Patents

Literature

35 results about "Polyamine Inhibitor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

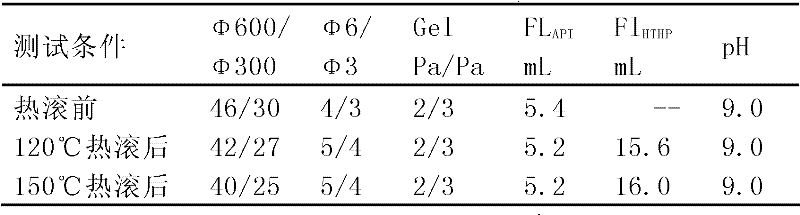

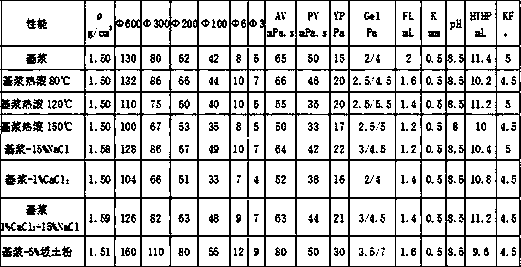

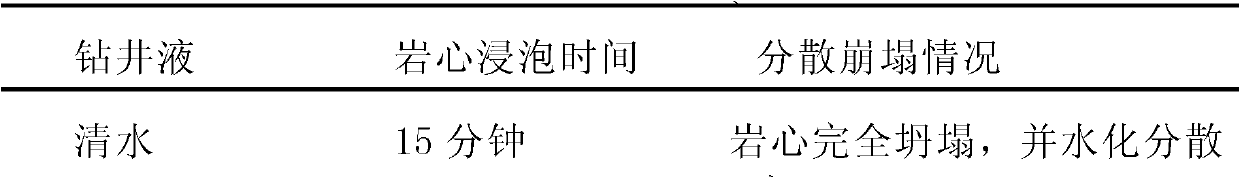

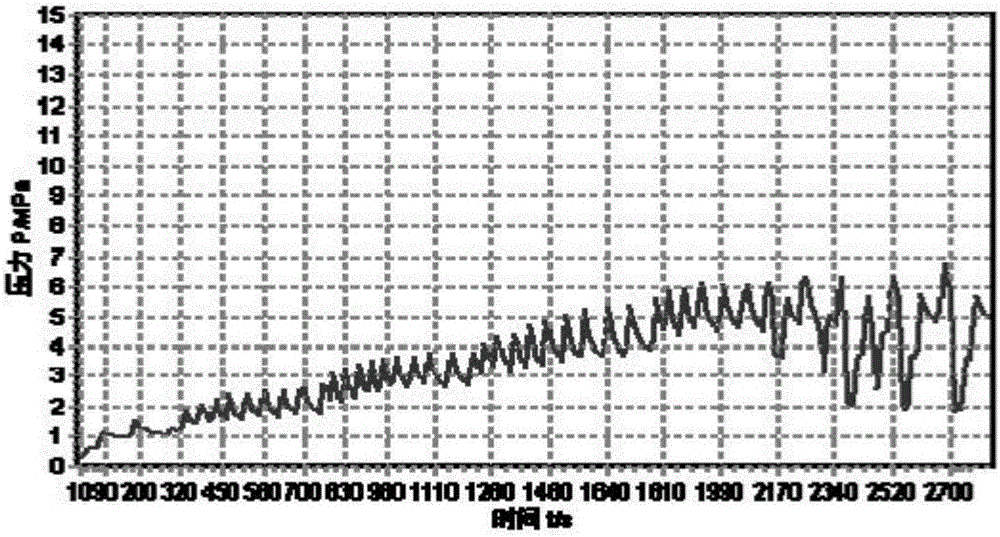

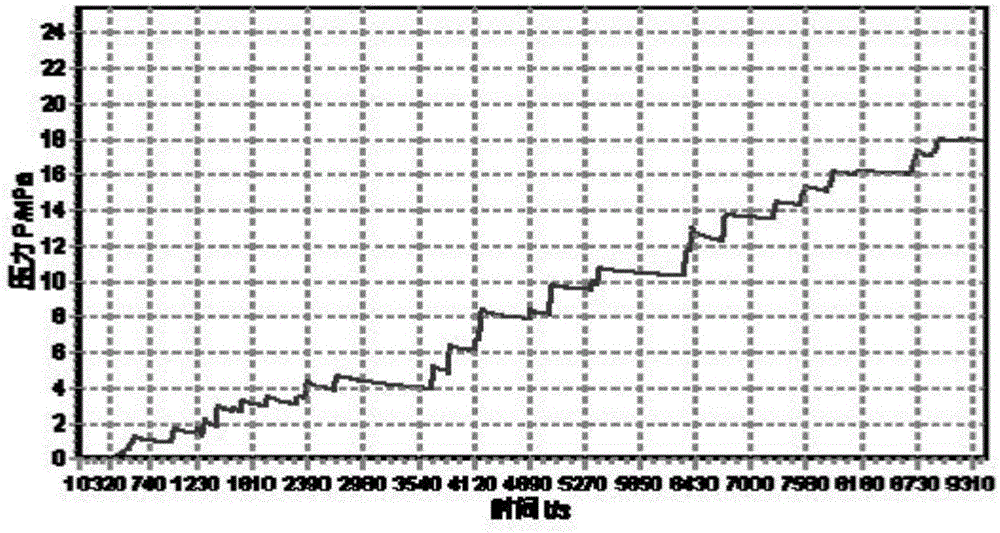

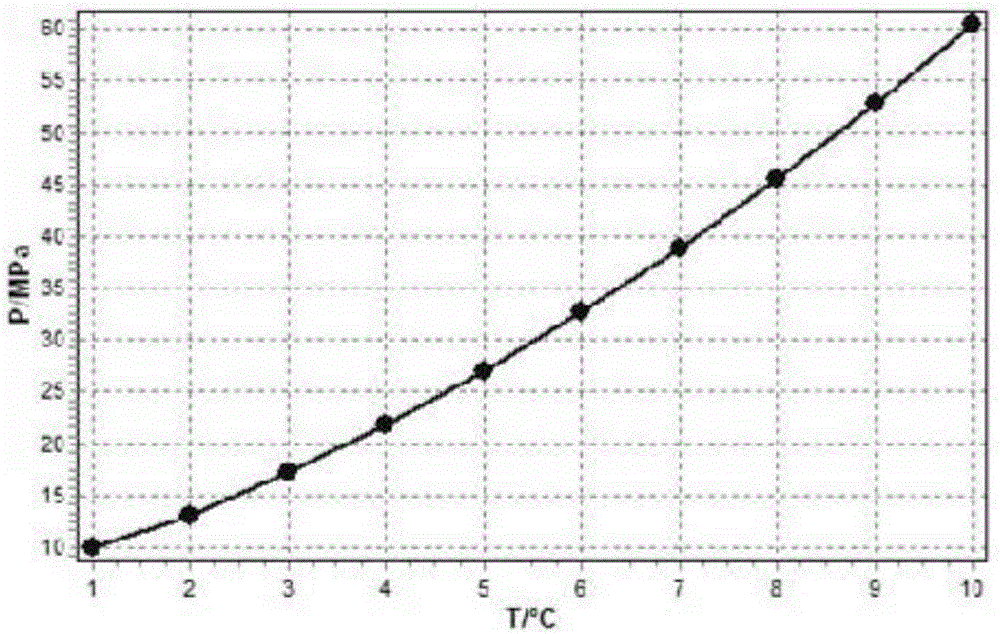

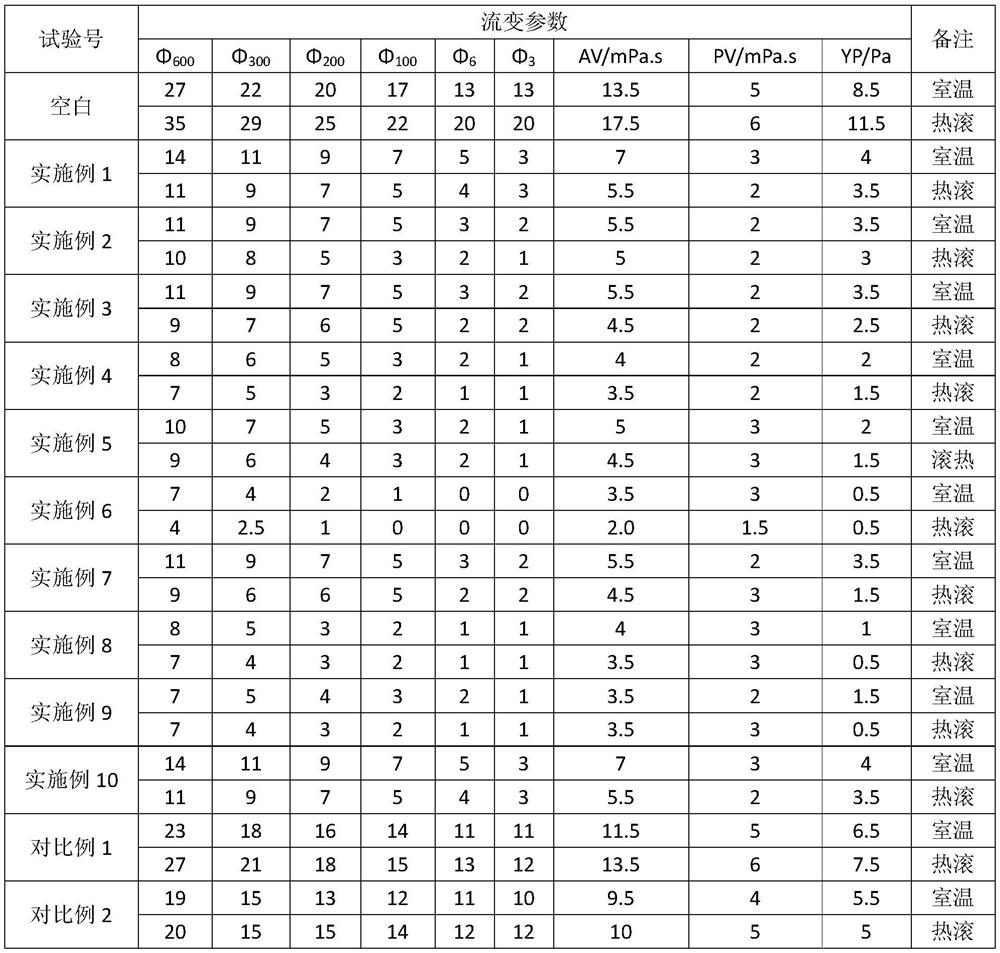

Strong-inhibition water-base drilling fluid

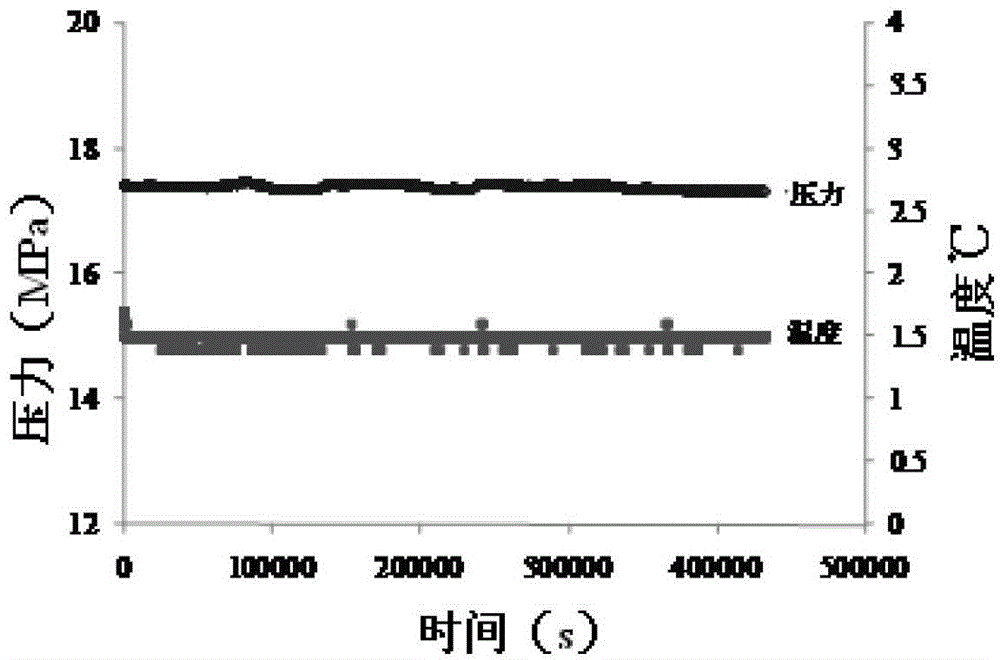

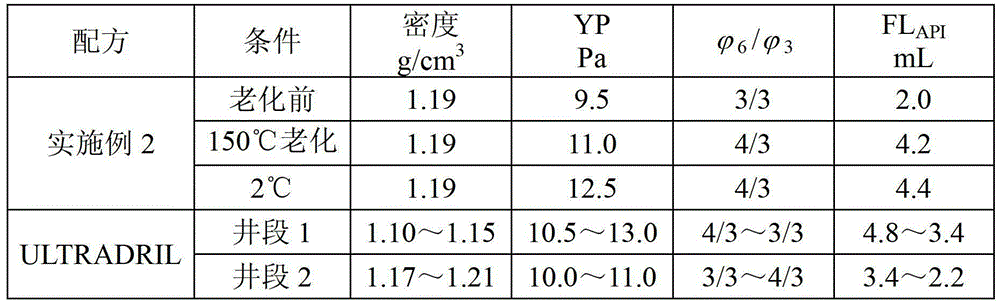

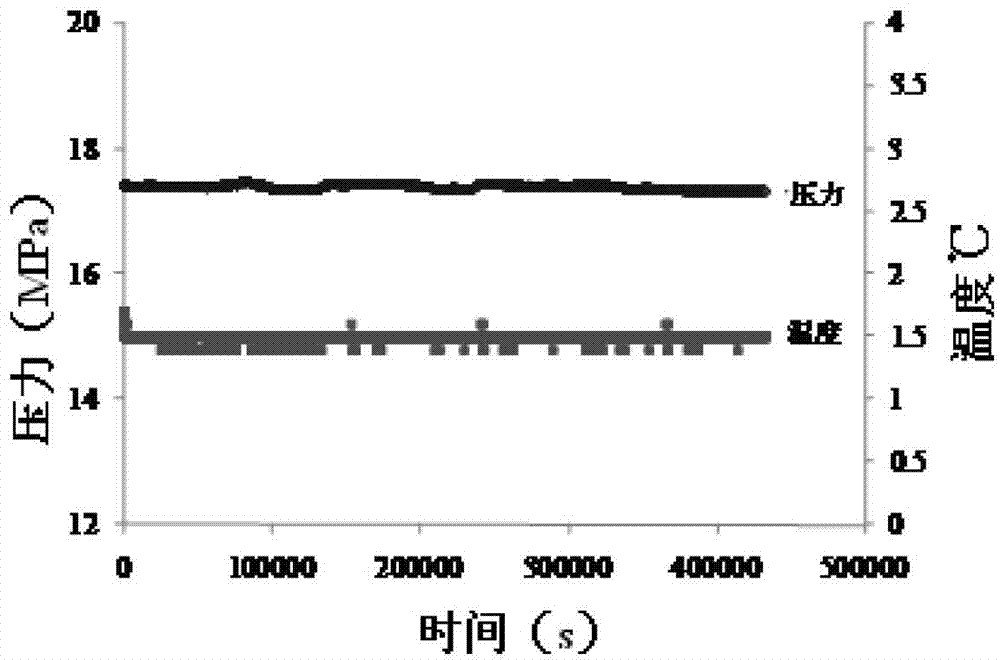

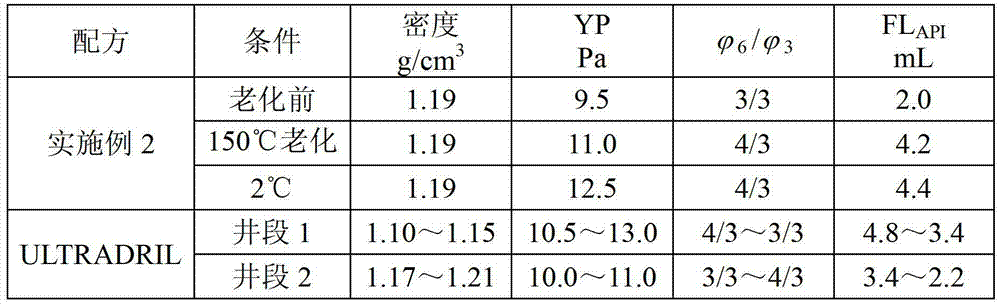

The invention discloses a strong-inhibition water-base drilling fluid which comprises the following components in parts by mass: 100 parts of water, 0.2-4 parts of polyamine inhibitor, 0.1-1 part of coating inhibitor, 10-25 parts of hydrate inhibitor, 0.1-1 part of tackifier, 0.5-5 parts of fluid loss agent and 0.5-3 parts of liquid lubricant. The polyamine inhibitor is an amino polymer polymerized from polyether diamine and epoxy alkane; and the mol ratio of the polyether diamine to the epoxy alkane is 1-10:1-20. The drilling fluid disclosed by the invention can effectively inhibit wellbore instability of deepwater shallow strata, and has equivalent inhibition capability to an oil-base drilling fluid. The drilling fluid disclosed by the invention can solve the problem of generation of hydrate in deepwater drilling, and is applicable to 3000m-deep drilling operation. The drilling fluid disclosed by the invention has favorable low temperature-high temperature stability, and is applicable to a deepwater large-temperature-difference environment (2-150 DEG C).

Owner:CHINA NAT OFFSHORE OIL CORP +1

Strong-inhibition water-base drilling fluid

The invention discloses a strong-inhibition water-base drilling fluid which comprises the following components in parts by mass: 100 parts of water, 0.2-4 parts of polyamine inhibitor, 0.1-1 part of coating inhibitor, 10-25 parts of hydrate inhibitor, 0.1-1 part of tackifier, 0.5-5 parts of fluid loss agent and 0.5-3 parts of liquid lubricant. The polyamine inhibitor is an amino polymer polymerized from polyether diamine and epoxy alkane; and the mol ratio of the polyether diamine to the epoxy alkane is 1-10:1-20. The drilling fluid disclosed by the invention can effectively inhibit wellbore instability of deepwater shallow strata, and has equivalent inhibition capability to an oil-base drilling fluid. The drilling fluid disclosed by the invention can solve the problem of generation of hydrate in deepwater drilling, and is applicable to 3000m-deep drilling operation. The drilling fluid disclosed by the invention has favorable low temperature-high temperature stability, and is applicable to a deepwater large-temperature-difference environment (2-150 DEG C).

