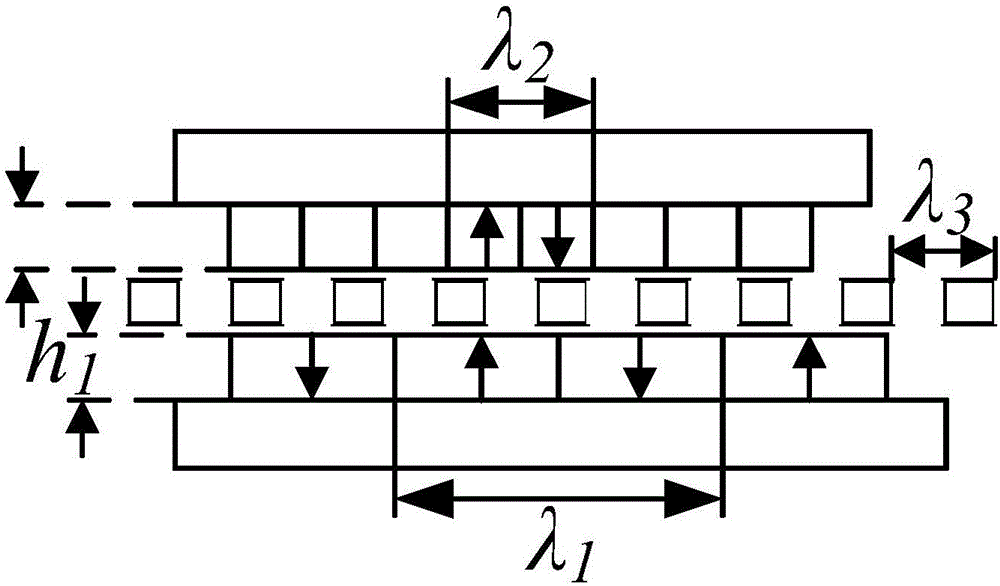

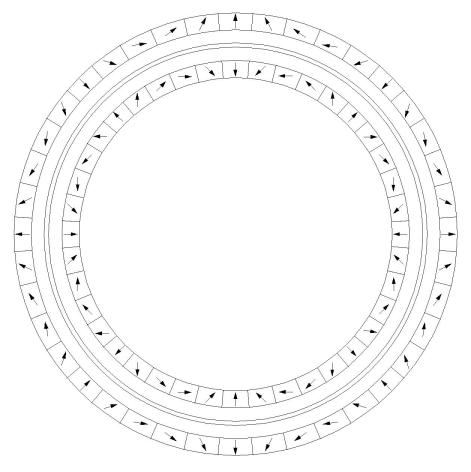

The invention discloses a concentric magnetic gear using a squirrel cage type magnetic field regulating device and relates to the technical field of engineering machine transmission. The gear is comprised of an internal permanent magnet structure, a middle magnetic filed regulating structure and an external permanent magnet structure, wherein the outside surface of the internal permanent magnet structure is provided with permanent magnets of which the N poles and S poles are arranged closely and alternately, and the number of the magnetic pole pairs is P1; the middle magnetic filed regulating structure is positioned between the internal permanent magnet structure and the external permanent magnet structure, a soft magnetic material is directly processed into to make a squirrel cage type structure or a combined squirrel cage type structure of a magnetic filed regulating block made of a nonconductive material and the soft magnetic material, and the number of cage bars is R; the inside surface of the external permanent magnet structure is provided with permanent magnets of which the N poles and S poles are arranged closely and alternately, and the number of the magnetic pole pairs is P2; and R is equal to the sum of the P1 and the P2. When the internal permanent magnet structure rotates, a rotary magnetic filed in which the number of the magnetic pole pairs is P1 is generated, the middle magnetic filed regulating structure modulates the rotary magnetic field into a rotary magnetic field in which the number of the magnetic pole pairs is P2, the rotation speed and direction of the rotary magnetic field in which the number of the magnetic pole pairs is P1 are changed at the same time to drive the external permanent magnet structure to rotate, and thus, the aim of changing the rotation speed is realized.

Owner:JIANGSU UNIV

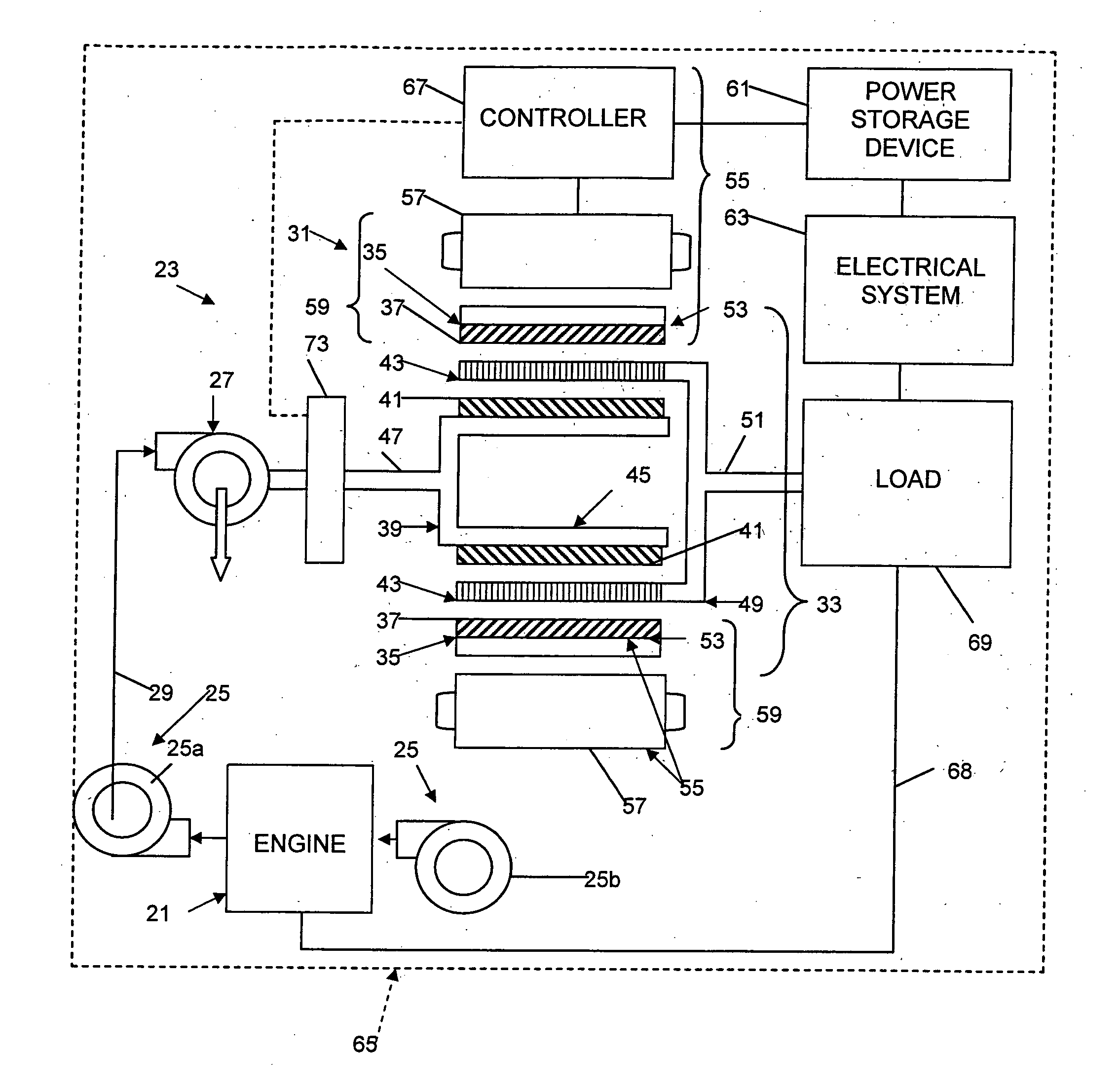

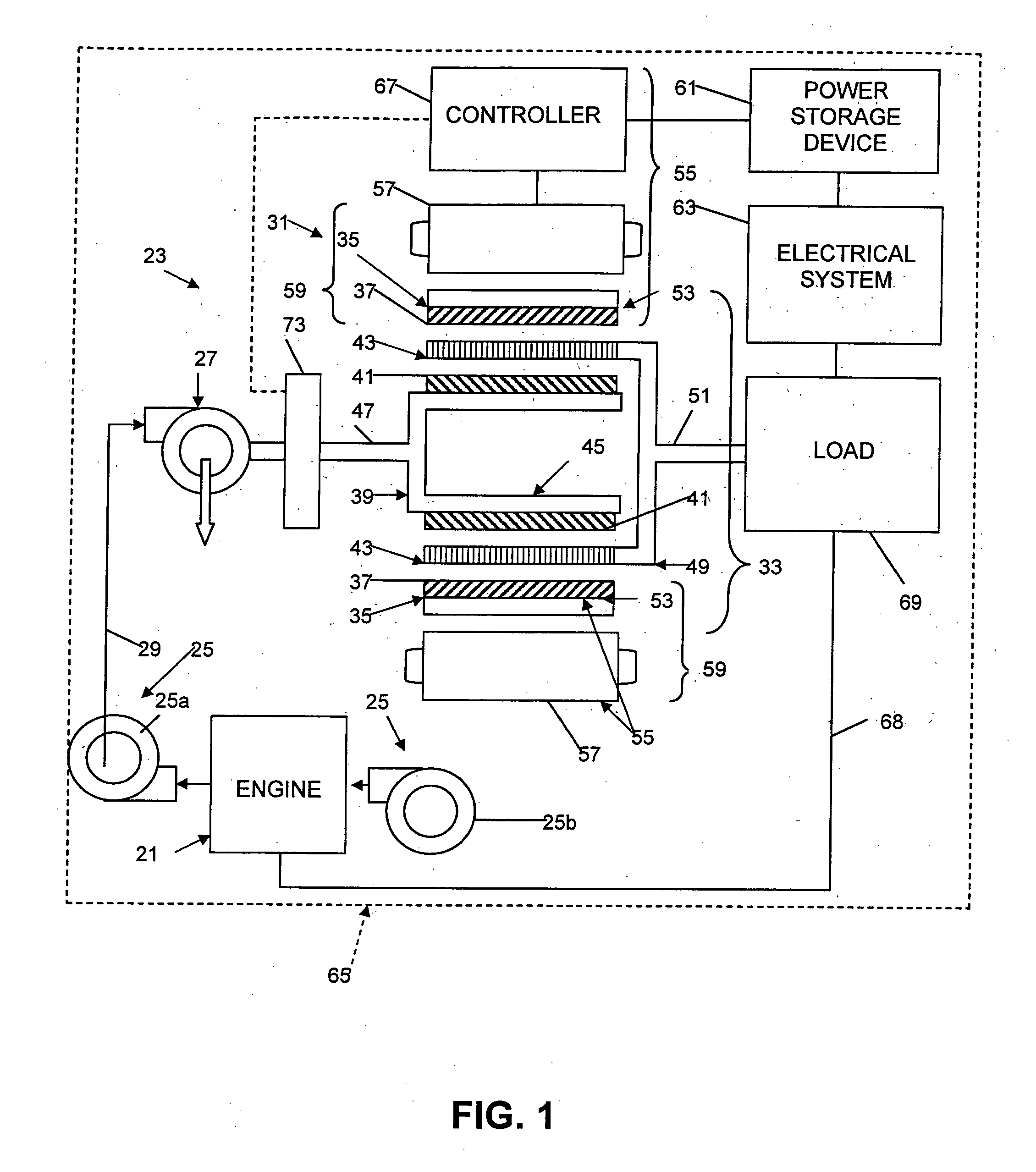

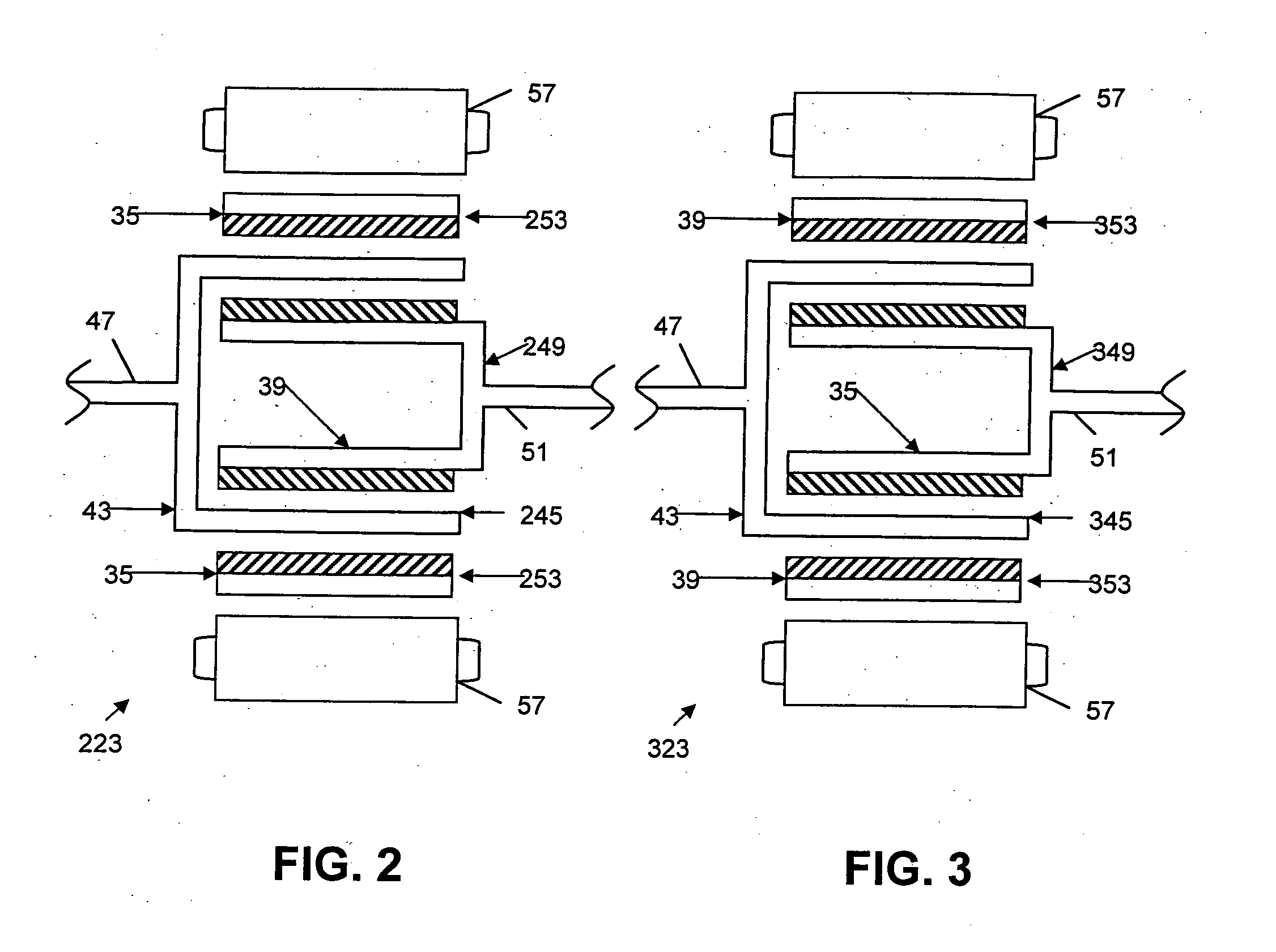

Electromagnetic, continuously variable transmission power split turbo compound and engine and vehicle comprising such a turbo compound

InactiveUS20120119509A1Reducing brake specific fuel consumptionElectric devicesInternal combustion piston enginesPower splitLow speed

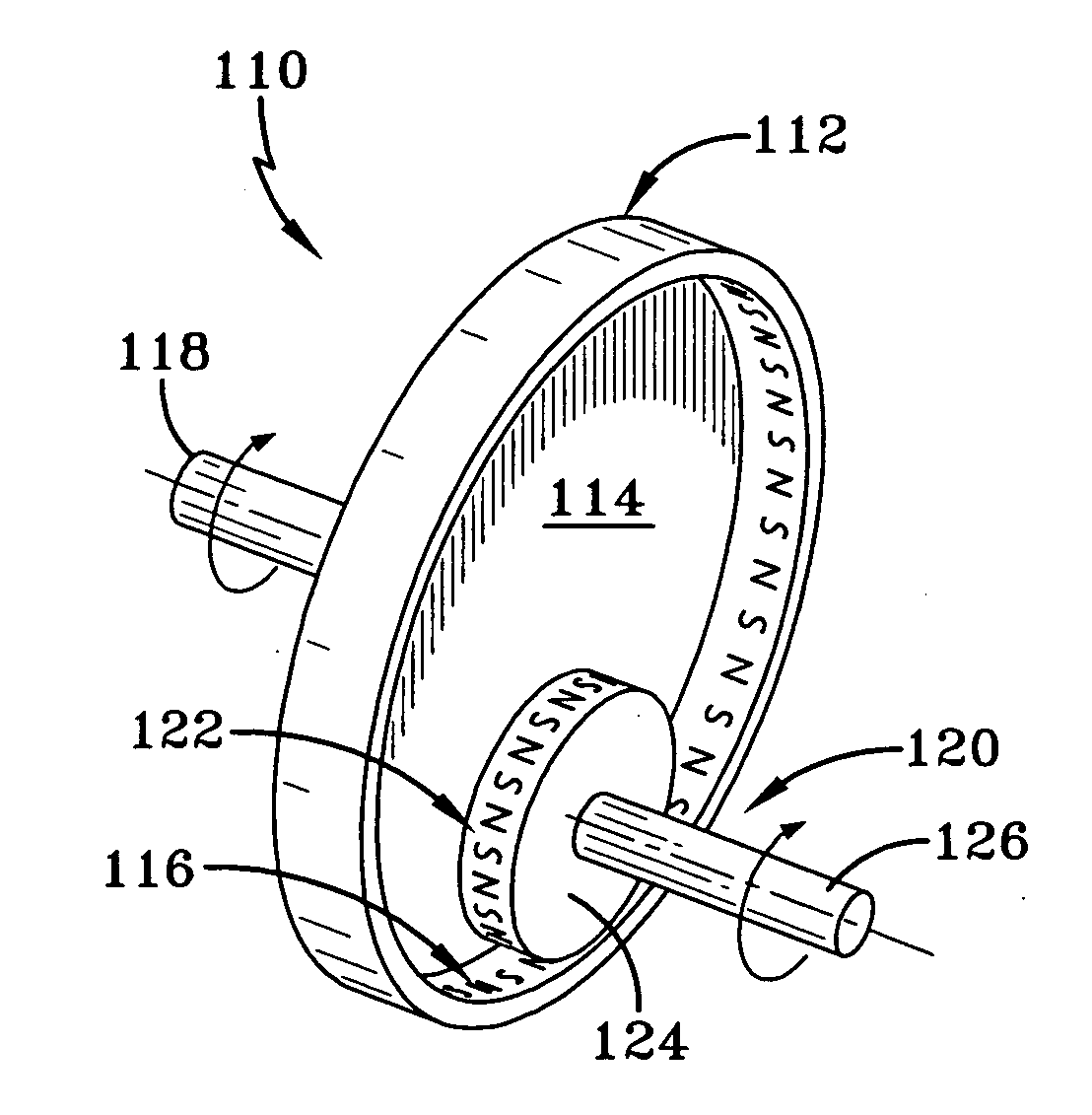

An electromagnetic, continuously variable transmission power split turbo compound includes a turbo compound turbine driven by exhaust gases from an internal combustion engine, and a power split device comprising a magnetic gear arrangement. The magnetic gear arrangement includes a high speed rotor comprising a first quantity of permanent magnets, a low speed rotor comprising a second quantity of permanent magnets, and a plural pole rotor between the high speed rotor and the low speed rotor. A first rotor of the high speed rotor, the low speed rotor, and the plural pole rotor includes a mechanical input drive adapted to be driven by the turbine. A second rotor of the high speed rotor, the low speed rotor, and the plural pole rotor includes a mechanical output drive. A third rotor of the high speed rotor, the low speed rotor, and the plural pole rotor is unconnected to a mechanical drive and includes a controlling rotor for controlling a ratio of input drive angular velocity to output drive angular velocity.

