Patents

Literature

154results about How to "Reduce control precision requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compliant passive gripper drawn by pneumatic ropes and provided with bent plate spring skeleton

ActiveCN102689309AIncreasing the thicknessIncrease stiffnessGripping headsEngineeringInjection molding machine

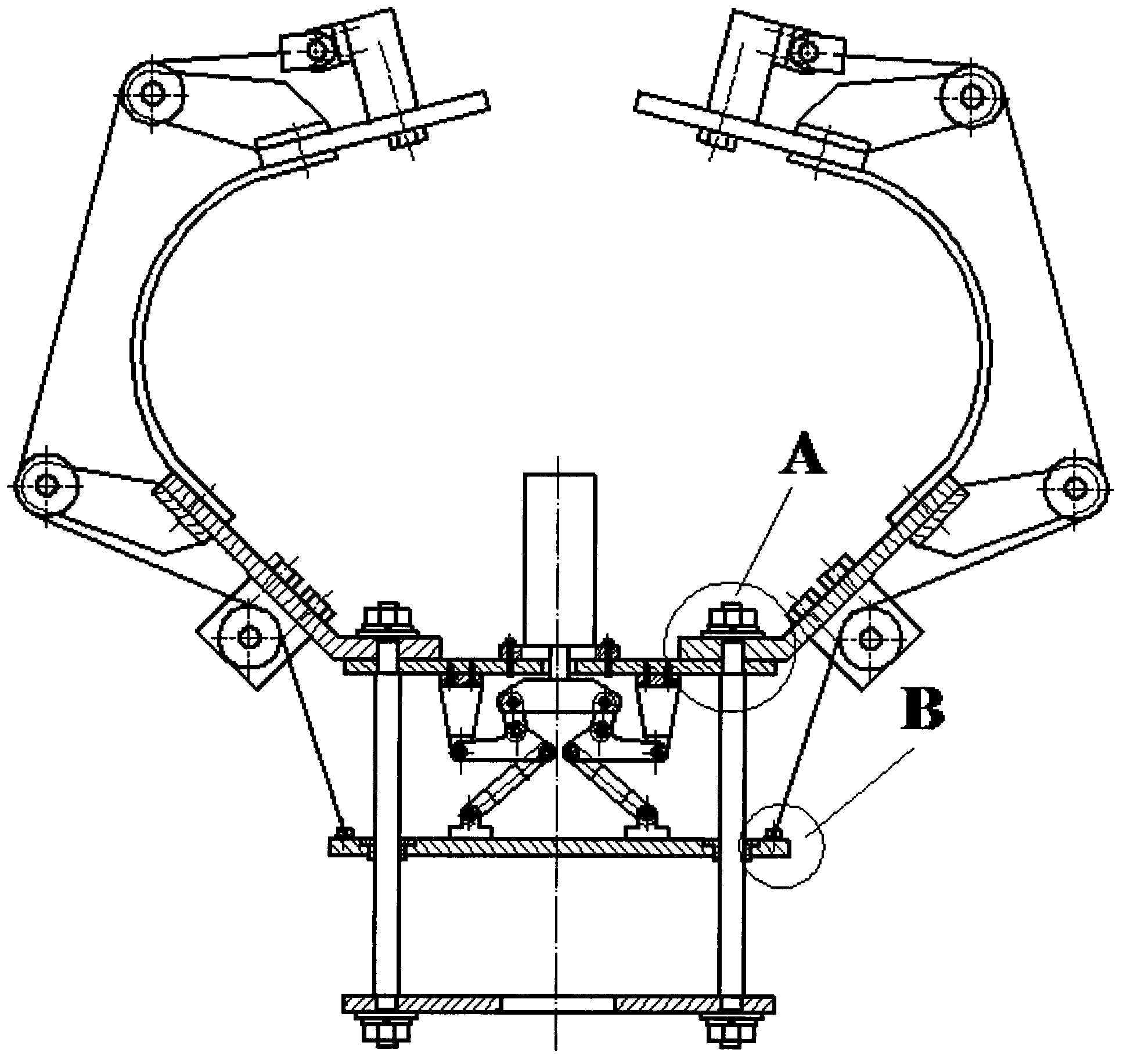

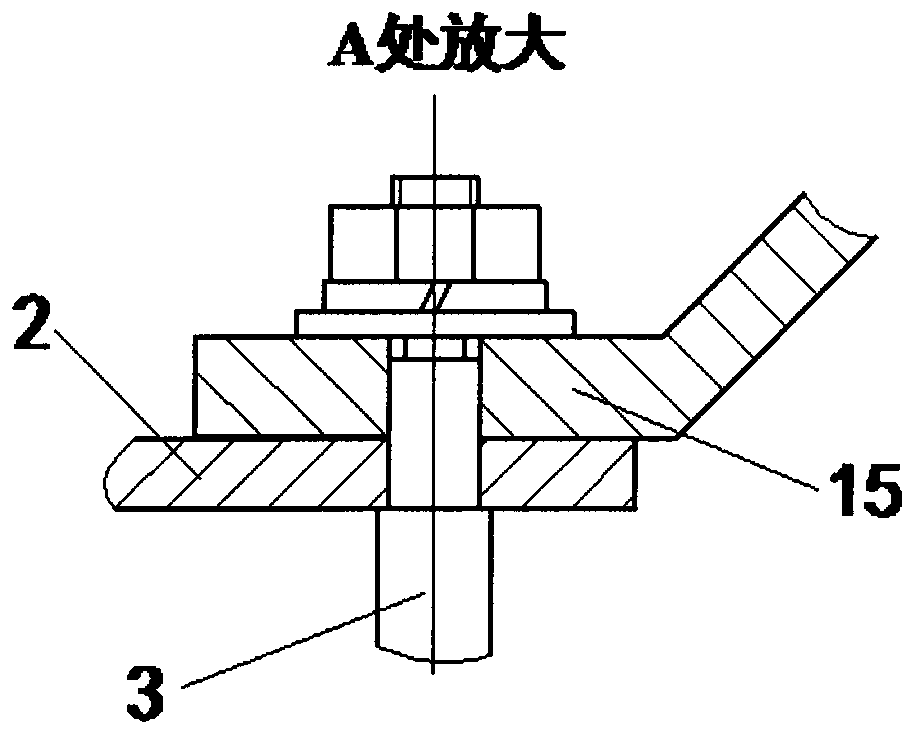

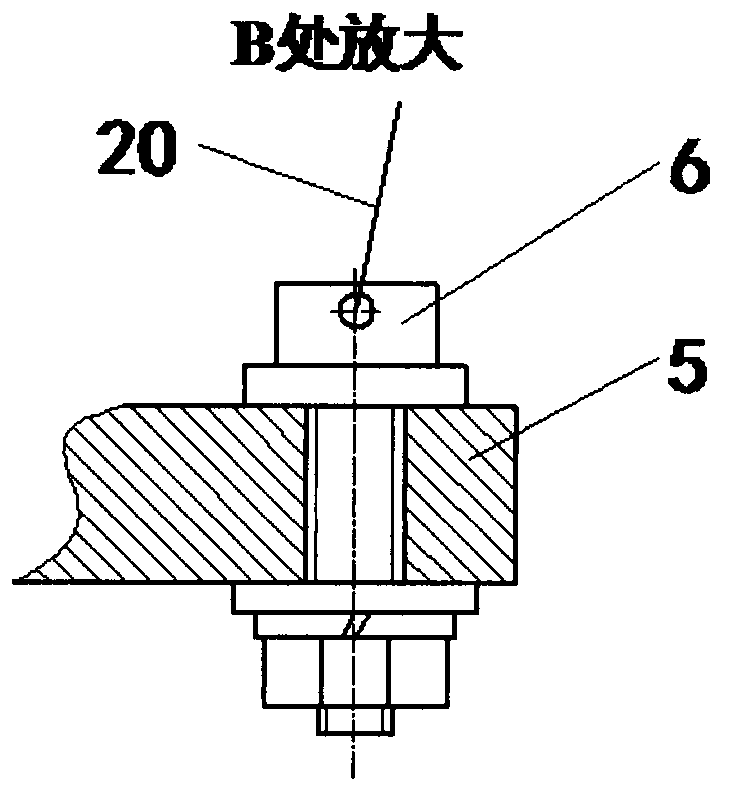

The invention relates to a compliant passive gripper drawn by pneumatic ropes and provided with bent plate spring skeletons. The gripper is provided with two fingers which take bent plate springs as skeletons and grip objects passively through elastic restoring forces of the bent plate spring skeletons; the two fingers are driven by a cylinder; the acting force of the cylinder is increased through a five-hinge skewed double-elbow reinforcement mechanism which is frequently used on an injection machine so as to drive drawing ropes of the fingers, overcome deformation resistance of the bent plate springs and open the passive gripper; and the opening degree of the gripper can be controlled by controlling the pressure of the cylinder. The gripper has the advantages of large driving force, wide applicable range, simple structure, less controlled objects, convenience in maintenance and low requirements on using environment, has the characteristics of flexibility in degree of freedom and resiliency in acting force, has good flexibility in adaptivity, can grip objects with varying shapes and sizes, and belongs to the technical field of application of robots and mechatronics.

Owner:兴化市聚鑫不锈钢有限公司

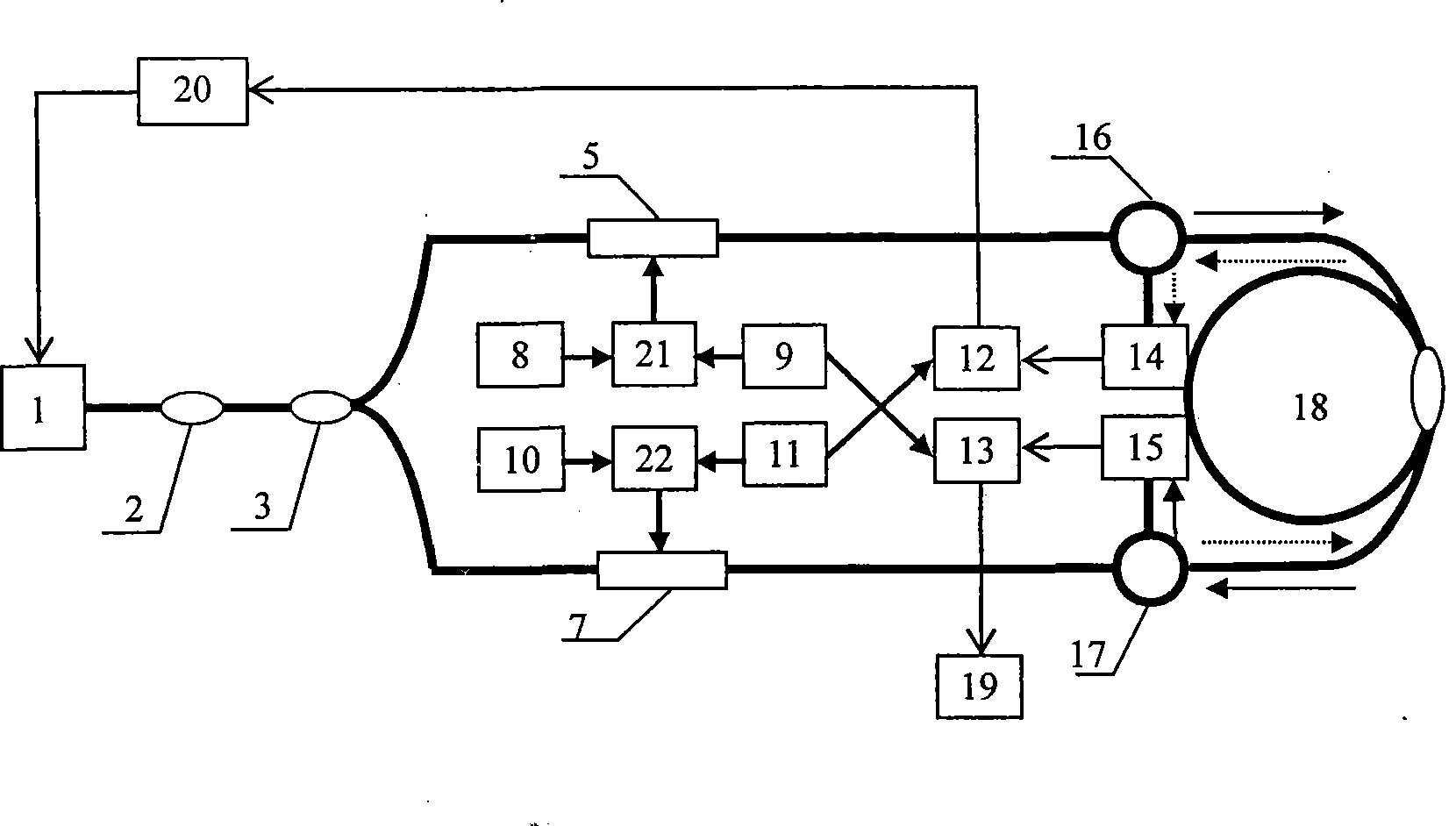

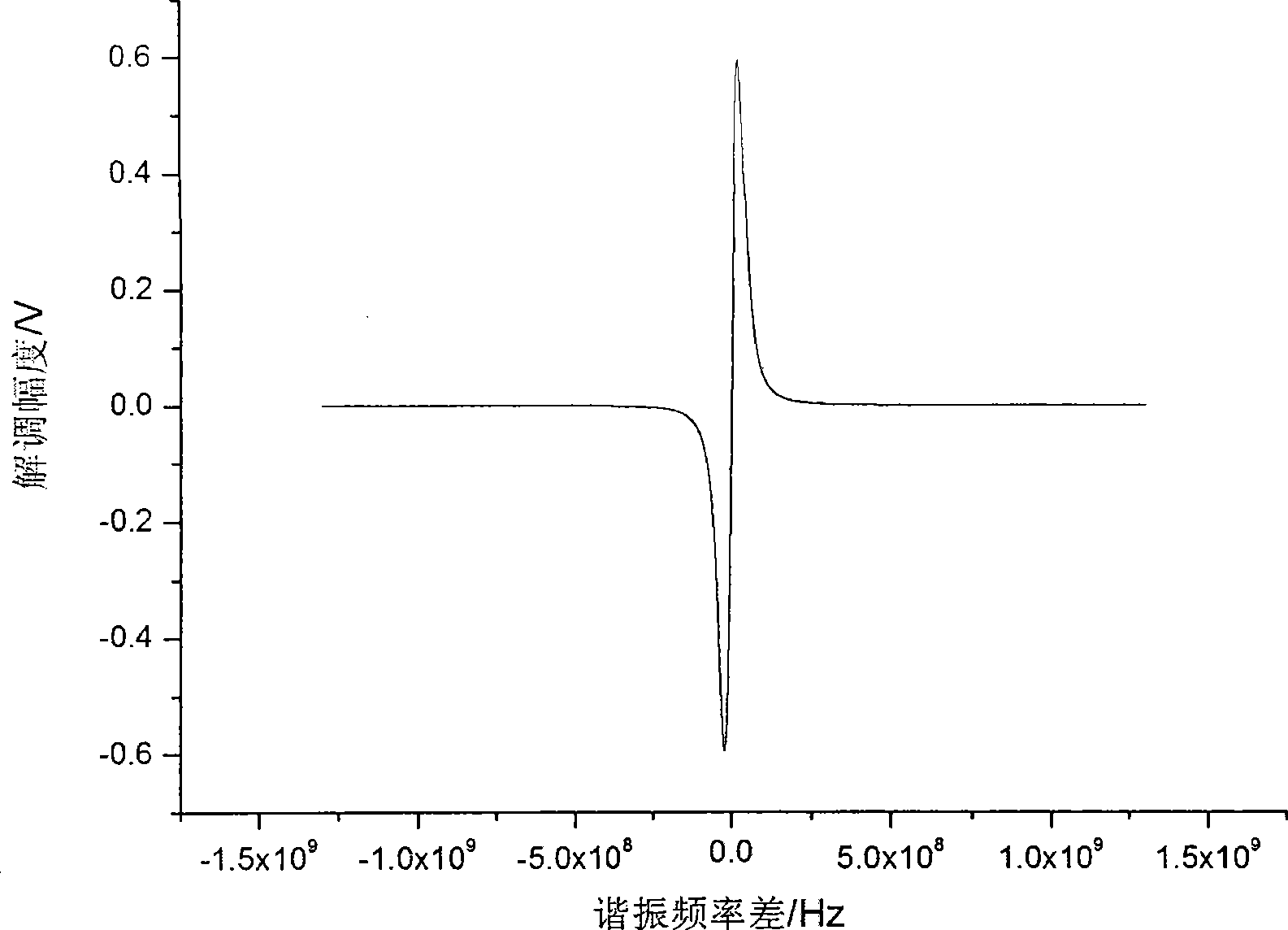

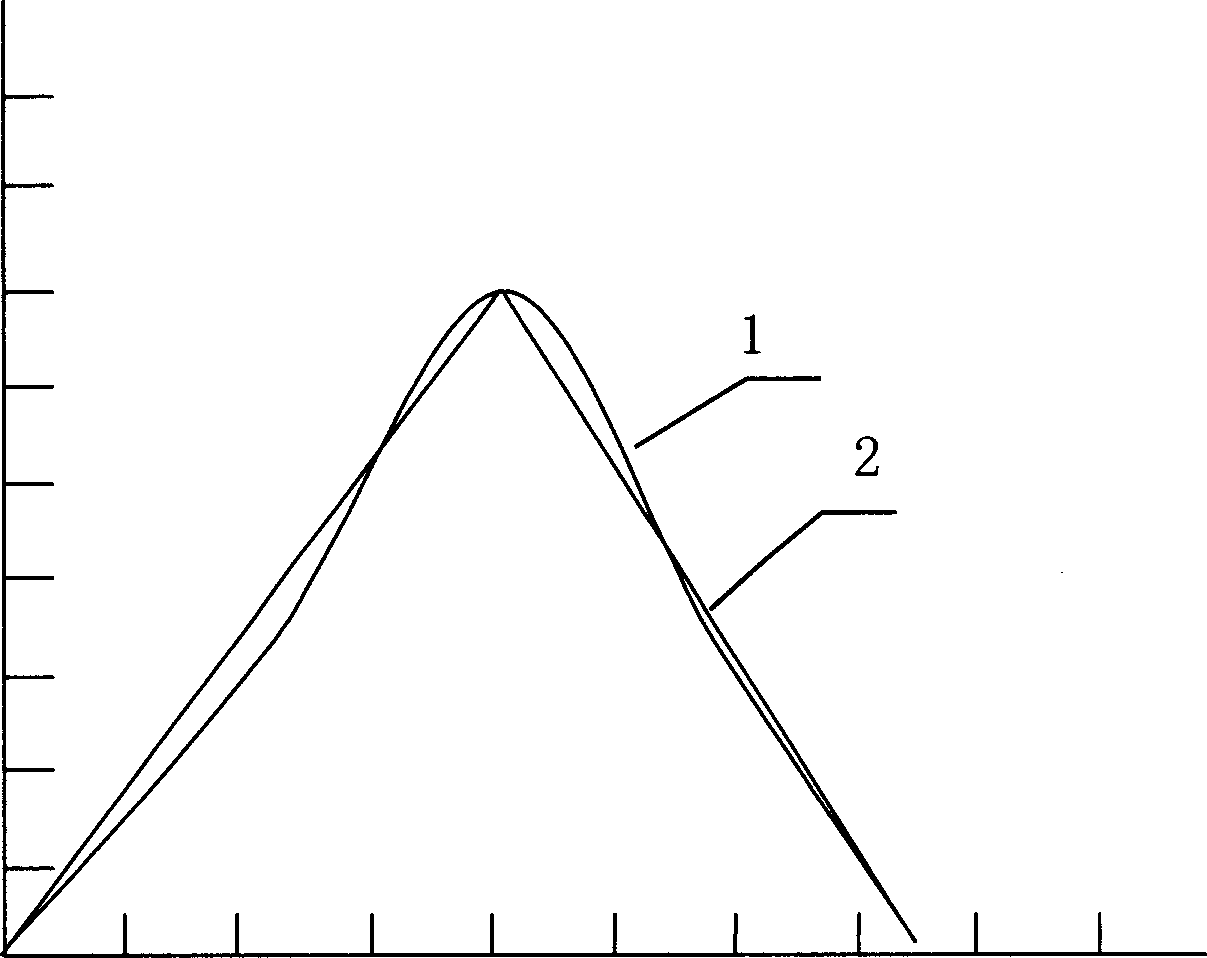

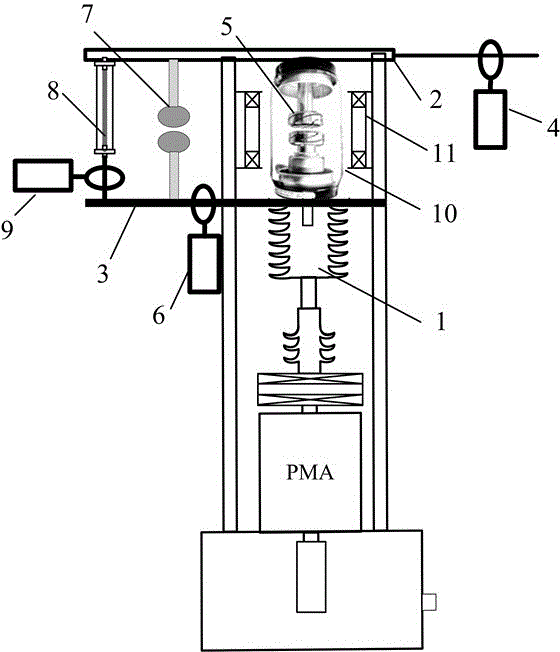

Detection apparatus and method for miniature resonance type optical gyroscope with double-signal combined modulation

InactiveCN101464151AEasy to implementMiniaturizationSagnac effect gyrometersResonant cavityOptical gyroscope

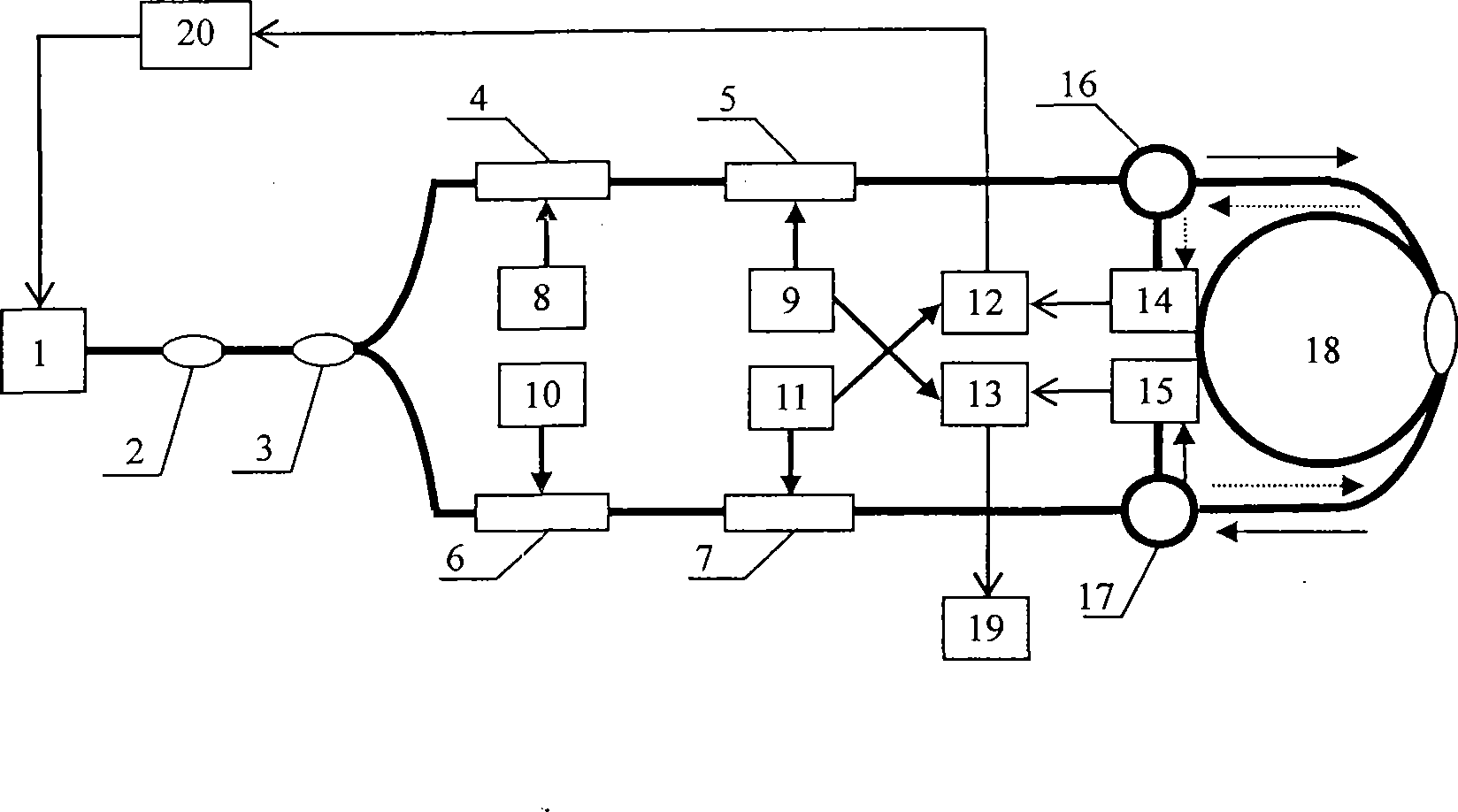

The invention discloses a device and a method for detecting a micro resonant mode optical gyro in dual-signal combined modulation. The method comprises the following steps: firstly, carrying out the dual-signal combined modulation to a laser input into the chip of a micro optical ring-shaped resonant cavity, and synchronously demodulating the clockwise and counterclockwise output signals of the optical ring-shaped resonant cavity, wherein, one demodulated signal controls the frequency of a laser device through a servo loop, so that the frequency of the output light of the laser device can be tracked and locked on the resonant frequency; and the other demodulated signal extracts the difference of the two resonant frequencies and outputs the difference as a gyro signal. The invention is favorable for realizing the micro resonant mode optical gyro in an integrated optical device and the miniaturization of the system, improves the output signal-to-noise ratio of the micro resonant mode optical gyro, suppresses the noise caused by backscattering, and reduces the control precision in modulation amplitude required by the system and improves the stability of the system at the same time.

