Patents

Literature

1849results about How to "Great driving force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

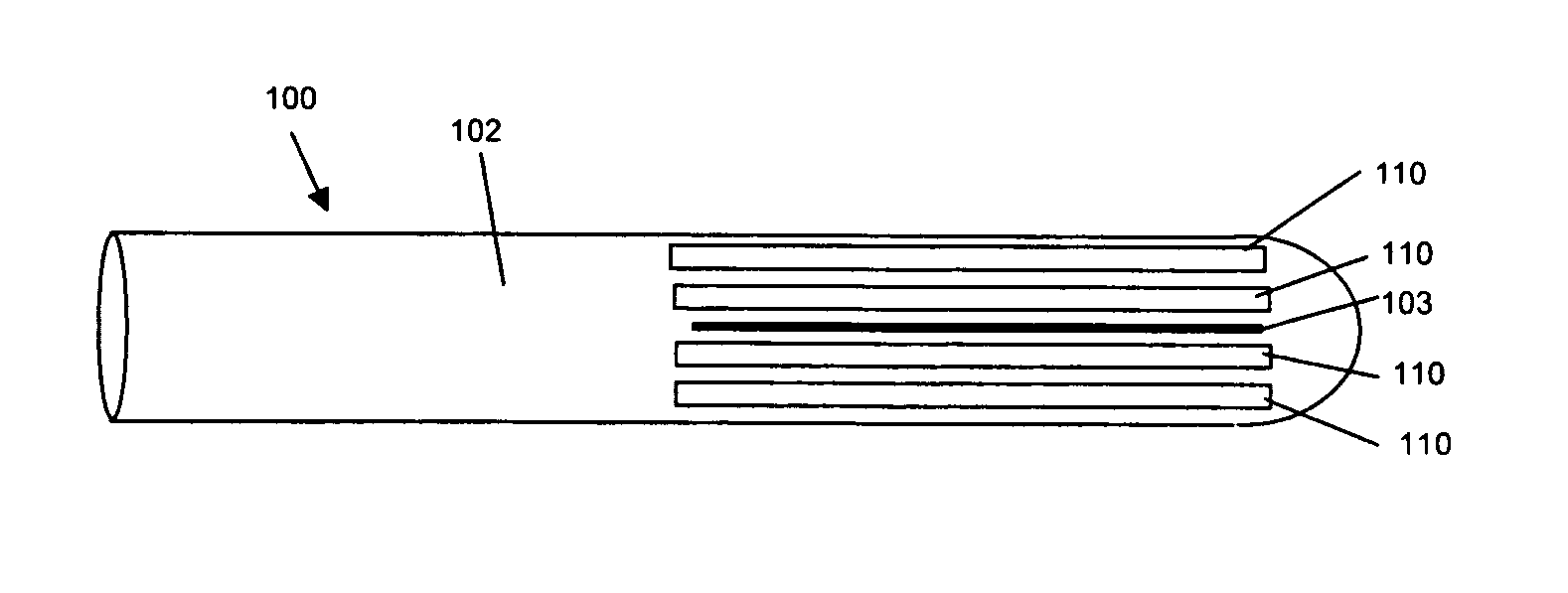

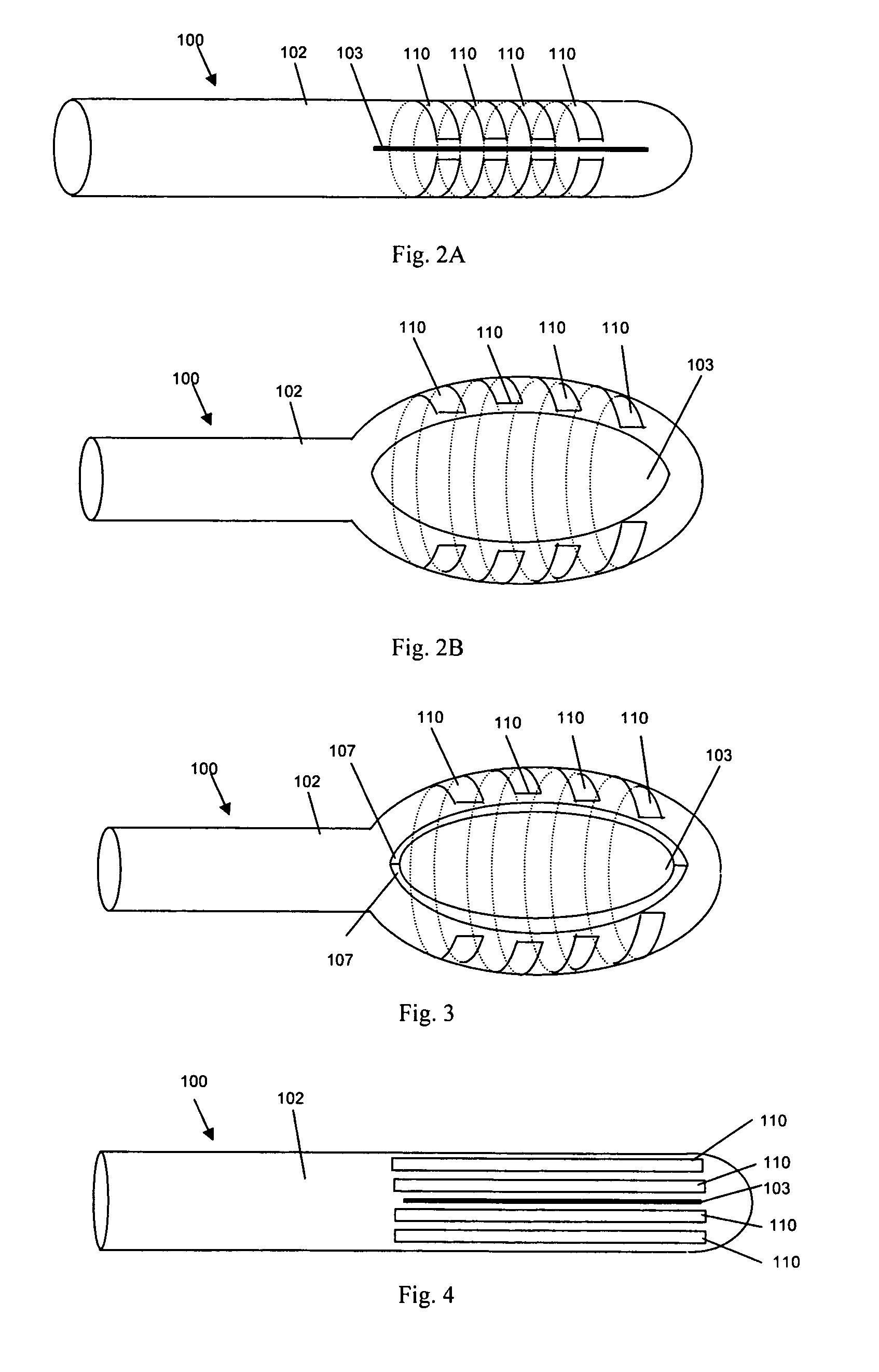

Electronically activated capture device

InactiveUS7063671B2Great driving forceSurgeryVaccination/ovulation diagnosticsControl signalElectroactive polymer actuators

A novel capture device apparatus comprising: (a) a capture device portion, at least a part of which is adaptable for insertion into a patient and (b) a control unit. The capture device portion comprises one or more apertures and one or more electroactive polymer actuators that open and close the one or more apertures based on control signals sent from the control unit. In another aspect of the present invention, a method of capturing a specimen within a patient's body of provided. The method comprises (a) providing a capture device apparatus like that above, (b) inserting at least a portion of the capture device portion of the apparatus into the patient such that the capture device portion is adjacent the specimen; and (c) closing the one or more apertures using the control unit, thereby capturing the specimen.

Owner:BOSTON SCI SCIMED INC

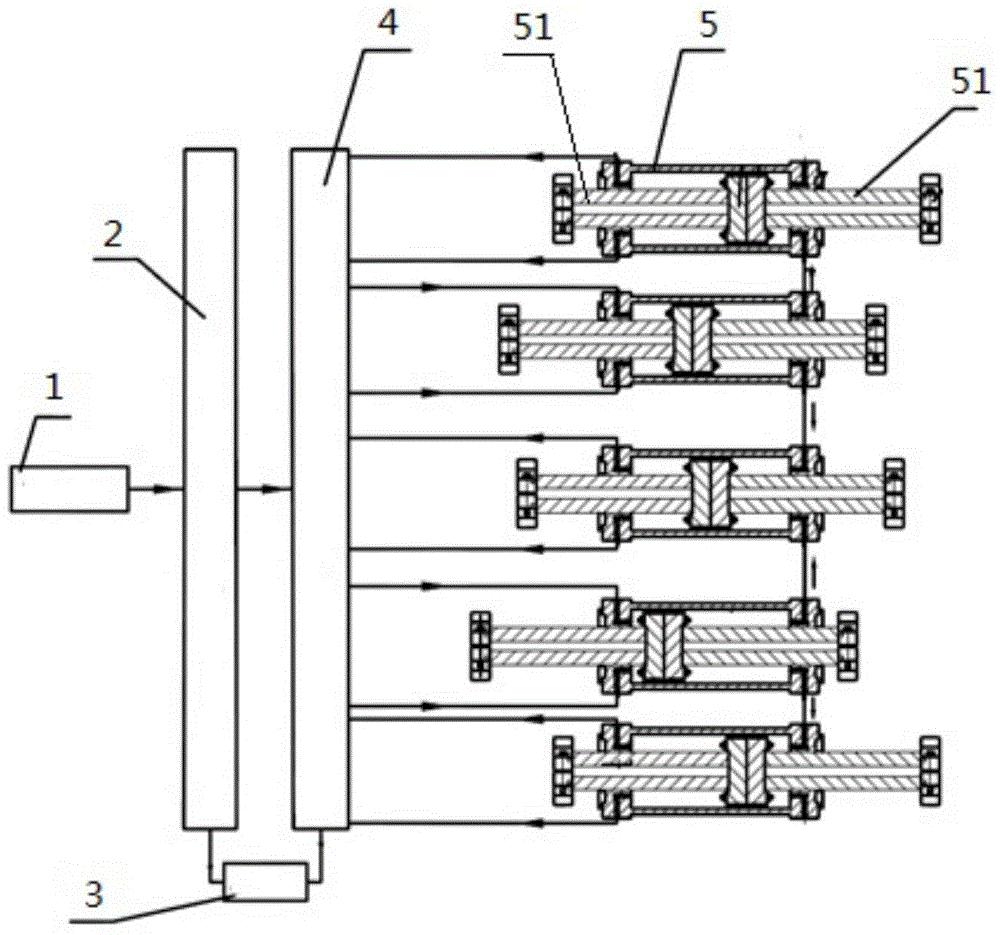

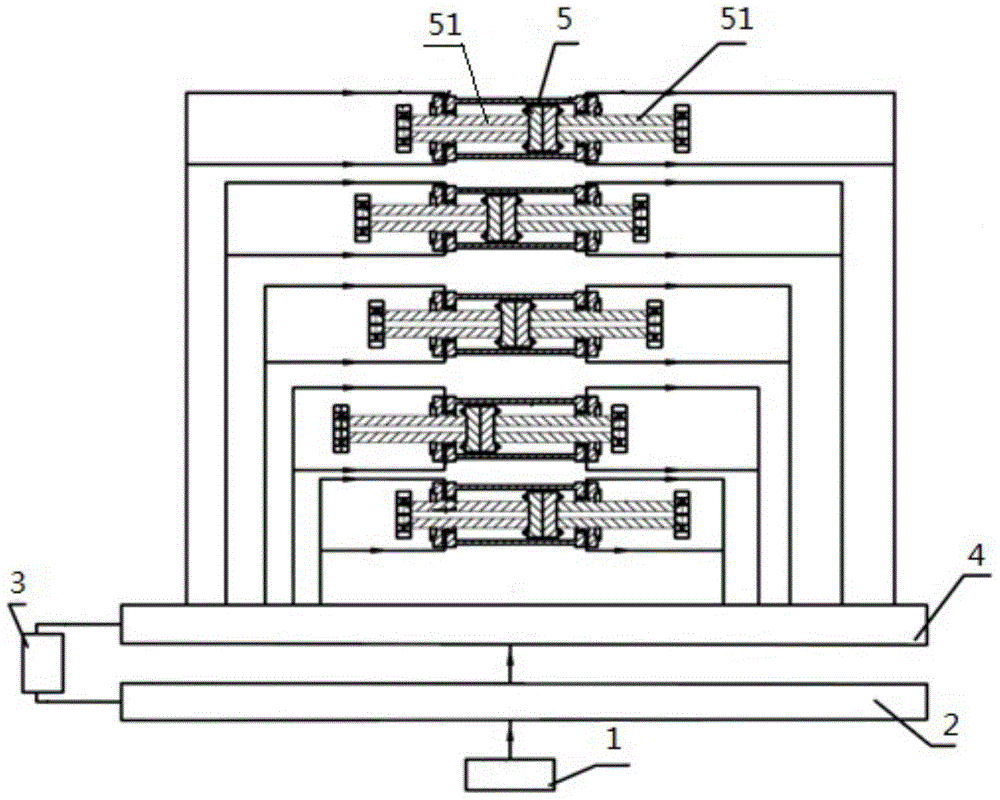

Hydraulic bidirectional pumping device

ActiveCN104612928AExtended service lifeImprove suction efficiencyPiston pumpsPositive-displacement liquid enginesHydraulic cylinderMotor drive

The invention relates to a hydraulic bidirectional pumping device which comprises a prime motor, a hydraulic oil pump, a hydraulic oil tank, a control valve, a double-action hydraulic cylinder and plunger pumps. The prime motor drives the hydraulic oil pump. The hydraulic bidirectional pumping device utilizes the double-action hydraulic cylinder to drive the plunger pumps on both sides; the cylinder number is increased; stroke times are reduced; the service lives of easily damaged parts are prolonged; the coverage range of flow is effectively enlarged; suction efficiency of fracturing fluid is effectively improved; complexity of the integral structure is reduced; cost of manufacturing, maintenance and the like is reduced; the requirements on a lubricating system are lowered; the double-action hydraulic cylinder reciprocates to do work, so that working efficiency is improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

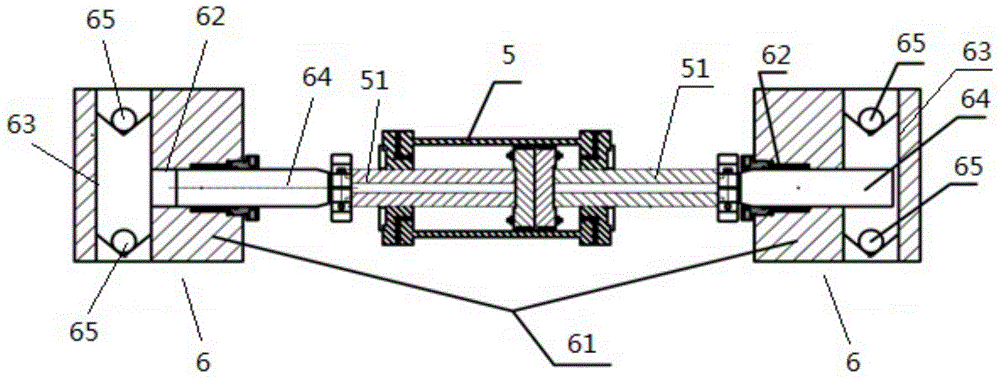

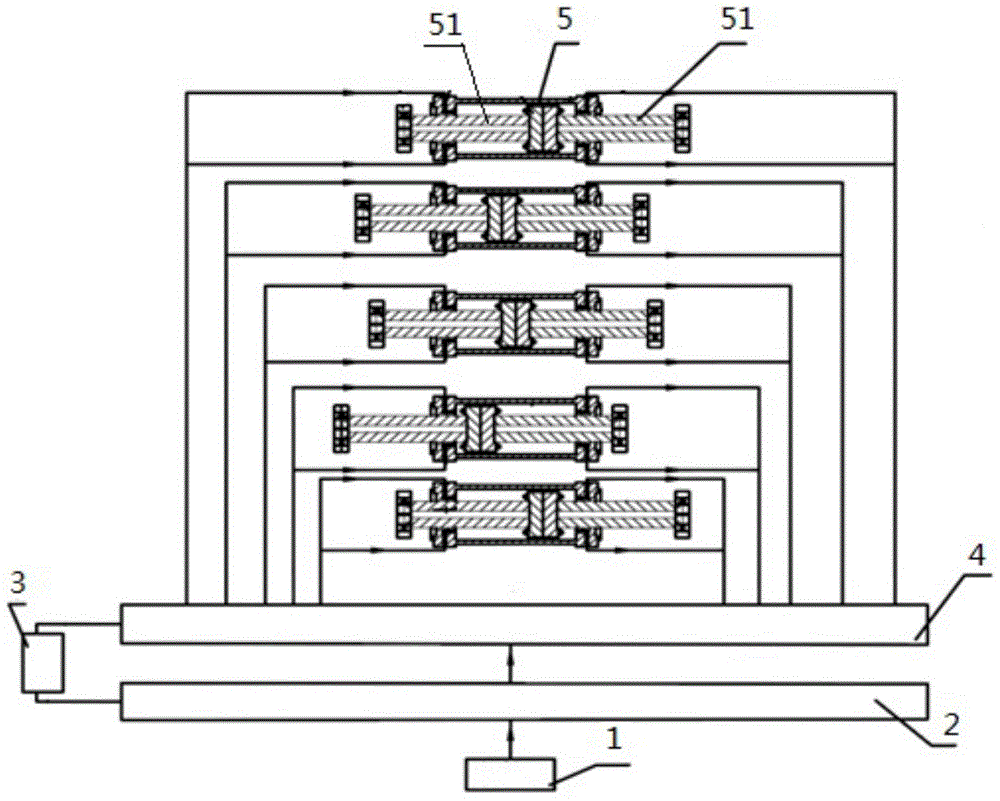

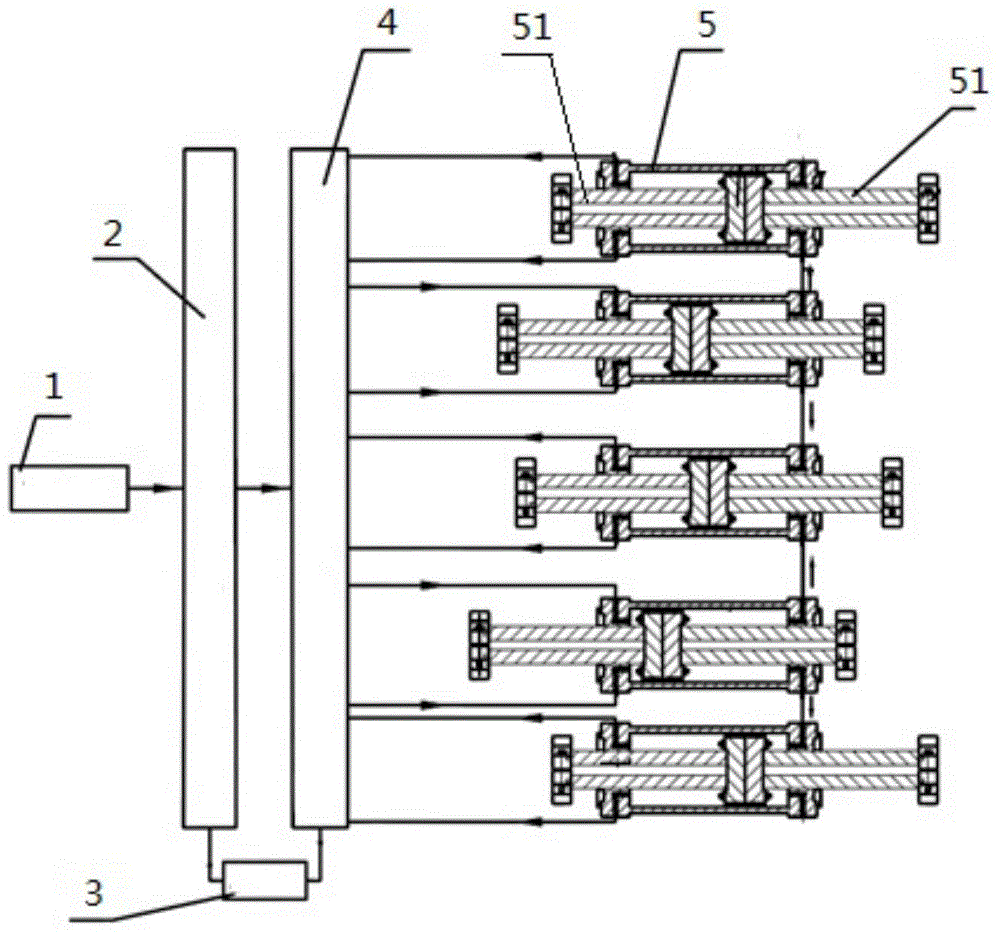

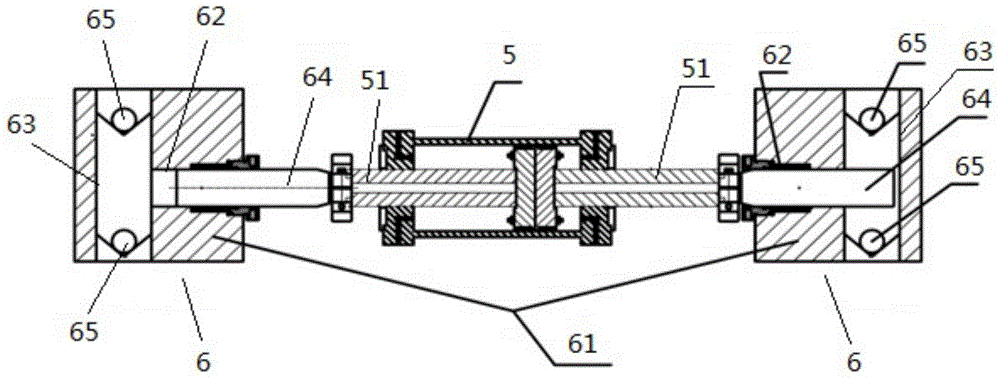

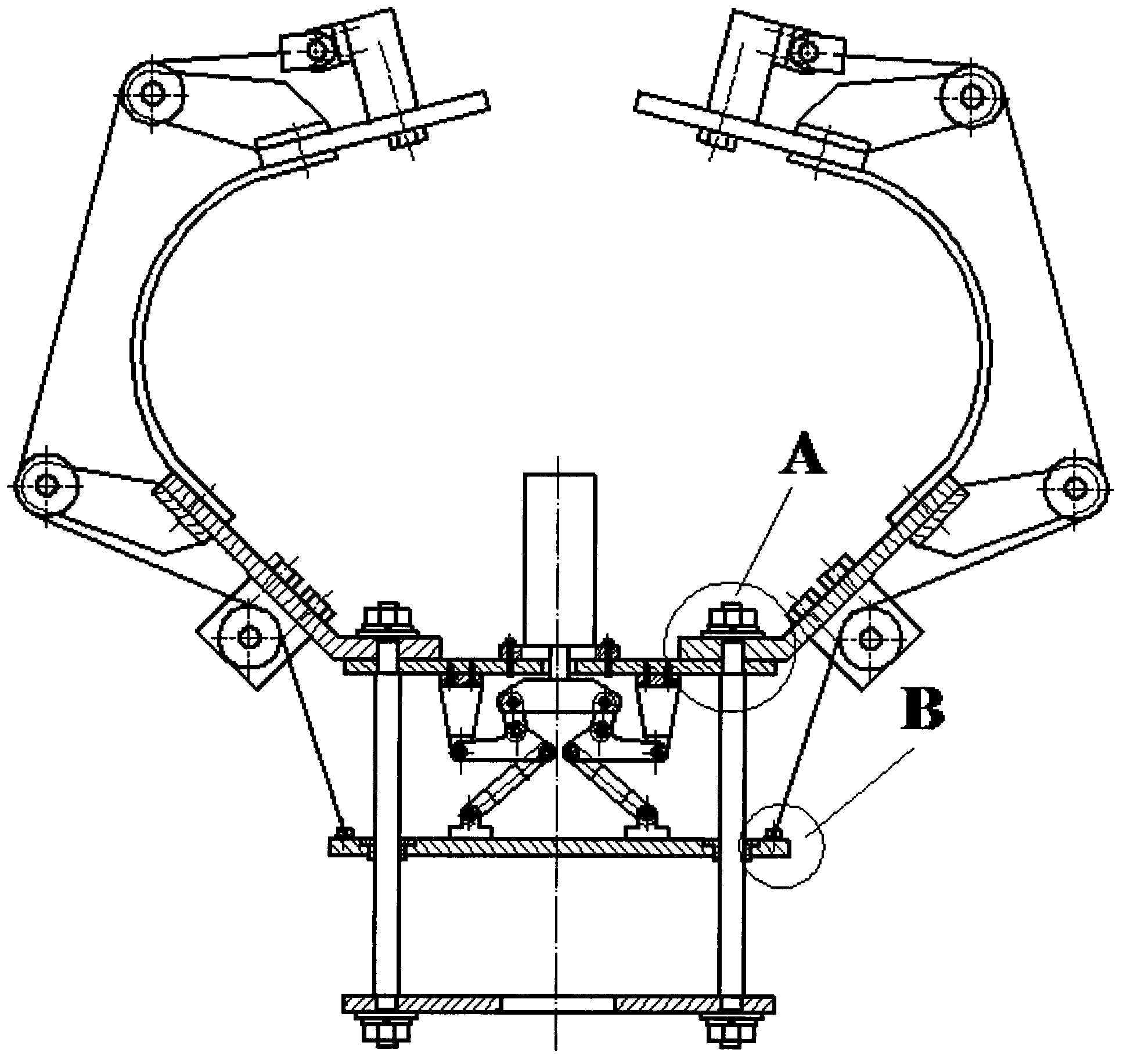

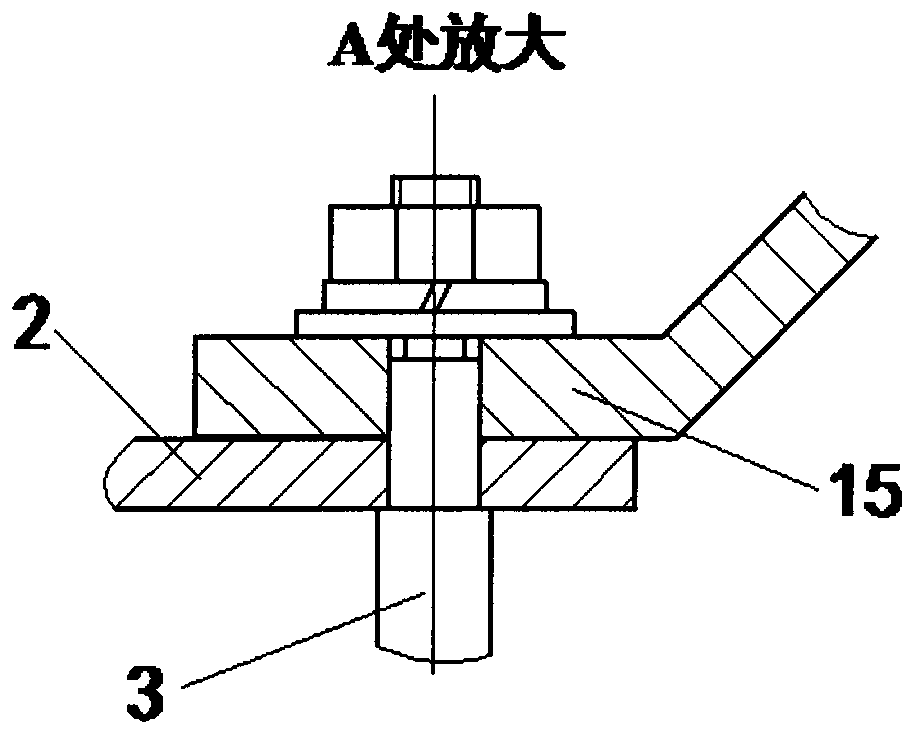

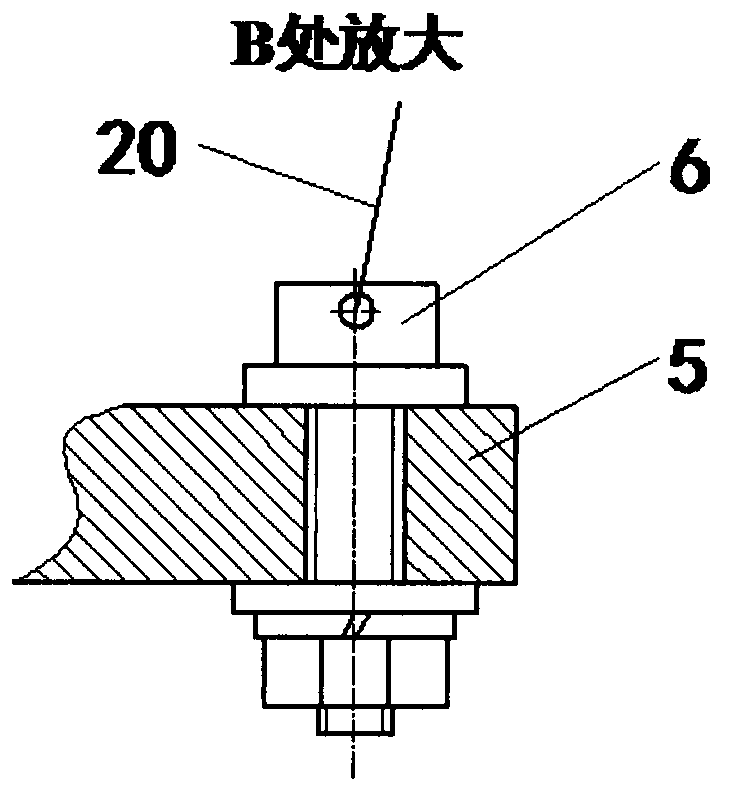

Hydraulic double acting pumping unit

ActiveCN104612928BExtended service lifeImprove suction efficiencyPiston pumpsPositive-displacement liquid enginesHydraulic cylinderMotor drive

The invention relates to a hydraulic bidirectional pumping device which comprises a prime motor, a hydraulic oil pump, a hydraulic oil tank, a control valve, a double-action hydraulic cylinder and plunger pumps. The prime motor drives the hydraulic oil pump. The hydraulic bidirectional pumping device utilizes the double-action hydraulic cylinder to drive the plunger pumps on both sides; the cylinder number is increased; stroke times are reduced; the service lives of easily damaged parts are prolonged; the coverage range of flow is effectively enlarged; suction efficiency of fracturing fluid is effectively improved; complexity of the integral structure is reduced; cost of manufacturing, maintenance and the like is reduced; the requirements on a lubricating system are lowered; the double-action hydraulic cylinder reciprocates to do work, so that working efficiency is improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

