Patents

Literature

839 results about "Slip sheet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slip sheets are thin pallet-sized sheets made of plastic, heavy laminated kraft paperboard, or corrugated fiberboard used in commercial shipping. Often, these replace the use of traditional wooden pallets. The unit load is usually stretch wrapped or shrink wrapped for stability.

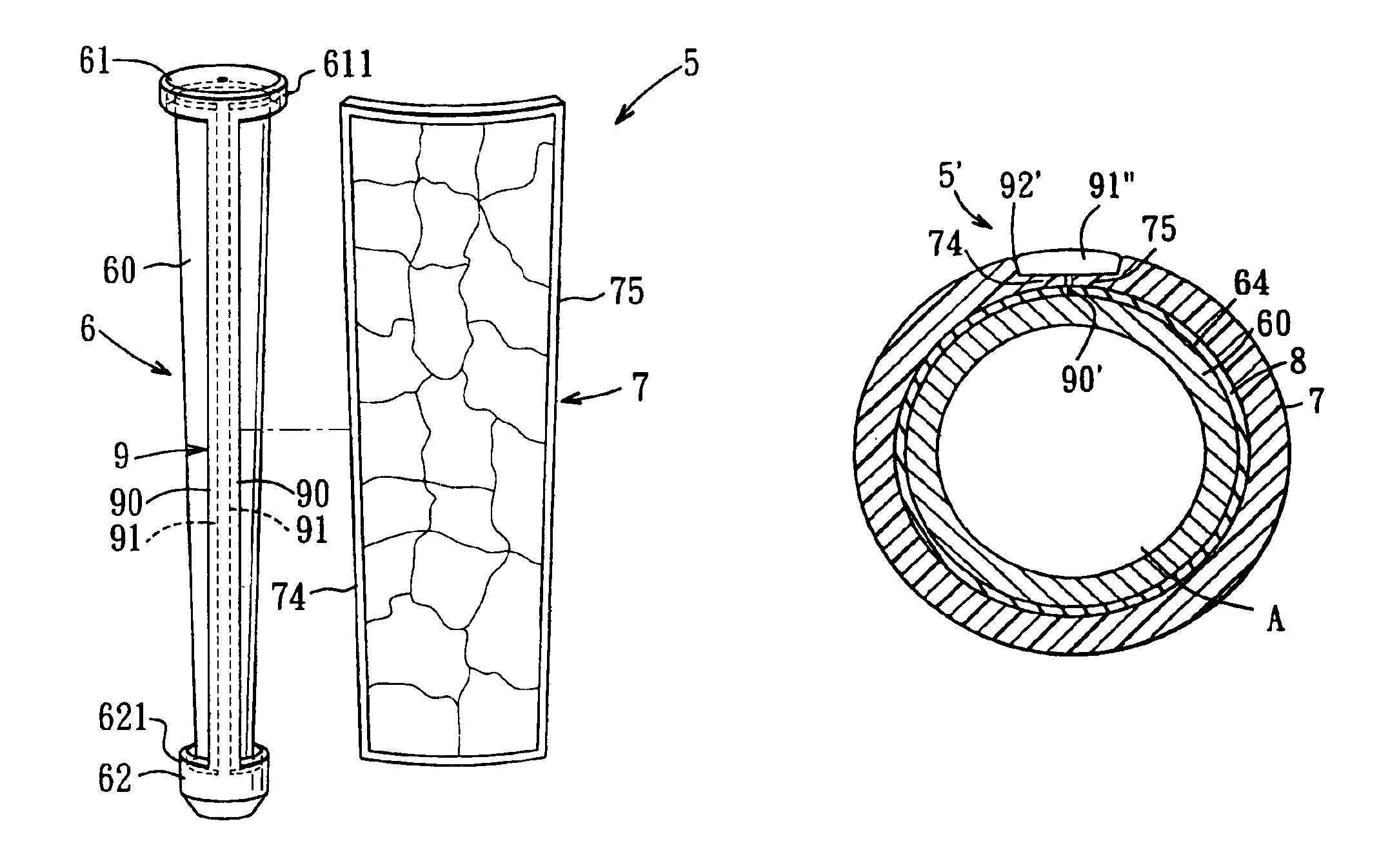

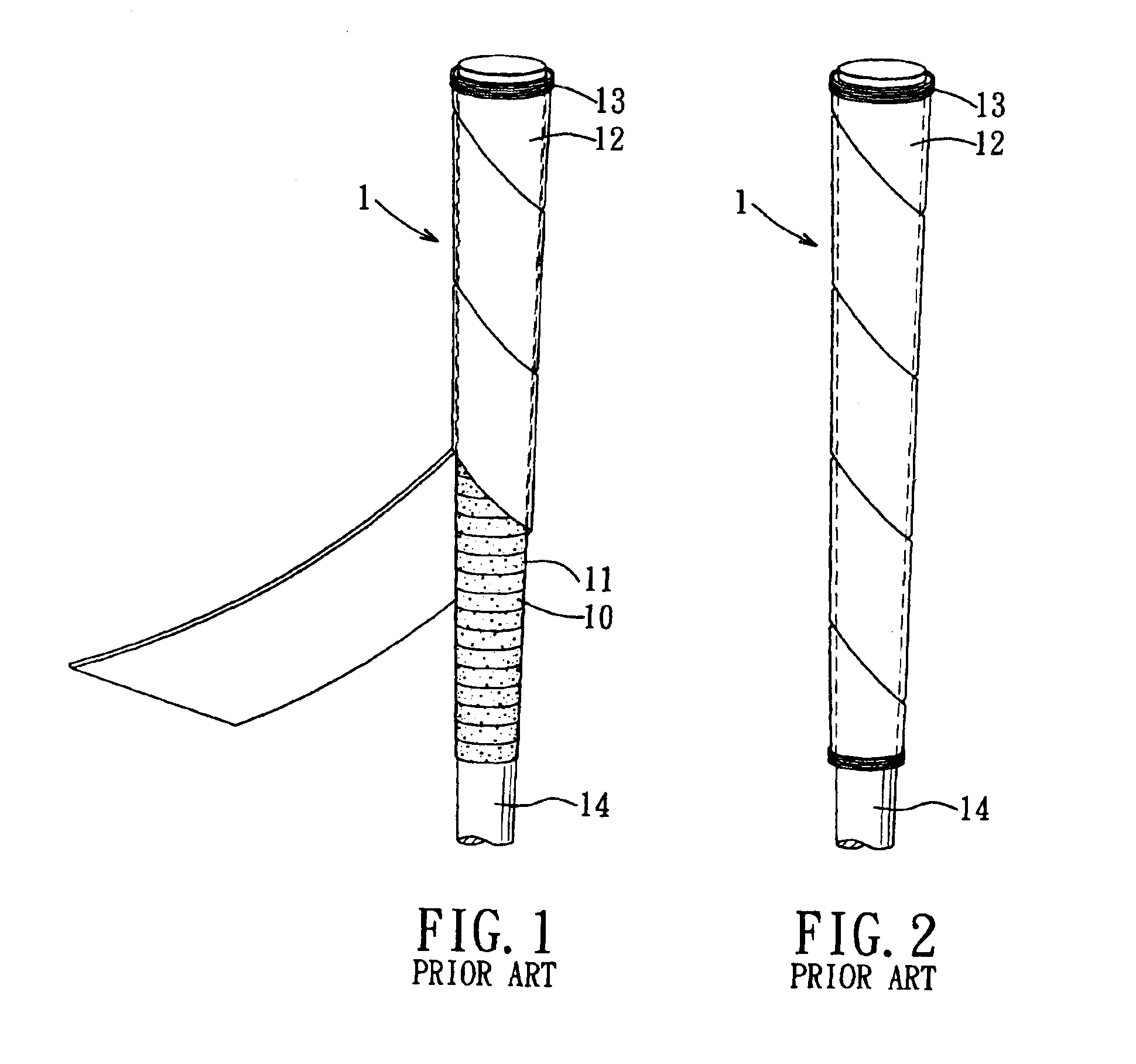

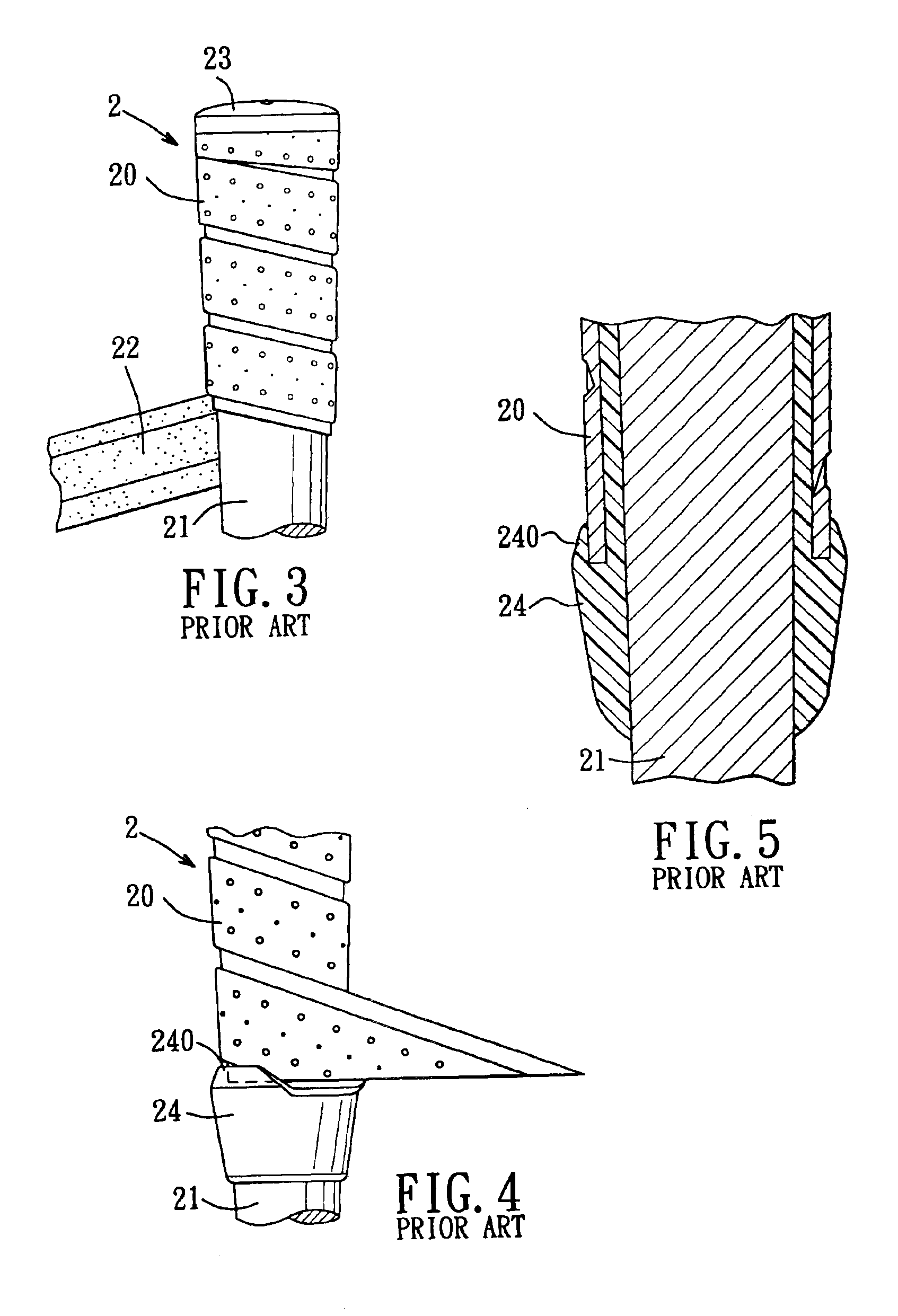

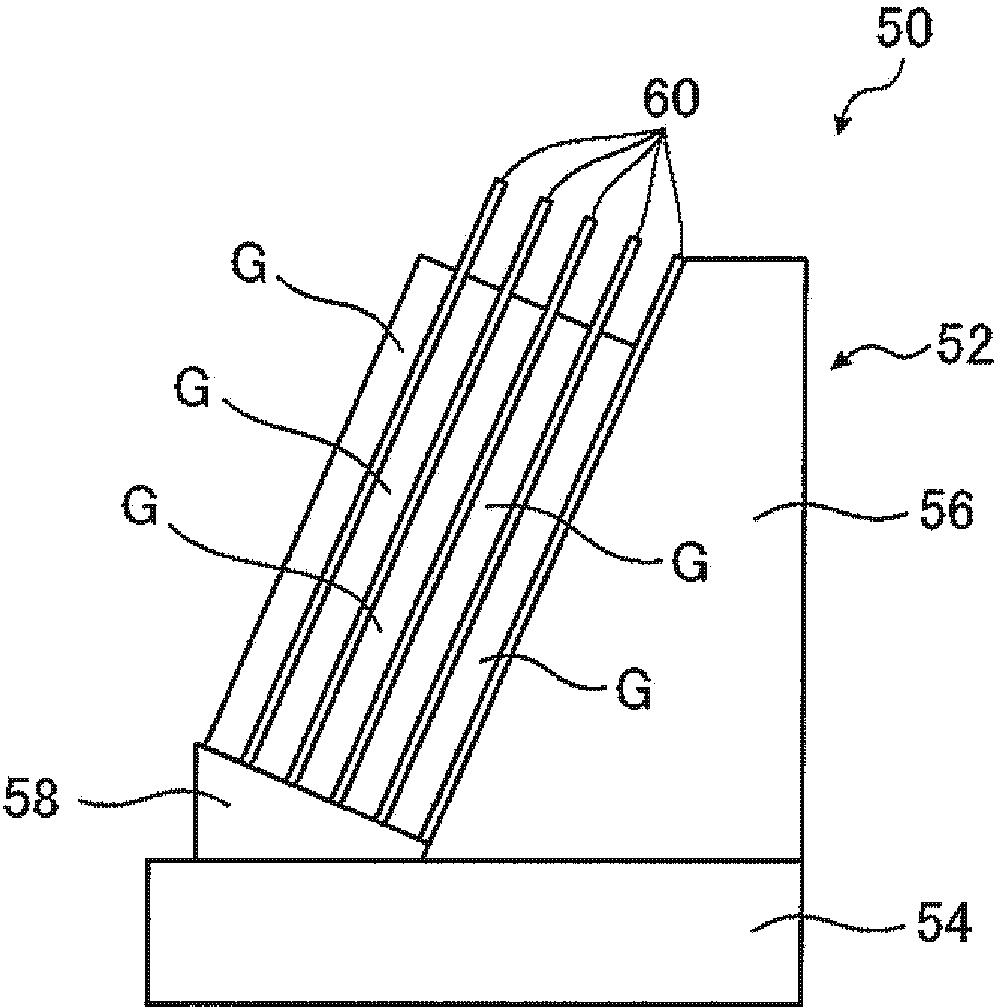

Golf club grip with a hem structure

A golf club grip includes a sleeve body having a top cap and a bottom protective rim, and an anti-slip sheet layer extending around the sleeve body between the cap and the protective rim. The sheet layer has a top circumferential margin which is hidden and hemmed by the cap. The sheet layer further includes two axial margin which extend near to each other and which are hemmed by an axial hem structure of the sleeve body. The axial hem structure extends from the cap to the protective rim to receive and hem the axial margins. As the margins of the sheet layer are hemmed and finished by the cap, the protective rim and the axial hem structure, no visible clearance is formed in the golf club grip.