Owner:ZHEJIANG UNIV

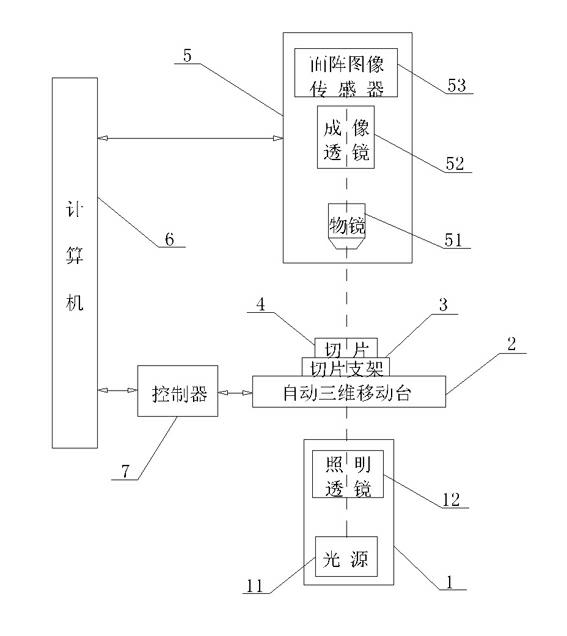

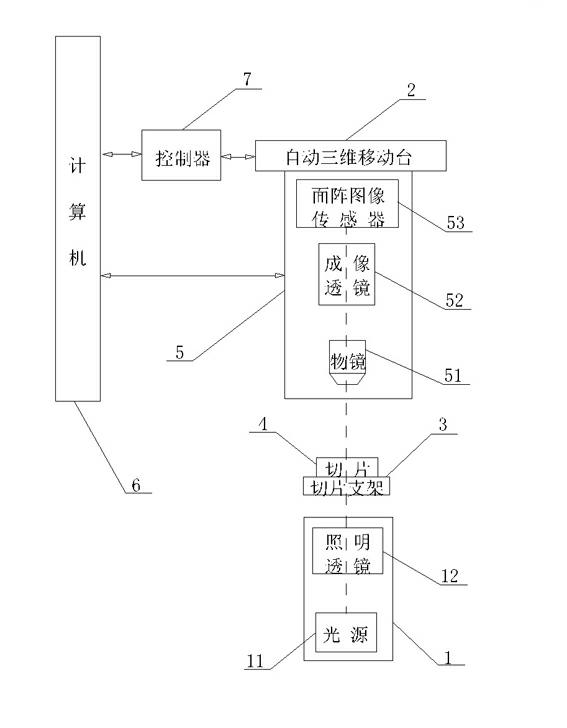

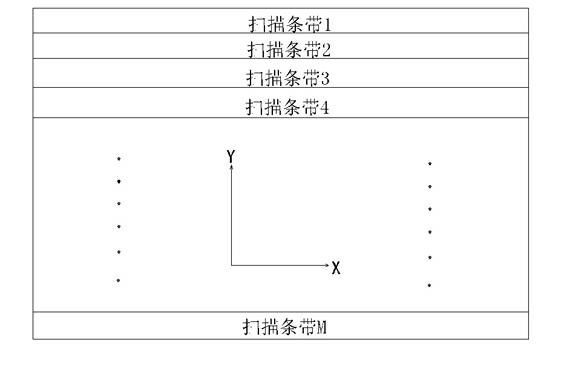

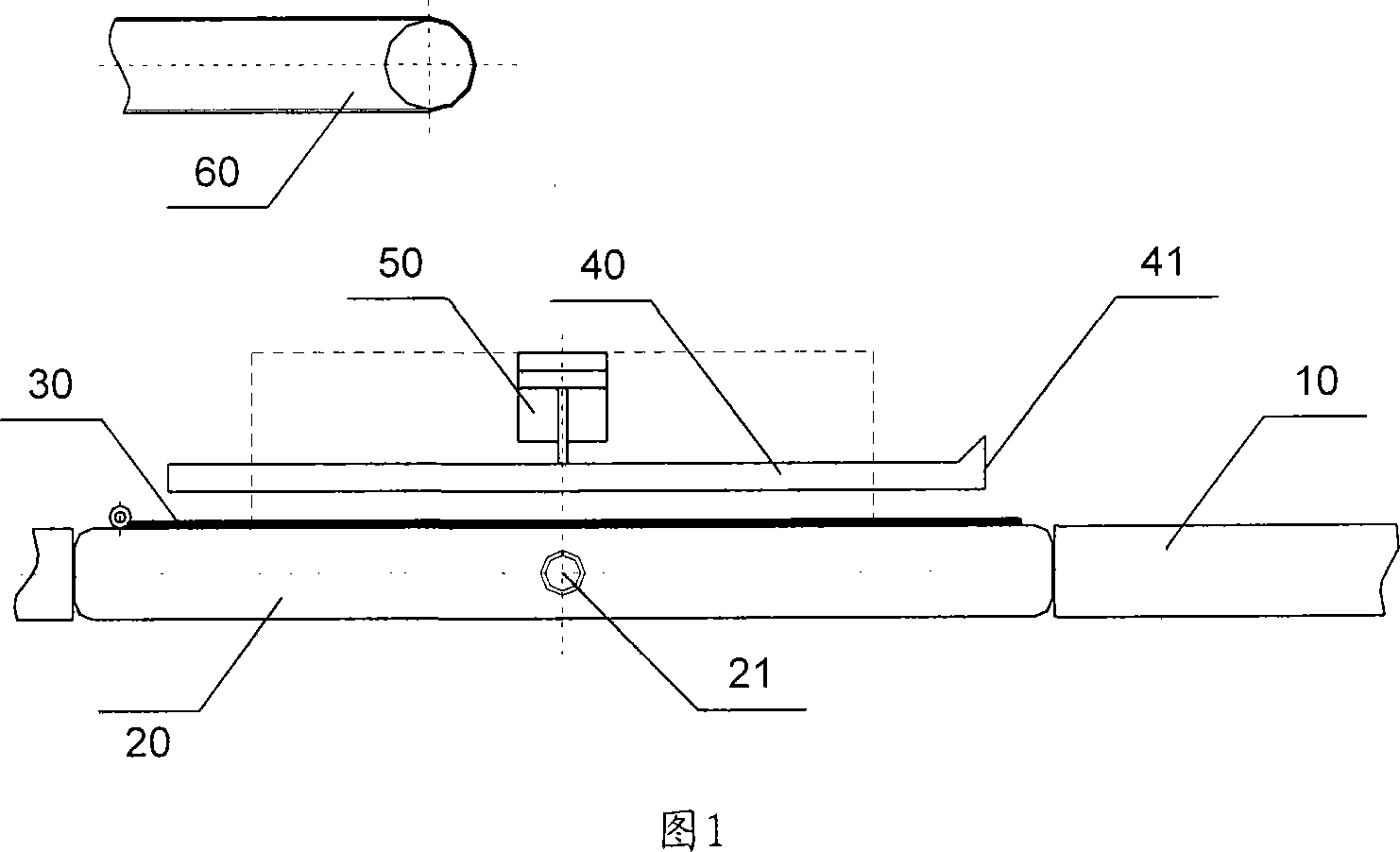

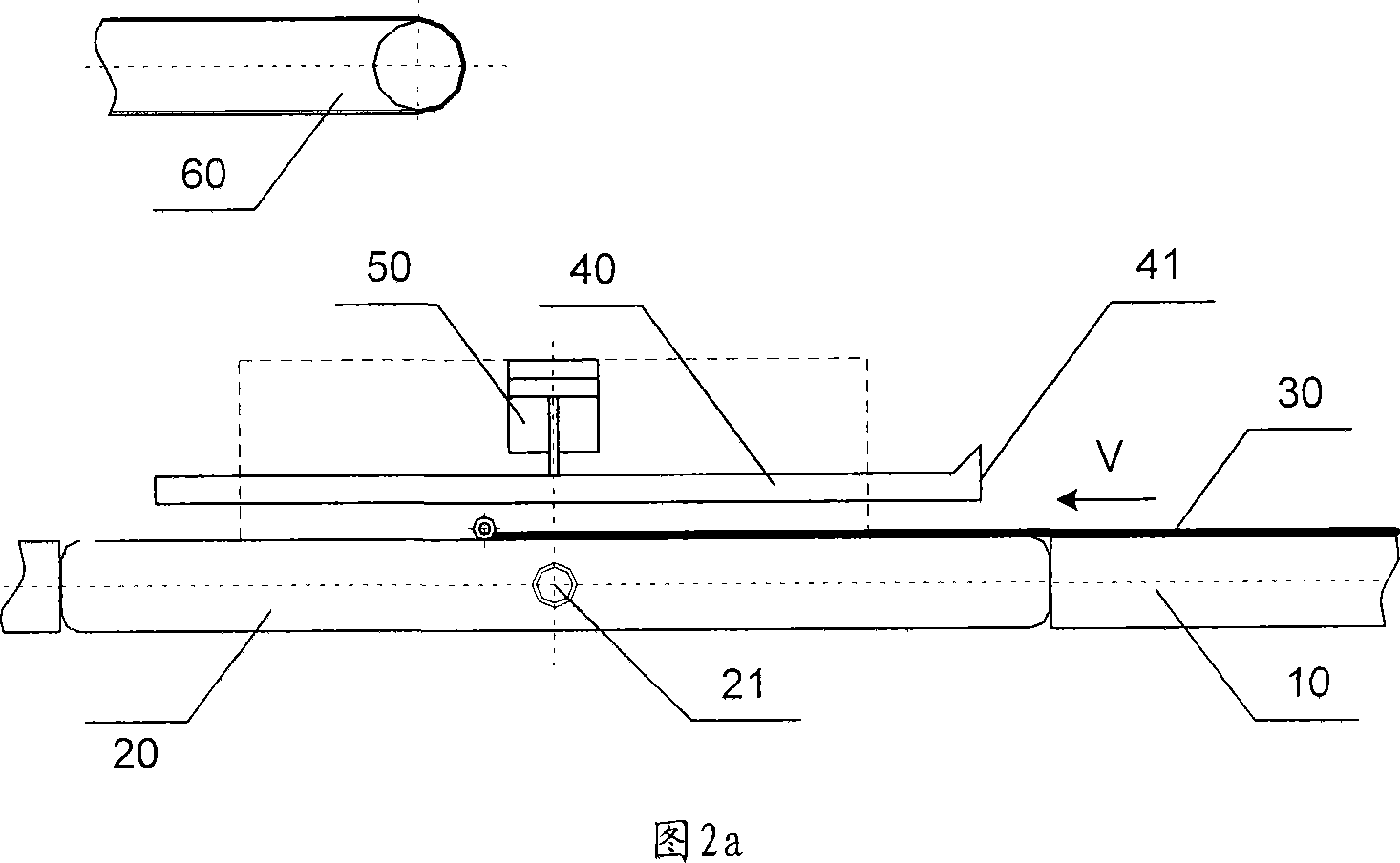

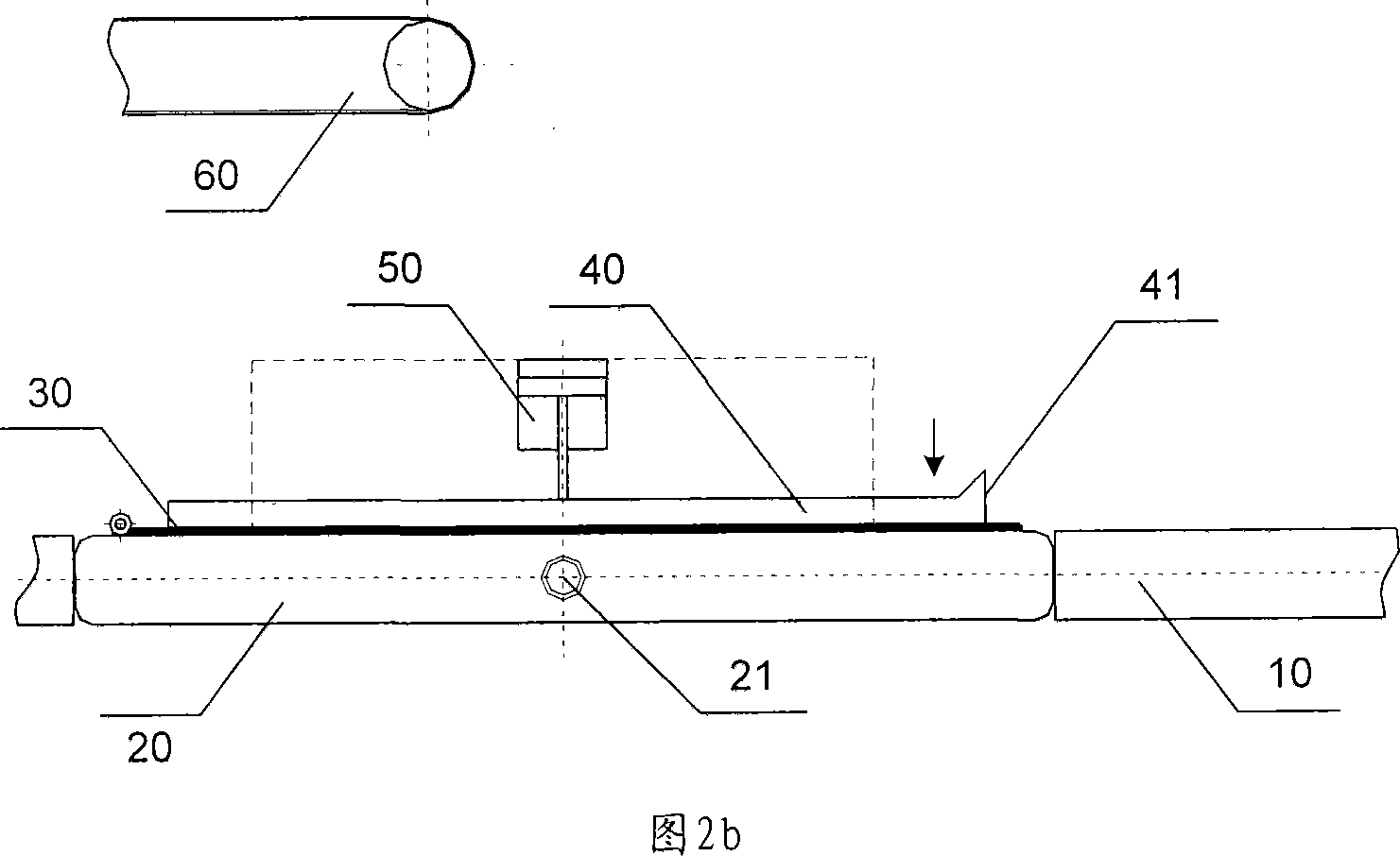

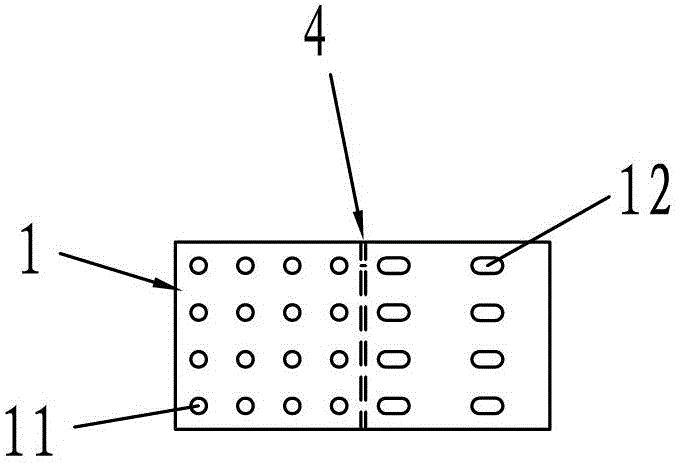

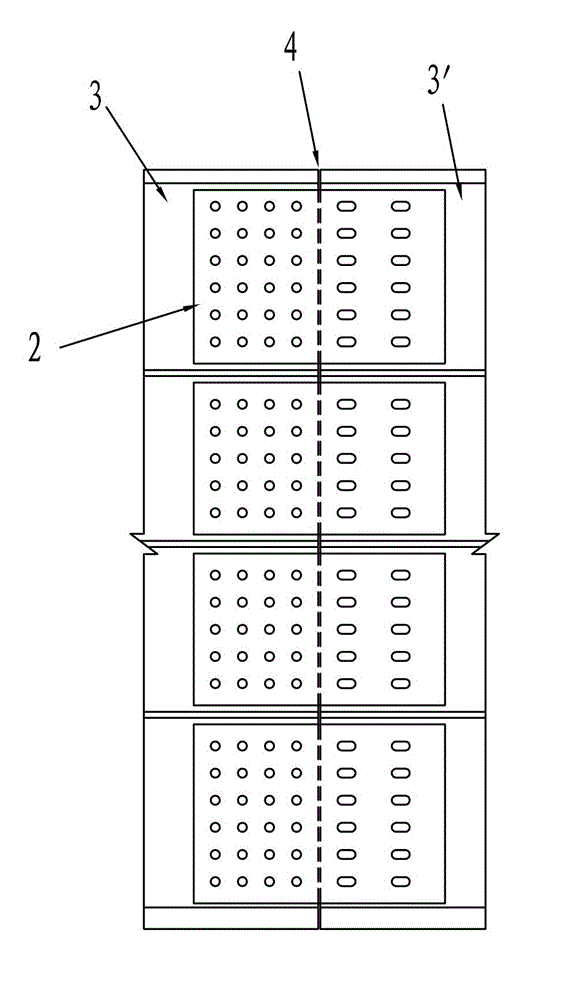

Scanning method and device for microscopic section

ActiveCN102427502AFast scanningReduce control precision requirementsMicroscopesPictoral communicationImage sensorLight source

The invention relates to a scanning method and device for microscopic sections; the scanning device comprises a computer, an automatic three-dimensional moving platform, a light source, section support frame and an imaging system, wherein the light source, the section support frame and the imaging system are sequentially and coaxially arranged; the automatic three-dimensional moving platform is connected with the section support frame or the imaging system and is controlled by a controller to drive the sections or the imaging system to move in a three-dimensional direction; and the controller and the imaging system are respectively and electrically connected with the computer. The scanning method comprises the following steps of; (1) dividing the sections to be measured along longitudinal and transverse directions; (b) leading the sections to continuously pass through an object field of the imaging system; (c) exposing the imaging system; (d) collecting image data; (4) storing data; (f) judging whether the scanning of a current scanning band is finished; (g) combining and storing data; and (h) judging whether the scanning of all scanning bands is finished. The scanning method has the advantages: during scanning, the sections continue to move relative to the imaging system in high speed; the requirement for control accuracy is low, thereby the cost is reduced; and a common planar array image sensor is directly used for establishing a focusing model without an additional auxiliary focusing device, thereby more cost is reduced.

Owner:MOTIC CHINA GRP CO LTD

Method for realizing shortcut nitration of high ammonia nitrogen wastewater

ActiveCN102311166AStrong toleranceStrong impact resistanceSustainable biological treatmentBiological water/sewage treatmentSludgeNitration

The invention discloses a method for realizing shortcut nitration of high ammonia nitrogen wastewater. The method comprises the following steps of: culturing nitrosation dominant flora; and performing ammonia sewage treatment by using the flora as an inoculum, namely adding the cultured nitrosation dominant flora into an aeration reactor to treat the ammonia wastewater, wherein the adding amount of the cultured nitrosation dominant flora accords with a condition that: sludge concentration is 800-2,000mg / L after the cultured nitrosation dominant flora is added; and the treatment conditions arethat: the temperature is 18-40DEG C, the dissolved oxygen is 0.1-3mg / L, and the pH is 7- 9. The unique nitrosation dominant flora culture method is adopted, stable and high-efficiency ammonia nitrogen wastewater treatment effect can be achieved, and the problem of instability of the shortcut nitration in actual application is solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

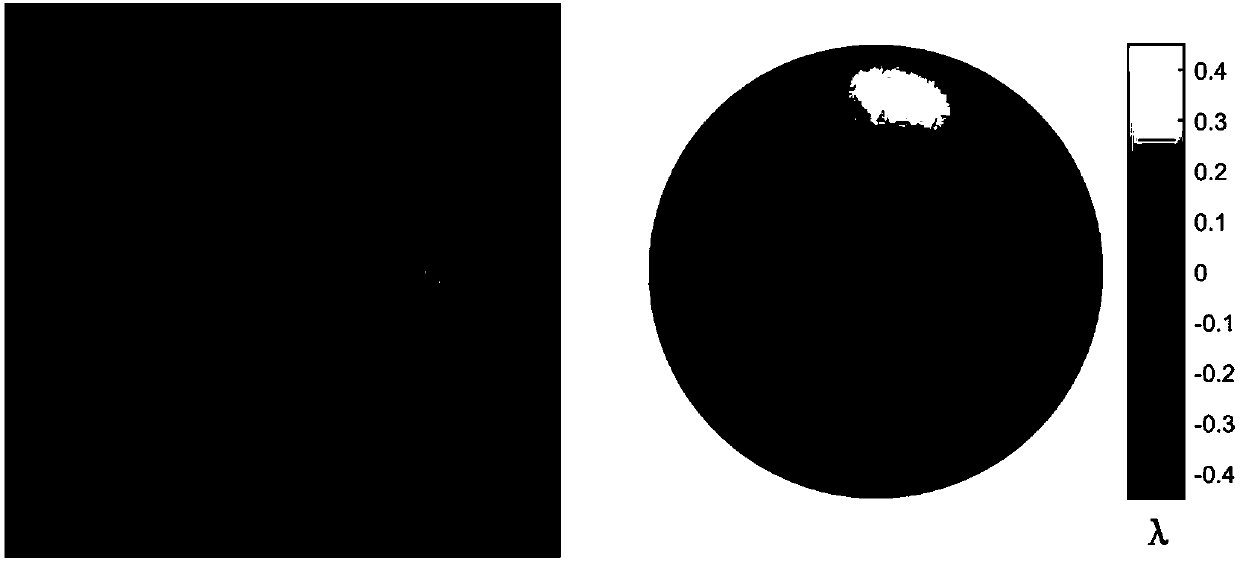

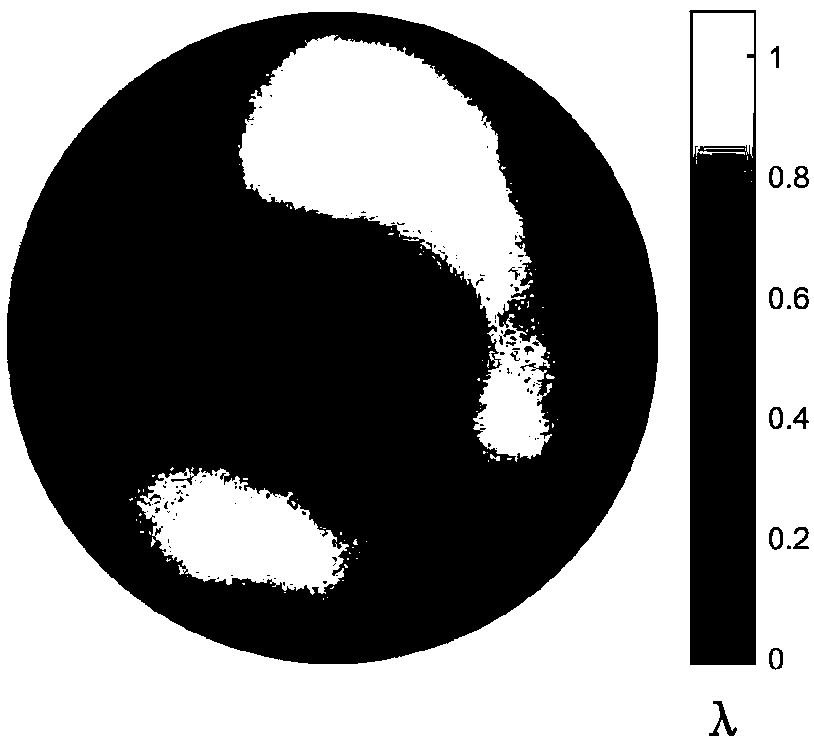

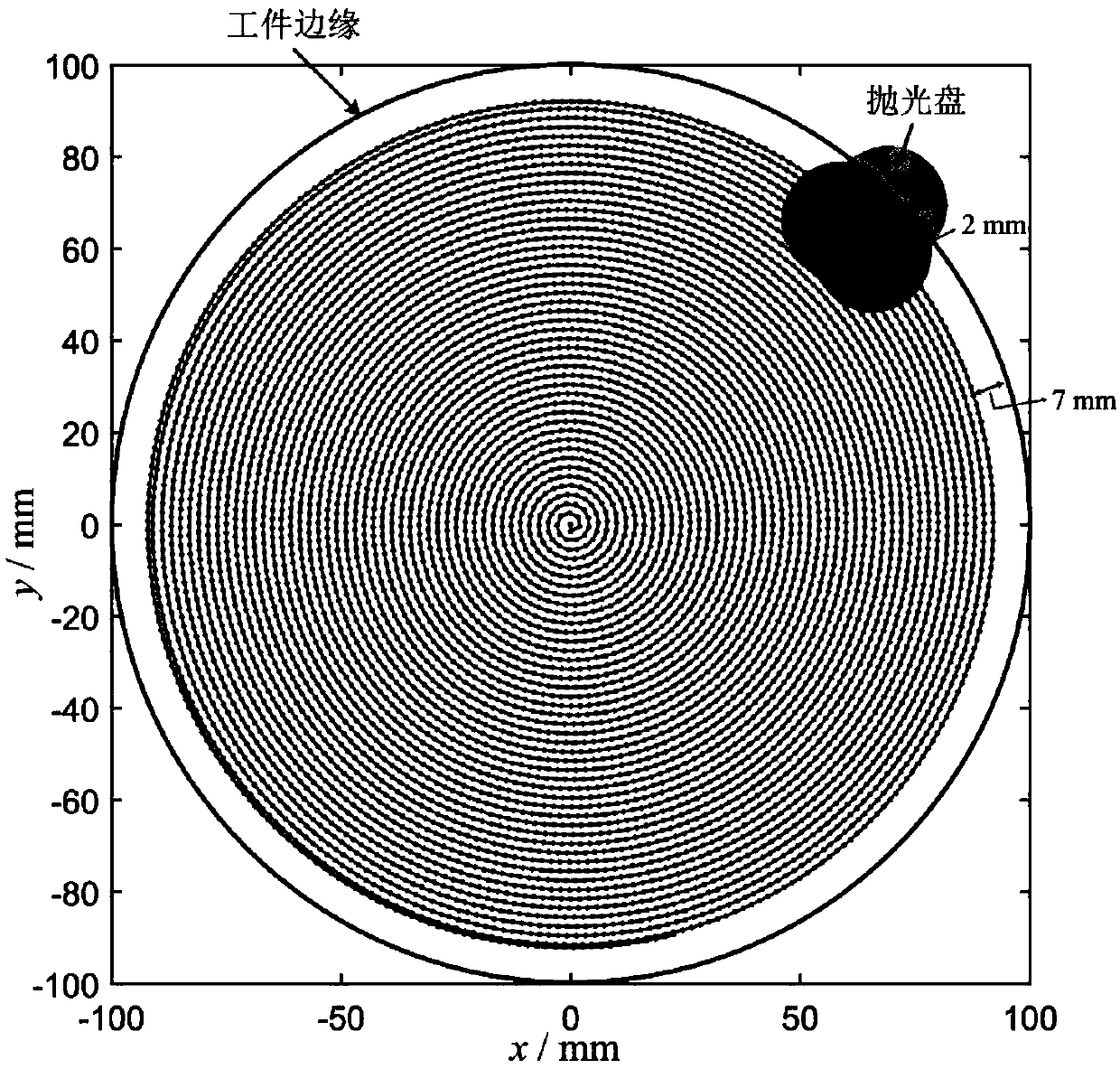

Edge error control method in optical lens small grinding head optical machining

ActiveCN108555729AReduced control accuracyReduce polishing costsOptical surface grinding machinesAutomatic grinding controlOptical processingSurface shape

The invention belongs to the technical field of optical element machining, and particularly discloses an edge error control method in optical lens small grinding head optical machining. The edge errorcontrol method comprises specific steps that firstly, a workpiece is measured to obtain a surface shape error, an appropriate quadratic term is added to the surface removing amount for adjustment, and the edge machining difficulty is lowered; meanwhile, a polishing path is abstracted to discrete sampling points, and a removing function of each sampling point is calculated according to a removingfunction model; then, the residence time is solved through a space variation deconvolution algorithm; and finally, a control program is generated according to the polishing path and the residence time, and polishing is carried out on the workpiece. The removing function changing along with the position is adopted to solve the residence time, and the removing amount of the edge part can be precisely controlled; the non-linear deconvolution algorithm can adapt to the shifting removing function; and by means of the surface shape adjusting technology, the convergence difficulty of the edge error is lowered to the maximum extent. According to the edge error control method, the requirement for the control precision of a polishing system is relatively low, and therefore the small grinding head polishing cost can be reduced, and the machining efficiency is improved.

Owner:FUDAN UNIV

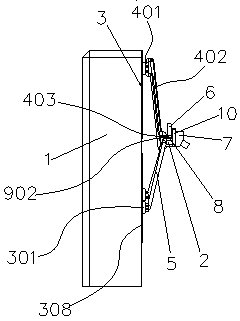

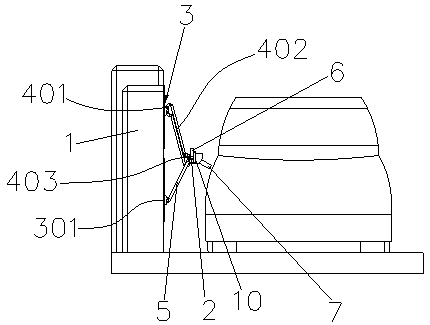

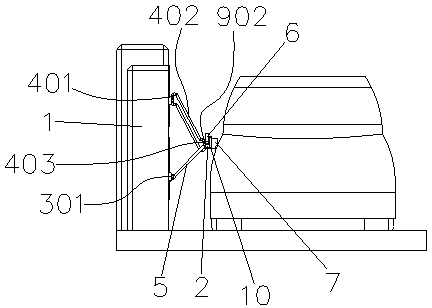

Flexible passive catcher with serial bent flexible hinge framework tracked by pneumatic rope

InactiveCN102699925AWide range of applicationsSimple and reliable control systemGripping headsSpring steelHinge angle

The invention relates to a flexible passive catcher with a serial bent flexible hinge framework tracked by a pneumatic rope. The catcher comprises two fingers which are installed with two serial bent flexible hinges as a framework. The serial bent flexible hinge framework is made of spring steel materials, and the objects are passively caught through the elastic return force of the serial bent flexible hinge framework. The two fingers are driven by a gas cylinder, and the deformation resistance of the serial bent flexible hinge framework can be prevented through enlarging the action force of the five-hinge diagonal double-toggle force amplifier which is frequently used on an injection machine and then driving the track rope of each finger, so that the flexible passive catcher can be stretched. The open degree of the catcher can be controlled through adjusting the pressure of the gas cylinder. The catcher has the advantages of large drive force, wide application range, simple structure, few control target, convenience for maintaining and low requirements on use environments, properties of flexible degree of freedom and buffered action force property, and good flexible adaptability, and can catch the objects of which the shapes and sizes are changed without feedback, and thus can be applied to the technical field of mechanical-electrical integration application of robots.