Owner:CHINA NAT OFFSHORE OIL CORP +1

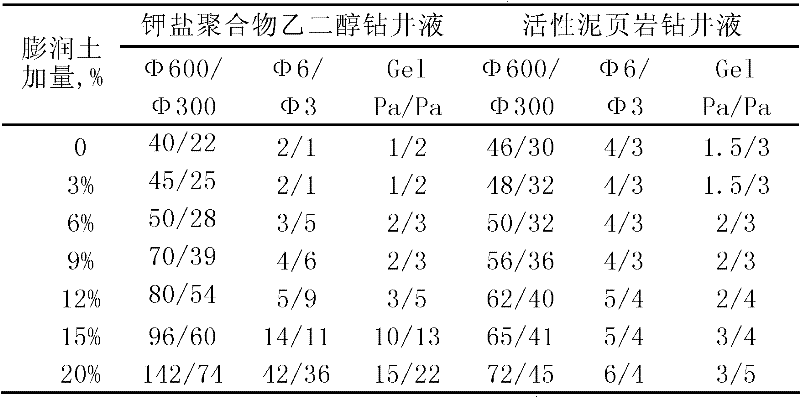

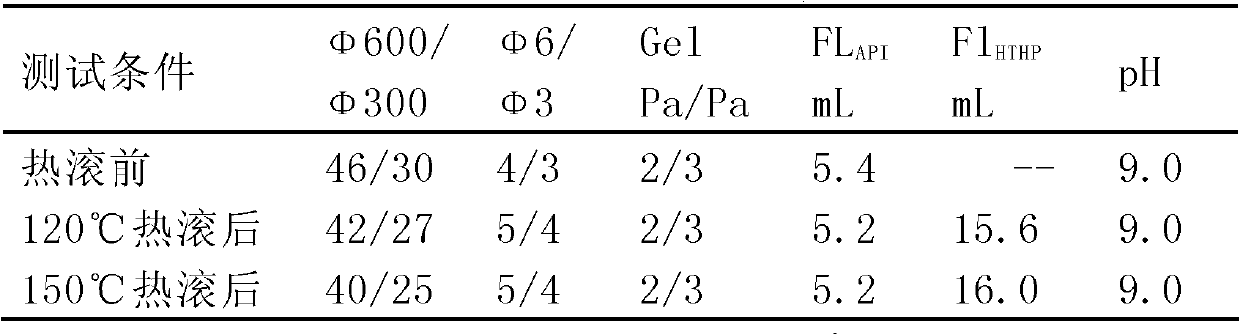

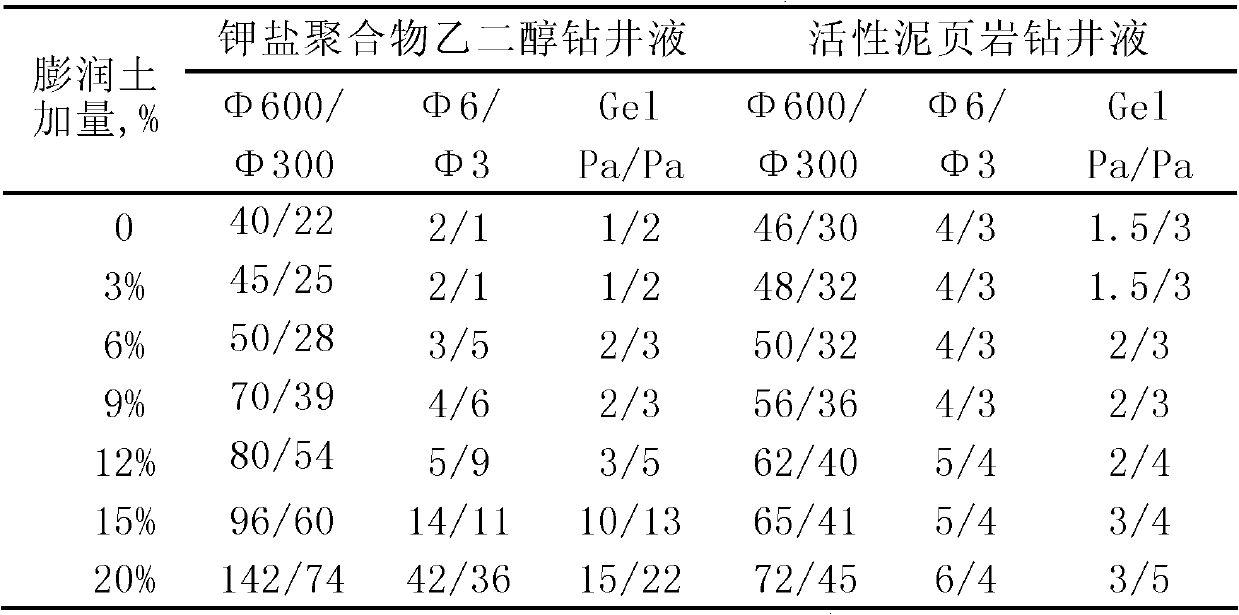

Drilling fluid used for active mud shale drilling

The invention relates to a drilling fluid used for active mud shale drilling, and the drilling fluid is used in oilfield drilling. The drilling fluid comprises the following components in percentages by weight: 2-6% of bentonite, 0.2-0.5% of coated inhibitor, 0.2-1.0% of flow pattern regulator, 0.2-0.5% of high-temperature-resistant polymer filtrate reducer, 4-7% of potassium chloride, 1-3% of polymeric alcohol, 0.5-1.0% of polyamine inhibitor, 0.5-1.0% of anti-balling fast drilling agent and 45-85% of water. The drilling fluid has the inhibition property and lubricating property approximate to that of an oil-based drilling fluid, solves the problems that the mud making of the mud shale is severe, mud escapes from a vibrating screen, the viscous shearing of the drilling fluid increases and the rheological properties of the drilling fluid deteriorates during strong-mud-making active mud shale drilling, prevents destabilization of the active mud shale, dispersion of drill cuttings, balling of drill bit, and adhesion and coalescence of the mud shale, and increases the drilling speed of the active mud shale.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

KCl blocking and anti-sloughing drilling fluid and preparation method thereof

InactiveCN104277803AGood anti-collapseImprove the lubrication effectDrilling compositionReducerAsphalt

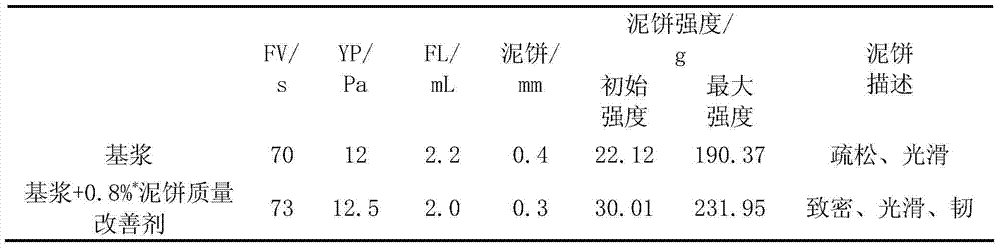

The invention discloses a drilling fluid prepared from the following components in percentage by mass: 3.2-3.5% of bentonite, 0.1-0.2% of Na2CO3, 0.3-0.5% of polymer encapsulating / inhibiting agent, 0.5% of polyamine inhibitor, 1.0-1.5% of compound ammonium salt, 3.0-3.5% of high-temperature-resistant filtrate loss reducer, 2.5-3.0% of salt-resistant filtrate loss reducer, 0.8-1.2% of mud cake quality improver, 4.0-5.0% of modified asphalt, 2.5-3.0% of efficient anti-sloughing agent, 3.0-3.5% of anti-sloughing lubricant, 0.3% of film forming and wall fixing agent, 2.0-2.5% of extreme pressure fluid lubricant, 0.2-0.3% of flow pattern regulator, 8.0-10.0% of KCl, 0.2-0.3% of NaOH and the balance of water. The invention also provides a preparation method of the drilling fluid. The drilling fluid has favorable anti-sloughing, lubricating, anti-blocking and wellbore cleaning abilities.

Owner:CNPC BOHAI DRILLING ENG

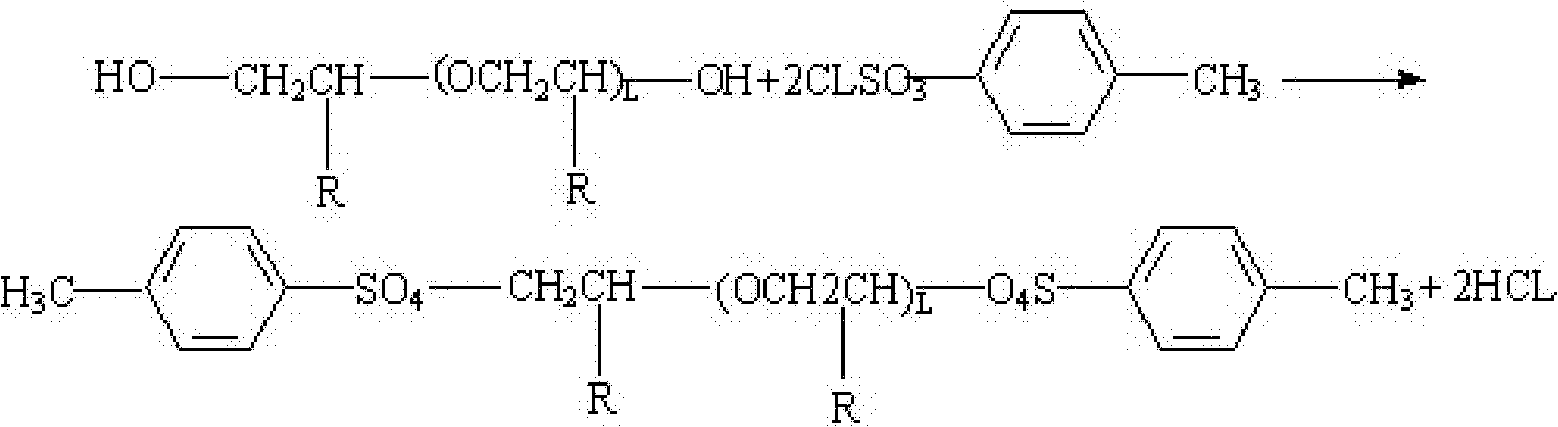

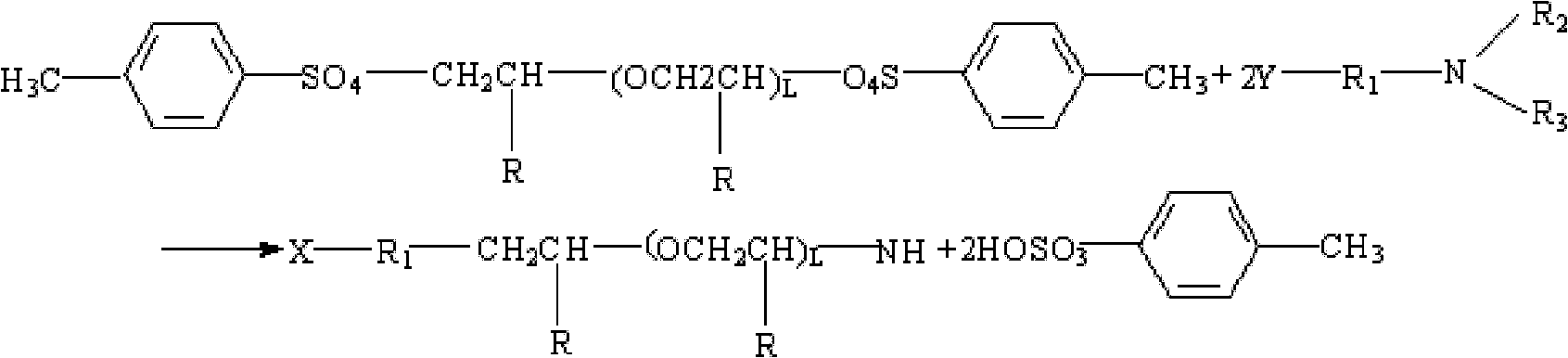

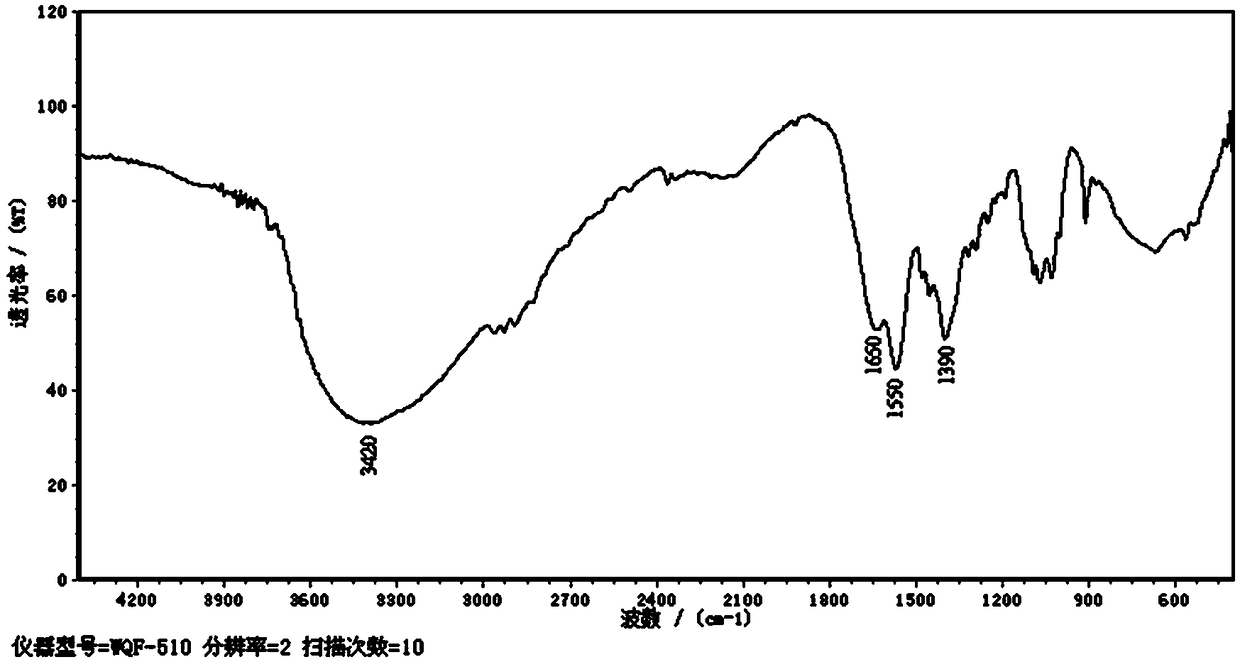

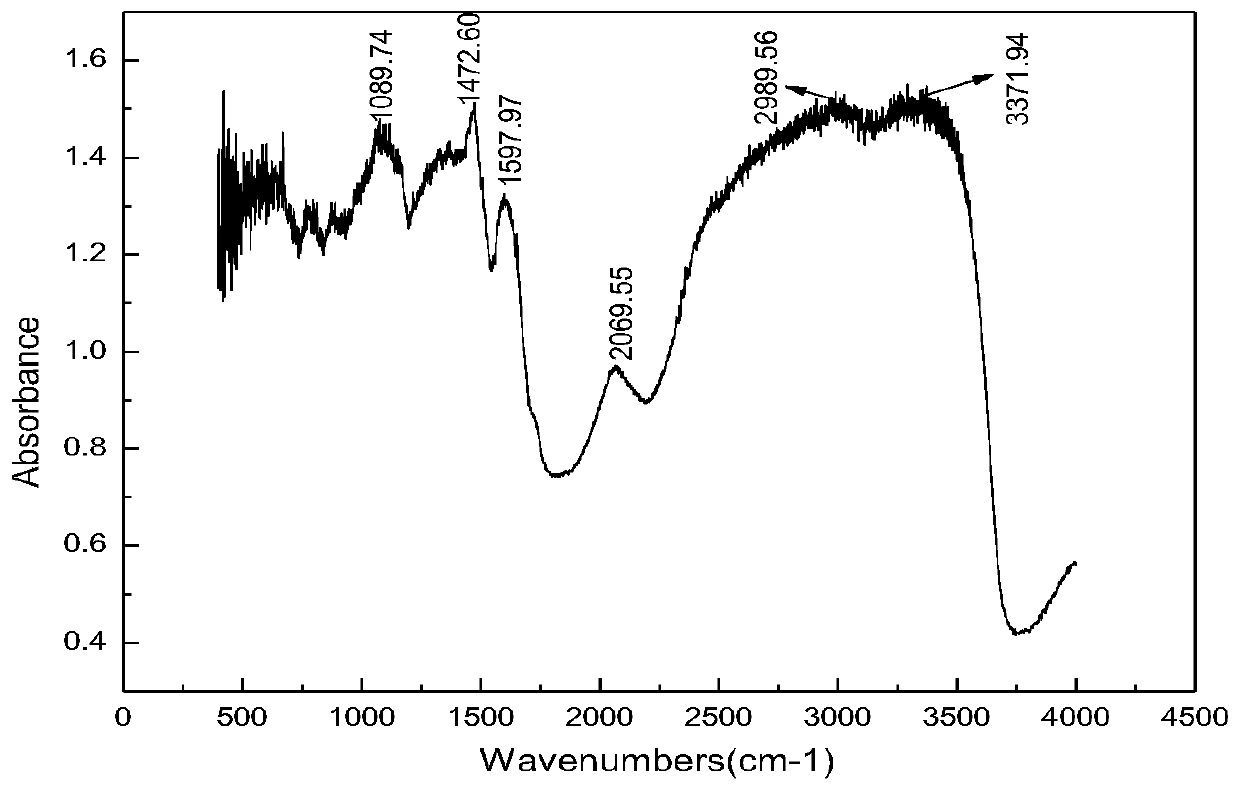

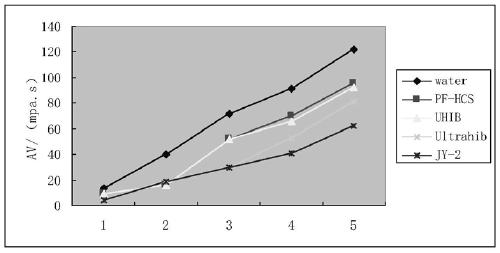

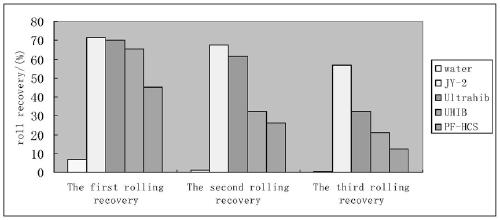

Polyamine inhibitor for drilling fluids and method for preparing polyamine inhibitor