Owner:VOLVO LASTVAGNAR AB

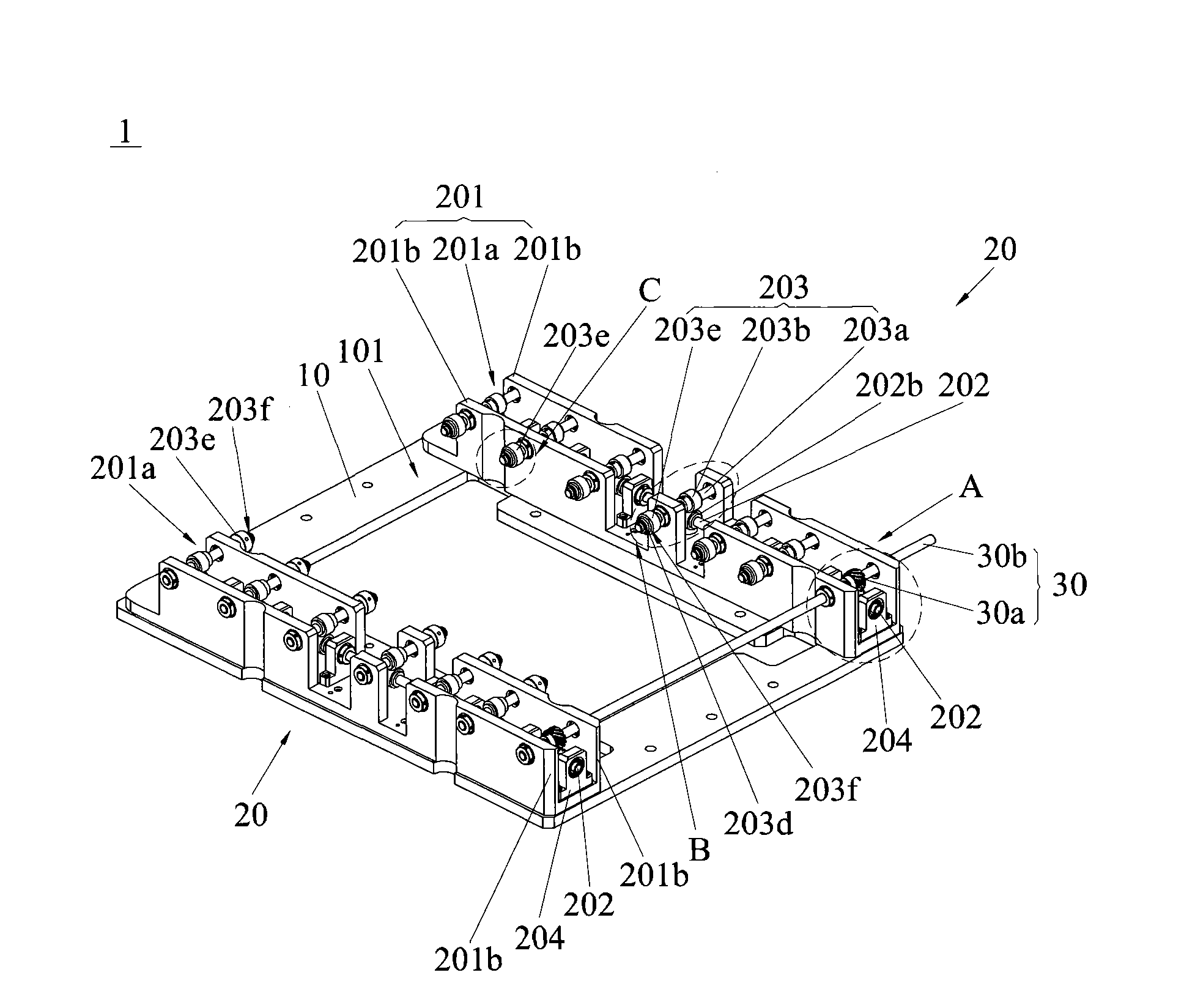

System and method for online automatically detecting defects on glass surface of touch screen

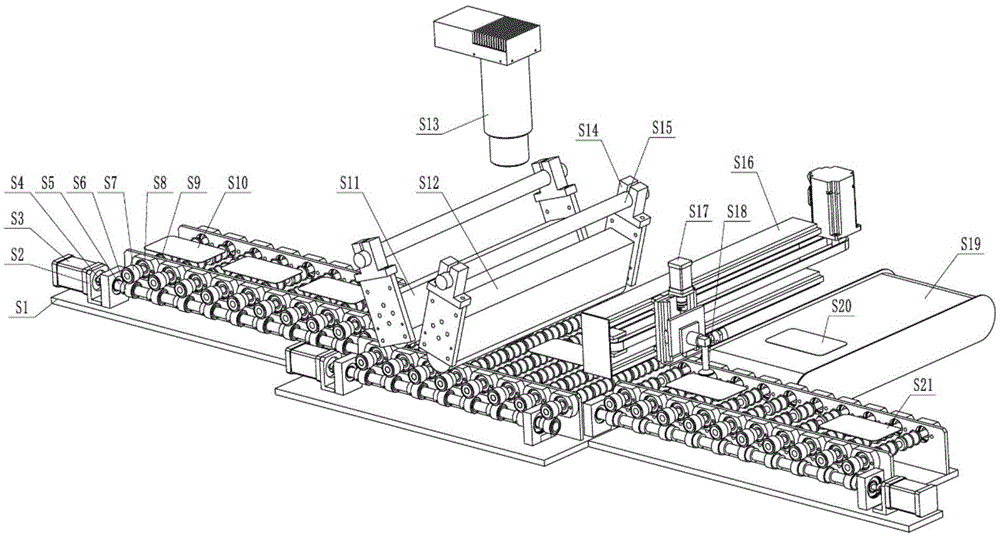

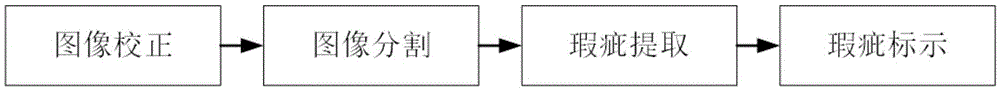

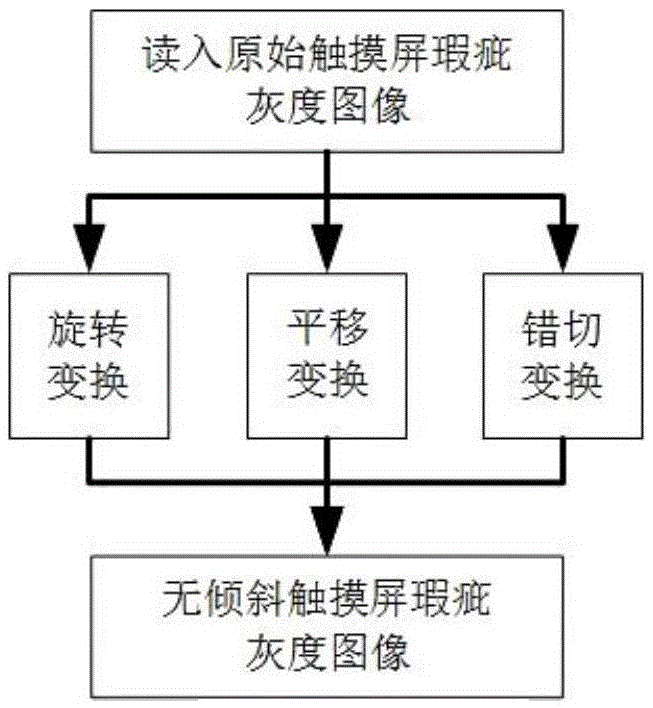

ActiveCN105548212ARealize online automatic detectionSimple structureMaterial analysis by optical meansGear driveDrive shaft

The invention discloses a system and a method for online automatically detecting defects on a glass surface of a touch screen. The system comprises a driving part, an imaging part and a screening part, wherein the driving part is used for sending touch screen glass to the imaging part; the imaging part is used for detecting if the glass surface of the touch screen has defects; the screening part is used for removing the touch screen glass having defects; the driving part comprises three driving units; the three driving units are fixedly connected with a bottom fixing plate; each driving unit comprises a bottom fixing plate, a servo motor, a driving shaft, a magnetic transmission gear driving wheel, a magnetic transmission gear driven wheel and a driven shaft; and the imaging part and the screening part are respectively arranged on the middle and last driving units. The system provided by the invention has the advantages of high detection precision, high efficiency and capability of quantitative recognition. Non-contact magnetic gear pairs serve as the driving media, so that the system provided by the invention has non-contact, noiseless, vibration-free and pollution-free characteristics and are fit for the detection process for the touch screen glass in a dust-free environment.

Owner:HANGZHOU JINGNAIKE OPTOELECTRONICS TECH CO LTD

Direct-drive composite type permanent magnet motor

InactiveCN101330234ACancel noiseEliminate vibrationMagnetic circuit rotating partsDynamo-electric gearsLow speedElectric machine

The invention relates to a direct-drive combined motor which comprises a self-control permanent-magnet motor and a concentric magnetic gear. The permanent-magnet motor and the magnetic gear are integrated by adopting the sleeve-type structure or the axial series connection structure. The combined permanent-magnet motor can automatically realize the high-speed low-torque power transfer and the low-speed high-torque power transfer therein without a mechanical gear case. The motor can serve as an electric motor and a power generator.

Owner:许晓华

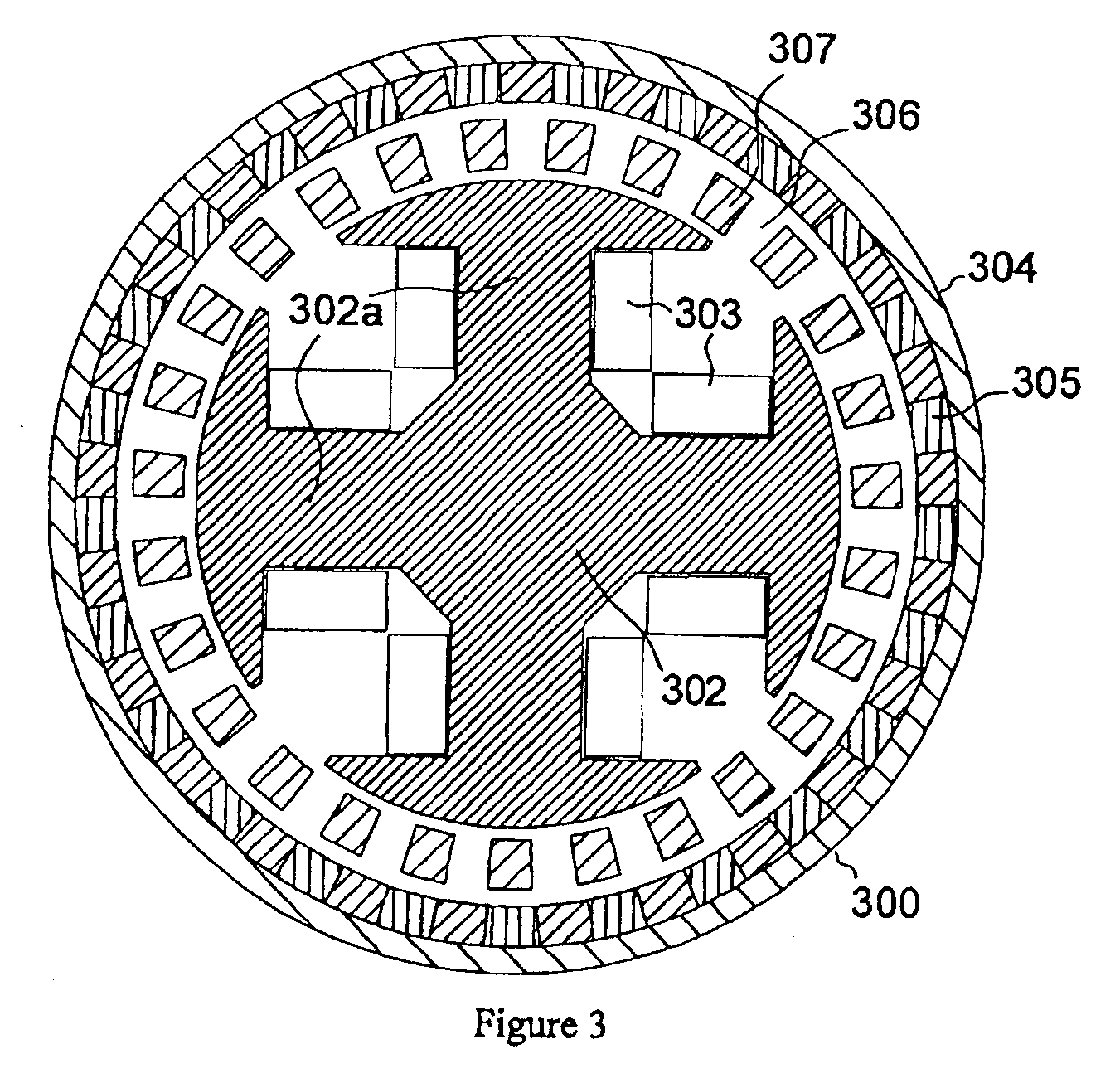

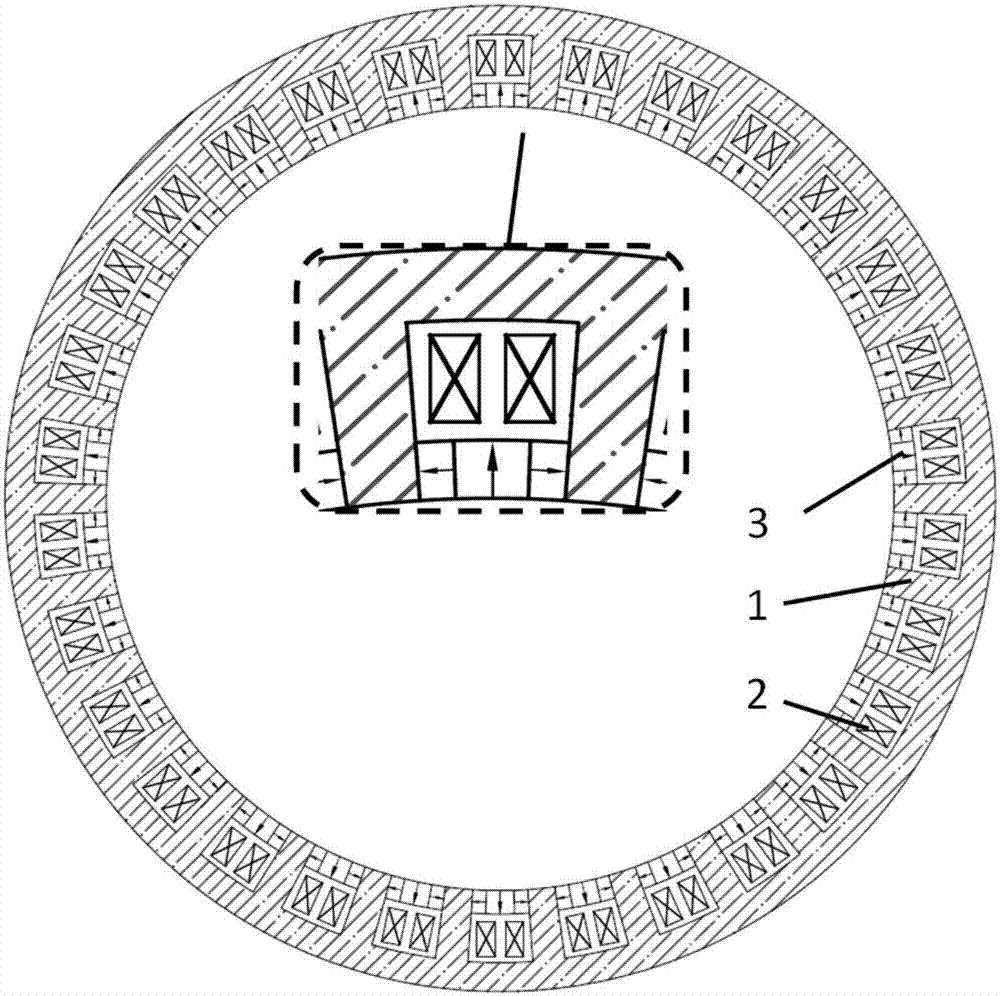

Magnetic gear composite motor

ActiveCN108011484AIncreased torque densityReduce Flux LeakageDynamo-electric machinesLow speedElectric machine

The invention discloses a magnetic gear composite motor. The magnetic gear composite motor comprises an outer stator, a modulation rotor and an inner rotor which are sequentially arranged in a concentrically nested manner from outside to inside, wherein air gaps are formed between the outer stator and the modulation rotor as well as between the modulation rotor and the inner rotor respectively; the outer stator is provided with a trapezoidal groove used for placing a fractional slot winding, and the groove opening is embedded with alternative-pole magnetic steel; the modulation rotor comprisesa plurality of magnet regulating yokes and a plurality of non-magnetic conductive materials embedded with punched holes respectively, and the adjacent magnet regulating yokes are embedded with the punched non-magnetic conductive materials therebetween; and the permanent magnet inner rotor comprises inner rotor permanent magnets and an inner rotor iron core which are concentrically nested to one another sequentially from outside to inside. According to the magnetic gear composite motor provided by the invention, a magnetic path of the magnetic gear motor on the stator is constructed through combining permanent magnets with different polarization directions, so that the magnetic path is enabled to be more efficient and reasonable, the flux leakage is reduced while low-speed and high-torquedirect drive output is realized, and the overall torque density and efficiency of the composite motor are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

