Patents

Literature

155results about How to "Efficient drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

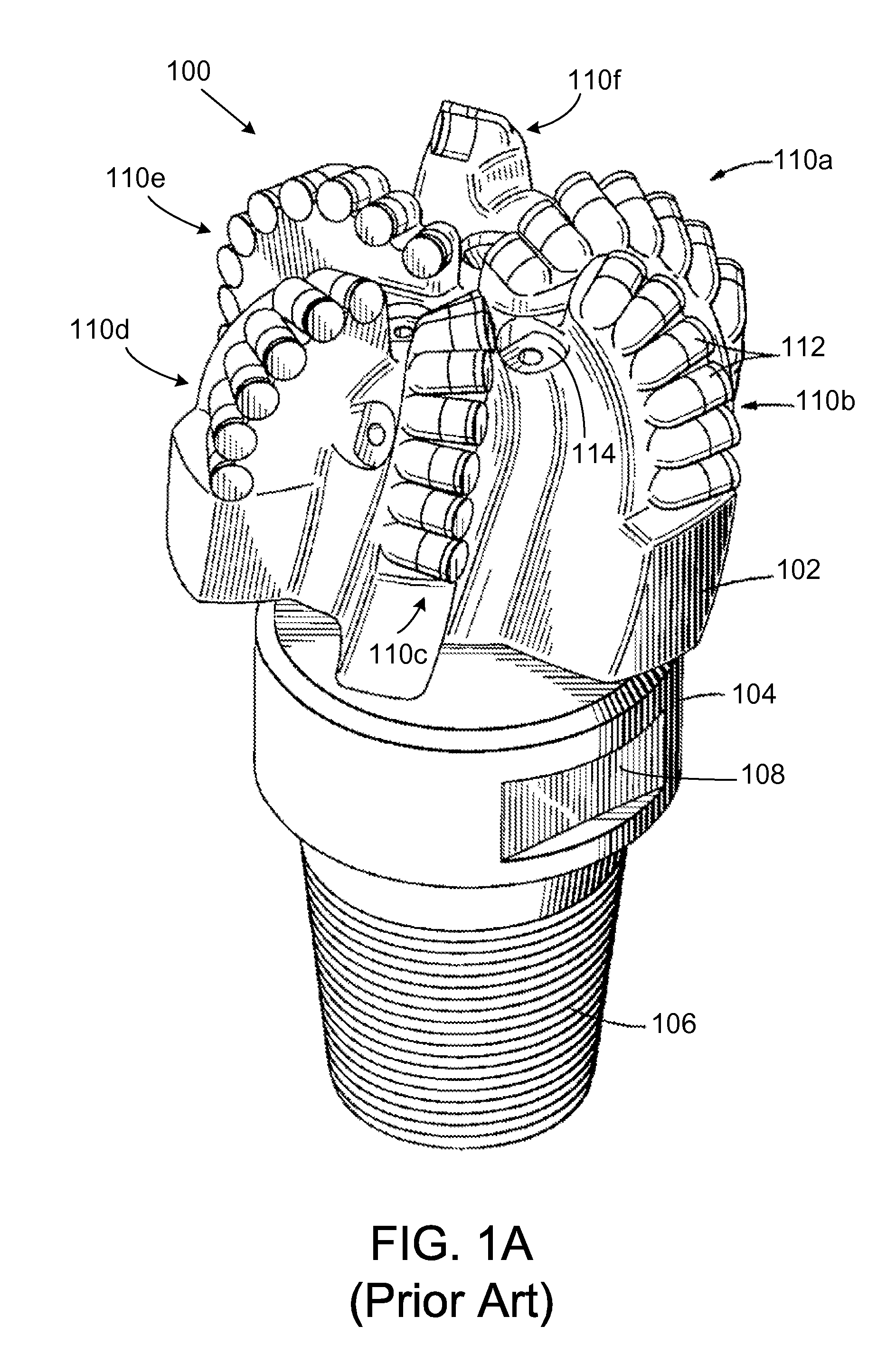

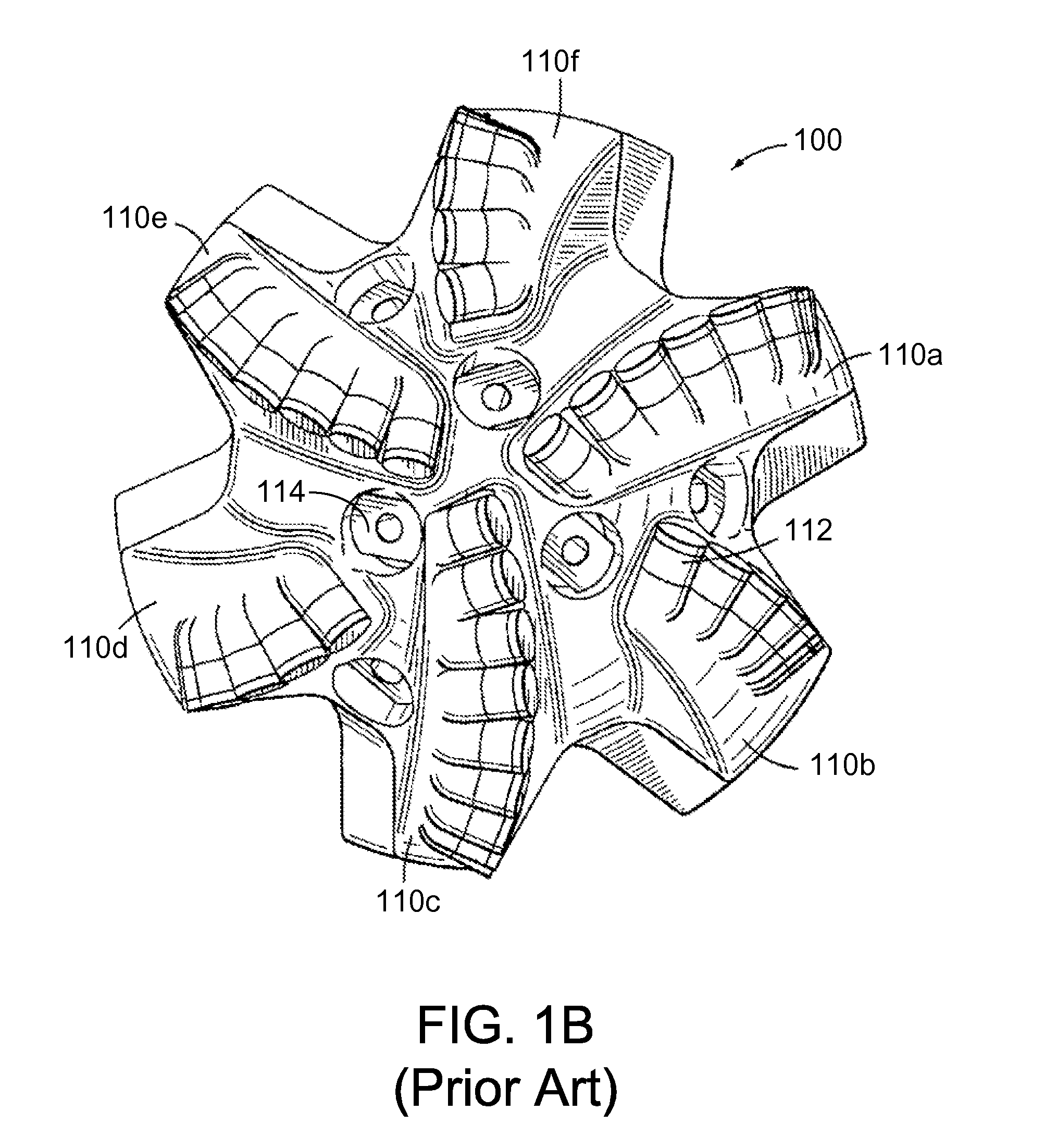

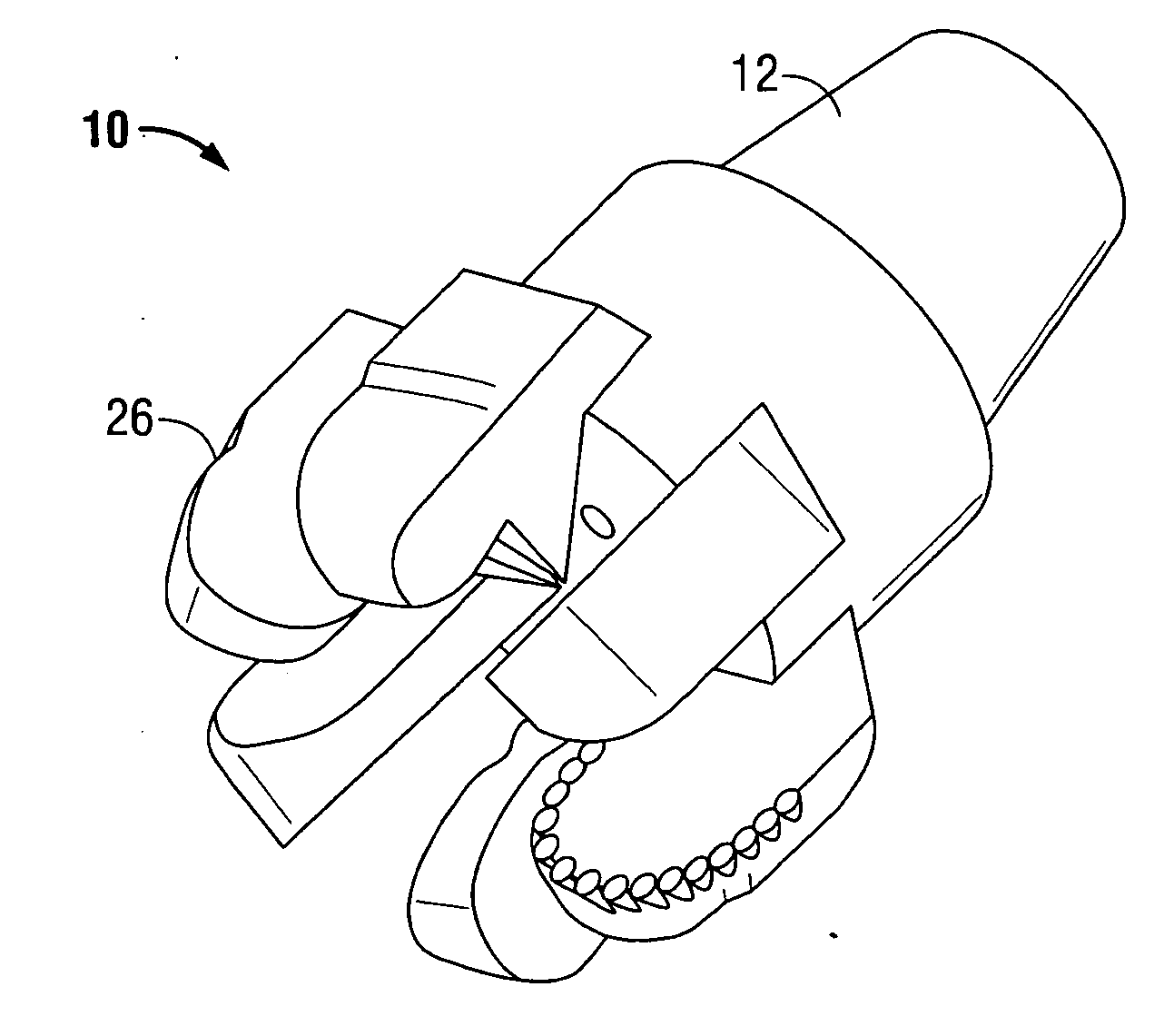

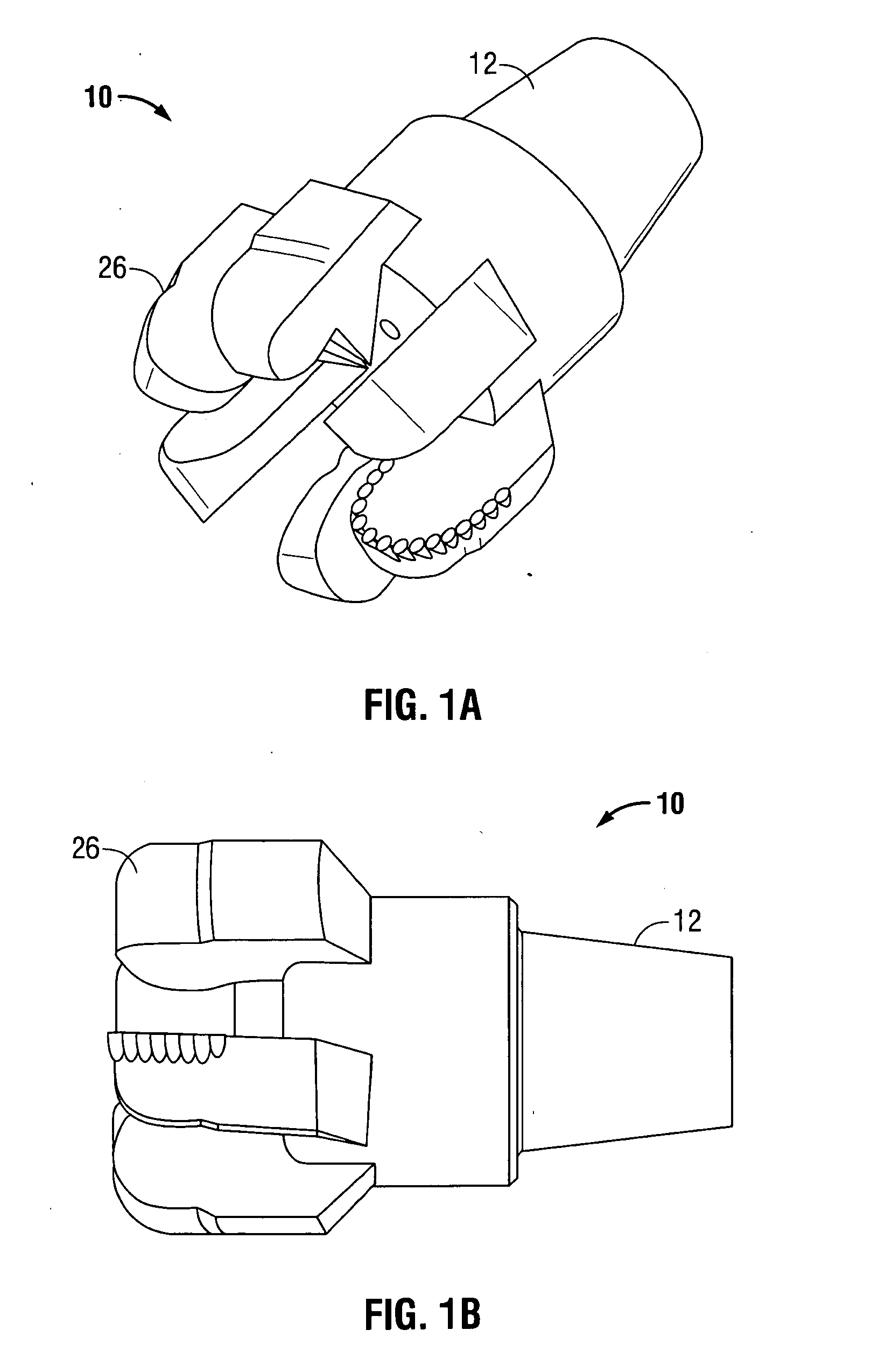

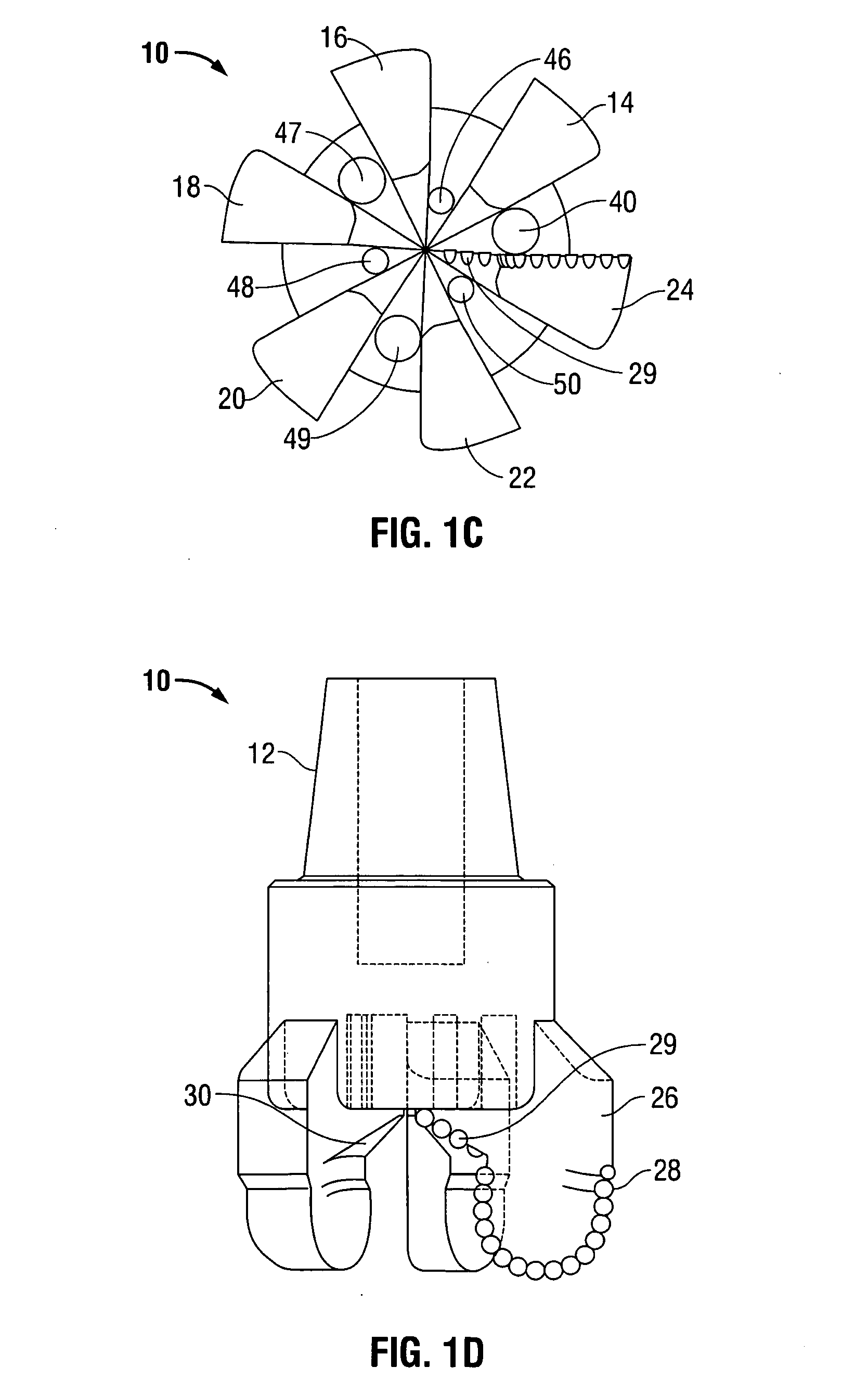

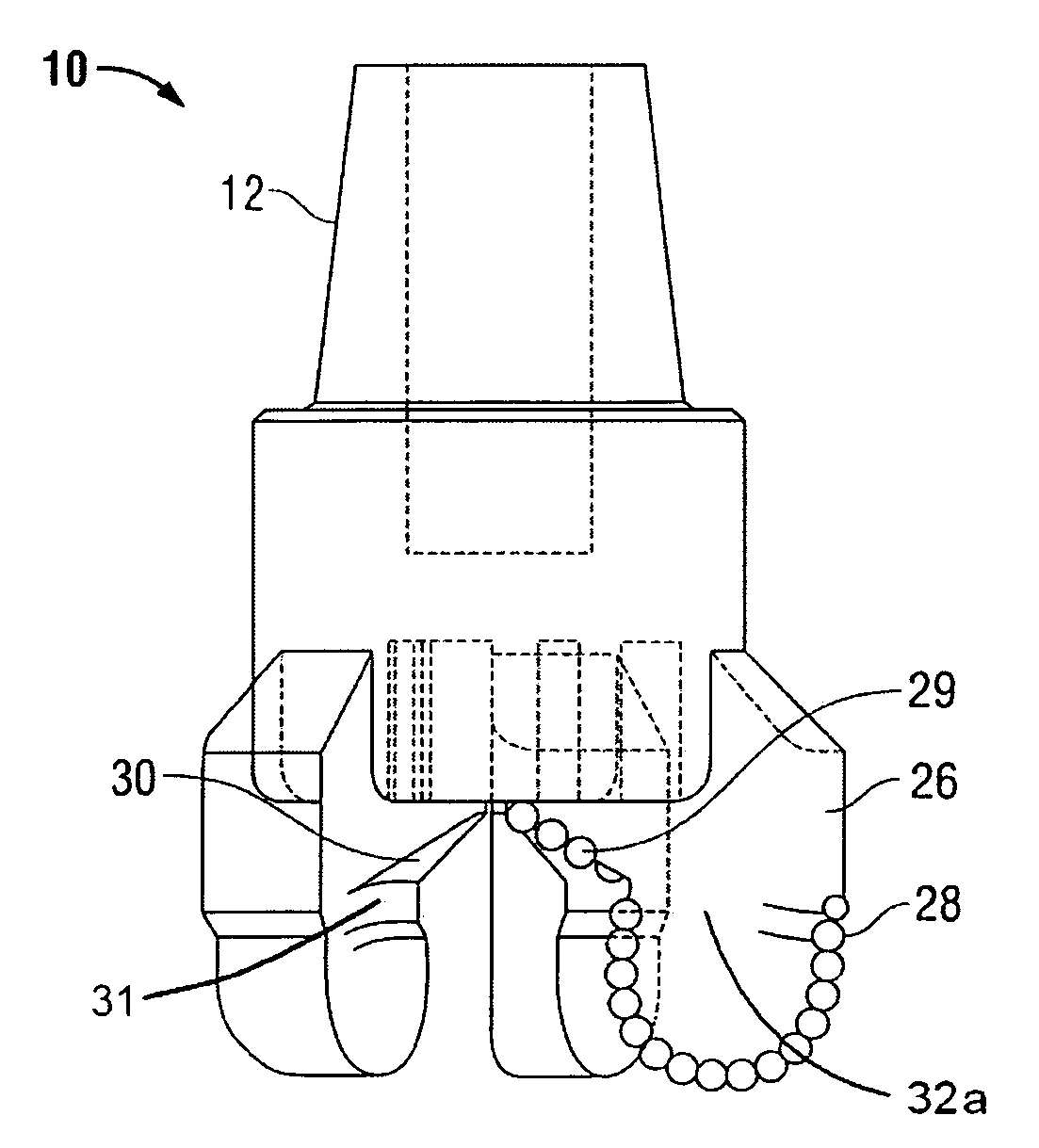

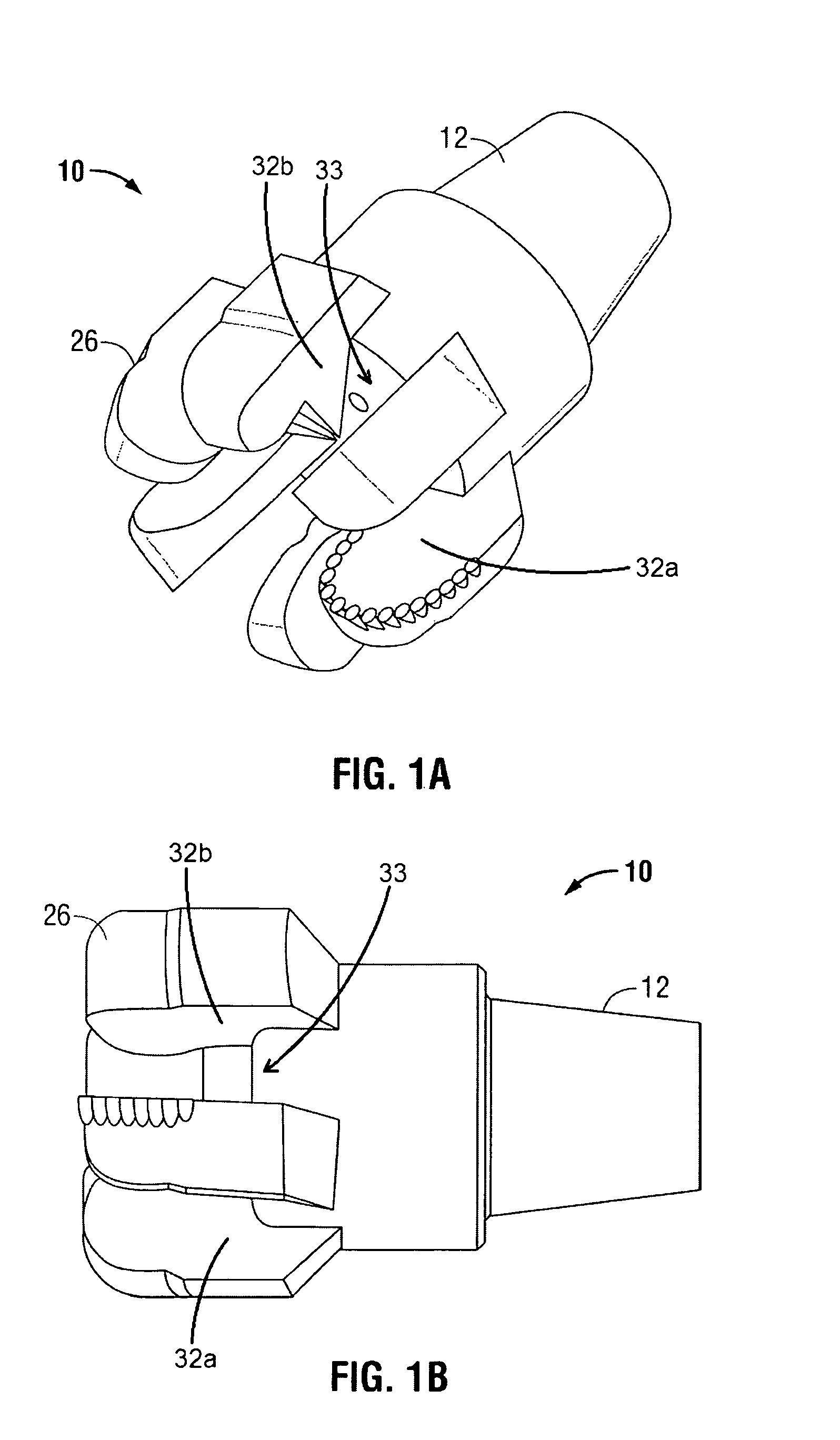

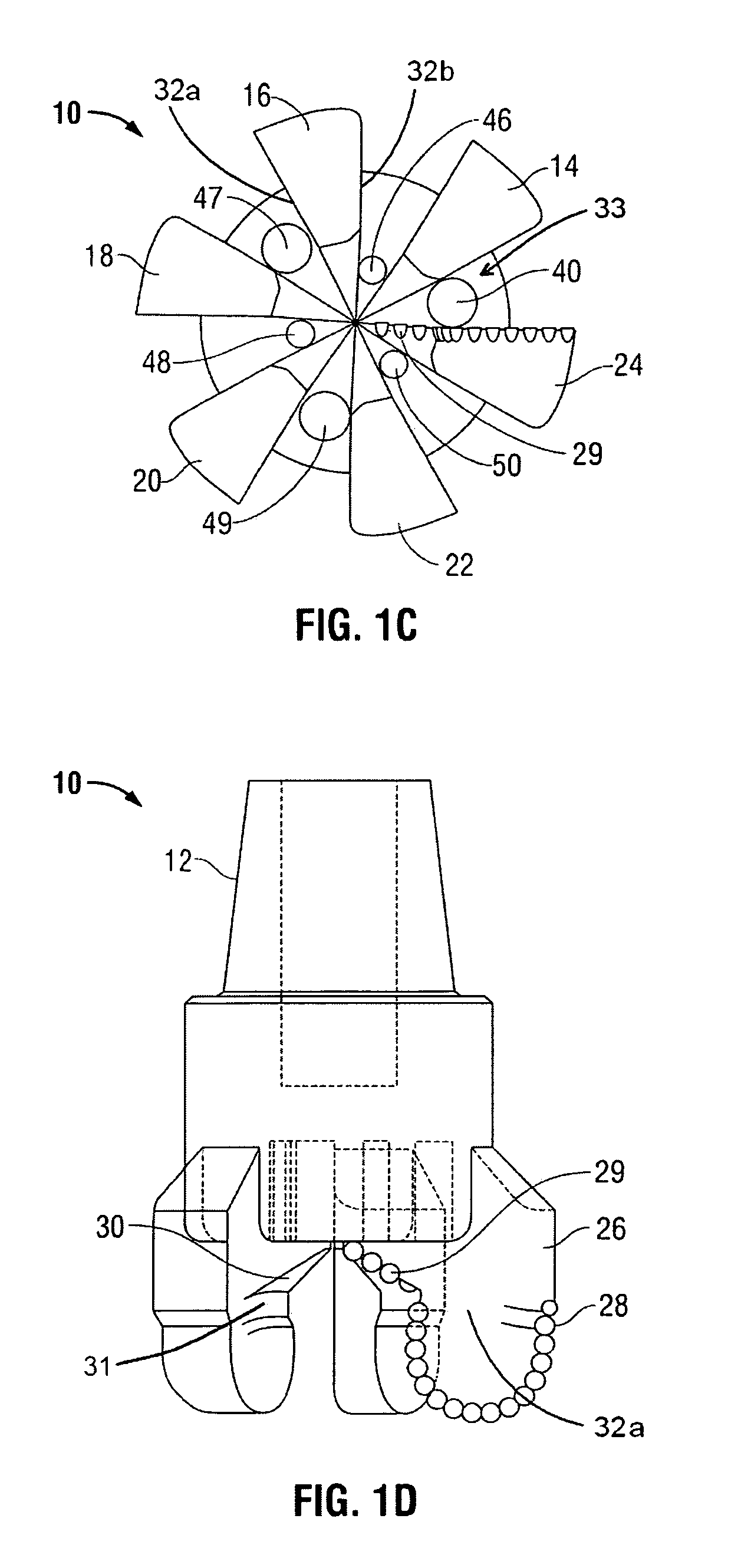

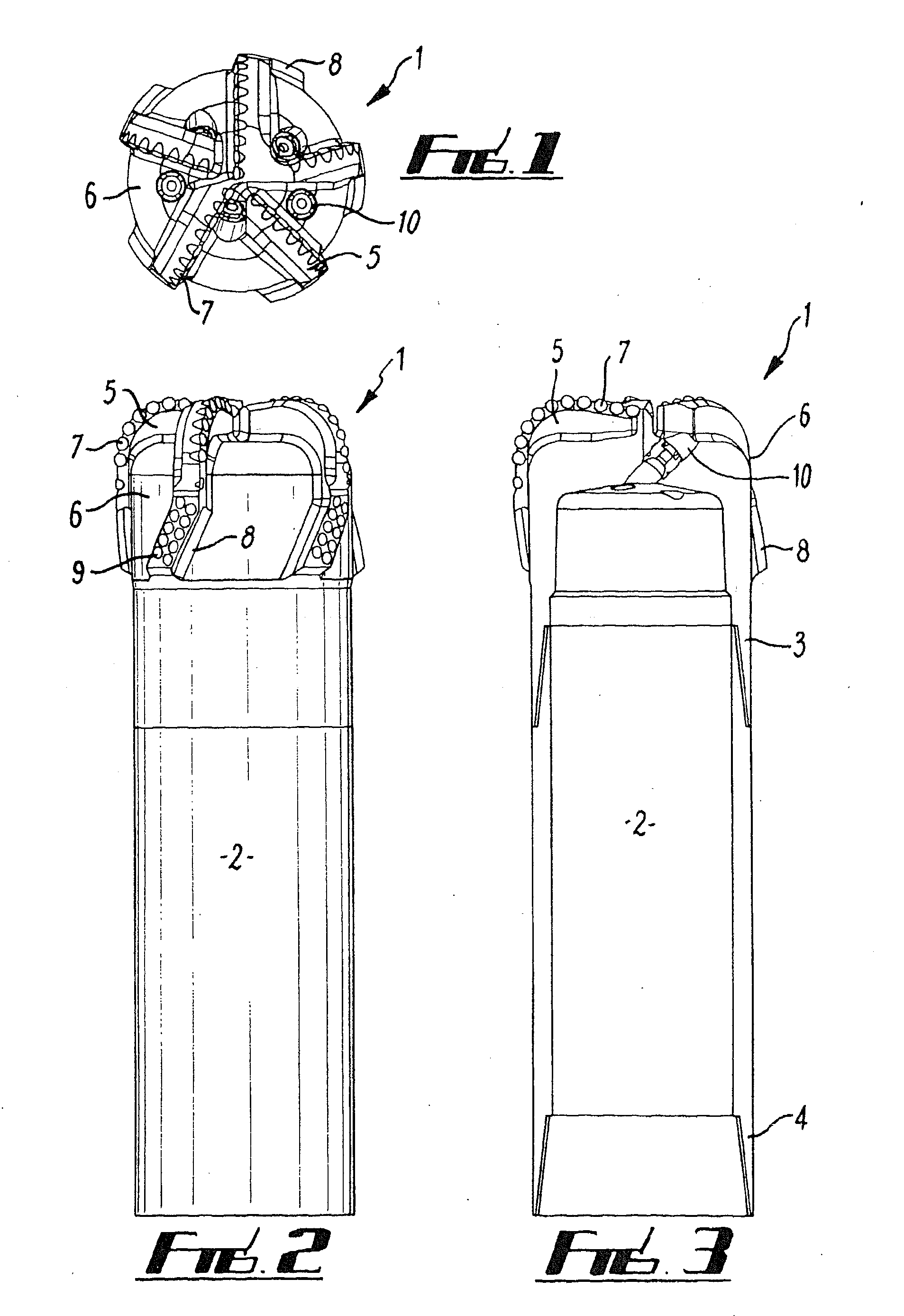

Modular kerfing drill bit

InactiveUS20060196699A1Component part be reduceQuickly assembleDrill bitsCutting machinesEngineeringDrill bit

