Patents

Literature

179 results about "Deepwater drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deepwater drilling, or Deep well drilling, is the process of creating holes by drilling rig for oil mining in deep sea. There are approximately 3400 deepwater wells in the Gulf of Mexico with depths greater than 150 meters.

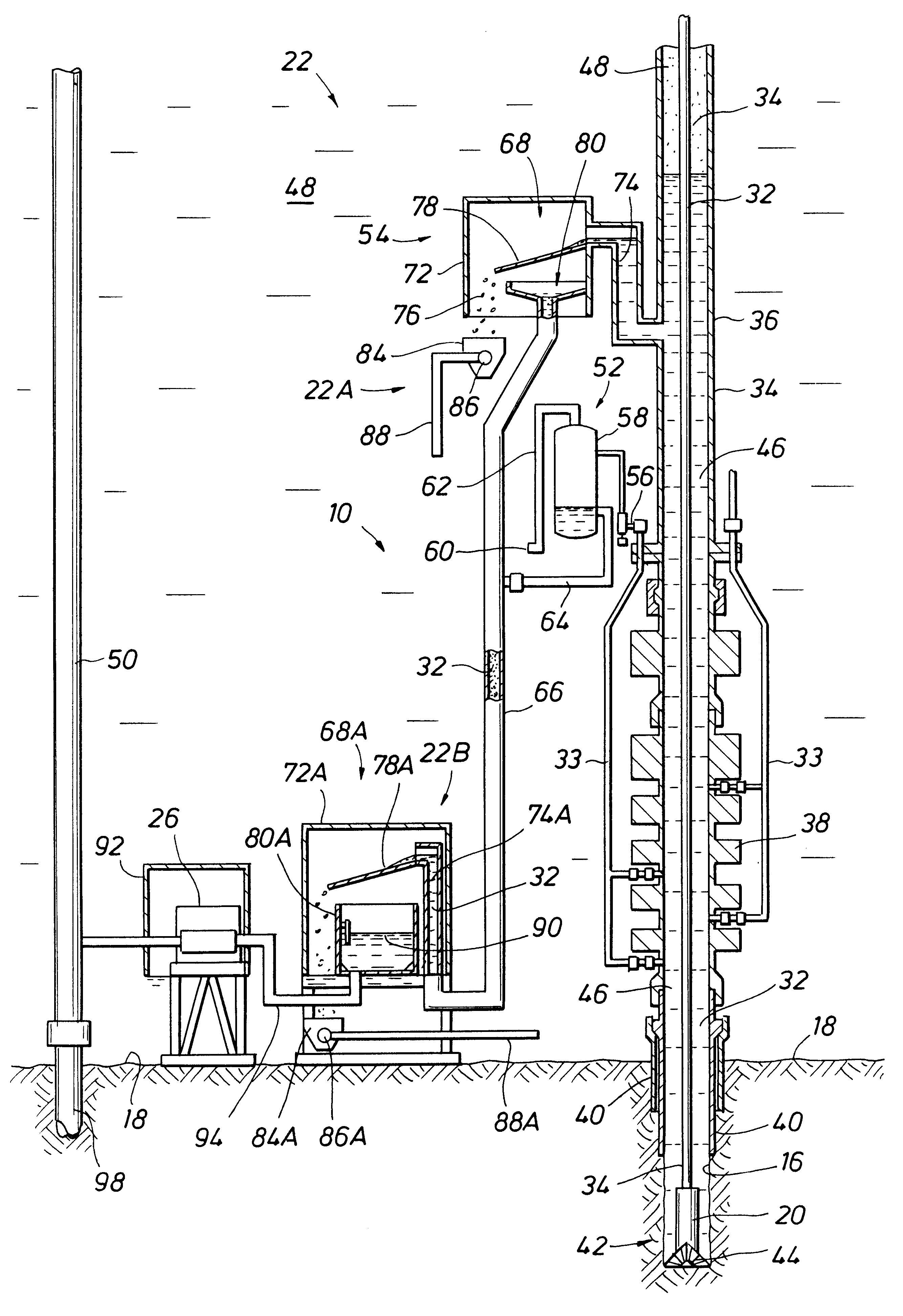

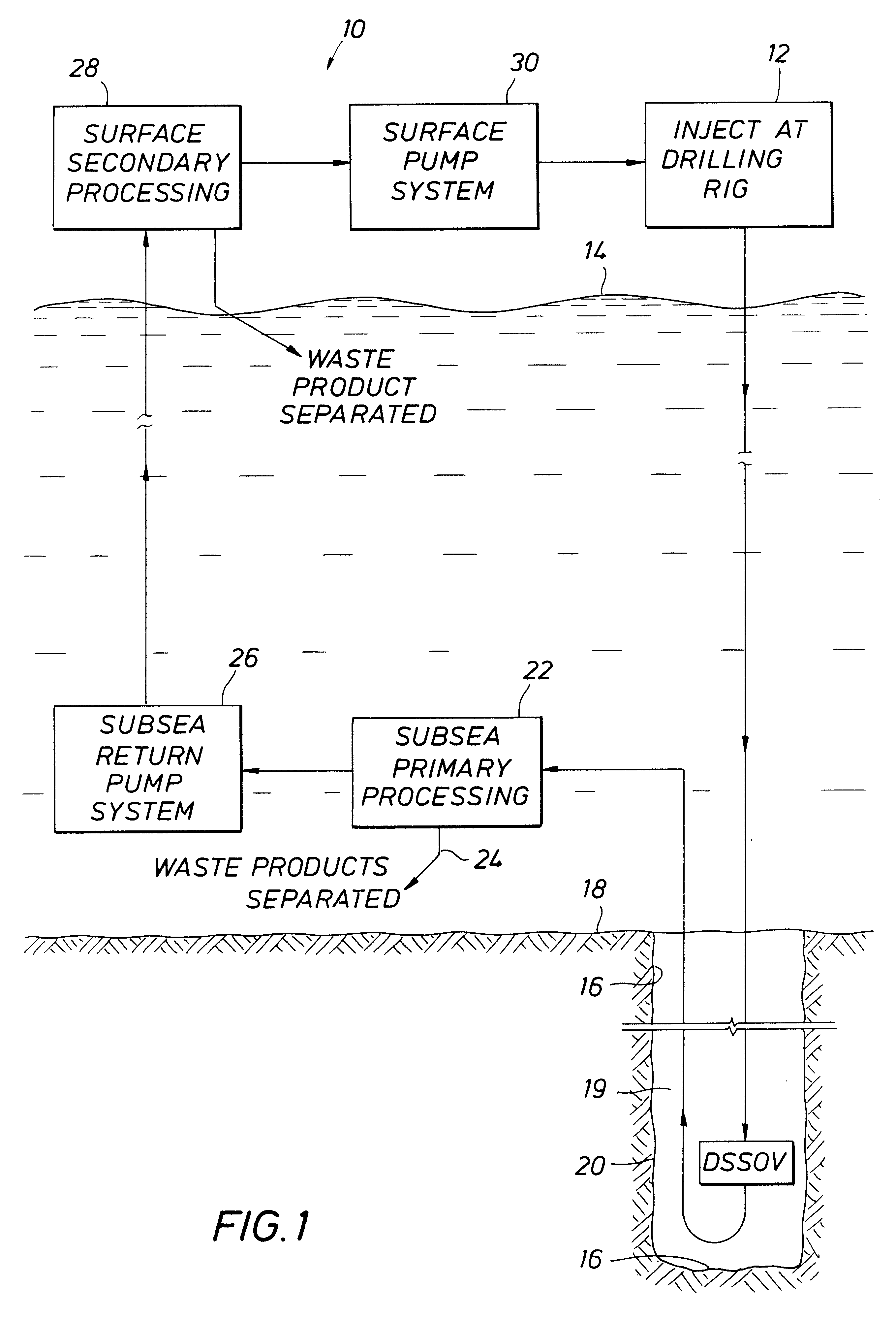

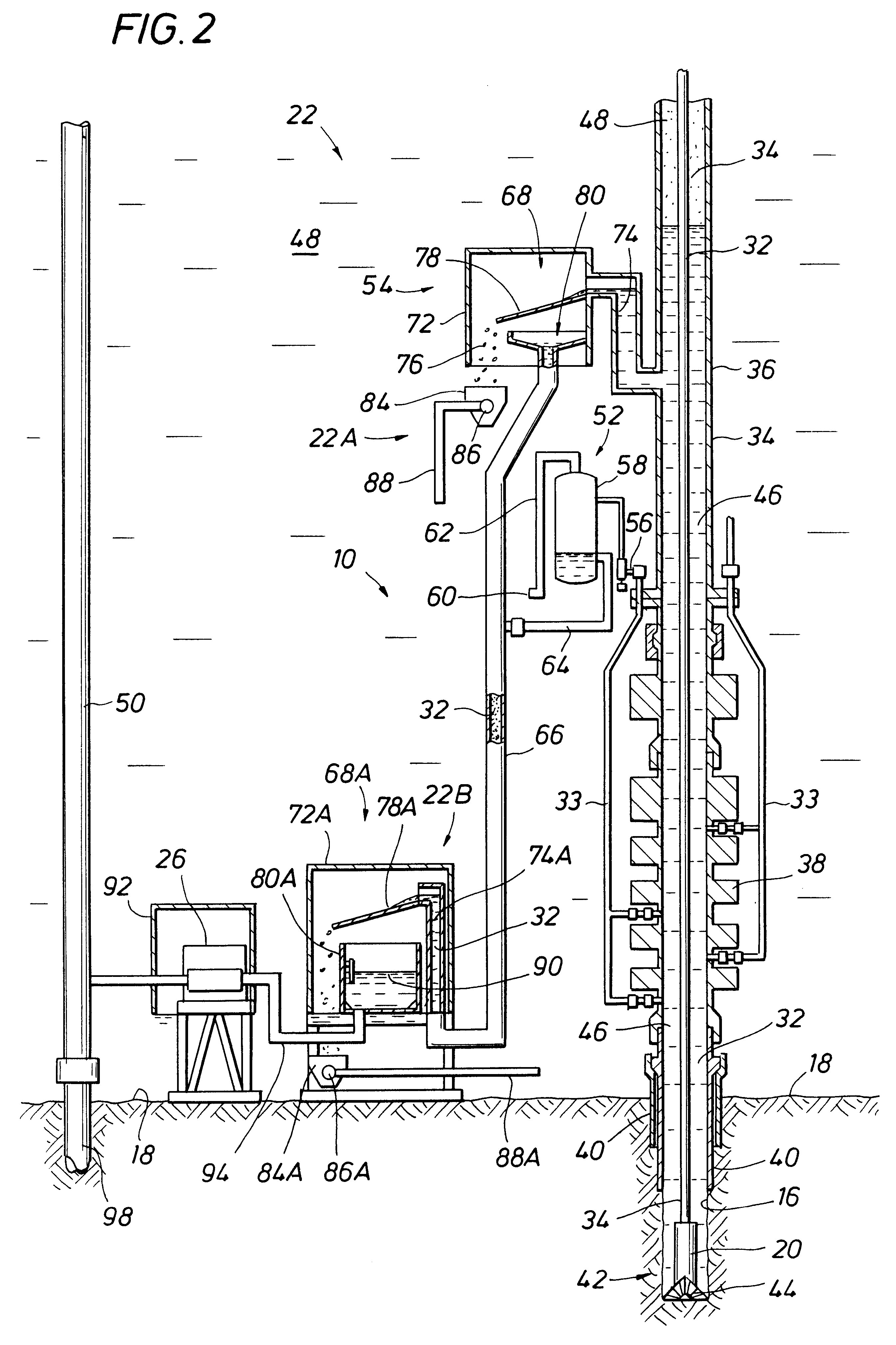

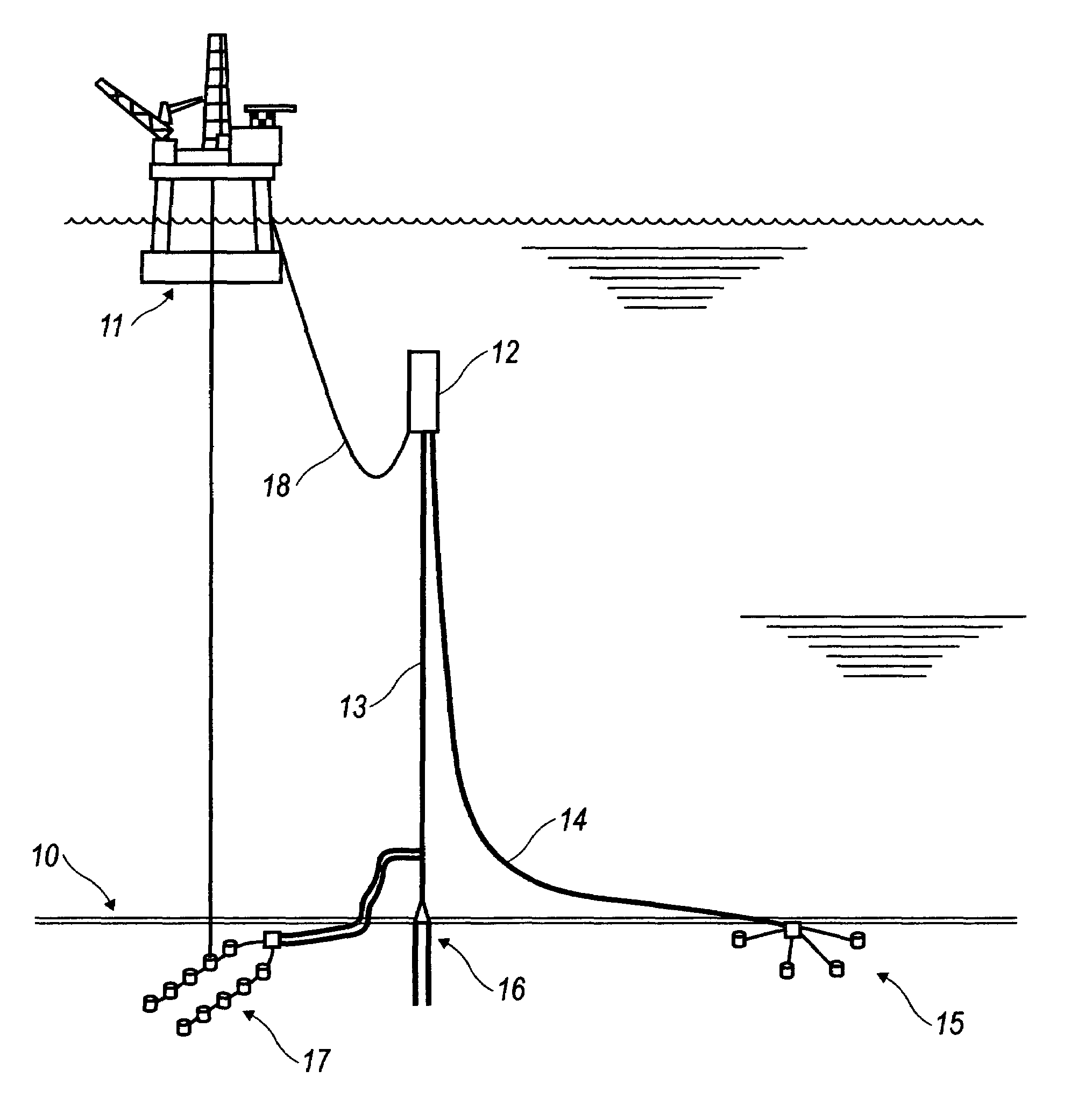

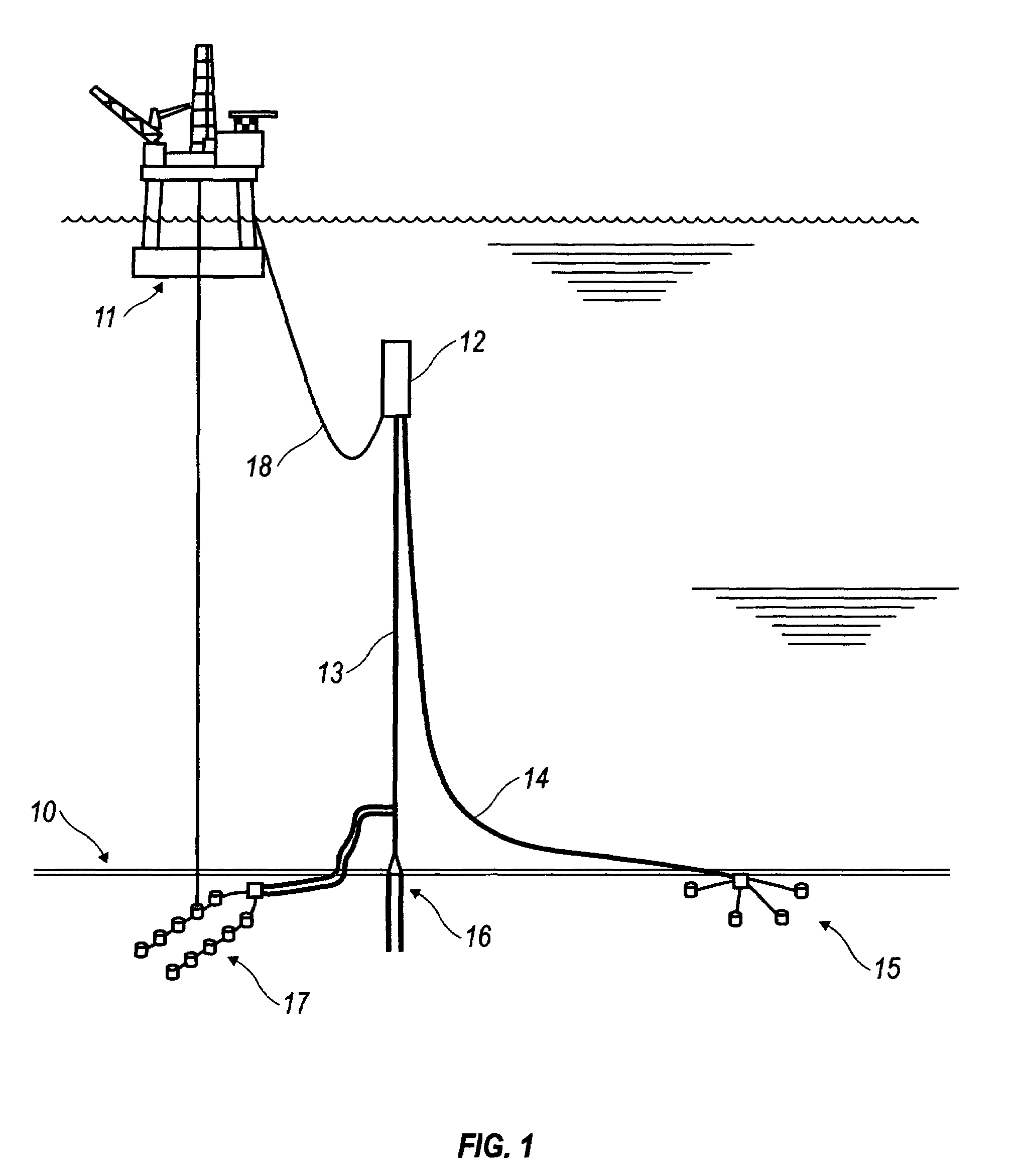

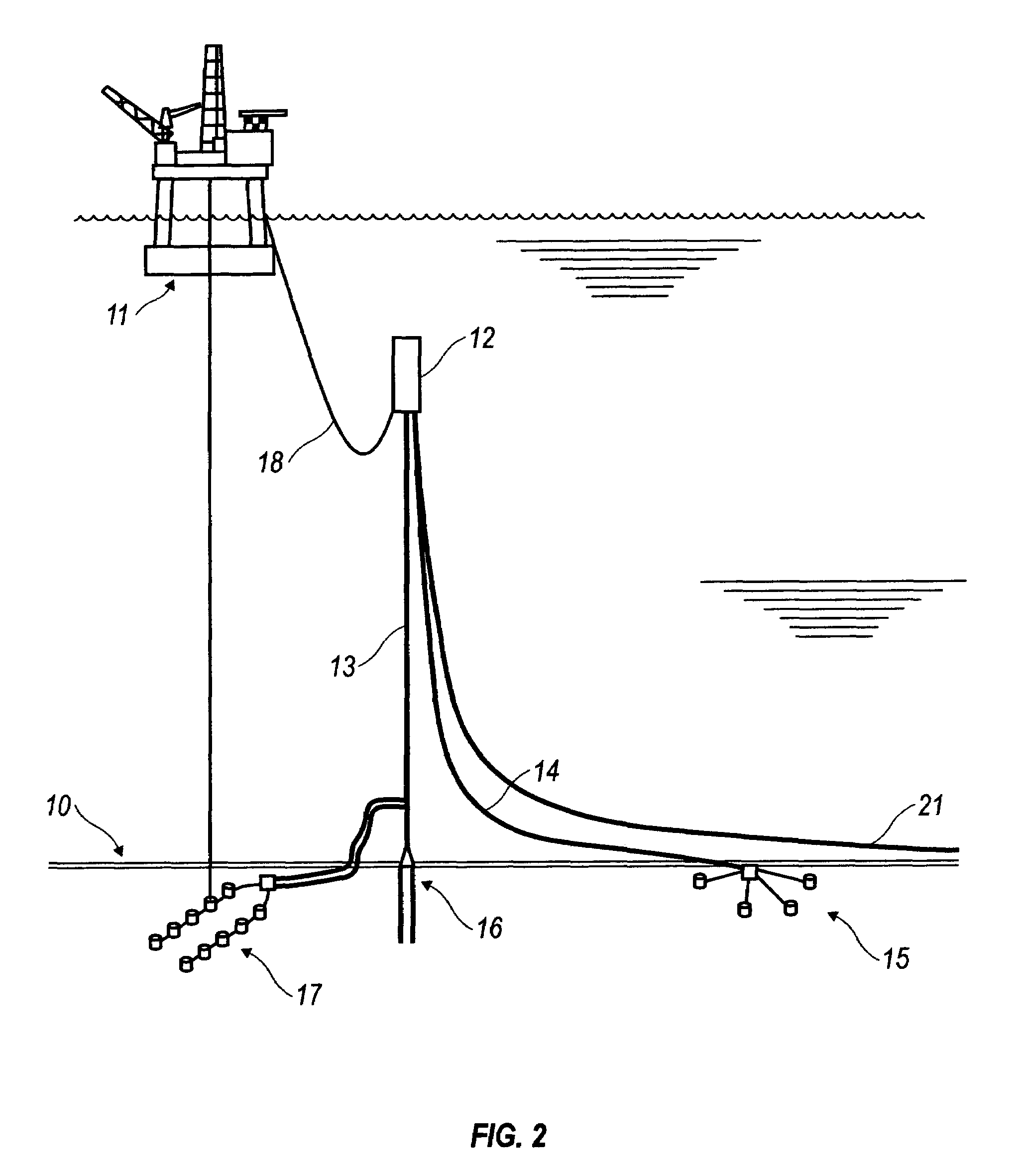

Subsea pumping system and method for deepwater drilling

A method is disclosed for offshore drilling in which a bit is driven at a far end of a drill string, drilling fluid is injected into the drill string from surface drilling facilities, and drilling fluid passes through the far end of the drill string and flushes the borehole at the bit and entrains cuttings into the drilling fluid which circulates up the casing / drill string annulus. The drilling fluid drawn off near the mudline and is treated through a subsea primary processing stage to removing the cuttings from the drilling fluid. The treated drilling fluid is then returned to the surface with a subsea return pump system and passes to surface drilling facilities for injection and recirculation.

