Dual mechanical port magnetic conductance harmonic type electromagnetic gear composite permanent magnet motor

A dual mechanical port, permanent magnet motor technology, applied in electromechanical devices, electromechanical transmission devices, electric brakes/clutches, etc., can solve the problems of the integration of magnetic gears and permanent magnet motors, no one has proposed, and the permanent magnetic field cannot be adjusted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

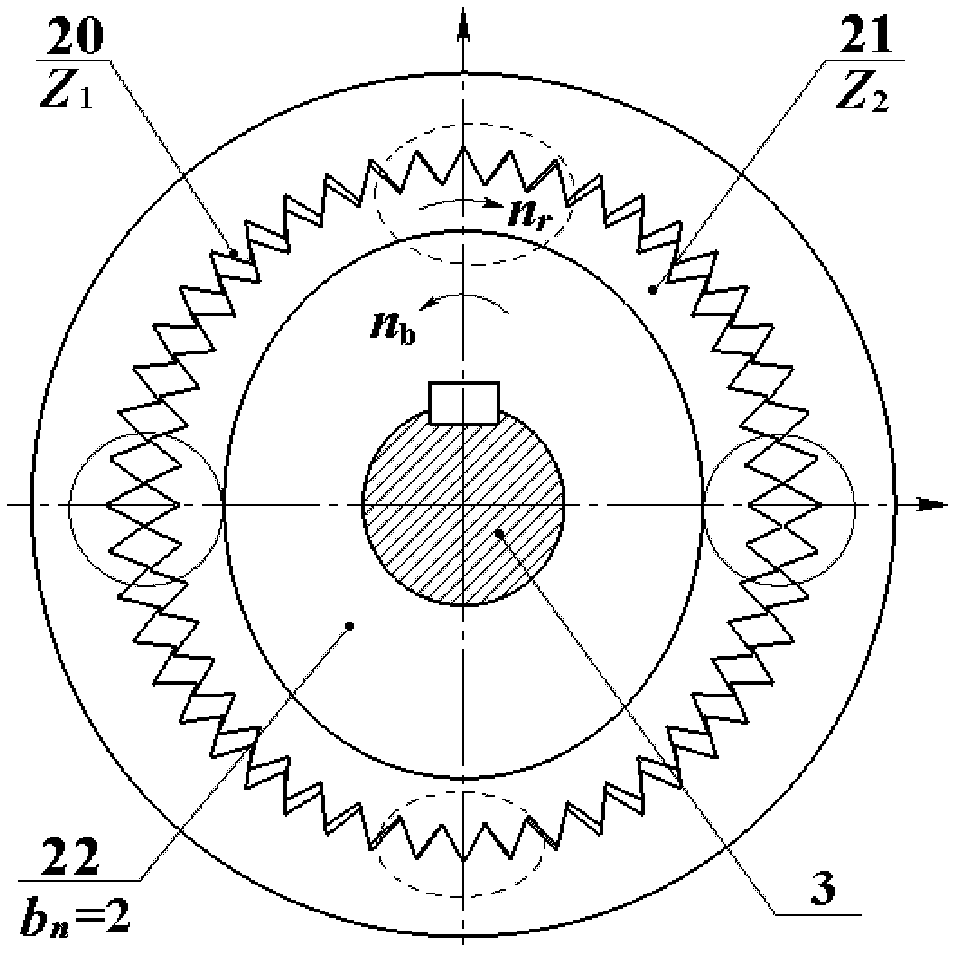

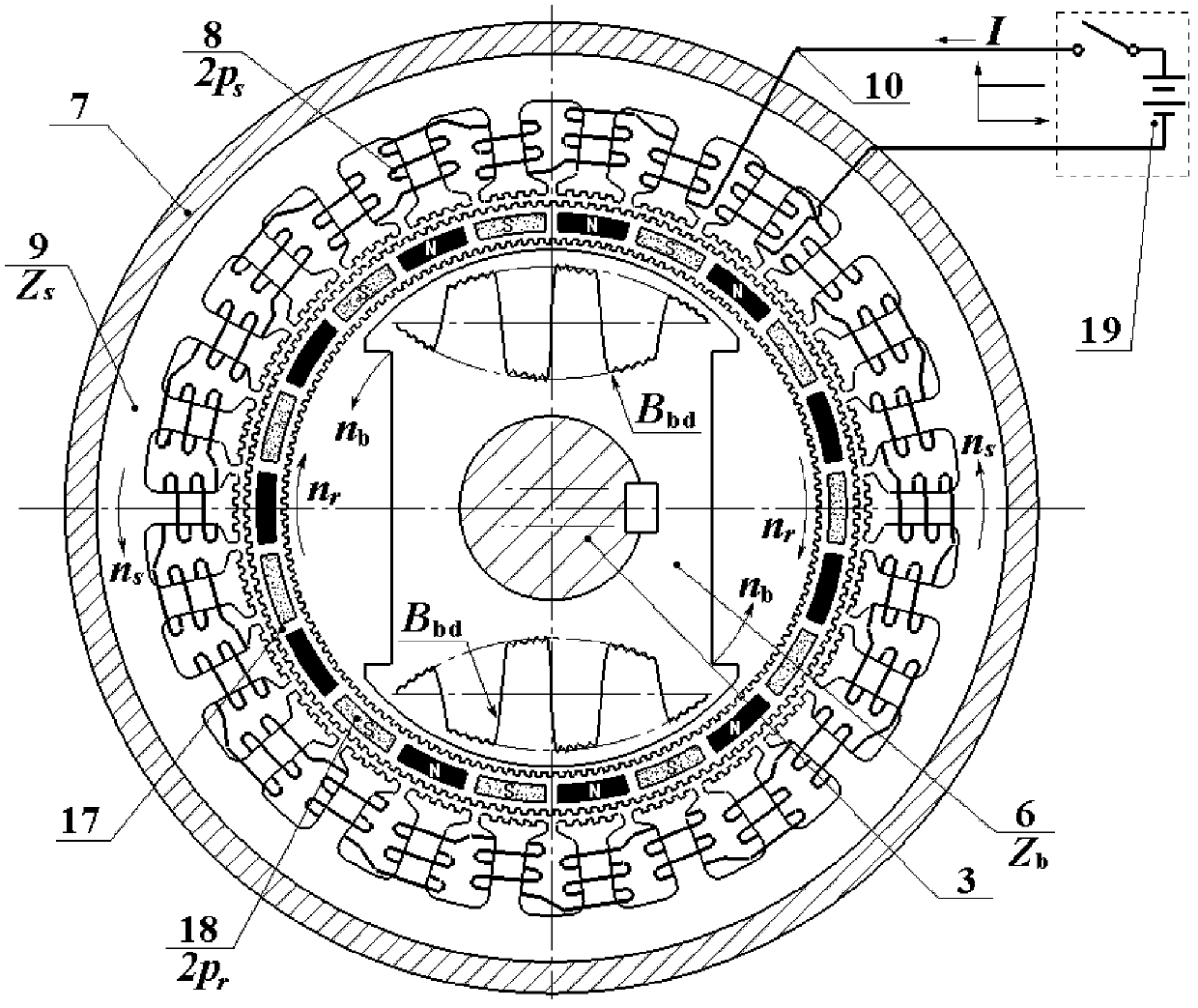

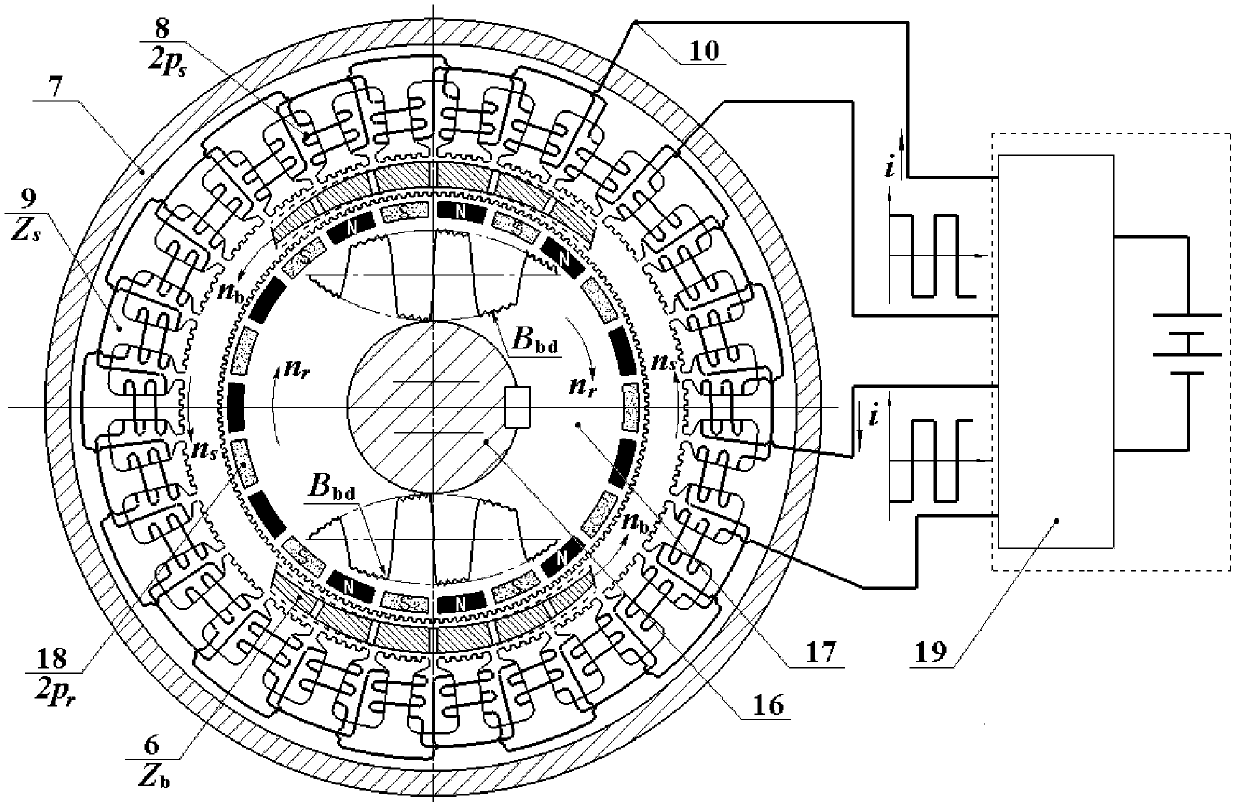

[0039] One, from figure 2 , image 3 It can be seen that the working principle of the double mechanical port permeance harmonic electromagnetic gear compound permanent magnet motor is: when the DC current I passes through the stator winding 8, the stator air gap will generate a static magnetic field with a fixed space, that is, figure 2 The rotational speed of the stator magnetic field n s = 0, the difference in the number of magnetic poles between the stator magnetic field and the rotor is very small, forming a fixed few-pole difference, and the principle of attracting the magnetic field with few pole differences to the salient-pole direct axis of the high-speed rotating salient-pole magnetic guided wave rotor 6 The areas are coupled with each other to drive the magnetic gear pair with less extreme difference to rotate at low speed, thus formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com