InactiveCN102504065AImprove performancePrevent hydrationOrganic compound preparationDrilling compositionWater basedDistillation

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

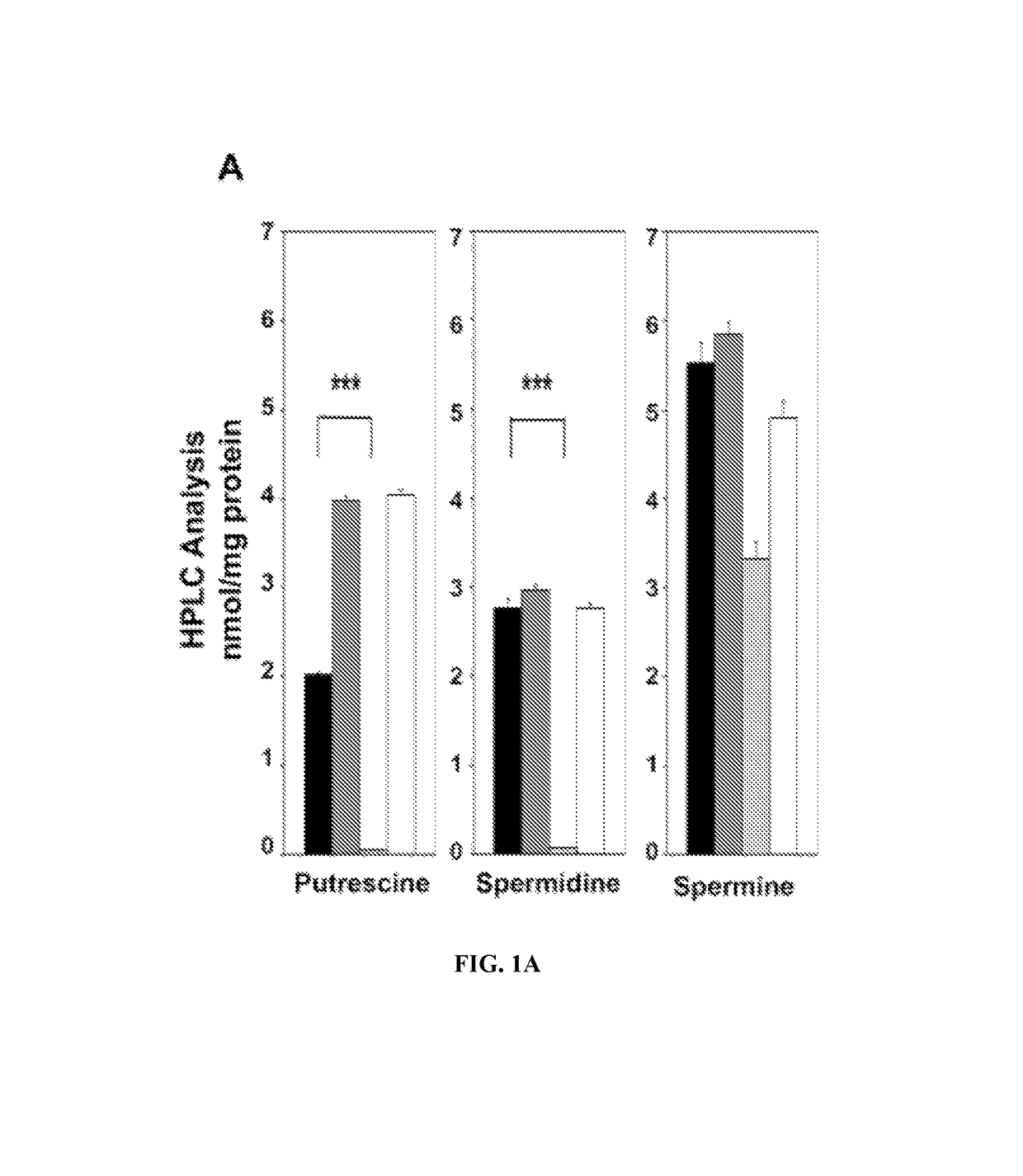

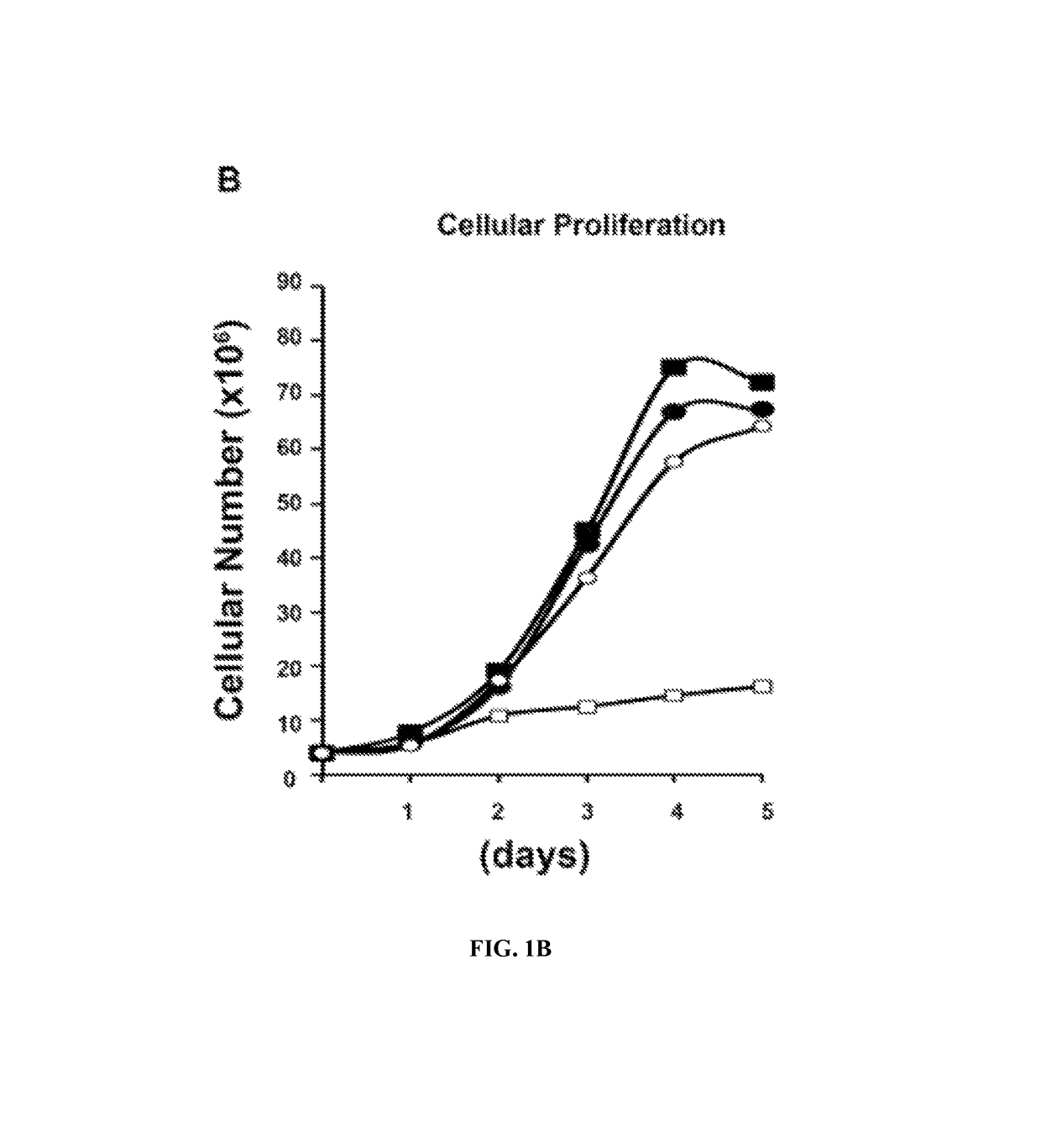

Cancer prevention and treatment methods based on dietary polyamine content

InactiveUS20130217743A1Reduce contentBiocidePeptide/protein ingredientsCancer preventionOrnithine decarboxylase antizyme

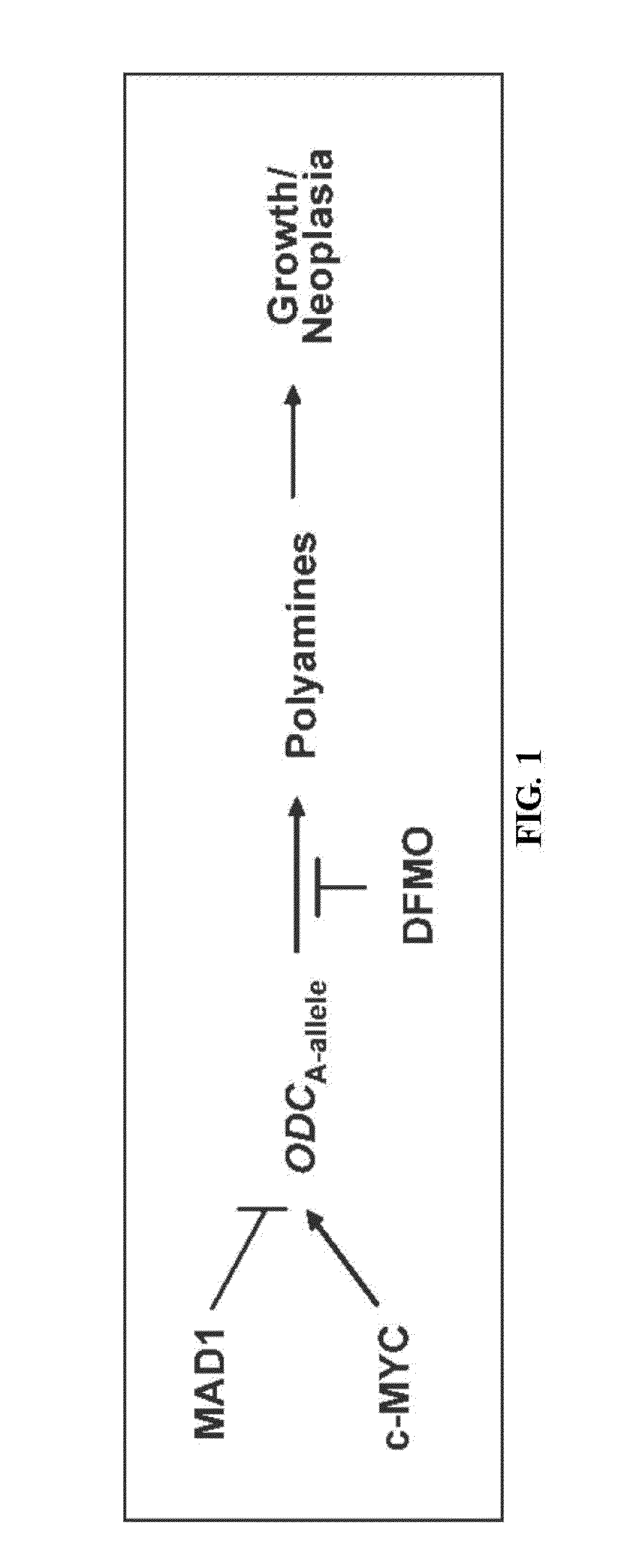

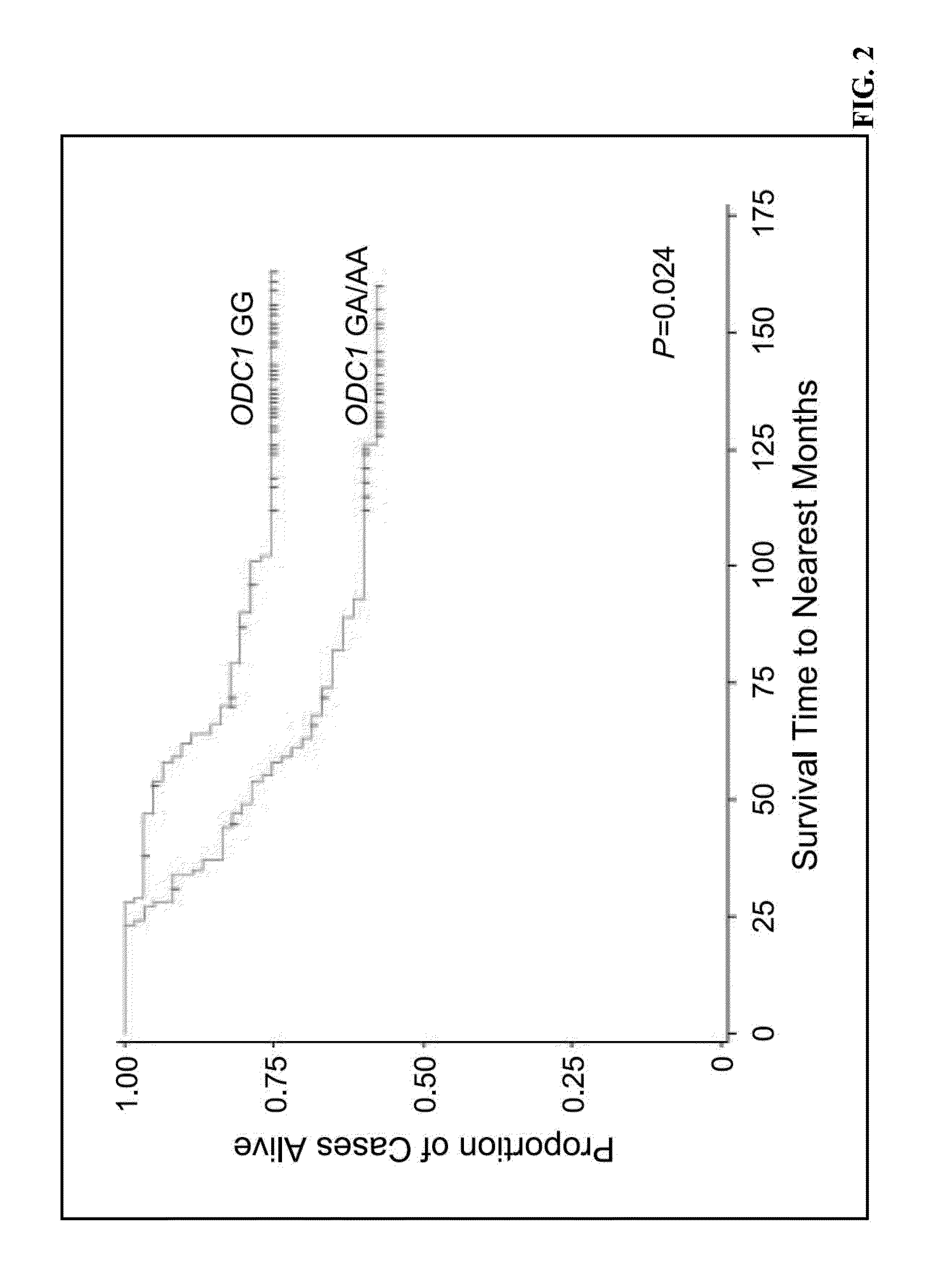

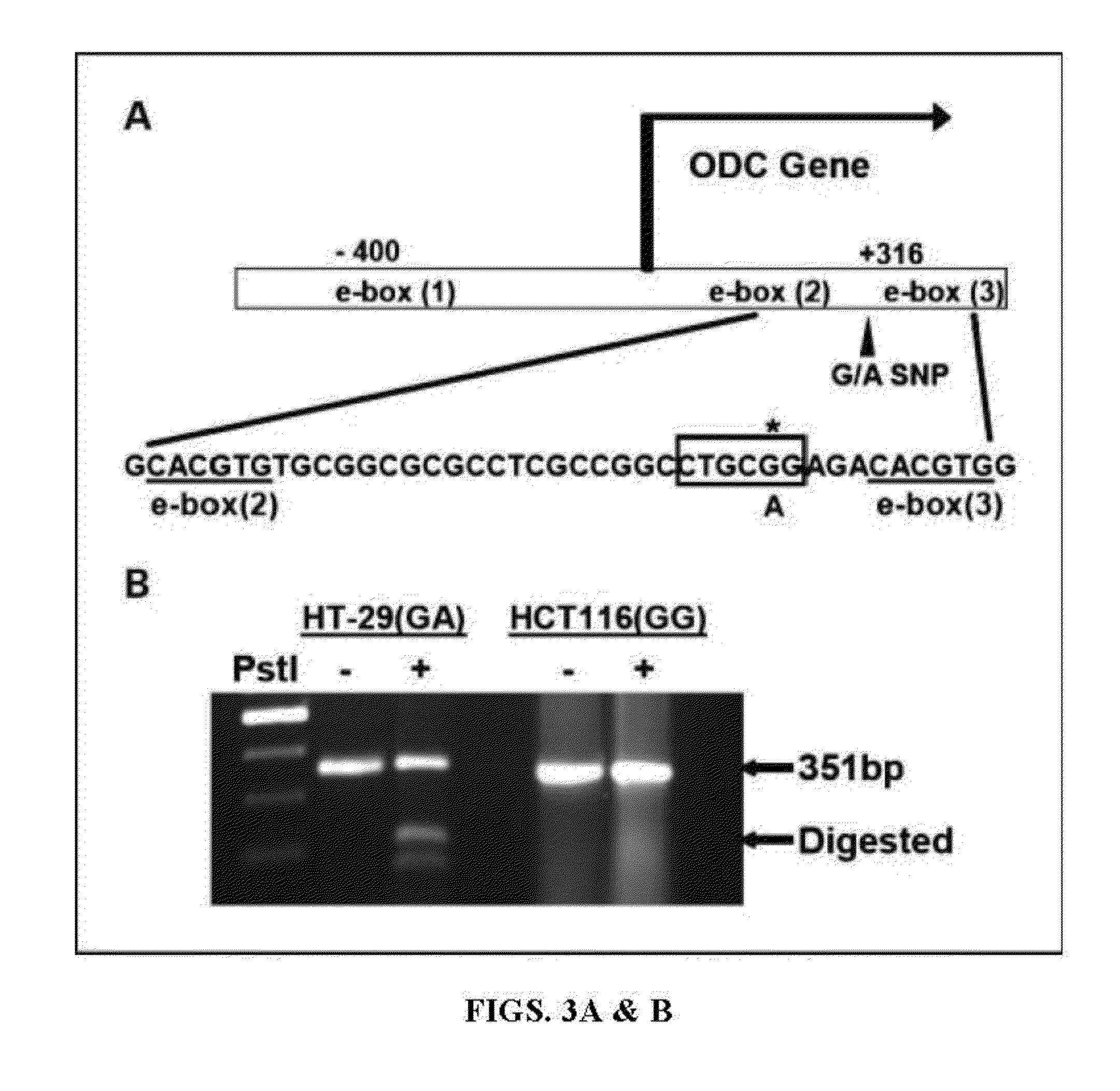

Controlling exogenous polyamines may be used, in some aspects, as an adjunctive strategy to chemoprevention with polyamine inhibitory agents, for example, anti-carcinoma combination therapies comprising ornithine decarboxylase (ODC) inhibitor and a spermidine / spermine N1-acetyltransferase expression agonist, optionally based on a patient's ODC1 promoter genotype. Assessing a tissue polyamine level or tissue polyamine flux may be used in some aspects, for predicting the efficacy of an anti-carcinoma combination therapy comprising, for example, an ornithine decarboxylase (ODC) inhibitor and an agent that modulates the polyamine pathway to reduce overall cellular polyamine content.