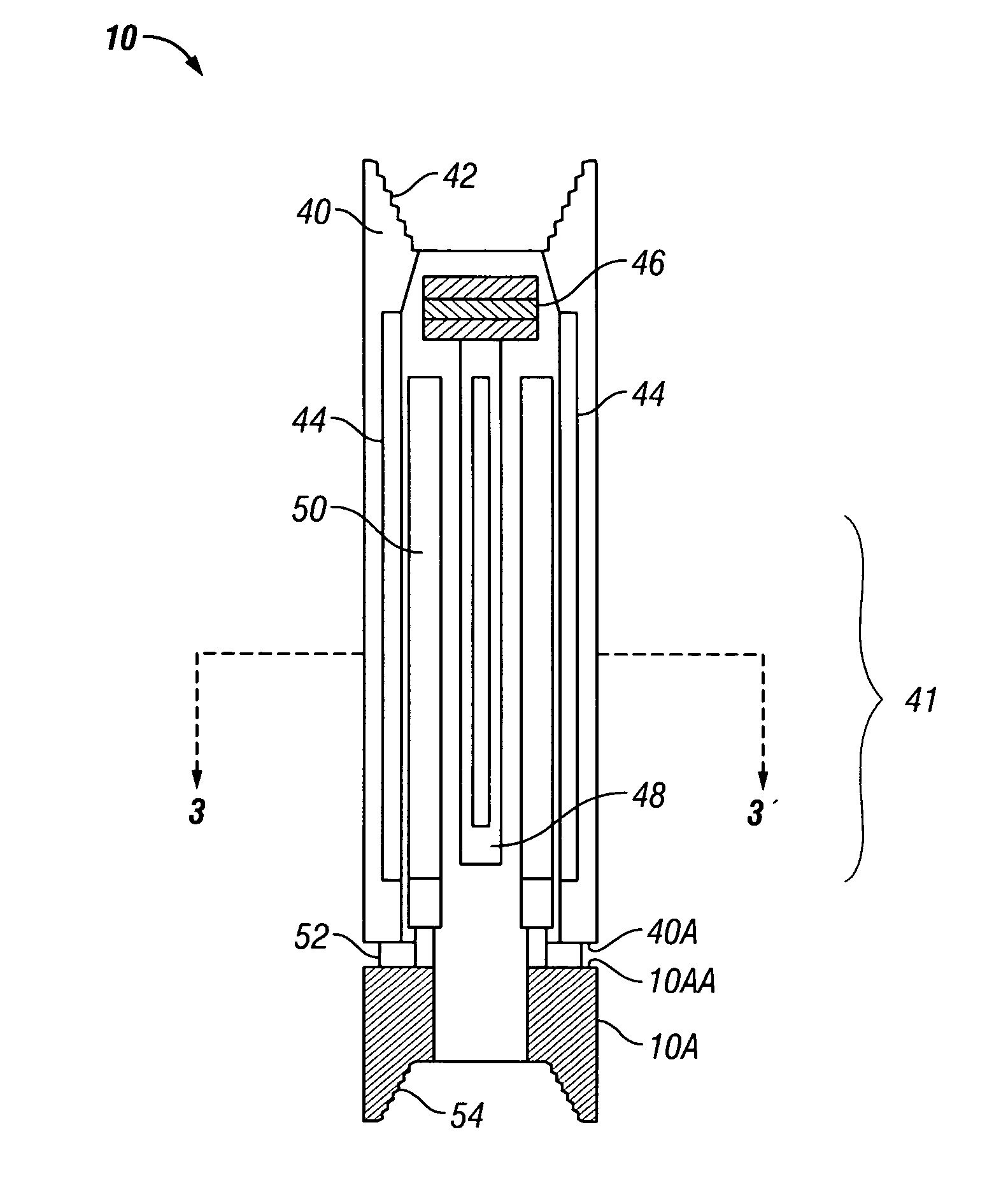

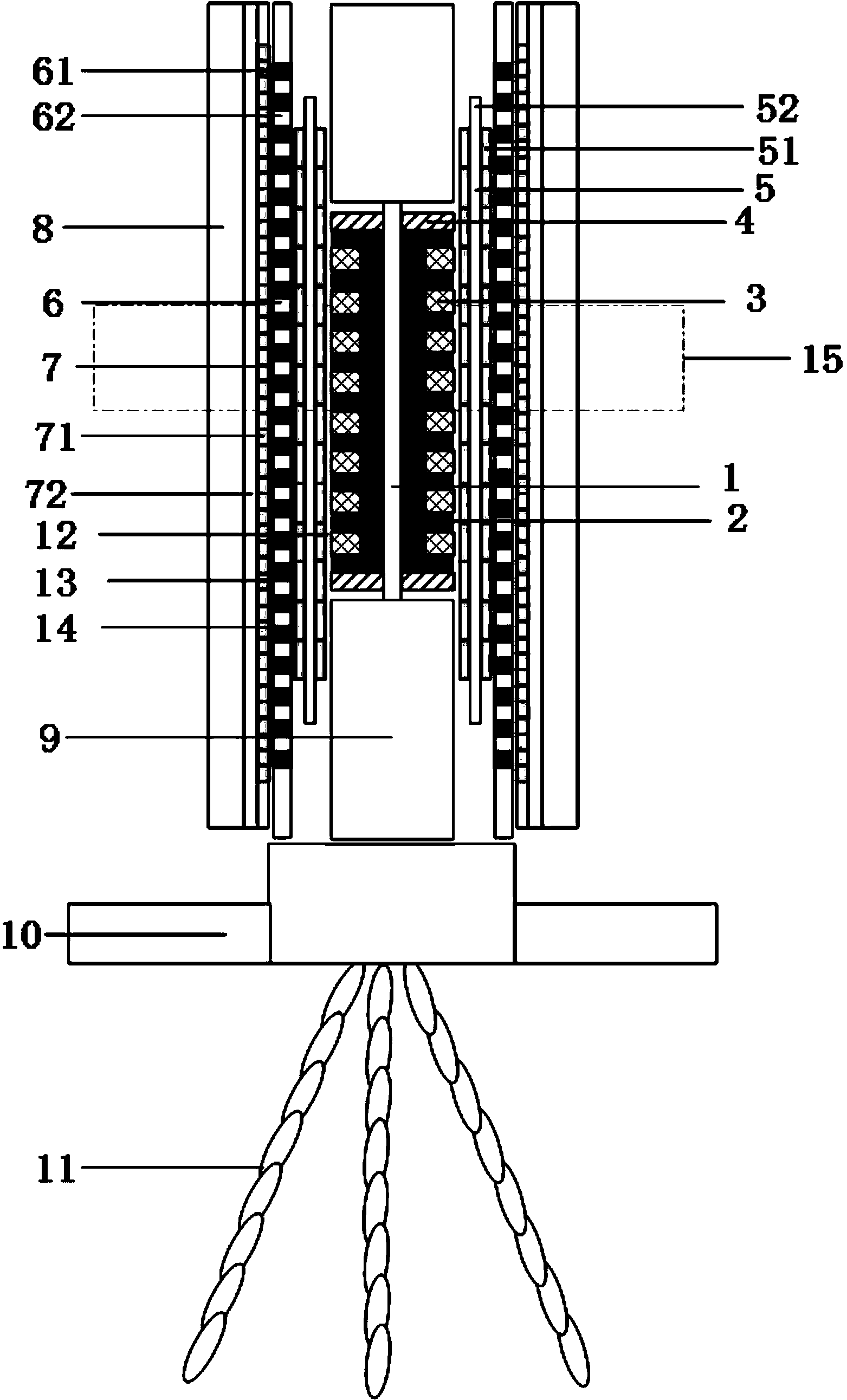

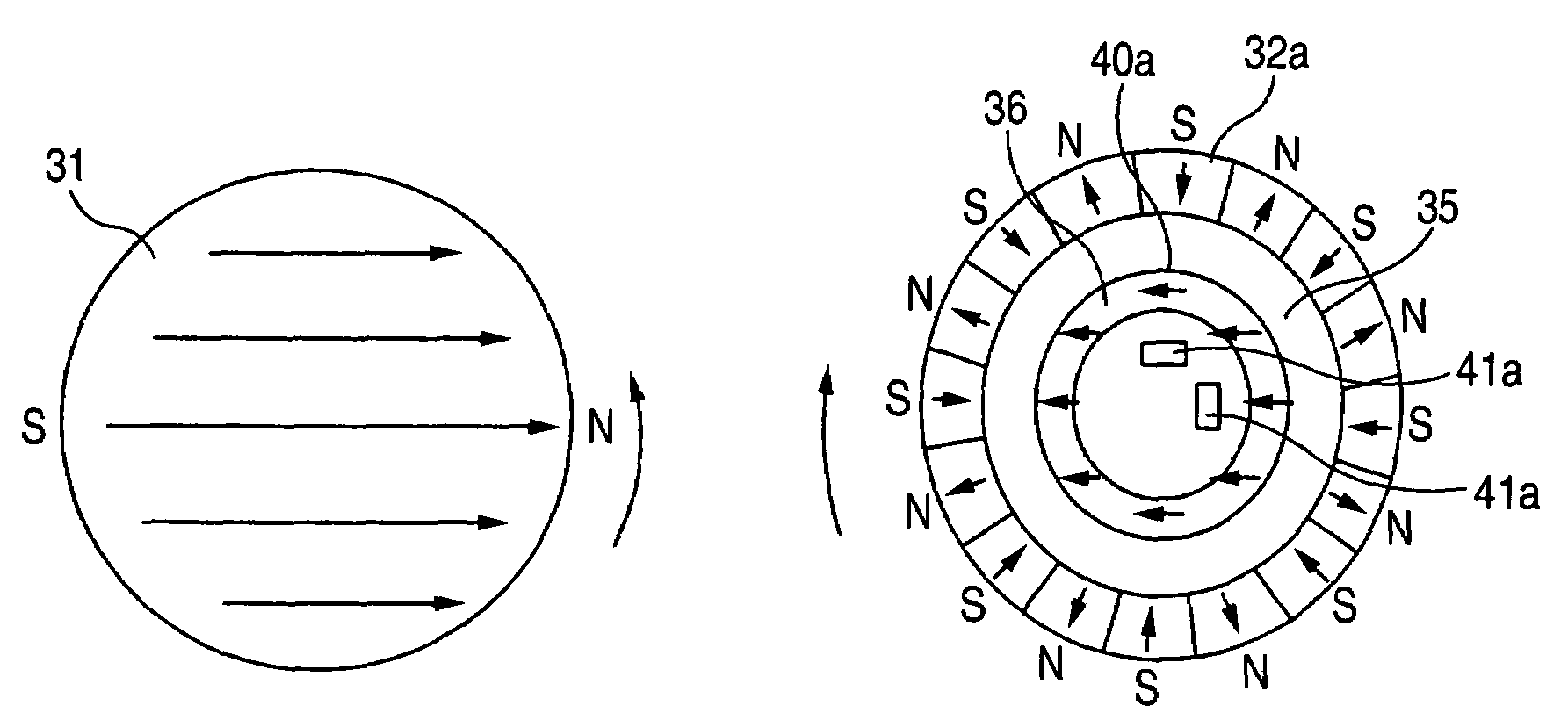

Multiple-Rotation Absolute-Value Encoder of Geared Motor

ActiveUS20090140731A1Simple configurationReduce speedElement comparisonUsing electrical meansAbsolute rotationRotation velocity

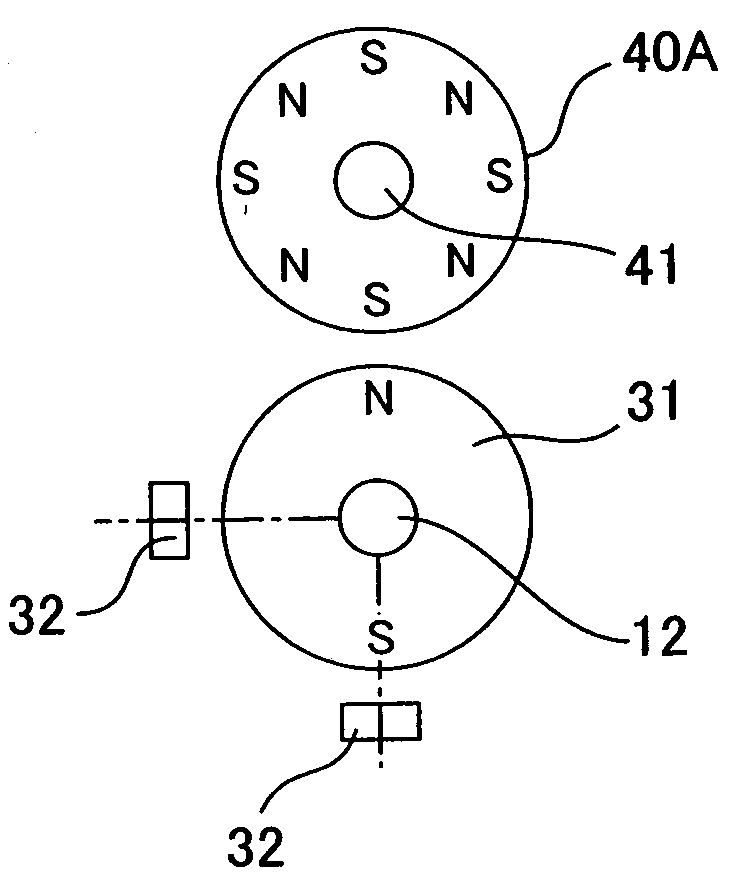

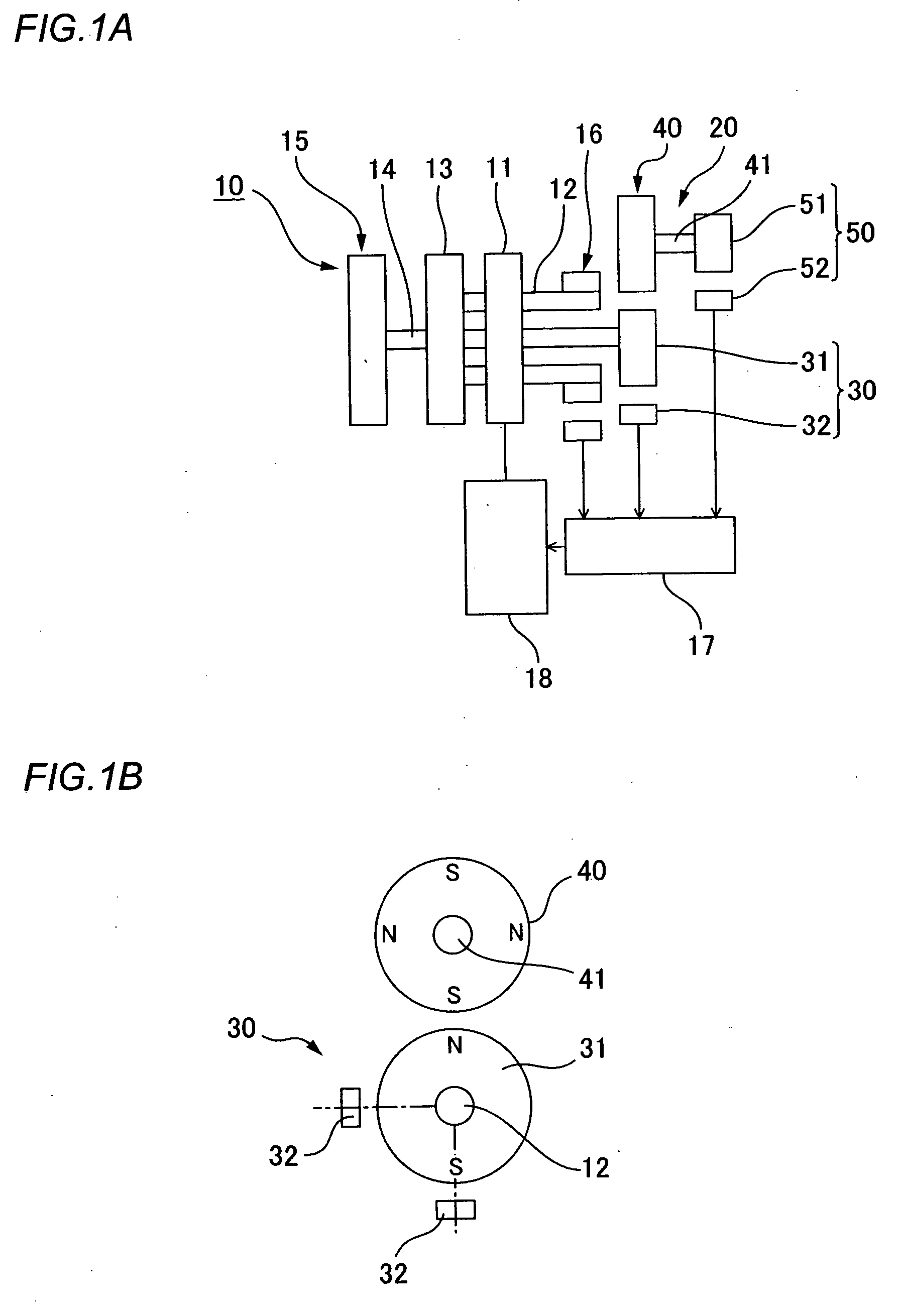

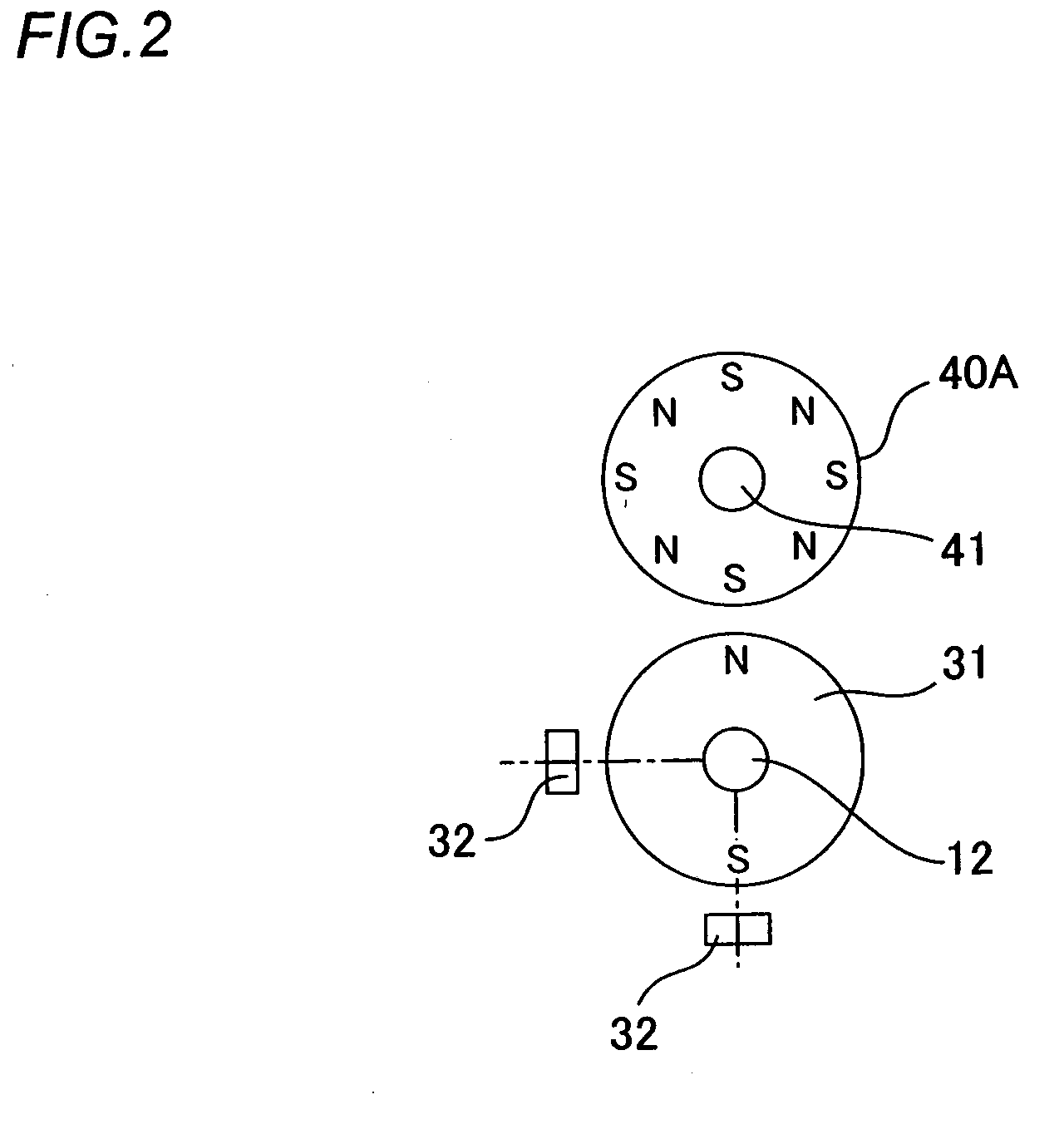

A multiple-rotation absolute-value encoder of a geared motor, wherein the geared motor (10) reduces the rotational speed of a motor shaft (12) and takes it out from a gear shaft (14) to drive a machine device (15) in an operating range corresponding to the two rotations of the gear shaft (14). The multiple-rotation absolute-value encoder (20) fitted to the geared motor (10) comprises a gear shaft absolute value encoder (30) detecting the absolute position of the gear shaft (14) and a load side absolute value encoder (50) having a two-pole magnet (51) and a magnetic sensor (52) rotating at a rotational speed reduced to half the rotational speed of the gear shaft (14) through the magnetic gear (40). Since the operating range of the machine device (15) corresponds to one rotation of the two-pole magnet (51), the absolute position of the machine device (15) is determined based on an output from the magnetic sensor (52). As a result, the original position of the machine device (15) can be established without requiring an additional rotating operation when the operation of the machine device is started.