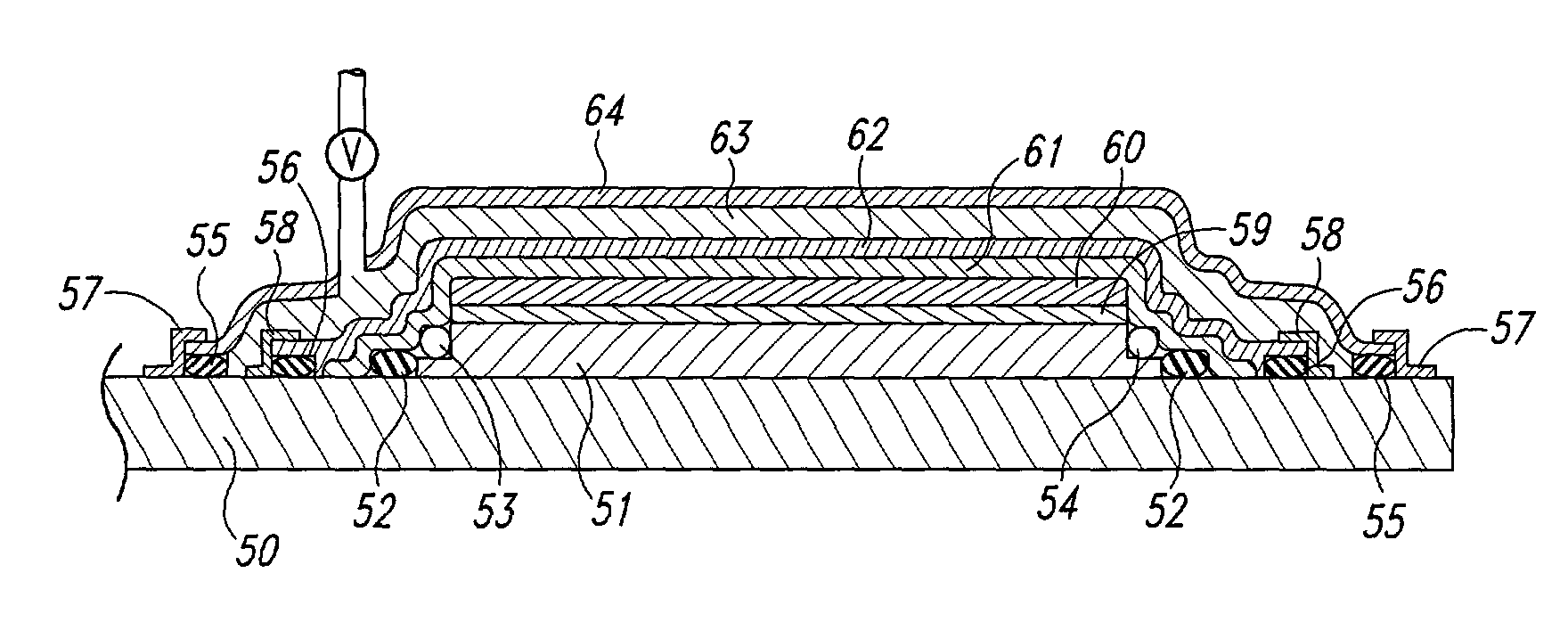

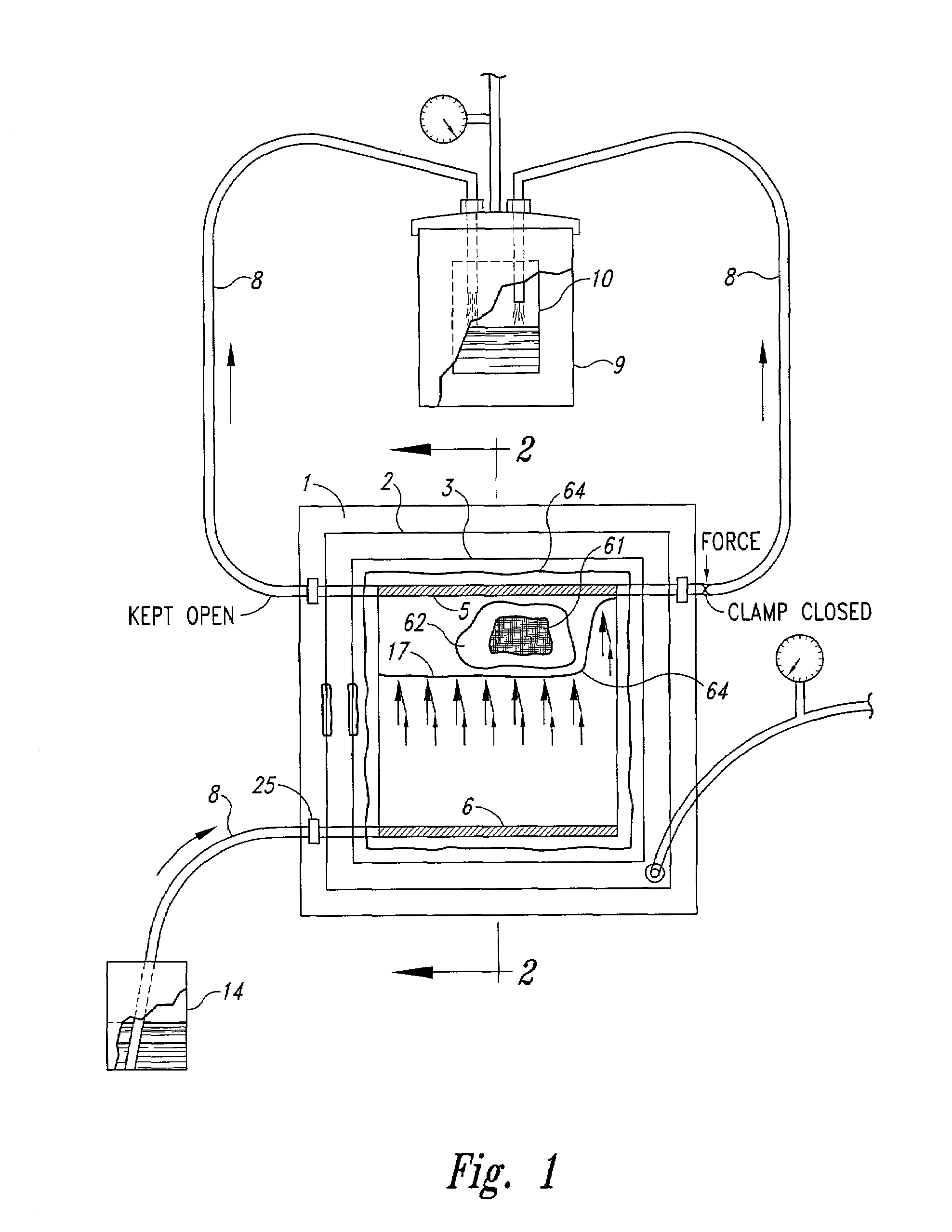

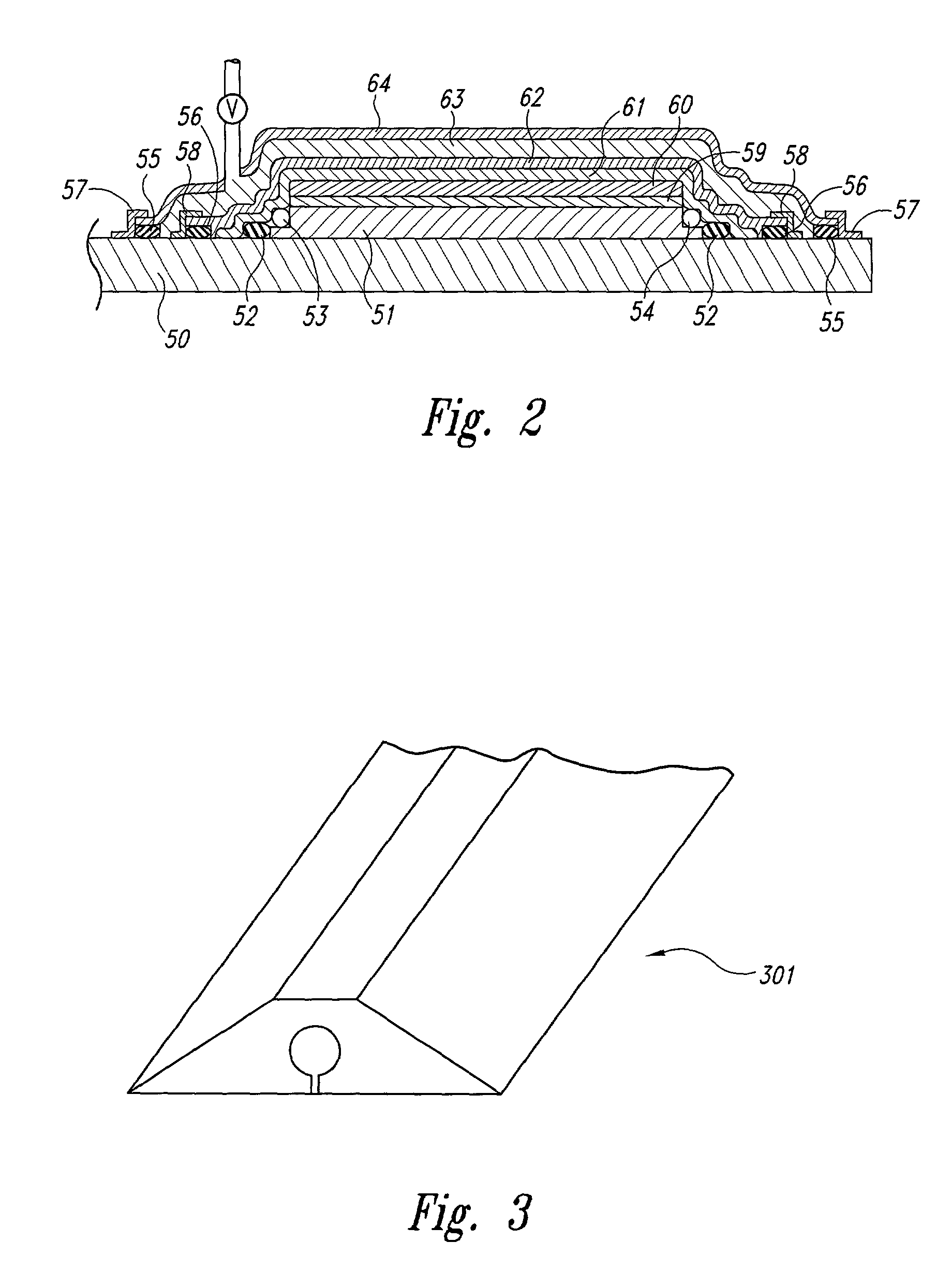

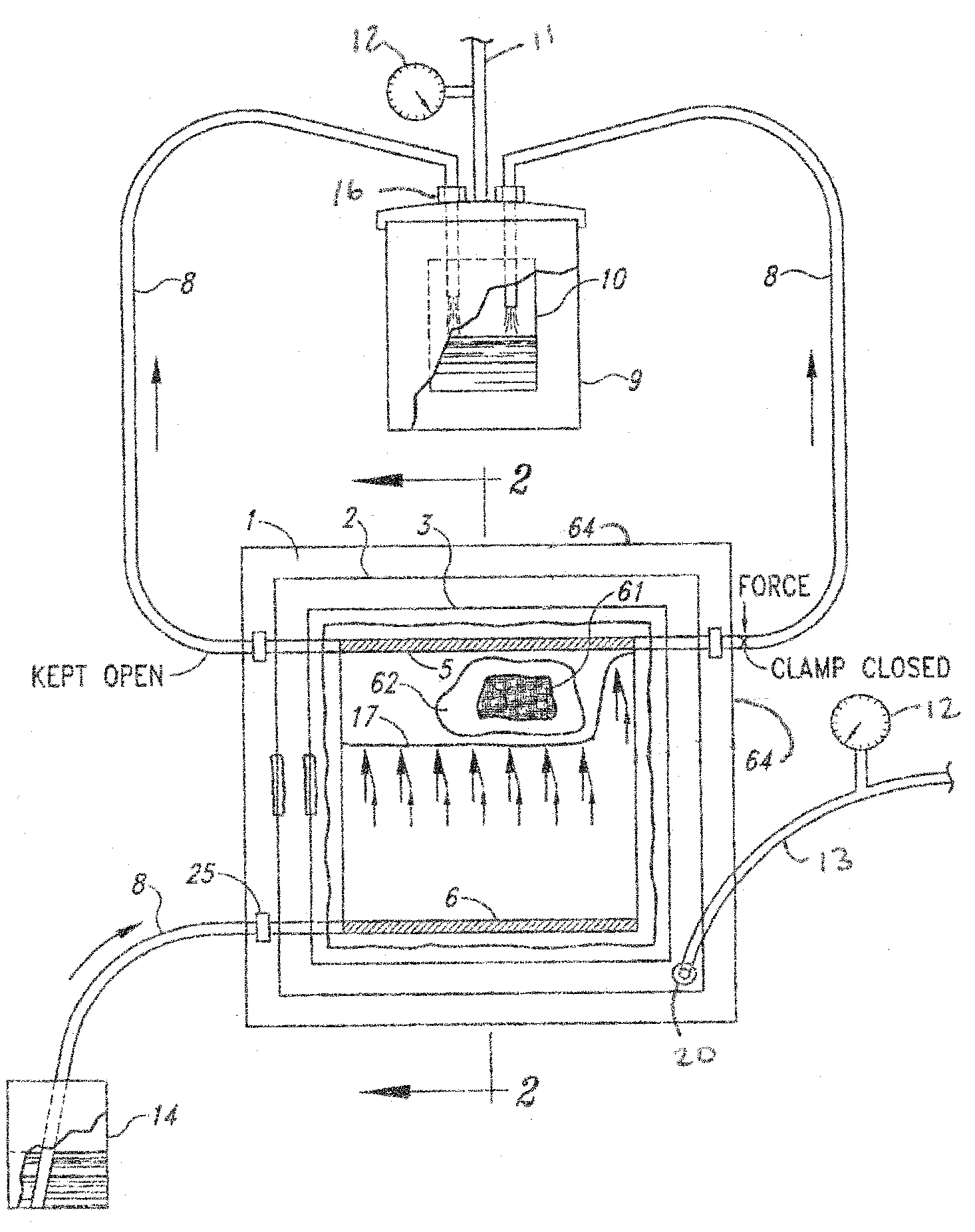

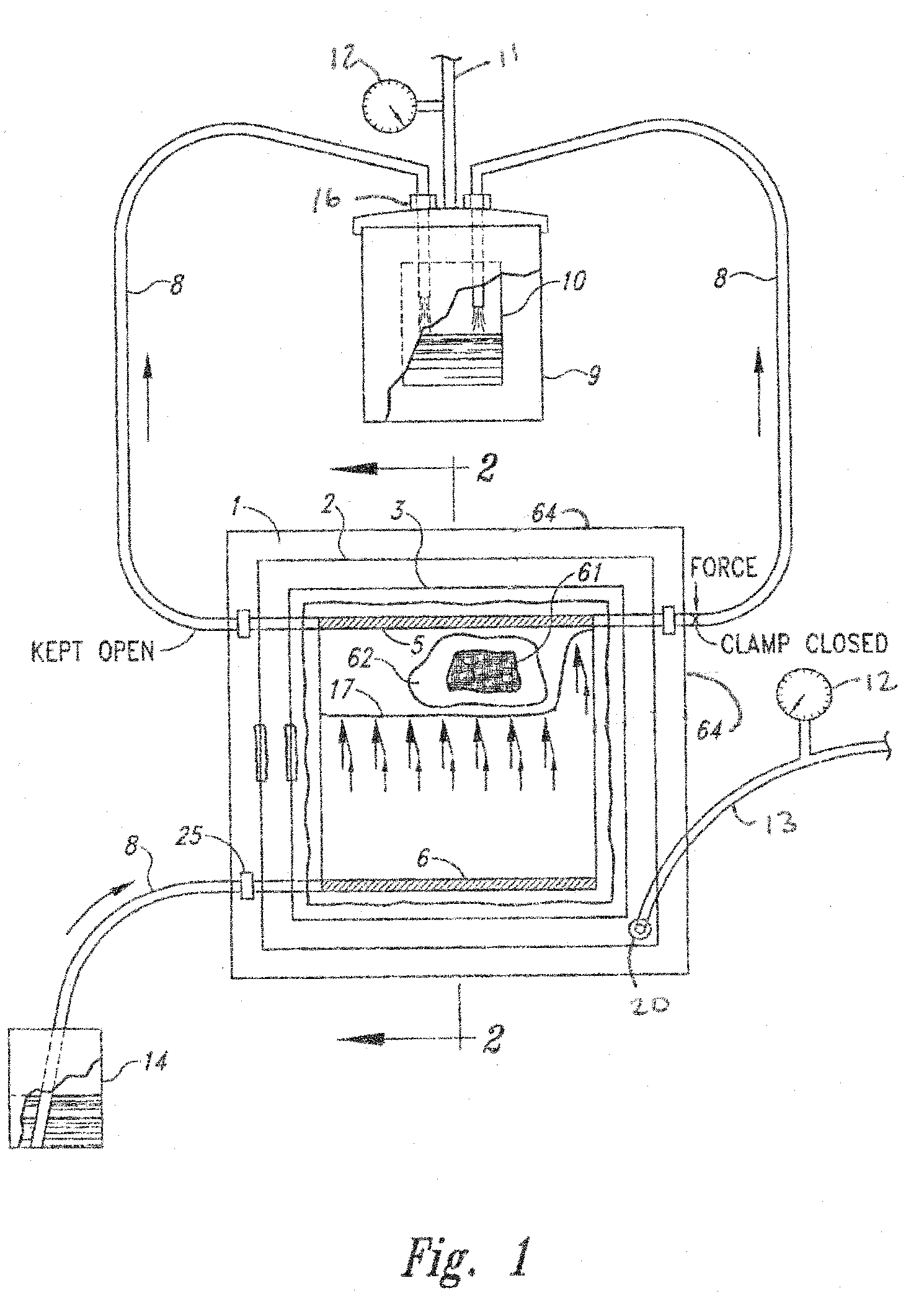

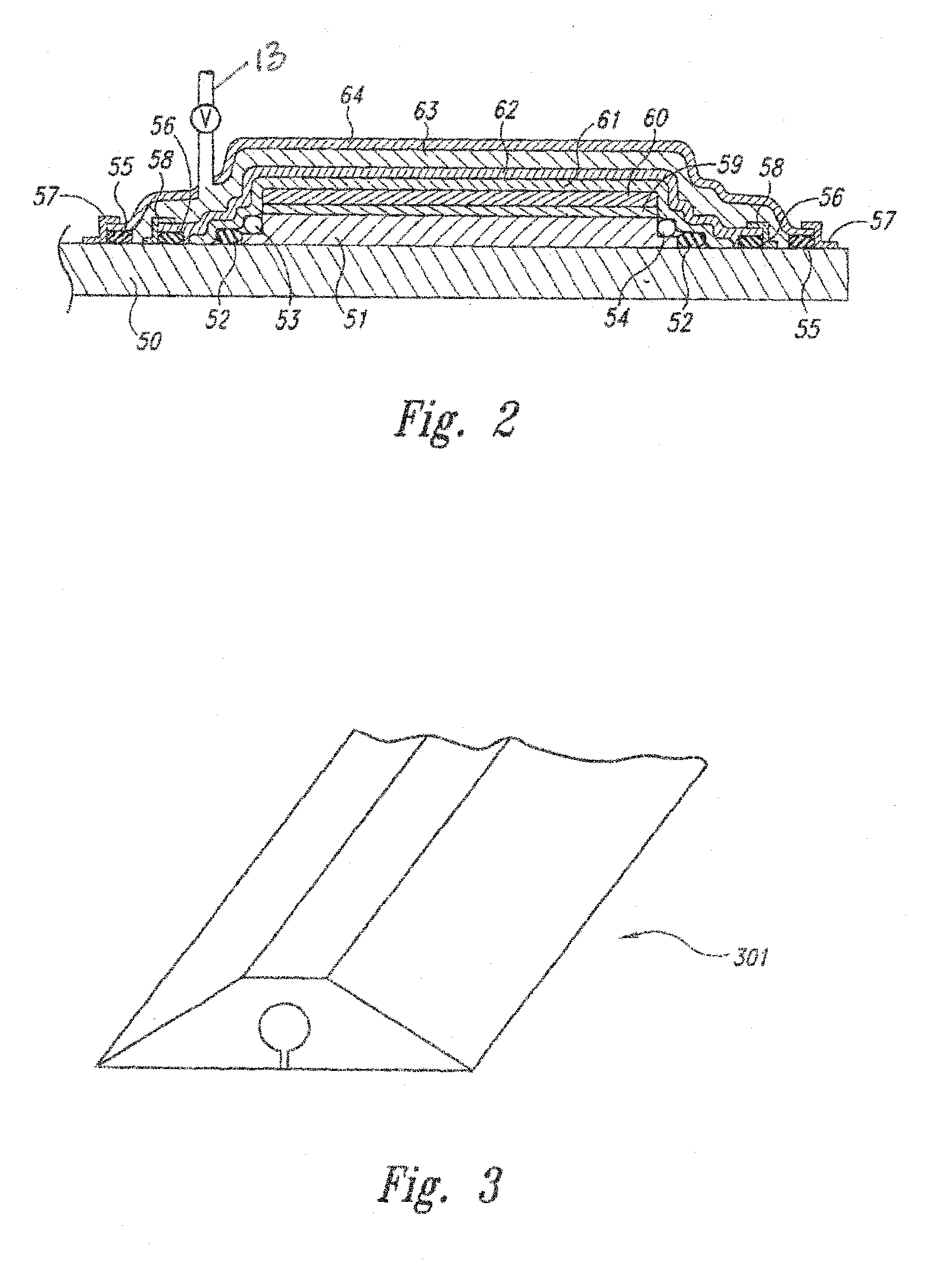

Double bag vacuum infusion process

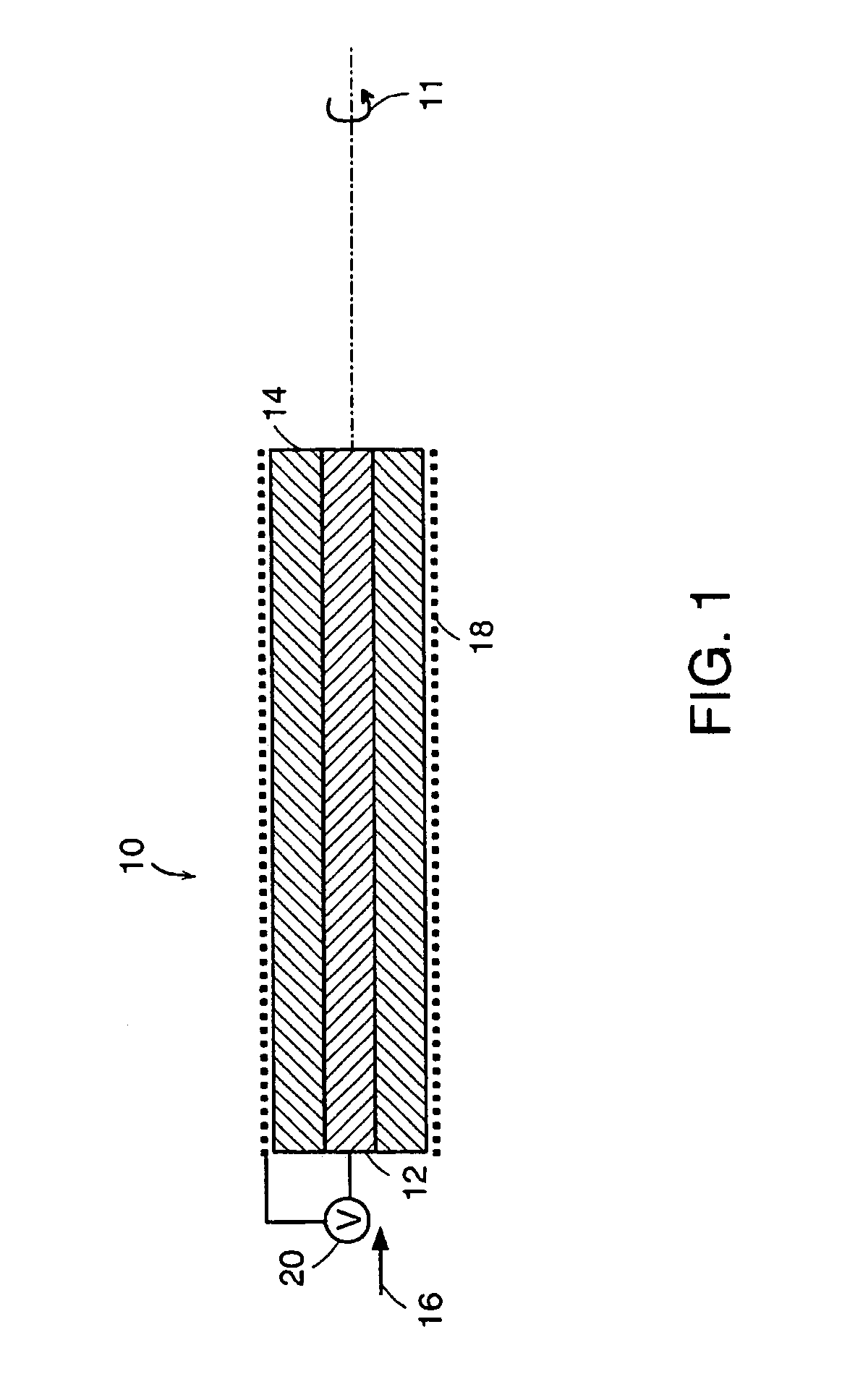

InactiveUS7413694B2Reduce porosityMinimal surface porositySynthetic resin layered productsLaminationMedia controlsFiber

The double bag vacuum infusion process of the present invention provides a low cost method for producing complex composite assemblies without an autoclave. It also enables the production of highly innovative structures. The quality of the composites produced using such an infusion process are comparable to composites made using prepregs, hand layup or fiber placement, and autoclave curing. Double bagging provides vacuum integrity, controls bag relaxation while flow media controls the flow front to allow high quality aerospace-grade products.

Owner:THE BOEING CO

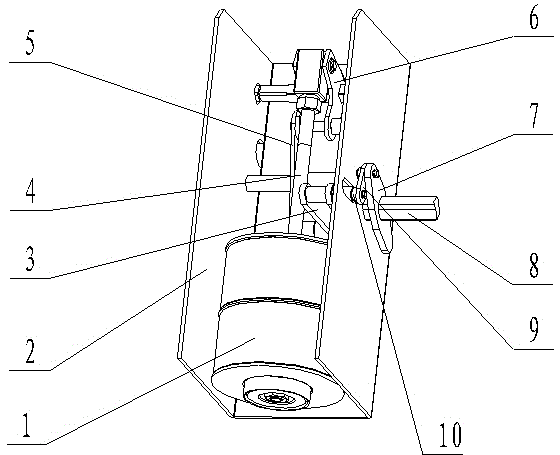

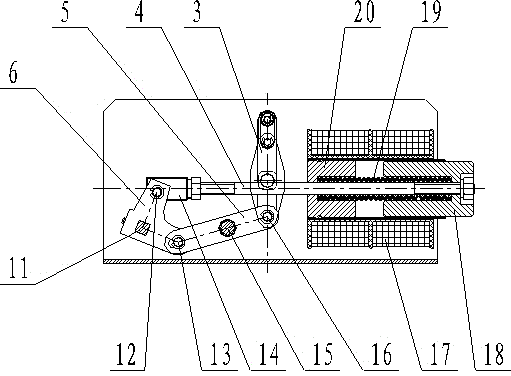

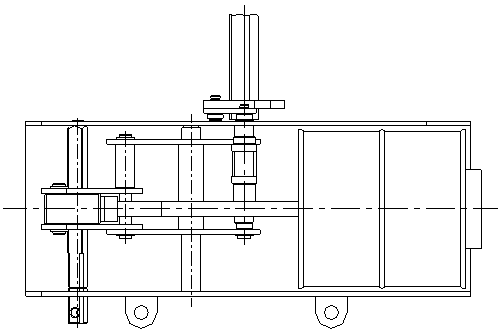

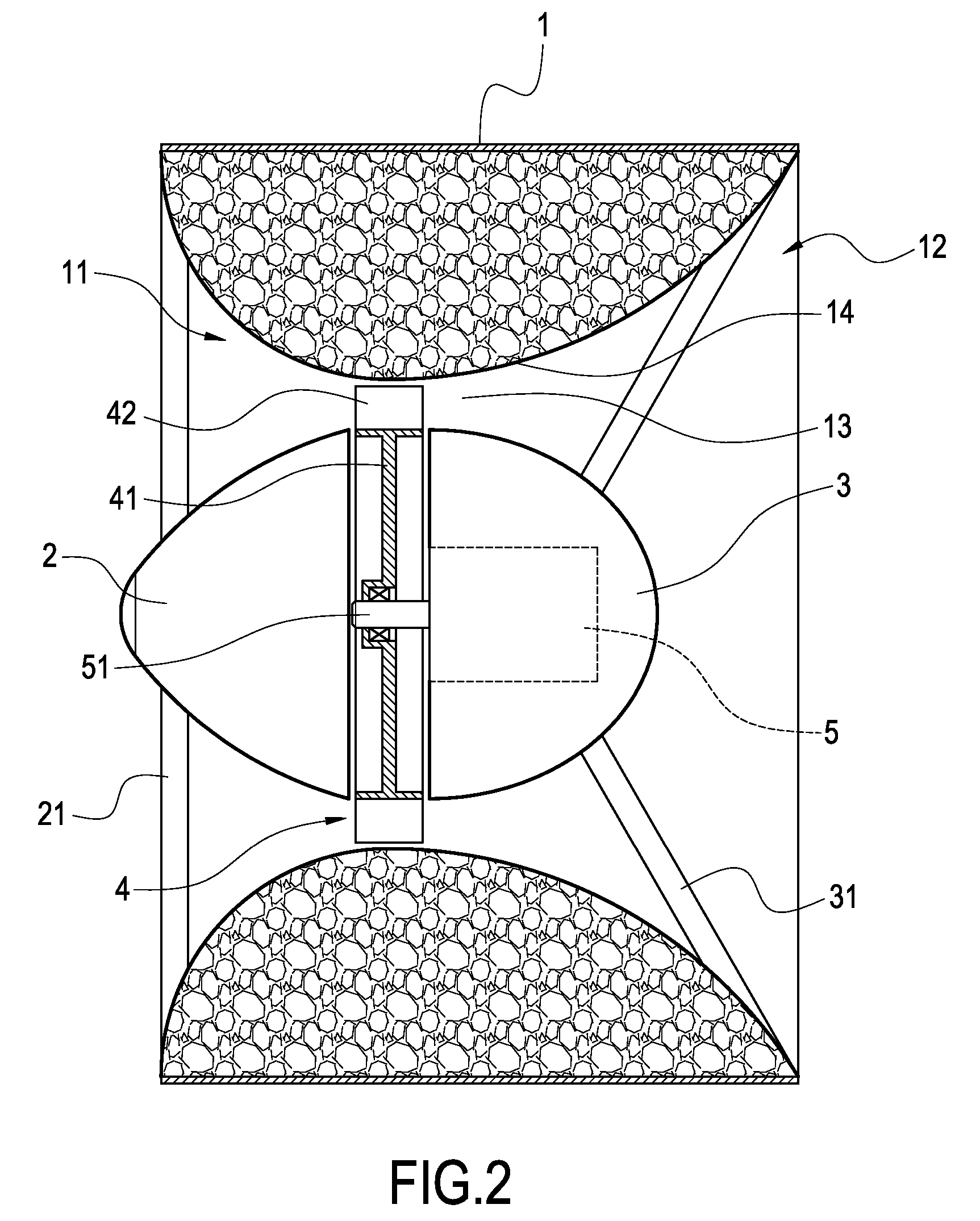

Driving mechanism of dual-power automatic transfer switch

InactiveCN104377053AGreat driving forceGood self-lockingContact driving mechanismsMotion directionSelf locking

The invention relates to a driving mechanism of a dual-power automatic transfer switch. The driving mechanism mainly comprises a driving electromagnet assembly, a mounting bracket, a connecting plate, a push rod, a lever, an oscillating deck, a crank, a main switch rotating shaft, a connecting rod, a pin shaft, a rotating shaft, a first hinged shaft, a second hinged shaft, a connecting block, a shaft, a third hinged shaft and a fourth hinged shaft; the driving electromagnet assembly is composed of a magnet exciting coil, a dynamic iron core, a spring and a static iron core. The driving mechanism is characterized in that in the driving electromagnet assembly, linear motion in the horizontal direction of the dynamic iron core and the push rod is converted into linear motion of the pin shaft in the vertical direction through the oscillating deck, the lever, the connecting plate and the like, and linear motion of the pin shaft is converted into swing of the main switch rotating shaft around the axis through the connecting rod and the crank. Reciprocating swing of the main switch rotating shaft completes switching on and switching off actions of the whole switch. The oscillating deck plays a role in changing the motion direction. The lever plays a role in increasing thrust. A connecting rod crank mechanism plays a role in self-locking and preventing reversion.

Owner:GUIZHOU TAIYONG CHANGZHENG TECH CO LTD

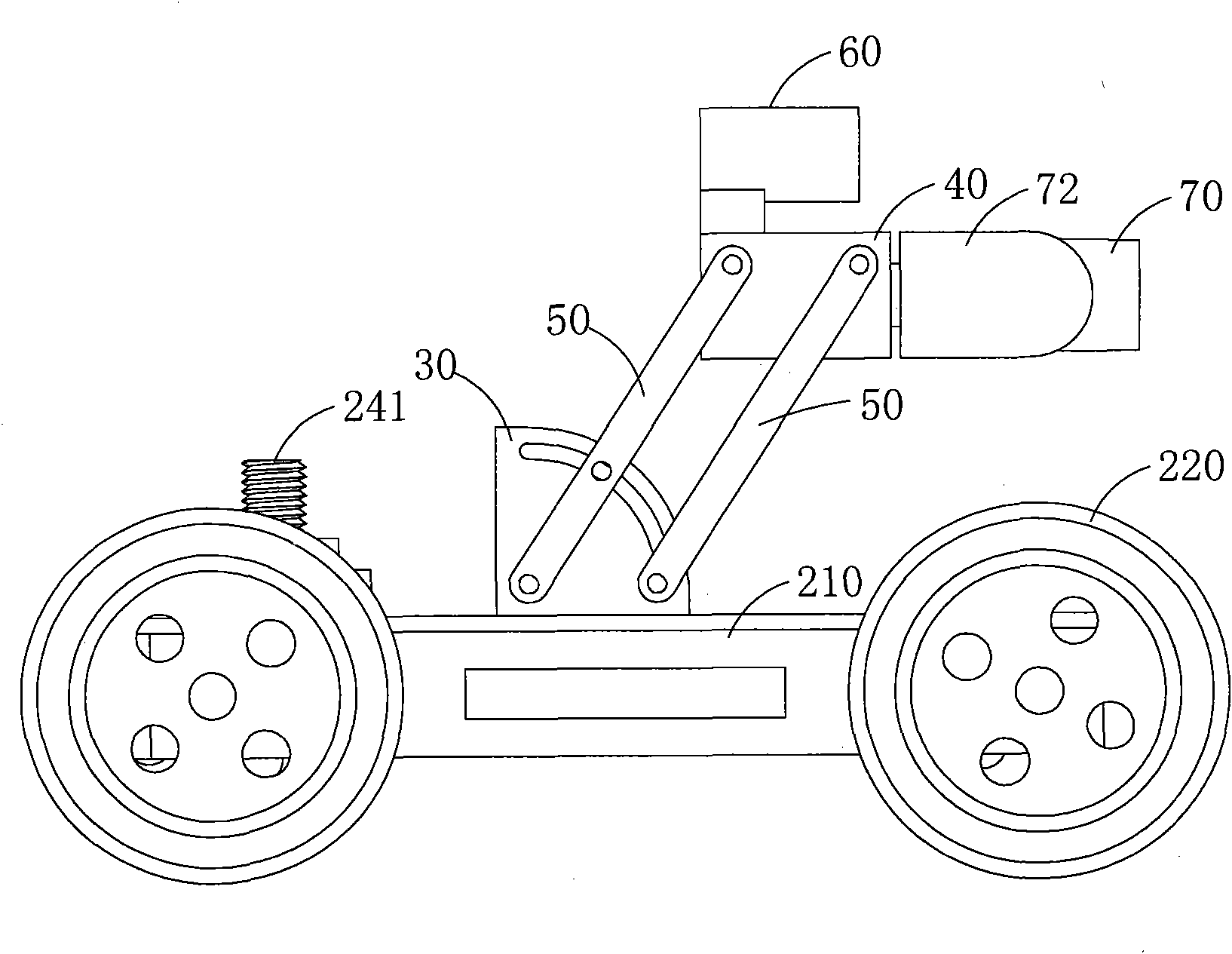

Pipeline robot

The invention relates to a pipeline robot, which comprises a main pipeline robot body. The main pipeline robot body comprises a moving carrier, and the moving carrier comprises a carriage body, wheels, flexible wheel shafts, a rocker and slider mechanism, and also comprises a robot base, a holder, a rod mechanism, a lighting lamp and a camera connected with the holder, wherein the flexible wheel shafts are used for connecting the carriage body and the wheels; the rocker and the slider mechanism is connected with the carriage body and the flexible wheel shafts and used for adjusting included angles between the wheels and the carriage body; the robot base is arranged on the moving carrier; the rod mechanism is used for connecting the holder and the robot base; and the lighting lamp is arranged on the holder. The included angles between the robot wheels and the carriage body are adjustable so as to ensure that when the robot works in pipelines with different diameters, the peripheries of the wheels are still in vertical contact with wall surfaces, therefore, a contact area between the peripheries and the pipeline wall surface is increased, the robot can operate more stably in the pipeline; and moreover, the structure can provide larger driving force. The flexible shafts are adopted for connecting the driving wheels and the carriage body so that the included angles between the wheels and the main pipeline robot body are adjustable and the sufficient driving force can be ensured.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