Owner:无锡锦臻自动化技术有限公司

Solid insulation ring main unit

ActiveCN103368096AReduce control precision requirementsGuaranteed to workSwitchgear arrangementsHigh-tension/heavy-dress switchesEngineeringVacuum switch

The invention discloses a solid insulation ring main unit, comprising a high-voltage switch unit; the high-voltage switch unit comprises a vacuum arc-extinguishing chamber and an isolation grounding switch device comprising an insulation cavity body; a line outlet end, a grounding end and a line inlet end electrically connected with a conductive rod are arranged on the insulation cavity body; a vacuum switch tube for grounding is fixedly arranged inside or outside the insulation cavity body; the static contact of the vacuum switch tube for grounding is electrically connected with the grounding end while the movable contact is provided with a grounding wiring part; the movable contact of the vacuum switch tube for grounding is in transmission connection with a grounding operative mechanism; an isolation disconnecting link is arranged in the insulation cavity body; one end of the isolation disconnecting link is a hinging end hinged to the line outlet end while the other end is a contact end; and a driving mechanism is connected onto the isolation disconnecting link in a transmission way. The isolation grounding switch is positioned in different work conditions by controlling the swinging of the isolation disconnecting link and the connecting / disconnecting states of the static and movable contacts in the vacuum switch tube.

Owner:STATE GRID CORP OF CHINA +2

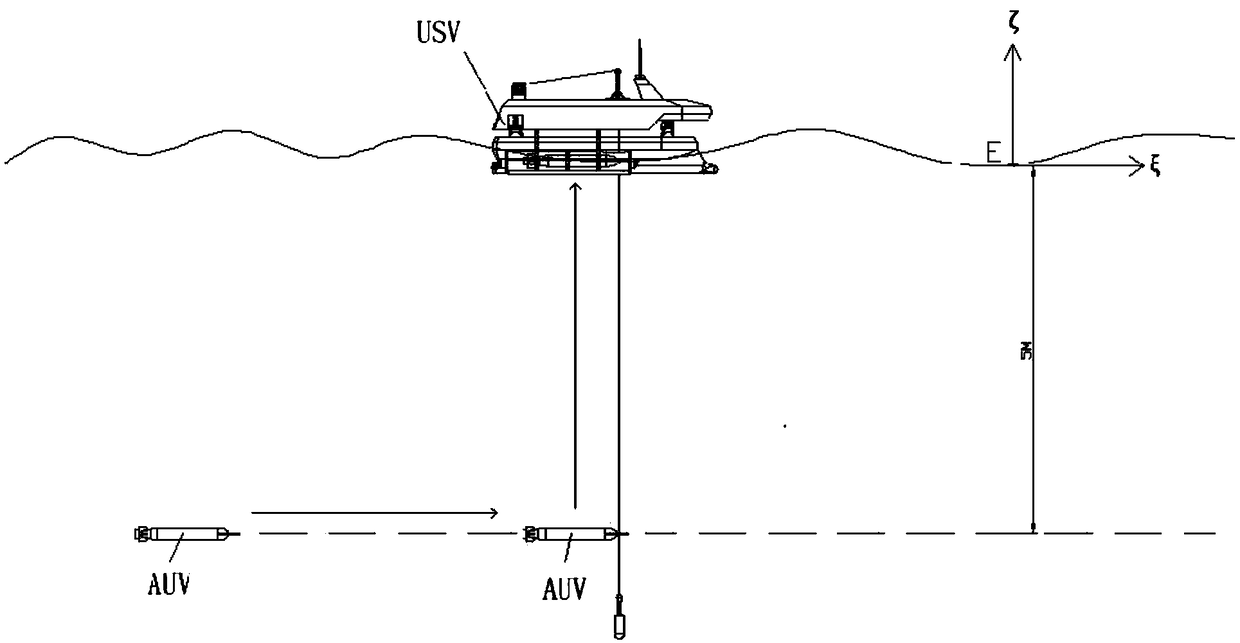

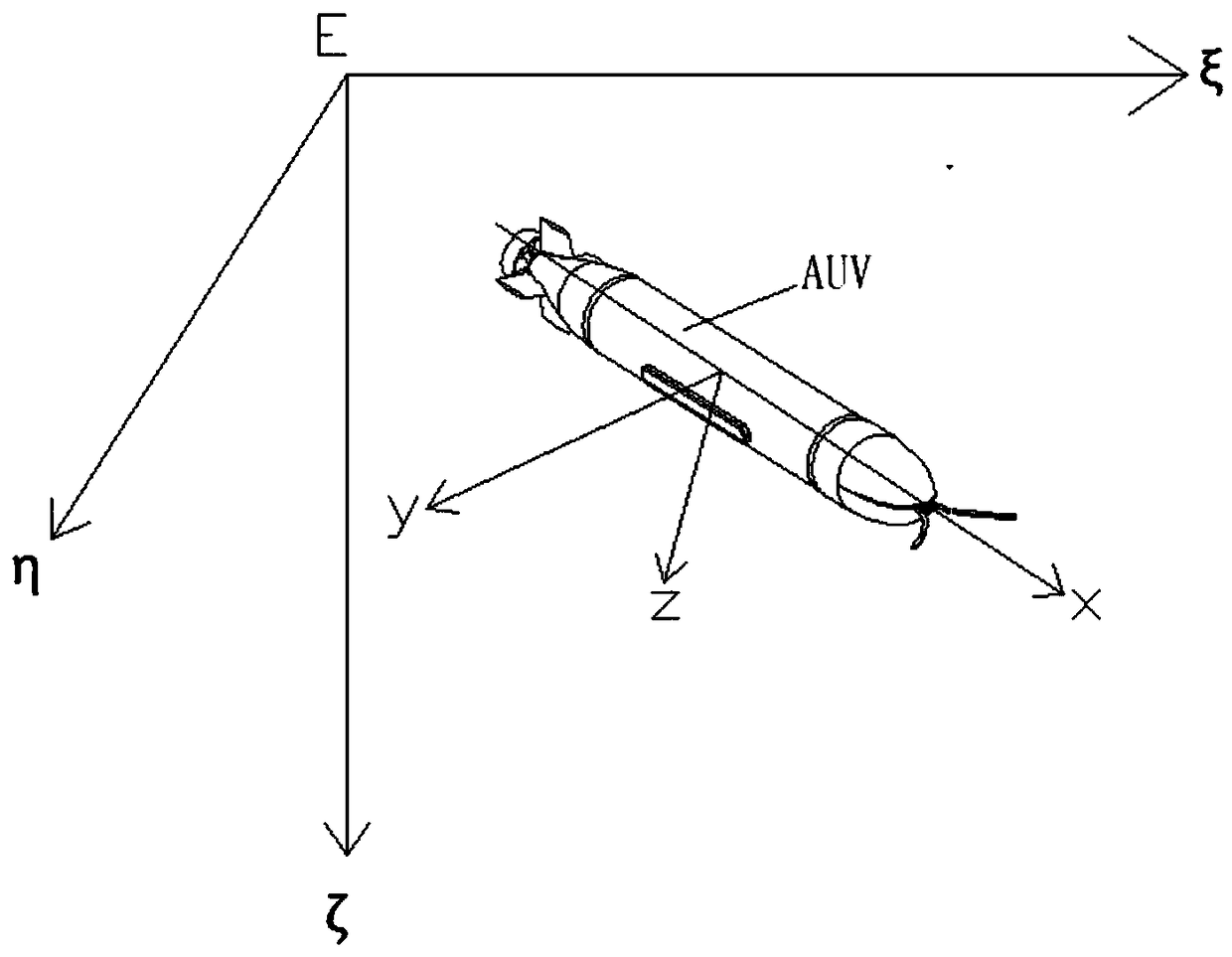

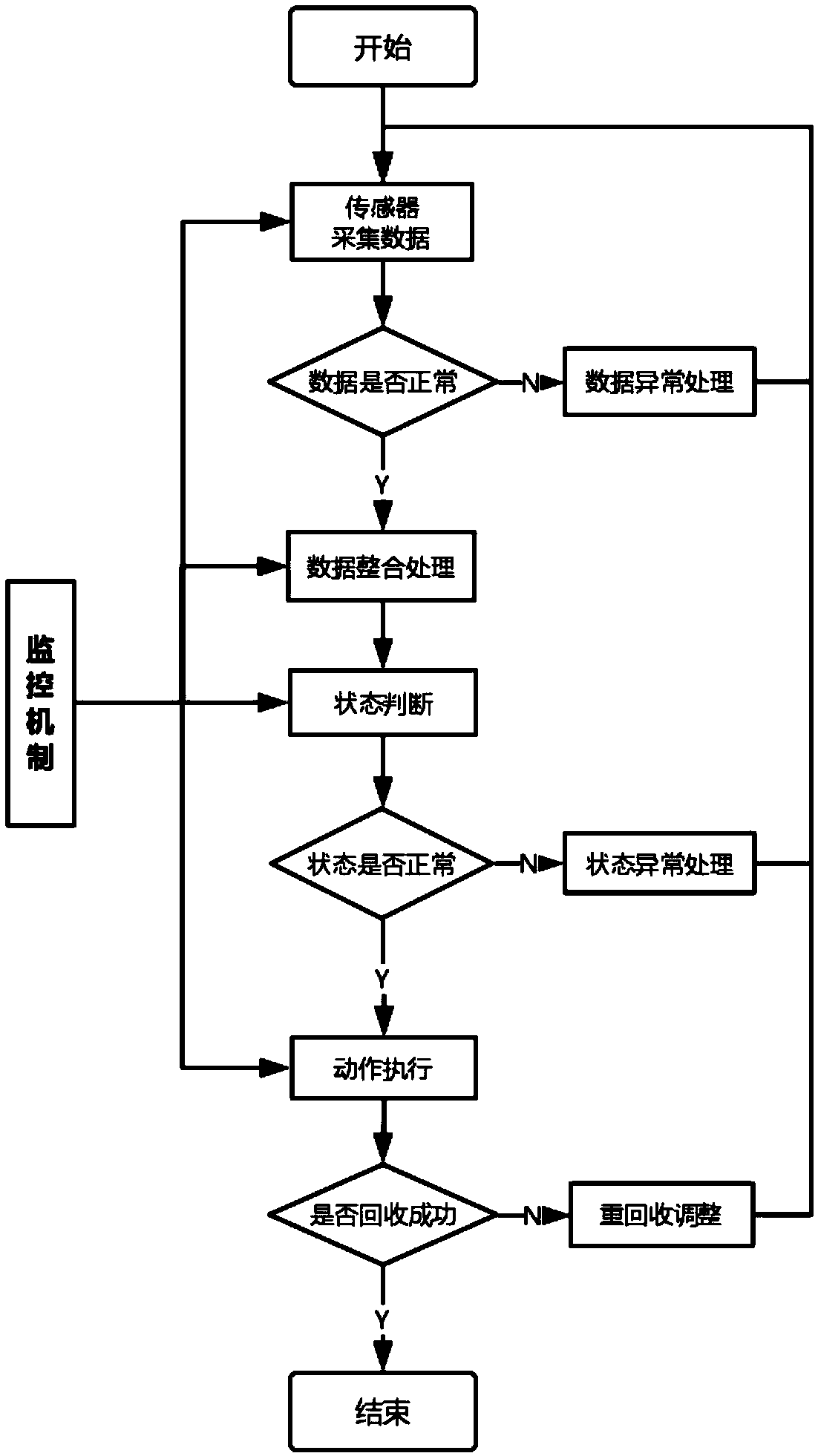

Planning method for recovering autonomous underwater vehicle (AUV) through guide cable of surface unmanned ship

ActiveCN109238291AIncrease success rateGuarantee effectivenessNavigational calculation instrumentsPosition/course control in three dimensionsPlanning approachPlanning method

The invention discloses a planning method for recovering an autonomous underwater vehicle (AUV) through a guide cable of a surface unmanned ship. The recovery logical flow comprises the following steps: firstly, starting a recovery process after the AUV ends a task; secondly, judging whether data are abnormal or not; thirdly, judging the state of the AUV, if the state of the AUV is abnormal, performing state exception processing, otherwise issuing an instruction, and executing a next step action; and finally, take whether the recovery is successful as a criterion for judging the end of a logical flow. The invention has the beneficial effects that a planning method of coordinated docking recovery between the autonomous underwater vehicle and the surface unmanned ship is proposed specific tothe operation process of autonomous recovery of the underwater vehicle by the surface unmanned ship. The planning method includes the control strategies of start / stop of a recovery task, coordinatedcontrol of docking and re-planning after docking failure; the effectiveness of the whole recovery process is ensured through whole process planning adjustment; and the success rate of autonomous recovery of the underwater vehicle by the surface unmanned ship is greatly improved.

Owner:HOHAI UNIV

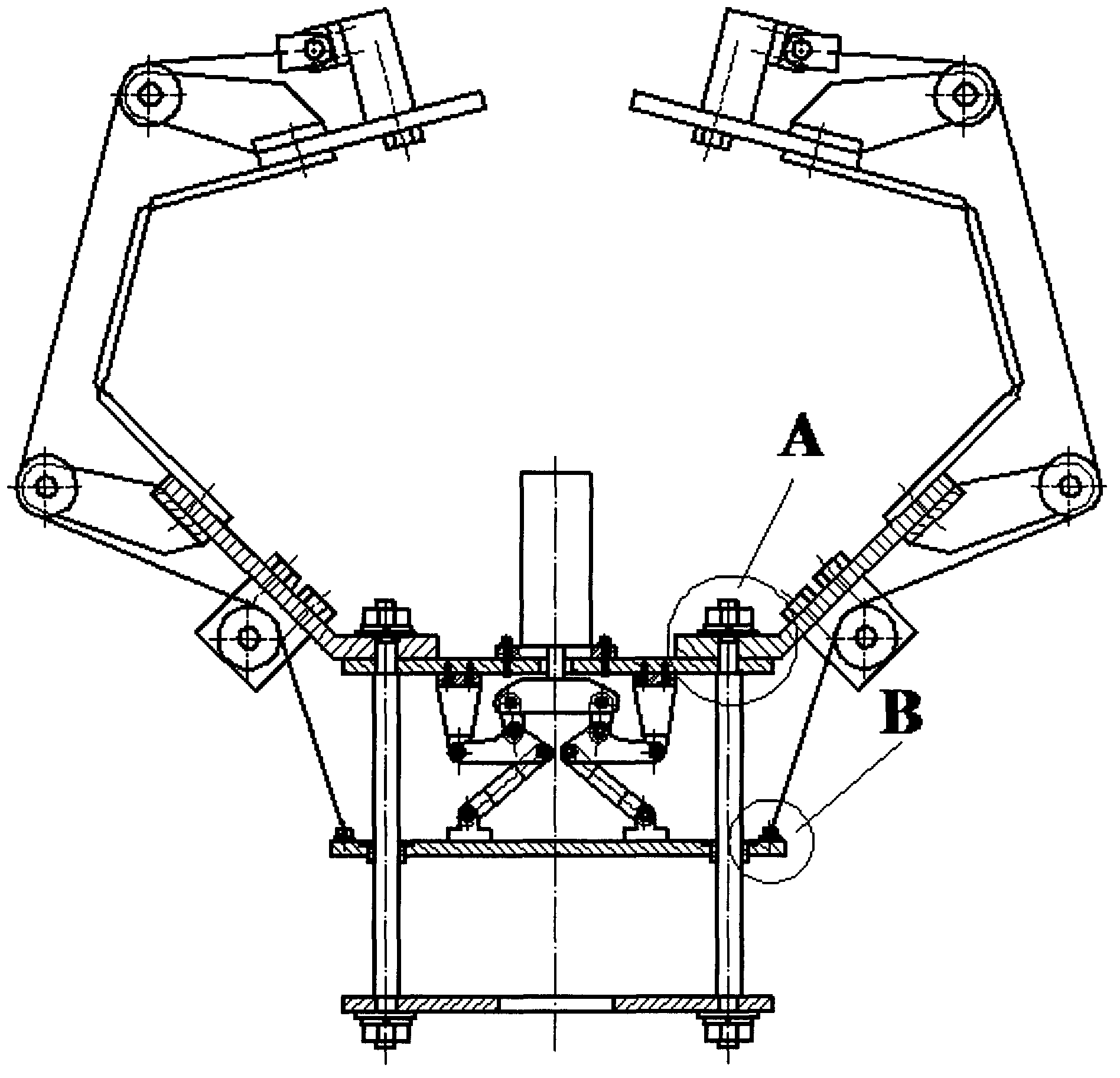

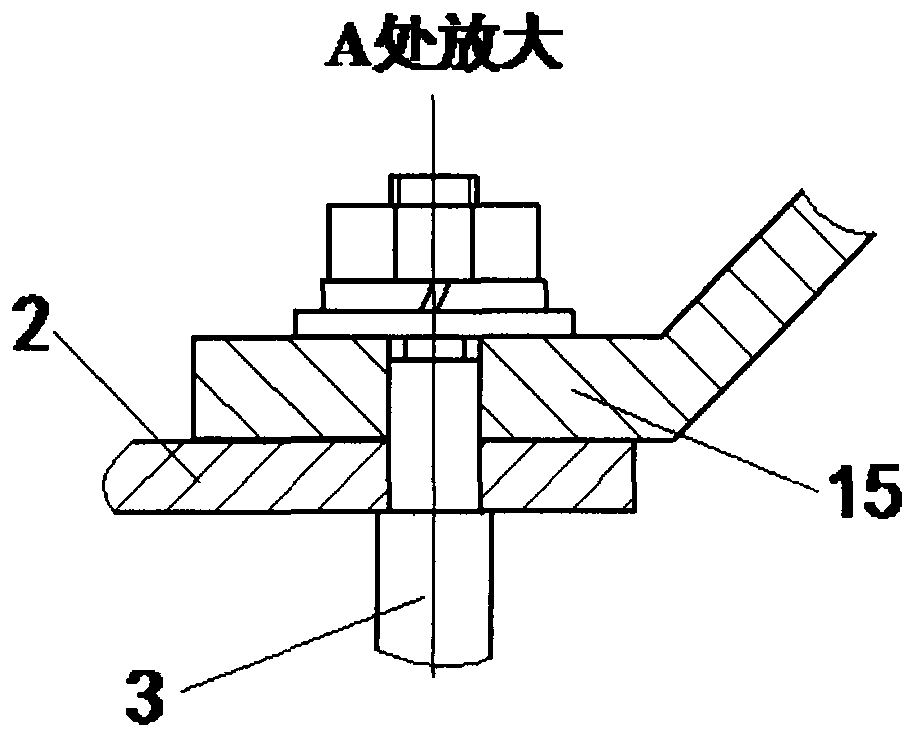

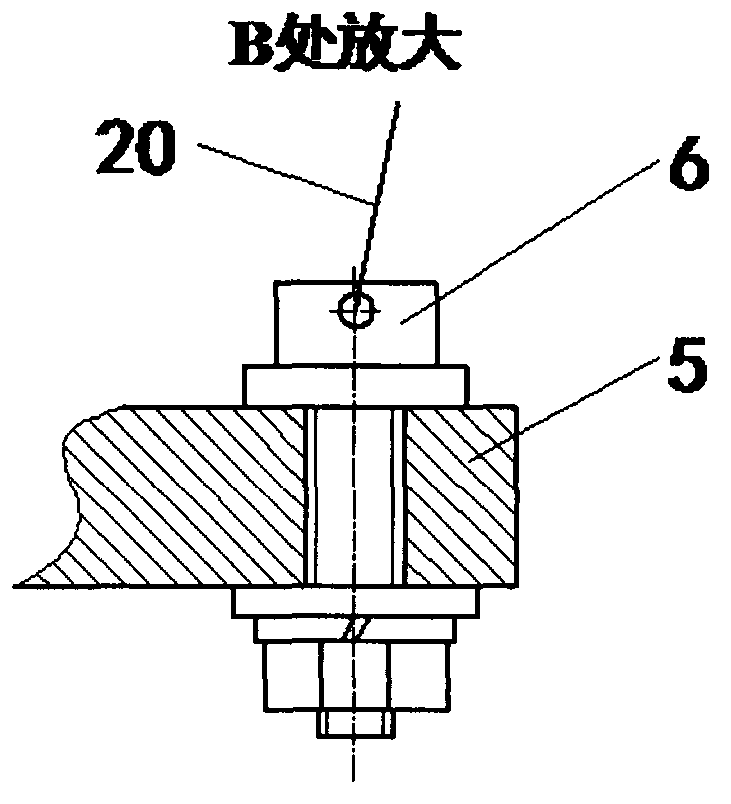

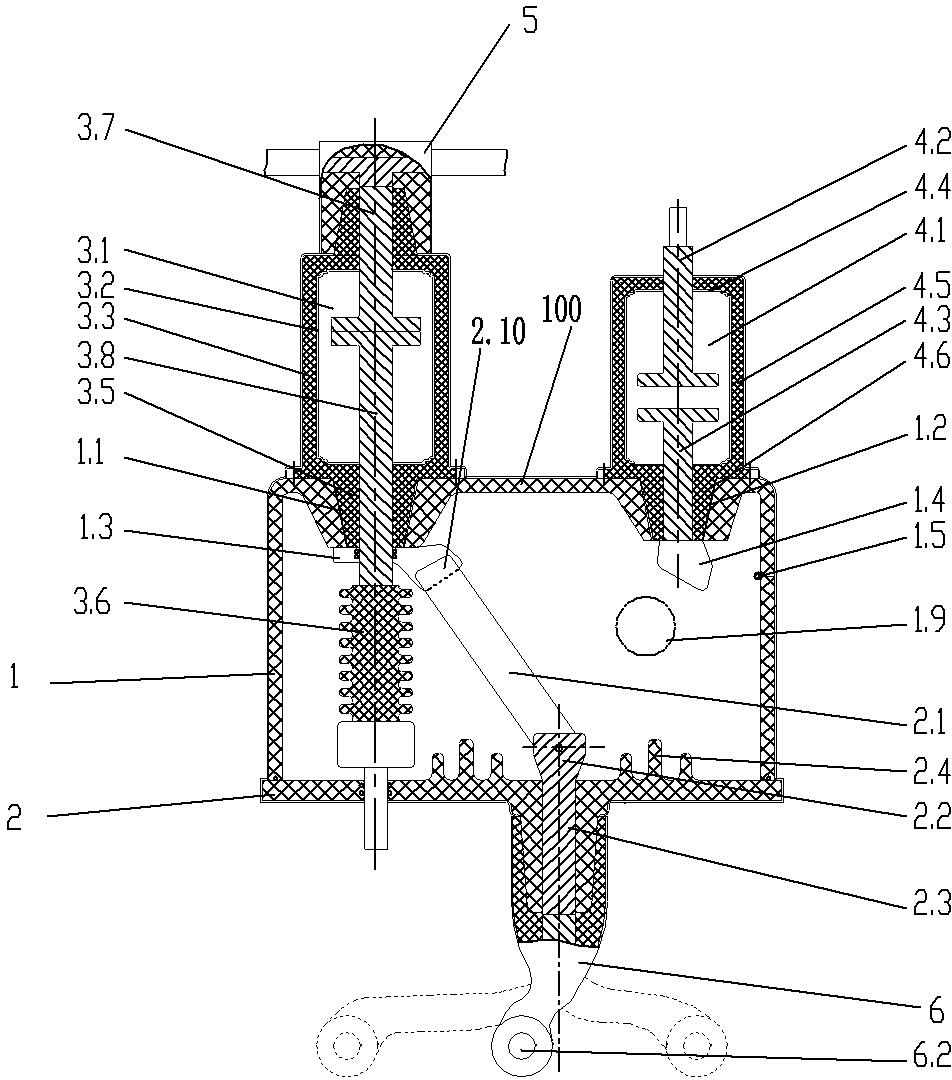

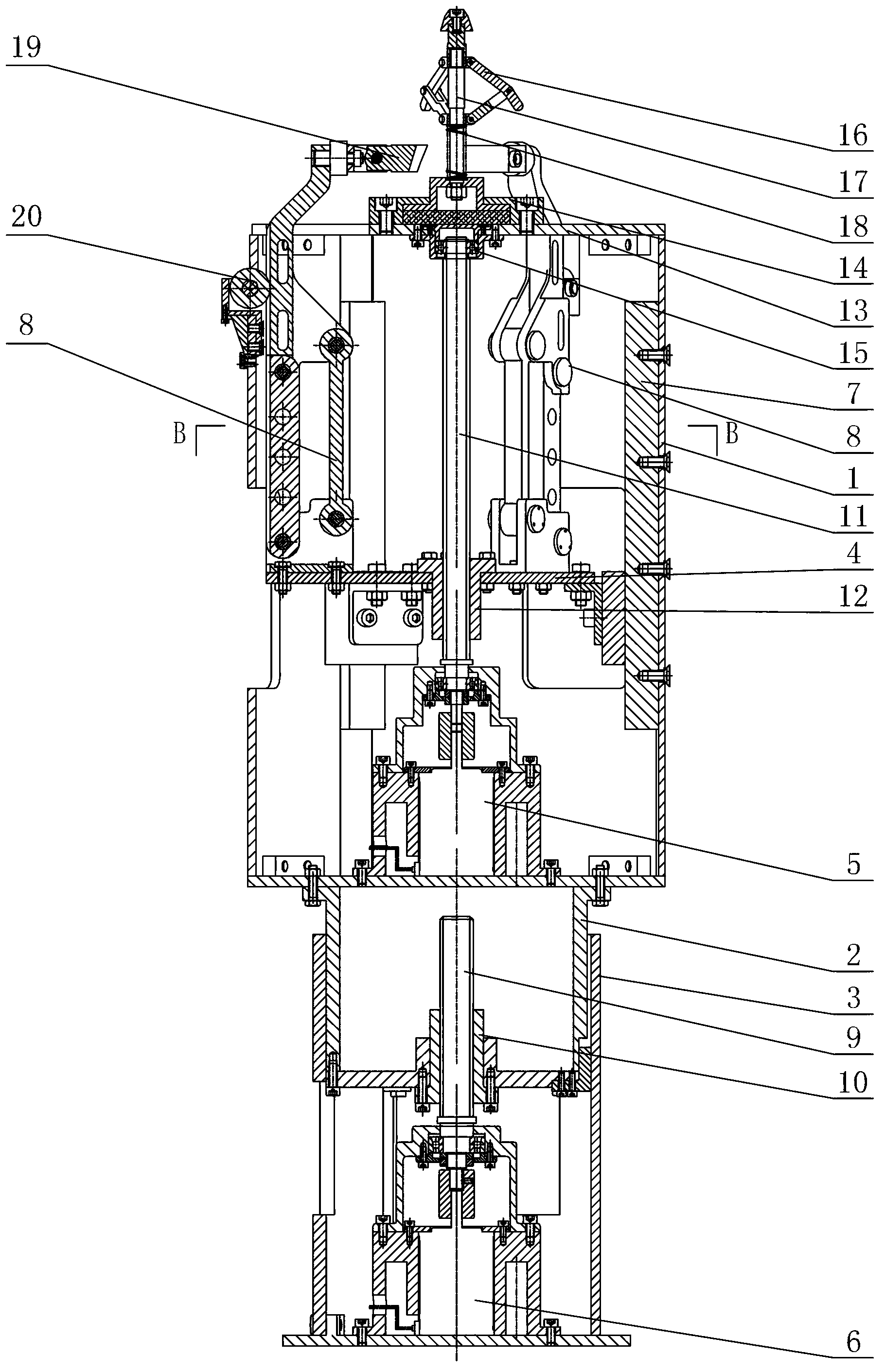

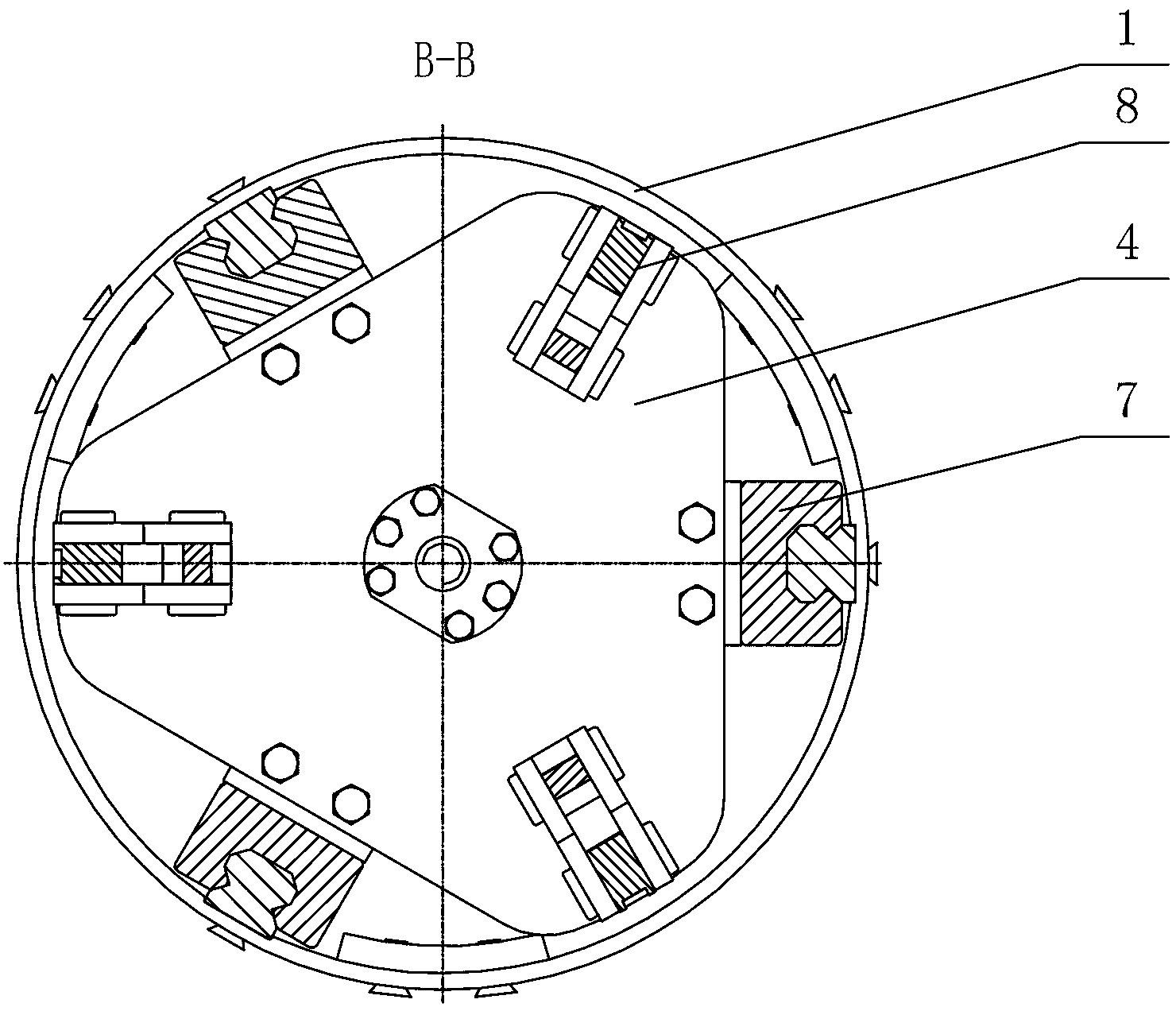

Space butt-joint capturing device for non-cooperative target satellites

ActiveCN103303499AIncrease contact areaWide envelopeCosmonautic component separationIsoetes triquetraButt joint

The invention relates to a space capturing device, in particular to a space butt-joint capturing device for non-cooperative target satellites, and aims at solving the problems that a conventional non-cooperative target butt-joint mechanism has higher requirements for motion control accuracy, and a sensitive sensor and an accurate spray pipe gesture recognition technology are required. The device is characterized in that the lower surface of an upper casing is fixedly connected with the upper surface of a lower slide body which is inserted into a lower casing; a lower motor is fixedly mounted on the bottom surface in the lower casing; an output shaft of the lower motor is connected with the lower surface of the lower slide body through a first screw nut mechanism; an upper motor is fixedly mounted on the bottom surface in the upper casing; an output shaft of the upper motor is connected with a connecting plate through a second screw nut mechanism; a mechanical arm is mounted on the upper surface of each angle of the equilateral triangle; a torsional spring is arranged in a connecting joint of each mechanical arm. The space butt-joint capturing device is used for capturing the non-cooperative satellites.