Owner:CHU HONG SUNG

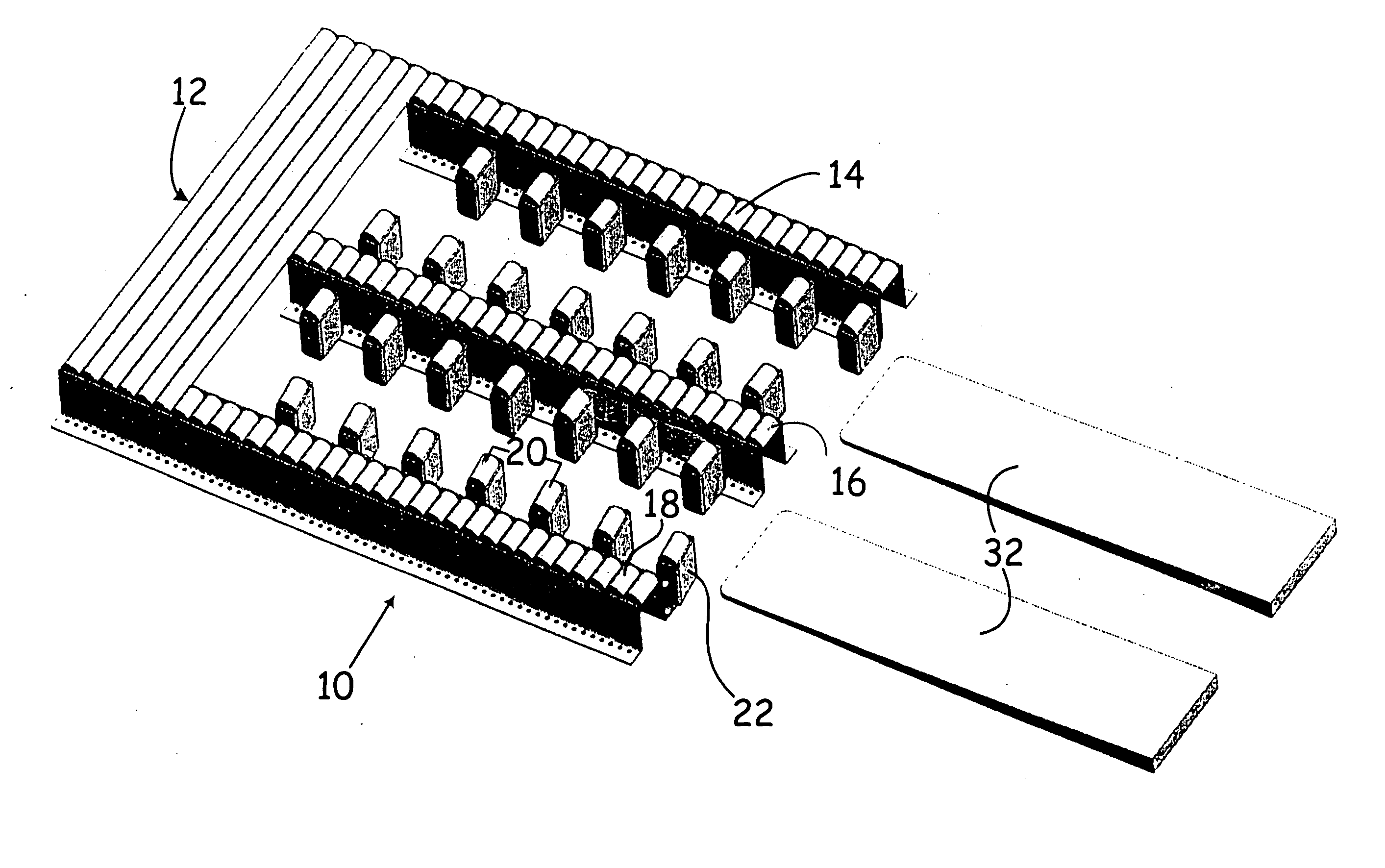

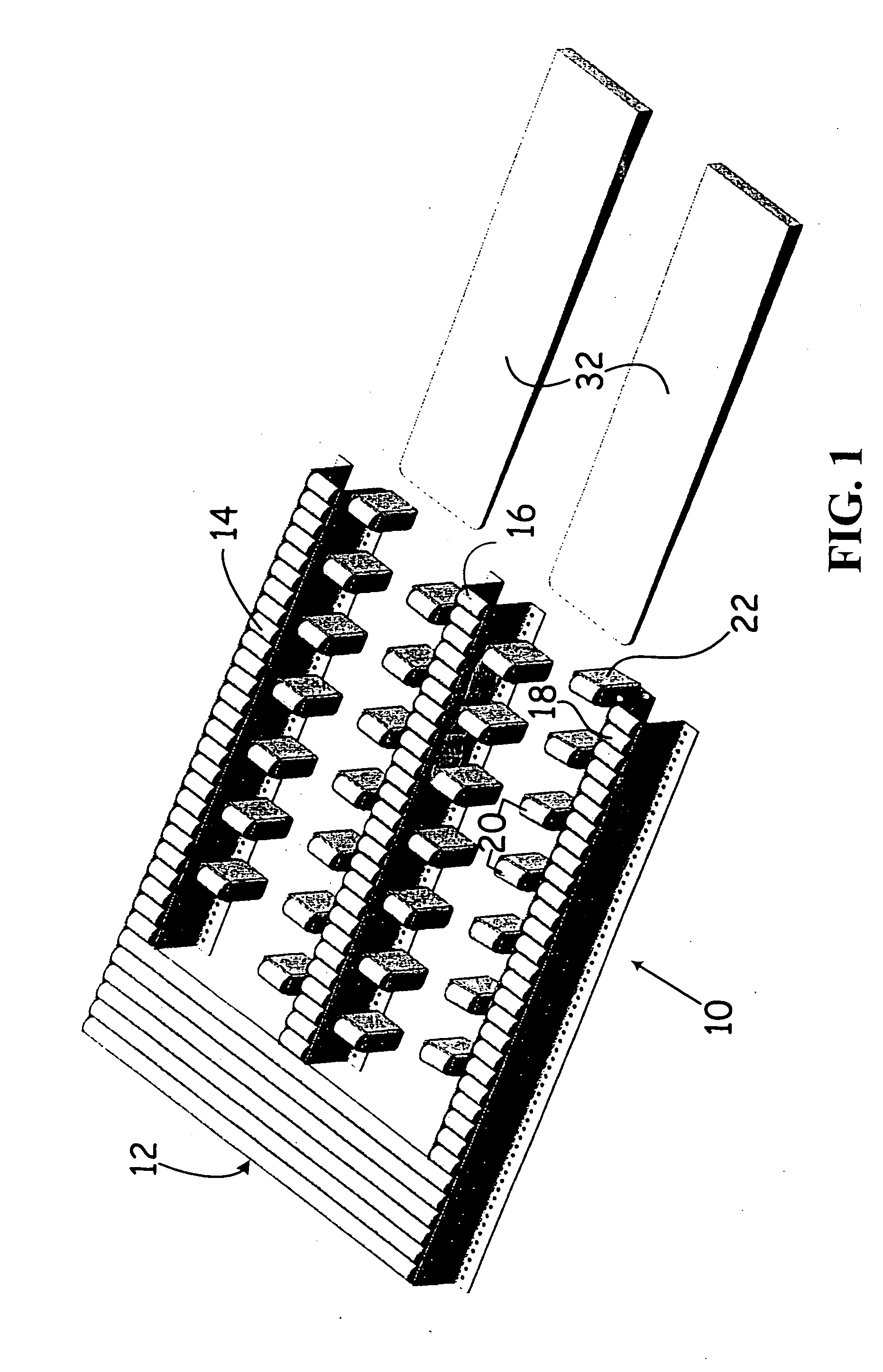

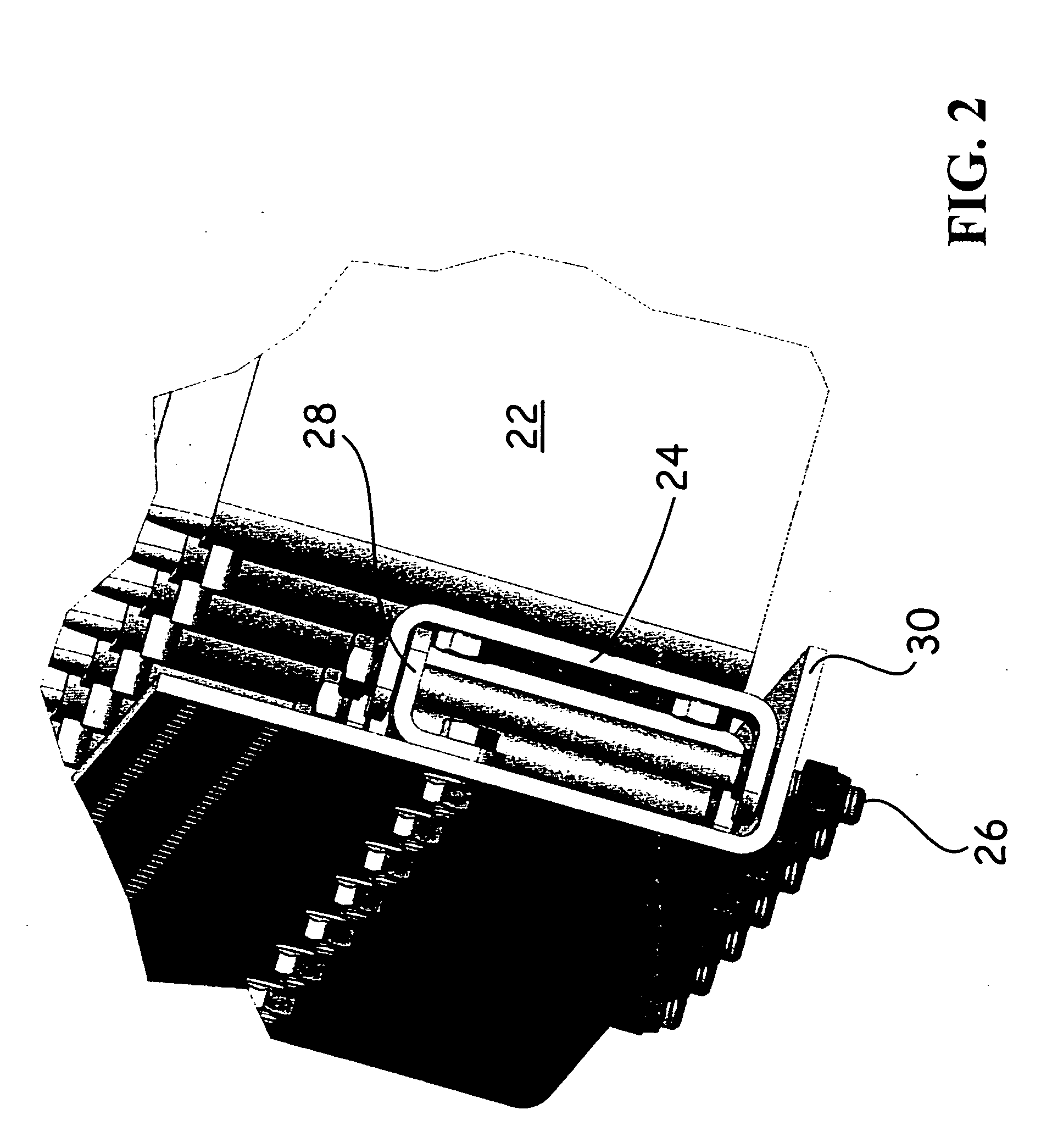

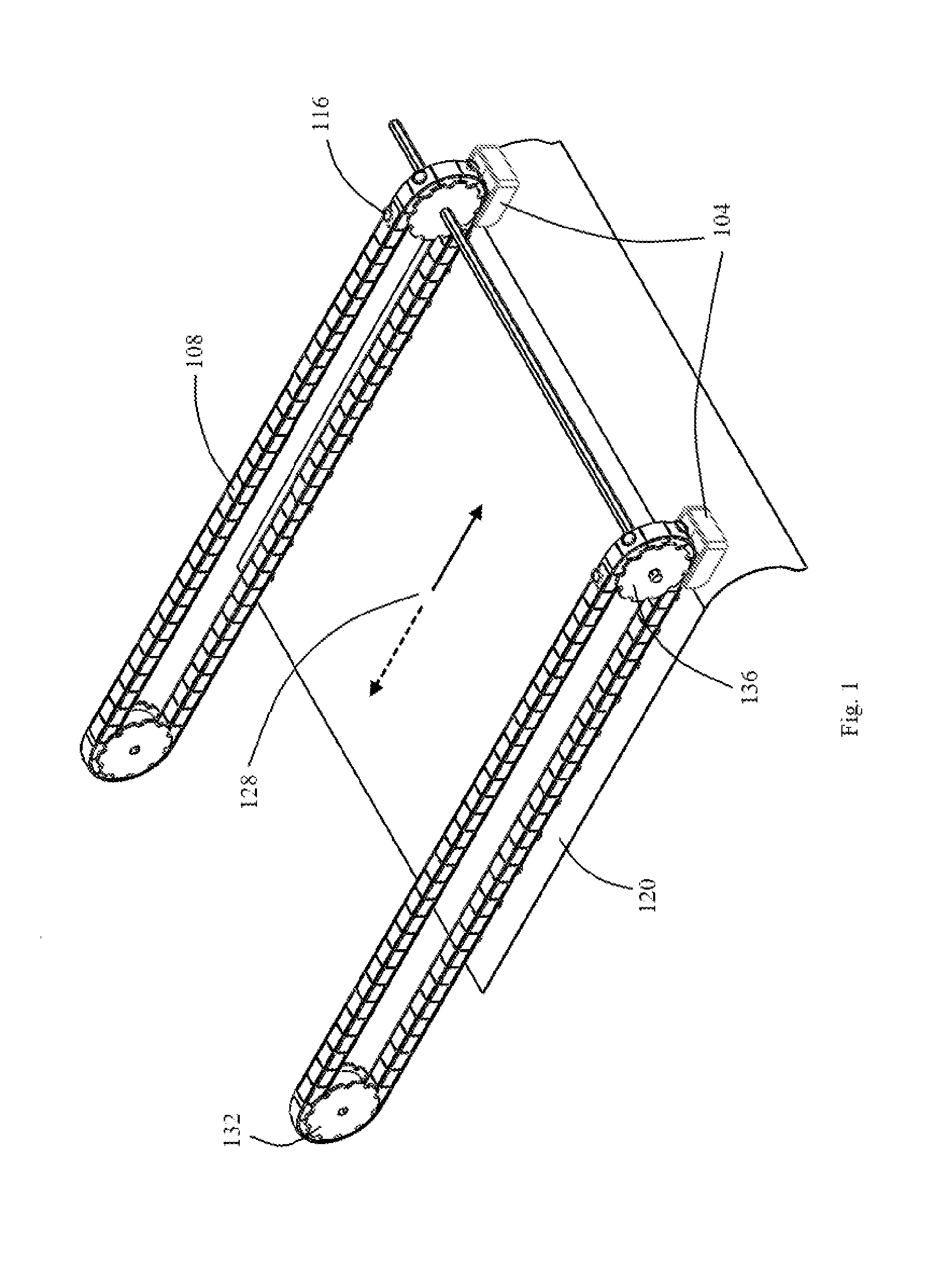

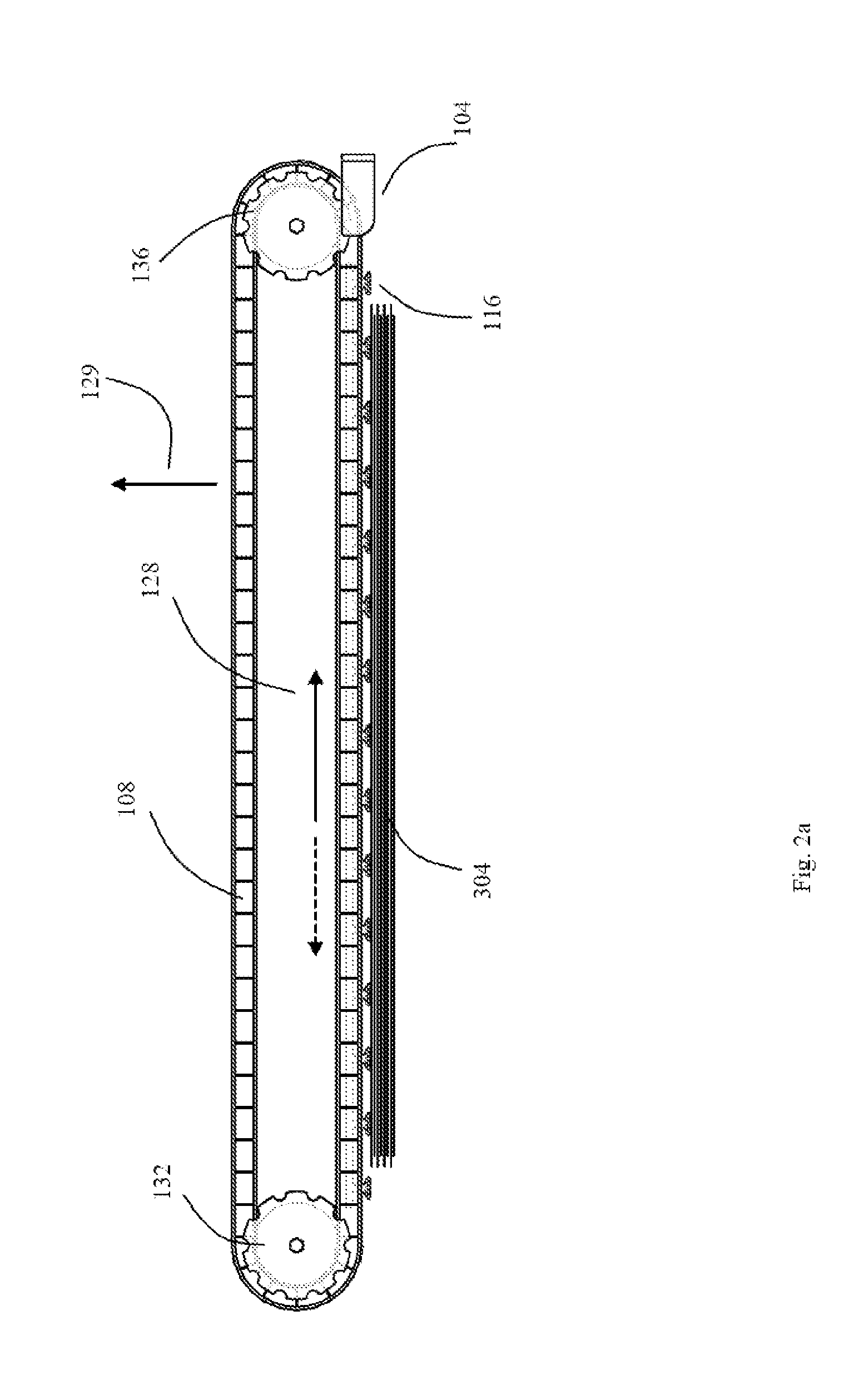

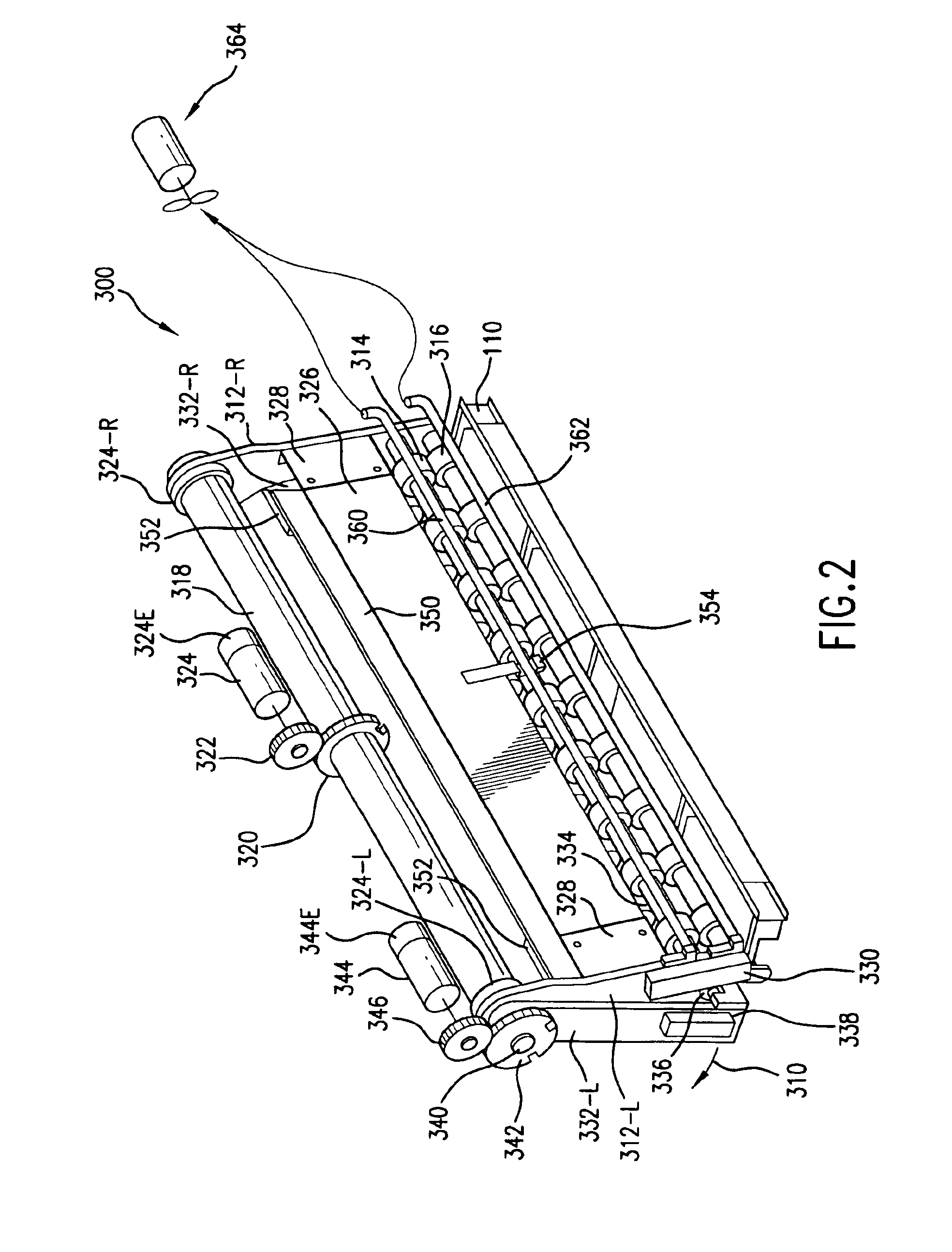

Conveyor system load transfer devices

Conveyor systems for storage and movement of goods on pallets and slip sheets. The transfer structures enable slip sheet mounted loads to be transferred to a roller conveyor by providing structures that cooperate with wide platen forks of a lift truck. The structures provide roller contact between a portion of the underside of the slip sheet at all times. In other areas there is alternatively contact between a lift truck platen or additional rollers that cooperate in a manner making it possible to move the slip sheet mounted load from the lift truck to an adjacent conveyor system.

Owner:CREATIVE STORAGE SYST

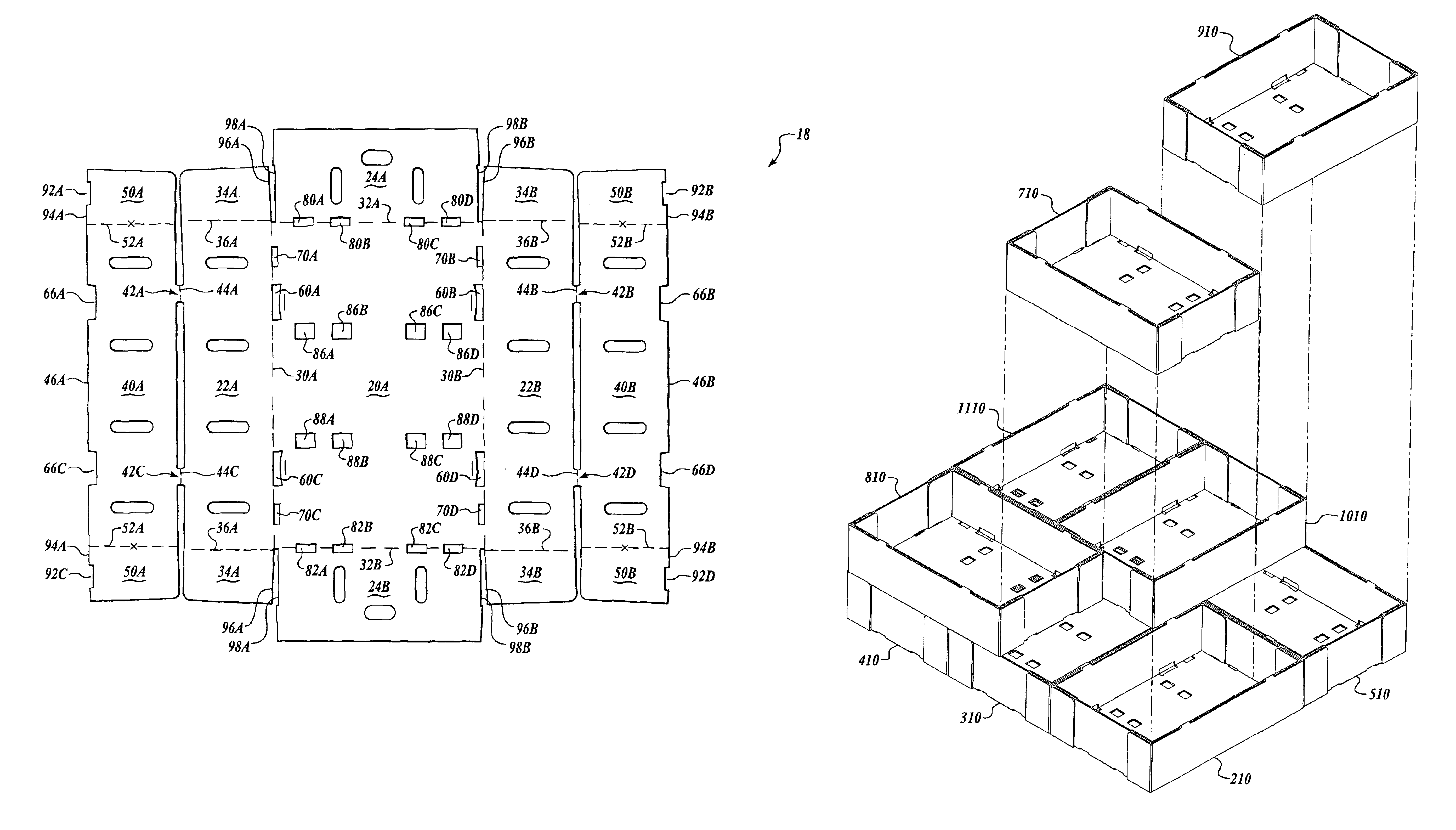

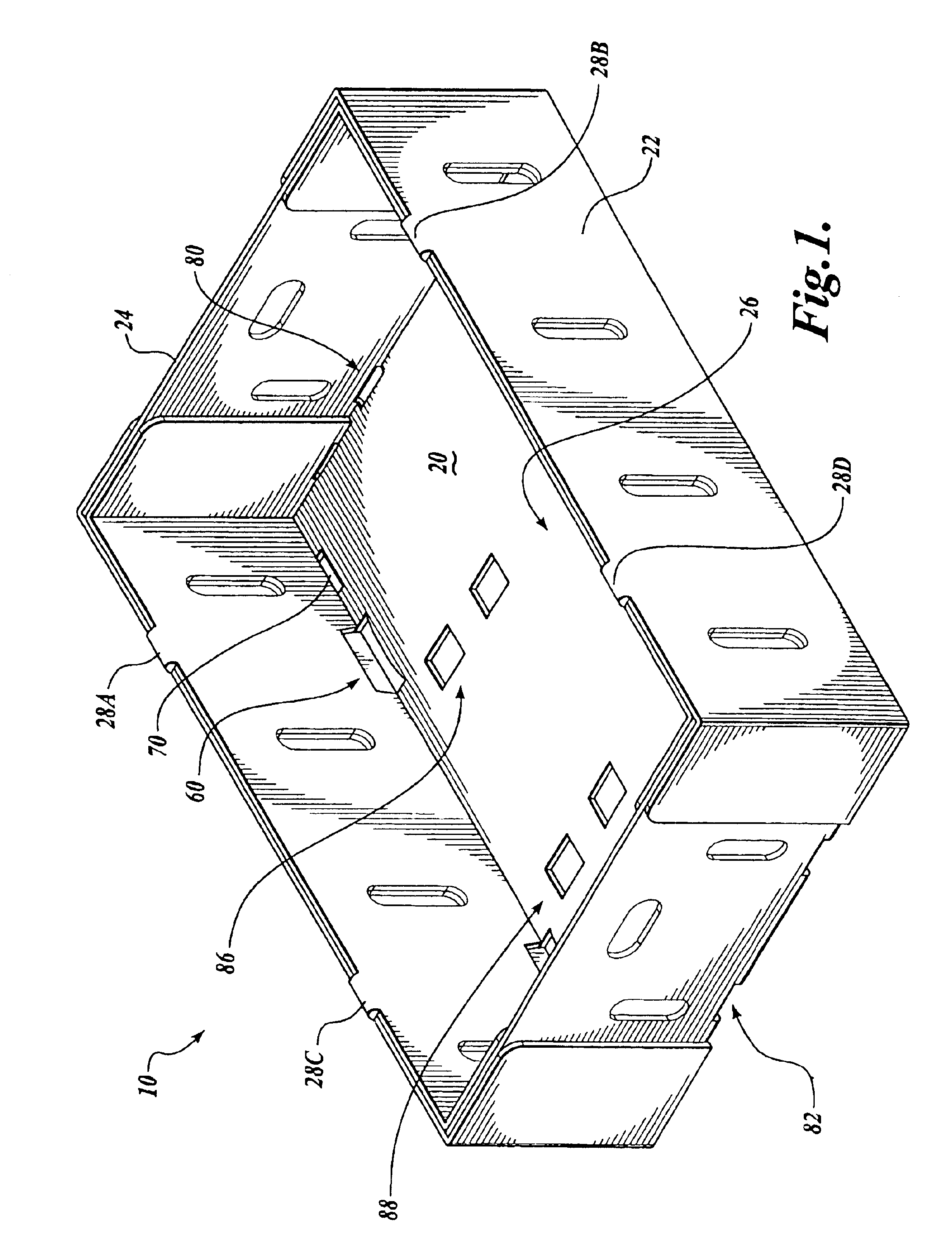

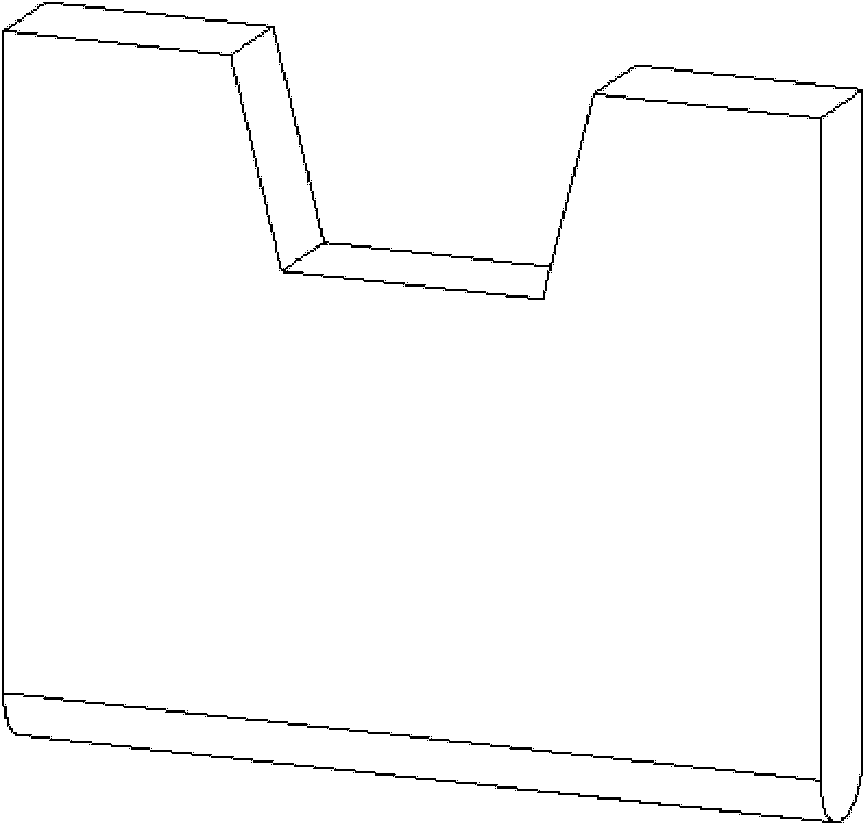

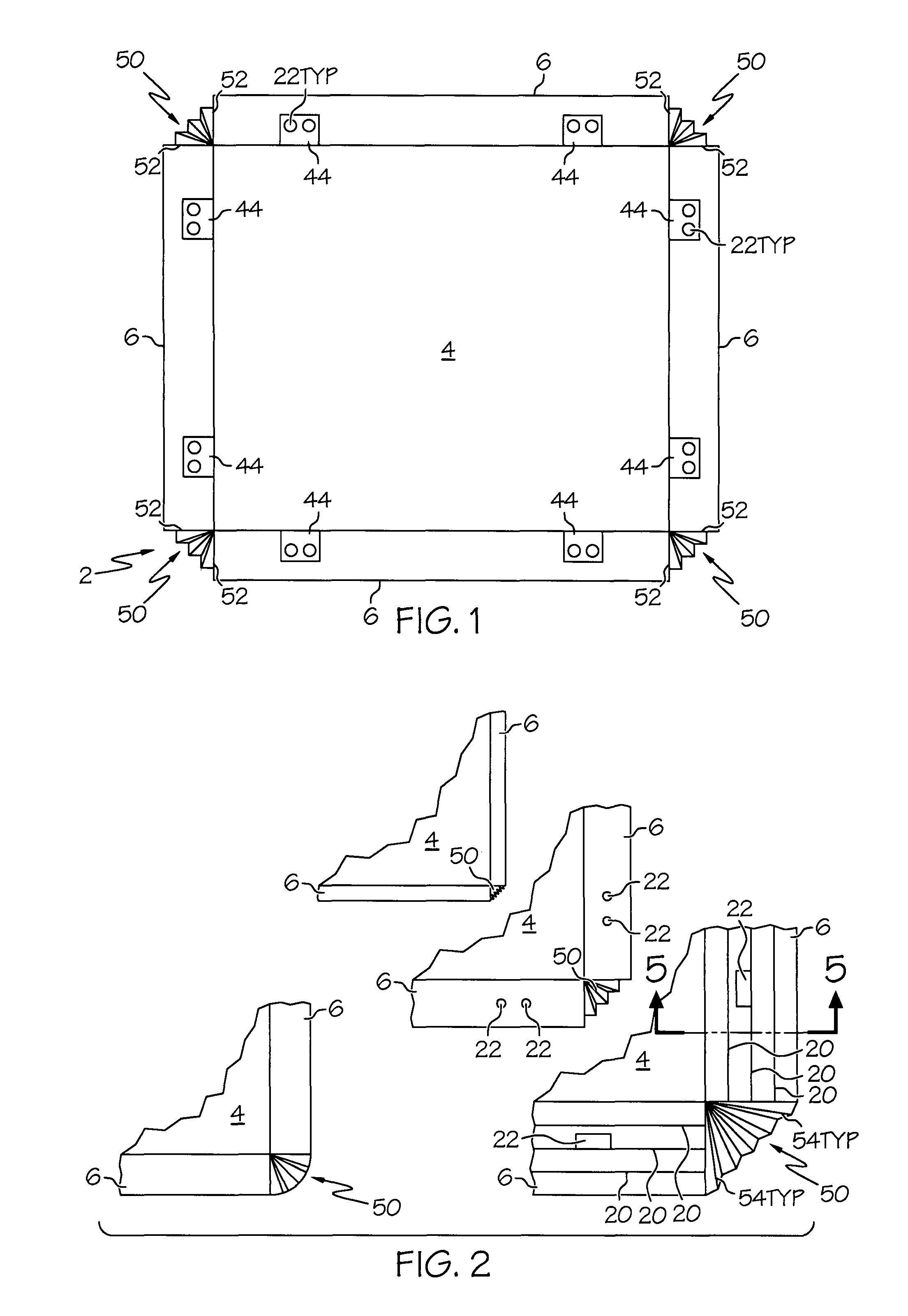

Stackable container with stack-tabs

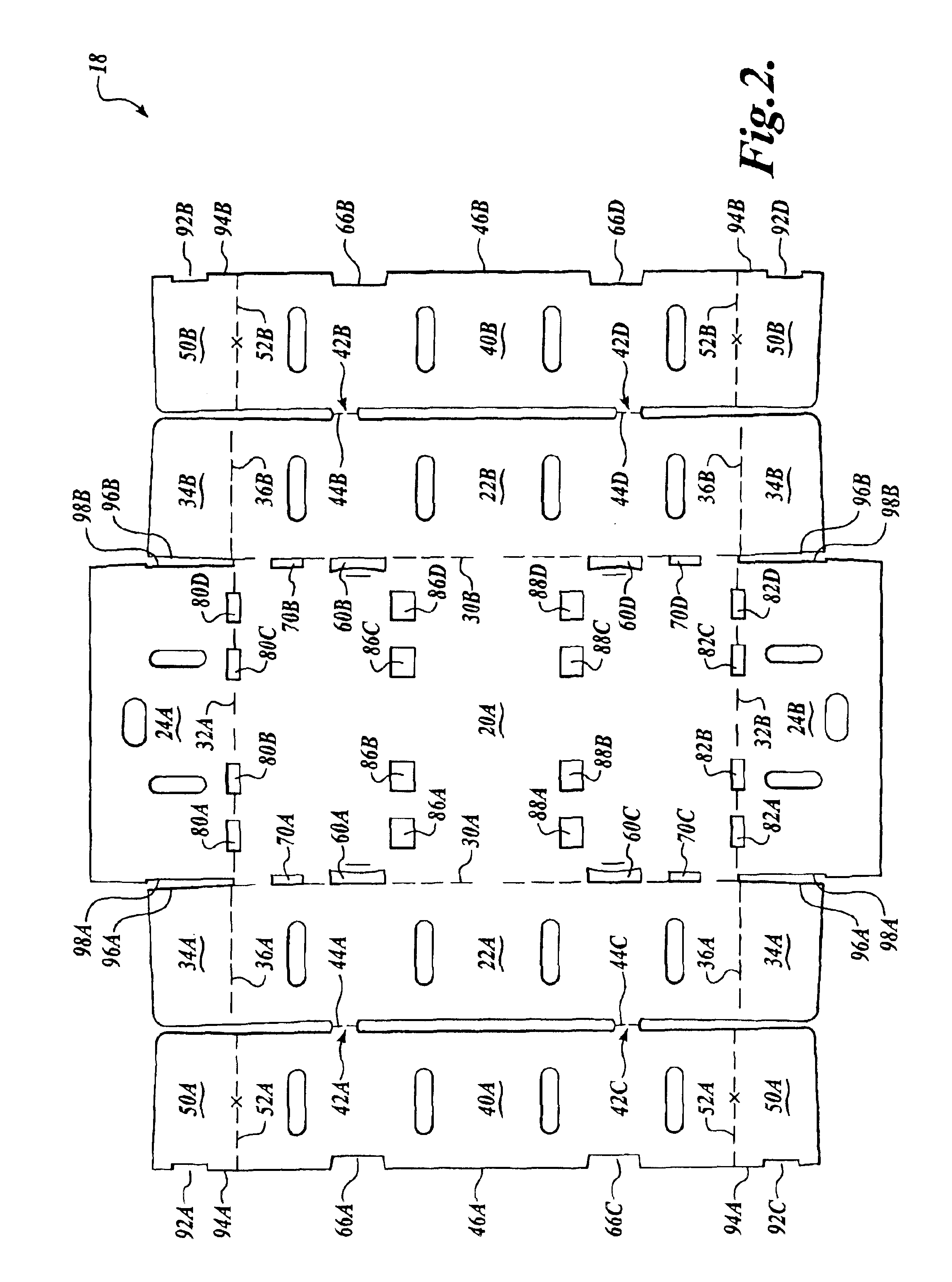

A tray-type container 10 includes a bottom wall 20, longitudinally-extending outer side walls 22, and laterally-extending end walls 24, the outer side walls 22 and the end walls 24 extending upwardly from the bottom wall 20 to form an inner cavity 26. As erected, the outer side walls 22 include a plurality of spaced-apart stacking tabs 28A-28D, and the bottom wall forms a plurality of spaced-apart apertures 60, 70, 80, 82, 86, and 88 for receiving the stacking tabs 28A-28D of like or similar containers. A plurality of tray-type containers 10 may be unitized in several stacked configurations utilizing the stacking tabs 28 and apertures 60, 70, 80, 82, 86, and 88. Typically, the plurality of unitized containers 10 are placed upon a shipping pallet or slip sheet, or placed within a shipping container to facilitate shipping by large carriers.