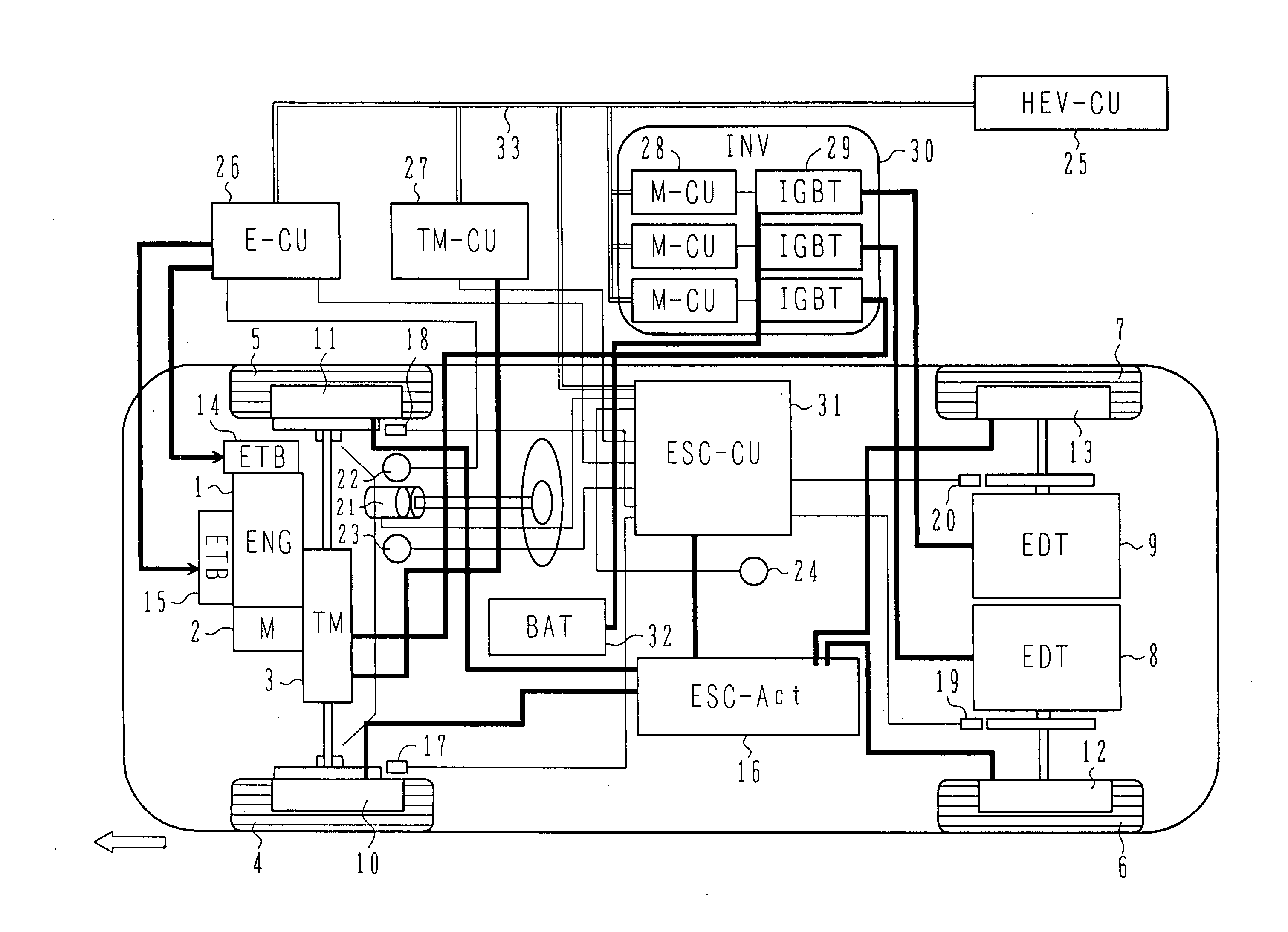

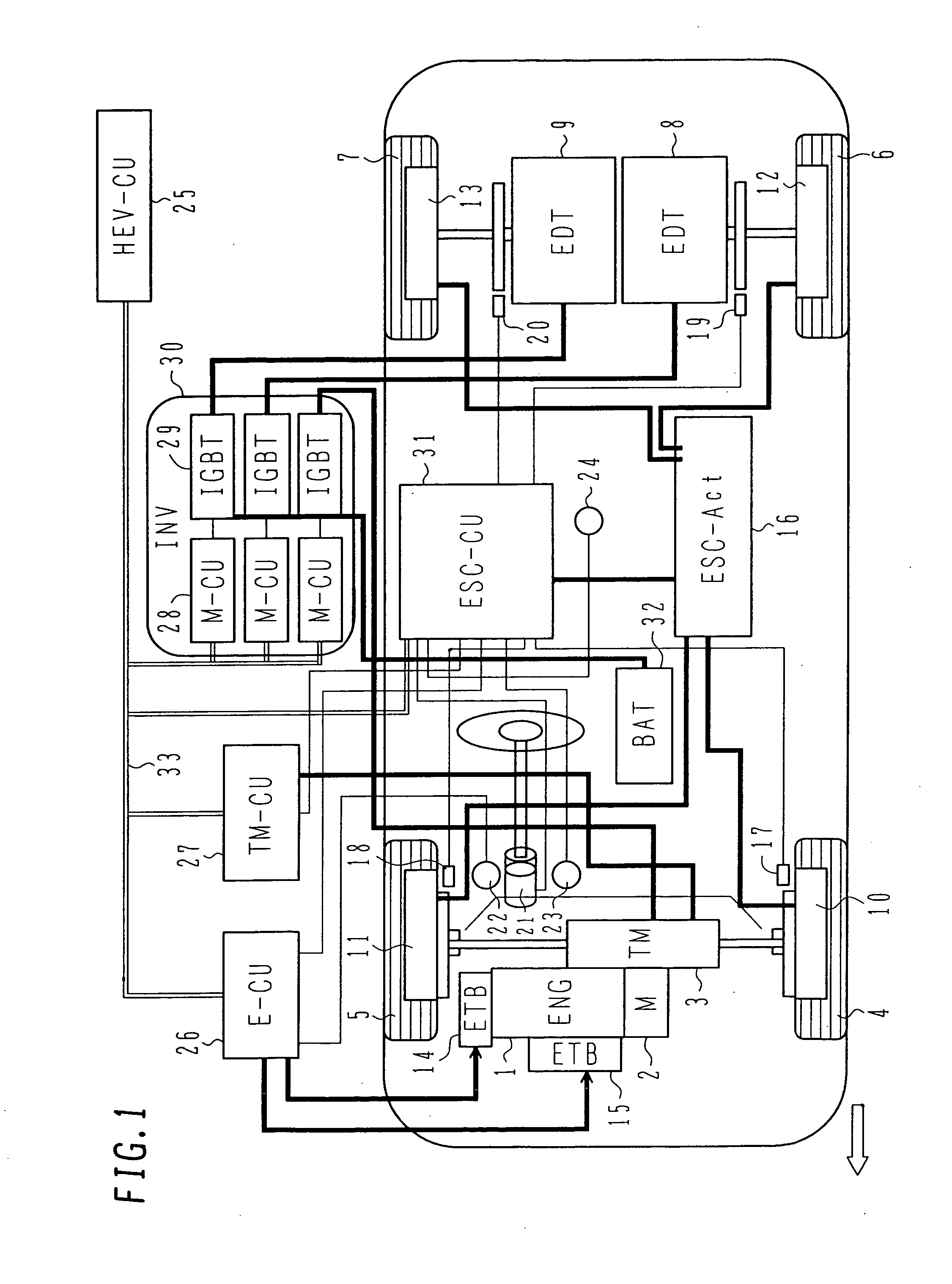

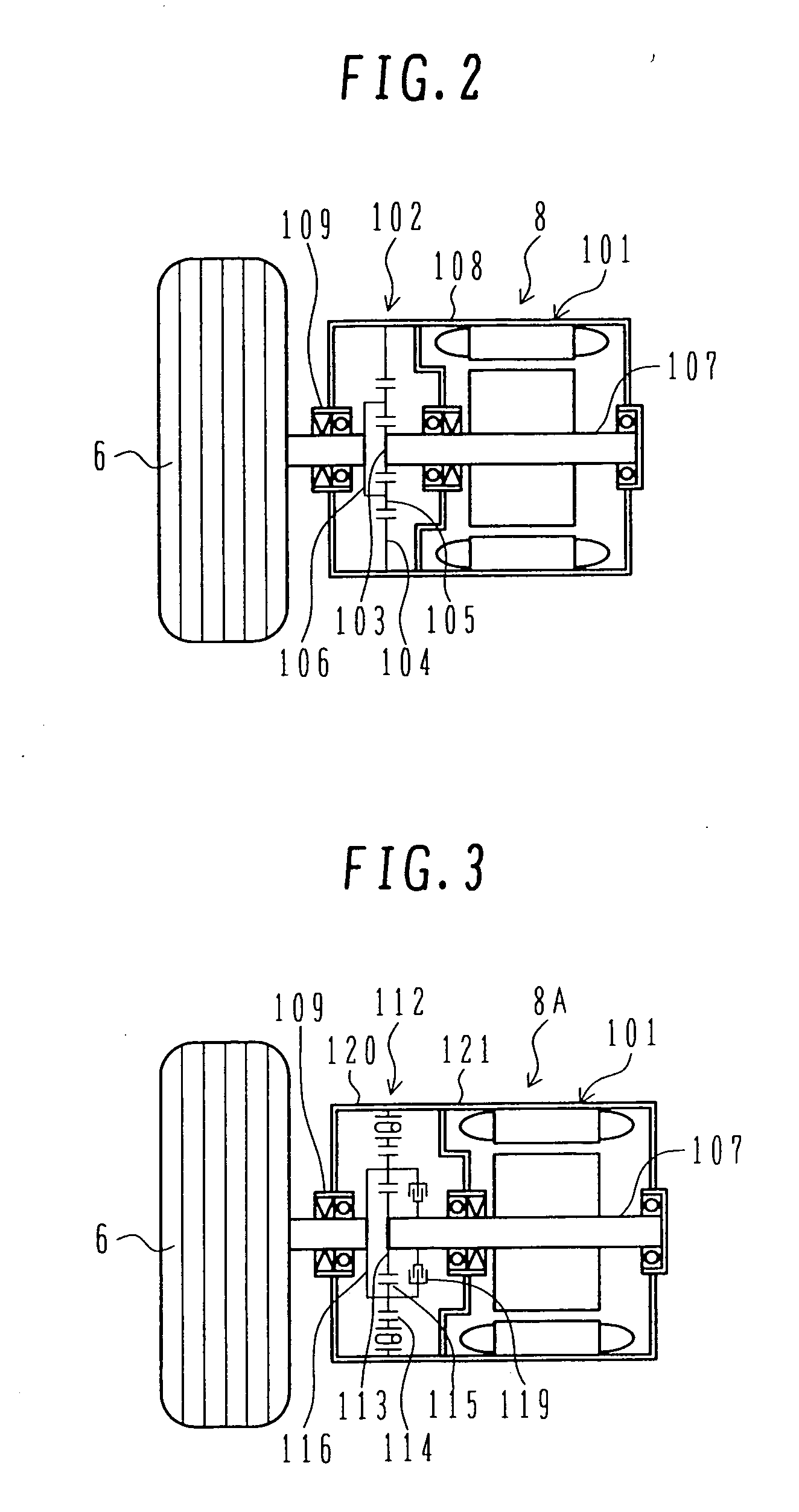

Running controller and electric running control system for electric vehicle

InactiveUS20070038340A1Maximizing coefficientGreat driving forceHybrid vehiclesDigital data processing detailsElectric vehicleElectricity

A running controller and an electric running control system for an electric vehicle, in which when a tire slip occurs during running of the vehicle, such as under driving, braking and turning, a motor output is controlled to always maximize the coefficient μ of road friction, thereby obtaining a maximum tire driving force and a maximum tire braking force. In the electric vehicle, wheels are driven and braked through control of electric driving apparatuss each including a motor. When slipping of any of the wheels is detected, ESC-CU executes powering and regenerative control of the motor to change, depending on road conditions, a target value to which a slip rate is to be converged. The ESC-CU calculates the coefficient μ of road friction based on a motor current and executes the powering and regenerative control of the motor such that the calculated coefficient μ of road friction is maintained in the vicinity of a maximum value thereof.

Owner:HITACHI LTD

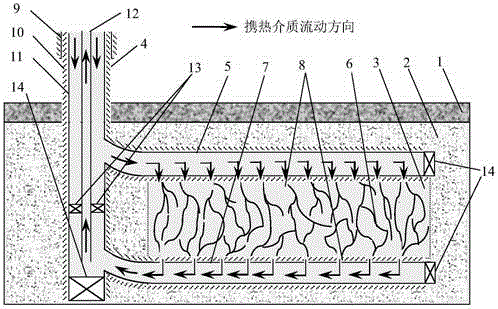

Method for self-circulation exploitation of geothermal energy of hot dry rock with multilateral well and volume fracturing technologies

InactiveCN105840146AAvoid the problem of not being able to connect efficientlyIncrease temperatureOther heat production devicesGeothermal energy generationInjection pressureDual action

The invention relates to the field of geothermal exploitation and provides a method for self-circulation exploitation of geothermal energy of hot dry rock with multilateral well and volume fracturing technologies. According to the method, firstly, multilateral well holes are drilled in different depths of a reservoir of the hot dry rock, the reservoir between upper and lower multilateral well holes is fractured with the volume fracturing technology, a high-permeability hot dry rock reservoir is constructed, and finally, thermal-carrying media are injected and exploited for geothermal exploitation. Annularly-injected low-temperature thermal-carrying media flow to the fractured reservoir of the hot dry rock along the multilateral well holes in the upper part of the reservoir, flow to the multilateral well holes in the lower part under the double actions of injection pressure and potential-energy difference and finally flow back to the ground along an oil pipe. According to the method, the multilateral well and fracturing technologies are sufficiently utilized, the reservoirs of the hot dry rock are effectively communicated, the problem about crack communication during conventional double-well fracturing for injection and exploitation is solved, the potential-energy difference in different depths can be further effectively utilized, and the flowing capability of the thermal-carrying media is greatly improved. With the use of the thermal insulation oil pipe, the thermal loss in the exploitation process of the thermal-carrying media is further reduced, and the exploitation efficiency of geothermal energy is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

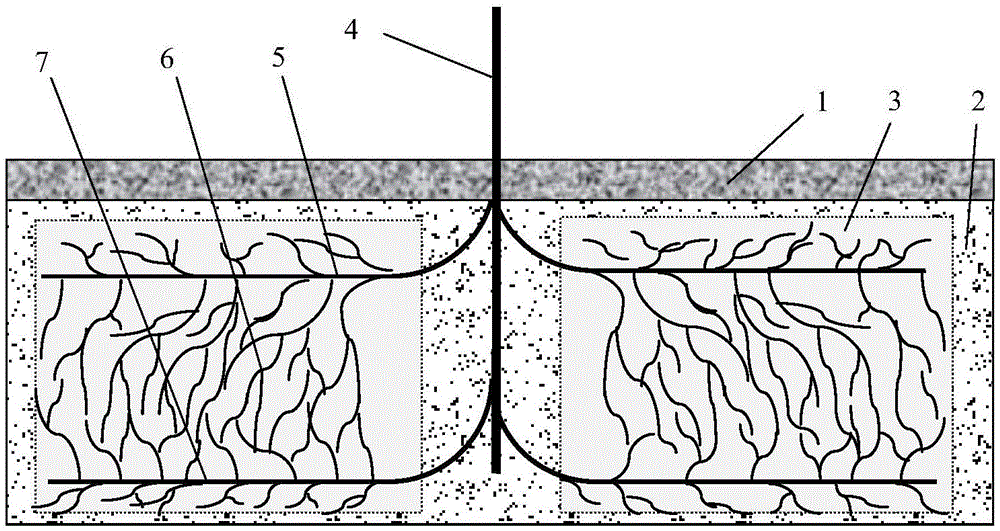

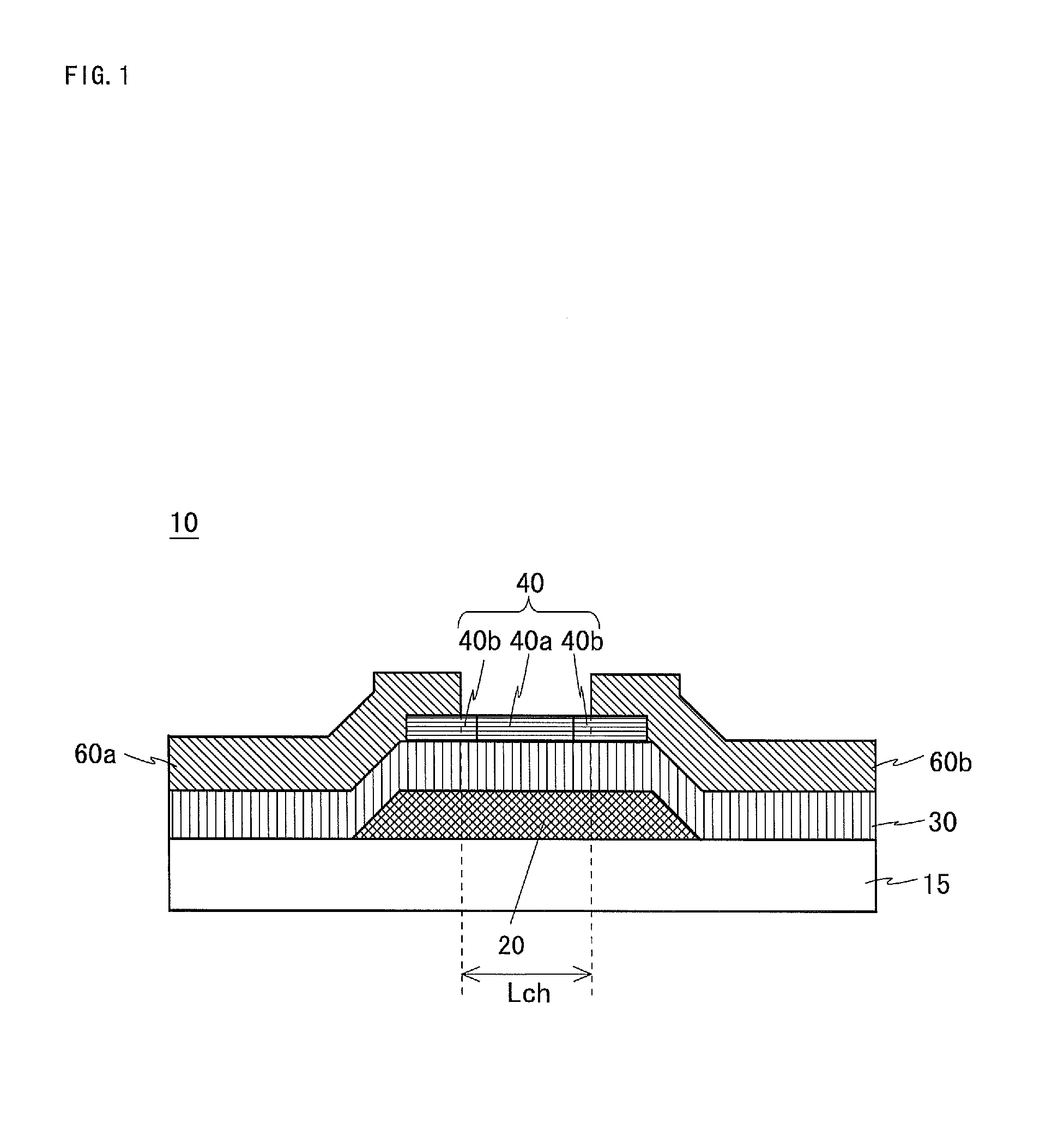

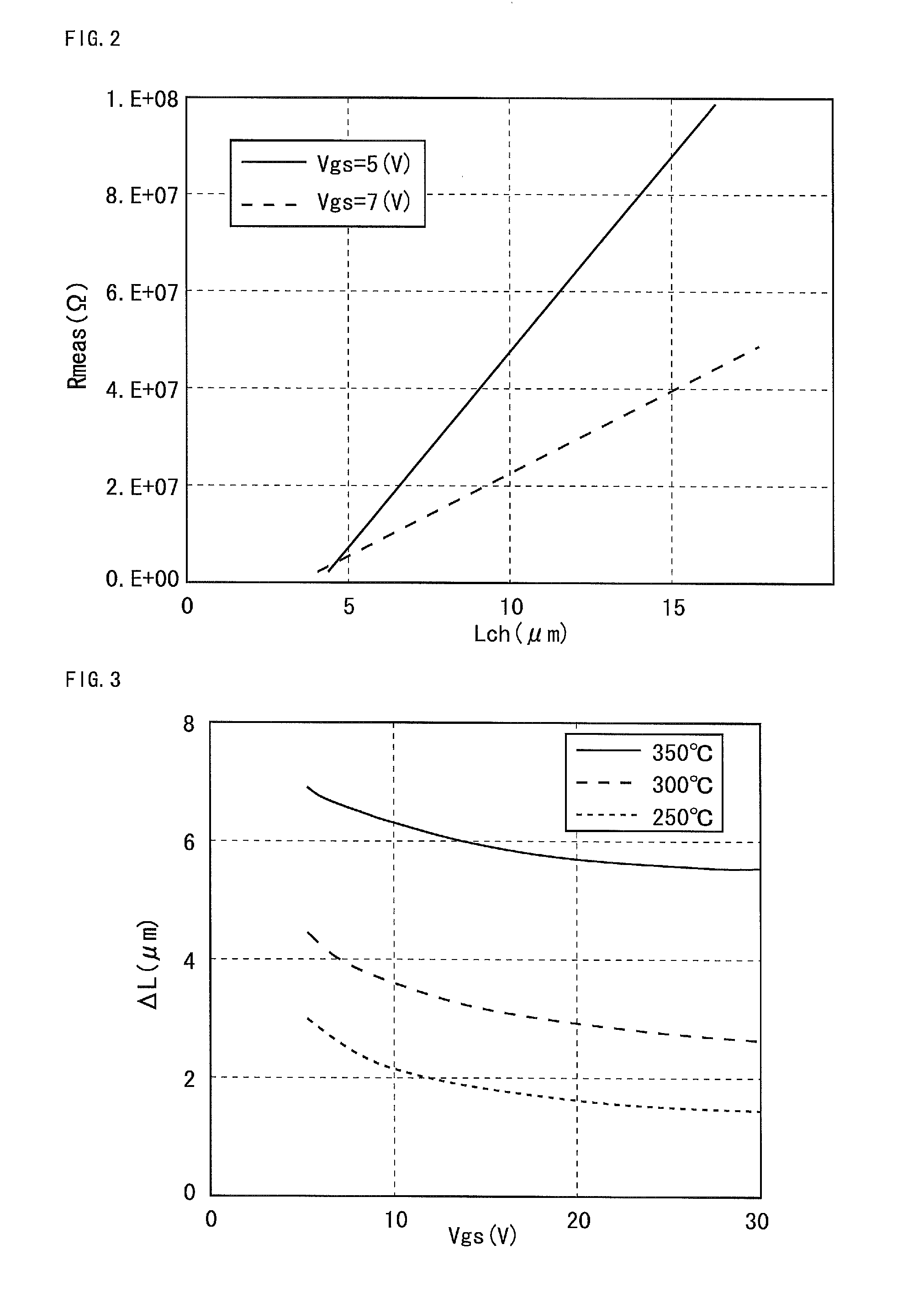

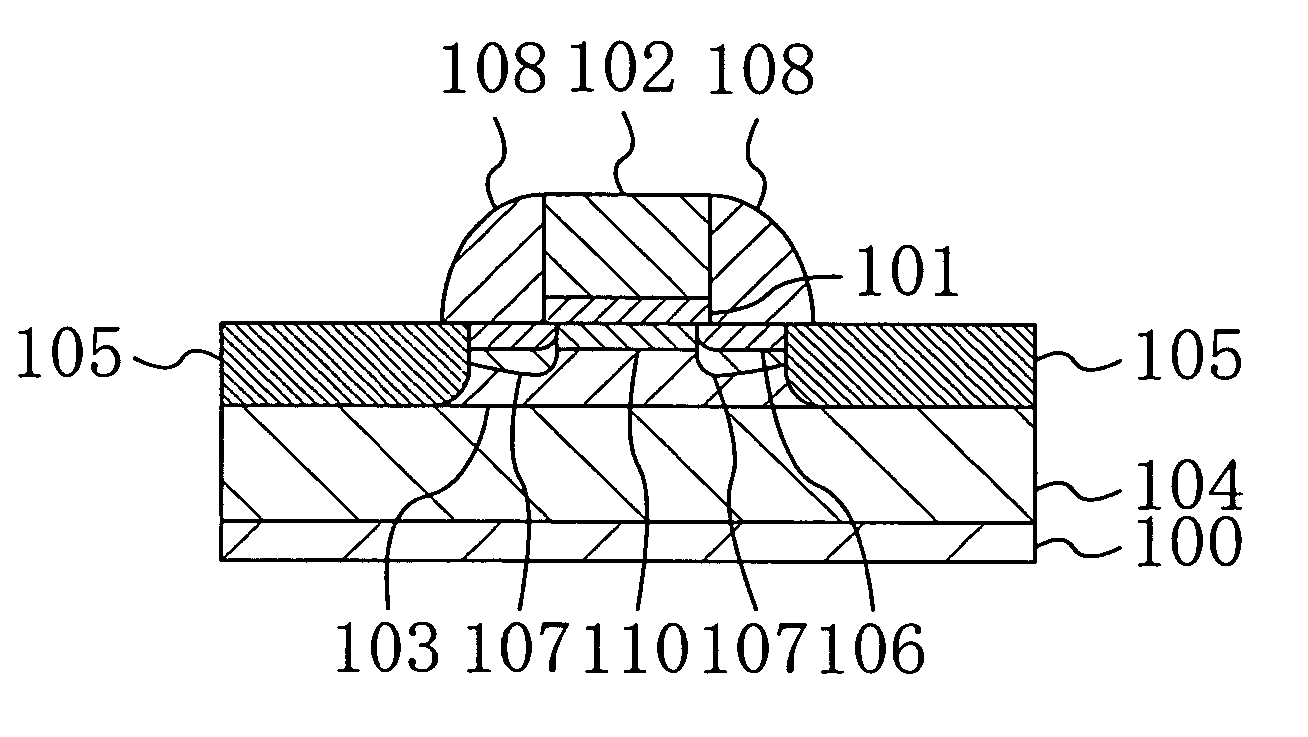

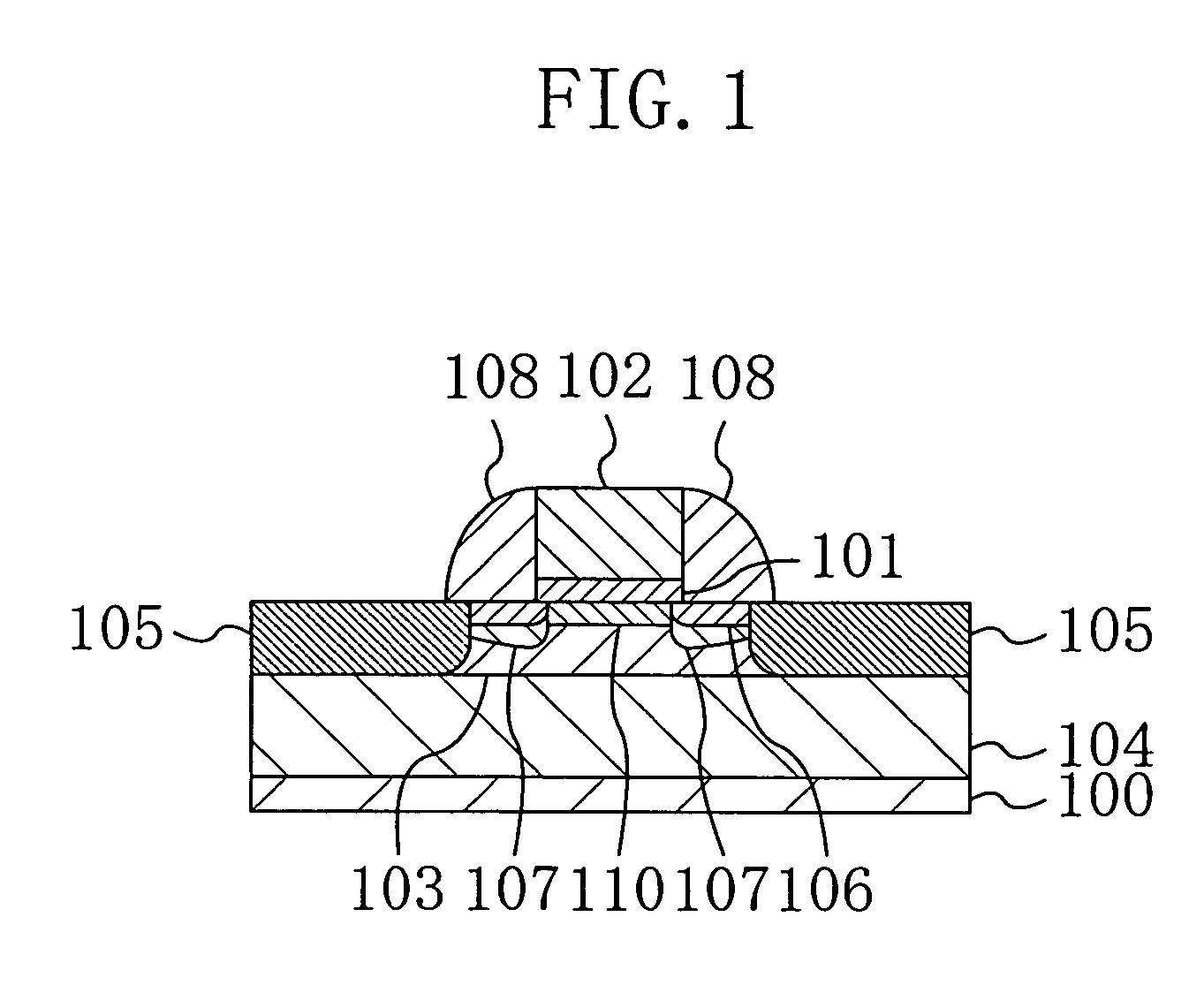

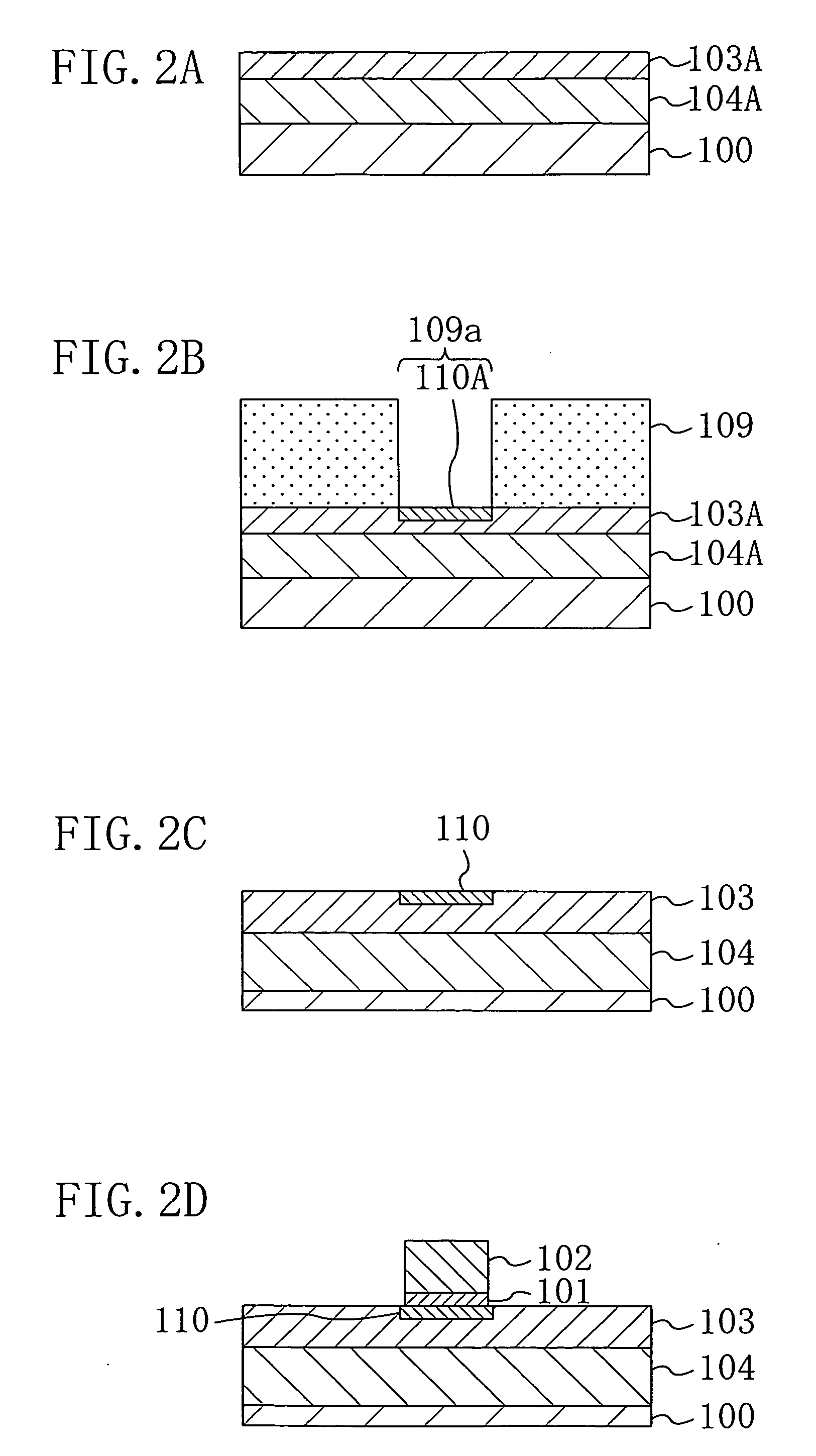

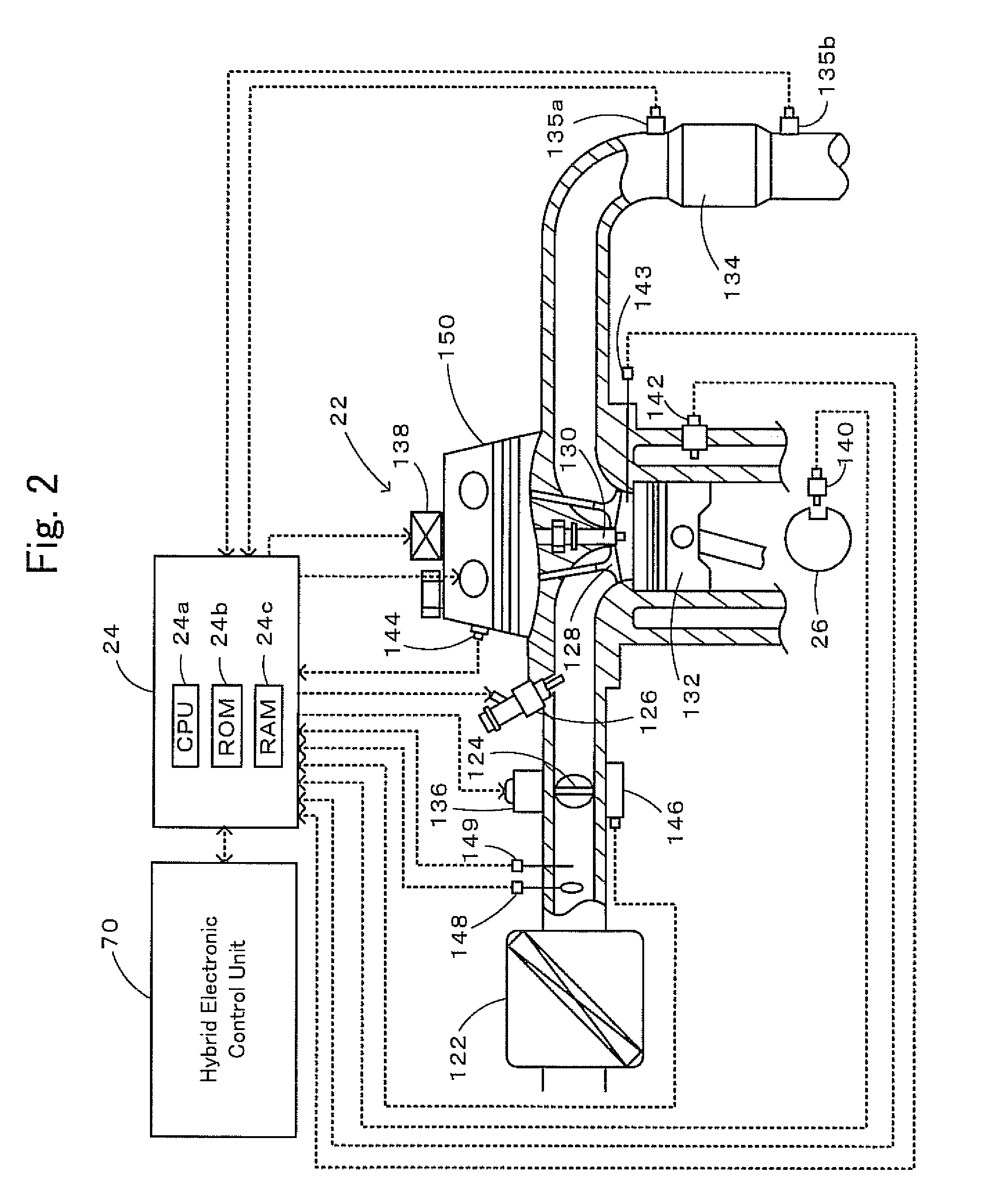

Thin film transistor and manufacturing method therefor, and display device

ActiveUS20140035478A1High currentShort channel lengthTransistorSolid-state devicesHigh resistanceTitanium electrode

The invention provides a thin film transistor having current driving force that can be substantially improved. By heat treatment, the IGZO layer (45) from which oxygen is taken away by the titanium electrodes (65) becomes the low resistance regions (40b), and the IGZO layer (45) from which oxygen is not taken away remains as the high resistance region (40a). In this state, when the gate voltage is applied to the gate electrode (20), electrons in the low resistance regions (40b) near the boundaries with the high resistance region (40a) move respectively to the titanium electrode (65) sides. As a result, the length of the low resistance regions (40b) becomes short, and oppositely, the length of the high resistance region (40a) becomes longer by the size of the shortened low resistance regions. However, the electrical channel length (Le) becomes shorter than the source / drain interval space (Lch) as the limit resolution of the exposure device, and the current driving force becomes large.

