Drilling fluid used for active mud shale drilling

A technology of activated mud and drilling fluid, applied in the field of drilling fluid, can solve the problems of borehole shrinkage, insufficient inhibitory rheological regulation, virtual thickness of mud cake, etc., to achieve the effect of high-efficiency drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

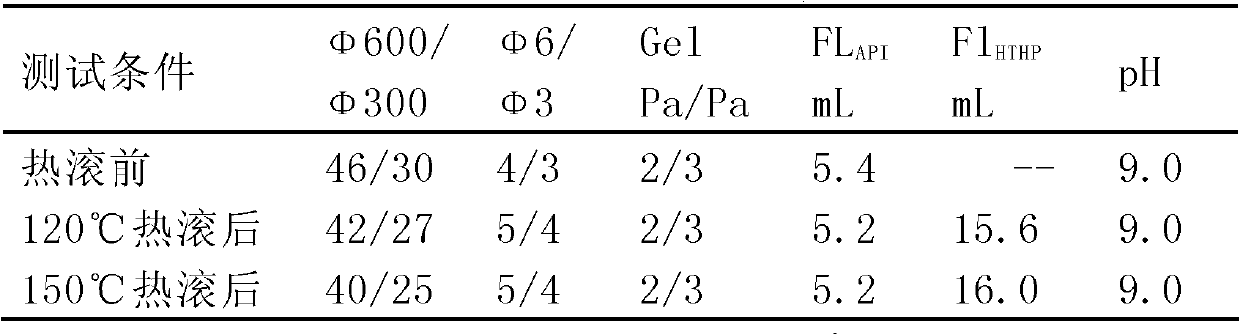

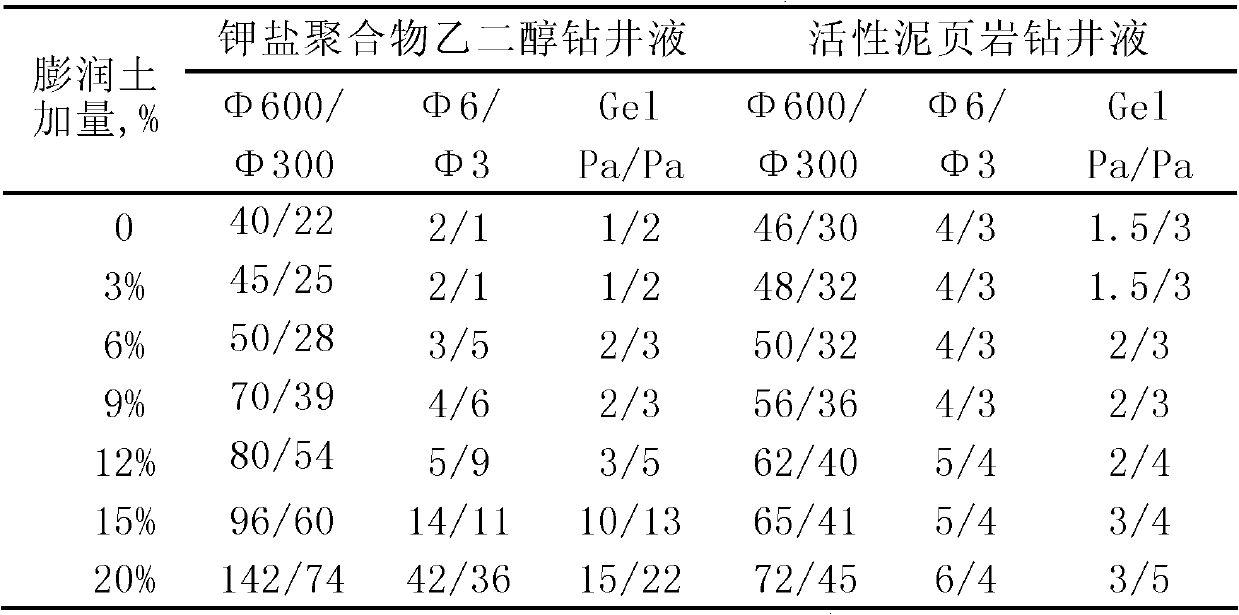

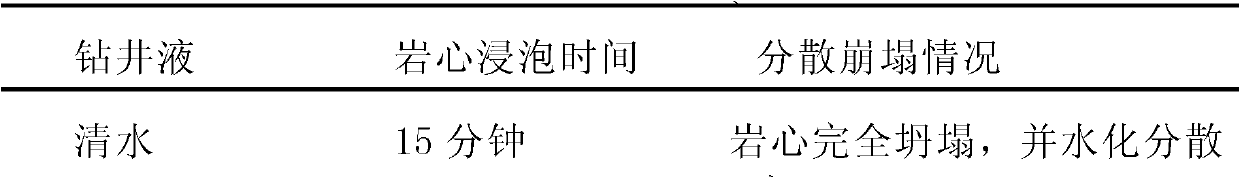

Embodiment 1

[0028] Embodiment 1: A kind of drilling fluid that is used for active mud shale drilling, each component weight percent is: bentonite 3.0%; What the flow pattern regulator adopts is low-viscosity polyanion cellulose 0.1% and low-viscosity carboxymethyl fiber 0.1%; 0.2% of the coating inhibitor is partially hydrolyzed polyacrylamide (PHPA), the degree of hydrolysis is 30% to 70%, and the molecular weight is 3-6 million; 0.5% of high temperature resistant polymer fluid loss reducer, high temperature resistant Polymer fluid loss reducer is sulfonate copolymer fluid loss reducer DSP-2 produced by Shandong Deshunyuan Petroleum Technology Co., Ltd.; potassium chloride 4%; polymer alcohol 2%, polymer alcohol is Henan Jinma Petroleum Technology Co., Ltd. Polymer alcohol anti-slump agent JMS-II produced by the company; polyamine inhibitor 1%, polyamine inhibitor CFY-01 produced by Chengfa Petroleum Technology Co., Ltd. in Renqiu City, Hebei Province; anti-mud bag fast drilling 0.8% of ...

Embodiment 2

[0030] Embodiment 2: A kind of drilling fluid that is used for active shale drilling, each component weight percent is: 6.0% bentonite; What the flow pattern regulator adopts is 0.1% low-viscosity anion cellulose and 0.1% starch; 0.3 % Coating inhibitor is partially hydrolyzed polyacrylamide (PHPA), the