Owner:INT PAPER CO

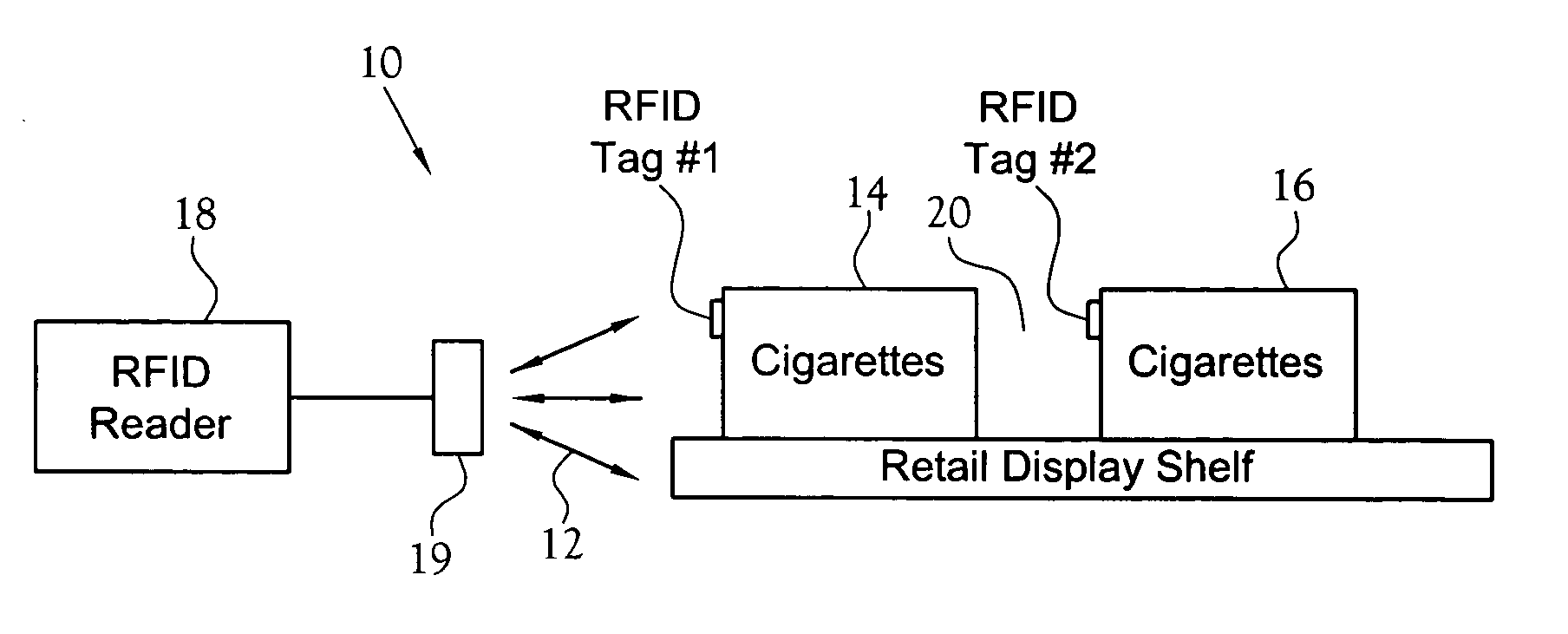

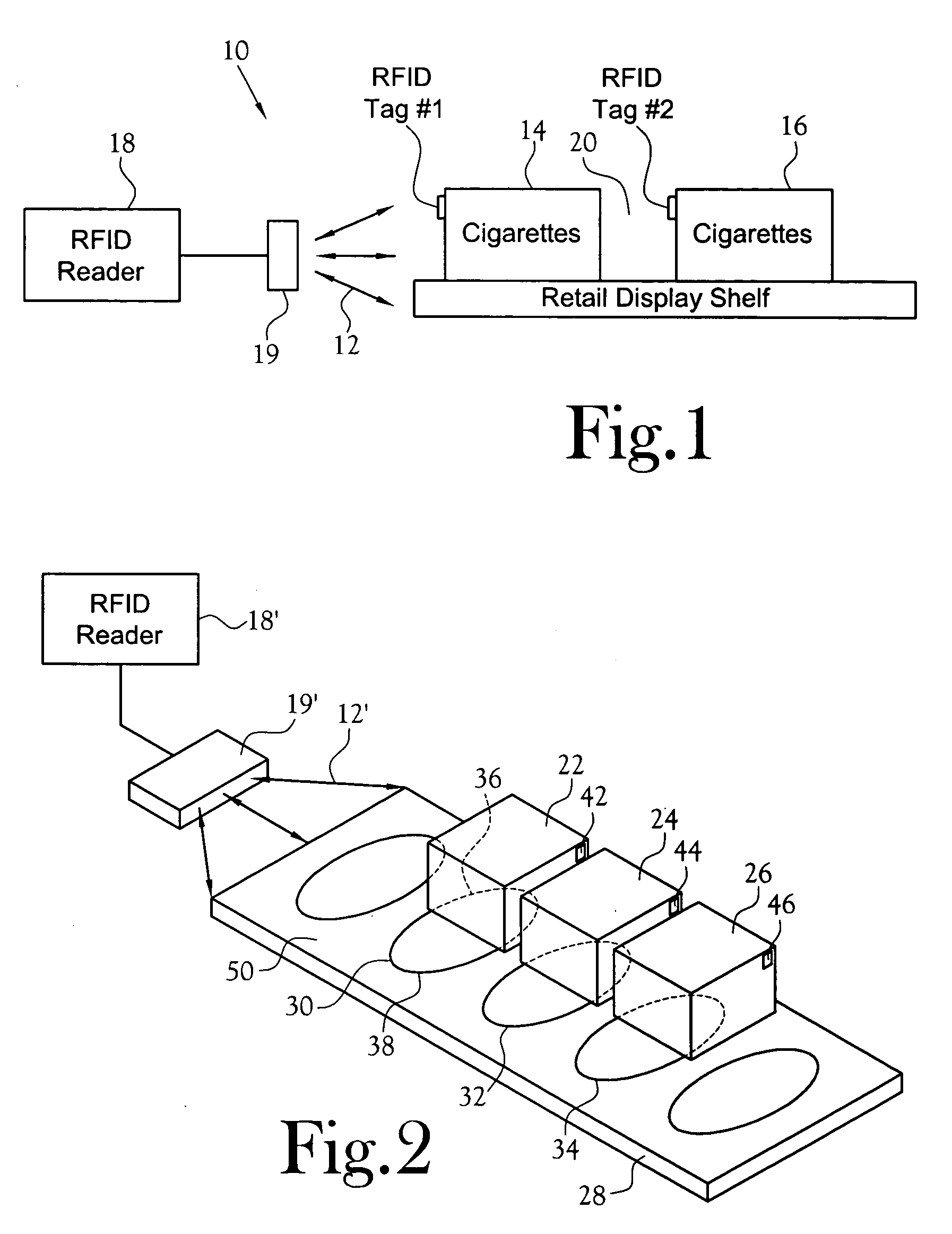

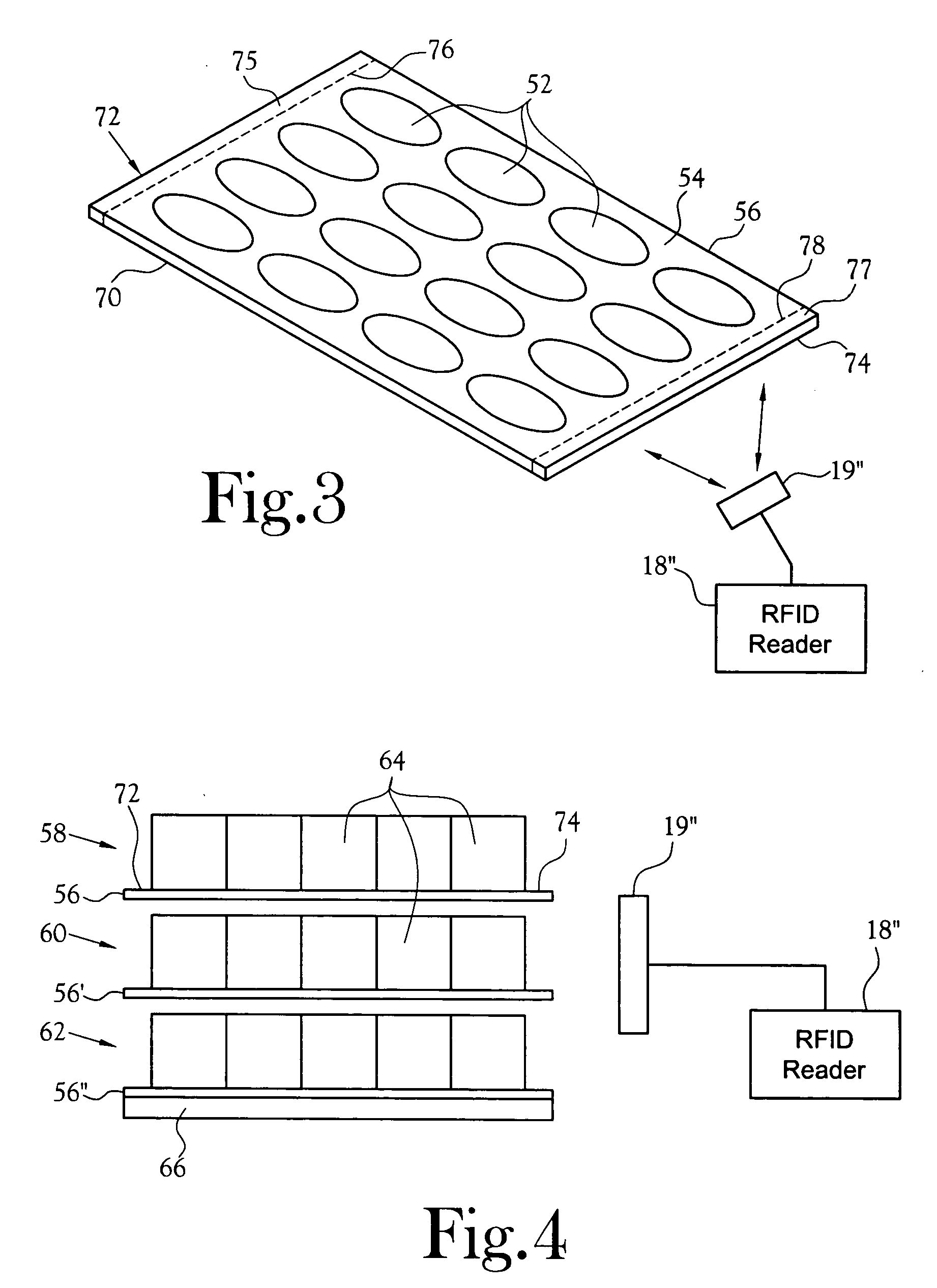

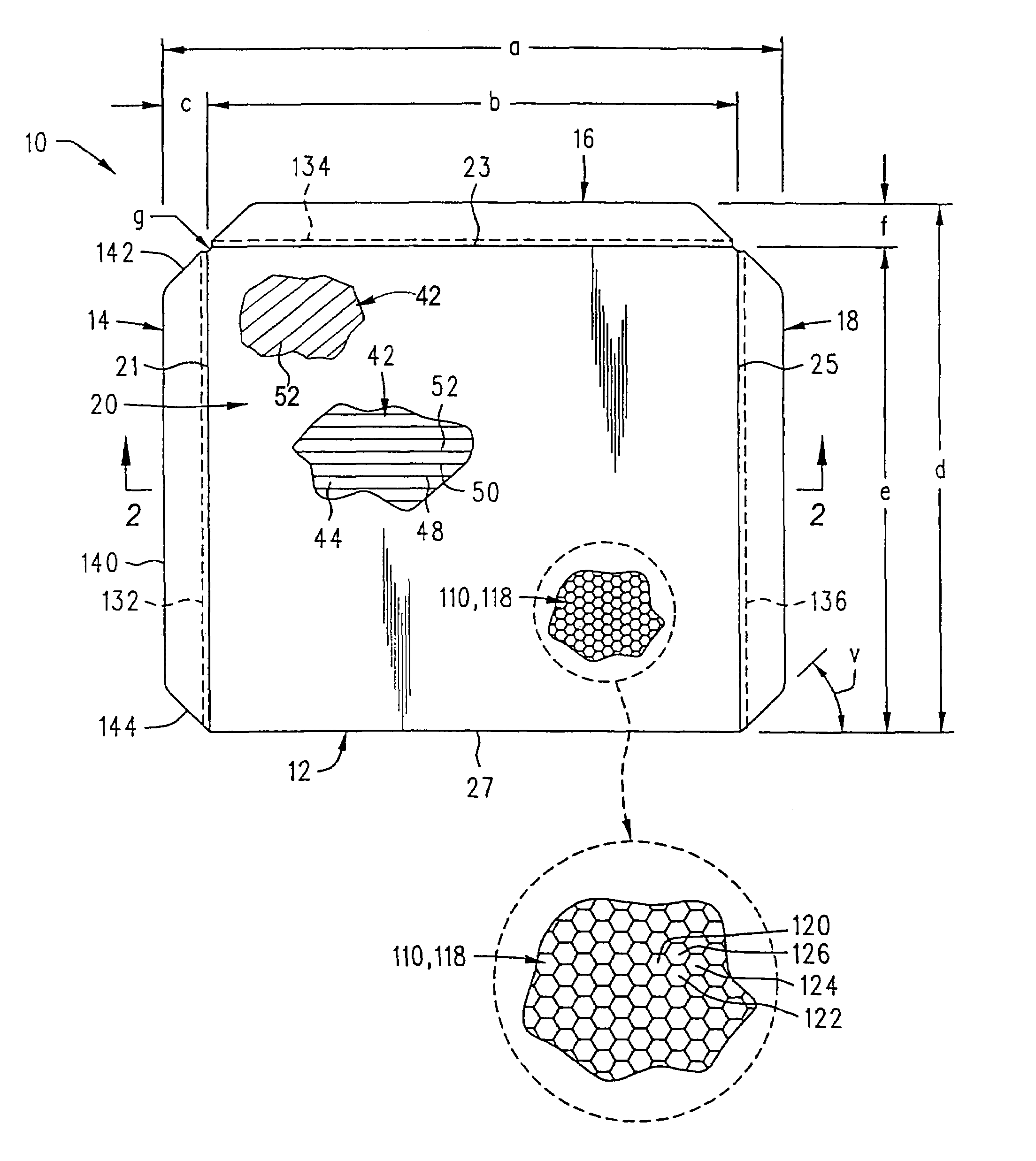

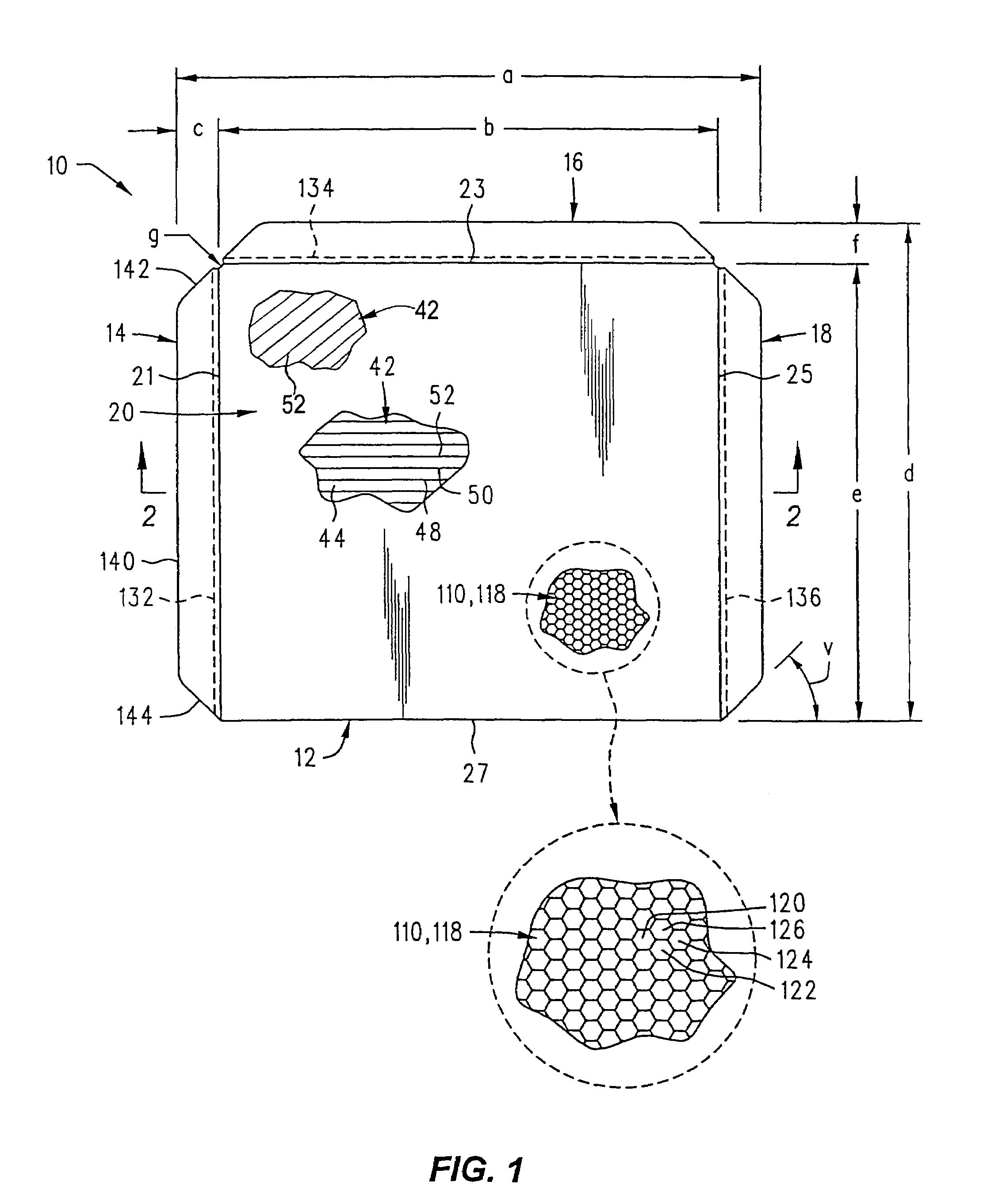

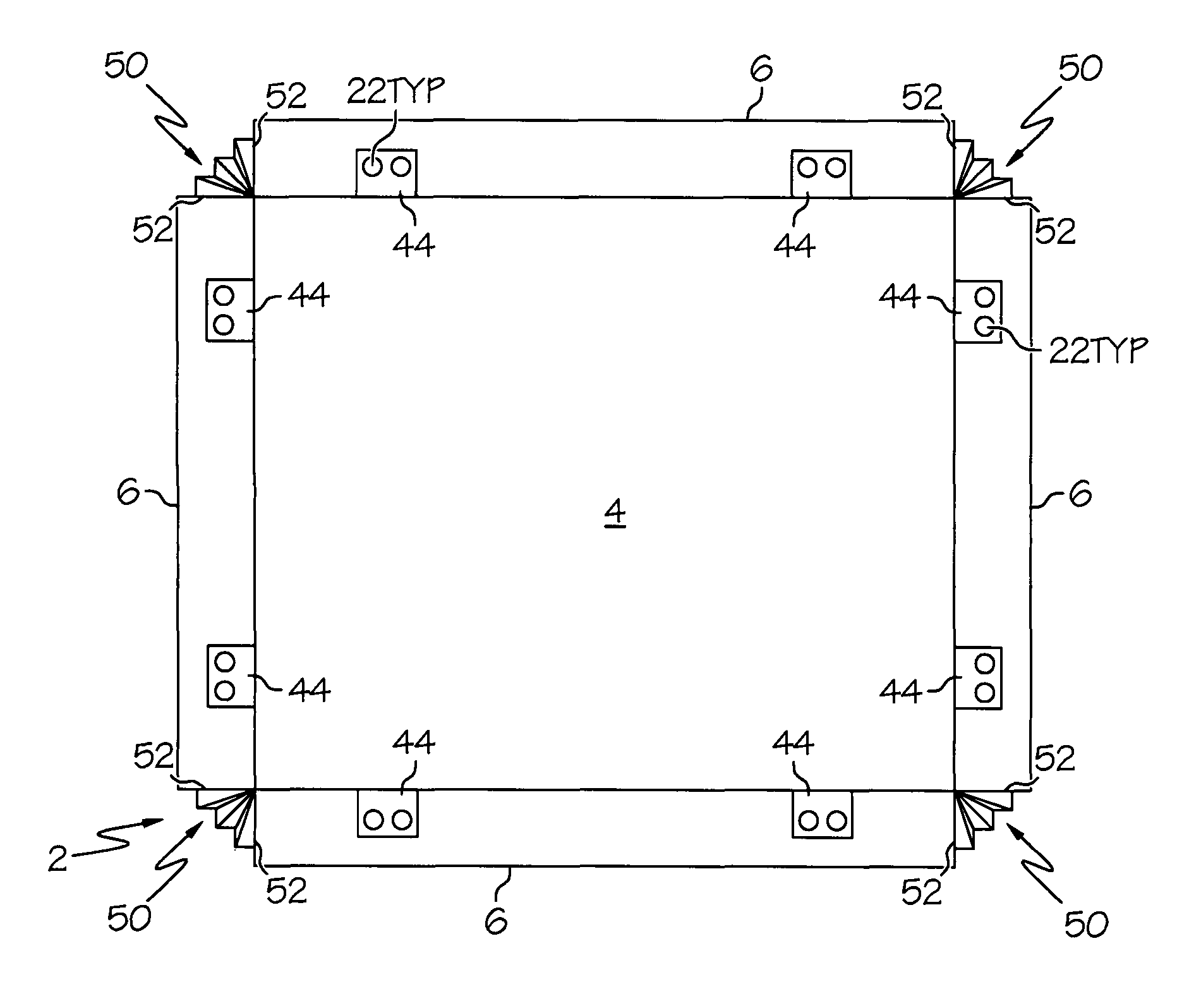

Electromagnetic pathways to eliminate RFID limitations

InactiveUS20060103532A1Alleviates RF transmission problemReduce decreaseSensing record carriersRecord carriers used with machinesEmbedded systemSlip sheet

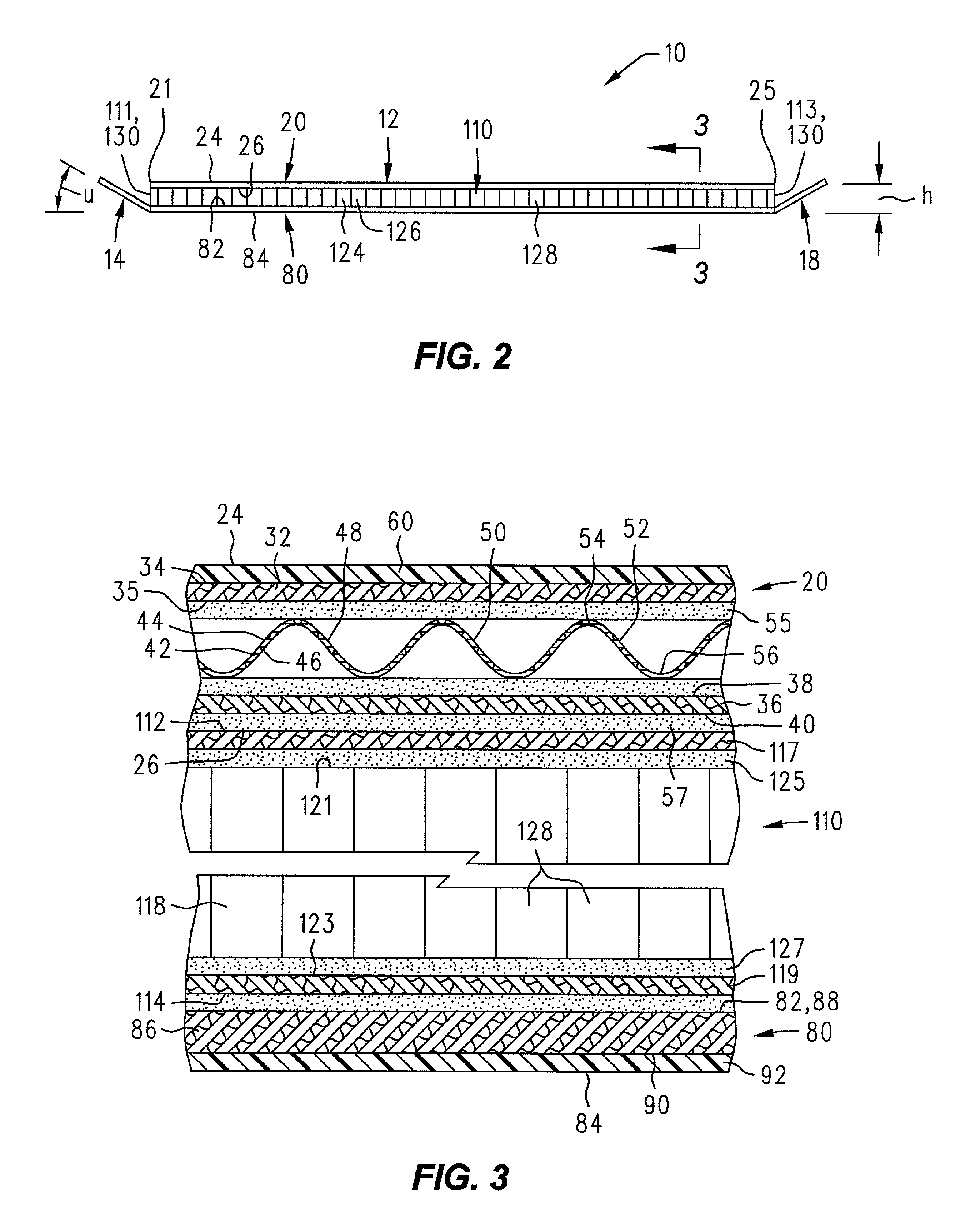

A system for enhanced substantially simultaneously monitoring multiple aggregated RFID-tagged products comprising an RFID reader disposed remote from said aggregated RFID-tagged products and a supplemental antenna disposed intermediate the RFID reader and the RFID-tagged products. The supplemental antenna includes at least a portion thereof in substantially non-interrupted communication with multiple ones of the RFID tags associated with the RFID-tagged products and at least a portion thereof being in substantially non-interrupted communication with said antenna associated with said RFID reader, whereby said supplemental antenna enhances the transmission of coded information between the reader and the RFID tags associated with the RFID tagged products. A slip sheet having a supplemental antennas associated therewith is disclosed.

