Whole-section quick-drilling drill carriage for parallel cut blasting of large empty holes in roadway

A full-section, hollow hole technology, applied to drilling equipment and methods, tunnels, earthwork drilling and mining, etc., to achieve the effect of safe operation, comfortable operation and large driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

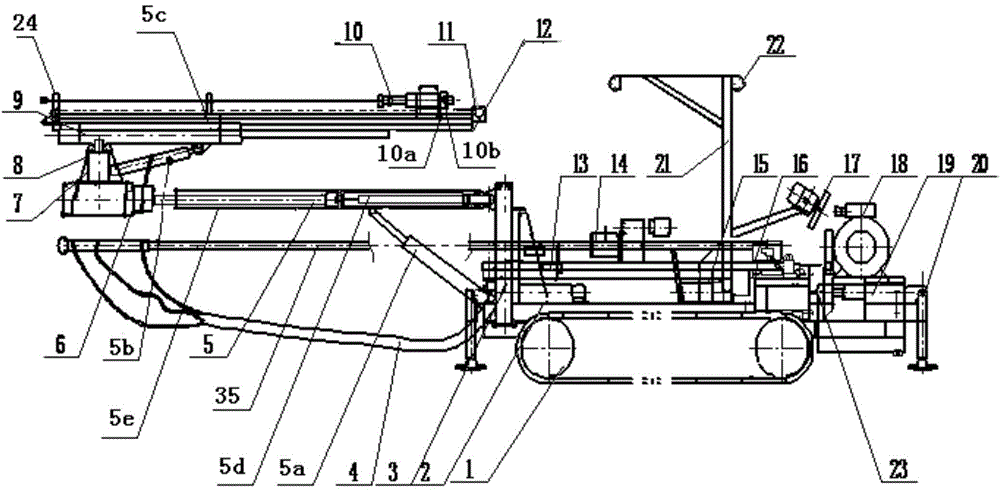

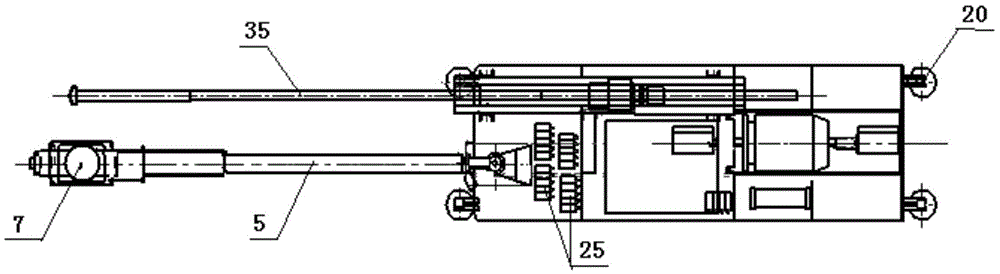

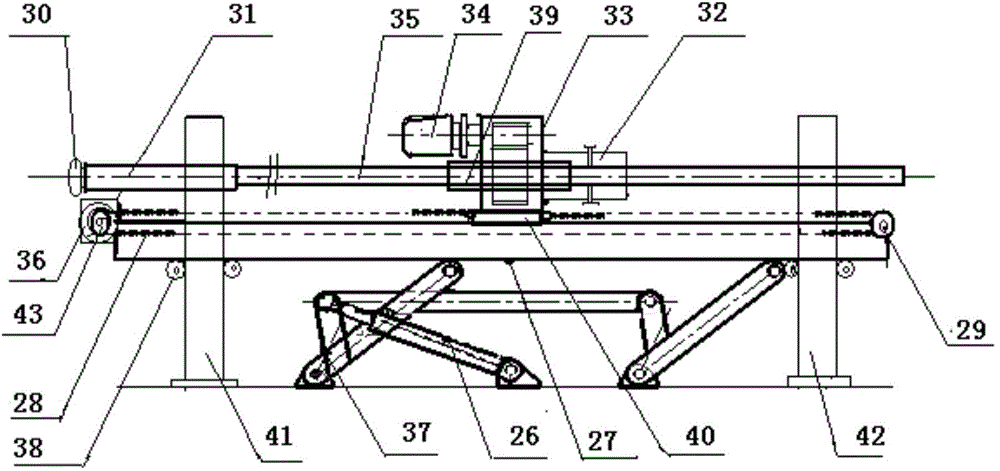

[0031] Such as figure 1 , figure 2 As shown, the full-section rapid drilling rig of the present invention is composed of a traveling mechanism, a vehicle frame, a hydraulic system, and two sets of drilling devices; wherein the first set of drilling devices in the two sets of drilling devices is used to drill ordinary blast holes, the second set of drilling device is used to drill holes with a diameter of more than 100mm;

[0032] The walking mechanism is a commonly used crawler-type walking chassis 1 with a design width of 1.0-1.2 meters. It consists of two sets of completely independent crawler frames on the left and right, a traveling motor, a reducer, a drive sprocket, a crawler chain, and a crawler tensioning mechanism. Each set of track frame is fixed with the frame by a vertical key, and then fastened with the frame with high-strength bolts; the reducer is connected with the track frame with high-strength bolts; the travel motor is driven by the reducer and the drive s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com