Owner:CANCER PREVENTION PHARMA +2

Environment-friendly type high-performance water-based drilling fluid and preparation method thereof

InactiveCN109321217AEnhanced inhibitory effectImprove the lubrication effectDrilling compositionWater basedCarboxymethyl cellulose

The invention provides environment-friendly type high-performance water-based drilling fluid and a preparation method thereof and belongs to the field of drilling fluid. The environment-friendly typehigh-performance water-based drilling fluid is mainly prepared from water and components based on the mass fraction of the water: 0 to 2 percent of bentonite slurry, 2 to 4 percent of a polyamine inhibitor, 12 to 17 percent of composite formate, 0.5 to 0.8 percent of a polymer strong coating agent, 1 to 2 percent of a polymer filtrate loss reducer, 0.5 to 0.8 percent of compound ammonium salt, 0.5to 0.8 percent of technical-grade low-viscosity carboxymethyl cellulose, 2 to 3 percent of low-fluorescence white asphalt, 0.3 to 0.5 percent of a biological polymer, 4 to 6 percent of a vegetable oil lubricant, 2 to 4 percent of light calcium carbonate, 1 to 2 percent of heavy calcium carbonate, 0.5 to 0.7 percent of potassium hydroxide and 50 to 120 percent of barite powder. The invention provides the environment-friendly type high-performance water-based drilling fluid which has an inhibitive property and a lubrication property comparable to oil-based drilling fluid, acceptable cost and high environmental friendliness, and can meet safe and rapid drilling requirements of a high-difficulty complex well as well as a large-displacement directional well and horizontal well, and the preparation method of the environment-friendly type high-performance water-based drilling fluid.

Owner:KARAMAY YOULIAN IND

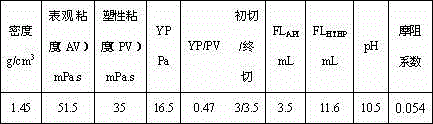

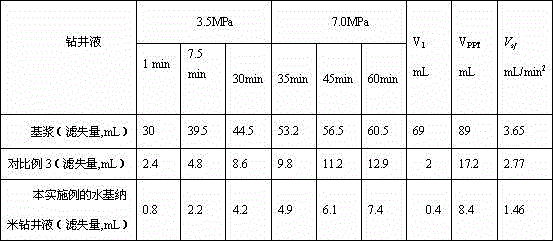

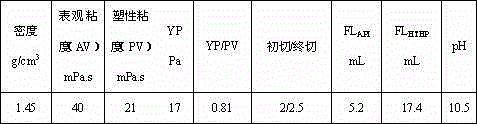

Water-based nano drilling fluid and preparation method thereof

InactiveCN104610943AEnhanced inhibitory effectStrong blocking abilityDrilling compositionWater basedSodium Bentonite

Owner:HILONG OIL SERVICE & ENG CO LTD

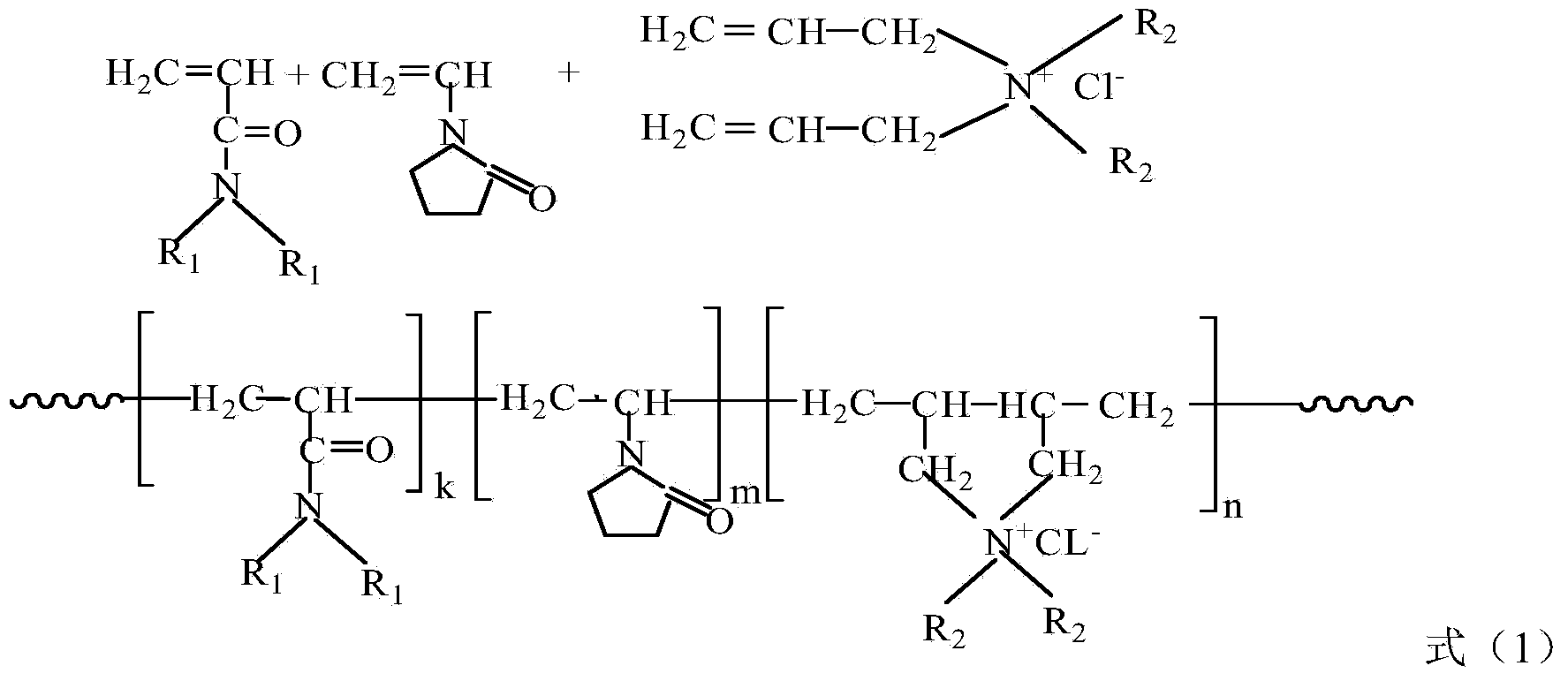

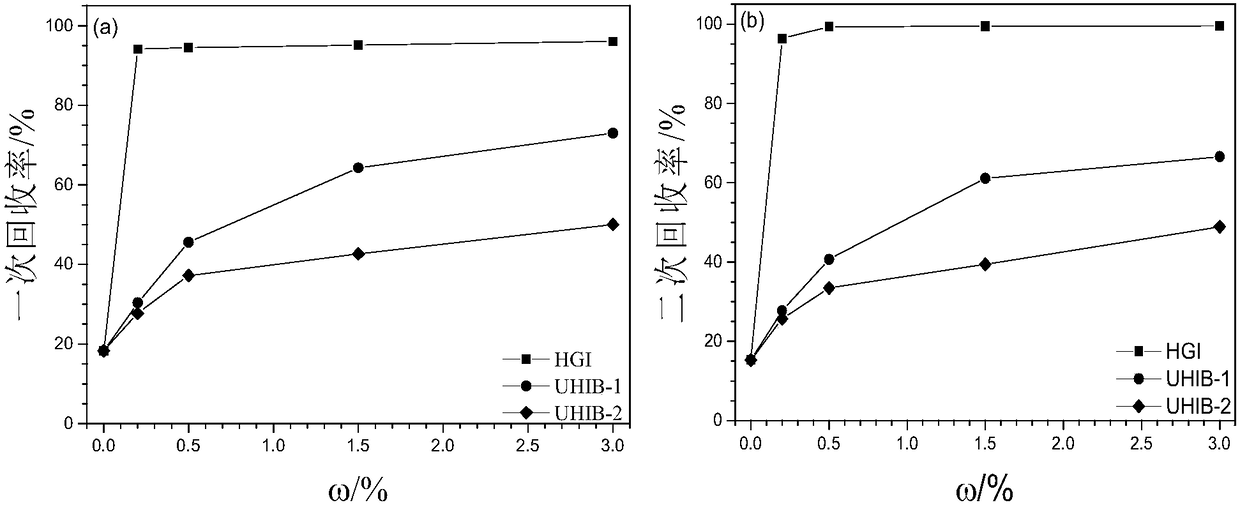

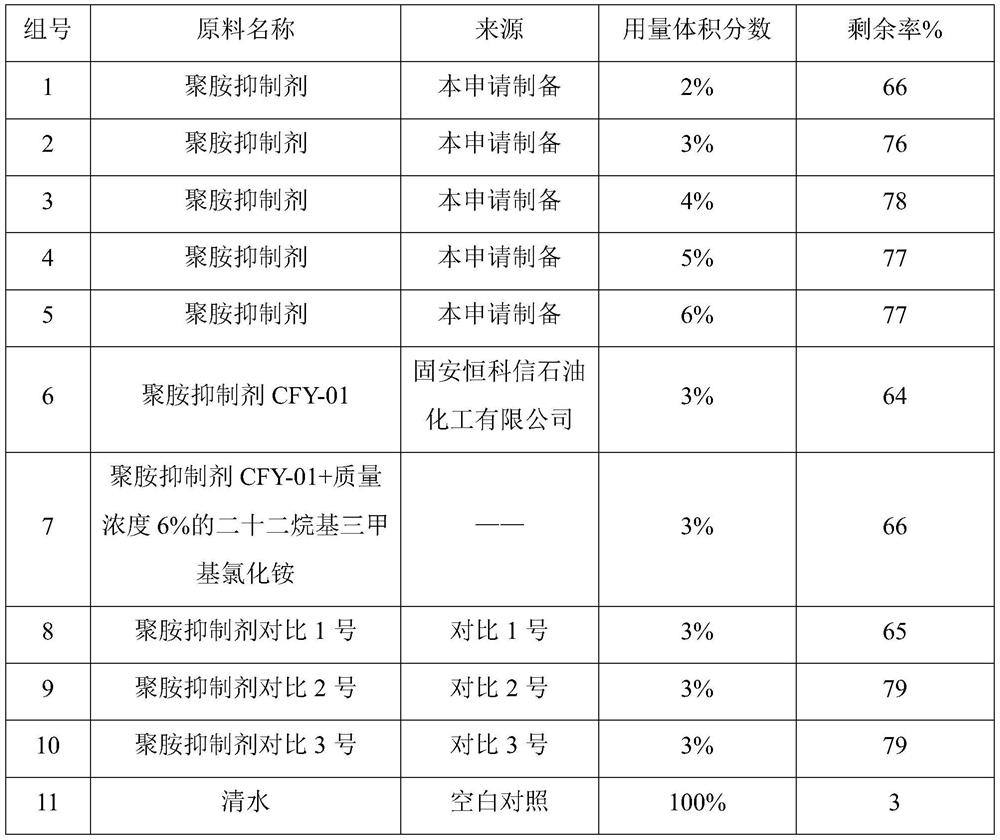

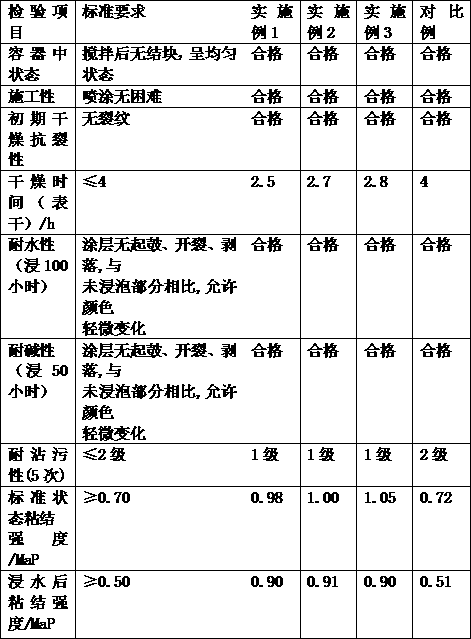

Polymer inhibitor for clay phase-free drilling fluid and preparation method thereof

ActiveCN104140490AInhibits hydration swellingMeet the needs of safe and fast drillingDrilling compositionIntrinsic viscosityHydrolysis

Belonging to the technical field of preparation methods for petroleum drilling oilfield chemistry macromolecular polymers, the invention discloses a polymer inhibitor for clay phase-free drilling fluid and a preparation method thereof. The polymer inhibitor is formed by copolymerization of an organic amide monomer A, an amido hydrolysis inhibiting monomer B and a cationic monomer C according to a mass percentage of (56-76):(10-25):(14-19) under the action of an initiator and a pH value regulator. The intrinsic viscosity number of the polymer inhibitor is 2.0-3.0dl / g. The shale with a clear water recovery rate of 3.6% is employed to perform shale recovery experiment on the obtained product. A 0.5% aqueous solution of the polymer inhibitor can reach a primary shale recovery rate of higher than 90% after 16h at 200DEG C and a relative shale recovery rate of higher than 98%, and a contrast example, i.e. a 2% high temperature resistant polyamine inhibitor solution only has a primary shale recovery rate of 64.2% after 16h at 200DEG C. With good sloughing inhibiting and preventing ability under high temperature conditions, the polymer inhibitor provided by the invention can be used for weak gel clay phase-free drilling fluid to effectively inhibit hydration expansion of mud shale and ensure safe and fast drilling of a special process well, thus further improving the wellbore wall stabilization capacity.