Owner:HARBIN INST OF TECH

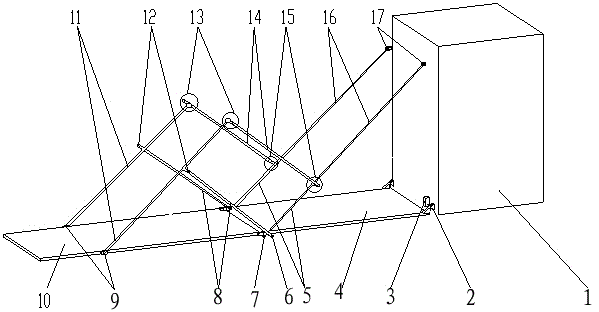

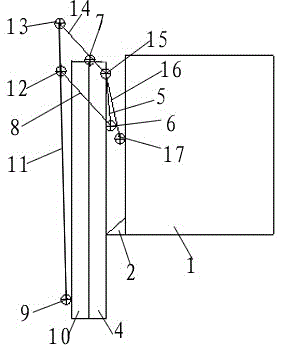

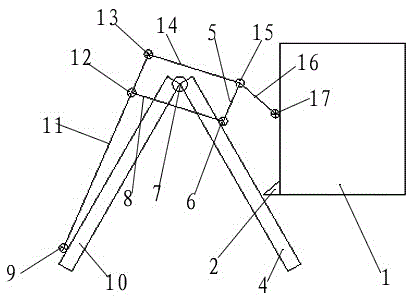

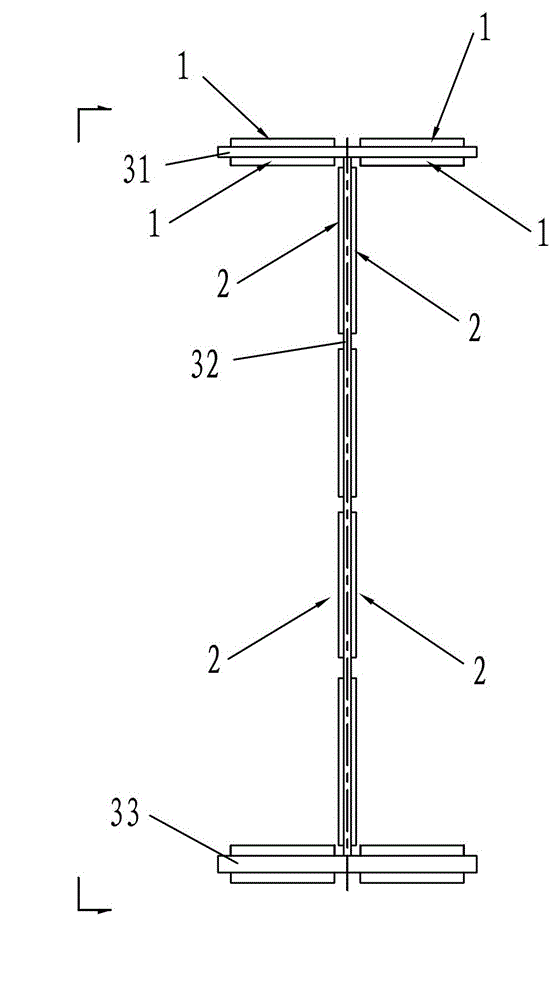

Satellite borne flat plate antenna articulated truss

ActiveCN105470619ASimple control systemReduce control precision requirementsCollapsable antennas meansAntenna supports/mountingsControl systemPetroleum engineering

The invention discloses a satellite borne flat plate antenna articulated truss. The satellite borne flat plate antenna articulated truss comprises at least one group of rod components; each group of rod components includes a first supporting rod, a second supporting rod, a third supporting rod, a linkage supporting rod and an auxiliary supporting rod; one end of the first supporting rod is connected with a satellite platform through a satellite body supporting seat hinge; the other end of the first supporting rod is connected with one end of the second supporting rod through a multi-joint hinge; the other end of the second supporting rod is connected with an antenna inner plate through a first inter-rod hinge; one end of the third supporting rod is connected with an antenna outer plate through a frame supporting seat hinge; the other end of the third supporting rod is connected with one end of the linkage supporting rod through a second inter-rod hinge; the other end of the linkage supporting rod is connected with a multi-joint hinge; one end of the auxiliary supporting rod is connected with the third supporting rod through a third inter-rod hinge; and the other end of the auxiliary supporting rod is connected with the first inter-rod hinge. According to the satellite borne flat plate antenna articulated truss provided by the invention, a control system and a truss system are simplified, and inter-plate driving links can be reduced.

Owner:SHANGHAI AEROSPACE SYST ENG INST

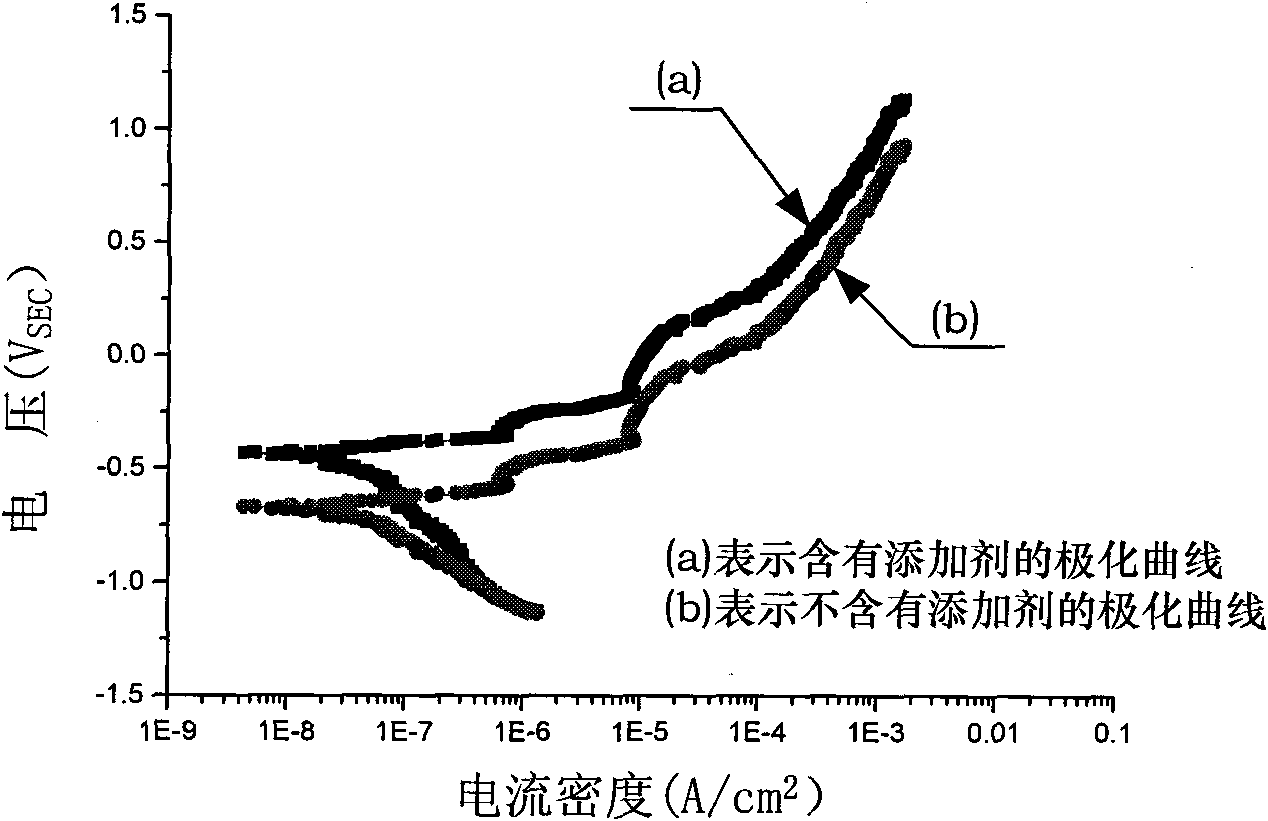

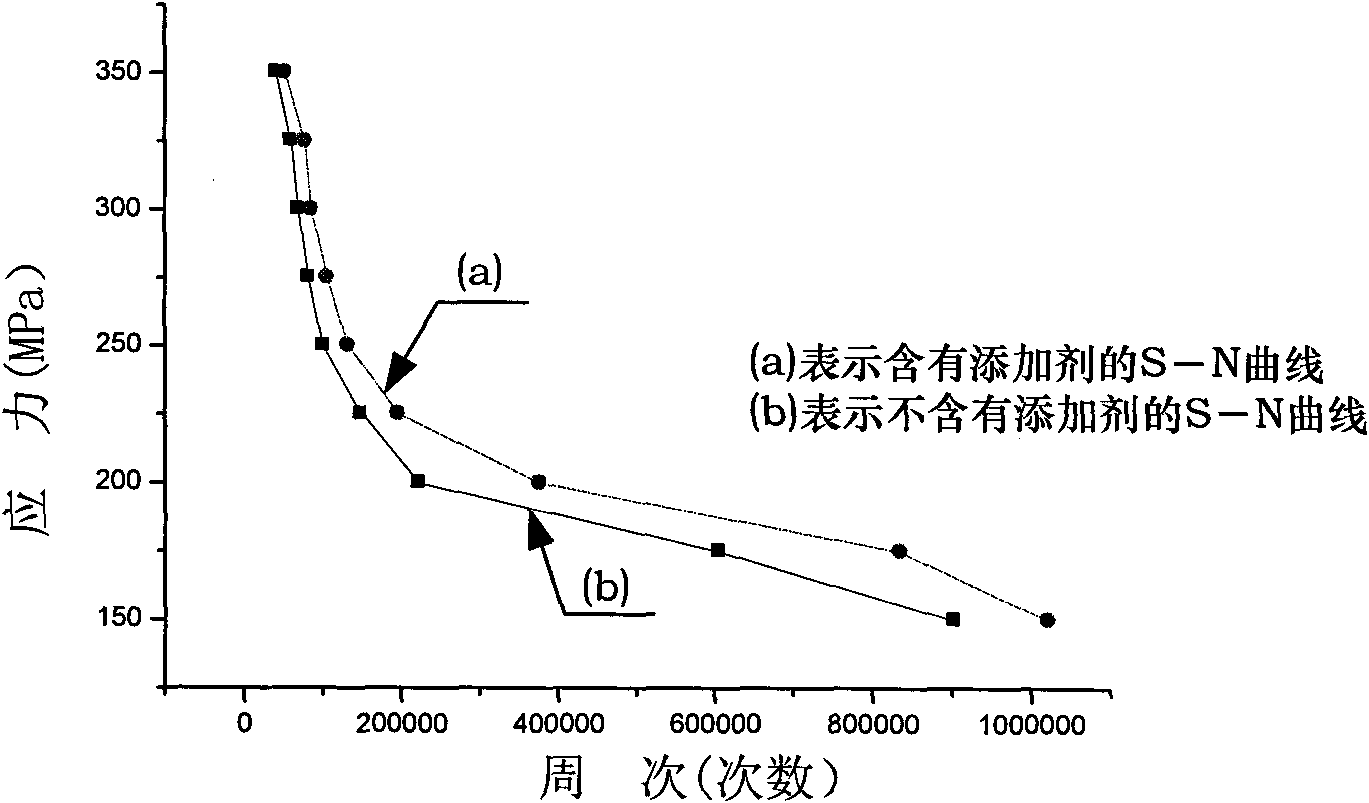

Sulfuric acid-boric acid-additive ternary anodizing fluid

InactiveCN101792920AImprove fatigue lifeIncrease the scope of applicationAnodisation8-HydroxyquinolineExcessive growth

The invention discloses a sulfuric acid-boric acid-additive ternary anodizing fluid, which is prepared by adding 1.6-7.6ml of sulfuric acid, 0.1-1.1g of boric acid and 5-100mg of additive into 100ml of deionized water. The additive is benzotriazole, 2-mercaptobenzothiazole, dithizone or 8-oxyquinoline. The anodizing fluid of the invention is the improvement of aluminium and aluminium alloy sulfuric acid-boric acid binary anodizing fluid, and cupreous efficient cathodic corrosion inhibitor is added to enable that preferential adsorption of the corrosion inhibitor is carried out on the copper-containing particle position of an aviation aluminum alloy surface, thus forming a compact reticulatepattern complexing product, providing targeted protection on copper-containing aluminum alloy phase particles, decreasing the current concentration tendency, and inhibiting excessive growth of oxidation film cavern defect at the position of the copper-containing aluminum alloy phase particles.

Owner:BEIHANG UNIV

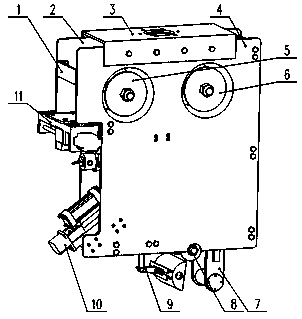

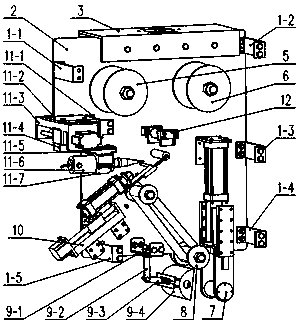

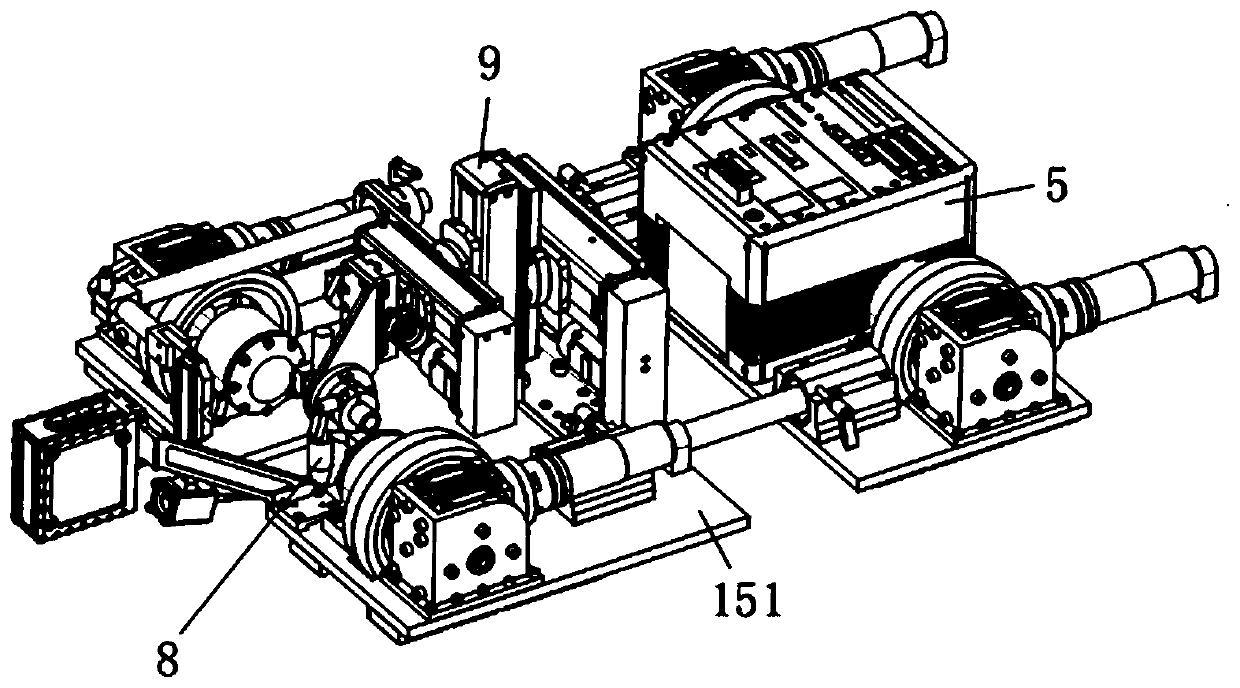

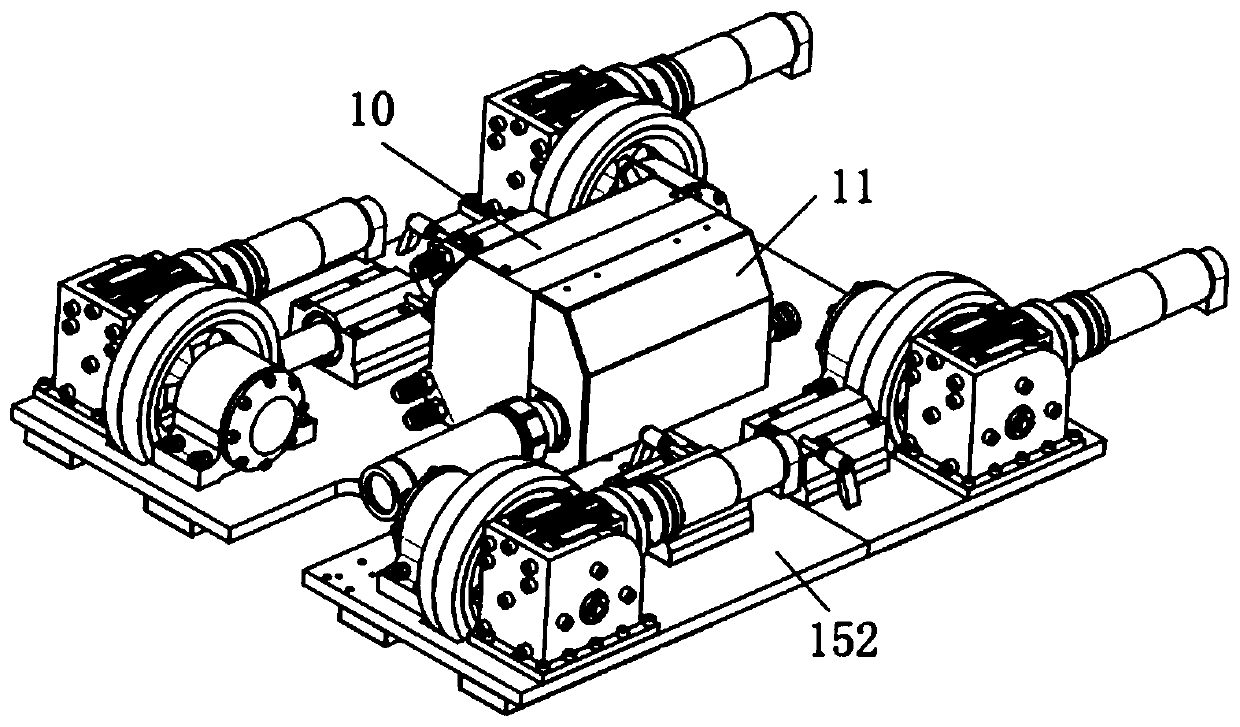

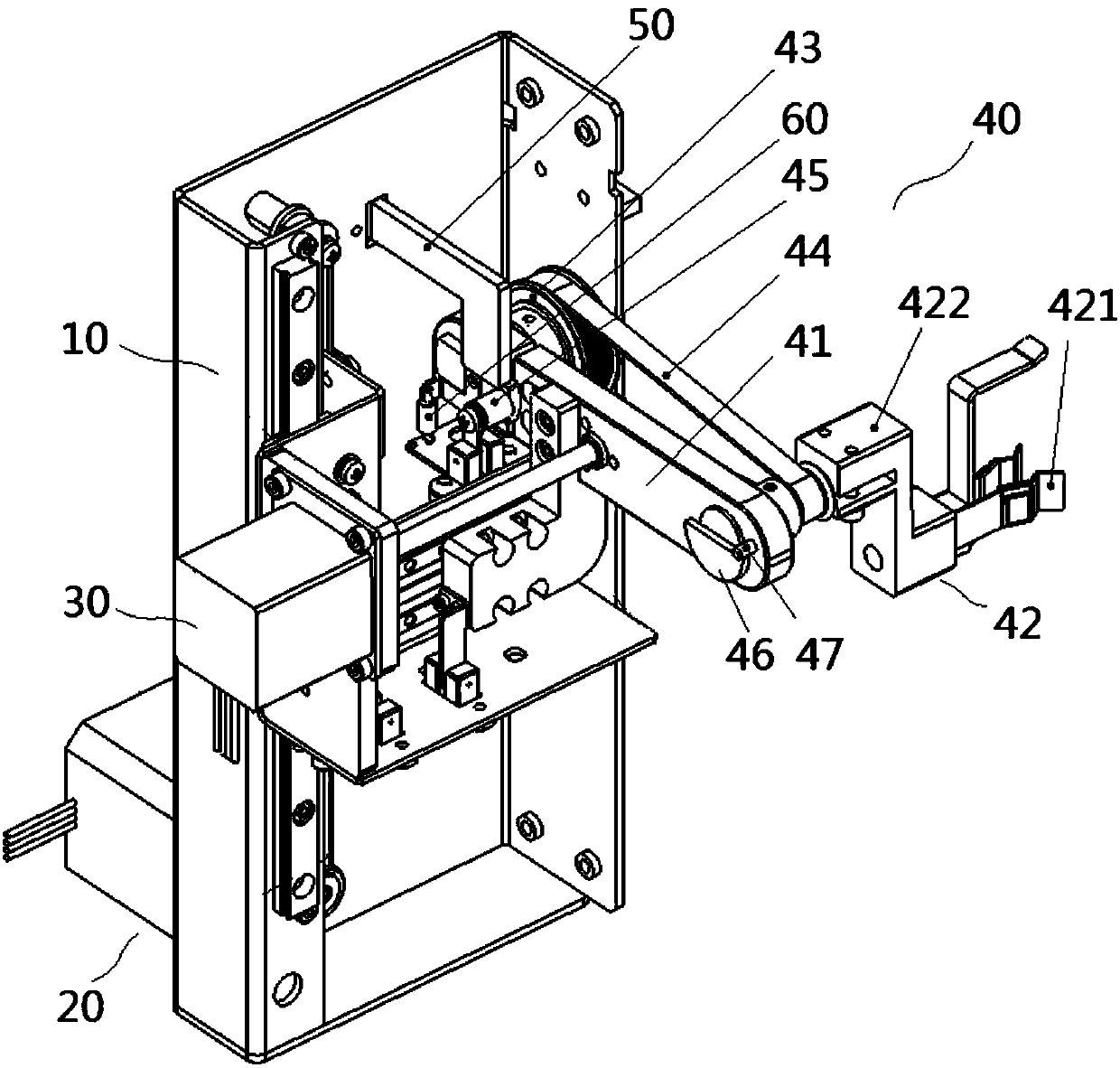

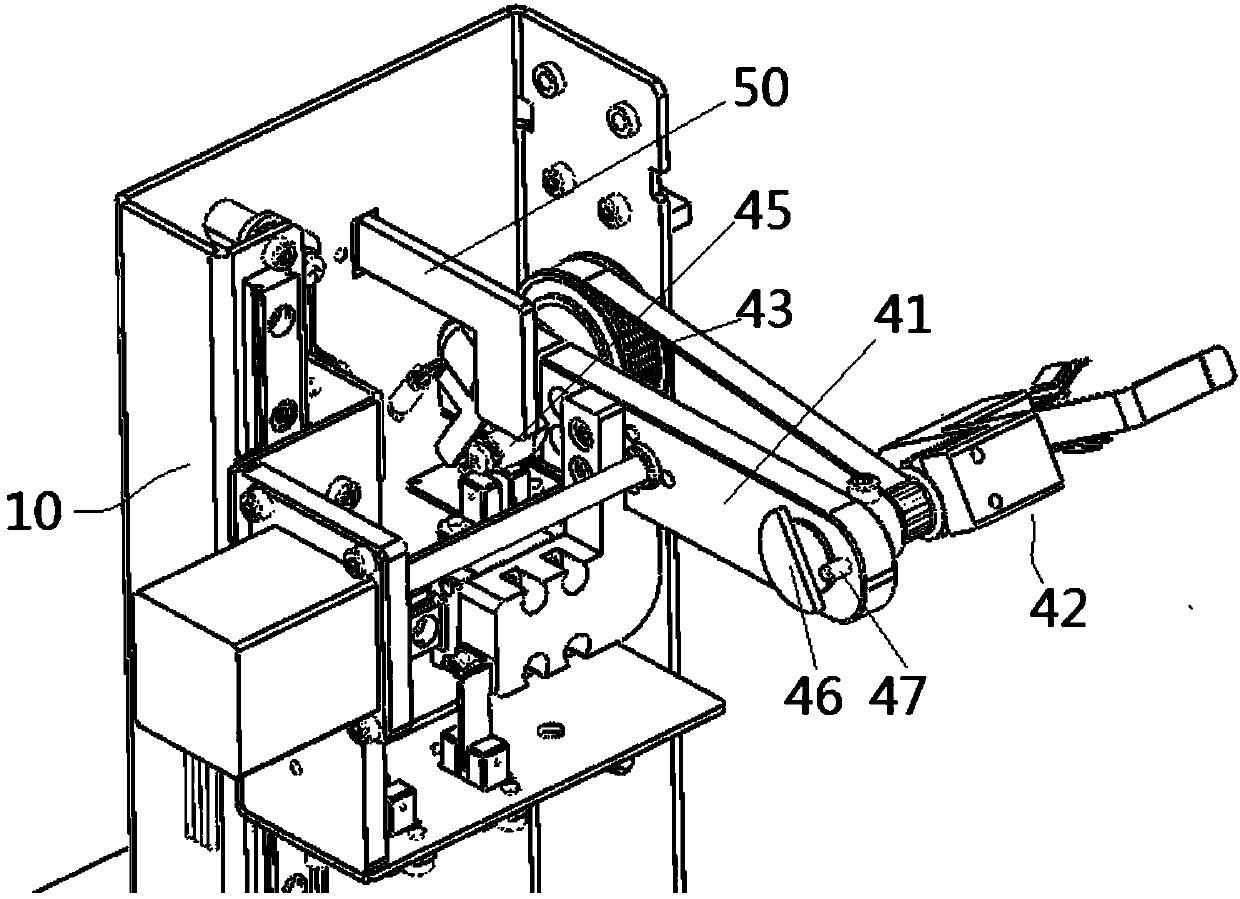

Automatic laying device for prestripping of composite material prepreg tape lining paper

ActiveCN111115333AImprove efficiencyQuality improvementUnfolding thin materialsArticle deliveryStructural engineeringSlip sheet

The invention discloses an automatic laying device for prestripping of composite material prepreg tape lining paper. The automatic laying device comprises an upper rack connected with a mechanical armflange, a left rack located at the left end of the upper rack, a right rack located at the right end of the upper rack, an ultrasound cutting mechanism, an infrared heating mechanism, a middle rack,a pressing roller mechanism, a transferring mechanism, a limiting mechanism, a winding mechanism, an unwinding mechanism and a stripping mechanism, wherein the left ends and the right ends of the ultrasound cutting mechanism, the infrared heating mechanism, the middle rack, the pressing roller mechanism, the transferring mechanism and the limiting mechanism are correspondingly connected with the left rack and the right rack; the winding mechanism and the unwinding mechanism are connected with the left rack; and the stripping mechanism is connected with the right rack. Therefore, according to the automatic laying device for prestripping of the composite material prepreg tape lining paper, functions of cutting, transferring, heating and laying composite materials can be realized, the automatic laying device for prestripping of the composite material prepreg tape lining paper has the characteristics of simple structure, high automation degree, high laying efficiency, low cost and the like, the problem of difficult control of the cutting depth of a traditional prepreg tape is effectively solved, and thus, the composite material laying process control is simple and reliable.

