Compliant passive gripper drawn by pneumatic ropes and provided with bent plate spring skeleton

A technology for bending plates and grippers, applied in the field of flexible passive grippers, can solve the problems of insufficient plate spring stiffness, limited pressure resistance of bellows, limited object weight, etc., so as to reduce the working time of grasping and improve flexibility. Self-adaptive, simple and reliable control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

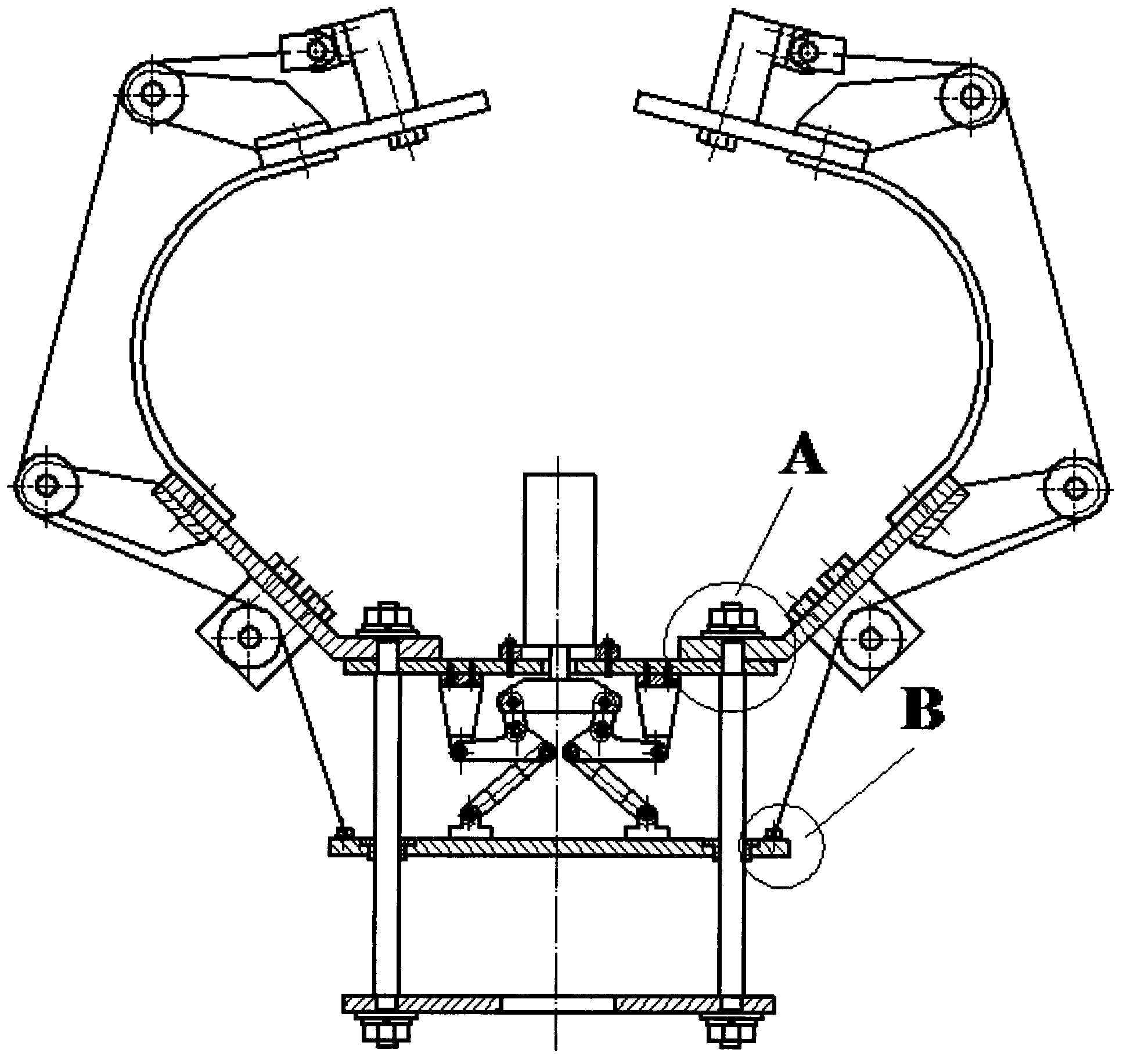

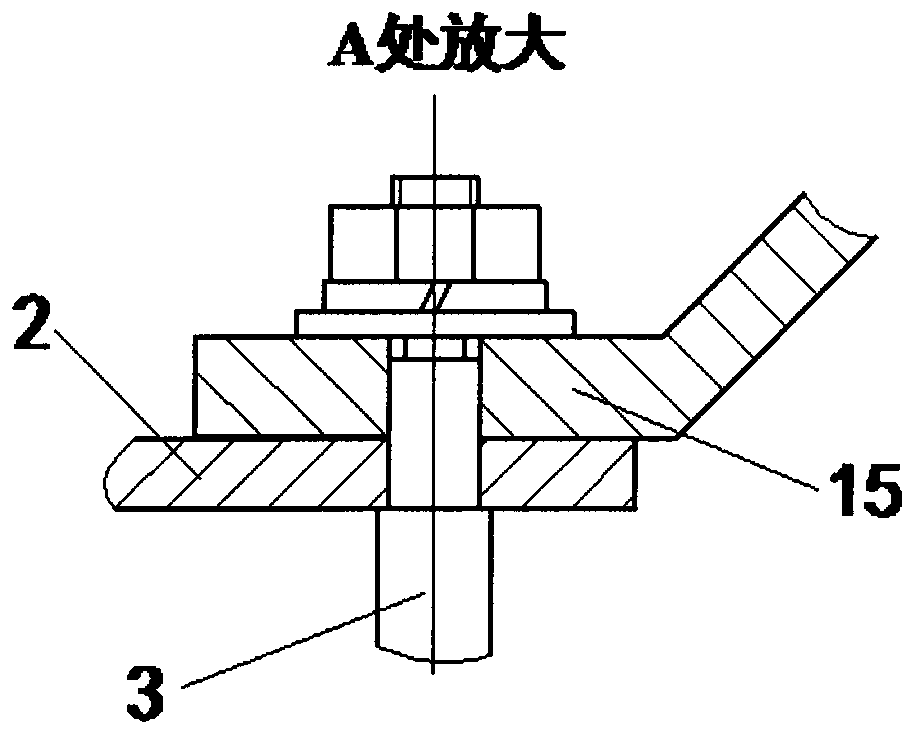

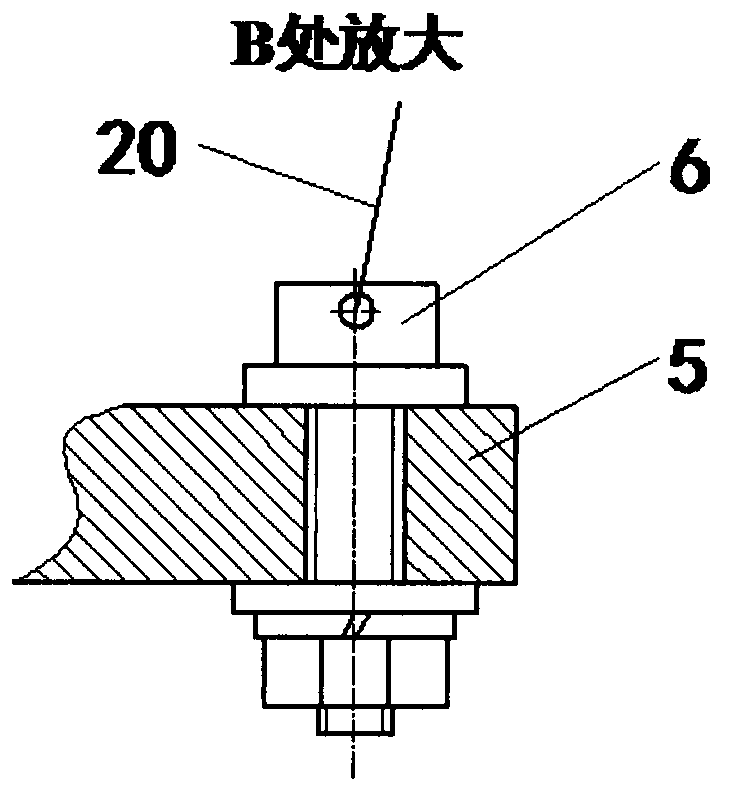

[0022] The flexible pneumatic rope traction bending plate spring frame passive gripper of the present invention consists of a double-acting cylinder 1, an upper plate 2, a guide post 3, a guide sleeve 4, a sliding plate 5, a traction rope fixing seat 6, a lower plate 7, and a front support 8. Cylindrical pin 9, front toggle lever 10, rear toggle lever 11, crosshead 12, connecting rod 13, rear support 14, finger tail joint 15, guide wheel seat 16, guide wheel 17, guide wheel bracket 18, curved plate Spring skeleton 19, traction rope 20, finger joint 21, small hinge 22, small hinge bearing 23, guide groove seat 24 constitute. Among them, parts 1-14 constitute the cylinder-driven five-hinge oblique row double toggle power-increasing mechanism components of the gripper, parts 15-24 constitute the curved plate spring skeleton finger parts of the gripper, and the holes on the lower plate 7 are used for Position and fix this gripper on the robotic arm.

[0023] Below is the working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com