Owner:SHELL OFFSHORE

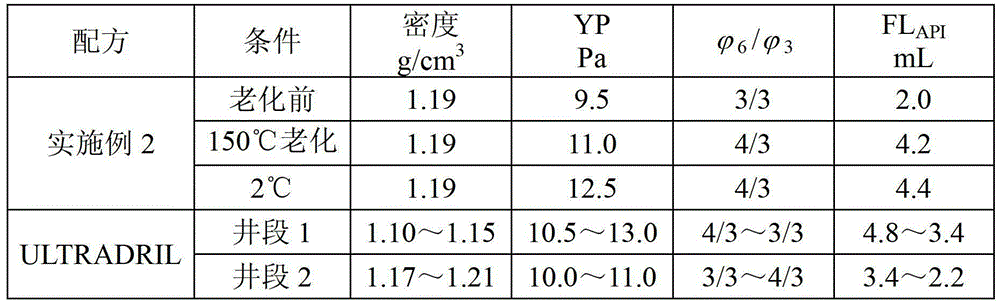

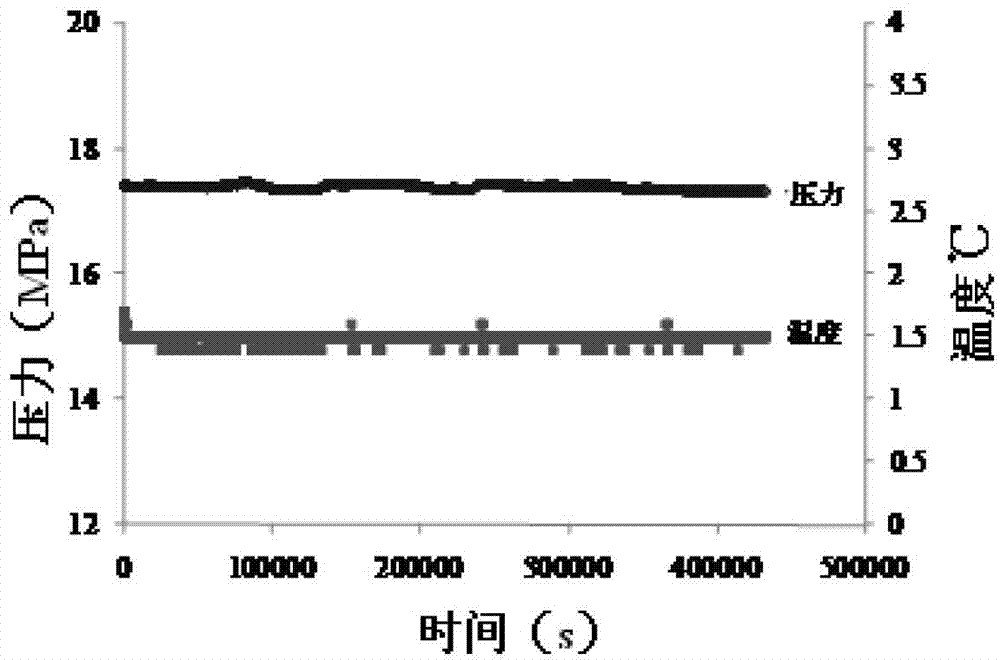

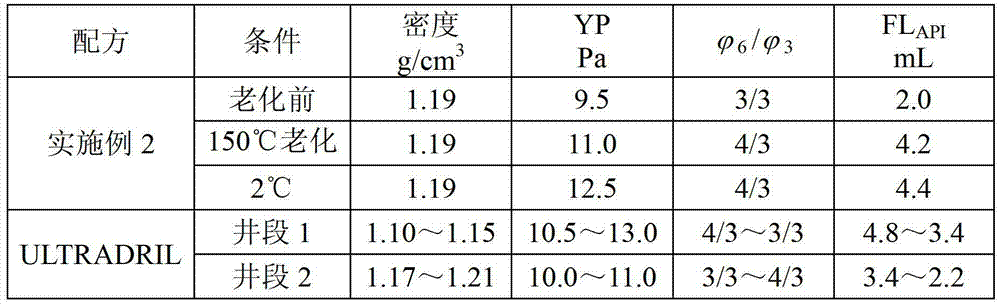

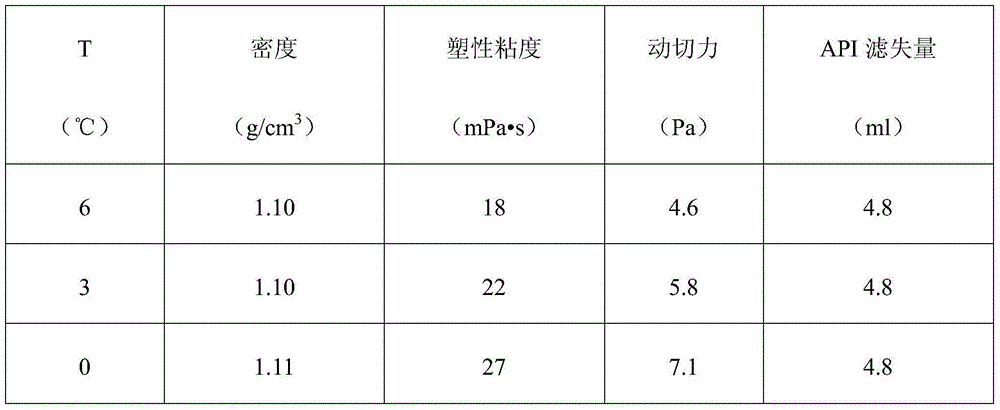

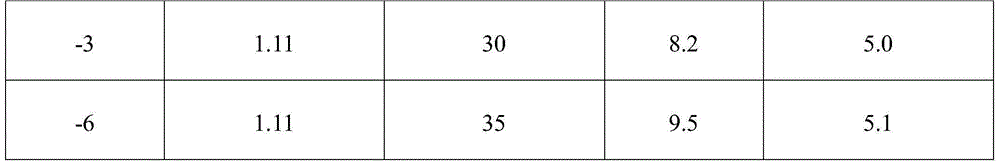

Strong-inhibition water-base drilling fluid

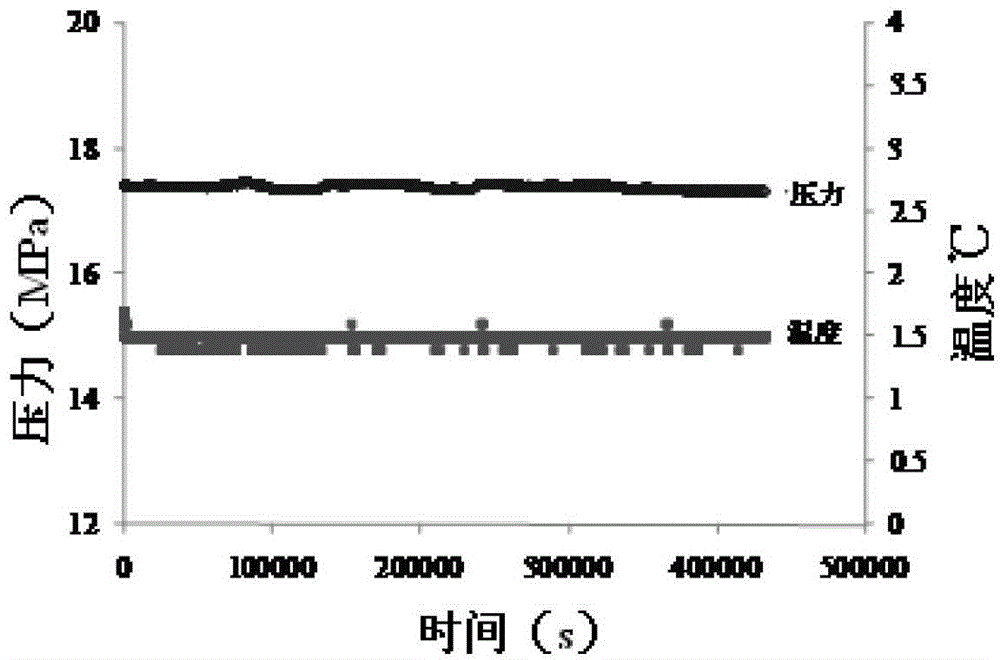

The invention discloses a strong-inhibition water-base drilling fluid which comprises the following components in parts by mass: 100 parts of water, 0.2-4 parts of polyamine inhibitor, 0.1-1 part of coating inhibitor, 10-25 parts of hydrate inhibitor, 0.1-1 part of tackifier, 0.5-5 parts of fluid loss agent and 0.5-3 parts of liquid lubricant. The polyamine inhibitor is an amino polymer polymerized from polyether diamine and epoxy alkane; and the mol ratio of the polyether diamine to the epoxy alkane is 1-10:1-20. The drilling fluid disclosed by the invention can effectively inhibit wellbore instability of deepwater shallow strata, and has equivalent inhibition capability to an oil-base drilling fluid. The drilling fluid disclosed by the invention can solve the problem of generation of hydrate in deepwater drilling, and is applicable to 3000m-deep drilling operation. The drilling fluid disclosed by the invention has favorable low temperature-high temperature stability, and is applicable to a deepwater large-temperature-difference environment (2-150 DEG C).

Owner:CHINA NAT OFFSHORE OIL CORP +1

Strong-inhibition water-base drilling fluid

The invention discloses a strong-inhibition water-base drilling fluid which comprises the following components in parts by mass: 100 parts of water, 0.2-4 parts of polyamine inhibitor, 0.1-1 part of coating inhibitor, 10-25 parts of hydrate inhibitor, 0.1-1 part of tackifier, 0.5-5 parts of fluid loss agent and 0.5-3 parts of liquid lubricant. The polyamine inhibitor is an amino polymer polymerized from polyether diamine and epoxy alkane; and the mol ratio of the polyether diamine to the epoxy alkane is 1-10:1-20. The drilling fluid disclosed by the invention can effectively inhibit wellbore instability of deepwater shallow strata, and has equivalent inhibition capability to an oil-base drilling fluid. The drilling fluid disclosed by the invention can solve the problem of generation of hydrate in deepwater drilling, and is applicable to 3000m-deep drilling operation. The drilling fluid disclosed by the invention has favorable low temperature-high temperature stability, and is applicable to a deepwater large-temperature-difference environment (2-150 DEG C).

Owner:CHINA NAT OFFSHORE OIL CORP +1

Hybrid tension-leg riser

This invention provides a production riser system that enables fluid communication in a deepwater drilling environment through the use of a variable buoyancy device supporting both a hybrid riser tower and an steel catenary riser (SCR) system. Fluid communication is enabled between a surface production facility or unloading buoy and local and remote subsea (or remote non-subsea) production and export systems.

Owner:EXXONMOBIL UPSTREAM RES CO

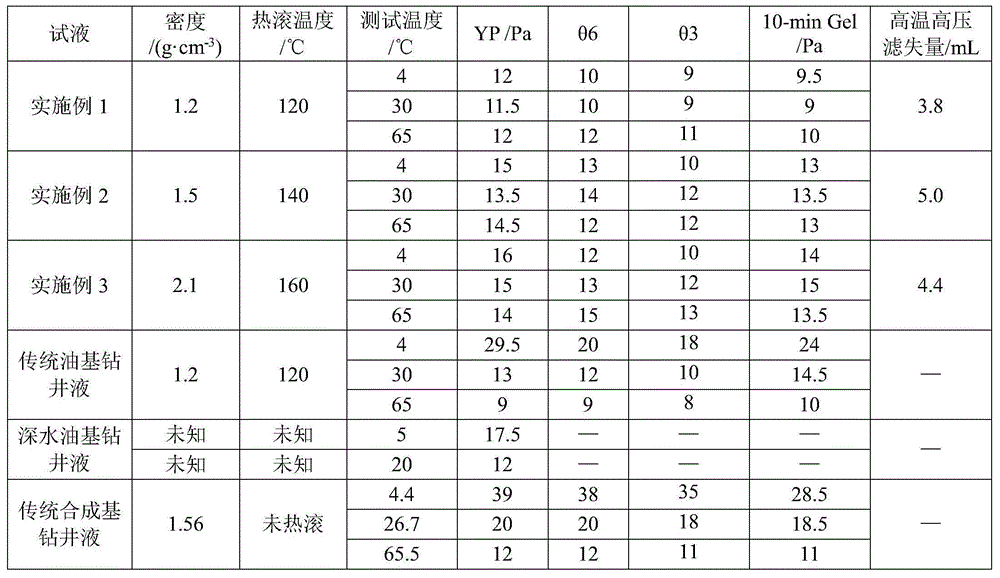

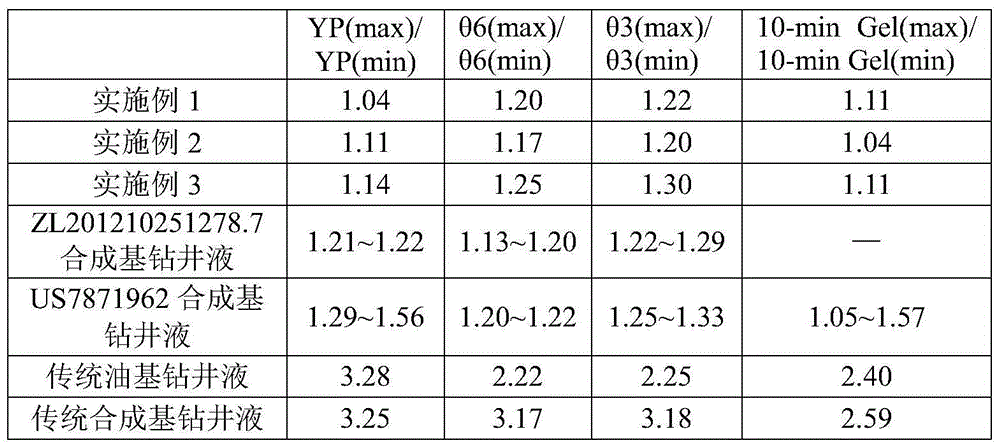

Deepwater constant-rheology oil base drilling fluid

ActiveCN104861944ARaw material requirements are relaxedLow costDrilling compositionDimer acidWhite oil

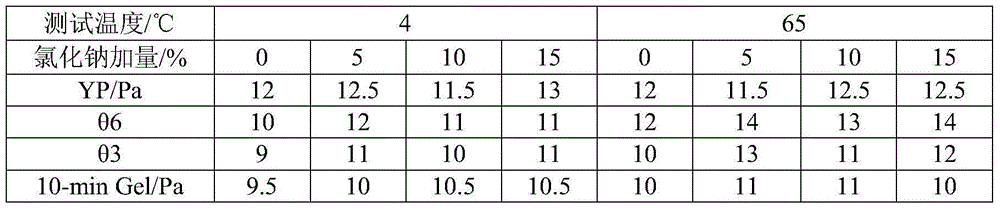

The invention discloses a deepwater constant-rheology oil base drilling fluid applicable for deep sea drilling. The deepwater constant-rheology oil base drilling fluid applicable for deep sea drilling comprises the following components in parts by weight: 70-100 parts of white oil, 0-30 parts of a calcium chloride aqueous solution, 1.5-5 parts of a fluid type conditioning agent, 1-4 parts of an emulsifying agent, 0.5-2.5 parts of a wetting agent, 1-3.5 parts of organic soil used for drilling fluid, 1.5-5 parts of a filtrate reducer, 0.2-0.6 parts of calcium oxide and 0-260 parts of a weighting agent. The fluid type conditioning agent is at least one of ethylene-propylene copolymer, polymethacrylate, trimeric acid, phenolic resin, copolymer generated from reaction of dimer acid, cholamine and polyethylene polyamine and copolymer generated from reaction of acrylamide, styrene and methacrylic acid. The movable shearing force and six-speed viscometer of the oil base drilling fluid is respectively less than 6 r / min and 3 r / min, and the 10-min static shearing force can be kept steady within 4-65 DEG C; constant eheology is realized in the temperature range of the barrel of the deepwater drilling, technical demands on sea deepwater drilling can be satisfied, requirements on base oil raw material are loose, and the cost is low.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

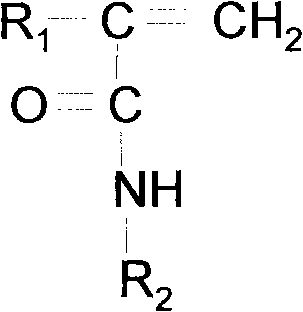

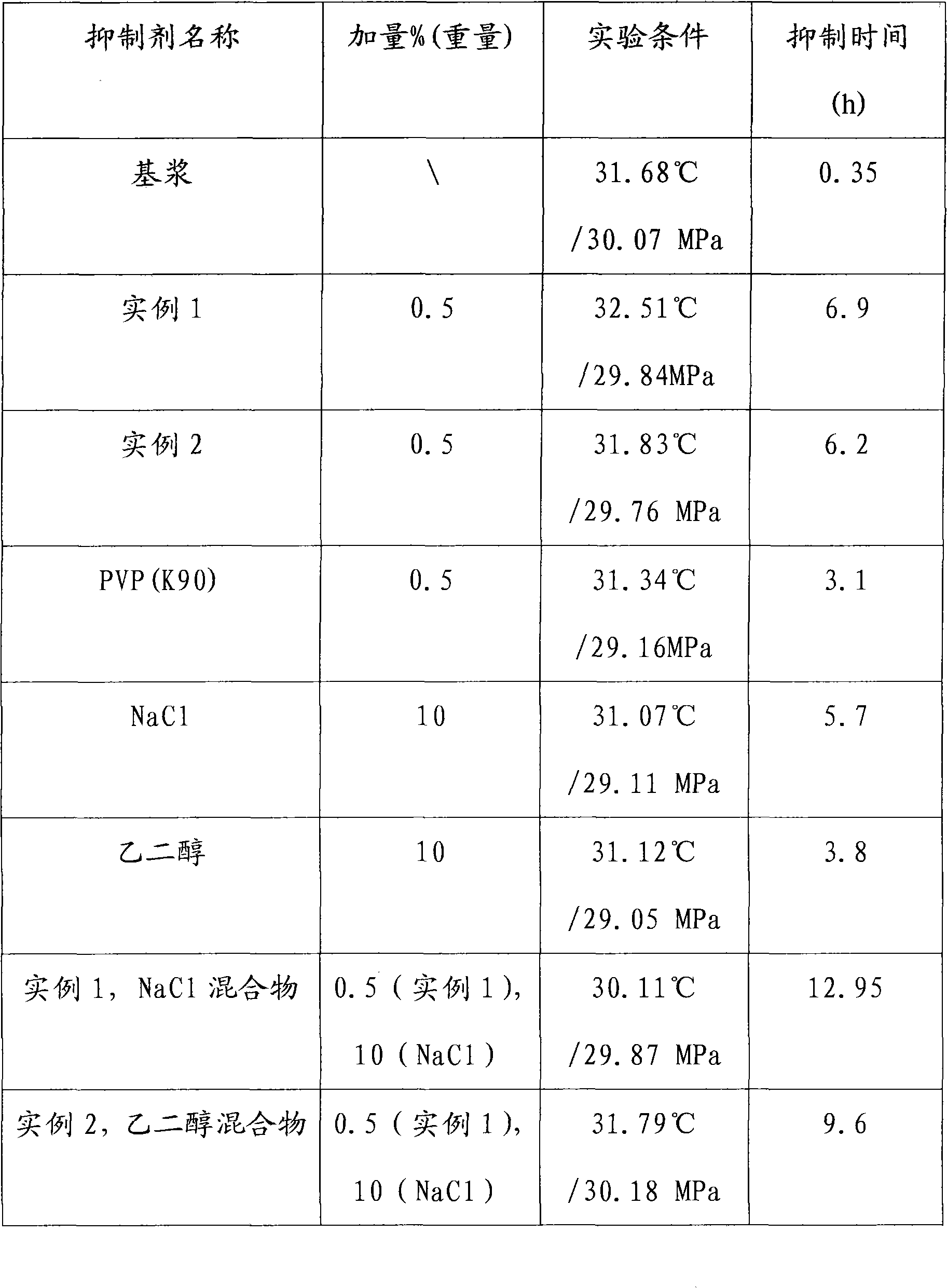

Compound low dosage natural gas hydrate inhibitor

The invention discloses a compound low dosage natural gas hydrate inhibitor. The hydrate inhibitor benchmarked against the mass of water in a deepwater drilling fluid completion fluid comprises, by mass, 0.1-2% of a hydrate kinetic inhibitor, 0.1-2% of a kinetic inhibitor synergist and 0-10% of a hydrate thermodynamic inhibitor. The hydrate kinetic inhibitor is at least one of polyvinyl pyrrolidone, polyvinyl caprolactam, and a copolymer generated through a reaction of vinyl pyrrolidone, vinyl caprolactam, alkenyl sulfonic acid and isopropylmethacrylamide. The kinetic inhibitor synergist is at least one of benzyltributylammonium chloride, tetraheptylammonium bromide, ethylene glycol phenyl ether, propylene glycol phenyl ether, polyoxyethylene and polyoxypropylene. The hydrate inhibitor can effectively inhibit generation of hydrates under a low dosage (0.2-10%), is suitable for deepwater and ultra-deep water drilling and completion, greatly reduces the cost and the logistical support burden, and has small harms to environment.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