Owner:INT PAPER CO

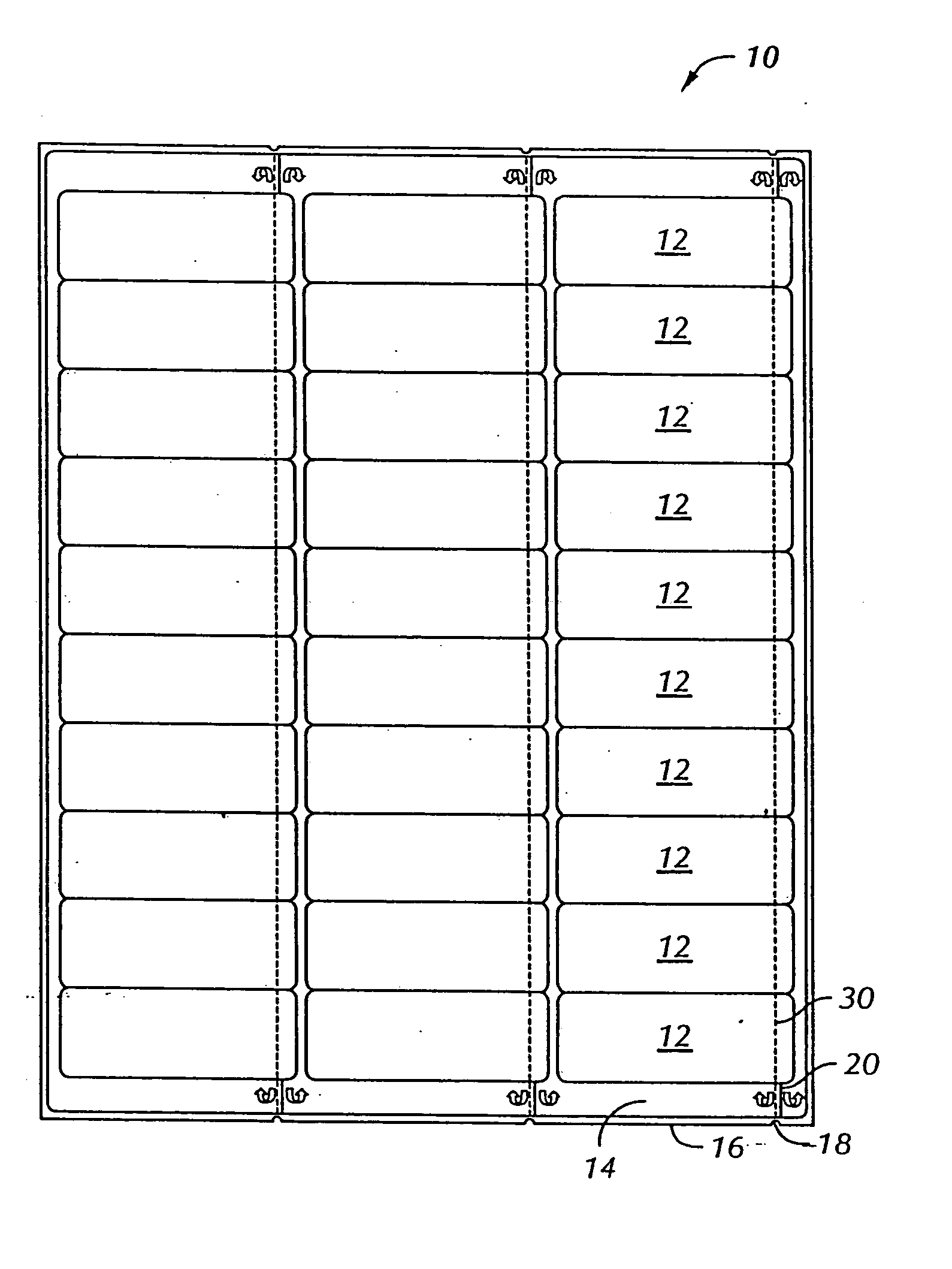

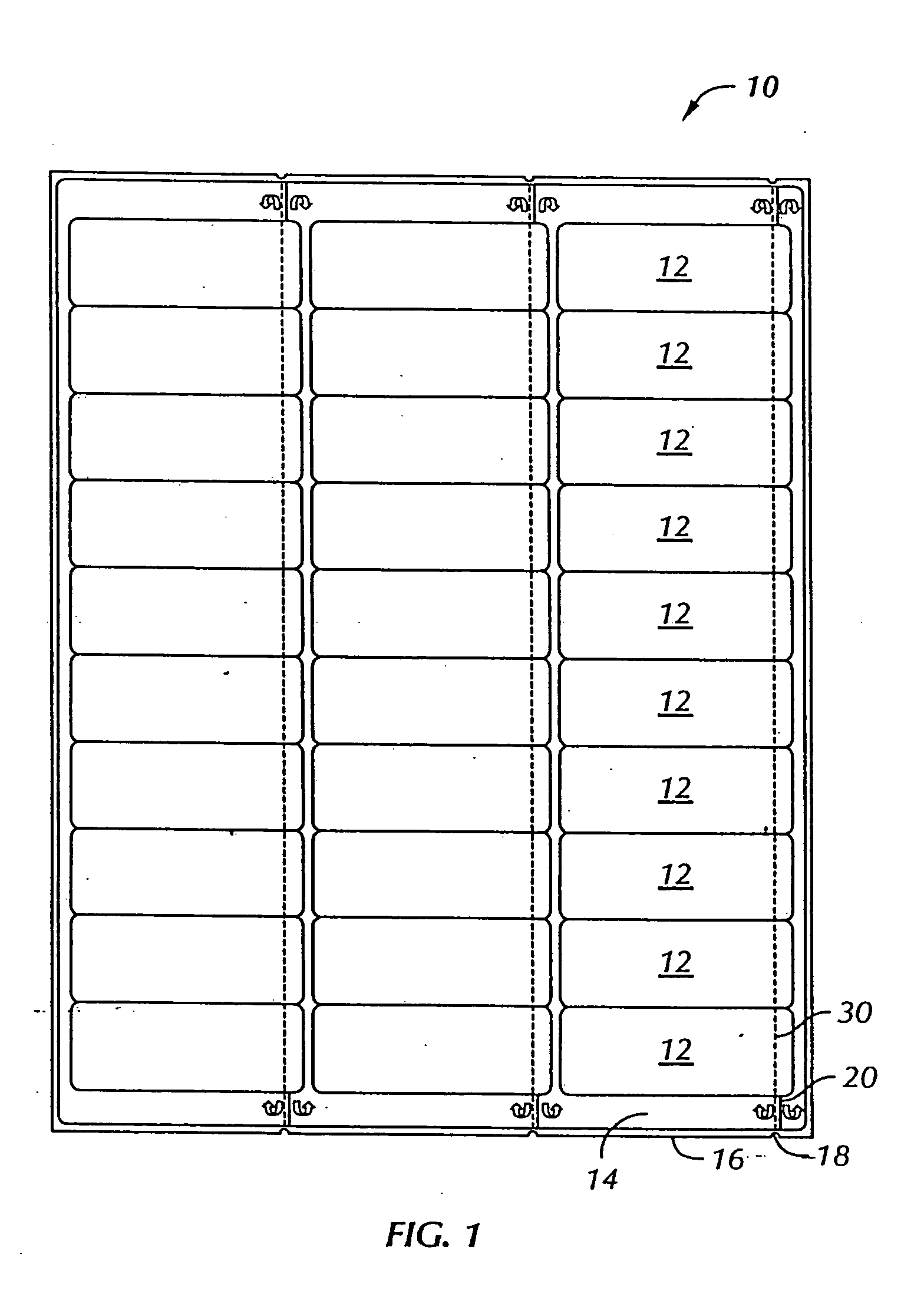

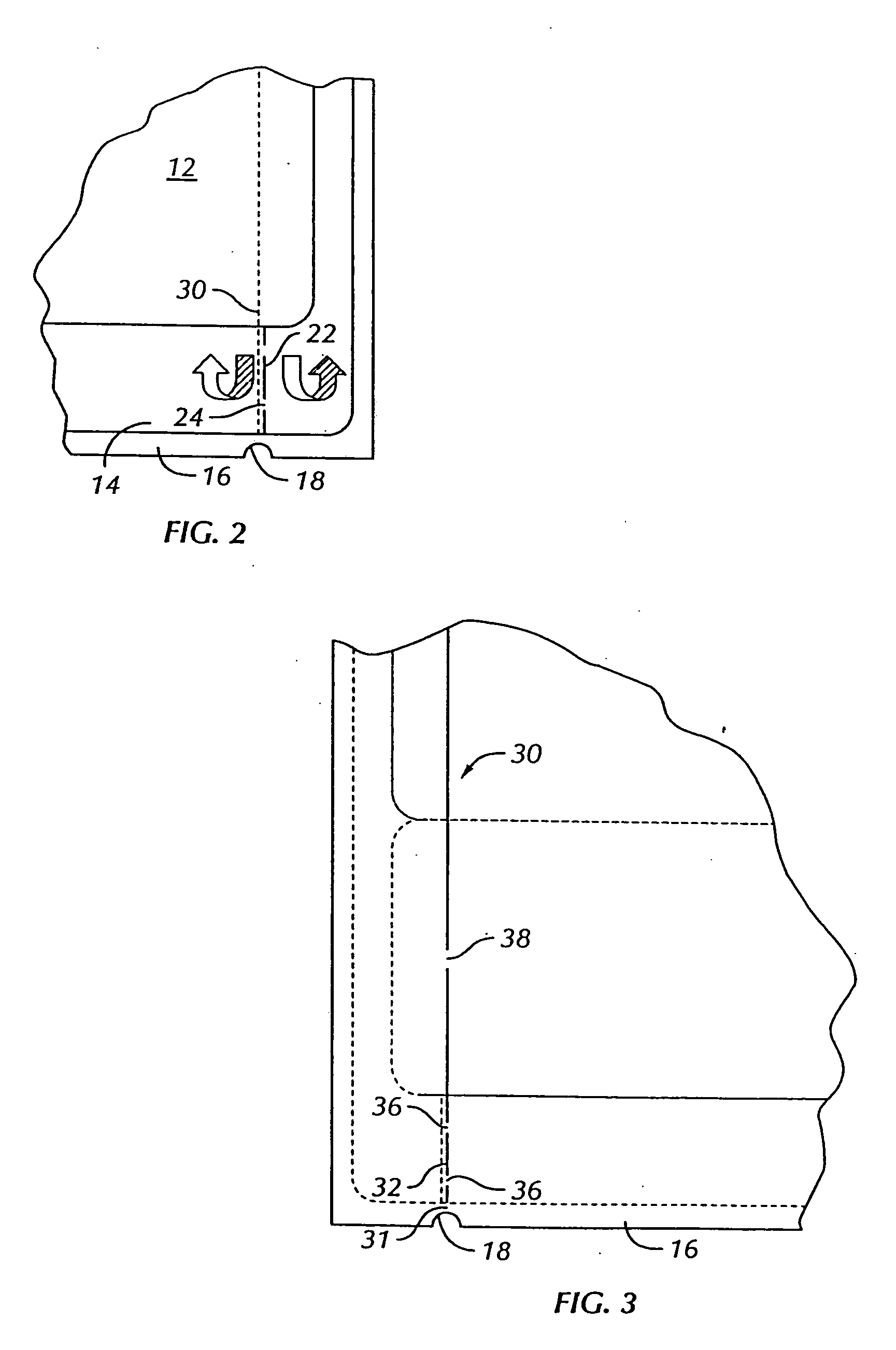

Foldable die cut self-adhesive label sheet for labeling cd-roms

Owner:CCL LABEL INC

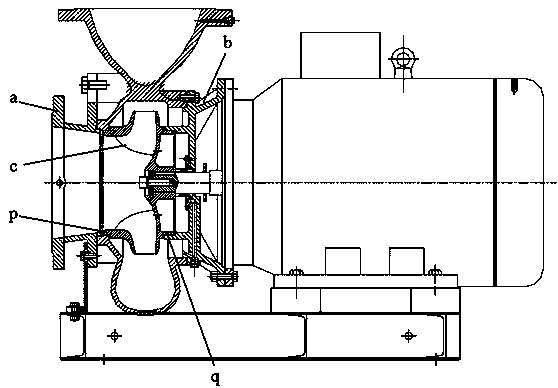

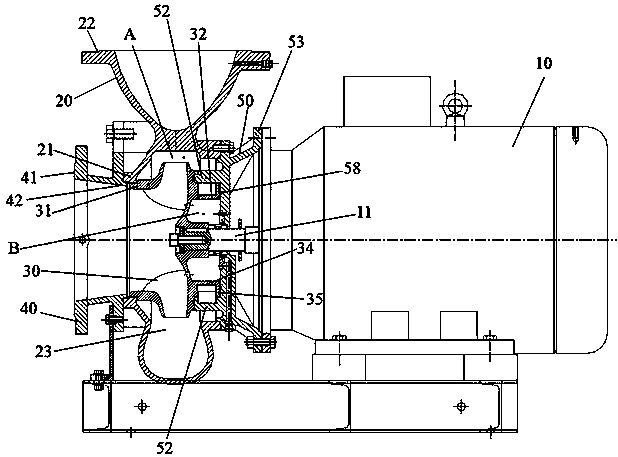

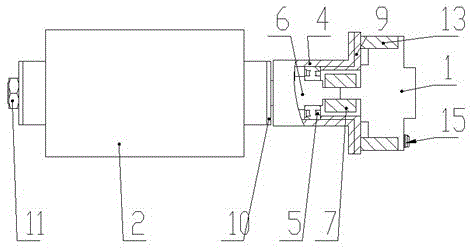

Centrifugal pump with impeller rotation boosting structure

The invention provides a centrifugal pump with an impeller rotation boosting structure, the centrifugal pump comprises a motor, a pump body, an impeller, and a front end cover and a rear end cover at the front and rear sides of the impeller, the impeller is provided with a rear seal ring, the rear end cover is provided with a seal baffle ring which extends toward the impeller and covers at the periphery of the rear seal ring, a seal cavity is formed between the seal baffle ring of the rear end cover and the rear seal ring of the impeller, and the rear seal ring is provided with a plurality of slip sheets capable of slipping into the seal cavity. Compared with the prior art, through adopting the improved design of the end cover and the impeller of the centrifugal pump and utilizing the improved structures (such as the seal cavity and the slip sheets) between the seal baffle ring and the rear seal ring, pressure difference between a high pressure area and a low pressure area at two ends of the seal cavity is converted into power for pushing the impeller to rotate during the rotation of the impeller, so that the torque output of the motor is reduced.

Owner:上海瑞晨环保科技股份有限公司

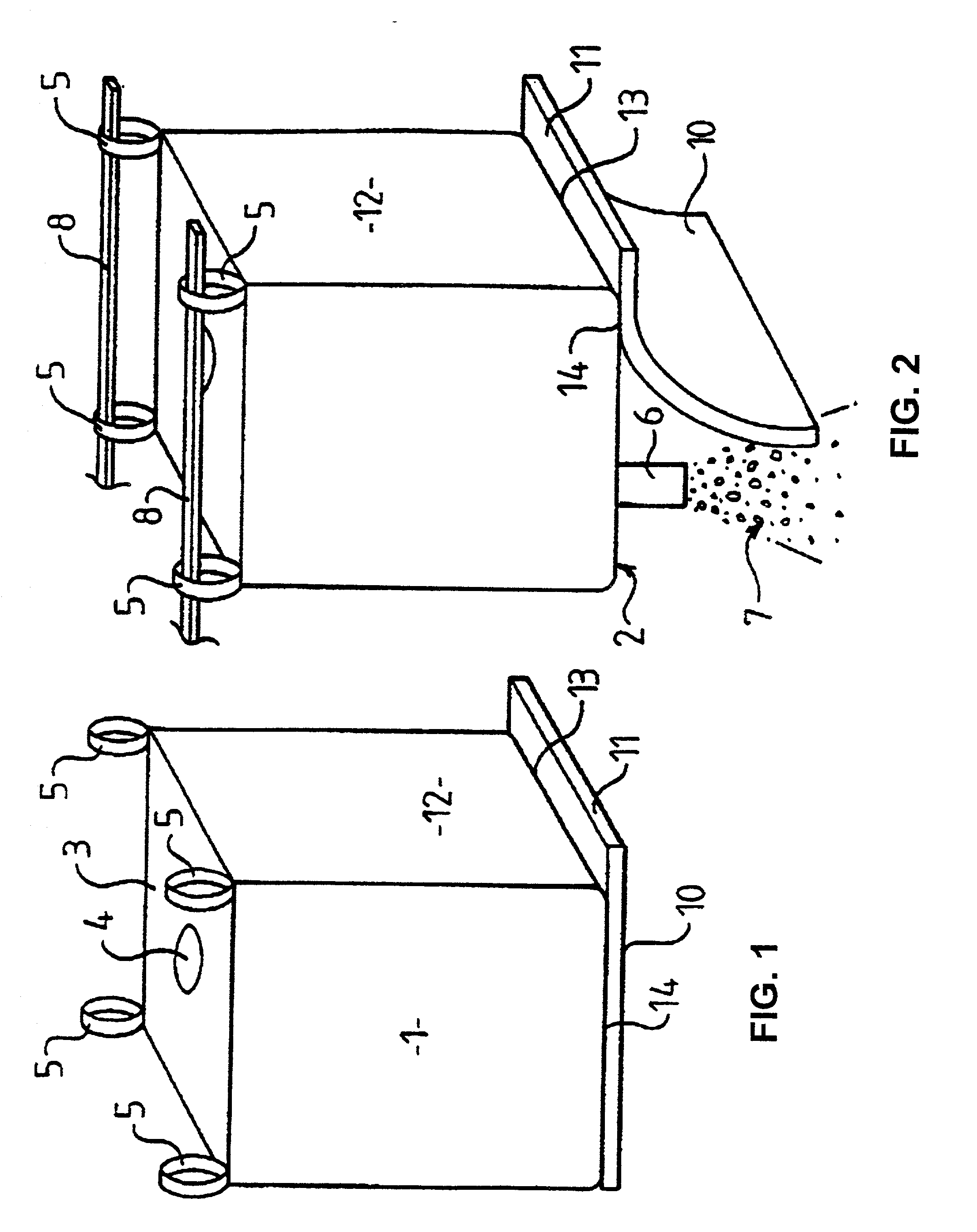

Slip sheet

InactiveUS7013814B2Substantial shock absorbingCompact and durableRigid containersEngineeringSlide plate

A slip sheet pallet comprising a first sheet engageable with a stacked array which is to be supported; a second sheet attached to the first sheet; at least one flap connected to and extending outwardly from at least one of the first and second sheets and gripable by a lift truck gripping assembly; at least one of the first and second sheets comprising a compound sheet with a plurality of distinct connected layers.

Owner:SIGNODE IND GRP

Moisture barrier protection system and method

InactiveUS6122887AImprove the immunityProtective foundationBuilding repairsSurface stressGeomembrane

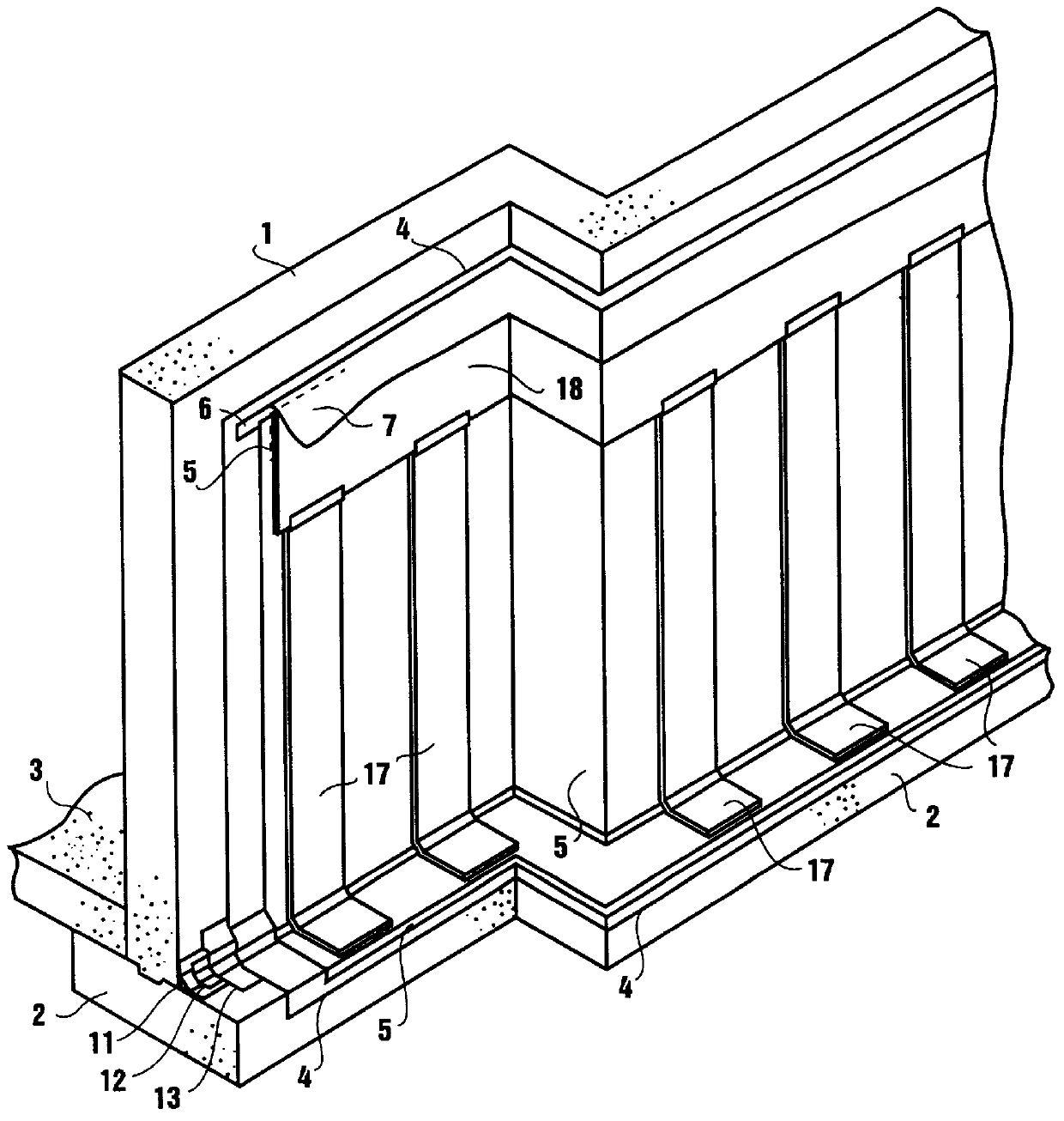

A tough, high-strength geomembrane made from a custom blend of polyethylene copolymers, for protecting waterproofing courses from impact and pressure damage of debris resting against the waterproof course. A slip sheet configuration reduces surfaces stress due to earth movement and subsurface cracking thereby maintaining the protective course intact without any effect on the waterproofing layers. The geomembrane is available as lightweight rolls which can be easily be handled by one man. The film is installed horizontally in continuous sheets with few adhesive joints. Installation begins by applying a thick brush coat of the selected waterproofing membrane material (usually a rubber coat but may be any waterpoofing material). The film is unrolled along the wall, held up into position and secured using plastic self-sealing plugs and / or plastic termination bars. Concrete nails are used to attach the self-sealing plugs or termination bar to the wall. If termination bar is selected the film is extended up beyond the bar approximately 8'' and folded down over the termination bar after attachment. Staples into the termination bar can be used to hold the film down creating a nicely detailed upper edge.

Owner:SOCOPAC

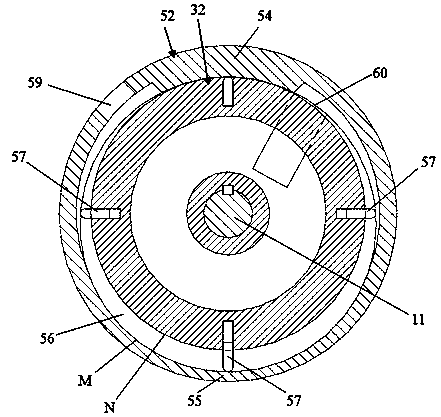

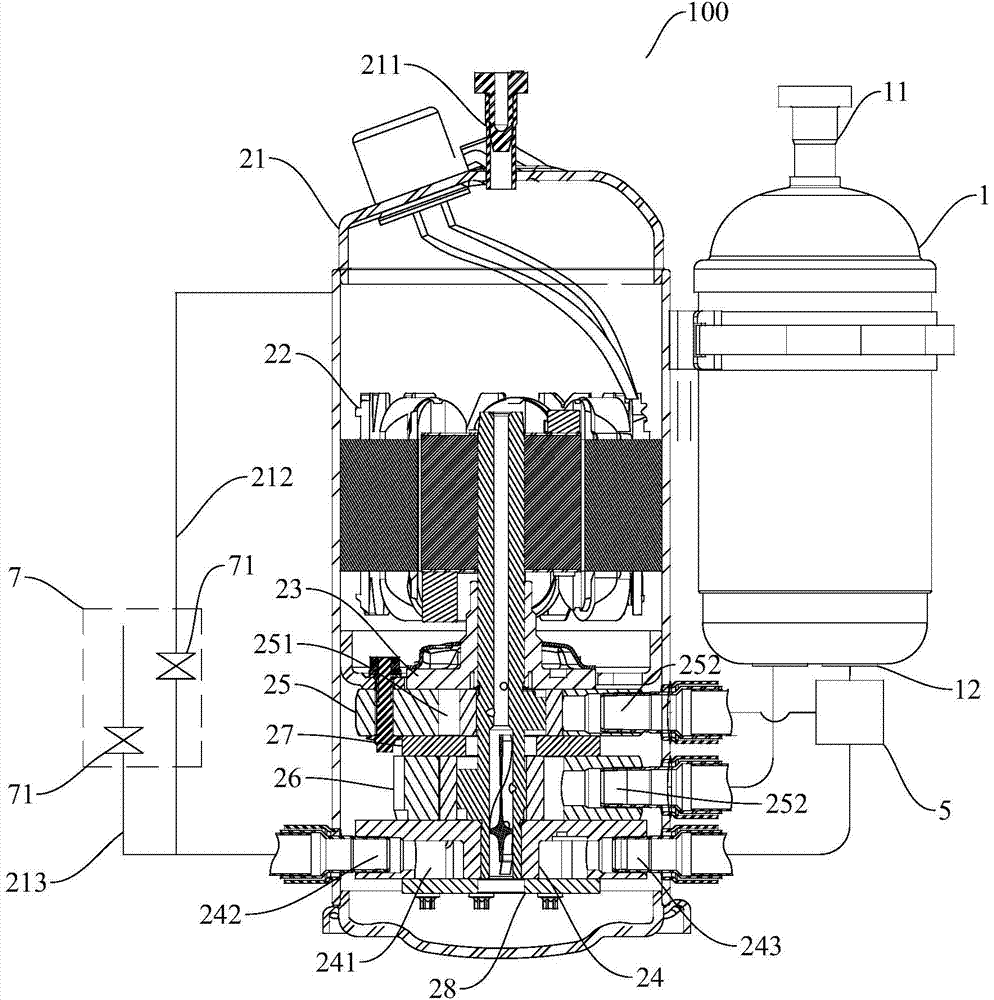

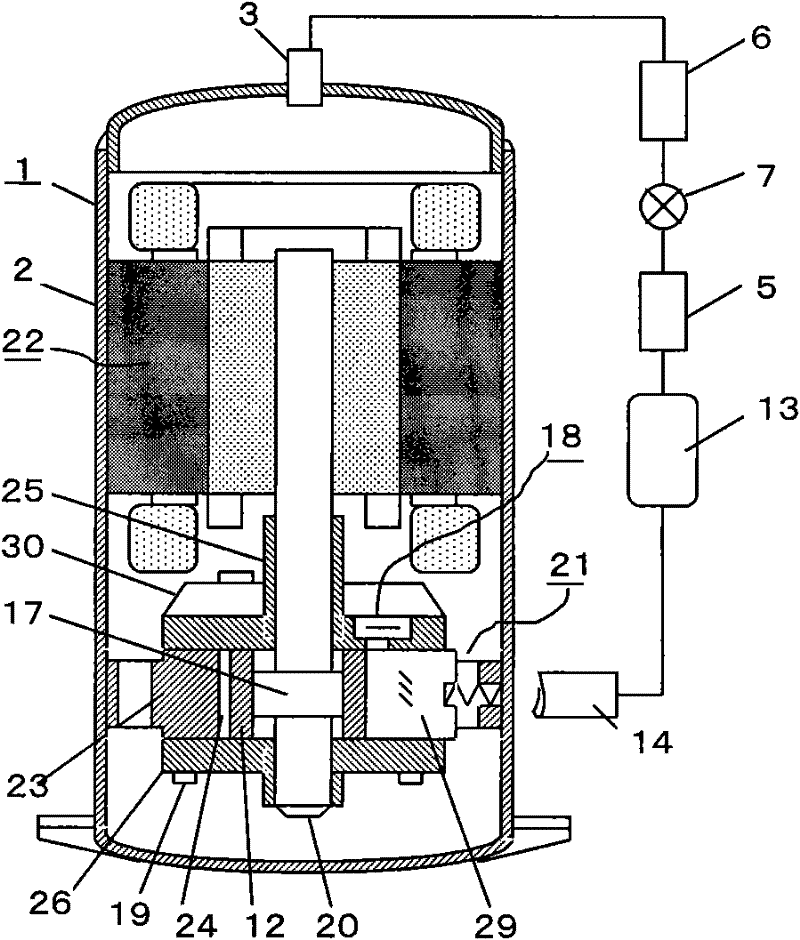

Compressor and air conditioner

ActiveCN103953544AImprove energy efficiencyImprove heating effectRotary/oscillating piston combinations for elastic fluidsLighting and heating apparatusSlip sheetEngineering

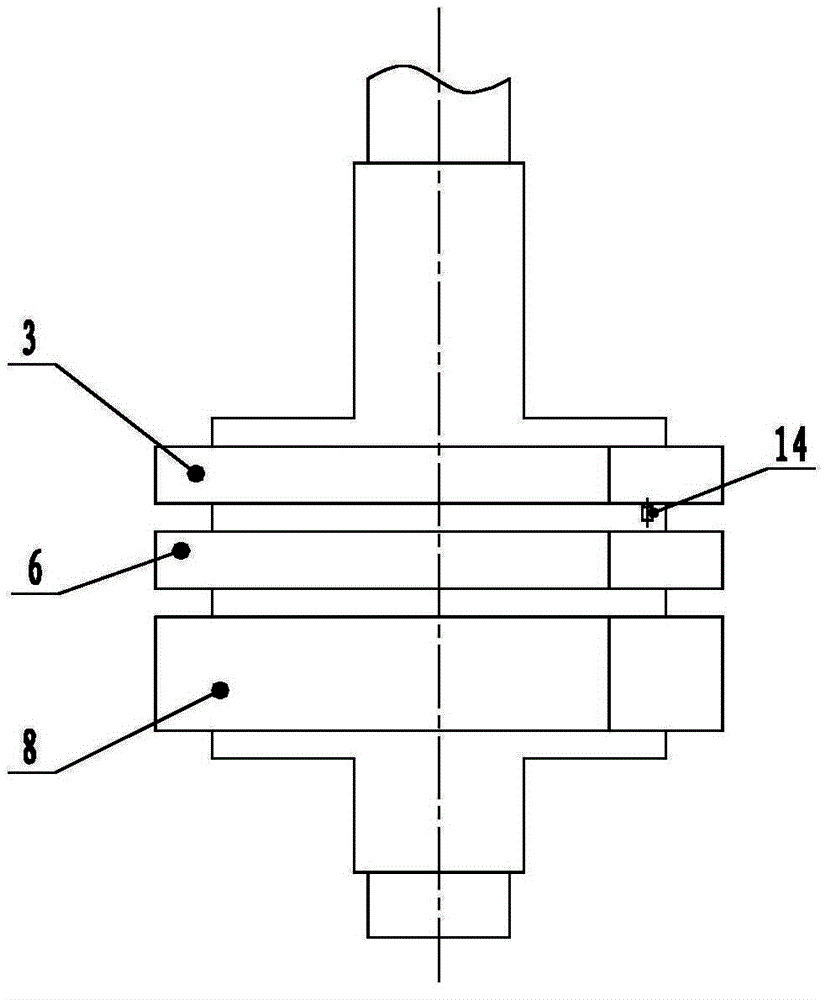

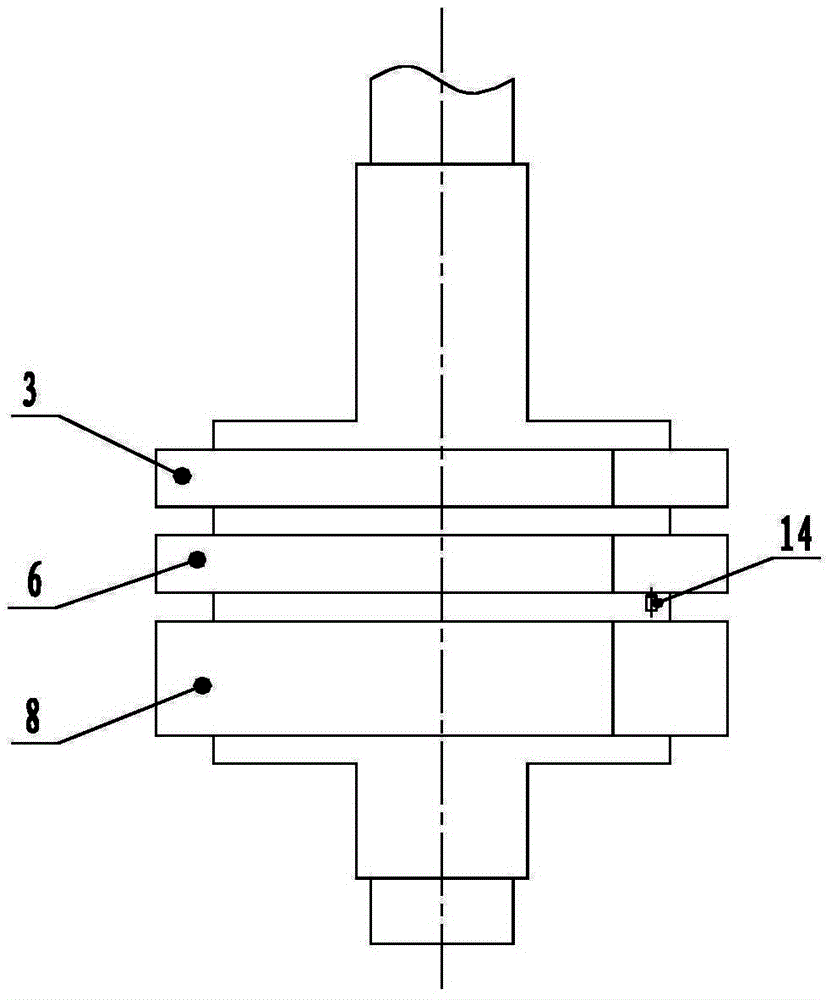

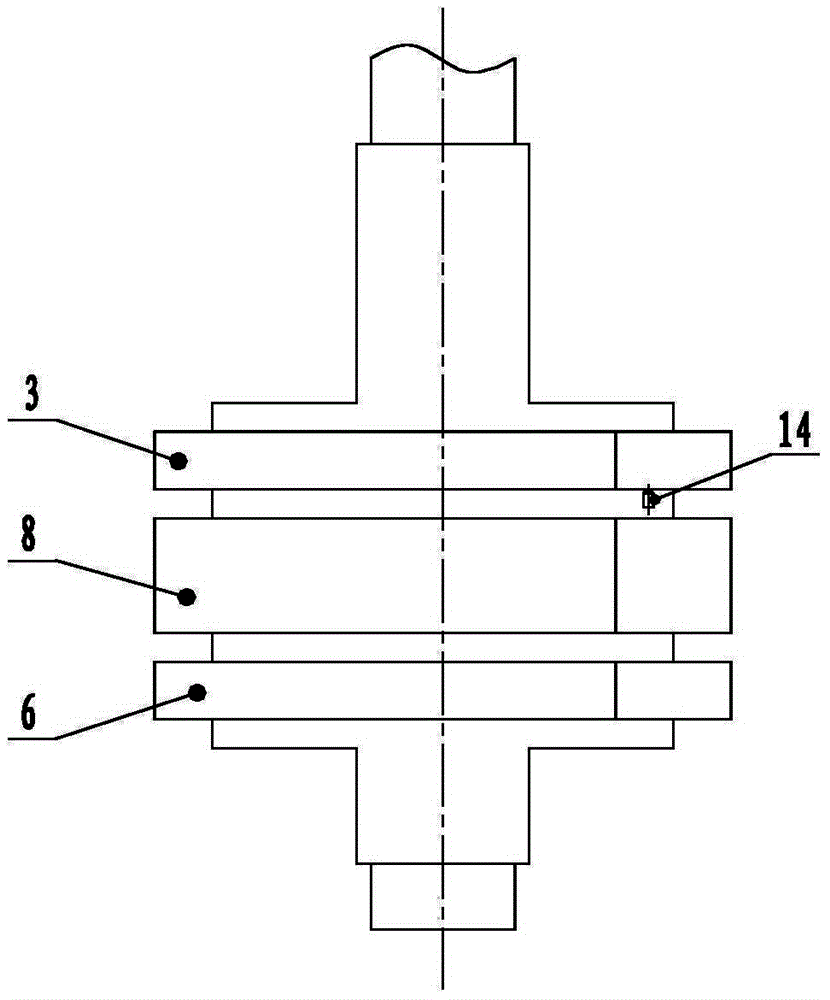

The invention provides a compressor. According to the compressor, a low-pressure cylinder, a first high-pressure cylinder and a second high-pressure cylinder are arranged in an overlapped way, and separation plates are arranged between two adjacent cylinders; the first high-pressure cylinder and the second high-pressure cylinder are both arranged at a same side of the low-pressure cylinder or respectively arranged at two sides of the low-pressure cylinder; a lower flange is disposed at the downside of the low-pressure cylinder, the first high-pressure cylinder and the second high-pressure cylinder; the first high-pressure cylinder is inside provided with a first slip sheet, the second high-pressure cylinder is inside provided with a second slip sheet, and the low-pressure cylinder is inside provided with a third slip sheet; the first high-pressure cylinder and the second high-pressure cylinder are arranged in a parallel way and then are connected with the low-pressure cylinder in a serial way; the first high-pressure cylinder or / and the second high-pressure cylinder is / are a capacity-variable cylinder; and the low-pressure cylinder is taken as a first-stage compression cylinder. The invention also relates to an air conditioner. By employing the compressor and the air conditioner disclosed by the invention, the quantity of working cylinders of a multi-cylinder compressor is convenient to adjust.