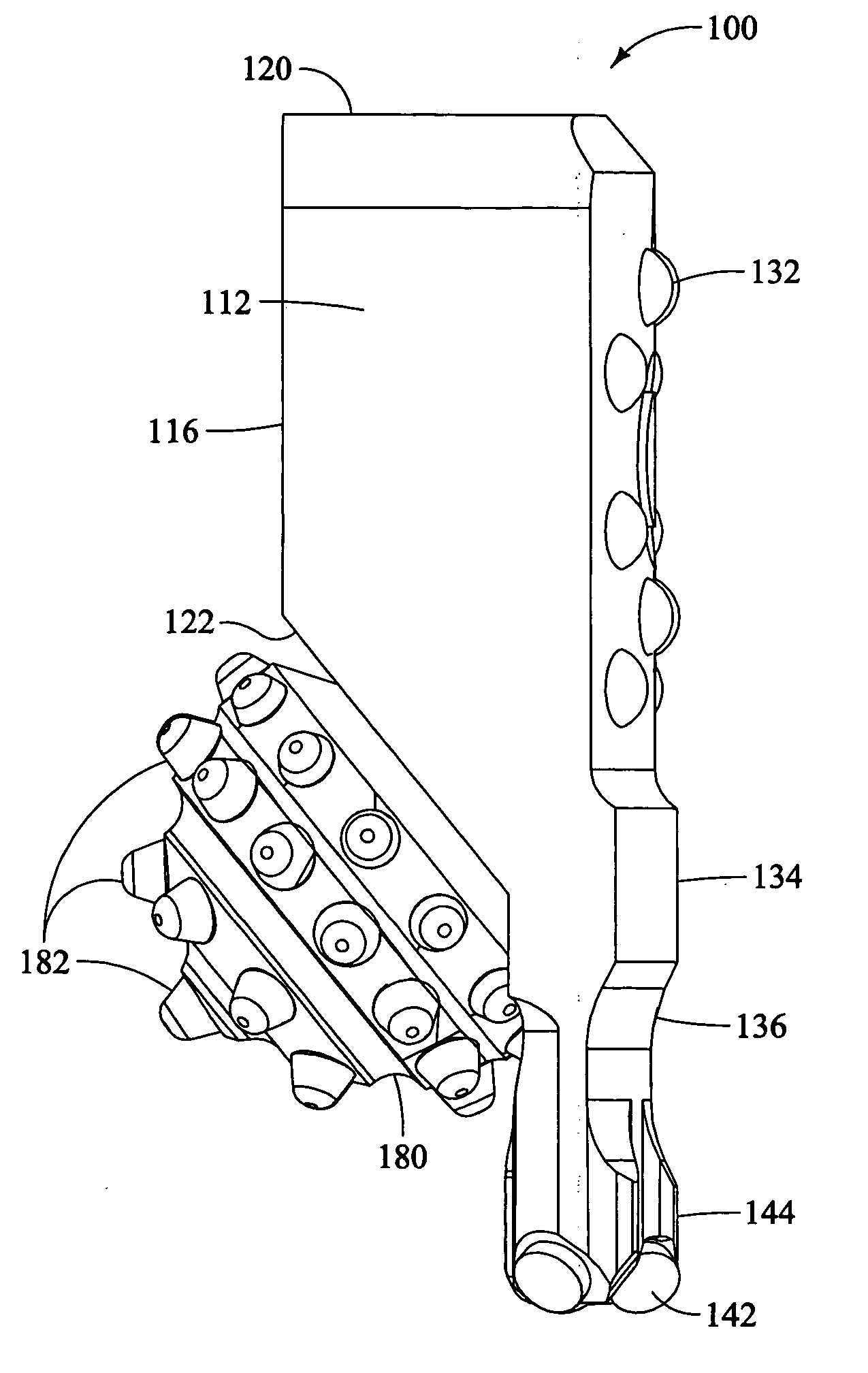

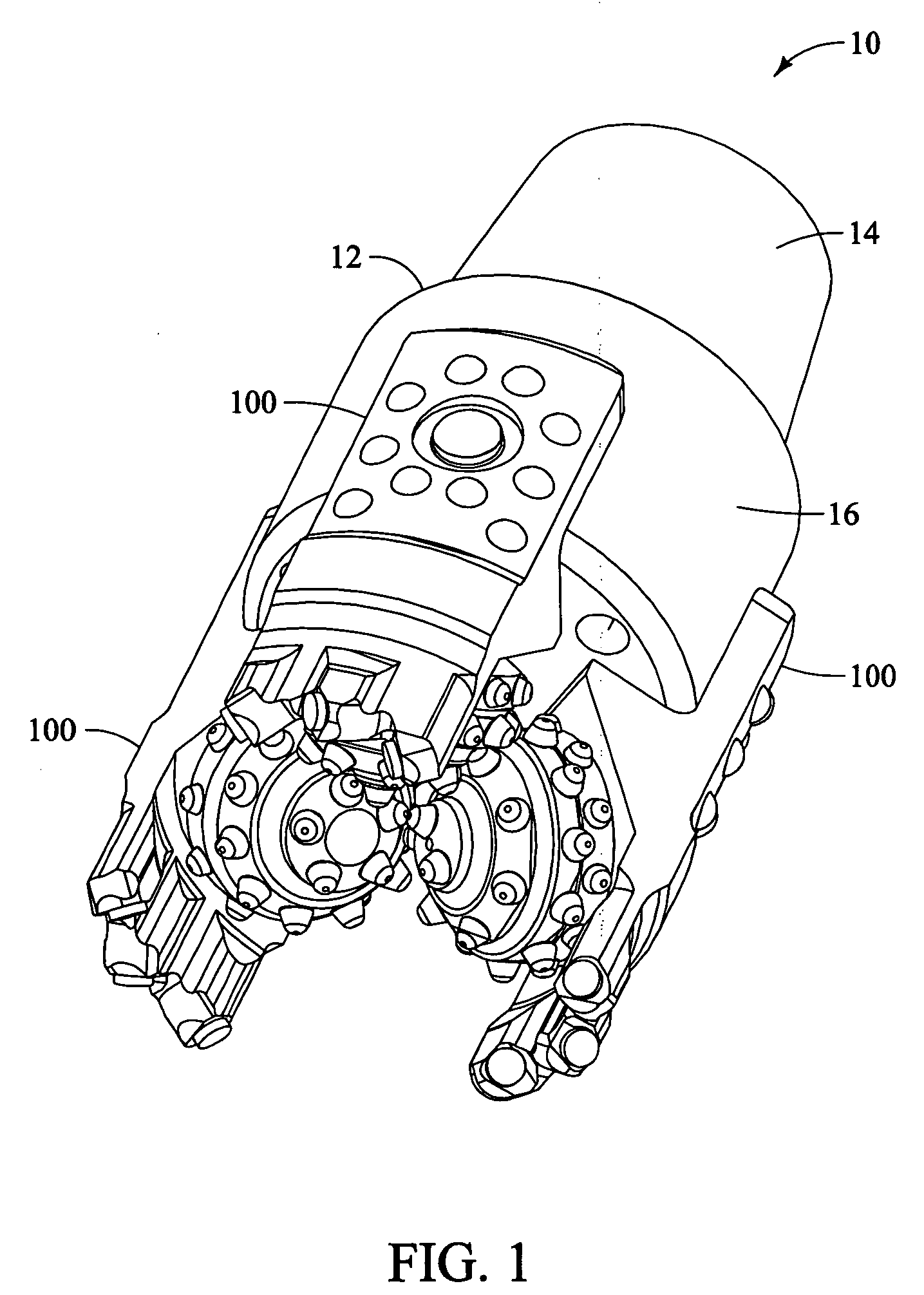

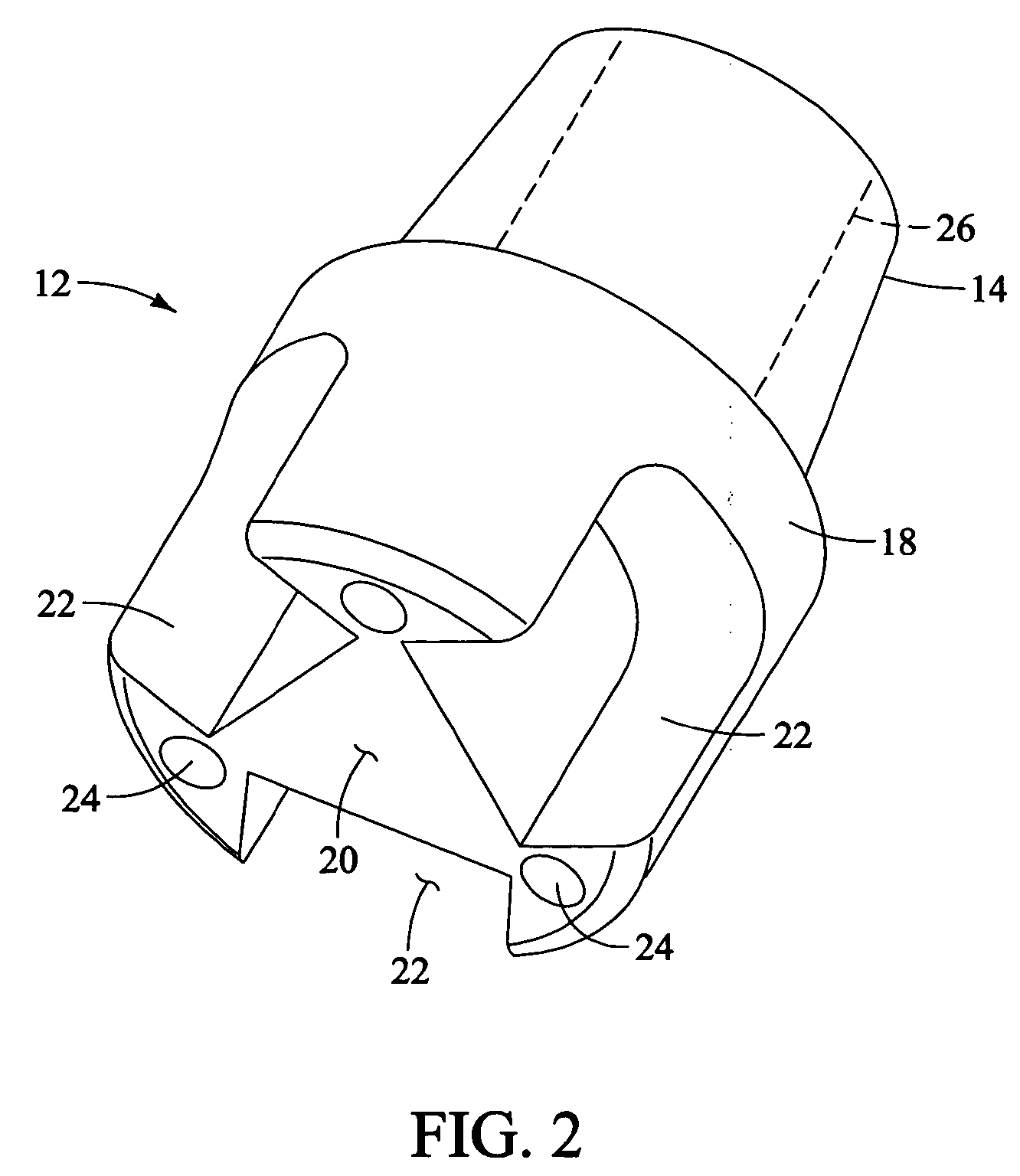

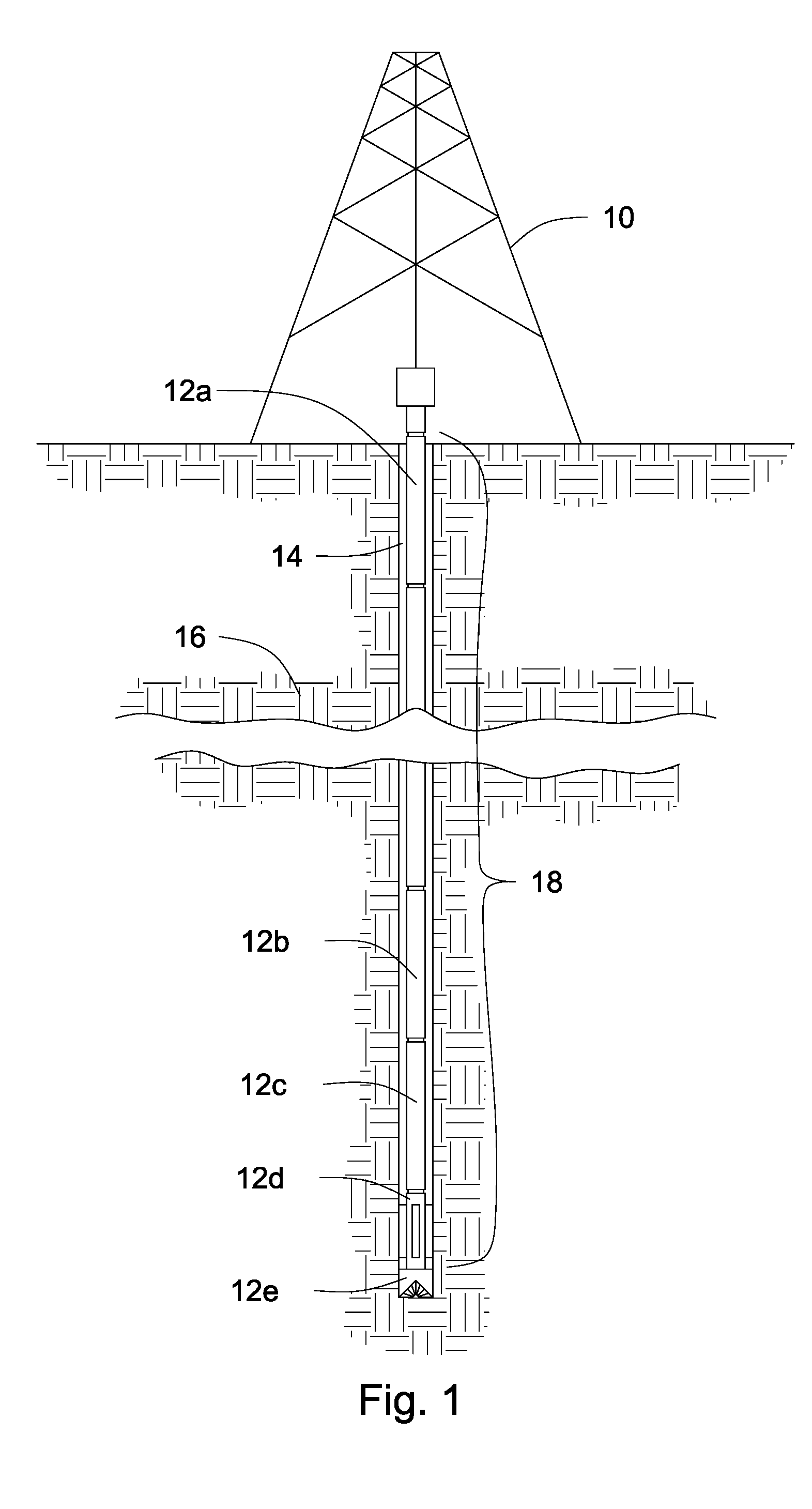

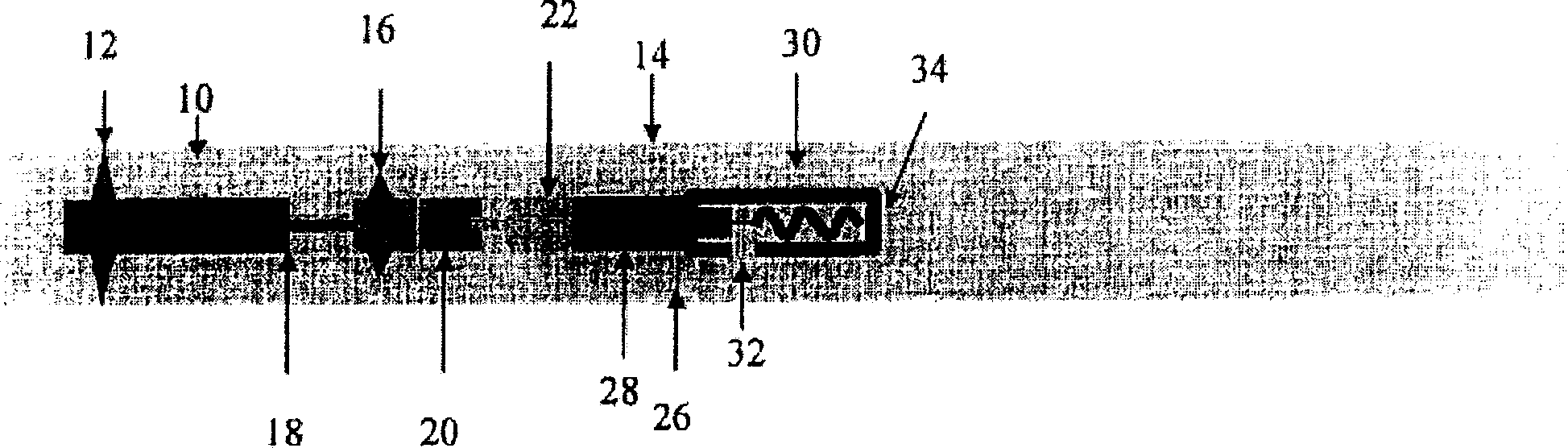

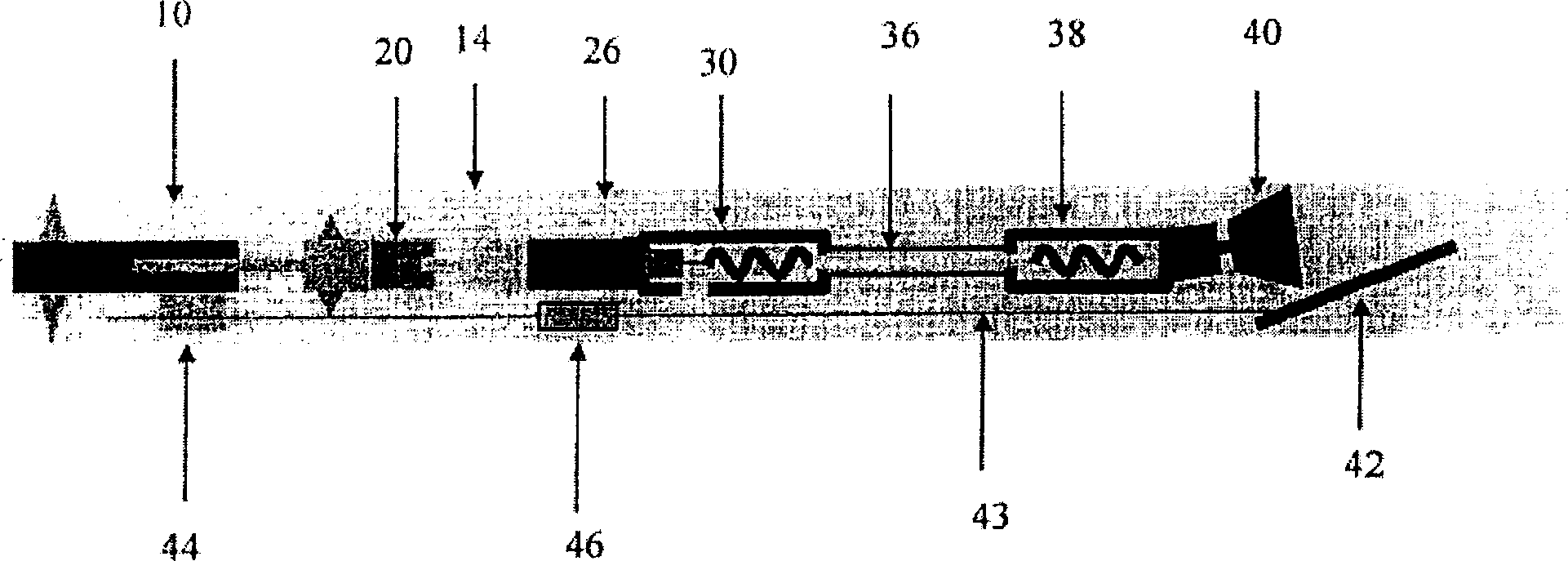

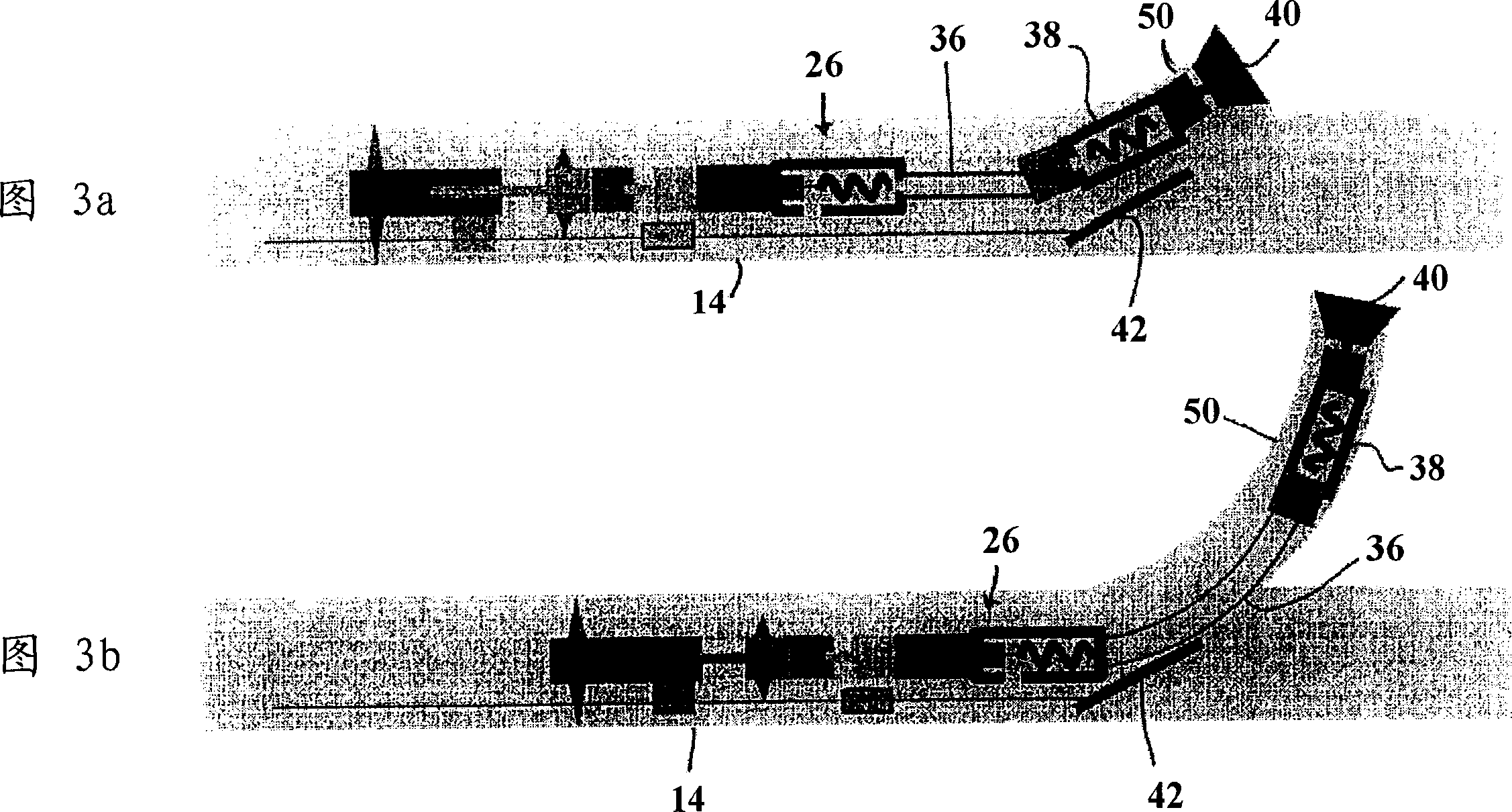

A modular kerfing rock drilling bit (10) is presented. Drill bit (10) comprises a bit body (12) having a connection (14) for attachment to a drill string member. A base portion (16) below the connection (14) has an outer portion (18) and a bottom (20). Slots (22) are formed in the base portion (16). A cutter assembly (100) comprises a leg (110) insertable into the slot (22) of the bit body (16). A journal (126) extends angularly downward and inward from the leg (110) for bearing support of a cone (180) rotatably mounted on the journal (126). A plurality of cutters (182) extend outward from the surface of the cone (180). A kerfing segment (140) extends downward from the leg (110) beyond the cone (180). A plurality of kerf cutters (142) are attached to the bottom of the kerfing segment (140).