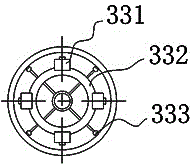

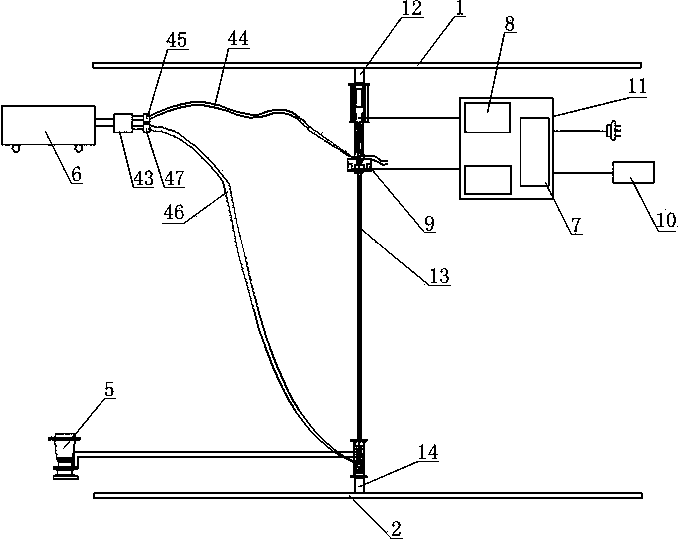

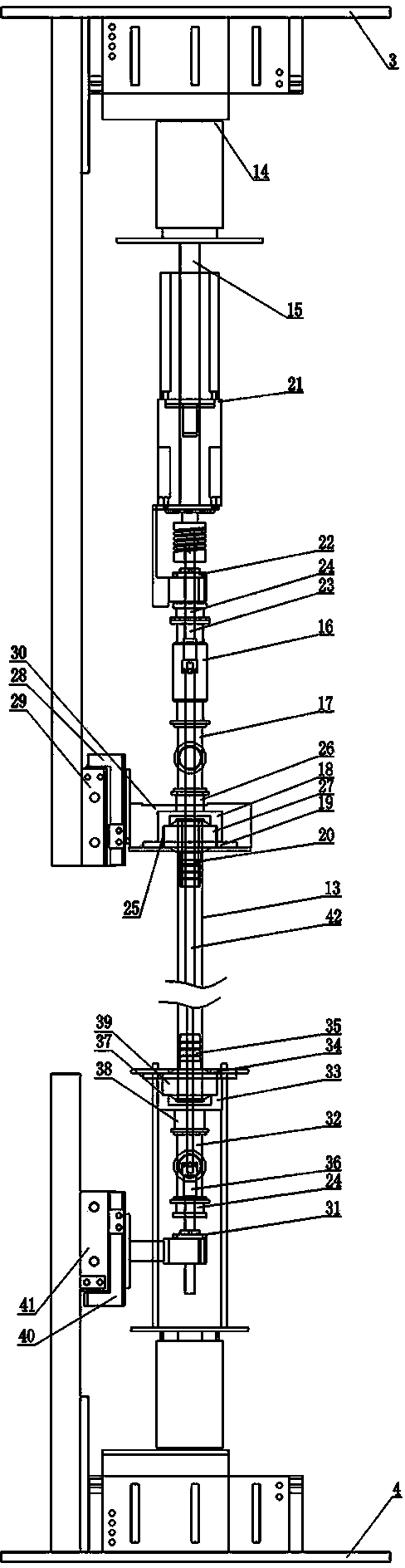

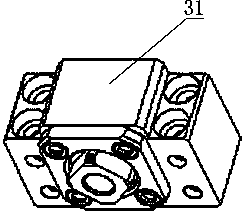

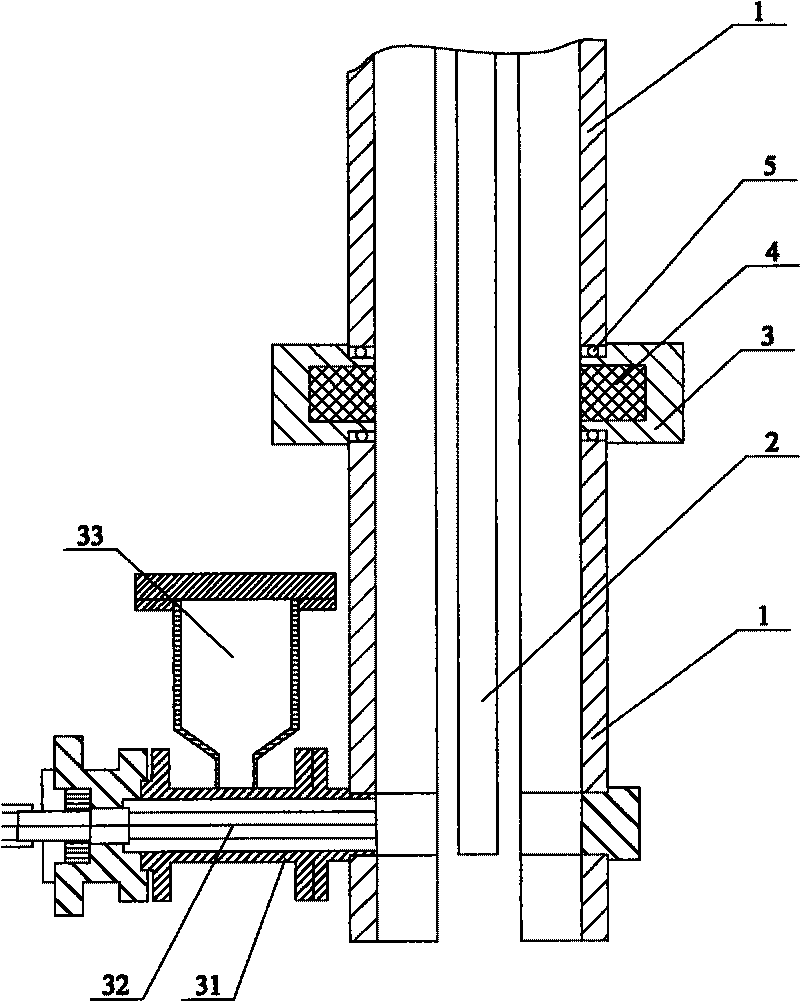

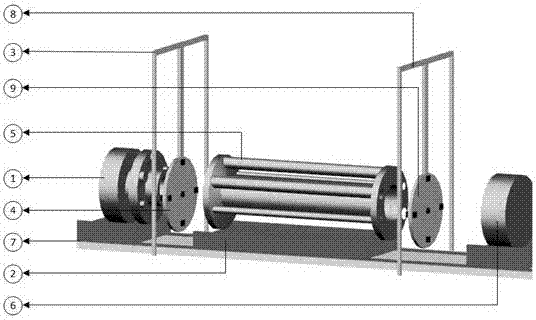

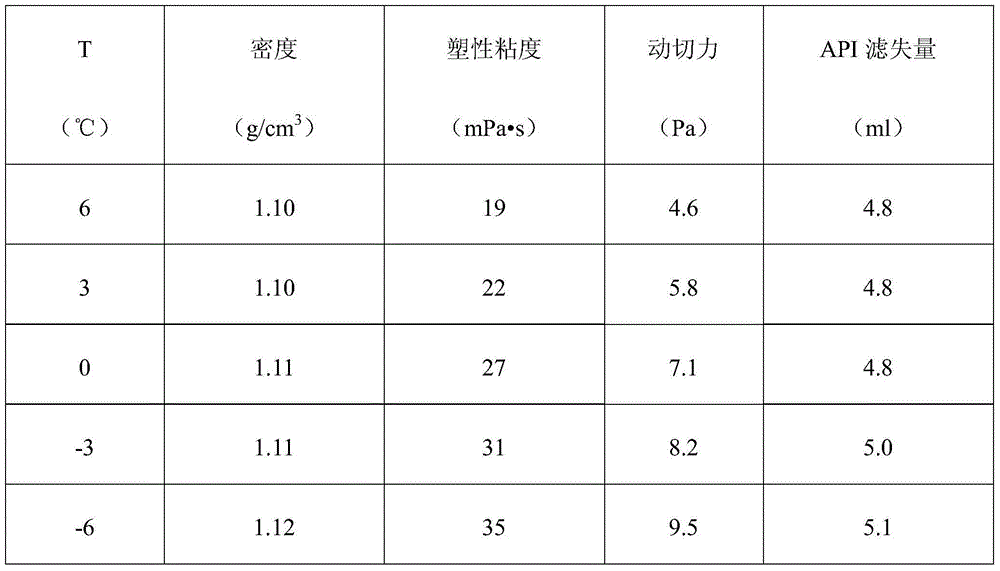

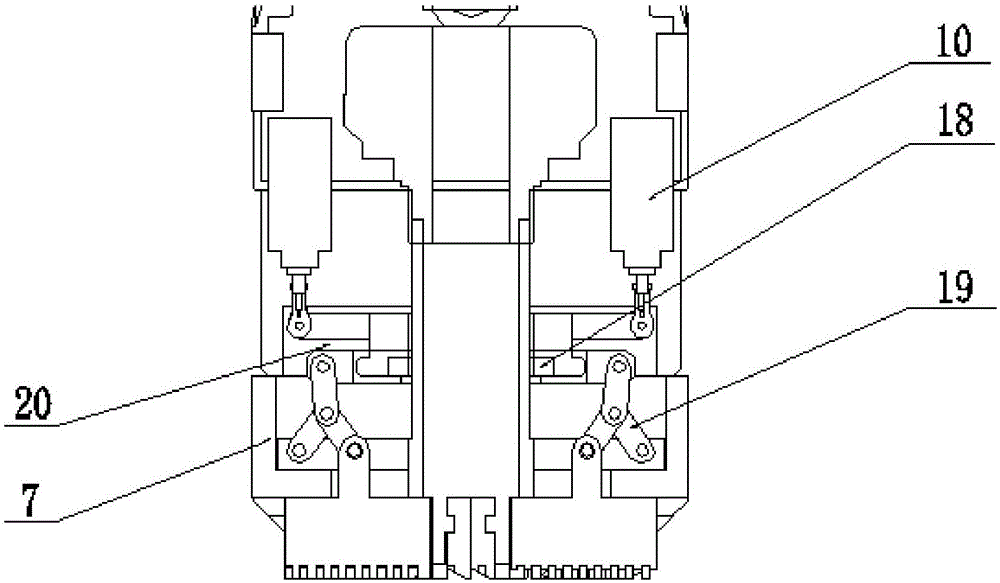

Test device and test method for simulating wear between deepwater drilling well marine riser and drill string

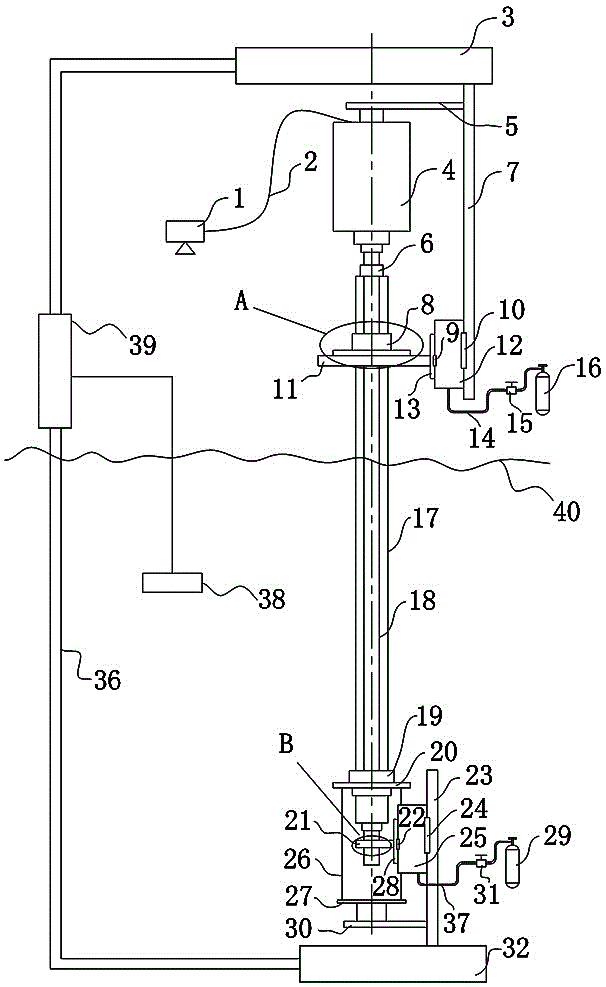

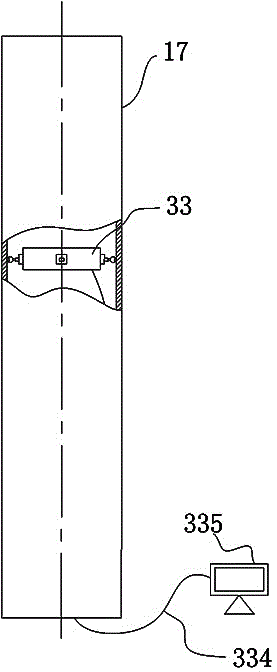

ActiveCN105136598AEasy to operateSimple structureInvestigating abrasion/wear resistanceDeepwater drillingEngineering

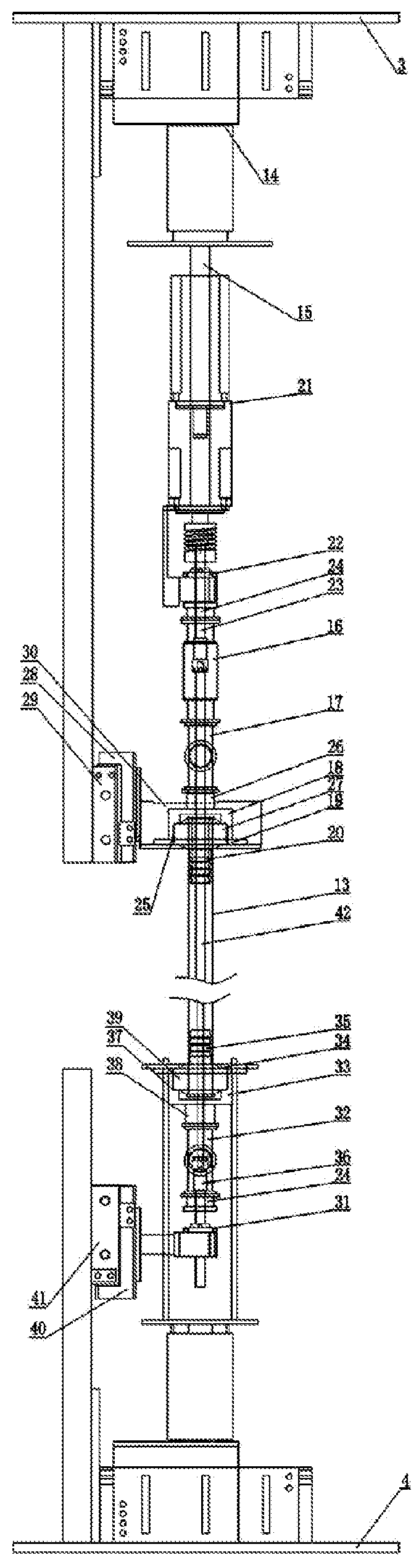

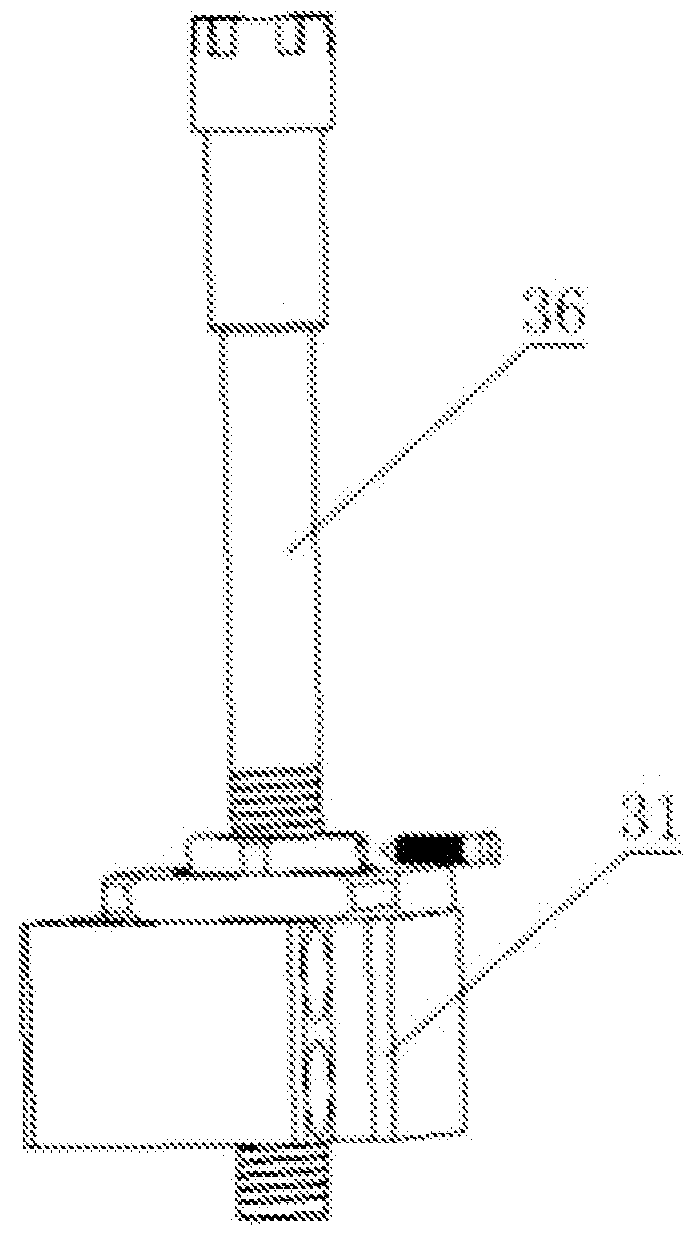

The invention relates to a test device for simulating the wear between a deepwater drilling well marine riser and a drill string. The test device comprises a telescopic test rack (36), a marine riser and drill string wear testing device, a marine riser inner surface wear measuring device (33), and a drill string outer surface wear measuring device (34); wherein the marine riser and drill string wear testing device comprises a servo motor (4), a marine riser model (17), a drill string model (18), an upper tension force applying mechanism, and a lower tension force applying mechanism. The invention also relates to a test method adopting the provided test device. The provided test device and test method can simulate the wear between a marine riser and a drill string under different conditions: different rotation speeds of drill string model, different tension forces on the marine riser model, and different tension forces on the drill string model; at the same time, the wear amount on the marine riser model and drill string model can be measured individually and effectively; and the device has the characteristics of convenient operation and simple structure and is capable of measuring the wear amount between a marine riser model and a drill string model under different work conditions.

Owner:SOUTHWEST PETROLEUM UNIV

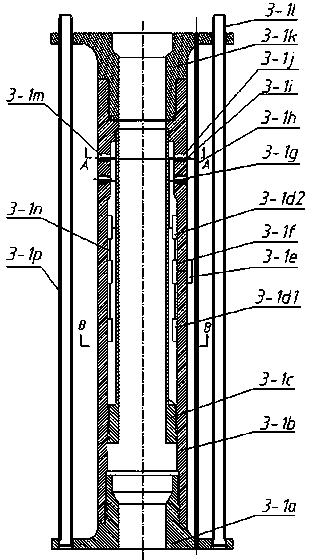

Deepwater drilling condition based marine riser mechanical behavior experiment simulation system and experiment method

Owner:SOUTHWEST PETROLEUM UNIV

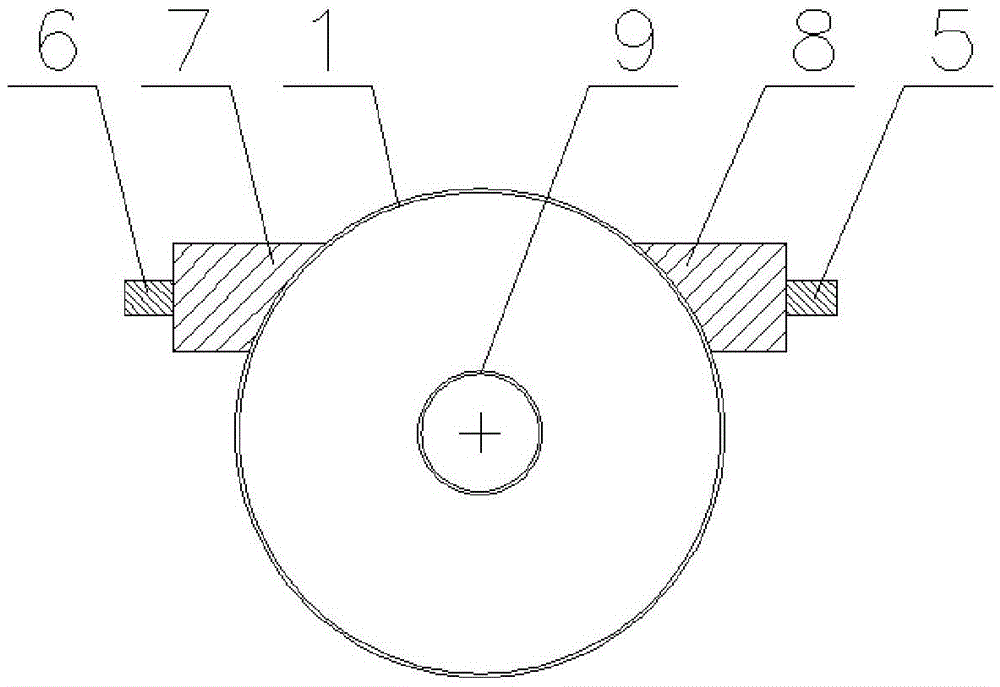

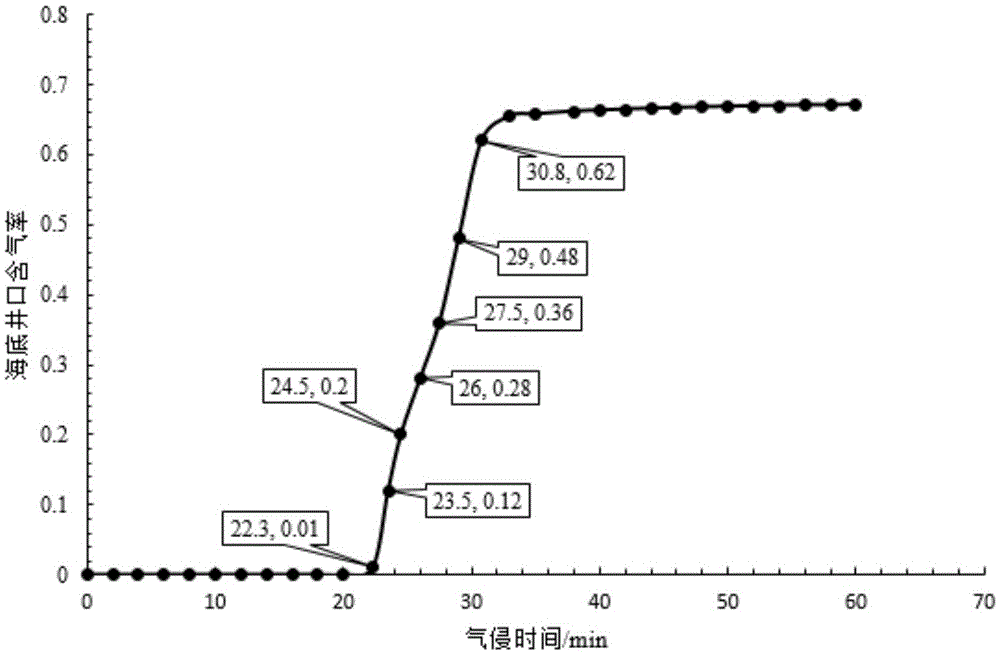

Deepwater drilling well gas cut monitoring method based on marine riser gas-liquid two-phase flow identification

ActiveCN105545285ARealize real-time quantitative descriptionAccurate detection of air intrusionSurveyUltrasound attenuationWell drilling

The invention belongs to the deepwater oil gas drilling well field, and specifically relates to a deepwater drilling well gas cut monitoring method based on marine riser gas-liquid two-phase flow identification; the method comprises the following steps: arranging ultrasonic transducers in contrapositions on bottom of the marine riser so as to monitor gas cut signals; according to a set quantification corresponding relation between sound wave signal attenuation and cross section gas contain rate, combining a deepwater drilling well shaft gas liquid two-phase flow model and a credibility containing stratum pressure prediction method so as to set up a shaft gas cut level inverse computation method based on marine riser gas cut monitoring data, thus spotting gas cut in advance, realizing real time quantification description of the shaft gas cut condition, and forming the deepwater drilling well gas cut monitoring method based on marine riser gas-liquid two-phase flow identification. The method can measure more real data, can fully reflect the cross section gas containing rate, and can correct bottom hole prediction originality pressure according to marine riser sound wave monitoring data, so the shaft gas cut level inverse computation result can be more closer to real conditions, and reasonable measurement can be taken to control gas cut.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

High efficient hydrate inhibitor and its preparation method

The invention provides a high efficient hydrate inhibitor and its preparation method. The hydrate inhibitor of the present invention is a copolymer generated by reacting vinyl caprolactam, vinyl pyrrolidone, allyl sulphonic acid and N-substituted acrylamide. The hydrate inhibitor has the advantages of low dosage and good inhibition performance, and can be individually used, as well as can be used with salt, alcohol and its mixture, the inhibitor of the invention is capable of preventing the hydrate formation of deepwater drilling fluid under low temperature condition, and can acquire the effects of low dosage and good inhibition performance.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

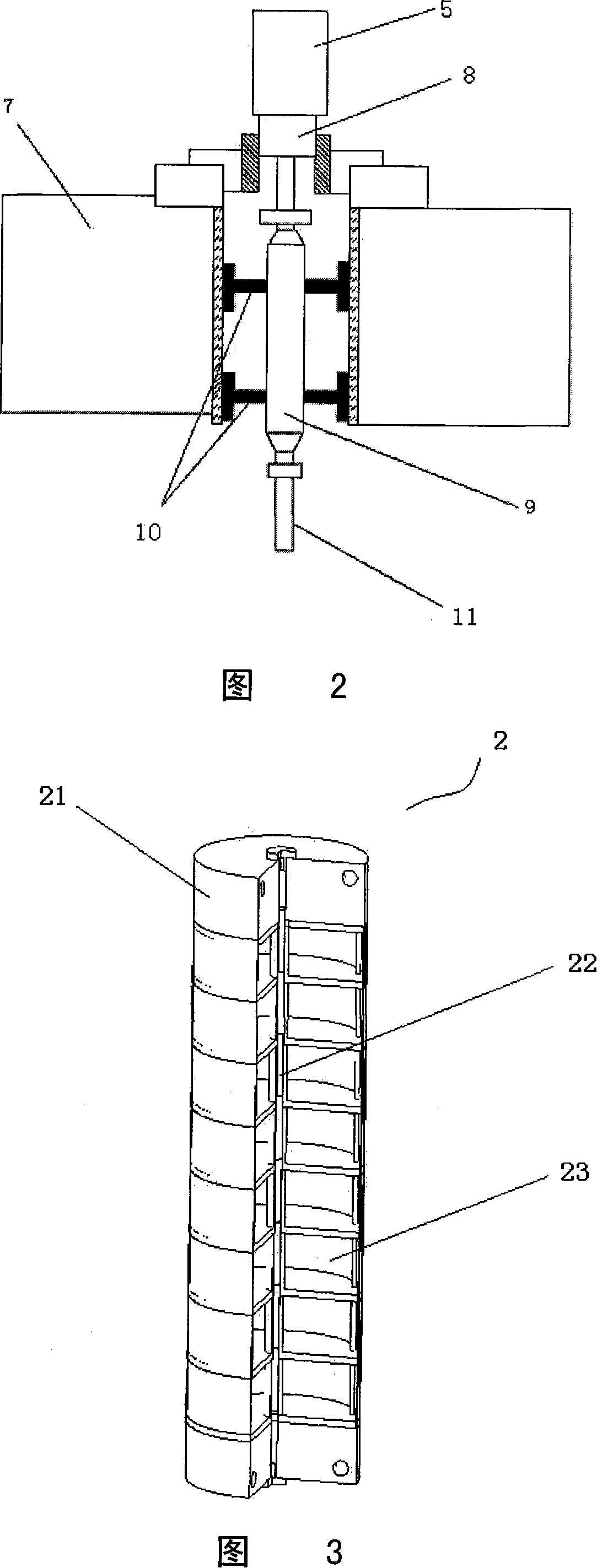

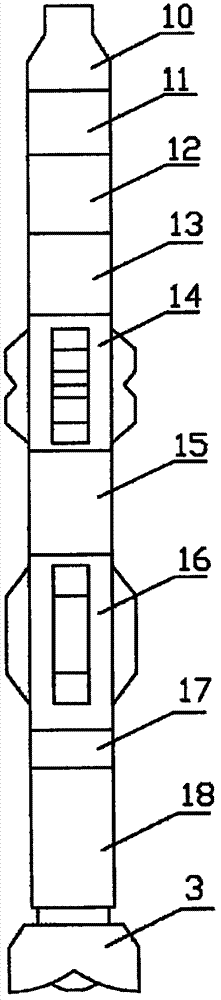

Deepwater drilling riser state monitoring system and working method thereof

InactiveCN103485761AAdjust the status in timeAvoid breakingConstructionsOcean bottomInformation processing

The invention discloses a technique for monitoring riser states in real time during deepwater oil development, belongs to the field of marine oil development, and relates to a deepwater drilling riser state monitoring system and a working method thereof. A riser provided with an information acquisition nipple comprises a riser body and the information acquisition nipples mounted on the riser body. Pressure sensors used for measuring water pressure values, electronic compasses used for measuring geographic orientation values and temperature sensors used for measuring water temperature are arranged in each information acquisition nipple, stress strain gauge devices for monitoring variation of stresses and a CPU (central processing unit) processing module for information processing are attached to the inner wall of each nipple, and signal transmission modules can transmit information outwards. Sea bed base stations and signal collectors can receive and transmit signals from the signal collection nipples as well as transmit the signals to a signal collection processing and controlling center. The riser provided with the signal collection nipples can effectively monitor self states during drilling, and capability of the riser for dealing with deepwater complex environments is improved.