Owner:GREE ELECTRIC APPLIANCES INC +2

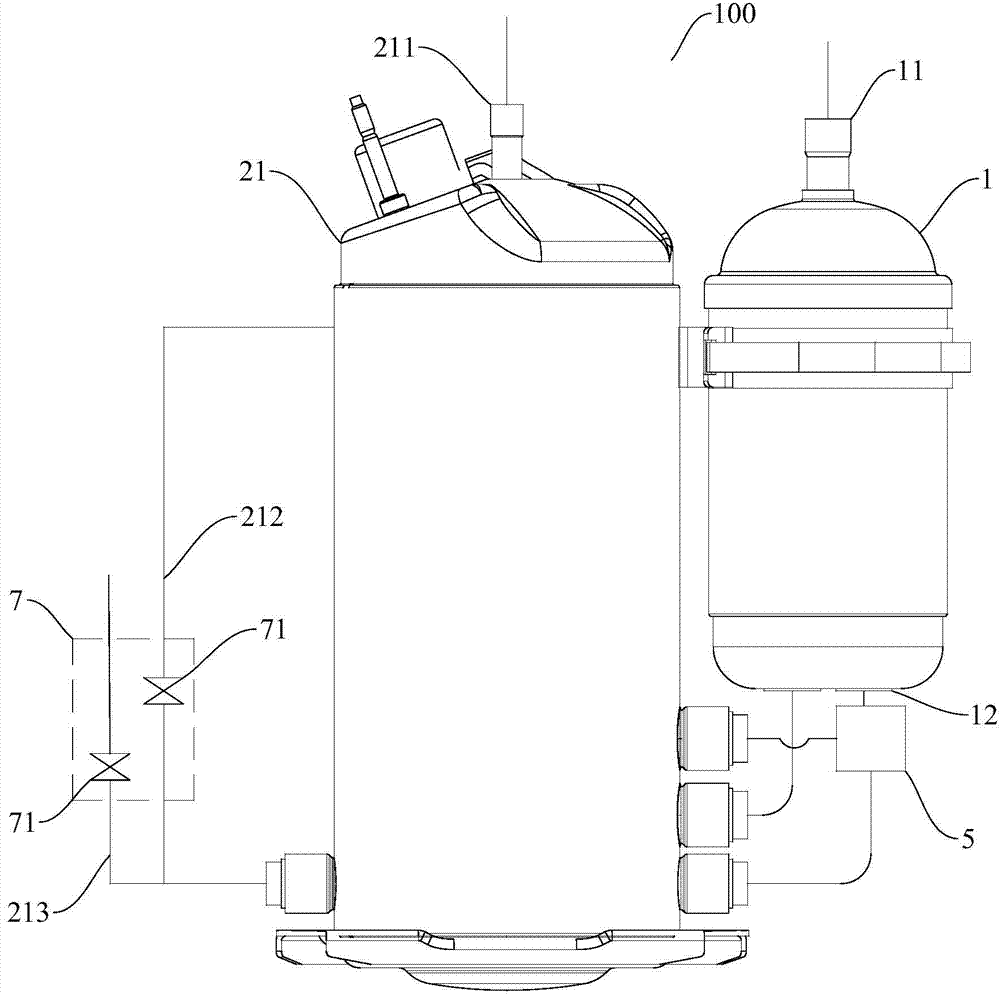

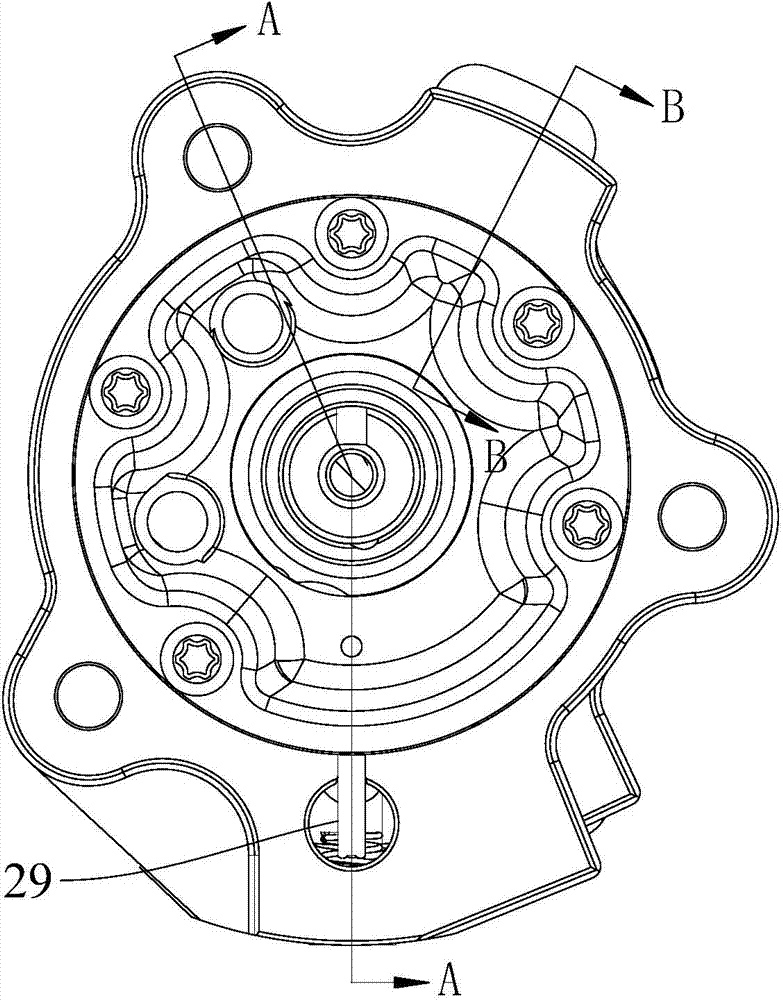

Air conditioning system and rotating compressor component thereof

ActiveCN104728109AImprove energy efficiencyAvoid overcompressionRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringSlip sheet

The invention discloses an air conditioning system and a rotating compressor component thereof, wherein the rotating compressor component comprises a liquid accumulator and a rotating compressor, the liquid accumulator is provided with an air outlet; the rotating compressor comprises a compressing mechanism which comprises a main bearing, an air cylinder component and a supplementary bearing, the air cylinder component comprises two air cylinders, a baffle plate and two slip sheets, each air cylinder is provided with a compression chamber, a first air entry and a slip sheet groove, and the compression chamber comprises an intake chamber and an exhaust chamber, the compressing mechanism is provided with a jet chamber, the exhaust chamber, of one of the two air cylinders, is connected with the jet chamber which is provided with a second air entry and an exhaust port, the second air entry is used for introducing a medium-pressure refrigerant and a high-pressure refrigerant, the first air entry, of one of the two air cylinders, is connected with the air outlet, the first air entry, of the other air cylinder, is connected with the air outlet or the exhaust port. According to the rotating compressor component thereof disclosed by the invention, the energy efficiency of a rotating compressor component is improved.

Owner:ANHUI MEIZHI PRECISION MFG +1

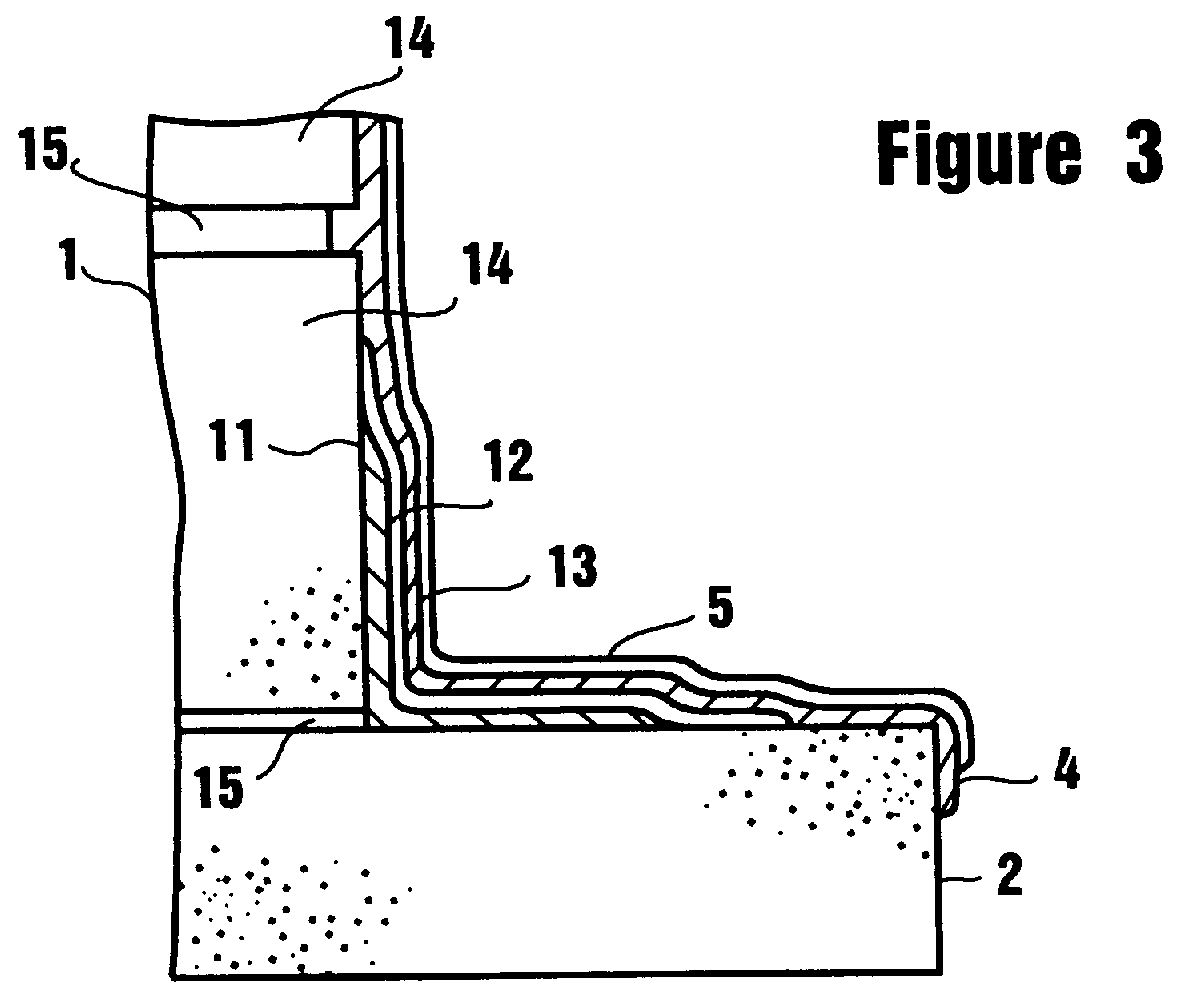

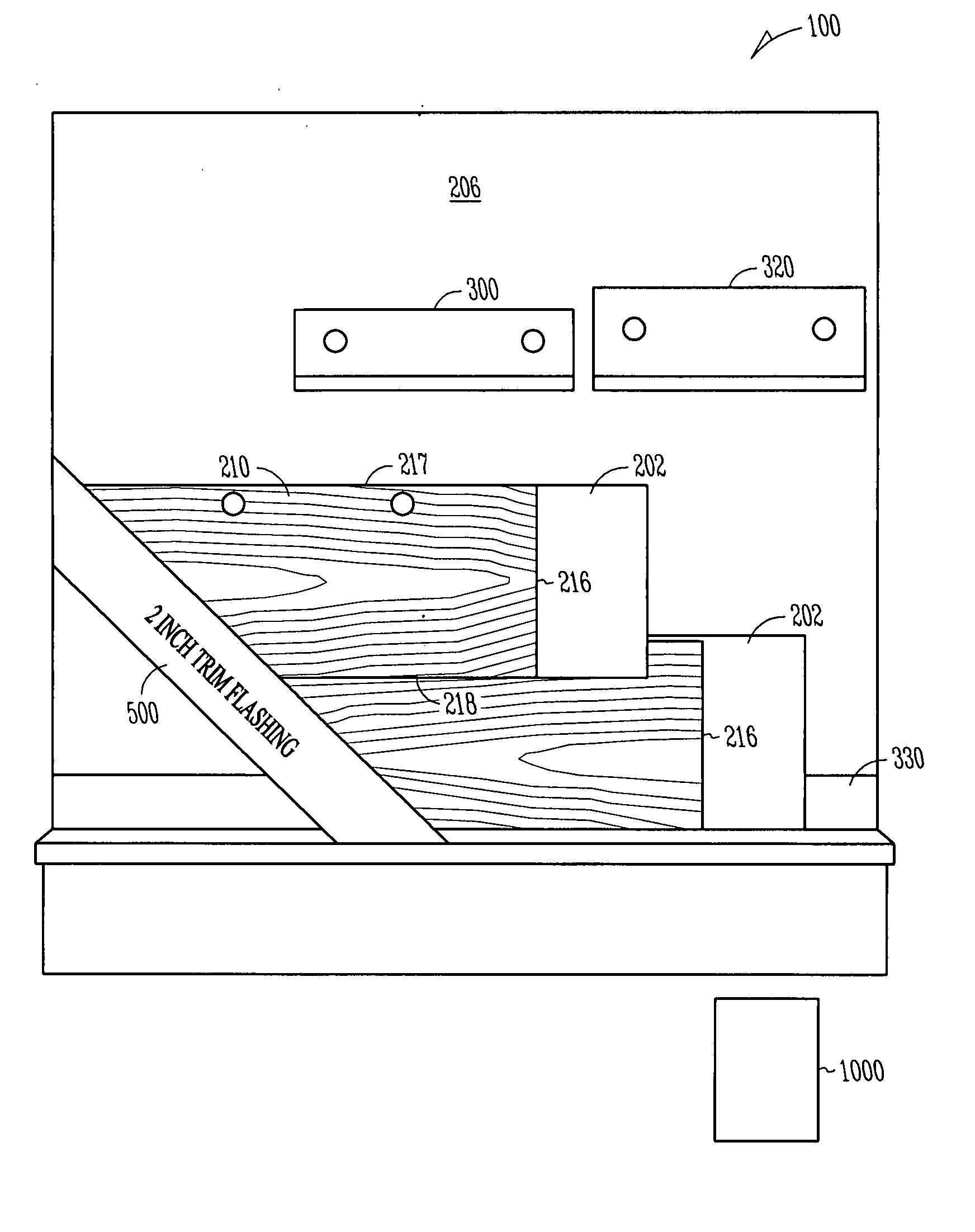

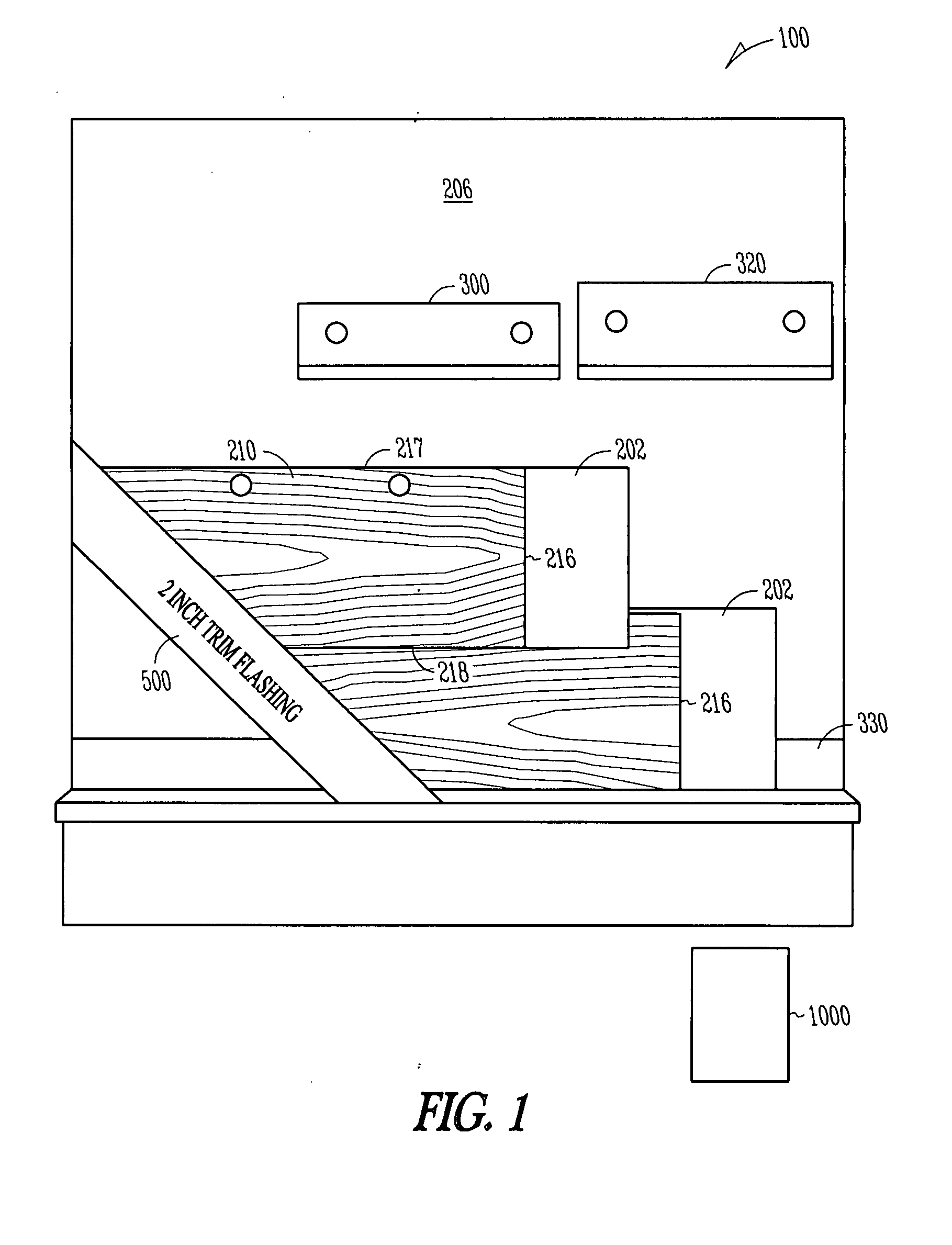

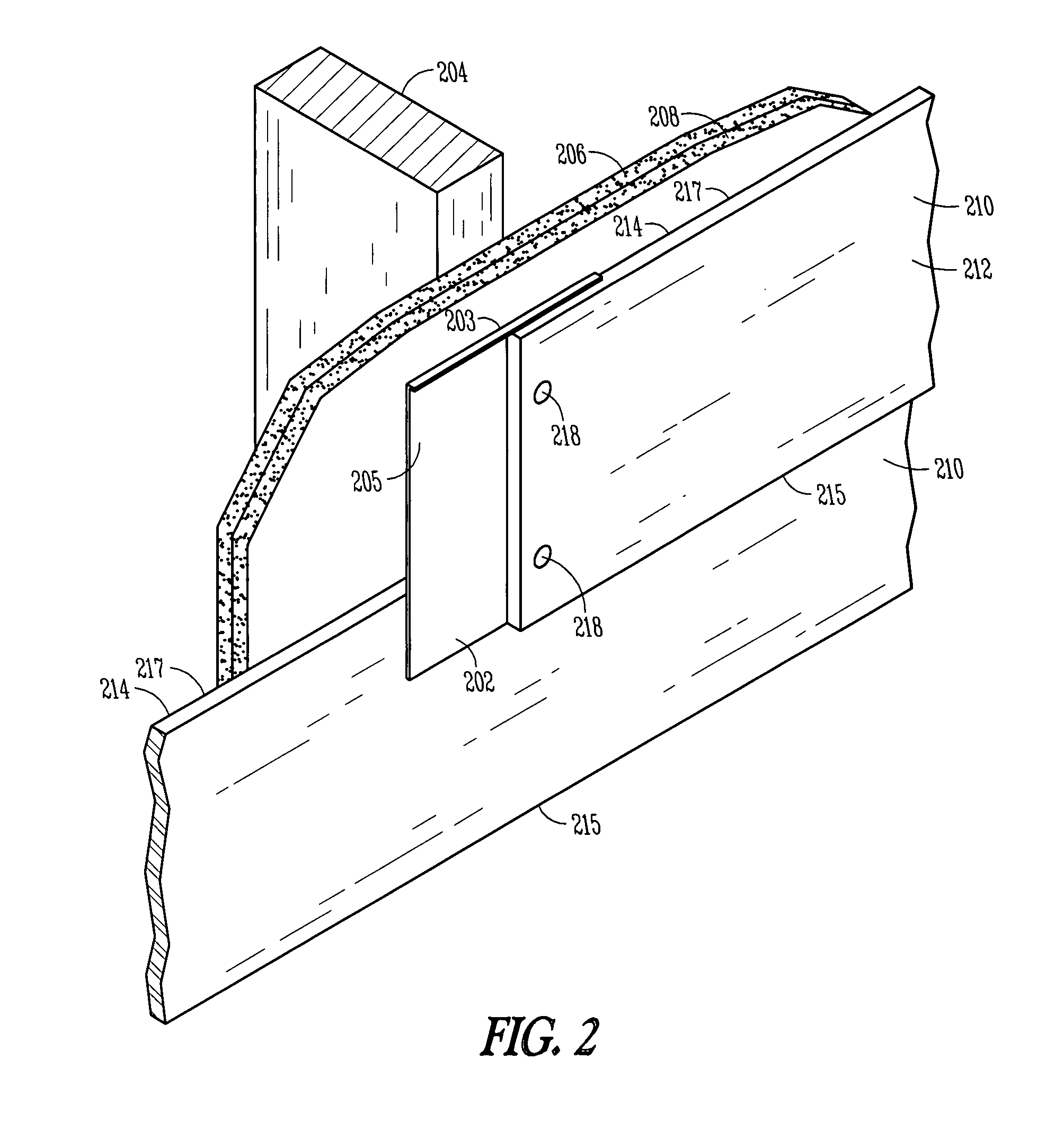

Siding system and method

ActiveUS20090064599A1Roof covering using slabs/sheetsRoof covering using tiles/slatesSlip sheetVisible surface

A system for siding a building includes at least two siding pieces each including an end that abuts the other of the siding pieces, and a slip sheet. The slip sheet includes a lip that catches a top surface of at least one of the siding pieces. The slip sheet is positioned behind the at least two siding pieces and backing the abutting ends of the at least two siding pieces. The system also includes a trim flashing apparatus which further includes a trim portion that includes a visible surface and a surface to abut a portion of a siding piece, and a flashing portion attached to the trim portion. The flashing portion is sufficiently thin so that at least a portion of the flashing portion is covered by at least one of the two siding pieces.

Owner:FLASHING BY DESIGN

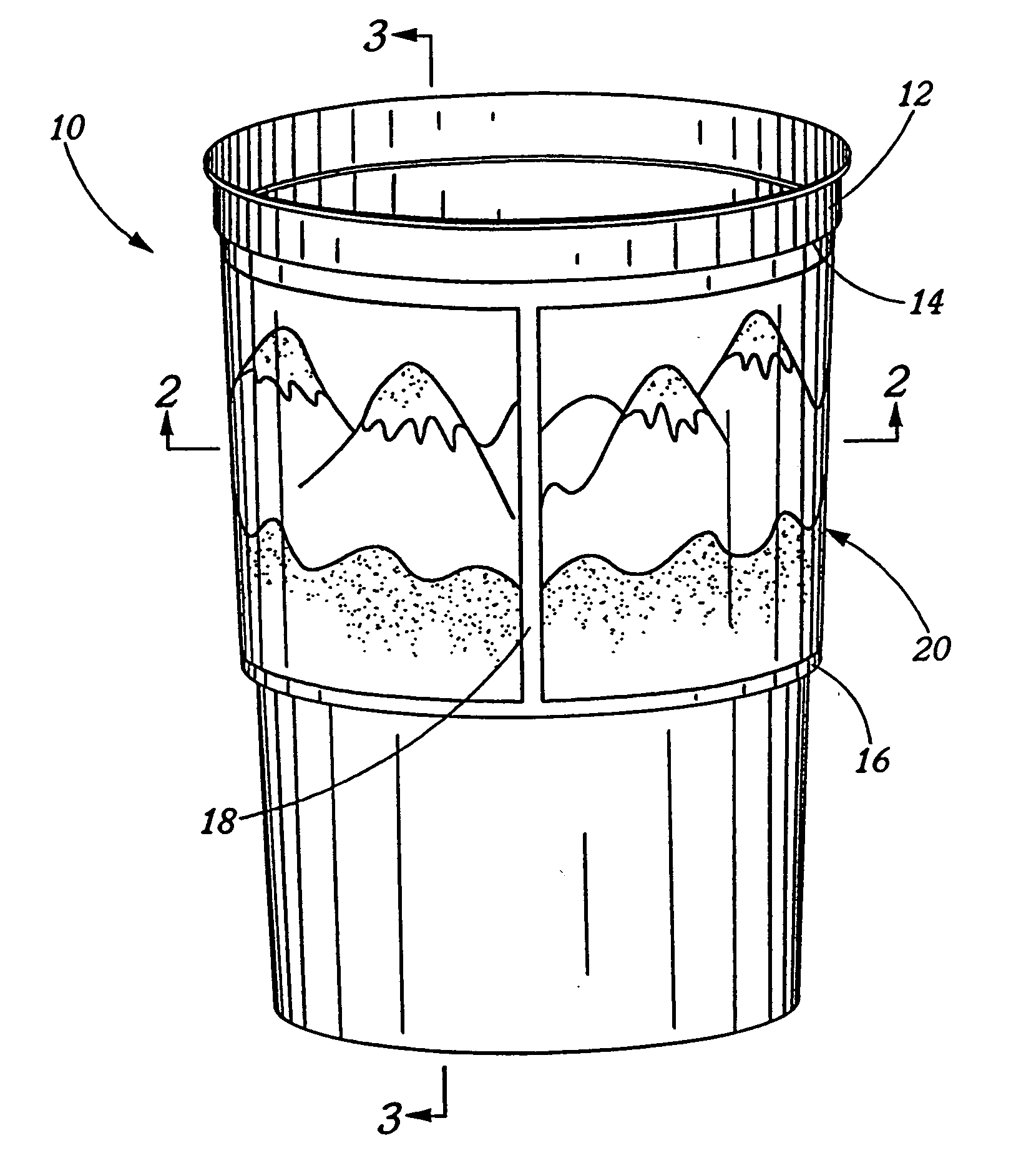

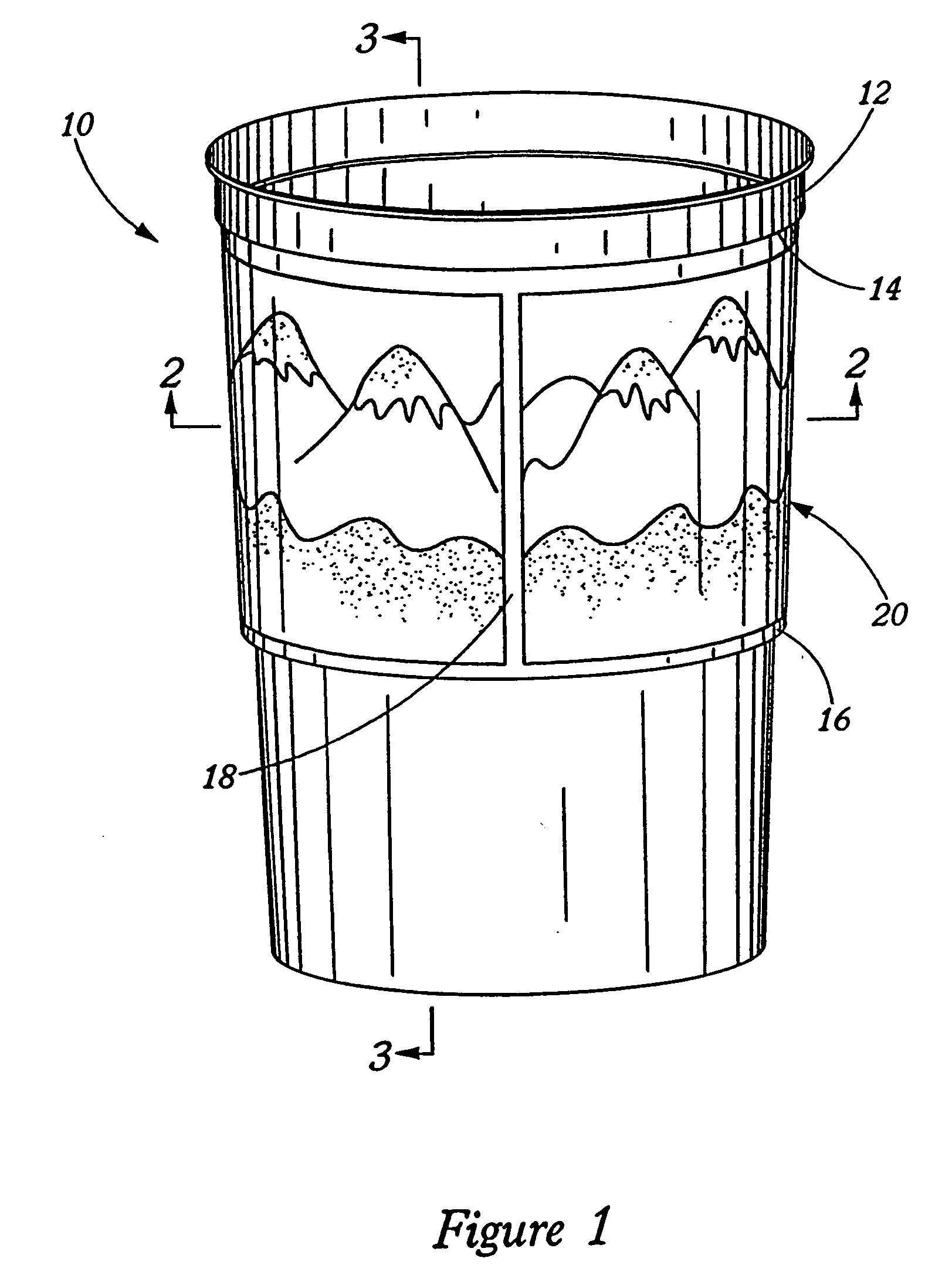

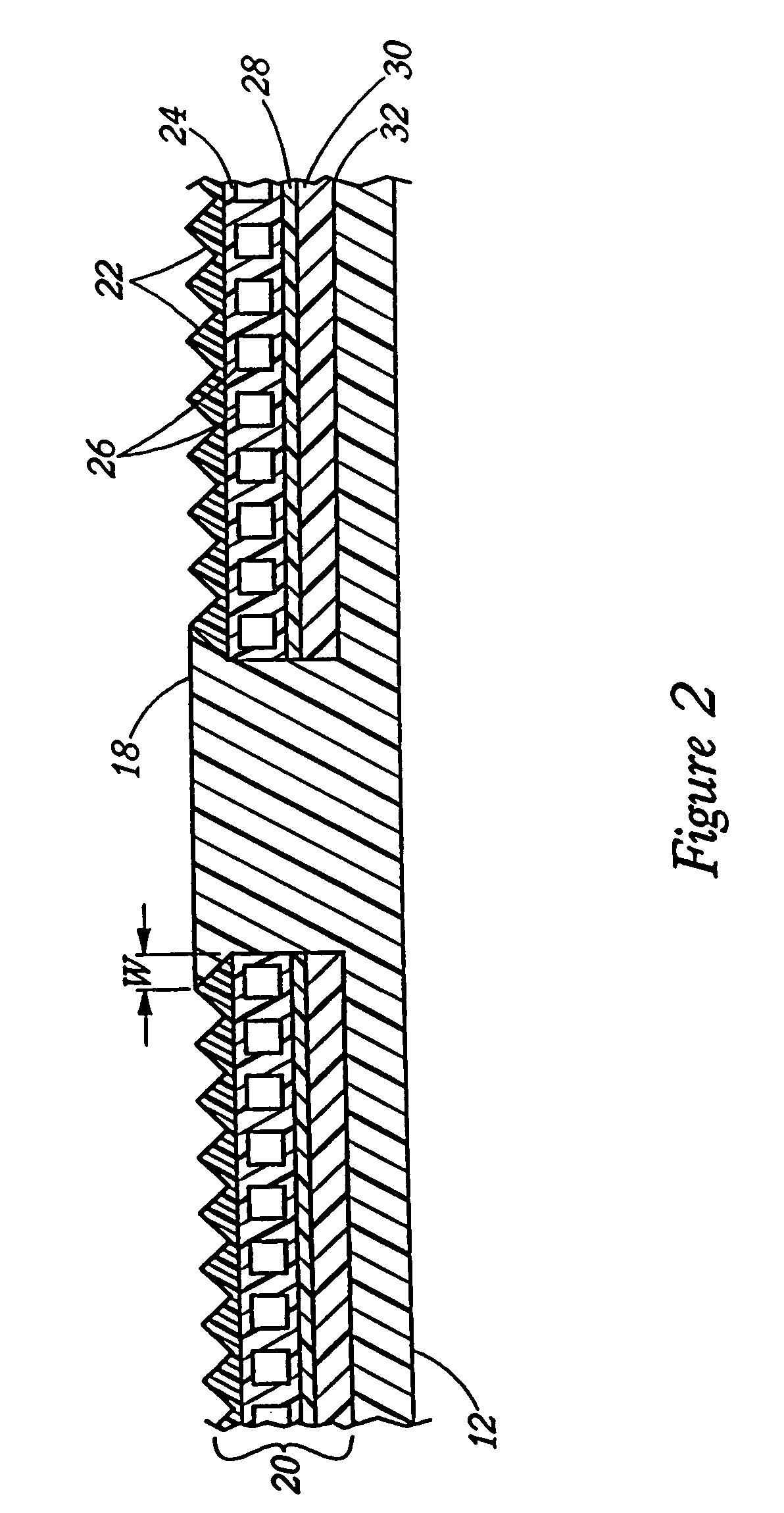

Method of bonding a lenticular lens sheet to plastic objects and objects made from same