Owner:HARMONIC DRIVE SYST IND CO LTD

Wellbore Motor Having Magnetic Gear Drive

ActiveUS20070215343A1RotationPrevent rotationDynamo-electric brakes/clutchesFluid removalGear wheelEngineering

A wellbore motor includes a source of rotational motive power disposed in a wellbore, a magnetic gear member operatively coupled at an input thereof to the source; and a magnetic gear member output coupled rotationally to a rotary wellbore tool.

Owner:MAGNOMATICS LTD

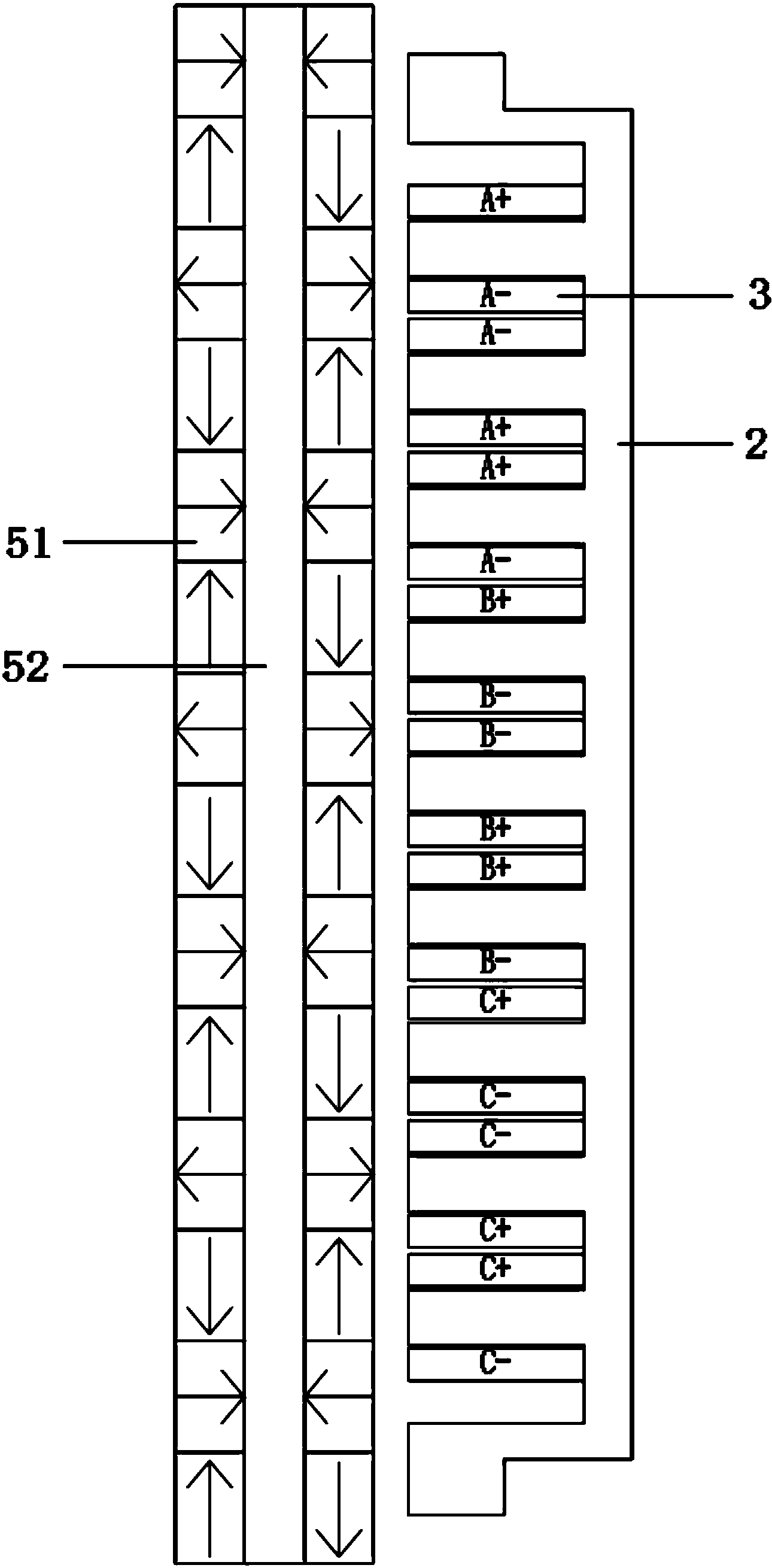

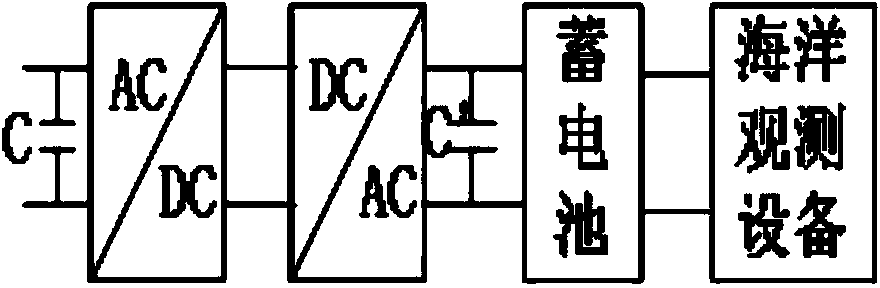

Wave power generation device based on linear magnetic gear motor

InactiveCN103807085AImprove power generation efficiencySimple structureMachines/enginesEngine componentsWave power generationLow speed

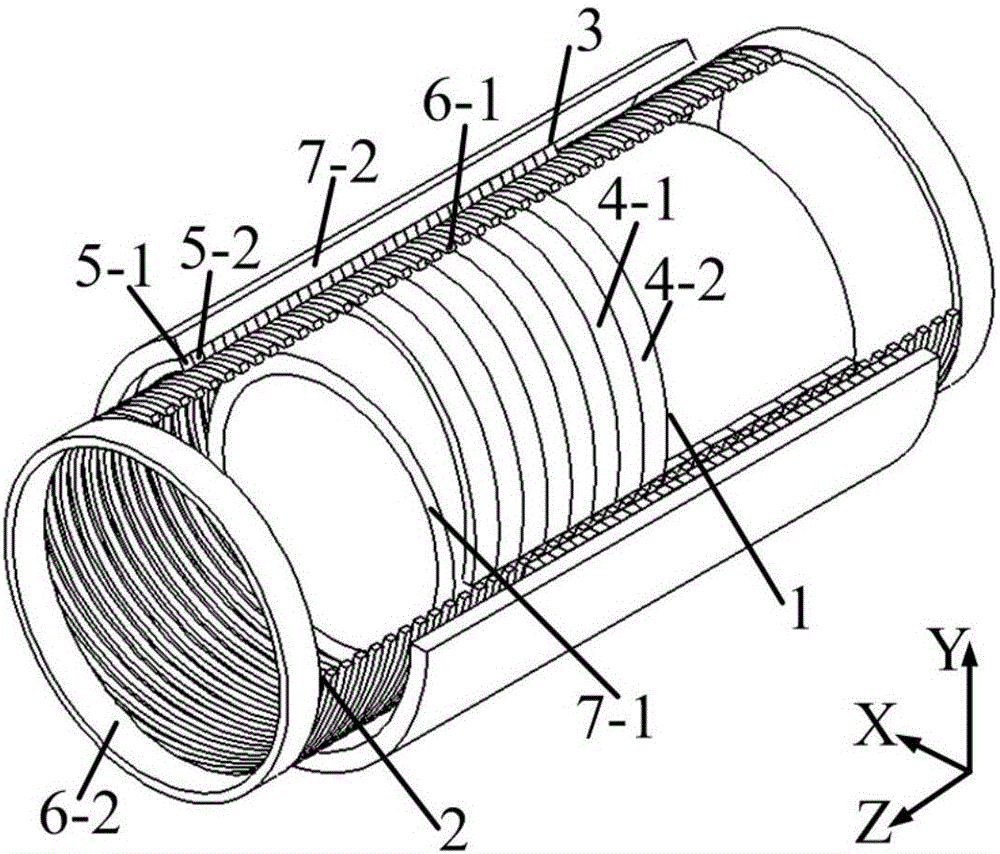

The invention discloses a wave power generation device based on a linear magnetic gear motor. The wave power generation device comprises a motor stator core, a motor converter, a magnetism regulating ring, a magnetic gear low-speed moving part, an inner floating barrel and an outer floating barrel. The motor stator core is sleeved with the motor converter, the motor converter is sleeved with the magnetism regulating ring, the magnetism regulating ring is sleeved with the magnetic gear low-speed moving part, the magnetic gear low-speed moving part is sleeved with the inner floating barrel, and the inner floating barrel is sleeved with the outer floating barrel. A first air gap is formed between the motor stator core and the motor converter, a second air gap is formed between the motor converter and the magnetism regulating ring, and a third air gap is formed between the magnetism regulating ring and the magnetic gear low-speed moving part. A motor stator shaft and the magnetism regulating ring are fixed in position, and the magnetic gear low-speed moving part and the inner floating barrel are fixed in position. The wave power generation device has the advantages that no huge speeders need to be additionally arranged, the size is small, energy capture and power generation efficiency is high, and convenience is brought to design, debugging and maintenance of an electrical control system through the whole floating suspended structure.

Owner:SOUTHEAST UNIV

Coaxial magnetic gear

ActiveCN102324821AIncreased torque densityHigh mechanical strengthDynamo-electric machinesGear wheelMagnetic poles

The invention discloses a coaxial magnetic gear comprising an external rotor, a static magnetic ring and an internal rotor which are lined from outside to inside and share the same axis. The external rotor is a circular magnetic conductor, and external rotor convex poles which are lined with equal spacing are arranged on the inner ring of the external rotor; the static magnetic ring is fixedly arranged between the internal rotor and the external rotor, and comprises permanent magnets and non-permanent magnets which are lined at intervals; internal rotor convex poles are lined on the outer ring of the internal rotor with equal spacing, and internal rotor permanent magnet bodies are arranged on the outer ring of the internal rotor; the internal rotor can be also in other structural forms capable of producing effective N-S magnetic poles; and in order to ensure the normal rotation of the internal rotor and the external rotor, air gaps are left between the three parts. Through the convex pole structure of the external rotor, the coaxial magnetic gear enables a static magnetic ring magnetic field to modulate a series of harmonic rotation magnetic fields on an inner air gap side, the number of the polar pairs of the selected internal rotor permanent magnet bodies is the same with that of the pole pairs of a required harmonic magnetic field, and the stable torque transmission is realized by the coupling action of the polar pairs of the selected internal rotor permanent magnet bodies and the pole pairs of a required harmonic magnetic field. The magnetic gear has the characteristics of high torque density, high mechanical strength of the external rotor, and convenience in processing and manufacturing.

Owner:SOUTHEAST UNIV

Magnetic-field modulated-type magnetic screw

ActiveCN106341031ADosage will not increaseImprove linear travelPermanent-magnet clutches/brakesNon magneticUltimate tensile strength

The invention discloses a magnetic-field modulated-type magnetic screw, belongs to the magnetic screw and linear magnetic gear field and relates to a contactless magnetic transmission linear driver. A rotor magnetic screw is formed by a radial magnetizing spiral permanent magnet and an electric iron bar. A linear mover is formed by a spiral electrician iron hoop and a non-magnetic material. A stator magnetic nut is formed by the radial magnetizing spiral permanent magnet and an electrician iron hoop. In the rotor magnetic screw, a permanent magnet surface is pasted to an external surface of the electric iron bar. In the stator magnetic nut, the permanent magnet surface is pasted to an internal surface of the electrician iron hoop. The linear mover is between the magnetic screw and the magnetic nut, and the three components are not contacted with each other and air gaps are arranged among the three components. Through mutual cooperation between the permanent magnet and a ferromagnetic material, an amount of the permanent magnets can be effectively reduced and simultaneously a linear stroke is added, and a thrust density and mechanical strength are increased.

Owner:JIANGSU UNIV

Magnetic gear arrangement

ActiveUS20130002075A1Increase flux densityAvoid assemblyManufacturing dynamo-electric machinesSynchonous clutches/brakesSuperconducting CoilsEngineering

A magnetic gear arrangement includes: a first gear member for generating a first magnetic field, a second gear member for generating a second magnetic field, and a coupling device which provides an arrangement of interpoles between the first gear member and the second gear member. The interpoles couple the first and second magnetic fields to produce a gearing between the first and second gear members. The first gear member has superconducting magnets or coils for generating the first magnetic field and / or the second gear member has superconducting magnets or coils for generating the second magnetic field.

Owner:ROLLS ROYCE PLC

Direct drive type sinusoidal magnetic field composite permanent magnet motor

ActiveCN102035320ACompact structureIncreased torque densityMagnetic circuit rotating partsMagnetic circuit stationary partsGear wheelElectric machinery