Owner:WUHAN UNIV

Vertical material-distributing device and material-distributing method

InactiveCN101077592AReduced splicing flatness requirementsGuaranteed decorative effectFeeding arrangmentsEngineeringClosed cavity

The present invention relates to one kind of vertical material distributing apparatus and process. The vertical material distributing apparatus includes one turnable platform capable of being turned into horizontal state or vertical state, one material box over the platform, one powder carrier with closed cavity, and one material feeder to fill the cavity with powdered material. The vertical material distributing process includes the following steps: setting the powder carrier on the turnable platform in horizontal state, forming one closed cavity with the material box and the powder carrier, turning the platform to vertical state, filling powdered material with the material feeder to the closed cavity, turning the platform reversely to horizontal state for the powdered material on the powder carrier, and feeding the powdered material with the powder carrier to the press for forming. The present invention has reasonable structure, high production efficiency and capacity of raising product quality.

Owner:KEDA INDUSTRIAL GROUP CO LTD

Preparing method for quadrpyramid microstructure array

InactiveCN1553223AGuaranteed Surface AccuracyIncreased etch depth rangePhotomechanical apparatusLensResistMaterials science

The method is as the follows, sectional drawing of terapyramid form microstructure array required to be prepared is calculated out according to required etching depth and etching aperture, exposure distribution required at surface of anticorrosion compound is calculated according to the sectional drawing, mask drawing is designed as per required exposure distribution and the required exposure distribution at anticorrosion compound surface can be obtained by controlling mask moving speed and exposing time as microstructure array is finally built after developing and film hardening.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Master-slave wall-climbing welding robot system suitable for large steel structural part

ActiveCN110814472ARealize all-position automatic weldingImprove working environmentElectrode holder supportersWelding accessoriesRobotic systemsRobot position

The invention relates to a master-slave wall-climbing welding robot system suitable for a large steel structural part. A master wall-climbing welding robot carries a welding gun and tracks a welding seam to move; a slave wall-climbing relay wire feeding robot loads welding related equipment, such as a wire feeder and a wire reel, bears cable drag force and follows the master wall-climbing weldingrobot to move to cooperate to complete field installing and welding operation; the overall weight of the master wall-climbing welding robot is relatively low and moves flexibly, which is beneficial toquick adjustment of robot positions and welding gun postures; the slave wall-climbing relay wire feeding robot is high in load capacity and relatively low in control precision requirement, and can feed a wire for the master wall-climbing welding robot in short distance for welding; the wire is output stably; the welding quality is easy to ensure; both the master wall-climbing welding robot and the slave wall-climbing relay wire feeding robot adopt a permanent magnet gap adsorption and wheel type motion mechanism; an adsorption mechanism is separated from a motion mechanism; the flexibility ofrobot motion is further improved; and the motion control precision of the robot is improved.

Owner:TSINGHUA UNIV +1

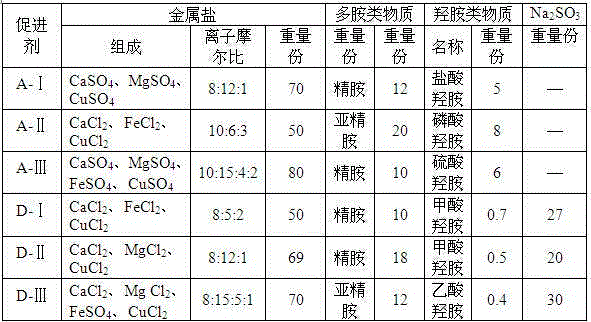

Culturing method for dominant nitrosation bacterial community

ActiveCN106754616ACultivate stableRapid cultivationChemical cell growth stimulationMicroorganismStart time

The invention relates to a culturing method for a dominant nitrosation bacterial community. The culturing method comprises the following three culturing stages: stage 1, enriching a mixed bacterial community of nitrosomas and nitromonas, wherein a microbial growth promoter A is used in the process of enrichment; stage 2, carrying out nitromonas elutriation by using a microbial growth promoter D and a high-temperature culture and normal-temperature culture alternate method so as to gradually improve the dominance of nitrosomas and beginning third-stage culture when a nitrosation rate is greater than 50%; and stage 3, reducing the content of dissolved oxygen or increasing a pH value, carrying out further nitromonas elutriation and stability domestication of nitrosomas by using the microbial growth promoter D and terminating culture when the nitrosation rate is stabilized and is 65% or more so as to obtain the dominant nitrosation bacterial community. The culturing method provided by the invention overcomes the problems of instability of partial nitrification in practical application, can shorten the starting time of nitrifying process, rapidly changes the process of a nitrifying reaction, broadens the application scope of partial nitrification and provides guarantee for actual application of a partial nitrification process to real projects.

Owner:CHINA PETROLEUM & CHEM CORP +1

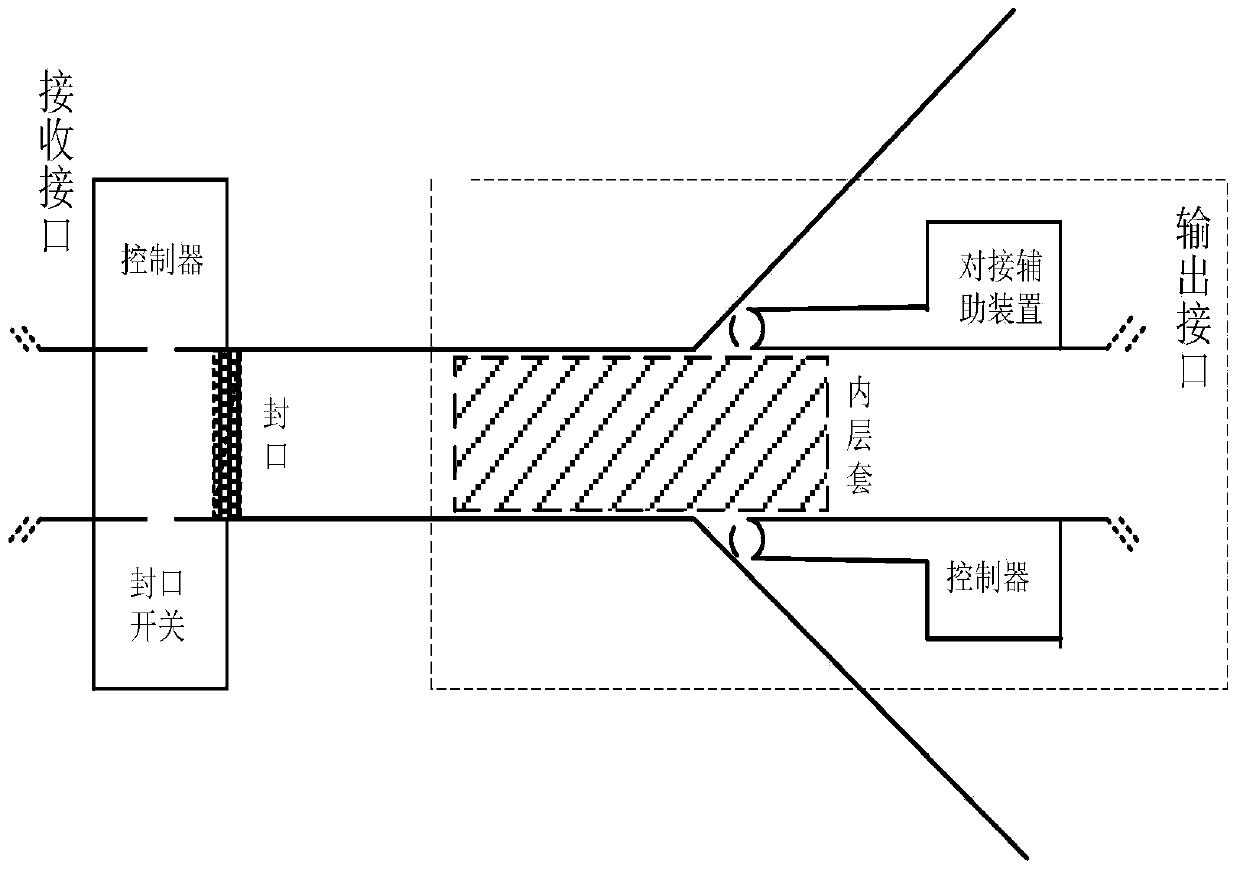

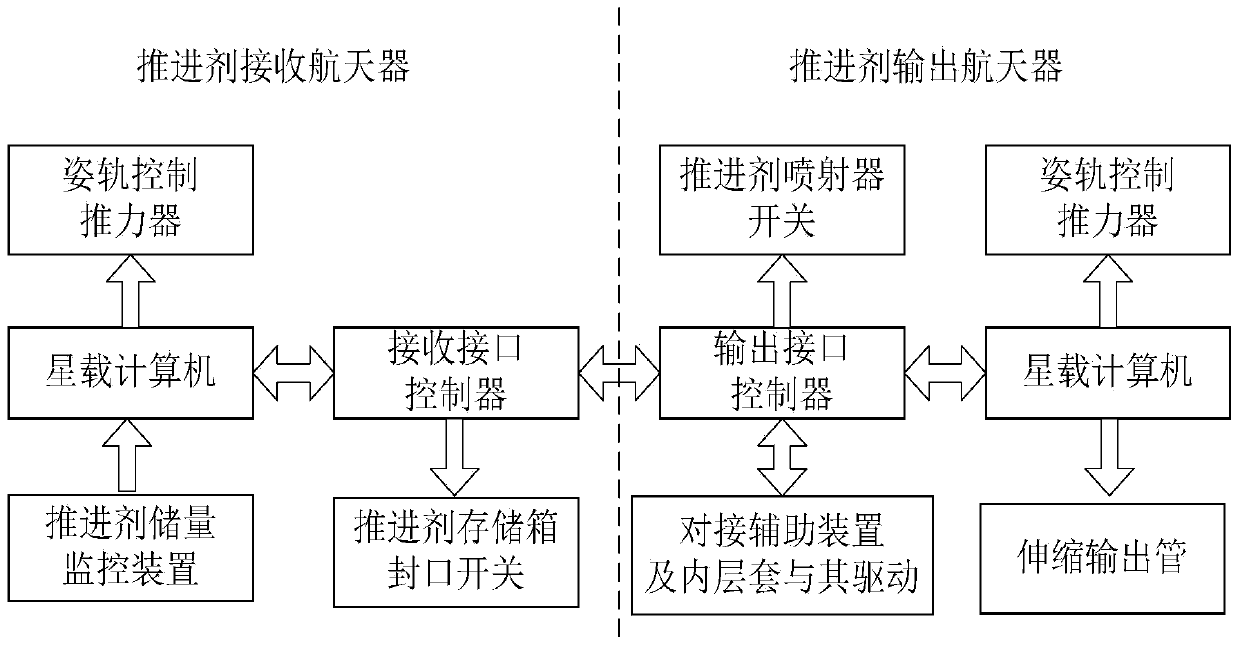

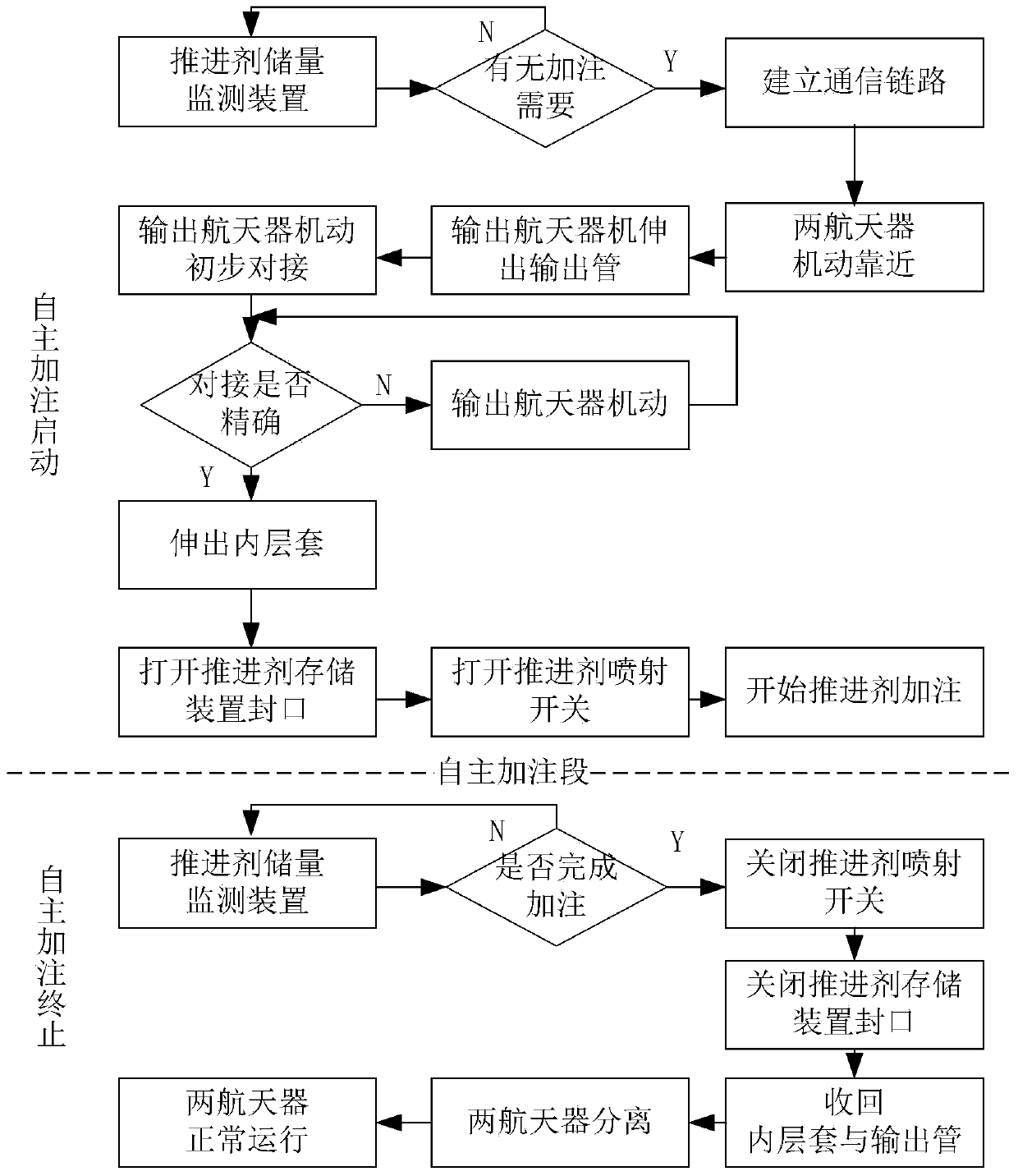

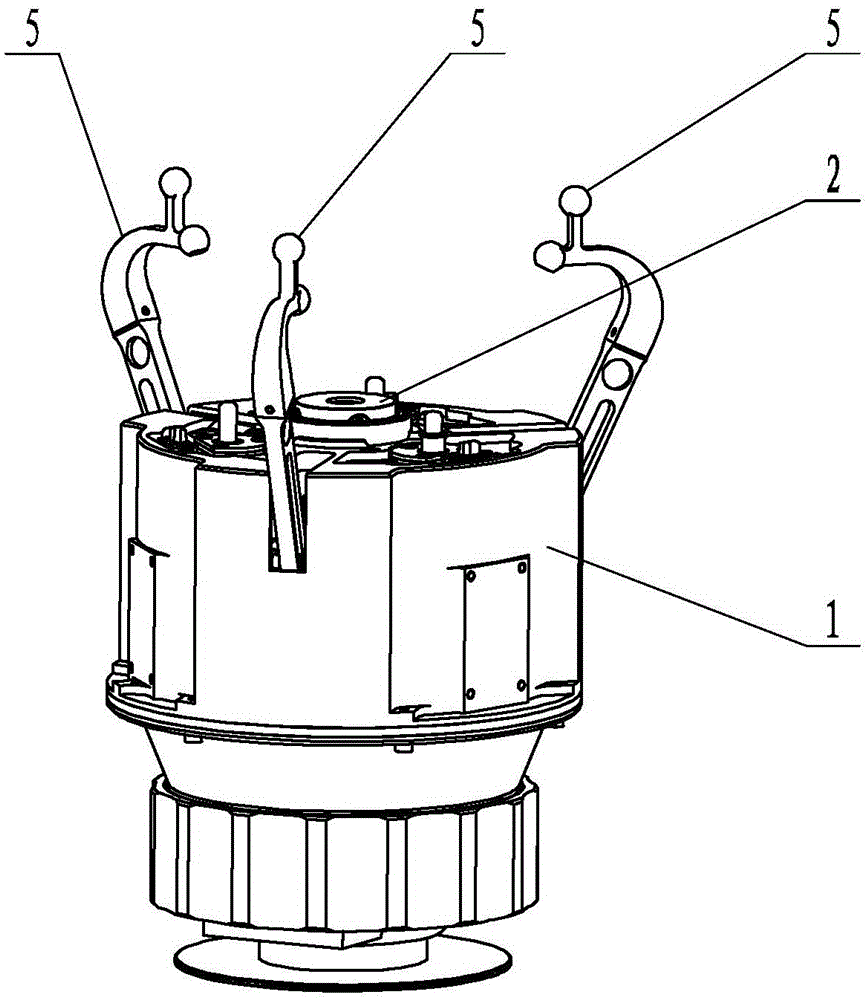

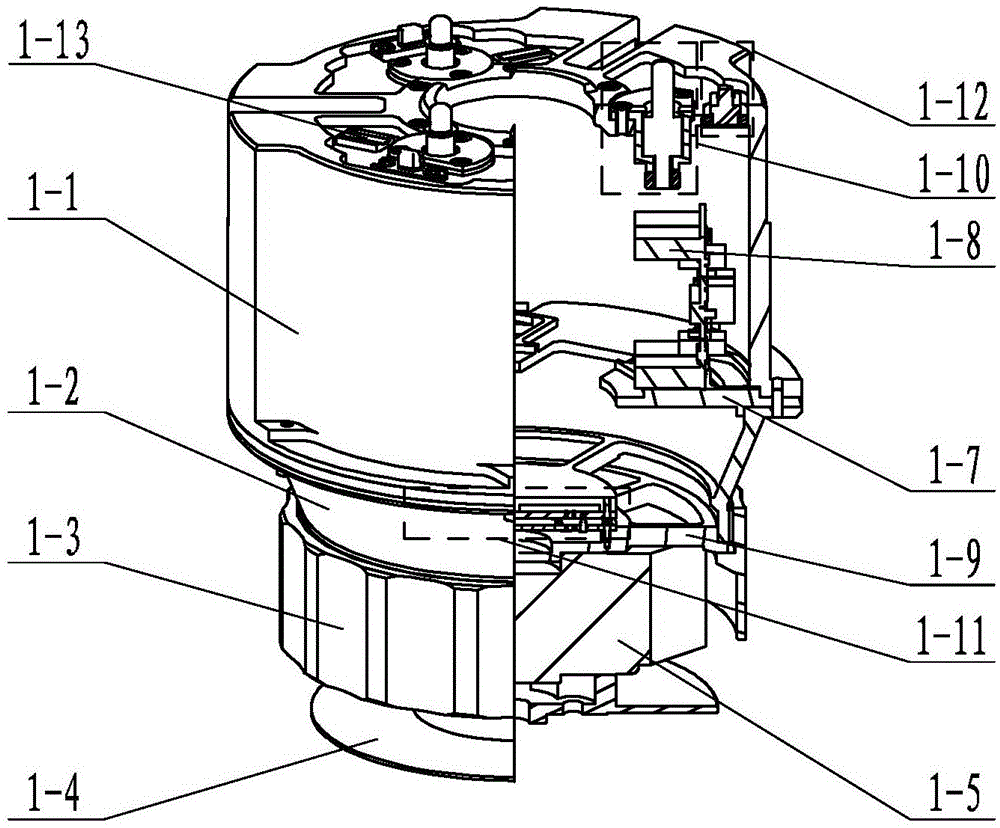

Automatic injecting interface

InactiveCN103434661ASelf-filling implementationSimple interactionCosmonautic component separationButt jointPressure sense

The invention provides an automatic injecting interface. A receiving interface is connected with a receiving platform; an output interface is connected with an output platform; one end of a tapered butt joint of the receiving interface is provided with an opened tapered outward-flared part, and the other end of the tapered butt joint is provided with a guide pipe; the guide pipe is connected with an injection storage device; a receiving interface controller is in communication with a receiving platform computer and controls a sealing switch to drive a seal for sealing the guide pipe so as to seal injection; auxiliary butting devices of the output interface are arranged at the two sides of the head of an output pipe; the head of the output pipe is subjected to spherical treatment and is internally provided with a pressure sensing device; when both the two sides of the head of the output pipe are pressed, accurate butting is achieved, and then an inner layer sleeve driver drives a hollow cylindrical inner layer sleeve inside the output pipe to extend into the receiving interface so as to form stable connection. The automatic injecting interface is simple in information interaction mode, the control accuracy requirement during butting can be lowered, and meanwhile, the automatic injecting interface has a disturbance resisting capability and is capable of automatically injecting fluids between platforms.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