InactiveUS20050053737A1Efficient and economicalQuality improvementEnvelopes/bags making machineryContainer decorationsPolyesterBond interface

A method of fabricating plastic objects having an insert of Lenticular lens material integrally bonded or otherwise attached therein. In one embodiment, the method is used to fabricate a container, such as a conical cup, by first manufacturing or providing a sheet of Lenticular material comprising layers of lens material and optical ridges and grooves and an ink layer printed on the flat side of the lens material. To protect the ink from the heat of molten or moldable plastic during later plastic processing, a thermally protective substrate is attached or bonded to the ink layer by using adhesives to attach a plastic substrate or by coating the ink with coating materials that thermally protect the ink from high temperatures. In one embodiment, the protective substrate is applied in a two step process of first placing a plastic hot melt onto a polyester or other material release liner and, after cooling of the hot melt, using heat and pressure to laminate or bond the hot melt plastic to the ink and then removing the liner. Lenticular inserts are cut out of the Lenticular material sheets and the inserts are positioned within a mold where the container is formed by injection, blow, or other molding process. In this step, the substrate acts as a bonding surface as it contacts the molten plastic, melts, and then cools forming a bonding interface with the plastic used to form the container.

Owner:TRAVEL TAGS

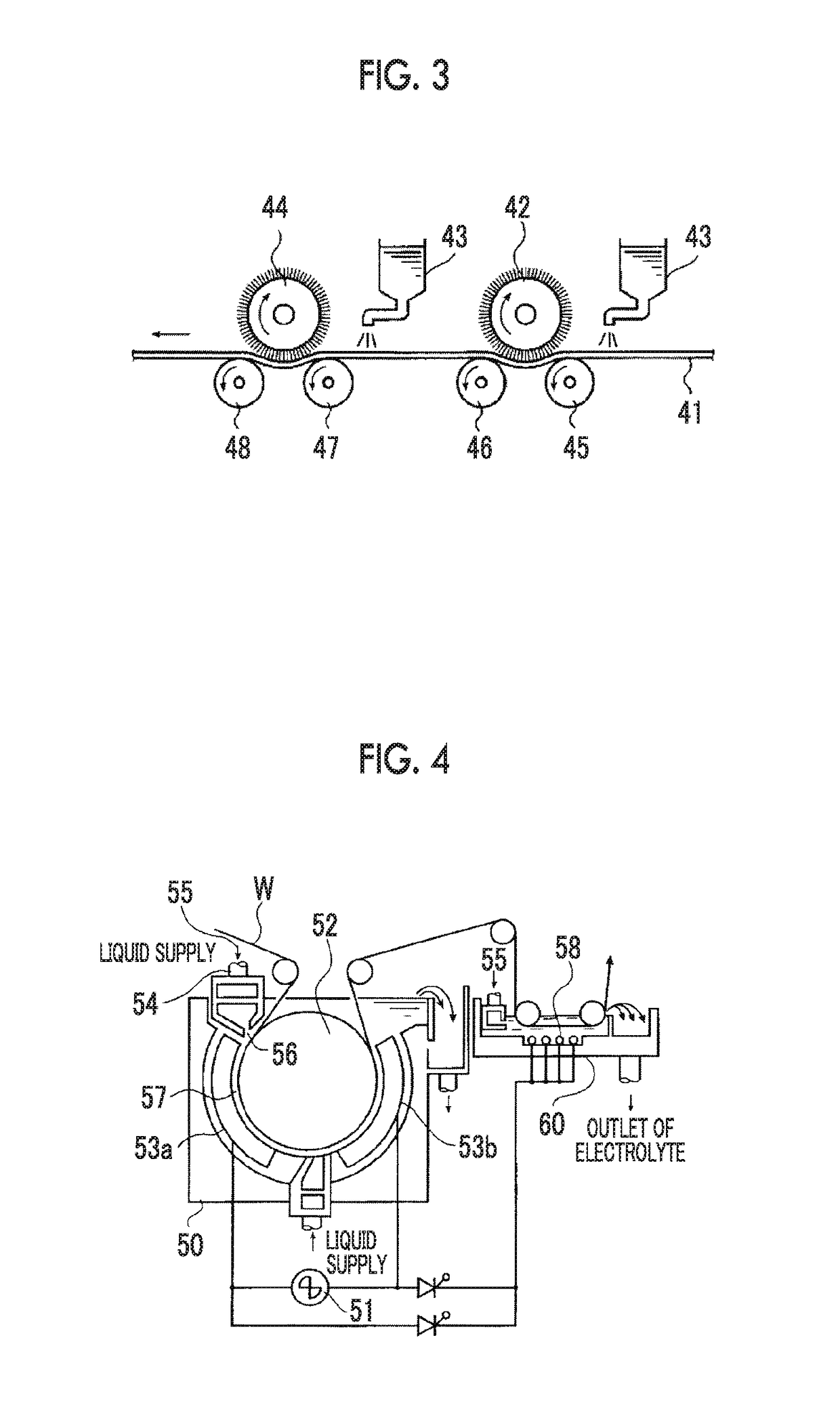

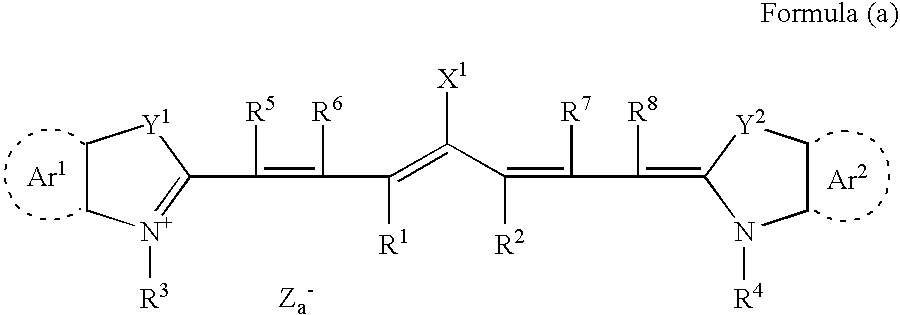

Lithographic printing plate precursor, method of producing same, and printing method using same

Provided are a lithographic printing plate precursor for furnishing a lithographic printing plate in which adhesion to interleaving paper is prevented, contamination inside a device is prevented, and edge stain does not occur; a method of producing the same; and a printing method using the same. The lithographic printing plate precursor includes: a support; and an image recording layer on the support, in which a region of a surface of the lithographic printing plate precursor at a side of the image recording layer, which is from an end portion of the lithographic printing plate precursor to a portion inside the end portion by 5 mm, contains at least one polymer selected from polyamide, polyurethane, polyurea, polyester and polycarbonate, and has a content of the polymer per unit area which is greater than a content of the polymer per unit area in a region other than the above-described region by an amount of 10 mg / m2 or greater.

Owner:FUJIFILM CORP

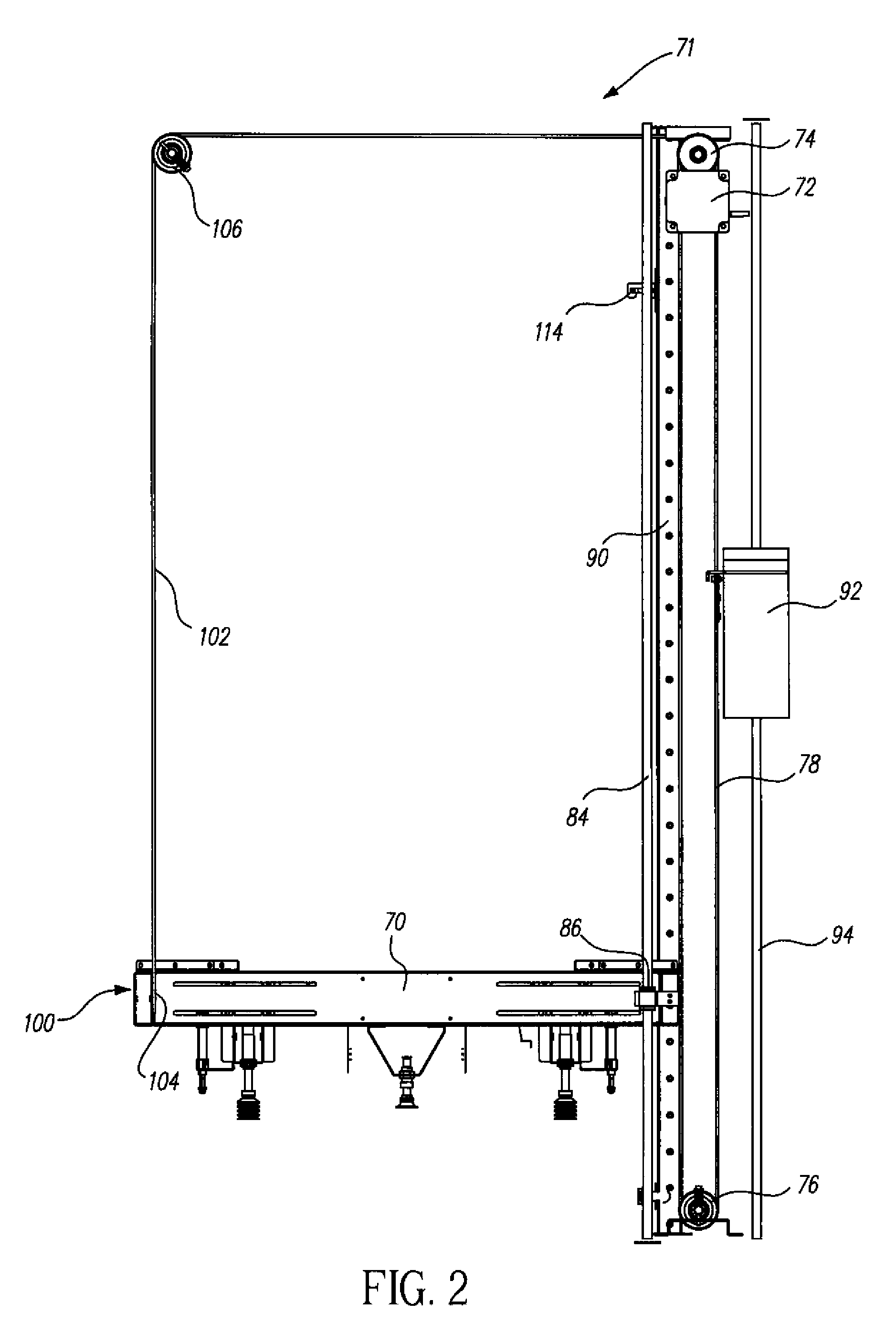

Slip sheet removal

A method of removing slip sheets from a printing plates stack is disclosed, wherein the slip sheets are interspersed between the printing plates includes moving at least two parallel energy chains. Each of the energy chains carries a plurality of vacuum cups over the stack of printing plates. The vacuum cups are attached to a top slip sheet placed on top of the printing plates stack and peel off sheets while vacuum is maintained and transferring the top slip sheet into a slip sheet bin.

Owner:EASTMAN KODAK CO

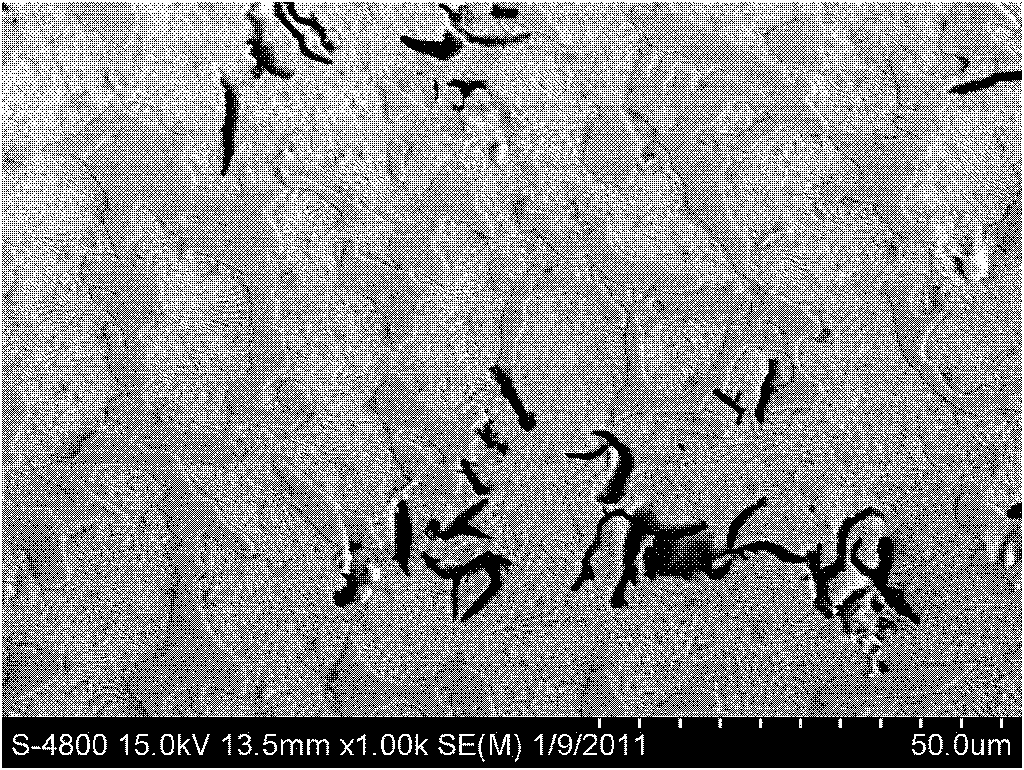

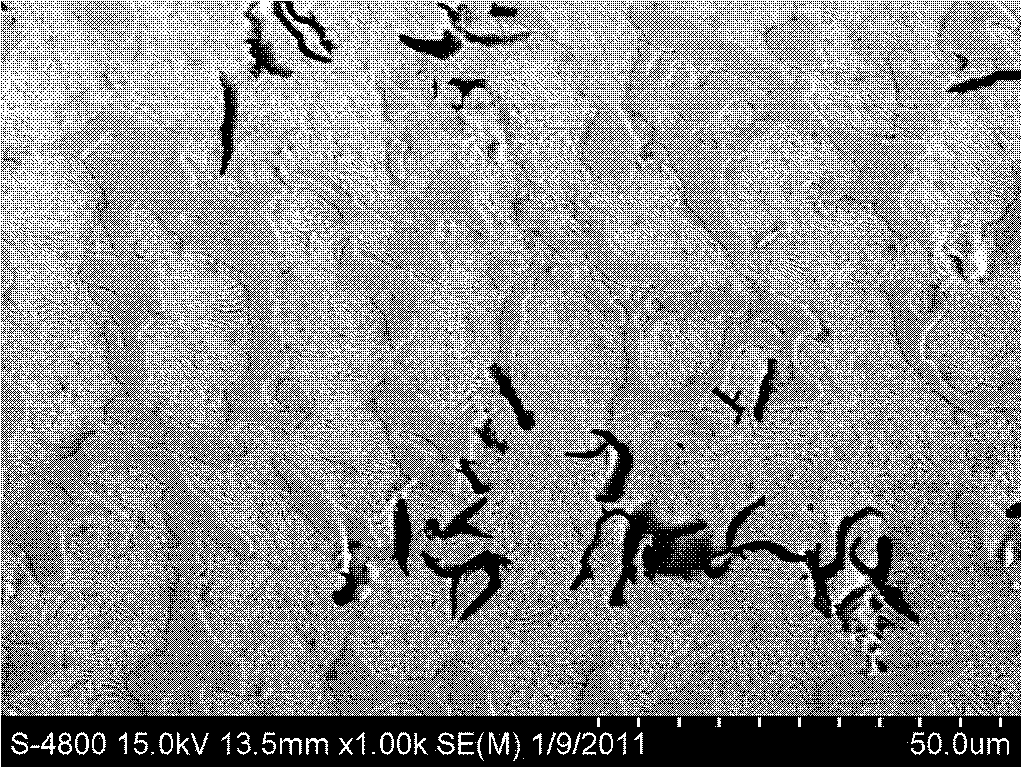

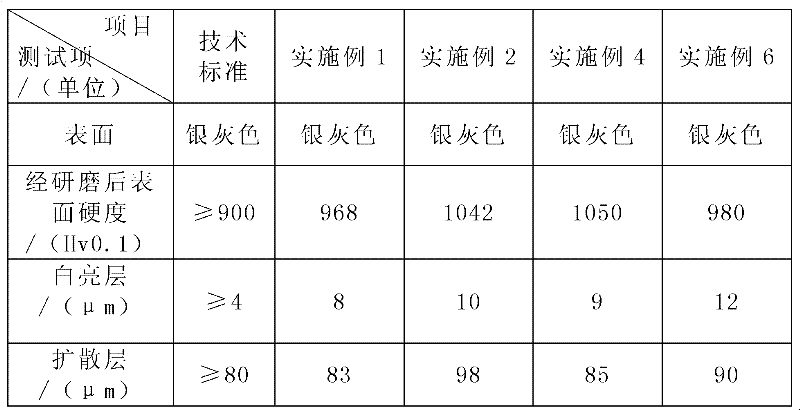

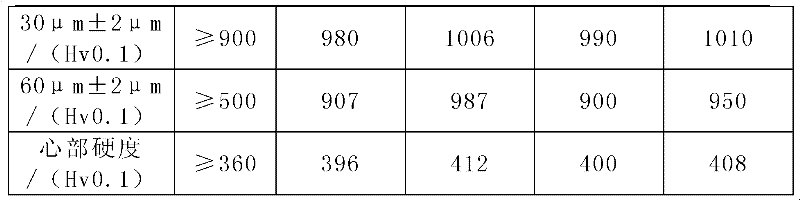

Slip sheet of refrigeration compressor and manufacturing method thereof

ActiveCN101629573AEasy to processNarrow selection of materialsRotary/oscillating piston pump componentsLiquid fuel engine componentsRefrigeration compressorChemical composition

The invention relates to a slip sheet of a refrigeration compressor, which is manufactured by the following chemical components in percentage by mass: 0.32-0.54% of C, 0.17-0.45% of Si, 0.30-1.20% of Mn, 0.80-1.65% of Cr, 0.15-0.30% of Mo, 0.60-1.10 Al, 0-0.2% of V, and the balance of Fe. The invention has narrower material selection range because prior slip sheet materials are all limited to high-speed tool steel and high-carbon stainless steel; the invention manufactures the slip sheet completely meeting the requirement of the slip sheet of a high-quality compressor on shape, surface rigidity and rigidity distribution through reasonable material selection, and has wide material selection range, easily obtained material and low cost; in addition, because the content of carbon is further reduced, the processing property of the slip sheet is better, and the good quality rate of products is enhanced.

Owner:NINGBO YONGWEI GROUP

Manufacture method of slip sheet of air conditioner compressor

InactiveCN102251166AImprove the lubrication effectImprove wear resistanceFoundry mouldsSolid state diffusion coatingCarbideSlip sheet

Owner:乐金电子(秦皇岛)有限公司 +1

Method for preparing stainless steel lining paper

InactiveCN1936182AImprove performanceSolve the problem of only producing high-weight paperNatural cellulose pulp/paperFlexible coversFiberParaffin wax

The invention discloses a manufacturing method for a stainless steel lining paper that includes the following steps: adopting white wood pulp as raw material, and white sulfate softwood pulp: white hardwood pulp =70-80wt%: 30-20wt%; adopting short fiber shiny beating method, and 330 disc mill basalt stone lapping to take jordaning; using chemical auxiliary agent that adding 5-20wt% olefin emulsion, 0.5-1.0wt% positive ion starch, 0.5-1.0wt% AKD, 1.0-2.0wt% silicone emulsion, 0.3-0.5wt% CPAM, and 0.25-0.75wt% PAE. It has the advantages of high intension, laceration endurable, super smooth, clean and high temperature endurable. It could fit different manufacture technology requests of stainless steel.

Owner:樊运民

Contained with repositionable slip-sheet to cover outlet

The subject invention provides a bulk bag comprising a container and a cover sheet at least partially attached to the lower surface. The cover provides a slip sheet for the container. In a preferred form, the container has an outlet in the lower surface thereof in normal use. The slip sheet is positioned so that it can optionally cover or at least substantially uncover the outlet.

Owner:BURKHARDT HENRI JACQUES

Method for manufacturing slip-sheet of compressor

InactiveCN101003880AEasy to processWide selection of materialsRotary piston pumpsRotary piston liquid enginesMetallurgyNitrogen

This invention provides a method for producing slip sheets for compressors. The method comprises: (1) selecting appropriate stainless steel material containing C 0.95-1.20 wt. % and Cr 16.0-18.0 wt. %; (2) wire-cutting the stainless steel material according to the shape of slip sheets, and milling to form grooves; (3) performing vacuum heat-treatment; (4) grinding and polishing the six faces of each slip sheets; (5) infiltrating nitrogen into the slip sheets by using ammonia; (6) finely grinding the slip sheets until qualified. The method has such advantages as wide raw material range and low cost. The obtained slip sheets, due to a lower carbon content, have such advantages as high processability and high qualification rate.

Owner:庄希平

Glass lining paper and glass plate package body

ActiveCN103879657ASuppress exception generationReduce manufacturing costSpecial paperInternal framesForeign matterPolymer science

The invention relates to a glass lining paper and a glass plate package body. The glass lining paper is applied during the laminating process of glass plates, wherein the wiring abnormality caused by metal foreign bodies transferred from the glass lining paper is prevented. Meanwhile, the above problem is solved through setting the metal content to be smaller than 0.1 mass% or setting the air permeability to be larger than 10 sec.