Owner:SHARP KK

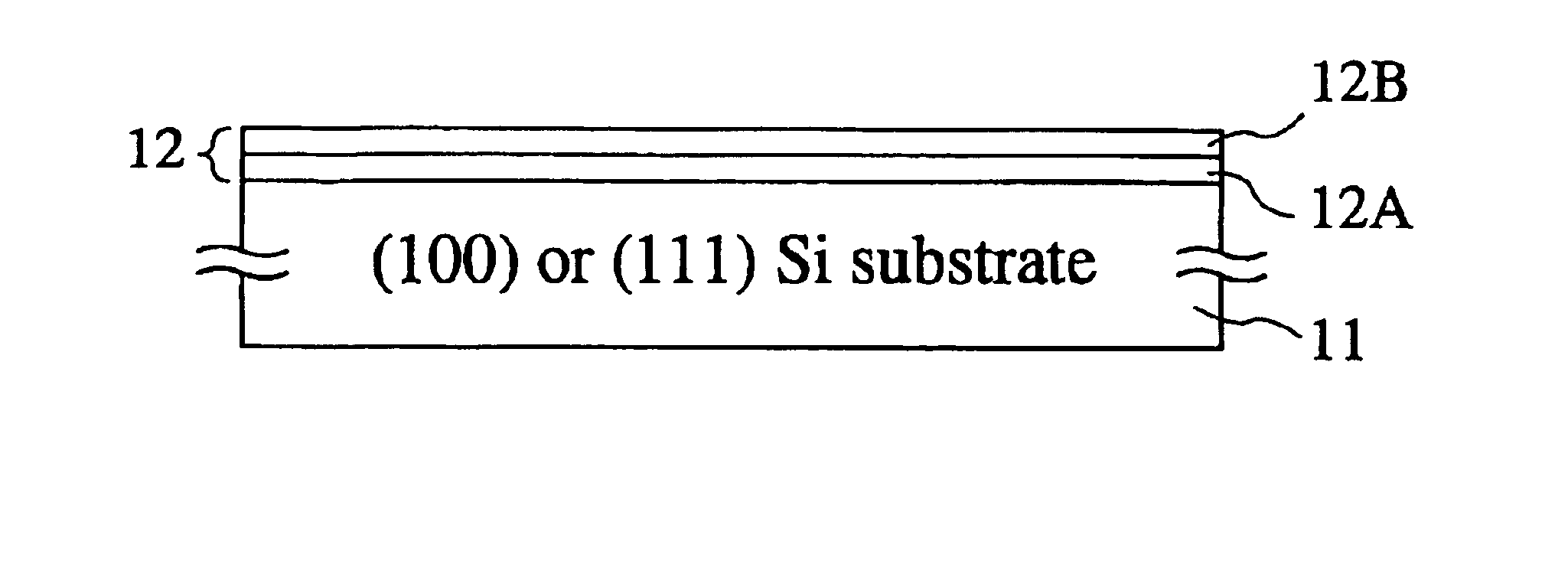

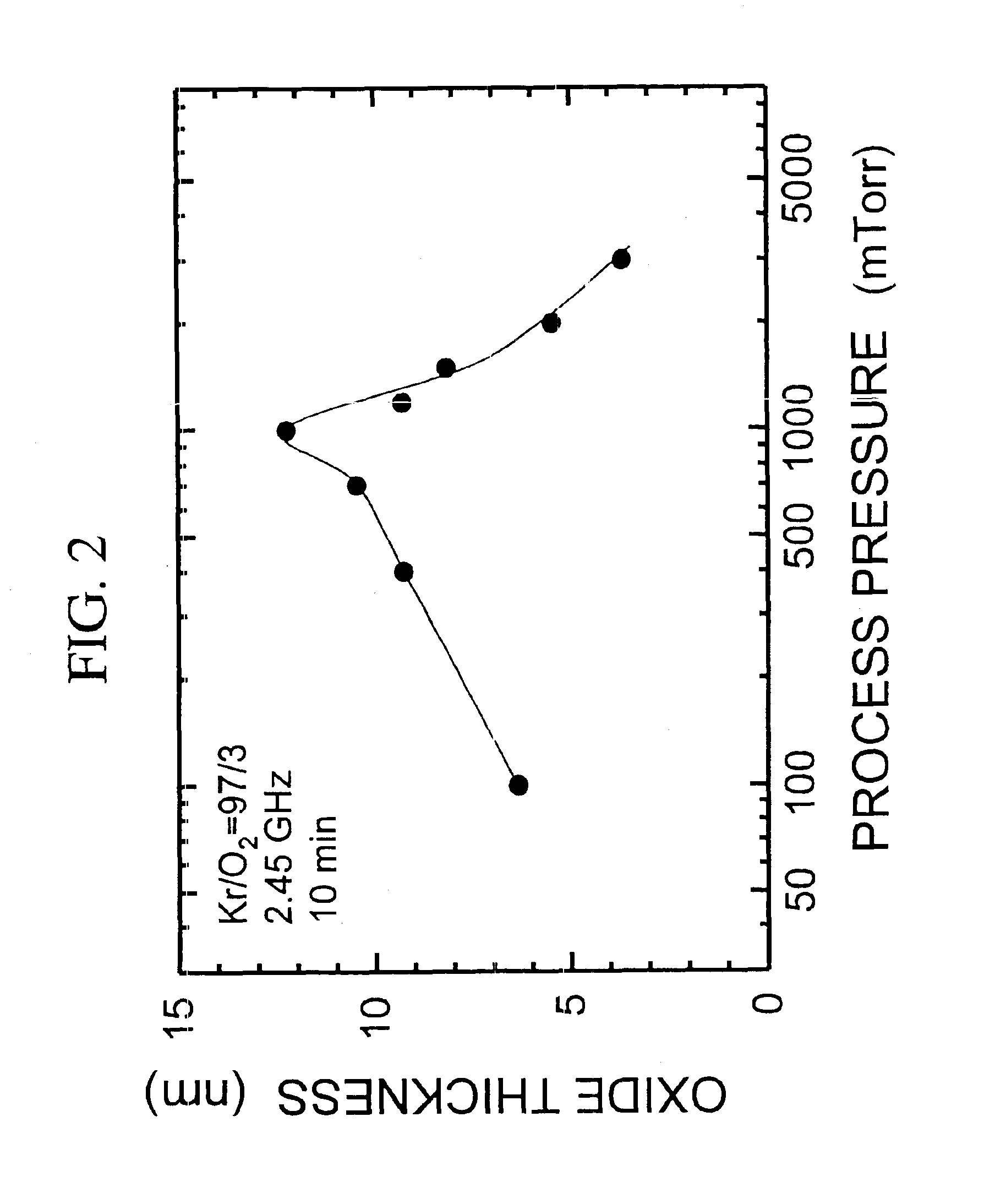

Semiconductor device formed on (111) surface of a Si crystal and fabrication process thereof

InactiveUS7012311B2Quality improvementEfficiently formedTransistorSolid-state devicesNitrideSemiconductor

Owner:OHMI TADAHIRO

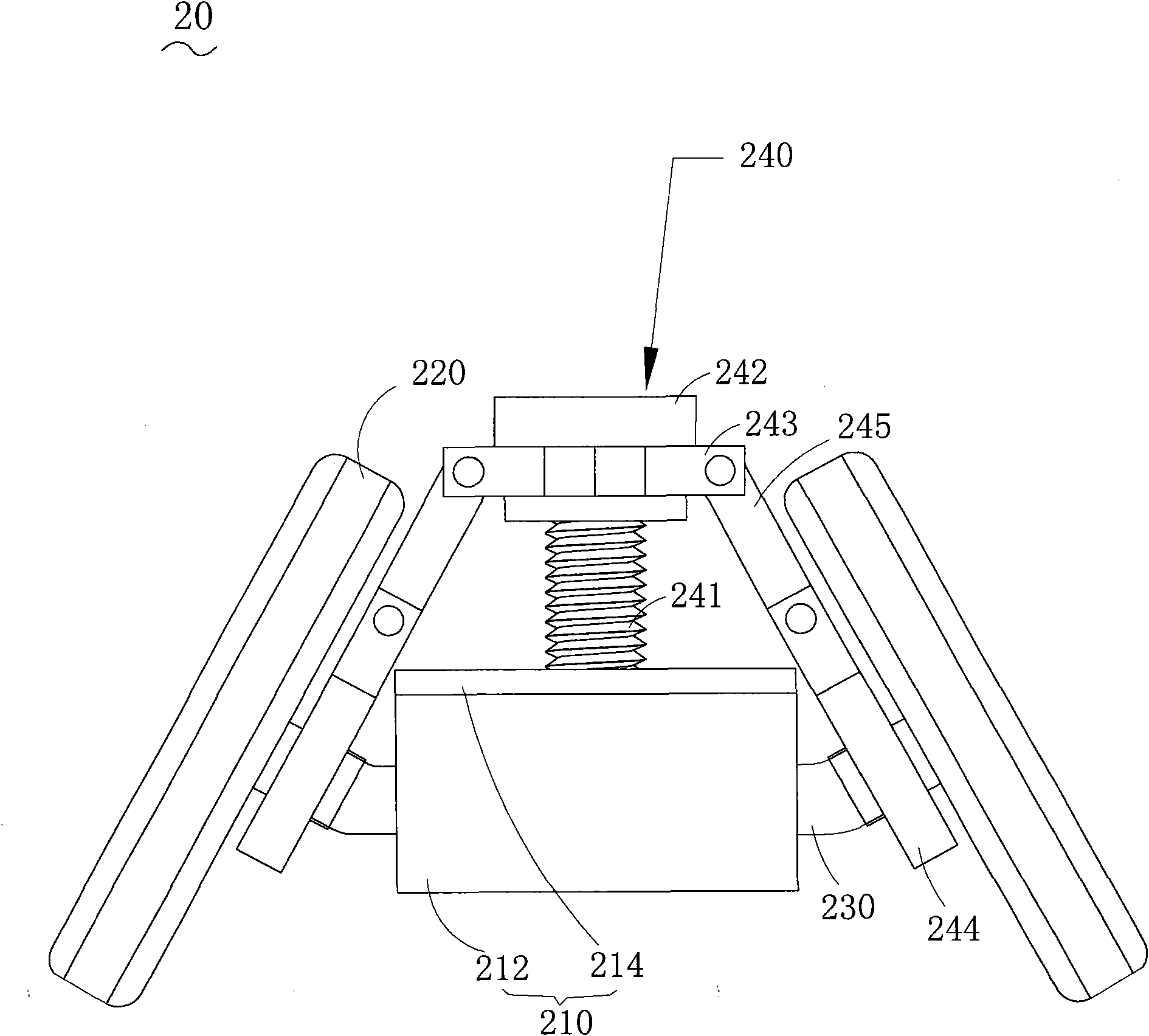

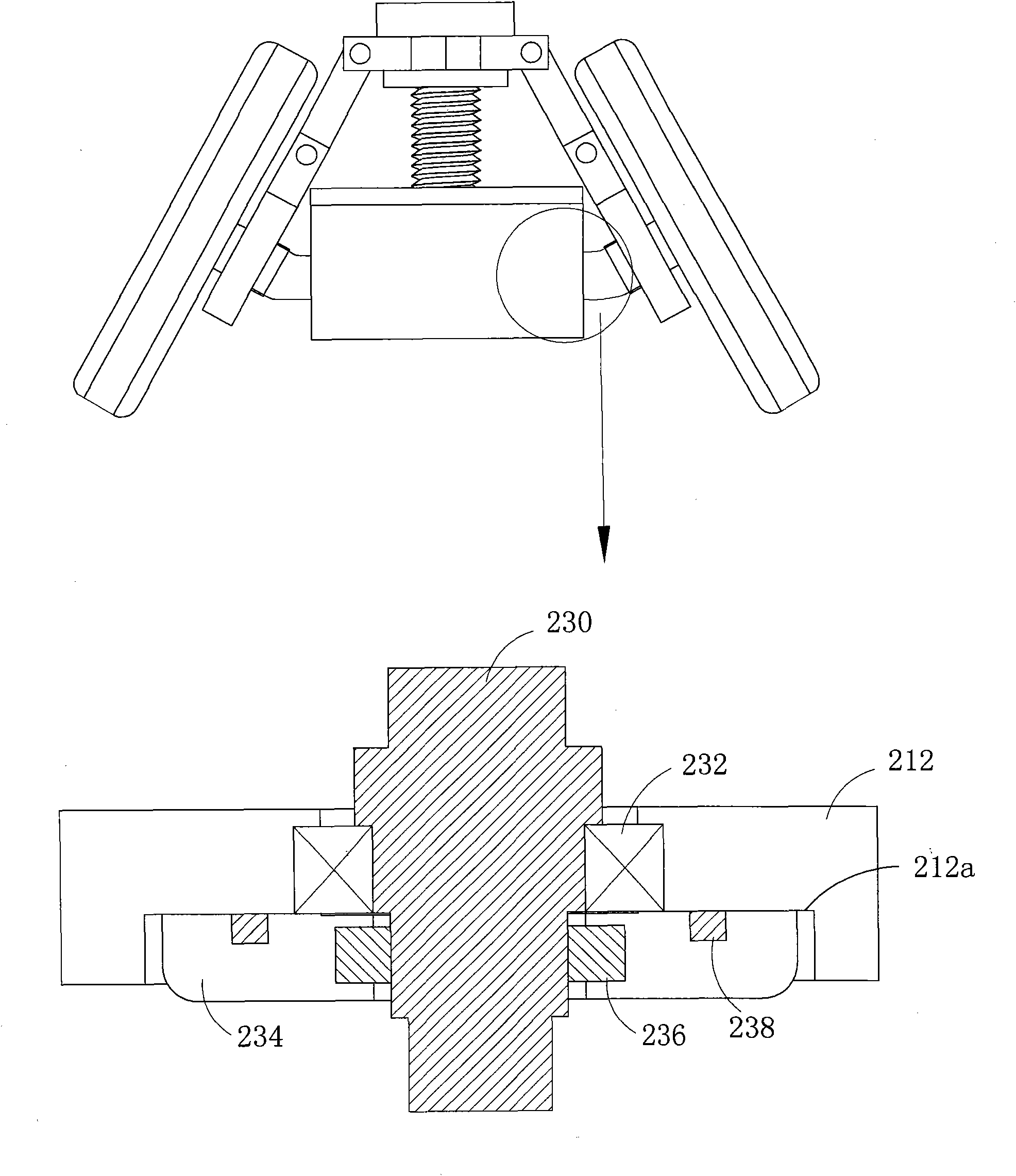

Compliant passive gripper drawn by pneumatic ropes and provided with bent plate spring skeleton

ActiveCN102689309AIncreasing the thicknessIncrease stiffnessGripping headsEngineeringInjection molding machine

The invention relates to a compliant passive gripper drawn by pneumatic ropes and provided with bent plate spring skeletons. The gripper is provided with two fingers which take bent plate springs as skeletons and grip objects passively through elastic restoring forces of the bent plate spring skeletons; the two fingers are driven by a cylinder; the acting force of the cylinder is increased through a five-hinge skewed double-elbow reinforcement mechanism which is frequently used on an injection machine so as to drive drawing ropes of the fingers, overcome deformation resistance of the bent plate springs and open the passive gripper; and the opening degree of the gripper can be controlled by controlling the pressure of the cylinder. The gripper has the advantages of large driving force, wide applicable range, simple structure, less controlled objects, convenience in maintenance and low requirements on using environment, has the characteristics of flexibility in degree of freedom and resiliency in acting force, has good flexibility in adaptivity, can grip objects with varying shapes and sizes, and belongs to the technical field of application of robots and mechatronics.

Owner:兴化市聚鑫不锈钢有限公司

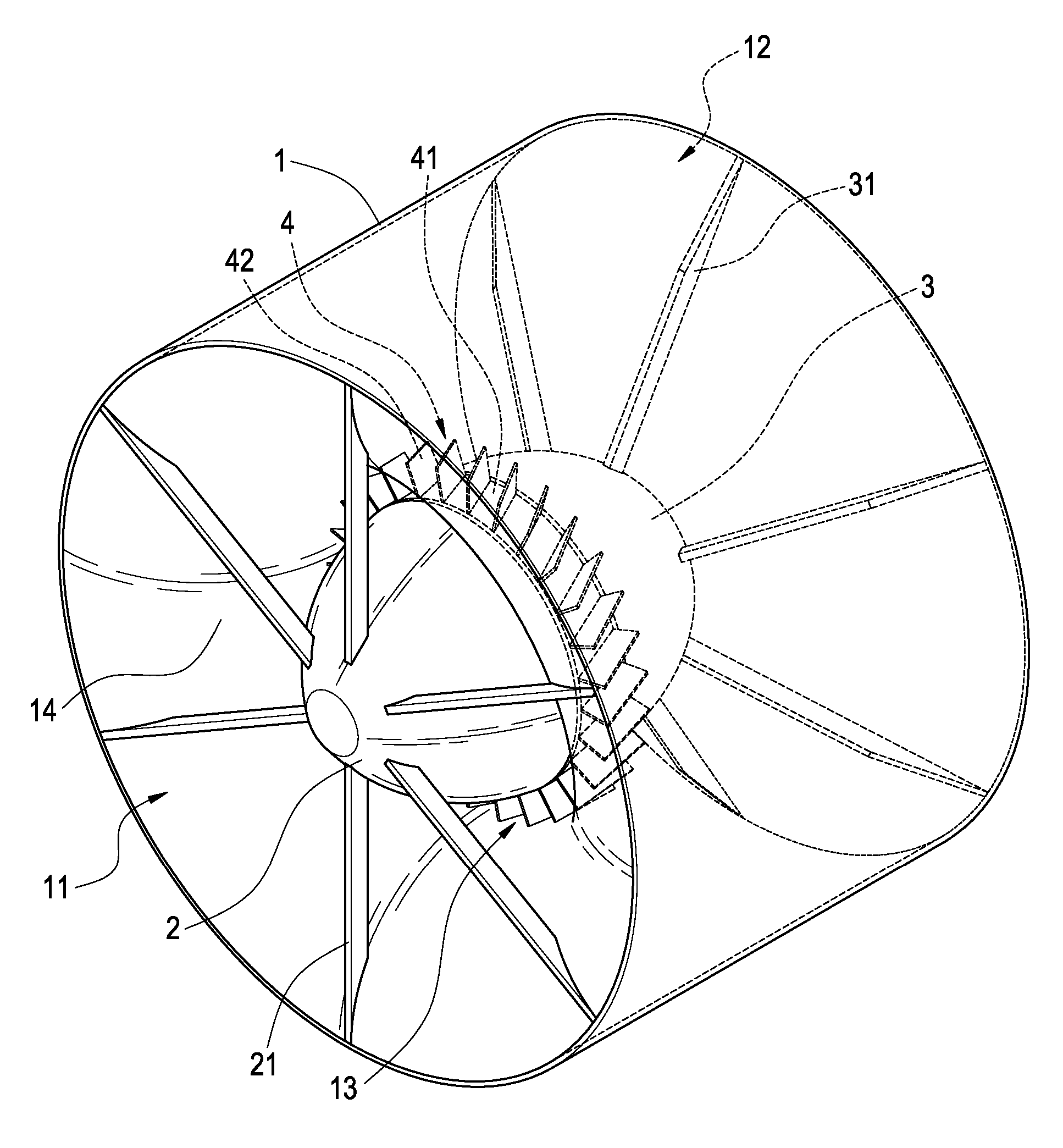

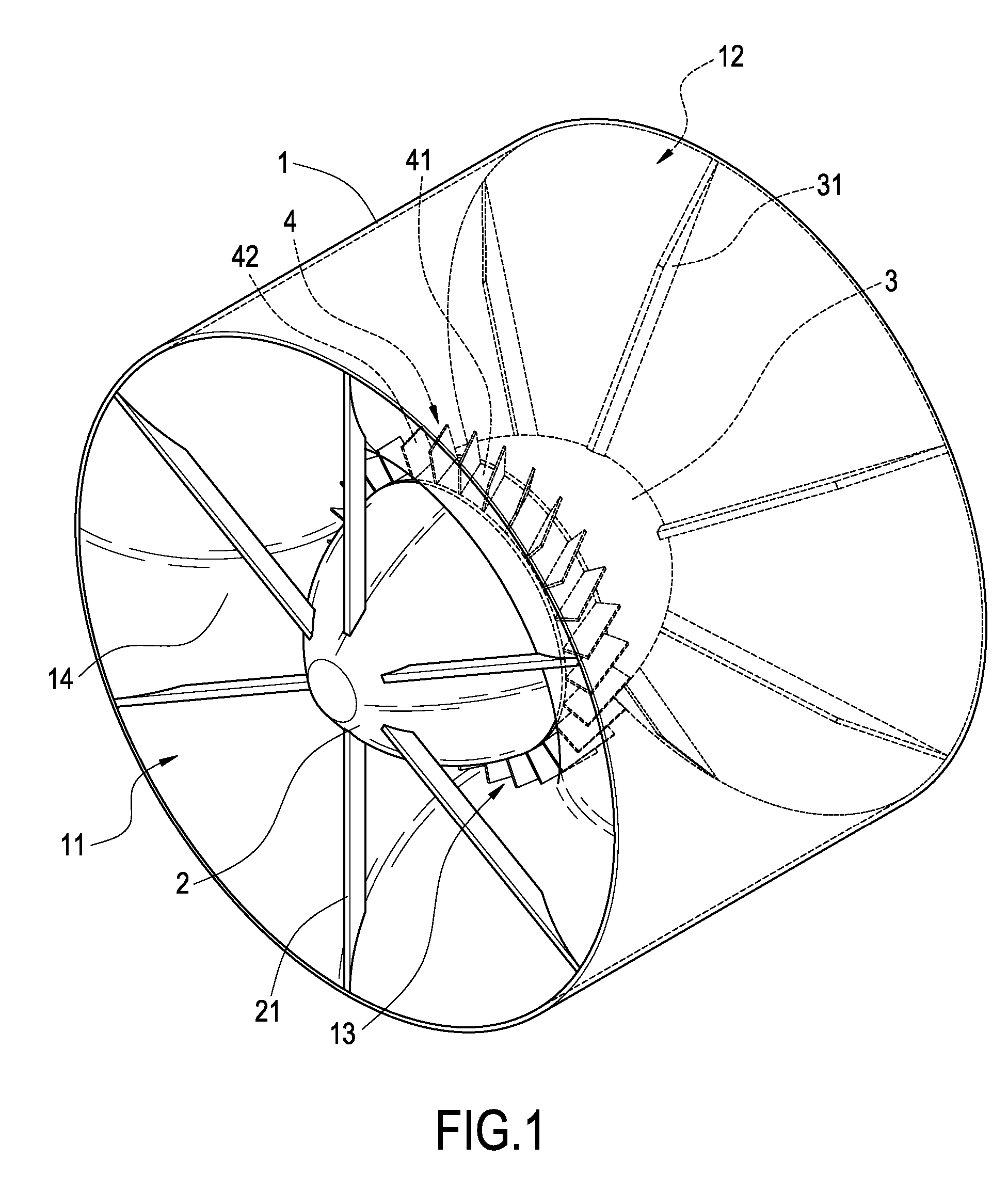

Wind Power Generator

InactiveUS20070013196A1Efficient windward areaGreat driving forceWind motor combinationsMachines/enginesElectricityWind force

A wind power generator includes a cover, a front nose cone, a rear nose cone and a vane unit. The cover has a curved air-guiding portion. The front nose cone and the rear nose cone have a plurality of supporting pillars fixedly connected to the front portion and rear portion of the inner wall of the cover, respectively. The vane unit is provided between the front nose cone and the rear nose cone. After the wind enters the passage formed between the curved surface of the front nose cone and the front portion of the curved air-guiding portion of the cover, the wind speed is accelerated due to the narrowing of the flowing path, thereby to generate a larger kinetic energy to cause the rotation of the vane unit. In this way, the generator within the rear nose cone obtains a greater capacity of generating electricity. Further, the generator can be still activated even under a lower wind speed.

Owner:CHEN SHIH H

Flapping wing unit of flapping wing aircraft

The present invention relates to flapping wing aircraft, and is especially an improved flapping wing unit of flapping wing aircraft. The motors on the base respectively drive the two symmetrical steering engine drivers to rotated through a speed reducer, the motor of the steering engine driver is hinged through crank-link rod mechanism to lever driving shaft with a first bearing seat in the end, the roll on the lever driving shaft is fitted to the slipway inside the shell of the steering engine driver, the rotation shaft with bearings and second bearing seats is mounted on the casing, the lever driving shaft has the other end hinged to link rod hinged to wing handle, and the wing handle has one end with mounted wing and the other end hinged to the support arm of the rotation shaft. The present invention makes the flapping wing aircraft possess great lifting power, propelling power and stable flying state.

Owner:李玺芳

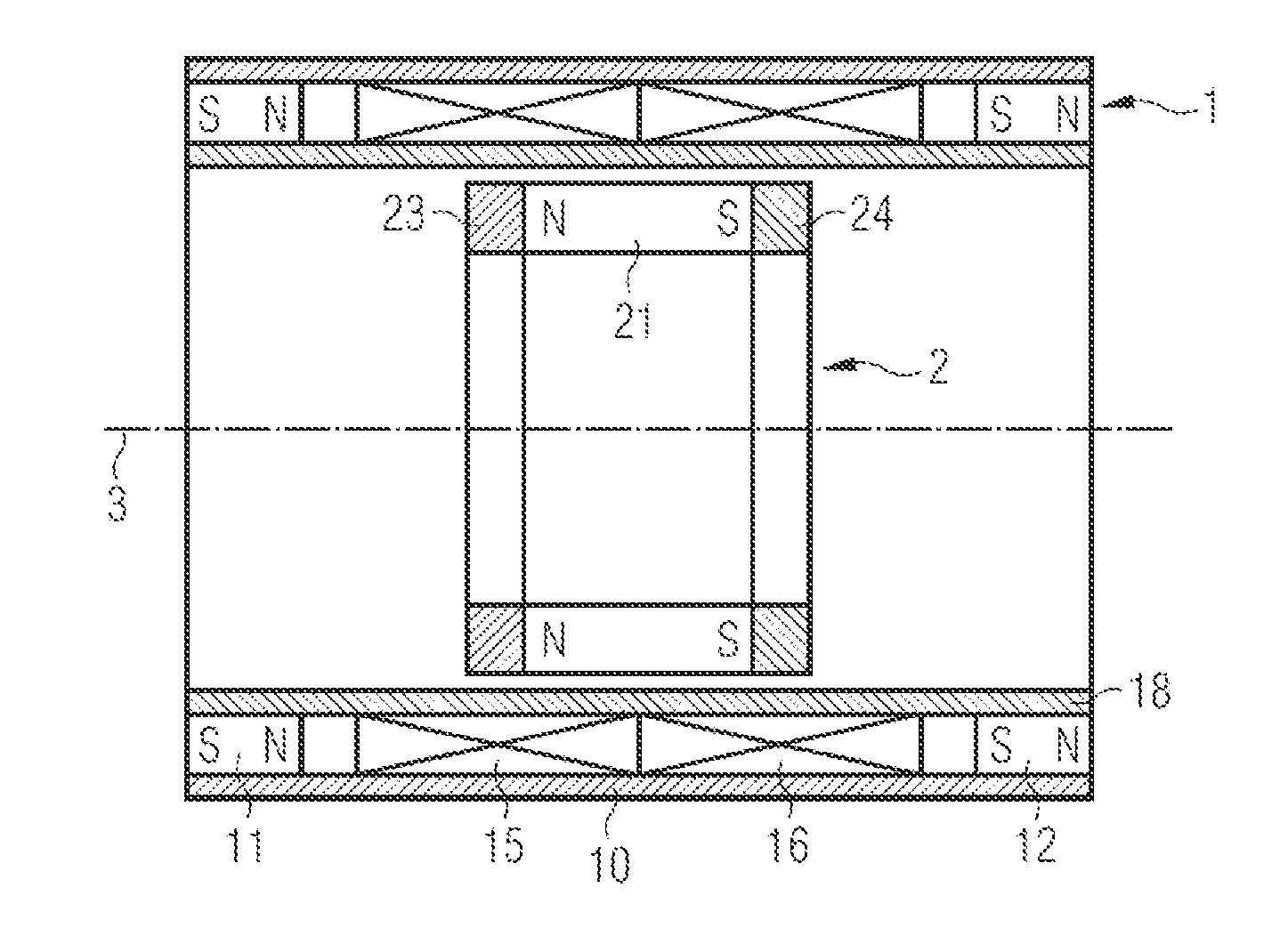

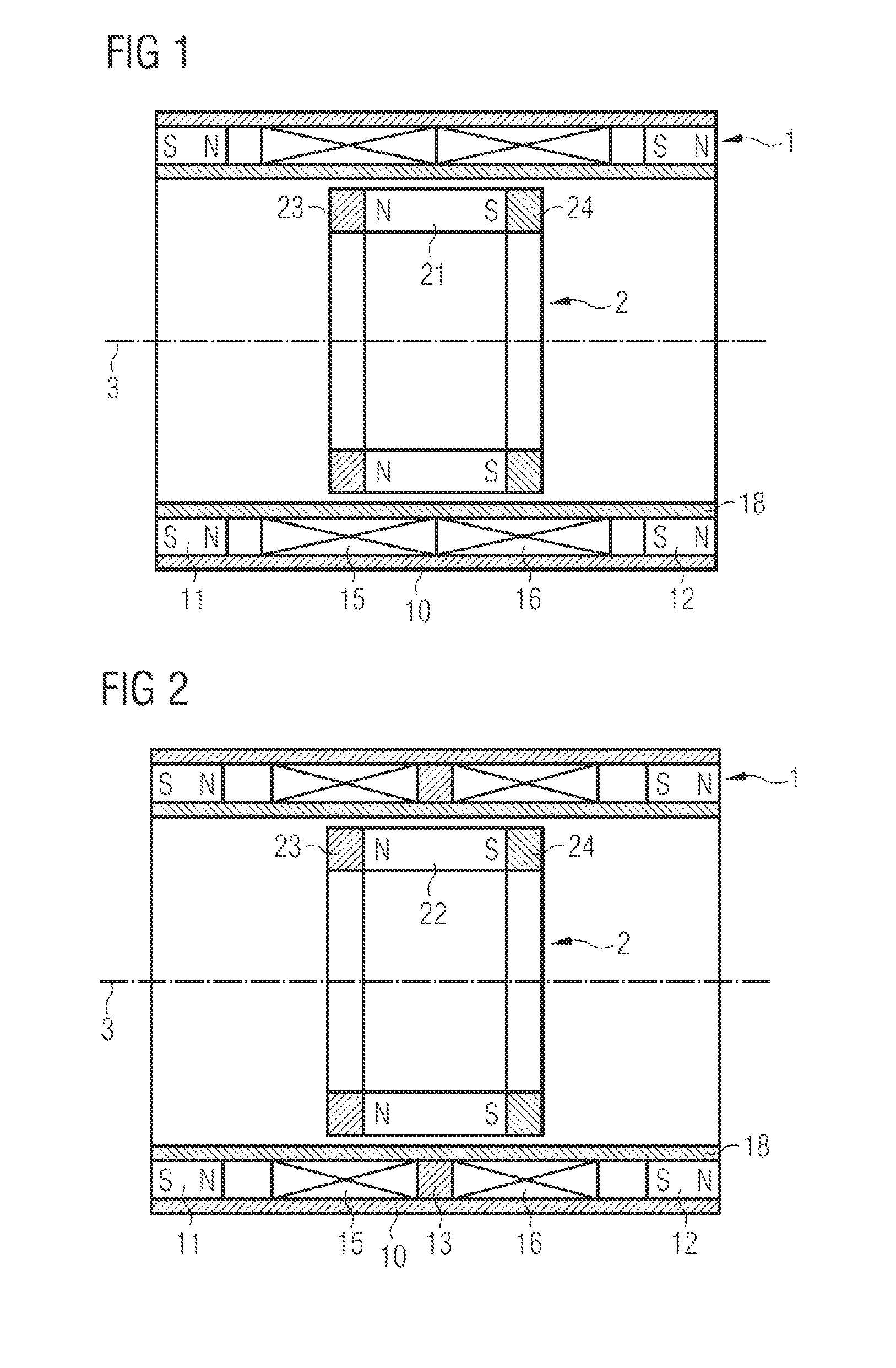

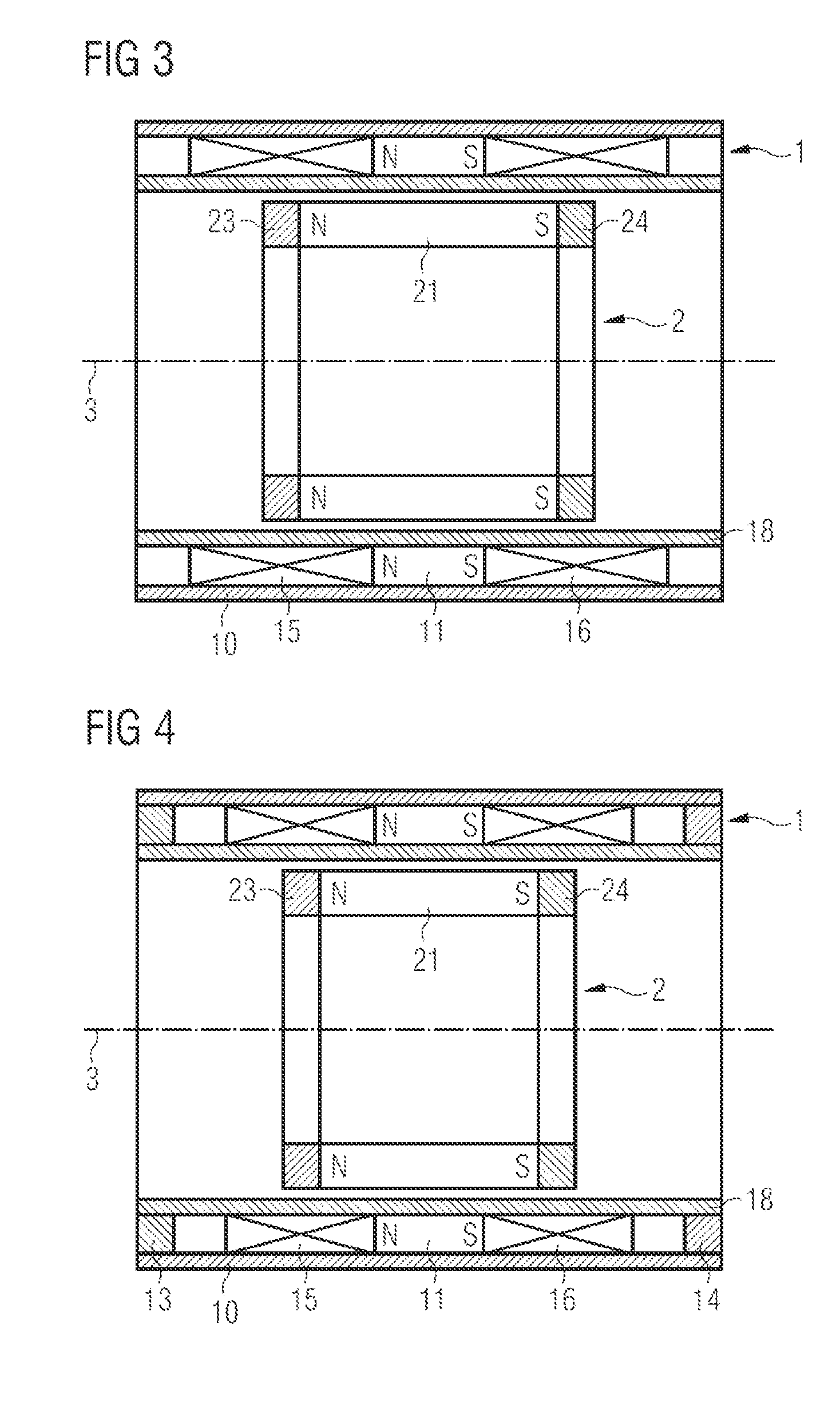

Linear motor with permanent-magnetic self-holding

A linear motor for optical systems, for example, endoscopes, is described. The motor has a stator with a magnetic guiding member and two adjacently disposed coils which are energized in opposite directions. Furthermore permanent magnets polarized in opposite directions and in the axial direction are provided on both sides of the pair of coils. The armature of the motor comprises a permanent magnet which is polarized in the opposite direction to the permanent magnet of the stator and is connected to a pole piece at each end. The pole pieces are arranged so that in the rest position each pole piece lies at the centre of one of the coils. By applying current to the coil, the armature can be displaced from a rest position in the longitudinal direction.