Owner:SHANGHAI UNIV

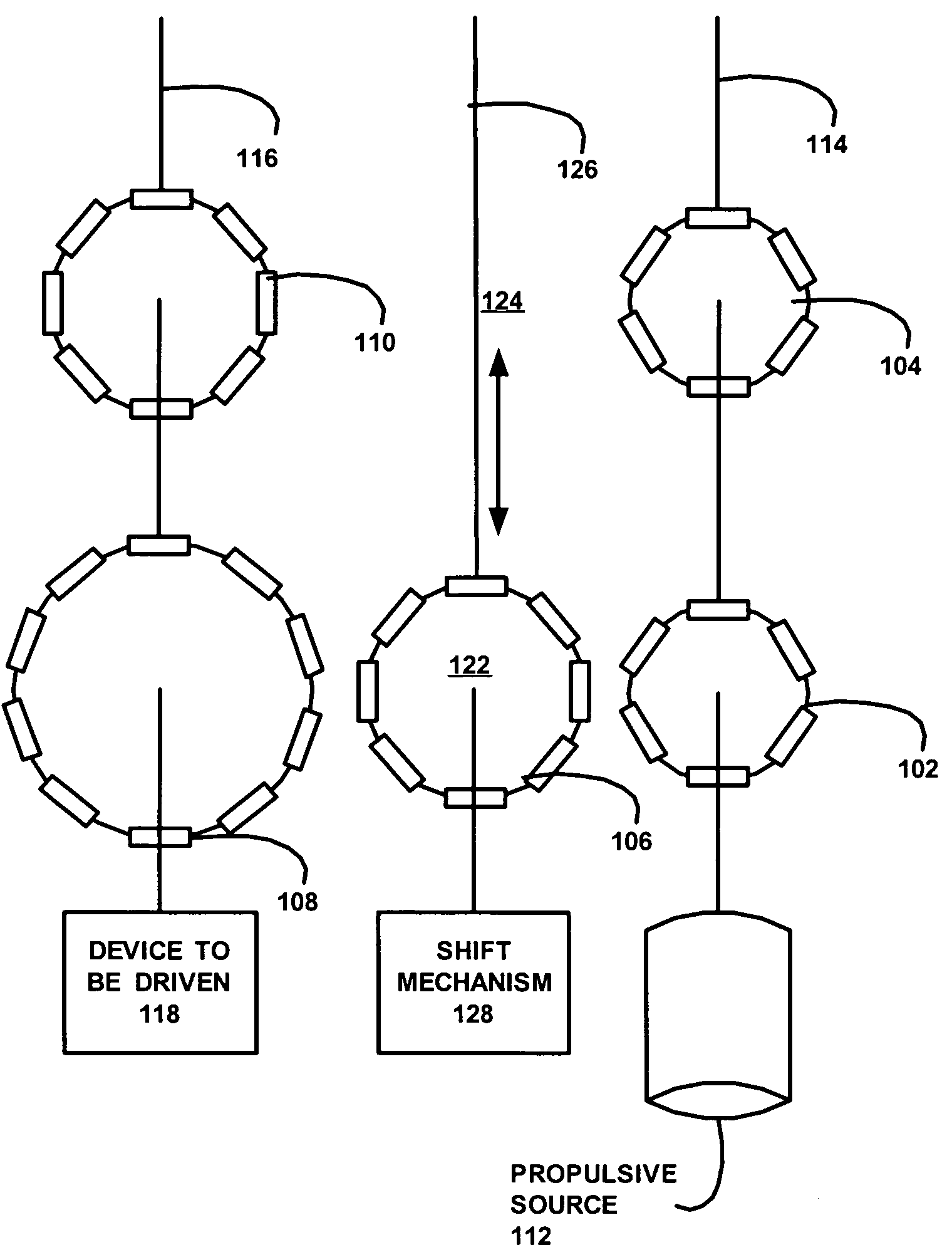

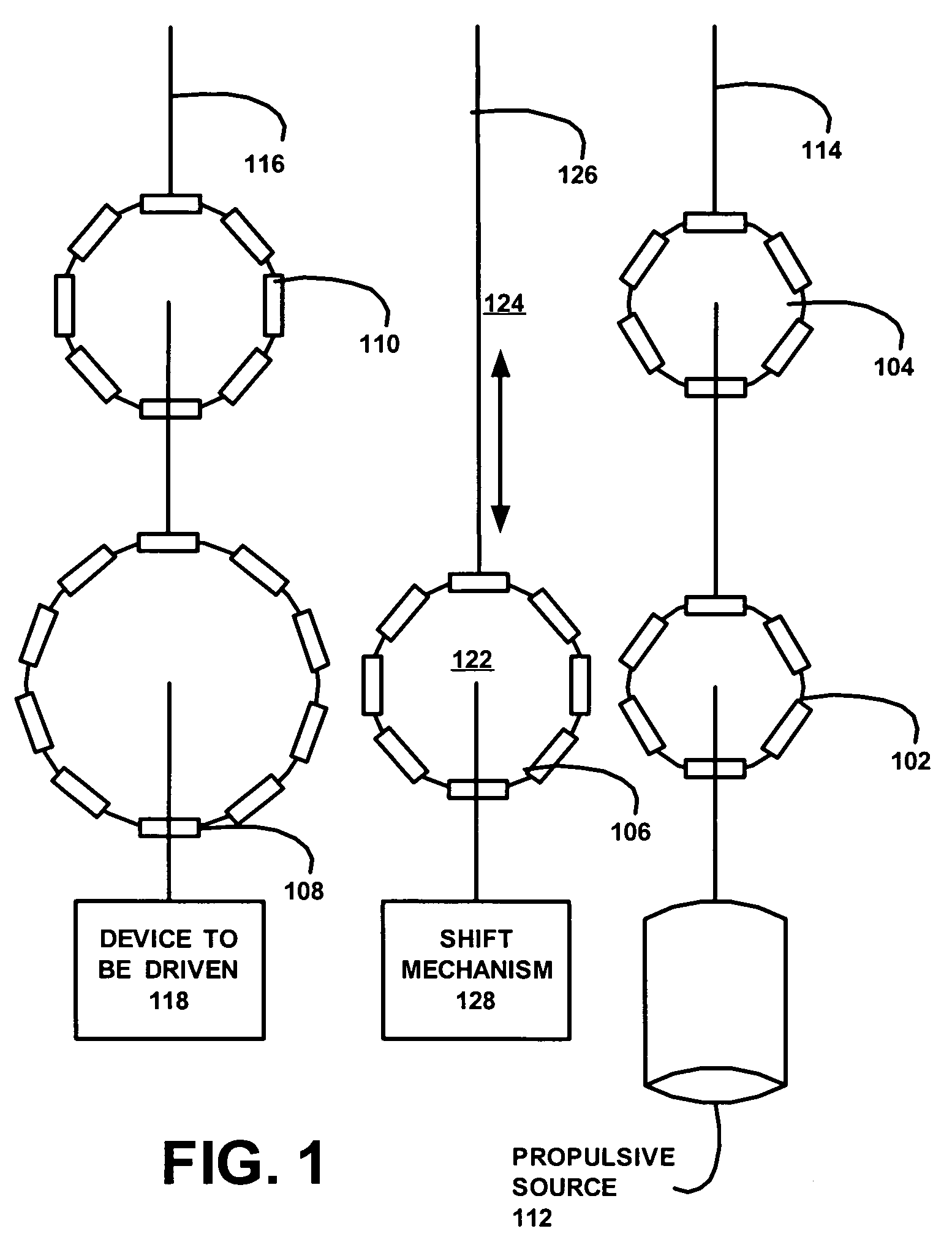

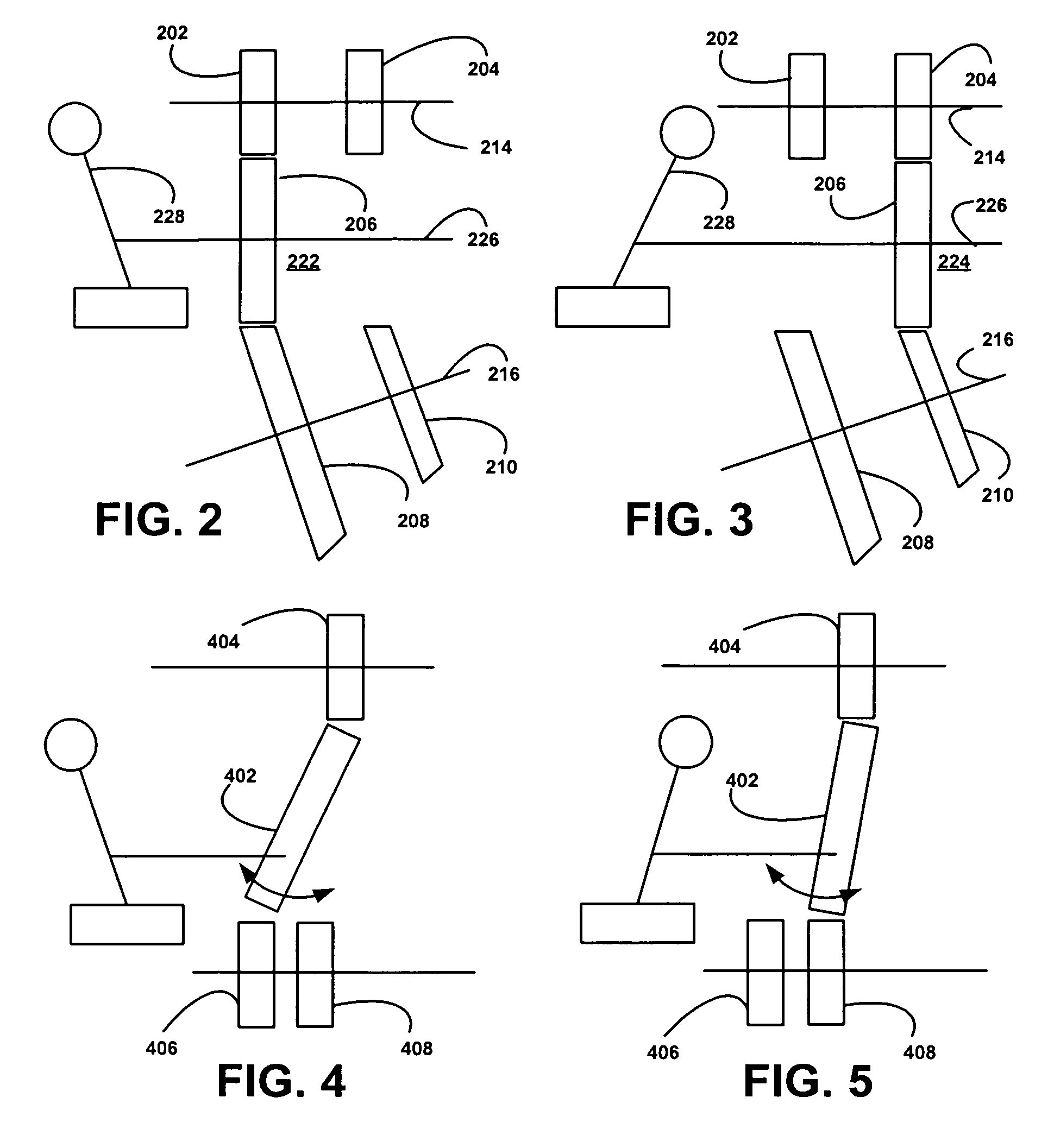

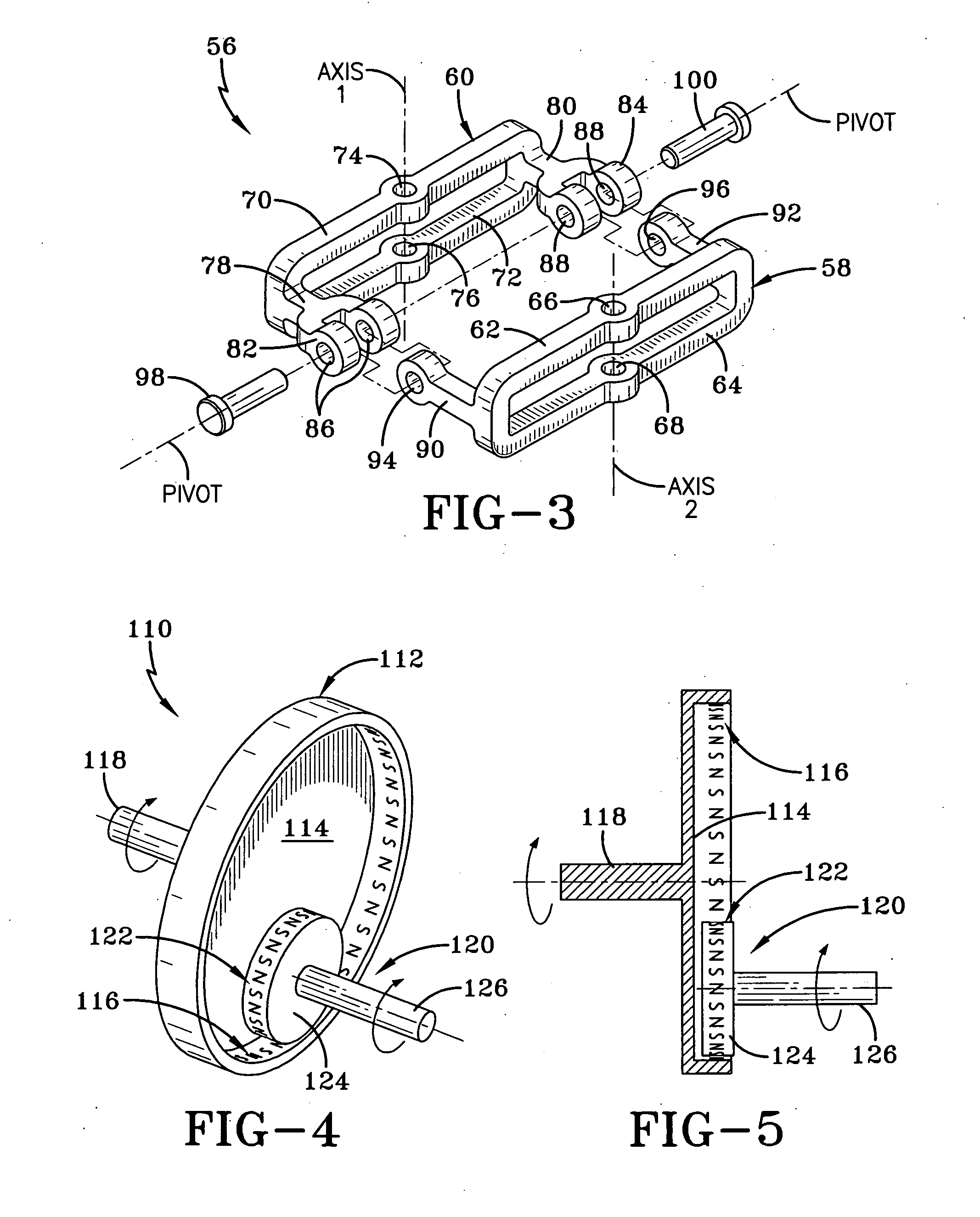

Inherently torque limiting magnetically-coupled wheels

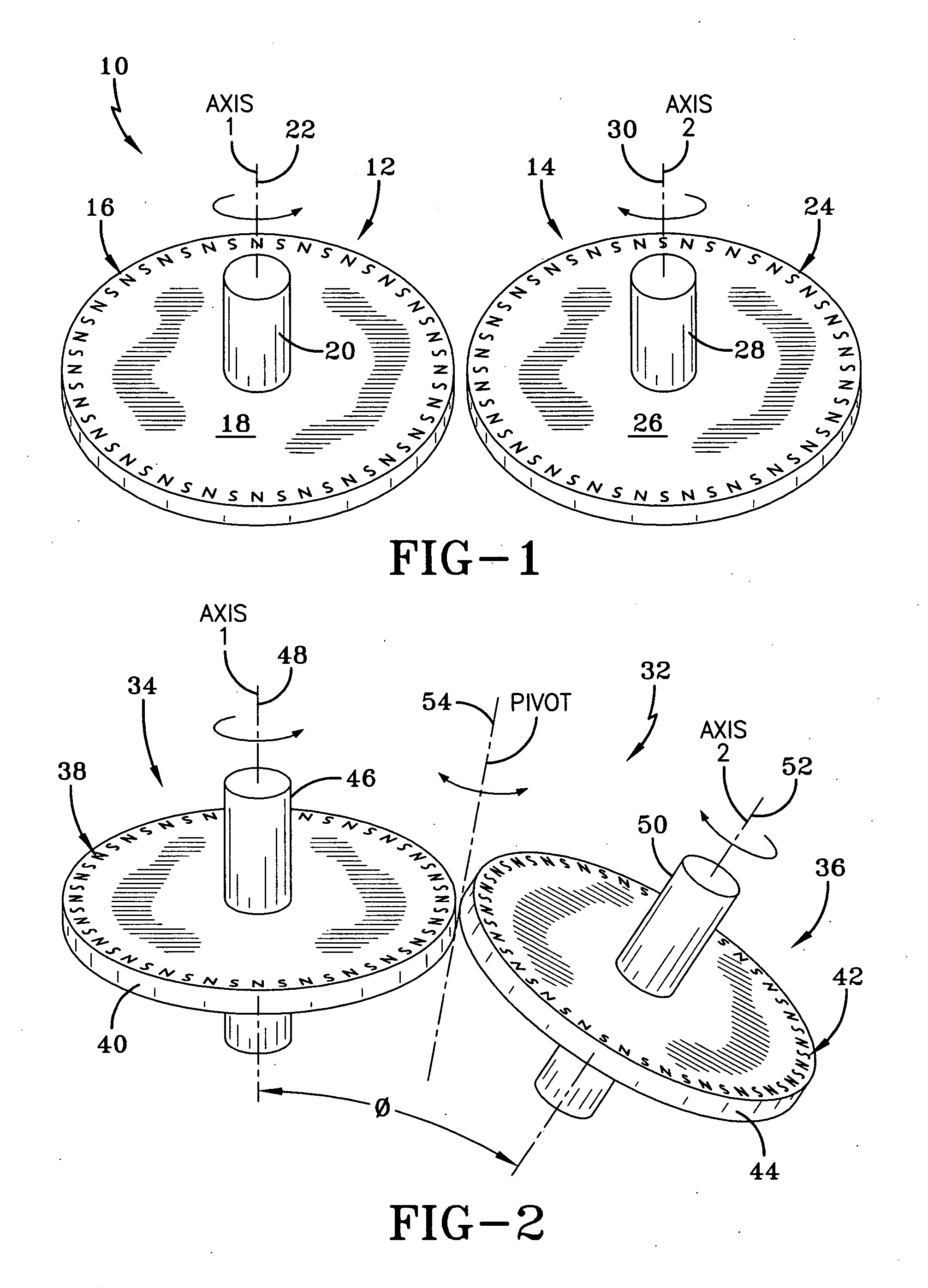

ActiveUS20110266902A1Sufficient effectInsignificant hysteresis lossesEfficient propulsion technologiesDepending on power plant typeElectrical polarityWatercraft

An apparatus having at least one rotatable driven object having an edge on which are disposed a series of adjacent magnets of alternating polarity and a driving object rotatable by an external motor torque and having a series of adjacent magnets of alternating polarity on a magnet supporting surface. The magnet supporting surface of the driving object is rotatable through a common region approximately centered about the point of closest approach to the magnet supporting edge of the driven object for sequentially placing magnets of the driving object in the region enveloping the effective interactive range between the two objects. The fields of magnets of opposite polarity of the driving object interact with the fields of the magnets on the driving object to effect rotation of the driven object. Disclosed are structures for torque limiting wheels, magnetic gear trains, reduction gears and ball joints, and propulsion systems for watercraft and aircraft.

Owner:WHITFIELD GEORGE WINSTON +1

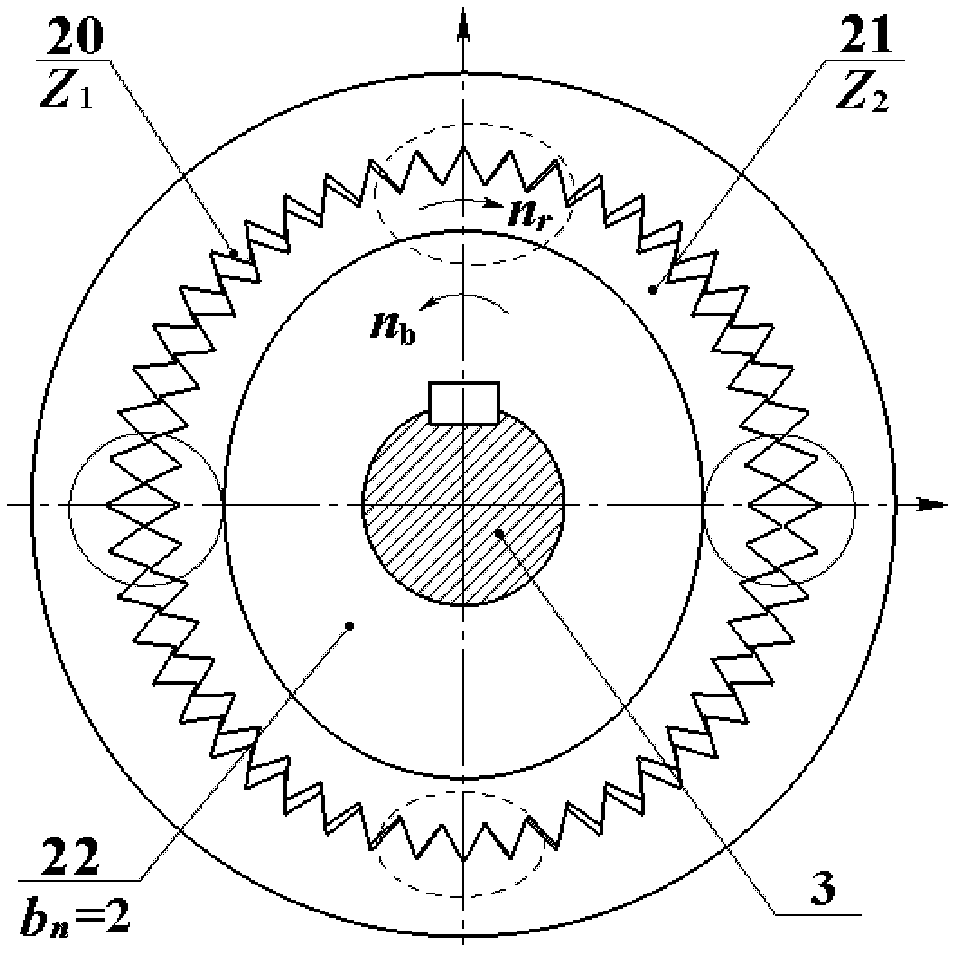

Steering system planetary gear absolute angle output corner sensor

InactiveCN101608898ALow environmental requirementsImprove performanceUsing electrical meansElectrical steeringGear wheelMagnetic poles

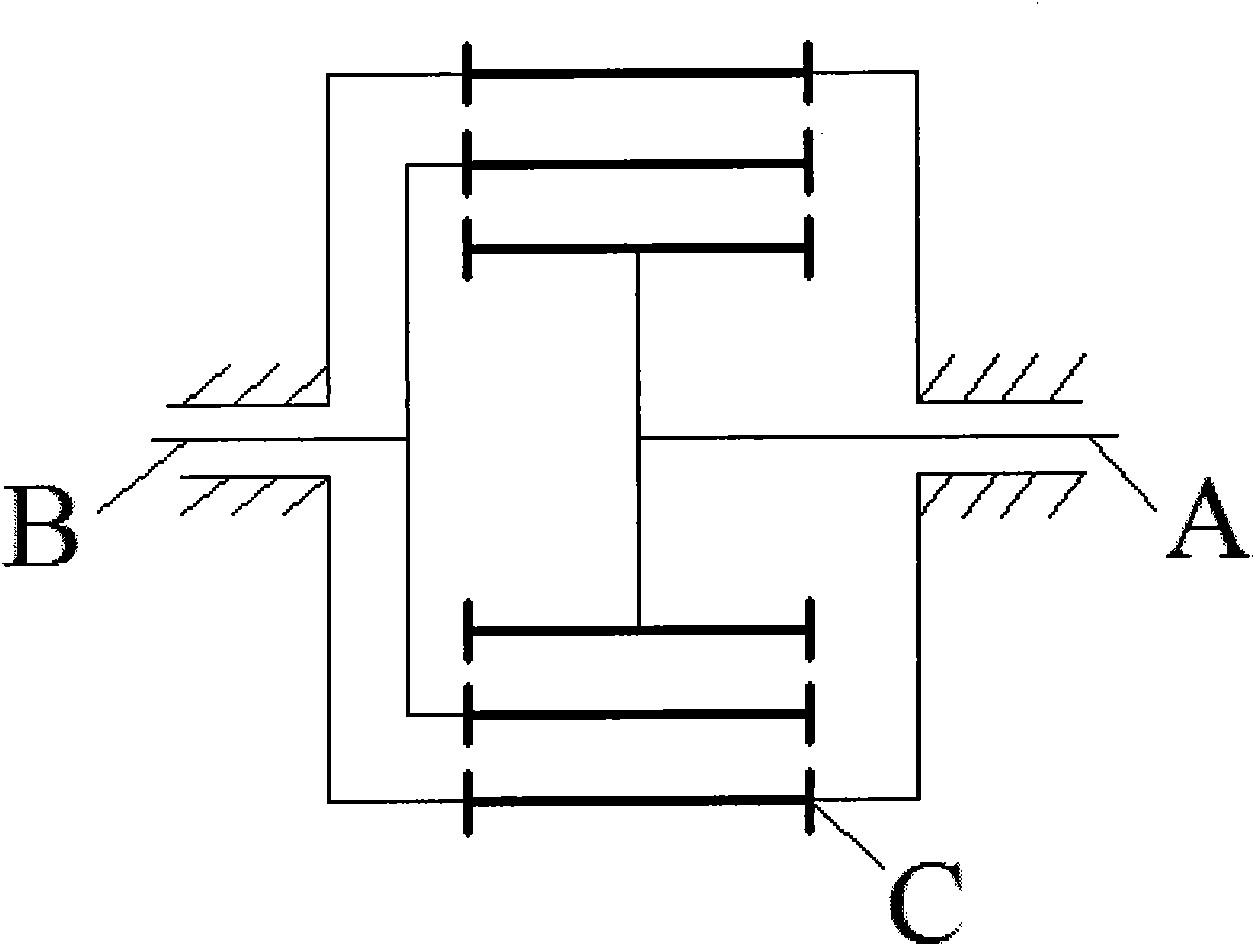

The invention relates to a steering system planetary gear absolute angle output corner sensor, mainly composed of a gear ring (1), a sun gear (3), planetary gears (7), a CPU control unit (11) and Hall sensors; wherein the sun gear is a magnetic gear, and the sun gear and the gear ring are all provided with a pair of magnetic poles; the sun gear is fixed on a steering column (9), and the steering column is fixedly connected with an auto steering wheel; the quantity of the planetary gears is three, the planetary gears are evenly distributed and fixedly arranged on a planet carrier (9) and are connected with the sun gear and the gear ring in a meshed way, and the planet carrier is fixed at the upper part of a sleeve; a pair of Hall sensors are respectively arranged near the sun gear and the magnetic poles of the gear ring, and each pair of Hall sensors are arranged in 90 degrees; and the Hall sensors are connected with the CPU control unit (11) by a data line. The invention has the advantages of low requirement on environment, high cost performance, wide measurement range, insensitivity to error caused by temperature and convenient installation.