Owner:GEN ELECTRIC CAPITAL +2

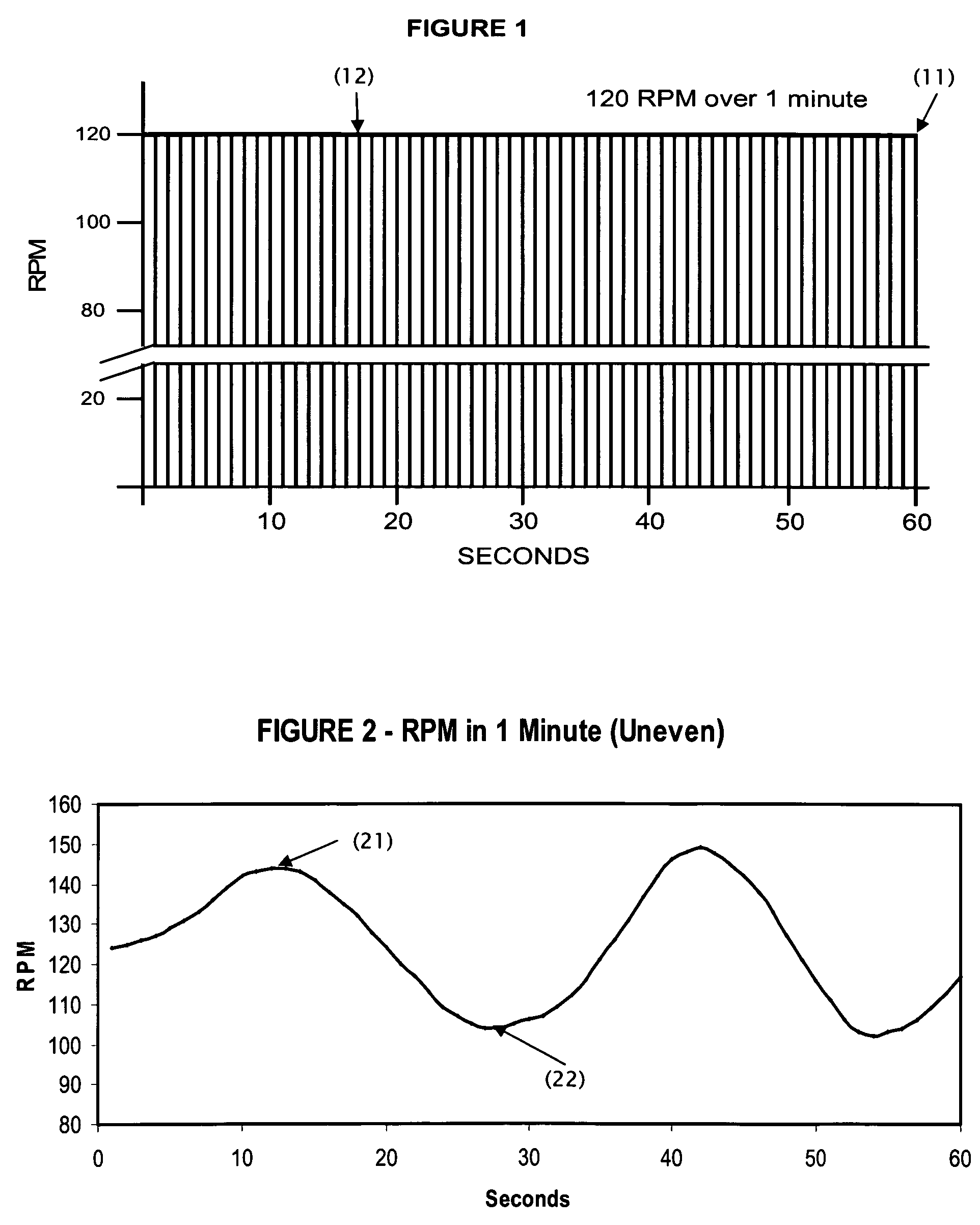

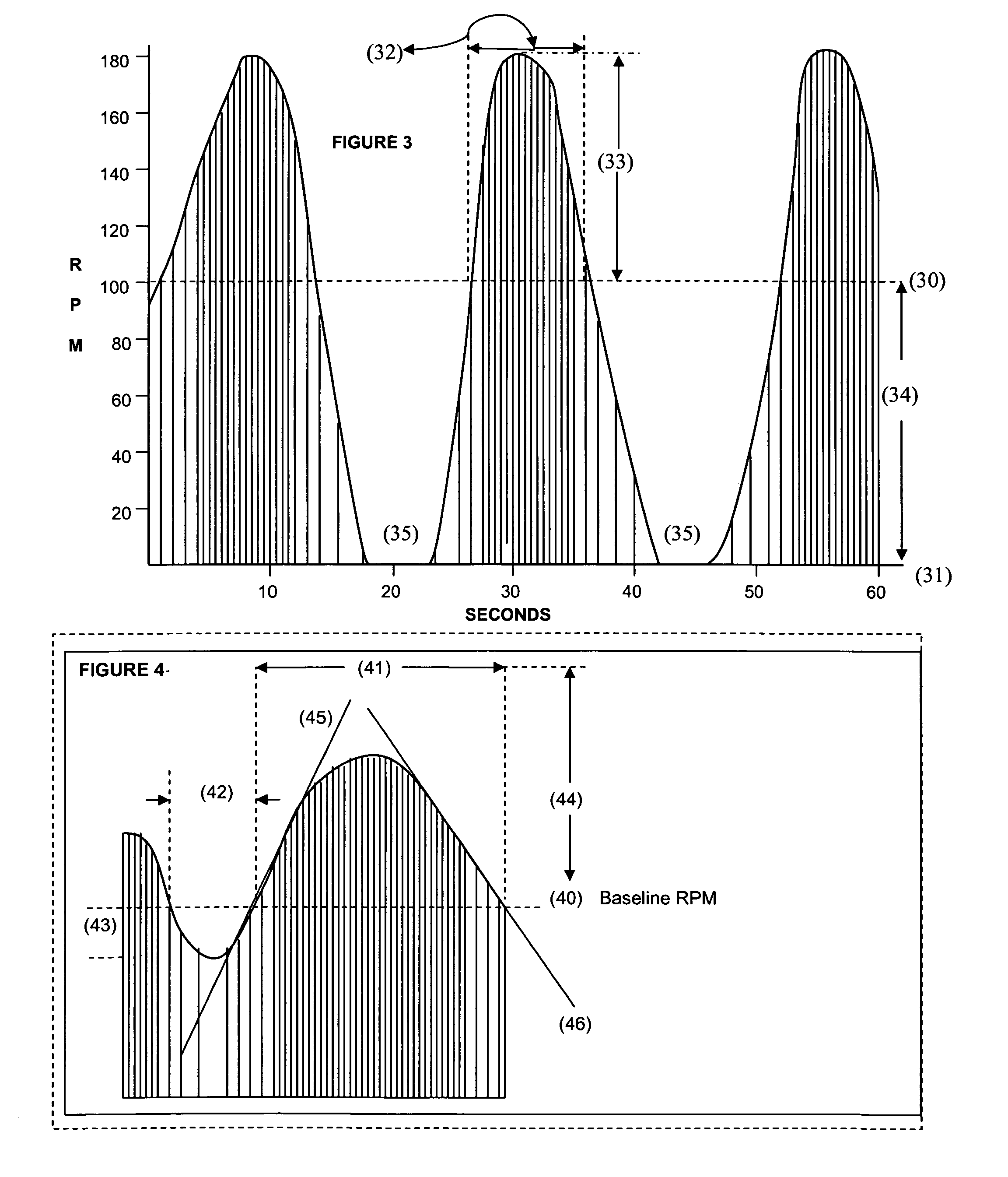

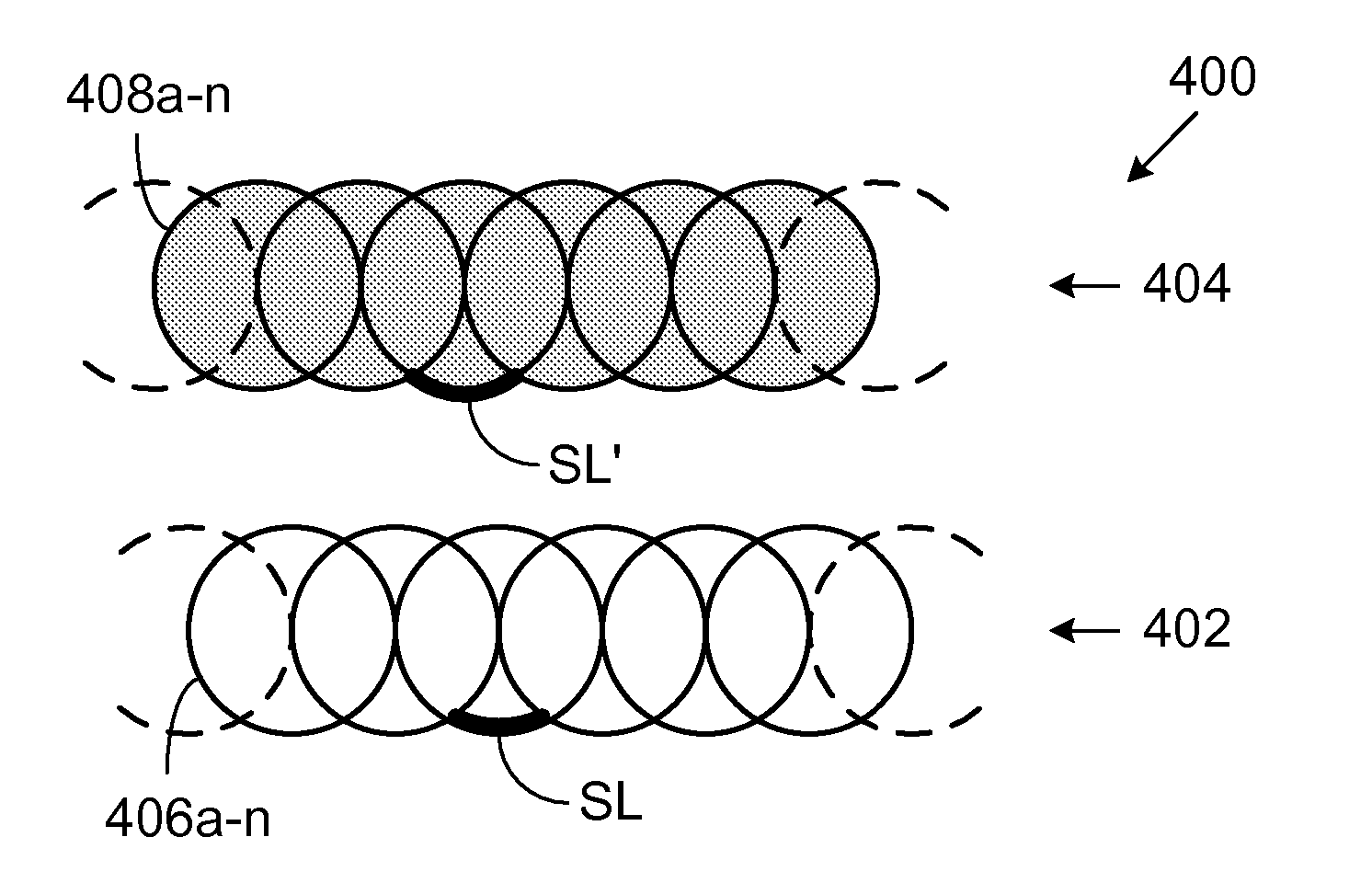

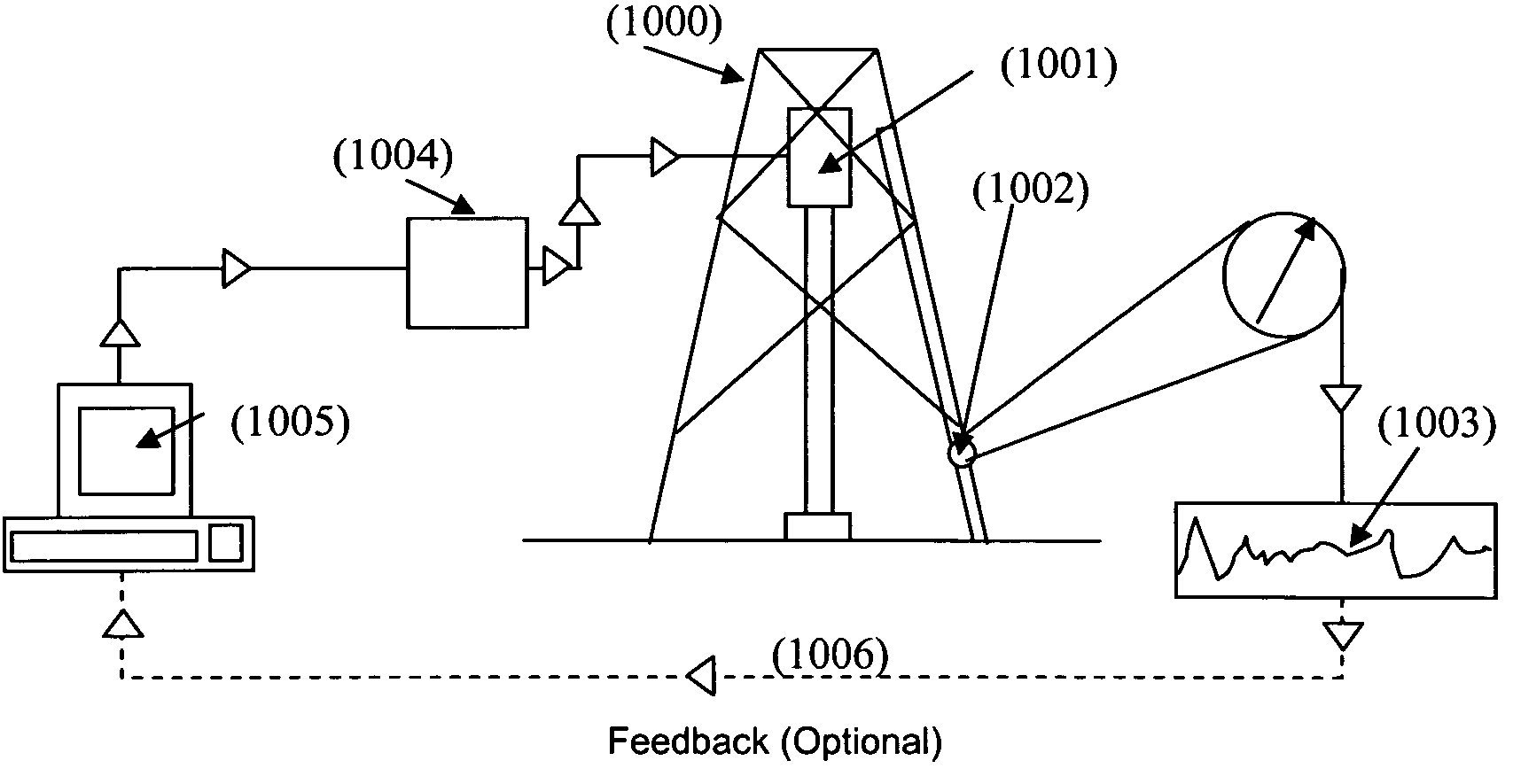

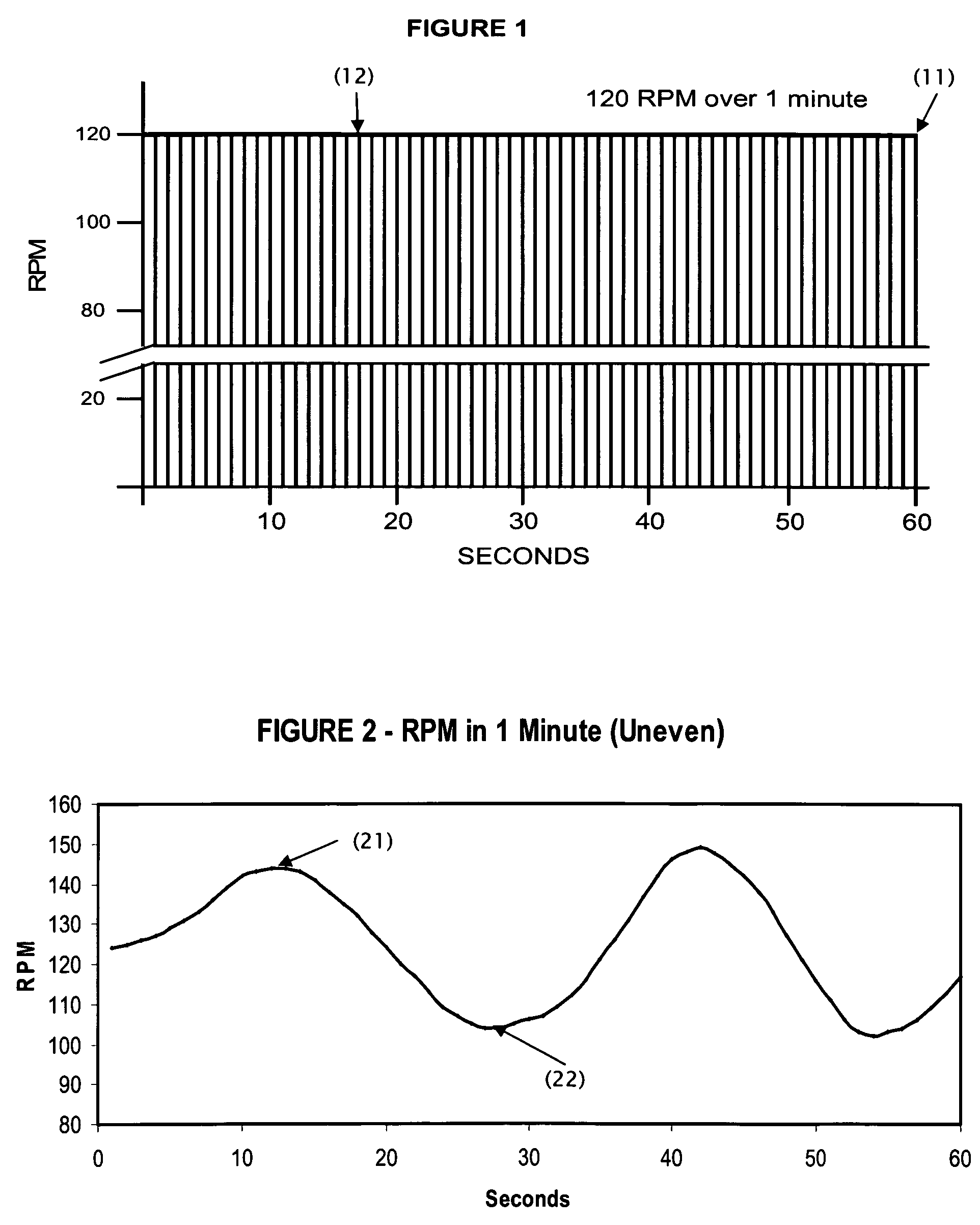

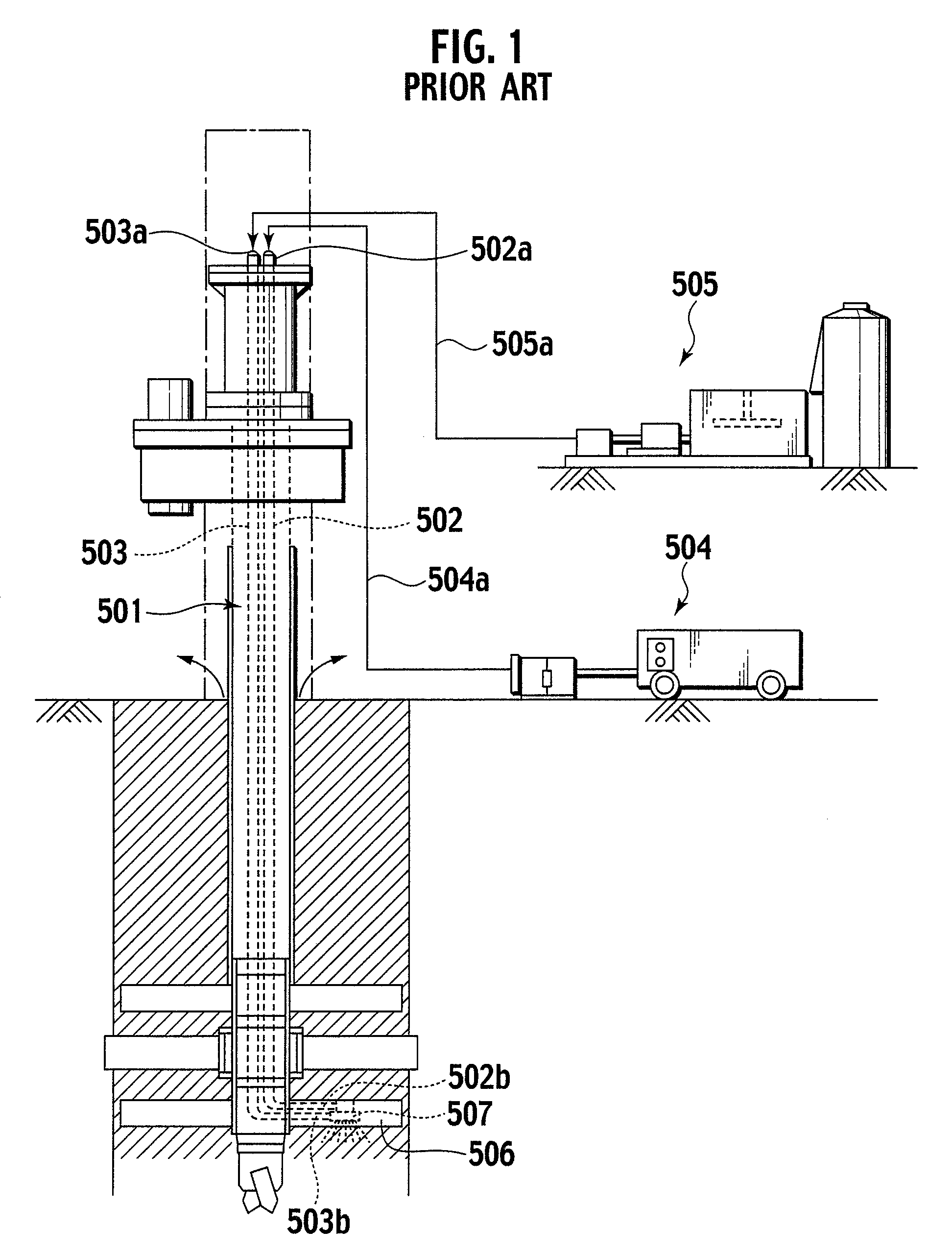

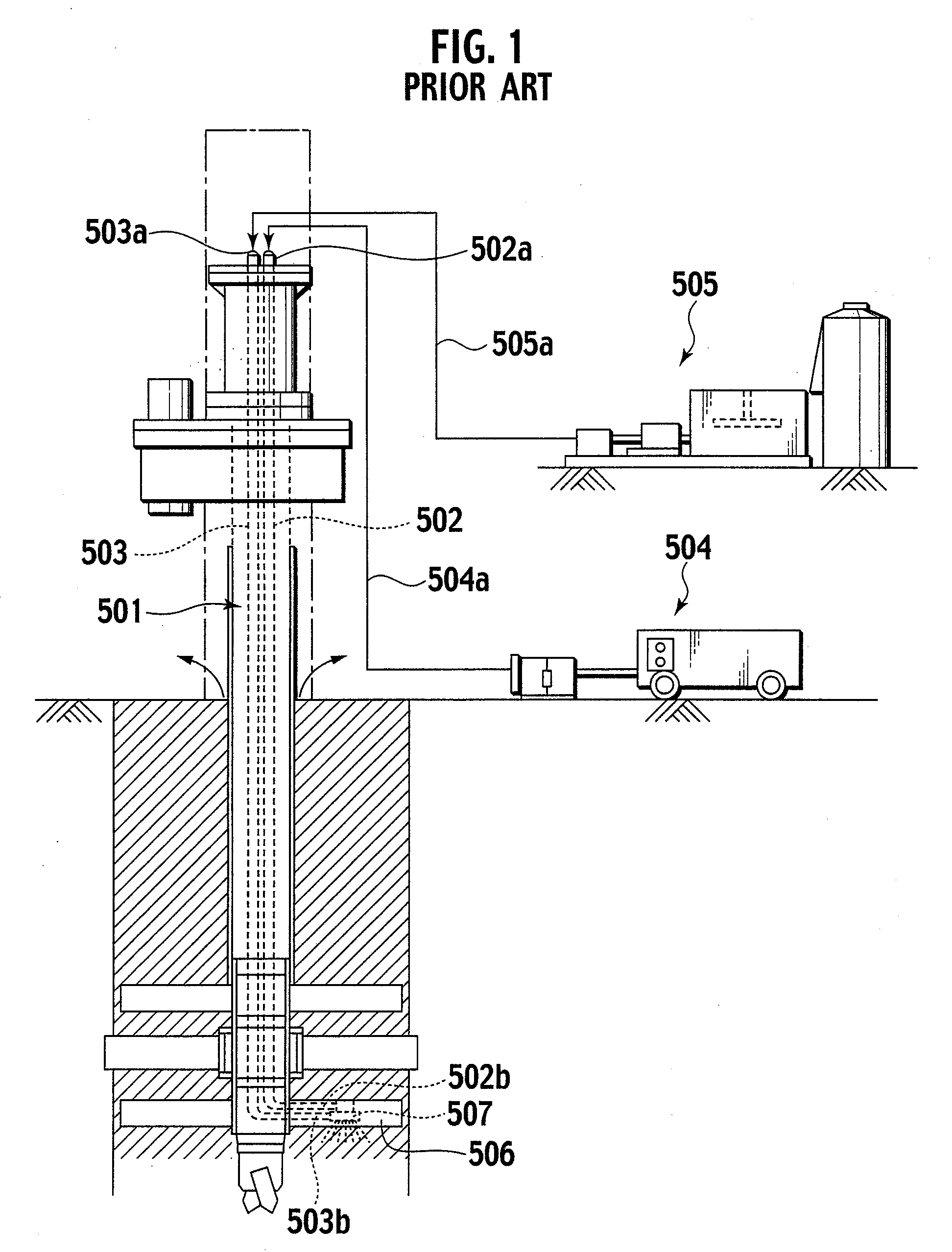

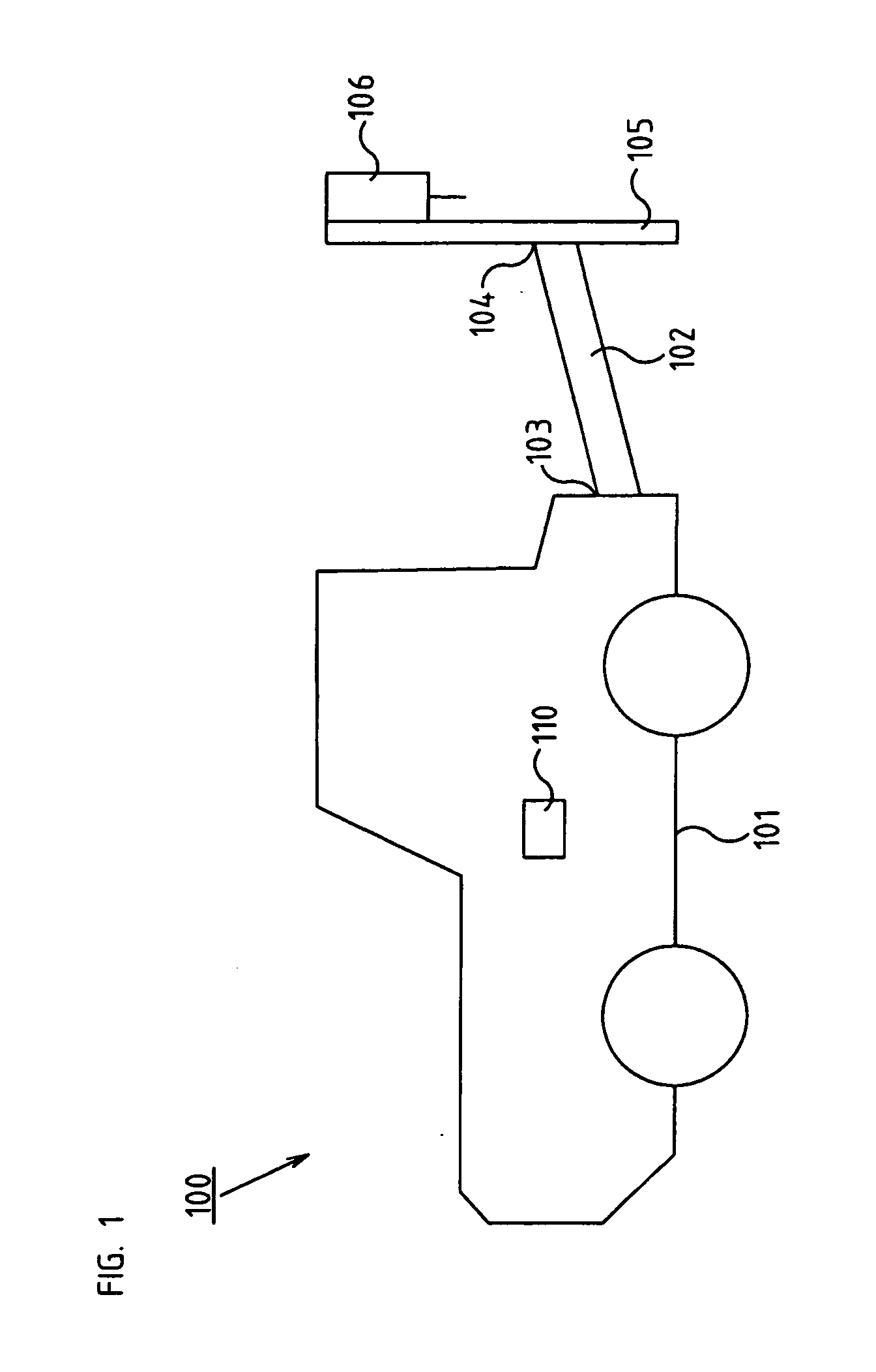

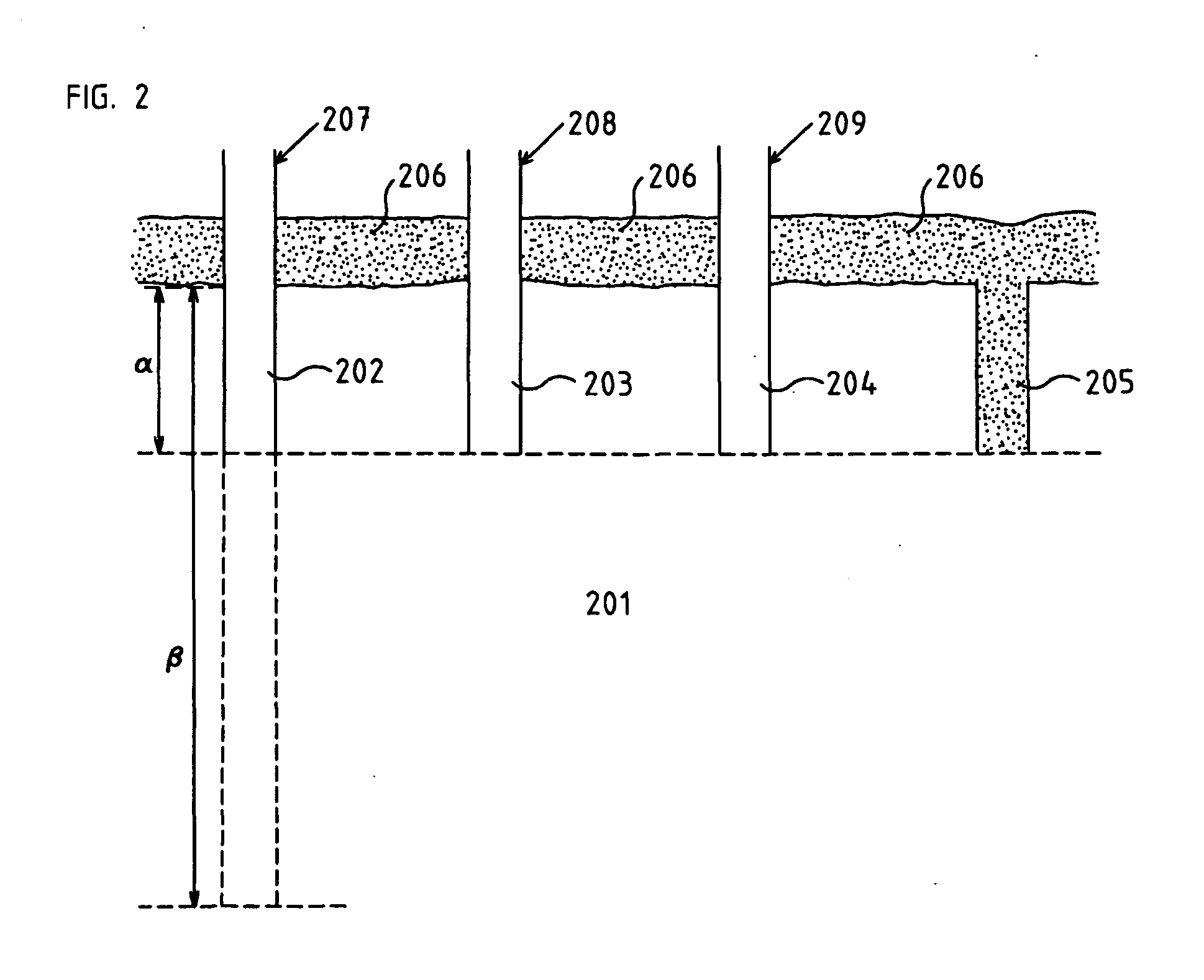

Adaptive apparatus, system and method for communicating with a downhole device

InactiveUS20080000688A1Less disruptiveAvoids and mitigatesSurveyCore removalData transmissionSelf adaptive

A system, apparatus and method for adaptive communication with a downhole device is disclosed. The instant invention proposes an adaptive system of communicating information from the surface of the earth to a device located downhole; thereby optimizing the drilling process by adaptively fitting the talkdown protocol around the existing drillstring RPM. A further economic benefit is that with this adaptive system the ΔRPM Offset between the optimized drilling condition and the RPM required for data transmission can be monitored and adjusted in real-time, resulting in less disruption to the drilling process. Several embodiments are given.

Owner:MV DRILLING & SERVICES

Drill bit with staged durability, stability and ROP characteristics

InactiveUS20070267227A1Different impact resistance characteristicCharacteristic be differentDrill bitsConstructionsRadial positionMultiple stages

Drill bit with multiple stages of durability and ROP characteristics is disclosed. The drill bit has multiple layers of cutters established by deploying the cutters on blades of different heights or maintaining the blades at the same height and deploying the cutters to have different heights on one or more blades. Each layer provides independent bottom hole coverage and has independent stabilization, ROP, and durability characteristics so as to effectively drill through different subsurface formations. Cutters deployed on the different layers have their respective centers at substantially different radial positions. Due to the different radial positions, cutters in different layers cut different swaths in the subsurface formation. Cutters in different layers may also have different initial peripheral portions or shear lengths, resulting in different impact resistance characteristics for the different layers. This changes the wear and / or cutter deterioration processes for the different layers, resulting in different and / or improved toughness characteristics.