Owner:KARL STORZ GMBH & CO KG

Double bag vacuum infusion process and system for low cost, advanced composite fabrication

Boeing is actively engaged in the production of lightweight composite airframes for both military and commercial applications. The double bag vacuum infusion process of the present invention provides a low cost, method for producing complex composite assemblies without an autoclave. It also enables the production of highly innovative structures. The quality of the composites produced using such an infusion process are comparable to composites made using prepregs, hand layup or fiber placement and autoclave curing.

Owner:THE BOEING CO

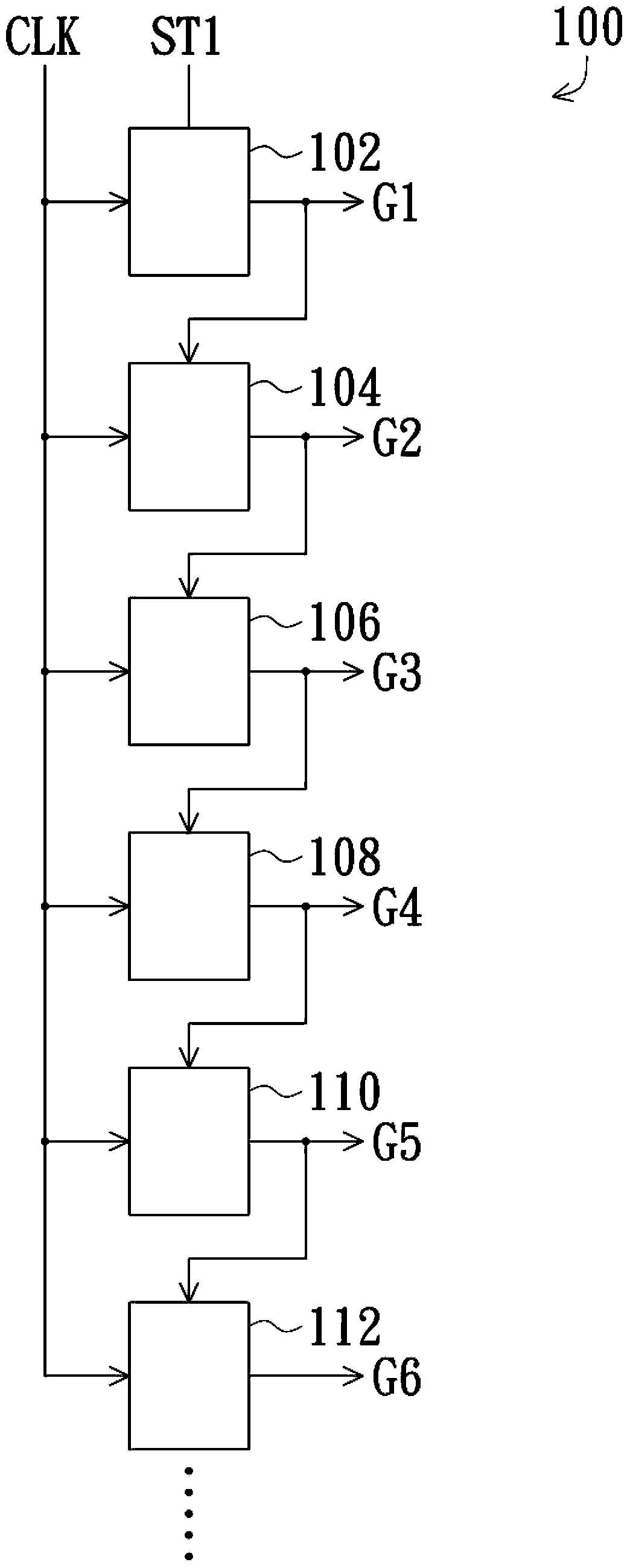

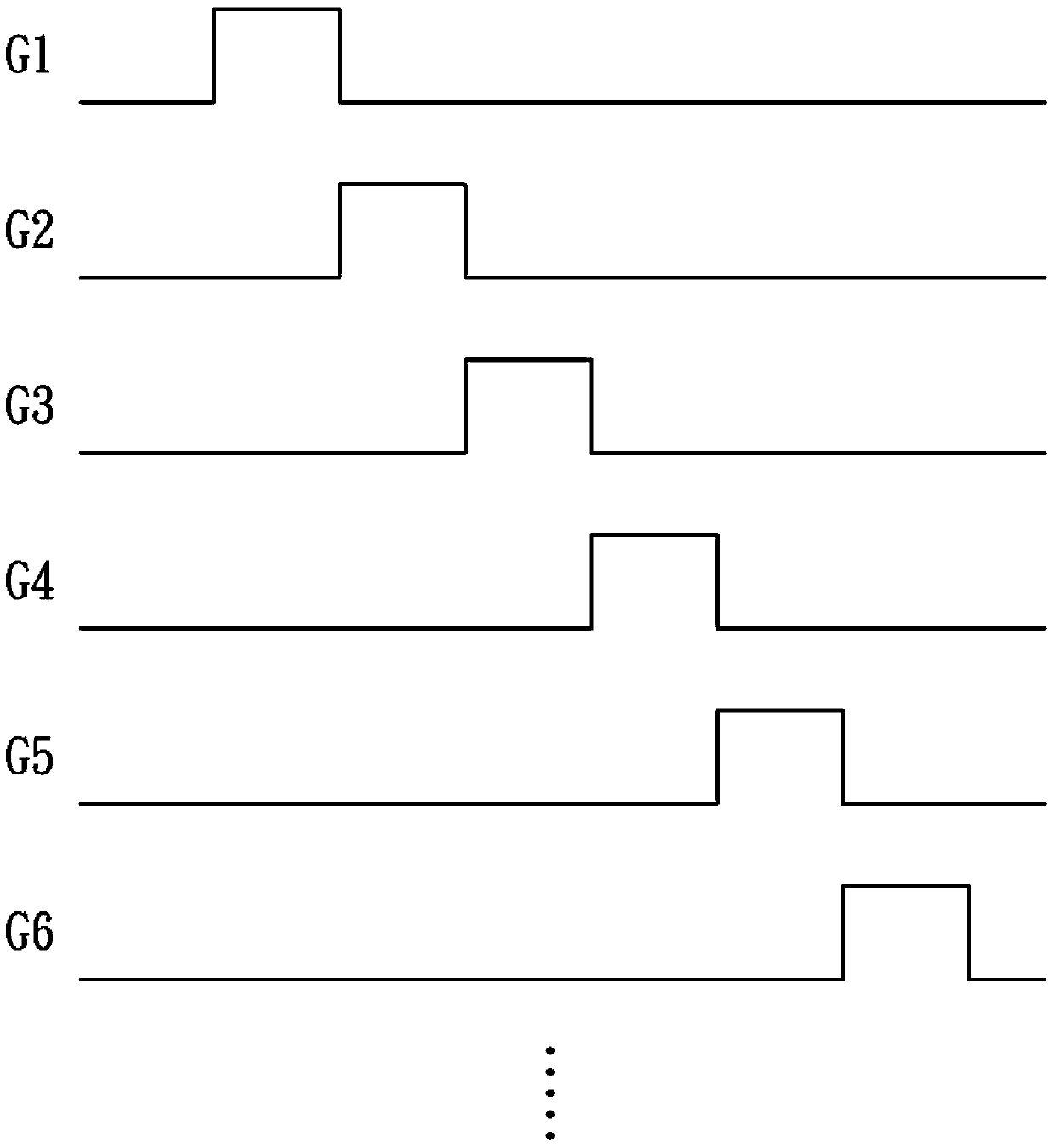

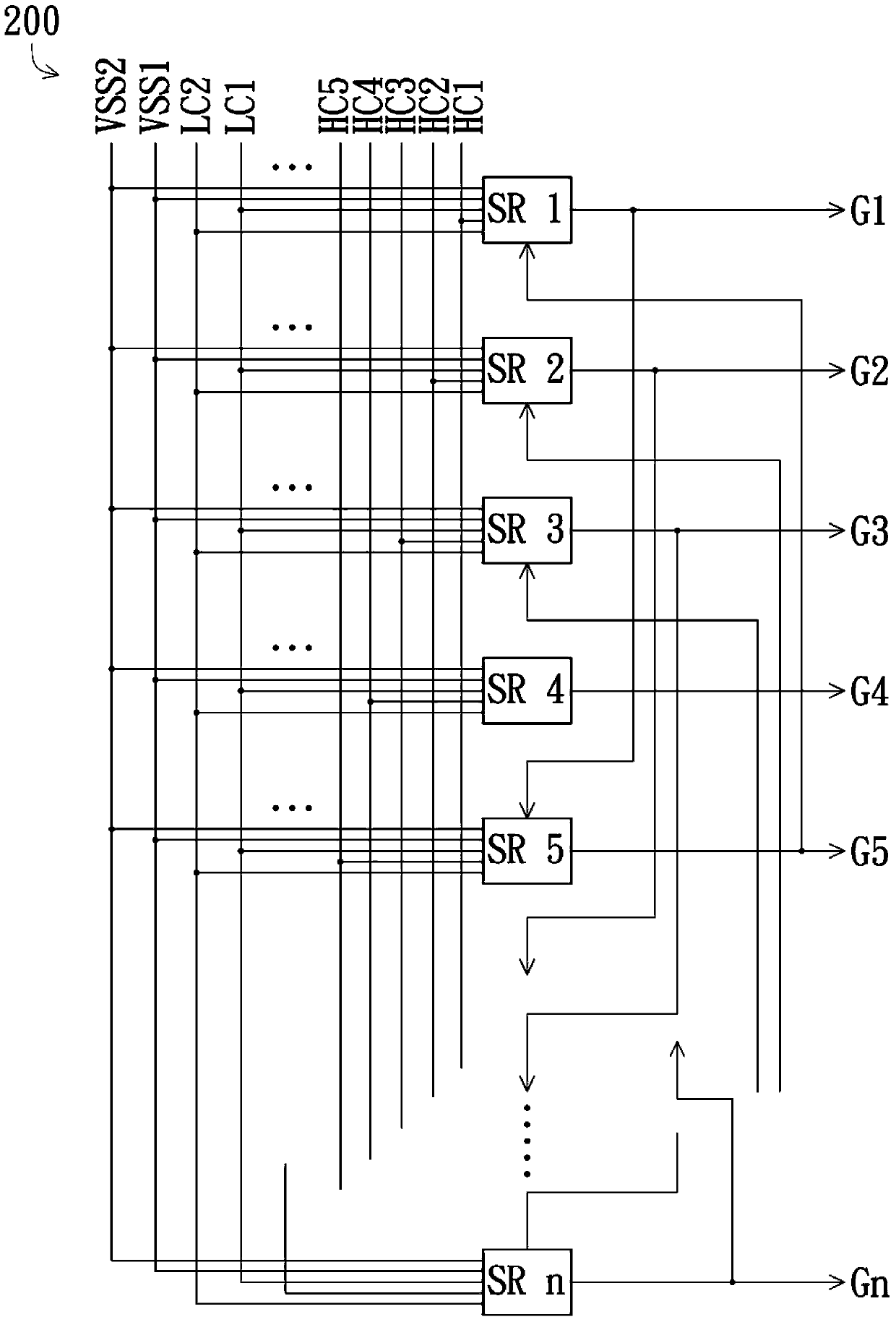

Voltage boost circuit, shift register and gate driving module

ActiveCN103500550AGreat driving forceStatic indicating devicesDigital storageShift registerProcessor register

A voltage boost circuit, a shift register and a gate driving module. The voltage boost circuit comprises a first switch, a second switch, and a third switch. The first switch can decide whether to transmit a first voltage signal to a second node according to a first driving signal. In addition, the second switch decides whether to transmit a voltage boost signal to a first node according to a second driving signal. The enabled time of the second driving signal is overlapped with the enabled time of the voltage boost signal, and the enabled time of the second driving signal is not overlapped with the enabled time of the first driving signal. Moreover, the frequency of the voltage boost signal can be greater than or equal to the frequency of the second driving signal. In addition, the third switch can decide to transmit a clock signal to an output end according to the state of the first node.

Owner:AU OPTRONICS CORP

Semiconductor device and method for fabricating the same

InactiveUS20060068556A1Suppresses enhanced diffusion of dopantHigh activation rateTransistorSemiconductor/solid-state device manufacturingDevice materialSemiconductor

The semiconductor device of the present invention includes: a gate insulating film formed on a semiconductor region of a first conductivity type; a gate electrode formed on the gate insulating film; and a channel doped layer of the first conductivity type formed in the semiconductor region beneath the gate electrode. The channel doped layer contains carbon as an impurity.

Owner:PANASONIC CORP

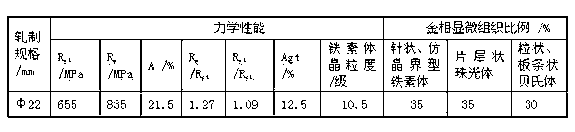

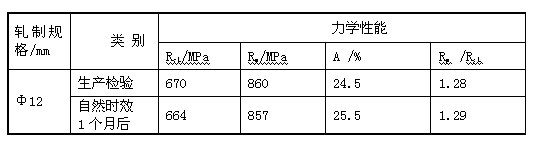

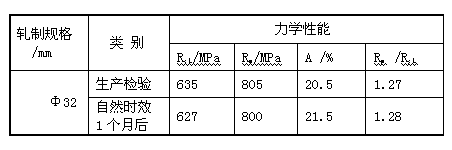

Niobium, titanium and boron microalloy hot-rolled ribbed bar (HRB) 600 high-performance aseismic reinforcing bar and production thereof

ActiveCN102796962ALow strain agingIncreased strain agingProcess efficiency improvementNiobiumTitanium

The invention provides a niobium, titanium and boron microalloy hot-rolled ribbed bar (HRB) 600 high-performance aseismic reinforcing bar and production of the niobium, titanium and boron microalloy hot-rolled ribbed bar (HRB) 600 high-performance aseismic reinforcing bar. Through molten steel smelting, molten steel casting, billet controlled rolling and controlled cooling, the niobium, titanium and boron microalloy HRB600 high-performance aseismic reinforcing bar is produced and comprises the following chemical constituents according to mass ratio: 0.14-0.18% of C, 0.30-0.50% of Si, 0.50-0.75% of Mn, 0.50-0.70% of Cr, 0.030-0.050% of Nb, 0.0015-0.0030% of B, 0.020-0.040% of Ti, no more than 0.045% of S, no more than 0.045% of P and the balance of Fe and unavoidable impurities. The niobium, titanium and boron microalloy HRB600 high-performance aseismic reinforcing bar has the characteristics of low production cost, technological applicability, strong controllability and the like, the steel microstructure is uniformly distributed and has good form, the refining effect of ferrite is obvious, and the niobium, titanium and boron microalloy HRB600 high-performance aseismic reinforcement has good low-strain timeliness, high strength, good toughness, good welding performance, excellent aseismic performance and excellent combination property.

Owner:WUKUN STEEL

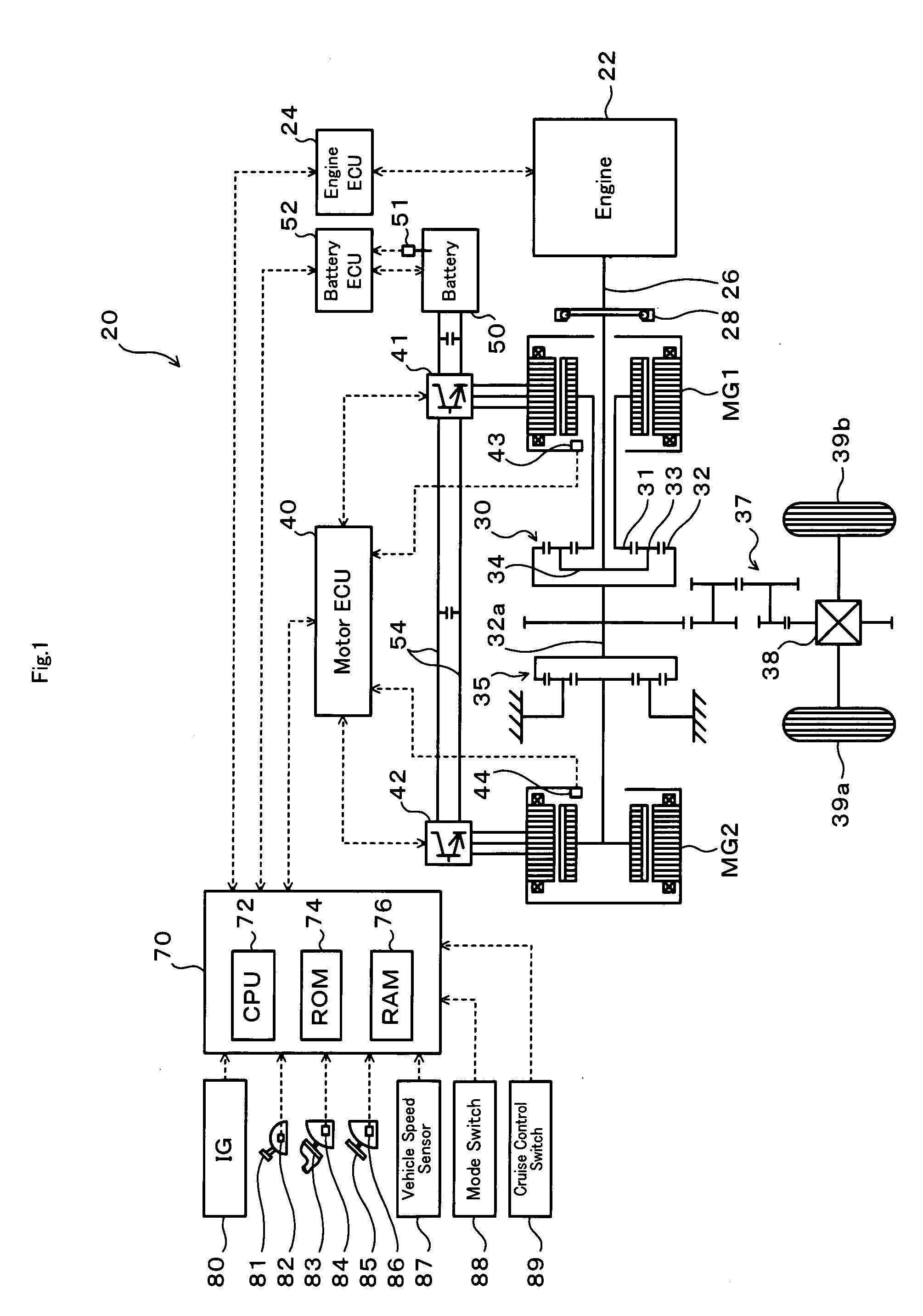

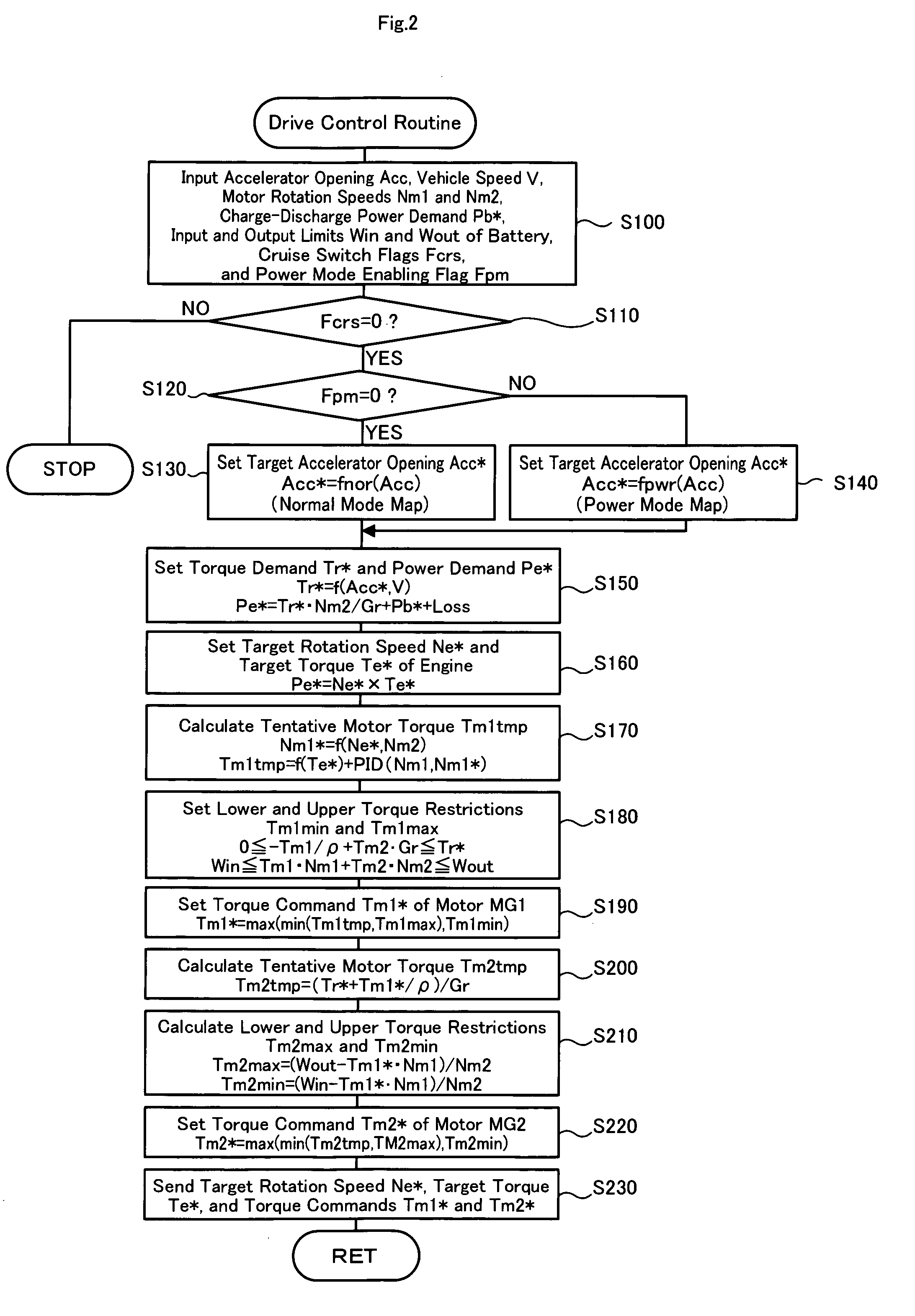

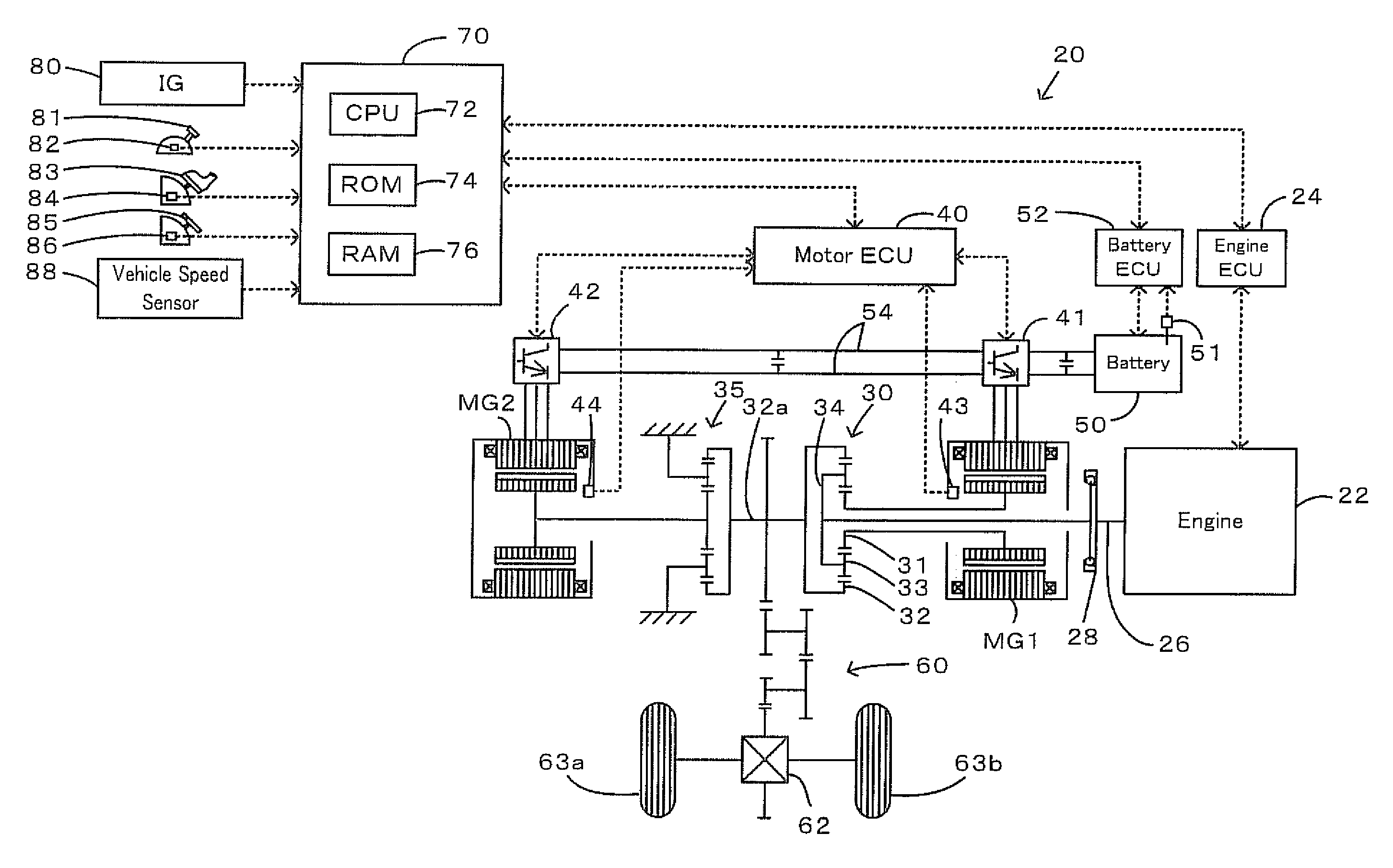

Hybrid vehicle and control method thereof

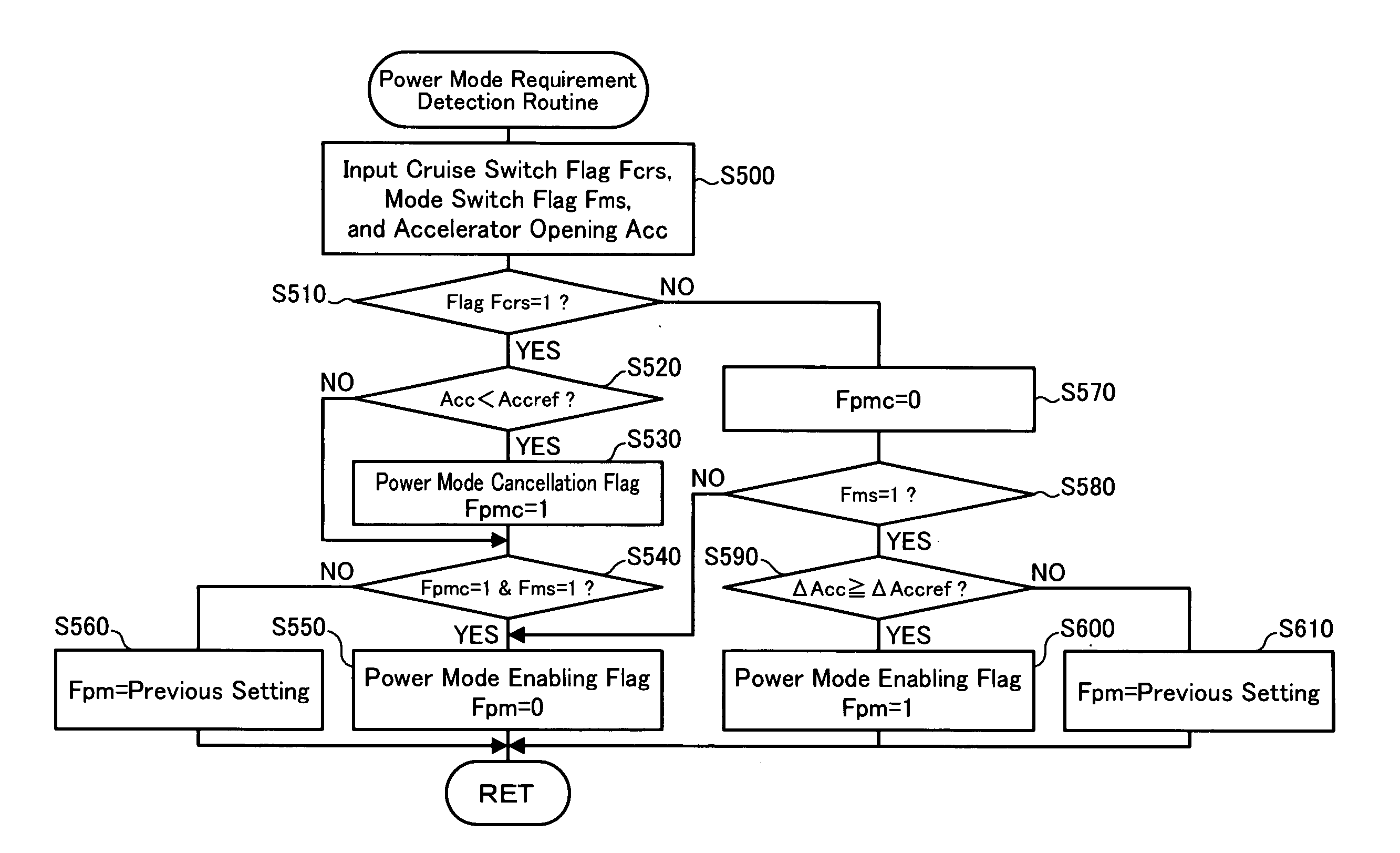

ActiveUS20080228334A1Executed sufficientlyPrevented from feelingVehicle fittingsDigital data processing detailsPower modeEngineering

During execution of an auto cruise function, in response to selection of a power mode, when an measured accelerator opening Acc is less than a preset opening Accref, a hybrid vehicle of the invention sets a power mode cancellation flag Fpmc to 1 and a power mode enabling flag Fpm to 0 (steps S540 and S550). This prohibits the use of an accelerator opening setting map in the power mode for execution of the auto cruise function. In the power mode, in response to an instruction for enabling the auto cruise function, the hybrid vehicle keeps the power mode enabling flag Fpm to the setting of 1 (step S560) as long as the measured accelerator opening Acc is not less than the preset opening Accref. This allows the use of the accelerator opening setting map in the power mode for execution of the auto cruise function.

