Automatic laying device for prestripping of composite material prepreg tape lining paper

A composite material, prepreg tape technology, applied in the direction of spreading thin soft materials, thin material processing, winding strips, etc., can solve problems such as difficulty in cutting depth control, achieve high laying efficiency and laying quality, The effect of easy cutting and low control precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

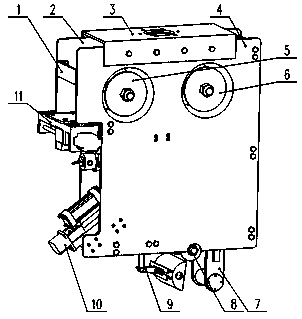

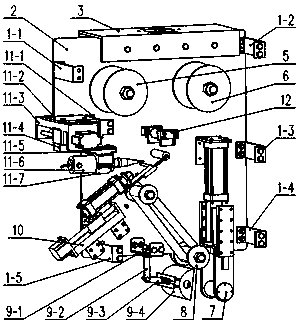

[0029] Such as figure 1 and figure 2 As shown, a composite material automatic laying device based on a six-axis mechanical arm of the present invention includes: a middle frame 1, a left frame 2, an upper frame 3, a right frame 4, a winding mechanism 5, and an unwinding mechanism 6. Pressure roller mechanism 7, transmission mechanism 8, infrared heating mechanism 9, peeling mechanism 10, ultrasonic cutting mechanism 11, limit mechanism 12. Among them, the upper frame 3 is connected to the sixth-axis flange of the six-axis robot arm through bolts, and the six-axis robot arm can perform six-degree-of-freedom movement within a certain space range, which can realize the overall motion control of the composite material automatic laying device.

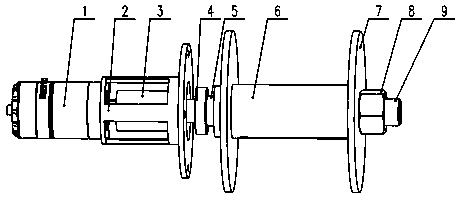

[0030] Such as image 3 As shown, the rewinding motor 5-1 in the rewinding mechanism 5 is installed on the rewinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com