Owner:WUHAN UNIV OF TECH +1

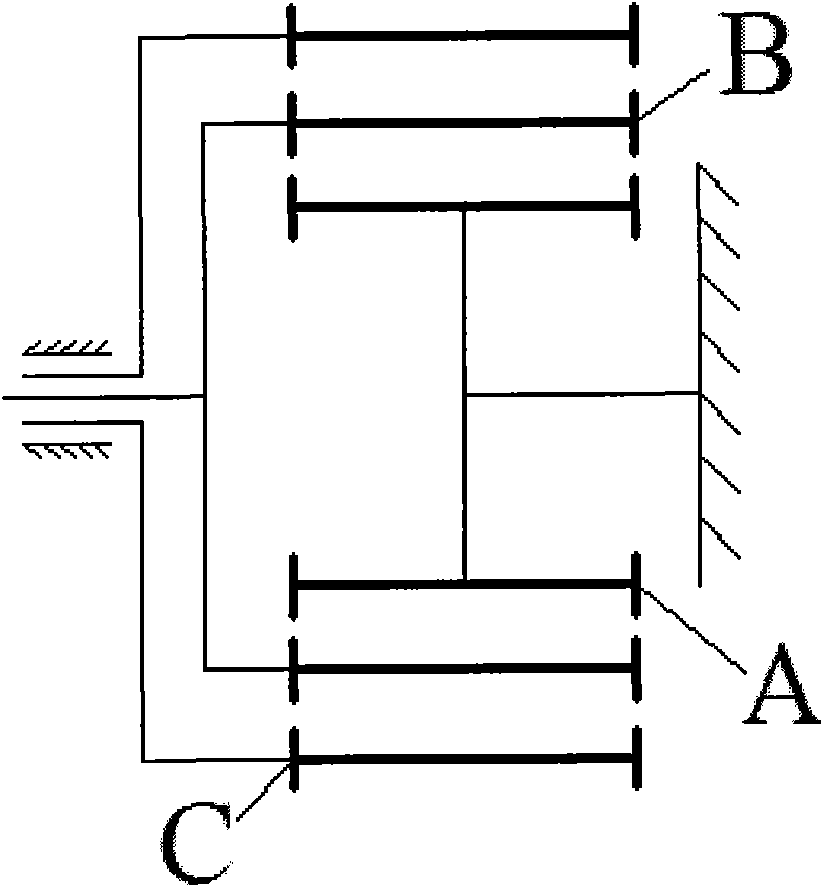

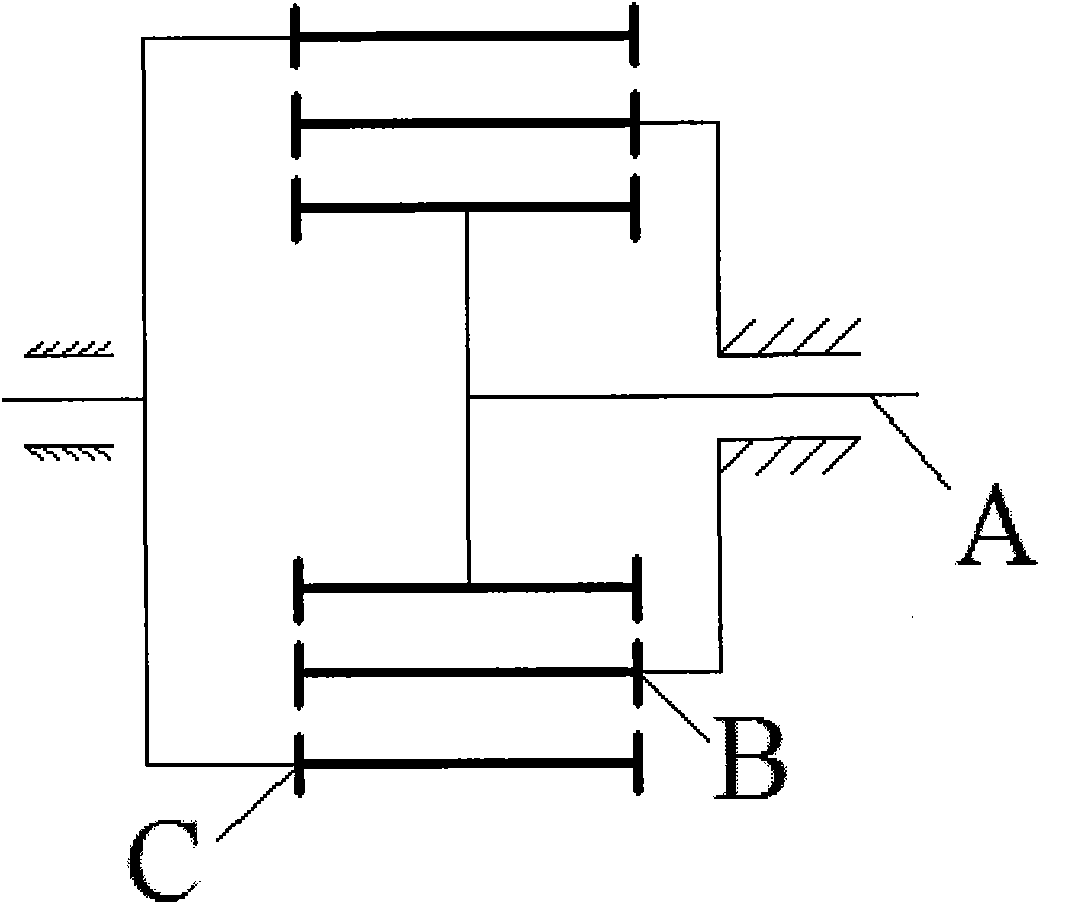

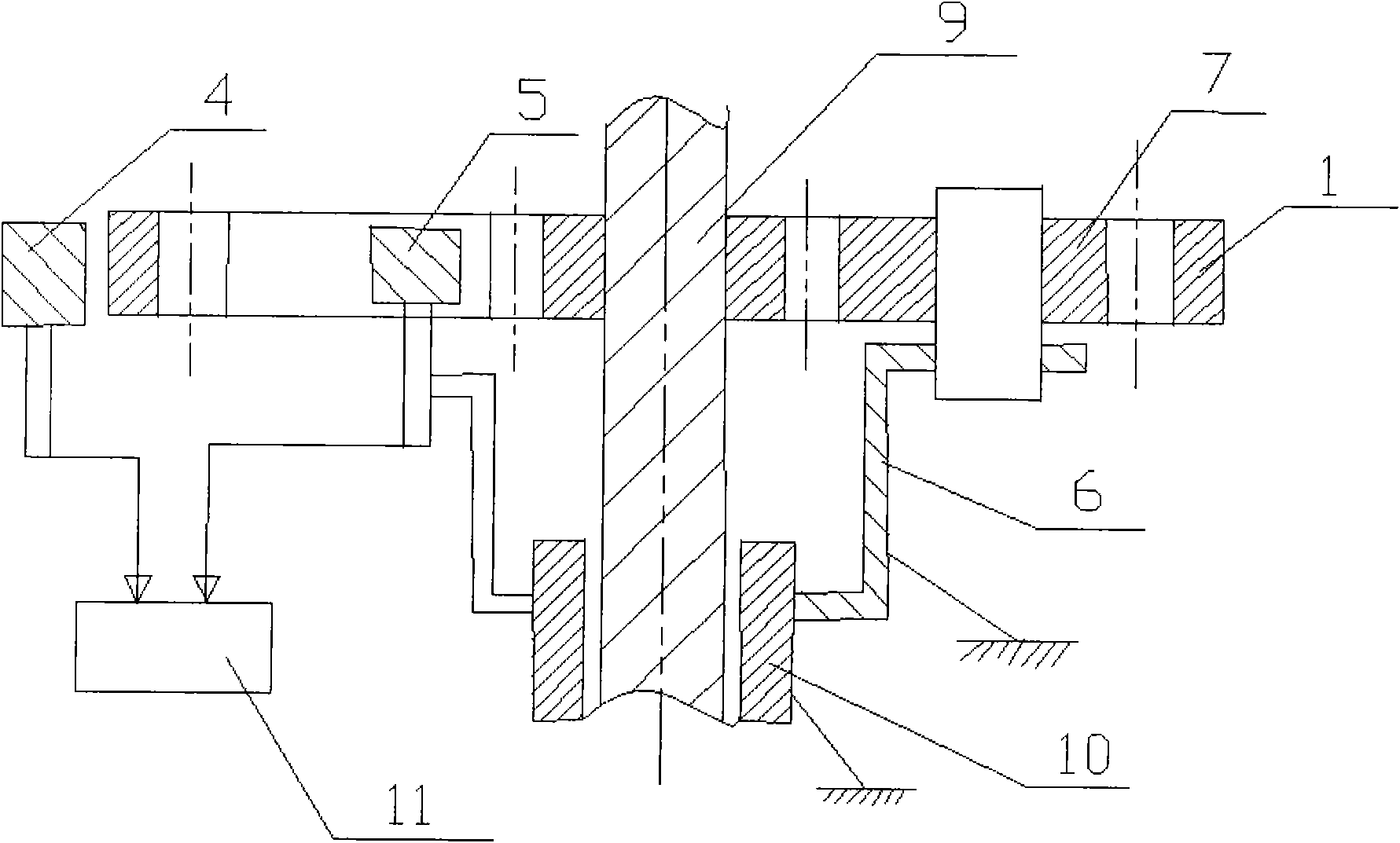

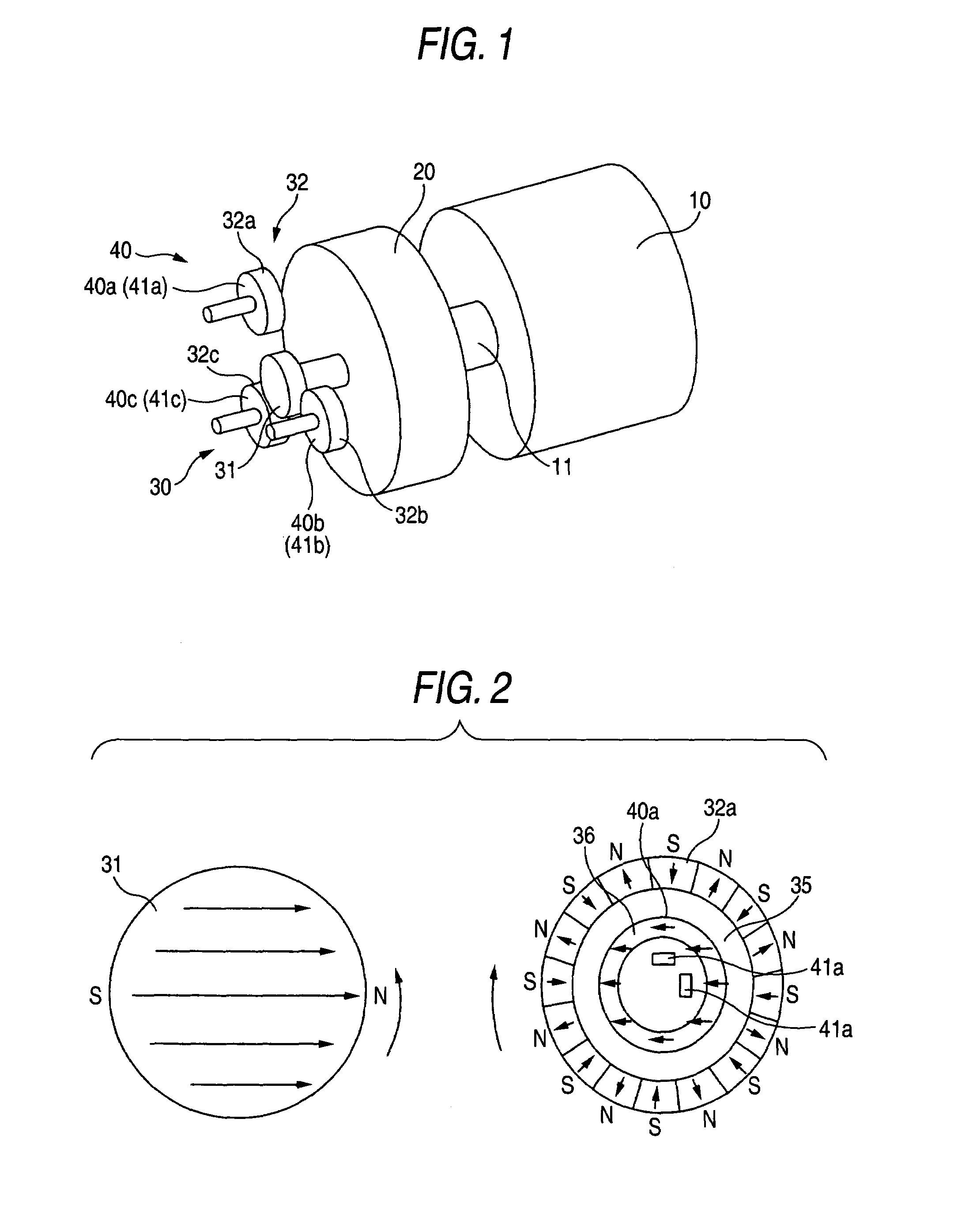

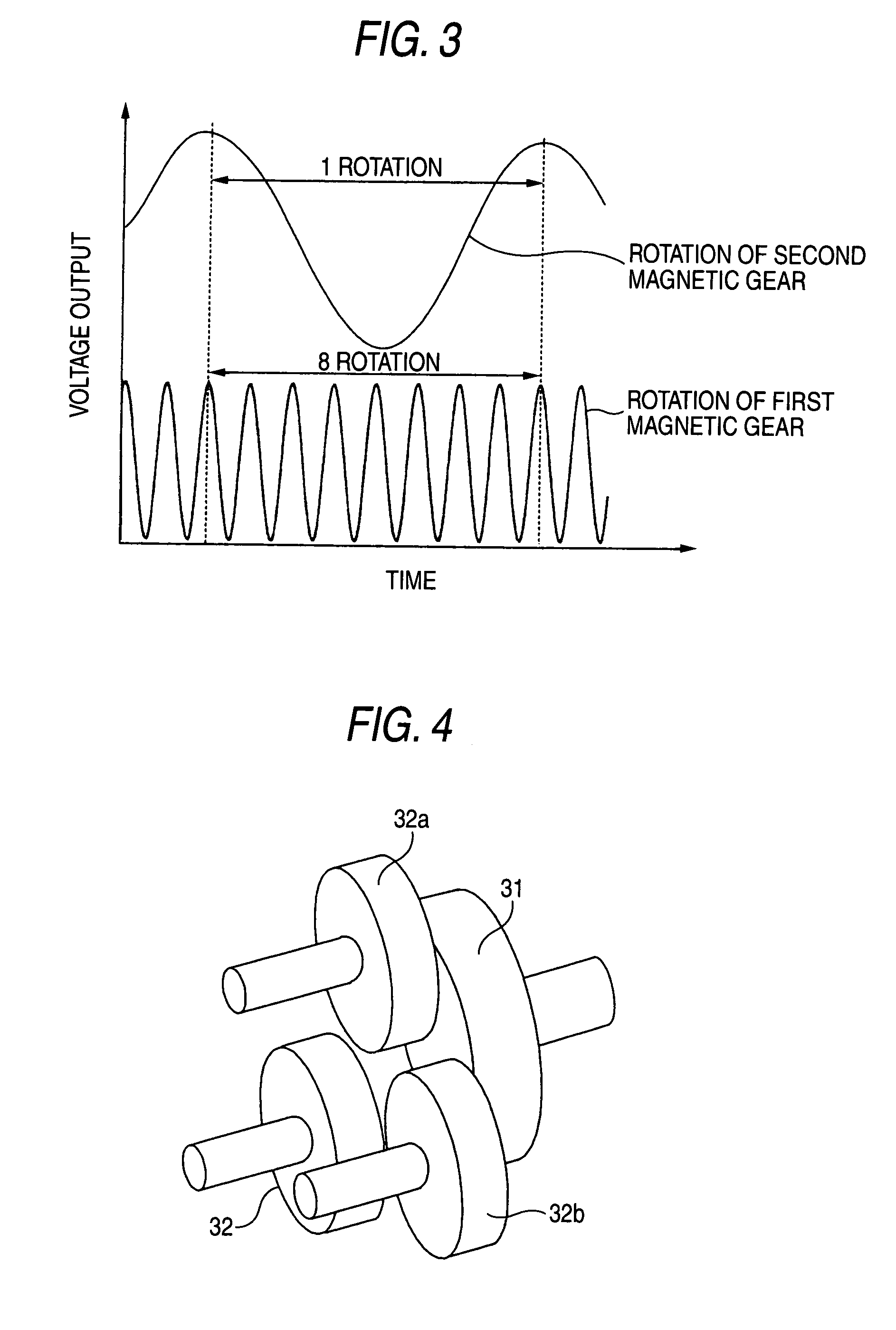

Multirotation type encoder

InactiveUS7042211B2Reduce rateSolution to short lifeElectric signal transmission systemsUsing electrical meansCouplingMagnetic poles

A multirotation type encoder of the invention includes a first encoder 20 attached to a rotating shaft 11 of a rotating machine 10 for detecting an absolute value rotational angle within one rotation, and a second encoder for counting a multirotation amount of the rotating shaft 11 by using a speed reducing mechanism 30 by magnetic coupling and the second encoder 40 is constituted by a first magnetic gear 31 directly connected to the rotating shaft and magnetized in multiple poles and at least one second magnetic gear 32 arranged to be opposed thereto in noncontact and magnetized in multiple poles by a number of magnetic poles larger than that of the first magnetic gear 31 and is constituted to count a multirotation amount by detecting a rotational angle of the second magnetic gear by the second encoder.