Owner:VAREL INT IND

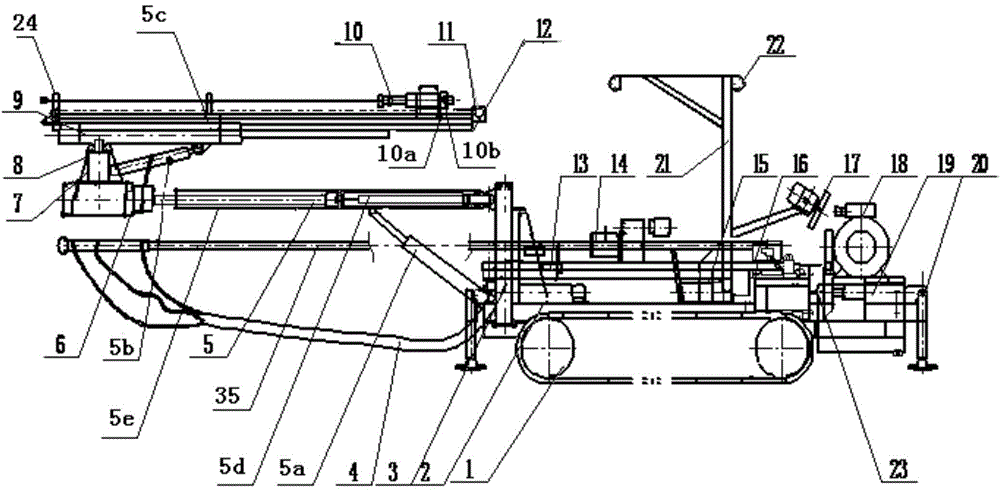

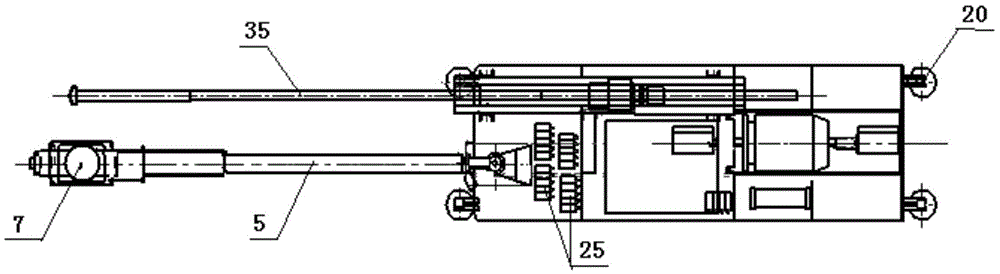

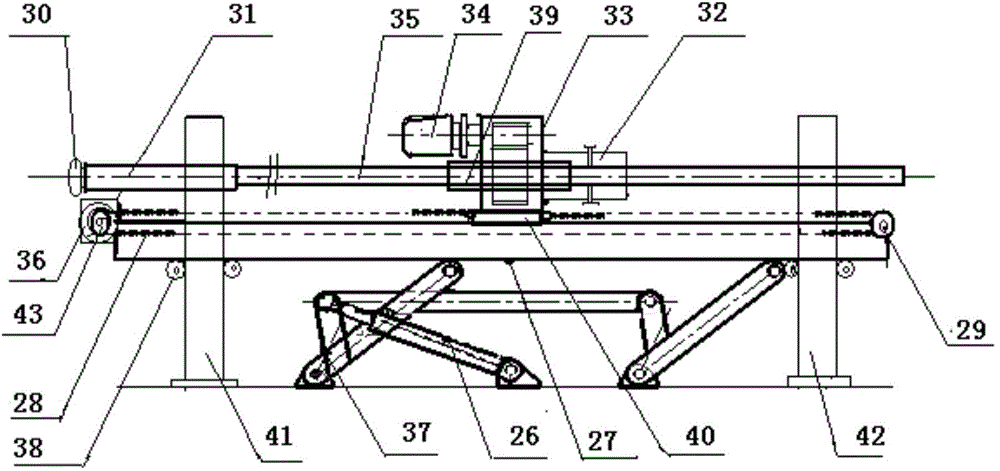

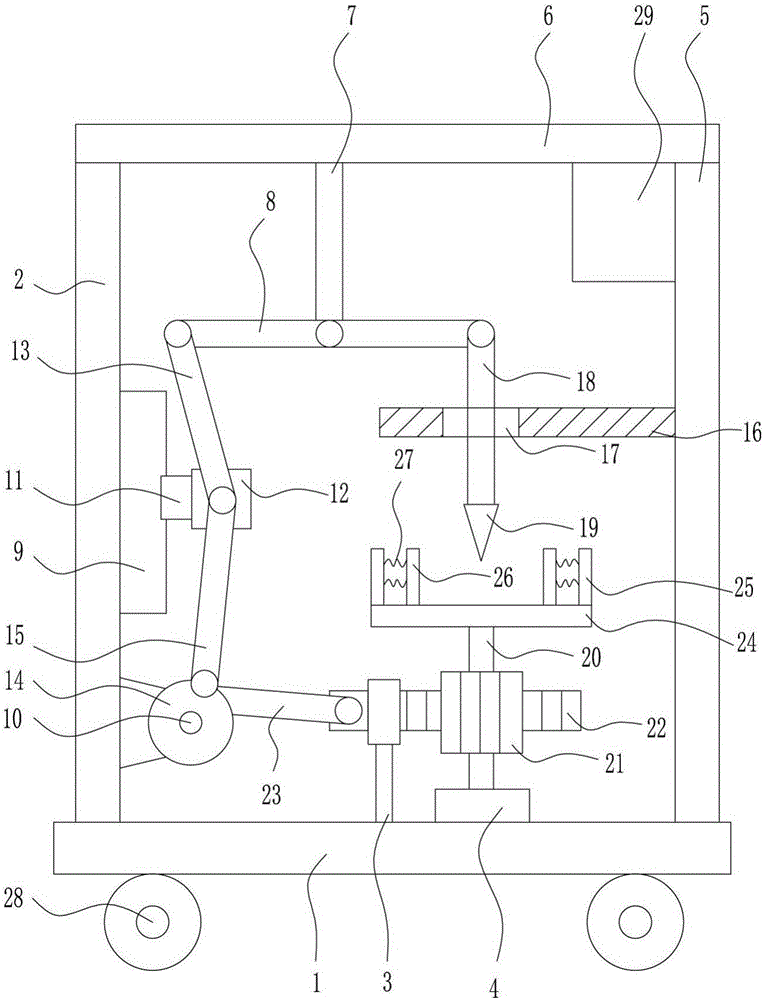

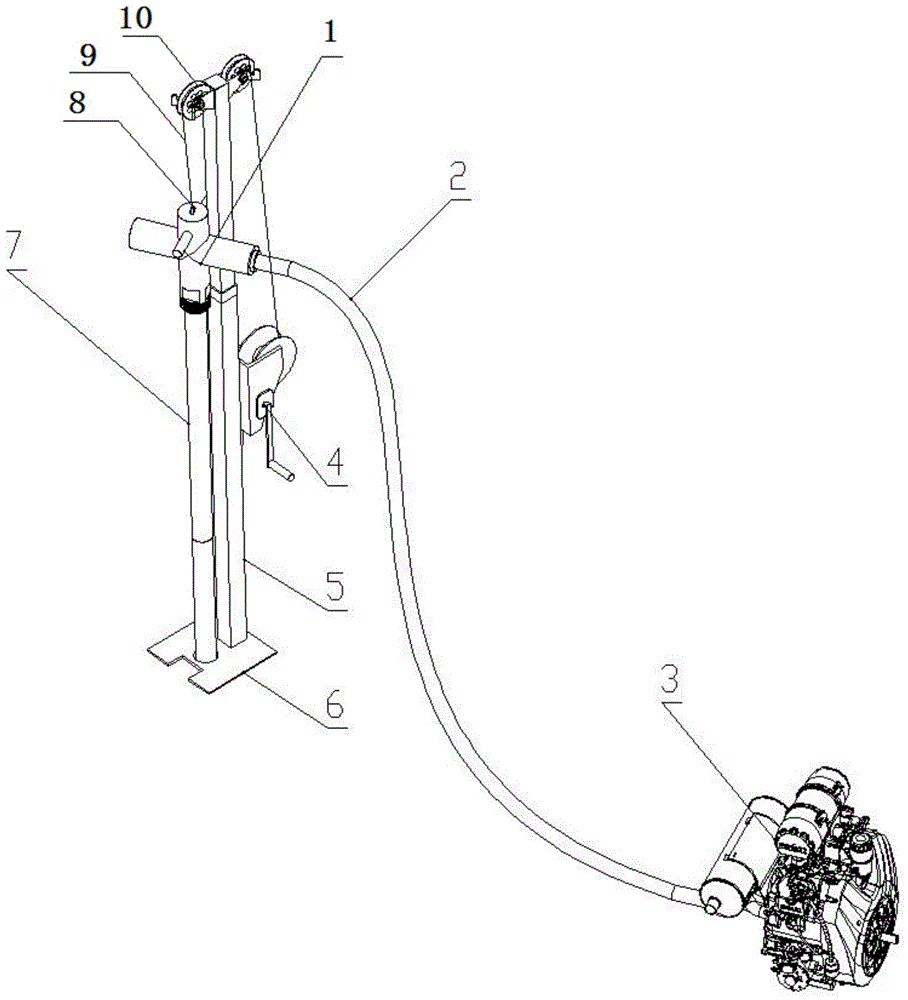

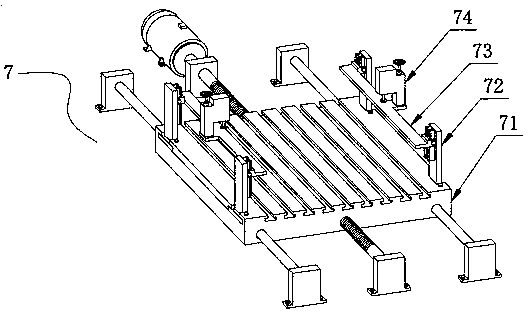

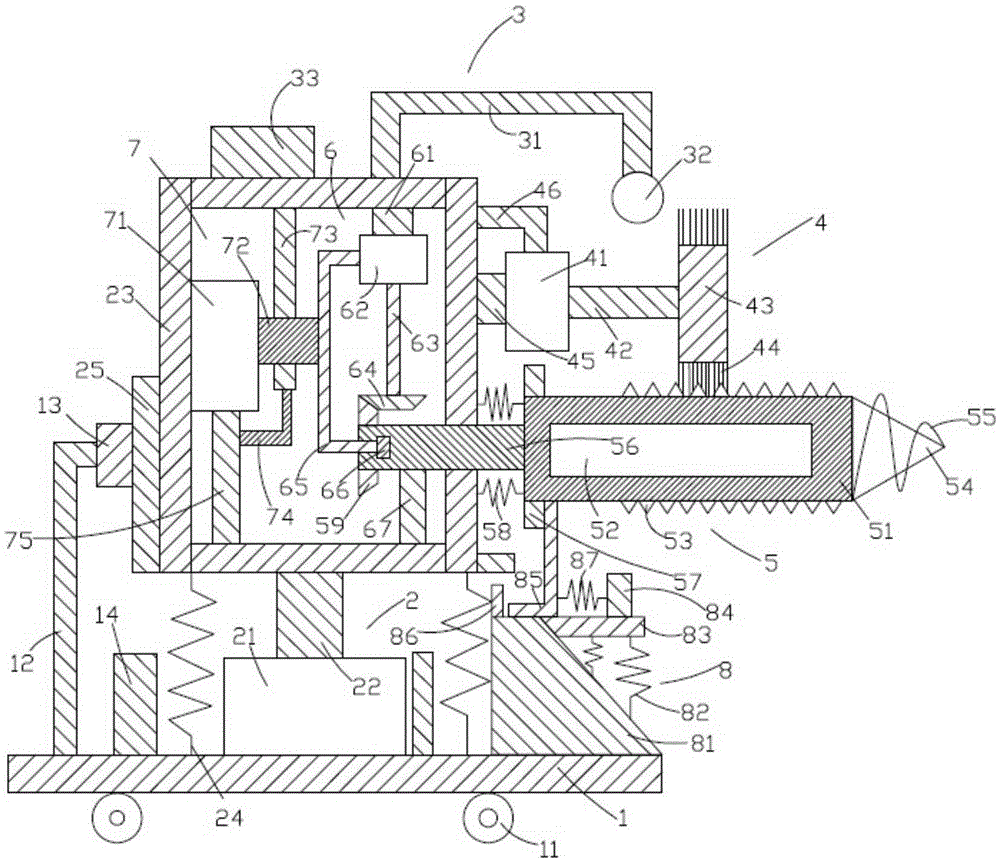

Whole-section quick-drilling drill carriage for parallel cut blasting of large empty holes in roadway

ActiveCN104612586ACompact chassisCompact structureDerricks/mastsDrilling drivesHydraulic motorReducer

The invention discloses a whole-section quick-drilling drill carriage specially used for parallel cut blasting of large empty holes in a roadway. The drill carriage is composed of a walking mechanism, a carriage frame, a hydraulic system, an electrical system and two drilling devices, wherein the first drilling device is used for drilling common blasting holes, and the second drilling device is used for drilling cut holes with the diameter of 100 mm or more. In the operating process of the drill carriage, a hydraulic motor drives a main chain wheel of a crawler-type walking chassis to rotate through a speed reducer; after a carriage body is stabilized, the first drilling device and the second drilling device are manipulated to select hole locations respectively; after the first drilling device and the second drilling device are located, the common blasting holes and the empty holes with the diameter of 100 mm or more can be drilled in rock simultaneously. The drill carriage is suitable for the roadway with the minimum section of 8 square meters and the maximum section of 23 square meters; by the adoption of a building block structural design, the drill carriage is convenient and fast to disassemble and assemble and convenient to transport; as a result, the drill carriage can be used when the length of the roadway under tunneling construction is seven meters or more, and accelerates tunneling mechanization and quick and efficient tunneling modernization.

Owner:SHANDONG UNIV OF SCI & TECH +1

Low-cost construction process for passing through goaf

InactiveCN104929567AEfficient drillingMeet the next fracturing construction processDrilling rodsBorehole drivesWell drillingWell cementing

The invention belongs to the technical field of coal gas mining, particularly relates to a low-cost construction process for passing through a goaf and aims to realize passing through a broken and collapsed belt of a permian formation to extract coal gas of carboniferous formation lower group coal. The low-cost construction process includes: adopting a three-holing well body structure for on-ground well drilling, and holing to bed rock for the first time; holing to a position of 22m below a baseplate of the goaf for the second time, lowering a bilayer sleeve, sealing and fixing a bottom port of the bilayer sleeve, and pouring cement between the bilayer sleeve and a well wall for well cementation; holing to a position of 50m below a baseplate of a lower group coal layer for the third time to finish drilling, lowering an inner-layer sleeve, performing well cementation and depth returning to the baseplate of the goaf, and performing well completion after solidification. No sleeve for replacing a drill rod is used, but conventional sleeves are adopted; red soil is filled between the bilayer sleeve and the well wall, cement paste is utilized to intrude the broken belt above the goaf, and the cement is utilized between the bilayer sleeve below the goaf and the well wall for well cementation to stabilize the goaf, so that the circumstance that a drill bit and a wellhole are buried caused by breaking and collapsing of the goaf can be prevented effectively.

Owner:山西蓝焰煤层气集团有限责任公司 +2

Soft rock and soil layer jet flow guiding hole forming-chamfering-hole collapse preventing integrated drilling method

InactiveCN104790873AImprove hole qualityImprove drilling efficiencyLiquid/gas jet drillingDirectional drillingDrill holeGeotechnical engineering

A soft rock and soil layer jet flow guiding hole forming-chamfering-hole collapse preventing integrated drilling method comprises the following steps that firstly, a soft rock and soil layer jet flow guiding hole forming-jet chamfering-hole collapse preventing guniting integrated drilling device is machined and tested; secondly, drilling technical parameters are designed; thirdly, guniting collapse preventing slurry fluid is prepared, and the solidification performance of the slurry fluid is tested; fourthly, the integrated drilling device is installed; fifthly, integrated drilling work is carried out; sixthly, after the design depth is achieved, drilling is stopped, clean water is used for cleaning a guniting pipeline and a slurry liquid nozzle, and a rod bit is pulled out; seventhly, the drilling effect is detected. The drilling efficiency and the hole forming quality of a horizontal or oblique long drill hole in the ground and an underground soft rock soil layer are greatly improved, the construction time for the horizontal or oblique long drill hole in the soft rock soil layer is shortened, and collapse destruction time of the horizontal or oblique long drill hole in the soft rock soil layer is greatly prolonged; the drilling track deviation of the horizontal or oblique long drill hole in the soft rock soil layer is reduced.

Owner:HENAN POLYTECHNIC UNIV

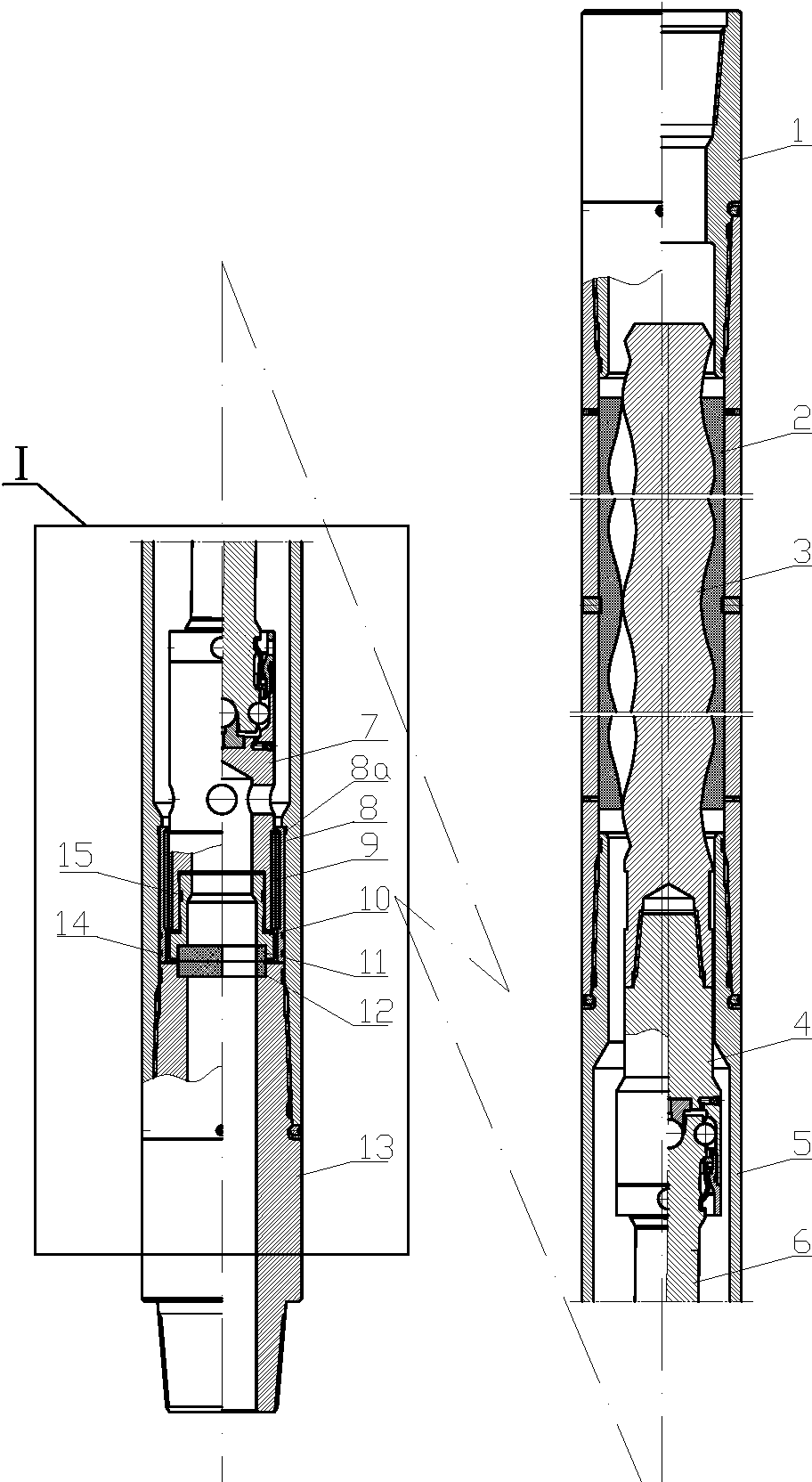

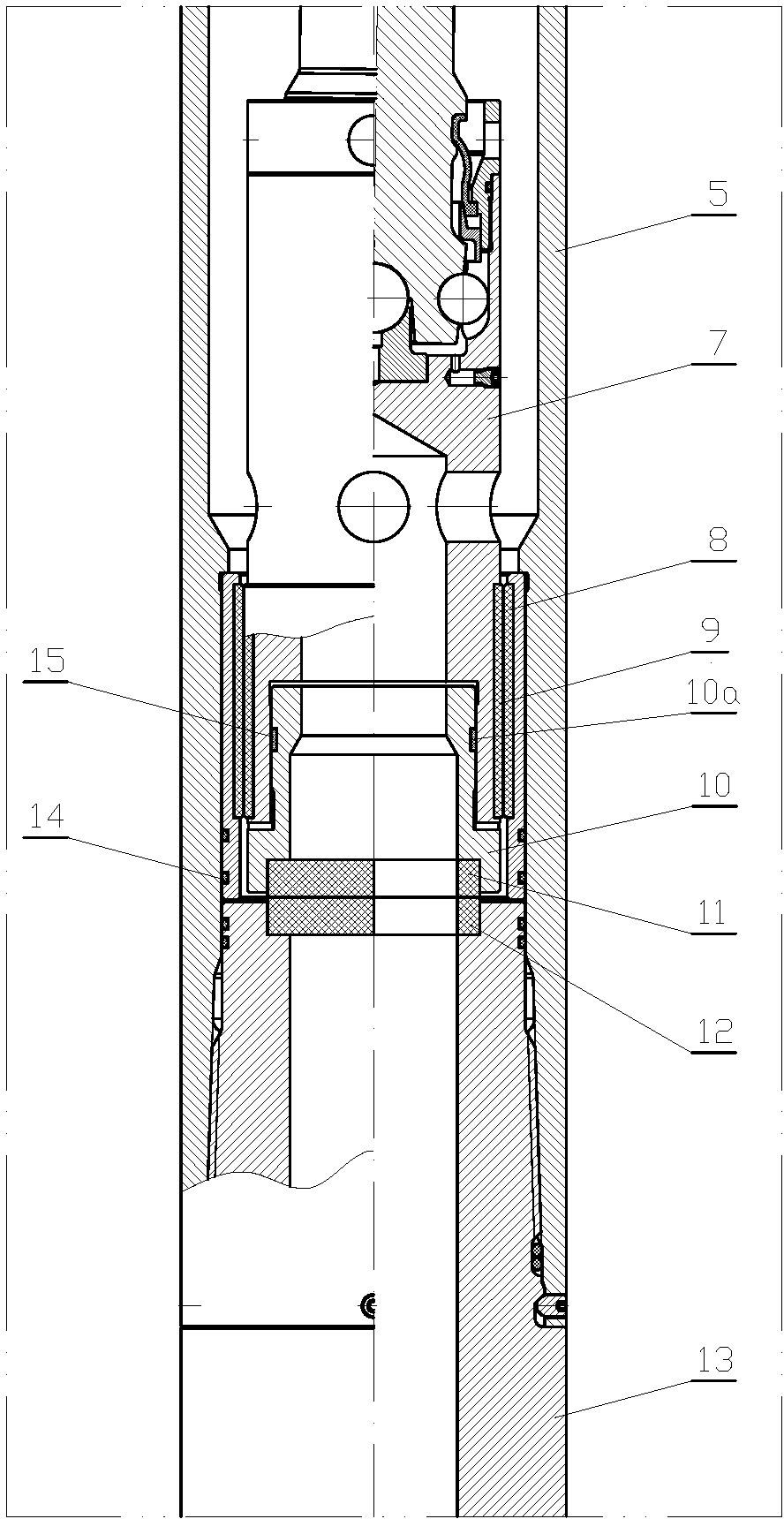

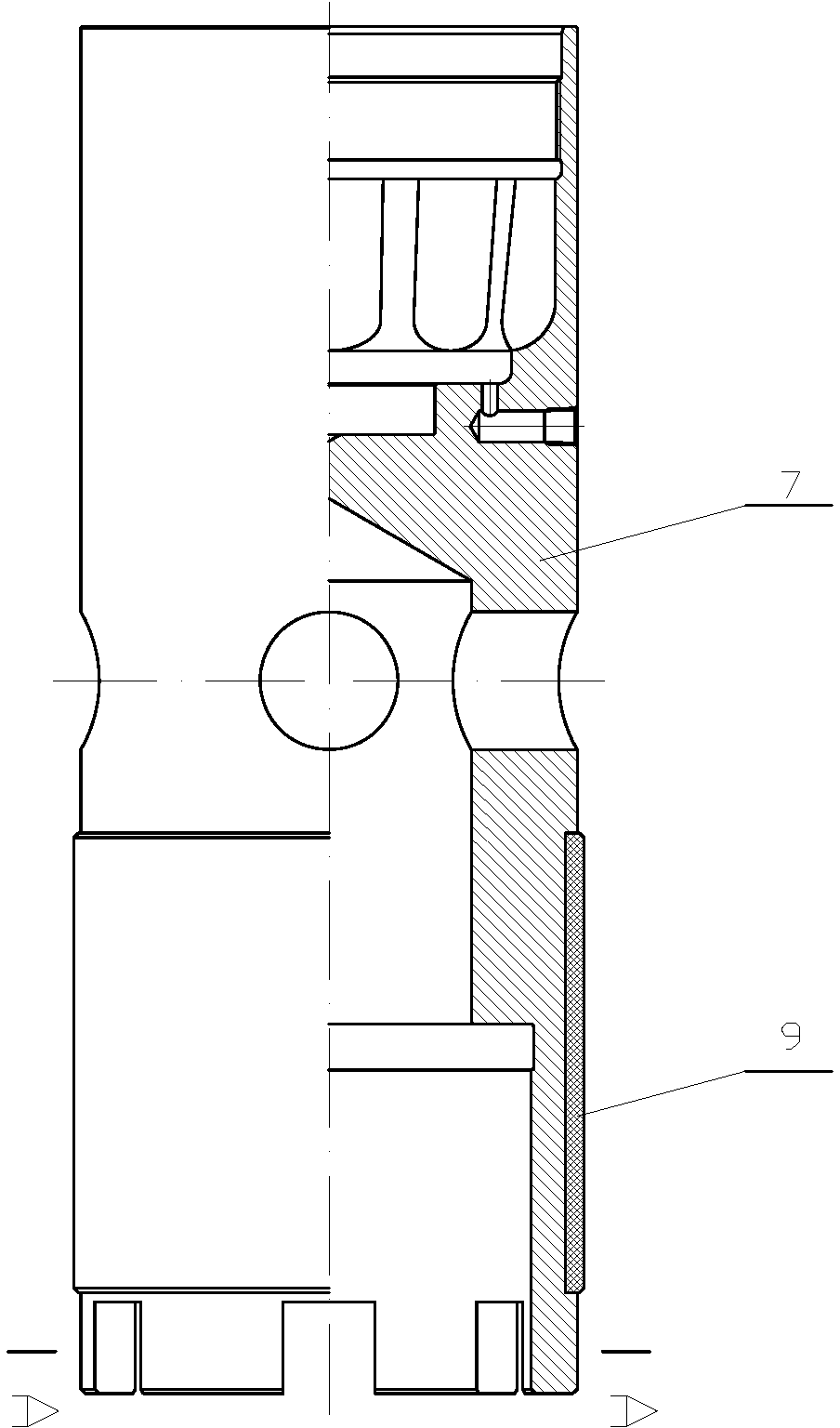

Waterpower oscillator

InactiveCN103410444AReal weight on bitEffectively exert pressure on bitVibration drillingWell drillingEngineering

The invention relates to a waterpower oscillator through which effective pressure can be exerted on a drill bit and well drilling efficiency can be improved in the technical field of oil exploitation. The waterpower oscillator comprises an upper connector, a stator, an outer shell and a lower connector all of which are sequentially connected in a sealed mode. A rotor is eccentrically arranged inside the stator, and the lower end of the rotor is sequentially connected with a cardan shaft upper connector, a cardan shaft and a cardan shaft transmission rod. The lower end of the cardan shaft transmission rod is connected with the outer shell in a sealed mode, the lower end of the outer shell is in threaded connection with the lower connector in a sealed mode, the lower end of the cardan shaft transmission rod is provided with a vibration valve in a matched and sleeved mode, and the vibration valve can do reciprocating sliding motion along the matched surface relative to the cardan shaft transmission rod. The lower end of the vibration valve is provided with a movable valve plate in a sealed and sleeved mode, wherein the movable valve plate and the vibration valve can do the synchronous movement, the upper end of the lower connector is correspondingly provided with a fixed valve plate attached to the movable valve plate, the movable valve plate and the fixed valve plate are respectively provided with a sector channel with the area larger than that of a half circle. An annular hollow part through which liquid can flow is formed among the rotor, the cardan shaft upper connector, the cardan shaft, the stator and the outer shell, the cardan shaft transmission rod is provided with a channel communicated with the annular hollow part, and the channel is communicated with a vibration valve cavity and the sector channels.

Owner:YANGZHOU TIANYE GASOLINEEUM MACHINERY

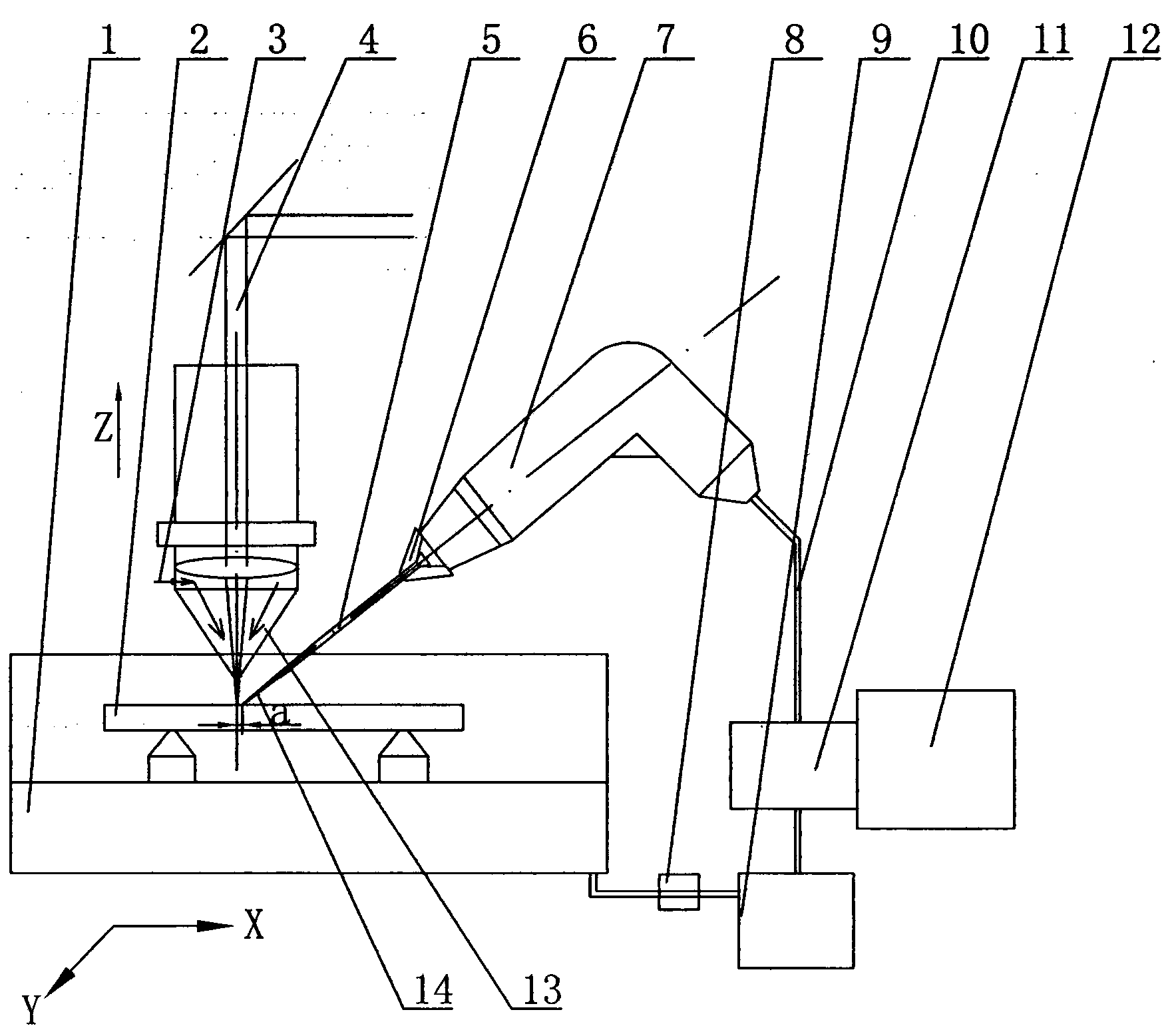

Laser composite punching method for ceramics

InactiveCN103831540AReasonable structureSimple and fast operationWelding/soldering/cutting articlesLaser beam welding apparatusPunchingSpray nozzle

The invention relates to a laser composite punching method for ceramics. The laser composite punching method for ceramics comprises the steps that 1, the punched position of a ceramic body is selected; 2, the water jet technology is adopted, and a water jet system is arranged on one side of a workbench, wherein the water jet system structurally comprises a motor, the motor is connected with a pump, the input end of the pump is connected with a water tank, the output end of the pump is connected with a spray gun through a pipeline, a nozzle is installed at the head portion of the spray gun, and jet water sprayed out from the nozzle is jetted to a ceramic board; 3, laser beams move along the punching outline for machining. The laser composite punching method for ceramics only needs the low-pressure jet water, cost is low, efficient and low-damage punching machining for ceramics can be achieved, the machining quality of the surfaces of ceramics is good, and production efficiency is high.

Owner:JIANGNAN UNIV

Combination coring bit and drill bit using fixed cutter PDC cutters

InactiveUS20100101870A1Improve drilling performanceLower the volumeArtificial islandsDrill bitsPolycrystalline diamondEngineering

A drill bit having fixed Polycrystalline Diamond Compact cutters is used to drill a borehole having a core stump therein. A plurality of additional fixed Polycrystalline Diamond Compact cutters are disposed in the dome of the bit and are usable to concentrate stresses in the top end of the core stump to facilitate the cutting down of the core stump.