Owner:CHINA PETROCHEMICAL CORP +1

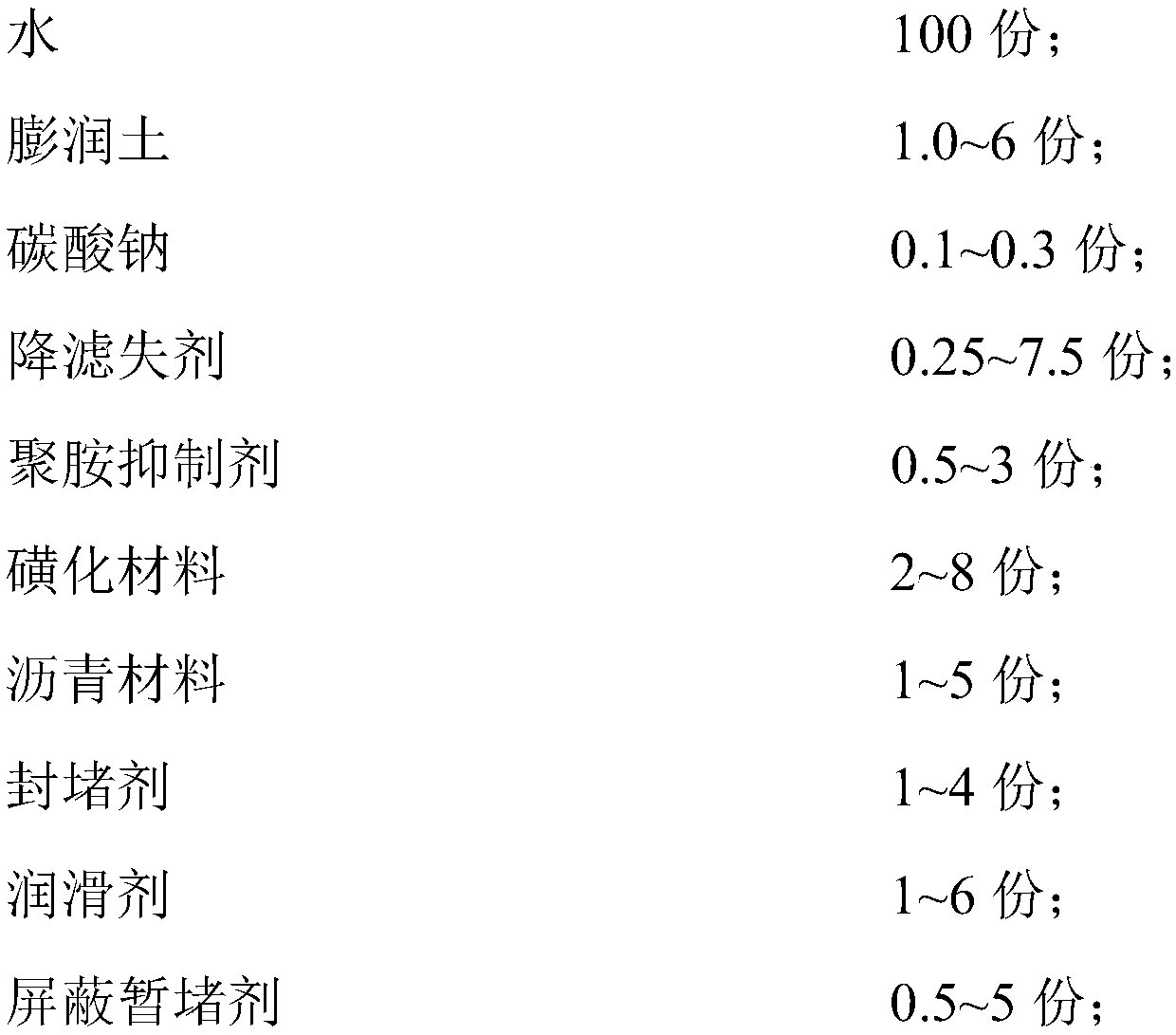

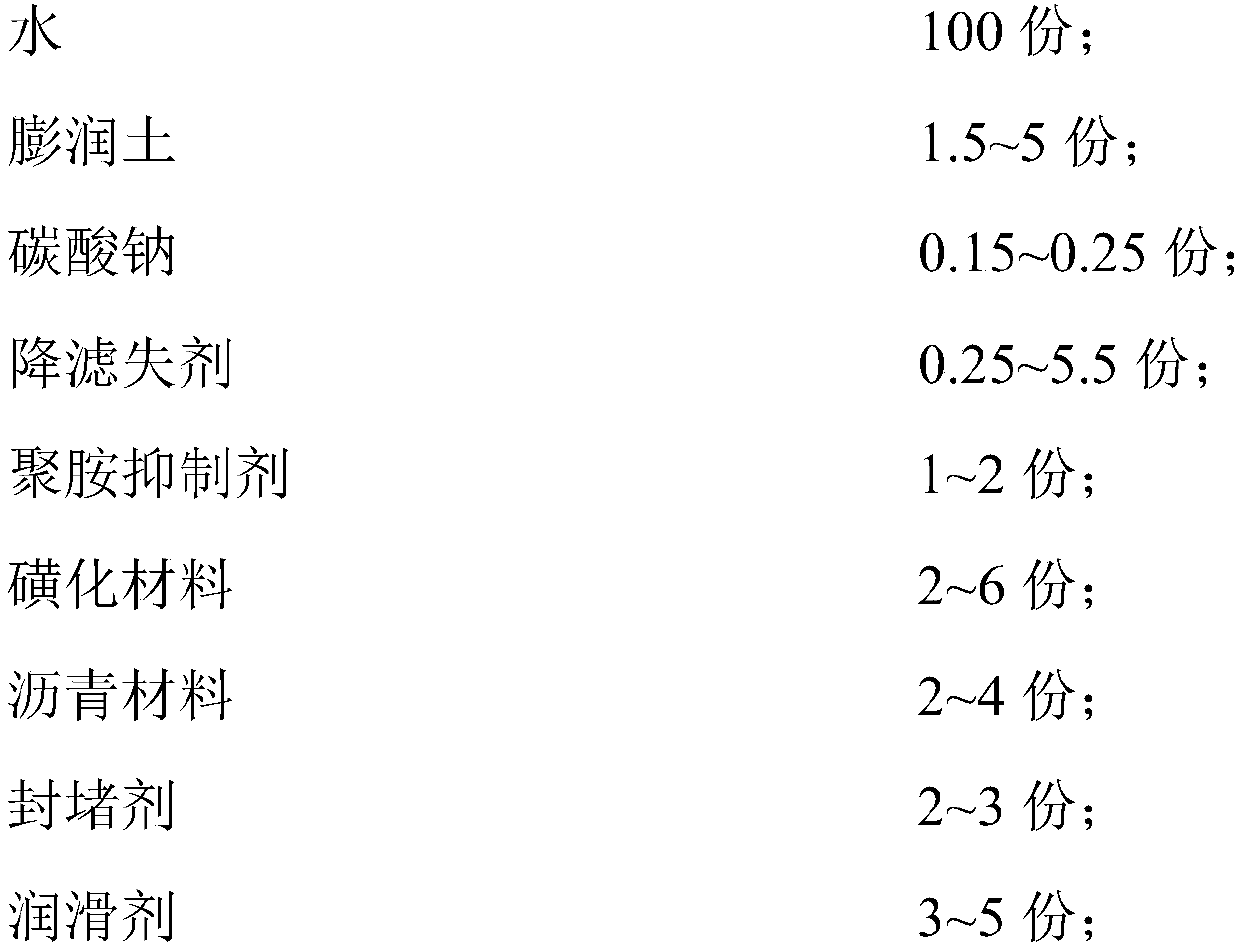

Anti-collapse drilling fluid for coal seams, and preparation method thereof

ActiveCN111117579AImprove rheologyStrong blocking effectDrilling compositionBorehole/well accessoriesMining engineeringWell drilling

The invention provides an anti-collapse drilling fluid used for a coal seam and capable of drilling a coal-bearing stratum, and a preparation method thereof. The anti-collapse drilling fluid comprises100 parts of water, 1.0-6 parts of bentonite, 0.1-0.3 part of sodium carbonate, 0.25-7.5 parts of a filtrate reducer, 0.5-3 parts of a polyamine inhibitor, 2-8 parts of a sulfonated material, 1-5 parts of an asphalt material, 1-4 parts of a plugging agent, 1-6 parts of a lubricant and 0.5-5 parts of a shielding temporary plugging agent, wherein the pH value of the anti-collapse drilling fluid is9-10, and the density of the anti-collapse drilling fluid is 1.10-2.00 g / cm<3>. The drilling fluid has the characteristics of good rheological property, good lubricating property, strong inhibiting and plugging capability, wide density application range and the like, meets the requirements of well wall collapse prevention in stratum drilling such as crack development within 180 DEG C, low strengthand the like, and is particularly suitable for drilling collapse prevention of coal-mudstone interaction stratums.

Owner:CHINA PETROLEUM & CHEM CORP +1

Water-based drilling fluid for shale gas wells and production method thereof

ActiveCN110628398AEnhanced inhibitory effectImprove the blocking effectDrilling compositionWater basedHorizontal wells

The invention relates to a water-based drilling fluid for shale gas wells and a production method thereof. The method sequentially includes the following steps of: (1) preparing the following raw materials: 1000 parts of water, 45-50 parts of sodium bentonite, 500 parts of a water-soluble inhibition weighting agent II; 100 parts of a water-soluble inhibition weighting agent III; 15-20 parts of aninhibiting and anti-collapse agent non-fluorescence white asphalt, 10-20 parts of solid polymeric alcohol, 10-20 parts of a filtrate reducer, 0.5-1 part of a polyamine inhibitor, 20-30 parts of ultrafine calcium carbonate, 10-25 parts of an extreme pressure lubricant, and 0.5-1 part of a coating inhibitor; (2) mixing the sodium bentonite and water, and performing curing for at least 24h at normaltemperature; and (3) adding the water-soluble inhibition weighting agent II and water-soluble inhibition weighting agent III under stirring, then adding the inhibiting and anti-collapse agent non-fluorescence white asphalt and the solid polymeric alcohol, then adding the filtrate reducer and the polyamine inhibitor, then adding the ultrafine calcium carbonate and the extreme pressure lubricant, finally adding the coating inhibitor, and then adjusting the pH value and density. The drilling fluid has the advantages of high plugging properties, strong inhibition and excellent lubricating properties, and can meet the safe drilling requirements of shale gas horizontal wells.

Owner:SINOPEC EAST CHINA PETROLEUM ENG CO LTD

Preparation method of polyamine inhibitor for drilling fluid

InactiveCN106190064AEnhanced inhibitory effectGood compatibilityDrilling compositionTetramineReaction temperature

The invention discloses a preparation method of a polyamine inhibitor for drilling fluid. The method comprises the following steps: an amine compound of low molecular weight and heterocyclic compounds are reacted in a setting condition for synthesis, and the amine compound is one of triethylene tetramine, trimethylethylamine hydroxide, N-methylethylamine, and trimethylhexamethylenediamine; the heterocyclic compound is 1,2-epoxypropane or 2,3-epoxybutane or 1,3-epoxybutane; the setting condition is as follows: alkali metal is used as a catalyst, and the reaction temperature is 80-100 DEG C; charging mol ratio between the amine compound and the heterocyclic compound is 1:2.5; the mass ratio between the amine compound and the alkali metal catalyst is 1200:1. The inhibitor has high inhibition capability for shale, and has good compatibleness to other common drilling fluid additives; the inhibitor is nontoxic and environmentally friendly.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

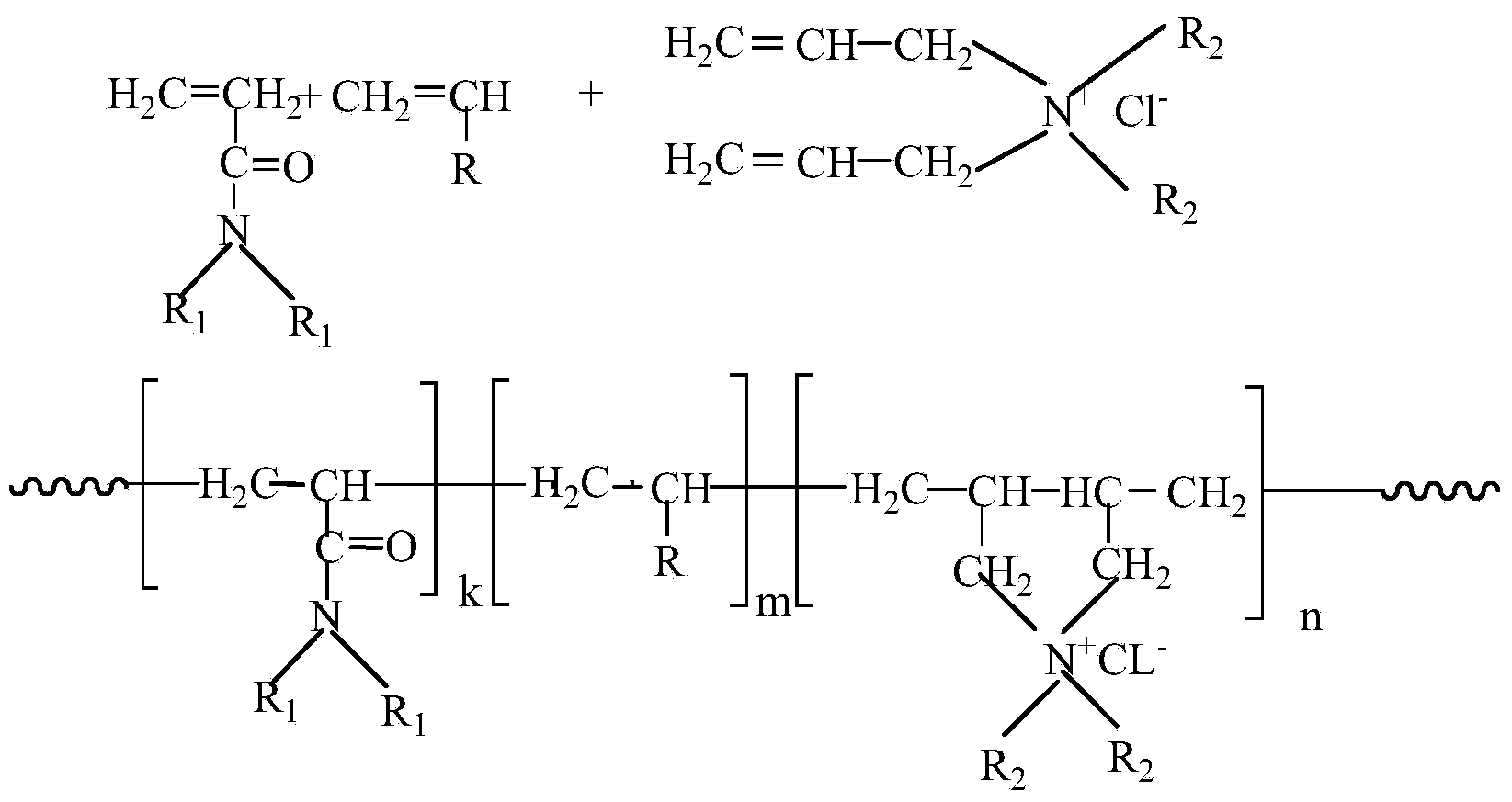

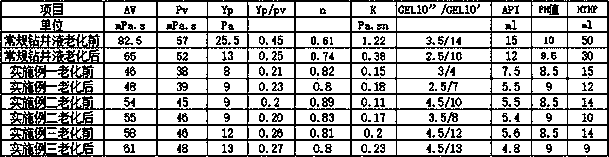

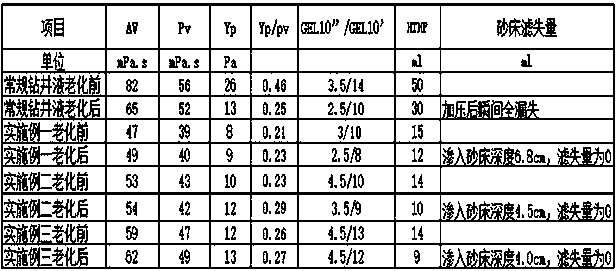

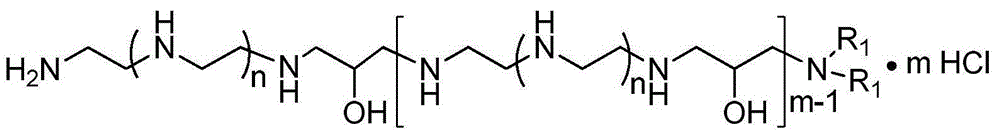

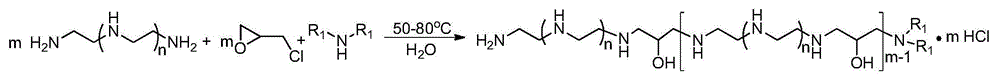

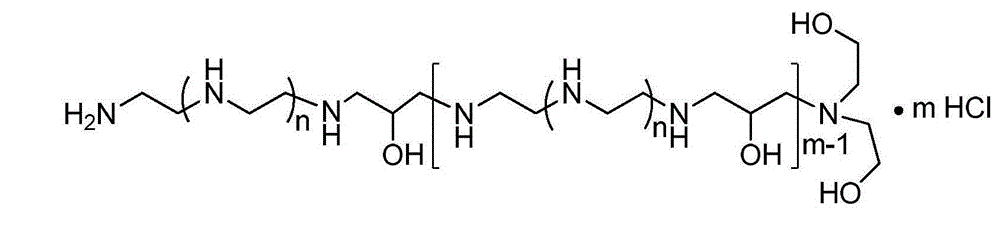

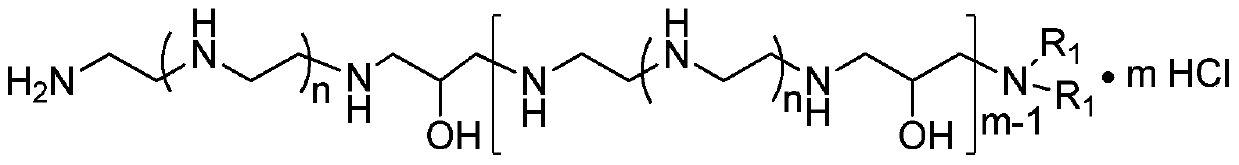

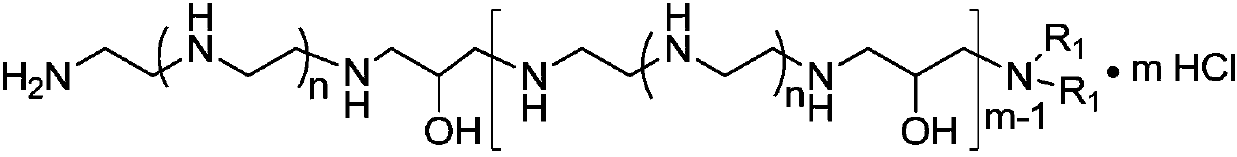

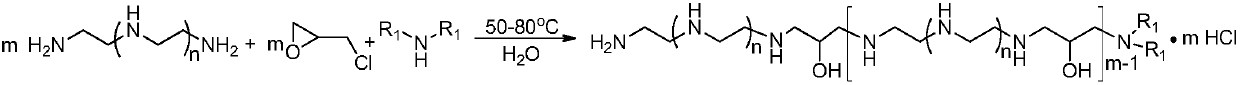

Polyamine inhibitor for water-based drilling fluid and method for preparing polyamine inhibitor

ActiveCN105086955AEnhanced inhibitory effectImprove temperature resistanceDrilling compositionSimple Organic CompoundsWater based

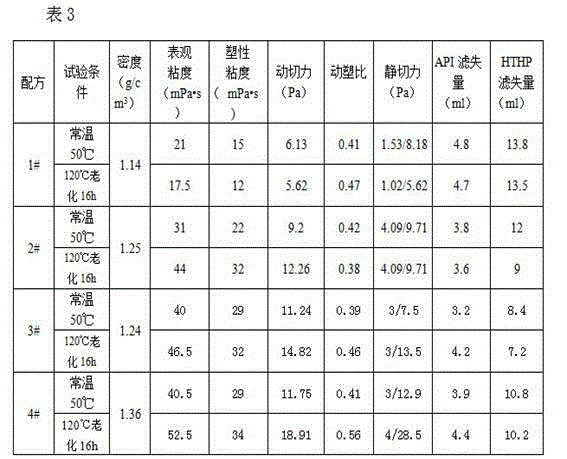

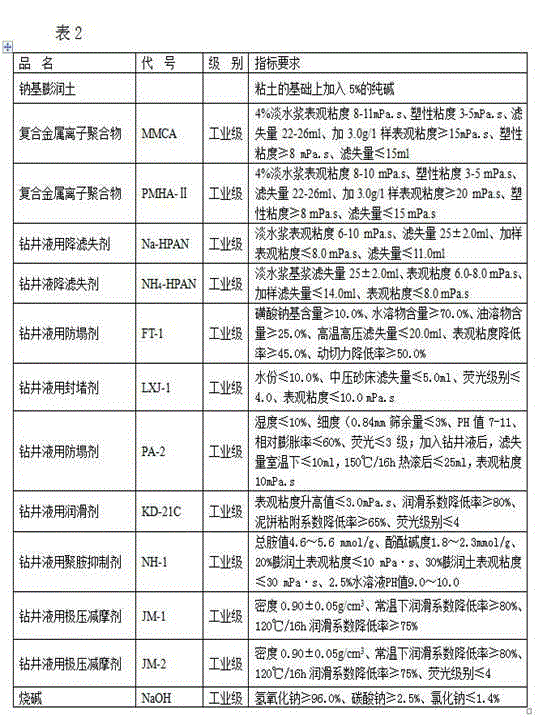

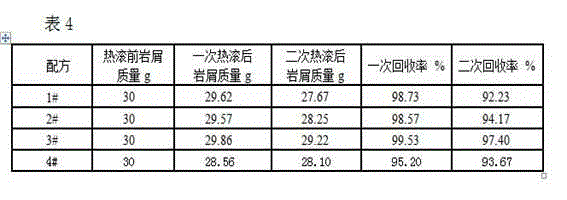

The invention discloses a polyamine inhibitor for water-based drilling fluid and a method for preparing the polyamine inhibitor. A structural formula of the polyamine inhibitor is shown, wherein an n can be 0 or 1 or 2 or 3; an m ranges from 100 to 200; an R<1> is -CH<3> or -CH<2>CH<3> or -CH<2>CH<2>OH. The method for preparing the polyamine inhibitor for the water-based drilling fluid includes mixing polyamine organic compounds and water with one another to obtain mixtures; slowly adding epichlorohydrin into the mixtures; enabling the epichlorohydrin and the mixtures to react with one another; adding chain growth terminators into the mixtures; cooling products until the temperatures of the products reach the room temperature after reaction is completed so as to obtain the polyamine inhibitor for the water-based drilling fluid. The polyamine inhibitor for the water-based drilling fluid and the method have the advantages that the polyamine inhibitor is excellent in shale inhibition and can be normally used under the condition of temperature of 180 DEG C; the method is simple and is easy to implement.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Site treatment technique for environment-friendly polyether alcohol amine drilling fluid

ActiveCN106121568APulse signal transmission is normalStable rheologyFlushingSites treatmentSodium Bentonite

The invention relates to a site treatment technique for environment-friendly polyether alcohol amine drilling fluid and belongs to the field of exploitation of oil and gas fields. The site treatment technique for the environment-friendly polyether alcohol amine drilling fluid comprises the stage of mixing and converting, the stage of performance maintenance and the stage of well completion preparation. According to the stage of mixing and converting, drilling is conducted to a deep shale well section, the content of bentonite in original well slurry is reduced to be 20-30 g / l, formate and a tackifier are added into the well slurry till the mass content of the formate reaches 3% and the mass content of the tackifier reaches 0.2%, 400-500 kg of polyether polyols is supplemented into the drilling fluid each circulation cycle to guarantee that the mass content of the polyether polyols in the drilling fluid is 1.5%-2.0%, a capsulating agent, a polyamine inhibitor, a filtrate reducer and an anti-collapse agent are then sequentially added till the mass content of the capsulating agent in the drilling fluid reaches 0.2%-0.3%, the mass content of the polyamine inhibitor in the drilling fluid reaches 0.2%, the mass content of the filtrate reducer in the drilling fluid reaches 2% and the mass content of the anti-collapse agent in the drilling fluid reaches 1.5%, and are full circulated, the PH value of the mixture is regulated to 8-9 with caustic soda after system conversion is completed, and then the drilling fluid is thickened to the required density. The site treatment technique can be applied to drilling processes in different strata to achieve effective lubricating, prevent drilling tools from getting stuck and stabilize well walls.