Owner:YASKAWA DENKI KK

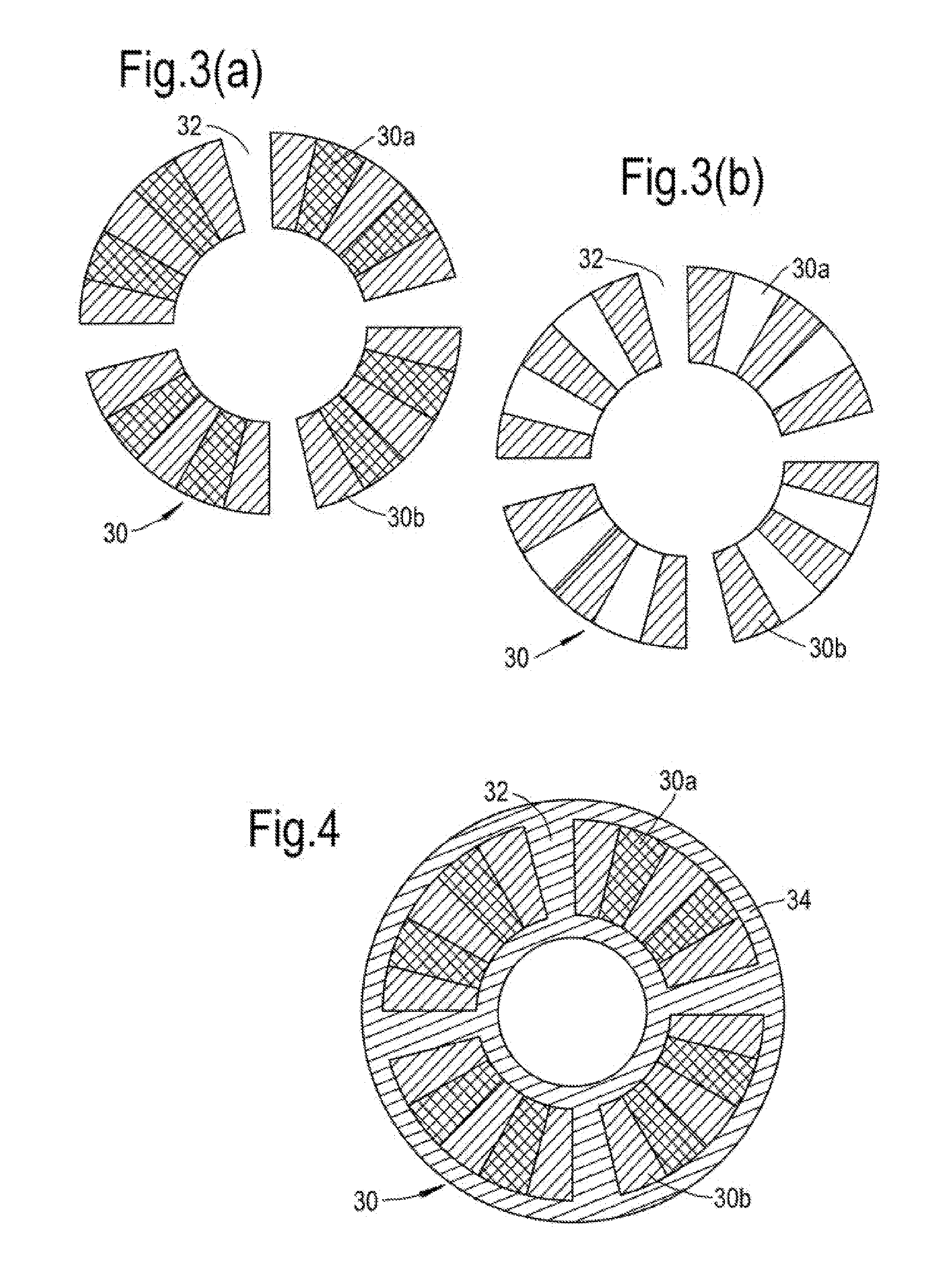

Concentric permanent magnetic gear magnetism regulation ring device and production method thereof

ActiveCN106452002AShorten the production cycleReduce manufacturing costPermanent-magnet clutches/brakesRing devicePole piece

Owner:DALIAN YULIN ELECTRIC MOTOR

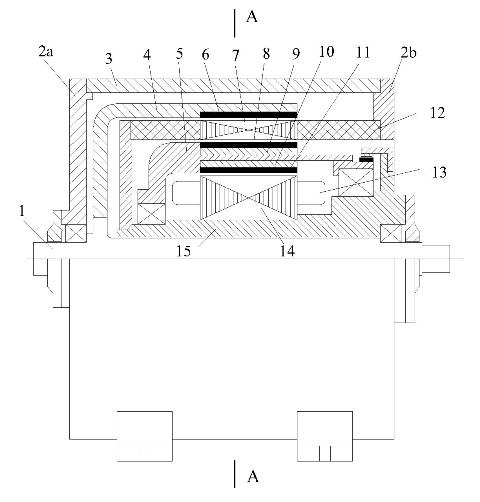

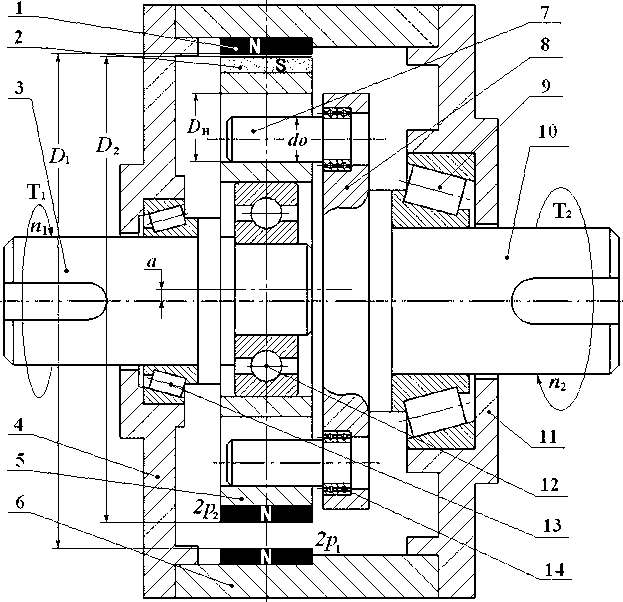

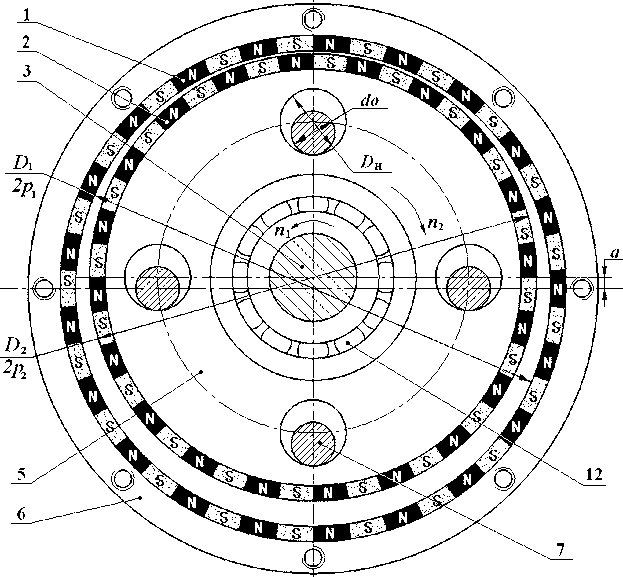

Little pole difference magnetic field coupling type magnetism transmission eccentricity gear pair of novel radial direction magnetic field

InactiveCN103107676ATo achieve technical and economic effectReduce lossDynamo-electric brakes/clutchesElectric machinesLow speedMagnetic field coupling

Disclosed is a little pole difference magnetic field coupling type magnetism transmission eccentricity gear pair of a novel radial direction magnetic field. The little pole difference magnetic field coupling type magnetism transmission eccentricity gear pair of the novel radial direction magnetic field can be applied widely in the field of industry transmissions of wind power generation, electric automobile, vessel driving and the like. The little pole difference magnetic field coupling type magnetism transmission eccentricity gear pair of the novel radial direction magnetic field is characterized in that a stator with a 2p1 stator permanent magnet 1 are distributed in the inner hole of a machine shell 6. A magnetism transmission gear pairs are formed by planet rotors of 2p2 planet rotor permanent magnet 2 are distributed on the excircle of a planet rotor iron core5. A number difference between the pole number 2p1 and 1p2 is small. The permanent magnets on the two magnetic gear pairs penetrate through an air gap magnetic field coupling of the radial direction eccentricity, and are connected to an eccentricity structure by the little pole difference two magnetic gear pairs. A second bearing 12 and a third bearing 13 are installed on an eccentricity input shaft 3. The planet rotor iron core 5 is driven by the eccentricity input shaft 3 to revolve in autogiration around the axis. A low speed autogiration of the planet rotor is output through a pin hole type output structure.

Owner:余虹锦

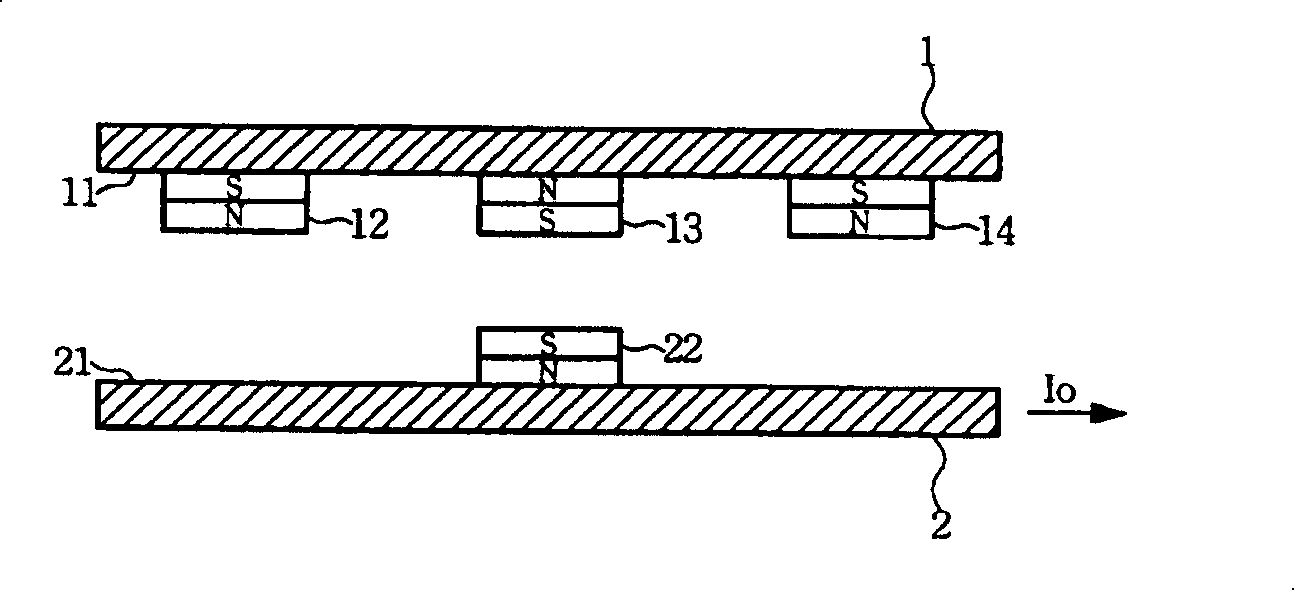

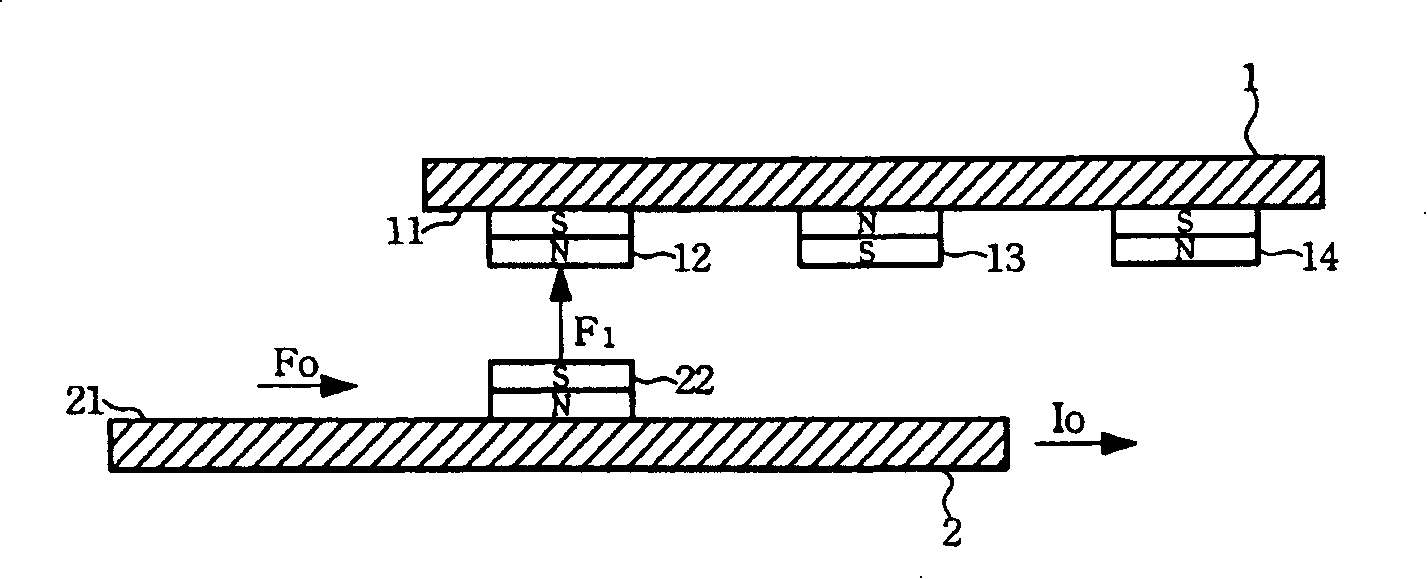

Magnetic force assistant slide locating mechanism

InactiveCN101207985ASmall sizeReduce electromagnetic interferenceCasings/cabinets/drawers detailsElectrical apparatus contructional detailsMagnetic tension forceMagnetic poles

The invention discloses a sliding locating mechanism assisted by magnets, and the mechanism comprises a first platform and a second platform. The first platform is combined with a double-sided rack and two first magnets. The two first magnets are arranged on the two ends of the double-sided rack and provided with first magnetic poles and second magnetic poles, and the first magnetic poles of the two first magnets are arranged oppositely to each other. The second platform is combined with two magnetic gear wheels which are articulated with the two sides of the double-sided rack, and the two magnetic gear wheels are both provided with the first magnetic poles and the second magnetic poles. When a relative sliding motion is acted between the first platform and the second platform, the two magnetic gear wheels are driven to rotate by meshing with the double-sided rack in a rotating way; when the two magnetic gear wheels are rotated to the middle of the double-sided rack, the first magnetic poles of the two magnetic gear wheels repel each other; when the two magnetic gear wheels are rotated to the two ends of the double-sided rack, the second magnetic poles of the two magnetic gear wheels and the first magnetic poles of the first magnets attract each other.