Owner:SOUTHWEST PETROLEUM UNIV

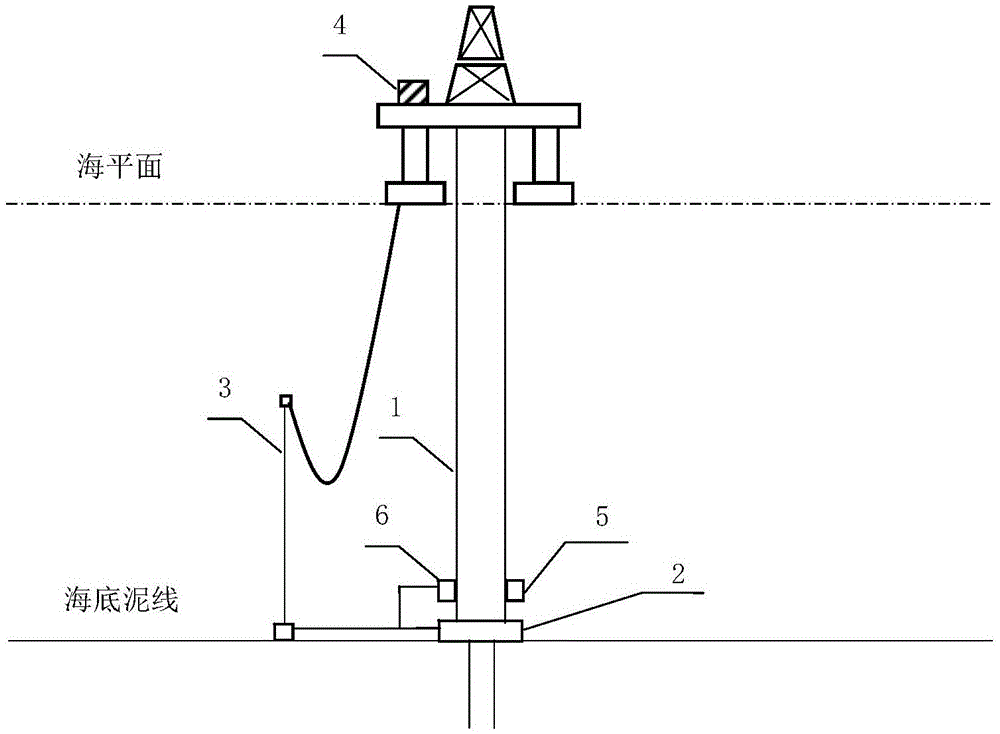

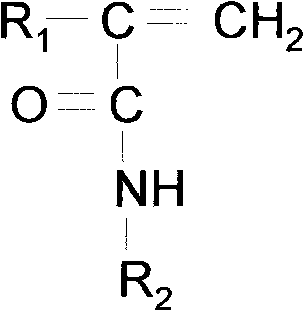

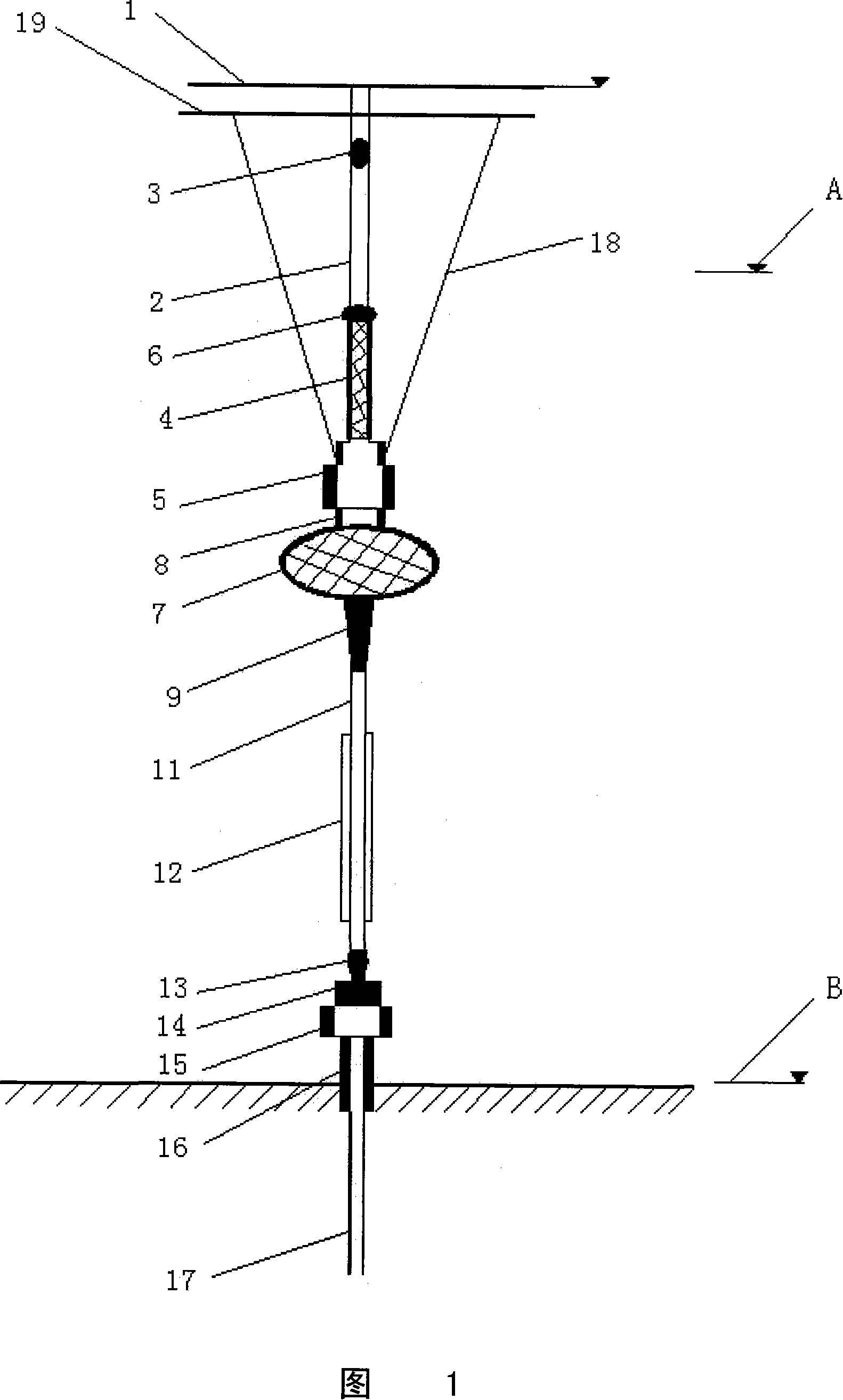

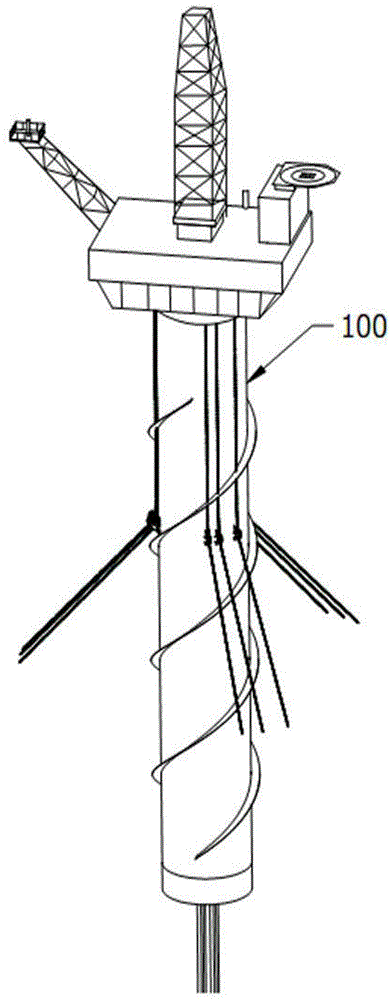

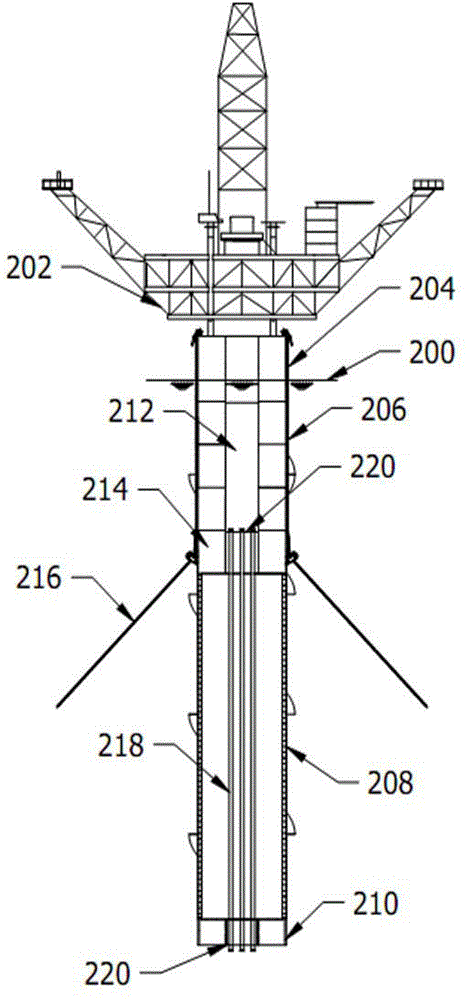

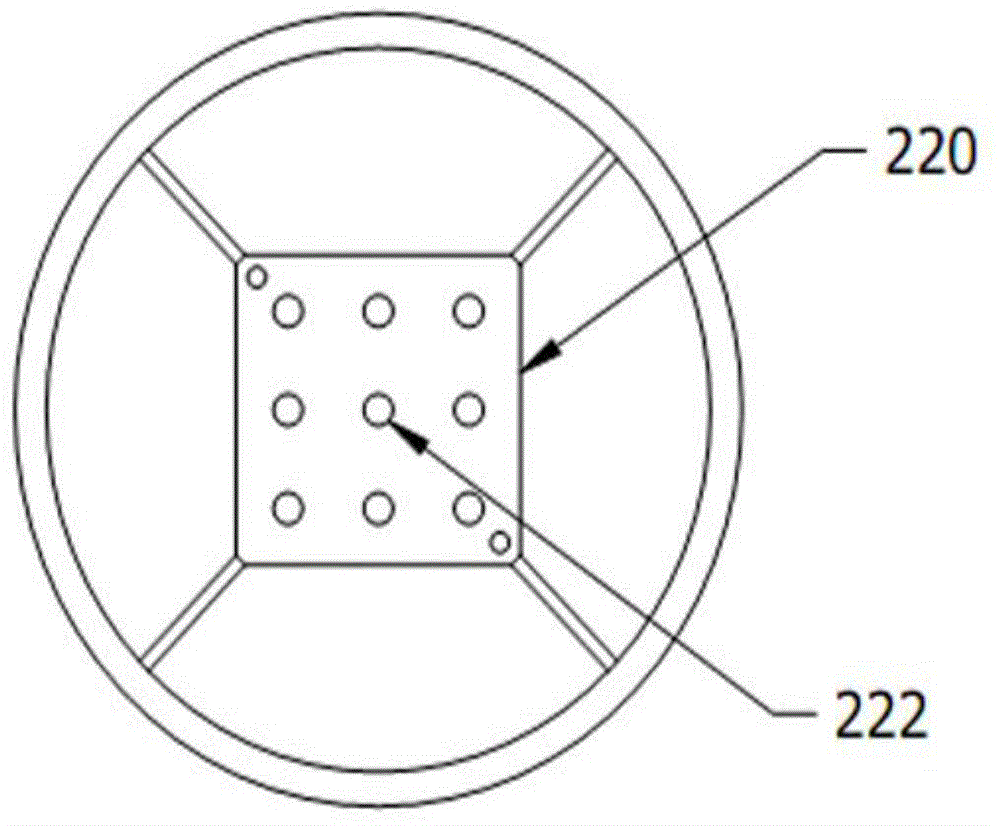

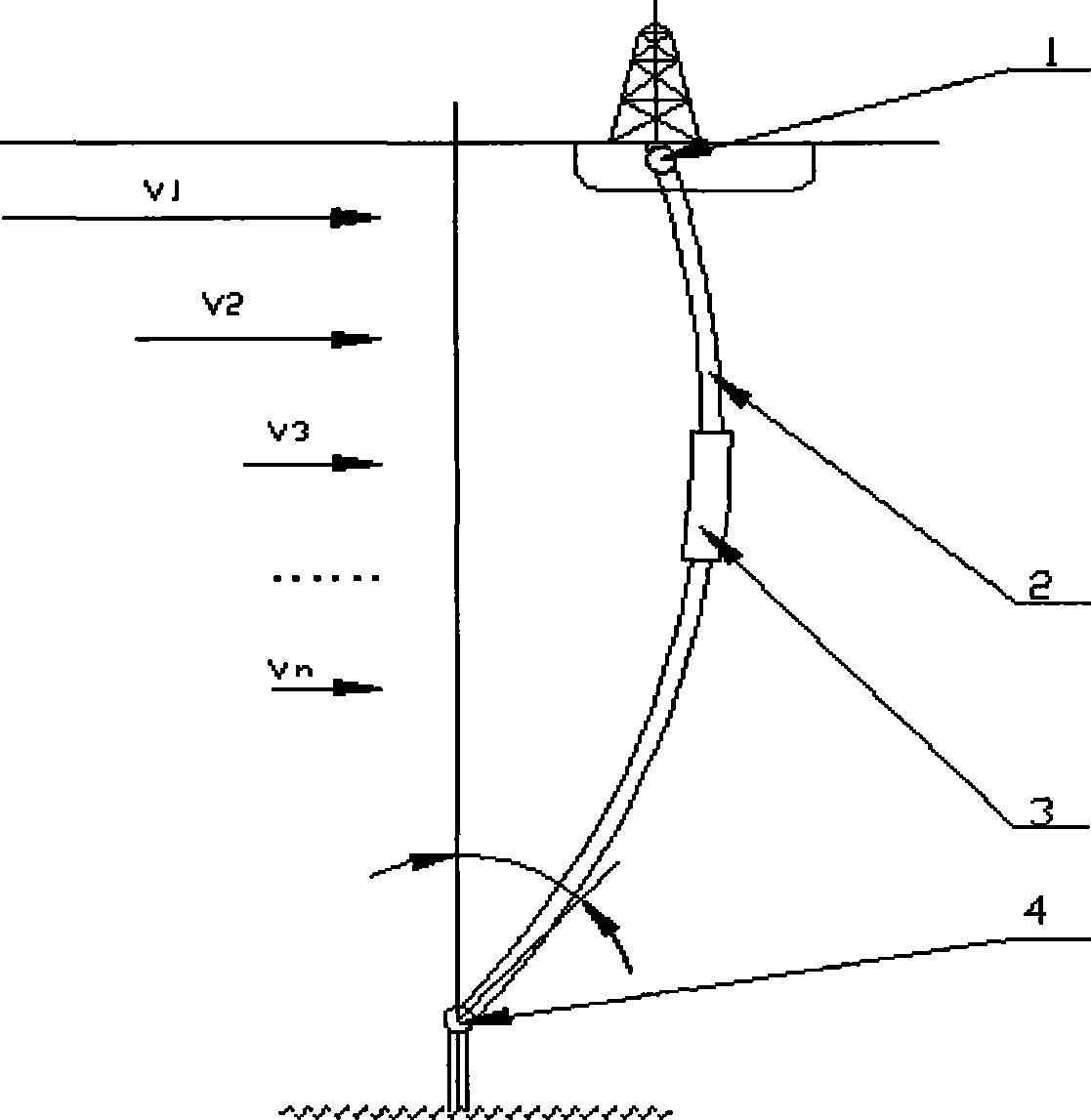

Deepwater drilling device based on near surface deviation

ActiveCN101109269AReduce lateral displacementConvenient for underwater workUnderwater drillingSealing/packingOcean bottomEngineering

The invention relates to a deep-water well-drilling device that is based on near-water-level disengagement, which is characterized in that, the drilling device comprises a water-isolating pipe connected with a well-drilling platform; in the middle of the water-isolating pipe, an upper flexible joint is arranged; the water-isolating pipe passes a float cabin and is connected with a blowout preventer; the upper end of the float cabin is connected with the water-isolating pipe through a disengaging mechanism; below the blowout preventer, a ballast tank is arranged; between the blowout preventer and the ballast tank, an upper wellhead is placed; the upper end of a stress joint connected with a centering guide goes deeply into the ballast tank and is connected with the upper wellhead, and the lower end of the stress joint is connected with a hi-pressure water-isolating pipe, out of which a float block is provided; the bottom end of the hi-pressure water-isolating pipe is connected in sequence with a lower flexible joint, a lower wellhead, a conduit and a casing pipe; the conduit and the casing pipe are fixed in the seabed; between the perimeter of the blowout preventer and the lower part of the opening of the moon pond of the well-drilling platform, at least three centering ropes are connected. The invention is of high applicability, steady performance, is convenient to disengage the water-isolating pipe, and can be widely used in deep-water well drilling.

Owner:CHINA NAT OFFSHORE OIL CORP +1

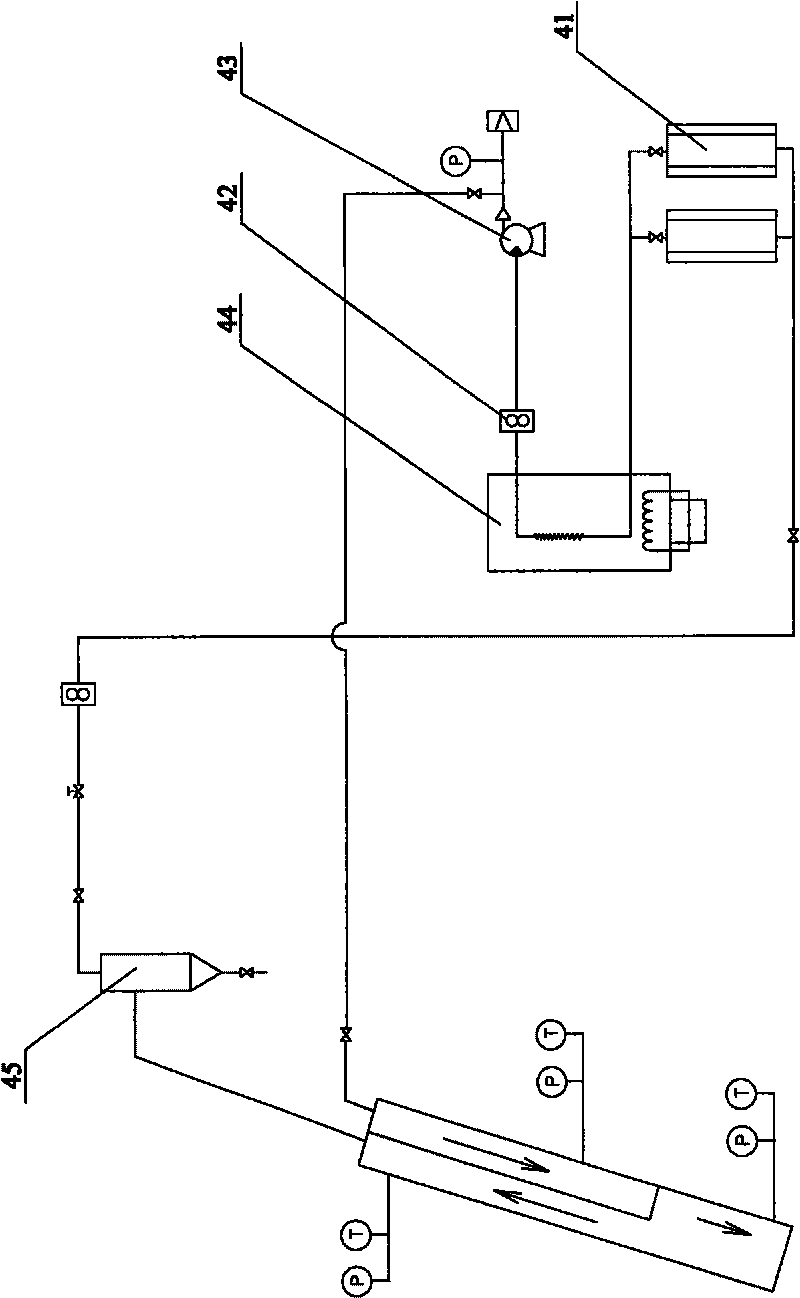

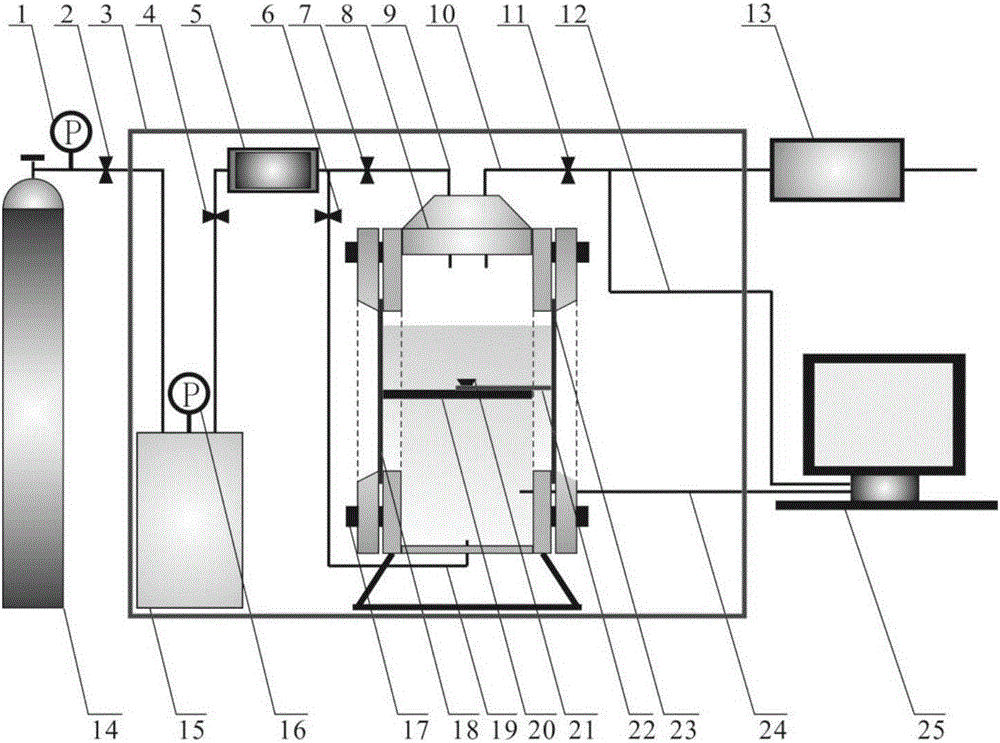

Simulation experiment device for migrating rock cuttings with circulation of deepwater drilling fluid and stabilizing well wall