degree of hydrolysis is 30% to 70%, and the molecular weight is 3-6 million; 0.4% high temperature resistant polymer fluid loss reducer, high temperature resistant polymer fluid loss reducer The sulfonate copolymer fluid loss reducer DSP-2 produced for Shandong Deshunyuan Petroleum Technology Co., Ltd.; 6% potassium chloride; Slumping agent JMS-II; 0.5% polyamine inhibitor, polyamine inhibitor CFY-01 produced by Chengfa Petroleum Technology Co., Ltd., Renqiu City, Hebei Province; 0.5% anti-mud bag fast drilling agent, anti-mud The fast drilling agent is made of fatty alcohol ether phosphate MOA-3P produced by Jiangsu Haian Petrochemical Plant; water 84.1%.

[0031] After each ...

Embodiment 3

[0032]Embodiment 3: A kind of drilling fluid that is used for active mud shale drilling, each component weight percentage is: bentonite 3.0%; What the flow pattern regulator adopts is the low-viscosity polyanion cellulose 0.1%; 0.3% coating inhibition The agent is partially hydrolyzed polyacrylamide (PHPA), the degree of hydrolysis is 30% to 70%, and the molecular weight is 3 to 6 million; the high temperature resistant polymer fluid loss additive is 0.5%, and the high temperature resistant polymer fluid loss additive is from Shandong The sulfonate copolymer fluid loss reducer DSP-2 produced by Deshunyuan Petroleum Technology Co., Ltd.; 7% potassium chloride; 3% polymer alcohol. Slumping agent JMS-II; polyamine inhibitor 1%, polyamine inhibitor is polyamine inhibitor CFY-01 produced by Chengfa Petroleum Technology Co., Ltd., Renqiu City, Hebei Province; anti-mud bag fast drilling agent 1%, anti-mud The fast drilling agent used is fatty alcohol ether phosphate MOA-3P produced b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cloud point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com