Owner:BENQ CORP

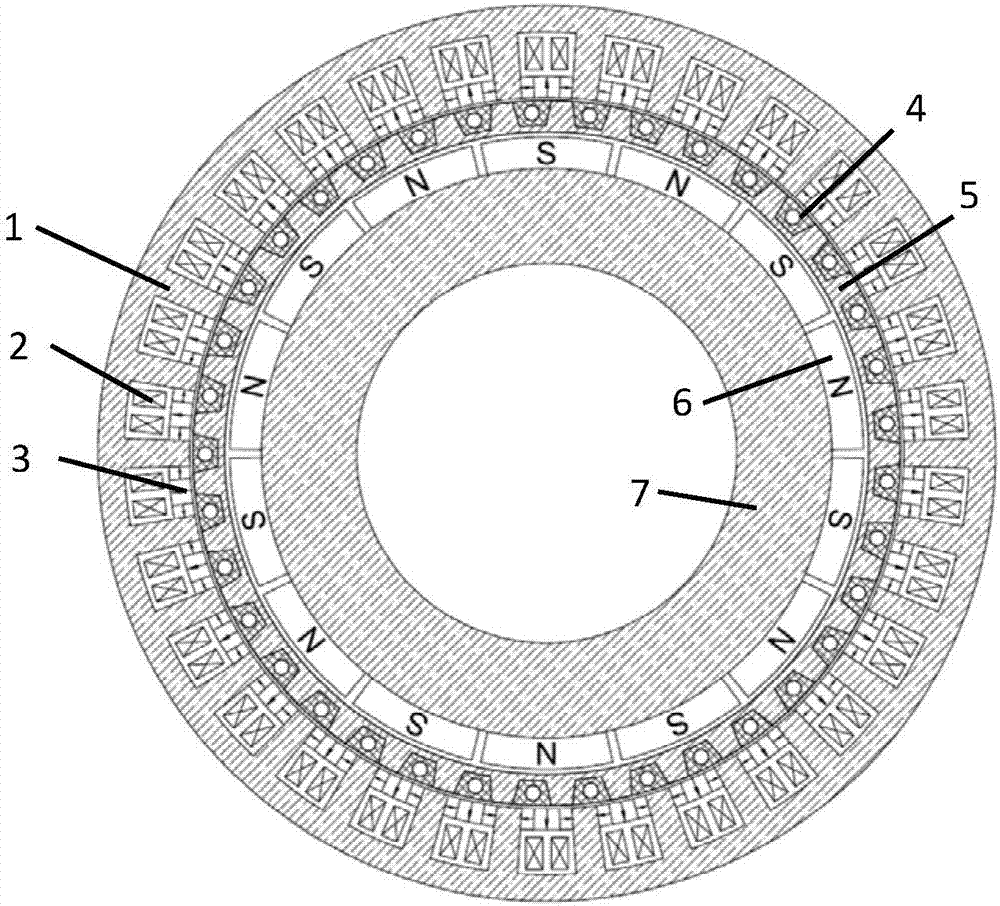

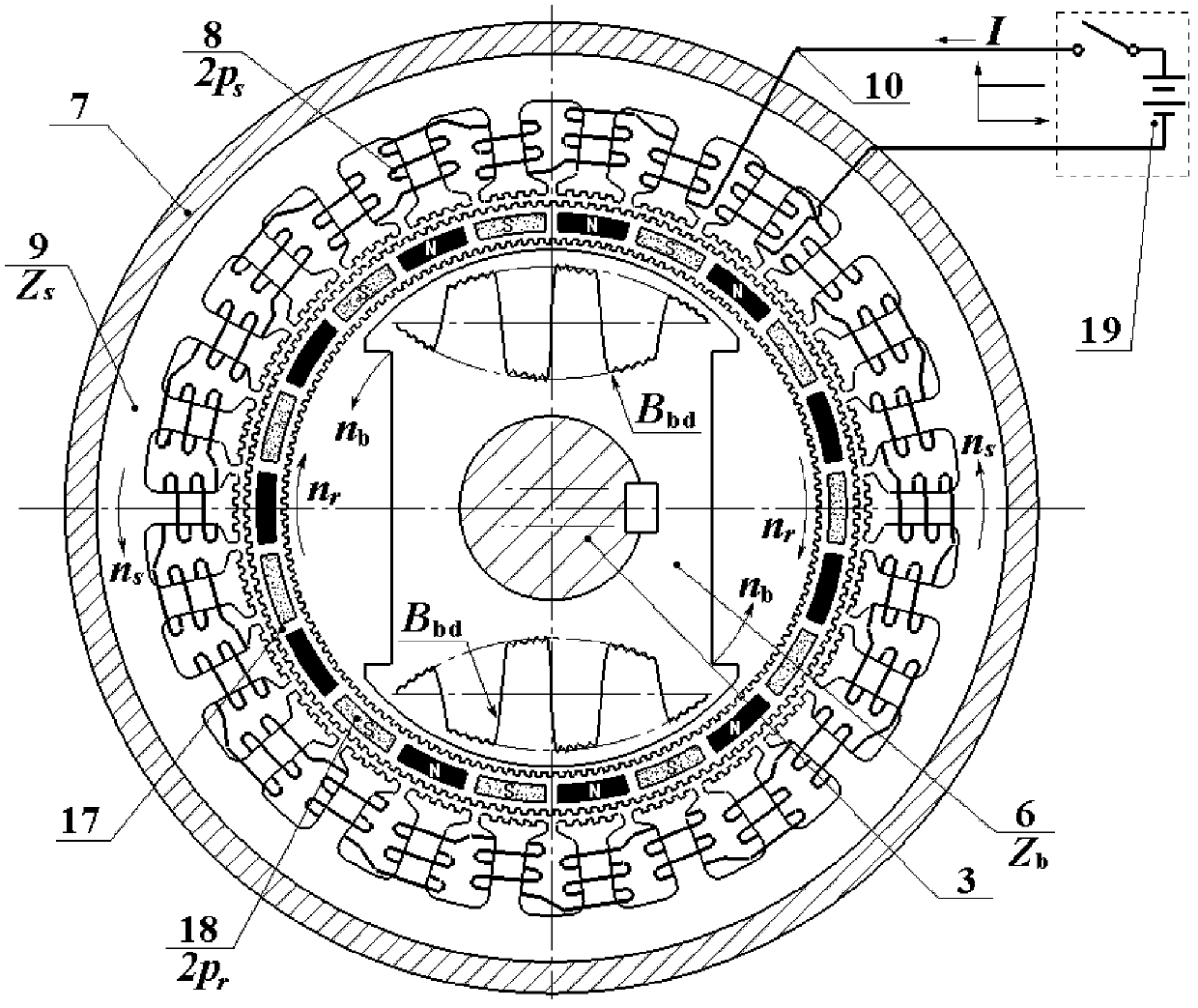

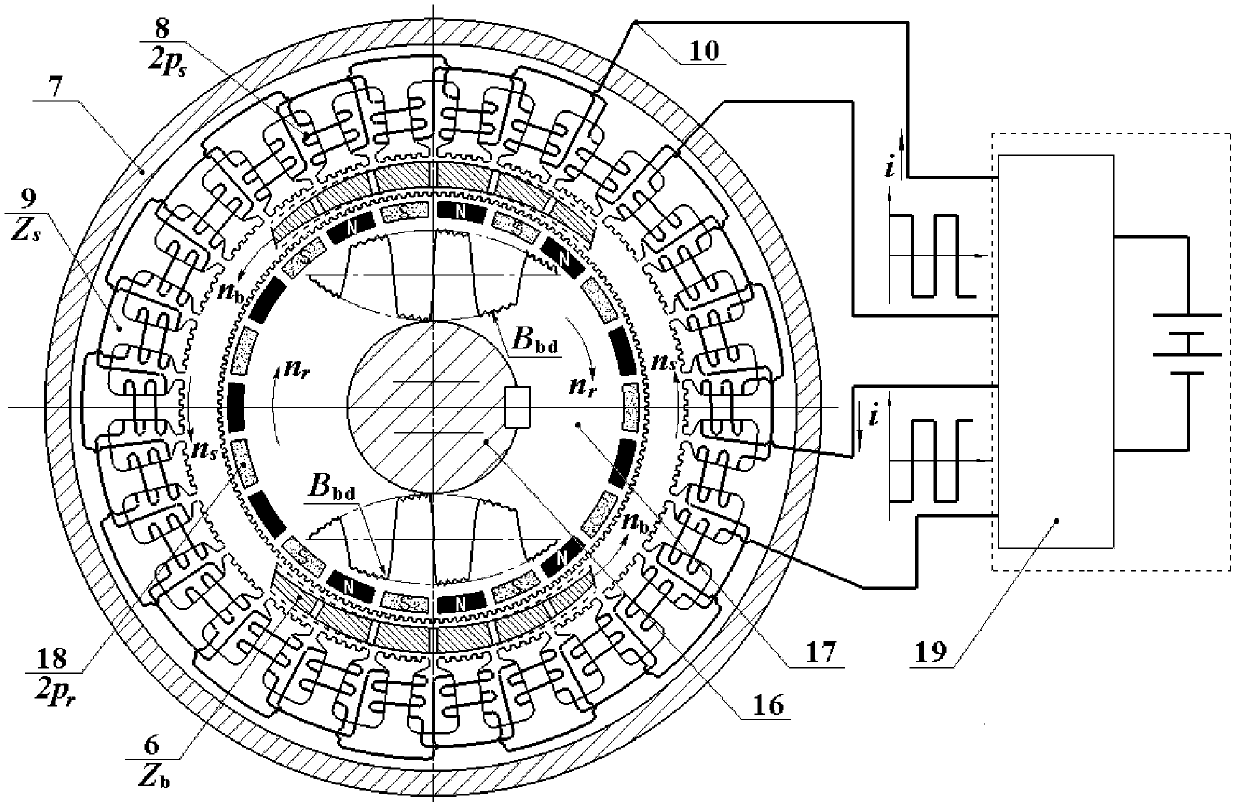

Dual mechanical port magnetic conductance harmonic type electromagnetic gear composite permanent magnet motor

InactiveCN103378711AEliminate contact frictionImprove transmission efficiencyDynamo-electric brakes/clutchesDynamo-electric gearsPermanent magnet rotorLow speed

Provided is a dual mechanical port magnetic conductance harmonic type electromagnetic gear composite permanent magnet motor which can be widely applied to industrial transmission fields such as wind power generation, electric automobiles, ship driving and server driving. The electromagnetic gear composite permanent magnet motor is characterized is that main transmission components of the electromagnetic gear composite permanent magnet motor consists of a stator formed of a stator iron core (9) and a stator winding (8) having 2ps poles, a permanent rotor formed of a rotor iron core (17) equipped with 2pr rotor permanent magnets (18) and an output shaft (16), and a salient pole magnetic conductance wave rotor (6) having Zb salient poles, wherein a numerical difference between the number of pole-pairs ps and pr is relatively small; and the stator, the permanent magnet rotor and the salient pole magnetic conductance wave rotor (6) are coaxially disposed, are mutually coupled through a radial air-gap magnetic field, and are mutually coupled in a salient pole straight axis area of the high-speed rotating salient pole magnetic conductance wave rotor (6) by using a principle of heteropolarity magnetic field attraction with a small pole difference so as to drive the permanent magnet rotor with a small pole difference to rotate at a low speed. Therefore, power speed changed and torque conversion controlled drive with no mechanical contact and no friction is realized.

Owner:余虹锦

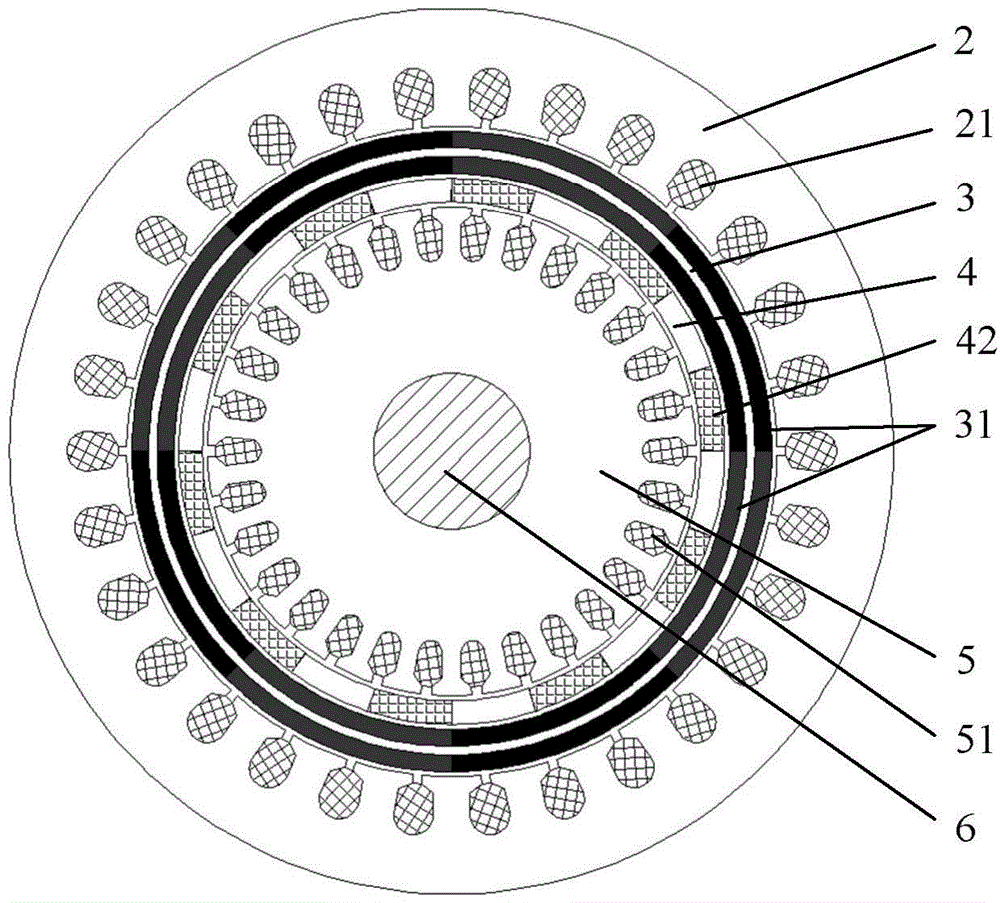

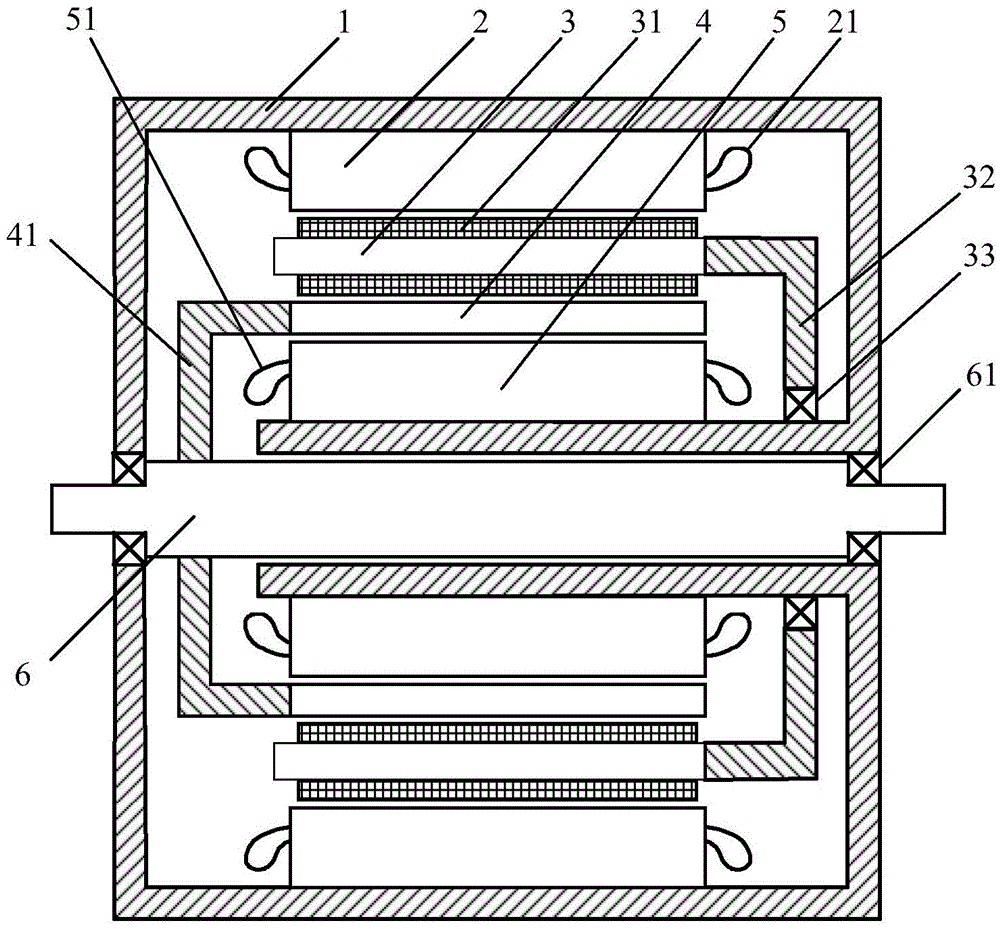

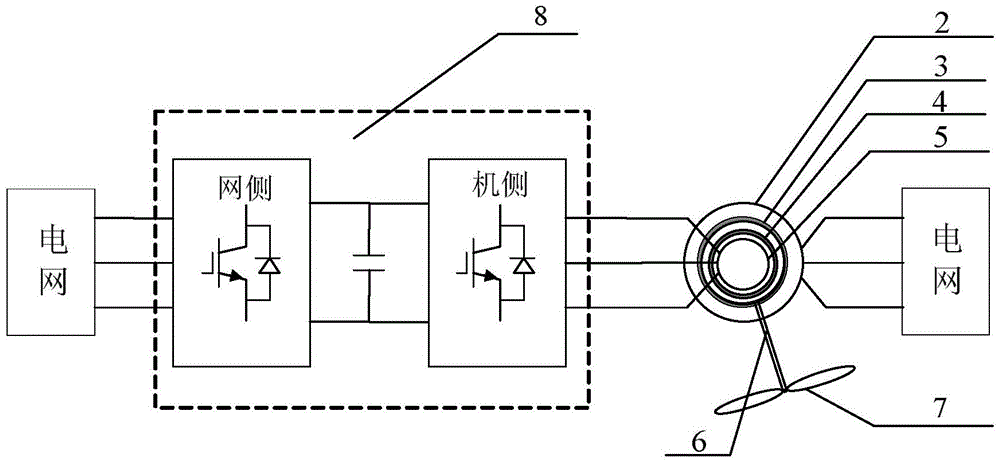

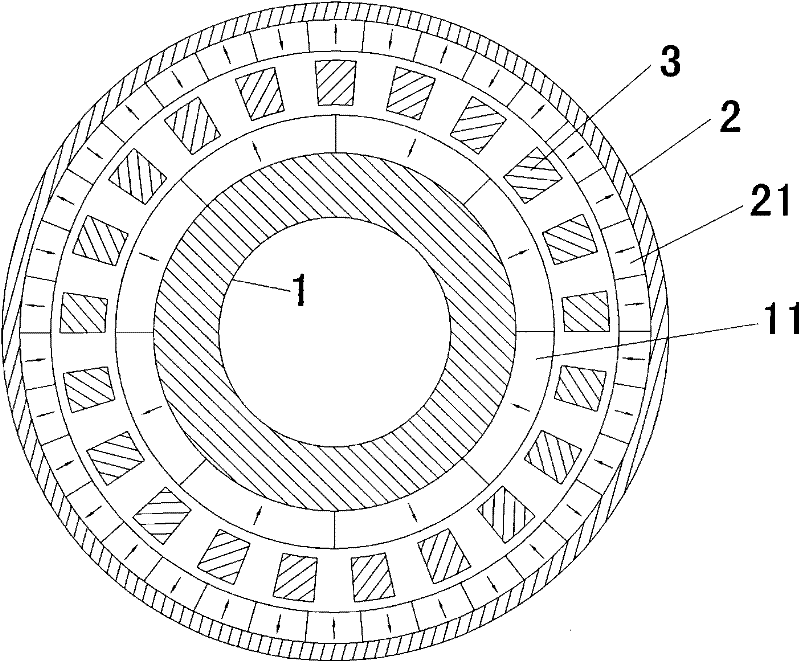

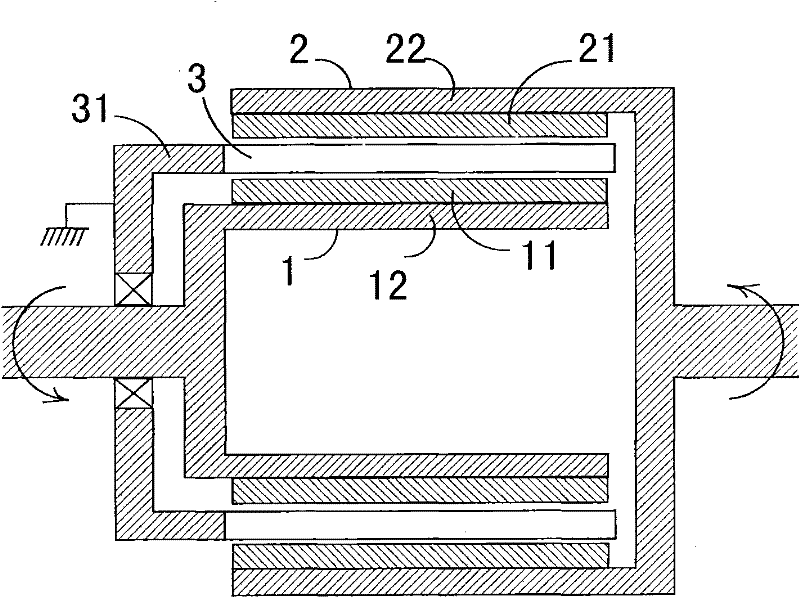

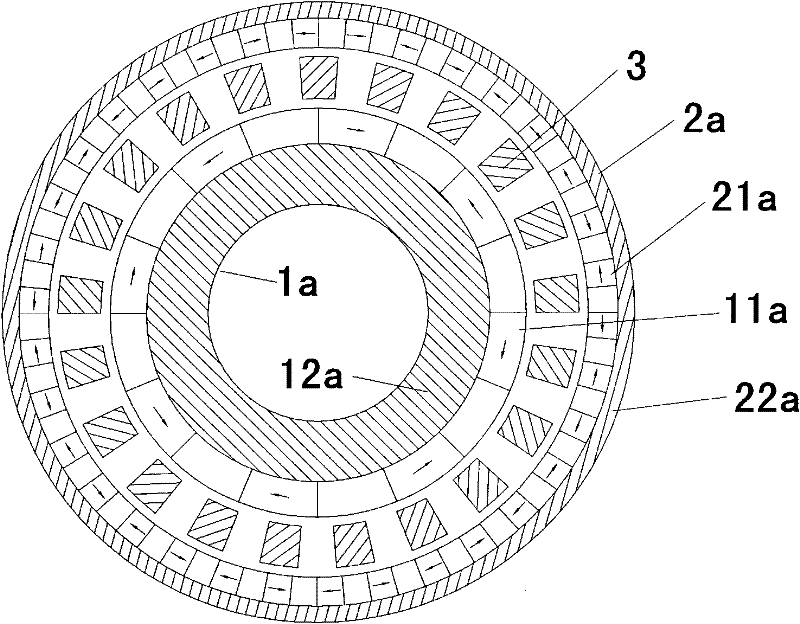

Double-stator permanent magnet brushless doubly-fed wind generator

ActiveCN104578630AImprove reliabilityIncreased torque densityWind energy generationDynamo-electric machinesPower gridConductor Coil

The invention discloses a double-stator permanent magnet brushless doubly-fed wind generator. An outer stator (2) and an inner rotor (4) are arranged on the outer circumference and the inner circumference of an outer rotor (3) respectively, and an inner stator (5) is arranged on the inner circumference of the inner rotor (4); the outer rotor (3) and the inner rotor (4) are coaxial and can freely rotate; the outer stator (2) is provided with a p-antipode power winding (21) and is connected with a power grid directly; the inner stator (5) is provided with a q-antipode control winding (51) and is connected with the power grid through an AC-DC-AC power converter; the inner surface and the outer surface of the outer rotor (3) are each provided with p pairs of permanent magnets (31); the inner rotor (4) is a magnetism modulation ring provided with p+q magnetic conductive blocks, magnetic fields generated by the permanent magnets (31) are modulated by the inner rotor (4), and then excitation magnetic fields can be provided for the control winding (51). The permanent magnet excitation is adopted in the double-stator permanent magnet brushless doubly-fed wind generator, so the power density of the doubly-fed wind generator is improved; magnetic gears are additionally arranged and a mechanical step-up gear box is eliminated, and therefore reliability is improved; relatively smaller harmonic magnetic fields of the permanent magnets are used for excitation for the small-power control winding.

Owner:SOUTHEAST UNIV

Magnetic gear and magnetic transmission device

The invention provides a new magnetic gear and a magnetic transmission device based on the magnetic gear, which are used for solving the problem of higher cost of the existing magnetic gear without lowering the torque density of the magnetic gear. For the magnetic gear, permanent magnets of the inner and outer rotors of the magnetic gear are separated by a magnetic material and are tangentially magnetized, and the supporting parts of the inner and outer rotors are made from a non-magnetic material. In the invention, as magnetic fields are converged to be enhanced at opposite sides of two groups of permanent magnets, the number of the permanent magnets is reduced by one half and the cost of the magnetic gear is lowered by one quarter in the case of equal torque density, and meanwhile the magnetic transmission device can obtain relatively higher torque density as well as a large transmission ratio by virtue of cycloidal motion between the first group of permanent magnets and the second group of permanent magnets.

Owner:东元总合科技(杭州)有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com