Owner:ASAHI GLASS CO LTD

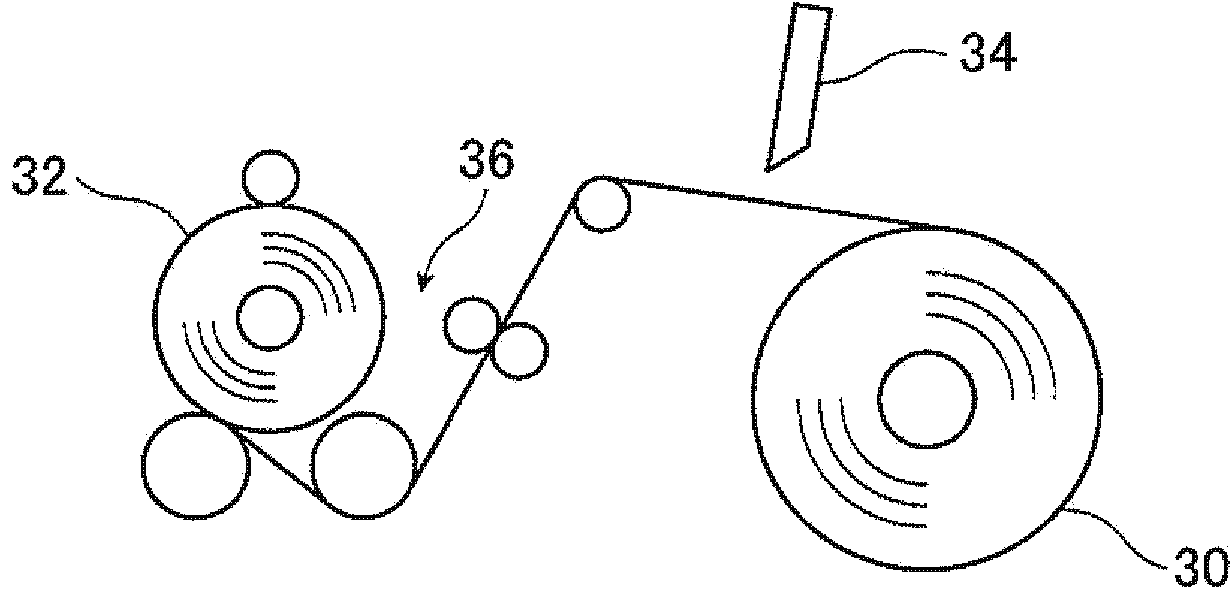

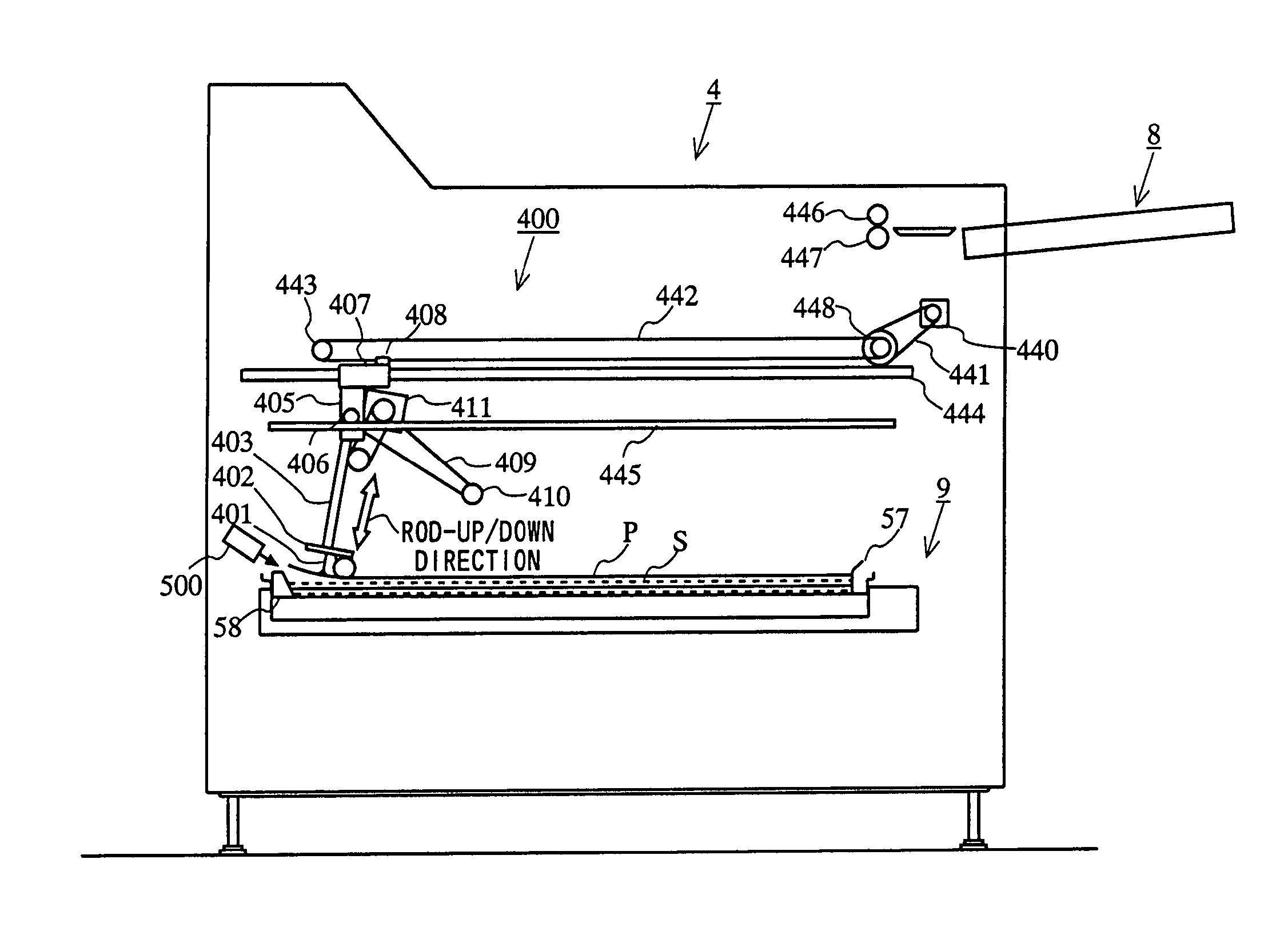

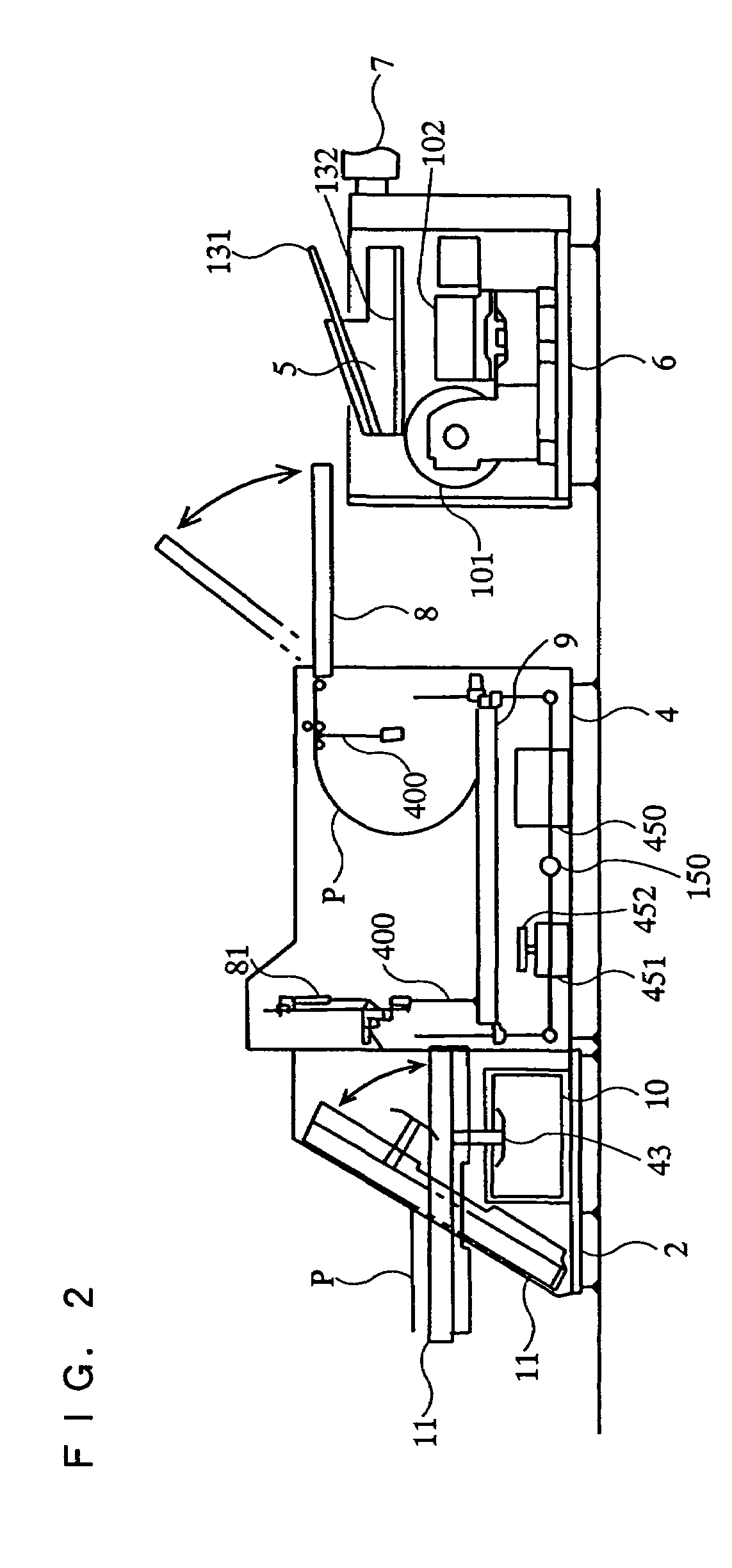

Plate supplying apparatus

InactiveUS6978716B2Preventing an image recording layer of a plate from being damagedReduce torqueAddressographsLetterpress printingSlip sheetEngineering

In the plate supplying apparatus of the present invention, various vibrations are provided to a plate secured via suction during a separating operation by causing pad rods 403 to repeat a slight ascent and a pause, and thereafter causing the pad rods 403 to make an abrupt descent, thereby reliably peeling off a slip sheet adhering to the back face of the plate. Further, vibration in the rod-up / down direction is provided to the plate during the separating operation, and the plate is not pushed hard. Thus, it is possible to prevent the plate from being damaged. A raising and lowering motor 52 is driven to lower the cassette 9. A separating operation for peeling off a slip sheet S adhering to the back face of the plate P is performed, and thereafter the plate P secured via suction is turned over and transferred.

Owner:DAINIPPON SCREEN MTG CO LTD

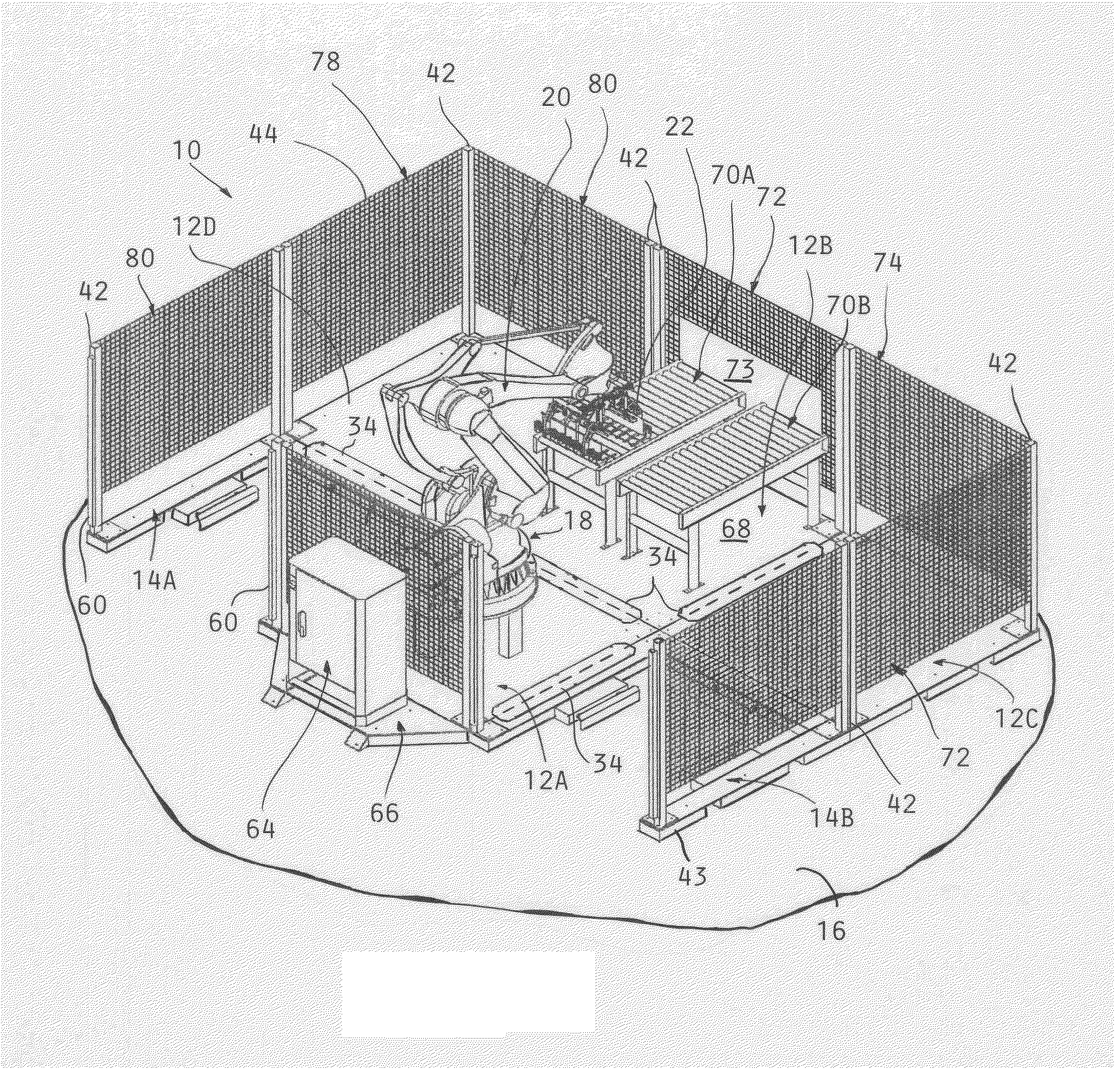

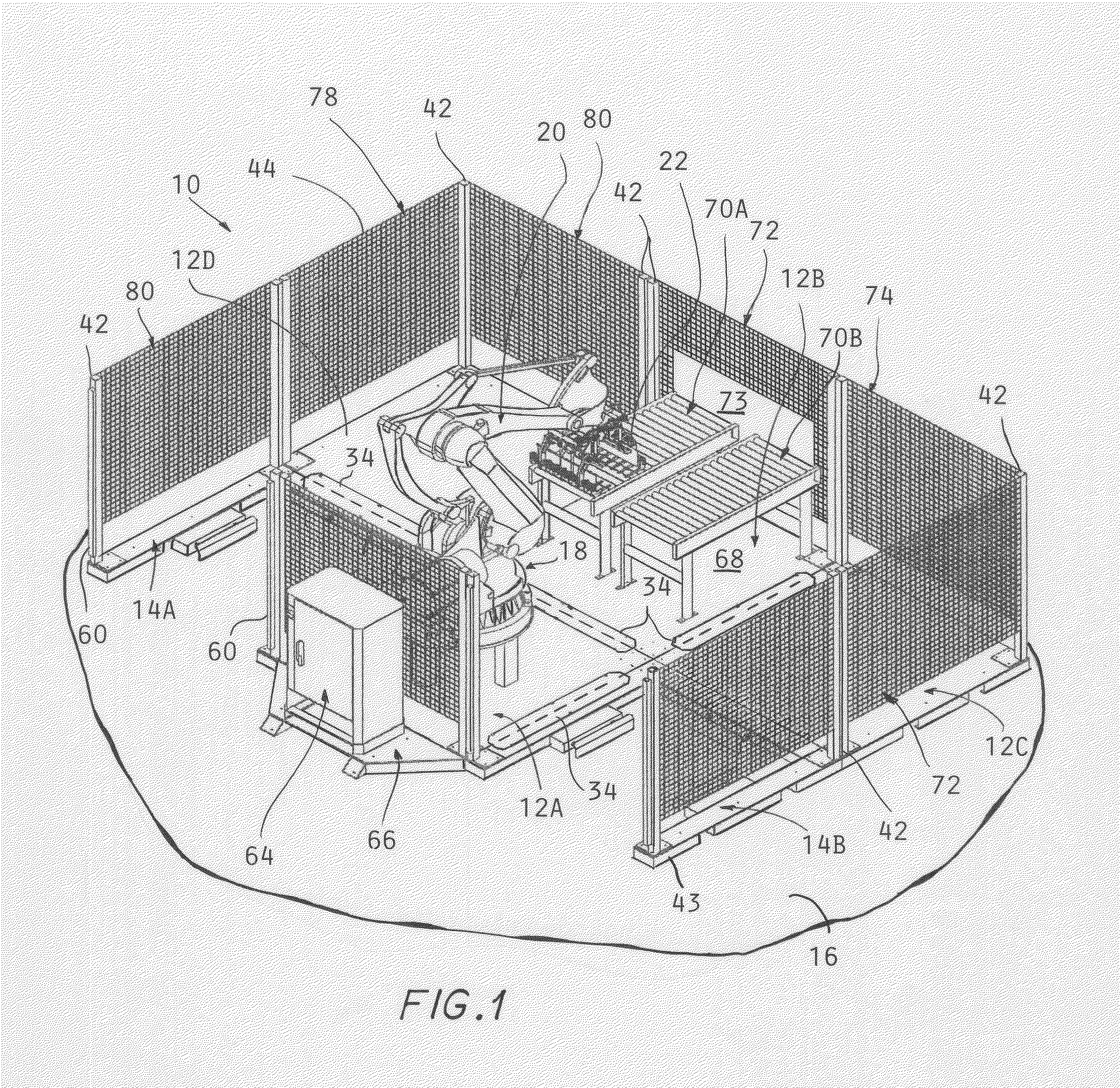

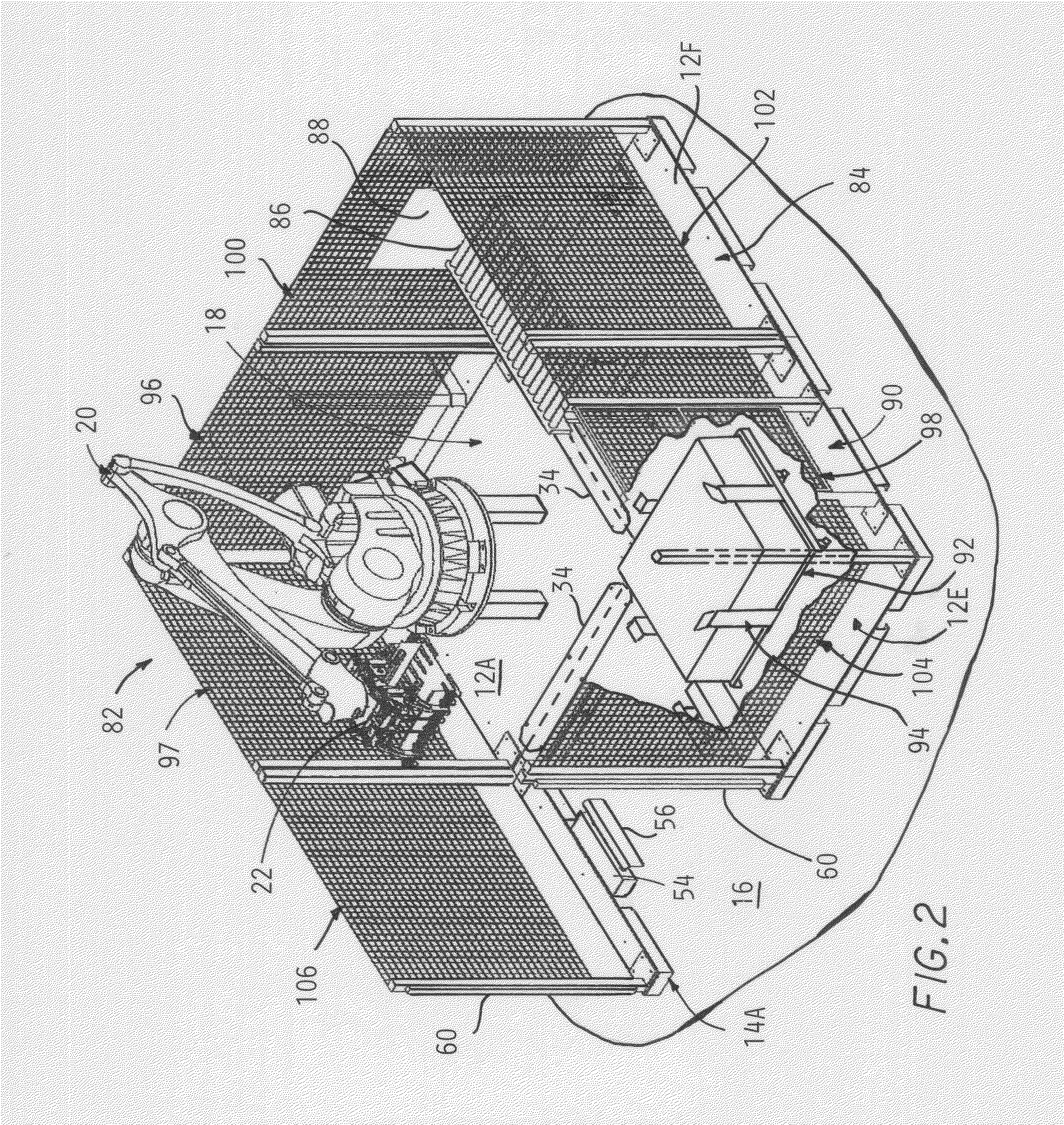

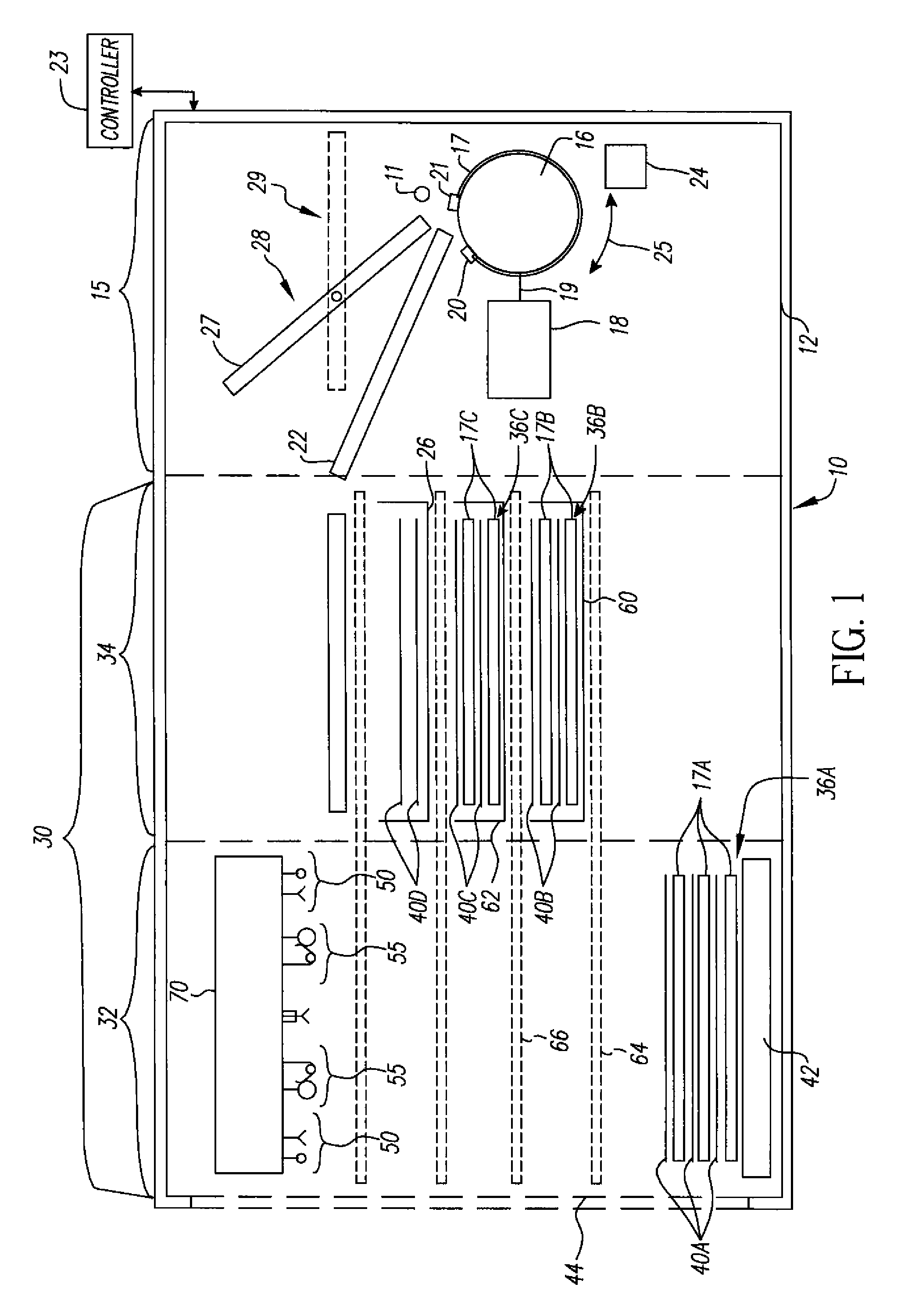

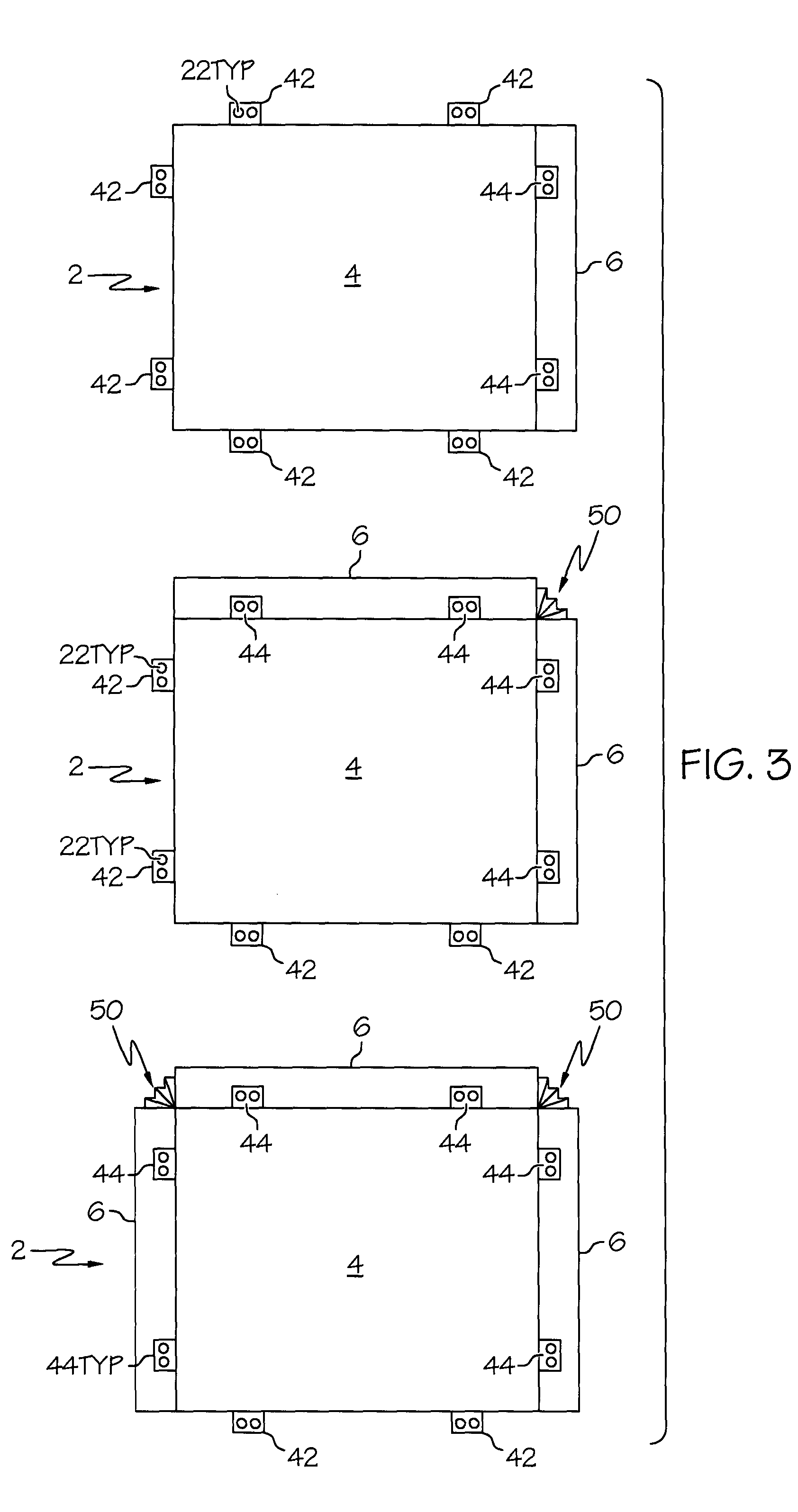

Robotic Palletizer Cell And Method Of Construction

A method of constructing a palletizer cell by providing square platform bases which are assembled into an array in abutment with each other, each platform base mounting a respective component of palletizing equipment, such as a robot, one or more conveyors, a slip sheet bin, a discharge module, etc. with one platform base anchored to the factory floor and the rest attached to one or another of the platform bases to form the array of platform bases thereby properly locating the various equipment with each other by the fitting together of the platform bases. Safety fencing sections are mounted atop one or more outer sides to substantially enclose the space within the palletizer cell. Each platform base is formed with side openings which may be engaged with the tines of a fork lift.

Owner:ROBERTS BRIAN THOMAS

Gas nitriding treatment method of 11Cr17 stainless steel slip sheet

ActiveCN102517541ASimple processReduce manufacturing costSolid state diffusion coatingSlip sheetQuality performance

The invention relates to a gas nitriding treatment method of 11Cr17 stainless steel slip sheet, belonging to the technical field of stainless steel treatment. The invention aims at solving the problems of large erosion on the equipment and products and large environmental pollution of the nitriding method of 11Cr17 stainless steel slip sheet in the prior art. The method of the invention comprisesthe steps of: degreasing and cleaning the slip sheet, performing a passive film removal treatment at 300-450 DEG C to remove the passive film on the surface of the slip sheet; continuously filling ammonia, performing a first stage nitriding treatment at 450-530 DEG C, and performing a second stage nitriding treatment at 530-580 DEG C, and cooling to obtain a nitrided 11Cr17 stainless steel slip sheet. The method of the invention has the advantages of simple technique process, low production cost, small environmental pollution, small erosion on the nitriding equipment and capability of prolonging the service life of the equipment; besides, the obtained product has good quality performance and high erosion resistance.

Owner:浙江百达精工股份有限公司

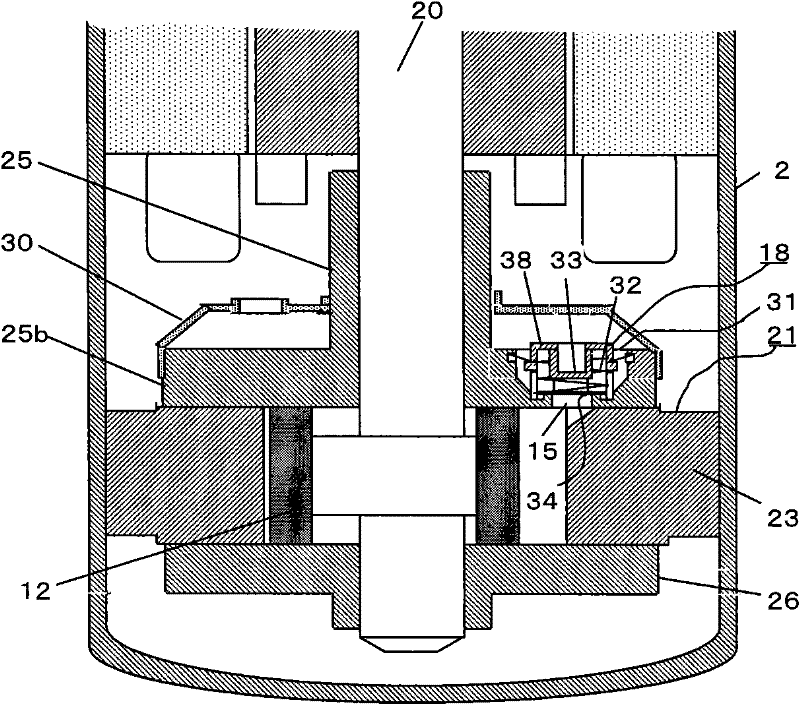

Rotary compressor

InactiveCN102235357AReduce rigidityImprove reliabilityRotary piston pumpsRotary piston liquid enginesSlip sheetCrankshaft

The invention discloses a rotary compressor. In the rotary compressor, a motor part and a compression mechanism part are arranged in a seal shell; and the compression mechanism part comprises cylinders, a piston which is eccentrically rotated in a cylinder compression cavity, a crankshaft which is rotated to drive the piston, a main bearing and an auxiliary bearing which are used for supporting the crankshaft and sealing the cylinder compression cavity, and a slip sheet of which the tip end is connected with the periphery of the piston. The rotary compressor is characterized in that: a discharge valve device is arranged on the main bearing and / or the auxiliary bearing and comprises assembly grooves, a discharge hole, a valve seat which are arranged on the main bearing and / or the auxiliary bearing, discharge valve plates which move up and down on the valve seat and are used for opening and closing the discharge hole, an up-and-down mechanism which is used for limiting the up-and-down operation ranges of the discharge valve plates, and a horizontal mechanism which is positioned on the outer side of the valve seat and is used for limiting the horizontal operation ranges of the discharge valve plates; one end of the discharge hole is communicated with the assembly grooves, and the other end of the discharge hole is communicated with the cylinder compression cavity; and the valve seat is arranged on the outer side of the discharge hole. The rotary compressor has the characteristics of high bearing intensity, low operation noise and high compression efficiency.