Owner:DIAMANT DRILLING SERVICES

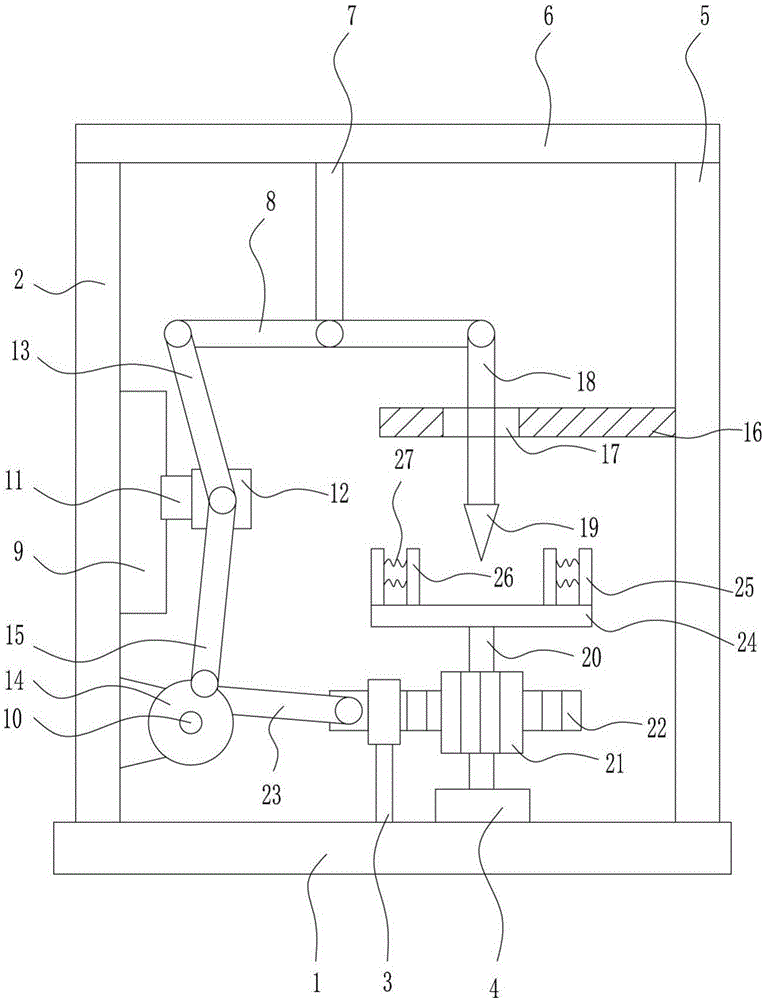

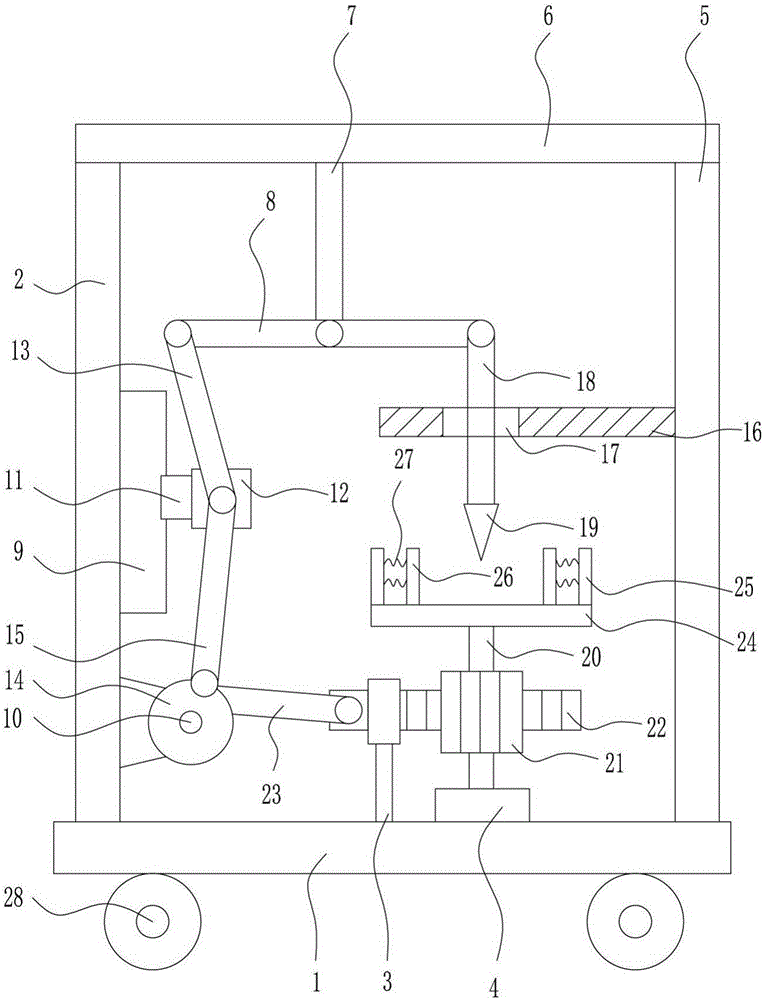

Shoe sole punching device for shoe production and processing

The invention relates to a shoe sole punching device, in particular to a shoe sole punching device for shoe production and processing. The technical problem to be solved in the invention is to provide the shoe sole punching device for shoe production and processing with the advantages of excellent punching effect, high punching speed and ideal punching. In order to solve the technical problem, the shoe sole punching device for shoe production and processing provided by the invention comprises a bottom plate, a left side plate, a guide sleeve, a bearing block, a right side plate, a top plate, a supporting rod, a swing rod, a sliding rail, a motor, a slide block, a connecting block, a first connecting rod, a disc, a second connecting rod, a guide plate, a connecting rod, a drill bit, a rotating shaft, a gear, a rack, a third connecting rod, a placement plate, a fixed baffle, a movable plate and a spring, wherein the left side plate, the guide sleeve, the bearing block and the right side plate are sequentially arranged on the bottom plate from the left to right; the top plate is arranged on the top between the left side plate and the right side plate. The device disclosed by the invention achieves the effects of excellent punching effect, high punching speed and ideal punching.

Owner:张浩杰

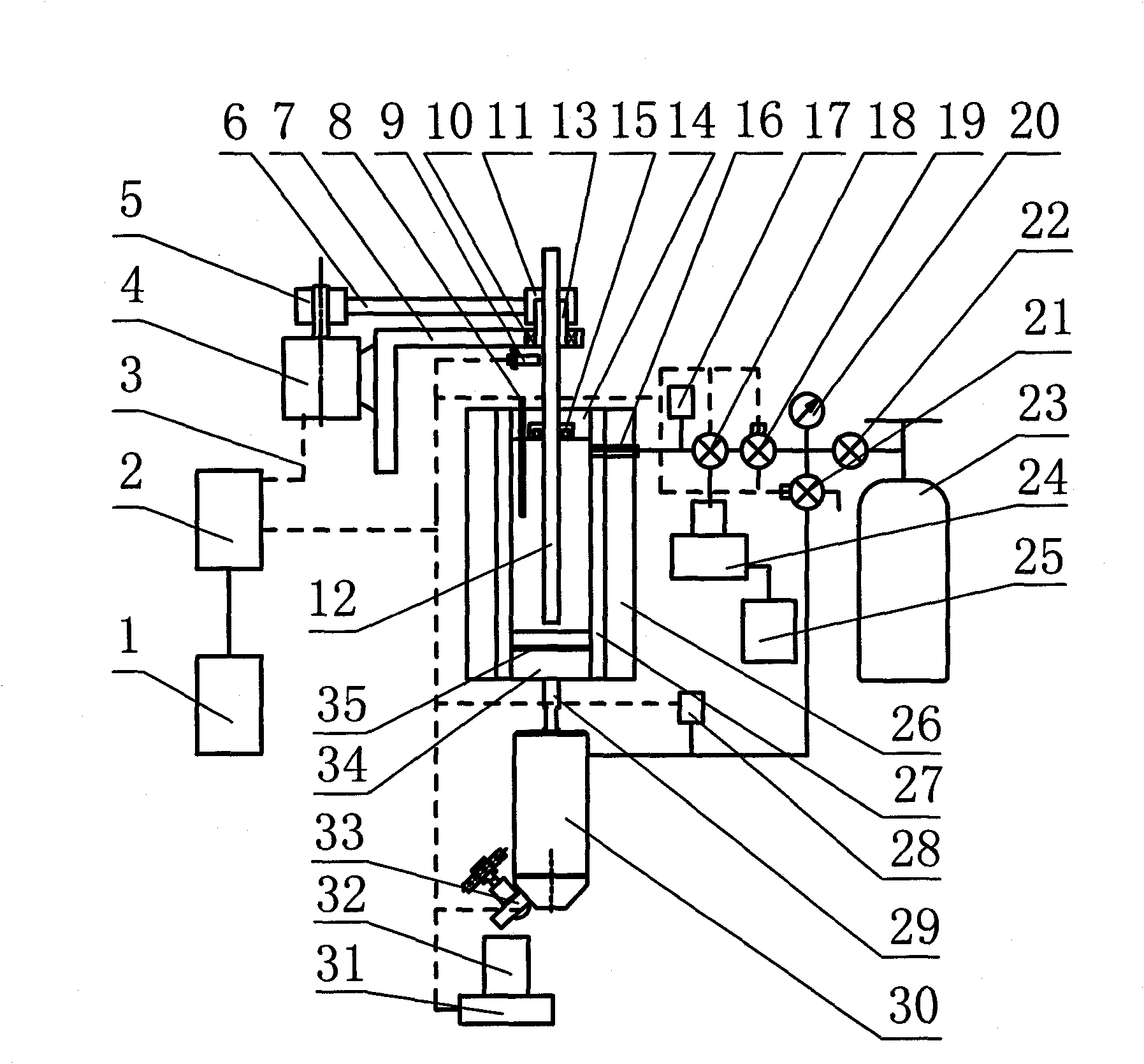

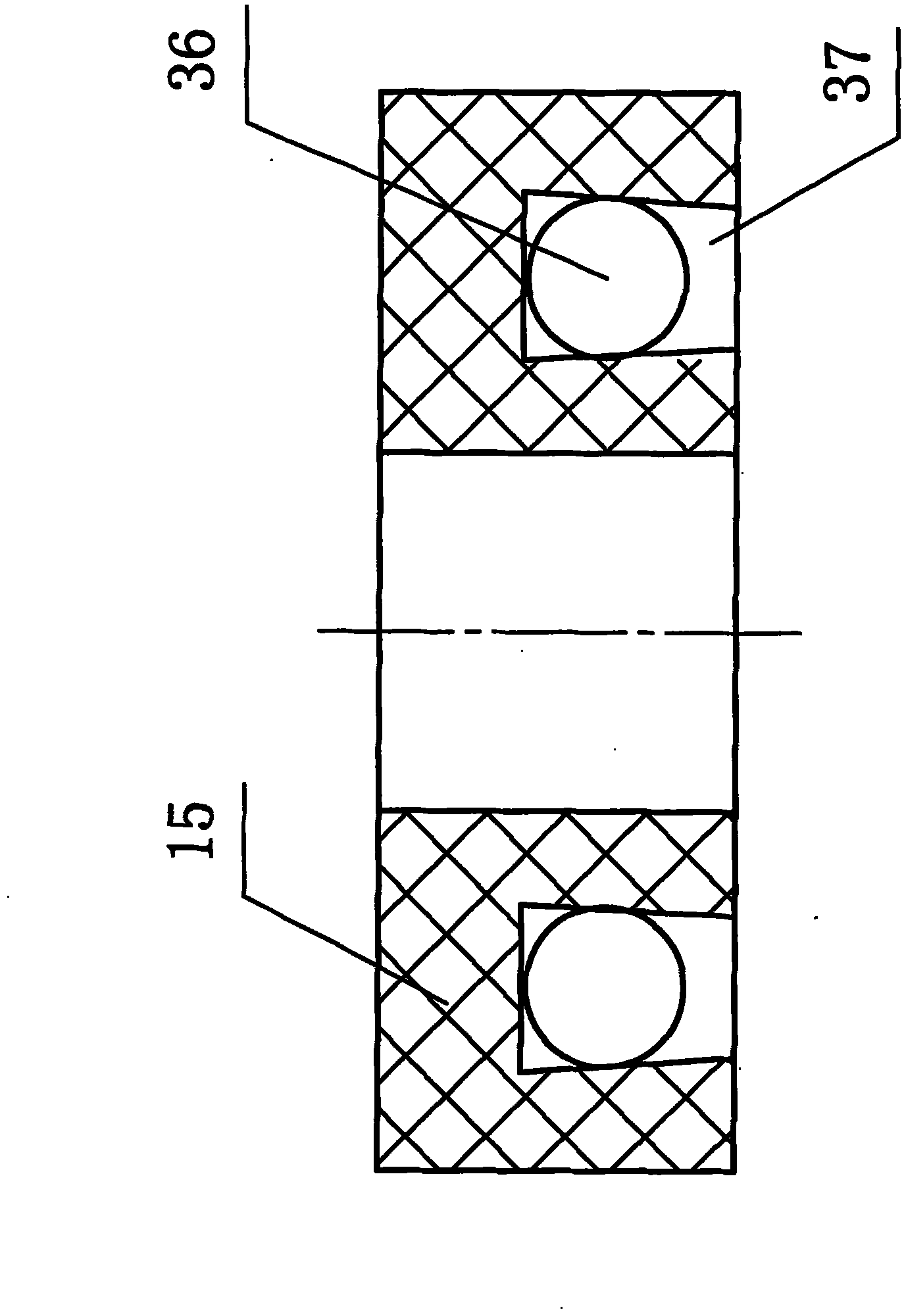

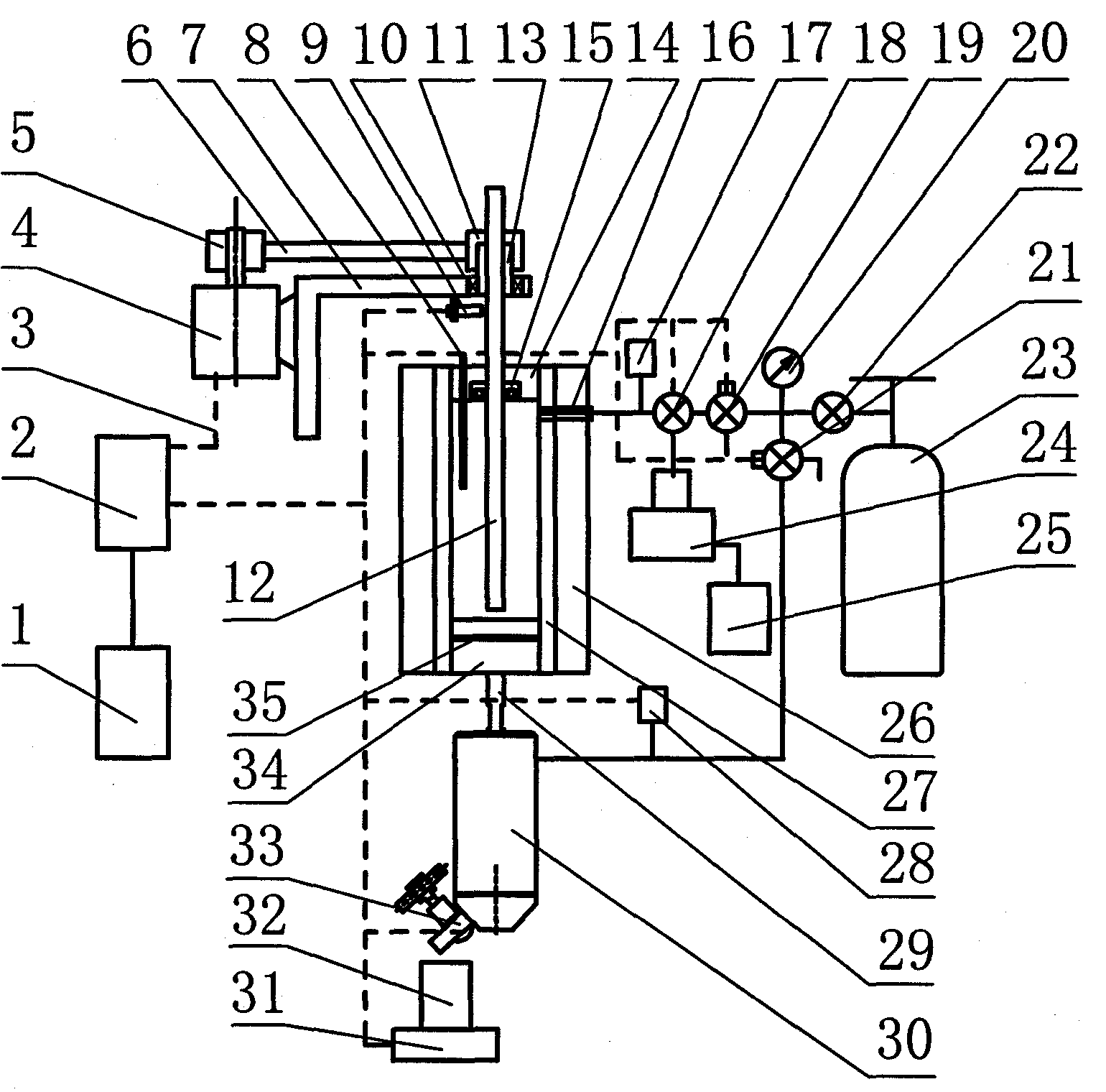

On-line tester for plugging capability of water-base mud

InactiveCN101788544ASimple designEasy to useBorehole/well accessoriesMaterial analysisWater basedData acquisition

The invention relates to an on-line tester for plugging capability of water-base mud, which belongs to the technical field of instruments for testing the plugging capability of drilling mud. The tester consists of an experimental reactor, a heater, a servo motor, a data acquiring-processing device, a back pressure receiver, a gauge and a pressure control device, wherein the heater is arranged on the experimental reactor; one side of the experimental reactor is provided with the servo motor; a photoelectric displacement sensor is arranged on a motor bracket; the data acquiring-processing device is arranged below the motor; the back pressure receiver and the gauge are arranged below the experimental reactor; and the other side of the experimental reactor is provided with the pressure control device. The tester can integrate static water loss, mud-cake thickness, mud-cake strength of water-base mud filtrate in the drilling process of simulated high-temperature high-pressure thickness static test in order to comprehensively evaluate the plugging capability of the water-base mud in the drilling process. The tester solves the problem that the experimental test of the conventional tester for the properties and strength of mud cakes in the drilling process can be only limited to separate test. In addition, the tester has the advantages of simple structure, use convenience and applicability to online test for various types of drilling mud.

Owner:JINGZHOU MODERN PETROLEUM TECH DEV CO LTD

Adaptive apparatus, system and method for communicating with a downhole device

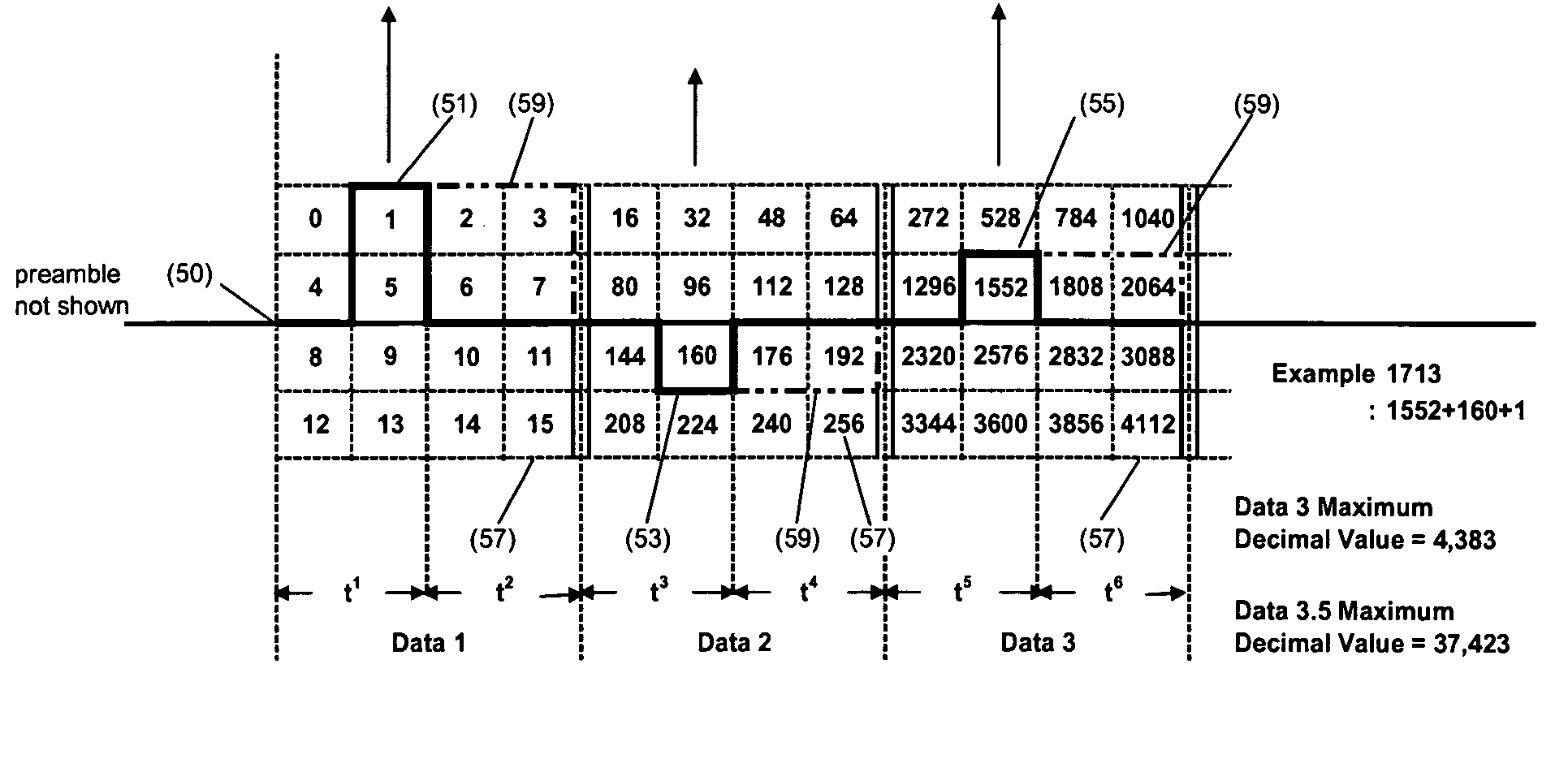

InactiveUS7540337B2Less disruptiveAvoids and mitigatesSurveyCore removalEconomic benefitsData transmission

A system, apparatus and method for adaptive communication with a downhole device is disclosed. The instant invention proposes an adaptive system of communicating information from the surface of the earth to a device located downhole; thereby optimizing the drilling process by adaptively fitting the talkdown protocol around the existing drillstring RPM. A further economic benefit is that with this adaptive system the ΔRPM Offset between the optimized drilling condition and the RPM required for data transmission can be monitored and adjusted in real-time, resulting in less disruption to the drilling process. Several embodiments are given.