Owner:TOYOTA JIDOSHA KK

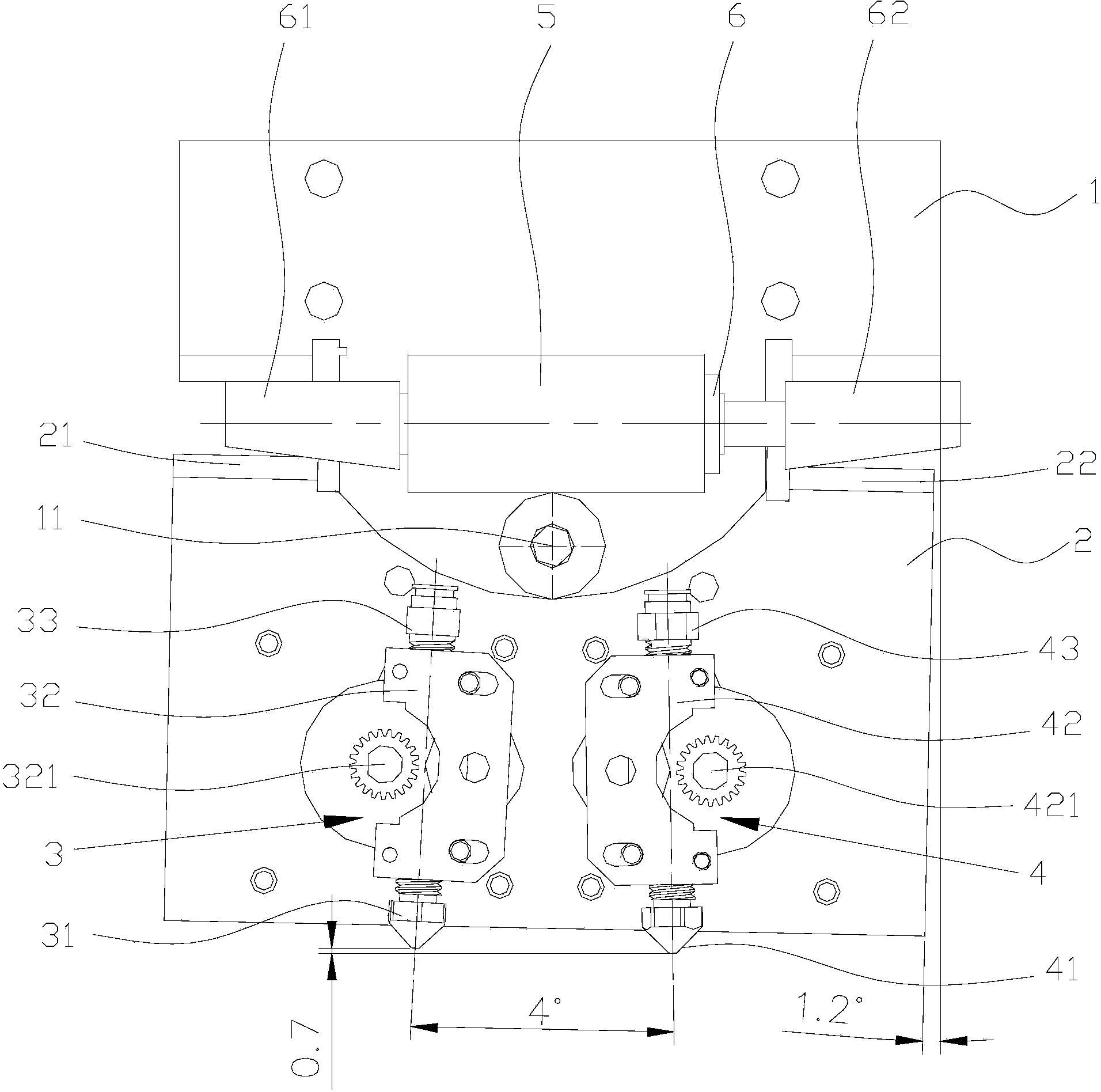

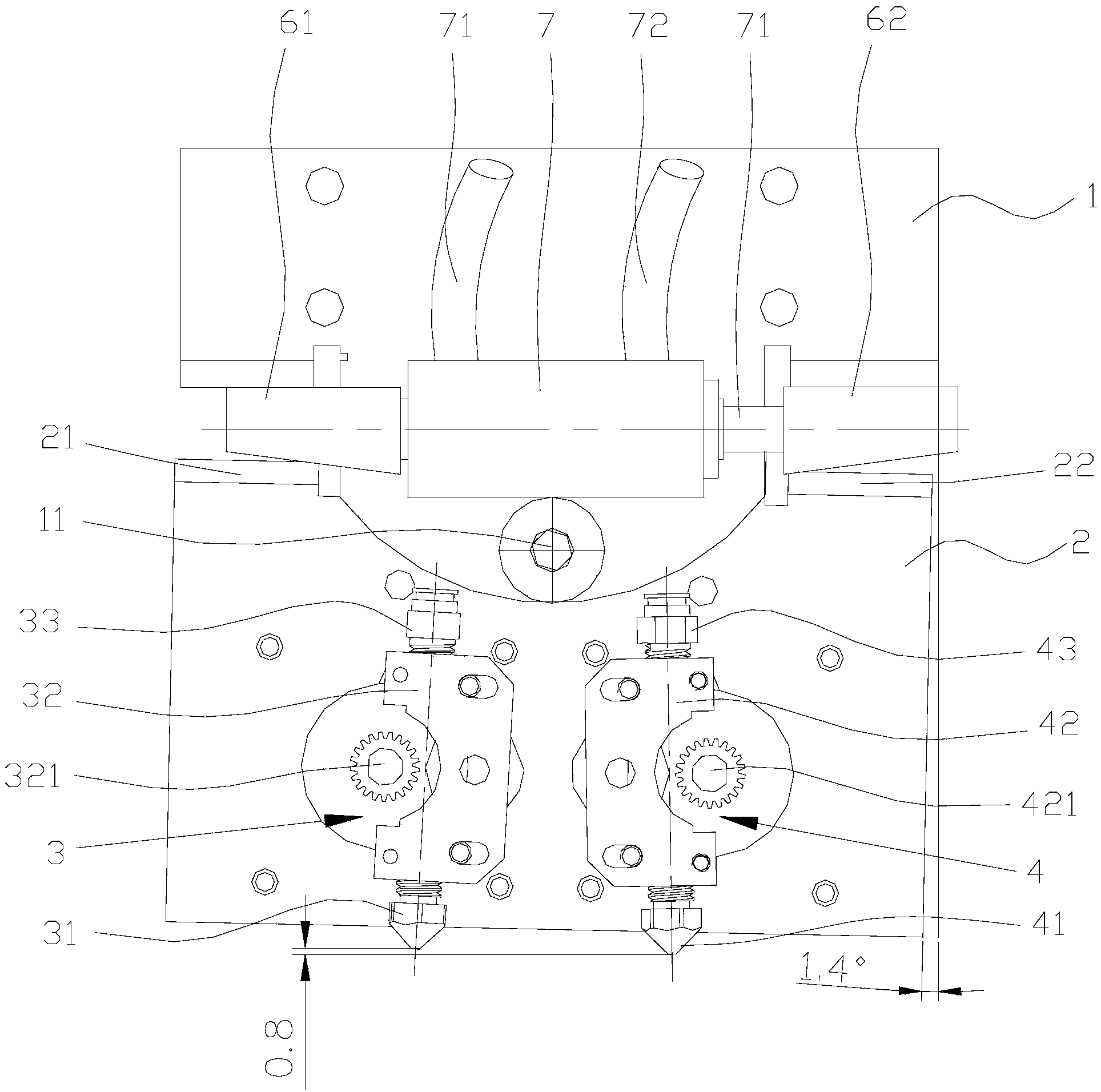

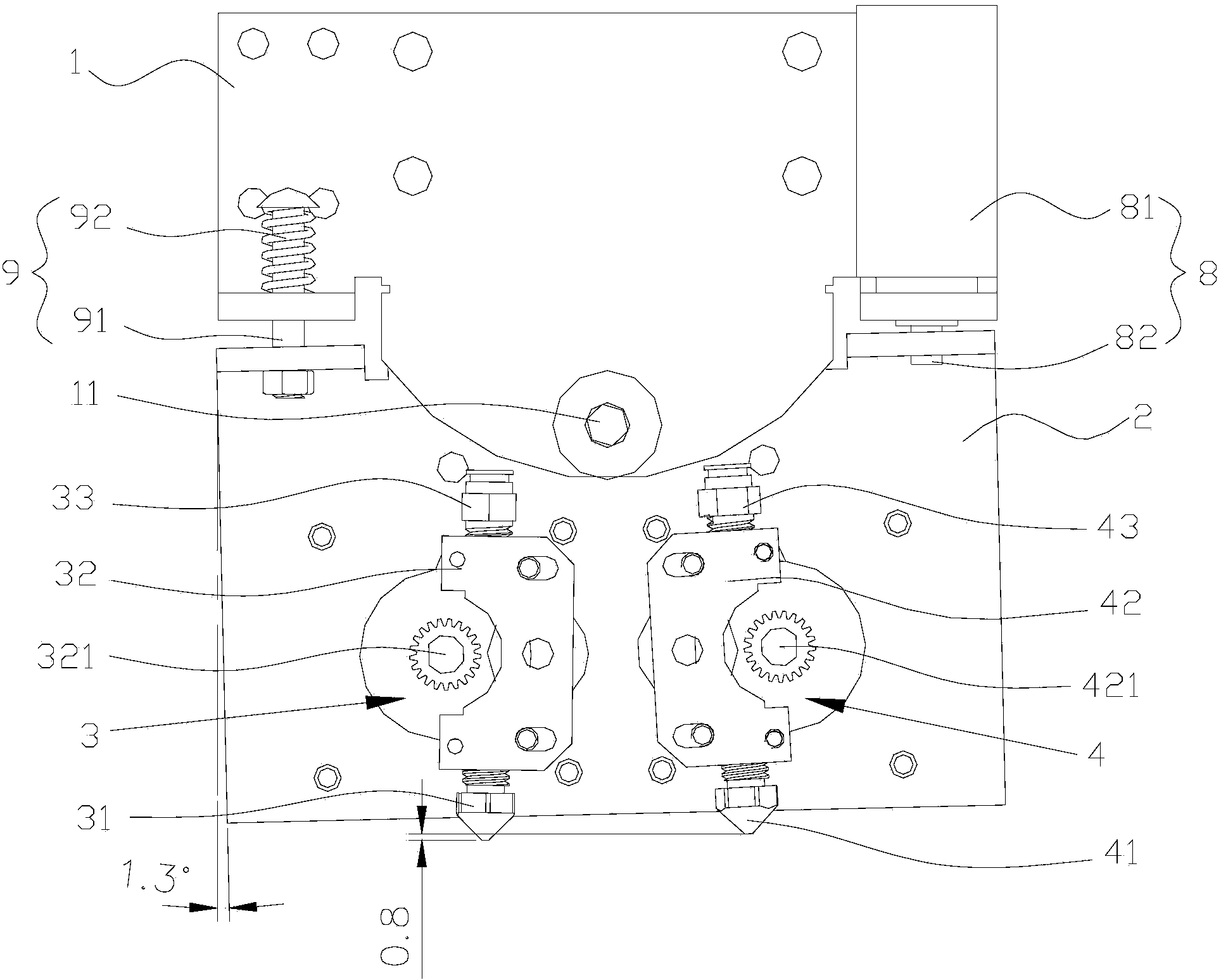

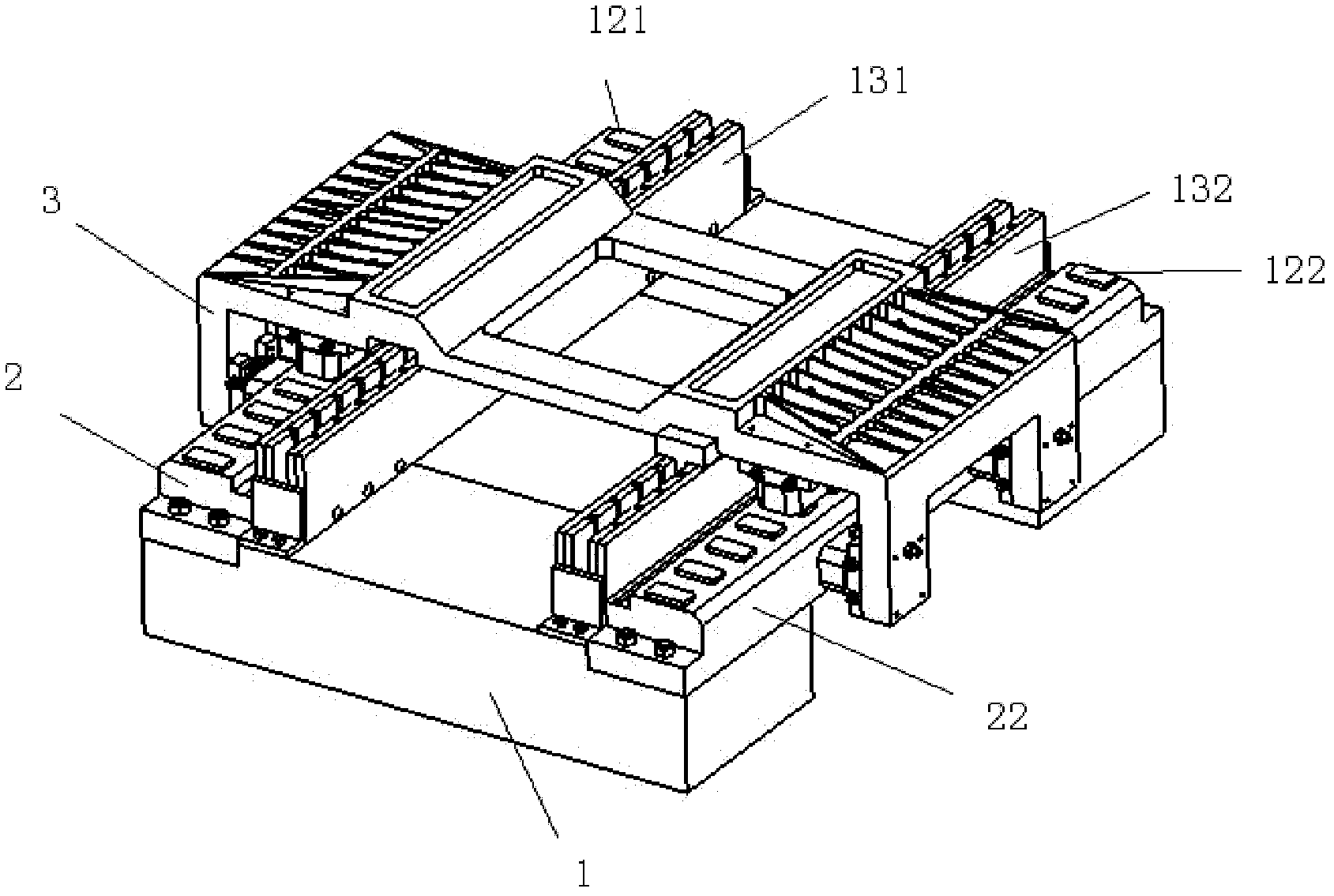

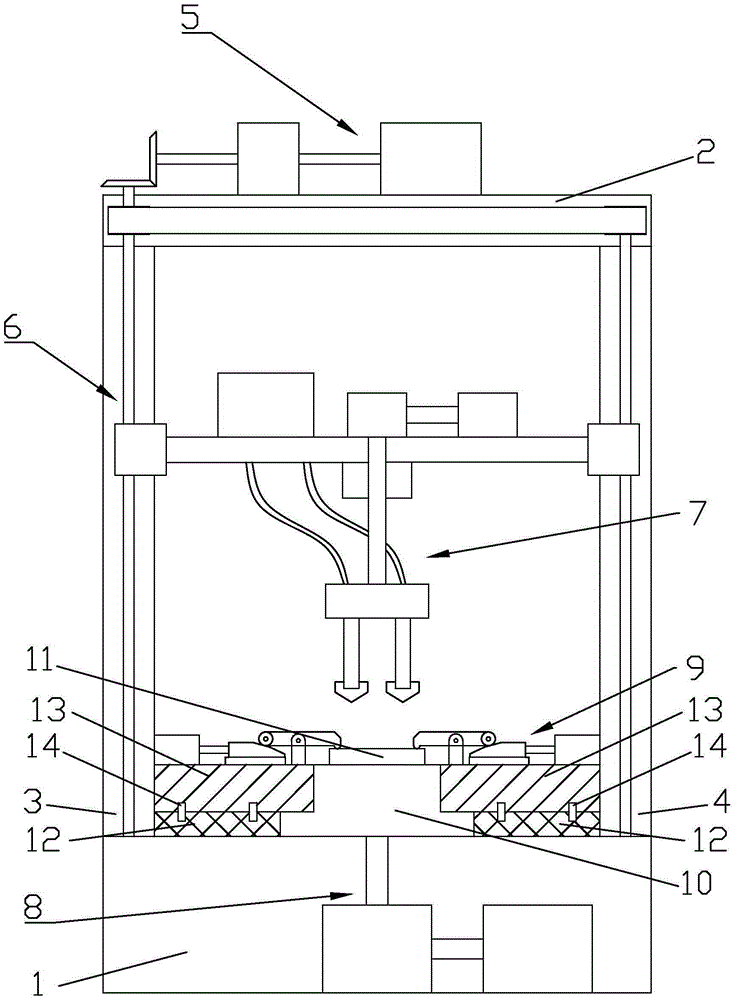

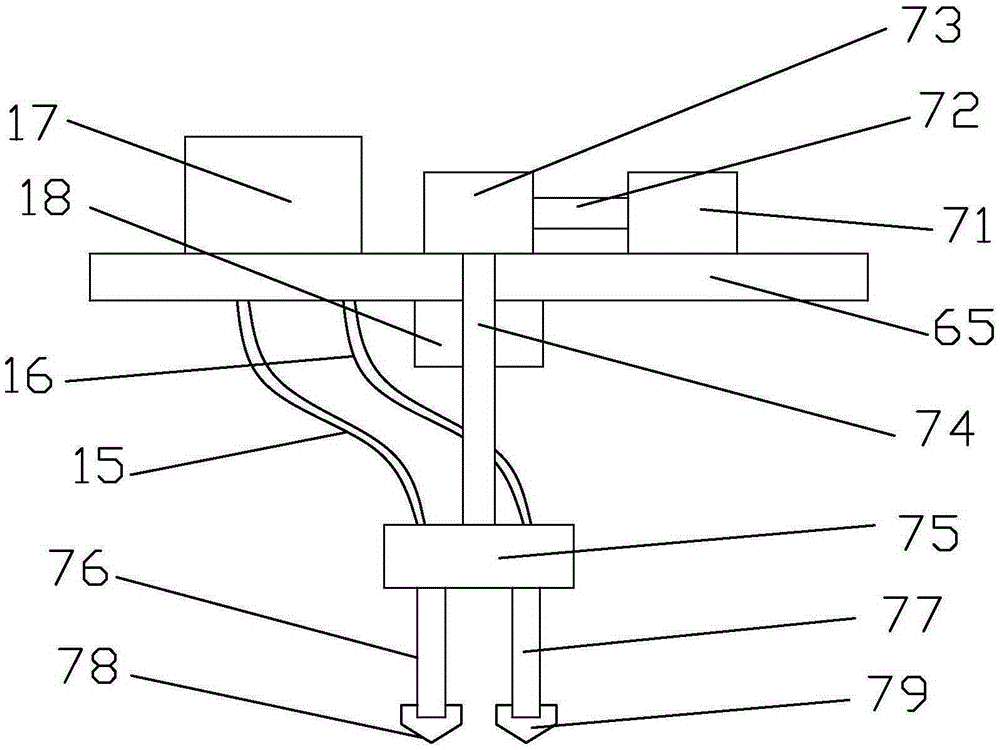

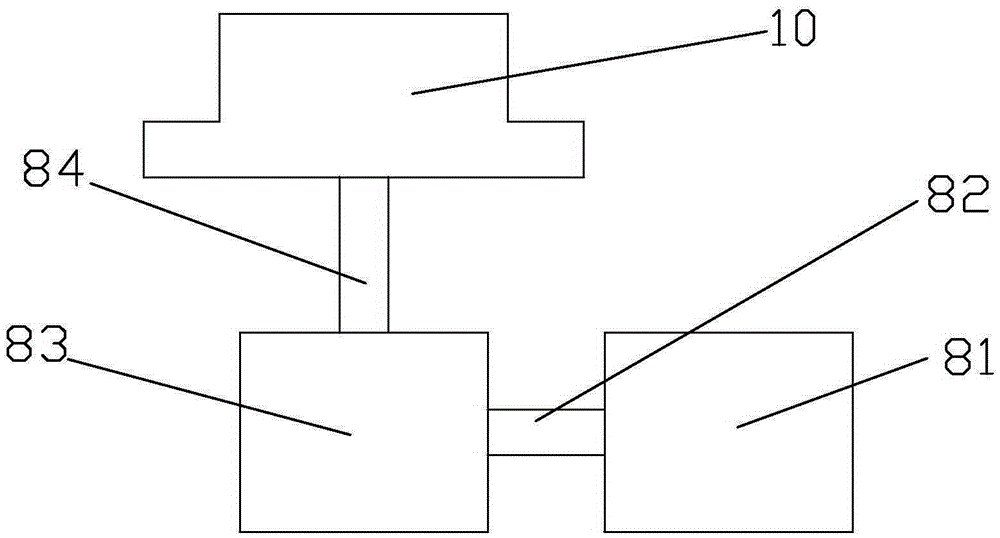

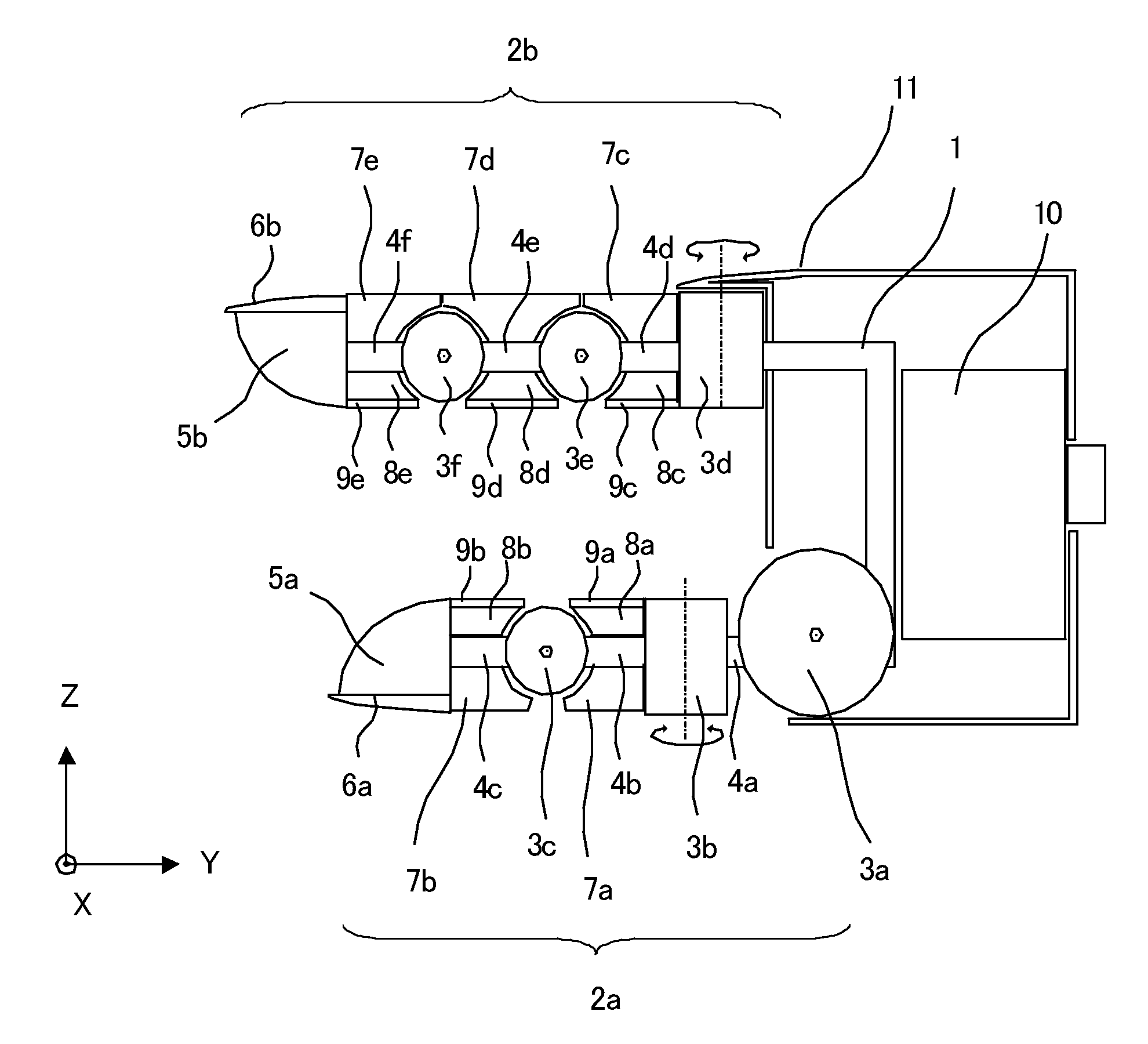

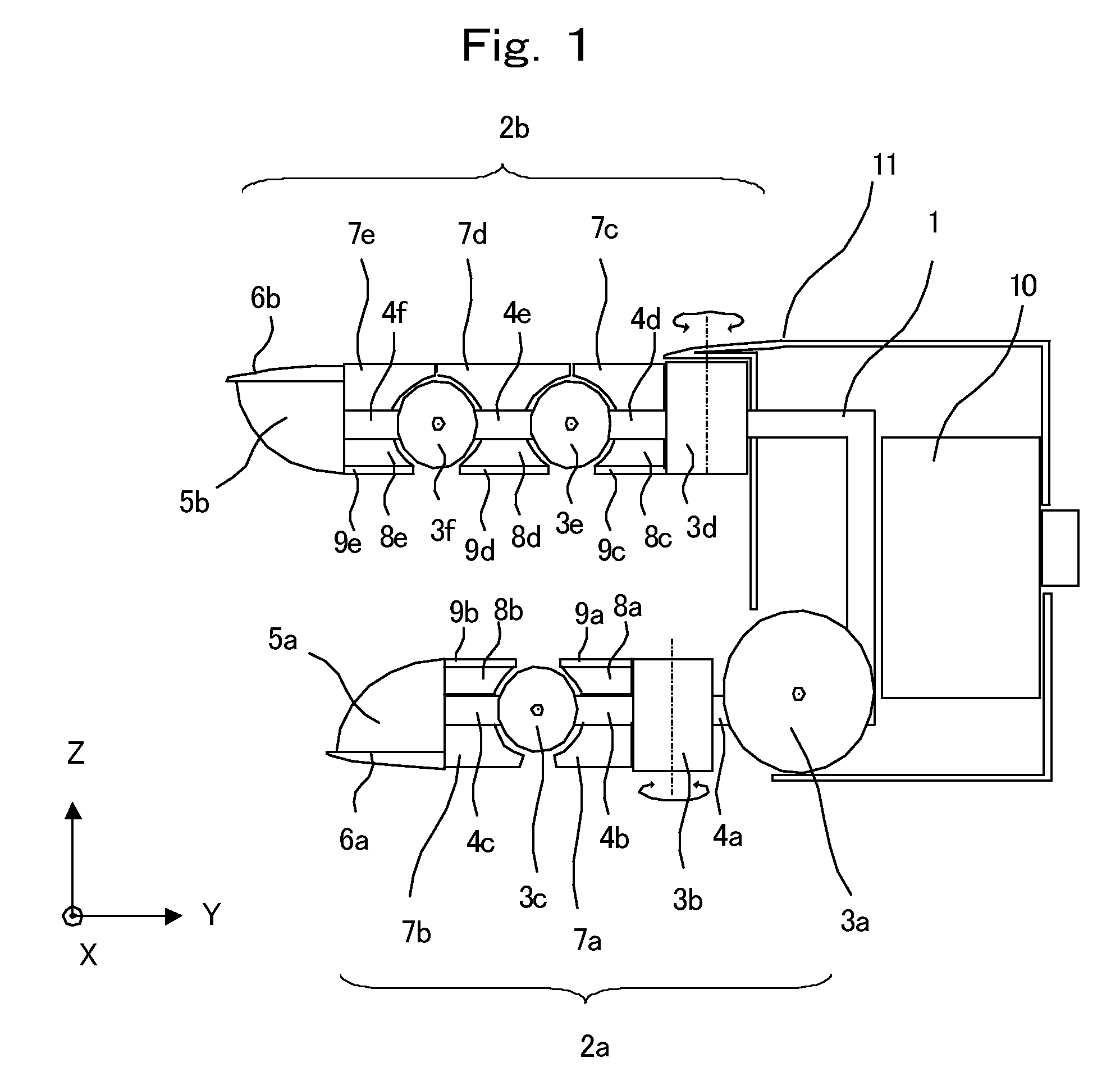

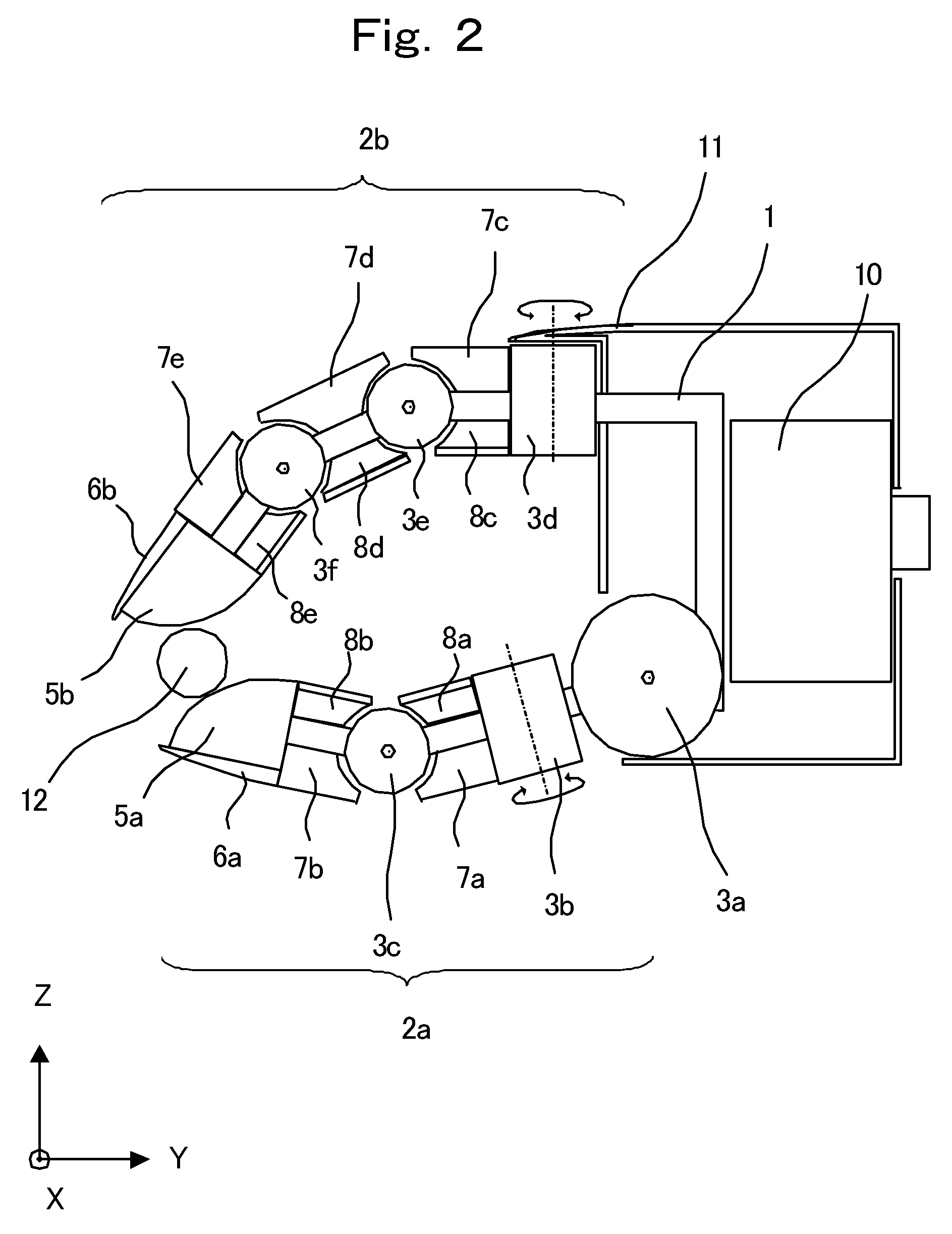

Dual-head 3D printer capable of rotatably switching printing heads

ActiveCN104228069AGuaranteed heightOvercoming problems with being at the same heightEngineering3d printer

Owner:苏州江南嘉捷光机电技术有限公司

Magnetic suspension linear motion platform based on combination of permanent magnets and electromagnets

The invention discloses a magnetic suspension linear motion platform based on the combination of permanent magnets and electromagnets. The electromagnets are vertically installed in a suspensoid, array permanent magnets are arranged on the surface of a guide rail, the suspension of the suspensoid can be realized by utilizing the principle of holopolarity repulsion between the electromagnets and the permanent magnets; and meanwhile, an eddy current displacement sensor is combined to realize the stable suspension of the suspensoid above the guide rail; two pairs of electromagnets are horizontally installed in the suspensoid, which can provide guidance for the linear motion of the platform by combining with the eddy current displacement sensor; a linear motor stator is fixed on a base, a linear motor rotor is fixed on the suspensoid, a grating ruler is arranged on the surface of the guide rail, and the reading head of the grating ruler is installed on the suspensoid, thus the precise linear positioning motion of the suspensoid can be realized. The platform provided by the invention can realize the functions such as super cleaning, high speed, long stroke, precise positioning motion and the like, which can not be realized by the traditional scheme that a rotary servo motor is utilized to drive, a precise ball screw is utilized to transmit and a slide guide is utilized to support, and has the advantages of good load bearing characteristic and stable suspension performance.

Owner:CENT SOUTH UNIV

Drilling device applied to graphite mold production

InactiveCN105414599ASolving Drilling ProblemsStrong targetingWorkpiecesTurning toolsElectric machineryReducer

The invention discloses a drilling device applied to graphite mold production. The drilling device comprises a frame and a drilling table; drilling longitudinal frames and a drilling transverse frame are arranged on the frame; the drilling longitudinal frames are positioned at the two sides of the frame; the drilling transverse frame is positioned between the drilling longitudinal frames, and is provided with a lifting driving mechanism and a lifting mechanism; the lifting mechanism includes lifting platforms and lifting lead screws; the lifting lead screws are mounted in the drilling longitudinal frames, and are connected with lifting lead screw connecting bases; the lifting lead screw connecting bases are connected with the lifting platforms; drilling mechanisms are arranged on the lifting platforms, and include drilling motors and drilling lead screws; the drilling motors are connected with drilling motor output shafts; the drilling motor output shafts are connected with drilling speed reducers; the drilling speed reducers are connected with the drilling lead screws; the drilling lead screws are connected with drilling bases; and the drilling bases are connected with drill rods. The machine is simple in structure, strong in pertinency, precise in positioning and excellent in drilling effect, and preferably solves the drilling problem in the graphite mold production.