Owner:GUANGDONG MEIZHI COMPRESSOR

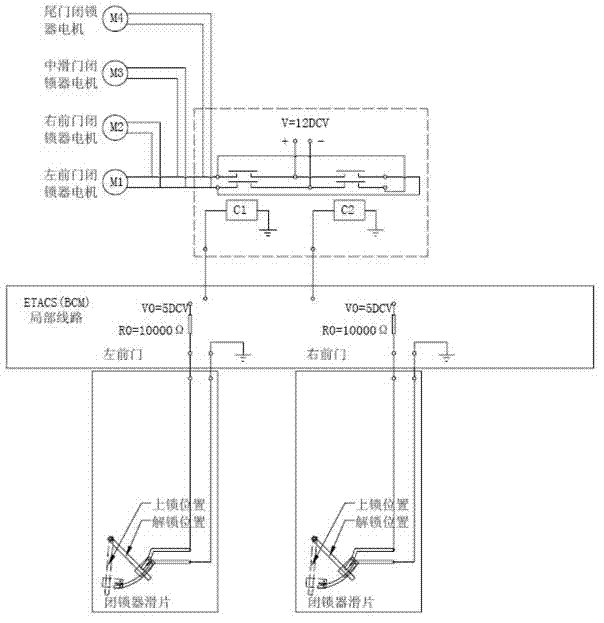

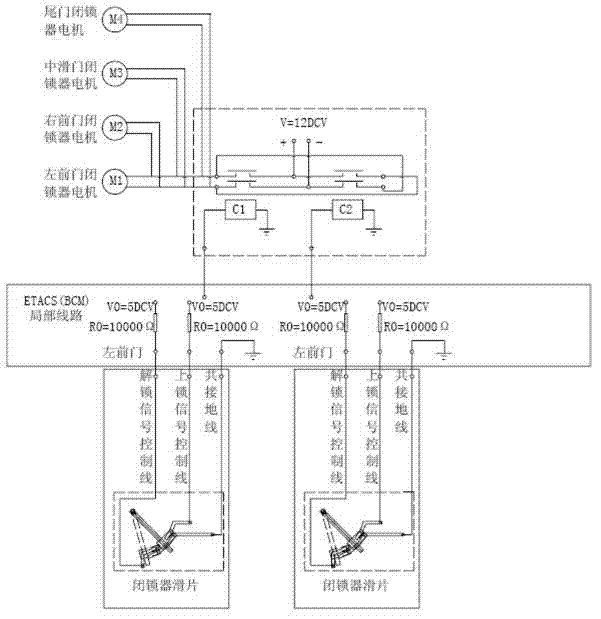

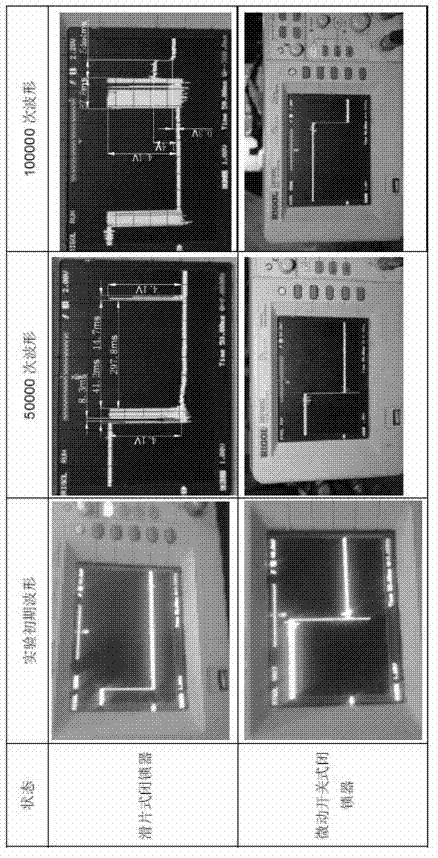

Micro-switch type automotive central door lock fastener and production process thereof

ActiveCN103114777ASimple structureThe signal is stable and reliableLocking wings simultaneouslyNon-mechanical controlsSlip sheetCam

The invention relates to a micro-switch type automotive central door lock fastener and a production process thereof. The micro-switch type automotive central door lock fastener comprises a shaft snap spring, a fastener action output oscillating bar, a sealing ring, a reset torsion spring, a worm gear, a locking cushion, a fastener output shaft, a sector gear, an unlocking bumper block, a driving cam bit, a worm gear rotating shaft, a lower fastener shell, a motor electrode, a micro-switch binding post, a micro-switch, a motor, a pinion, a worm and an upper fastener shell. A signal extraction mechanism of the central door lock fastener utilizes the high-performance micro-switch to substitute for a reed and a slip sheet of a traditional fastener, and corresponding mechanisms of the fastener are appropriately designed and adjusted.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

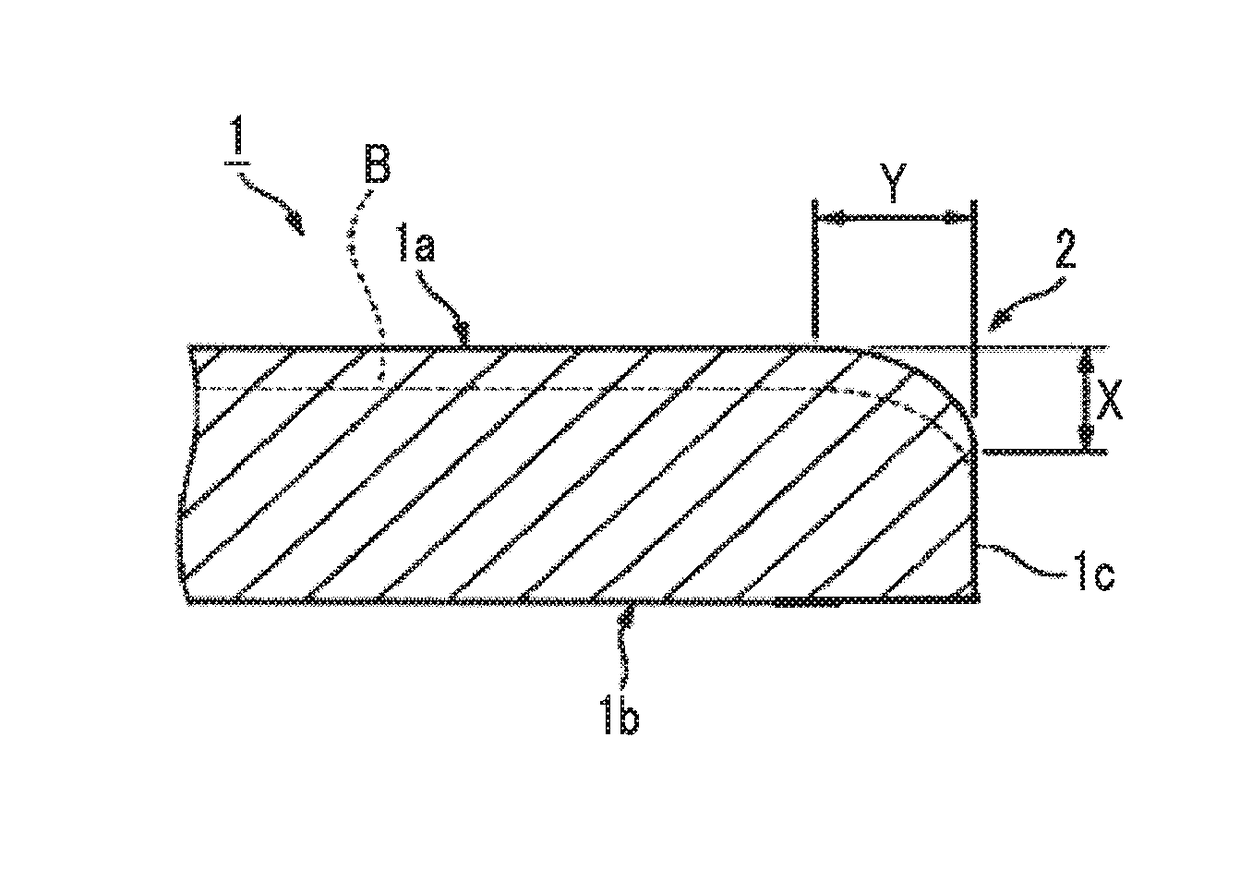

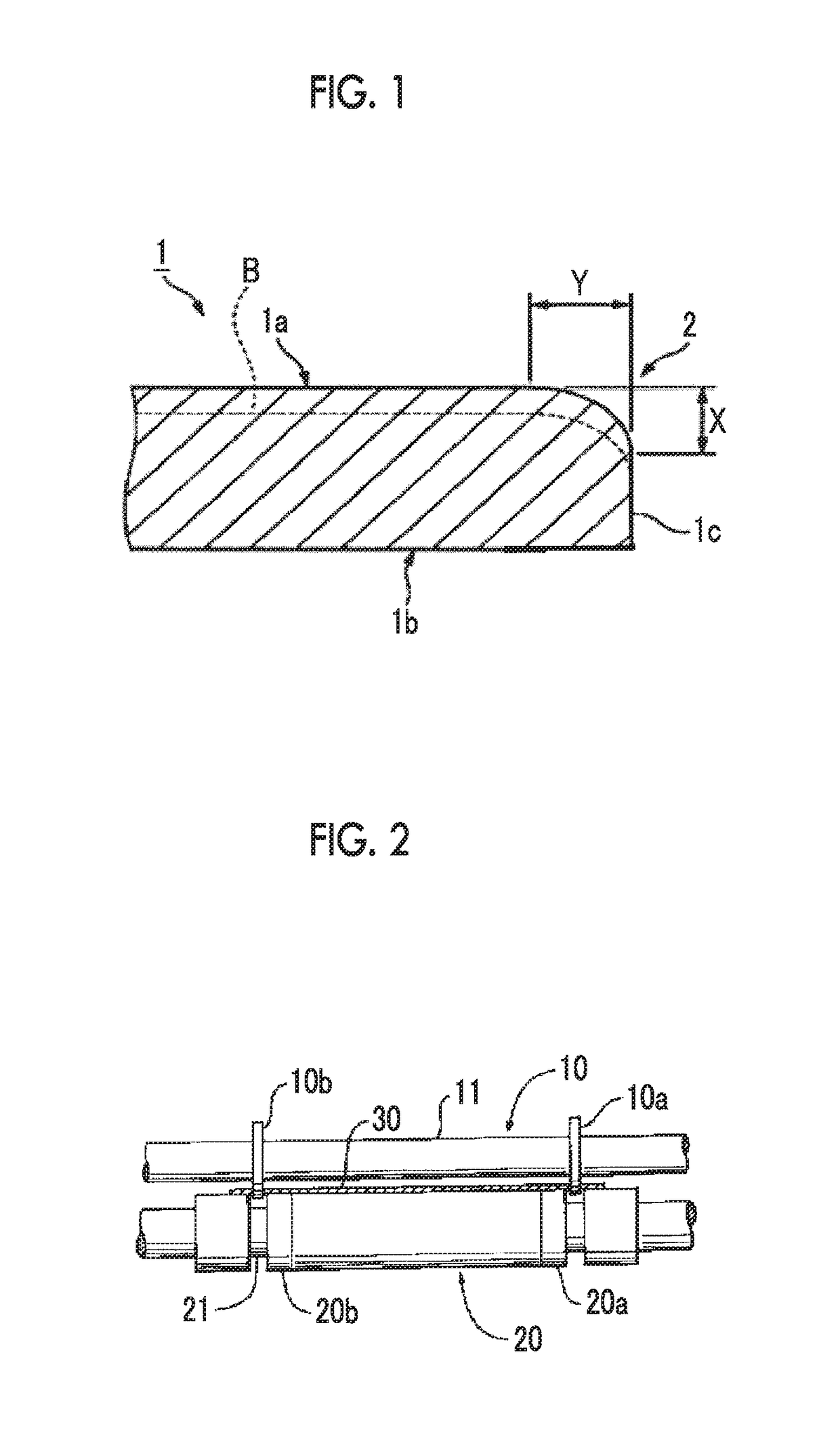

Planographic printing plate precursor and stack thereof

ActiveUS20080113296A1Impart propertyPhotosensitive materialsPhotomechanical apparatusProduction rateEpoxy

The invention provides a planographic printing plate precursor that is writable by laser exposure and is composed of a support, a photosensitive recording layer formed on the support, and a backcoat layer containing an epoxy resin, the backcoat layer being formed on the side of the support opposite to the photosensitive recording layer side; and a stack of the planographic printing plate precursors. According to the invention, scratches on the photosensitive recording side of the planographic printing plate precursor can be prevented when brought into contact with another planographic printing plate precursor in the stack without interleaving slip sheets, and productivity in a plate making process can be improved.

Owner:FUJIFILM CORP

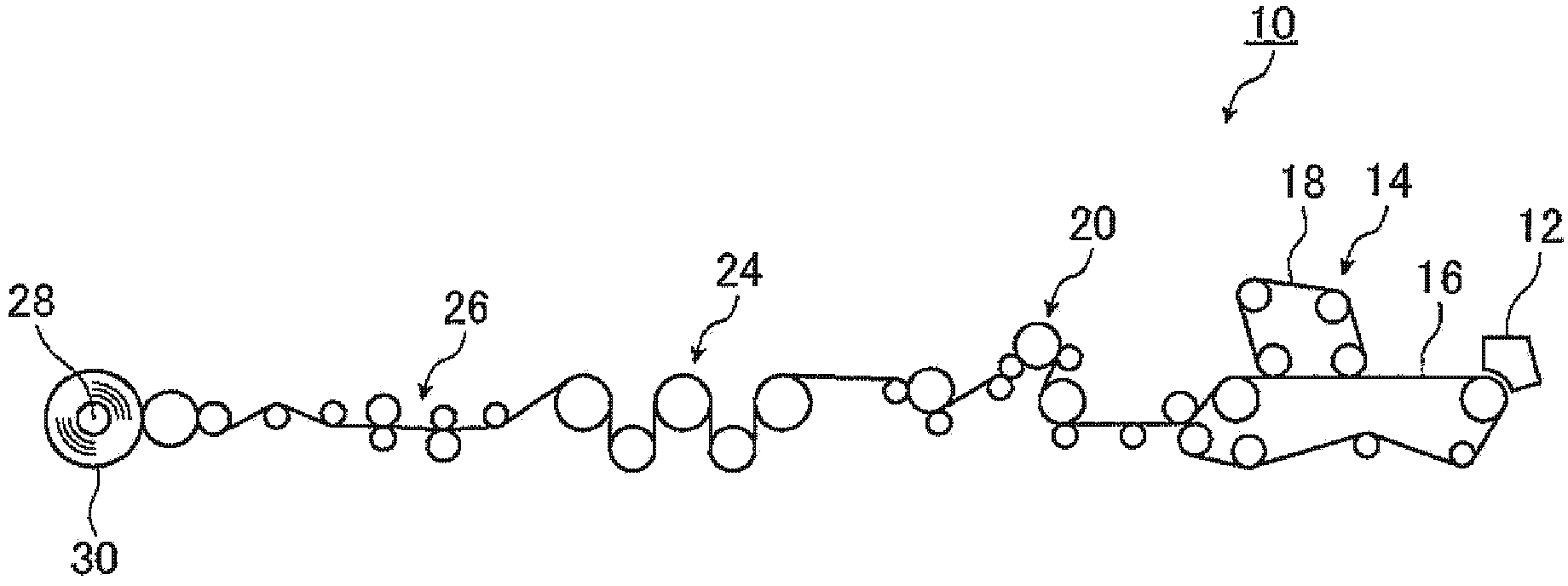

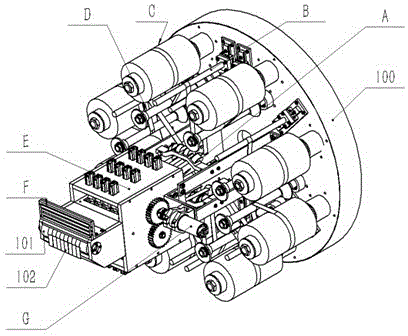

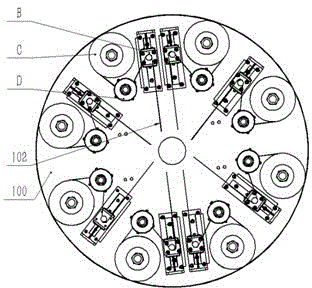

Modularized wire pavement head for automatically paving composite material and method

The invention relates to a modularized wire pavement head for automatically paving a composite material and a method. A six-axial robot-based platform design is used for paving a composite material member. The modularized wire pavement head is mainly characterized in that the wire pavement head is based on a completely modularized design, and comprises a wire coil mounting module (C), a gasket paper collecting module (D), a tension detection module (B), a tow steering module (A), a shearing, clamping and tow-reconveying module (E), a heater (F), a compression roller and the like. The modularized wire pavement head has the capability of simultaneously paving 8 bundles of composite material presoaking yarns; each tow is independently controlled; shearing of the tows and reconveying after shearing can be independently carried out; on the basis of rapid-exchange structure design, mounting and dismantling of the wire pavement head and mounting and exchanging of the tows can be conveniently carried out; on the basis of bared yarn duct design, cleaning of the wire pavement head can be conveniently carried out; and the widths of the used composite material presoaking yarns are 3.17mm, 6.35mm and 12.7mm.

Owner:WUHAN UNIV

Method and apparatus for separating media combinations from a media stack

Owner:EASTMAN KODAK CO

Slip sheet for transporting goods

A slip sheet for use with unitized loads has a plurality of banding anchors. The banding anchors extend from an edge of the slip sheet or from a portion of the slip sheet tab. The banding anchors may be provided on one, two, three, or four edges of the slip sheet. The banding anchors may be folded up against the side of a unitized load to provide a place for packaging bands to engage the slip sheet. Portions of at least one slip tray sidewall are separated from the remaining sidewall to form flaps that may be folded down to function as tabs that help lift vehicles get under the slip tray.

Owner:TRICKETT HOWARD J

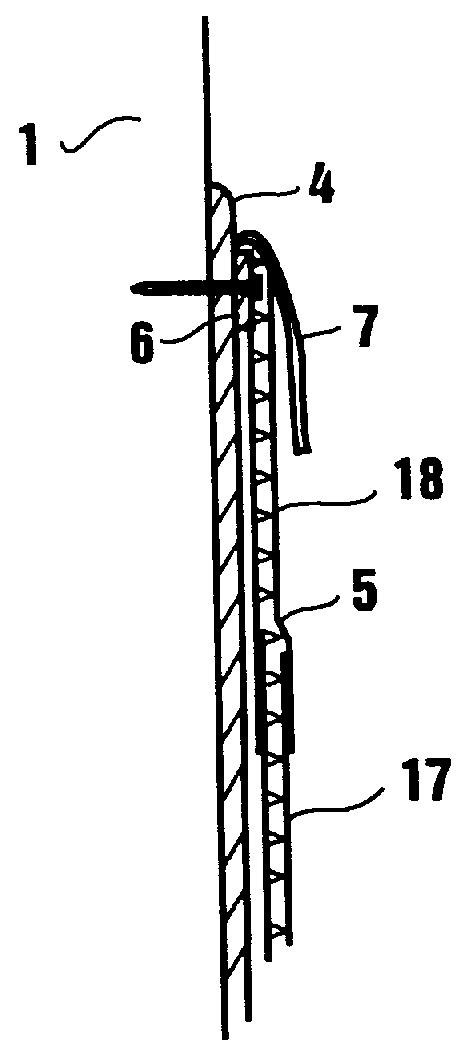

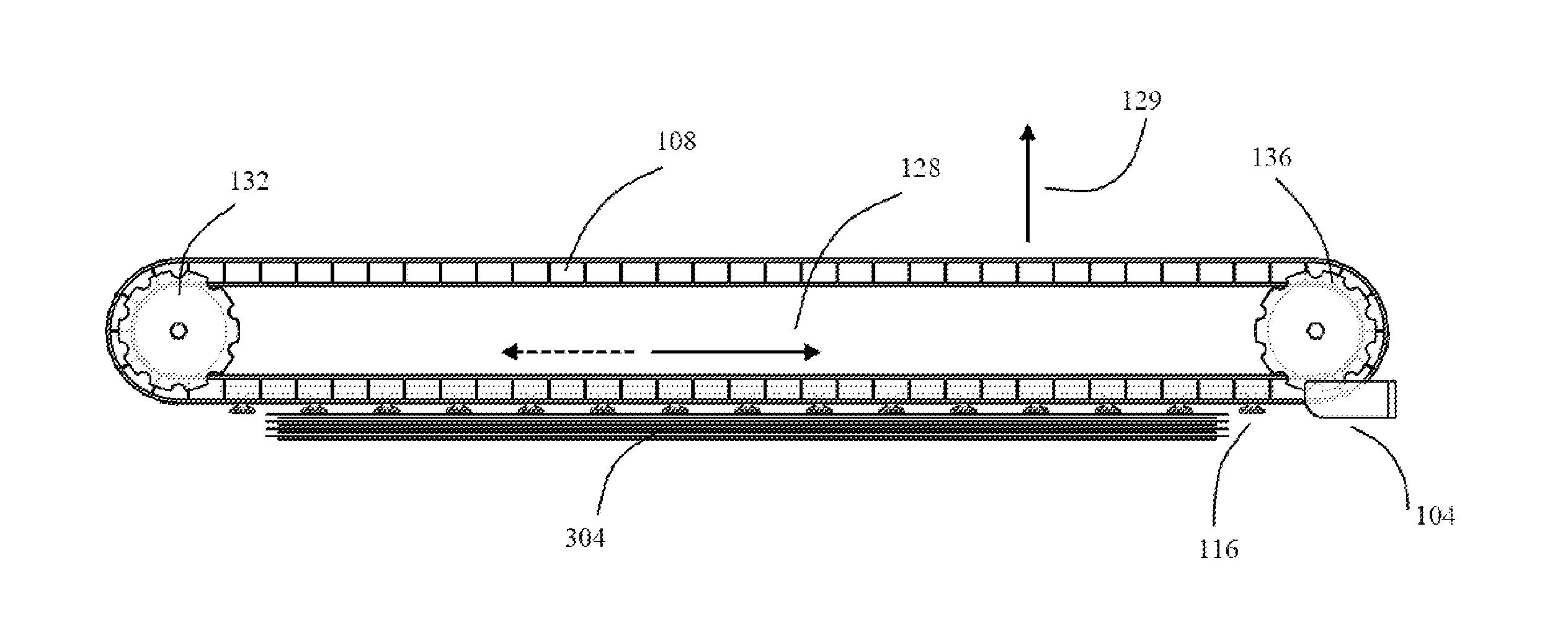

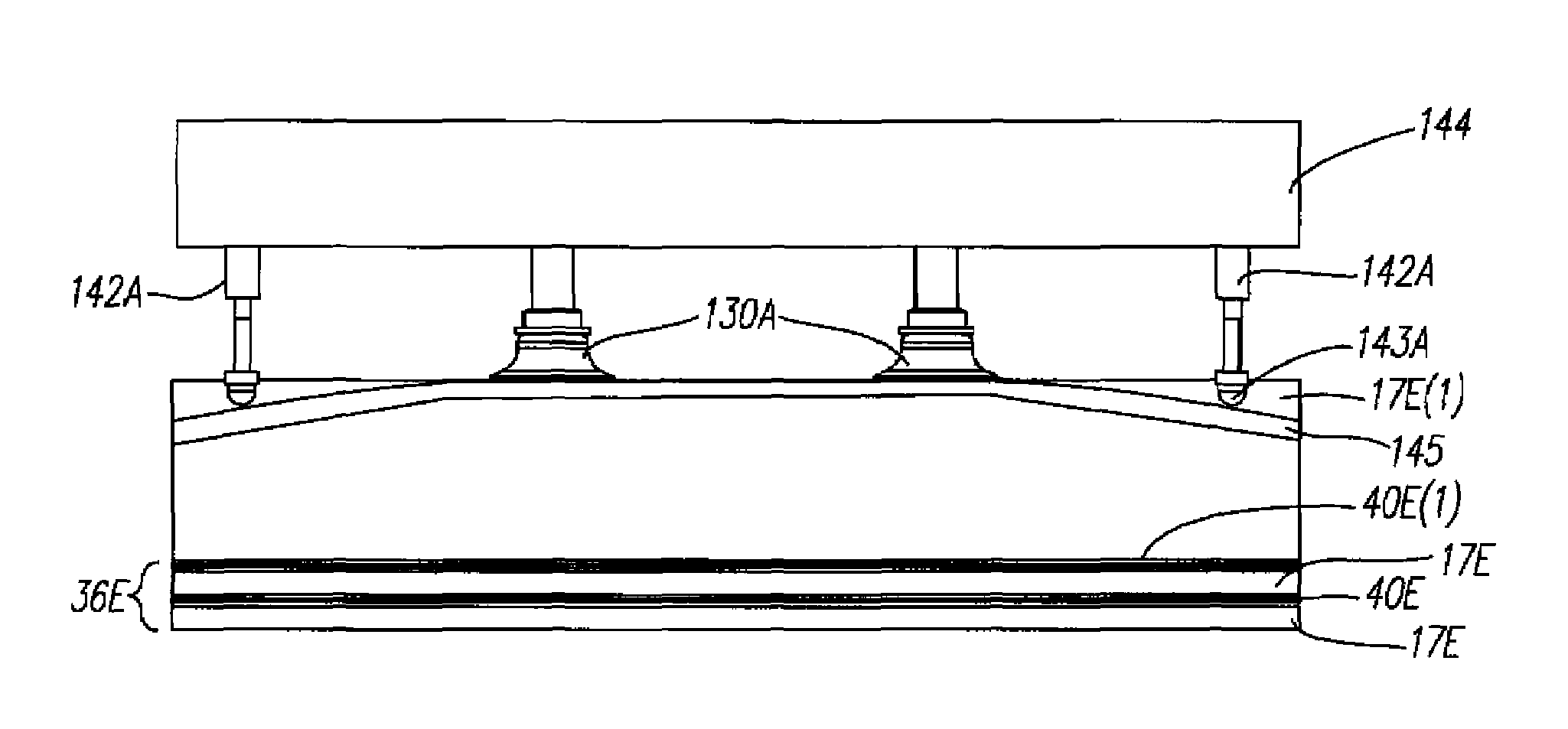

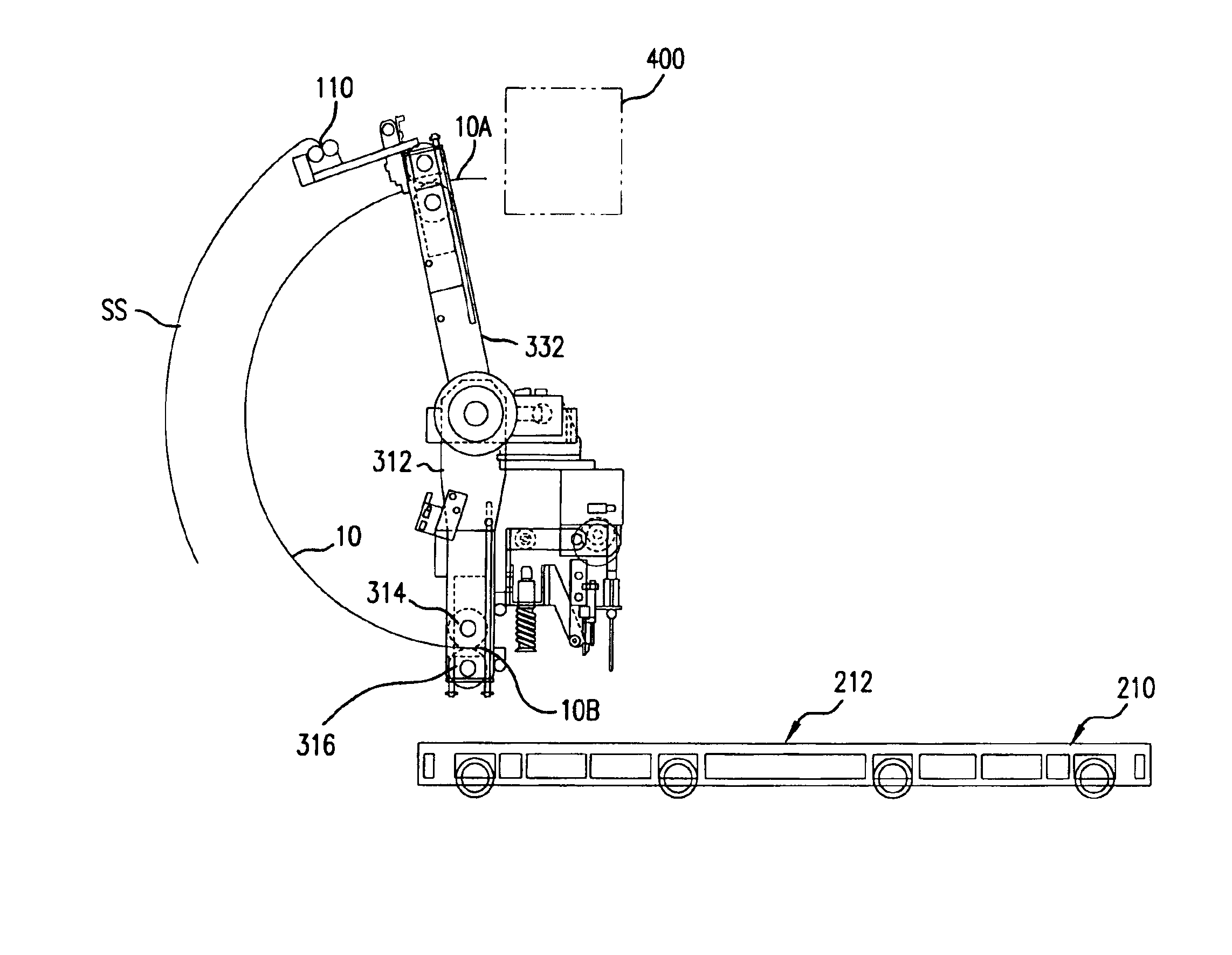

Slip sheet capture mechanism and method of operation

A substrate manager for a substrate exposure machine is used, in one example, as a platesetter. As such, it comprises a substrate storage system, containing one or more stacks of substrates, such as plates in one implementation. A substrate picker is provided for picking substrates from the stack of substrates. The substrates are then handed to a transfer system that conveys the substrates to an imaging engine. According to the invention, a substrate inverter system is also provided. This system inverts the substrates from being imaging or emulsion side down to emulsion side up in the present implementation. This allows plates, for example, which are stored emulsion side down in cassettes to be flipped to an emulsion side up orientation, and then transferred, using the substrate transfer system to the imaging engine. This flipping process has two advantages. First, the plates can be emulsion side up during the transfer. This prevents any damage to the sensitive plate emulsions. Moreover, the plates, now in an emulsion side up configuration are in the right orientation for being installed on the outside of a drum on an external drum imaging system, as is common in many platesetters. Also, the plates are picked from the non emulsion side. Thus the system is less sensitive to emulsion formulation changes. A slip sheet capture mechanism is also provided to pass slip sheets separating the plates to a storage location.

Owner:AGFA CORPORATIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com