Owner:MV DRILLING & SERVICES

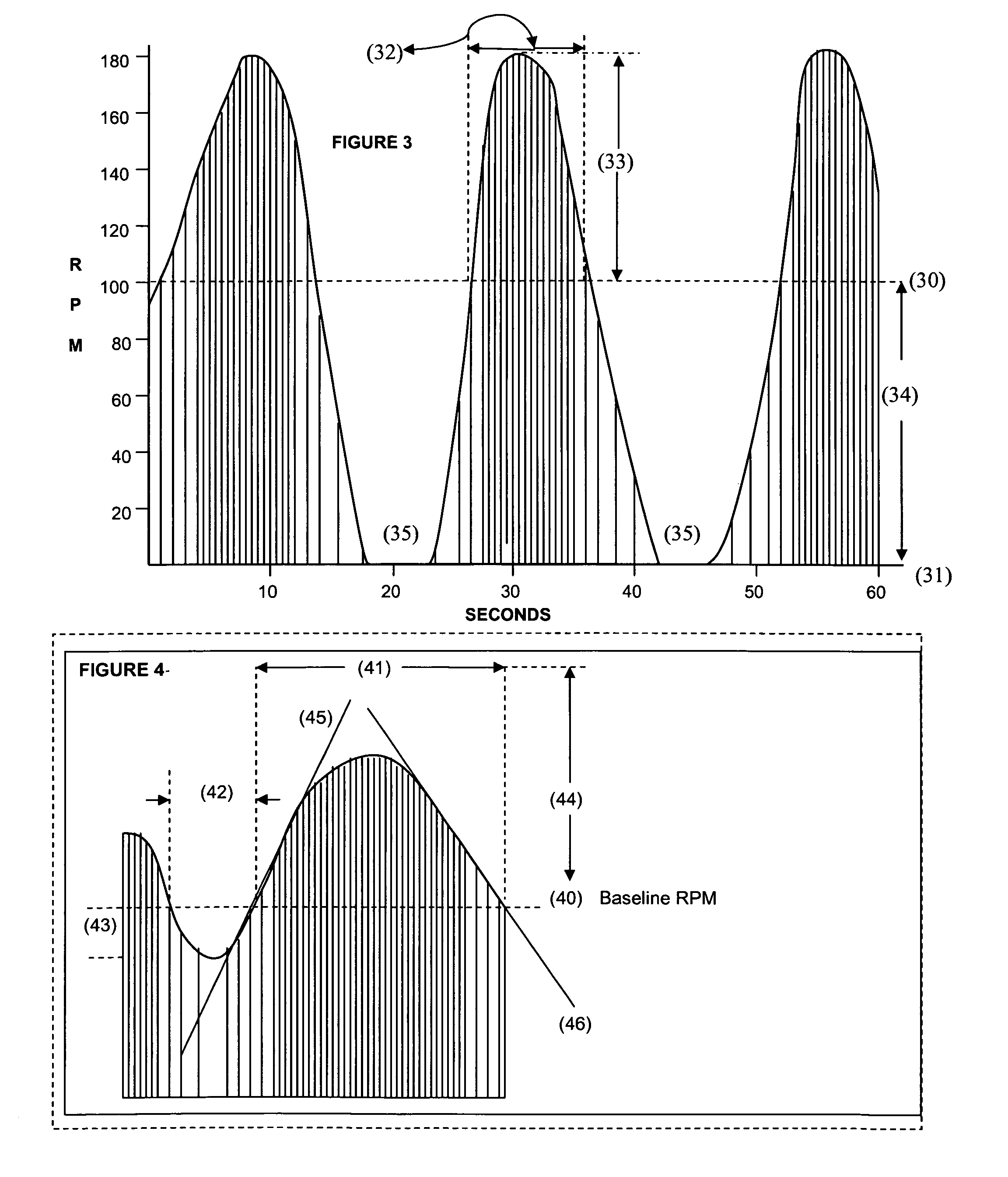

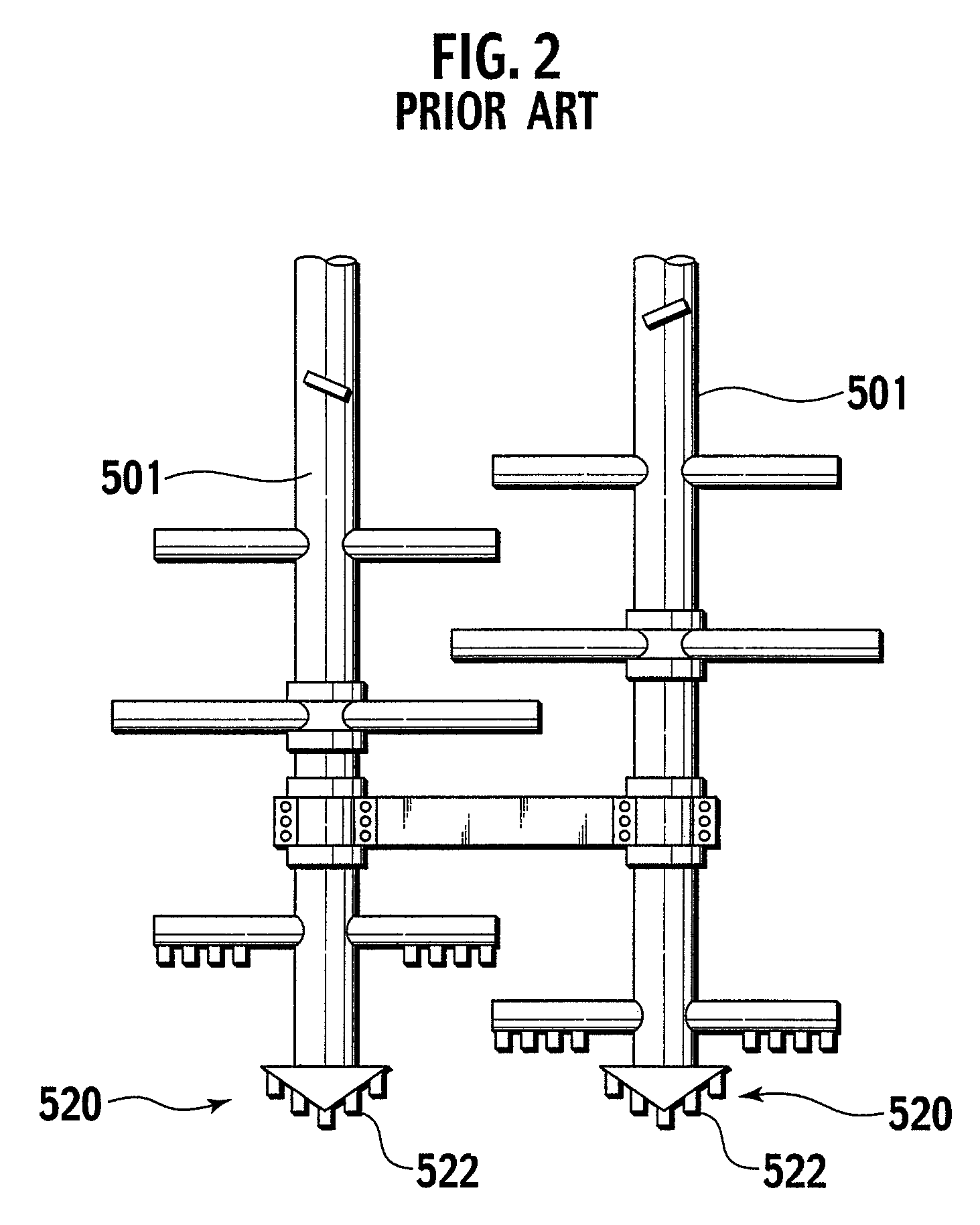

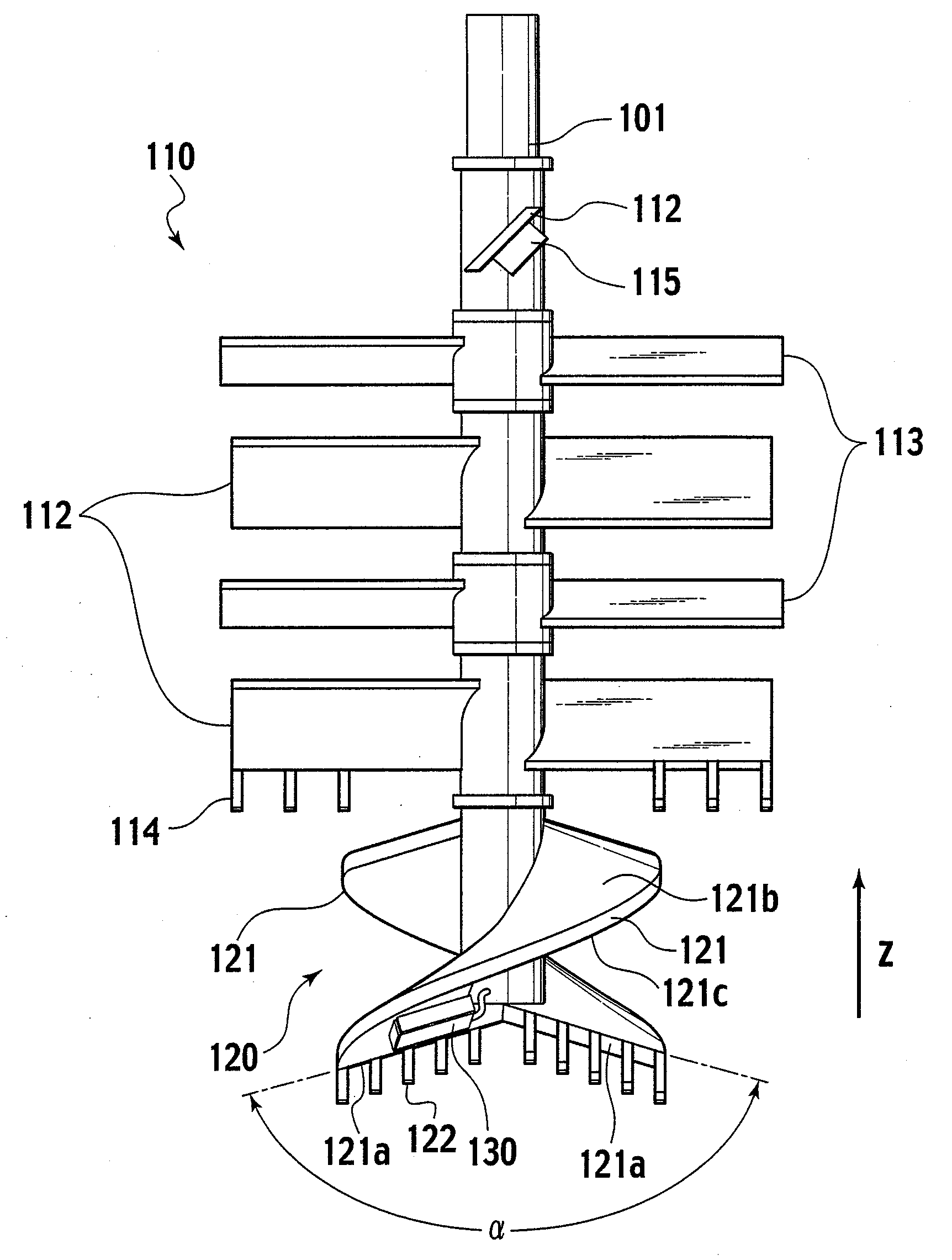

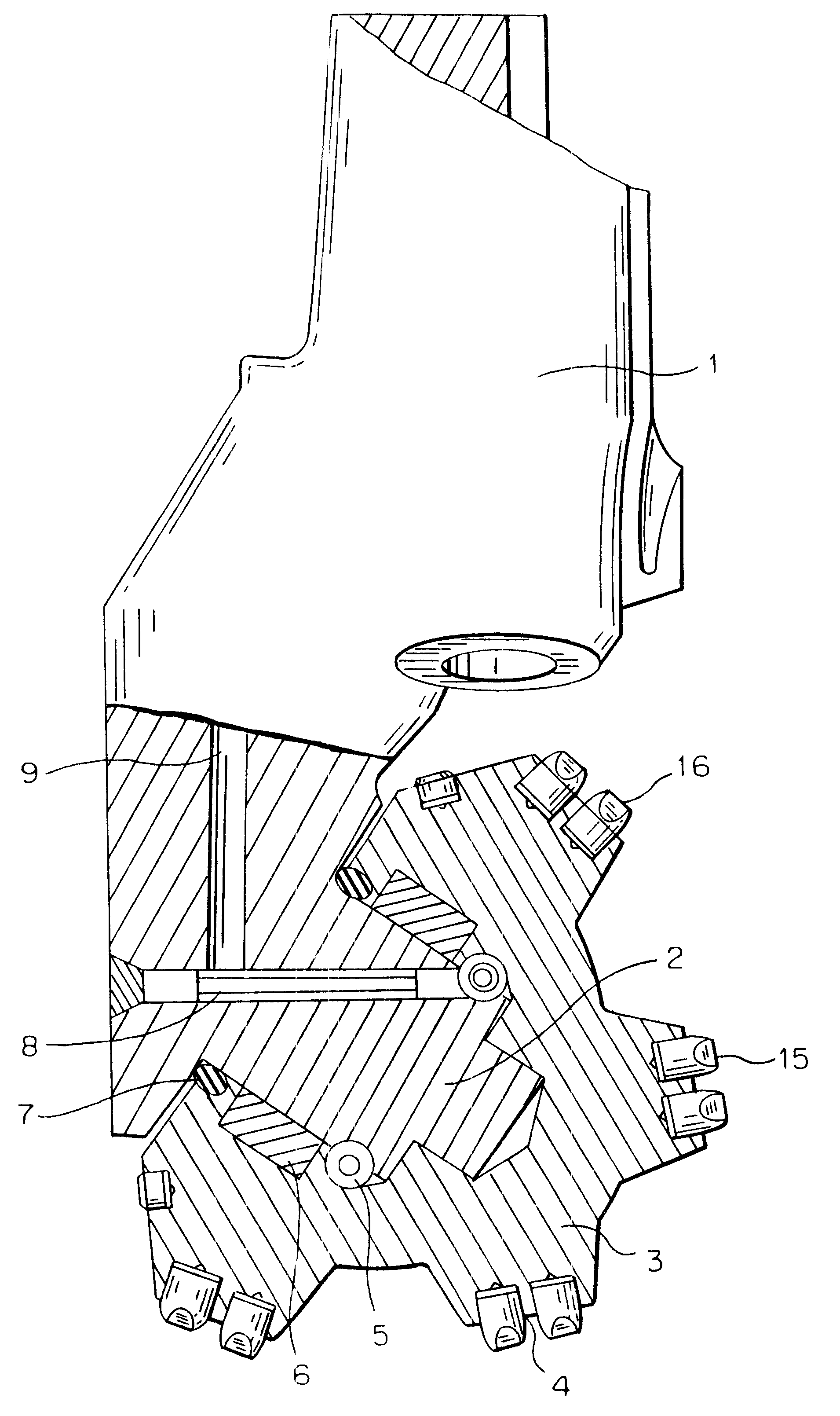

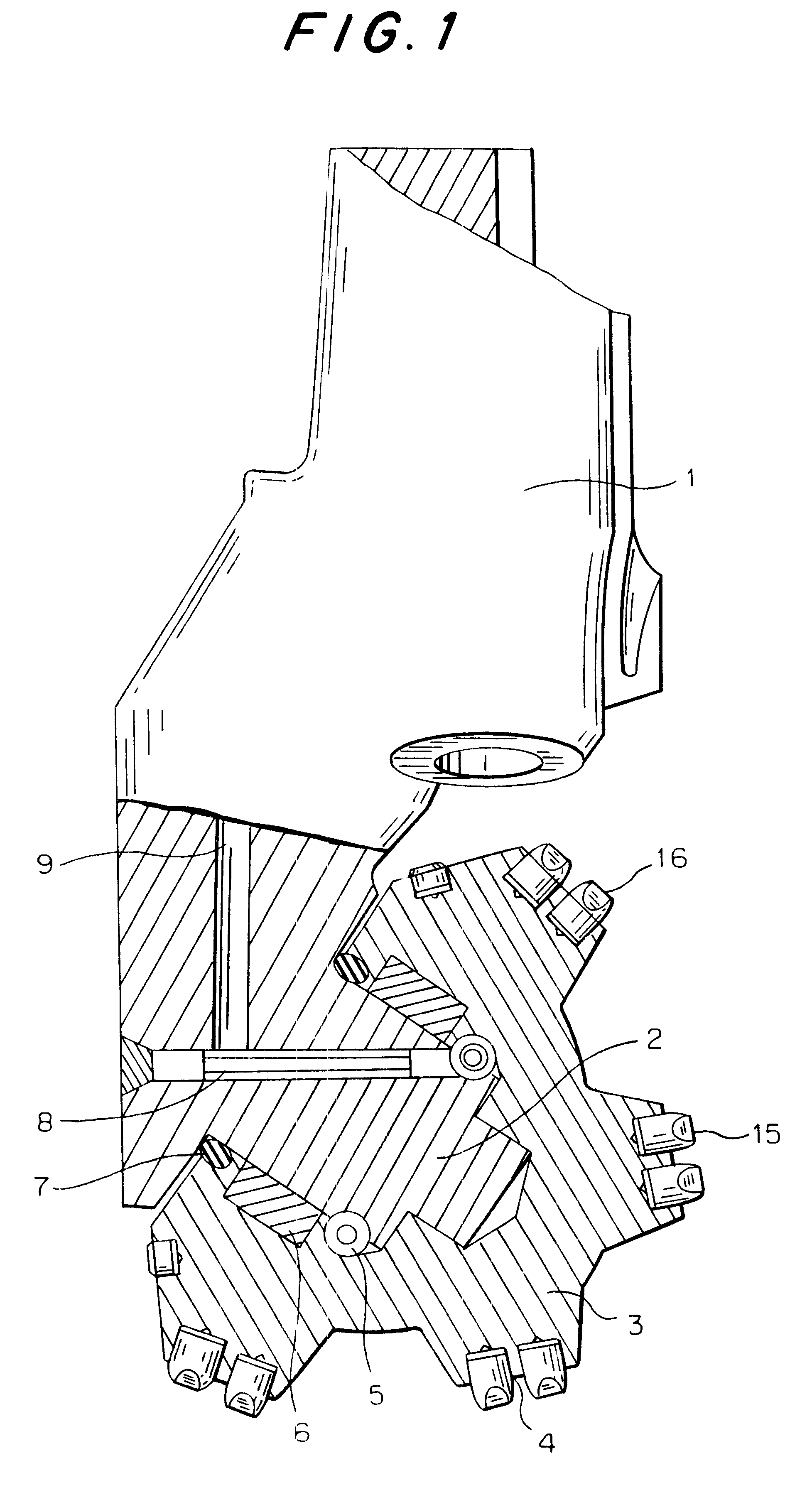

Drilling head, method of soil improvement work and apparatus thereof

InactiveUS7651301B2Reduce frictionImprove the mixing effectDrill bitsOrganic fertilisersEngineeringDrill bit

A method of soil improvement work drills the ground with a drilling head arranged at a lower end of a rotary shaft and sends the rotary shaft into the ground. The method mixes pressurized water with compressed air on the ground, to prepare a fluid mixture, feeds the fluid mixture through a feed path arranged along the rotary shaft into an ejector arranged on the drilling head, and ejects the fluid mixture from the ejector toward the ground to drill. An envelope defined by a front end of the drilling head has a conical shape.

Owner:FUDO CONSTR

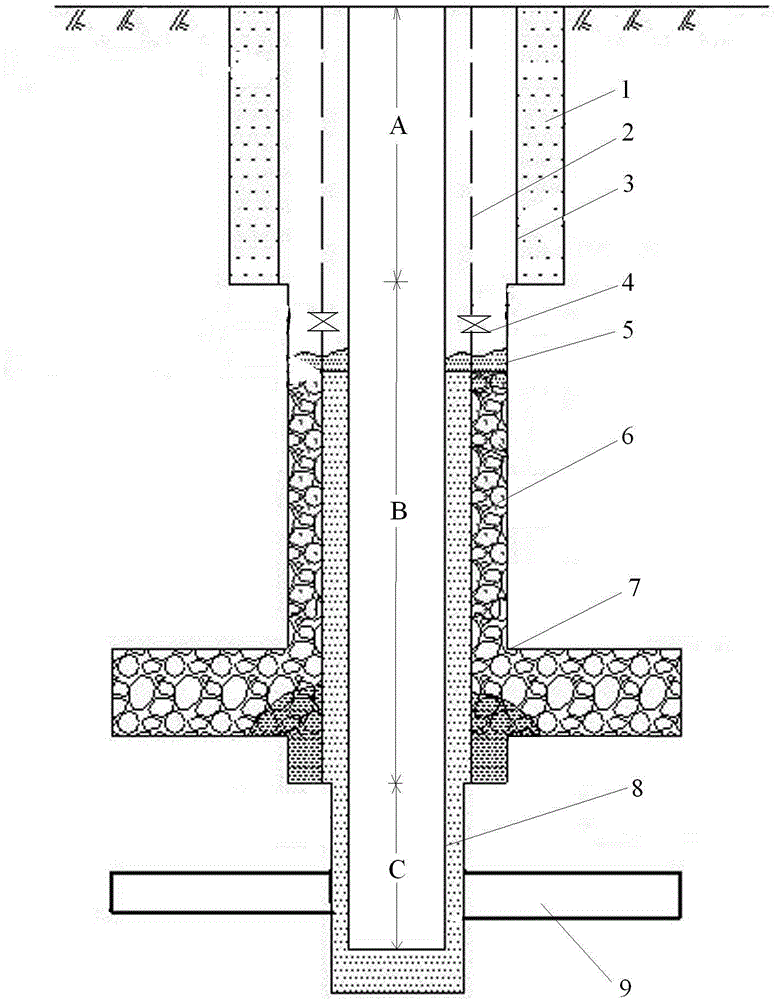

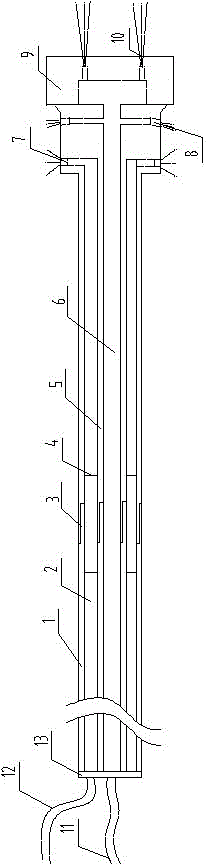

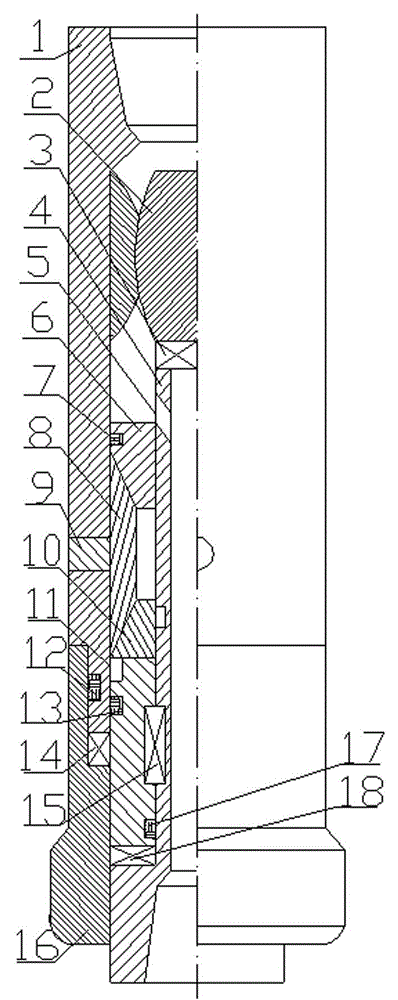

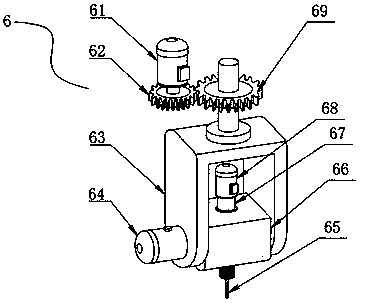

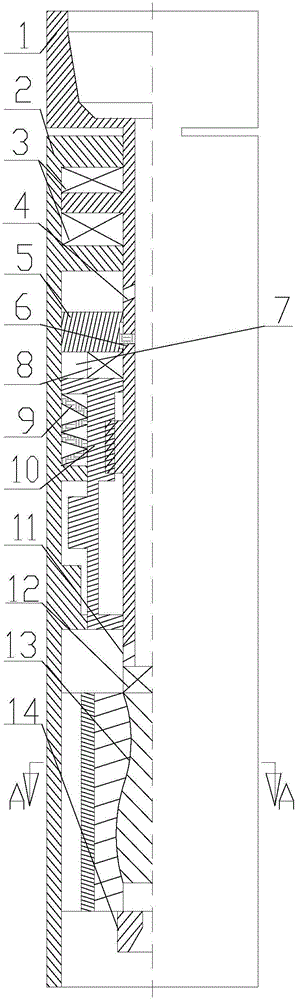

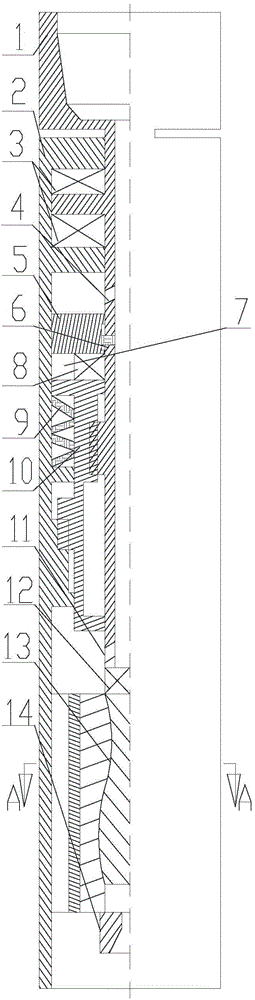

Double-stage double-rotating-speed well drilling device

The invention relates to a double-stage double-rotating-speed well drilling device, and belongs to the industrial fields of oil and gas well drilling, geological prospecting, mine drilling, coal-bed gas development and the like. The double-stage double-rotating-speed well drilling device comprises an outer shell 1, a power assembly 2, a universal shaft coupling 3, a central shaft 4, a variable-speed reversing input assembly 6, a variable-speed reversing conversion assembly 8, a variable-speed reversing output assembly and a secondary drill bit and primary drill bit joint. The device is arranged on the lower part of a shaft bottom drilling tool combination, a small-sized guide hole is drilled according to the characteristic of high rock breaking speed of a primary small drill bit, and a part of the stress of rock is released, so that the rock breaking difficulty of a secondary large-sized drill bit is lowered, the overall well drilling speed is increased, and the control of a well deviation direction and stick-slip vibration is facilitated; the double-stage double-rotating-speed well drilling device has important practical significance to increase of the drilling speed of deep wells and super deep wells and prolonging of the service lives of a drill stem and drill bits. Meanwhile, the double-stage double-rotating-speed well drilling device further has the advantages of simple structure, convenience in operation, convenience in installation, safety and reliability.

Owner:CHINA PETROCHEMICAL CORP +1

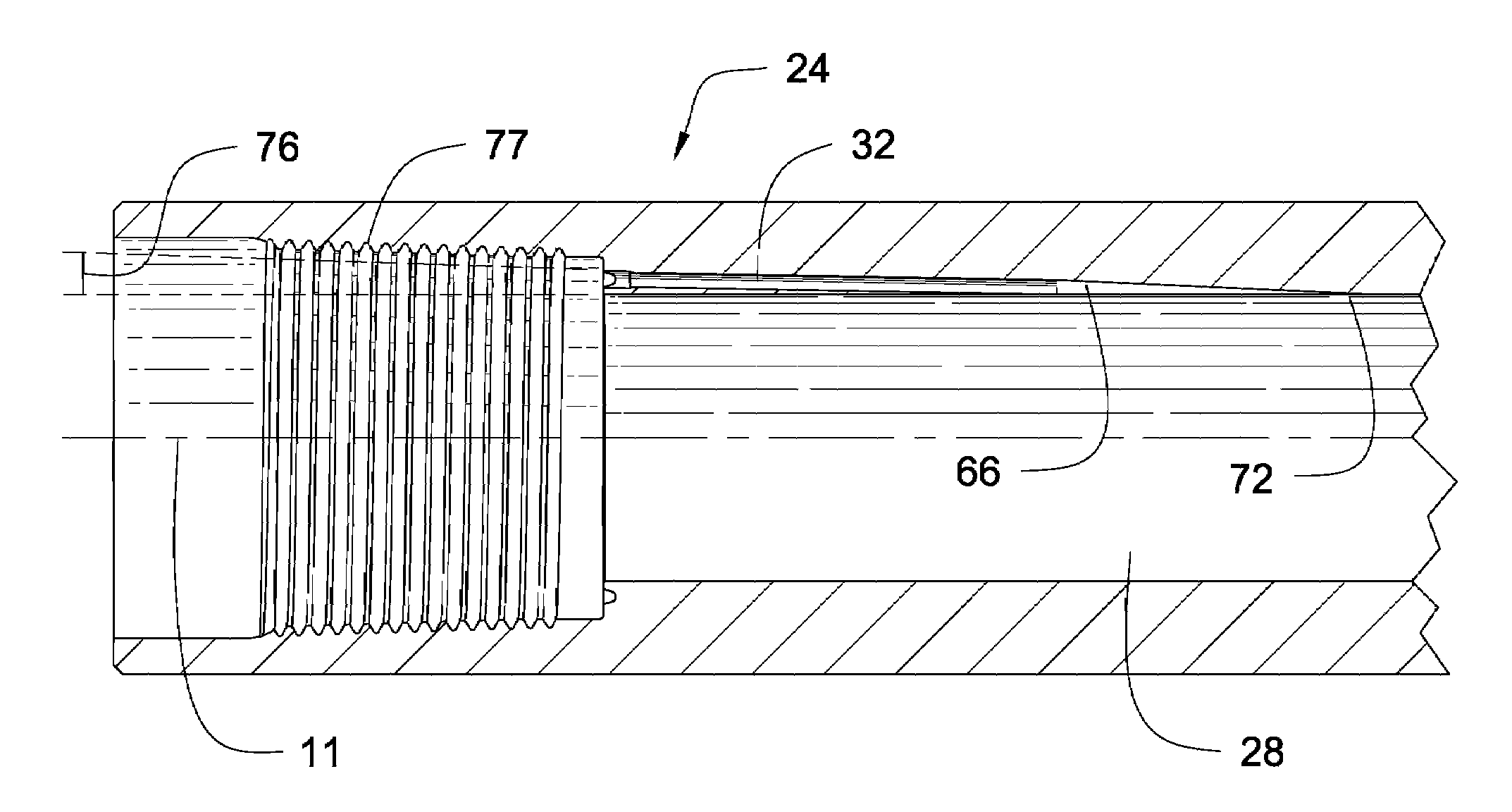

Apparatus and method for routing a transmission line through a downhole tool

ActiveUS7069999B2Prevent kinkingEfficient drillingDrilling rodsFluid removalEngineeringMechanical engineering

A method for routing a transmission line through a tool joint having a primary and secondary shoulder, a central bore, and a longitudinal axis, includes drilling a straight channel, at a positive, nominal angle with respect to the longitudinal axis, through the tool joint from the secondary shoulder to a point proximate the inside wall of the centtral bore. The method further includes milling back, from within the central bore, a second channel to merge with the straight channel, thereby forming a continuous channel from the secondary shoulder to the central bore. In selected embodiments, drilling is accomplished by gun-drilling the straight channel. In other embodiments, the method includes tilting the tool joint before drilling to produce the positive, nominal angle. In selected embodiments, the positive, nominal angle is less than or equal to 15 degrees.

Owner:INTELLISERV LLC

Drilling head, method of soil improvement work and apparatus thereof

InactiveUS20080060851A1Reduce frictionImprove the mixing effectDrill bitsOrganic fertilisersEngineeringDrill bit

A method of soil improvement work drills the ground with a drilling head arranged at a lower end of a rotary shaft and sends the rotary shaft into the ground. The method mixes pressurized water with compressed air on the ground, to prepare a fluid mixture, feeds the fluid mixture through a feed path arranged along the rotary shaft into an ejector arranged on the drilling head, and ejects the fluid mixture from the ejector toward the ground to drill. An envelope defined by a front end of the drilling head has a conical shape.

Owner:FUDO CONSTR

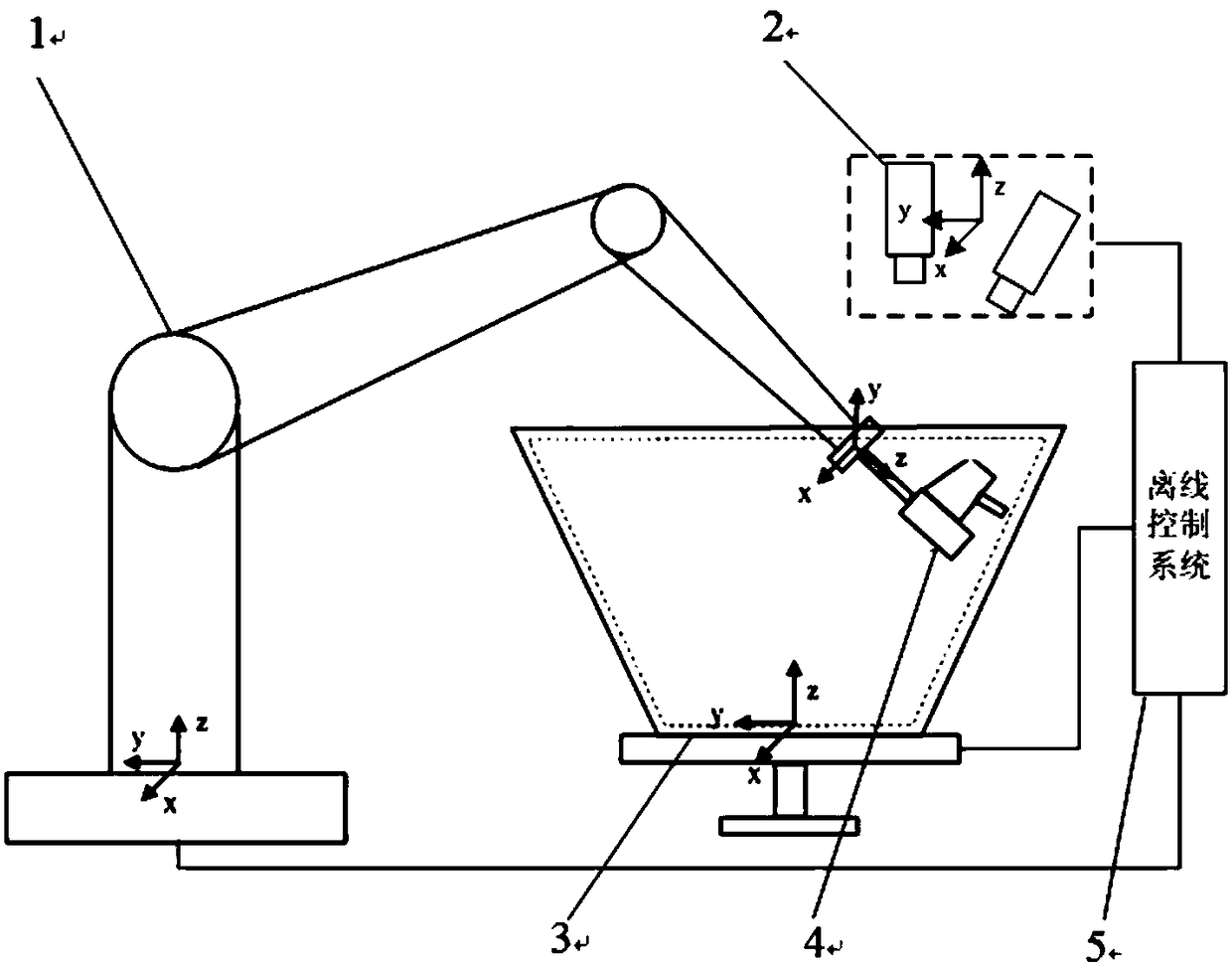

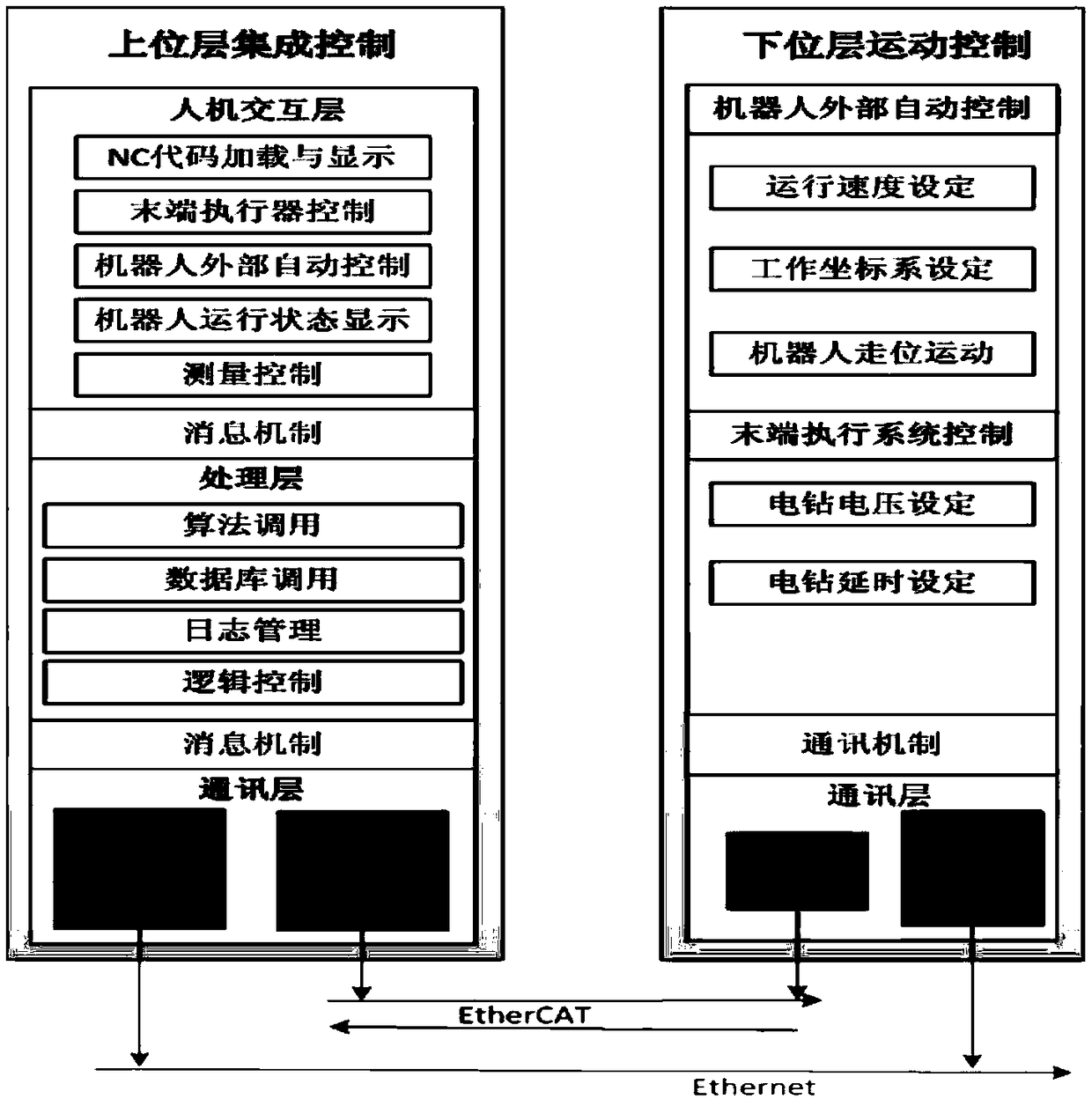

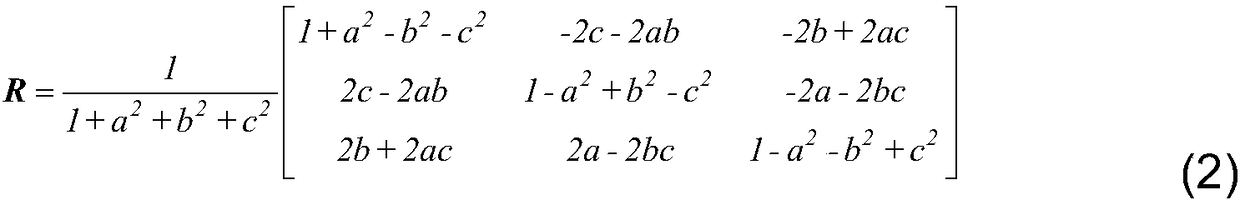

Robot automatic accurate positioning hole making device and method oriented to composite material cabin section

ActiveCN109352663AHigh positioning accuracyAvoid singularity problemsProgramme-controlled manipulatorControl systemActuator