Owner:SHENGZHOU SIGMA TECH

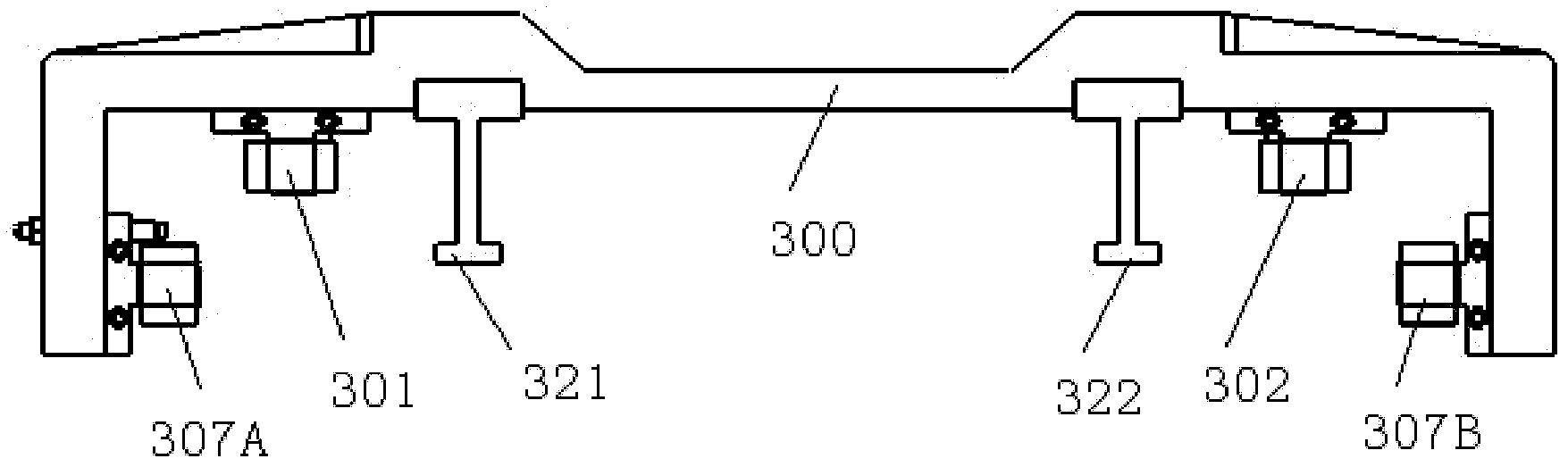

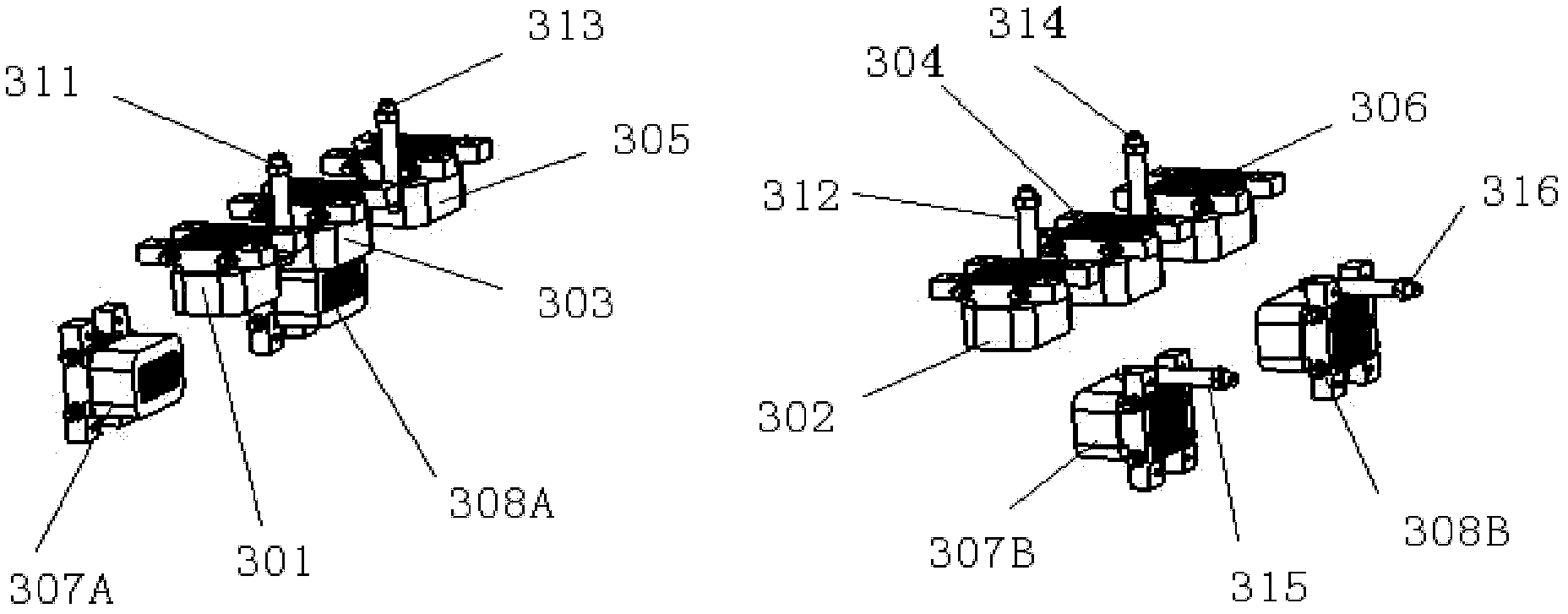

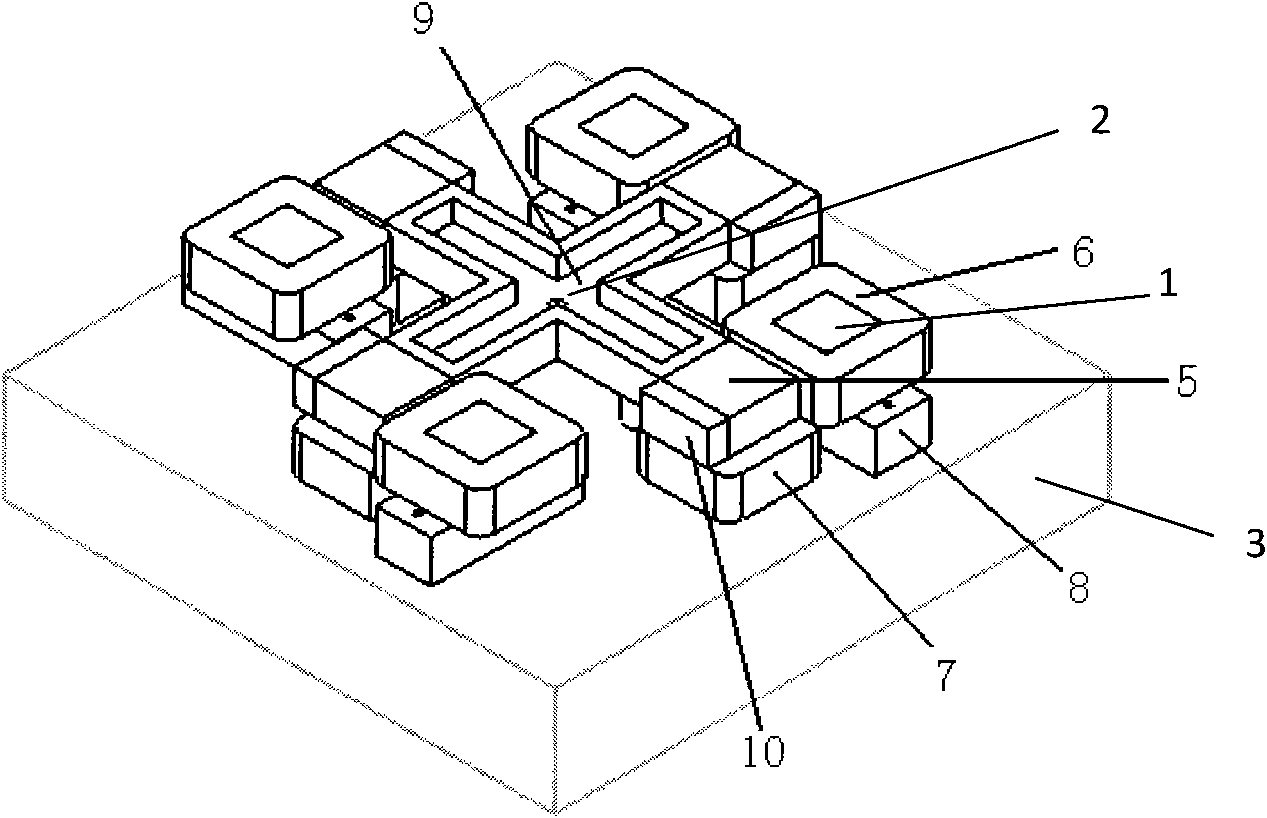

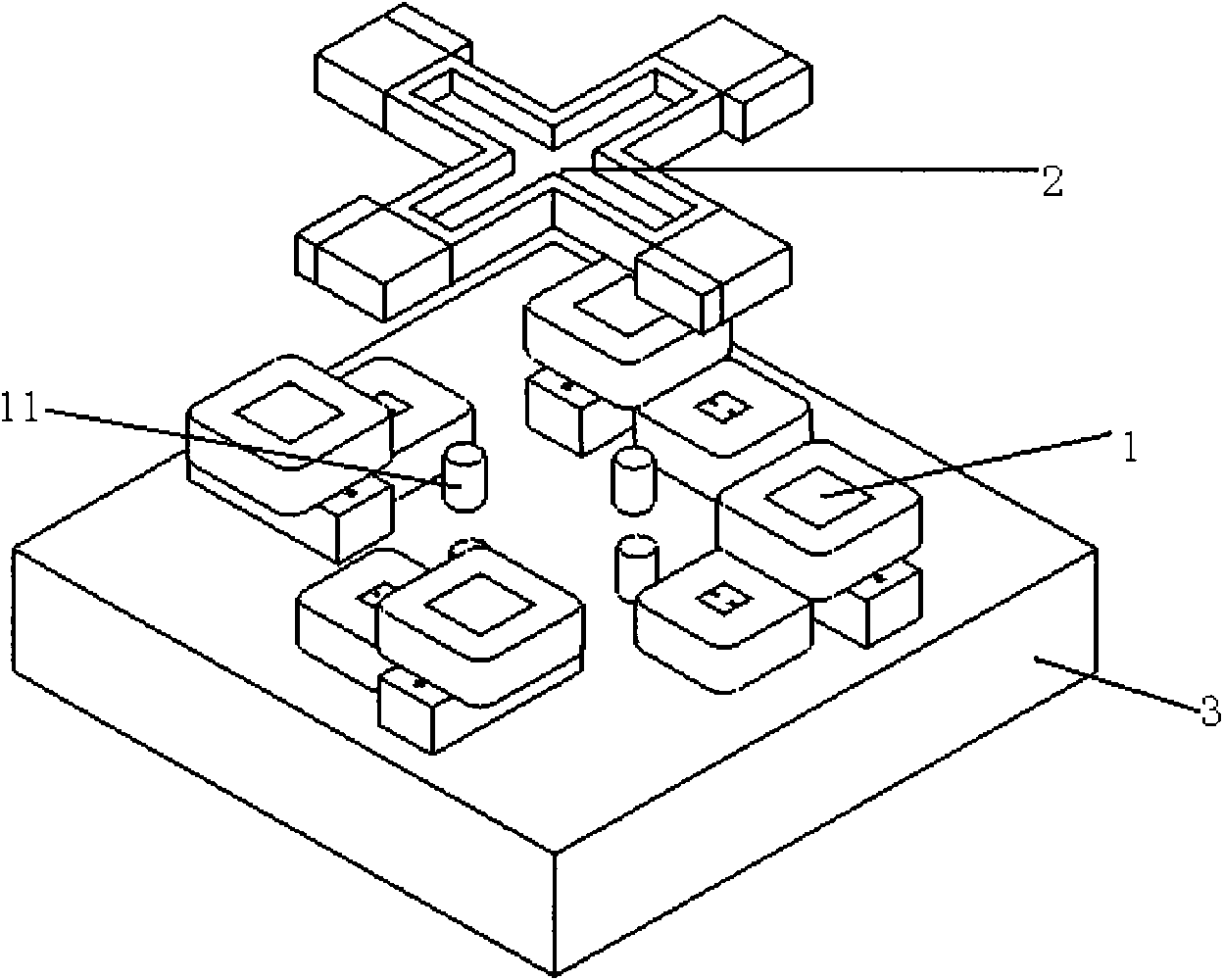

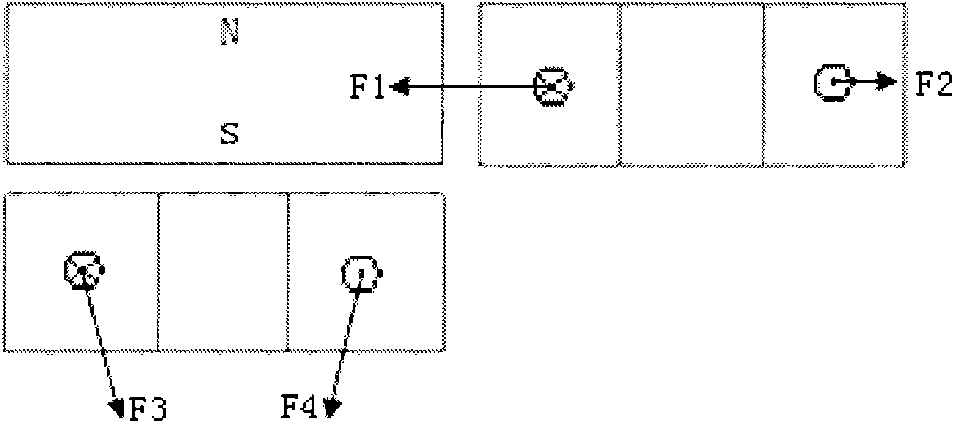

Nano-precision six-freedom-degree magnetic suspension jiggle station and application

ActiveCN101807010ASimple structureGreat driving forcePhotomechanical exposure apparatusMicrolithography exposure apparatusSix degrees of freedomStator

The invention discloses a nano-precision six-freedom-degree magnetic suspension jiggle station and application. The jiggle station is mainly applied to semiconductor photoetching equipment. The jiggle station comprises a cross stand and four two-freedom-degree actuators. Each two-freedom-degree actuator comprises permanent magnets polarized along the vertical direction, a horizontal force coil and a vertical force coil, wherein the permanent magnet is fixed at the tail end of the cross stand, and the horizontal force coil and the vertical force coil are arranged on the lateral surface and the underside of the permanent magnet respectively and keep a clearance with the permanent magnet; the cross stand and four permanent magnets polarized along the vertical direction form a rotor of the jiggle station; the horizontal force coil and the vertical force coil are fixed by a coil framework respectively to form a stator of the jiggle station; and the stator is fixed on a pedestal of the jiggle station. The combination of two jiggle stations and a two-freedom-degree large-stroke linear motor can form a positioning system of a double silicon wafer station of a photoetching machine. The jiggle station has the characteristics of simple structure, large driving force, light mass and no cable disturbance, and easily realizes high-precision and high-acceleration six-freedom-degree jiggle.

Owner:TSINGHUA UNIV +1

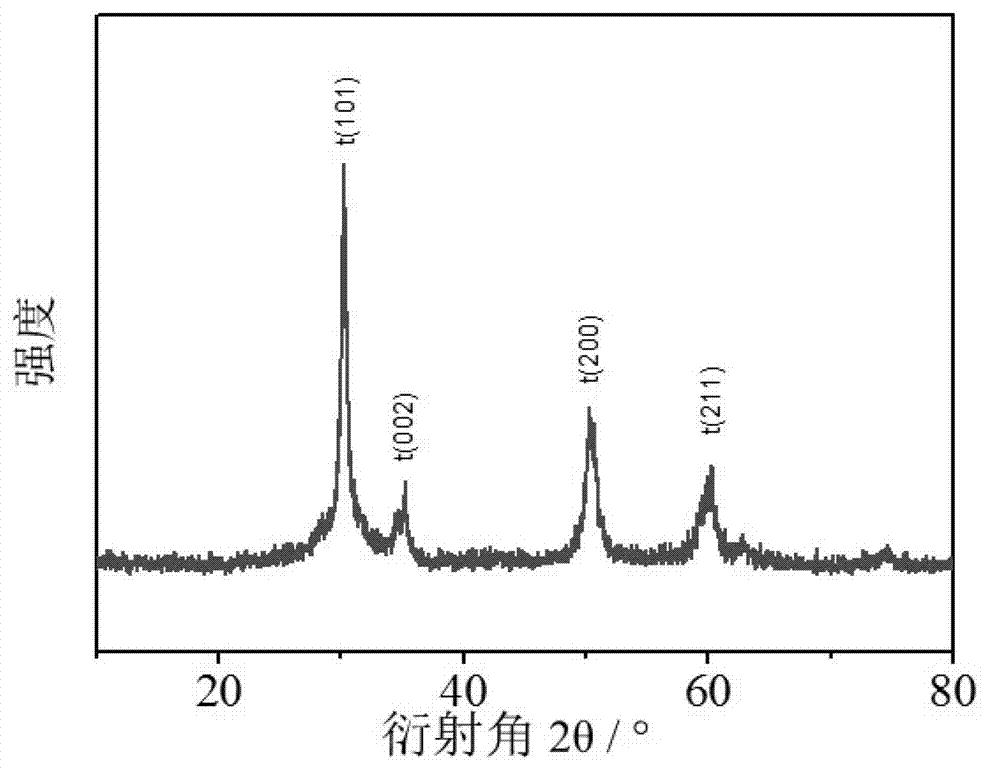

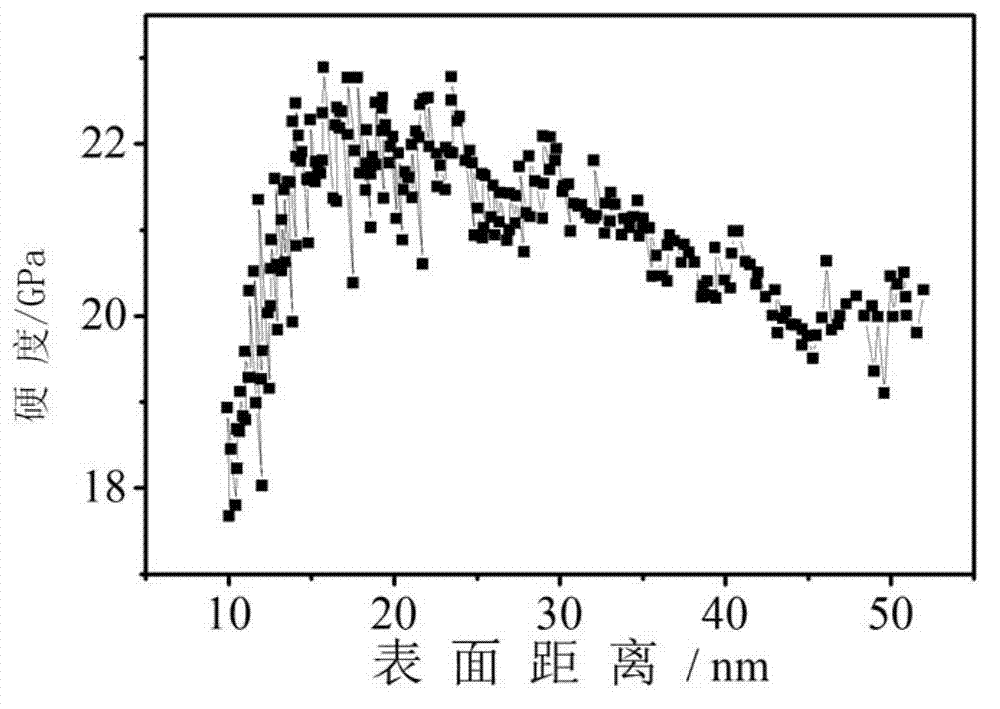

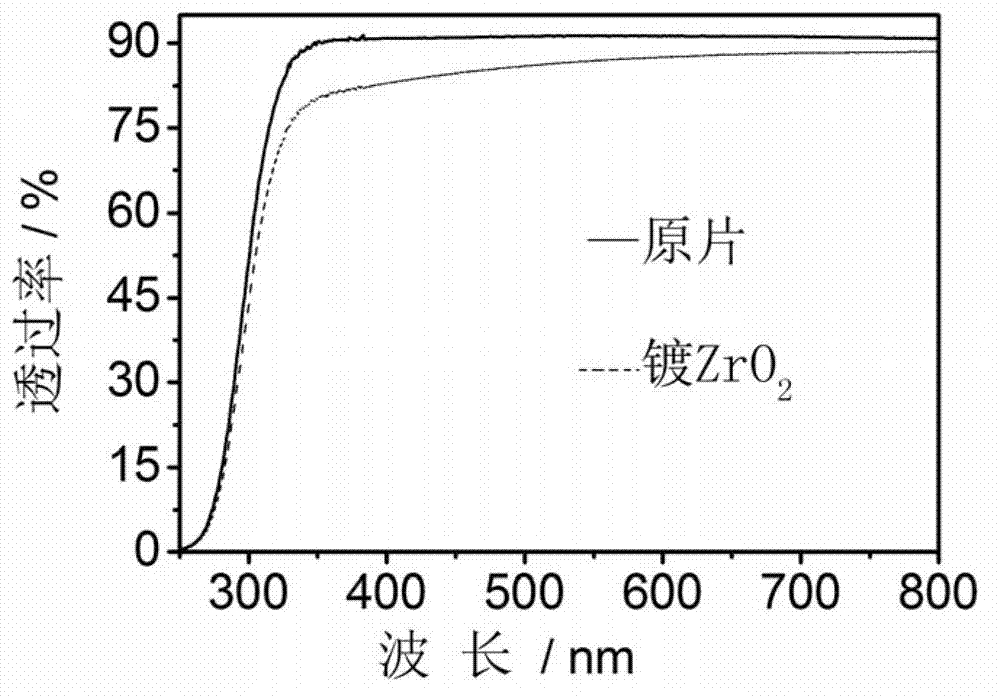

Preparation method of chemical toughened glass product with wearing-resisting film

ActiveCN102951850AHigh surface hardnessImprove bending strengthGlass tempering apparatusRoom temperatureMolten salt

The invention discloses a preparation method of a chemical toughened glass product with a wearing-resisting film. The preparation method comprises the following steps of: (1), plating an oxide film on the surface of the clean glass product so as to obtain the glass product with a wearing-resisting coating; and (2), putting the glass product (obtained in the first step) with the wearing-resisting coating into molten salt, carrying out ion exchange to be strengthened for 8-18 hours at 400-500 DEG C, and subsequently cooling to the room temperature and washing so as to obtain the chemical toughened glass product. According to the method, the particularly prepared molten salt is adopted for ion exchange and tempering, the wearing-resisting coating with high hardness is combined with the surface of the glass product more tightly, and a part of surface crack can also be healed, so that the surface hardness and the anti-bending strength of the product are improved, and the application field of the chemical toughened glass product is expanded.

Owner:ZHEJIANG UNIV

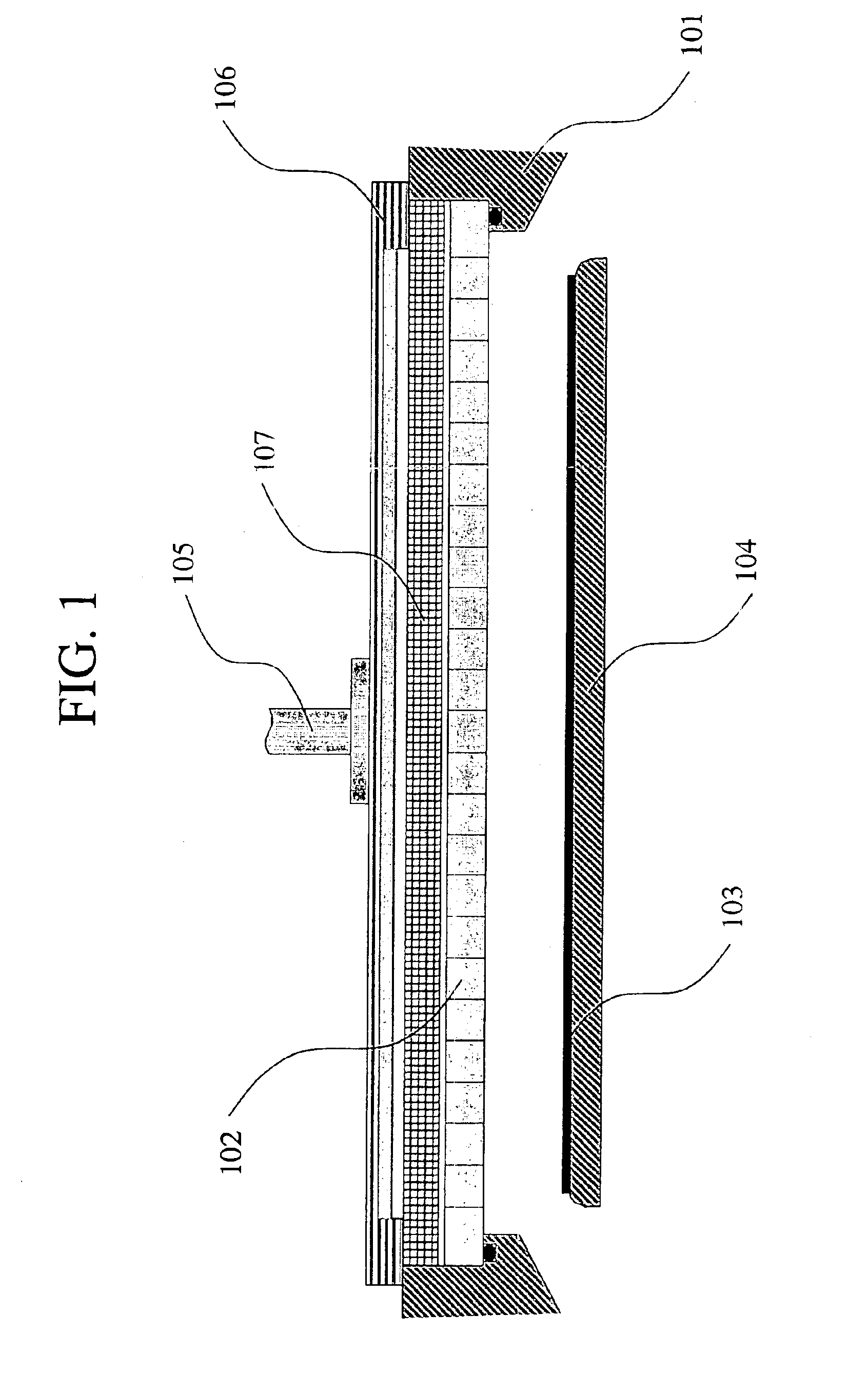

Robot

InactiveUS20100010670A1Great driving forceProgramme-controlled manipulatorMechanical apparatusControl theoryControl unit

A robot includes a base unit, at least two link mechanisms arranged on the base unit, drive units capable of bending and expanding the link mechanisms, and a control unit controlling the drive units. At least one drive unit has a drive force larger than those of the other drive units, and the other drive units are passively displaced by external forces larger than their own drive forces.

Owner:YASKAWA DENKI KK

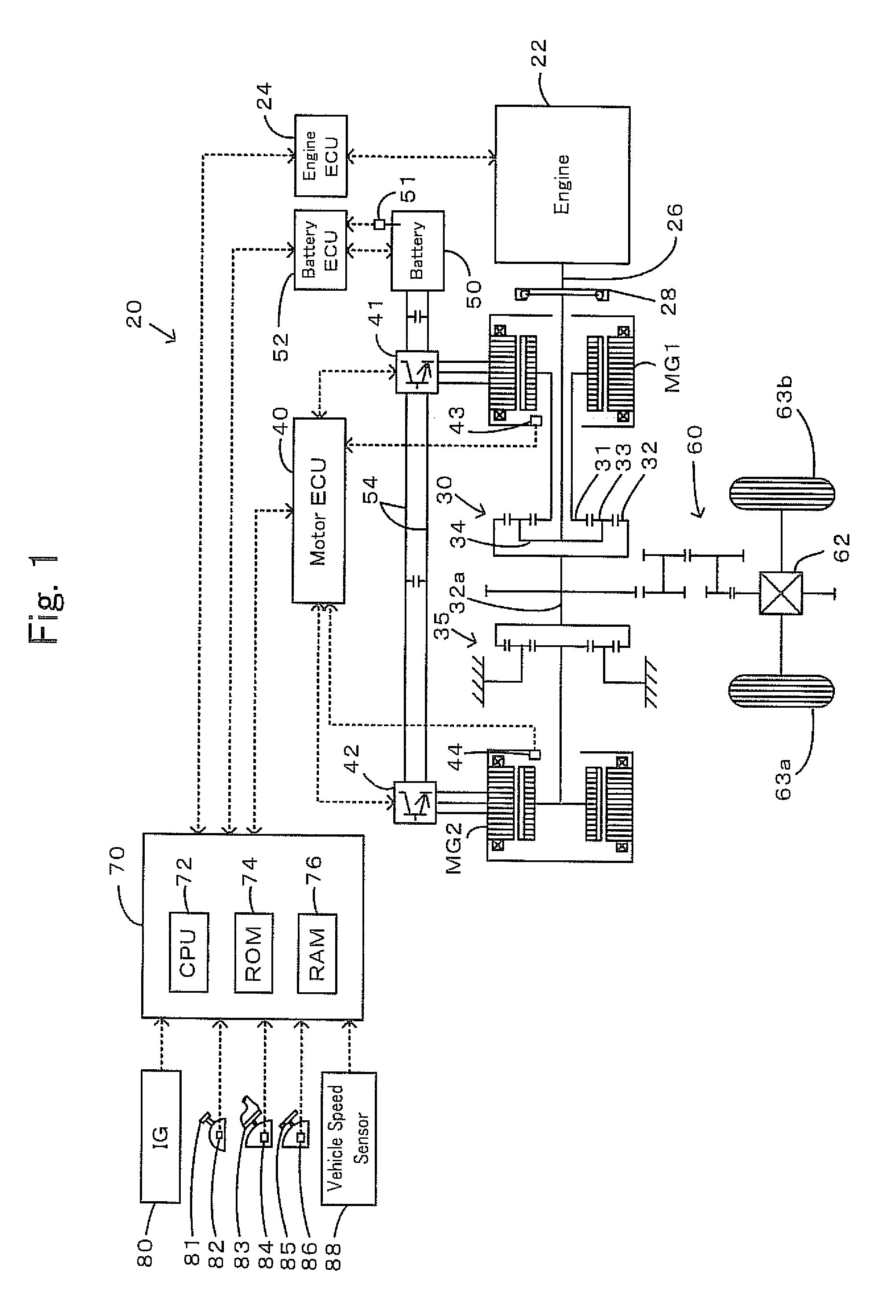

Hybrid vehicle and control method thereof

InactiveUS20100204864A1Avoid emissionsAvoid exhaust emissionsHybrid vehiclesExhaust apparatusHybrid vehiclePower demand

When the catalyst warm-up is not completed and the driving power Pdrv is larger than the battery output allowable power (k·Wout), the power demand Pe* to be output from the engine 22 is set as a power obtained by subtracting the battery output allowable power from the driving power Pdrv (S130) and the engine 22 and the motors MG1 and MG2 are controlled so that the engine 22 outputs the power demand Pe* and the hybrid vehicle 20 is driven with the driving power Pdrv (S160, S190 through S230). This arrangement enables the hybrid vehicle 20 to be driven with output of the driving power Pdrv while preventing more the emission of exhaust from becoming worse, in comparison to the case where the power demand Pe* is set as the driving power Pdrv and the control is performed.

Owner:TOYOTA JIDOSHA KK

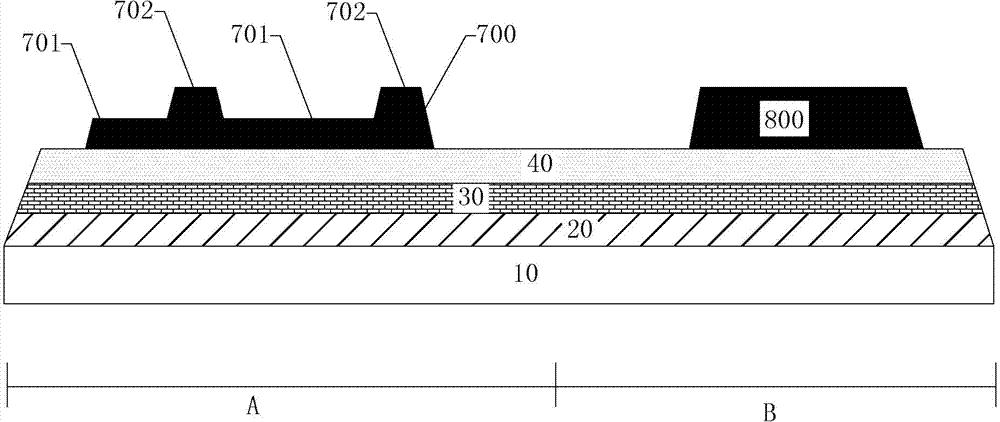

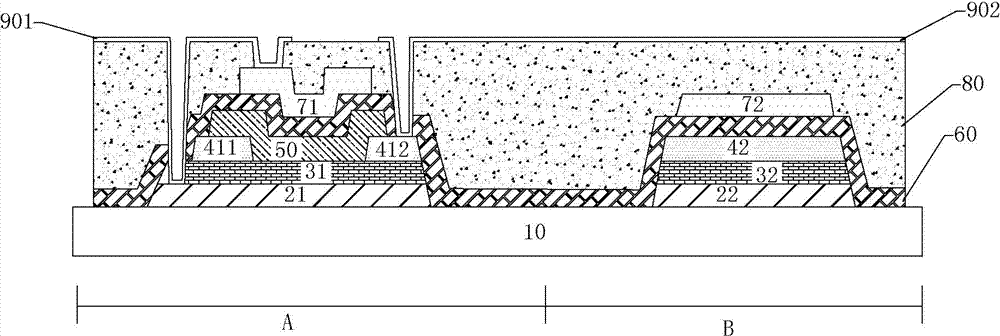

Array substrate preparation method, array substrate, and organic light-emitting display device

ActiveCN104716091ASimple manufacturing processLow costSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceDisplay device

The invention discloses an array substrate preparation method, an array substrate, and an organic light-emitting display device. The preparation method comprises the following steps: (1) sequentially forming a first metal layer, a first insulating material layer and a second metal layer, which cover a thin-film transistor region and a capacitor device region, on a substrate; and (2) etching the second metal layer, the first insulating material layer and the first metal layer with photoresist and a half-tone mask on the second metal layer, forming a source and a drain which are separated, a gate insulating layer and a bottom gate in the thin-film transistor region, and forming a second electrode, a first dielectric layer and a first electrode in the capacitor device region. Thus, the source, the drain, the gate insulating layer and the bottom gate of the thin-film transistor can be etched by one half-tone mask, the second electrode, the first dielectric layer and the first electrode of the capacitor device are formed at the same time, and the process is simplified. The array substrate of the invention has a dual-gate thin-film transistor and a capacitor device connected in parallel with two capacitors. The capacitor capacity is improved on the basis of increasing the driving force.