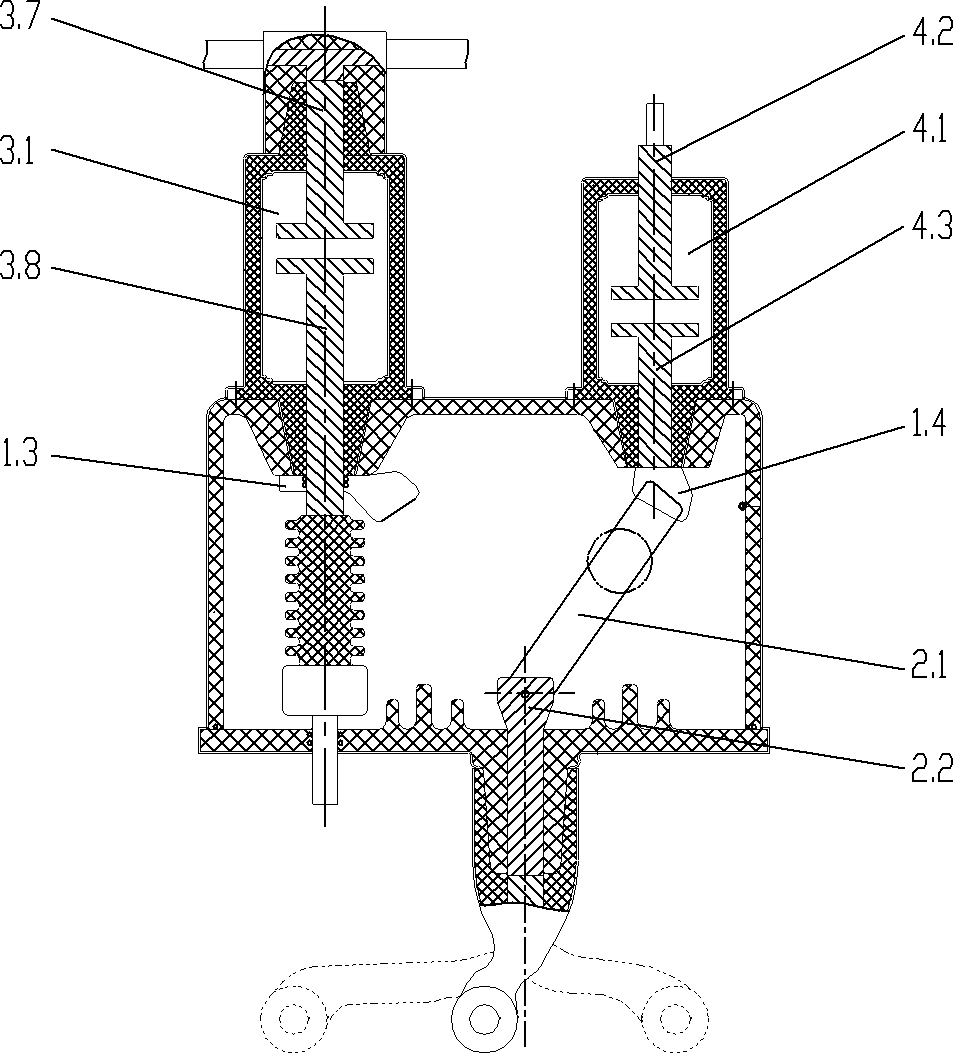

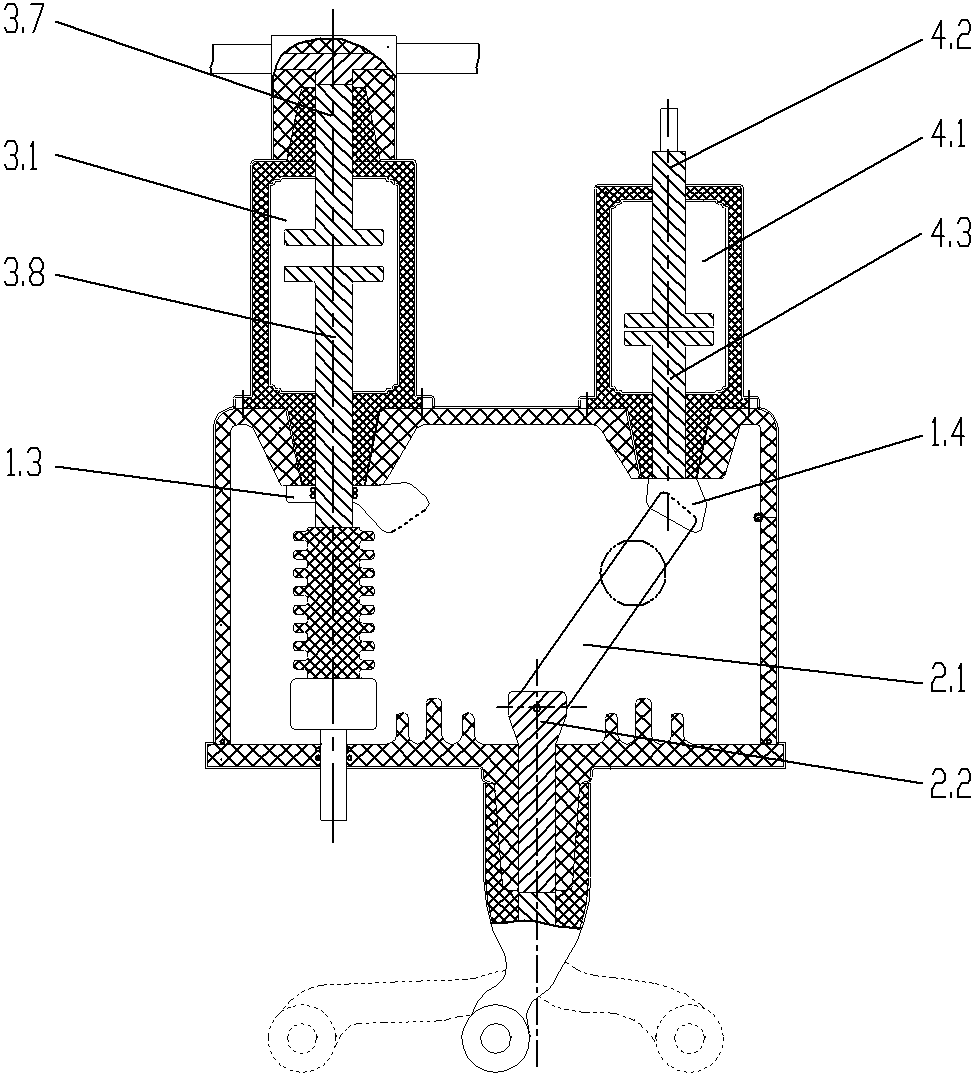

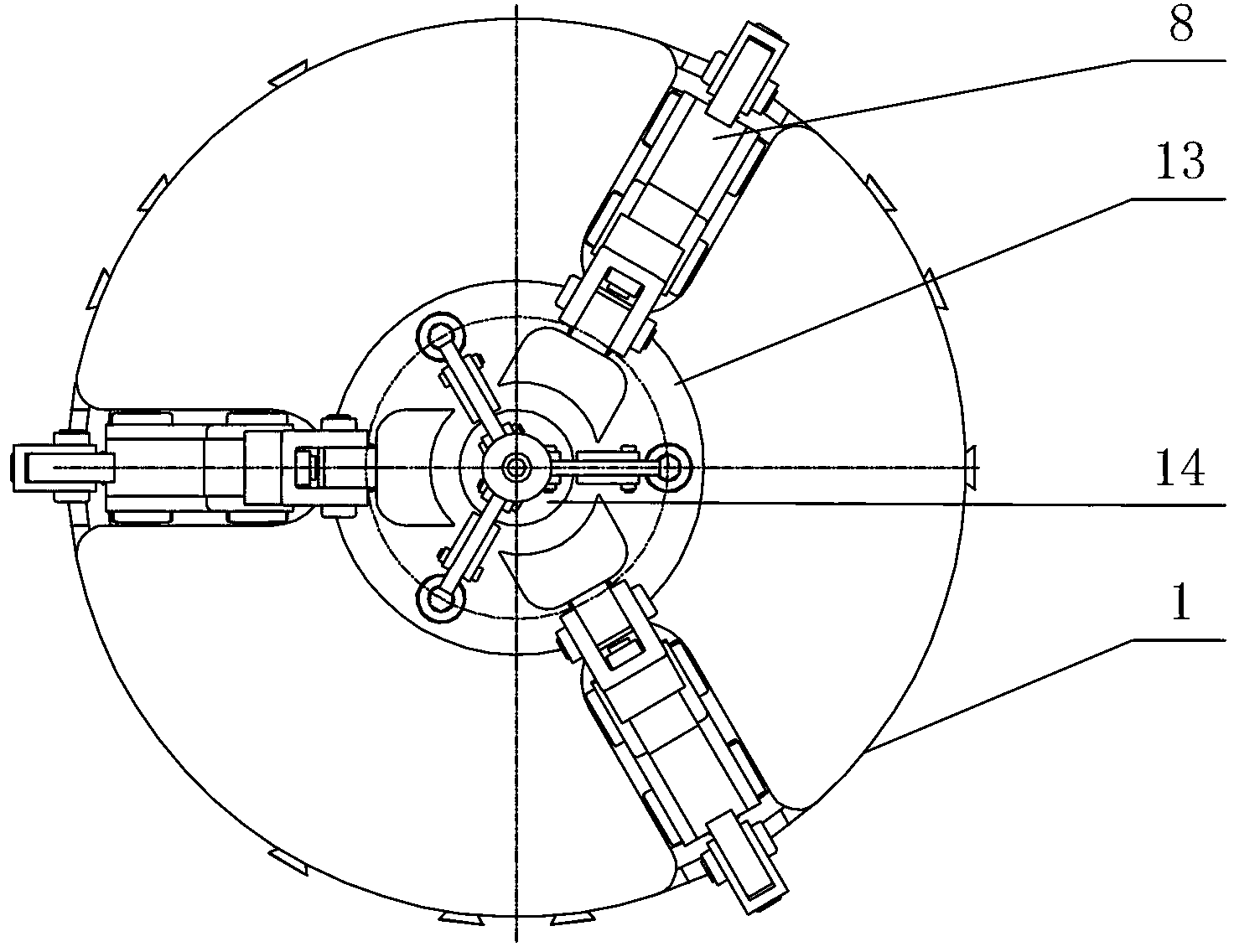

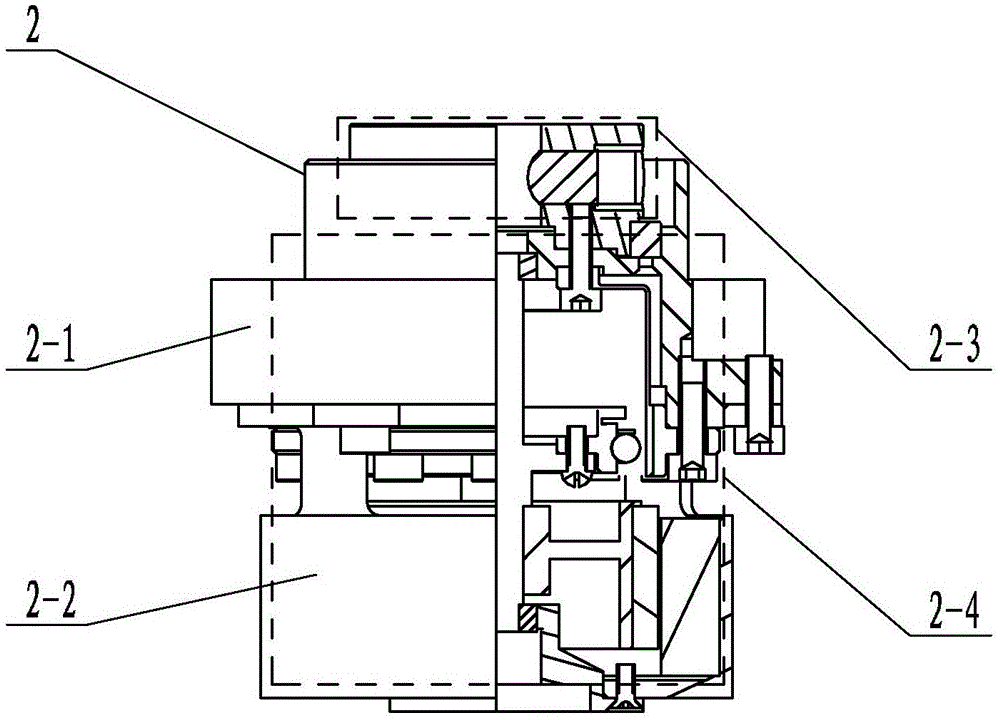

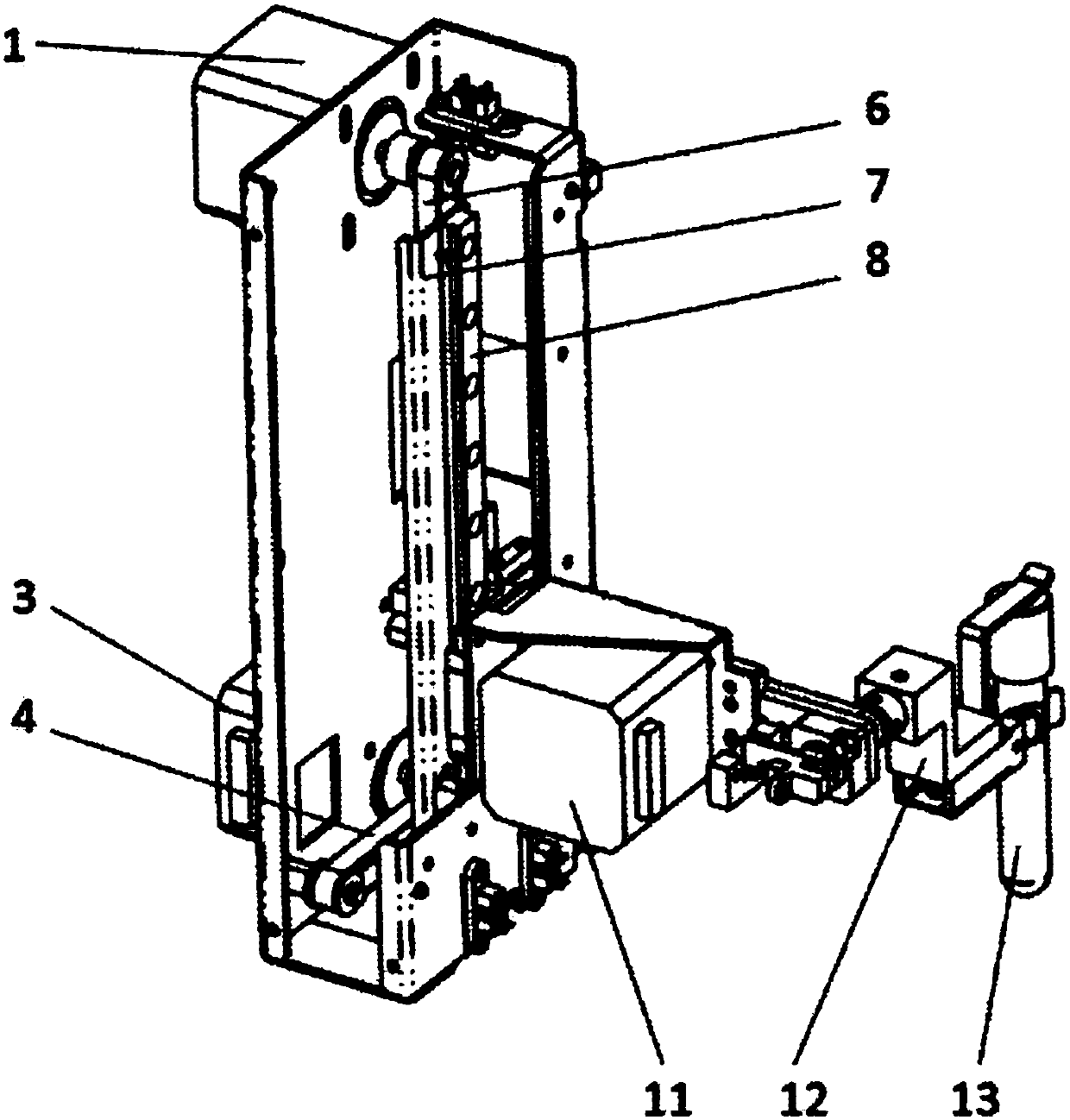

Large-tolerance mini-sized end effector having electromechanical output function

ActiveCN105082169AReduce control precision requirementsSmall Volume Tolerance RatioGripping headsAviationComputer module

The invention discloses a large-tolerance mini-sized end effector having an electromechanical output function and relates to an end effector. The large-tolerance mini-sized end effector having the electromechanical output function aims at solving the problems that an existing space manipulator end effector does not have an electromechanical output function and is poor in operability, small in tolerance and large in energy consumption. The large-tolerance mini-sized end effector comprises a shell module, a power output module, a sensor module, a plurality of motion driving modules and a plurality of capturing motion chains; a motion chain shell, a driving shell, a thread fixing shell and a manipulator connecting piece are communicated in sequence from top to bottom; a motion fixing seat is installed between the motion chain shell and the driving shell; the power output module is arranged inside the motion chain shell in a penetrating mode; the motion driving modules and the power output module are coaxial and are fixed to the motion fixing seat; each capturing motion chain is fixedly connected to the motion fixing seat and driven by the corresponding motion driving module to move; a plurality of connection detecting assemblies are located at the top end of the motion chain shell and distributed at the periphery of the power output module uniformly; the motion fixing seat is fixedly connected to the bottom of the motion chain shell. The large-tolerance mini-sized end effector having the electromechanical output function is applied to the field of space flight and aviation.

Owner:HARBIN INST OF TECH

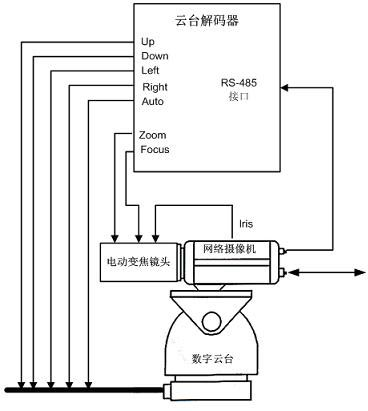

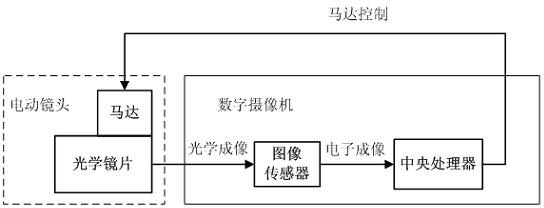

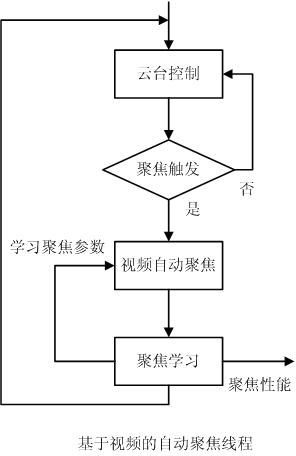

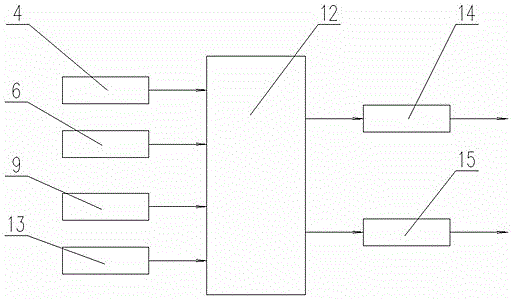

Automatic focusing control system for electric lens of digital camera

InactiveCN102387309AReduce control precision requirementsShorten the timeTelevision system detailsColor television detailsCamera lensPhysics

The invention discloses an automatic focusing control system for an electric lens of a digital camera. The automatic focusing control system is characterized by comprising an electric lens part and a digital camera part, wherein the optical imaging signal output end of an optical lens in the electric lens part is connected with the signal input end of an image sensor in the digital camera; a motor in the electric lens part is connected with the optical lens; the electronic imaging signal output end of the image sensor in the digital camera part is connected with the signal input end of a central processor; and the signal output end of the central processor is connected with the signal input end of the motor in the electric lens part. The automatic focusing control system has the advantages that: automatic focusing of a uniform electric lens is realized by a standard RS-485 focusing control motor; a precise, real-time and automatic focusing function can be realized easily by upgrading a camera firmware without changing hardware and functions of the standard electric lens in the market and modifying a hardware design of the camera; the precision is improved and the cost is reduced; and the automatic focusing control system is in accordance with an intelligent tendency of development of the digital camera.

Owner:王兴国

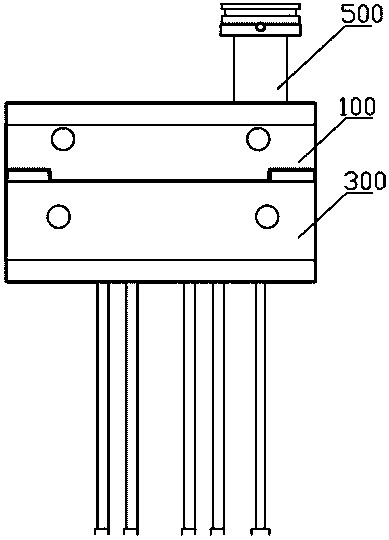

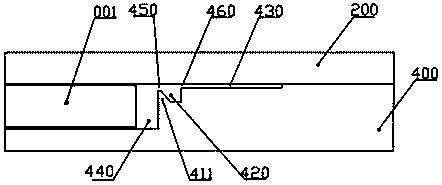

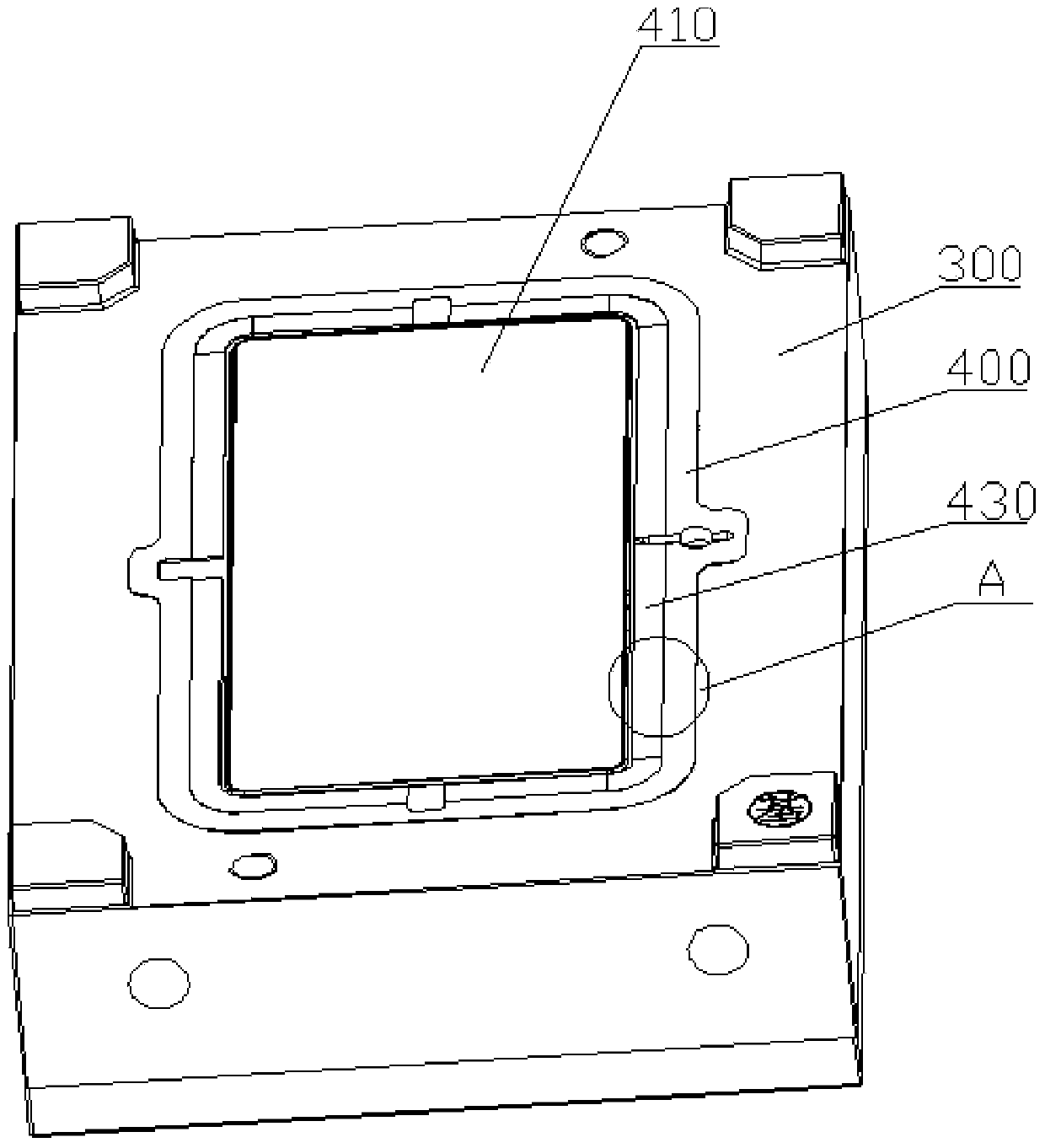

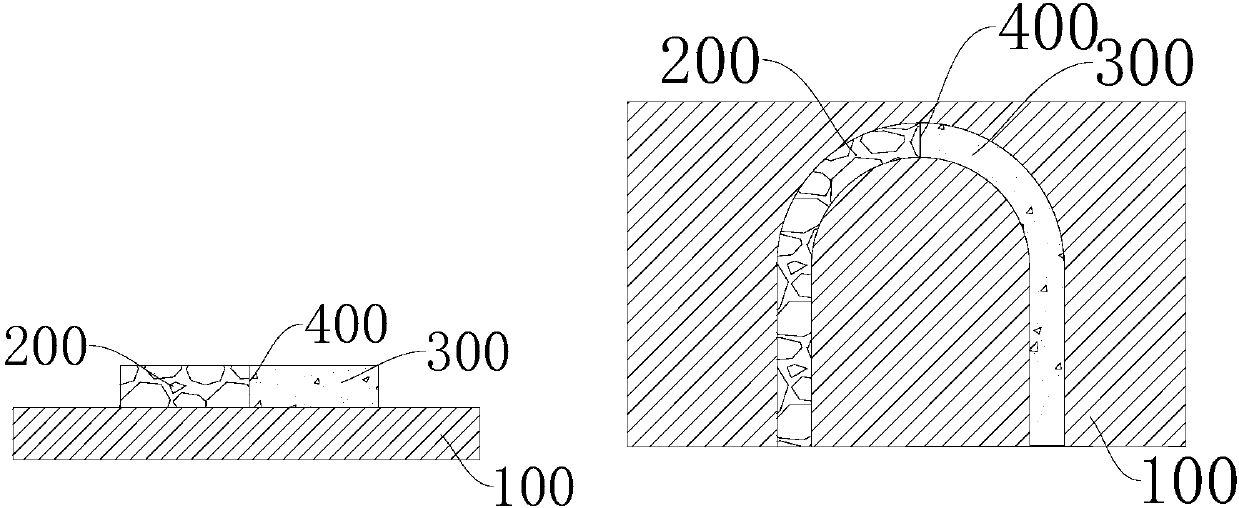

Liquid silicone rubber injection mold

The invention discloses a liquid silicone rubber injection mold used for injection forming of a rubber edge structure at the side edge of a basal body. The liquid silicone rubber injection mold includes a front mold plate, a front mold core, a back mold plate, a back mold core and a pouring sleeve, and is characterized in that: the back mold core is provided with a basal body fixing groove, a rubber inlet groove communicated with the pouring sleeve, and a rubber overflow area; the basal body fixing groove is used for fixing the basal body, and a silicone rubber edge forming cavity is formed between the side edge of the basal body and the sidewall of the basal body fixing groove after the basal body is fixed and the mold is clamped; the rubber inlet groove is arranged along the sidewall of the basal body fixing groove; after mold clamping, a rubber inlet channel for communicating the rubber inlet groove and the silicone rubber edge forming cavity is formed between the top of the sidewall of the basal body fixing body and the front mold core; the rubber overflow area is arranged along one side, far away from the rubber edge forming cavity, of the rubber inlet groove, and is communicated with the rubber inlet groove through a rubber overflow channel; and the bottom of the rubber inlet channel is lower than the bottom of the rubber overflow channel. The liquid silicone rubber injection mold has the advantage of being good in injection effect and easy to control.

Owner:DONGGUAN HUAQING OPTICAL TECH

Closing construction method for steel bar-concrete superposed beam cable-stayed bridge

ActiveCN103147409AReduce control precision requirementsReduce waiting timeBridge erection/assemblyCable stayedSteel bar

A closing construction method for a steel-concrete superposed beam cable-stayed bridge comprises the following steps: manufacturing a handy elliptical hole tool splicing plate, closing at a fixed time, tool splicing plate temporarily fixing construction, construction of a permanent splicing plate replacing tool a splicing plate, and the like. According to the invention, the construction of the handy elliptical hole tool splicing plate is adopted for accomplishing timed closing construction to the steel-concrete superposed beam cable-stayed bridge, and then in-plant punching manufacture and on-site replacement construction are performed on the permanent splicing plate according to the position size of a blot hole of the closed tool splicing plate, so as to achieve midspan closing. The orderliness and the definitiveness of organization of closing construction procedures can be enhanced, the construction efficiency is improved, and construction quality and safety are ensured.

Owner:CCCC FIRST HIGHWAY XIAMEN ENG

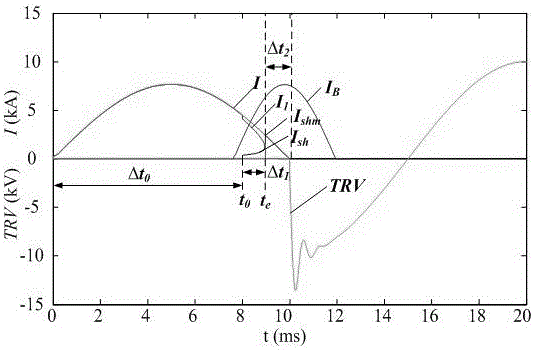

Post arc current measurement method based on current transfer characteristics and magnetic blowout

InactiveCN106597271AAvoid interfering with the signalReduce control precision requirementsCurrent/voltage measurementCircuit interrupters testingPeak valueEngineering

The present invention relates to a post arc current measurement method without ground interference and with high precision based on current transfer characteristics and magnetic blowout. With the current transfer characteristics as a basis, with magnetic field arc blow as auxiliary, the isolation measurement of a measurement circuit and a main circuit is realized, and a ground interference signal is effectively avoided. At the same time, through transfer branch resistance parameter design and a magnetic blowout effect, the current of a resistance branch can be effectively controlled, thus a vacuum switch is switched off after a main current peak, and thus the control precision requirement of the vacuum switch is low. The method has the advantages of high measurement precision, less interference, and high reliability. In addition, through optical fiber isolation control and data communication, the on-line measurement of the post arc current of a power system can be satisfied.