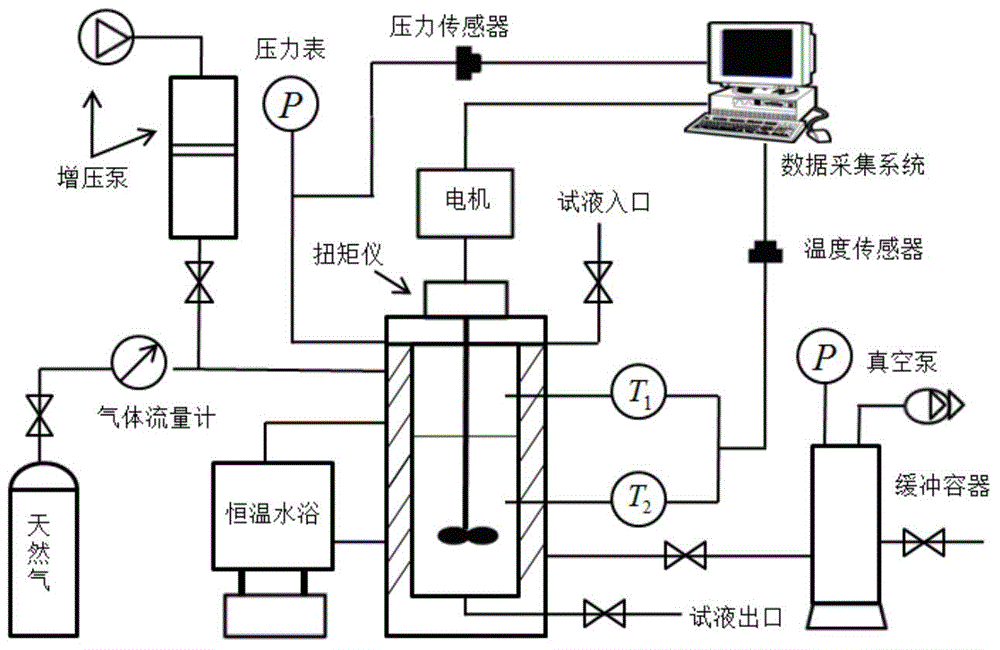

InactiveCN101701520AAchieve low temperature flow characteristicsAchieve rock-carrying propertiesSurveyConstructionsRock cuttingTemperature and pressure

The invention discloses a simulation experiment device for migrating rock cuttings with circulation of deepwater drilling fluid and stabilizing well wall. The device comprises a plurality of simulation wellholes, simulation drill pipes, and a drilling fluid delivering device; simulation well wall is arranged between an upper simulation wellhole and a lower simulation wellhole; the simulation drill pipes are provided with a drilling fluid inflow passage along axial direction; the drilling fluid circular delivering device comprises a drilling fluid circulation loop formed by sequentially connecting fluid storage tank, cooling device, flowmeter, fluid pump, inlet of the drilling fluid inflow passage, outlet of the drilling fluid inflow passage, liquid-solid separator and again the fluid storage tank by pipelines; and the inner wall of the simulation wellholes is provided with a plurality of temperature and pressure sensors, and transmits the signals to a data processor for processing. The invention can simulate the circulation process of deepwater drilling fluid, can carry out property researches such as low temperature flow, rock cutting migrating and well wall stabilizing, and provide an experimental method and research means for deepwater drilling fluid research.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

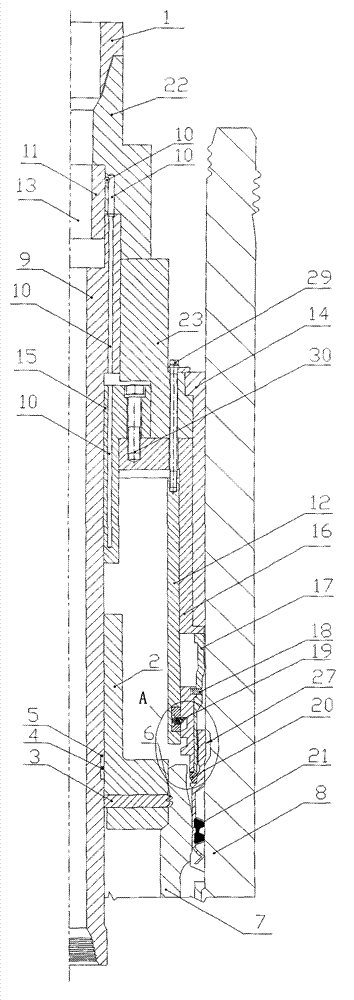

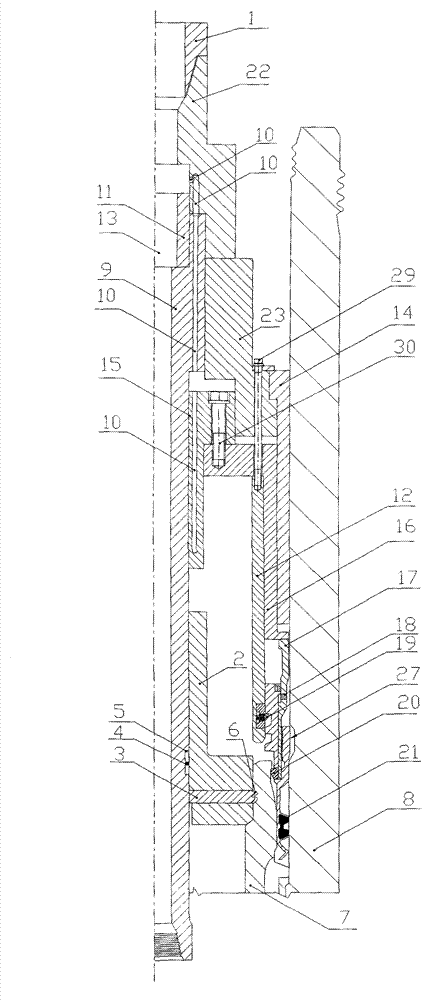

Feeding-in tool for surface guide tube during deepwater drilling

ActiveCN105041248AAchieve lockingAchieve unlockFluid removalSealing/packingDeepwater drillingWell drilling

The invention belongs to the field of ocean oil and gas drilling, and particularly relates to a feeding-in tool for a surface guide tube during deepwater drilling. The feeding-in tool for the surface guide tube during deepwater drilling is used for feeding the guide tube in place, and then a drill rod can be released to continue drilling. The feeding-in tool for the surface guide tube during deepwater drilling comprises a mandrel, an inner sleeve, an outer sleeve and a body, wherein the inner sleeve, the outer sleeve and the body are sequentially arranged outside the mandrel; the inner sleeve can slide vertically relative to the mandrel but cannot rotate; the outer sleeve is connected with the inner sleeve through a transmission thread pair; the body is seated on the inner sleeve; a locking claw penetrates in the body and can slide horizontally along the radial direction; and an anti-rotating pin penetrates in the body and the outer sleeve so that the outer sleeve only can move vertically in the body but cannot rotate. By the feeding-in tool, a drilling tool can be separated from the guide tube and then continues second section drilling, drilling fluid with rock wastes can be discharged from the side direction, the circumstances that the rock wastes are accumulated nearby a wellhead and observation of an indicating bar is stopped are avoided, an effective supporting force can be provided for the body of the tool, and an effect of preventing the feeding-in tool and a guiding tube head from rotating is achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

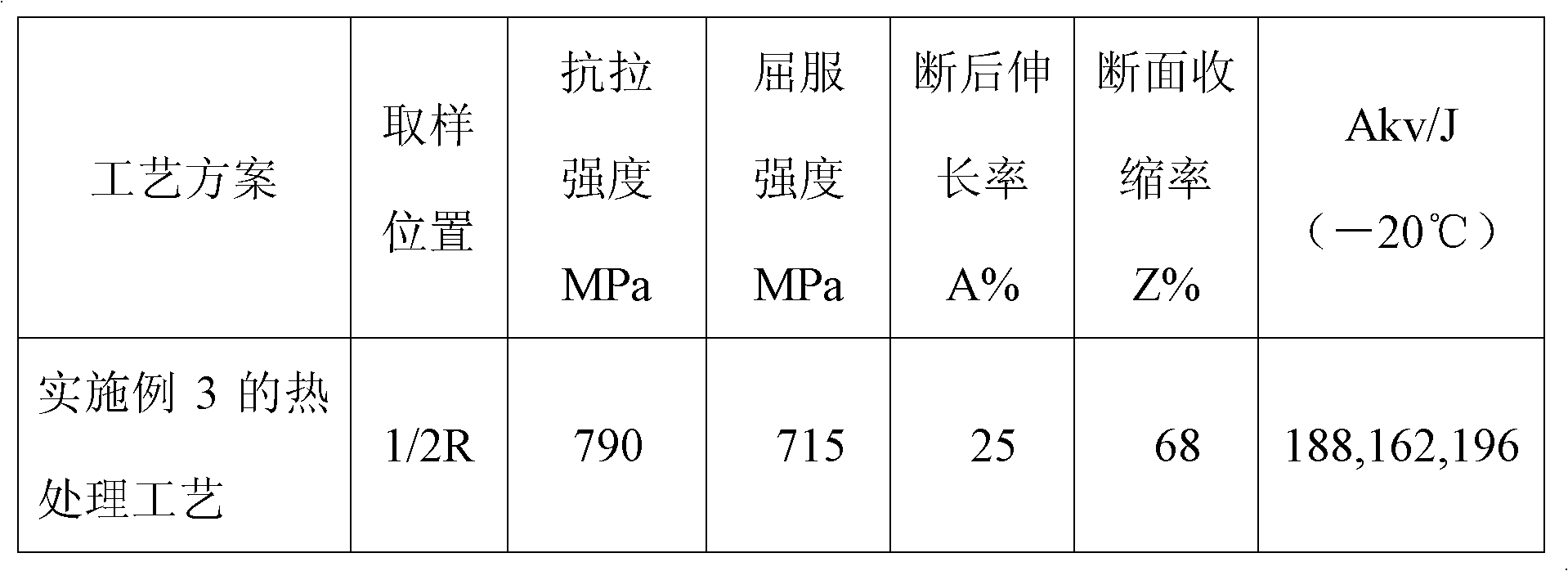

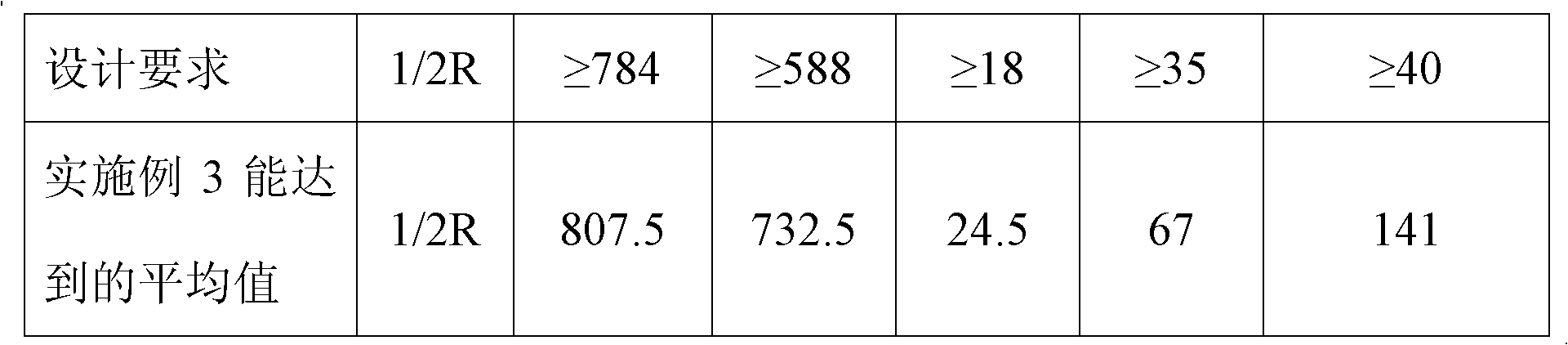

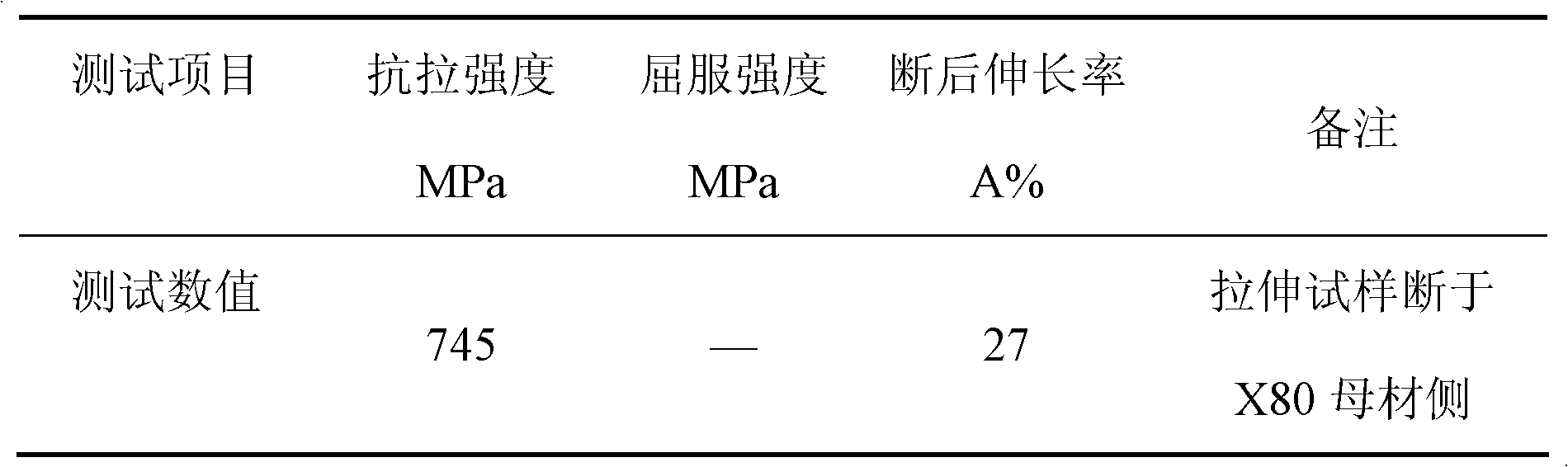

Steel for marine riser flange of marine deepwater drilling and manufacturing method of marine riser flange

InactiveCN102191442AImprove strength and toughnessMeet the technical requirements of low-carbon high-strength toughnessDrilling rodsDrilling casingsElectric arc furnaceDeepwater drilling

The invention discloses steel for a marine riser flange of marine deepwater drilling. The steel comprises the following components in percentage by weight: 0.13 to 0.21 percent of C, 1.65 to 1.95 percent of Mn, 0.25 to 0.35 percent of Mo, 0.03 to 0.09 percent of Nb, 0.02 to 0.08 percent of V, less than or equal to 0.015 percent of Ti, 0.5 to 0.9 percent of Ni, 0.07 to 0.2 percent of Cu, less than or equal to 0.15 percent of Cr, less than or equal to 0.22 percent of Si, less than or equal to 0.01 percent of S, less than or equal to 0.02 percent of P and the balance of Fe. The invention also discloses a manufacturing method of the marine riser flange of marine deepwater drilling. The method comprises the following steps of: preparing the materials according to the content of the components, and smelting the materials in an arc furnace to obtain molten steel, and heating the molten steel with arc in vacuum and stirring the molten steel by blowing argon to degas the molten steel; casting a steel ingot, blowing an inert gas through a blowing sliding water gap, balancing the components and the temperature and purifying the molten steel; forging the obtained steel ingot and annealing the steel ingot after forging; machining and polishing the steel ingot; and performing die forging on the steel ingot to obtain the finished product of the marine riser flange. By the manufacturing method, each mechanical property of the steel and the marine riser flange meets the requirements on API related steel for marine riser flange by setting the best component proportion and a heat treatment process.

Owner:BAOJI PETROLEUM MASCH CO LTD

Device and method for measuring hydrate reservoir decomposition rate in drilling process

ActiveCN105178953AAchieve electrical impedanceRealize measurementSurveyDecompositionDeepwater drilling

The invention belongs to the field of natural gas development, and particularly relates to a device and a method for measuring hydrate reservoir decomposition rate in a drilling process. The device for measuring hydrate reservoir decomposition rate and hydrate decomposition air flow in the drilling process comprises a hydrate generating and decomposing unit, an auxiliary unit and a measuring unit. The hydrate generating and decomposing unit simulates environmental conditions of a hydrate reservoir in the drilling process, and provides a place for generation and decomposition of hydrate; the auxiliary unit provides an air source and a liquid source for generation of the hydrate; and the measuring unit measures the decomposition rate and the decomposition air flow of the hydrate reservoir. By the device and the method, conditions of hydrate reservoir decomposition and output gas after decomposition of a hydrate reservoir can be simulated in a drilling process, and safety of deepwater drilling can be evaluated.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Deepwater drilling production vertical oil storage platform and operating method thereof

The present invention provides a deepwater drilling production vertical oil storage platform and an operating method thereof, wherein the vertical oil storage platform comprises a vertical oil storage cabin for storing oil through an oil-water replacement method, an oil caisson connected to a top of the oil storage cabin, a water caisson connected to a bottom of the oil storage cabin, an isolation pad arranged between an oil-water interface of the oil storage cabin and capable of freely floating along with an oil-water interface layer, a water pipeline extending from a water collecting tank at a top of a center well of the platform to the water caisson at the bottom of the platform, a water channel extending to a water outlet at a lower end of the water caisson at the bottom of the platform along the center well, and an oil-conveying pipe extending from an upper facility of the platform to the oil caisson. The present invention also provides an oil-water replacement and oil-water separation method and process of an oil storage process of the vertical oil storage platform, wherein the method comprises the steps of discharging the water obtained by the oil-water replacement from the water caisson to the water collecting tank at the top of the center well through the water pipeline to perform oil-water secondary separation, then enabling the water to pass through the center well and the water channel to reach the water outlet at the bottom of the platform, and discharging the water into the sea.

Owner:CHINA NAT OFFSHORE OIL CORP +2

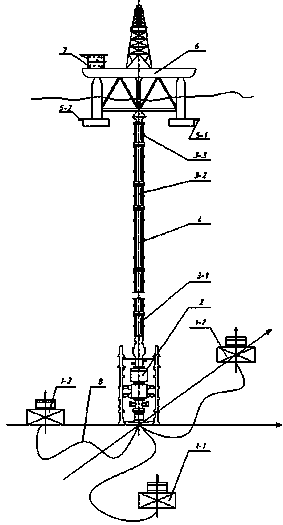

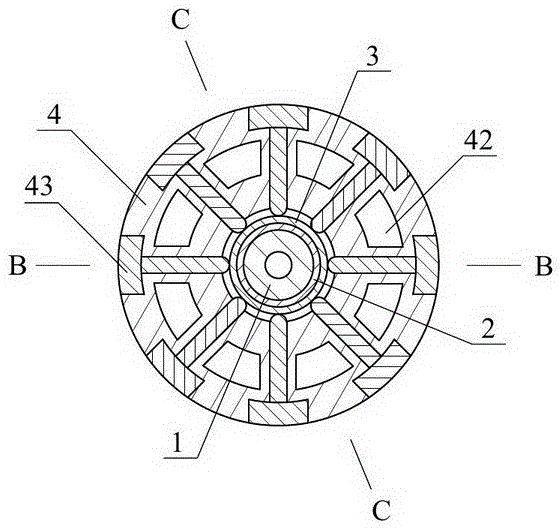

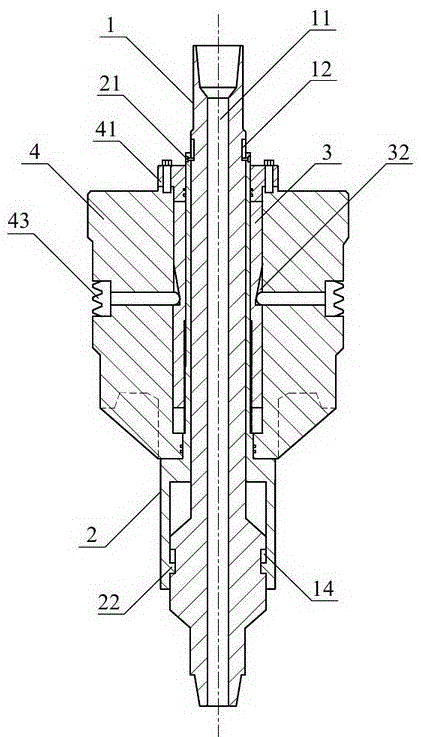

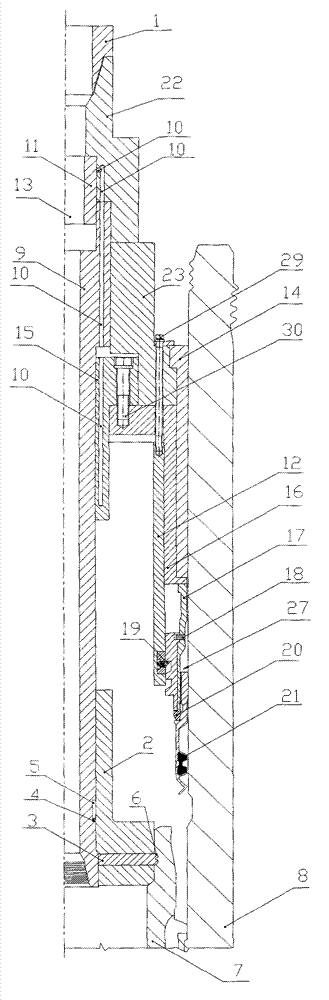

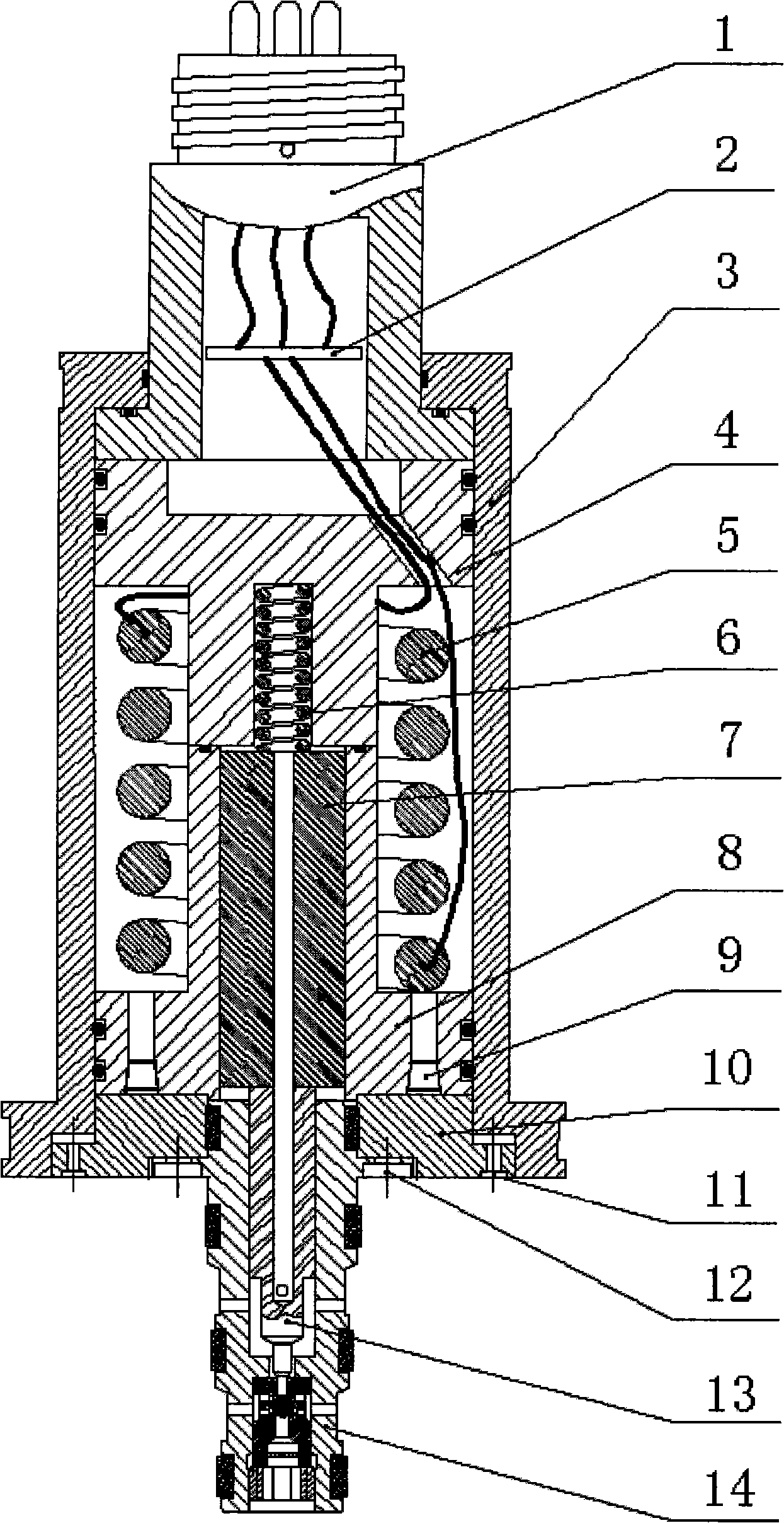

Casing hanger and seal lowering tool for ocean deepwater drilling

The invention discloses a casing hanger and seal lowering tool suitable for ocean deepwater drilling, which is used for lowering a casing hanger and a seal and mounting a sealing assembly in the ocean deepwater drilling process. The tool mainly comprises a central shaft, a lower tool and an upper tool, wherein the lower tool mainly comprises a lower tool body, a pin and a locking block; the upper tool mainly comprises an upper component, a lower component, a variable channel piston, a hydraulic auxiliary lowering piston, a pressing sleeve, a suspension sleeve and an outer sleeve; a Z-shaped groove on the lower part of the central shaft and the lower tool body can be matched with each other through the pin at three matching positions, and the central shaft is moved up and down to reach an initial sealing position firstly by changing the matching positions; and the pressing sleeve is connected with the hydraulic auxiliary lowering piston, moves downwards together with the hydraulic auxiliary lowering piston, and presses the locking sleeve of the sealing assembly downwards in the downward moving process to ensure that the inner locking ring of the sealing assembly is locked in the casing hanger, so that the sealing assembly can be mounted in a sealed mode.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