Owner:CHINA PETROLEUM & CHEM CORP +1

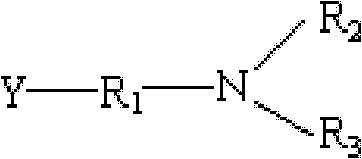

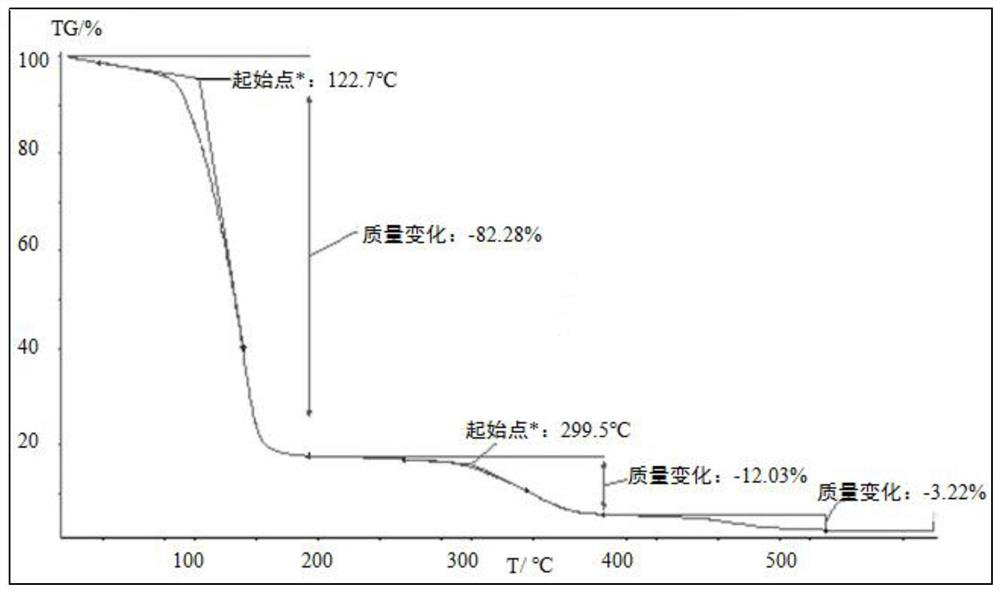

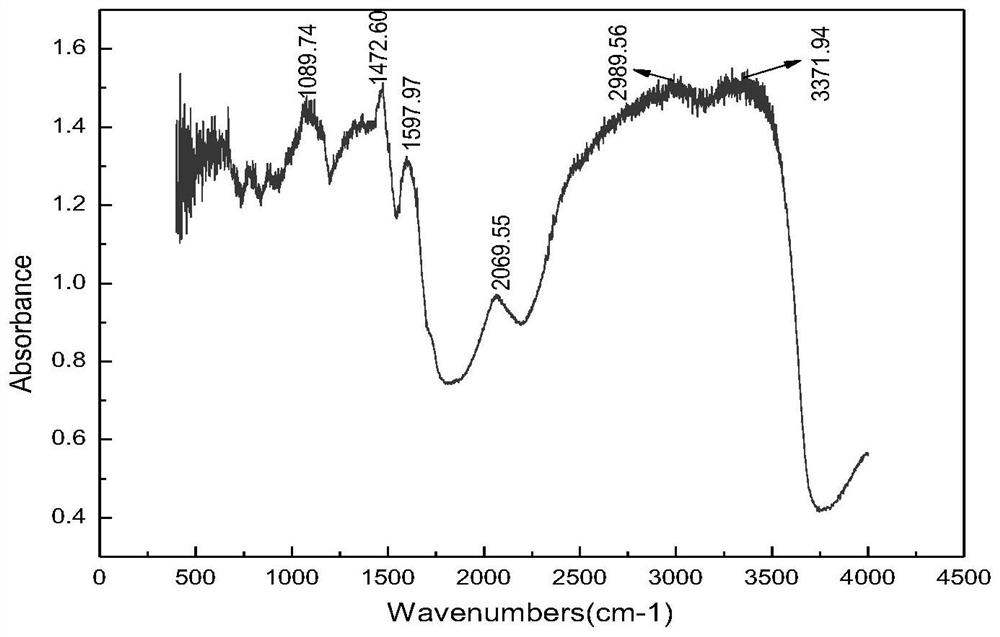

Polyamine inhibitor for water-based drilling fluid and preparation method of polyamine inhibitor

InactiveCN108148564AEnhanced inhibitory effectInhibition of hydration dispersionOrganic compound preparationDrilling compositionWater basedAcetic acid

The invention discloses a polyamine inhibitor for a water-based drilling fluid and a preparation method of the polyamine inhibitor. The structural formula of the polyamine inhibitor is as shown in thespecification. The preparation method includes the steps of firstly, weighing, by weight, 75-80 parts of maleic anhydride, 210-215 parts of triethanolamine, 8-12 parts of glacial acetic acid and 348-352 parts of tap water; secondly, placing the weighed maleic anhydride and triethanolamine in a reaction kettle under normal temperature; thirdly, rising the temperature in the reaction kettle to 80-90 DEG C in 4 minutes, and keeping the temperature for 30 minutes; fourthly, rising the temperature to 180 DEG C after the heat preservation, and using a vacuum pump to keep pressure in the reaction kettle in a 20mm mercury column state to perform reaction for 4 hours; fifthly, after the reaction, cooling and performing pressure relief, and cooling to 90 DEG C; sixthly, adding the glacial acetic acid and the tap water when required temperature is reached, and performing reaction for 2 hours to obtain the polyamine inhibitor. The polyamine inhibitor is applicable to a shale gas water-based drilling fluid system.

Owner:SOUTHWEST PETROLEUM UNIV

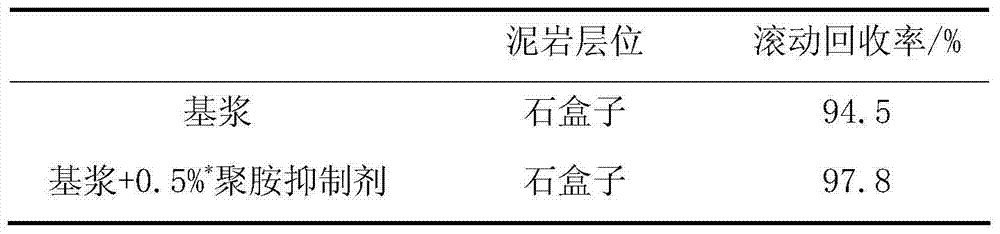

Drilling fluid used for active mud shale drilling

ActiveCN102250595BInhibition of hydration pulpingPrevent hydrationDrilling compositionHigh activityPolymer

The invention relates to a drilling fluid used for active mud shale drilling, and the drilling fluid is used in oilfield drilling. The drilling fluid comprises the following components in percentages by weight: 2-6% of bentonite, 0.2-0.5% of coated inhibitor, 0.2-1.0% of flow pattern regulator, 0.2-0.5% of high-temperature-resistant polymer filtrate reducer, 4-7% of potassium chloride, 1-3% of polymeric alcohol, 0.5-1.0% of polyamine inhibitor, 0.5-1.0% of anti-balling fast drilling agent and 45-85% of water. The drilling fluid has the inhibition property and lubricating property approximate to that of an oil-based drilling fluid, solves the problems that the mud making of the mud shale is severe, mud escapes from a vibrating screen, the viscous shearing of the drilling fluid increases and the rheological properties of the drilling fluid deteriorates during strong-mud-making active mud shale drilling, prevents destabilization of the active mud shale, dispersion of drill cuttings, balling of drill bit, and adhesion and coalescence of the mud shale, and increases the drilling speed of the active mud shale.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Water-based drilling fluid system and preparation method and application thereof

InactiveCN106010483AGood compatibilityImprove securityDrilling compositionWater basedVolumetric Mass Density

A water-based drilling fluid system is prepared from water-based liquid, sodium carbonate, a polyamine inhibitor, modified starch, xanthan gum, a low-molecular-weight encapsulating inhibitor, a density reducing agent, a bit balling prevention lubricant, a pressure-bearing plugging agent, sodium chloride and ethylene glycol, wherein with respect to 100 parts by weight of the water-based liquid, the sodium carbonate accounts for 0.2-0.3 part by weight, the polyamine inhibitor accounts for 3-4 parts by weight, the modified starch accounts for 1-2 parts by weight, the xanthan gum accounts for 0.2-0.3 part by weight, the low-molecular-weight encapsulating inhibitor accounts for 0.3-0.7 part by weight, the density reducing agent accounts for 1-3 parts by weight, the bit balling prevention lubricant accounts for 2-3 parts by weight, the pressure-bearing plugging agent accounts for 1-2 parts by weight, the sodium chloride accounts for 10-20 parts by weight, and the ethylene glycol accounts for 10-20 parts by weight. The invention also provides a preparation method and application of the water-based drilling fluid system. The water-based drilling fluid system can be effectively applicable to deep-water narrow-density window operation.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Extreme pressure antifriction type drilling fluid and production method thereof

InactiveCN104371677AGood anti-frictionHigh coefficient of extreme pressure frictionDrilling compositionReducerVolumetric Mass Density

The invention relates to an extreme pressure antifriction type drilling fluid used for oil and gas field mining. The extreme pressure antifriction type drilling fluid is prepared by adopting the following method: mixing 100 parts by weight of water with 4-6 parts by weight of sodium bentonite, stirring at a stirring speed of 1000-4000rpm for 30-60 minutes, then stirring a stirring speed of 6000-10000rpm for 30-40 minutes, and maintaining at normal temperature for at least 24 hours; then adding 0.2-0.8 part by weight of a coating agent for the drilling fluid and 0.5-3 parts by weight of a filtrate reducer for the drilling fluid into the mixture while stirring at a stirring speed of 4000-6000rpm, and then adding 1-5 parts by weight of an anti-collapse agent for the drilling fluid, 0-3 parts by weight of a blocking agent for the drilling fluid, 0.1-1 part by weight of a polyamine inhibitor for the drilling fluid, 0-8 parts by weight of a lubricating agent for the drilling fluid and 0.5-5 parts by weight of an extreme pressure antifriction agent for the drilling fluid; then adjusting pH value of the mixture to be 8-9 by adopting caustic soda; and finally adding a weighting agent for the drilling fluid into the mixture, and uniformly stirring, so that the extreme pressure antifriction type drilling fluid is obtained, wherein the density of the extreme pressure antifriction type drilling fluid is 1.12-1.50g / cm.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polyamine inhibitor for water-based drilling fluid and preparation method thereof

ActiveCN105086955BEnhanced inhibitory effectImprove temperature resistanceDrilling compositionWater basedRoom temperature

The invention discloses a polyamine inhibitor for water-based drilling fluid and a method for preparing the polyamine inhibitor. A structural formula of the polyamine inhibitor is shown, wherein an n can be 0 or 1 or 2 or 3; an m ranges from 100 to 200; an R<1> is -CH<3> or -CH<2>CH<3> or -CH<2>CH<2>OH. The method for preparing the polyamine inhibitor for the water-based drilling fluid includes mixing polyamine organic compounds and water with one another to obtain mixtures; slowly adding epichlorohydrin into the mixtures; enabling the epichlorohydrin and the mixtures to react with one another; adding chain growth terminators into the mixtures; cooling products until the temperatures of the products reach the room temperature after reaction is completed so as to obtain the polyamine inhibitor for the water-based drilling fluid. The polyamine inhibitor for the water-based drilling fluid and the method have the advantages that the polyamine inhibitor is excellent in shale inhibition and can be normally used under the condition of temperature of 180 DEG C; the method is simple and is easy to implement.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

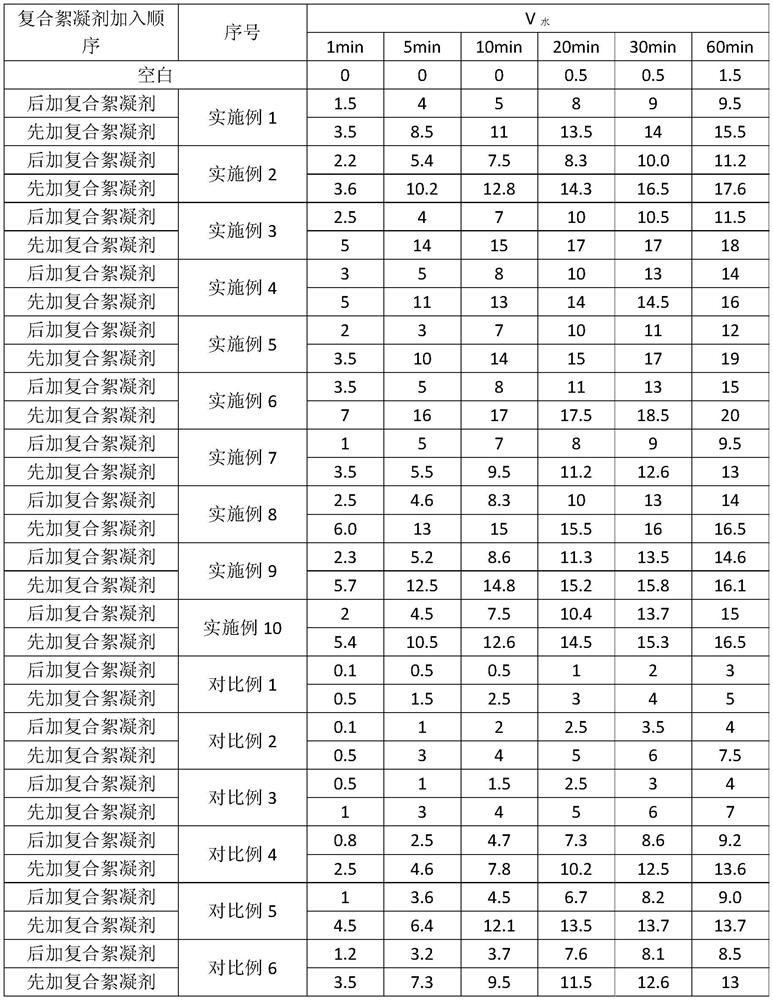

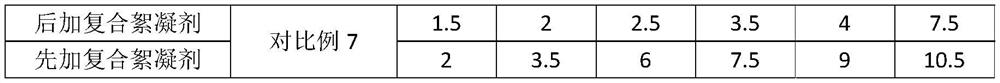

Composite flocculant, water-based drilling fluid and application of water-based drilling fluid

ActiveCN112760087AGood synergyGood flocculation effectDrilling compositionInorganic saltsFlocculation

The invention relates to the technical field of petroleum drilling fluids, in particular to a composite flocculant, a water-based drilling fluid and application of the water-based drilling fluid. The composite flocculant disclosed by the invention is prepared from the following components in parts by weight: 0.05-0.3 parts of polyacrylamide, 2-20 parts of inorganic salt and 1-10 parts of a polyamine inhibitor. According to the composite flocculant disclosed by the invention, the flocculation effect of the composite flocculant is improved by mainly utilizing the synergistic effect of the macromolecular polyacrylamide and the polyamine inhibitor. The composite flocculant can reduce clay hydration and accelerate solid-phase particle flocculation and sedimentation, is used for rapid drilling of an upper stratum, improves the flocculation degree and realizes effective solid-phase control.