Owner:DALIAN UNIV OF TECH

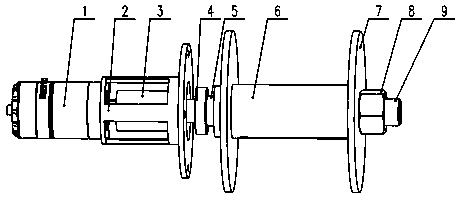

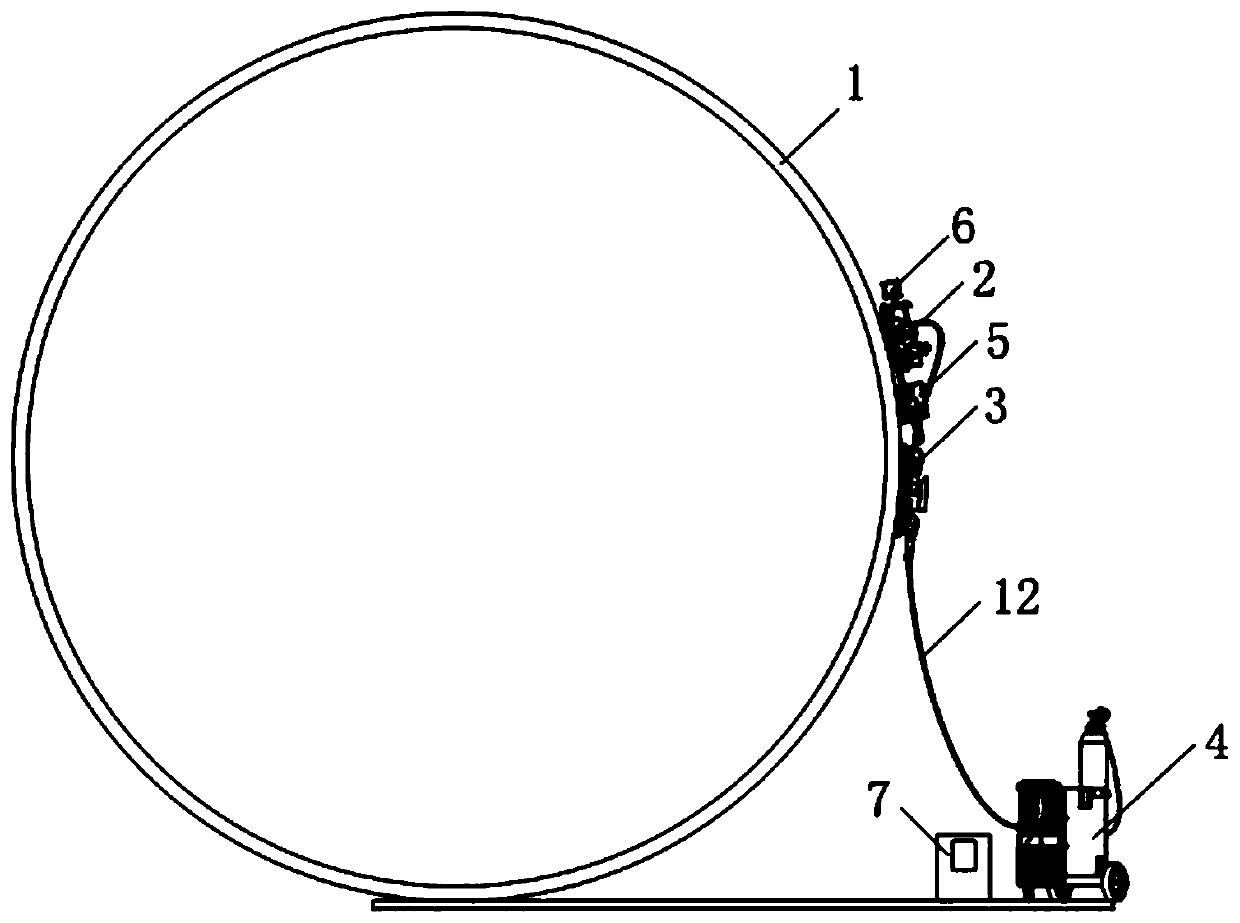

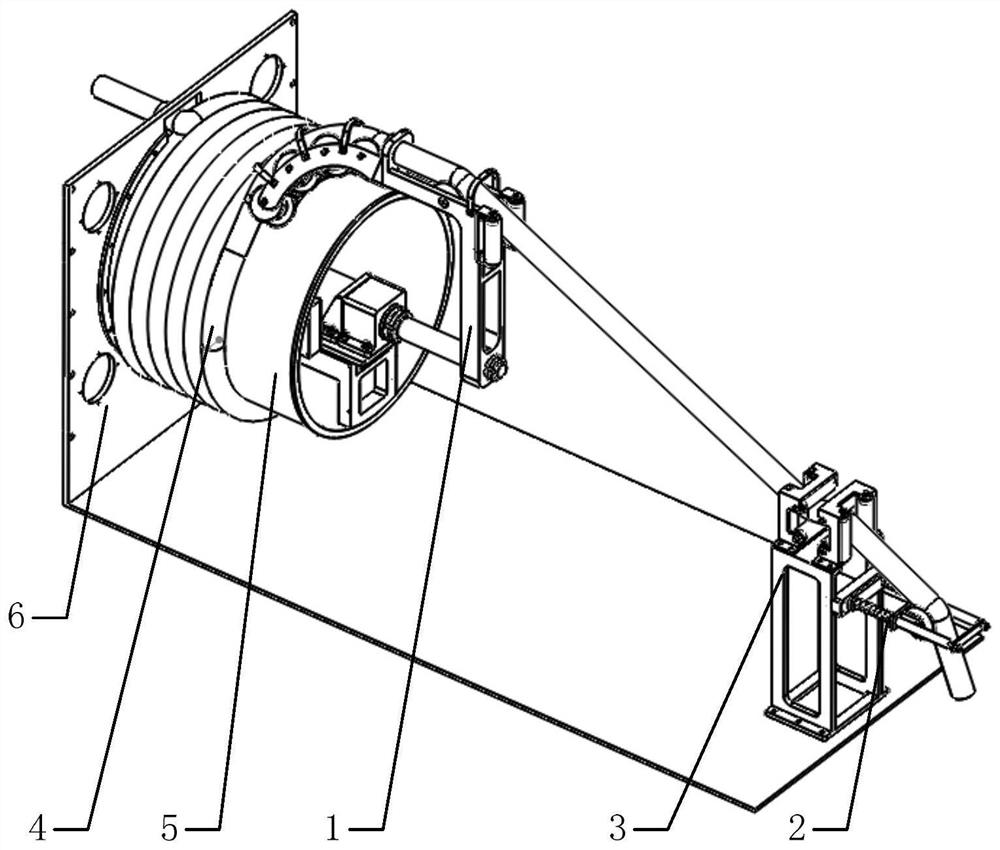

Tension-controllable non-slip-ring type take-up and pay-off mechanism

The invention relates to take-up and pay-off equipment, in particular to a tension-controllable non-slip-ring type take-up and pay-off mechanism. The tension-controllable non-slip-ring type take-up and pay-off mechanism comprises a winding arm, a cable positioning assembly, a cable, a winding reel and a support; the cable positioning assembly and the winding reel are arranged on the support, and a winding arm base is arranged in the winding reel; one end of the cable is wound around the winding reel, and the other end of the cable sequentially passes through the winding arm and the cable positioning assembly; and the winding arm has two degrees of freedom which are correspondingly used for winding, unwinding and arranging cables, and the cable positioning assembly is used for positioning the cables. The two-degree-of-freedom winding arm is used for actively winding the cables, the real-time dynamic following type power supply requirement of a mobile robot in the extreme environment can be met, and the power supply safety and reliability are greatly improved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

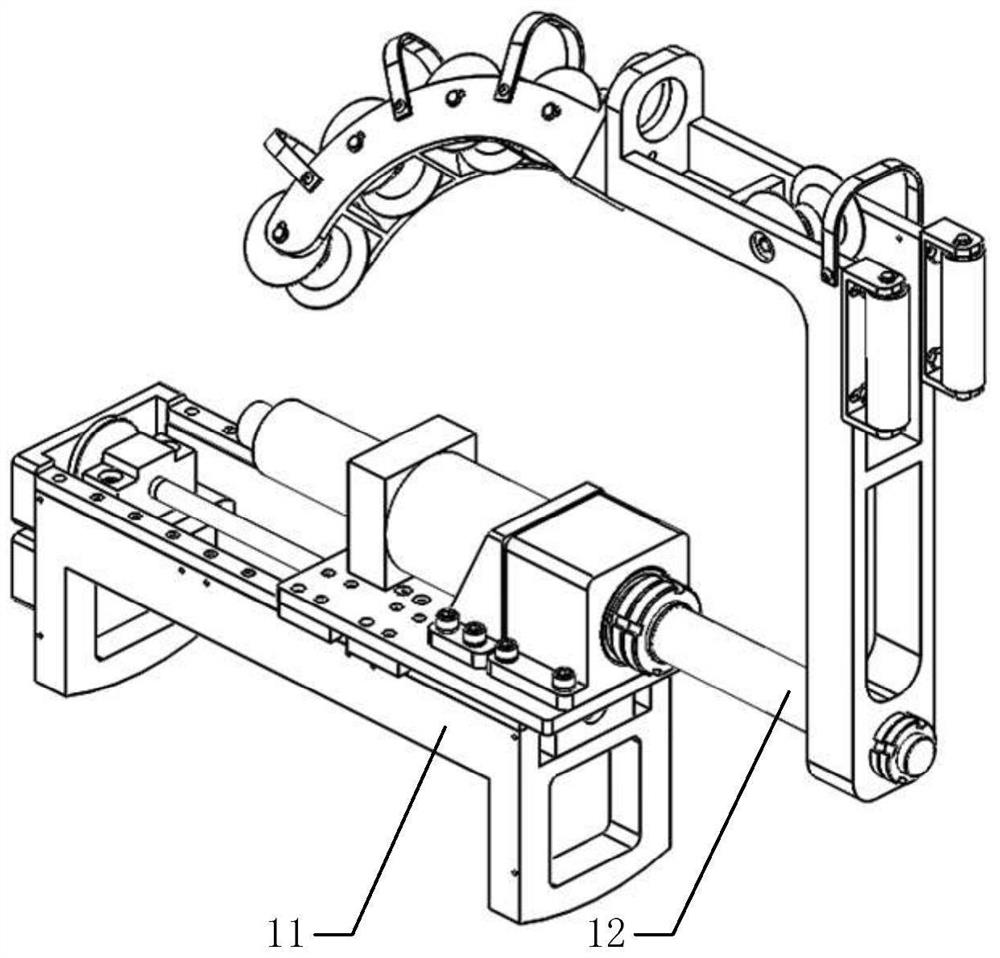

Axial feeding device and charging docking device

PendingCN110217122AAchieve regulationSimple structureCharging stationsElectric vehicle charging technologyLinear motionElectric machinery

The invention belongs to the technical field of mechanical arms, and particularly relates to an axial feeding device and a charging docking device; the axial feeding device comprises a base and an adjusting seat; one side of the base is provided with three linear driving devices, and each linear driving device comprises a linear motion assembly; the middle linear motion assembly is rotationally connected with a limiting rod; swing rods are hinged to two ends of the limiting rod, and a movable rod is hinged between the two swing rods; the limiting rod, the two swing rods and the movable rod form a parallelogram mechanism; the movable rod is installed on the adjusting seat; the linear motion assemblies on two sides are connected with connecting rods through universal ball joints, and the twoconnecting rods are connected to the adjusting seat through universal ball joints; a first motor is mounted on the adjusting seat, and an output shaft of the first motor is connected to the movable rod; the adjusting seat is used for installing operation tools. The device has the beneficial effects that the adjusting seat can rotate leftwards and rightwards to adjust the operation tool to a required operation direction, and / or the axial feeding operation is carried out after the operation position of the operation tool is adjusted.

Owner:GUOCHUANG INNOVATION CENTER OF MOBILE ENERGY (JIANGSU) CO.,LTD.

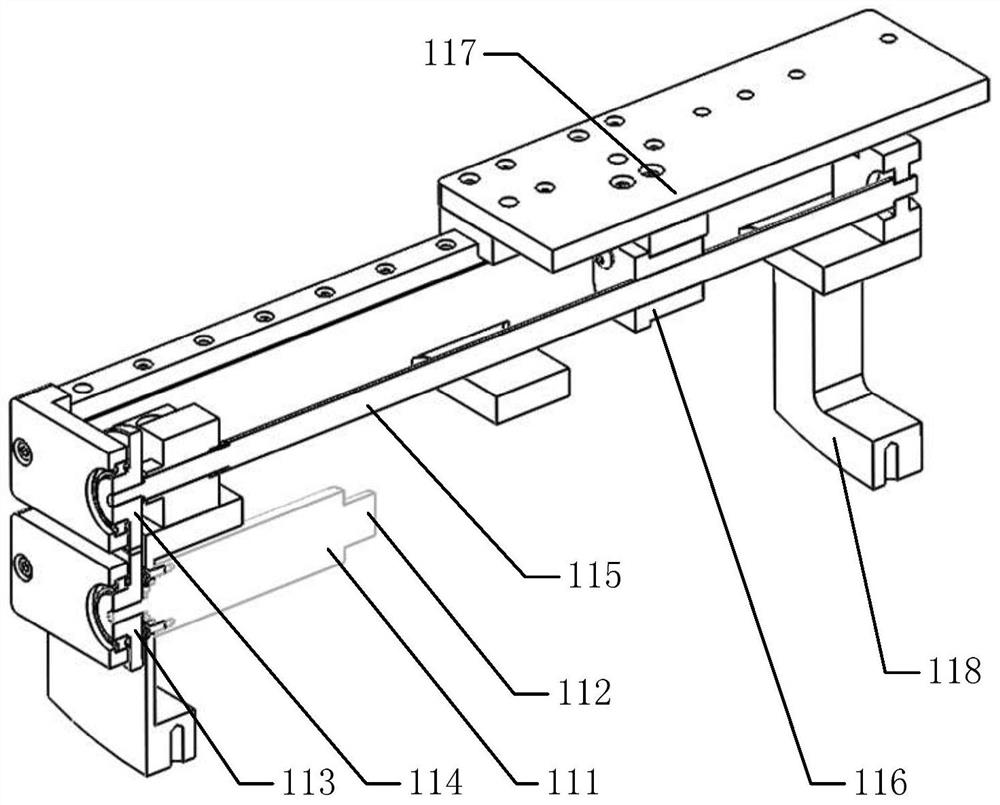

Test tube mixing device

ActiveCN108014700AImprove stabilityLow matching accuracy requirementsShaking/oscillating/vibrating mixersTransportation and packagingEngineeringTest tube

The invention provides a test tube mixing device. The test tube mixing device comprises a shell, a vertical moving mechanism, a horizontal moving mechanism, a test tube pick and place assembly and a driving rod, wherein the vertical moving mechanism is arranged on the shell, the horizontal moving mechanism is arranged on the vertical moving mechanism, and the test tube pick and place assembly is rotatably mounted on the horizontal moving mechanism. The drive rod is fixedly arranged on the shell and is positioned on the vertical moving track of the test tube pick and place assembly. When the test tube pick and place assembly moves towards the driving rod in the vertical direction, the test tube pick and place assembly press against the driving rod and is stirred by the driving rod to rotate. According to the technical scheme provided by the invention, power driving parts are reduced, so that the requirement of overall matching precision and overall control precision of the whole test tube mixing device is reduced, and the stability of the use of the test tube mixing device is improved.

Owner:SHANDONG EXCELLENCE BIOTECHNOLOGY CO LTD

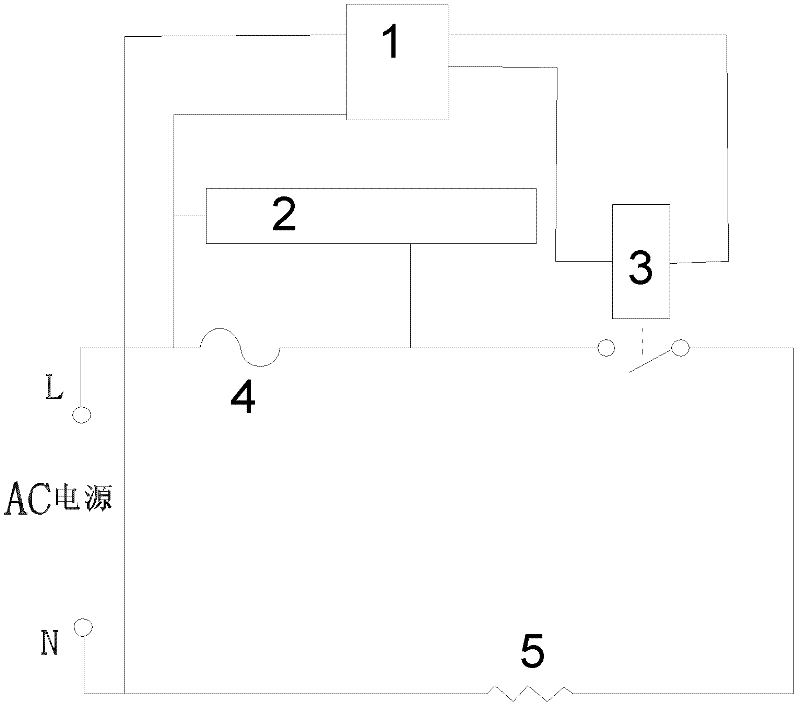

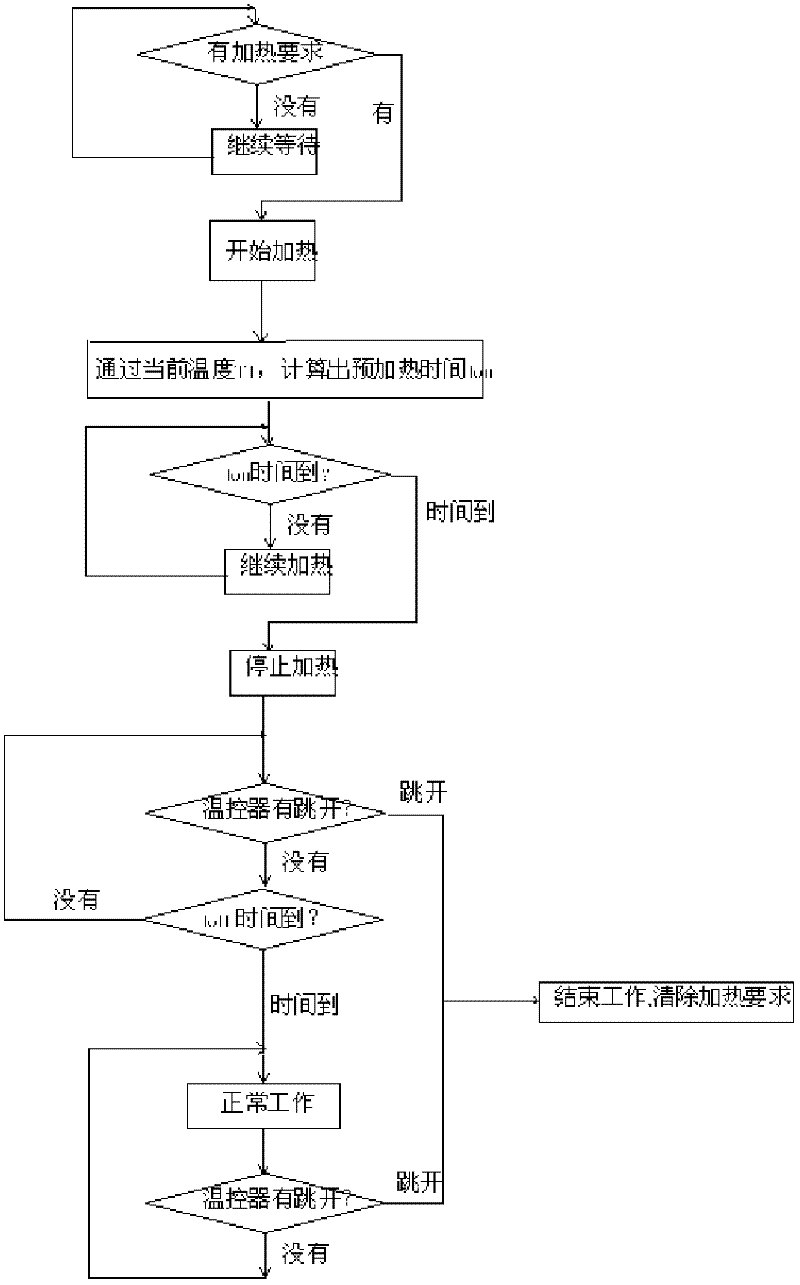

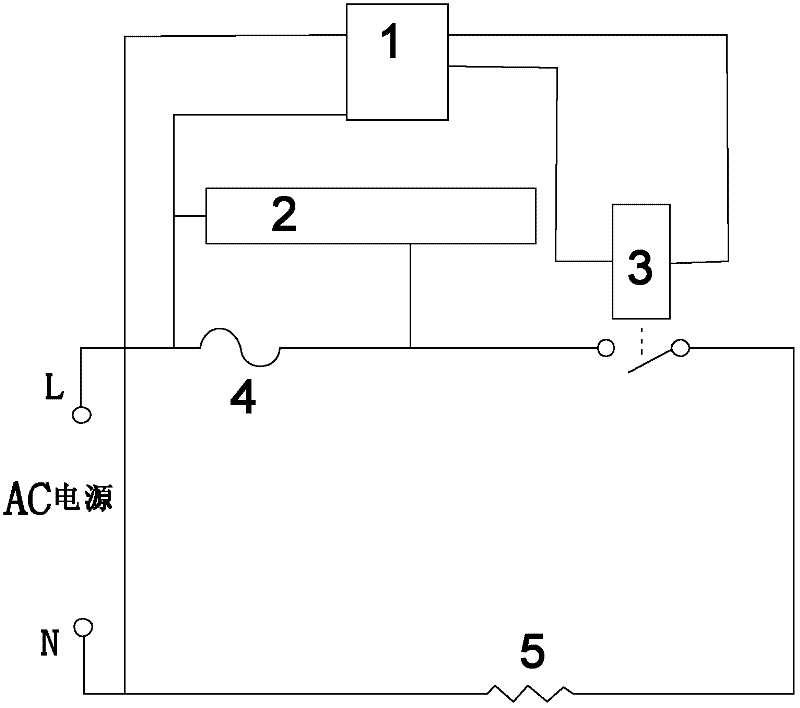

Dry heating protection control method for liquid electric heater

ActiveCN102589137AAccurately control dry burning timeSave temperature sensorFluid heatersStop timeHeating power

A dry heating protection control method for a liquid electric heater relates to protection control methods for liquid electric heaters. The method includes steps: A, mounting a temperature controller on the liquid electric heater, serially connecting the temperature controller with a heater heating element and a control relay, and arranging detection modules at two ends of the temperature controller, wherein the detection module is used for detecting on and off of the temperature controller; B, allowing a microprocessor controlled by programs to perform a short-time heating program when the liquid electric heater is started for heating, namely allowing the heating element of the heater to heat in a short time and then stopping heating in a short time, wherein the heating time and the stop time are determined according to intrinsic power and the size of the heating element; and C, using the microprocessor to judge whether the liquid electric heater is in dry heating or not according to variation of on and off conditions of the temperature controller, and timely cutting off a heating power source of the heating element if the liquid electric heater is in dry heating. Using the dry heating protection control method can accurately control dry heating time, save the temperature sensor, overcome the defect that slow response of a mechanical temperature controller results in overhigh temperature of the heating element and influences the service life of the heating element, lower the requirement on control precision of the mechanical temperature controller, and reduce purchase cost of control circuit components.

Owner:深圳市北鼎晶辉科技有限公司

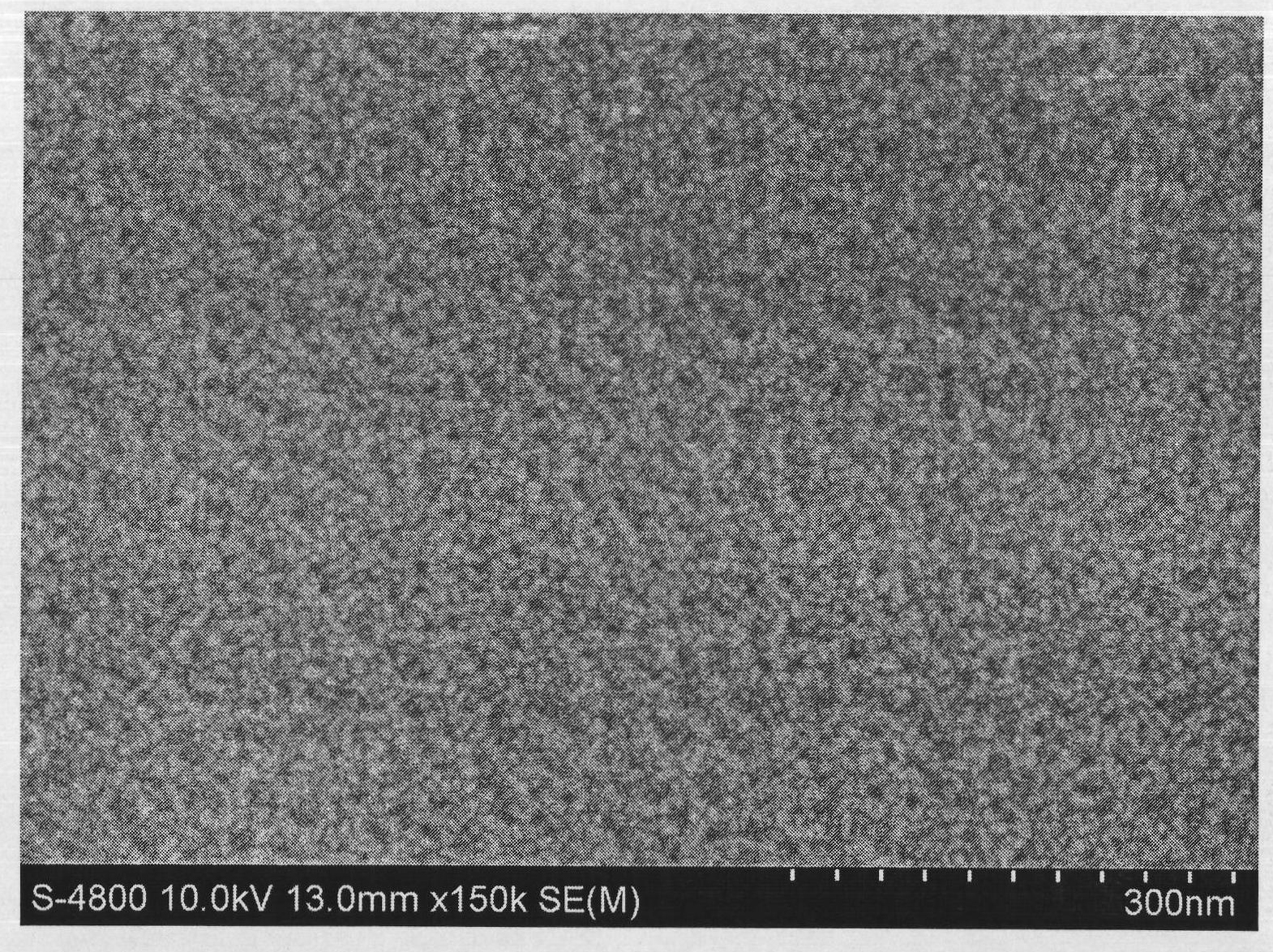

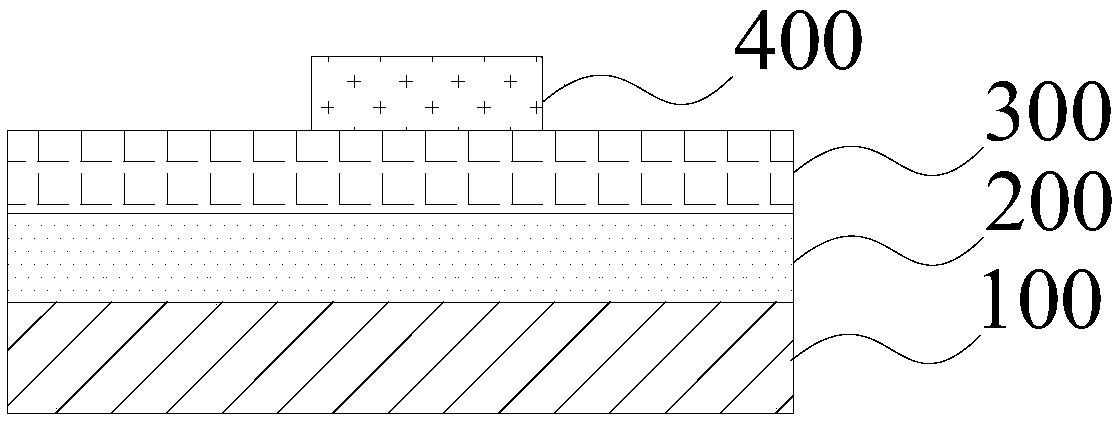

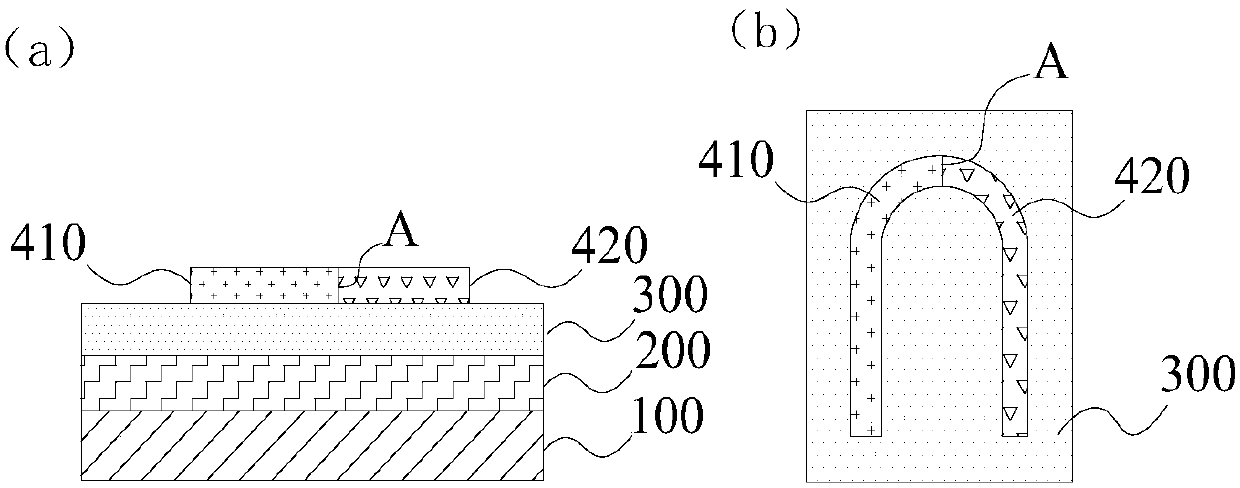

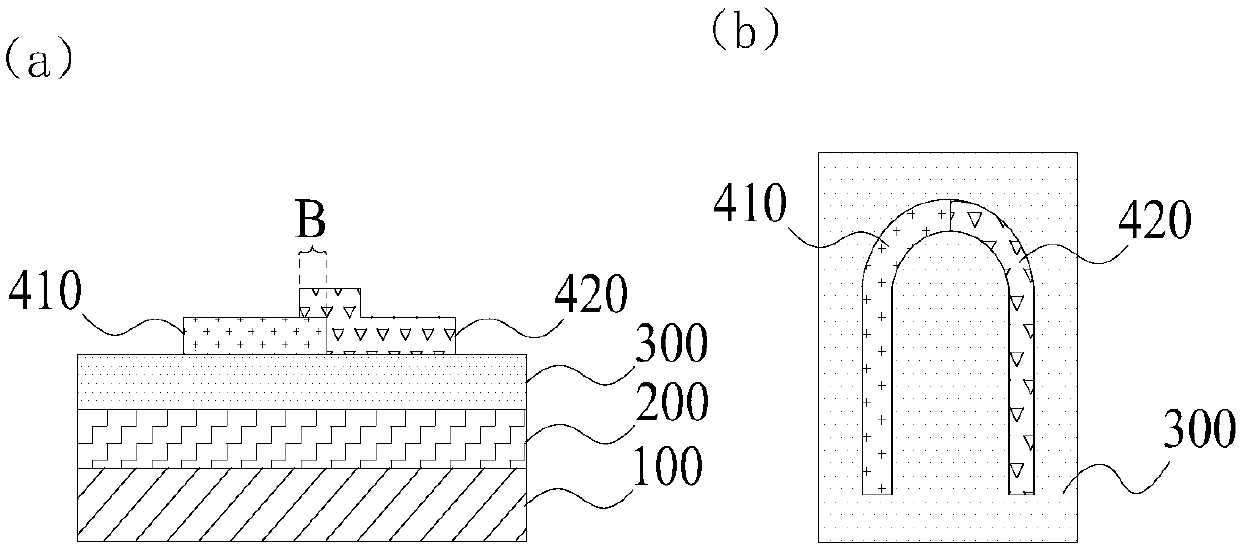

Thermocouple, preparation method thereof, and electric appliance

ActiveCN110129851AImprove performanceConvenient oxidation treatmentAnodisationMolten spray coatingPore diameterTemperature resistance

The invention discloses a thermocouple, a preparation method thereof, and an electric appliance. The thermocouple comprises a metal substrate, an oxide film layer, an insulation coating and an electrode layer; at least part of the surface of the metal substrate is covered with the oxide film layer, the surface of the oxide film layer is covered with the insulation coating, and the electrode layeris arranged on the side, away from the metal substrate, of the insulation coating, wherein the pore diameter of the insulation coating is not greater than 10 nm. Therefore, the binding performance ofthe insulation coating and the metal substrate in the thermocouple is excellent, the insulation coating is good in high temperature resistance and corrosion resistance, and stability is good; and theinsulation coating is good in compactness and excellent in insulation performance.