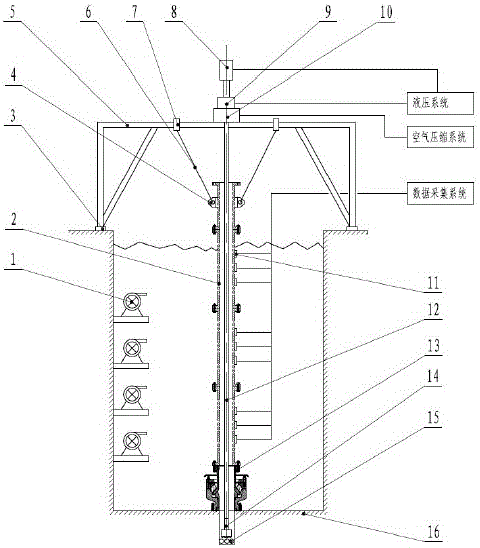

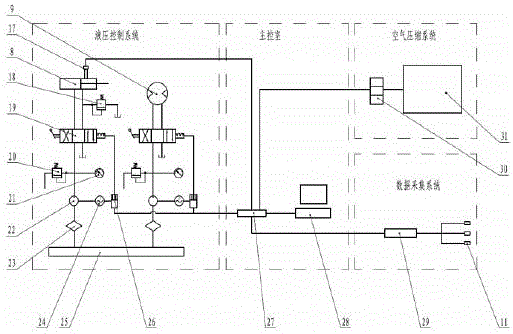

Test apparatus for simulating mechanics characteristics of water-resisting pipe under deepwater drilling well conditions

InactiveCN105890869AThe mechanical properties are good for gettingEasy to fixHydrodynamic testingStrength propertiesAir compressionWell drilling

The invention relates to a test apparatus for simulating mechanics characteristics of a water-resisting pipe under deepwater drilling well conditions. The test apparatus comprises a supporting device, an ocean wave simulating device, a drilling well simulating device, a water-resisting pipe tensioning system, a water-resisting pipe deflection system, a hydraulic system, an air compression system and a data acquisition system, wherein the drilling well simulating device is connected with the supporting device through the water-resisting pipe tensioning system and the water-resisting pipe deflection system, the supporting device comprises a pool and a bracing frame body erected above the pool, the water-resisting pipe tensioning system comprises a connecting rack, a tensioning ring and a steel wire rope, the ocean wave simulating device comprises four submersible pumps and a water supply system, the drilling well simulating device comprises a drilling rod, a drill bit, an oil cylinder and an oil motor, the hydraulic system is connected with the oil cylinder and the oil motor of the drilling well simulating device, the air compression system is connected on the drilling well simulating device, and the data acquisition system comprises a foil gauge and a foil gauge data acquisition instrument. The apparatus can simulate different conditions encountered by a water-resisting pipe during deepwater well drilling, and is wide in application scope, and high in universality.

Owner:SOUTHWEST PETROLEUM UNIV

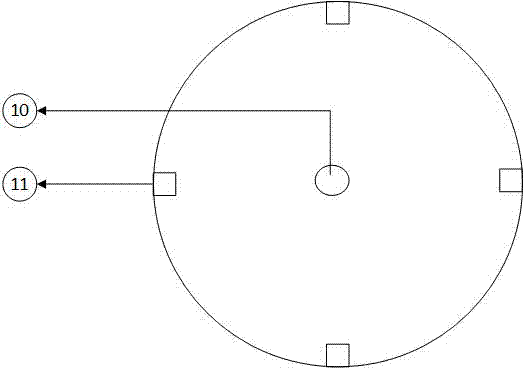

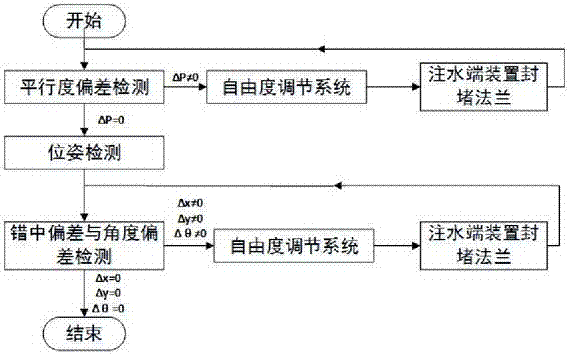

Deepwater drilling riser pipe automatic connection pose detection method based on machine vision

ActiveCN106885514AImprove detection accuracyReduced measurement timeUsing optical meansMachine visionDeepwater drilling

The invention relates to a deepwater drilling riser pipe automatic connection position detection method based on machine vision. For the identification of the poses of a drilling well riser pipe, a water injection end device and a plugging end device in riser pipe automatic connection installation and the guidance of a freedom degree regulation system to complete the calculation of a connection installation deviation needed by pose regulation, with the connection installation of the riser pipe and the water injection end device as an example, the riser pipe automatic connection position detection method based on machine vision is provided. According to the method, the realization of the automation of the connection installation of the riser pipe in a riser pipe detection and inspection process can be helped, the detection and inspection efficiency of the riser pipe is improved, the labor intensity of an operator is reduced, and the safety of the riser pipe inspection and detection is improved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Device and method for drilling by using full-automatic composite material continuous pipe

InactiveCN102787804AReduce weightImprove fatigue performanceSurveyDirectional drillingDeepwater drillingWell drilling

The invention discloses a device and a method for drilling by using a full-automatic composite material continuous pipe and relates to the technical field of drilling in the oil and gas industry. The upper end of a drill is connected with an electric motor driving the drill to rotate, a composite material continuous pipe with an embedded cable is wound on a continuous pipe roller and provided with a mud flow channel, and the lower end of the composite material continuous pipe is connected with a continuous pipe connector. The continuous pipe connector, a measuring mechanism and a steering tool are connected with the electric motor sequentially. A ground power supply is connected with the measuring mechanism, the steering tool and the electric motor through the cable embedded in the composite material continuous pipe. The device and the method achieve transmission of electric power to the underground through the composite material continuous pipe, bi-direction real-time communication between the underground and the ground and drilling through the electric motor. The device and the method can be applied to the fields of underbalanced drilling, deepwater drilling, directional drilling, re-drilling of an old well and drilling of a well containing high sulfur content.

Owner:CHINA PETROCHEMICAL CORP +1

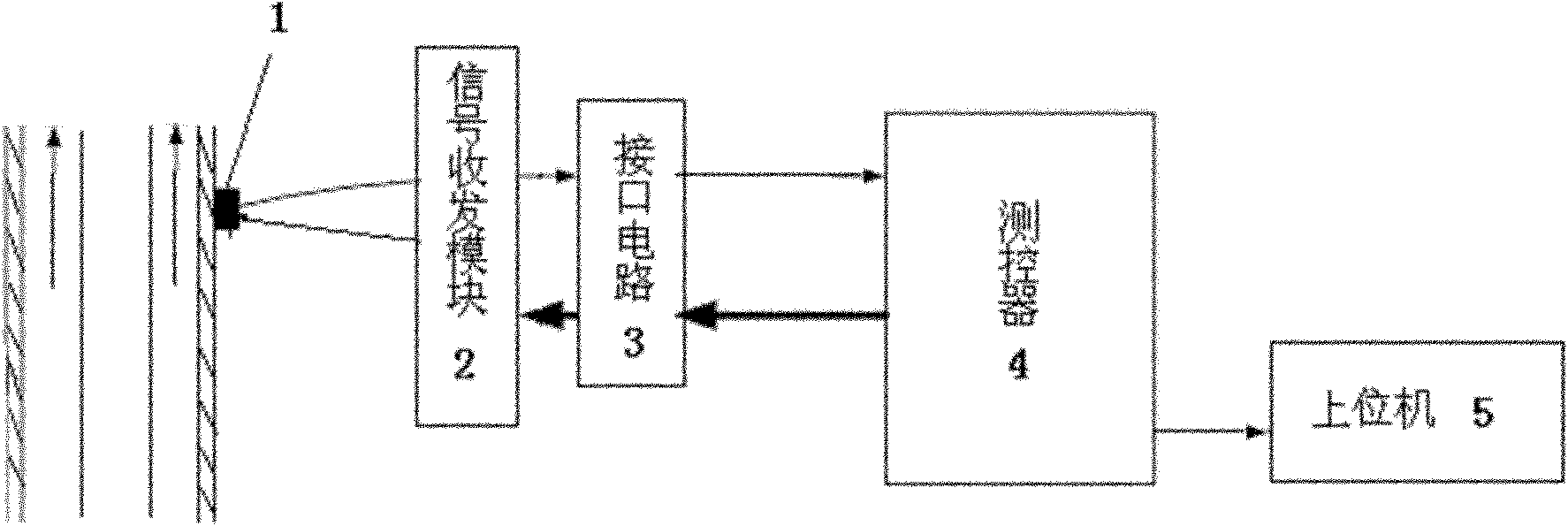

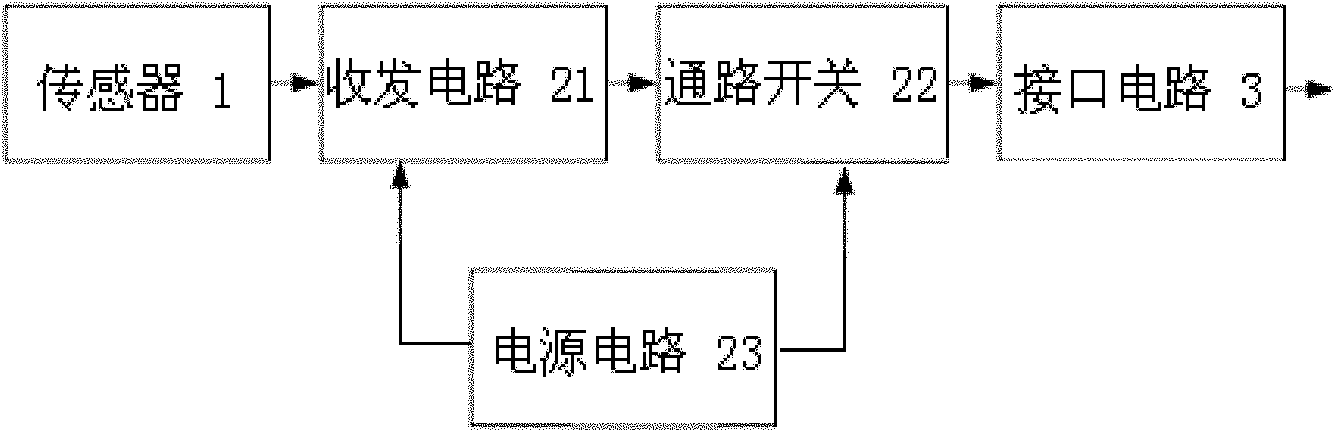

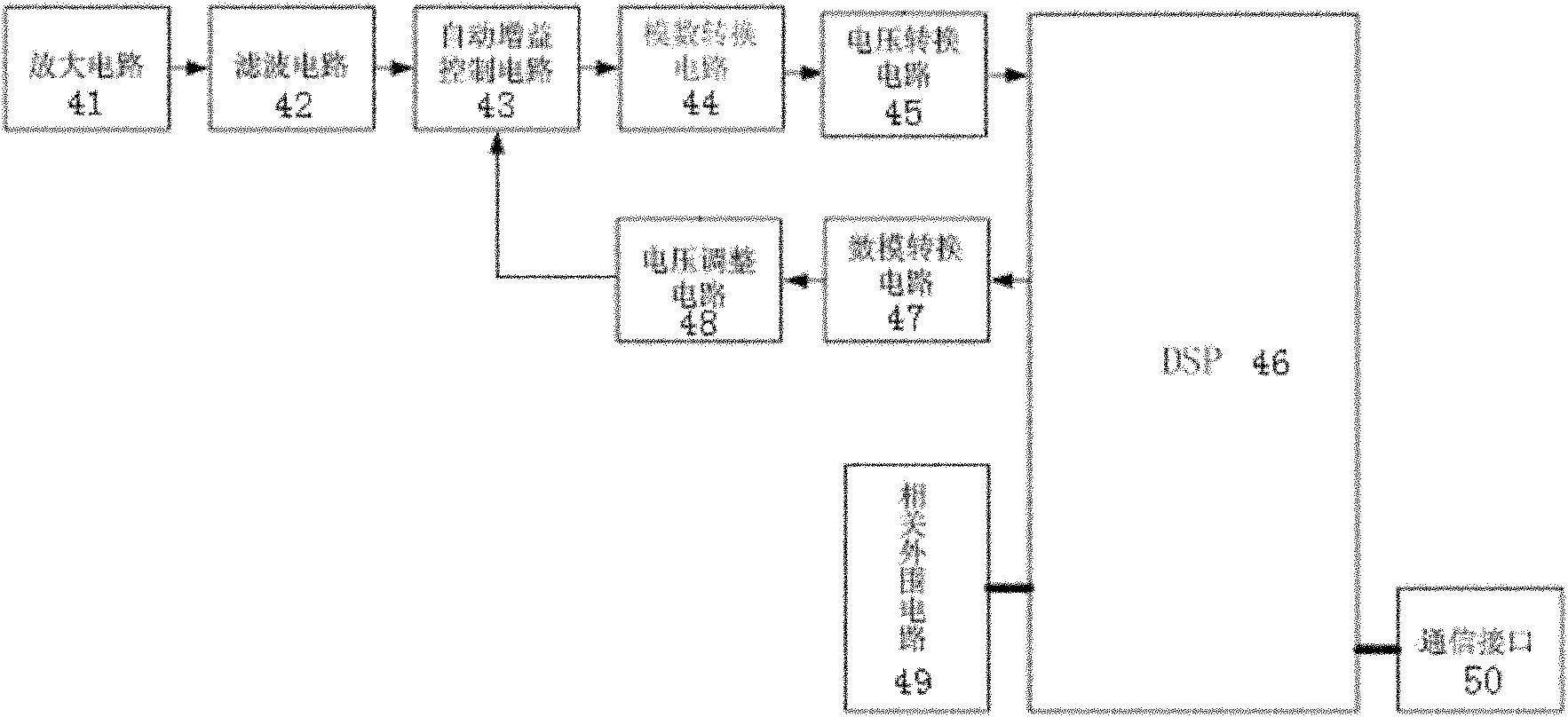

Circuit for monitoring well kick at deepwater drilling mud line

The invention relates to a circuit for monitoring well kick at a deepwater drilling mud line. The circuit comprises an ultrasonic transceiving module connected with an ultrasonic sensor, and a measurement and control module which is connected with the transceiving module through an interface circuit and communicates with an upper host position, and is characterized in that: the ultrasonic transceiving module comprises a transceiving circuit, a passage switch and a power circuit; a microprocessor is arranged in the transceiving circuit, and generates an electric pulse driving signal with a certain frequency, a certain pulse width and a certain output power to excite the ultrasonic sensor; the measurement and control module comprises an amplifying circuit, a filtering circuit, an automatic gain control circuit, an analog-to-digital converter, a voltage conversion circuit and a digital signal processor which are connected with one another according to an input and output sequence; and the output end of the digital signal processor is connected with a digital-to-analog conversion circuit and a voltage regulation circuit sequentially. The circuit is arranged by the measurement of a Doppler effect, and can measure flows of a seabed marine riser and an annular drilling column in real time so as to immediately determine underground overflow situations.