Owner:中石化石油工程技术服务有限公司 +2

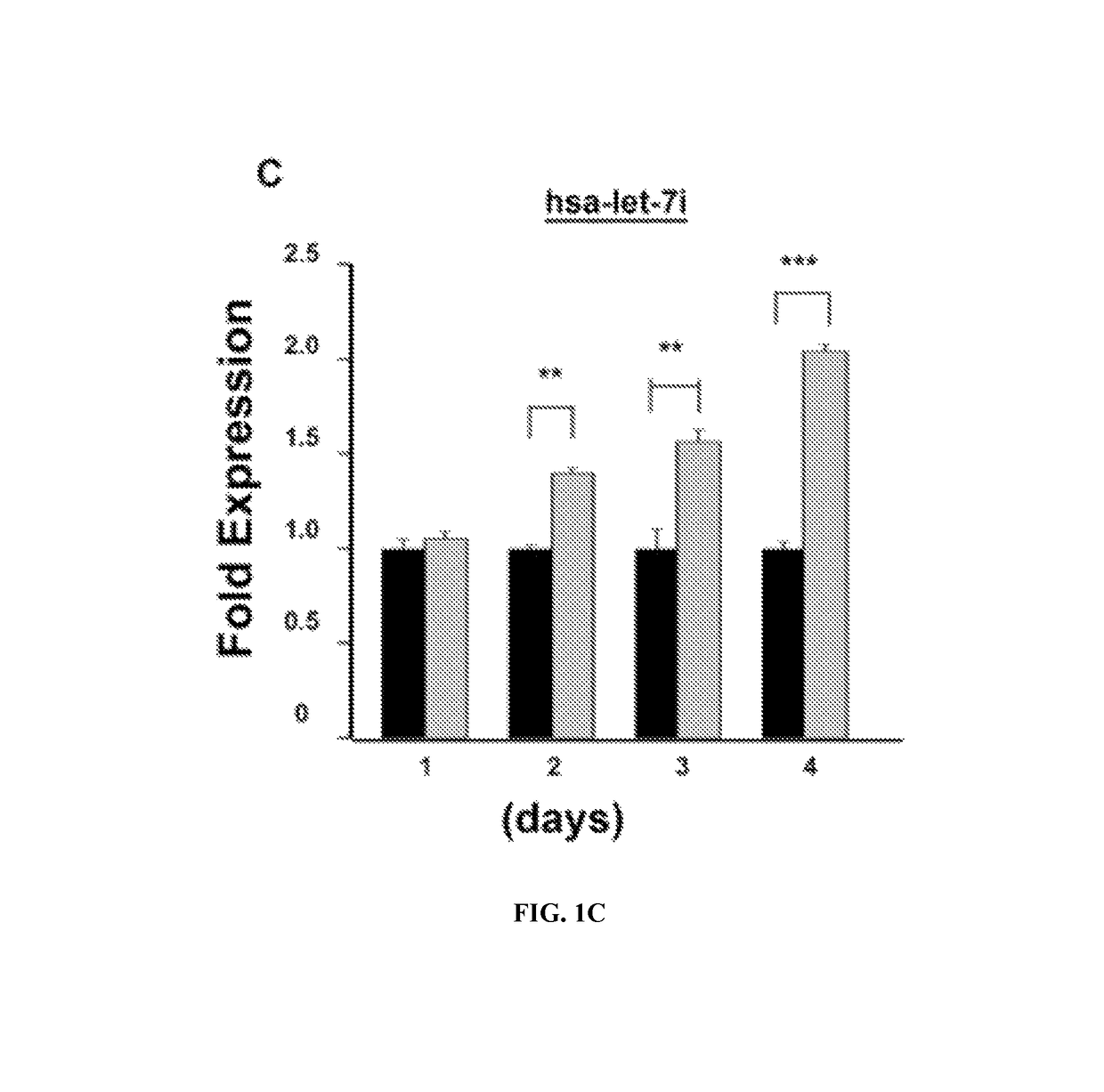

Predictive markers for polyamine inhibitor cancer therapies

The present disclosure relates to therapeutic methods and medical uses comprising the identification and use of cancer marker surrogates for increased polyamine expression. These markers may be used to identify patients who may be treated for diseases and disorders that are susceptible to polyamine synthesis inhibitors, and they can also be used to monitor therapeutic responses when such agents are used. More specifically, reduced levels of let-7 miRNA and elevated levels of LIN28 and HMGA2 proteins were found to correlate with elevated levels of polyamines and may be used for predicting the efficacy of cancer therapy using an ornithine decarboxylase (ODC1) inhibitor such as eflornithine (DFMO), suitably in combination with an NSAID such as sulindac.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

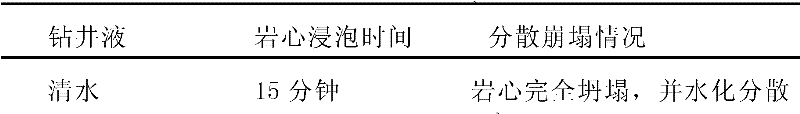

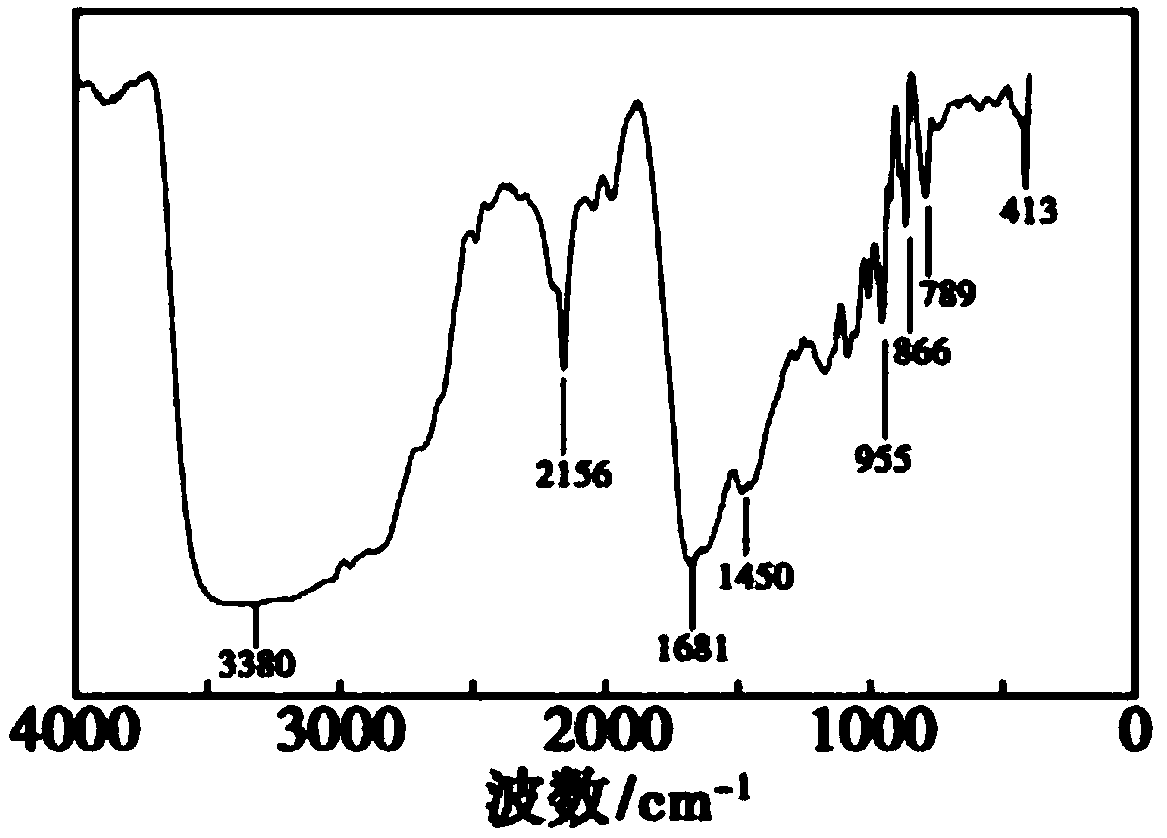

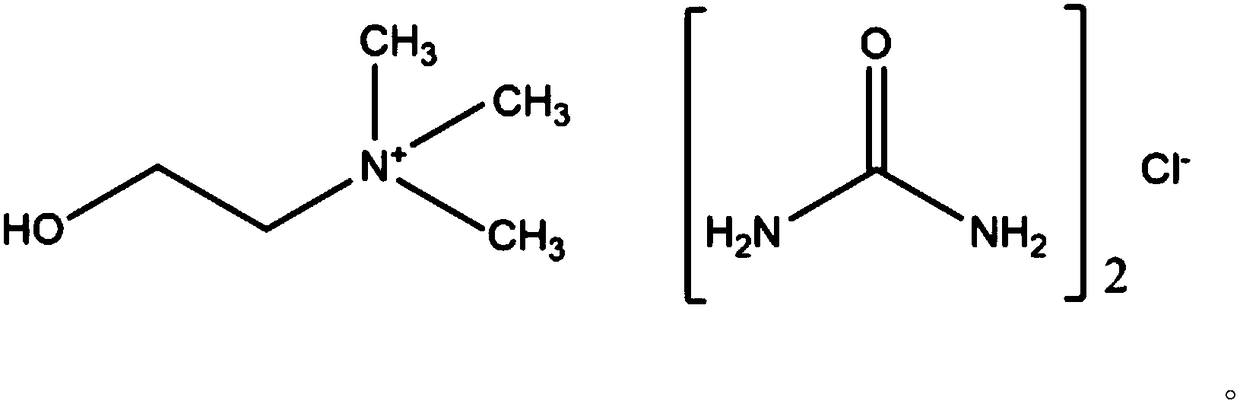

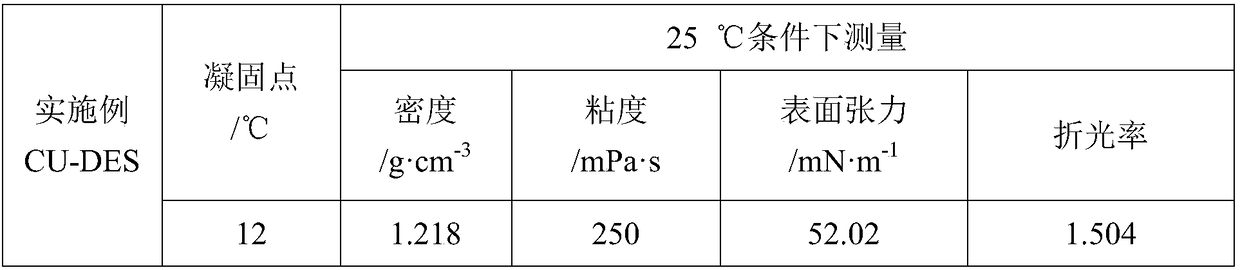

Low eutectic shale inhibitor, and preparation method and application thereof

InactiveCN109180503AInhibit swellingInhibition dispersionUrea derivatives preparationOrganic compound preparationInorganic saltsWell drilling

The invention relates to the field of well-drilling fluid inhibitors, and in particular, relates to a low eutectic shale inhibitor, and a preparation method and an application thereof. The low eutectic shale inhibitor is prepared by stirring and heating choline chloride and urea in an 80-100 DEG C oil bath for 2-4 h until the reaction mixture is a transparent liquid. Compared with other common inorganic salts, polymers and polyamine inhibitors in the market, the low eutectic shale inhibitor has cheap raw materials, is simple to synthesize, is environmentally friendly and non-toxic, has remarkable effects in inhibiting mud making in shale, shale expansion and shale dispersion, still has excellent inhibiting performance under a condition of high temperature, and has potential market value.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