Owner:CHENGDU VISTAR OPTEOLECTRONICS CO LTD

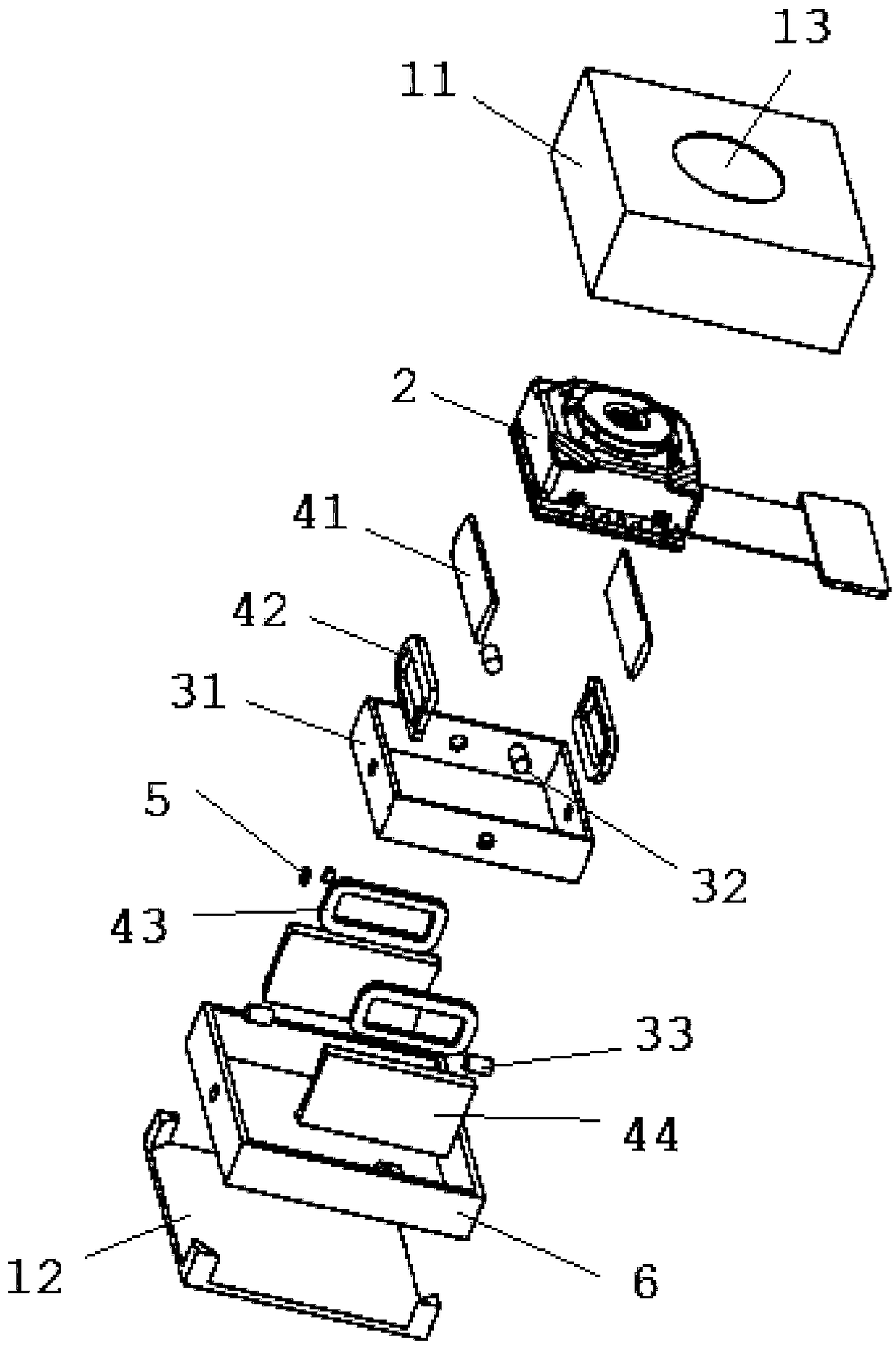

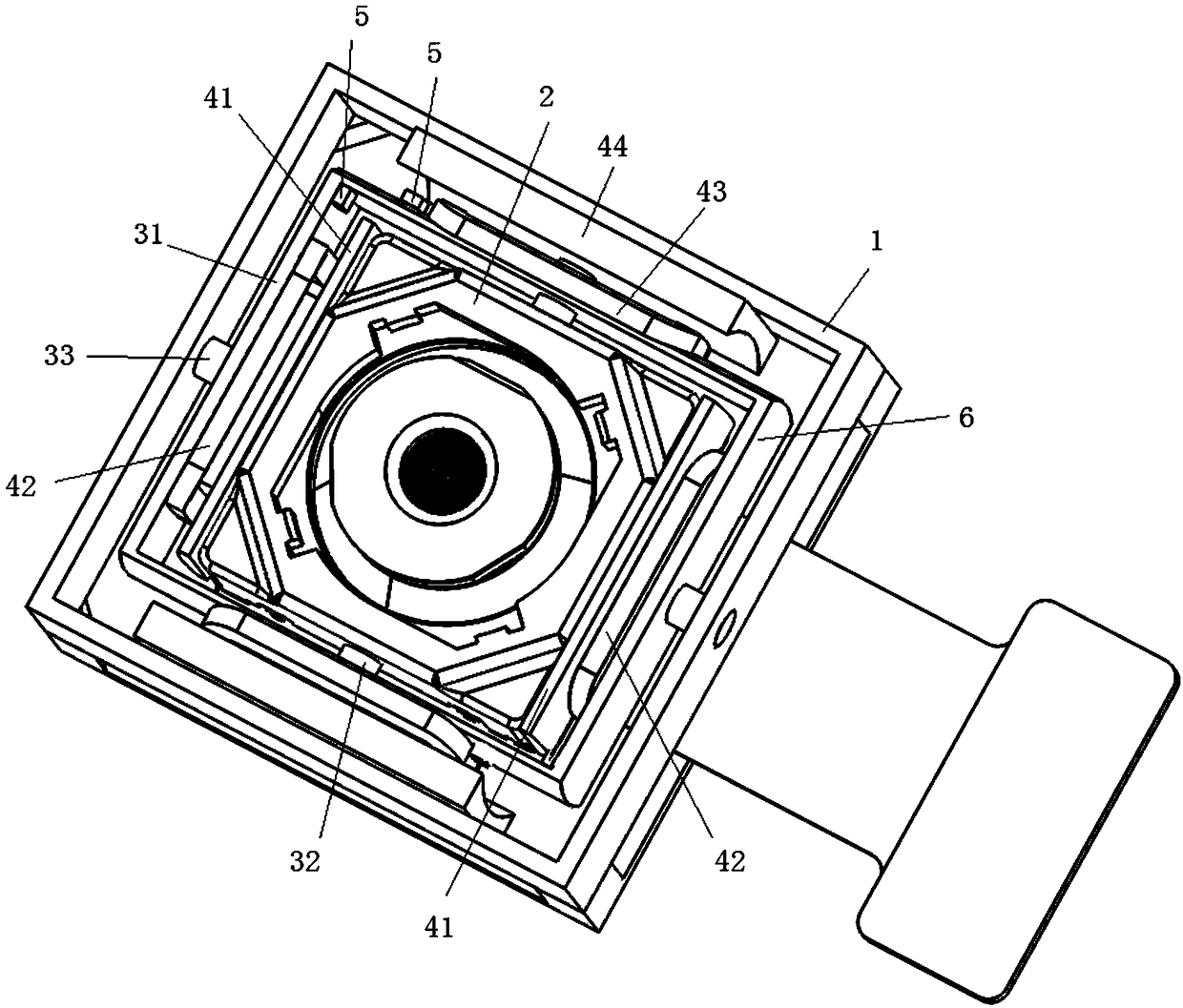

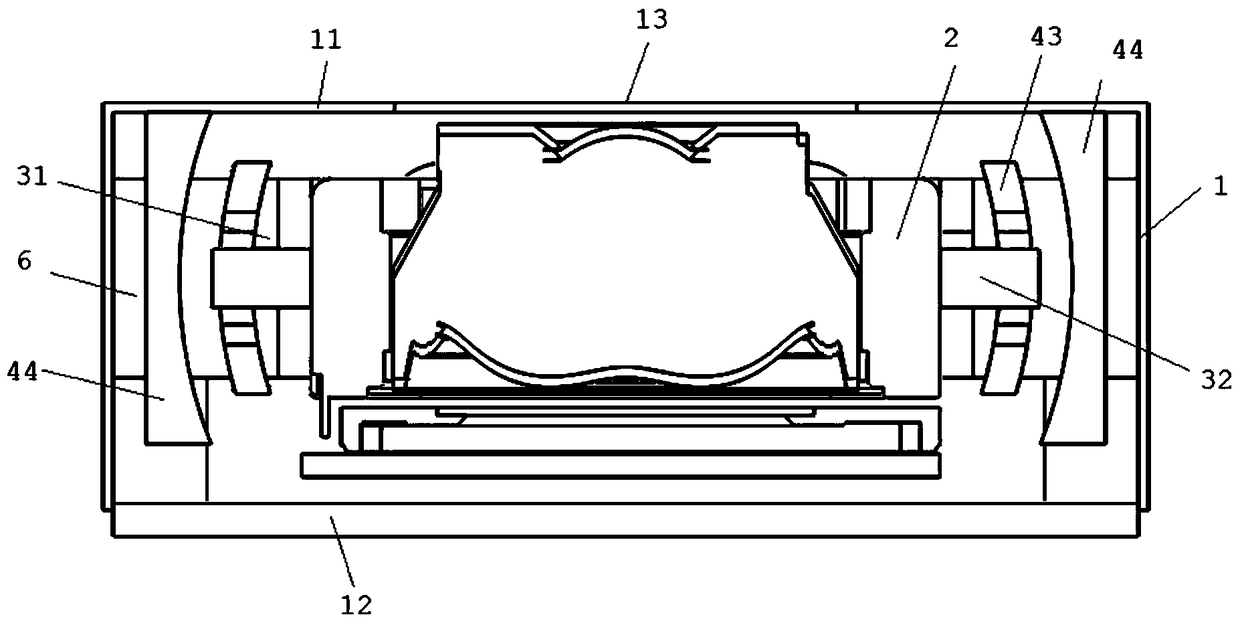

Driving structure and optical anti-shake camera

PendingCN109413316AEven by forceDeflection movement stabilizationTelevision system detailsColor television detailsCamera lensImage sensor

The invention relates to the technical field of camera driving devices, in particular to a driving structure and an optical anti-shake camera. The driving structure comprises a base body, a module body, a module driving component, a deflection component and an anti-shake driving component, wherein the module body is disposed in the base body, and has a fixedly disposed image sensor and a lens moveably disposed relative to the image sensor along an optical axis direction therein; the module driving component is disposed in the module body and connected to the lens, and drives the lens to move toward or away from the image sensor; the deflection component is installed in the base body relative to the movement of the base body, and provided with the module body; and the anti-shake driving component is disposed in the base body, and coupled to the module body for driving the module body to deflect relative to the optical axis. The optical anti-shake camera with the driving structure provided by the invention is higher in imaging quality.

Owner:DONGGUAN PRECISION PHOTONICS LTD

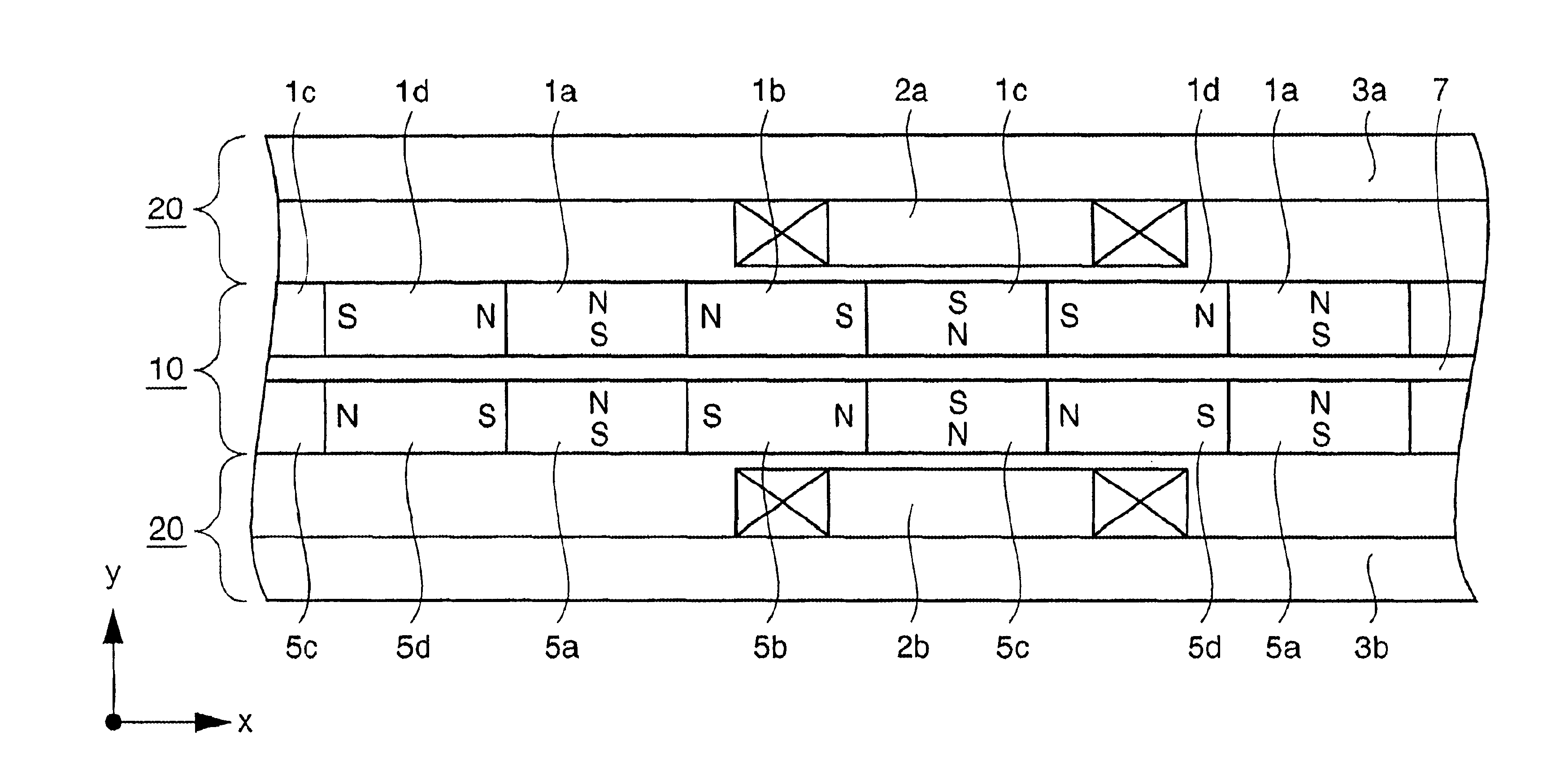

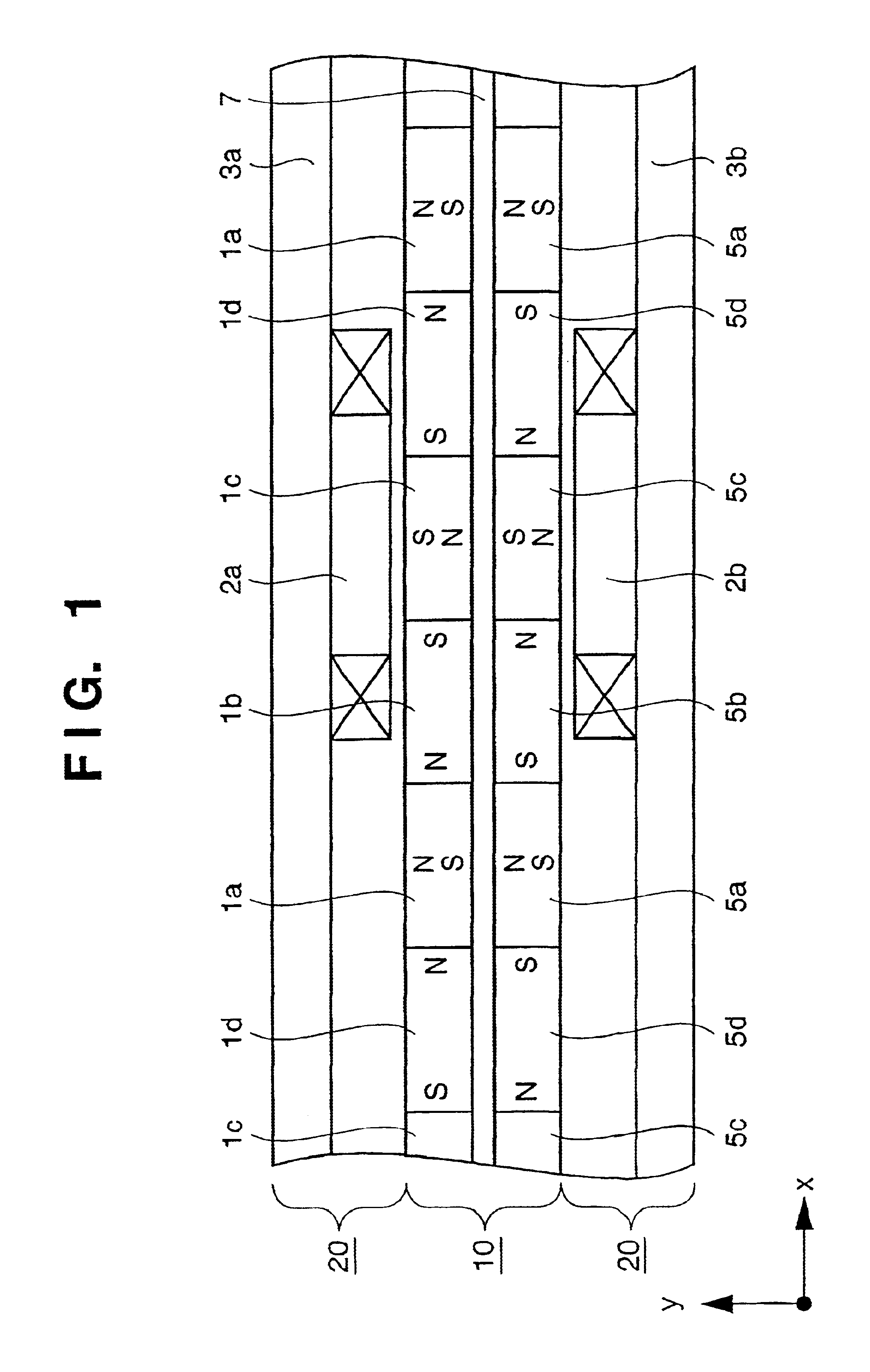

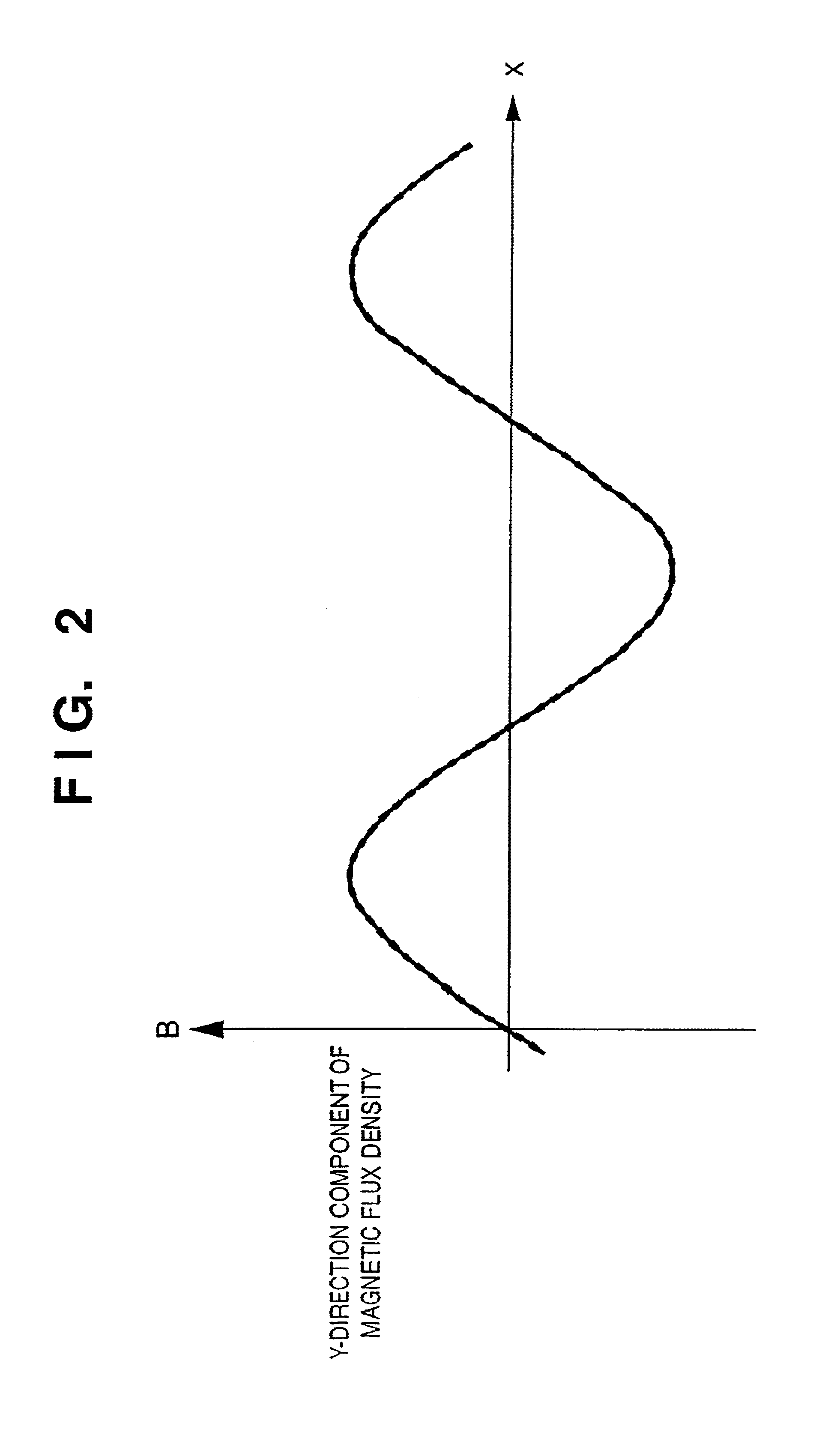

Linear motor and stage apparatus, exposure apparatus, and device manufacturing method using the same

InactiveUS6870284B2Improve driving effectLittle changeSemiconductor/solid-state device manufacturingInstrumental componentsEngineeringLinear motor

A linear motor includes a magnet array having a plurality of first magnets arrayed such that polarization directions thereof are periodically opposite, and a plurality of second magnets arrayed such that polarization directions thereof are periodically opposite and intersect those of the first magnets. The linear motor further includes an electromagnetic coil disposed to oppose the magnet array to generate a Lorentz force in cooperation with the magnet array and a yoke integrated with the coil at a first side opposite to a second side of the coil disposed opposite to the magnet array.

Owner:CANON KK

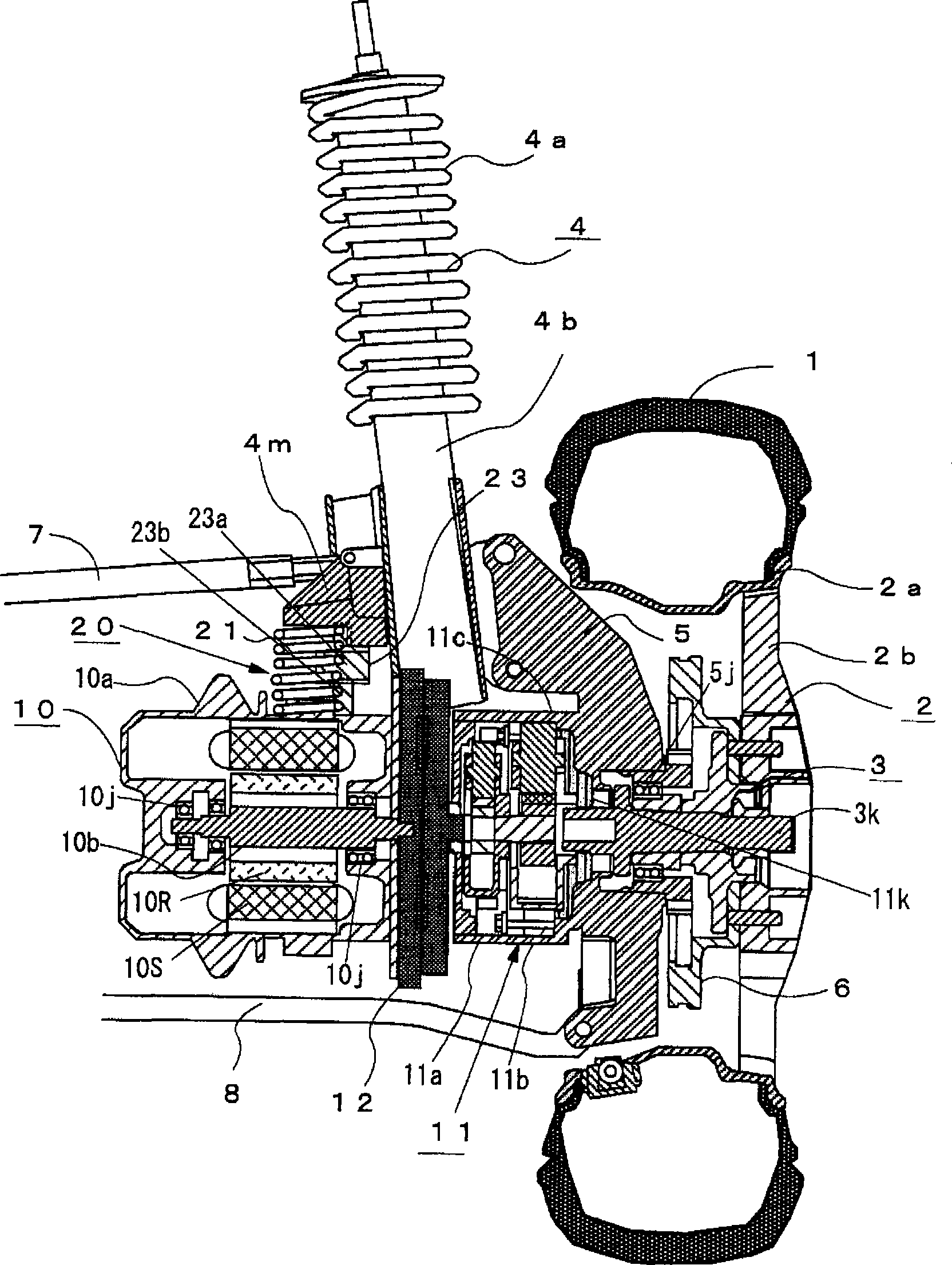

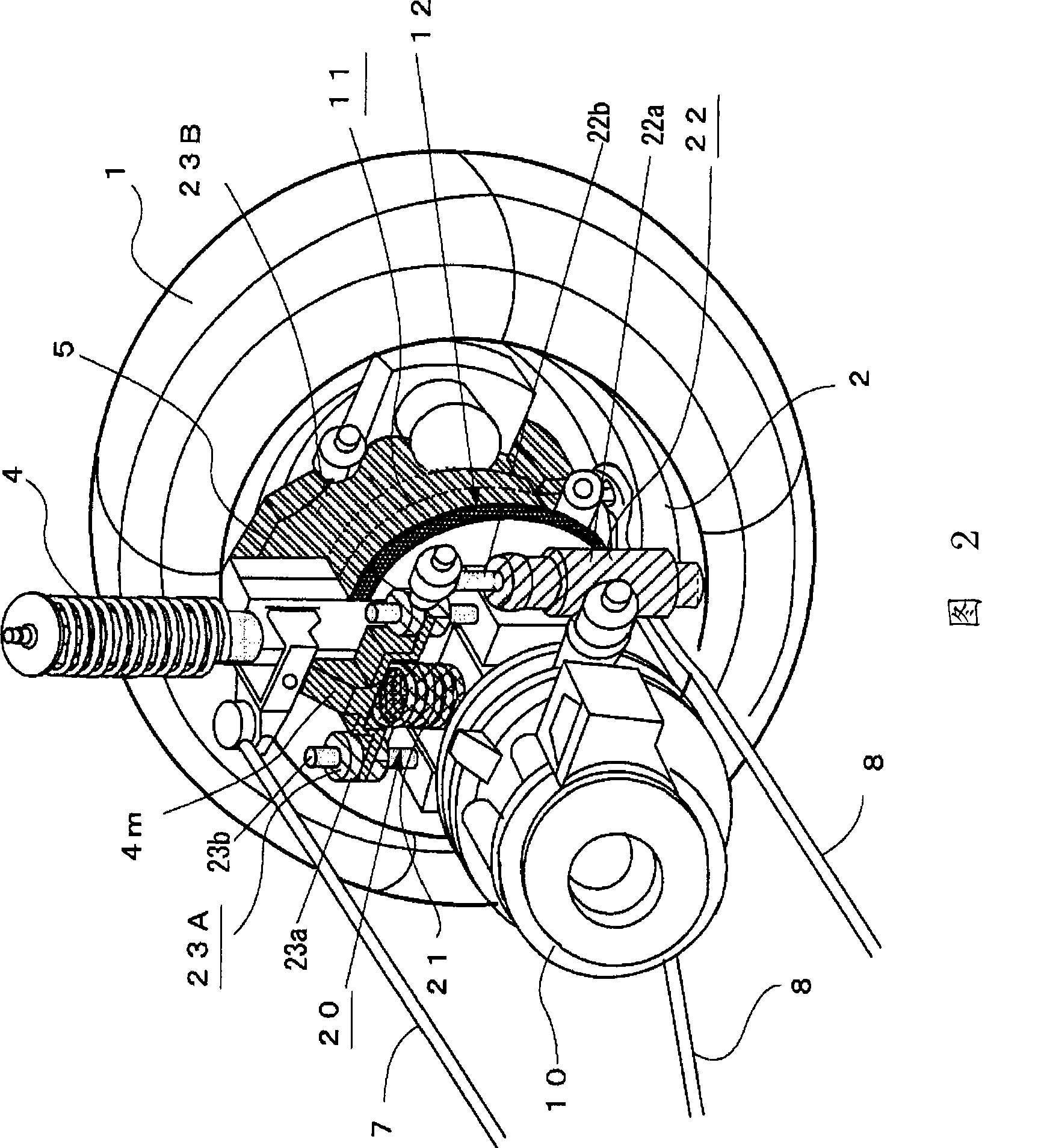

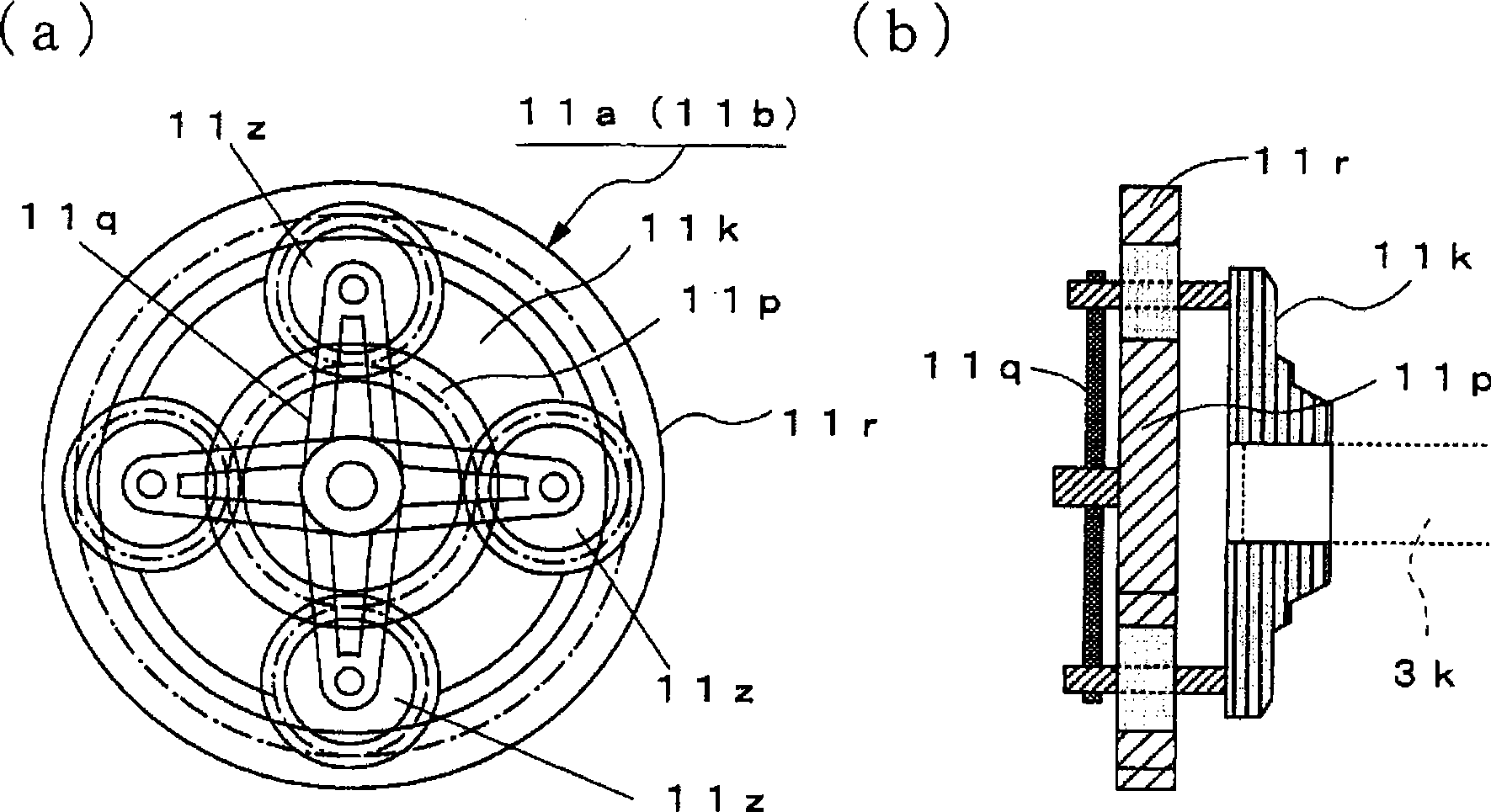

In-wheel motor system

InactiveCN101370678AGood grounding effectImprove durabilitySpeed controllerElectric devicesGround contactCoupling

An electric motor (10) and a speed reduction gear mechanism (11) are coupled by a flexible coupling (12) that is a power transmission mechanism such as an Oldham's coupling. A casing (11c) of the speed reduction gear mechanism (11) is formed integrally with a knuckle (5) as a component of vehicle's unsprung portion, or alternatively, is attached to the knuckle (5). Further, a motor case (10a) of the electric motor (10) is attached to a motor installation member (4m) via a shock absorbing mechanism (20), the motor installation member (4m) being provided on the lower side of a strut (4) for supporting the knuckle (5). The shock absorbing mechanism (20) has a spring member (21), a damper, and two guide members (23) for guiding the direction of operation of the spring member (21) and the damper. The construction allows the mass of the motor (10) to act as the mass of a dynamic damper. An in-wheel motor system thus obtained improves ground contact performance and ride quality of a vehicle traveling on a bad road and has good space efficiency.

Owner:BRIDGESTONE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com