Owner:CHINA NAT OFFSHORE OIL CORP +1

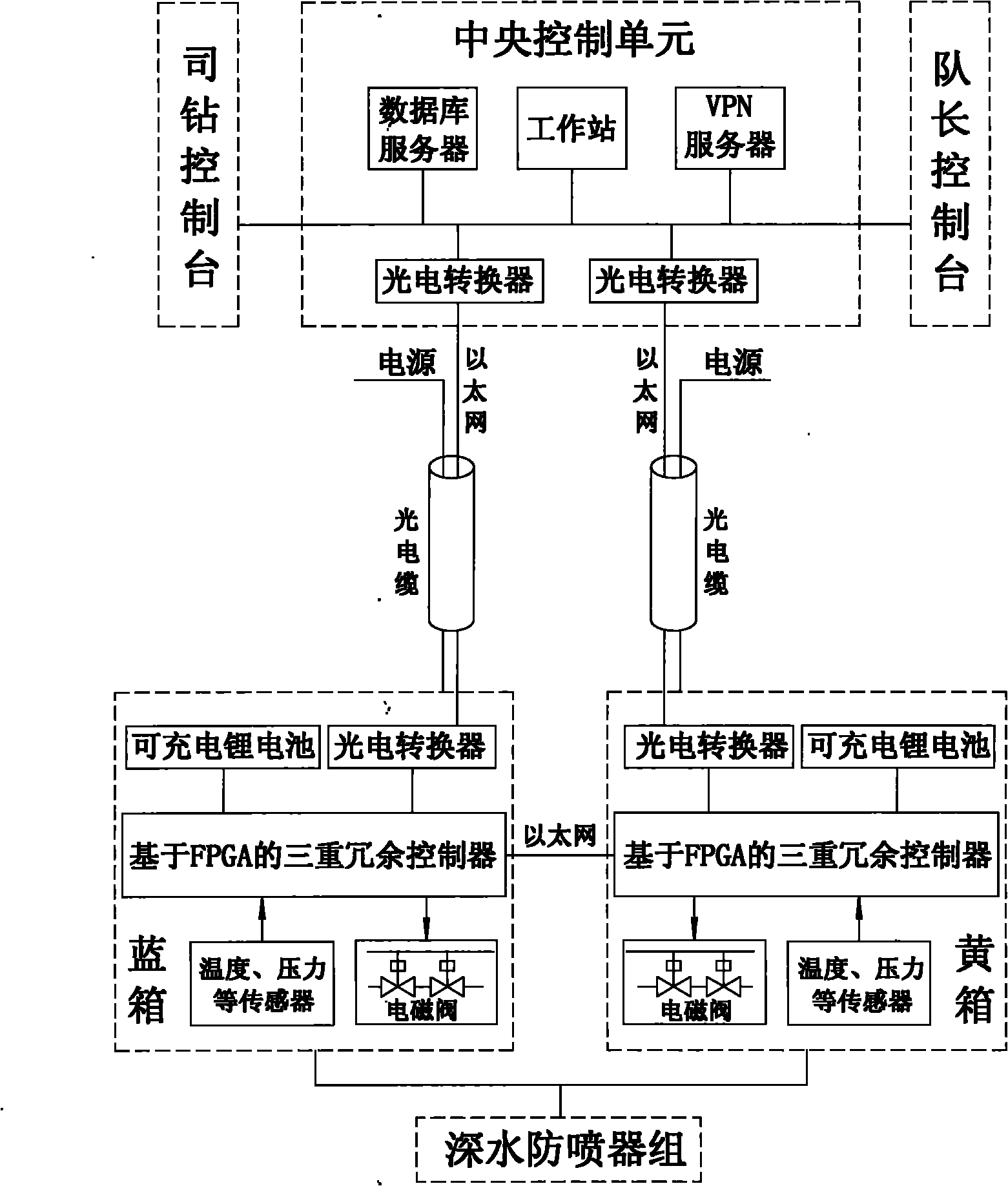

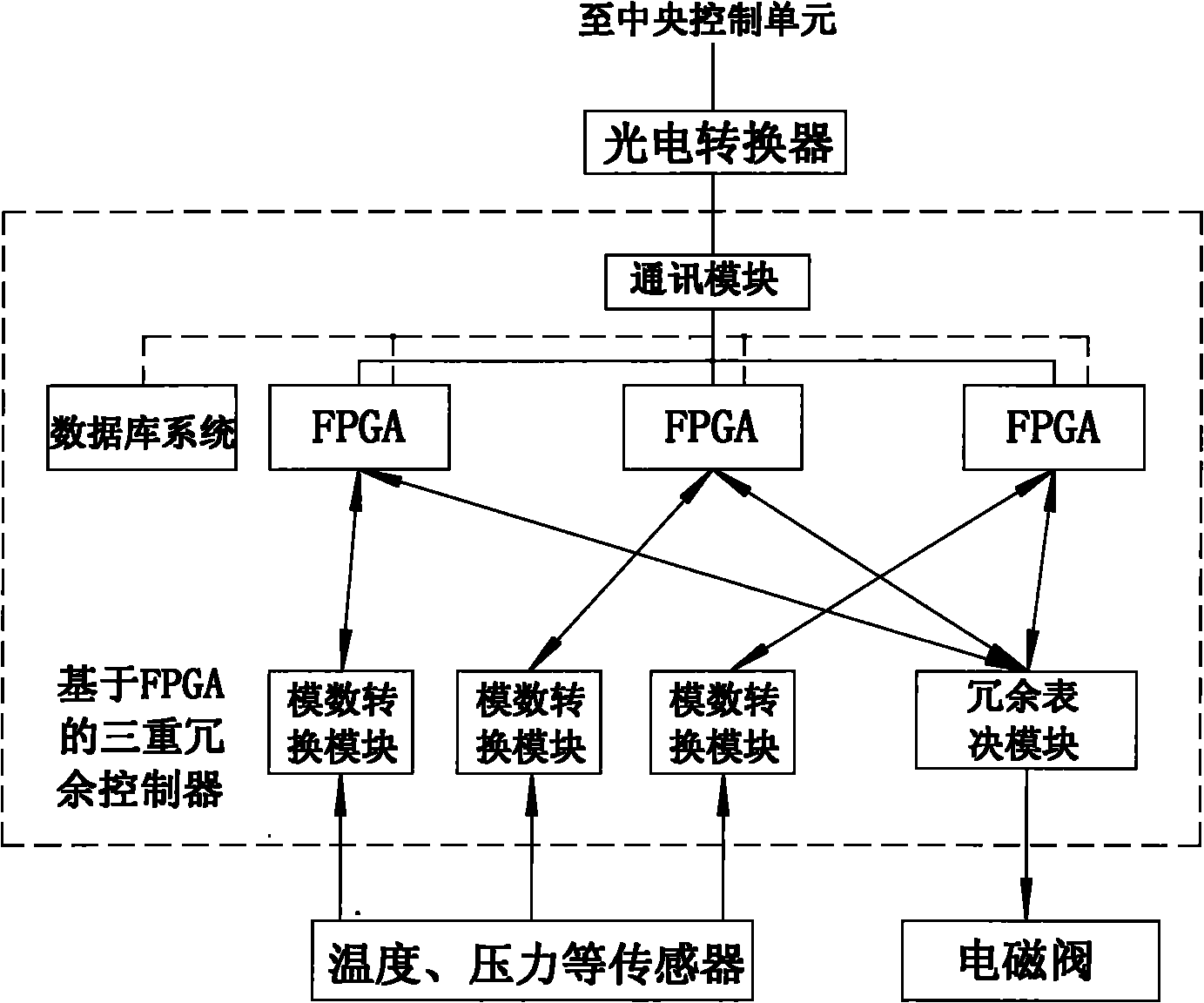

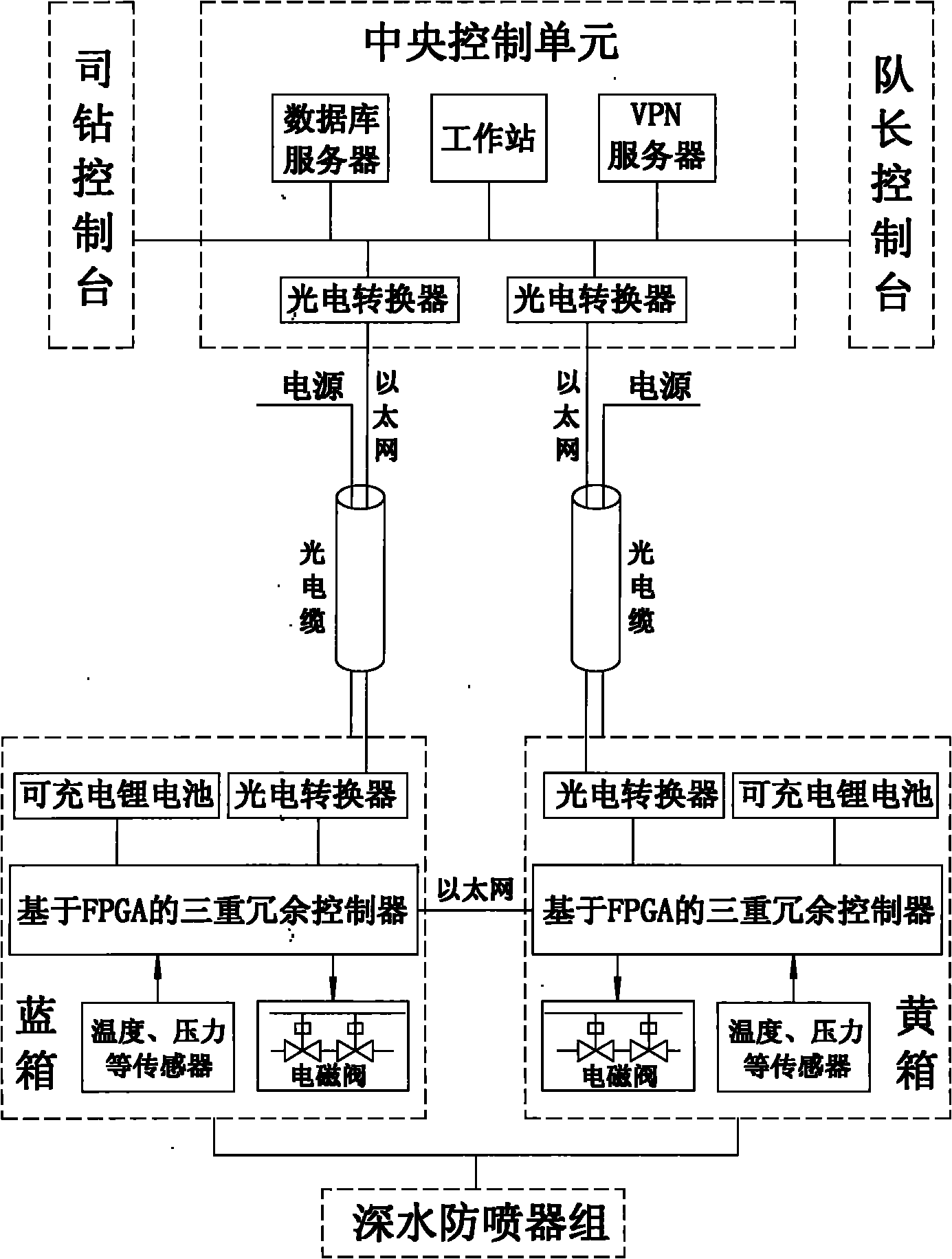

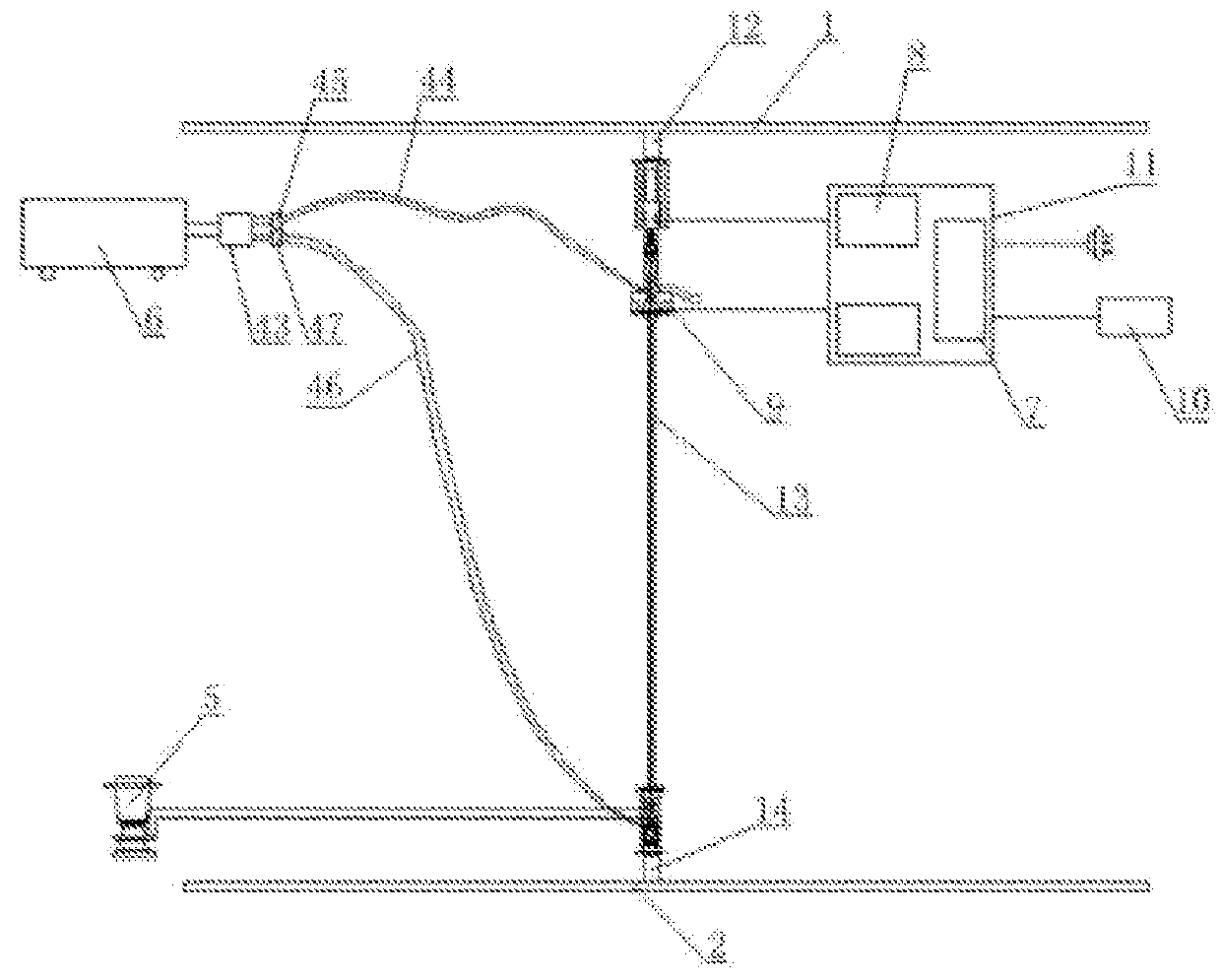

Deepwater blowout preventer set electric control system based on FPGAs (Field Programmable Gate Arrays)

ActiveCN101886530ACompact structureReduce volumeSafety arrangmentsSealing/packingPrivate networkWorkstation

The invention belongs to the control field of deepwater drilling equipment and relates to a deepwater blowout preventer set electric control system based on FPGAs (Field Programmable Gate Arrays). The system comprises an overwater electric control system, an underwater electric control system and a transmission optical cable for connecting the overwater electric control system and the underwater electric control system. The overwater electric control system mainly comprises a central control unit, a driller control console and a captain control console. A working station, a database server, aVPN (Virtual Private Network) server and the like are arranged in the central control unit. The underwater electric control system comprises a blue-box electronic module and a yellow-box electronic module which are backed up mutually. The main parts of the underwater electronic modules are triple redundancy controllers based on the FPGAs, the controllers comprise three FPGAs and relevant peripheral circuits, and input signals and output signals need to be subjected to redundancy voting in redundancy voting modules of the controllers. The invention has the advantages that the underwater electronic modules have compact structure so that the size of an electronic sealing cabin is reduced; and due to the adoption of two triple redundancy controllers, the reliability of the system is greatly improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

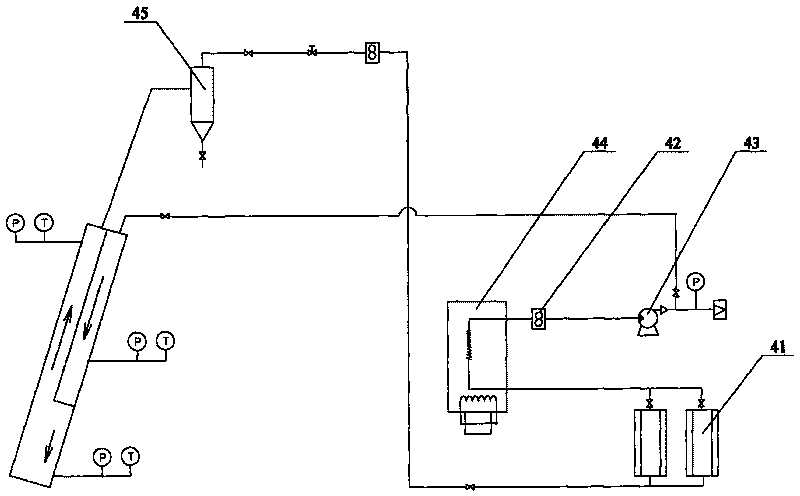

Deepwater drilling condition based marine riser mechanical behavior test simulation system and test method

InactiveUS20160032704A1Stable and reliableAccurately simulating the mechanical behavior of the marine riserDrilling rodsWeather/light/corrosion resistanceDeepwater drillingDynamometer

The present invention discloses a deepwater drilling condition based marine riser mechanical behavior test simulation system. An upper three-component dynamometer, an tipper connecting structure, a marine riser, a lower connecting structure and a lower three-component dynamometer are connected between an upper trailer connecting plate and a lower trailer connecting plate in sequence. The invention further discloses a test method. The present invention has the advantages that the mechanical behavior of the marine riser under deepwater drilling condition and marine environment coupling effect can be simulated comprehensively and accurately, and the apparatus can simulate ocean current environment, apply top tension to the marine riser, simulate circulation of internal drilling fluids at different current rates, simulate rotation of the drill stem at different rotational speeds and apply different drill pressures.

Owner:SOUTHWEST PETROLEUM UNIV

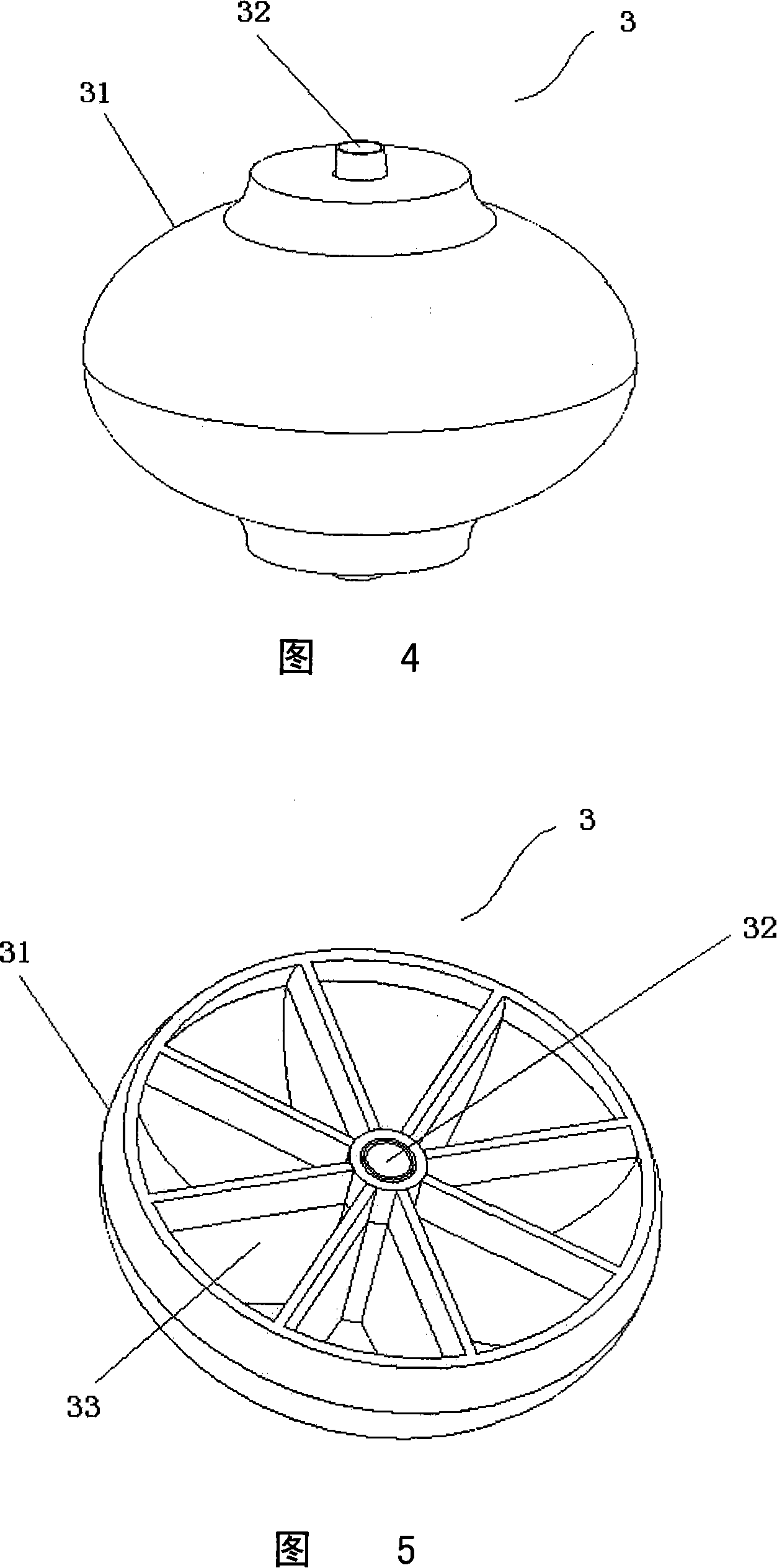

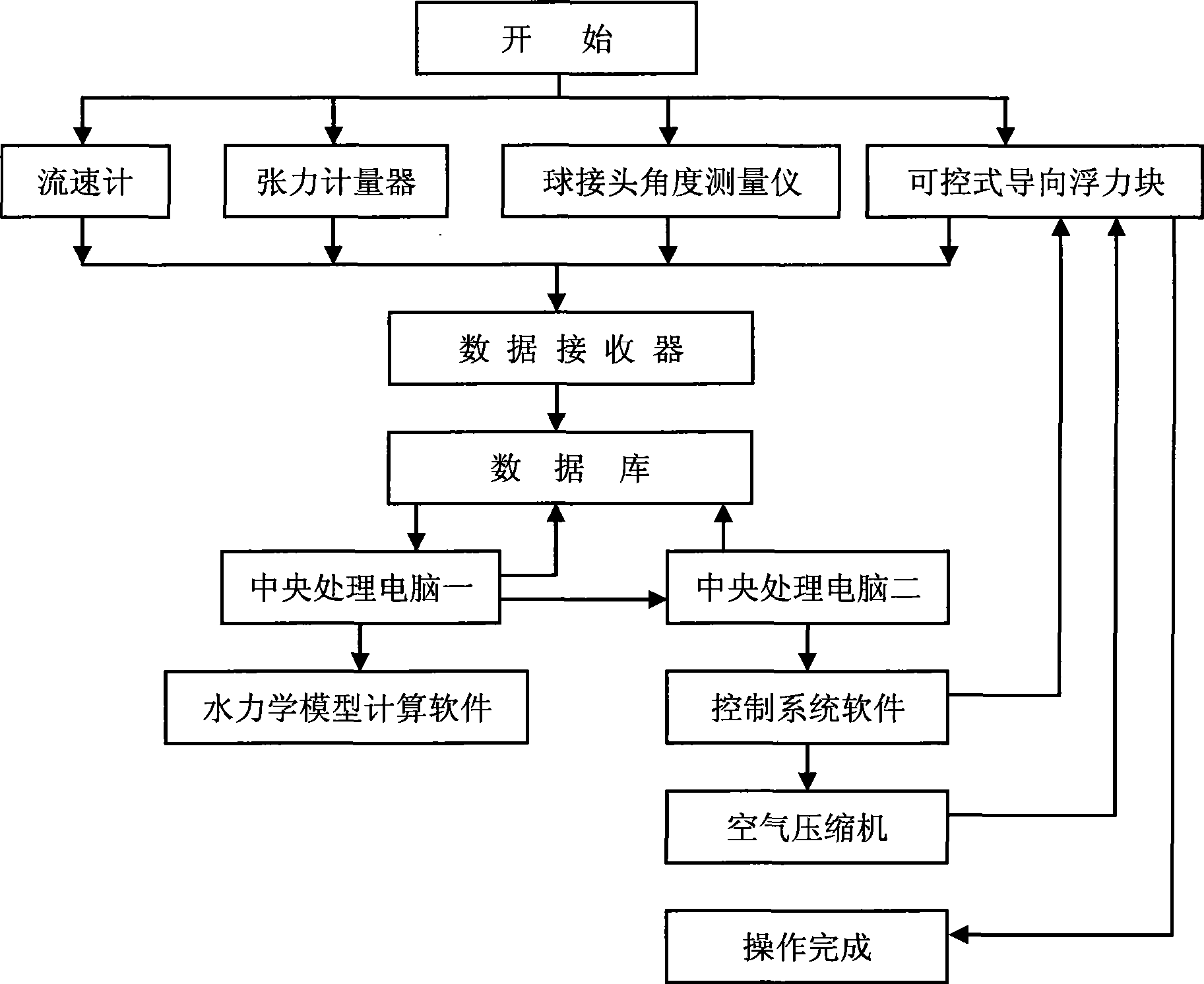

Deep water riser buoyance block closed-loop control system

InactiveCN101509379AReduce agitationReduces eddy current induced vibrationMineral miningAutomatic control for drillingLoop controlMechanical models

The invention relates to a set of buoyancy block closed loop control system applied to a deepwater marine riser, belonging to a specialized control system applied in the field of oceanic deepwater drilling engineering, aiming at providing a set of buoyancy block closed loop control system which can strengthen mechanical properties of the marine riser such as bending deflection resistance and fatigue failure resistance and improve safety and operation efficiency of deepwater drilling operation. In the control system of the invention, a data receiver is connected with a current meter, at least 3 tensiometers, a group of controllable guidance buoyancy blocks and two ball joint angular measuring meters; a database interacts with a central processing computer 1, a mechanical model calculation software, a central processing computer 2 and a control system software; the control system software is connected with an air compressor and the controllable guidance buoyancy blocks, the key component of the control system is a novel streamline controllable guidance buoyancy block. The key point of the technical proposal of the invention is: in accordance with actual calculating data of marine environment load, dynamic control of the operation conditions of marine riser system is realized by using the system software to control the buoyancy provided by the controllable guidance buoyancy blocks.