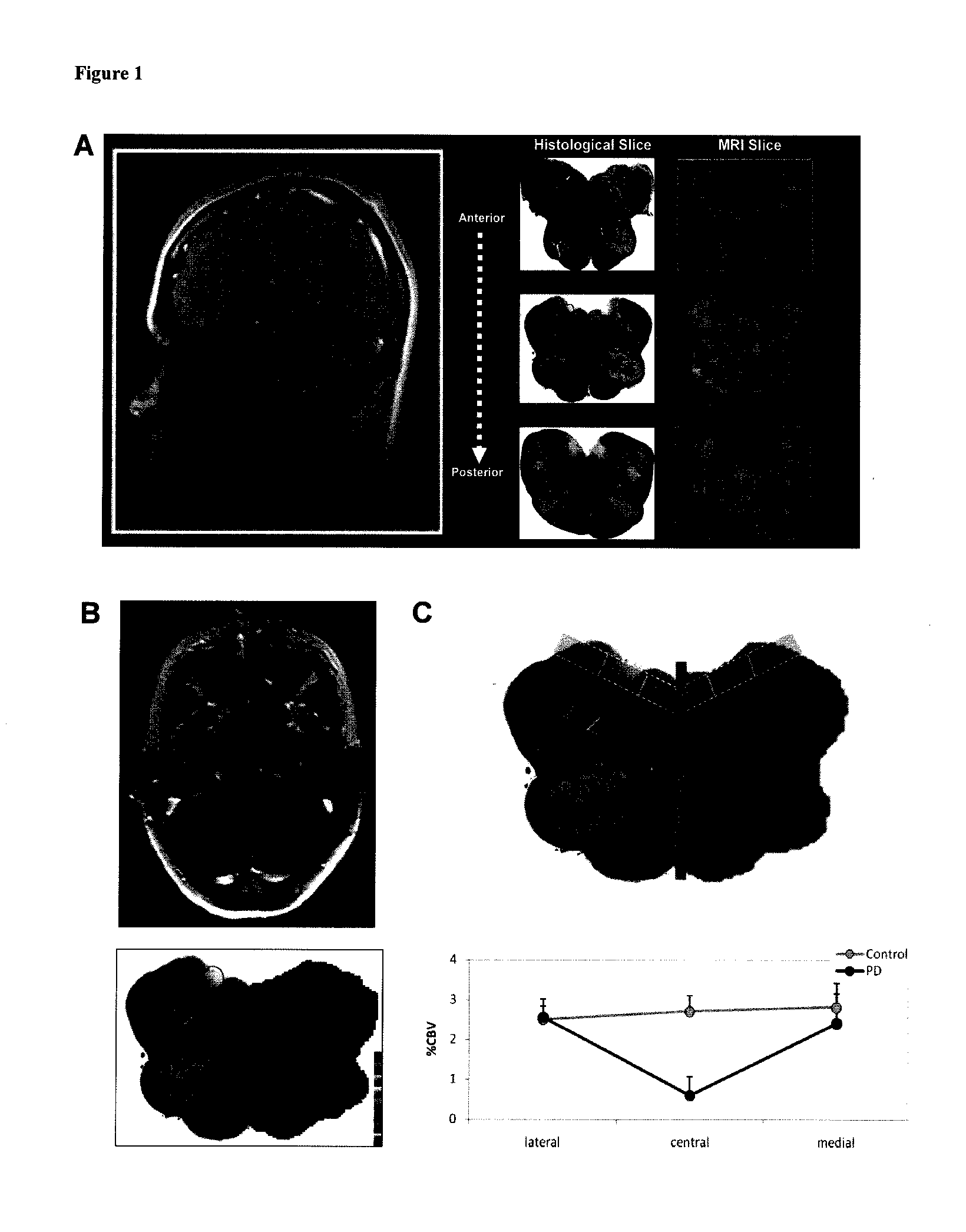

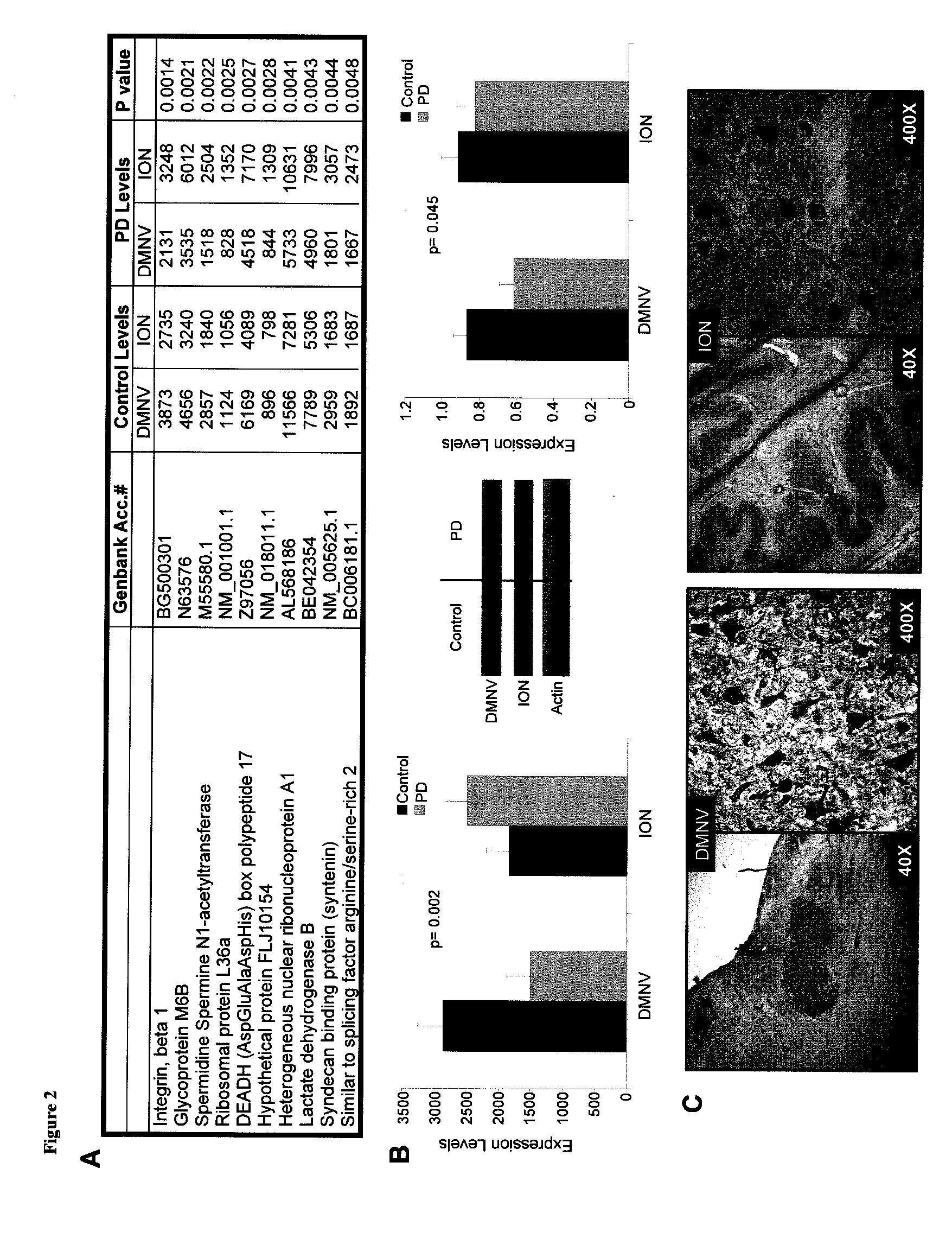

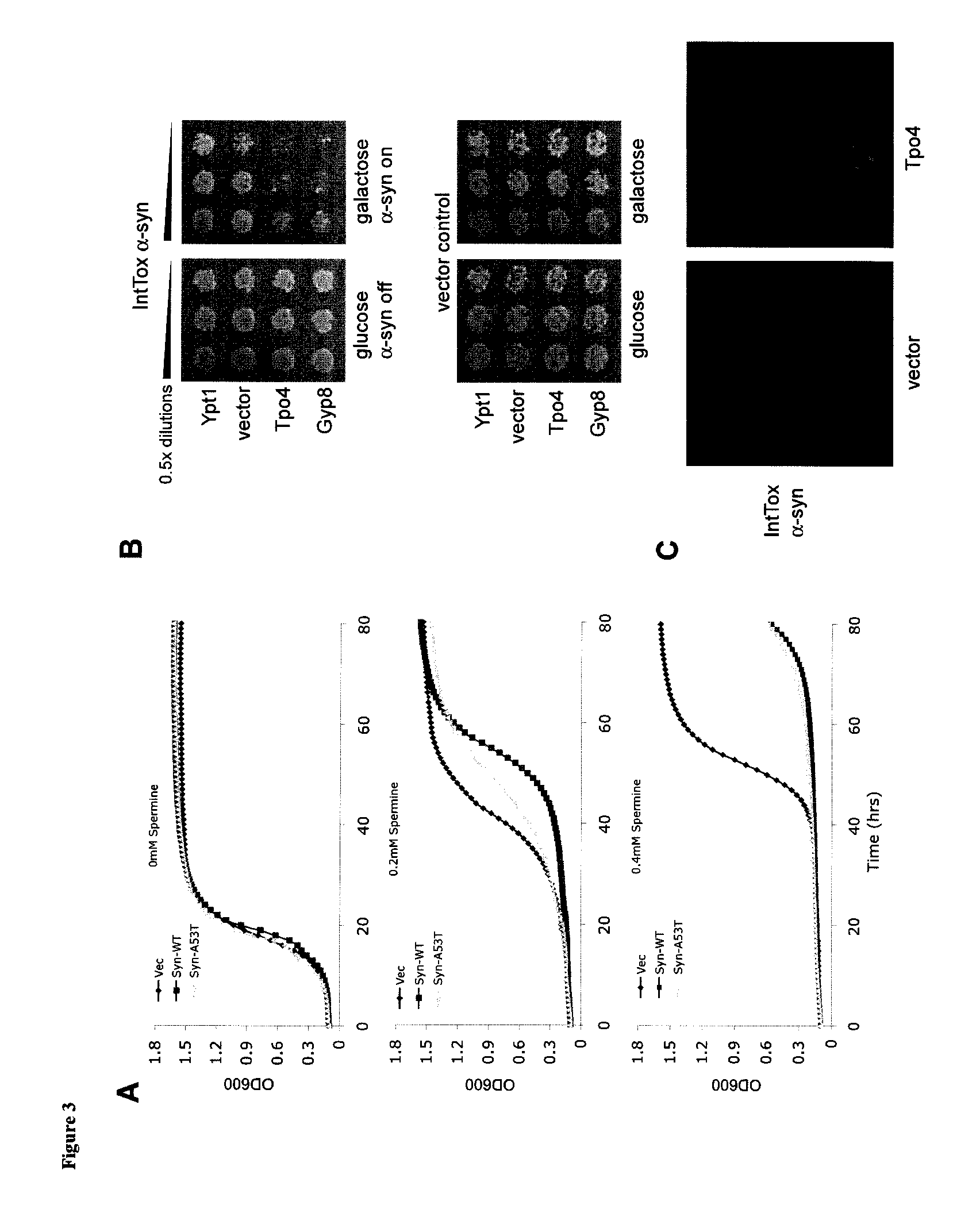

Polyamine inhibitors for the treatment and prevention of parkinson's disease

InactiveUS20120129939A1Reduce aggregationInhibit synthesisBiocideNervous disorderMedicinePolyamine synthesis

Disclosed herein are methods for treating a disease involving α-synucleic aggregation using (1) a compound which reduces the amount of polyamines in an amount effective to reduce α-synucleic aggregation; (2) a compound which inhibits polyamine synthesis in an amount effective to reduce α-synucleic aggregation; or (3) a compound which inhibits α-synucleic aggregation in an amount effective to reduce α-synucleic aggregation. Also disclosed are methods for reducing the amount of α-synucleic aggregation in a brain cell using (1) a compound which reduces the amount of polyamines in an amount effective to reduce α-synucleic aggregation; (2) a compound which inhibits polyamine synthesis in an amount effective to reduce α-synucleic aggregation; or (3) a compound which inhibits α-synucleic aggregation in an amount effective to reduce α-synucleic aggregation. Disclosed herein are also compounds which can be used in the above described methods.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

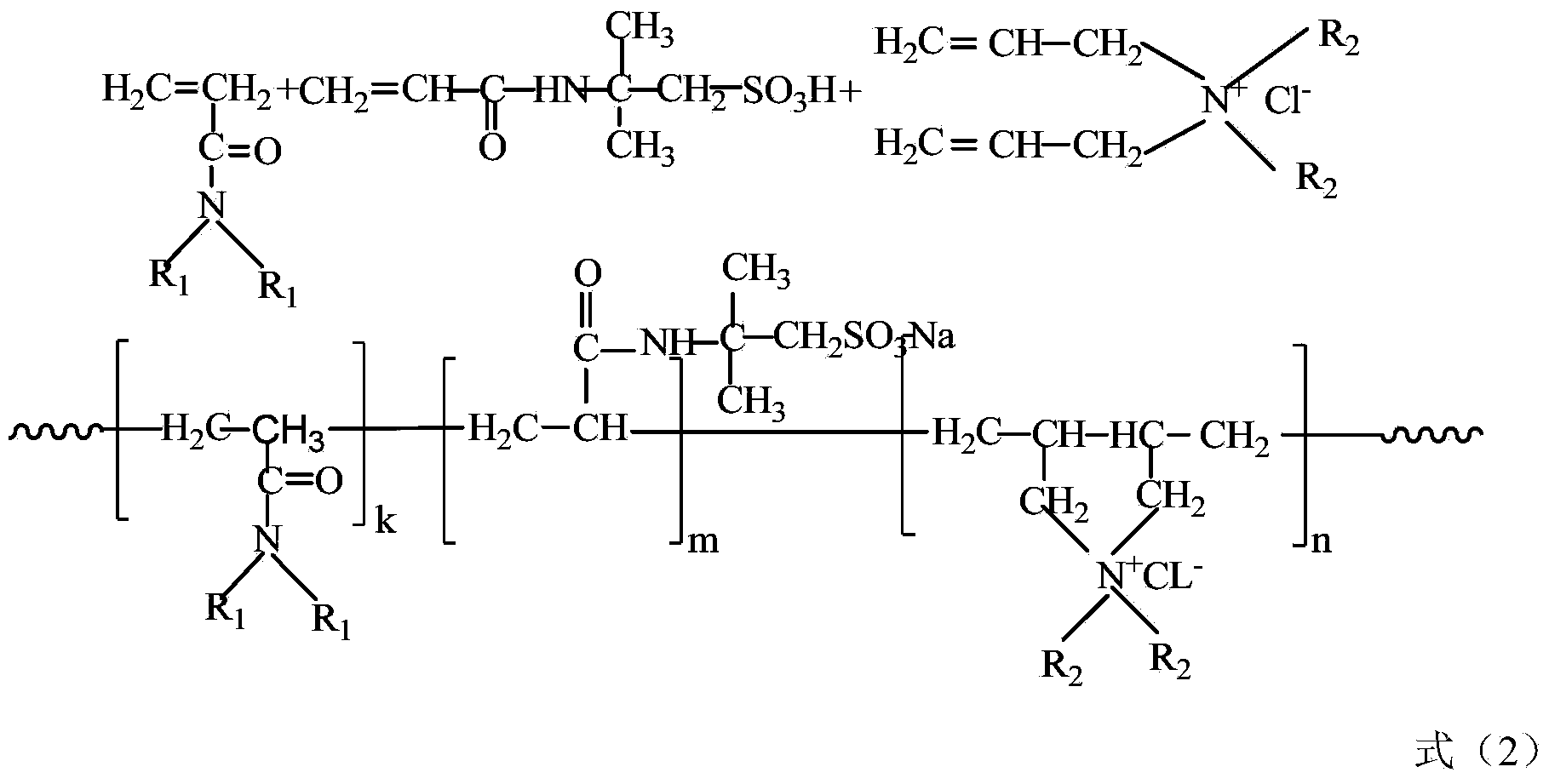

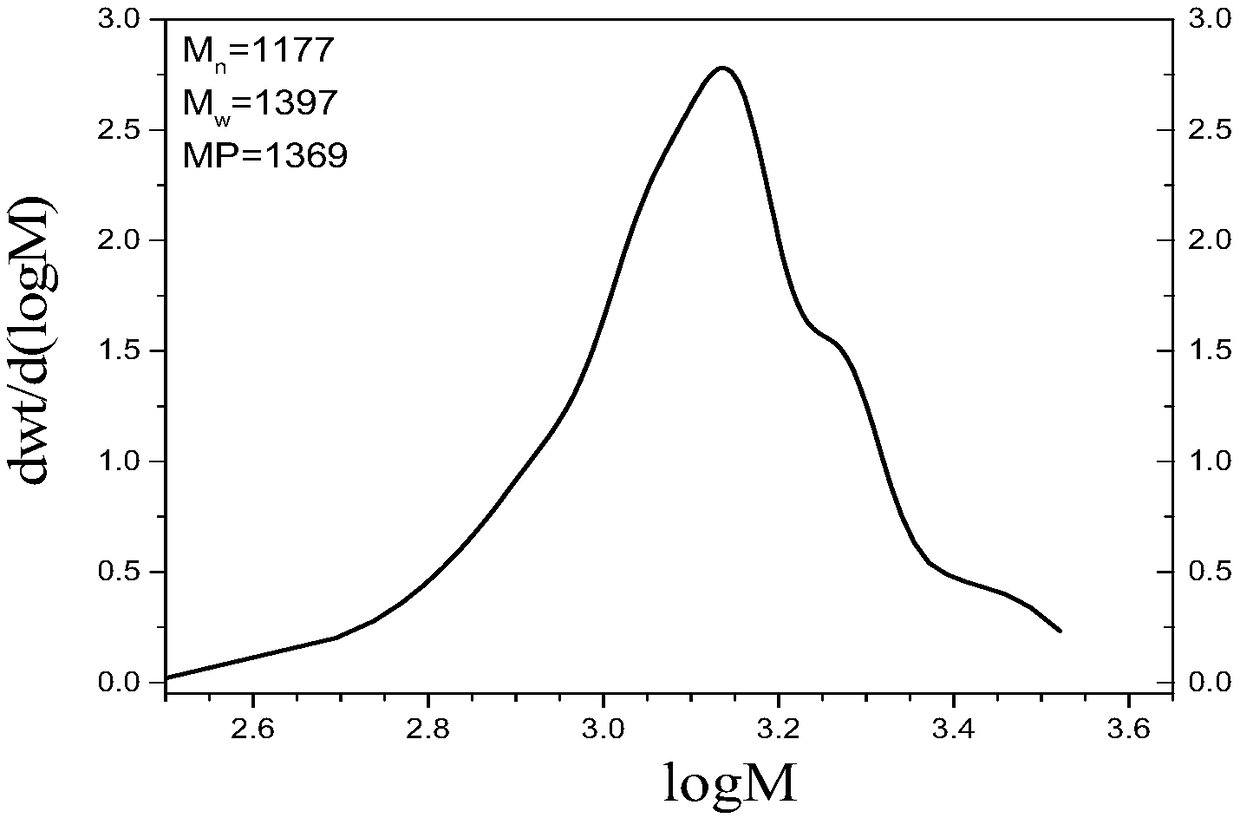

A kind of preparation method of anti-high temperature binary copolymerization low molecular weight polyamine inhibitor for water-based drilling fluid

ActiveCN111334261BGood compatibilityStrong shale suppression abilityDrilling compositionPtru catalystMetal catalyst

The invention relates to a preparation method of a high-temperature-resistant binary copolymerization low-molecular-weight polyamine inhibitor for water-based drilling fluid. It mainly solves the problems of poor temperature resistance and stability of the existing inhibitors. The preparation method of the inhibitor is composed of monomer A and monomer N-vinylpyrrolidone in a molar ratio of 1:2 to 1:10, under the action of metal catalysts such as sodium borohydride and Raney nickel, through catalytic hydrogenation The method is a low-molecular-weight polymer inhibitor synthesized by aqueous solution polymerization through multi-step reaction. The water-based drilling fluid uses a high-temperature resistant binary copolymer low-molecular-weight polyamine inhibitor, which has stronger temperature resistance and stability, can improve the inhibitory effect of the water-based drilling fluid on the shale formation, improve the stability of the well wall, and reduce downhole complex, promote the advancement of water-based drilling fluid technology and the smooth progress of oil and gas exploration.

Owner:DAQING PETROLEUM ADMINISTRATION +1

Reservoir drilling fluid system and preparation method thereof

ActiveCN114539994AEnhanced inhibitory effectGood compatibilityDrilling compositionCalcium formateActive agent

The invention relates to the technical field of oilfield chemical agent preparation, in particular to a reservoir drilling fluid system and a preparation method thereof. Nano microcrystalline cellulose is extracted from natural plant raw materials, a polyamine inhibitor is synthesized from specific raw materials, and the nano microcrystalline cellulose and the polyamine inhibitor are scientifically compounded with calcium formate, a lubricant, a surfactant, a filtrate reducer and other components, so that the obtained drilling fluid system has excellent rheology, filtrate reduction, temporary plugging removal, lubrication and other properties, and the system is low in biotoxicity and good in environmental protection performance; and the preparation method is simple, convenient and feasible, and can realize large-scale production

Owner:山东维斯特尔石油科技有限公司

Polyamine composite salt water-based drilling fluid and preparation method thereof

ActiveCN114539995AImprove the lubrication effectImprove thermal stabilityDrilling compositionFiltrationPhysical chemistry

The invention relates to the technical field of oilfield chemical agent preparation, in particular to a polyamine composite salt water-based drilling fluid and a preparation method thereof. Specific raw materials are used for synthesizing the polyamine inhibitor, and the polyamine inhibitor is scientifically compounded with various salt substances, so that the prepared drilling fluid has excellent rheology, filtration loss reduction, lubrication and other properties, the aging performance of the drilling fluid after high-temperature hot rolling is not obviously reduced, the biotoxicity grade of the drilling fluid is non-toxic, environment-friendly and pollution-free, and the preparation method is simple, convenient and feasible, and can be used for large-scale production.

Owner:山东维斯特尔石油科技有限公司

Preparation method of high-temperature-resistant binary copolymerized low-molecular-weight polyamine inhibitor for water-based drilling fluid

ActiveCN111334261AImprove stabilityIncrease mud contentDrilling compositionPtru catalystPyrrolidinones

The invention relates to a preparation method of a high-temperature-resistant binary copolymerized low-molecular-weight polyamine inhibitor for water-based drilling fluid. The problem that an existinginhibitor is poor in temperature resistance and stability is mainly solved. The preparation method of the inhibitor comprises the following steps: performing multi-step reaction on a monomer A and amonomer N-vinyl pyrrolidone according to a molar ratio of (1: 2)-(1: 10) through a catalytic hydrogenation method under the action of metal catalysts such as sodium borohydride and Raney nickel, and synthesizing the low-molecular-weight polymer inhibitor in an aqueous solution polymerization manner. The low-molecular-weight polyamine inhibitor for the water-based drilling fluid is higher in temperature resistance and stability, the inhibition effect of the water-based drilling fluid on a shale stratum can be improved, the well wall stability is improved, underground complexity is reduced, andprogress of the water-based drilling fluid technology and smooth oil-gas exploration are promoted.

Owner:DAQING PETROLEUM ADMINISTRATION +1

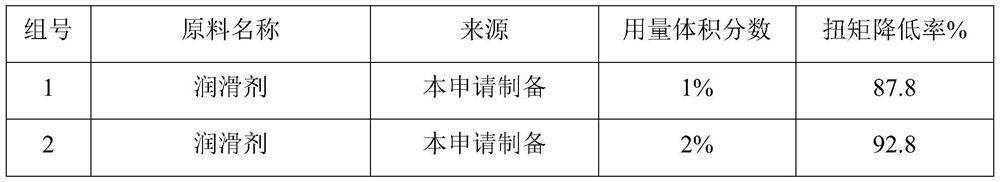

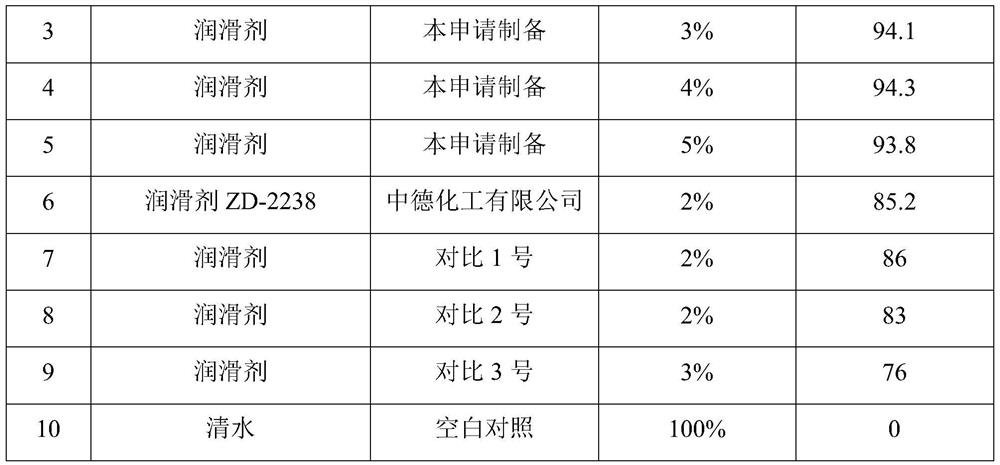

Preparation method and product of oil-like drilling fluid

ActiveCN113372888BEnhanced inhibitory effectMeet environmental protection requirementsDrilling compositionCelluloseDrill cuttings

The invention discloses a method for preparing an oil-based drilling fluid, which is mainly prepared by mixing the following components: polyamine inhibitor, cationic polyacrylamide, low-viscosity polyanionic cellulose, xanthan gum, lubricant, and appropriate amount of water , wherein, the final concentrations of the components in the oil-like drilling fluid are respectively: the volume fraction of the polyamine inhibitor is 2-4%, and the mass concentration of the cationic polyacrylamide is 5-10 kg / m 3 , the mass concentration of the low viscosity polyanion cellulose is 5~15kg / m 3 , the mass concentration of the xanthan gum is 1~5kg / m 3 , The volume fraction of the lubricant is 1-3%. The preparation method is simple. The invention also discloses an oil-like drilling fluid prepared by the above-mentioned preparation method, which has strong inhibitory properties and is close to oil-based drilling fluid. Chips and waste mud beneficial effects.

Owner:BEIJING DADE GUANGYUAN PETROLEUM TECH SERVICE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com