The invention provides a robot automatic accurate positioning hole making device and method oriented to a composite material cabin section. A tail end executor is installed at the tail end of a jointarm robot, and a to-be-machined cabin section is fixedly mounted on an assembling rotary table; an off-line control system sends an instruction to the assembling rotary table, and the assembling rotary table is controlled to drive the to-be-machined cabin section to rotate to the operation position; the off-line control system sends an instruction to the joint arm robot, the tail end executor is driven to reach the initial preset position, a vision measuring system monitors the pose of the tail end executor, the acquired pose information is transmitted to an off-line control system, and the offline control system is used for comparing the acquired pose information with the expected pose, the posture adjusting instruction is determined to be sent to the joint arm robot, and the joint arm robot is used for carrying out posture adjusting according to the posture adjusting instruction; when the tail end executor reaches the expected pose, the offline control system sends a drilling instruction to the end executor, the tail end executor conducts drilling after receiving the drilling instruction, and after the drilling operation is completed, the drilling operation is fed back to the off-line control system, the off-line control system sends an instruction to control the joint arm robot to drive the tail end executor to return to the preset position, and the one-time operation process is completed.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

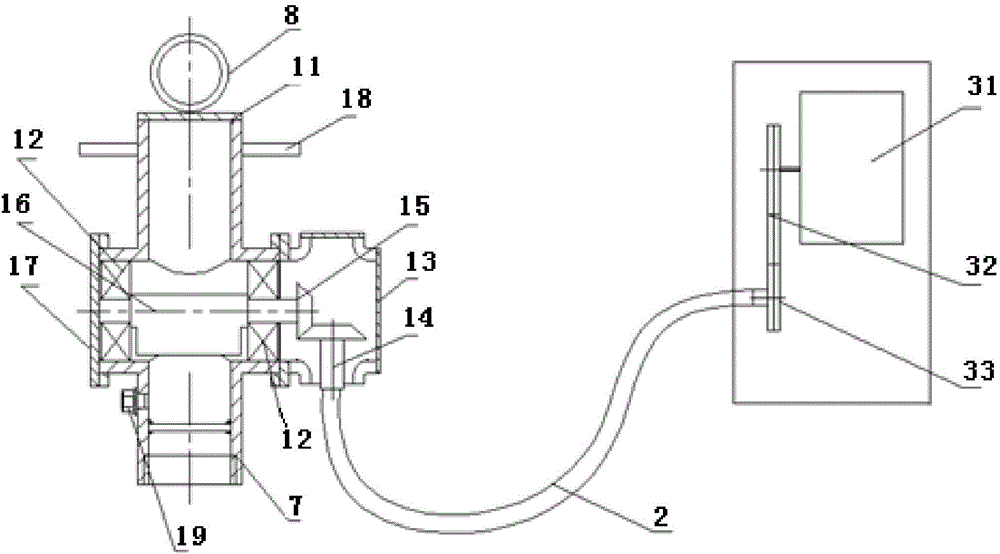

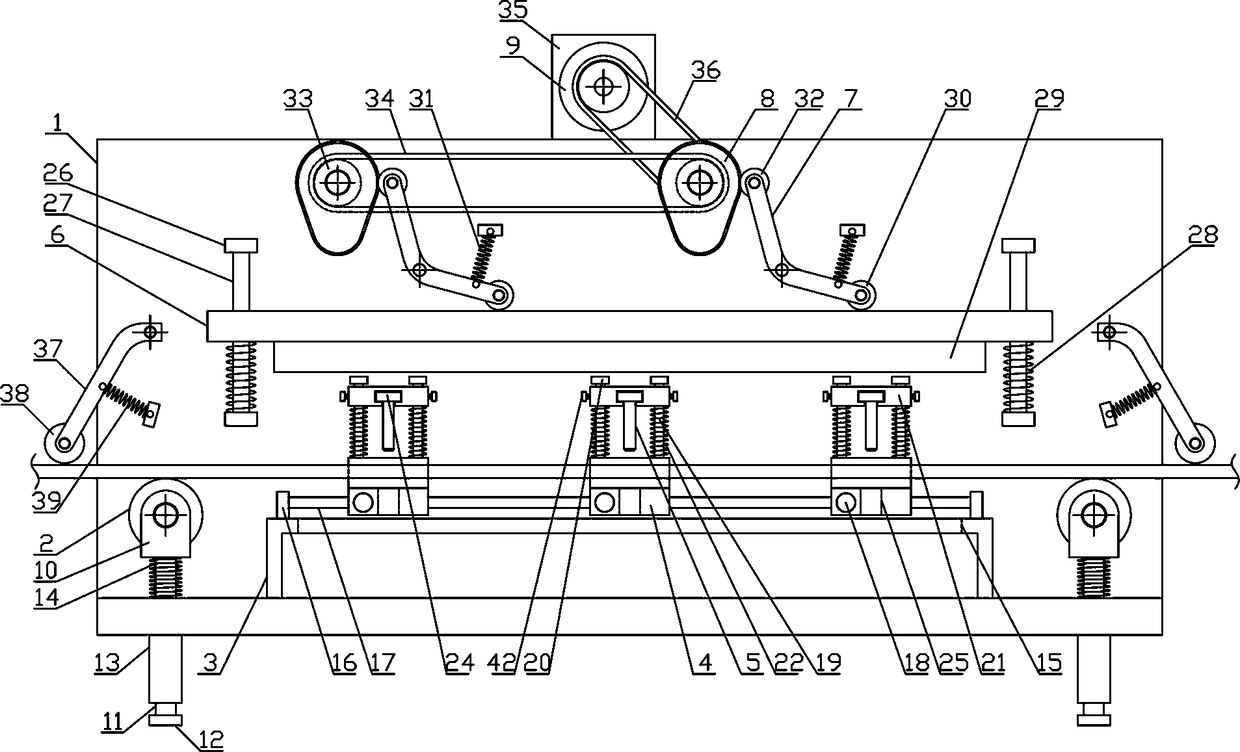

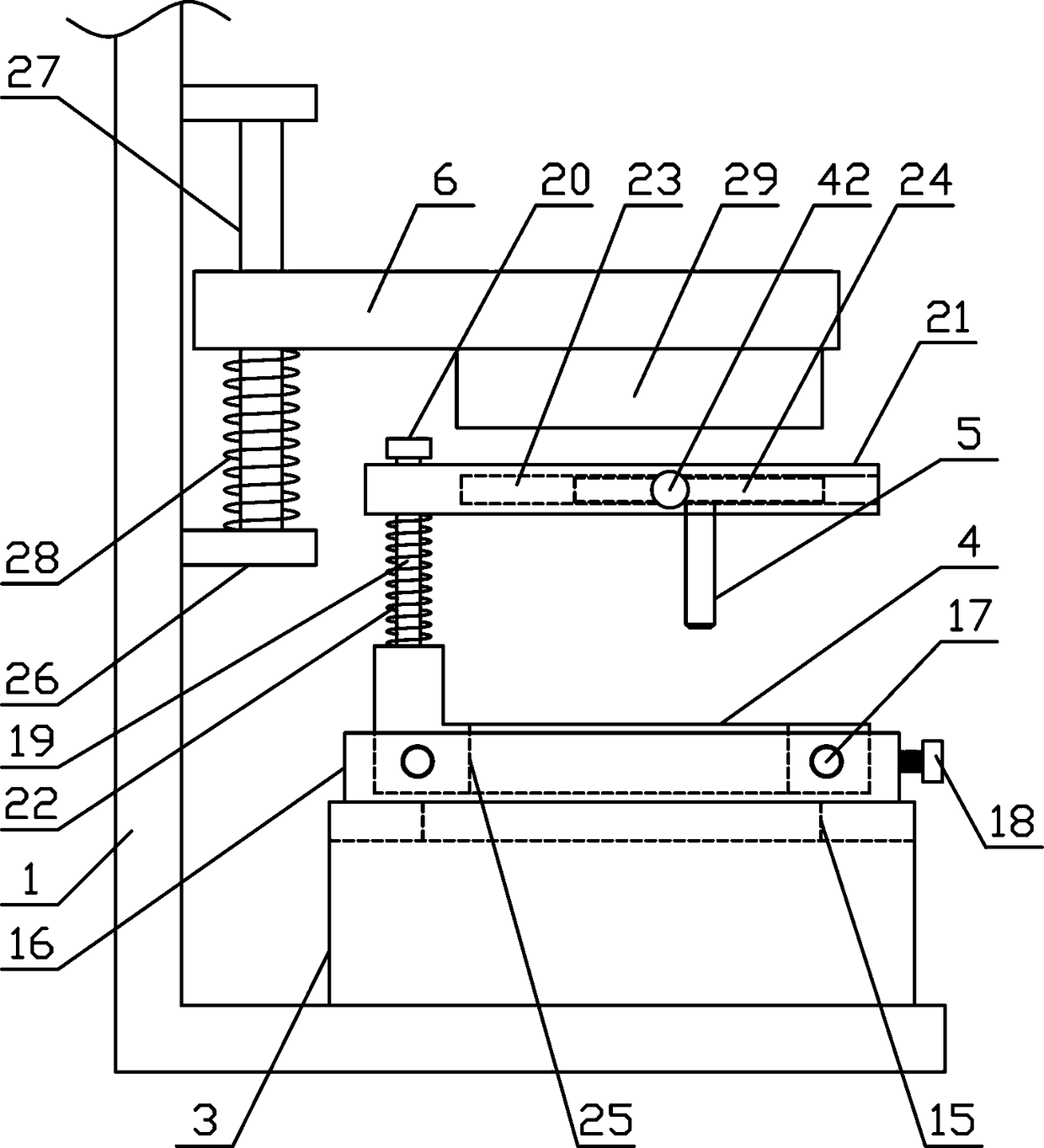

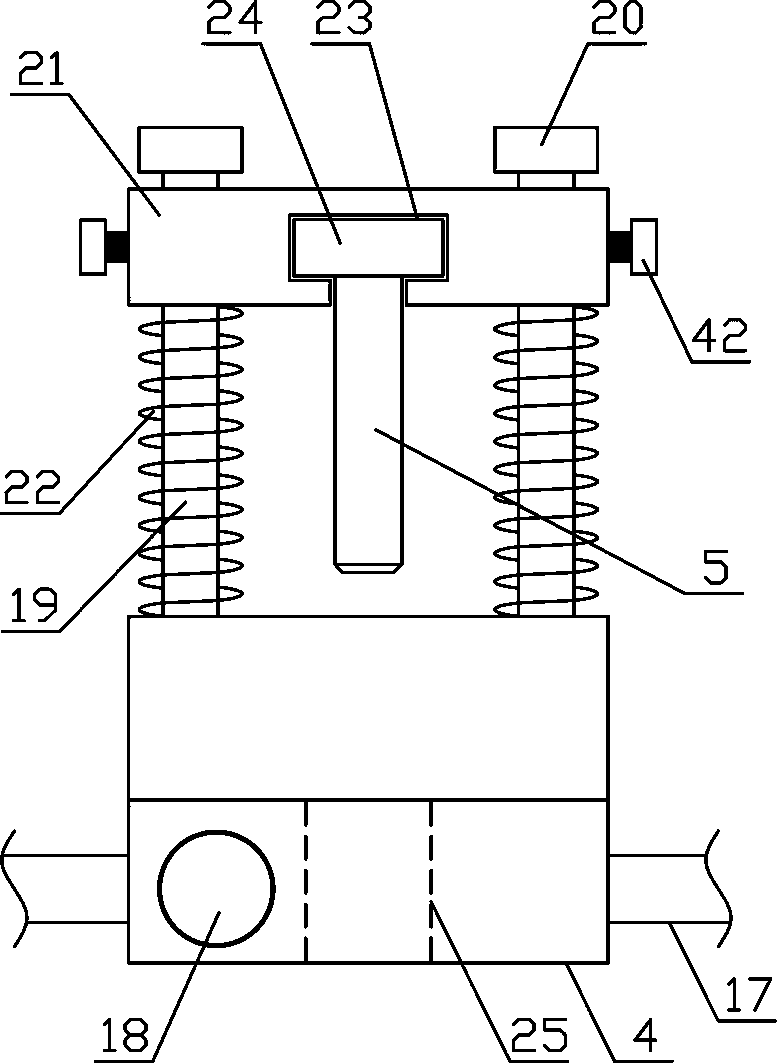

Portable mechanical acoustic frequency vibration sampling drill

InactiveCN104879125ARealize sound frequency vibration drillingAdjust frequencyVibration drillingBorehole/well accessoriesEngineeringDrill

The invention relates to a portable mechanical acoustic frequency vibration sampling drill which comprises a base, an upright column, an acoustic frequency vibration device, a lifting device, a flexible transmission shaft and a power output device, wherein the upright column is fixed on the base; the upper end of the acoustic frequency vibration device is fixed at one end of a steel wire rope, the lower end of the acoustic frequency vibration device is connected with a drilling tool, and the other end of the steel wire rope goes around a pulley arranged at the top end of the upright column and is connected with the lifting device; the lifting device is fixed on the upright column; the power input end of the acoustic frequency vibration device is connected with the power output device through the flexible transmission shaft. According to the portable mechanical acoustic frequency vibration sampling drill, an eccentric mechanism is driven to generate acoustic frequency vibration and excitation force through purely mechanical transmission, namely the acoustic frequency vibration device is driven by the flexible transmission shaft, the acoustic frequency vibration device generates the vibration frequency and excitation force of up to 200 Hz, and the excitation force is transferred to the drilling tool, so as to realize the acoustic frequency vibration drilling of the drilling tool.

Owner:BEIJING INST OF EXPLORATION ENG

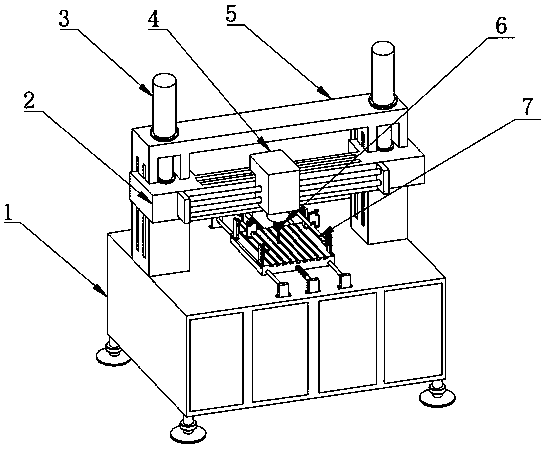

Clamping-type drilling device used for machining communication equipment

ActiveCN109648117AImprove practicalityQuick clampingFeeding apparatusPositioning apparatusHydraulic cylinderMotor drive

The invention discloses a clamping-type drilling device used for machining communication equipment, and relates to the technical field of communication equipment machining. The clamping-type drillingdevice comprises a device body. A machining platform is mounted at the top end of the device body and is close to the inner side of a portal frame. Hydraulic cylinders are arranged on the two sides ofthe top end of the portal frame in a penetrating mode. A drilling mechanism is arranged at the bottom end of a movable box in an embedded mode. According to the clamping-type drilling device, a firstmotor drives a rotary frame to rotate in an X-axis plane and a Y-axis plane of the three-dimensional space, a second motor drives a spindle box to rotate in the Y-axis plane and the Z-axis plane of the three-dimensional space, and a third motor drives a drill bit to rotate so that holes at any inclination angles can be drilled in the surface of the communication equipment; the to-be-machined communication equipment can be rapidly and firmly clamped through the clamping mechanism so that holes can be rapidly and efficiently drilled in the surface of the communication equipment; and a sliding mechanism drives a supporting mechanism to slide to fine adjust the vertical height of the machining platform relative to the drilling mechanism so that communication equipment with different sizes canbe machined.

Owner:安徽轩纬科技有限公司

Aluminum product continuous punching mechanism

InactiveCN108787856AEasy to assemble and disassembleReasonable structural designMetal-working feeding devicesStripping-off devicesPunchingEngineering

The invention discloses an aluminum product continuous punching mechanism and belongs to the field of sectional material machining equipment. Rotating roller brackets on the two sides of a space belowa material conveying bracket are rotationally connected with material guide rotating rollers; a plurality of punching brackets are arranged on a horizontal movement guide rod in a sliding manner in the horizontal direction; punching pressure rods are vertically and fixedly arranged at the middle parts of the lower sides of adjusting guide plates; a punching pressure plate is horizontally and fixedly arranged on the lower side of a lifting pressure plate; rotating pressure rods are correspondingly and vertically arranged at the parts, on the two sides of a space above the lifting pressure plate, on the material conveying bracket; pushing rod cams are arranged at the parts, on one sides of the rotating pressure rods, on the material conveying bracket; and the output end of a rotary electromagnet is in transmission connection with the pushing rod cam on one side of the material conveying bracket by a punching belt. The structural design is reasonable, aluminum products can be subjected to punching machining conveniently, rapidly, stably and efficiently in the conveying process according to the requirement, scratched marks on the surfaces of the aluminum products in the machining process can be avoided, the punching machining efficiency and the punching machining quality of the aluminum products are improved, and the machining and using requirements are met.

Owner:蔡燕

Soil layer drilling equipment for construction

Soil layer drilling equipment for construction comprises a baseplate, an air cylinder device, an illuminating apparatus, a cleaning device, a rotary apparatus, a motor device, a pushing device and a positioning device, wherein the baseplate is provided with idler wheels, a first support, a first magnet and a first positioning rod; the air cylinder device comprises a first air cylinder, a first pushing rod, a first frame body, a first spring and a second magnet; the illuminating apparatus comprises a first connecting rack, a lamp bulb and a balancing weight; the cleaning device comprises a first motor, a first rotary shaft, a first turning wheel, brush bristle, a first connecting block and a second connecting rack; the rotary apparatus comprises a second rotary shaft, a cavity, crushing teeth, a drill, a screw rod, a third rotary shaft, a baffle ring, a second spring and a first gear wheel; the motor device comprises a second motor, a second connecting block, a fourth rotary shaft, a second gear wheel, a first fixed mount, a fixed leg and a second positioning rod; the pushing device comprises a second air cylinder, a second pushing rod and a first vertical bar; according to the soil layer drilling equipment provided by the invention, drilling operations can be performed on different soil layers, and the drilling efficiency is high.

Owner:南京思特通工程机械有限公司

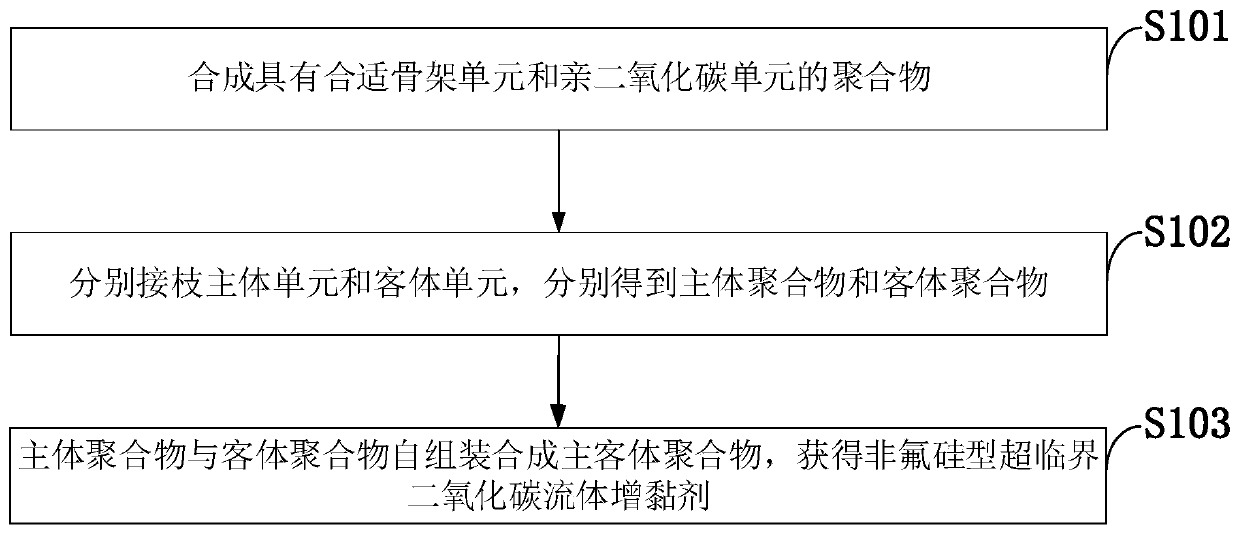

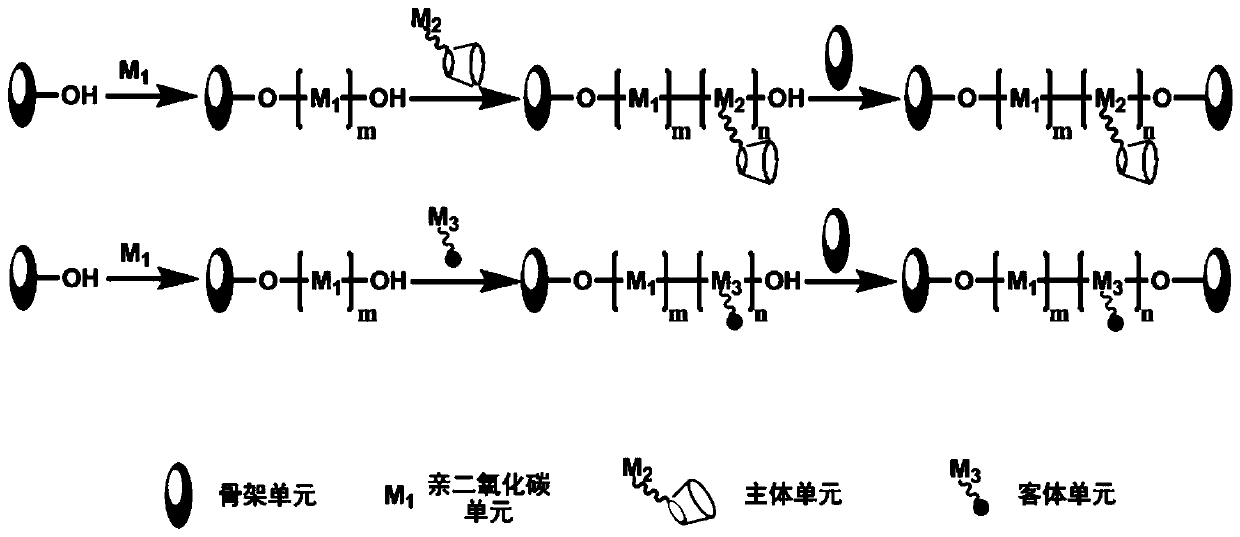

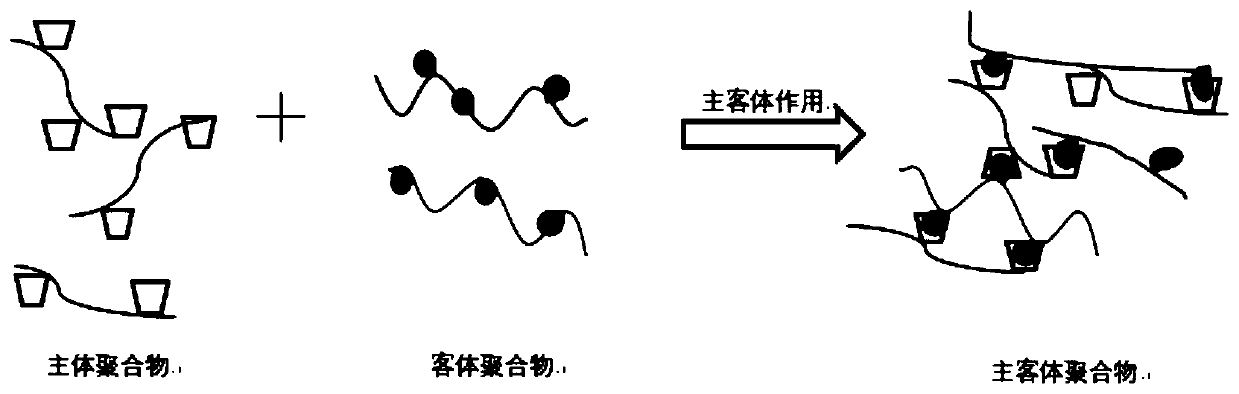

Non-fluorosilicon supercritical carbon dioxide fluid tackifier, preparation method and application thereof

PendingCN110746943AIncrease viscosityEasy for industrial useDrilling compositionBulk chemical productionCyclodextrinEther

The invention belongs to the technical field of tackifier, and discloses a non-fluorosilicon supercritical carbon dioxide fluid tackifier, a preparation method and an application thereof. Cyclodextrinand its derivatives are taken as host compounds and alkyl, aromatic or ether compounds are taken as guest compounds. Polymers with suitable skeleton units and carbon dioxide-friendly units are synthesized; the host unit and the guest unit respectively are grafted to obtain the host polymer and the guest polymer respectively; the host-guest polymer is synthesized by self-assembly of the host polymer and the guest polymer to obtain a non-fluorosilicon supercritical carbon dioxide fluid tackifier. According to the invention, the greenhouse effect gas CO2 can be recycled, waste can be turned intotreasure, and economy can be created; it can improve the comprehensive benefits of oil and gas drilling and development, including reducing losses by increasing drilling speed, increasing oil and gasproduction by protecting reservoirs and improving oil and gas recovery ratio. Therefore, the expected economic and social benefits after industrialization are considerable.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Combination coring bit and drill bit using fixed cutter PDC cutters

InactiveUS8820441B2Improve drilling performanceLower the volumeArtificial islandsDrill bitsPolycrystalline diamondEngineering

A drill bit having fixed Polycrystalline Diamond Compact cutters is used to drill a borehole having a core stump therein. A plurality of additional fixed Polycrystalline Diamond Compact cutters are disposed in the dome of the bit and are usable to concentrate stresses in the top end of the core stump to facilitate the cutting down of the core stump.

Owner:DIAMANT DRILLING SERVICES

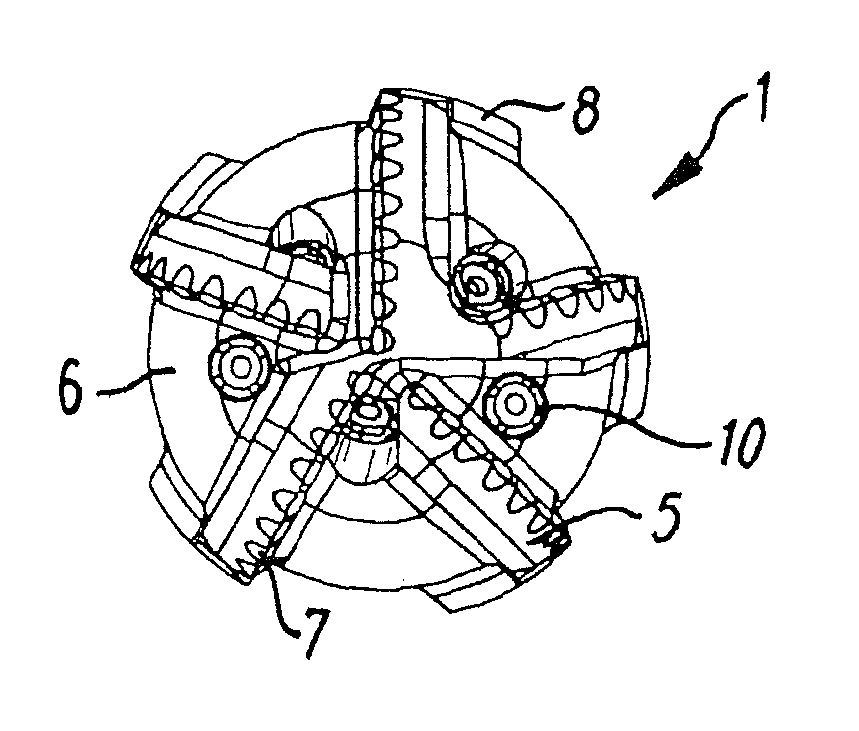

Drill bit

InactiveUS20130098692A1Time takenLow efficiencyPigmenting treatmentDrill bitsPolycrystalline diamondBoron nitride

The present invention provides a drill bit (1), and a method for its manufacture, that is suitable for use within a casing drilling process. The drill bit (1) comprises a monolithic body (5, 6, 8) made from bronze, e.g. aluminium bronze or nickel aluminium bronze, and a relatively hard material mounted thereon. The hard material may comprise polycrystalline diamond (PDC), tungsten carbide or cubic boron nitride. In one embodiment the monolithic body comprises a crown (6) and a plurality of cutting members (5). The hard material may be mounted directly on the crown or, alternatively, on the cutting members (5). The described drill bit (1) facilitates the drilling of hard rock formations while still being capable of being drilled through by a standard oilfield drill bit.

Owner:TESCO CORPORATION

Roller bit parallel inlayed compacts

This invention relates to a roller bit applying for the oil, natural gas, mine and geological drilling, and more particularly relates to a kind of roller bit with the parallel inlayed compacts, it includes head and cone, the compact land and the teeth-groove are arranged on the cone, the difference is that there are 2 to 3 compacts having the cylindrical body being arranged on the top of the base teeth along the teeth direction.The cutting performance of the present invention is similar to that of the oblate compacts, and, by utilizing the conventional cylindrical compacts, it is not only easy to process and with low manufacturing cost, but the bit can effectively drill through the stringered earth formation with both hard and soft formation and thus better economic benefit from drilling the stringered formation can be obtained.