Owner:SOUTHWEST PETROLEUM UNIV

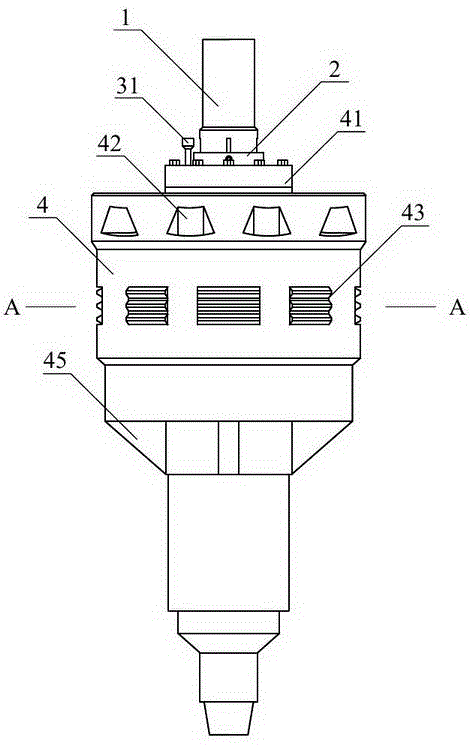

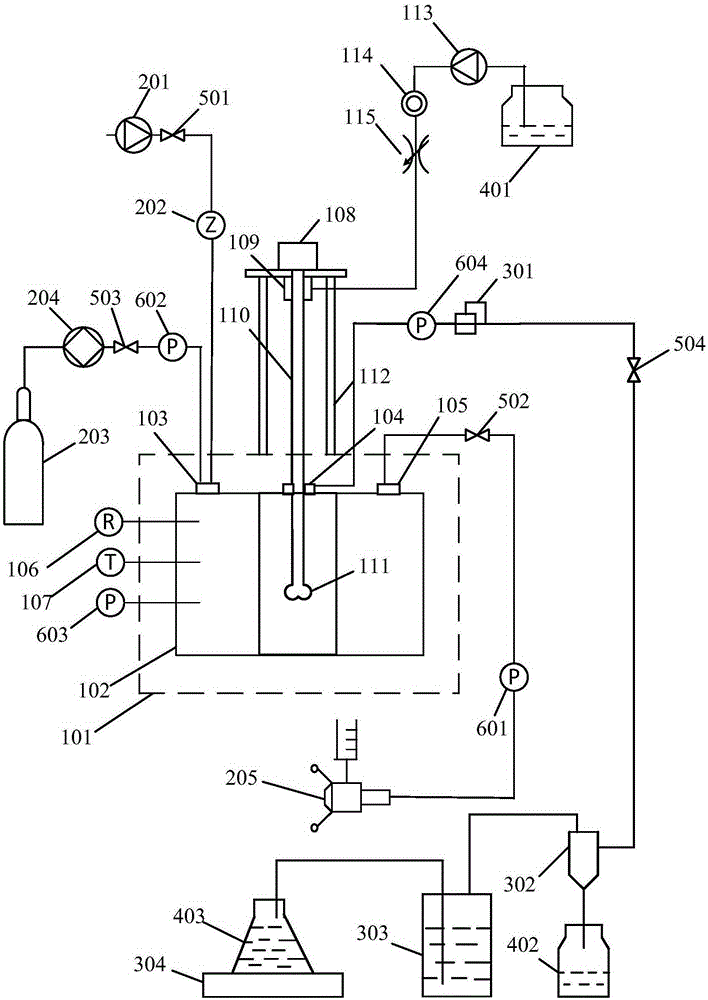

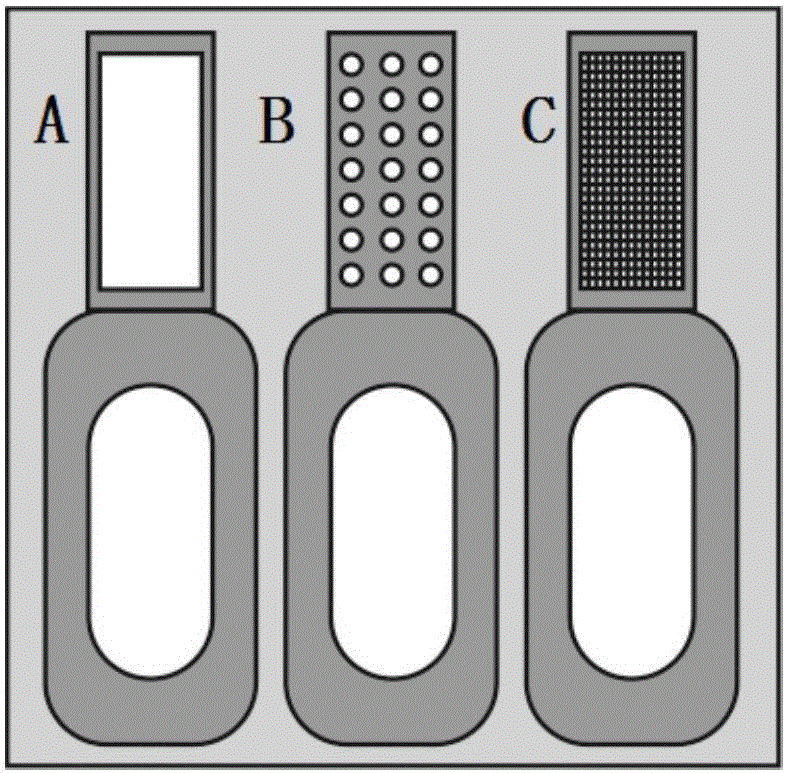

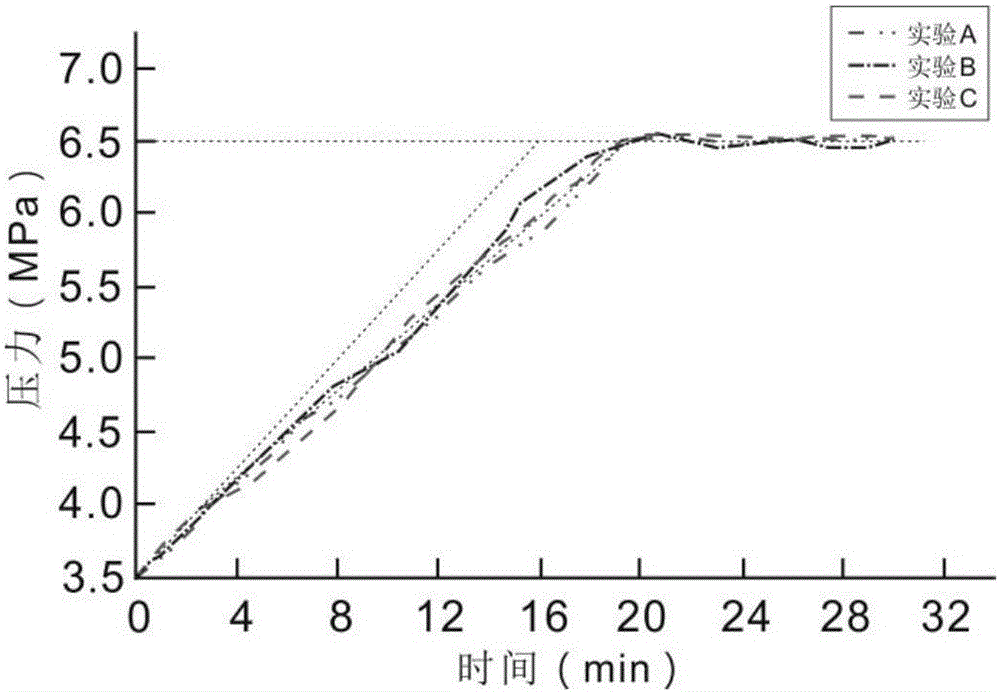

Experimental device and method for evaluating formation and aggregation behavior of hydrate in deepwater drilling

ActiveCN106814166AInhibition formationInhibit aggregation behaviorMaterial analysisDecompositionData acquisition

The invention discloses an experimental device and method for evaluating formation and aggregation behaviors of hydrate in deepwater drilling. The experimental method comprises a high-pressure reaction kettle, a high / low-temperature incubator, a gas control system, a return pressure unloading system and a data acquisition system, wherein a middle barrier and a side barrier are arranged in the inner cavity of the high-temperature reaction kettle; a fluid flowing channel is formed in one side of the side barrier; an air inlet and an air outlet are formed in the top of the high-pressure reaction kettle; a lower air inlet is formed in the bottom of the high-pressure reaction kettle; both the upper air inlet and the lower air inlet are connected with the gas control system; the air outlet is connected with the return pressure unloading system. The experimental device aims at drilling fluid systems of natural gas hydrate stratum drilling, frozen earth drilling and ocean drilling, the process that decomposition gases or shallow gases of hydrate in drillings or stratums enter shaft annuluses to form hydrate can be simulated, and furthermore the influence of annulus circulation channels upon formation and aggregation behaviors of the hydrate and the capability of drilling fluid upon the formation and aggregation behaviors of the hydrate can be evaluated and simulated.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Deepwater drilling fluid

ActiveCN104559969AAvoid damageEnhanced inhibitory effectDrilling compositionSlurrySODIUM DODECYL BENZENE SULFONATE

The invention discloses a deepwater drilling fluid. Every 1L of base slurry is composed of 1g of xanthan gum XC, 10-20g of sodium carboxymethyl cellulose, 20-30g of sulfonated phenol formaldehyde resin SMP-2, 30-50g of sodium silicate, 10g of polyvinylpyrrolidone PVP-K90, 15g of high modified asphalt KAHM, 50-100g of sodium chloride, 0.5g of sodium dodecyl benzene sulfonate, 0.5-1g of graphite and 0.2-0.5g of polyformaldehyde. The drilling fluid has the advantages of stable properties under cold conditions, favorable rheological behavior, high debris carrying capacity, excellent mud shale hydration expansion inhibition capacity, excellent hydrate generation inhibition capacity, low economic cost and small environmental pollution, and is especially suitable for deepwater drilling.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

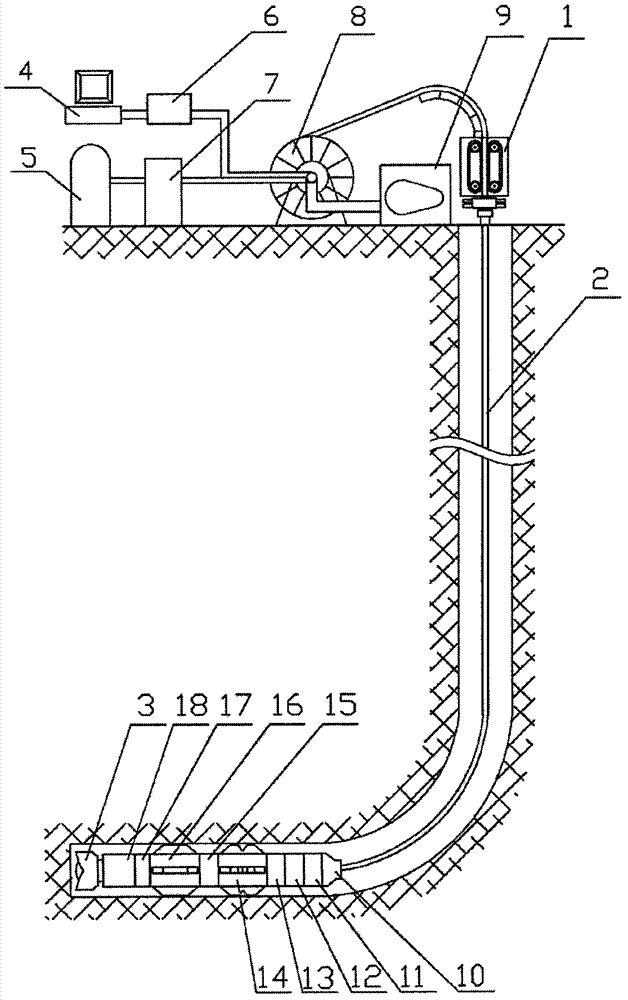

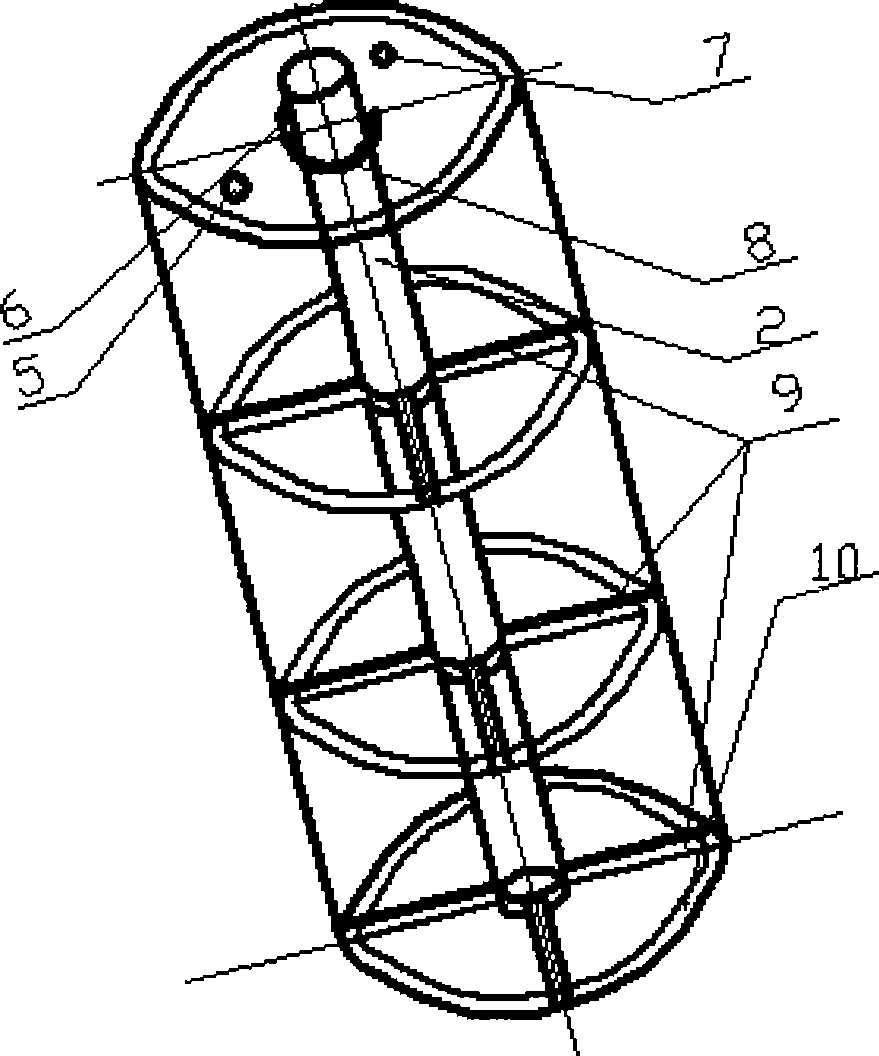

Deepwater drilling sand sampling robot

ActiveCN106368693AGood applicability in underwater environmentEasy to measure in situDrill bitsConstructionsHydraulic motorDeepwater drilling

The invention provides a deepwater drilling and sampling robot. The deepwater drilling and sampling robot comprises a front drilling unit, a rear drilling unit, a hydraulic telescopic device and a sample detecting unit. The front drilling unit comprises a first hydraulic motor, a front tool rest, fixed drill bits and variable drill bits, and is used for drilling and coring. The rear drilling unit comprises reaming bits, a rear tool rest and a second hydraulic motor, and is used for conducting reaming operation to clear roadblocks away through the reaming bits when the deepwater drilling and sampling robot returns. The hydraulic telescopic device is used for controlling the variable drill bits to expand and contract so as to achieve integration of drilling and coring. The sample detecting unit is used for analyzing and treating samples obtained, and sending experimental data back in real time. Compared with the prior art, integration of the drilling function and the coring function is achieved through expanding and contracting of the variable drill bits, the coring size is accurately controlled accordingly, a sea surface drilling platform is not needed, and the cost and time are reduced.

Owner:NINGBO JIELIANG ROBOT TECH CO LTD

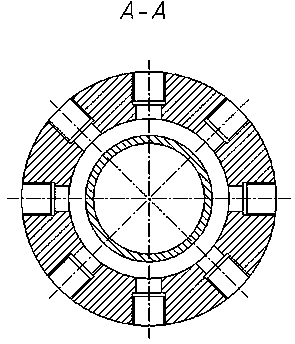

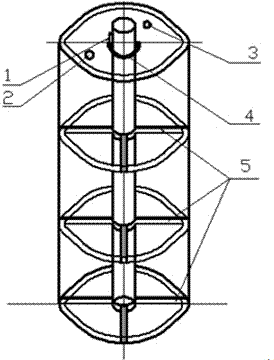

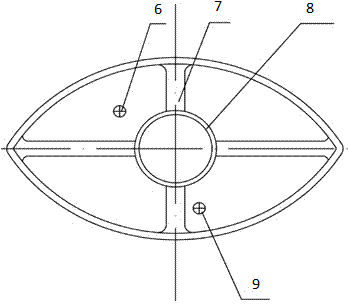

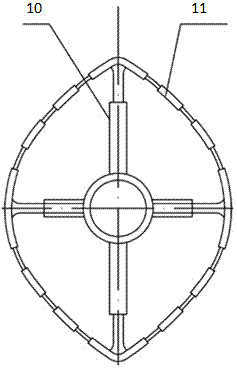

Offshore drilling controllable buoyant block

InactiveCN103883269AReduce shock loadReduce inputDrilling rodsDrilling casingsWell drillingMarine engineering

The invention discloses an offshore drilling controllable buoyant block with a guide ring, and belongs to buoyant blocks special for ocean deepwater drilling engineering. The offshore drilling controllable buoyant block is suitable for the complex environment of on-sea oil and gas exploitation. According to the offshore drilling controllable buoyant block, energy input to a marine riser by water flow can be reduced, water flow stirring and eddy vibration can be reduced, ocean current and sea wave impact loads borne by the marine riser are minimum, and variable buoyancy can be further provided for the marine riser. The offshore drilling controllable buoyant block is composed of a deflection spring, an air inlet valve, an air outlet valve, the guiding ring, stretchable supporting rings and an outer cavity, and the core parts of the offshore drilling controllable buoyant block are the stretchable supporting rings composed of stretchable chains and stretchable arms. The state of the offshore drilling controllable buoyant block can be adjusted by the guiding ring at the top according to the water flow direction to enable the water passing face and the water facing face of the offshore drilling controllable buoyant block to be minimum. In addition, when the offshore drilling controllable buoyant block suffers severe sea conditions, control software used in a mated mode computes real-time loads borne by the marine riser and the offshore drilling controllable buoyant block and sends a command to a compressor after data are processed, a proper amount of air is inflated into or discharged out from the offshore drilling controllable buoyant block through the compressor, and the function of providing the variable buoyancy for the marine riser is achieved.

Owner:SOUTHWEST PETROLEUM UNIV

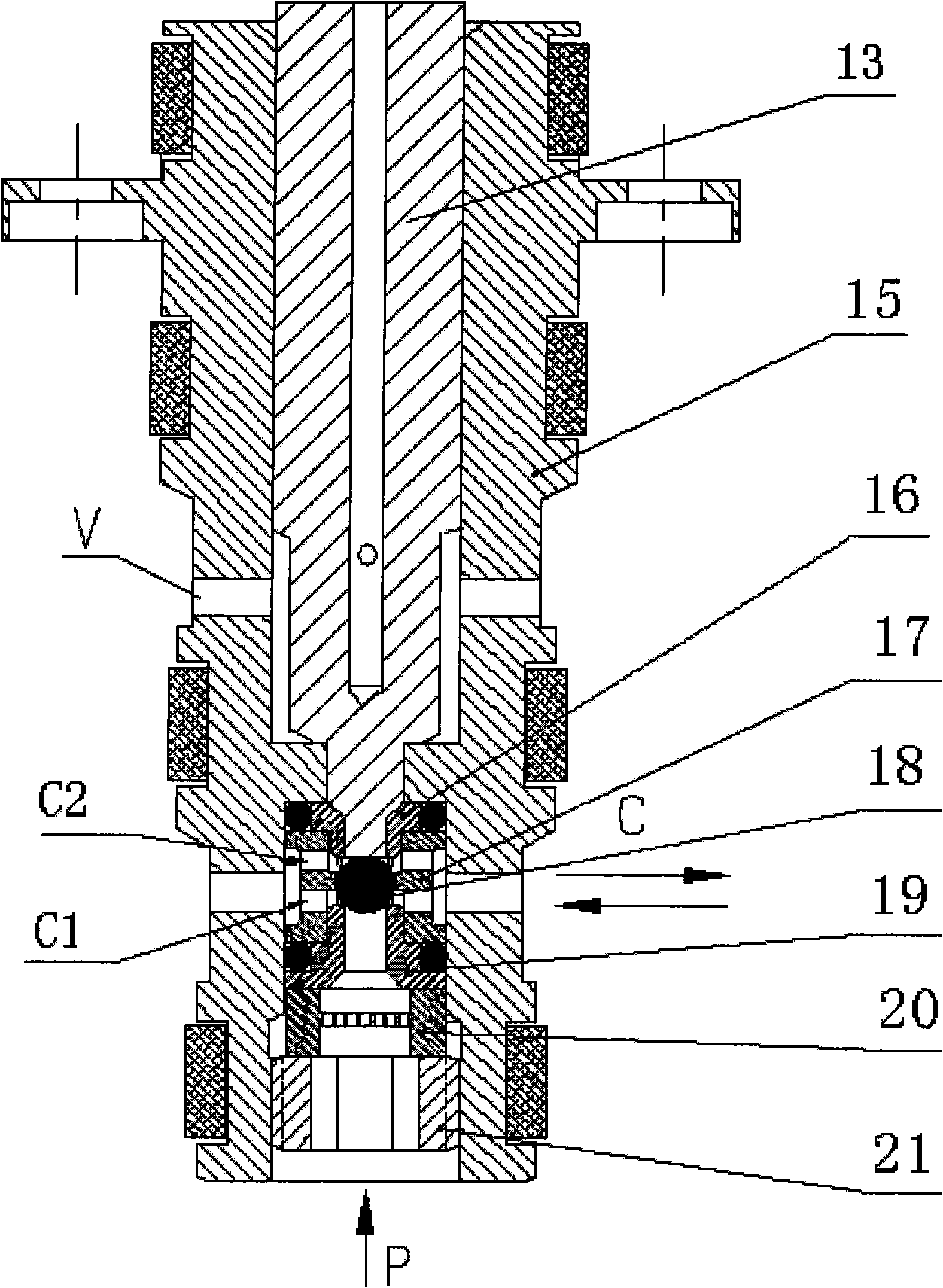

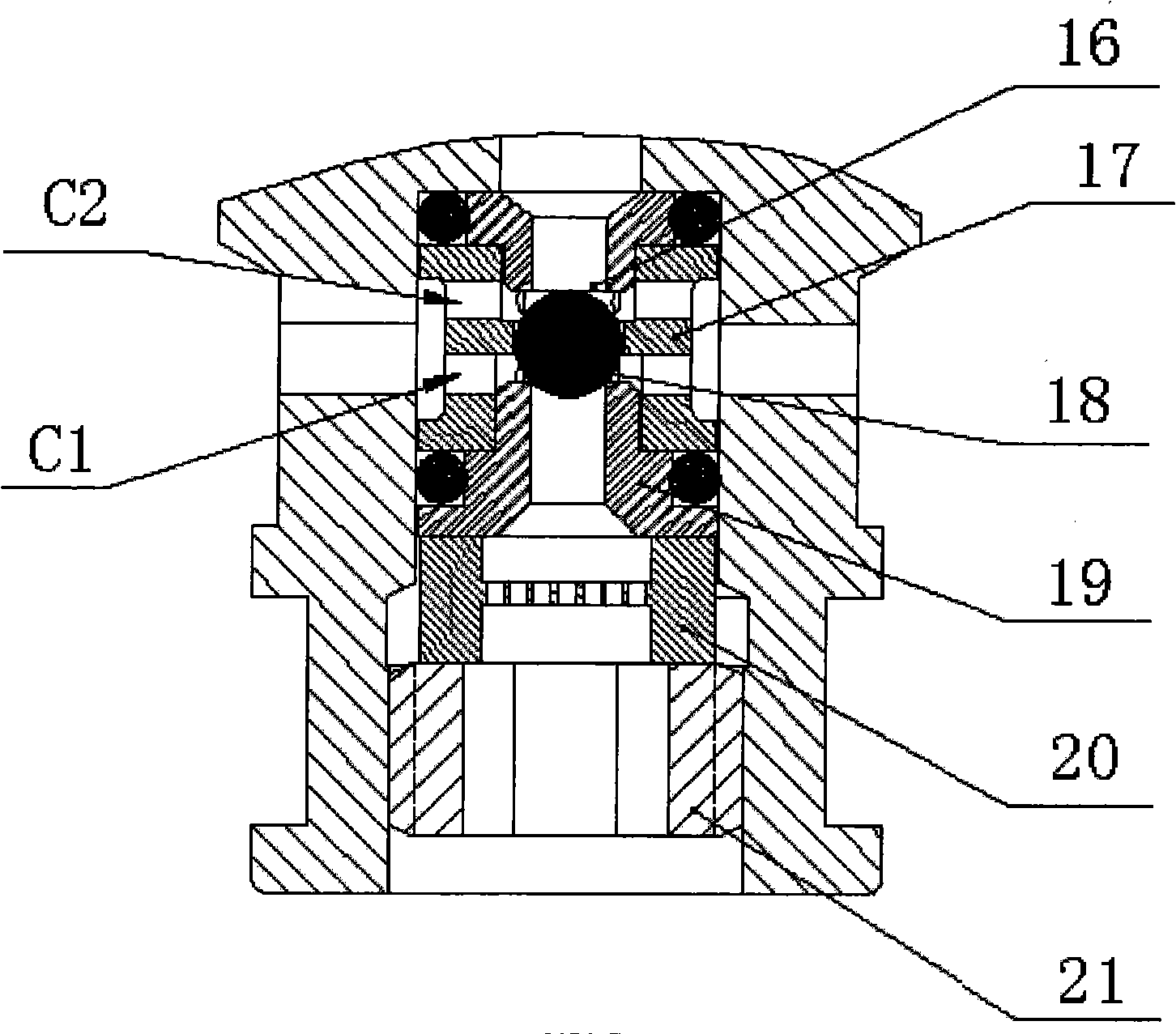

Underwater electrohydraulic control valve

ActiveCN101324179AMeet the requirements of quick responseMeet the requirements of the occasionOperating means/releasing devices for valvesWell/borehole valve arrangementsDeepwater drillingMagnetic valve

The invention relates to an underwater electro-hydraulic control valve which is applied on a well control device used for deepwater drilling construction. A magnetic valve consists of an electromagnetic part and an oil pressure end. A spring sleeve and an iron core sleeve are arranged in the interior of a shell, sealing rings are arranged between the outer wall of the spring sleeve and the inner wall of the shell and between the outer wall of the iron core sleeve and the inner wall of the shell. A mandril is arranged at the lower part of the cylindrical iron core. When a magnetic coil generates magnetic force, the iron core and the mandril move. The oil-pressure end is fixed in the central hole of a pressing cover; the mandril is arranged at the upper part of the central hole of the valve body and a ball valve is arranged at the lower part of the central hole of the valve body. The control valve has the effect that: the valve can be used for controlling fluid with high pressure and small flow and is suitable for working in severe deepwater environment. The control valve meets the requirement of fast responsiveness, can work normally in a high pressure guiding fluid system simultaneously, and has iron core and mandril lubricating function, with simple structure, compactness, reliable sealing performance and fast response speed.

Owner:河北华北石油荣盛机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com