Owner:GUANGDONG MIDEA WHITE HOME APPLIANCE TECH INNOVATION CENT CO LTD +1

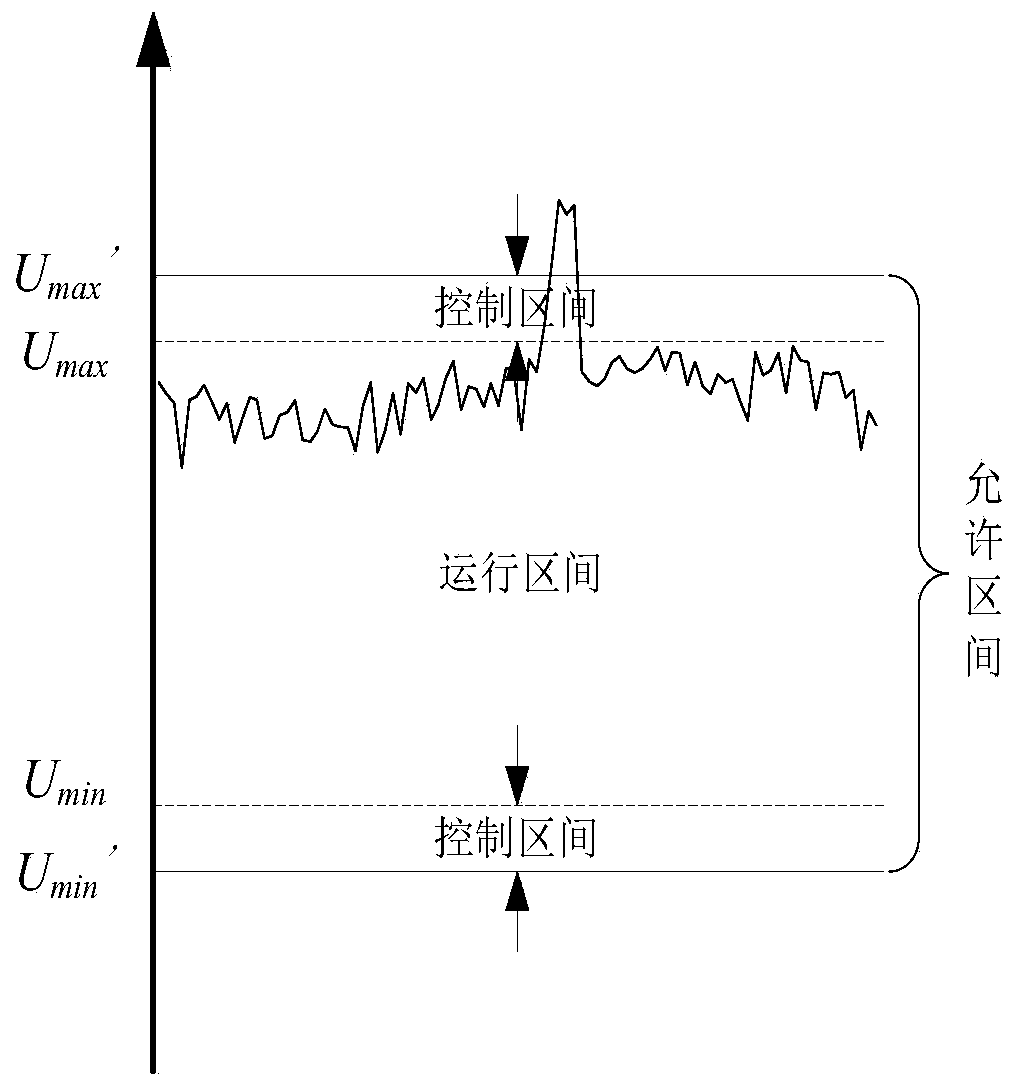

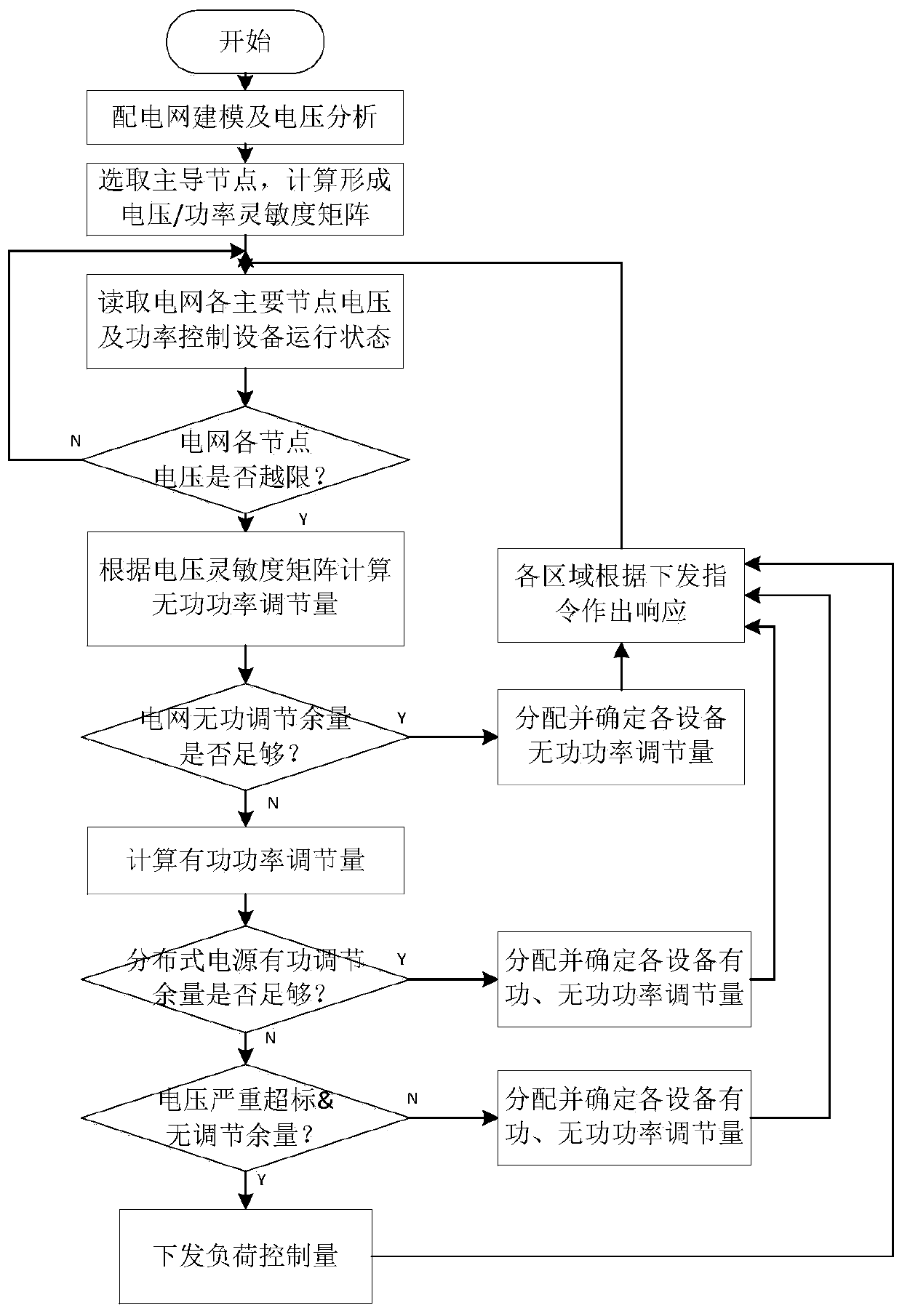

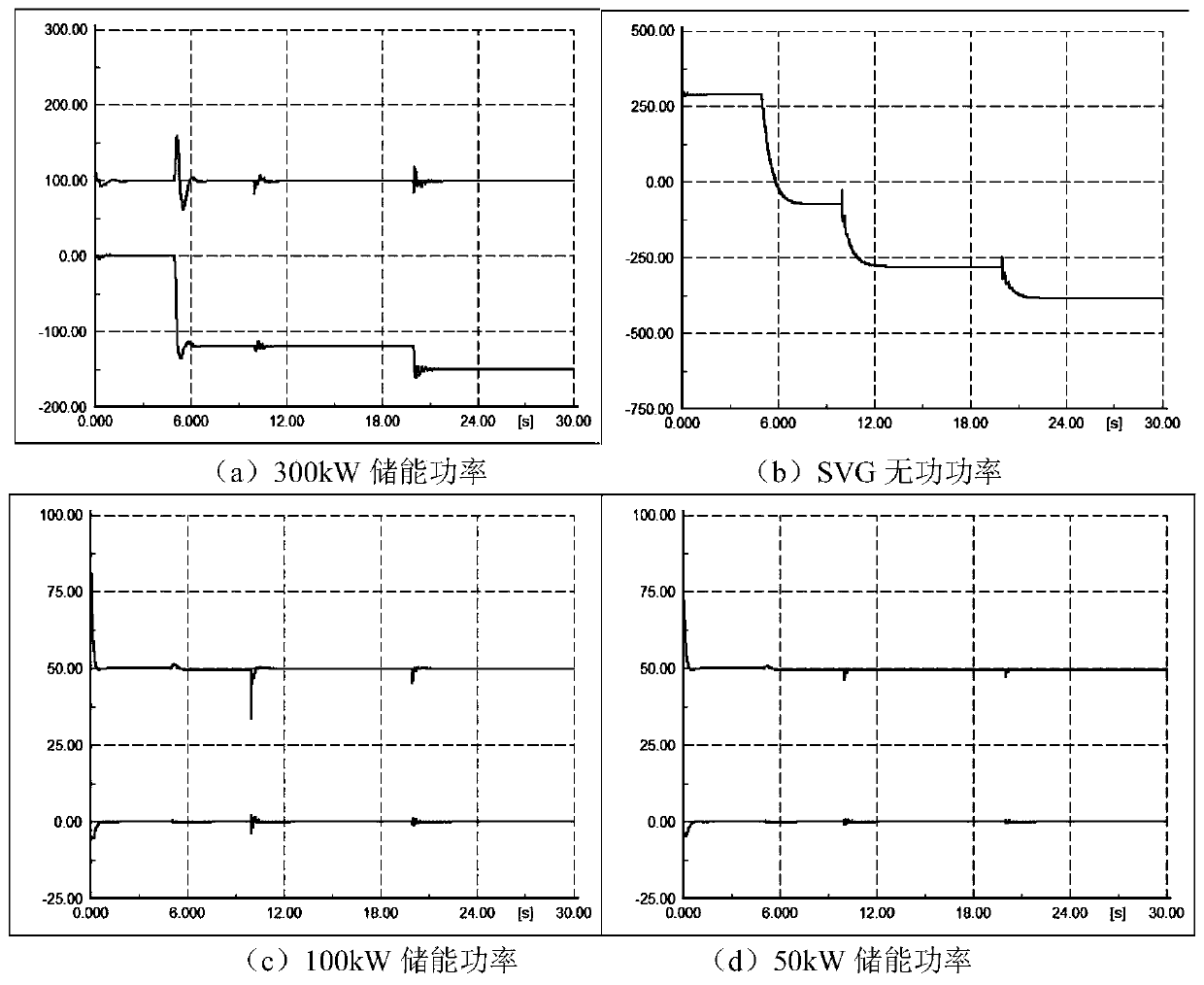

Active power distribution network voltage control method based on power voltage sensitivity analysis

InactiveCN110233482AEasy to implementReduce data volumeAc network voltage adjustmentEngineeringSensitivity analyses

The invention discloses an active power distribution network voltage control method based on power voltage sensitivity analysis. The active power distribution network voltage control method comprisesthe following steps of 1, acquiring power distribution network parameters, establishing a power distribution network simulation model, and carrying out voltage simulation analysis; 2, determining themain nodes in the power distribution network as voltage control objects; 3, obtaining a sensitivity matrix of the main node voltage and active-reactive power of a power distribution area; 4, dividingthe main node voltage control area into an allowable interval, an operation interval and a control interval; 5, monitoring the main node voltage in the power distribution network and each power control equipment (comprising distributed generation), wherein when the sampling voltage of the main nodes continuously exceeds the allowable interval for three times, a power regulation target value is issued to each power control equipment according to the sensitivity matrix, and voltage control is carried out; and 6, realizing power adjustment of each equipment by control, so that the voltages of themain nodes are controlled within the operation interval. The method is simple, practical and easy to implement.

Owner:JIANGSU ELECTRIC POWER CO +2

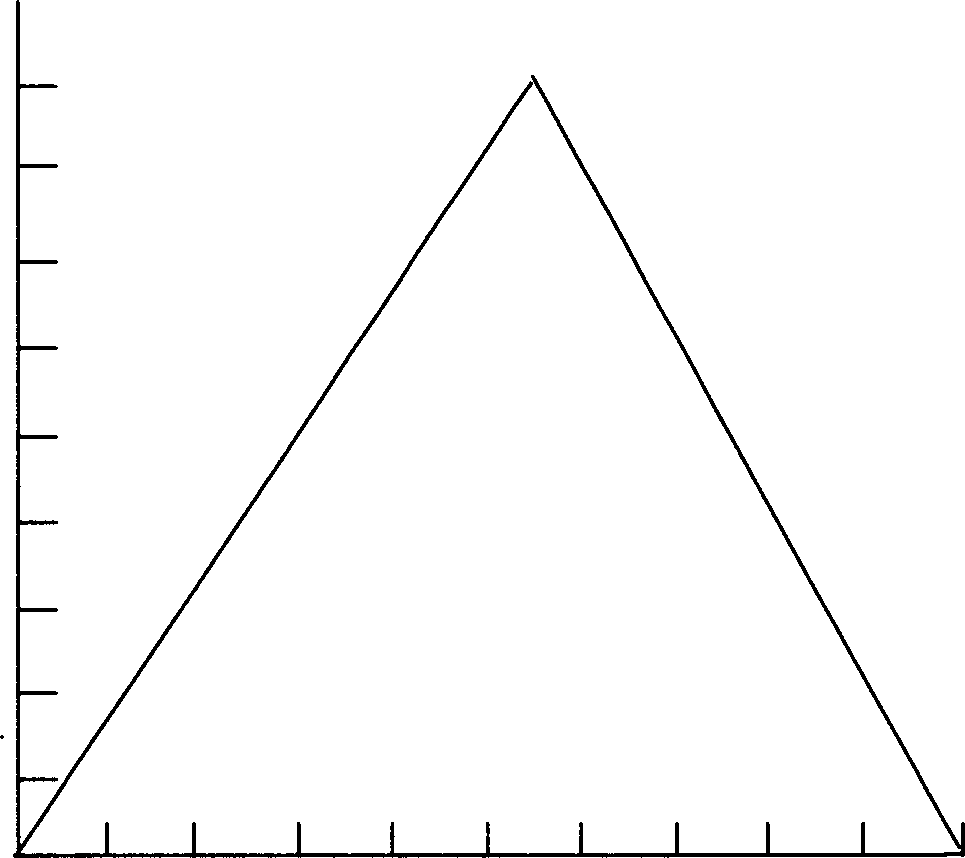

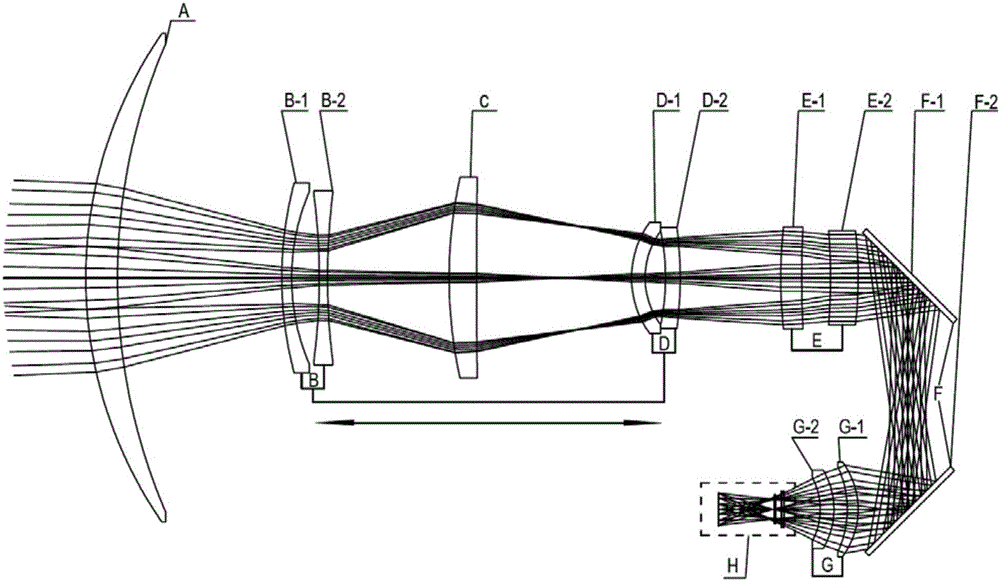

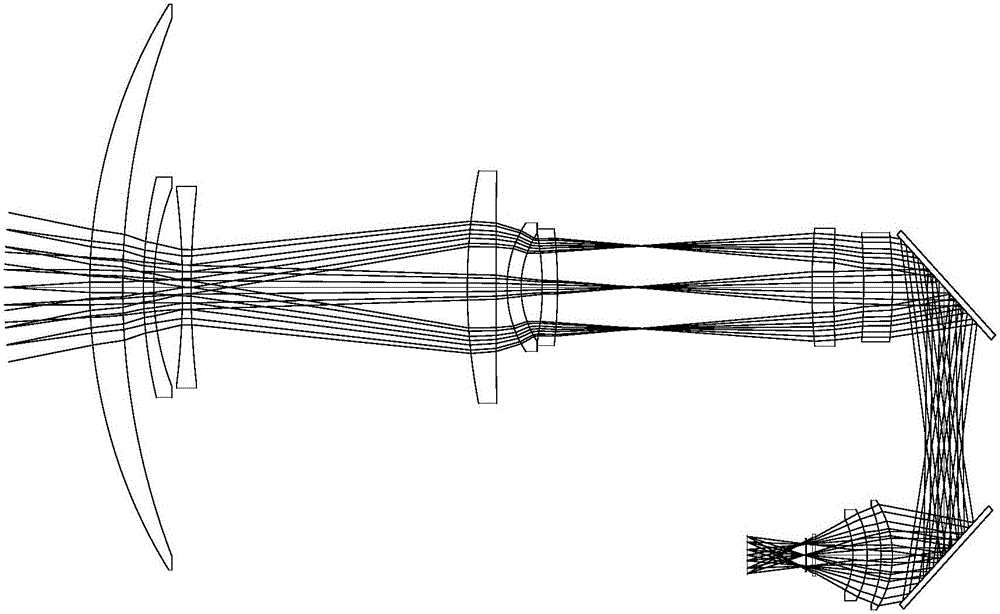

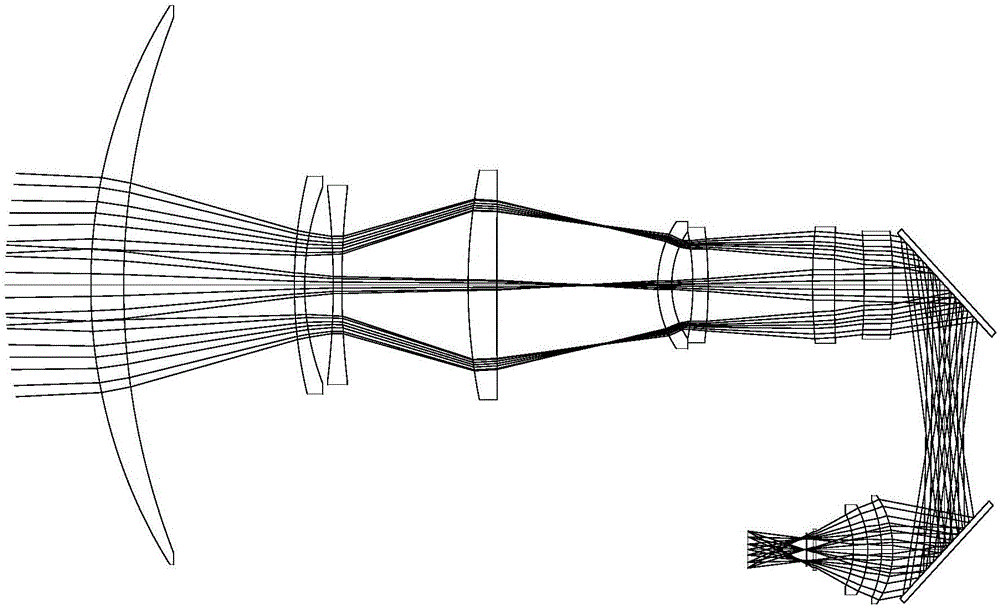

Optical compensation type long-wave infrared continuous zooming optical system

ActiveCN105676432ALong focal lengthHigh zoom ratioCamera body detailsOptical elementsOptical axisControl system

The invention relates to an optical compensation type long-wave infrared continuous zooming optical system, the system comprises a front fixed lens set, a front movable lens set, a middle fixed lens set, a rear movable lens set and a rear fixed lens set, the front movable lens set is formed by a first movable lens and a second movable lens arranged in sequence, the rear movable lens set is formed by a third movable lens and a fourth movable lens arranged in sequence, and the front movable lens set and the rear movable lens are ganged forward and backward with equal interval, equal speed and same direction to realize optical compensation type continuous zooming. The optical compensation type system has a simple structure which is easy to manufacture, and has relatively low precision requirement for controlling the system. A shortcoming that a mechanical compensation system needs precise cooperation of a complex cam structure or double leading screws to ensure image keeping clear in zooming process is overcome.

Owner:凯迈(洛阳)测控有限公司

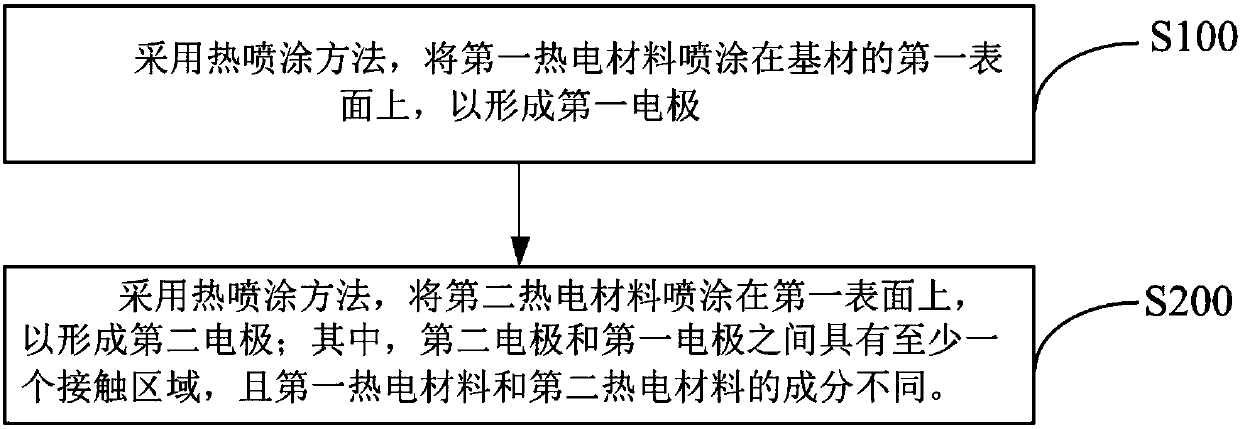

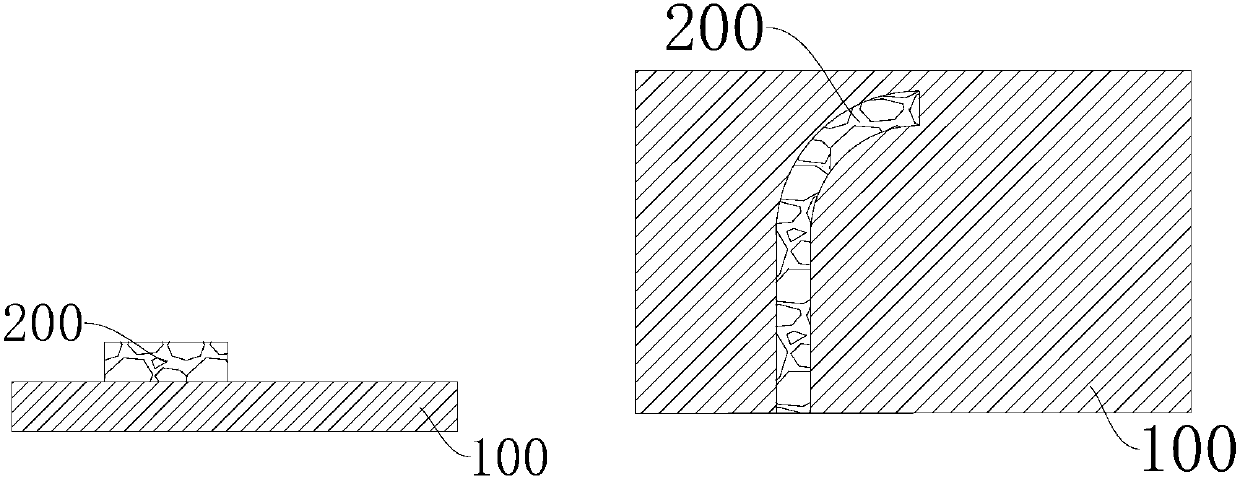

Contact temperature measuring sensor, preparation method thereof, and cooking equipment

PendingCN110129706AReduce control precision requirementsImprove experienceThermometer detailsMolten spray coatingThermoelectric materialsThermal spraying

The invention provides a contact temperature measuring sensor, a preparation method thereof, and cooking equipment. The preparation method of the contact temperature measuring sensor comprises the steps that a thermal spraying method is adopted to spray a first thermoelectric material on the first surface of a substrate, so that a first electrode is formed; and the thermal spraying method is adopted to spray a second thermoelectric material on the first surface, so that a second electrode is formed, wherein one or more contact areas are arranged between the second electrode and the first electrode, and the ingredients of the first thermoelectric material and the second thermoelectric material are different. The preparation method of the contact temperature measuring sensor is easy and convenient to operate and easy to realize, the requirements for control precision of technological parameters are low, feasibility is high, reliability is good, the cost is low, the production efficiencyis high, and actual industrial production is easy.

Owner:MIDEA GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com