Owner:KINGDREAM PLC CO

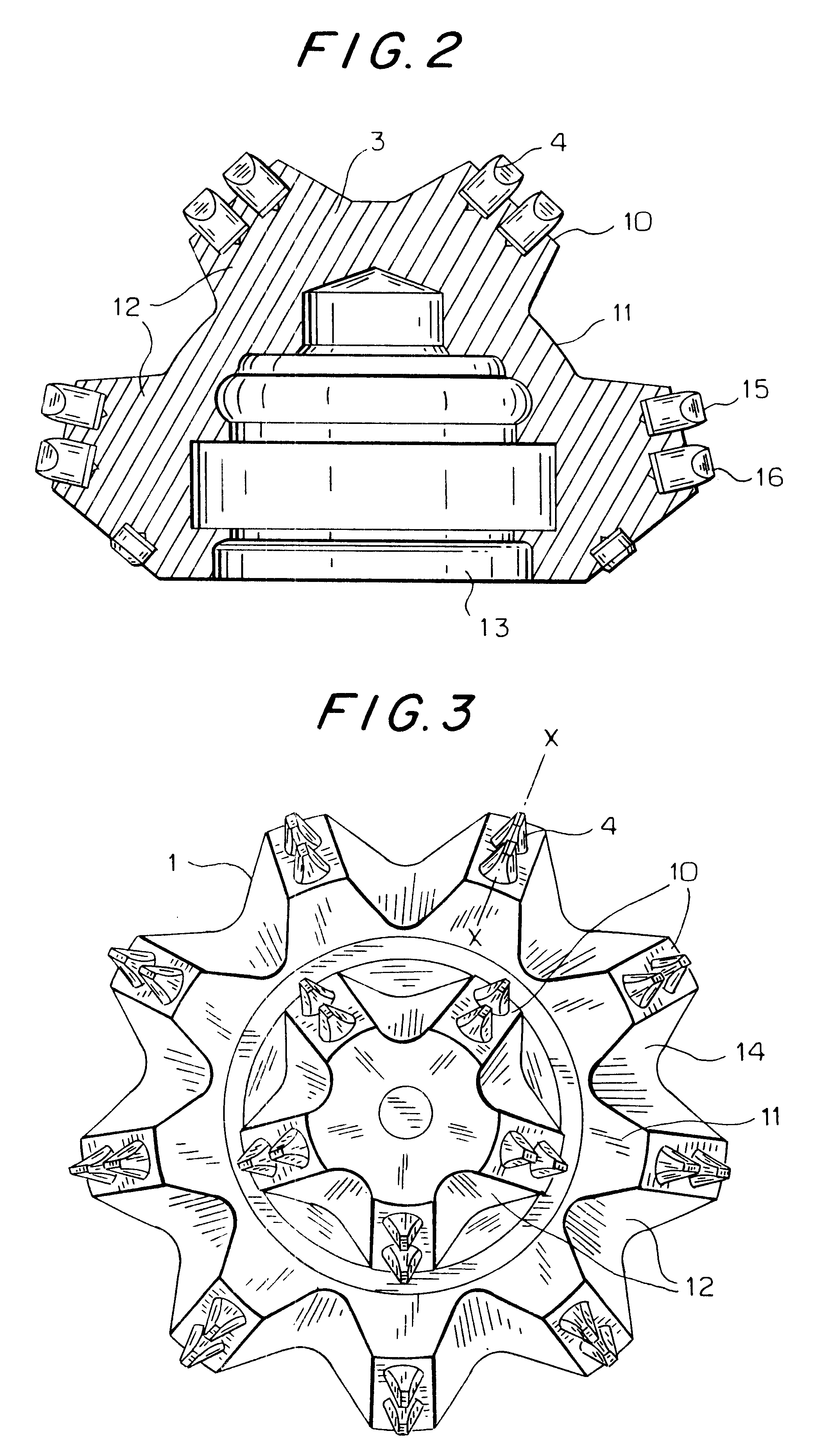

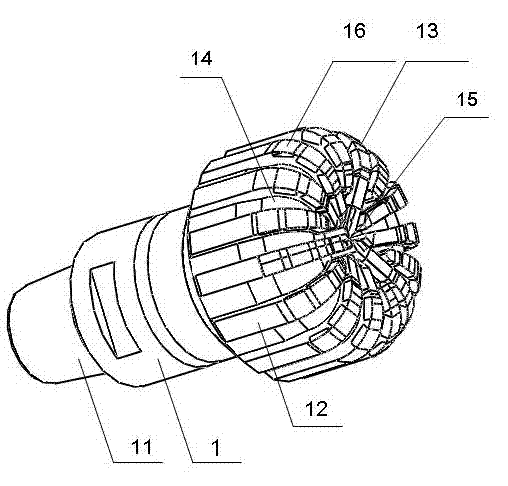

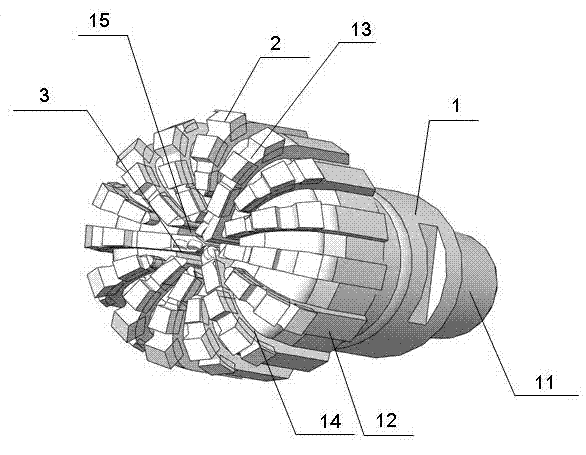

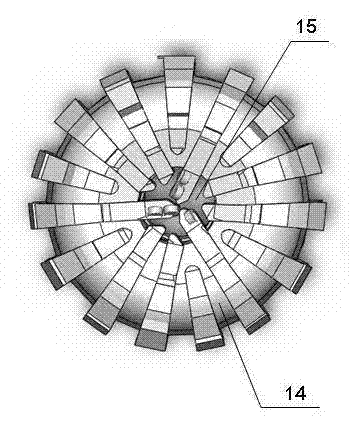

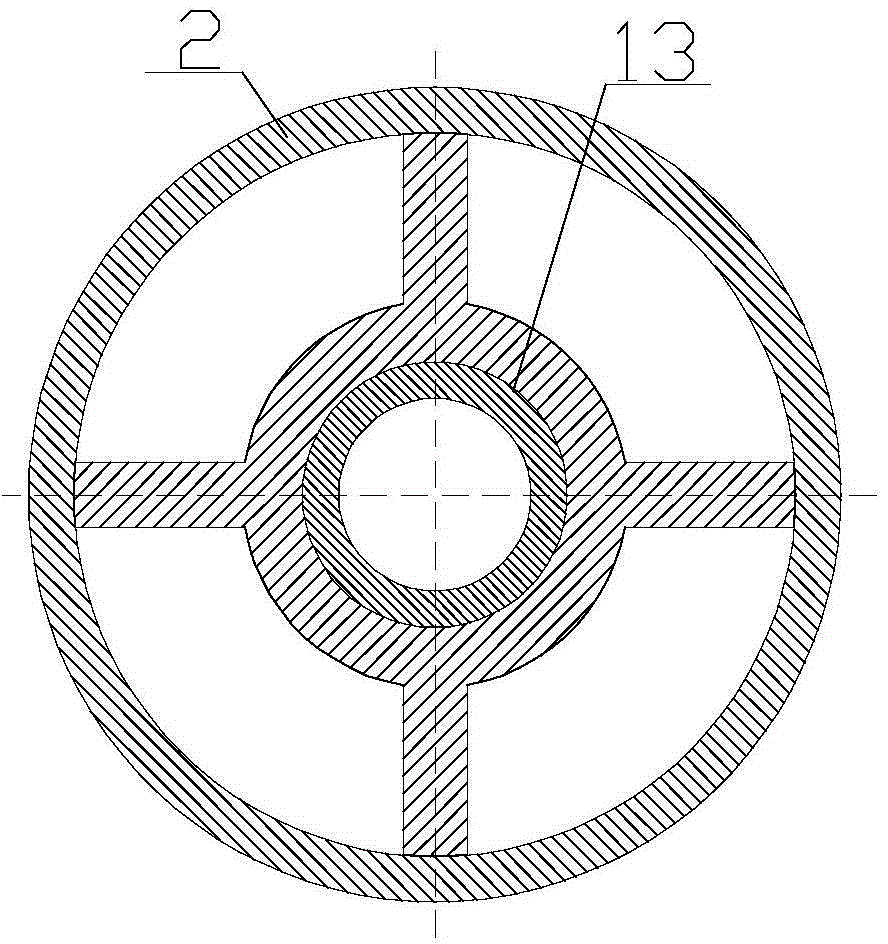

Composite inserted tooth blade diamond comprehensive drill bit

ActiveCN102852462AImprove efficiencyEfficient drillingDrill bitsSuperhard materialPolycrystalline diamond

The invention discloses a composite inserted tooth blade diamond comprehensive drill bit. A drill bit matrix (1) consists of a joint (11), a gauge protection surface (12), a blade (13), a waterway (14) and a center water hole (15). A replacement block 16 is reserved in the blade 13. The replacement block 16 is used for carrying out welding-on on a cutting abrasion block 2 and a PDC (Polycrystalline Diamond Compact) 3. According to the invention, the special high-intensity high wear resistance superhard material cutting abrasion block is subjected to welding-on on the blade of the drilling bit matrix and the composite inserted tooth blade diamond comprehensive drill bit is matched with a downhole motor assembly to implement high-efficiency drilling in a stiff-plastic compact mud rock and glutenite interlayer; the composite inserted tooth blade diamond comprehensive drill bit has the characteristics of high efficiency, long service life and low cost; and the difficult problems of short service life and low construction efficiency of a conventional roller bit and a conventional PDC drill bit can be effectively solved.

Owner:BEIJING INST OF EXPLORATION ENG

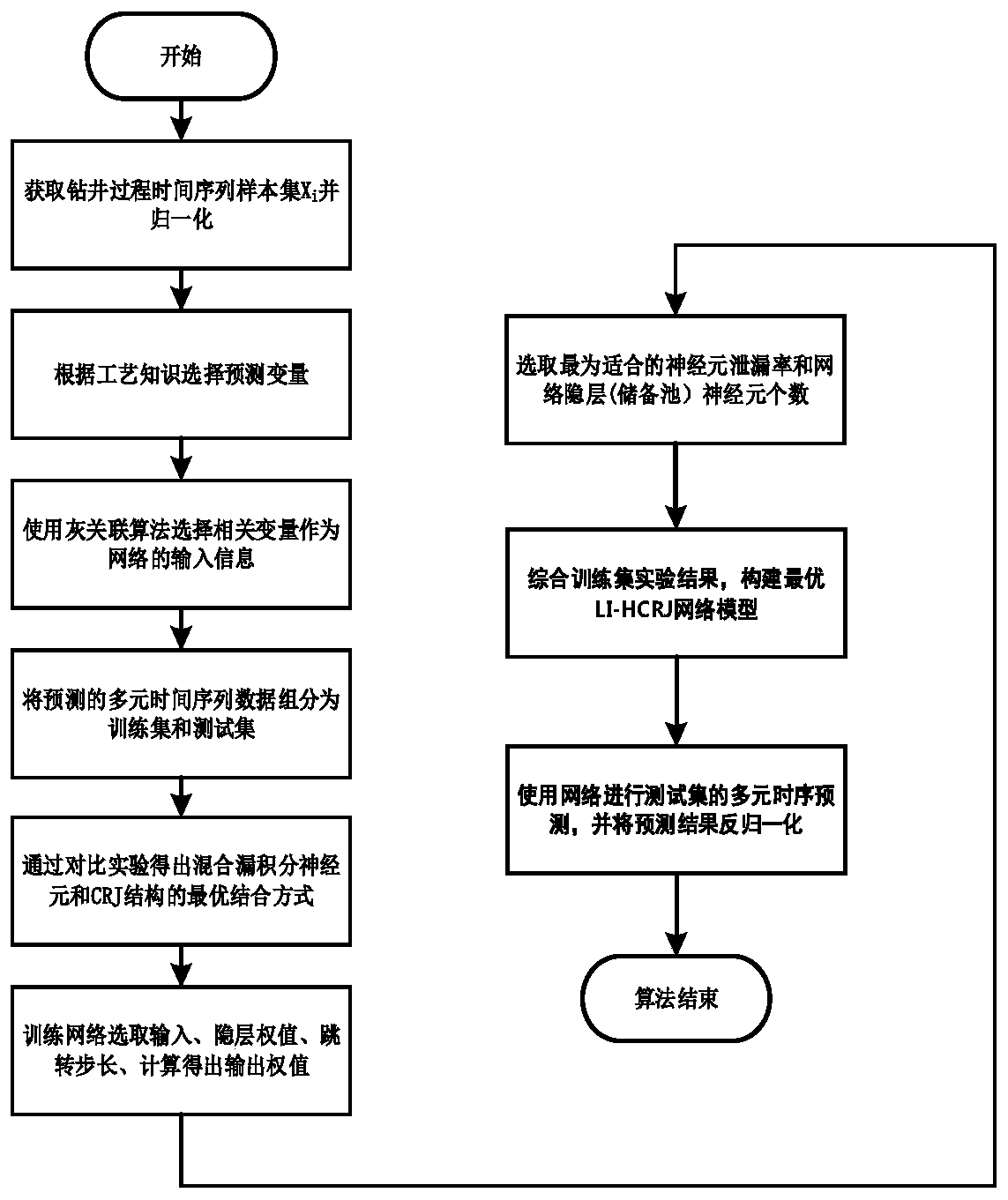

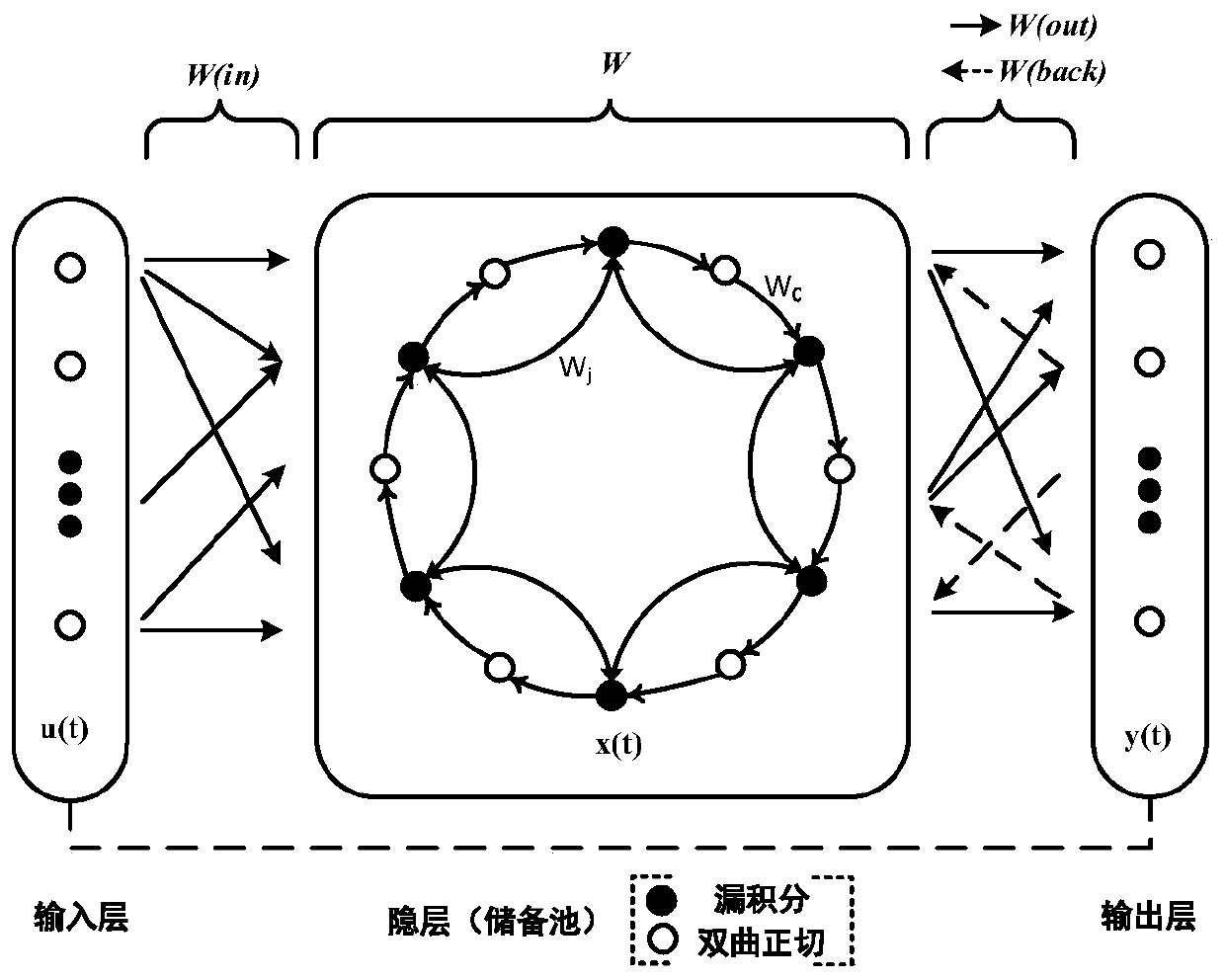

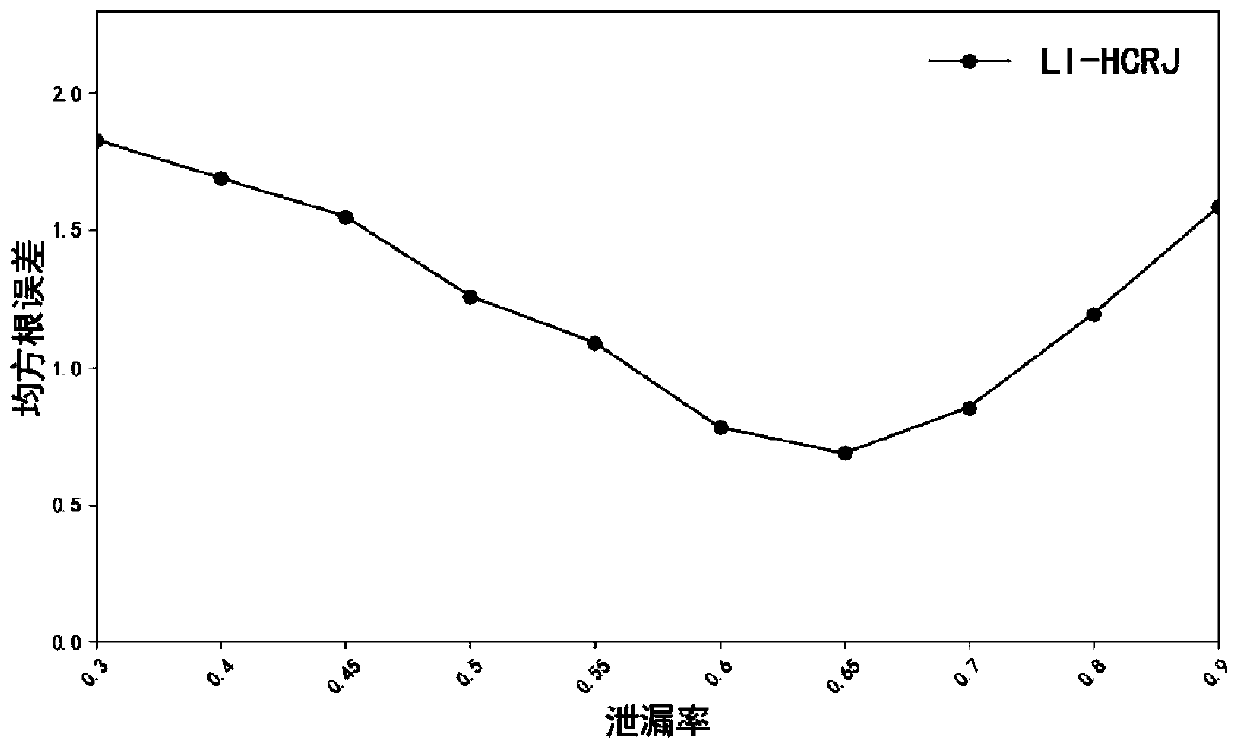

Multivariate drilling time sequence prediction method based on mixed leakage integral CRJ network

ActiveCN110222387AImprove dynamicsImprove predictive performanceSpecial data processing applicationsMeasurement devices for drillingNetwork modelNeuron

The invention discloses a multivariate drilling time sequence prediction method based on a mixed leakage integral CRJ network. The method comprises the following steps of firstly, obtaining a time sequence data sample and performing data preprocessing on the data sample; secondly, selecting a high-correlation variable of a prediction variable as a network input by using a grey correlation algorithm; then, optimizing a traditional CRJ network model; combining a hybrid leakage integral neuron with stronger memorability mutually with a CRJ network to improve the dynamic characteristic and the prediction performance of the network; obtaining an optimal combination mode and an optimal leakage rate through a comparison experiment; constructing the mixed leakage integral CRJ network model based on an experiment result; and finally, using the trained mixed leakage integral CRJ network for carrying out time sequence prediction on the key variables of the drilling process. through the predictionresult, the change condition of the parameters are known in advance, and a corresponding adjustment strategy can be adopted in advance, and therefore it is ensured that drilling engineering is carried out safely and efficiently.

Owner:BEIJING UNIV OF CHEM TECH

Hydraulic torque converter

ActiveCN105525871AImprove safety and reliabilityExtended service lifeDirectional drillingWell drillingControl theory

The invention discloses a hydraulic torque converter and mainly relates to the field of oil and gas well drilling. The hydraulic torque converter is installed between a bottom drilling tool combination and a drill column. The hydraulic torque converter is mainly composed of a center shaft, an outer shell, bearing devices, an adjustor, a spring, a hydraulic clutch, a coupler, a torque generator and a nozzle. Due to the special structure and the special connecting function relation among the center shaft, the outer shell, the bearing devices, the adjustor, the spring, the hydraulic clutch, the coupler, the torque generator and the nozzle, the hydraulic torque converter can achieve drill column rotation on the premise that reactive torque of the bottom drilling tool combination is balanced and a tool face is stabilized and can also complete tool face adjustment or composite rotation well drilling work. The drilling speed of a well of a complex structure can be better increased, the well track control precision can be better improved, in addition, a conventional sliding well drilling manner can be changed into a rotation well drilling manner, sliding friction resistance of the drill column is effectively reduced, and the hydraulic torque converter is of great significance in improving the well drilling efficiency of the well of the complex structure. Meanwhile, the hydraulic torque converter has the beneficial effects of being simple in structure, convenient to operate and install, safe and reliable.

Owner:CHINA PETROCHEMICAL CORP +1

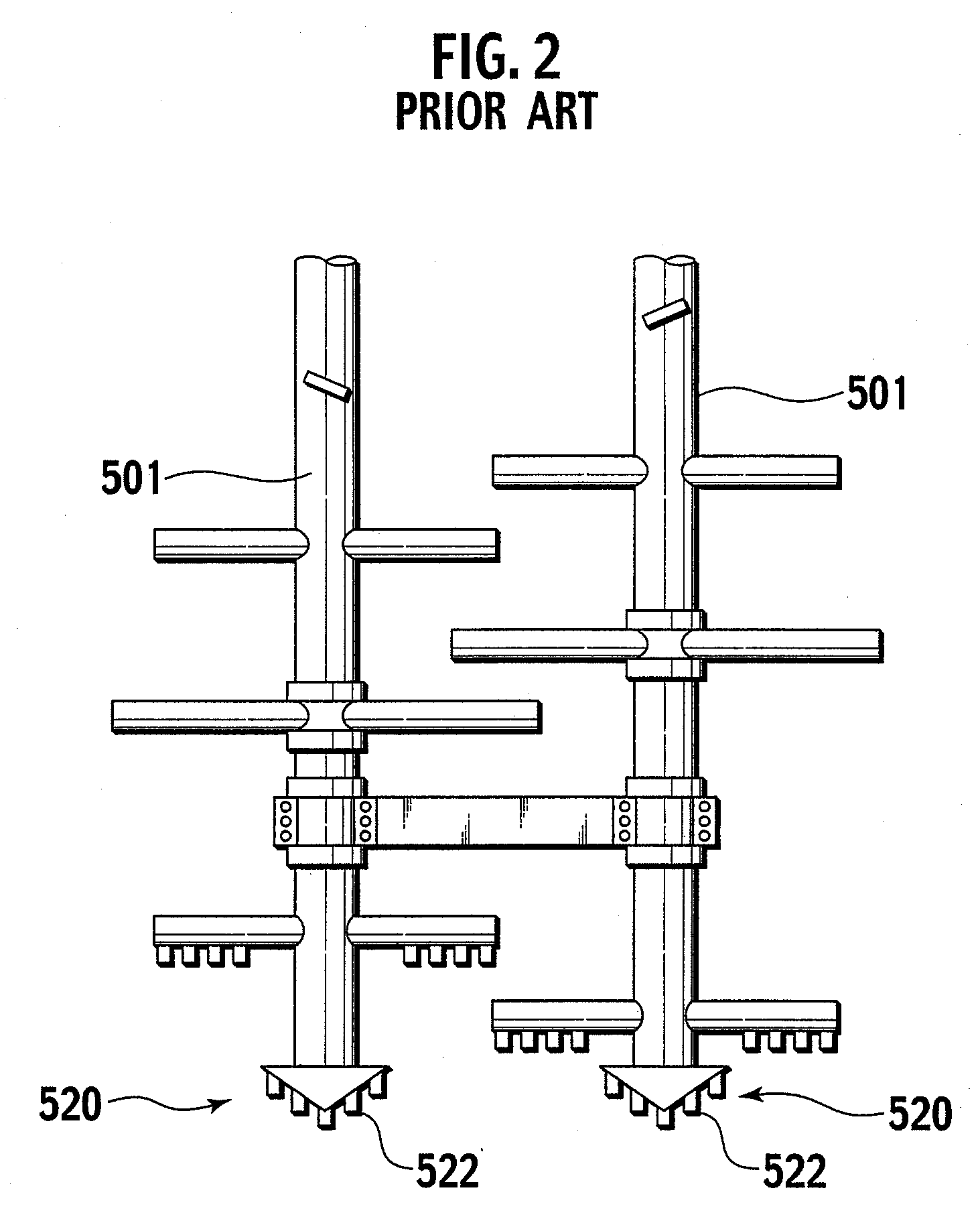

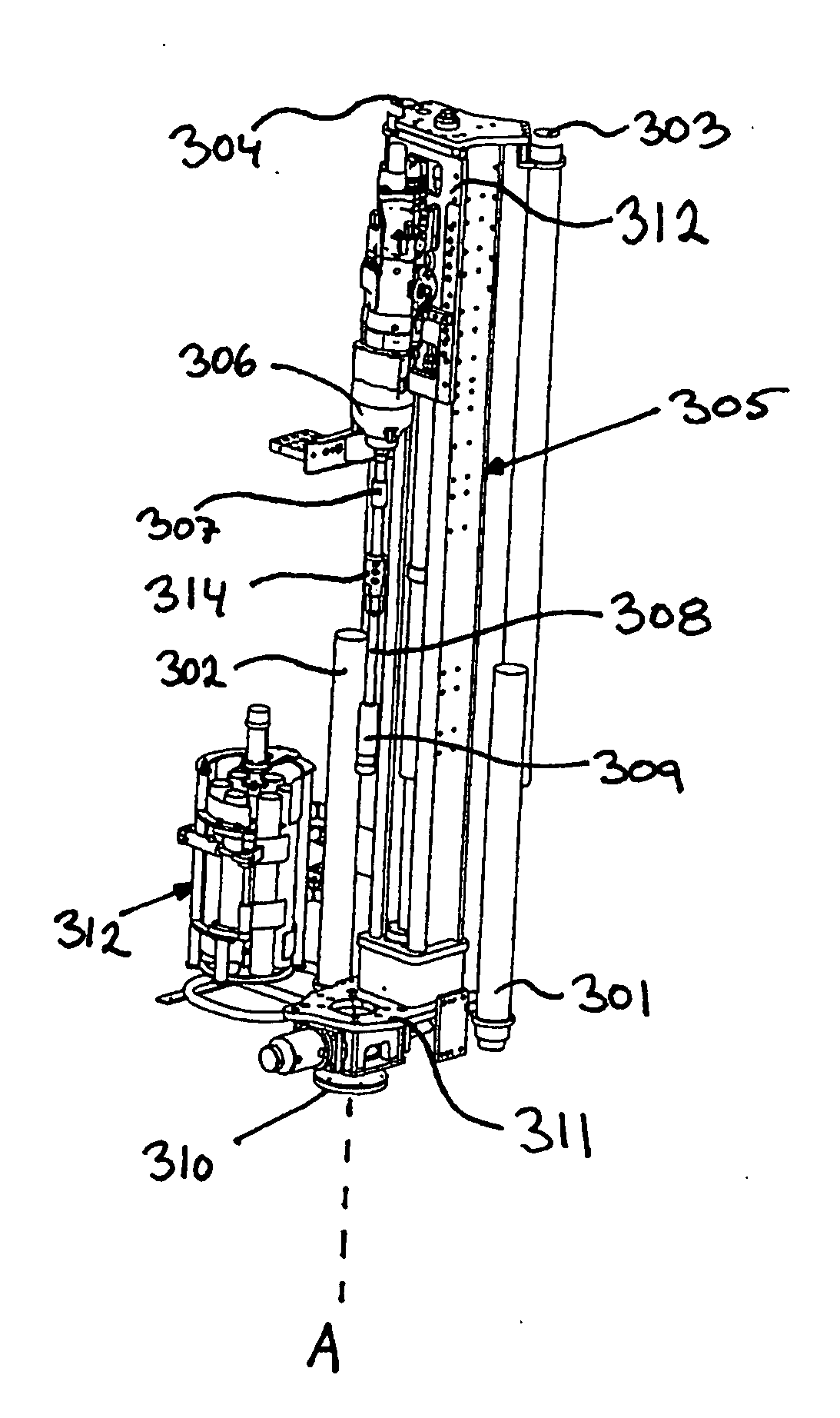

Method, System And Rock Drilling Apparatus For Installing A Pipe In Drilled Holes In Rock Drilling

The present invention relates to a method for installing a pipe (313) when drilling a first hole with the aid of a rock drilling apparatus (100), wherein a tool (309) which can be connected to a drilling machine (306) via one or more drill rods (308) is used in said drilling, which method comprises—drilling a first part of said first hole,—installing a pipe (313) in at least a part or said first drilled part of said first hole, wherein the method further comprises:—installing said pipe (313) in said first hole while drilling of said first part of said first hole is in progress.—pulling said drill rod (308) out of said first hole before finishing drilling of said first hole to the desired, compared with said first part, deeper depth. The invention also relates to a system and to a rock drilling apparatus.

Owner:ATLAS COPCO ROCK DRILLS

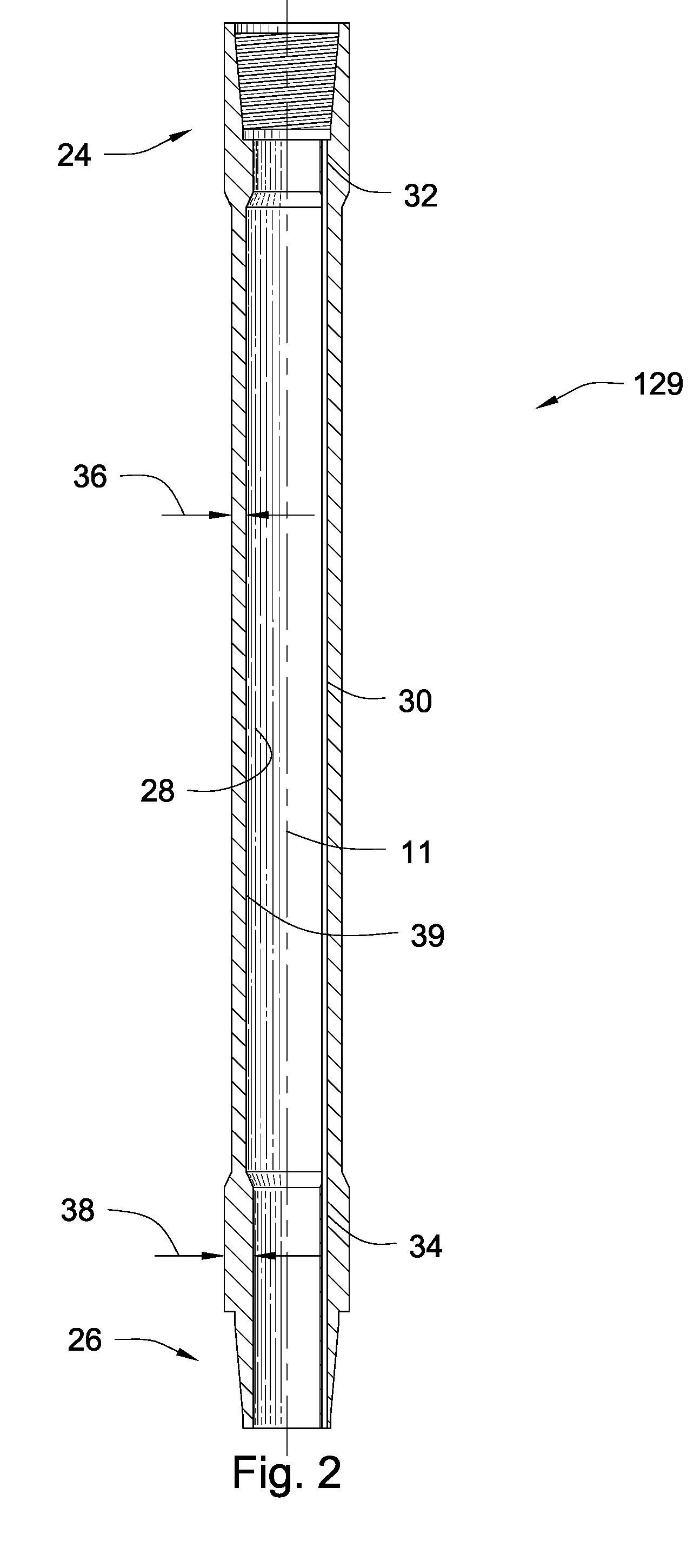

Downhole tool

InactiveCN1748073AEfficient drillingDirectional drillingBorehole drivesElectric machineHydraulic pump

A downhole tool comprising: an axial drive unit ( 10 ) having a connection for an electric power cable extending up the borehole, and including an anchoring mechanism ( 12, 16 ) operable in the borehole between a first configuration in which the anchoring mechanism resists rotational and axial movement of the unit, and a second configuration in which the anchoring mechanism is moveable axially in the borehole, an axial drive mechanism that moves the anchoring mechanism axially down the borehole when in the second configuration; a motor ( 28 ) mounted on the drive unit at the downhole end thereof; an hydraulic pump ( 30 ) connected to the motor, the pump providing a source of hydraulic power; and a functional unit connected below the hydraulic pump and powered thereby, operation of the axial drive mechanism acting to move the functional unit axially down the borehole.

Owner:PRAD RES & DEV LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com